Patents

Literature

236results about How to "Easy to Plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

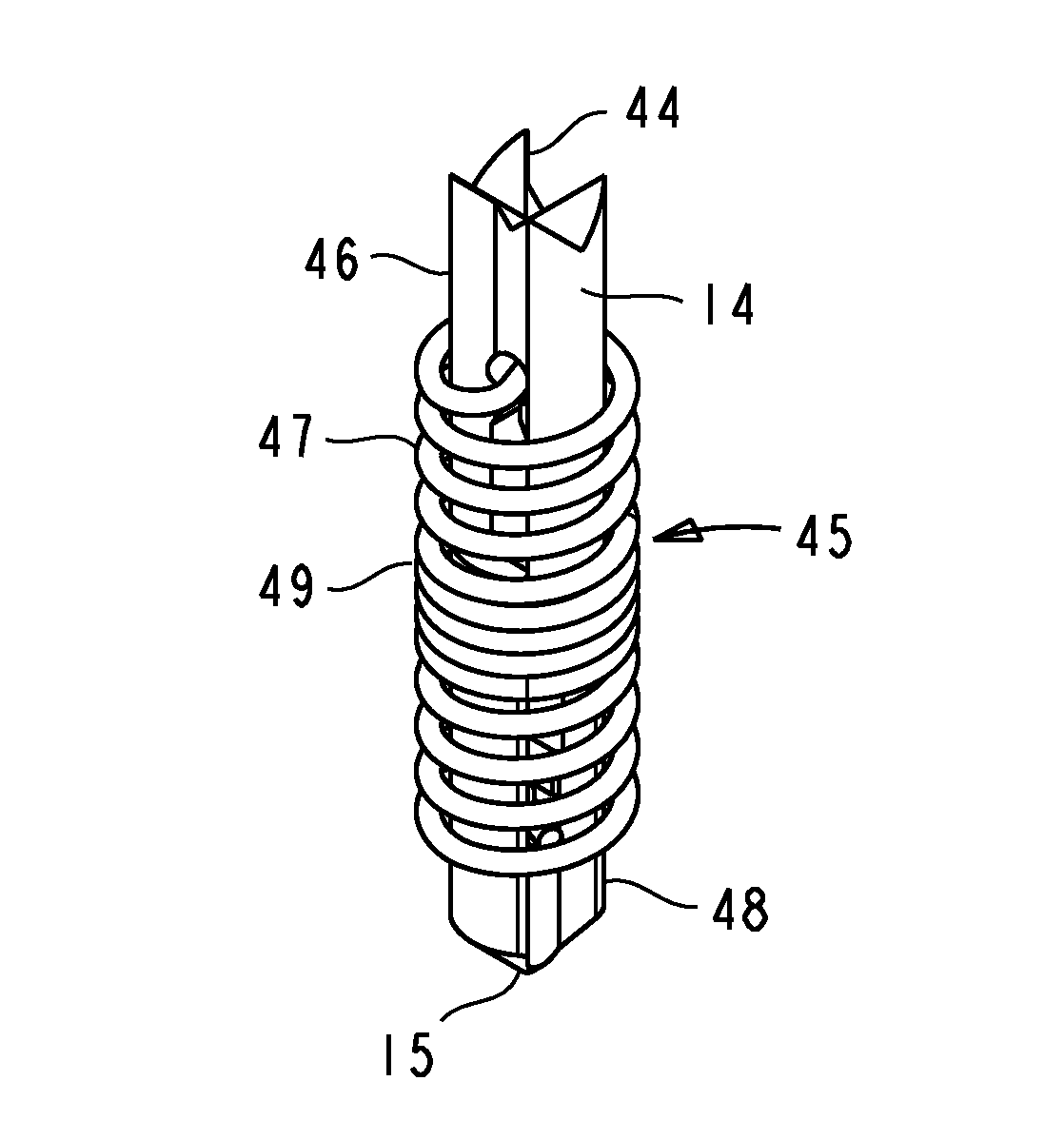

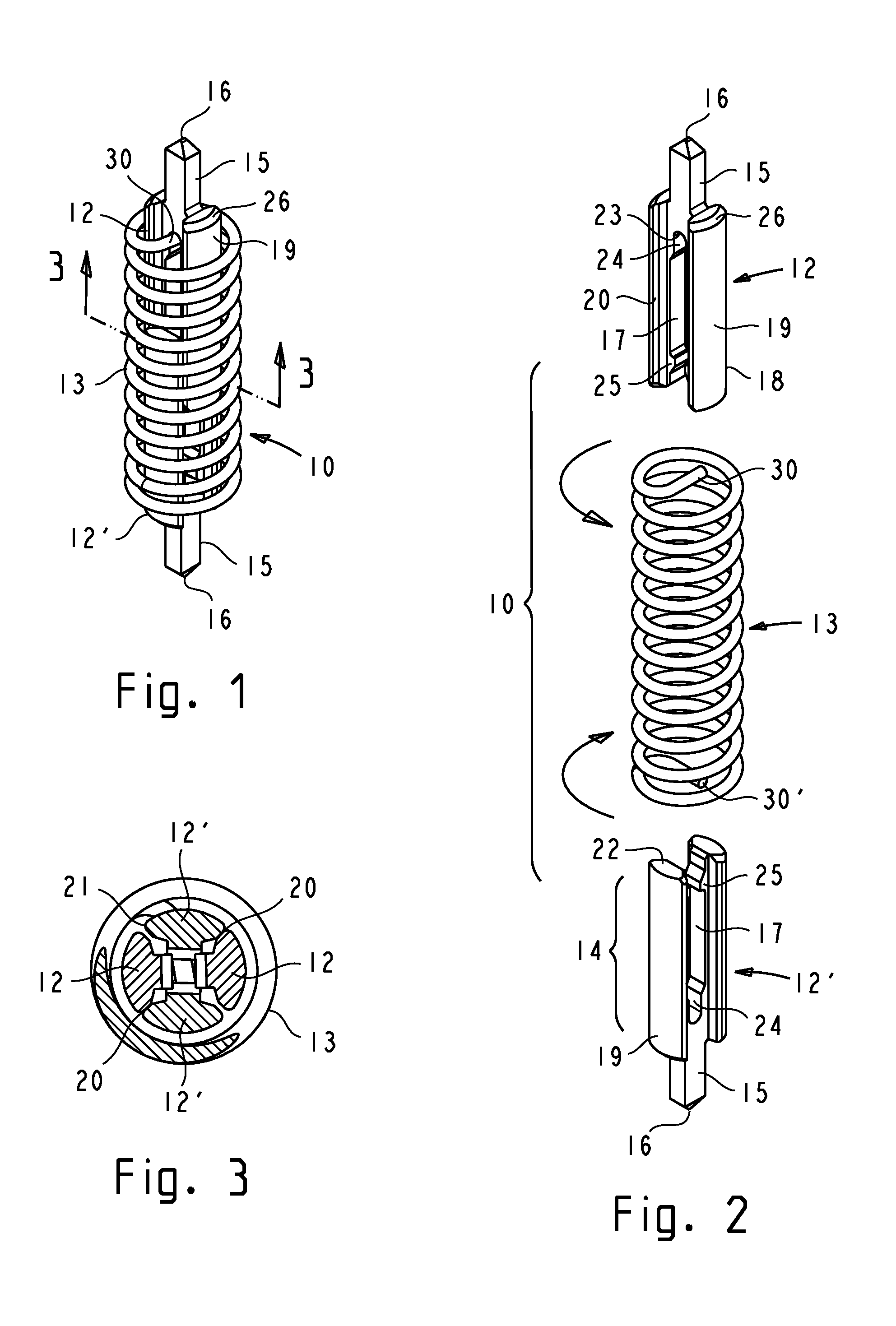

Low inductance contact probe with conductively coupled plungers

InactiveUS8373430B1Electrical effect is reducedPrevent rotationContact member manufacturingElectrical measurement instrument detailsAxial displacementCoupling

A low inductance contact probe comprises conductively coupled plungers. The plungers have coupling means which enable them to be slidably and non-rotatably engaged. A coil spring is attached to the plungers in a manner that prevents rotation of the spring's ends. The spring provides an axial plunger bias, and a torsional bias for conductive coupling between the plungers. The torsional bias is generated by an axial displacement of the spring and by twisting the spring a predetermined angle prior to attachment to the plungers. Torsion-induced contact forces between the plungers assure a direct conductive path through the plungers. The torsional bias further enables a positive attachment of the spring to the plungers. Plungers with hermaphroditic coupling means can be fabricated from a drawn profiled stock by stamping or machining. Essential plunger coupling features can be prefabricated in a drawn profiled stock with a high degree of dimensional accuracy and reproducibility.

Owner:SOCHOR JERZY ROMAN

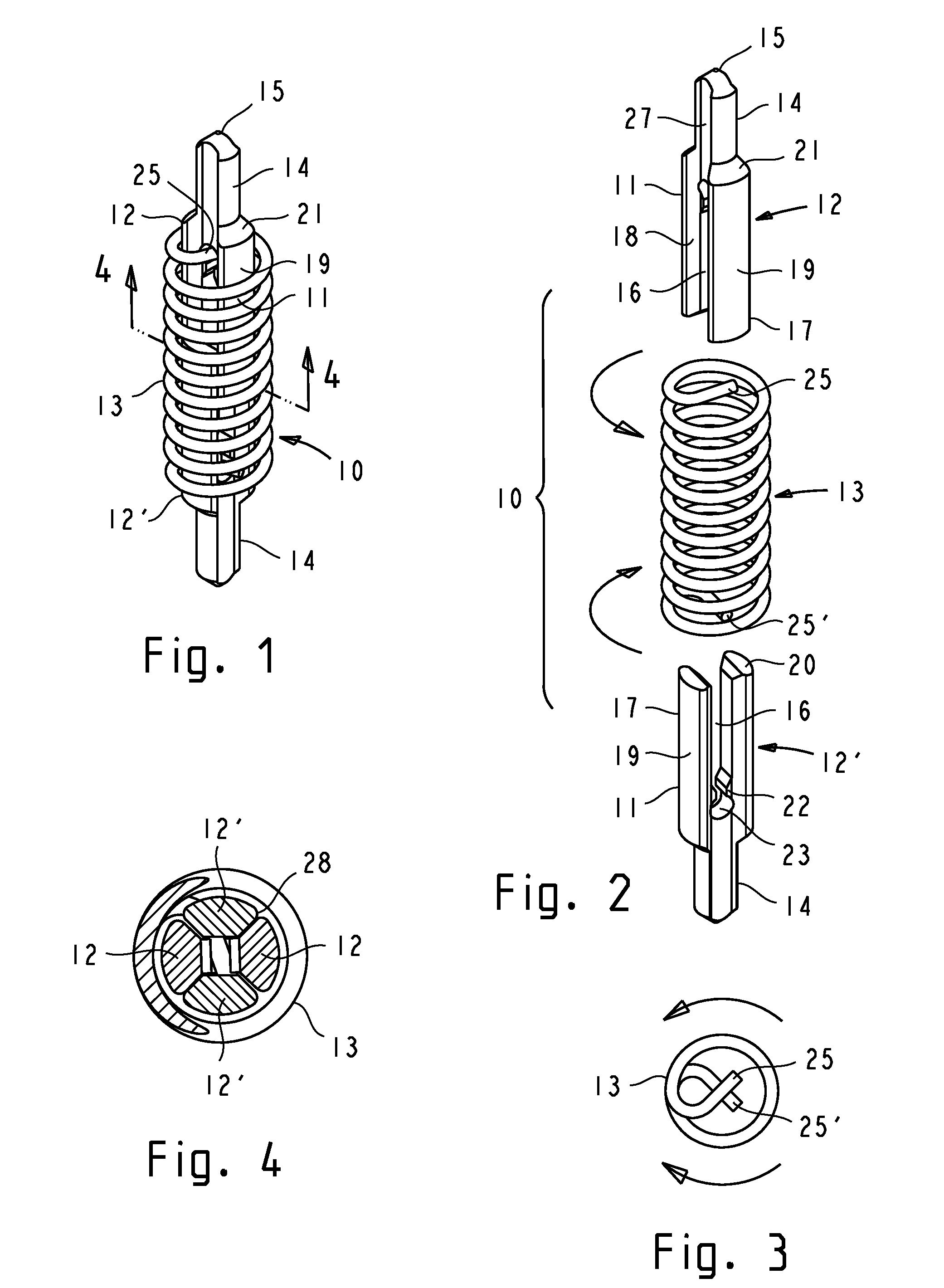

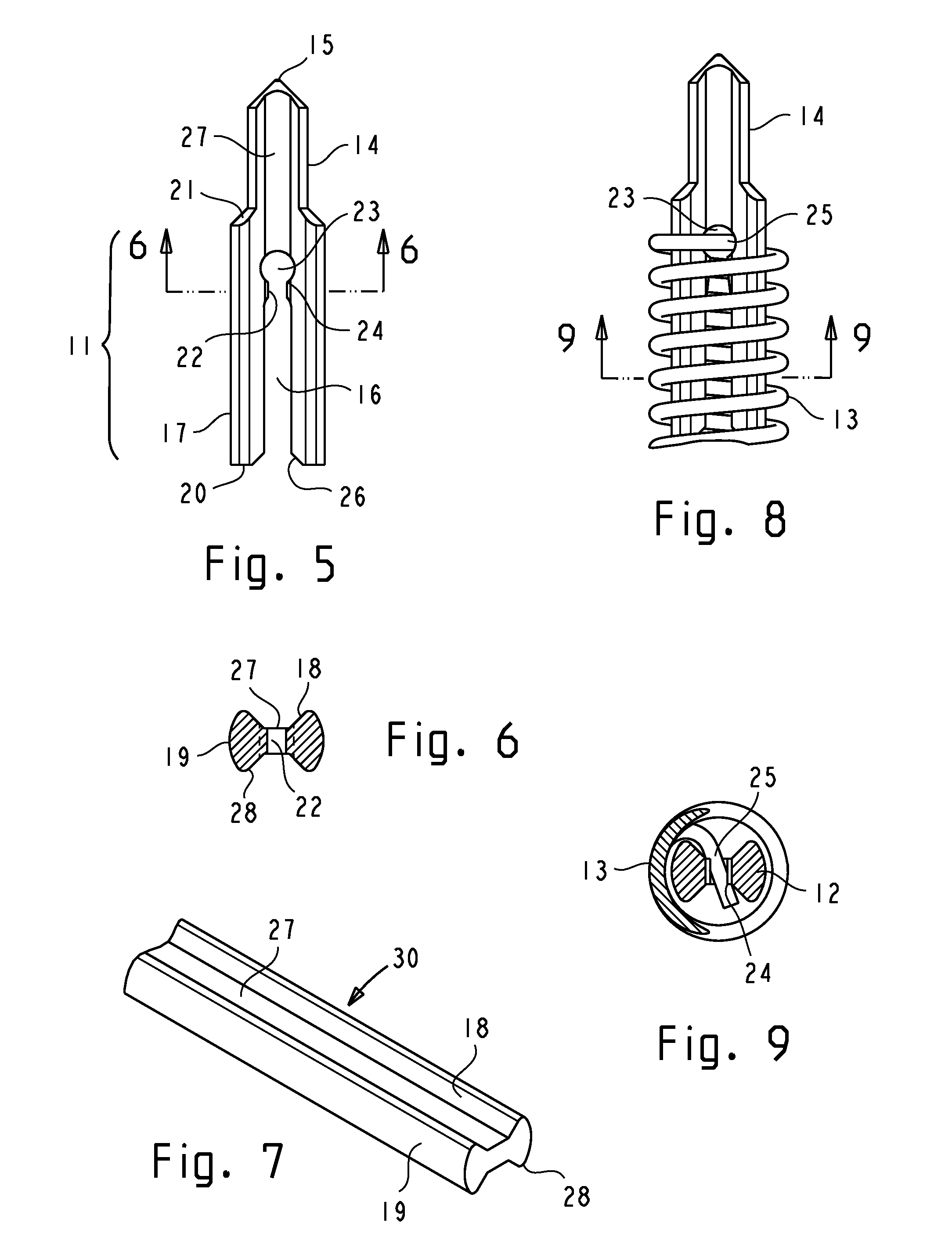

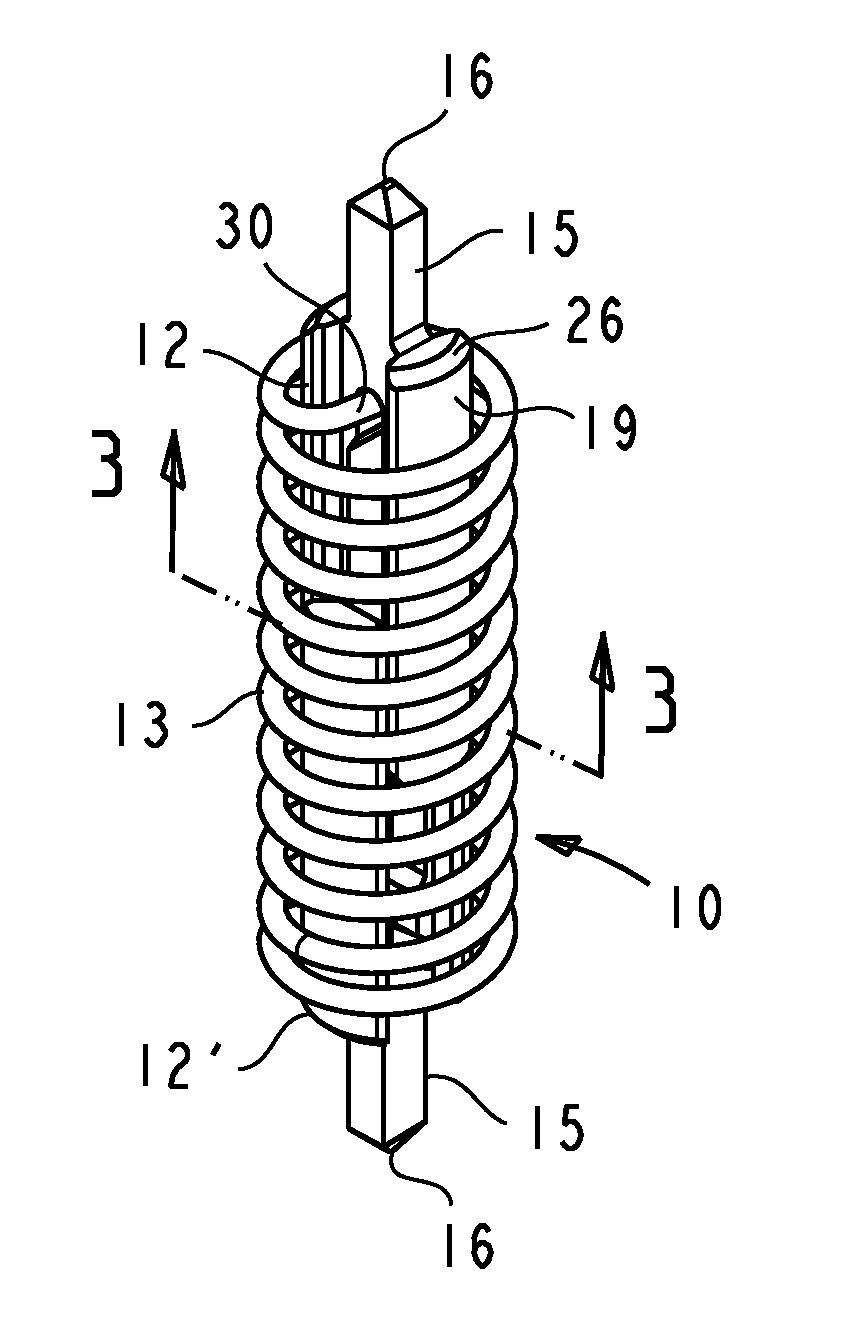

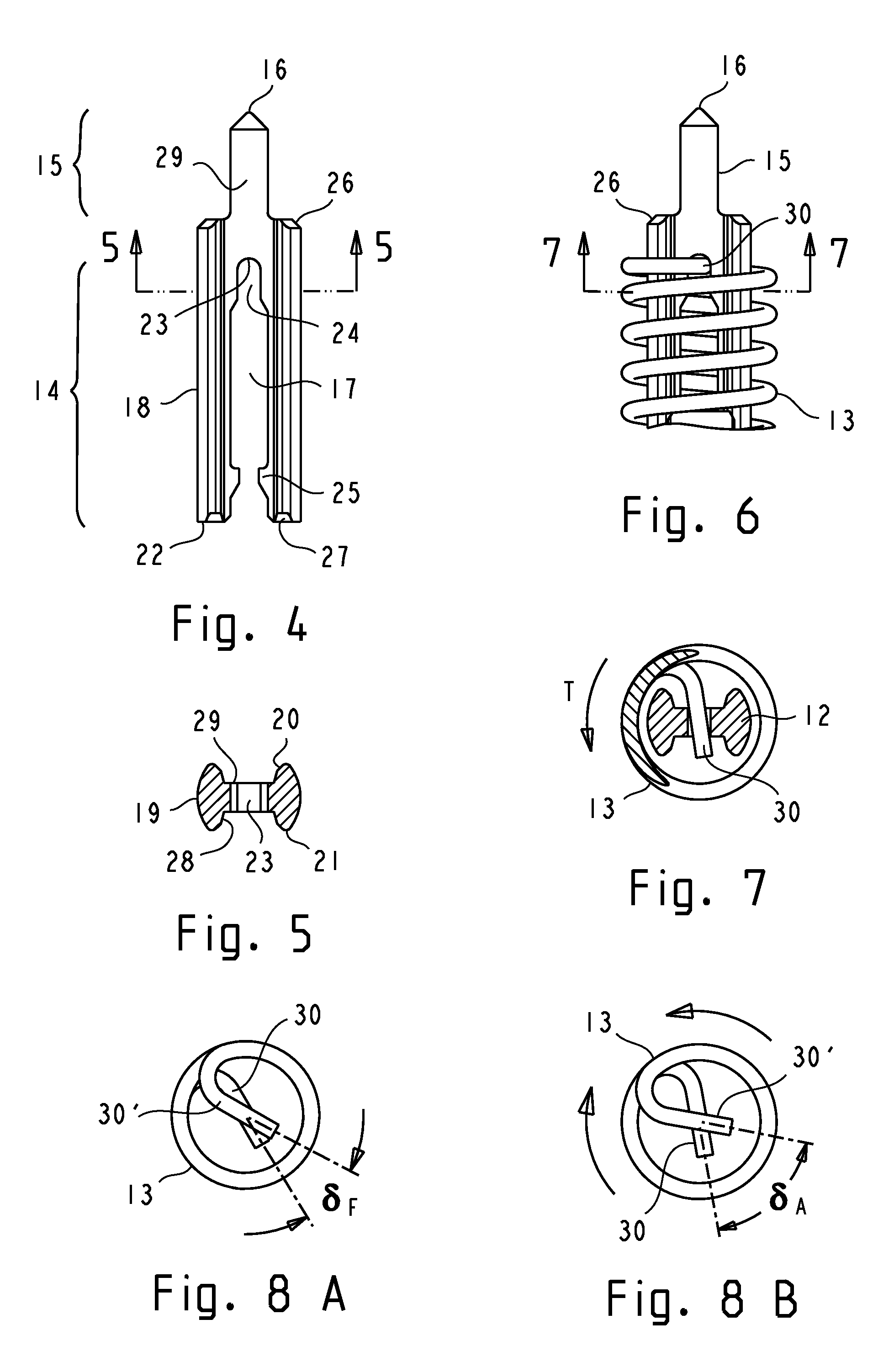

Contact probe with conductively coupled plungers

InactiveUS8547128B1Electrical effect is reducedPrevent rotationElectrical measurement instrument detailsCoupling device detailsCouplingCoil spring

A contact probe comprises conductively coupled plungers and a coil spring. The plungers have coupling means which enable them to be slidably and non-rotatably engaged. The spring is attached to the plungers in a manner that prevents rotation of the spring's ends. A desired magnitude of torsional bias is generated by twisting the spring a predetermined angle prior to attachment of the spring to the plungers. An additional torsional bias is generated by the tendency of the spring to twist when the spring is axially displaced. The resultant torsional bias rotatably biases the coupling means of the plungers against each other, generating contact forces for a direct conductive coupling between the plungers. The plungers are self-latching or are retentively attached to the spring using the torsional bias of the spring. Plungers with hermaphroditic coupling means can be fabricated from a sheet metal or a profiled stock by stamping or machining.

