UV solidified liquid optical cement and preparation method and application thereof

An optical glue, liquid technology, applied in the direction of adhesives, non-polymer organic compound adhesives, film/flake adhesives, etc. Effects of ductility, high adhesion, low cure shrinkage

Inactive Publication Date: 2016-01-06

SOUTH CHINA AGRI UNIV

View PDF4 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the use of optical glue involves two bonded interfaces, the stress and volume defects caused by volume shrinkage during the curing process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

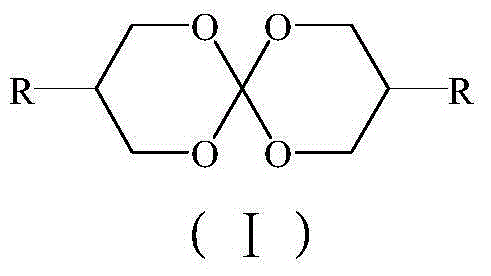

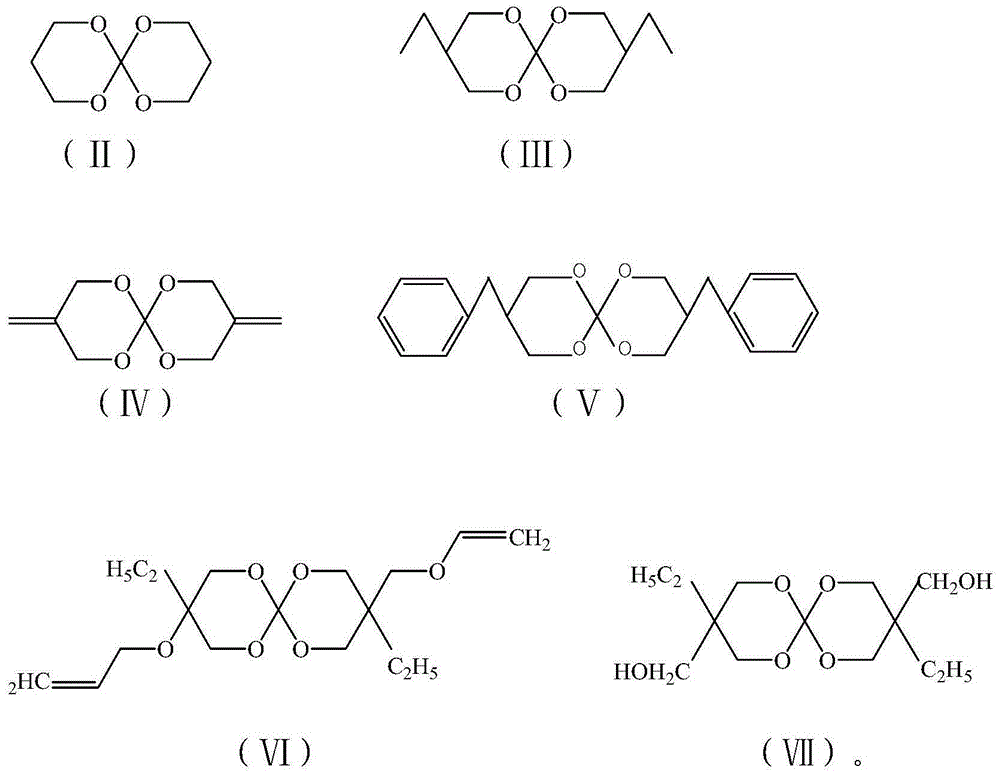

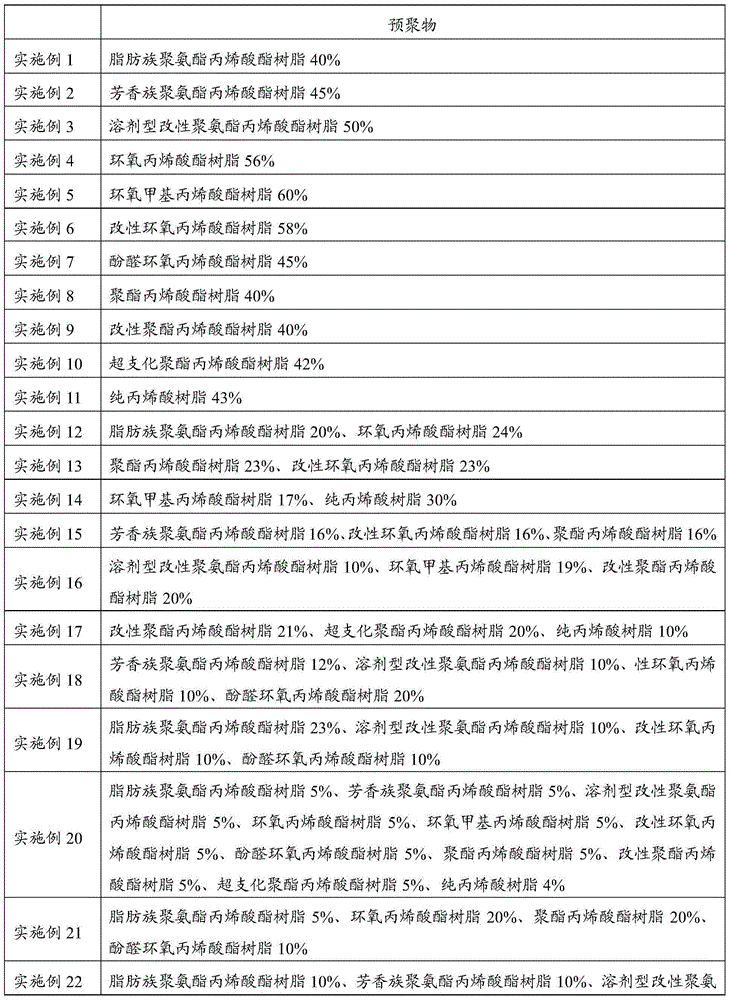

The invention discloses UV solidified liquid optical cement. The UV solidified liquid optical cement is prepared from, by weight, 40%-60% of prepolymer, 5%-25% of expanding monomer, 15%-30% of reactive diluent, 1%-8% of photoinitiator, 5%-20% of plasticizer, 5%-20% of coupling reagents and 0.5%-3% of auxiliaries. The invention further discloses a preparation method and application of the UV solidified liquid optical cement. The UV solidified liquid optical cement has a low curing shrinkage rate, high light transparency, high binding force and rapid curing capacity, an obtained solidified layer has high ductility and relatively-low hardness, and the UV solidified liquid optical cement can be widely used for binding optical elements, for example, various electronic elements including capacitive screens, display lenses and the like.

Description

technical field [0001] The invention relates to the field of adhesives, in particular to a UV-curable liquid optical adhesive. The invention also relates to the preparation method and application of the optical glue. Background technique [0002] UV curable liquid optical adhesive has achieved rapid development since its inception. Compared with traditional tapes, UV curable liquid optical adhesive has good leveling properties, low odor, fast curing speed, high bonding strength, low production energy consumption, and excellent curing process. The advantages of automatic operation and so on. [0003] At present, most (95%) of UV-curable liquid optical adhesives are still acrylate systems. The curing mechanism of this system is free radical polymerization, which is characterized by a large curing shrinkage rate, generally above 5%. Since the use of optical glue involves two bonded interfaces, the stress and volume defects caused by volume shrinkage during the curing process...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J175/14C09J163/10C09J167/06C09J4/02C09J4/06C09J11/06C09J11/08C09J7/02

Inventor 杨卓鸿黄家健袁腾周健周闯

Owner SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com