Preparation method of water-based UV ink (ultraviolet) of unsaturated polyester polyurethane segmented copolymer

A polyester polyurethane and block copolymer technology, applied in inks, household appliances, applications, etc., can solve the problems of reducing mechanical properties, reducing curing shrinkage, etc., achieving small curing shrinkage, good printability, and low VOC emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

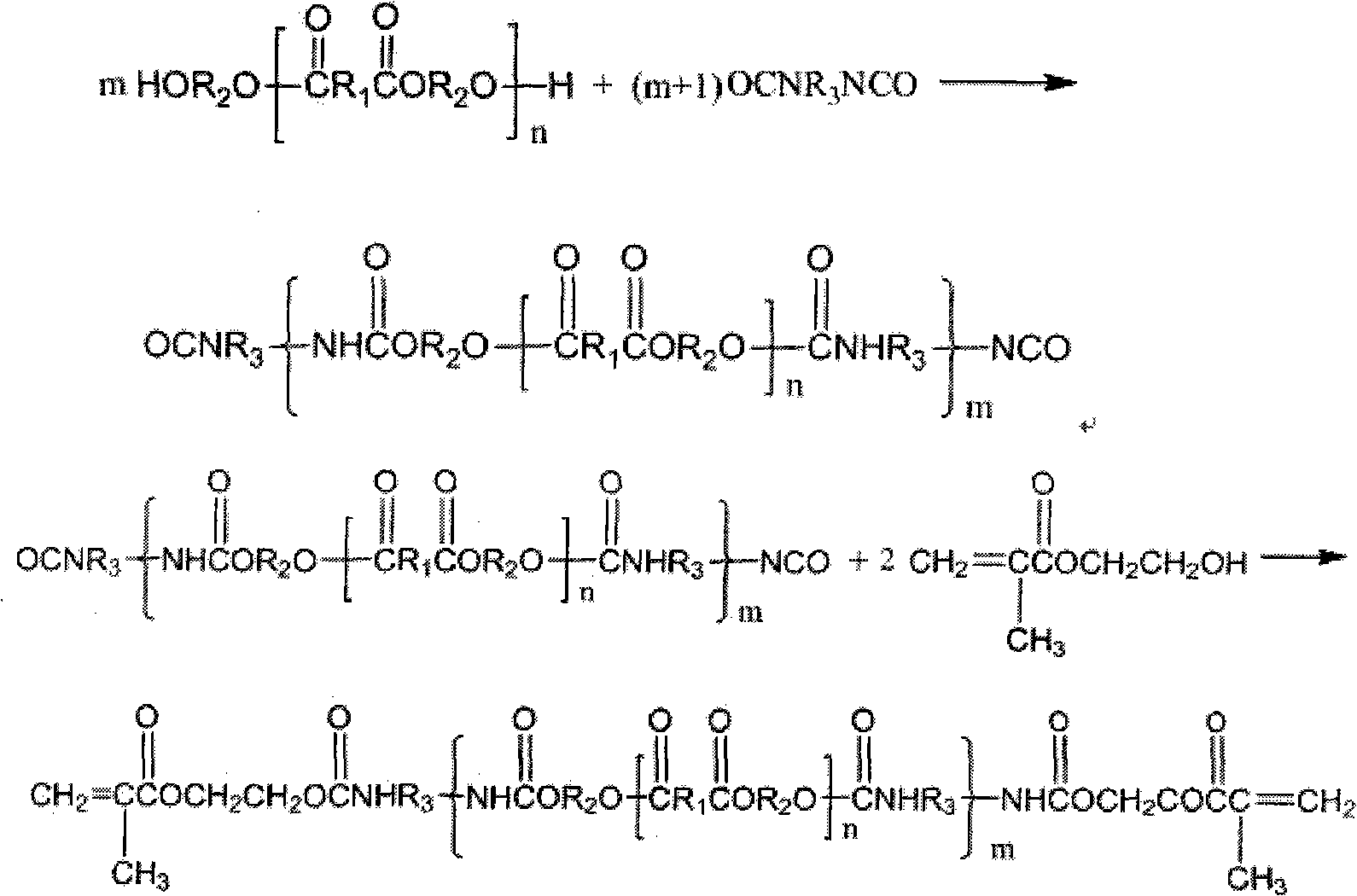

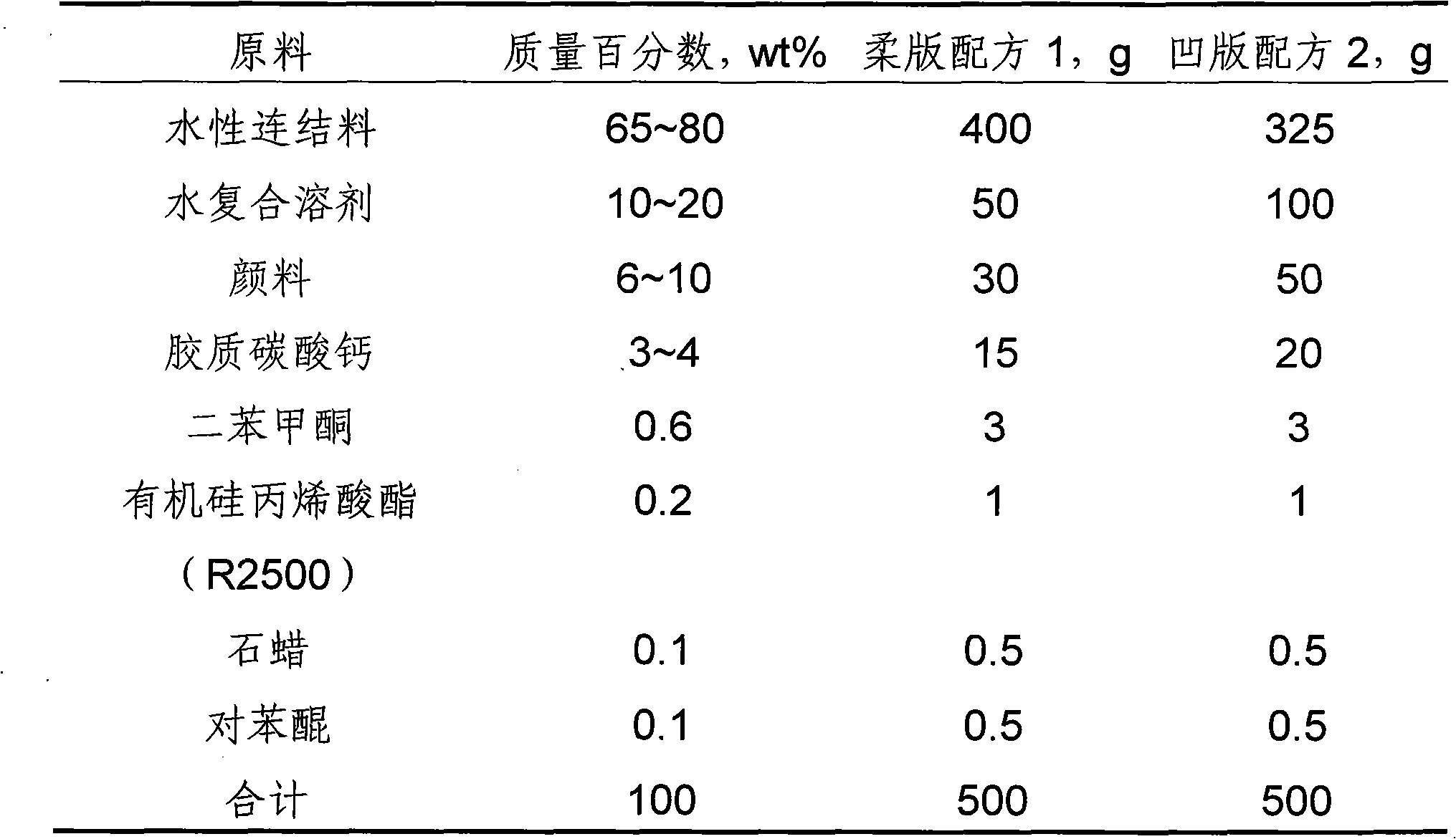

[0017] The present invention is the preparation method of unsaturated polyester polyurethane block copolymer aqueous UV printing ink, and its steps are:

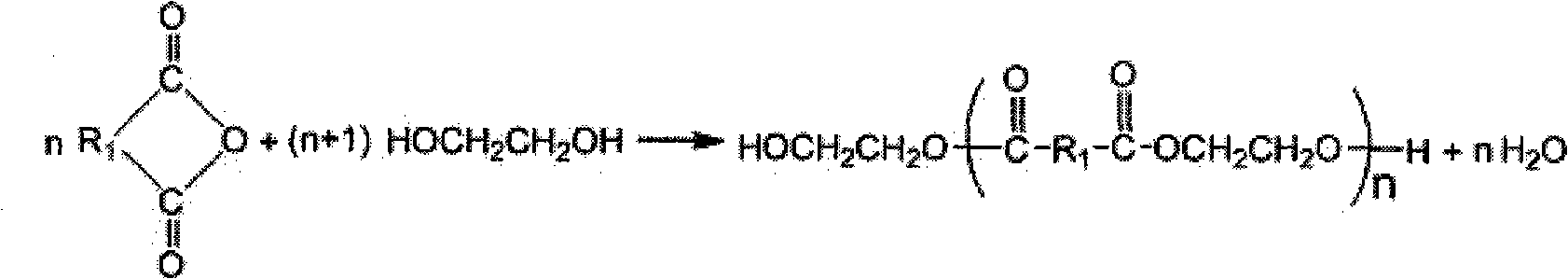

[0018] (1) Add the measured maleic anhydride, phthalic anhydride, ethylene glycol, xylene, and catalysts into the reaction vessel equipped with electric stirring, water separator, thermometer, and electric heating mantle in turn. The dibasic anhydride is phthalic anhydride. Saturated acid anhydride, maleic anhydride is an unsaturated acid anhydride, the molar ratio of phthalic anhydride to maleic anhydride is 2:1 to 3:1, the excess molar percentage of hydroxyl is 50% to 100%, and the number average molecular weight of the oligomer is 500 to 1000 ;Heat until the solid dissolves, start stirring, and raise the temperature to 150°C, react for 2 hours, raise the temperature to 190±2°C and react for 1 hour, cool down to 150°C and add the measured diol, vacuumize until the hydroxyl value meets the requirements, Evaporate the solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com