Patents

Literature

119results about How to "Excellent electromagnetic wave shielding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

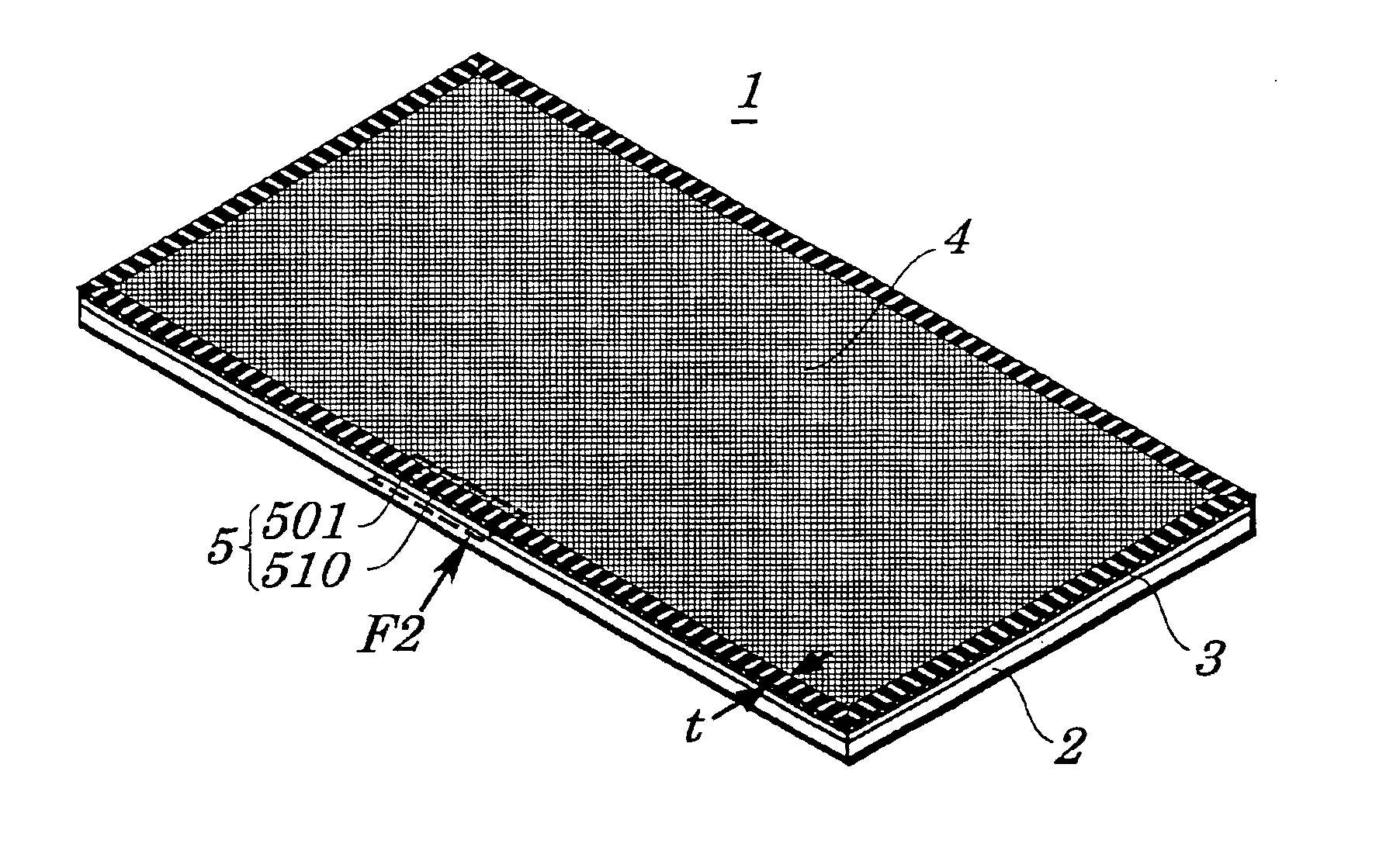

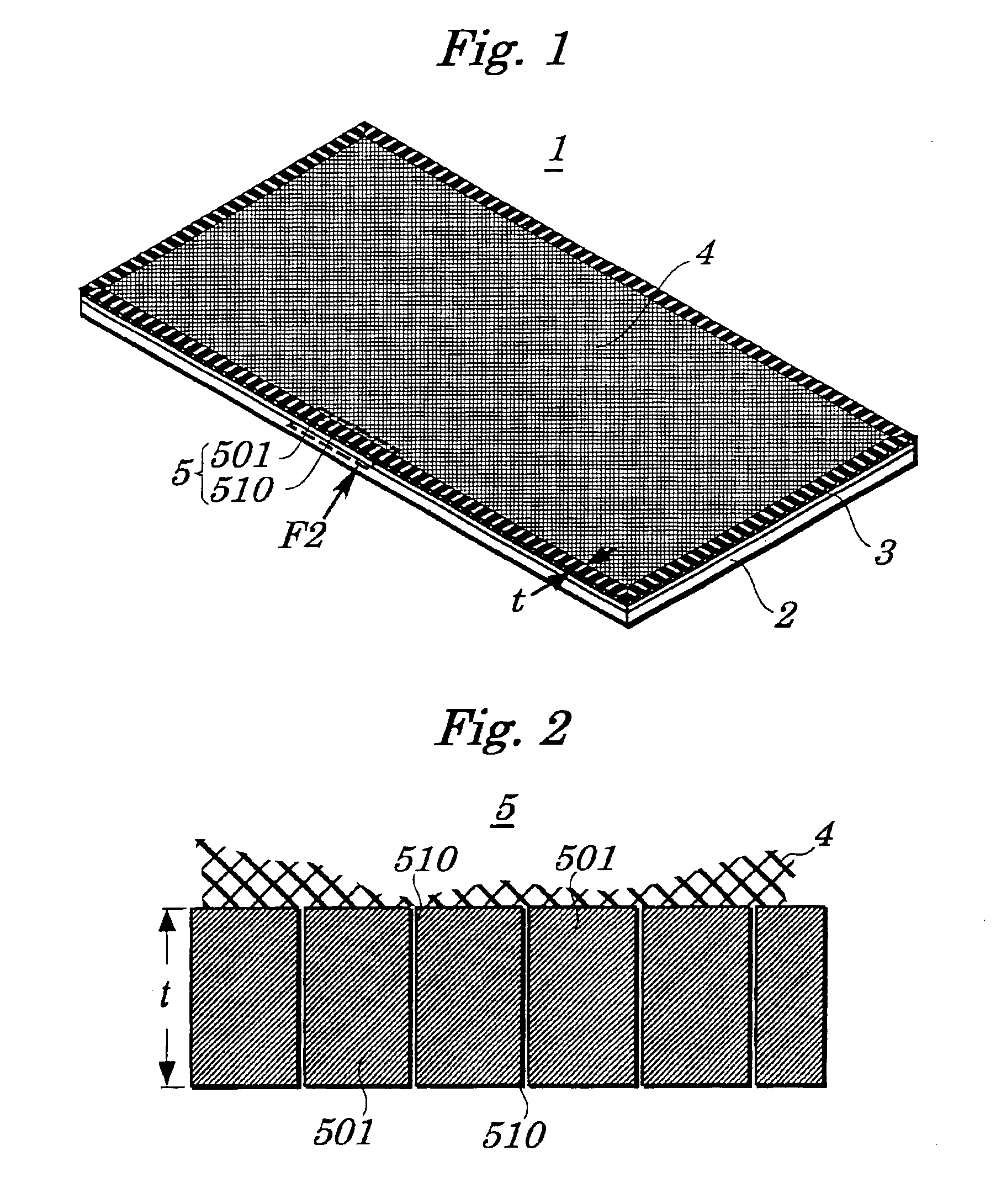

Electromagnetic shield film, electromagnetic shield unit and display

InactiveUS6884936B2Avoid creasesPreventing the earth portion from being creasedTelevision system detailsMagnetic/electric field screeningElectrical conductorAdhesive

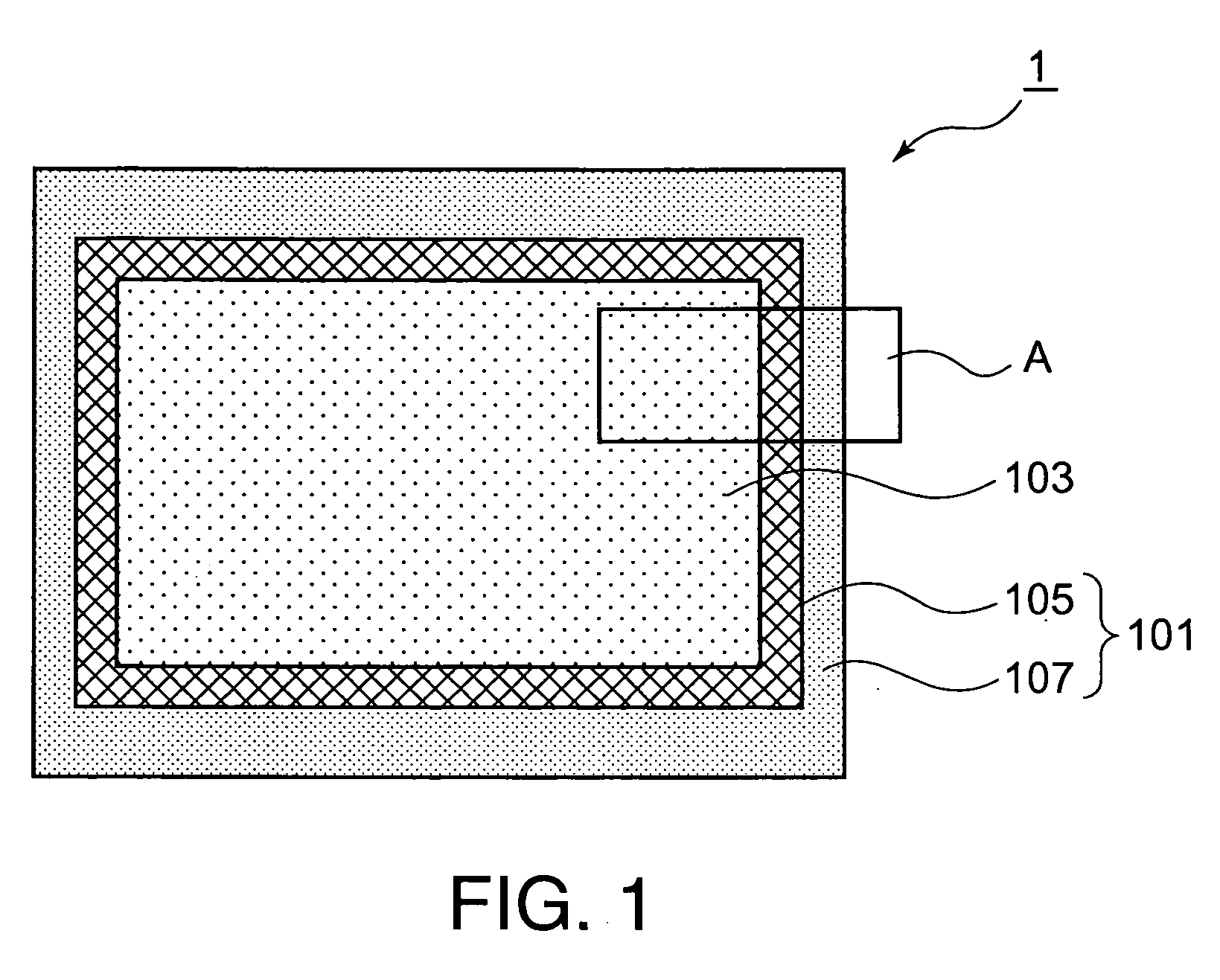

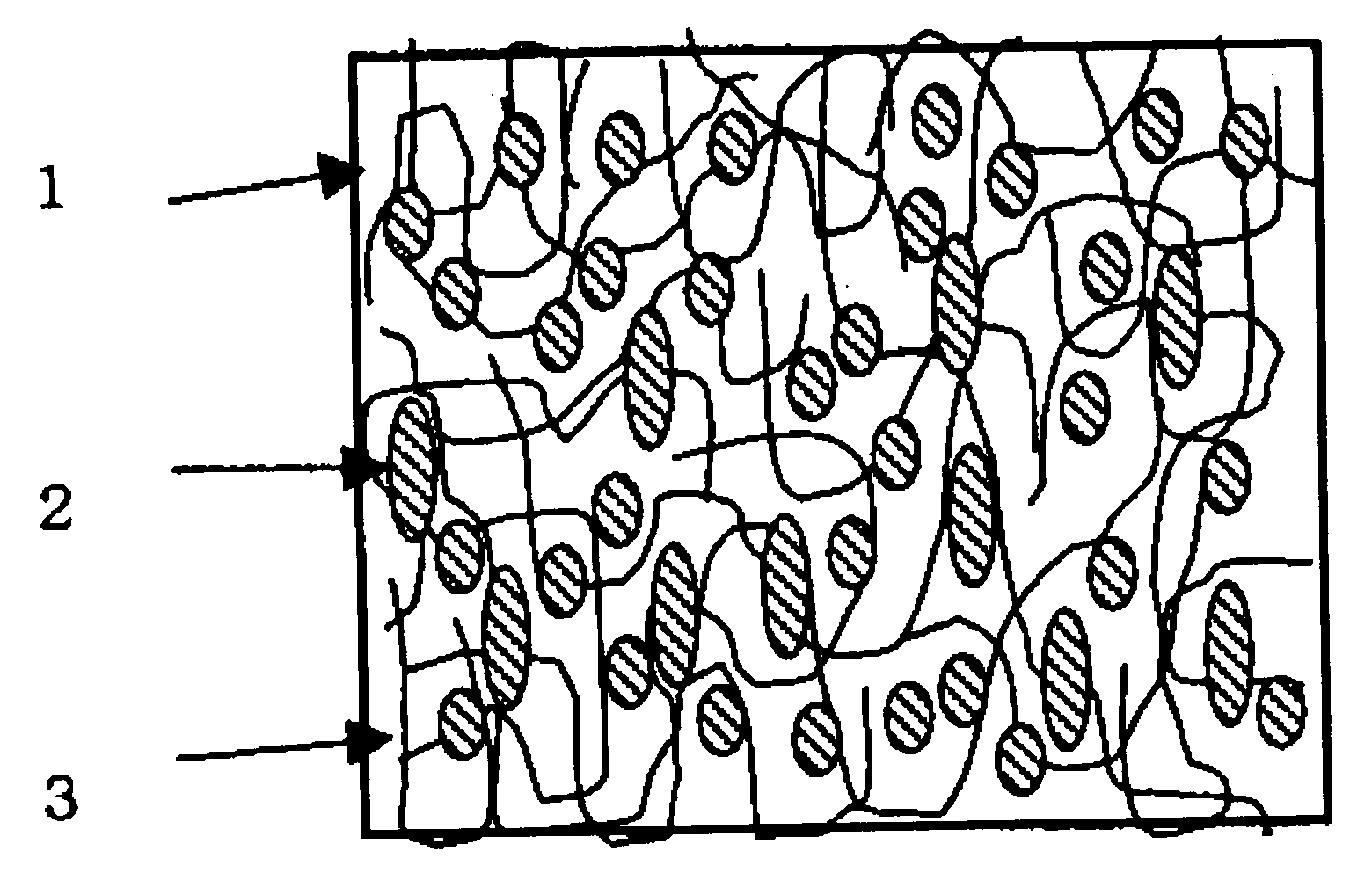

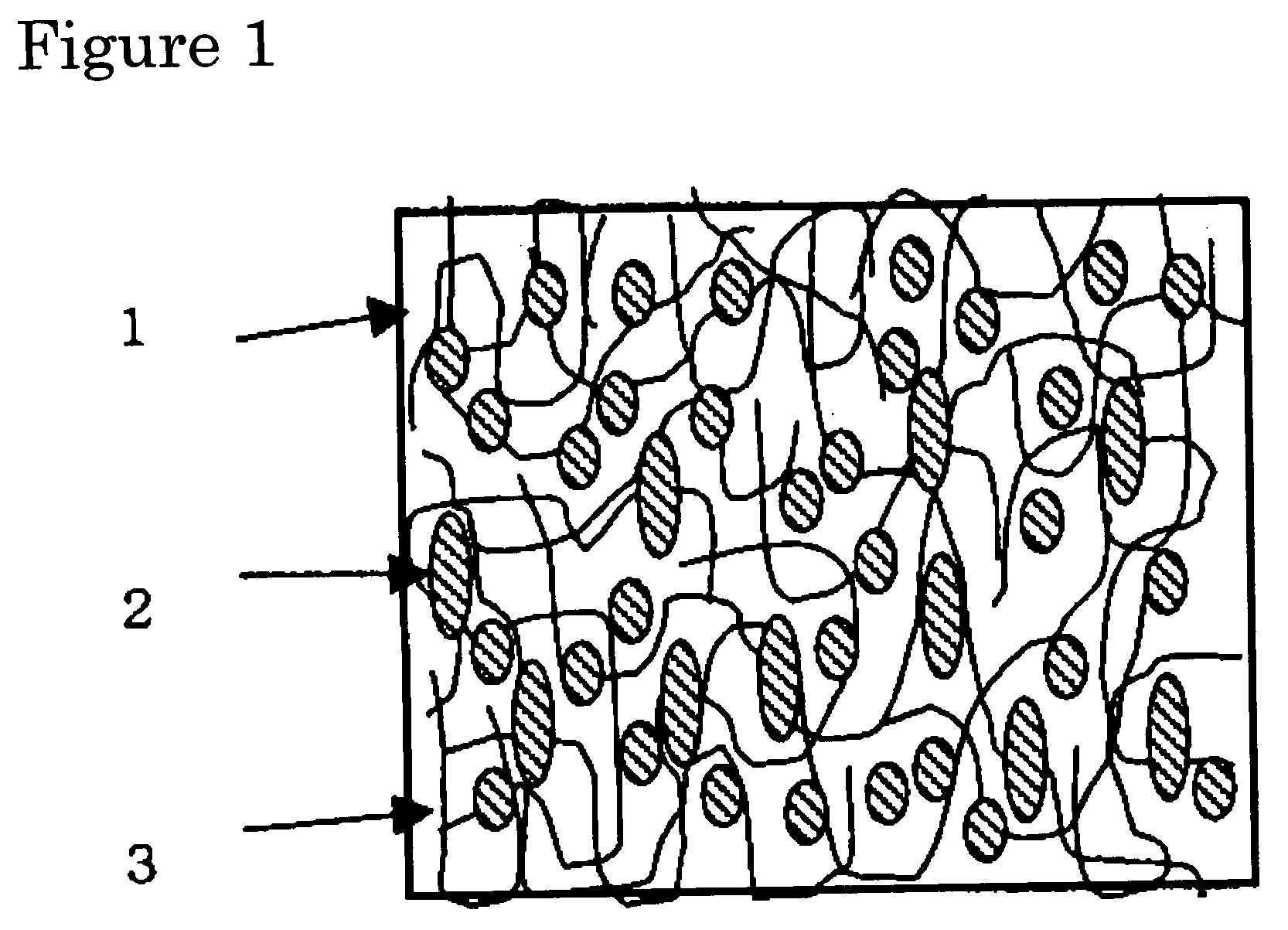

An electromagnetic wave shield film (1) comprises a transparent base (2), a conductor (4) positioned on the transparent base (2) via an adhesive (3) and having a mesh geometric pattern, and an earth portion (5) arranged around the conductor (4) and including conductive regions (501) which absorb electromagnetic waves, and non-conductive regions (510) which prevent the earth portion (5) from being creased.

Owner:HITACHI CHEM CO LTD

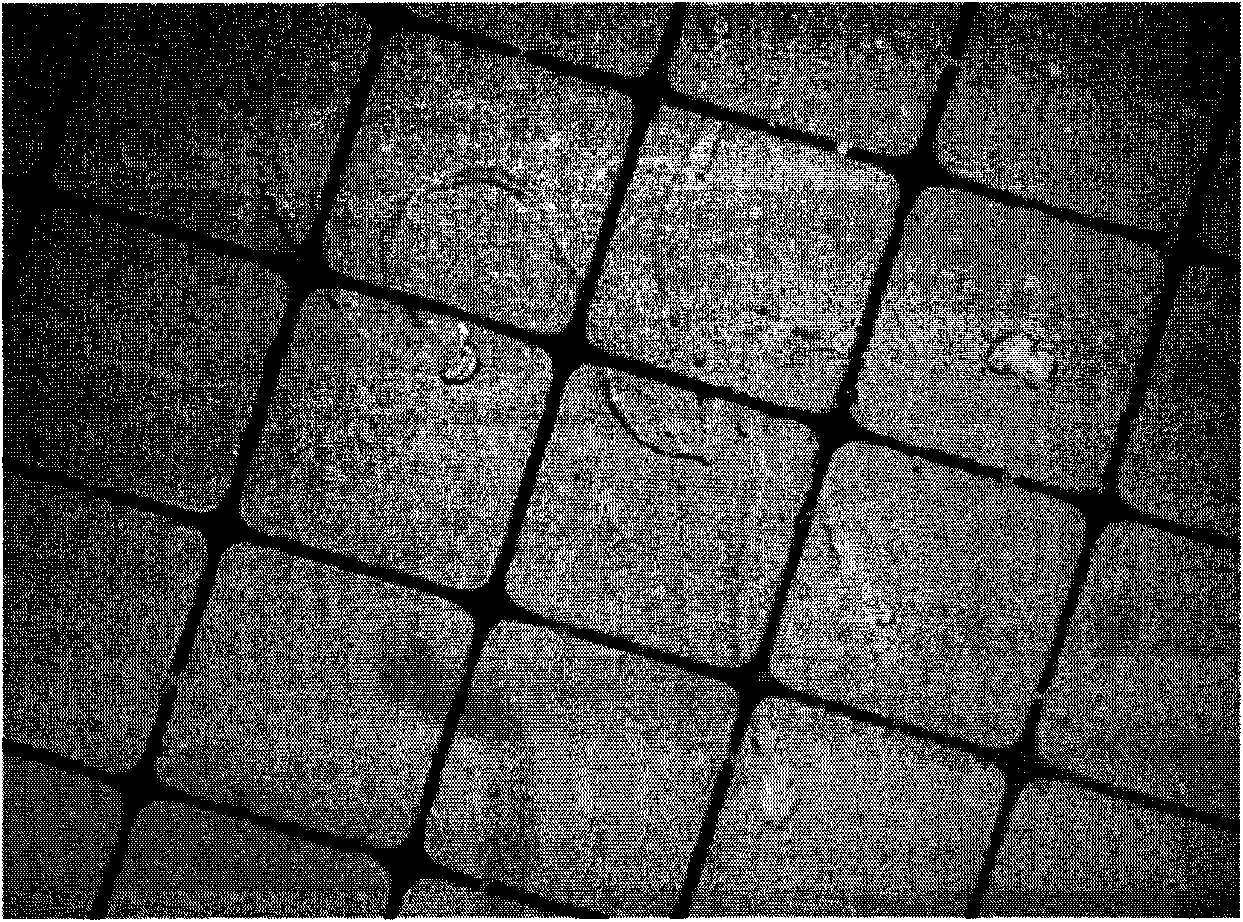

Transparent electromagnetic wave shield

InactiveUS6210787B1Improve the level ofHigh strengthMagnetic/electric field screeningDecorative surface effectsOptoelectronicsPolymer

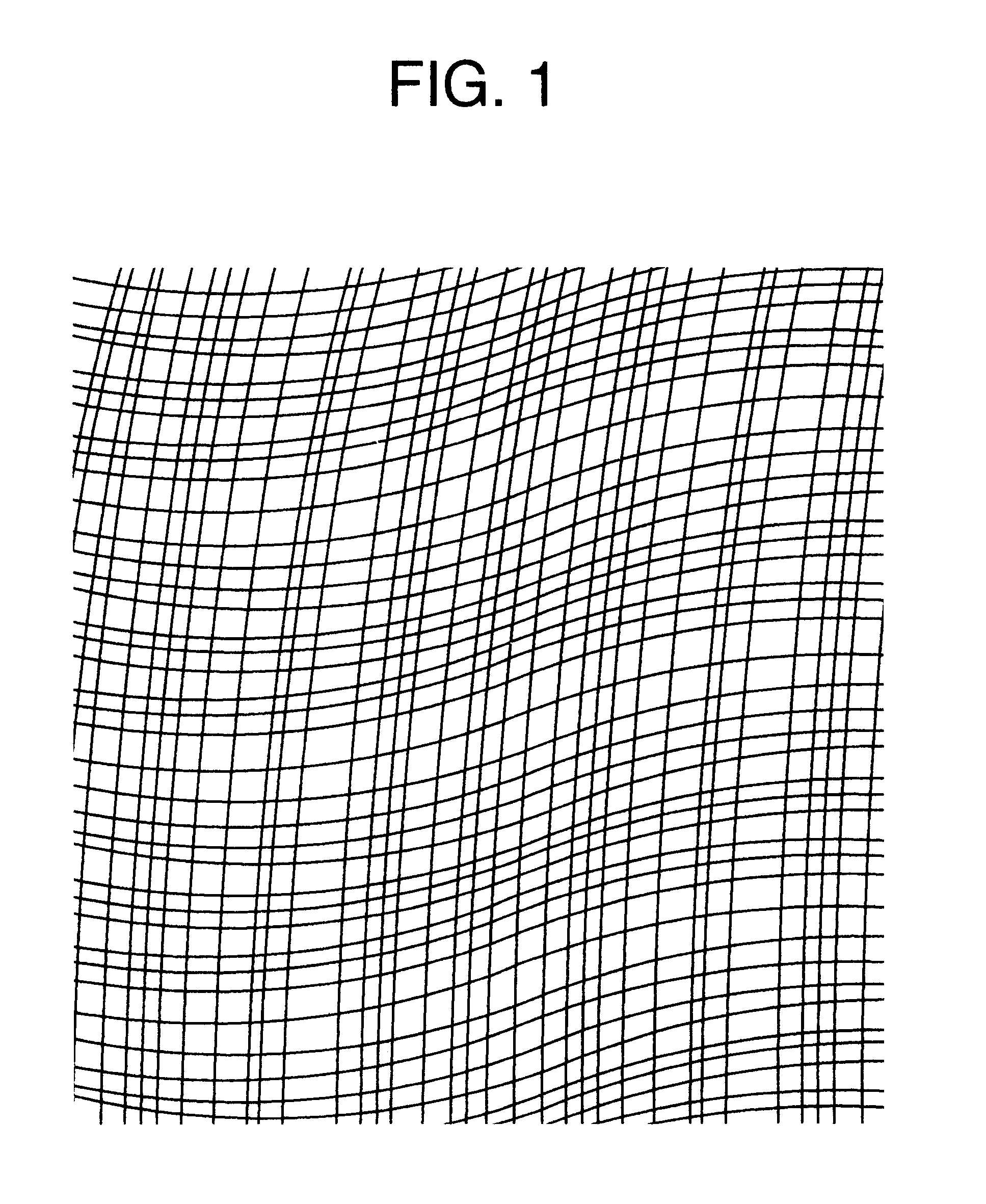

A transparent electromagnetic wave shield comprising a transparent polymer film and a conductive layer of a linear pattern shape formed on at least one side of said film, wherein the line intervals in said linear pattern are random between 20 mum and 1 mm.

