Efficient three-dimensional laser equipment capable of better guaranteeing plating performance of LAP

A three-dimensional, laser equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor plating, slow processing efficiency, etc., to achieve convenient plating, improve efficiency, and good surface carbonization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

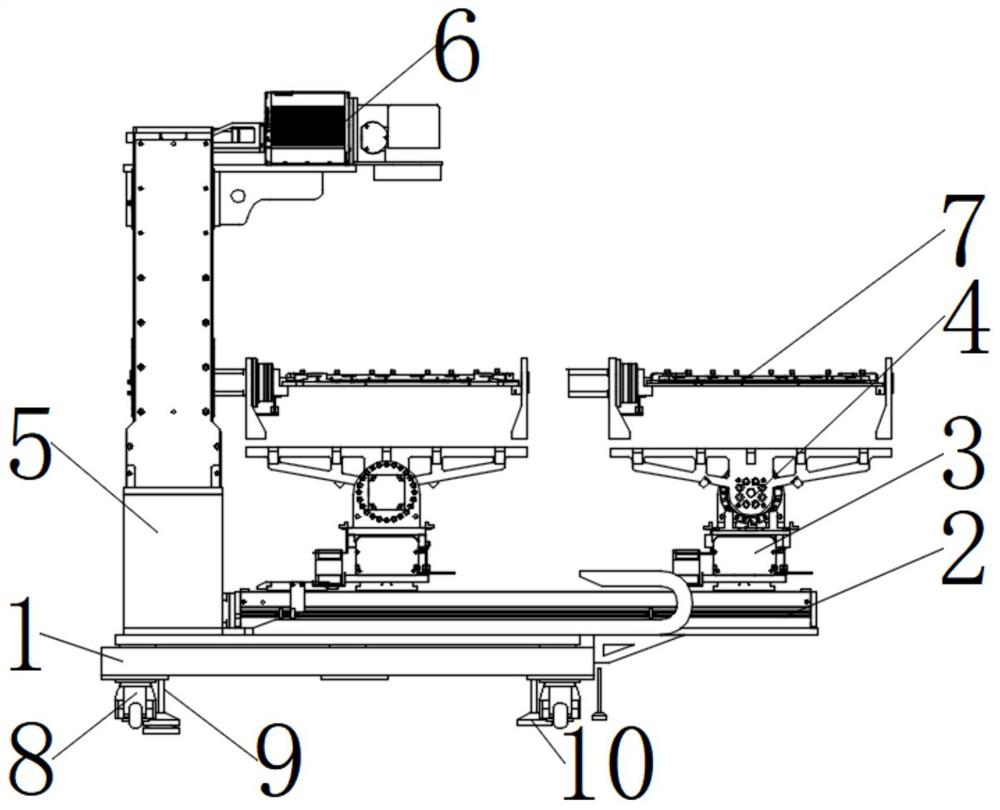

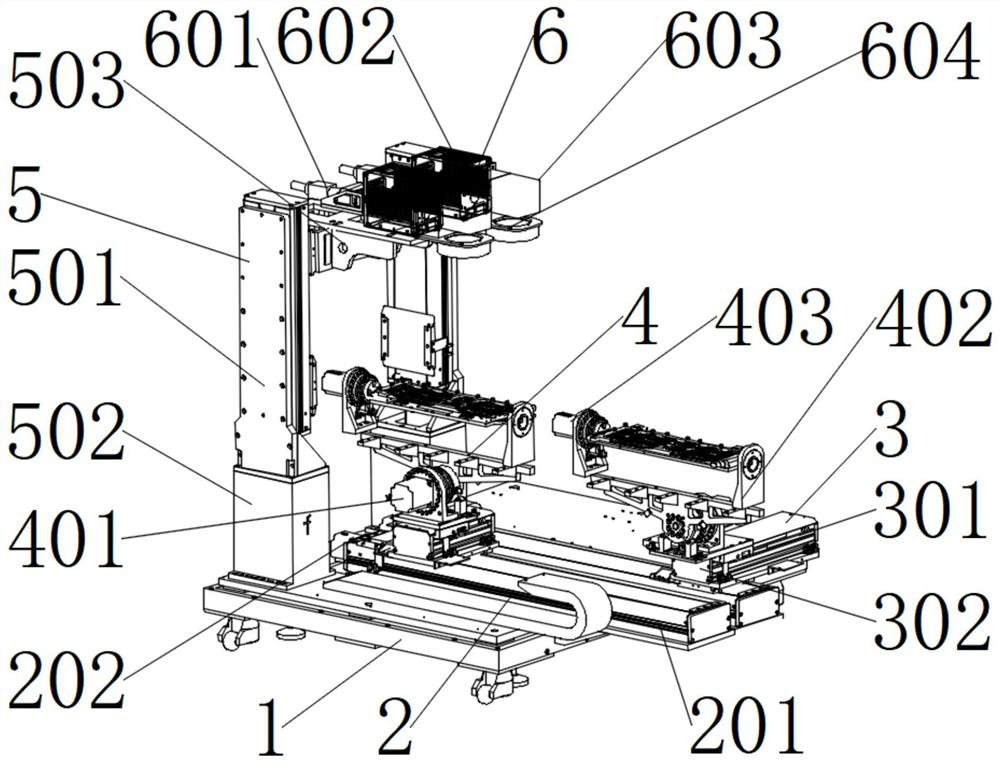

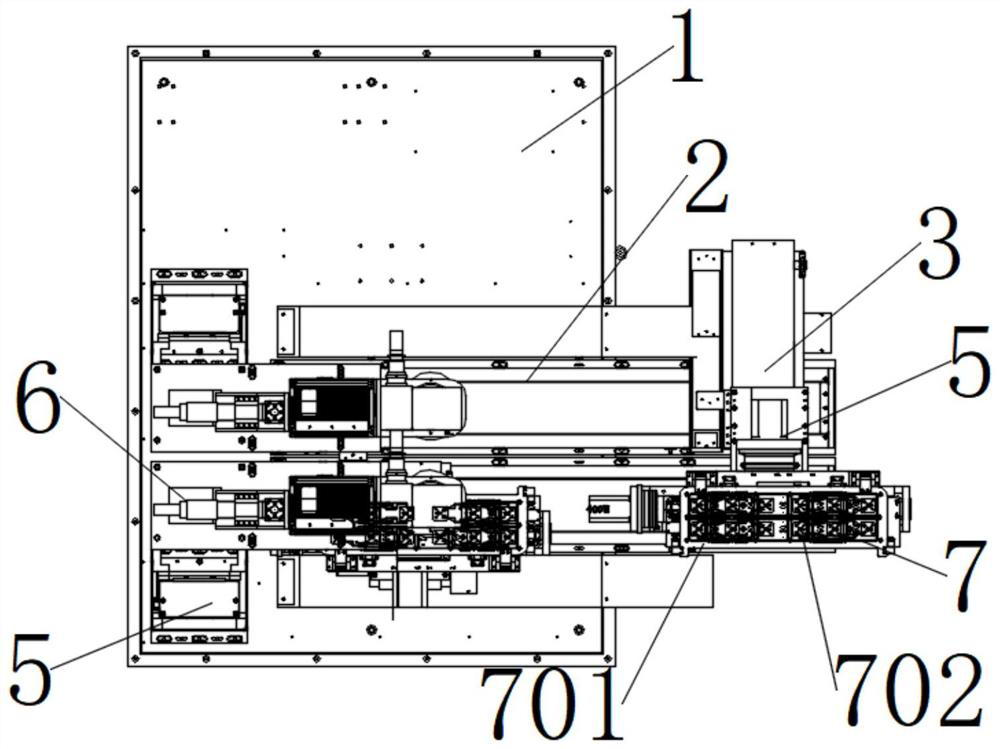

[0033] Such as Figure 1-4 As shown, the embodiment of the present invention provides an efficient three-dimensional laser device that better guarantees the coating performance of LAP, including a base plate 1 and a holding device. The upper surface of the base plate 1 is provided with an X-direction module 2 for performing X-direction Move, and the maximum distance of movement is 100mm. The X-direction module 2 includes the X mold frame 201, and the Y-direction module 3 is placed. The inside of the X mold frame 201 is provided with a first linear motor 202, which provides power and moves. The output end of a linear motor 202 is fixedly connected with the Y-direction module 3 through a moving block.

[0034] The upper surface of the X-direction module 2 is provided with a Y-direction module 3 for Y-direction movement, and the maximum moving distance is 300mm. The Y-direction module 3 includes a Y mold frame 301, a support angle adjustment module 4, and a Y The inside of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com