Patents

Literature

77results about How to "Reduce pressure head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

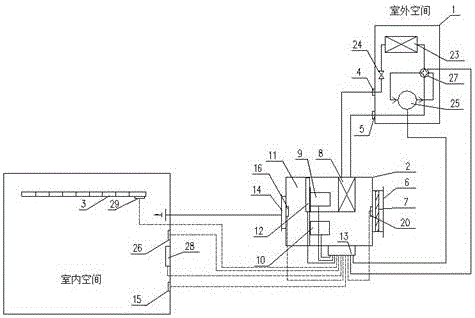

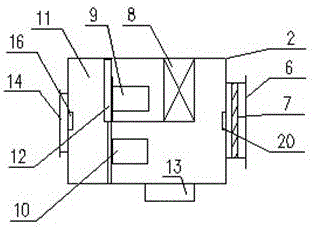

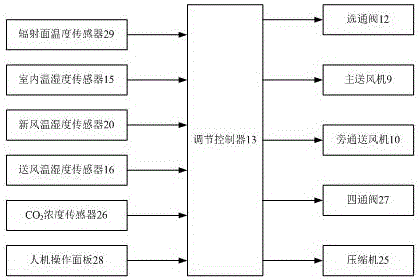

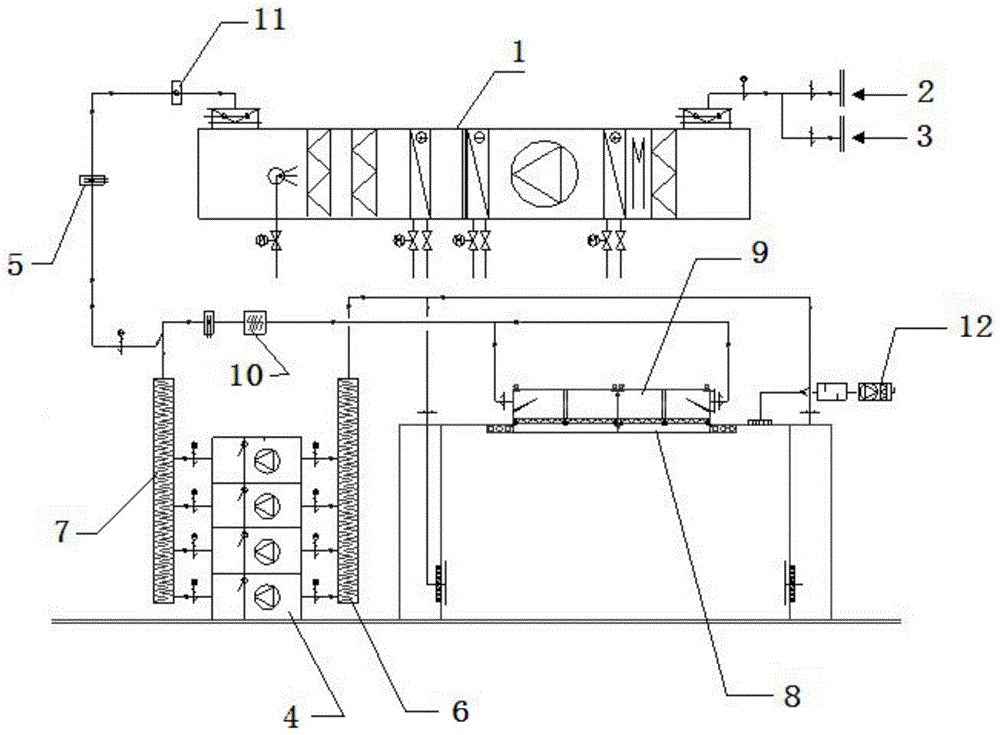

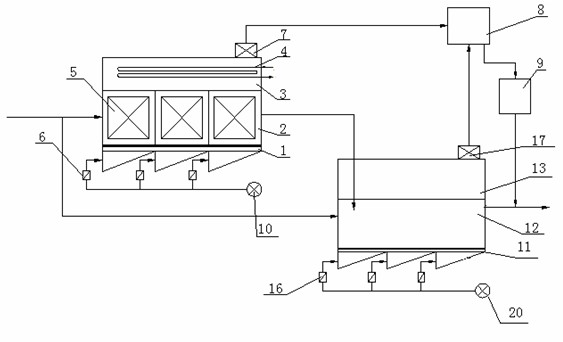

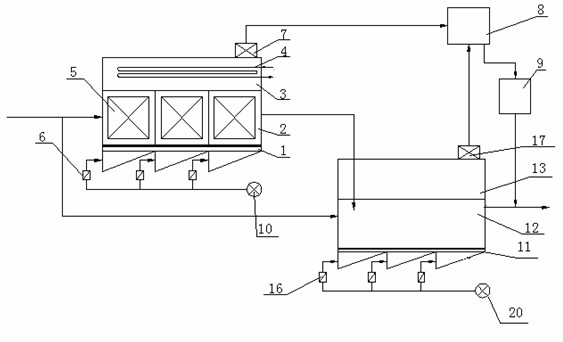

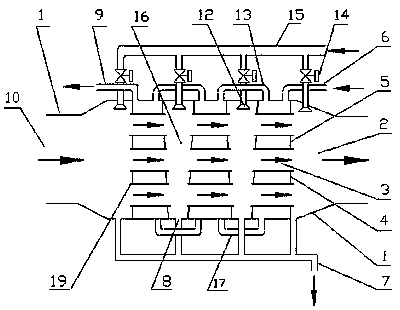

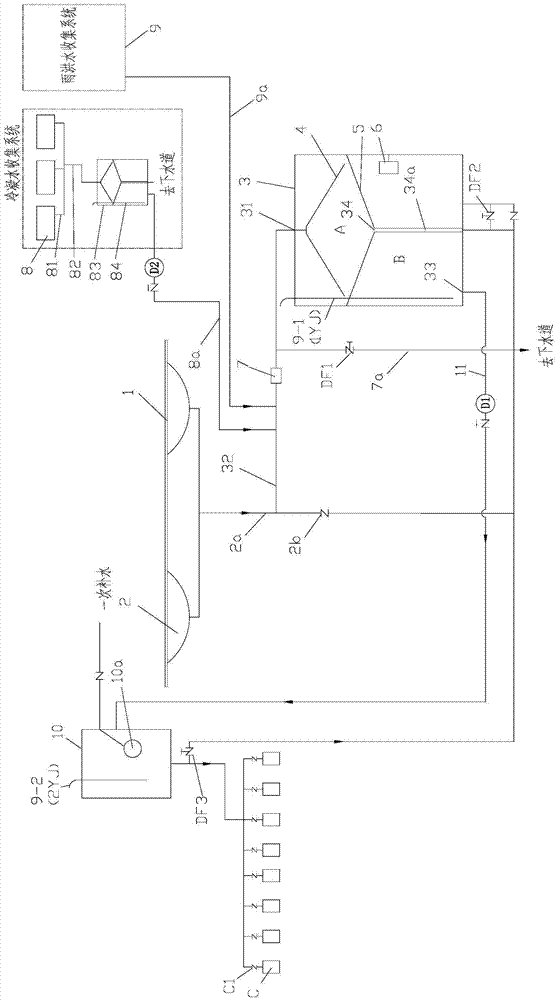

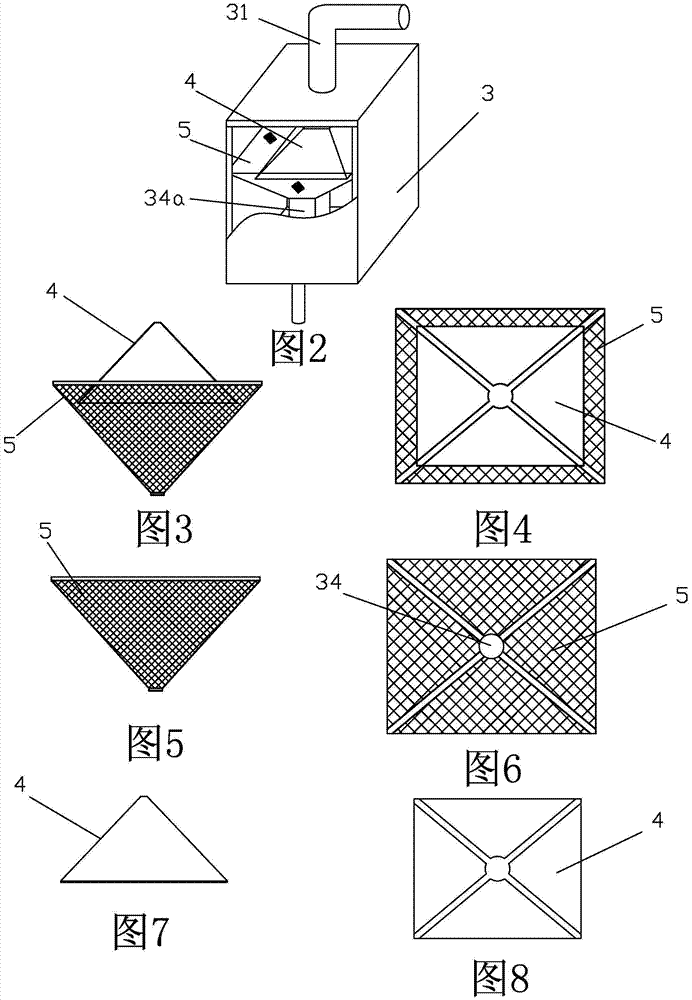

Fresh air handling unit adjusting and controlling system suitable for radiant air conditioner and controlling method of fresh air handling unit adjusting and controlling system

ActiveCN106678991AProper dehumidificationSolve the problem of insufficient transmission energy efficiency ratioDucting arrangementsMechanical apparatusFresh airEngineering

The invention provides a fresh air handling unit adjusting and controlling system suitable for a radiant air conditioner and a controlling method of the fresh air handling unit adjusting and controlling system. The fresh air handling unit adjusting and controlling system is used by cooperating with a radiant air conditioner system in an indoor space; a fresh air dehumidifying unit is adopted to bear the fresh air load, the humidity load and part of indoor sensible heat load; a fresh air handling unit can achieve the different functions of filtering, cooling, dehumidifying, auxiliary heating, ventilating and the like according to season requirements and the outdoor fresh air state; in addition, two air supply channels, that is, the main air channel and the bypass air channel are designed in a fresh air handling unit indoor unit, gating is conducted through a gating valve, and thus the fresh air handling unit indoor unit can operate in different working modes through free switching; and through control of an adjusting and controlling device over the operation modes, an auxiliary radiating system adjusts the air environment of the indoor space, the indoor environment comfort level and the system operation energy efficiency ratio can be effectively increased, and the problems that the fresh air conveying energy efficiency ratio in the transition season is insufficient, the room temperature and humidity are unreasonable, moisture condensates on the surface of a radiant panel, and energy sources are consumed excessively are solved.

