Patents

Literature

498results about How to "Curing shrinkage is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual-curing coating and preparation method thereof

InactiveCN102181192ACuring shrinkage is smallIncrease crosslink densityCoatingsInformation layerCoating system

The invention discloses a dual-curing coating. The coating contains ultraviolet curing resin monomers, a low polymer, a photo-initiator, polymer resins, an adjuvant and an organic solvent. In the invention, the dual-curing coating is prepared by synergistic copolymerization of an ultraviolet curing coating system and a solvent-based polymer system. The preparation method of the coating comprises the following steps: firstly thermocuring, and then processing information layers and photocuring at the same time; or firstly photocuring, then processing the information layers, and finally heating with an oven or infrared-heating for further cross-linking curing. Therefore, the dual-curing coating has better comprehensive performances such as fast curing speed, small film-coating cure shrinkage and high crosslinking density so as to achieve the characteristics of chemical corrosion resistance, strong wear resistance, strong high temperature resistance, excellent flexibitity, excellent adhesive force and the like; and the coating can be used for laser anti-counterfeit marks of plastics, cosmetic preparations, ceramic materials, glass, paper, leather, wooden products and metal products as well as production of pigment preparations and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

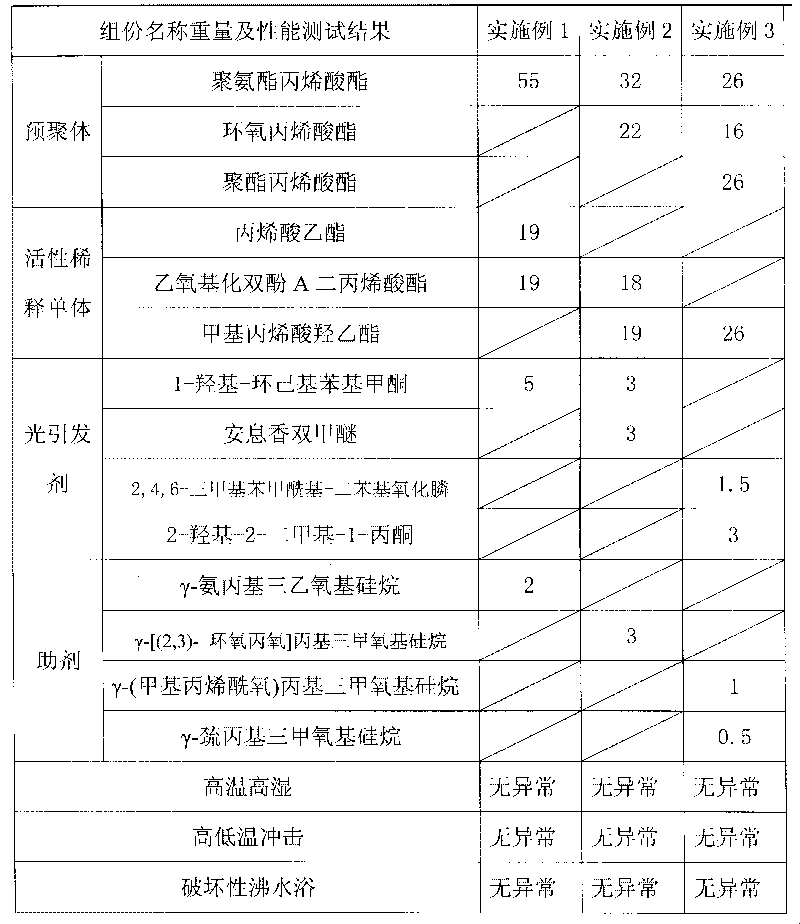

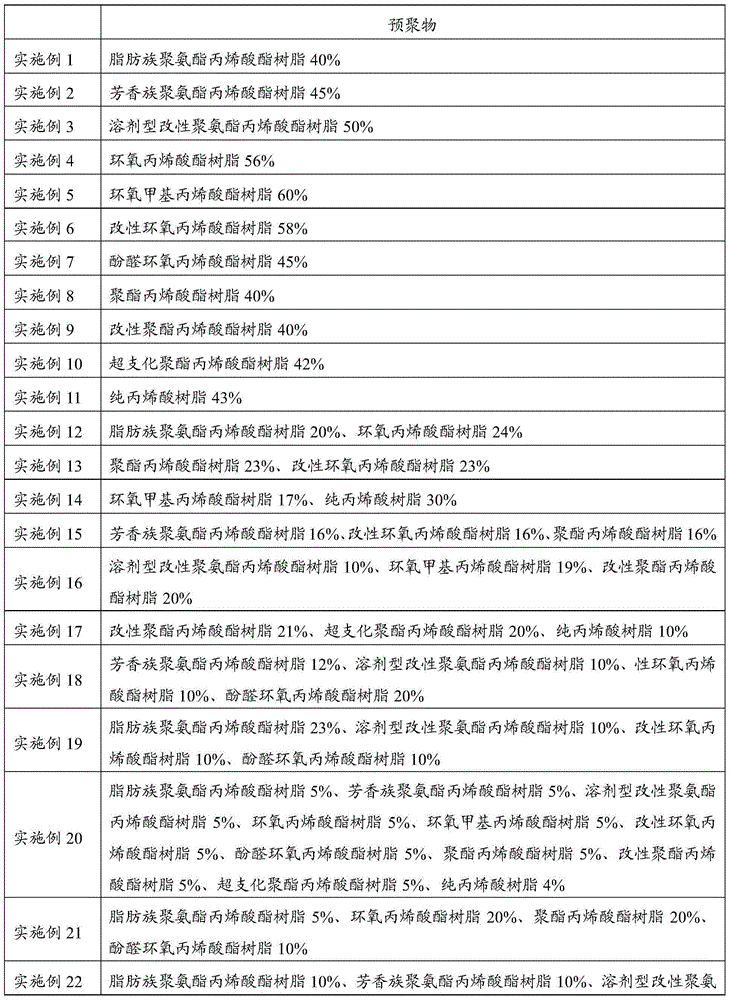

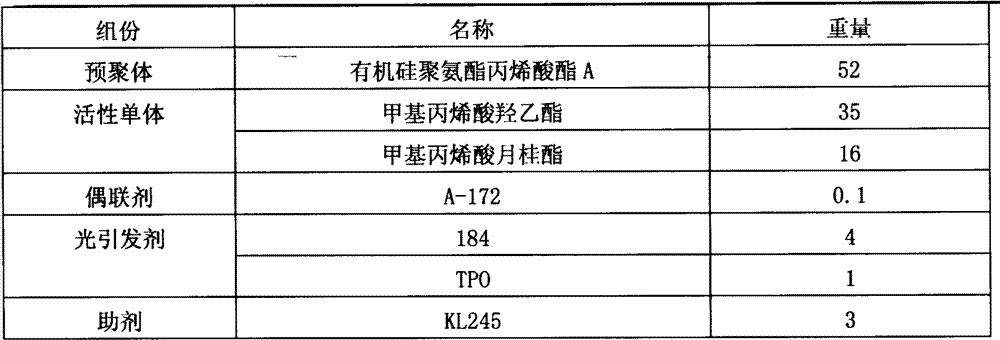

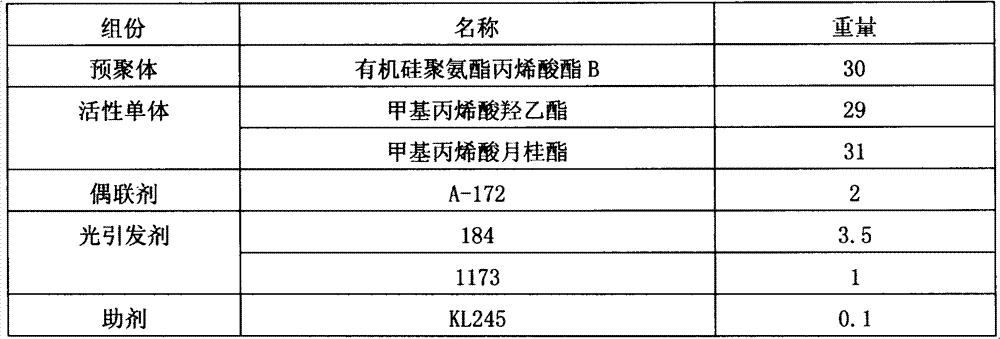

UV curing packaging adhesive for liquid crystal display

InactiveCN101724374AFast curingCuring shrinkage is smallOther chemical processesPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

The invention provides a UV curing packaging adhesive for a liquid crystal display. Based on 100 weight parts, the adhesive consists of following components: 40 to 70 parts of prepolymer, 20 to 50 parts of active diluent monomer, 1 to 8 parts of photoinitiator, and 0.1 to 5 parts of assistant. The prepolymer is one or a mixture of more of the urethane acrylate, epoxy acrylate and polyster acrylate. The UV curing packaging adhesive for the liquid crystal display has the characteristics of high curing speed, low shrinkage rate and excellent damp heat resistance.