Owner:SUMITOMO BAKELITE CO LTD

Low-silver-loaded electromagnetic wave shielding fabric preparation method

InactiveCN101613931AHigh bonding strengthImprove conductivityMagnetic/electric field screeningFibre typesPolyesterUltrasound - action

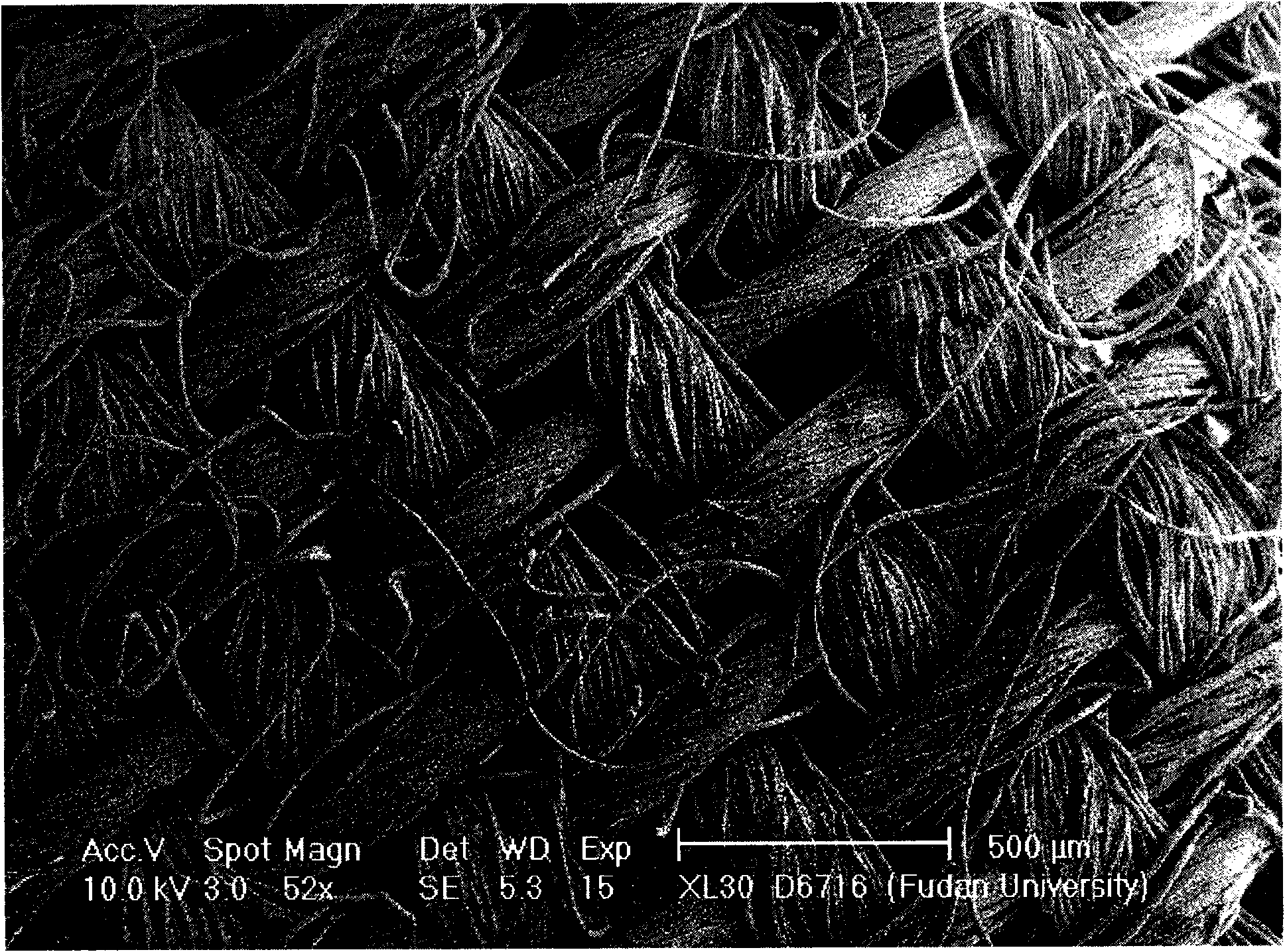

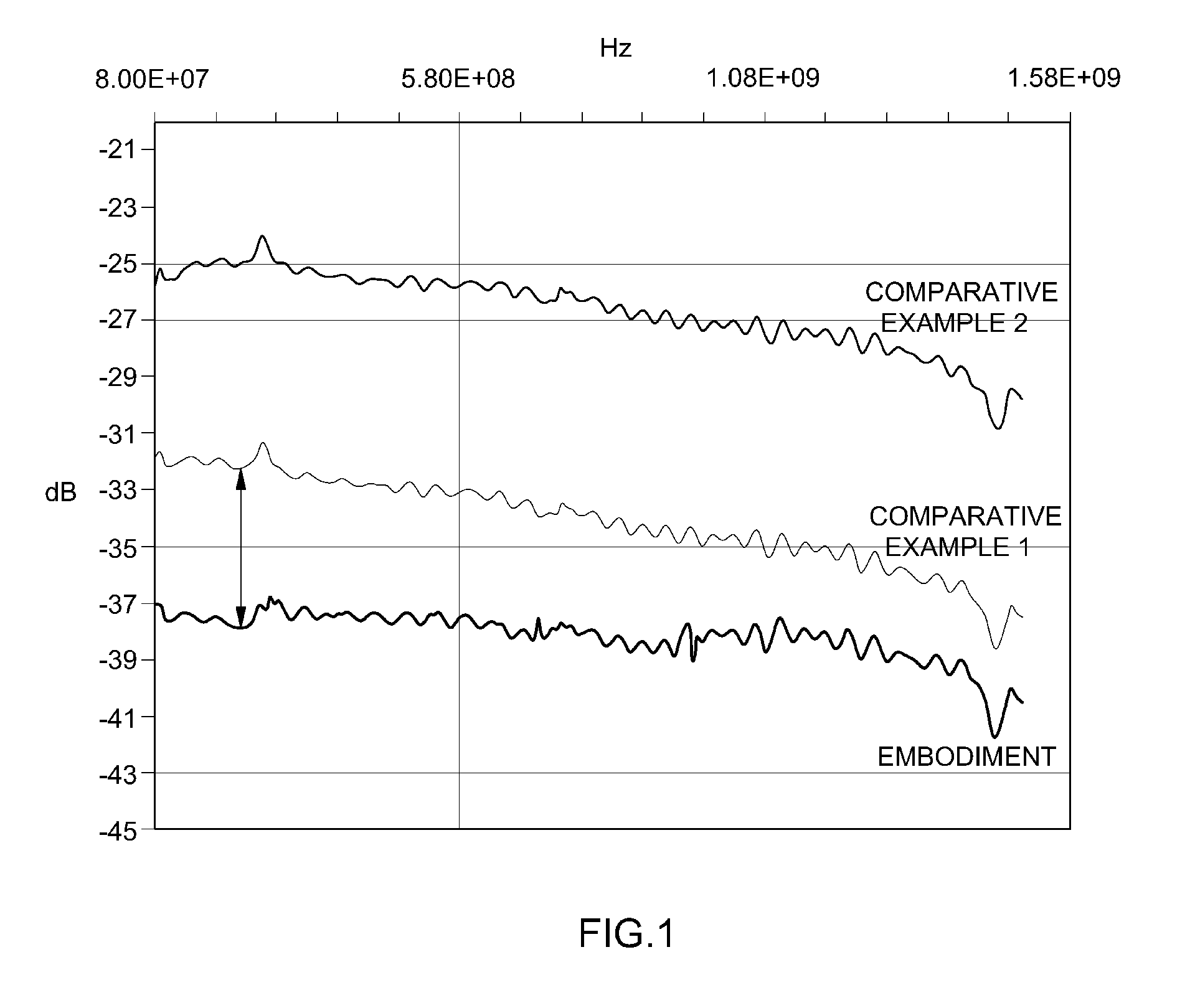

The invention belongs to the technical field of electromagnetic wave shielding material and relates to a low-silver-loaded electromagnetic wave shielding fabric preparation method, comprising the following specific steps: modifying the surface of polyester fabric, introducing an active group--sulphydryl under the premise of not increasing the surface area of the fabric, and then plating silver with ultrasonic wave; wherein, Ag-S chemical bond is formed between sulphydryl and silver so that the compactness of the silver coating and the adhesion force of the fabric substrate are increased; in the process of chemical plating, fresh plating solution is always on the surface of the fabric and the materials which are absorbed on the surface of the fabric through physical adsorption are removed timely owning to the action of ultrasonic wave so that the continuity and compactness of the silver coating can be improved further; the silver loading content of the prepared silver-loaded electromagnetic wave shielding fabric is 6.7-7.0% by weight; the fabric is more resistant to the corrosion of the air and water, the electromagnetic shielding effectiveness is more than 32dB in the range of 0.01-18GHz, namely the anti-electromagnetic radiation rate is more than 99.9%; the fabric can be widely used in electromagnetic wave antiradiation clothes and in the field of electromagnetic wave shielding for special departments such as military, national defense and the like.

Owner:FUDAN UNIV

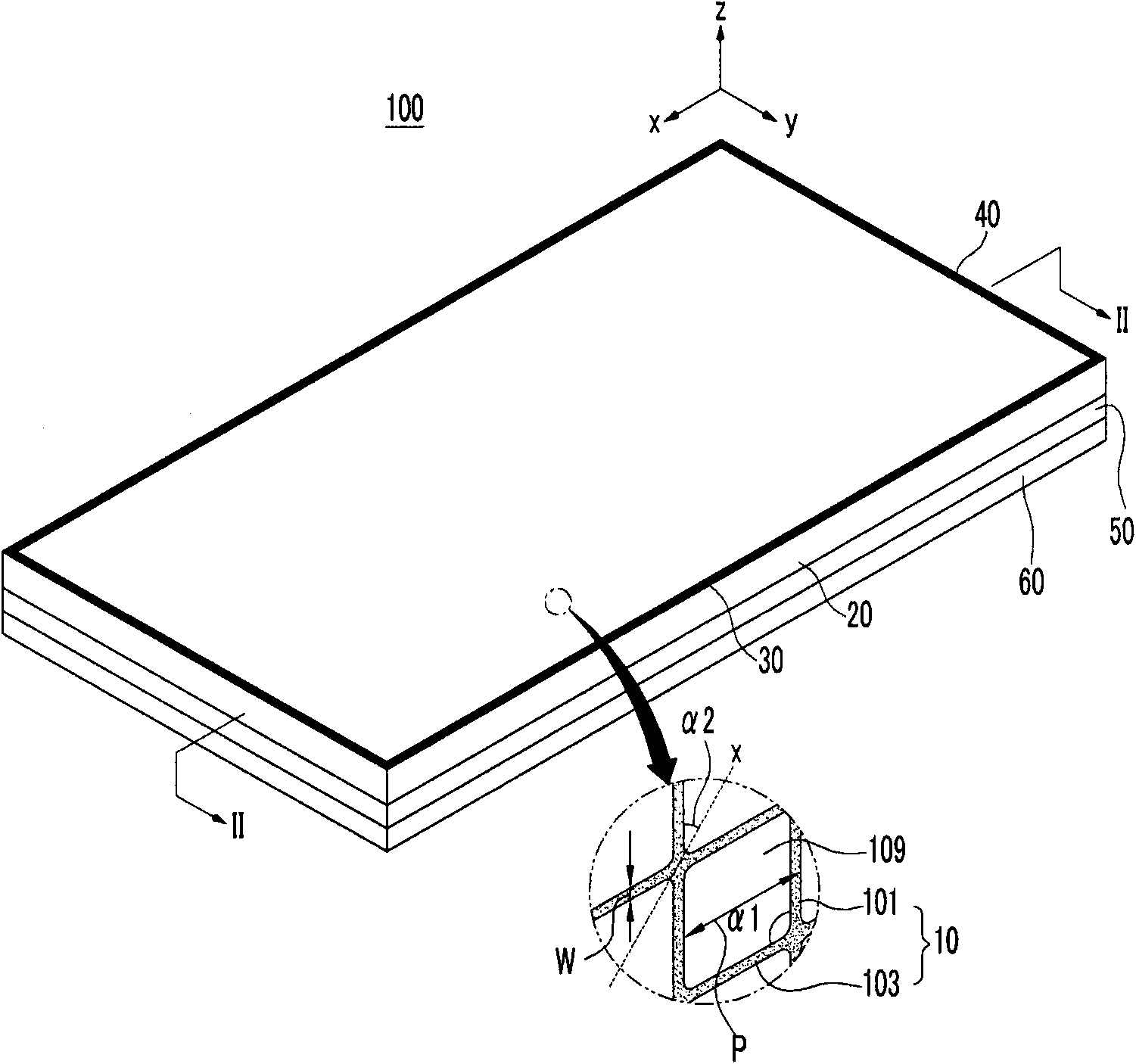

Electromagnetic Wave Shielding Device

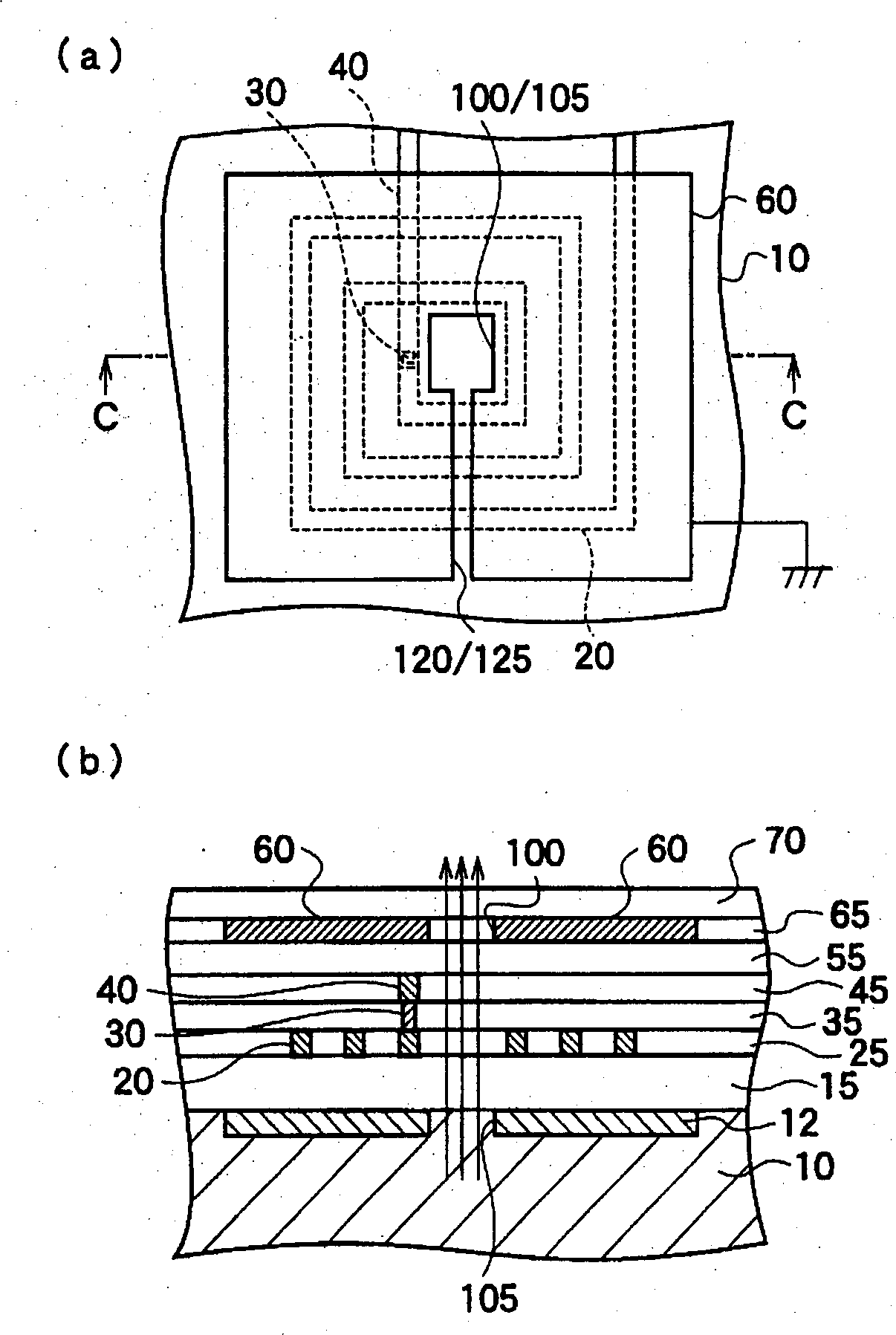

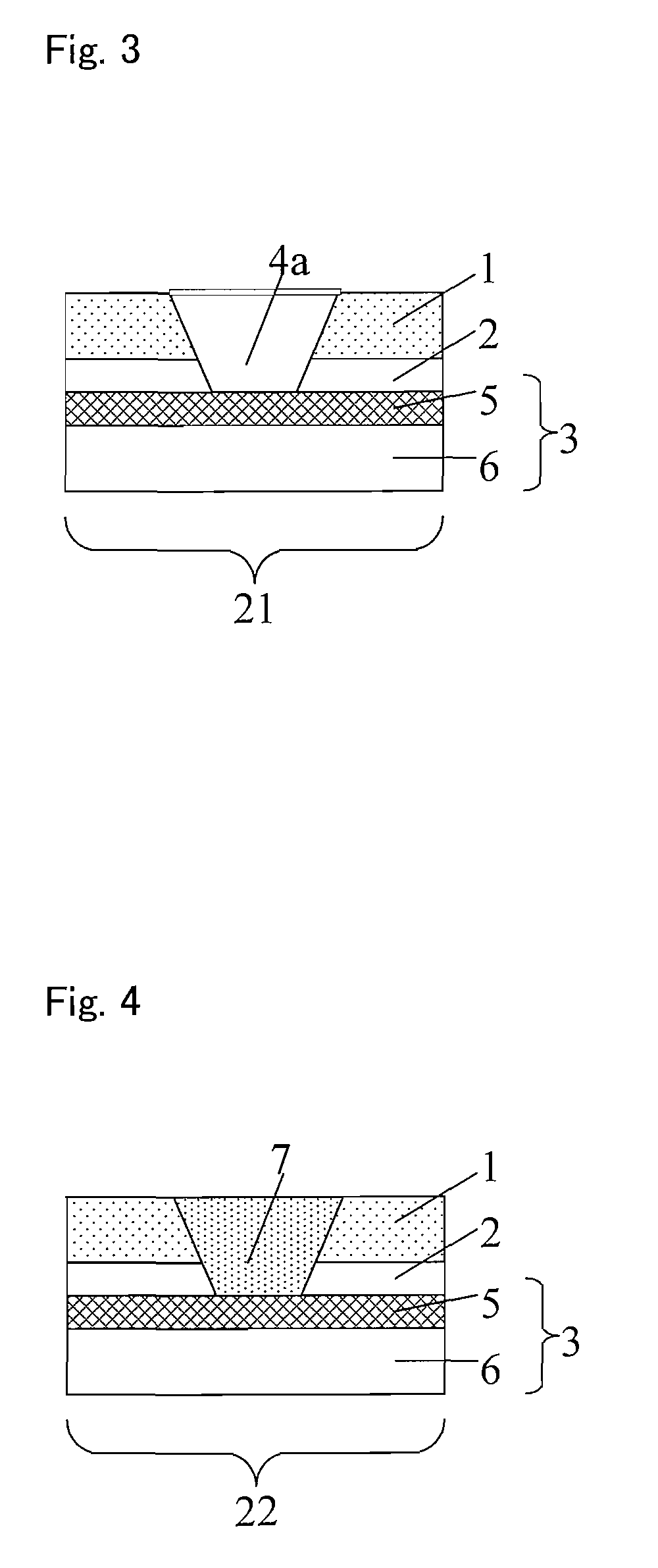

InactiveUS20080084681A1Excellent electromagnetic wave shielding performanceModerate transparencyMagnetic/electric field screeningPrinted circuitsComputational physicsImage display

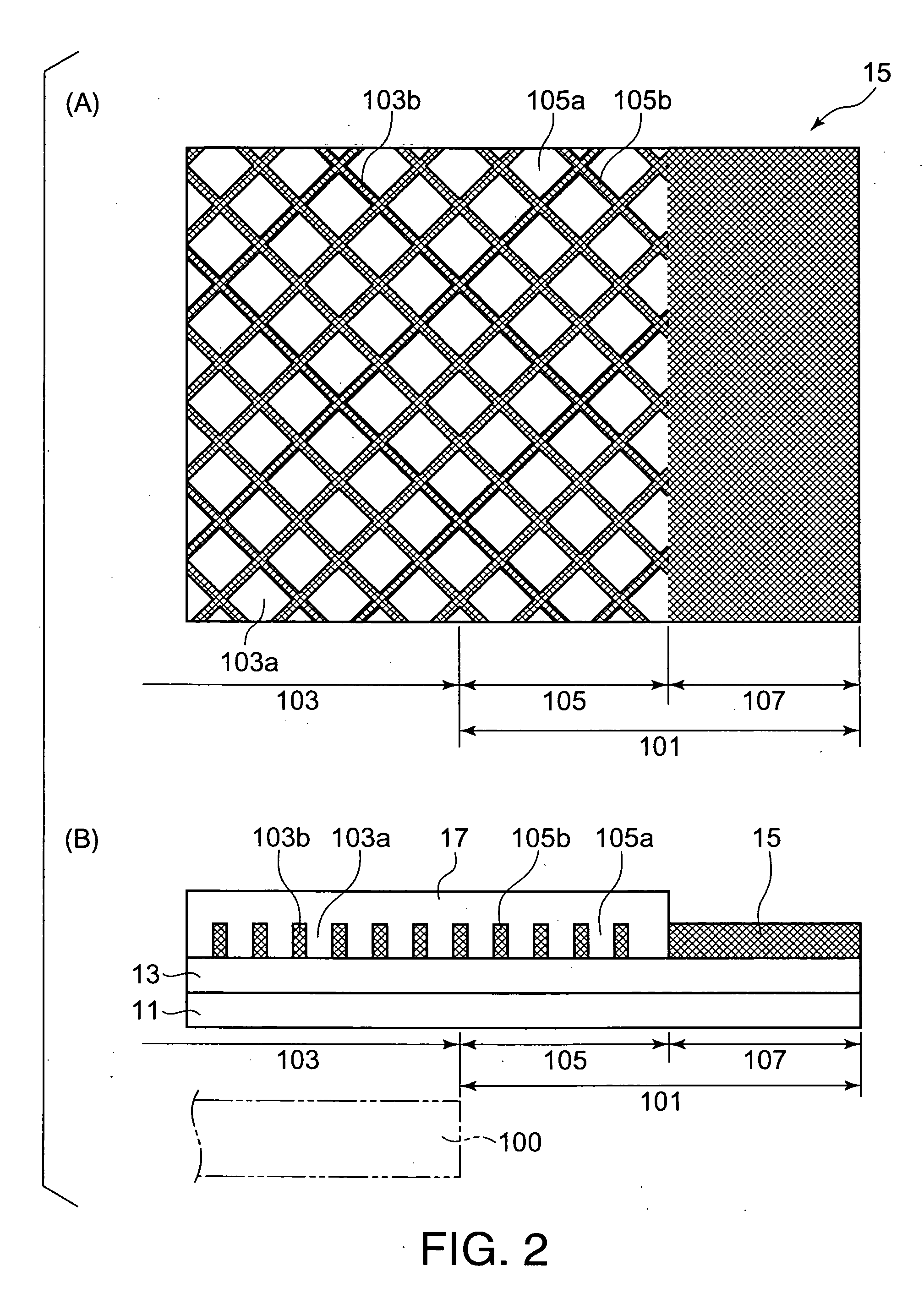

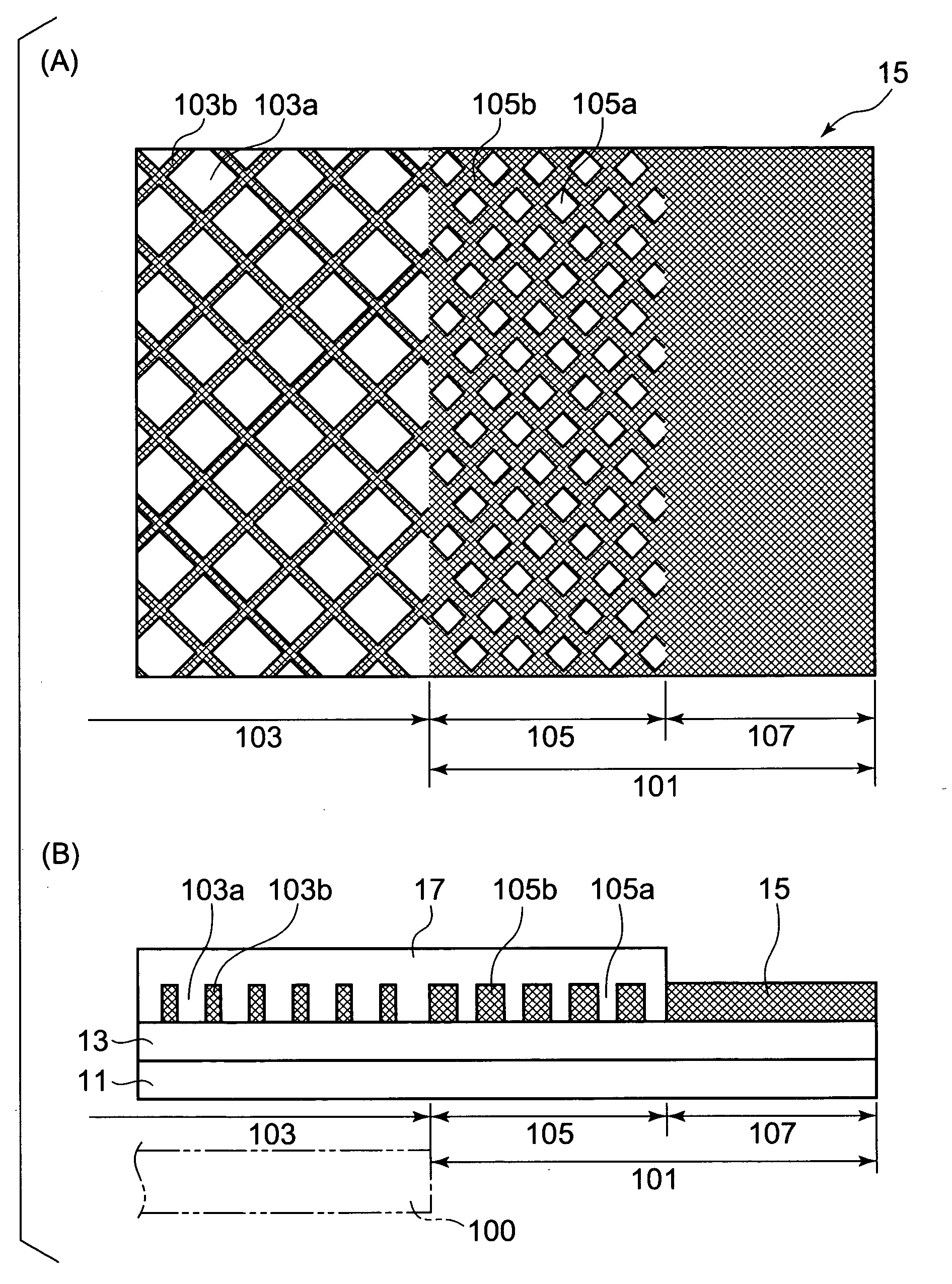

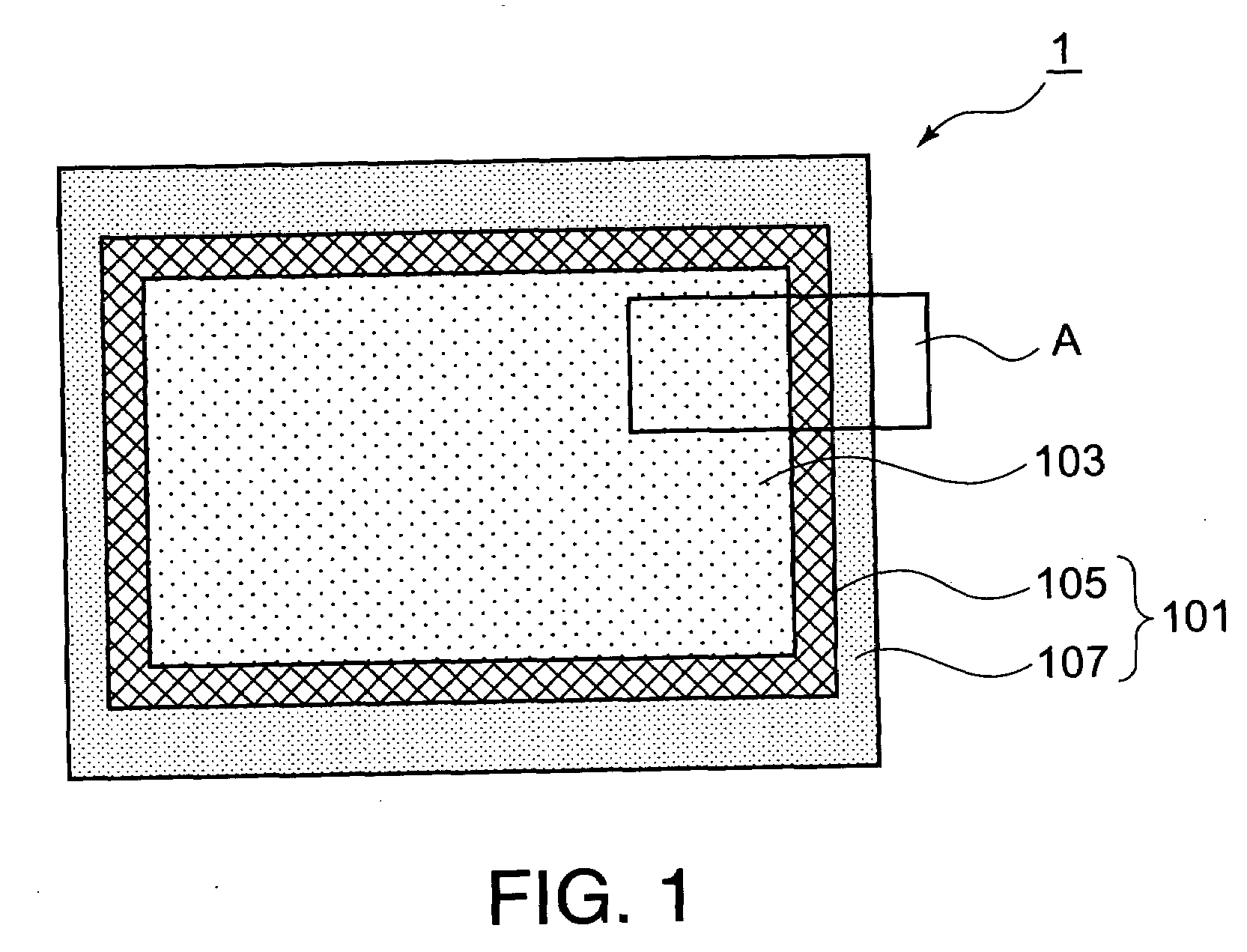

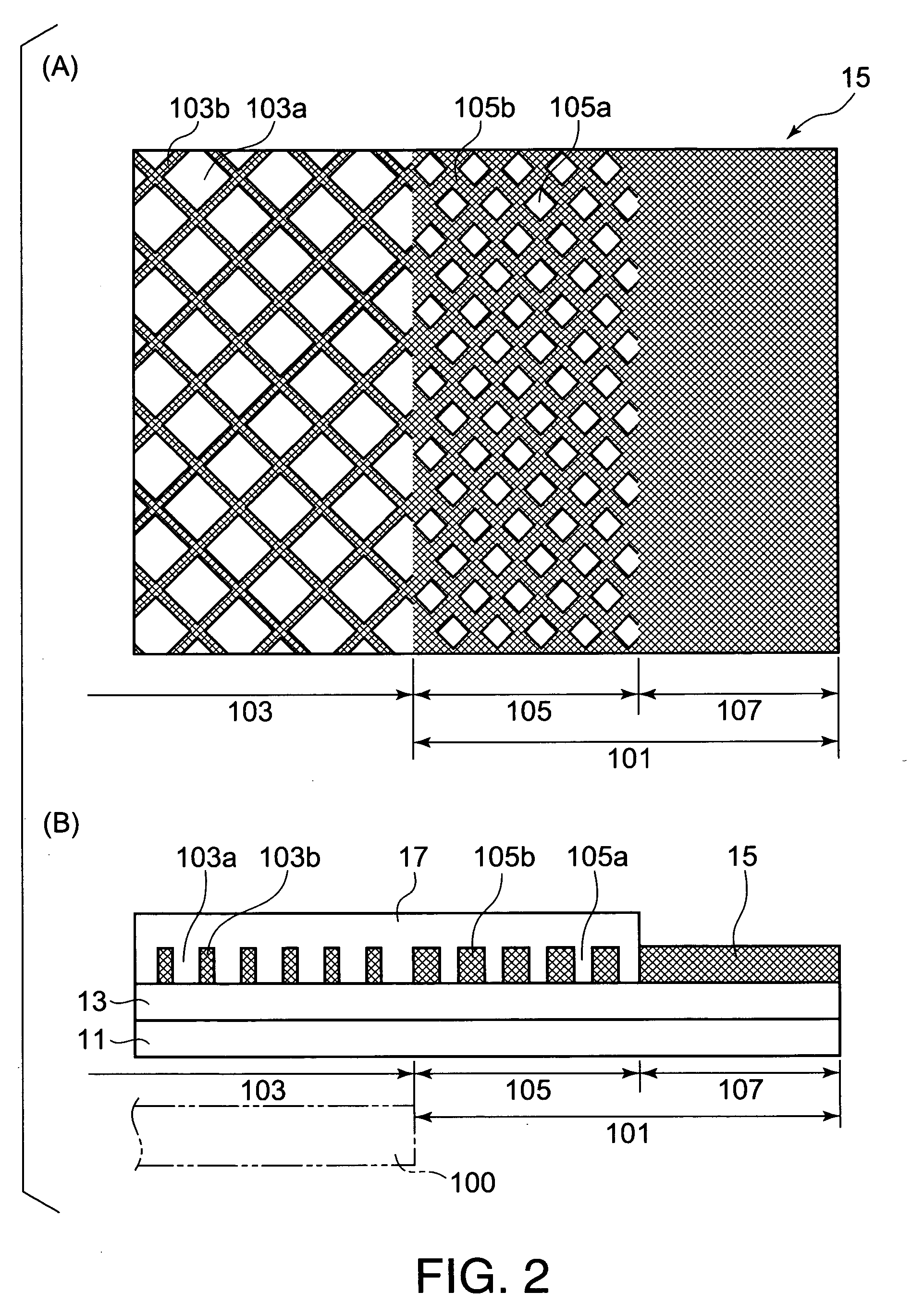

An electromagnetic wave shielding device 1 comprises a transparent substrate 11, an adhesive layer 13 which is provided as needed, an electromagnetic wave shielding layer 15, and a transparent resin layer 17. The electromagnetic wave shielding layer 15 includes a mesh portion 103 facing a screen portion 100 of an image displaying device, a transparent resin layer anchoring portion 105 surrounding a periphery of the mesh portion 103, and including openings 105a having the same opening ratio as that of the openings 103a of the mesh portion 103, and a frame portion 107 surrounding an outer periphery of the transparent resin layer anchoring portion 105, and not having openings. The transparent resin layer 17 is provided such that it covers the surfaces of the mesh portion 103, and the transparent resin layer anchoring portion 105, and fills the openings 103a, 105a.

