Patents

Literature

107 results about "Media dispenser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A media dispenser or a culture media dispenser is a device for repeatedly delivering small fixed volumes (typically between 1 ml and 50 ml) of liquid such as a laboratory growth medium like molten agar or caustic or volatile solvents like toluene into a series of receptacles (Petri dishes, test tubes, Fernbach flasks, etc.). It is often important that such dispensers operate without biological or chemical contamination, and so must be internally sealed from the environment and designed for easy cleaning and sterilization before use. At a minimum, a media dispenser consists of some kind of pump connected to a length of discharge tubing or a spout. Dispensers used in laboratories are also frequently connected to microcontrollers to regulate the speed and volume of the medium as it leaves the pump.

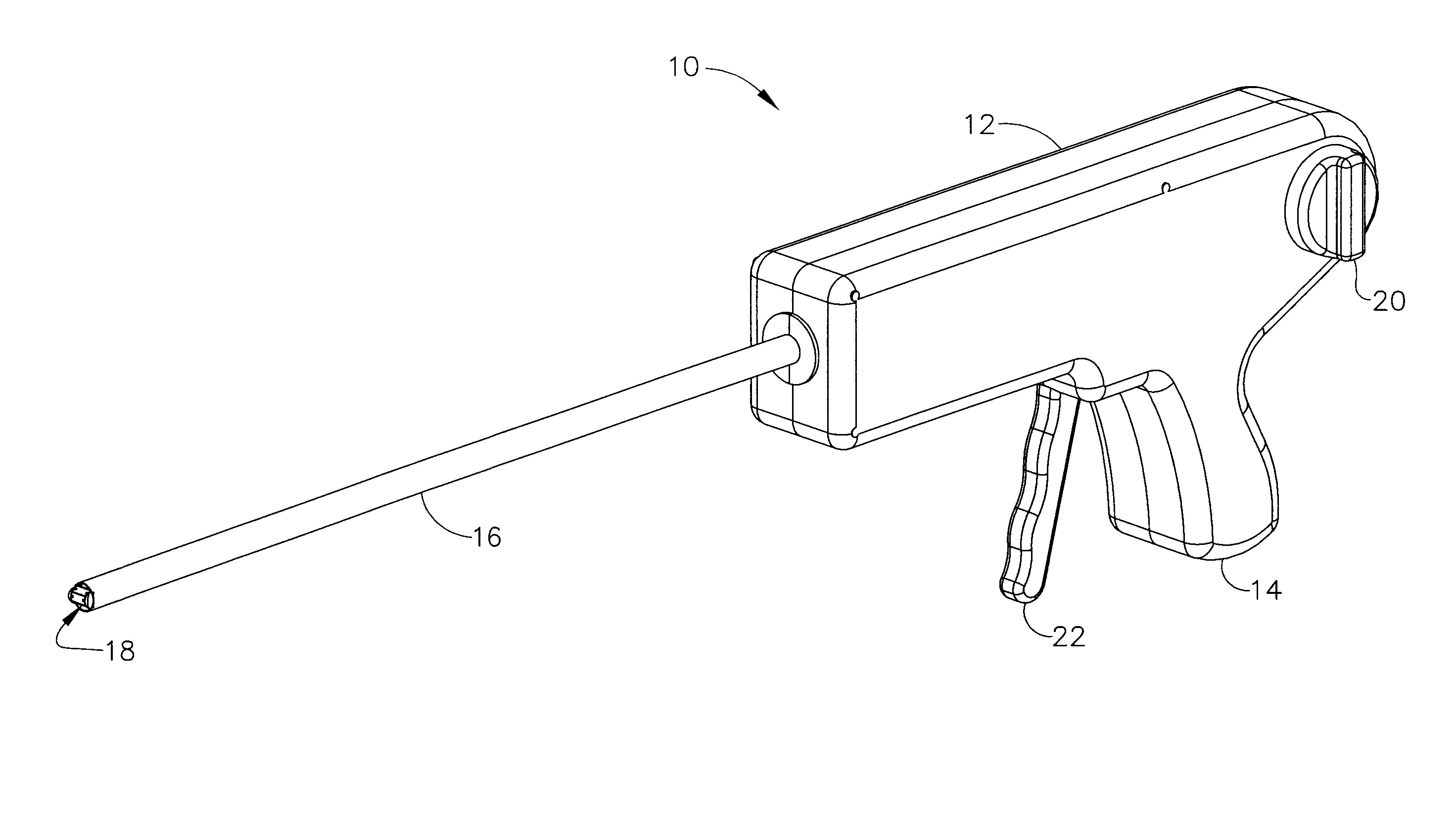

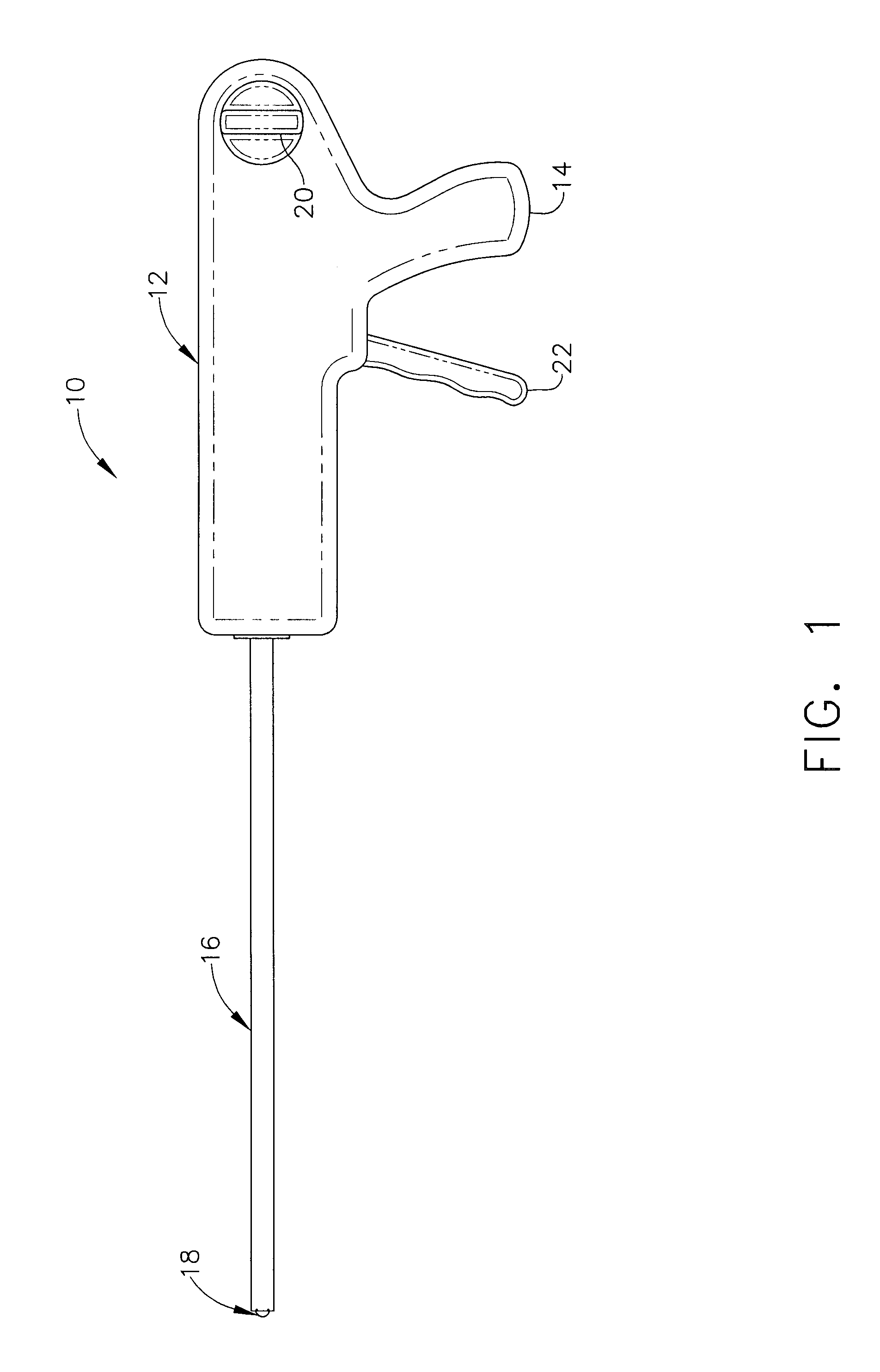

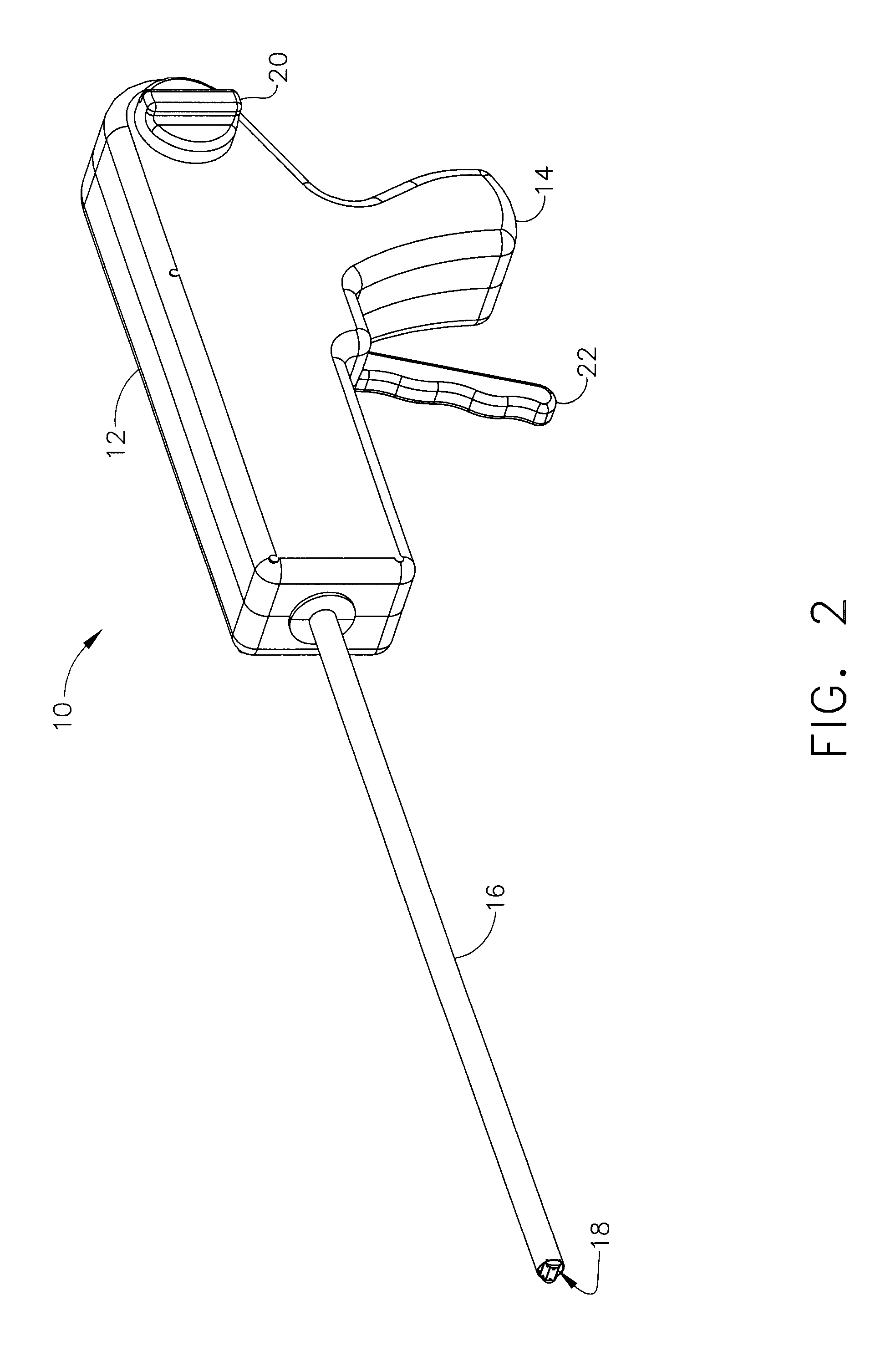

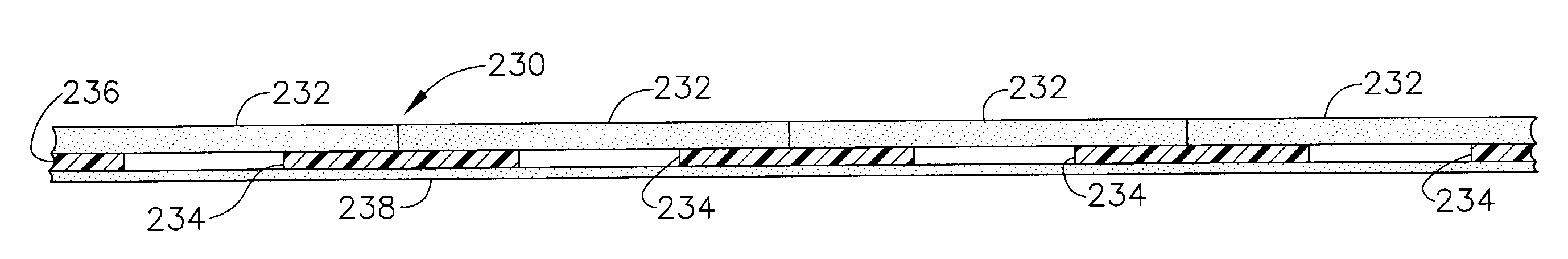

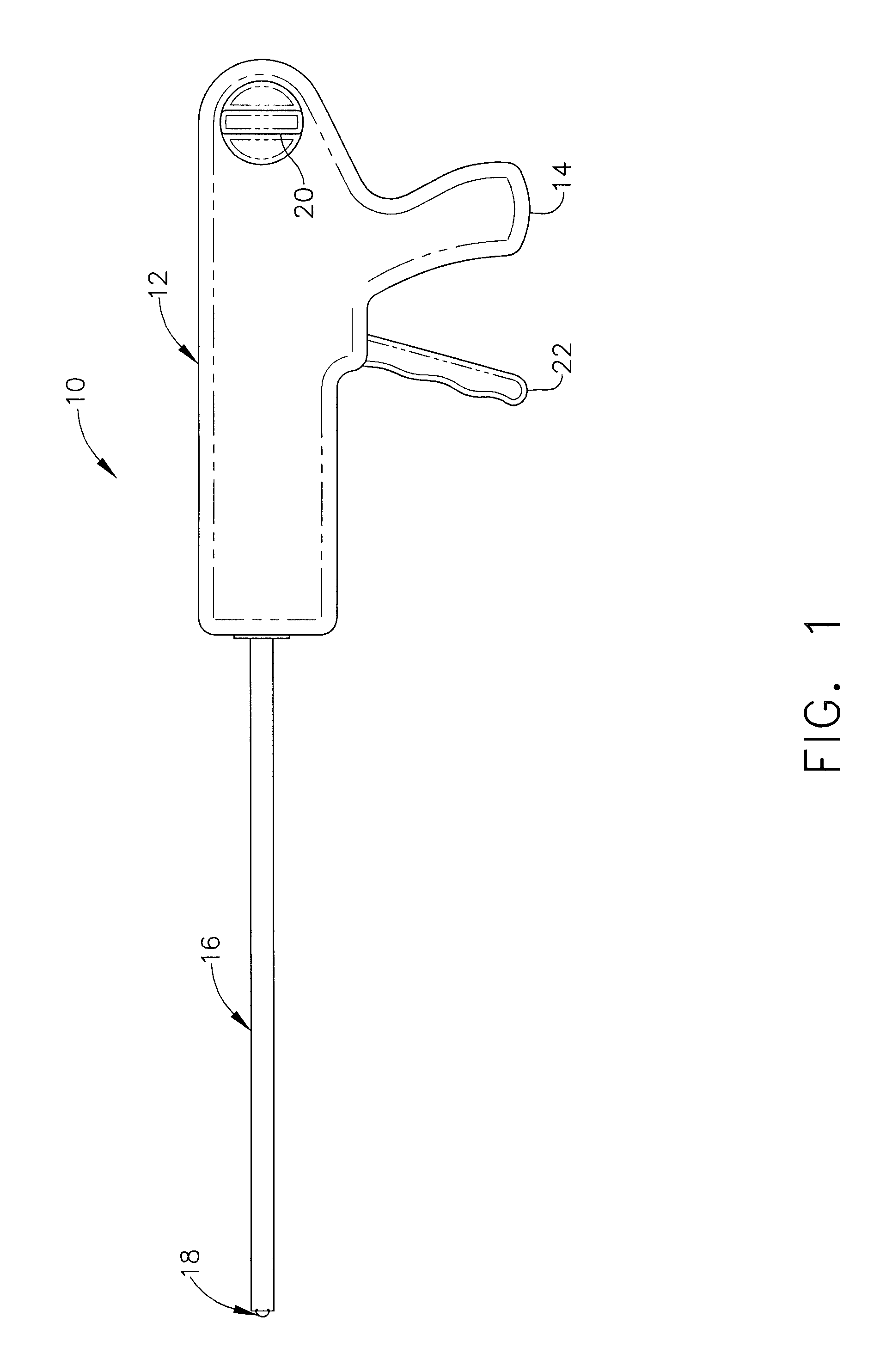

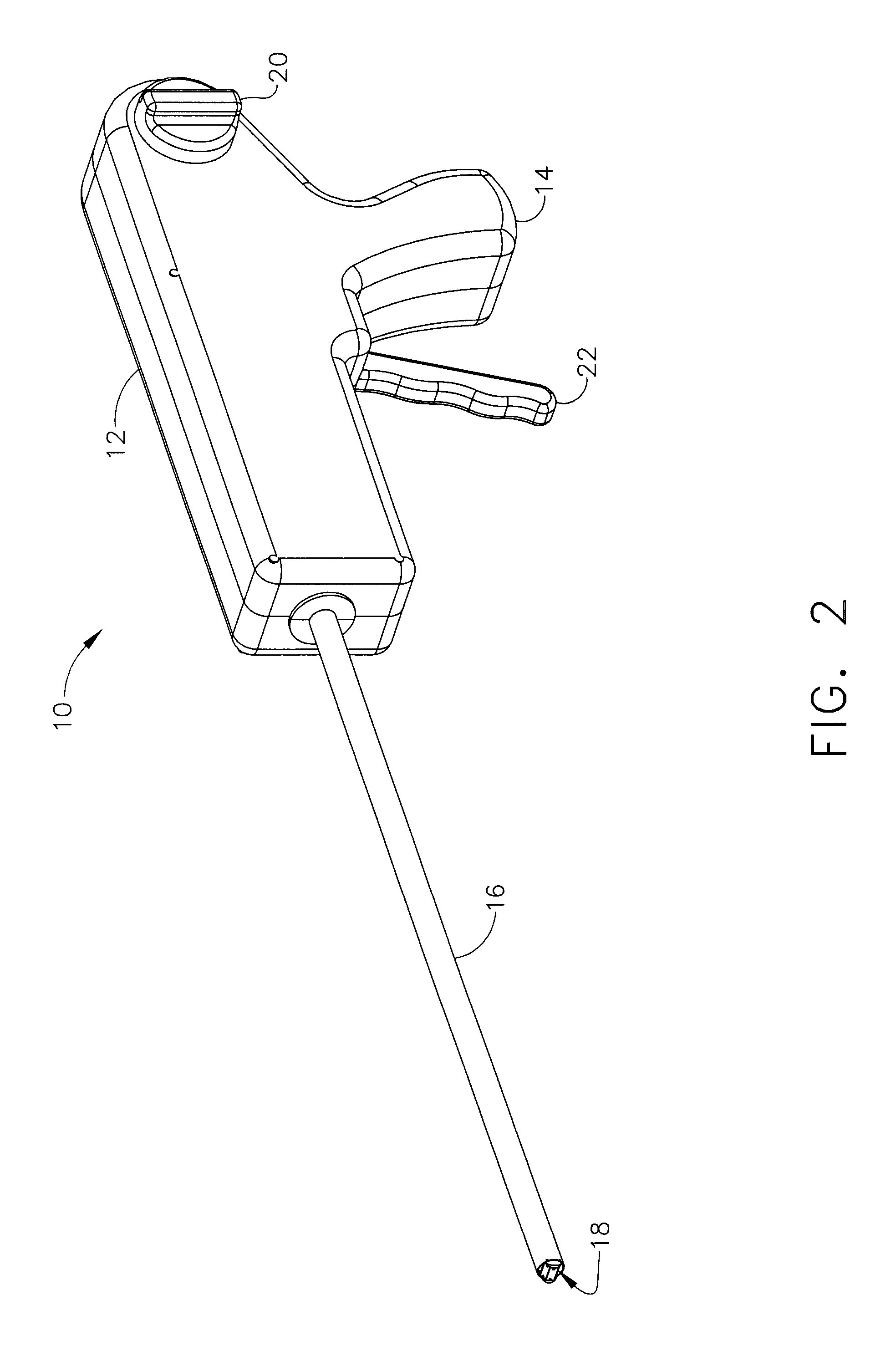

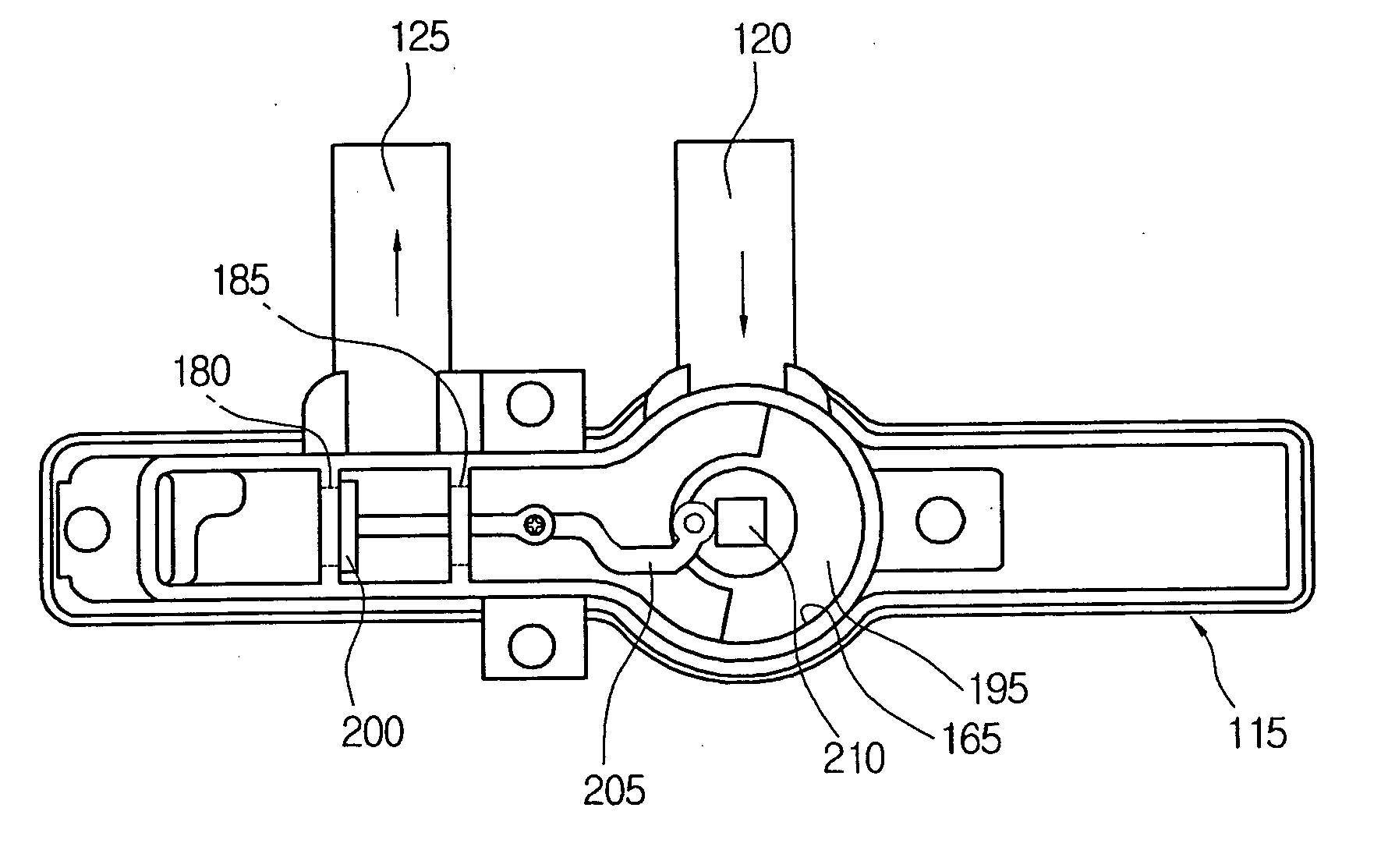

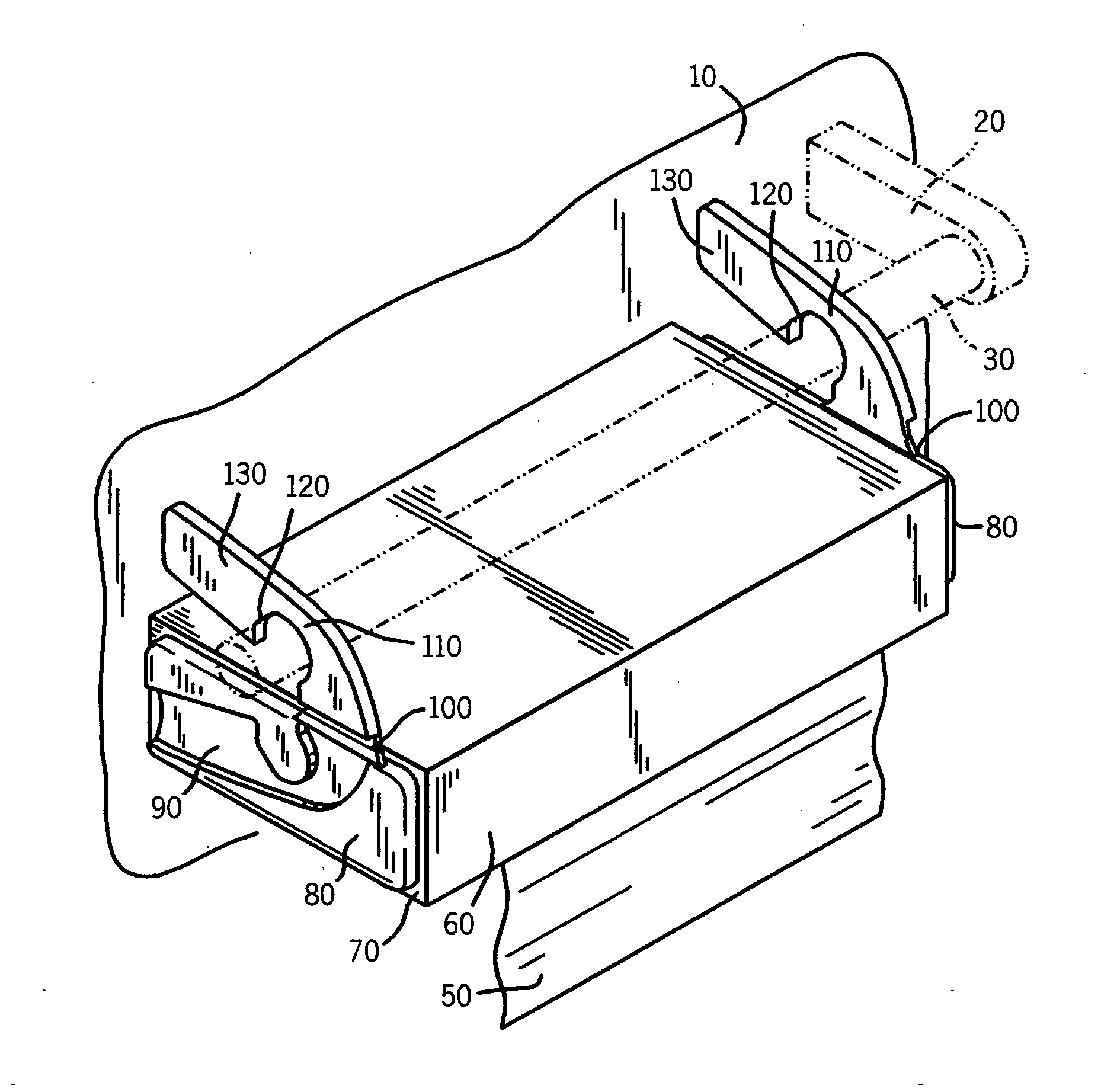

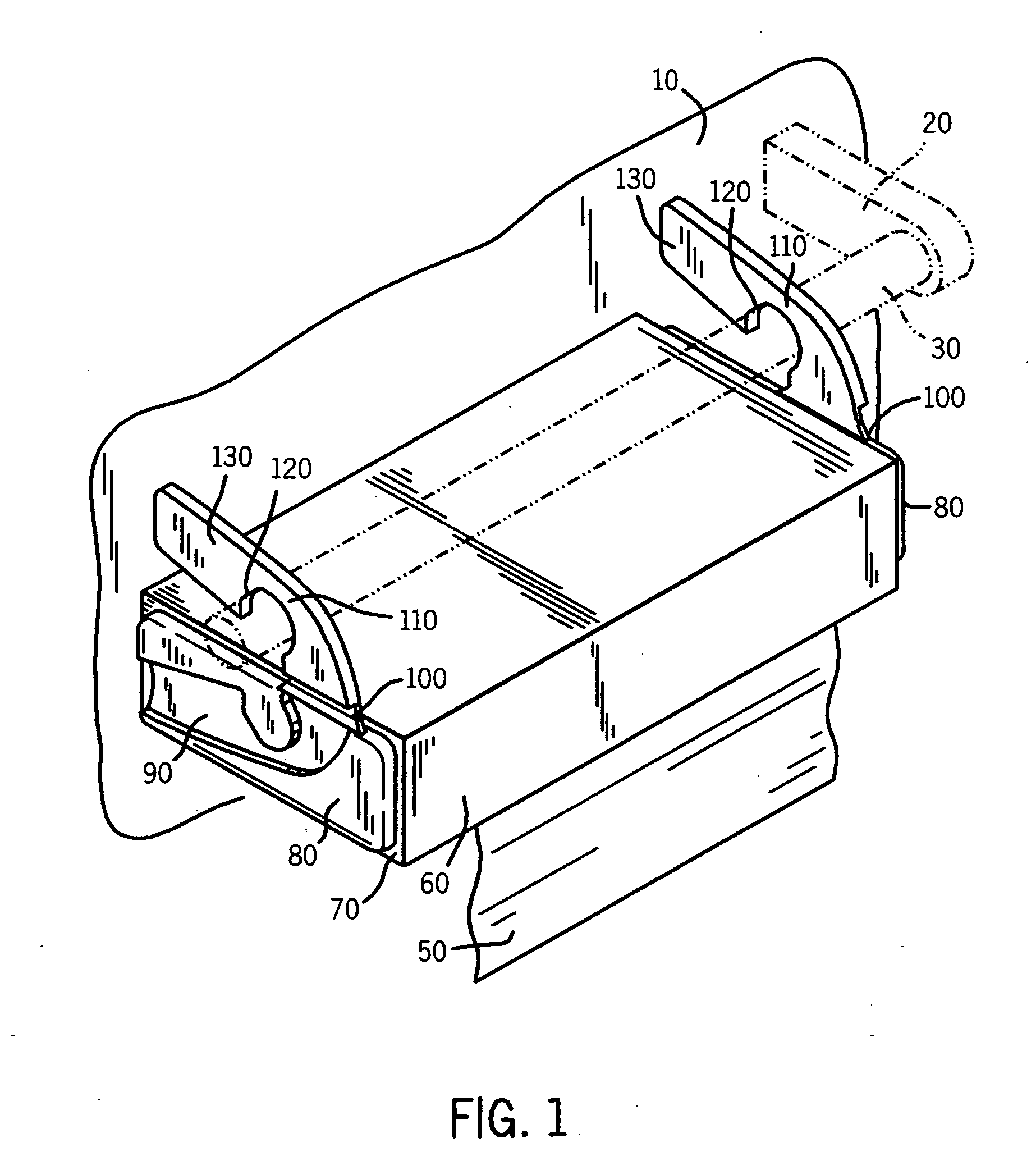

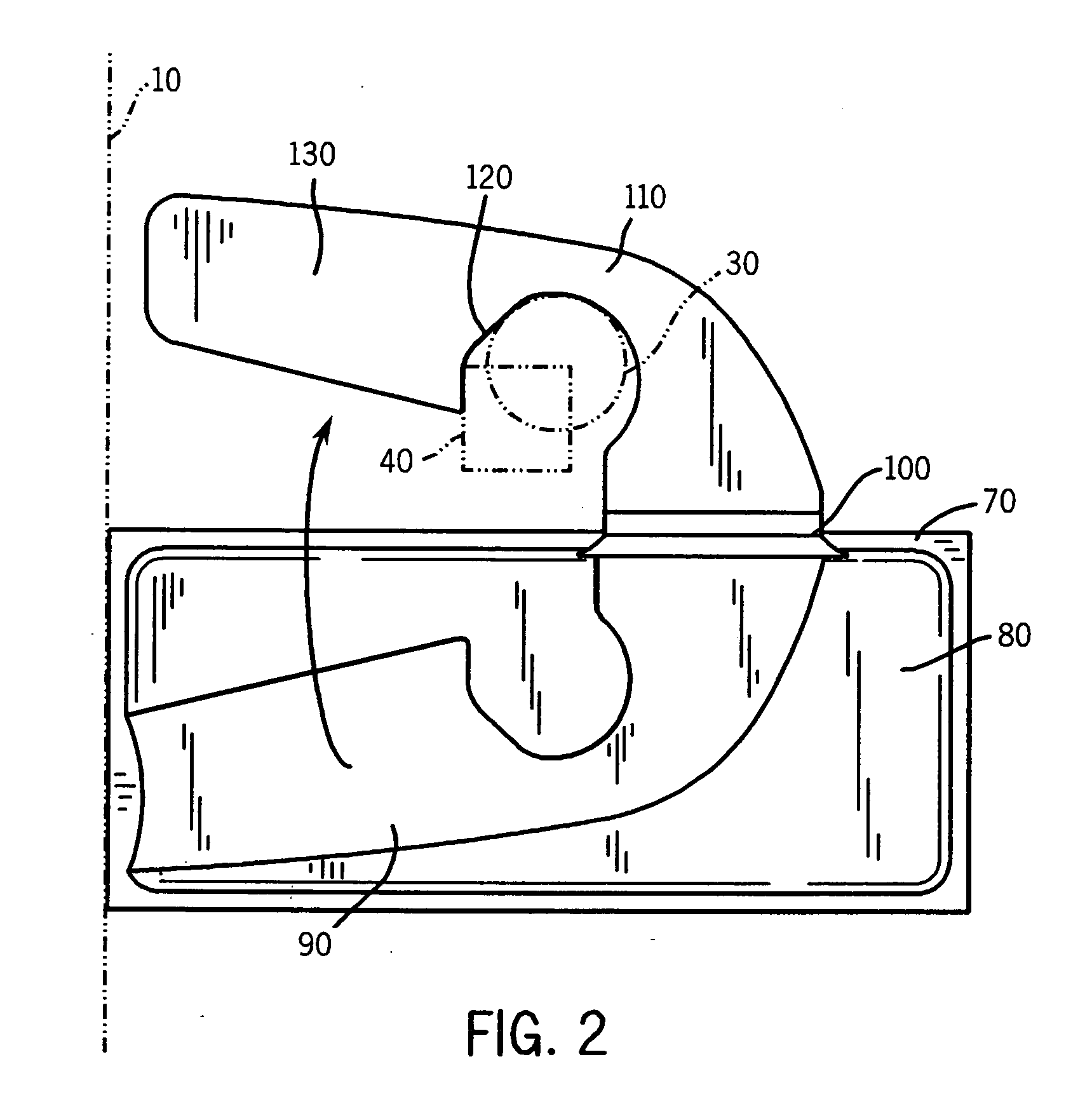

Surgical band fluid media dispenser

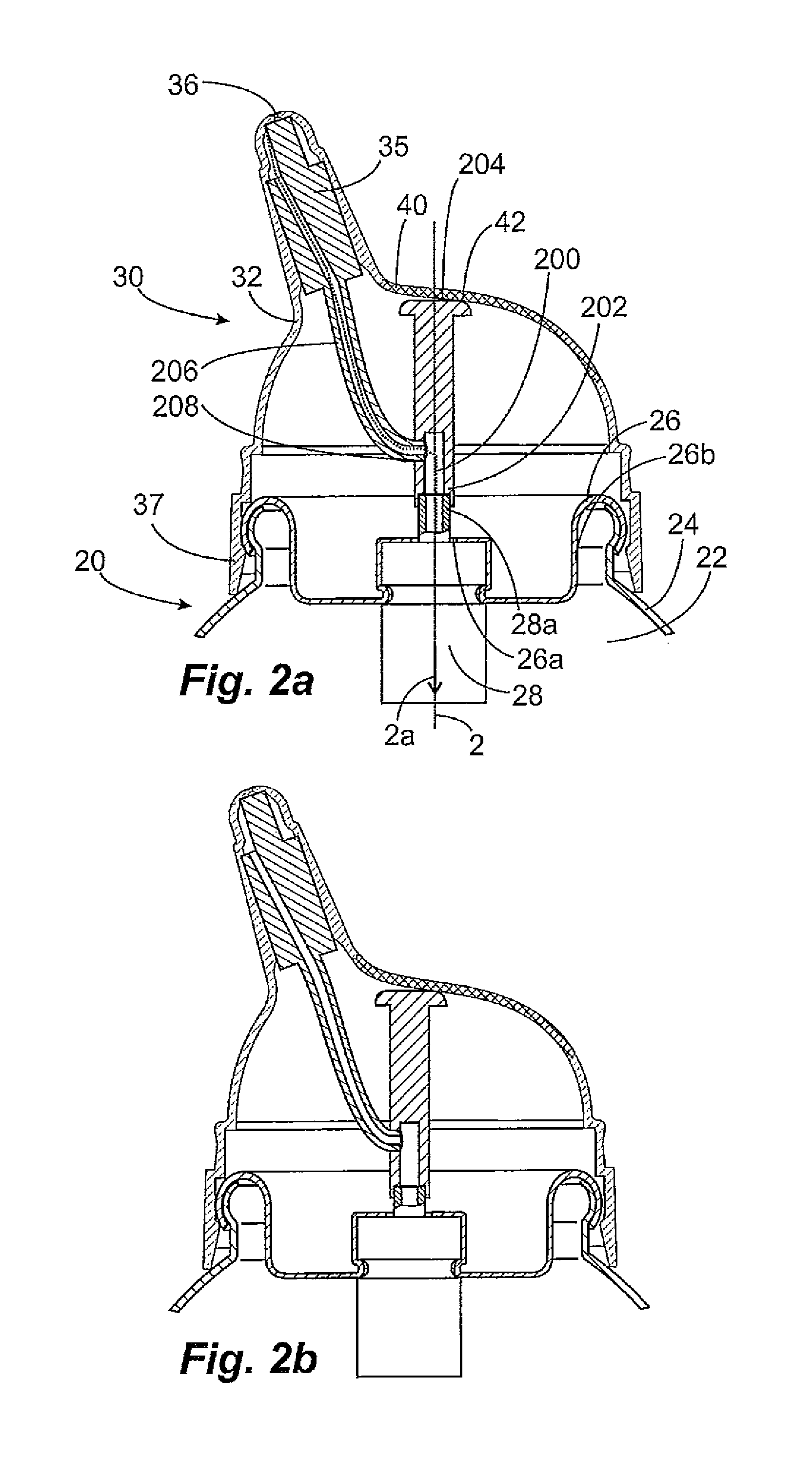

A multiple use fluid dispenser dispenses a flowable material in a precise pattern and quantity with leaking and clogging between dispensing avoided by employing a trigger fired syringe plunger to expel a fixed volume through a band. Between strokes, an advancement knob rotates the band over a distal dispensing tip to a nondispensing location that wipes excess flowable material and seals a dispensing orifice in a fluid conduit. The advancement knob further may rotate the band to a dispensing position wherein a combination of one or more dispensing holes produce a desired pattern and rate of flow with material over the dispensing hole(s) serving to initiate the flowable material, to control placement, serve as a detachable bandage or buttress material, etc.

Owner:ETHICON ENDO SURGERY INC

Surgical Band Fluid Media Dispenser

A multiple use fluid dispenser dispenses a flowable material in a precise pattern and quantity with leaking and clogging between dispensing avoided by employing a trigger fired syringe plunger to expel a fixed volume through a band. Between strokes, an advancement knob rotates the band over a distal dispensing tip to a nondispensing location that wipes excess flowable material and seals a dispensing orifice in a fluid conduit. The advancement knob further may rotate the band to a dispensing position wherein a combination of one or more dispensing holes produce a desired pattern and rate of flow with material over the dispensing hole(s) serving to initiate the flowable material, to control placement, serve as a detachable bandage or buttress material, etc.

