Patents

Literature

420results about How to "Reduced flow area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

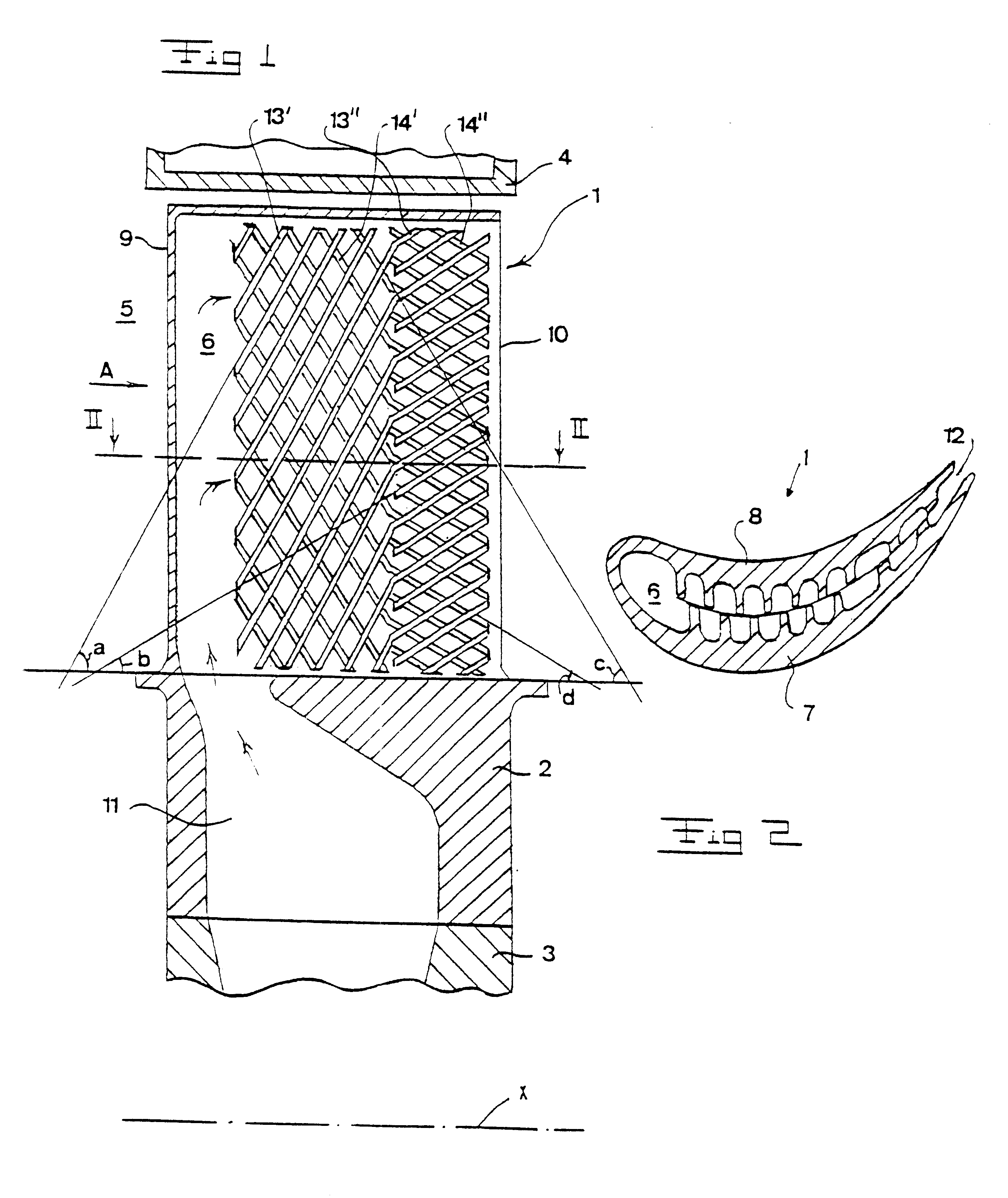

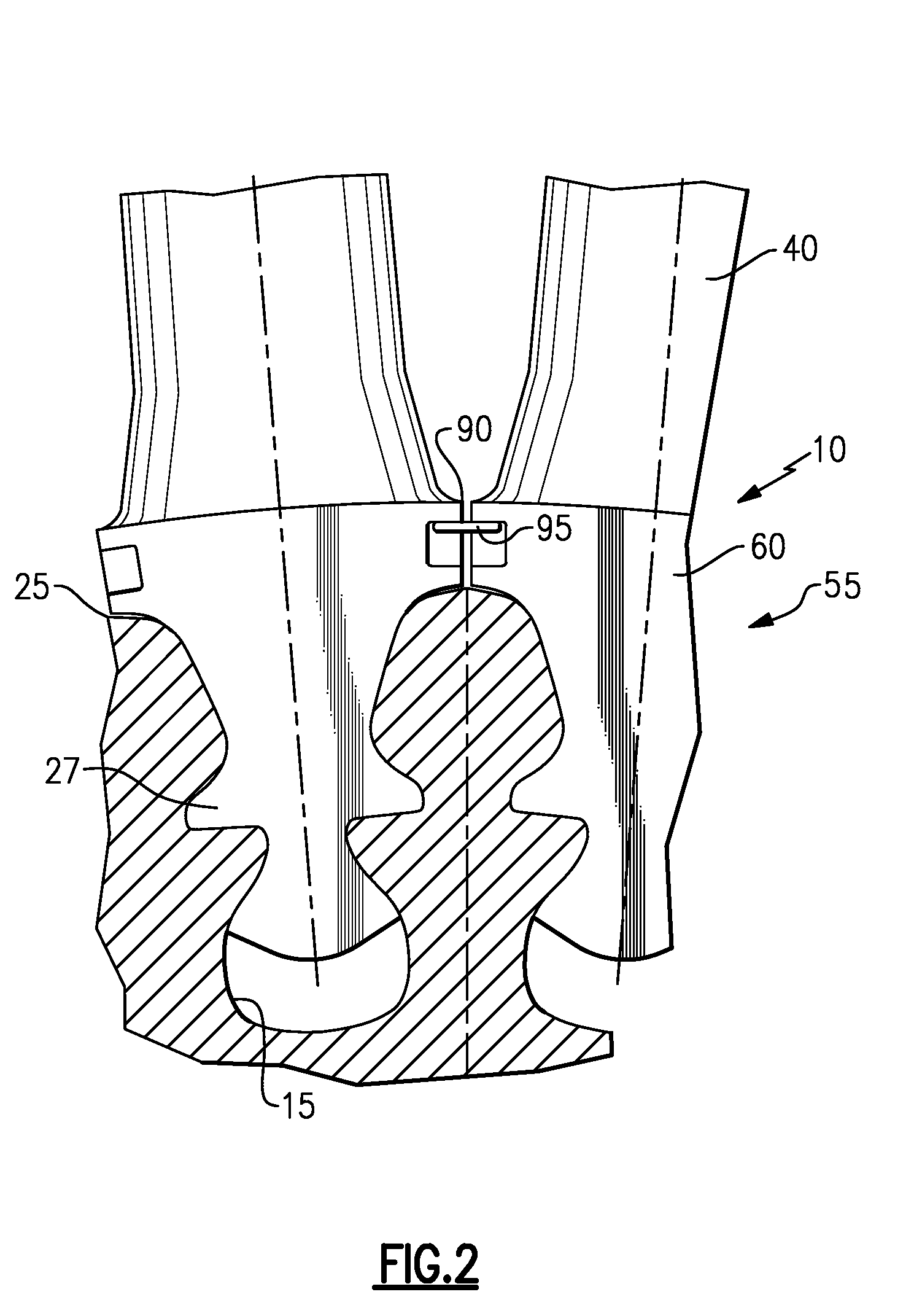

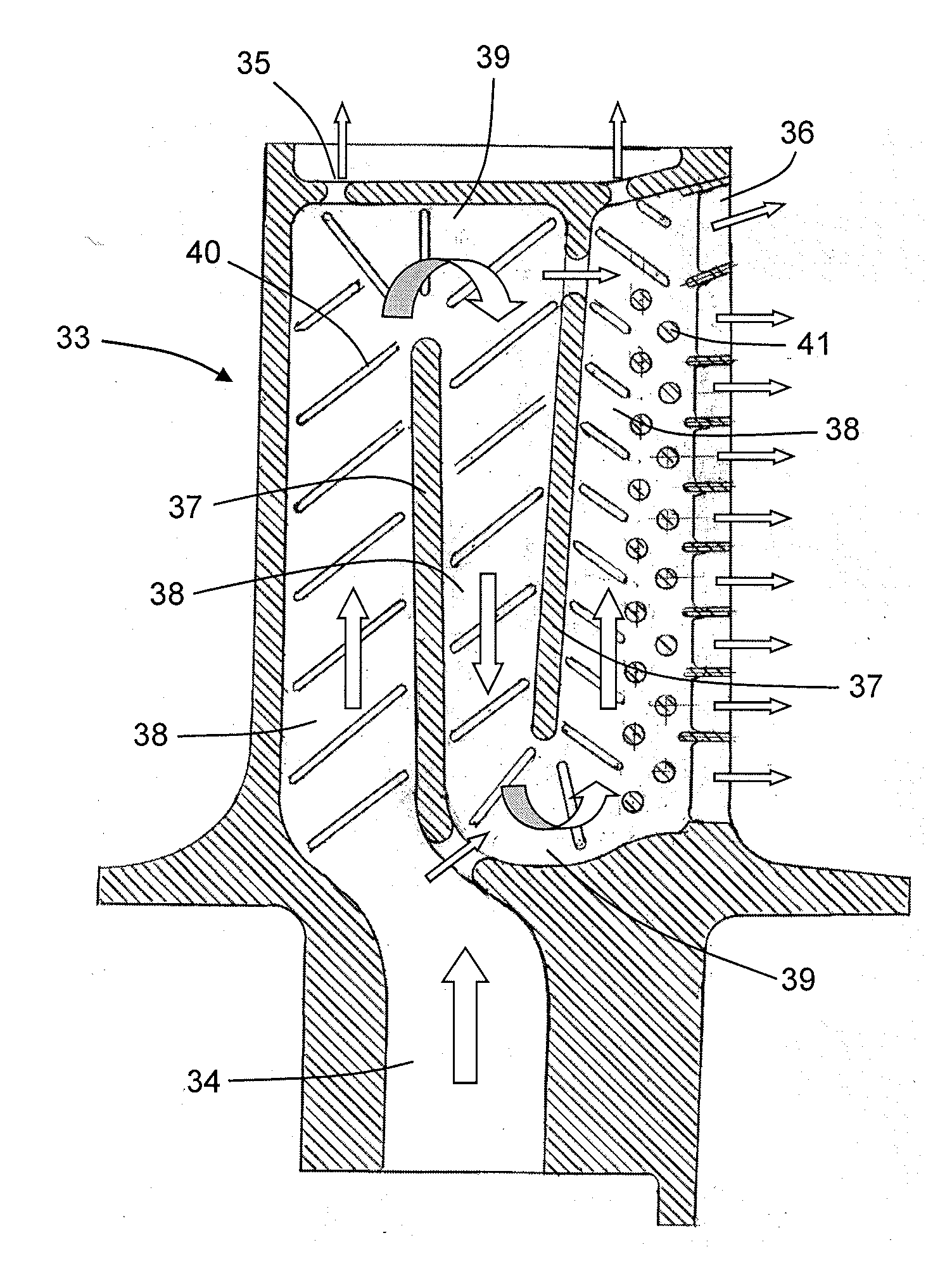

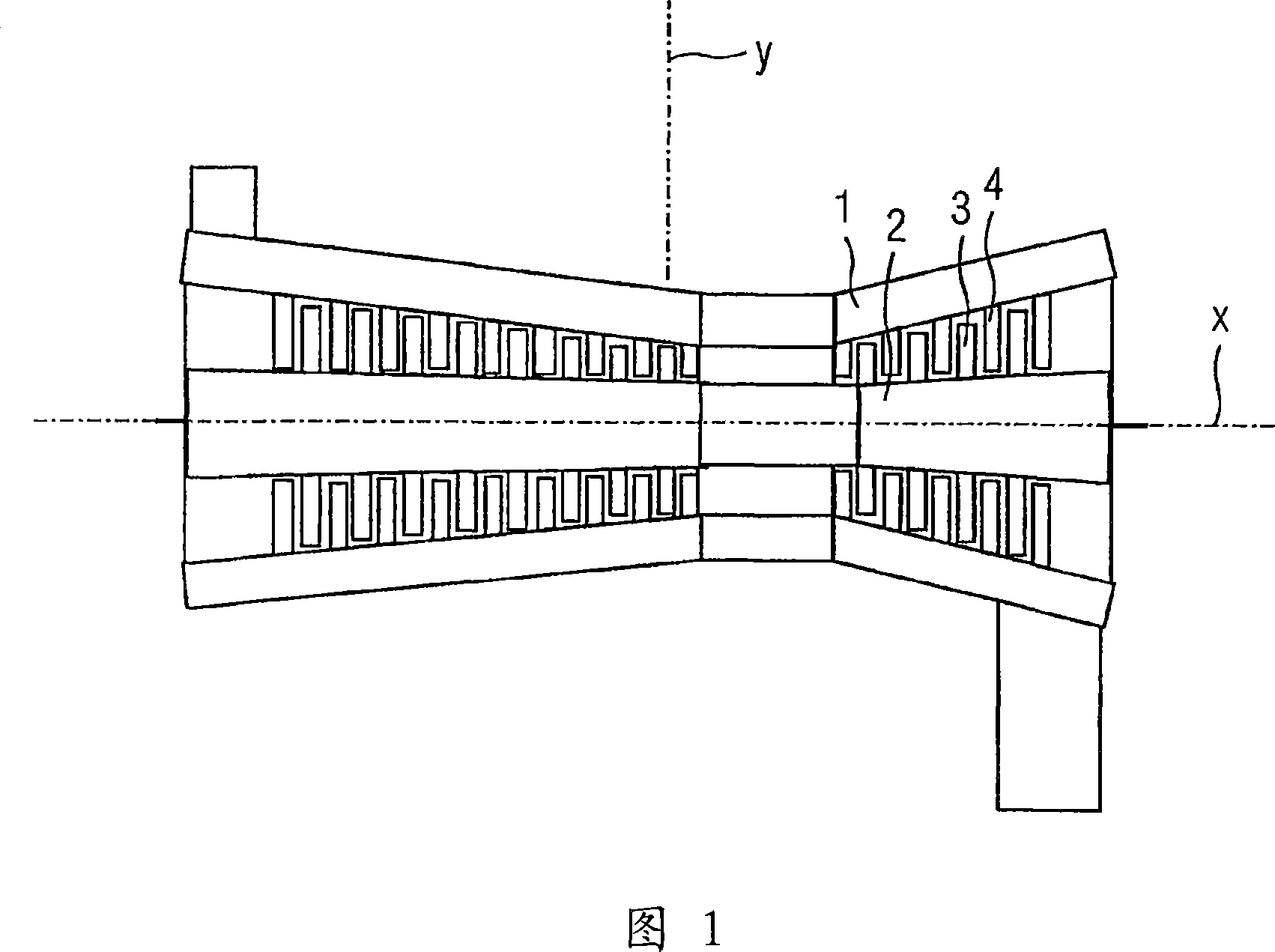

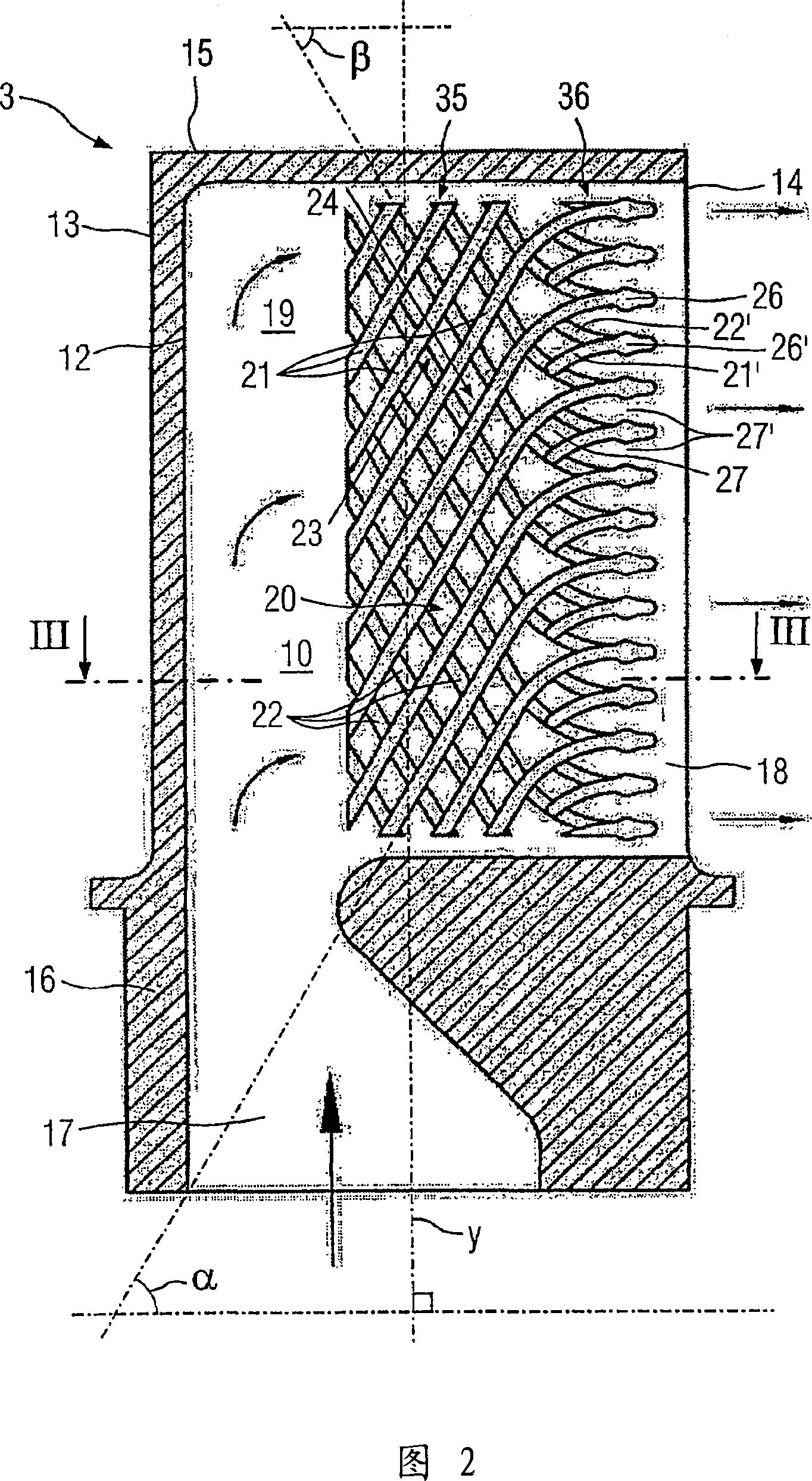

Component for a gas turbine

InactiveUS6382907B1Improve cooling effectIncreases stiffness thus strength reliabilityPump componentsEngine fuctionsRotary machineInterior space

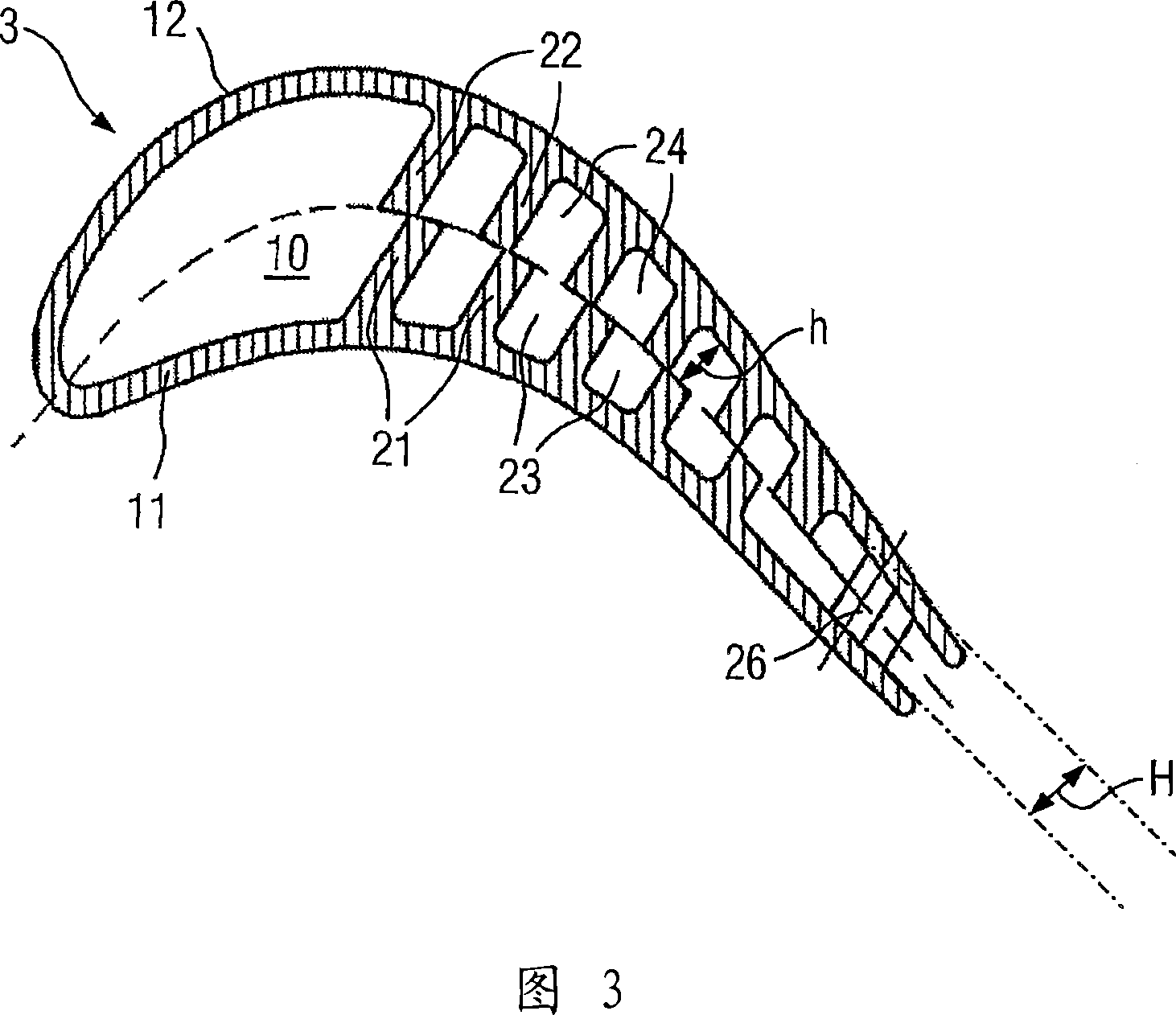

The invention refers to a component defining a blade or a vane for a rotary machine having a rotor rotatable about an axis. The component includes an inner space forming a passage for a cooling fluid between first and second walls. First ribs project from the fist wall and extend essentially in parallel to each other to form fist channels for the fluid from a leading part of the inner space to a trailing part of the space. The first ribs extend in a first direction forming a first angle of inclination to the axis in the leading part and in a second direction forming a second angle of inclination to the axis in the trailing part. The first angle is greater than the second angle.

Owner:SIEMENS AG

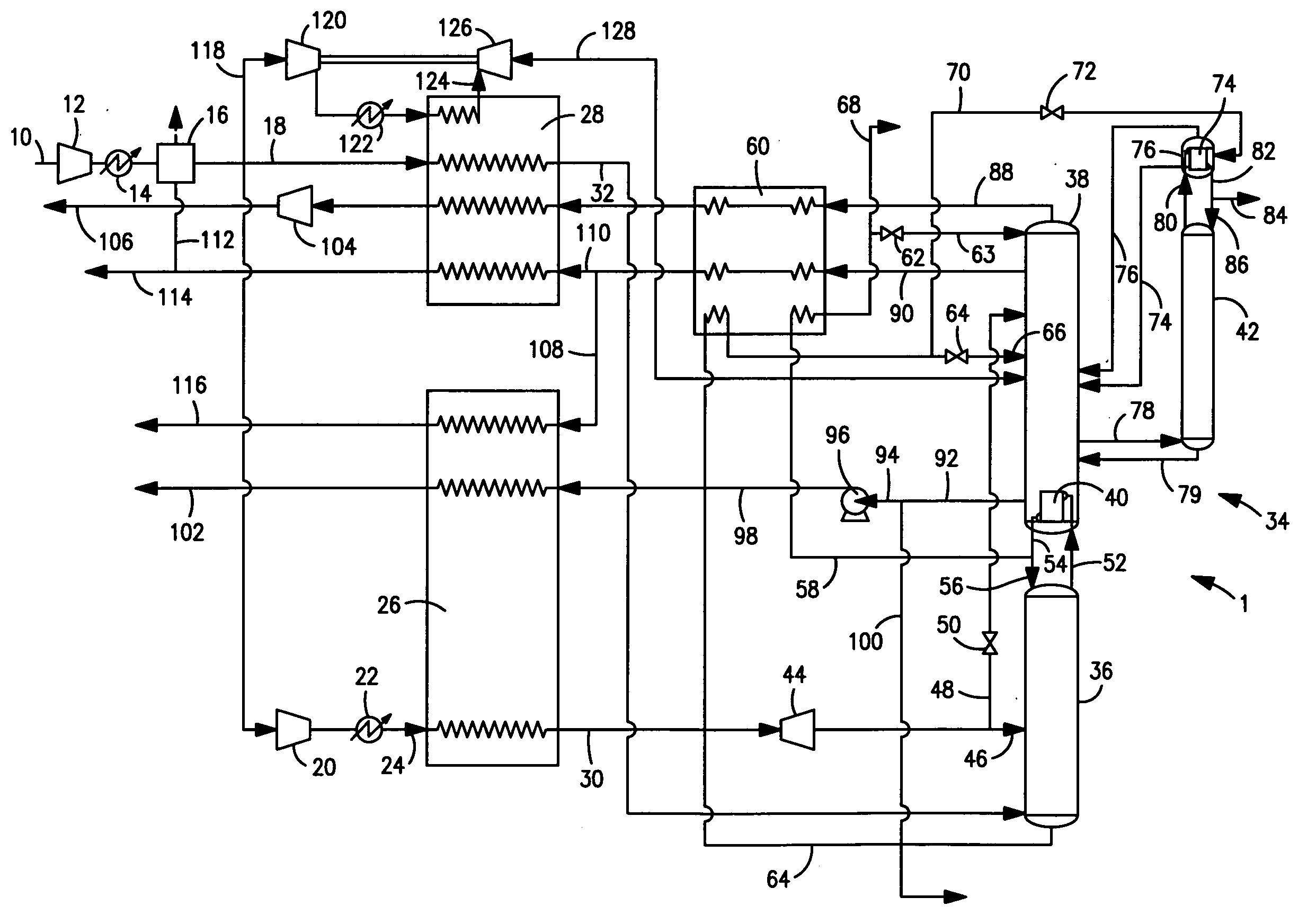

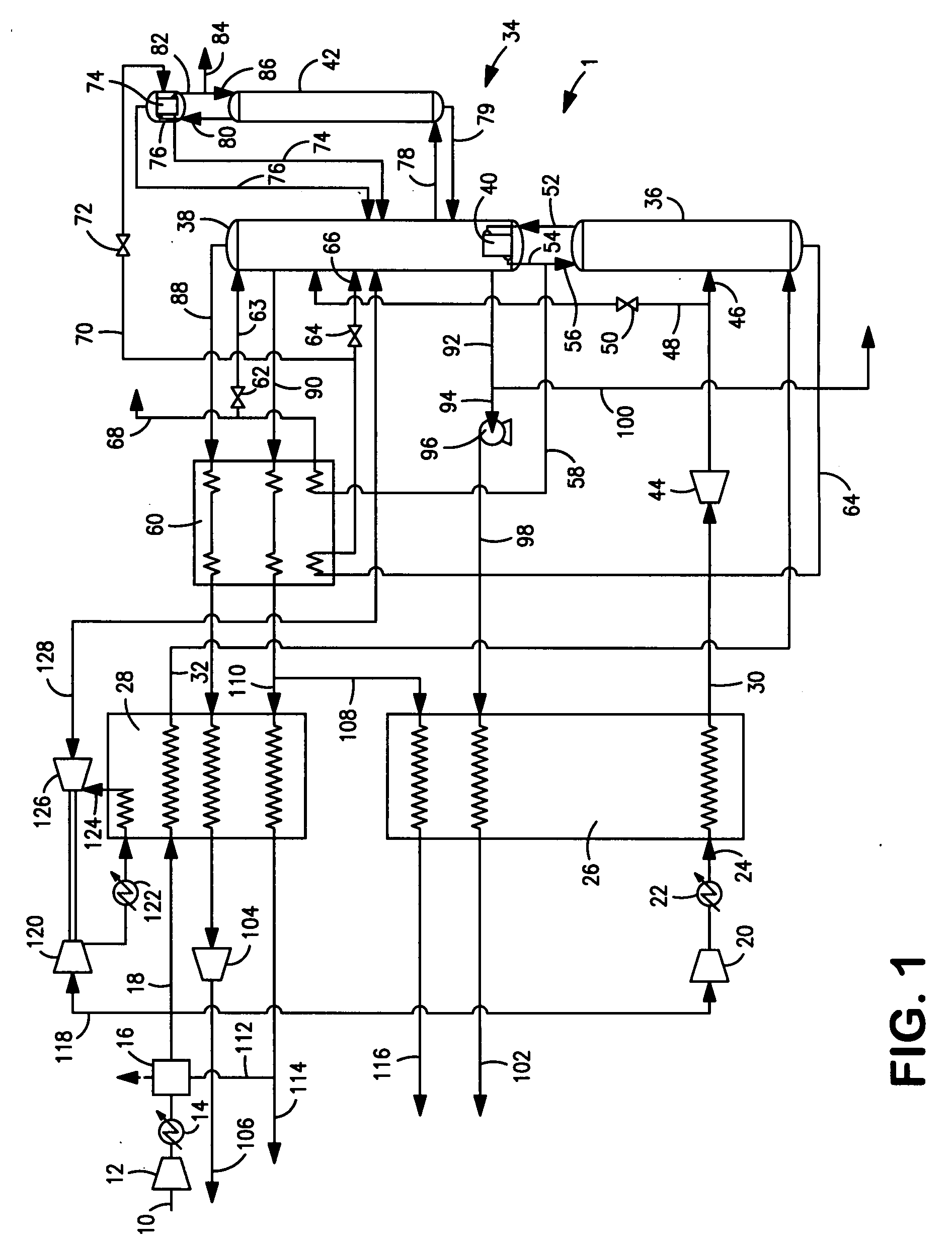

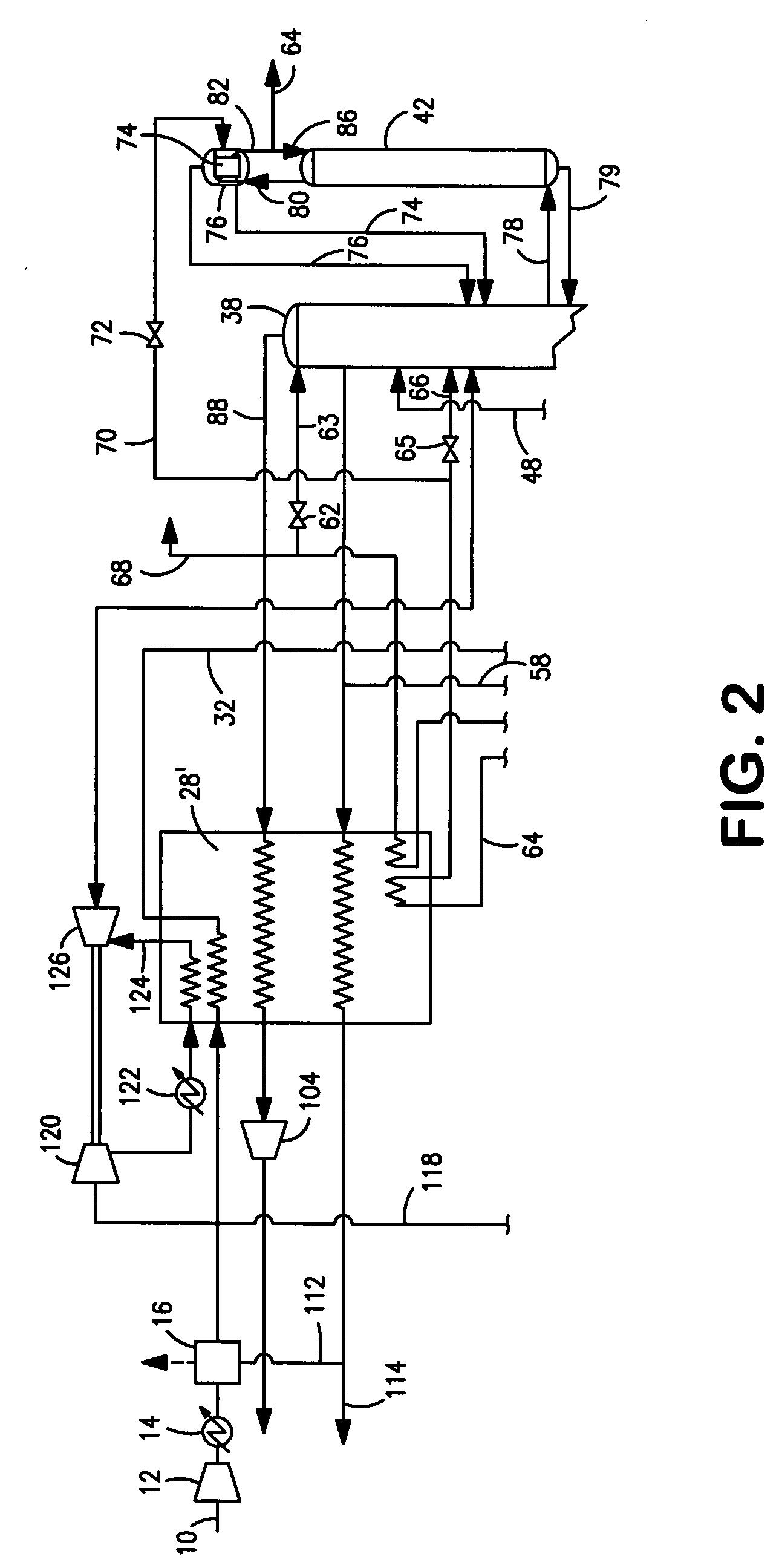

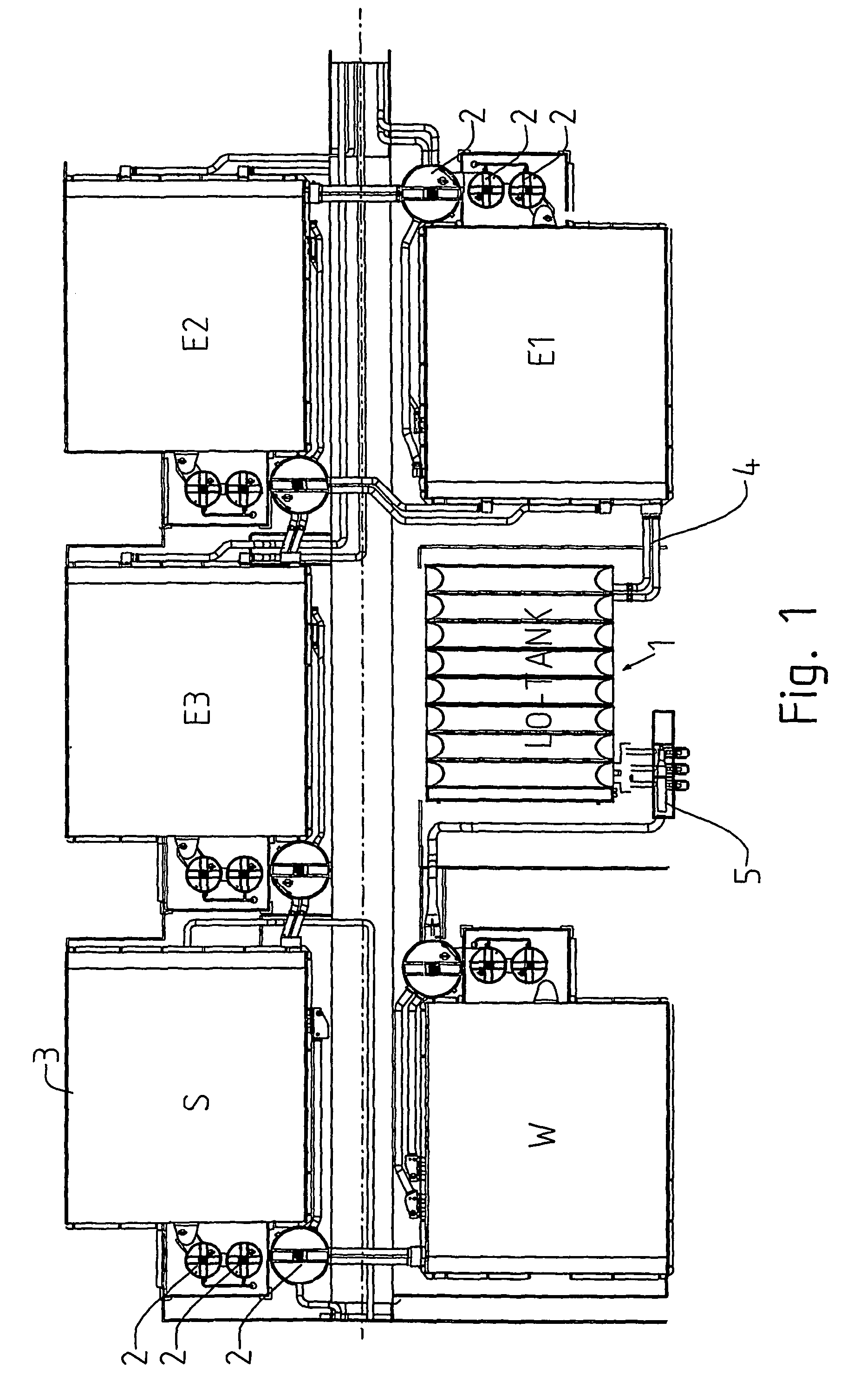

Air separation method and apparatus

InactiveUS20080307828A1Reduced flow areaHigher cross-sectional flow areaSolidificationLiquefactionLiquid productNitrogen

A compressed air stream is cooled to a temperature suitable for its rectification within a lower pressure heat exchanger and a boosted pressure air stream is liquefied or converted to a dense phase fluid within a higher pressure heat exchanger in order to vaporize pumped liquid products. Thermal balancing within the plant is effectuated with the use of waste nitrogen streams that are introduced into the higher and lower pressure heat exchangers. The heat exchangers are configured such that the flow area for the subsidiary waste nitrogen stream within the higher pressure heat exchanger is less than that would otherwise be required so that the subsidiary waste nitrogen streams were subjected to equal pressure drops in the higher and lower pressure heat exchangers. This allows the higher pressure heat exchanger be fabricated with a reduced height and therefore a decrease in fabrication costs.