Owner:DAI NIPPON PRINTING CO LTD

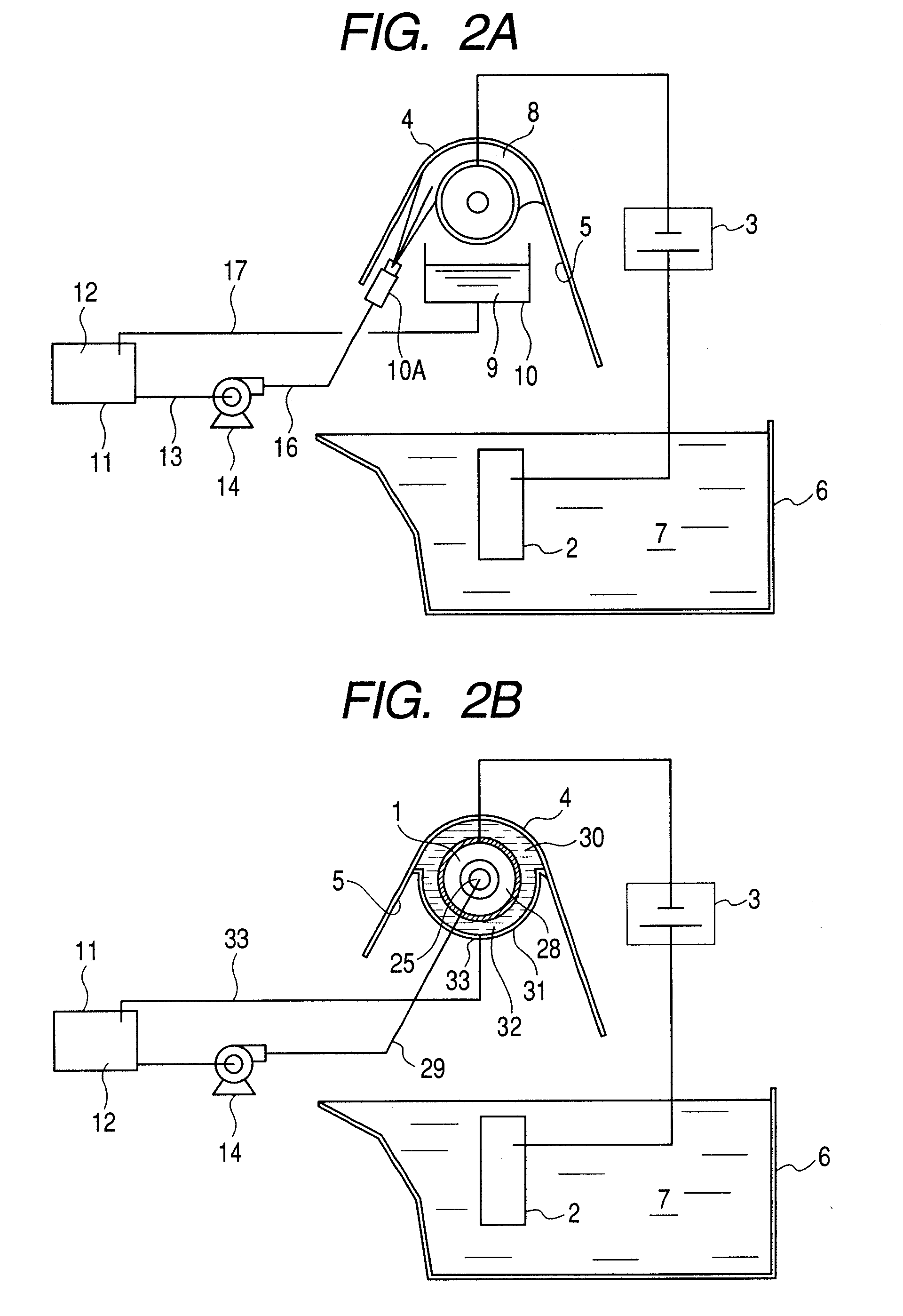

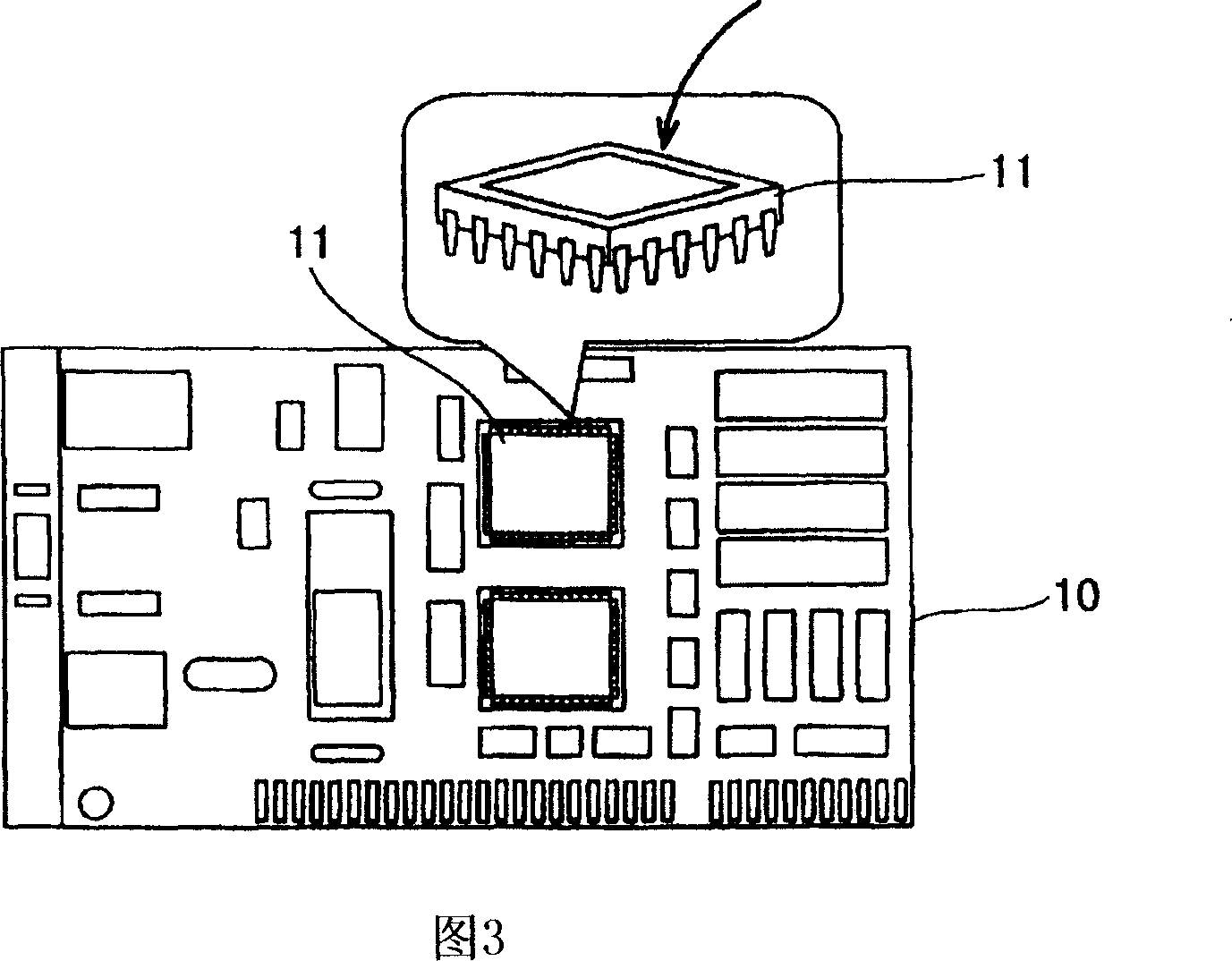

Semi-conductor device

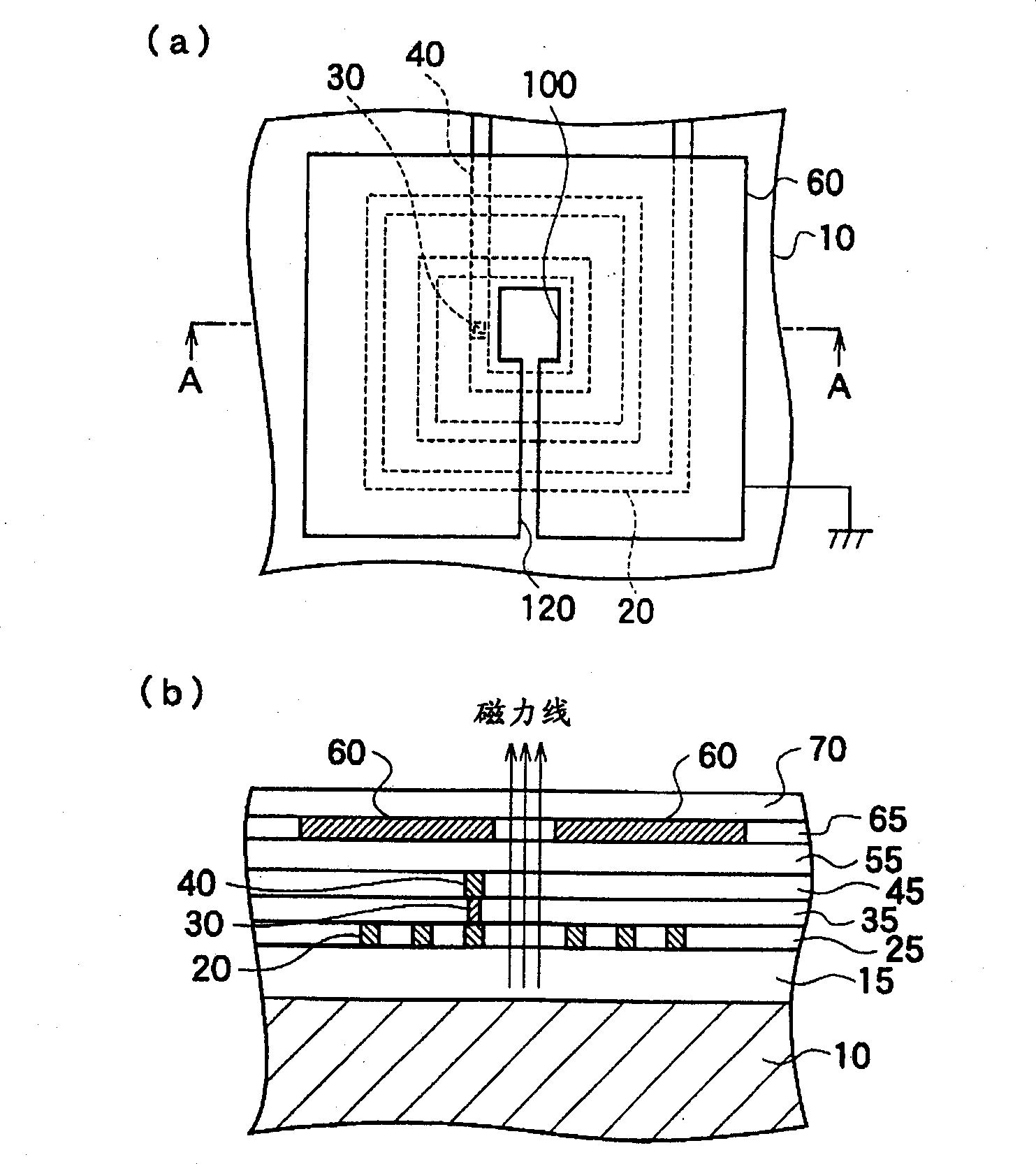

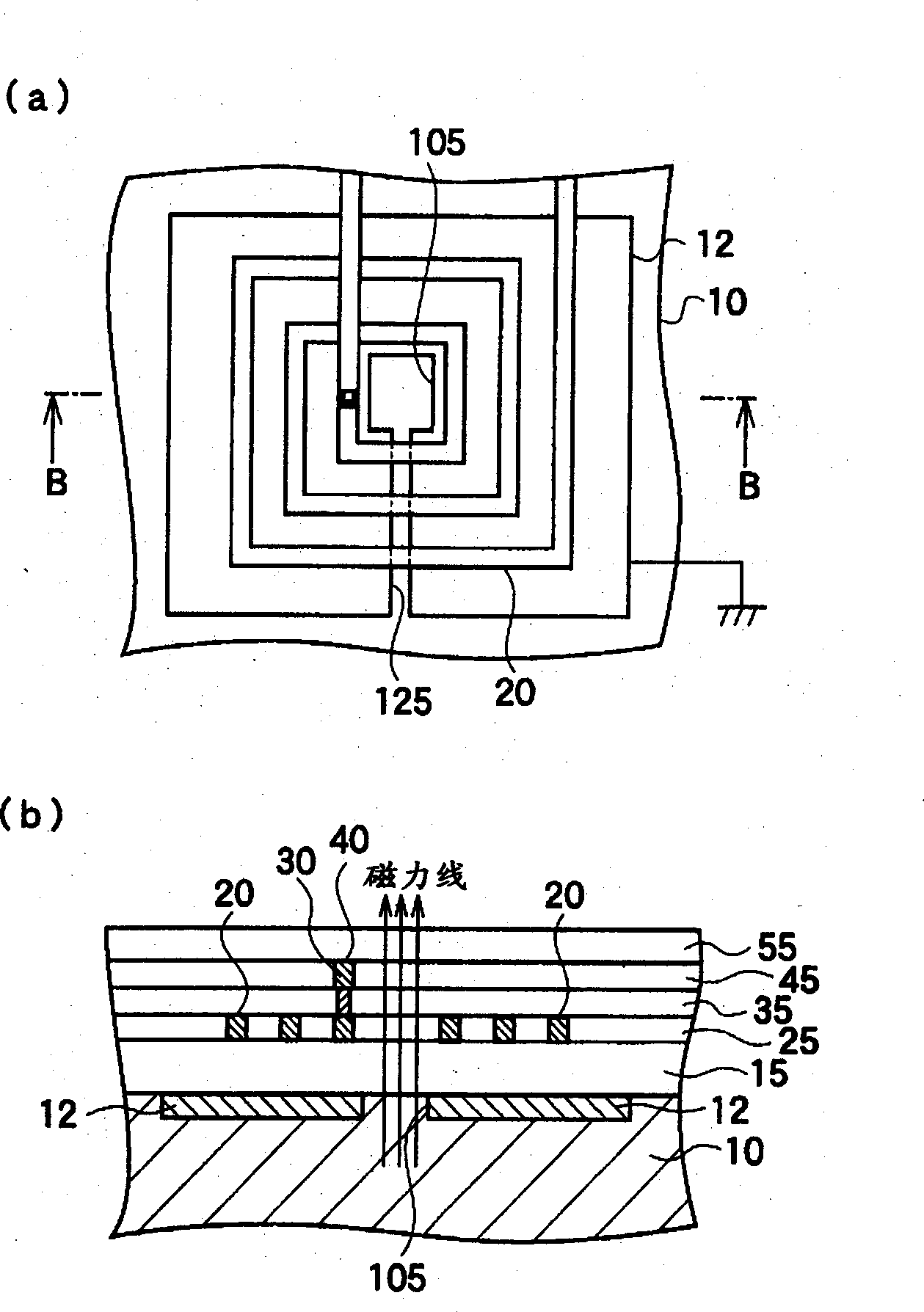

InactiveCN1361550AInhibitionExcellent electromagnetic wave shielding performanceMagnetic/electric field screeningSemiconductor/solid-state device detailsSpiral inductorMagnetic flux

The invention provides a semiconductor device provided with a spiral inductor and an electromagnetic wave shielding layer for demonstrating an excellent electromagnetic wave shielding effect without degrading a Q value. In the electromagnetic wave shielding layer arranged above or below the spiral inductor provided with a spiral pattern, an opening part in a magnetic flux passing area generated at the center of the spiral pattern by the spiral inductor and a slit from the opening part to a peripheral edge are formed.

Owner:KK TOSHIBA

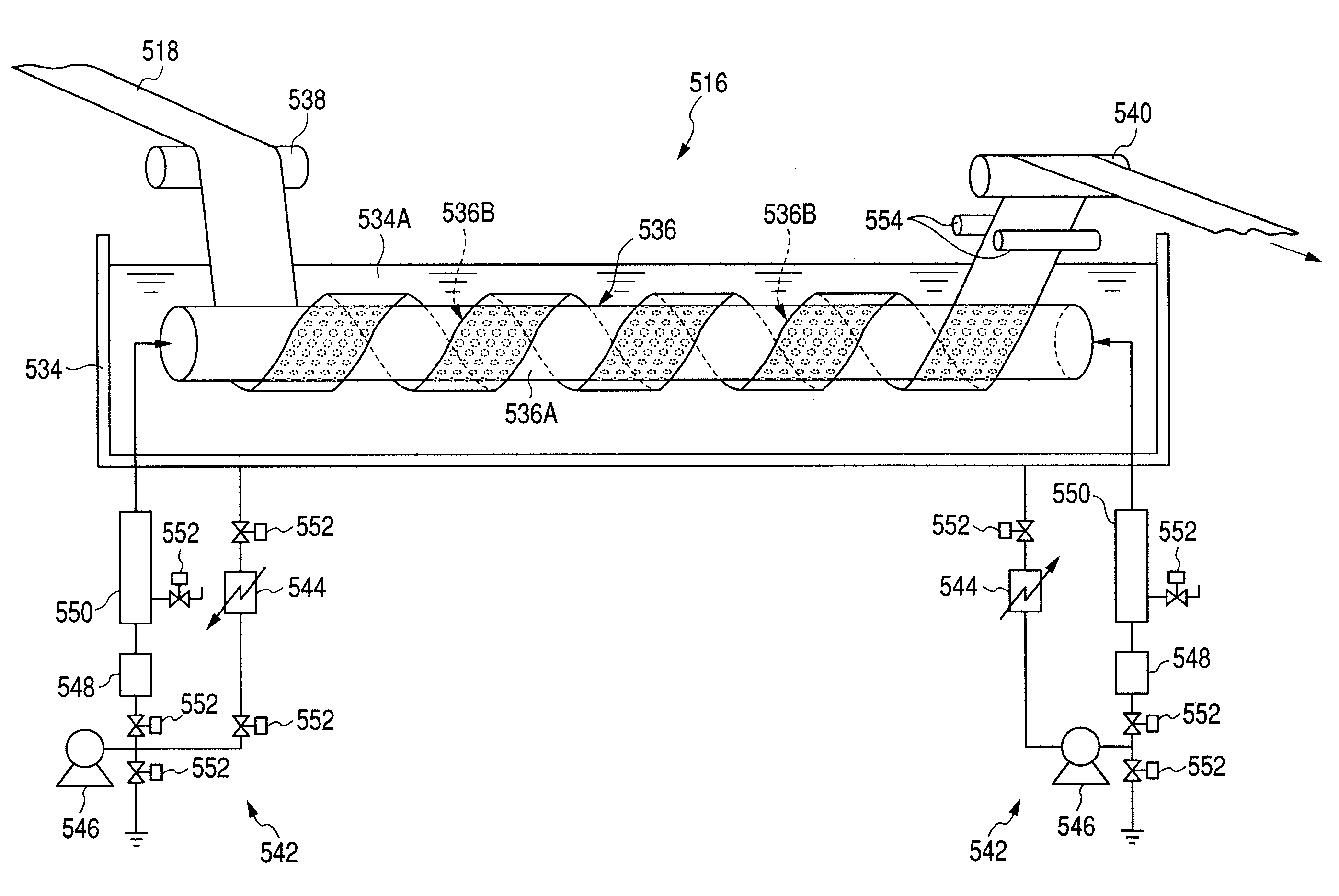

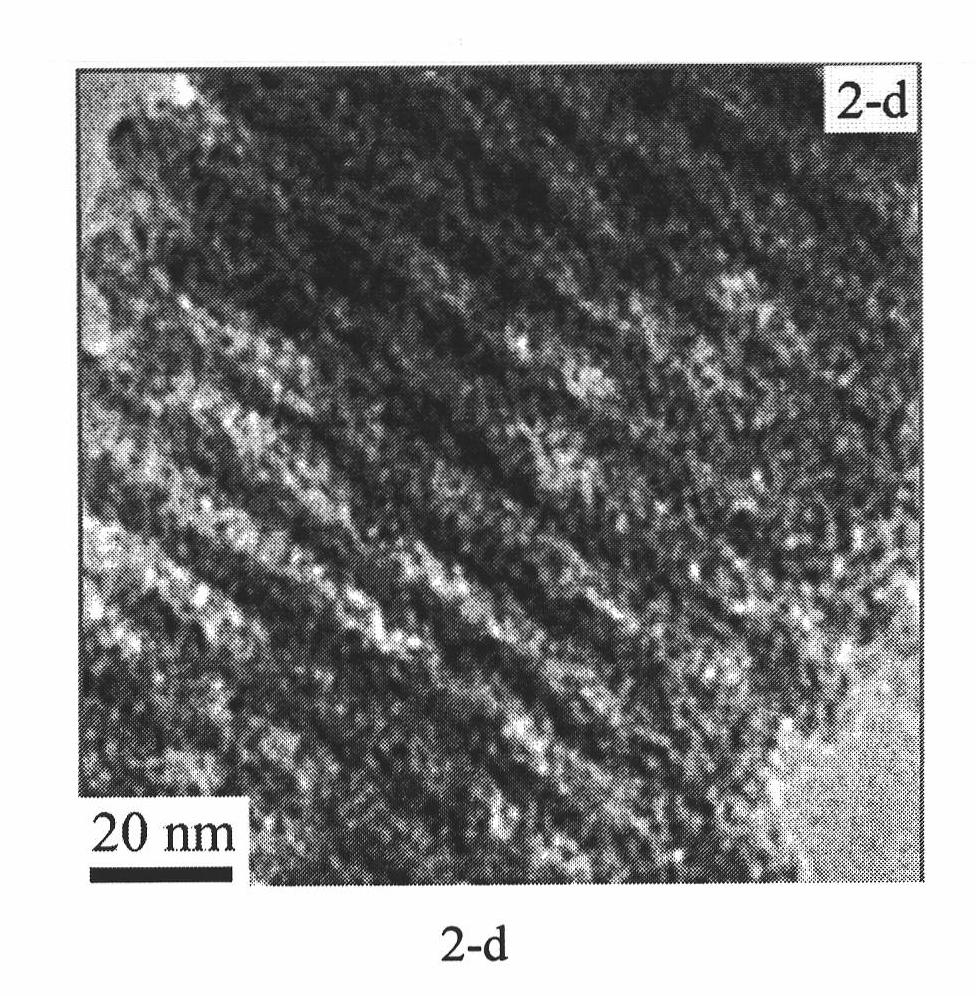

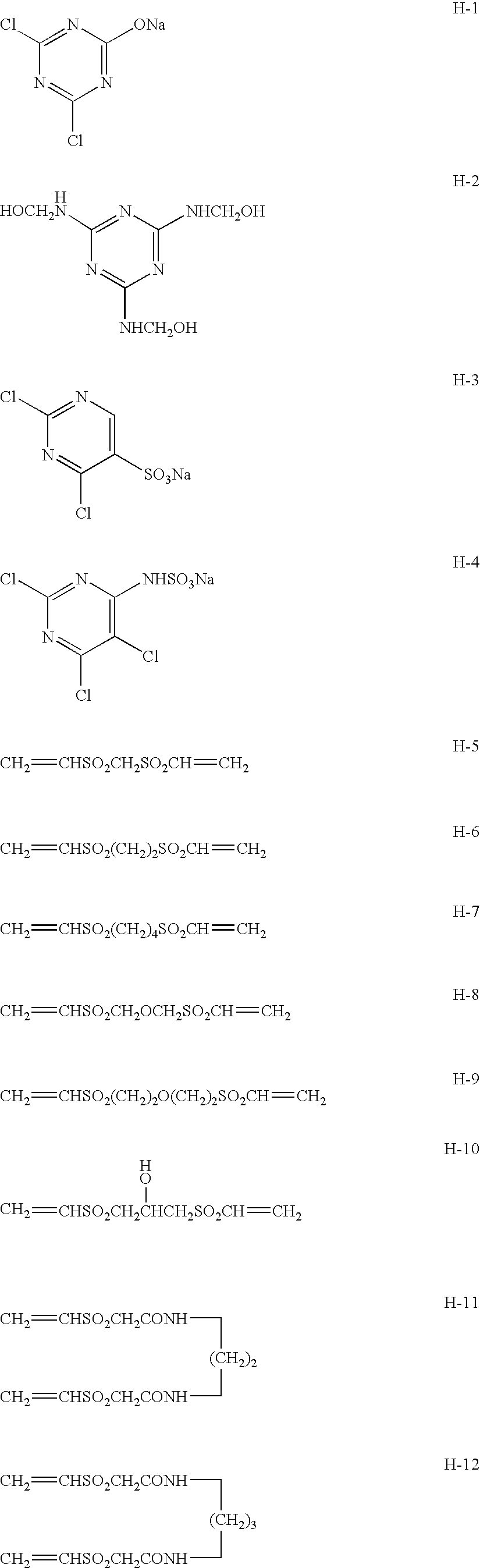

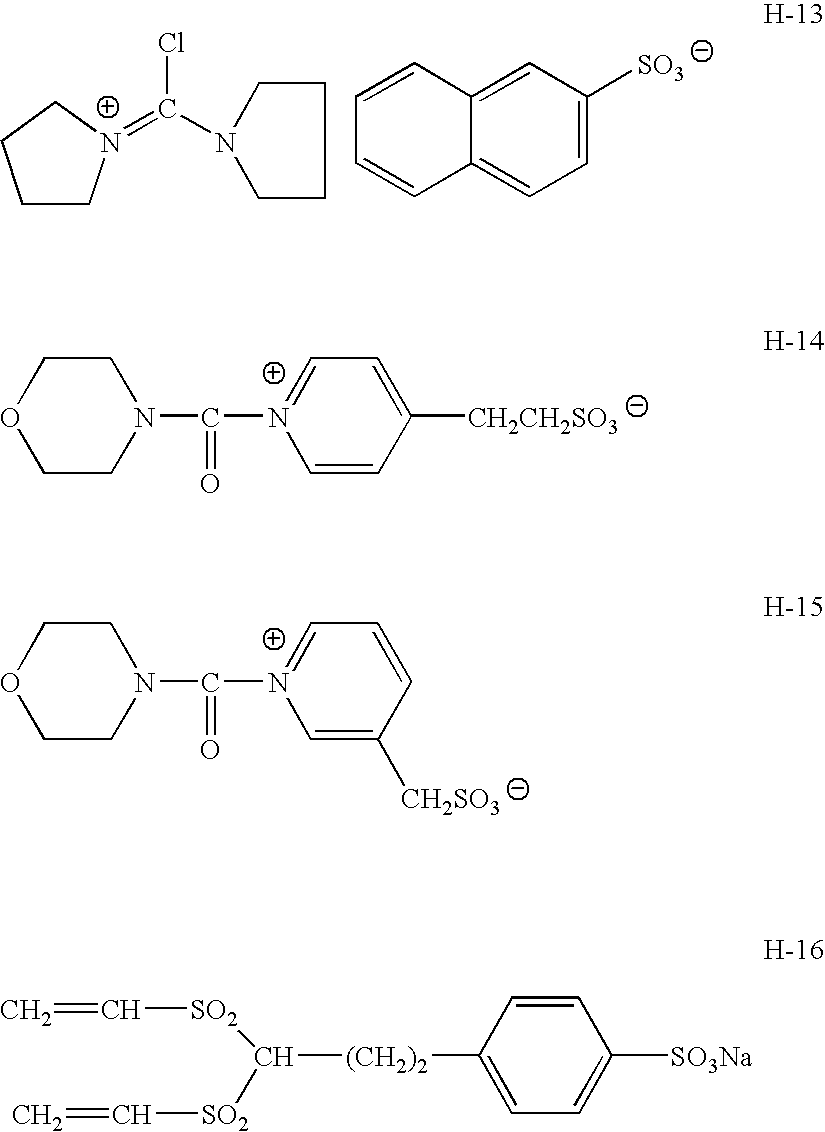

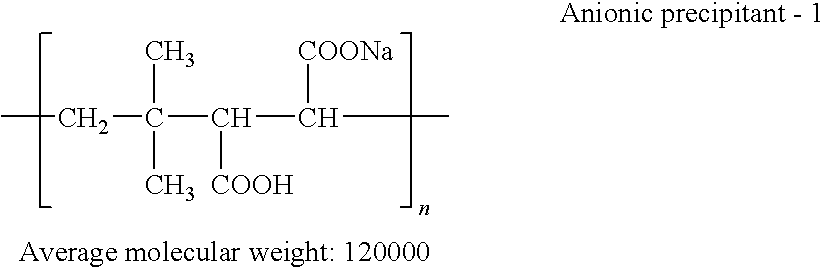

Photosensitive material for forming conductive film, conductive film, light transmitting electromagnetic wave shielding film and method for manufacturing the same

InactiveUS20090029125A1Excellent electromagnetic wave shielding performanceImprove pressure resistanceSemiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialEmulsionAntioxidant

To provide a conductive film forming photosensitive material from which a conductive film having high electromagnetic wave shielding properties and high transparency simultaneously can be manufactured and which is reduced with respect to pressure properties.A conductive film forming photosensitive material including a support having thereon an emulsion layer containing a silver salt emulsion and capable of manufacturing a conductive film by exposing the emulsion layer, performing a development treatment and further performing physical development and / or plating treatment, wherein the emulsion layer is disposed substantially in an uppermost layer; and the emulsion layer contains an antioxidant.

