Gravure alcohol ester plastic in-print environment-friendly ink

A plastic and environmentally friendly technology, applied in ink, household utensils, applications, etc., can solve problems such as substandard adhesion fastness, poor film-forming performance, poor light resistance and aging resistance, and achieve good light resistance and outdoor resistance Aging resistance and other excellent properties, good blade adaptability, and excellent film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

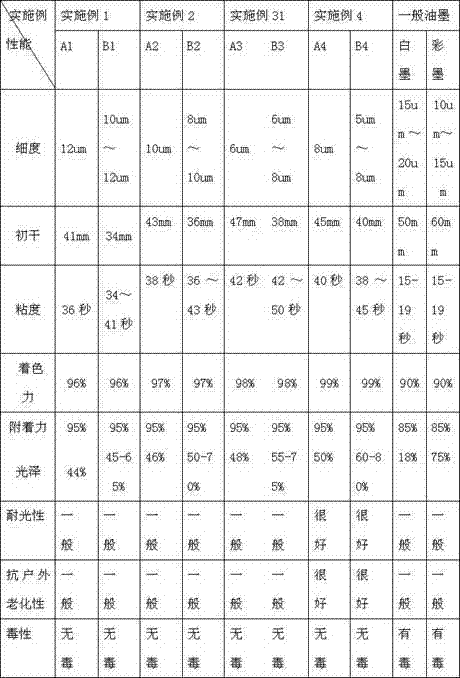

Embodiment 1

[0056] Embodiment 1 Preparation of white ink A1 and color ink B1

[0057] Weigh 24g of polyurethane resin, 12g of ternary vinegar resin, 2.5g of aldehyde and ketone resin, 1g of phenolic resin, 0.3g of dispersant, 0.3g of defoamer, 0.3g of leveling agent, 0.8g of antistatic agent, adhesion promoter Add 1.5g of whitening agent, 0.05g of whitening agent, 0.05g of wax powder, 20g of titanium dioxide, and 20g of diluent into the material barrel for mixing, stirring and dispersing. The mixer adopts FS series high-speed disperser, disperses at low speed for 3-5 minutes, and then disperses at high speed for 10-15 minutes. First low speed and then high speed can make the material disperse more evenly. The mixer should be cleaned very clean, and attention should be paid to controlling viscosity, fineness, tinting strength, adhesion, etc. when mixing.

[0058] After the mixture is evenly stirred, the material is ground. The particle size of the material after grinding is 5um-6um. Due ...

Embodiment 2

[0065] The preparation of embodiment 2 white ink A2 and colored ink B2

[0066] Weigh 26g of polyurethane resin, 14g of ternary vinegar resin, 3.5g of aldehyde and ketone resin, 2g of phenolic resin, 0.5g of dispersant, 0.5g of defoamer, 0.5g of leveling agent, 1g of antistatic agent, adhesion promoter 2g, 0.1g of whitening agent, 0.1g of wax powder, 26g of titanium dioxide, and 23.8g of diluent were put into the material bucket for mixing, stirring and dispersing. The mixer adopts FS series high-speed disperser, disperses at low speed for 3-5 minutes, and then disperses at high speed for 10-15 minutes.

[0067] After the mixture is evenly stirred, the material is ground. The particle size of the material after grinding is 5um-6um. Due to the high temperature during grinding, circulating water is needed to cool down. The printing ink horizontal sand mill with application number CN201120238526.5 is used for grinding. Machine, through the cooling water in the grinding cylinder,...

Embodiment 3

[0074] Embodiment 3 The preparation of white ink A3 and color ink B3

[0075] Weigh 28g of polyurethane resin, 16g of ternary vinegar resin, 4.5g of aldehyde and ketone resin, 3g of phenolic resin, 0.7g of dispersant, 0.7g of defoamer, 0.7g of leveling agent, 1.2g of antistatic agent, adhesion promoter Put 2.5g of whitening agent, 0.15g of whitening agent, 0.15g of wax powder, 30g of titanium dioxide, and 25g of diluent into the material bucket for mixing, stirring and dispersing. The mixer adopts FS series high-speed disperser, disperses at low speed for 3-5 minutes, and then disperses at high speed for 10-15 minutes. First low speed and then high speed can make the material disperse more evenly. The mixer should be cleaned very clean, and attention should be paid to controlling viscosity, fineness, tinting strength, adhesion, etc. when mixing.

[0076] After the mixture is evenly stirred, the material is ground. The particle size of the material after grinding is 5um-6um. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com