Owner:SOCHOR JERZY ROMAN

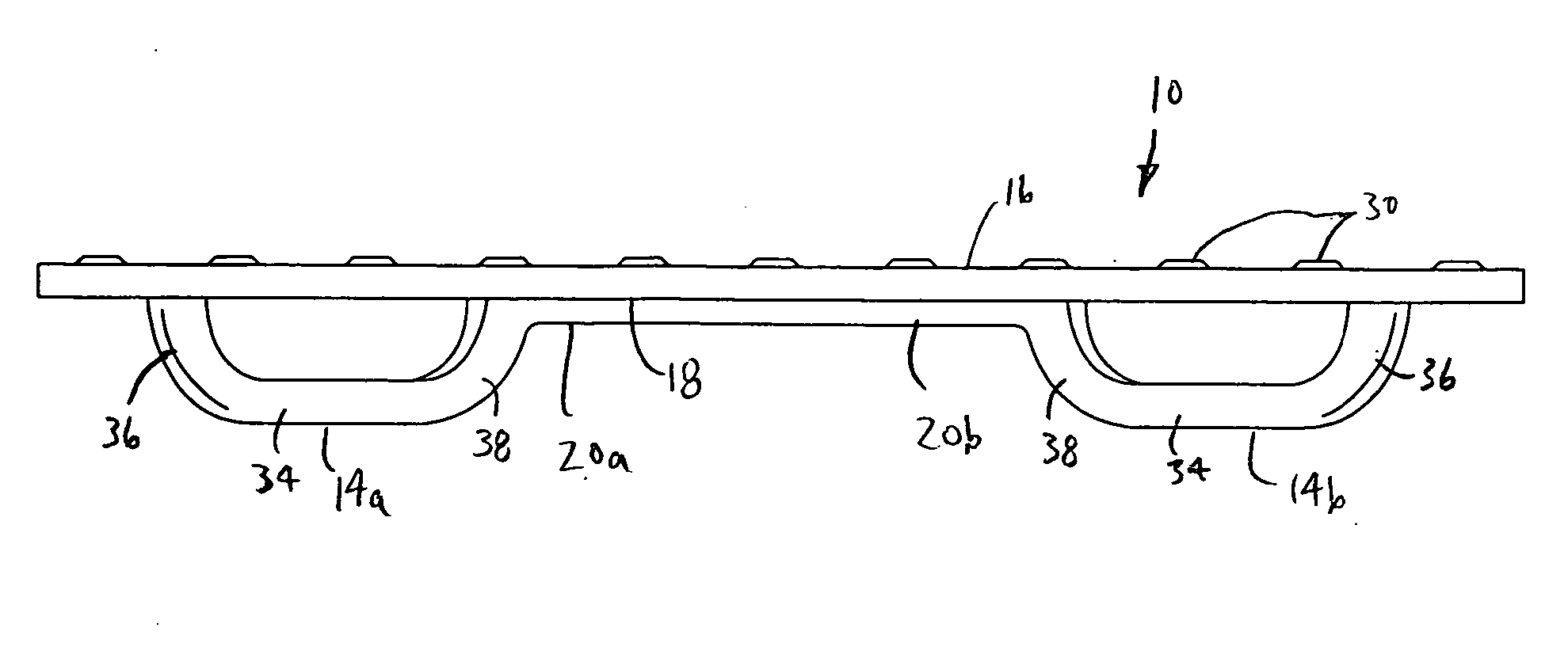

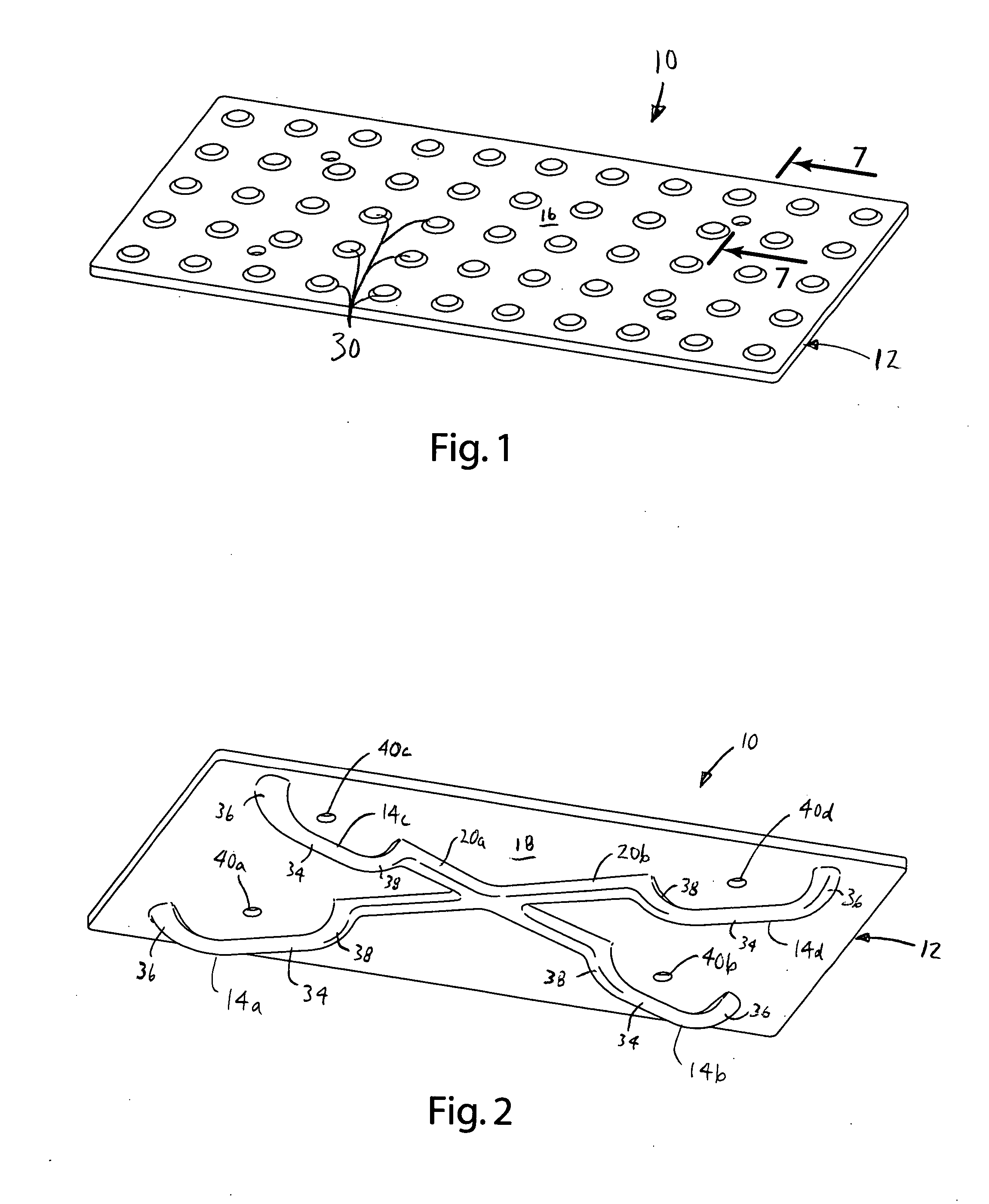

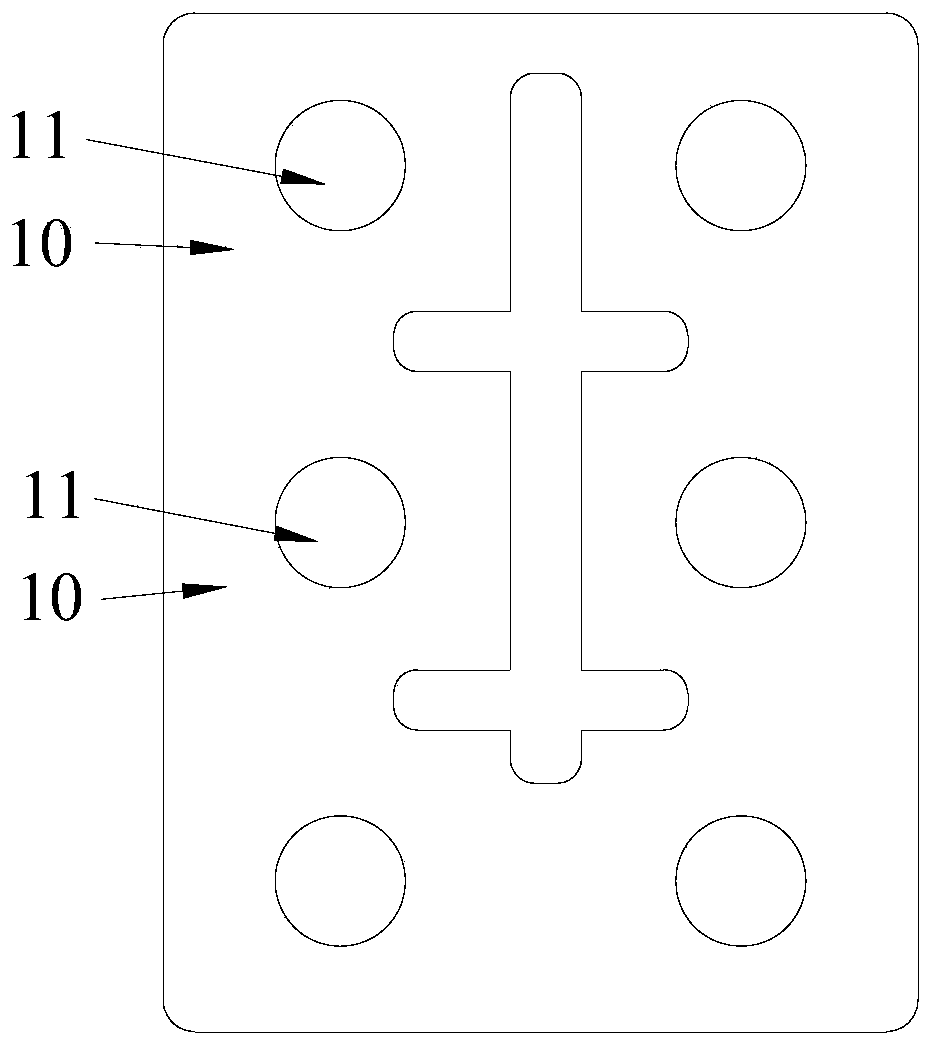

Detectable warning plate

Owner:EAST JORDAN IRON WORKS

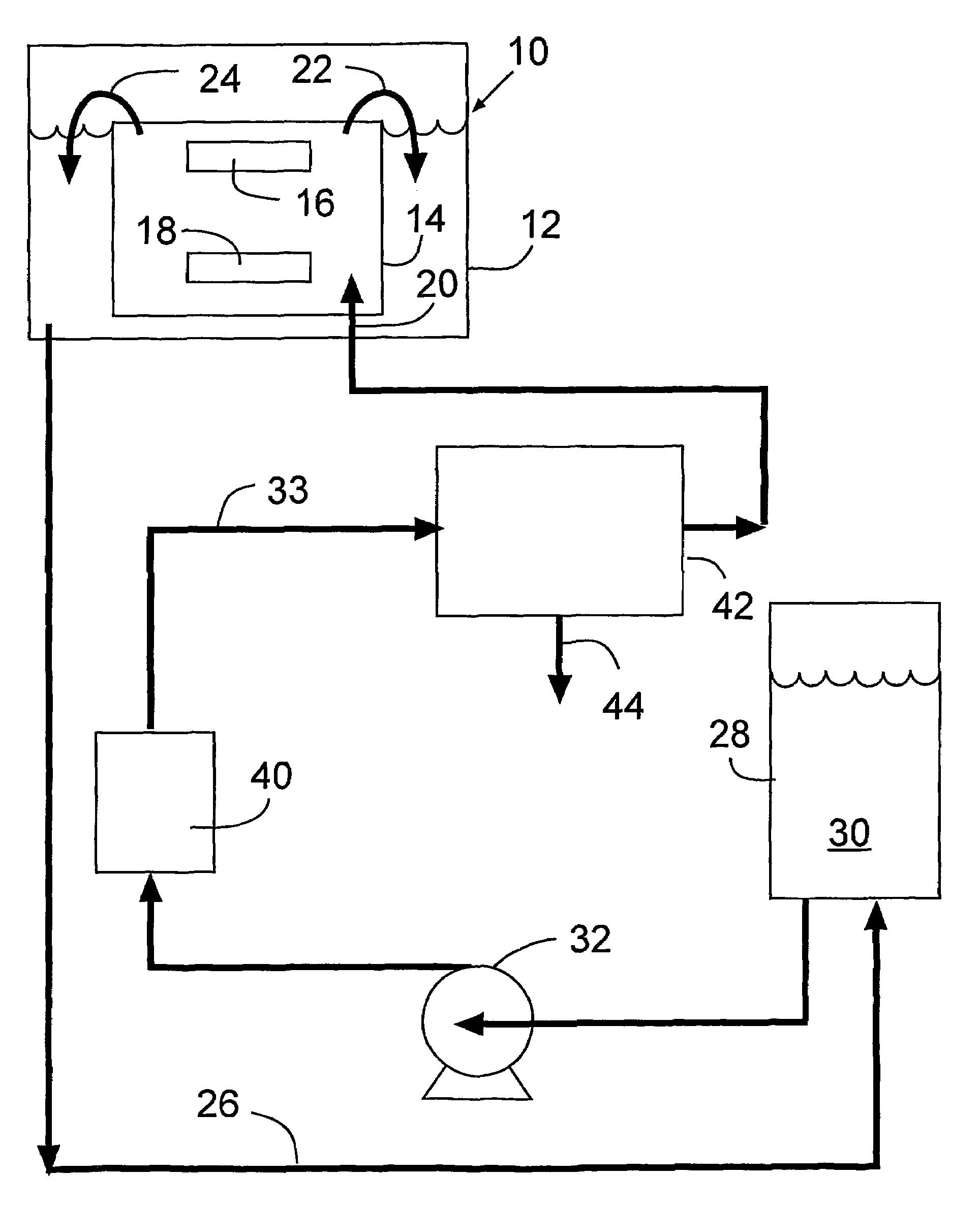

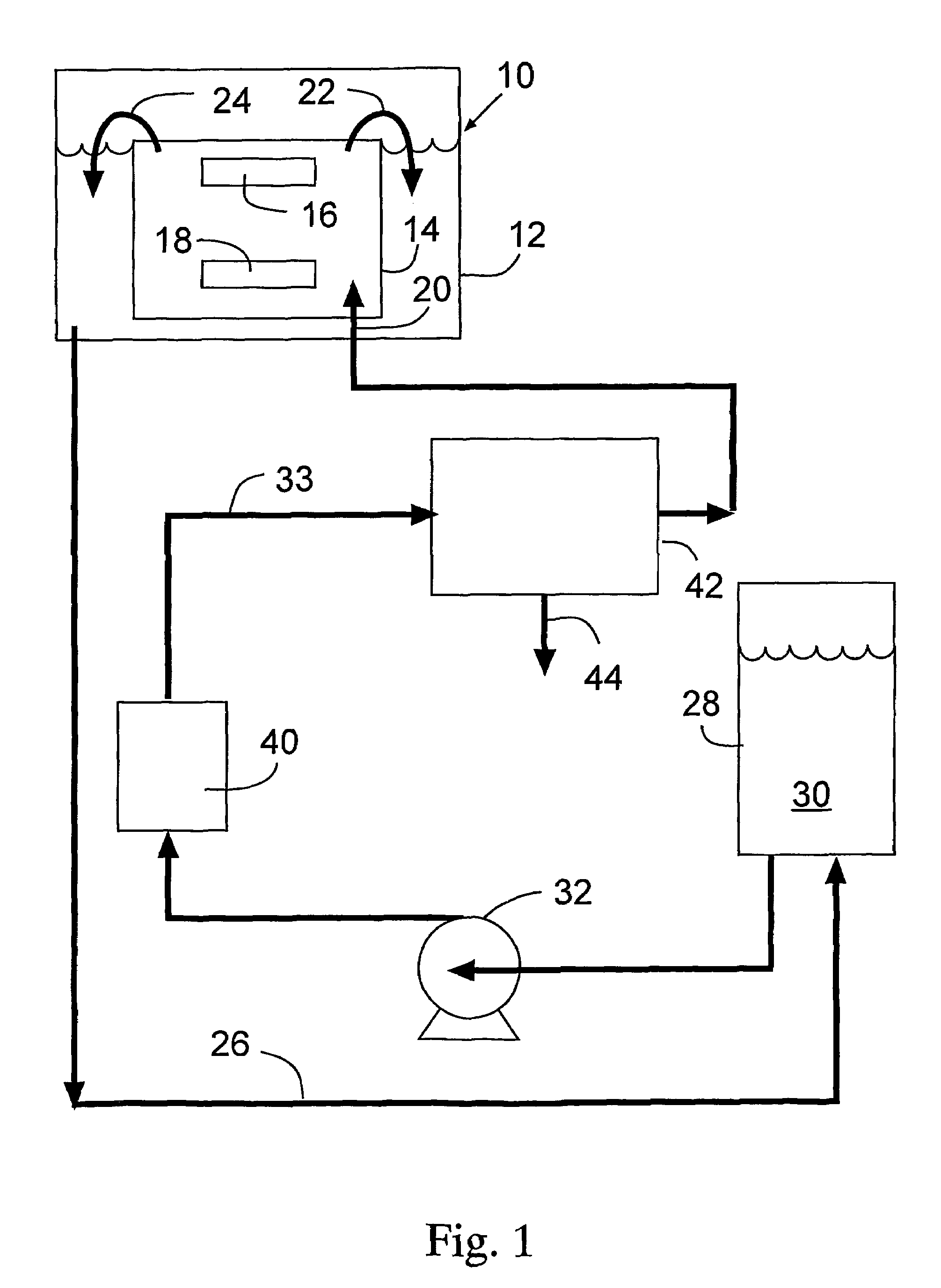

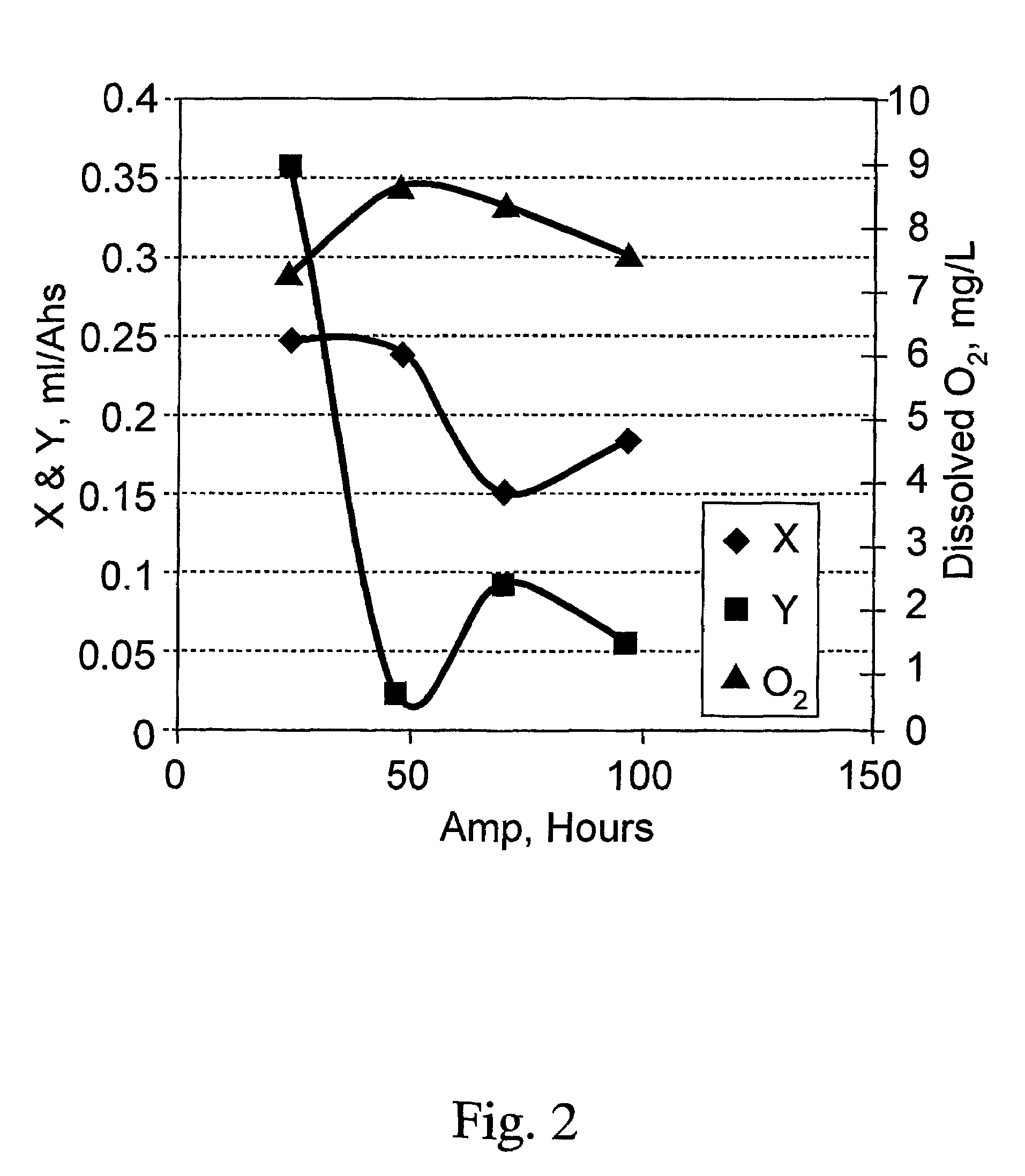

Process for degassing an aqueous plating solution

A process for removing oxygen from a copper plating solution is provided. The solution is passed through a degasser comprising a shell and hollow hydrophobic fiber porous membranes wherein the shell while a vacuum is drawn on the surfaces of the fibers opposite the fiber surfaces contacted by the solution. Gas passed through the fiber walls while liquid is prevented from infiltrating the fiber pores. The composition of the solution is monitored so that the composition can be retained substantially constant by adding components of the solution as needed.