Owner:FUJIFILM CORP

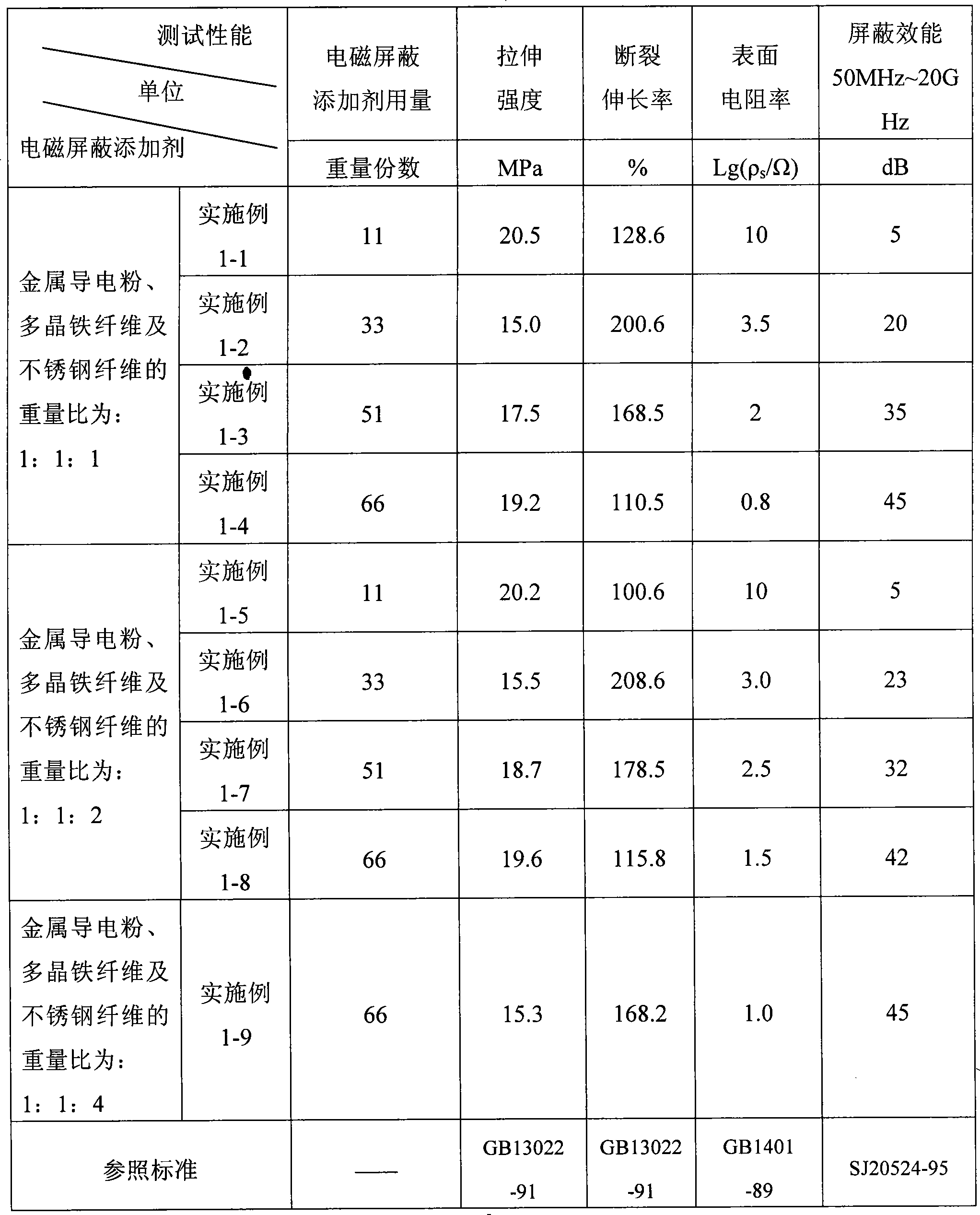

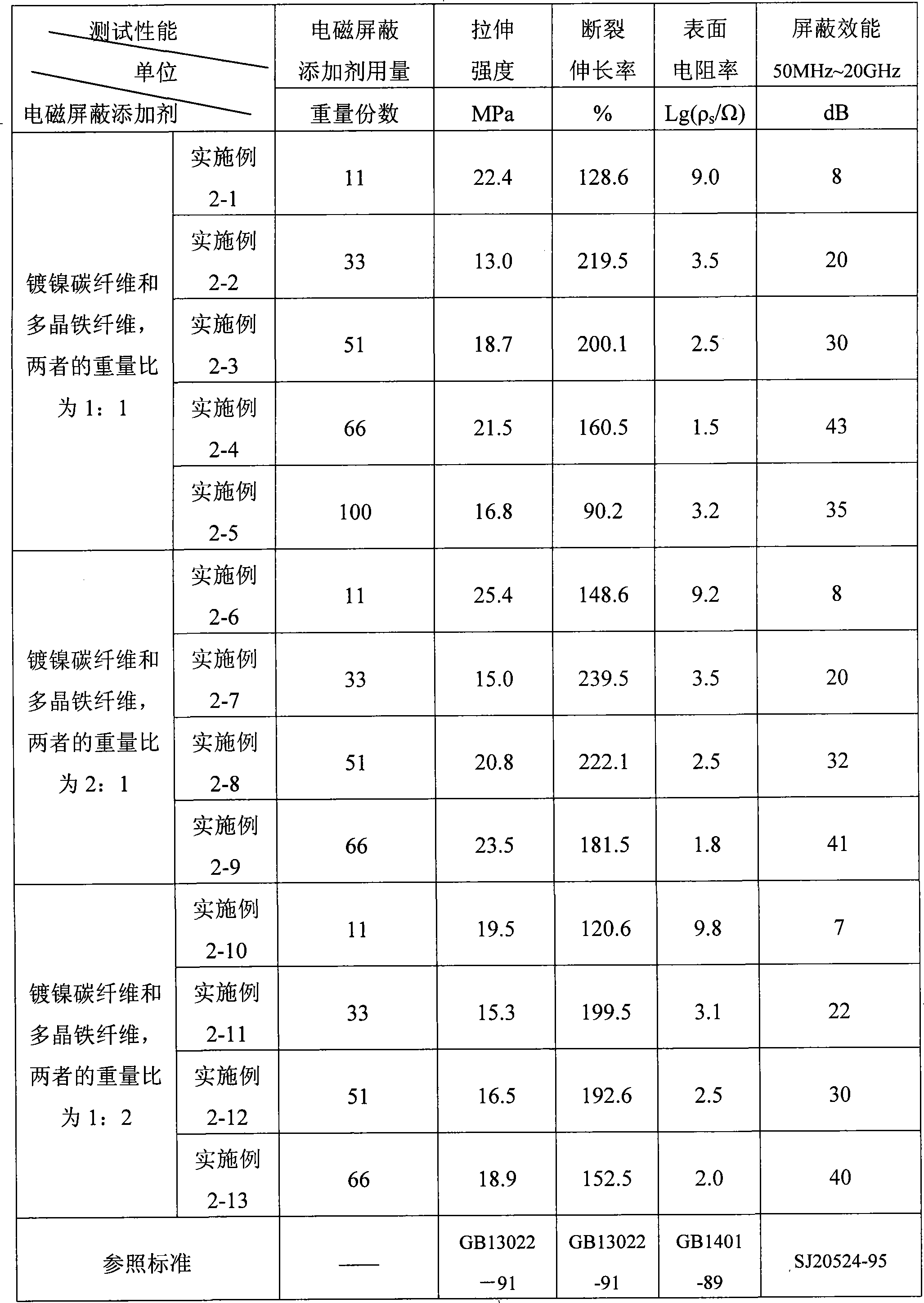

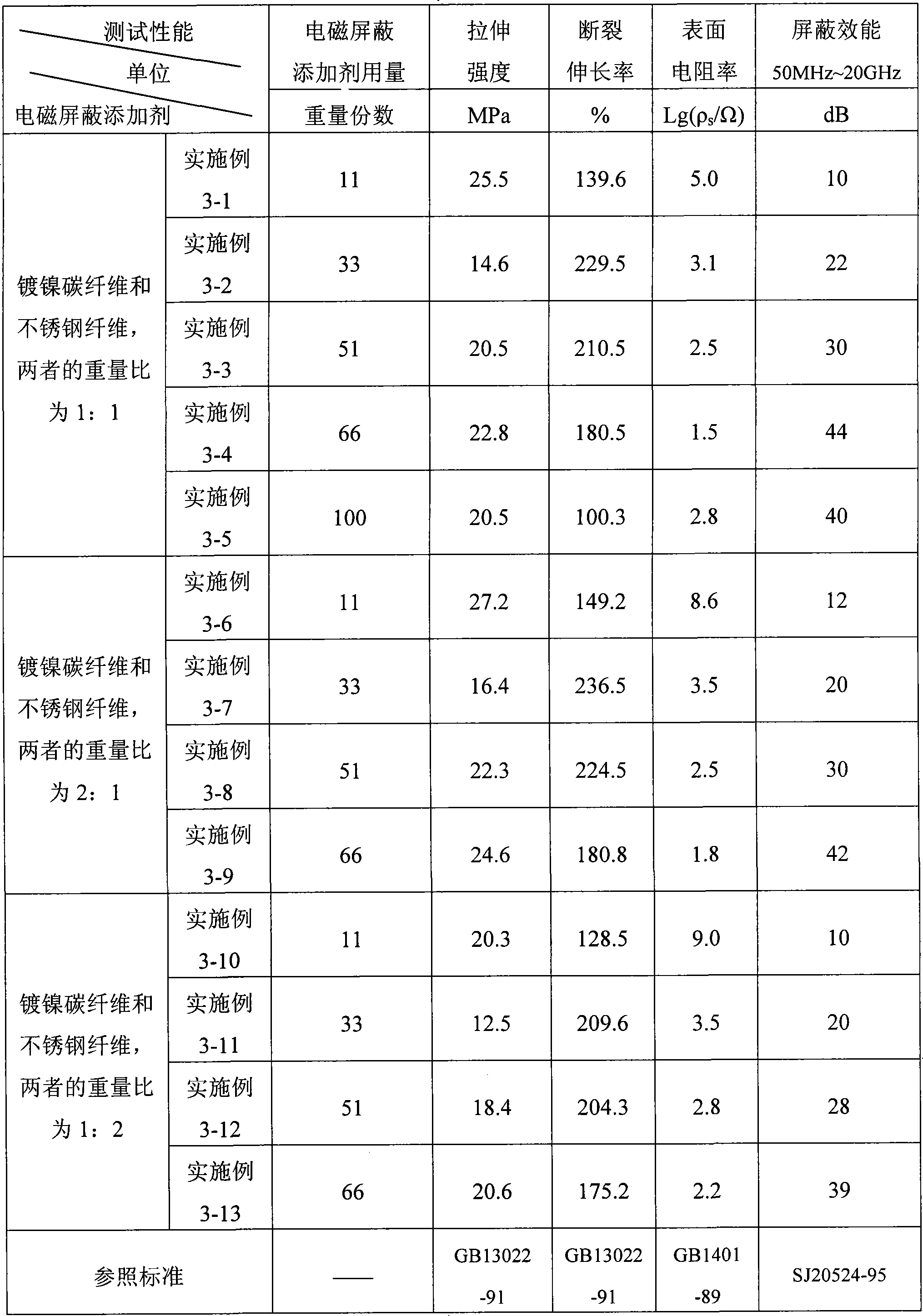

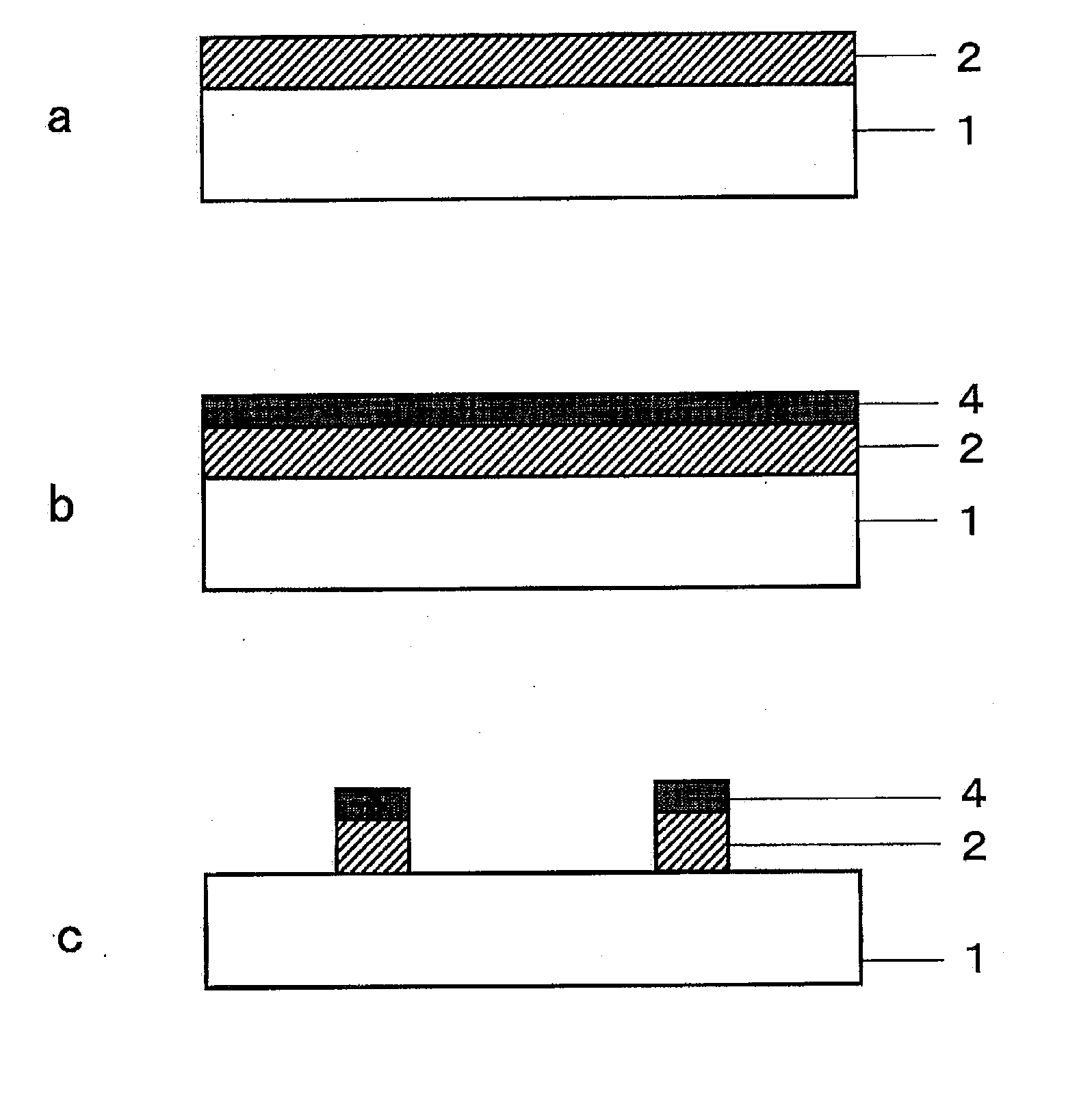

Polyethylene composite film for shielding wideband electromagnetic wave and its preparing method

InactiveCN101072493AImprove shielding effectivenessWide shielding rangeMagnetic/electric field screeningScreening apparatusAluminiumCopper

The composite membrane of polythene (CMP) includes basal body membrane (BBM) and surface coating for BBM. BBM is polyvinyl resin membrane of containing additive for shielding electromagnetic wave. The weight of additive is 10-100 weight portions if the said polyvinyl resin is in 100 weight portions. The additive includes two kinds: (1) one is admixture of metal fibers and metal conduction powder; the metal fibers are admixtures of polycrystal iron fiber and stainless steel fiber; the metal conduction powders include nickel powder, copper powder, iron powder, or aluminum powder; (2) the other is admixture of metal fibers and carbon fibers; the metal fibers are polycrystal iron fiber or stainless steel fiber; carbon fibers are nicarbazin fiber or nickel plated graphite fiber. Surface coating of BBM is metallic coating with average thickness being as 1-20 micros. CMP provides effect for shielding electromagnetic wave reaching about 45dB in range 50MHz-20GHz.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

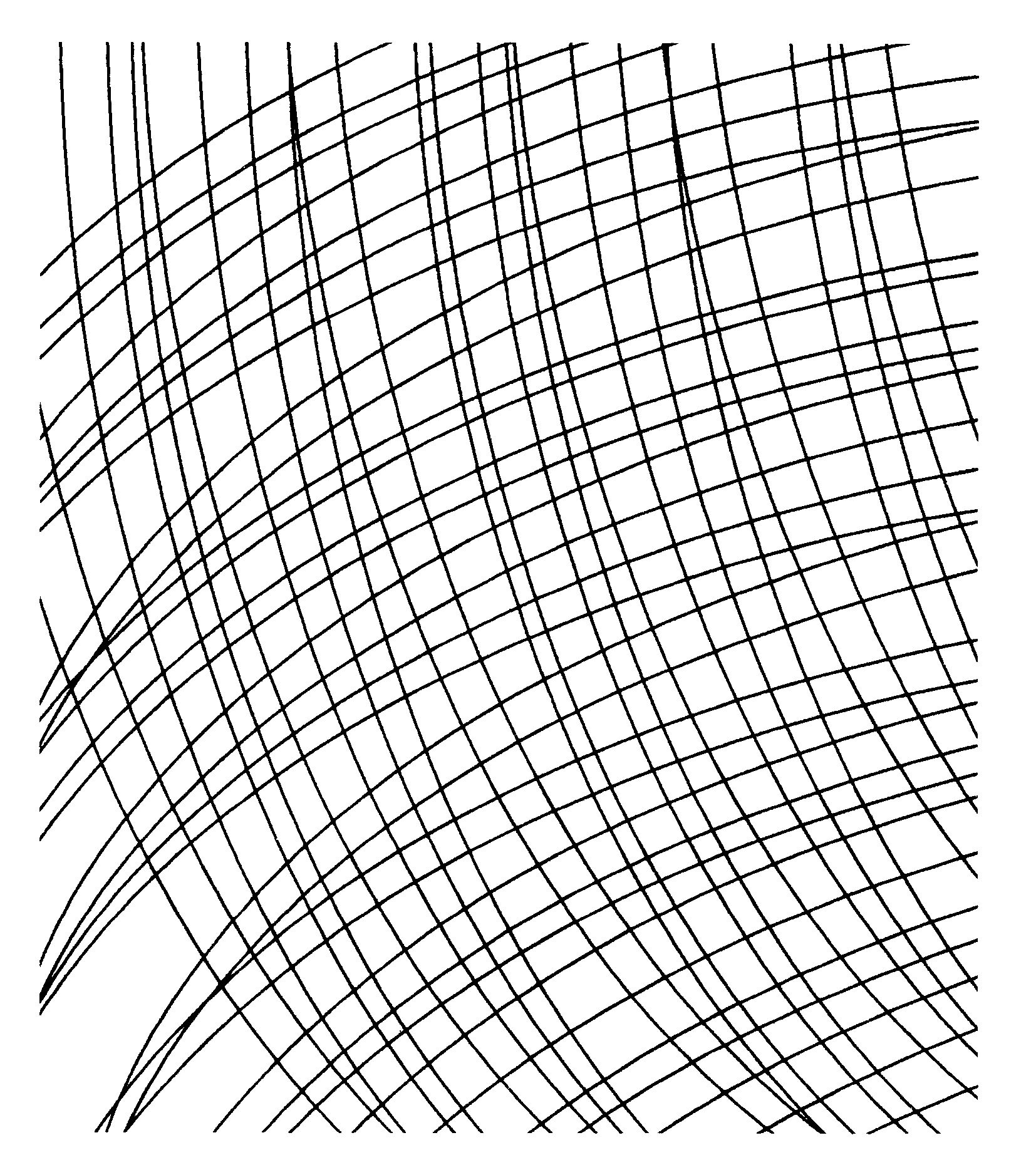

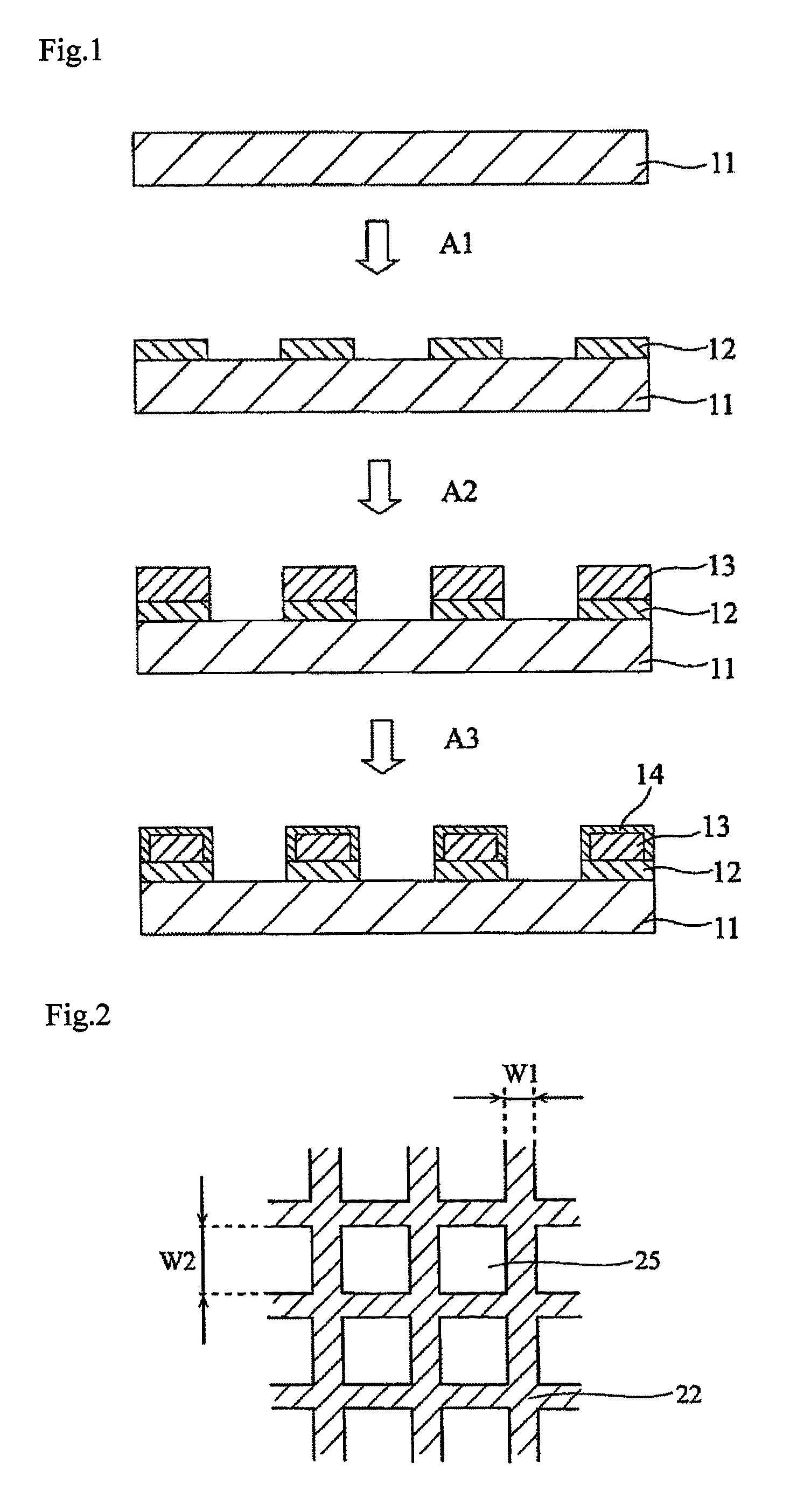

Transparent electromagnetic wave shield member and method for manufacturing the same

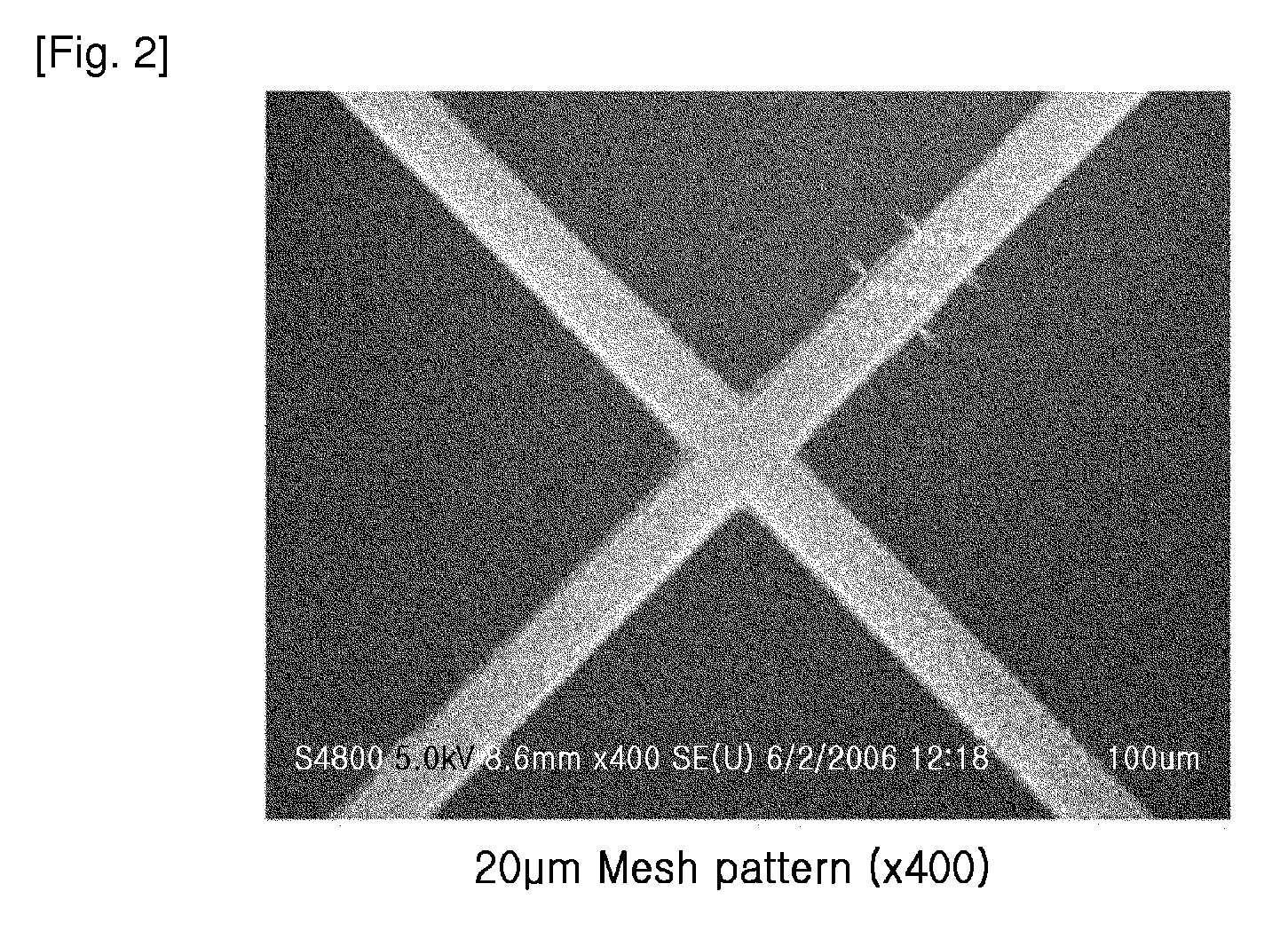

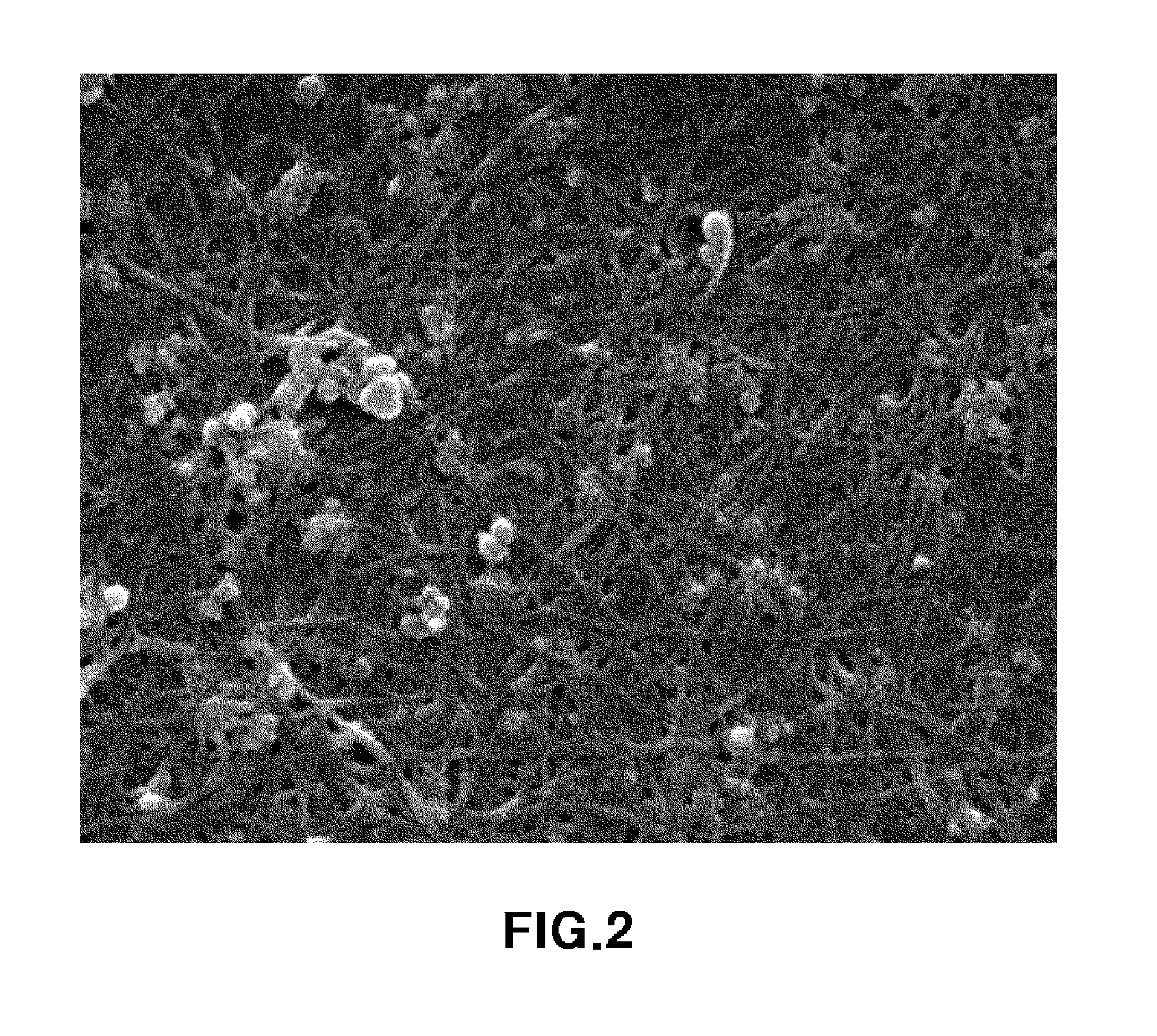

InactiveUS20100206628A1Excellent electromagnetic wave shielding performanceSufficient light transmittanceMagnetic/electric field screeningVacuum evaporation coatingNetwork structureOptical transmittance

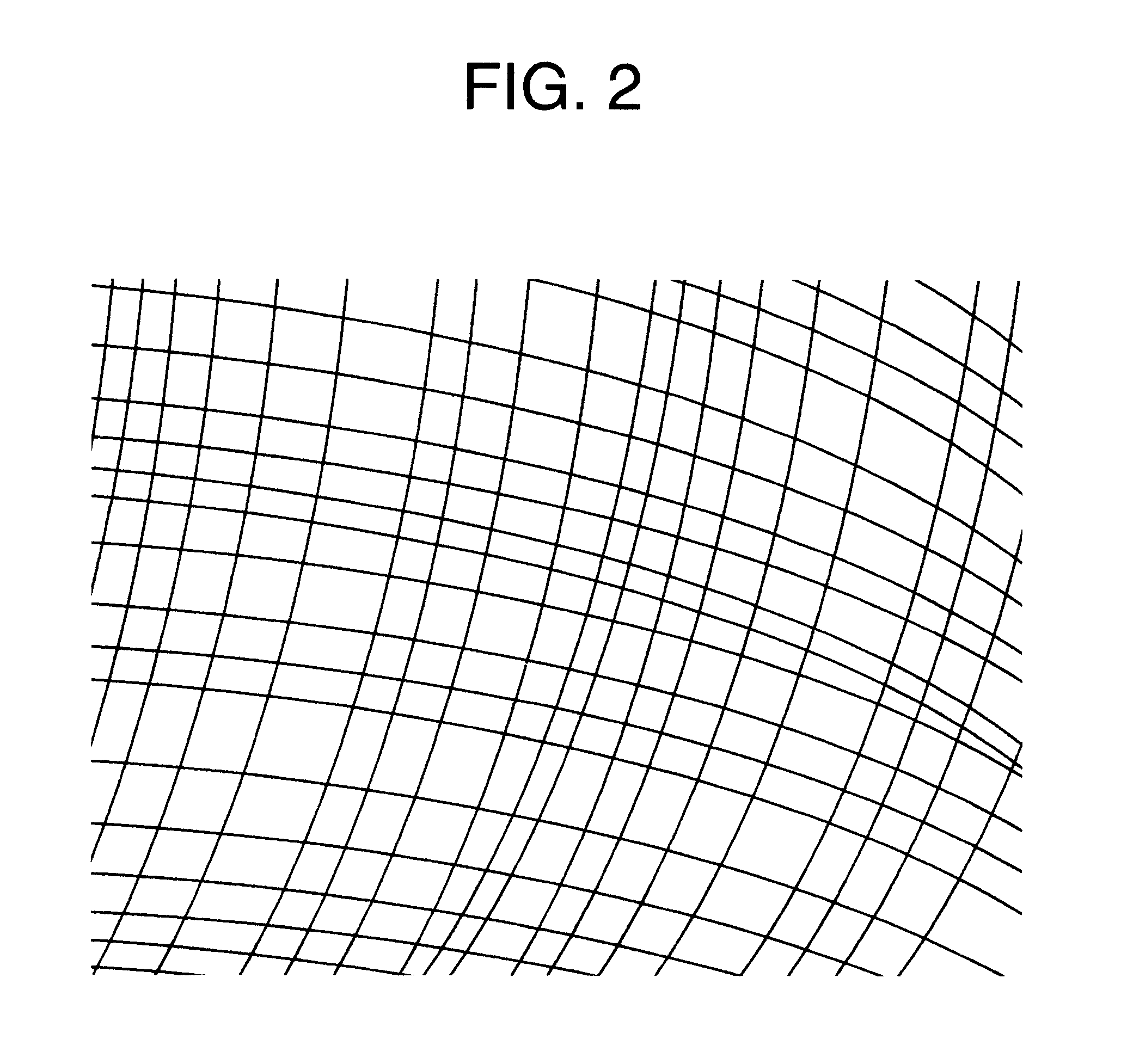

The present invention aims to provide a transparent electromagnetic wave shield member, which is free from a moirè phenomenon which could not be solved by the prior art, and in which an excellent electromagnetic wave shielding properties and a sufficient total light transmittance based on an appropriate network structure are compatible, and a method for manufacturing the same.The transparent electromagnetic wave shield member of the present invention is a transparent electromagnetic wave shield member in which a metal layer of an electroconductive metal network structure having a geometrical shape is formed on a transparent substrate, and which is characterized in that a spacing of said network structure is 200 μm or less, an opening ratio of the network structure is 84% or more, and in addition, a thickness of the electroconductive metal layer is 2 μm or less.Furthermore, the method for manufacturing such transparent electromagnetic wave shield member is a method for manufacturing a transparent electromagnetic wave shield member in which a metal layer of a network structure having a geometrical shape is formed on a transparent substrate, which is characterized in that a metal layer of a thickness of 2 μm or less is provided on a transparent substrate and the metal layer is removed by laser abrasion to form a metal layer of a network structure having a spacing of the network structure of 200 μm or less, and in addition, an opening ratio of the network structure of 84% or more.