Owner:CHONGQING UNIV

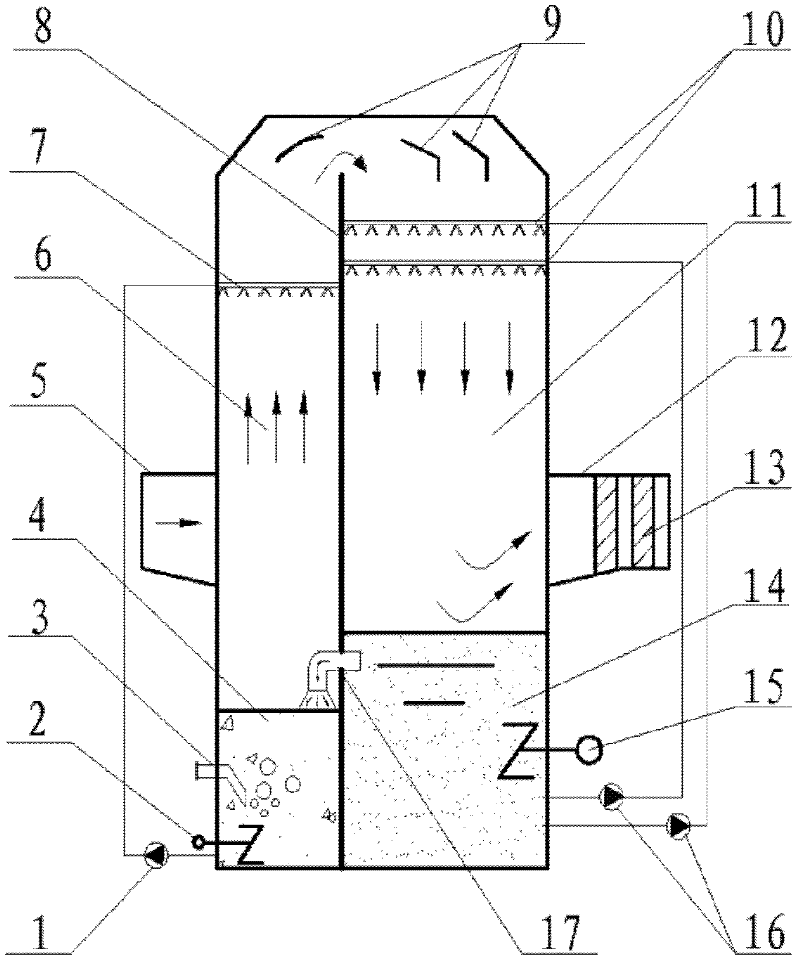

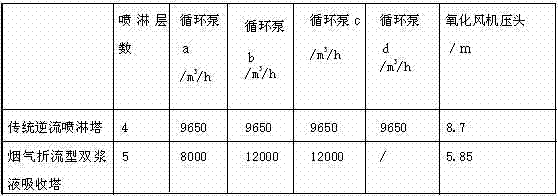

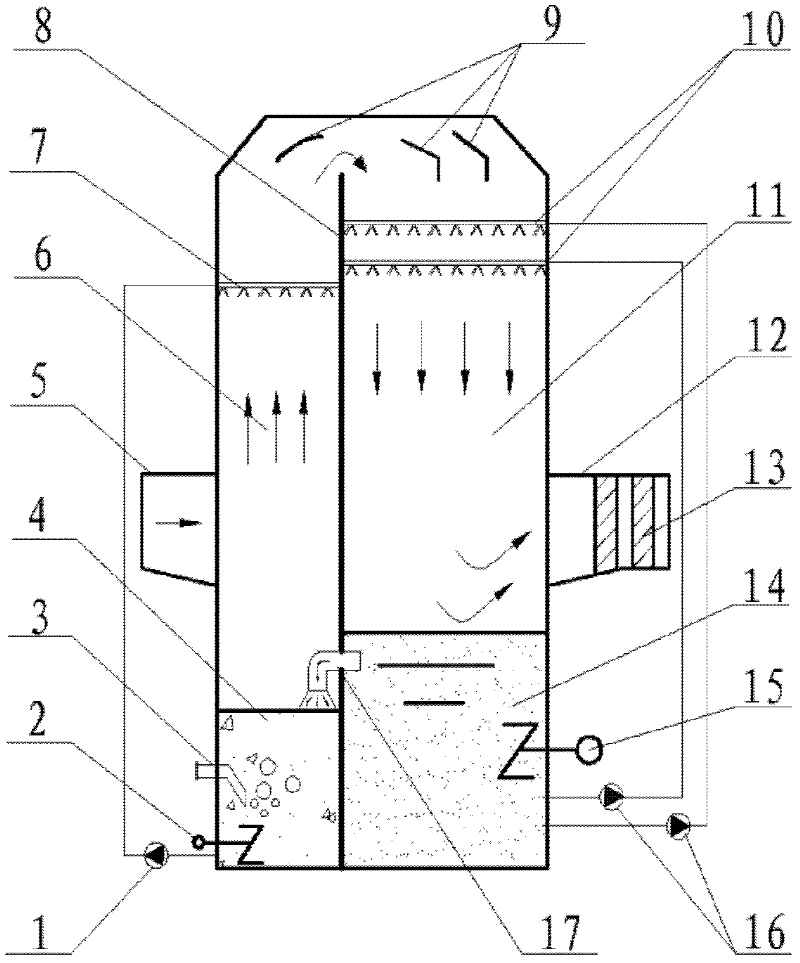

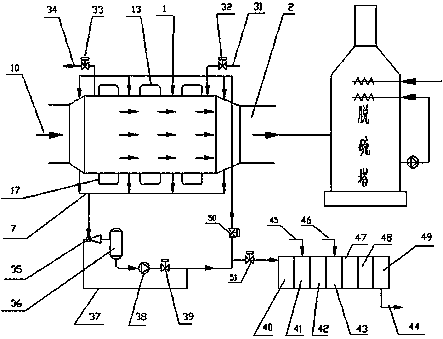

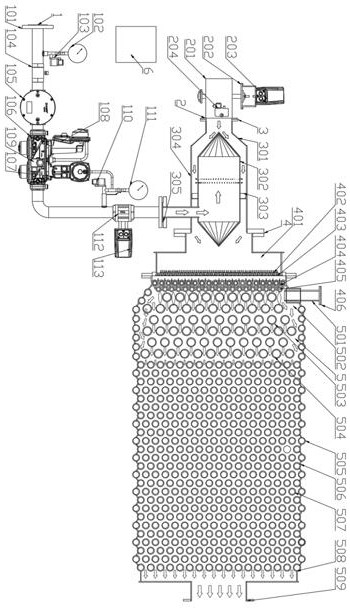

Flue gas baffling double-slurry pool absorbing tower

InactiveCN102350198AHigh removal ratePromote oxidationDispersed particle separationFlue gasProcess engineering

The invention relates to a flue gas baffling double-slurry pool absorbing tower, characterized in that: the interior of the absorbing tower is separated into an independent prescrubbing section slurry pool and an independent absorption section slurry pool by baffle plates, a corresponding upper gas-liquid contact area is separated into a prescrubbing section and an absorption section, the baffle plates have a distance from the tower top, the tower top is provided with guide vanes; a demister is arranged in an export of flue gas; the pH value of the slurry in the prescrubbing section slurry pool is lower than the pH value of the slurry in the absorption section slurry pool, and an unidirectional conveying pipeline is arranged between the two slurry pools and communicated with the two slurry pools. According to the invention, by slurry pools with different pH values and the baffling flue gas path, the desulphurization system has strong SO2 buffering ability, the desulphurization efficiency does not fluctuate with the flue gas flux and the load change of SO2 in the flue gas, the utilization rate of limestone is greatly increased, and the gypsum rain is effectively prevented.

Owner:中建中环新能源有限公司

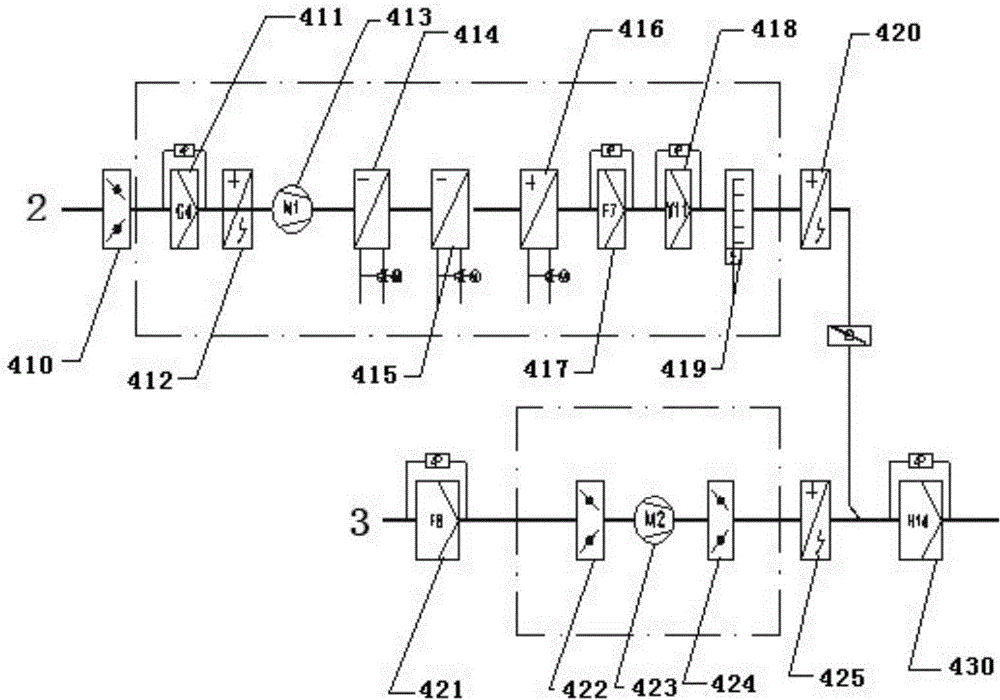

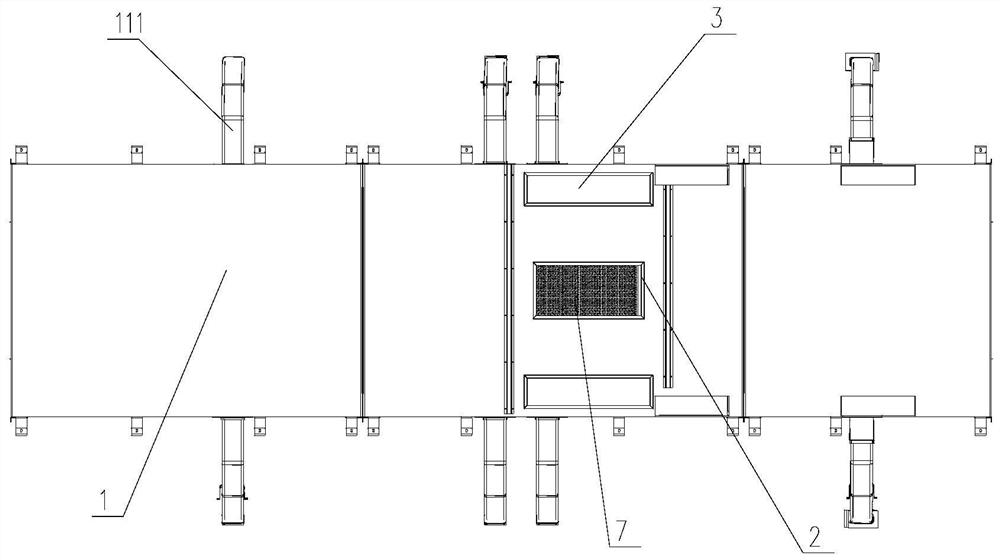

Intelligent energy-saving air handling system for operation room

InactiveCN104819521AReal-time air volume adjustmentReduce power consumptionDucting arrangementsMechanical apparatusFresh airEngineering

The invention discloses an intelligent energy-saving air handling system for an operation room. The intelligent energy-saving air handling system comprises an air handling unit (1), an electric heating unit (5) and a noise elimination static pressure tank group which are sequentially connected through an air pipe, the air handling unit (1) is used for filtering outdoor fresh air (2) and indoor fresh air (3), the electric heating unit (5) is an air duct type electric heater and arranged on an outlet air output pipeline of the air handling unit (1) and used for electrically heating outputted air, the noise elimination static pressure tank group includes a first noise elimination static pressure tank (6) and a second noise elimination static pressure tank (7) which are connected by a plurality of circulating fan (4) parallel pipelines, and the electrically heated fresh air and return air subjected to noise elimination by the noise elimination static pressure tank group are mixed by a three-way valve, heated, sterilized and inputted to the operation room through an air supply static pressure tank (9) arranged at the top of the intelligent operation room. According to the intelligent energy-saving air handling system for the operation room, energy is saved by more than 50%.