Owner:BEIJING HYSTIC NEW MATERIALS

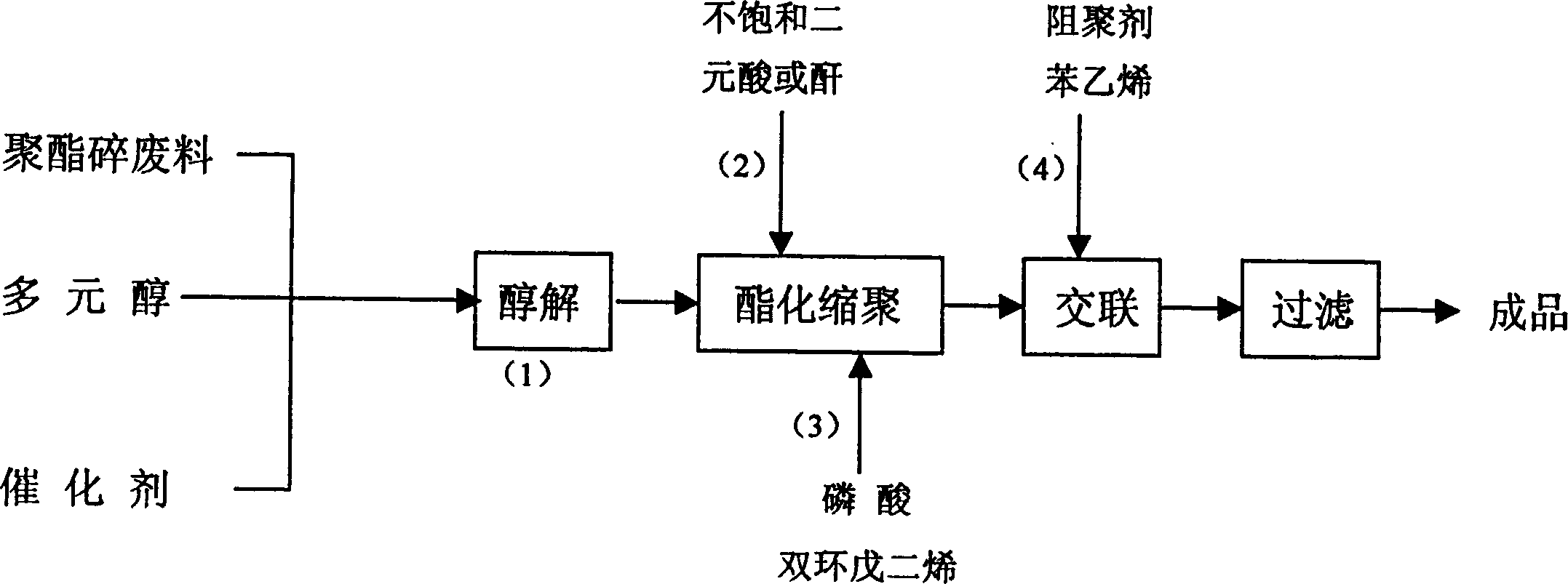

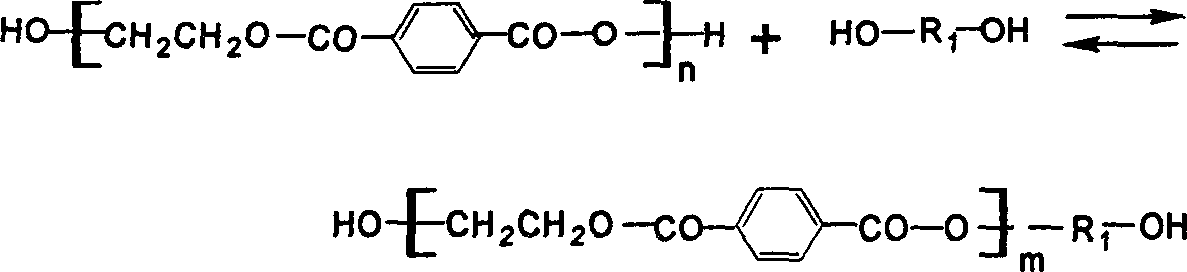

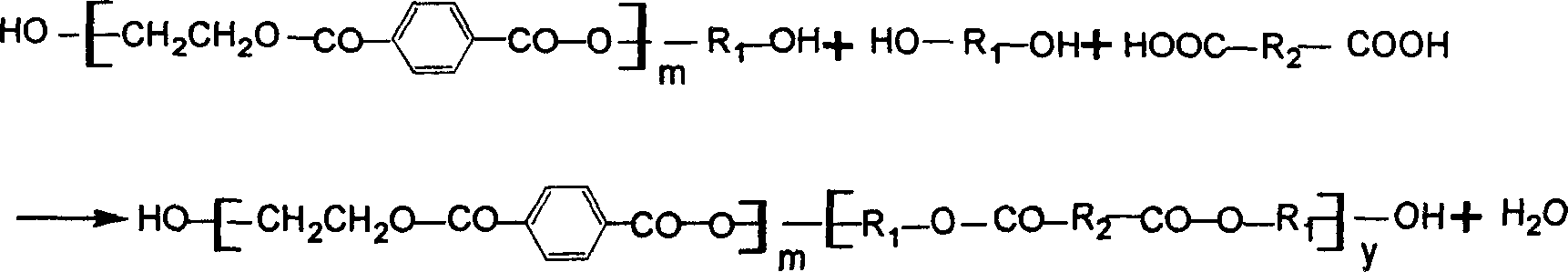

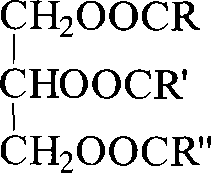

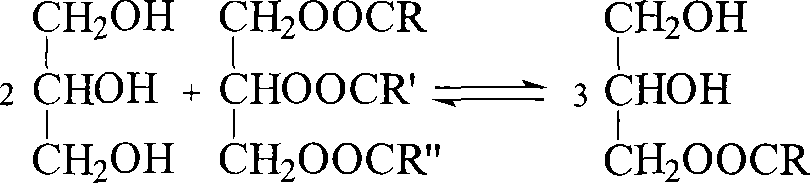

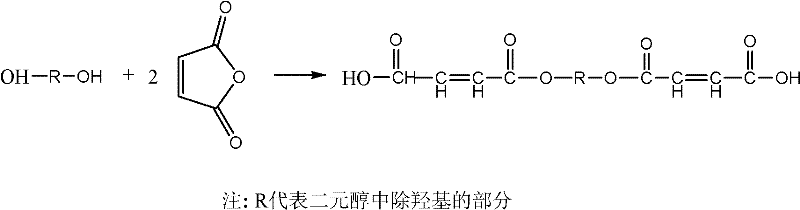

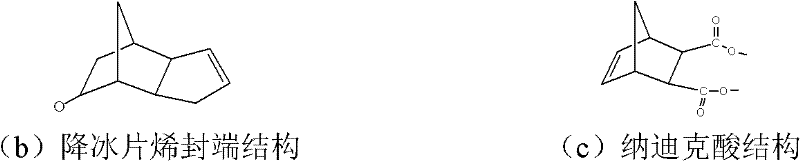

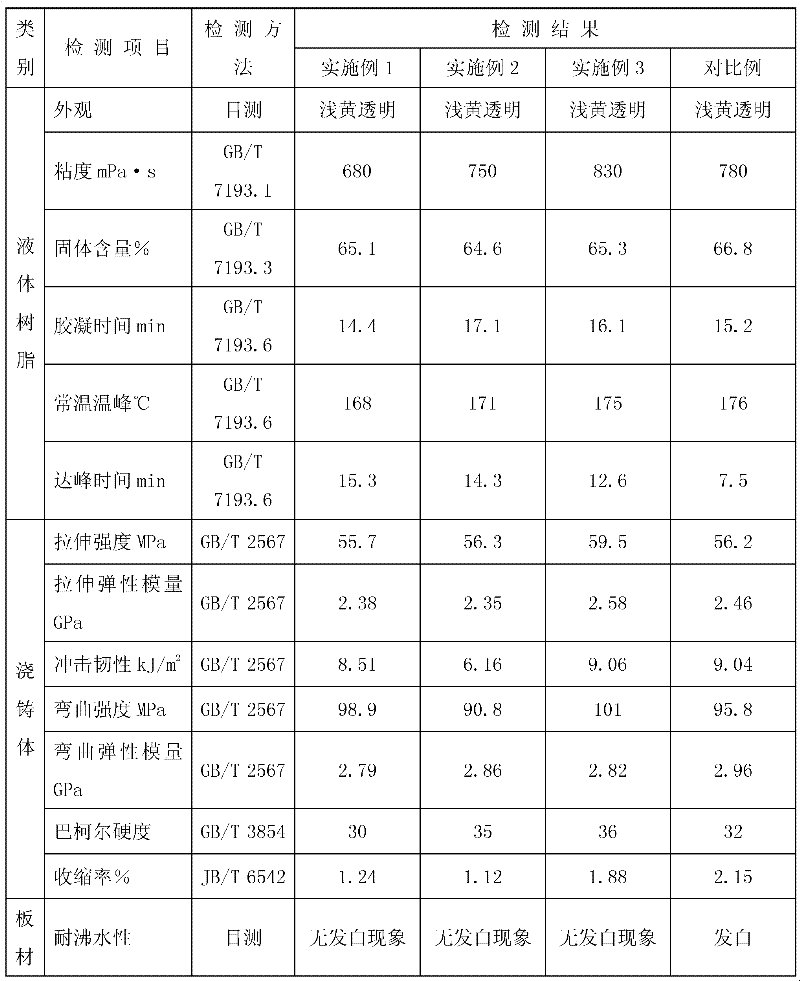

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Modified benzoxazine resin capable of using for RTM and process for preparing same

A modified benzoxazine resin able to be used for RTM is prepared through feeding low-voscosity benzoxazine intermediate and epoxy resin (or arylacetylene resin) proportionally into a reactor, mixing,reaction at 50-100 deg.C for 5-10 min, adding catalyst, and reaction for 5-10 min. It can also be prepared from low-viscosity benzoxazine intermediate and bimaleimide resin.

Owner:SICHUAN UNIV

Method for synthesizing unsaturated polyester resin

The invention relates to a process for synthesizing unsaturated polyester resin with renewable vegetable fat, which comprises generating acid ester through conducting alcoholysis reaction for vegetable oil and organic polyatomic alcohol, using as modified dihydric alcohol and being leading to the typical synthesis formulation of unsaturated polyester resin, completely replacing conventional dihydric alcohol, using for synthesizing unsaturated polyester, and then mixing with cross-linking monomer. The resin which is synthesized has excellent hue, appropriate viscosity, excellent heat stability, favorable alkali resistivity, wonderful flexible property and low shrinking rate, which is suitable for various composite material shaping technology such as hand lay-up, winding and spraying and the like. Renewable raw material of vegetable oil with cheap price is applied in the synthesis process of the invention, and the stability of product is excellent.

Owner:江苏大力士云石护理材料有限公司

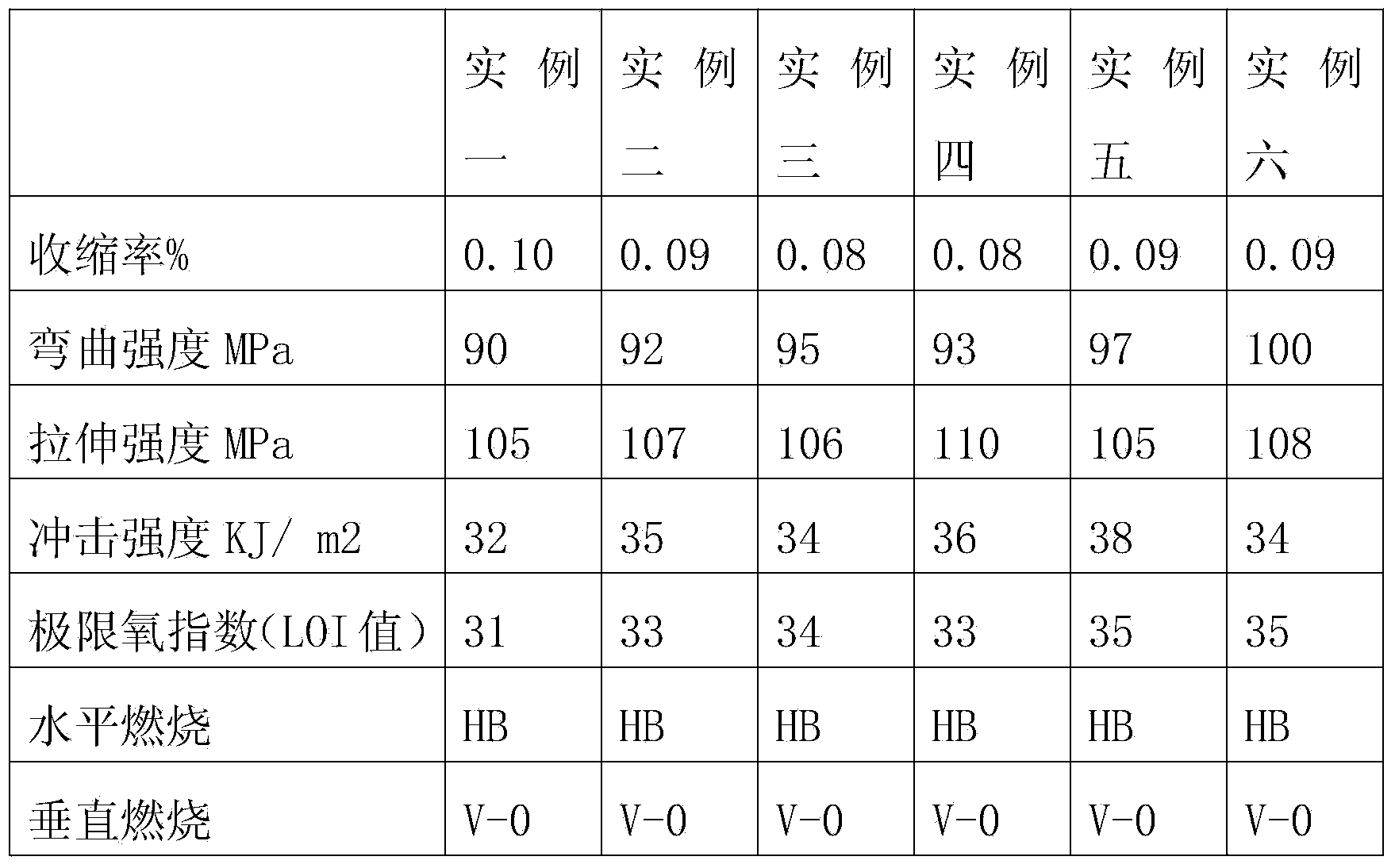

Low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and preparation method thereof

The invention discloses a low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and a preparation method thereof. The low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board is prepared from the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 20-30 parts of a low-shrinkage additive, 1-3 parts of an accelerant, 0.5-2 parts of an initiator, 2-5 parts of a medium-temperature curing agent, 0.1-0.5 part of a thickening agent, 8-15 parts of a novel halogen-free flame retardant, 100-130 parts of inorganic filler, 2-3 parts of a release agent and 100-150 parts of fiberglass. The curing degree, the bending strength and the flexibility of the low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board can be improved; residual styrene in the fiberglass reinforced plastic board is reduced.

Owner:扬州万盛实业有限公司

Two-component epoxy resin adhesive for stone skin patching and preparation thereof

ActiveCN101314704AHigh surface glossGood yellowing resistanceEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to a double-component epoxy resin adhesive for repairing stone surface and the preparation method thereof. The double epoxy resin adhesive is composed of a component A consisting of epoxy resin and diluting agent, and a component B consisting of curing agent, optical stabilizer and UV absorber. The double-component epoxy resin adhesive is used for repairing microcrack on stone surface and ant road, and has the advantages of moderate curing speed, good yellowing-resistant performance, good permeability, high glossiness after cured and polished, easily-obtained environment-friendly material, simple process, etc.