Owner:ETHICON ENDO SURGERY INC

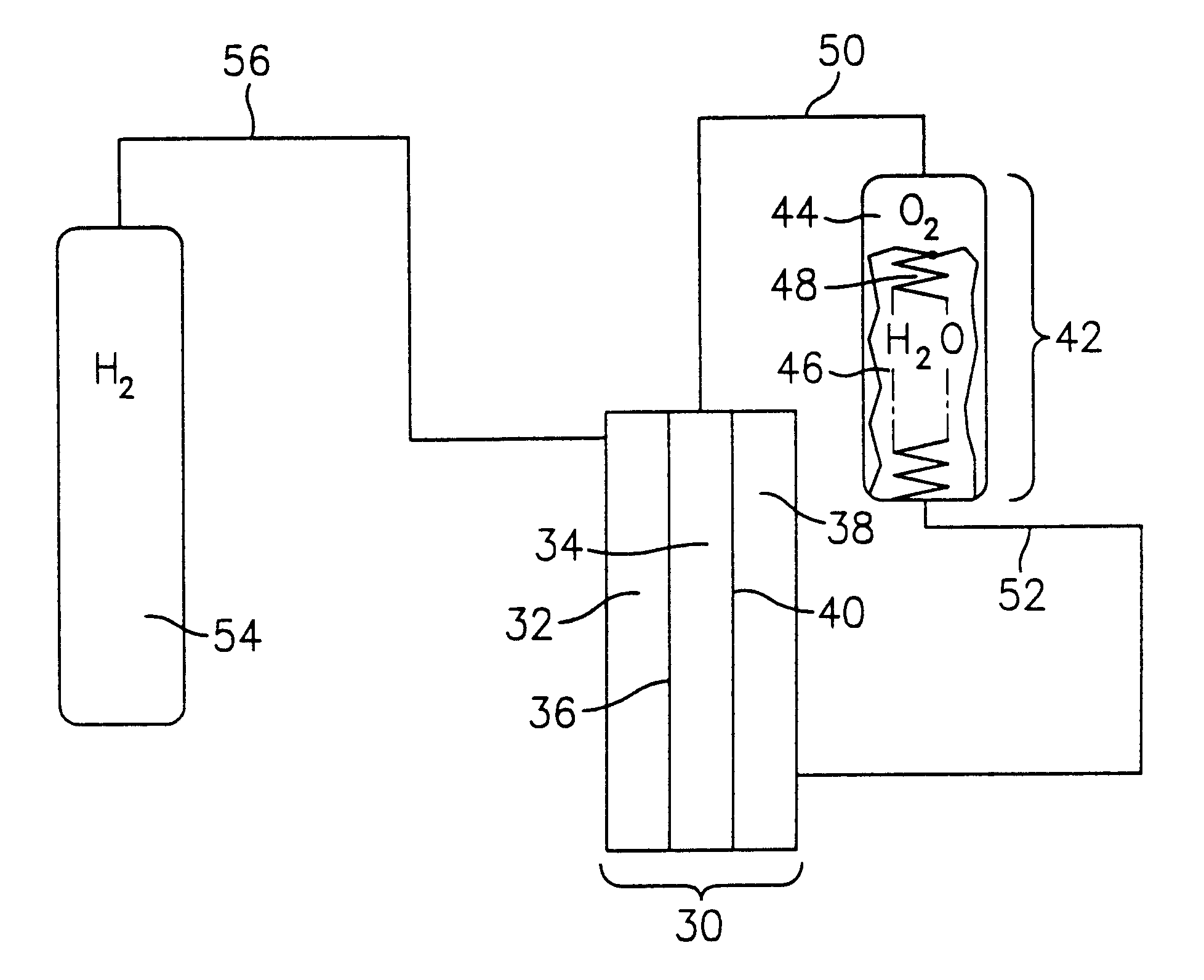

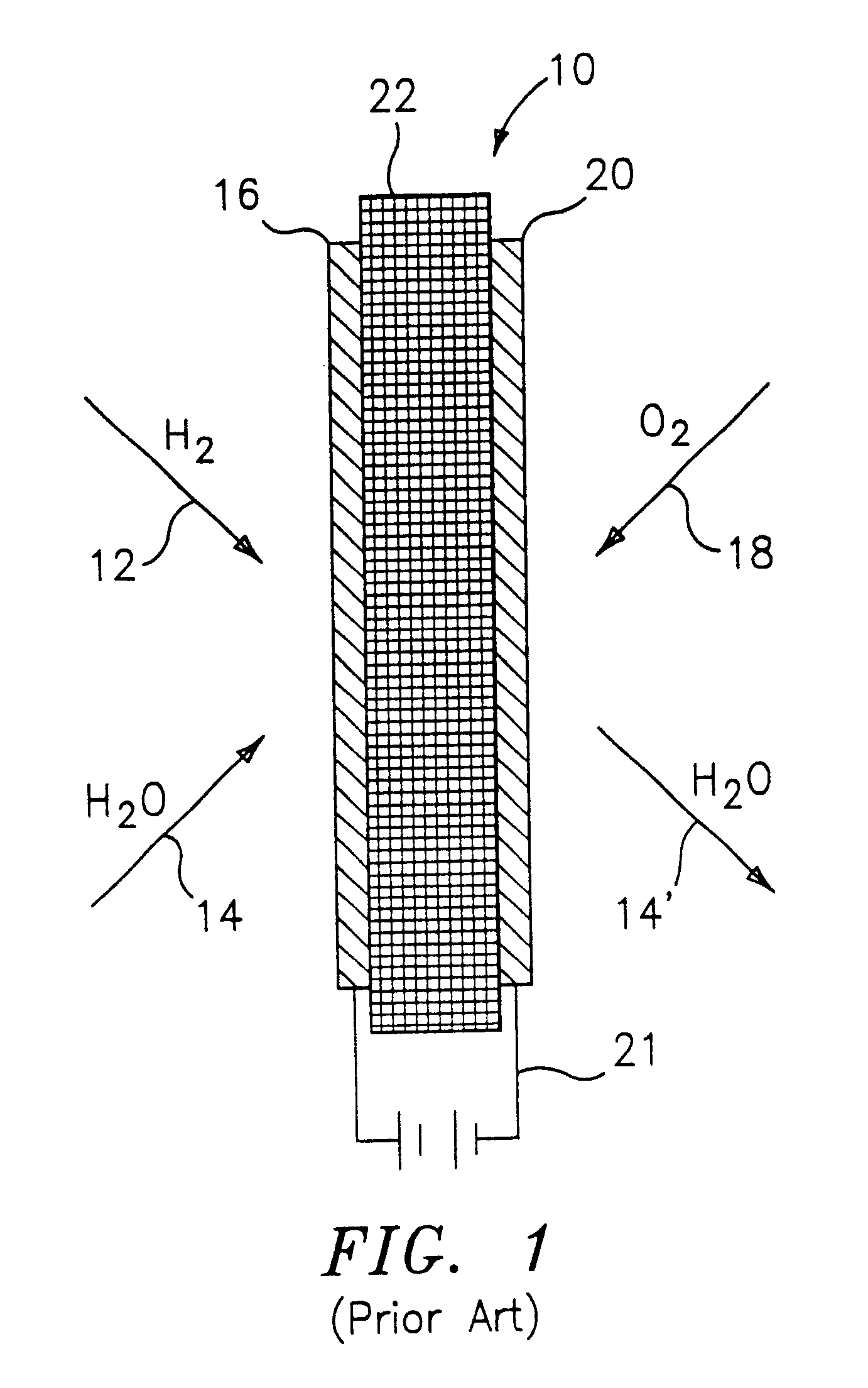

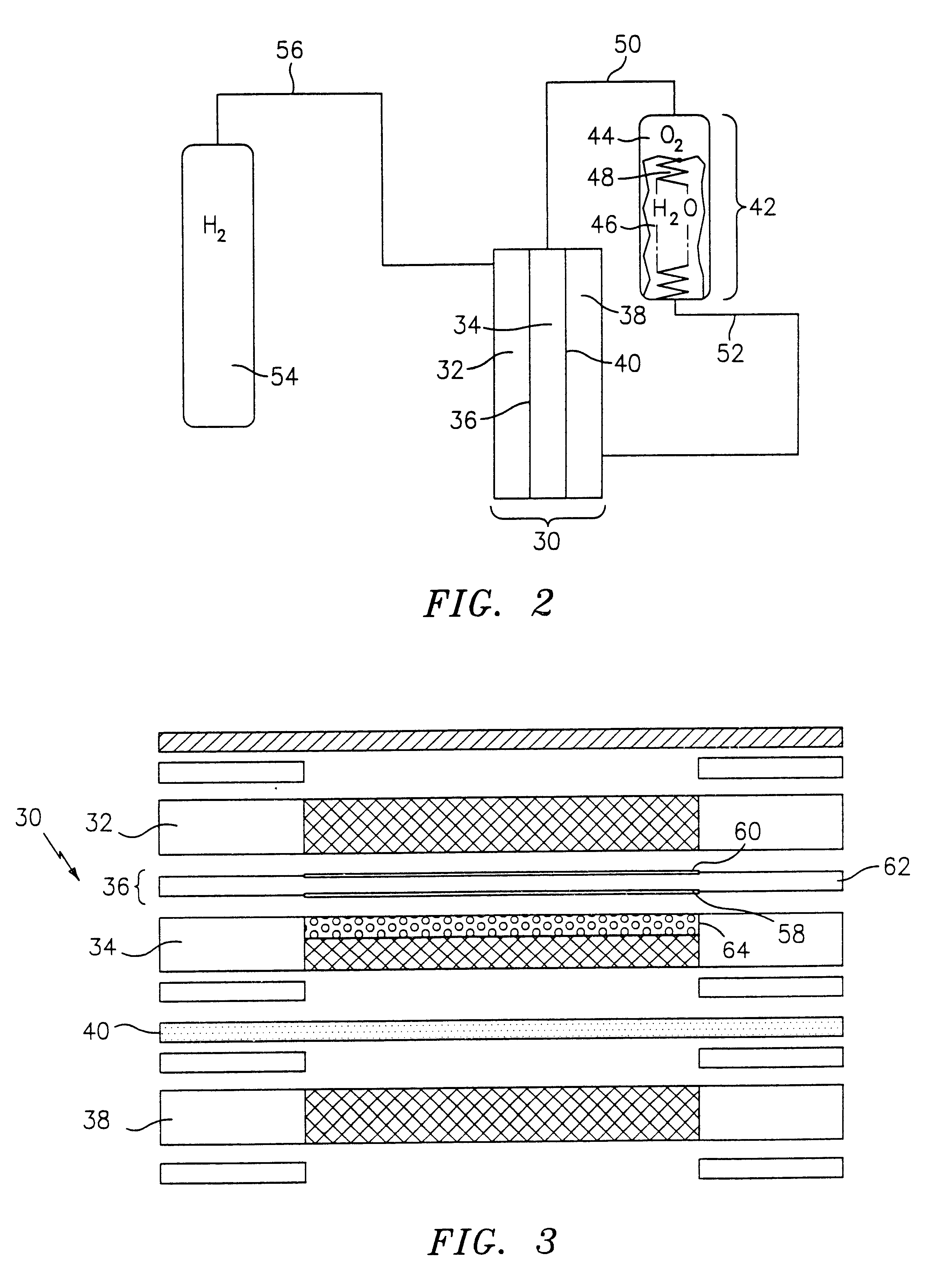

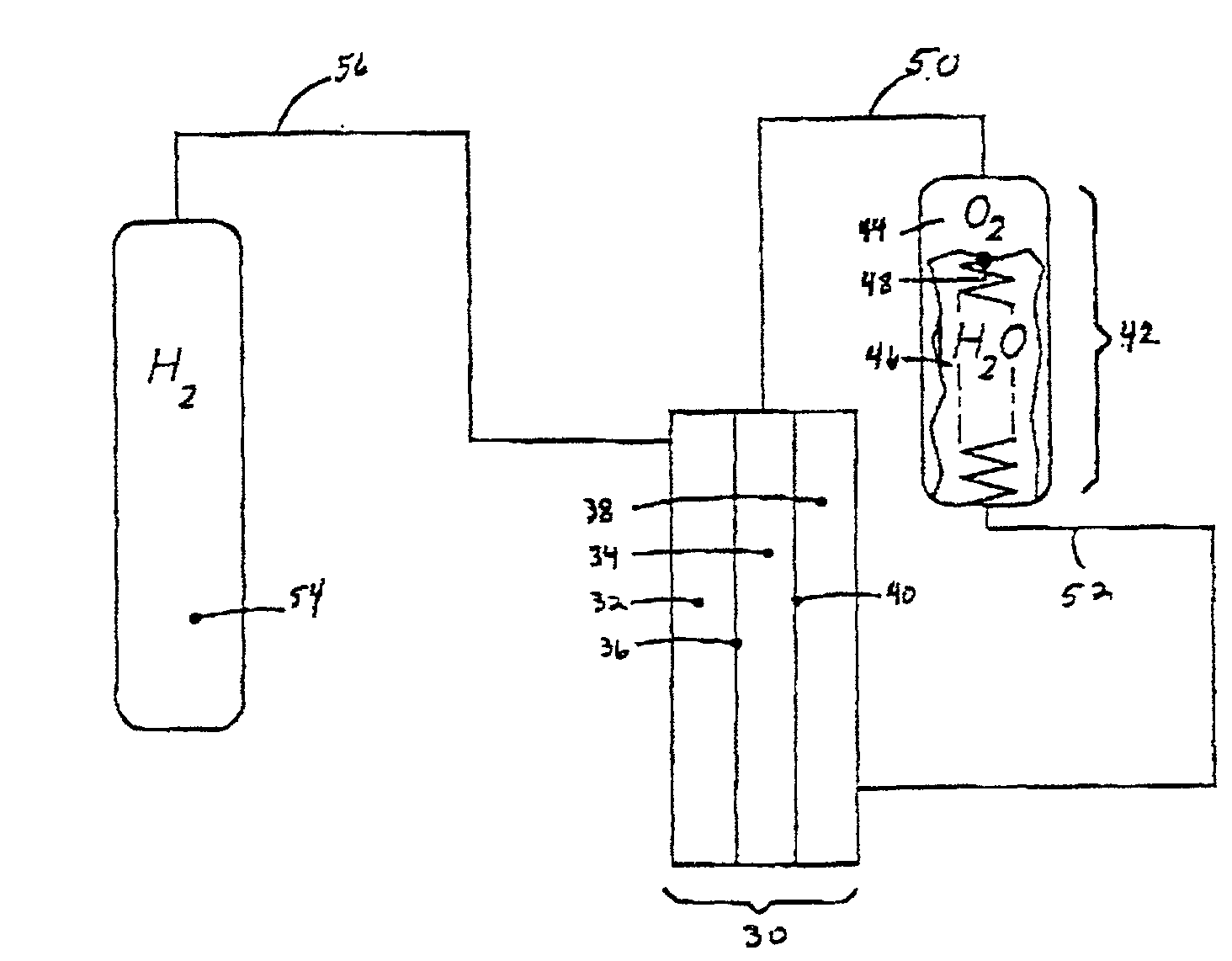

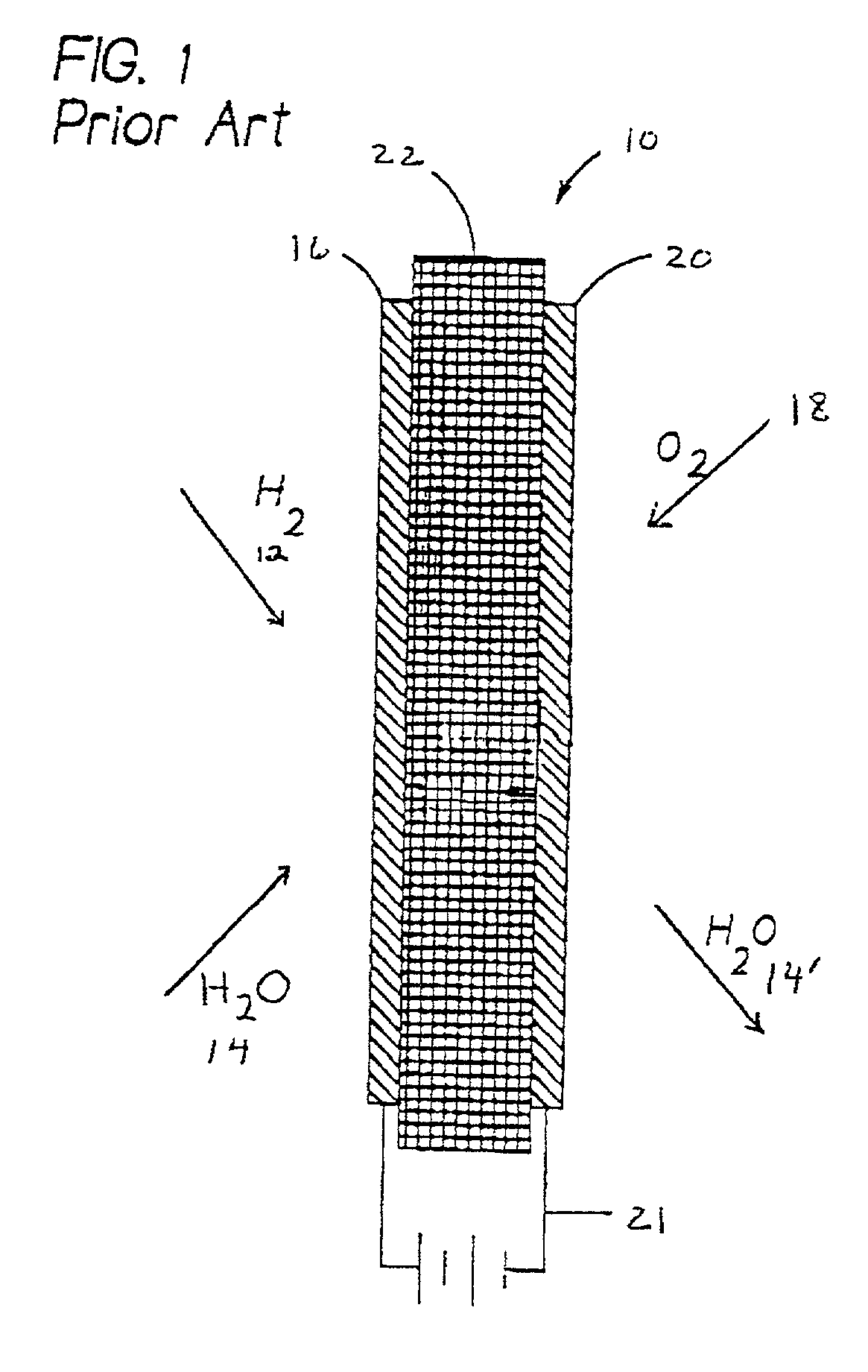

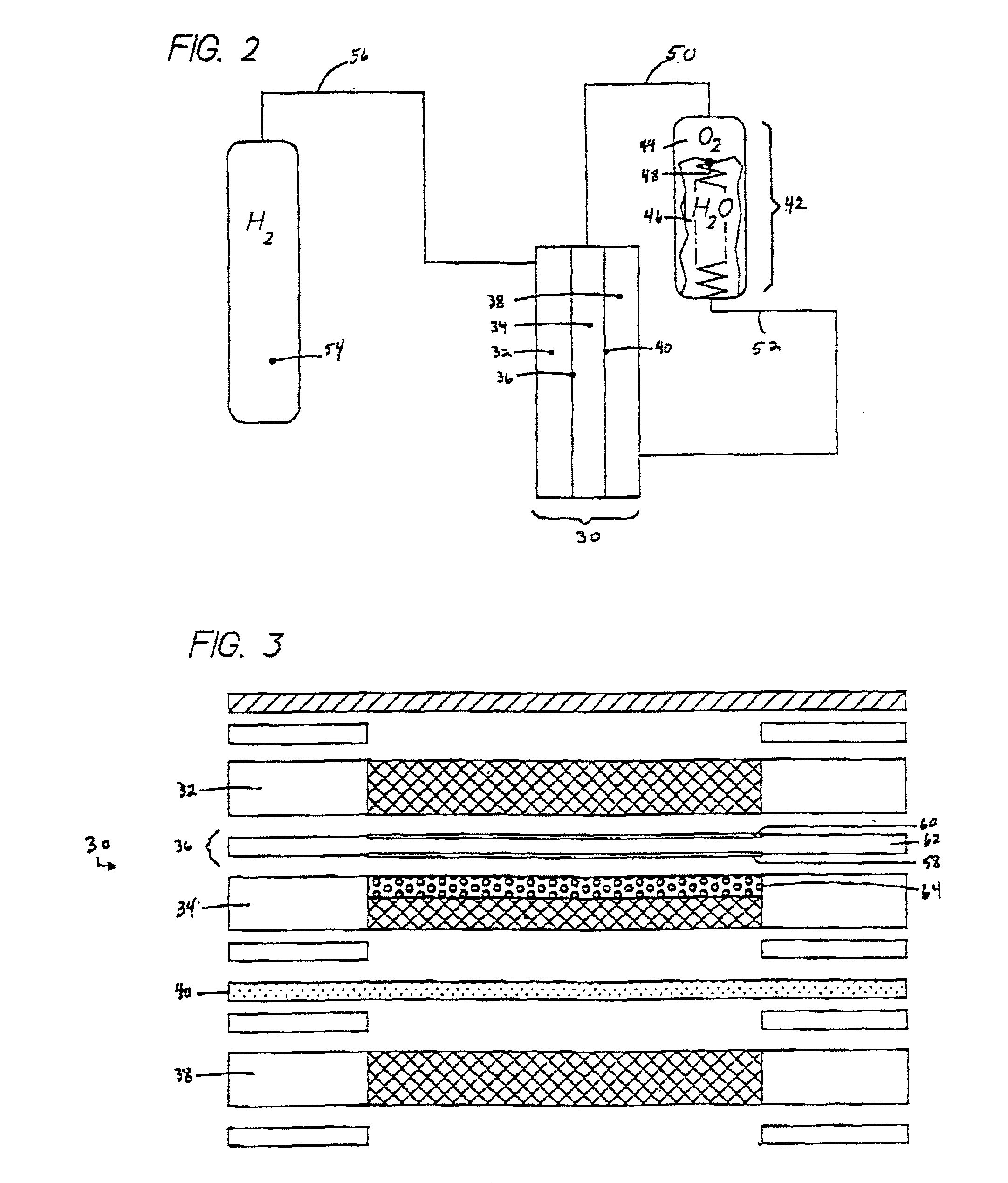

Low gravity electrochemical cell

An electrochemical cell system includes a hydrogen electrode; an oxygen electrode; a membrane disposed between the hydrogen electrode and the oxygen electrode; and a compartmentalized storage tank. The compartmentalized storage tank has a first fluid storage section and a second fluid storage section separated by a movable divider. The compartmentalized storage tank is in fluid communication with the electrochemical cell. Further, an electrochemical cell includes a hydrogen electrode; an oxygen electrode; an electrolyte membrane disposed between and in intimate contact with the hydrogen electrode and said oxygen electrode; an oxygen flow field disposed adjacent to and in intimate contact with the oxygen electrode; a hydrogen flow field disposed adjacent to and in intimate contact with the hydrogen electrode; a water flow field disposed in fluid communication with the oxygen flow field; and a media divider disposed between the oxygen flow field and the water flow field.

Owner:PROTON ENERGY SYST

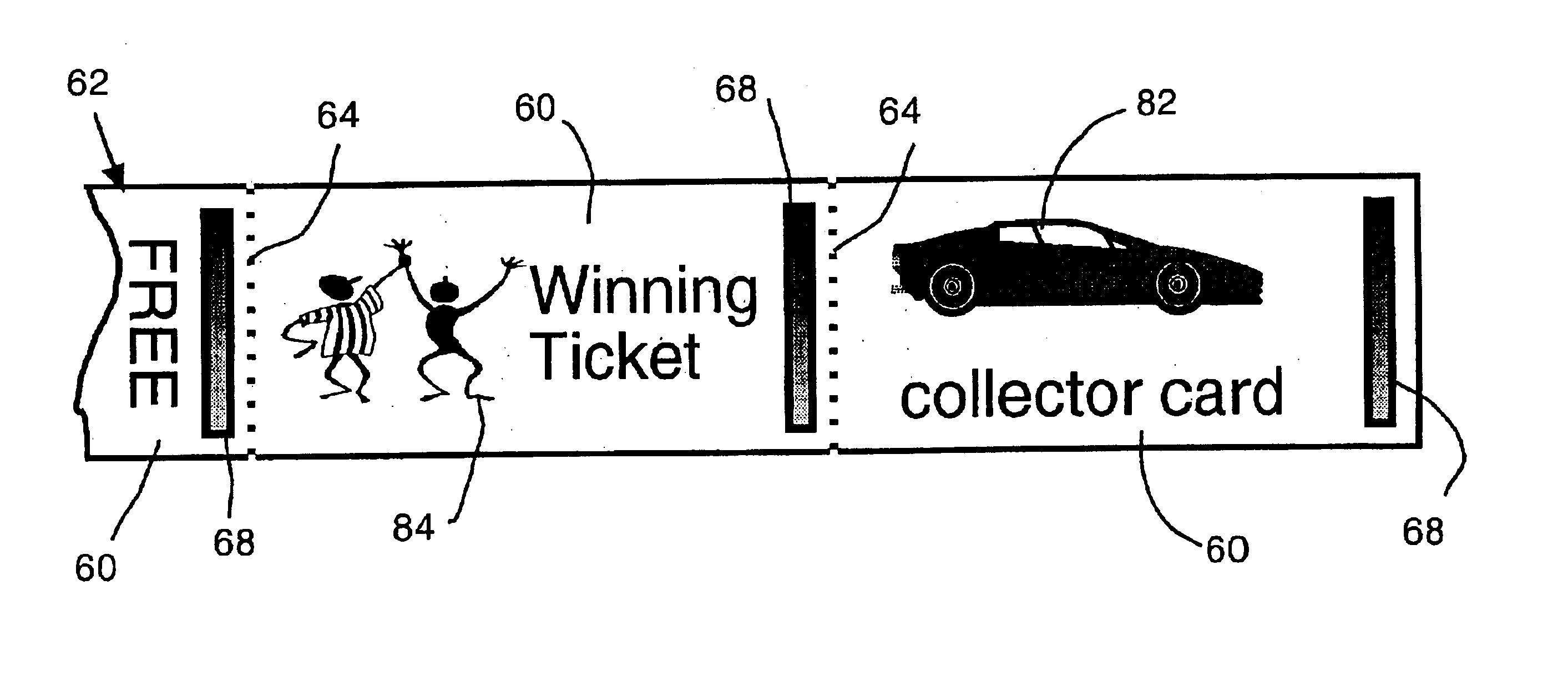

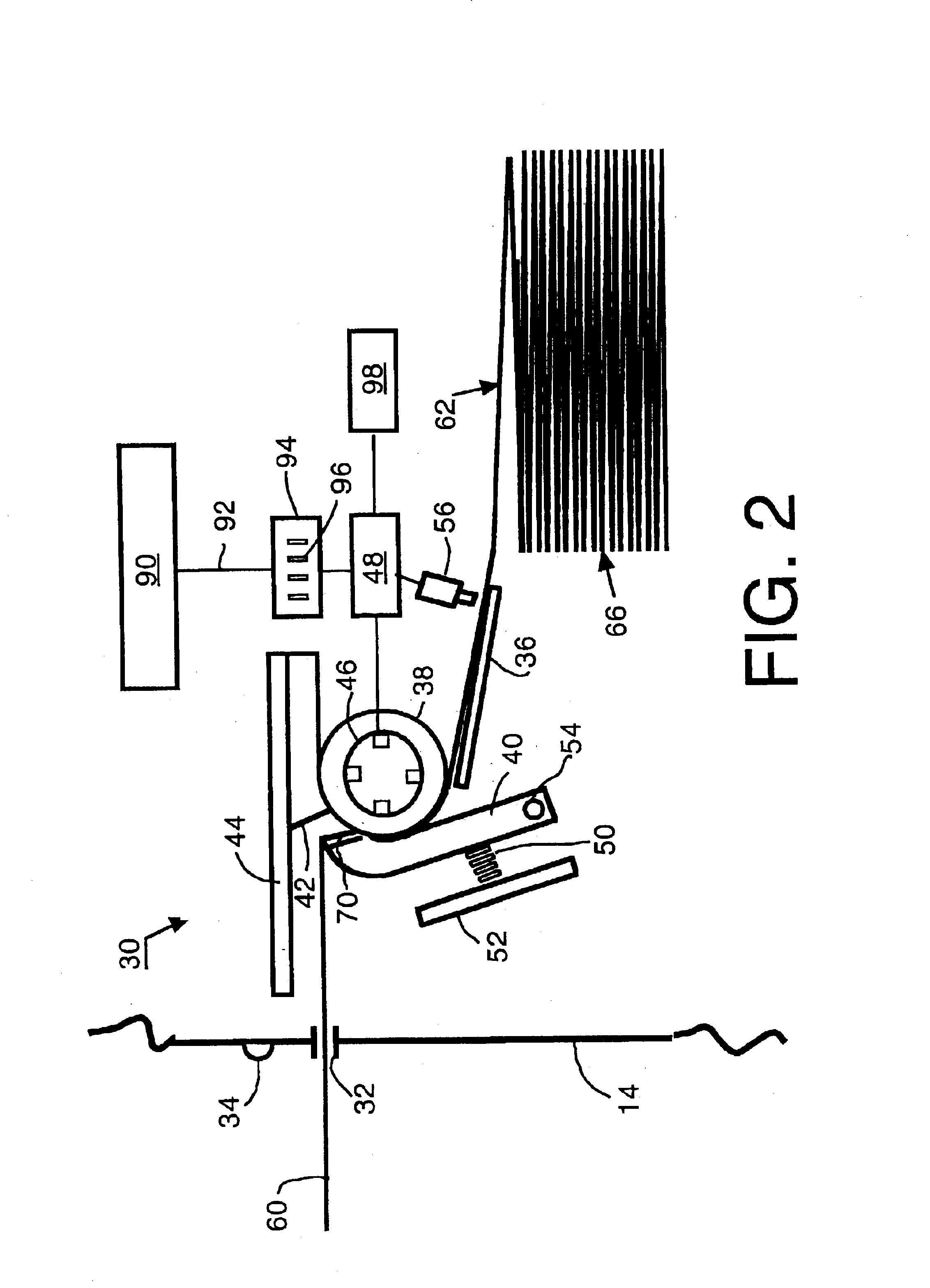

Media dispenser for vending machines

InactiveUS6874612B1Increase valueGood serviceAcutation objectsPublic buildingsMedia dispenserVoucher

