Smart device to measure tissue thickness

A tissue-thick, intelligent technology, applied in the field of medical devices, can solve the problems of not being able to provide sufficient data accuracy support for doctors, low linearity and resolution of strain gauge output, and unexplained resolution, etc., to achieve a wide range of pressure settings and operation Convenient, Measuring Accurate Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

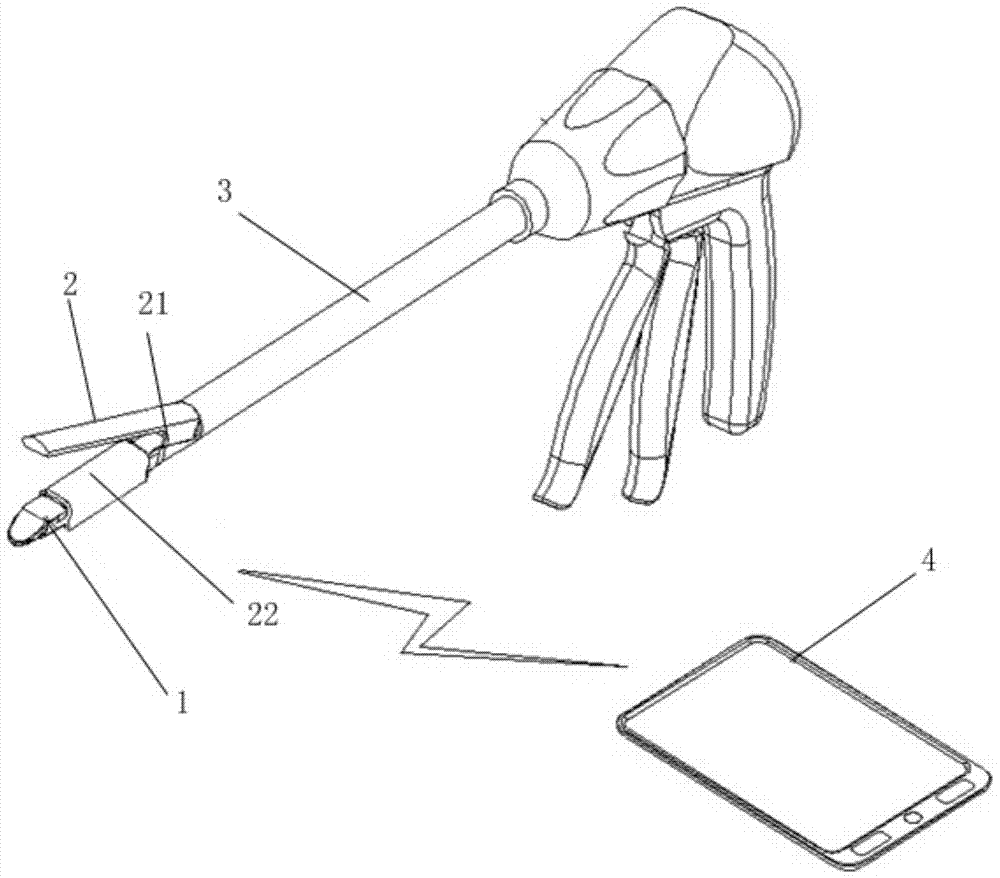

[0069] Please refer to figure 1 , figure 1 It is a structural schematic diagram of an intelligent instrument for measuring tissue thickness of the present invention. An intelligent instrument for measuring tissue thickness, the intelligent instrument comprises an intelligent button battery type intelligent thickness measuring clip 1, a nail anvil 2, a linear cutting stapler 3, and an external remote control device 3; the button type intelligent thickness measuring clip and nail The anvil 2 forms a jaw 21; the nail anvil 2 is made of stainless steel; the external remote control device 3 includes a mobile phone, a computer, and a tablet computer.