Owner:TORAY IND INC

Method for manufacturing high-performance electromagnetic wave shielding fabric

InactiveCN101302719AImprove folding resistanceImprove oxidation discolorationPhysical treatmentMagnetic/electric field screeningSputteringFolding endurance

The invention discloses a production method for a high-efficiency electromagnetic wave shielding fabric in the production of textile industries, comprises the working procedures of vacuum sputtering metallic film plating, chemical metallic film plating and protective layer applying of a fabric substrate, and is characterized in that an applied protective layer takes mixed wave absorbing materials, which comprises acrylic ester paste, carbon powder, ferrite, nano ferrite, titanium dioxide, an organic silicone softening agent and an dispersing agent, the mixed wave absorbing materials are applied onto the surface of a fabric that passes through the vacuum sputtering metallic film plating and the chemical metallic film plating through the ways of extrusion coating with a serum roller, blade coating with a knife or printing coating with a circular screen, and are solidified at high temperature. The invention has the advantages that the high-efficiency electromagnetic wave shielding fabric produced achieves the superimposed effect of electromagnetic wave reflecting and absorbing and plasma activating, improves the electromagnetic wave shielding performance further to be larger than 90 dB, simultaneously raises the combining fastness between a plated film and the fabric substrate, and improves the folding resistance of the product and the oxidative stain property of the metallic film.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

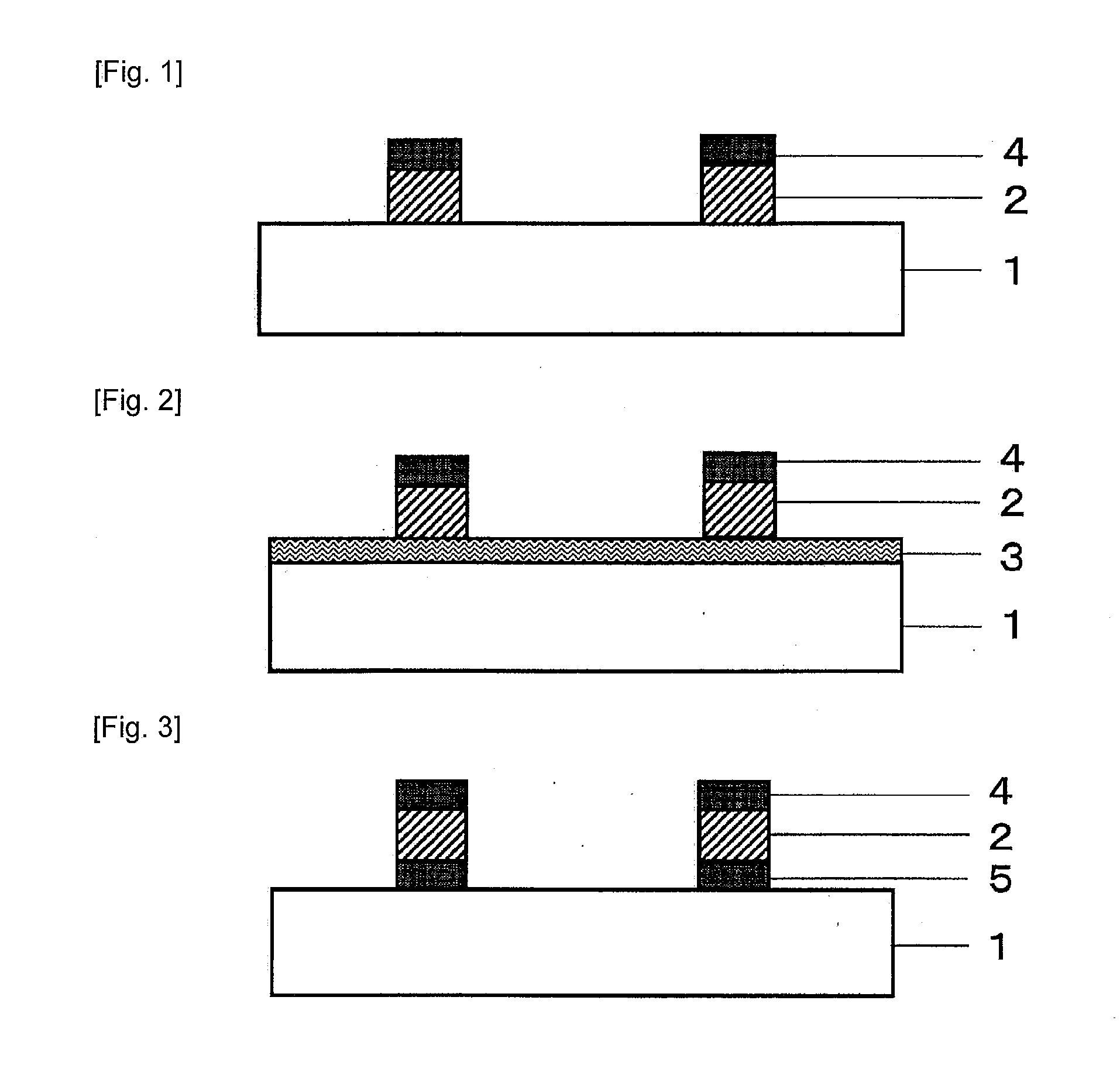

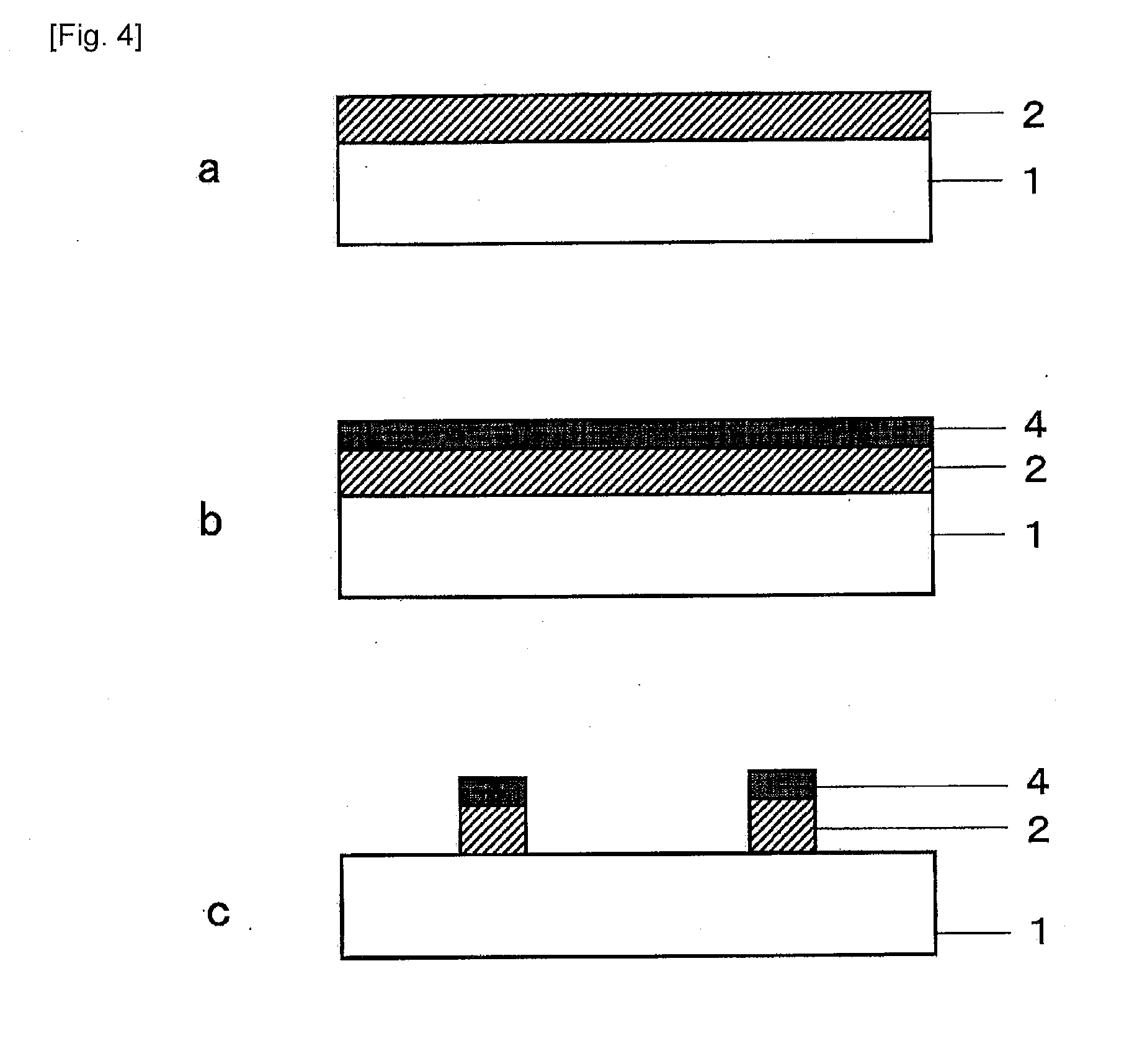

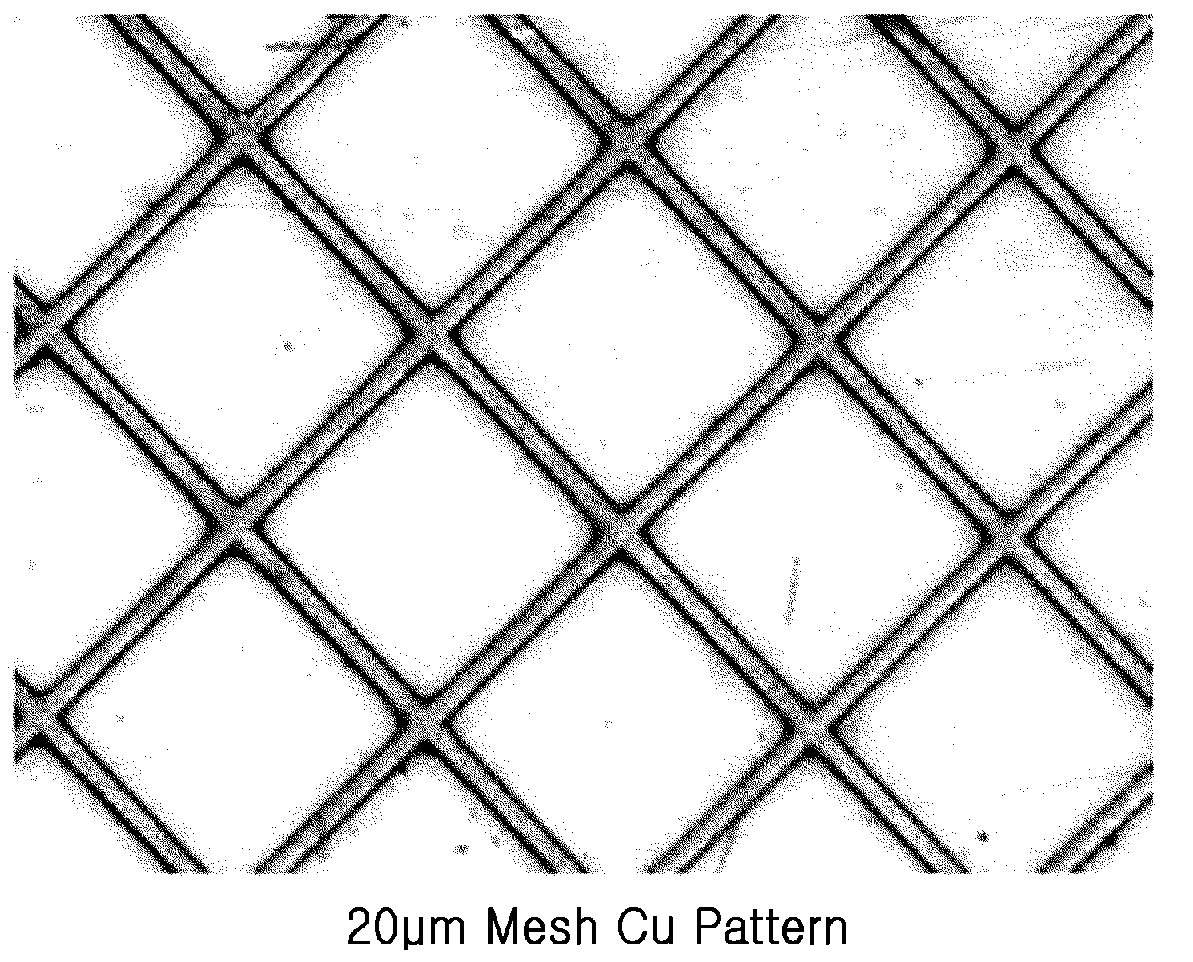

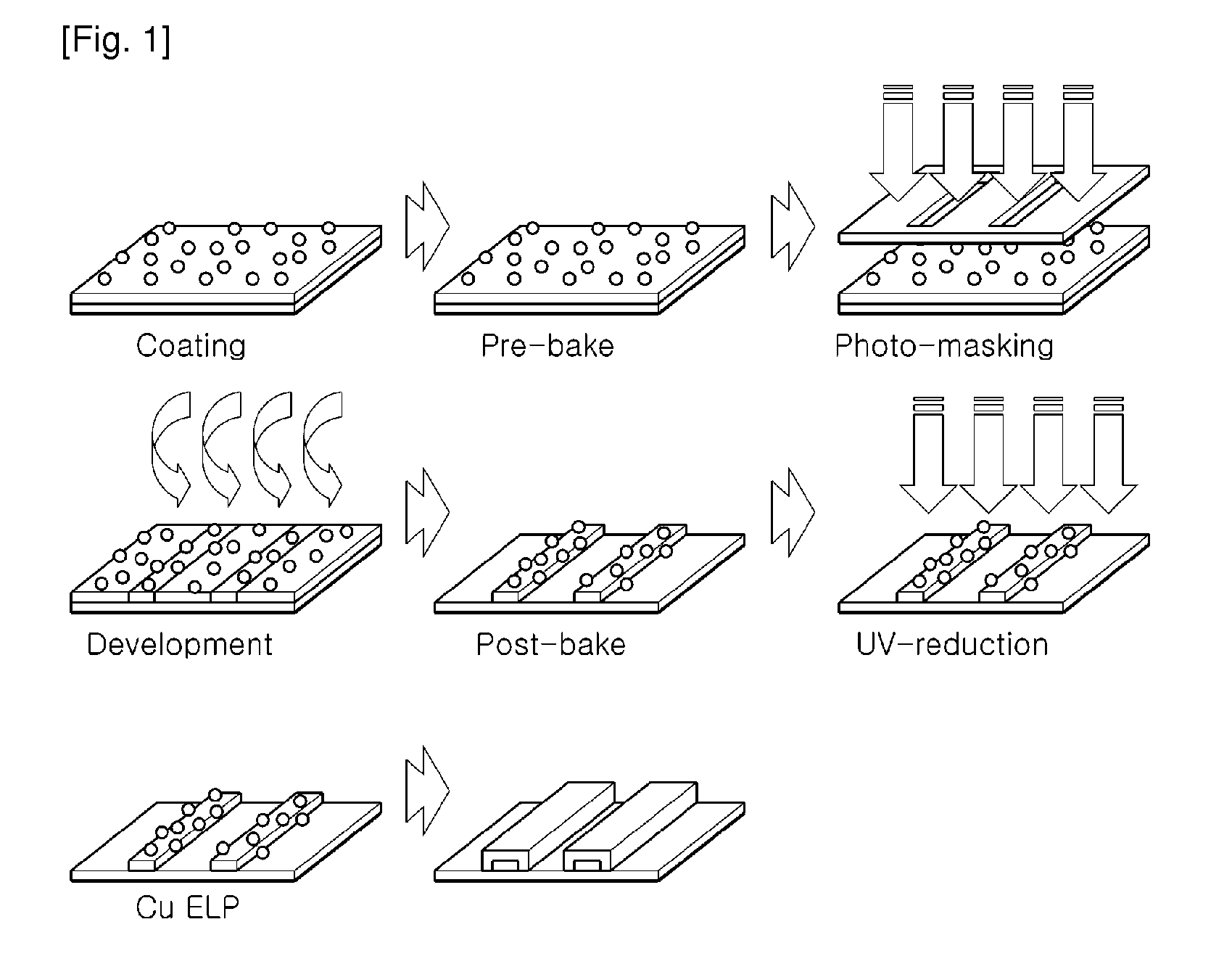

Resin composition containing catalyst precursor for electroless plating in forming electro-magnetic shielding layer, method of forming metallic pattern using the same, and metallic pattern formed by the same method

ActiveUS20100167081A1Accurate thicknessImprove adhesionPhotosensitive materialsMagnetic/electric field screeningPolymer resinOrganic solvent

A catalyst precursor resin composition includes an organic polymer resin; a fluorinated-organic complex of silver ion; a monomer having multifunctional ethylene-unsaturated bonds; a photoinitiator; and an organic solvent. The metallic pattern is formed by forming catalyst pattern on a base using the catalyst precursor resin composition reducing the formed catalyst pattern, and electroless plating the reduced catalyst pattern. In the case of forming metallic pattern using the catalyst precursor resin composition, a compatibility of catalyst is good enough not to make precipitation, chemical resistance and adhesive force of the formed catalyst layer are good, catalyst loss is reduced during wet process such as development or plating process, depositing speed is improved, and thus a metallic pattern having good homogeneous and micro pattern property may be formed after electroless plating.

