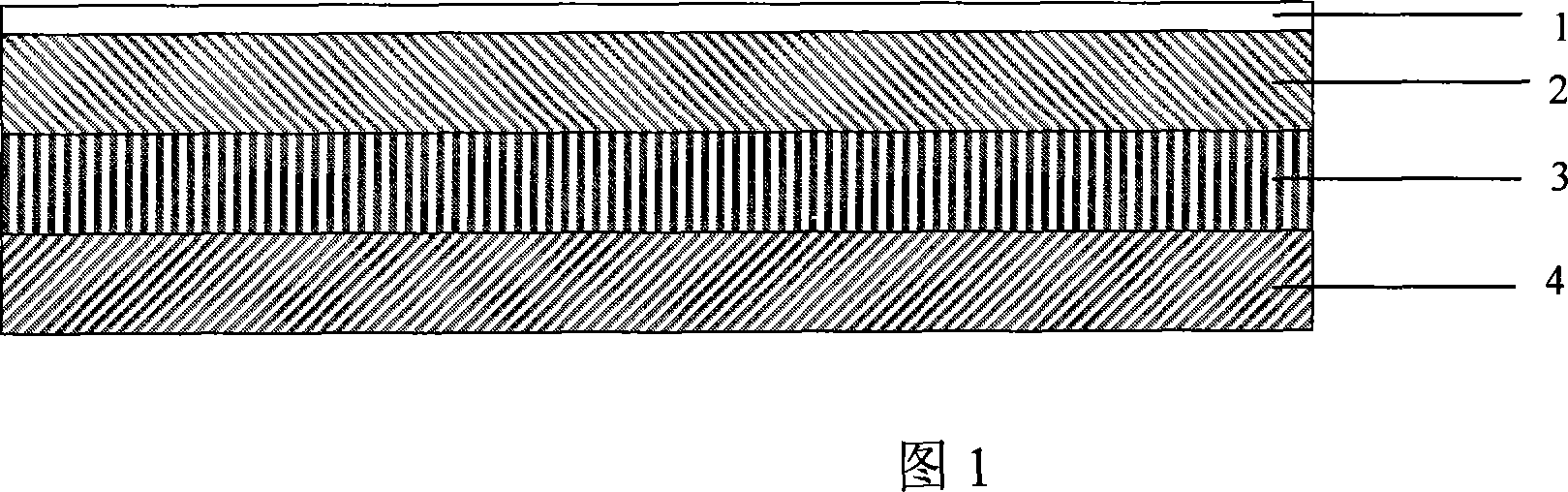

Flame-resisting anti-static polythene compound film for shielding wide band electromagnetic wave and its preparing method

A technology of flame-retardant polyethylene and polyethylene film, applied in the direction of static electricity, magnetic field/electric field shielding, electrical components, etc., can solve the problems of inability to shield electromagnetic waves, etc., achieve good flame-retardant effect, good processing dispersion, and broaden the shielding range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0065] Pellet preparation of flame retardant polyethylene film:

[0066] Take PNPIC and nano-layered kaolin and dry them in a blast drying oven for 2 hours at a temperature of 95°C. Add the dried flame retardant system and polyethylene resin to a high-speed mixer for preliminary mixing. Get diluted titanate coupling agent NDZ-101 (the addition of coupling agent NDZ-101 is 1.25 parts based on polyethylene resin as 100 parts by weight, and liquid paraffin of the same weight is added in the coupling agent to dilute the coupling agent. Joint agent) into the high-speed mixer, at 1200 rpm, 70 ° C under high-speed mixing for 10 minutes. The mixed pellets are added to the main feeding port of the twin-screw extruder, and the feeding speed is respectively: the screw rotation speed of the twin-screw extruder is 1000r / min, and the feeding speed of the main feeding port is 400r / min. Among them, the temperature of zone 1 to zone 7 on the extruder is 150°C, 155°C, 160°C, 170°C, 170°C, 170°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com