Patents

Literature

489results about How to "Accurate thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

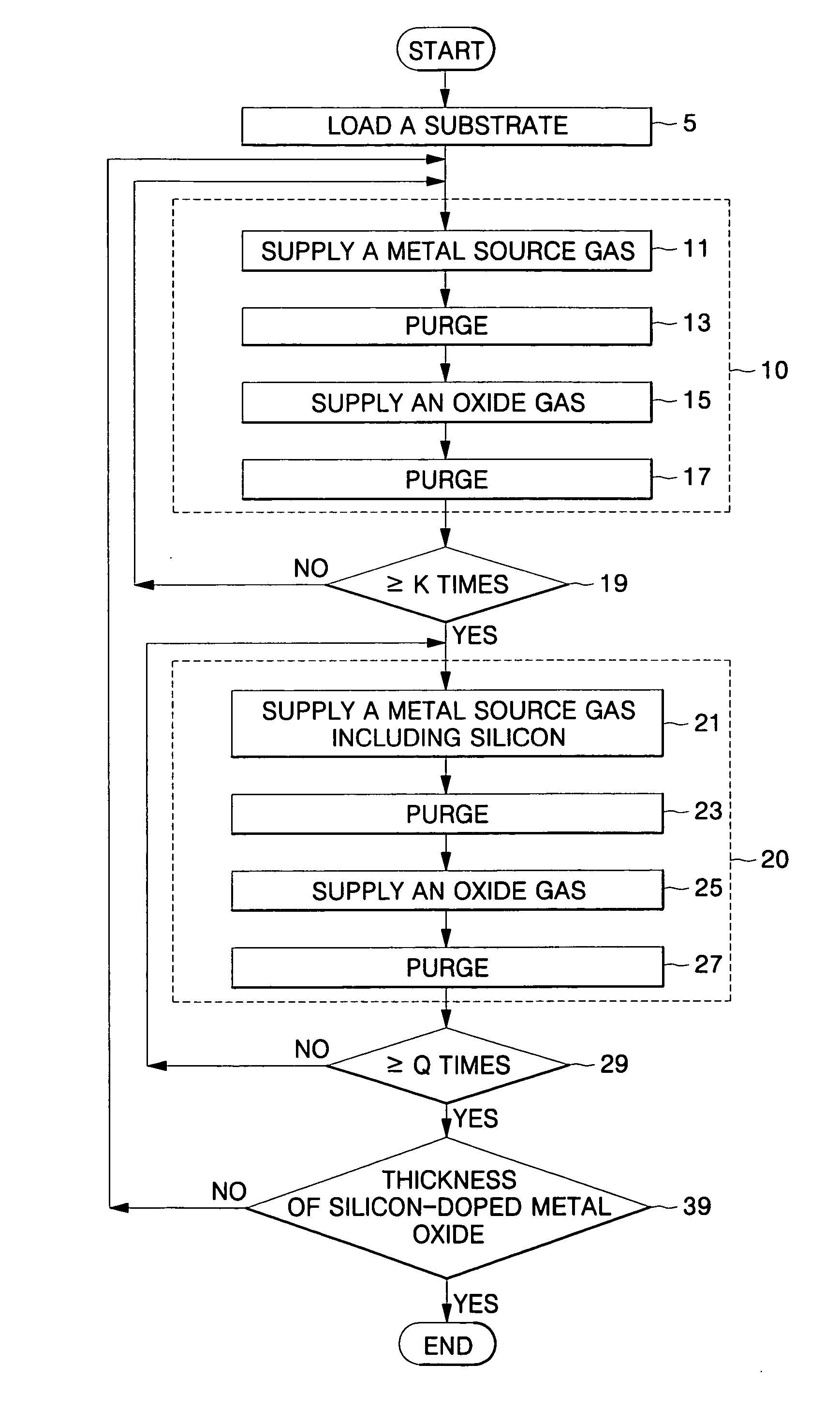

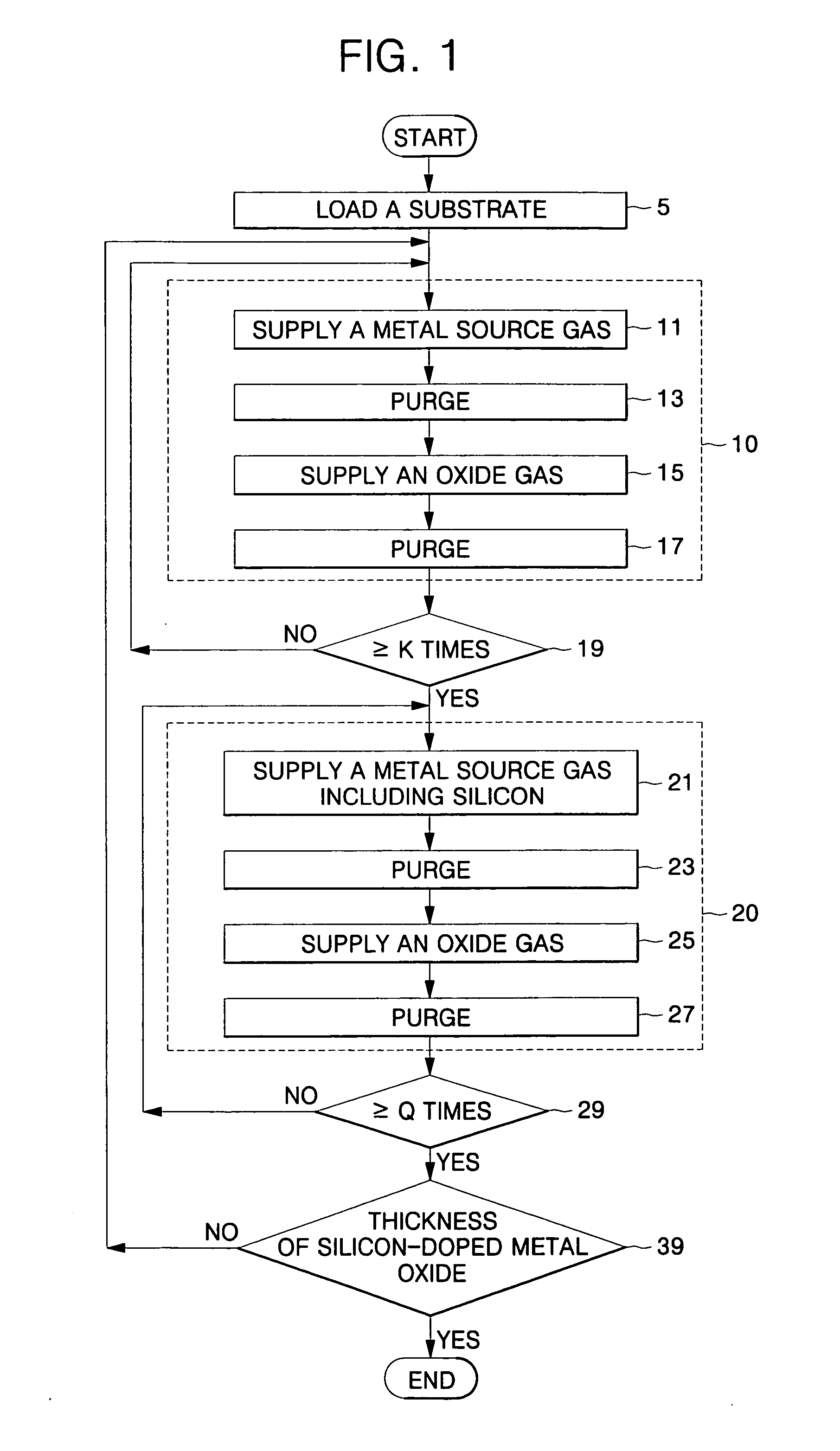

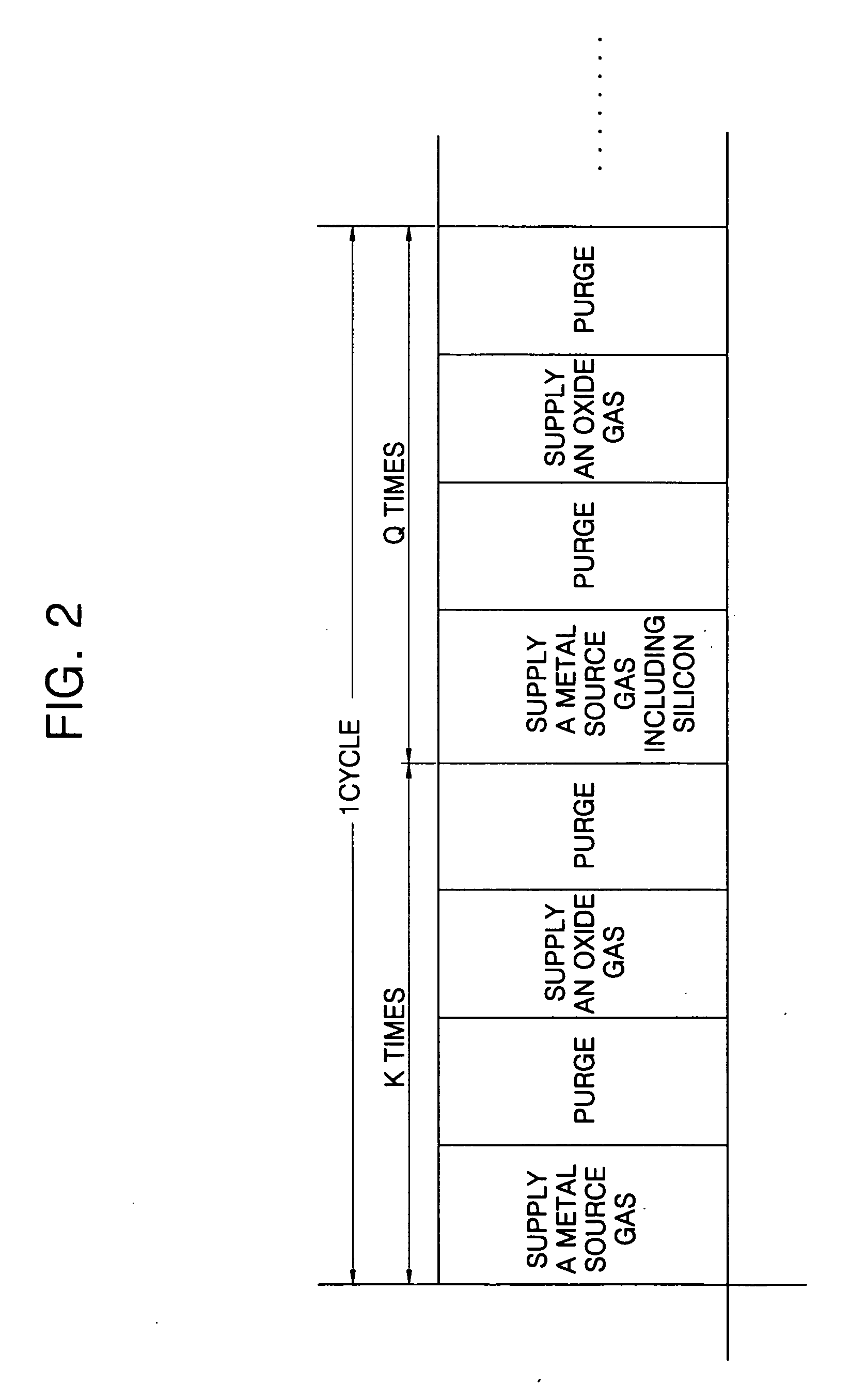

Method of fabricating silicon-doped metal oxide layer using atomic layer deposition technique

InactiveUS20060257563A1Uniform thicknessAccurate thicknessChemical vapor deposition coatingHafnium oxideOxide

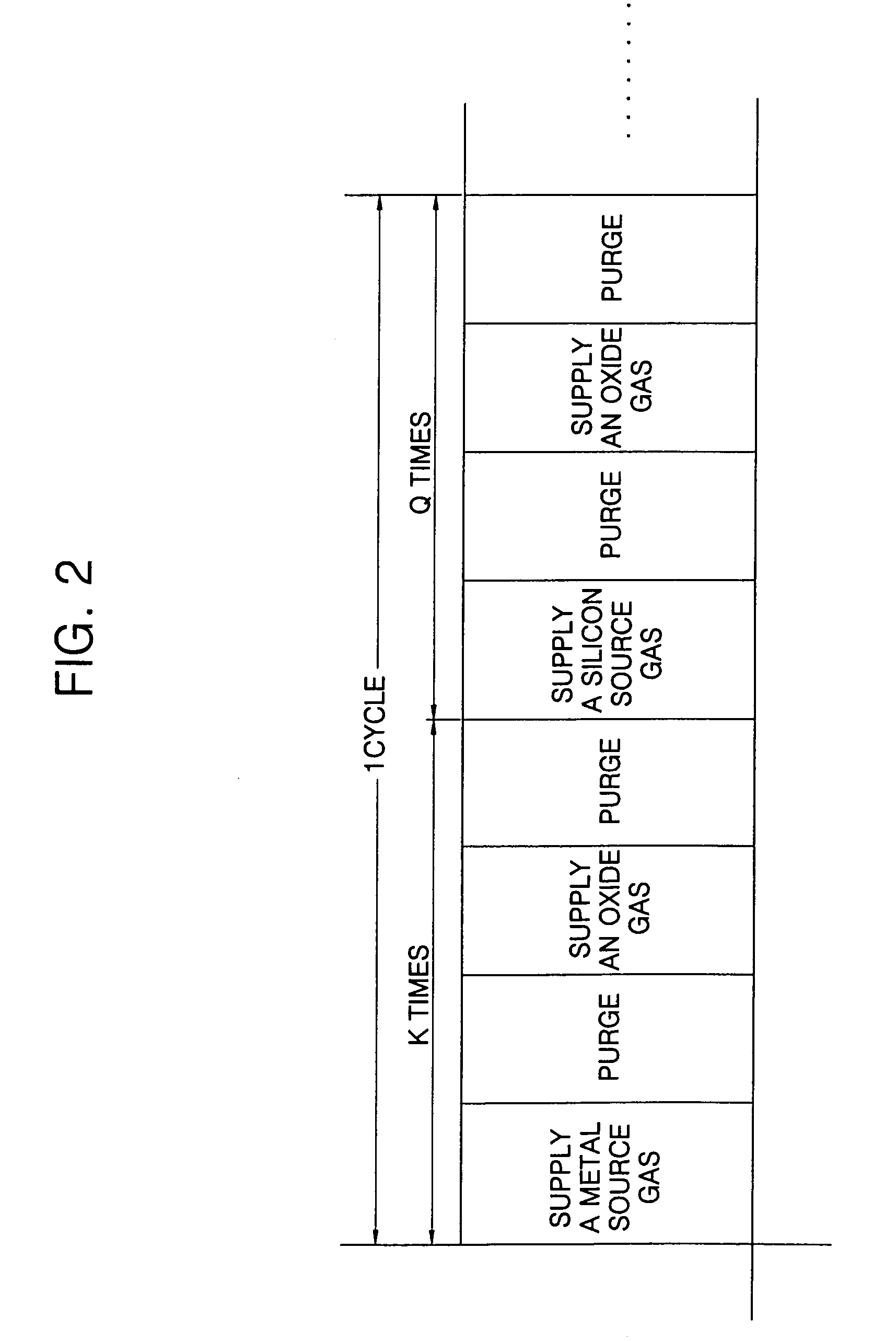

There are provided methods of fabricating a silicon-doped metal oxide layer on a semiconductor substrate using an atomic layer deposition technique. The methods include an operation of repeatedly performing a metal oxide layer formation cycle K times and an operation of repeatedly performing a silicon-doped metal oxide layer formation cycle Q times. At least one of the values K and Q is an integer of 2 or more. K and Q are integers ranging from 1 to about 10 respectively. The metal oxide layer formation cycle includes the steps of supplying a metal source gas to a reactor containing the substrate, and then injecting an oxide gas into the reactor. The silicon-doped metal oxide layer formation cycle includes supplying a metal source gas including silicon into a reactor containing the substrate, and then injecting an oxide gas into the reactor. The sequence of operations of repeatedly performing the metal oxide layer formation cycle K times, followed by repeatedly performing the silicon-doped metal oxide layer formation cycle Q times, is performed one or more times until a silicon-doped metal oxide layer with a desired thickness is formed on the substrate. In addition, a method of fabricating a silicon-doped hafnium oxide (Si-doped HfO2) layer according to a similar invention method is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