Owner:PRAXAIR TECH INC

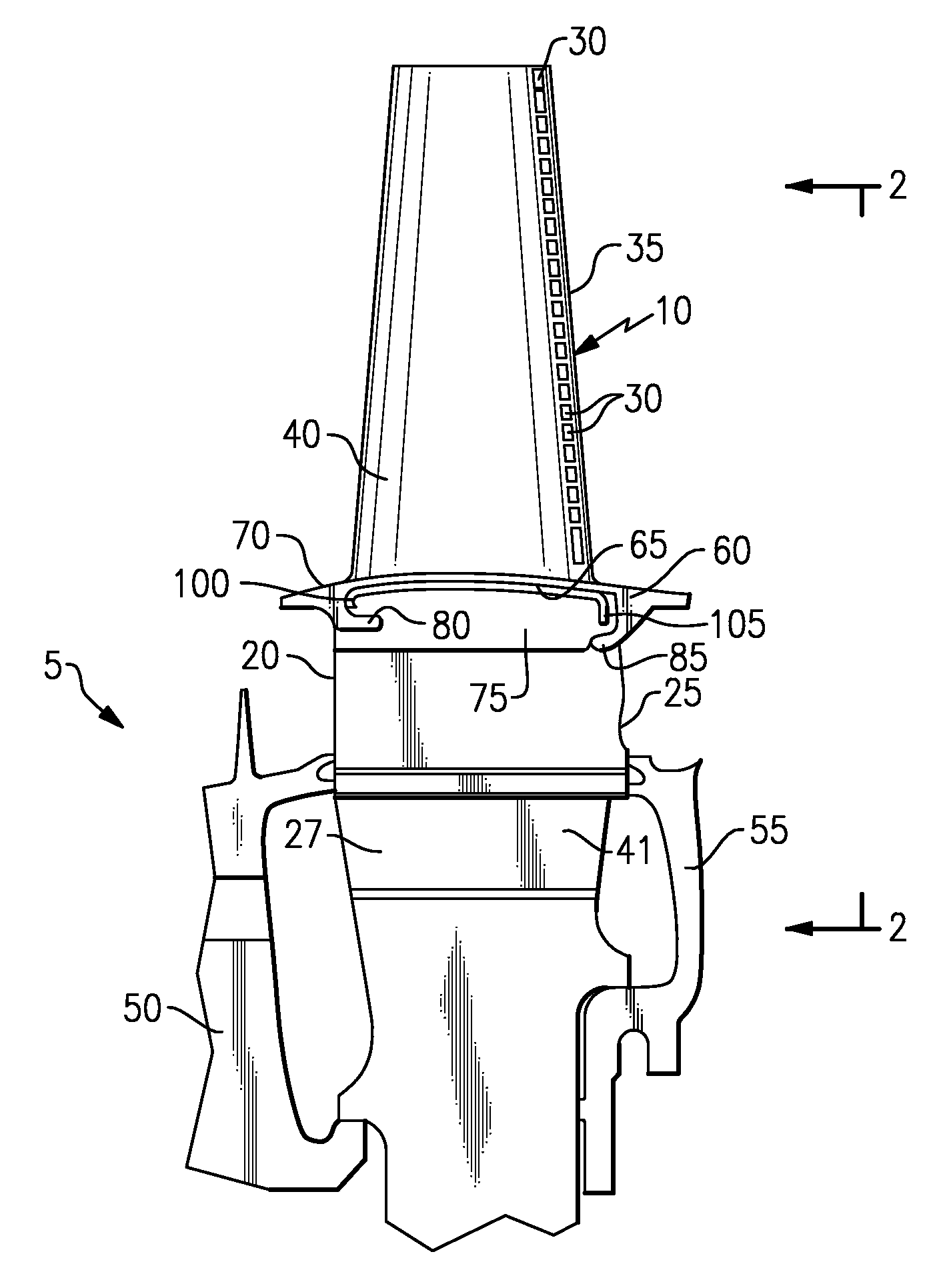

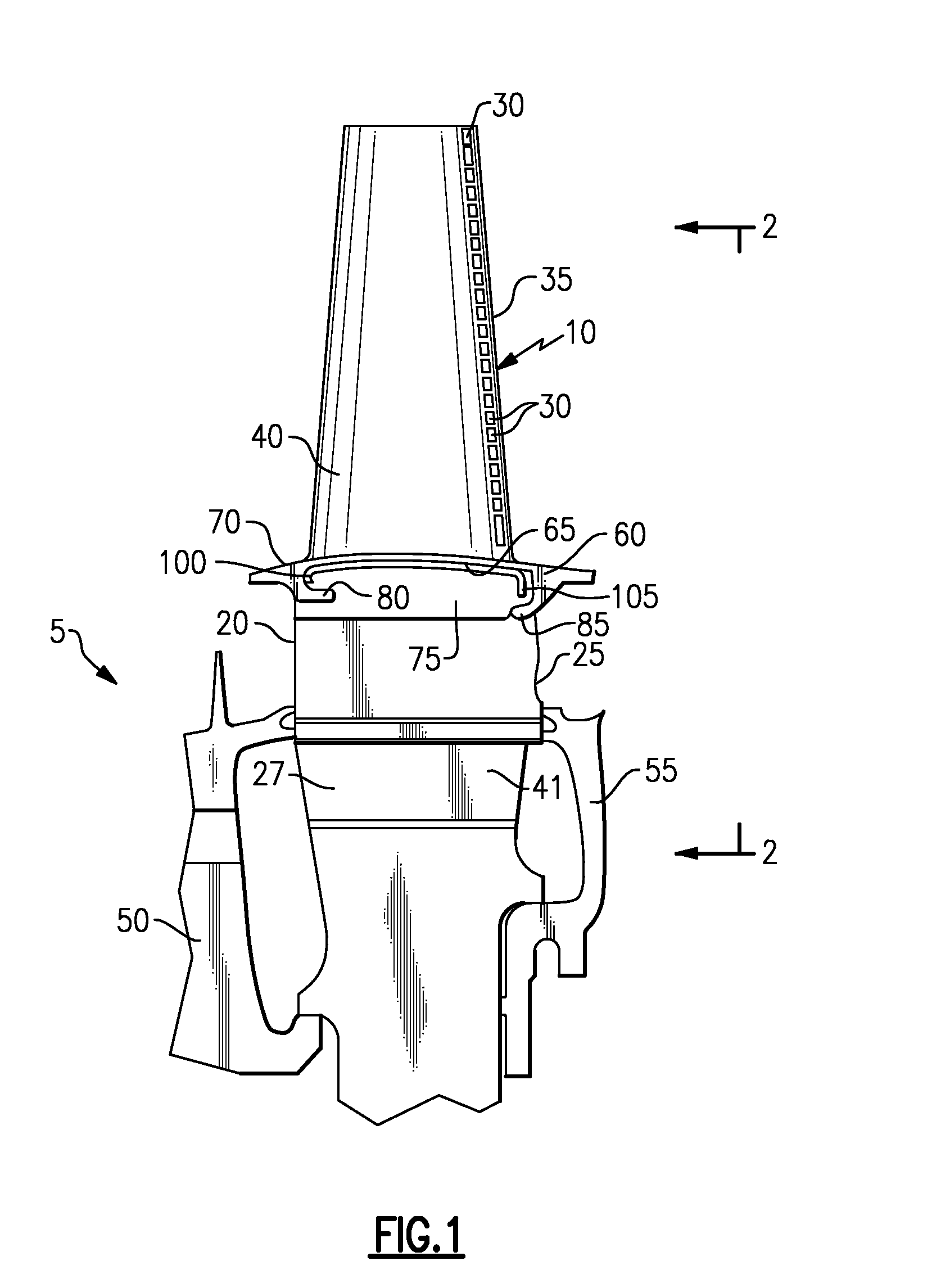

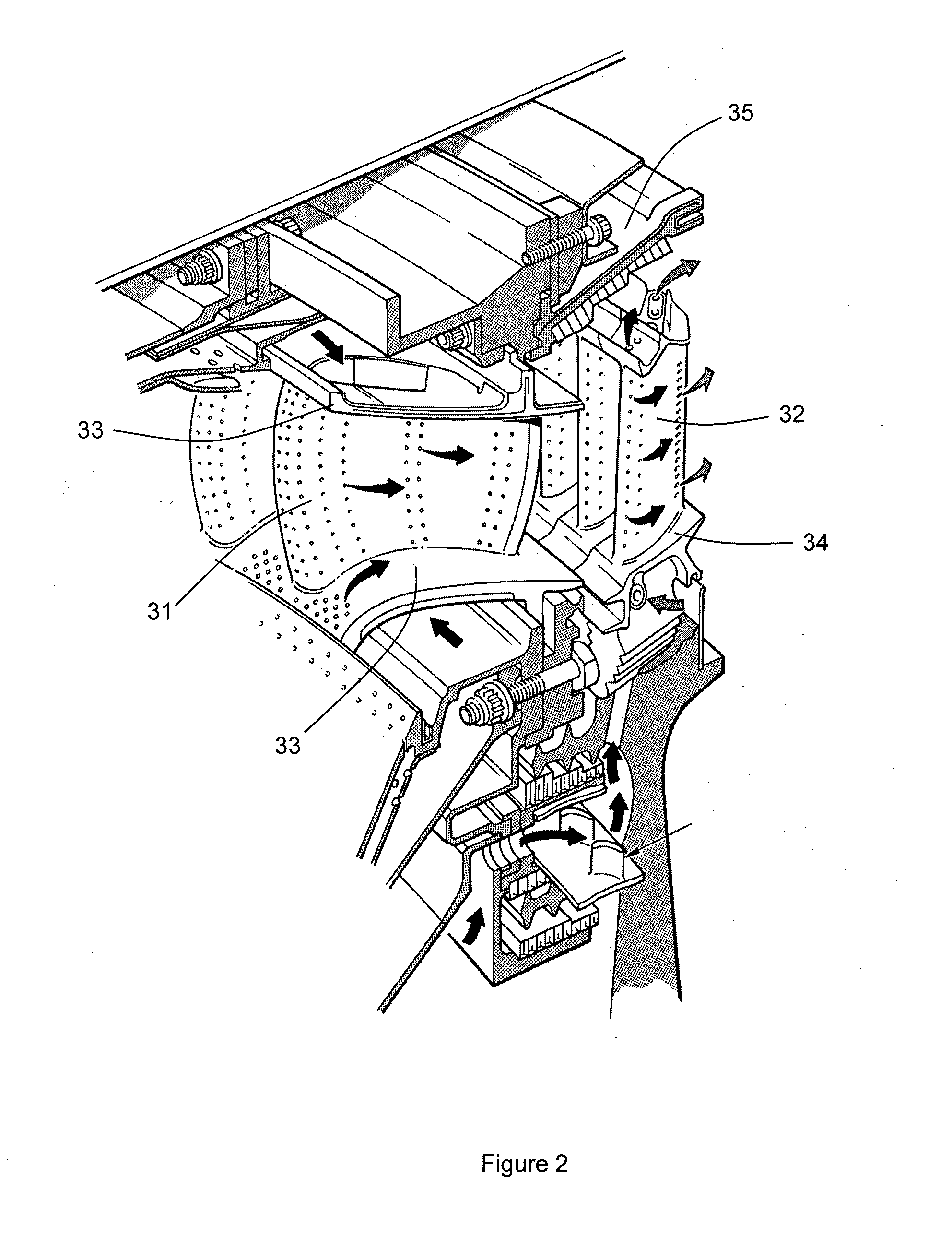

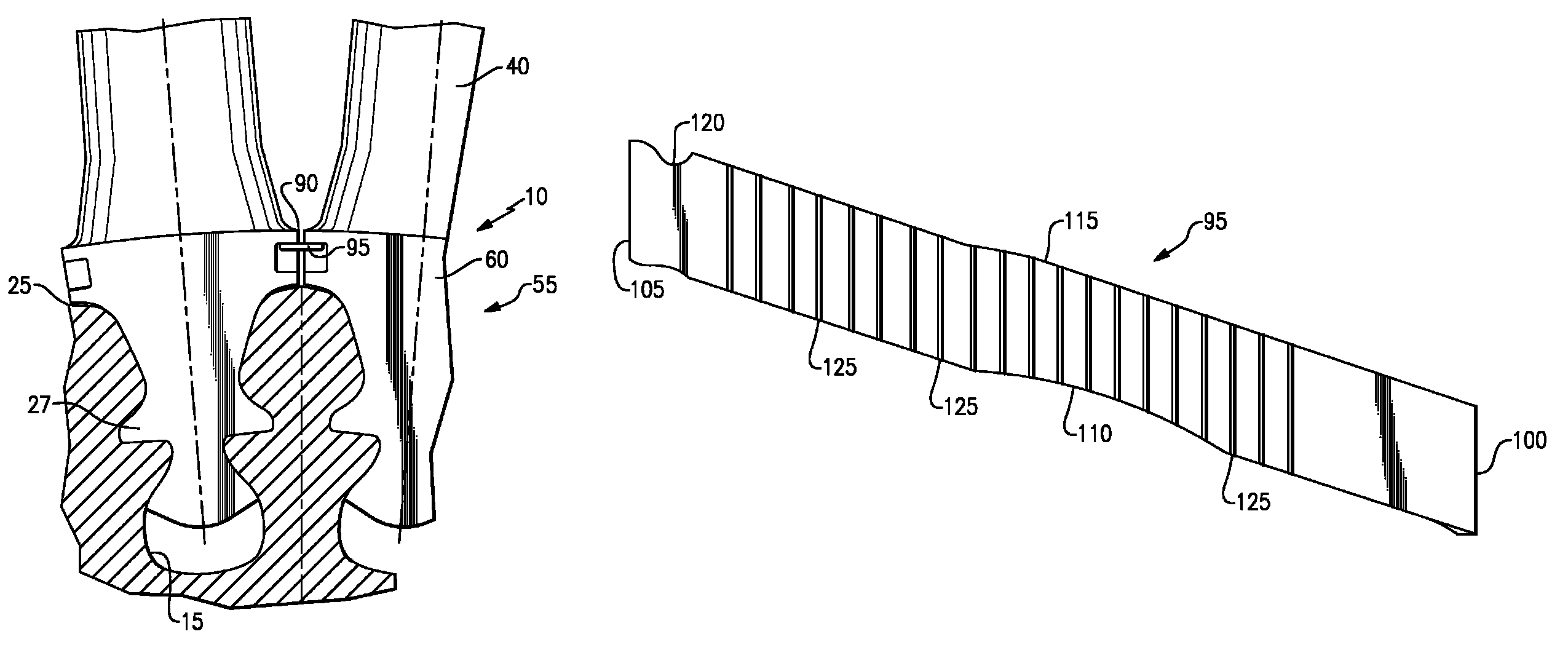

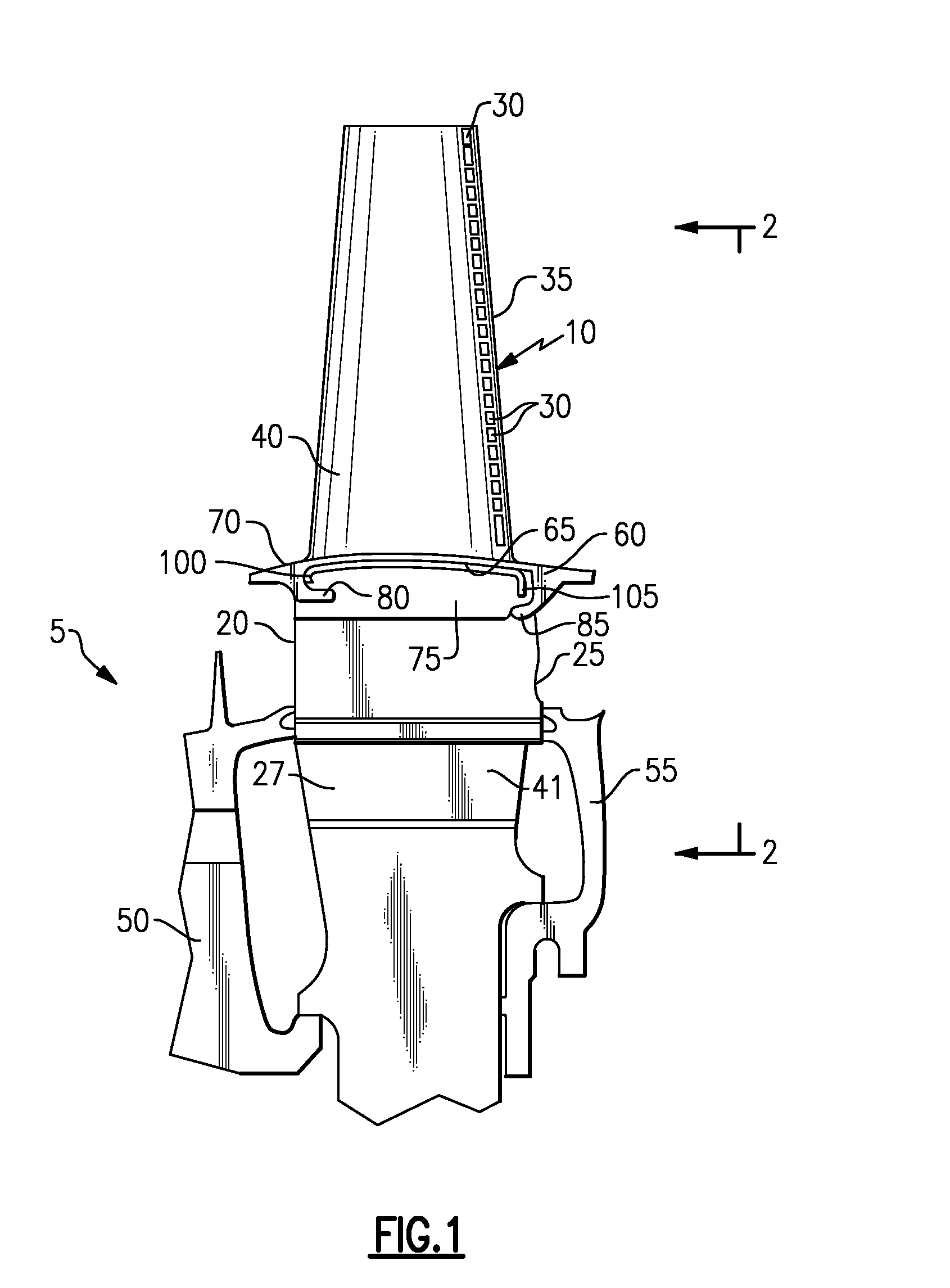

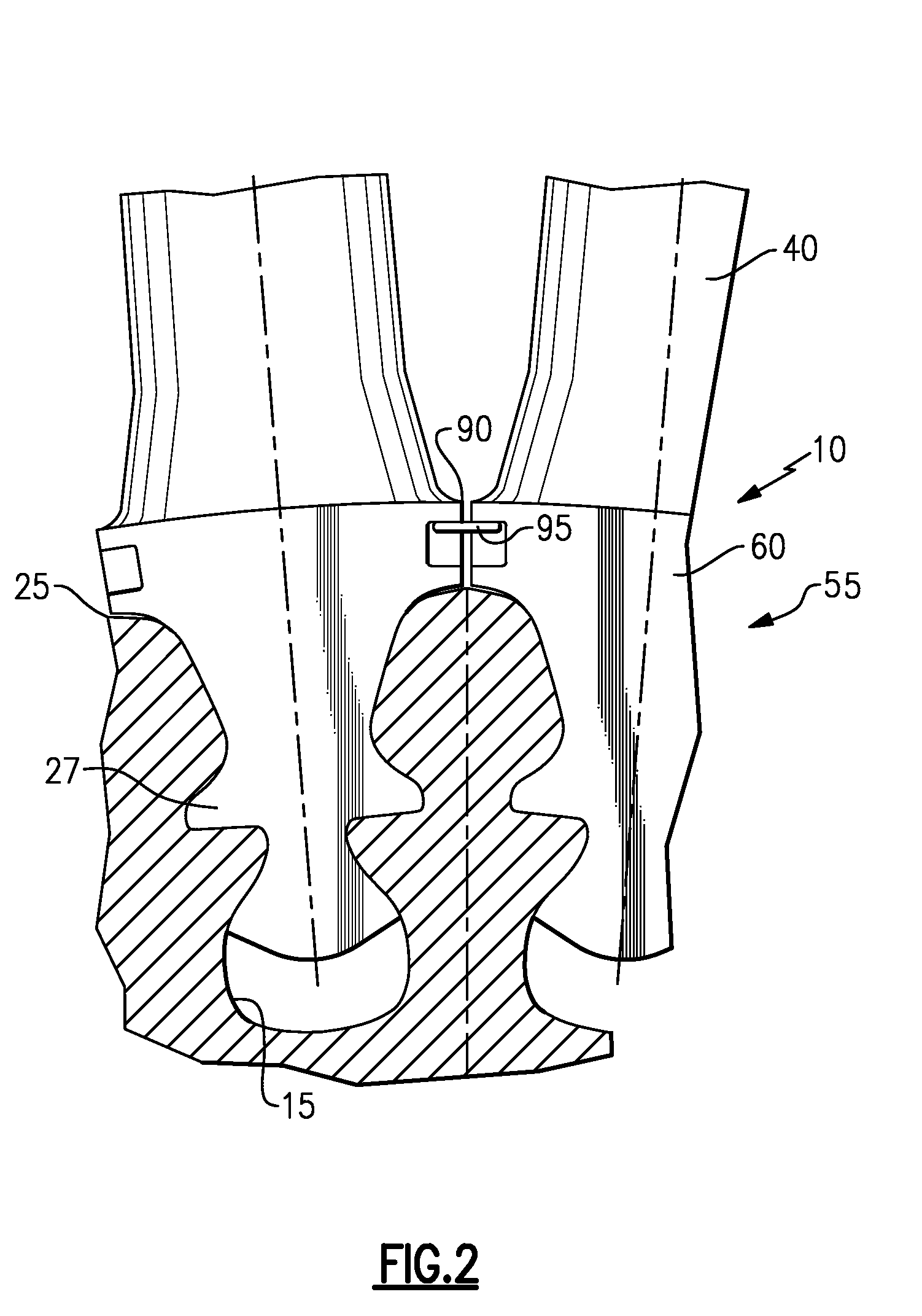

Turbine airfoil with platform cooling

ActiveUS20090116953A1Improve cooling effectLow experience requirementPump componentsTurbine/propulsion engine coolingEngineeringTurbine

Convective cooling of gas turbine engine airfoil platforms is enhanced by grooving the interface of the platforms with corresponding platform-to-platform seals, thereby accelerating cooling airflow over the platform surfaces.

