Patents

Literature

206results about How to "Solve Adhesion Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

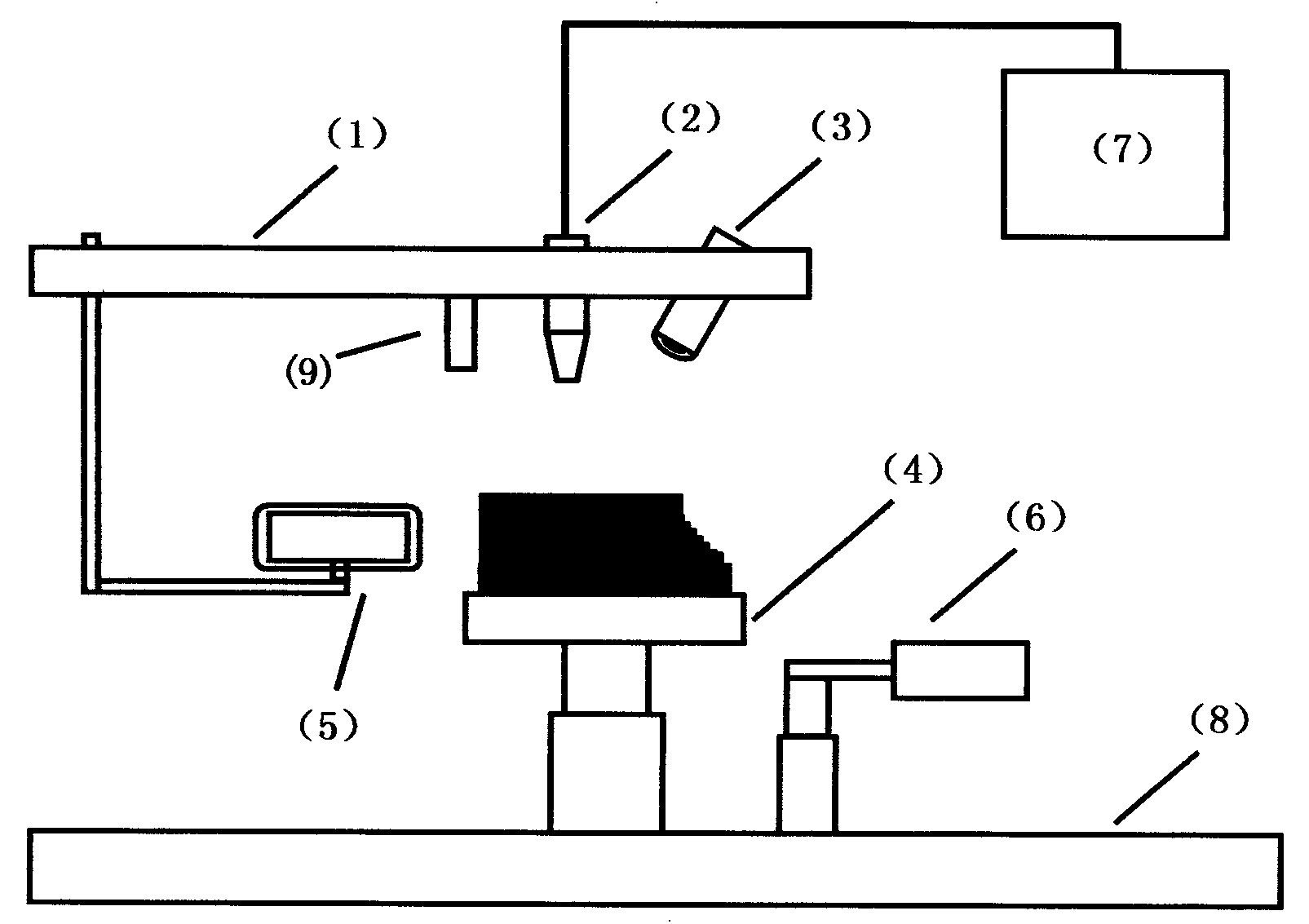

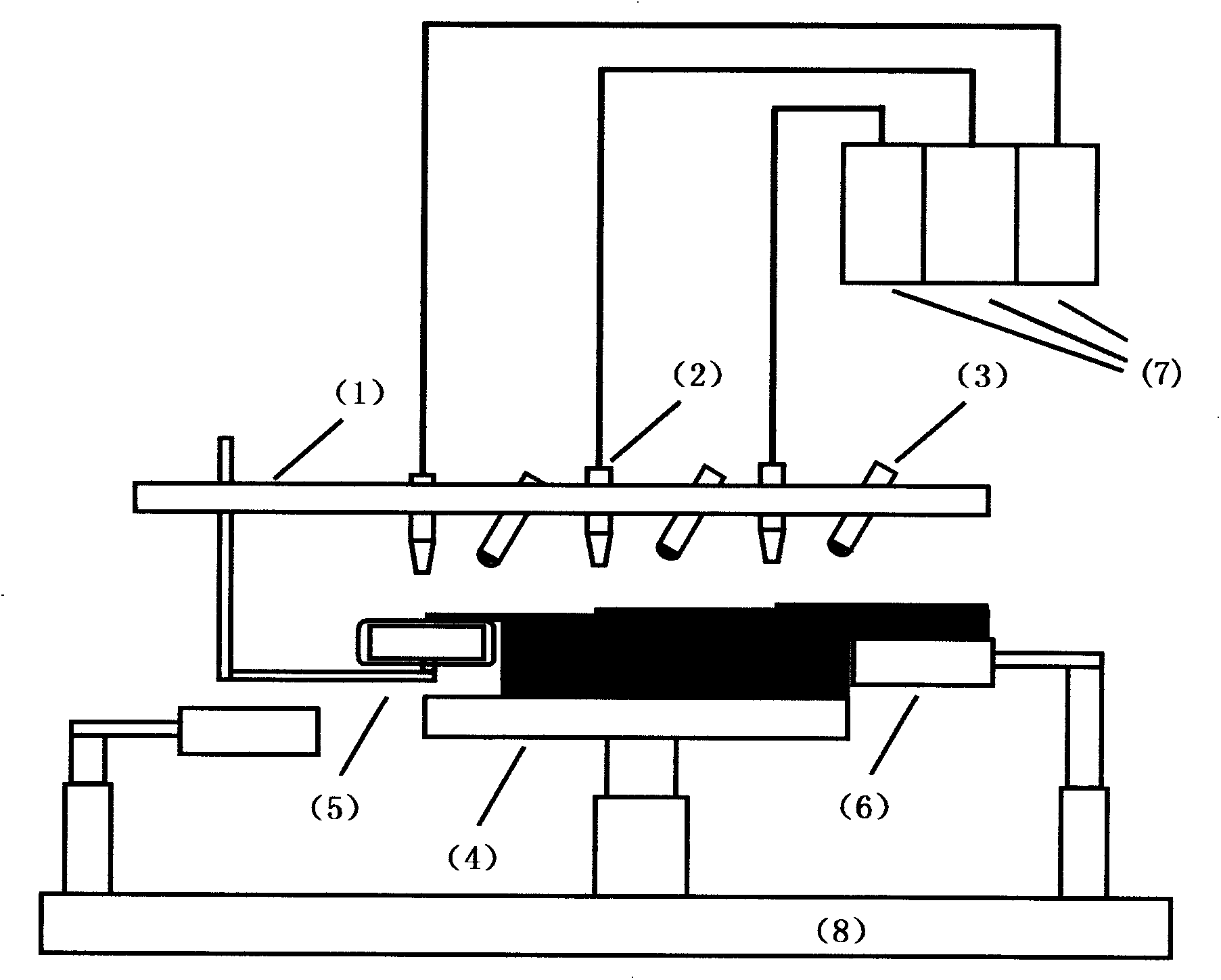

Three-dimensional (3D) printer and method for preparing three-dimensional products by use of 3D printer

The invention discloses a three-dimensional (3D) printer, the 3D printer comprises an X-Y working platform, spray heads installed on the X-Y working platform, light-emitting diode (LED) ultraviolet (UV) light sources, moving supporting frames, a base, fixed supporting frames, a supporting platform and UV resin material-feeding units, wherein the fixed supporting frames and the supporting platform are installed on the base, and the spray heads are connected with the UV resin material-feeding units. Through use of the 3D printer, one-way single-layer printing and one-way multi-layer printing can be carried out, multi-material printing, color printing, coating printing and other effects can be realized, and the printing efficiency is improved by times compared with that of the traditional 3D printers.

Owner:徐州泰铭电气有限公司

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Steel rope grease with high dropping point and preparation method of steel rope grease

InactiveCN102618371AAlleviate lubrication and corrosion problemsExtended service lifeLubricant compositionAntioxidantBase oil

The invention relates to steel rope grease with high dropping point and a preparation method of the steel rope grease. The steel rope grease with high dropping point comprises the following compositions in percentage by weight: 65%-85% of base oil, 5%-20% of thickening agent, 2%-15% of adhesion agent, 1%-6% of rust inhibitor, 0-5% of antioxidant, 0-5% of polar additive and 0.5%-6% of solid lubricant. According to the steel rope grease, the dropping point of the steel rope grease is high (no less than 100 DEG C), the adhesion property is good (a slump test is qualified), the low temperature performance is good, superior adhesion property and oil film forming capacity are realized, and comprehensive performances such as waterproofing, corrosion resistance, oxidation resistance and wear resistance are also realized; and high-quality steel rope grease products required by the imported steel rope products can be partially replaced by the steel rope grease, so that the production cost is reduced for enterprises, the lubrication and corrosion resistant problems of the steel rope can be relieved, and the service life of the steel rope can be greatly prolonged.