Owner:ENTEGRIS INC

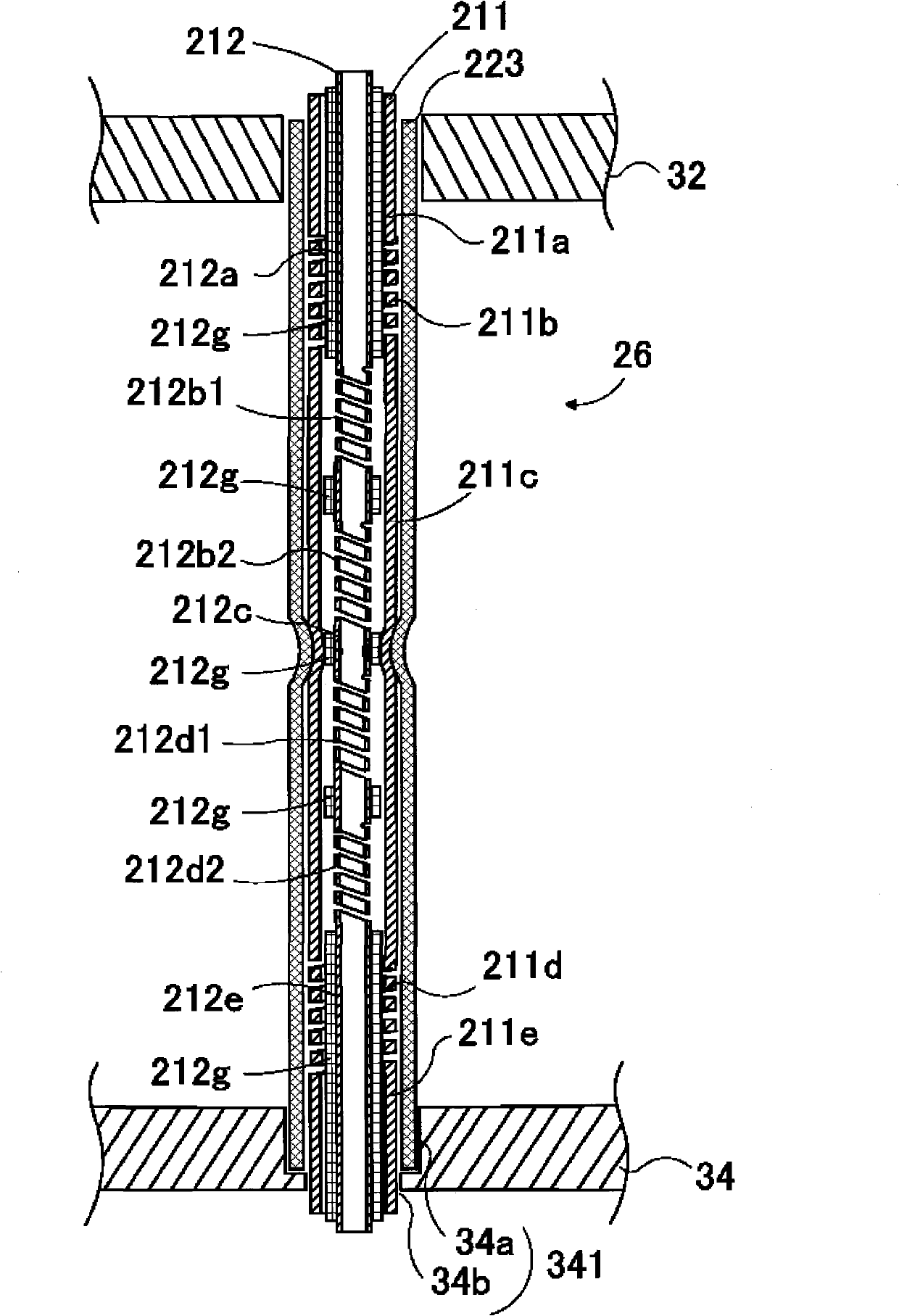

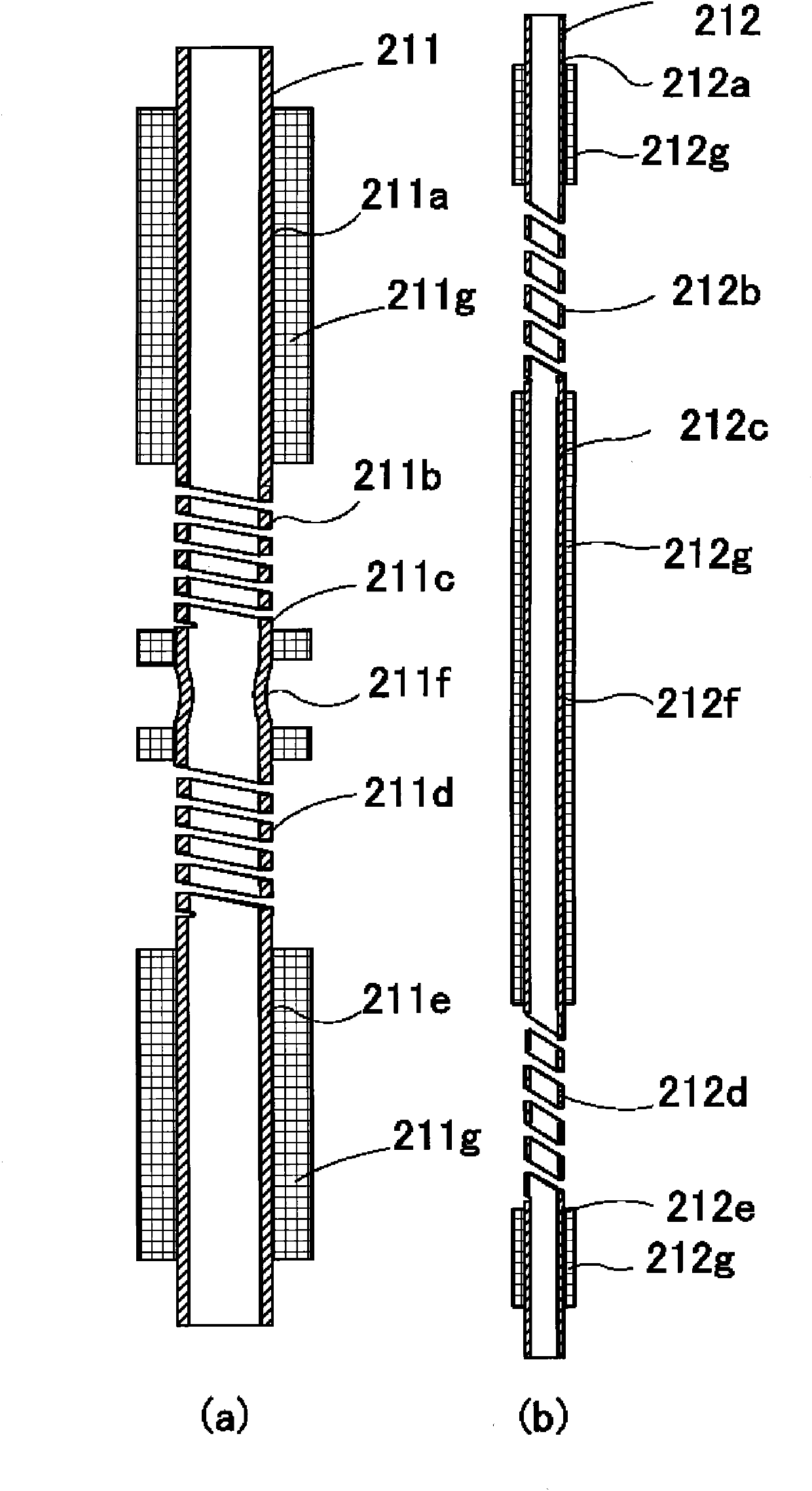

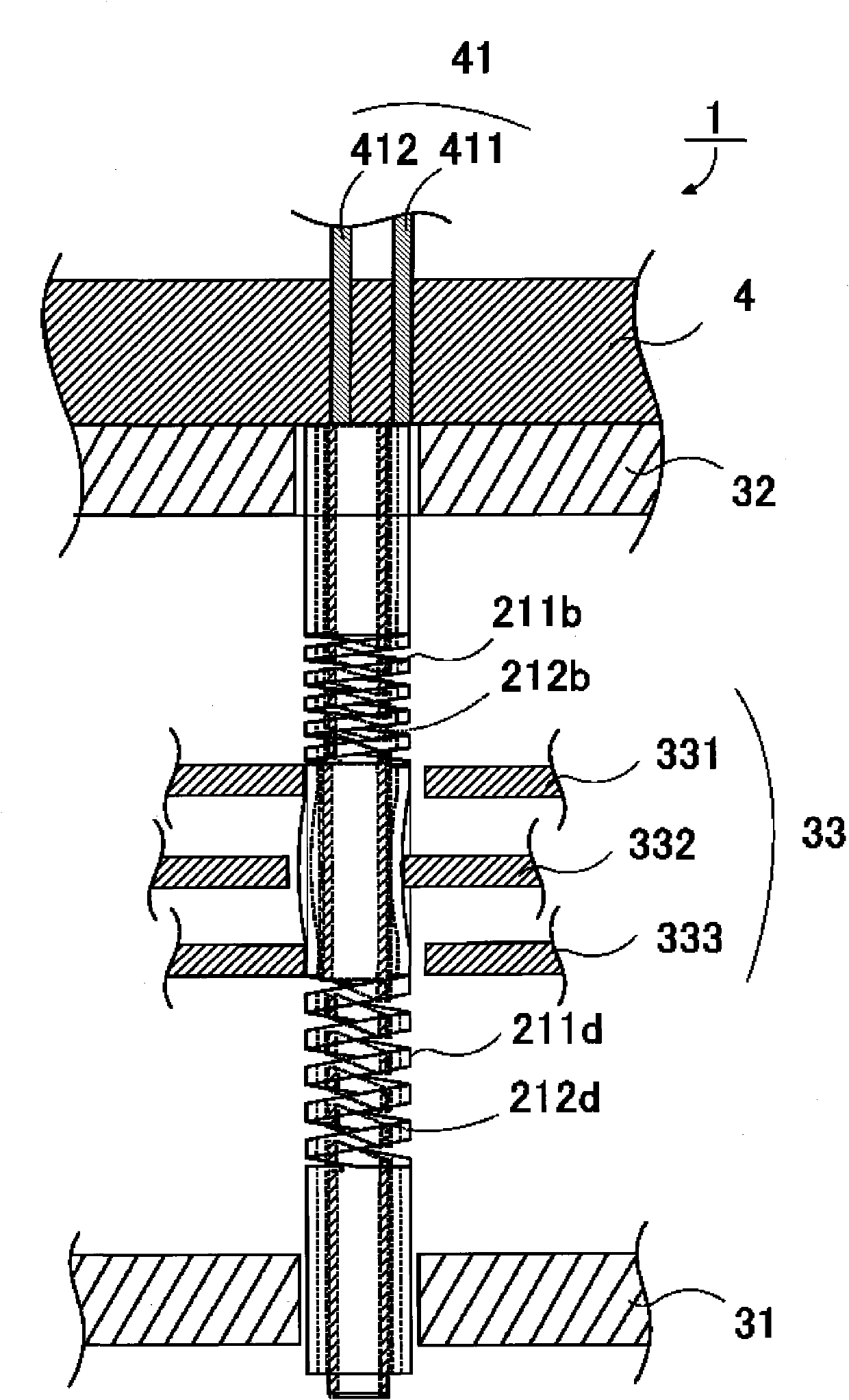

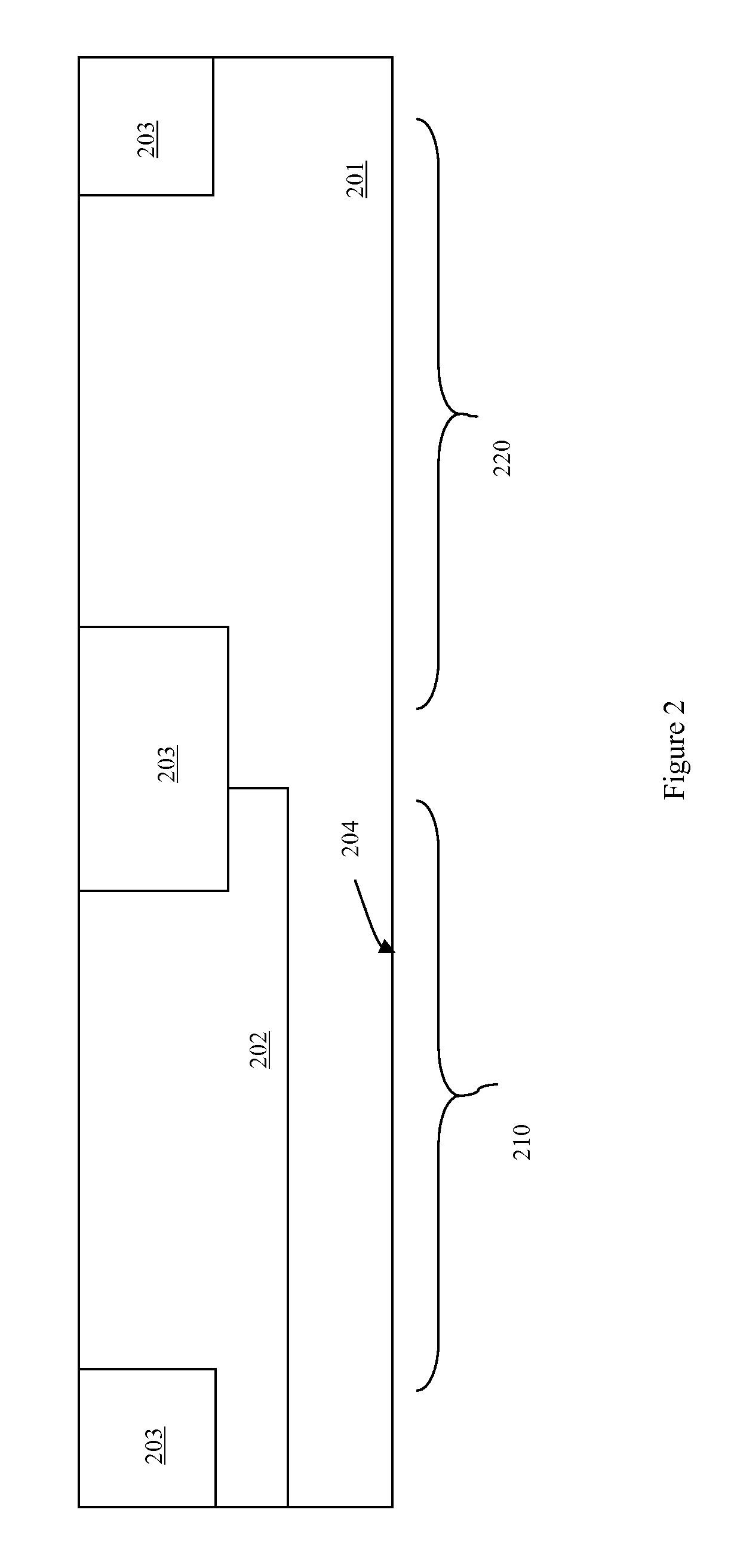

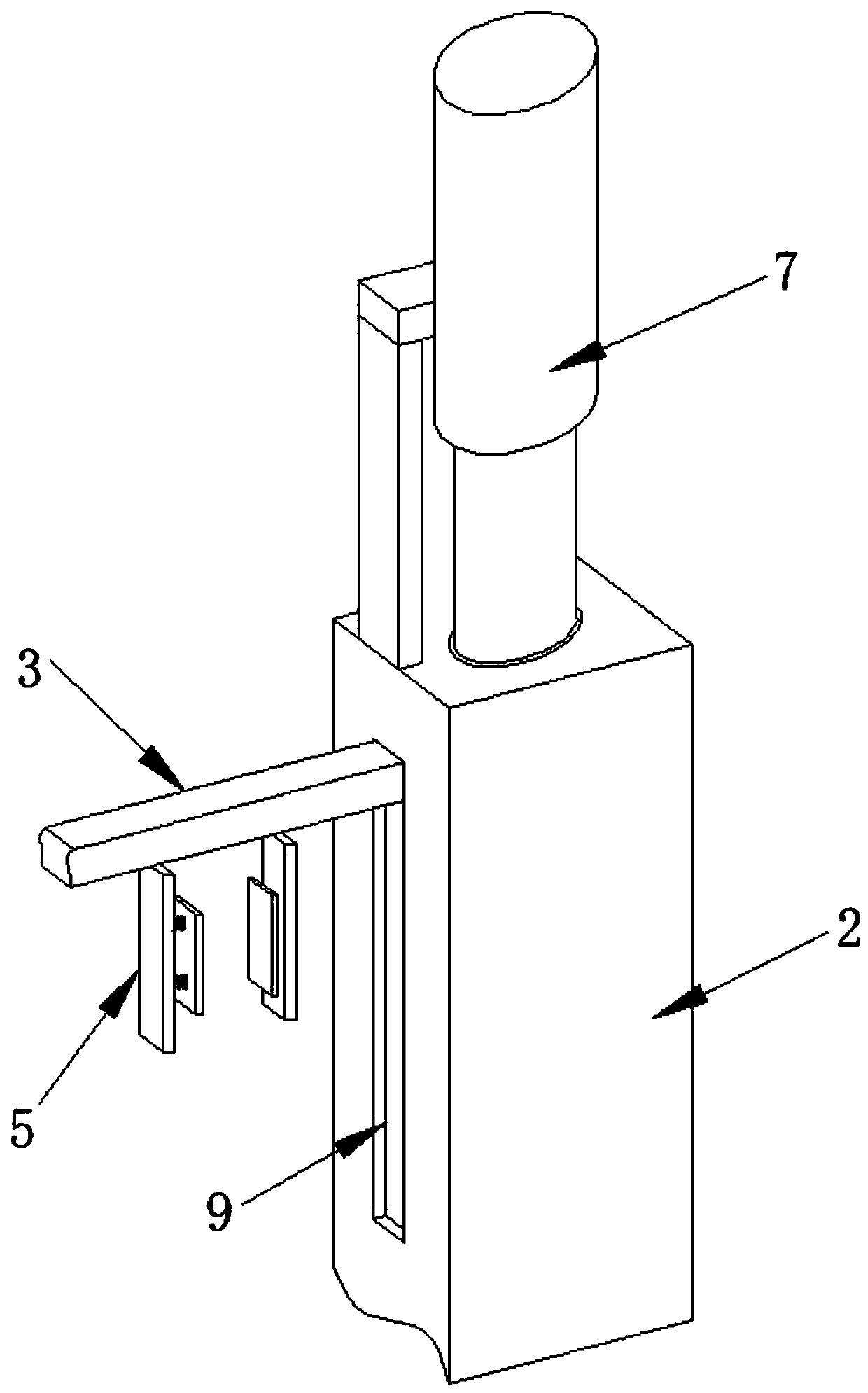

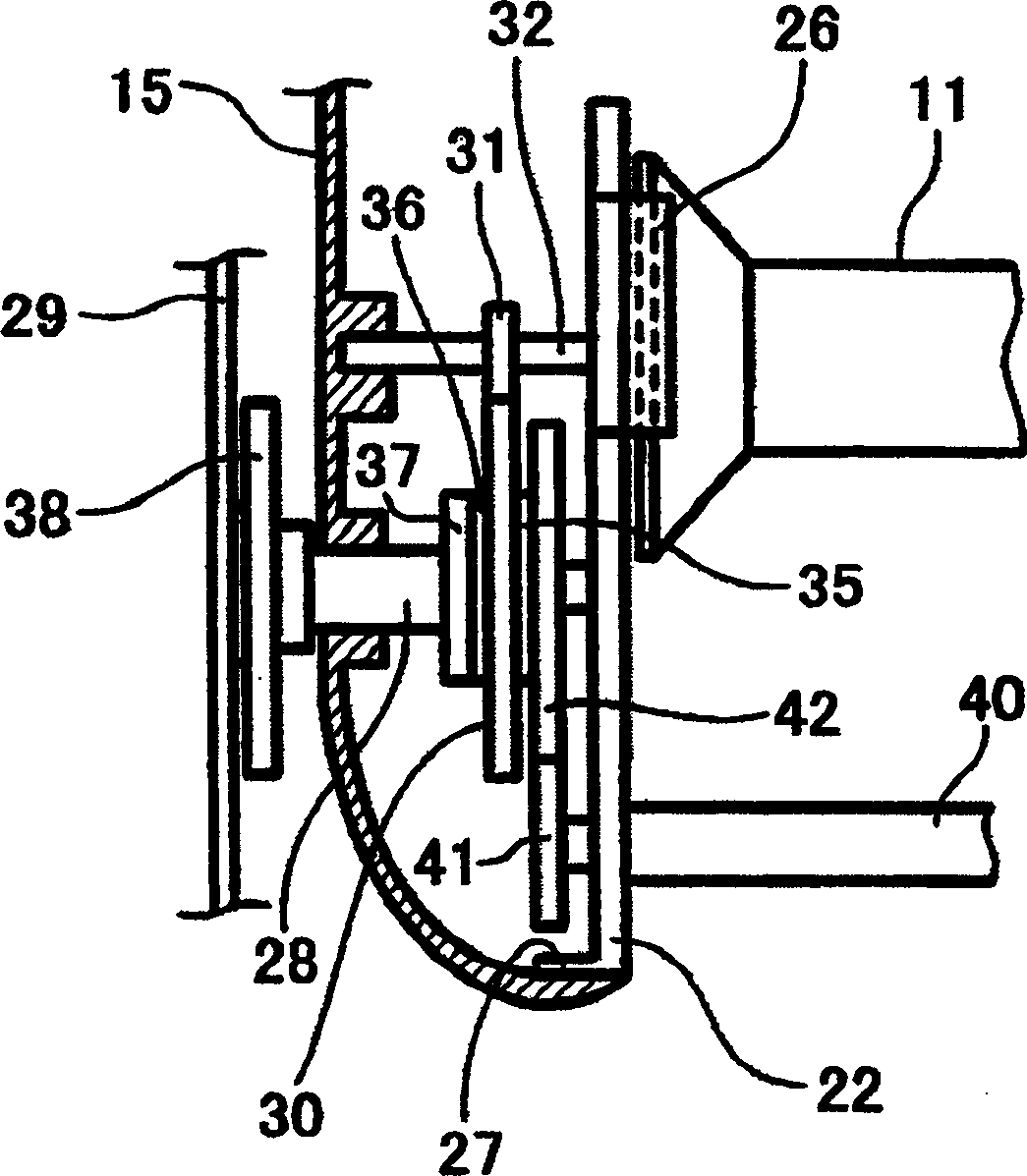

Inspection fixture and inspection probe

ActiveCN101907642AEasy to plateGuaranteed flexibilityElectronic circuit testingManufacture of electrical instrumentsEngineeringLong axis

The invention provides an inspection fixture and inspection probe. The inspection fixture has probe for four terminal measuring, capable of coping substrate small size and complication and having simplification structure with reduced component number. The inspection fixture for electric connection of the object to be inspected and the inspection device, has: an electrode part electrically connected to the inspection device; a conductive barrel shaped first barrel, one end of whose is in pressure welding to the inspection part and the other end is in pressure welding to the electrode part; anda conductive barrel shaped second barrel, roughly coaxially configured in the first barrel, wherein one end of the second barrel is in pressure welding to the inspection part and the other end is in pressure welding to the electrode part, two expansion parts formed on the spiral incision part of the barrel wall part in the long axis direction are provided on the first barrel and the second barrelpartitioned with intermediate parts, and the first barrel and the second barrel are fixed on their own intermediate parts.

Owner:NIDEC-READ CORPORATION

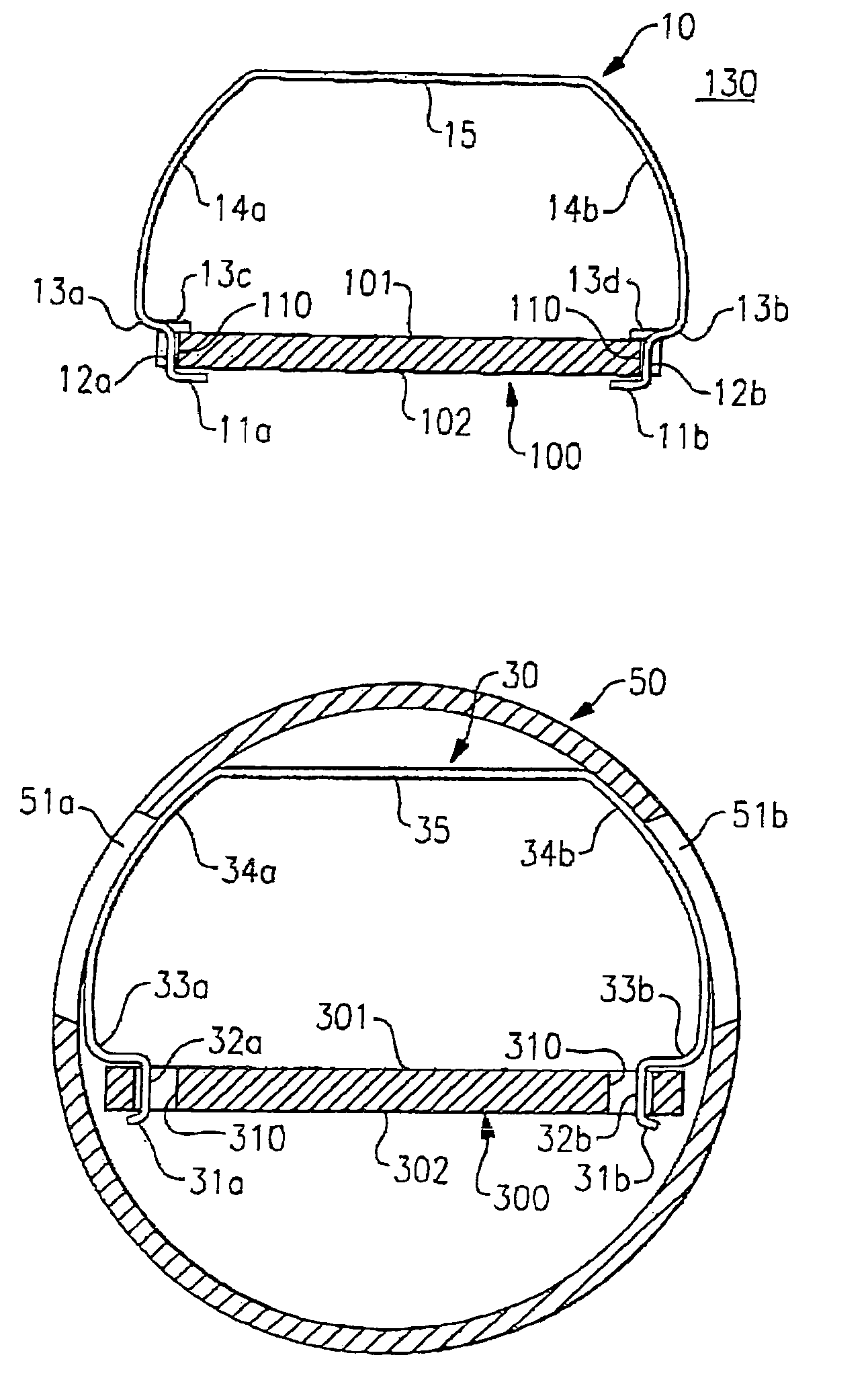

Circuit board sub-assemblies, methods for manufacturing same, electronic signal filters including same, and methods, for manufacturing electronic signal filters including same

InactiveUS6989994B2High strengthIncrease productivityPrinted circuit assemblingPrinted circuit groundingGround StrapEngineering

An electronic signal filter includes a cylindrical housing and a circuit board positioned therein having a plurality of peripheral edges and at least two circular through-holes formed therein. Each through-hole is inwardly spaced from one of the peripheral edges of the circuit board, defining a first distance between a respective one of the through-holes and a respective peripheral edge of the circuit board and defining a second distance between the through-holes. The filter also includes a ground strap attached to and spaced a distance above the circuit board. The ground strap includes a first portion, an integral second portion residing in and extending through each through-hole, and an integral third portion that contacts a portion of the second surface of the circuit board. At least a portion of the first portion of the ground strap contacts the inner peripheral surface of the cylindrical housing to ground the circuit board.

Owner:EAGLE COMTRONICS

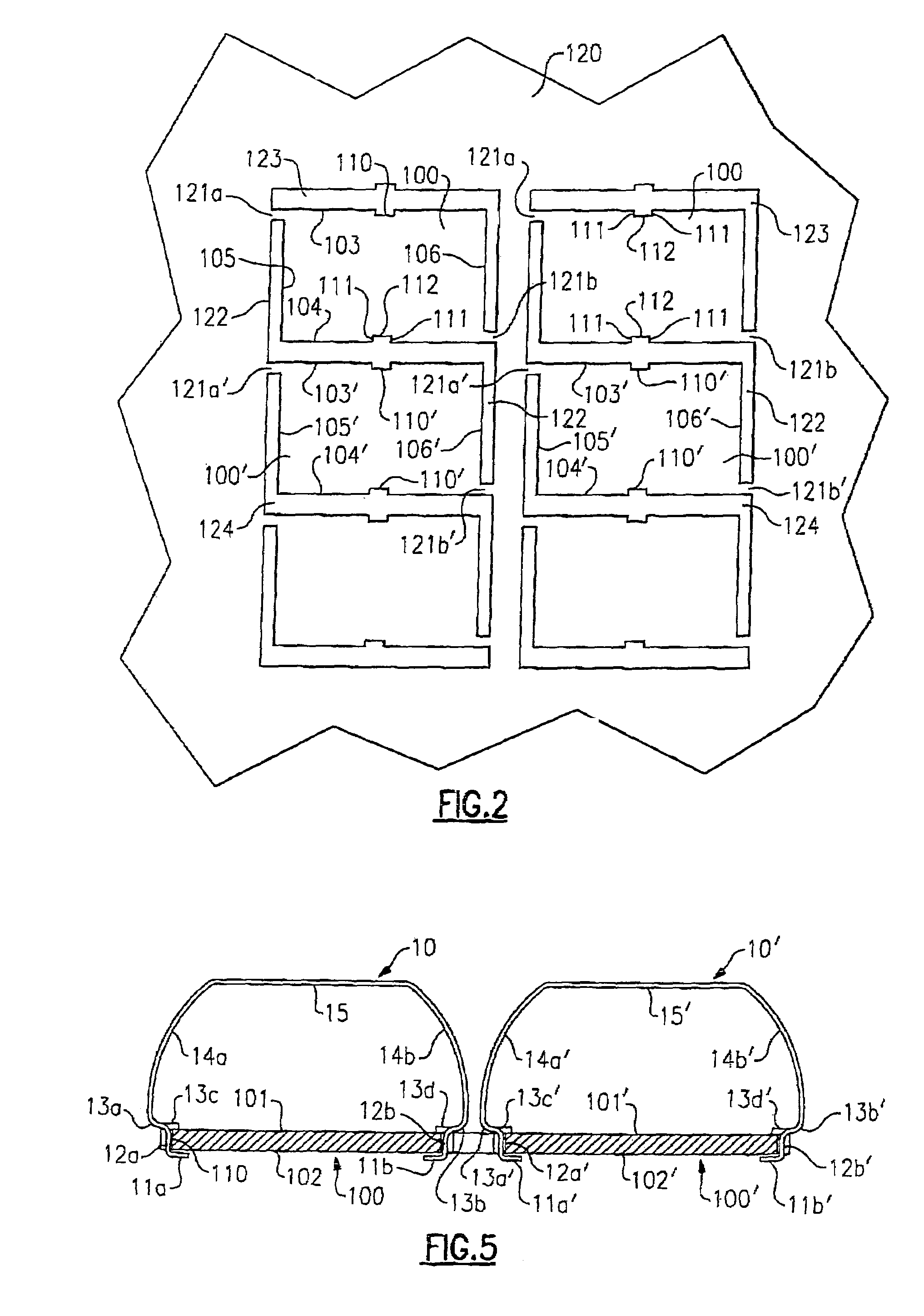

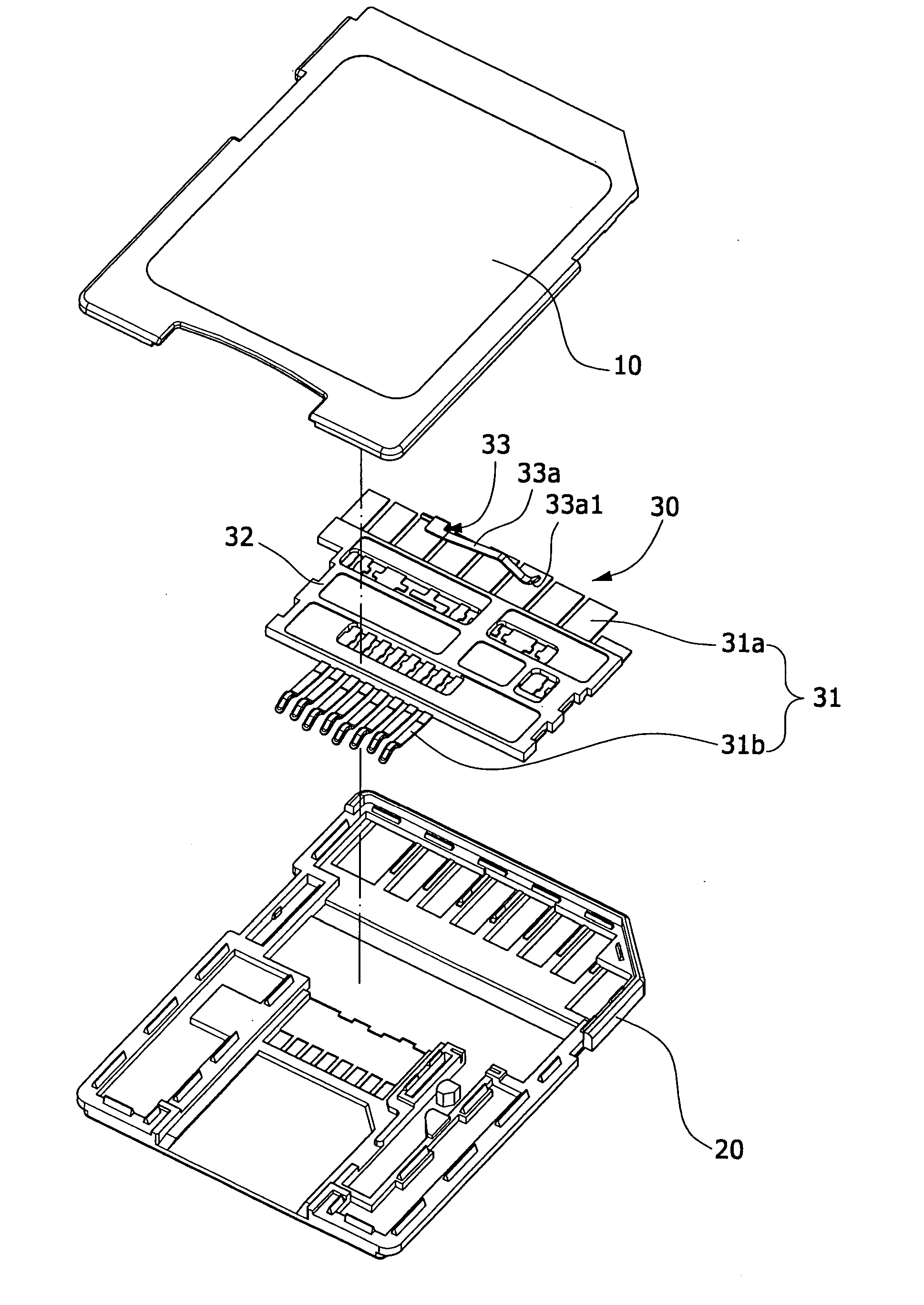

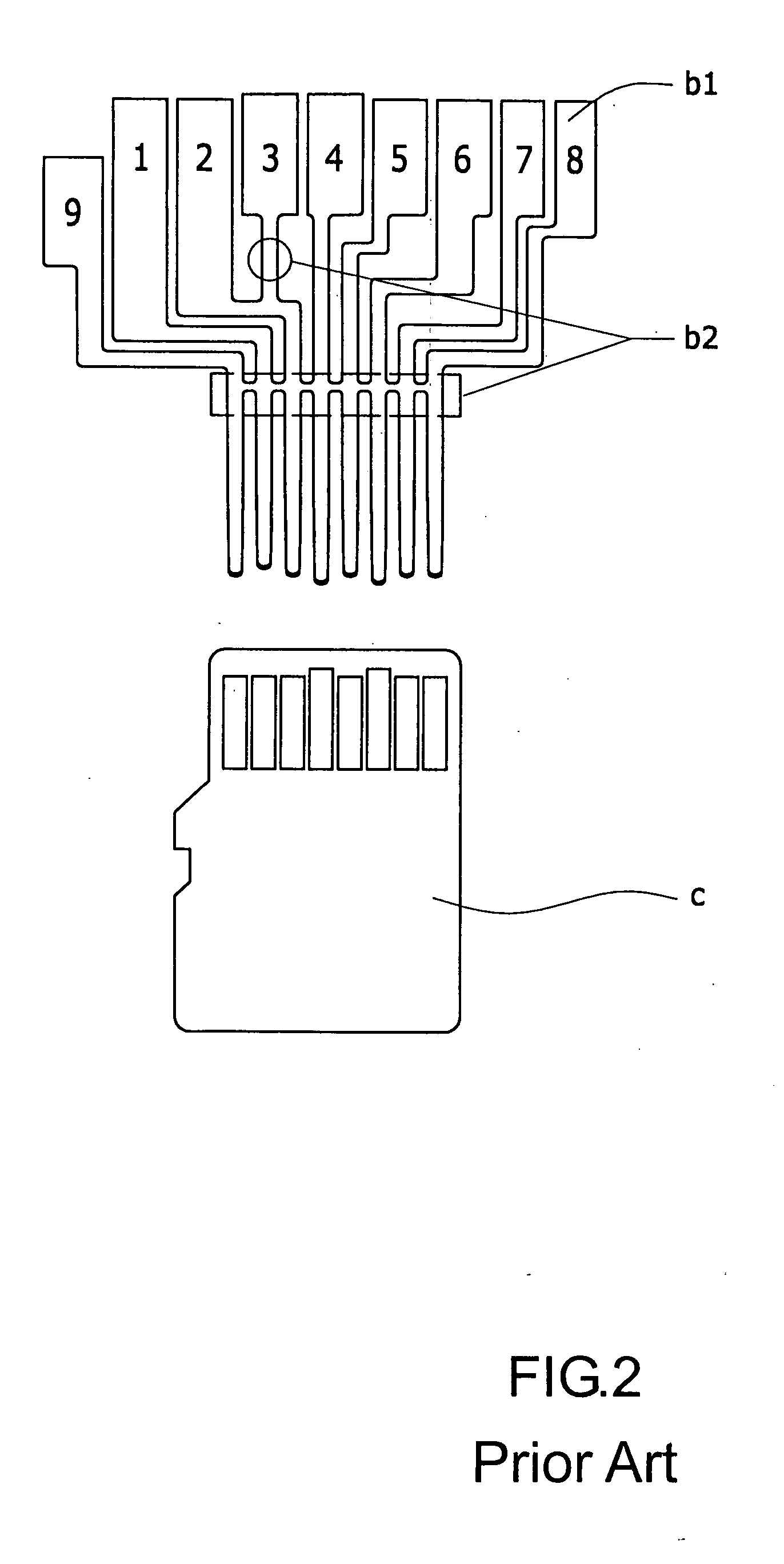

Transflash-to-SD adaptive card structure

InactiveUS20070218768A1Easy to assembleEasy to processTwo-part coupling devicesEngineeringFixed position

Owner:LEE YUN HSIU

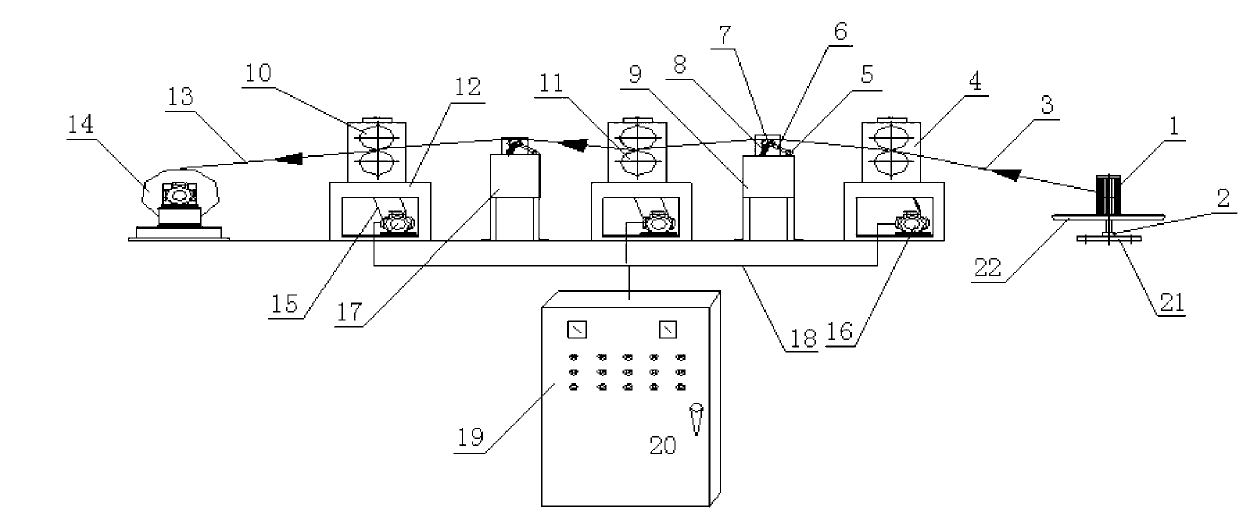

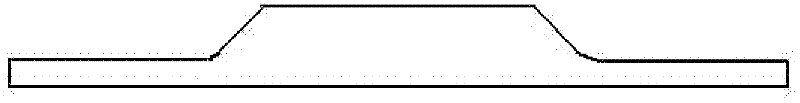

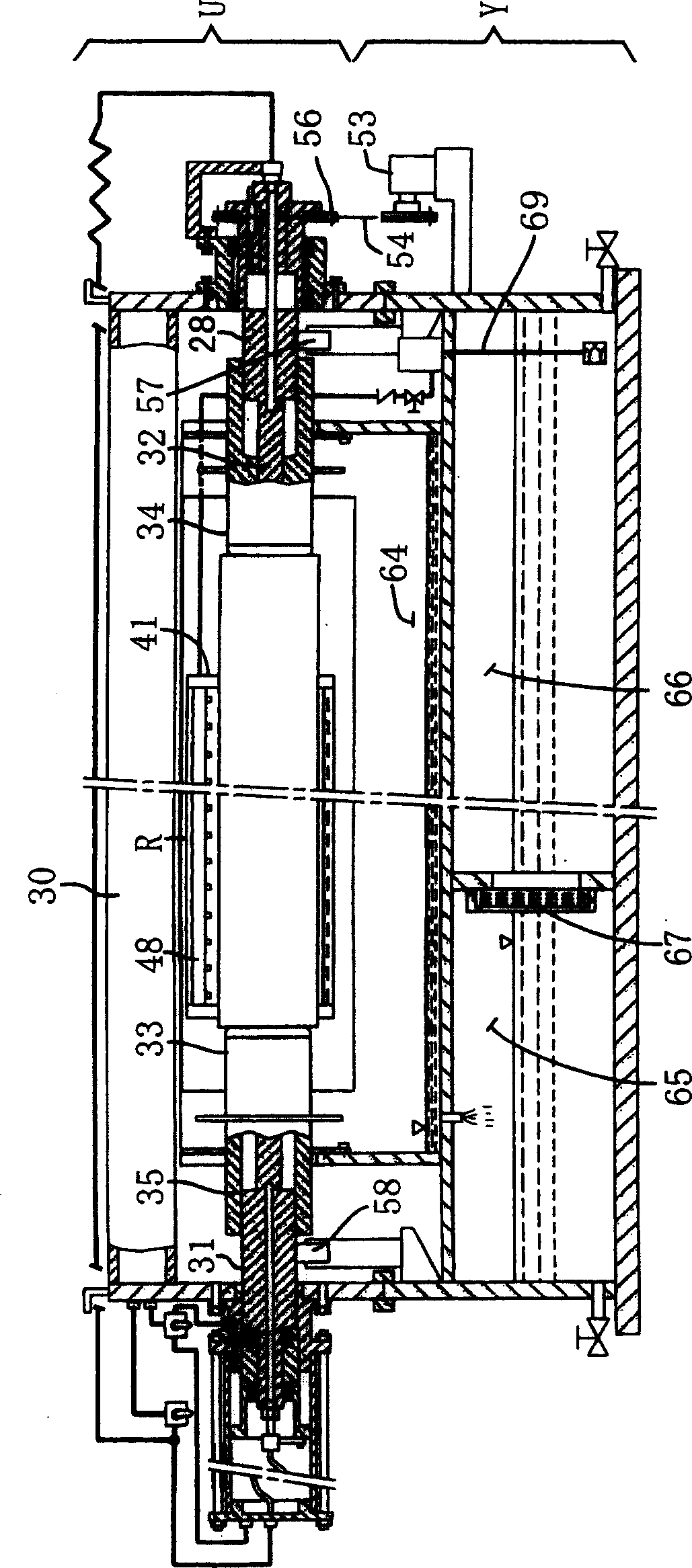

Rolling device for forming of copper alloy flat wires

InactiveCN103272840AImprove rolling precisionDimensionally stableMetal rolling arrangementsControl systemElectrical control

The invention discloses a rolling device for forming of copper alloy flat wires. The rolling device comprises a wire-unwinding mechanism, a plurality of sets of rolling mills, a synchronous tension mechanism, an electrical control system and a wire-rewinding machine. The wire-unwinding mechanism comprises a wire-unwinding plate and a halt air brake device. The rolling mills are composed of more than two stand-alone mills, and each rolling mill is composed of a rolling roller, a support, an electromotor and a belt. The synchronous tension mechanism is composed of a potentiometer, a connection rod, a guide wheel and a spring support. The electrical control system is composed of an electric cabinet, an electrical element, electric wires and cables and provides power for each rolling mill. According to the rolling device, a multi-channel continuous rolling method is utilized, the rolling device is high in accuracy, processing procedures of the copper alloy flat wires are shortened, operation speed is 1.5-2.0 times that of a conventional stand-alone mill, and production efficiency is improved. Meanwhile, as gradual rolling during a rolling process is utilized, the rolling size is very stable, the surfaces of the flat wires are smooth and bright, the fact that grooves and roughness of the surfaces of the flat wires occur in a drawing process of a traditional mould is avoided, and product quality is improved.