Owner:RTX CORP

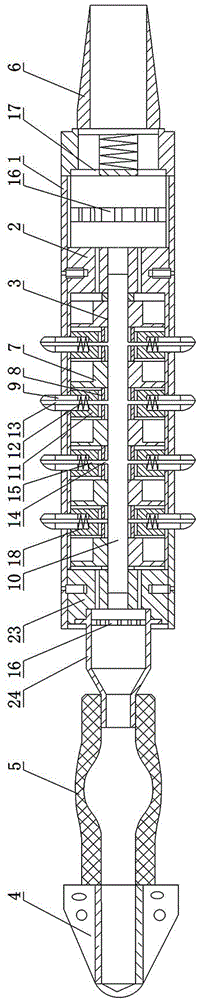

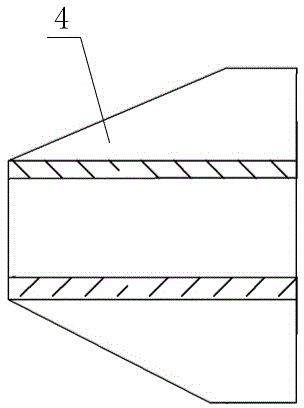

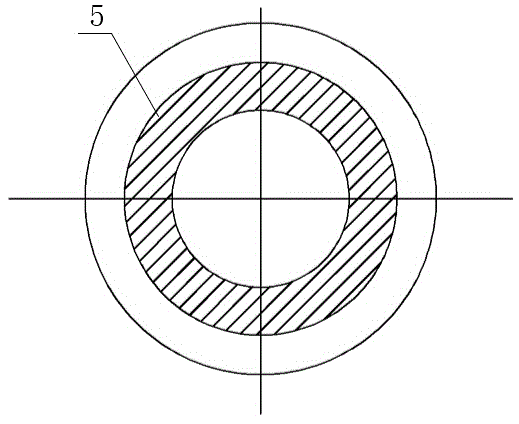

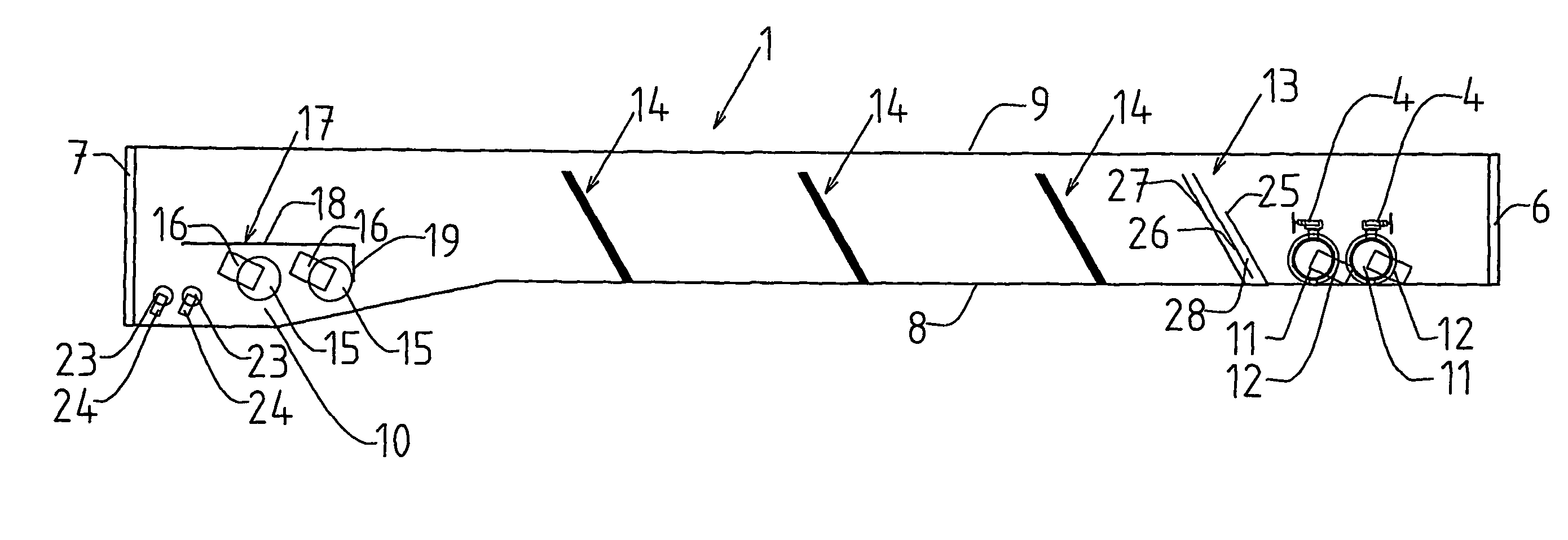

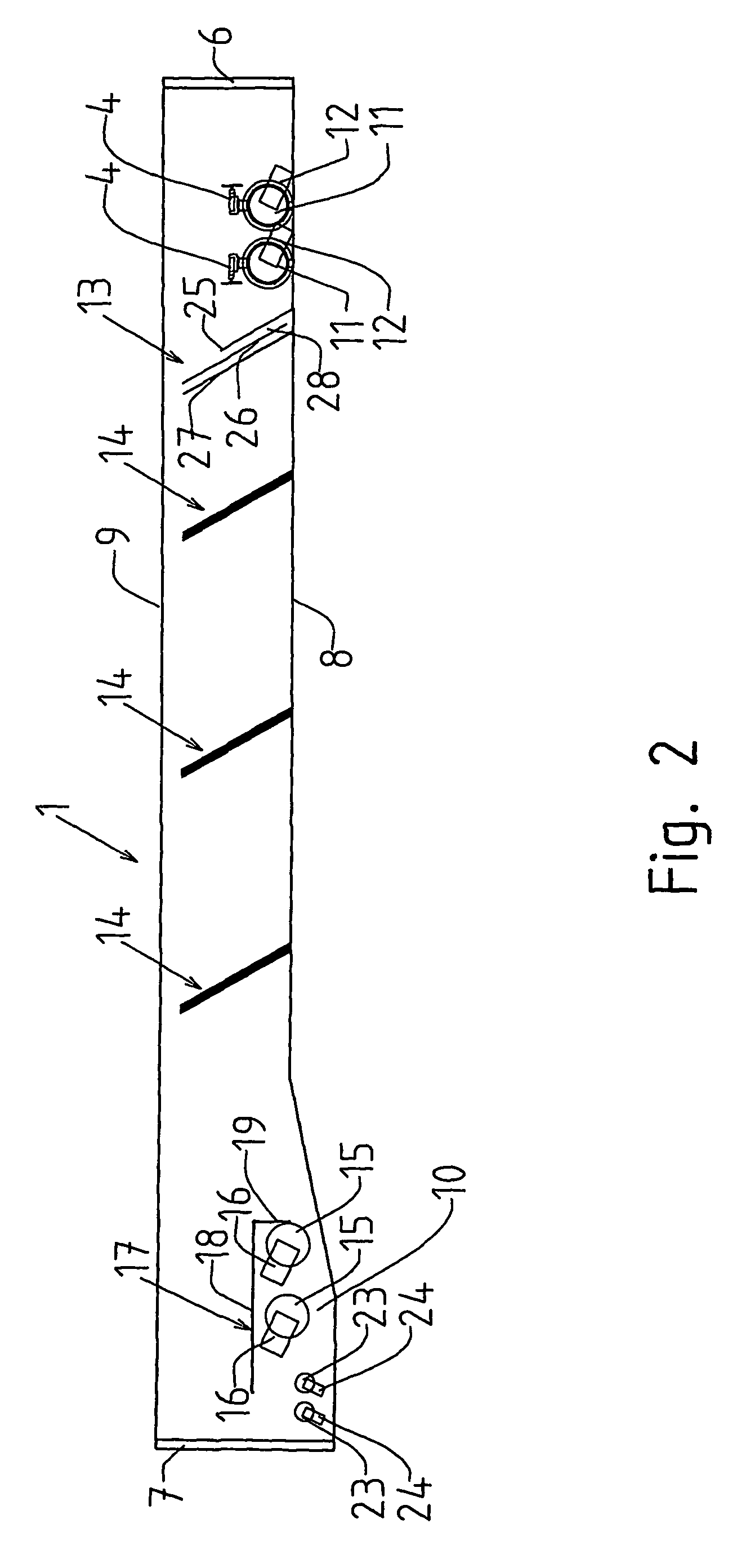

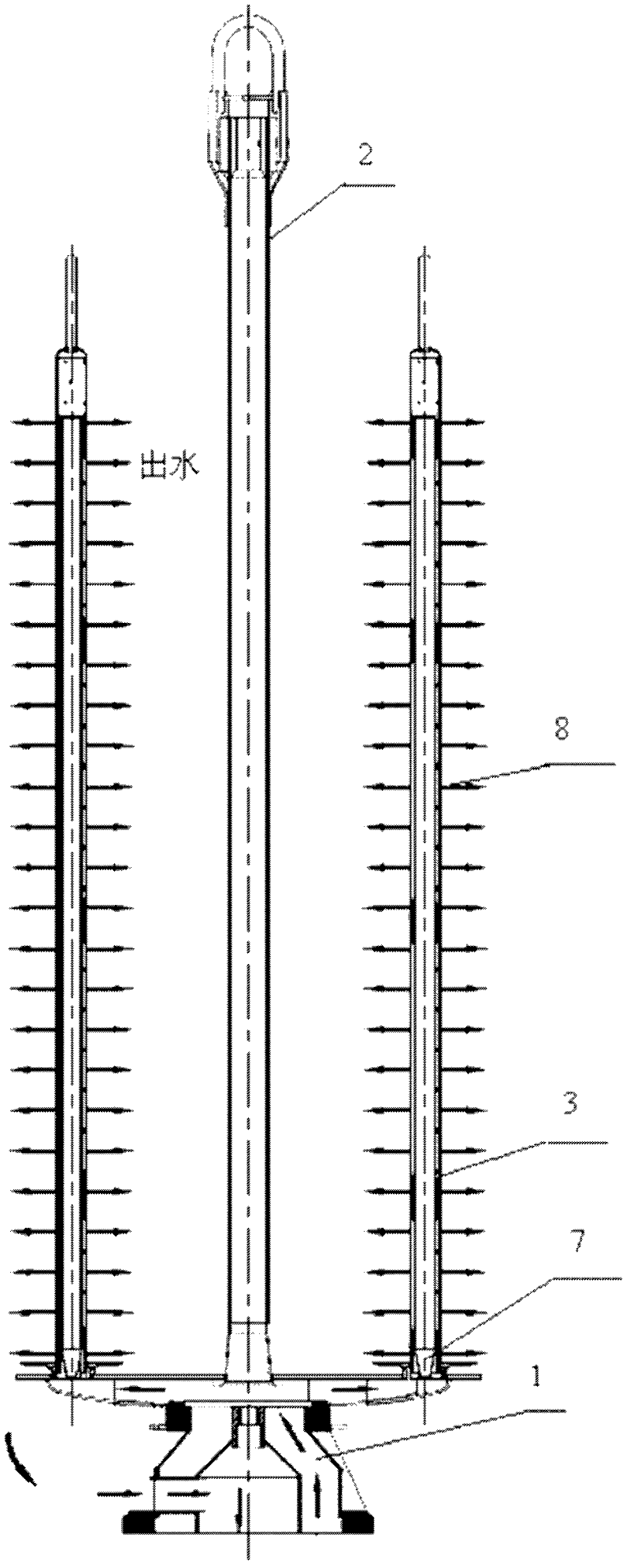

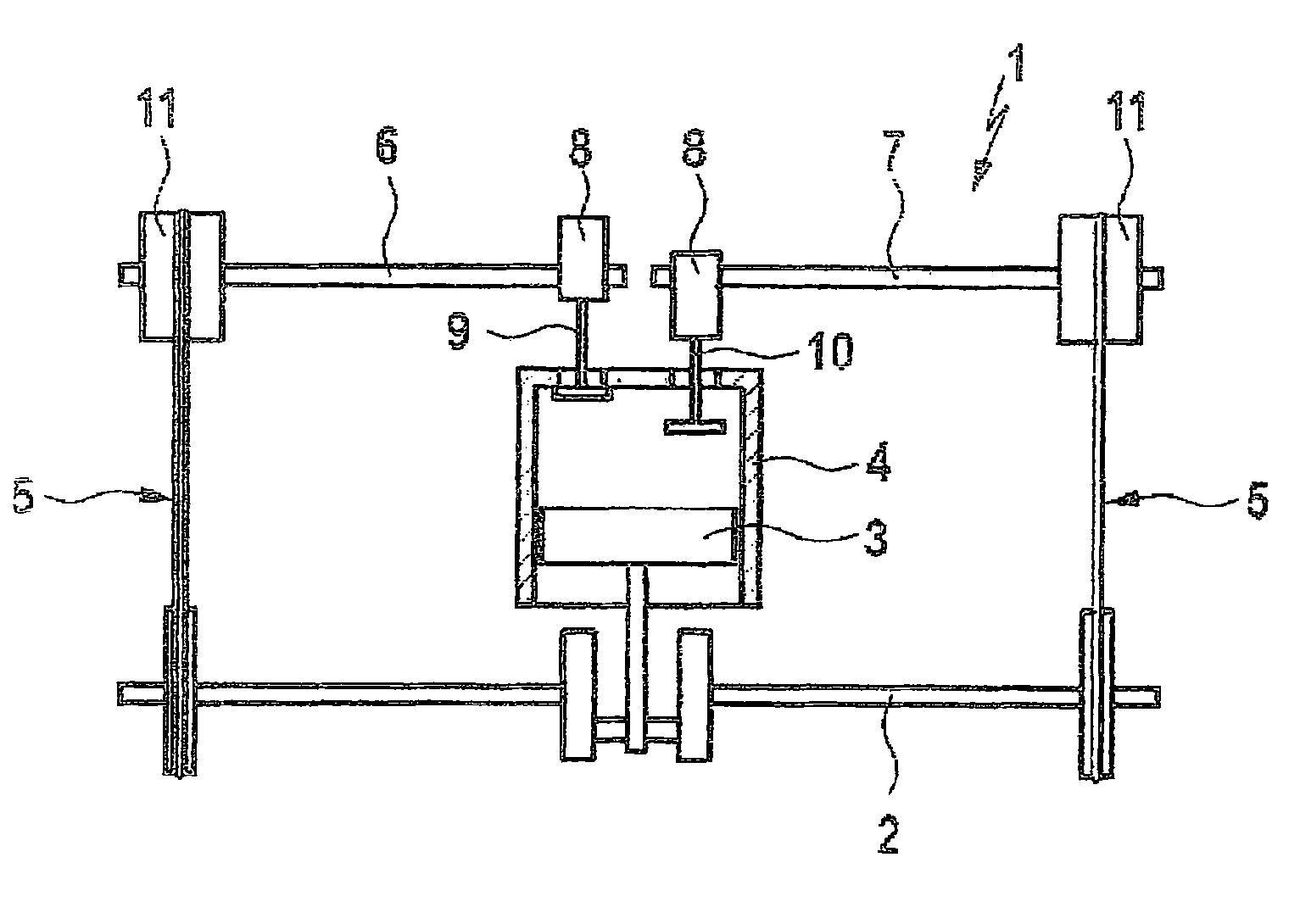

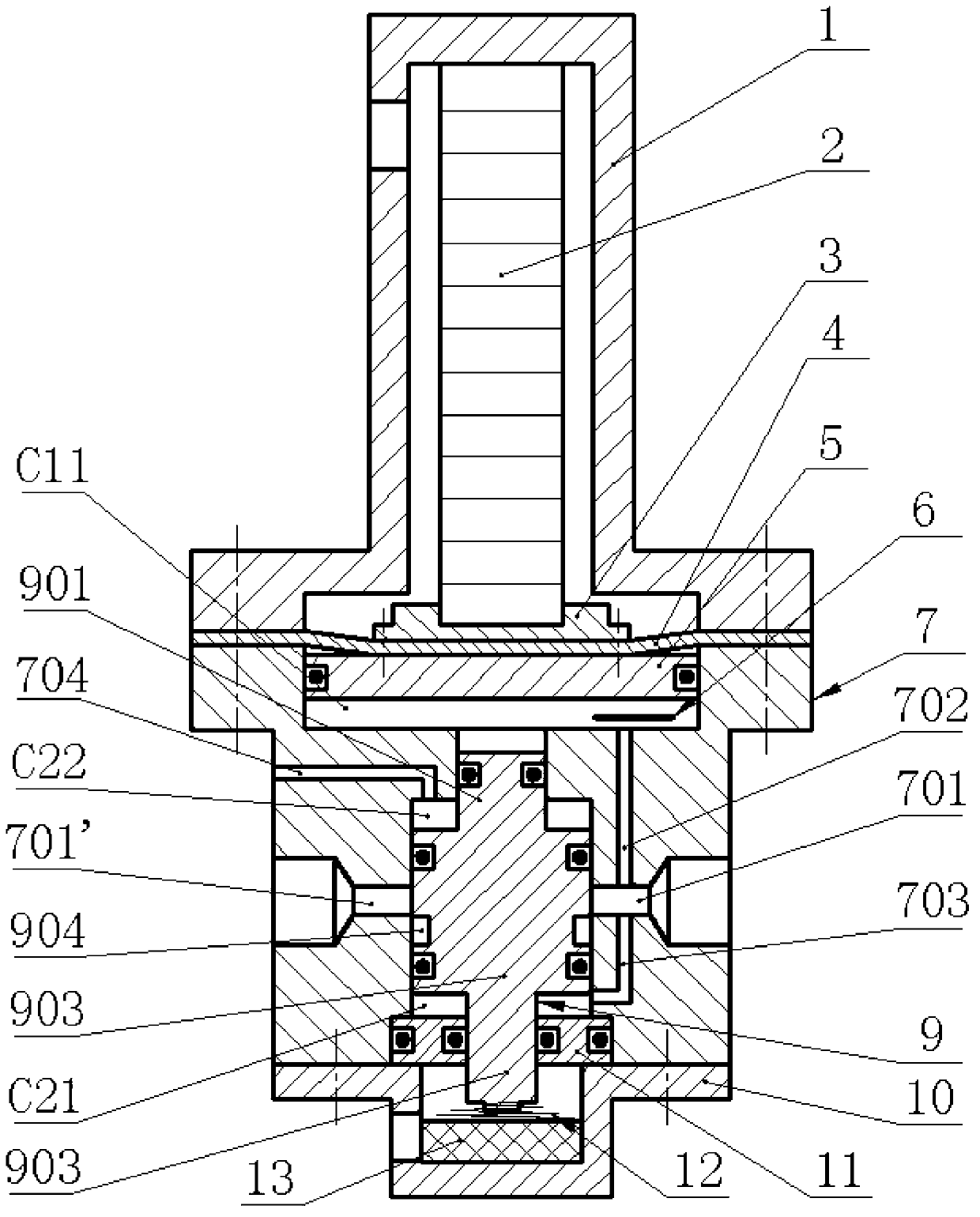

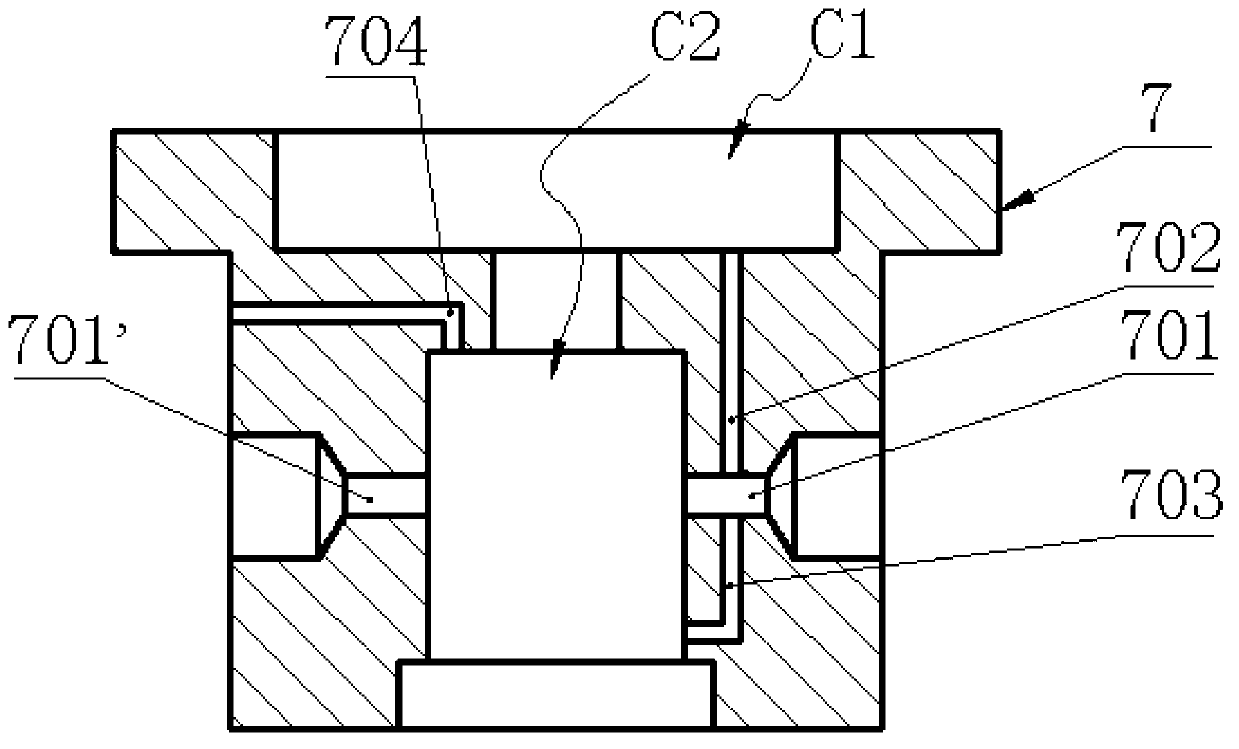

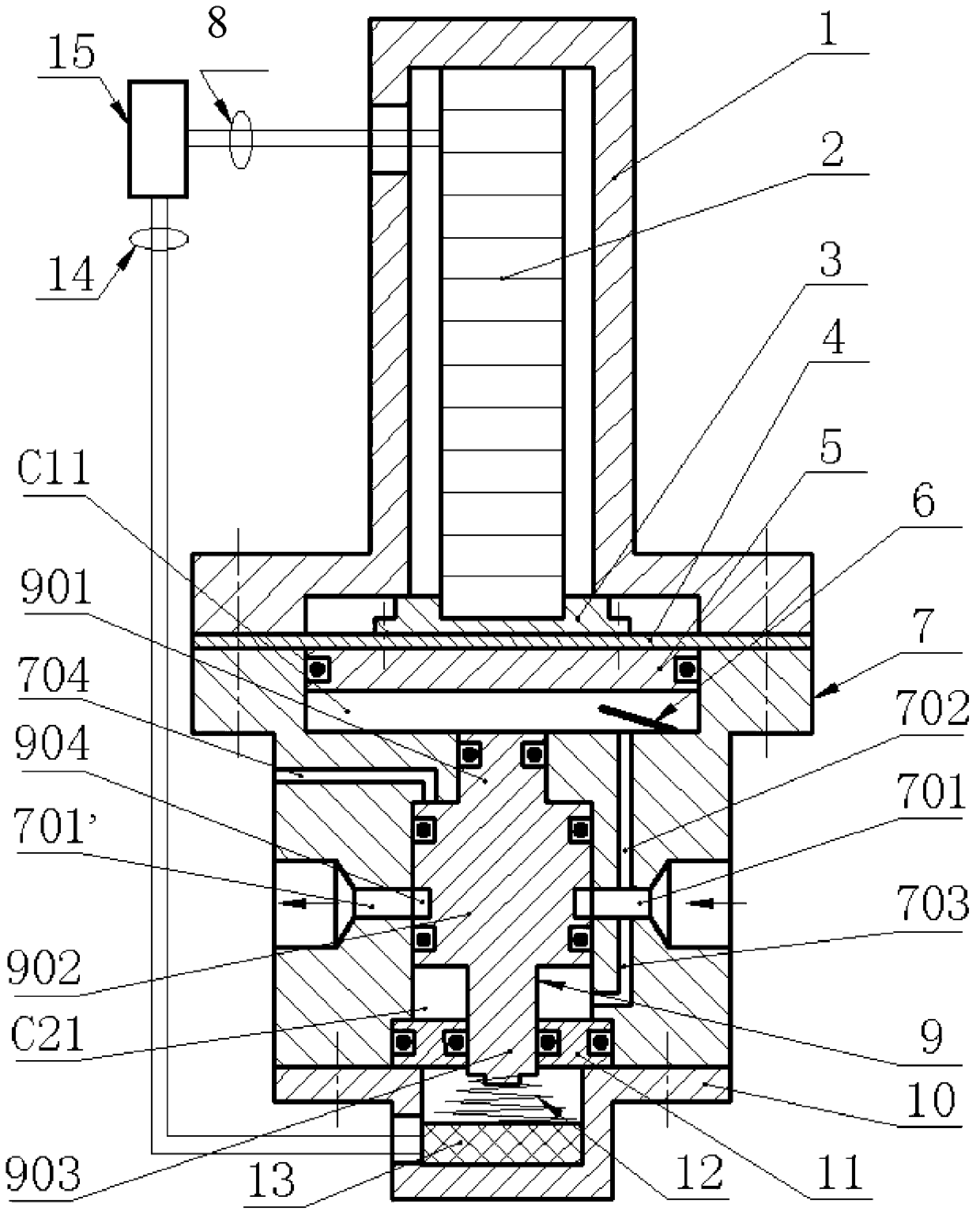

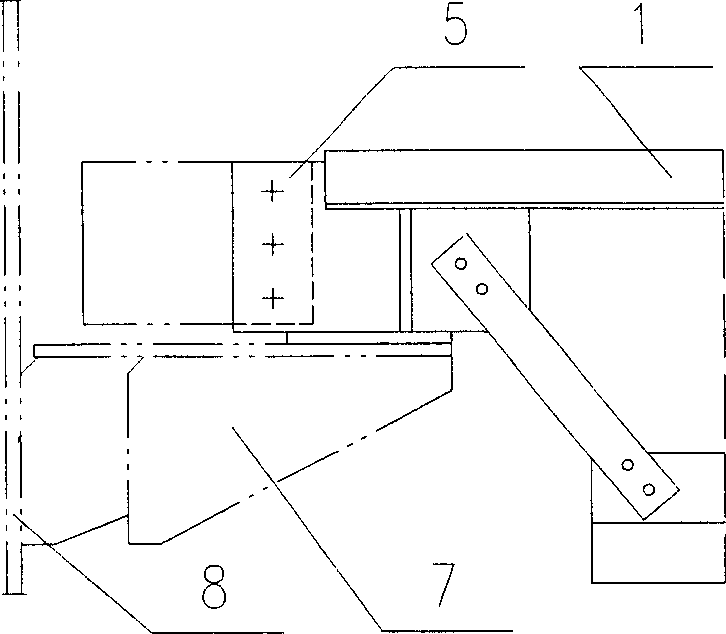

Automatic descaling device and method for shafts

ActiveCN104100231AReduce card rotationEnhanced descaling abilityCleaning apparatusImpellerEngineering

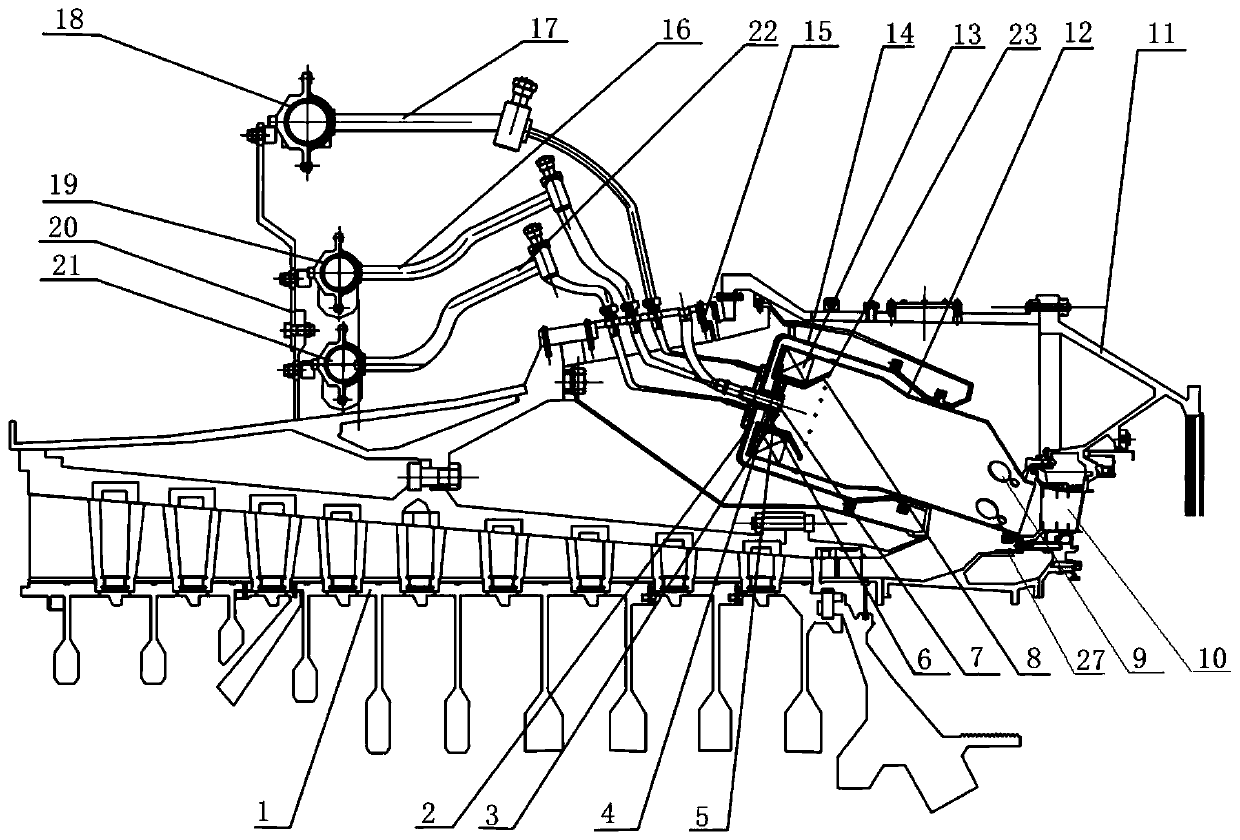

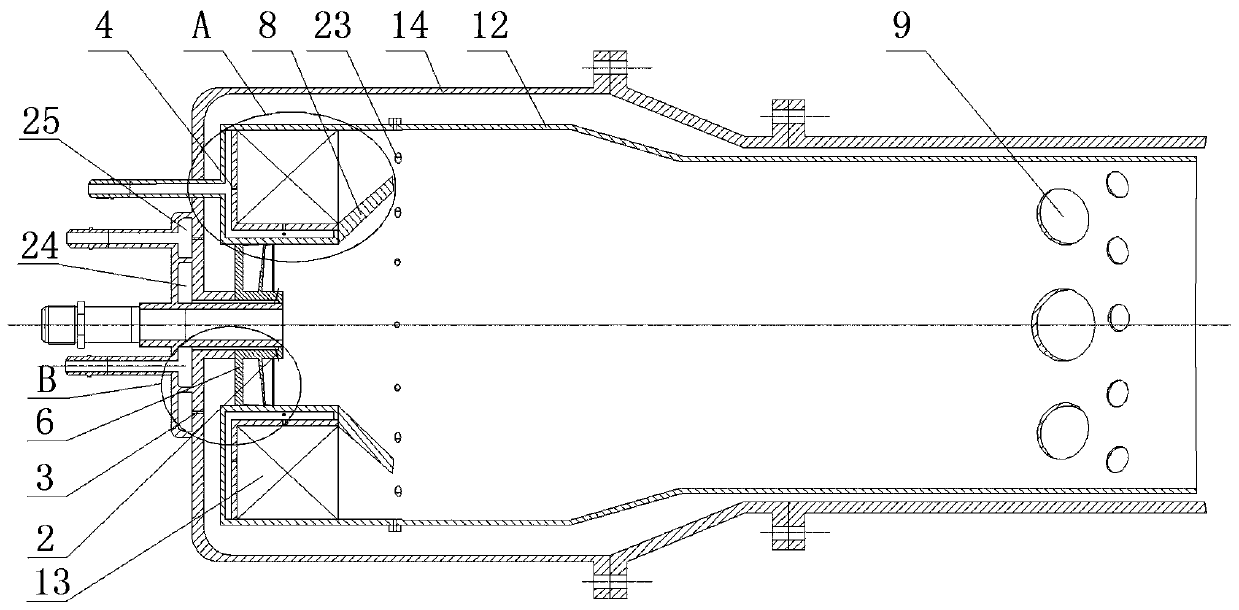

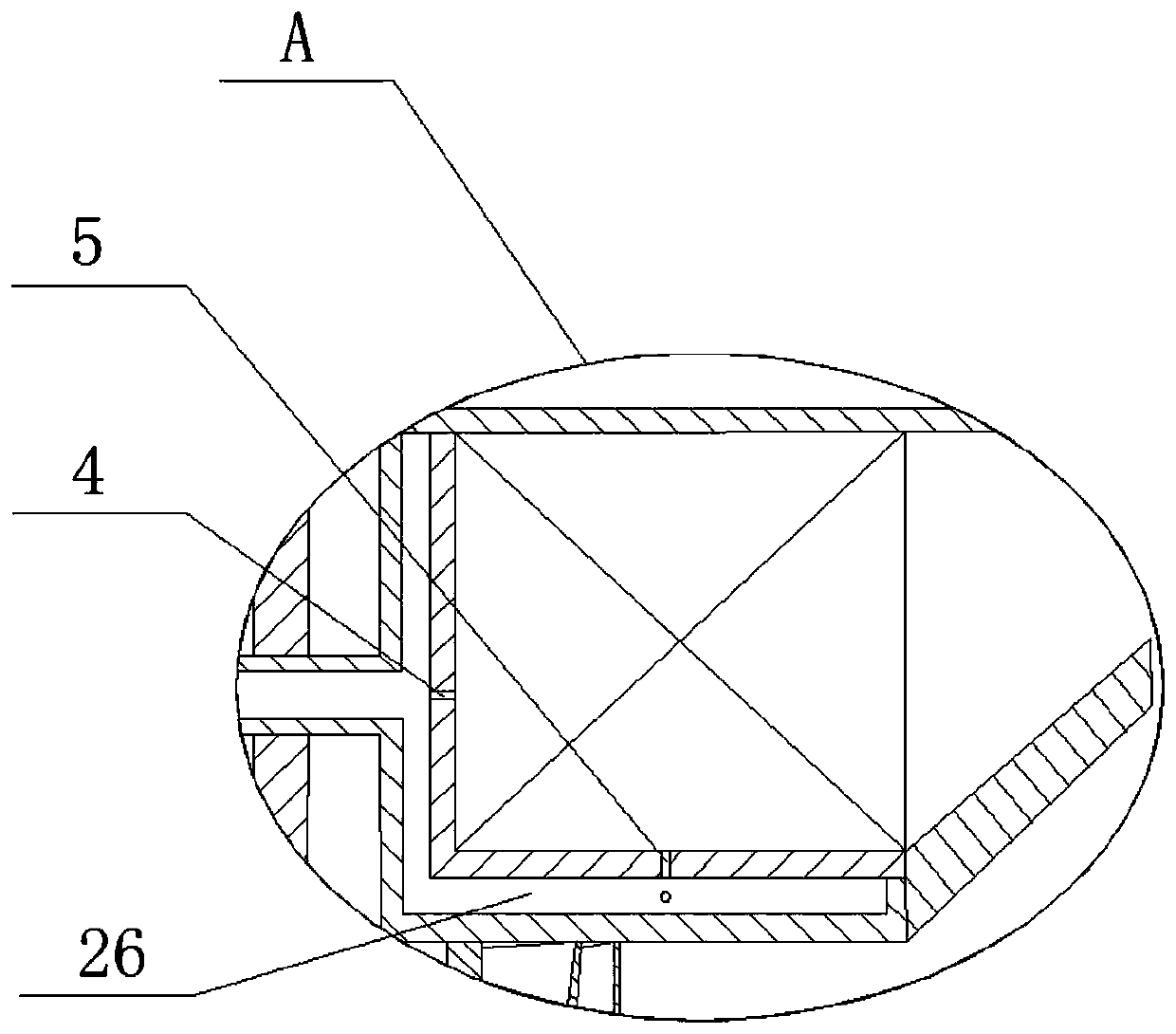

The invention discloses an automatic descaling device for shafts. The automatic descaling device comprises a pump shell (1), a pump body, a mandrel (3), an inflow head (4), a rubber sleeve (5), a connector (6), impellers (7) and scraper devices. The mandrel (3) is fixedly connected with the pump body. The impellers (7) and blade wheels (11) are mounted on the mandrel (3) at intervals. The scraper devices are mounted on the outer peripheries of the blade wheels (11). The inflow head (4) and the rubber sleeve (5) are communicated with the water inlet end of the mandrel (3). The water outlet end of the pump shell (1) is sequentially connected with a pressure control valve (17) and the connector (6). The invention further discloses a descaling method. The automatic descaling device and method has the advantages that downhole gas-liquid kinetic energy is converted into operation mechanical energy of the descaling device so as to achieve automatic descaling, descaling time is shortened, and combination of high-speed gas-liquid descaling and mechanical descaling is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

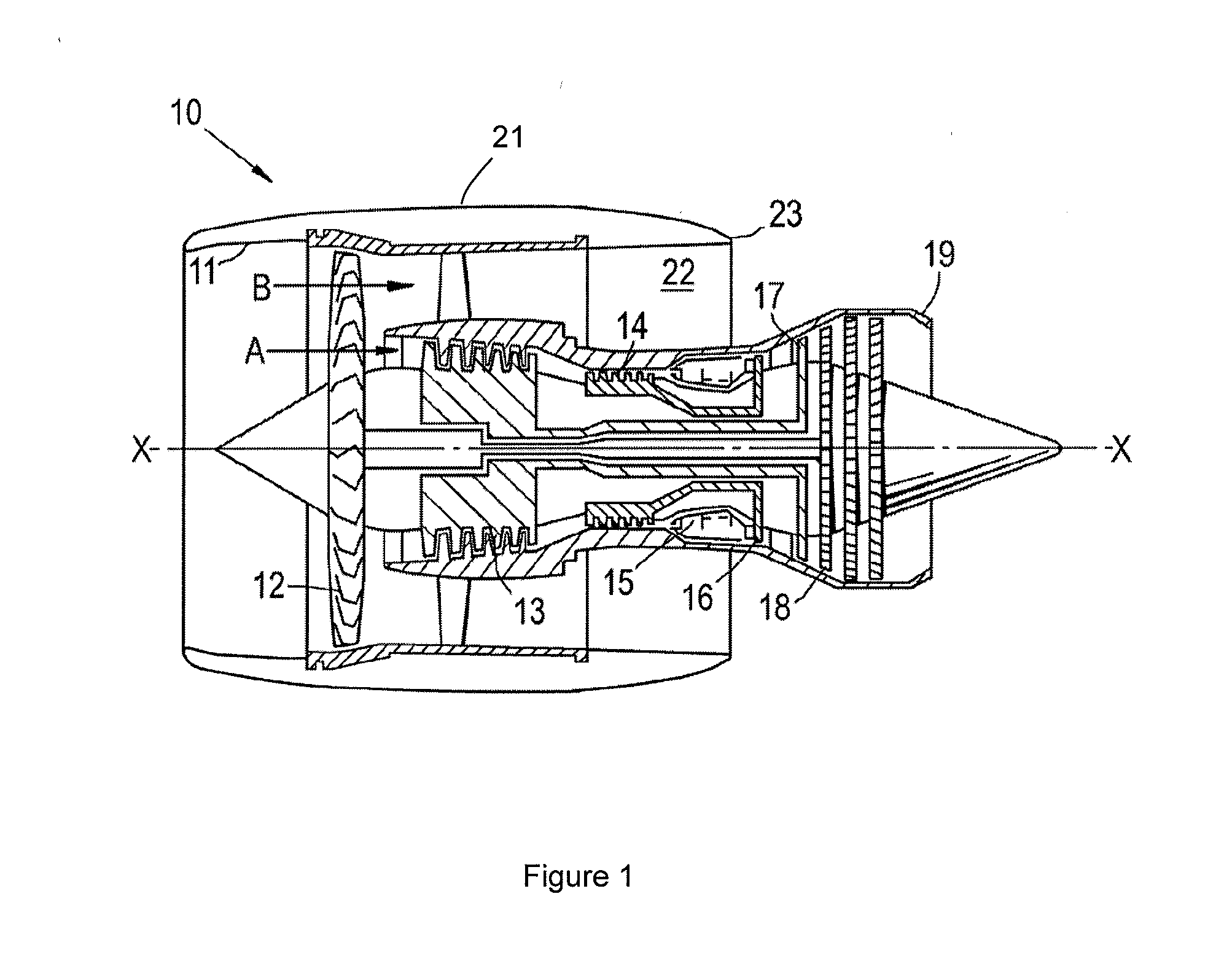

Aerofoil cooling

ActiveUS20140140860A1Improve efficiencyReduce thicknessPropellersEngine manufactureEngineeringProduct gas

An aerofoil component of a gas turbine engine is provided. The component has a longitudinally extending aerofoil portion which spans, in use, a working gas annulus of the engine. The aerofoil portion contains an internal chamber for a flow of coolant. The chamber includes a helical passage which spirals in a plurality of turns around an axis that extends in the length direction of the aerofoil portion.

Owner:ROLLS ROYCE PLC

Method and equipment for purifying an extraction solution from aqueous entrainment and impurities

InactiveUS7731853B2Reduced flow areaEffect of solutionComponent separationSolid sorbent liquid separationPhysical separationImpurity

The invention relates to a method and equipment with which an organic solution extraction solution is purified from entrainment of aqueous solution and impurities during hydrometallurgical liquid-liquid extraction. The method treats an organic extraction solution, which is loaded with a valuable metal or valuable substance from the aqueous solution. The purpose is to carry out the physical separation of water droplets and the chemical removal of impurities from the organic extraction solution simultaneously.

Owner:OUTOTEC OYJ

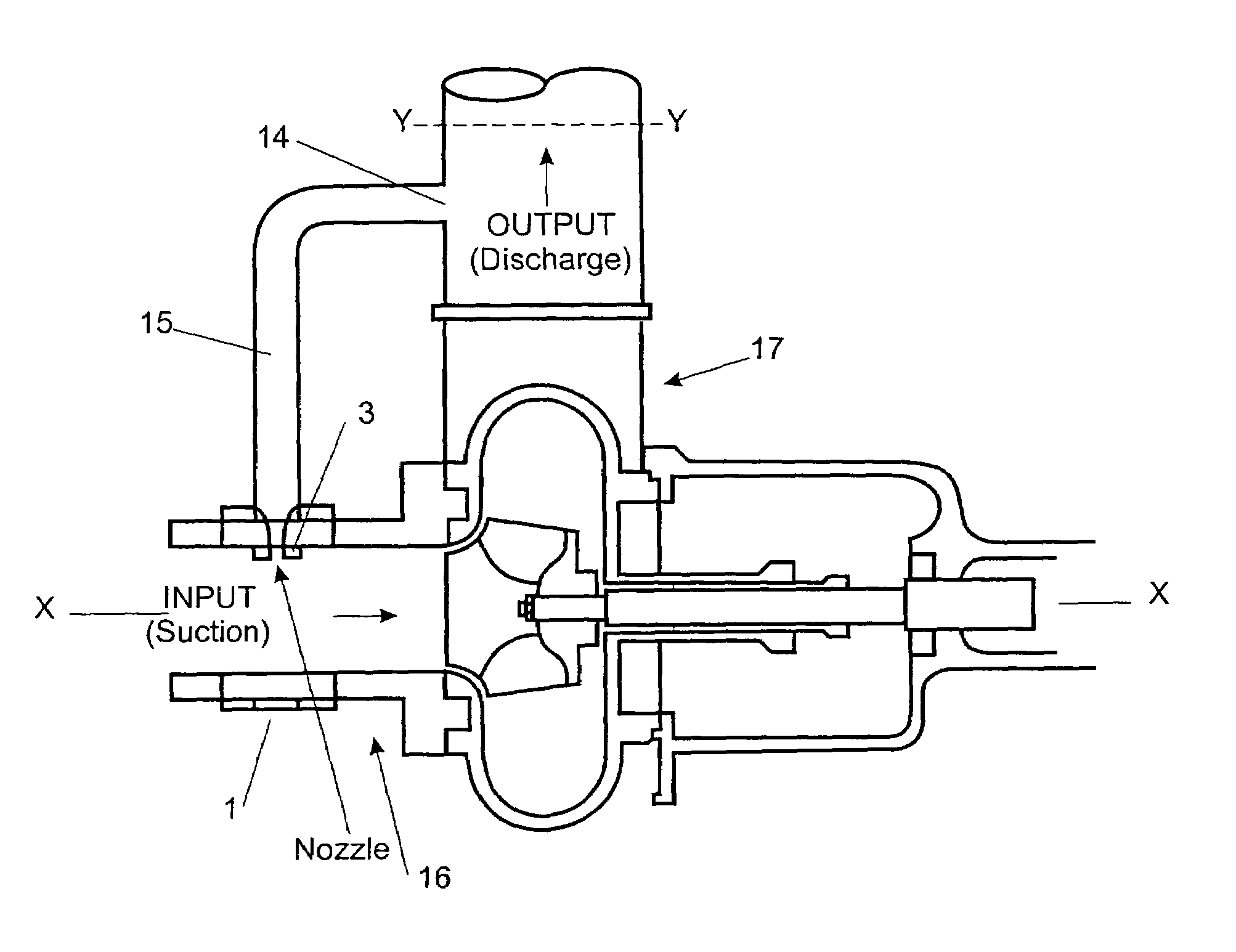

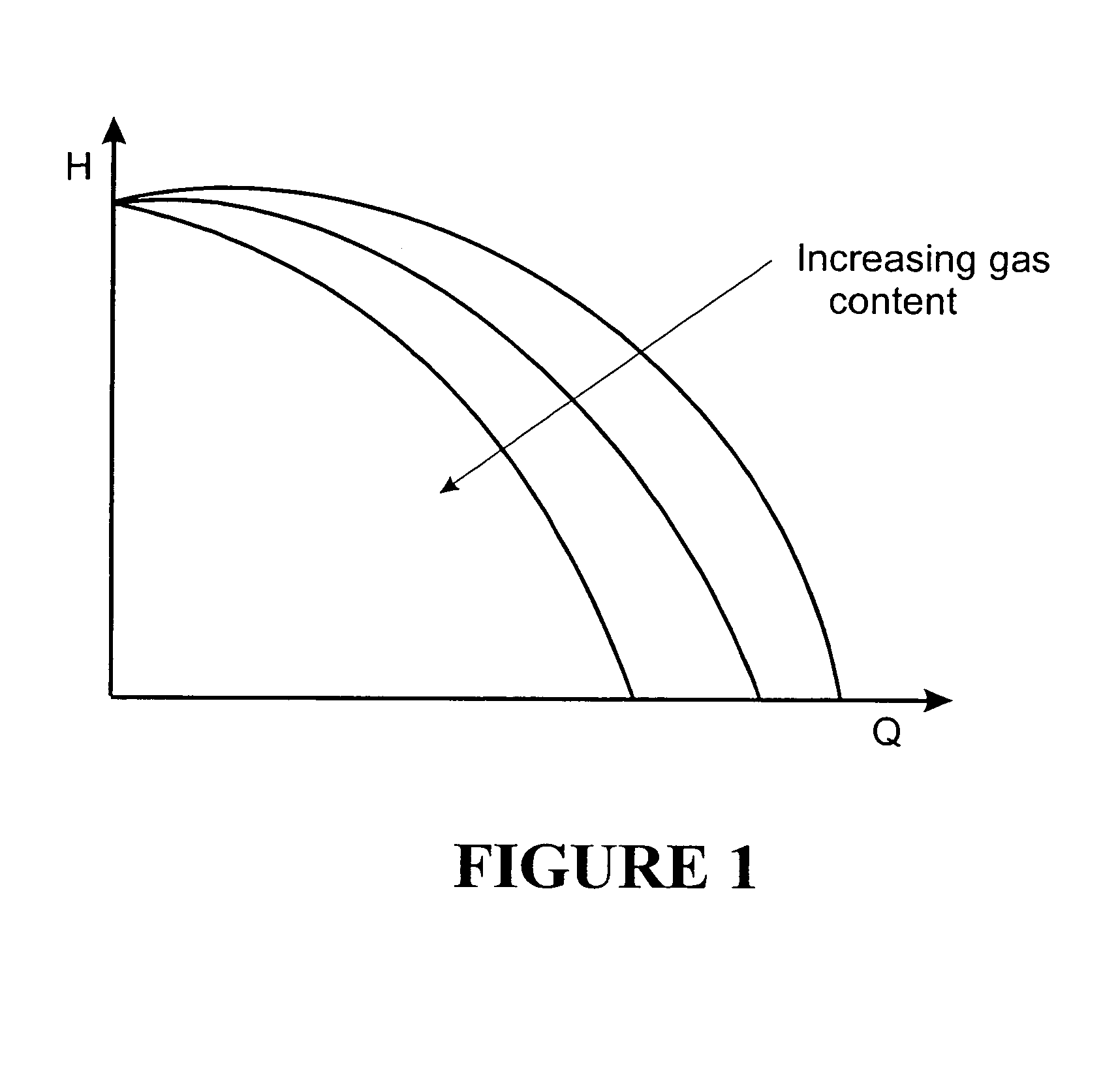

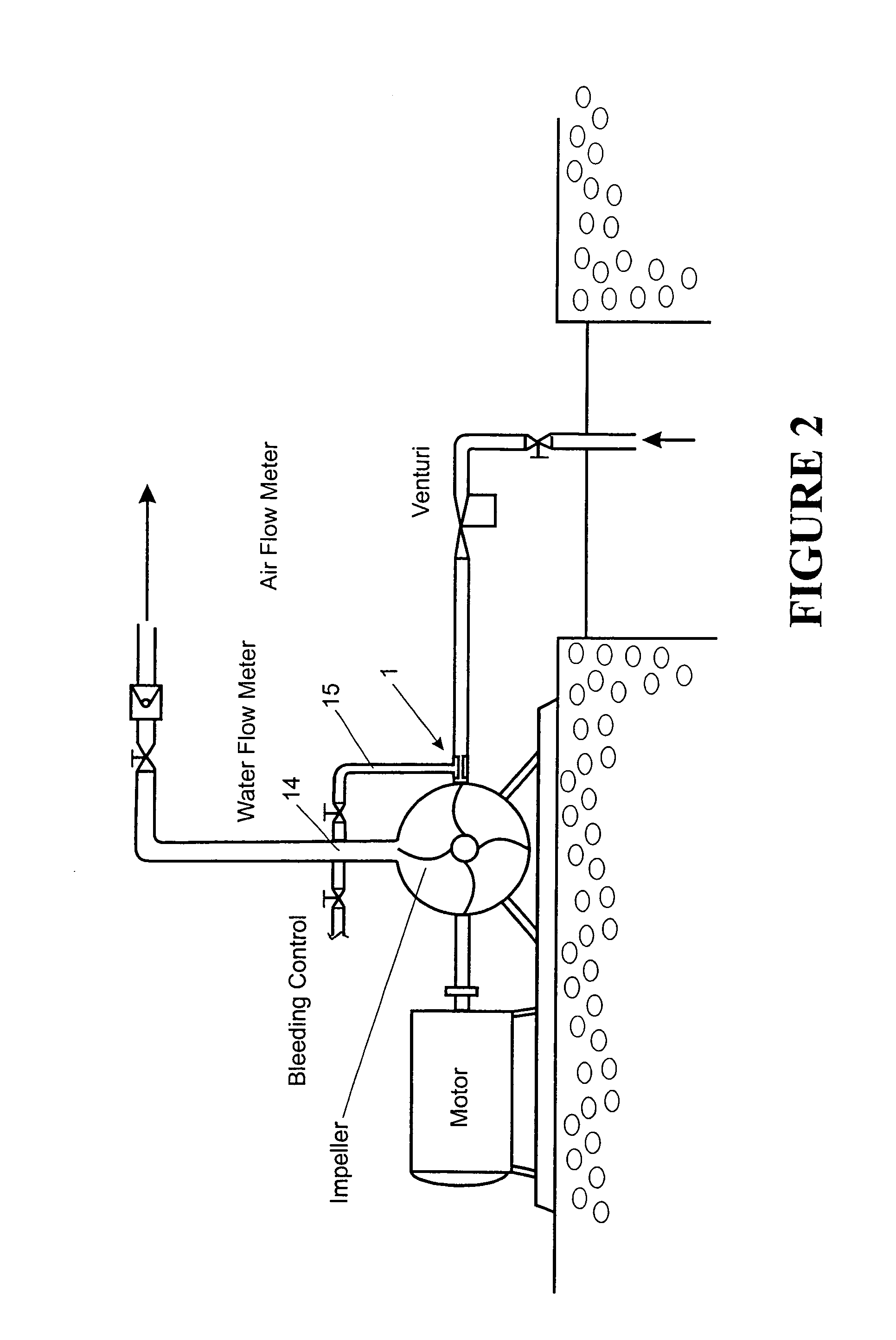

Multi-phase flow pumping means and related methods

InactiveUS7094016B1Reduce disadvantagesReduce problemsPump componentsPump controlEngineeringHigh pressure

A method of pumping and related arrangement for multi-phase fluid flow wherein a centrifugal pump is used for the suction and delivery of the multi-phase fluid which has a fluid communication providing portion to provide a communication of fluid bled from the outlet at a higher pressure to be injected into the inlet conduit of the centrifugal pump in operation. The centrifugal pump is provided with an impeller which has a plurality of vanes configured to define there between larger passageways when compared to a conventional centrifugal pump which would operate in or near optimum conditions when pumping liquid only.