Owner:HUNAN SHENLI IND

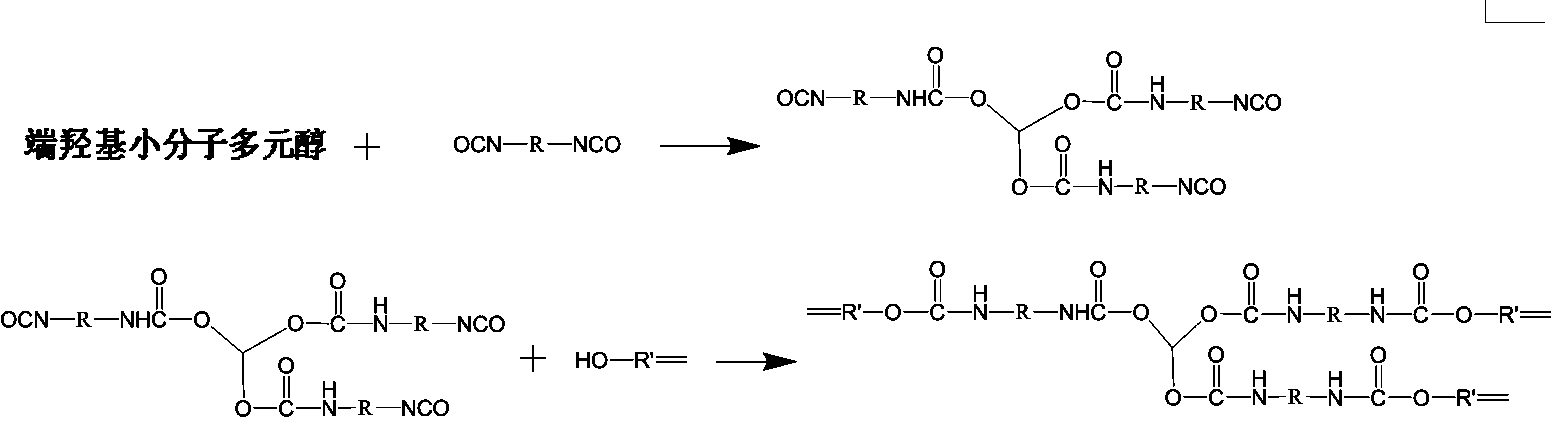

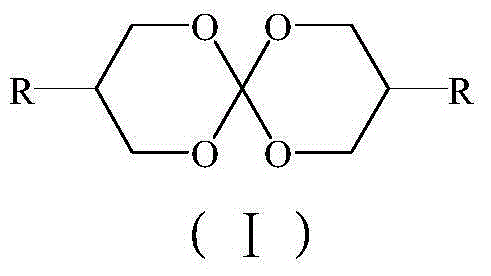

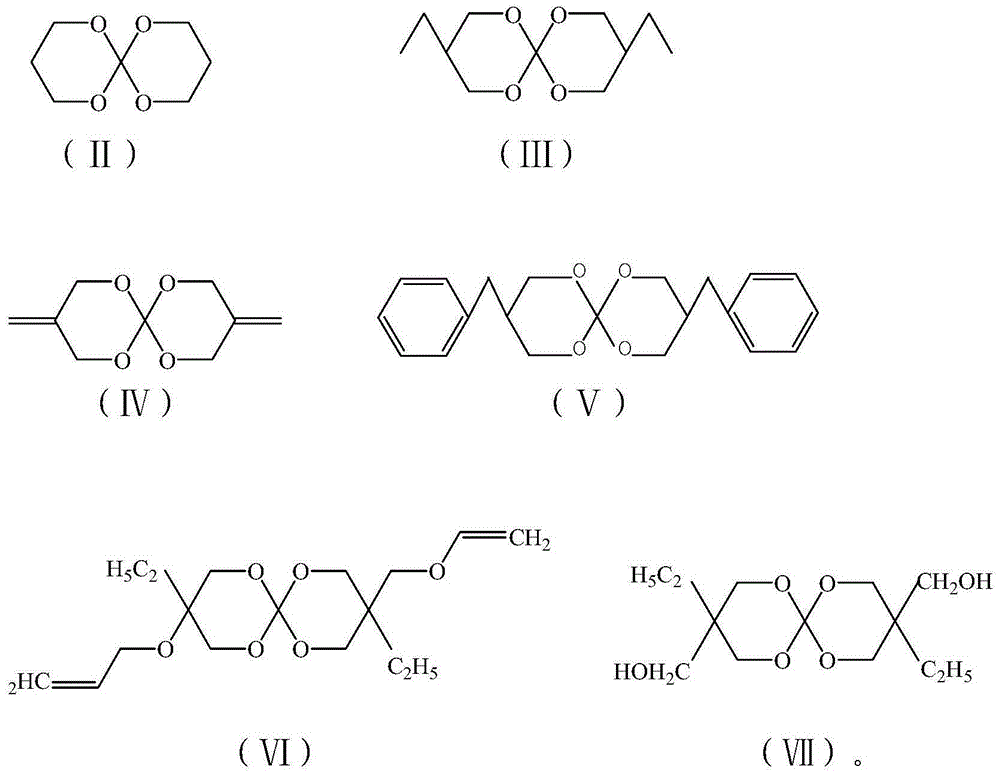

Unsaturated hyperbranched polyurethane prepolymer as well as preparation method and application thereof

The invention discloses an unsaturated hyperbranched polyurethane prepolymer as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing hydroxyl-terminated small molecular polyol with diisocyanate, heating to 80 DEG C, reacting for 2-4 hours, cooling to 40 DEG C after the reaction is finished, adding an end-capping agent, heating to 80 DEG C, reacting for 3-5 hours, cooling to 50 DEG C, and discharging to obtain the unsaturated hyperbranched polyurethane prepolymer. The prepolymer can be used for preparing LED photocured three-dimensional printing resin; a hyperbranched technology is adopted for preparing the prepolymer, so that the photocuring time is shortened; moreover, a photo-initiated free radical polymerization and epoxy latent curing combined technology is adopted for quickly curing a material. The scheme has the advantages that the curing speed (curing by irradiating for 2 seconds by a 12 W lamp bead) is high, the curing shrinkage rate is low, the curing process cannot be influenced by moisture and oxygen in air, and the material obtained after the curing process is high strength (6-15 MPa) and small in curing shrinkage rate (not more than 3%).

Owner:安徽思敬齐环保材料有限公司

UV solidified liquid optical cement and preparation method and application thereof

InactiveCN105219339ACuring shrinkage is smallHigh light transmittanceNon-macromolecular adhesive additivesFilm/foil adhesivesPrepolymerPhotoinitiator

Owner:SOUTH CHINA AGRI UNIV

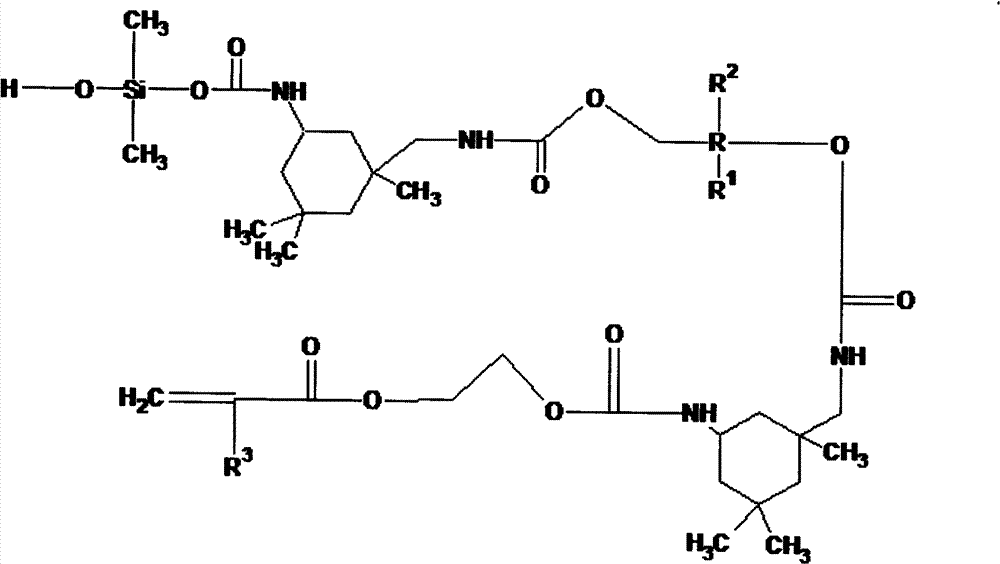

Ultraviolet (UV)-moisture double-curing liquid optical transparent adhesive and preparation method thereof

InactiveCN102816551AHigh transparencyHigh bonding strengthPolyureas/polyurethane adhesivesAdhesiveUltraviolet

The invention relates to liquid optical transparent adhesive, in particular to ultraviolet (UV)-moisture double-curing liquid optical transparent adhesive and a preparation method thereof. The adhesive comprises, by weight, 30-60 parts of prepolymer, 5-50 parts of activated monomer, 0.1-7 parts of coupling agent, 1-10 parts of photoinitiator and 0.1-3 parts of auxiliaries. The prepolymer has a special molecular structural formula. The adhesive has the advantages of being good in transparency, adhesive strength and flexibility ductility, suitable for bonding of different materials, small in curing shrinkage percentage, resistant to yellowing and the like and can be used for attaching process on some special occasions such as touch screens. The preparation method includes: vacuum dewatering a reactive diluent for 1-2h at the temperature of 110-120 DEG C, cooling to room temperature, adding prepolymer, coupling agent and photoinitiator, stirring, dissolving, and adding auxiliaries to obtain the adhesive. The preparation method has the advantages of being simple in synthetic reaction process, easy to operate, low in cost and wide in product use range.

Owner:HB FULLER CO

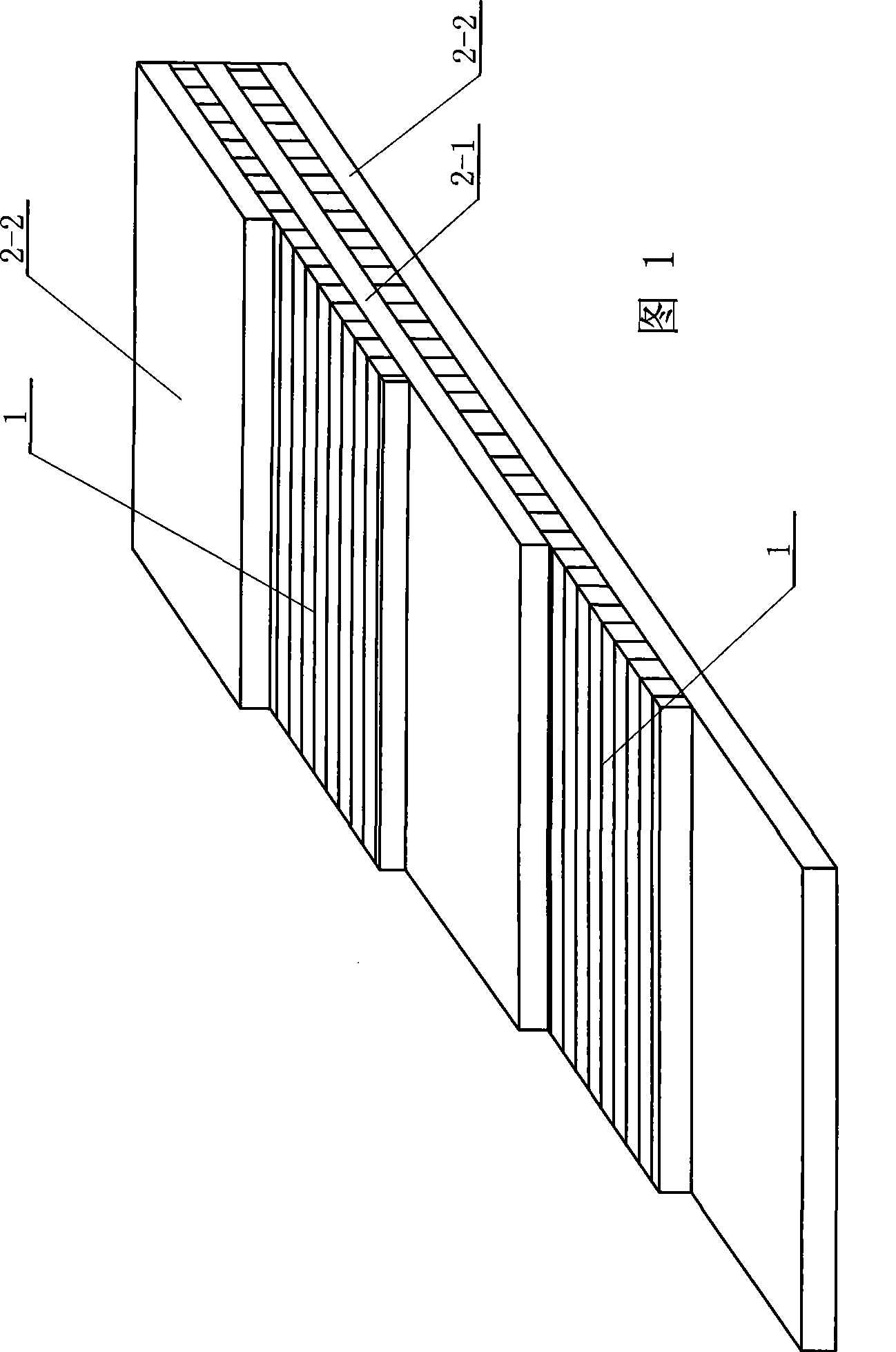

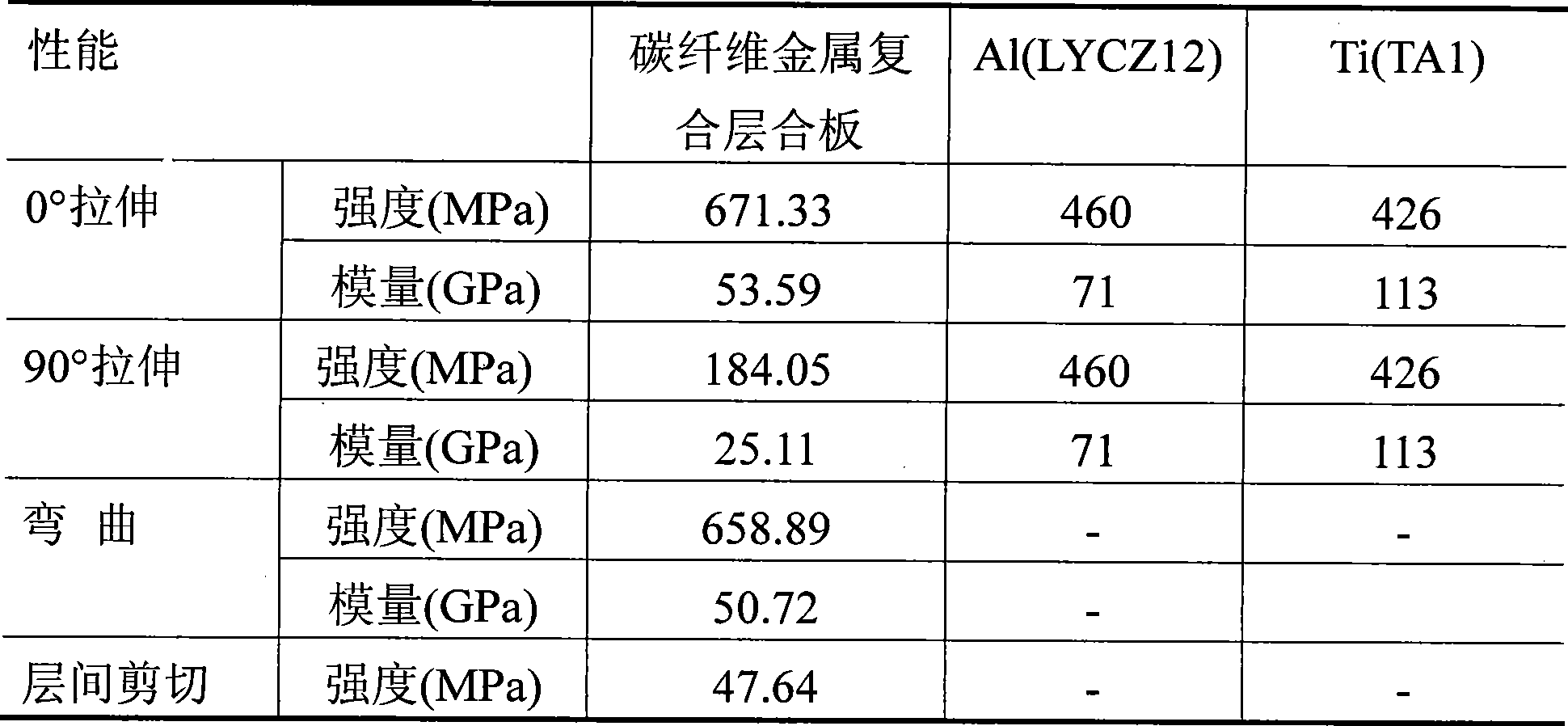

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524AFlame retardantImpact resistantLamination ancillary operationsLaminationFiberEpoxy

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidification by adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

Coating method of winding amorphous iron core insulating coating

ActiveCN103128039AWith strengthUniform thicknessPretreated surfacesInductances/transformers/magnets manufactureEpoxyCoated surface

The invention relates to a coating method of a winding amorphous iron core insulating coating. The coating method comprises a first step that a whole amorphous iron core is arranged in epoxy glue to conduct vacuum impregnation, a second step that the surface of the amorphous iron core is coated with epoxy resin, and a third step of heating and solidifying after the amorphous iron core is coated with the modified epoxy glue coating. Gaps between amorphous strips are sealed and have certain strength after the epoxy glue impregnation, the coating is neat in surface and uniform in thickness, vibration and noises of the iron core are reduced, and integrated installation is convenient. The coating is thinner than general coating technique and solidifying time is shortened. The epoxy glue enables solidifying contraction percentage to be low, the epoxy glue coating has good adhesiveness and elasticity and has little stress to the iron core, and the coating has little influence on initial magnet conductivity and inductance of the amorphous iron core. The amorphous iron core dealt with the coating method can greatly reduce no-load loss.