Owner:殷晓冬

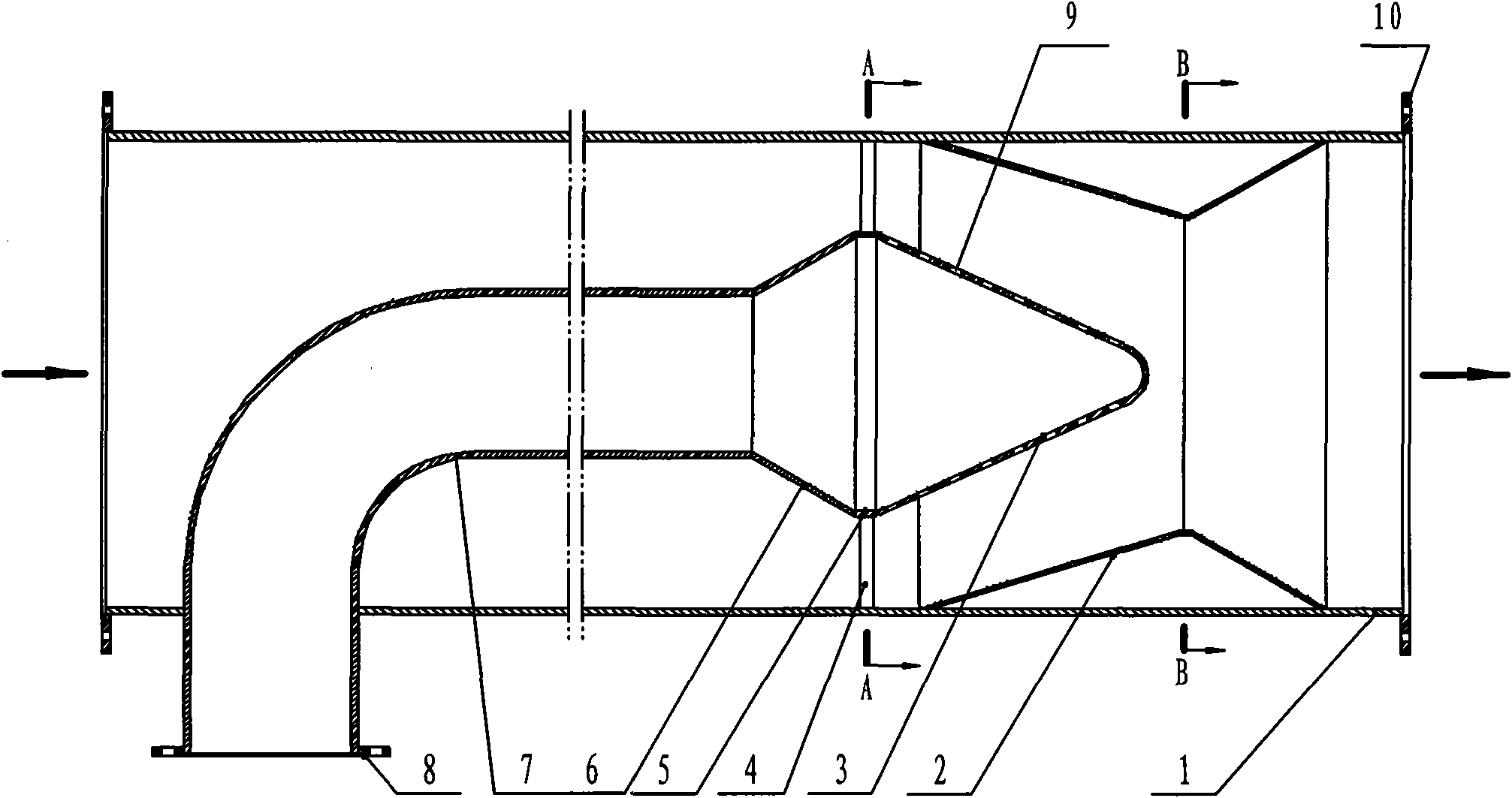

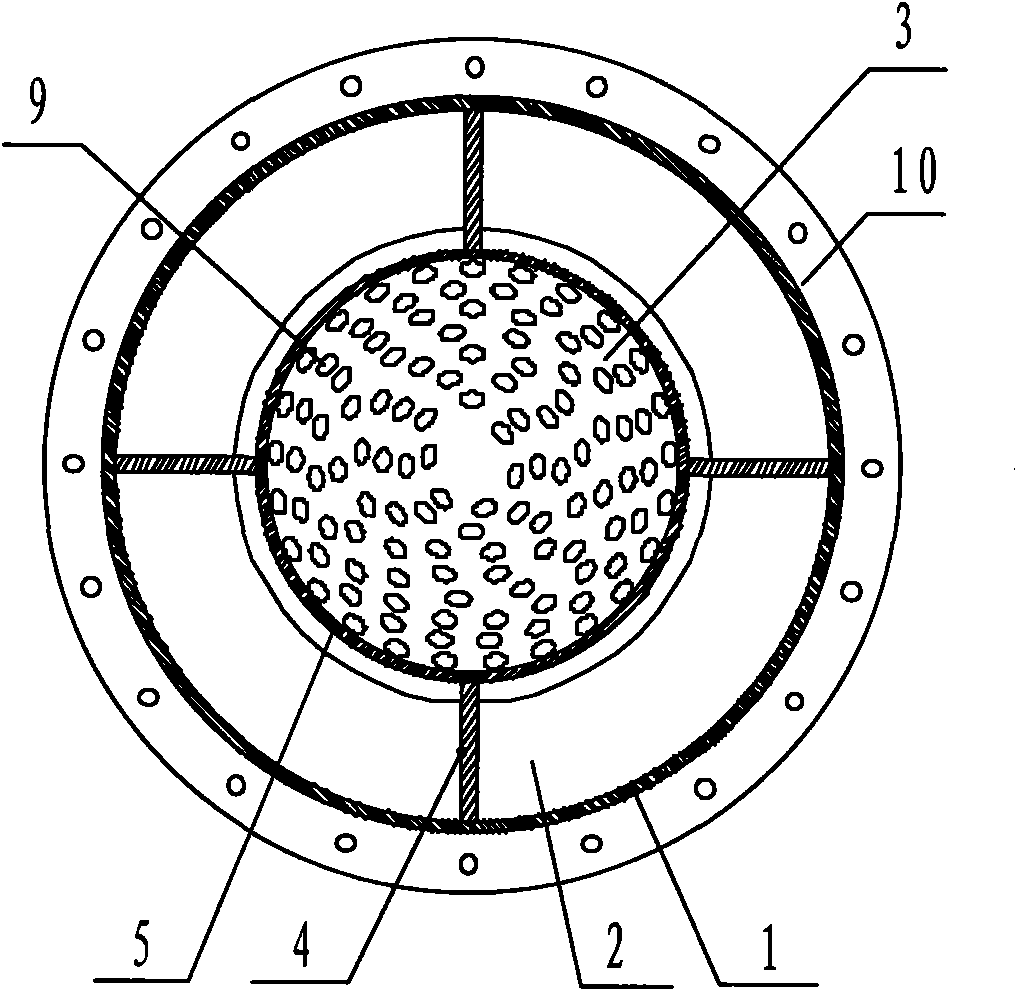

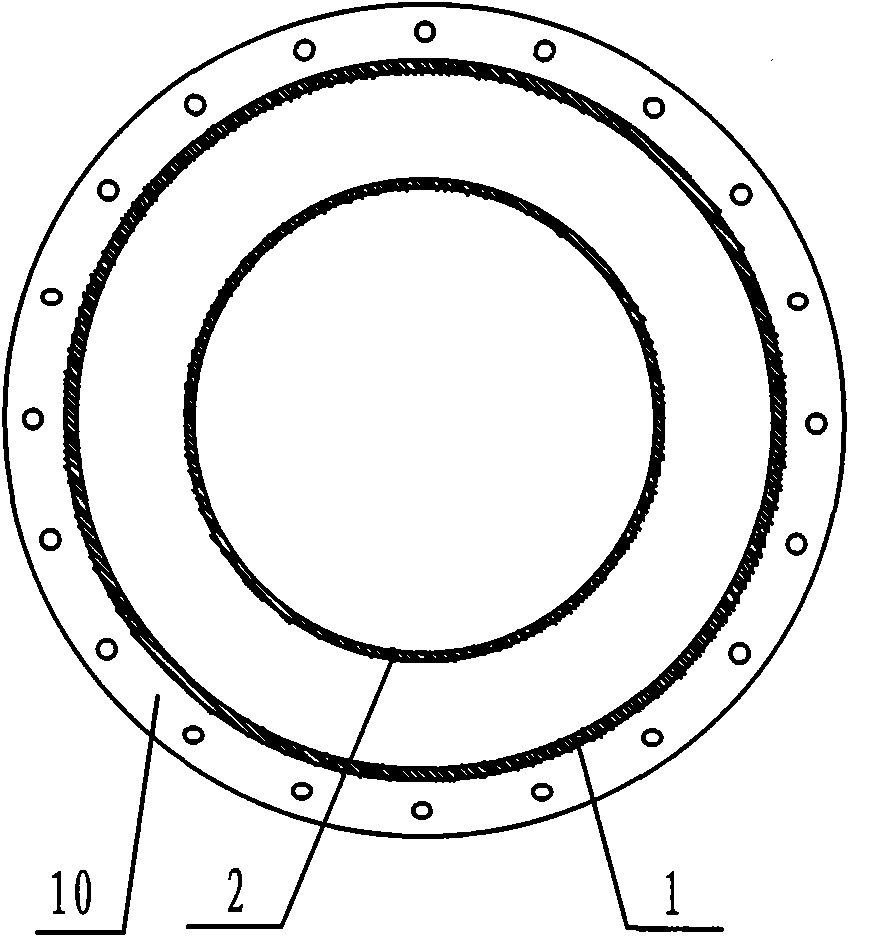

Mixer of coal mine extracted gas and ventilation gas

The invention relates to a mixer of coal mine extracted gas and ventilation gas, which is characterized by comprising a tubular shell, a gas ejection tube and a fairing, wherein two flanges arranged at both ends of the shell, the gas ejection tube is formed by sequentially connecting an inlet flange, an inlet tube, an expansion tube, a transition tube and a conical tail tube, the inlet end of the inlet flange is arranged outside the shell, the inlet tube, the expansion tube, the transition tube and the conical tail tube are arranged in the shell facing the outlet of the shell, the end of the conical tail tube adopts arc transition, small holes are uniformly distributed on the wall surface of the conical tail tube, a plurality of stiffeners are arranged between the transition tube and the shell, the fairing is arranged in the shell behind the stiffeners and encircles the conical tail tube, and the end of the fairing is near the outlet of the shell. The invention has the advantages of uniformly mixing, low energy consumption on extracted gas transportation and the like.