Owner:UNITEC INST OF TECH +1

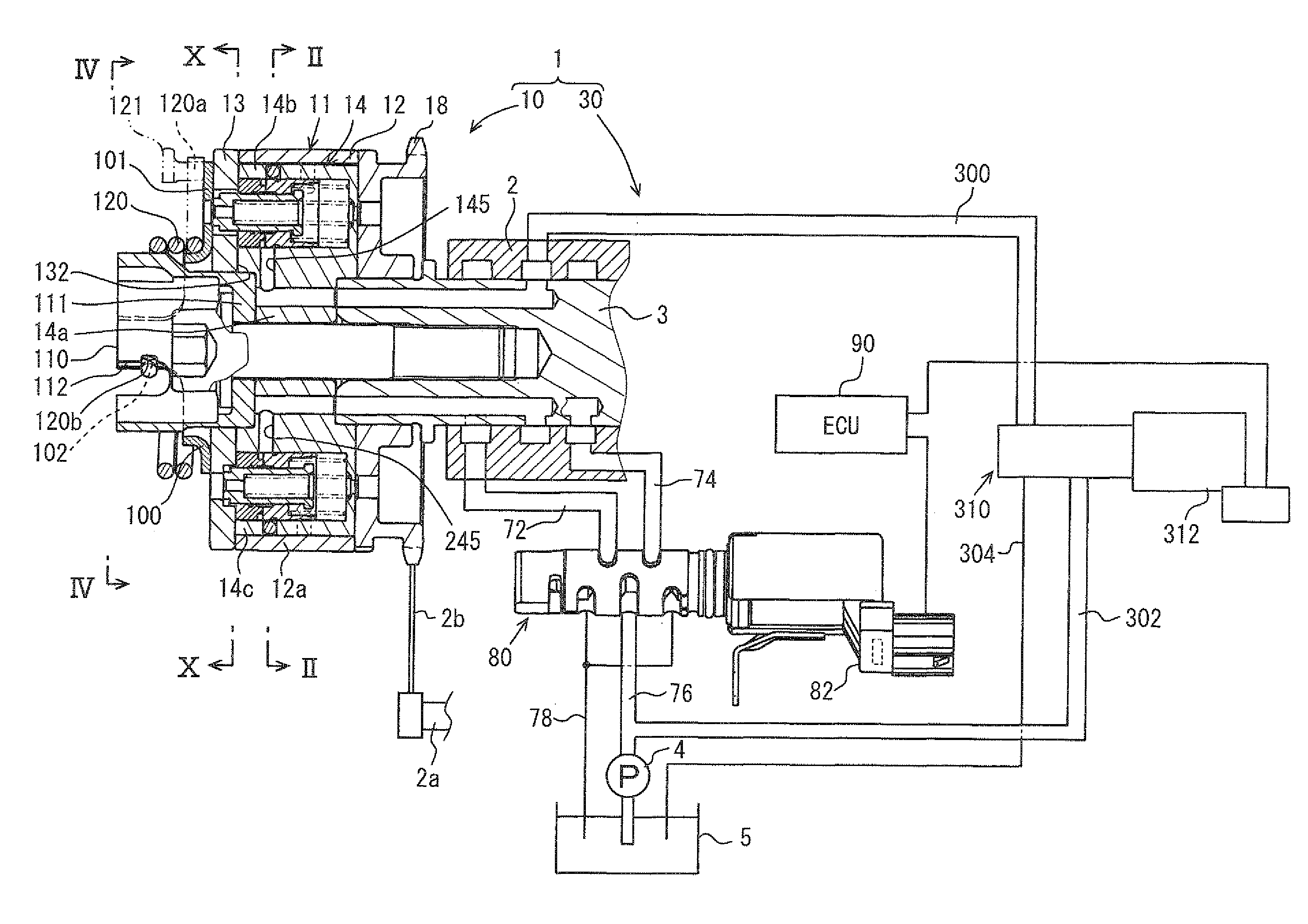

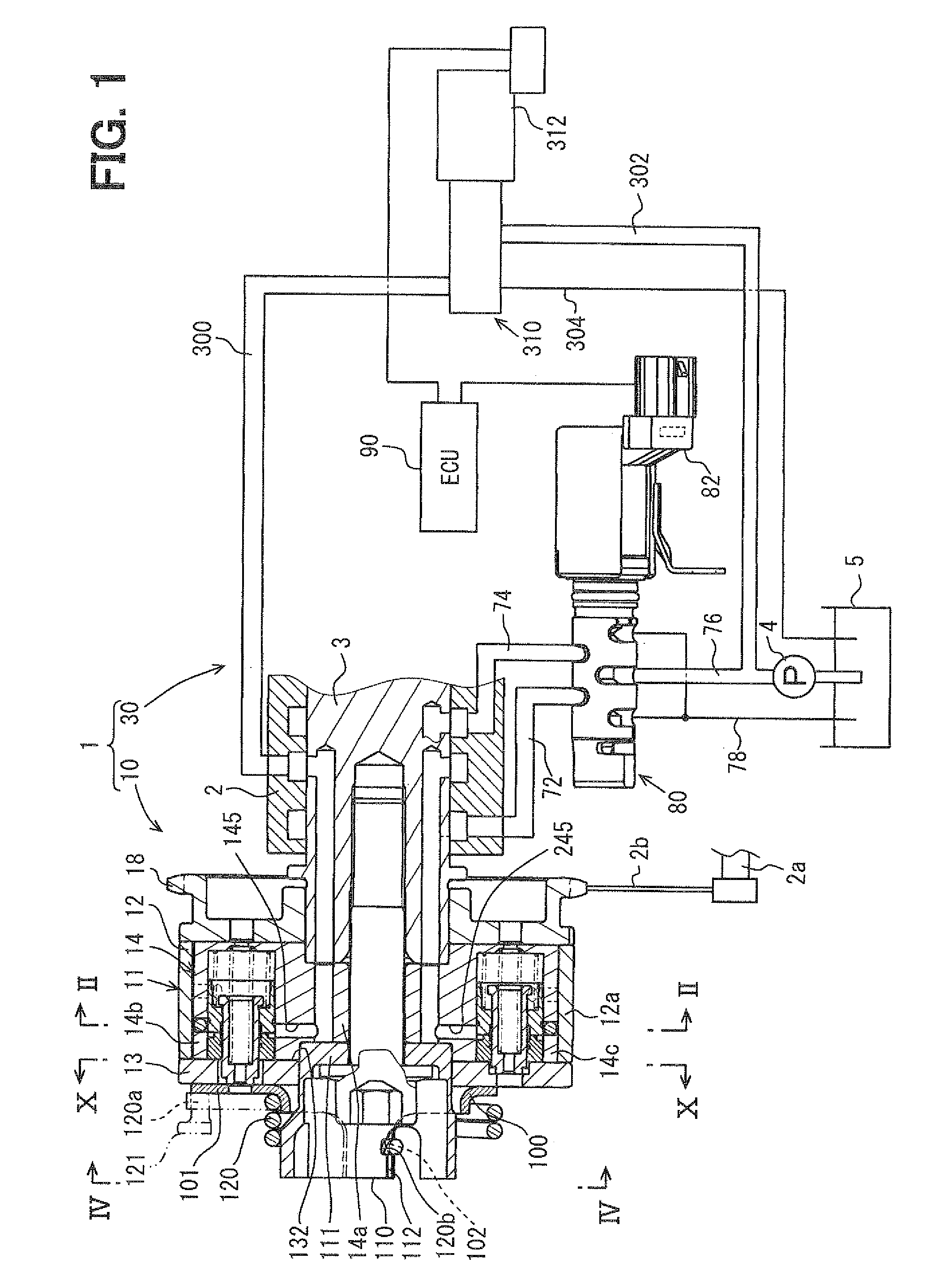

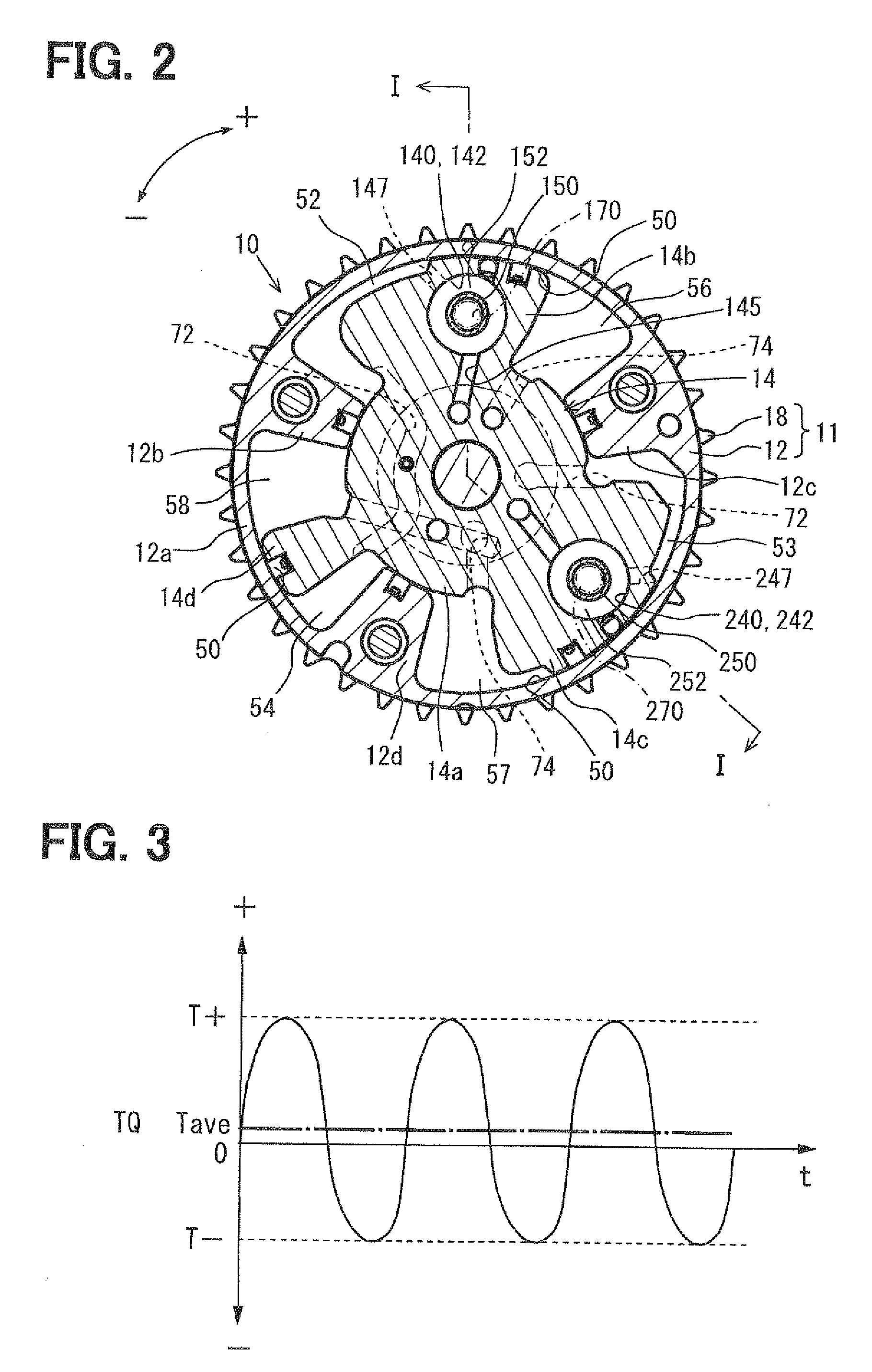

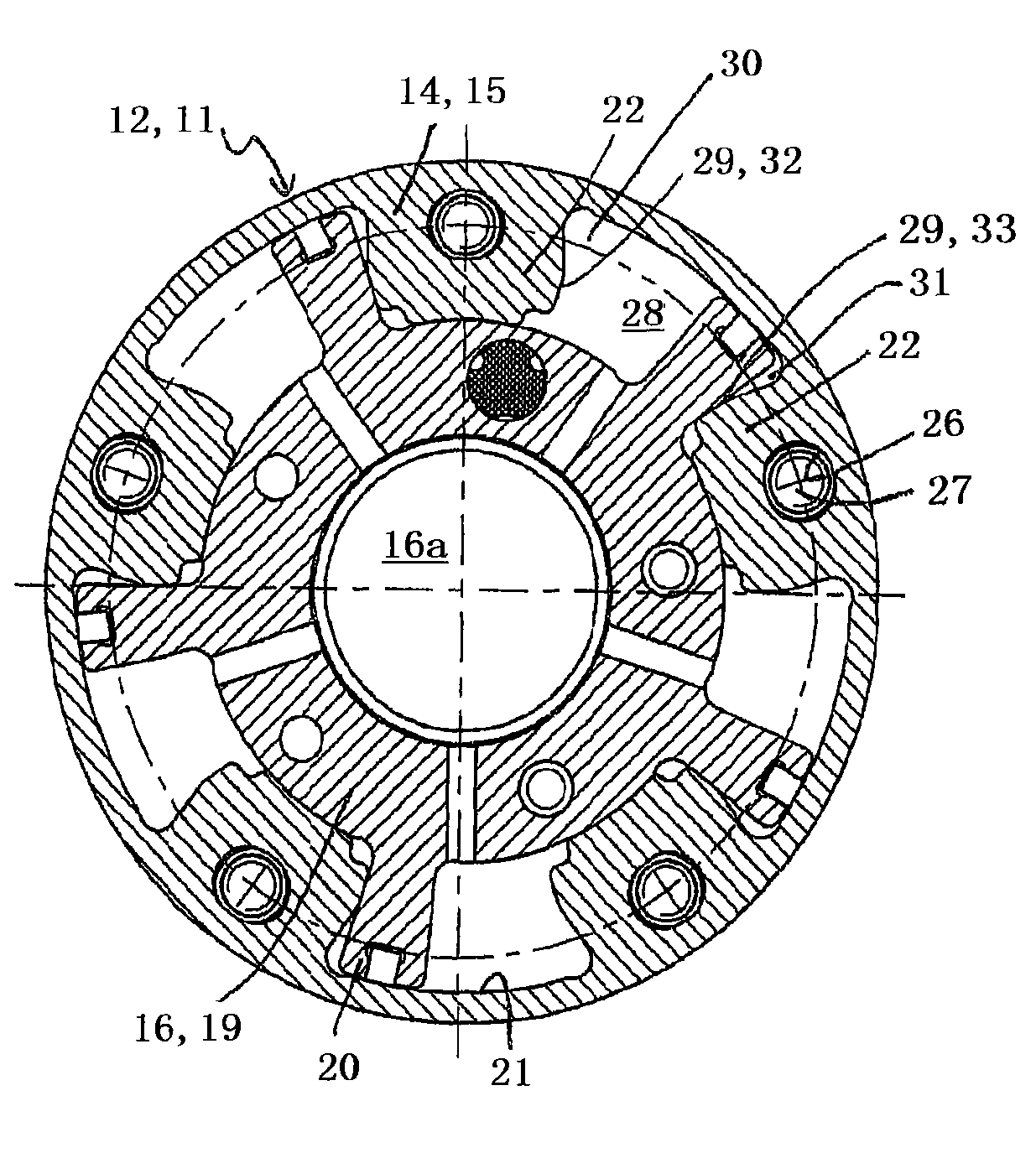

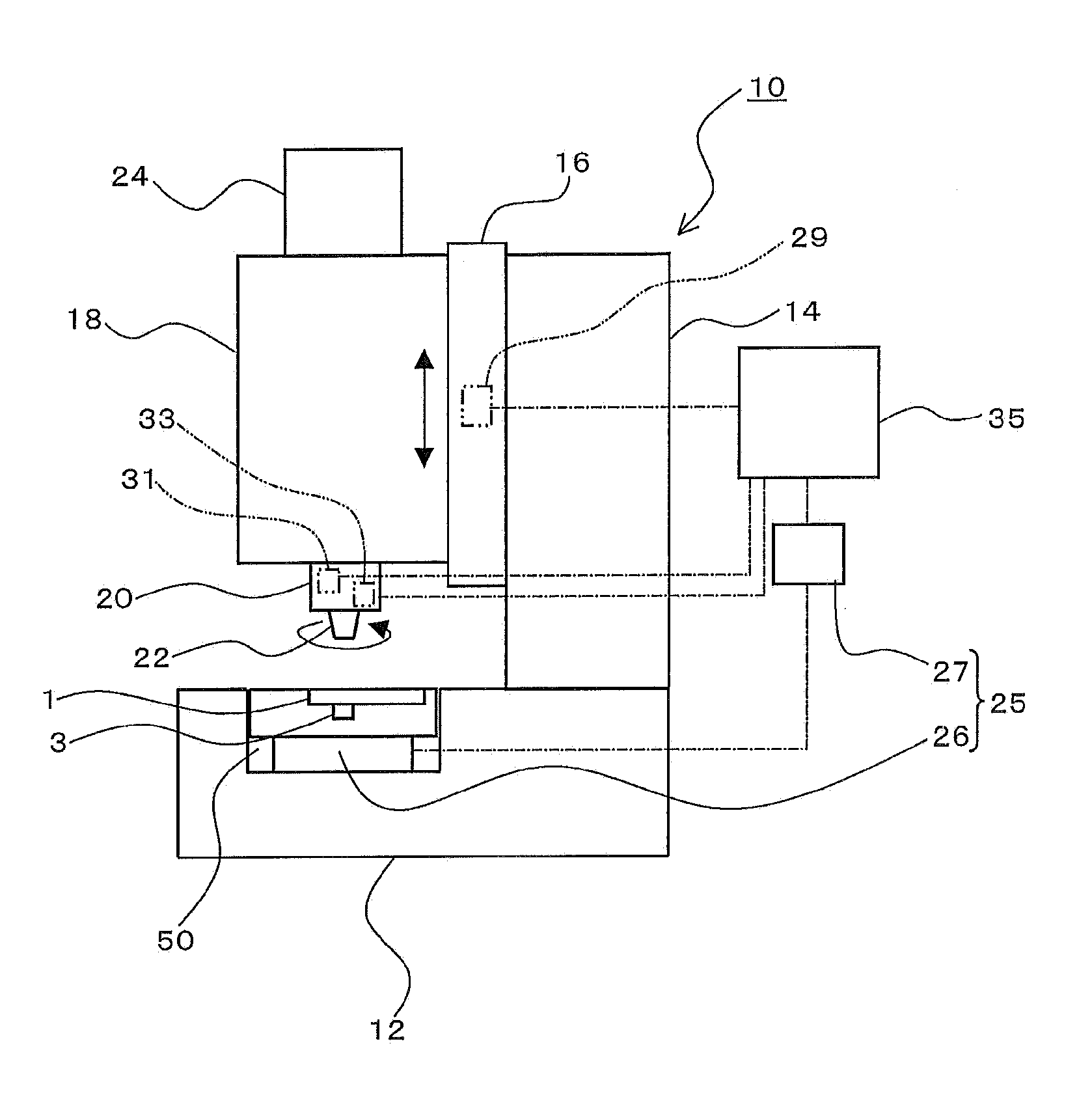

Valve timing control apparatus

ActiveUS20110162601A1Prohibit communicationContainment leakValve arrangementsMachines/enginesEngineeringHydraulic fluid

A valve timing control apparatus has a regulation member to fix a phase. The regulation member has a main regulation member and a sub regulation member. The main regulation member is inserted into a recess part to regulate the phase. The sub regulation member has an engagement part engageable with the main regulation member in an escape direction Y and disengageable from the main regulation member in an insertion direction X. Further, the sub regulation member has a pressure reception part that receives pressure in the escape direction Y from hydraulic fluid in an operation chamber. The main regulation member is urged in the insertion direction X by a main resilient member. Further, the sub regulation member is urged in the insertion direction X by a sub resilient member. The main regulation member moves in the escape direction Y only by hydraulic fluid, and moves in the insertion direction X only by the resilient member.

Owner:DENSO CORP

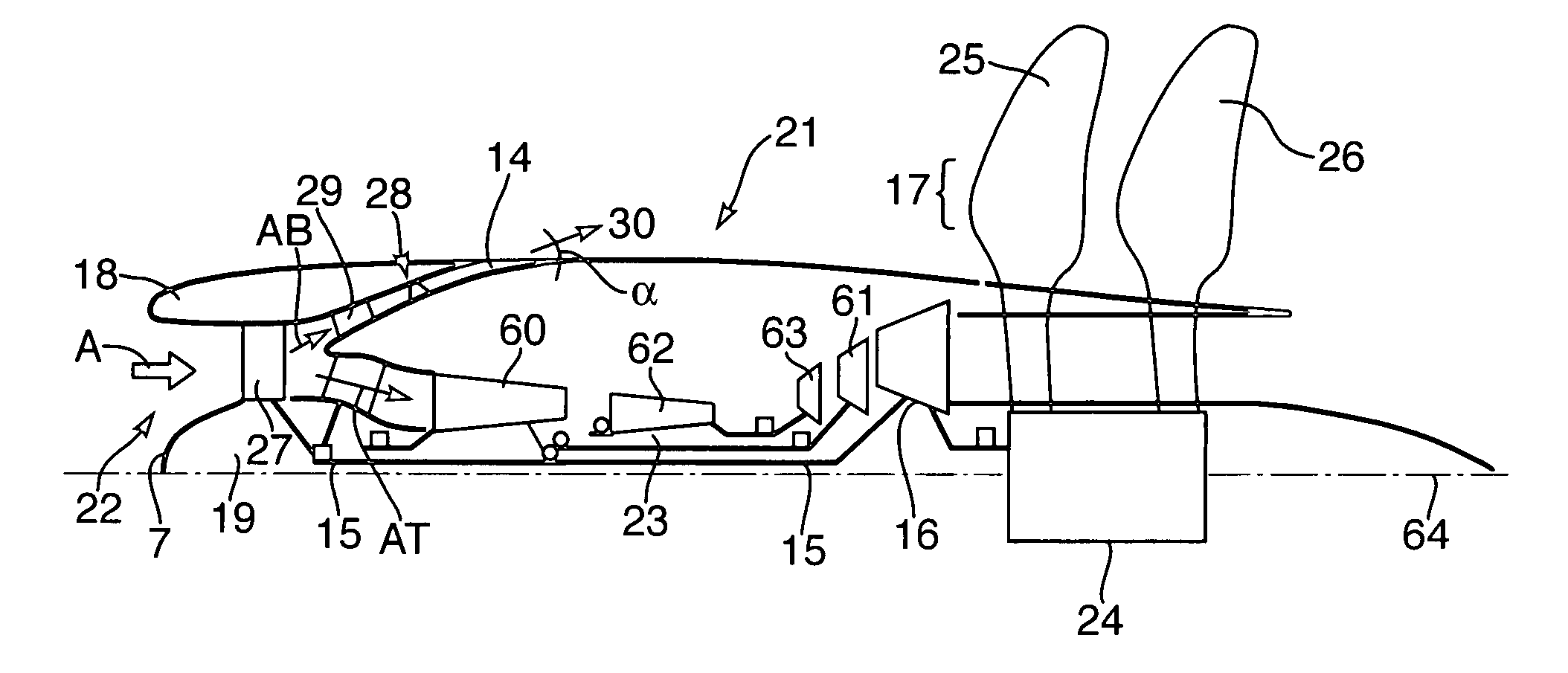

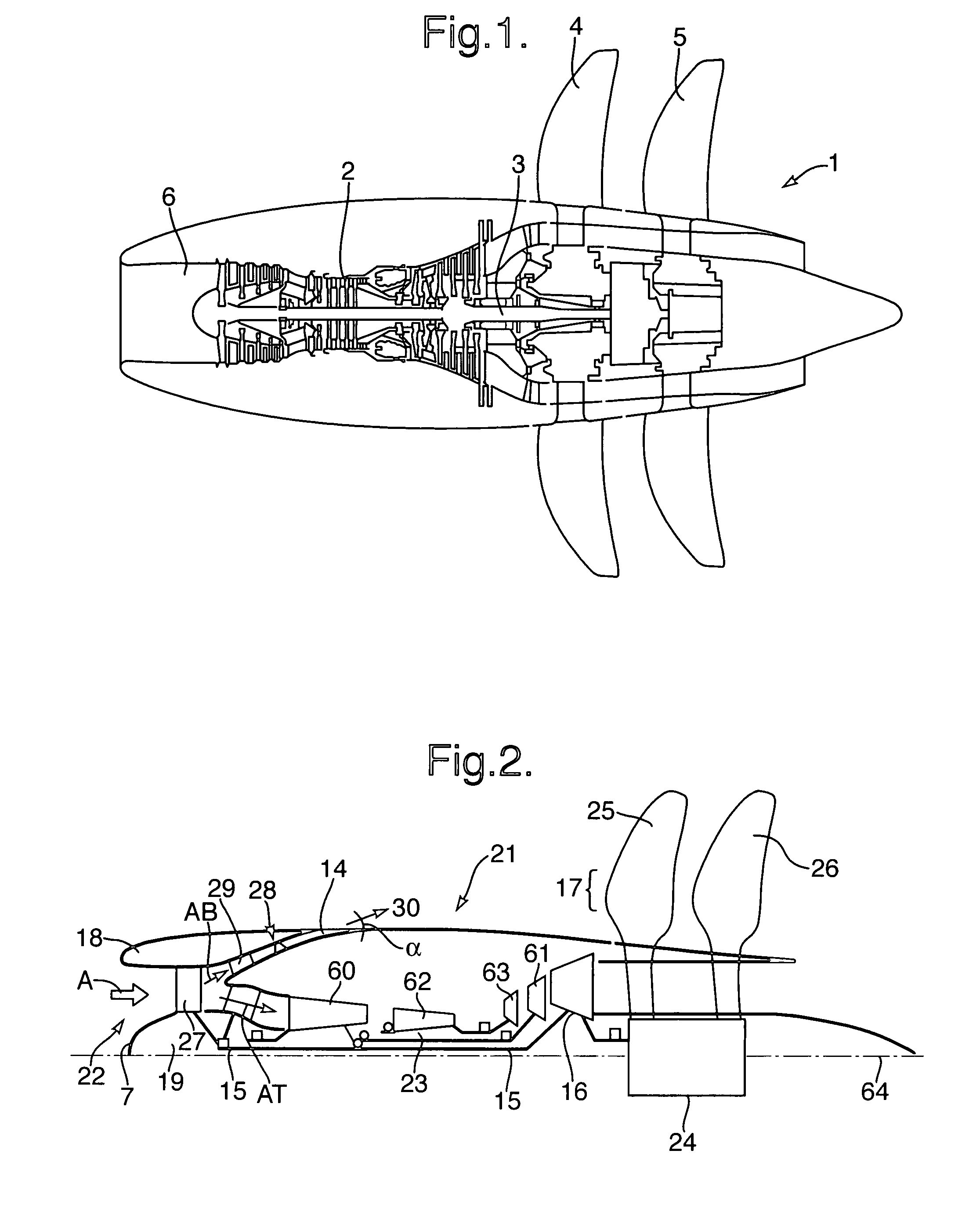

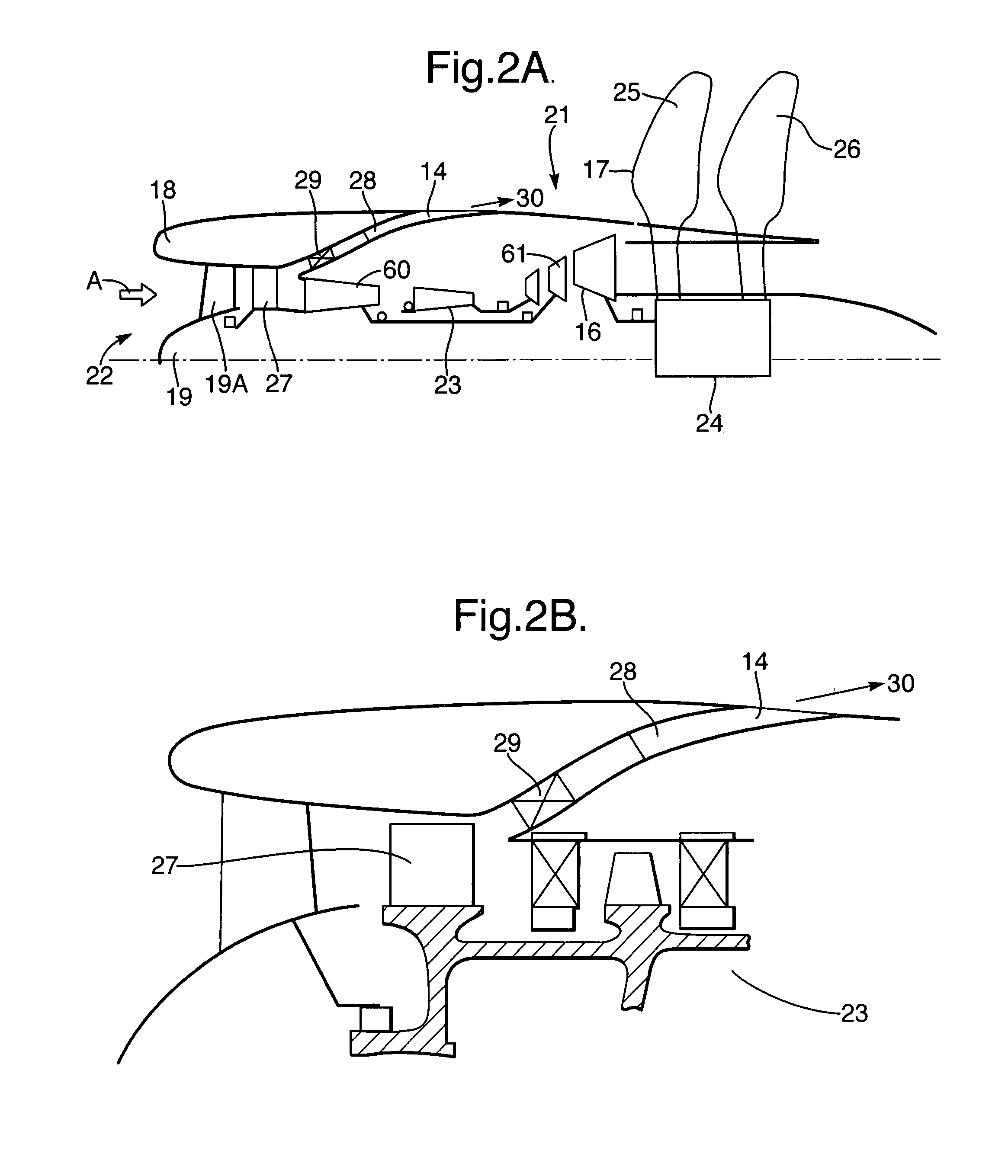

Engine

ActiveUS7891163B2Facilitate pressureCompensation for pressure lossWind motor controlCombination enginesParticulatesPropeller

In prop fan and contra fan gas turbine engines particularly utilized with regard to pusher configurations towards the aft of an aircraft, there is a significant problem with regard to debris and bird strikes resulting in particulate matter which may damage the engine thrust core. By providing an inlet rotor which fragments and creates a centrifugal aspect to the inlet flow, particulate matter can be directed to a bypass chute normally in the form of an annular section extending into a number of chute exits. In such circumstances, the particulate matter is removed continuously from the inlet flow and the chutes are normally angled to project any particulate matter towards propellers of the engine at robust positions.

Owner:ROLLS ROYCE PLC

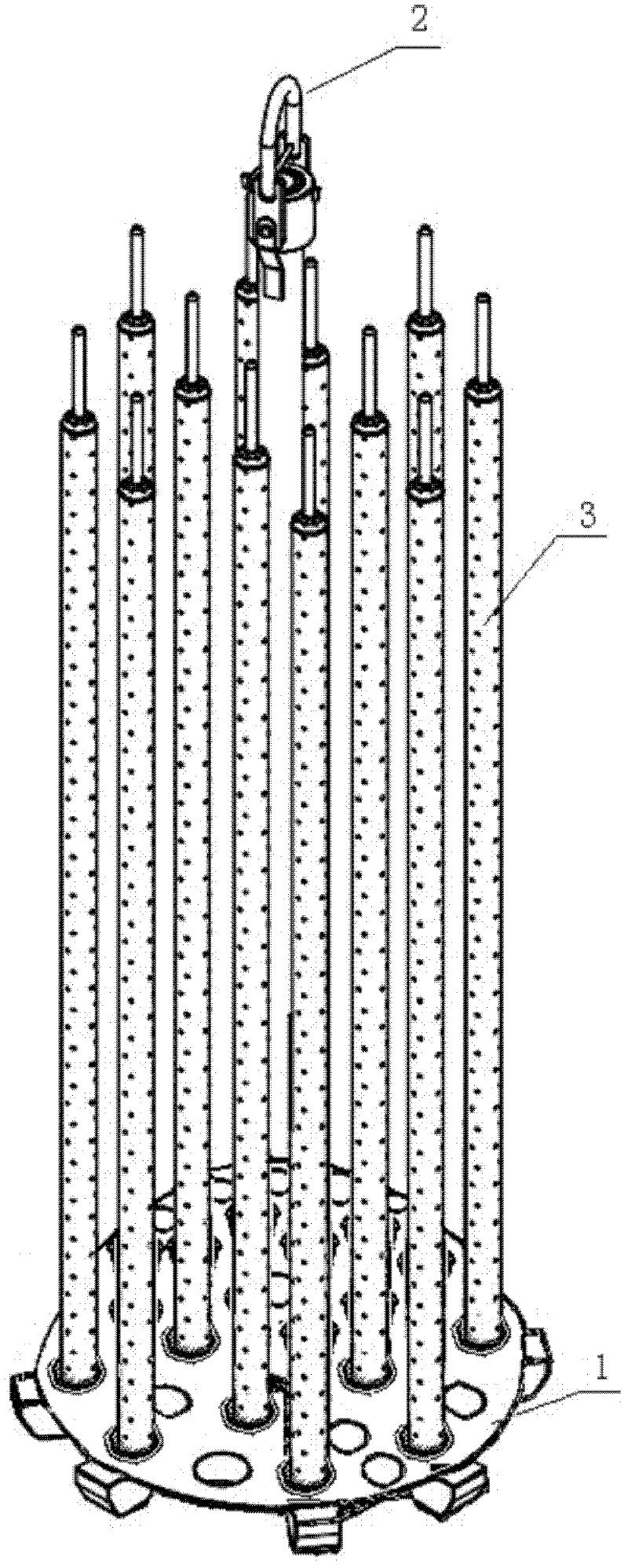

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

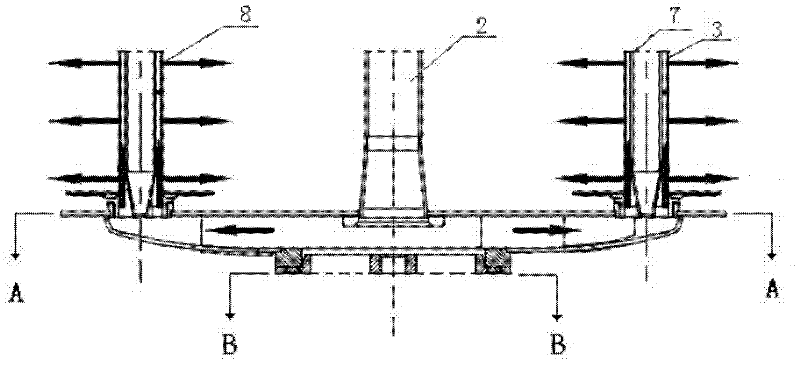

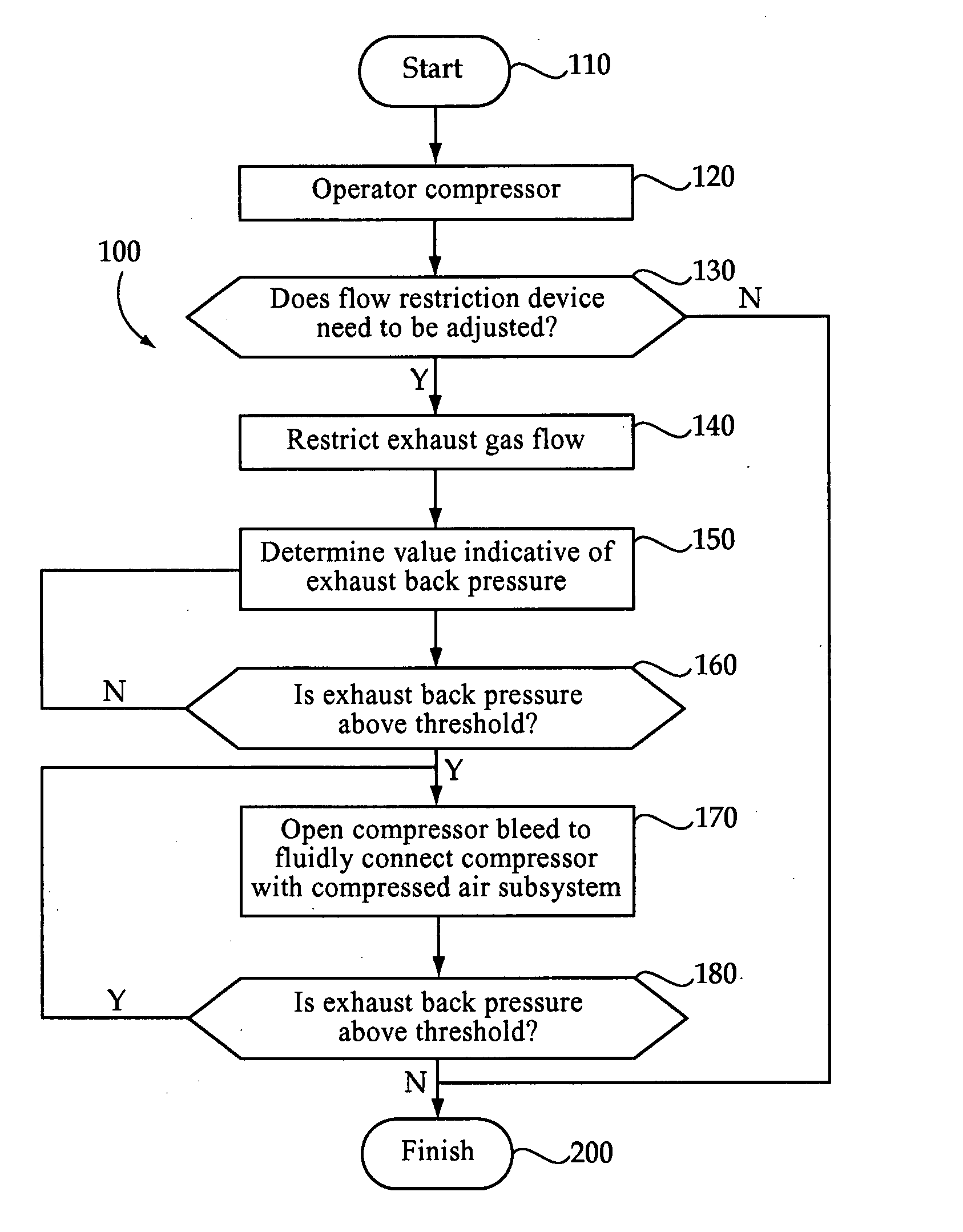

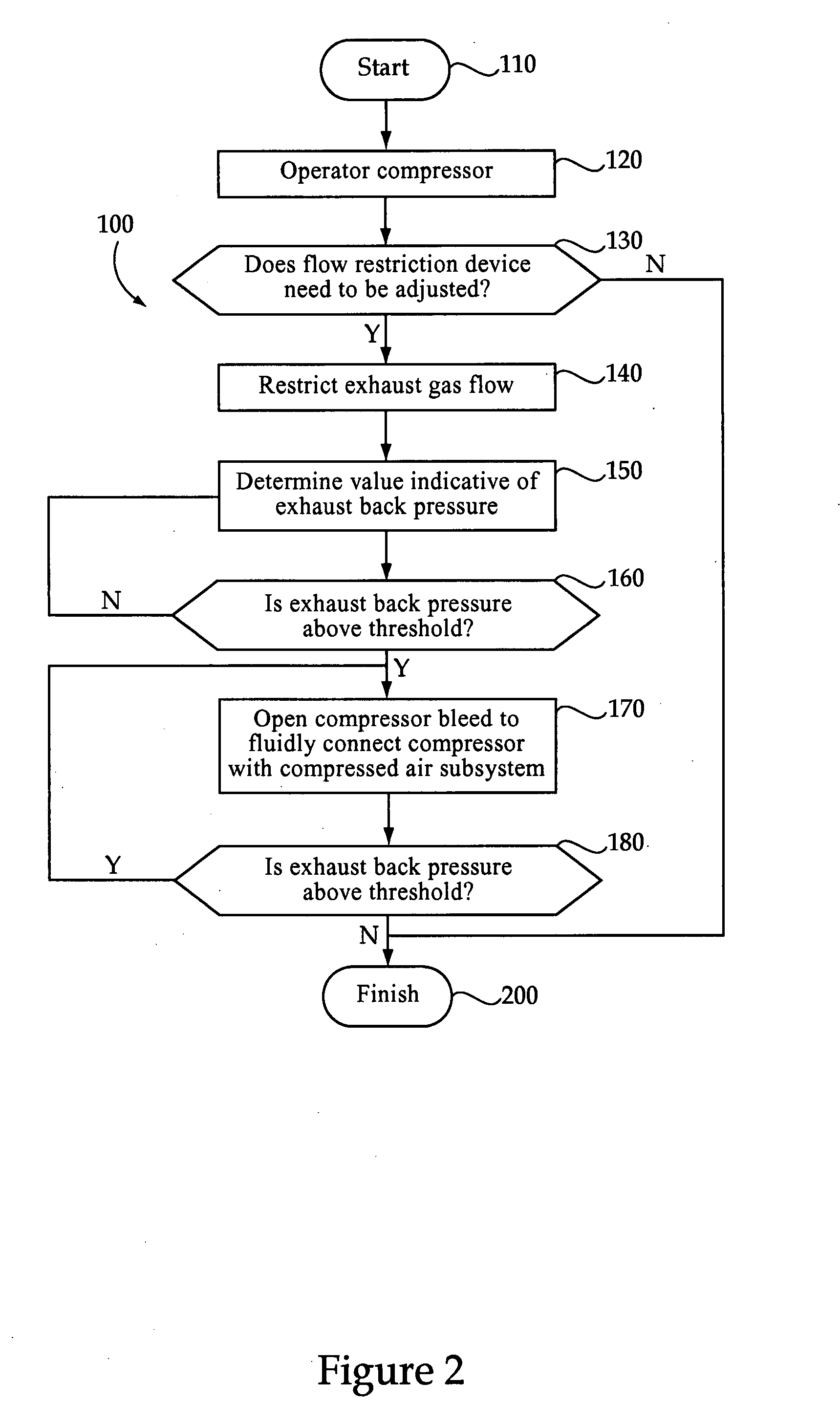

Machine, engine system and operating method

InactiveUS20090056311A1Large flow areaReduced flow areaInternal combustion piston enginesExhaust apparatusPressure controlTraffic volume

A method of operating an engine system includes compressing intake air, restricting exhaust flow from the engine via a flow restriction device, and supplying compressor air to a compressed air subsystem of the engine during restricting exhaust flow. Supplying of compressor air may occur by selectively actuating a pressure control device to fluidly connect an inlet of a compressed air subsystem with the compressor. An associated machine and engine system include a compressor, a flow restriction device, a compressed air subsystem and a pressure control device to selectively fluidly connect the compressed air subsystem with the compressor when the flow restriction device is in a relatively more closed configuration.