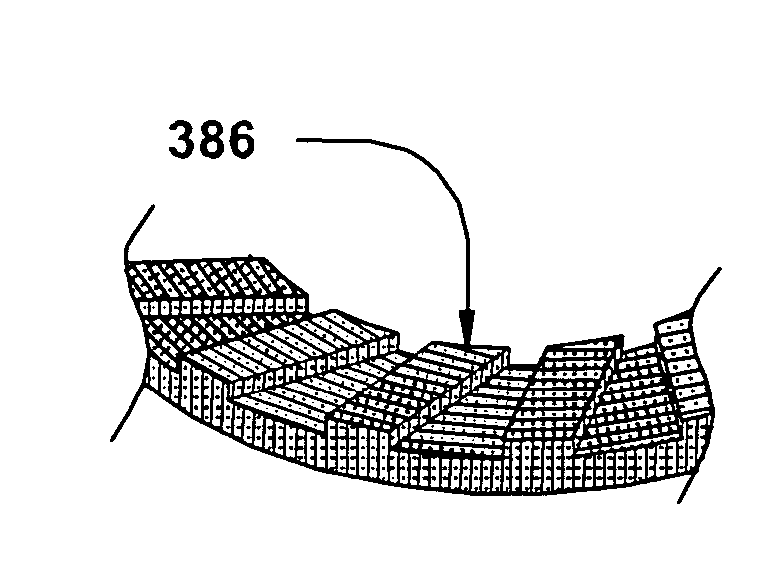

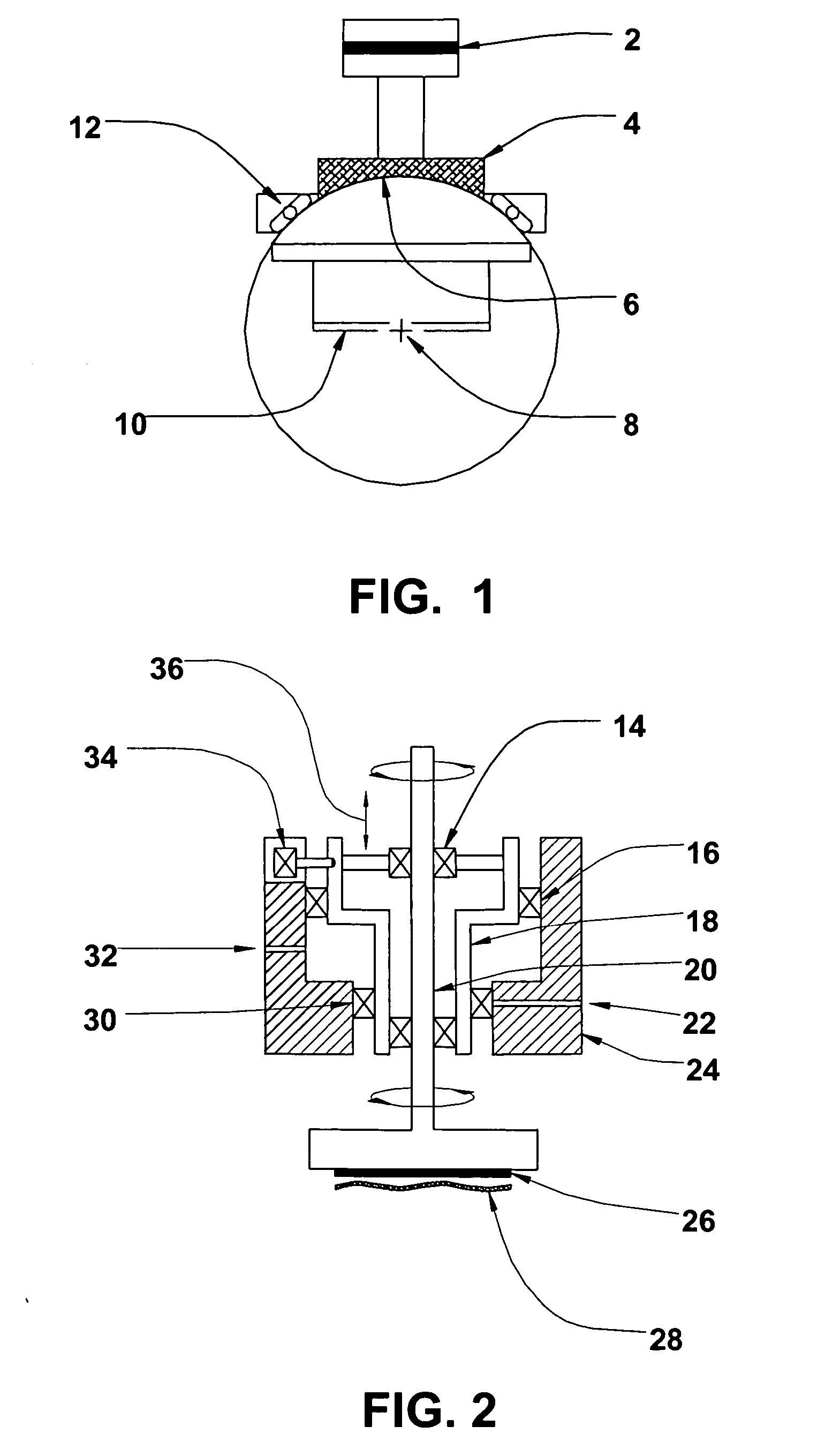

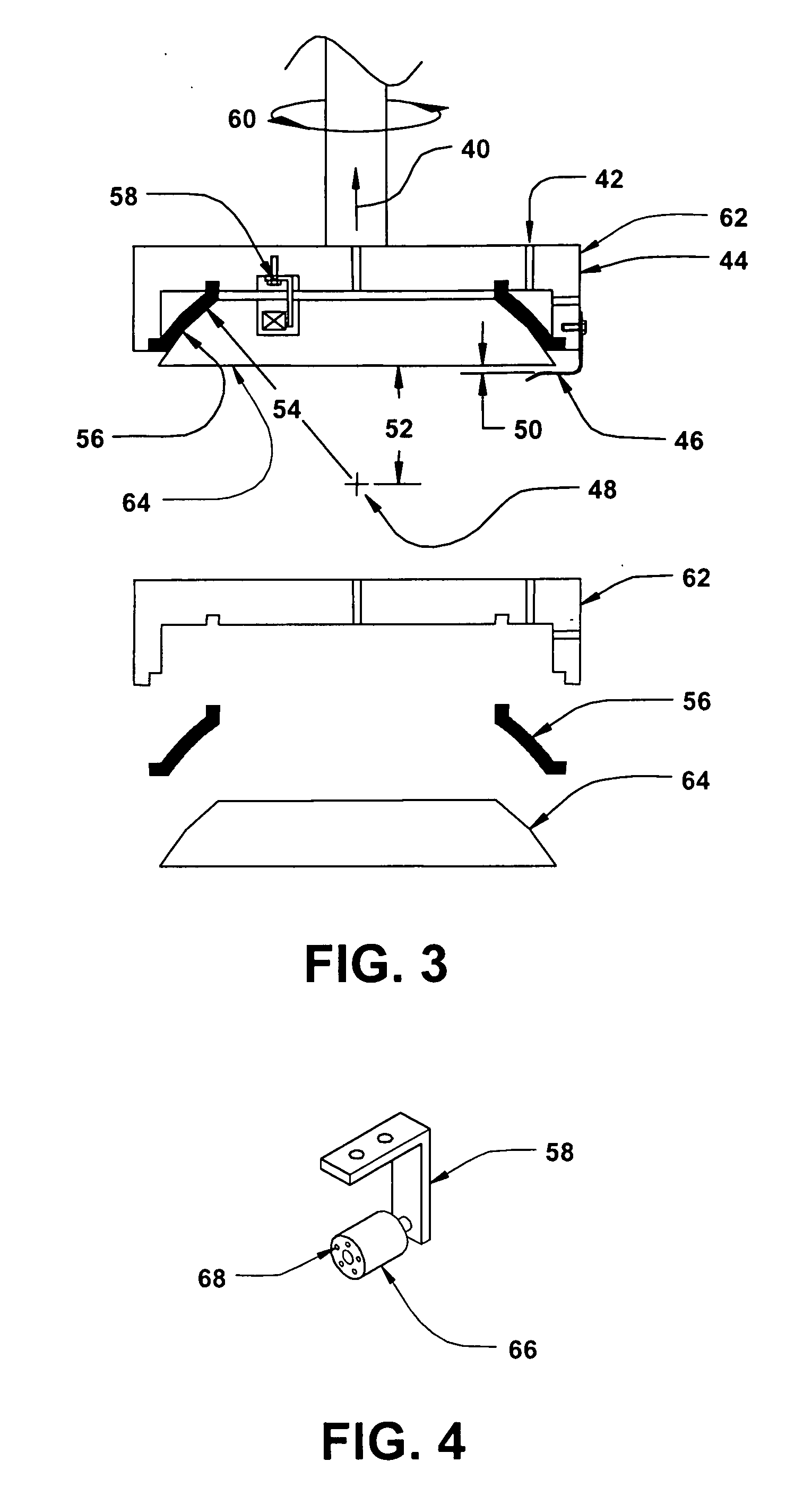

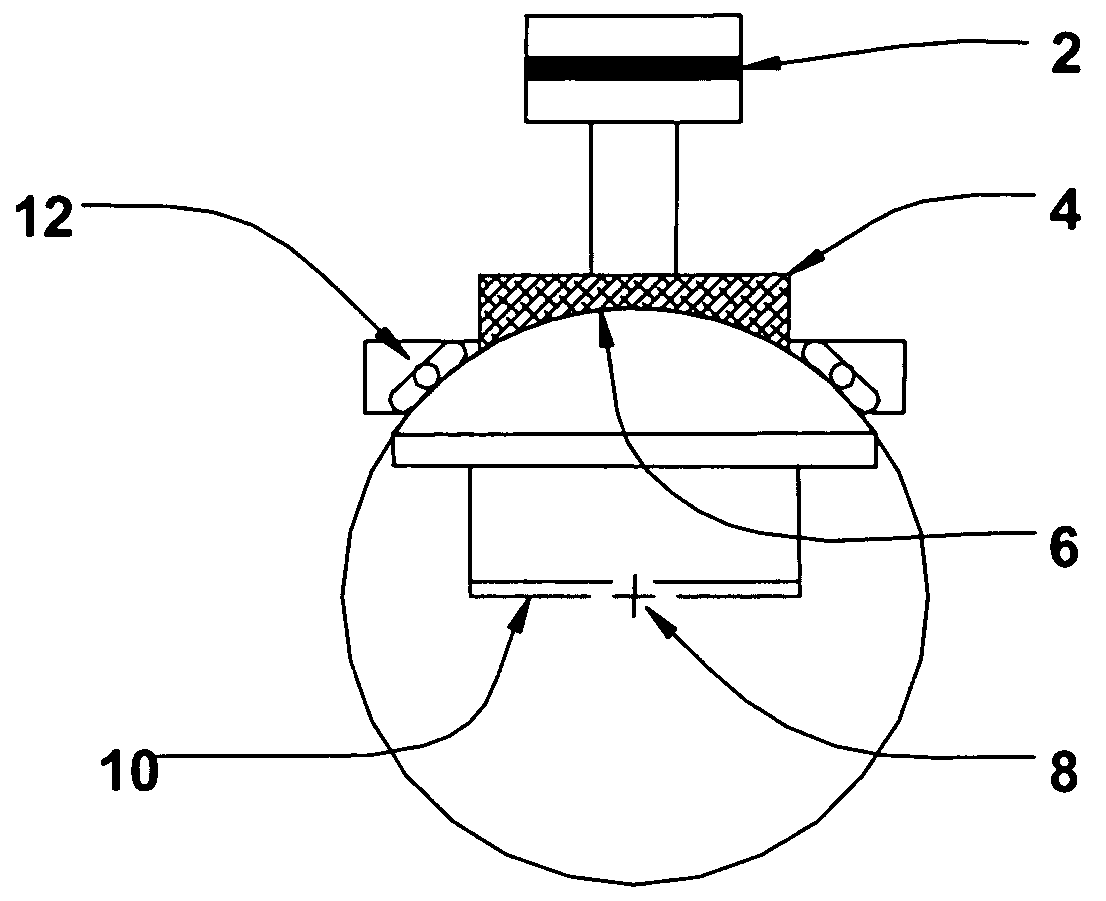

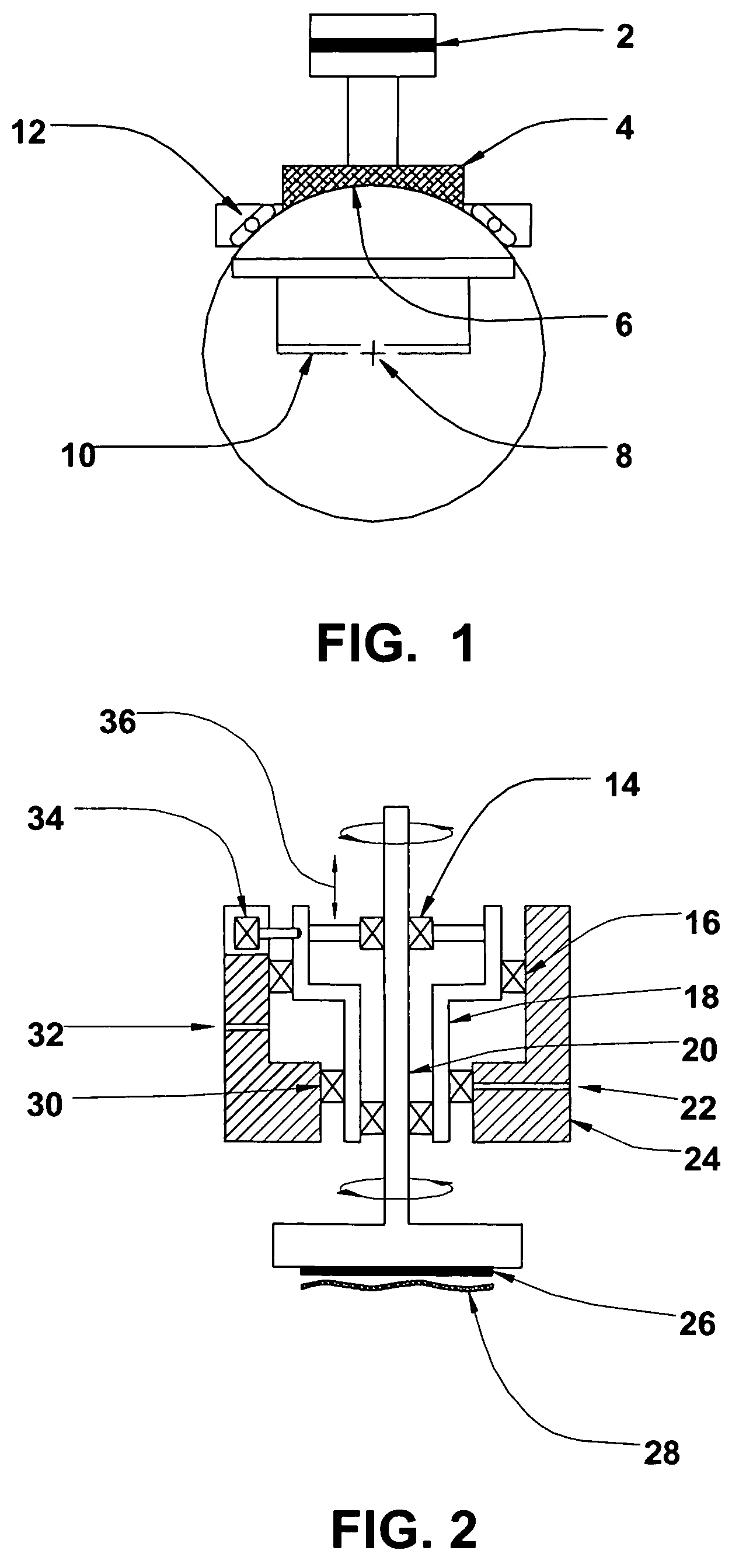

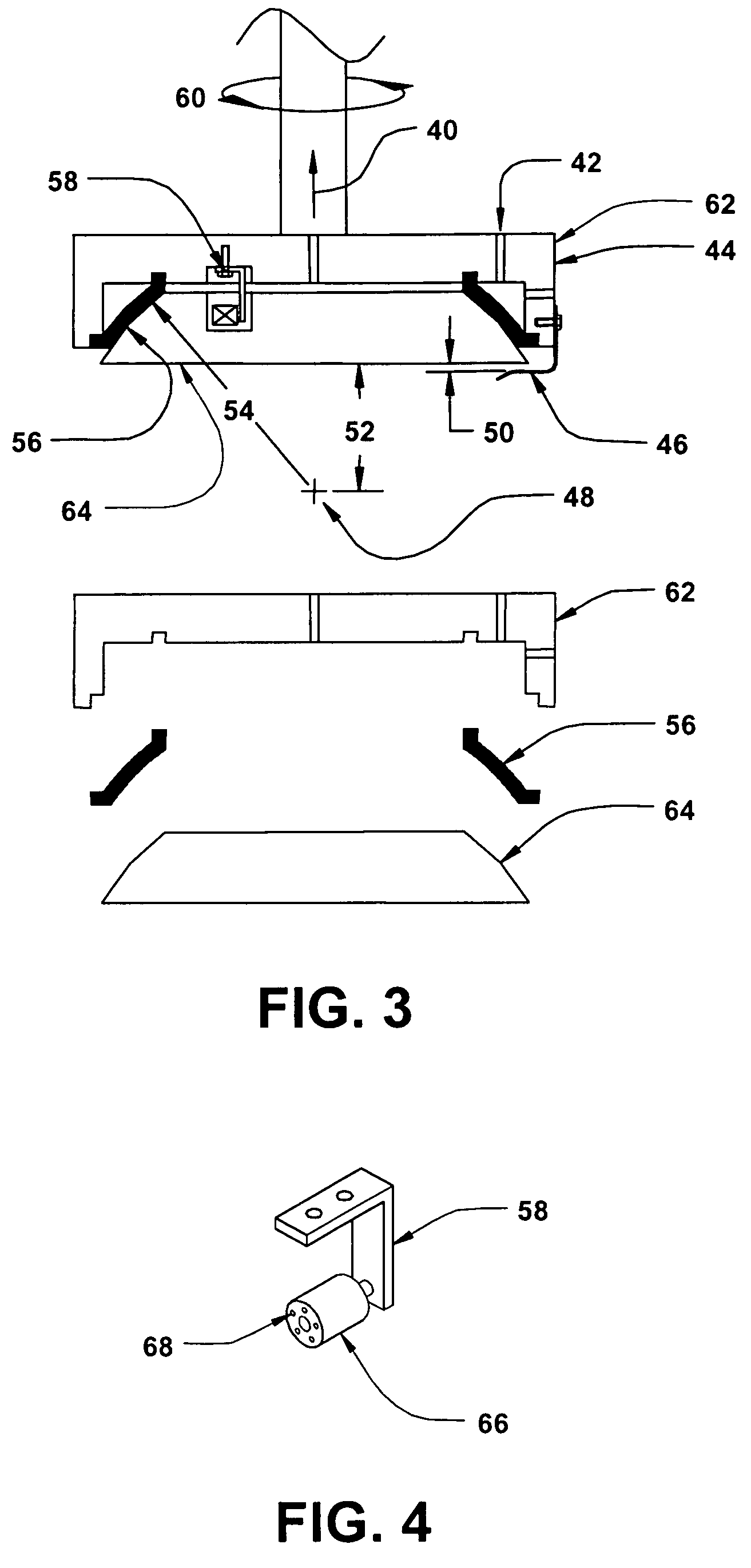

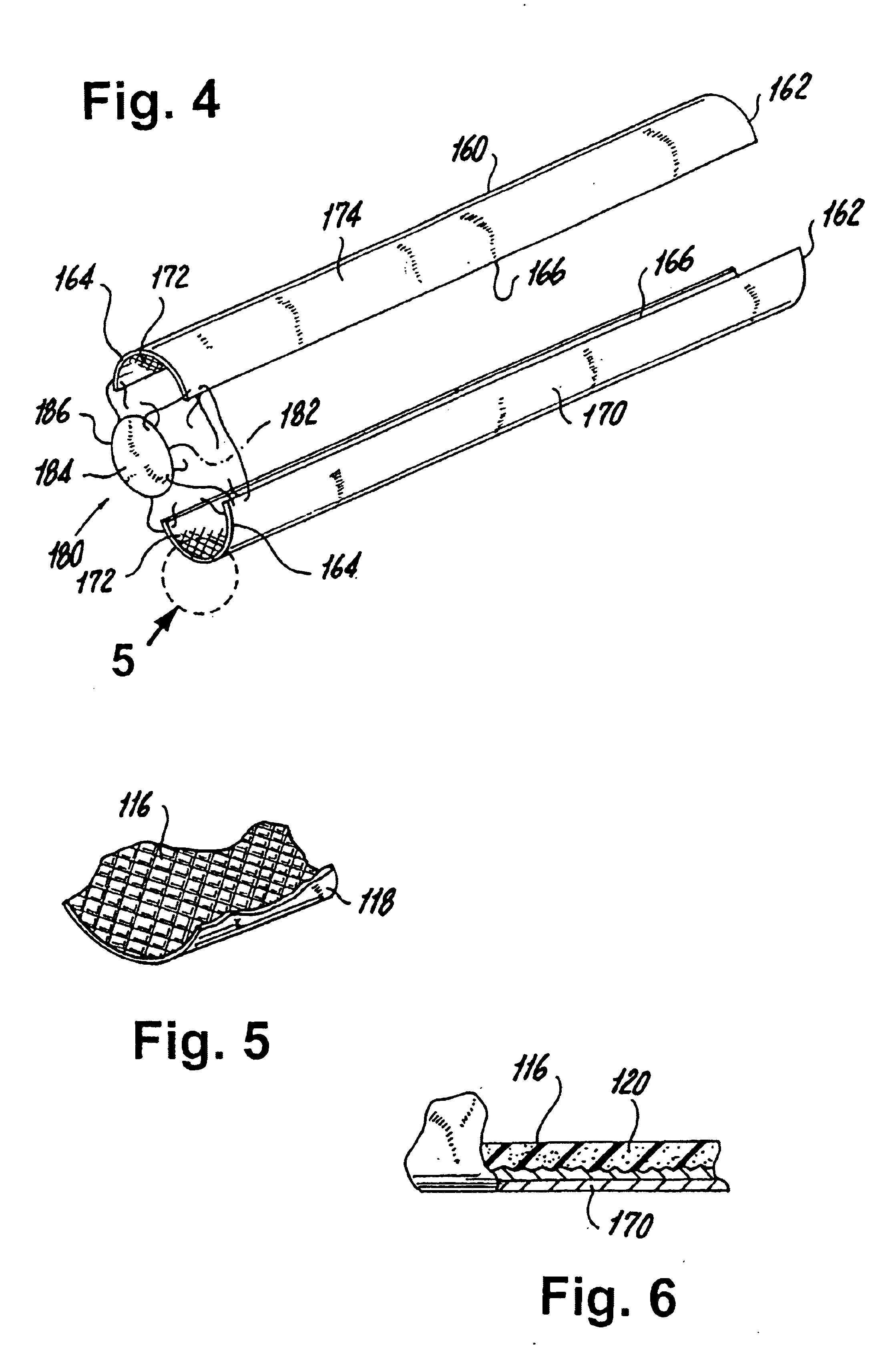

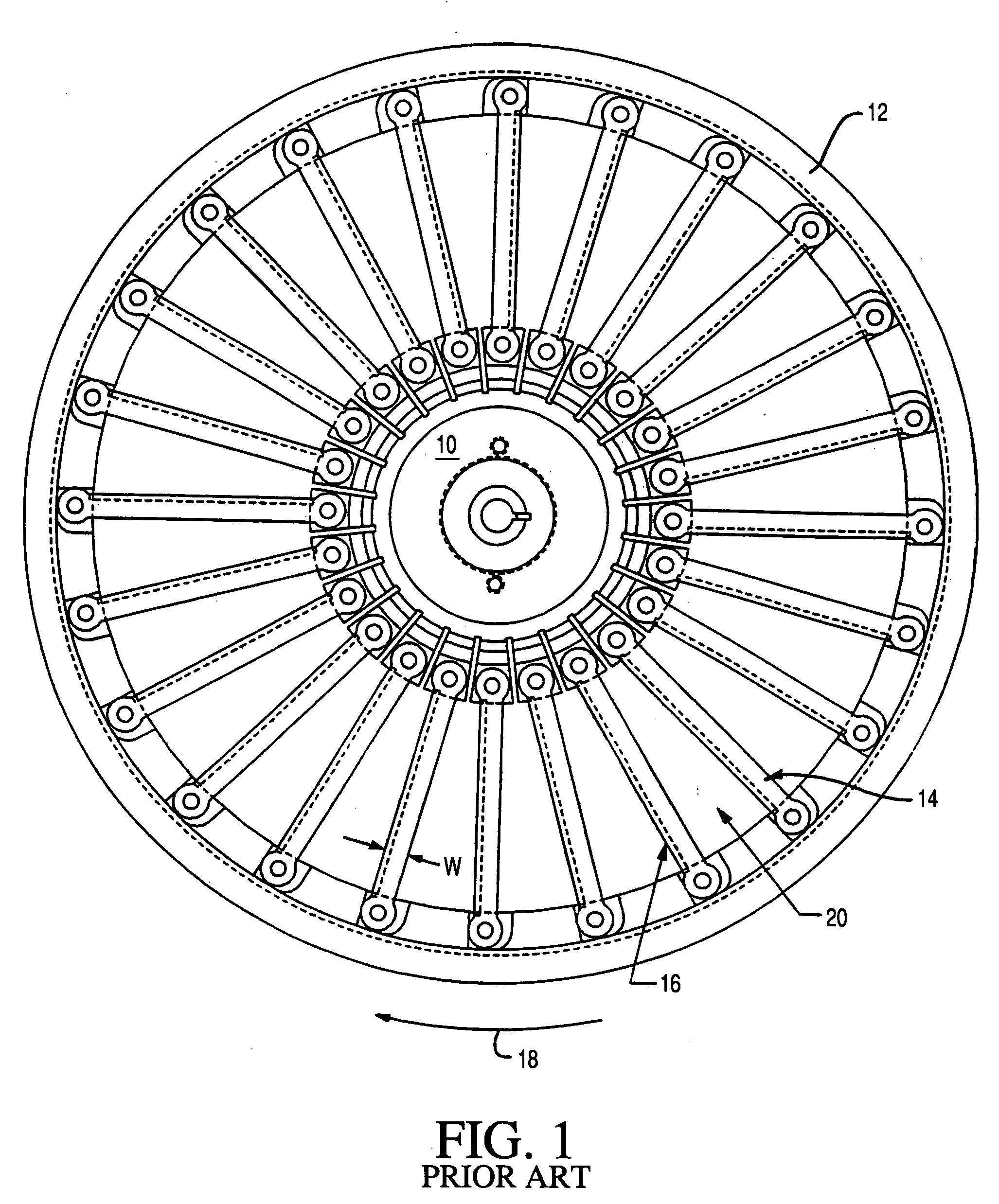

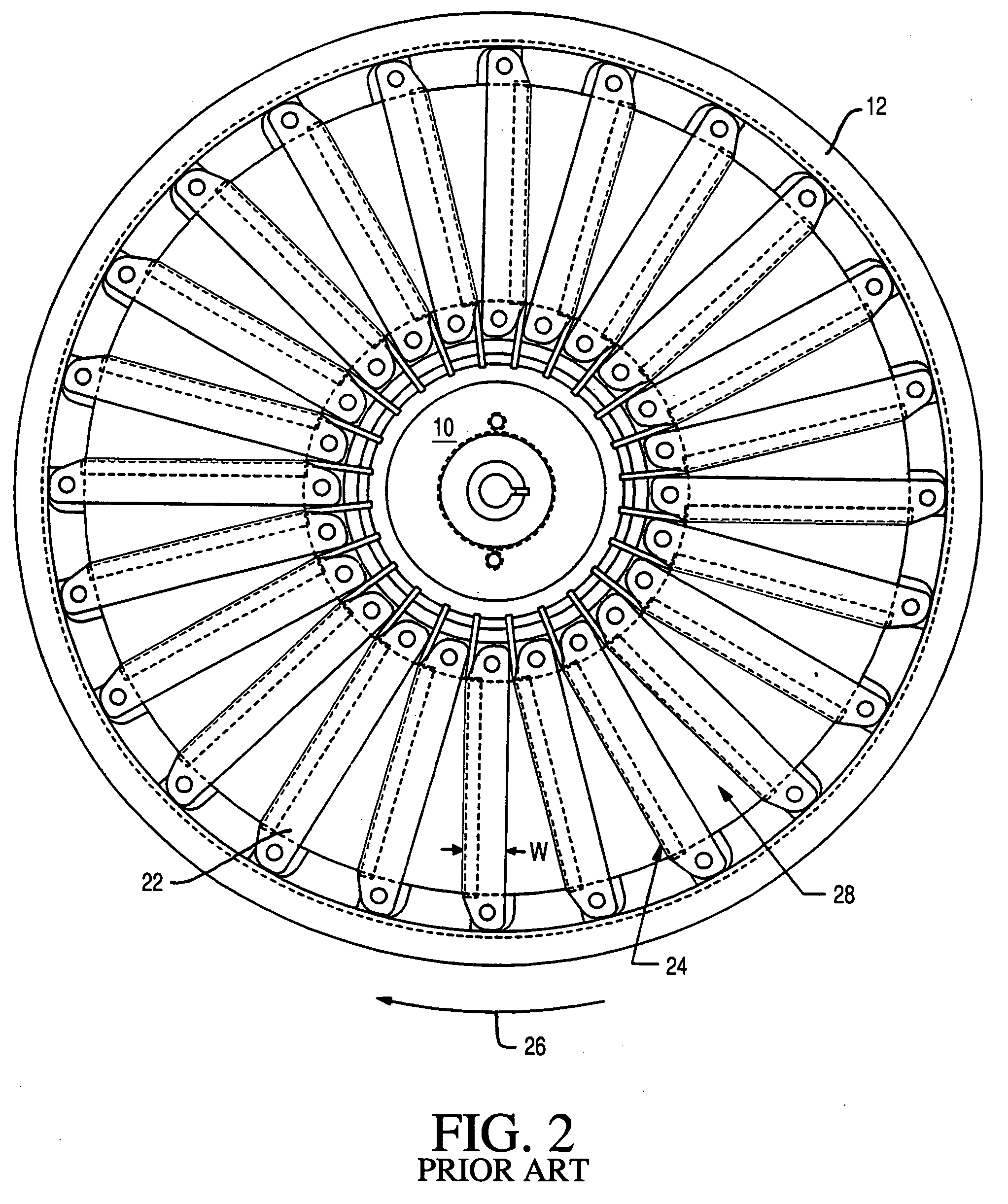

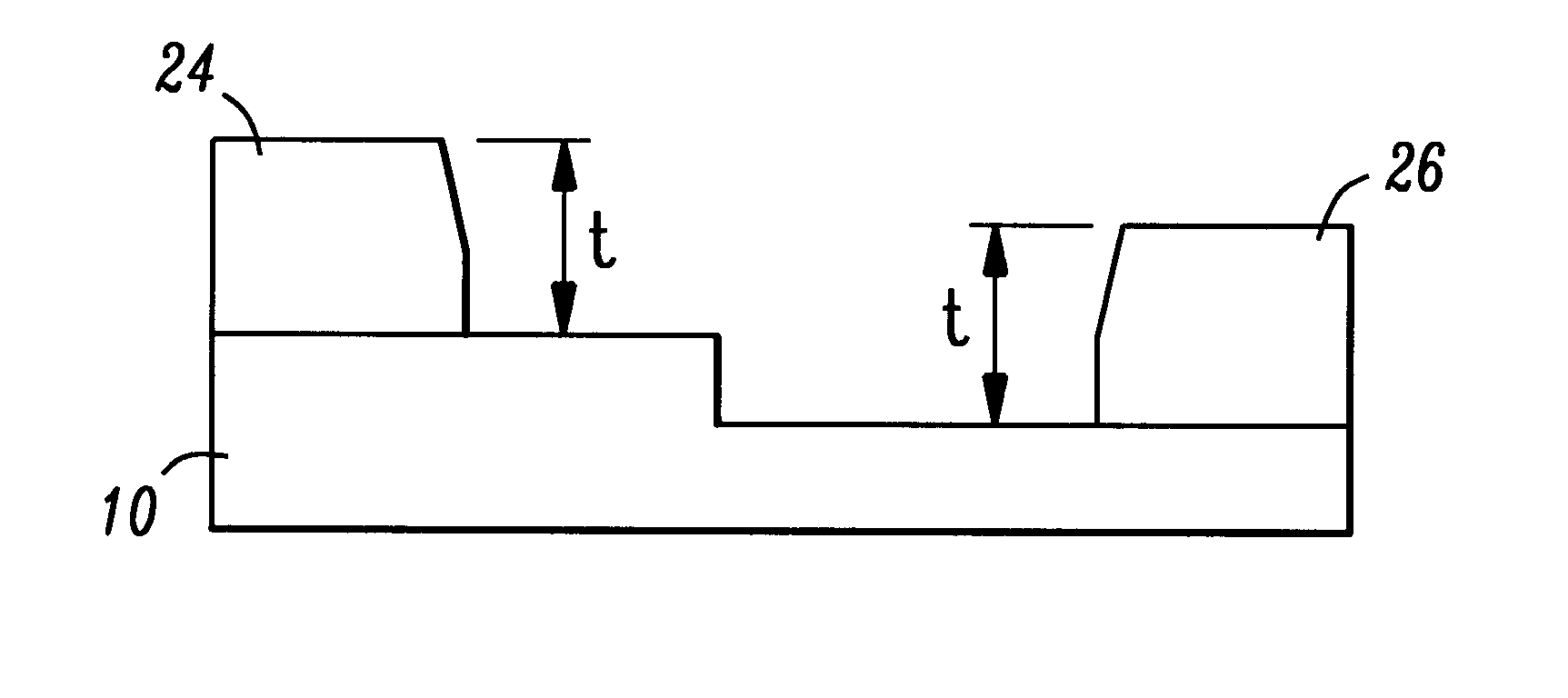

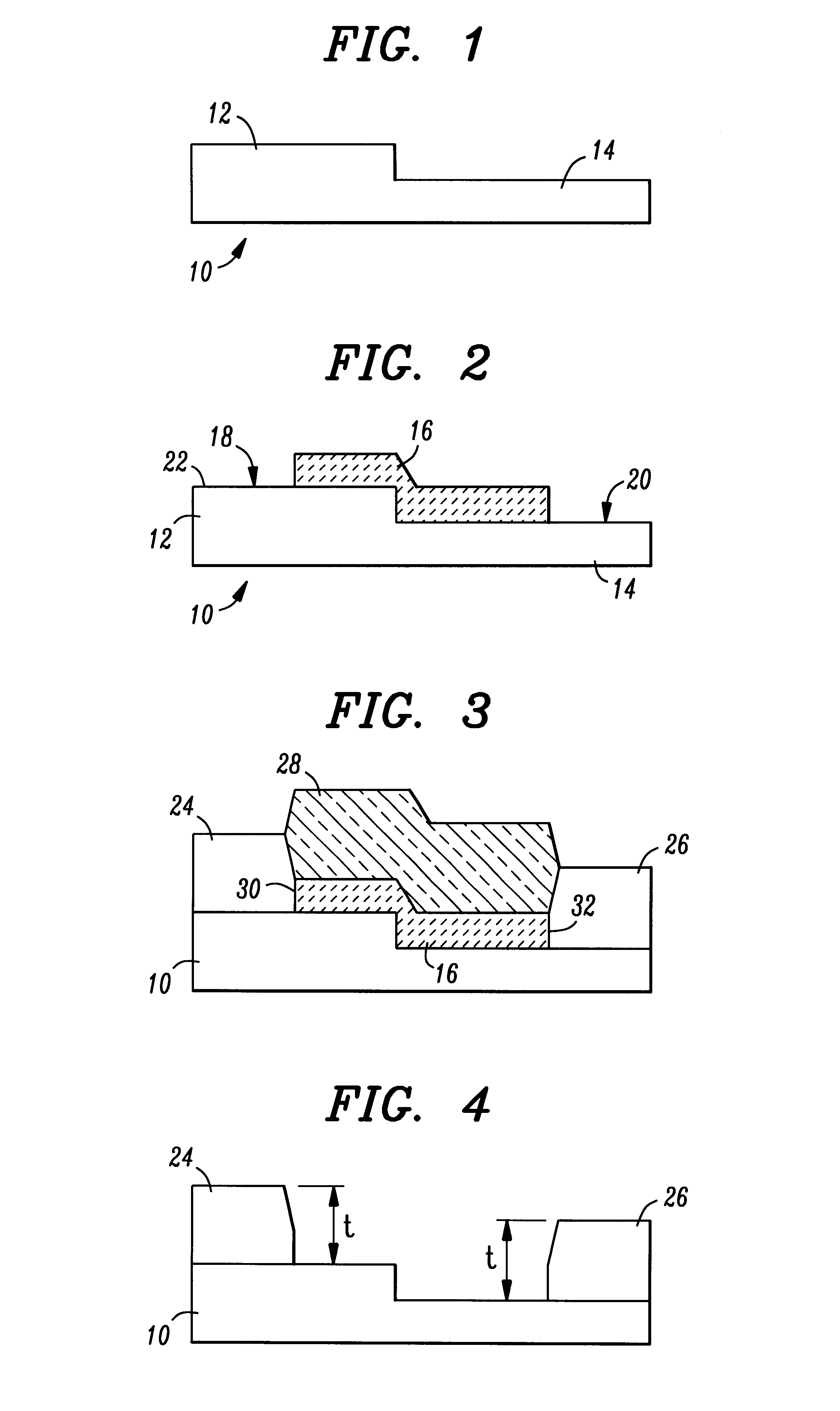

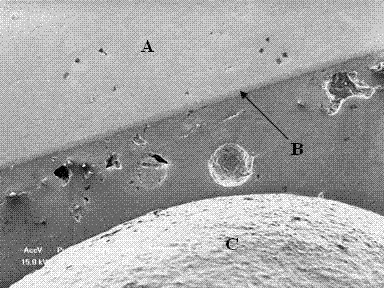

Raised island abrasive, lapping apparatus and method of use

InactiveUS20050032469A1Provide supportReduce workpiece tiltingRevolution surface grinding machinesOther chemical processesMono layerAgglomerate

Flexible abrasive sheet materials having annular bands of precise height flat-topped raised island structures that are coated with a mono layer of abrasive particles or abrasive agglomerates, processes for manufacture of the abrasive sheet materials, processes for using the abrasive sheeting in high speed lapping / abrading processes, and apparatus for using the abrasive sheeting are described. The process for manufacturing the abrasive sheeting provides an economical method for providing an improved configuration of abrasive sheeting that can provide precisely flat workpiece surfaces that are also highly polished.

Owner:DUESCHER WAYNE O

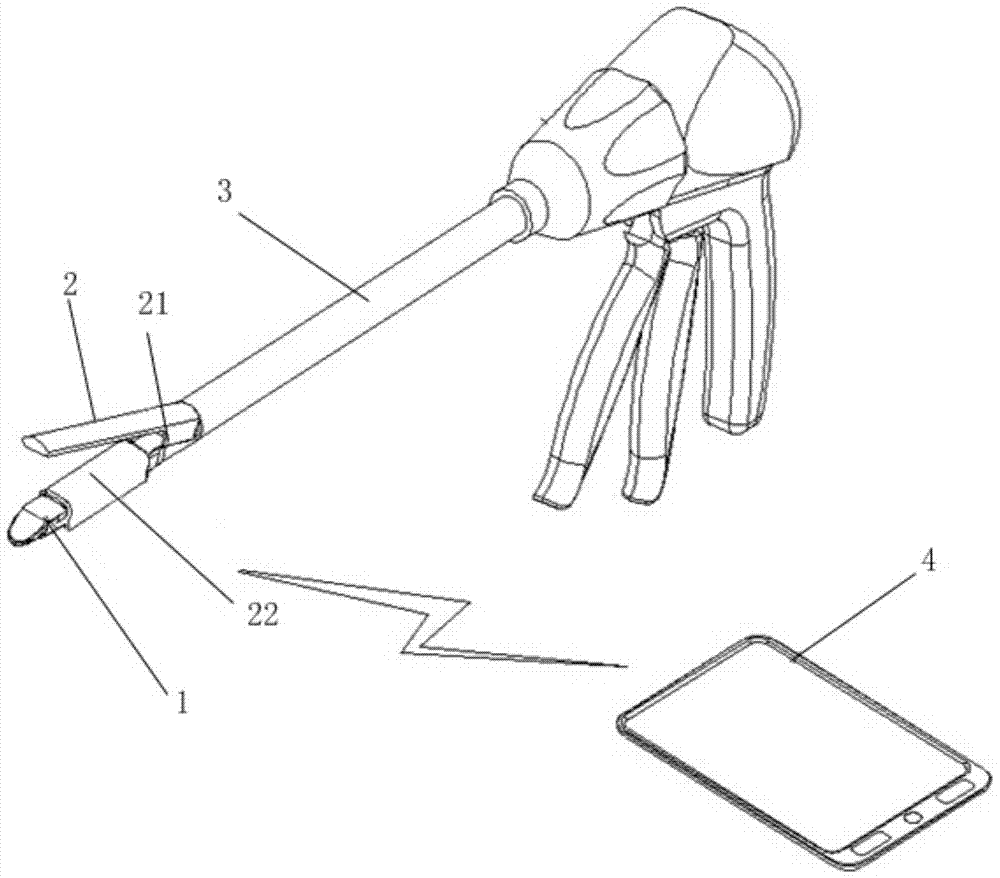

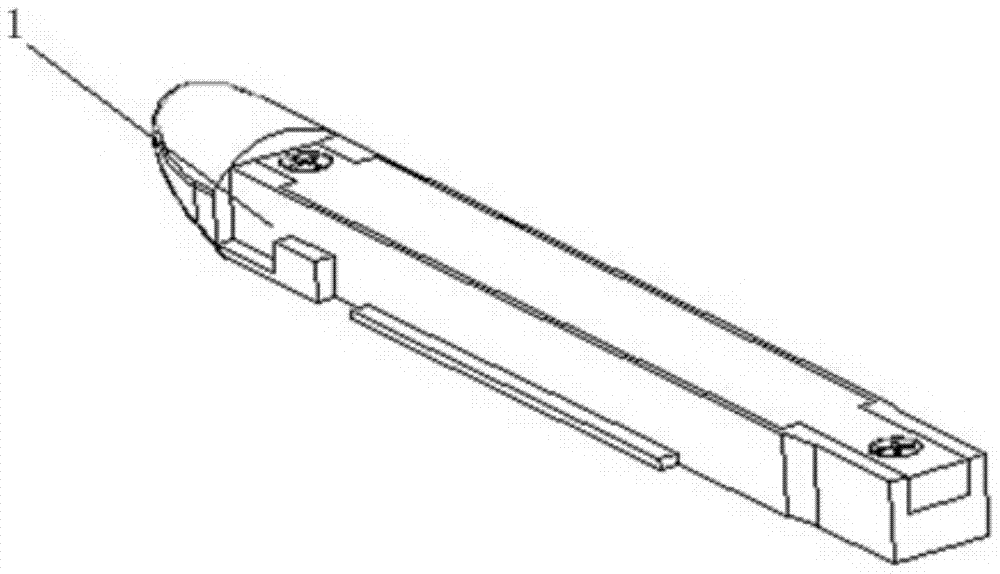

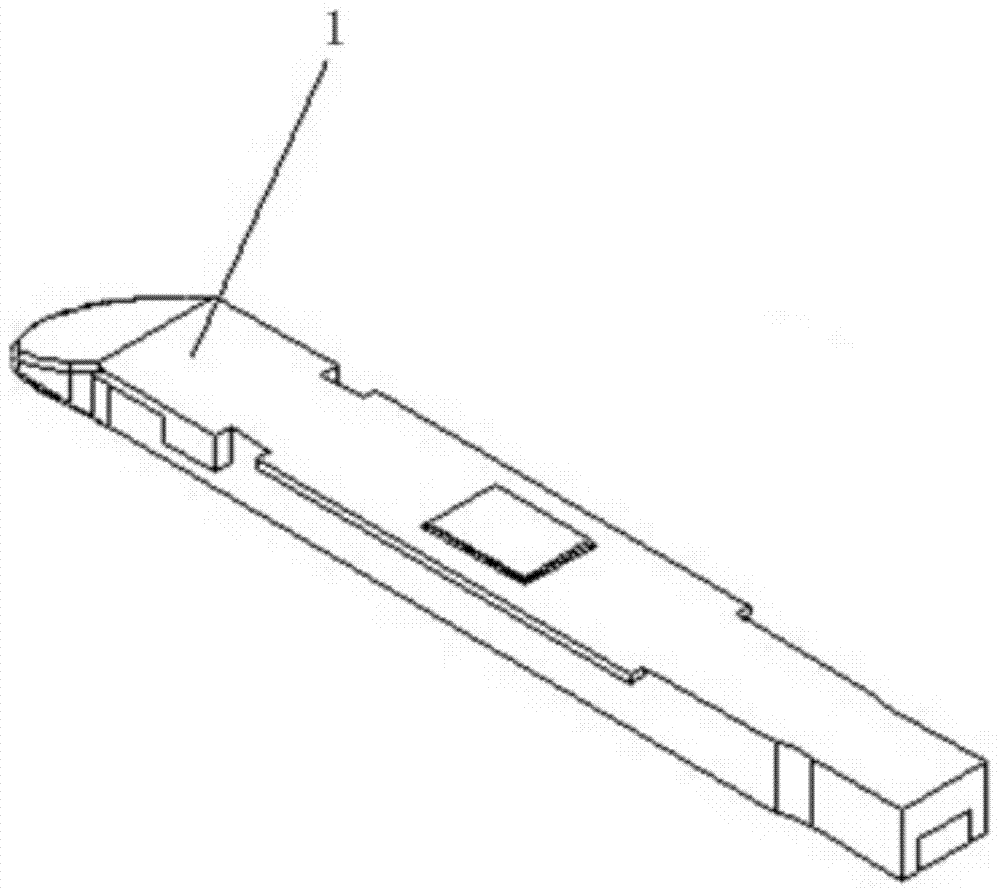

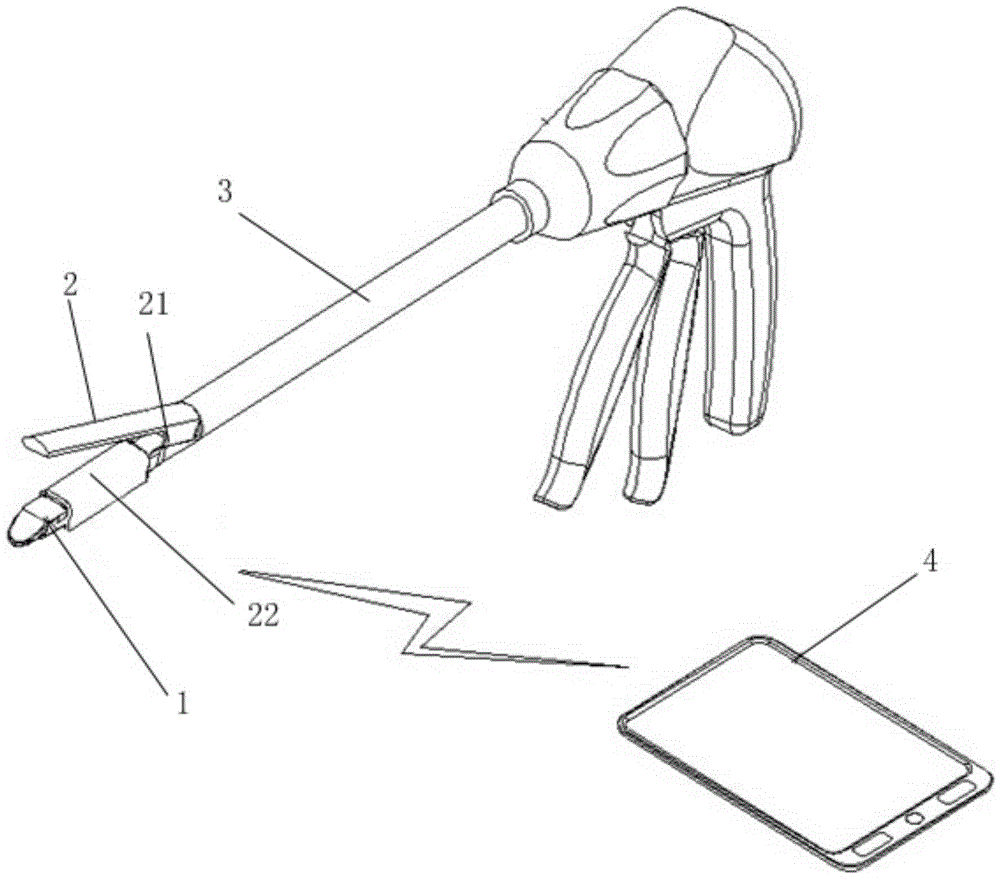

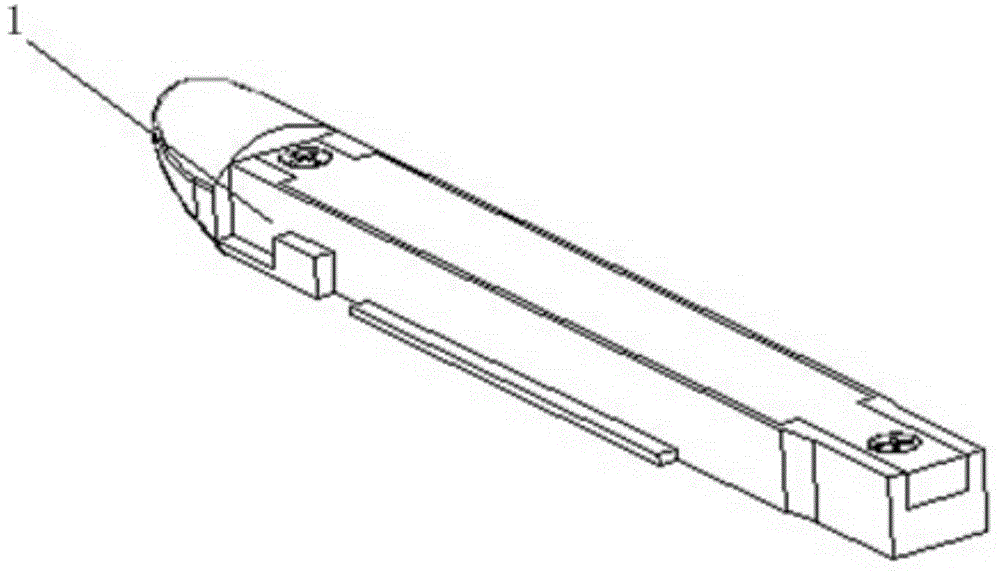

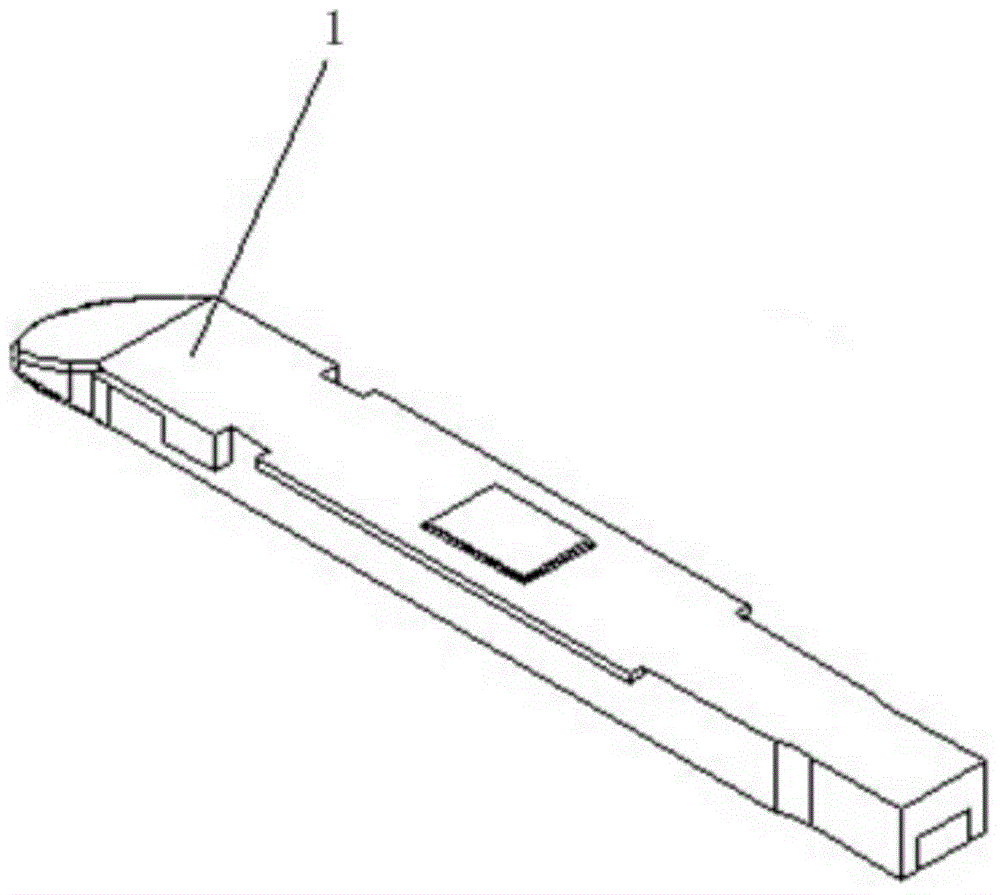

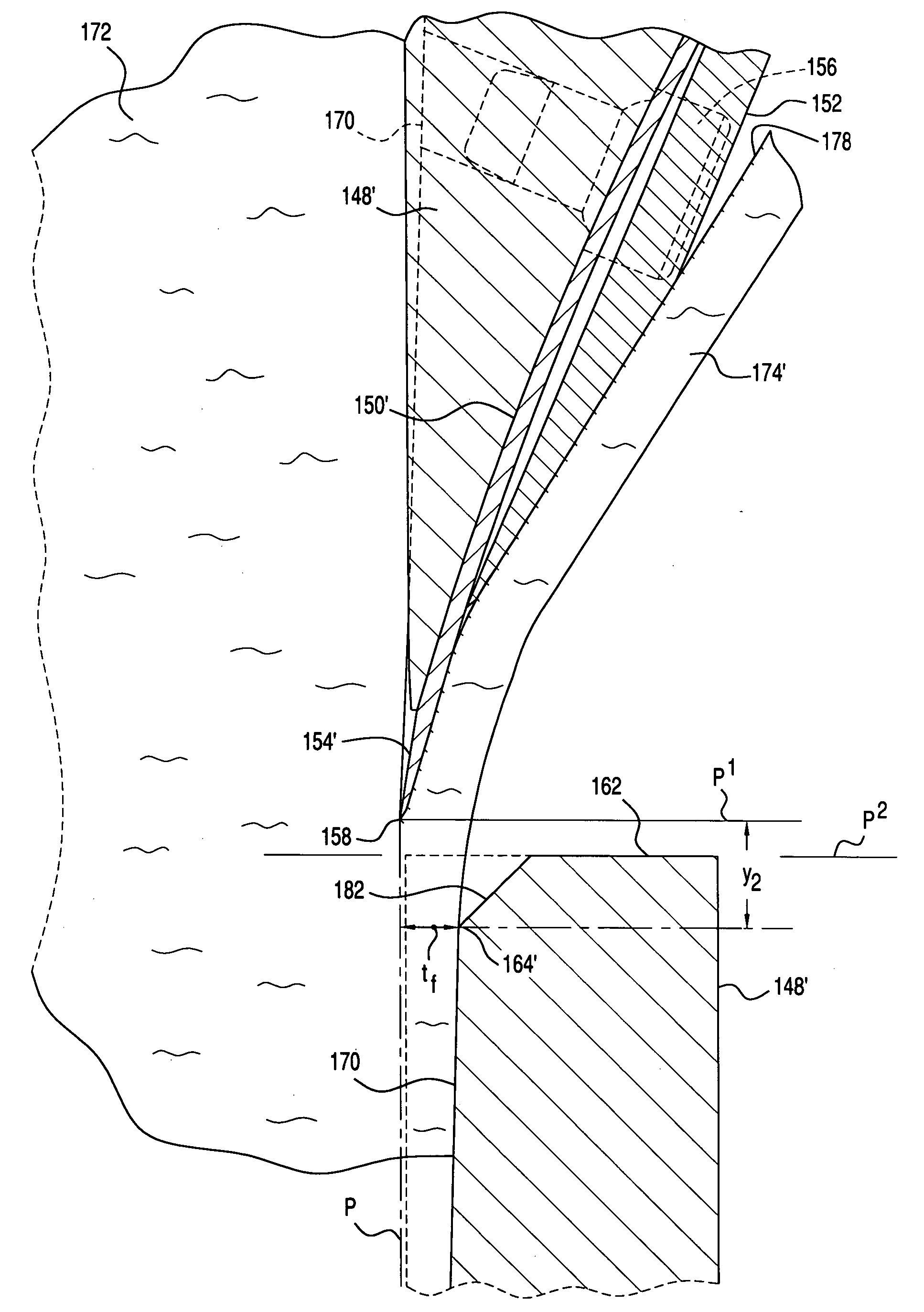

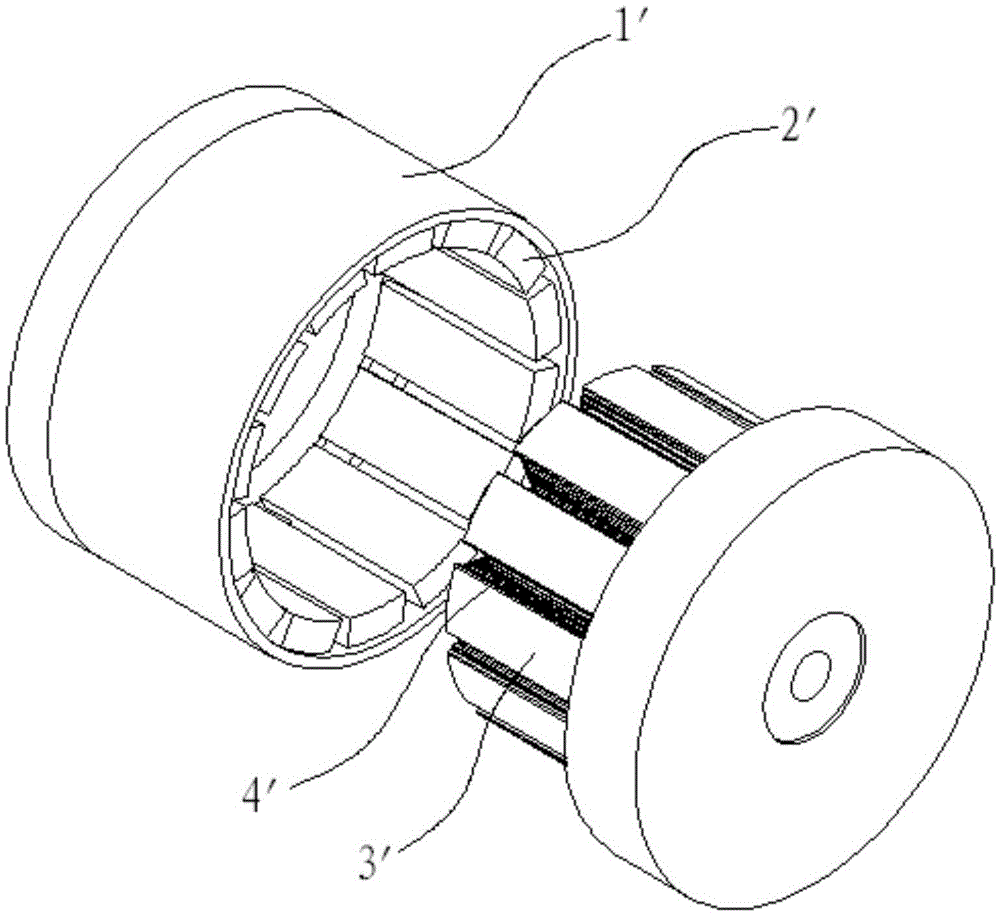

Smart device to measure tissue thickness

InactiveCN104921730BWon't hurtNo tissue damageDiagnostic recording/measuringSensorsButton batteryMeasuring instrument

The invention relates to an intelligent instrument for measuring the tissue thickness. The intelligent instrument comprises a button cell type intelligent thickness measuring clip or an external power supply type intelligent thickness measuring clip, a linear incision anastomat or a manual thickness measuring instrument or an automatic thickness measuring instrument, and a staple anvil. The button cell type intelligent thickness measuring clip comprises an outer shell, a pressing key, waterproof soft glass, an integrated circuit board and a bottom cover. The waterproof soft glass is arranged between the pressing key and the integrated circuit board and covers the surface of the pressing key. A button cell, a power module, a display module, a tissue pressure intensity measuring module, a tissue thickness measuring module, a control module and a wireless transmission module are mounted on the back face of the integrated circuit board. An eddy-current transducer and a pressure sensor are mounted on the front face of the integrated circuit board. The button cell type intelligent thickness measuring clip is matched with a wireless transmission device. The intelligent instrument for measuring the tissue thickness has the advantages that the tissue thickness can be measured in a quantitative mode, tissue thickness measurement is accurate, corresponding anastomotic staple cartridges can be selected conveniently, and the success rate of anastomotic surgery is increased.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Raised island abrasive, lapping apparatus and method of use

InactiveUS7520800B2Reduce workpiece tiltingAccurate thicknessRevolution surface grinding machinesOther chemical processesMono layerMaterials science

Flexible abrasive sheet materials having annular bands of precise height flat-topped raised island structures that are coated with a mono layer of abrasive particles or abrasive agglomerates, processes for manufacture of the abrasive sheet materials, processes for using the abrasive sheeting in high speed lapping / abrading processes, and apparatus for using the abrasive sheeting are described. The process for manufacturing the abrasive sheeting provides an economical method for providing an improved configuration of abrasive sheeting that can provide precisely flat workpiece surfaces that are also highly polished.