Owner:HENAN COAL SCI RES INST

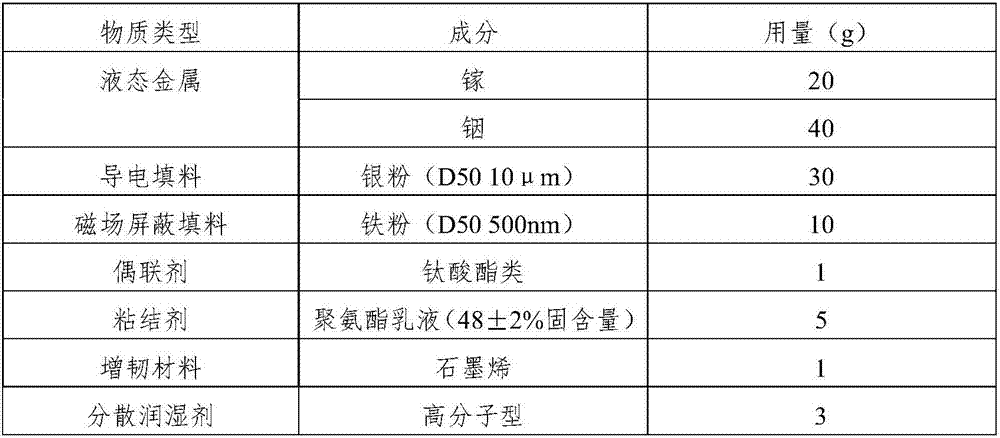

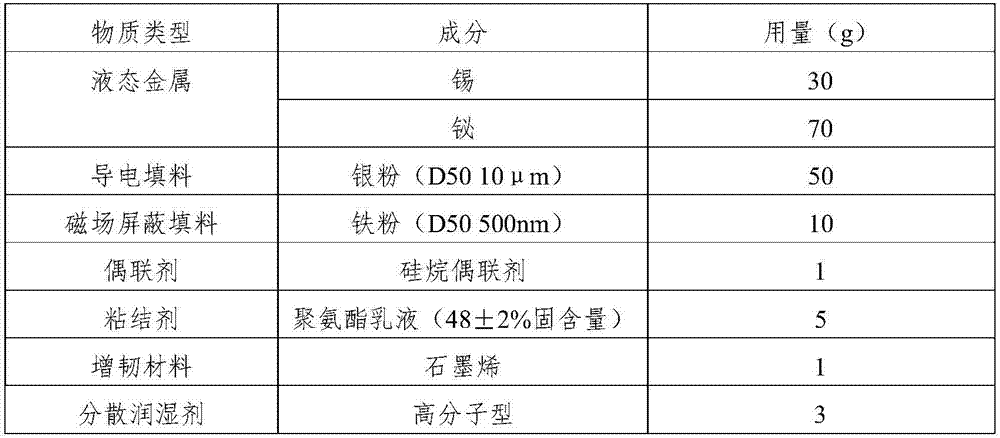

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

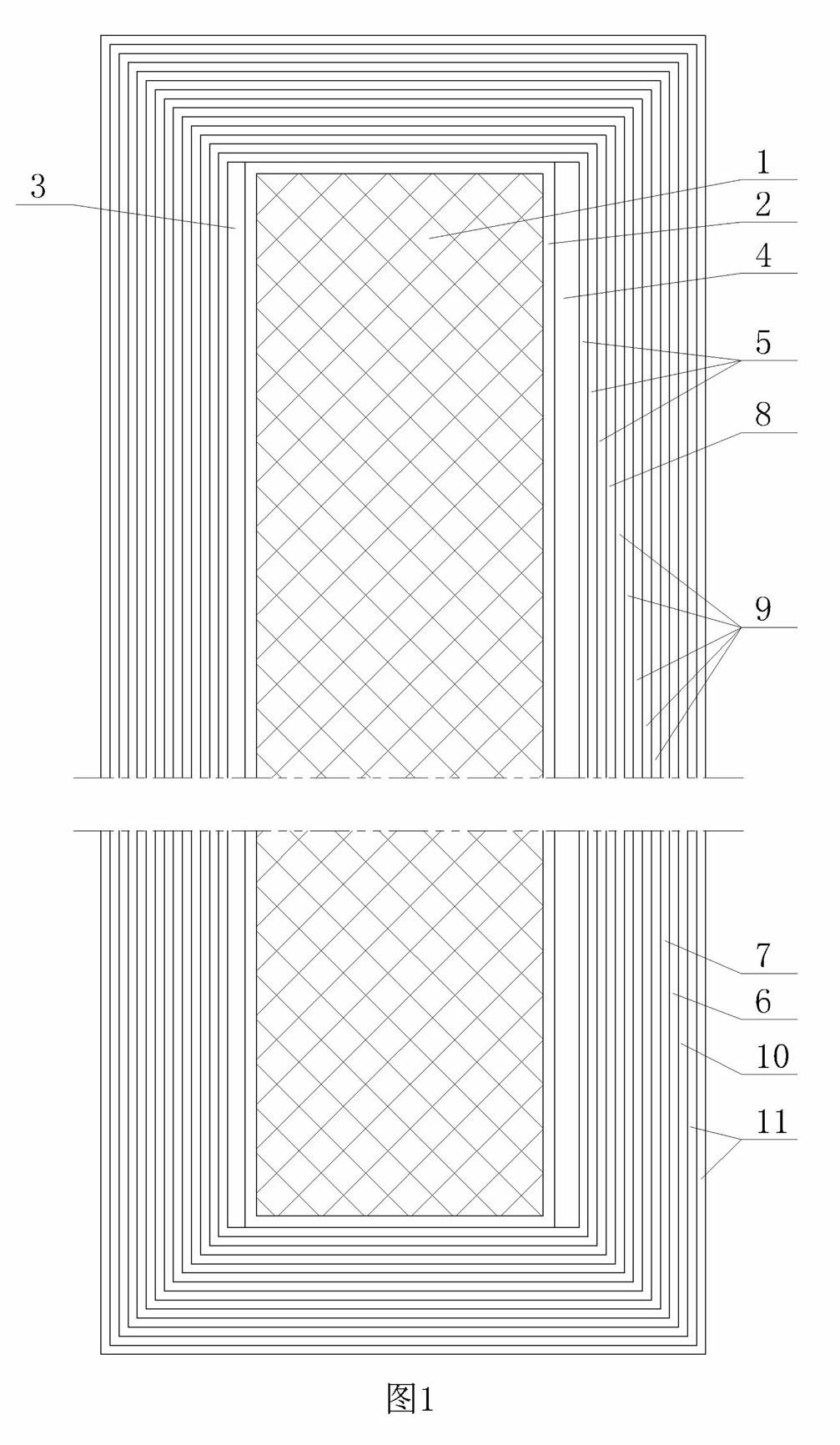

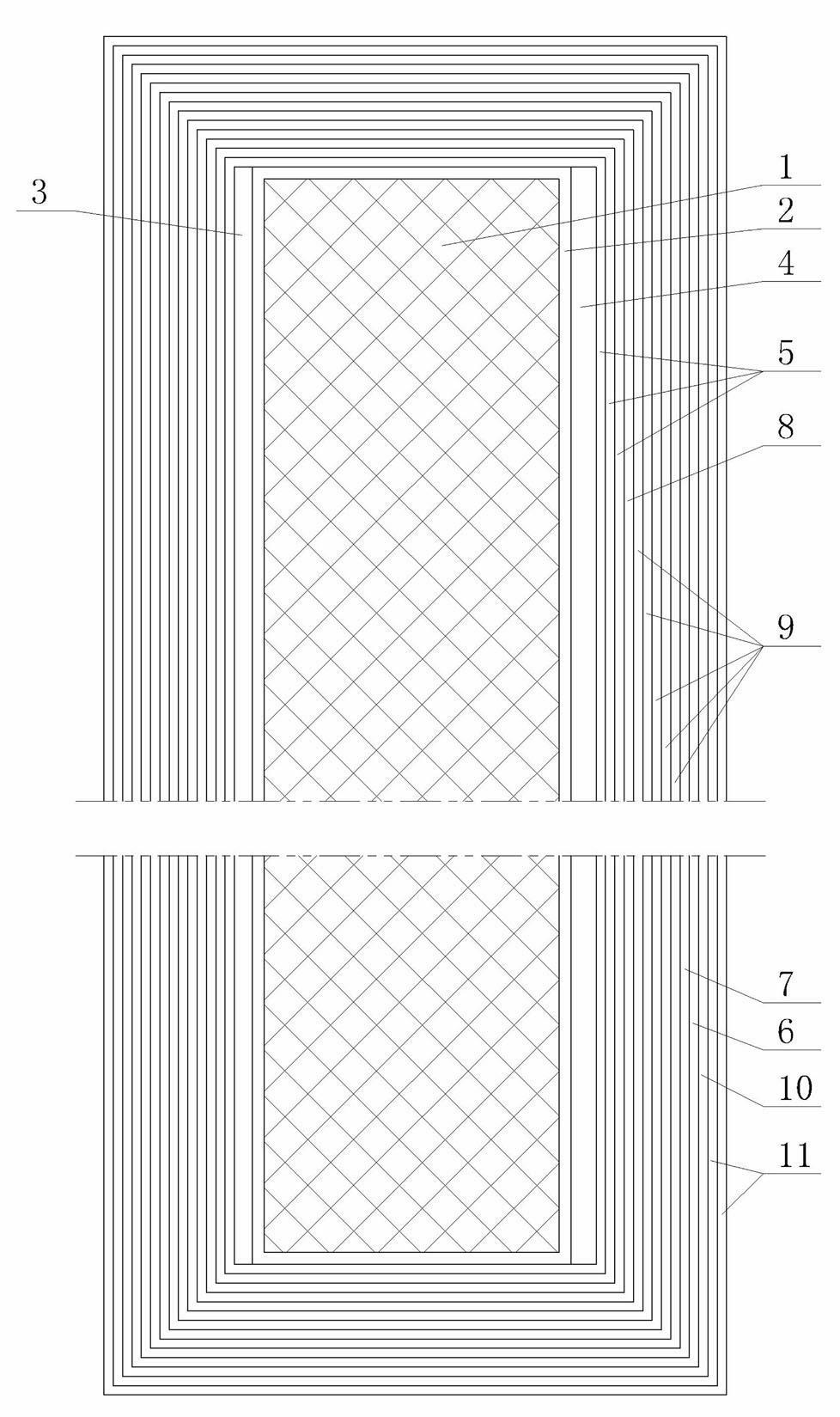

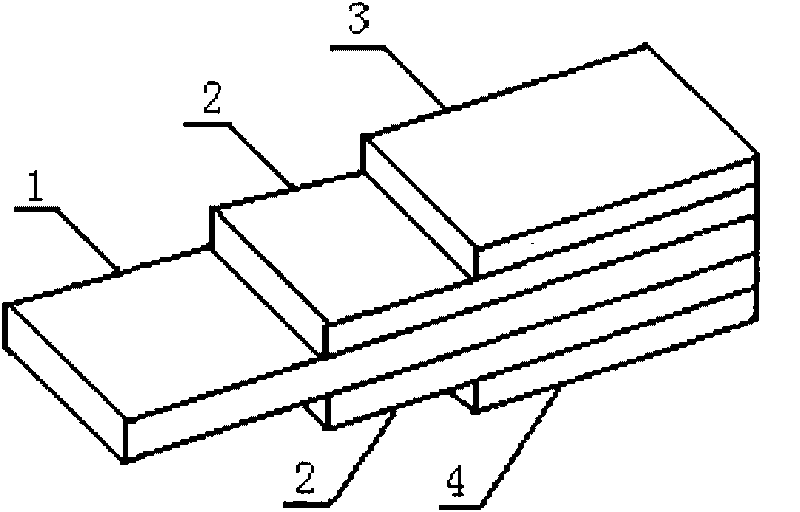

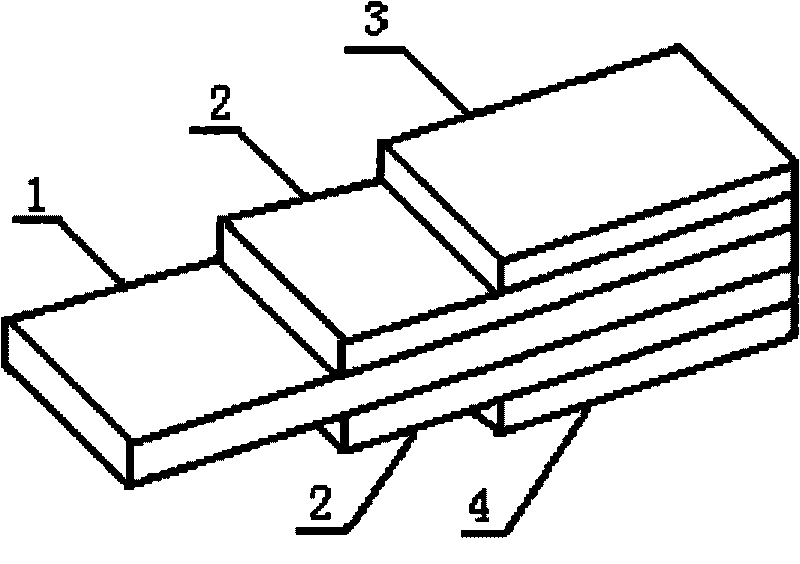

Building inner and outer wall decorating plate and manufacturing method thereof

ActiveCN102425284ASolve Adhesion ProblemsSolve the problems of transfer printing technologyCovering/liningsPretreated surfacesCalcium silicateCross-link

The invention discloses a method for building inner and outer wall decorating plate, which comprises two flows, each flow including steps of: a primer line processing flow: (1) thickness sanding and dedusting, (2) roller painting back seal coat and curing into a first UV seal coat layer, (3) roller painting UV penetrant twice, (4) leveling by infrared ray, (5) coating UV putty at the front and UV curing and generating a UV putty layer, (6) roller painting the UV seal coat for three times and respectively curing and generating three second UV seal coat layers, (7) fine sanding; and a roller painting finish line flow: (1) dedusting, (2) roller painting UV glue and generating a first UV glue layer, (3) coating the UV finish for five times and curing and generating five UV finish layers. The decorating plate can solve the problems that a UV curing penetrating agent is strongly, quickly and deeply penetrated into a fiber reinforced calcium silicate slab or a fiber cement slab, deeply cured to form a film and subjected to stereo chemical netlike cross-linking reaction with UV putty and UV sealing paint, and thoroughly solves the problem of adhesive force between the decorative surface layer and a substrate.

Owner:山东鲁泰装配式装修材料有限公司

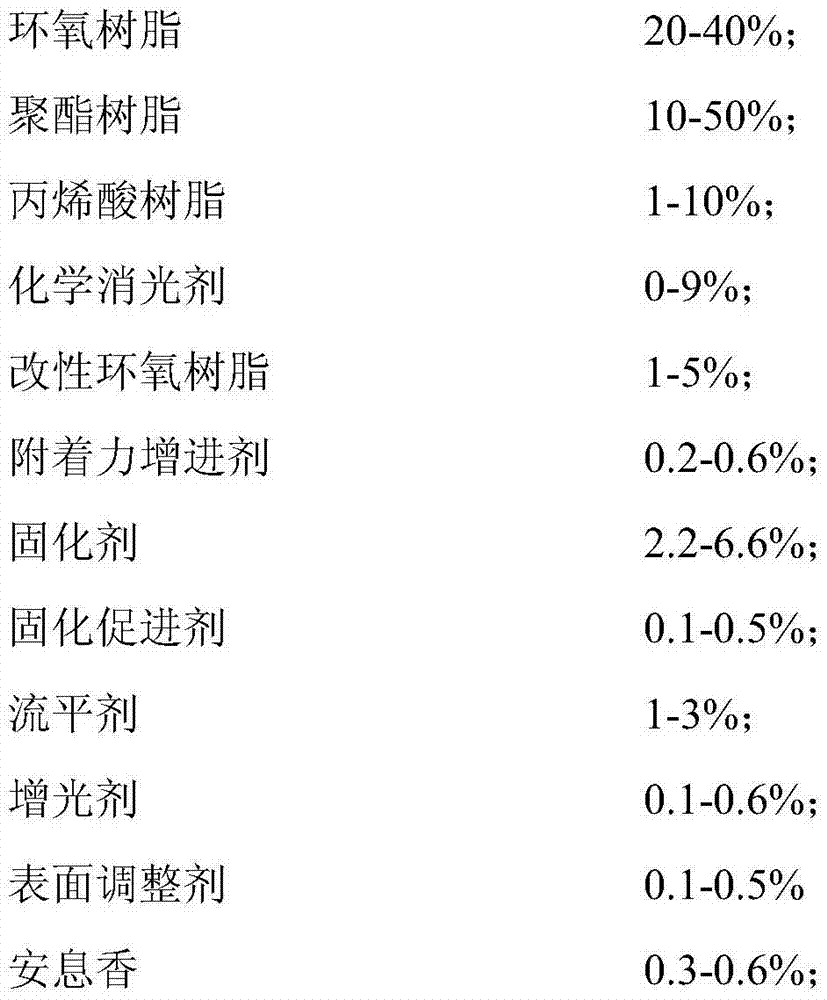

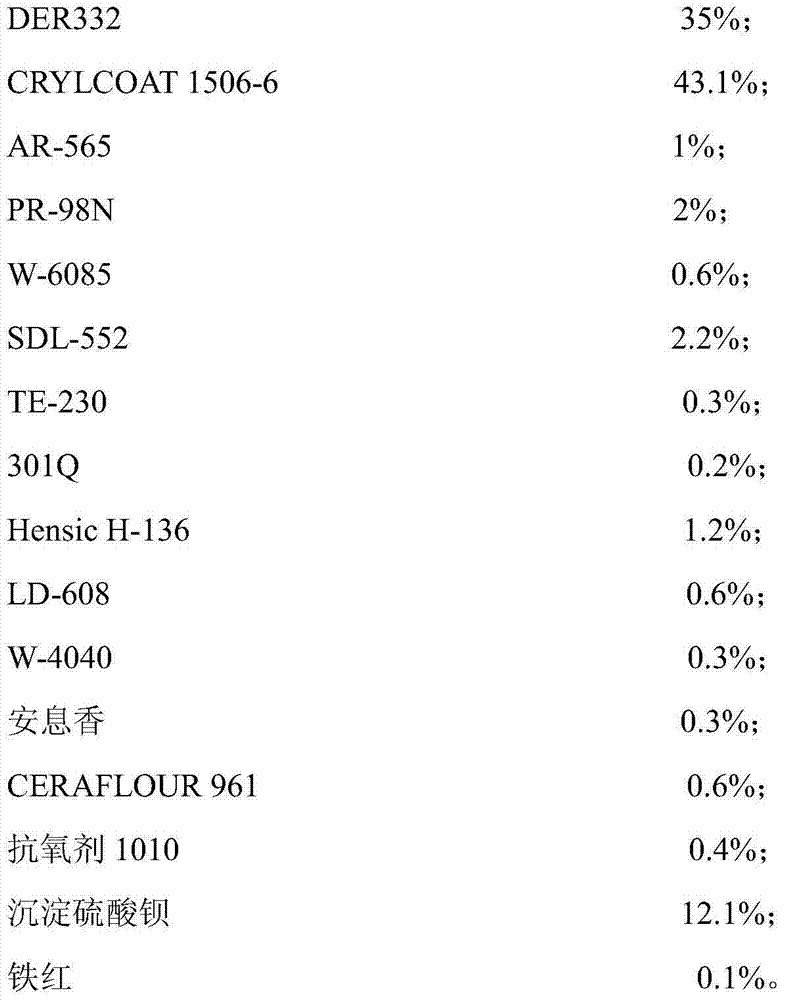

Super-levelling low-temperature curing powder coating for MDF

PendingCN104497797AAdjust glossImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of functional powder coatings, and particularly relates to a super-levelling low-temperature curing powder coating for an MDF. The powder coating is prepared from the following raw materials in percentage by weight: 20%-40% of epoxy resin, 10%-50% of polyester resin, 1%-10% of acrylic resin, 0-9% of a chemical flatting agent, 1%-5% of modified epoxy resin, 0.2%-0.6% of an adhesion promoter, 2.2%-6.6% of a curing agent, 0.1%-0.5% of a curing accelerator, 1%-3% of a flatting agent, 0.1%-0.6% of a gloss enhancer, 0.1%-0.5% of a surface conditioning agent, 0.3%-0.6% of benzoin, 0.2%-0.8% of a degassing agent, 0.3%-0.7% of an antioxidant, and 10%-20% of filler and pigment. According to the super-levelling low-temperature curing powder coating, the glossiness is adjusted by adjusting the amount of acrylic resin and the chemical flatting agent; highlight, matt and flat coats can be prepared; and the super-levelling low-temperature curing powder coating has the advantages of excellent levelling property, good adhesive force and low curing temperature.

Owner:山东朗法博粉末涂装科技有限公司

Ultraviolet light curing hardening liquid

The invention discloses a kind of ultraviolet light sodifying hardening liquor, comprising 5-40wt% of high function aliphatics urethane acrylate, 5-15wt% of annular single function acrylic ester monomer, 5-10wt% of double function 2 functional aliphatics urethane acrylate, 5-25wt% of 2 functional acrylic ester, 1-5wt% of photoinitiator, 20-60wt% of diluent, 0.01-1wt% of auxiliary agent, suitable for optical thin film; resin lens of optical level such as PMMA, PS, PC, CR, PVC; liquid crystal screen; vehicle space and rupture membrane; glass lens and so on. The high crosslinking density provides great hardness. The annular single function acrylic ester monomer has low viscosity to provide levelling property and annular structure to ensure the good hardness of the resin lens.