Owner:WUHU CHUJIANG ALLOY COPPER

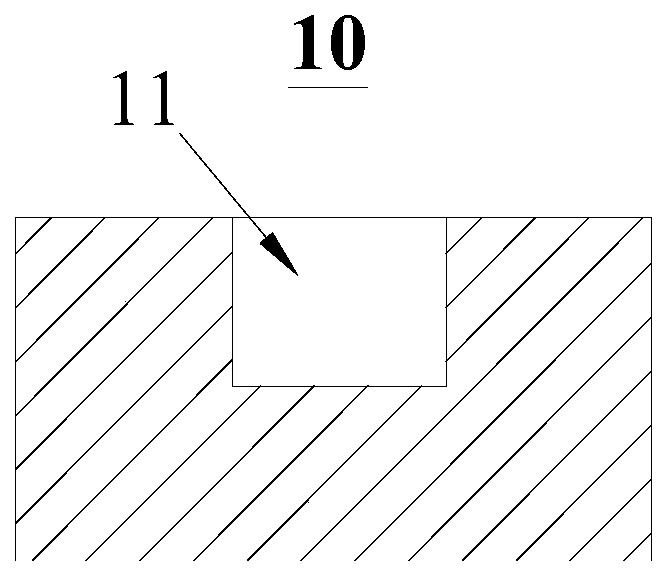

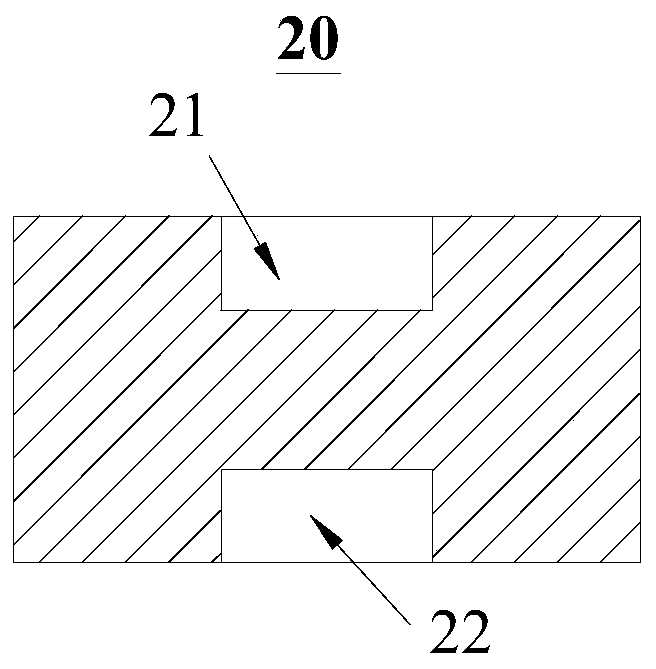

Ceramic dielectric waveguide filter

The invention is applicable to the field of filters, and provides a ceramic dielectric waveguide filter. The ceramic dielectric waveguide filter includes at least one ceramic resonator. A first blindhole with an upward opening is arranged downward in the upper surface of the ceramic resonator, and a second blind hole with a downward opening is arranged upward in the lower surface. The first blindhole and the second blind hole are oppositely arranged, and the first blind hole and the second blind hole are both used for frequency tuning. On the premise of keeping the working mode frequency ofthe ceramic resonator unchanged, the frequency of part of adjacent high-order modes can be raised and kept away from the working frequency, so as to improve the far end suppression performance of thefilter. In addition, the depth required for the first blind hole of the ceramic resonator provided by the invention can be reduced the under the same design size and working frequency, so that the ceramic resonator can be machined and formed, electroplated and debugged in the later period more easily.

Owner:MOBI TECH SHENZHEN CO LTD +4

Full-automatic anti-residue automatic electroplating device

InactiveCN111501084AScientific and reasonable structureEasy to useCellsTanksMetallurgySurface cleaning

The invention discloses a full-automatic anti-residue automatic electroplating device. The full-automatic anti-residue automatic electroplating device comprises an installation bottom plate, wherein support bottom columns are fixedly connected to four corners of the top end of the installation bottom plate, support sliding rails are fixedly connected to the top ends of the support bottom columns,belt winding rollers are fixedly connected to the position, corresponding to the inner position of a lifting installation box, of the outer side of a lifting rotating shaft, and a surface cleaning mechanism is fixedly connected to the position, corresponding to the inner positions of support vertical plates, of the bottom end of a traction belt. A rotating motor drives a transmission rotating shaft and transmission bevel gears to rotate, the transmission bevel gears drive rotating vertical shafts and rotating bevel gears to rotate, then workpieces are driven to rotate through material hangingmechanisms, and in the rotating process of the workpieces, electroplate liquid and washing liquid left on the surfaces of the workpieces are separated from the workpieces under the action of centrifugal force, so that residual electroplate liquid and washing liquid are effectively prevented from being left on the workpieces and affecting next layer of electroplating of the workpieces, and the coating quality of the workpieces is improved.

Owner:刘理仁

Conductive silver paste for ferrite core inductance and method for producing same

ActiveCN102610326AAvoid crackingNot easy to electroplateTransformers/inductances coils/windings/connectionsNon-conductive material with dispersed conductive materialSilver pasteInductance

The invention discloses a conductive silver paste for a ferrite core inductance and a method for producing the same, wherein the method comprises the following steps that: (1) lead-free glass powder is produced and contains an inorganic additive I which occupies 1-4% of the total quantity of the lead-free glass powder; (2) an organic carrier is produced; (3) superfine silver powder, silver flake, the lead-free glass powder and an inorganic additive II are mixed to produce the powder, the powder is uniformly stirred and then added into the organic carrier, after high-speed stirring and dispersion, the powder is rolled by a three-roller mill to the fineness of lower than 10mum, and is screened by a screen of 200 meshes for producing the conductive silver paste for the ferrite core inductance. The ferrite conductive silver paste can effectively solve the defects of the silver paste for the ferrite core inductance on corrosion resistance, adhesive force and electroplating performance, has good quality, is low in cost, and is an ideal substitute product for lead-bearing paste. The adopted technology can ensure the stability and consistency of the silver paste.

Owner:广东羚光新材料股份有限公司

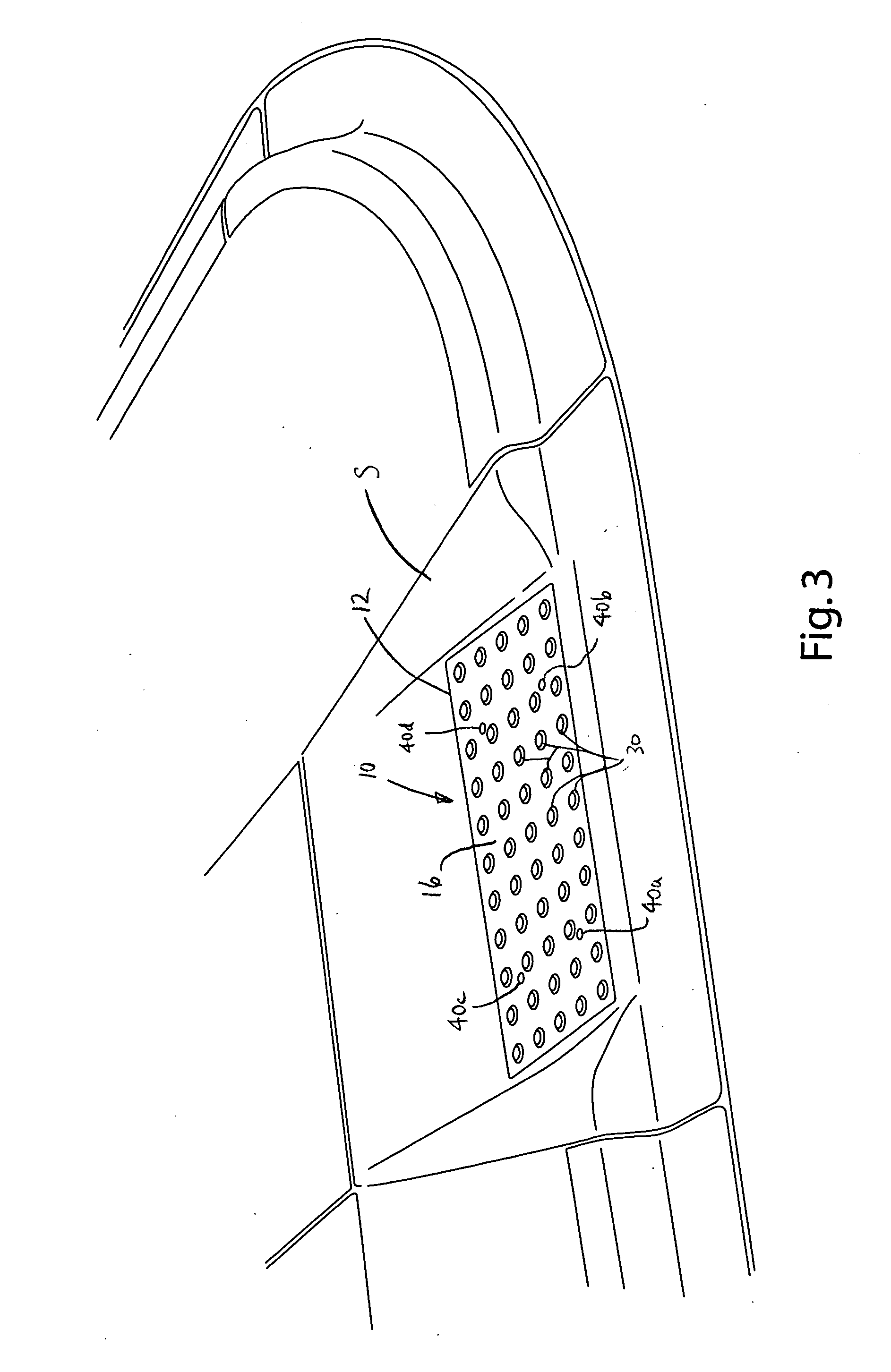

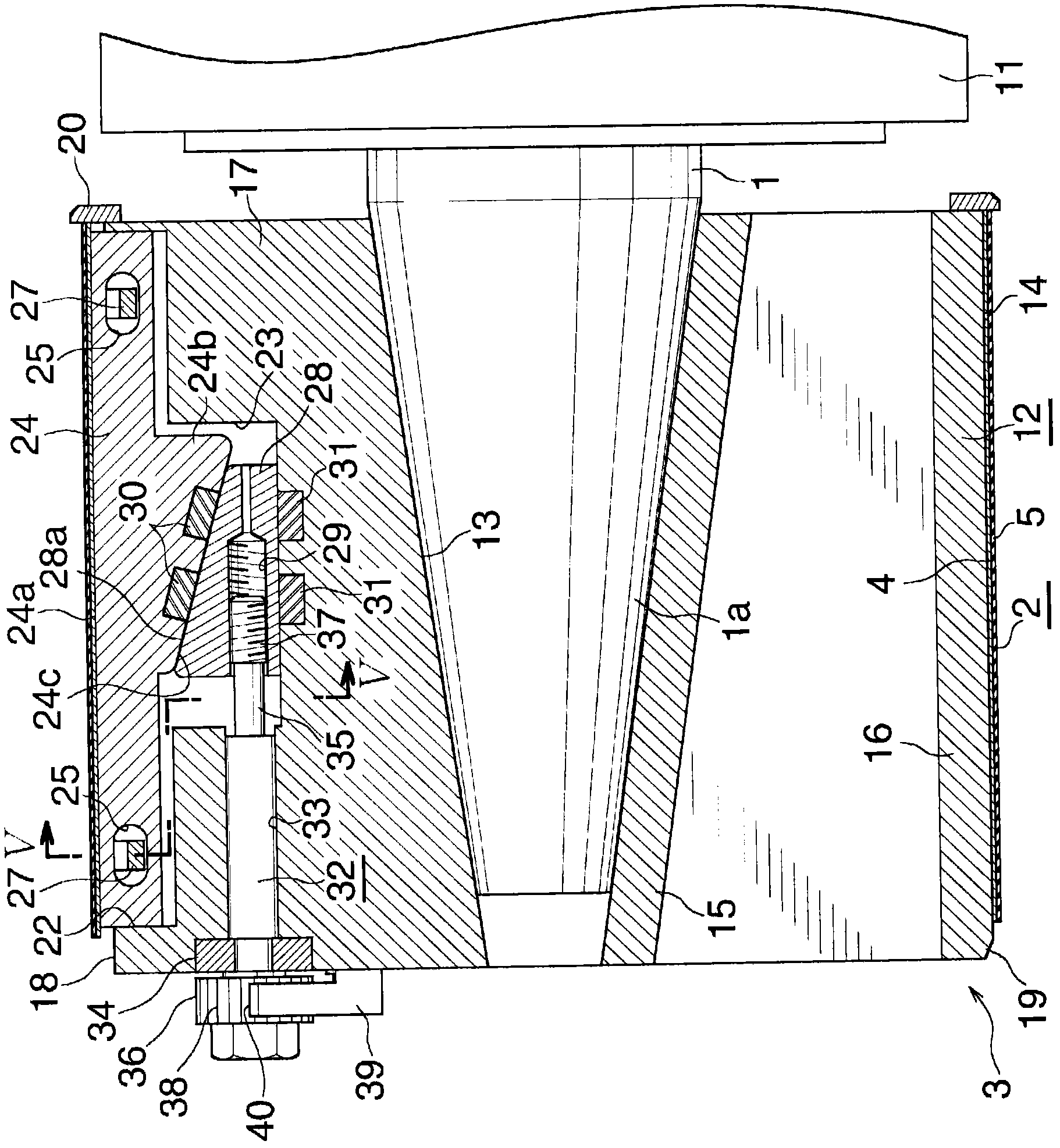

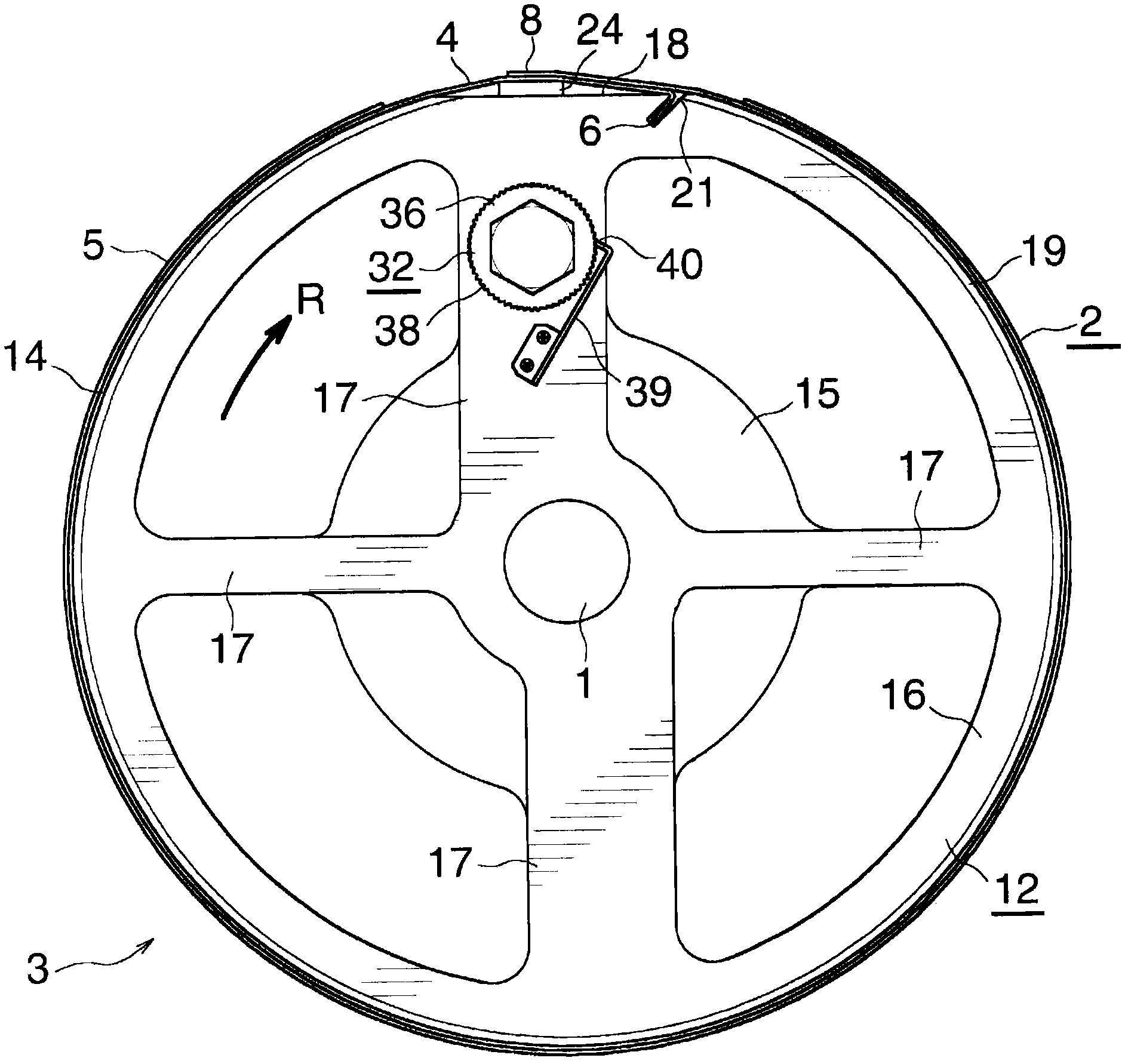

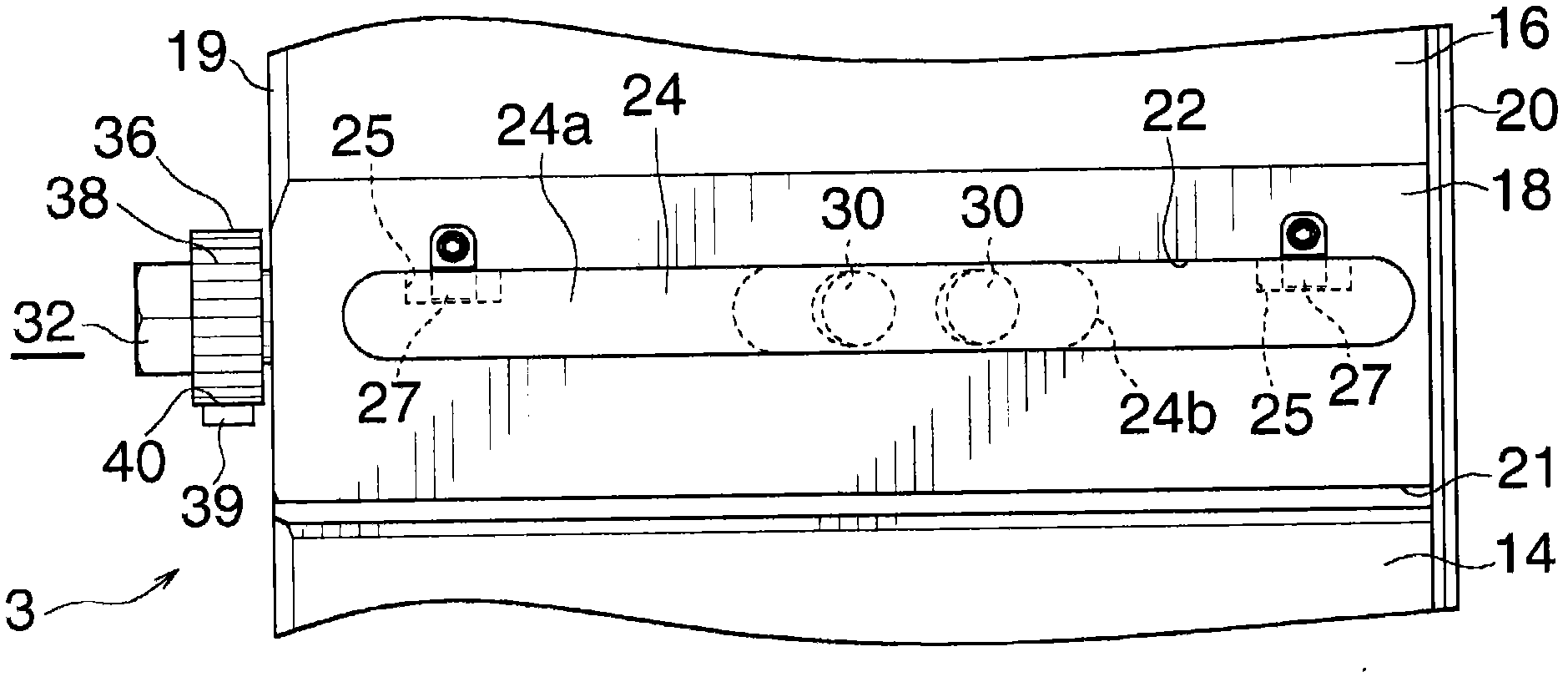

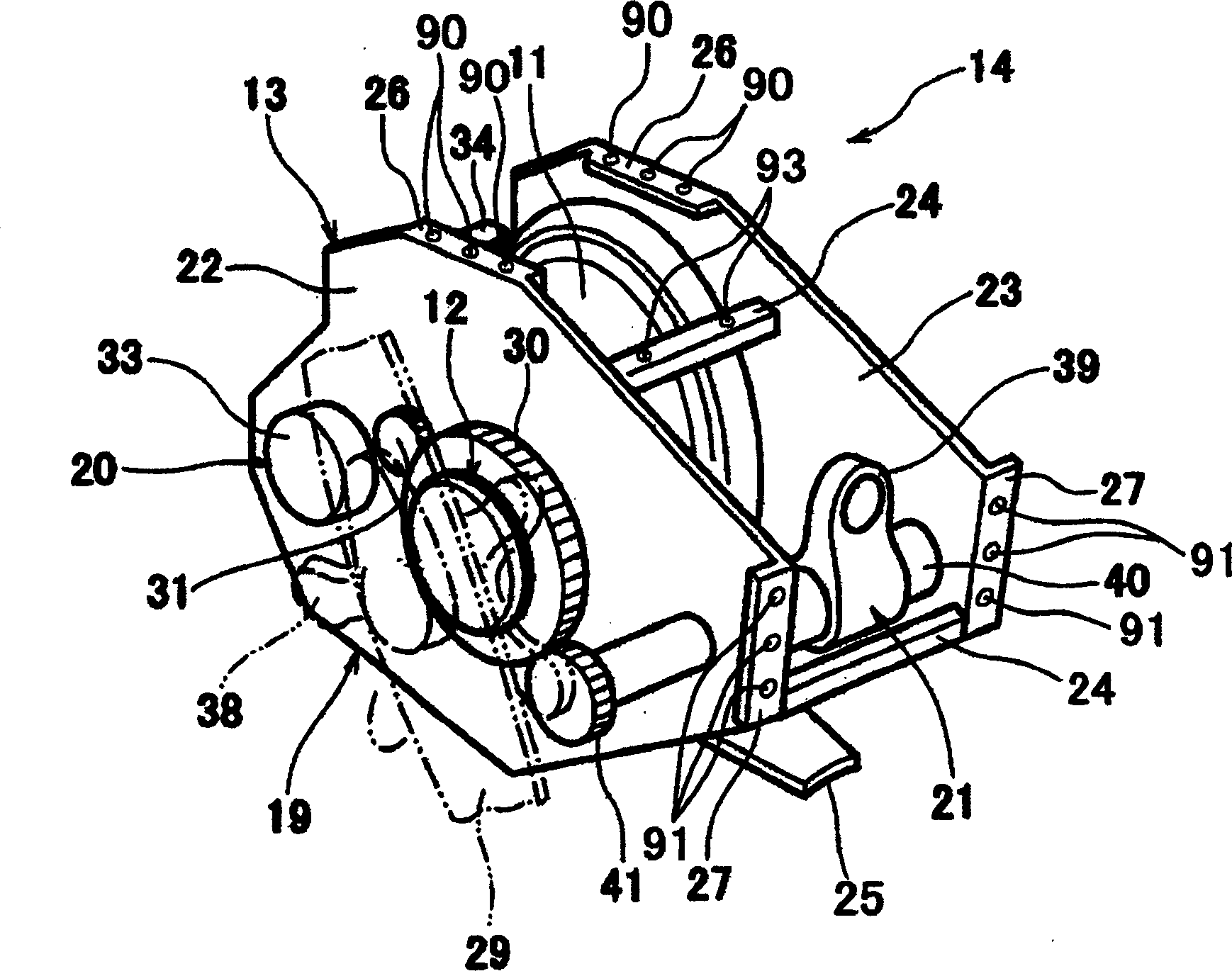

Device for attaching printing plate to printing press and printing press

Provided is a device for attaching a printing plate to a printing press wherein a tubular printing plate can be fixed more easily and accurately to a printing press. A device (3) for attaching a printing plate is provided fixedly on the printing plate drive shaft (1) of a printing press in order to fix a printing plate (2) provided with a printing plate portion (5) at a part of the outer circumferential surface of a printing plate body (4) formed tubularly of an elastic material, and having an engaging portion (6) formed on the inner circumference of the printing plate body (4) to project inward and to extend in the axial direction. The device (3) for attaching a printing plate is equipped with a printing plate cylinder portion (12) which is provided fixedly on the printing plate drive shaft (1) and provided, on the outer circumference thereof, with a tubular printing plate attachment surface (14) to which the printing plate (2) is attached from the distal end side of the printing plate drive shaft (1). On the outer circumference of the printing plate cylinder portion (12), a circumferential positioning groove (21) in which the engaging portion (6) of the printing plate (2) is fitted from the distal end side of the printing plate drive shaft (1), an axial positioning stopper (20) against which the end of the printing plate (2) abuts, and a printing plate fixing member (24) for fixing the printing plate (2) tightly to the printing plate attachment surface (14) of the printing plate cylinder portion (12) by pushing a part of the printing plate (2) attached to the printing plate cylinder portion (12) where there is no printing plate portion (5) from the radial inside to the radial outside.

