Mixer of coal mine extracted gas and ventilation gas

A technology for extracting gas and wind gas, which is applied in the fields of ultra-low concentration methane thermal countercurrent oxidation and low-density energy recovery, and achieves the effects of good mixing uniformity, reduced pressure head and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

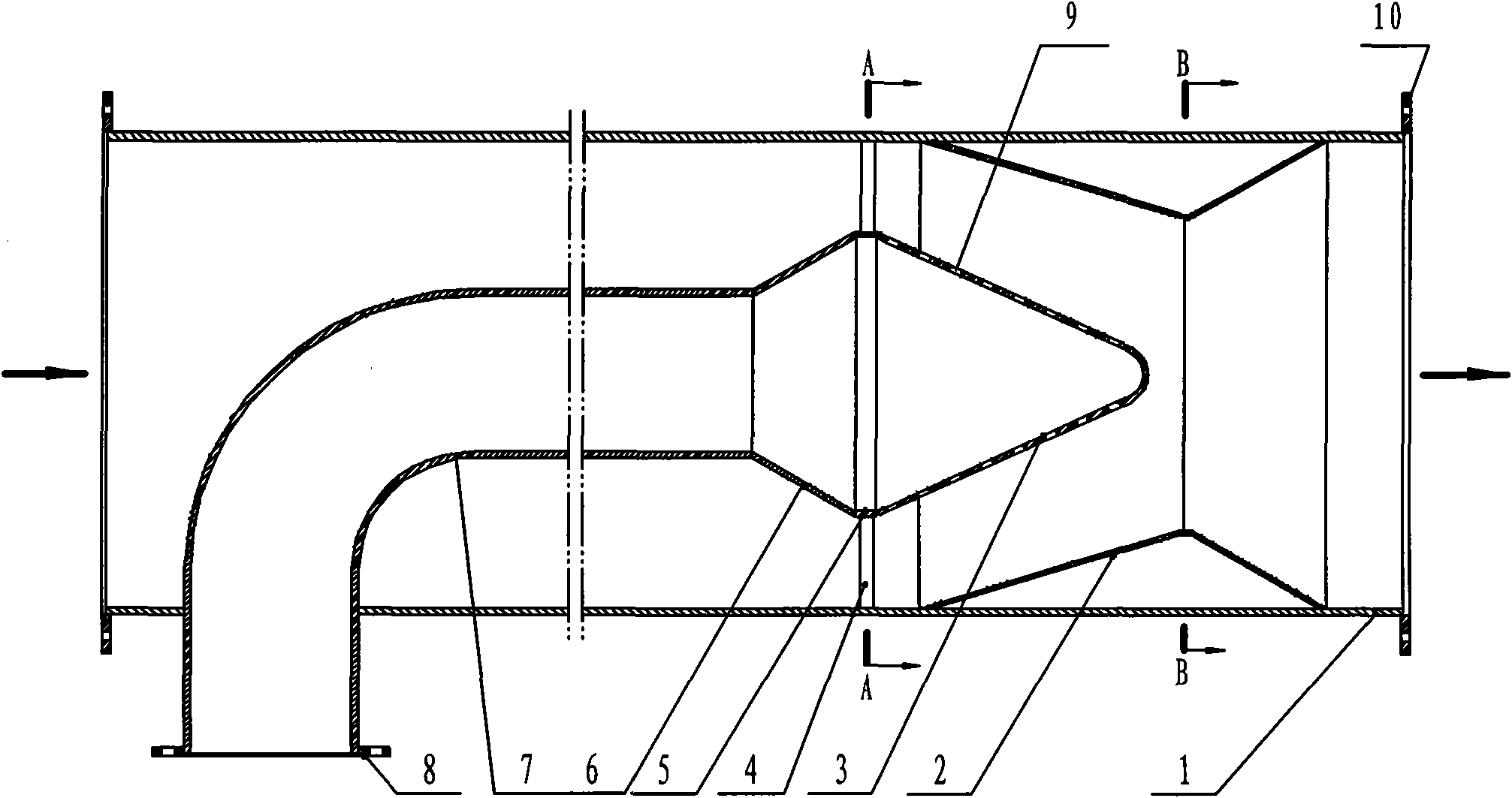

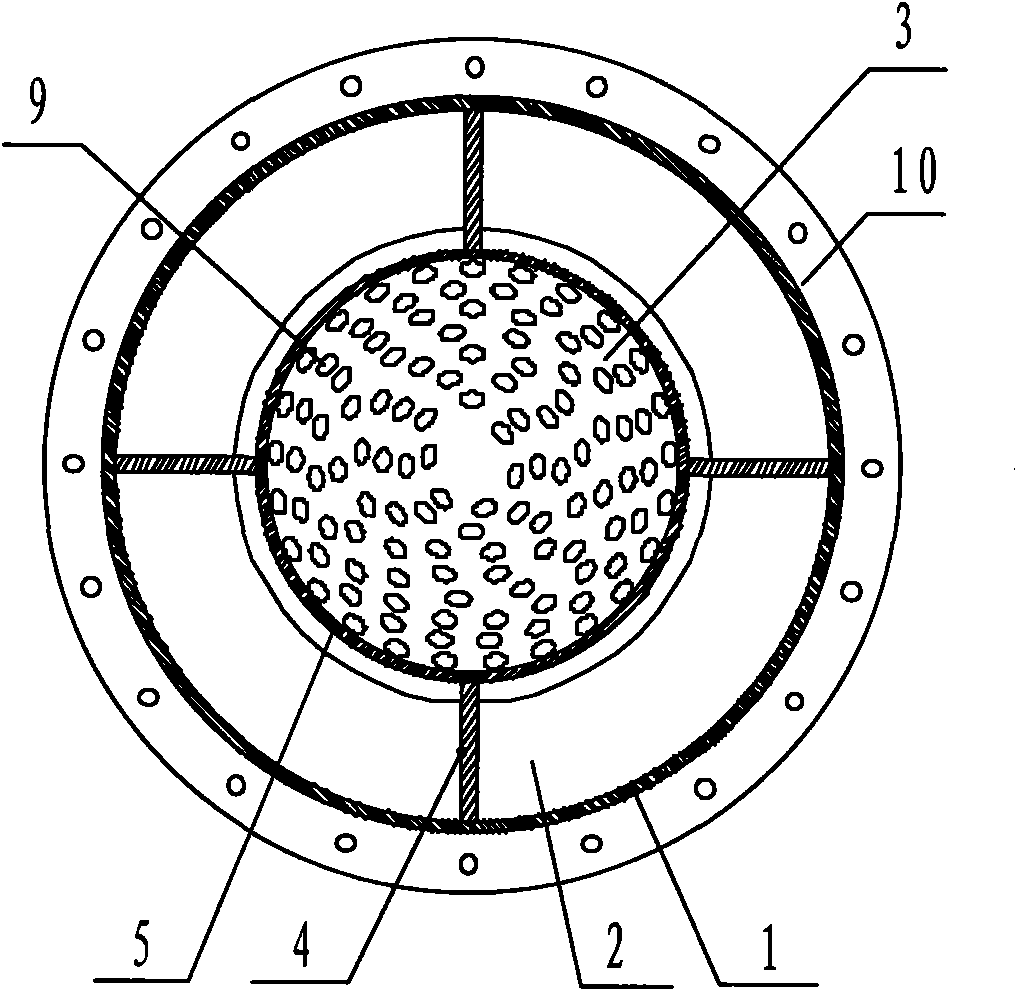

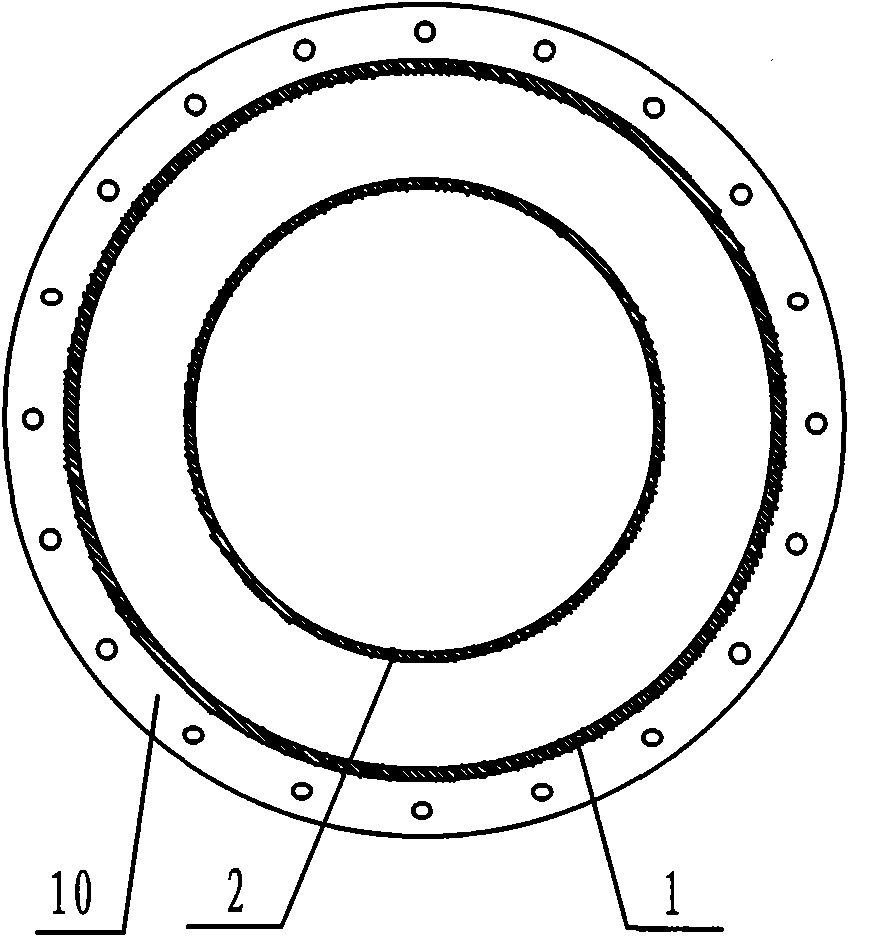

[0018] exist Figure 1~3 In the shown embodiment: the two ends of the casing 1 are provided with flanges 10, and the gas injection pipe is formed by successively connecting the inlet flange 8, the inlet pipe 7, the expansion pipe 6, the transition pipe 5 and the conical tail pipe 3, Wherein the inlet pipe 7 is bent to 90°, the inlet end is arranged outside the housing 1, the front end straight pipe section of the inlet pipe 7 penetrates the housing 1, and the rest are arranged in the housing 1 and towards the outlet of the housing 1; the inlet pipe 7 The axes of the end straight pipe section, the expansion pipe 6, the transition pipe 5 and the conical tailpipe 3 are located at the center of the housing 1, and the length of the end straight pipe section of the inlet pipe 7 is not less than 10 times the diameter of the inlet pipe 7; the conical tailpipe 3 There are small holes 9 evenly distributed on the wall, and the end adopts a circular arc transition, and the cone angle is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com