Owner:SHANDONG UNIV OF TECH

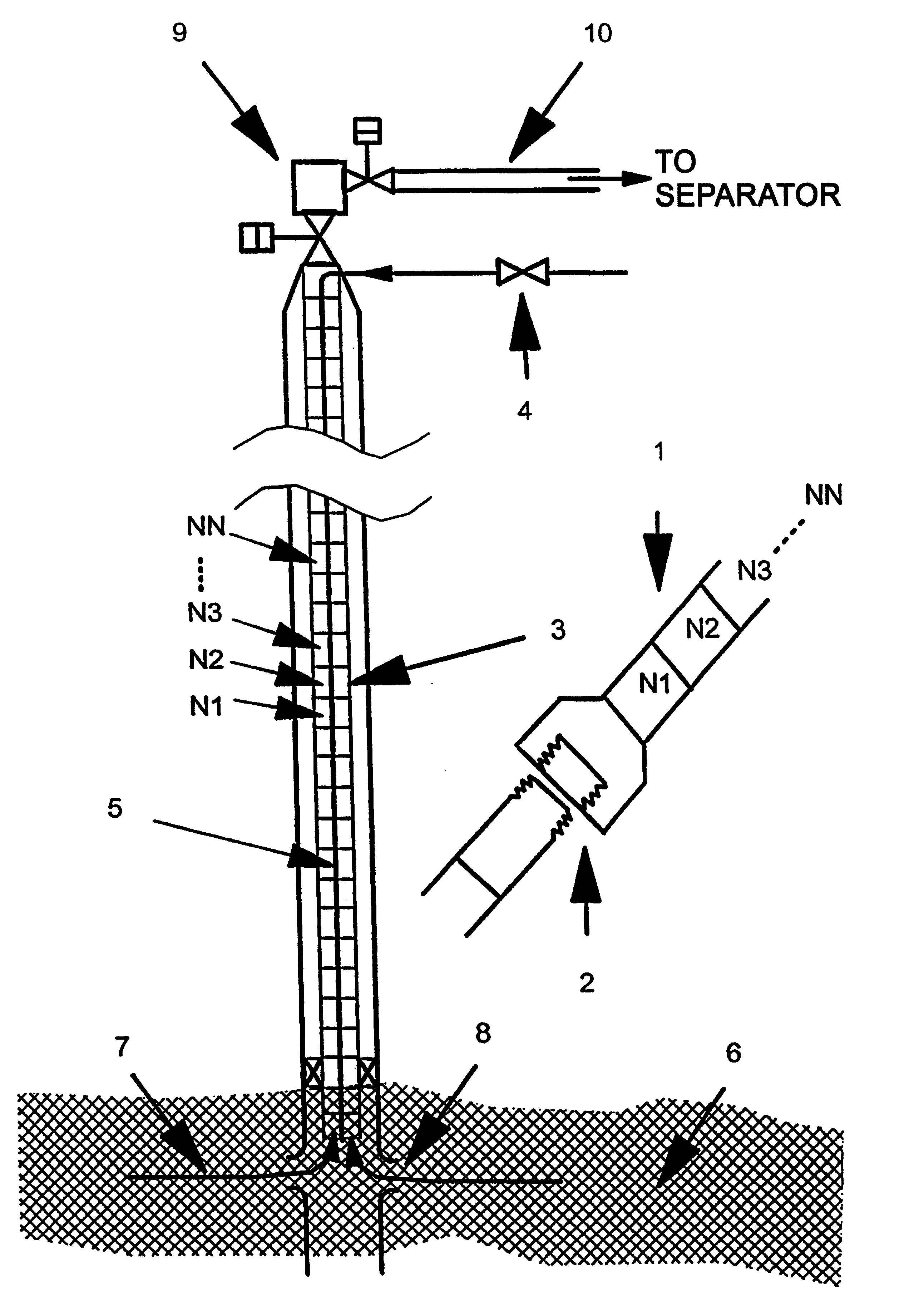

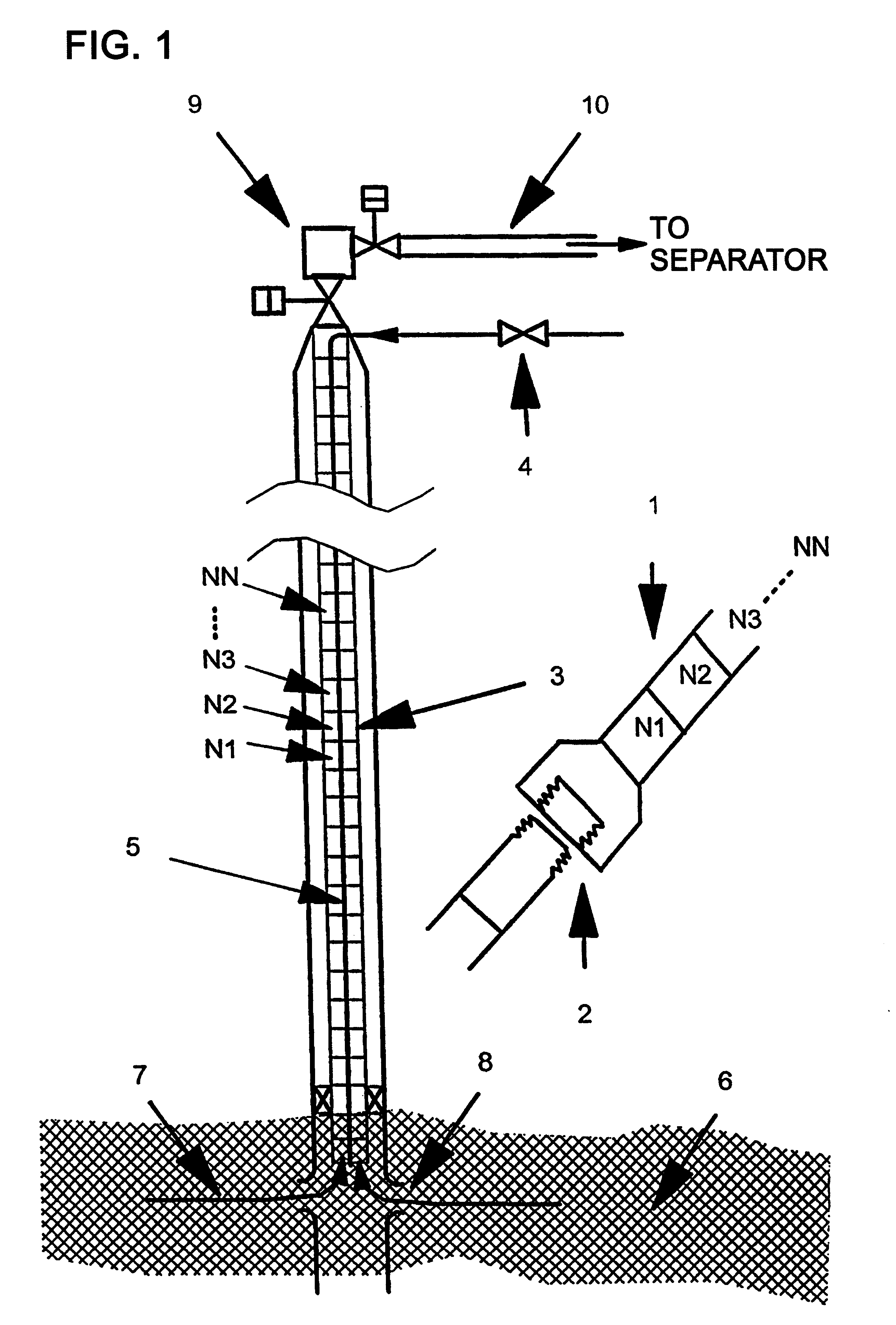

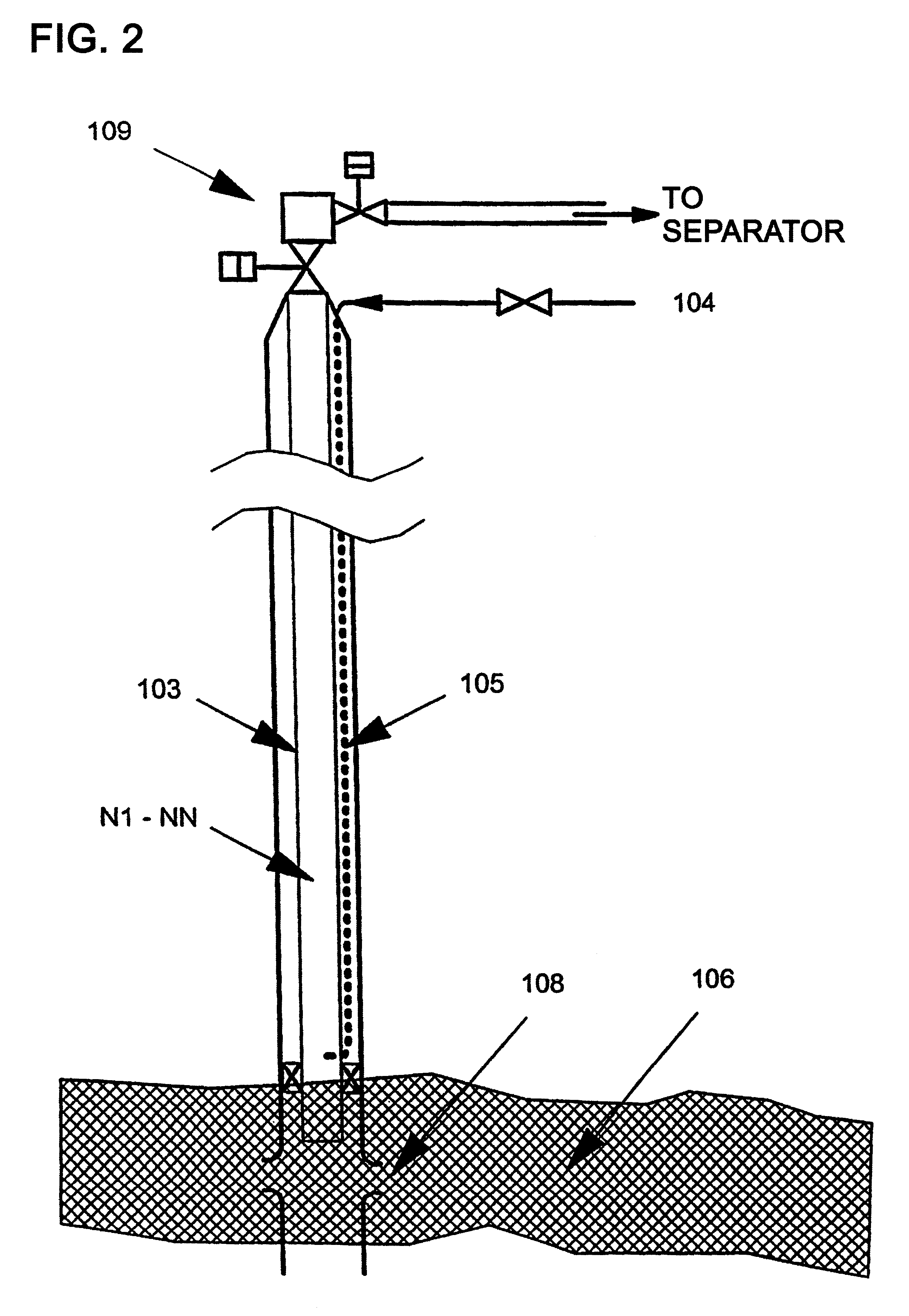

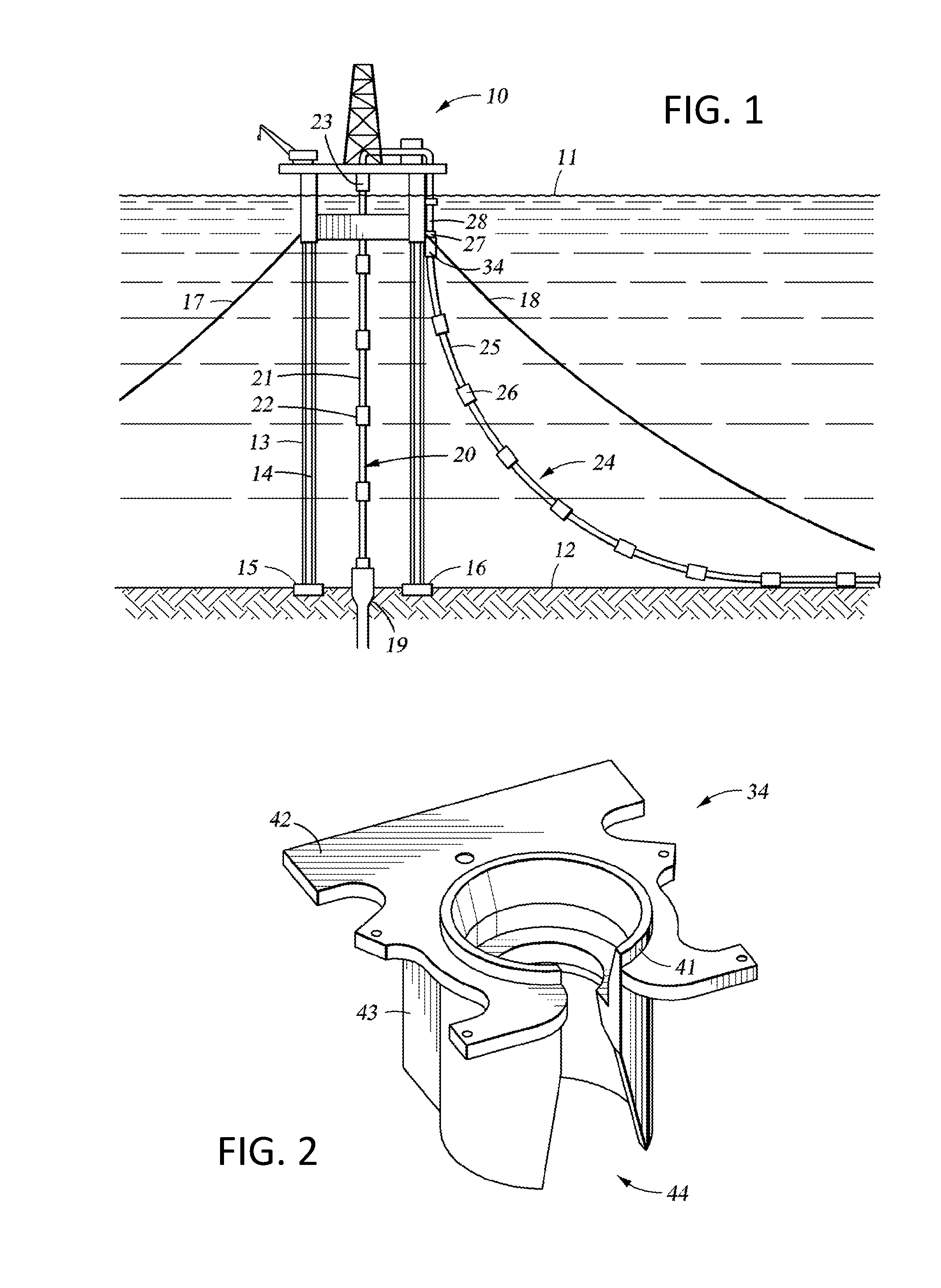

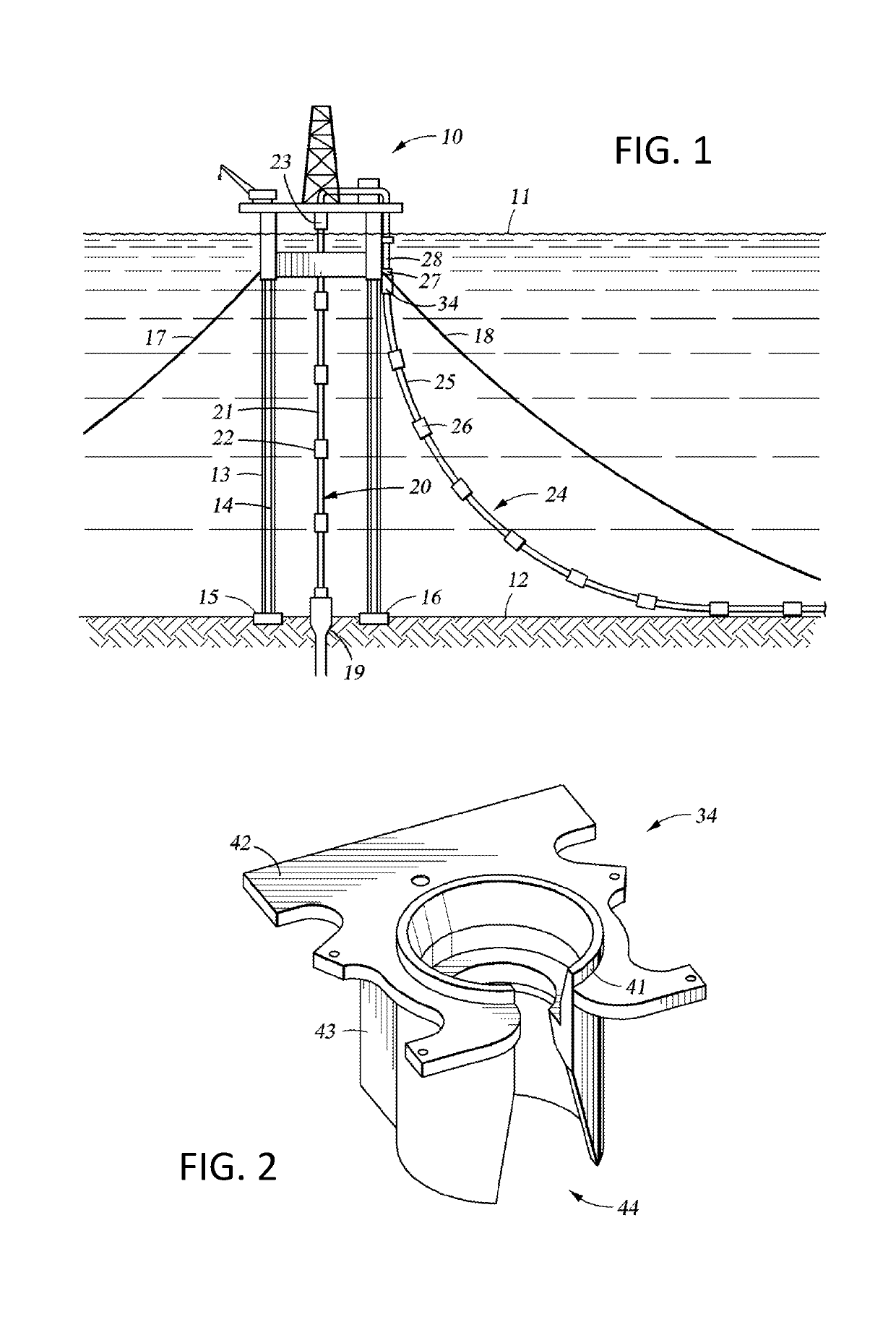

Use of static mixing element in connection with flow of gas and liquids through a production tubing

InactiveUS6260628B1Effective average densityReduce pressure headDrilling rodsPressure pumpsEngineeringProduct gas

The present invention relates to a method and a device in connection with a method for transport or flow of gas and liquid in a pipe, by which method there is in the overall or part of the pipe mounted static mixing elements for achieving favorable flows in the pipe, and for the purpose of being able to stimulate petroleum wells which have terminated production or almost terminated production due to high pressure head resistance, it is according to the invention suggested that the pipe which is used, is a production tubing or production string extending substantially vertically from a production reservoir having a low pressure, and that the mixing elements residing in the tubing is arranged in such a manner that the gas bubbles in the oil are distributed optimally as carriers in the oil, for thereby reducing and evening out the pressure head resistance in the tubing.

Owner:MAGNUS ARNE JOHANNES

Non-ventilation-pipeline inducing type ventilation and smoke exhaust system and ventilation and smoke exhaust method thereof

ActiveCN105318477AReduce the overall heightDuct cross-sectional area reductionSpace heating and ventilation safety systemsLighting and heating apparatusFloor slabSmoke exhaust ductwork

The invention discloses a non-ventilation-pipeline inducing type ventilation and smoke exhaust system and a ventilation and smoke exhaust method thereof. The system comprises an independent smoke exhaust system body and a non-underground-ventilation-pipeline inducing type ventilation system body. The independent smoke exhaust system body comprises a smoke exhaust fan, smoke exhaust ports, a smoke exhaust pipeline and a smoke exhaust fire damper. The smoke exhaust ports are formed in a ceiling or a wall face close to the ceiling. The smoke exhaust fire damper is installed at an inlet of the smoke exhaust pipeline. The non-underground-ventilation-pipeline inducing type ventilation system body comprises an inducing fan set, an air feeder, an exhaust blower, an exhaust pipeline, an exhaust port and an electric air valve. The inducing fan set is arranged on the lower portion of a floor slab. The electric air valve is installed on the exhaust pipeline. The ventilation and smoke exhaust method comprises the steps that during ventilation, the smoke exhaust fire damper is closed, the electric air valve is opened, and the exhaust port is opened for ventilation; and during a fire, the electric air valve is closed, the smoke exhaust fire damper is opened, and the smoke exhaust ports are opened for smoke exhaustion. The ventilation effect and the smoke exhaust effect are good, the noise pollution is reduced, the energy consumption is low, and the investment cost is low.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