Owner:CATERPILLAR INC

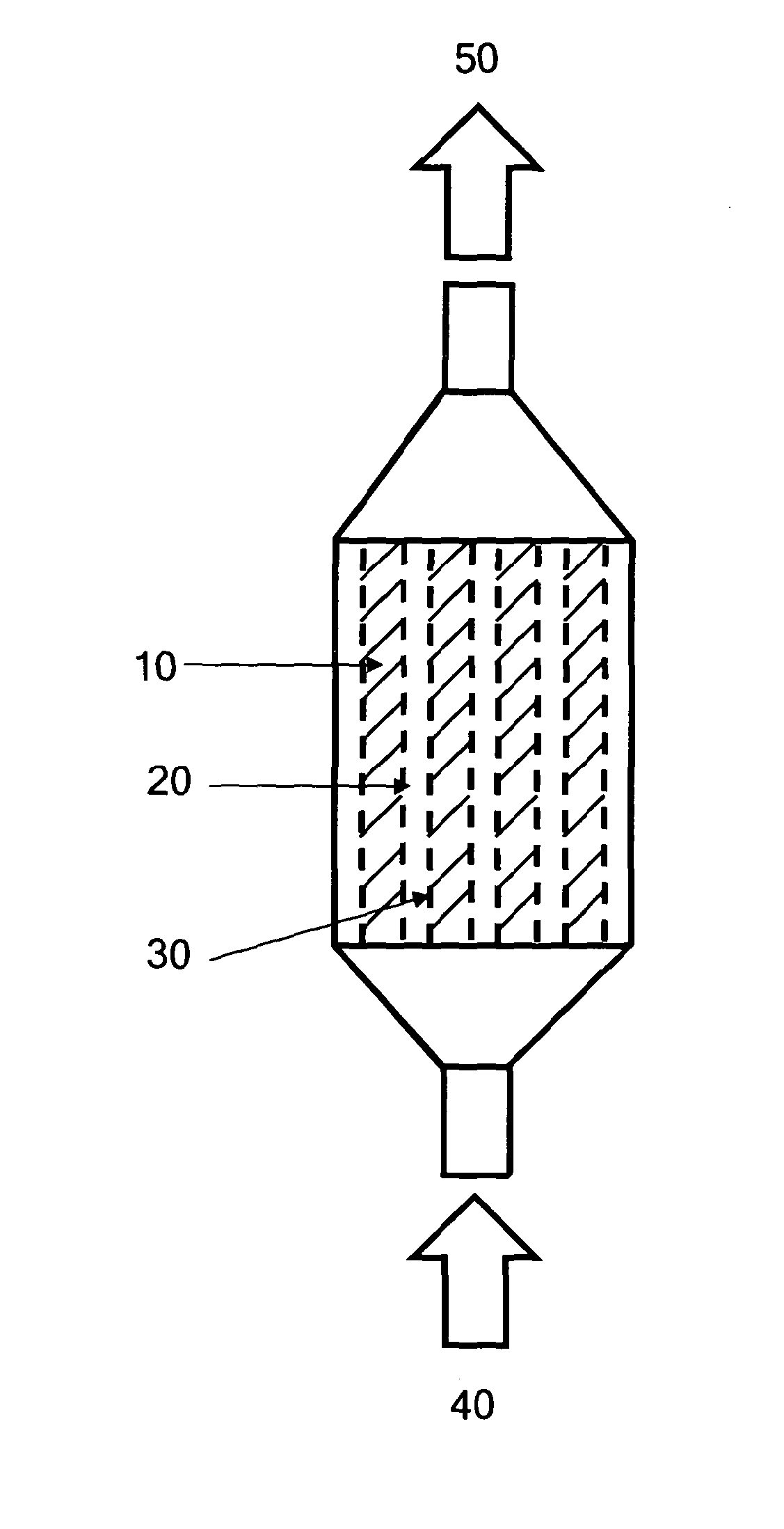

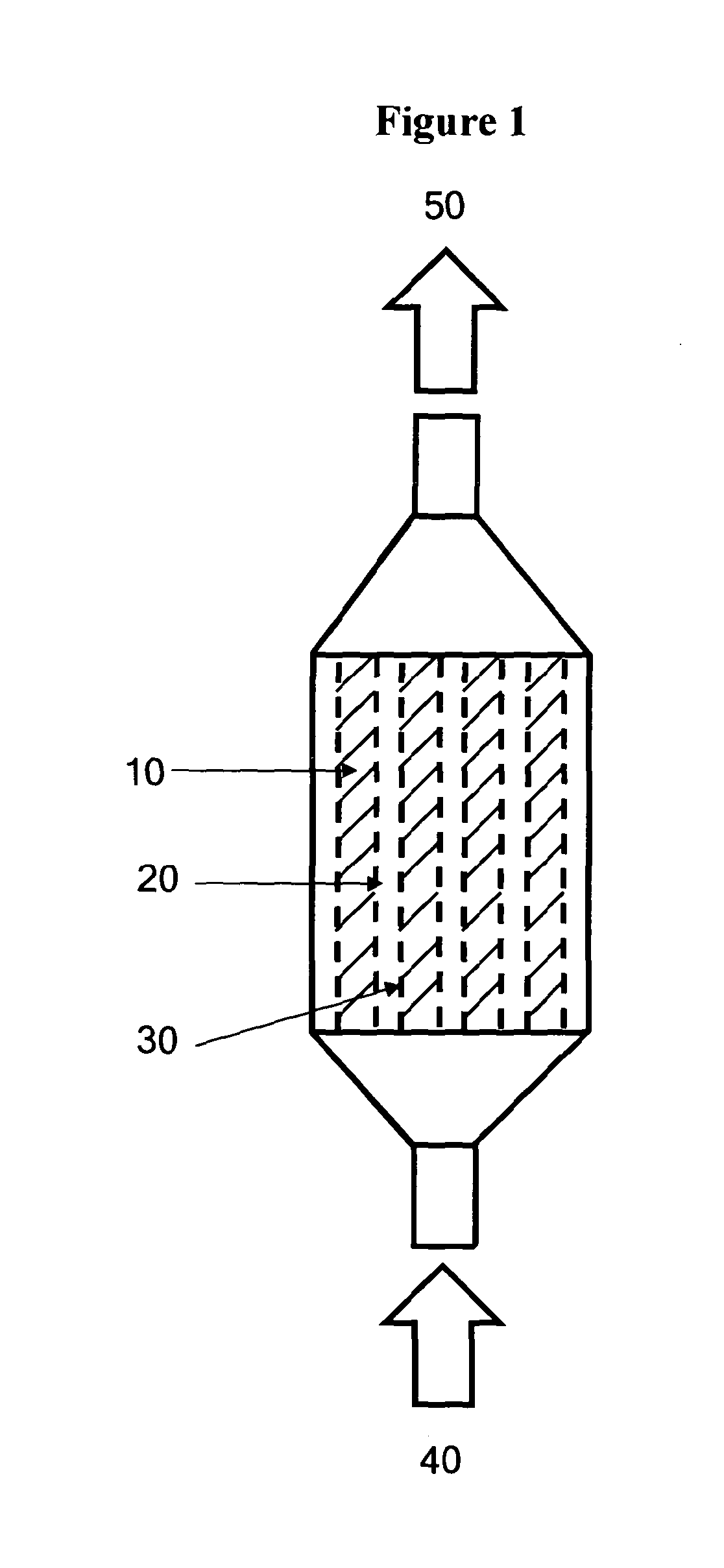

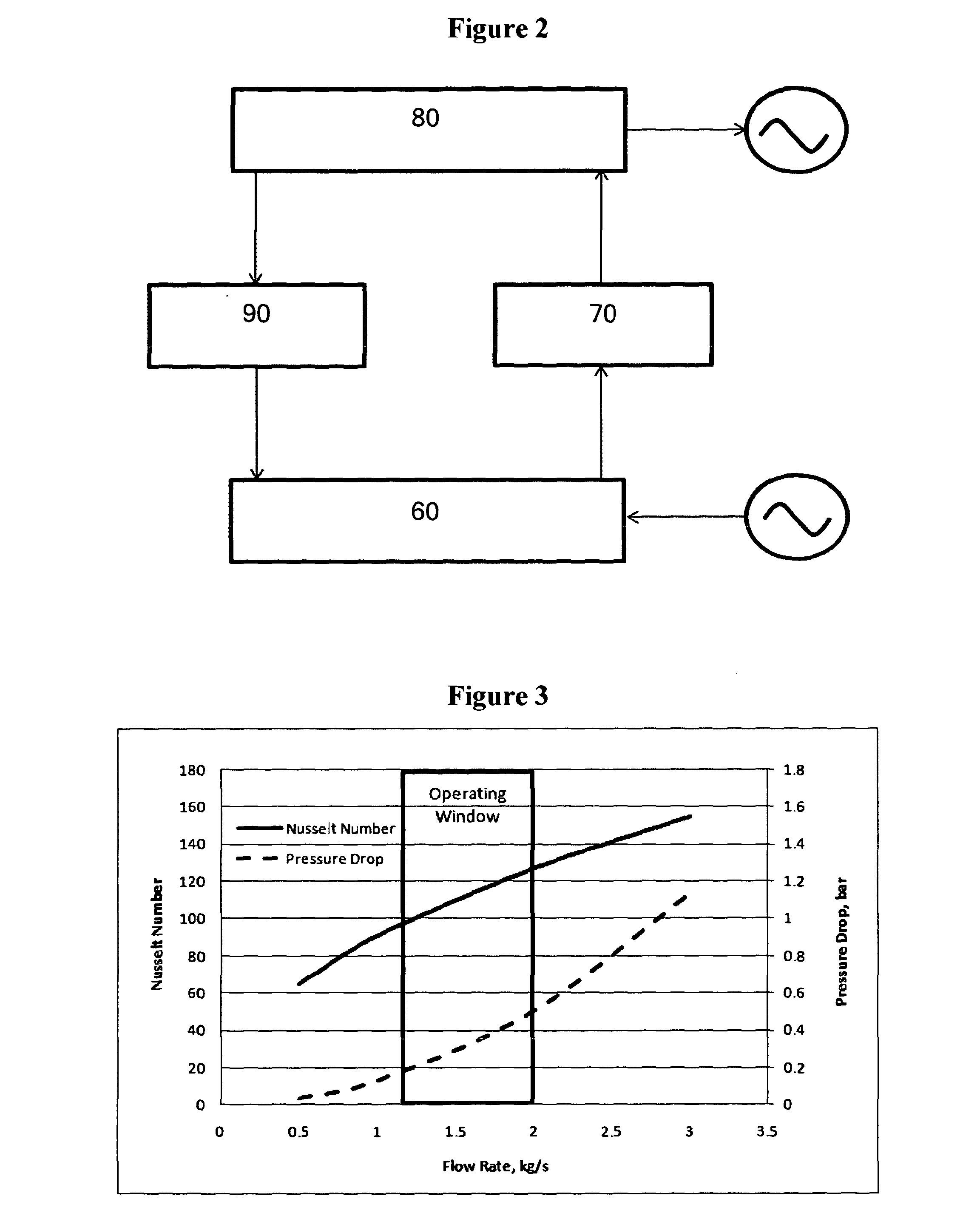

Method and apparatus for storing thermal energy

ActiveUS20130240171A1Maximizes thermal efficiencyDifferent flow rateHeat storage plantsHeat exchange apparatusThermal energyCharge and discharge

Methods and apparatus for storing thermal energy are disclosed. The thermal energy may be hot or cold. The methods and apparatus allow the thermal store to be charged and discharged at different rates. The methods and apparatus also allow the thermal store to be charged and discharged with multiple and / or interrupted phases.

Owner:HIGHVIEW ENTERPRISES LTD

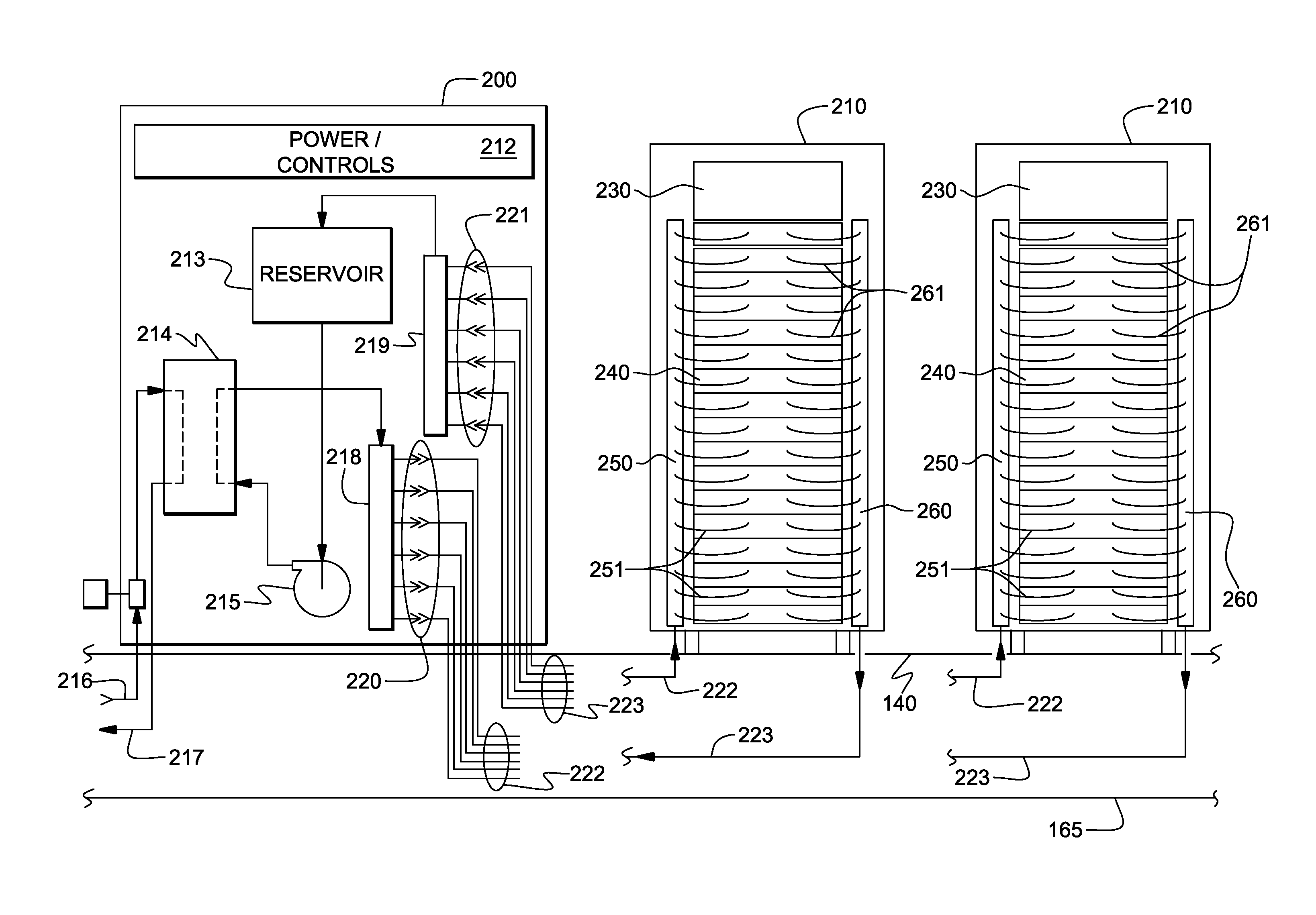

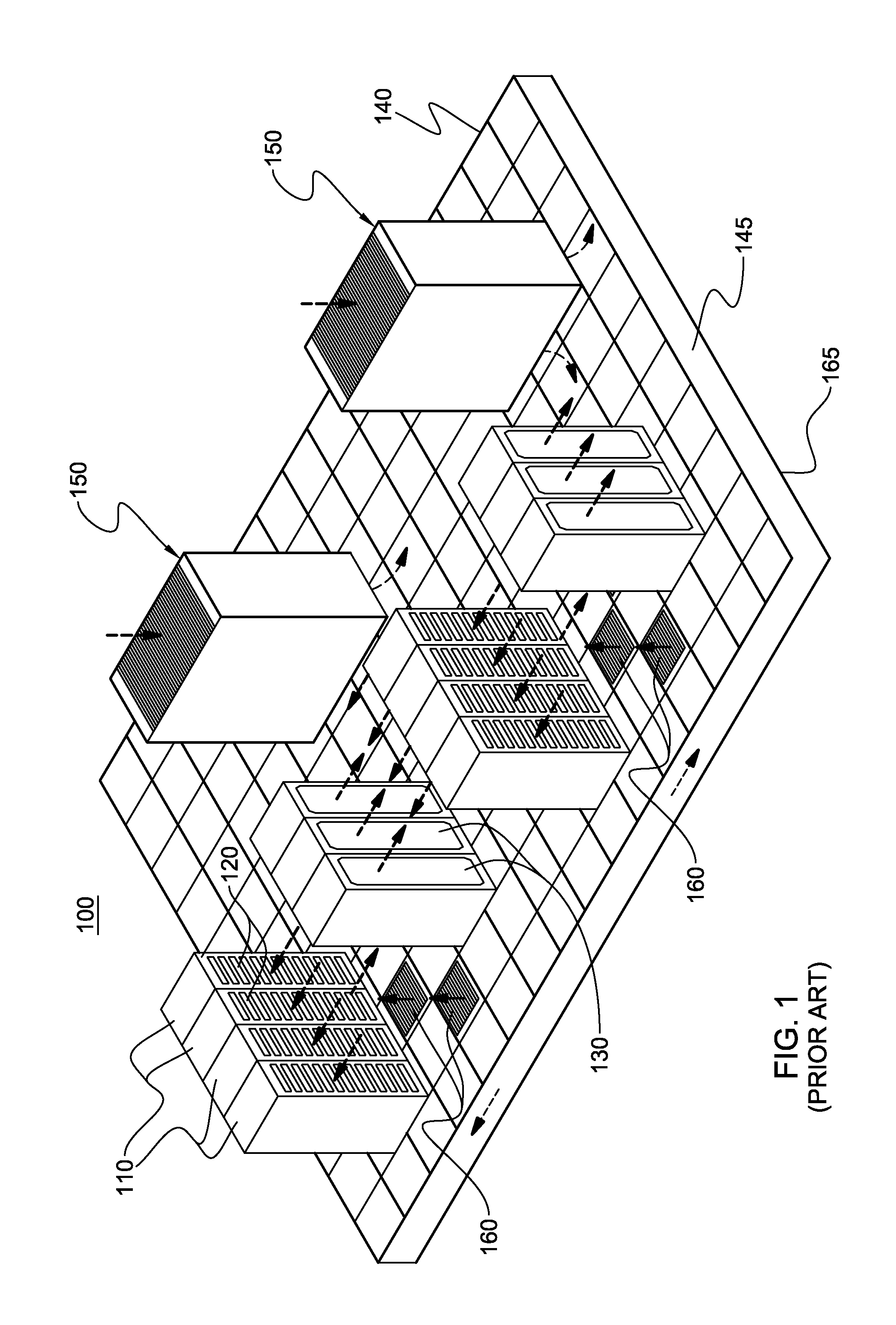

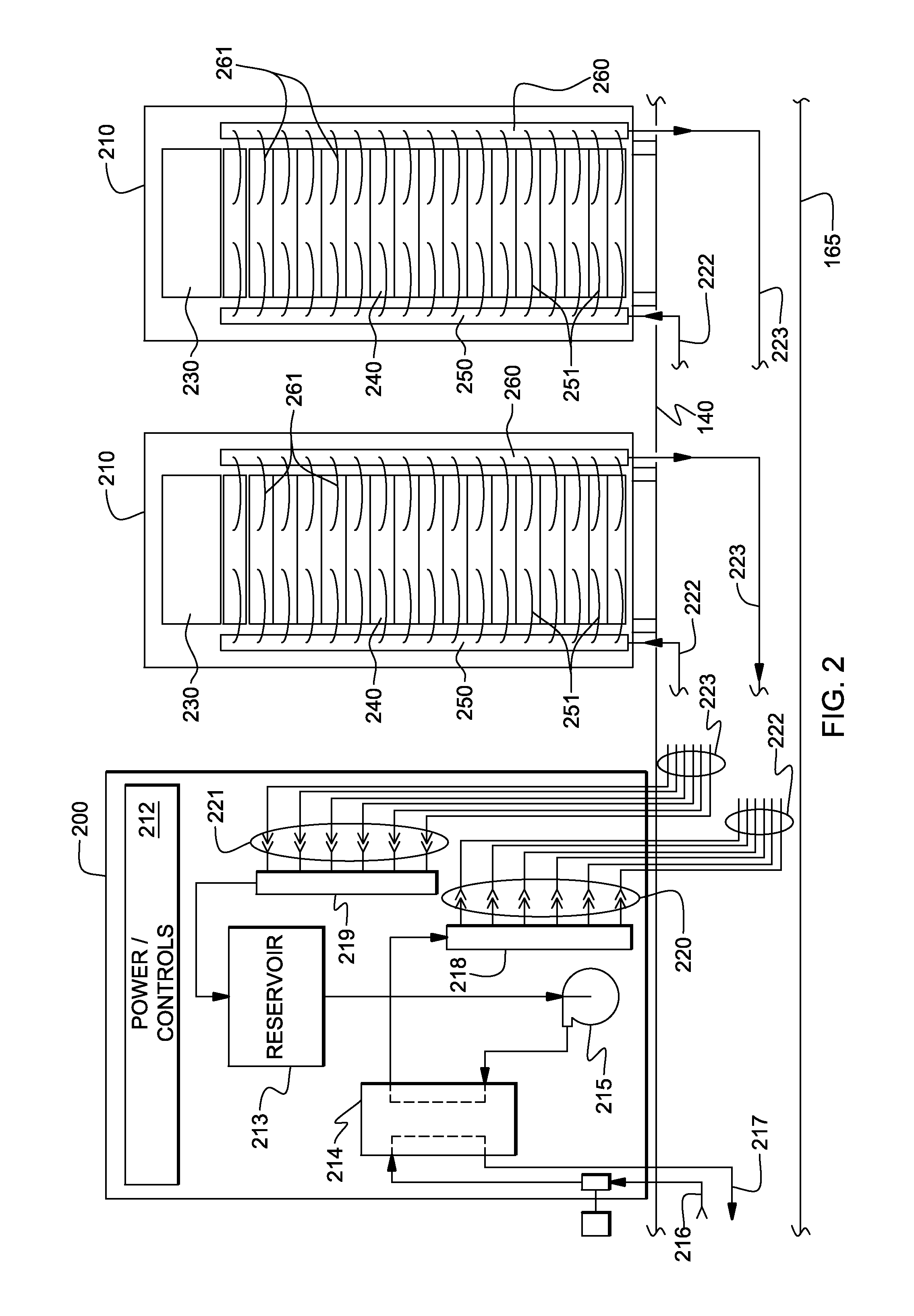

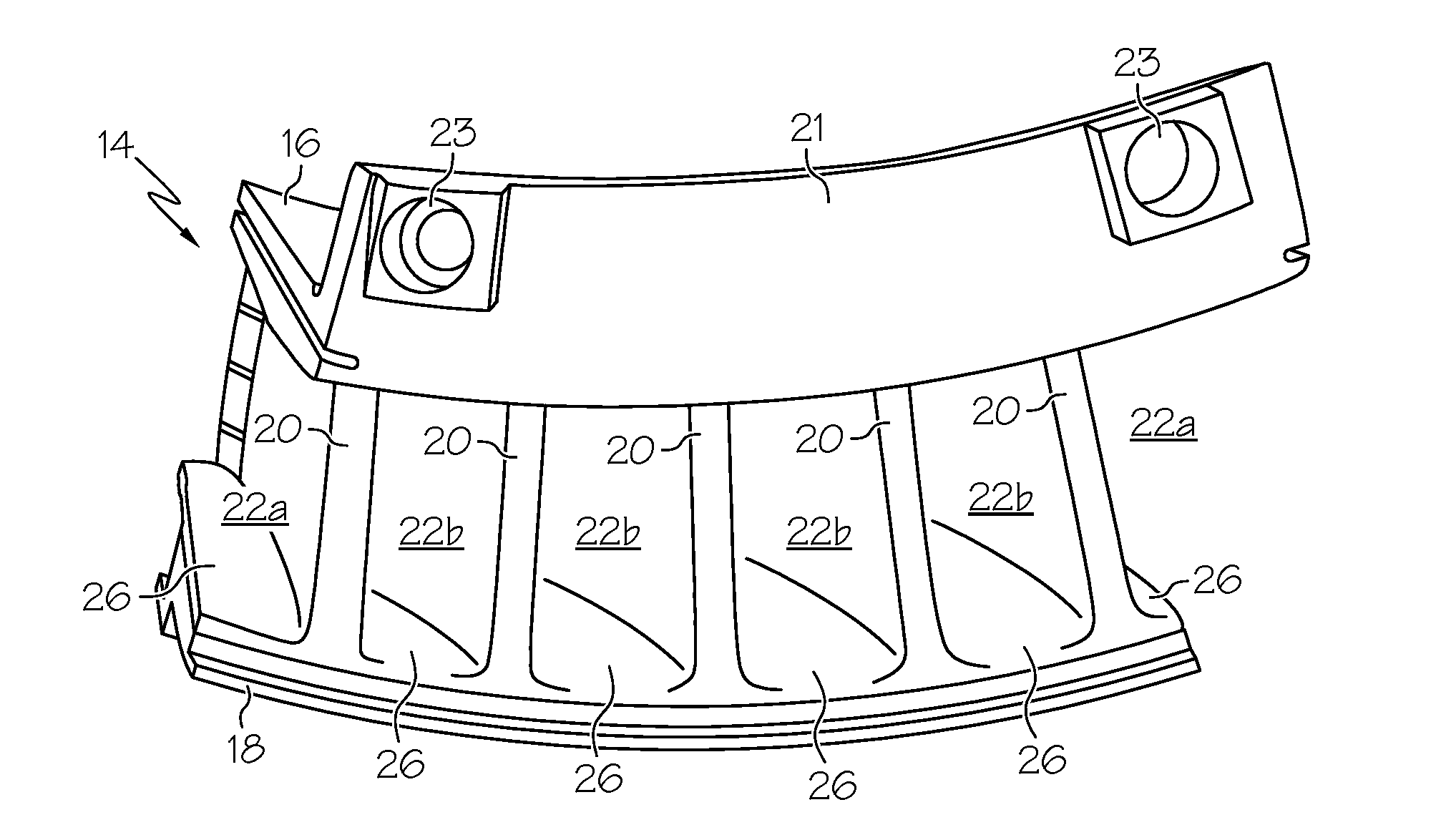

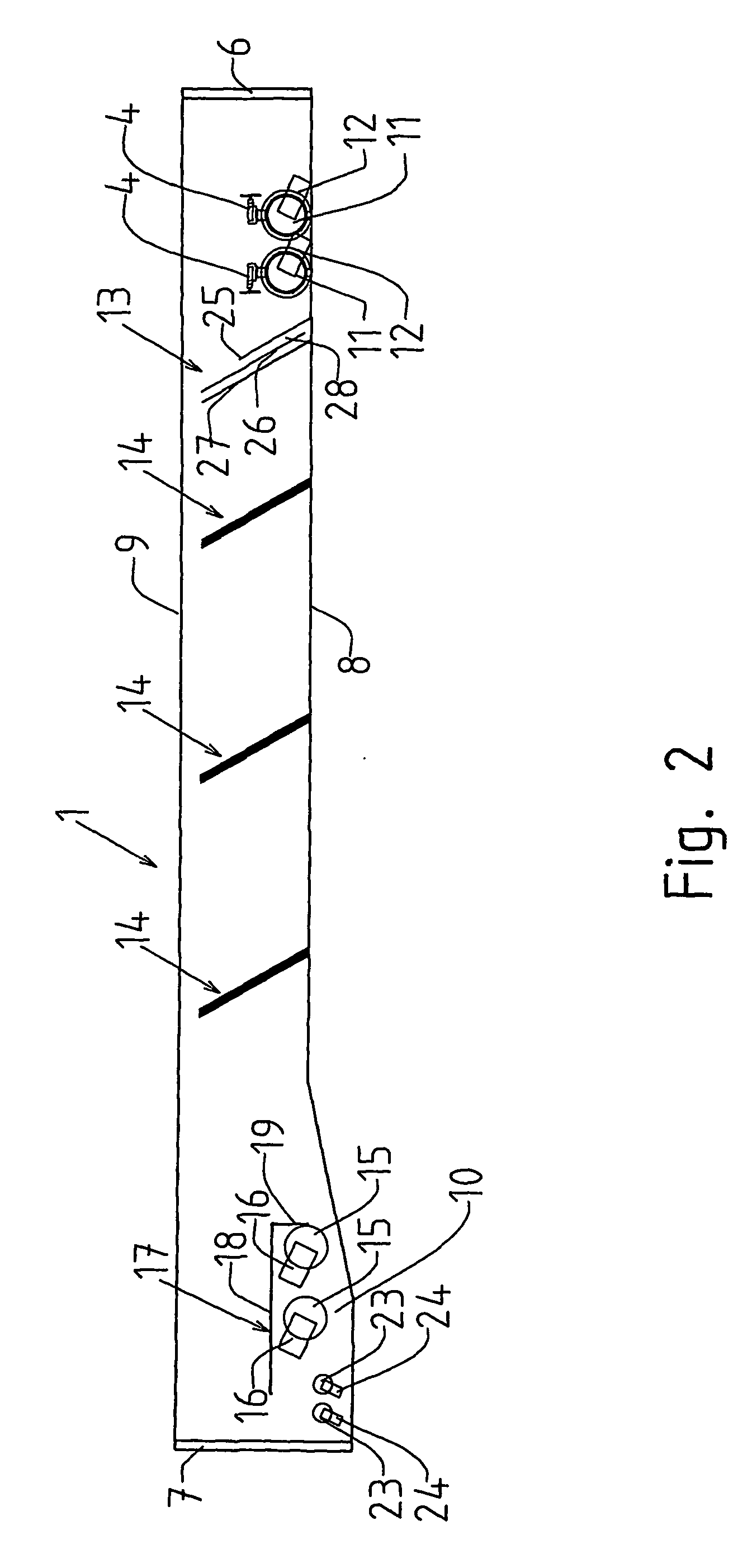

Coolant-cooled heat sink configured for accelerating coolant flow

InactiveUS20150107801A1Facilitate flow of coolantDecreasing cross-sectional coolant flowIndirect heat exchangersModifications by conduction heat transferEngineeringHeat transfer coefficient

Cooling apparatuses, cooled electronic modules, and methods of fabrication are provided which facilitate heat transfer from one or more electronic components to a coolant. The cooling apparatus includes a coolant-cooled heat sink with a thermally conductive structure having a coolant-carrying compartment including a varying cross-sectional coolant flow area through which coolant flows in a direction substantially parallel to a main heat transfer surface of the structure coupled to the electronic component(s). The coolant-cooled heat sink includes a coolant inlet and a coolant outlet in fluid communication with the coolant-carrying compartment, and the coolant flow area of the coolant-carrying compartment decreases, at least in part, in a direction of coolant flow through the coolant-carrying compartment. The decreasing coolant flow area facilitates an increasing effective heat transfer coefficient between the main heat transfer surface and the coolant by, at least in part, accelerating the coolant flow within the coolant-carrying compartment.