Owner:井爪雅幸

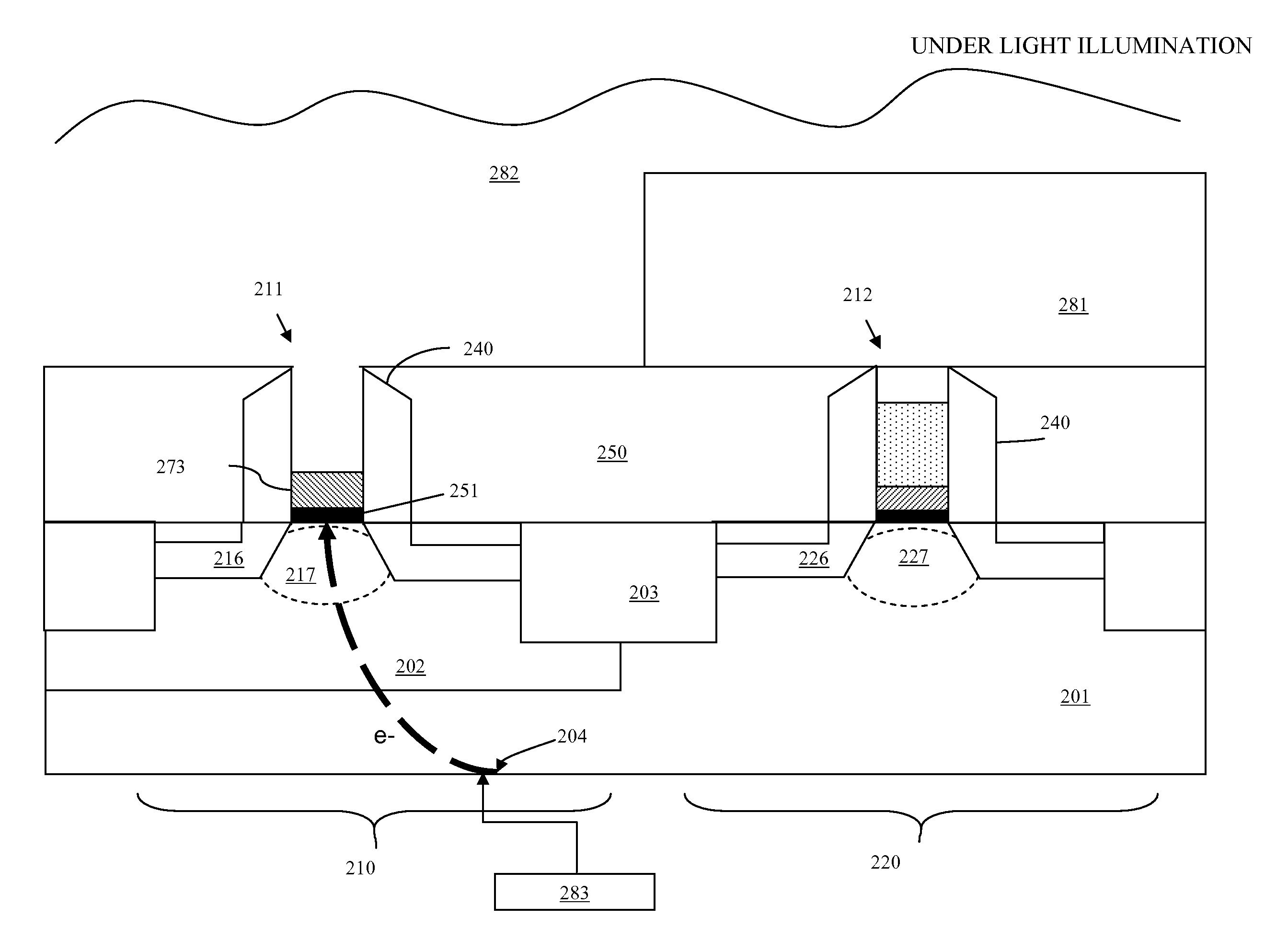

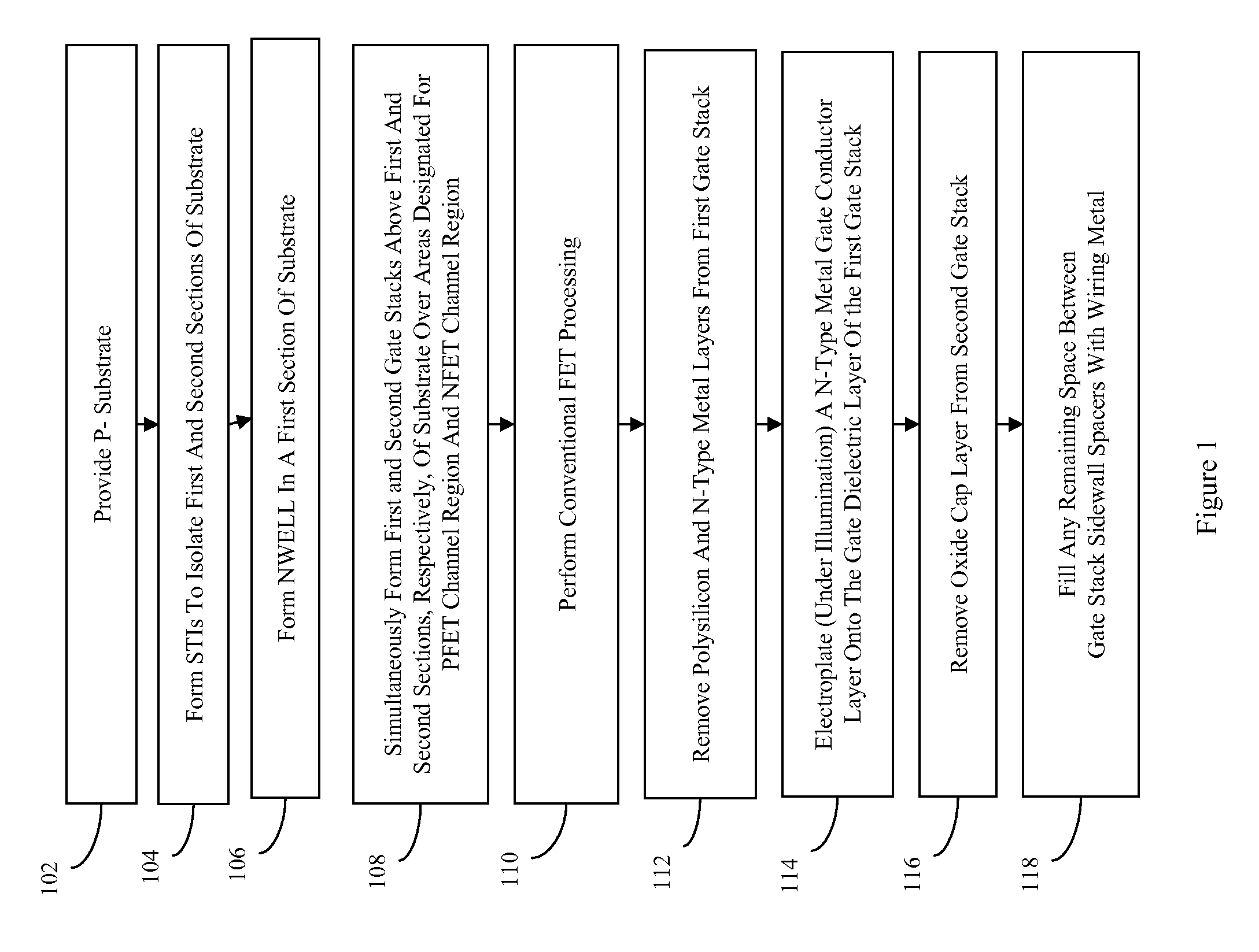

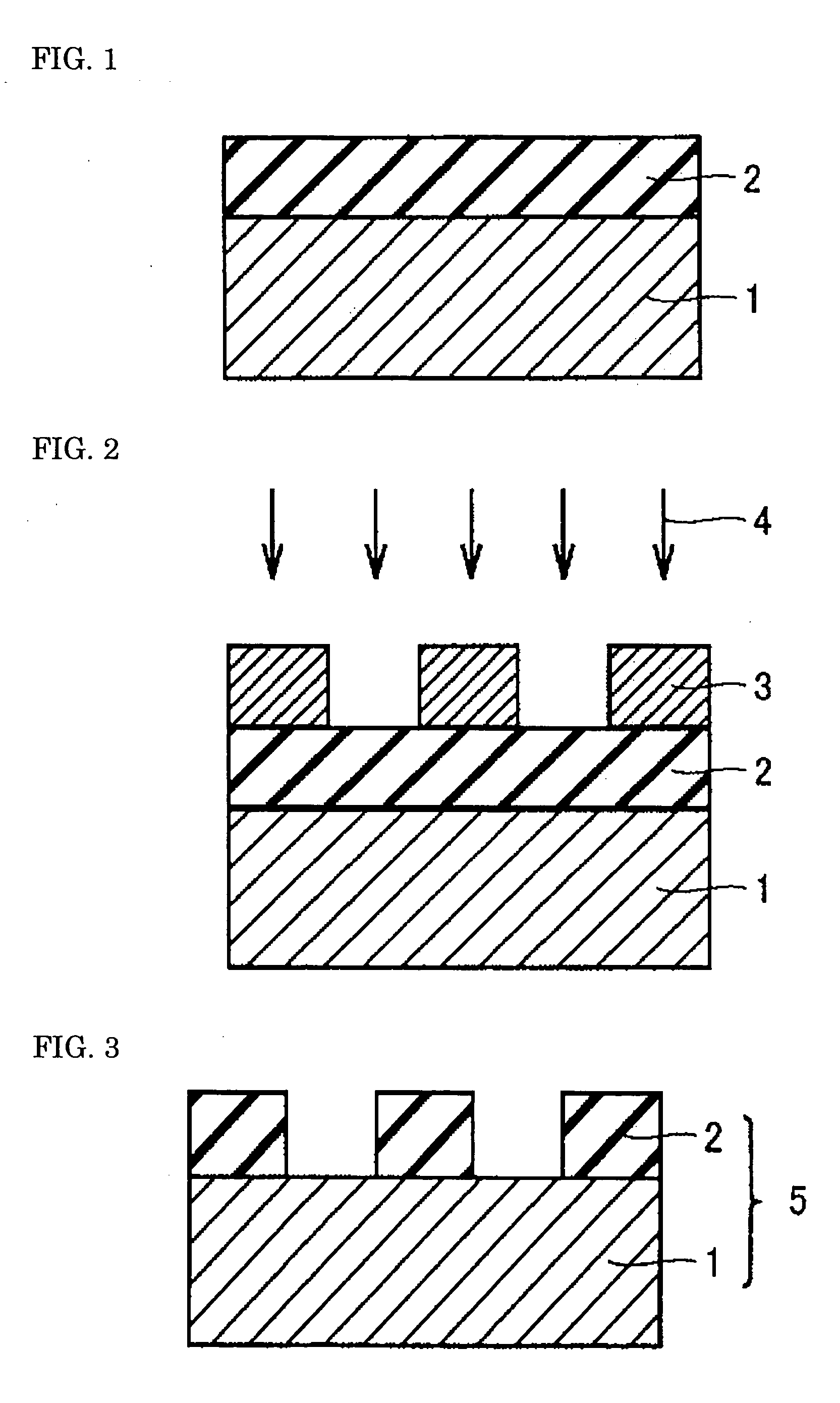

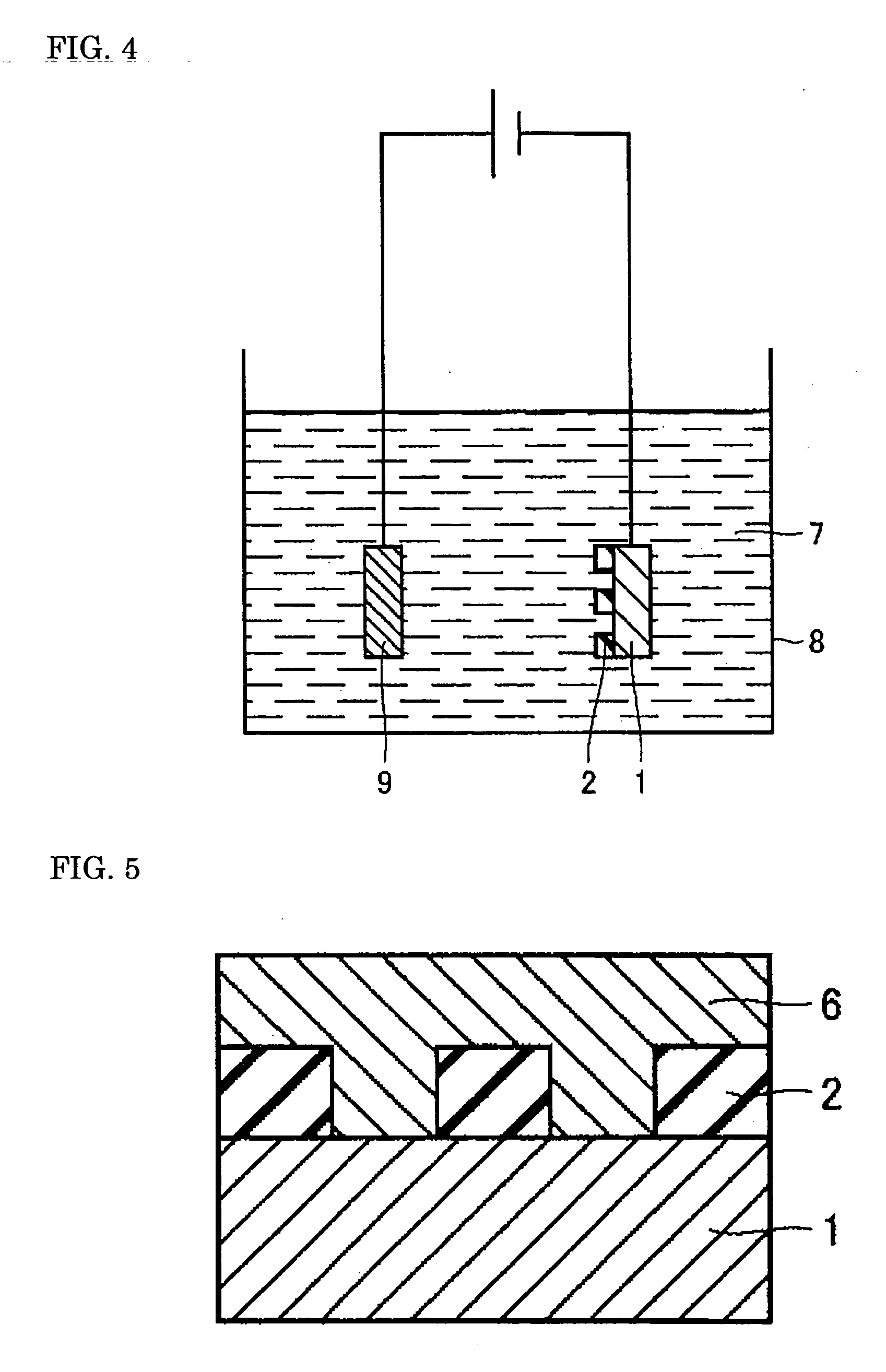

Complementary metal oxide semiconductor device with an electroplated metal replacement gate

InactiveUS7776680B2High trafficEasy to PlatingSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorGate dielectric

Disclosed herein are embodiments of a method of forming a complementary metal oxide semiconductor (CMOS) device that has at least one high aspect ratio gate structure with a void-free and seam-free metal gate conductor layer positioned on top of a relatively thin high-k gate dielectric layer. These method embodiments incorporate a gate replacement strategy that uses an electroplating process to fill, from the bottom upward, a high-aspect ratio gate stack opening with a metal gate conductor layer. The source of electrons for the electroplating process is a current passed directly through the back side of the substrate. This eliminates the need for a seed layer and ensures that the metal gate conductor layer will be formed without voids or seams. Furthermore, depending upon the embodiment, the electroplating process is performed under illumination to enhance electron flow to a given area (i.e., to enhance plating) or in darkness to prevent electron flow to a given area (i.e., to prevent plating).

Owner:GLOBALFOUNDRIES INC

Synthetic opal and photonic crystal

InactiveUS8936683B2Rapid precipitationQuality improvementAfter-treatment apparatusFrom gel statePhotonic bandgapPhotonics

A colloidal suspension of particles is rapidly self-assembled with a minimum number of defects into a densely packed array of particles on a substrate under simultaneous sedimentation and annealing forces. The particles may be ordered as an opal structure. Optionally, the synthesized structure may incorporate an electrolyte and be used as a sacrificial form for micromolding an inverse structure. The inverse structure may exhibit a photonic band gap. Optionally, necking between particles may be adjusted after micromolding. Furthermore, a shell may alter physical properties, such as protecting a thermally stimulated photonic band gap device. These low cost methods allow more applications to become commercially viable.

Owner:PRACTICAL TECH

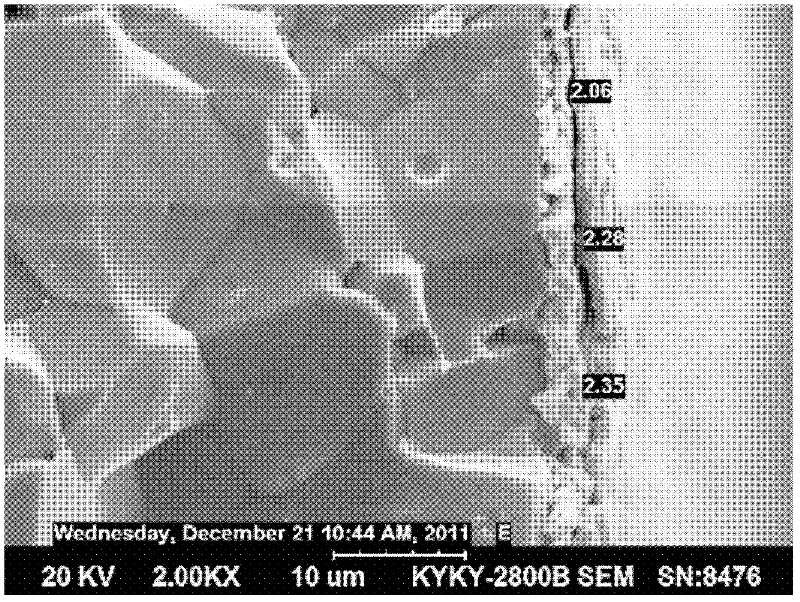

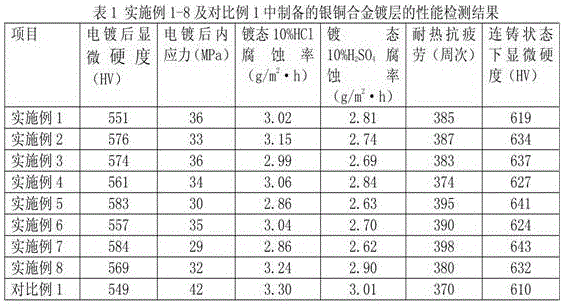

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

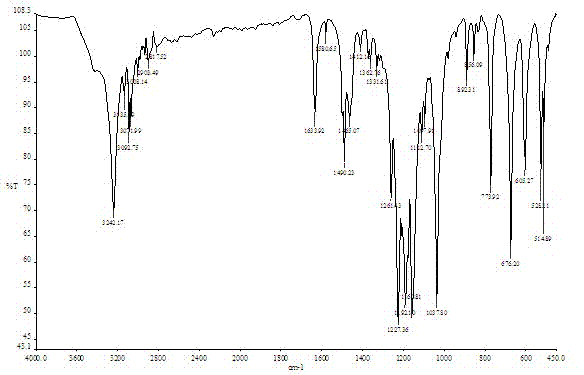

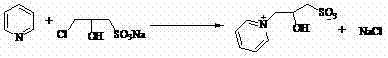

Production method of high-purity PPS-OH

InactiveCN102491942AHigh purityReduce sodium chloride contentOrganic chemistryInorganic saltsOrganic solvent

The invention discloses a production method of high-purity PPS-OH. The production method of the high-purity PPS-OH comprises the following steps of dropwisely adding pyridine into a sodium 3-chloro-2-hydroxypropanesulfonate aqueous solution, carrying out a reflux reaction process for multiple hours, removing the pyridine and water by pressure reduction, carrying out drying to obtain white solids, dissolving the white solids in one or more organic solvents, filtering to remove inorganic salts, adding one or more organic solvents into the filtrate, filtering, and drying to obtain the high-purity PPS-OH. The PPS-OH obtained by the production method has high purity, is convenient for transportation, has low common salt content, does not contain pyridine and has good electroplating effects.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

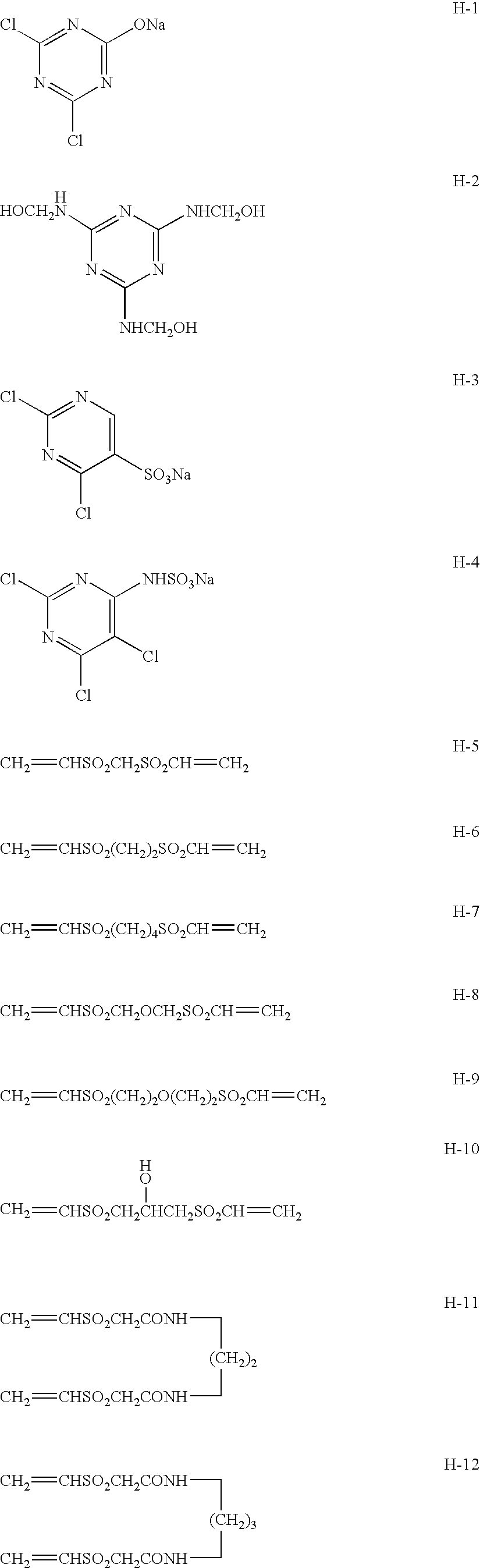

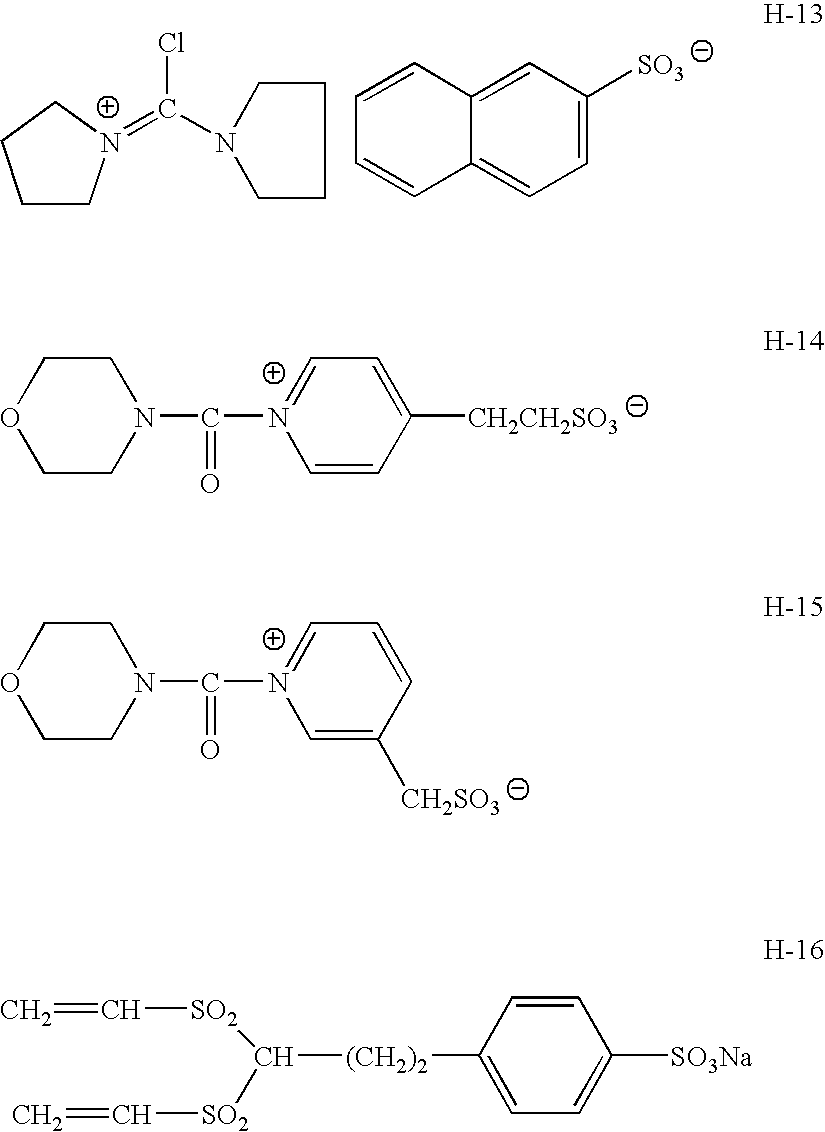

Photosensitive material, method of manufacturing conductive metal film, conductive metal film and light-transmitting film shielding electromagnetic wave for plasma display panel

InactiveUS7829270B2Excellent electromagnetic wave shielding performanceEasy to PlatingMulticolor photographic processingSemiconductor/solid-state device manufacturingEmulsionSilver salts

Owner:FUJIFILM CORP

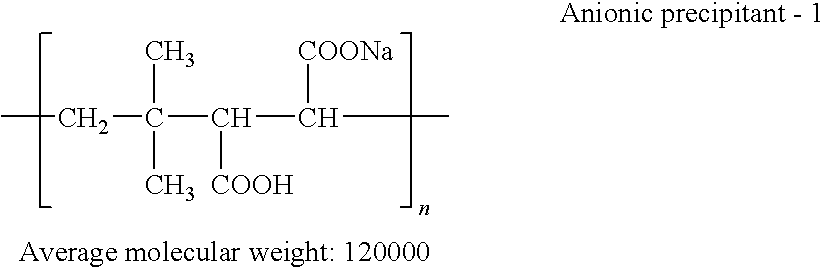

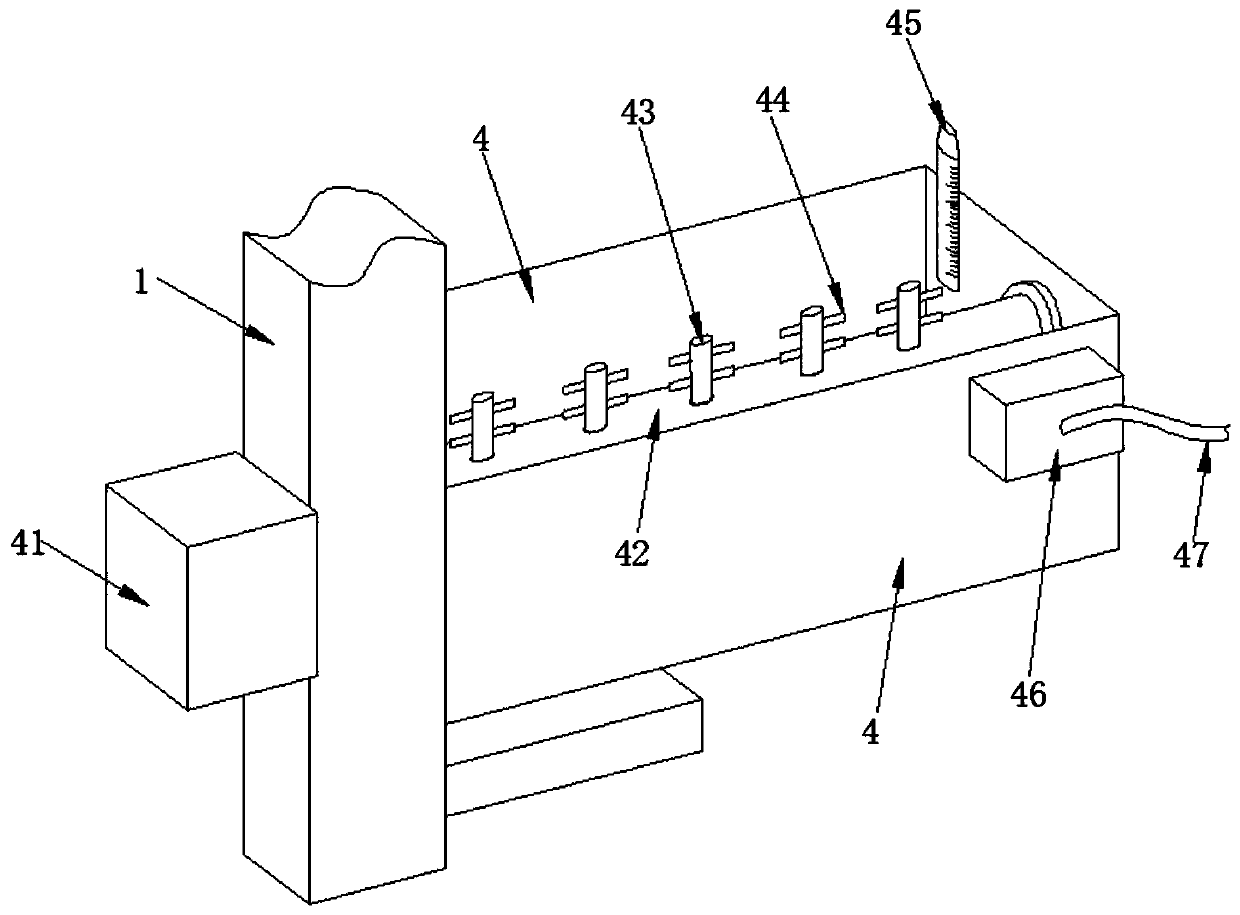

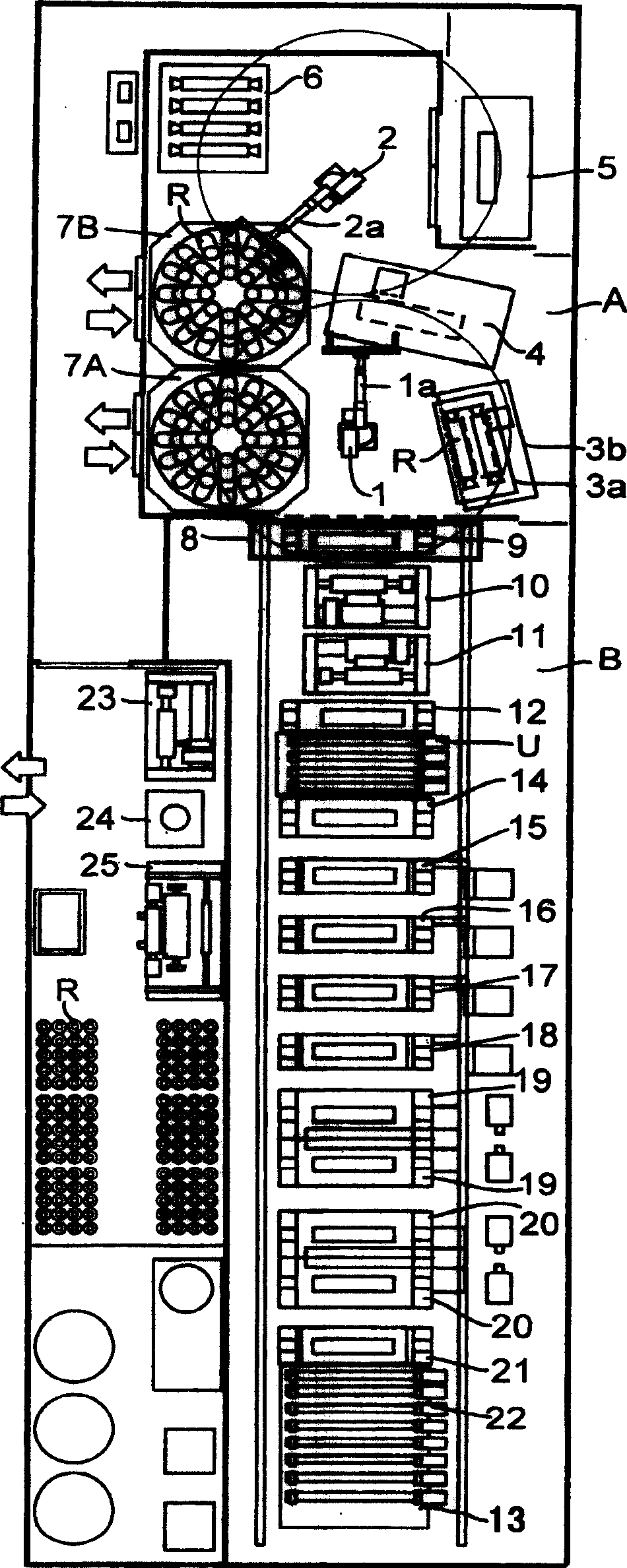

Automatic electroplating device and method for bolts

InactiveCN111394762AEasy to clamp and fixEasy to PlatingCellsElectric machineryStructural engineering

The invention discloses an automatic electroplating device and method for bolts, and relates to the technical field of electroplating. The automatic electroplating device comprises a first stand column, a second stand column, a movable plate, an electroplating box, a clamp mechanism, a filter box and a hydraulic telescopic rod, wherein the first stand column and the second stand column are arranged in parallel; the movable plate is movably arranged between the first stand column and the second stand column; the clamp mechanism used for clamping the bolts is fixedly arranged at the bottom of the movable plate; the electroplating box positioned between the first stand column and the second stand column is arranged under the clamp mechanism; and electroplating liquid is filtered, when a filter screen needs to be cleaned regularly, two clamping blocks are lifted upwards, then the filter screen can be taken out and cleaned, and thus the using effect is improved. The structure is simple, theelectroplating liquid can be filtered and cleaned easily, a motor is used for driving a rotary shaft to rotate, then stirring blades on the rotary shaft are driven to rotate, thus the electroplatingliquid can be fully and evenly stirred, the concentration of the electroplating liquid is uniform, the electroplating quality is improved, and the electroplating efficiency is improved easily.