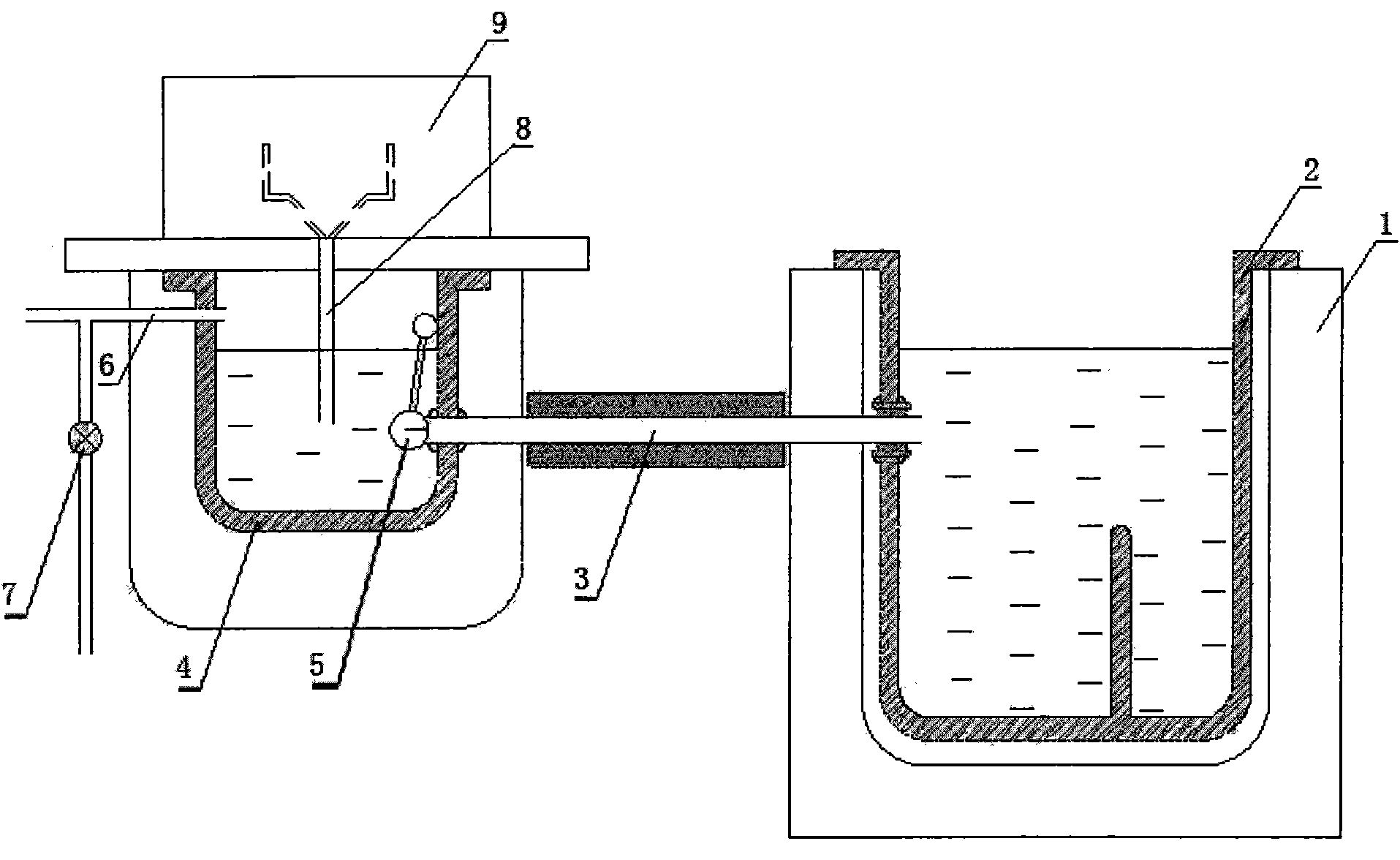

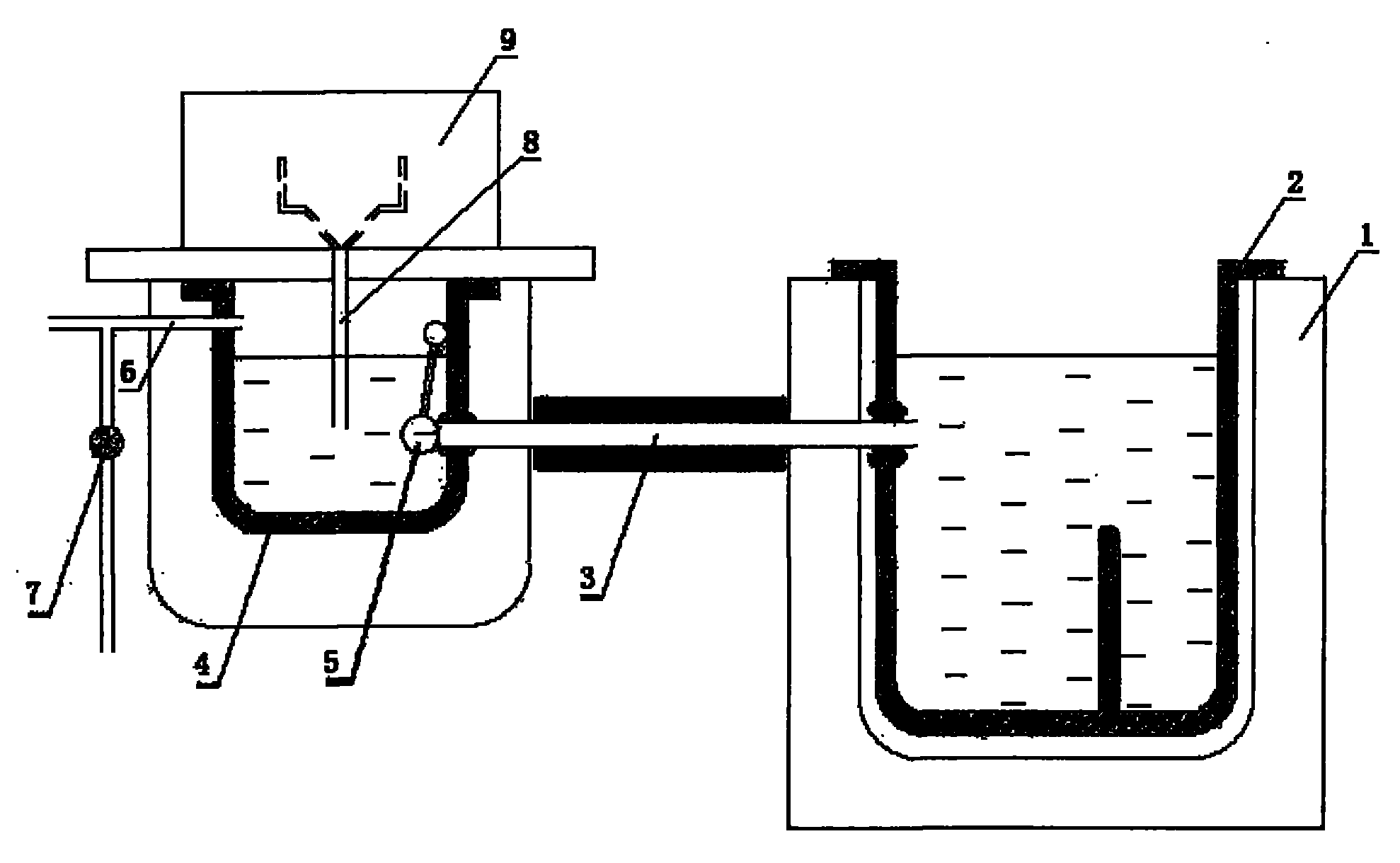

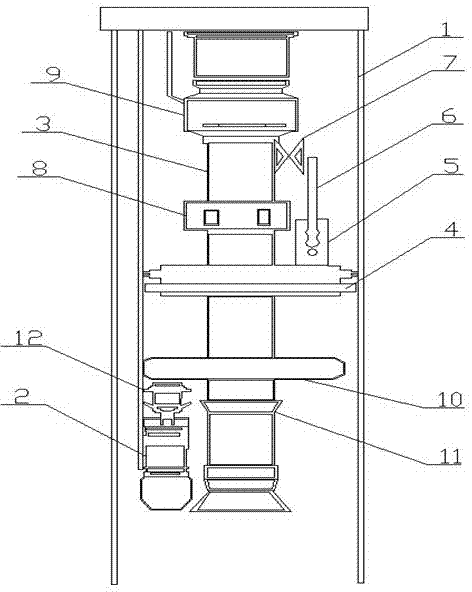

Bi-crucible low pressure casting method for magnesium alloy hub and equipment thereof

The invention aims to provide a method for producing a magnesium alloy hub based on bi-crucible low pressure casting equipment, thus improving production efficiency, enabling production process to be convenient and safe and enhancing quality of magnesium alloy automobile hub castings. The aim of the invention can be realized by adopting the bi-crucible low pressure casting equipment which mainly comprises a melting heat preservation furnace (1), a melting heat preservation crucible (2), a communicating tube (3), a casting crucible (4), an one-way valve (5), an intake tube (6), an air bleeder (7), a riser tube (8), a casting crucible (9), a casting mould (10) and a control system (11), wherein metal liquid in the melting heat preservation crucible (2) is controlled by the one-way valve (5), and liquid levels in the two crucibles are maintained to be same by communicating the communicating tube (3) and the casting crucible (4).

Owner:山西银光华盛镁业股份有限公司

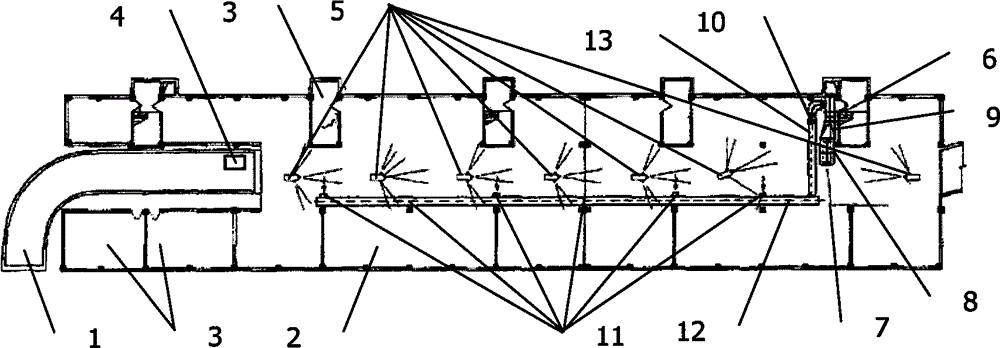

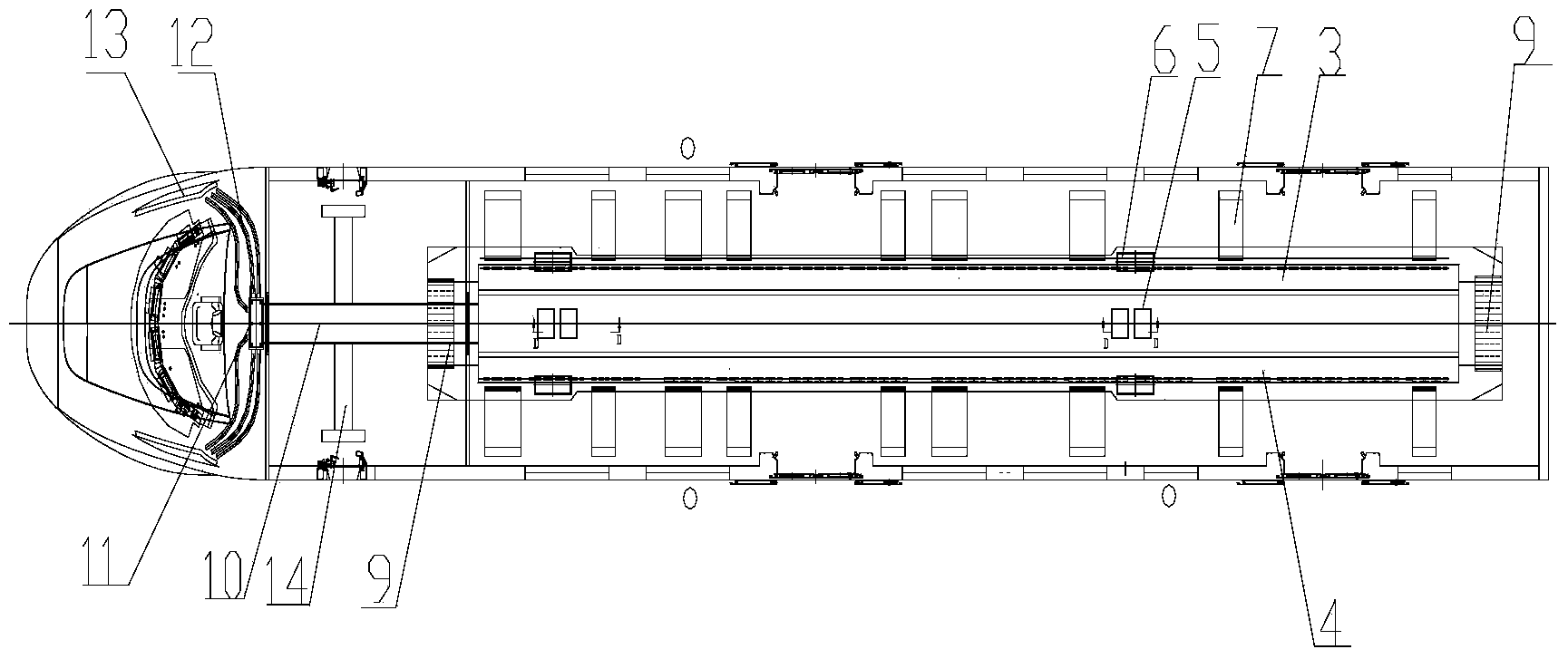

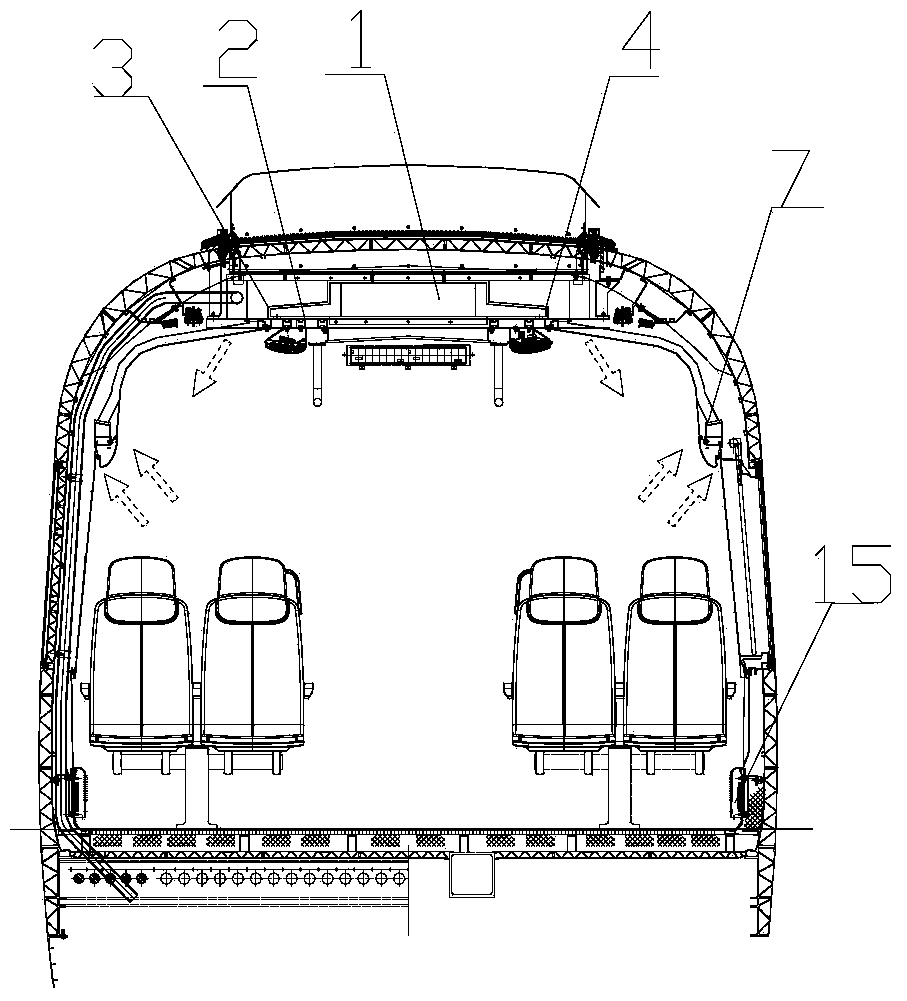

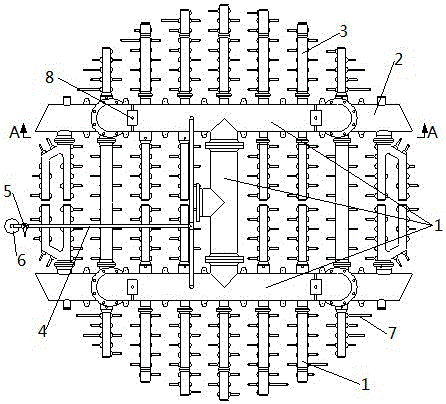

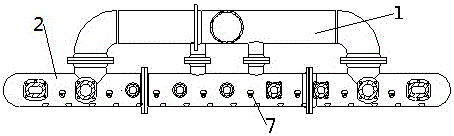

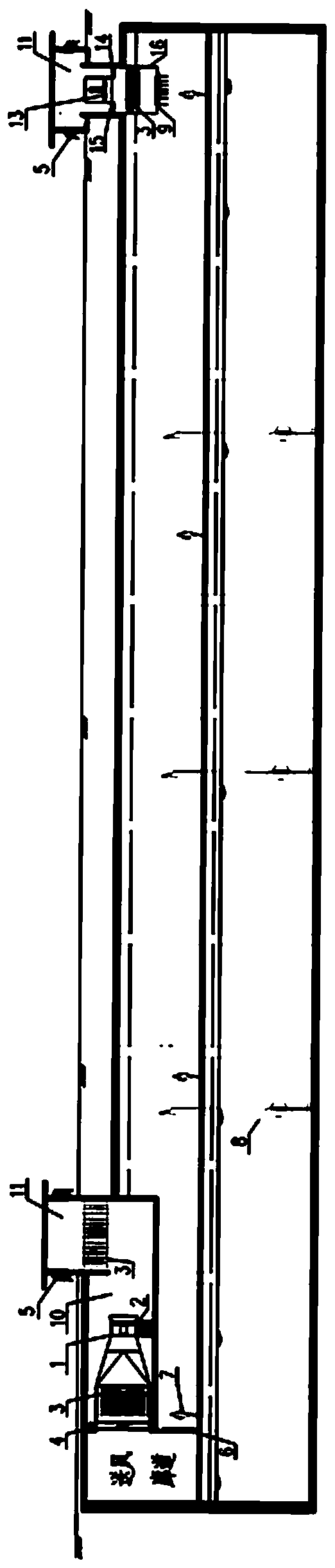

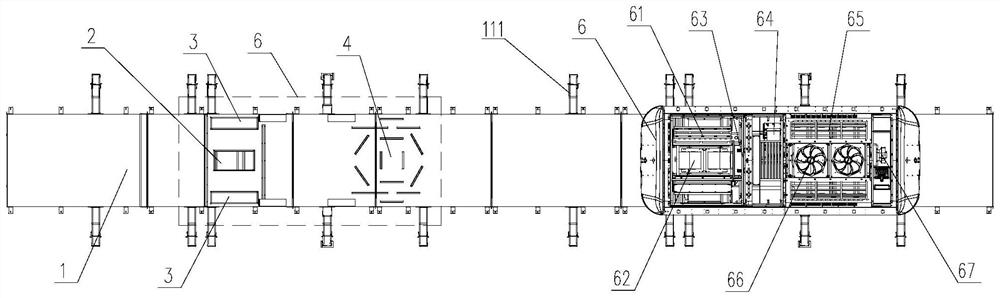

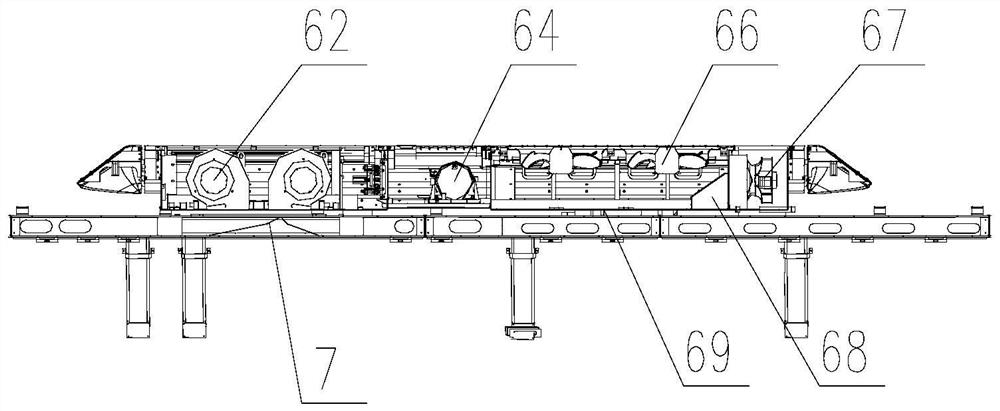

Air-conditioner unit air duct system for vehicle

ActiveCN103661458AReduce return air resistanceReduce pressure headRailway heating/coolingEnergy consumptionAir dispersion