Owner:SHANGHAI ELECTRICGROUP CORP

Application of low-viscosity light-cured resin in 3D (three-dimensional) printing materials

ActiveCN104893224ALow viscosityFast curing rateAdditive manufacturing apparatusPolymer scienceAcrylate ester

The invention relates application of low-viscosity light-cured resin in 3D (three-dimensional) printing materials. The low-viscosity light-cured resin is (branched) polyether acrylate or heterocyclic amine modified (branched) polyether acrylate. A 3D printing material prepared from the low-viscosity light-cured resin is of low viscosity and high curing speed, is low in curing shrinkage, low in yellowing property, moderate in rigidity and flexibility, high in forming speed and high in product dimensional precision, is free of curing incompleteness, edge warping and the like, and is very suitable for being applied to 3D printing materials based on the SLA (stereolithography) or 3DP (three-dimensional printing) technology.

Owner:新丰博兴聚合材料有限公司

Low styrene volatilization unsaturated polyester gel coat resin and preparation method thereof

The invention relates to a low styrene volatilization unsaturated polyester gel coat resin used for the surface of a composite material, and a preparation method thereof. The gel coat resin which is prepared by carrying out high speed dispersion on an unsaturated polyester resin, a thixotropic agent, a filler, styrene, a defoamer, a styrene volatilization inhibitor and the like is suitable for spraying. The unsaturated polyester resin for preparing the gel coat resin, which has the characteristics of low viscosity, high solid content and high strength, is a special unsaturated polyester resin developed for the low styrene volatilization unsaturated polyester gel coat resin. The low styrene volatilization unsaturated polyester gel coat resin of the invention, which can be widely applied to the surface of the composite material, can decorate and protect the composite material; and simultaneously the gel coat resin can greatly reduce the styrene volatilization in the gel coat construction process, so the gel coat resin is in favor of the environmental protection.

Owner:CHANGZHOU HUAKE POLYMERS

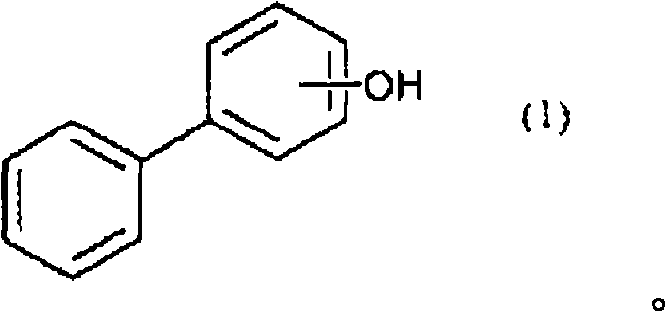

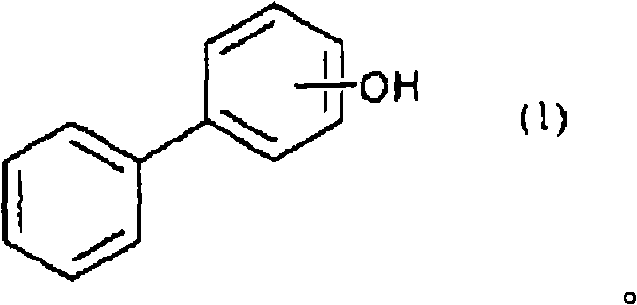

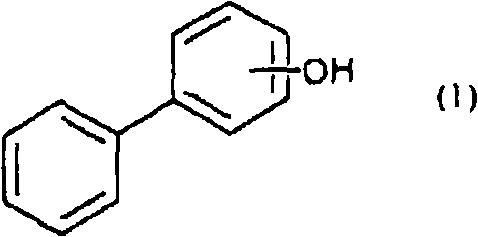

(meth)acrylate compound, resin composition containing the same, cured product of the resin composition, and energy ray-curable resin composition for optical lens sheet and cured product thereof

Disclosed is a photosensitive resin which is excellent in transparency, while having high refractive index and high adhesion by the resin itself. This photosensitive resin provides a cured product having a sufficient hardness. Also disclosed is a resin composition for optical lens sheet, which is excellent in mold releasability, mold reproducibility, adhesion to a base, while having high refractive index, high glass transition temperature and good light resistance. Specifically disclosed is a urethane compound (A) characterized by being obtained by reacting an epoxy resin (a), which is obtained by reacting a compound represented by the general formula (1) below with epihalohydrin, a monocarboxylic acid compound (b) having an ethylenically unsaturated group in a molecule, and an aromatic polyisocyanate compound (c). Also specifically disclosed is an energy ray-curable resin composition for optical lens sheet, which is characterized by containing the urethane compound (A) and a photopolymerization initiator (B).

Owner:NIPPON KAYAKU CO LTD

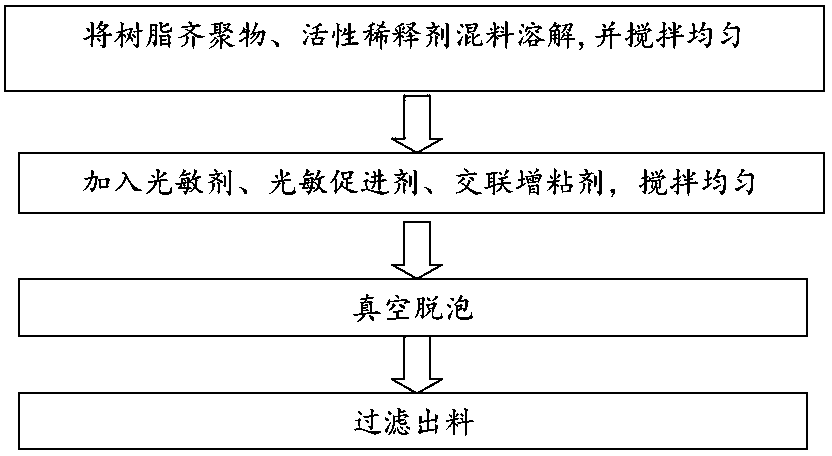

Liquid optical adhesive and preparation method thereof

InactiveCN103555210AIncrease productivityHigh bonding strengthOrganic non-macromolecular adhesivePolymer scienceAdhesive

The invention relates to a liquid optical adhesive which can be cured through ultraviolet light and is capable of achieving fixed adhesion between glass and touch control sensing screens in the process that a capacitance type touch screen is manufactured, and a preparation method of the liquid optical adhesive. The liquid optical adhesive is prepared from the following raw materials in percentage by weight: 35-48% of a resin oligomer, 50-63% of a reactive diluent, 0.5-1.3% of a photosensitizer, 0.8-1.6% of a photosensitive prompter and 0.4-1.4% of a cross-linking tackifier. The resin oligomer can be prepared by mixing and dissolving urethane acrylate or epoxy acrylate or a mixture of the two acrylic esters, by defoaming in vacuum and by filtering. The resin oligomer has the advantages of sufficient solidification in ultraviolet light, high production efficiency, high adhesion strength, high light permeability, small solidification shrinkage, yellowing resistance, simple manufacturing process, environmental friendliness and the like.

Owner:深圳市中显微电子有限公司 +1

Method for synthesizing unsaturated polyester resin for artificial marble

ActiveCN102212173ACuring at room temperature with gentle exothermCuring shrinkage is smallWater dischargeAlcohol

The invention provides a method for synthesizing unsaturated polyester resin for artificial marble, which mainly comprises the following steps of: (A) putting unsaturated dibasic acid, unsaturated dibasic acid anhydride, dicyclopentadiene and partial dihydric alcohol in a reaction kettle, heating and performing reflux reaction under the protection of nitrogen, and then heating and performing reflux reaction until a certain acid value is reached; (B) changing the state of the system to a distillation state, adding the residual dihydric alcohol to perform polycondensation reaction, and evacuating to discharge water forcibly when the water discharge quantity reaches 85% to 90% of a theoretical quantity, so that the reaction continues to be below the certain acid value; and (C) lowering the temperature and adding a polymerization inhibitor, diluting with styrene, and cooling and filtering to obtain the finished unsaturated polyester resin. The method provided by the invention is steady and controllable in the reaction process, fast in polycondensation reaction and small in quantity of generated waste water, and the obtained product has the characteristics of steady and slow curing and heat release at normal temperature, small rate of curing shrinkage, excellent boiling water resistance and the like, and can meet the quality demand of the artificial marble.

Owner:ZHAOQING FUTIAN CHEM IND

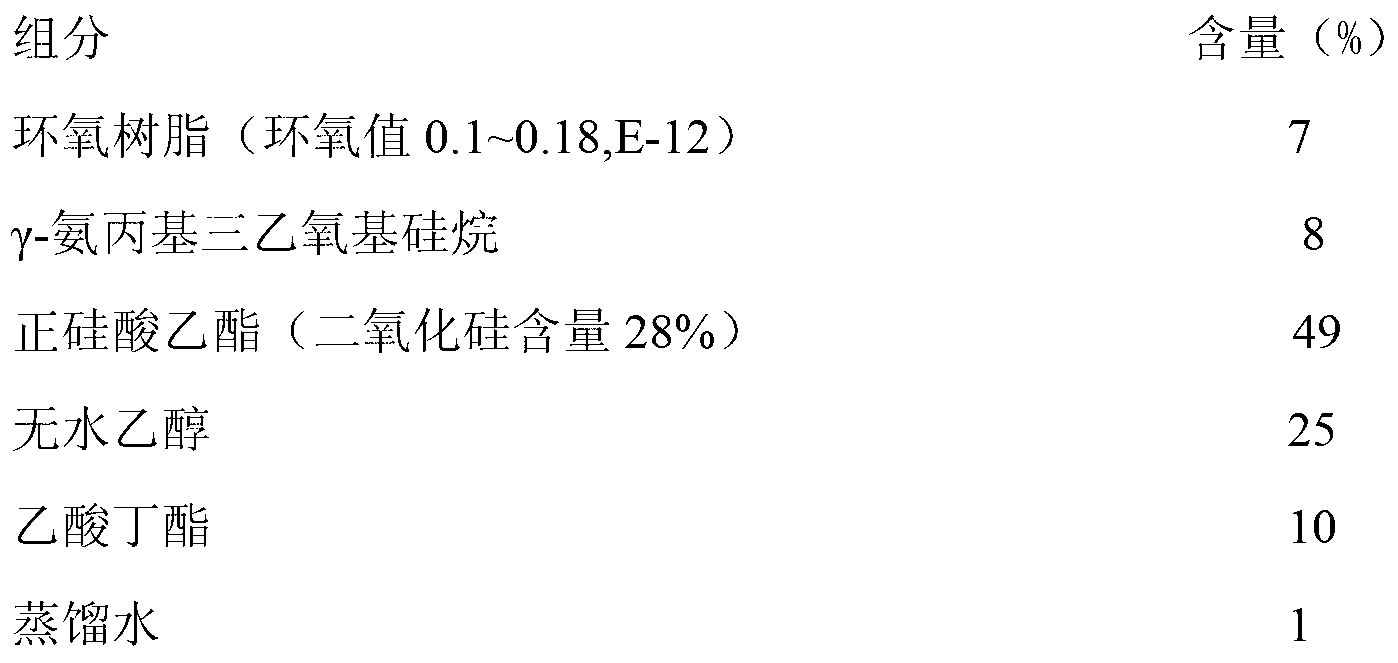

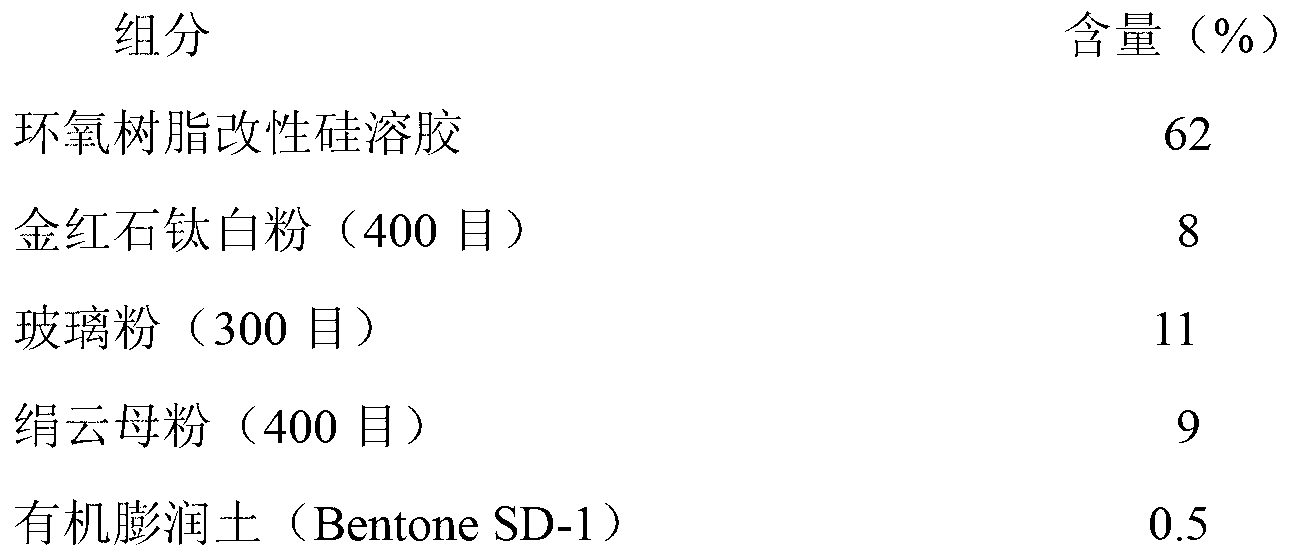

Epoxy resin modified silica sol based high-temperature-resistant hydrophobic coating and preparation method thereof