Owner:LG CHEM LTD

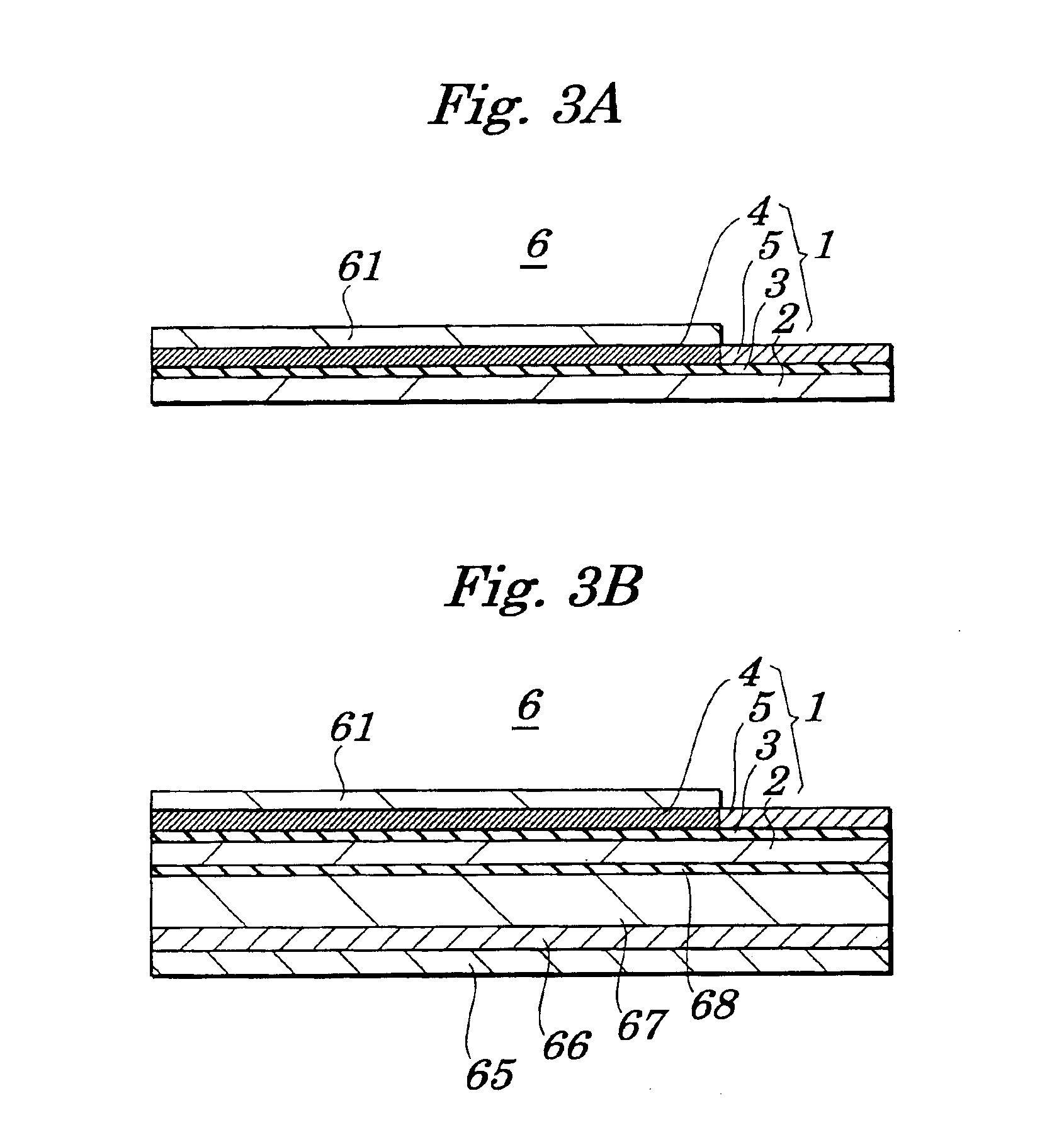

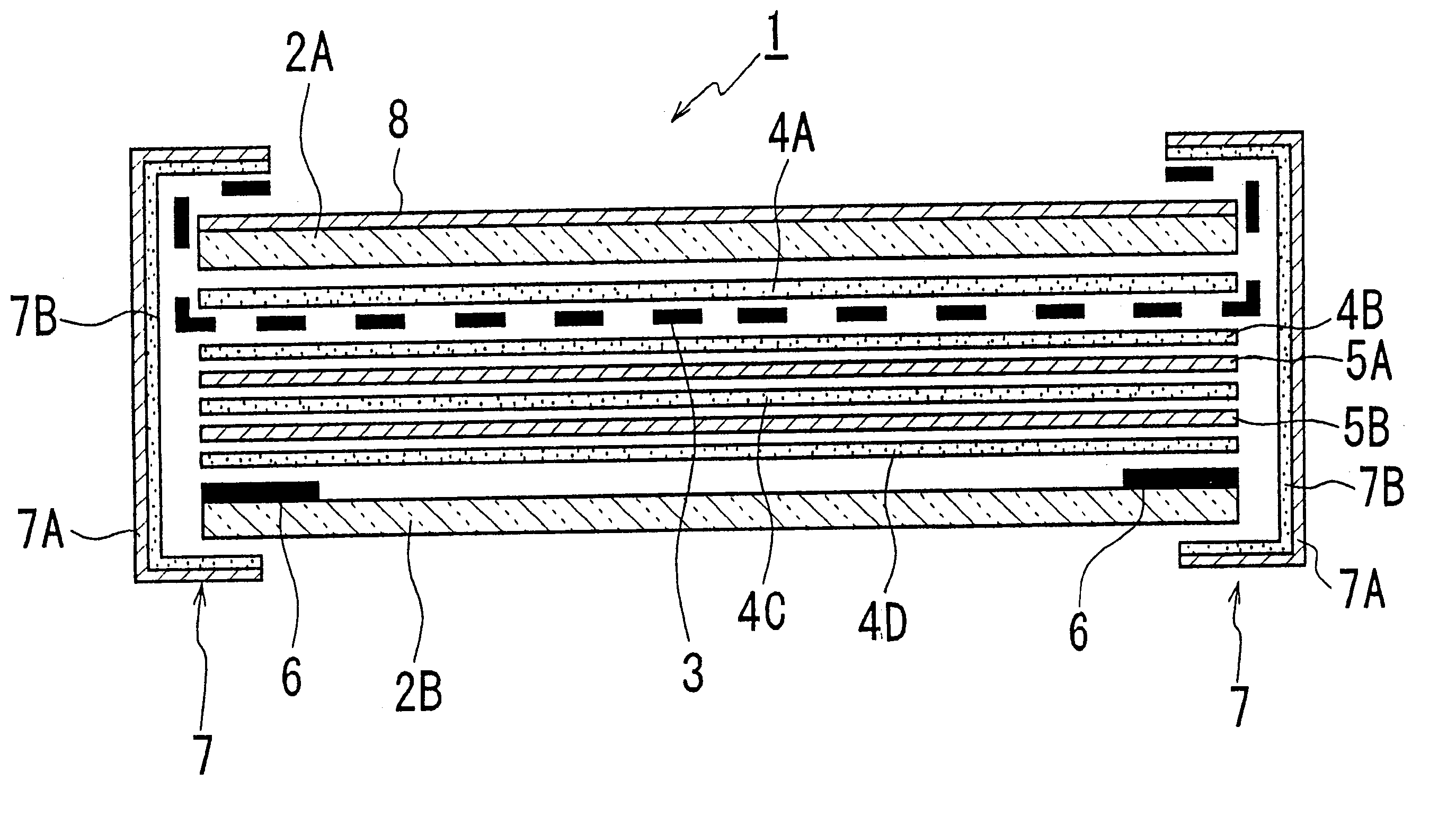

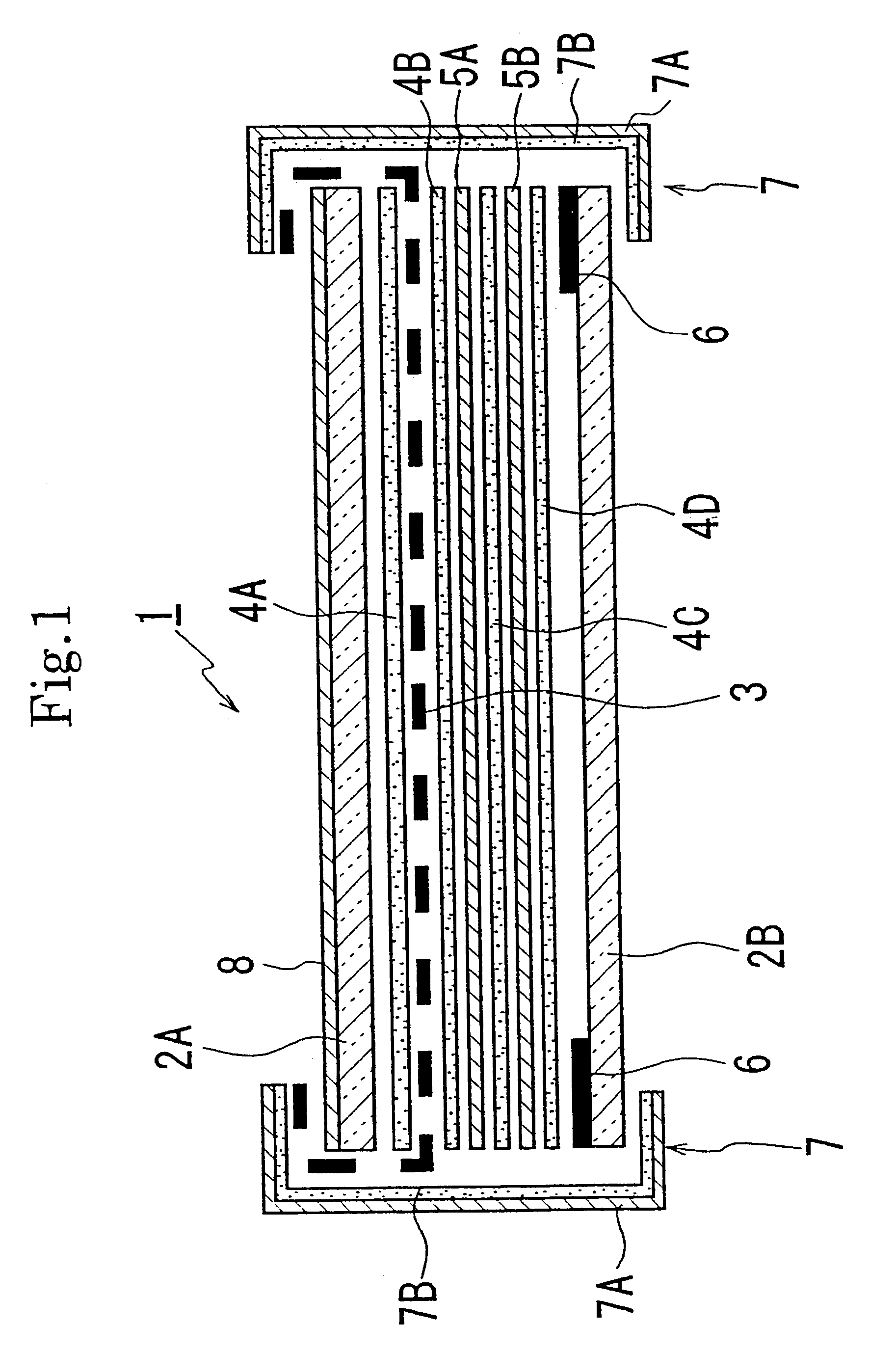

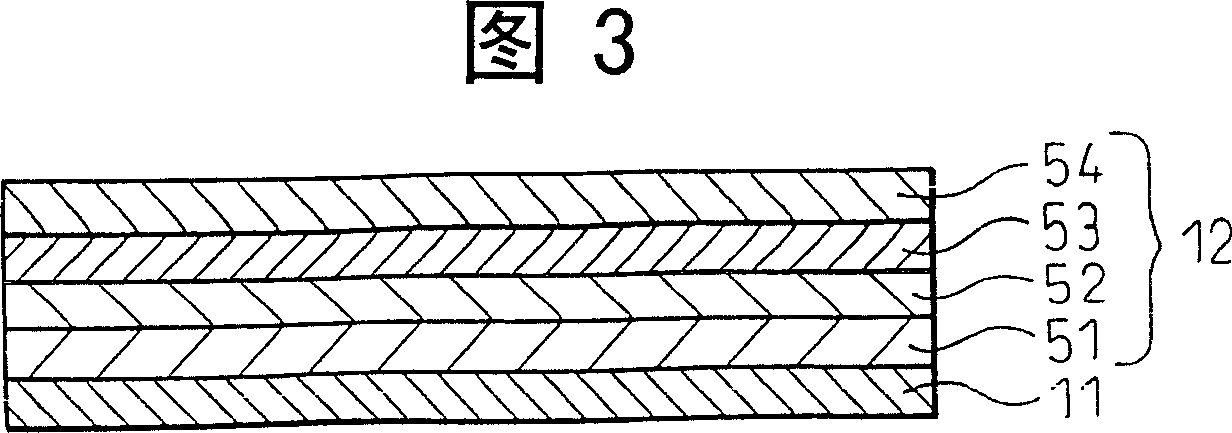

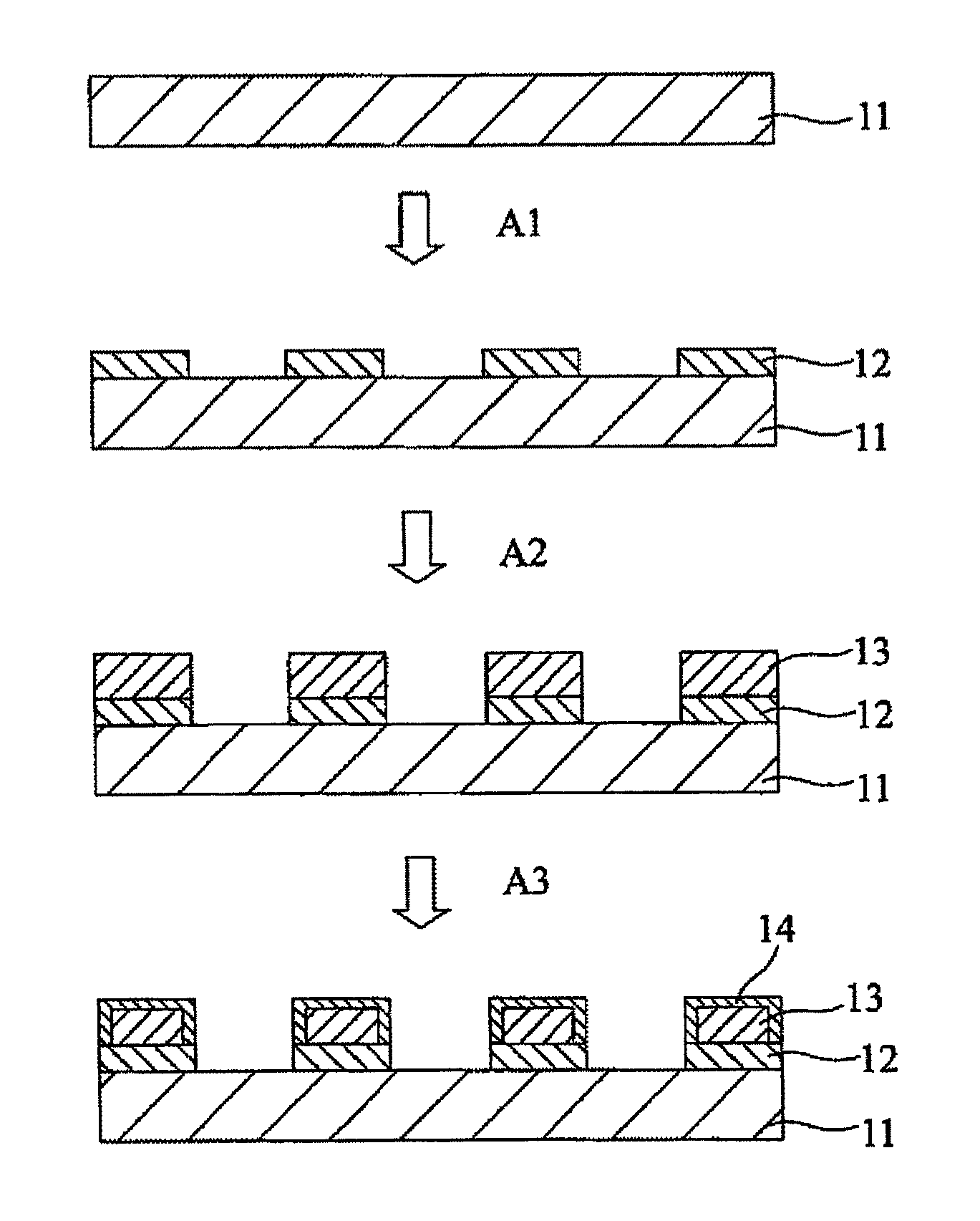

Electromagnetic Wave Shielding Device

InactiveUS20080245563A1Excellent electromagnetic wave shielding performancePrevent peelingMagnetic/electric field screeningLayered productsComputational physicsElectromagnetic shielding

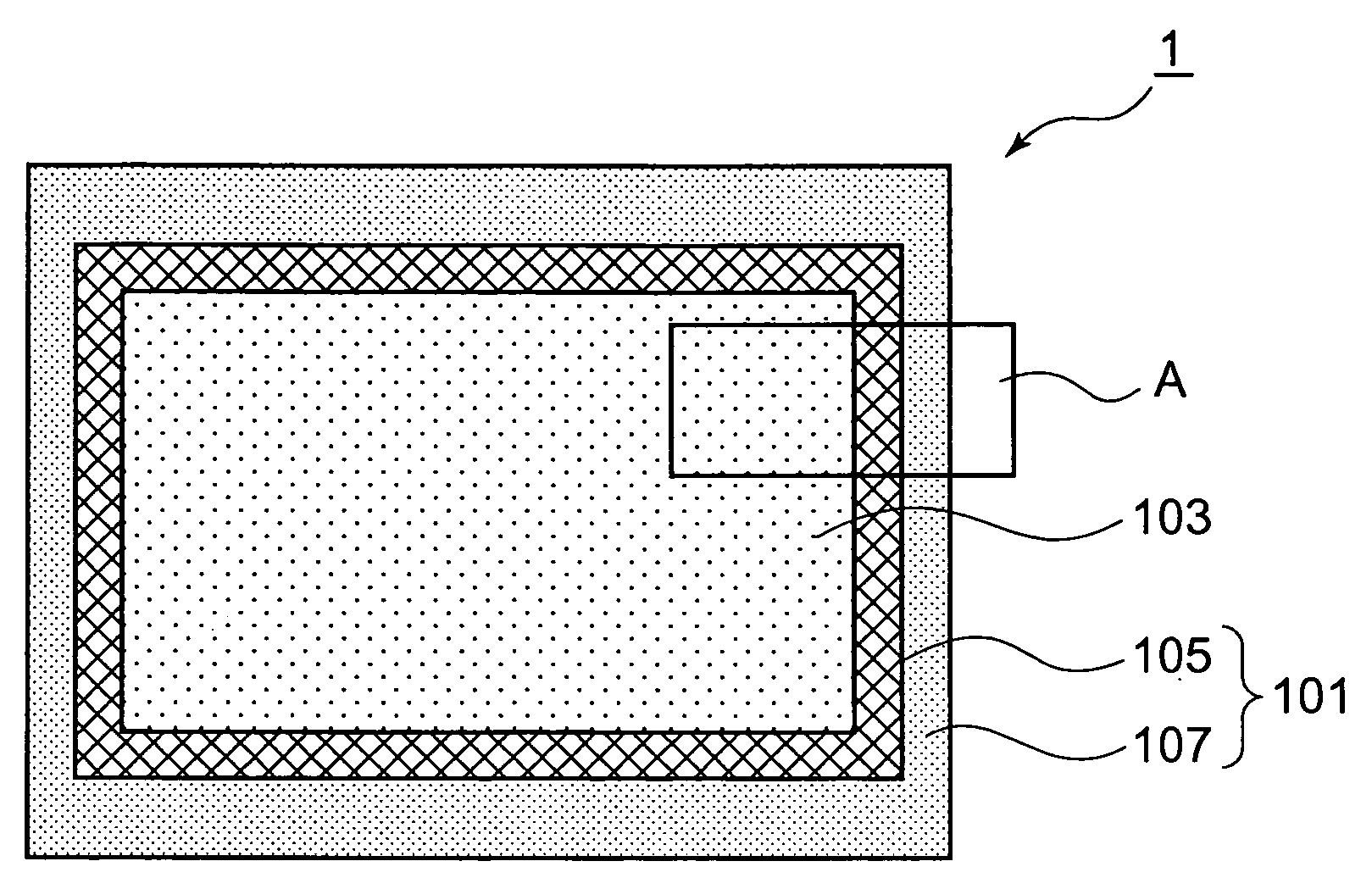

An electromagnetic wave shielding layer 1 comprises a transparent substrate 11, an adhesive layer 13 which is provided as needed, an electromagnetic wave shielding layer 15, and a transparent resin layer 17. The electromagnetic shielding layer 15 includes a mesh portion 103 facing a screen portion 100 of an image displaying device, a transparent resin layer anchoring portion 105 surrounding a periphery of the mesh portion 103 and including openings 105a having an opening ratio lower than that of openings 103a of the mesh portion 103, and a frame portion 107 surrounding an outer periphery of the transparent resin layer anchoring portion 105 and not having openings. The transparent resin layer 17 is provided such that it covers the surfaces of the mesh portion 103 and the transparent resin layer anchoring portion 105 and fills the openings 103a, 105a.

Owner:DAI NIPPON PRINTING CO LTD

Shielding electrically conductive printing ink and preparation method thereof

InactiveCN101792627ALarge conductive pathExcellent electromagnetic wave shielding performanceInksFiberPrinting ink

The invention relates to a shielding electrically conductive printing ink and a preparation method thereof. The shielding electrically conductive printing ink is prepared by the following raw materials in percentage by mass: 20-25% of thermosetting resin, 1-6% of solvent, 70-75% of metal fibre, 1-5% of metal powder, 2-5% of curing agent and 0-1% of antioxidant. The preparation method of the electrically conductive printing ink comprises: after weighting, fully mixing the thermosetting resin, solvent, metal fibre and metal powder; grinding and dispersing for 2-5 times by a three-roll grinder to form an even mixed phase; then, adding the curing agent and antioxidant; and grinding and dispersing for 2-5 times by the three-roll grinder to form the even mixed phase so as to obtain the electrically conductive printing ink. The electrically conductive printing ink has the characteristics of high electrical conductivity, high electromagnetic shielding efficiency, simple spraying operation and the like.

Owner:IRICO

Conductive heat-dissipating sheet, and electrical parts and electronic devices comprising same

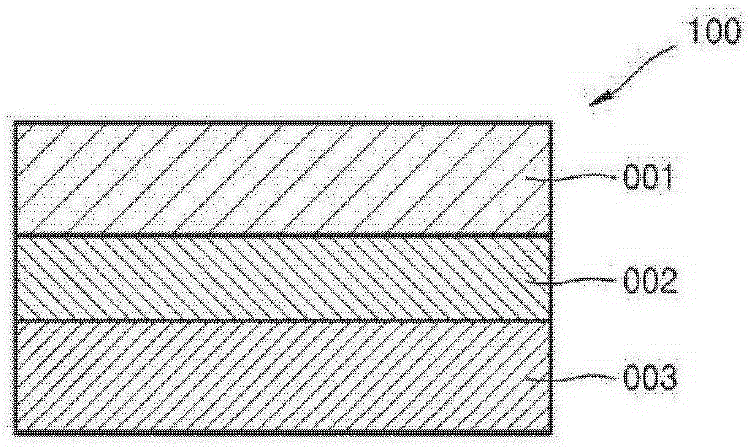

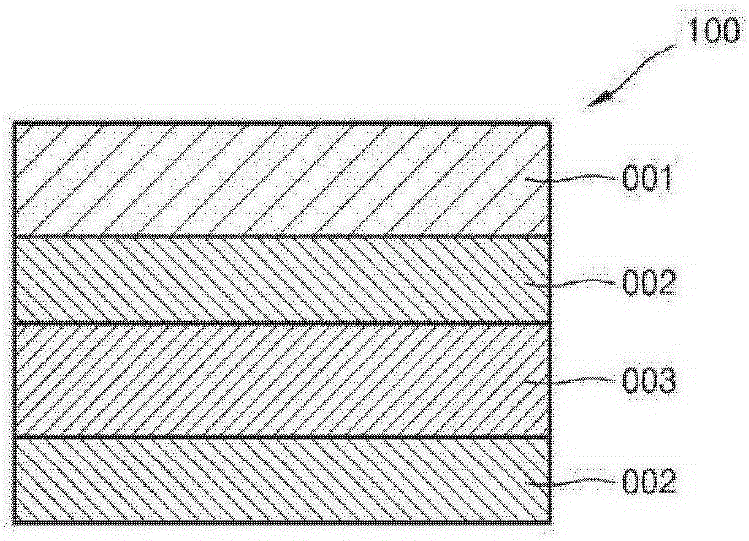

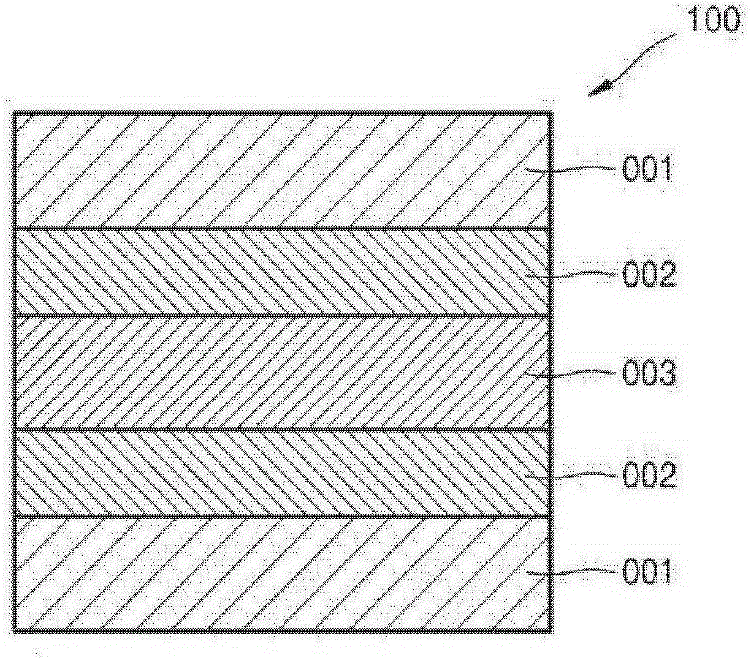

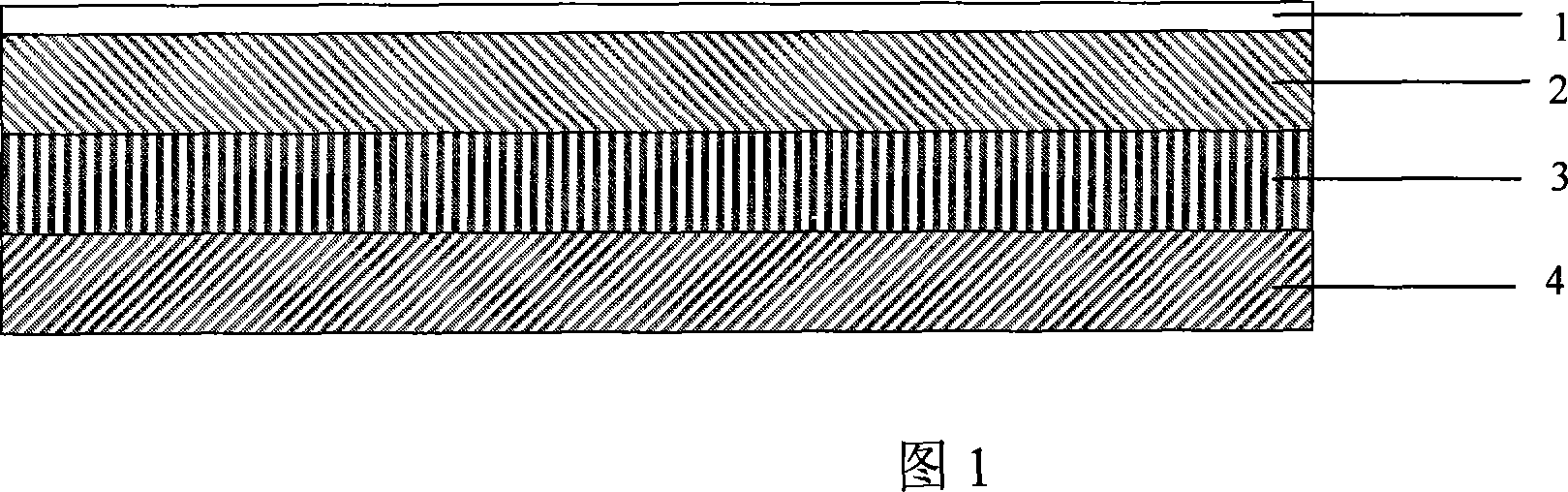

InactiveCN105325067AExcellent thermal diffusion performanceExcellent electromagnetic wave shielding performanceMagnetic/electric field screeningSemiconductor/solid-state device detailsHeat sinkMetallic materials

Disclosed herein are a conductive heat-dissipating sheet comprising a heat diffusion layer formed using metal materials; a heat conduction layer which is disposed on one surface or both surfaces of the heat diffusion layer and which is formed using inorganic materials including at least one material from the group consisting of metal oxides and alloys; and an adhesive layer disposed on one surface or both surfaces of the heat conduction layer; and an electrical part and an electronic device comprising the conductive heat-dissipating sheet.

Owner:ILJIN MATERIALS CO LTD

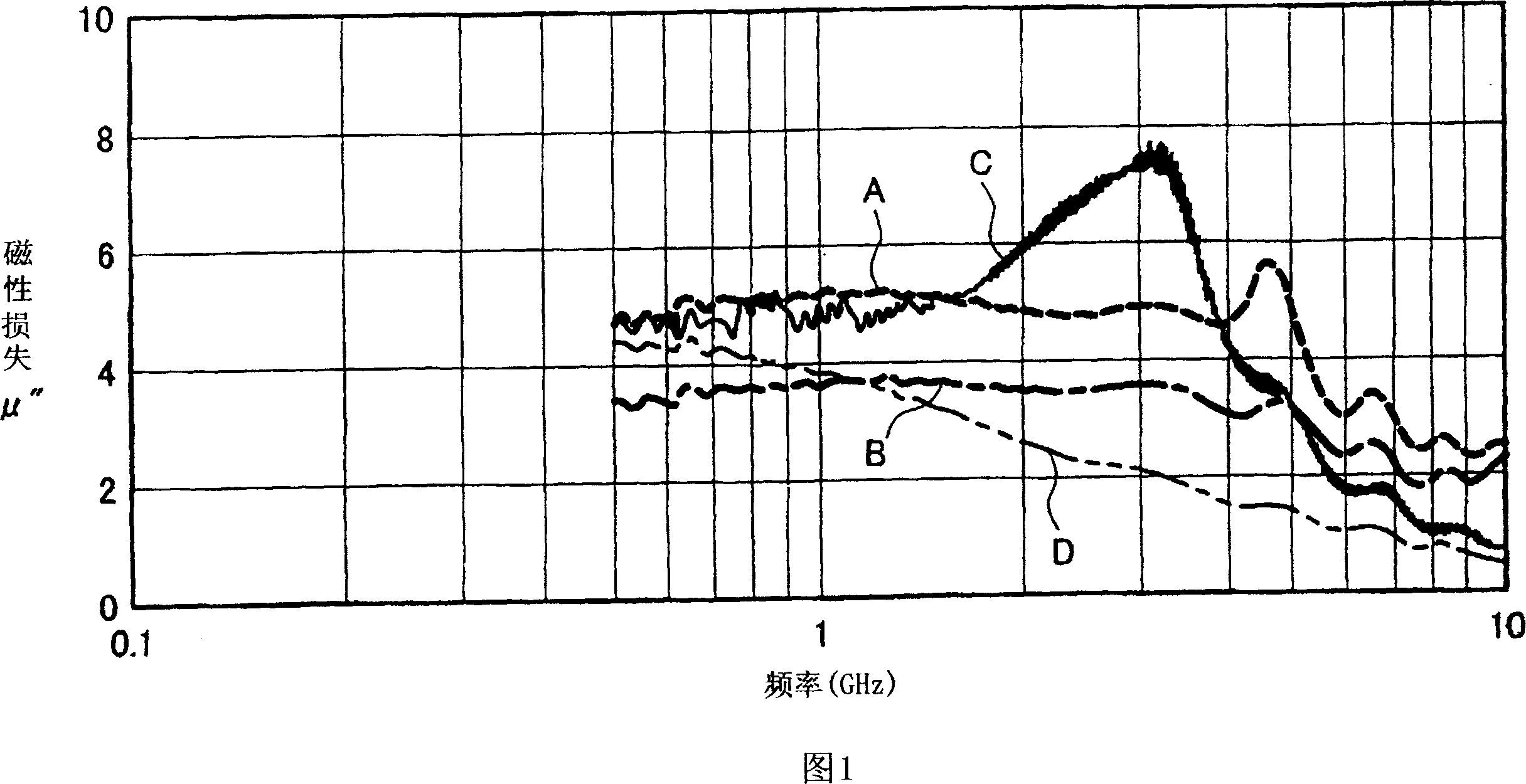

Electromagnetic wave absorber

InactiveCN1926936AExcellent electromagnetic wave absorption performanceImprove thermal conductivityMagnetic/electric field screeningInorganic material magnetismHigh resistanceElectromagnetic wave absorber

An electromagnetic wave absorber comprising (a) soft ferrite having its surface treated with a silane compound having no functional group, (c) magnetite and (d) silicone, or comprising (a) soft ferrite having its surface treated with a silane compound having no functional group, (b) flat soft magnetic metal powder, (c) magnetite and (d) silicone, which electromagnetic wave absorber excels in electromagnetic wave absorption, heat conduction and flame resistance, exhibiting less temperature dependence, and which electromagnetic wave absorber is soft, excelling in adhesion strength and further excelling in high resistance high insulation properties and in energy conversion efficiency being stable in MHz to 10GHz broadband frequency. There is further provided a laminated electromagnetic wave absorber comprising the above electromagnetic wave absorber overlaid with a reflection layer of conductor, which laminated electromagnetic wave absorber can be closely stuck onto an unwanted electromagnetic wave emission source such as a high-speed operating device, having such an adhesive strength that even when stuck to a horizontal glassy-surface ceiling face of resin-made cage, would not fall.

Owner:GELTEC

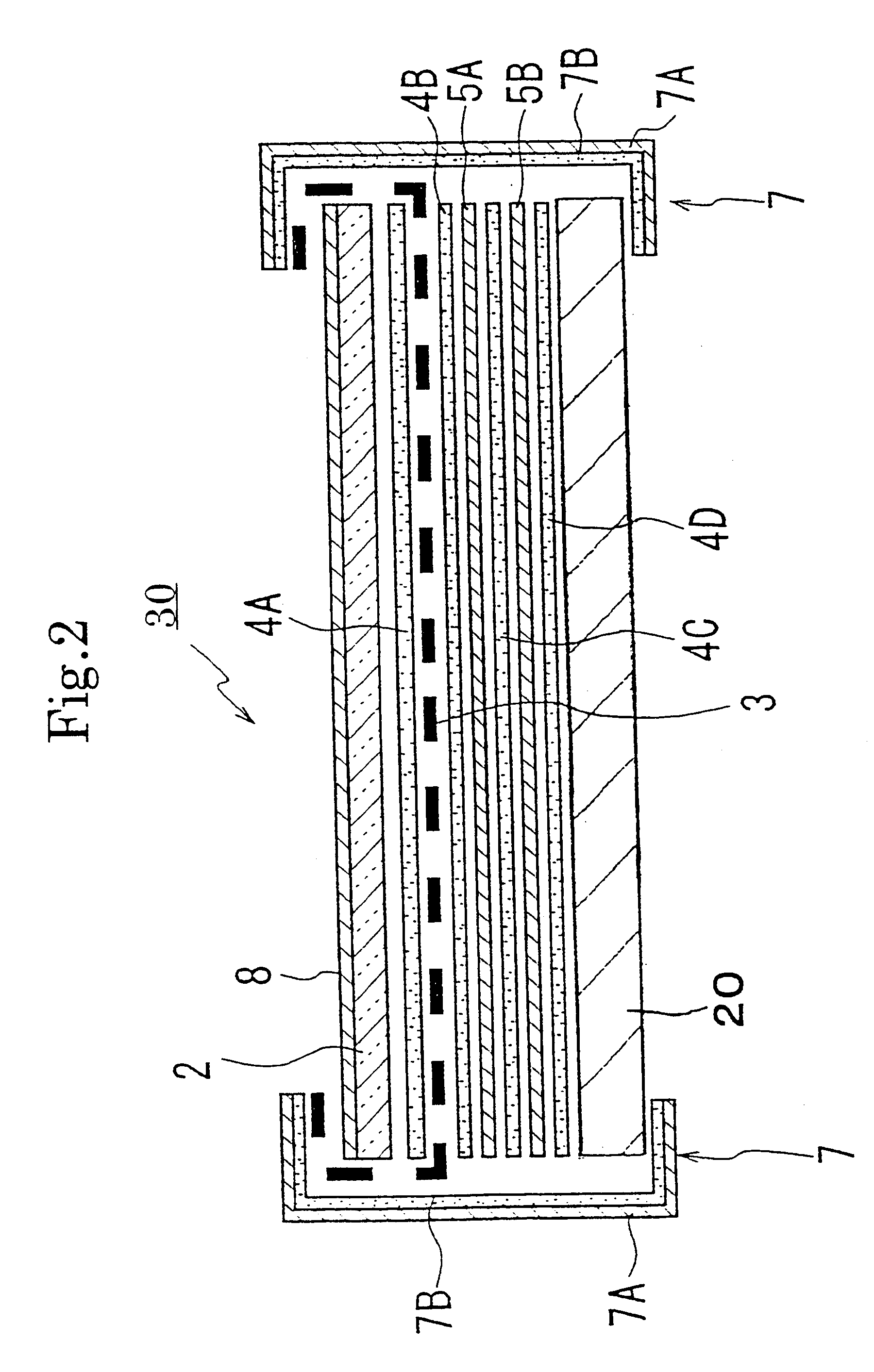

Electromagnetic-wave shielding and light transmitting plate and panel laminated plate

InactiveUS6469440B1Improve securityAvoid damageMagnetic/electric field screeningAlternating current plasma display panelsEngineeringBlocking layer

An electromagnetic-wave shielding and light transmitting plate is formed by two transparent base plates, a conductive mesh member, and a near infrared ray blocking film, wherein the conductive mesh member and the near infrared ray blocking film are interposed between the transparent base plates and are integrally bonded together. A panel laminated plate is formed by a transparent base plate, a PDP body, a conductive mesh member, and a near infrared ray blocking film, wherein the conductive mesh member and the near infrared ray blocking film are interposed between the transparent base plate and the PDP body and are integrally bonded together. Either in the above electromagnetic-wave shielding and light transmitting plate or in the panel laminated plate, the near infrared ray blocking film is a combination of two or more of near infrared ray blocking layers.