The invention discloses an air-conditioner unit air duct system for a vehicle. The air-conditioner unit air duct system comprises a main air supply duct, a first air return duct and a second air return duct. The first air return duct and the second air return duct are arranged on the two sides of the main air supply duct. The main air supply duct is communicated with a compartment. Air-conditioner unit air return inlets communicated with an air-conditioner unit are formed in the first air return duct and the second air return duct. An air-conditioner unit air supply inlet communicated with the air-conditioner unit is formed in the main air supply duct. The air-conditioner unit air duct system further comprises a plurality of air return branch pipes communicated with the first air return duct and the second air return duct. One end of each air return branch pipe is communicated with the first air return duct or the second air return duct, and the other end of each air return branch pipe is communicated with the compartment. It can be seen from the technical scheme that the air return branch pipes are arranged on the first air return duct and the second air return duct and used for dispersing air entering the first air return duct and the second air return duct, return air dispersion is achieved, the resistance of return air inside the first air return duct and the second air return duct is reduced, a pressure head is reduced, the energy consumption of the air-conditioner unit is reduced, and the aim of reducing energy waste is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

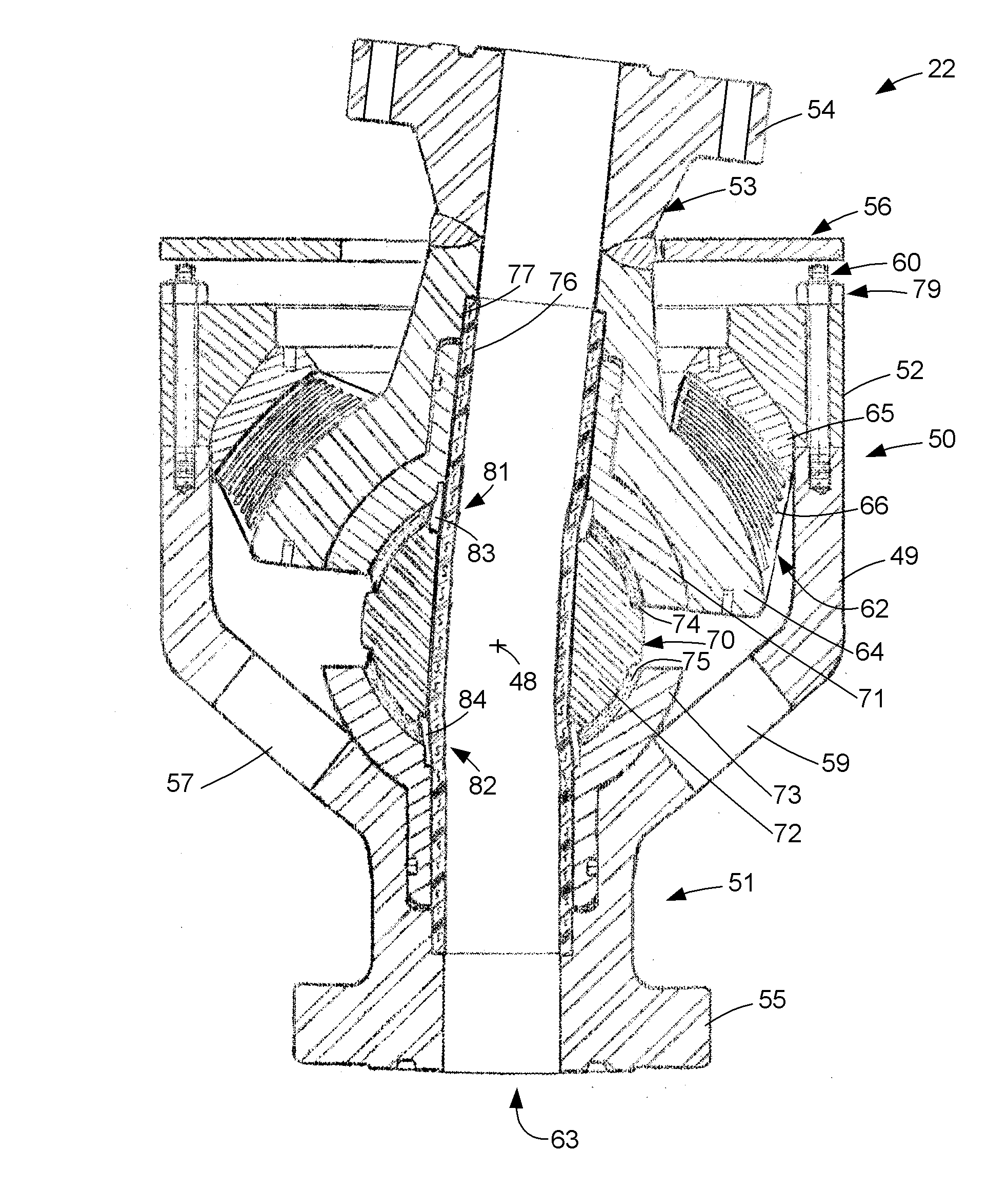

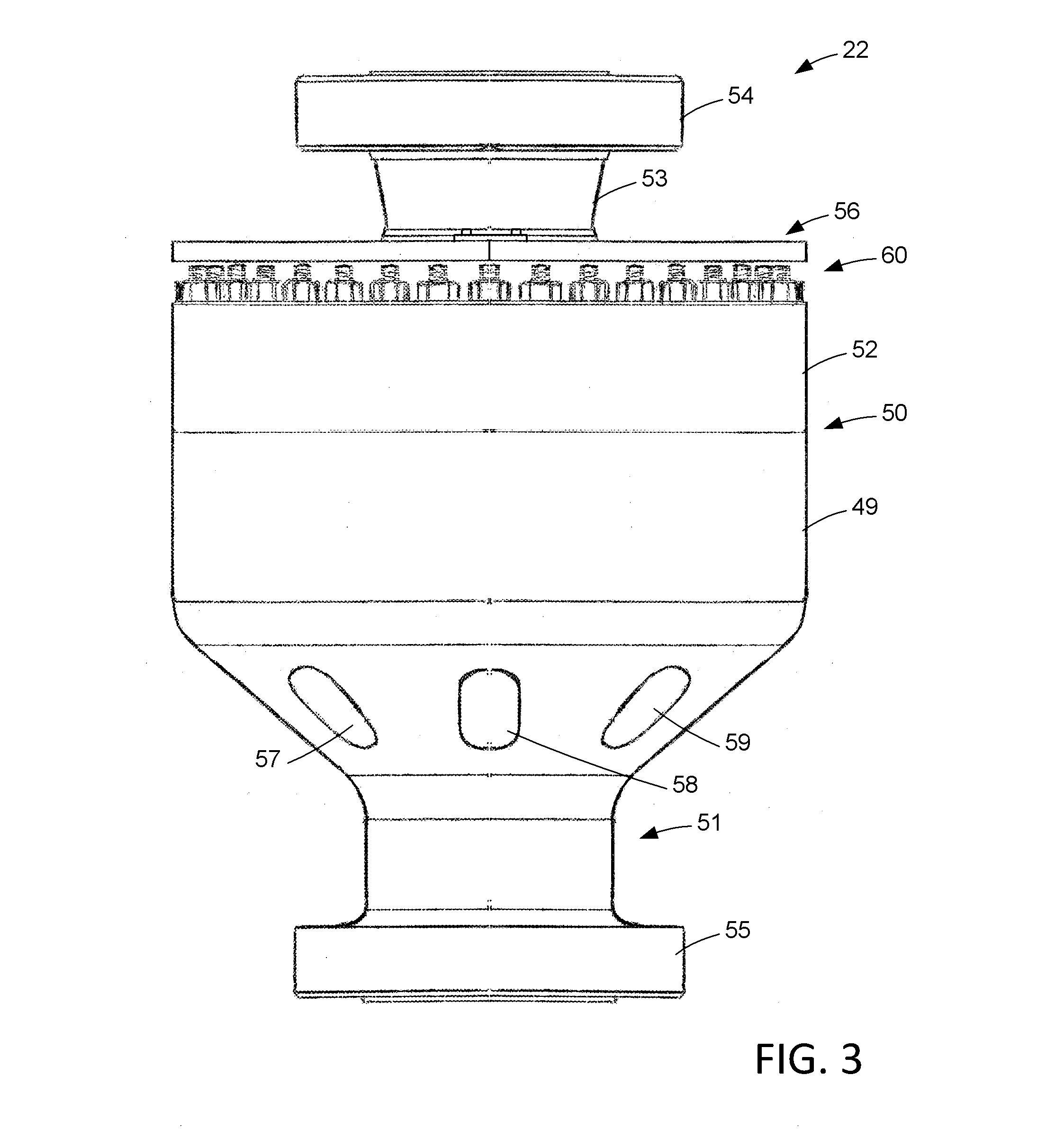

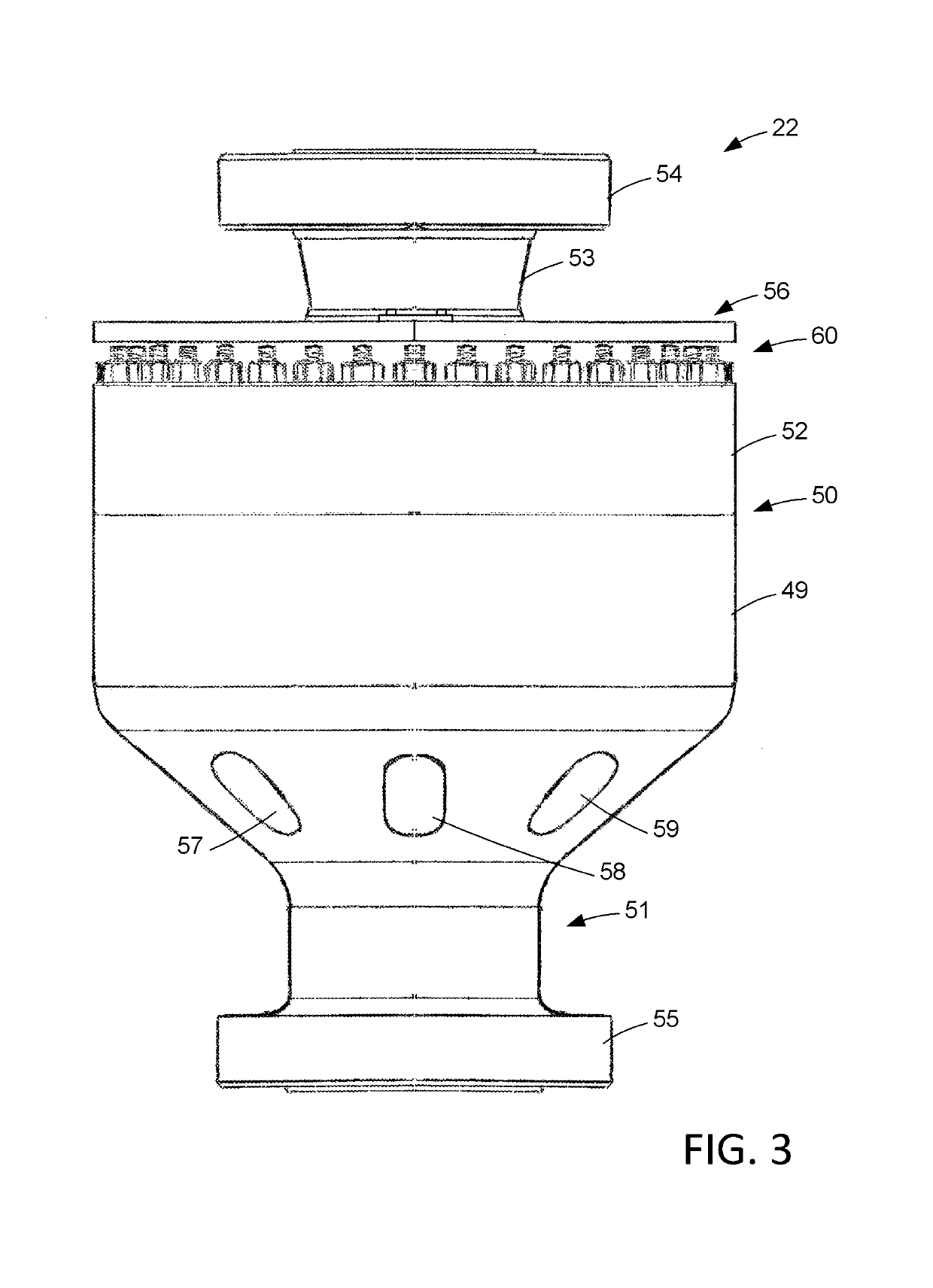

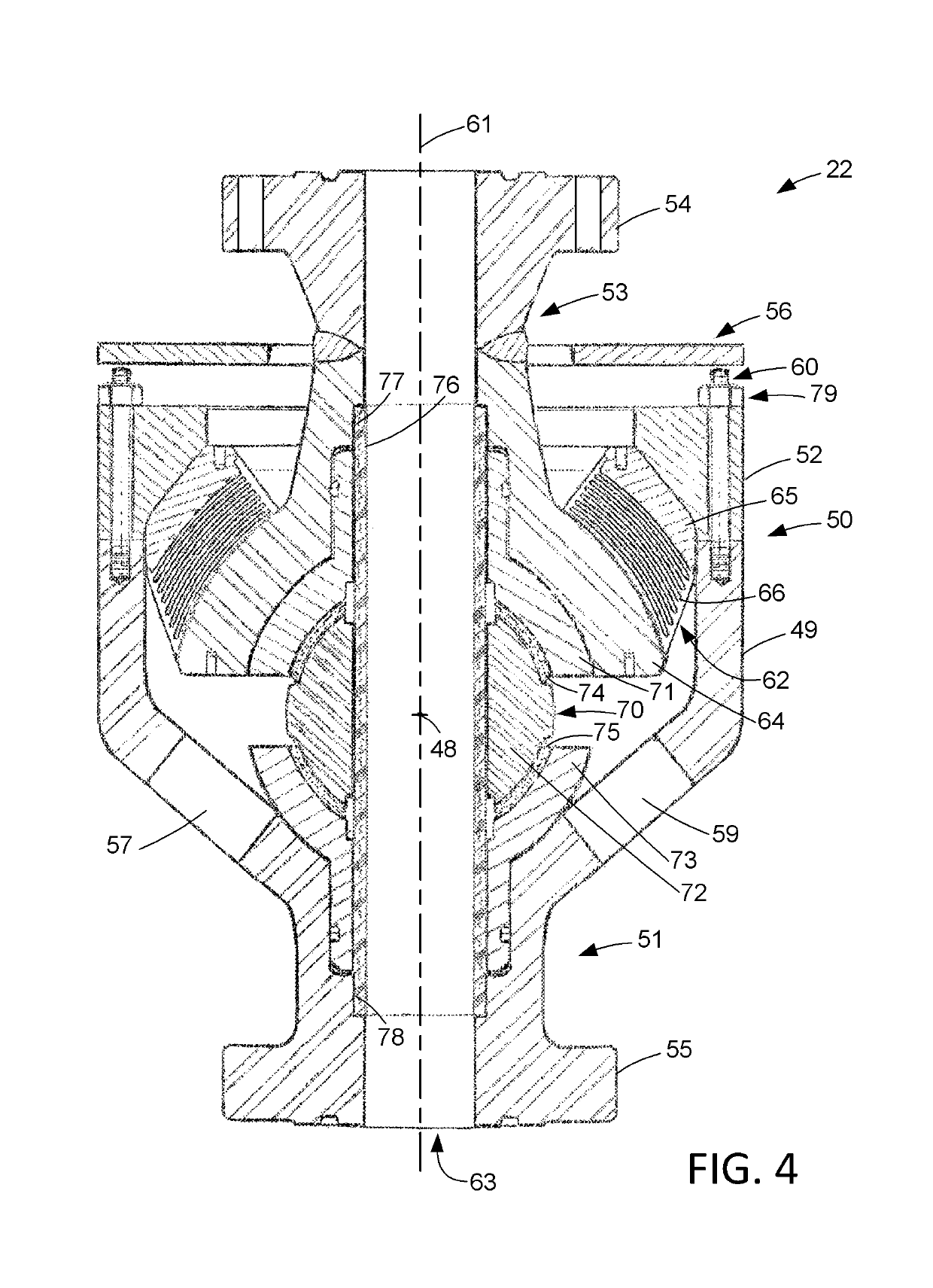

Flexible pipe joint having an annular flexible boot thermally or chemically insulating an annular elastomeric flexible element

ActiveUS20160348819A1Reduce manufacturing costSmallDrilling rodsThermal insulationElastomerEngineering

A flexible pipe joint has a body and an annular elastomeric flexible element flexibly coupling an extension pipe to the body for pivoting of the extension pipe with respect to the body. The flexible pipe joint also has an annular flexible boot for thermally or chemically insulating the annular elastomeric flexible element from the fluid flowing through a lumen of the flexible pipe joint. The annular flexible boot encircles the lumen, and the annular flexible boot has a first annular end attached to the extension pipe and a second annular end mounted so that pivoting of the extension pipe with respect to the body causes a flexing of the annular flexible boot, and a majority of the annular flexible boot has a shape conforming to shape of neighboring components of the flexible pipe joint.

Owner:WELLS FARGO BANK NAT ASSOC +1

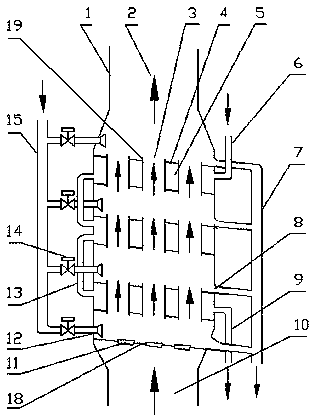

System for conditioning through coking charge coal humidity difference

ActiveCN102585867AExpand the adjustment rangeImprove controllabilityCoke ovensProcess engineeringCoal