Owner:WISCONSIN LABEL CORP CORP

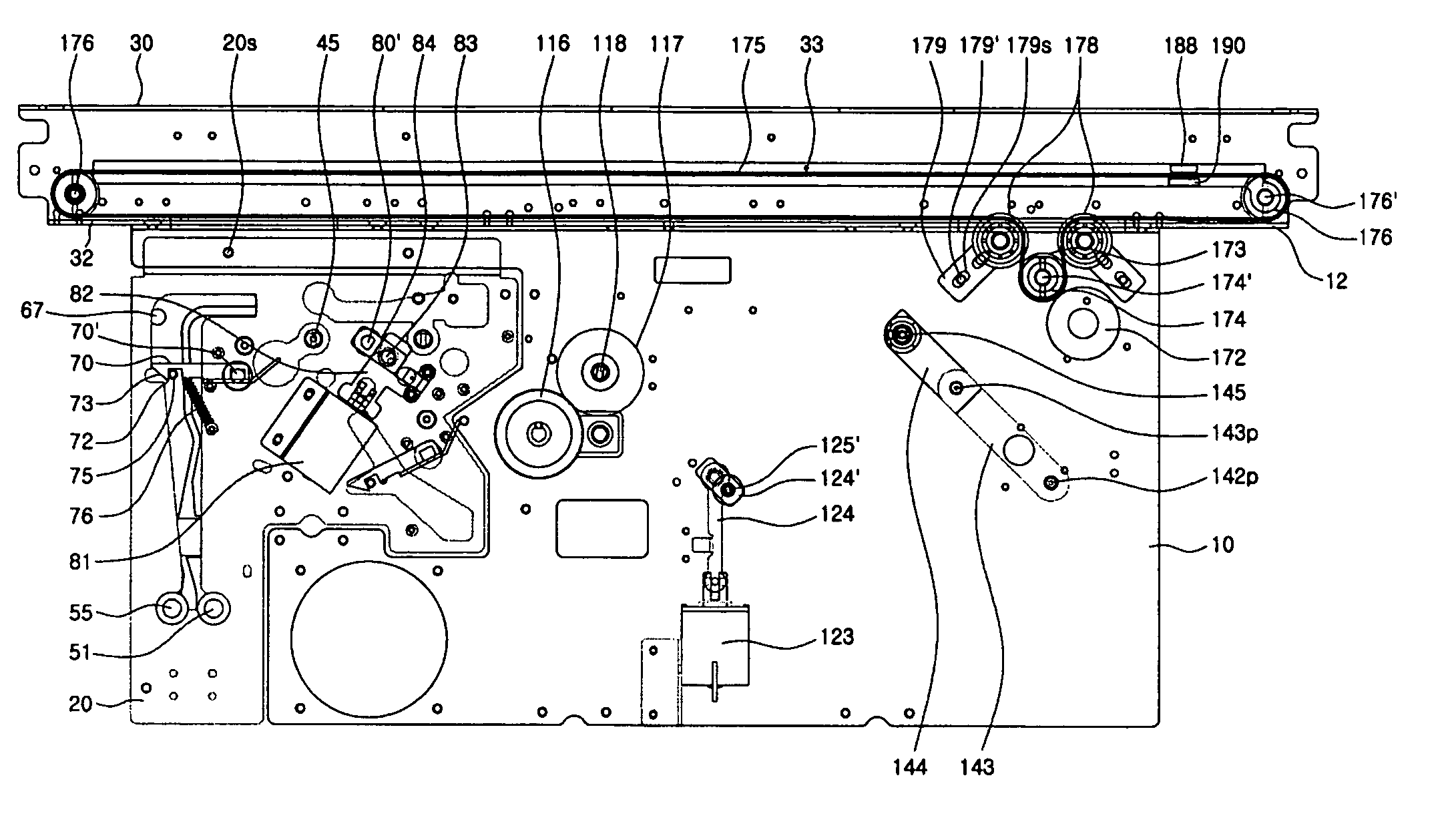

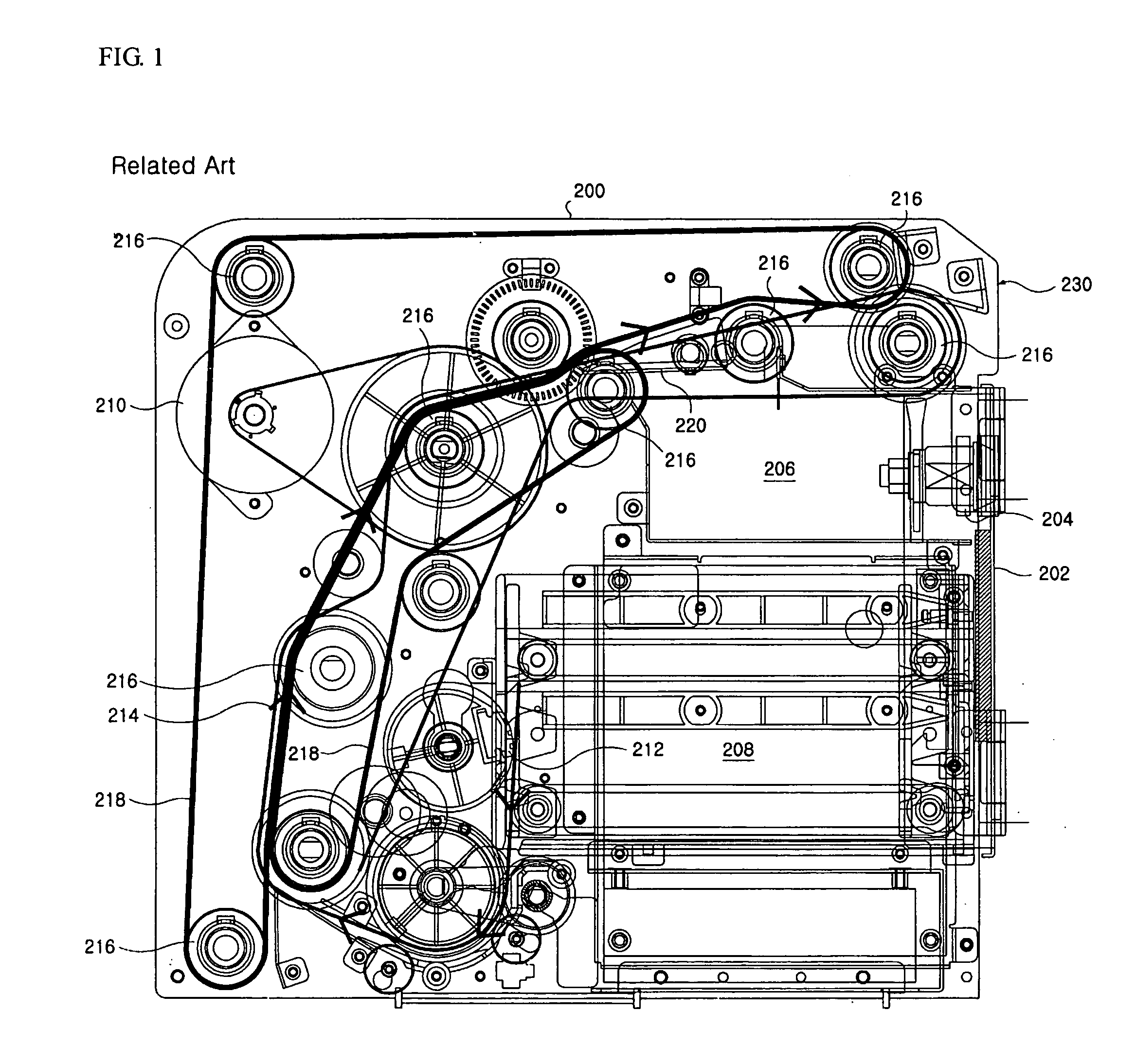

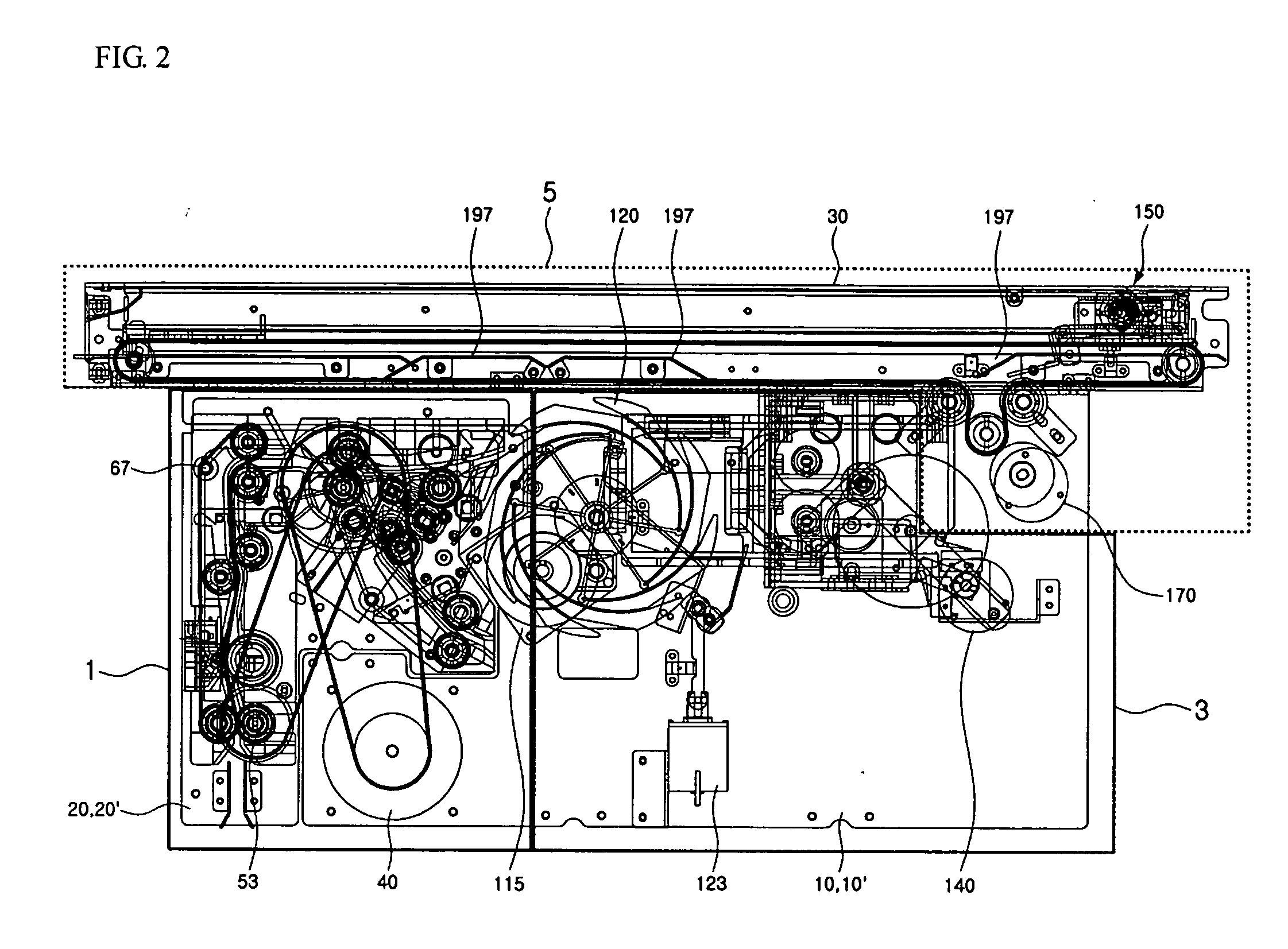

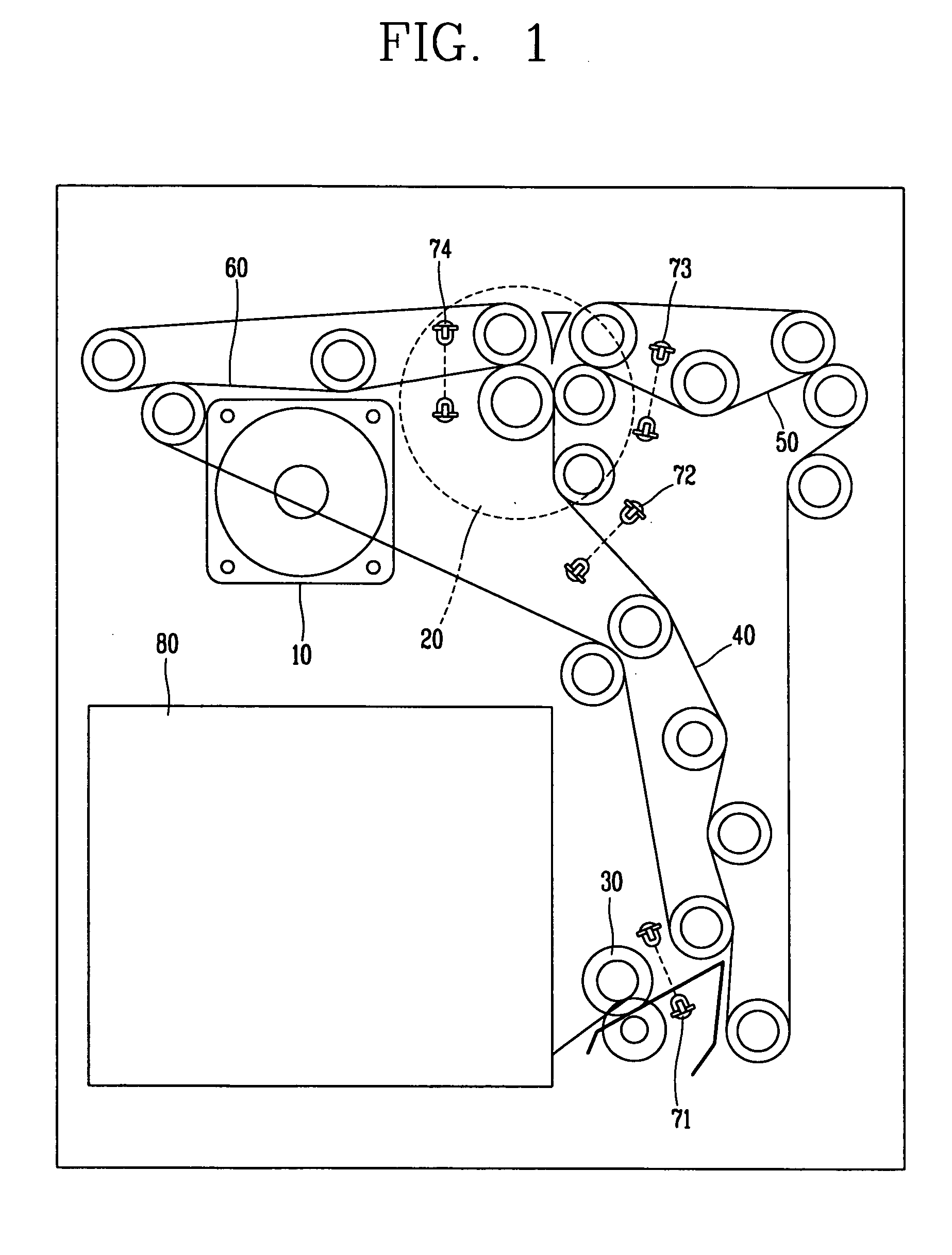

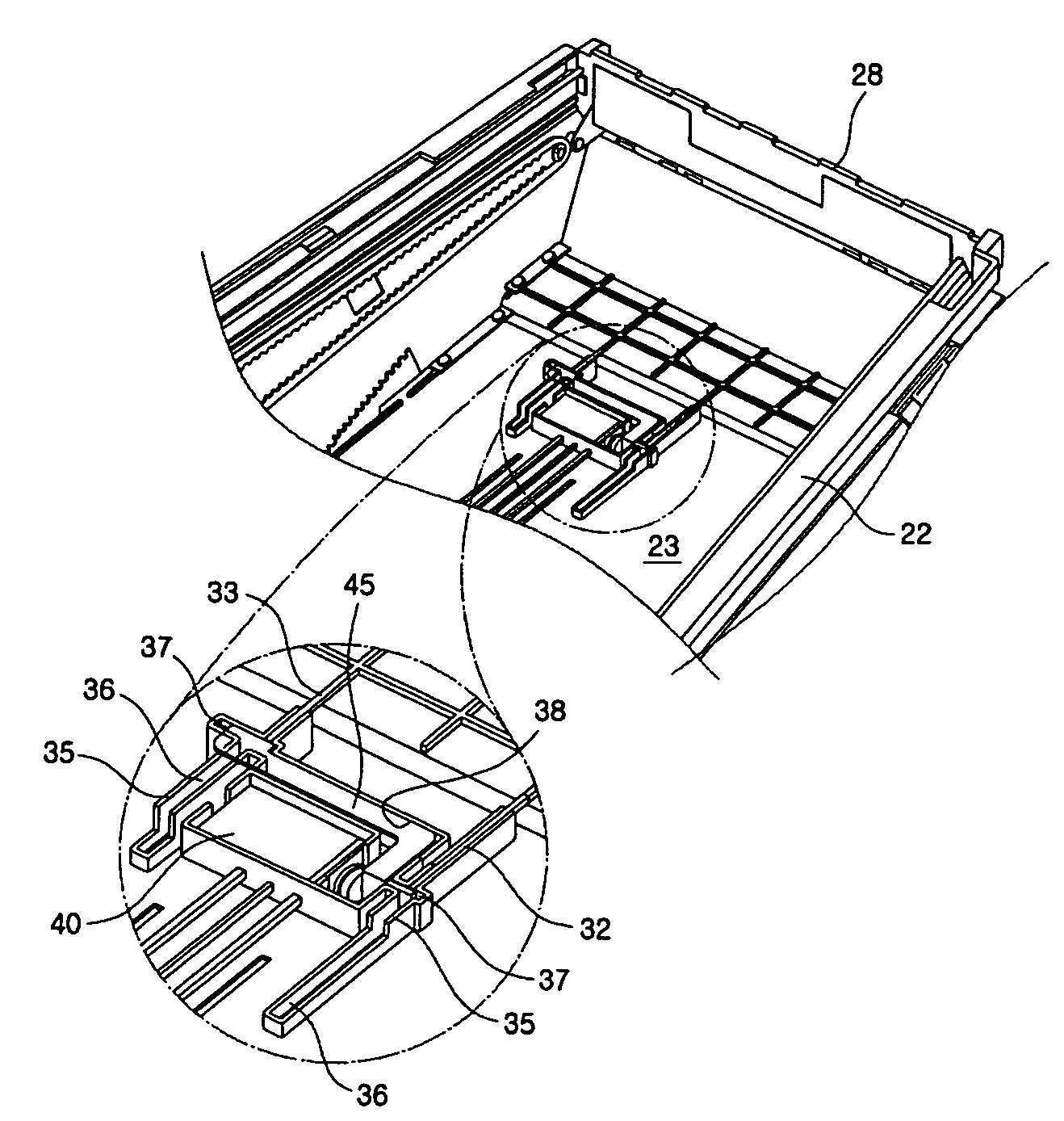

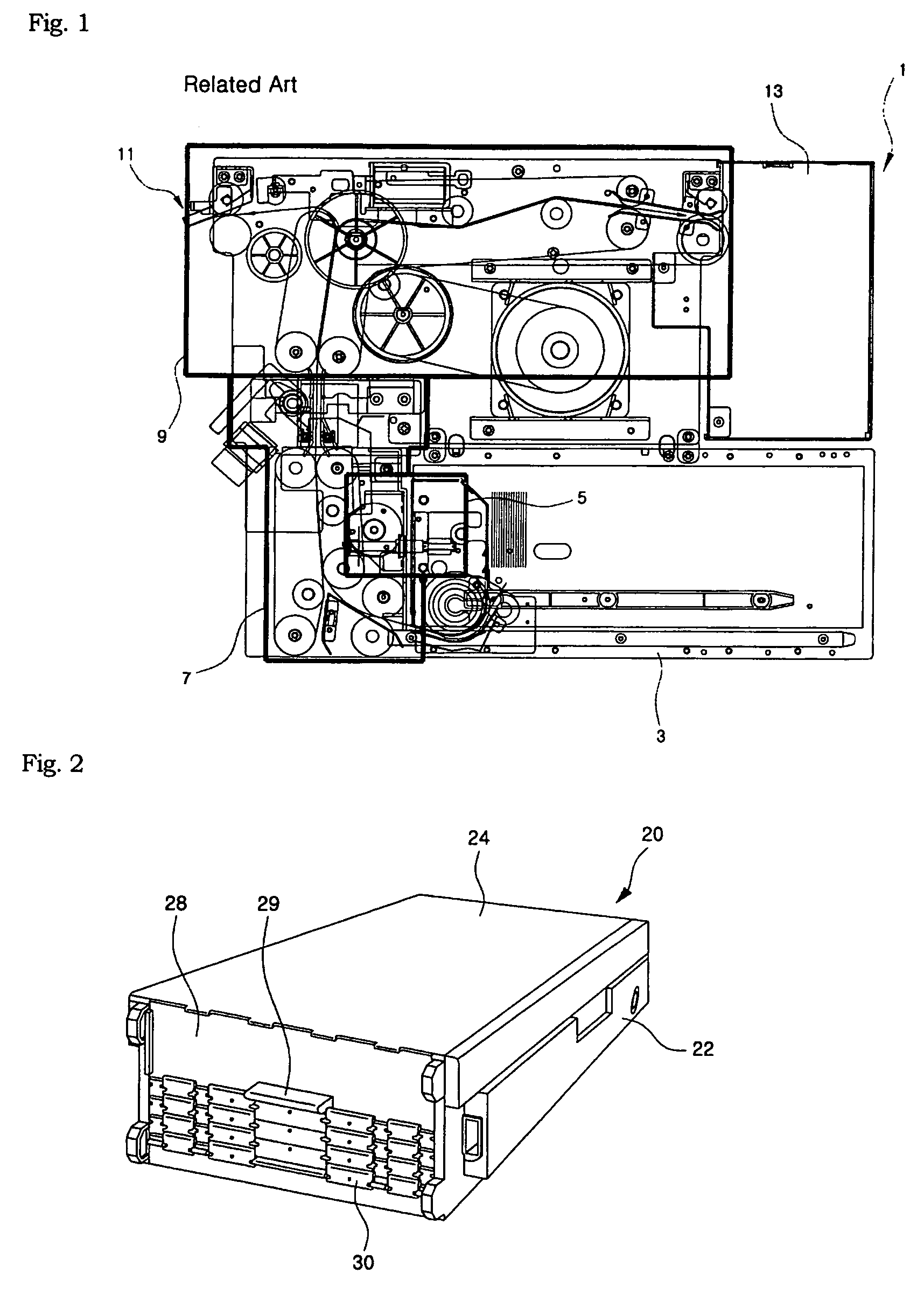

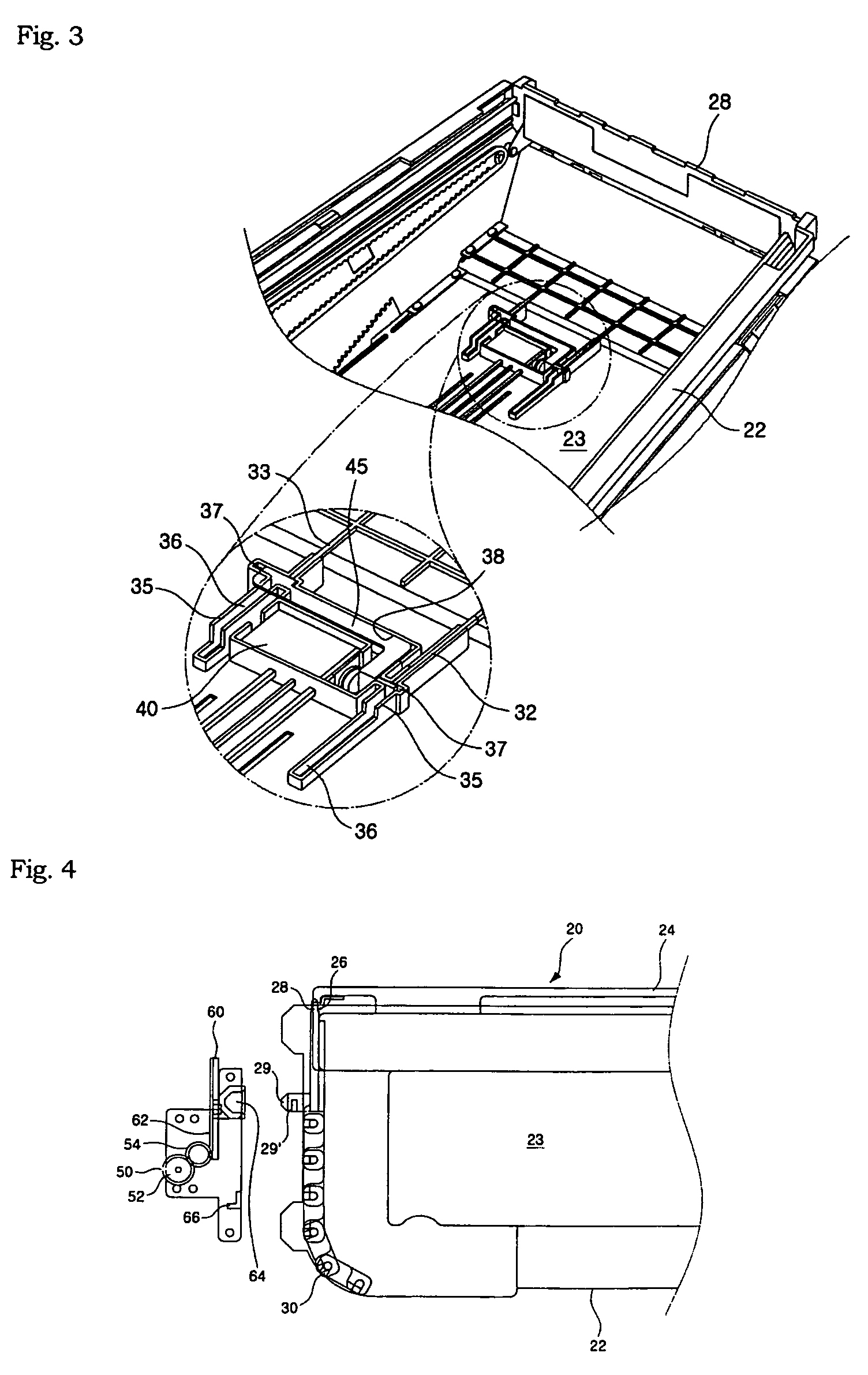

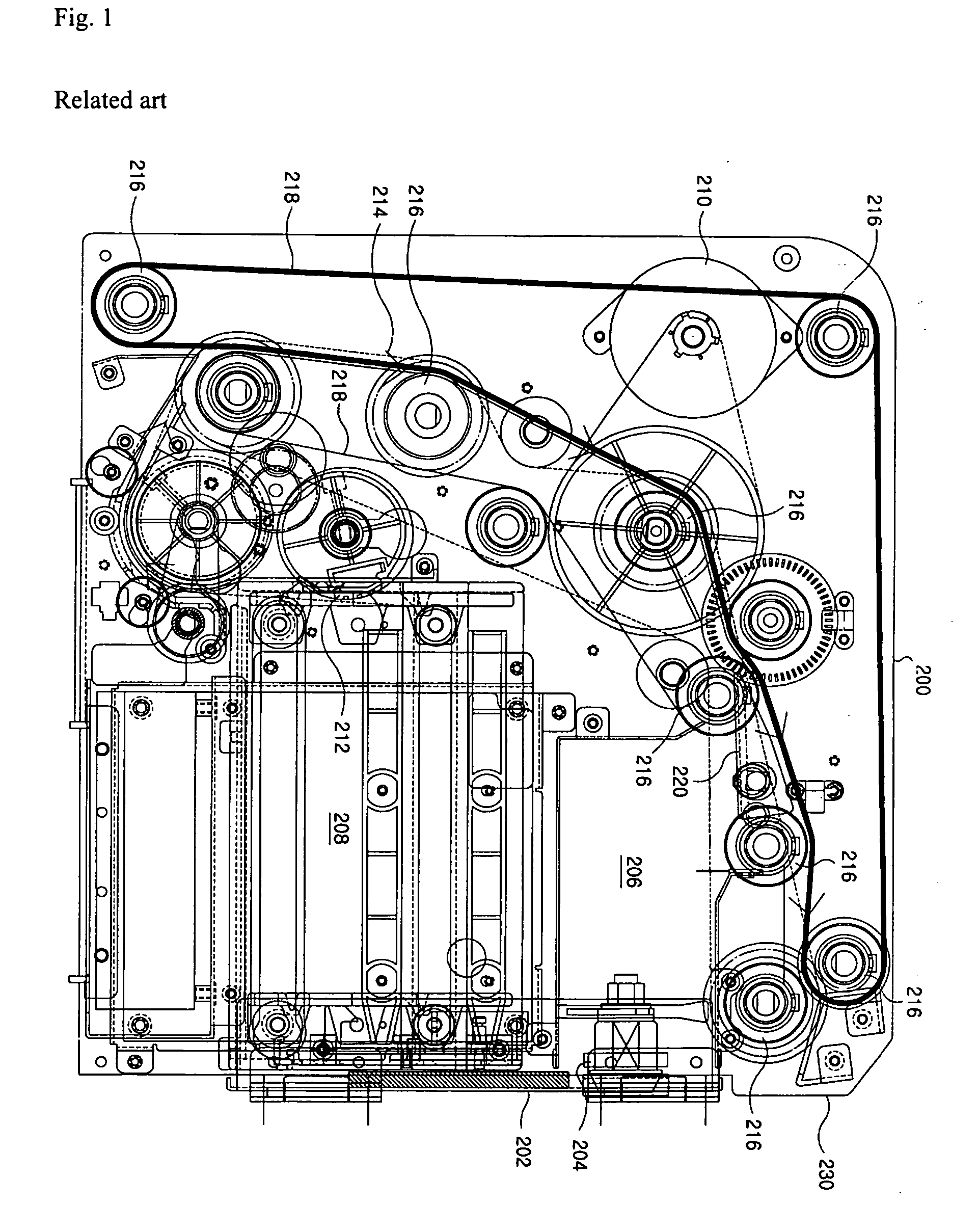

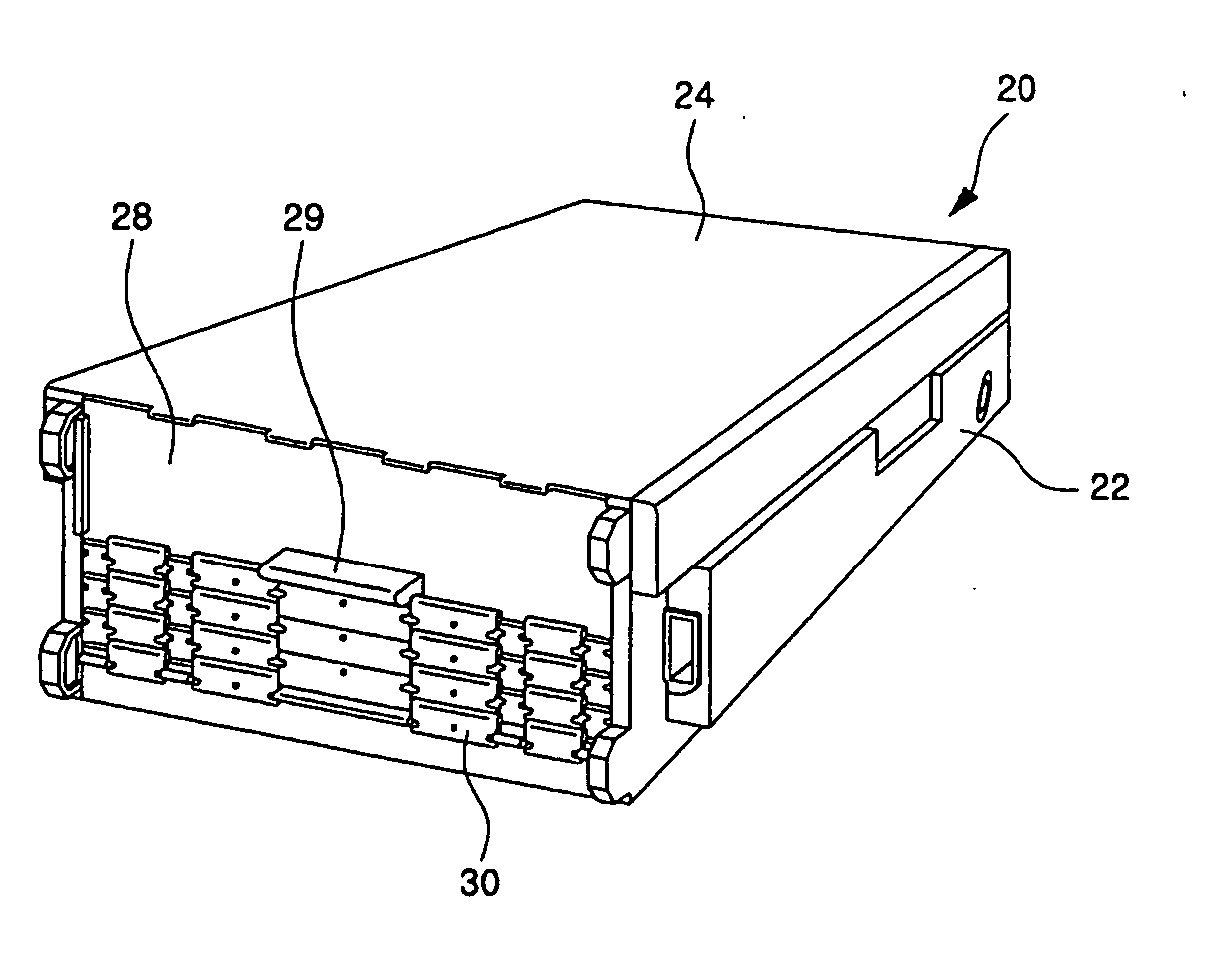

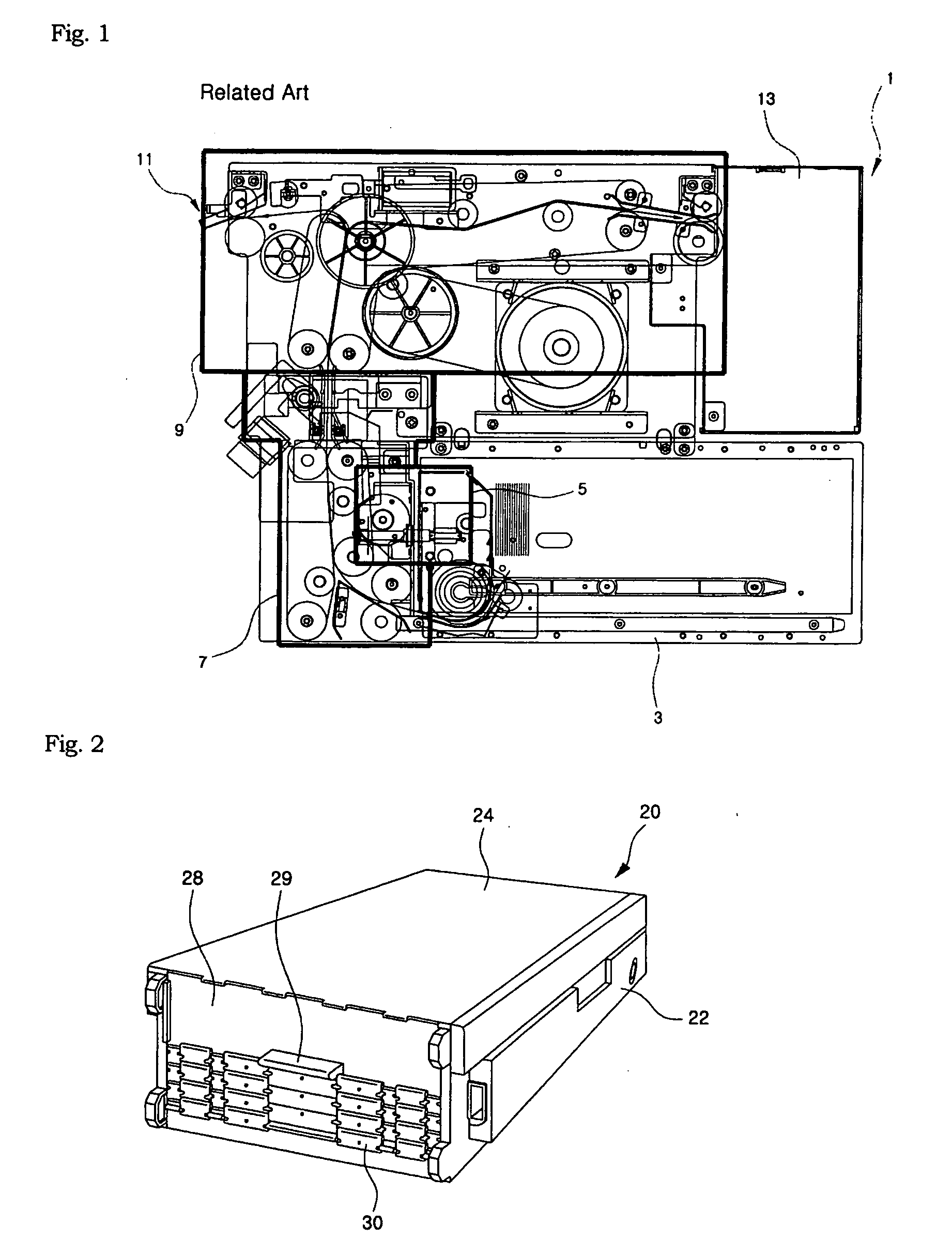

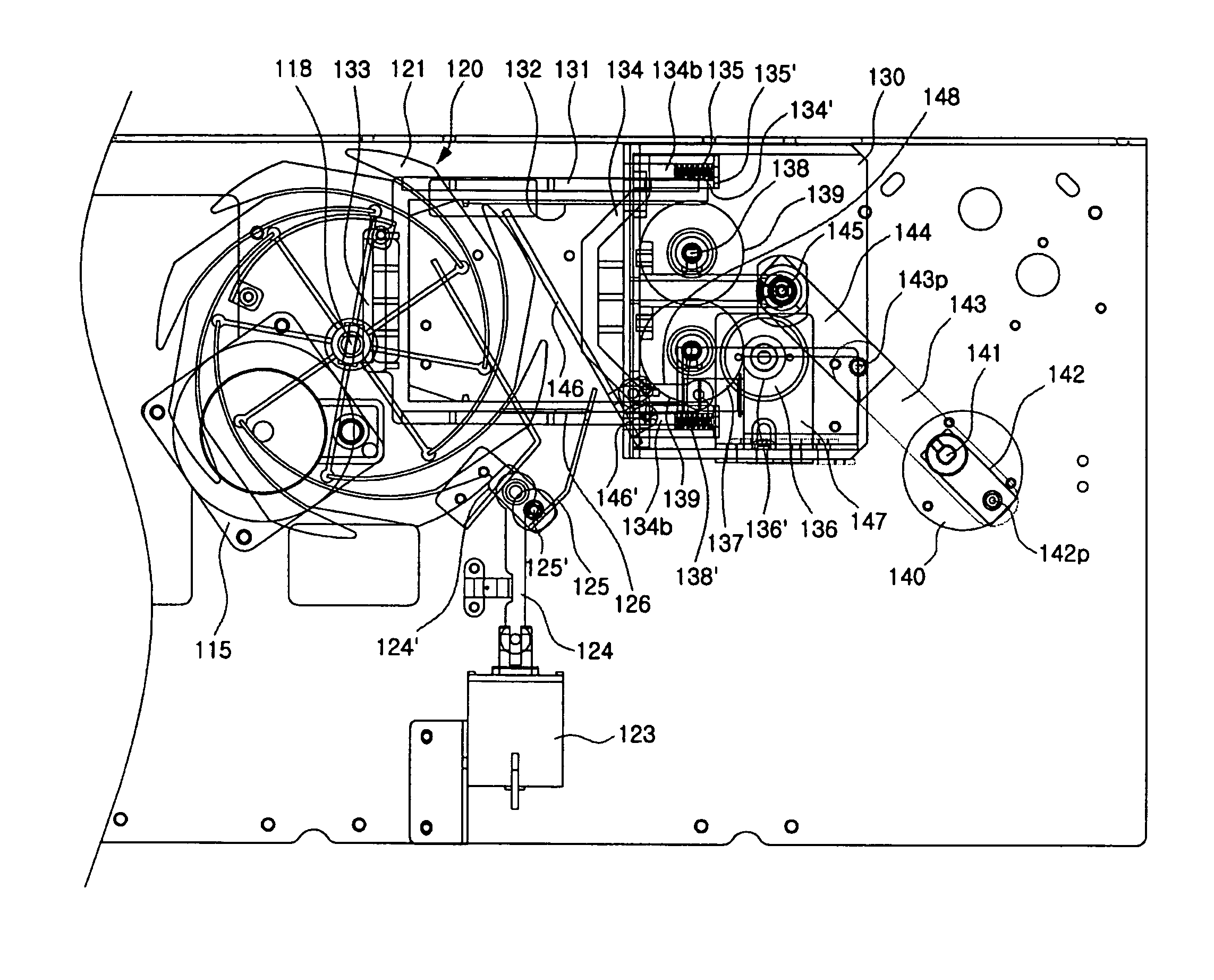

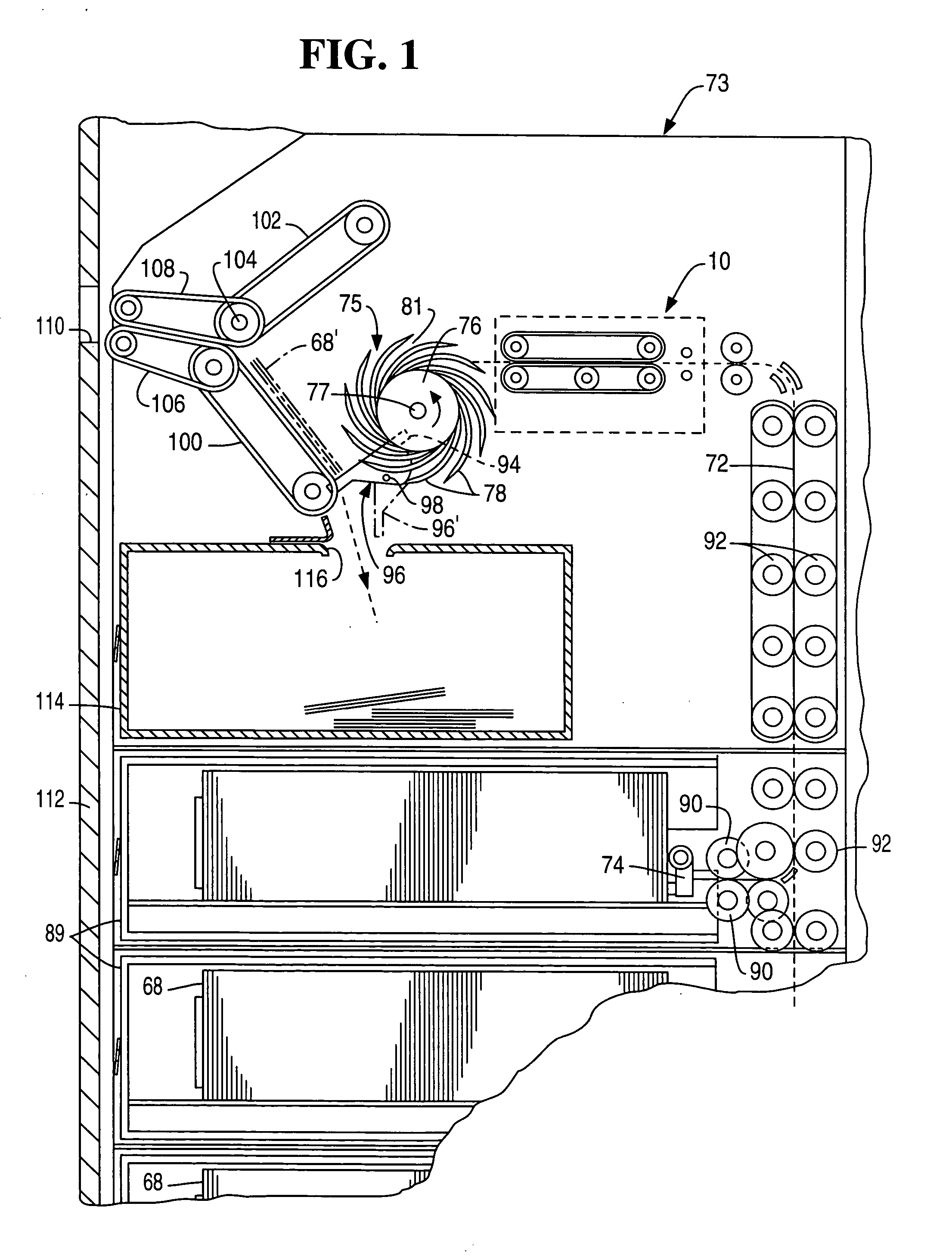

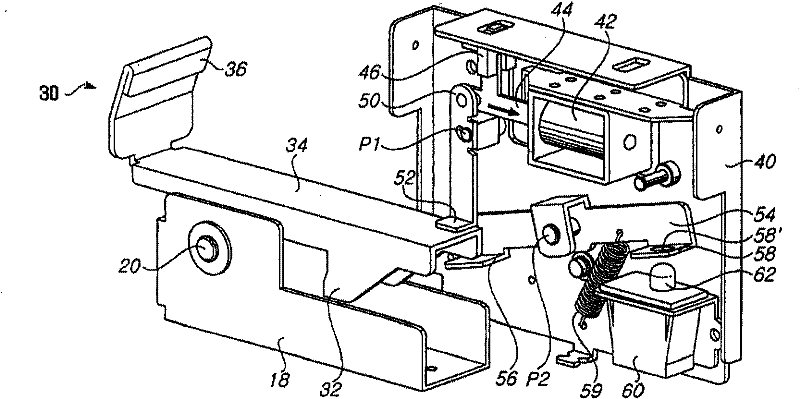

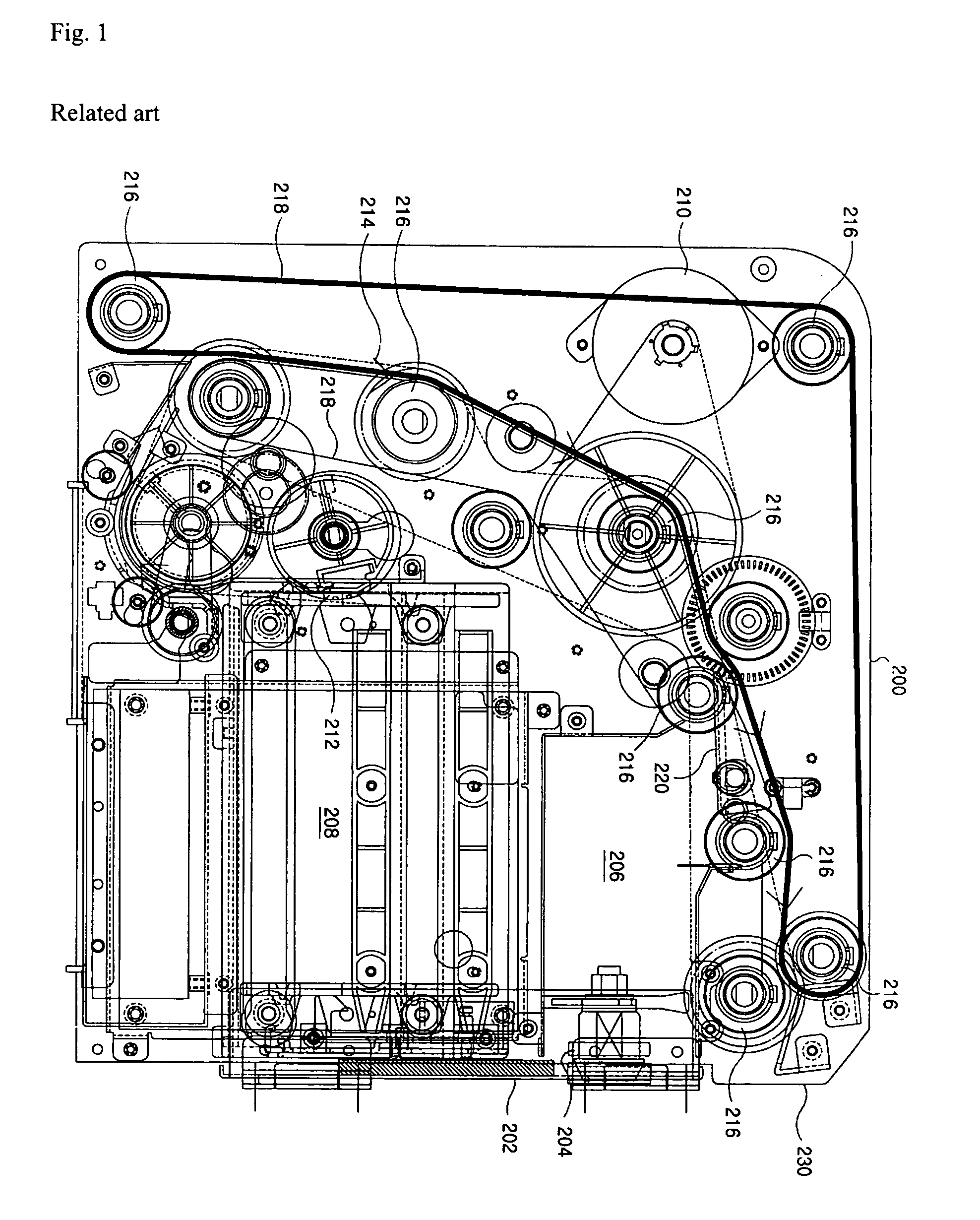

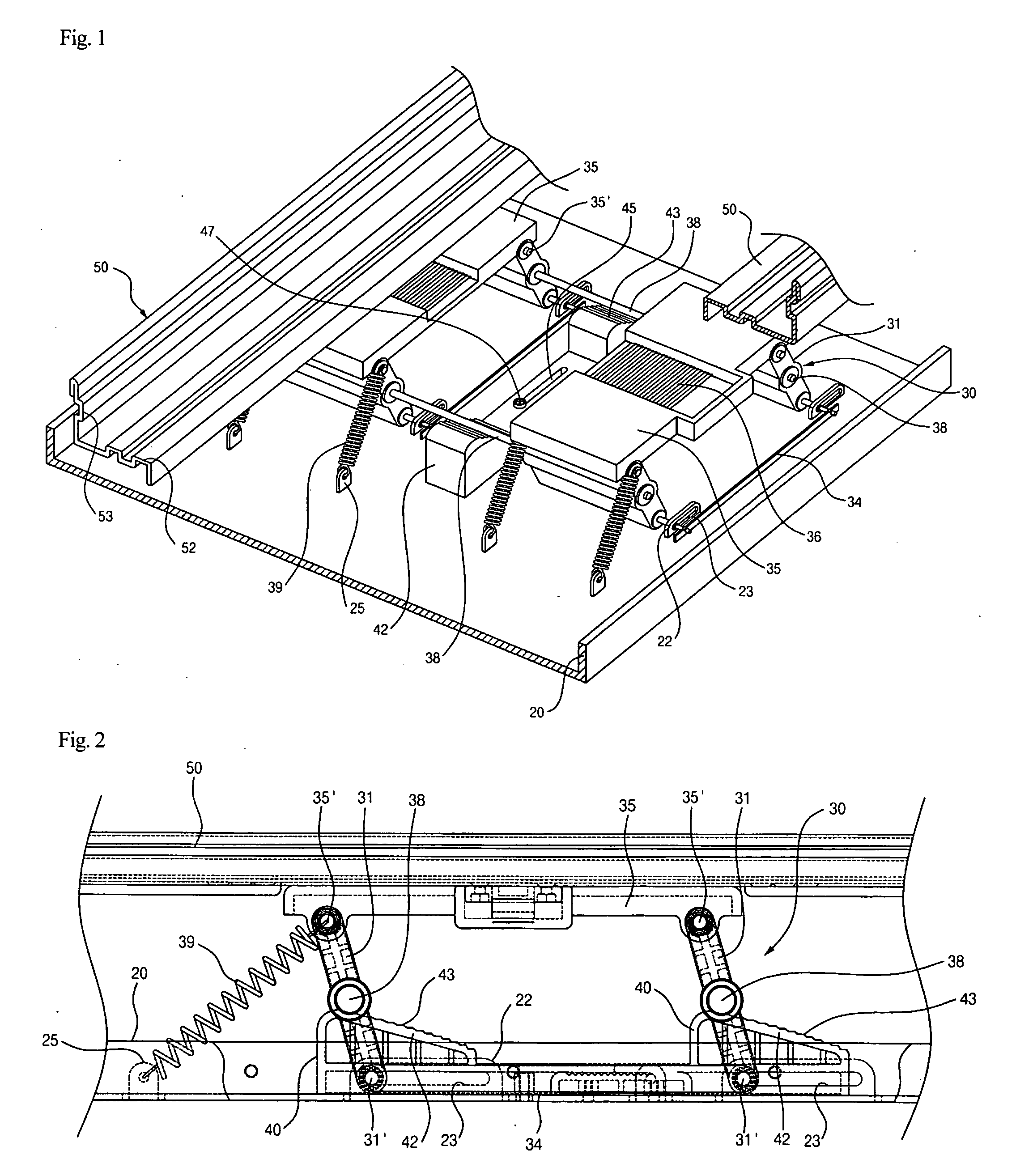

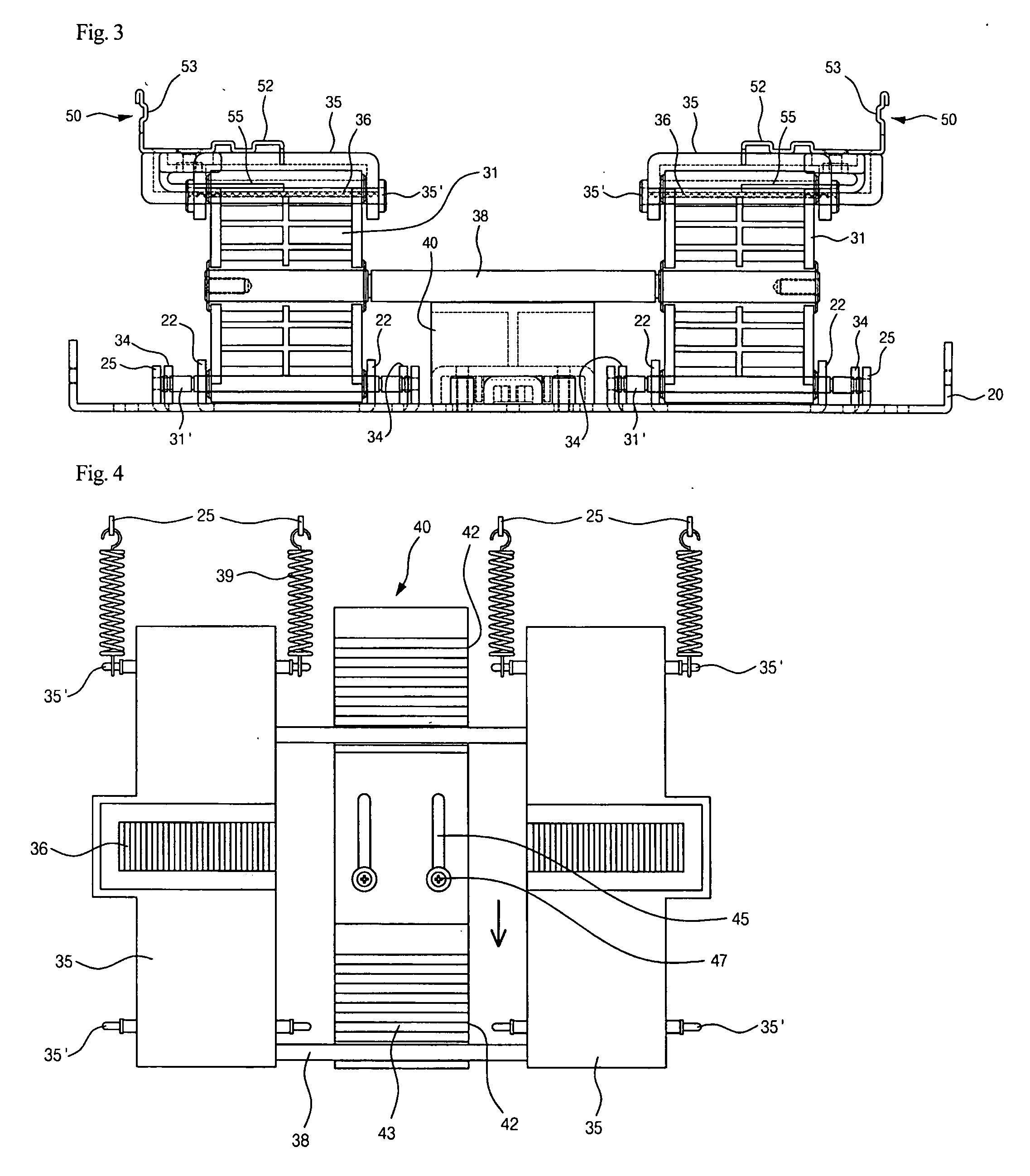

Media discharging unit for media dispenser

ActiveUS20050189693A1Easy accessAccurate thicknessComplete banking machinesCoin/currency accepting devicesEngineeringMedia dispenser

The present invention relates to media discharging unit for a media dispenser. The present invention includes a delivery module, which selectively feeds media fed from a media box to a discharge position and a reject position one-by-one using belts and rollers. A stacking module is separable from the delivery module, and collects the media, which are fed by the delivery module, one-by-one upon the rotation of a stacking wheel and then feeds the collected media as a stack at one time. A stack delivery module is separable from the stacking module, and clamps the stacked media, which are collected in the stacking module, and feeds the stacked media to a position where a customer can take the media.