The invention discloses an epoxy resin modified silica sol based high-temperature-resistant hydrophobic coating which is composed of the following components in percentage by mass: 60-65% of epoxy resin modified silica sol, 7-9% of rutile titanium dioxide, 8-12% of glass dust, 9-10% of sericite powder, 0.5-1% of organic bentonite and 9-14% of butyl acetate. The preparation method is implemented through the following steps of: preparing epoxy resin modified silica sol firstly, reacting gamma-triethoxypropylsilane with epoxy resin, and then adding tetraethoxysilane for carrying out hydrolytic condensation; adding filler and a solvent in the prepared product in proportion, and carrying out high-speed mixing and grinding on the obtained mixture until the fineness of the obtained product is below 50 mu m so as to obtain the coating disclosed by the invention. A film prepared by dying and solidifying the coating disclosed by the invention has the advantages of good mechanical properties, excellent hydrophobic properties, good high temperature resistance and weather resistance, and the like. The coating is applicable to the high-temperature-resistant protection and decoration of metal substrates such as aluminum plates, tinplate and steel plates.

Owner:JIANGSU UNIV OF SCI & TECH

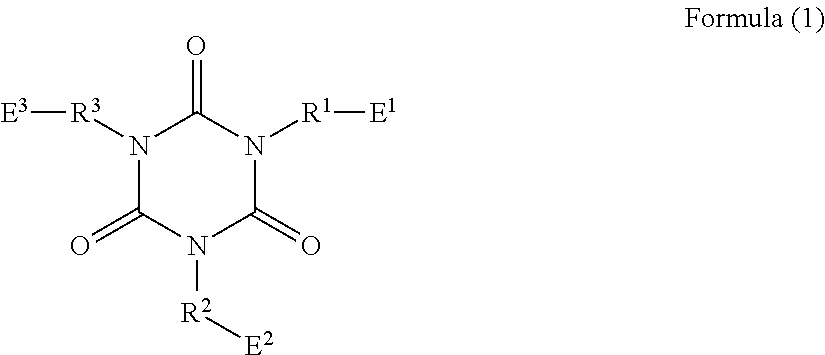

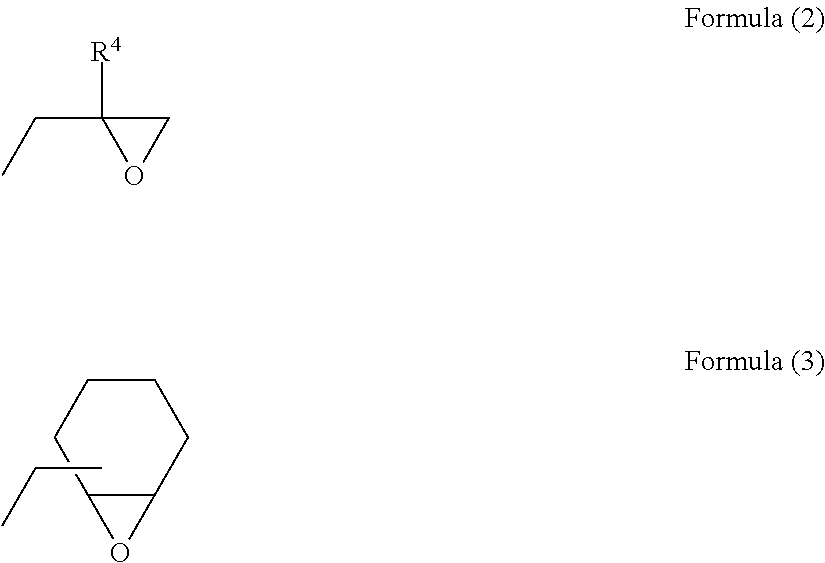

Long-chain alkylene-containing curable epoxy resin composition

ActiveUS20120295199A1Reduce contentGood storage stabilityPhotosensitive materialsEpoxy resin adhesivesEpoxyHydrogen atom

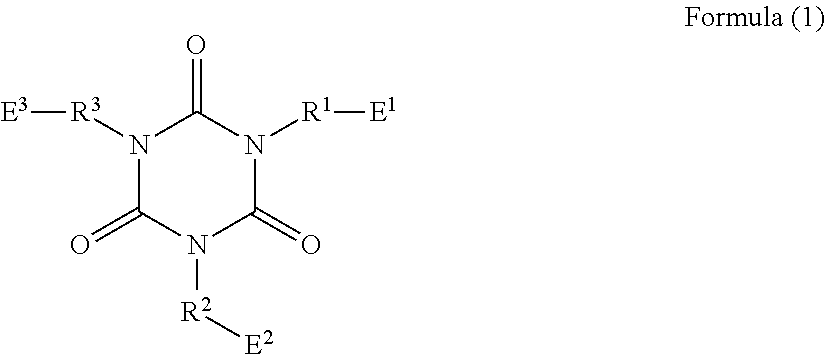

A curable composition that maintains good handleability in the liquid form and that can be photo- or heat-cured to form a cured product having physical properties including both high transparency and high flexural strength. A curable composition includes, an epoxy compound of (1):[where each of E1, E2, and E3 is independently an organic group of Formula (2) or Formula (3); and each of R1, R2, and R3 is independently an optionally branched alkylene group or oxyalkylene group:(where R4 is a hydrogen atom or a methyl group)]; and an acid generator.

Owner:NISSAN CHEM IND LTD

Light mixing cured coating composition and preparation method thereof

InactiveCN101709196AImprove physical and chemical propertiesExcellent system performanceEpoxy resin coatingsUltraviolet lightsSpray coating

The invention discloses a light mixing cured coating composition which comprises epoxy acrylic acid monoester, ultraviolet light-heat mixing curing agent or ultraviolet light free radical-cation mixing curing agent, pigmented filler, reactive diluent, dispersing agent, defoaming agent and flatting agent. The invention also discloses a preparation method of the light mixing cured coating composition. The coating composition of the invention has small cure shrinkage and high bonding strength, can be applied to dark systems, can be used for coating some components with complicated structures, and can be used for coating surfaces of wood products, plastics, metals and the like by the construction methods of brush coating, spray coating, curtain coating, roller coating and the like.

Owner:SHENZHEN POLYTECHNIC

Product prepared by light-curing rapid prototyping process and preparation method thereof

InactiveCN109280395AImprove mechanical propertiesHigh tensile strengthAdditive manufacturing apparatusLiquid lineDouble bond

The invention discloses a product and a preparation method thereof. The product is prepared by a light-curing rapid prototyping process, and a raw material used in the light-curing rapid prototyping process is a liquid photosensitive resin material. The product has an excellent mechanical property, and is high in tensile strength and tensile modulus, smooth and clean on surface, small in cure shrinkage, stable in size and good in mechanical property. The liquid photosensitive resin material contains liquid polycarbosilane having a line-ring structure and containing unsaturated double bond andis good in stability and easy to store, and the synthetic route of the material is green and environmentally friendly without corrosion; and a liquid line-ring polycarbosilane active group is large indensity, fast in curing speed, high in cured product strength, low in molecular weight and viscosity, good in fluidity and printable performance, and especially suitable for a 3D printing technologyof light-curing rapid prototyping.

Owner:BEIJING HENGCHUANG ADVANCED MATERIALS & ADDITIVE MFG INST CO LTD

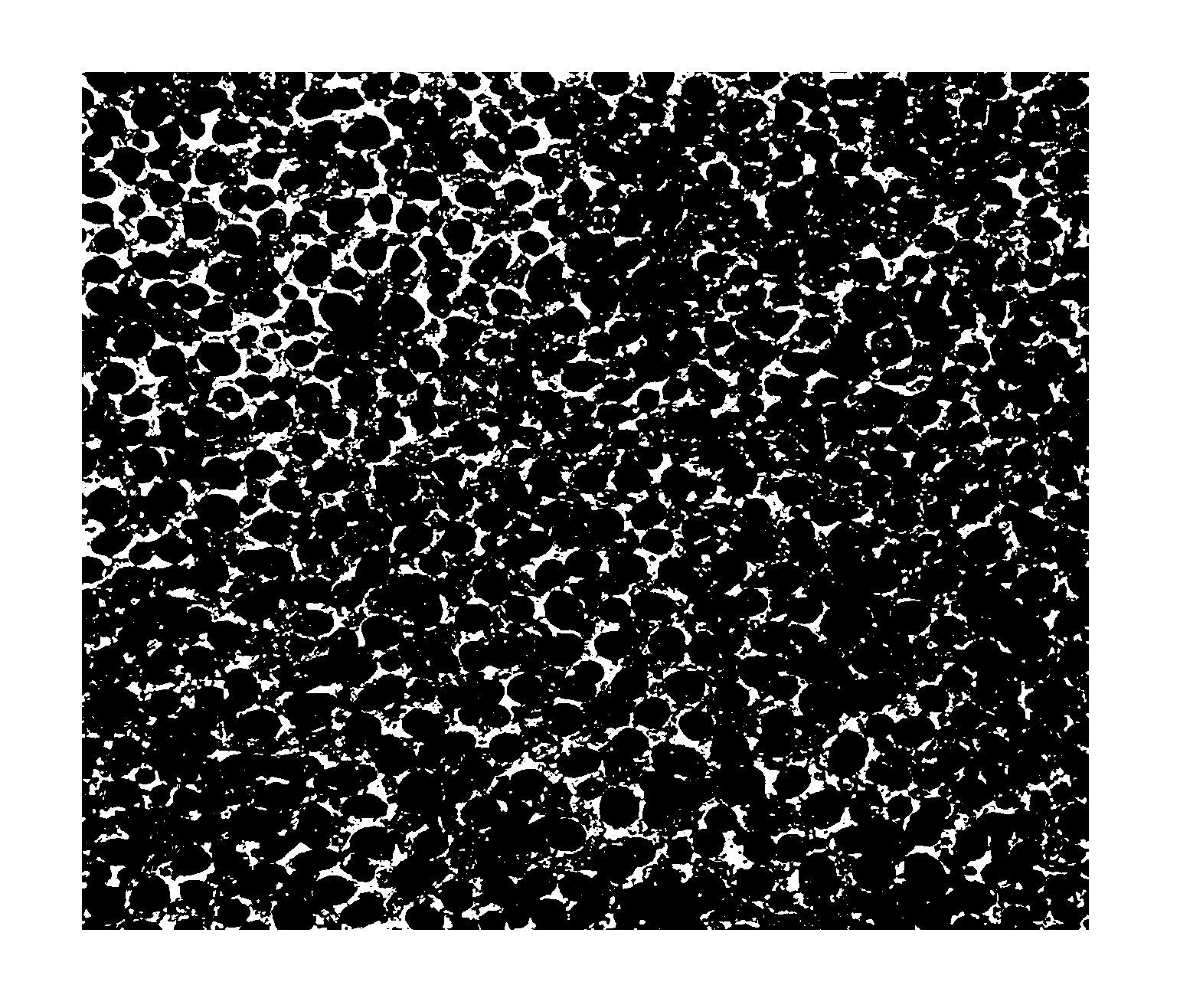

Floating body material and manufacturing technique thereof

The invention relates to a floating body material, in particular to a floating body material and a manufacturing technique thereof for an observation platform at the bottom of the sea. The floating body material comprises bisphenol A type epoxy resin, modified acrylonitrile-butadiene rubber latex, hollow glass microsphere, polyether amine, gamma-glycidoxypropyltrimethoxysilane, a silane coupling agent and polyvinyl alcohol fiber; and the floating body material comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 0-10 parts of modified acrylonitrile-butadiene rubber latex, 12-18 parts of hollow glass microsphere, 15-20 parts of polyether amine, 2-3 parts of gamma-glycidoxypropyltrimethoxysilane, 1-2 parts of silane coupling agent and 2 parts of polyvinyl alcohol fiber. The invention provides the floating body material and the manufacturing technique thereof for the observation platform at the bottom of the sea; and the observation platform adopting the floating body material can be soaked in the seawater for use in a long term.