Owner:GUIYANG BAIYUN AVIATION FASTENERS

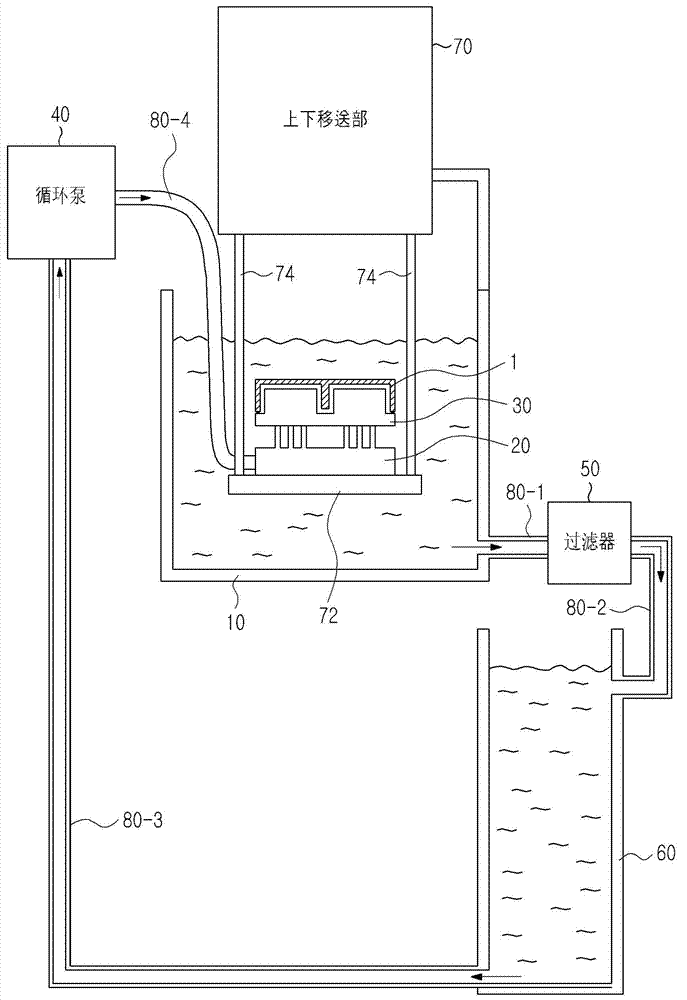

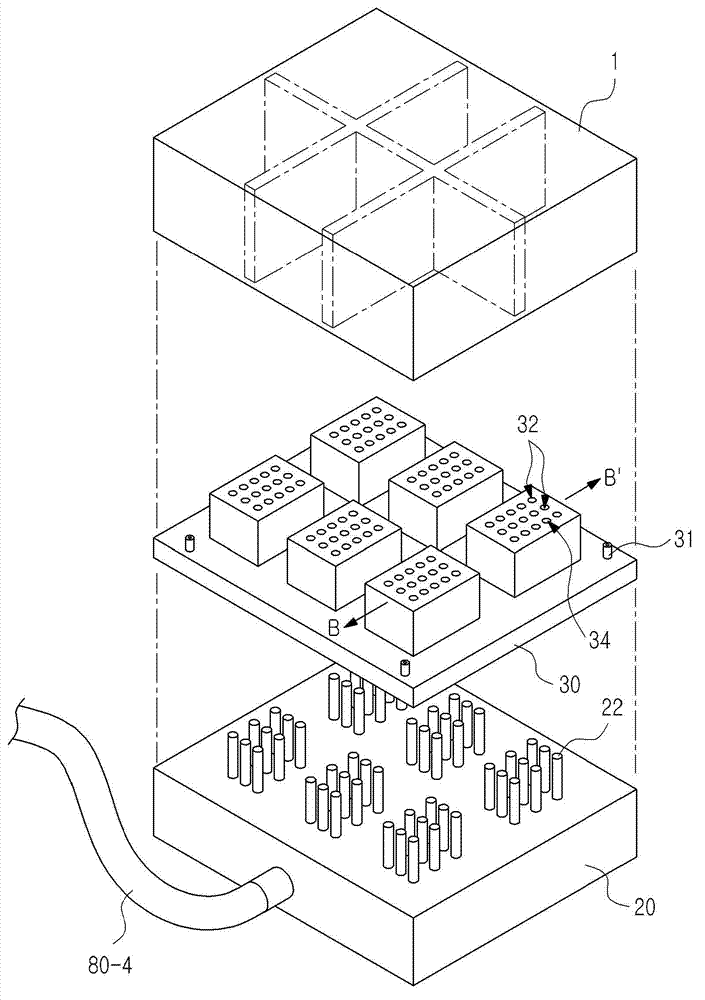

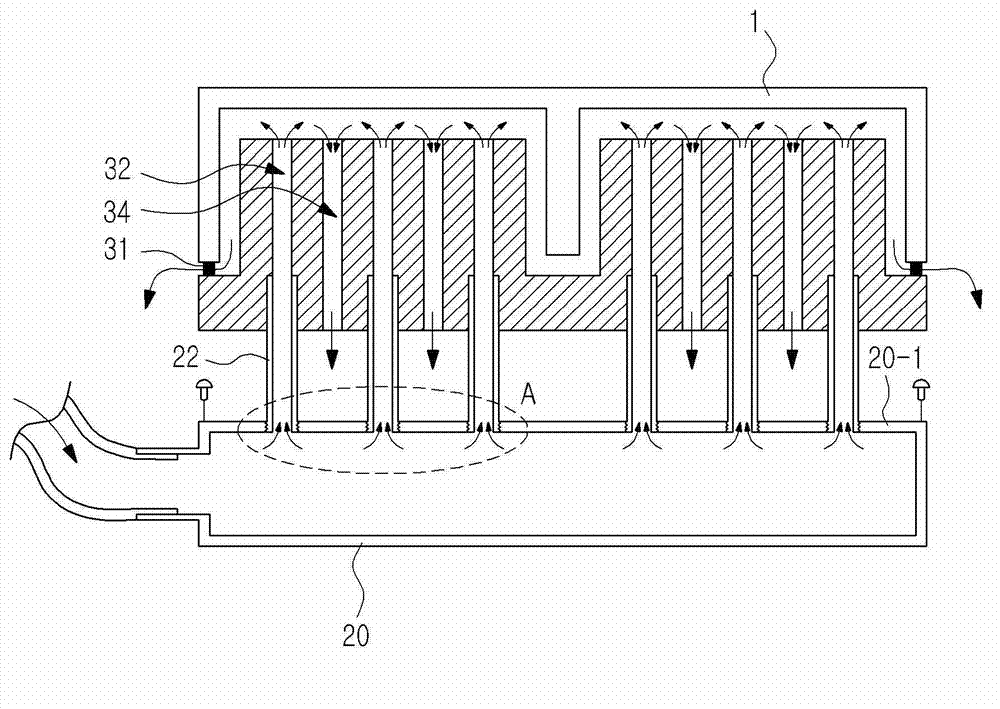

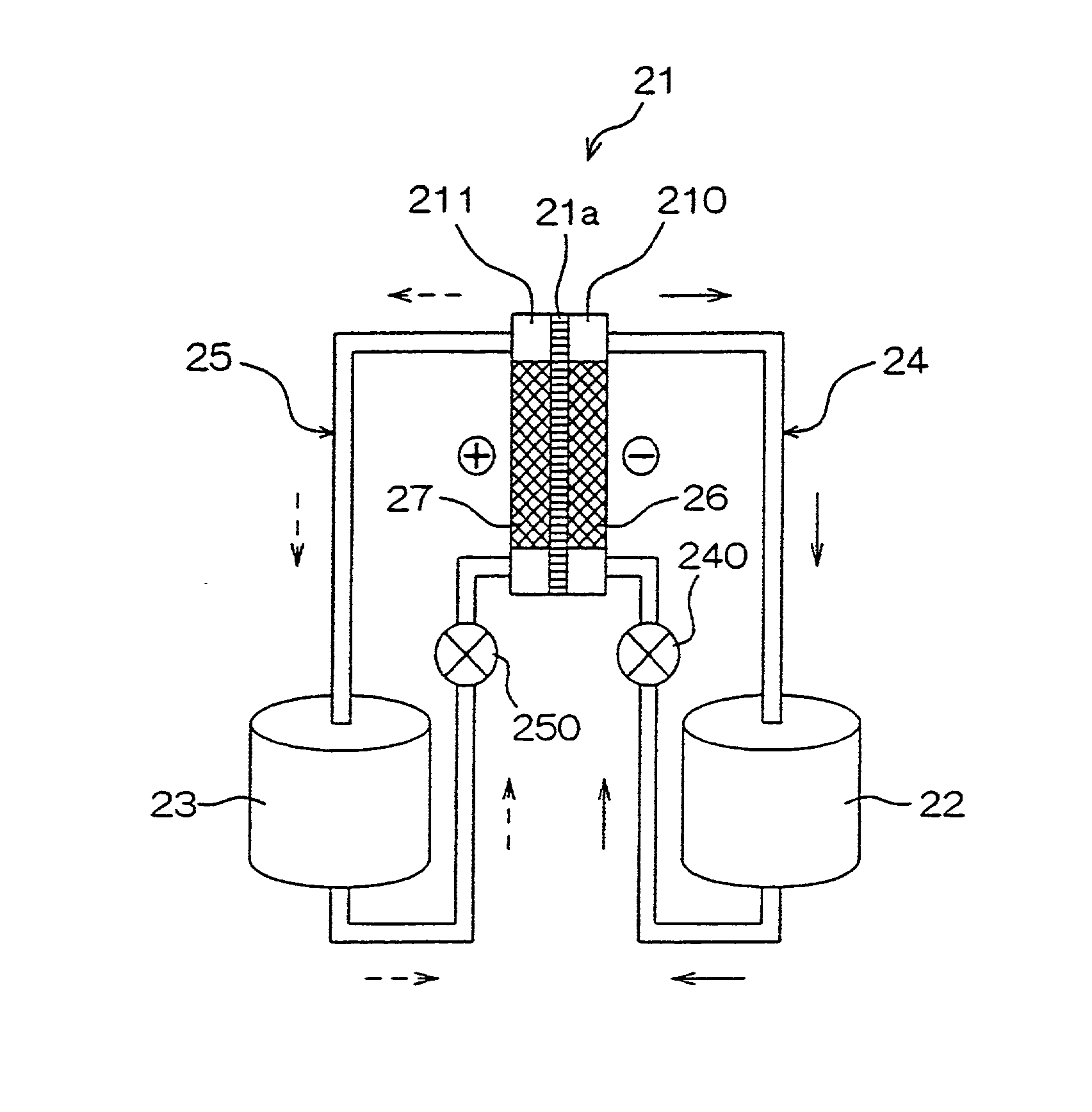

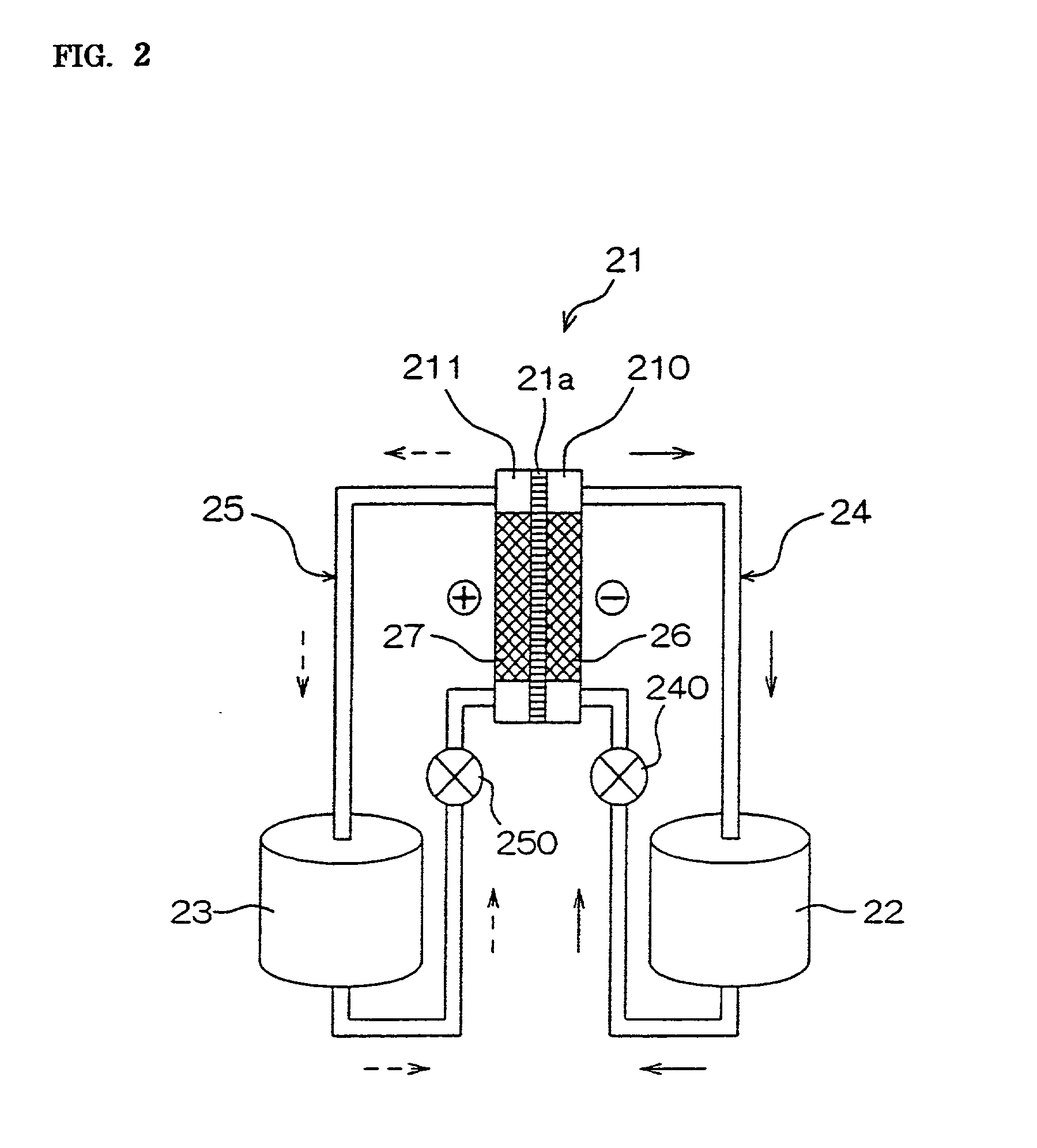

Electroplating apparatus

Owner:KMW INC

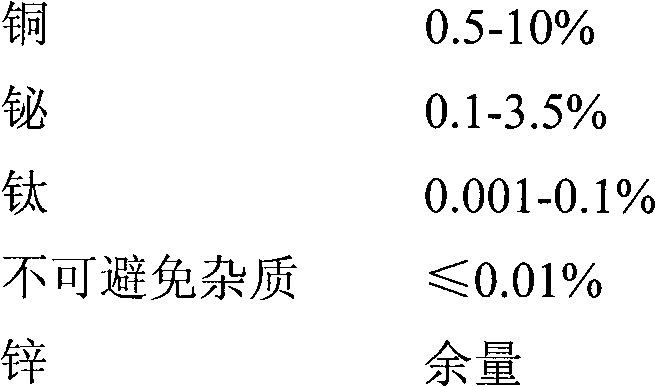

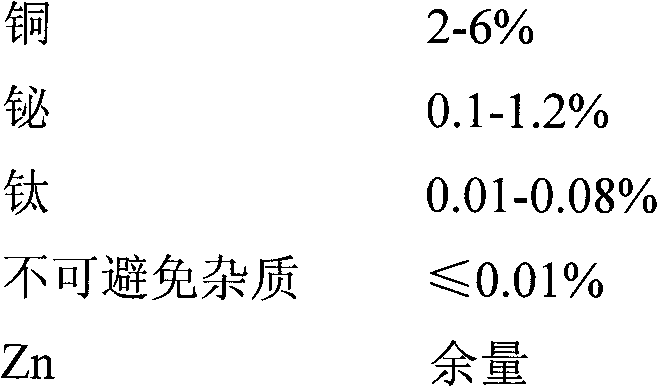

Easy-cutting zinc-copper-base wrought zinc alloy and preparation method thereof

The invention relates to an easy-cutting zinc-copper-base wrought zinc alloy and a preparation method thereof. The easy-cutting zinc-copper-base wrought zinc alloy is characterized by comprising the following components in percentage by weight: 0.5-10% of copper, 0.1-3.5% of bismuth, 0.001-0.1% of titanium, at most 0.01% of inevitable impurity and the balance of zinc. The alloy fusion casting technique comprises the following steps: smelting in a line frequency furnace, intermediate frequency or reverberatory furnace, and carrying out continuous casting or metal mold casting to obtain a casting blank; and carrying out hot extrusion at 180-400 DEG C, and finally carrying out cold drawing to obtain various sizes of rods, wires and section products. The obtained products can be used in the fields of automatic lathes, drill presses, instrument lathes and the like. Compared with the prior art, the alloy provided by the invention has the characteristics of favorable cutting property, moderate mechanical properties and the like, and is easy for processing and electroplating.

Owner:NINGBO POWERWAY ALLOY MATERIAL

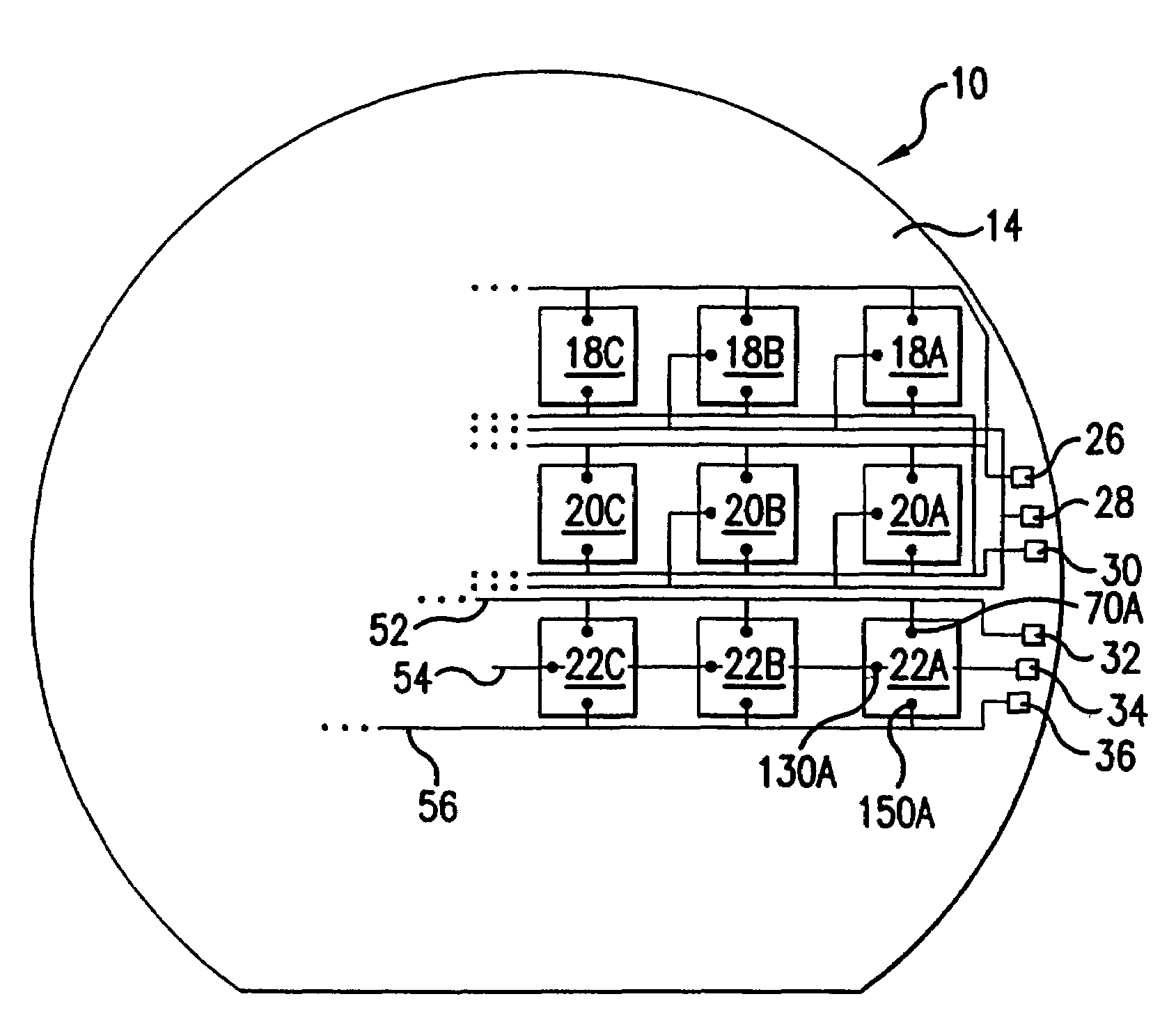

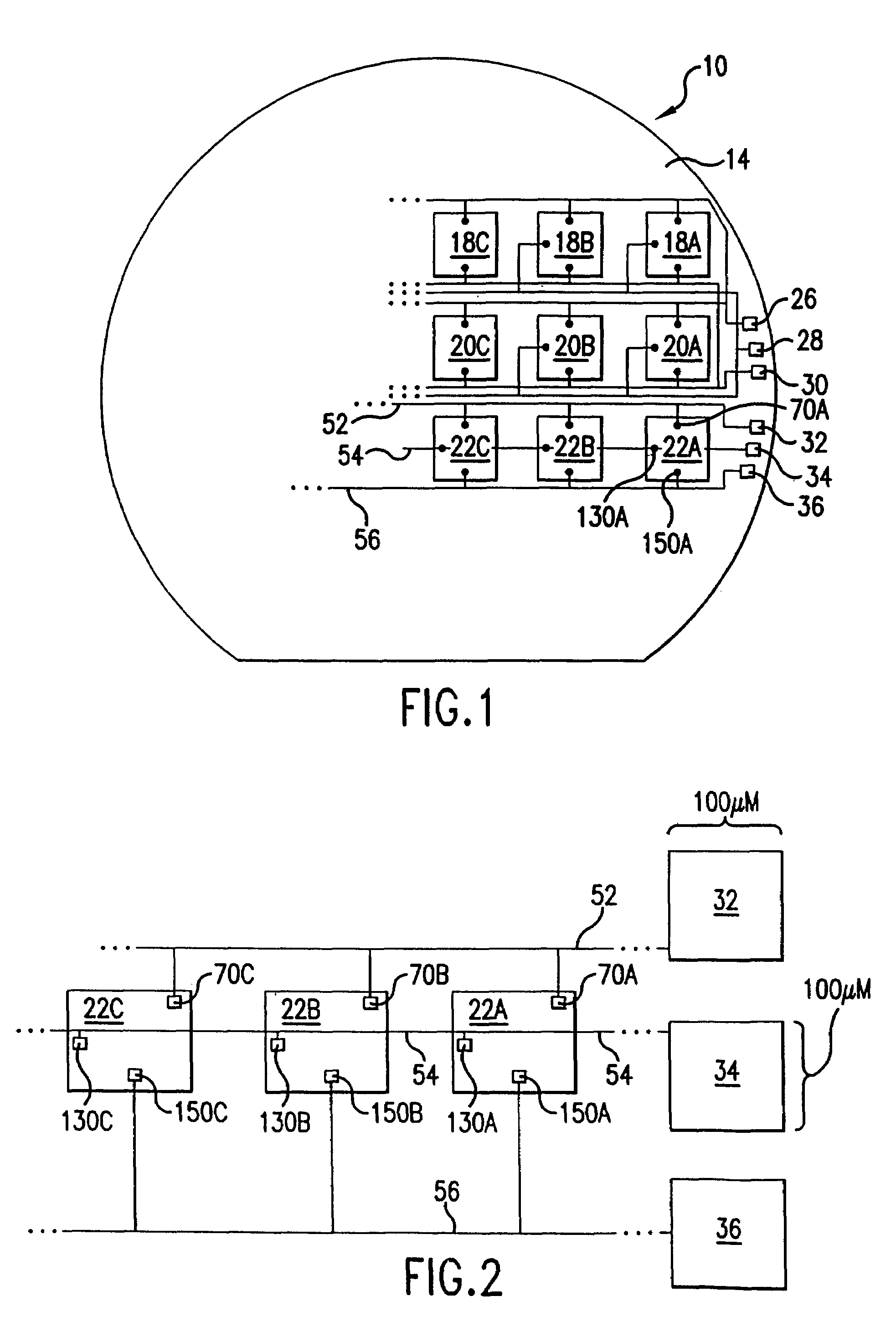

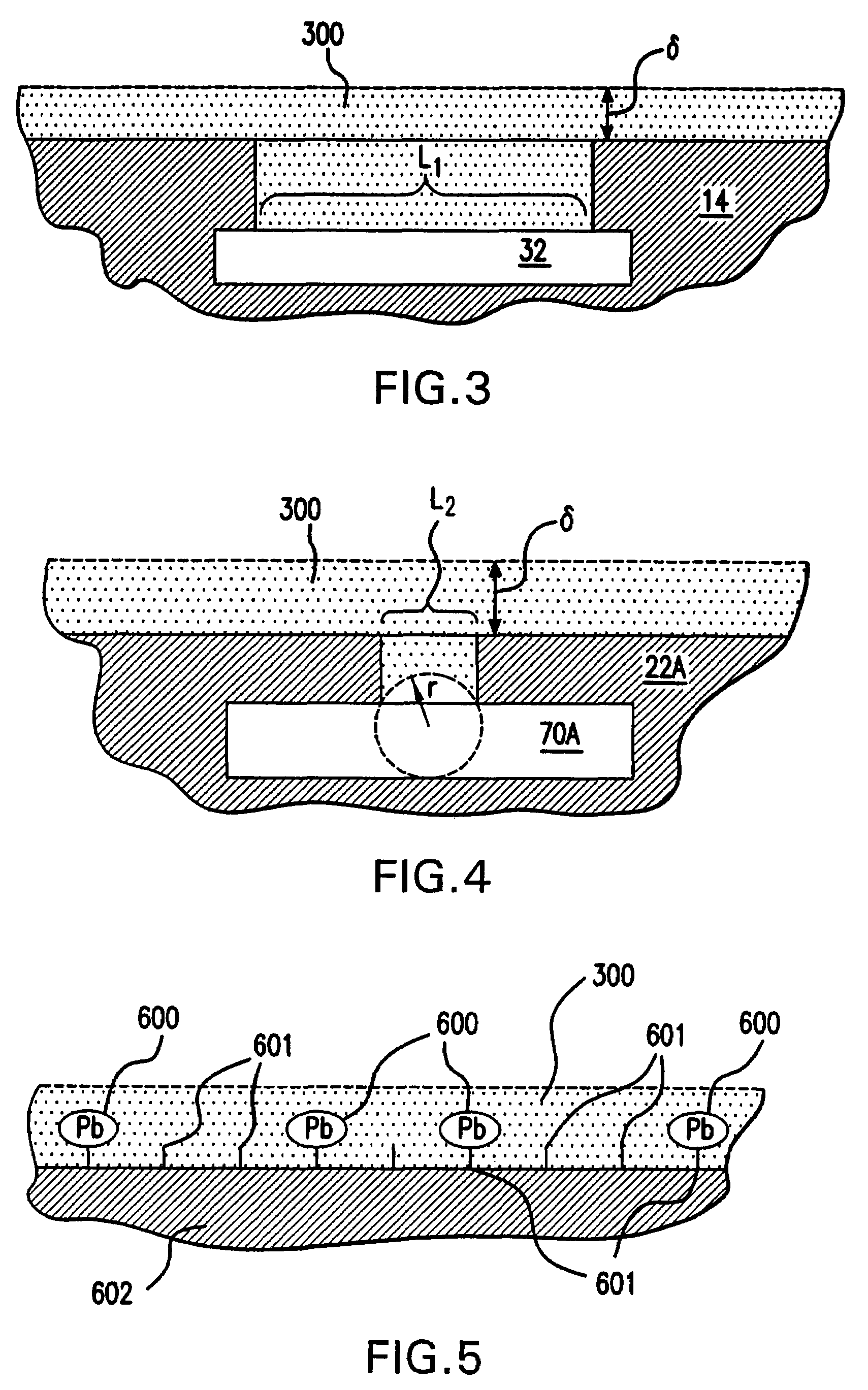

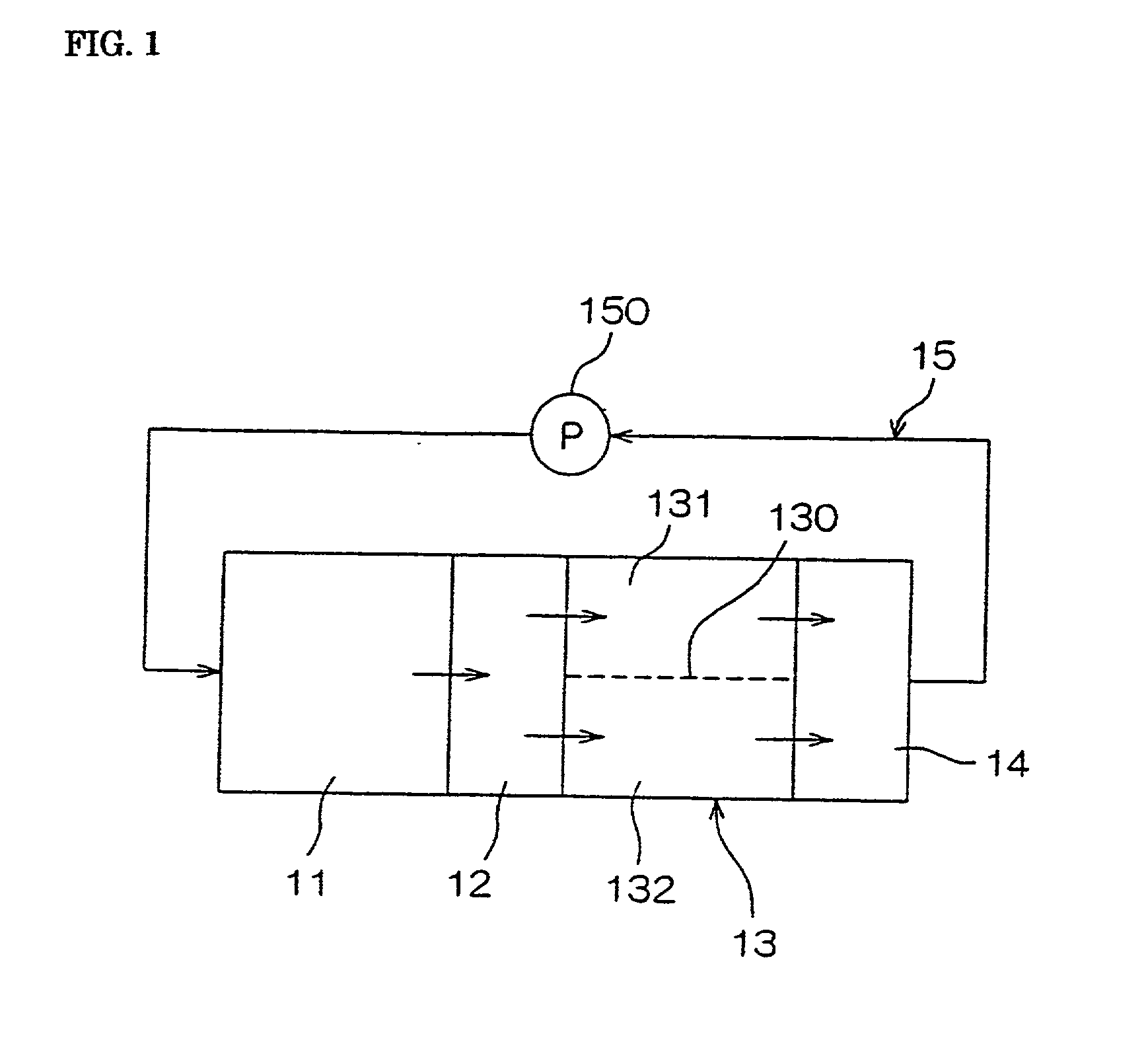

Stable electroless fine pitch interconnect plating

InactiveUS7052922B2Easy to PlatingPlating solution is stableSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringMechanical engineering

A method and apparatus for plating facilitates the plating of a small contact feature of a wafer die while providing a relatively stable plating bath. The method utilizes a supplemental plating structure that is larger than a die contact that is to be plated. The supplemental plating structure may be located on the wafer, and is conductively connected to the die contact. Conductive connection between the die contact and the supplemental plating structure facilitates the plating of the die contact. The supplemental plating structure also can be used to probe test the die prior to singulation.