The invention discloses a system for conditioning through the coking charge coal humidity difference. The system comprises an internal fluidized bed type drying and conditioning machine, a fluidized bed type dry-wet coal mixing conditioning machine, a deduster (8) and a granulator (9), the coking charge coal humidity difference conditioning machine is formed by the internal fluidized bed type drying and conditioning machine and the fluidized bed type dry-wet coal mixing conditioning machine, the internal fluidized bed type drying and conditioning machine deeply dehumdifies partial wet coal needing conditioning, and sends the dried partial coal to the fluidized bed type dry-wet coal mixing conditioning machine, and the dried partial coal and the other welt coal needing conditioning are subjected to hybrid conditioning in a fluidization state. The system has the advantages of simplified flow, reduced heat transfer and heating surfaces, simple structure, good interchangeability, convenient examination and maintenance, reliable operation, reliable and flexible conditioning control and adjustment, full and reasonable energy utilization, and reduction of the size of standby equipment of present conditioning systems.

Owner:WUXI YIEN TECH

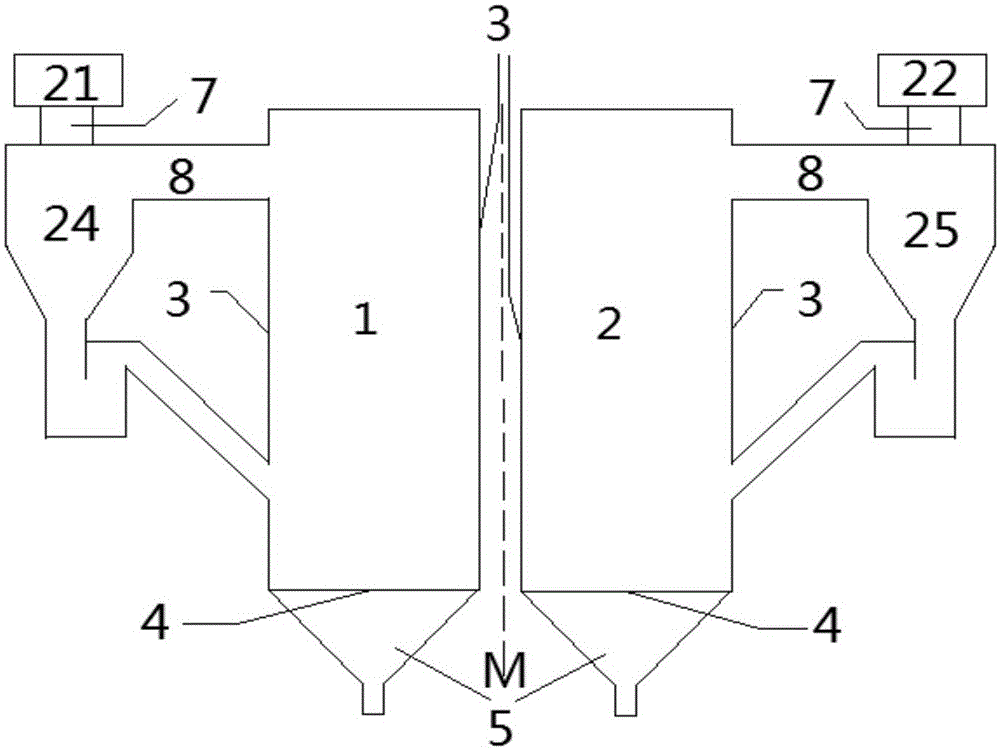

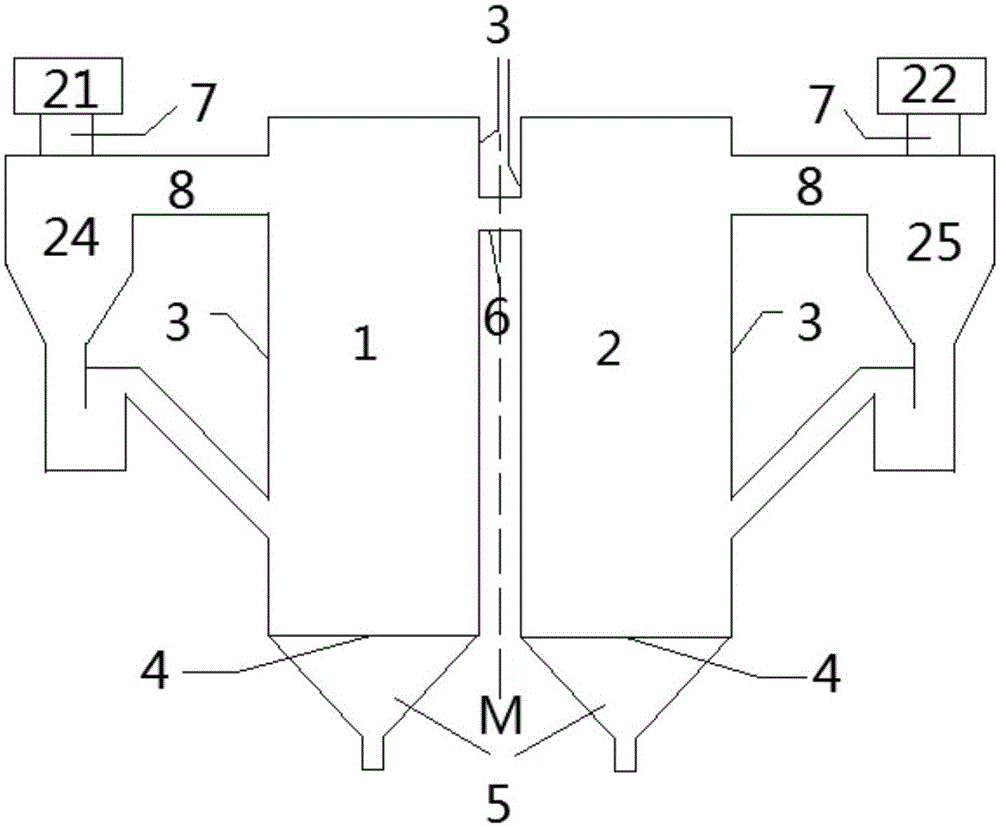

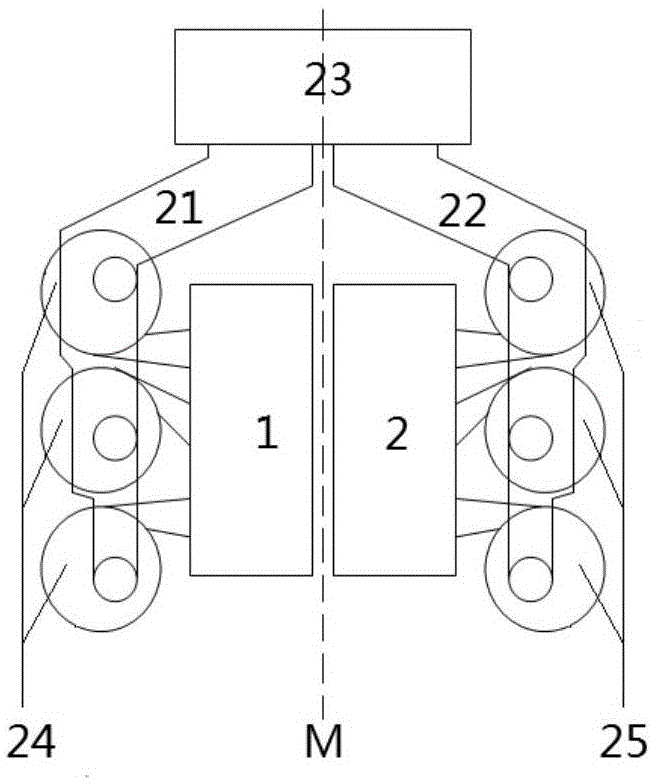

Double-hearth circulating fluidized bed boiler

ActiveCN105157021ASimple designAvoid heat load differencesFluidized bed combustionSteam boilersCycloneHearth

The invention discloses a double-hearth circulating fluidized bed boiler. The double-hearth circulating fluidized bed boiler comprises two completely separate hearths which are arranged side by side; a gap is reserved between the two hearths; a separate air distribution device and an air chamber are arranged at the lower part of each hearth; one group of cyclone separators with the same structures are arranged on the outer side of the surface opposite to each of adjacent surfaces of the two hearths; the two hearths, the two groups of separators and a common connection smoke channel are symmetrically arranged about the vertical center surface of the double-hearth circulating fluidized bed boiler; the two groups of cyclone separators are connected to the same tail convection smoke channel through the common connection smoke channel respectively. According to the double-hearth circulating fluidized bed boiler, single side of each water-cooled walls of each hearth is heated; the heat load difference between parallel tube screens and the table-tilting phenomenon caused by bed pressure fluctuation can be avoided; the reliability and the adjustment flexibility of the control system in the running process are further improved; the power consumption rate of the boiler factory is reduced; the favorable condition is provided for the arrangement of the high-temperature heated surface of the secondarily-heated supercritical circulating fluidized bed boiler; meanwhile, the hearths are simple in design and convenient to enlarge.