Owner:SECOND INST OF OCEANOGRAPHY MNR

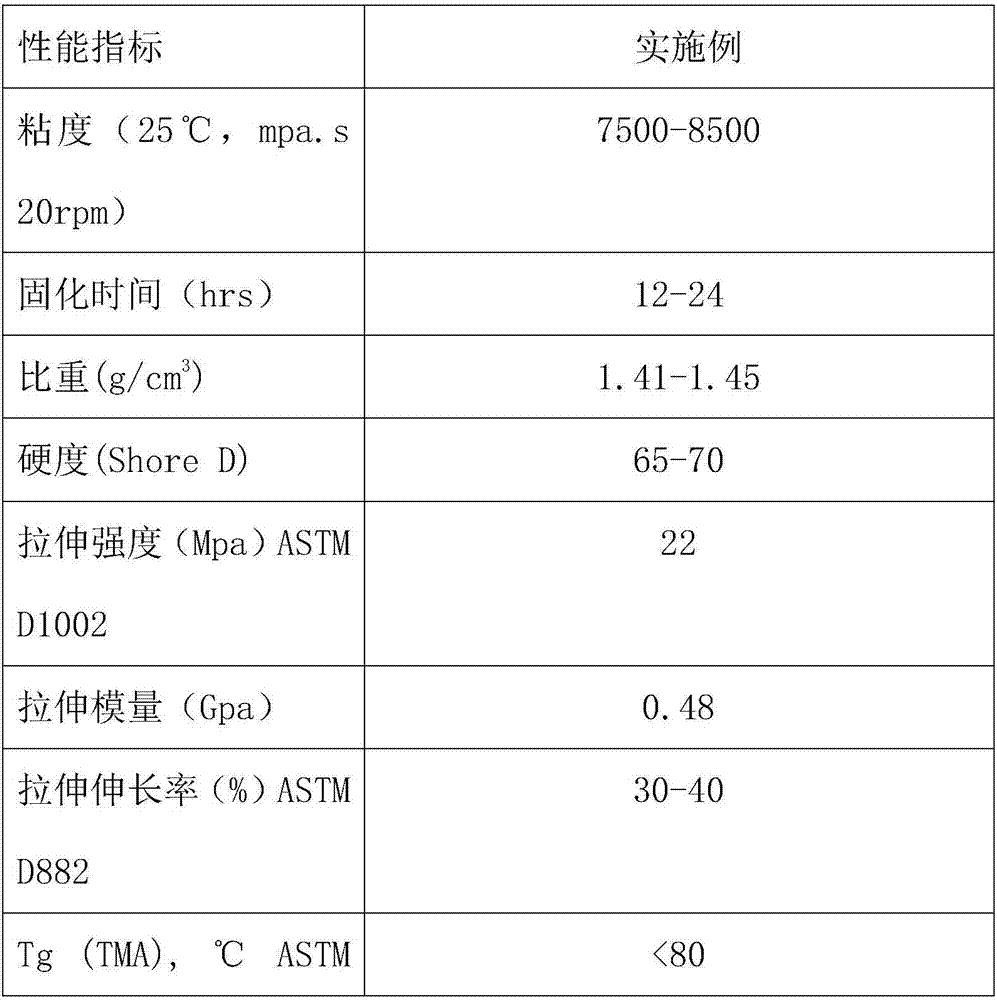

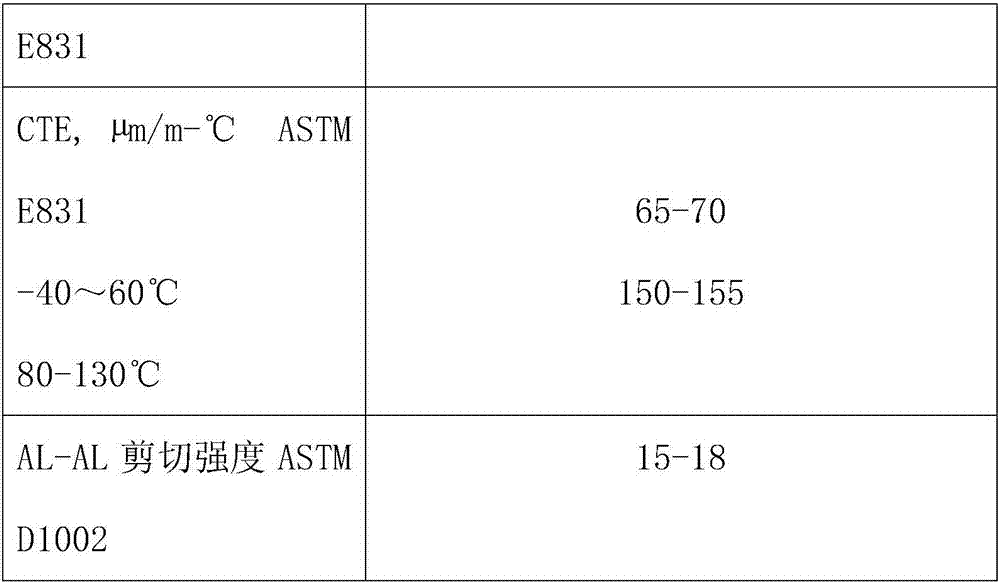

Photocurable 3D printing material as well as preparation method and application thereof

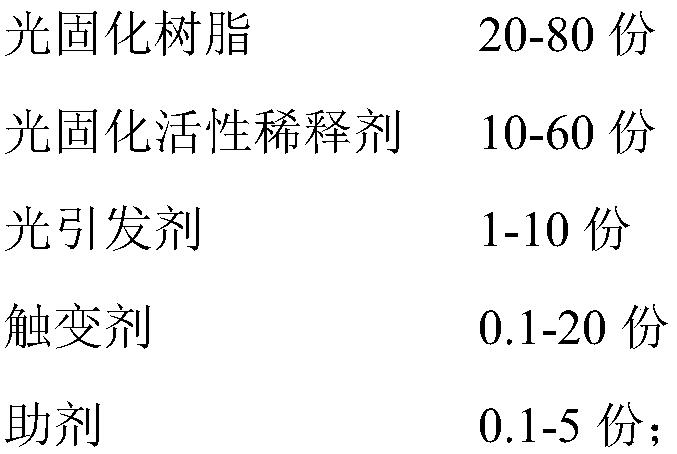

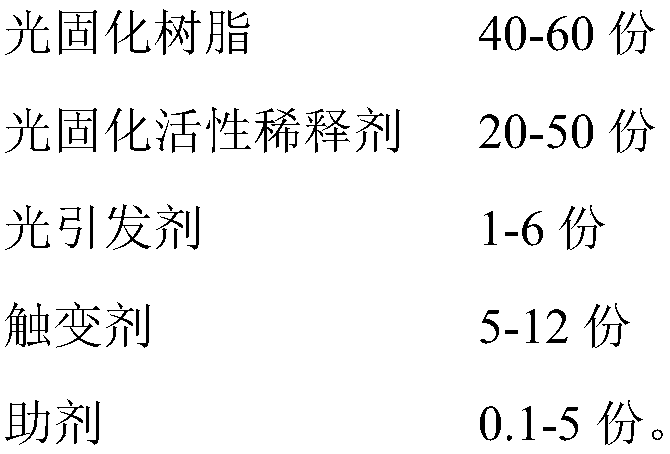

ActiveCN108410162AImprove thixotropyHigh forming precisionAdditive manufacturing apparatusSodium BentonitePolyamide

The invention relates to a photocurable 3D printing material as well as a preparation method and application thereof. The photocurable 3D printing material is prepared from the following raw materialcomponents in parts by weight: 20 to 80 parts of photocurable resin, 10 to 60 parts of photocurable active diluent, 1 to 10 parts of photo-initiator, 0.1 to 20 parts of thixotropic agent and 0.1 to 5parts of auxiliaries, wherein the thixotropic agent is at least one of attapulgite, montmorillonite, bentonite, fumed silica, polyamide wax and mica powder; the photocurable resin is at least one of aliphatic polyurethane and aliphatic epoxy resin. The photocurable 3D printing material has high thixotropy, and can be applied to the nozzle printing process of FDM (Fused Deposition Modeling). Compared with an SLA (Stereolithigraphy Apparatus), the photocurable 3D printing material has the advantages that the production cost of 3D printing products can be lowered effectively, high molding speed and high precision are achieved, complex-contour or large-sized 3D printing products can be made.

Owner:广州有得新材料科技有限公司

Synthesis technique of alkide resin modified epoxy vinyl esters resin

The invention relates to the technique to synthesize alkide resin modified epoxy vinyl resin. According to a certain compounding ratio, diphyenylol propane epoxy resin, organic monobasic unsaturated carboxylic acid, biatomic acid, catalyst agent and inhibitive substance are fed into a reactor to do ring cleavage esterification, then based on the existence of inhibitive substance, crosslinked monomer is added to deliquate and modified alkide resin and accelerating agent are added to accelerate in advance. The invention has the beneficial effects that: in ring cleavage esterification, the biatomic acid is employed as chain extender, and the alkide resin is added in the deliquating process (45 to 120 mg KOH / g hydroxyl value and 5 to 15 mgKOH / g acid value) to mix and modify, which largely strengths resin ductility, causes resin casting tension set is more than 8 percent, impact strength is above 20 KJ / m2; meanwhile largely reduces the resin solidification shrinkage ratio, improves the bonding strength, meets special compound material need as a result. The synthetic technique of the invention is simple, conformity with environmental protective and has good production stability without producing waste gas, waste water, and waste residue.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Epoxy resin pouring sealant and preparation method thereof

InactiveCN107163888AImprove crack resistanceImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAging resistance

The present invention relates to an epoxy resin pouring sealant and a preparation method thereof, the epoxy resin pouring sealant includes A and B components, the A component includes, by weight, 40-70 parts of bisphenol F epoxy resin, 20-50 parts of an active polyurethane toughening agent, 10-20 parts of an active diluent, 30-50 parts of an inorganic filler and 1-10 parts of an additive; the B component includes, by weight, 40-70 parts of modified alicyclic amine; 30-60 parts of polyetheramine and 3-10 parts of a promoter. The weight ratio of A to B is 2-4:1. The epoxy resin pouring sealant has better aging resistance and strong resistance to cold and hot impact, and meets the high temperature and cold impact requirement of electronic sealing.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

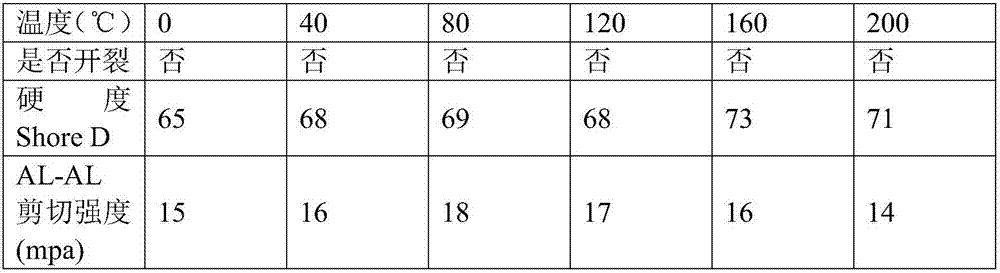

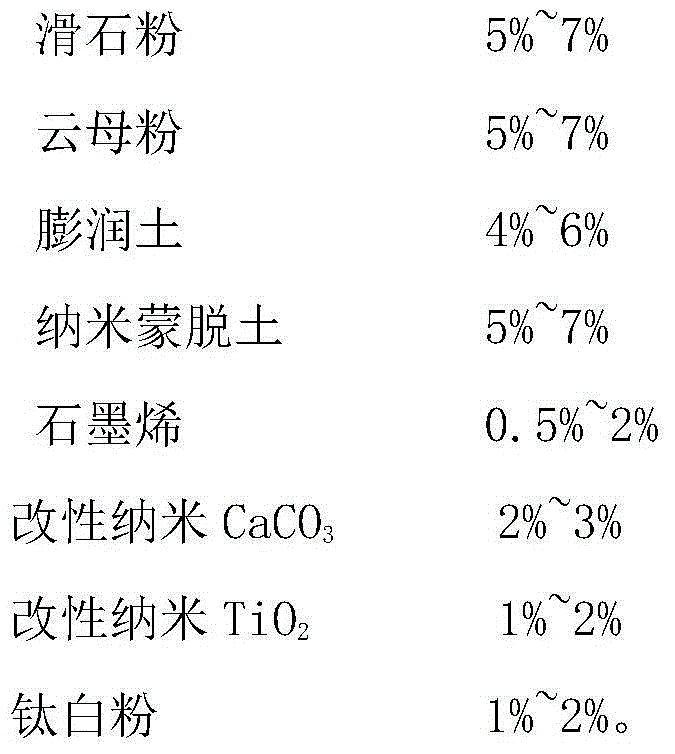

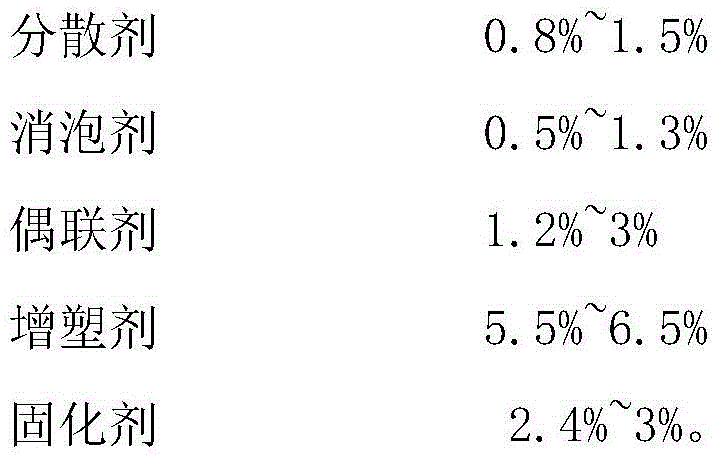

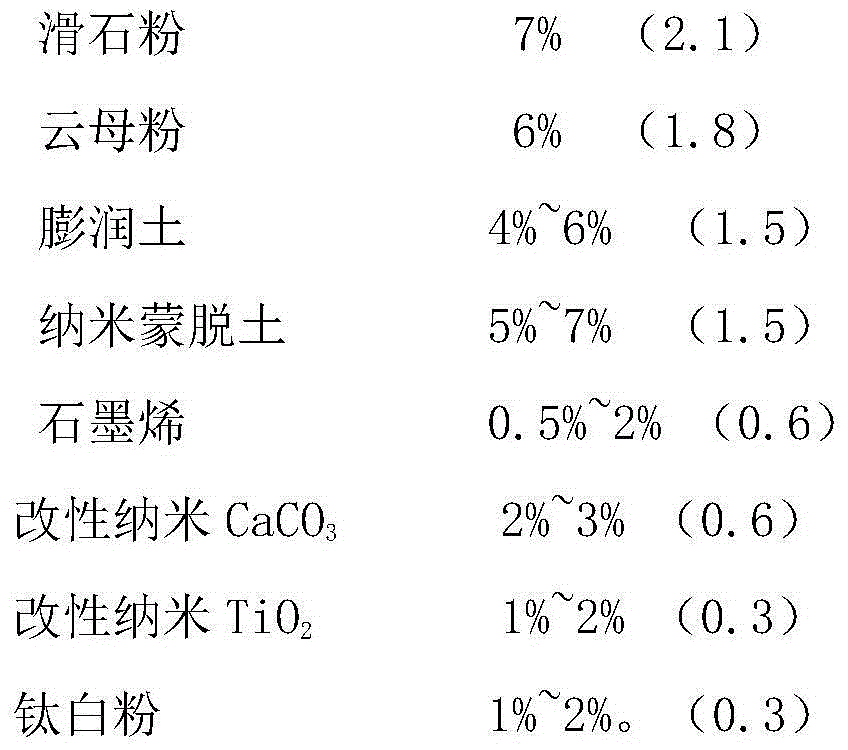

Epoxy resin coating in marine steel pipe 3PE anticorrosive coating and preparation method thereof