Owner:DUESCHER WAYNE O

Intelligent instrument for measuring tissue thickness

InactiveCN104921730AWon't hurtNo tissue damageDiagnostic recording/measuringSensorsWireless transmissionButton battery

The invention relates to an intelligent instrument for measuring the tissue thickness. The intelligent instrument comprises a button cell type intelligent thickness measuring clip or an external power supply type intelligent thickness measuring clip, a linear incision anastomat or a manual thickness measuring instrument or an automatic thickness measuring instrument, and a staple anvil. The button cell type intelligent thickness measuring clip comprises an outer shell, a pressing key, waterproof soft glass, an integrated circuit board and a bottom cover. The waterproof soft glass is arranged between the pressing key and the integrated circuit board and covers the surface of the pressing key. A button cell, a power module, a display module, a tissue pressure intensity measuring module, a tissue thickness measuring module, a control module and a wireless transmission module are mounted on the back face of the integrated circuit board. An eddy-current transducer and a pressure sensor are mounted on the front face of the integrated circuit board. The button cell type intelligent thickness measuring clip is matched with a wireless transmission device. The intelligent instrument for measuring the tissue thickness has the advantages that the tissue thickness can be measured in a quantitative mode, tissue thickness measurement is accurate, corresponding anastomotic staple cartridges can be selected conveniently, and the success rate of anastomotic surgery is increased.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

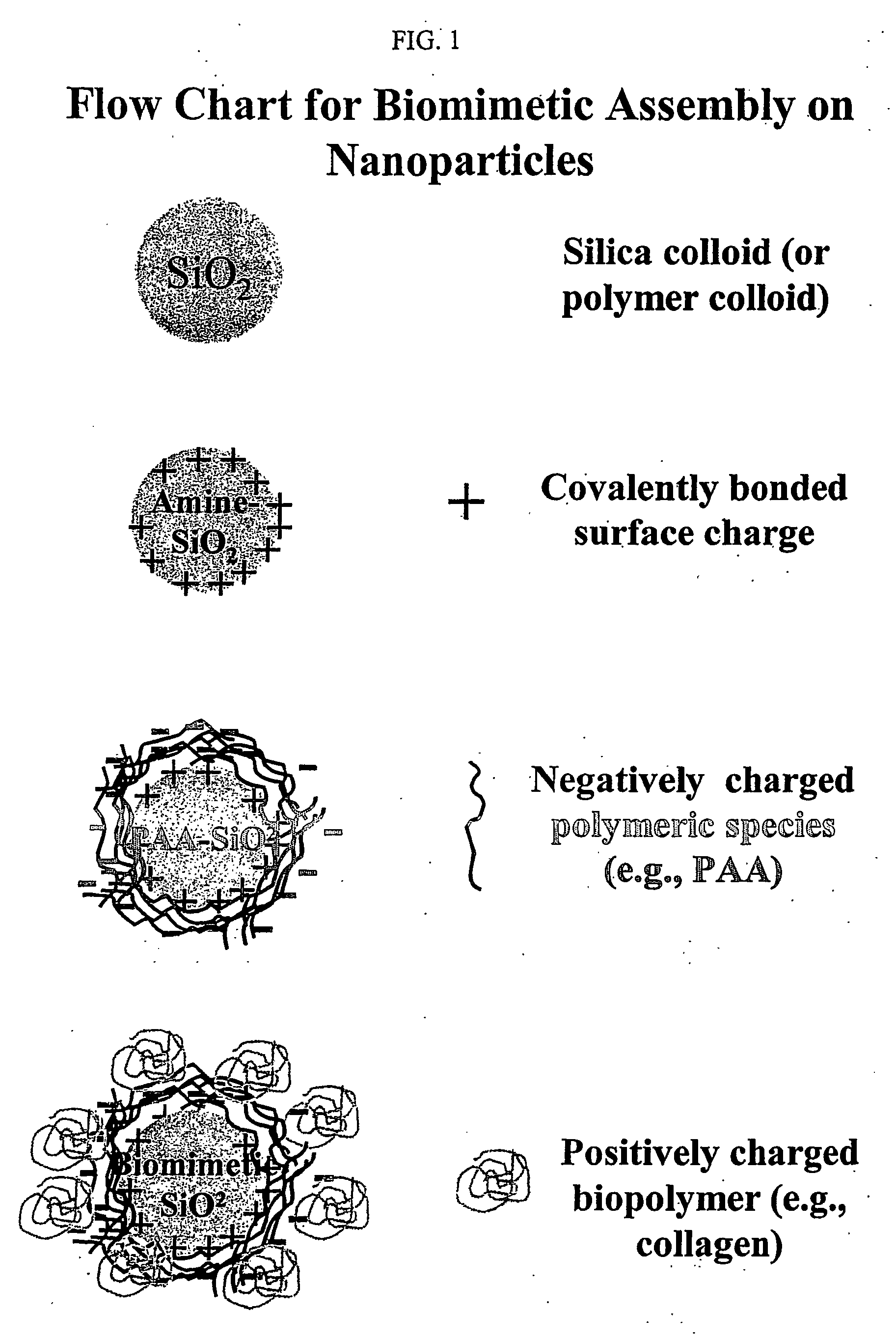

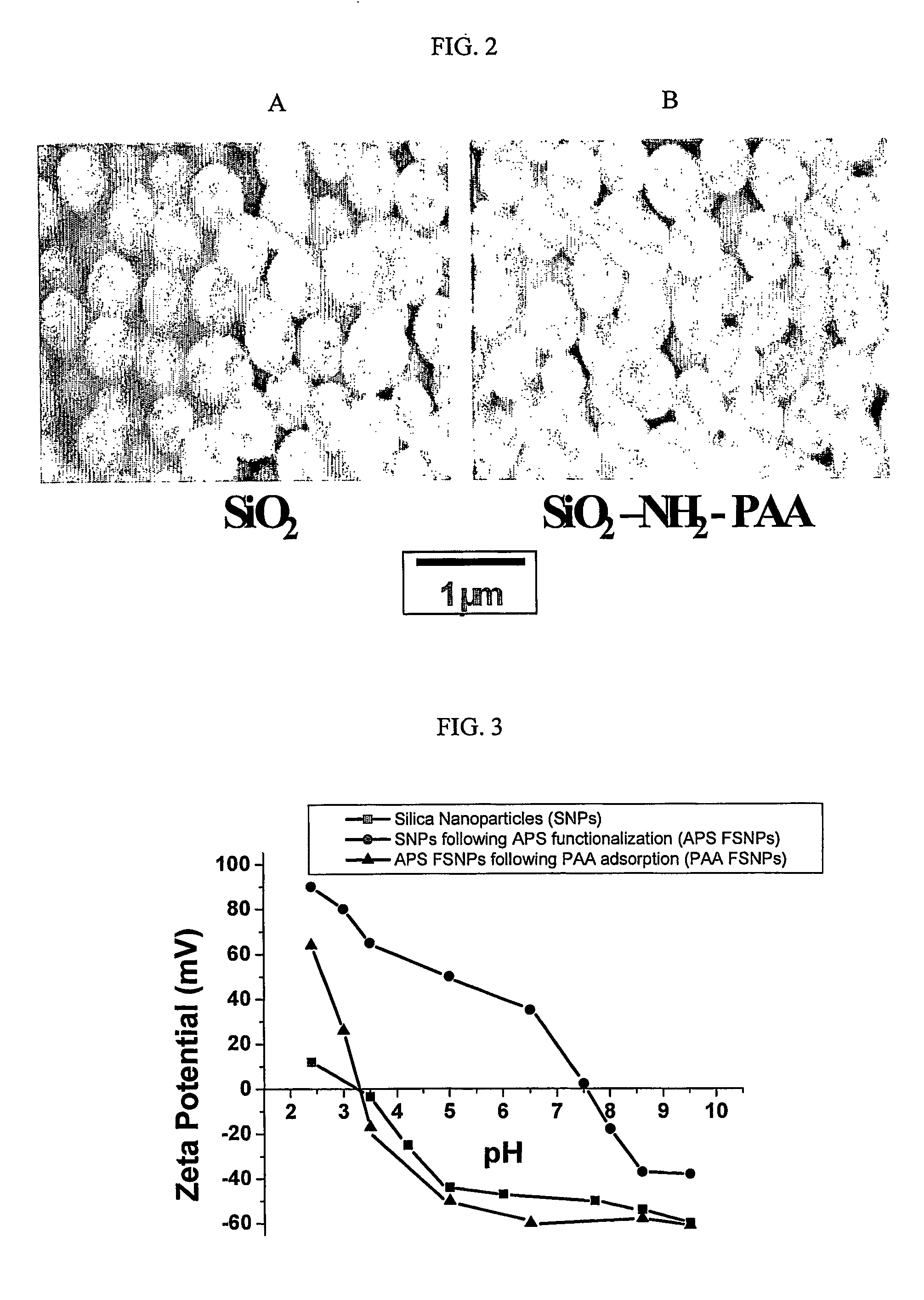

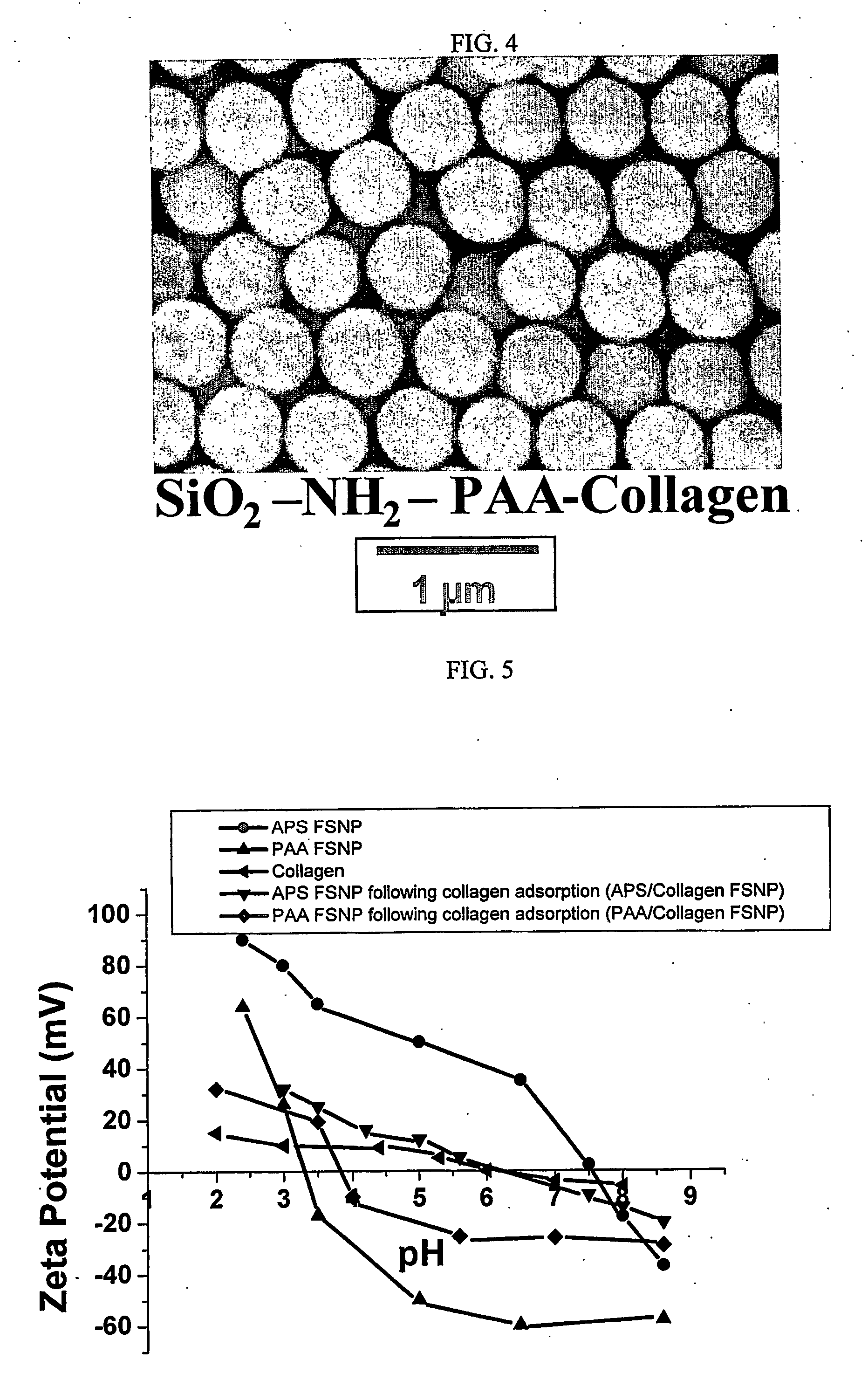

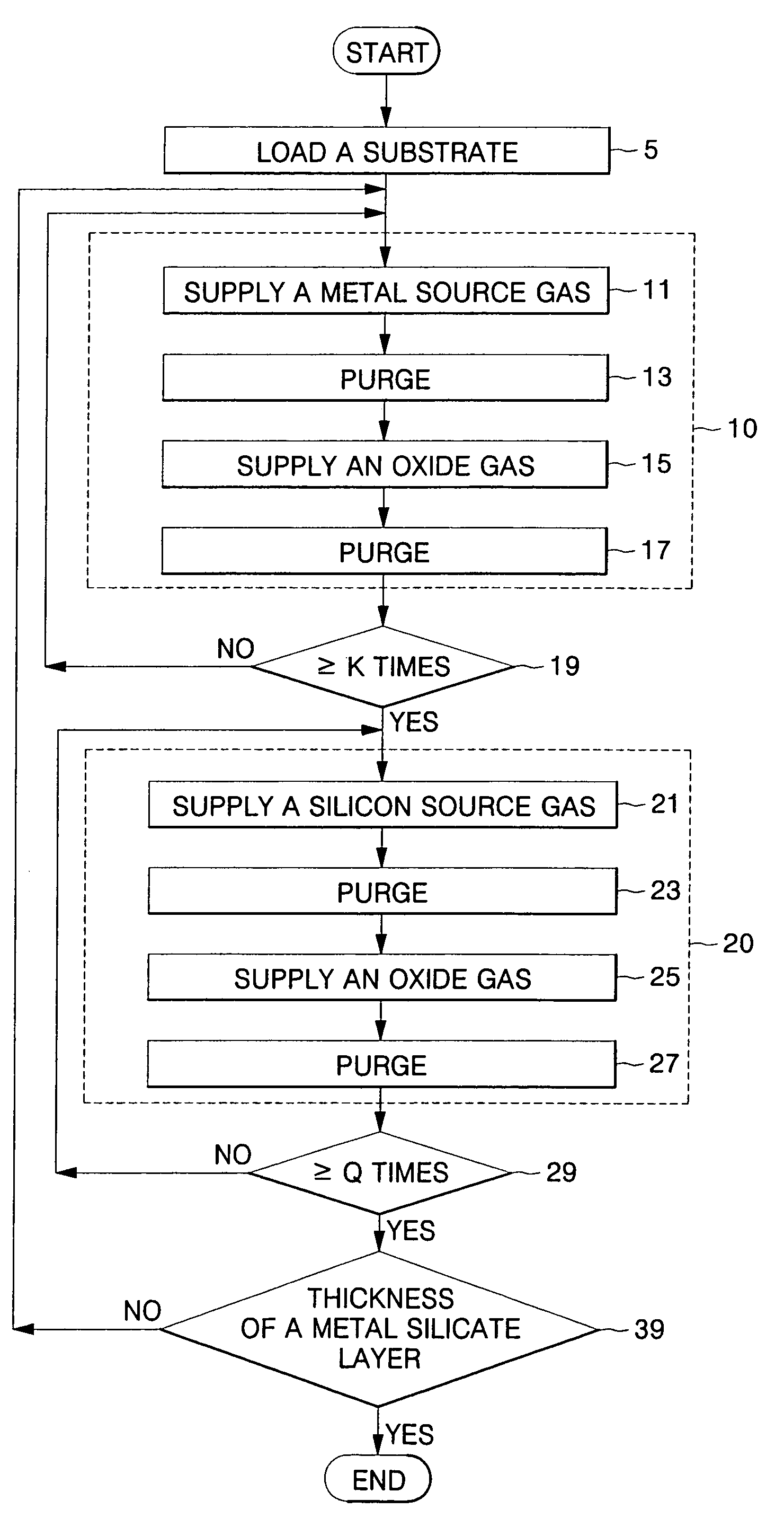

Biommetic hierarchies using functionalized nanoparticles as building blocks

InactiveUS20070026069A1Improve responseAccurate thicknessPowder deliveryBiocideFunctionalized nanoparticlesVolumetric Mass Density

The invention provides a three-dimensional construct including a polymeric matrix and a nanoparticle as shown in FIG. 1 having a diameter of about 5 nm to about 10 microns, wherein the nanoparticle is (a) coated with at least two monomolecular layers each carrying biological information and (b) dispersed in the polymeric matrix at a density of at least 0.01 vol %. The invention further provides a method of presenting biological information to a cell or a tissue and thereby affecting at least one parameter of the cell or the tissue, the method involves providing the three-dimensional construct and contacting it with the cell or the tissue to present the biological information and thereby affecting at least one characteristic of the cell or the tissue. In certain embodiments, the diameter, the biological information and the density are selected to affect at least one characteristic of the cell or the tissue.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

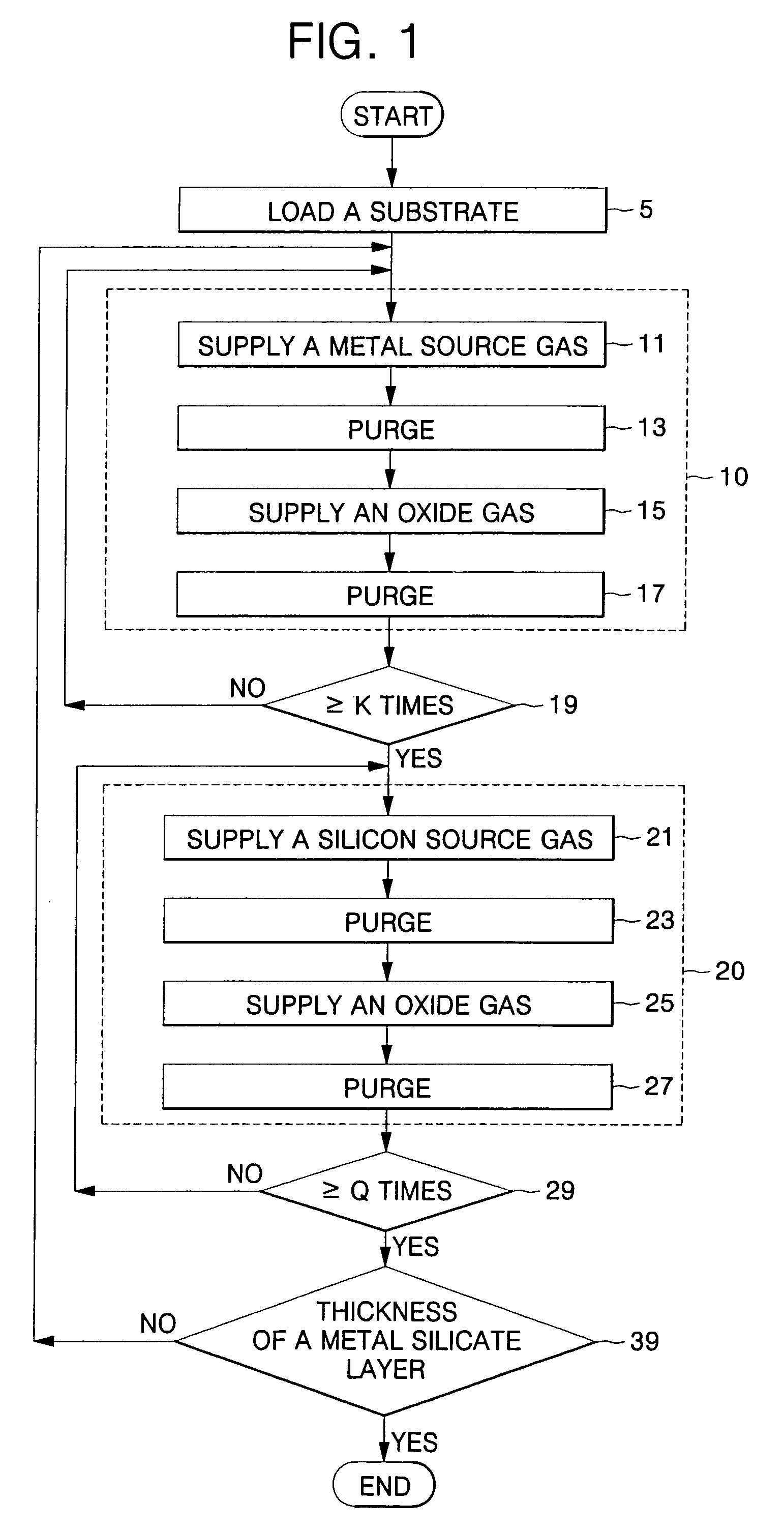

Method of fabricating metal silicate layer using atomic layer deposition technique

ActiveUS7651729B2Accurate thicknessDigital storageChemical vapor deposition coatingSilicon oxideAtomic layer deposition

There are provided methods of fabricating a metal silicate layer on a semiconductor substrate using an atomic layer deposition technique. The methods include performing a metal silicate layer formation cycle at least one time in order to form a metal silicate layer having a desired thickness. The metal silicate layer formation cycle includes an operation of repeatedly performing a metal oxide layer formation cycle K times and an operation of repeatedly performing a silicon oxide layer formation cycle Q times. K and Q are integers ranging from 1 to 10 respectively. The metal oxide layer formation cycle includes the steps of supplying a metal source gas to a reactor containing the substrate, exhausting the metal source gas remaining in a reactor to clean the inside of the reactor, and then supplying an oxide gas into the reactor. The silicon oxide layer formation cycle includes supplying a silicon source gas, exhausting the silicon source gas remaining in the reactor to clean the inside of the reactor, and then supplying an oxide gas into the reactor.

Owner:SAMSUNG ELECTRONICS CO LTD

Reflector with resistant surface

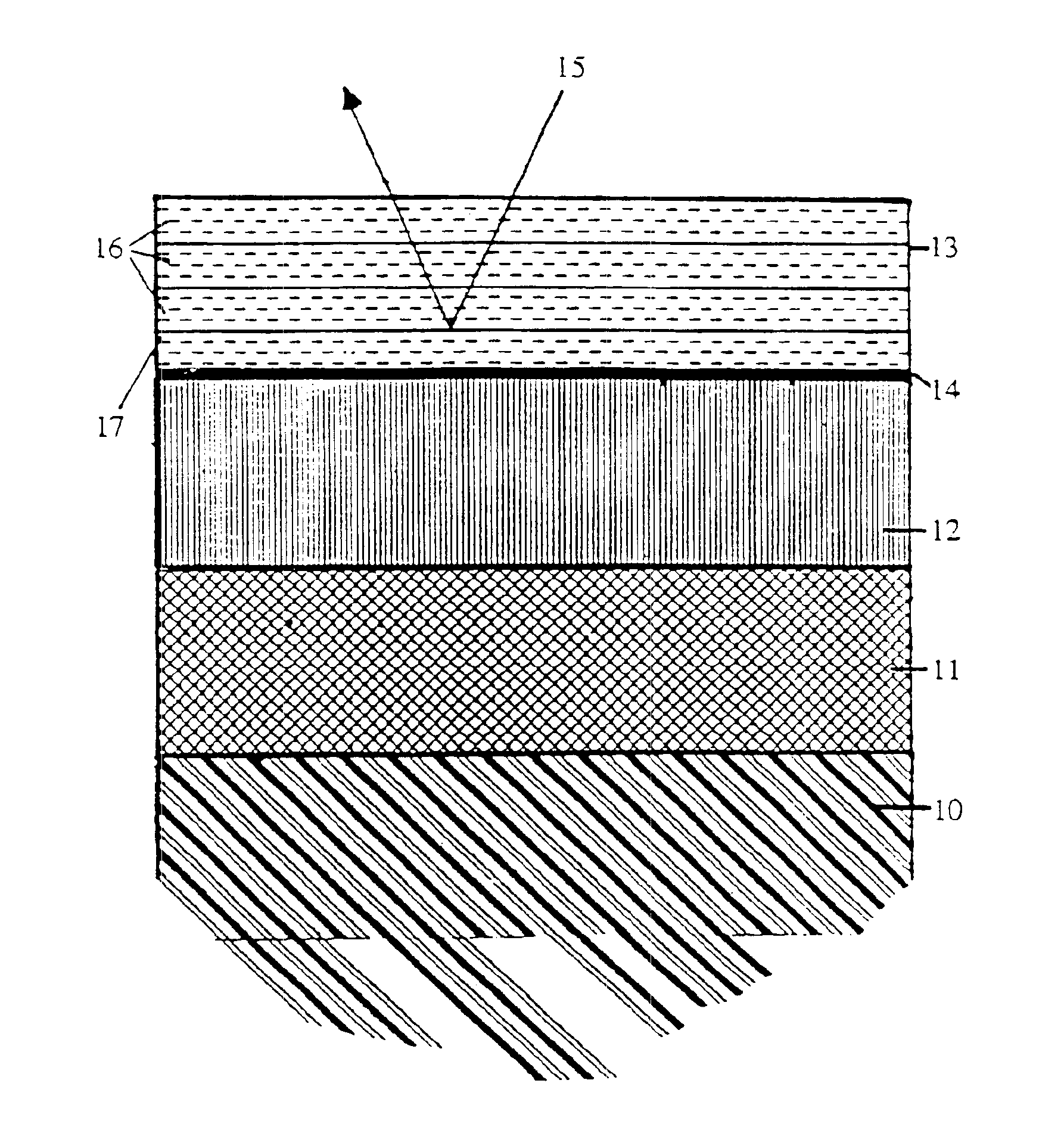

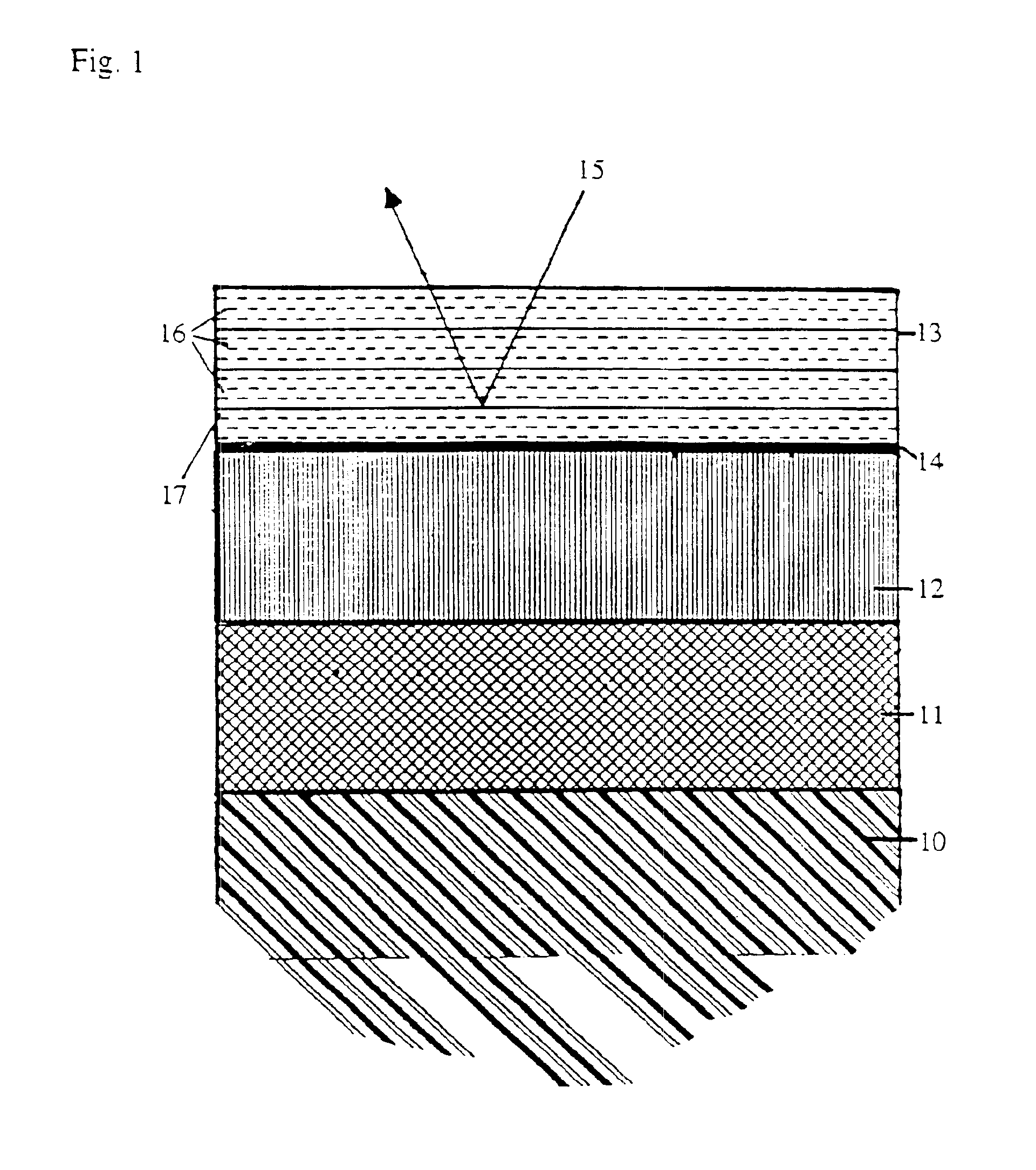

InactiveUSRE39790E1High mechanical strengthAccurate thicknessMirrorsSurface reaction electrolytic coatingSurface layerThin layer

Reflectors, for example, for lamps used for technical lighting purposes, having a surface which is resistant to mechanical and chemical attack and has high total reflectivity. The body (10) of the reflector, which is, for example, a rolled aluminum product such as a foil, a strip of a sheet, has a surface layer in the form of a layer system containing (a) a pretreatment layer (11), onto which is deposited (b) a functional layer (12) with silanes, having organo-functional groups, of a metal compound, and onto which is deposited (c) a metal-containing reflective layer (13). Layer (a) is deposited on the reflector body and increases the strength of bonding to the above lying layers (a) and (b). Layer (b) effects a flattening and increase in the mechanical strength of the above lying layer (c). The pretreatment layer can be a layer produced by anodic oxidation. The functional layer (b) can be a sol-gel layer. The reflective layer (c) can be a metallic reflective layer, in some cases with one or more protective layers, which are deposited, e.g., by vacuum thin layer deposition process.