Owner:ATEC AP CO LTD

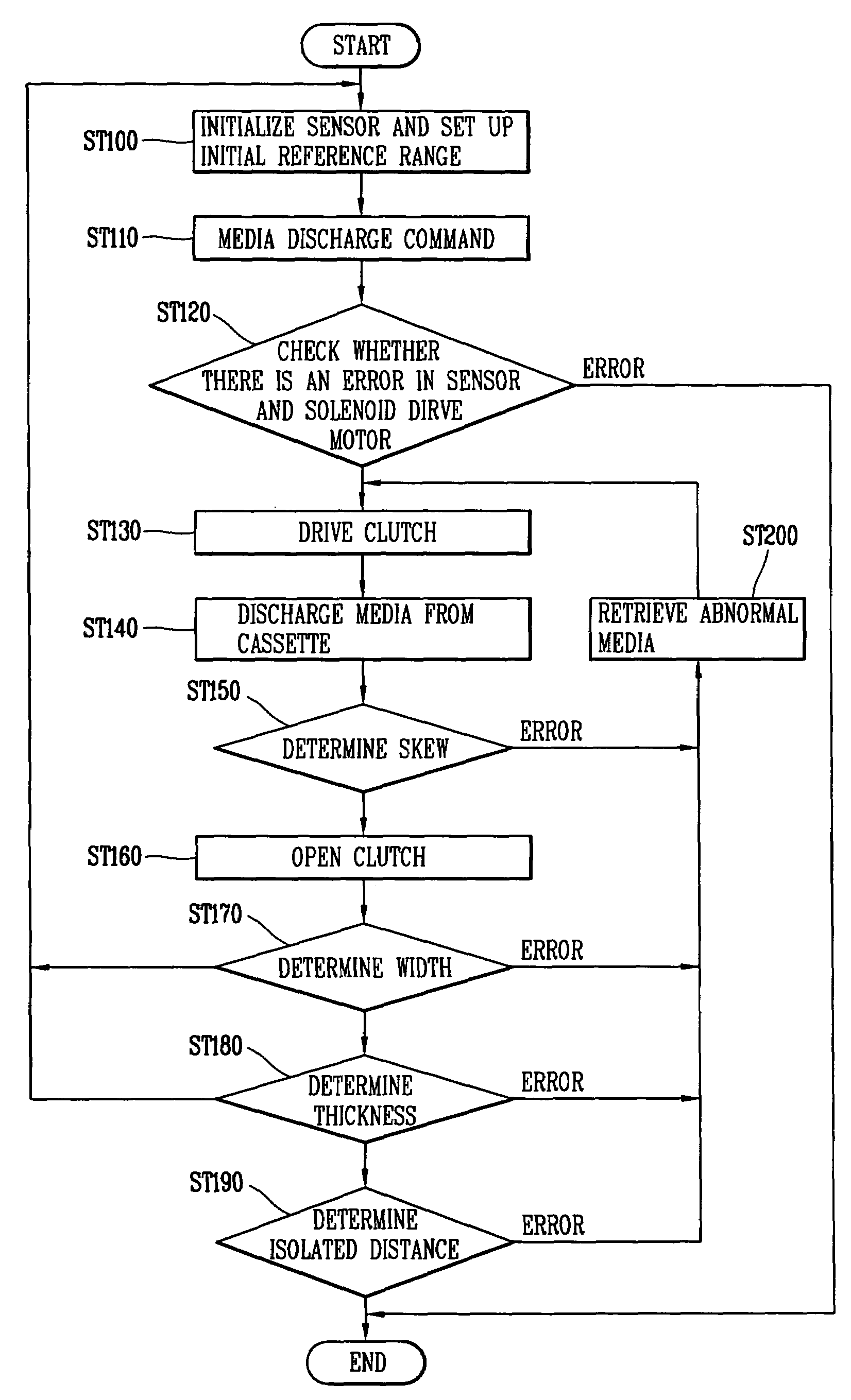

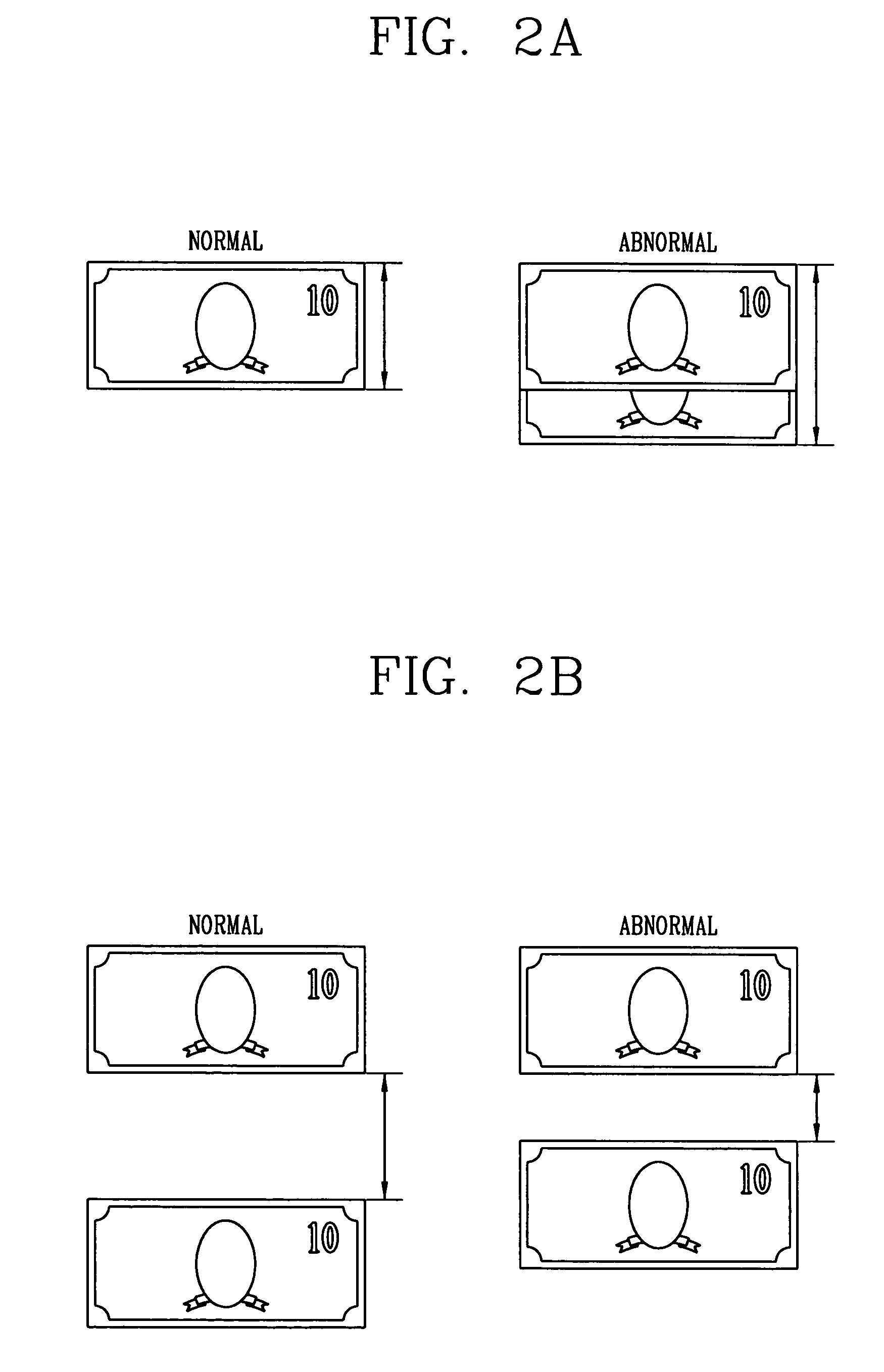

Media sensing method of media dispenser

ActiveUS7255343B2Accurate identificationAccurately determinedPaper-money testing devicesCoin-freed apparatus detailsMedia dispenserReference range

A media sensing method of a media dispenser is disclosed capable of discriminating various media and accurately discriminating whether a media is normal by using the least sensors. The media sensing method of a media dispenser includes: setting an initial reference range for width and thickness of a media; comparing the initial reference range and a reference range of a currently discharged media; and variably setting a new initial reference range on the basis of the comparison value, thereby discriminating whether media is normal or abnormal. Accordingly, without using an additional sensor, a cost in manufacturing the media dispenser can be reduced, an error caused by various environmental conditions or a deflection taking place in setting sensors can be effectively prevented, a multi-media overlap can be accurately discriminated, and the thickness of discharged multimedia can be precisely measured.

Owner:ATEC AP CO LTD

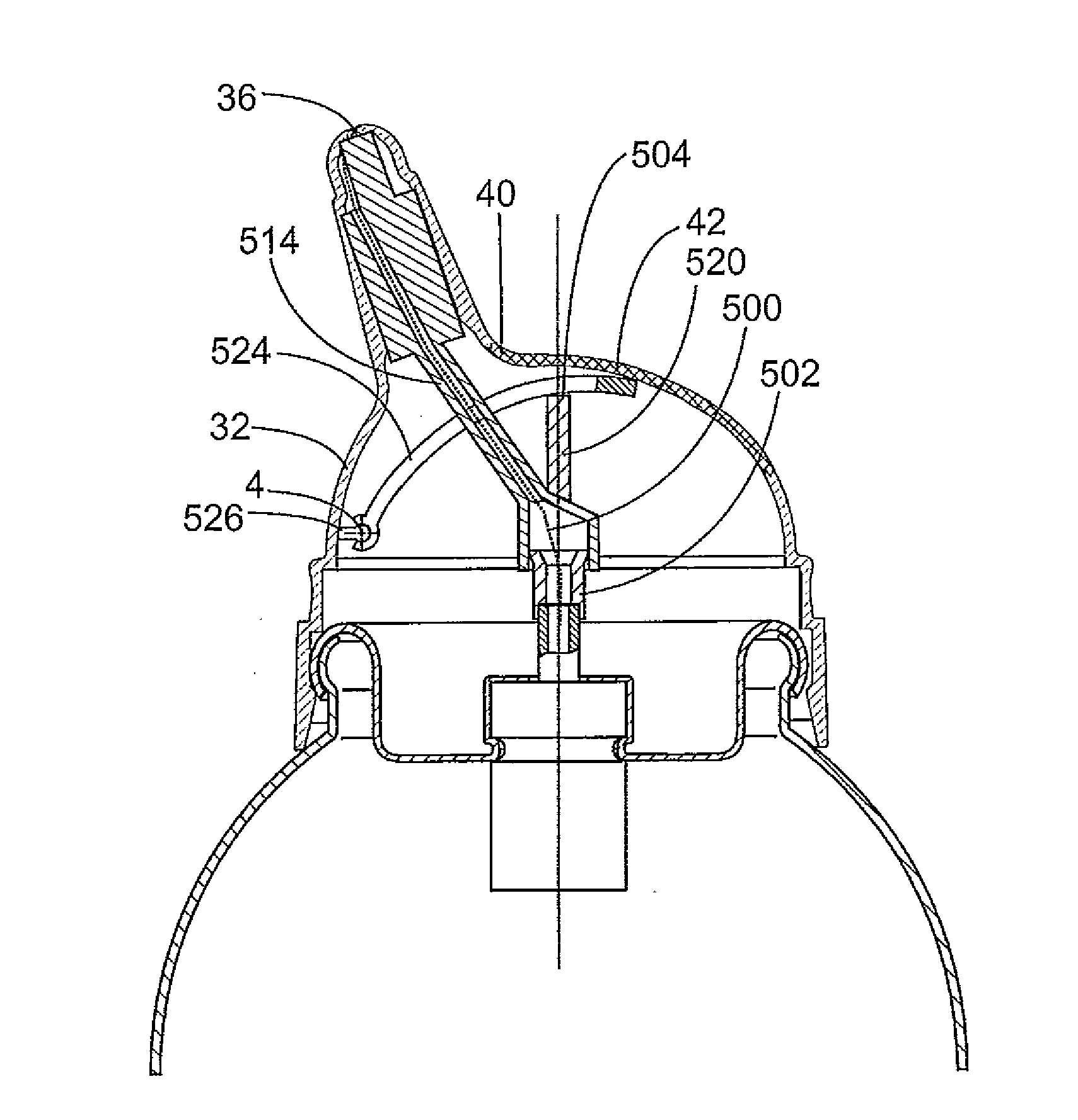

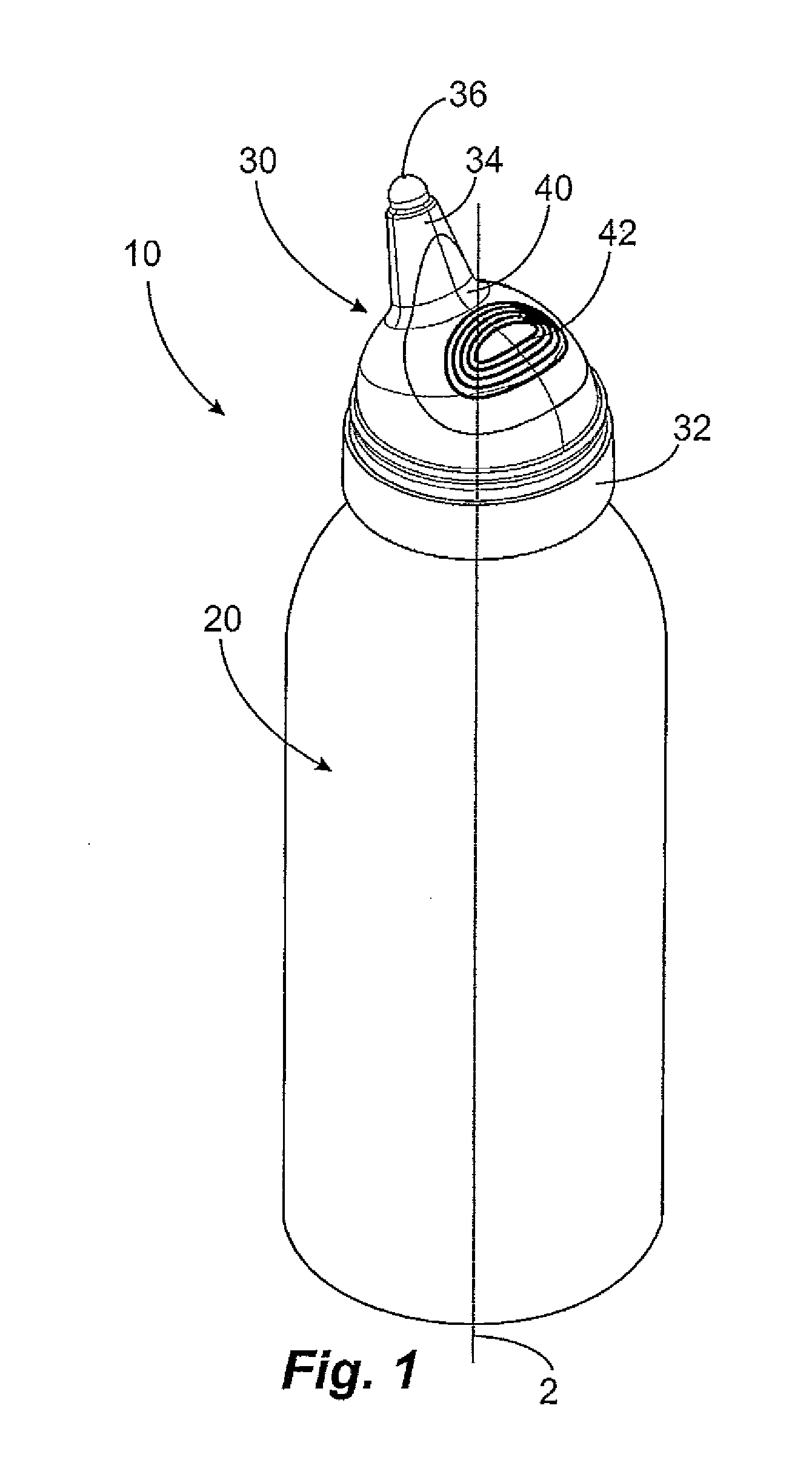

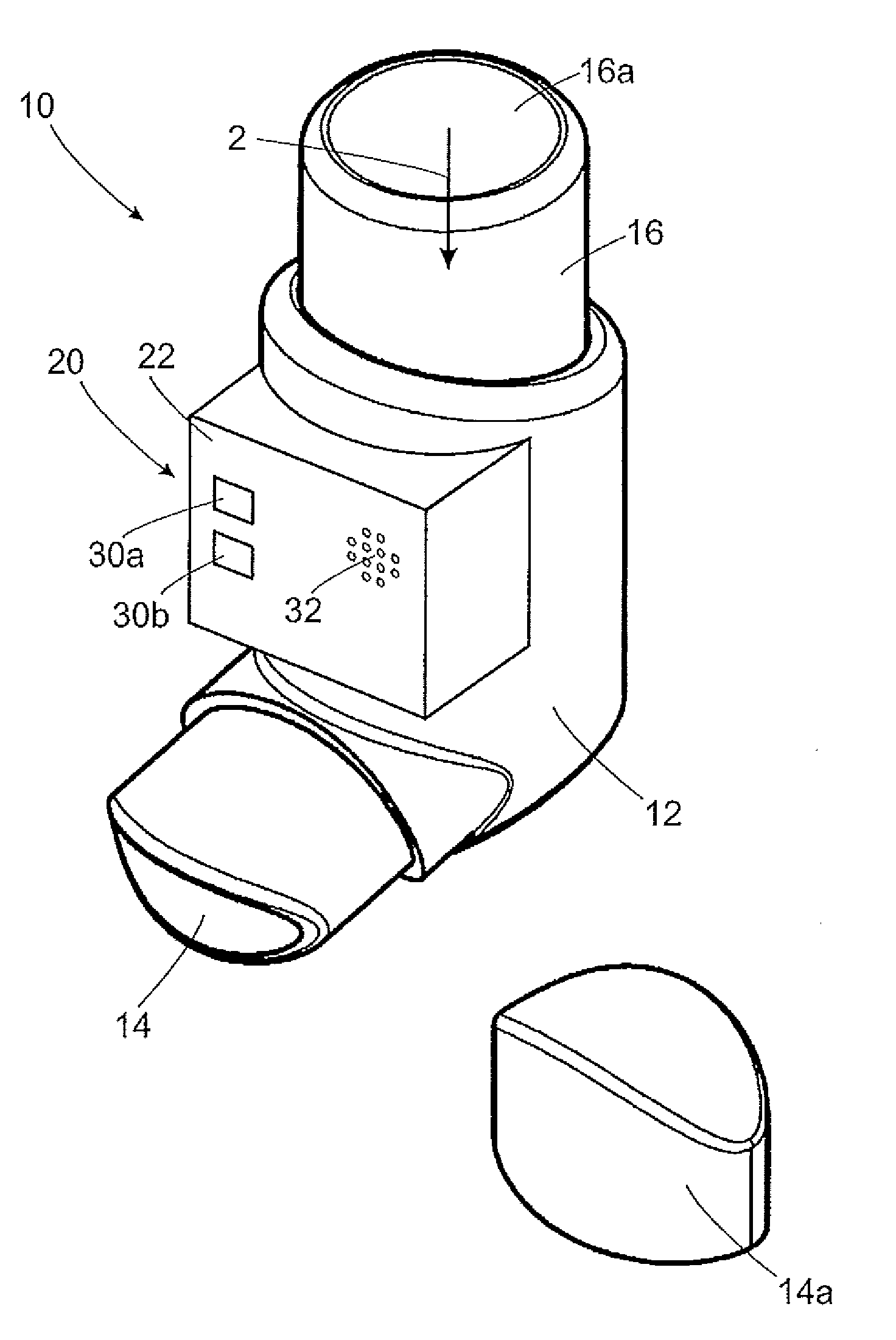

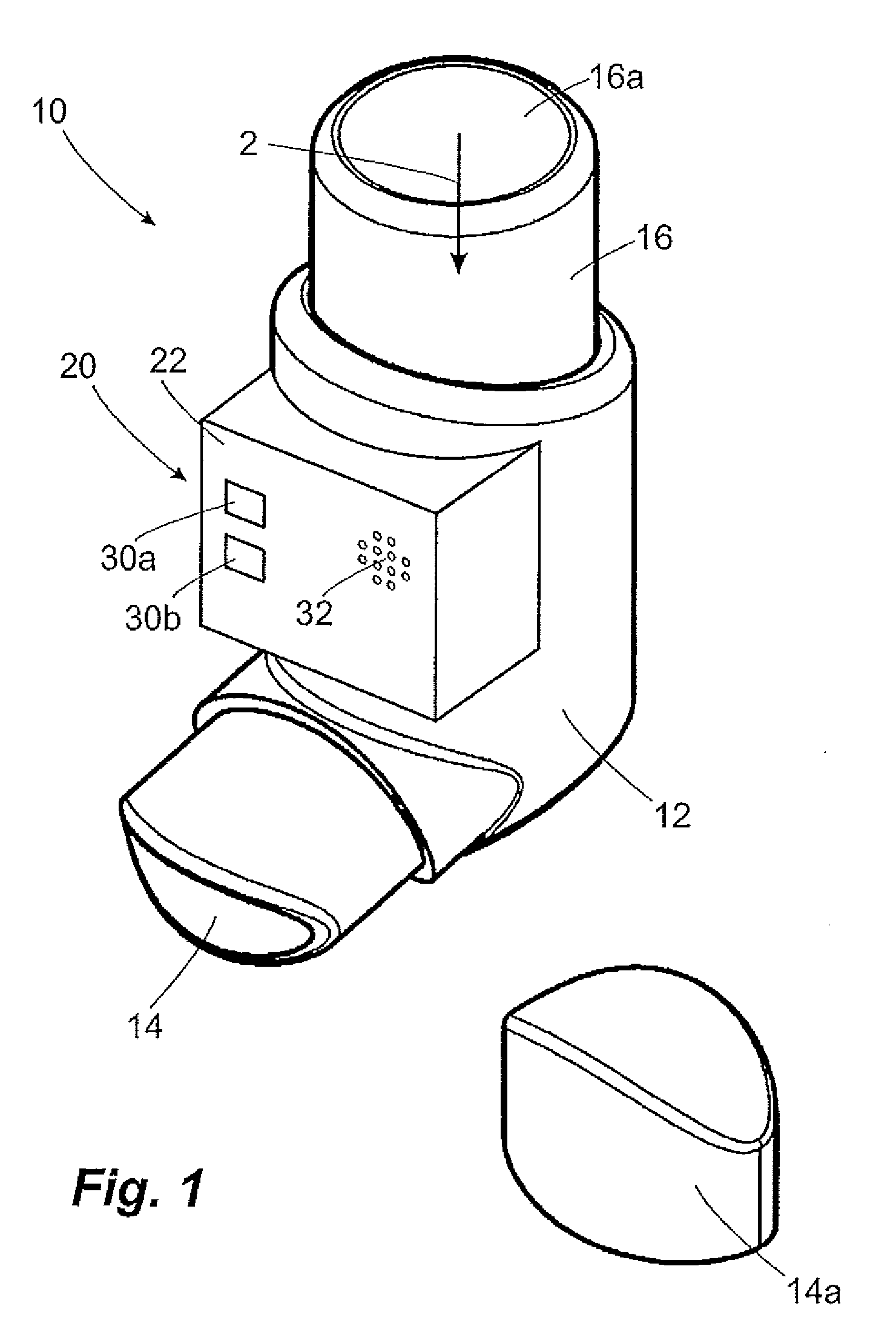

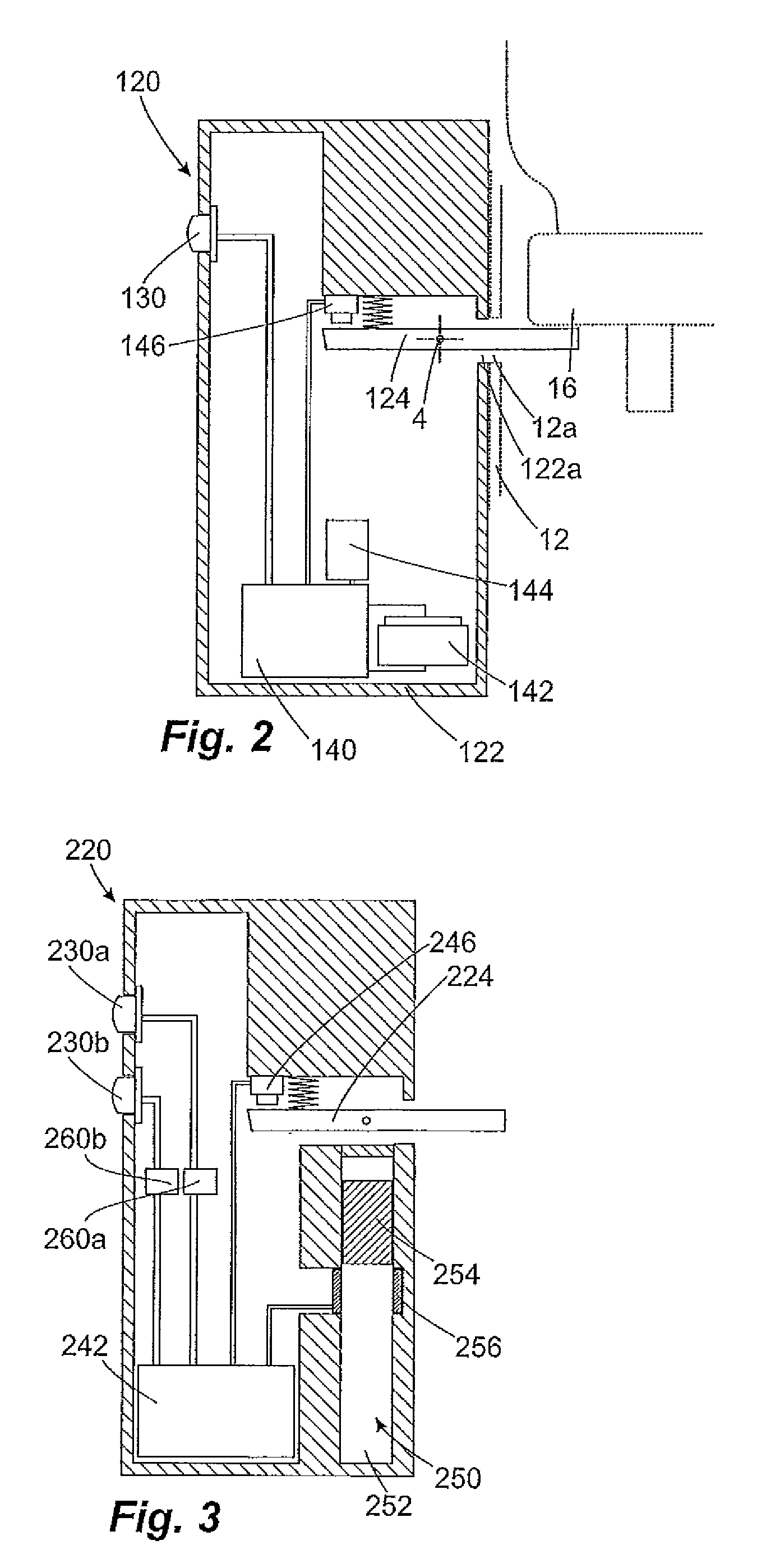

Media dispenser

ActiveUS20150014368A1Precise targeted deliveryEasy to assembleDispensing apparatusSpraying apparatusLiquid mediumEngineering

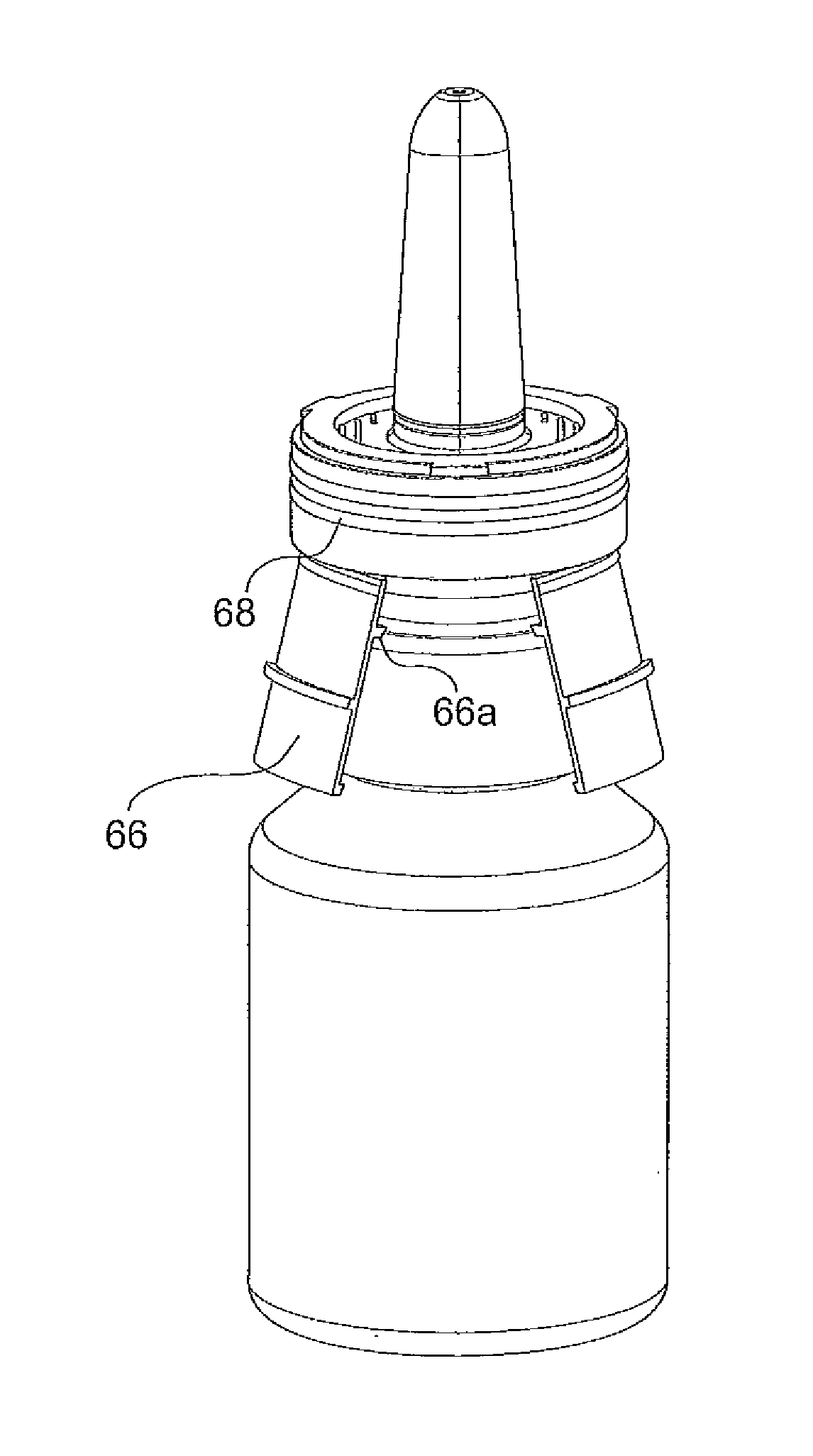

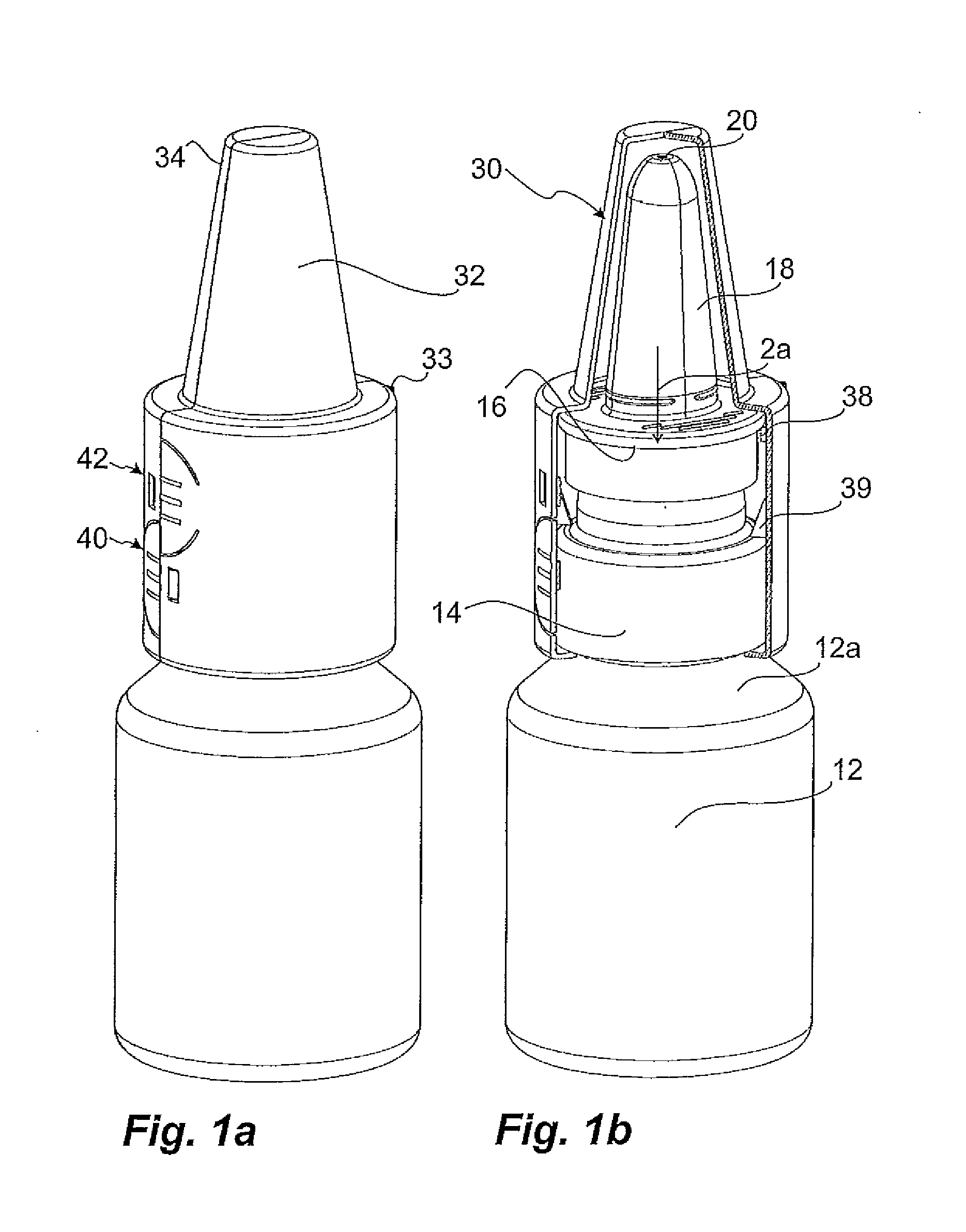

Dispenser for the delivery of liquid media, having a base unit and a delivery head with a delivery opening. The delivery head includes a first portion which includes a fastening device by means of which the first portion is fastened or fixed in position with respect to a media storage unit on the base unit, and which includes the delivery opening. The delivery head includes a second portion realized so as to be movable in relation to the first portion and includes an actuating handle which is operatively coupled with the coupling piece such that a displacement of the actuating handle in relation to the first portion leads to a displacement of the coupling piece in relation to the first part portion.

Owner:APTAR RADOLFZELL

Dispenser with child-proof lock

ActiveUS20140097207A1Sufficient deformabilityAccessibility preventedClosure using stoppersMedical devicesCouplingEngineering

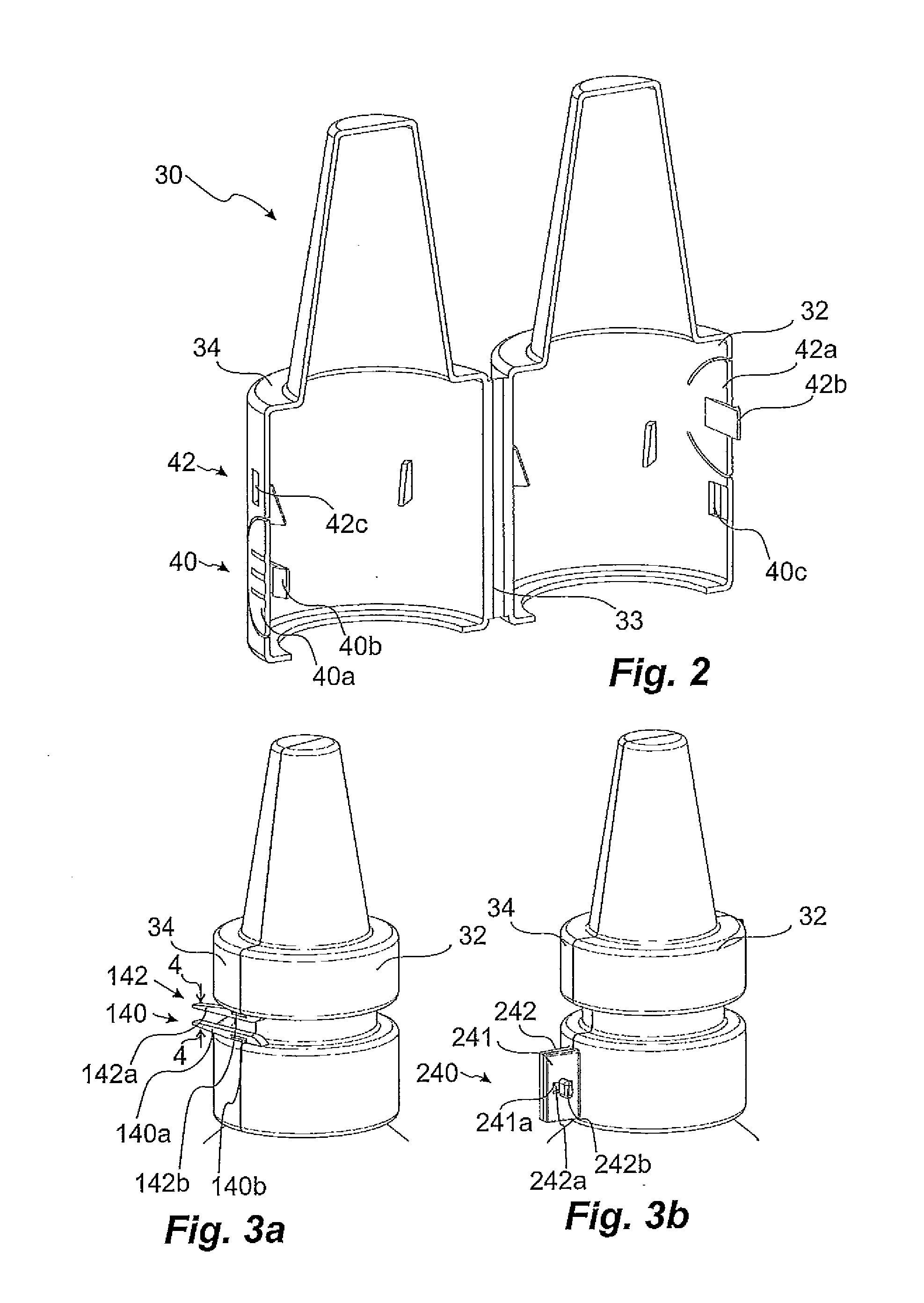

A dispenser including a medium reservoir, a discharge opening, and a feeding device for feeding medium from the medium reservoir to the discharge opening, wherein an actuating handle is displaceable relative to the medium reservoir in an actuation direction to discharge medium.The dispenser includes a protective device with two partial shells interconnected in a protective condition by a coupling device for repeated decoupling and coupling wherein the protective device is attachable to the feeding device in a protective position such that in the protective condition the accessibility and / or maneuverability of the actuating handle is prevented, and upon releasing the coupling device an enable condition of the protective device is achievable in which the partial shells are displaceable relative to another so that the protective device is removable from the feeding device, and thus accessibility or maneuverability of the actuating handle is obtainable thereby.

Owner:APTAR RADOLFZELL

Media cassette with internal lock

ActiveUS7464832B2Reduce the possibilityComplete banking machinesAcutation objectsLocking mechanismMedia dispenser

Owner:ATEC AP CO LTD

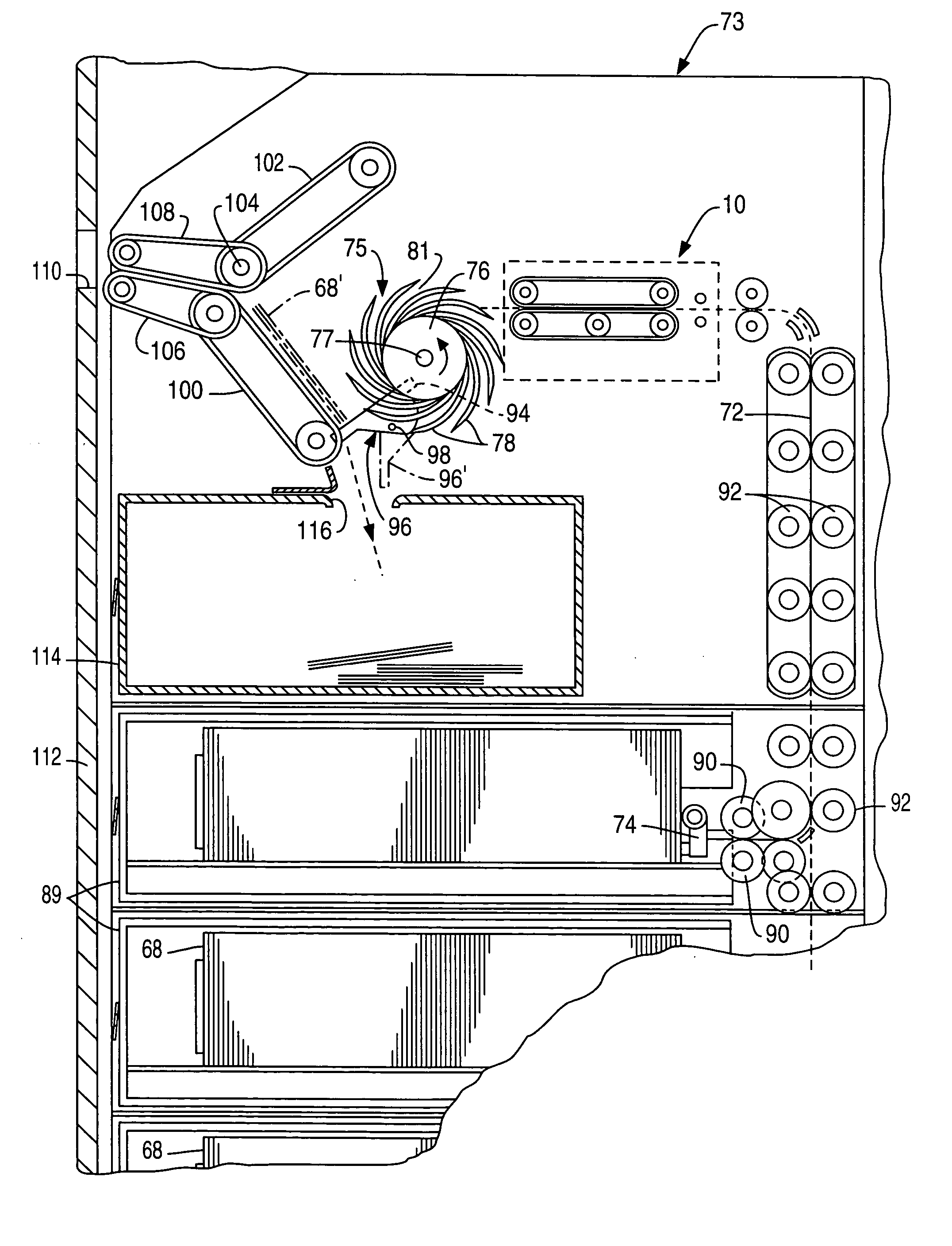

Media dispenser and method for rejecting media

ActiveUS20060012114A1Simple designConvenient to rejectComplete banking machinesPile receiversComing outEngineering

The present invention relates to a media dispenser and a method for rejecting media. According to the present invention, there is provided a media dispenser and a method for rejecting media. The media dispenser comprises a delivery module for feeding media, which come out of a media box, one by one; a stacking module for stacking the media, which are fed through the delivery module, on a stacking plate as many as a customer wants; and a delivery clamp module for clamping the media stacked on the stacking module and delivering the clamped media to the customer, and for feeding the media, which the customer did not take out, to the stacking plate, wherein a path through which the media clamped by the delivery clamp module are fed to a reject box is opened by moving the stacking plate of the stacking module. The method for rejecting media which a customer did not take out of the media dispenser as claimed in any one of claims 1 to 7, comprising the steps of: returning the media onto the stacking plate by a clamp assembly; opening a reject slot by allowing a driving plate to be moved by a driving source and the stacking plate to be moved together with the driving plate; and dropping the media as the clamp assembly unclamps the media through the opened reject slot. In the present invention, there are advantages in that it is convenient to reject the media and easy to design the structure for rejecting the media, and in that the media are prevented from being stolen.