Owner:HUIZHOU CHANGRUNFA PAINT

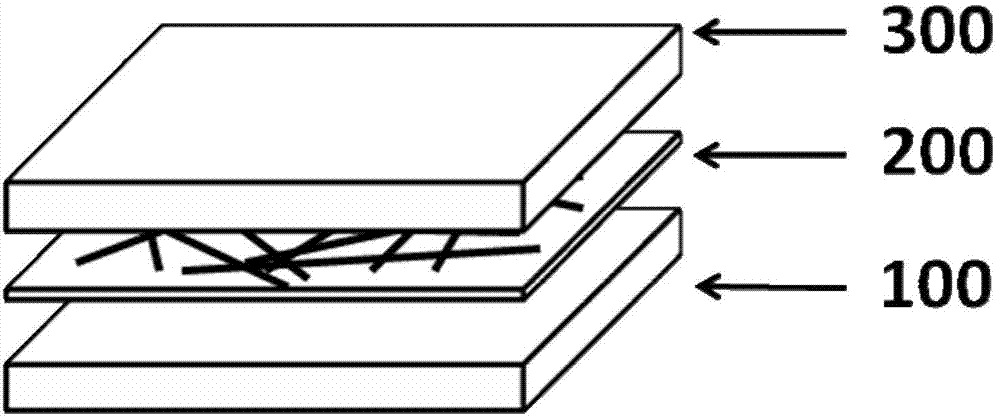

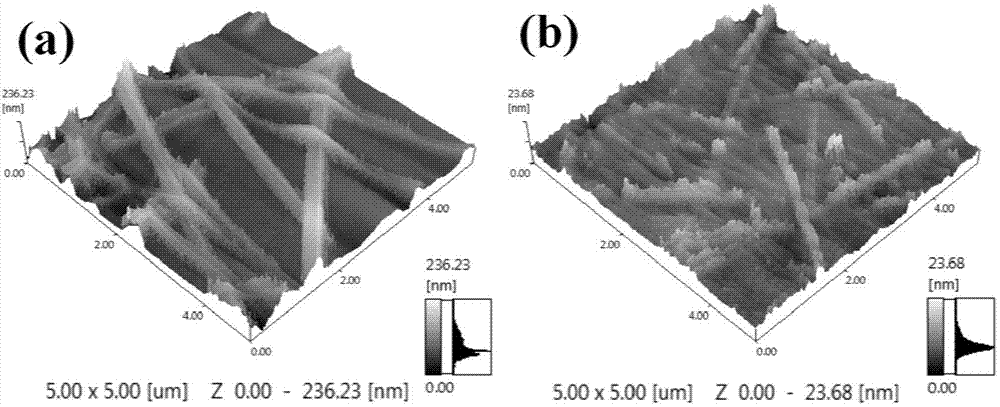

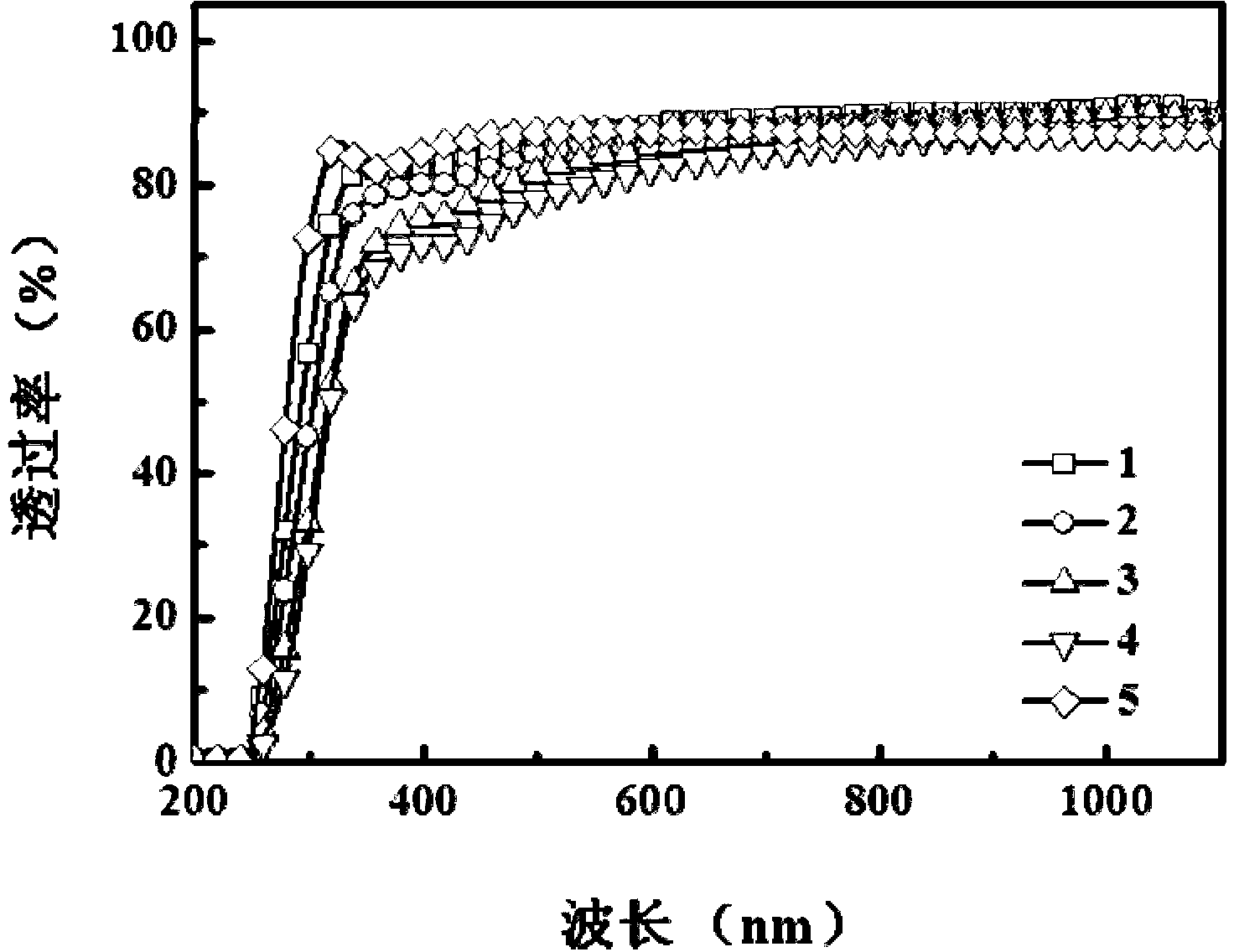

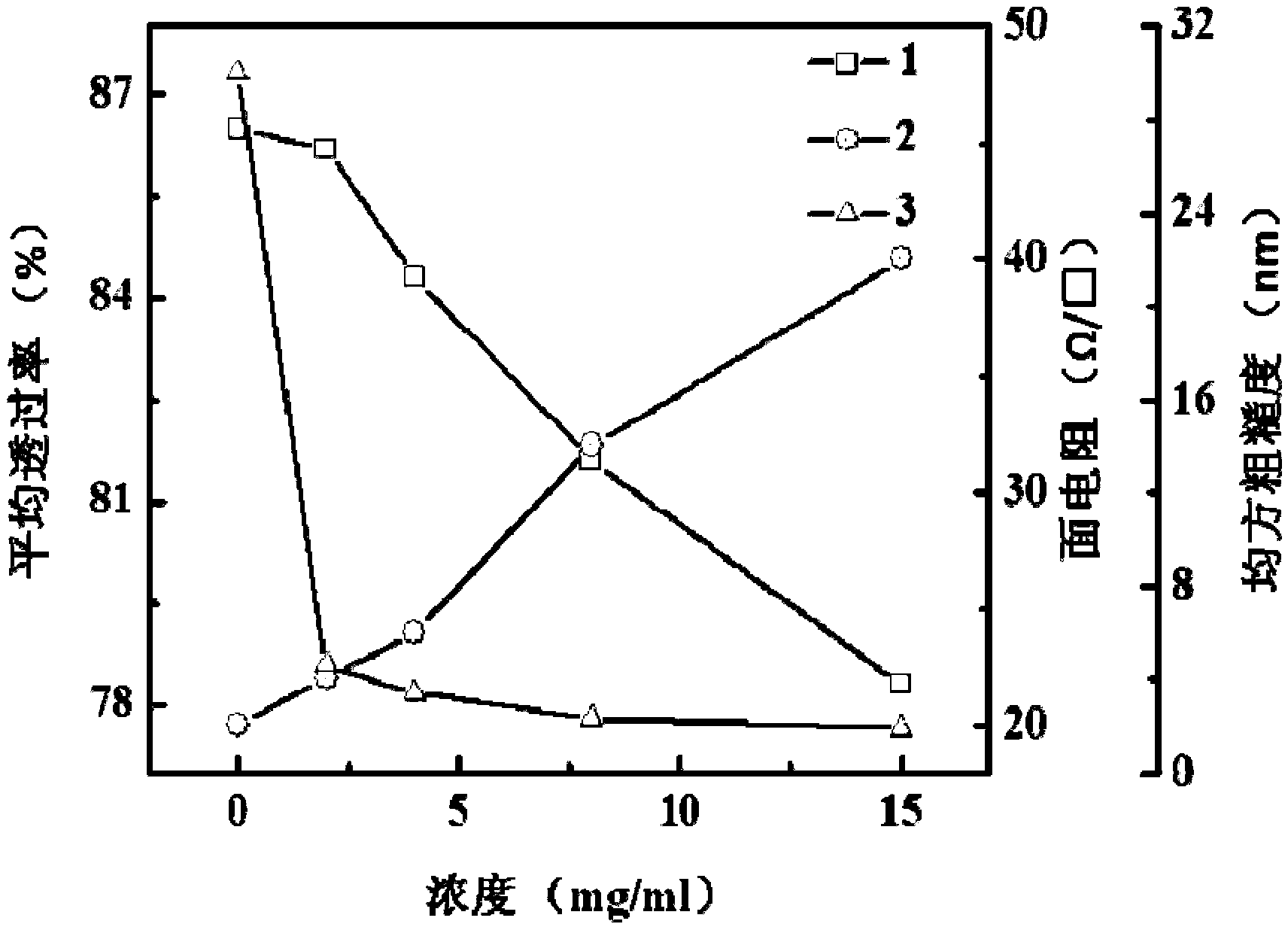

Method for making flexible, transparent and conductive film made of metal nanowires

InactiveCN103594195AImprove conductivityGood visible light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingAdhesion forcePlanar substrate

The invention provides a method for making a flexible, transparent and conductive film made of metal nanowires, and belongs to the technical field of conductive film materials. A layer of metal nanowire film is made on a rigid plane substrate according to a solution processing method, then a layer of transparent and flexible substrate is made on the metal nanowire film according to the solution processing method, and finally the flexible substrate with the metal nanowires on the surface is removed from the plane substrate to form the flexible, transparent and conductive film made of the metal nanowires. Compared with a traditional flexible, transparent and conductive film made of metal nanowires directly on a flexible substrate, the flexible, transparent and conductive film made of the metal nanowires through the method has the advantages of being high in surface flatness, large in adhesion force and the like and effectively solving the problems that a flexible, transparent and conductive film made of metal nanowires is large in roughness and small in adhesion force. The flexible, transparent and conductive film made of the metal nanowires has the potential of being applied in the fields of photoelectric devices like film solar cells and organic light-emitting diodes.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

ActiveCN103173087ANovel structureImprove conductivityAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention discloses an anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and a preparation method thereof and relates to the technical field of production of a coating. According to the invention, carbon nano tube is selected as an antistatic additive; and a film forming matter is waterborne acrylate grafted epoxy resin emulsion. The characteristics of the acrylate resin and epoxy resin can be effectively integrated into a whole; the prepared anti-corrosion antistatic coating is good in storage stability, good in construction property, fast to dry after being coated, smooth in dried film, and excellent in mechanical behavior, antistatic property, acid resistance, alkali resistance, salt water resistance and the like.

Owner:扬州市伊丽特高分子材料科技有限公司

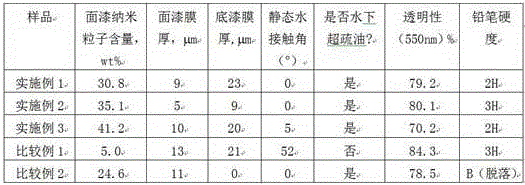

Superhydrophilic/underwater superoleophobic coating material and preparation method thereof

ActiveCN106634275AImprove mechanical propertiesHigh transparencyAntifouling/underwater paintsPretreated surfacesNano structuringAcrylic resin

The invention relates to a superhydrophilic / underwater superoleophobic coating material and a preparation method thereof. The coating material is composed of a primer layer and a finish coat layer, wherein the primer layer is mainly composed of a hydroxy acrylic resin and a curing agent thereof; the finish coat layer is composed of polyvinyl alcohol and nanoparticles; and the curing agent in the primer can produce chemical crosslinking reaction with the polyvinyl alcohol. The preparation method comprises the following steps: applying the primer layer on the substrate surface; applying the finish coat layer, and precrosslinking by drying at room temperature or low temperature to initiate the chemical bonding between the primer layer finish coat layer; soaking the coating in a crosslinking agent water solution for some time; and taking the coating out of the crosslinking agent water solution, and sufficiently curing the primer layer by drying at room temperature or high-heat treatment. The coating material obtained by the method has a gradient micro / nano structure surface, and has the advantages of outstanding superhydrophilicity and underwater superoleophobicity, high binding force with the substrate and favorable transparency. The coating material can be used as an antifogging coating, and can also be used as a self-cleaning antifouling coating on the surface of an underwater facility.