InactiveCN104449249AReduce dosageAvoid crackingAnti-corrosive paintsEpoxy resin coatingsEpoxyShrinkage rate

The invention discloses an epoxy resin coating in a marine steel pipe 3PE anticorrosive coating and a preparation method thereof. The epoxy resin anticorrosive coating comprises the following components in percentage by weight: 55-65 percent of epoxy resin, 23.5-36 percent of filler and pigments and 10.4-15.3 percent of aids, wherein the epoxy resin comprises the following components in percentage by weight: 39-47 percent of E-12 epoxy resin and 16-23 percent of novolac epoxy resin. Talcum powder, mica powder, bentonite and titanium dioxide are properly added into the epoxy resin to serve as partial fillers. The use amount of the resin can be relatively reduced, the cost is reduced, the physical and mechanical properties can be improved; particularly, the elasticity modulus is increased, the cure shrinkage rate is reduced, the seawater impact resistance is increased, and the seawater resistance is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of alkali-resistant bisphenol A type unsaturated polyester resin

ActiveCN102115540AThe synthesis process is simpleMeet the special needs of manufacturingAlcoholOrganic synthesis

The invention relates to a preparation method of alkali-resistant bisphenol A type unsaturated polyester resin, which belongs to the technical field of organic synthesis. The preparation method comprises the following steps of: adding 1-8 percent of dihydric alcohol, 29-40 percent of bisphenol A derivative and 12-20 percent of unsaturated dibasic acid into a reaction kettle, gradually raising the temperature to 170-190 DEG C, keeping the temperature of a fracture head below 105 DEG C and undergoing a reaction until the acid value is between 40 mgKOH / g and 50 mgKOH / g, wherein the total molar ratio of acid to alcohol is (1.09-1.02):1.0; cooling to 110-130 DEG C and adding 2-8 percent of bisphenol A type unsaturated polyester resin; controlling the temperature between 100 DEG C and 130 DEG C, undergoing a reaction until the acid value is between 20 mgKOH / g and 35 mgKOH / g, adding a polymerization inhibitor and stirring uniformly; and finally cooling to 100 DEG C and adding 38-45 percent of crosslinkable monomer. The method has the advantages that: a bisphenol A gene is introduced into the unsaturated polyester resin, and an end is sealed by bisphenol A type epoxy resin, so that the alkali resistance and the temperature resistance of the unsaturated polyester resin are remarkably enhanced; meanwhile, cure shrinkage is lowered and bonding force with a substrate is enhanced; and high product stability and a simple synthesis process are achieved.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

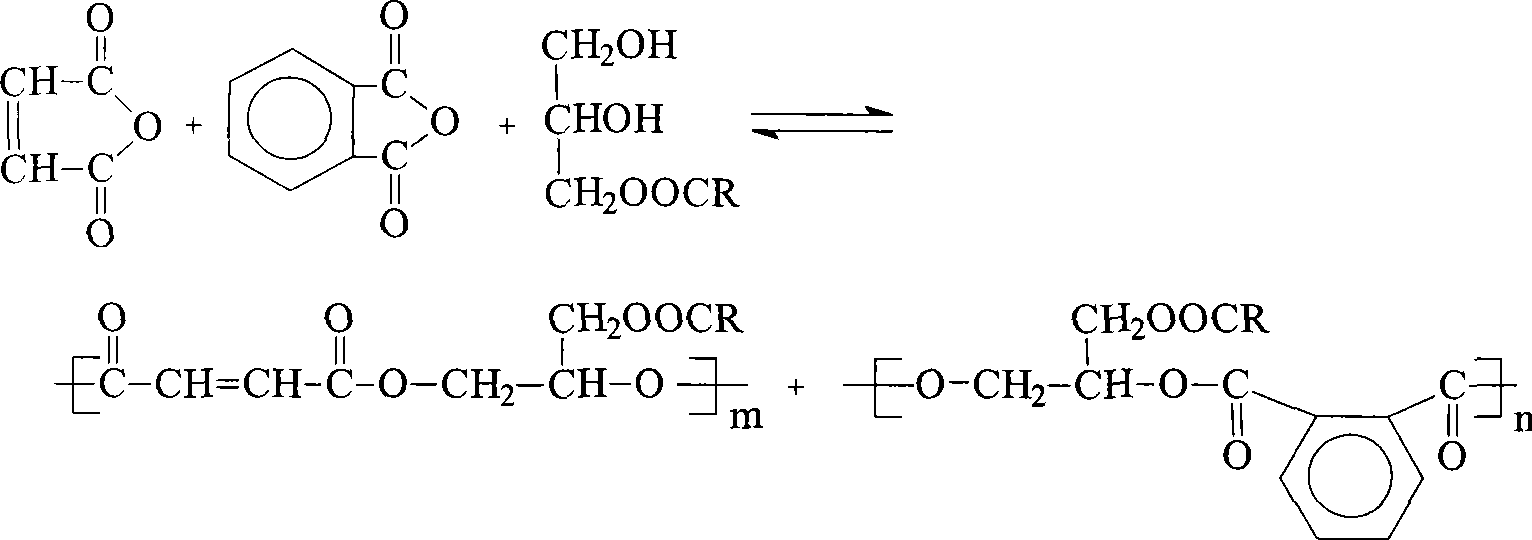

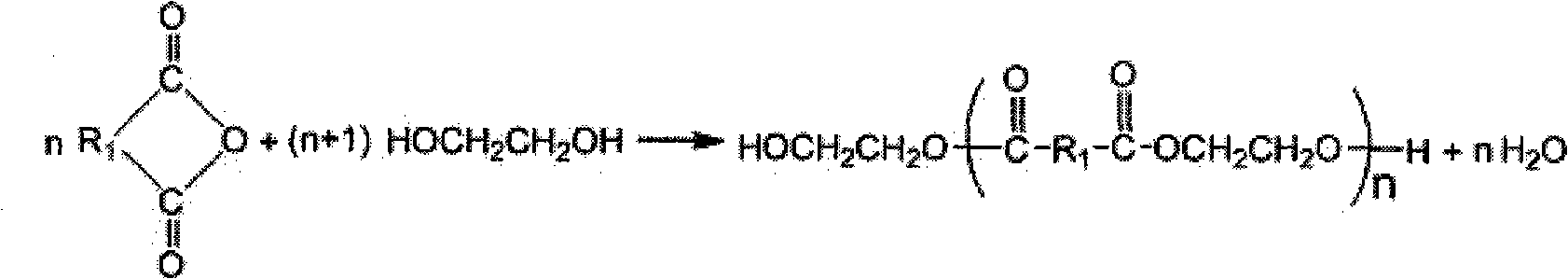

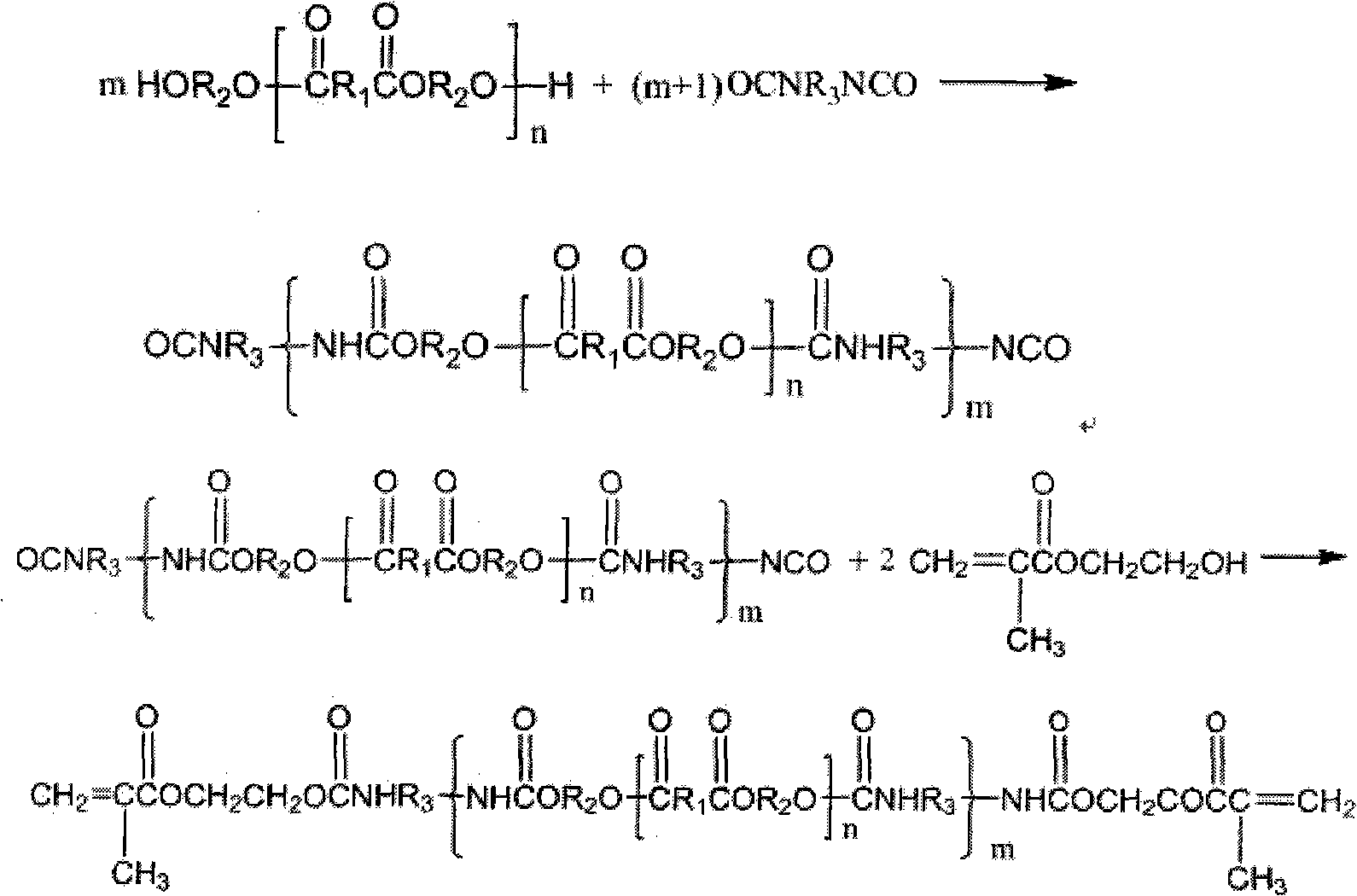

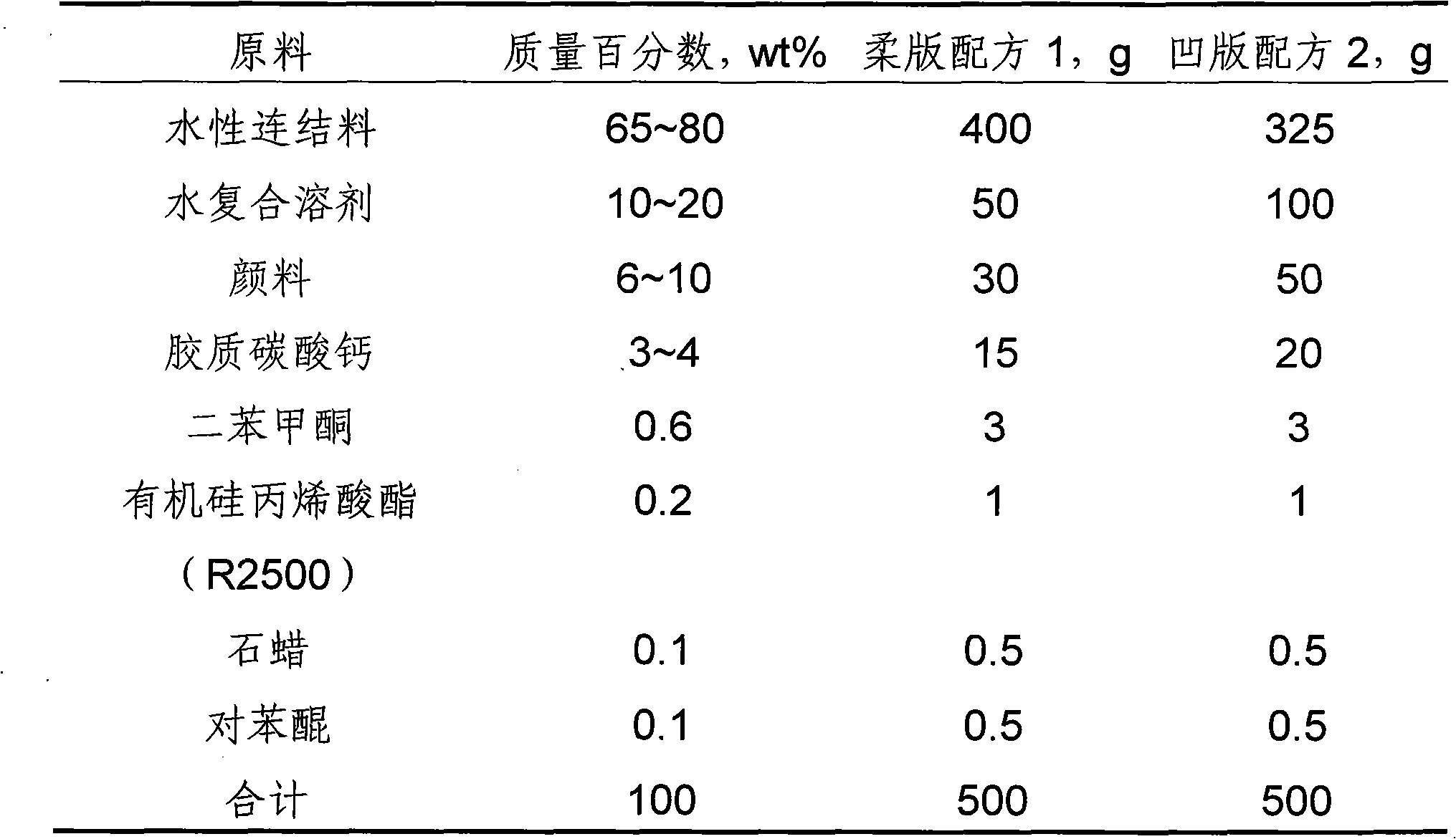

Preparation method of water-based UV ink (ultraviolet) of unsaturated polyester polyurethane segmented copolymer