Owner:ATEC AP CO LTD

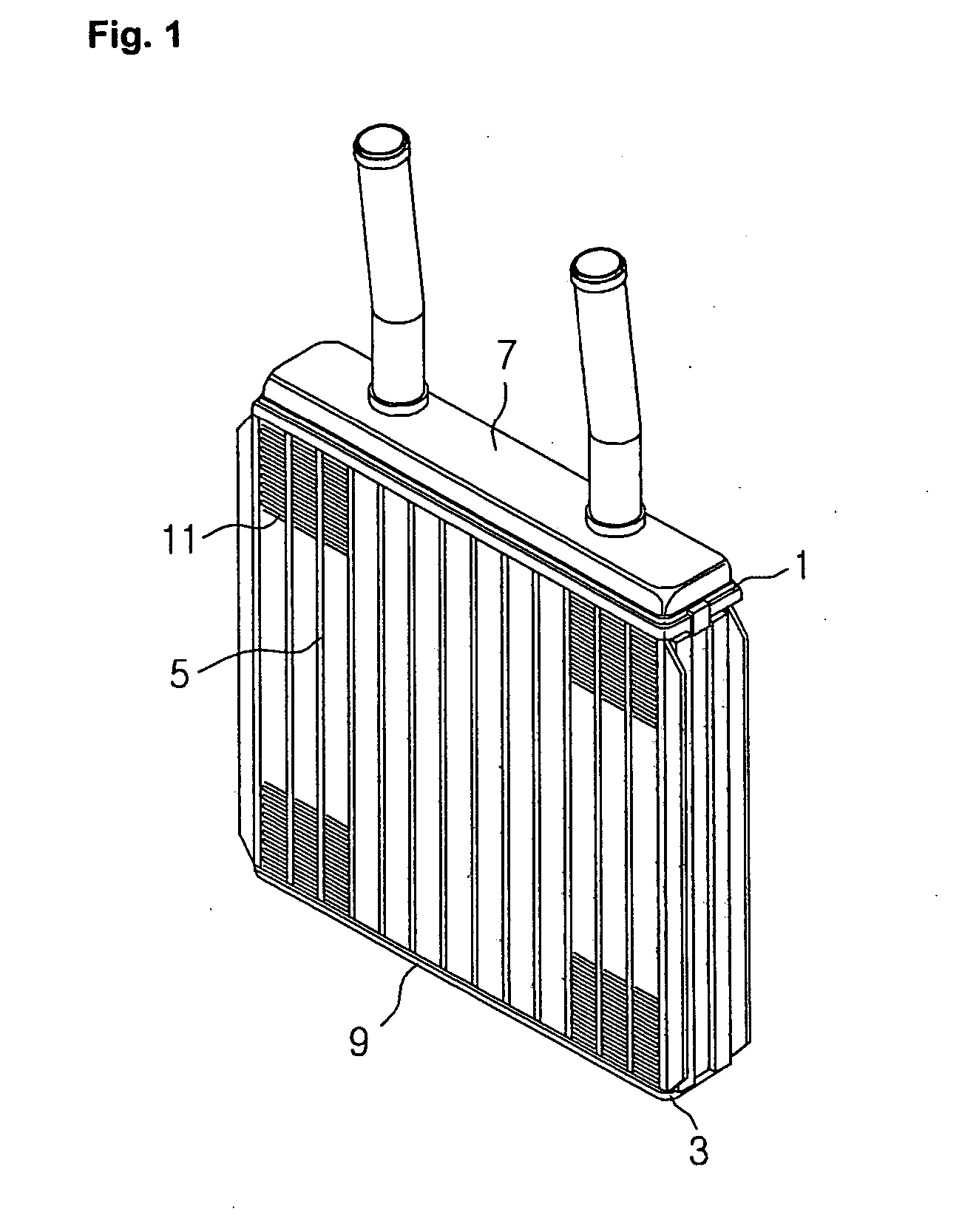

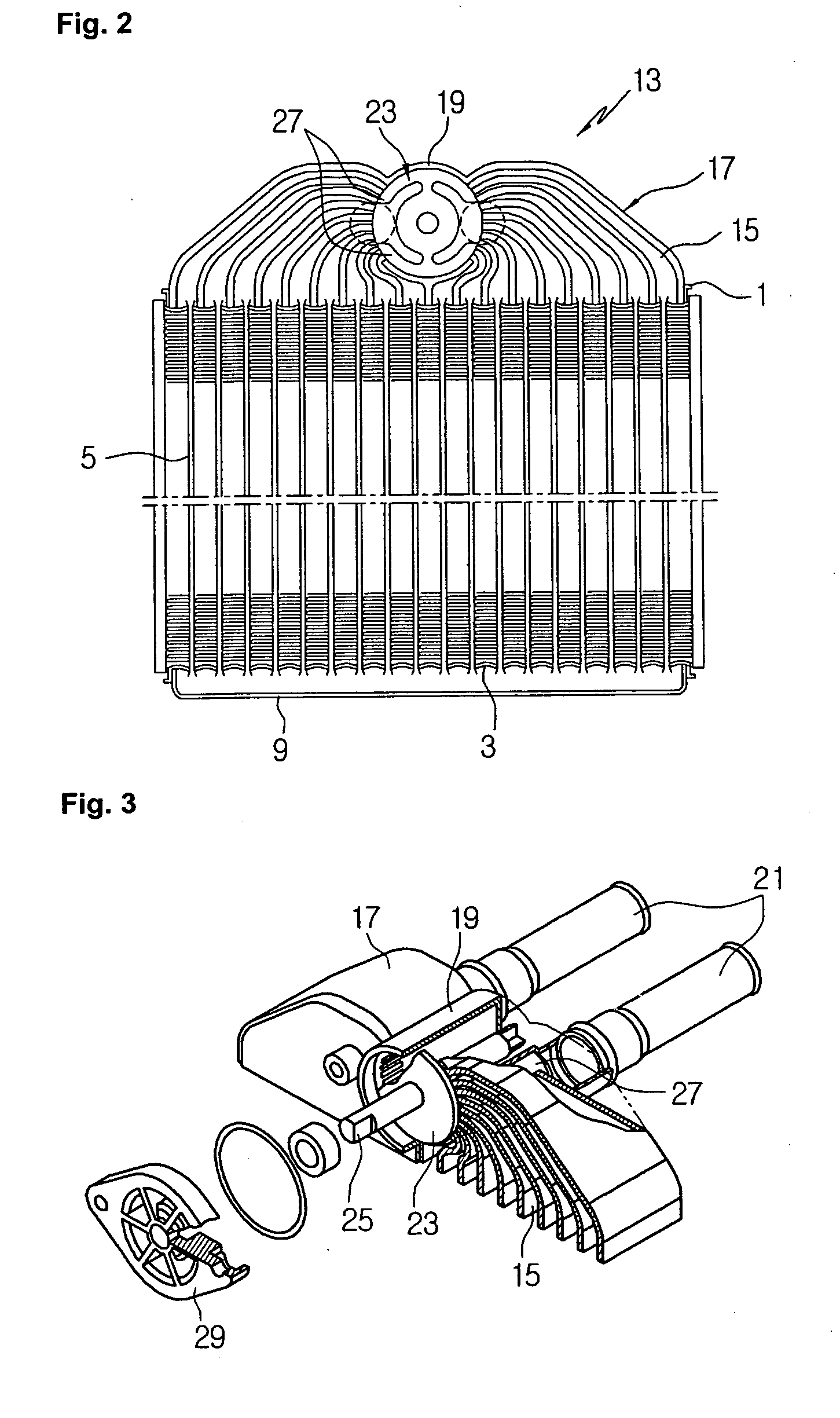

Heat exchanger

InactiveUS20050056402A1Minimizing temperature variationEvenly distributedTemperatue controlStationary conduit assembliesControl signalEngineering

The present invention relates to a heat exchanger which can suitably regulate the quantity, the feeding position or the feeding order of heat exchange medium fed into tubes to adjust heat exchange performance according to cooling and heating load. The heat exchanger comprises a plurality of tubes placed at least one header, each tube having both ends fixed to the header, medium-distributing means installed at the header for feeding heat exchange medium to the specific tubes, a tank placed over the medium-distributing means, the tank having a medium-inlet pipe, a medium-outlet pipe and distribution passages for feeding heat exchange medium to specific regions of the medium-distributing means, and medium-regulating means installed at the tank and operated in response to a control signal for adjusting the feed of the heat exchange medium.

Owner:HANON SYST

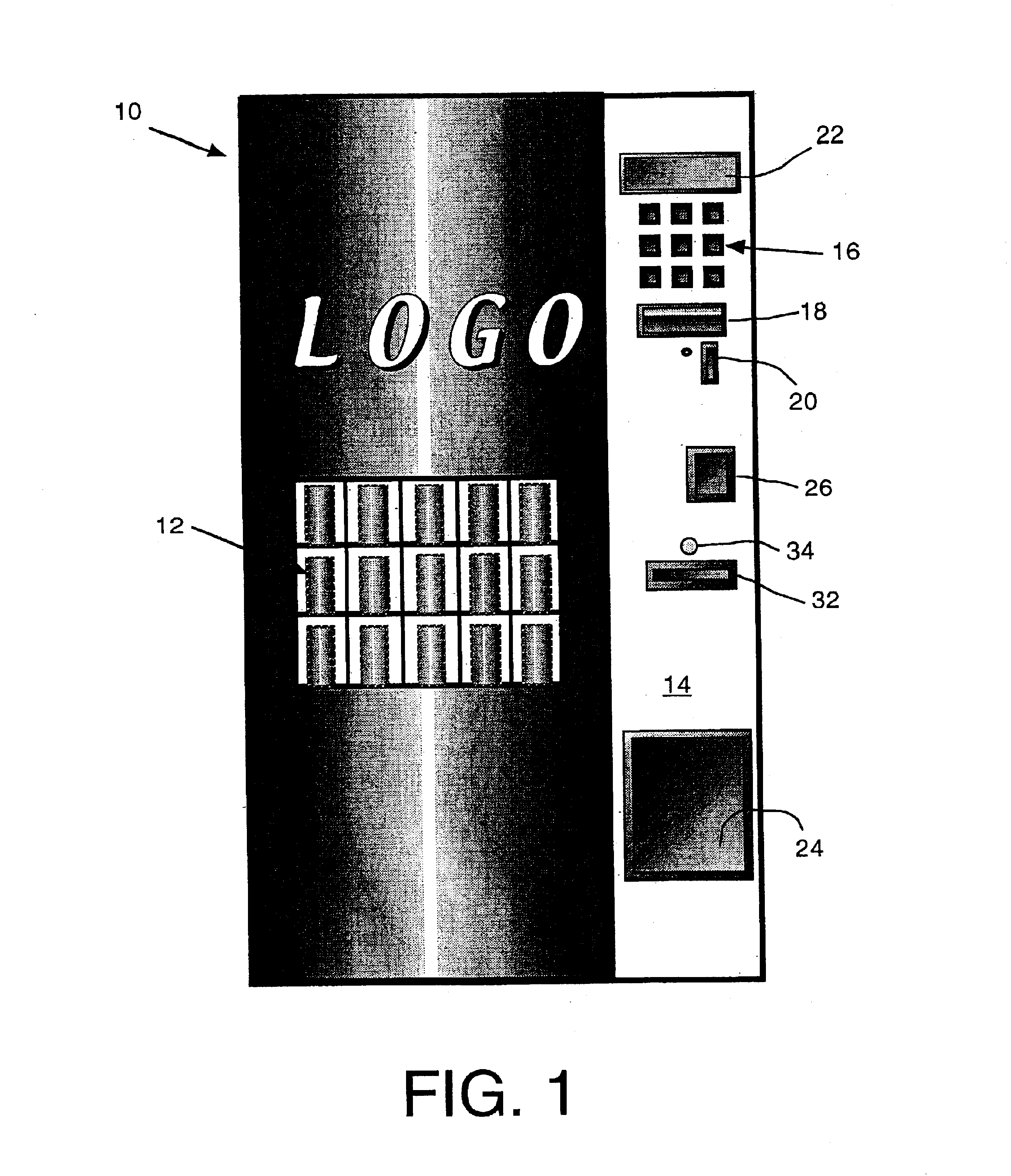

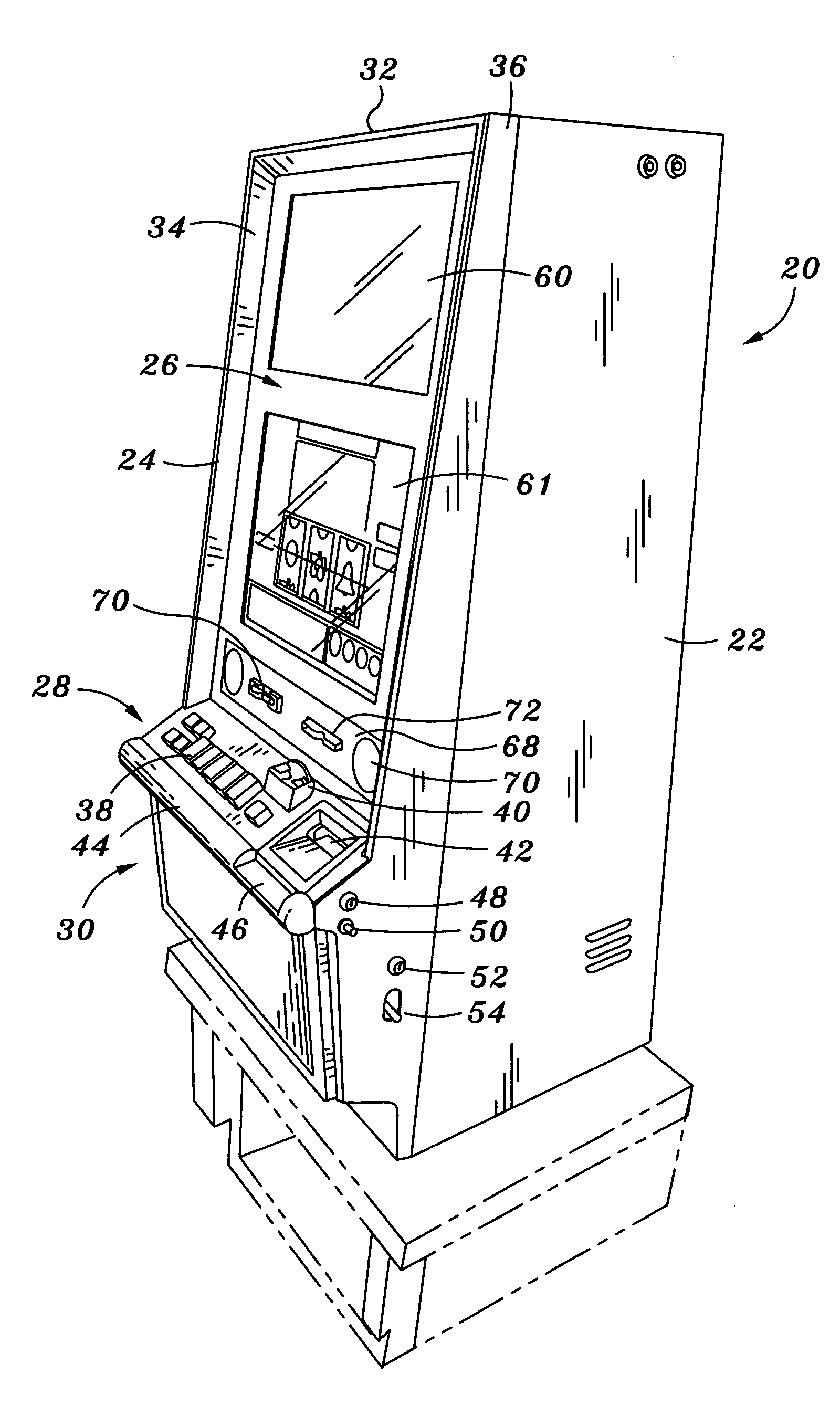

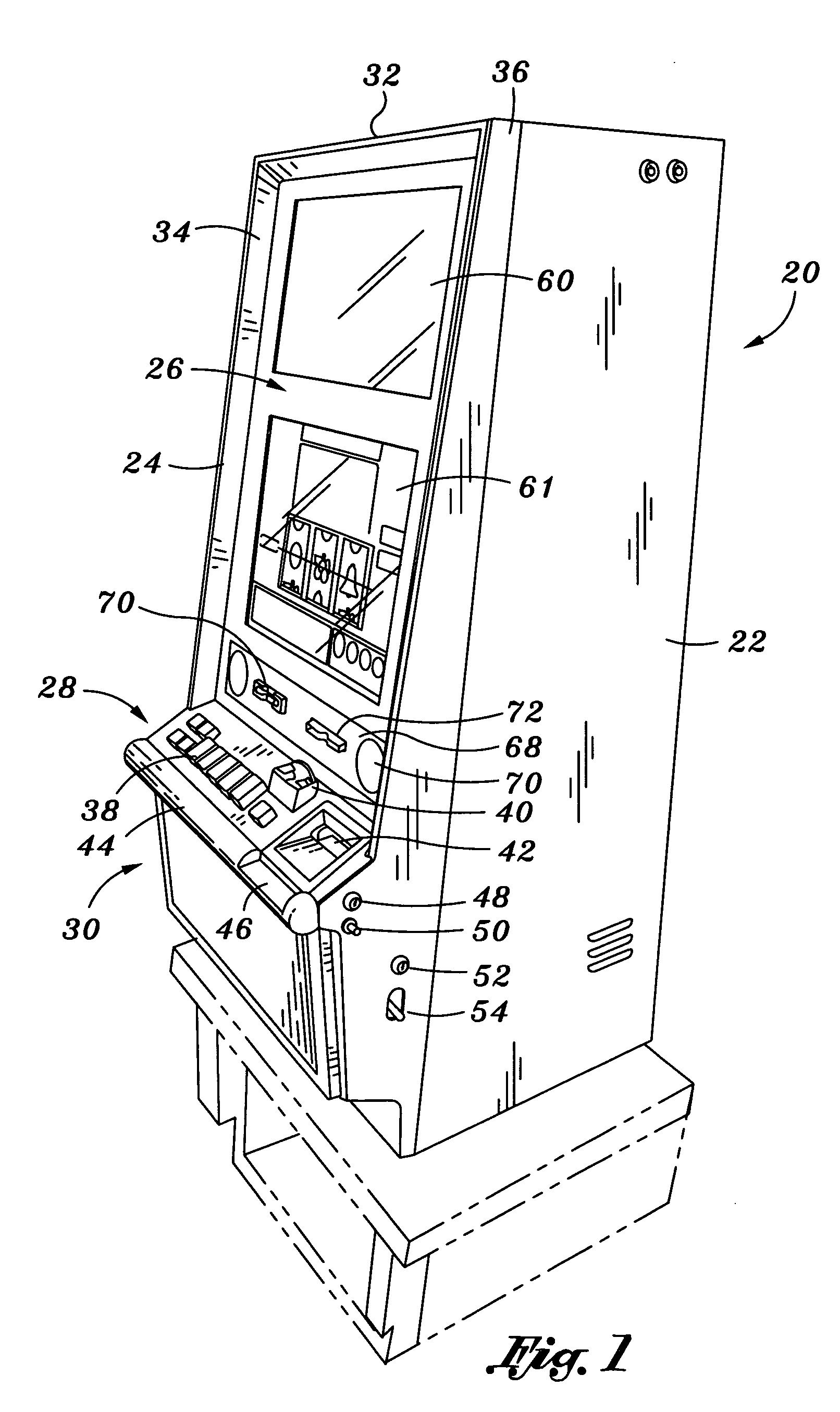

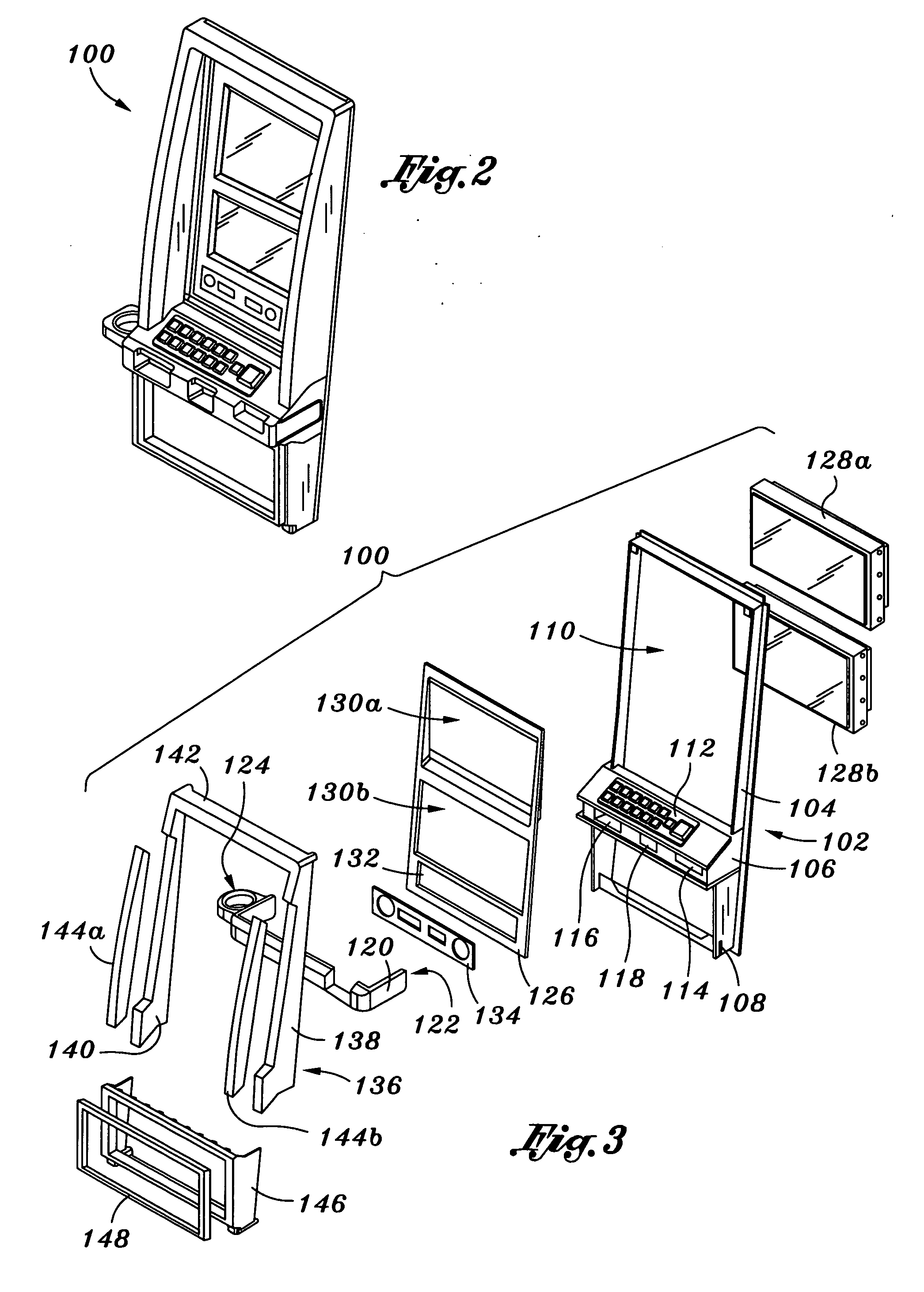

Gaming machine configured for component accessibility

InactiveUS20080227554A1Improved component accessibilityApparatus for meter-controlled dispensingVideo gamesDisplay deviceMedia dispenser

A gaming machine is configured for improved component accessibility. In one embodiment, the gaming machine has a component area having at least one display and a console located below the component area and extending outwardly towards a player of the gaming machine. At least one gaming machine component such as a currency validator and / or media dispenser is associated with the console and is accessible at a front of the console. In another embodiment, one or more components are located behind an access door located at a belly of the gaming machine.

Owner:COLE KEPRO INT

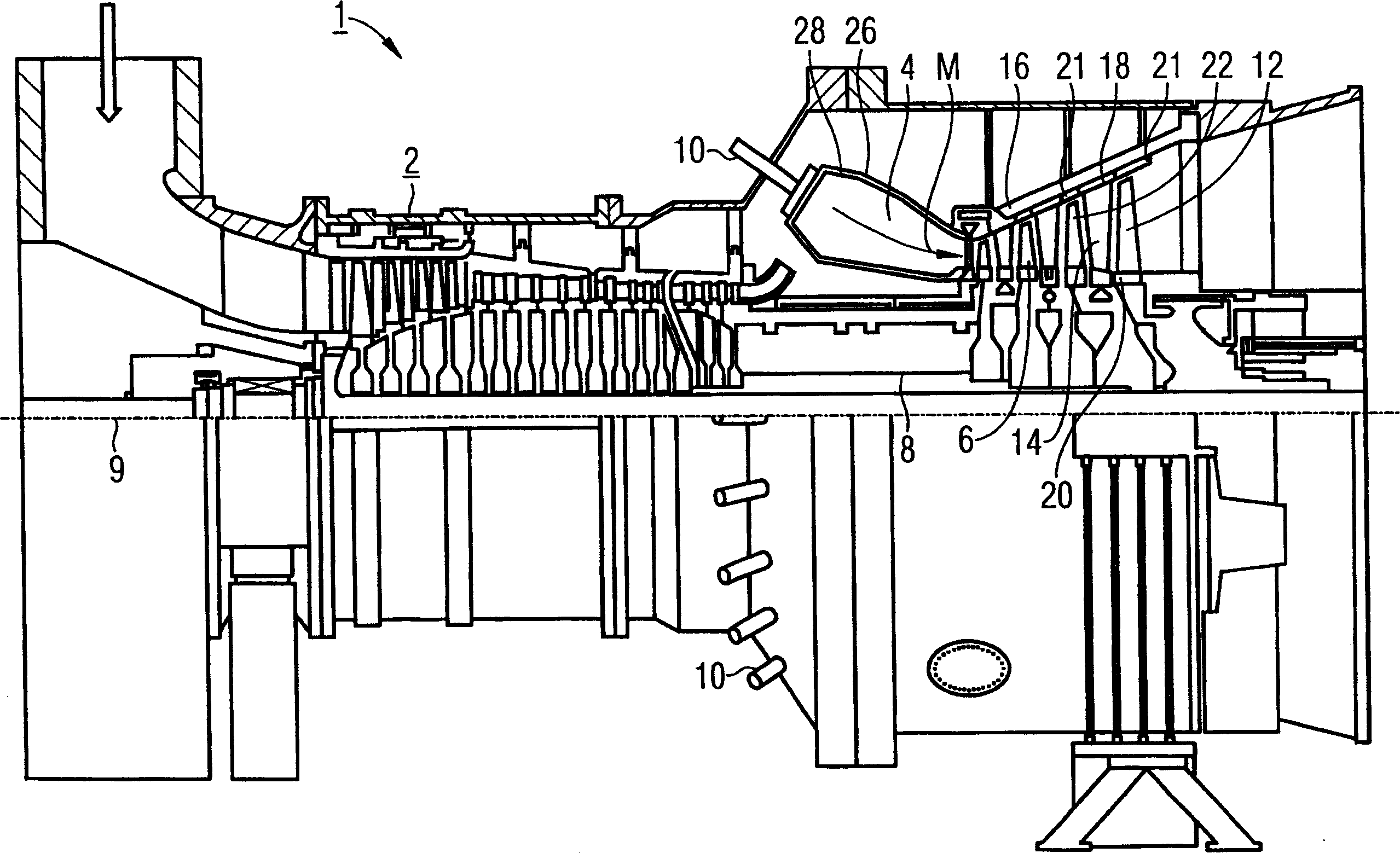

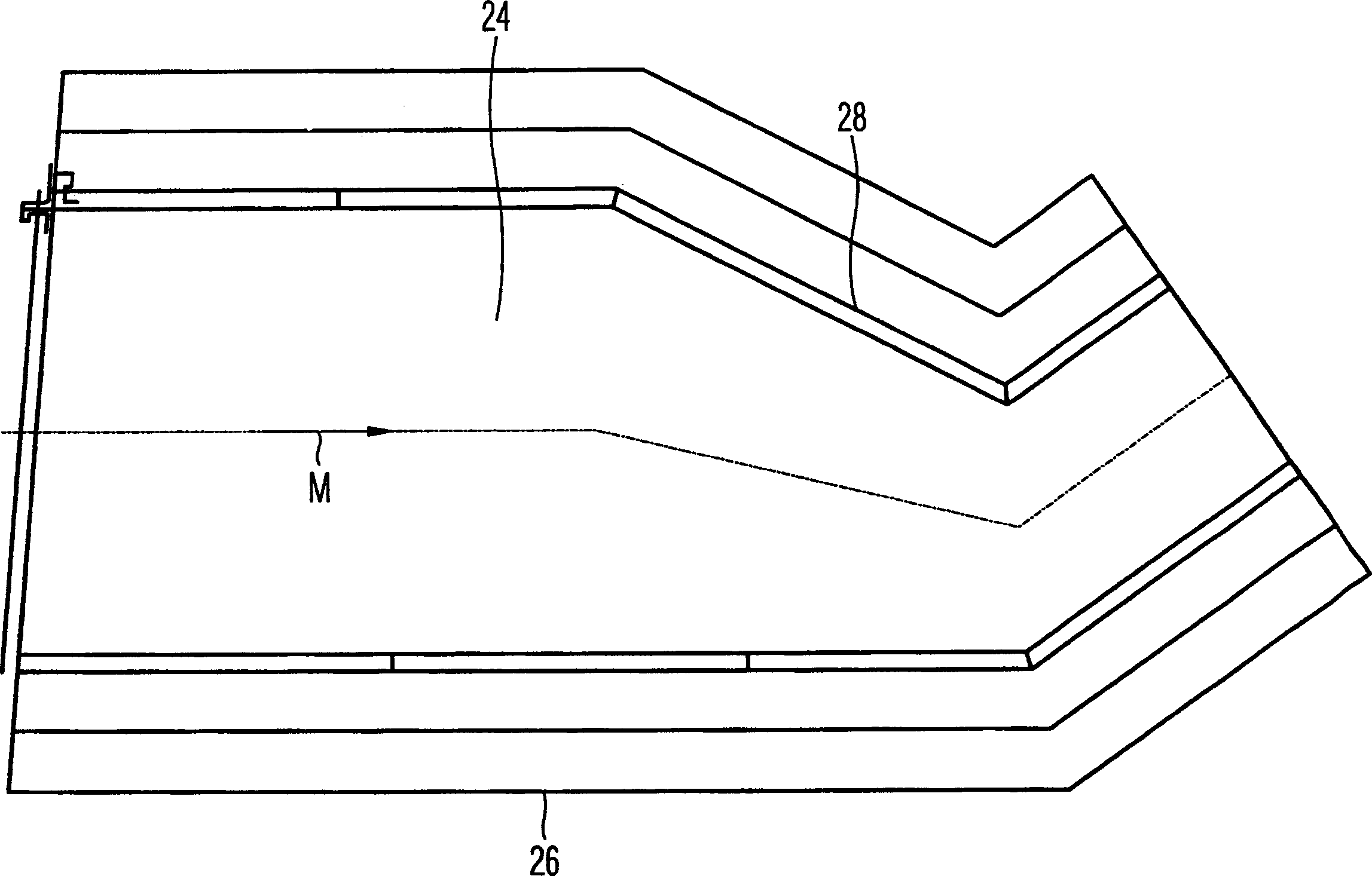

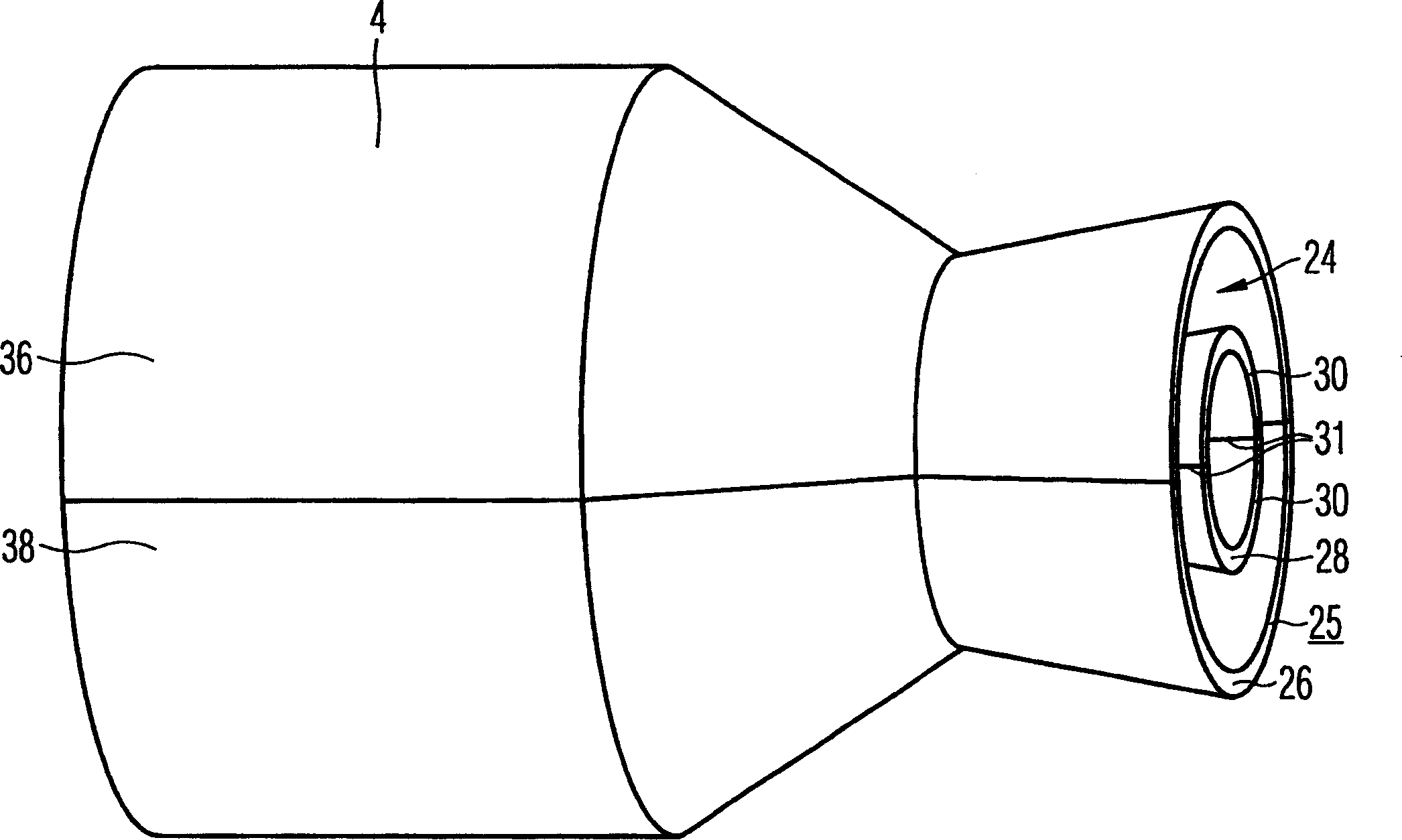

Combustion chamber

InactiveCN1519507AImprove equipment efficiencyCutting costsContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberCombustion

A combustion chamber (4) of a gas turbine (1), the combustion space (24) of which is bounded by an annular combustion chamber inner wall (28) and a combustion chamber outer wall,(26), in which in order to generate a working medium (M) a supplied fuel is brought into reaction with supplied combustion air, and the combustion chamber wall (25) of which is provided on the inside with a lining formed from a plurality of heat shield elements (38), with the or each heat shield element (38) together with the combustion chamber wall (25) forming an inner space (40) to which a cooling medium (K) can be applied, is to be designed so as to provide a high level of system efficiency at the same time as having a comparatively simple structure and it should also be possible to disassemble the combustion chamber inner wall (28) in a time-saving manner. For this purpose according to the invention there is disposed in each case in the respective inner space (40) a cooling medium distributor (42) via which a cooling medium supply line (44) is connected to a plurality of cooling medium exit openings (46) and the combustion chamber inner wall (28) is formed from a plurality of wall elements (30) abutting each other at a horizontal parting joint (31), whereby the abutting wall elements (30) of the combustion chamber inner wall (28) are connected to one another at their horizontal parting joint (31) by means of a plurality of screw connections (32) oriented at an angle to the inner wall surface.

Owner:SIEMENS AG

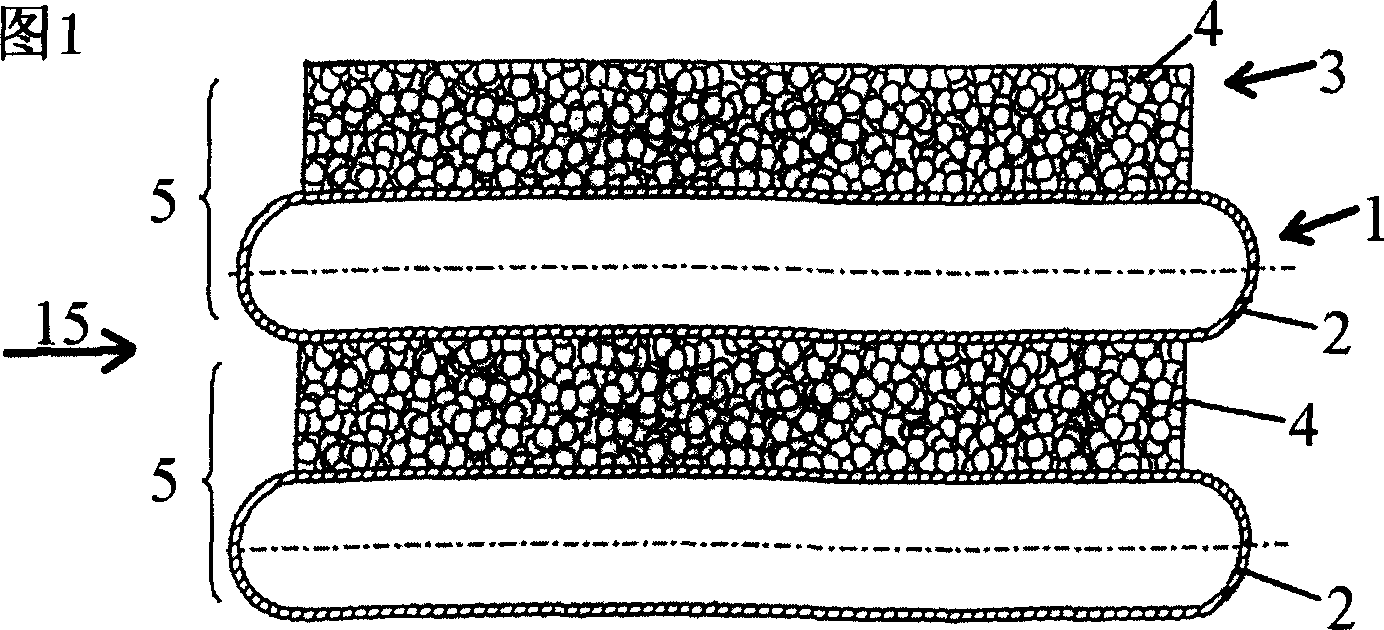

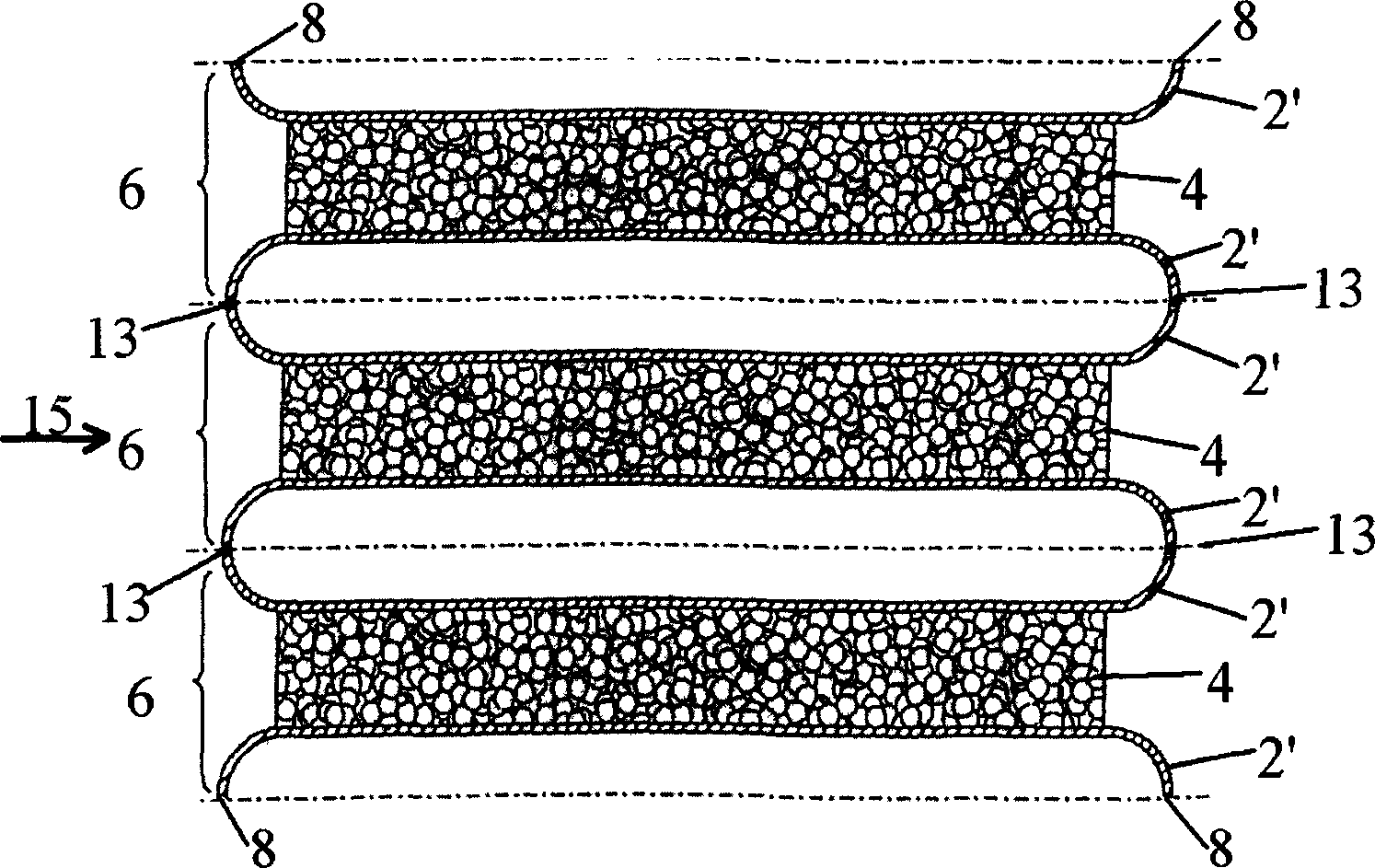

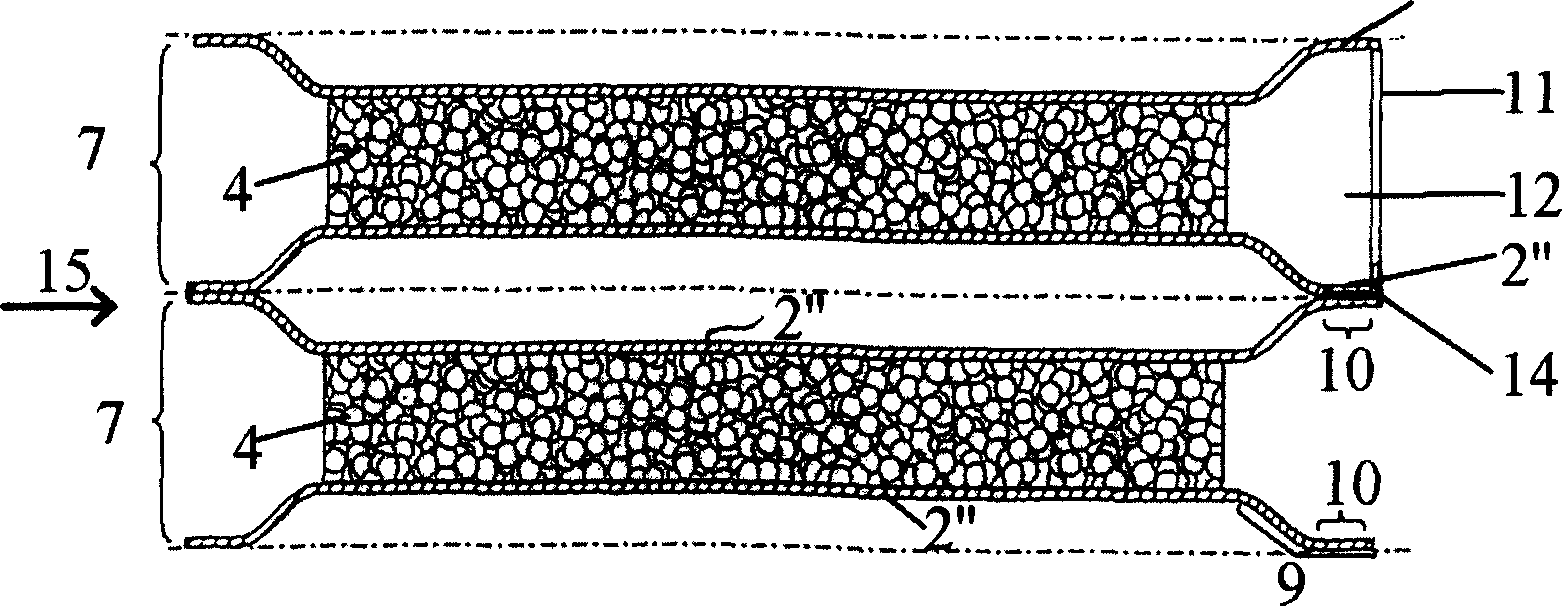

Heat exchanger for industrial installations

InactiveCN1645030ALow mechanical stabilityFirmly connectedStationary conduit assembliesHeat transfer modificationPlate heat exchangerIndustrial systems

Heat exchanger for industrial systems, especially power plants, comprises at least one distributor for a fluid medium and at least one heat exchanger element fixed on the distributor. The heat exchanger is formed by a sandwich arrangement of distributors and heat exchanger elements consisting of metal foam bodies (4). The distributors consist of a pipe or at least interconnected half pipes (2''). Adjacent pipes / half pipes are connected to each other via the metal foam bodies. - Preferred Features: The metal foam body consists of an aluminum foam.

