Conductive silver paste for ferrite core inductance and method for producing same

A technology of ferrite magnetic core and conductive silver paste, which is applied in the direction of cable/conductor manufacturing, transformer/inductor coil/winding/connection, conductive materials dispersed in non-conductive inorganic materials, etc., which can solve the problem of non-dense silver layer , the silver layer is easy to fall off, cracks and other problems, to achieve the effect of not easy to crack, ensure stability and consistency, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

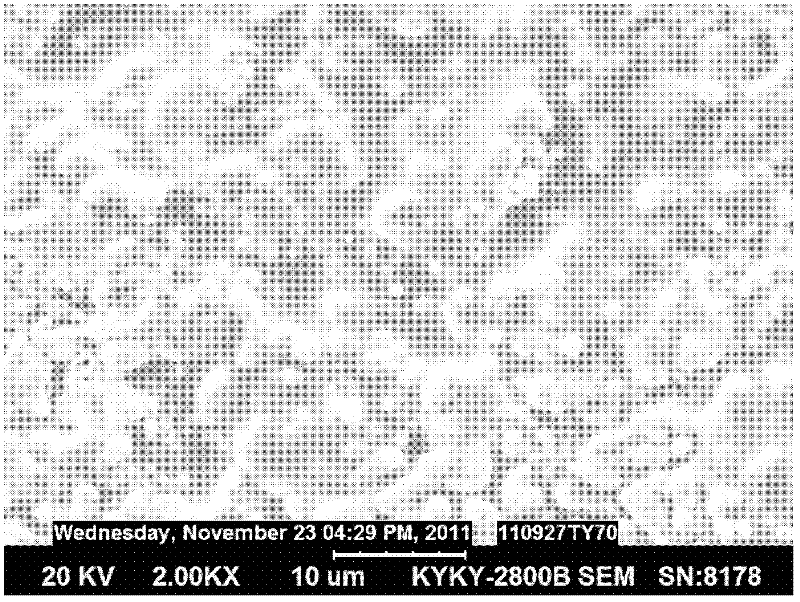

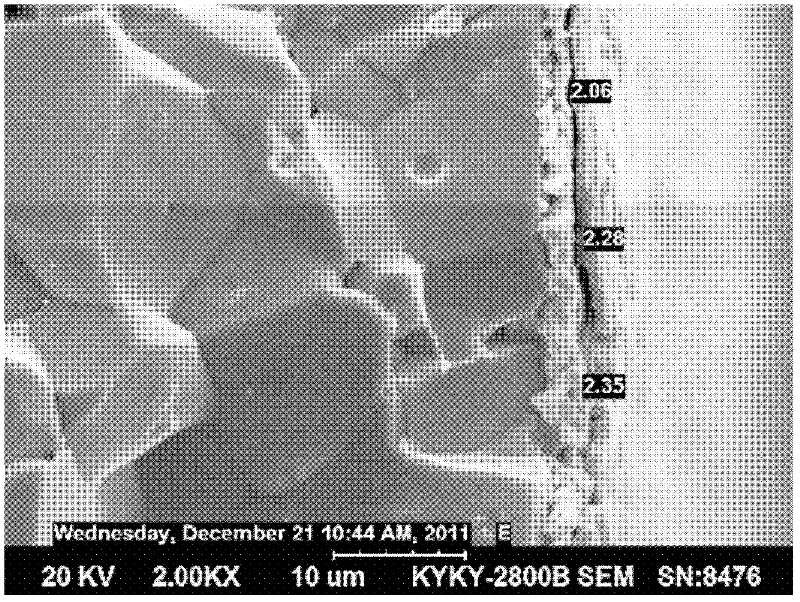

Image

Examples

Embodiment 1

[0031] Carry out the preparation of silver paste for ferrite core inductors according to the following steps:

[0032] (1), preparation of lead-free glass powder

[0033] Batching according to the following mass percentages:

[0034] Na 2 O 20Wt%, CaO 20Wt%, SiO 2 55wt%, Al 2 o 3 3.5Wt%, inorganic additive HfO 2 1.5 wt%.

[0035] Mix evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 10 μm, filter and dry.

[0036] (two), the preparation of organic carrier

[0037] Batching according to the following mass percentages:

[0038] 25% ethyl cellulose, 20% terpineol, 45% diethylene glycol butyl ether, and 10% organic additive polyacrylate. After mixing the above materials, heat and dissolve them at 80-100°C to obtain a transparent glue.

[0039] (3), according to the following mass percentage ingredients:

[0040] Ultrafine silver powder 45%, flaky silver powder 25%, lead-free g...

Embodiment 2

[0043] Carry out the preparation of silver paste for ferrite core inductors according to the following steps:

[0044] (1), preparation of lead-free glass powder

[0045] Batching according to the following mass percentages:

[0046] Na 2 O 22Wt%, CaO 25Wt%, SiO 2 48wt%, Al 2 o 3 3wt%, inorganic additive CeO 2 2%.

[0047] Mix evenly with a pot mill, preheat at 450°C for 30 minutes, melt at 1200°C for 60 minutes, quench, ball mill until the particle size is less than 10 μm, filter and dry.

[0048] (two), the preparation of organic carrier

[0049] Batching according to the following mass percentages:

[0050] Ethyl cellulose 20%, terpineol 25%, diethylene glycol butyl ether 50%, organomodified polysiloxane 5%,

[0051] After the above materials are mixed, heat and dissolve at 80-100°C to obtain a transparent glue solution.

[0052] (3), according to the following mass percentage ingredients:

[0053] 55% superfine silver powder, 15% flake silver powder, 3% glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com