Nano low-frequency electromagnetic shielding coating and preparation method thereof

An electromagnetic shielding coating and nanotechnology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of incompatibility with high-efficiency industrial coating, low shielding efficiency, complex processing technology, etc., and achieve low-frequency electromagnetic shielding range. Wide, fast drying, good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

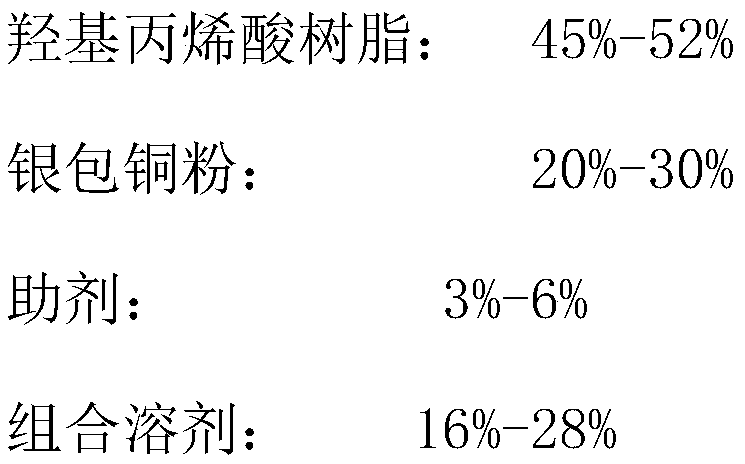

Method used

Image

Examples

Embodiment 1-3

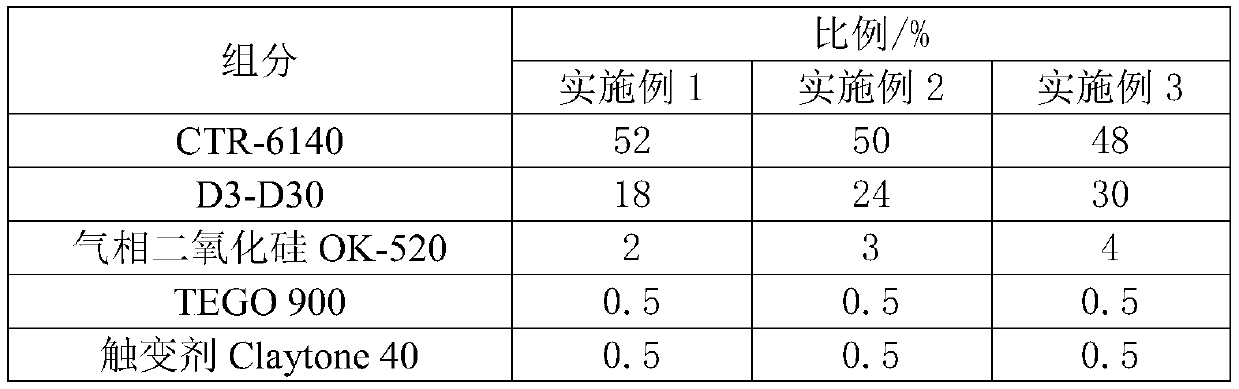

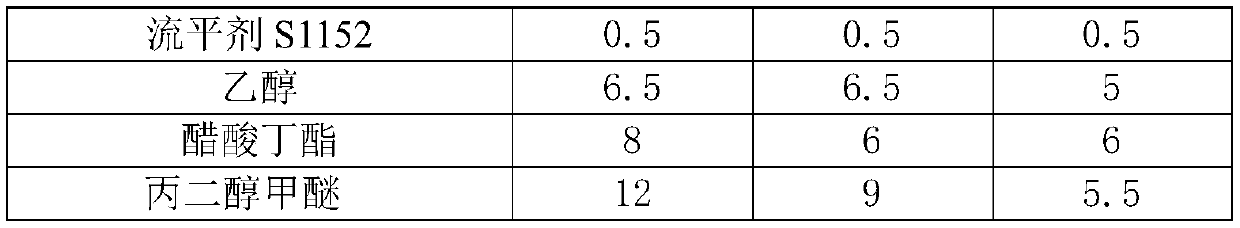

[0023] Adopt the components and proportions shown in Table 1 respectively

[0024] The preparation methods are as follows: add the raw materials of the three formula ratios in Table 1 into three tanks according to the resin-solvent-powder process, mix evenly in a high-speed mixer, and add volatile ethanol solvent to adjust the viscosity to reach Tu 4# cup 180- After 240 seconds, the mixture is mixed and sampled for inspection, and if it is qualified, it can be filtered and packaged with a 150-mesh filter.

[0025] Spraying environment: temperature: 5-30°C, relative humidity: 30-75%.

[0026] Wet film thickness: 30~60μm.

[0027] Spray viscosity: 4# viscosity cup: 20-26 seconds.

[0028] Spraying times: once.

[0029] Maintenance environment: temperature 20±5℃, relative humidity: 50±5%, maintenance time 7 days.

[0030] The first component of the coating of table 1. embodiment 1-3 and ratio table thereof

[0031]

[0032]

Embodiment 4

[0034] The component A product obtained in Example 1-3 is proportioned with the component B product in Table 2 respectively. Components A and B were mixed evenly and placed for 10 minutes, and coated on a 1.5mm thick ABS engineering plastic plate with a coating thickness of 45μm. The indicators were tested respectively, and the results are shown in Table 3:

[0035] Table 2. Embodiment 1-3 A and B component ratio table

[0036] project Example 1 Example 2 Example 3 A:B ratio 100::8.48 100::8.15 100:7.8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com