Owner:BALCKE DURR AG

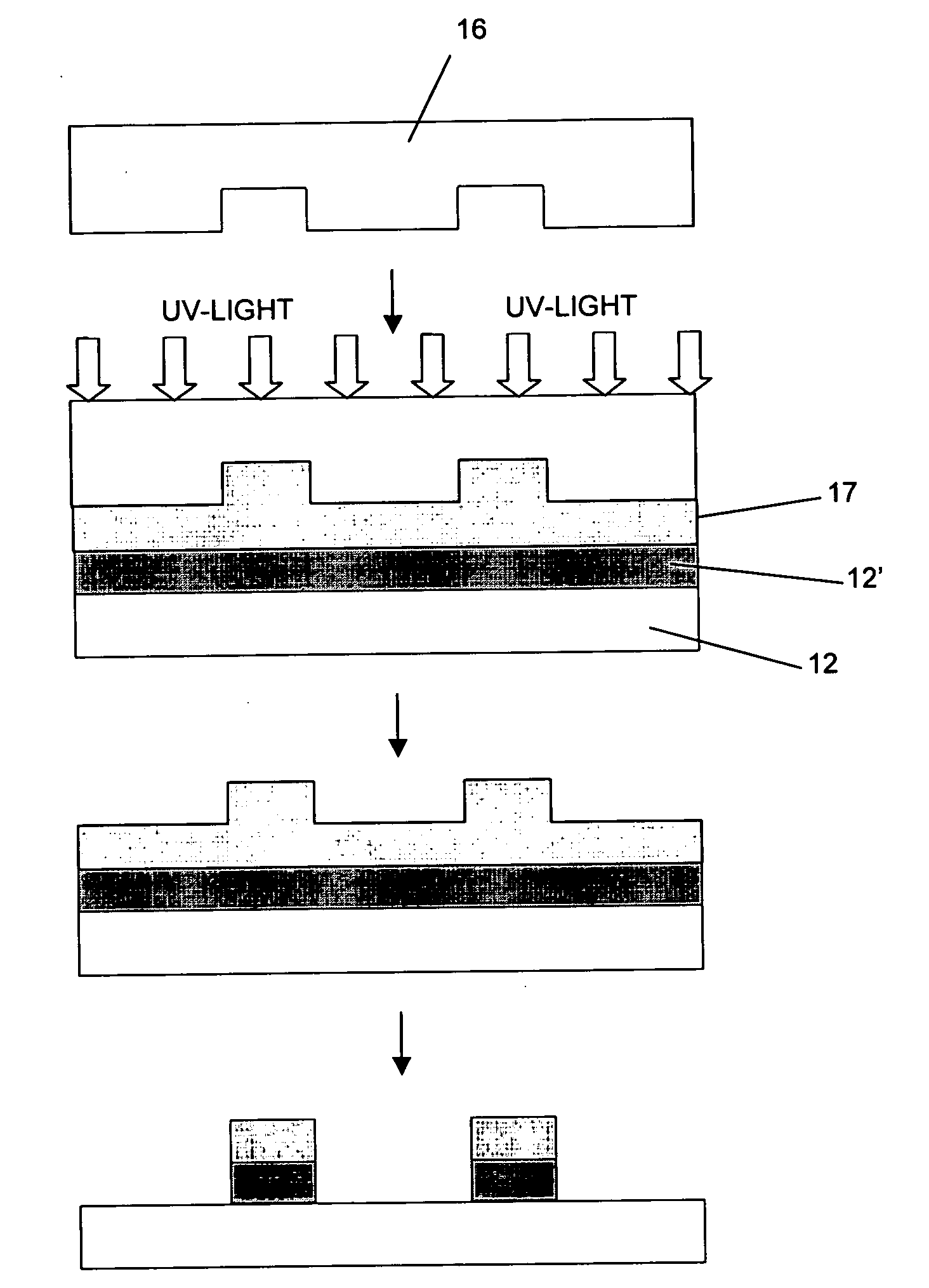

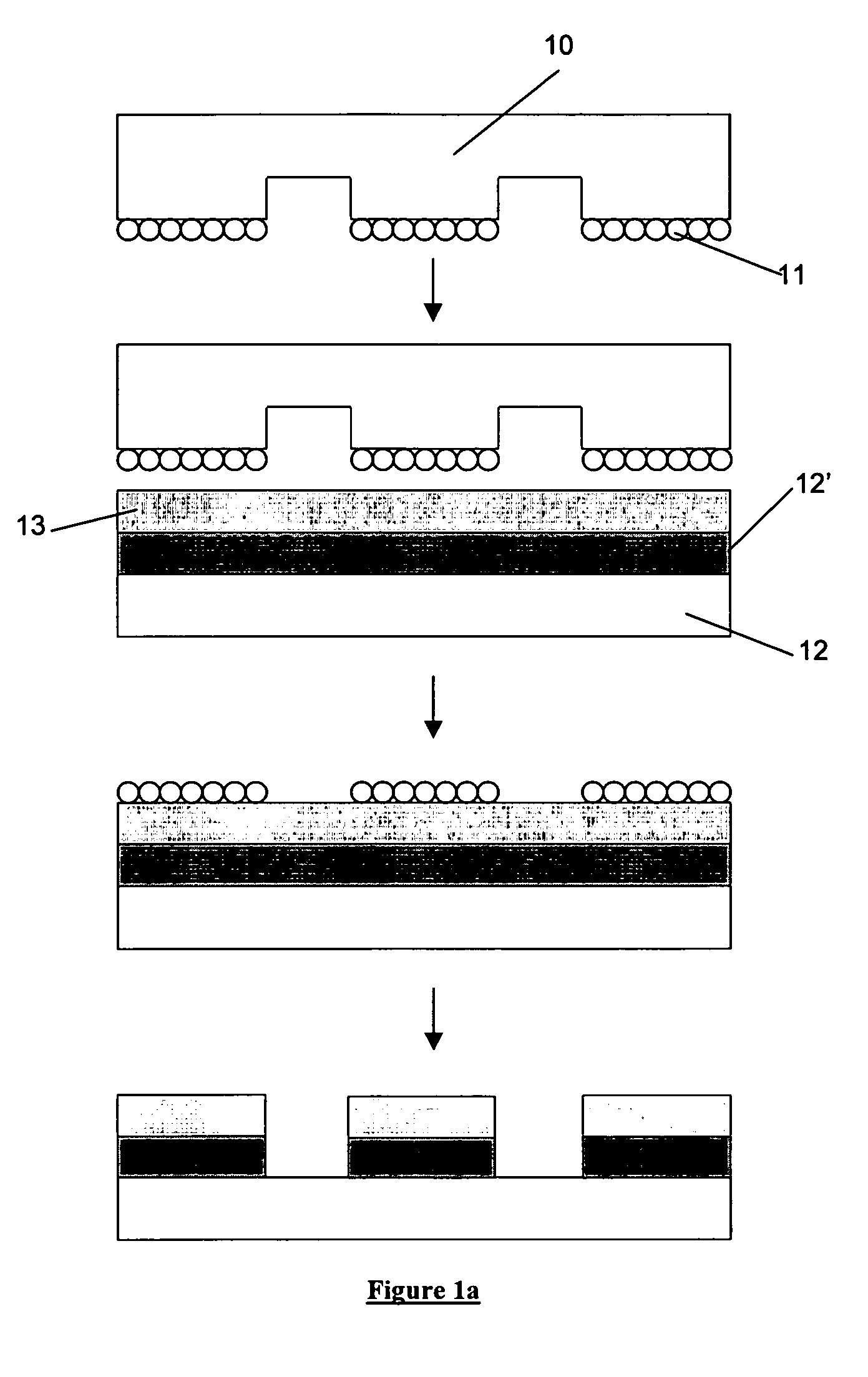

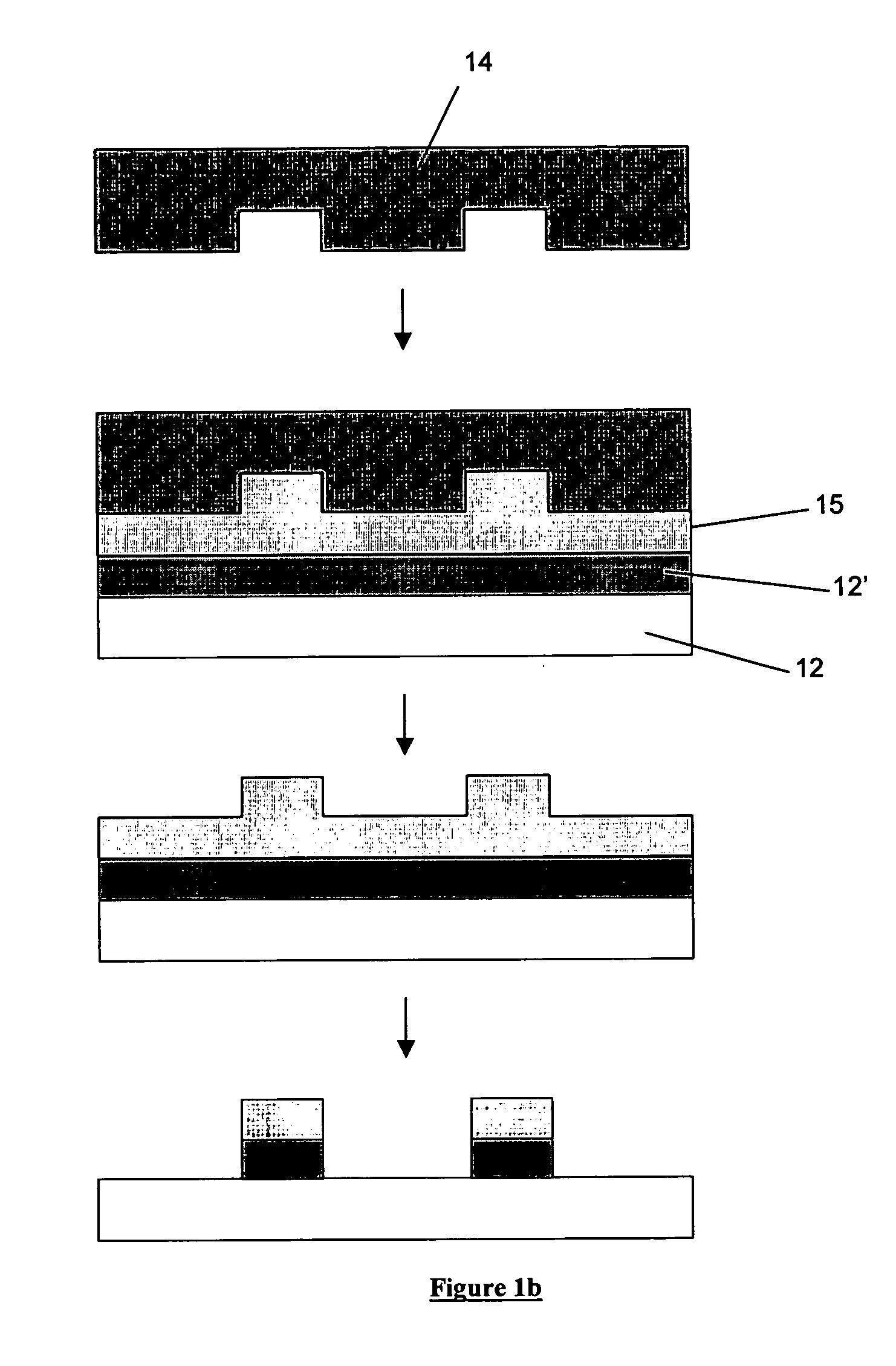

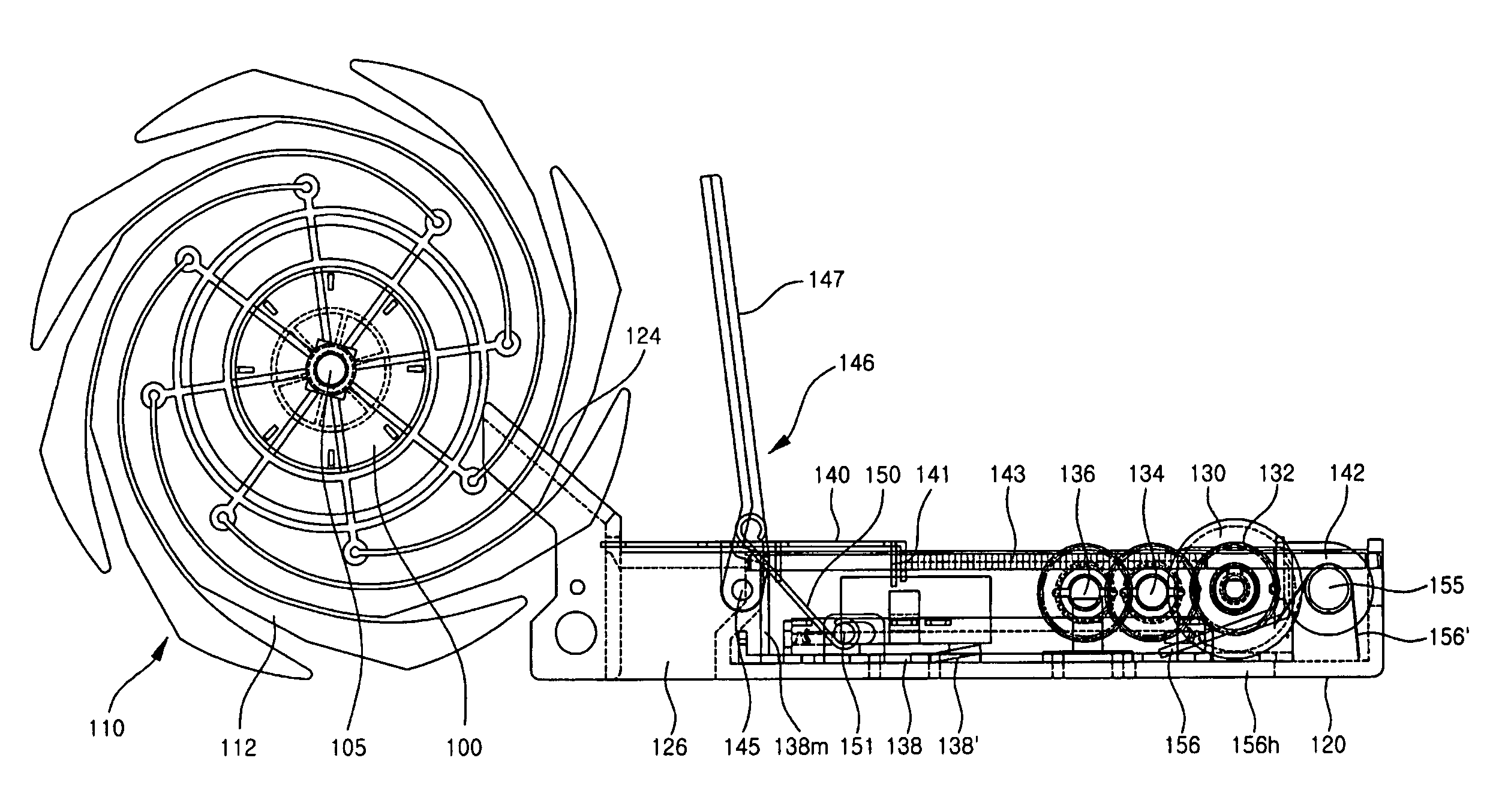

Imprintable medium dispenser

An imprintable medium dispenser includes a chamber, a nozzle, and an actuator connected to the chamber and configured to be actuated and thereby generate a pressure wave within the chamber such that imprintable medium is dispensed from the nozzle. The imprintable medium dispenser is provided with a control circuit which includes a monitoring apparatus configured to receive a transient oscillation signal generated when the actuator is actuated, and to monitor the operation of the imprintable medium dispenser by monitoring the transient oscillation signal.

Owner:ASML NETHERLANDS BV

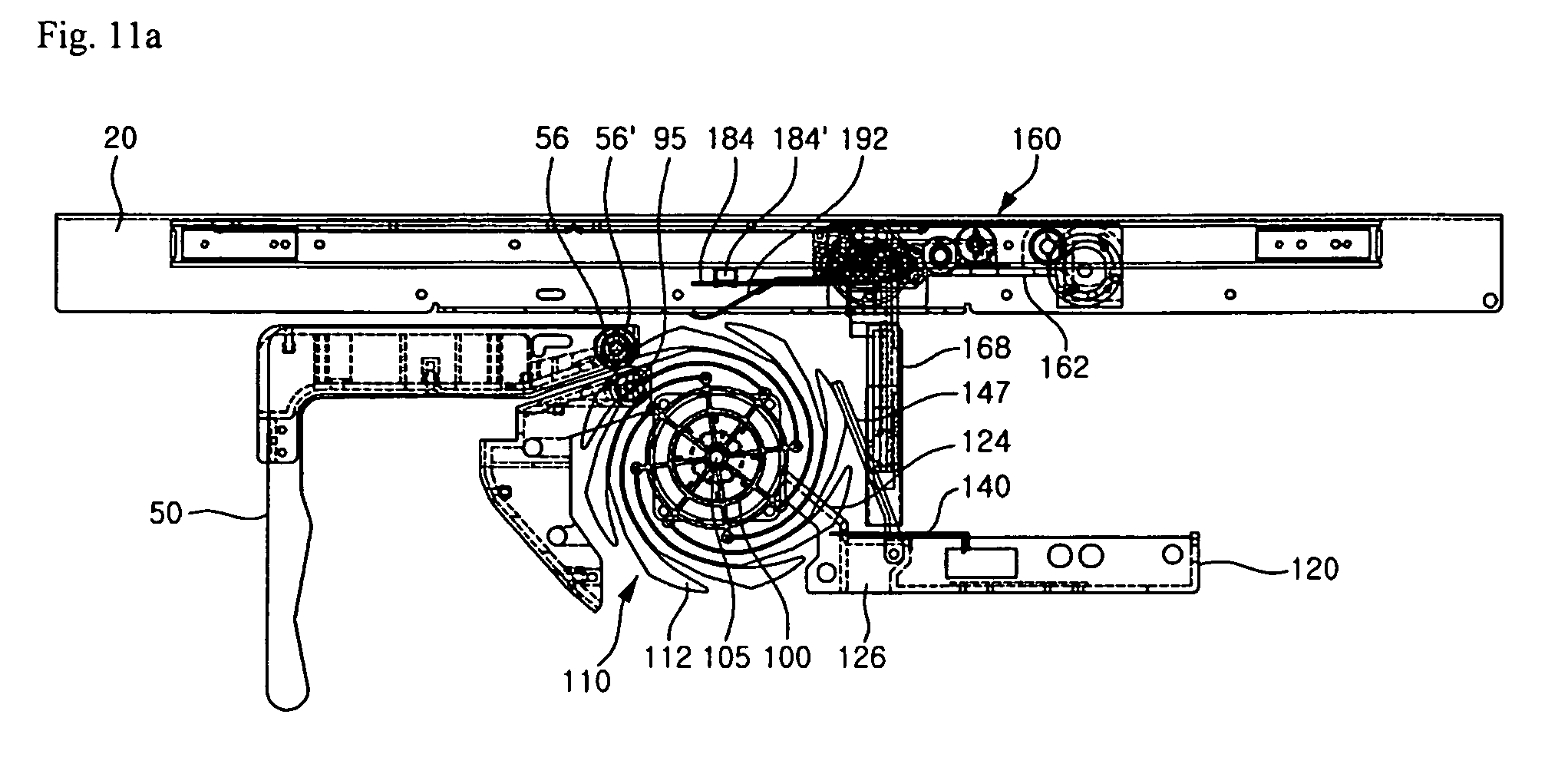

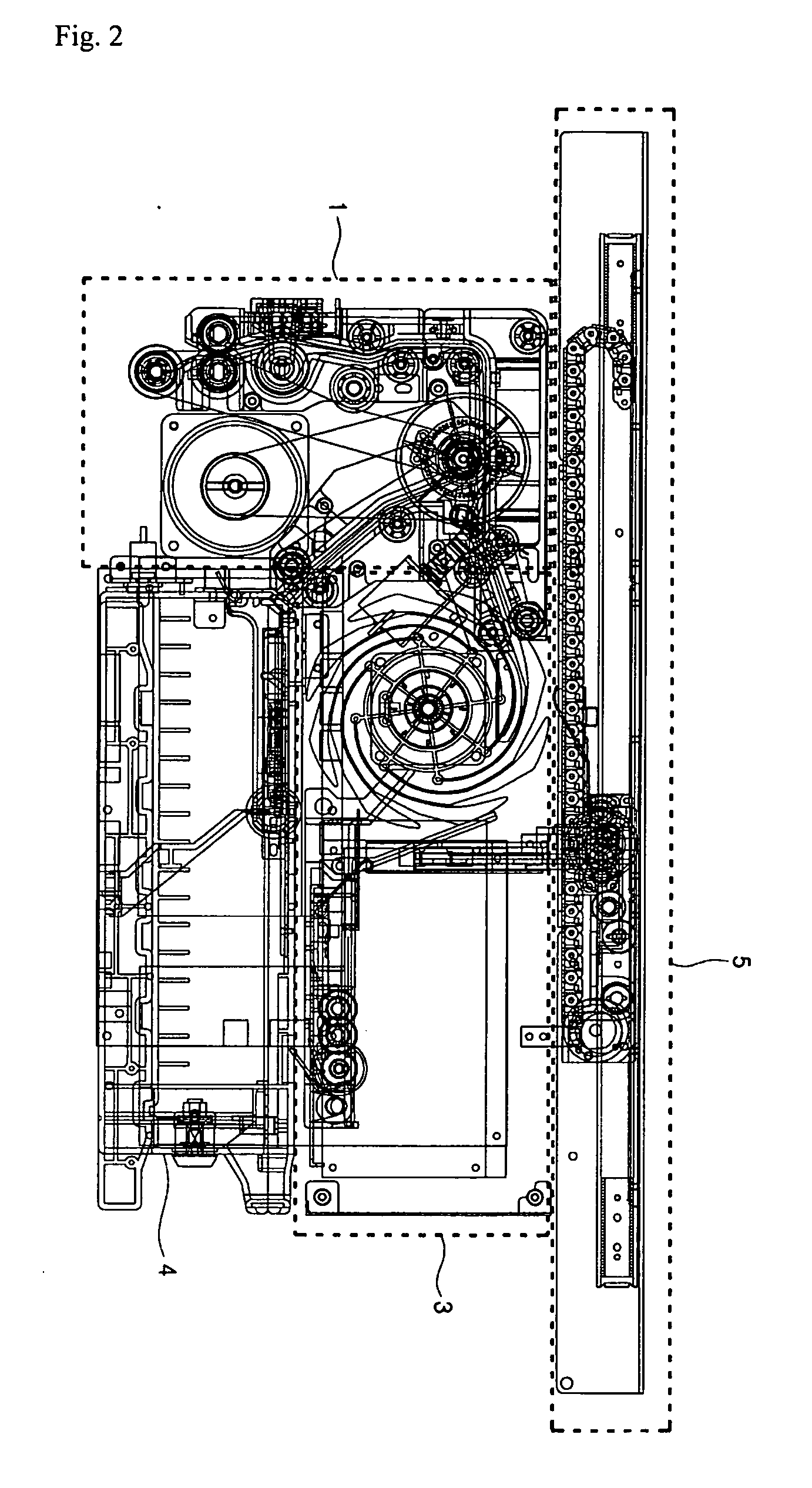

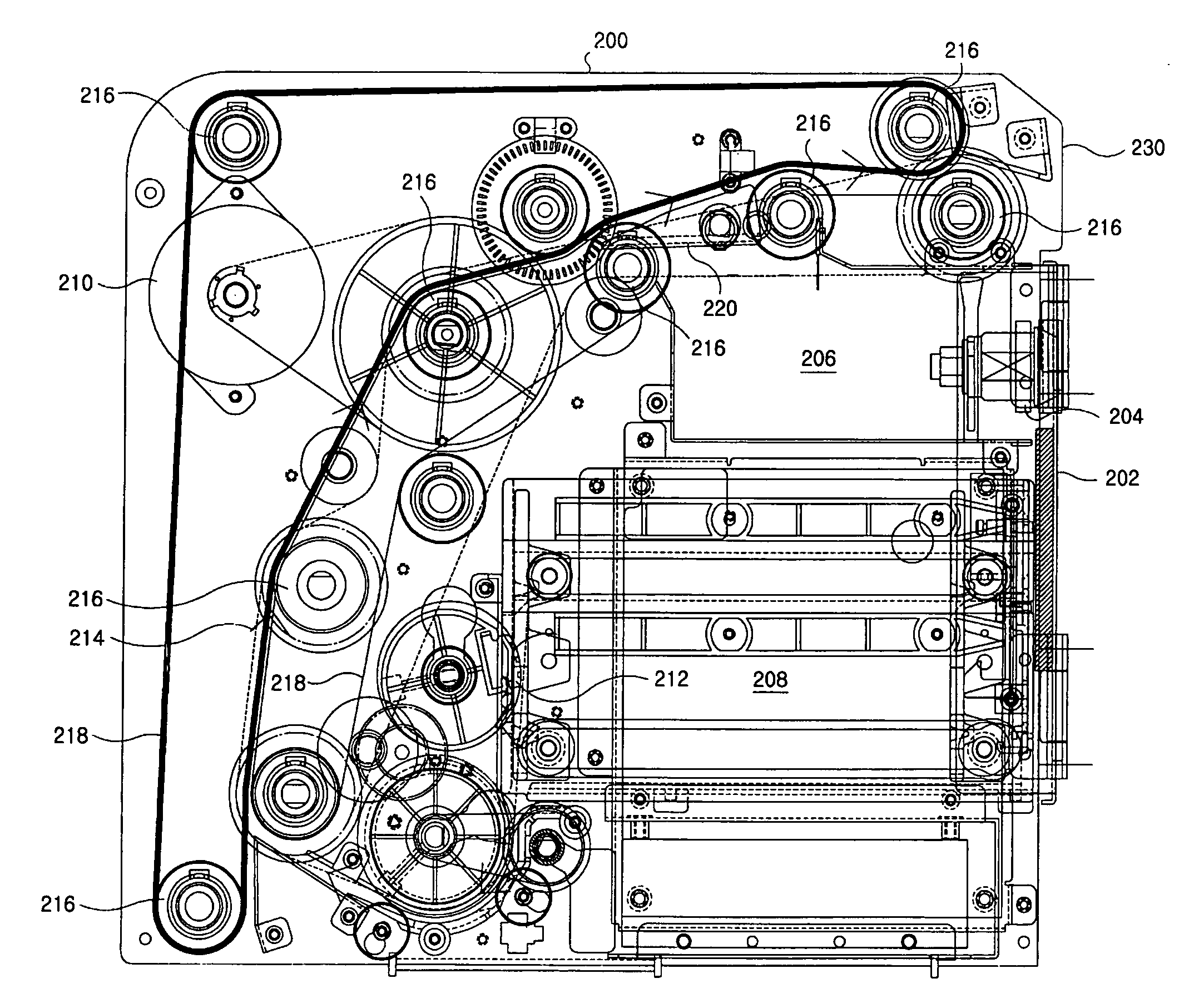

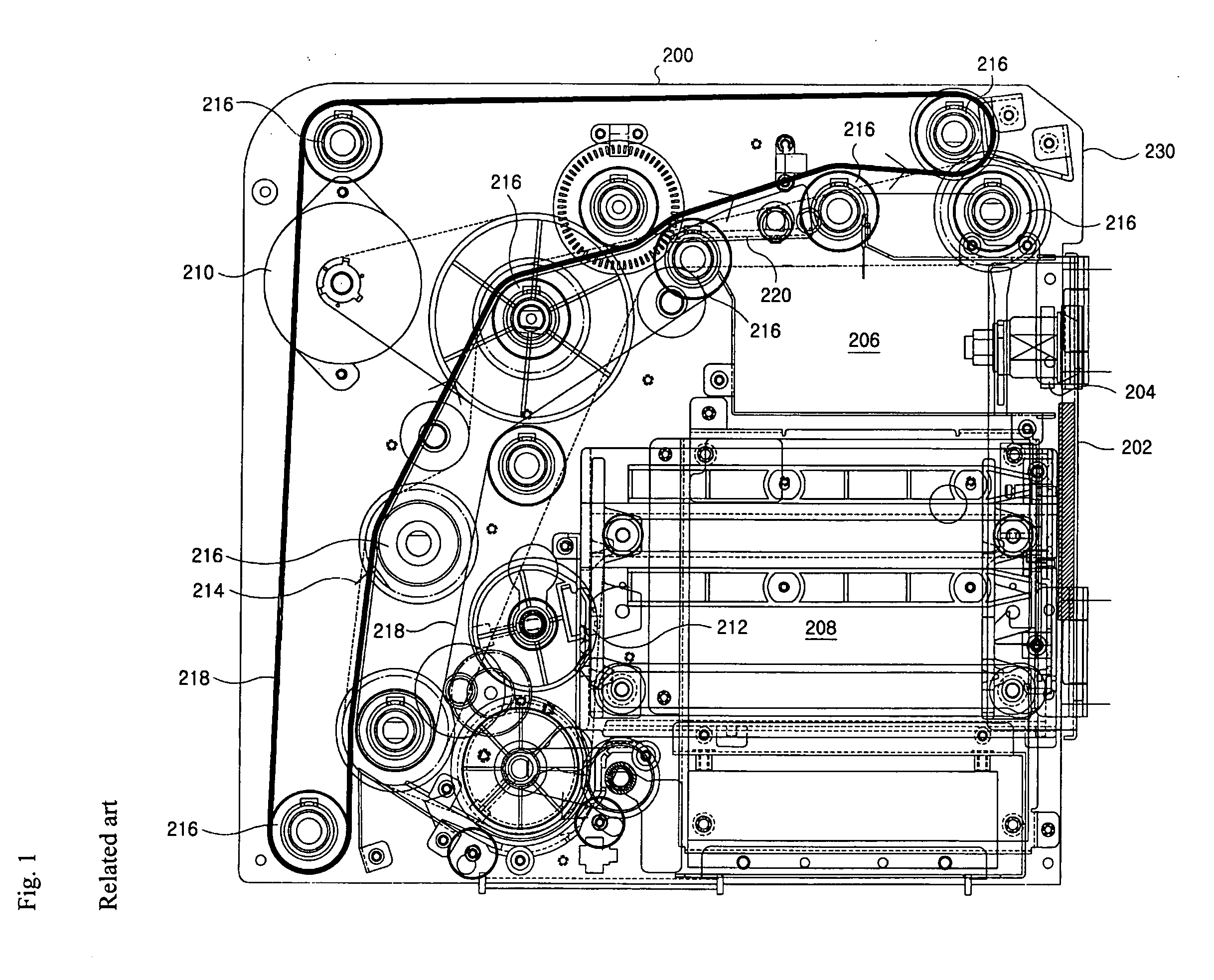

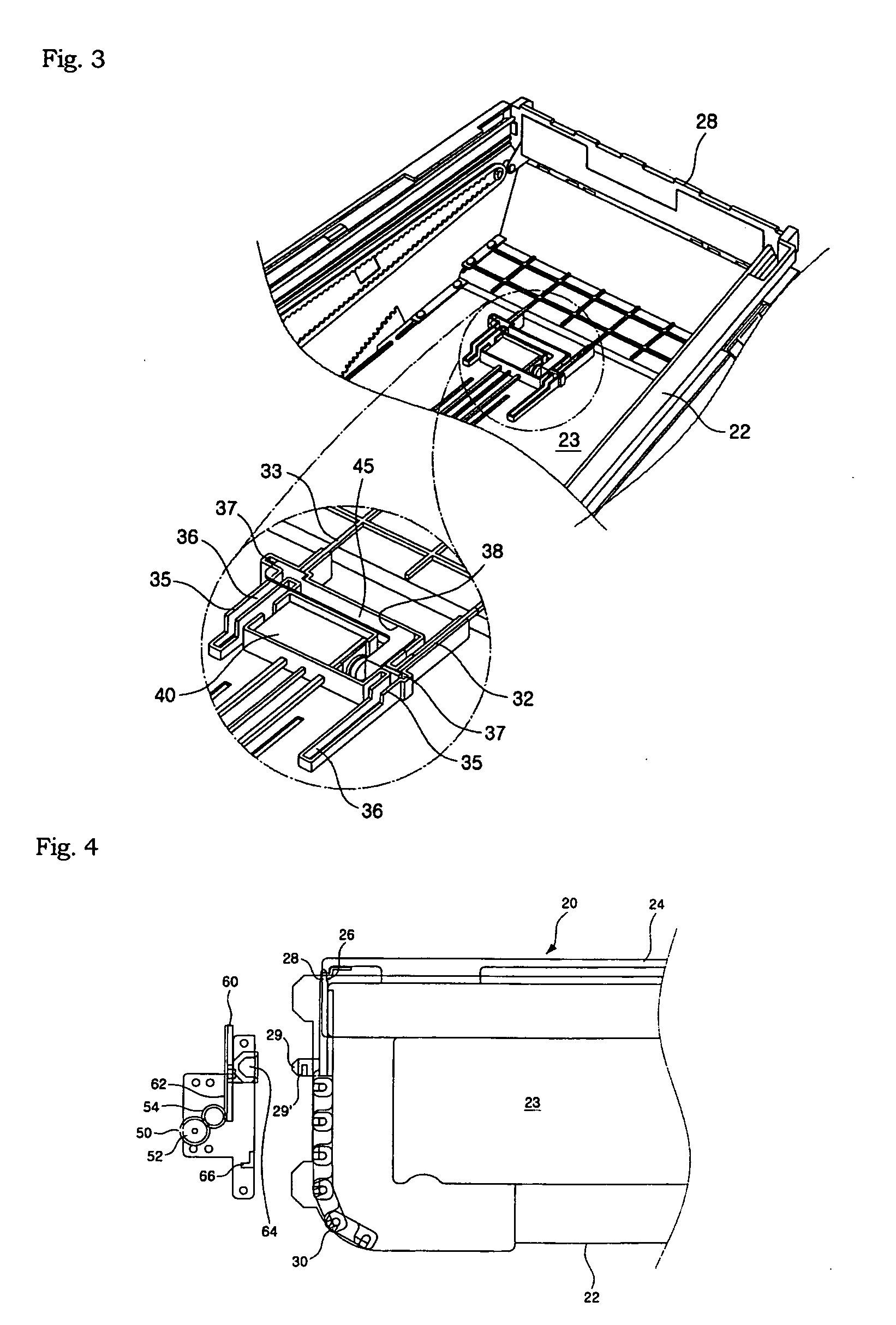

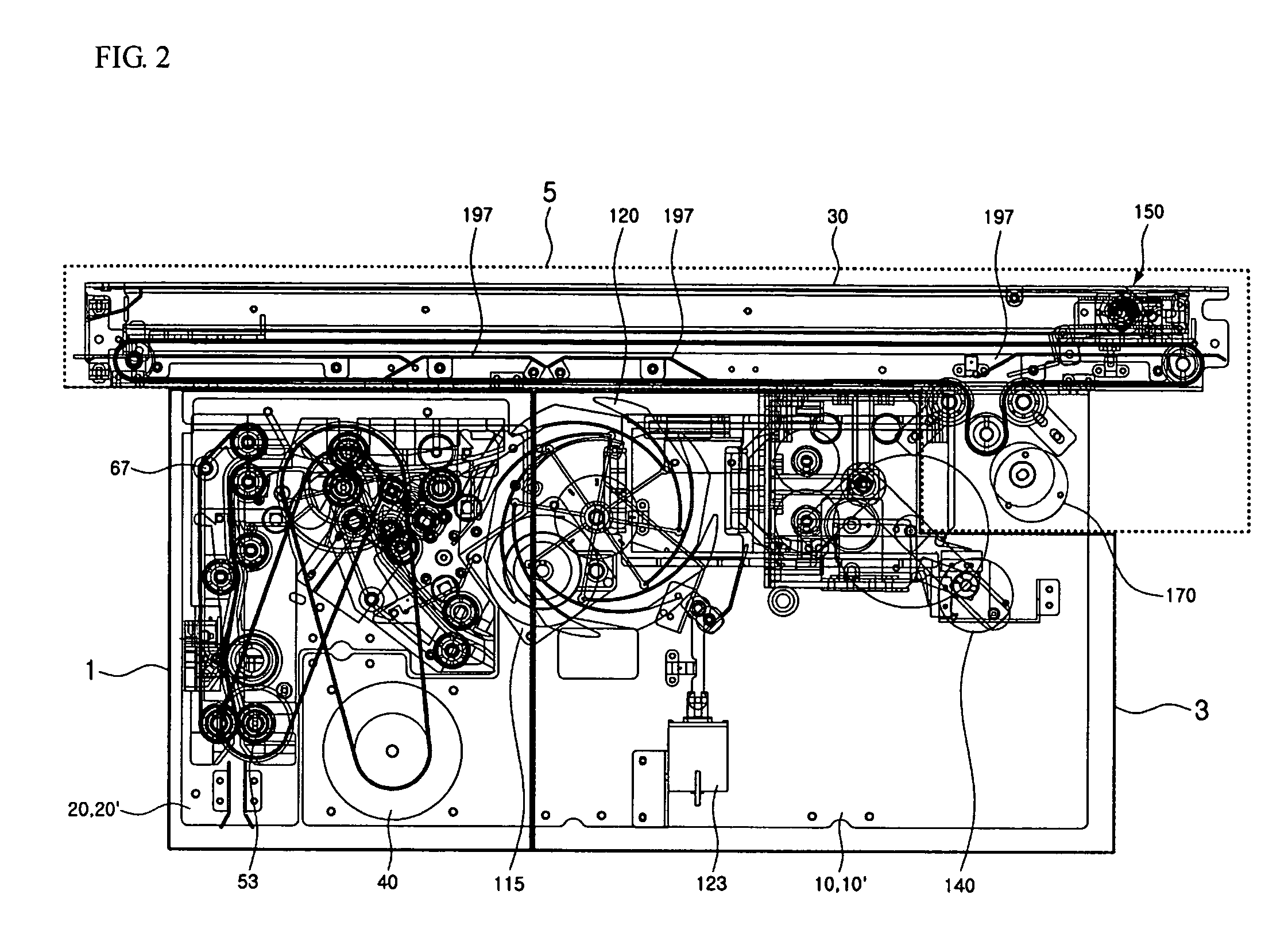

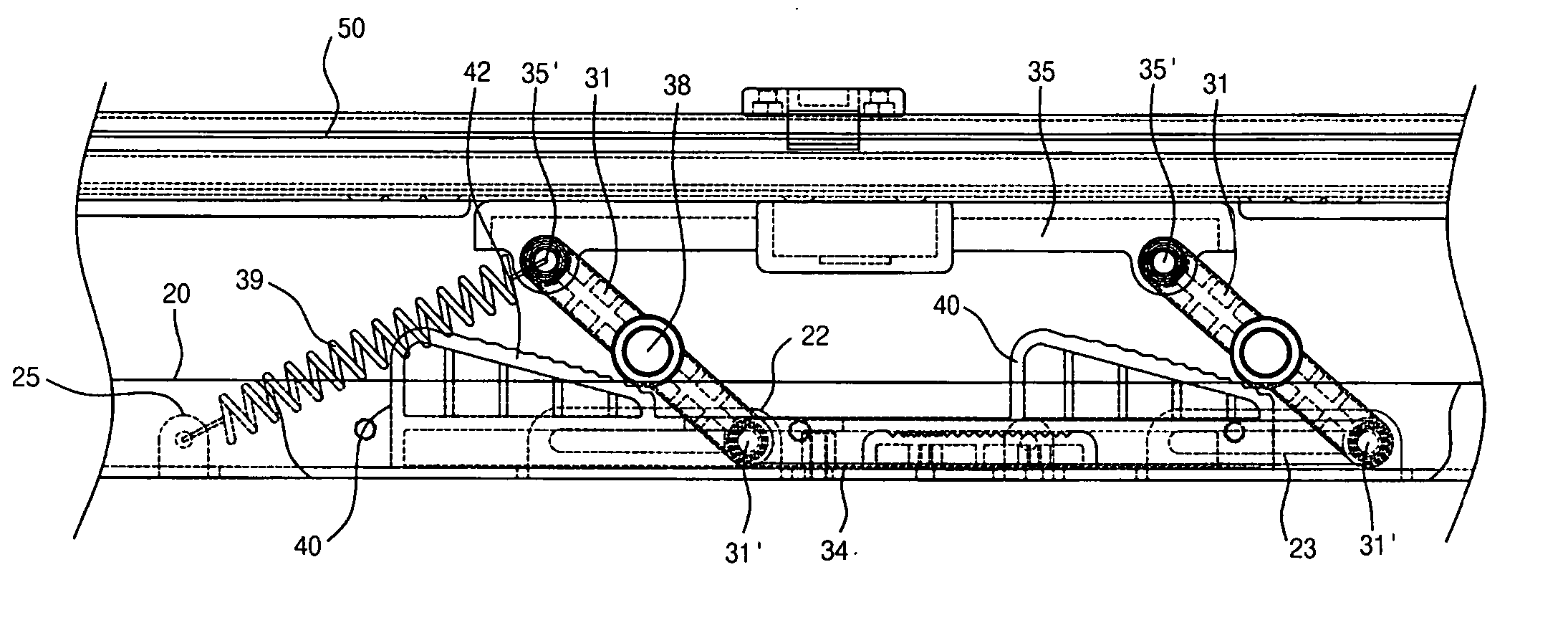

Delivery clamp module of media dispenser and control method thereof

ActiveUS20060097443A1Invention is simpleInterference componentPile receiversArticle deliveryEngineeringMedia dispenser

The present invention relates to a delivery clamp module and a control method thereof. According to the present invention, there is provided a delivery clamp module. The delivery clamp module comprises a clamp guide with a movement guide rail included therein; a delivery tray movable along the rail of the clamp guide by means of a driving force of a tray delivery motor; a clamp base rotatably connected to a front end of the delivery tray through a connecting arm, rotated within a predetermined angular range by a base rotating motor, and supporting a surface of the stacked media; and a clamp arm installed on the clamp base, including push fingers for pushing the media onto the clamp base by an elastic force, and rotated with respect to the clamp base within a predetermined angular range by an arm rotating motor. According to the present invention so constructed, since the media stacked on the stacking module are clamped directly by the delivery clamp module, and delivered to the customer or rejected if the customer did not take out the media, there is an advantage in that the general configuration of the present invention is relatively simplified. In addition, the media can be always securely pushed to the clamp base and clamped by an elastic force of the push finger of the clamp arm regardless of the number of the media. Further, there is an advantage in that it is possible for a media sensor to sense whether or not the media are clamped, taken out, and the like by installing the media sensor and a reflecting member to the clamp base and the clamp arm.