Owner:CONSTELLIUM SWITZERLAND

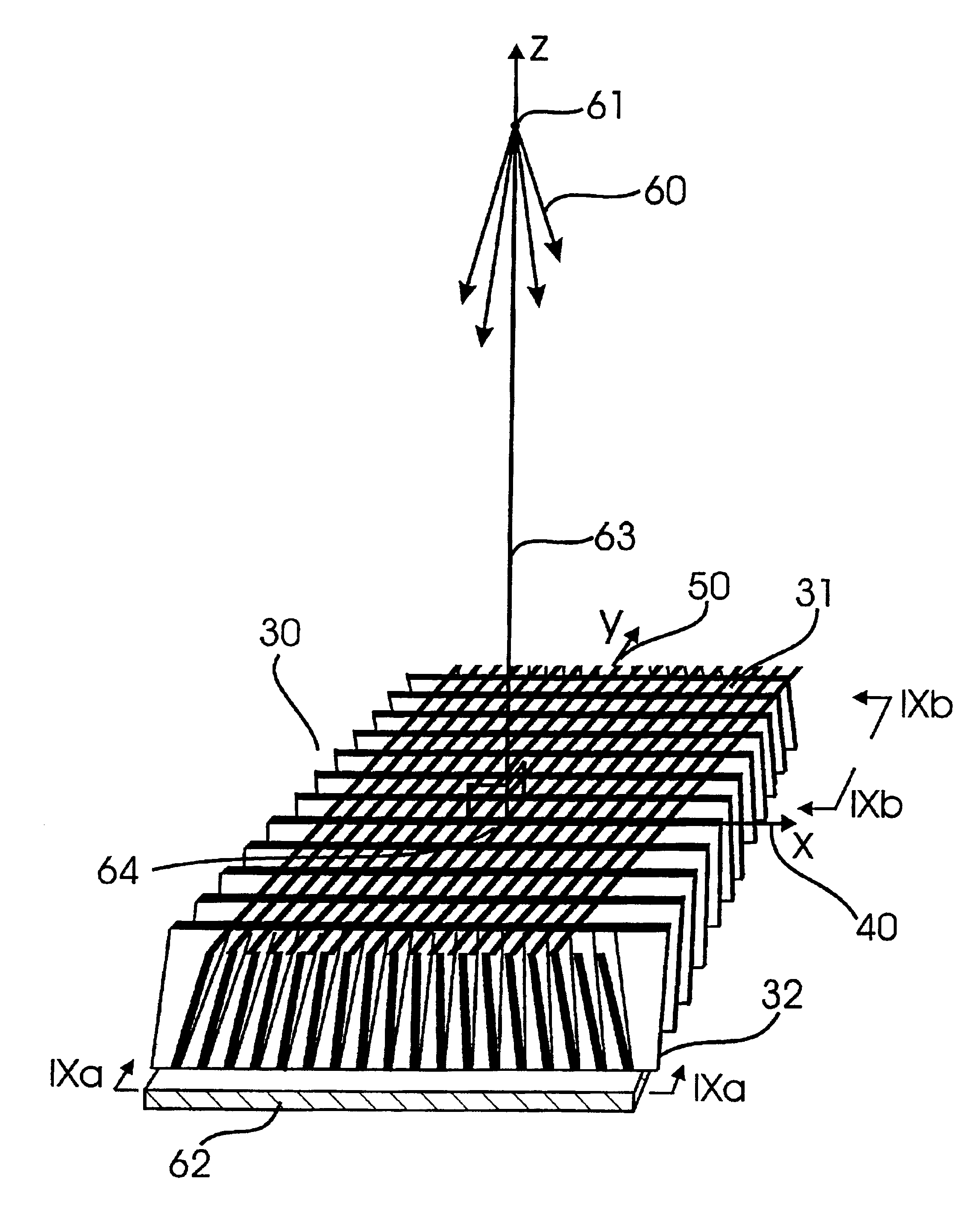

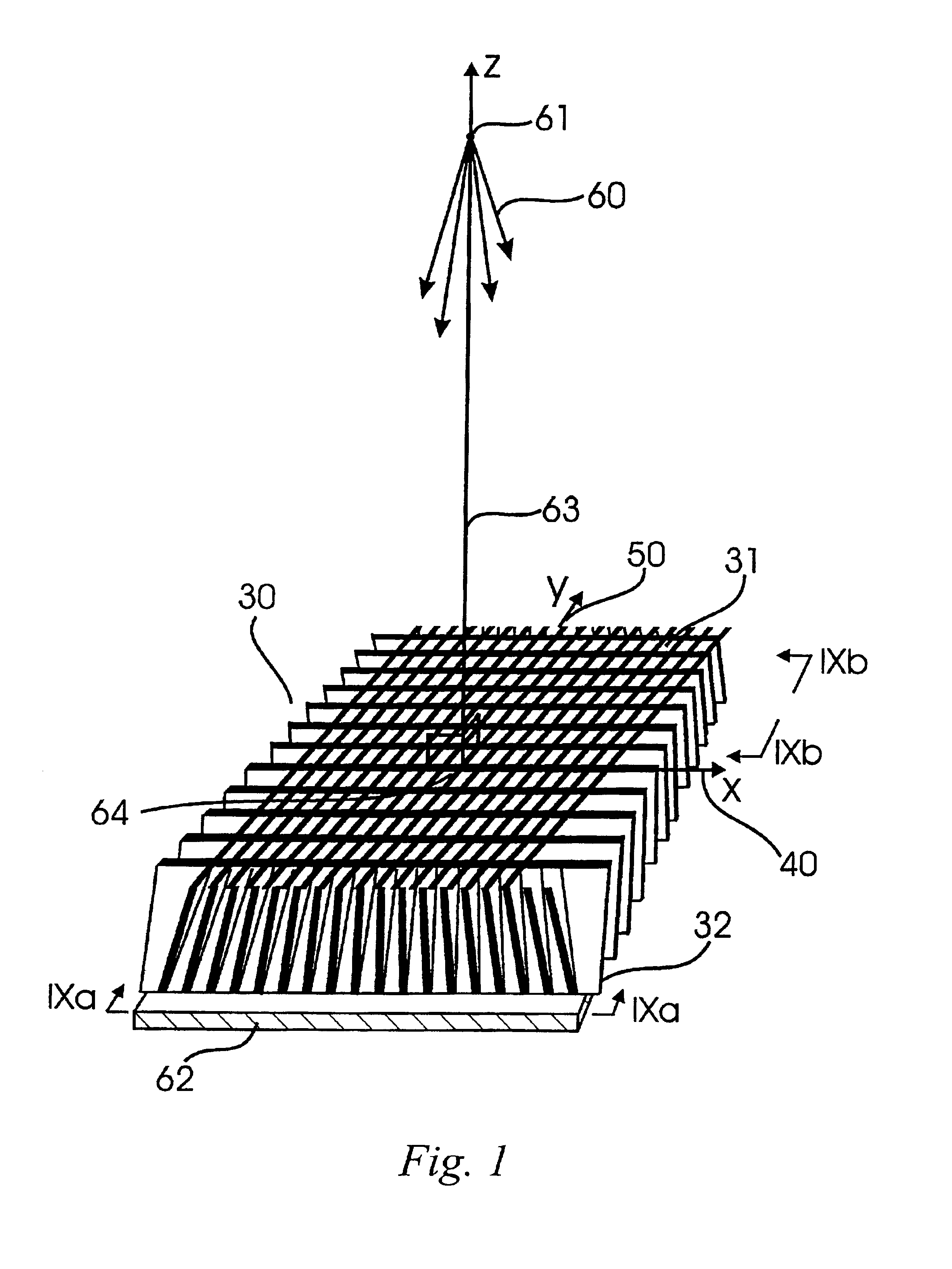

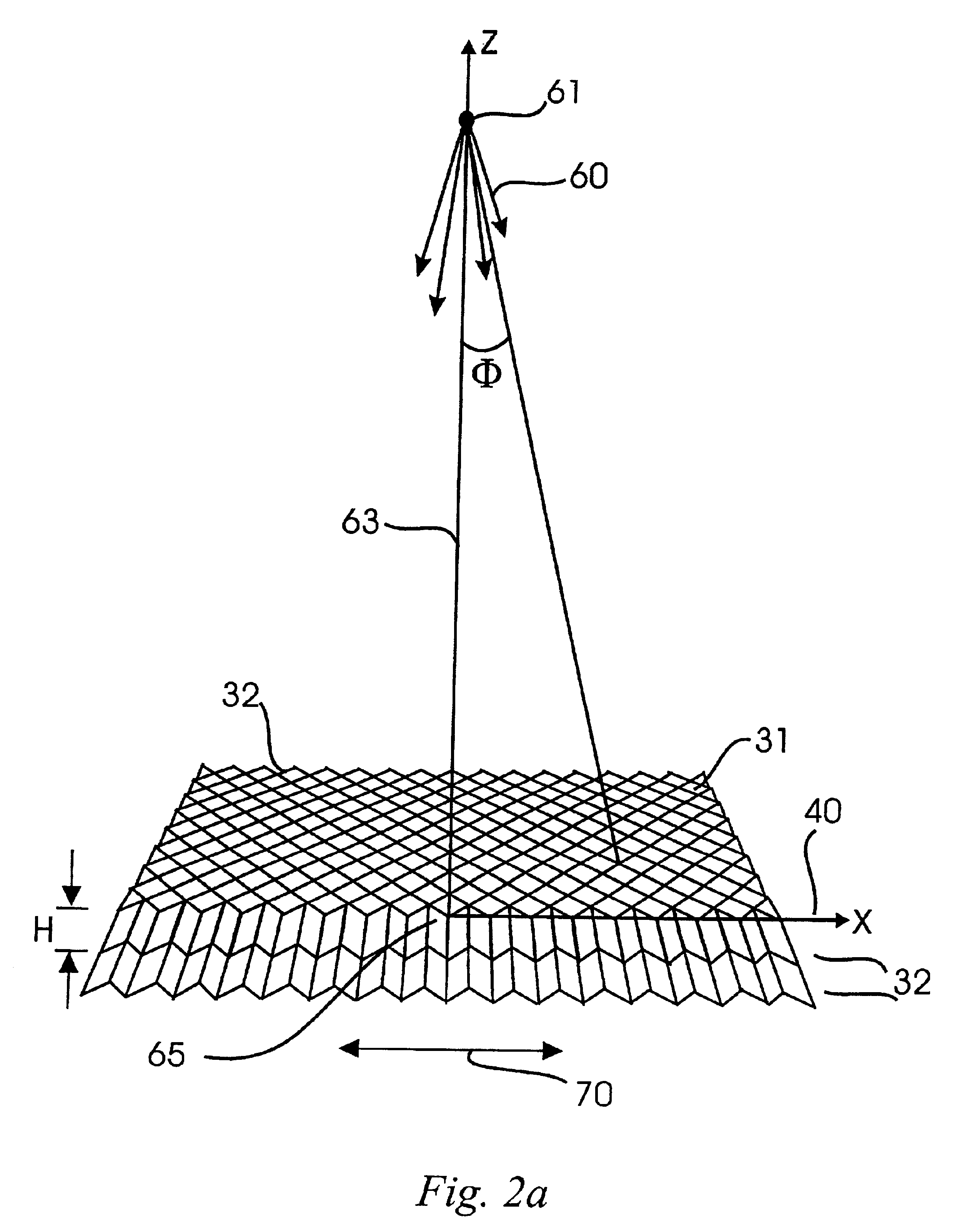

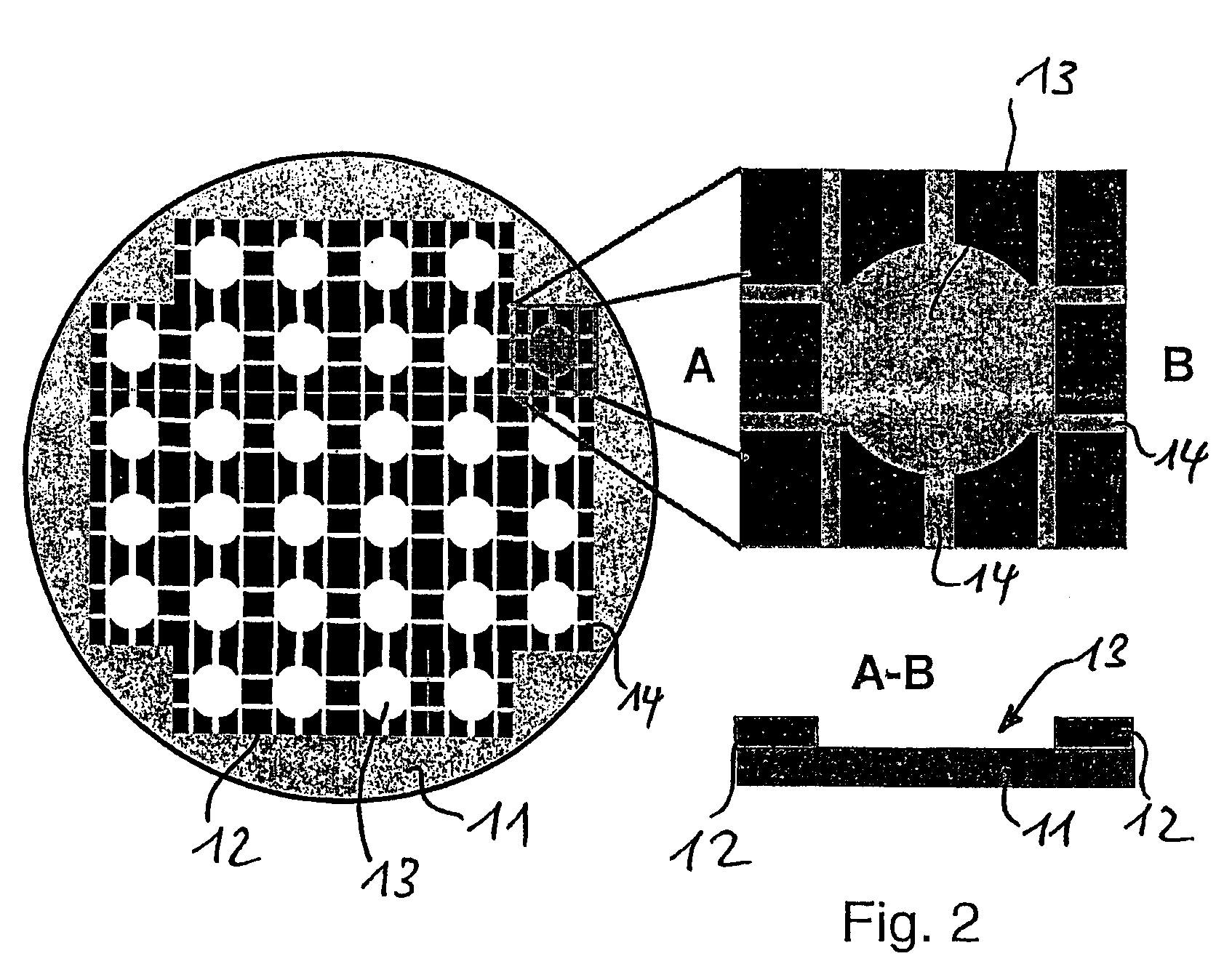

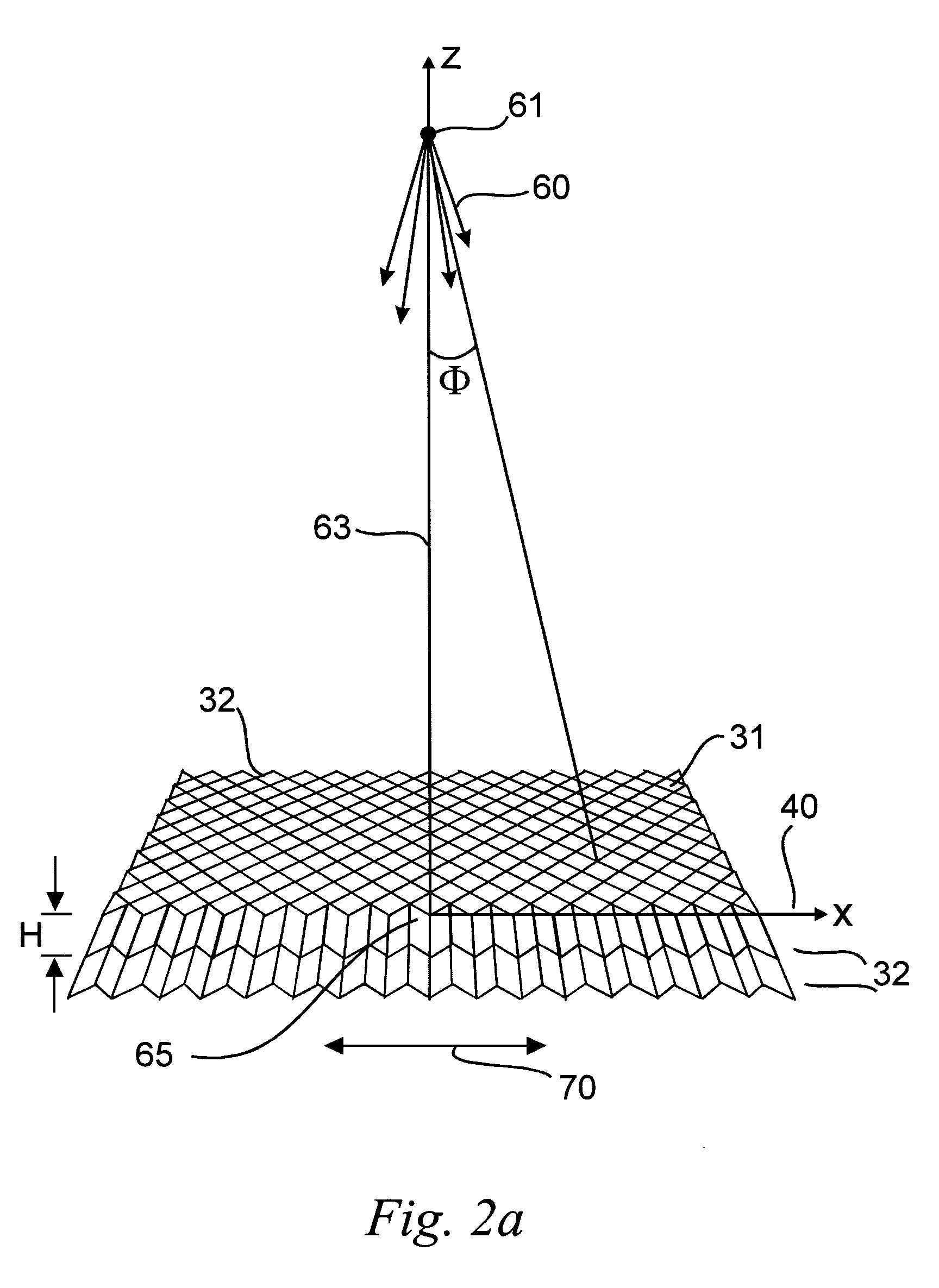

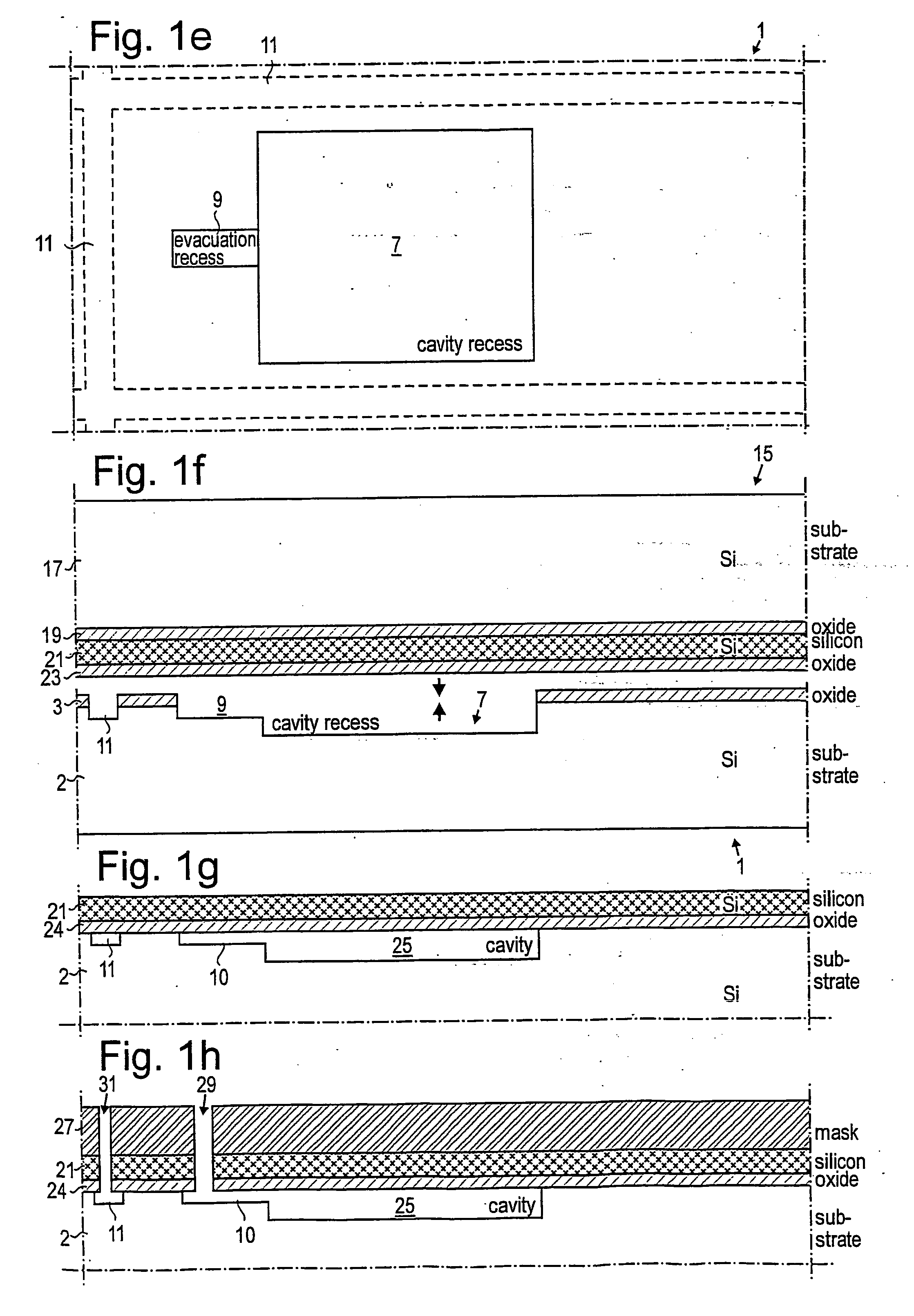

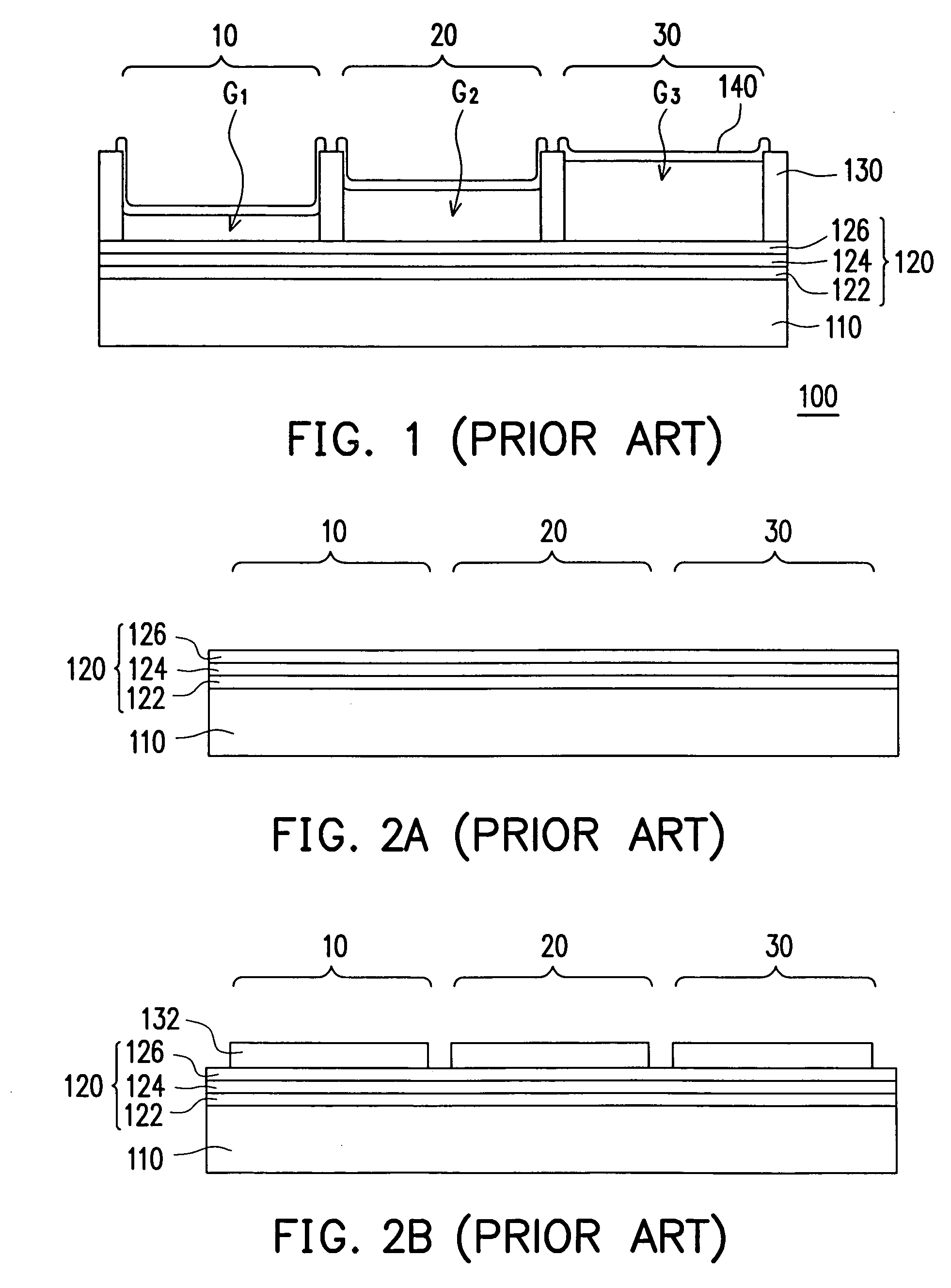

Anti-scatter grids and collimator designs, and their motion, fabrication and assembly

InactiveUS6987836B2Minimize shadowsMinimize overexposureHandling using diaphragms/collimetersCopperMechanical engineering

Grids and collimators, for use with electromagnetic energy emitting devices, include at least a metal layer that is formed, for example, by electroplating / electroforming or casting. The metal layer includes top and bottom surfaces, and a plurality of solid integrated walls. Each of the solid integrated walls extends from the top to bottom surface and has a plurality of side surfaces. The side surfaces of the solid integrated walls are arranged to define a plurality of openings extending entirely through the layer. At least some of the walls also can include projections extending into the respective openings formed by the walls. The projections can be of various shapes and sizes, and are arranged so that a total amount of wall material intersected by a line propagating in a direction along an edge of the grid is substantially the same as another total amount of wall material intersected by another line propagating in another direction substantially parallel to the edge of the grid at any distance from the edge. Methods to fabricate these grids using copper, lead, nickel, gold, any other electroplating / electroforming materials or low melting temperature metals are described.

Owner:CREATV MICROTECH

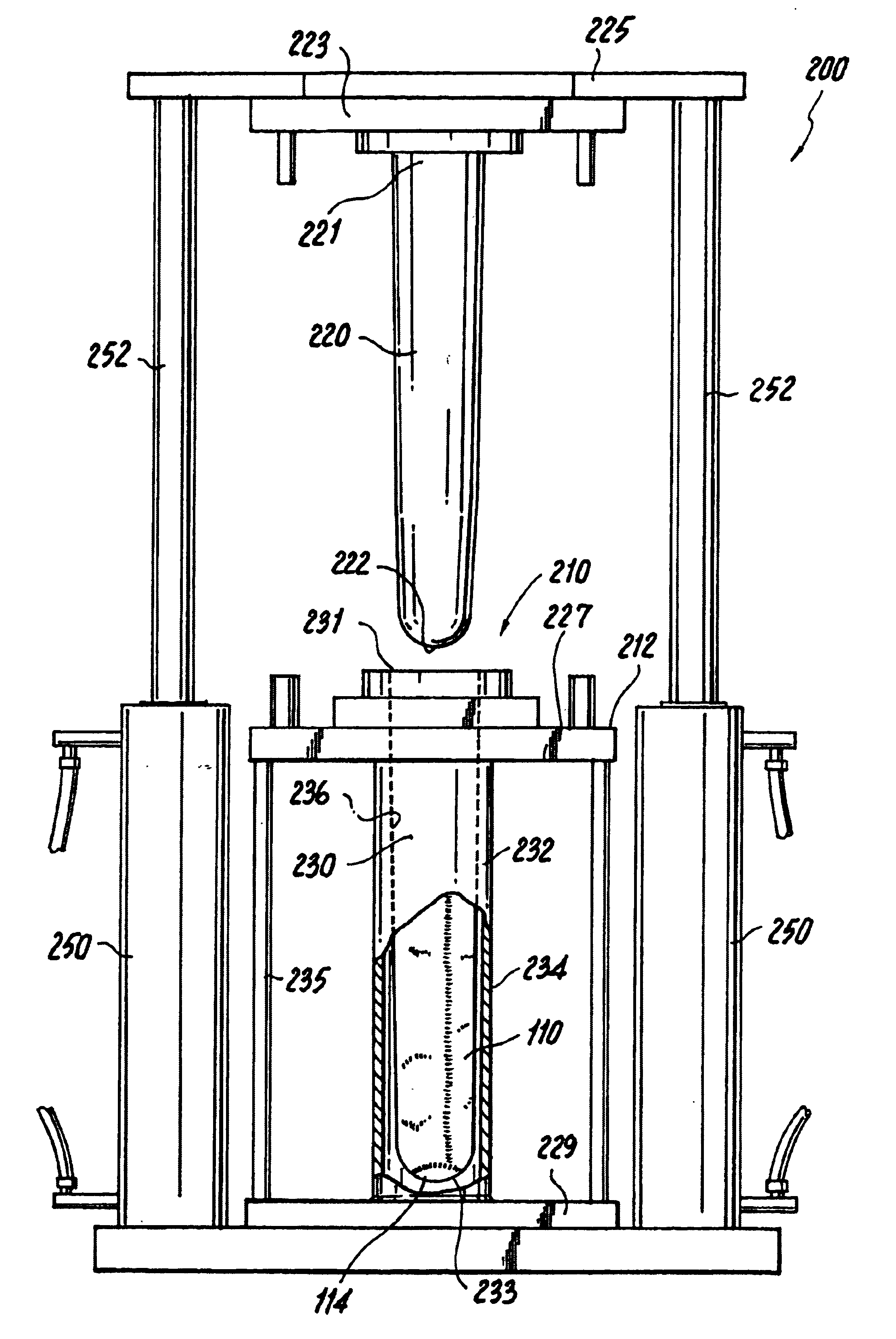

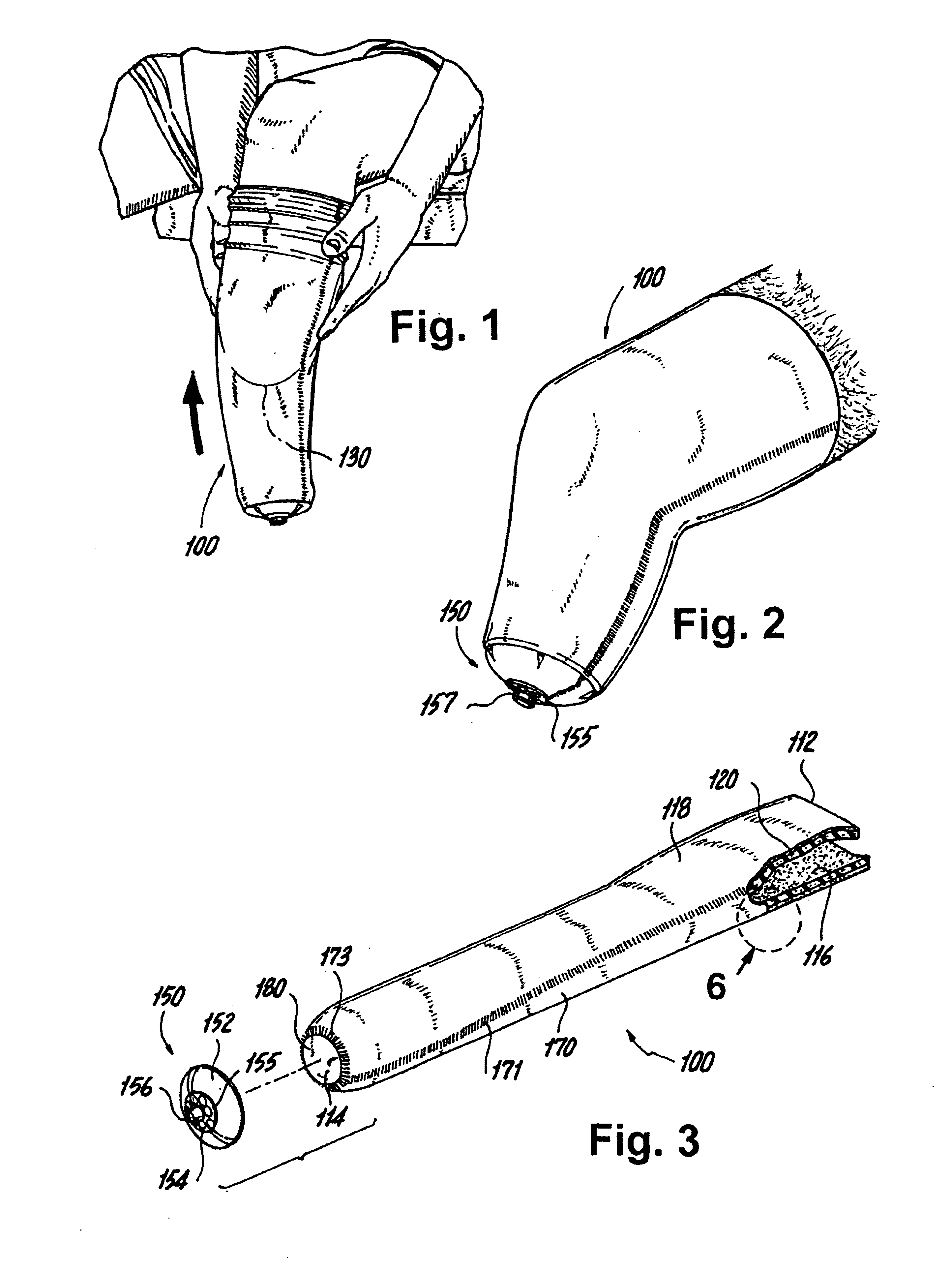

Process for applying a cushion material to an article

InactiveUS6852269B2High precisionAccurate thicknessLaminationWood working apparatusCushioningEngineering

A process for forming a cushion layer of a preselected thickness on an inside of a prosthetic liner body is provided and includes the steps of introducing the liner body into a mold cavity; disposing a sufficient amount of cushioning material into the inside of the liner and directing a mandrel into the inside of the liner body. The driving action of the mandrel causes the cushioning material to be dispersed between the mandrel and the liner body, thereby forming the cushioning layer of preselected thickness.

Owner:SILIPOS

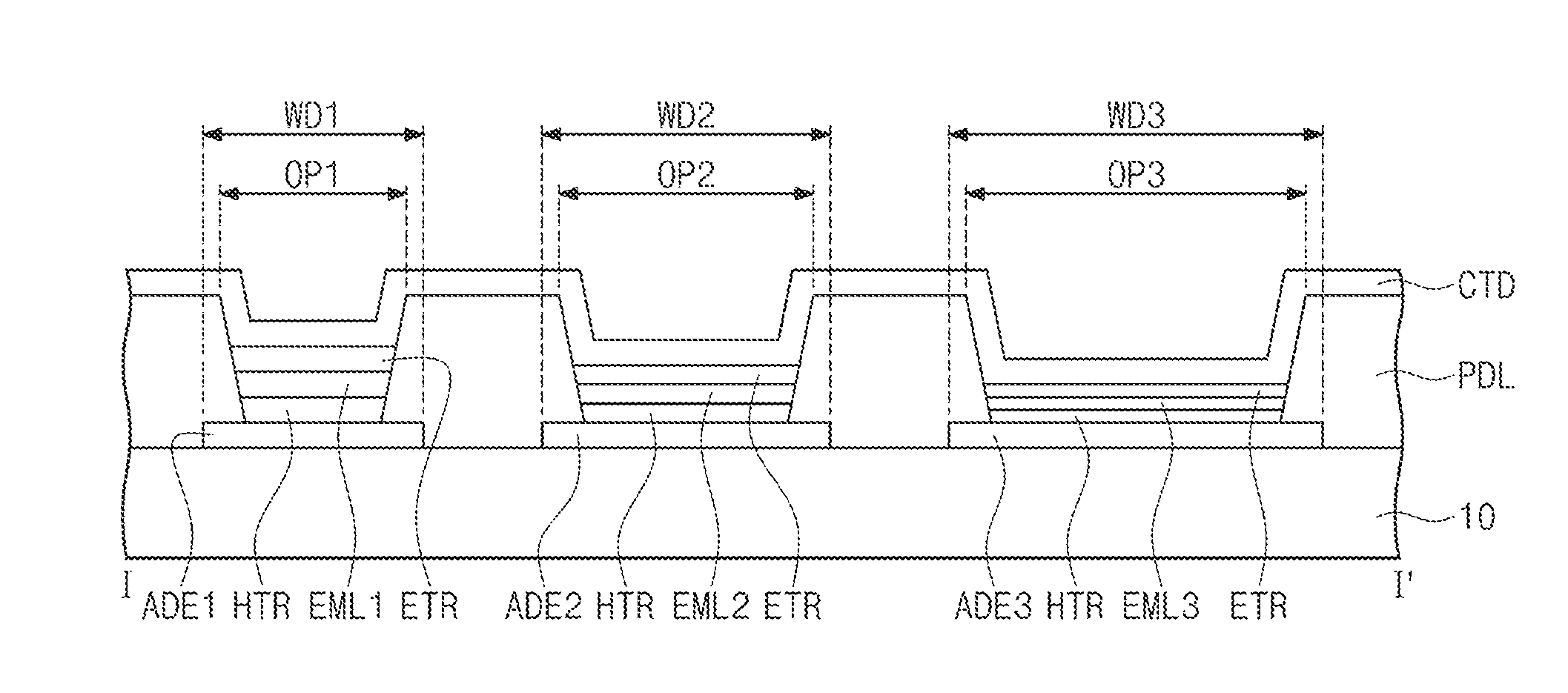

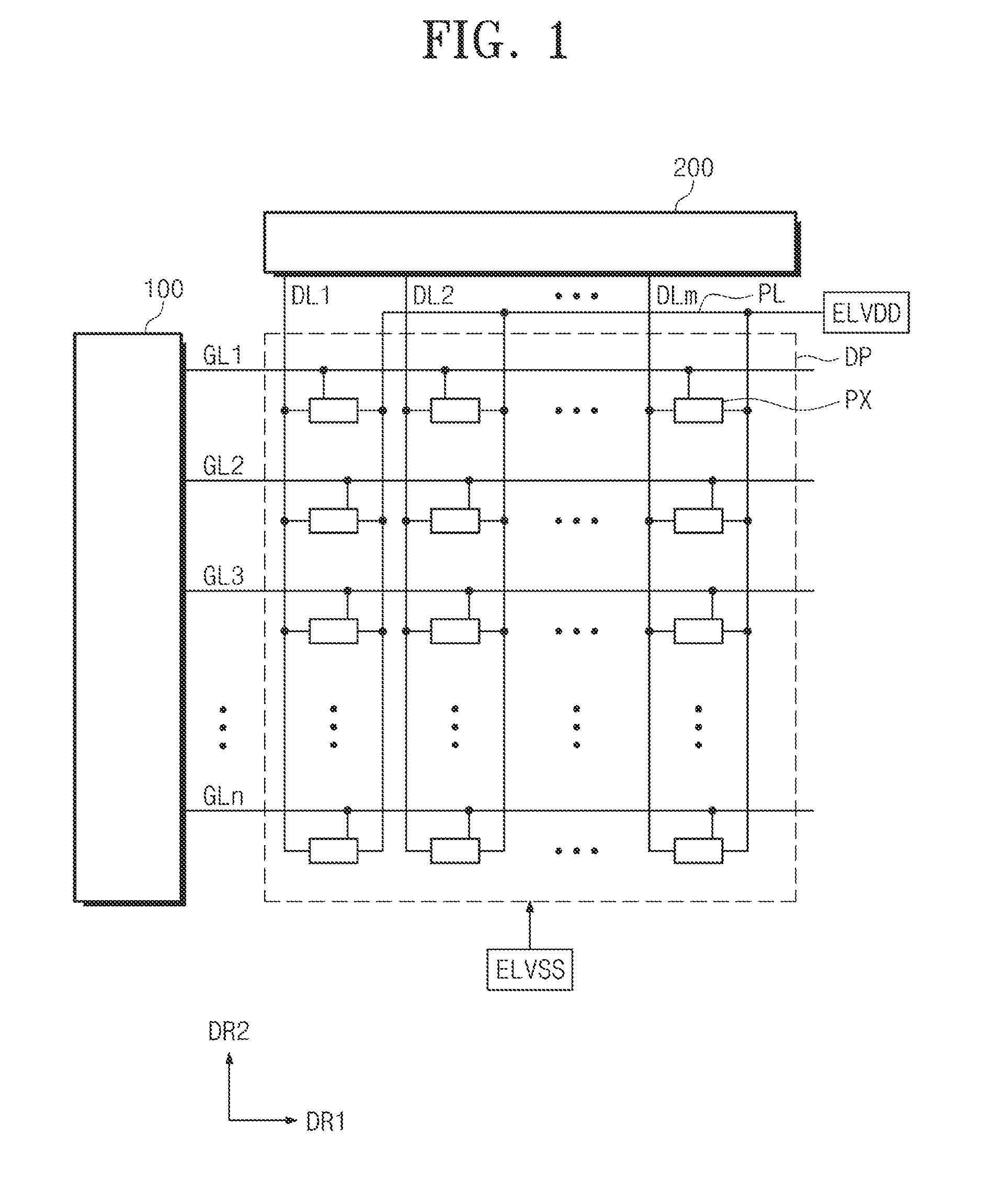

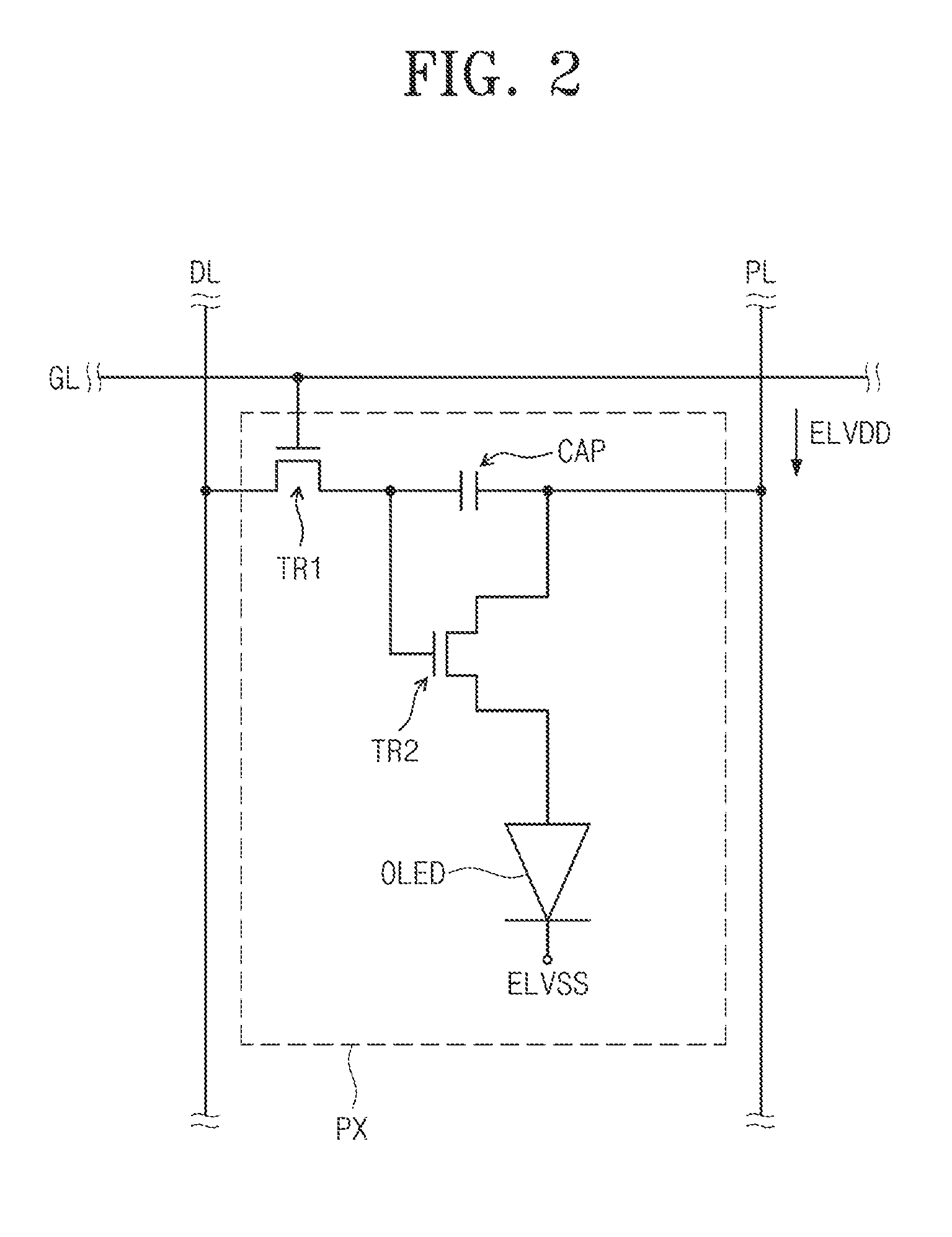

Organic light emitting display panel and method of manufacturing the same

ActiveUS20160276615A1Simple manufacturing processControl thicknessSolid-state devicesSemiconductor/solid-state device manufacturingMaterials scienceOptics

An exemplary embodiment discloses an organic light emitting display panel including a base substrate comprising first pixels configured to emit a light having a first wavelength and second pixels configured to emit a light having a second wavelength and a pixel definition layer disposed on the base substrate. The pixel definition layer includes first and second openings. The first opening corresponds to light emitting areas of n (n is a natural number equal to or greater than 2) first pixels among the first pixels. The second opening corresponds to light emitting areas of m (m is a natural number equal to or greater than 1 and smaller than n) second pixels among the second pixels. An area of the light emitting area of each of the first pixels is smaller than an area of the light emitting area of each of the second pixels.