Owner:FUDAN UNIV

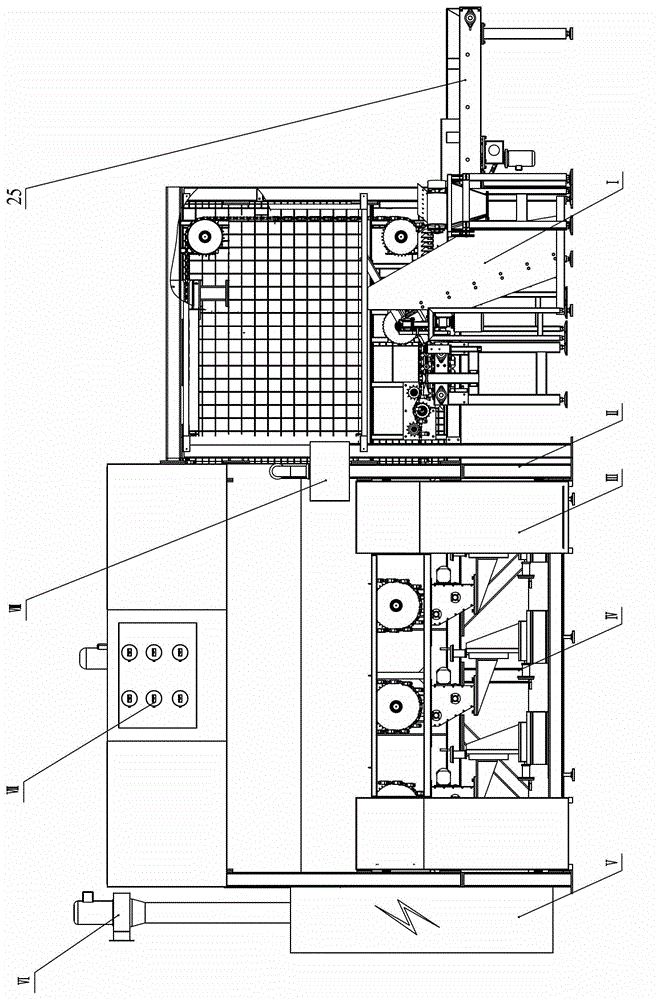

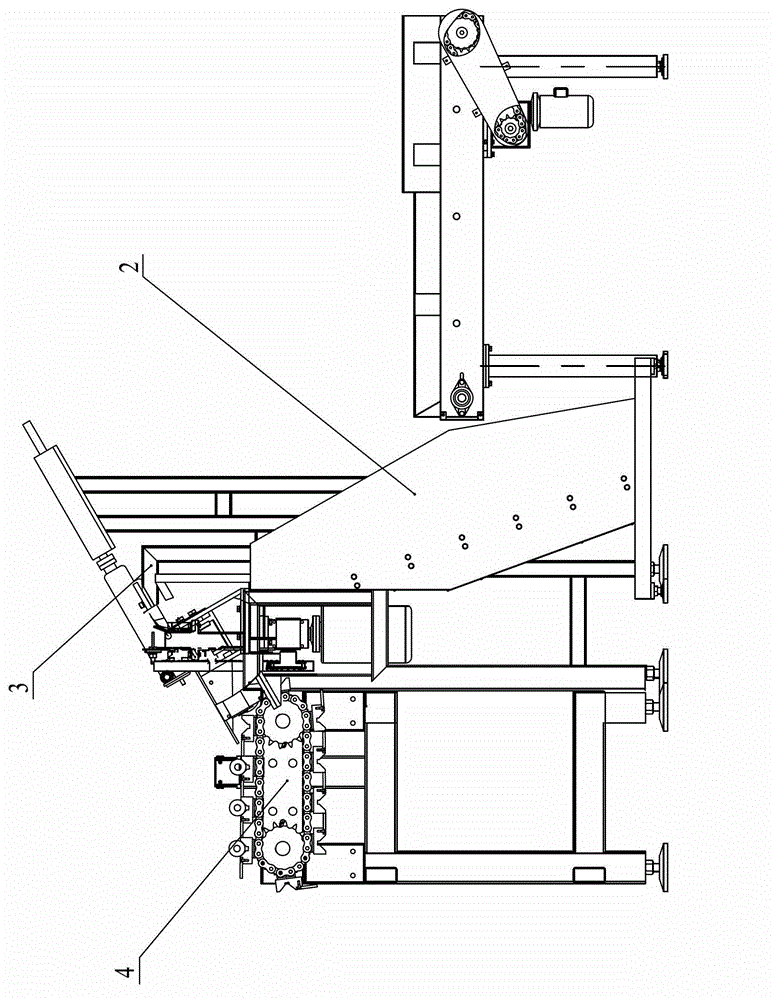

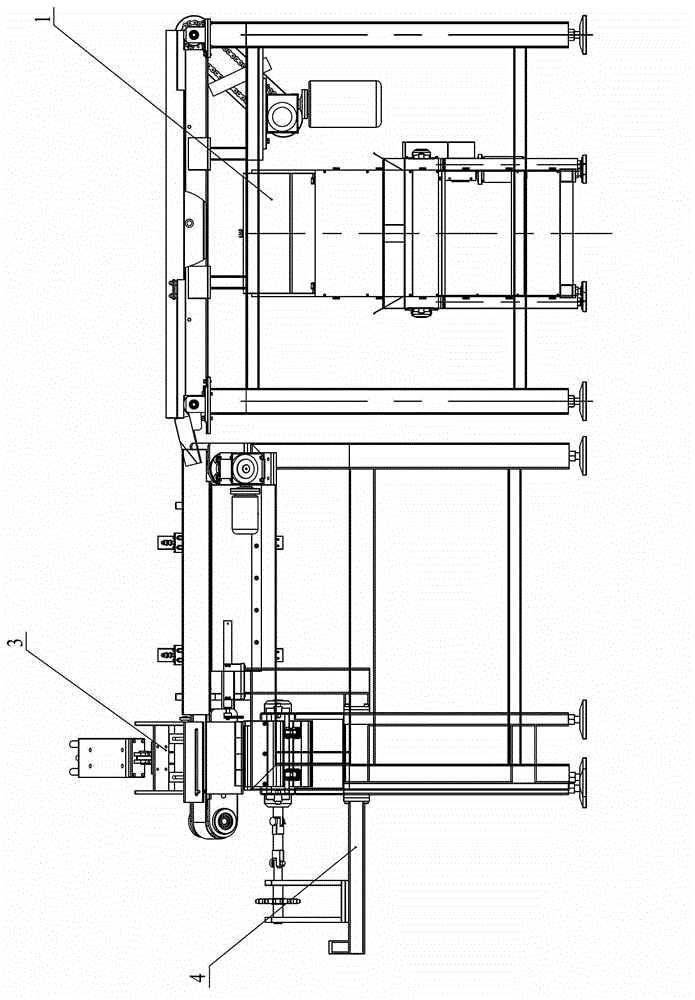

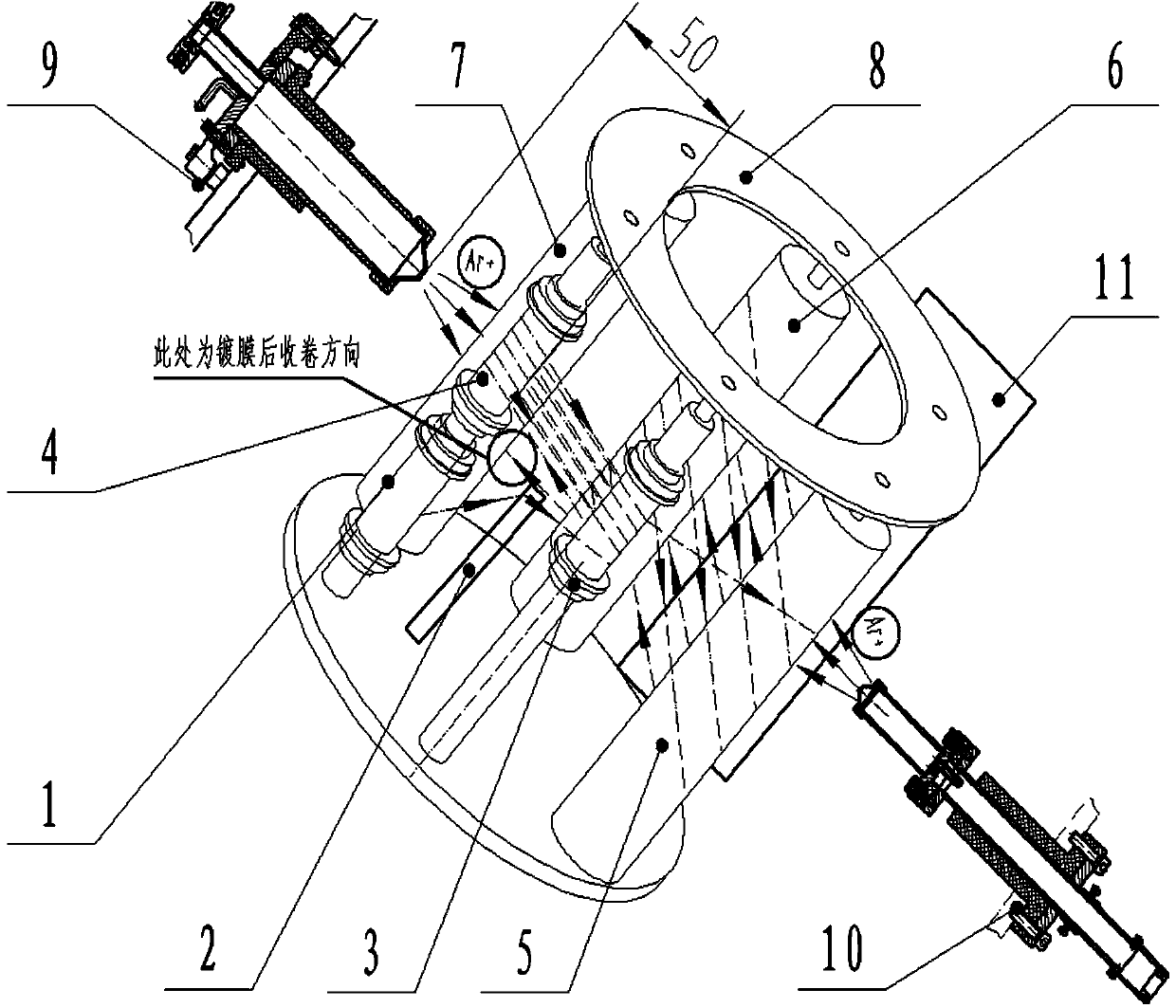

Roller coating machine

ActiveCN102974498ASolve Adhesion ProblemsSolve for uniformityPretreated surfacesCoatingsMachineIndustrial engineering

The invention relates to a roller coating machine. Workpieces needing to be coated are pushed into a material turnover frame of a material turnover mechanism; the material turnover mechanism rotates the material turnover frame; the workpieces are turned and are poured into a material blocking hopper; the workpieces are conveyed to a material storage hopper of a discharge mechanism by a discharge conveying machine; the workpieces are lifted by the discharge mechanism, then are arranged in order and roll into a vibration transmission rack according to a certain rule; the workpieces are conveyed to a synchronous material-pushing mechanism; the workpieces arranged tidily are pushed to a V-shaped groove of a synchronous material-loading mechanism by the synchronous material-pushing mechanism; the workpieces are subjected to position adjustment by the synchronous material-loading mechanism and then are pushed to a material hanging mechanism on a workpiece transmission rack; the material hanging mechanism drives the workpieces and feeds them into an automatic glue-rolling device; a glue liquid is uniformly roll-coated on the surfaces of the workpieces by the automatic glue-rolling device; the workpieces coated with the glue liquid are fed to an unloading mechanism by the workpiece transmission rack; and the workpieces coated with the glue liquid are fed to a material receiving hopper by the unloading mechanism, then are fed into a workpiece delivery wagon and then are output. The roller coating machine adopts a roll-coating technology to realize workpiece surface treatment, is efficient, saves energy, is environmentally friendly and is suitable for large-scale glue-rolling of tubular workpieces.

Owner:WUXI HUANENG SURFACE TREATMENT

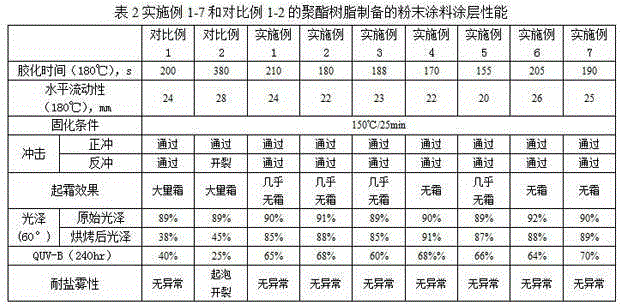

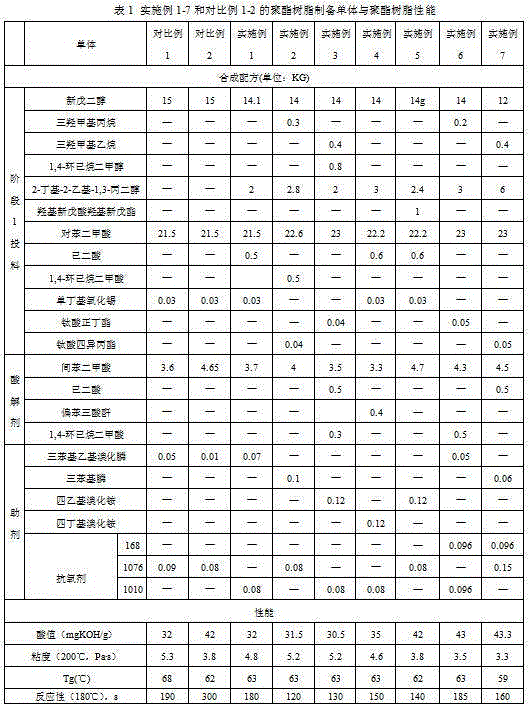

Polyester resin for powder coating for structural member of engineering machine and preparation method of polyester resin

ActiveCN105254860ALow curing temperatureGood curingAnti-corrosive paintsPowdery paintsAntioxidantLow temperature curing

The invention discloses polyester resin for a powder coating for a structural member of an engineering machine. The polyester resin has the acid value of 29-45mgKOH / g, the hydroxyl value of smaller than 6mgKOH / g, the glass transition temperature of 55-65 DEG C, the melt viscosity of 3-6Pa.s and the 180-DEG C reactivity of 80-200S and is mainly prepared by cocondensing the following raw materials in percentage by weight: 30-45% of polyalcohol, 45-55% of aromatic polyacid, 0-2% of aliphatic polyacid, 0-2% of a branching agent, 5-15% of an acidolysis agent, 0.005-0.15% of an esterification catalyst, 0.04-0.3% of a curing accelerator and 0.1-1% of an antioxidant. The invention also discloses a preparation method of the polyester resin. The polyester resin disclosed by the invention is of a TGIC-cured type, has favorable weather resistance, corrosion resistance, mechanical property and low-temperature curing characteristics and can be used for solving the problems of frosting and curing incompleteness existing at present when being applied to the powder coating for the structural member of the engineering machine.