Owner:ATEC AP CO LTD

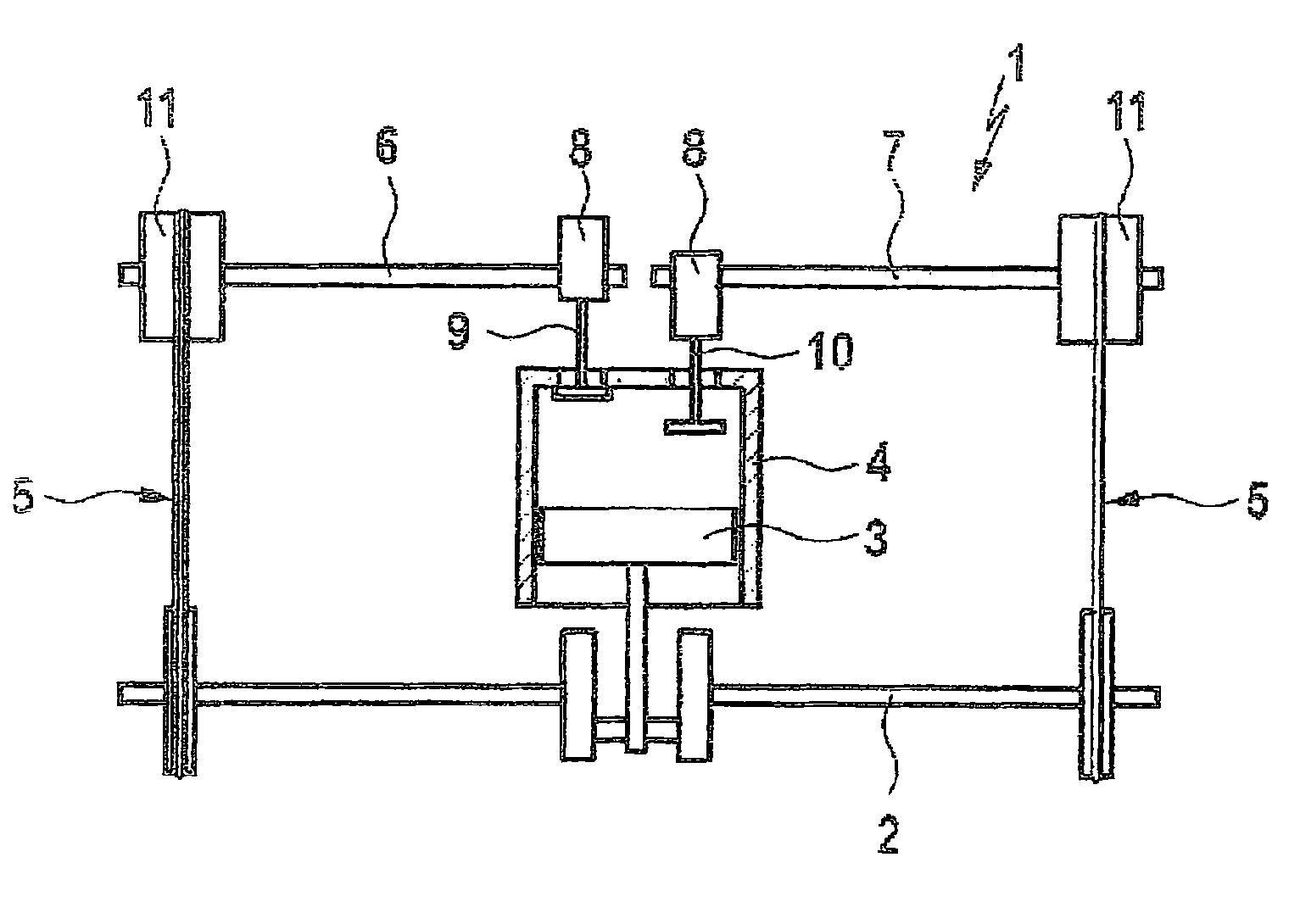

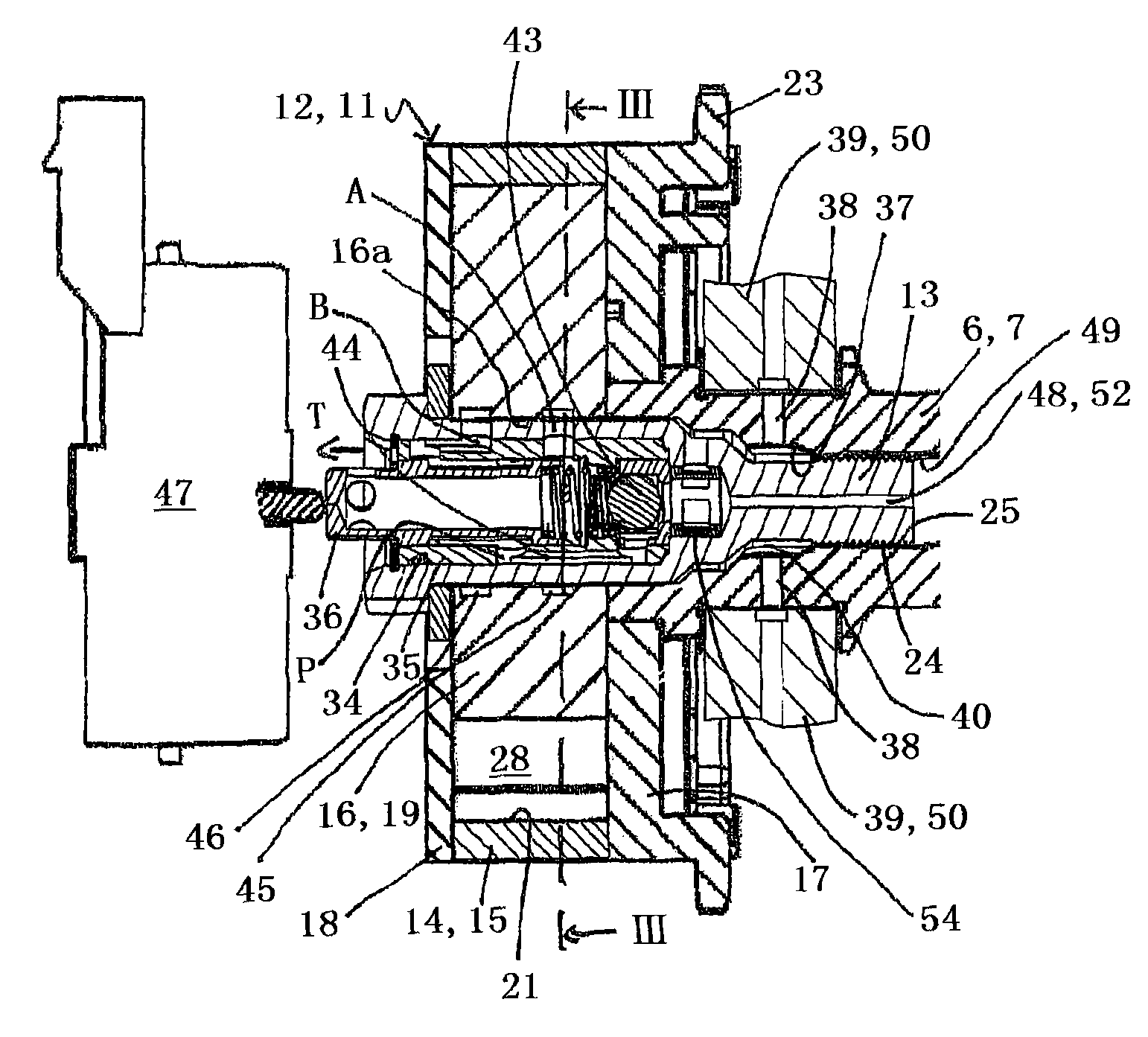

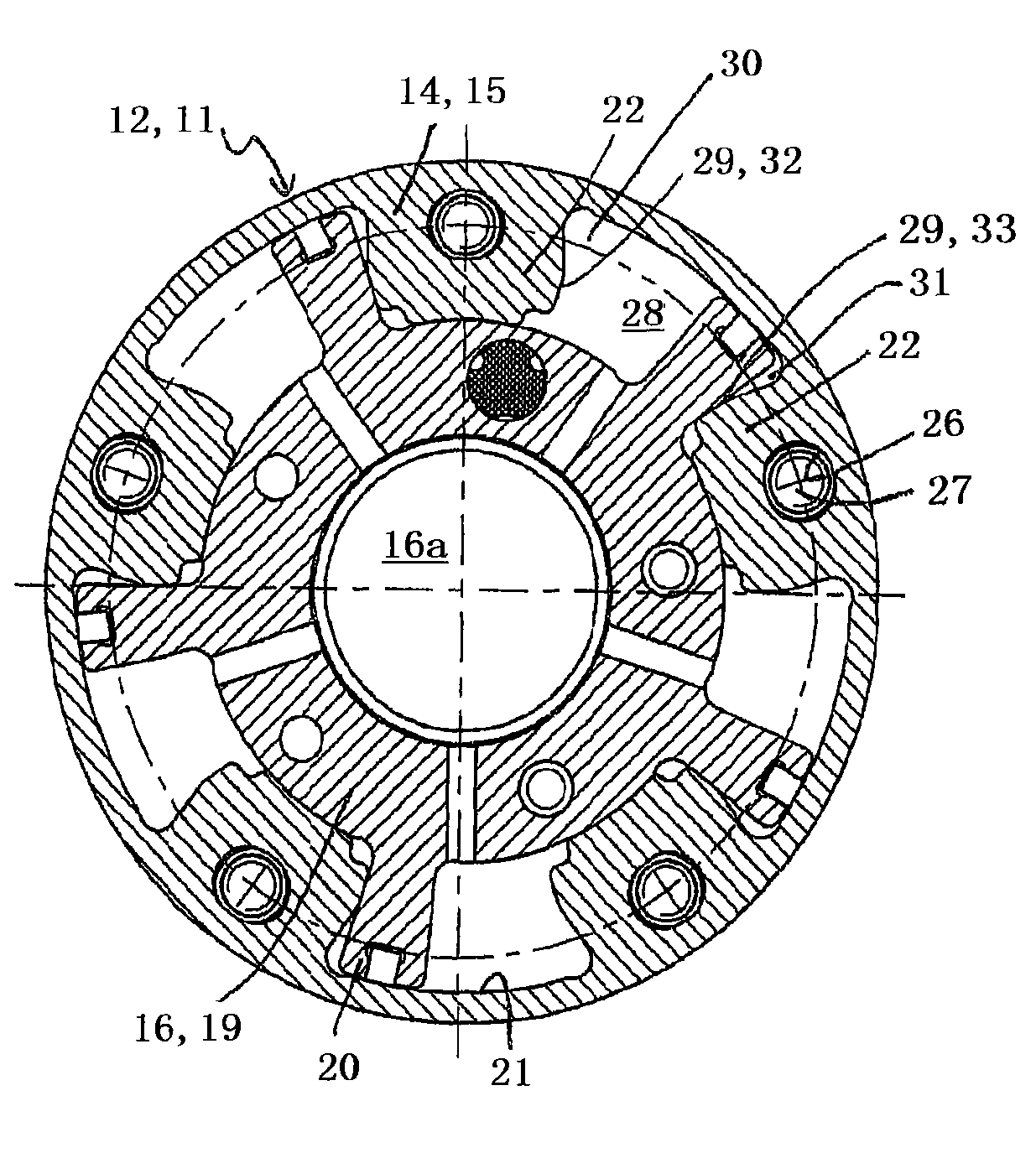

Device for variable adjustment of timing of gas exchange valves of internal combustion engine

InactiveCN102112707AReduced flow areaReduce loadValve arrangementsMachines/enginesPhase shiftedExternal combustion engine

The invention relates to a device (11) for the variable adjustment of the timing of gas exchange valves (9, 10) of an internal combustion engine (1), comprising a hydraulic phase shifting device (12), a camshaft (6, 7) and a pressurizing means distributor (13), wherein the phase shift device (12) can be caused to come into drive linkage with a crankshaft (2) and is rigidly connected to the camshaft (6, 7), wherein a phase position of the camshaft (6, 7) relative to the crankshaft (2) can be variably adjusted by way of the phase shift device (12), wherein the interior of the camshaft (6, 7) comprises a cavity (49) that communicates with one or more camshaft bearings (50) designed to be separate from a rotating pressurizing means conveyor (39), wherein the pressurizing means distributor (13) is disposed in a receiving area (37) of the camshaft (6, 7), wherein the camshaft (6, 7); comprises an opening (38) in the area of the pressurizing means distributor (13), said opening communicatingon the one hand with the interior of the camshaft (6, 7) and on the other hand with the rotating pressurizing means conveyor (39), wherein a pressurizing means path (40) is designed inside the camshaft (6, 7), said path communicating on the one hand with the opening (38) and on the other hand with the hydraulic phase shift device (12).

Owner:SCHAEFFLER TECH AG & CO KG

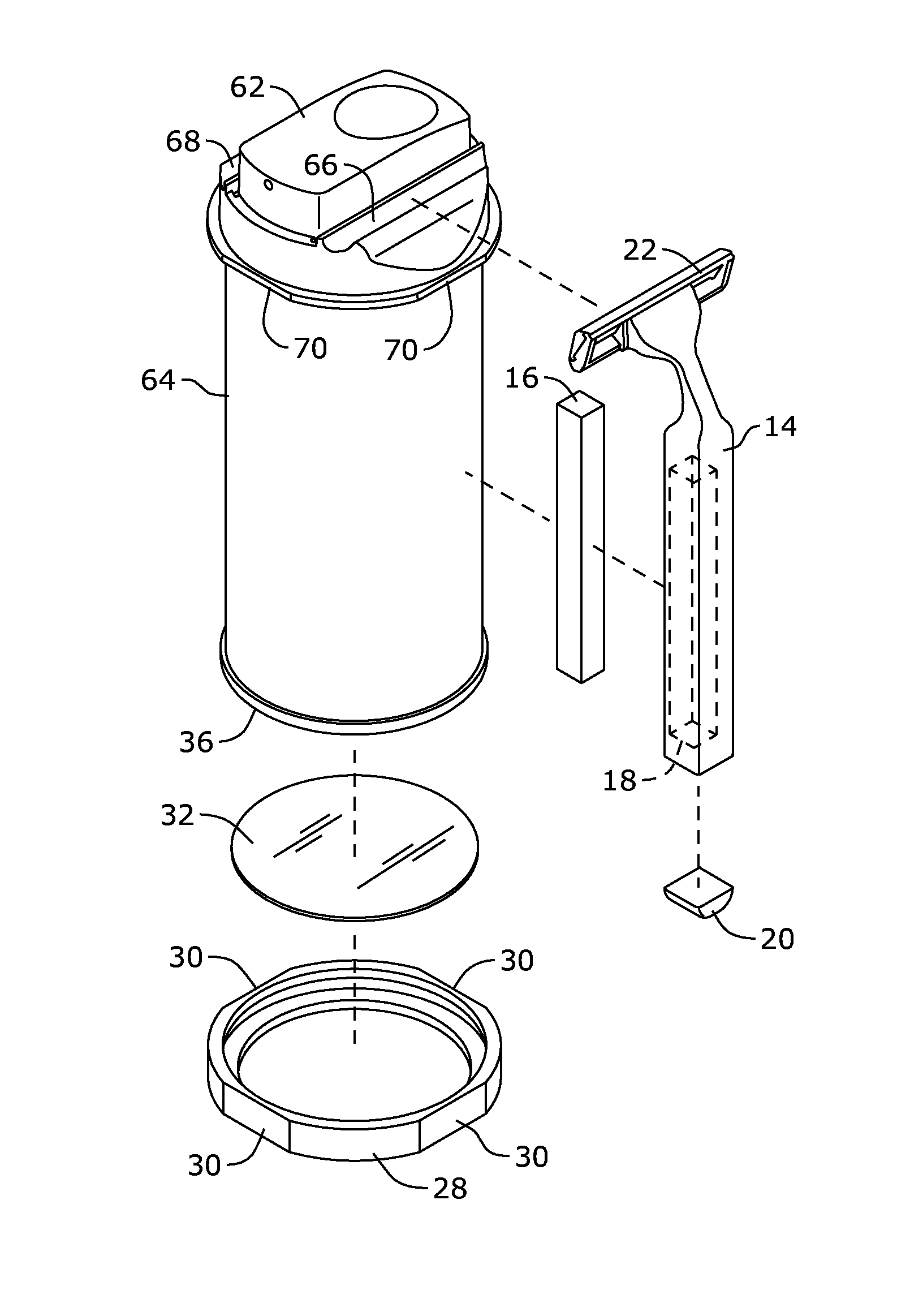

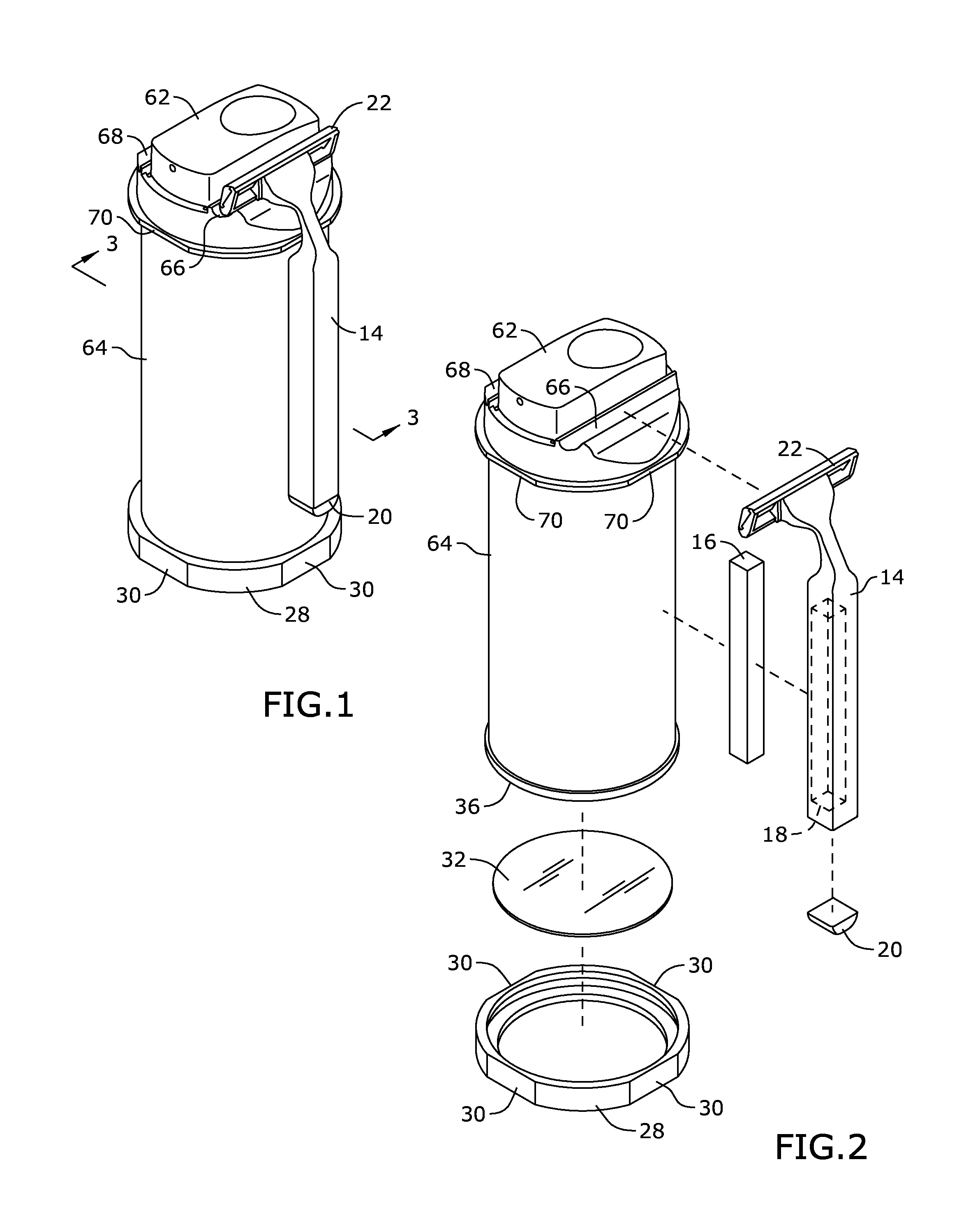

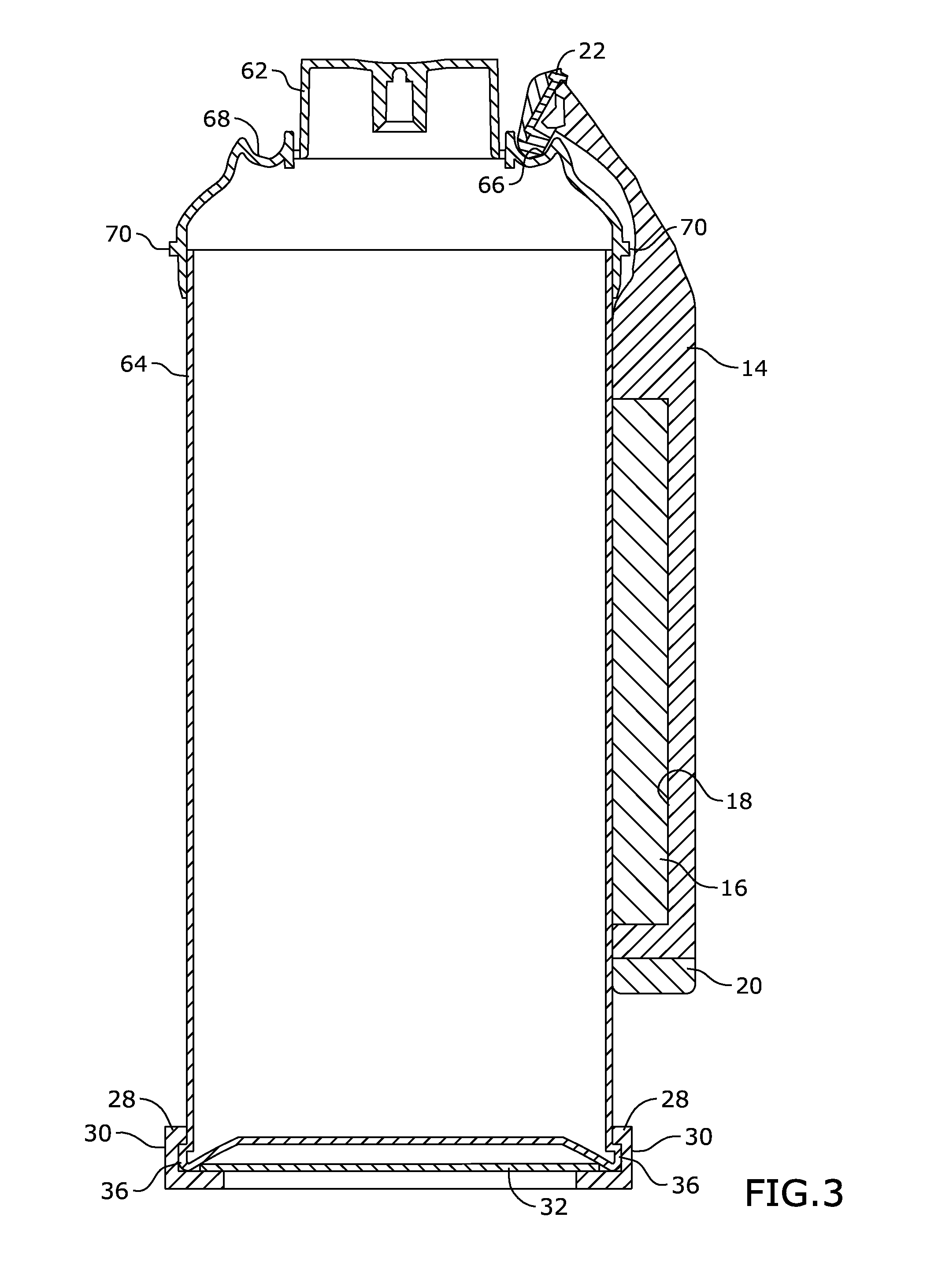

Shaving system

An advantageous combination of a novel shaving medium dispenser and a novel shaving razor is provided. The dispenser may be made of ferromagnetic material configured in a generally cylindrical, cuboid, or trapezoidal prism shape. A mirror may be disposed near a lower portion of the dispenser's shape. Along the lower portion and an upper portion of the dispenser, two complementary flat surfaces for supporting itself in a prone orientation may be disposed. One or both of the upper and lower portions may provide a cradle for removably securing a head portion of the shaving razor. The shaving razor may also provide a magnetized handle portion and a styptic portion thereon.

Owner:GUZAK JOHN WAYNE

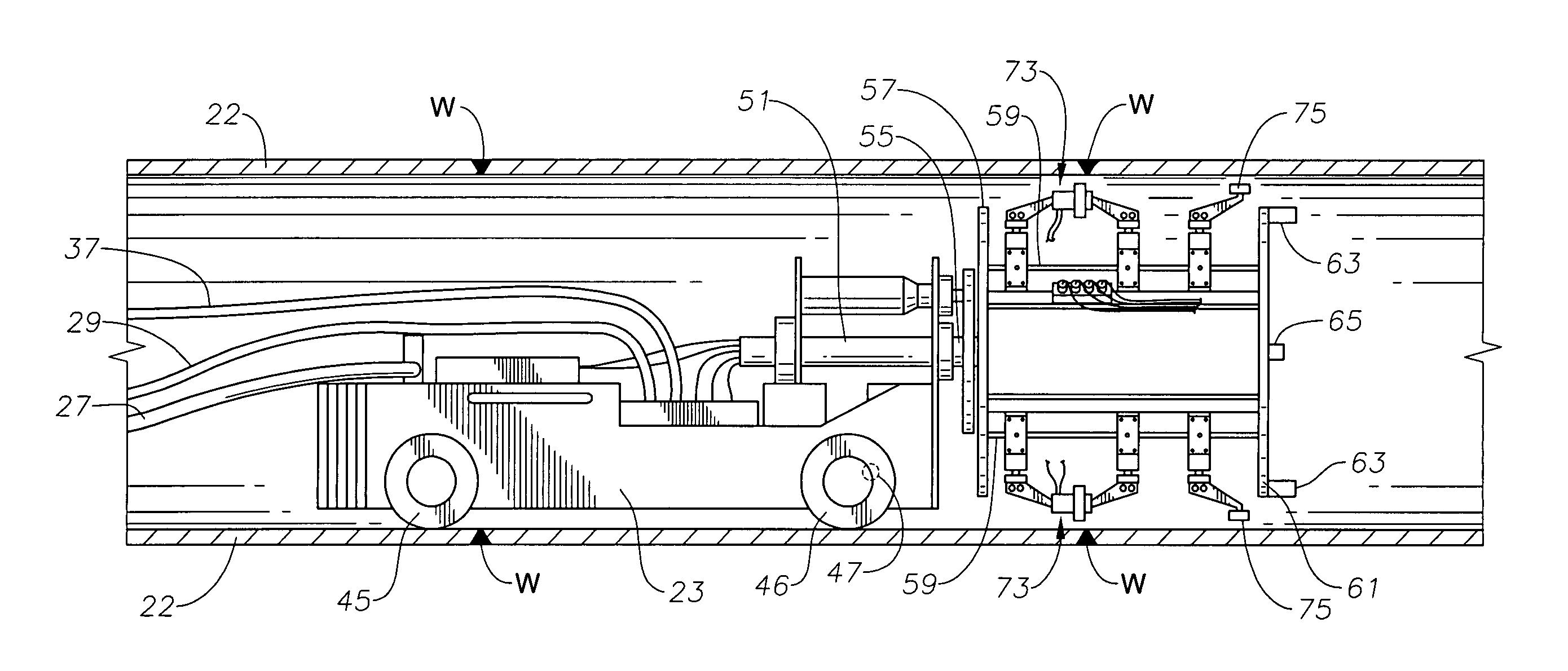

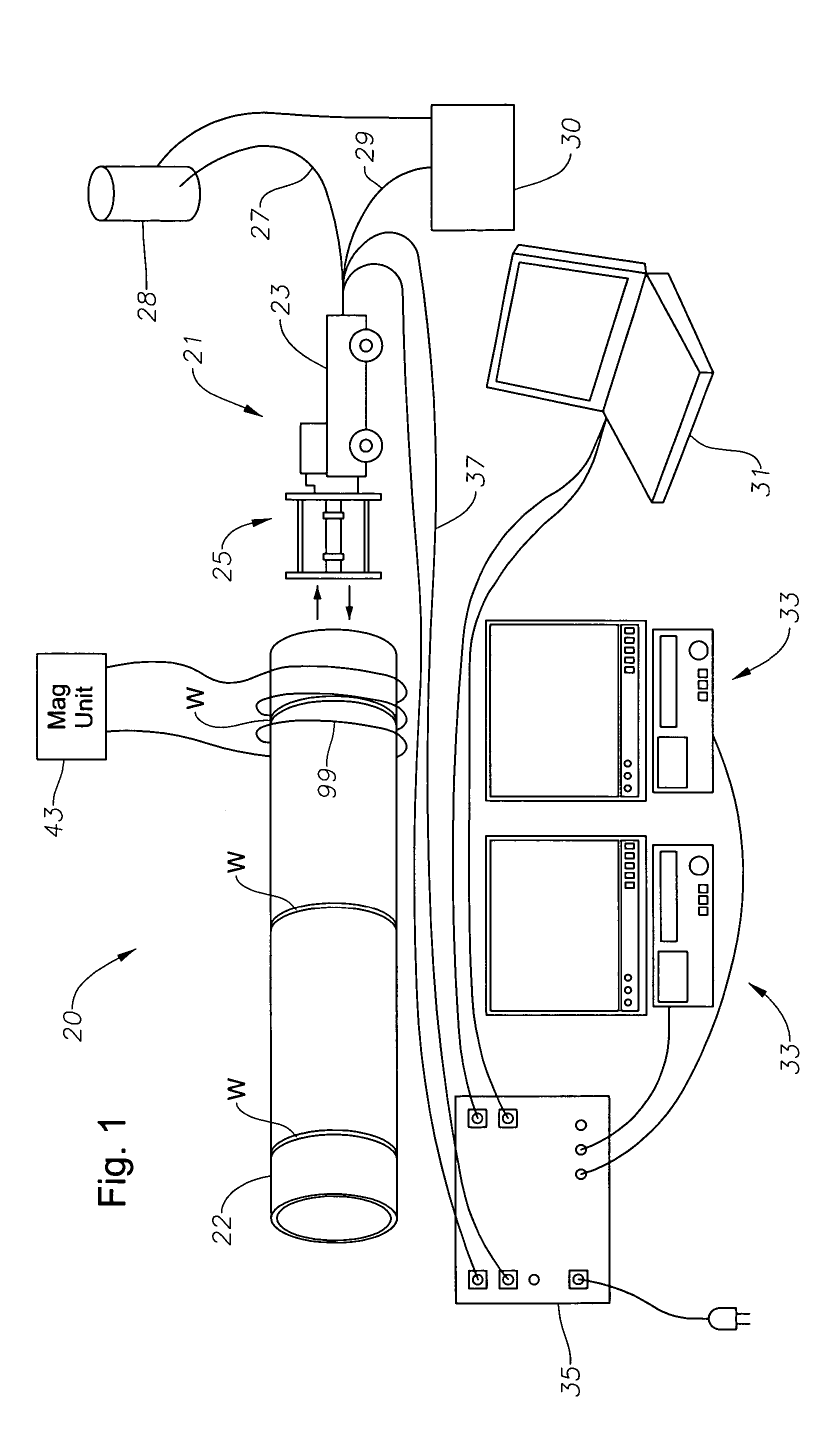

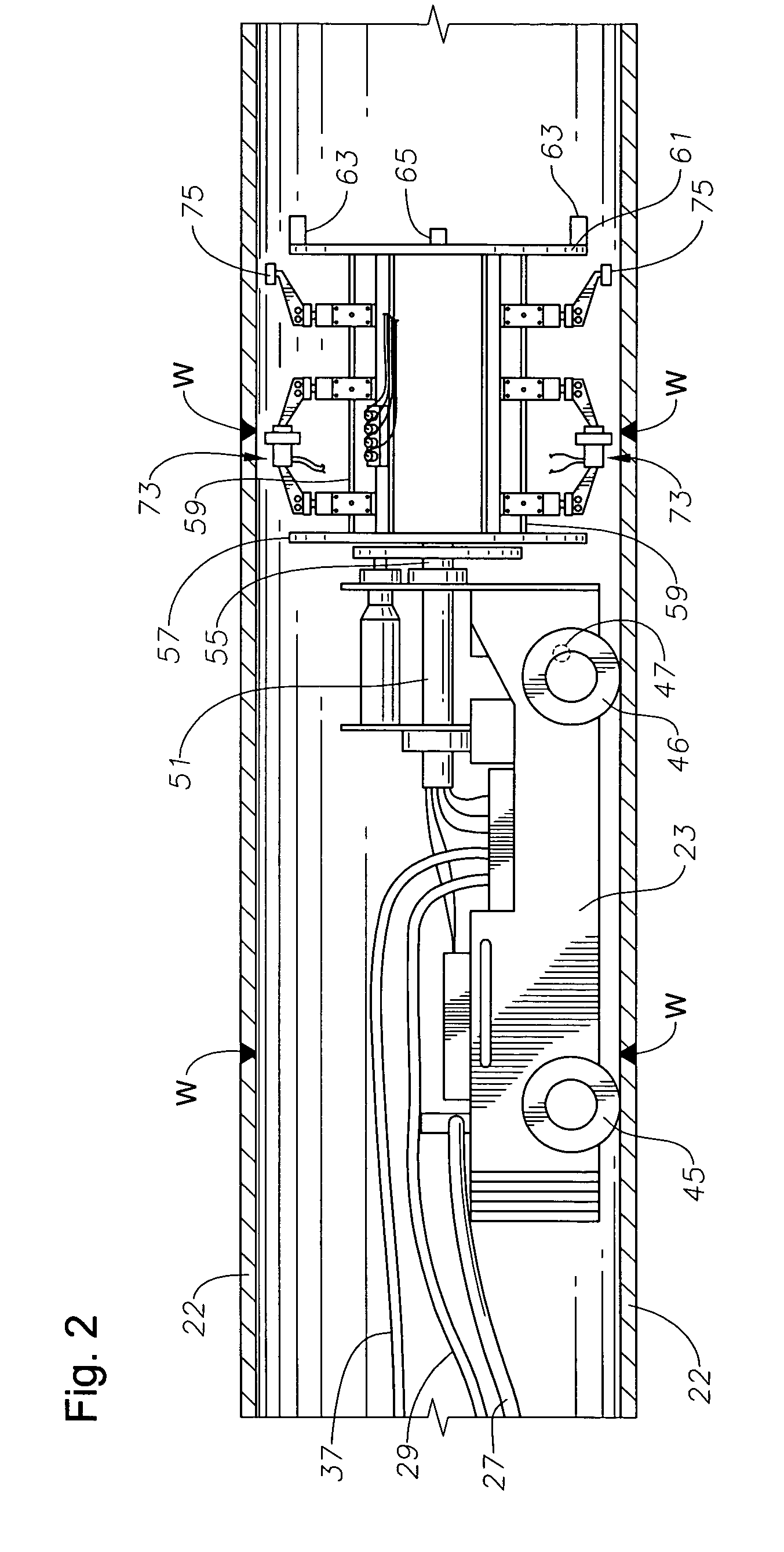

Internal riser inspection system, apparatus and methods of using same

InactiveUS7107863B2Prevent accidental contactImprove acquisitionSurveyAnalysing solids using sonic/ultrasonic/infrasonic wavesDrive wheelMagnetic particle imaging

A system for inspecting a pipe weld from within a pipe through use of magnetic particle imaging “MPI” includes an apparatus having a head unit that carries a wire wheel brush for cleaning an inspection area along an inner diameter of a pipe weld, and an MPI medium dispenser for spraying an MPI medium upon the inspection area, both controlled by an operator. The head unit also includes a video inspection device controlled by the operator and used for viewing at least portions of the inspection area after being sprayed with the MPI medium and when under the influence of a magnetic field to determine if the weld has any defects. The head unit is connected to a drive unit. The drive unit includes a frame having a longitudinal axis and mounted on a set of drive wheels, and a set of support wheels spaced axially from the drive wheels. A linear drive motor mounted to the frame and coupled to the drive wheels moves the head unit linearly along an interior of the pipe between weld inspection areas to allow the operator to locate and inspect the welds from within the pipe.

