Polyester resin for powder coating for structural member of engineering machine and preparation method of polyester resin

A powder coating and engineering machinery technology, applied in the field of polyester resin, can solve the problems of poor mechanical properties, poor corrosion resistance, insufficient curing degree, etc., and achieve the effect of good curing degree, good adhesion and mechanical properties, and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is the specific implementation of the present invention. What needs to be explained is that the invention is aimed at the polyester resin for powder coating of construction machinery structural parts. Other parts of construction machinery, such as thin parts and small parts, do not exist. The structural parts are larger and thicker. Therefore, the product of the present invention is also applicable to other parts of construction machinery. For those skilled in the art, these should be regarded as the scope of protection of the present invention without violating the principle of the present invention.

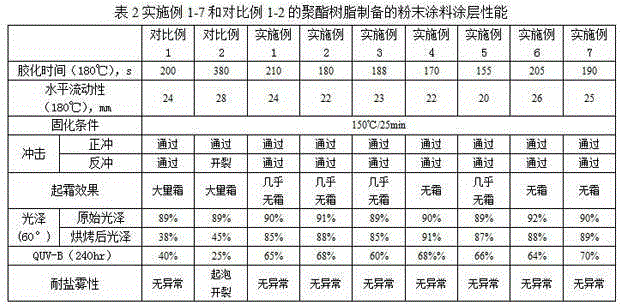

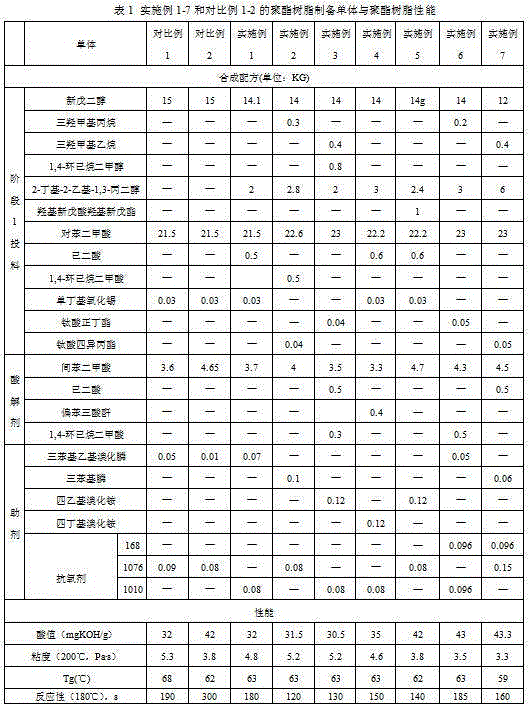

[0032] Some specific examples are listed below to illustrate the present invention. It should be pointed out that the following specific examples are only used to further illustrate the present invention, and do not represent limitations to the protection scope of the present invention. Some non-essential modifications and adjustments made by others accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com