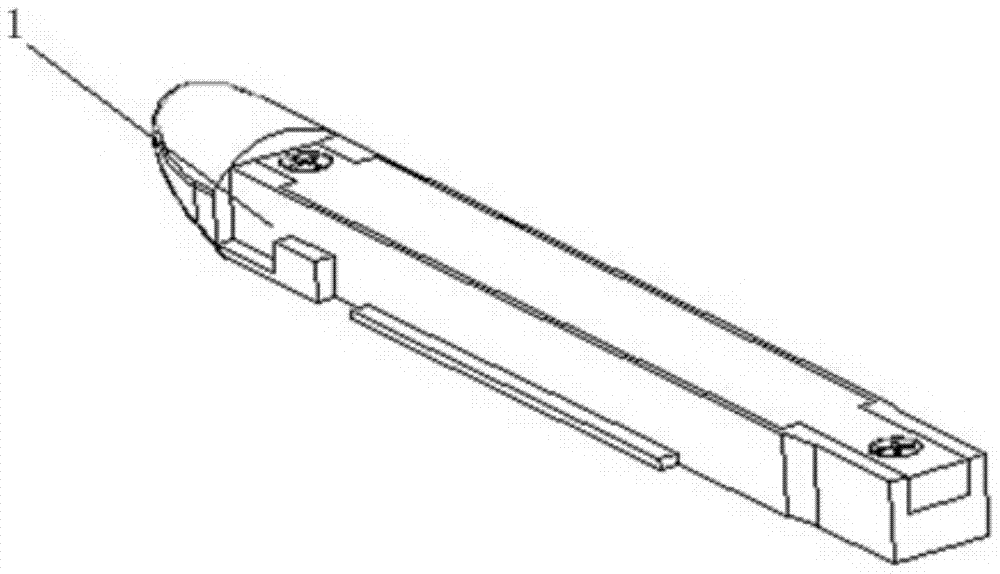

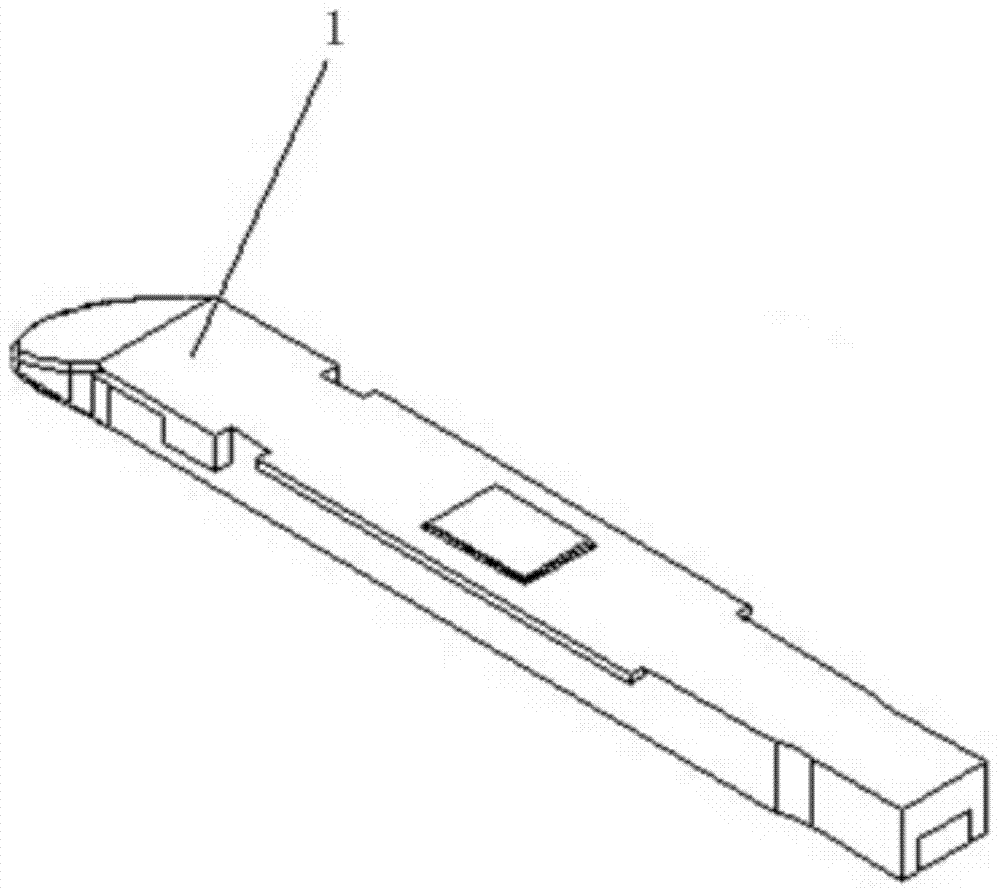

[0070] Please refer to figure 2 , figure 2 It is a schematic diagram of the lower surface structure of the button battery type intelligent thickness measuring clamp. The button battery type intelligent thickness measuring clip 1 has a linear proximal end and an arc-shaped distal end, and the arc-shaped distal end forms an inclin...

Embodiment 2

[0078] Please refer to Figure 8 , Figure 8 It is a structural schematic diagram of another intelligent instrument for measuring tissue thickness of the present invention. The intelligent instrument includes an external power supply type intelligent thickness measuring clamp 5 and a manual thickness measuring instrument 6; the external power supply type intelligent thickness measuring clamp 5 and the nail anvil 2 form a jaw 21; the nail anvil 2 is made of stainless steel The manual thickness measuring instrument 6 includes a handle body 61, a movable handle 62, a fixed handle 63, a turnable head 64, a human-computer interaction device 65, and a battery compartment 66; the human-computer interaction device 65 is embedded on one side of the handle body 61 .

[0079] Please refer to Figure 9 , Figure 9 It is a schematic diagram of the lower surface structure of the external power supply type intelligent thickness measuring clamp. The proximal end of the external power sup...

Embodiment 3

[0087] Please refer to Figure 15 , Figure 15 It is a structural schematic diagram of another intelligent instrument for measuring tissue thickness of the present invention. This embodiment is basically the same as Embodiment 2, except that the power cord 69 in the manual thickness measuring instrument 6 in this embodiment replaces the battery compartment 66 in Embodiment 2. And the smart device is powered directly through the external power cord 69 without changing the battery.

[0088] It should be noted that the external power supply type intelligent thickness measuring clip 5 can be replaced as a consumable, and the manual thickness measuring instrument 6 can be reused after being sterilized. Manual thickness measuring instrument 6 Figure 14 , Figure 15 The type shown may include other structures similar to the linear cutting stapler 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com