Owner:HYDRIL USA DISTRIBUTION LLC

Medium dispenser

ActiveUS9072846B2Raise the possibilityEasy to implementMedical devicesInhalatorsMedia dispenserEngineering

Owner:APTAR RADOLFZELL

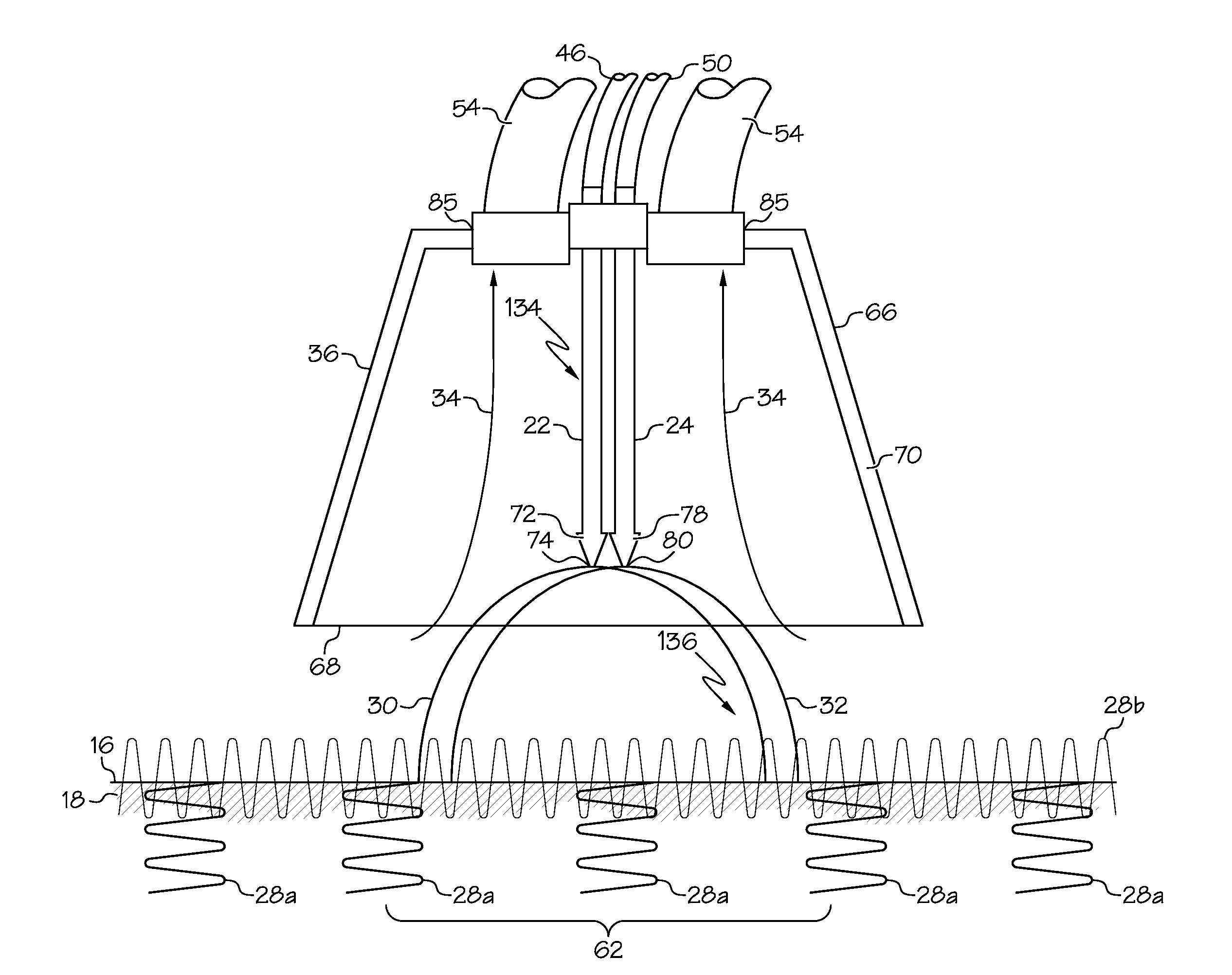

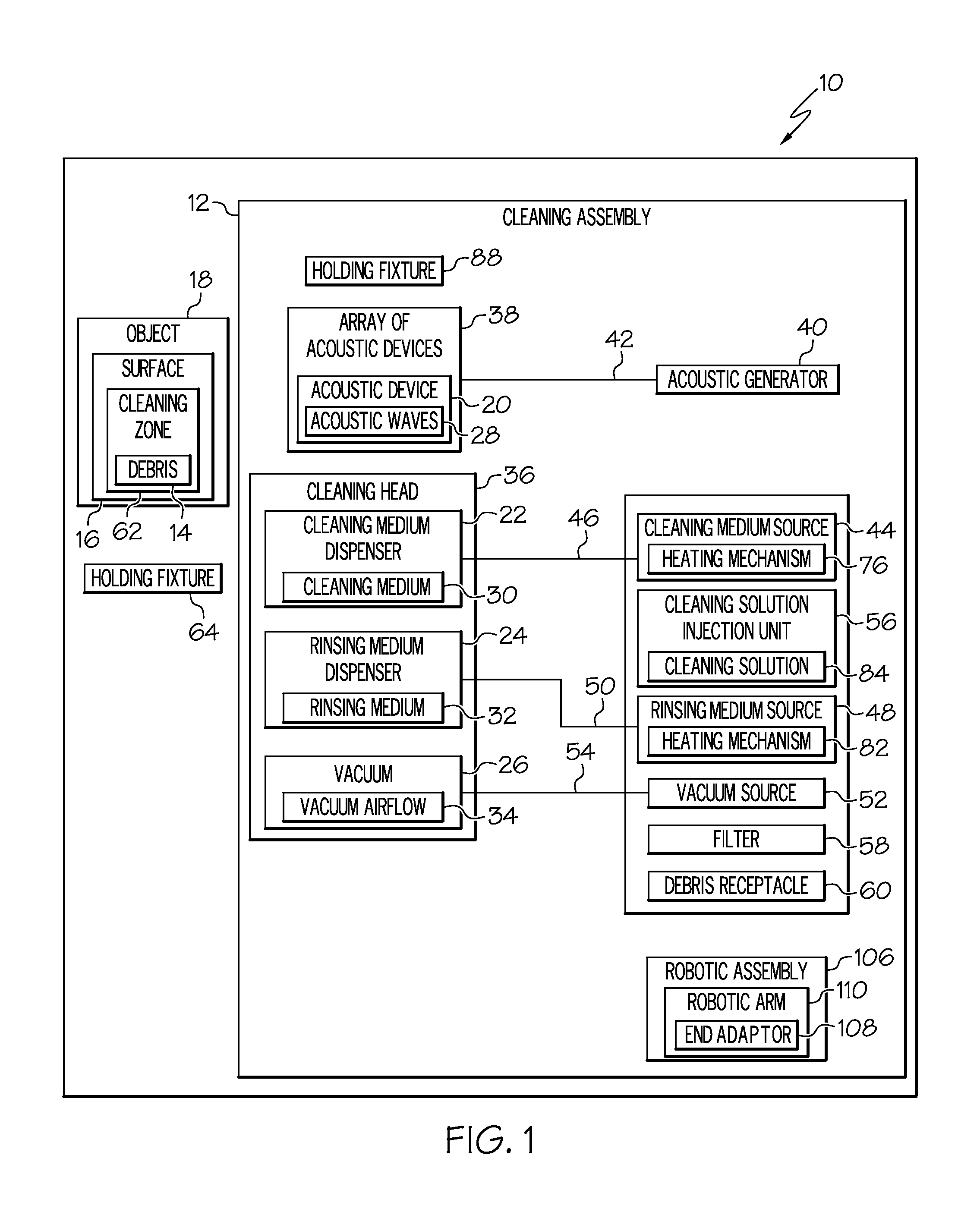

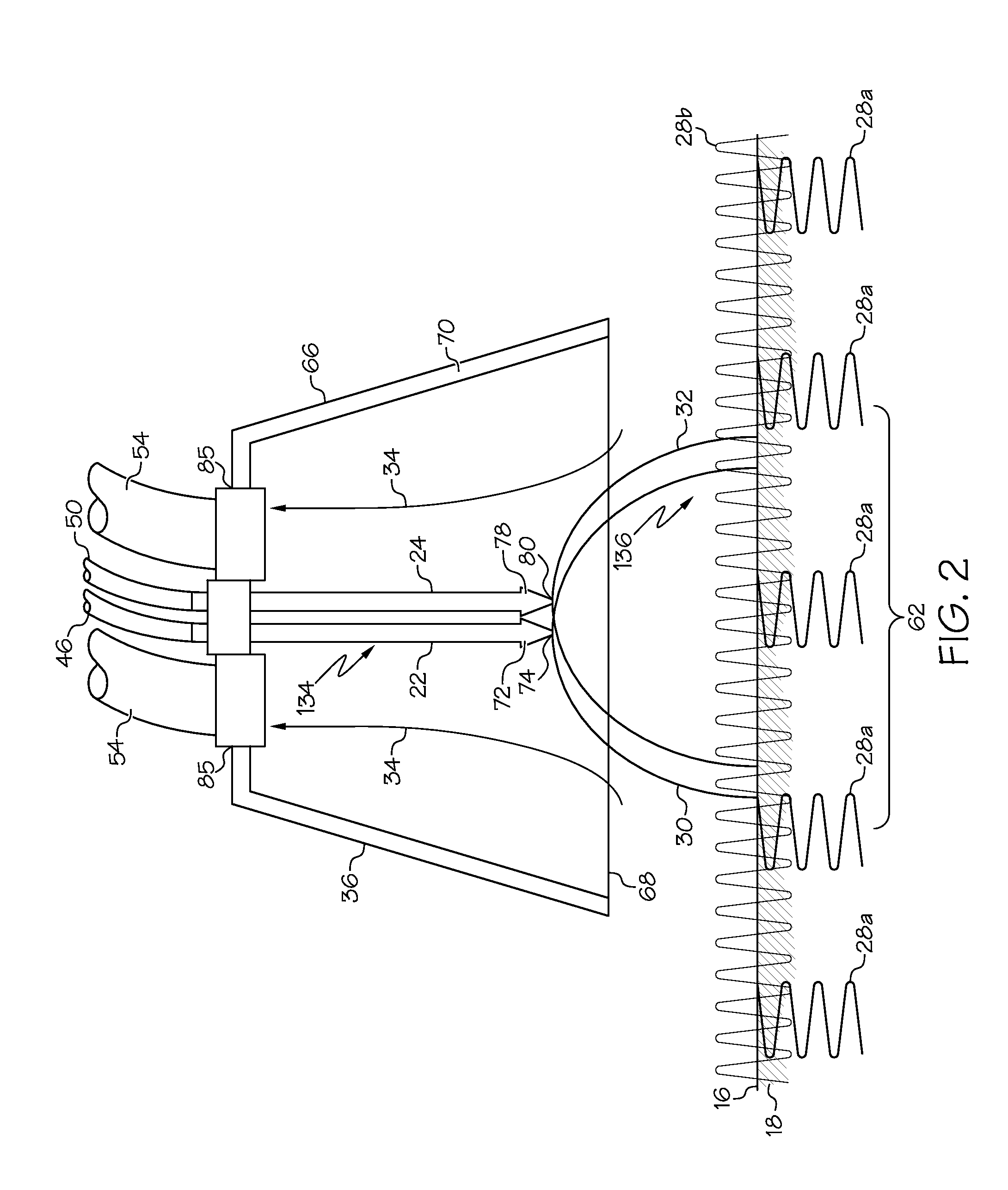

System and Method for Surface Cleaning

A system for cleaning an object may include an acoustic device configured to deliver acoustic waves to the object, a cleaning medium dispenser configured to deliver a cleaning medium to a surface of the object, a rinsing medium dispenser configured to deliver a rinsing medium to the surface, a vacuum configured to deliver a vacuum airflow proximate the surface, wherein the acoustic waves generate acoustic vibrations in the object to dislodge debris from the surface, acoustically treat the cleaning medium and the rinsing medium, and atomize the cleaning medium, the debris collected by the cleaning medium and the rinsing medium.

Owner:THE BOEING CO

Low gravity electrochemical cell

An electrochemical cell system includes a hydrogen electrode; an oxygen electrode; a membrane disposed between the hydrogen electrode and the oxygen electrode; and a compartmentalized storage tank. The compartmentalized storage tank has a first fluid storage section and a second fluid storage section separated by a movable divider. The compartmentalized storage tank is in fluid communication with the electrochemical cell. Further, an electrochemical cell includes a hydrogen electrode; an oxygen electrode; an electrolyte membrane disposed between and in intimate contact with the hydrogen electrode and said oxygen electrode; an oxygen flow field disposed adjacent to and in intimate contact with the oxygen electrode; a hydrogen flow field disposed adjacent to and in intimate contact with the hydrogen electrode; a water flow field disposed in fluid communication with the oxygen flow field; and a media divider disposed between the oxygen flow field and the water flow field.

Owner:PROTON ENERGY SYST

Sheeted cleaning media dispenser with rotation limiting hanger

Owner:RAPALA GREGG R

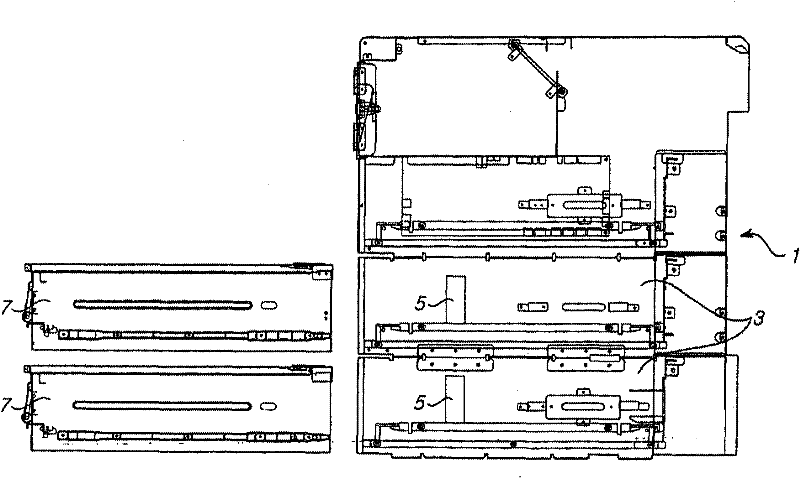

Media cassette with internal lock

ActiveUS20050140084A1Reduce the possibilityComplete banking machinesFinanceLocking mechanismMedia dispenser

The media cassette for a media dispenser includes a cassette body including a storage space in which media are filled. A media discharging opening is provided at a side thereof. A discharging door is movable along one surface of the cassette body and driven by means of a driving source provided at a main body of the media dispenser for opening and closing the media discharging opening. Supporting rods are connected to the door. A locking mechanism for selectively blocking ends of the supporting rods is provide in the cassette body and selectively locks / unlocks the door in accordance with an electrical signal transmitted from the main body of the media dispenser. The door cannot be manually unlocked from outside of the media cassette.

Owner:ATEC AP CO LTD

Media discharging unit for media dispenser

ActiveUS7464928B2Easy accessAccurate thicknessComplete banking machinesCoin/currency accepting devicesComputer moduleEngineering

The present invention relates to media discharging unit for a media dispenser. The present invention includes a delivery module, which selectively feeds media fed from a media box to a discharge position and a reject position one-by-one using belts and rollers. A stacking module is separable from the delivery module, and collects the media, which are fed by the delivery module, one-by-one upon the rotation of a stacking wheel and then feeds the collected media as a stack at one time. A stack delivery module is separable from the stacking module, and clamps the stacked media, which are collected in the stacking module, and feeds the stacked media to a position where a customer can take the media.

Owner:ATEC AP CO LTD

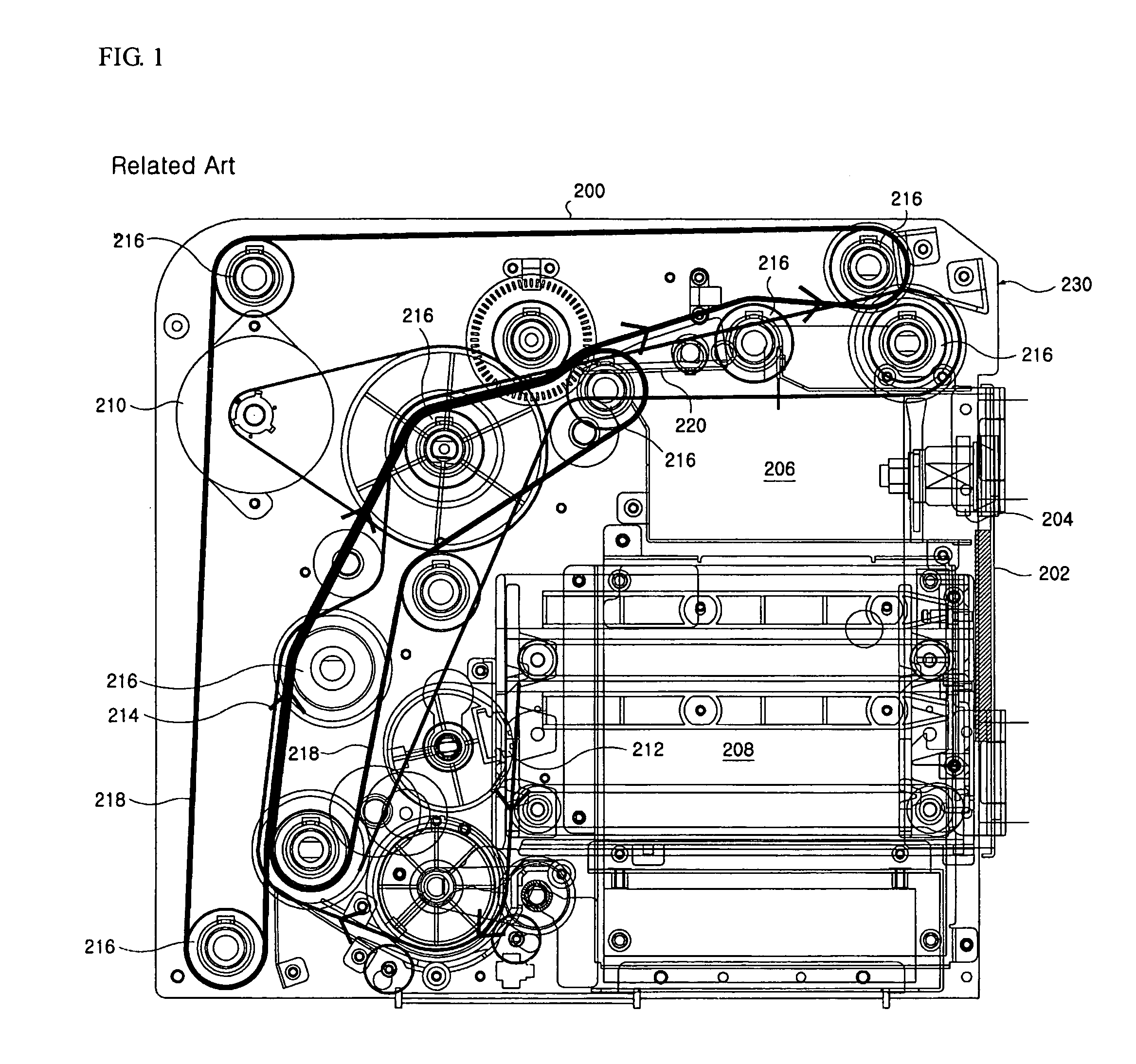

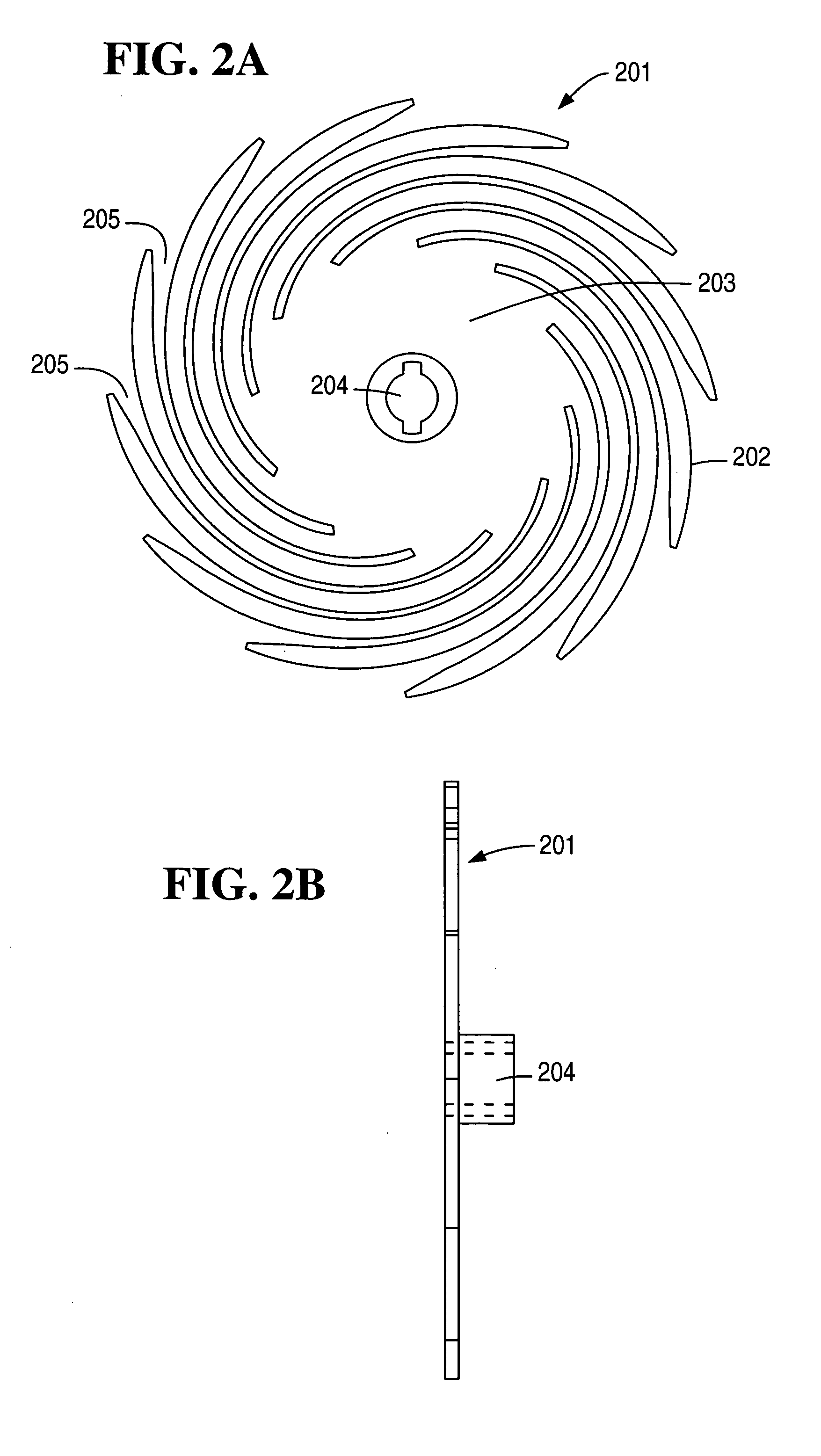

Stacker wheel

InactiveUS20070257427A1Large openingEasy to insertArticle deliveryMedia dispenserBiomedical engineering

The invention relates to a stacker wheel for handling media, suitable for use in a media dispenser within an automated teller machine. The stacker wheel comprises a plurality of curved tines attached to a central hub. Each curved tine has a thickness that reduces with increased distance from the central hub over substantially the whole length of the tine, such that the spacing between adjacent tines increases with increased distance from the central hub over substantially the whole length of the tine.

Owner:NCR CORP

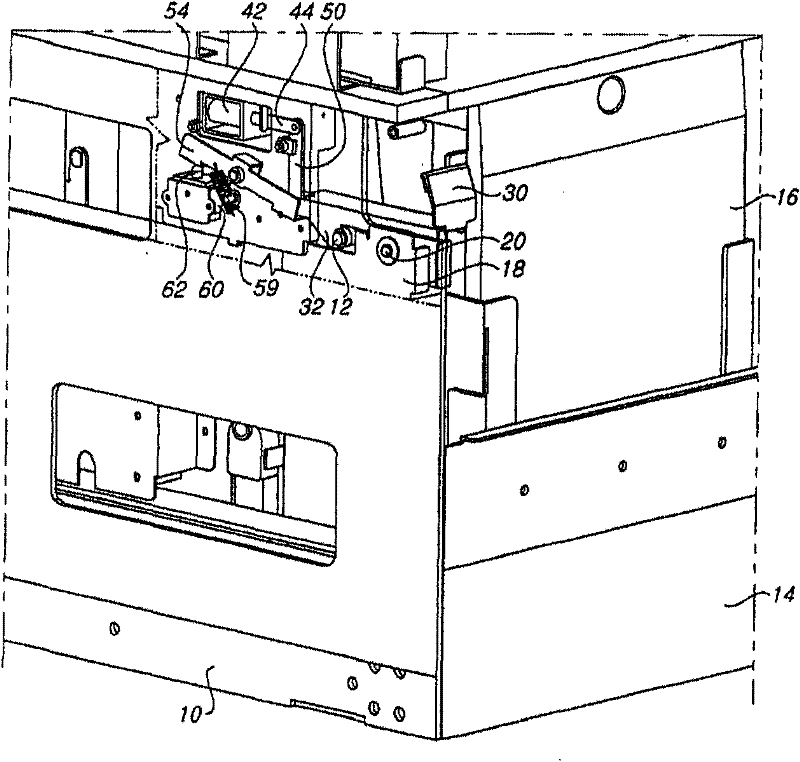

Locking device for boxes

ActiveCN102265313AEasy to operateNo troubleComplete banking machinesCoin/currency accepting devicesEngineeringMedia dispenser

The present invention relates to a locking device for a cassette box where medium cassettes are housed. The cassette box locking device of the present invention comprises: a locking pin which is provided on one side of a main body in order to lock a cassette box where medium cassettes are housed; a release lever which is rotatably provided on the cassette box and is selectively latched onto the locking pin; and a locking means whereby the release lever is latched onto the locking pin while an automatic media supply mechanism is operating, and whereby the release lever releases the latching of the locking pin if power supply to the automatic media supply mechanism is cut off. The present invention, which is configured as described hereinabove, has the advantageous effect that it allows stable operation without the worry of disruption occurring in the automatic media supply mechanism, and that, even if an abnormality does occur in a medium cassette or the like and the power source is disconnected, repairs can be effected by detaching only the medium cassette from the automatic media supply mechanism and without taking apart the automatic media supply mechanism.

Owner:ATEC AP CO LTD

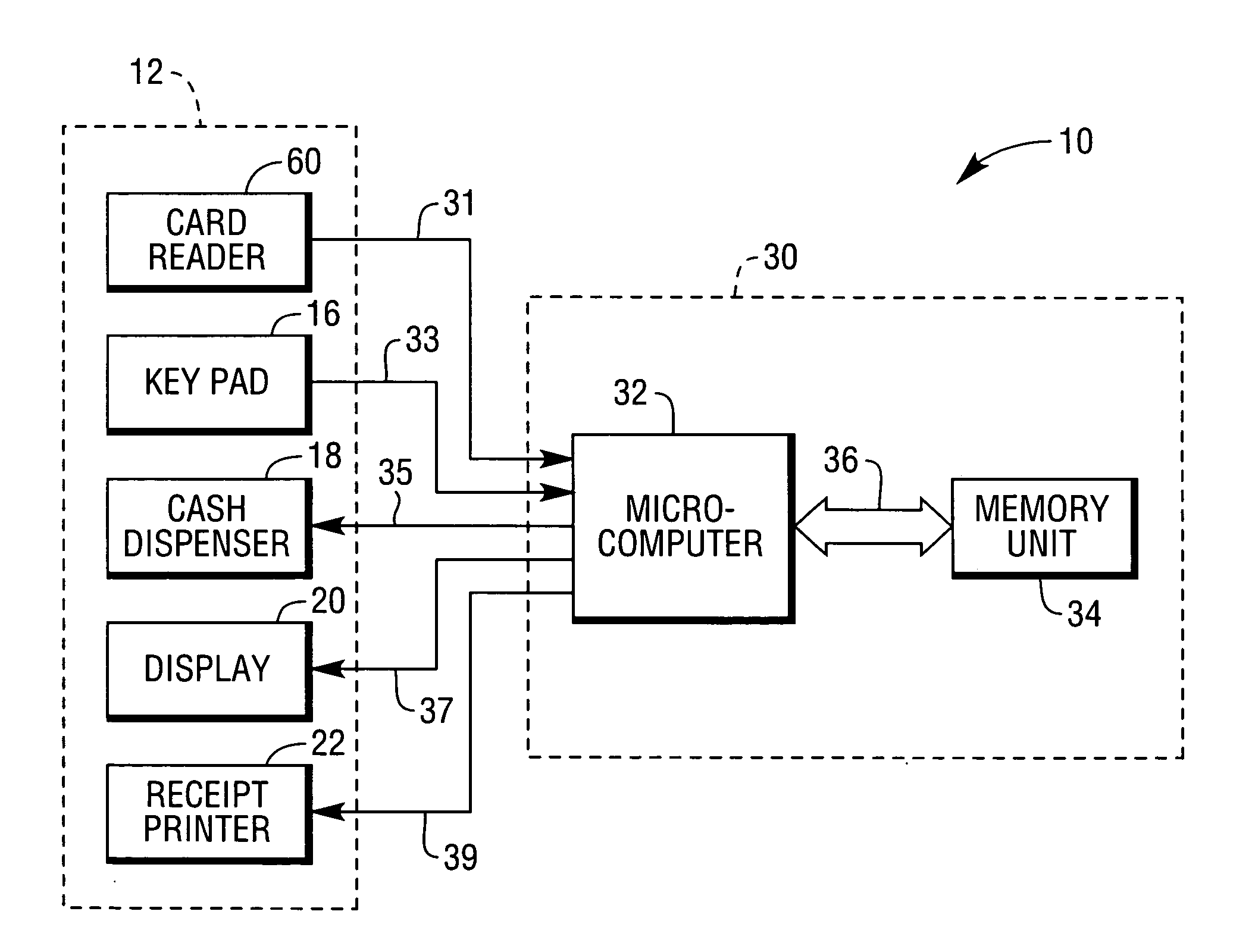

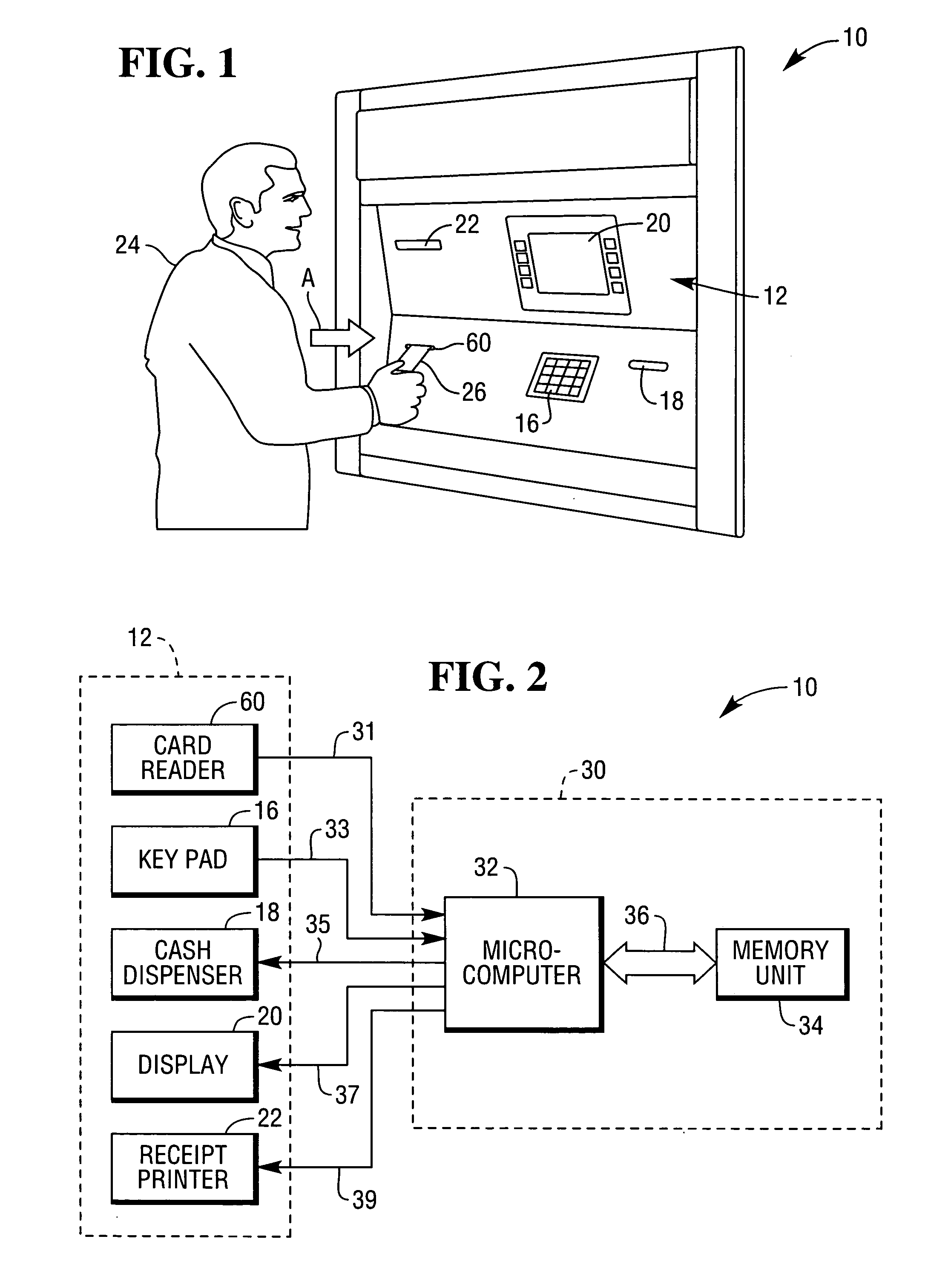

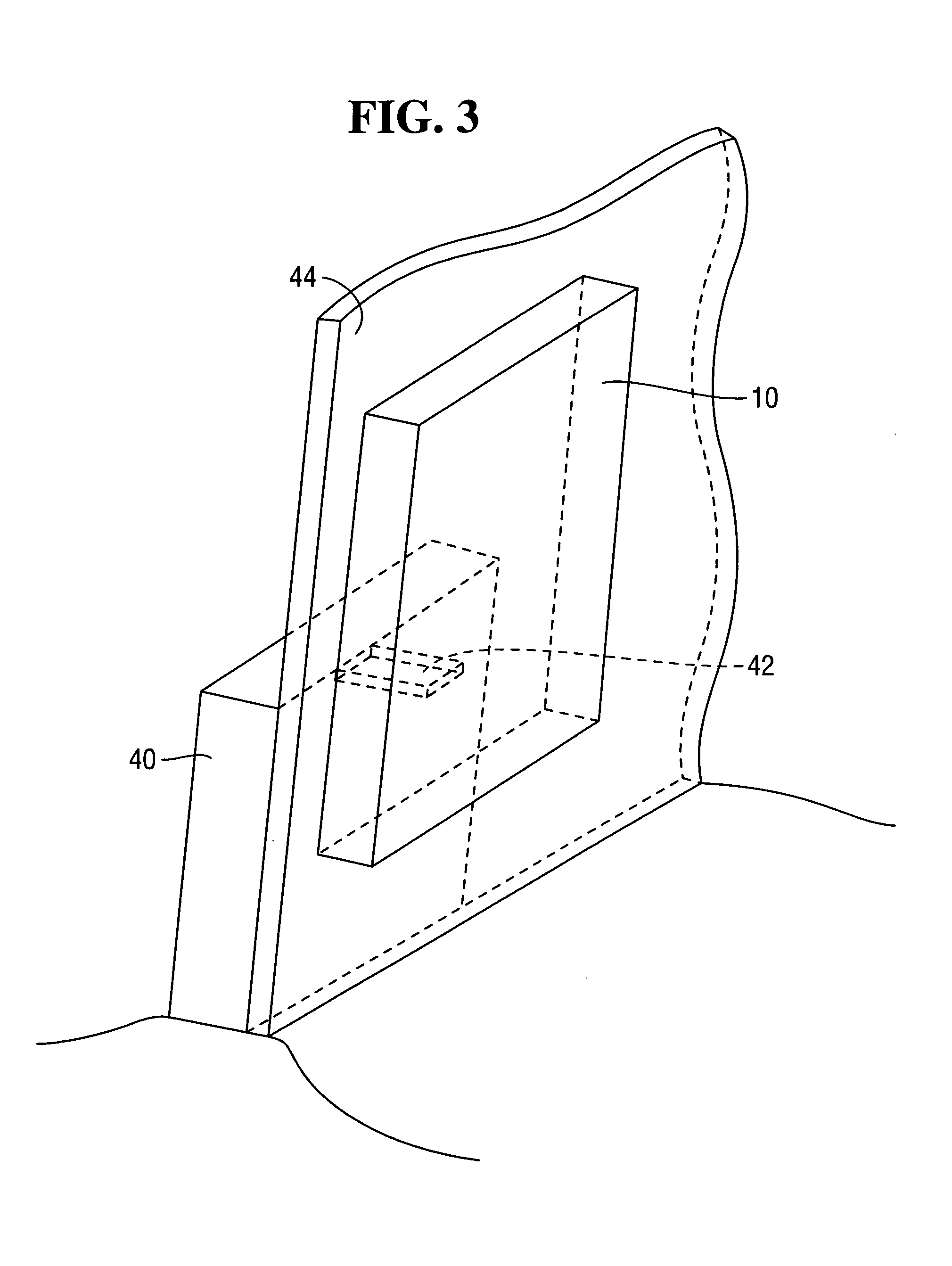

Automated teller machine

An ATM comprises a) an ATM head unit in the form of a housing within which are housed user interface components of an ATM; and b) a security enclosure within which is located an ATM media dispenser. The security enclosure and the head unit are discrete physically separate units, which are coupled so that media from the security enclosure can be dispensed to a user through interaction with the head unit, when in use.

Owner:NCR CORP

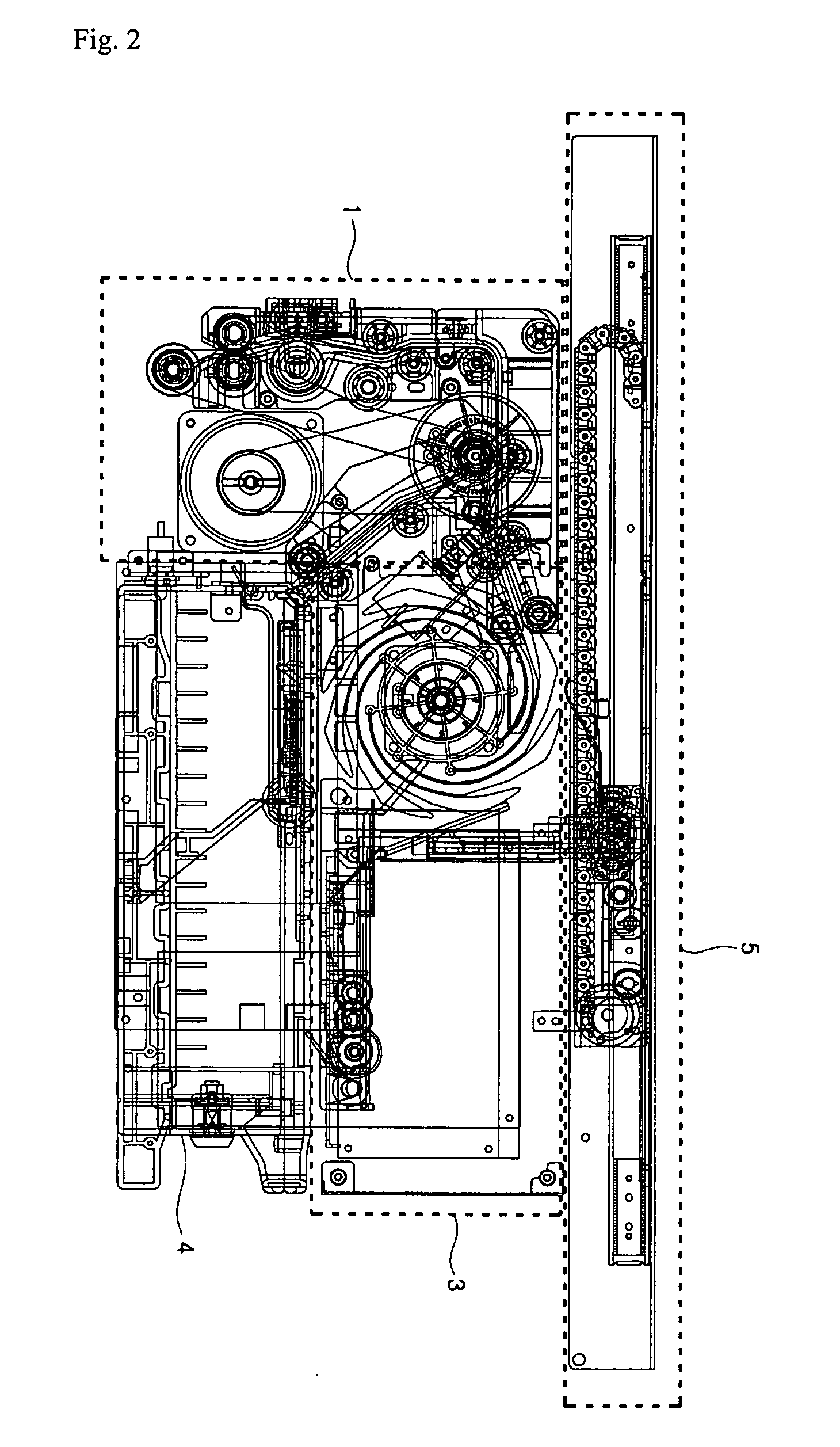

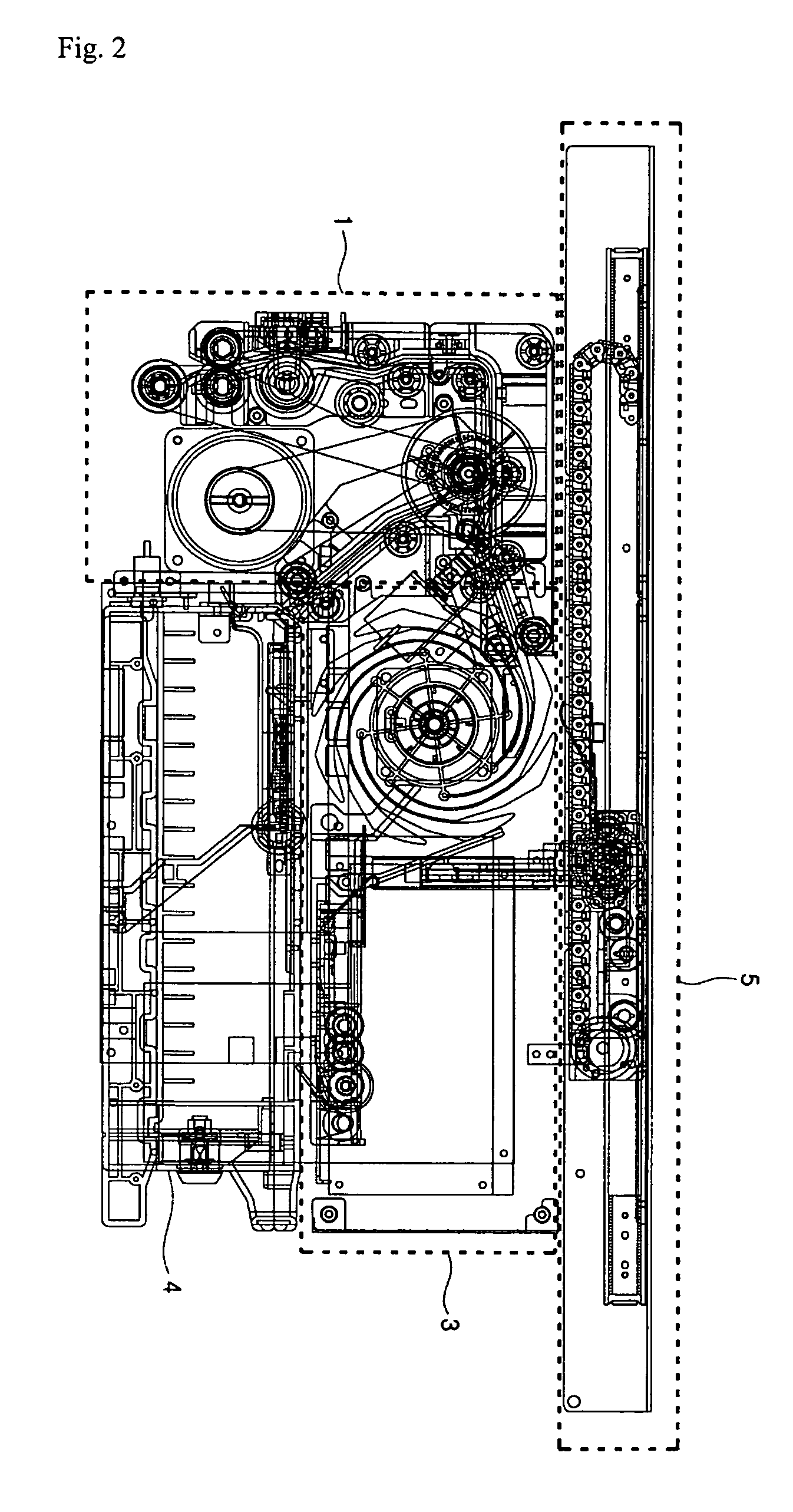

Stacking module of media dispenser and control method thereof

ActiveUS7651093B2Simple structureEasy maintenanceComplete banking machinesPile receiversDrive motorMedia dispenser

The present invention relates to a stacking module of a media dispenser and a control method thereof. According to the present invention, there is provided a stacking module of a media dispenser. The stacking module comprises: stacking wheels rotated by a driving source to rotate the media fed from the delivery module with the media inserted between tangent wings of outer peripheral surfaces of the stacking wheels one by one; a separation plate for separating the media from the stacking wheels and guiding the separated media; a stacking plate on which the media separated from the separation plate are erected one by one; a shuttle member rotatably installed on the stacking plate and including a push bar for pushing the media erected on the stacking plate toward the stacking wheels; and a driving plate moved by an additional driving source to selectively drive the stacking plate and the shuttle member. The stacking wheels and the driving source are provided between guide plates installed to face each other with a predetermined spacing therebetween; and the separation plate, the stacking plate, the shuttle member, and the driving plate are provided on a stacking base supported in the guide plates. In the present invention, since most of the components of the stacking module are provided on the stacking base, it is easy to repair the media dispenser. Further, since the media are collected on the stacking module and delivered to the customer at a time, it is easy for the customer to take out the media. Furthermore, since the stacking module is designed so that the one driving motor drives a plurality of the components, the number of the parts can be reduced.

Owner:ATEC AP CO LTD

Media support apparatus for media cassette of automatic media dispenser

ActiveUS20050184444A1Easy to adjustComplete banking machinesCoin/currency accepting devicesHorizontal pitchMedia dispenser

A media support apparatus for a media cassette of an automatic media dispenser includes a base plate having a guide piece which is provided with a guide slot. A link mechanism has at least one connection pin, which is moved along the guide slot, and two connection link plates, the height of which, relative to the base plate, can be adjusted. A media seat is seated on each connection link plate. The horizontal spacing between the media seats can be adjusted. The apparatus is advantageous in that a single media cassette can be adapted to supply media of various sizes.

Owner:ATEC AP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com