Owner:GUANGZHOU KINTE IND

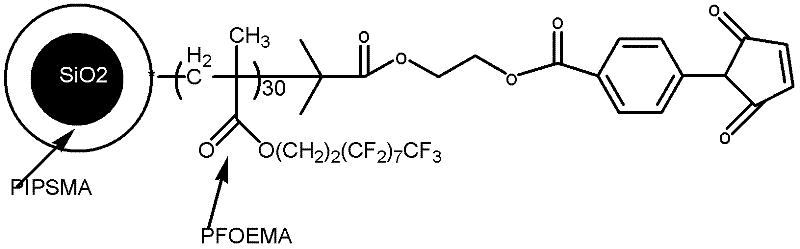

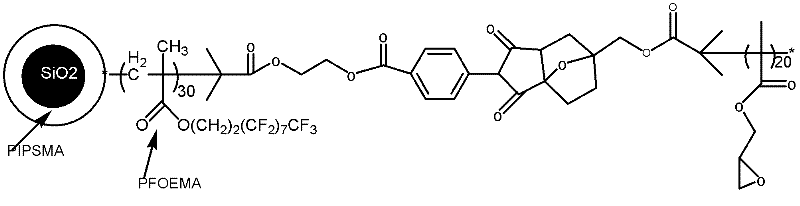

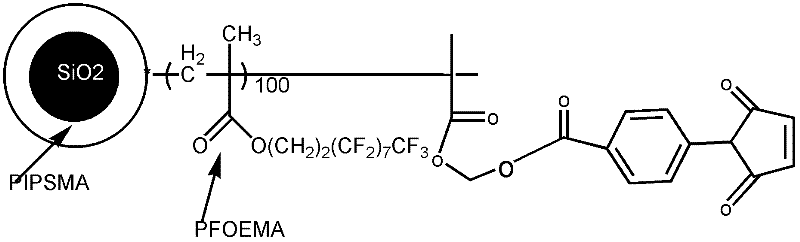

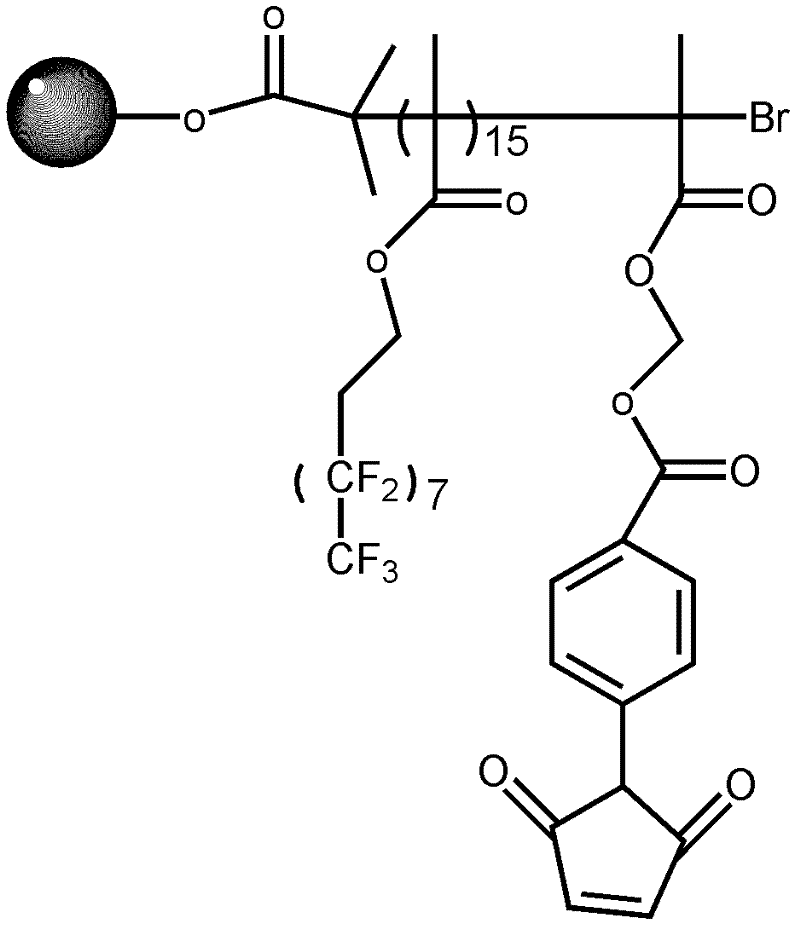

Fluorine-containing nanoparticles with high dispersibility and bonding property and superamphiphobic surface

The invention discloses fluorine-containing nanoparticles with high dispersibility and bonding property and a superamphiphobic surface prepared from the nanoparticles. The fluorine-containing nanoparticles with high dispersibility and bonding property are prepared by the steps of grafting a fluorine-containing polymer with an upper terminal group to be a compound D on the surfaces of the nanoparticles, and reacting an epoxy resin polymer with a terminal group to be a compound A with the fluorine-containing polymer through a heat-breaking Diels-Alder reaction. The superamphiphobic surface disclosed by the invention is prepared by the steps of dispersing the fluorine-containing nanoparticles with high dispersibility and bonding property in a low-boiling-point fluorine-free solvent, uniformly mixing with an epoxy resin curing agent, carrying out spray coating on the surface of a substrate material, and carrying out vacuum drying. According to the fluorine-containing nanoparticles disclosed by the invention, the epoxy resin polymer with high dispersibility is introduced, as the epoxy functional group contained in the dispersing polymer can take place a curing reaction with the epoxy group by using the epoxy resin curing agent in the solvent to fix the fluorine-containing nanoparticles on the surfaces of most substrates, the bonding problem of the fluorine-containing nanoparticles on the substrate surface is solved.

Owner:中科瑞丽分离科技无锡有限公司

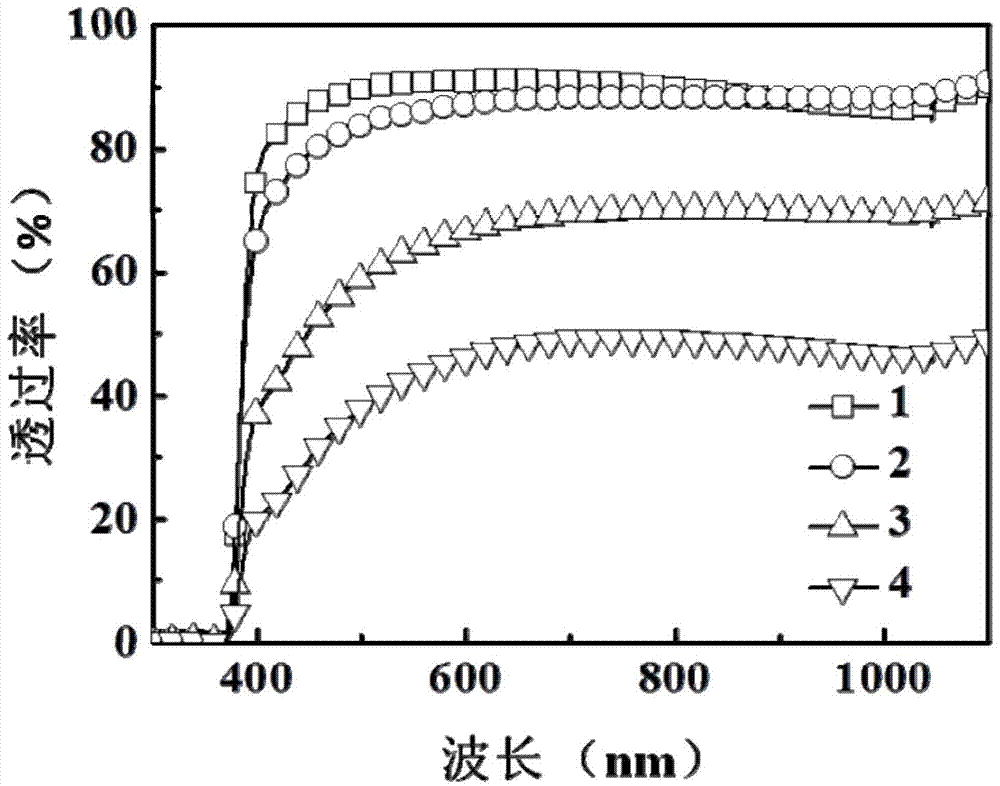

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AReduce energy consumptionFlexible constructionPolyurea/polyurethane coatingsEpoxy resin coatingsSolventPhotoinitiator

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

Ultraviolet (UV) cured roller coating embellishing clear finish coating

InactiveCN102516837ASolve the difficulty of one-time color correctionSolve Adhesion ProblemsCoatingsAdhesion forcePolyester

The invention discloses a UV cured roller coating embellishing clear finish coating which relates to the chemical engineering field, and aims to solve problems of bad adhesion force and difficult embellishing of general UV embellishing finishes. The UV cured roller coating embellishing clear finish coating comprises, by weight, 35-50 parts of an epoxy acrylate, a polyester acrylate or a mixture of the epoxy acrylate and the polyester acrylate, 30-42 parts of an active diluent, 0.2-0.5 parts of a defoamer, 0.5-1 part of a functional assistant, 0.1-0.3 parts of a leveling agent, 8-13 parts of a filler and 9-12 parts of a photoinitiator. The coating has the advantages of good drying performance, good adhesion force, simple one-time UV embellishing, and strong maneuverability.

Owner:CHENGDU ZHANCHEN PAINT

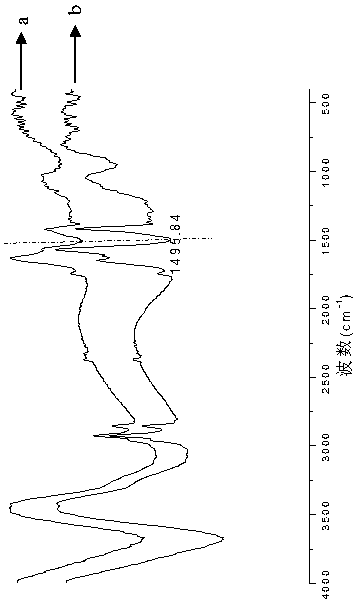

Ultraviolet-cured high-adhesion scraping-resistant agent for heat insulating film

The invention relates to an ultraviolet-cured high-adhesion scraping-resistant agent for a heat insulating film, which comprises the following components in part by mass: 15 to 25 parts of urethane acrylate oligomer, 10 to 17 parts of acrylate reactive diluent, 40 to 50 parts of solvent, 8 to 12 parts of adhesion promoter, 0.5 to 1 part of leveling agent and 5 to 10 parts of photoinitiator. The urethane acrylate oligomer is taken as matrix resin, has urethane bonds and forms various hydrogen bonds among molecular chains of high polymer, so that the cured product has excellent wear resistance and flexibility; and the solvent is used for enhancing the dissolution and dispersion of the components so as to solve the problem of formation of crystals. The adhesion promoter forms molecular anchor with a base material, and forms physical bonding or a firm chemical bond with the base material to enhance the adhesion. The ultraviolet curing speed is high, equipment cost is low, the pollution is light, and the invention provides a new energy-saving and environment-friendly technology.

Owner:西安航天三沃化学有限公司

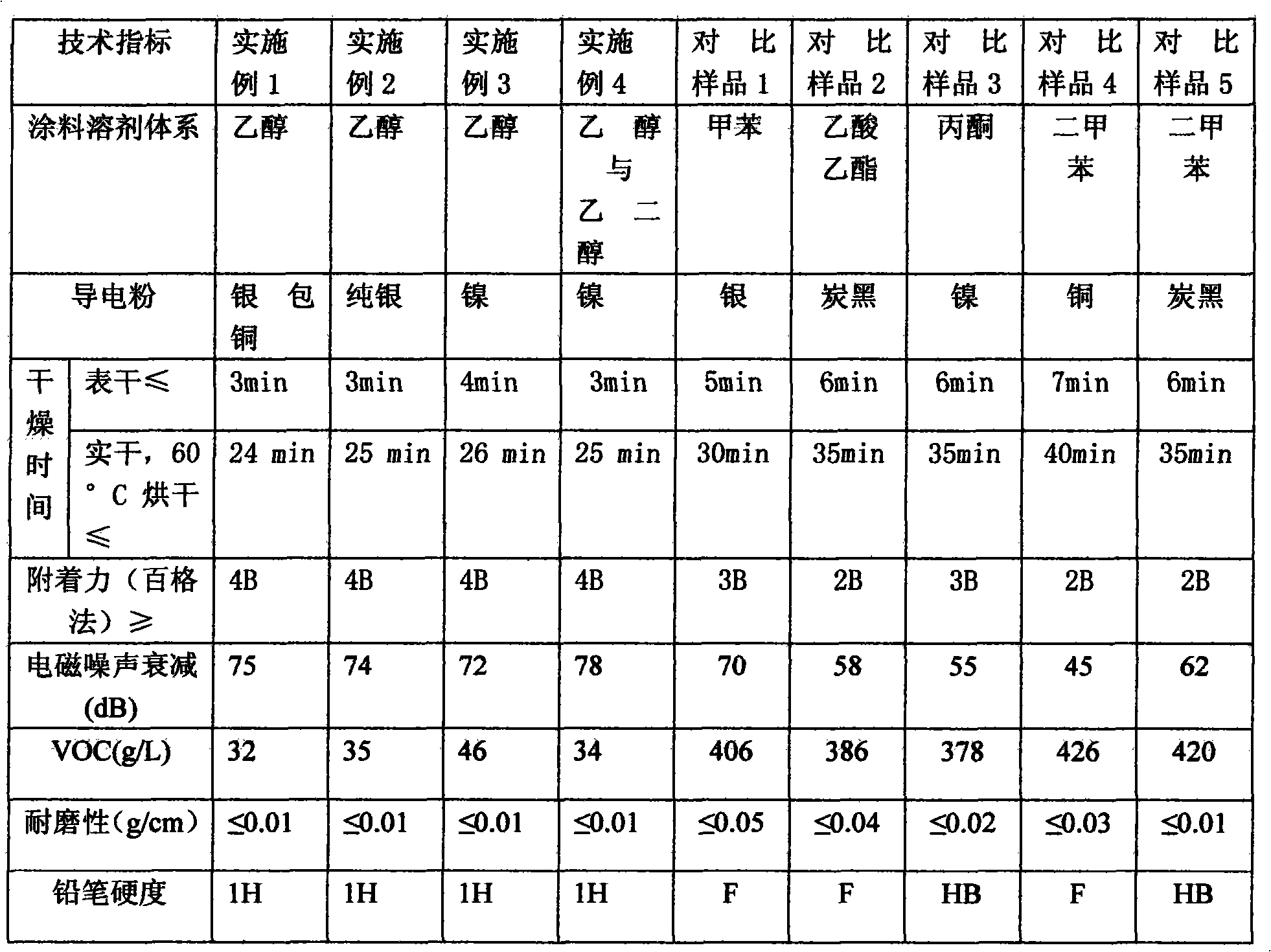

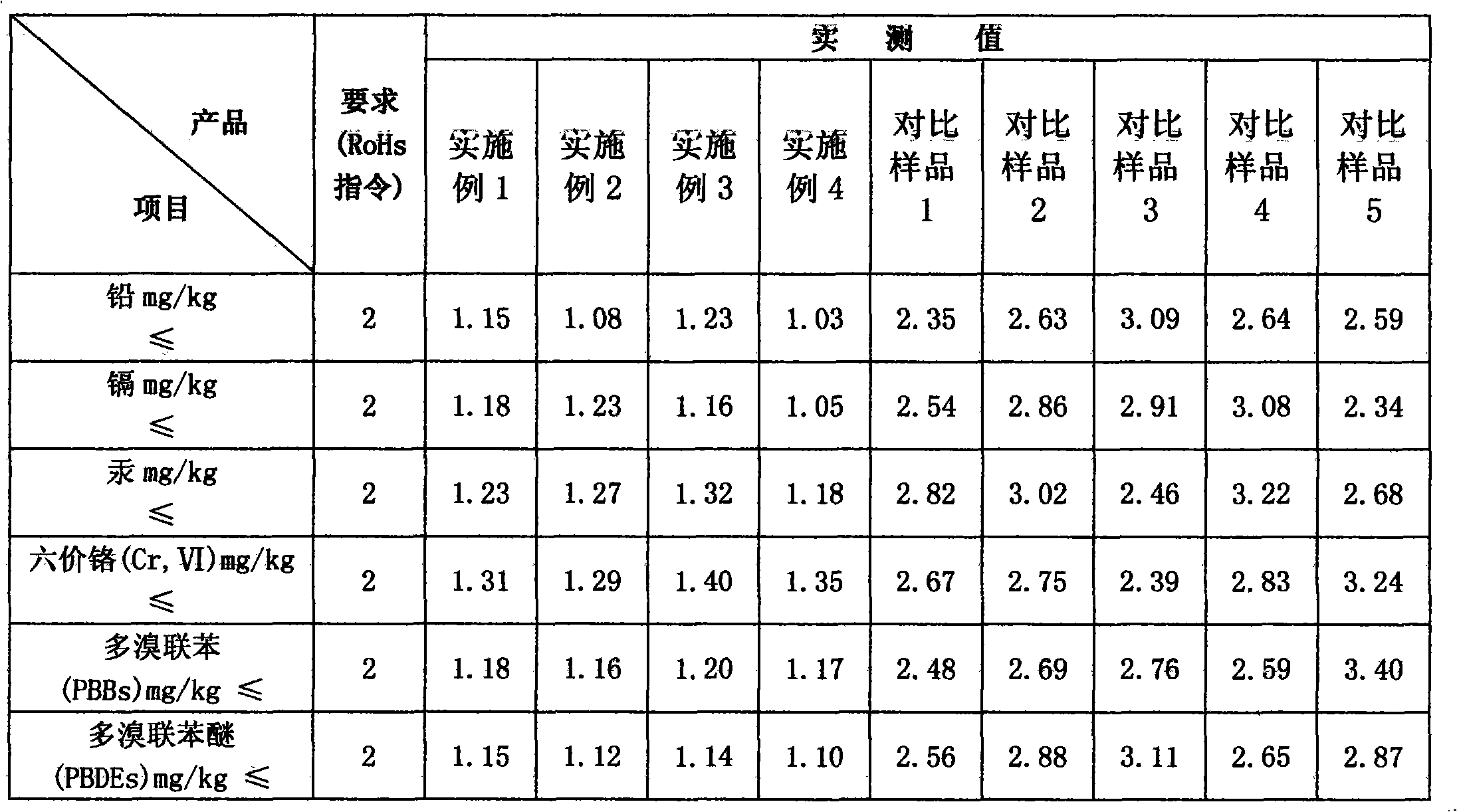

Alcohol-soluble electromagnetic wave shielding coating

InactiveCN101880499ATo achieve the purpose of directional arrangementSpecific photoelectric propertiesMagnetic/electric field screeningEpoxy resin coatingsAlcoholSolvent

The invention discloses an alcohol-soluble electromagnetic wave shielding coating, which comprises the following components by weight percentage: 20-50 percent of conductive powder, 25-45 percent of conductive resin, 0.5-2 percent of coupling agent, 2-4 percent of dispersing agent, 0.5-3 percent of alignment agent and 17-50 percent of alcohol solvent. The invention aims to overcome the defects ofthe domestic electromagnetic wave shielding coating at present, and provides a coating which can shield electromagnetic waves and effectively reduce the electromagnetic radiation pollution.