Owner:SAMSUNG DISPLAY CO LTD

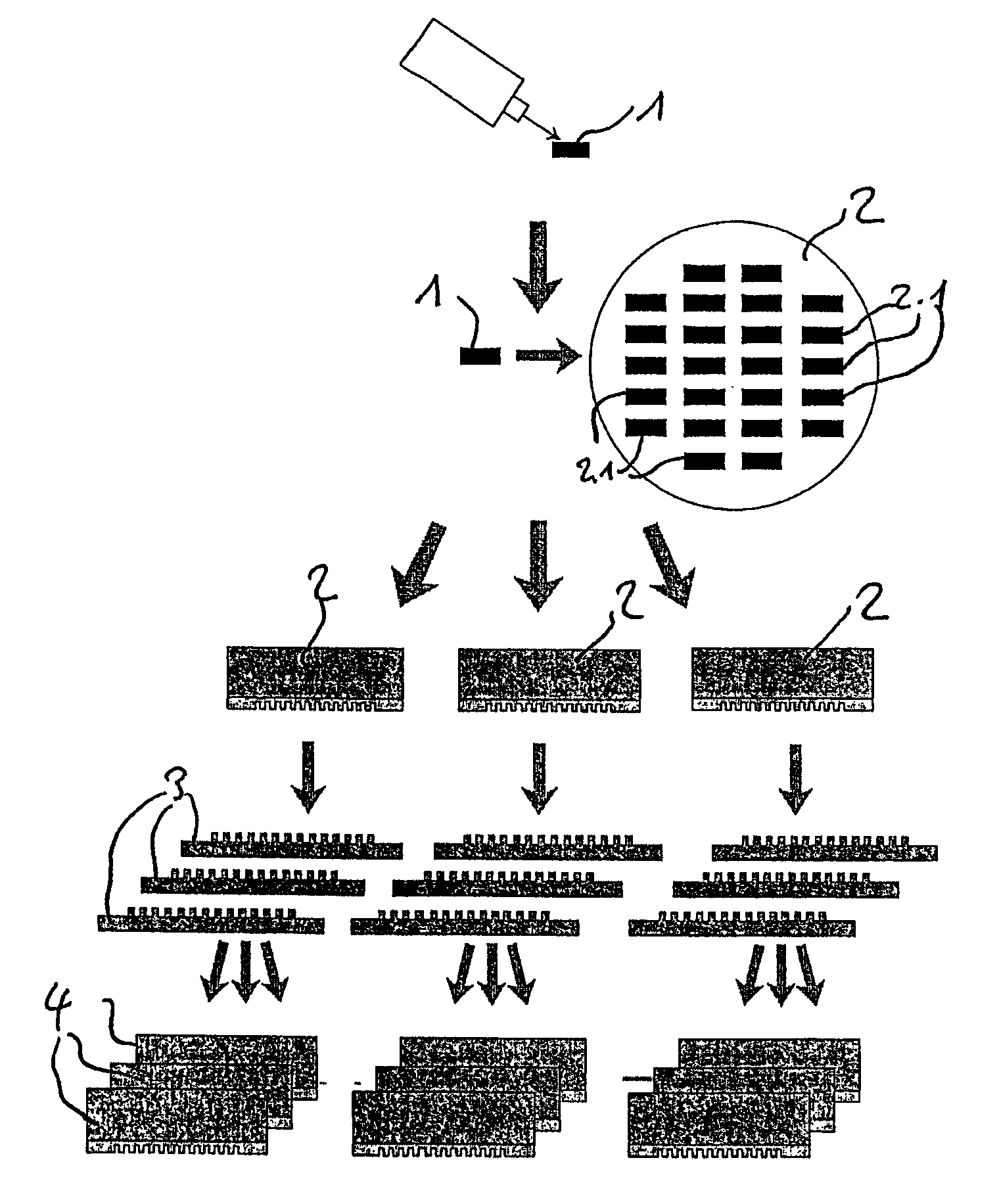

Manufacturing a replication tool, sub-master or replica

ActiveUS20060259546A1Easy to implementLarge scaleNanoinformaticsConfectioneryStructuring elementManufacturing engineering

Owner:AMS SENSORS SINGAPORE PTE LTD

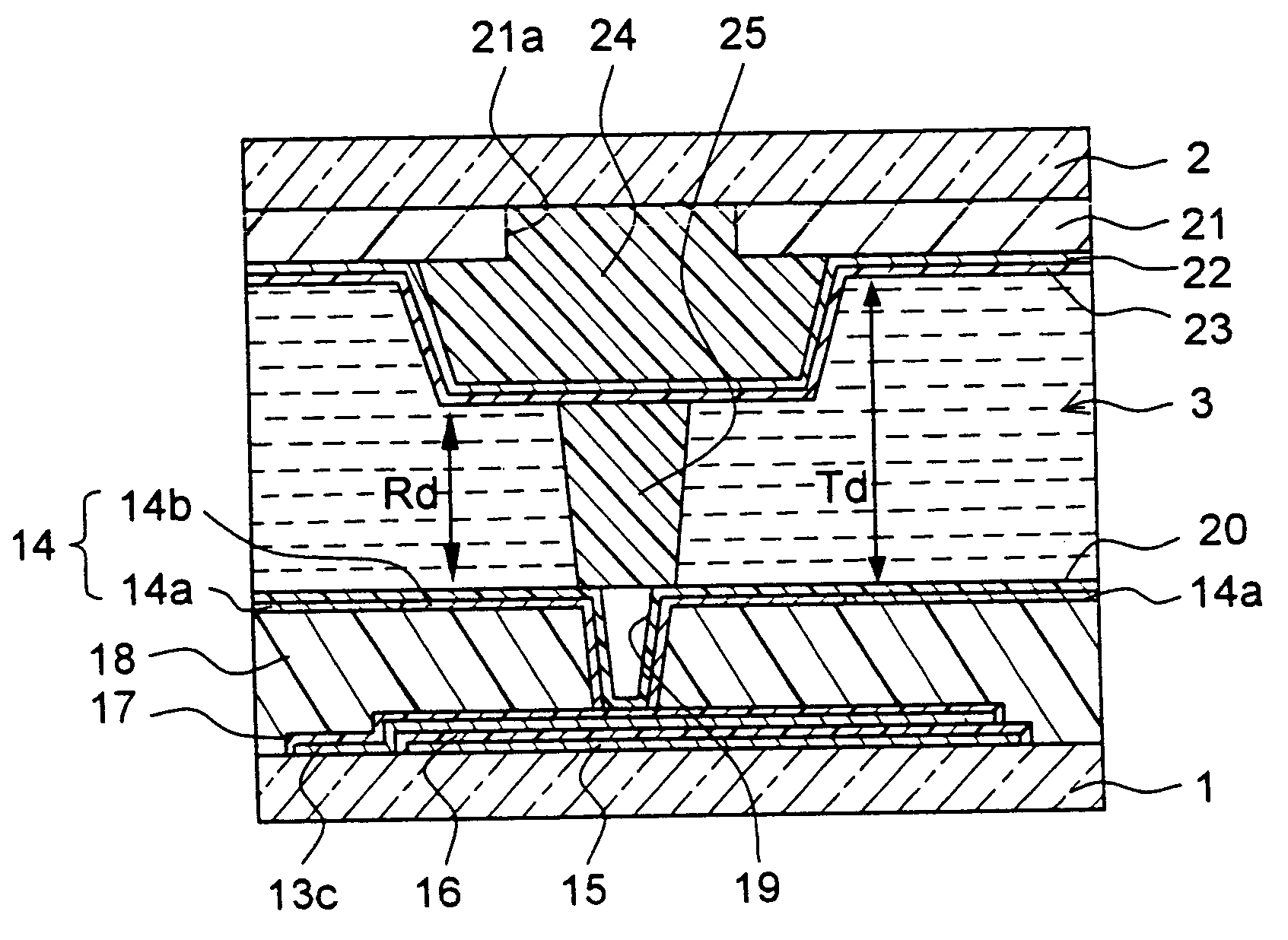

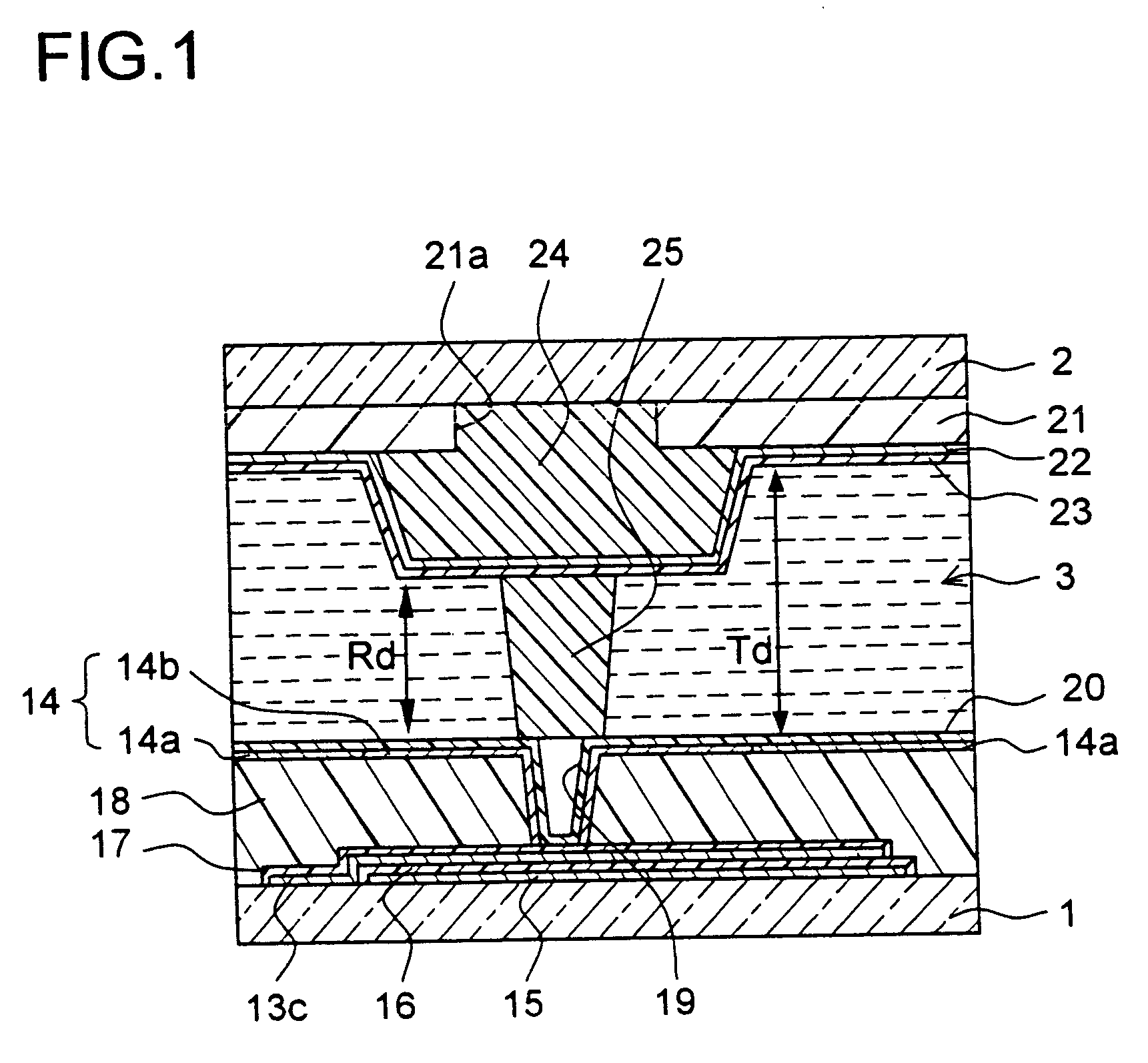

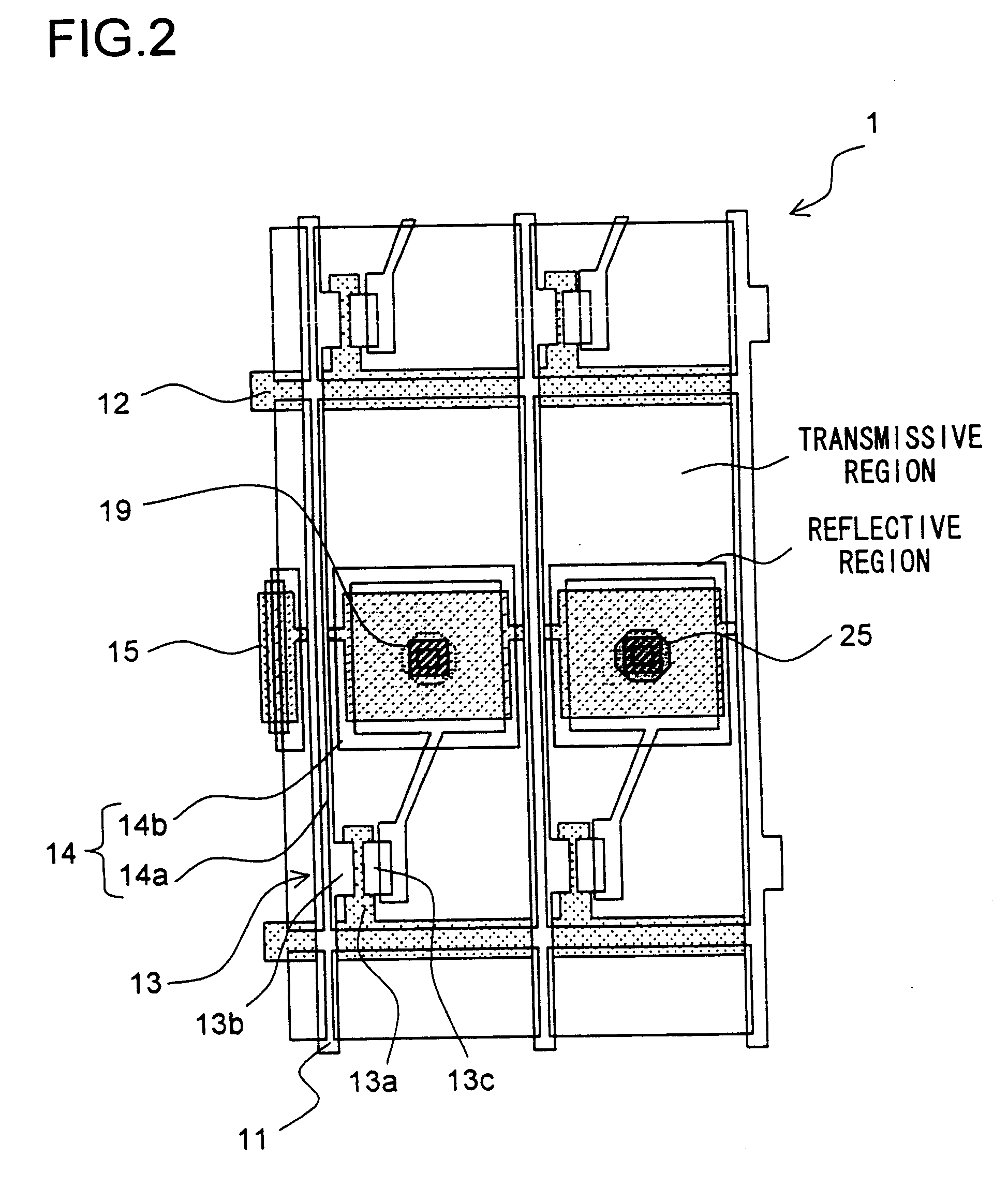

Liquid crystal display apparatus

ActiveUS20050052607A1Improve display qualityEffective areaNon-linear opticsLiquid-crystal displayEngineering

A columnar spacer is interposed between a first substrate and a second substrate for holding a liquid crystal layer between them. The columnar spacer is formed in such a manner as to have an area superposed, in each pixel, with the contact hole formed in the first substrate and an area not superposed with said contact hole. Even in the case where the first and second substrates attached to each other are displaced from each other, the columnar spacer never falls in the contact hole and a desired cell gap can be positively secured. Also, since the columnar spacer is not located in the contact hole, no margin for substrate attachment is required to form the contact hole in the first substrate, thereby improving the open area ratio effective for display for improved display quality.

Owner:UNIFIED INNOVATIVE TECH

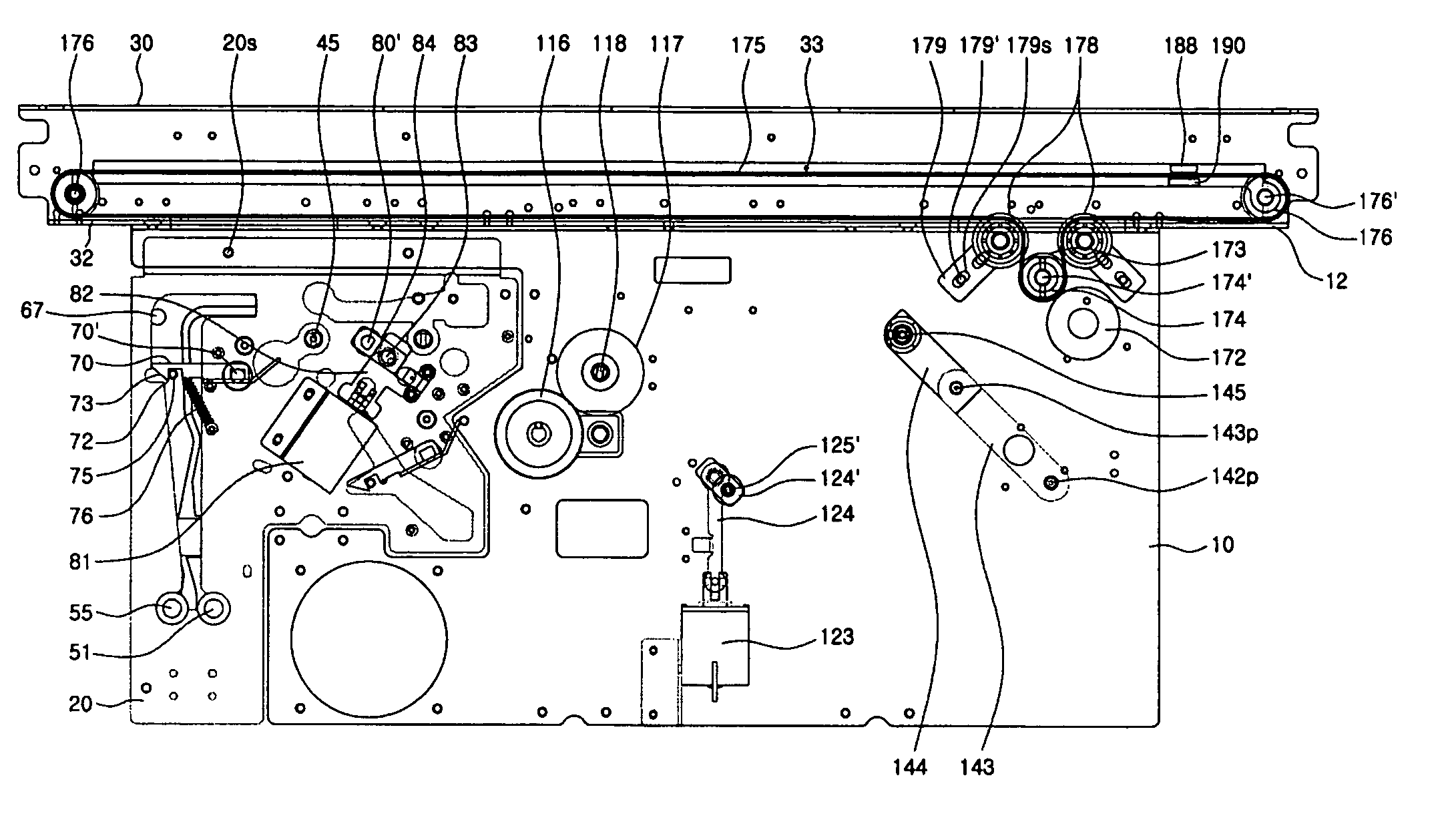

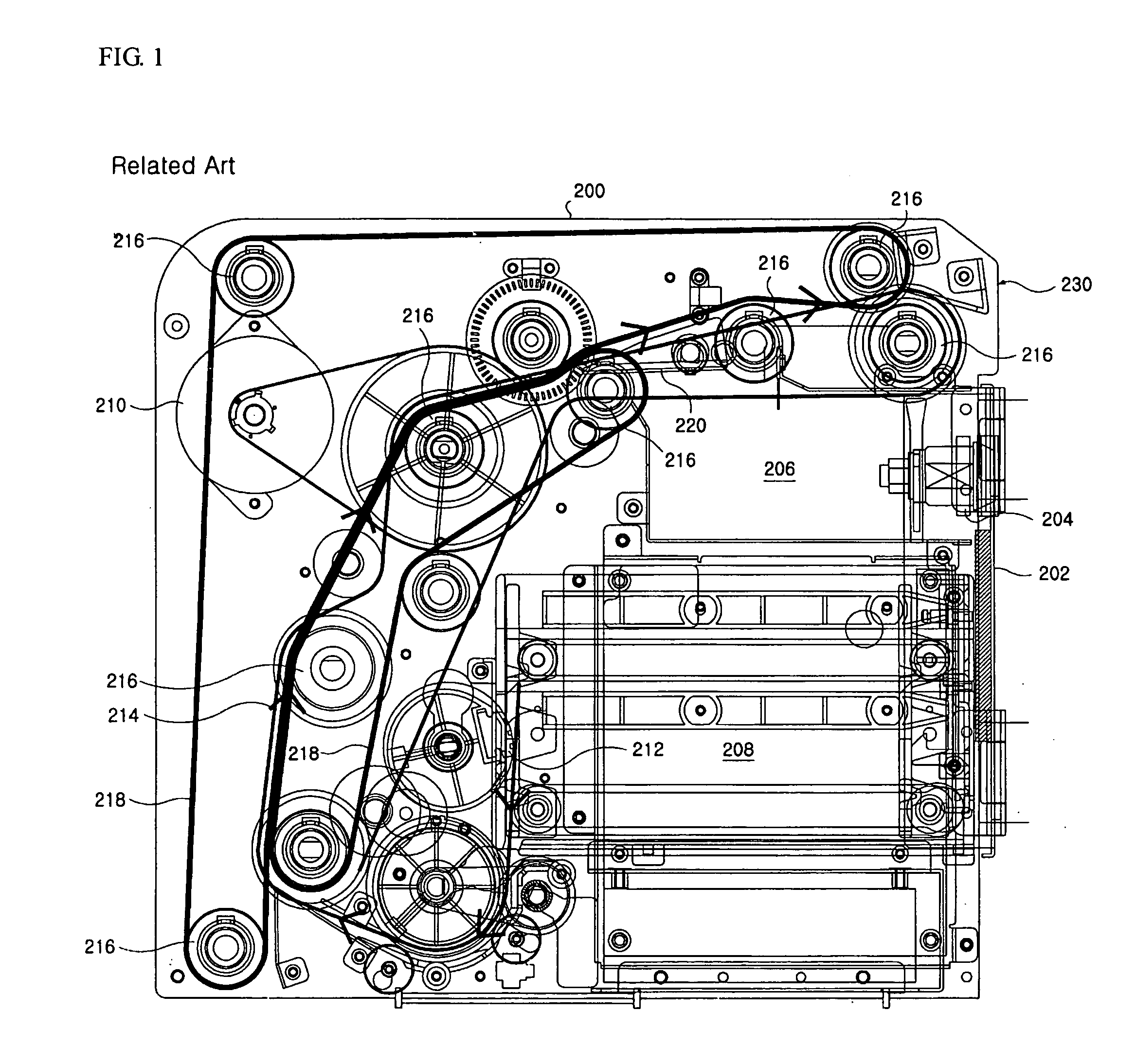

Media discharging unit for media dispenser

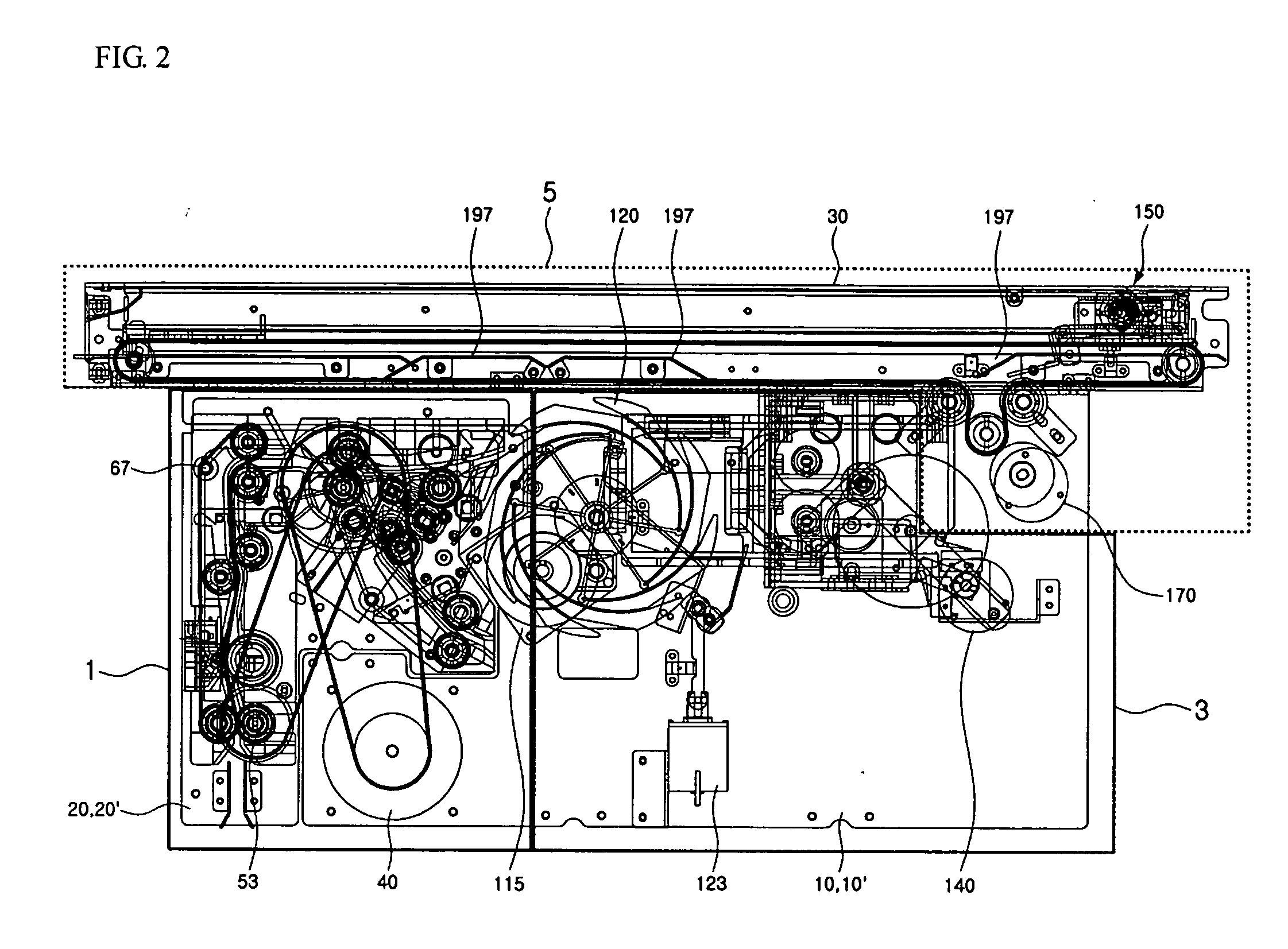

ActiveUS20050189693A1Easy accessAccurate thicknessComplete banking machinesCoin/currency accepting devicesEngineeringMedia dispenser

The present invention relates to media discharging unit for a media dispenser. The present invention includes a delivery module, which selectively feeds media fed from a media box to a discharge position and a reject position one-by-one using belts and rollers. A stacking module is separable from the delivery module, and collects the media, which are fed by the delivery module, one-by-one upon the rotation of a stacking wheel and then feeds the collected media as a stack at one time. A stack delivery module is separable from the stacking module, and clamps the stacked media, which are collected in the stacking module, and feeds the stacked media to a position where a customer can take the media.

Owner:ATEC AP CO LTD

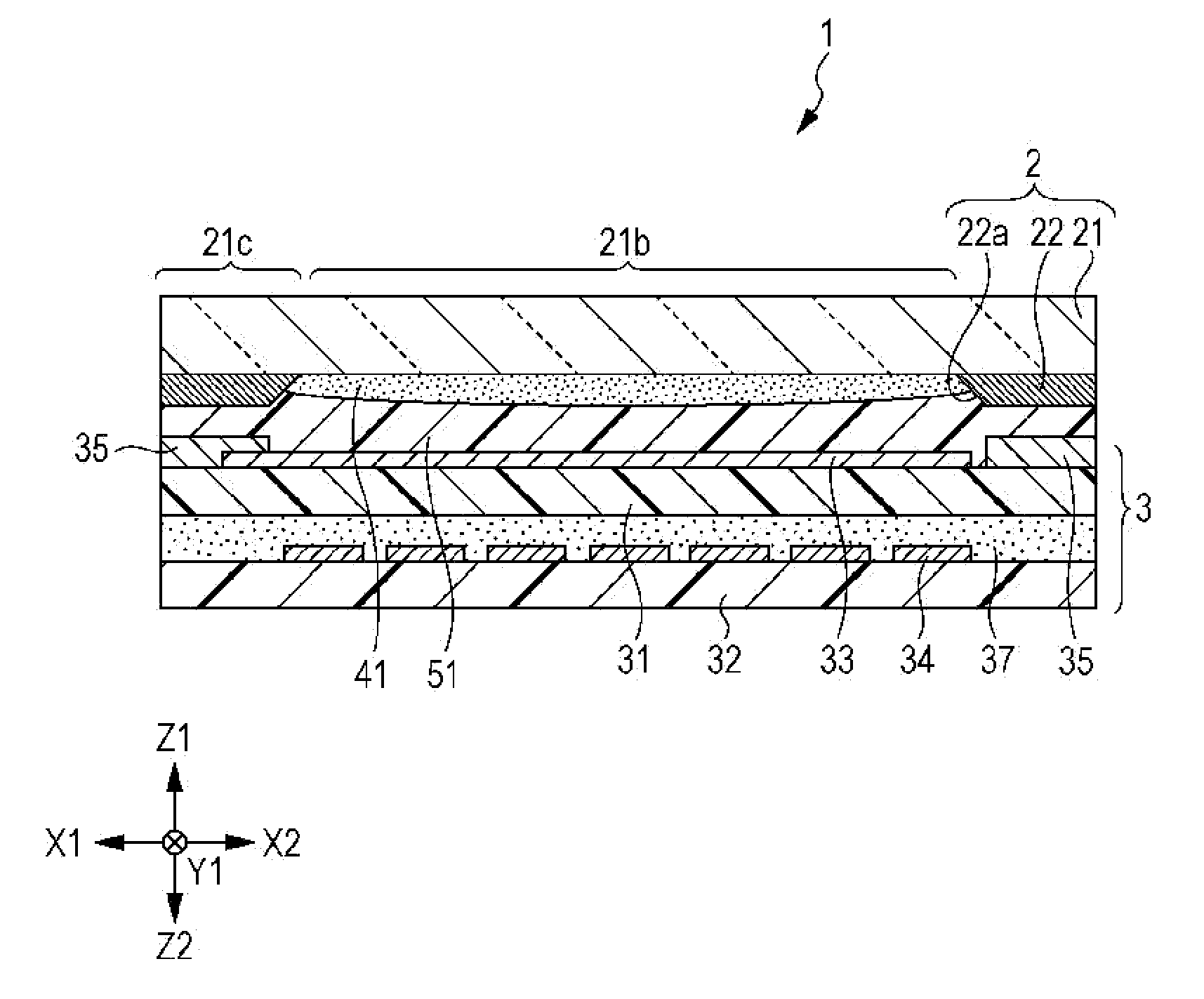

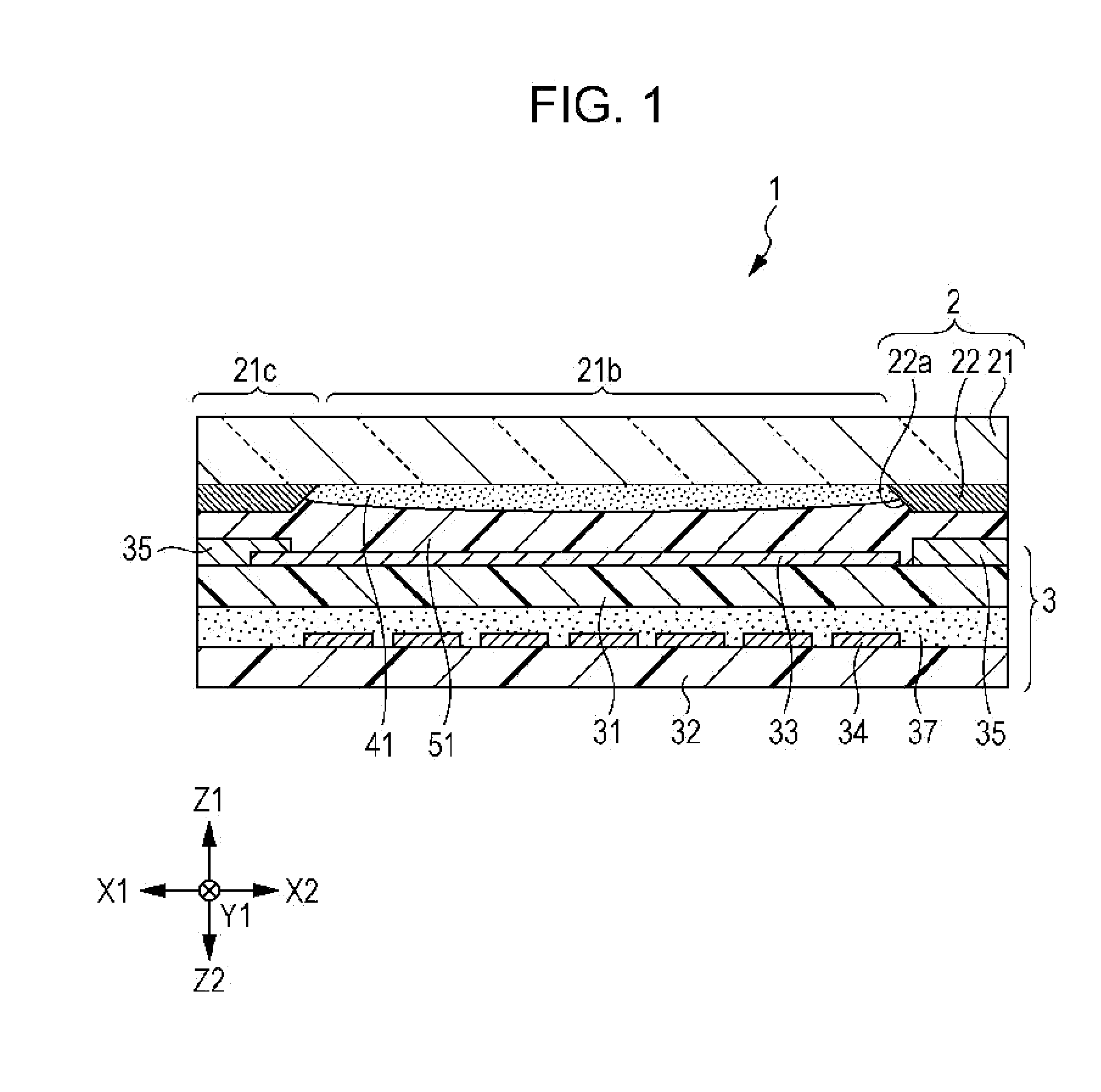

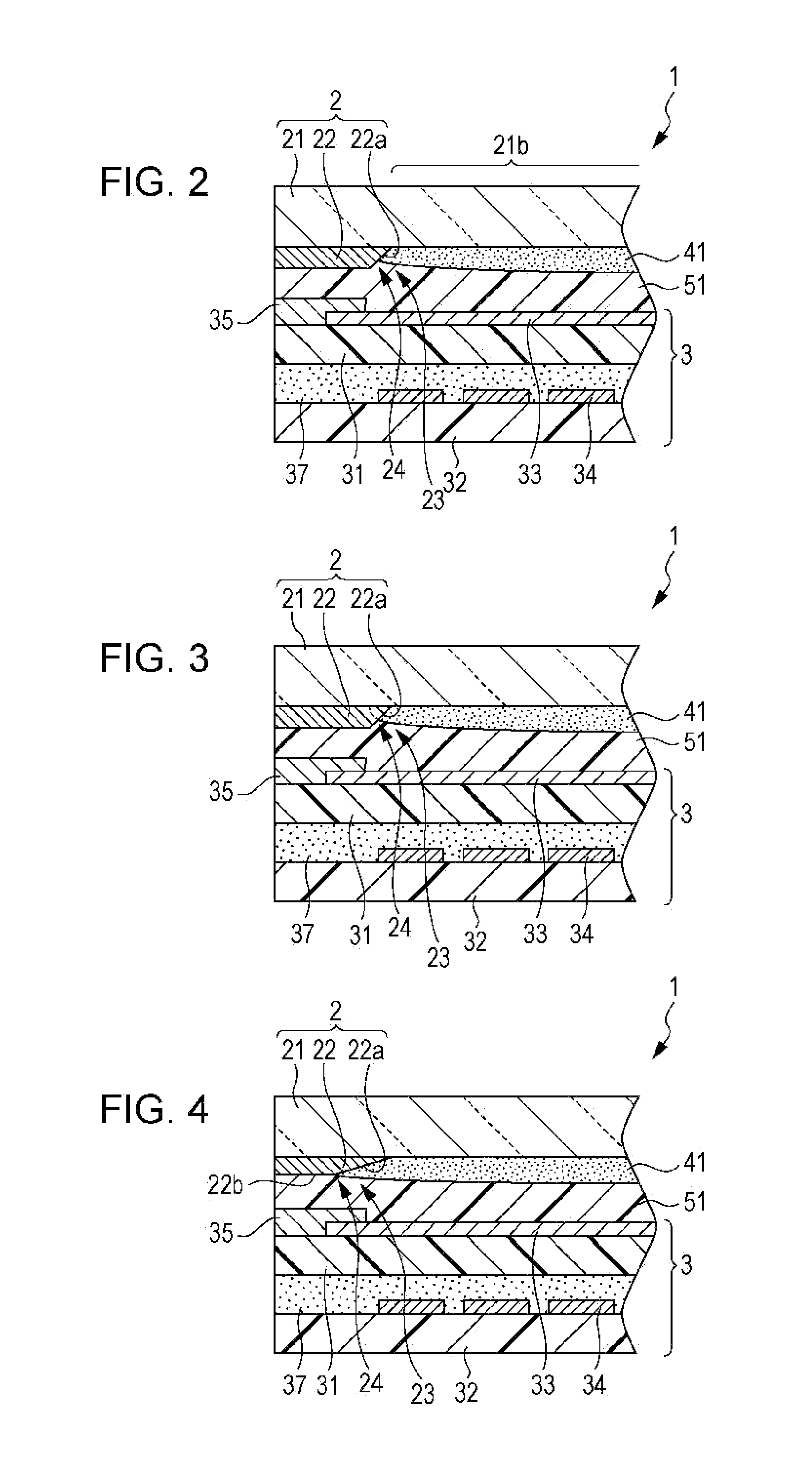

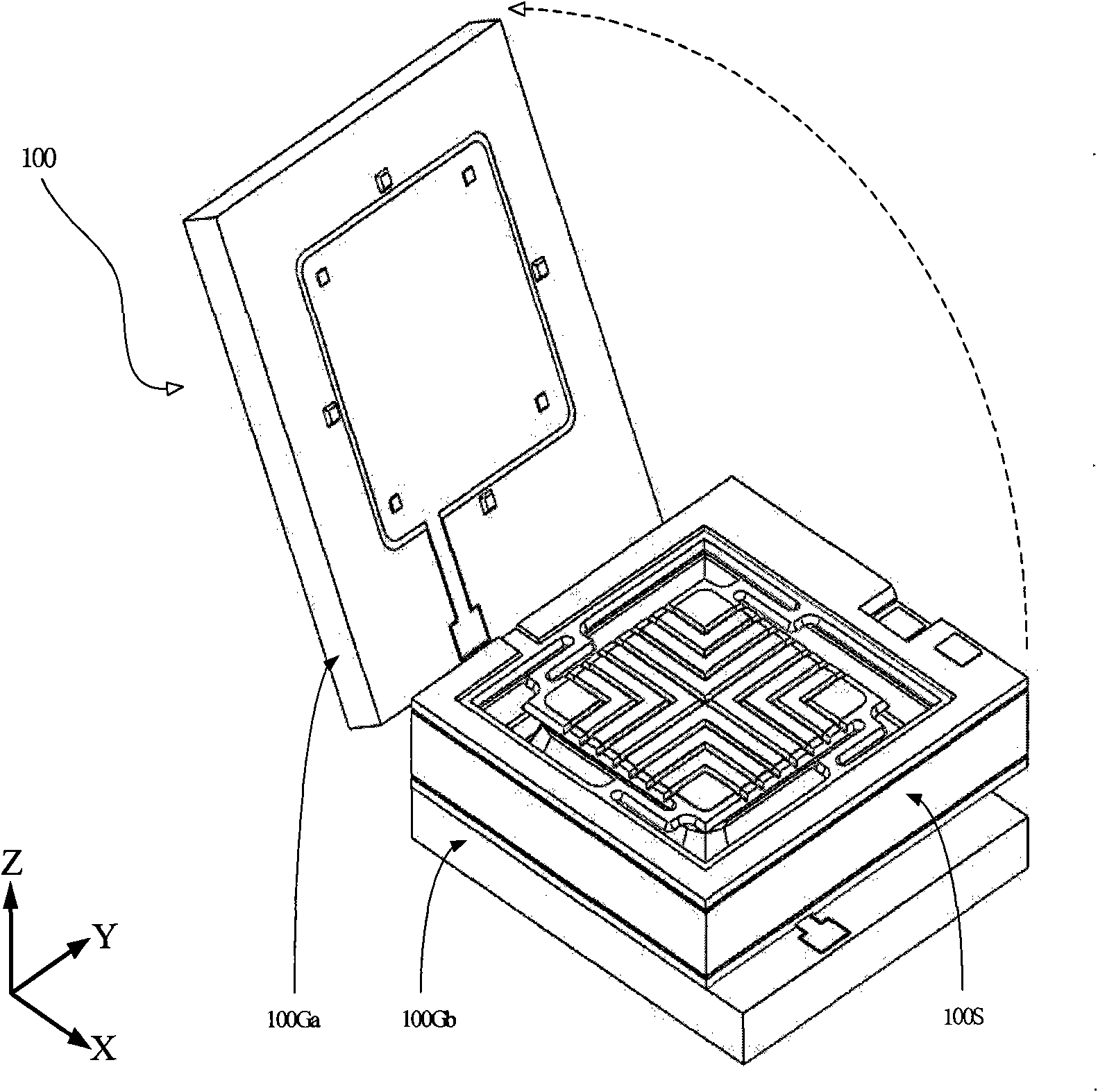

Input device and method of producing input apparatus

ActiveUS20120098551A1Control thicknessAccurate thicknessResistance/reactance/impedenceSynthetic resin layered productsEngineeringInput device

An input device includes a sensor member that detects input position information; and a protective member that protects the sensor member, wherein the protective member includes a window-shaped light-transmissive region transmitting light in the thickness direction, a transparent substrate having an input surface on a first surface, and a decorative layer disposed on a second first of the transparent substrate. The decorative layer is stacked on the transparent substrate so as to surround the light-transmissive region, and an inclined section is provided at the inner edge of the decorative layer; the transparent filler is stacked on the second surface of the transparent substrate to cover the light-transmissive region and the inclined section; and the sensor member and the protective member are bonded together with the adhesive layer disposed on the transparent filler and the decorative layer.

Owner:ALPS ALPINE CO LTD

Knife arrangement for minimizing feathering during high speed cutting of food products

InactiveUS20050000344A1Minimize pressure appliedPrecise consistencyMetal working apparatusSlice thicknessKnife cuts

A cutting wheel using knives with slice thickness gauging surfaces defining, with the knife cutting edges, a thickness dimension of sliced food products and a throat dimension measured perpendicular to the wheel cutting plane between each knife cutting edge and the terminal edge of the adjacent gauging surface, wherein the knives each have a single primary bevel extending practically tangent to the cutting plane on the side of the knife facing towards the cutting plane and a smooth transition area on the opposite side of the knife, and the ratio of throat dimension to slice thickness dimension is equal to or more than 1 to 1.7.

Owner:URSCHEL LAB

Selective growth process for group III-nitride-based semiconductors

InactiveUS6265322B1More controllableAccurate thicknessPolycrystalline material growthSemiconductor/solid-state device manufacturingDifferential growthSingle crystal

A method of forming selected Group III-nitride regions uses a masking layer to cause differential growth between single crystal Group III-nitride material and polycrystalline Group III-nitride material. The epitaxial process is chosen to provide vertical growth so as to allow for replication of the mask edges at the defined limits for the selected regions. By using an etchant that is selective between polycrystalline and single crystal Group III-nitride material, the polycrystalline material (that grew over the mask layer) can be removed, leaving only the single crystal Group III-nitride (that grew over the exposed substrate material).

