Combustion chamber

A combustion chamber and combustion cavity technology, which is applied in the field of combustion chambers, can solve problems such as installation costs, operation downtime costs, high maintenance and repair costs, and labor-intensive assembly work, and achieve small cooling medium pressure loss, low manufacturing costs, and reduced Effect of small cooling medium pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

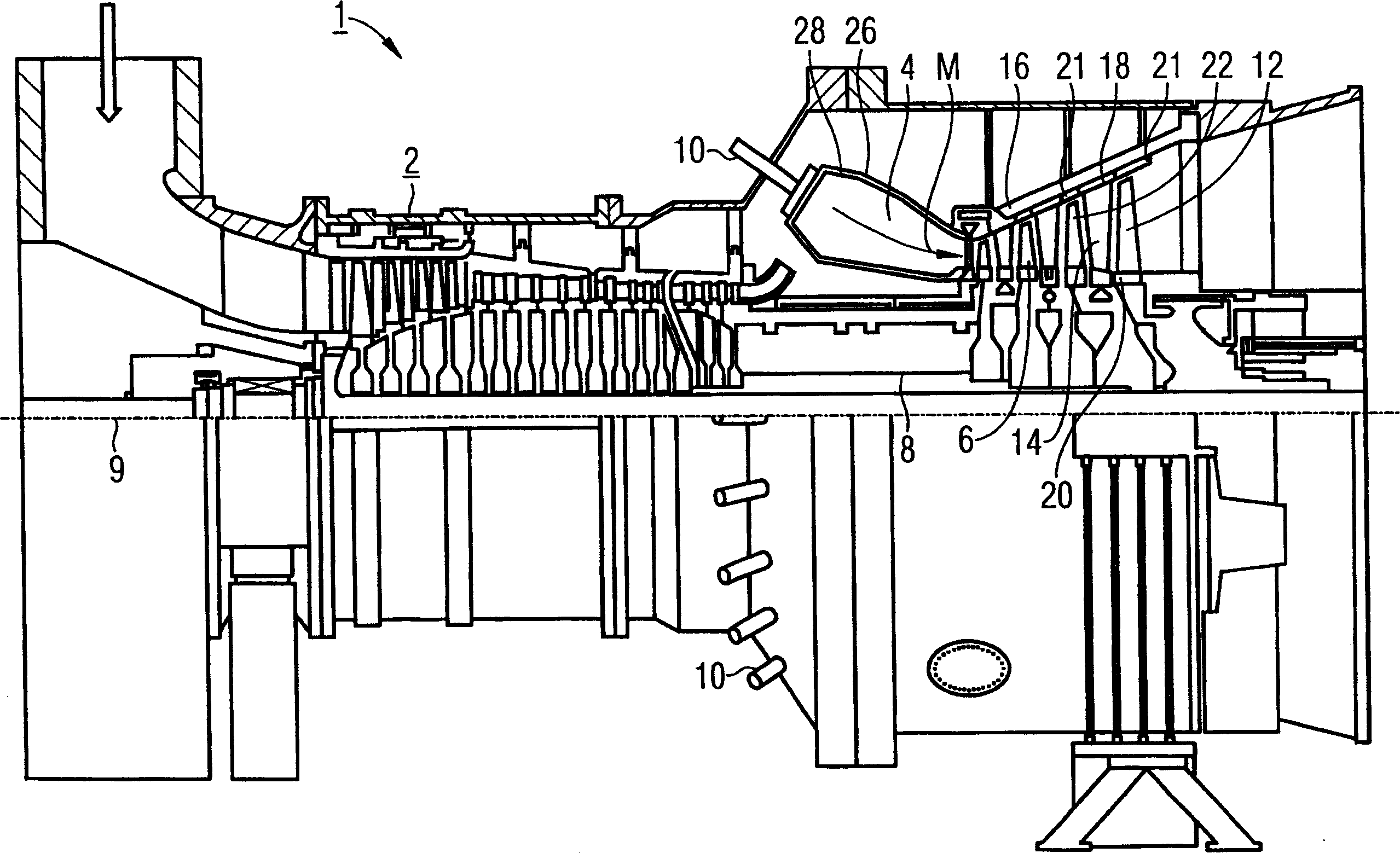

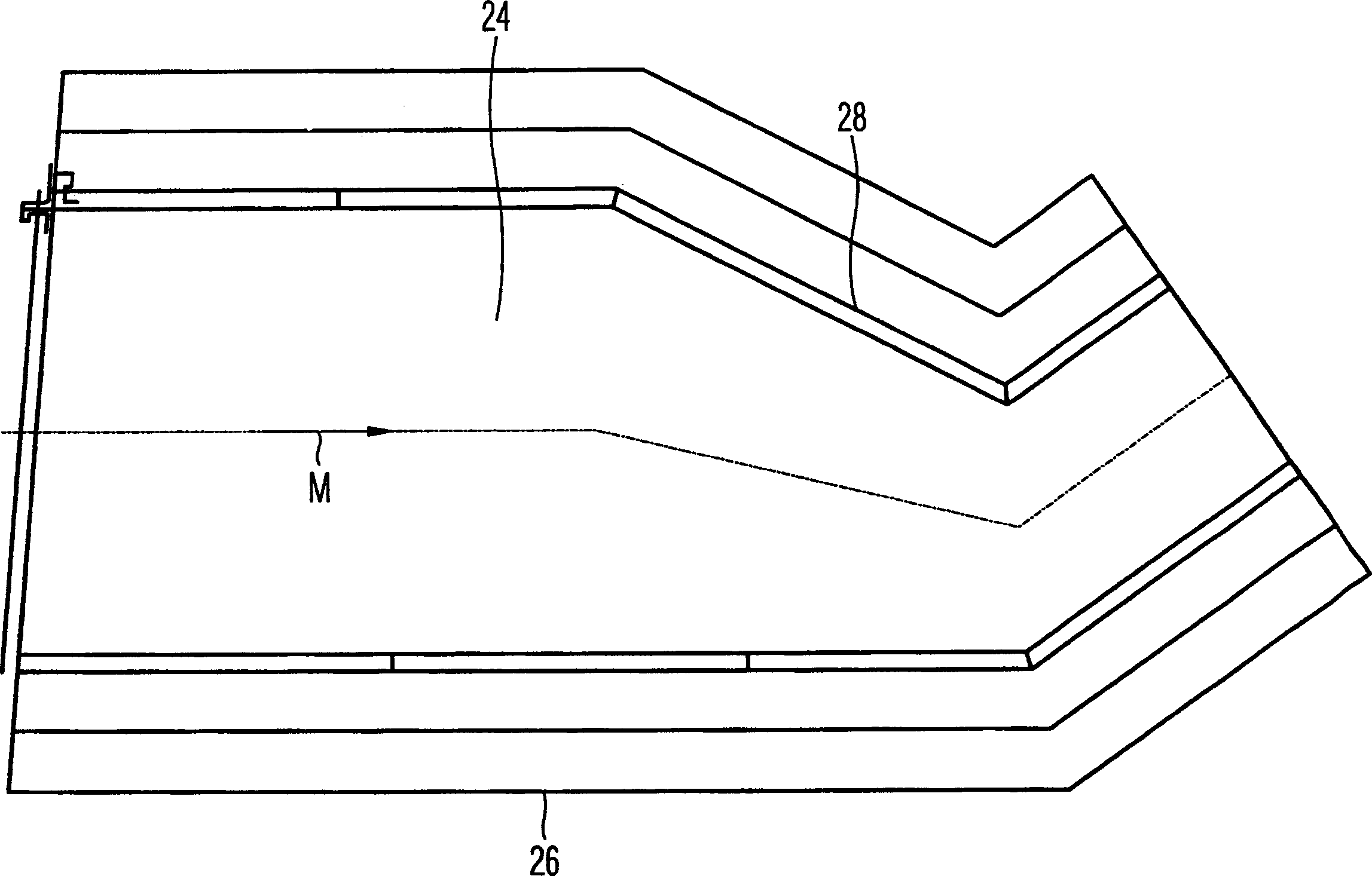