Owner:广东杜威科技有限公司

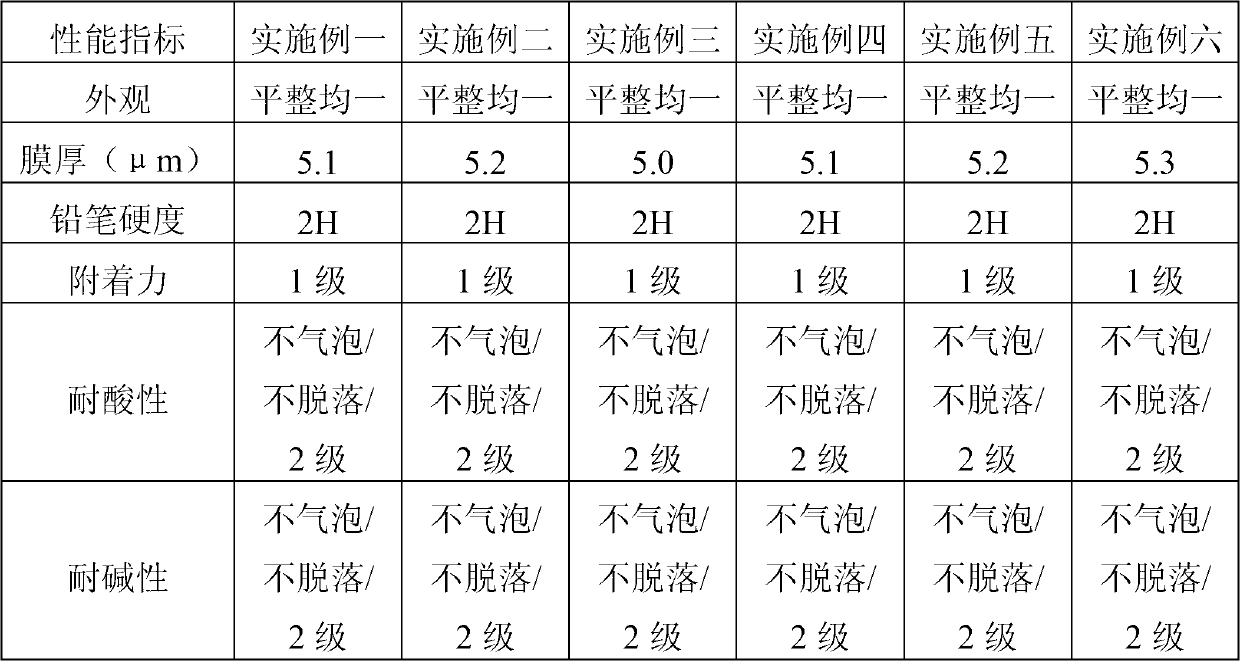

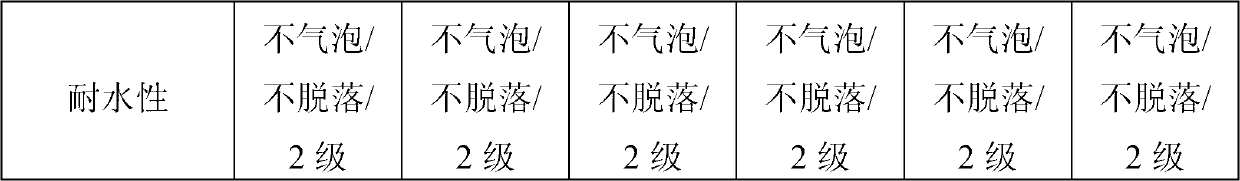

Finish paint for plastic

InactiveCN102775902AGood spray viscositySave electricityPolyurea/polyurethane coatingsPaints with free metalsCelluloseLacquer

The invention discloses a finish paint for plastics. The finish paint comprises the following components in percentage by weight: 5-10% of aliphatic polyurethane acrylate, 10-15% of aromatic polyurethane acrylate, 0-2% of high polymer containing paint affinity group, 0-0.3% of unsaturated polyamic acid homo-polymer, 0-0.2% of organic silicon, 10-35% of cellulose ester, 2-10% of mixture of pearl powder, aluminum silver powder and paint, 3-5% of nano filler, 10-20% of hydroxy acrylic resin, 5-10% of styrene maleic anhydride modified chloride resin vinegar, 5-10% of poly-functional-group reactive diluent, 2-5% of dual-functional-group reactive diluent, 3-5% of three-functional-group reactive diluent, 1-3% of crack-type photo-initiator, and 0.5-1% of acyl phosphine oxide photo-initiator. The curing time of the finish paint for plastics is only 3min to 4min, so a large amount of power is saved; and the finish consumption of each electric car is respectively reduced by 48% and 53%. With the adoption of the combination of the polyurethane acrylates and the hydroxy acrylic resin, the problem on adhesion among three layers of plastic substrate, finish paint and priming paint is solved.

Owner:KUSN WANSHENG CHEM

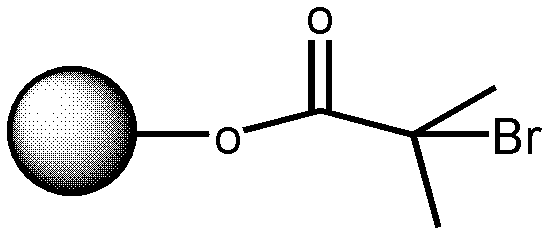

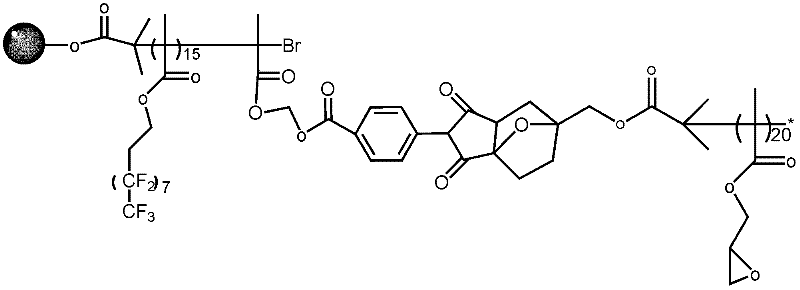

Functional fluorine-containing microsphere and self-cleaning surface built by same

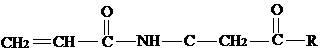

InactiveCN102585243AImprove hydrophobicity and oleophobicityReduce usageCoatingsSolventBoiling point

The invention discloses a functional fluorine-containing microsphere and a self-cleaning surface built by the same. The high-dispersibility high-adhesion fluorine-containing microsphere disclosed by the invention is prepared by using the following method steps: reacting microspheres and a base amine catalyst with alpha-halogenated acyl bromide or alpha-halogenated acyl chloride to obtain a microsphere the surface of which is grafted with ATRP (atom transfer radical polymerization) initiator; carrying out ATRP random copolymerization or segmented polymerization reaction on the microsphere the surface of which is grafted with ATRP initiator, a monomer F and a monomer D so as to obtain a monomer D polymer microsphere, wherein the surface of the monomer D polymer microsphere is grafted with the monomer F and can perform D-A reaction; and reacting the monomer D polymer microsphere with an epoxy resin type polymer the terminal group of which is a compound A to obtain the fluorine-containingmicrosphere having high dispersibility and high adhesion. The self-cleaning surface disclosed by the invention is obtained by dissolving the fluorine-containing microsphere having high dispersibilityand high adhesion into a low-boiling-point solvent, then adding an epoxy resin solidifying agent E for evenly mixing and spraying a mixture on the surface of a substrate material and drying in vacuum. According to the invention, the use of a fluorine-containing solvent is avoided in the self-cleaning surface, and the obtained self-cleaning surface has strong adhesion on the surface of the substrate material.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

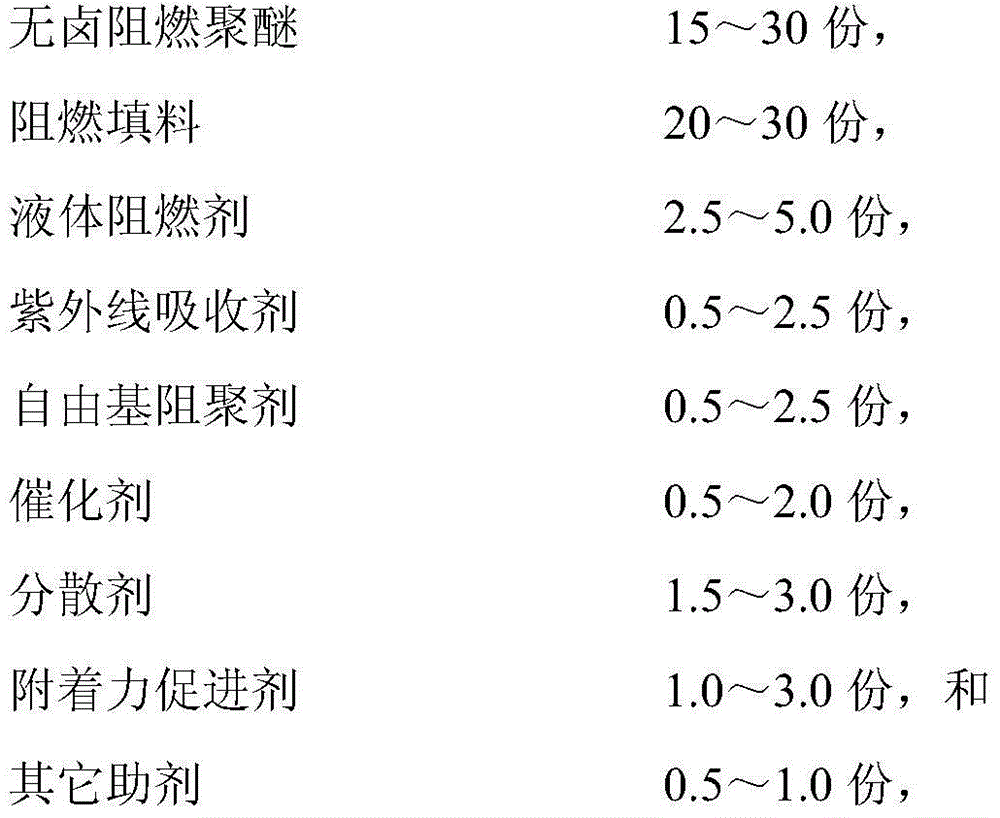

Surface flame retardant coating of rubber as well as preparation method of coating

ActiveCN103555185AIncrease elasticityLess corrosiveFireproof paintsPolyurea/polyurethane coatingsPolymer scienceUltraviolet lights

The invention discloses a surface flame retardant coating of rubber as well as a preparation method of the coating. The surface flame retardant coating comprises components A and B. The preparation method comprises the following steps: mixing and stirring a diluent, a dispersant, an adhesive force accelerant, a chain extender, halogen-free flame retardant polyether, a liquid flame retardant and flame retardant filler to obtain coarse mill base; grinding the coarse mill base to fine mill base; adding a free radical polymerization inhibitor, an ultraviolet light absorber, a catalyst and a defoamer into the fine mill base to stir to obtain the component A; adding an isocyanate curing agent and other assistants into the diluent to stir to obtain the component B; and mixing and stirring the components A and B to obtain the surface flame retardant coating of rubber. The flame retardant coating disclosed by the invention has the advantages of efficient flame retardance, low smoke and low toxicity, good weather ability and long service life, and the preparation method is simple in process, easy for production on a large scale and lower in production cost.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

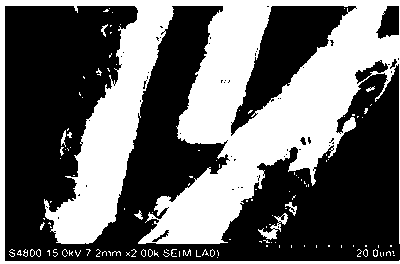

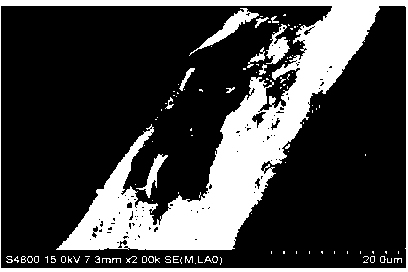

Preparation method of composite transparent conductive film of metal nanowires and metallic oxides

InactiveCN103236323AHigh surface flatnessImprove adhesionConductive layers on insulating-supportsCable/conductor manufactureHigh surfaceLight-emitting diode

The invention provides a preparation method of a composite transparent conductive film of metal nanowires and metallic oxides. The preparation method is characterized in that mixed solution of the metal nanowires and the metallic oxides is prepared by mixing metal nanowire solution and metallic oxide solution in different proportions, and then the composite transparent conductive film of the metal nanowires and the metallic oxides is prepared on a rigid or flexible planar substrate by a solution processing method. Compared with a metal nanowire transparent conductive film prepared by the metal nanowire solution individually, the composite transparent conductive film of the metal nanowires and the metallic oxides has the advantage of high surface evenness, strong adhesive force, good environmental stability and the like; and the problems of low surface evenness, weak adhesive force, poor environmental stability of the metal nanowire transparent conductive film are solved effectively. The composite transparent conductive film of the metal nanowires and the metallic oxides has application potential in the field of photoelectric devices of film solar cells, organic light-emitting diodes and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