Owner:AVAGO TECH INT SALES PTE LTD

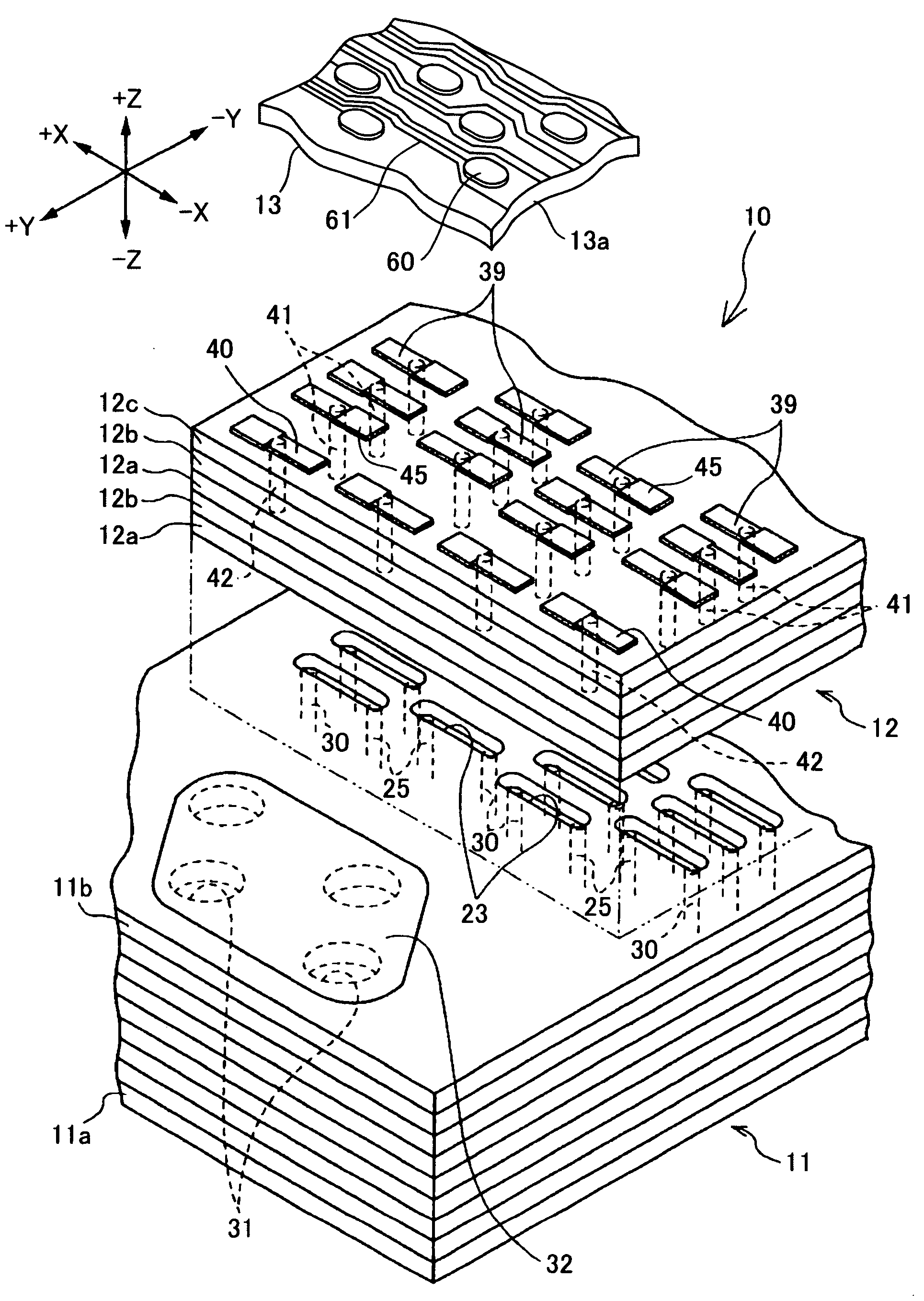

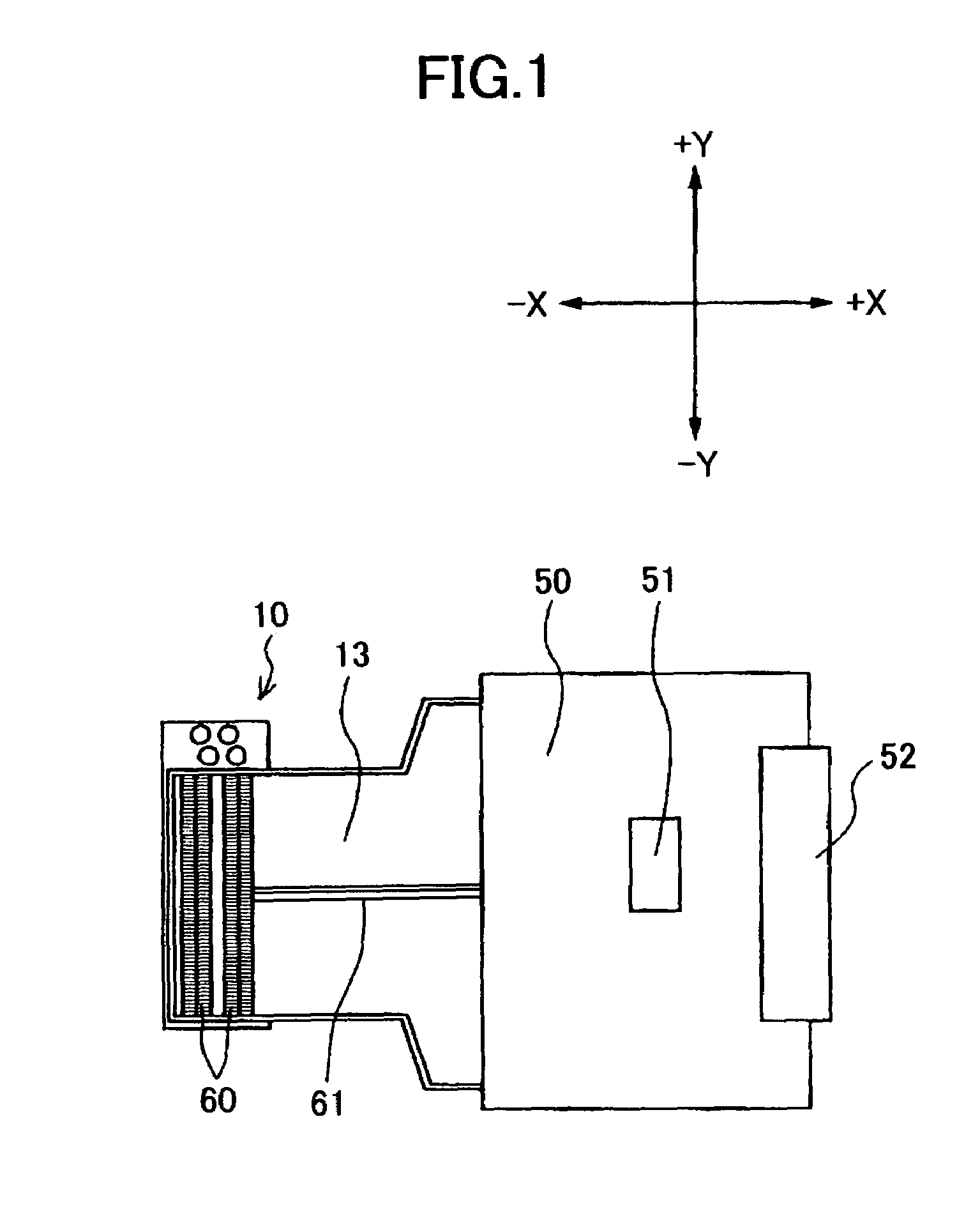

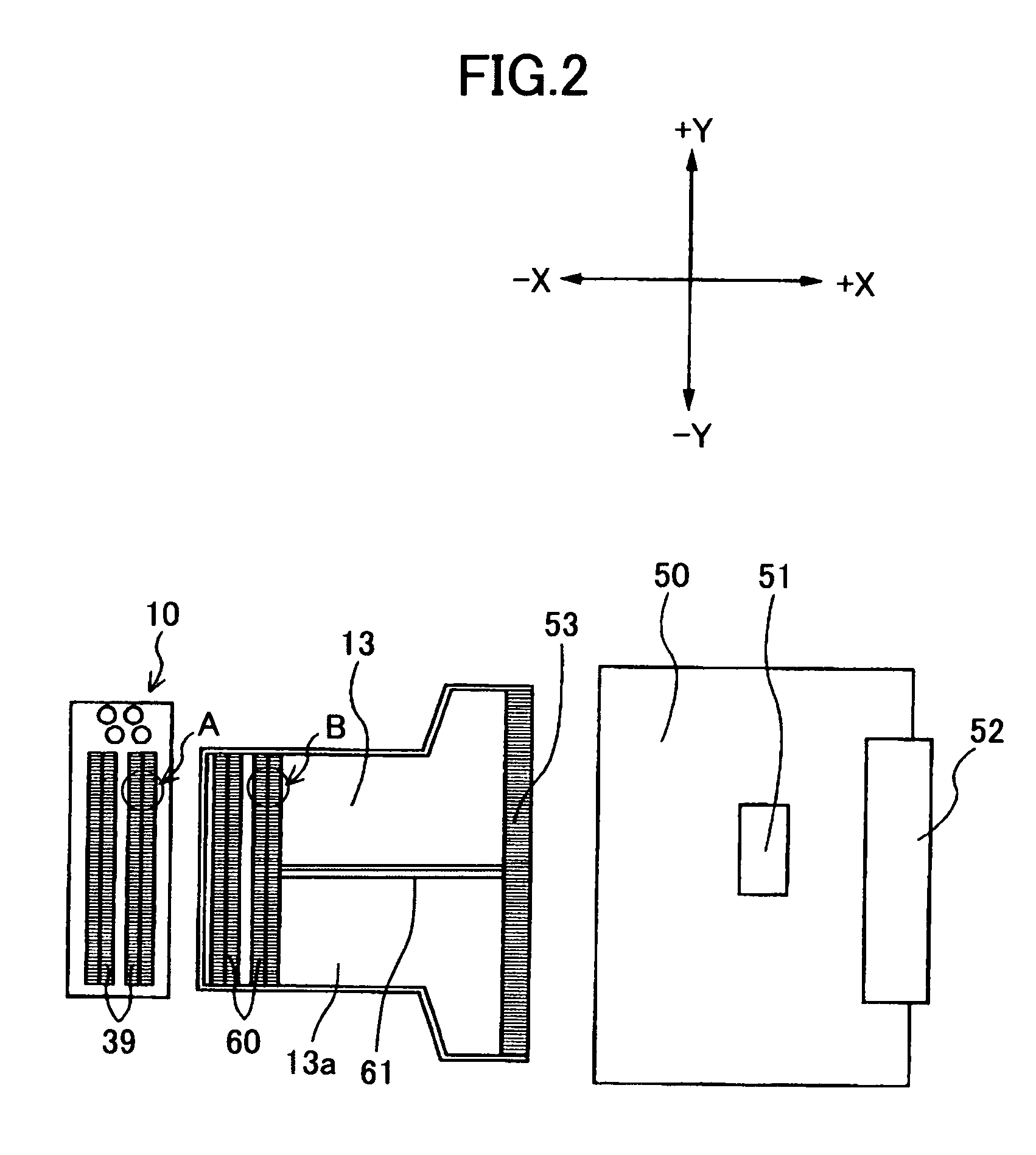

Structure and method for connecting flexible printed circuit board to inkjet print head

ActiveUS7055936B2Accurate shapeAccurate thicknessPrinted circuit assemblingPrinted circuit aspectsFlexible electronicsPrinted circuit board

A plurality of lands and a plurality of conducting wires connected independently to each land are formed on one side surface of an insulating substrate of a flexible printed circuit board. Through-holes are formed through the insulating substrate for exposing the lands to the other side surface. Solder is provided in the through-holes. The solder connects the lands to the head terminals on an inkjet head, which is located facing the other side surface of the insulating substrate. The insulating substrate separates the solder from areas between the conducting wires and from areas between the lands, thereby preventing short circuits from occurring when manufacturing the connecting structure with a low tolerance grade.

Owner:BROTHER KOGYO KK

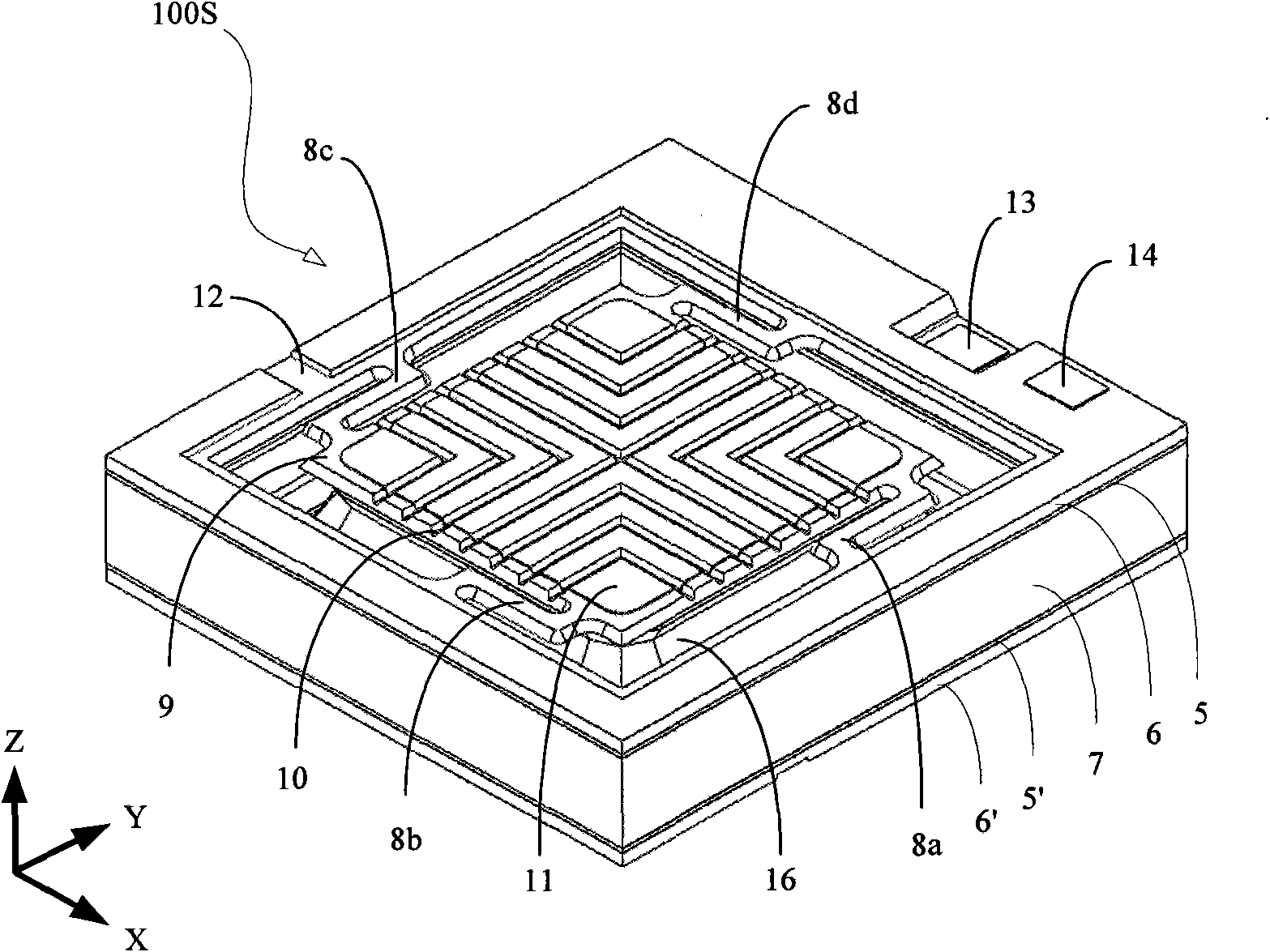

Processing method of differential type high-precision accelerometer

ActiveCN101786593AReduce process difficultyLow process temperatureTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStress ProblemMonocrystalline silicon

The invention discloses a processing method of a differential type high-precision accelerometer. The accelerometer comprises an upper electrode cover plate, a movable silicon structural assembly with a beam-mass block structure and a lower electrode cover plate which are sequentially connected from top to bottom. The method comprises the following steps of: processing the upper electrode plate and the lower electrode plate by using a glass sheet or a monocrystalline silicon wafer as a substrate; processing the movable silicon structural assembly with the beam-mass block structure by using a double-device-layer SOI (Silicon-On-Insulator) monocrystalline silicon wafer as a substrate; and connecting the upper electrode plate and the lower electrode plate which are processed by using the substrates with the movable silicon structural assembly based on a bonding mode. In the invention, only one monocrystalline silicon wafer is adopted to process the movable silicon structural assembly, thereby avoiding the condition that a frequently used high-temperature silicon-silicon bonding process is used for preparing the movable silicon structural assembly, reducing the process difficulty, lowering the highest process temperature and eliminating bonding stress problems introduced by silicon-silicon bonding; and moreover, the beam-mass block structure has generality.

Owner:PEKING UNIV

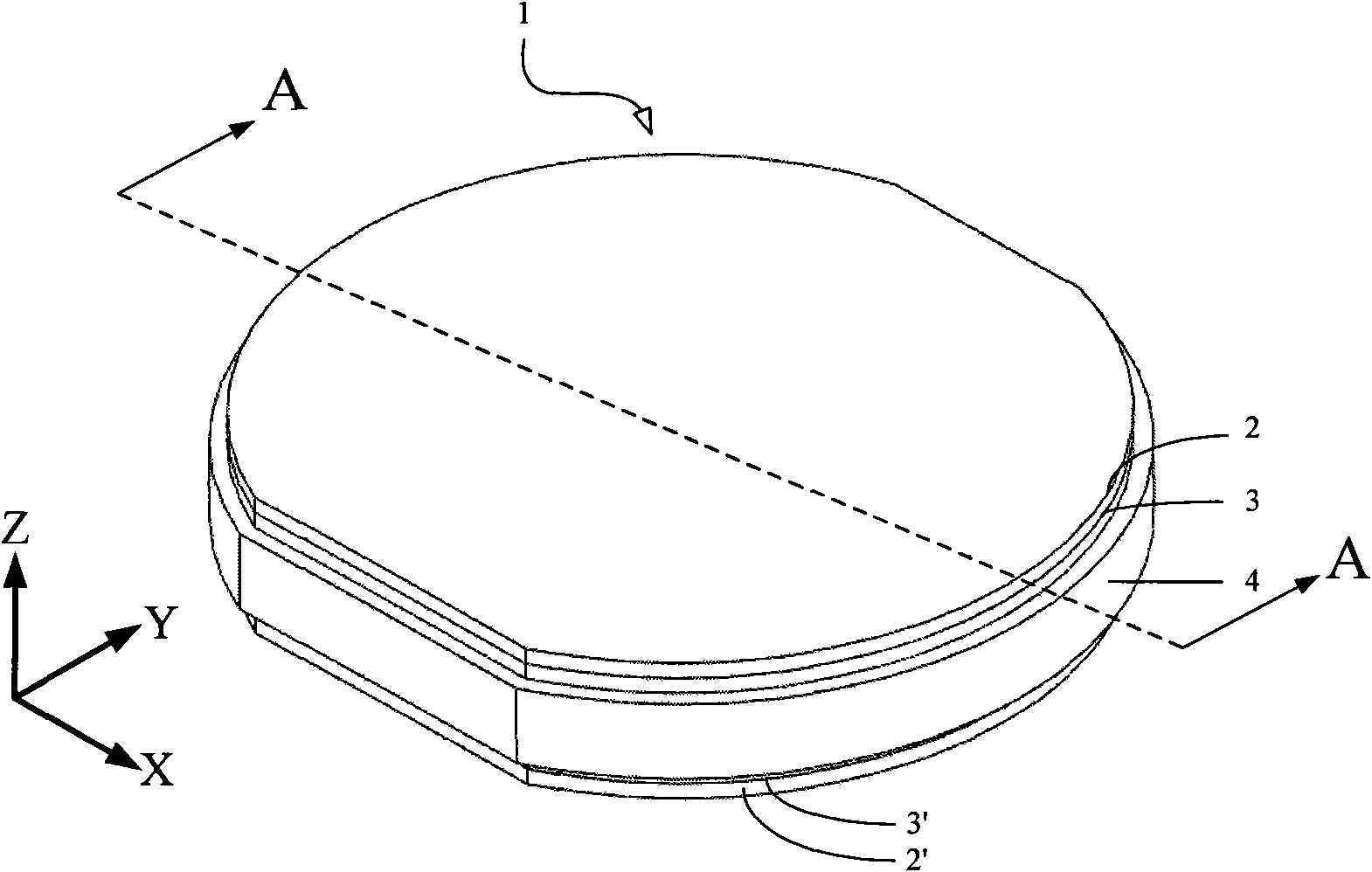

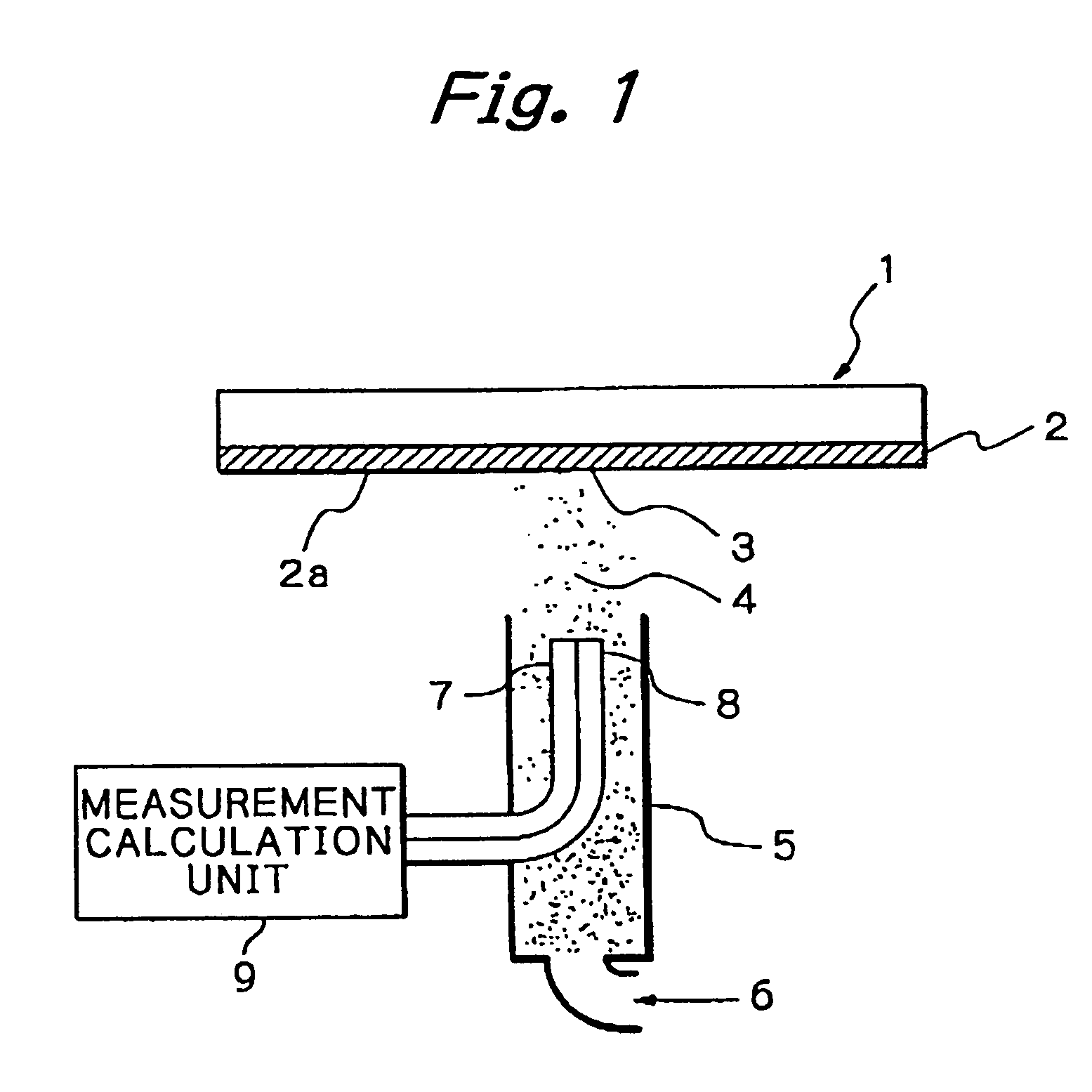

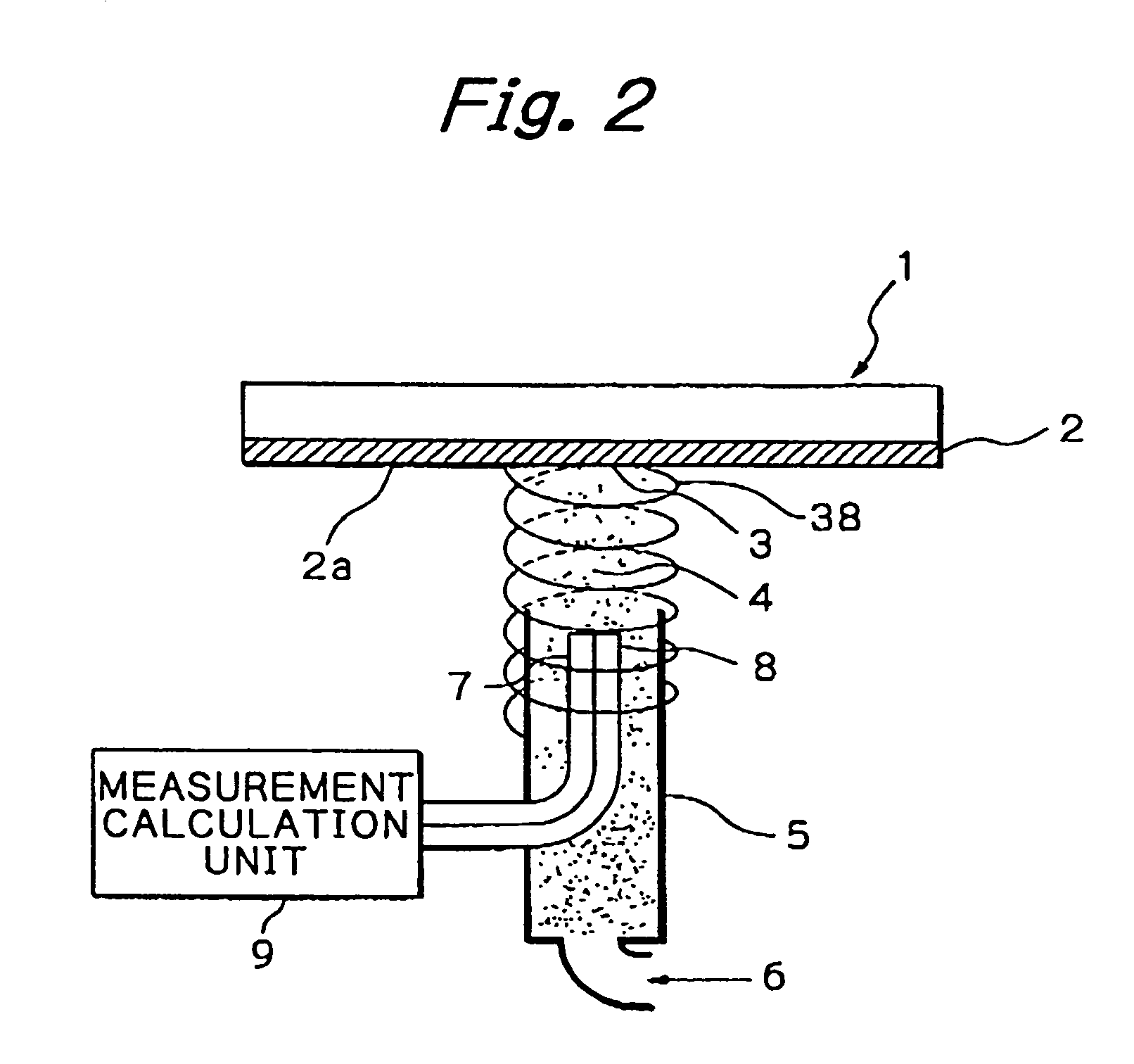

Substrate film thickness measurement method, substrate film thickness measurement apparatus and substrate processing apparatus

InactiveUS7072050B2Convenient ArrangementAccurate film thicknessSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingFiberOptoelectronics

A jet of water in a cylindrical form is supplied from a jet nozzle onto a measurement surface of a substrate to form a column of the water extending between the nozzle and the measurement surface. Light is emitted from an irradiation fiber and transmitted through the column of water to the measurement surface. The light reflected by the measurement surface is received by a light-receiving fiber through the column of water. A measurement calculation unit measures the thickness of a film formed on the substrate, based on the intensity of the reflected light.

Owner:EBARA CORP

Anti-scatter grid and collimator designs, and their motion, fabrication and assembly

ActiveUS20080088059A1Minimize shadowsMinimize overexposureRadiation/particle handlingDecorative surface effectsEngineeringMechanical engineering

Grids and collimators, for use with electromagnetic energy emitting devices, include at least a metal layer that is formed, for example, by electroplating / electroforming or casting. The metal layer includes top and bottom surfaces, and a plurality of solid integrated walls. Each of the solid integrated walls extends from the top to bottom surface and has a plurality of side surfaces. The side surfaces of the solid integrated walls are arranged to define a plurality of openings extending entirely through the layer. At least some of the walls also can include projections extending into the respective openings formed by the walls. The projections can be of various shapes and sizes, and are arranged so that a total amount of wall material intersected by a line propagating in a direction along an edge of the grid is substantially the same as another total amount of wall material intersected by another line propagating in another direction substantially parallel to the edge of the grid at any distance from the edge. Methods to fabricate these grids using copper, lead, nickel, gold, any other electroplating / electroforming materials, metal composites or low melting temperature metals are described.

Owner:CREATV MICROTECH

Method for protection of adhesives used to secure optics from ultra-violet light

InactiveUS7081278B2Reduce the amount requiredLight deteriorationAdhesive processesNanostructure manufactureAdhesiveUltraviolet

A method for reducing the scattered light emitted through an optical element is provided that protects adhesive used to hold the optical element in place from light induced deterioration. In one embodiment, the method includes applying a thin coating of an organoxy metallic compound to a region on an optical element where adhesive will be applied and exposing the organoxy metallic compound to ultra-violet light. Exposure to ultra-violet light converts the organoxy metallic compound to its corresponding metal oxide forming an optically inert, light absorbing coating that protects adhesive used to hold the optical element in place from light induced deterioration.