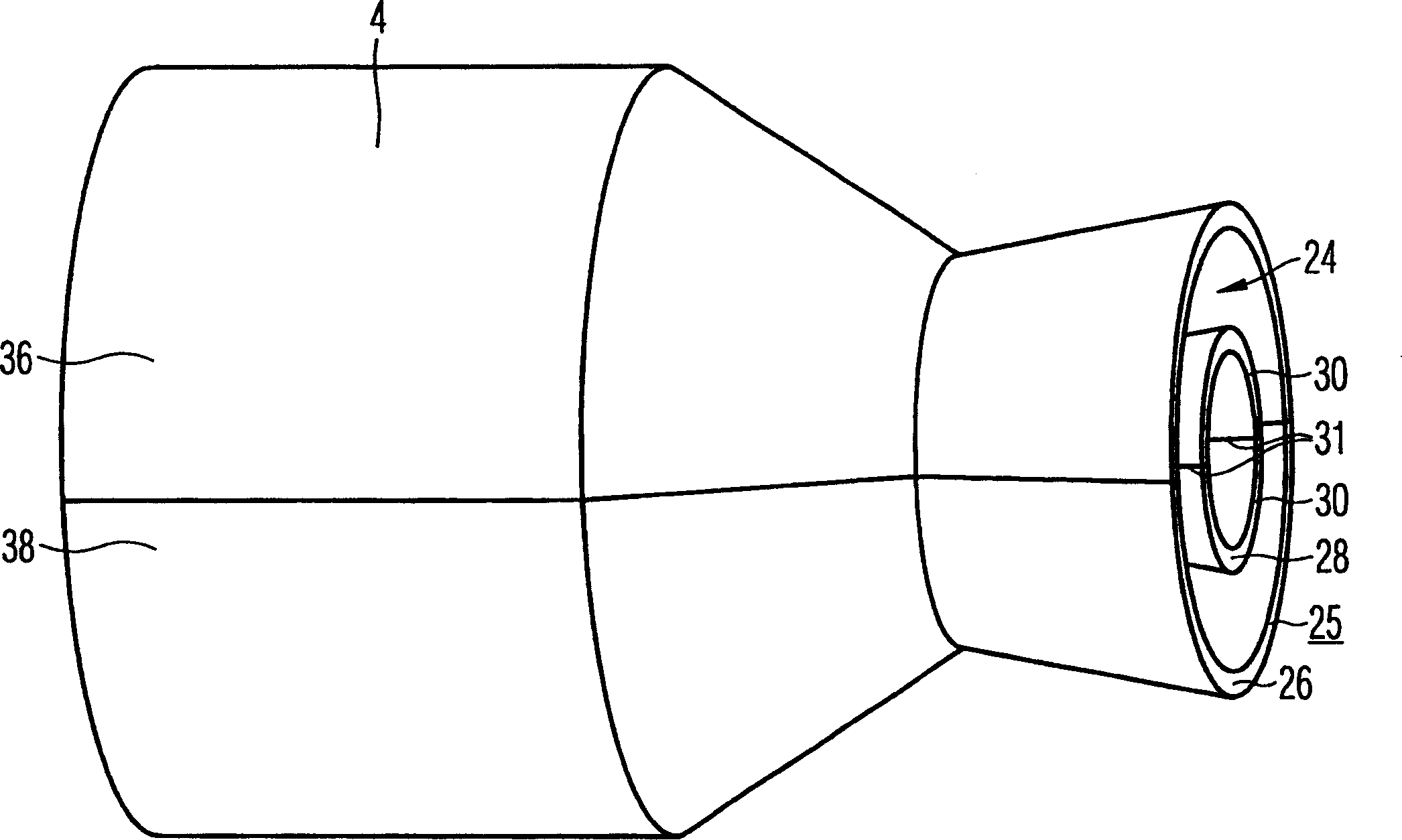

[0029] figure 1 The gas turbine 1 shown has a compressor 2 for providing combustion air, a combustion chamber 4 and a turbine 6 for driving the compressor 2 and a generator or working machine not shown in the figure . Here, the turbine 6 and the compressor 2 are mounted on a common turbine shaft 8 , also referred to as the turbine rotor, to which the generator or power machine is connected. And the turbine shaft is mounted rotatably about its axis 9 . The combustion chamber 4, designed in the form of an annular combustion chamber, is equipped with burners 10 for burning a fuel in liquid or gaseous form.

[0030] The turbine 6 has rotatable rotor blades 12 connected to the turbine shaft 8 . The rotor blades 12 are mounted in a circle on the turbine shaft 8 and thus form rotor blade groups. In addition, the turbomachine 6 also includes stationary guide vanes 14 which are likewise fastened in the inner housing 16 of the turbomachine 6 in the shape of a circle while forming a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com