Owner:IBM CORP

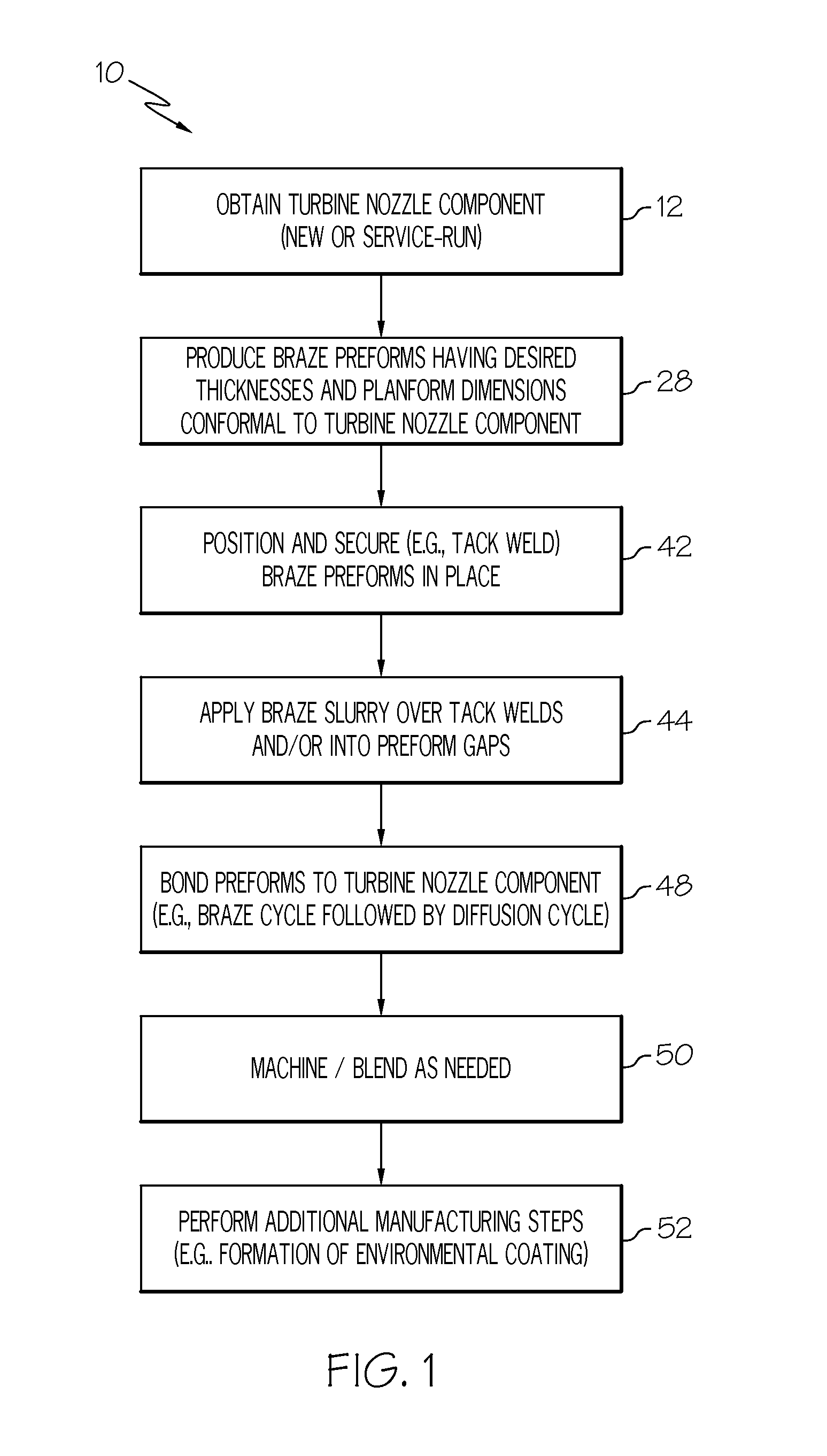

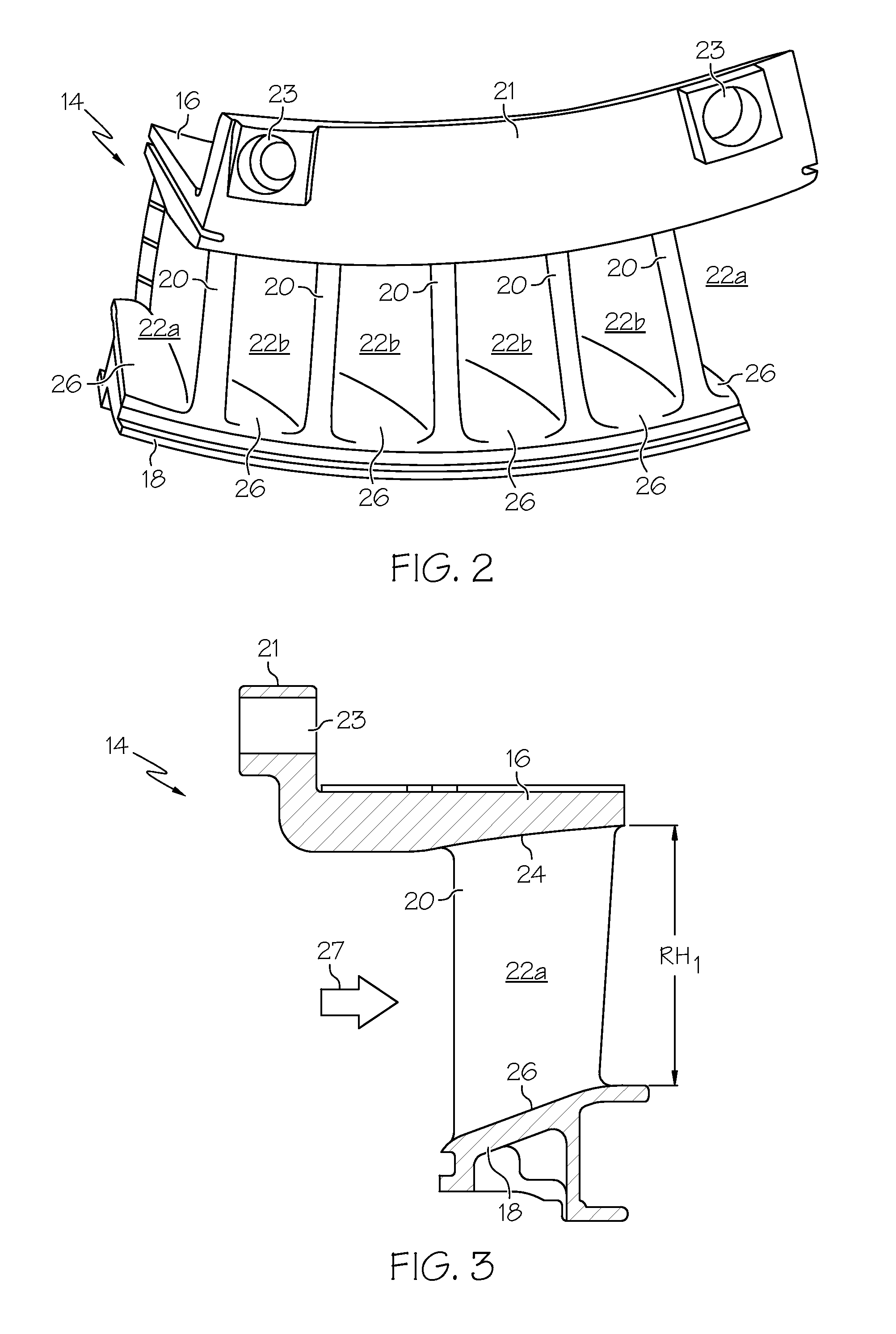

Methods for the controlled reduction of turbine nozzle flow areas and turbine nozzle components having reduced flow areas

Embodiments of a method for controllably reducing of the flow area of a turbine nozzle component are provided, as are embodiments of turbine nozzle components having reduced flow areas. In one embodiment, the method includes the steps of obtaining a turbine nozzle component having a plurality of turbine nozzle flow paths therethrough, positioning braze preforms in the plurality of turbine nozzle flow paths and against a surface of the turbine nozzle component, and bonding the braze preforms to the turbine nozzle component to achieve a controlled reduction in the flow area of the turbine nozzle flow paths.

Owner:HONEYWELL INT INC

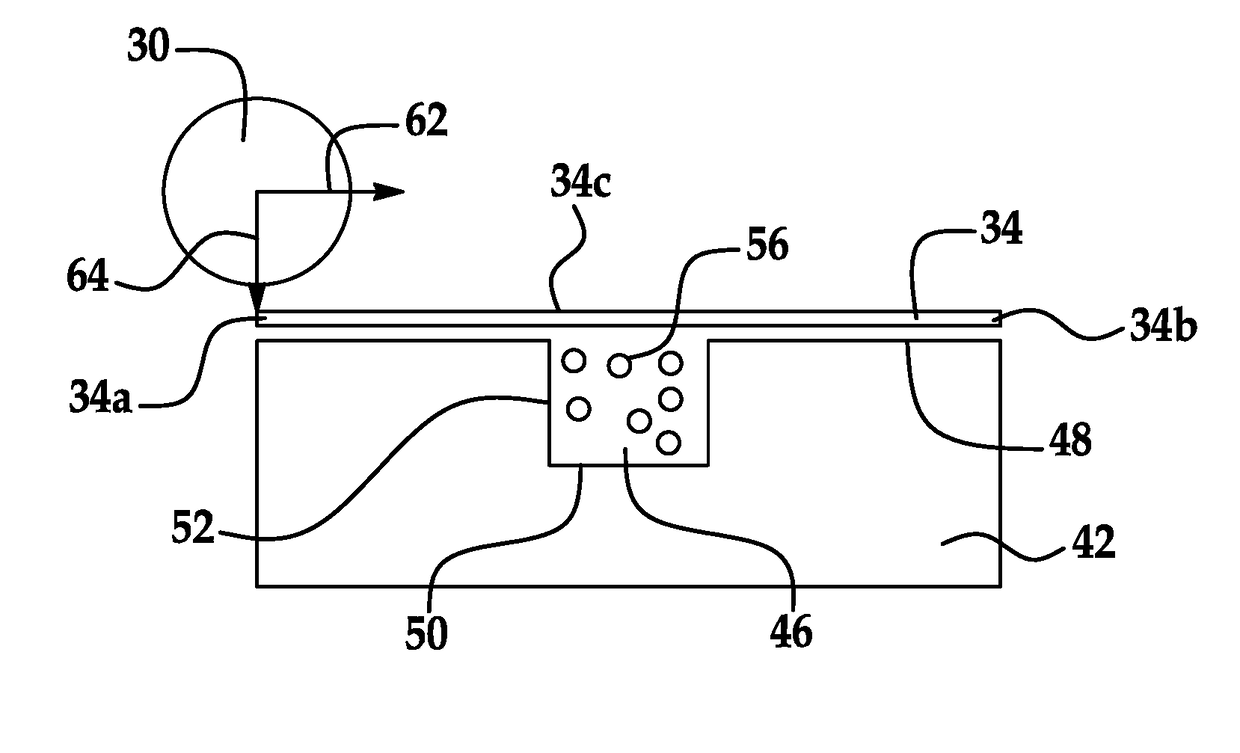

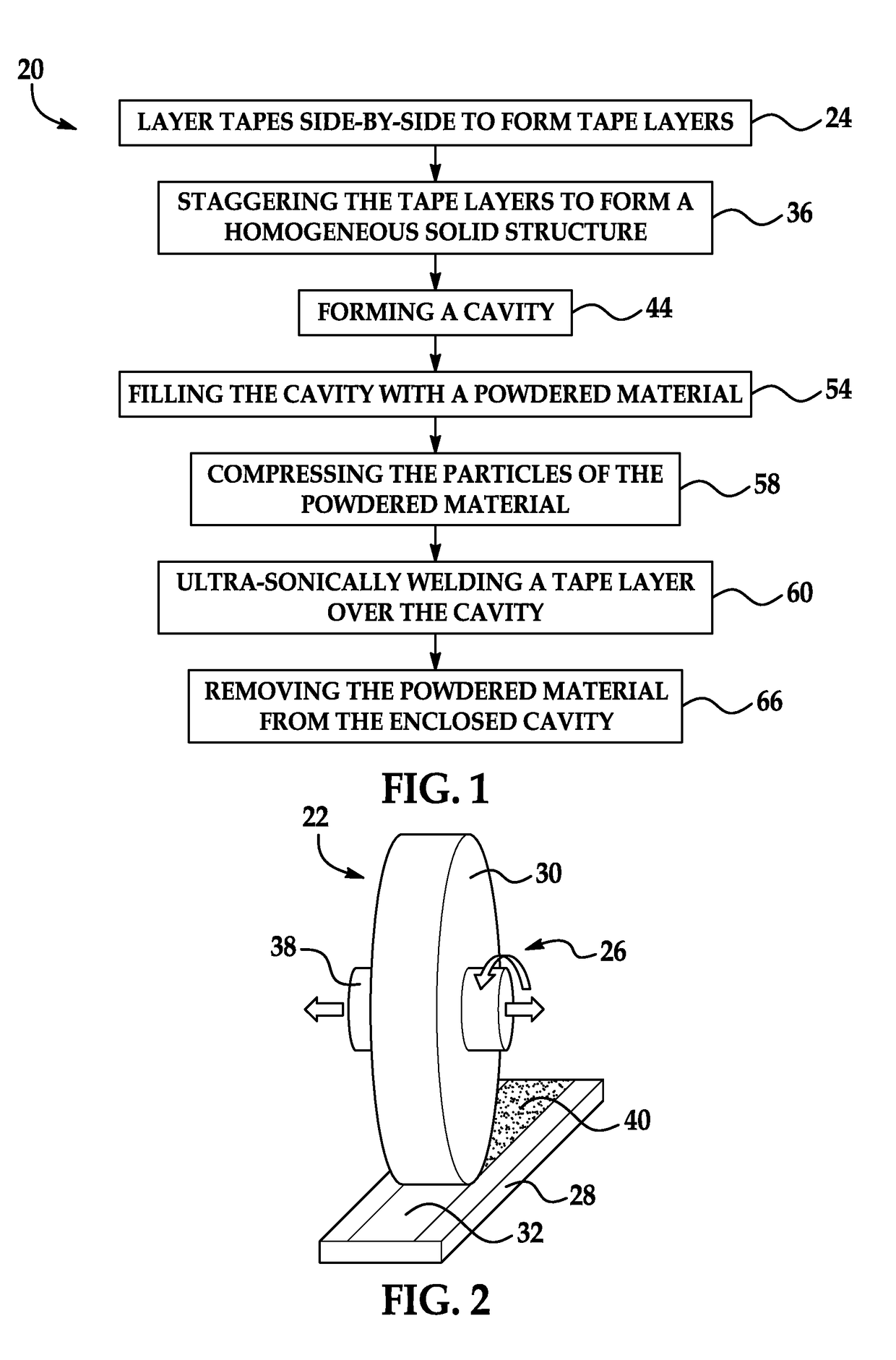

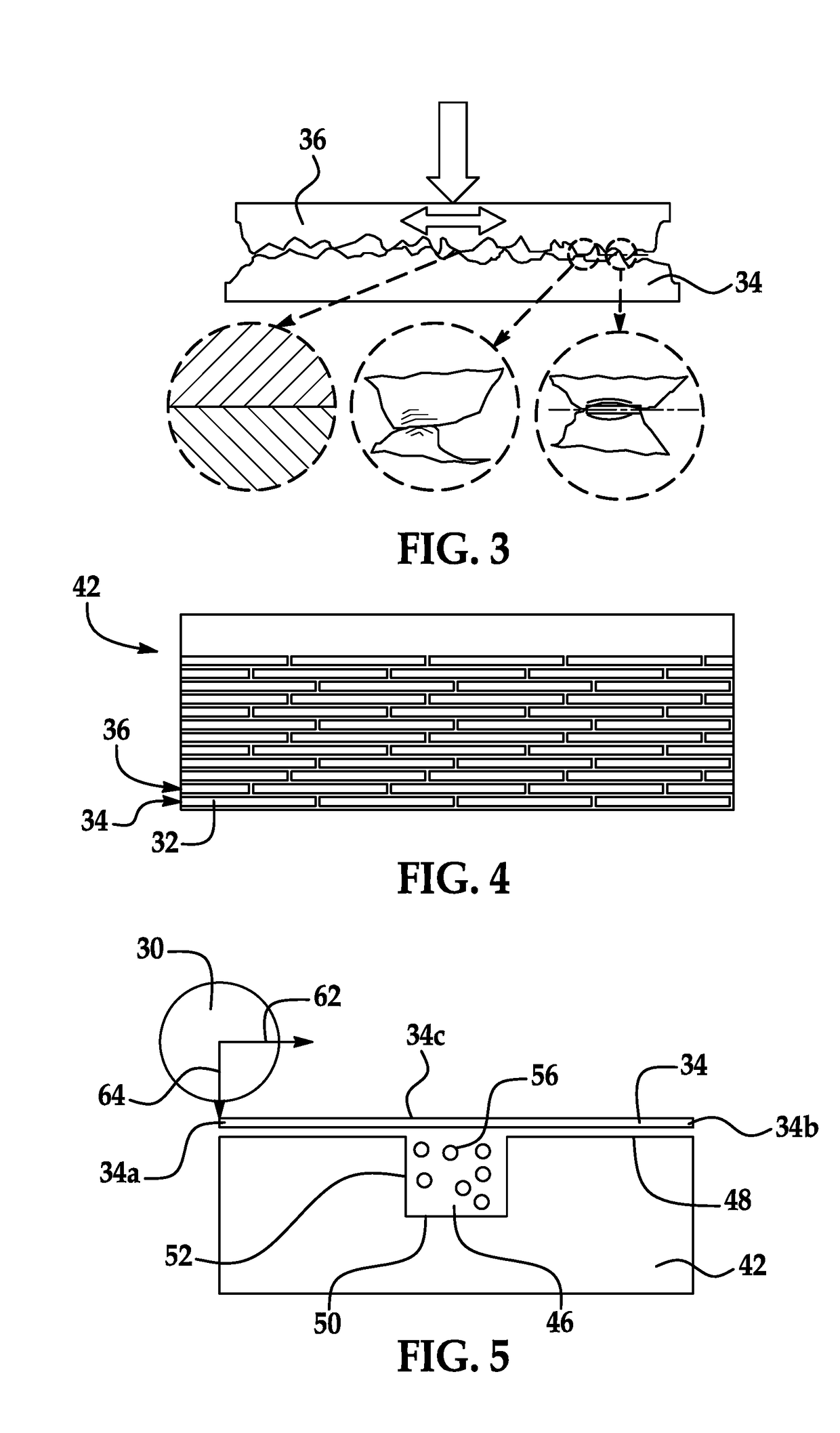

Powdered metal as a sacrificial material for ultrasonic additive manufacturing

ActiveUS20170304964A1Efficient heat transferReduced flow areaAdditive manufacturing apparatusWelding/cutting auxillary devicesSolid componentVolumetric Mass Density

A manifold structure and method of forming a structure having at least one enclosed cavity includes using an ultrasonic additive manufacturing (UAM) process to build up a solid component, forming a cavity in the solid component, filling the cavity with a sacrificial material, using a UAM process to build up a finstock layer over the cavity filled with the powder material to enclose the cavity and form the enclosed cavity, and removing the sacrificial material from the enclosed cavity after the finstock layer is ultrasonically welded to the solid component. The sacrificial material has an adequate density to support the UAM process of forming the finstock layer over the cavity and the material may be removed from the enclosed cavity, resulting in an enclosed cavity having smooth surfaces with an optimal fluid flow area therethrough.

Owner:RAYTHEON CO

Method and equipment for purifying an extraction solution from aqueous entrainment and impurities

InactiveUS20060113246A1Reduced flow areaEffect of solutionGold compoundsLiquid displacementPhysical separationImpurity

The invention relates to a method and equipment with which an organic solution extraction solution is purified from entrainment of aqueous solution and impurities during hydrometallurgical liquid-liquid extraction. The method treats an organic extraction solution, which is loaded with a valuable metal or valuable substance from the aqueous solution. The purpose is to carry out the physical separation of water droplets and the chemical removal of impurities from the organic extraction solution simultaneously.

Owner:OUTOTEC OYJ

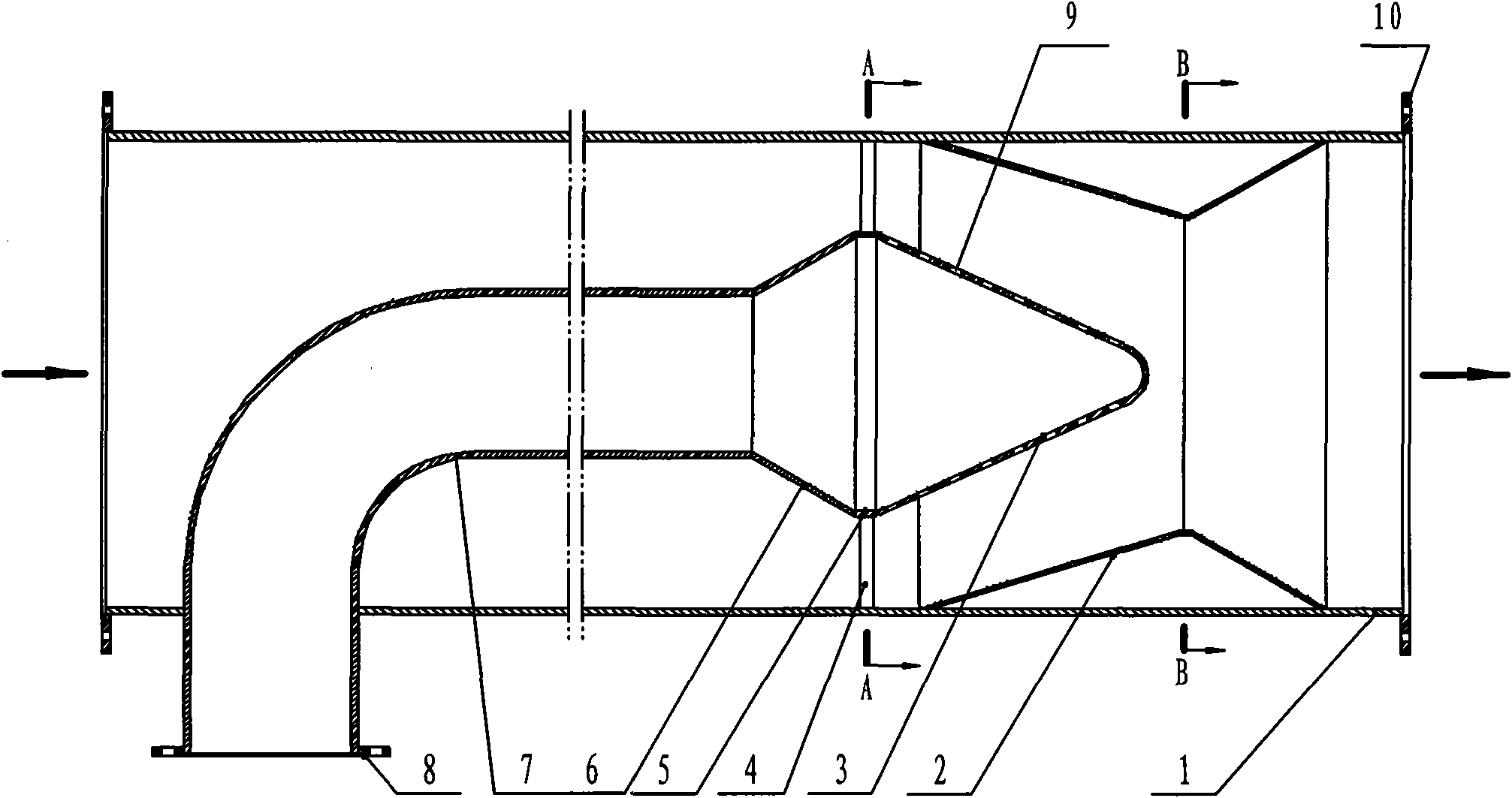

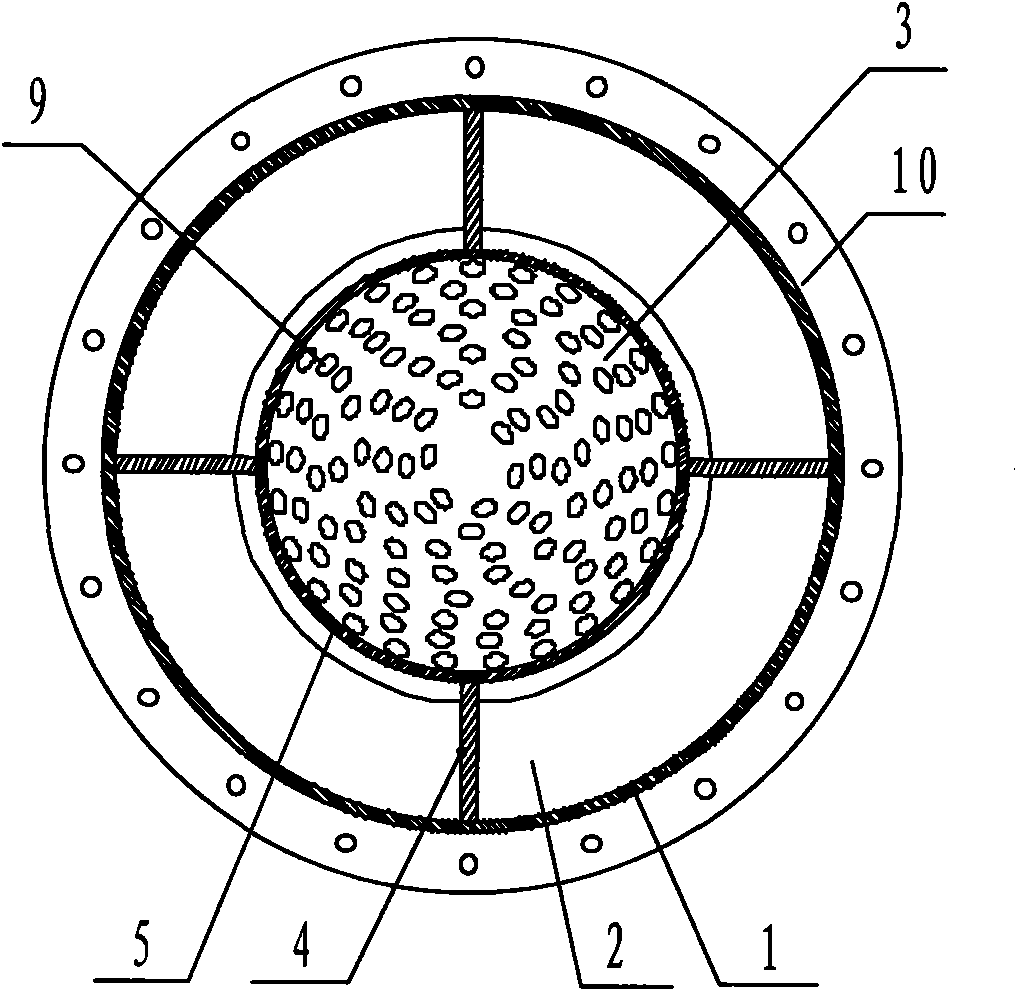

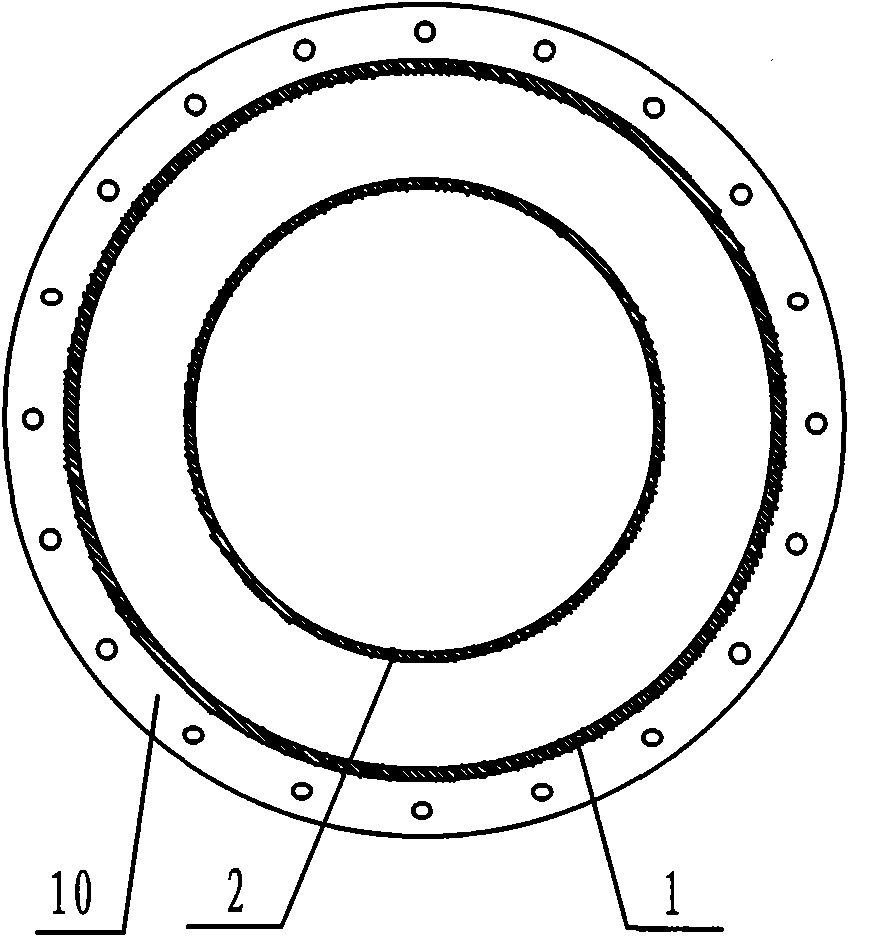

Mixer of coal mine extracted gas and ventilation gas

The invention relates to a mixer of coal mine extracted gas and ventilation gas, which is characterized by comprising a tubular shell, a gas ejection tube and a fairing, wherein two flanges arranged at both ends of the shell, the gas ejection tube is formed by sequentially connecting an inlet flange, an inlet tube, an expansion tube, a transition tube and a conical tail tube, the inlet end of the inlet flange is arranged outside the shell, the inlet tube, the expansion tube, the transition tube and the conical tail tube are arranged in the shell facing the outlet of the shell, the end of the conical tail tube adopts arc transition, small holes are uniformly distributed on the wall surface of the conical tail tube, a plurality of stiffeners are arranged between the transition tube and the shell, the fairing is arranged in the shell behind the stiffeners and encircles the conical tail tube, and the end of the fairing is near the outlet of the shell. The invention has the advantages of uniformly mixing, low energy consumption on extracted gas transportation and the like.

Owner:SHANDONG UNIV OF TECH

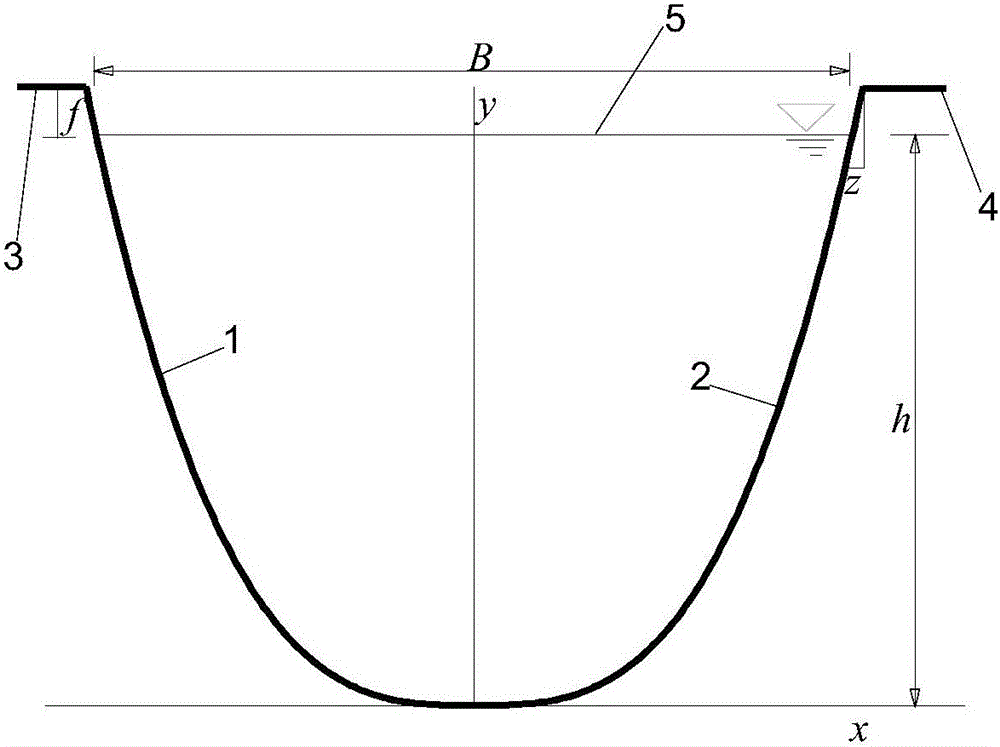

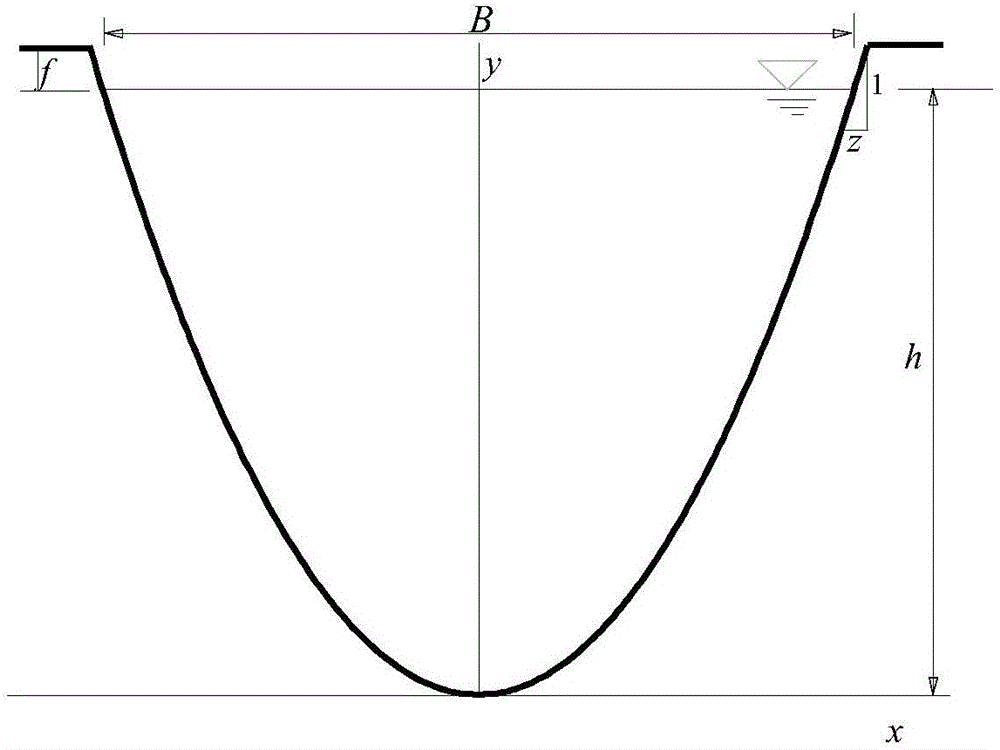

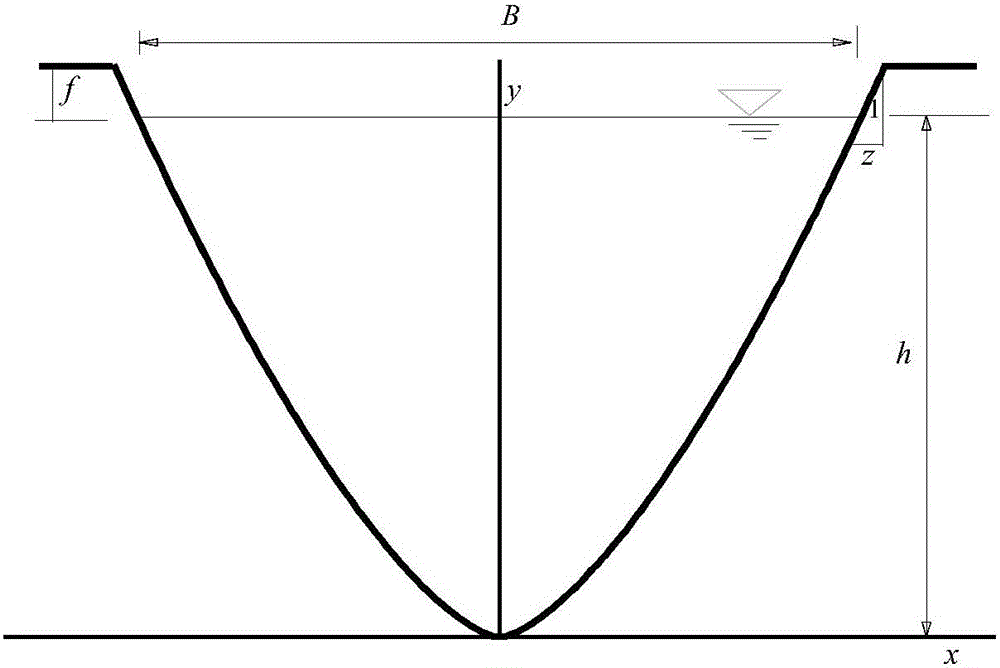

Waterpower optimal section of cubic parabola shaped water conveying open channel, and solving method for cubic parabola shaped waterpower optimal section

The invention discloses a cubic parabola shaped waterpower optimal section of a water conveying open channel, and a solving method for the cubic parabola shaped waterpower optimal section. The waterpower optimal section employs a cubic parabola shaped section, and is expressed as y=ax<3>, wherein the optimal width to depth ratio is B / h=2.1139, the shape coefficient a=0.8469h<-2>, and the side slope coefficient of a water surface is z=1 / 6* B / h=0.3523. The solving method comprises the steps: firstly designing the shape of the waterpower section of the water conveying open channel as the cubic parabola shaped waterpower section, and solving the characteristics of the waterpower section; secondly building a solving model for the waterpower optimal section; thirdly solving a differential equation of the waterpower optimal section through employing the Lagrangian multiplier method; fourthly enabling a wetted perimeter to be expressed as an expression of a complete elliptic integral function in a complex field range; and finally converting an optimal section problem into an equation with one unknown quantity in the complex field range, and obtaining the width to depth ratio of the waterpower optimal section. The waterpower optimal section is larger in discharge capacity under the condition of equal area or wetted perimeter, facilitates the improvement of the water conveying efficiency, and is low in construction cost.

Owner:UNIV OF JINAN

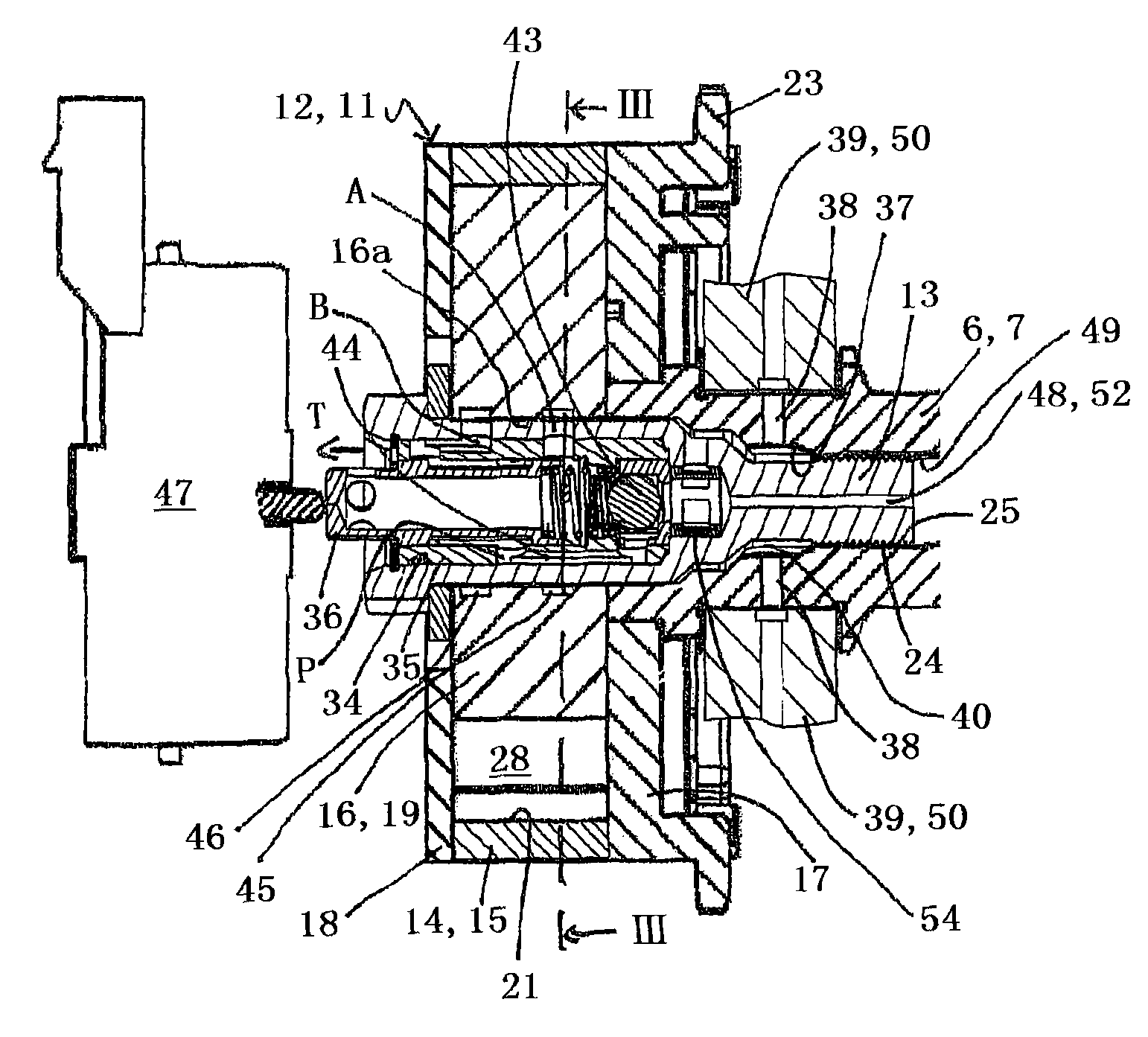

Device for variable adjustment of timing of gas exchange valves of internal combustion engine

InactiveCN102112707AReduced flow areaReduce loadValve arrangementsMachines/enginesPhase shiftedExternal combustion engine

The invention relates to a device (11) for the variable adjustment of the timing of gas exchange valves (9, 10) of an internal combustion engine (1), comprising a hydraulic phase shifting device (12), a camshaft (6, 7) and a pressurizing means distributor (13), wherein the phase shift device (12) can be caused to come into drive linkage with a crankshaft (2) and is rigidly connected to the camshaft (6, 7), wherein a phase position of the camshaft (6, 7) relative to the crankshaft (2) can be variably adjusted by way of the phase shift device (12), wherein the interior of the camshaft (6, 7) comprises a cavity (49) that communicates with one or more camshaft bearings (50) designed to be separate from a rotating pressurizing means conveyor (39), wherein the pressurizing means distributor (13) is disposed in a receiving area (37) of the camshaft (6, 7), wherein the camshaft (6, 7); comprises an opening (38) in the area of the pressurizing means distributor (13), said opening communicatingon the one hand with the interior of the camshaft (6, 7) and on the other hand with the rotating pressurizing means conveyor (39), wherein a pressurizing means path (40) is designed inside the camshaft (6, 7), said path communicating on the one hand with the opening (38) and on the other hand with the hydraulic phase shift device (12).