The invention relates to a preparation method of water-based UV ink (ultraviolet) of unsaturated polyester polyurethane segmented copolymer. The preparation method includes the steps as follows; dihydric alcohol, maleic anhydride and phthalic anhydride are adopted to generate unsaturated polyester oligomer of hydroxyl end group by progressive polycondensation; after progressive addition polymerization with reactive diluent as the solvent, the unsaturated oligomer, polyethylene glycol ether and diisocyanate are subjected to chain extension with water functional monomer to generate unsaturatedpolyester polyurethane segmented prepolymer solution of isocyanate end group and with hydrophilic function; and after the prepolymer is end-sealed with methacrylic acid-beta hydroxyethyl, monoethanolamine is taken as neutralizer that is dispersed in water while stirred to obtain water-based joining material of unsaturated polyester polyurethane segmented prepolymer. The water-based joining material and the pigment filler, the photosensitizer and the assistant are formulated to prepare water-based UV ink of unsaturated polyester polyurethane segmented prepolymer.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

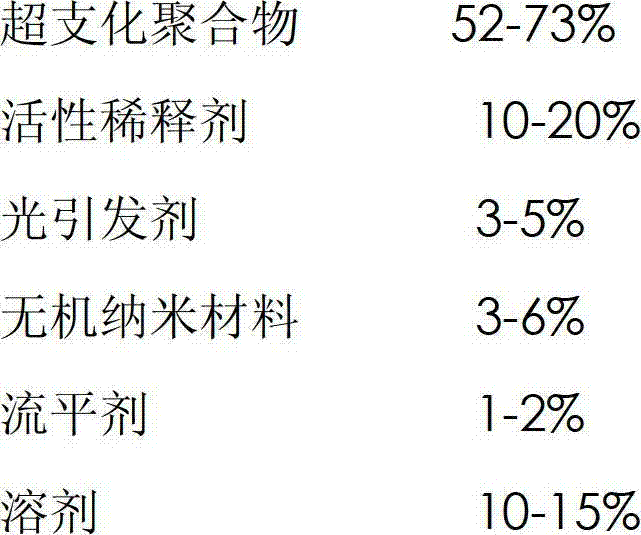

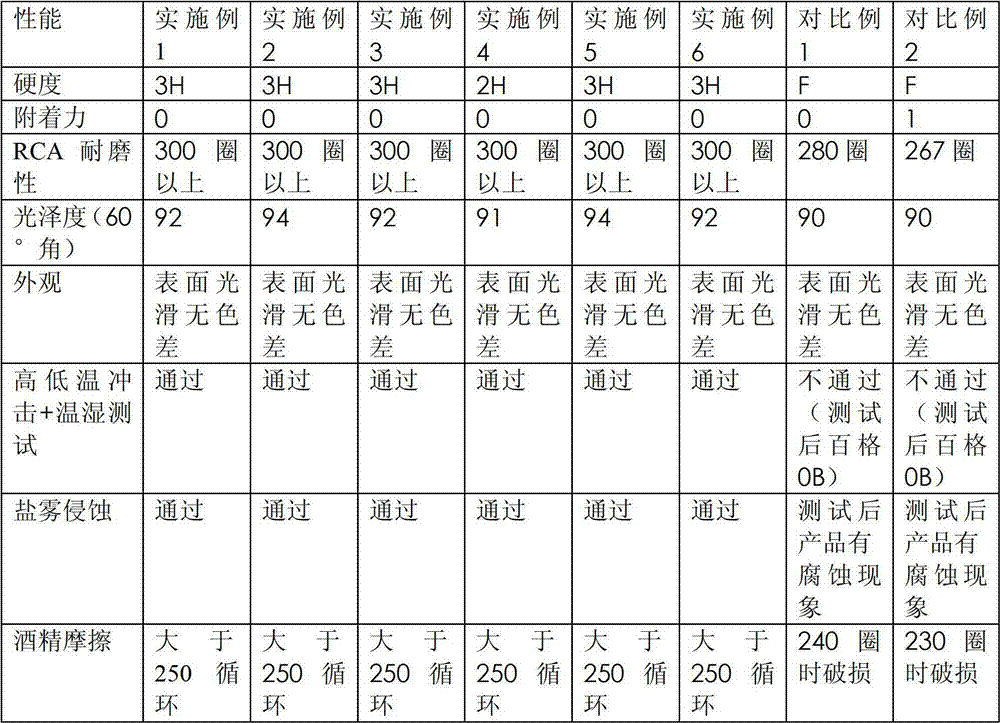

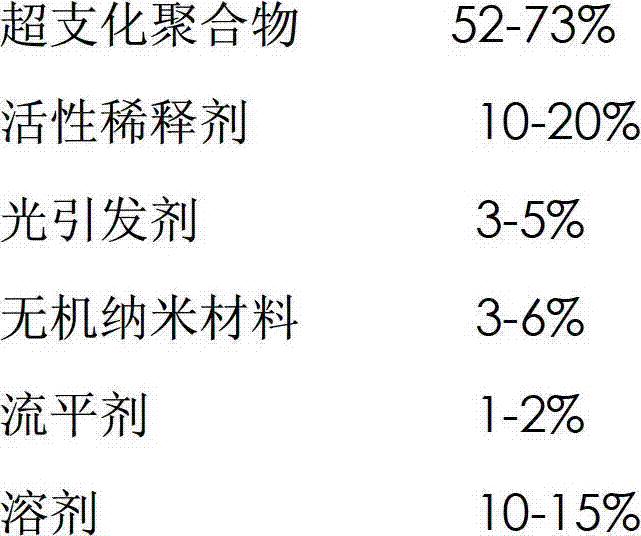

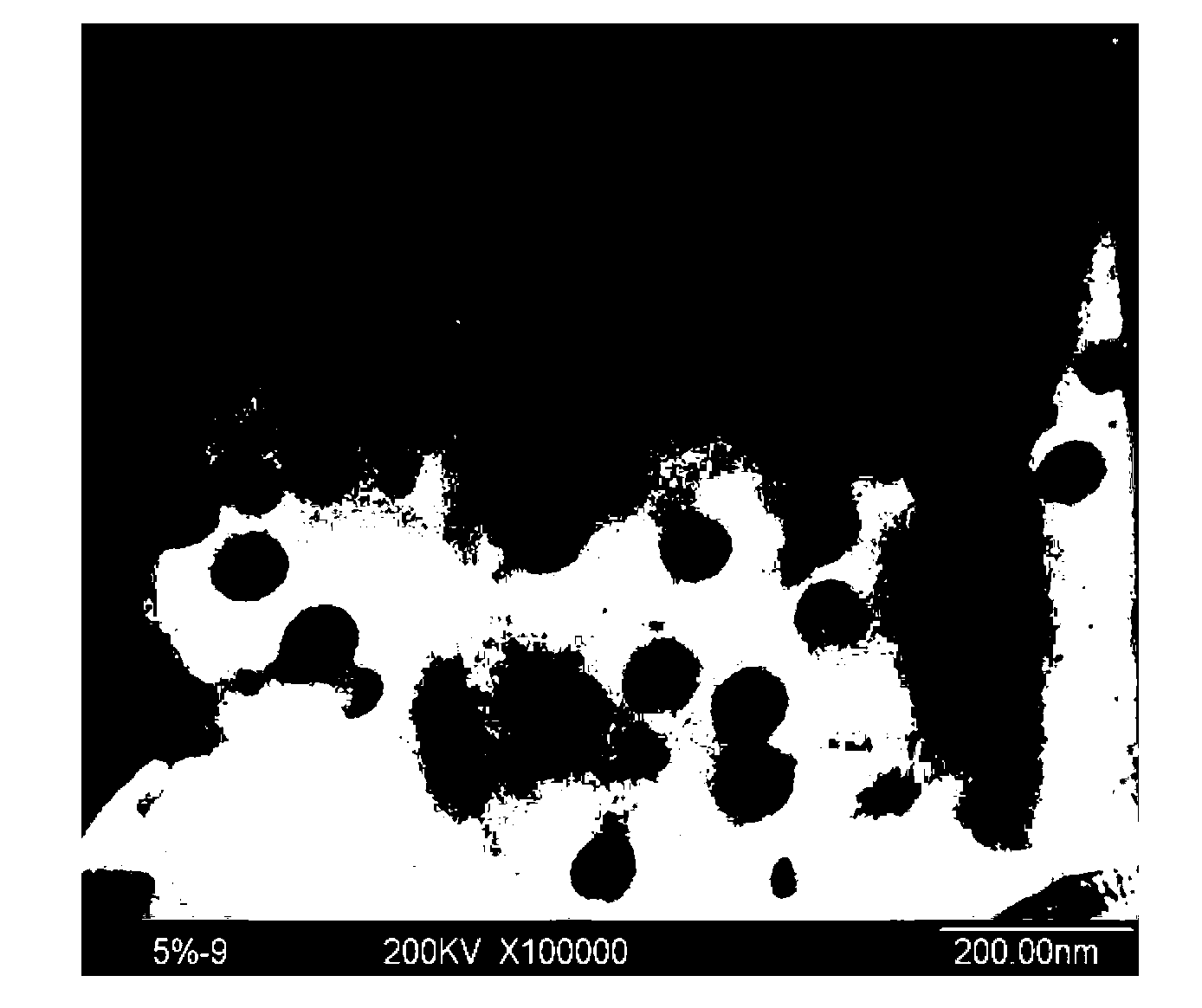

Ultraviolet-curing light oil for plastic top-coat and preparation method thereof

InactiveCN102775889AGood flexibilityGood film formingPolyurea/polyurethane coatingsPolyester coatingsSolventCrusher

The invention discloses ultraviolet-curing light oil for plastic top-coat and a preparation method of the light oil. The ultraviolet-curing light oil is prepared from the following components by weight: 52-73% of hyperbranched polymer, 10-20% of reactive diluent, 3-5% of photoinitiator, 3-6% of inorganic nanomaterial, 1-2% of flatting agent and 10-15% of solvent. The preparation method comprises the steps of: uniformly dispersing modified nano SiO2 (silicon dioxide) into the reactive diluent in advance by adopting a high-speed shear dispersing machine and an ultrasonic cell crusher in preparation, adding hyperbranched polyester acrylate, the initiator, the flatting agent and the solvent, fully mixing and agitating the mixture uniformly to obtain the ultraviolet-curing light oil. According to the invention, the hyperbranched polymer is used as an organic component; the nanomaterial is used as an inorganic component, and the advantages of high hardness, durability, heat resistance and weather fastness of the inorganic nanomaterials as well as low viscosity and compatibility with the inorganic nanoparticles of the hyperbranched polymer are comprehensively utilized.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing organic nanometer rubber particle enhanced epoxy resin self-repairing microcapsule

ActiveCN102698669AUniform particle size distributionGood dispersionMicroballoon preparationMicrocapsule preparationEpoxyMechanical property

A method for preparing organic nanometer rubber particle enhanced epoxy resin self-repairing microcapsule includes: (1) dispersing organic nanometer rubber particles into mixture of epoxy resin and diluent of the epoxy resin, evenly stirring, and performing grinding treating through a three-roller grinder to obtain stably dispersed nanophase enhaced epoxy resin; (2) dissolving emulsifier in deionized water to obtain aqueous solution of the emulsifier; and (3) mixing urea, ammonium chloride and resorcinol, adding the mixture into the aqueous solution of the emulsifier, stirring the mixture until the mixture is fully dissolved to obtain a mixed liquor, regulating the pH value of the mixed liquor to be 3.5, adding nanophase enhanced epoxy resins into the mixed liquor, performing emulsification, dropwise adding formaldehyde solution with the concentration of 37wt% into the emulsified liquid, heating the mixture to be 50 DEG C to 60 DEG C to react for 4 hours, filtering, cleaning a filter cake for several times through absolute ethyl alcohol or acetone, and drying to obtain powder. The microcapsule manufactured by the method can further improve solidification toughness of repairing agents and improve mechanical property of composite materials.

Owner:北京睿曼科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com