Owner:ASML HLDG NV

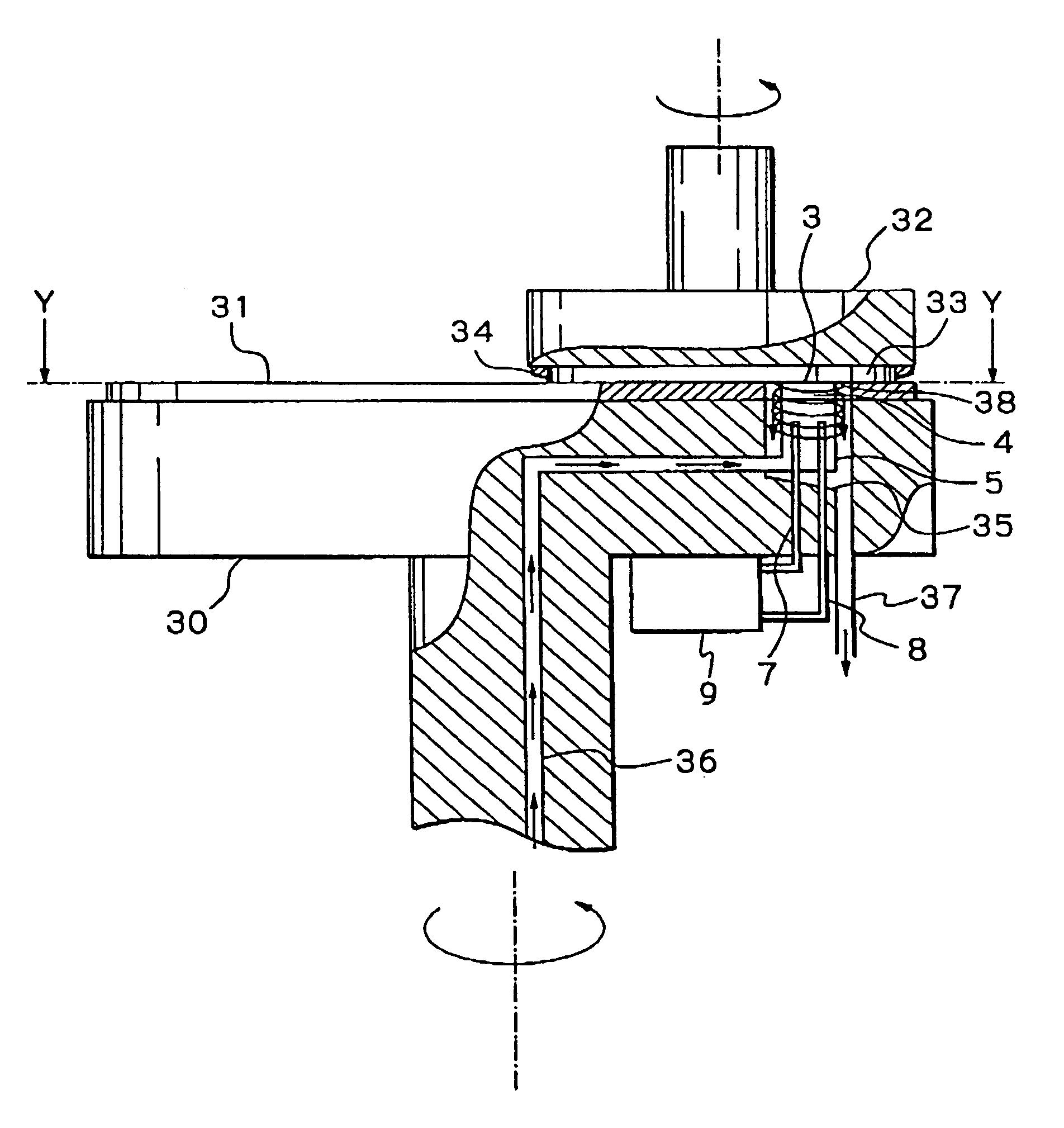

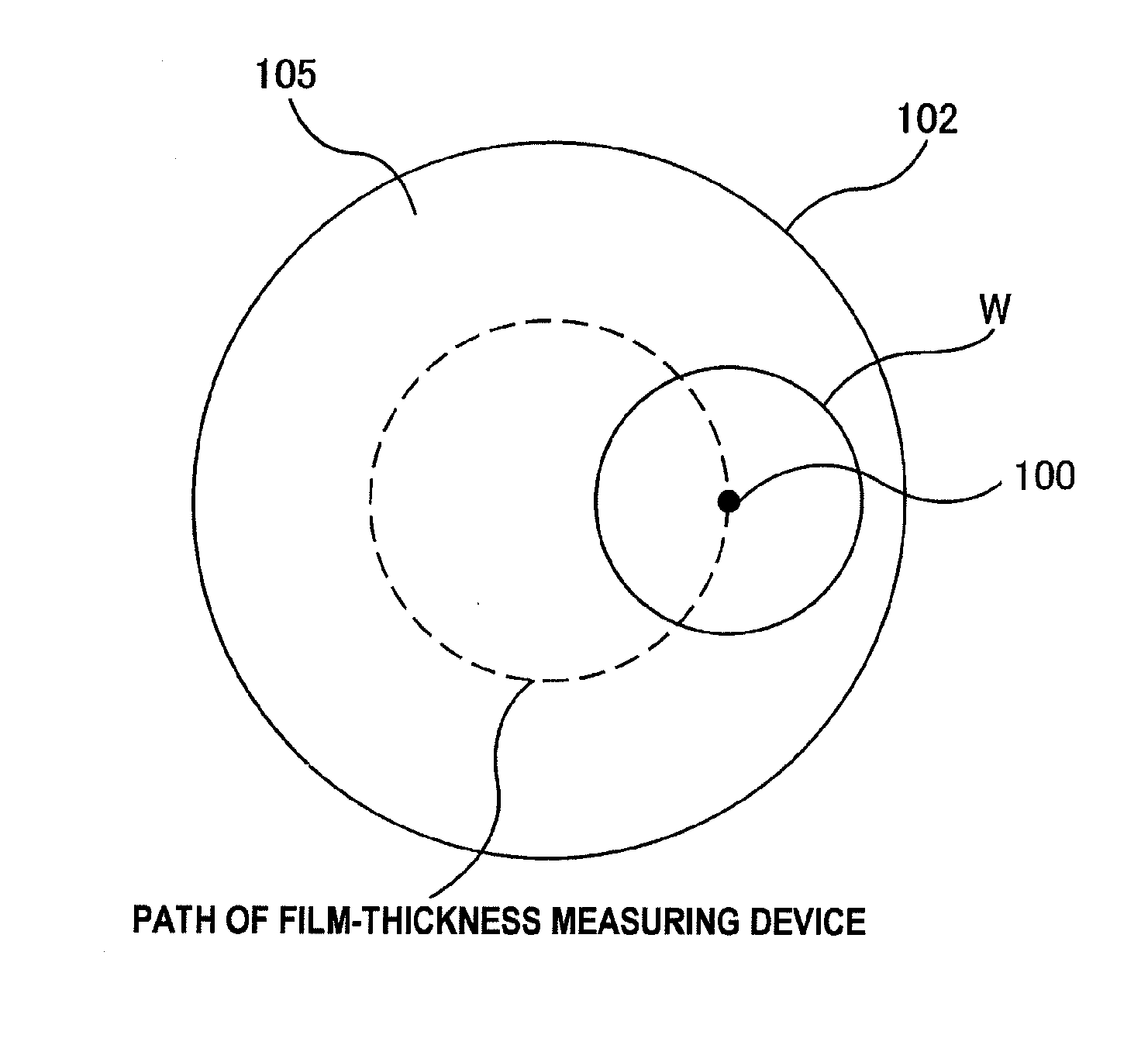

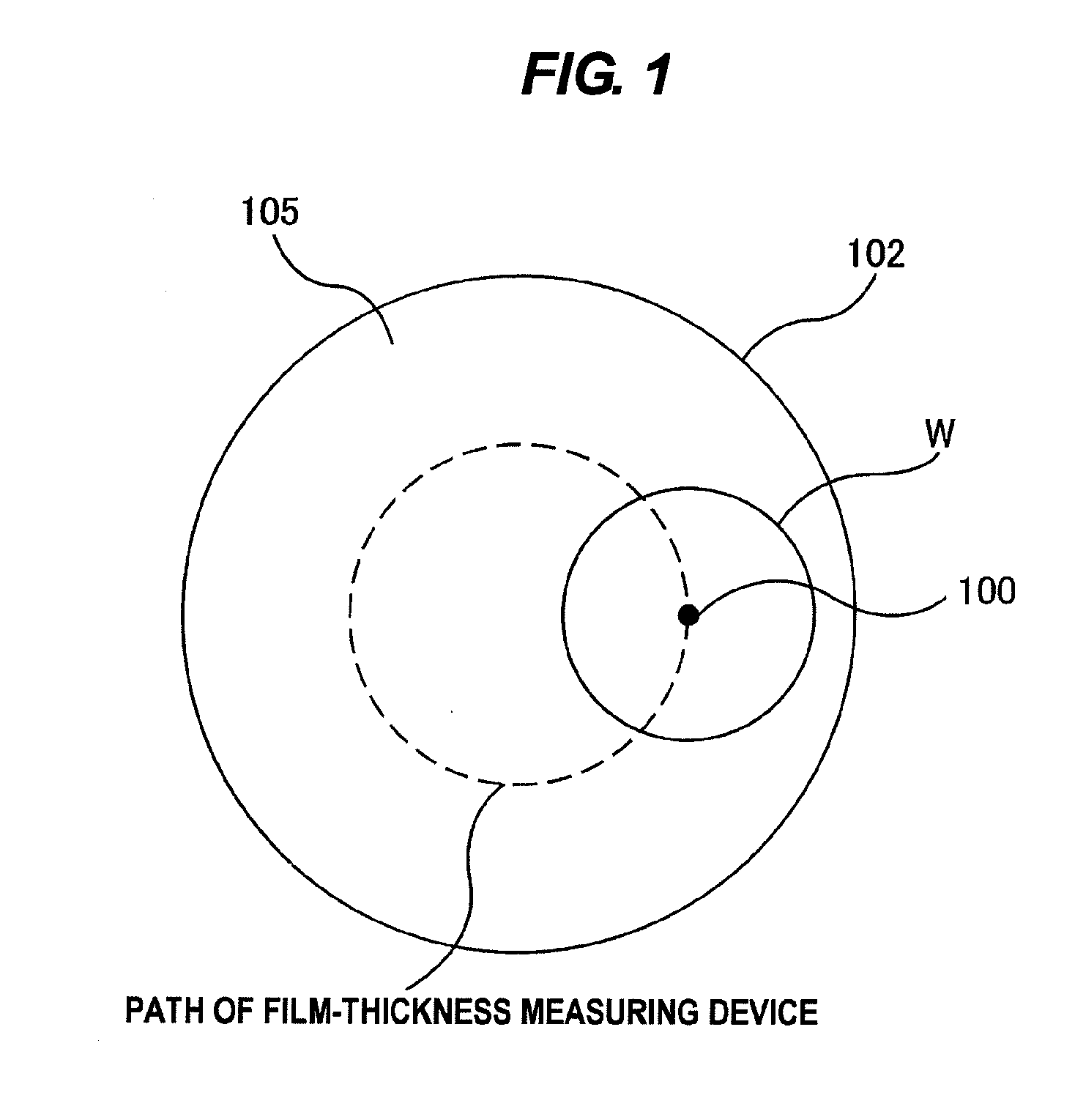

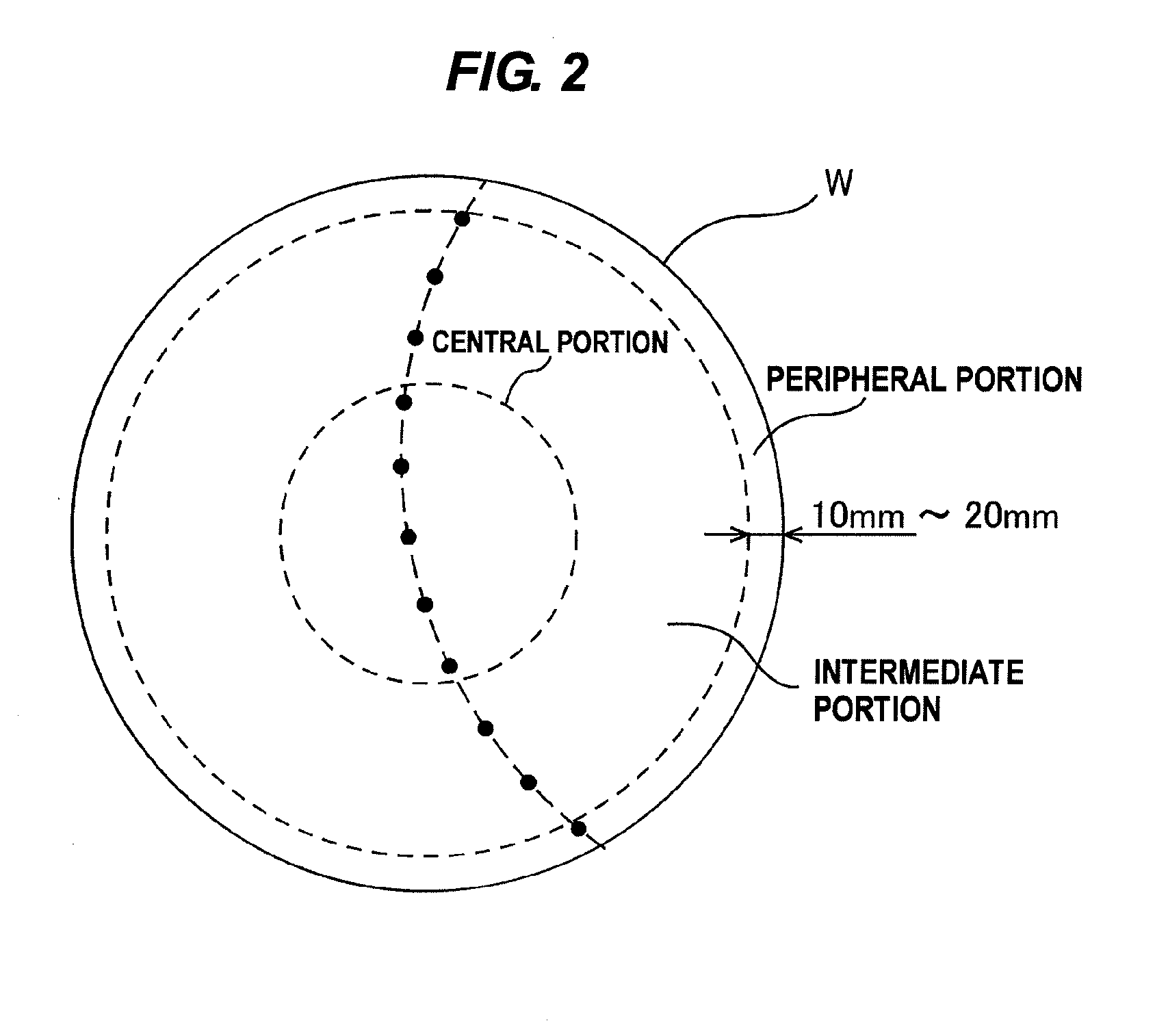

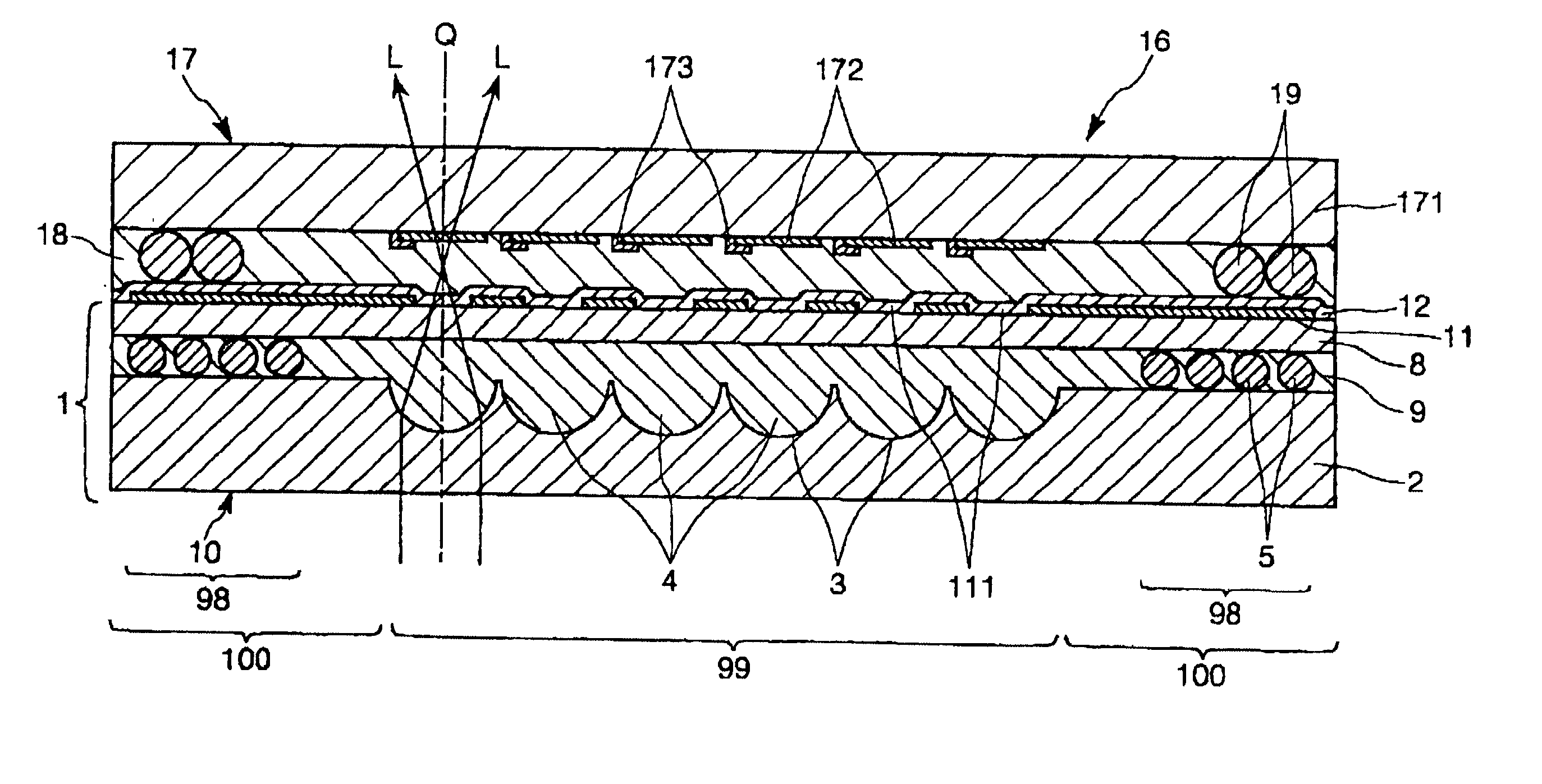

Polishing apparatus and polishing method

ActiveUS20120164917A1Highly accurate film thicknessIncrease pointsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLength waveUltimate tensile strength

A polishing apparatus for polishing a substrate is provided. The polishing apparatus includes: a polishing table holding a polishing pad; a top ring configured to press the substrate against the polishing pad; first and second optical heads each configured to apply the light to the substrate and to receive reflected light from the substrate; spectroscopes each configured to measure at each wavelength an intensity of the reflected light received; and a processor configured to produce a spectrum indicating a relationship between intensity and wavelength of the reflected light. The first optical head is arranged so as to face a center of the substrate, and the second optical head is arranged so as to face a peripheral portion of the substrate.

Owner:EBARA CORP

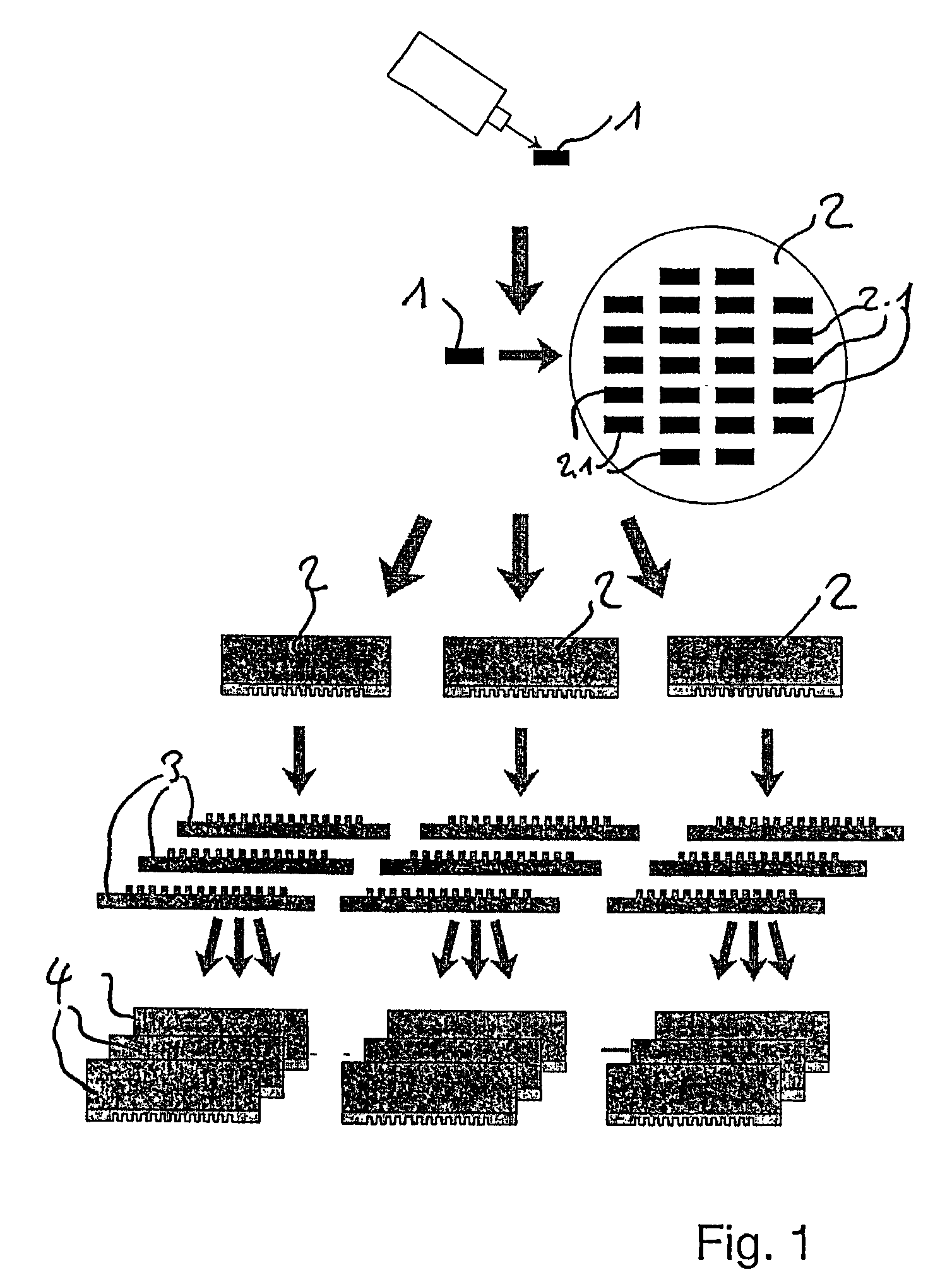

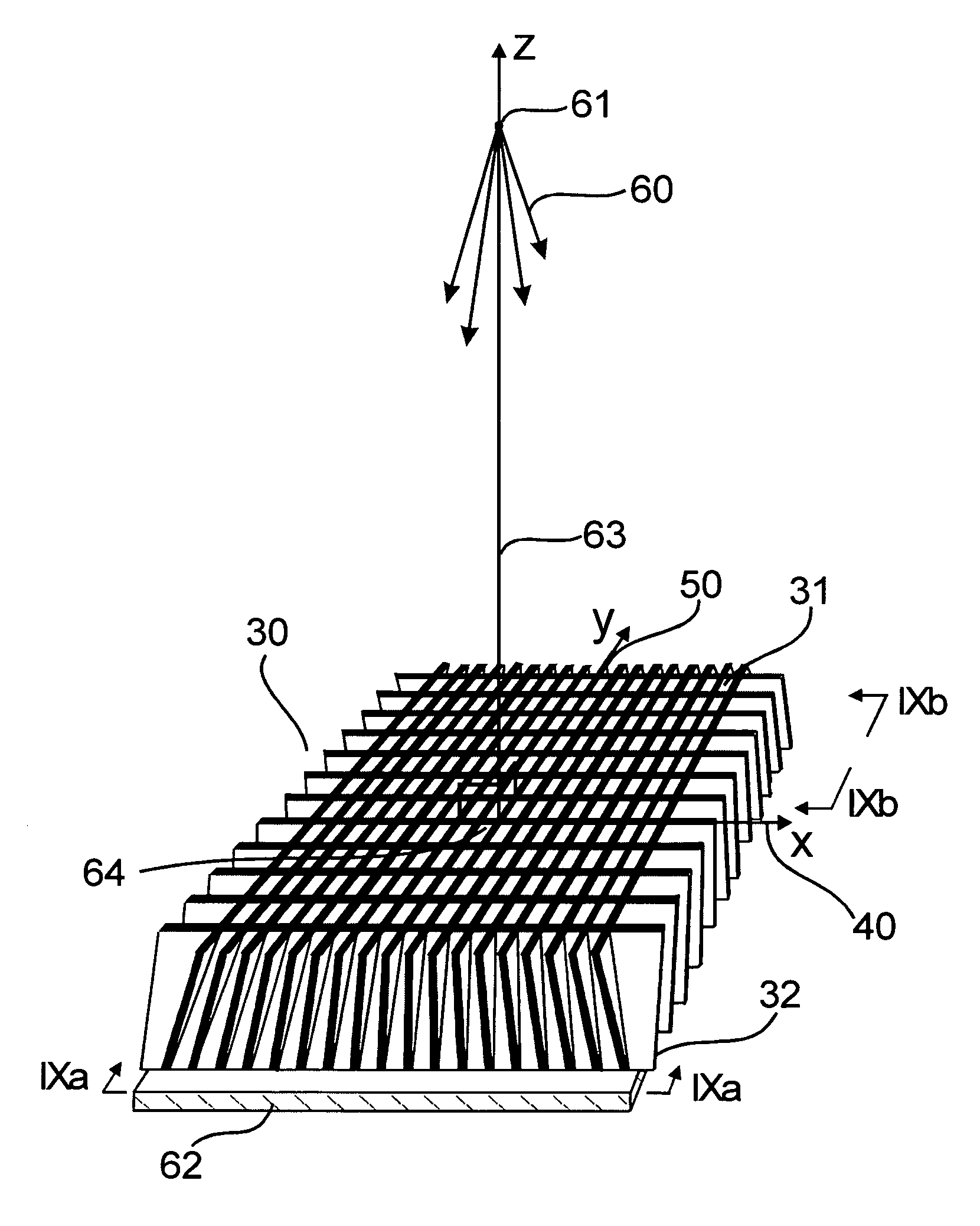

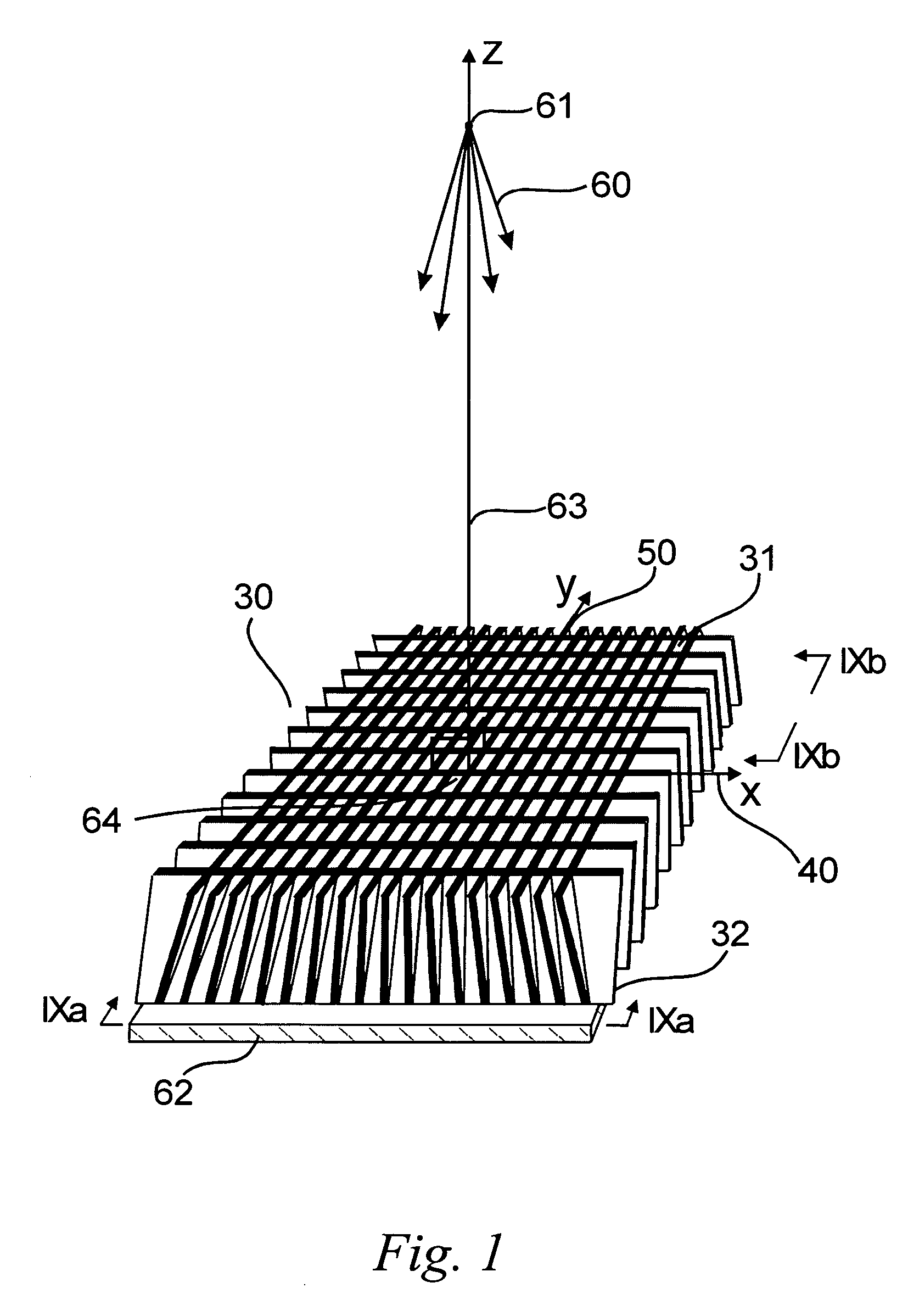

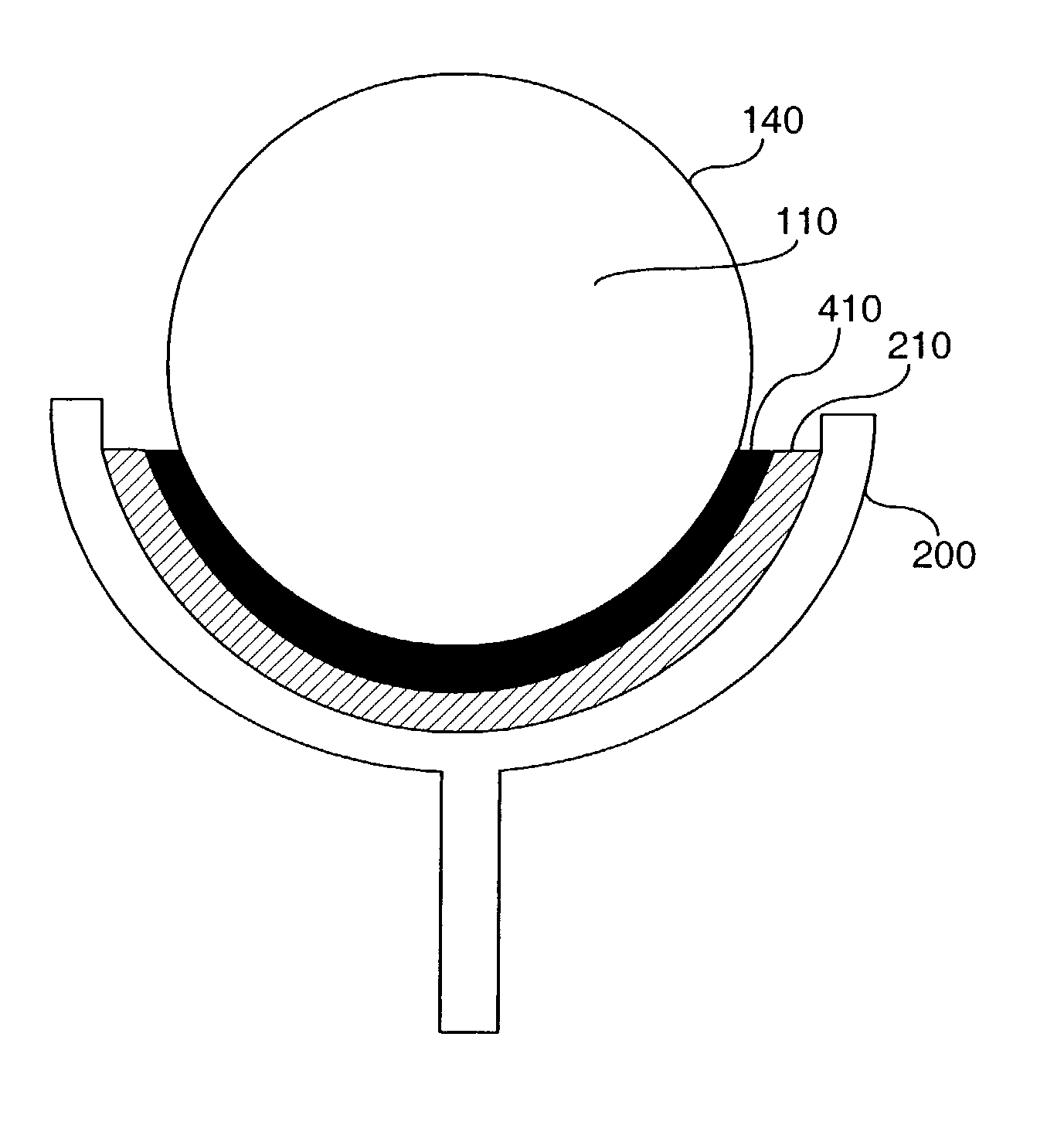

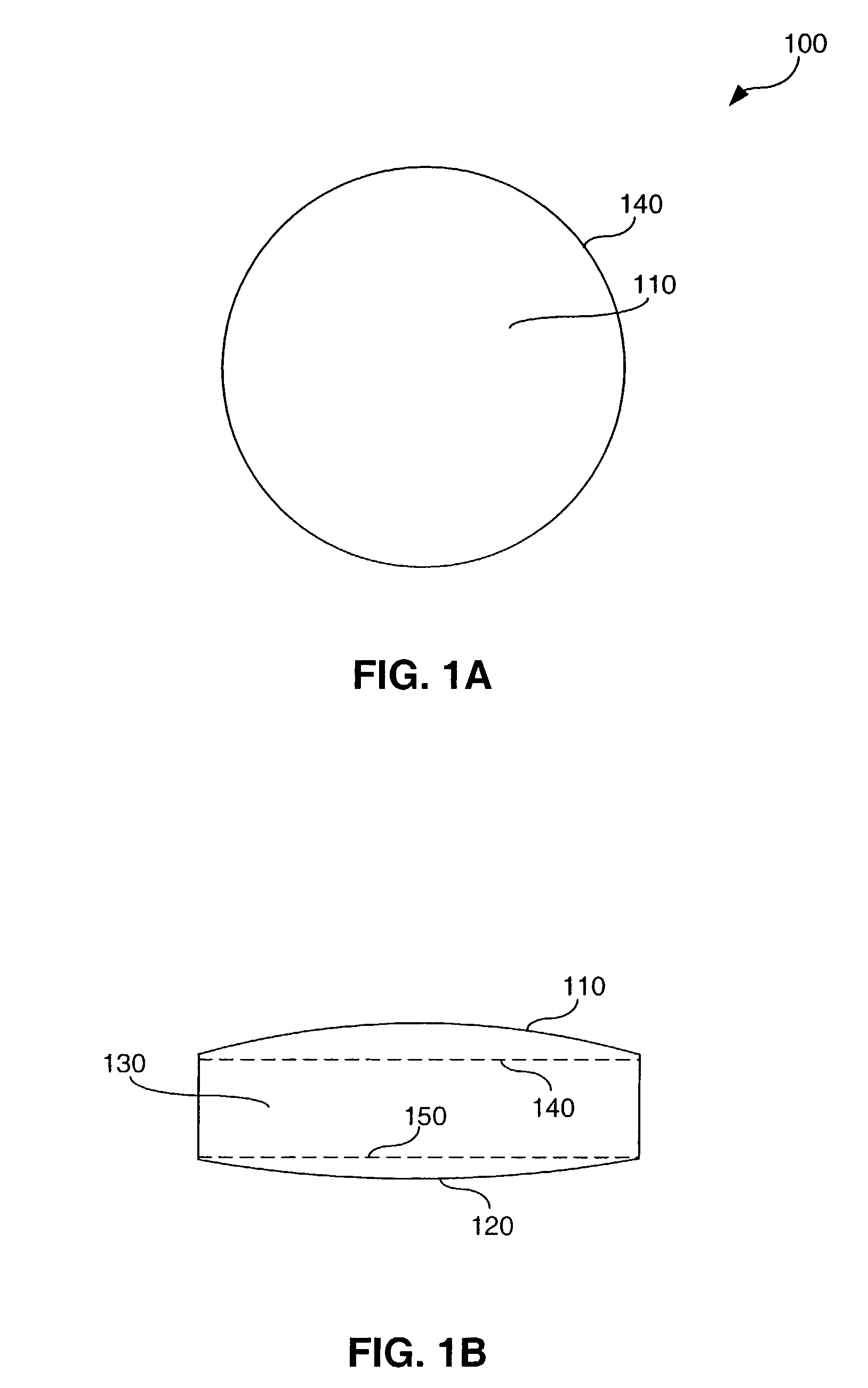

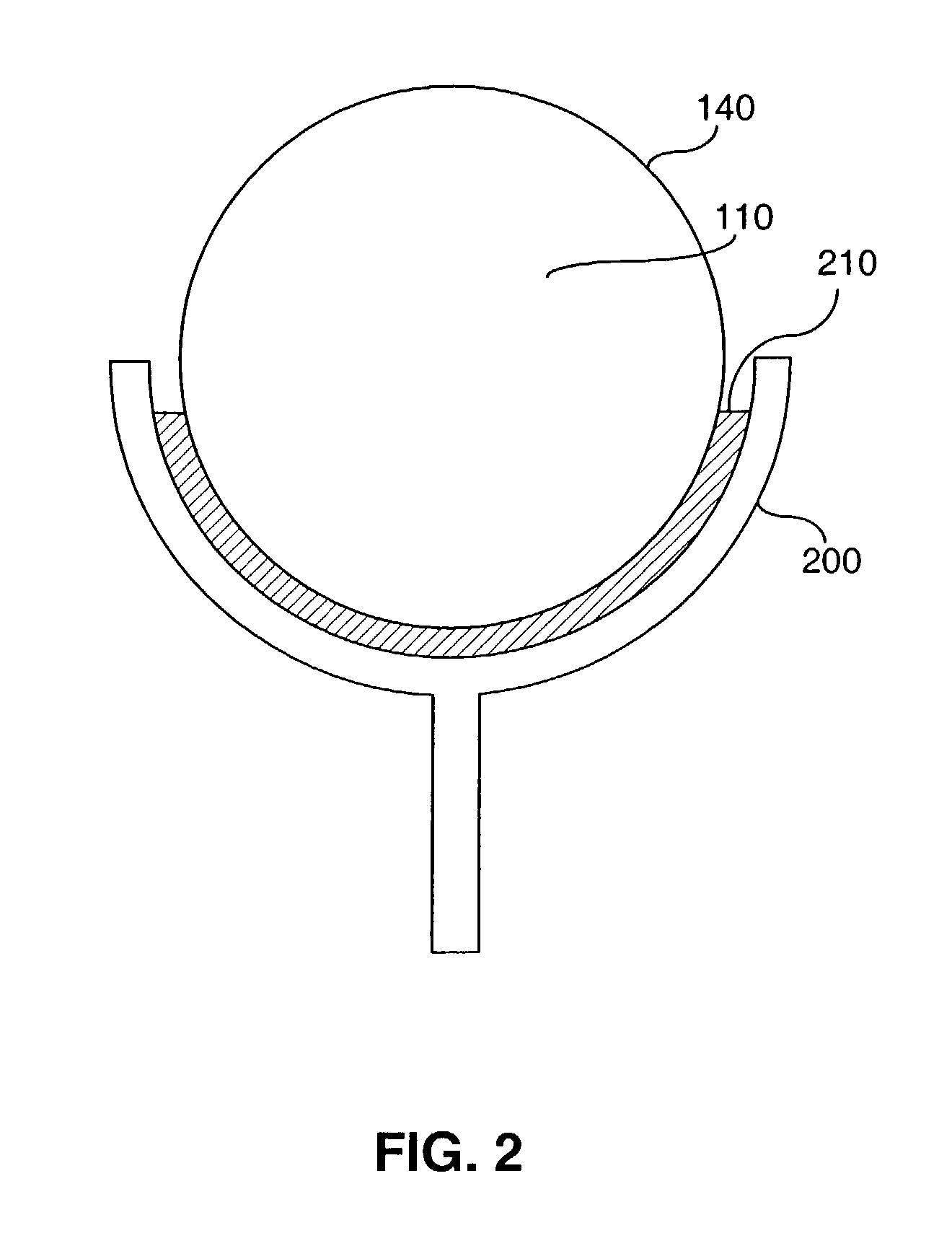

Method for manufacturing microlens substrate, microlens substrate, opposing substrate for liquid crystal panel, liquid crystal panel, and projection display apparatus

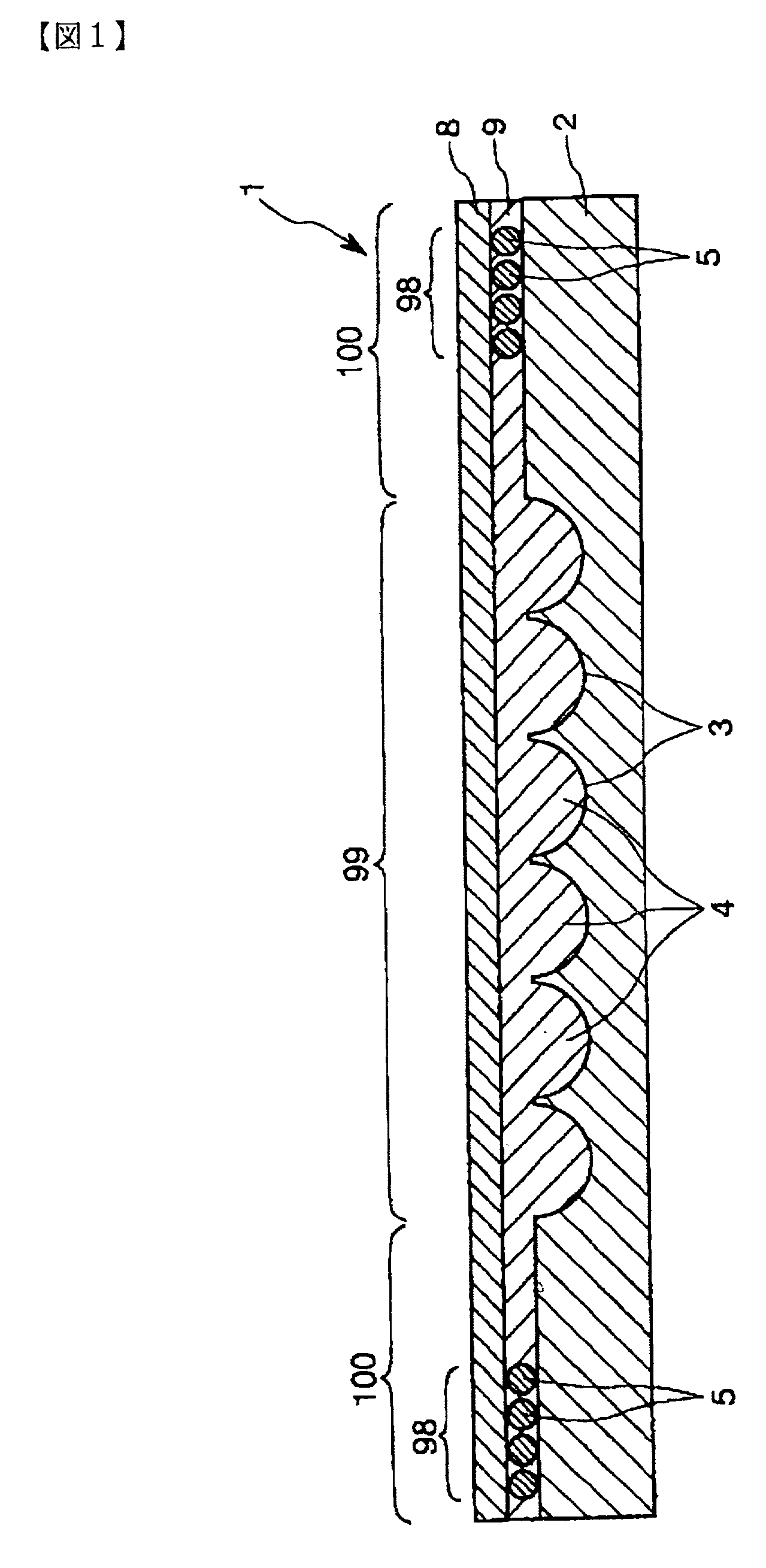

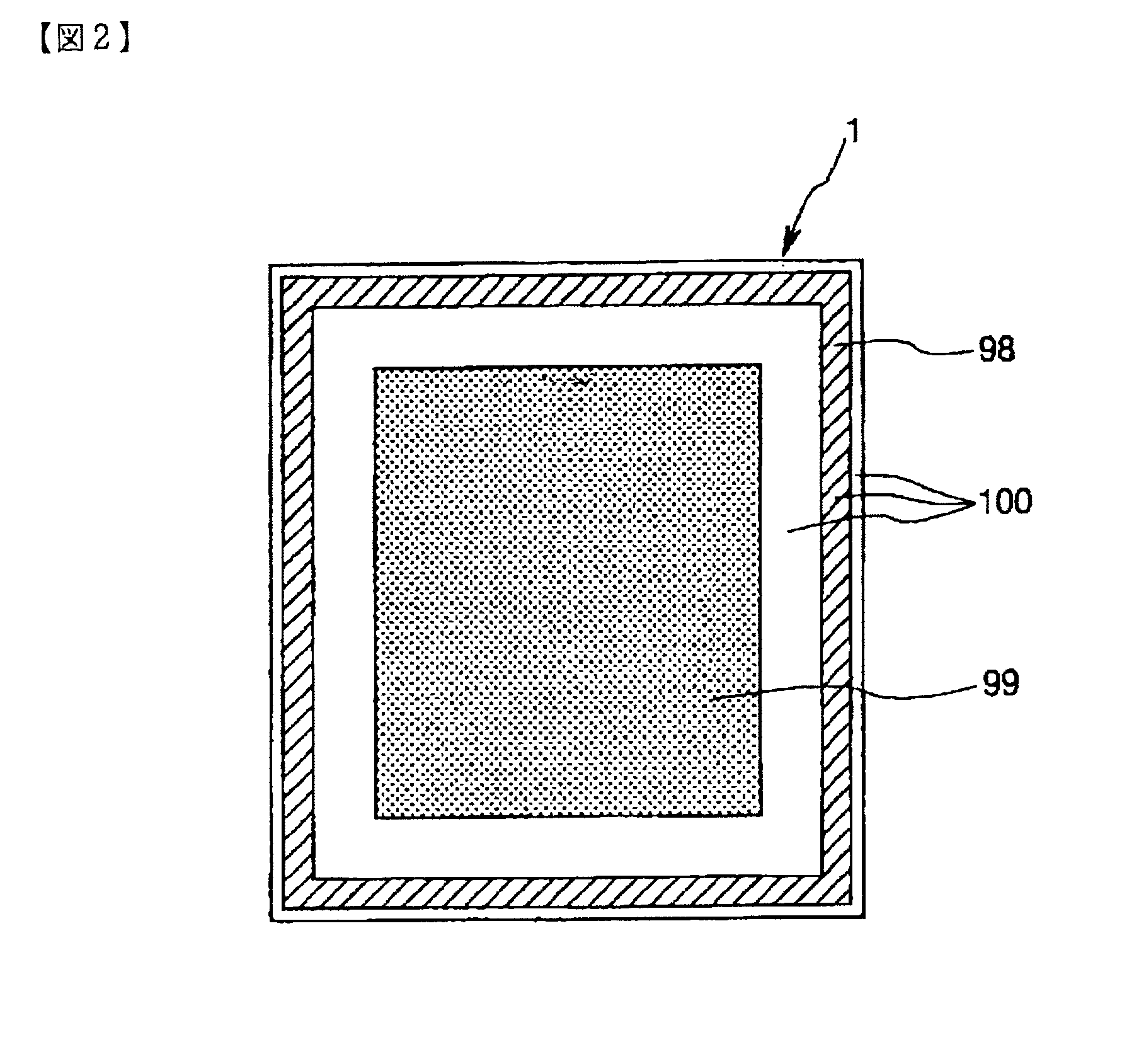

InactiveUS20020021386A1Reduce riskRisk of problemProjectorsOptical articlesLiquid-crystal displayVolumetric Mass Density

An object is to provide a microlens substrate capable of regulating the thickness of a resin layer with high accuracy. A microlens substrate 1 includes a transparent substrate 2 provided with a plurality of concavities 3 having concave surfaces, an outer layer 8 bonded to the transparent substrate 2 at a surface thereof provided with the concavities 3 via a resin layer 9, and spacers 5 for regulating the thickness of the resin layer 9. The resin layer 9 includes microlenses 4 formed with a resin filling the concavities 3. The spacers 5 include globular particles. The standard deviation of particle-size distribution of the spacers 5 is preferably not greater than 20% of an average particle size of the spacers 5. The density of the spacers 5 is preferably in the order of 0.5 to 2.0 g / cm3. A value rho1 / rho2 is preferably in the order of 0.6 to 1.4, in which rho1 denotes the density (g / cm3) of the spacers 5, and rho2 denotes the density (g / cm3) of a resin forming the resin layer 9.