Owner:SCHAEFFLER TECH AG & CO KG

Turbine airfoil with platform cooling

ActiveUS8240981B2Improve cooling effectEnhances the convective coolingPump componentsBlade accessoriesTurbineGas turbines

Convective cooling of gas turbine engine airfoil platforms is enhanced by grooving the interface of the platforms with corresponding platform-to-platform seals, thereby accelerating cooling airflow over the platform surfaces.

Owner:RTX CORP

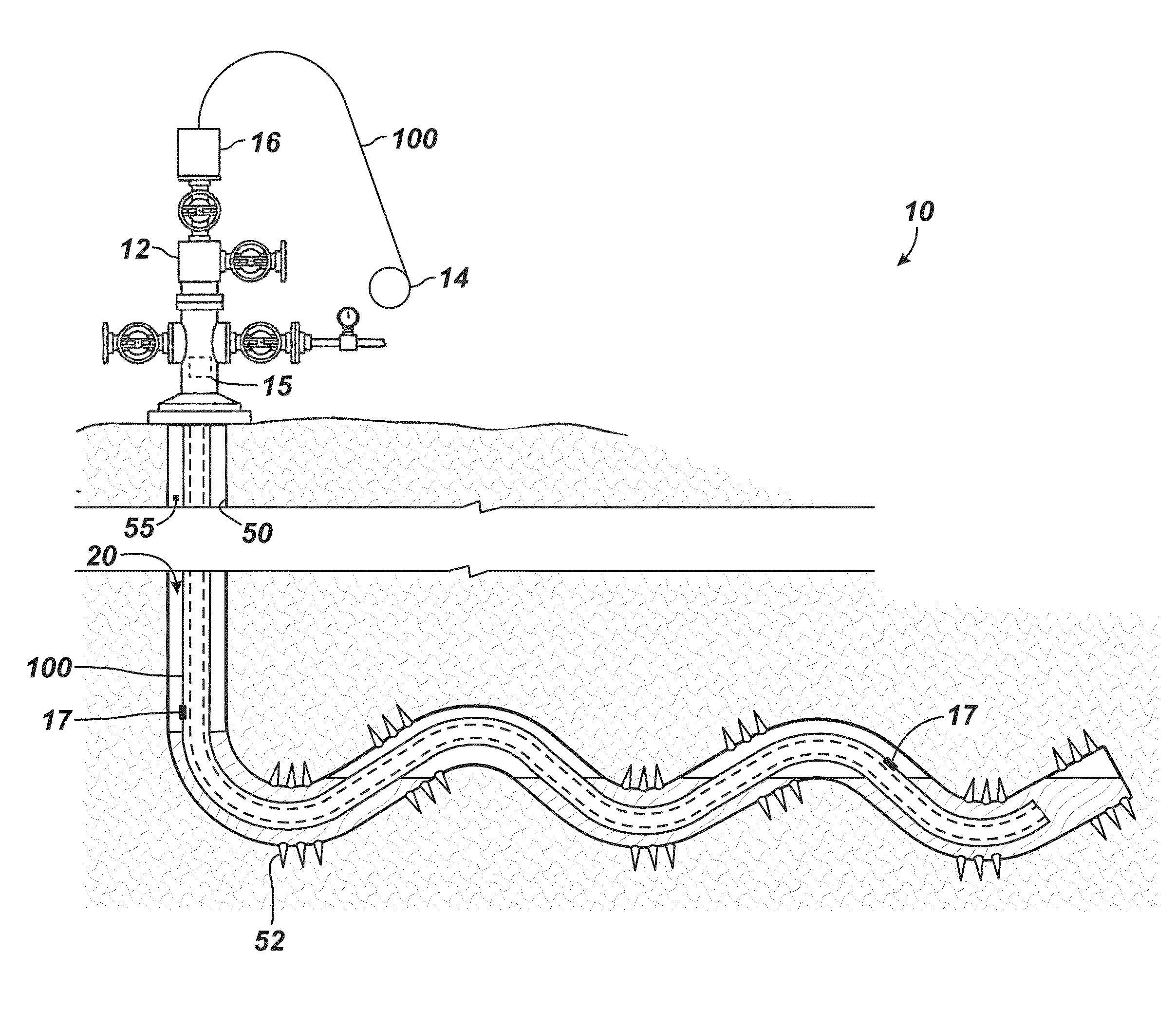

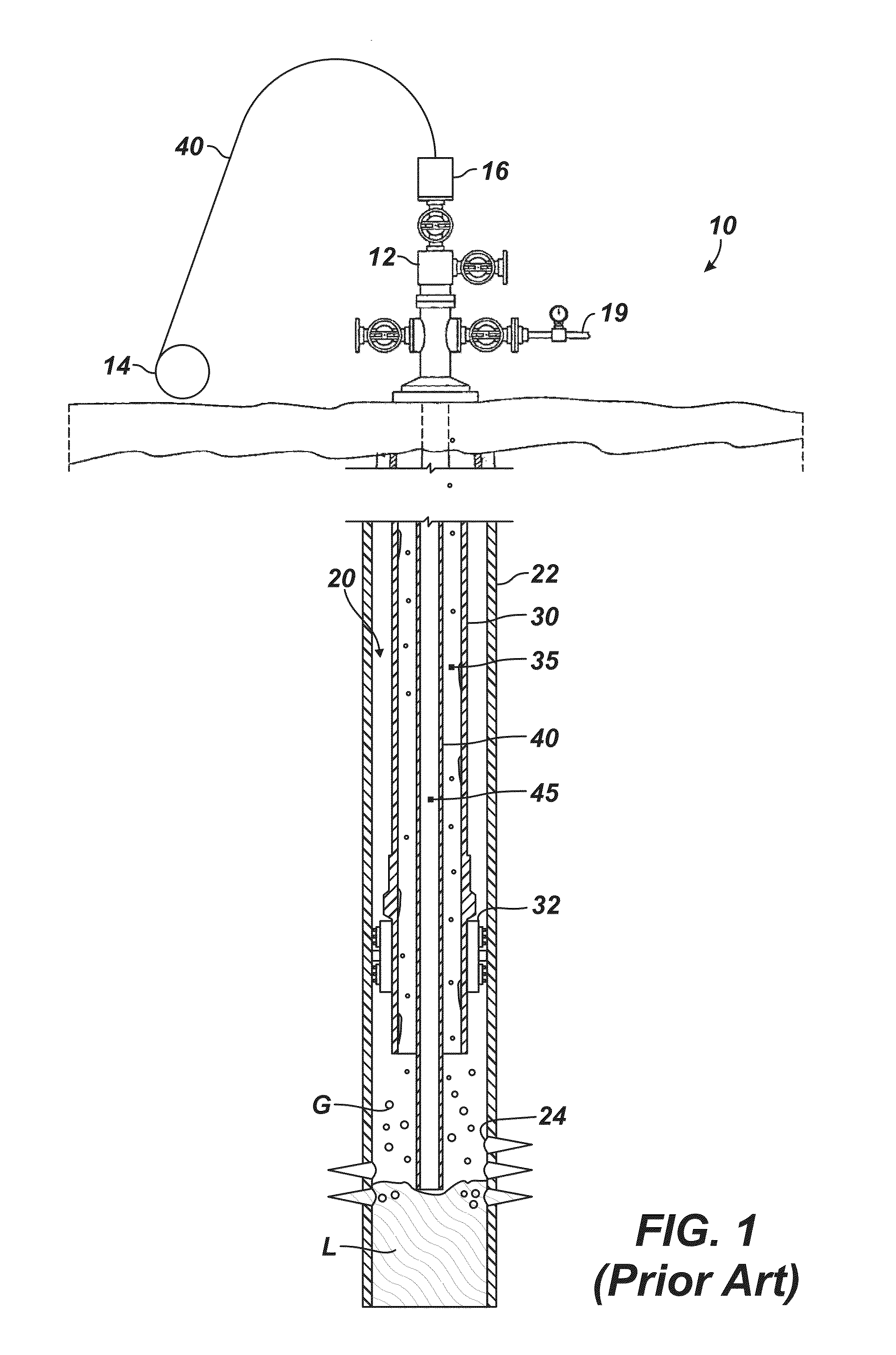

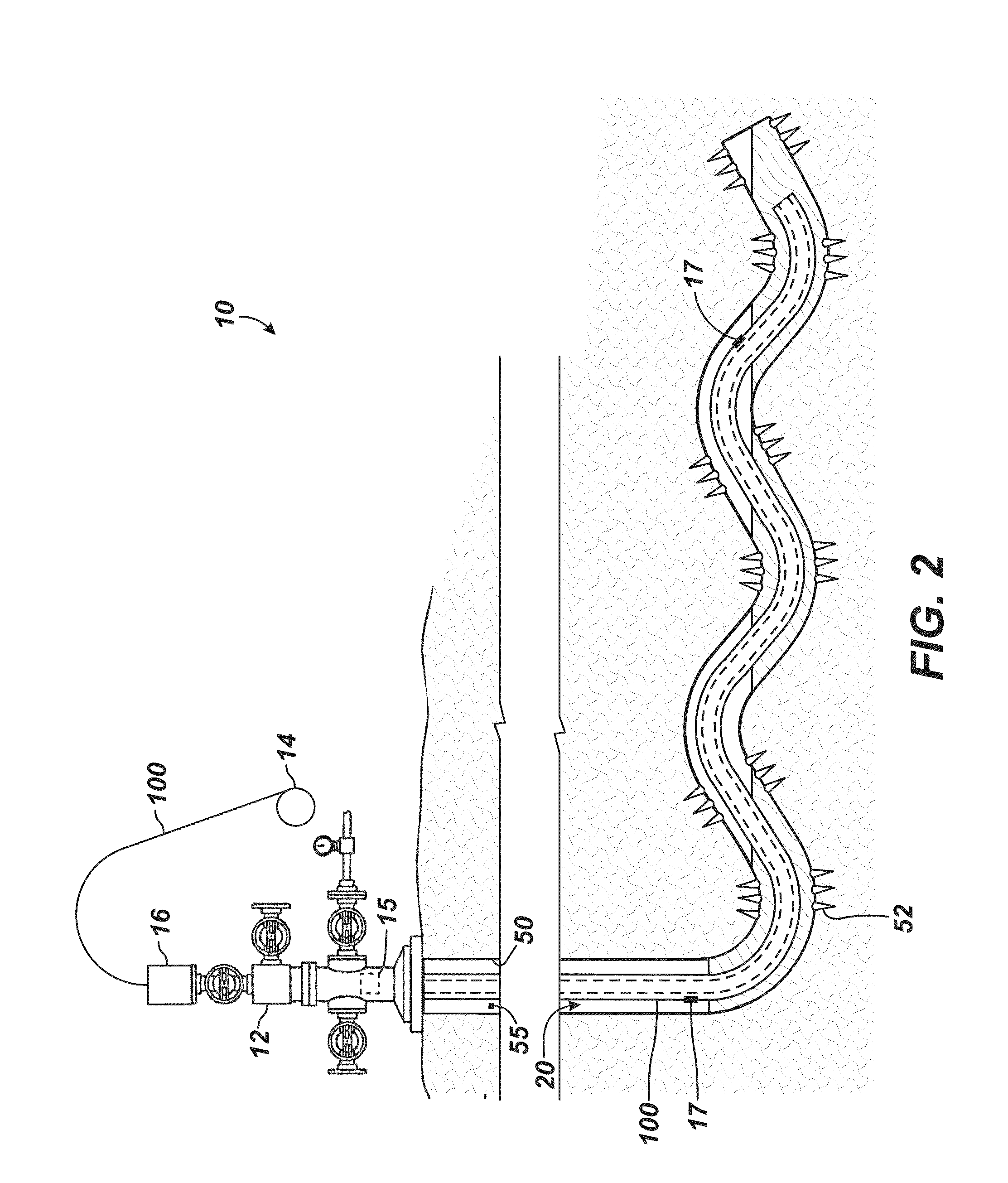

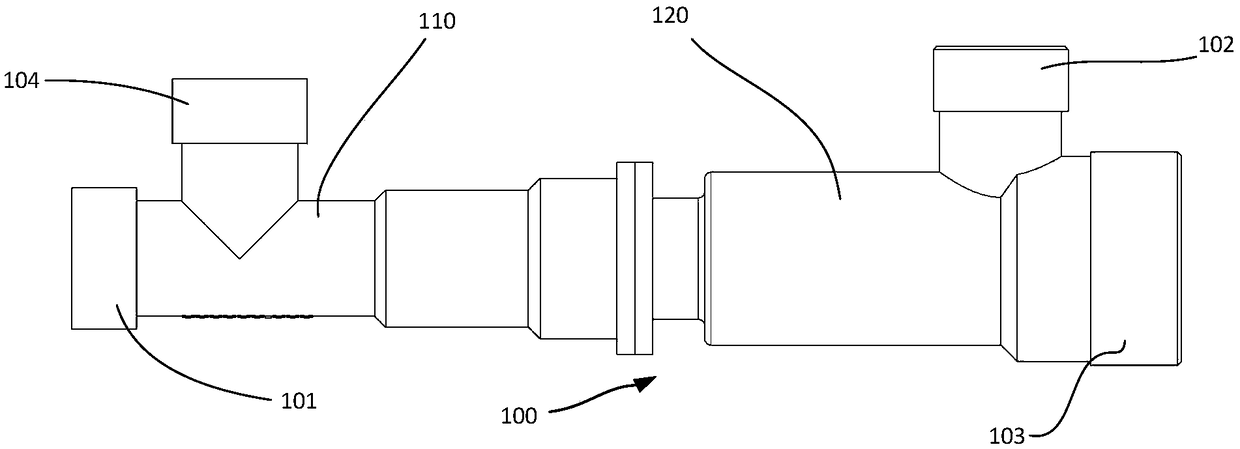

Gas Lift System Having Expandable Velocity String

ActiveUS20130199794A1Increase internal dimensionReduced flow areaFluid removalWell/borehole valve arrangementsEngineeringGas lift

A velocity string deploys in production tubing of a gas well (or a gassy oil well) to help lift fluid toward the surface. The velocity string reduces flow area in the production tubing so that a critical flow velocity can be reached to lift liquid. Overtime, the reservoir pressure and resulting gas flow may decrease such that less liquid is produced toward the surface. At such a stage, operators then expand the velocity string to further decrease the flow area in the production tubing, which can produce the needed critical flow velocity to allow produced liquid to be lifted toward the surface.

Owner:WEATHERFORD TECH HLDG LLC

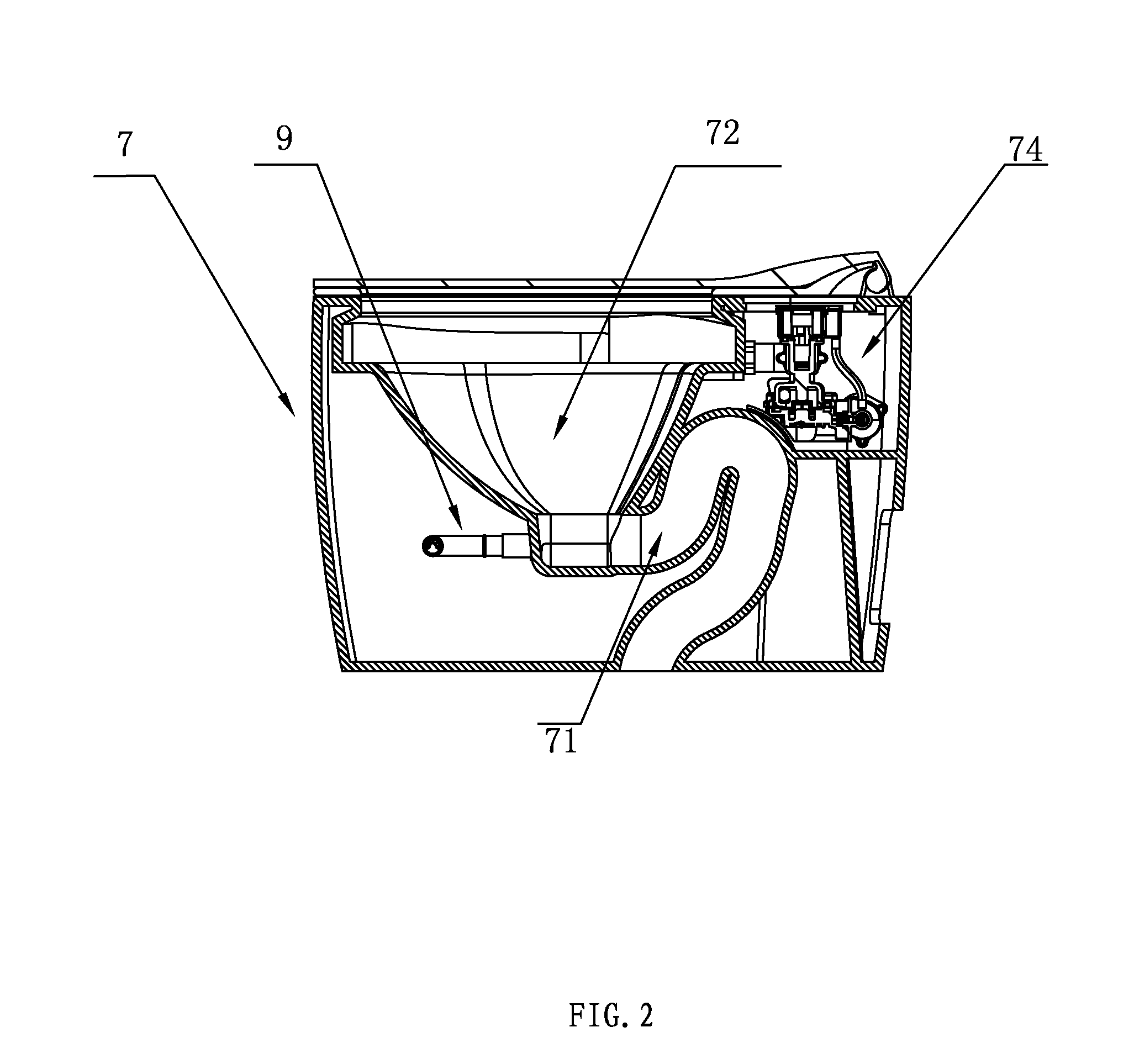

Valve and hot water system thereof

ActiveCN108758012AReduce chance of accidental openingReduced flow areaFluid heatersCheck valvesWater useEngineering

The invention discloses a valve and a hot water system thereof. The valve is provided with a first opening part, a second opening part and a one-way valve arranged between the first opening part and the second opening part. When the one-way valve is opened, first liquid input from the first opening part is allowed to flow to the second opening part. The valve is provided with a third opening part.The third opening part is used for outputting second liquid input from the second opening part. The valve is further provided with a valve element assembly located on the downstream part of the one-way valve. The valve element assembly communicates with the one-way valve and the second opening part when the one-way valve is opened. By means of the valve element assembly, when the second liquid isinput through the second opening part, the open area between the one-way valve and the second opening part is reduced. By means of the valve, the situation that hot water is output when a user uses cold water can be effectively avoided, and the water using experience is improved.