Owner:BRIDGESTONE CORP

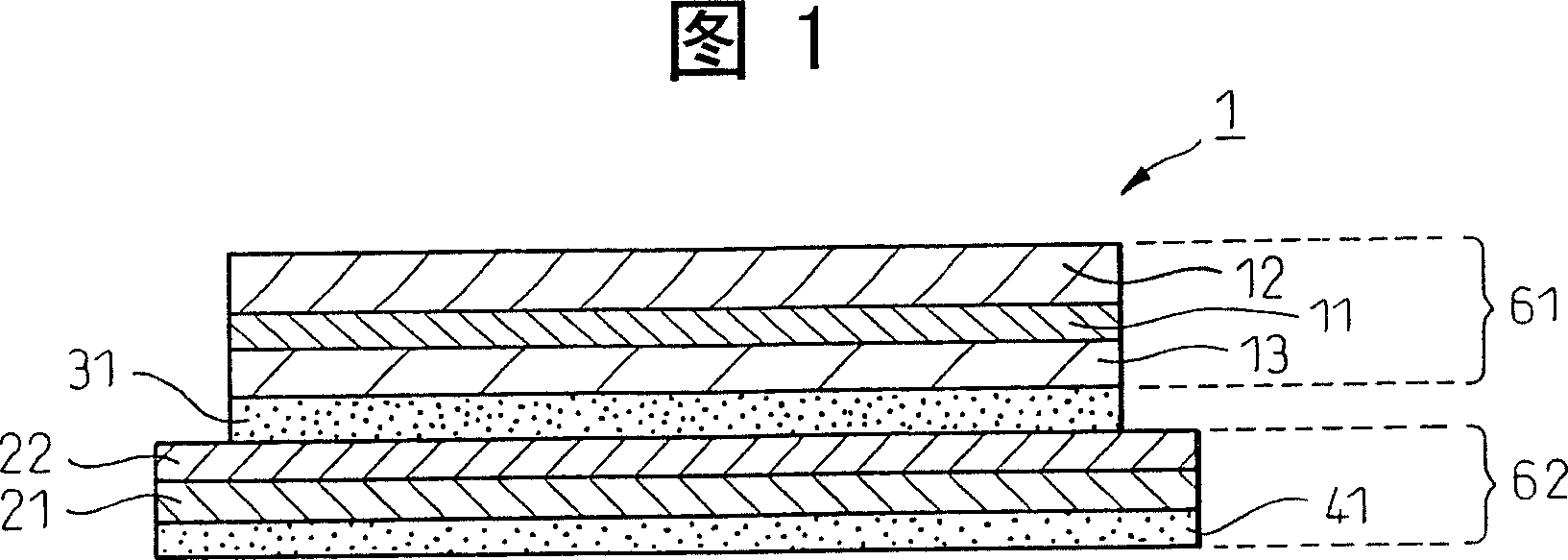

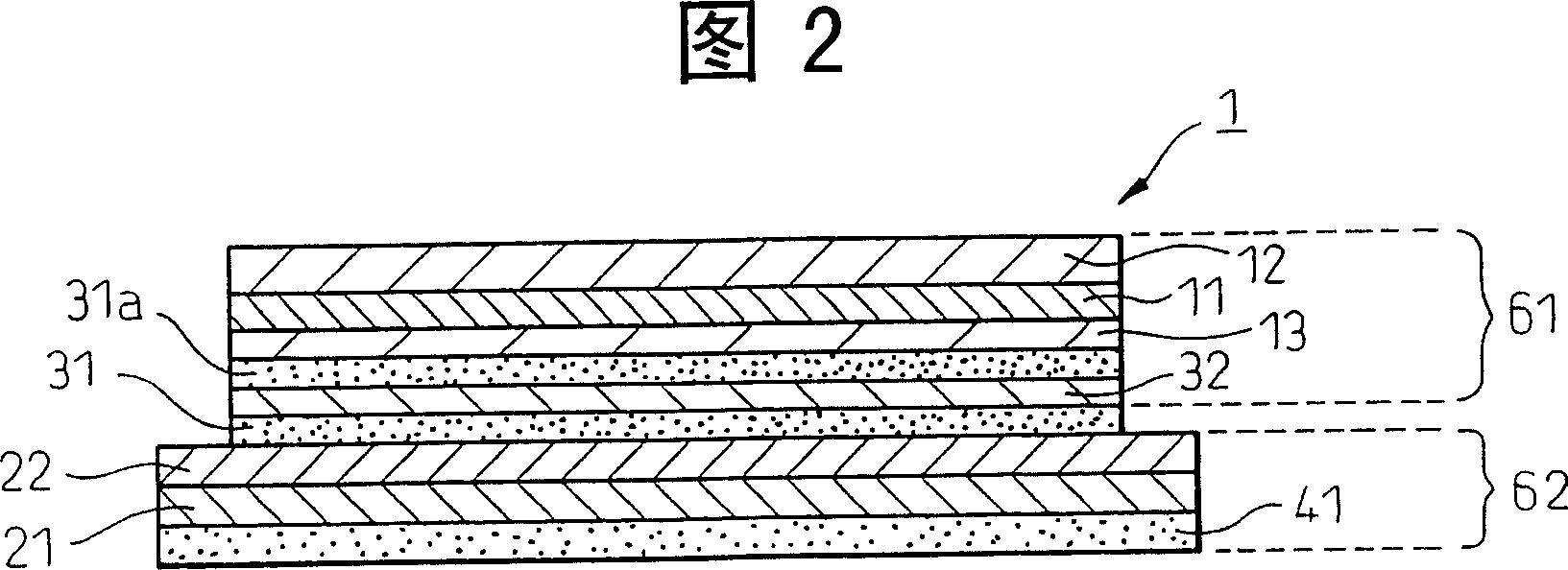

Transparent laminate

InactiveCN1930599AGood anti-reflection performanceExcellent electromagnetic wave shielding performanceElectric discharge tubesOptical filtersVisibilityMetal mesh

A transparent laminate useful as an optical filter having an excellent anti-reflection property, a near-infrared ray absorption property, an electromagnetic wave-shielding property, durability, visibility and reduced weight. The transparent laminate comprises a first laminate portion including a first transparent substrate, an anti-reflection layer and a near infrared ray-absorption layer respectively formed on the front and back surfaces thereof; and a second laminate portion including a second transparent substrate and an electromagnetic wave-shielding layer formed on one surface thereof. The first transparent substrate and the second transparent substrate are integrally jointed together; i.e., the near infrared ray-absorption layer and the electromagnetic wave-shielding layer or a metal mesh layer are integrally joined together via an adhesive layer.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Flame-resisting anti-static polythene compound film for shielding wide band electromagnetic wave and its preparing method

InactiveCN101056531AWide range of shieldingGood processing dispersibilityMagnetic/electric field screeningLayered productsMetal coatingScreening effect

The invention provides a fire retardant antistatic polyethylene compound film for screen broadband electromagnetic wave and the producing method thereof. The compound film includes three layers film structure, wherein, the medium layer is the polyethylene film for screen electromagnetic wave, the outer layer are respectively retardant polyethylene film and pure polyethylene film. A metal coating with an average thickness of 1-20 mum is coated on the outer surface of the film. The film comprises 10-100 portion by weight of electromagnetic wave screening additive, 20-35 portion by weight of halogen-free flame retardant, 5-10 portion by weight of anti-dripping agent, which has the polyethylene resin as 100 portion. There are two kinds of screening additive, one is a mixture of metal fiber and metal conductive powder; the other is a mixture of metal fiber and carbon fiber. The halogen-free flame retardant is ammonium polyphosphate pentaerythritol. The anti-dripping agent is silicate mine. The inventive polyethylene compound film has a good electromagnetic wave screening effect and retardant effect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

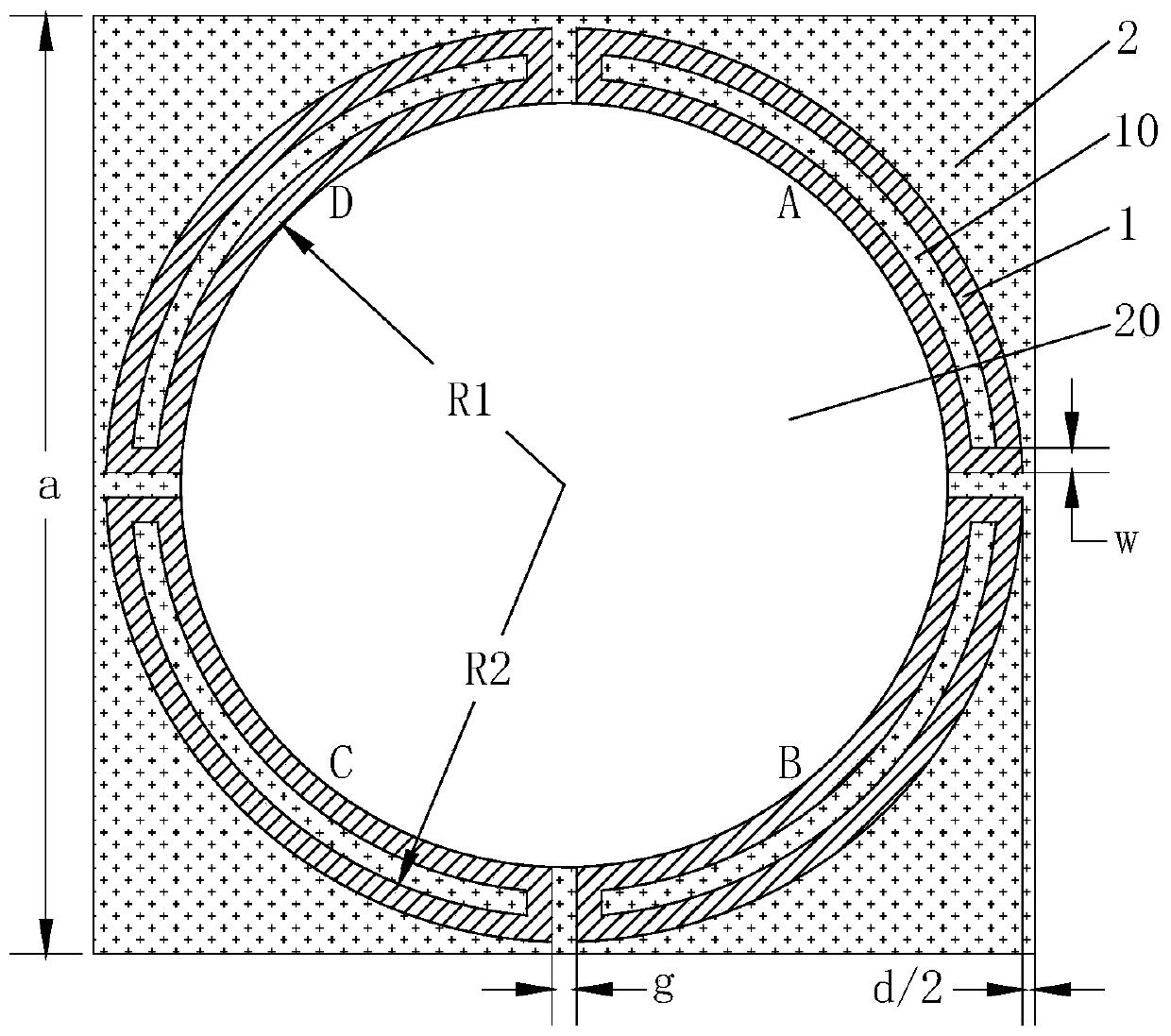

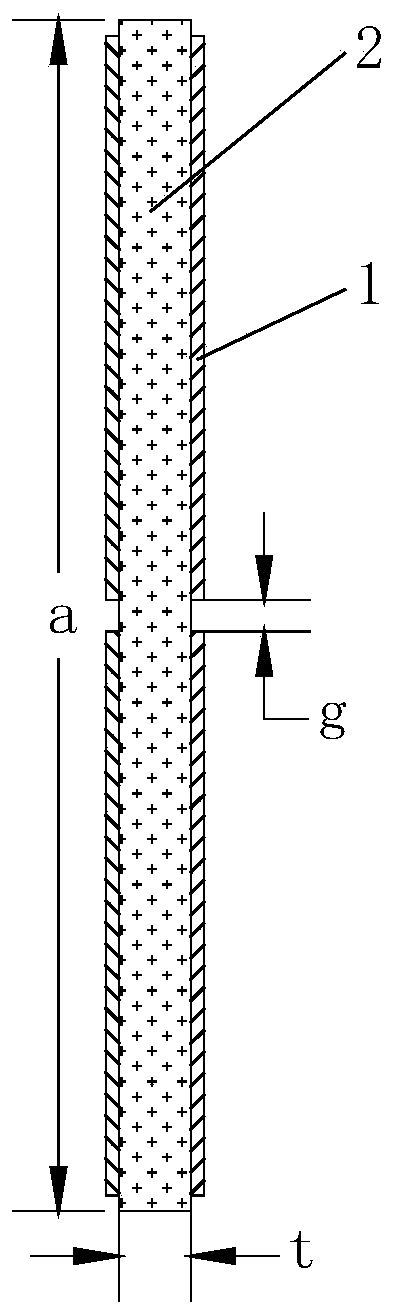

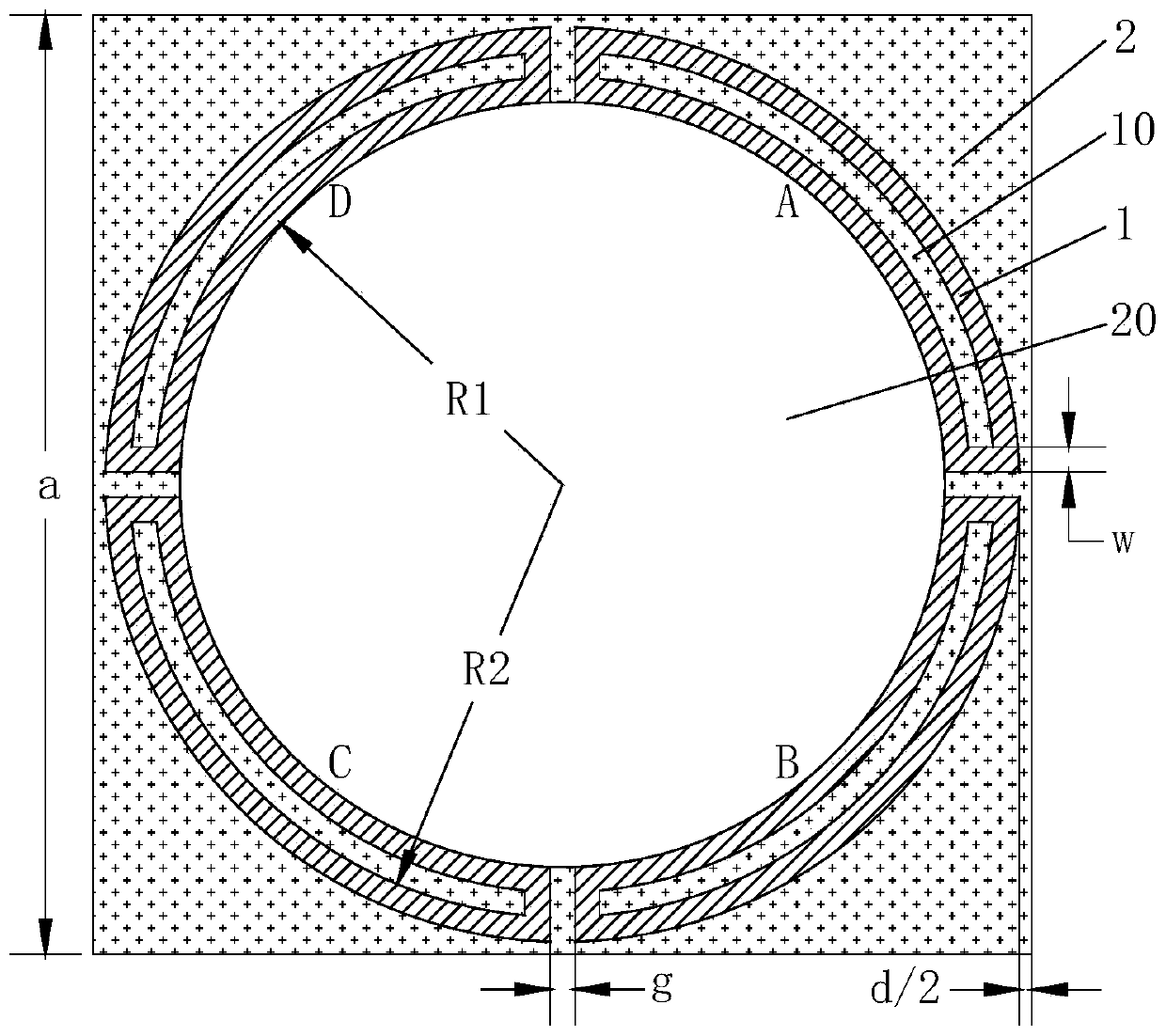

Electromagnetic shielding cover

ActiveCN110248529AImprove shielding effectImprove design flexibilitySubstation/switching arrangement detailsScreening casingsClosed loopDielectric substrate

The invention relates to an electromagnetic shielding technology. The invention discloses an electromagnetic shielding cover which comprises a dielectric substrate and conductive bands attached to the two faces of the dielectric substrate. Each conductive band is provided with a slotted structure, and through holes are formed in the dielectric substrate in the areas defined by the conductive bands. The conductive bands are divided into n sections, each section of the conductive band is provided with a closed loop, and gaps exist between the conductive bands, wherein n is an integer, and n >= 2. The beneficial effects of the invention are that the double-layer conductive bands and the slotted structure are adopted, so the electromagnetic wave shielding effect is improved, and when electromagnetic waves are emitted in different polarization modes and angles, quite high shielding efficiency can be achieved in a large bandwidth. The working frequency of the structure can be adjusted to a certain extent by segmenting the conductive bands and adjusting the size of medium holes, and the design flexibility is improved. In addition, through the medium holes, the structure is enabled to have good ventilation and heat dissipation effects. The cover is particularly suitable for shielding requirements of 5G communication related equipment, thereby facilitating improvement of equipment performance.

Owner:SICHUAN UNIV

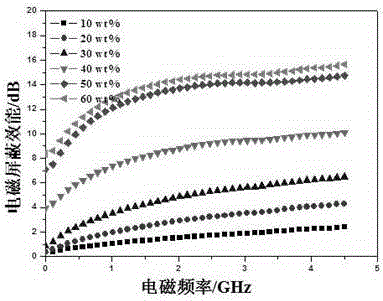

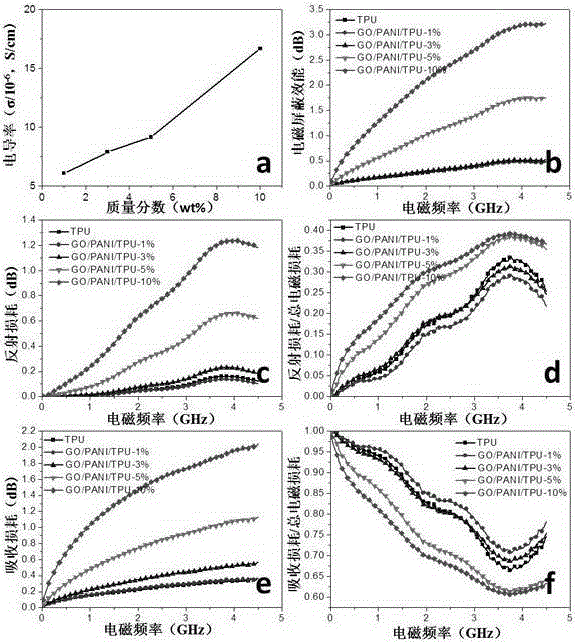

Preparation method of graphene oxide-polyaniline composite electromagnetic shielding material

InactiveCN105273186AImprove conductivityEnhanced interfacial polarizationAmmonium sulfatePolyaniline composite

The invention discloses a preparation method of a graphene oxide-polyaniline composite electromagnetic shielding material. The method comprises the steps that ultrasonic dispersion is performed on graphene oxide in an aqueous perchloric acid solution, aniline is added, and the mixture is mixed evenly under magnetic stirring to obtain a first solution; ammonium persulfate is put into the aqueous perchloric acid solution, and ultrasonic dispersion is performed to obtain a second solution; the second solution is added in the first solution, continuous stirring and reacting are performed in an ice bath for 24 h to obtain a dispersing solution of a product, the dispersing solution is sequentially washed with deionized water, ethyl alcohol and acetone until the pH value is 6-7, filtering and drying are performed, and then the graphene oxide-polyaniline composite electromagnetic shielding material is obtained. According to the preparation method of the graphene oxide-polyaniline composite electromagnetic shielding material, a layer of directional polyaniline nanorods grow on the surface of the graphene oxide, the electric conductivity of the graphene oxide is improved through the conductive property of the polyaniline, interfacial polarization of contact layer faces of the graphene oxide and polyaniline is improved, and therefore the good electromagnetic wave shielding effectiveness is achieved; the technological processes are simple, the raw materials are easy to obtain, and application and popularization are easy.

Owner:ZHEJIANG UNIV

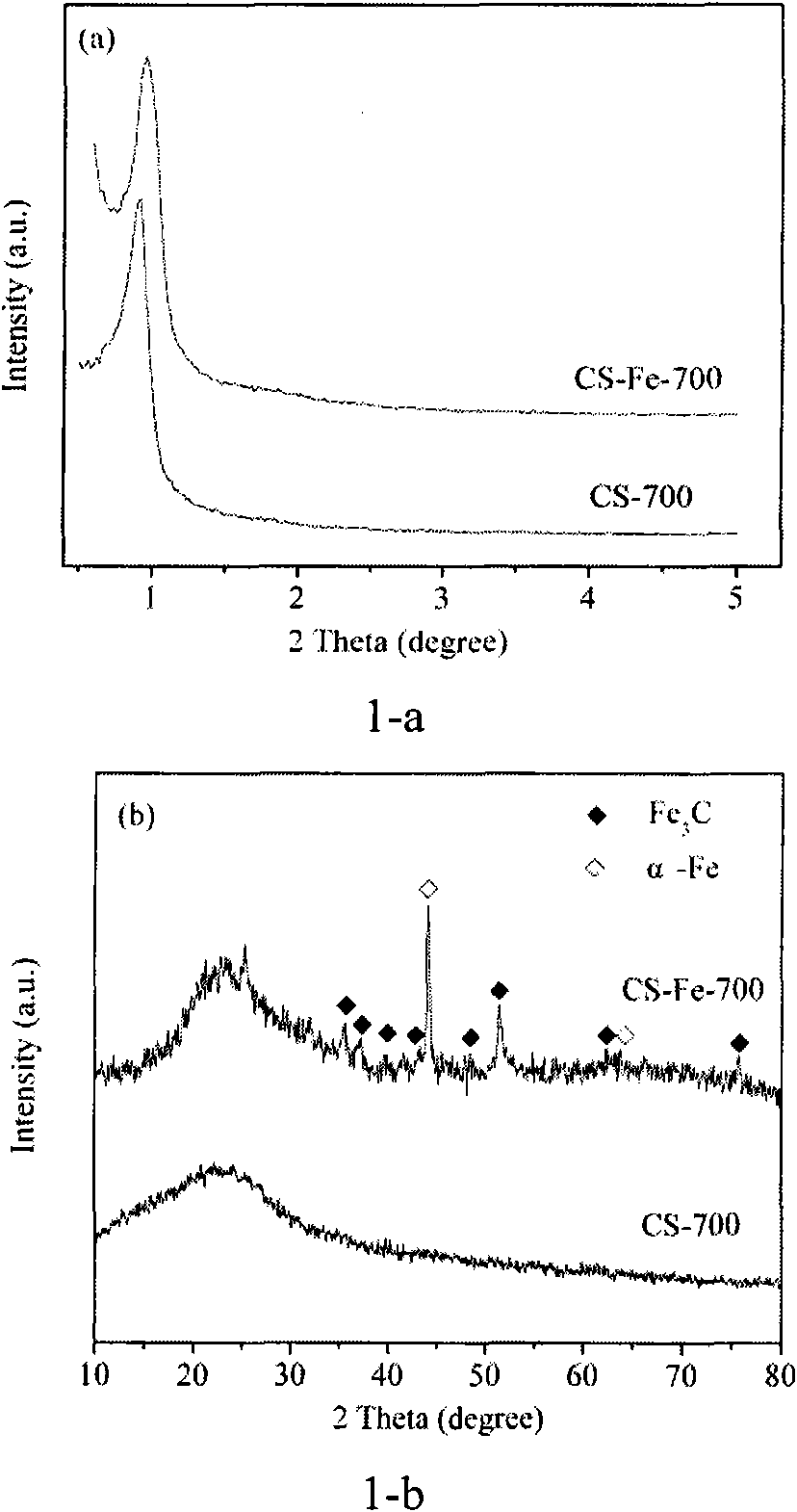

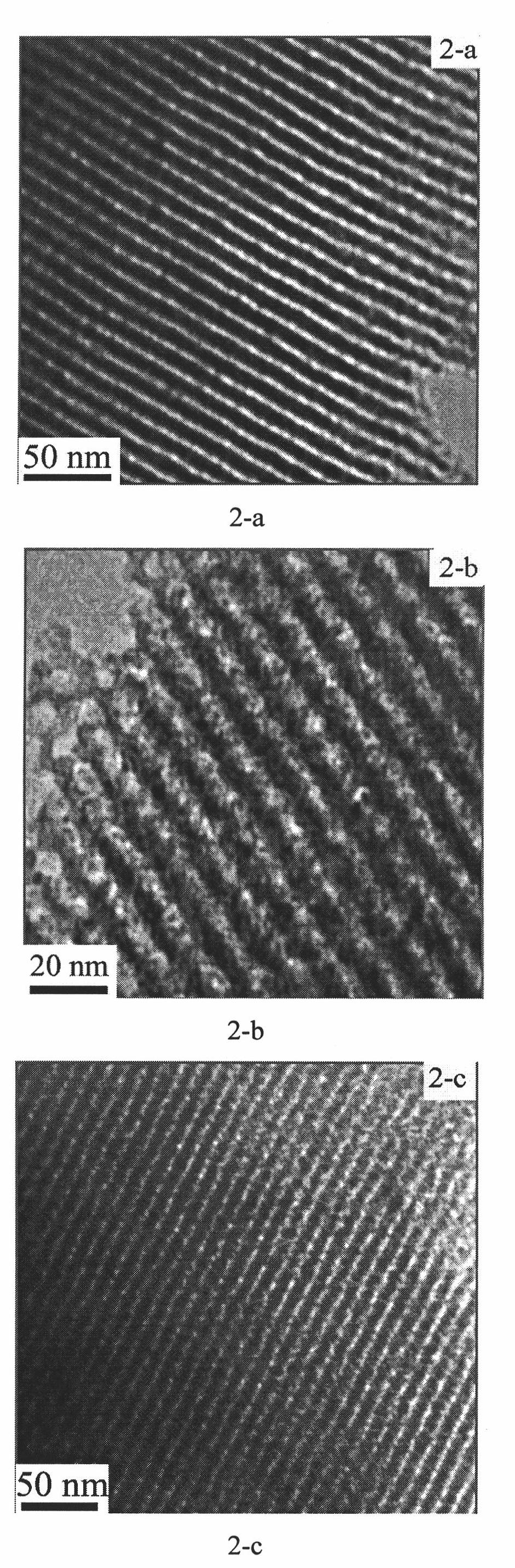

Method for preparing C-SiO2-Fe/M magnetic mesoporous composite material for electromagnetic wave adsorption coating

ActiveCN101819842AGood dispersionImprove stabilityInorganic material magnetismRadiation-absorbing paintsMetal particleSilicon oxide

The invention relates to a method for preparing a C-SiO2-Fe / M magnetic mesoporous composite material for an electromagnetic wave adsorption coating and belongs to the method for preparing the electromagnetic wave adsorption coating. In the method, magnetic metals are introduced into an ordered mesoporous carbon-silicon oxide compound by combining a solvent evaporation induced self-assembly method with in-situ carbothermic reduction technology, wherein triblock copolymer F127 serves as a structure directing agent; furfuryl alcohol serves as a carbon source; TEOS serves as a silicon source, ferric chloride and M salt serve as metal sources. Metal ions are reduced into metal particles in the carbonation process and the metal particles are highly dispersed in a carbon matrix, so that the ordered mesoporous structure of the compound does not be damaged. Therefore, in the preparation method, the operation of inducing the magnetic components and forming holes can be simultaneously completed, effective adsorption of the electromagnetic wave is ensured, the adsorption frequency range is convenient to expand, the aim of the 'thin, light, wide and strong' composite material is fulfilled, and the method can be widely applied to civilian and military and is more practical.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electromagnetic wave shielding fabric and manufacturing method thereof

InactiveCN102618994AFunctional persistenceImprove conductivityFibre treatmentWoven fabricsTextile technologyIron powder

The invention discloses an electromagnetic wave shielding fabric and a manufacturing method thereof. The fabric is characterized by being prepared by blending conductive fibers and wave absorbing fibers in a weight part ratio of 1.5:8.5-6:5 through a conventional textile technology; the conductive fibers are stainless steel fibers, silver-plated fibers, aluminum-plated fibers, copper-plated fibers, nickel-plated fibers or copper and nickel-plated fibers, the diameters of the conductive fibers are 3 to 10 microns, and the length of the conductive fibers is 36 to 50 millimeters; the wave absorbing fibers are functional fibers containing magnetic powder and metal powder, wherein the magnetic powder is iron sesquioxide, ferroferric oxide, strontium ferrite, barium ferrite, neodymium iron boron, nickel iron boron, samarium iron nitrogen or neodymium iron nitrogen; the metal powder is iron powder, nickel powder or cobalt powder; the magnetic powder and metal powder content of the functional fibers accounts for 10 to 30 percent of the total amount, and the preparation ratio of the magnetic powder to the metal powder is 1:1-3:1; and the fineness of the functional fibers is 2 to 5 dtex. The composition of the electromagnetic wave shielding fabric and the conventional textile technology are adopted in the manufacturing method.

