Inspection fixture and inspection probe

A fixture and contact technology, applied in the field of inspection fixtures, can solve the problems of impracticality, difficult assembly of inspection fixtures, extremely difficult formation of coiled coil springs, etc., and achieves the effect of ensuring elasticity and easy plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

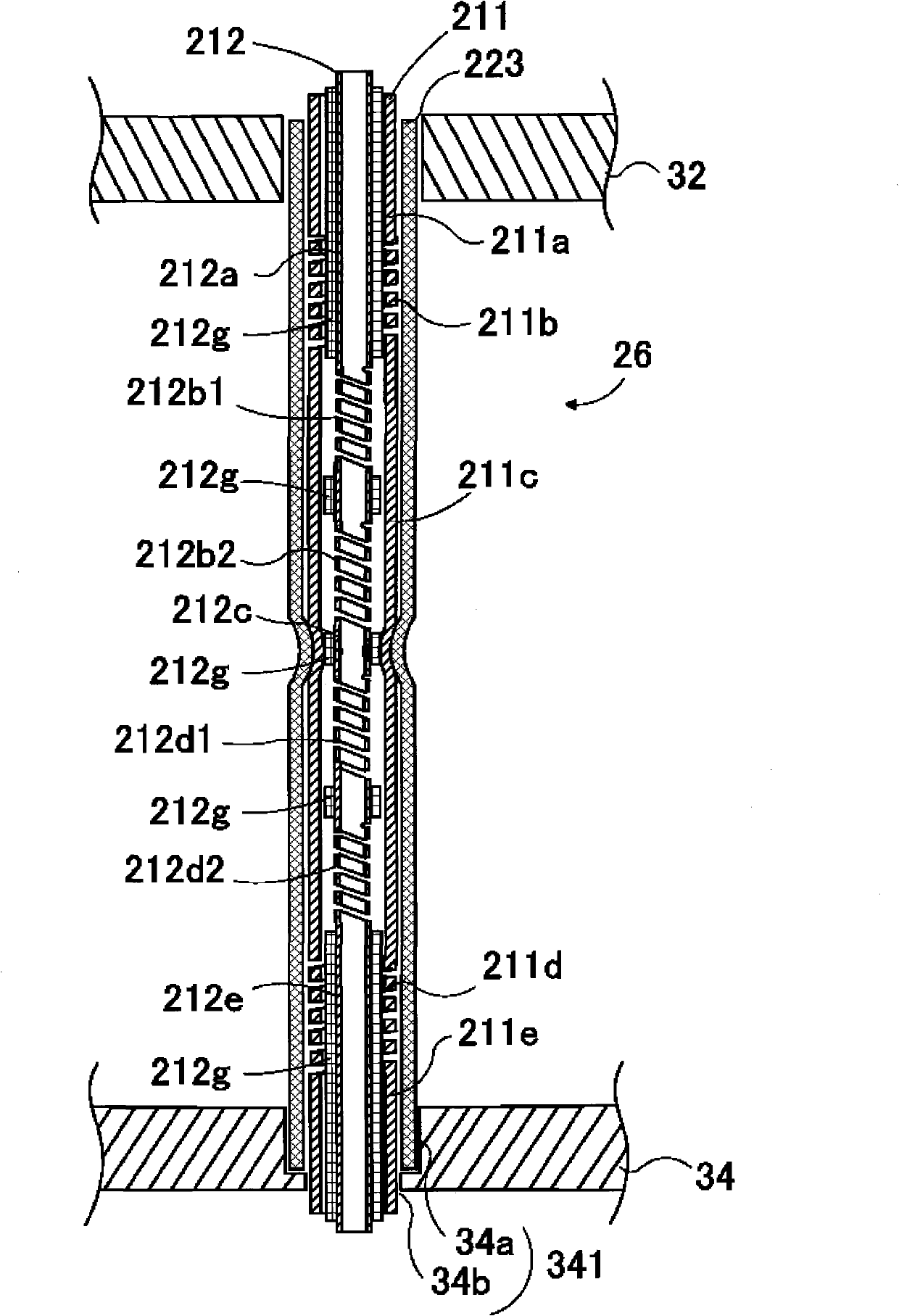

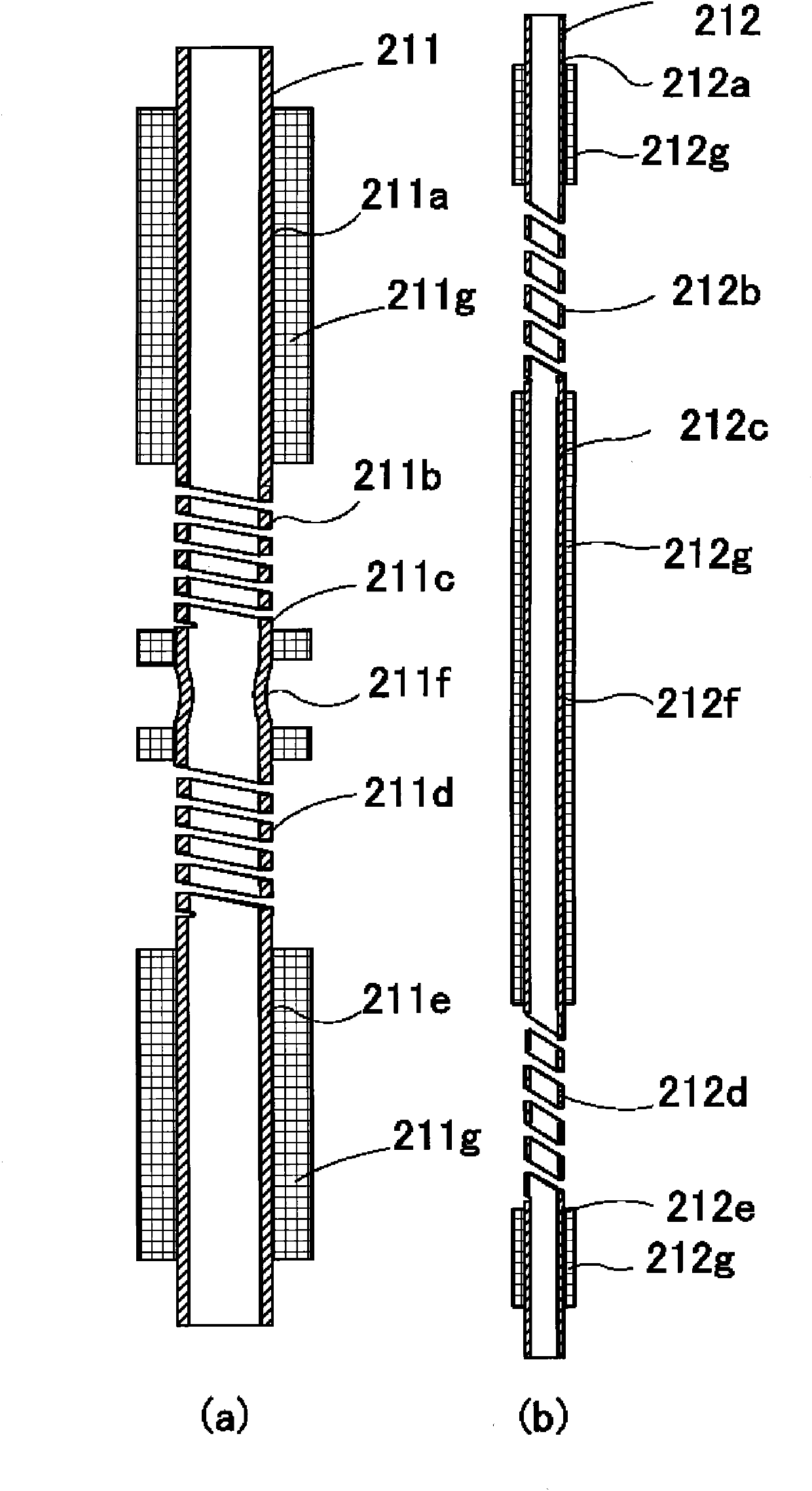

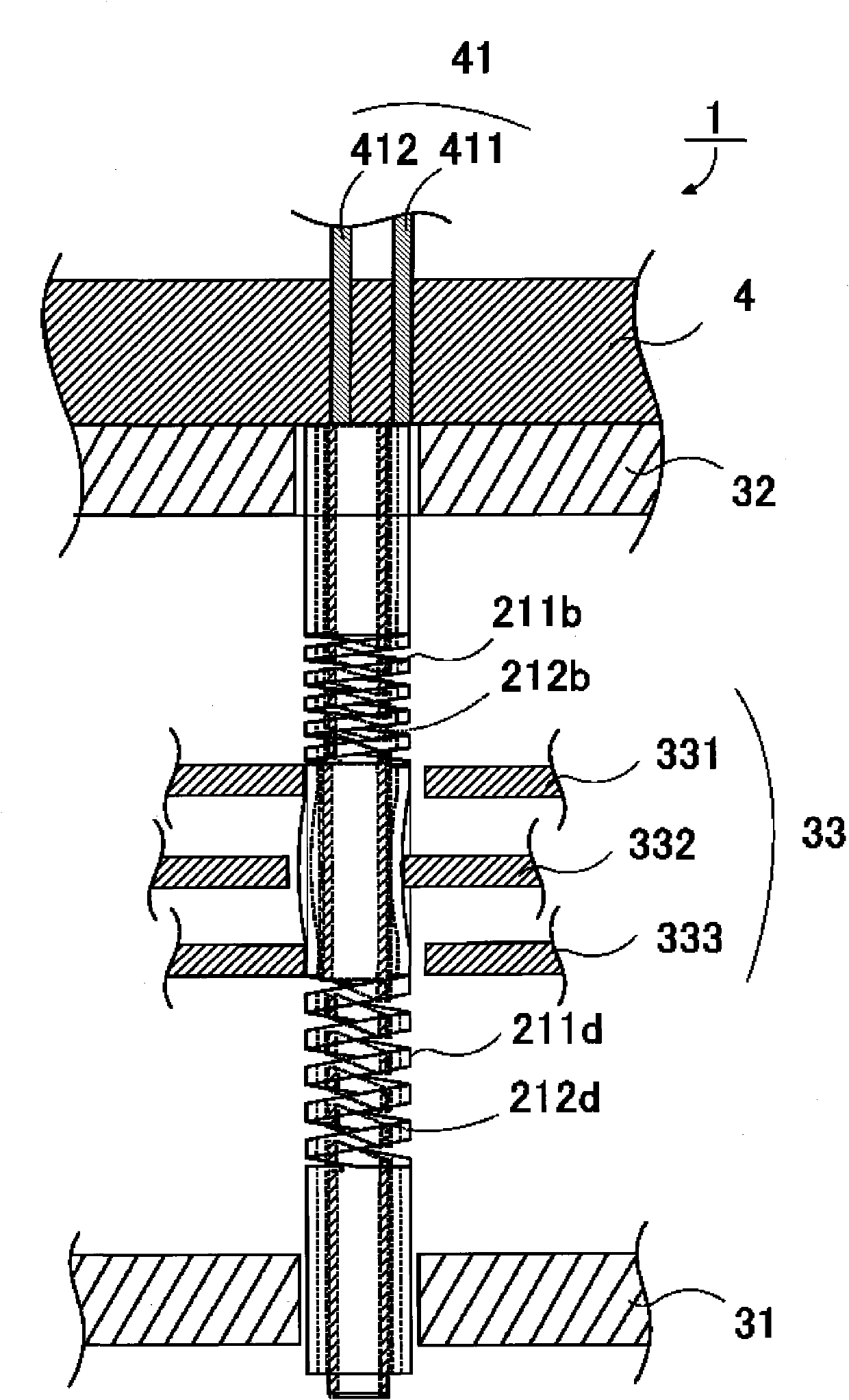

[0052] Modes for implementing the present invention will be described. figure 1 It is a schematic configuration diagram showing an embodiment of the inspection jig according to the present invention. The inspection jig 1 according to the present invention has a plurality of contacts 2, a holding body 3 holding these contacts 2 in a multi-needle shape, and an electrode that supports the holding body 3 and contacts the contacts 2 to be in a conductive state. Section 41 (see Figure 5 ) connected to the electrode body 4, and the lead portion 5 provided to extend from the electrode portion 41 and electrically connected thereto.

[0053] also, figure 1 Although three contacts are shown as a plurality of contacts 2 and three corresponding lead parts 5 are shown in the figure, they can be determined according to the inspection points set by the substrate of the inspection object, and are not limited to three. root.

[0054] The main feature of the present invention is that two co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com