Owner:A O SMITH CHINA WATER HEATER CO LTD

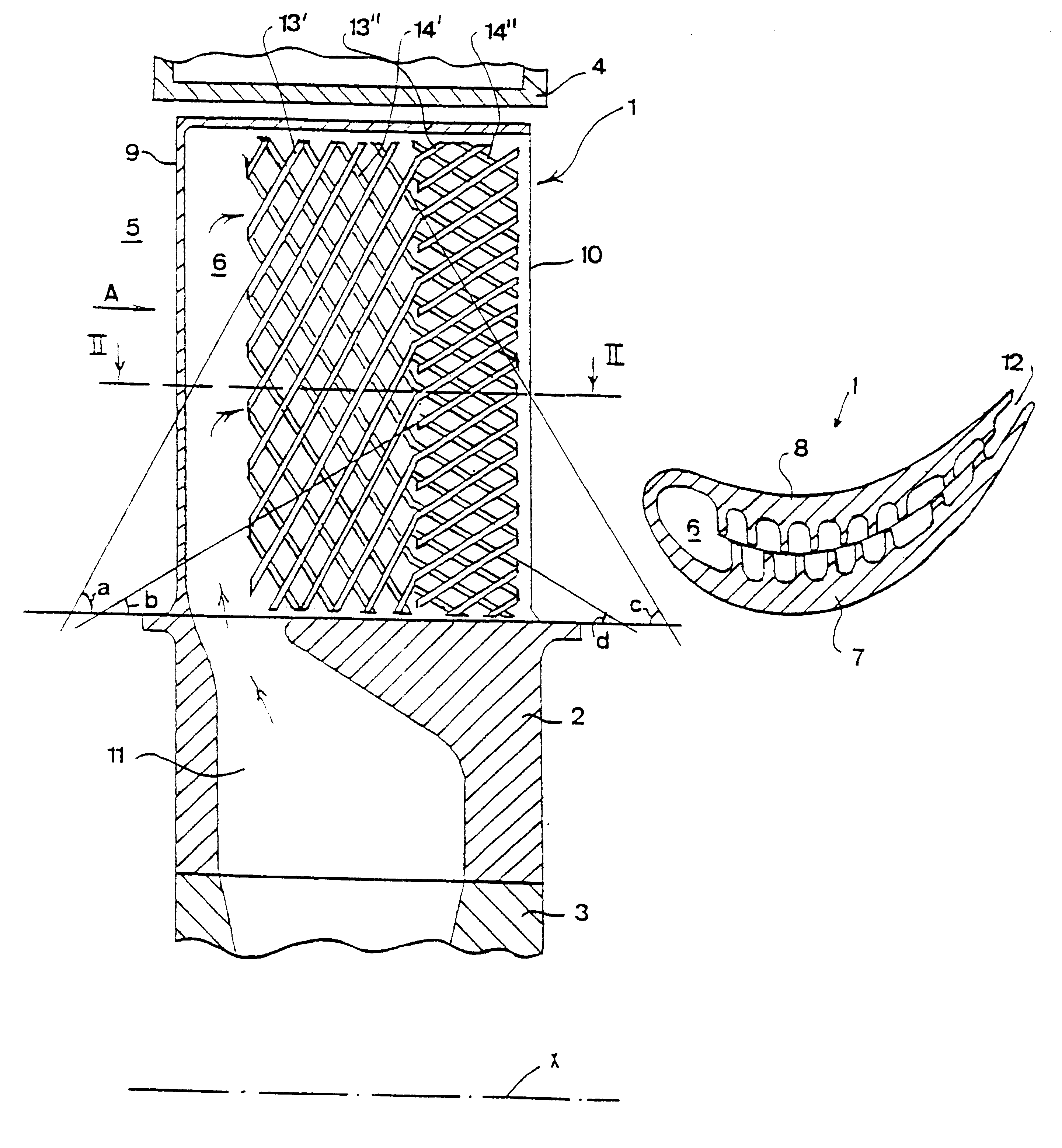

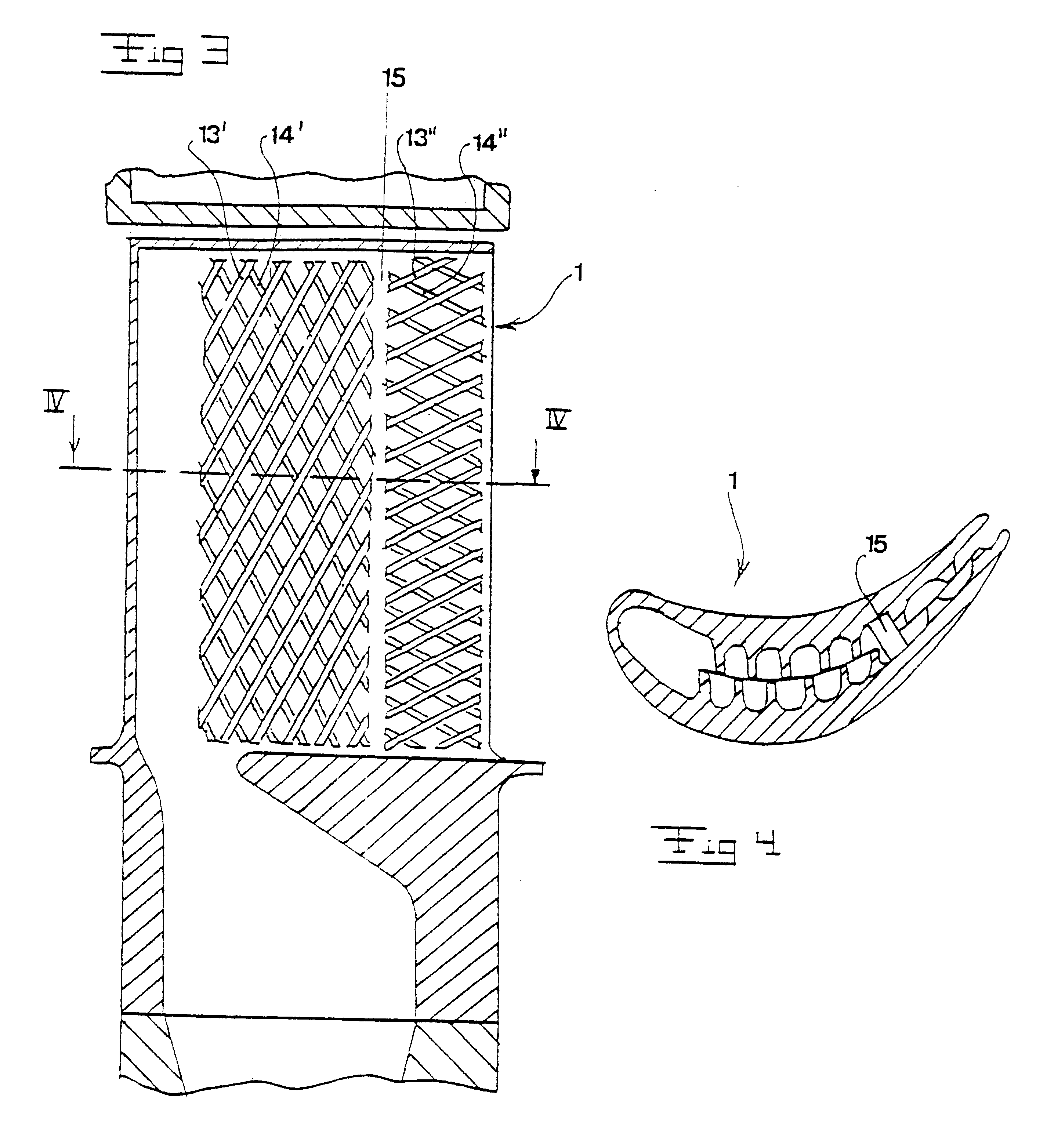

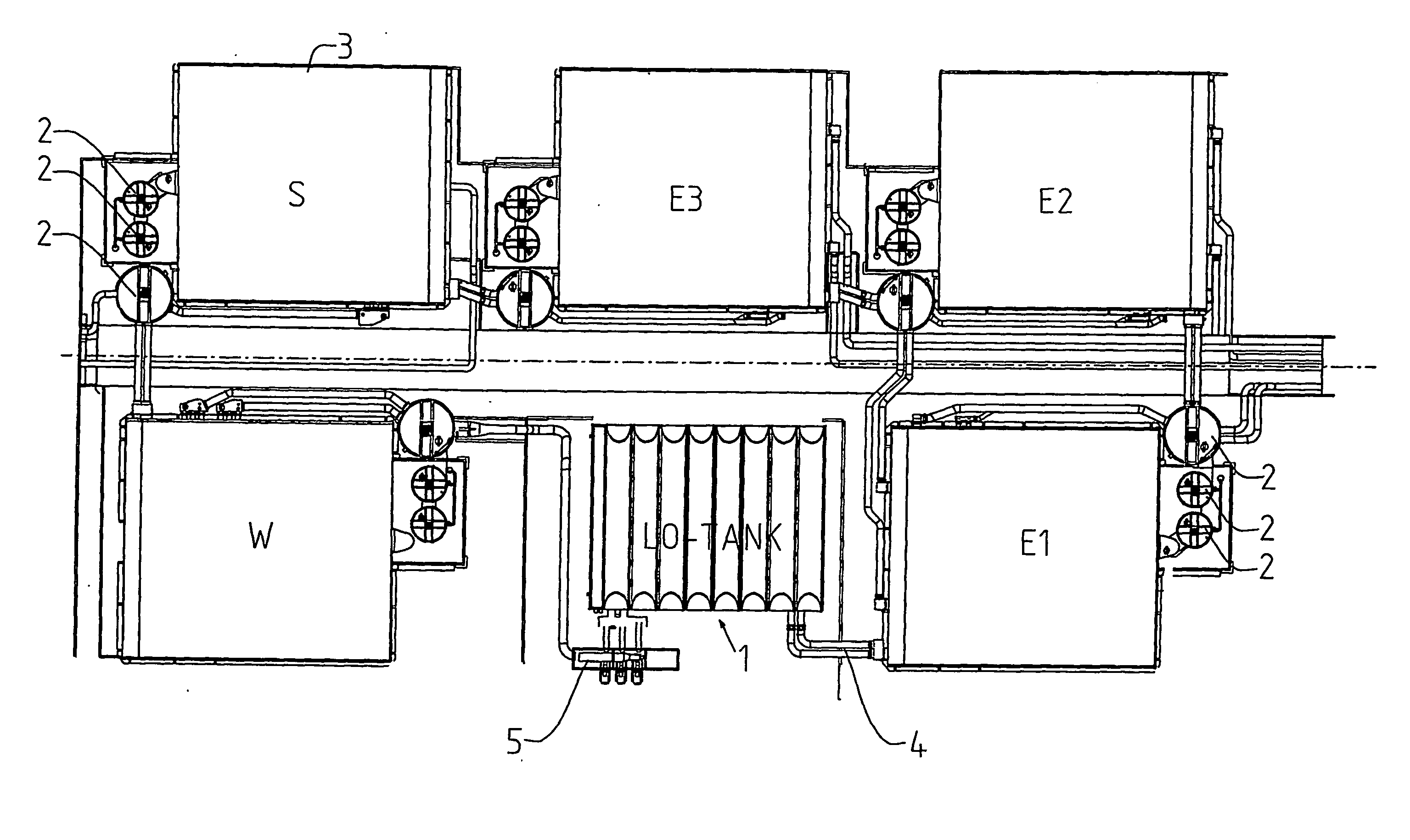

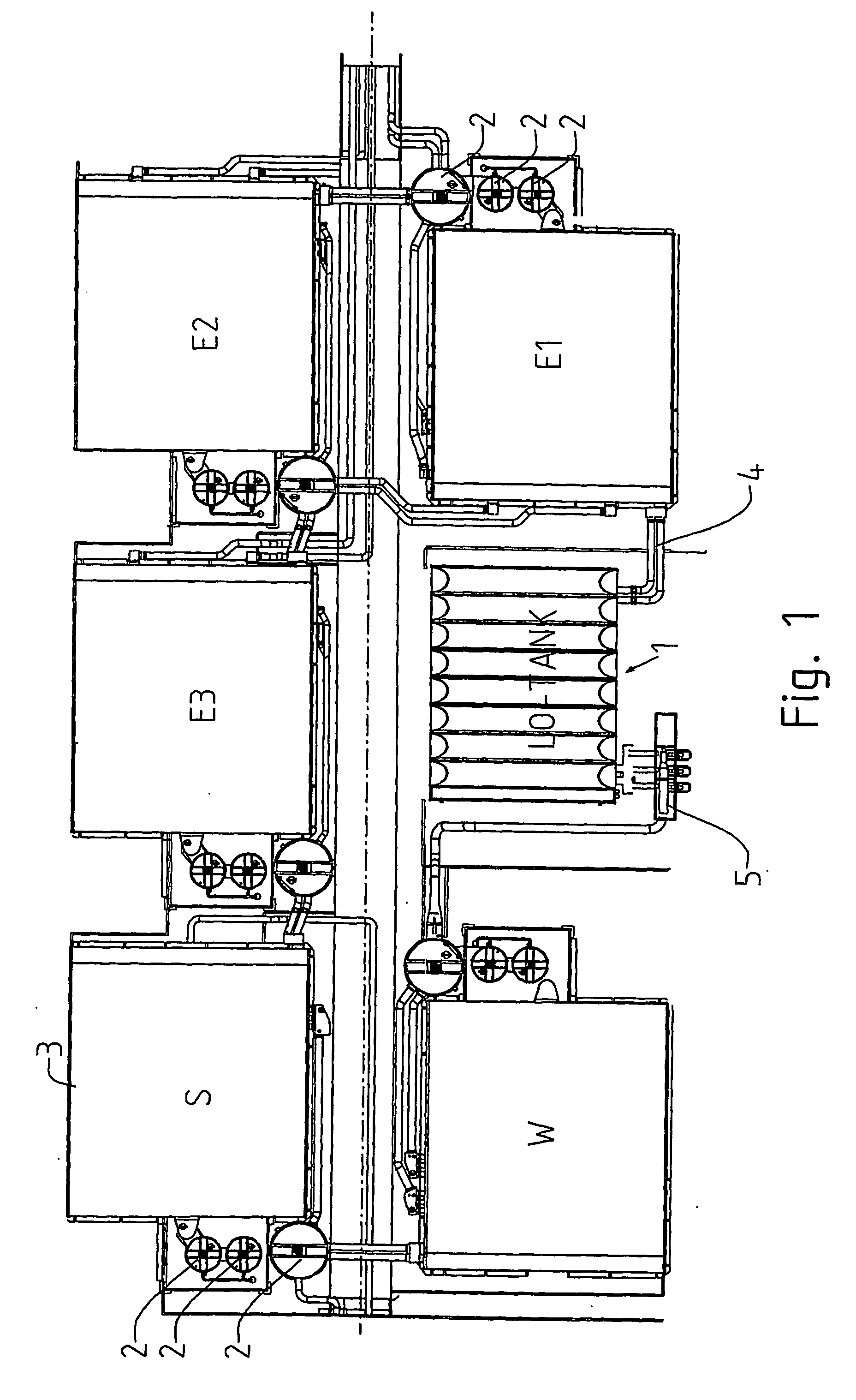

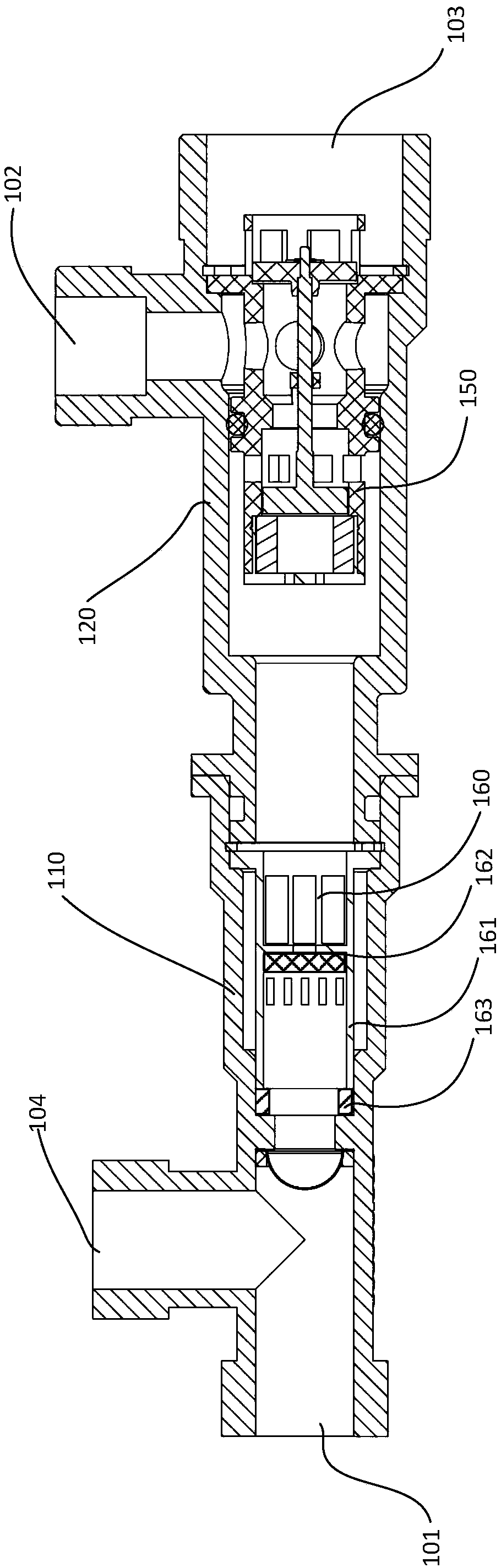

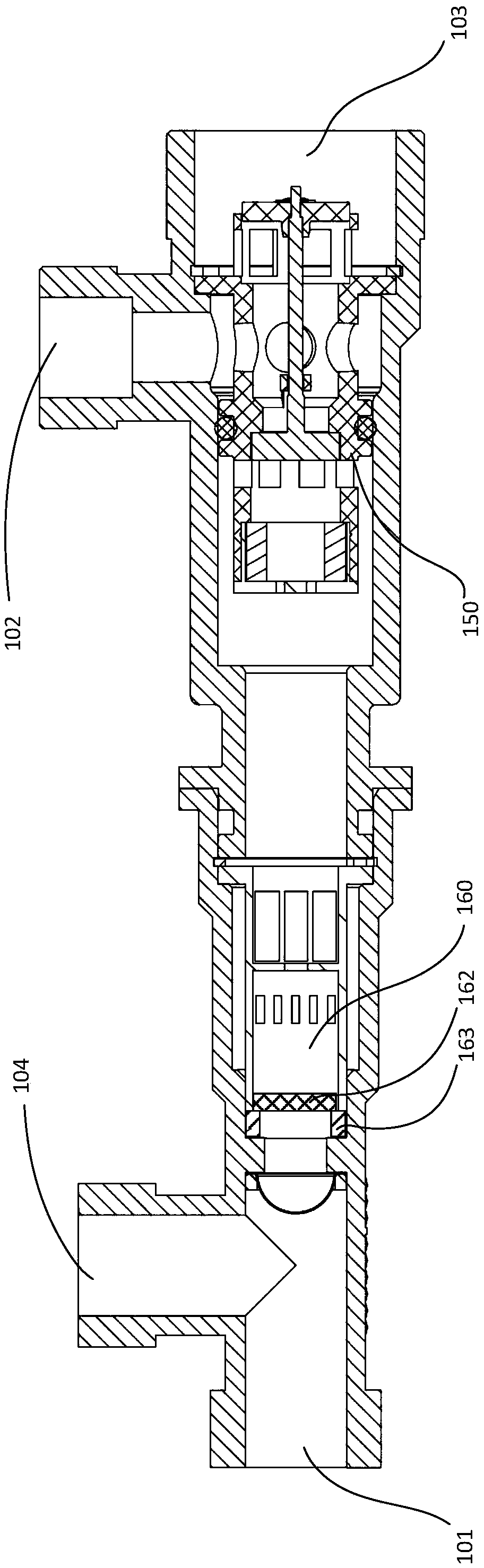

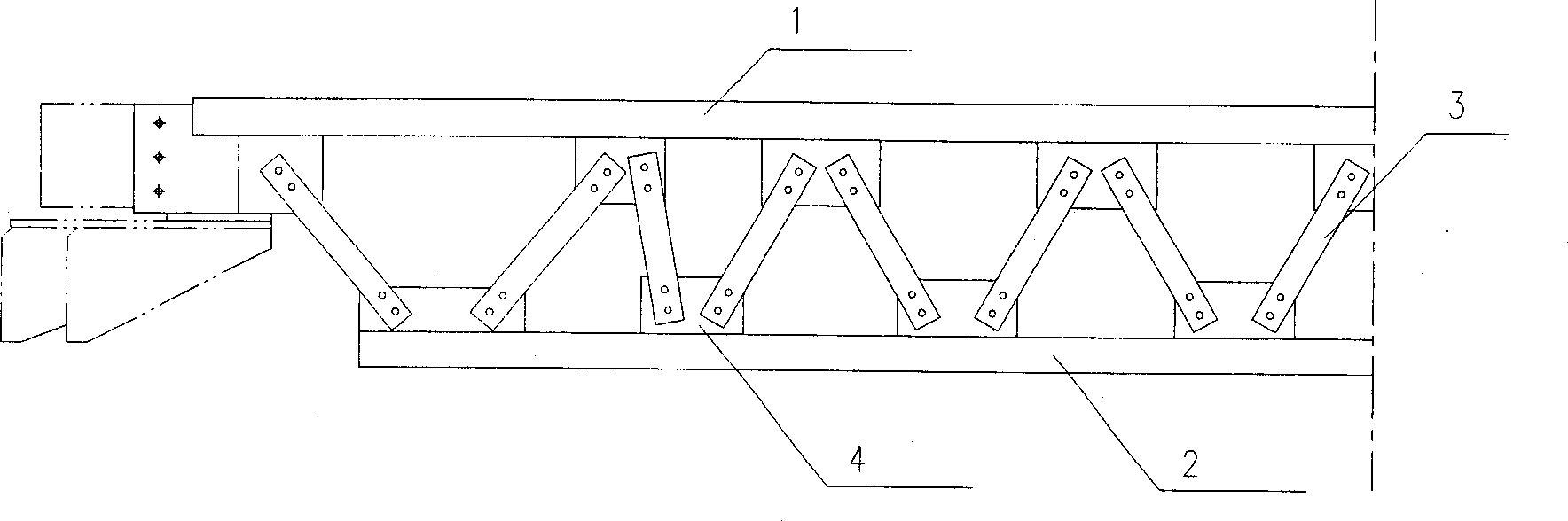

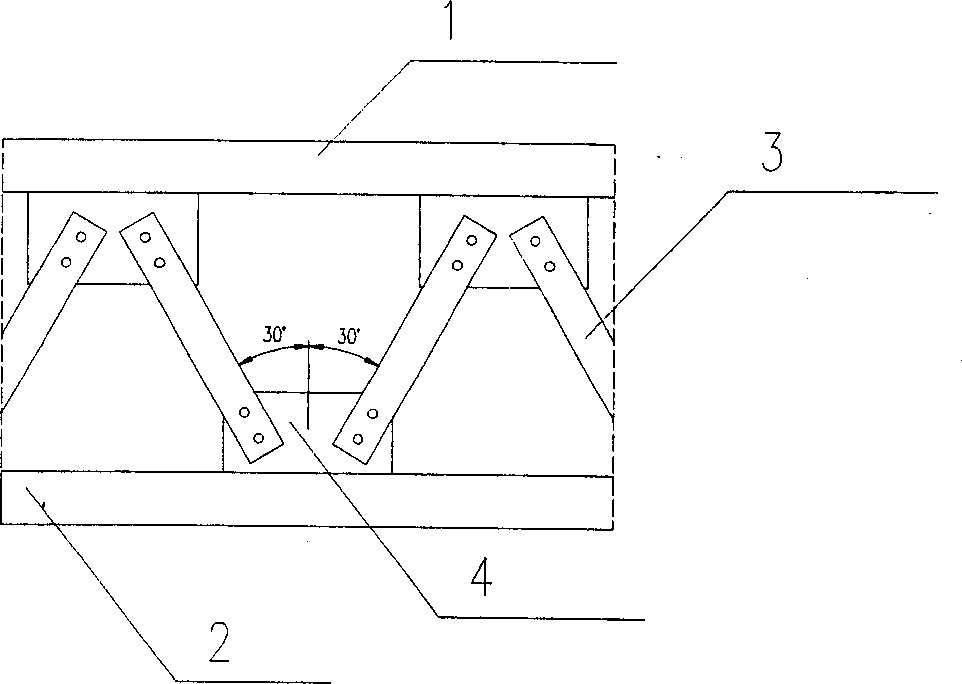

Blade or vane for a rotary machine

InactiveCN1997810AReduce cloggingIncrease contact areaEngine fuctionsBlade accessoriesInterior spaceEngineering

A component defines a blade or a vane for a rotor rotatable about a rotary axis (x). An inner space (10) of the component is limited by first and second walls (12), and forms a passage for a cooling fluid. First and second ribs (21, 22) project form the first and second walls, respectively, and extend in parallel to each other to form channels for the fluid from a leading end to a trailing end of the ribs. The ribs extend along a first and a third direction, respectively, in the proximity of the leading end and along a second direction and fourth direction, respectively, in the proximity of the trailing end. The first direction is inclined in relation to the second direction. The third direction is inclined in relation to the fourth direction. The first direction intersects with the third direction. The ribs extend from the leading end to the trailing end along a continuously curved path.

Owner:SIEMENS AG

Intelligent large-flow electro-hydraulic valve

InactiveCN102996838ALarge displacementLarge adjustment rangeOperating means/releasing devices for valvesSlide valveElectricityElectro hydraulic

The invention relates to an intelligent large-flow electro-hydraulic valve, and belongs to a hydraulic valve. An upper housing and a lower housing are fixed on a valve seat; an elastic diaphragm is pressed between the valve seat and the upper housing; a partition board is pressed between the valve seat and the lower housing; a valve body is sleeved inside a valve cavity; the valve body is composed of a valve core, and an upper post rod and a lower post rod; a top block and a piston are fixed at two sides of the elastic diaphragm; the top block presses a piezoelectric stack inside the upper housing; the piston, the valve seat, the upper post rod and a one-way valve form an upper compression chamber; the valve core, the lower post rod, the valve seat and the partition board form a lower compression chamber; an inlet and an outlet are communicated through a valve core ring slot and form a valve hole; the inlet is communicated with the upper compression chamber and the lower compression chamber; the lower post rod presses a disk spring and a sensor inside the lower housing; and the sensor and the piezoelectric stack are respectively connected with an electric control unit through lead groups. The intelligent large-flow electro-hydraulic valve has the advantages that the displacement of the valve core is increased by the compression chambers; the movement state of the valve core can be measured by the sensor; and the intelligent large-flow electro-hydraulic valve is large in valve flow and damping regulating range, high in flow control accuracy and high in reliability, and especially suitable for large-scale precise flow and damping regulation.

Owner:ZHEJIANG NORMAL UNIVERSITY

Gas turbine low-emission combustion chamber using gas fuels

InactiveCN110131750AReduced flow areaGood mixing effectContinuous combustion chamberAutomotive engineeringCombustion chamber

The invention discloses a gas turbine low-emission combustion chamber using gas fuels, and belongs to the technical field of gas turbines. The combustion chamber comprises an on-duty grade, a main combustion grade, a high-pressure igniter, a mixing hole, an exhaust outlet, a bearing machine box, a flame cylinder, the flame cylinder outer machine box, a flange, a first on-duty grade gas fuel pipeline, a main combustion grade gas fuel pipeline, a main combustion grade fuel main pipe, a first on-duty grade fuel main pipe, a pipeline bracket, a second on-duty grade fuel main pipe, a second on-dutygrade gas fuel pipeline, an air conditioning device, a first on-duty grade fuel tank, a second on-duty grade fuel tank and a main combustion grade fuel tank; when a gas turbine is started in low-loadstates, only the on-duty grade works; when the gas turbine is started in high-load states, the on-duty grade and the main combustion grade work together; and through diffusion combustion of on-duty grade fuels, a stable ignition source is provided to a main combustion area, so that the low emission requirement is guaranteed, the combustion stability and the combustion efficiency are fully considered, and the performance requirements of the combustion chamber are comprehensively met.

Owner:SHENYANG AEROSPACE UNIVERSITY

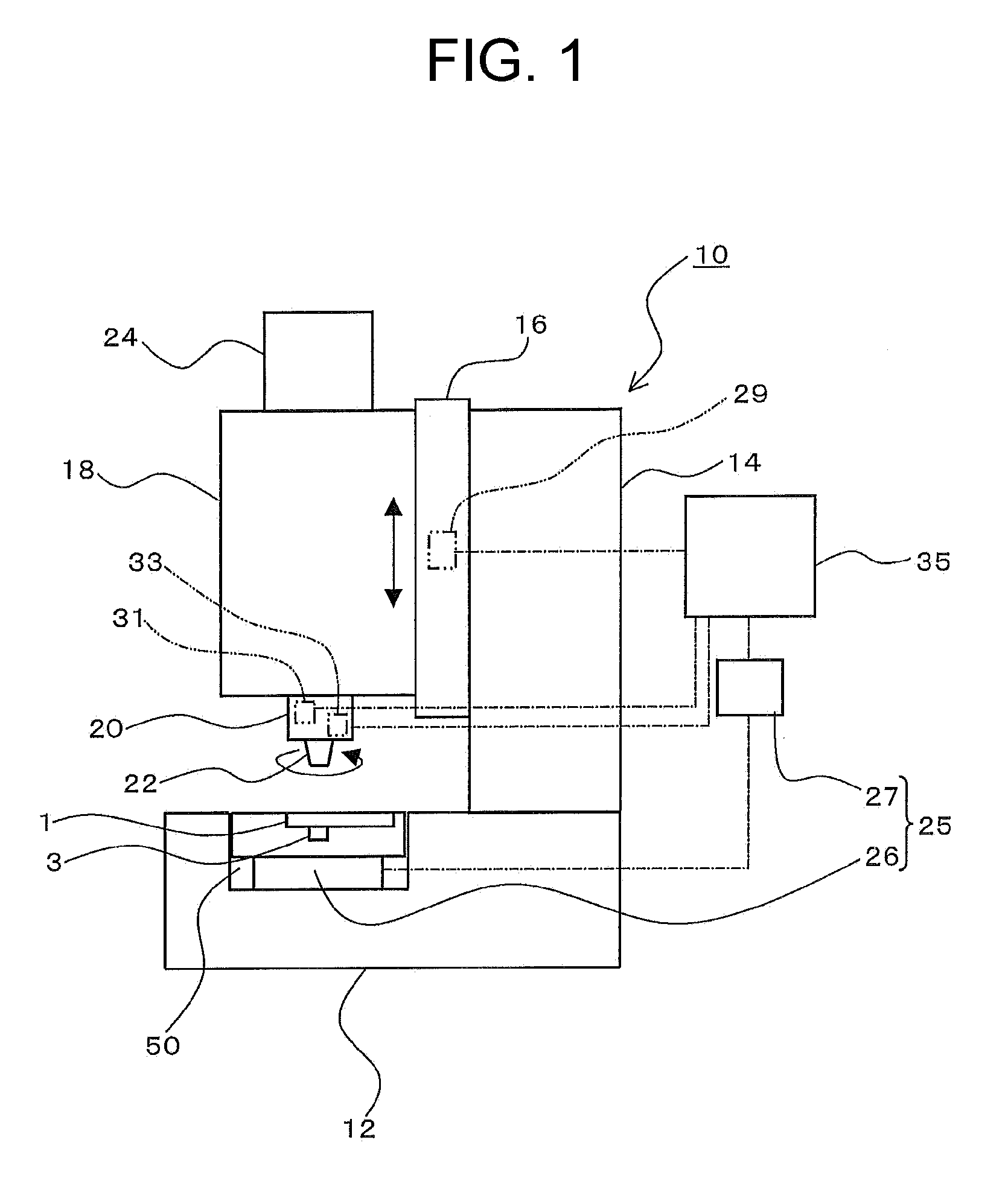

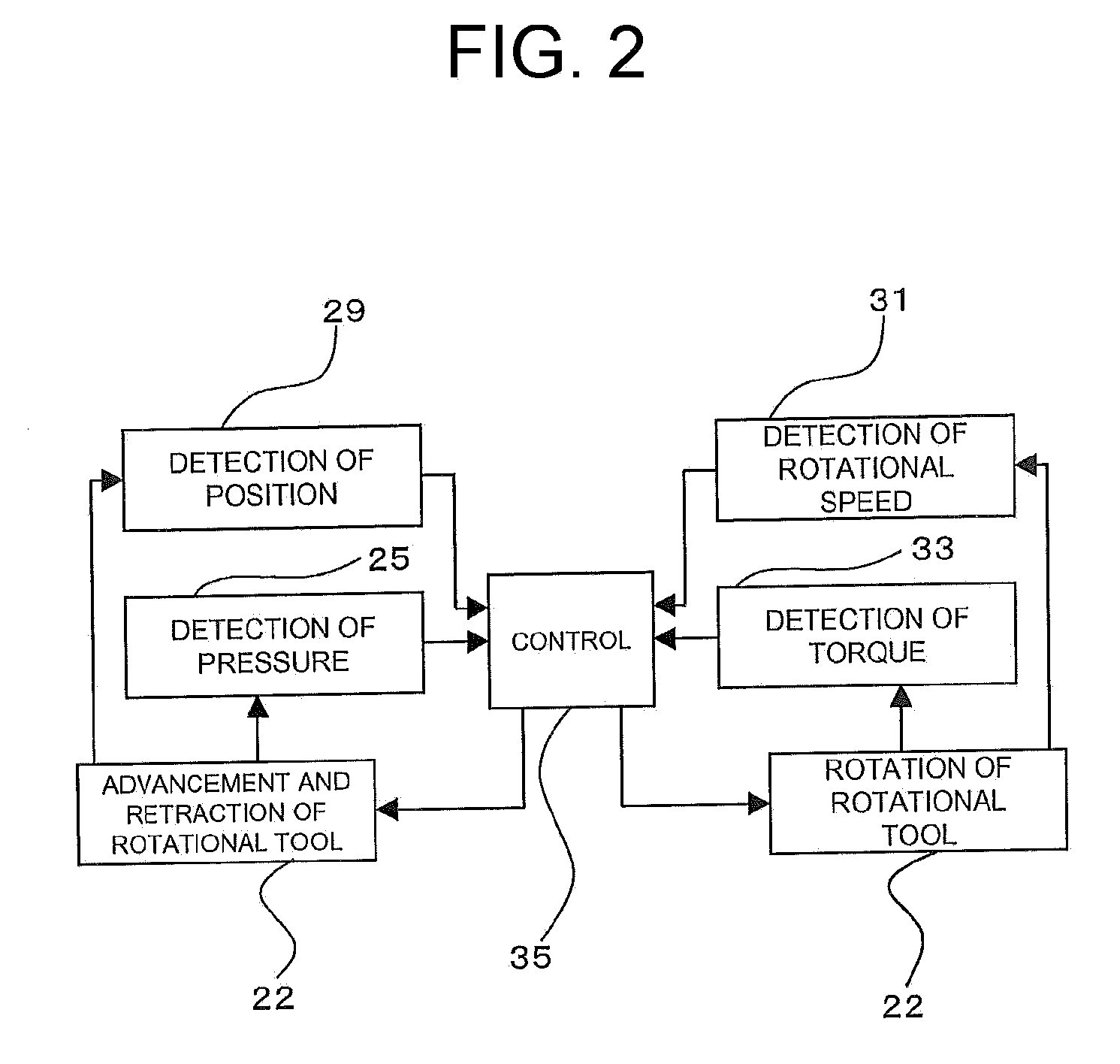

Manufacturing method of electric contact and manufacturing equipment of electric contact

InactiveUS20110099808A1No fluctuation in qualityShorten the timeContact member assembly/disassemblyElectric switchesMetalDiffusion welding

A manufacturing method of an electric contact and manufacturing equipment of the electric contact. A contact and a metal base are superimposed and support by a jig, and a rotational tool, which rotates at a predetermined speed and advances / retracts to / from the jig, is pressed into a surface, which is not contacted with the contact, of the metal base while being rotated, so that the contact and the metal base are joined by solid state diffusion welding by using frictional heat generated by friction between the rotational tool and the metal base, and then the rotational tool is retracted from the metal base.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

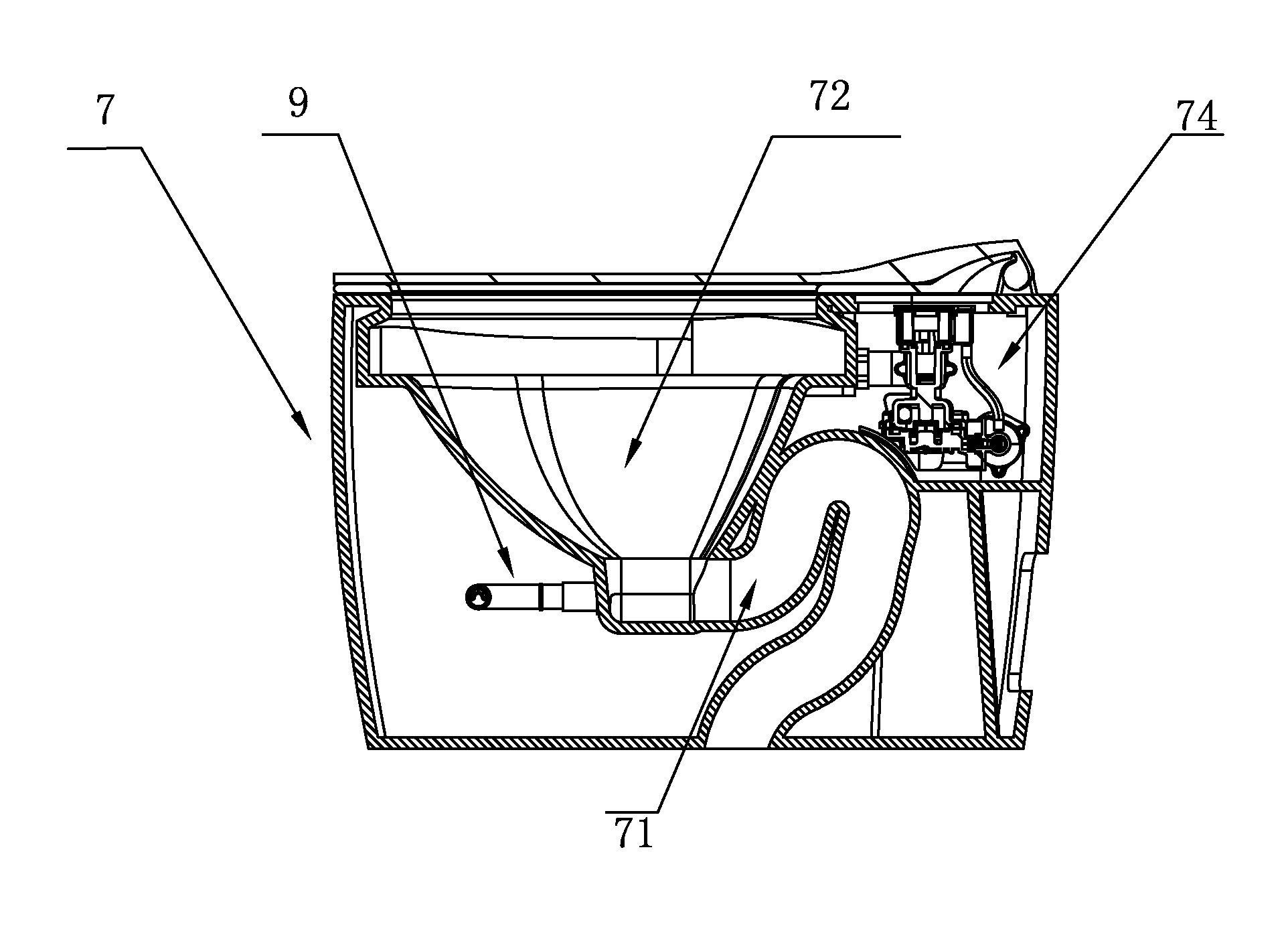

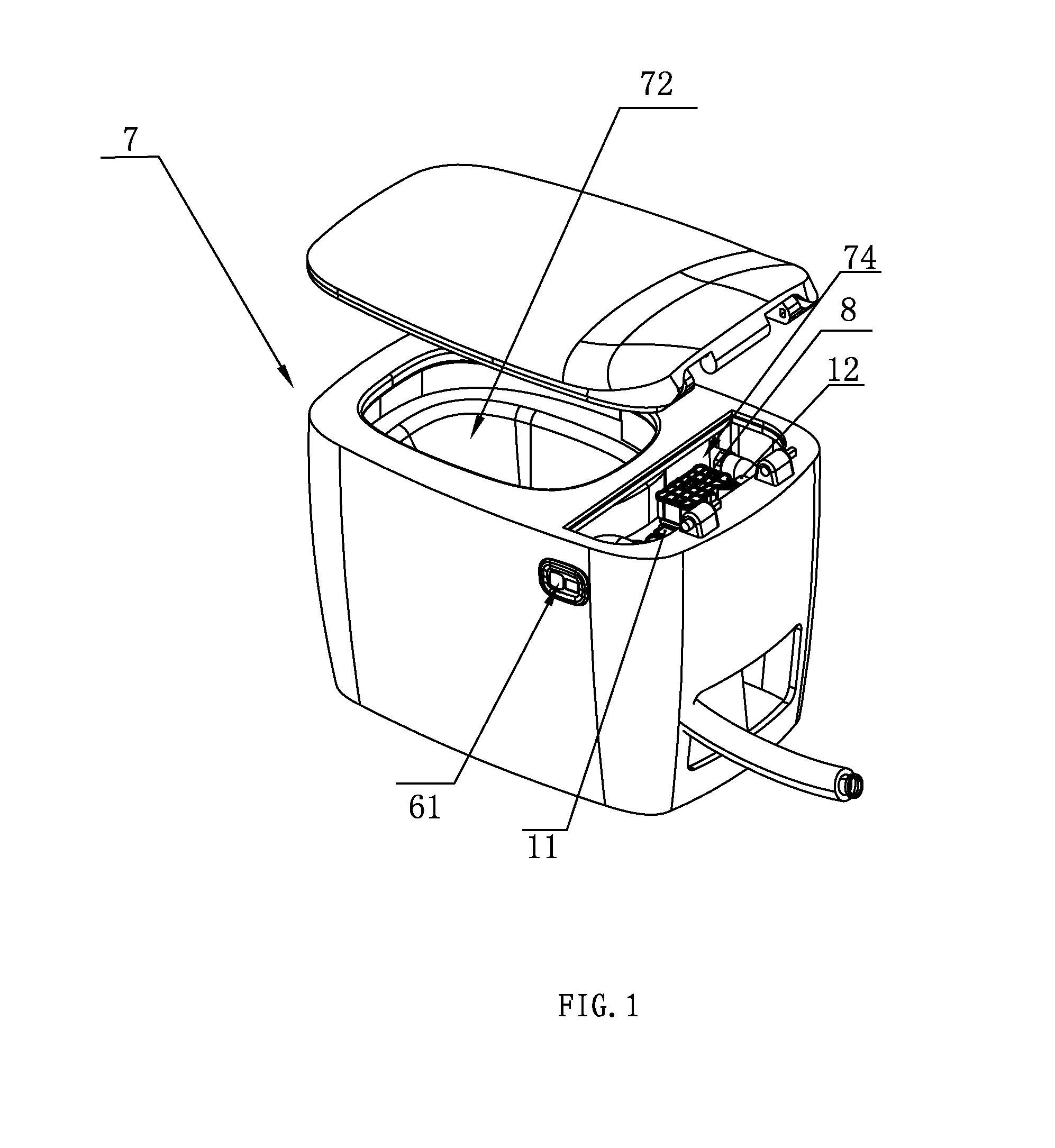

Water-saving toilet bowl without water tank

InactiveUS20130031709A1Small sizeConserve waterWater closetsFlushing devicesWater savingDraining tube

A water-saving toilet bowl without a water tank is provided, which comprises a flush pipe, a discharging pipe and a flush device. The flush device comprises a control cavity and a control valve that controls a drive motor to open or close the control cavity. A linkage rod links with a motor shaft of the drive motor. A through hole is provided in a partition. A control valve core is linked with the linkage rod via the through hole so that the control valve core is slid so as to open or close the through hole, and thereby the pressure change is controlled. The flush pipe of the toilet bowl is connected to two outlet passages of the flush device. An inlet passage is communicated with the outlet passages through a connection passage, and effluent water enters the flush pipe to flush the toilet bowl.

Owner:CHEN FUHUAN

Truss beam of tower appts.

A support beam of truss in tower used for chemical industry is prepared as connecting truss main beam with truss sub beam by support structural unit, connecting two ends of truss main beam to support base and connecting it with wall of tower by debber, hanging two ends of truss sub beam in the air.

Owner:TIANJIN UNIV +1

Novel controllable nanobubble generation device

The invention relates to a bubble generation device. The generation device comprises a bubble generator itself and a circuit control system. An air outlet end of an air inlet pipe is connected with aventuri tube on a gradual contraction section, the upper end of the air inlet pipe is connected with a solenoid valve and an air pump, a pressure sensor is located in a throat outlet, a control circuit is connected with the solenoid valve and the pressure sensor, and the joint of a gradual expansion section and an outlet section is provided with multiple rings of porous disks which are equidistantly distributed and have cavitation holes of the same number in the radial direction. The pressure sensor transmits a pressure signal in the throat outlet to a control circuit, and the control circuitcontrols opening and closing of the solenoid valve according to the pressure of the throat outlet, thereby achieving the effect of controlling the air inlet amount of the air pump. The control circuitis used for detecting the pressure of the outlet to control the air flow amount, thereby ensuring that the air melting amount of the bubble generator is in a most moderate state.

Owner:傅开彬 +1

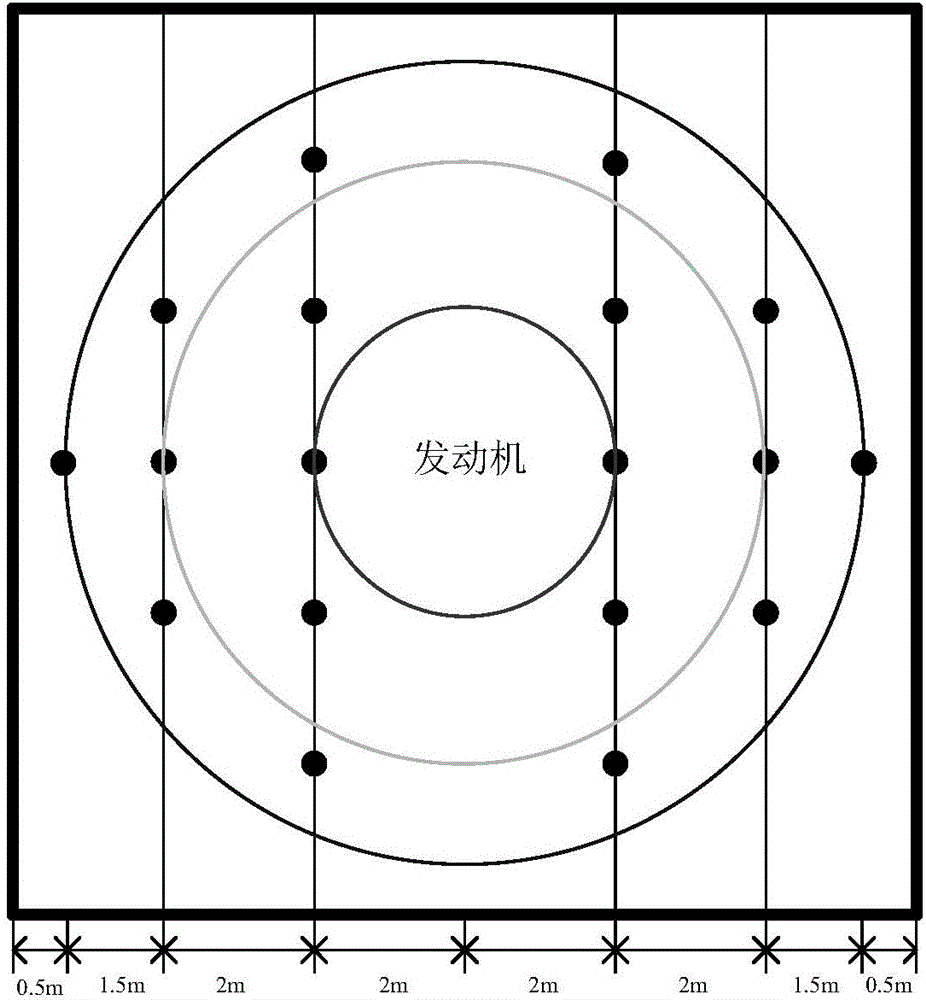

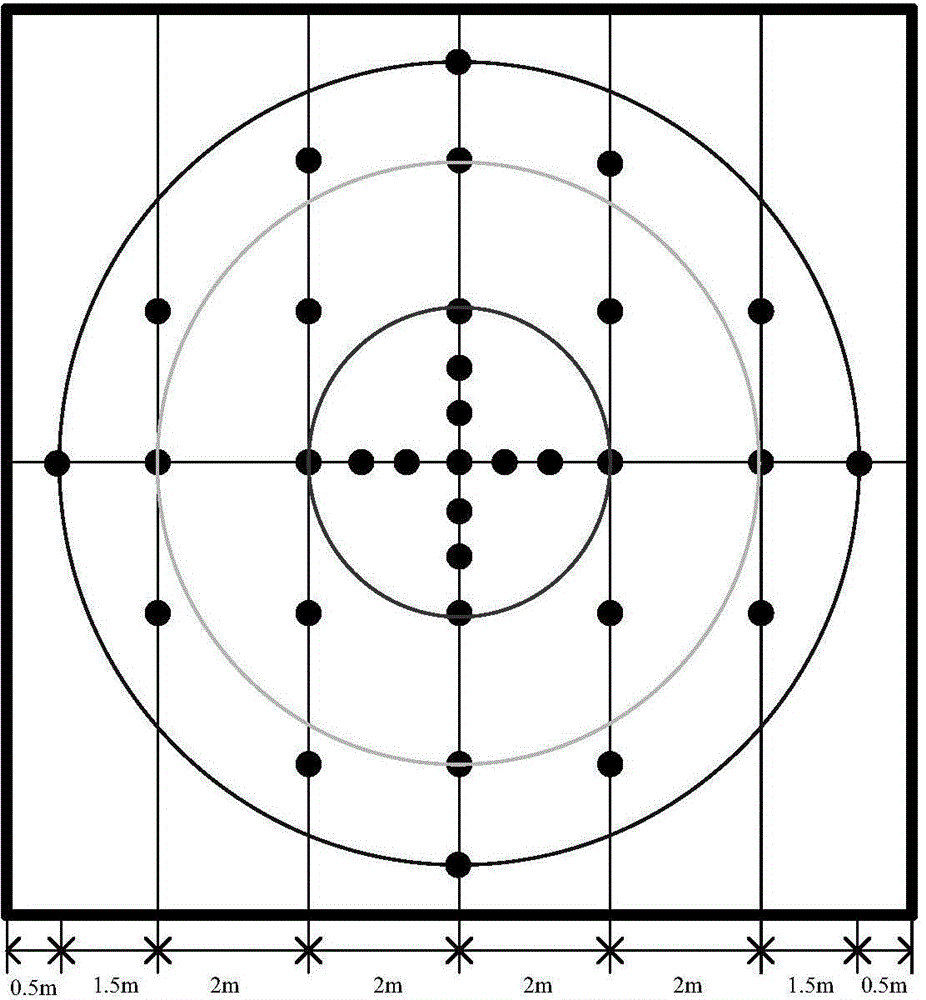

Real thrust measuring and calculating method for test run of aero-engine on indoor test bed

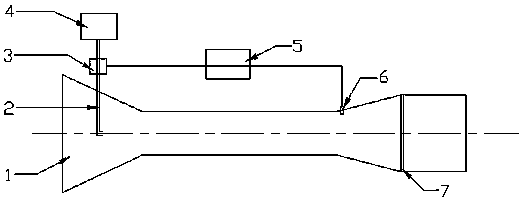

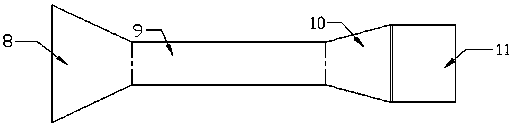

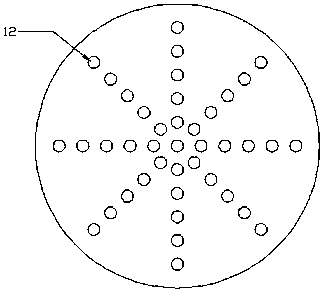

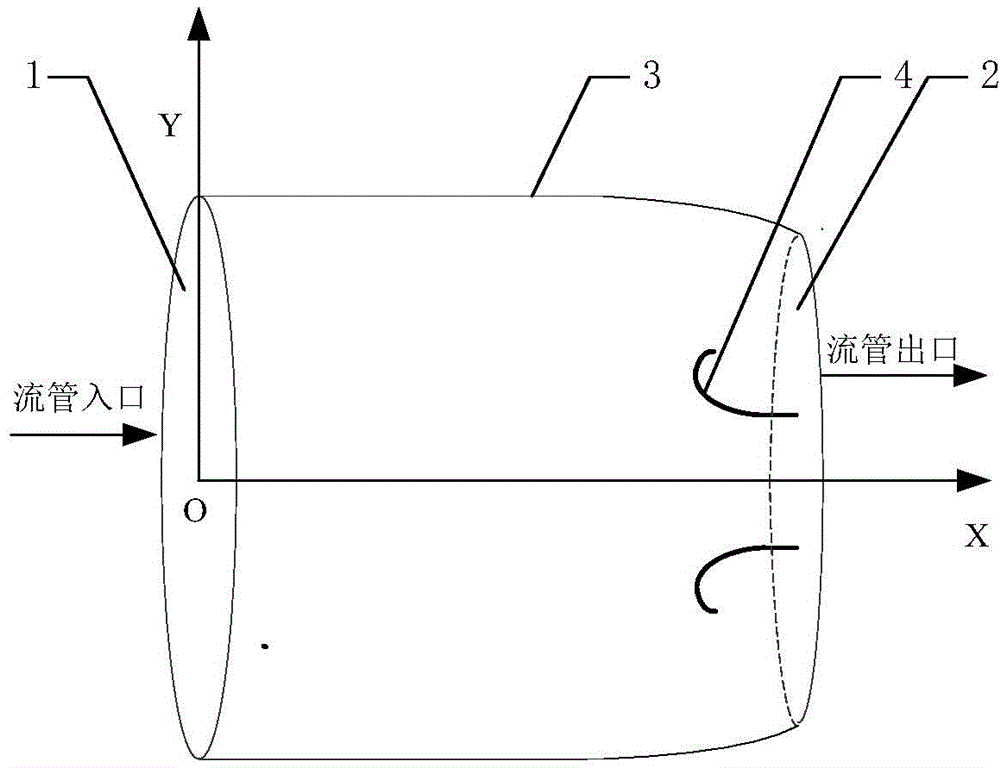

The invention belongs to the technical field of aero-engines and particularly relates to a real thrust measuring and calculating method for test run of an aero-engine on an indoor test bed. The real thrust measuring and calculating method specifically comprises the steps of 1 determining the spatial position of a control body, 2 arranging a rear cross section measuring point on a lip rear cross section (2), 3 arranging front cross section measuring point on a far front cross section (1), 4 obtaining wind speed values and static pressure values on the measuring points, and 5 obtaining a real thrust value of the test run of the aero-engine on the indoor test bed. According to the real thrust measuring and calculating method, the area of air intake cross section of the engine is reasonably selected, the flow pipe surface for air flowing in a test run workshop serves as a control face, an air intake channel additional resistance correction formula is derived and real thrust is calculated by applying momentum theorem. The real thrust measuring and calculating method has the advantages of being clear in control body division, fewer in correction terms, simple and convenient to calculate and the like, and the problem of real thrust measurement and calculation during the test run of the aero-engine on the indoor test bed can be solved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com