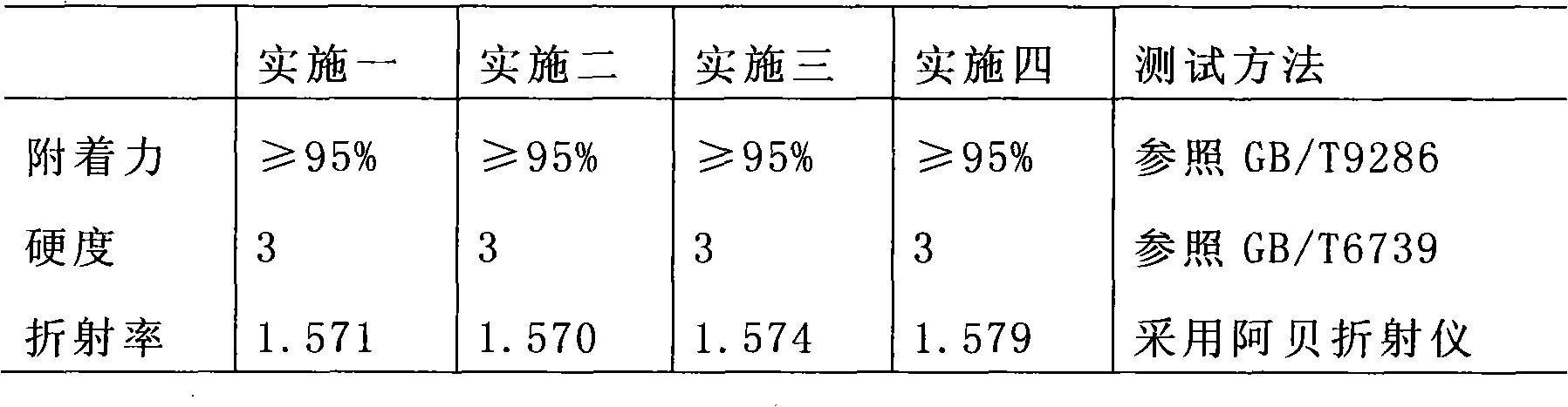

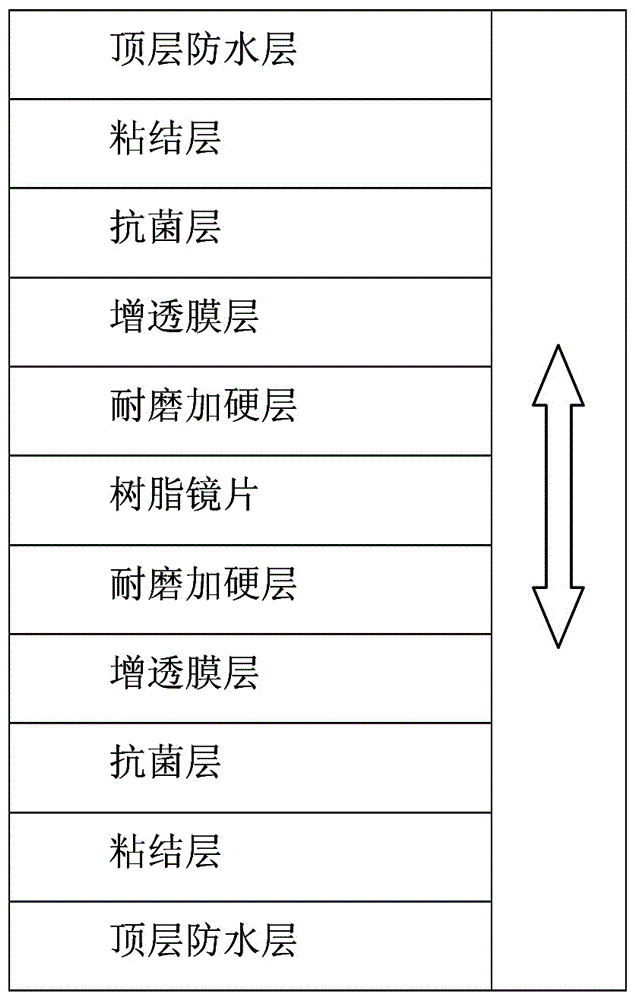

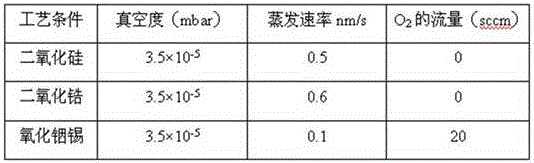

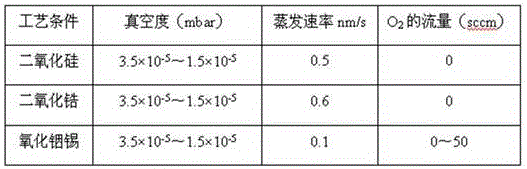

Antimicrobial coated resin lens and manufacturing method thereof

ActiveCN106772713AImprove bonding fastnessImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingSputteringWear resistant

The invention discloses an antimicrobial coated resin lens and a manufacturing method thereof. The manufacturing method of the antimicrobial coated resin lens is characterized by including steps: 1, manufacturing a wear-resistant hardening layer on the surface of a resin lens by adopting dip-coating technology; 2, plating an antireflection film layer on the surface of the wear-resistant hardening layer by adopting vacuum sputtering coating technology and ion source assisted coating technology; 3, plating an antimicrobial layer on the surface of the antireflection film layer by adopting the vacuum sputtering coating technology and the ion source assisted coating technology; 4, plating an adhesive layer on the surface of the antimicrobial layer by adopting the vacuum sputtering coating technology and the ion source assisted coating technology; 5, continuing adopting the vacuum sputtering coating technology for plating a top wear-resistant layer on the surface of the adhesive layer. The manufacturing method of the antimicrobial coated resin lens adopts the vacuum sputtering coating technology and the ion source assisted coating technology, and thereby increases adhesion stress among all the film layers, and achieves the purpose of enabling obtained glasses products to not only keep original performance of the antireflection film layer, but also have long-term effective excellent antibacterial performance.

Owner:SHANGHAI CONANT OPTICS CO LTD

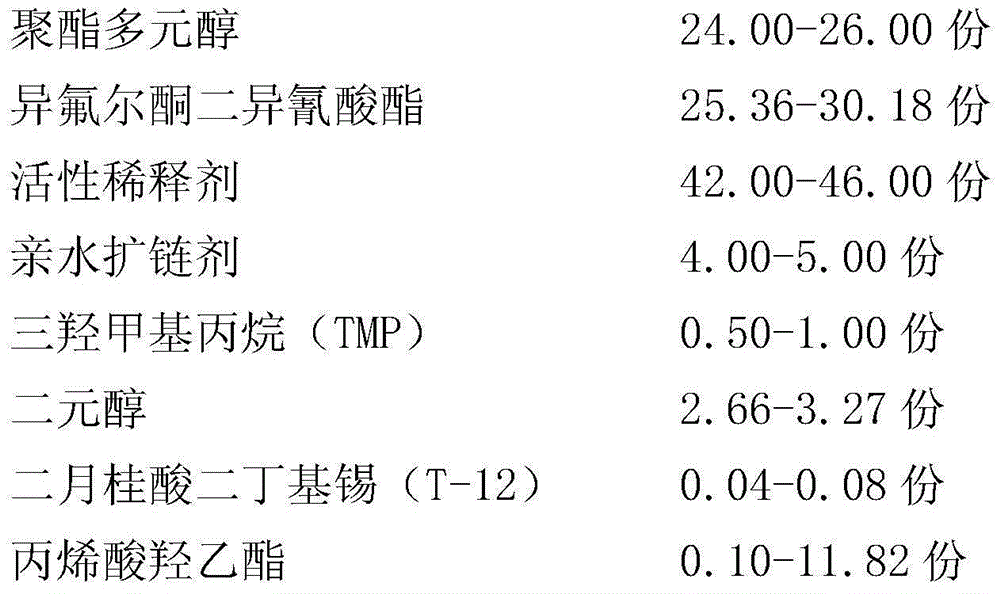

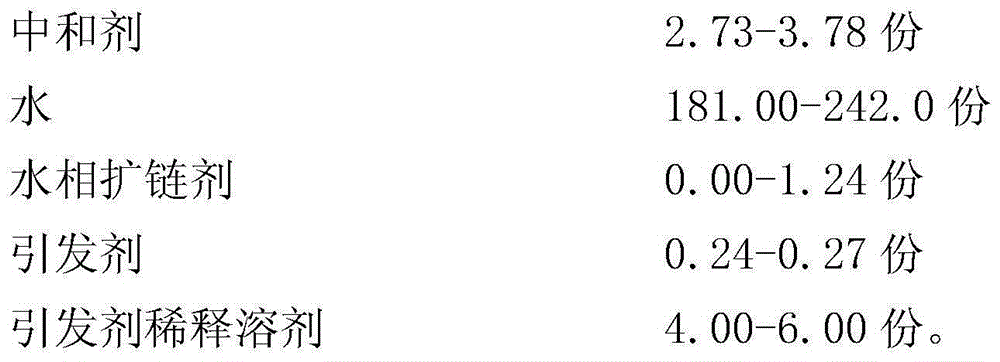

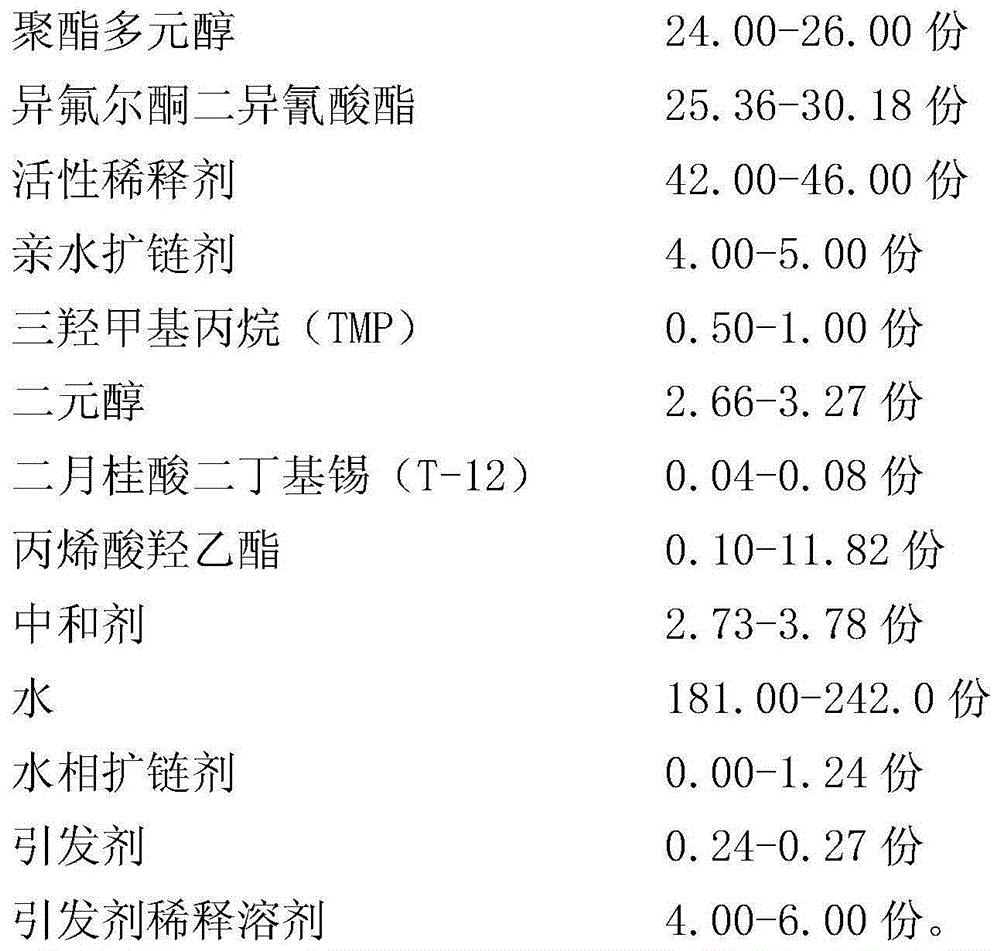

Polyurethane-acrylic ester composite emulsion of core-shell interpenetrating polymer network structure and preparation method thereof

The invention relates to polyurethane-acrylic ester composite emulsion of a core-shell interpenetrating polymer network structure and a preparation method thereof. The polyurethane-acrylic ester composite emulsion is prepared from polyester polyol, isophorone diisocyanate, reactive diluent, a hydrophilic chain-extending agent, trimethylolpropane, dihydric alcohol, dibutyltin dilaurate, hydroxyethyl acrylate, a neutralizing agent, water, an aqueous phase chain-extending agent, an initiating agent and initiating agent diluting solvent. The polyurethane-acrylic ester composite emulsion and the preparation method thereof have the following advantages that the problem that water resistance is lowered due to addition of emulsifier is solved; pollution caused by organic solvent and tediousness of the later-period organic solvent extraction technology are avoided. The emulsion is polyurethane-acrylic ester copolymer emulsion of a core-shell crosslinking interpenetrating polymer network structure.

Owner:SKSHU PAINT

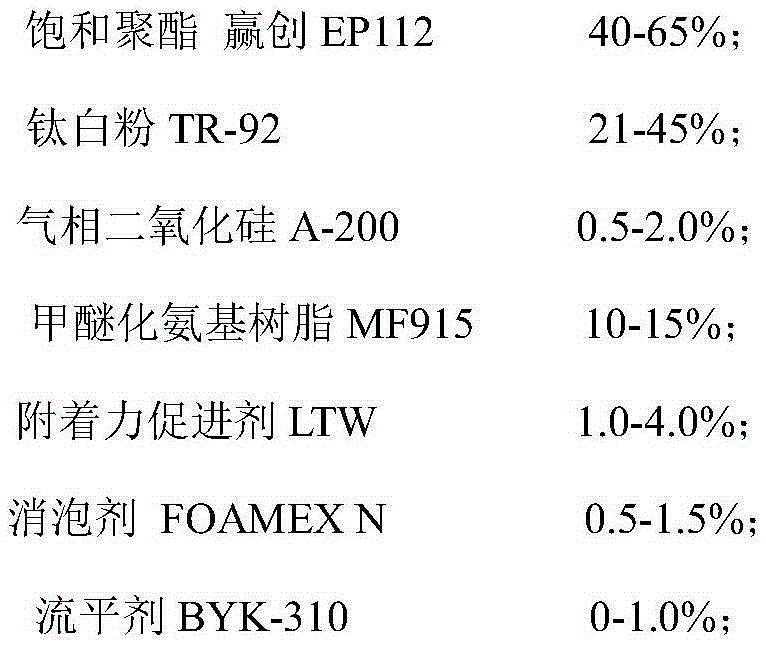

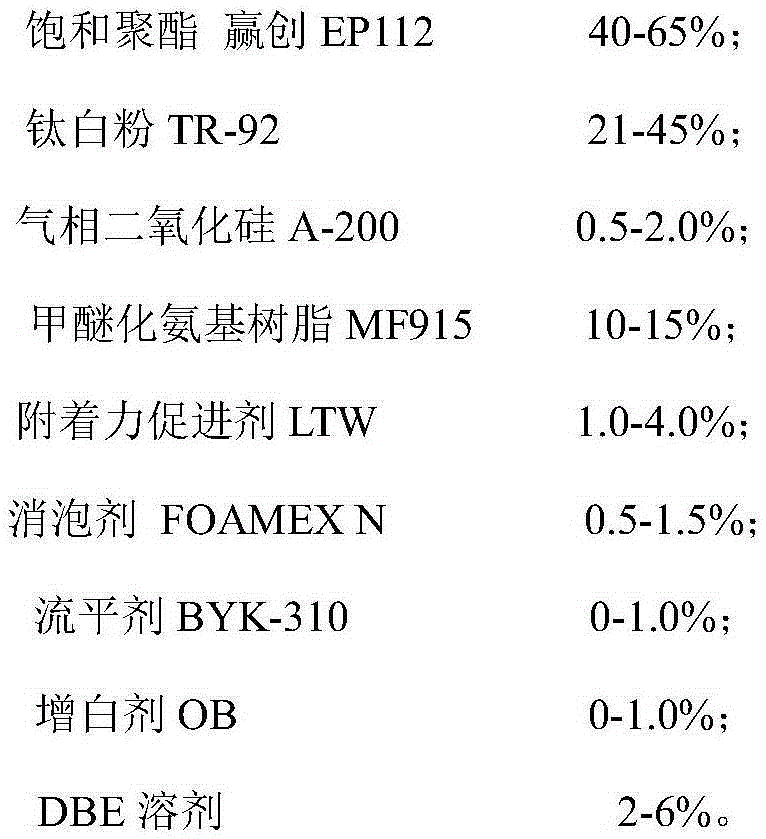

Thermosetting type glass screen printing ink and preparation method thereof

The invention discloses thermosetting type glass screen printing ink. The thermosetting type glass screen printing ink includes, by weight, 40%-65% of Evonik EP112 saturated polyester, 21%-45% of titanium dioxide TR-92, 0.5%-2.0% of fumed silica A-200, 10%-15% of methylated amino resin MF915, 1.0%-4.0% of adhesion promoters LTW, 0.5%-1.5% of antifoaming agents FOAMEXN, 0-1.0% of flatting agents BYK-310, 0-1.0% of brightening agents OB and 2%-6% of DBE solutions. A preparation method of the thermosetting type glass screen printing ink includes the steps that the saturated polyester, the titanium dioxide and the fumed silica are firstly stirred evenly, then the methylated amino resin, the adhesion promoters, the antifoaming agents, and / or the flatting agents, and / or the brightening agents are added into the mixture, and the DBE solutions are added finally. The thermosetting type glass screen printing ink has good adhesion, water resistance, acid and alkali resistance, cold and hot impact resistance, butanone dissolution resistance, fast yellowing resistance, high temperature yellowing resistance, flexibility, constructability and ultraviolet resistance.