Owner:SEIKO EPSON CORP

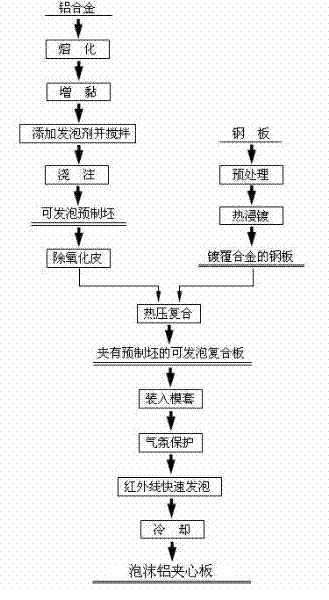

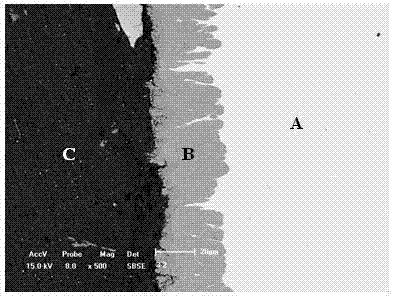

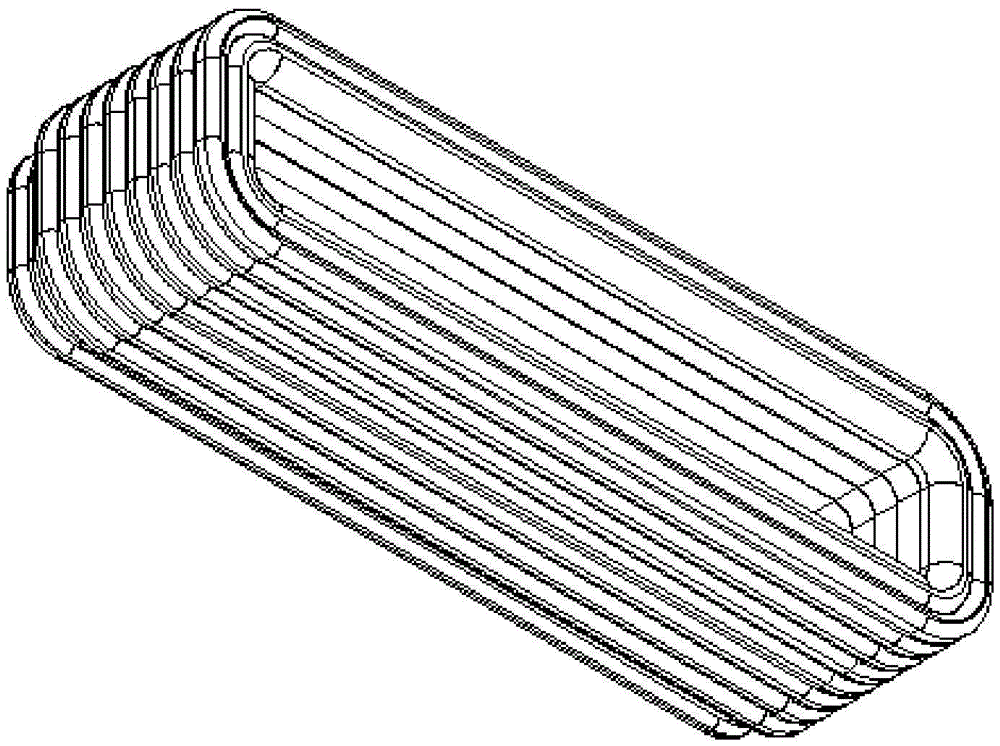

Preparation method of foamed aluminum sandwich plate

ActiveCN102390135AImprove mechanical propertiesAccurate thicknessLaminationLamination apparatusFoaming agentComposite plate

The invention relates to a preparation method of a layered composite material, in particular to a preparation method of a foamed aluminum sandwich plate. The method comprises the following steps of: firstly, uniformly mixing an aluminum alloy, a tackifier and a foaming agent to obtain a platy or blocky foamable precast blank material; then, performing hot-pressing compounding of the precast blankand a steel plate after the surface plating to obtain a foamable composite plate sandwiching the precast blank; placing the foamable composite plate sandwiching the precast blank in a mould sleeve closed around, and delivering into an infrared foaming furnace heating at the upper and lower parts at the same time so as to heat and foam the composite plate sandwiching the precast blank under infrared radiation; and finally, pulling the mould sleeve out of the foaming furnace, and cooling to obtain a foamed aluminum sandwich plate with a fixed thickness. The foamed aluminum sandwich plate prepared by the method provided by the invention has an accurate thickness, a uniform structure and a high yield; and moreover, the preparation processes in the invention can be automatically controlled, thereby being favorable for realizing semi-continuous preparation of the foamed aluminum sandwich plate.

Owner:NORTHEASTERN UNIV

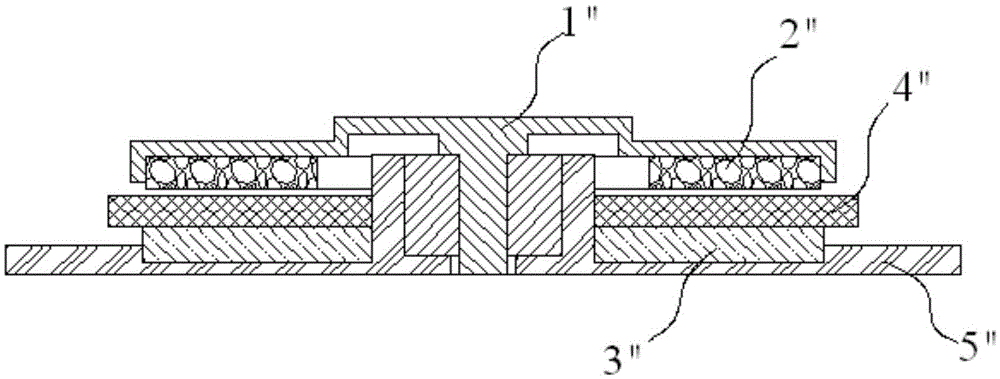

Single-phase winding coiling method used for p axial magnetic field motors and winding structures thereof, printed circuit board and motor

ActiveCN105490476ALow costIncrease profitManufacturing dynamo-electric machinesSynchronous machines with stationary armatures and rotating magnetsSingle phasePrinted circuit board

The invention provides single-phase winding structures used for axial magnetic field motors and a coiling method thereof, a printed circuit board and a motor. The windings are arranged on 2N layers of PCB. The windings arranged on all layers of PCB except for the first layer of PCB are provided with winding cycle rings of which the number is the same with that of motor magnetic poles. The adjacent winding layers are serially connected via connecting holes arranged at the central parts of the winding cycles. The head end and the tail end of the winding end parts are arranged on the first layer of PCB. Cost of the windings is relatively low; the motor coefficient of the windings is relatively high; and the windings are realized through the mode of the PCB so that the shape of the 2D windings can be arbitrary, and the size and the thickness of the windings can be accurately controlled. The aforementioned is important for realization of the thin motor structure and enhancement of motor performance; and the lines of a motor driving circuit, a Hall sensor circuit and other electronic devices can be manufactured on the same PCB forming the motor windings so that utilization rate of motor space can be enhanced.

Owner:FORTIOR TECH SHENZHEN

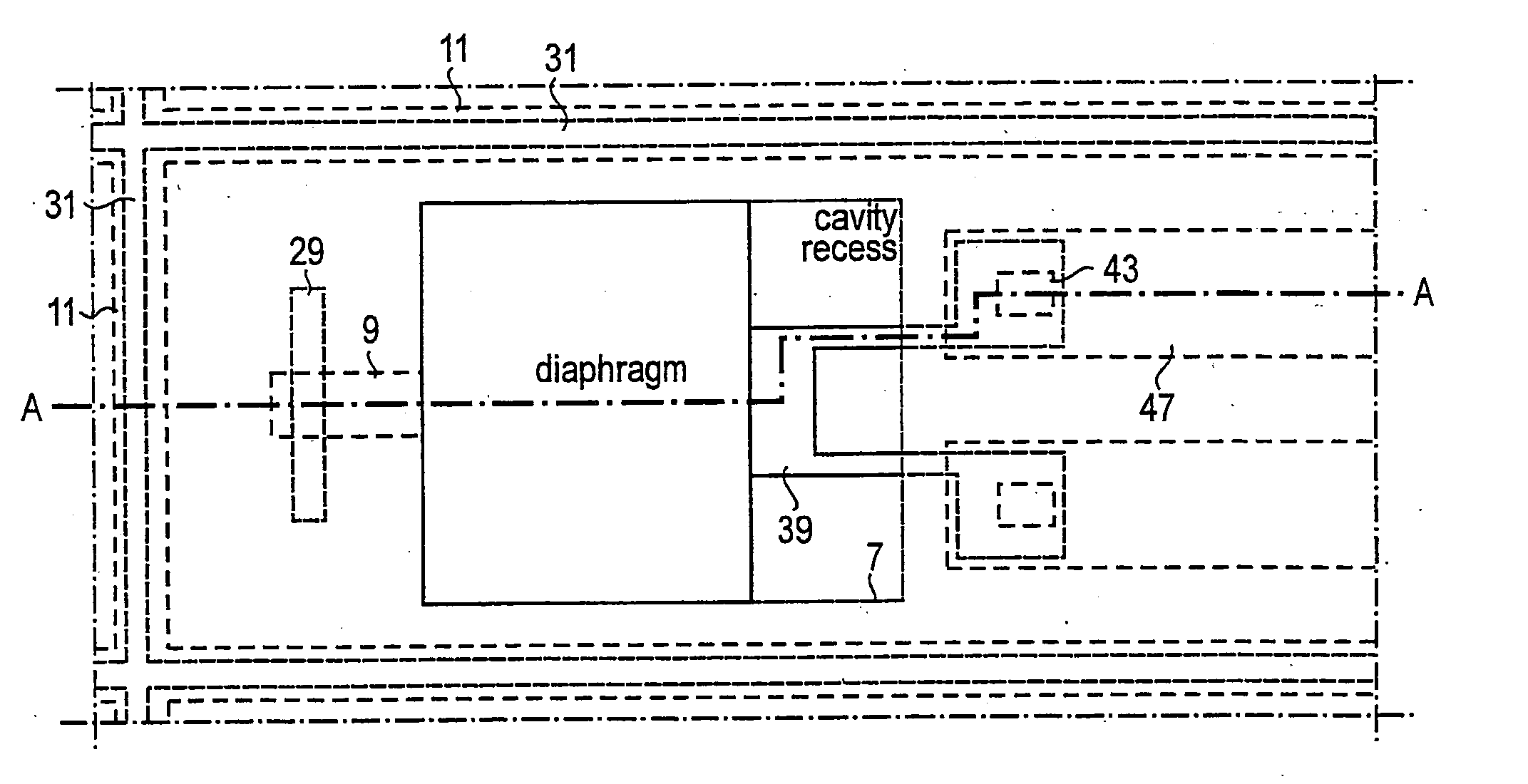

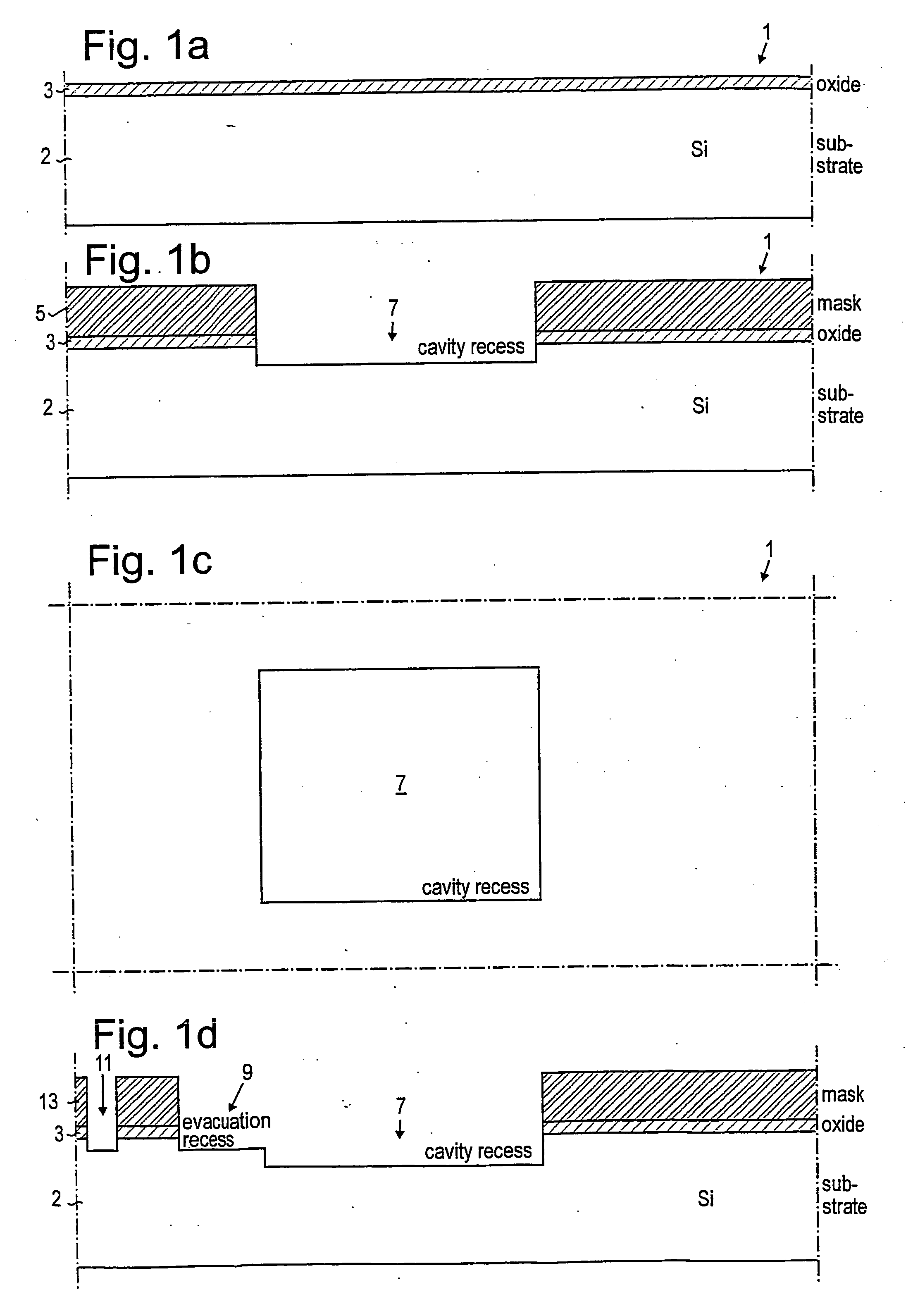

Pressure sensor

InactiveUS20060032039A1High yieldPrecise definitionWave amplification devicesElectronic circuit testingSingle crystalForce sensor

In manufacturing a pressure sensor a recess that will form part of the sensor cavity is formed in a lower silicon substrate. An SOI-wafer having a monocrystalline silicon layer on top of a substrate is bonded to the lower silicon substrate closing the recess and forming the cavity. The supporting substrate of the SOI-wafer is then etched away, the portion of the monocrystalline layer located above the recess forming the sensor diaphragm. The oxide layer of the SOI-wafer here acts as an “ideal” etch stop in the case where the substrate wafer is removed by dry (plasma) or wet etching using e.g. KOH. This is due to high etch selectivity between silicon and oxide for some etch processes and it results in a diaphragm having a very accurately defined and uniform thickness. The cavity is evacuated by forming a opening to the cavity and then sealing the cavity by closing the opening using LPCVD. Sensor paths for sensing the deflection of the diaphragm are applied on the outer or inner surface of the diaphragm. The monocrystalline diphragm gives the sensor a good long-term stability. Also the sensor path can be made of monocrystalline material, this giving the sensor even better good long-term characteristics. An increased sensitivity can be obtained by making active portions of the sensor paths freely extending, unsupported by other material of the pressure sensor, by suitable etching procedures.

Owner:SILEX MICROSYST

Method of manufacturing optical interferance color display

InactiveUS20060177950A1Better air gapAccurate thicknessSolid-state devicesSemiconductor/solid-state device manufacturingInterference colorDisplay device

The method of manufacturing an optical interference color display is described. A first electrode structure is formed over a substrate first. At least one first area, second area and third area are defined on the first electrode structure. A first sacrificial layer is formed over the first electrode structure of the first area, the second area and the third area. Moreover, a second sacrificial layer is formed over the first sacrificial layer inside the second area and the third area. In addition, a third sacrificial layer is formed over the second sacrificial layer inside the third area. The etching rates of all sacrificial layers are different. Then, a patterned support layer is formed over the first electrode structure. Next, a second electrode layer is formed and the sacrificial layers are removed to form air gaps. Therefore, the air gaps are effectively controlled by using the material having different etching rates.

Owner:SNAPTRACK

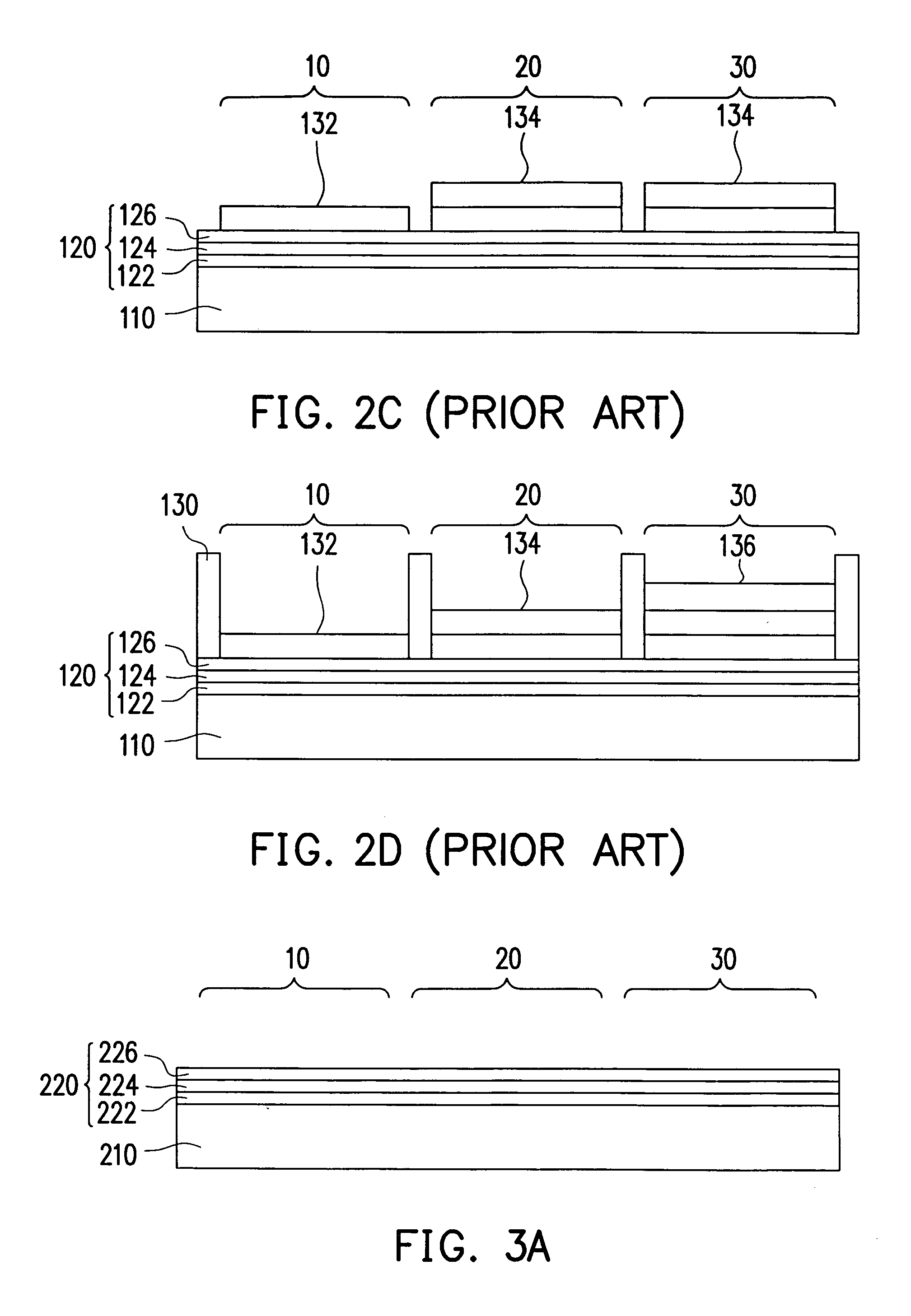

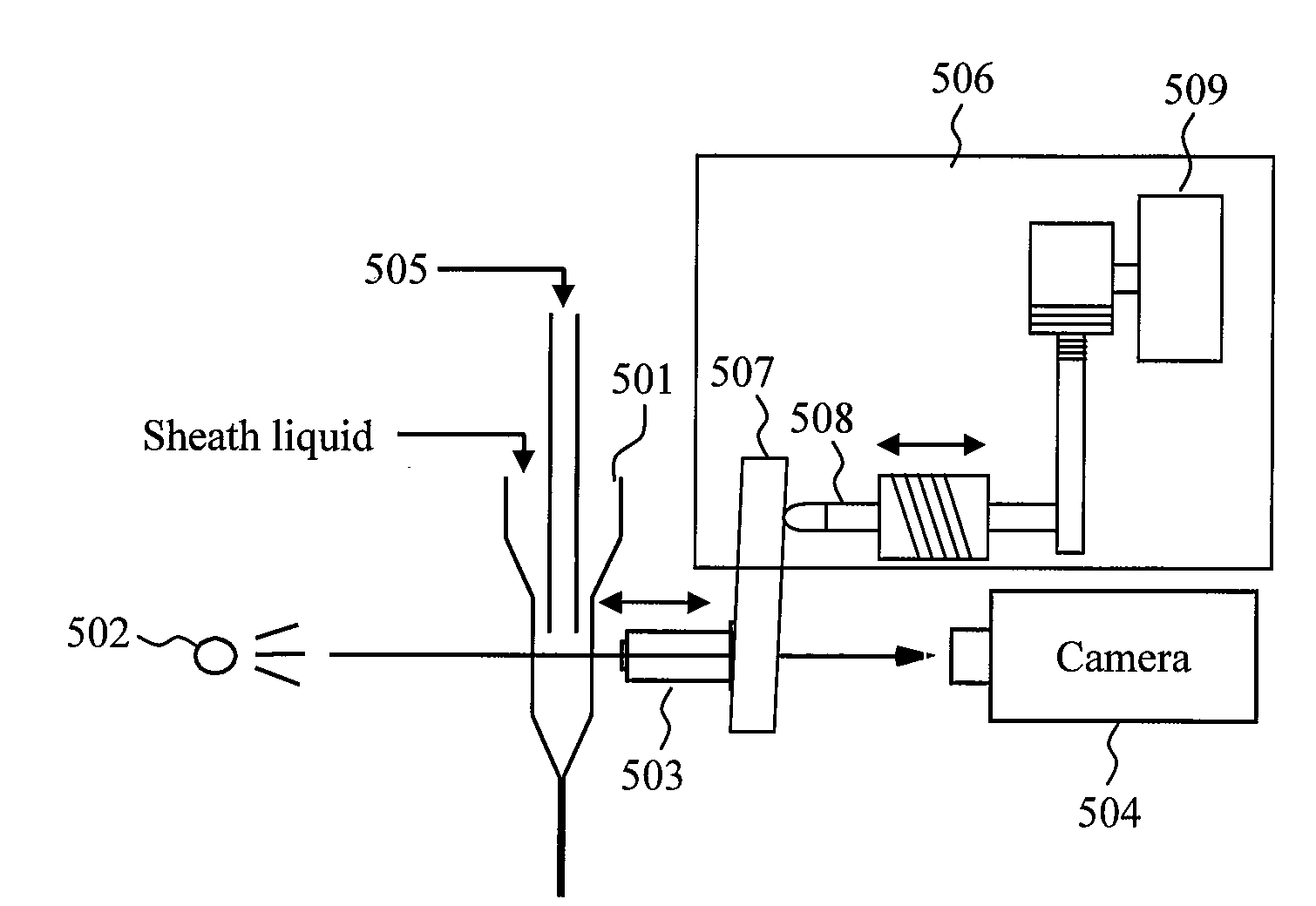

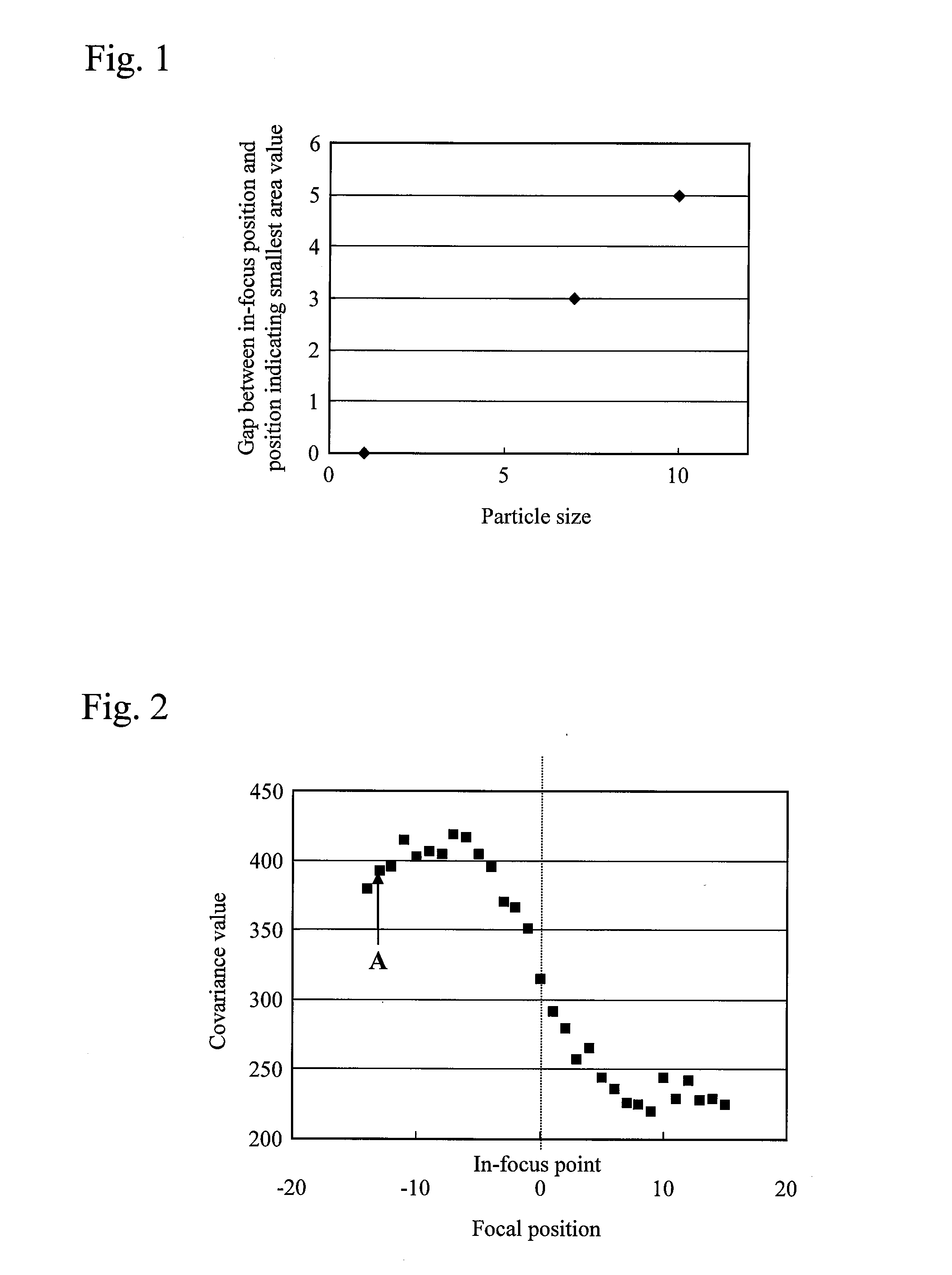

Flow type particle image analysis method and device

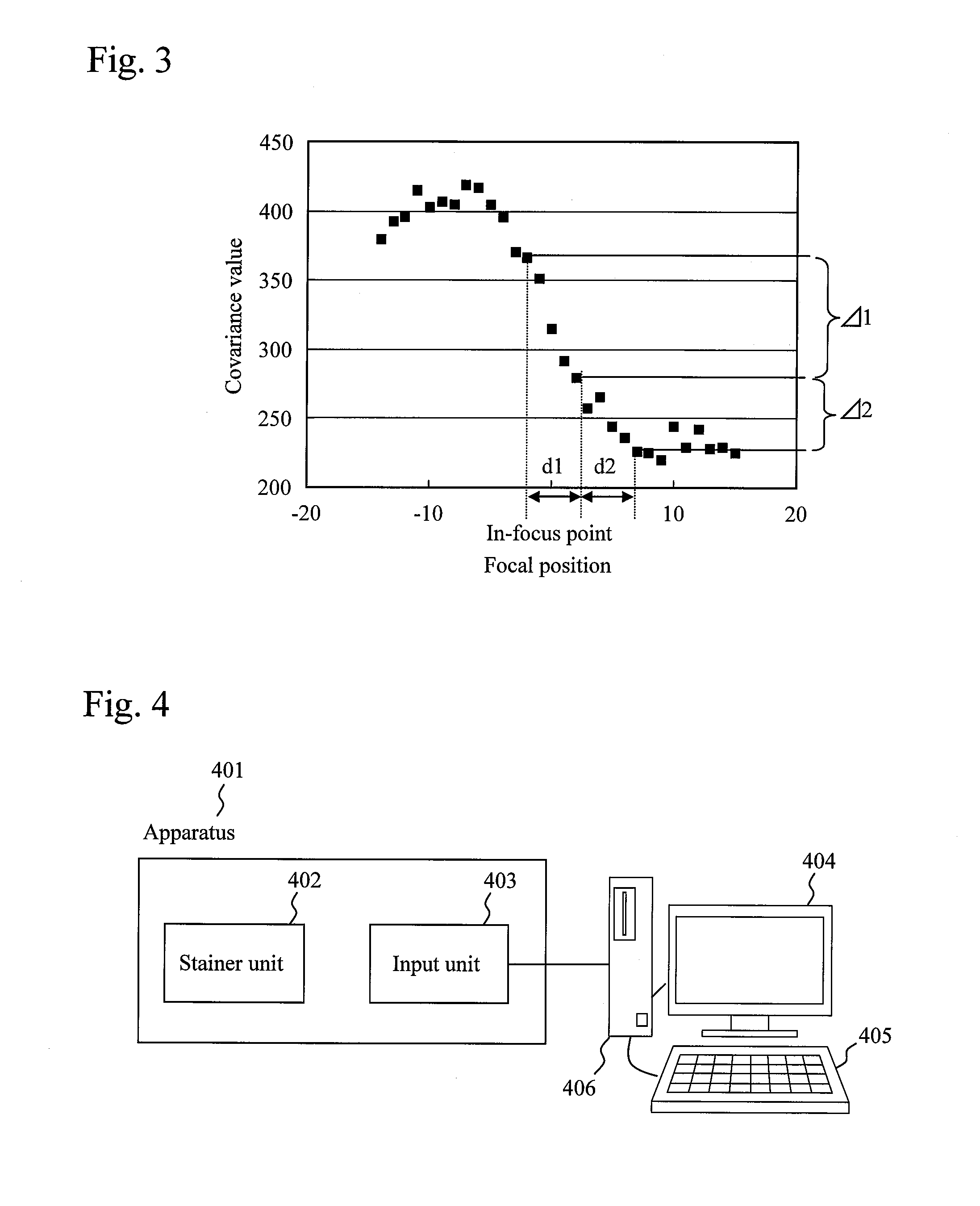

ActiveUS20120076349A1Accurately checkAccurately and efficiently perform in-focus point adjustmentCharacter and pattern recognitionMaterial analysisComputational physicsImage analysis

Owner:HITACHI HIGH-TECH CORP

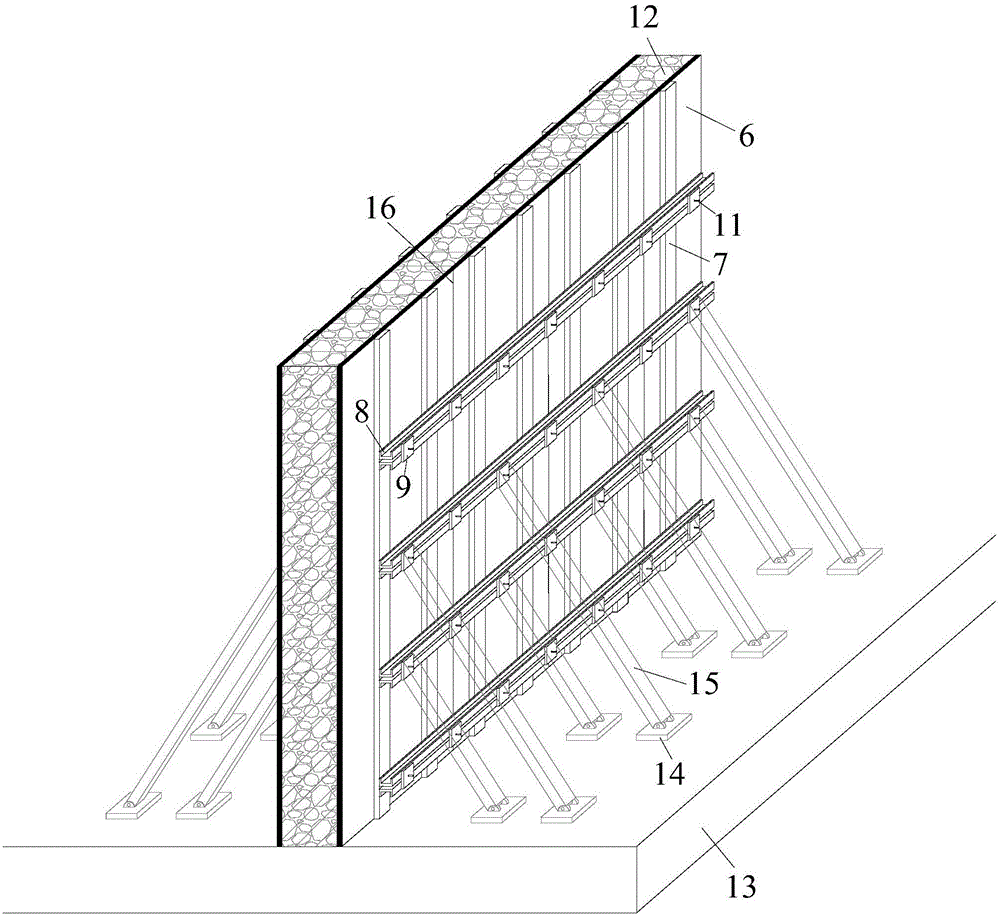

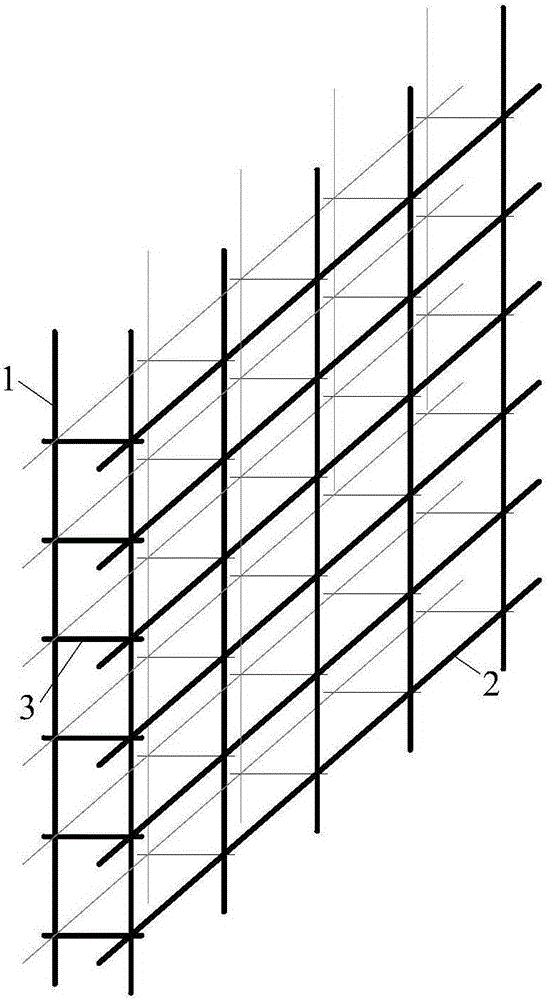

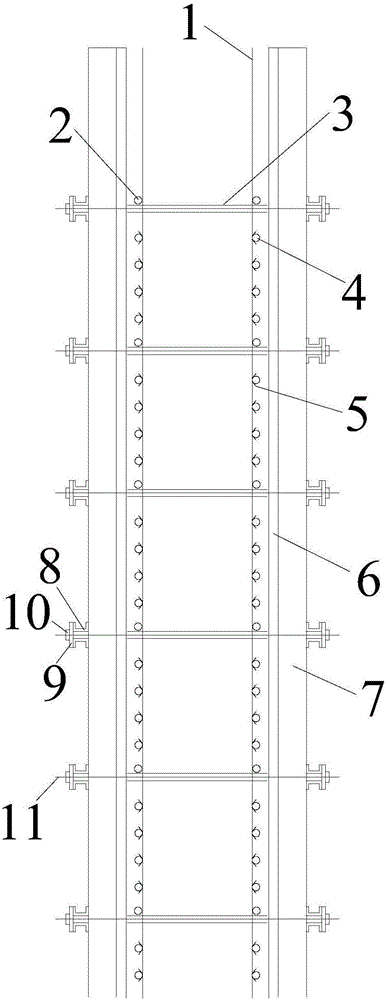

Reinforced concrete shear wall with positioning prefabricated member inside and construction method of reinforced concrete shear wall

ActiveCN105888108AEasy to install and combineFast demouldingWallsMouldsFloor slabReinforced concrete

The invention relates to a reinforced concrete shear wall with a positioning prefabricated member inside and a construction method of the reinforced concrete shear wall. The construction method includes: manufacturing the prefabricated member; arranging the prefabricated member on a floor slab structure; making positioning ladder rebars; binding rebars; mounting the prefabricated member; mounting steel formworks; setting up a steel formwork inclined strut. During constructing the reinforced concrete shear wall, vertical ladder rebars and horizontal ladder rebars are adopted as a positioning supporting frame for rebar binding, and the positioning prefabricated member is clamped in horizontally-vertically-distributed rebars, so that thickness of a protection layer is guaranteed and connection of rebar nets is enhanced; the assembly steel formworks are arranged on two sides of the rebar nets, oppositely-puling threaded rods penetrate connecting steel pipes to be fastened on embedded members of the steel formwork inclined strut and the floor slab structure through screws, and concrete is poured to form a shear wall structure. By using the construction method, construction site order and construction efficiency are improved, related measures guarantee construction quality of the shear wall, rebar positioning accuracy and thickness accuracy of the protection layer are improved remarkably, and the construction method has good technical and economic benefit.

Owner:ZHONGDA CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com