Novel fiber reinforced cellular board and preparation method thereof

A fiber-reinforced, honeycomb panel technology, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of complex honeycomb core forming and manufacturing process, low efficiency honeycomb panels, and many product defects, and achieve difficult products. Defects, simple mold making, simple and easy forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

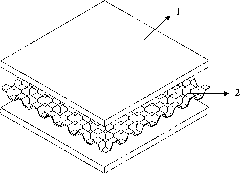

[0018] New fiber reinforced honeycomb panels (such as image 3 ) is formed by combining and affixing the panel 1 and the honeycomb core 2 with a pyramidal structure.

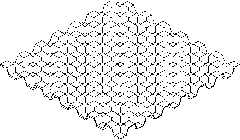

[0019] The new fiber-reinforced honeycomb panel consists of an upper panel, a lower panel and a pyramid-shaped honeycomb core. The pyramid-shaped honeycomb core is made of 10mm to 30mm high-strength scattered chopped fibers pre-impregnated with an epoxy resin matrix to form a premix, or chopped fiber cotton The / felt is molded by injecting epoxy resin colloid. The honeycomb core is composed of a series of concave and convex staggered small pyramid shapes. The oblique facade 3 of the small pyramid body is the supporting rib, and the pyramid tip is A small plane 4, such that the oblique ribs and the small plane constitute an interdependent integral concave-convex pyramid-shaped structure. The upper pyramid table of the honeycomb core is fixedly connected to the lower plane of the upper panel, and the lower pyrami...

specific Embodiment approach 2

[0021] This implementation method and steps are as follows:

[0022] (1) Step 1: The mold for making the fiber-reinforced pyramidal honeycomb core is composed of upper and lower templates. Small pyramid concave-convex platforms are processed on the template, and its size is made according to the requirements of the honeycomb sandwich panel to be processed. The height of the concave-convex platforms is the same. Neatly arranged, after the upper and lower templates are molded, the concave and convex tables are arranged in a staggered manner with equal gaps. The size of the template is determined according to the required workpiece and the hot press, and the release agent is applied.

[0023] (2) Step 2:

[0024] 1. The method of injection molding:

[0025] Place the 2mm thick random glass chopped fiber cotton / felt reinforcement between the upper template 5 and the lower template 6, close the mold and clamp the mold, inject epoxy resin through the injection hole 7 under the pres...

specific Embodiment approach 3

[0030] The high-performance fiber-reinforced material used in this embodiment may also be glass fiber, carbon fiber, aramid fiber and the like. The matrix can be thermosetting such as unsaturated polyester resin, epoxy resin, vinyl resin or thermoplastic resin such as nylon and polycarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com