Owner:WUHU CHUNFENG NEW MATERIAL

Composite emulsion for water-based plastic base paint and preparation method of composite emulsion

The invention discloses composite emulsion for water-based plastic base paint and a preparation method of the composite emulsion. The composite emulsion is prepared by blending water-based room temperature self-crosslinked polyacrylate copolymer emulsion with high adhesive force and polyacrylate copolymer emulsion of water-based core-shell structure with high drying speed and high hardness, wherein both the water-based room temperature self-crosslinked polyacrylate copolymer emulsion and the polyacrylate copolymer emulsion of the water-based core-shell structure are emulsion with core-shell structures prepared by adopting a seminal emulsion polymerization method. The raw materials have low price, the synthesis method is simple, the reaction conditions are mild, synthesis of the material can be finished in a reaction vessel, and the method has wide applicability. The composite emulsion for the water-based plastic base paint can have high adhesive force with multiple plastic base materials, and has high drying speed and good paint film performance. The composite emulsion for the water-based plastic base paint can be used for the plastic base materials, can also be used for substances which cannot be baked at a high temperature such as woodenware and the like, and has energy conservation in application and good performance.

Owner:HUAZHONG UNIV OF SCI & TECH +1

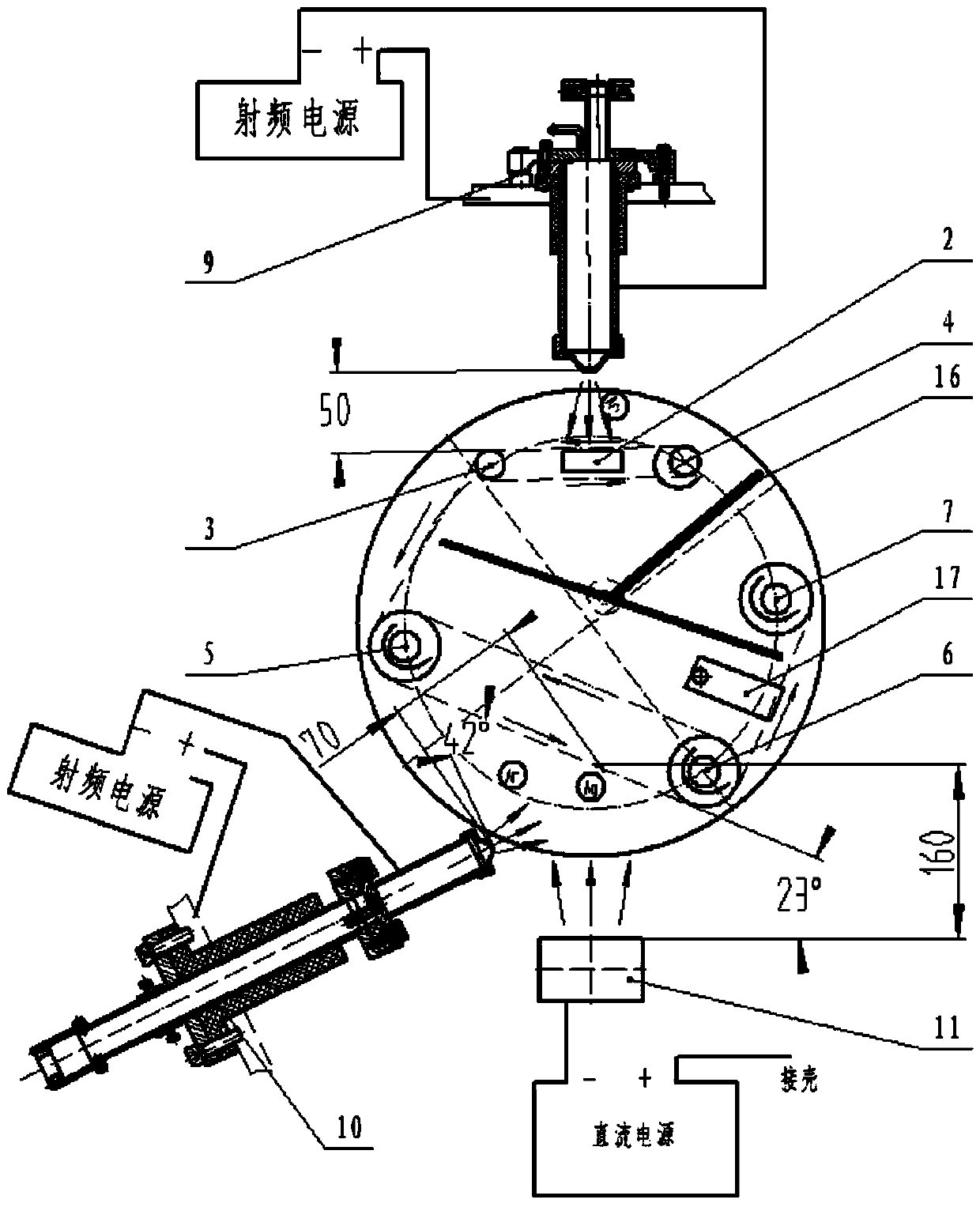

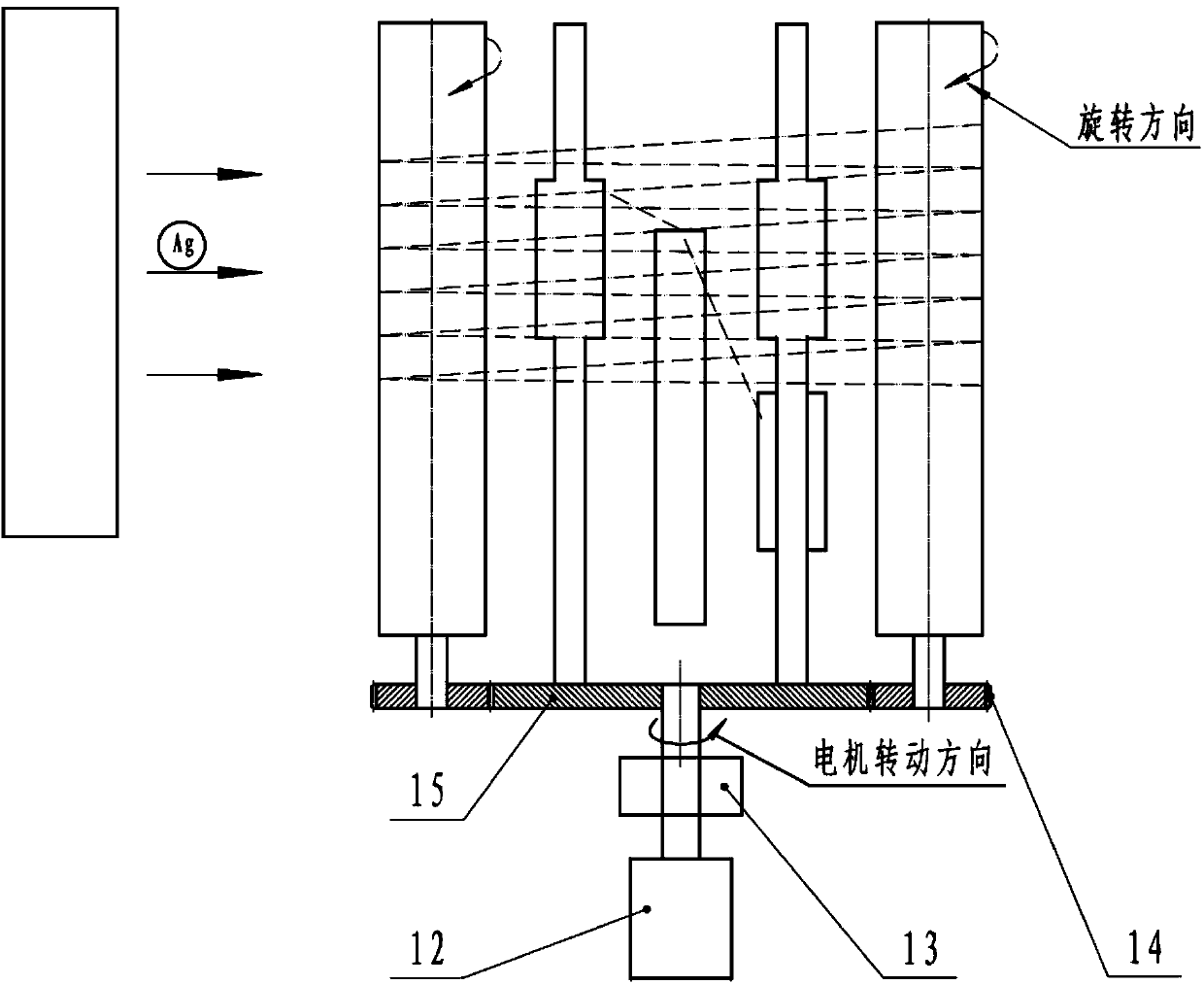

Device and method for continuously coating fiber with metallic conductive function film through magnetron sputtering

The invention discloses a device and a method for continuously coating a fiber with a metallic conductive function film through magnetron sputtering, and belongs to the field of vacuum film coating. The method comprises the following steps: winding fiber filaments around an unwinding device; putting the unwinding device into a vacuum chamber for filament moving; cleaning and roughening the fiber filaments unwound by the unwinding device through a plasma cleaning device repeatedly in parallel; performing film coating on the cleaned fiber filaments through an auxiliary plasma film coating device and a rectangular magnetron sputtering target repeatedly in parallel; winding the film-coated fiber filaments around a winding device so as to complete film coating. During cleaning and surface roughening through the plasma cleaning device, introduced gas is mixed gas of oxygen and argon, oily substances on the fiber are decomposed, and meanwhile, the surface of the fiber is roughened to increase the adhesion force of the film. The auxiliary plasma film coating device is used for increasing the adhesion force of the film through ion bombardment. According to the device and the method, the defects of pollution, high operation cost, poor adhesion force and the like in the prior art are overcome. The device and the method have the advantages of uniform coating, impurity elimination, high adhesion force and the like.

Owner:BEIJING UNIV OF TECH

Melamine fumiture surface paper coated with ultrasonic violet curing coating and preparation method

InactiveCN101748654ASolve the problem of recoatabilitySolve Adhesion ProblemsPaper coatingPhysical paper treatmentMelamineMaterials science

The invention belongs to the field of building decoration material, in particular to melamine fumiture surface paper coated with an ultrasonic violet curing coating which is formed by applying the ultrasonic violet curing coating on the surface, and a preparation method thereof. A common paper substrate is dipped into melamine for once and then taken out and dried; and then a layer of ultrasonic violet curing coating is applied on one surface of the common paper dipped with the melamine, and is radiated and cured by ultrasonic violet; and the a layer of melamine is applied on the other surface of the common paper dipped with the melamine and dried, to obtain the melamine fumiture surface paper coated with the ultrasonic violet curing coating. After being coated at high temperature, the melamine fumiture surface paper coated with the ultrasonic violet curing coating obtained through the invention of the invention has the advantages of good adhesion of the surface ultrasonic violet curing coating and the melamine layer and good recoatability of the ultrasonic violet curing coating surface, and has better recoatability than the prior commonly used melamine fumiture surface paper.

Owner:ZHUHAI DONGCHENG UV MATERIALS

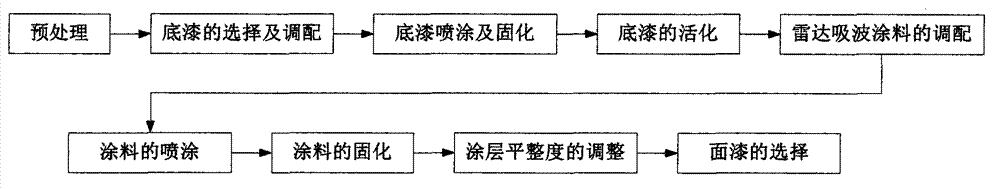

Coating method of radar wave absorbing coating

InactiveCN102861712ASolve Adhesion ProblemsFix stability issuesCoatingsSpecial surfacesAdhesion forceCoated surface

The invention belongs to the field of surface treatment, particularly relates to a coating method of a radar wave absorbing coating and aims at guaranteeing the performance of the wave absorbing coating. The method comprises the steps of: pre-treating a bottom substrate of the radar wave-absorbing coating; selecting and mixing a primer; spraying and curing the primer; activating the primer; mixing the radar wave absorbing coating; spraying the radar wave absorbing coating; curing the coating; and adjusting the surface flatness of the coating and selecting a finish. According to the method disclosed by the invention, the problems that the adhesion force of the wave-absorbing coating is poor are solved, the performance is not stable, and an operation process has no quality control points and the like, and engineering requirements can be met; and the coating quality reaches to design requirements of products.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Conductive silver paste for ferrite core inductance and method for producing same

ActiveCN102610326AAvoid crackingNot easy to electroplateTransformers/inductances coils/windings/connectionsNon-conductive material with dispersed conductive materialSilver pasteInductance

The invention discloses a conductive silver paste for a ferrite core inductance and a method for producing the same, wherein the method comprises the following steps that: (1) lead-free glass powder is produced and contains an inorganic additive I which occupies 1-4% of the total quantity of the lead-free glass powder; (2) an organic carrier is produced; (3) superfine silver powder, silver flake, the lead-free glass powder and an inorganic additive II are mixed to produce the powder, the powder is uniformly stirred and then added into the organic carrier, after high-speed stirring and dispersion, the powder is rolled by a three-roller mill to the fineness of lower than 10mum, and is screened by a screen of 200 meshes for producing the conductive silver paste for the ferrite core inductance. The ferrite conductive silver paste can effectively solve the defects of the silver paste for the ferrite core inductance on corrosion resistance, adhesive force and electroplating performance, has good quality, is low in cost, and is an ideal substitute product for lead-bearing paste. The adopted technology can ensure the stability and consistency of the silver paste.

Owner:广东羚光新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com