Owner:TIANJIN POLYTECHNIC UNIV

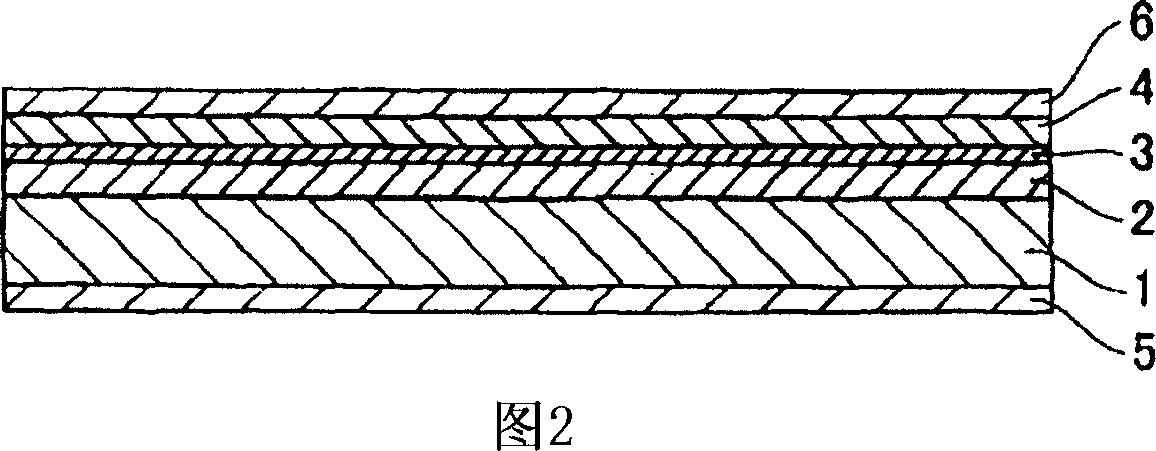

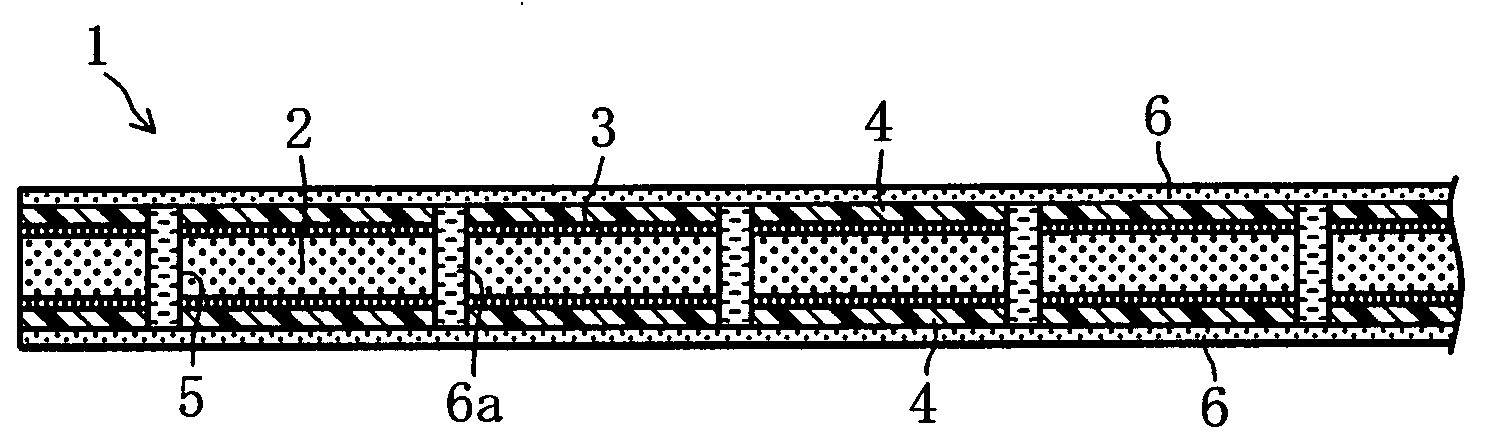

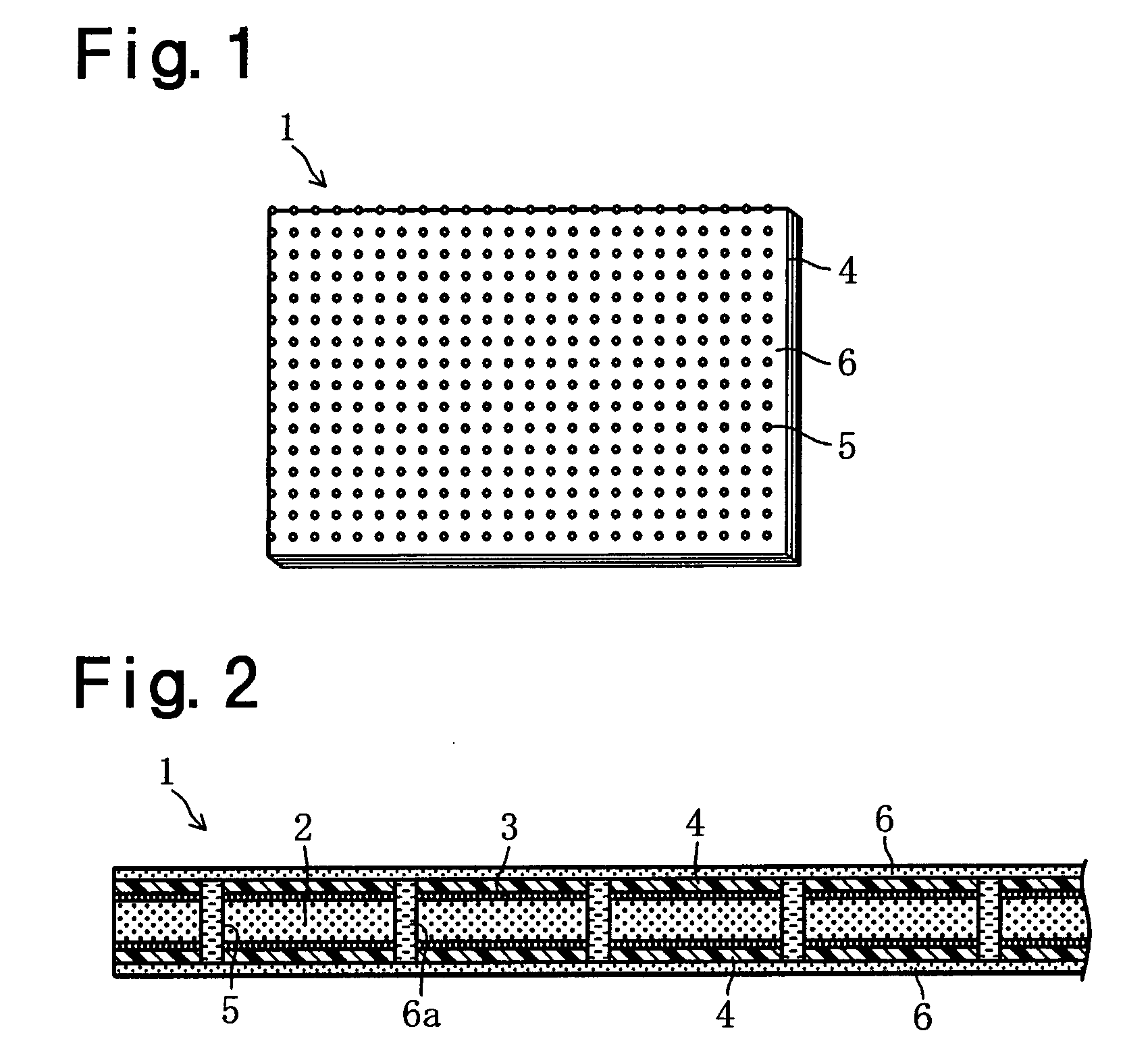

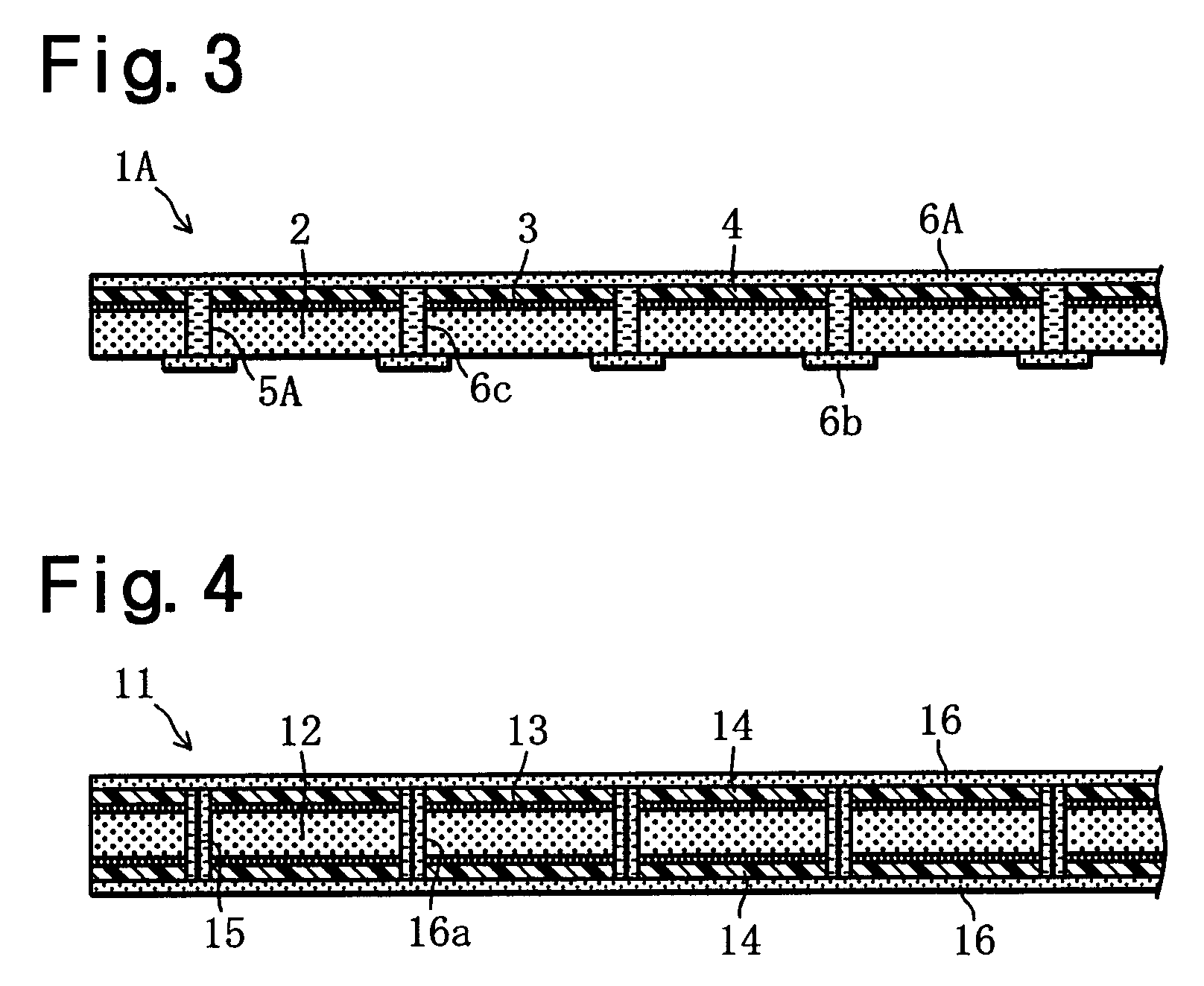

Electromagnetic wave shield gasket and its manufacturing method

InactiveUS20050173145A1Maintain good propertiesNot impairing resiliencyConductive layers on insulating-supportsScreening gaskets/sealsConductive coatingEngineering

Synthetic resin films 4, 4 are bonded to a thin foam sheet 2 on both sides. Numerous through-holes 5 are formed in the laminated sheet from the front to back side. A conductive coating material is applied to the surfaces of the films 4, 4 and fill the numerous through-holes 5 to form conductive layers 6, 6 on the surfaces of the films 4, 4 and numerous conductive passages 6a in the numerous through-holes 5 connected to conductive layers 6, 6. In another structure, a film and a conductive layer are formed on one side of the foam sheet, numerous conductive coating segments are formed near the openings of numerous through-holes on the back, and the conductive layer and numerous conductive coating segments are connected via numerous conductive passages.

Owner:ZIPPERTUBING (JAPAN) LTD

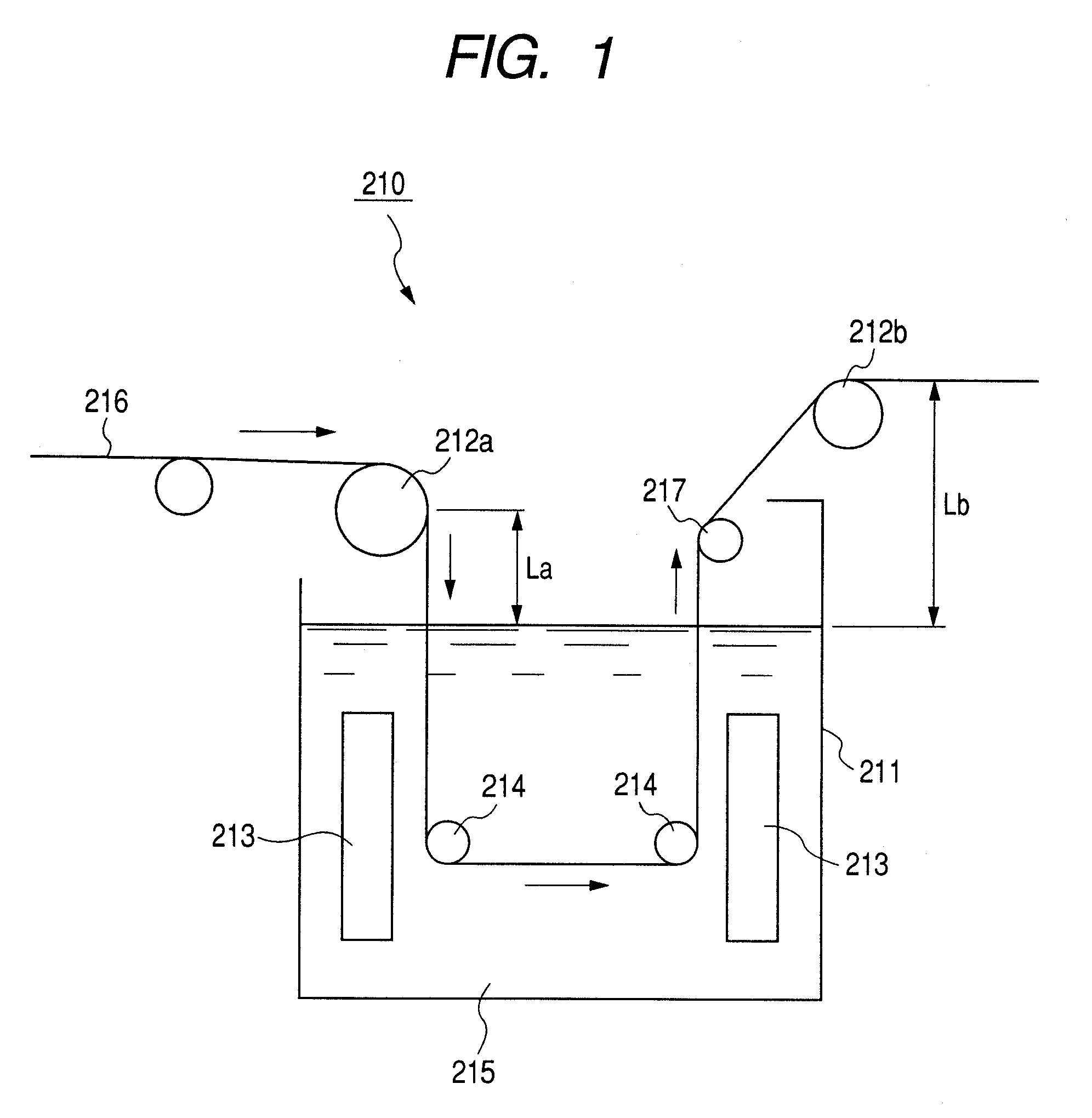

Flat-panel display member and its manufacturing method and flat-panel display and its manufacturing method

InactiveUS20090190078A1Increase production capacityExcellent electromagnetic wave shielding performanceTube/lamp screens manufactureMagnetic/electric field screeningFlat panel displayElectrically conductive

Owner:TORAY ADVANCED FILM CO LTD

Photosensitive material, method of manufacturing conductive metal film, conductive metal film and light-transmitting film shielding electromagnetic wave for plasma display panel

InactiveUS7829270B2Excellent electromagnetic wave shielding performanceEasy to PlatingMulticolor photographic processingSemiconductor/solid-state device manufacturingEmulsionSilver salts

Owner:FUJIFILM CORP

Conductive cushion material and process for producing the same

InactiveUS20060110998A1Excellent electromagnetic wave shielding performanceGood cushioningShielding materialsSynthetic resin layered productsFiberEngineering

A conductive cushion material that can effectively shield electromagnetic wave leaking from a housing of an information device such as a cellular phone and also has a cushioning function to protect electronics parts comparatively fragile to impact, as well as a method for manufacturing the same, where manufacturing processes are simple and easy, are provided. More specifically, a conductive cushion material comprising a fiber aggregate (A) composed of conductive fine wires and an elastic resin (B) containing a conductive filler (C), characterized in that at least a part of edges of the fiber aggregate (A) is exposed out of the external surface of the cushion material, while the rest of the edges are embedded in the cushion material, and that the elastic resin (B) has many cavities therein, while uniformly mixed with the conductive filler (C), and a method for manufacturing the same are provided.

Owner:NISSHINBO IND INC

Process for preparing light transmissive electromagnetic wave shielding material, light transmissive electromagnetic wave shielding material and display filter

InactiveUS7931518B2High dimensional accuracyImprove adhesionMagnetic/electric field screeningVacuum evaporation coatingDisplay devicePre treatment

Owner:BRIDGESTONE CORP

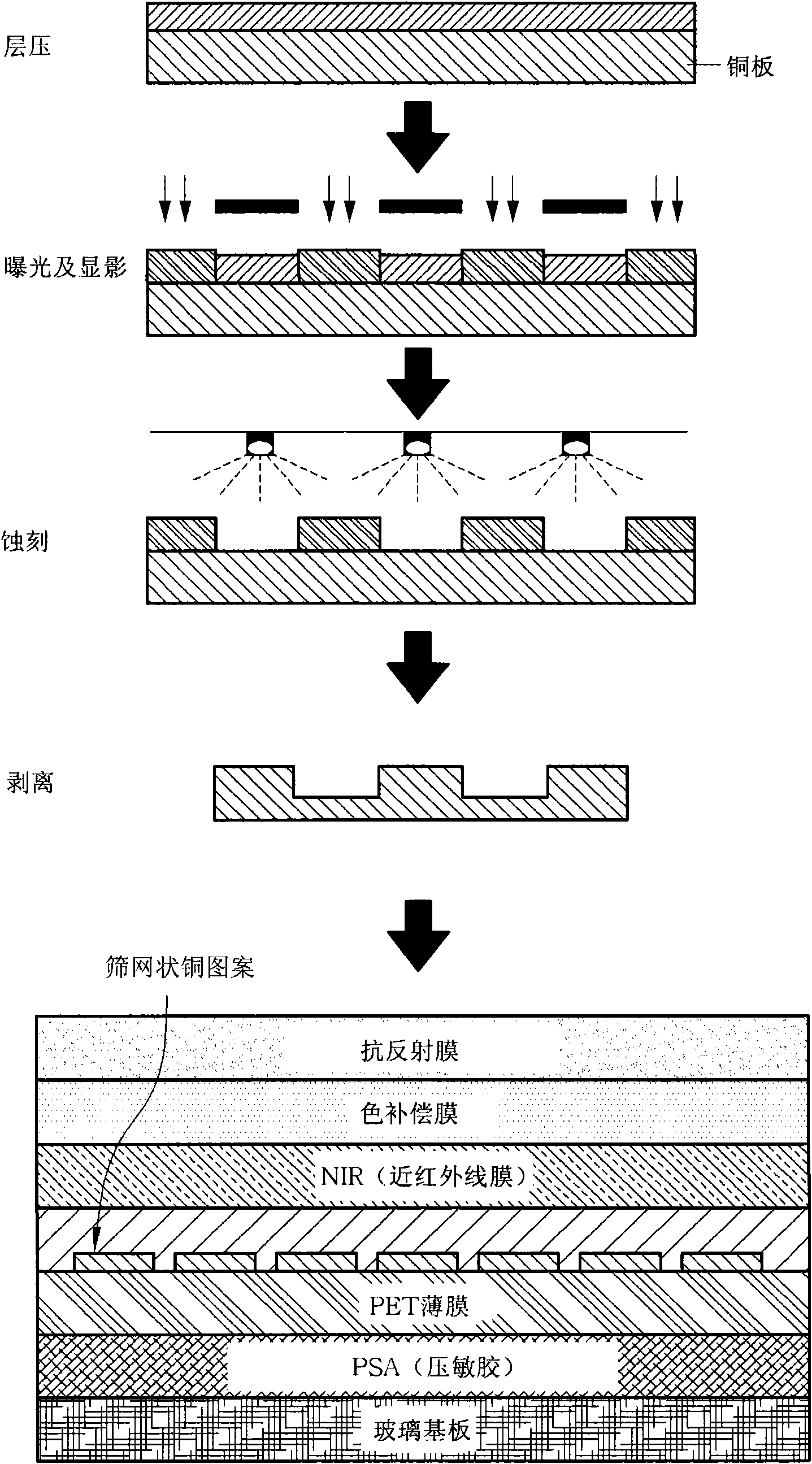

Electromagnetic wave preventing filter, manufacturing method thereof and display comprising the filter

InactiveCN101600332AReduce reflectionReduce the problem of poor moisture resistanceMagnetic/electric field screeningScreening apparatusElectromagnetic electron waveDisplay device

The present invention relates to an electromagnetic wave preventing filter and a display with the same. The electromagnetic wave preventing filter comprises the following components: a transparent strengthened glass substrate which has a tin surface with more tin abundance and has an air surface with less tin abundance compared with the tin surface; and an electromagnetic wave shielding part which is formed on the tin surface of the transparent strengthened substrate with a screen mesh shape. The filter is used for shielding the electromagnetic wave in a plasma display panel. Furthermore the external light reflection can be reduced and the blackness can be increased according to appropriate yellowing phenomenon of the conductive metal in the tin surface and the electromagnetic shielding part. Additionally the wet fastness problem can be reduced furthest even the printing layer in the final product is exposed in the external gas environment.

Owner:DONGJIN SEMICHEM CO LTD

Applying fluid for forming transparent coating film and base material with transparent coating film, and display device

ActiveUS20060234087A1Poor adhesionExcellent in hardnessCoatingsNatural mineral layered productsDisplay deviceSolvent

A transparent film-forming coating liquid is provided which is capable of forming a transparent film that is excellent not only in scratch resistance, film hardness, scratch strength and adhesion to a substrate but also in haze and anti-glare properties. Also provided is a display device having a front panel constituted of a substrate with such a transparent film applied thereto. The transparent film-forming coating liquid comprises inorganic oxide particle groups, in each of which 2 to 10 inorganic oxide particles on an average are linked in the form of a chain, and a polar solvent. In the transparent film-forming coating liquid, the inorganic oxide particles have an average particle diameter of 4 to 200 nm. The inorganic oxide particles are silica particles, and the silica particles are porous particles and / or hollow particles each having a cavity inside.

Owner:JGC CATALYSTS & CHEM LTD

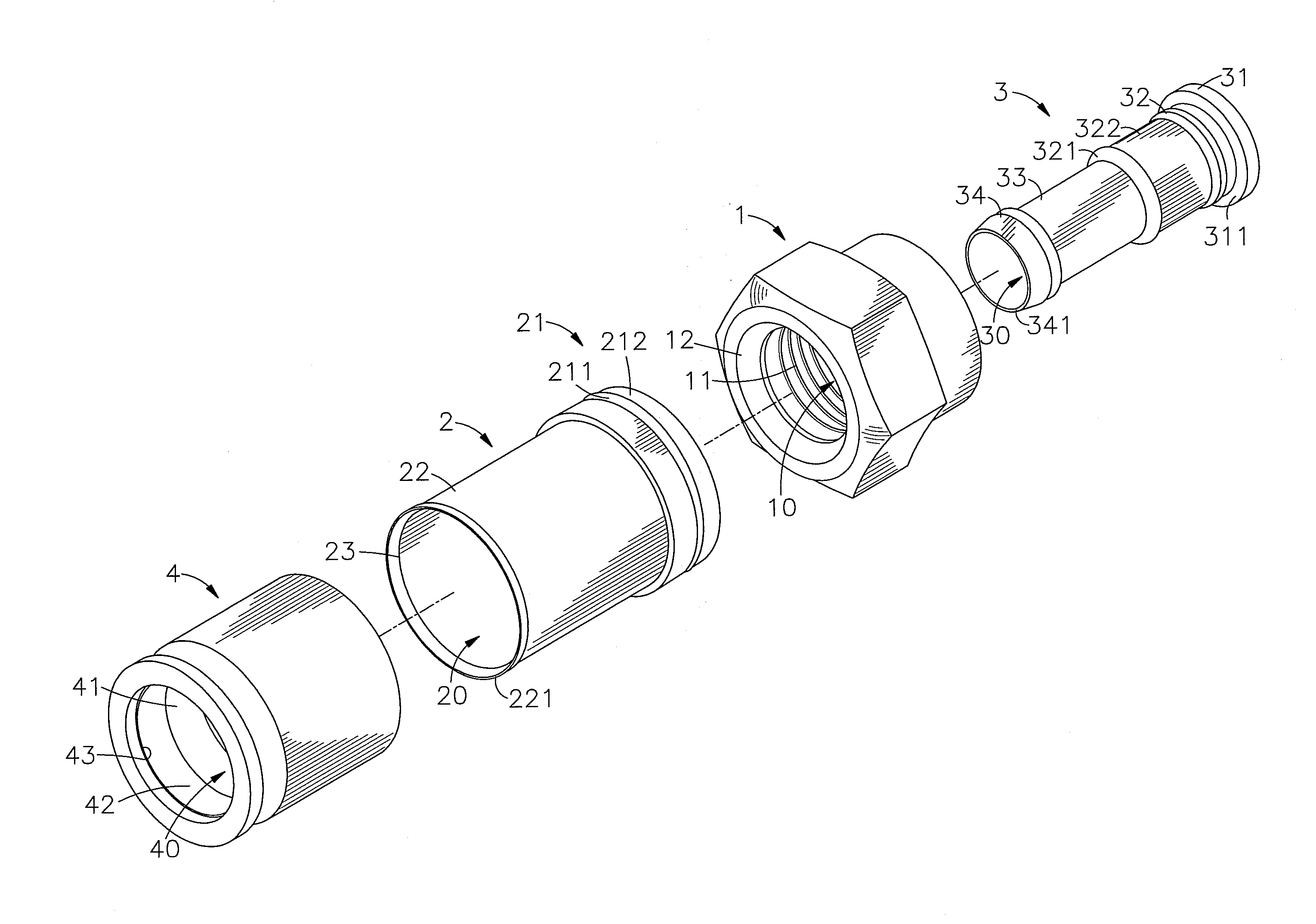

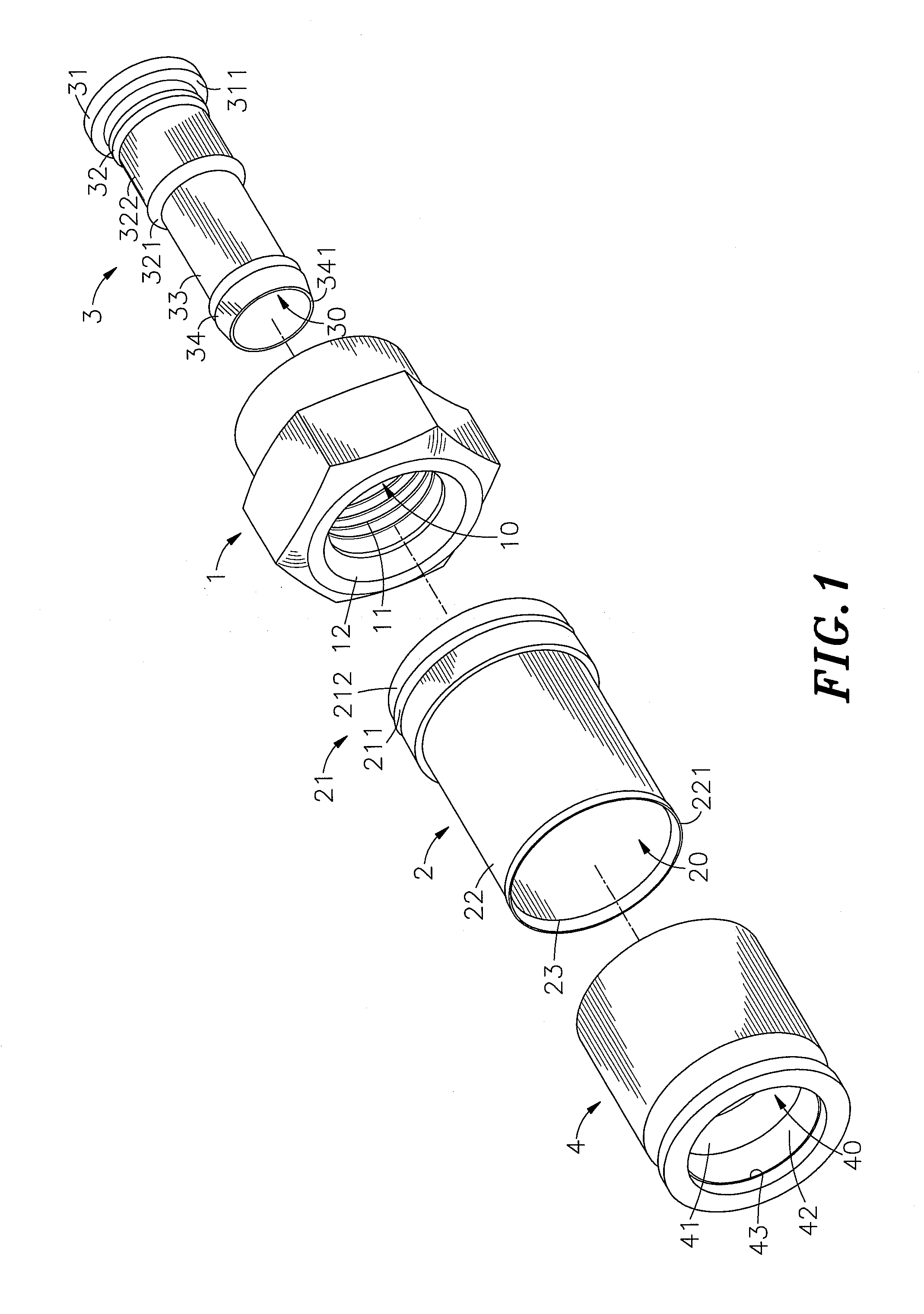

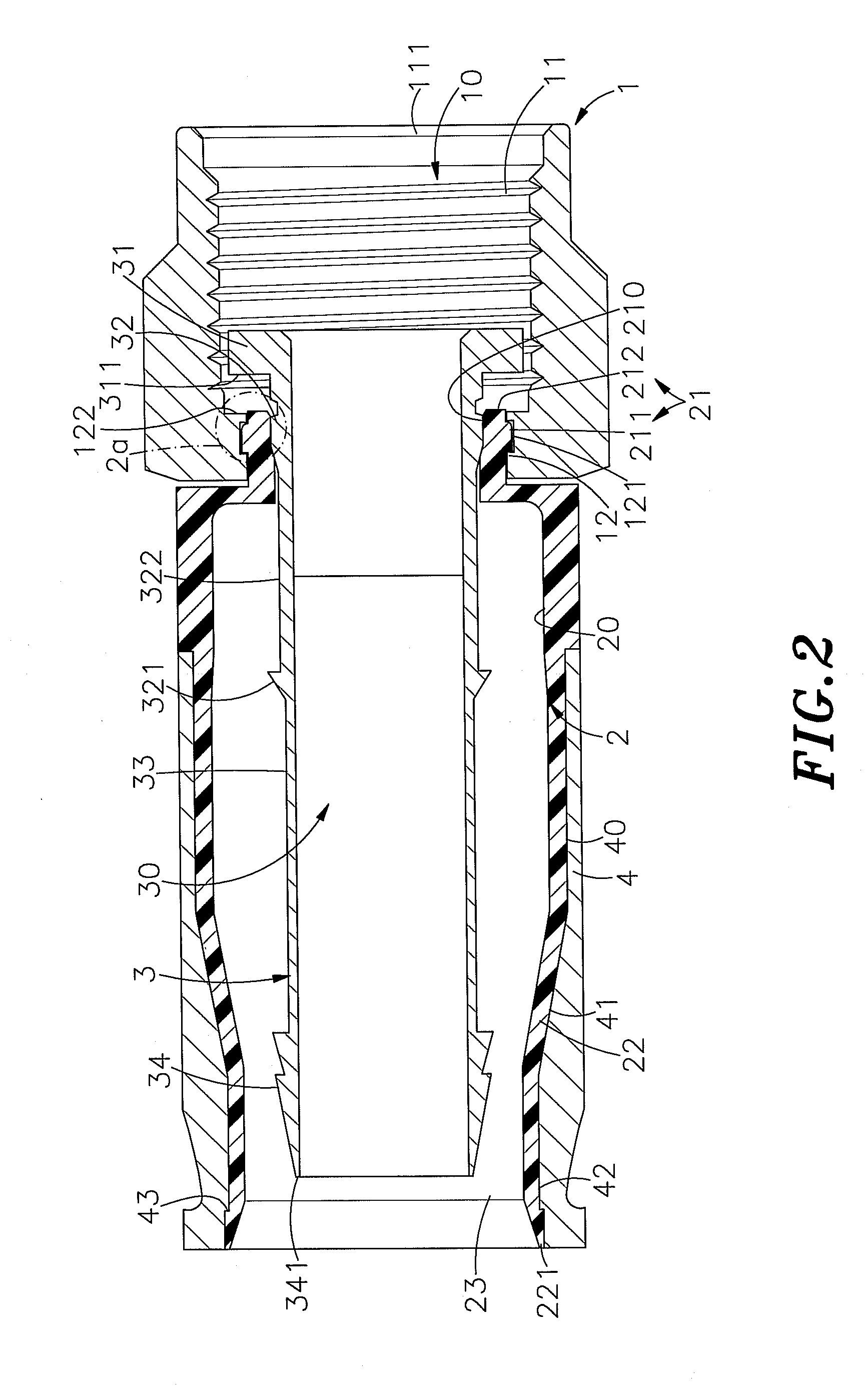

Cable-end connector

InactiveUS20110263153A1Avoid electromagnetic interferenceEffectively seals off outside moistureElectrically conductive connectionsCoupling device detailsFlangeLocknut

A cable-end connector includes a metal locknut having an axially extending center through hole, a rear orifice and a retaining structure, the retaining structure of the locknut defining a retaining groove and a stop edge, an elastically deformable cylindrical casing having an axial hole and a retaining structure for engagement with the retaining structure of the locknut and defining with the retaining structure of the locknut a clearance, the retaining structure of the cylindrical casing having a retaining flange for engaging the retaining groove of the retaining structure of the locknut, and a metal core tube mounted in the locknut and the cylindrical casing and having a rear stop flange for stopping against the stop edge of the locknut to block the clearance and to force the retaining flange of the retaining structure of the cylindrical casing into engagement with the retaining groove of the retaining structure of the locknut tightly, thereby sealing off outside moisture and enhancing the electromagnetic wave shielding effect.

Owner:LU YUEH CHIUNG

Polymer nanocomposite containing glass fiber coated with metal-carbon nanotube and graphite and method of preparing the same

InactiveUS20130200296A1Maximizing shielding performanceExcellent electromagnetic wave shielding performanceMaterial nanotechnologyLamination ancillary operationsGlass fiberCarbon nanotube

The present disclosure relates to a polymer nanocomposite including a metal-carbon nanotube coated glass fiber and graphite, in which a metal-carbon nanotube coated glass fiber serving as an electromagnetic wave shielding material is hybridized with graphite having an excellent heat conductivity, thereby improving the electromagnetic wave shielding performance in a low frequency range. The polymer nancomposite according to the disclosure is broadly applicable to a variety of fields requiring electromagnetic wave shielding performance such as, for example, various electronic component housings for a vehicle, components of an electric vehicle, a mobile phone, and a display device, and a method of preparing the polymer nanocomposite.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com