Owner:MICRON TECH INC

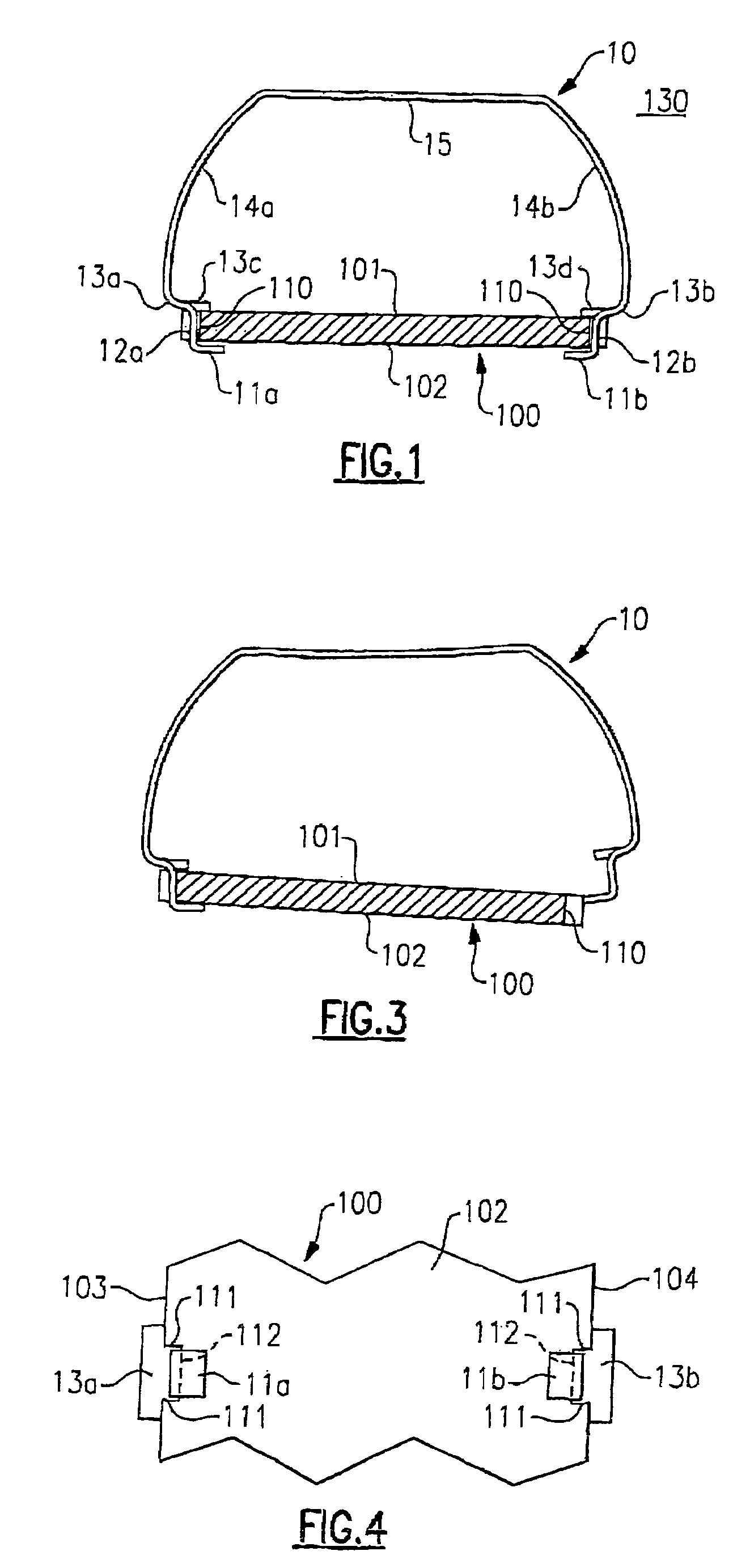

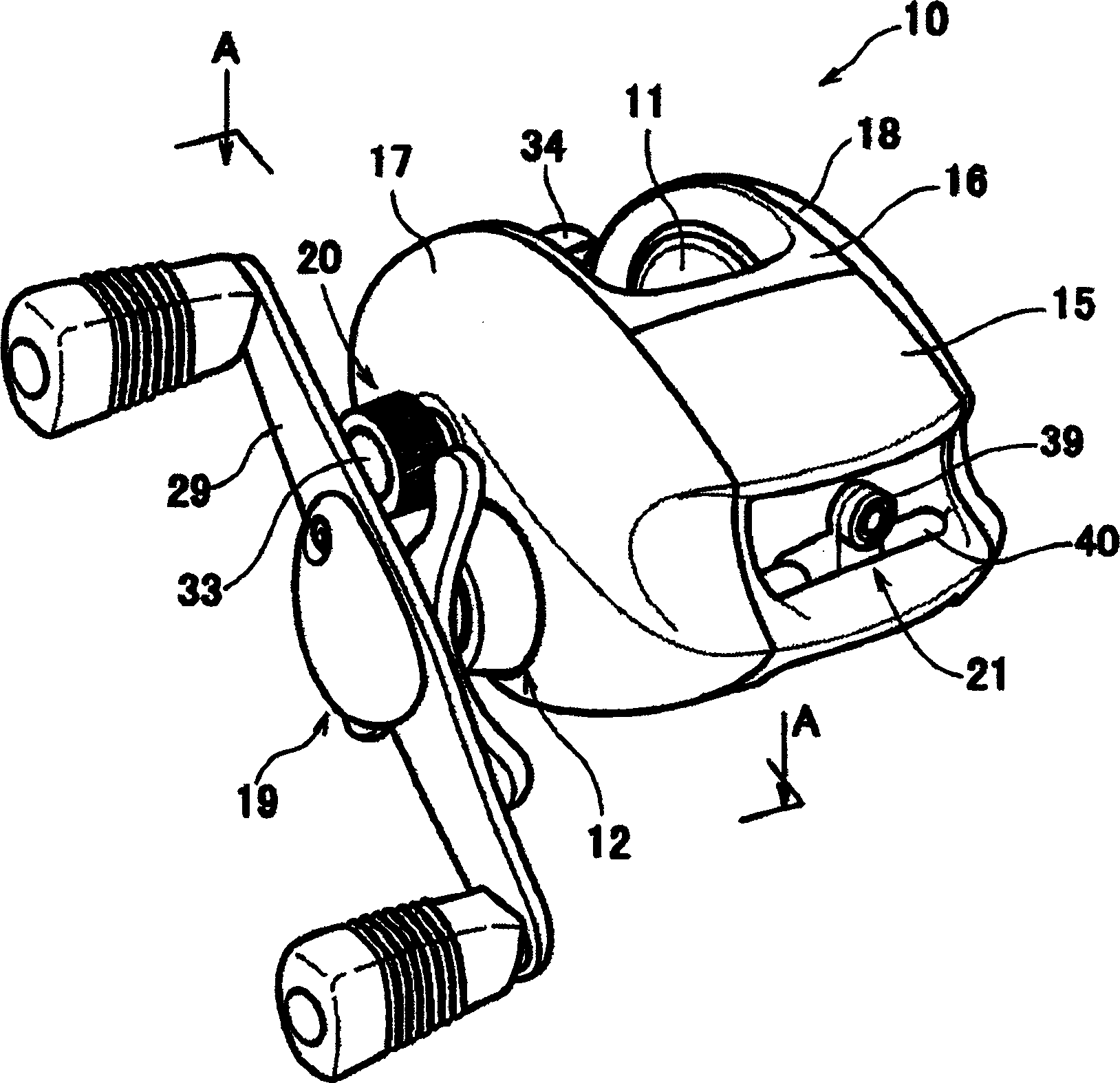

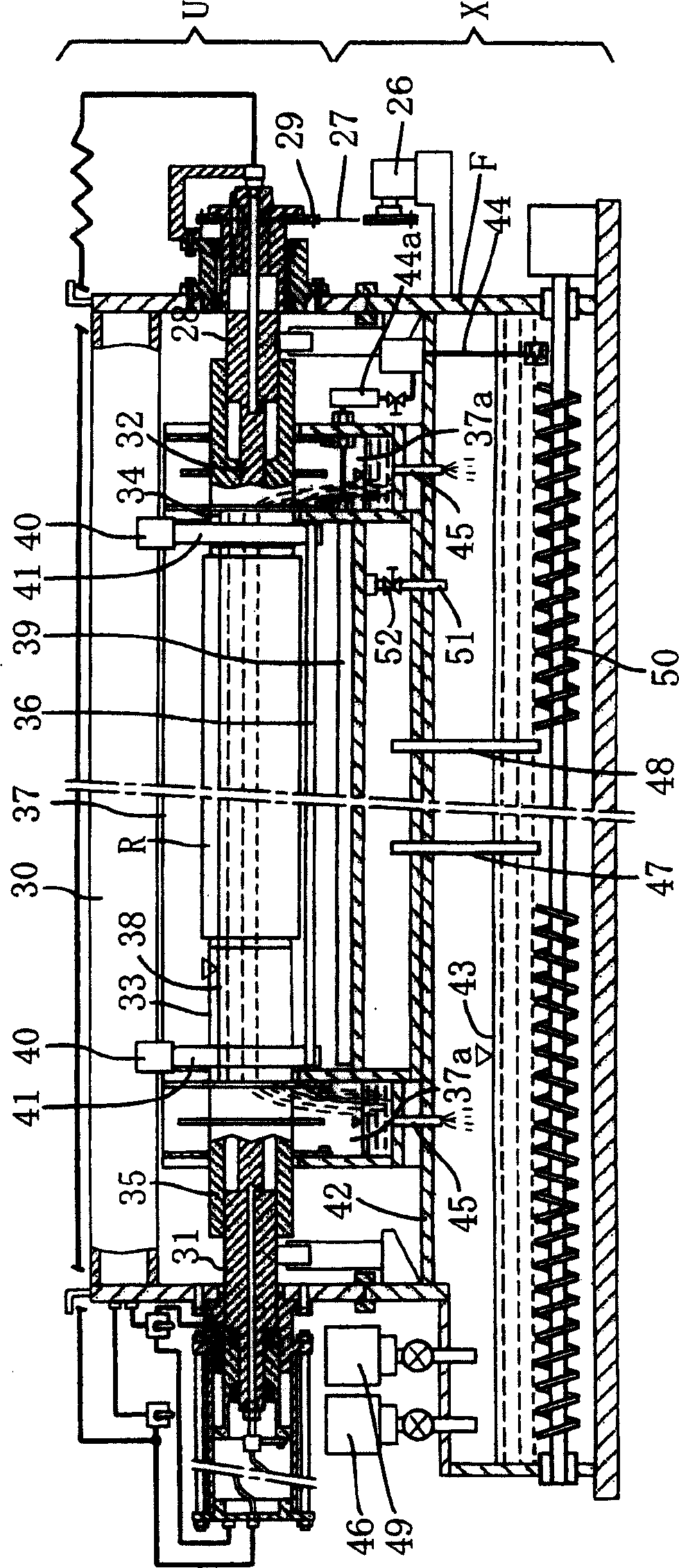

Bait-feeding type reel

The bait casting reel includes a basic unit that includes a spool, a spool driving mechanism, and an attachment frame, and outer plate members that are attached to the attachment frame. All the functional members are installed in the attachment frame, such that the basic unit can perform all the indispensable functions of the bait casting reel. The outer plate members are attached to the attachment frame such that the outer plate members form the surface of the bait casting reel. The present invention allows easy and more flexible ornamental design of bait casting reel while securing its indispensable functions. The present invention also provides a common part of a bait casting reel, which can be used in bait casting reels of other models.

Owner:SHIMANO INC

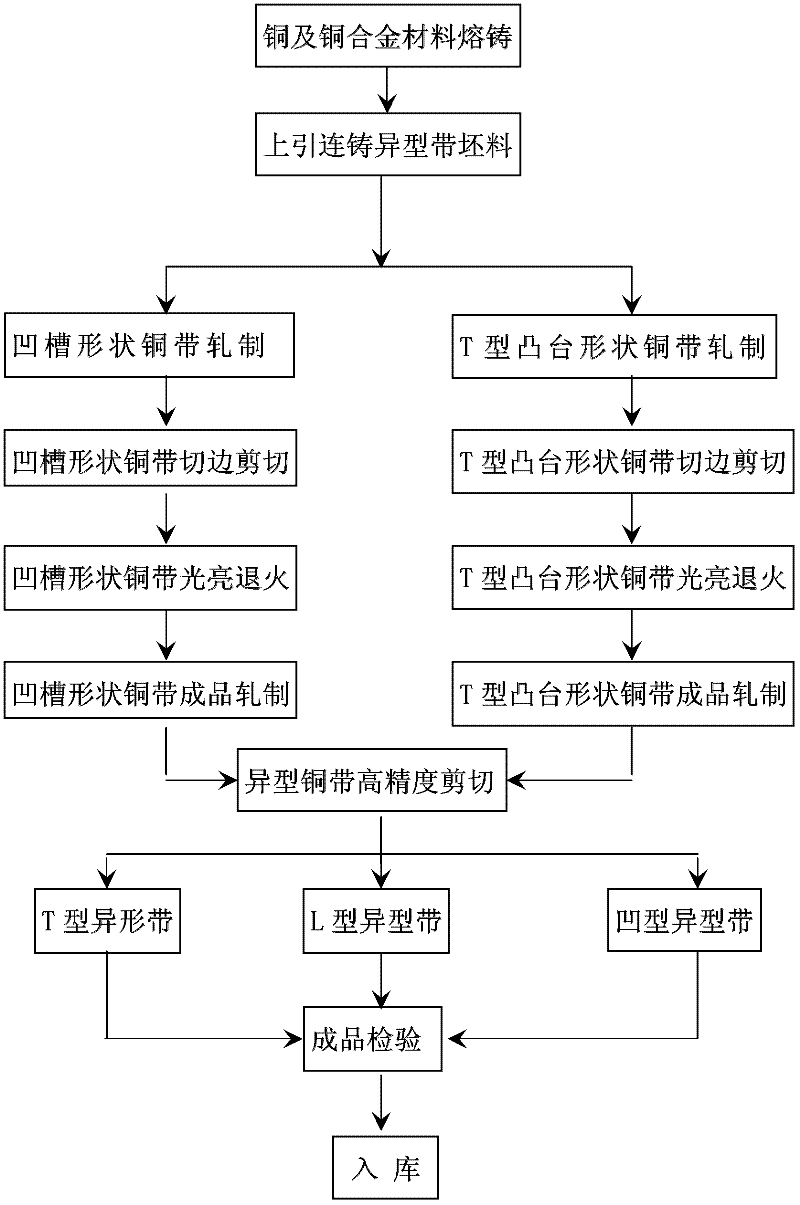

A processing technology for producing special-shaped cross-section brass strips

A processing technology for producing brass strips with special-shaped cross-sections, comprising the following steps: melting, casting, high-precision rolling, bright annealing, finished product rolling, and finished product shearing, characterized in that the casting adopts upward continuous casting to prepare billets , and the round crystallizer tooling equipped with graphite molds used for wire rod production by upward continuous casting was transformed into a design cross-section crystallizer tooling for strip production. Compared with the original processing method for producing brass strips with special-shaped cross-sections, it has the characteristics of low manufacturing cost and cheap tooling molds. The surface of the blank obtained by the invention is bright, the crystal texture is uniform, and the surface milling is not required in the subsequent processing. At the same time, the method has low energy consumption, and is a high-efficiency, low-cost method for producing brass strip blanks with special-shaped cross-sections.

Owner:赤峰京铜铜业有限公司 +1

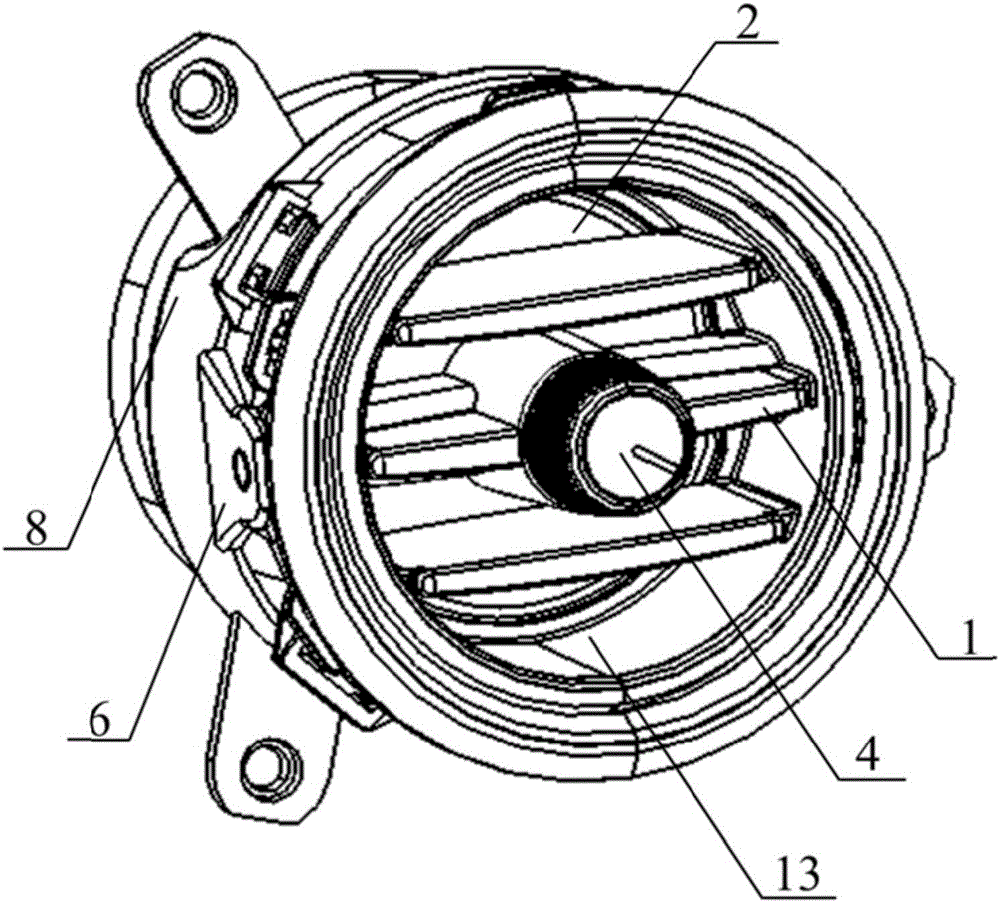

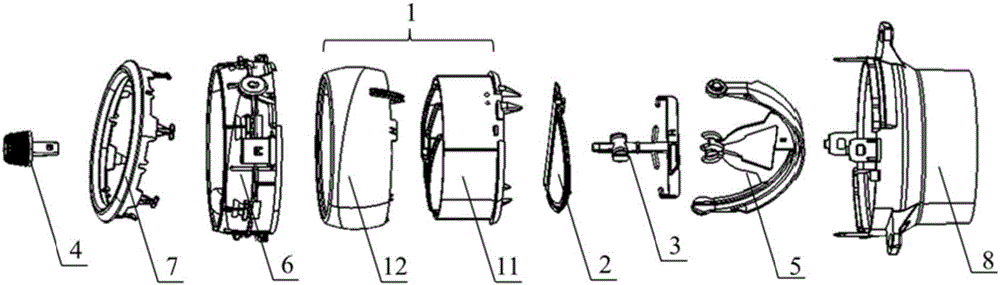

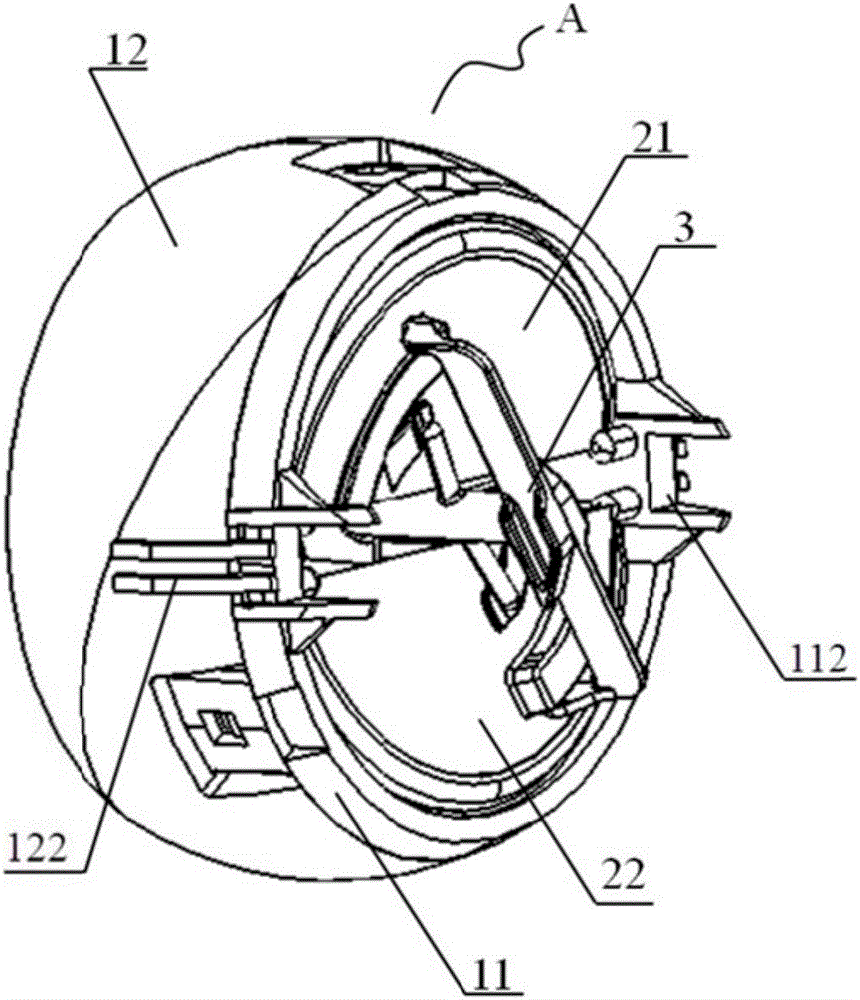

Circular wind outlet assembly of air conditioner of automobile

ActiveCN106274377AImprove aestheticsEasy to PlatingAir-treating devicesVehicle heating/cooling devicesEngineeringElectroplating

The invention provides a circular wind outlet assembly of an air conditioner of an automobile. Components such as a throttle assembly, a rotating connecting rod and buttons are mounted on a main body, and a first outer decorating ring is connected to the outer surface of the main body, so that a base consisting of the main body and the outer decorating ring is used as a rotating body of the wind outlet assembly, and the adjustment of a wind outlet direction is realized through the rotation of the rotating body. Few structures need to be arranged on the first outer decorating ring, so that various modeling treatment such as electroplating and flame plating can be conveniently performed on the outer surface of the first outer decorating ring; and when the rotating body rotates to the directions, the outer surface after modelling treatment is performed can be observed all the time. Compared with a circular wind outlet structure with single appearance surface in prior art, diversifying treatment of appearance can be performed on the circular wind outlet structure of the air conditioner of the automobile disclosed by the invention, so that the beauty of the circular wind outlet structure is greatly improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Plating method and plating bath precursor used therefor

InactiveUS20020079226A1Composition of easilyImprove concentrationCellsBearing componentsIonChemistry

To provide a plating method, which enables wide industrial use of the redox system electroless plating method having excellent characteristics, and a plating bath precursor which is preferable for the plating method. The plating method comprises a process oxidizing first metal ions of a redox system of a plating bath from a lower oxidation state to a high oxidation state, and second metal ions of said redox system are reduced and deposited onto the surface of an object to be plated, wherein a process is provided in which by supplying the electrical current to the plating bath, the first metal ions are reduced from said lower oxidation state to thereby activate the plating bath. The plating bath precursor is formed stabilizing the plating bath so that reduction and deposition of the second metal ions substantially do not occur in order to improve its storing performance.

Owner:DAIWA FINE CHEM +1

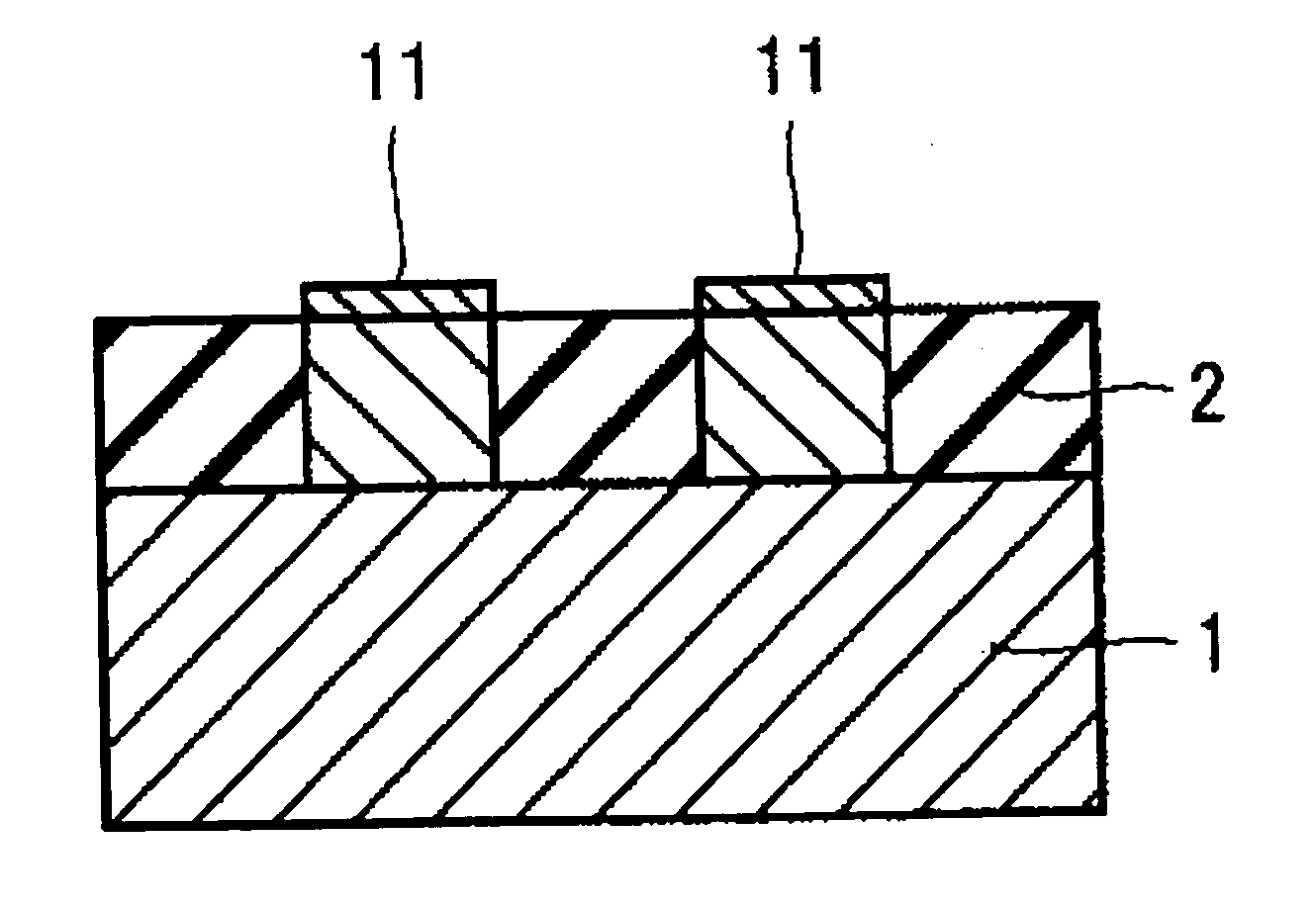

Method of manufacturing electrical parts

InactiveUS20060046455A1Easy to PlatingReduce contact resistanceSemiconductor/solid-state device manufacturingPrinted circuit manufacturePhotoresistContact resistance

A method of manufacturing electrical parts is provided, which method comprises the steps of: forming a photoresist on a part of the surface of a substrate; forming a metal layer on the surface of the substrate after the photoresist has been formed; removing a part of the metal layer; removing a metal oxide film formed on the: surface of the metal layer as a result of removing a part of the metal layer; and removing the photoresist. With this method the contact resistance on the surfaces of the electrical parts can be decreased.

Owner:SUMITOMO ELECTRIC IND LTD

Barrel plating method of trivalent color zinc

The invention relates to the field of electroplating, in particular to a barrel plating method of trivalent color zinc. The barrel plating method comprises the steps of step I, carrying out thermal degreasing; step II, carrying out pickling; step III, carrying out electroplating; step IV, carrying out bright dipping; step V, carrying out trivalent color zinc plating; step VI, cleaning with hot water; and step VII, placing a treated product in a tray. According to the barrel plating method, a new product is subjected to oil removing and derusing through clean water cleaning and pickling, the technological process is reduced, and the cost is reduced.

Owner:CHONGQING PENGLEI AUTO PARTS CO LTD

Method for electroplating and grinding plate rolls before forming pore

An electroplating and grinding technology for the plate-making roller before microholes are formed includes such steps as lifting insoluble anode to make it close to lower surface of plate-making roller, supplying the filtered electroplating liquid, electroplating, fixing the liquid-infiltratable abrasive particles and flexible body or superfibres to the surface of grinding head with electrode, supplying electrolyzing liquid, moving the grinding head back and forth along the surface of said roller for electrolytic grinding.

Owner:THINK LABORATORY CO LTD

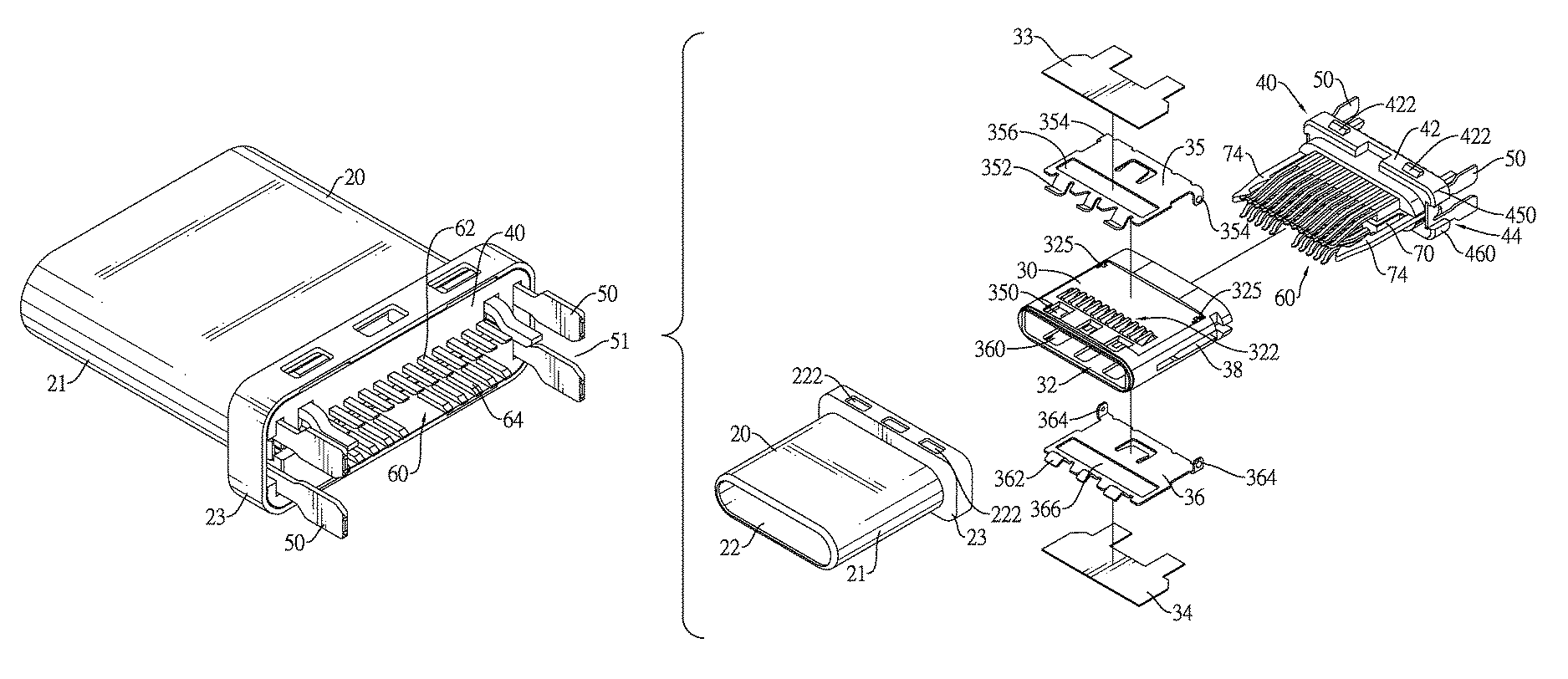

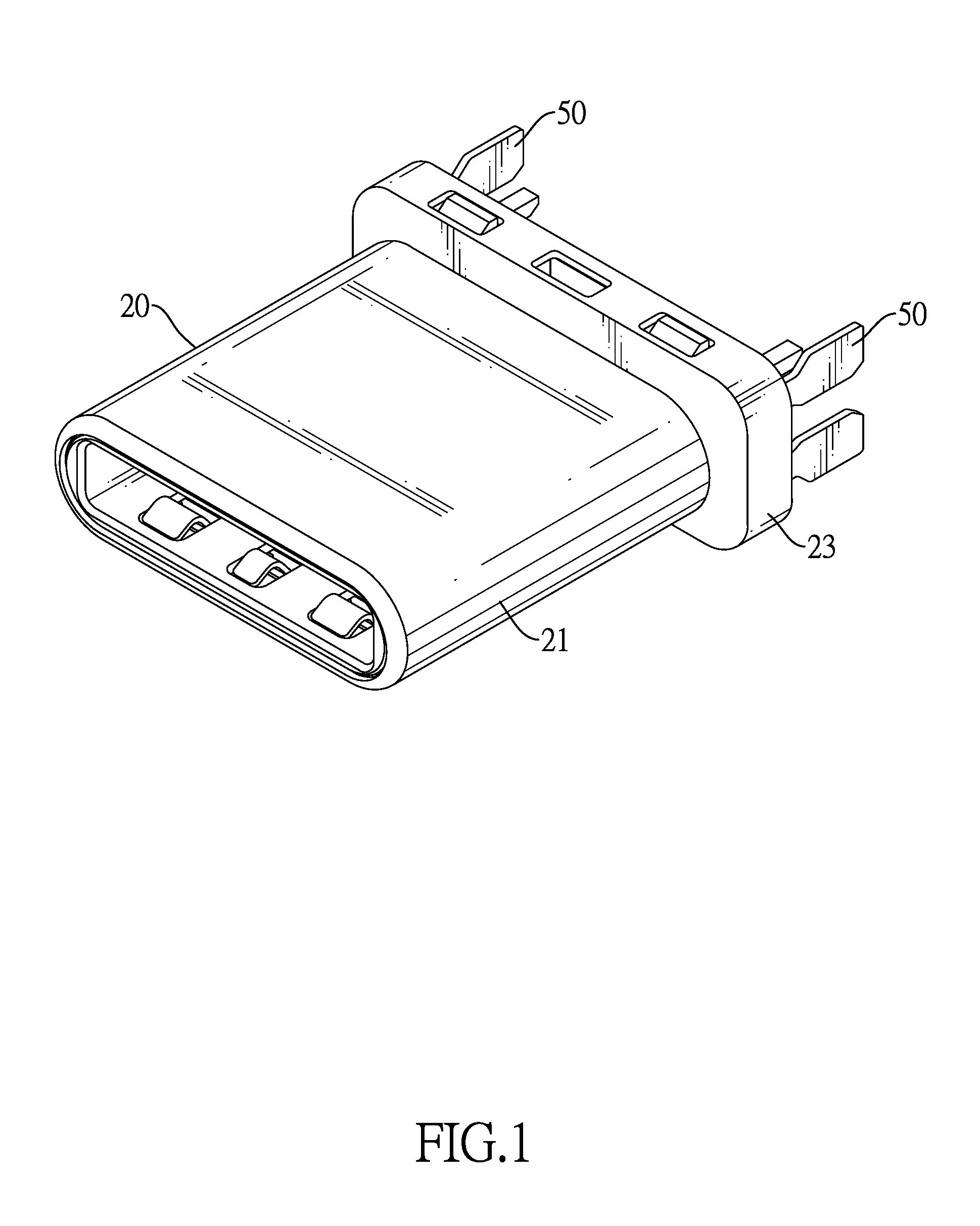

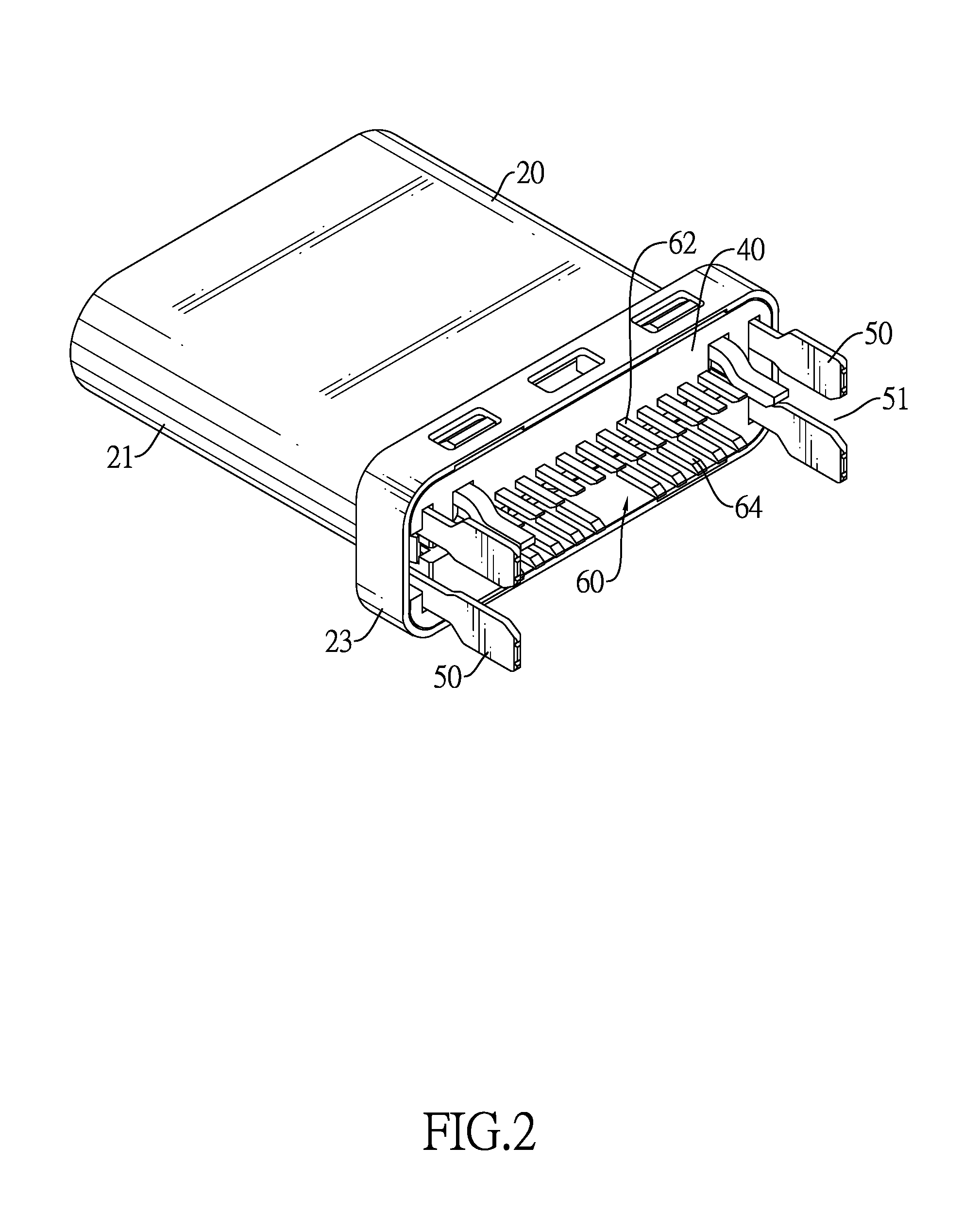

Electrical connector having holding pieces with a notch for holding a circuit board

ActiveUS9577360B2High strengthEasy to PlatingIncorrect coupling preventionTwo-part coupling devicesElectrical connectorMechanical engineering

An electrical connector has a base, a terminal set, a pair of holding pieces, an insulating body and a shell. The base has two holding piece slots respectively formed in two sides of the bottom of base. The pair of holding pieces is assembled into the holding piece slots respectively. Each holding piece is C-shaped and has a notch formed in a rear end of the holding piece and serving to hold a PCB board. A front end of each holding piece is assembled into the base. Given the pair of holding pieces with an assemblable structure, the size of the holding pieces can be tailored to the requirement of customers. The shell is formed by a two-stage of drawing process to enhance overall strength of the shell to facilitate the plating process afterwards.

Owner:ADVANCED CONNECTEK INC

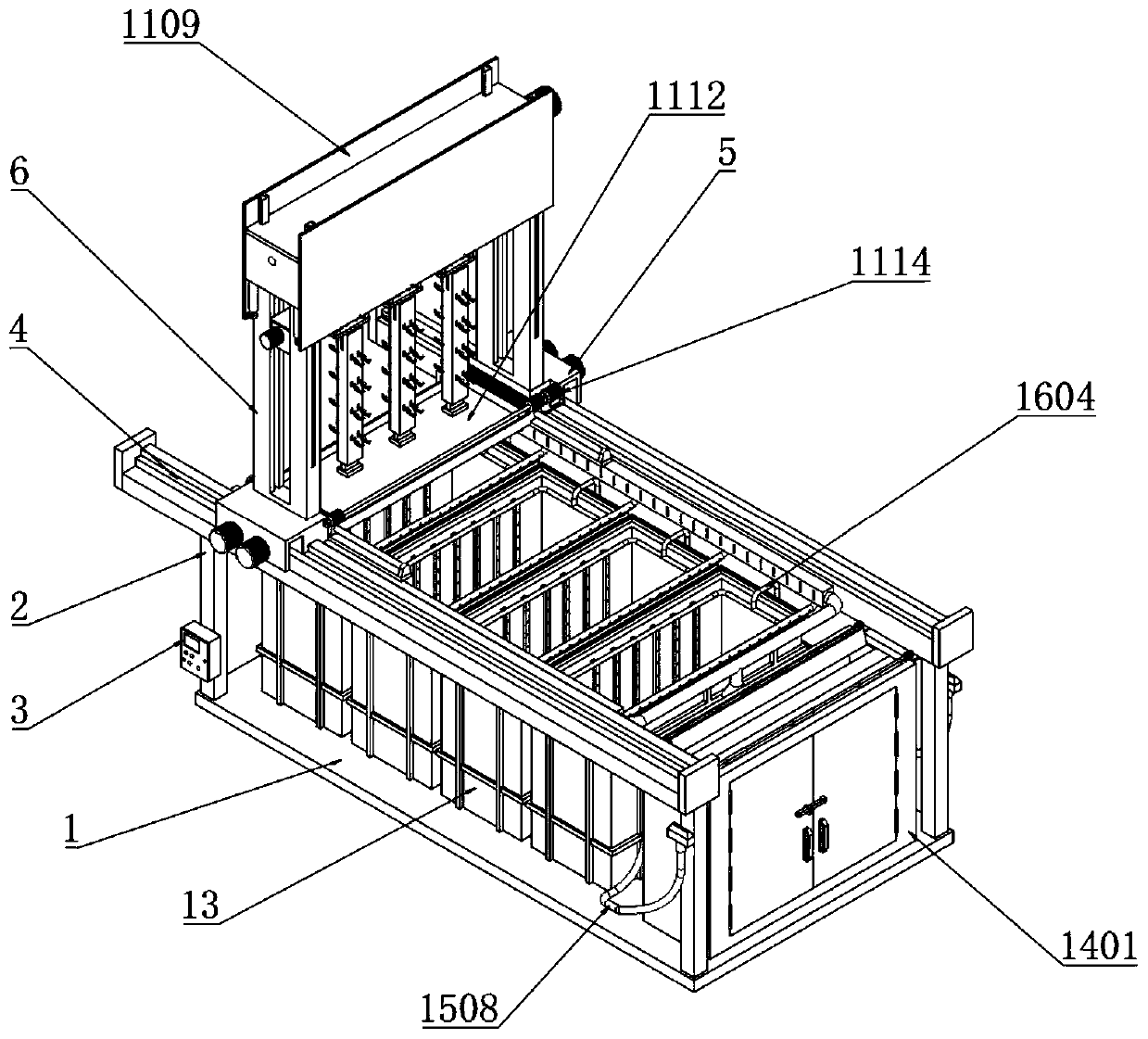

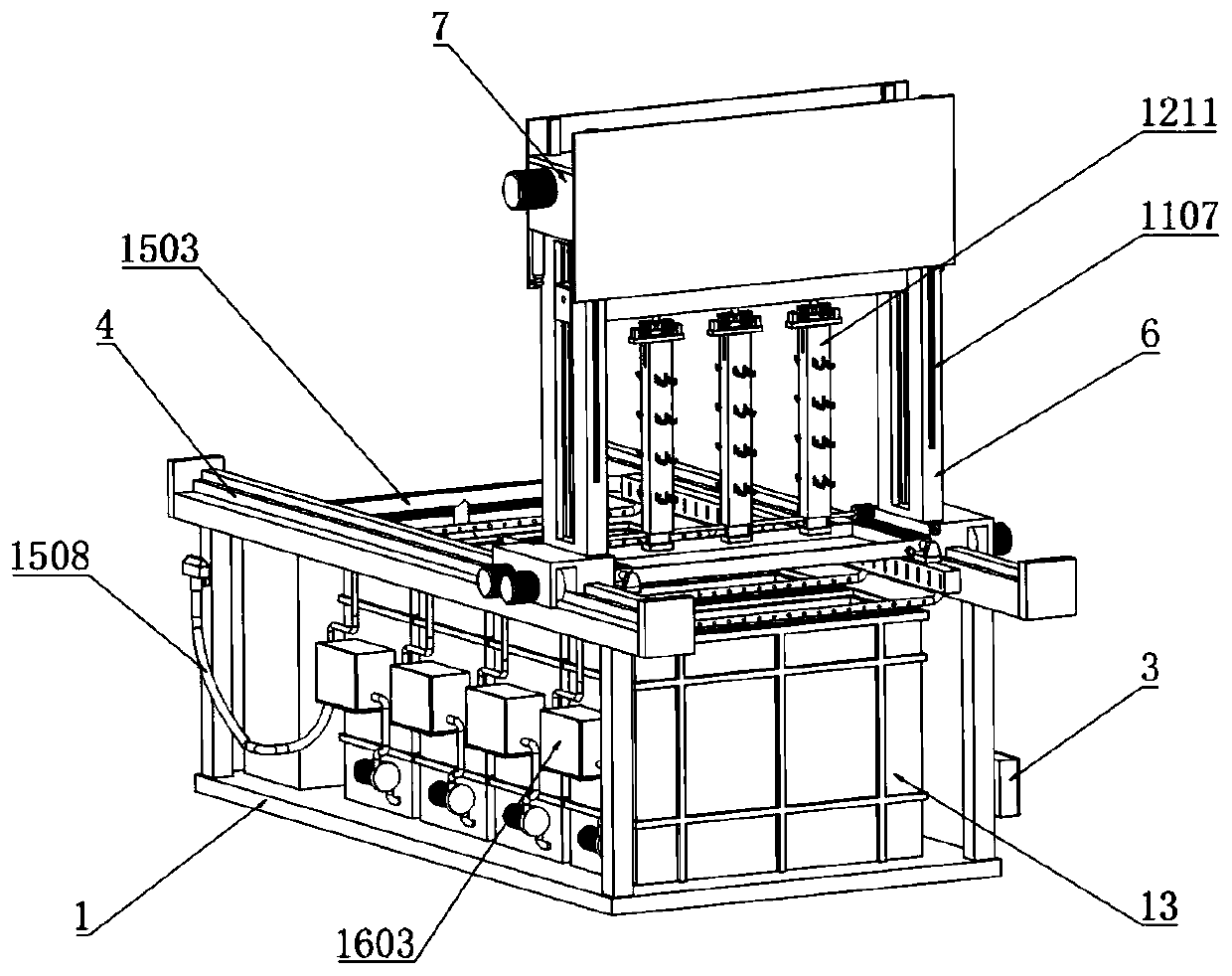

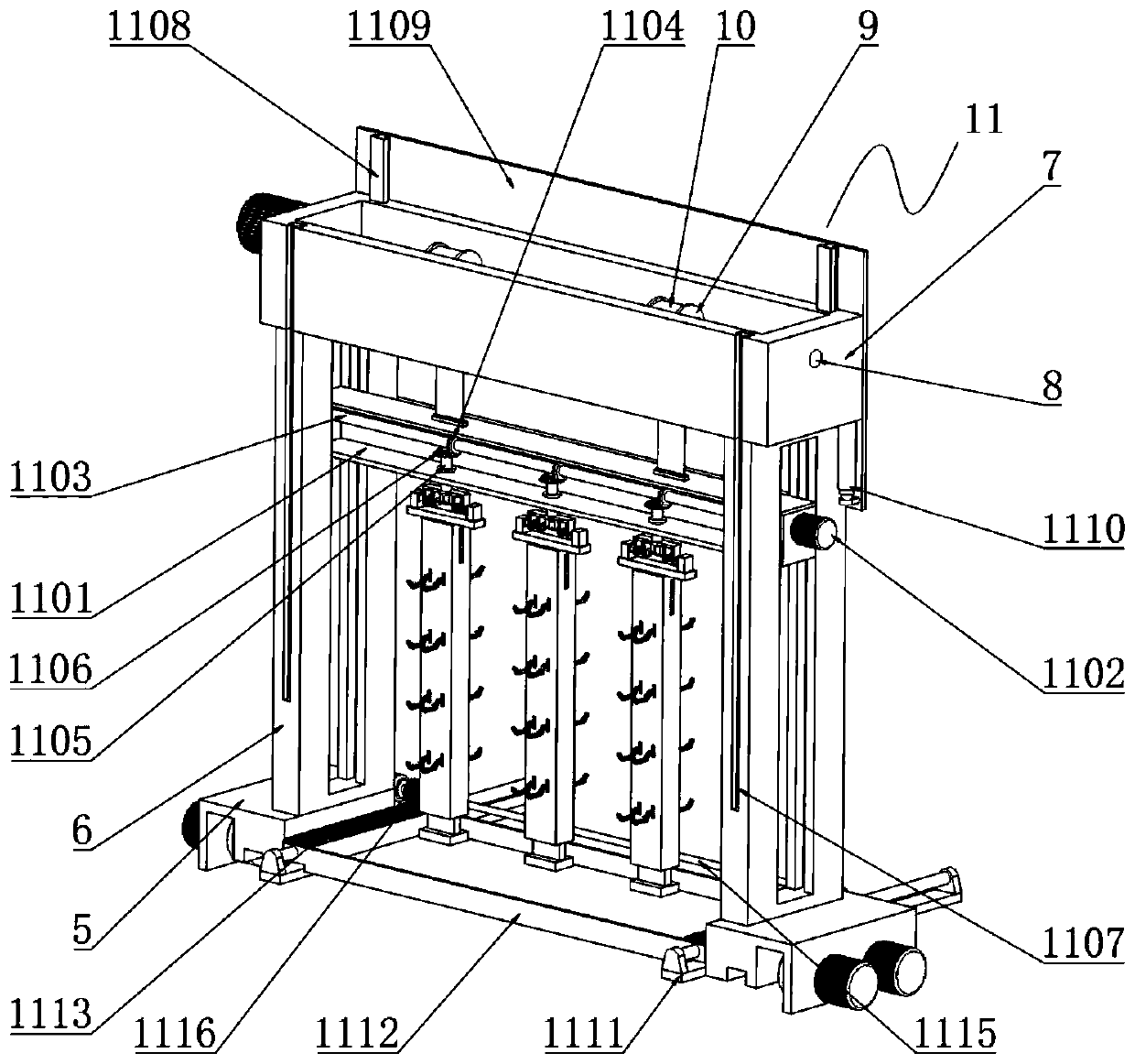

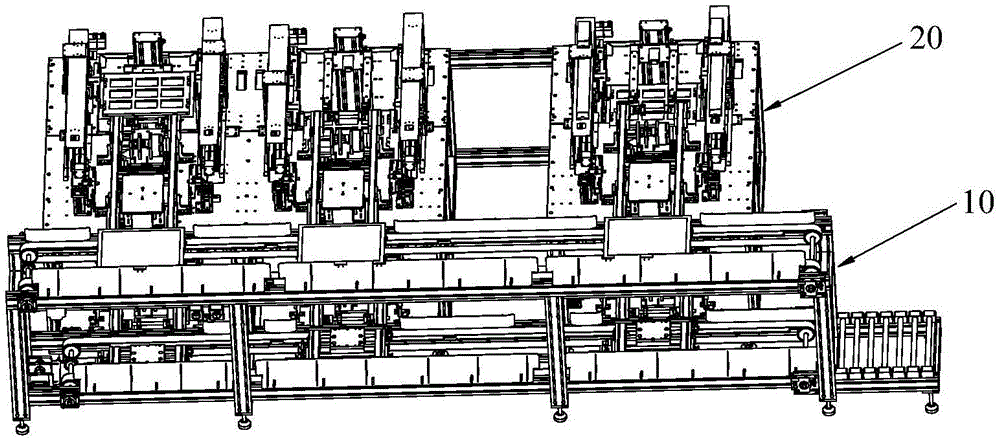

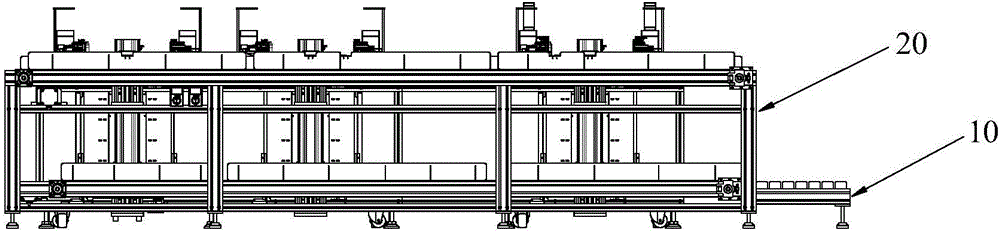

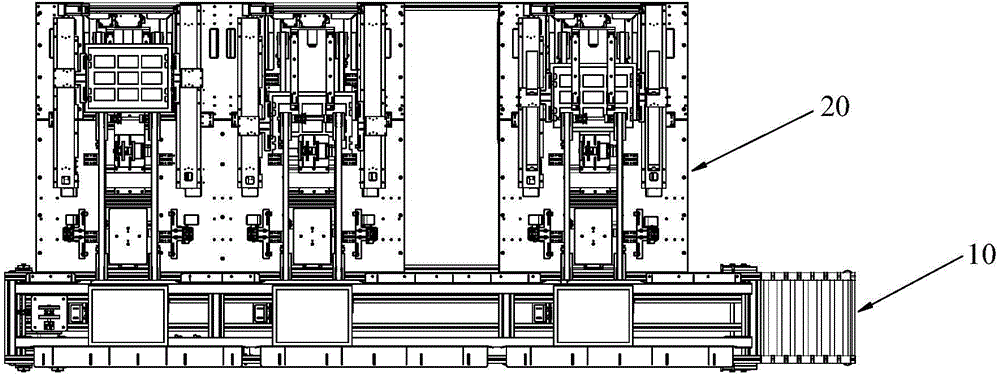

Tray conveying device for liquid crystal module classified packaging

ActiveCN104528037AEasy to PlatingImprove efficiencyConveyorsPackagingOutput deviceMechanical engineering

The invention discloses a tray conveying device for liquid crystal module classified packaging. The tray conveying device for liquid crystal module classified packaging comprises a tray input and output device and a tray moving device. The tray input and output device comprises a support, a tray input mechanism used for conveying stacked empty trays and a tray output mechanism used for conveying the stacked trays full of liquid crystal modules out. The tray moving device comprises a rack, a receiving and lifting mechanism used for receiving the stacked empty trays conveyed by the tray input mechanism and lifting the stacked empty trays to the upper layer of the rack, a carrying mechanism used for conveying the stacked empty trays lifted by the receiving and lifting mechanism in batches, a transmission mechanism used for sequentially conveying the trays which are conveyed by the carrying mechanism and are full of the liquid crystal modules on a single layer and transmitting the trays which are full of the liquid crystal modules and located on a stacking mechanism to the tray output mechanism, and the stacking mechanism used for stacking the trays which are conveyed in batches and are full of the liquid crystal modules. The tray conveying device for liquid crystal module classified packaging is small in occupied space and high in tray loading efficiency and classified packaging efficiency.

Owner:KUSN JINGXUN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com