Owner:TSINGHUA UNIV

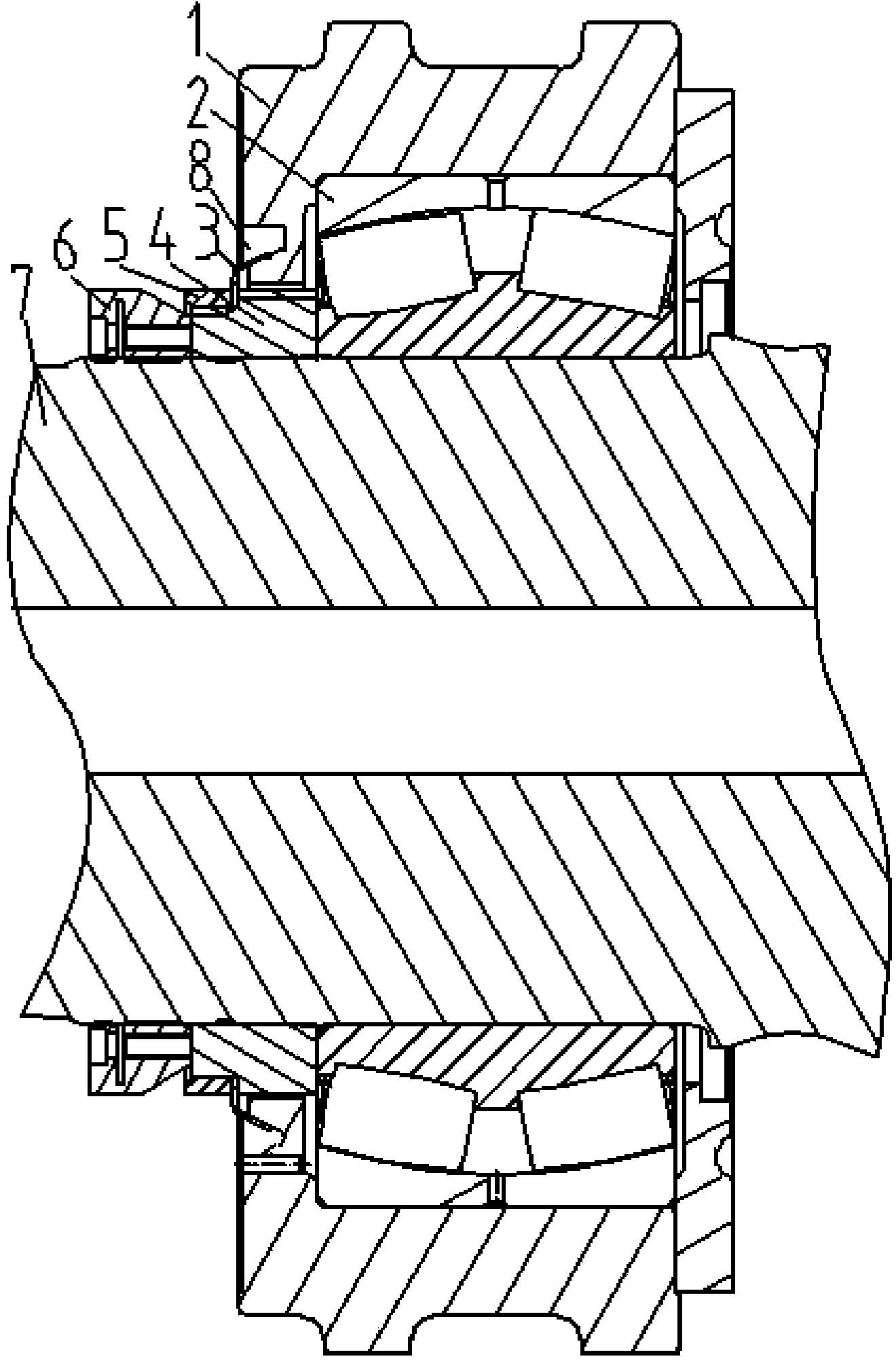

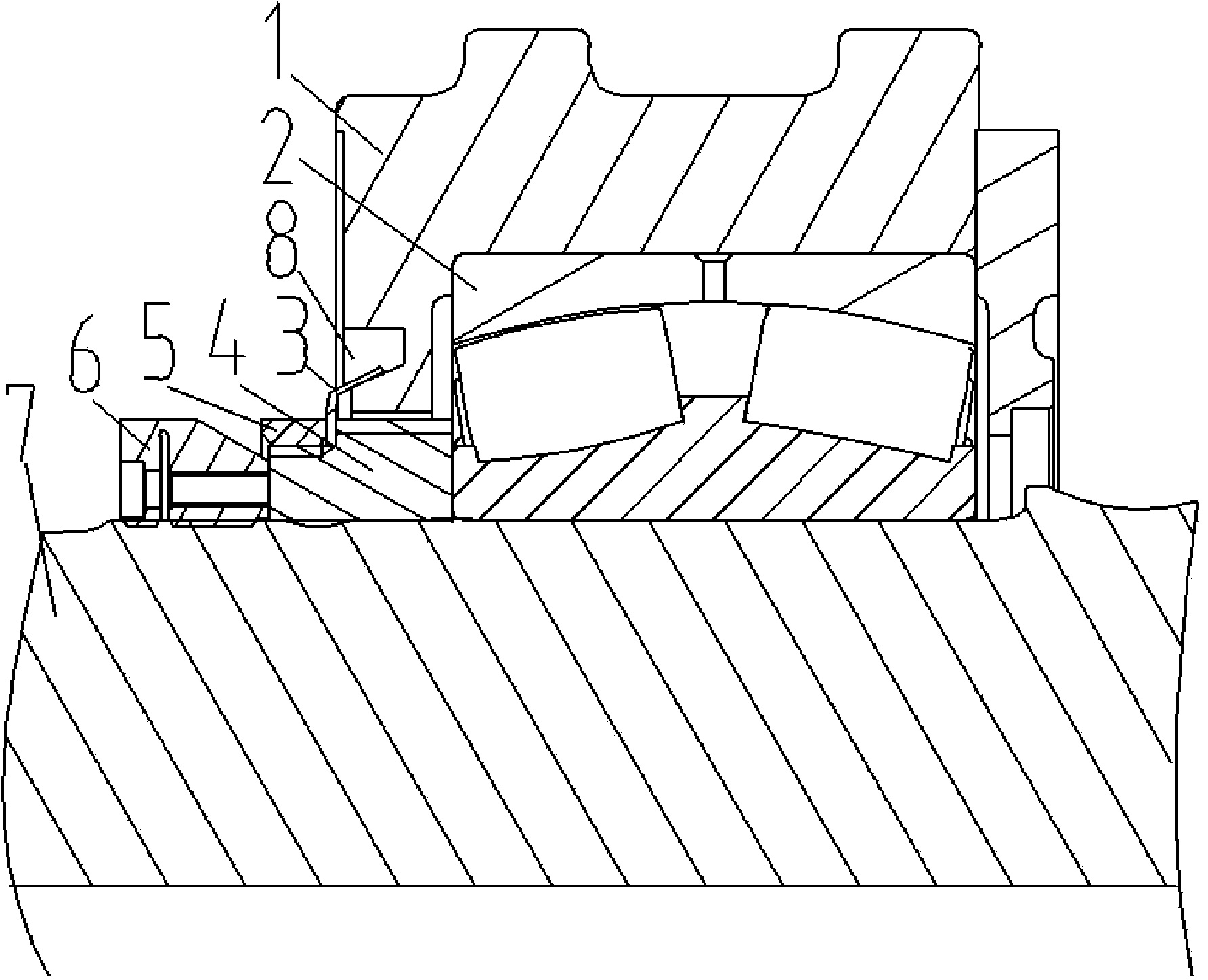

Bearing sealing device

InactiveCN104295749ASolution to short lifeReduce pressure headEngine sealsBearing componentsEngineeringSpherical roller bearing

The invention belongs to technical field of rotating component sealing, and discloses a bearing sealing device. A rotating shaft is installed in a bearing inner ring. A bearing pedestal is installed on a bearing outer ring. The bearing sealing device is characterized by comprising an annular groove formed in the outer end face of the bearing pedestal, wherein the annular groove and the rotating shaft are coaxial, the inner annular face of the annular groove is arranged to be a conical face, the diameter of the opening of the conical face is smaller than the diameter of the bottom of the conical face, a disc-spring-shaped sealing ring matched with the inner annular face is arranged in the annular groove, a check ring is installed on the rotating shaft, one end of the check ring is attached to the outer end face of the bearing inner ring, the other end of the check ring extends out of the outer end face of the bearing pedestal, and the disc-spring-shaped sealing ring and the check ring are fixed together. The bearing sealing device is simple in structure, good in sealing effect, particularly applicable to oil sealing of a self-aligning roller bearing and long in service life.

Owner:INNER MONGOLIA GEOHO ENERGY EQUIP

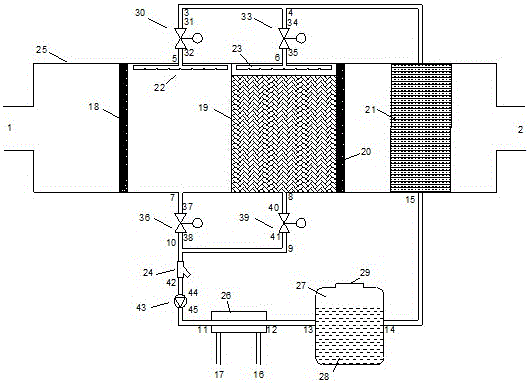

Boiler smoke and steam energy-saving low-carbon haze reducing system

ActiveCN108072045AImprove work efficiencyImprove suction effectMultistage water/sewage treatmentWater/sewage treatment by neutralisationWater treatment systemSteam condensation

The invention relates to a boiler smoke and steam energy-saving low-carbon haze reducing system. The boiler smoke and steam energy-saving low-carbon haze reducing system comprises a boiler smoke and steam energy-saving micro-emission device, a condensate water recycling device and a condensate water treatment system. The boiler smoke and steam energy-saving micro-emission device is used for treating smoke exhausted by a boiler in a heat exchange manner, the water content in the smoke is reduced, smoke and steam micro emissions are achieved, four-phase dividing of steam condensation, smoke exhausting, condensate water extraction and dust deposition is achieved in the heat exchange process, and extracted condensate water is supplied into the condensate water recycling device through a condensate water drainage pipeline. The condensate water recycling device is used for collecting the condensate water extracted by the boiler smoke and steam energy-saving micro-emission device and supplying the condensate water into the condensate water treatment system. The condensate water treatment system is used for further treating the acidic condensate water, and the discharge or reusing standardis met. According to the system, steam in the smoke can be effectively condensed and exhausted, gasification latent heat of the steam is utilized, salt generated when acidic gas ingredients in the smoke directly or indirectly react with alkaline matter in the presence of water is controlled or reduced, and then atmosphere haze pollution related with the smoke is controlled or reduced.

Owner:山东天境环保科技有限公司

Air dewetting and dedusting integrated device and dewetting and dedusting method

ActiveCN106091132AAchieve dust removalRealize integrationEnergy recovery in ventilation and heatingMechanical apparatusParticulatesEngineering

The invention discloses an air dewetting and dedusting integrated device. The air dewetting and dedusting integrated device comprises a box, a first water stopping plate, a second water stopping plate, a dewetting device, a dedusting device and a connecting device, wherein the first water stopping plate, the second water stopping plate, the dewetting device and the dedusting device are arranged inside the box; the connecting device is arranged outside the box; the first water stopping plate and the second water stopping plate are fixedly connected to the inner wall of the box; the first water stopping plate is close to an air feeding end of the box; the dewetting device and the dedusting device are positioned between the first water stopping plate and the second water stopping plate; compared with the dewetting device, the dedusting device is closer to the air feeding end of the box; and the connecting device is respectively connected with the dewetting device and the dedusting device, so that a circulating loop is formed. According to the device and the dewetting and dedusting method, two circulations are carried out by the same solution, dewetting, dedusting and reheating are organically combined, therefore, a system has the advantages of energy conservation and environmental protection on solution dewetting, meanwhile, extra filter equipment is not required, but a function of removing particulate matters and pollutants in air can be fulfilled, air supply resistance of the system is reduced, and energy is saved.

Owner:NANJING TECH UNIV

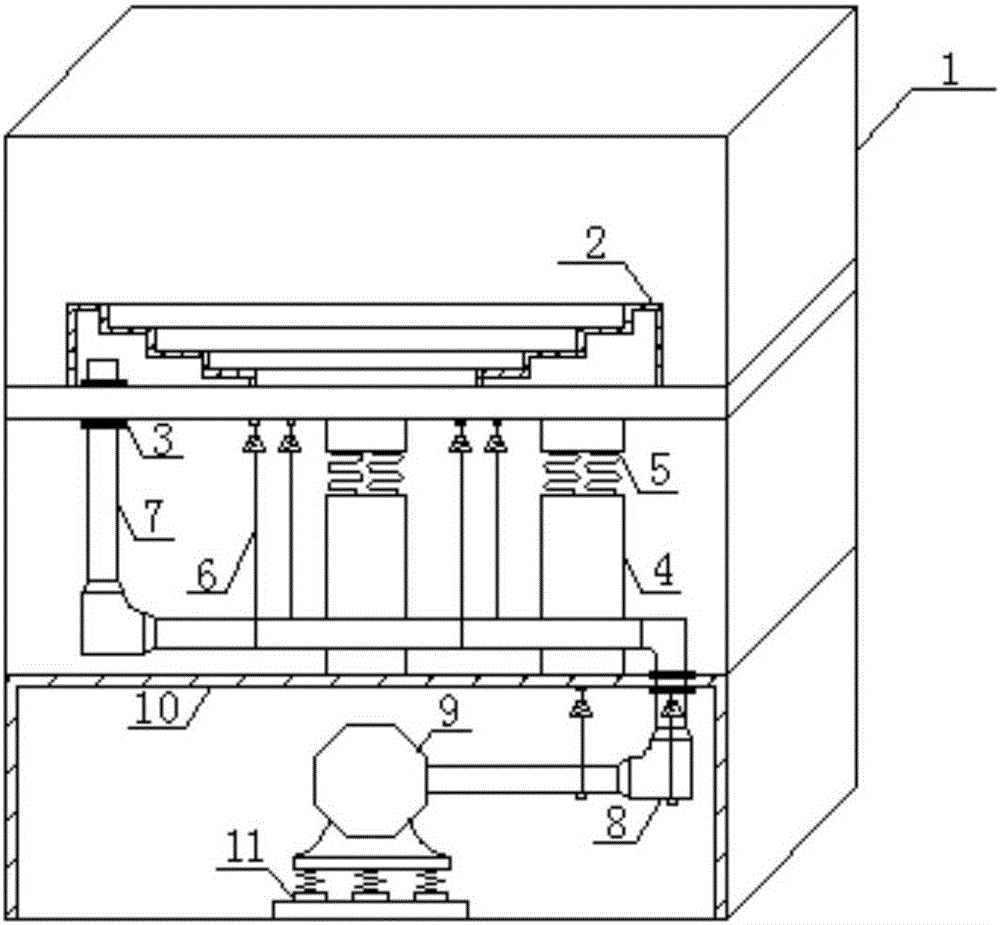

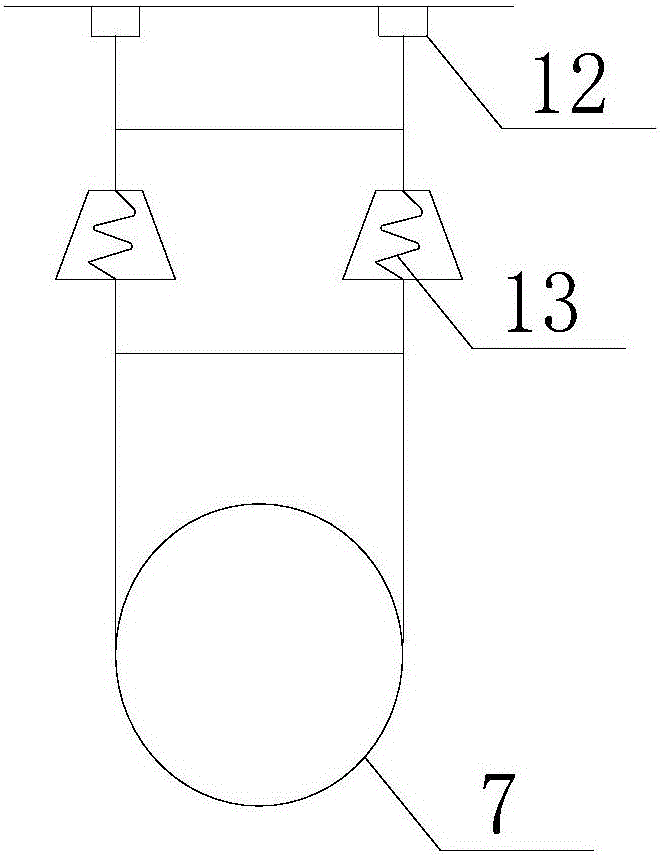

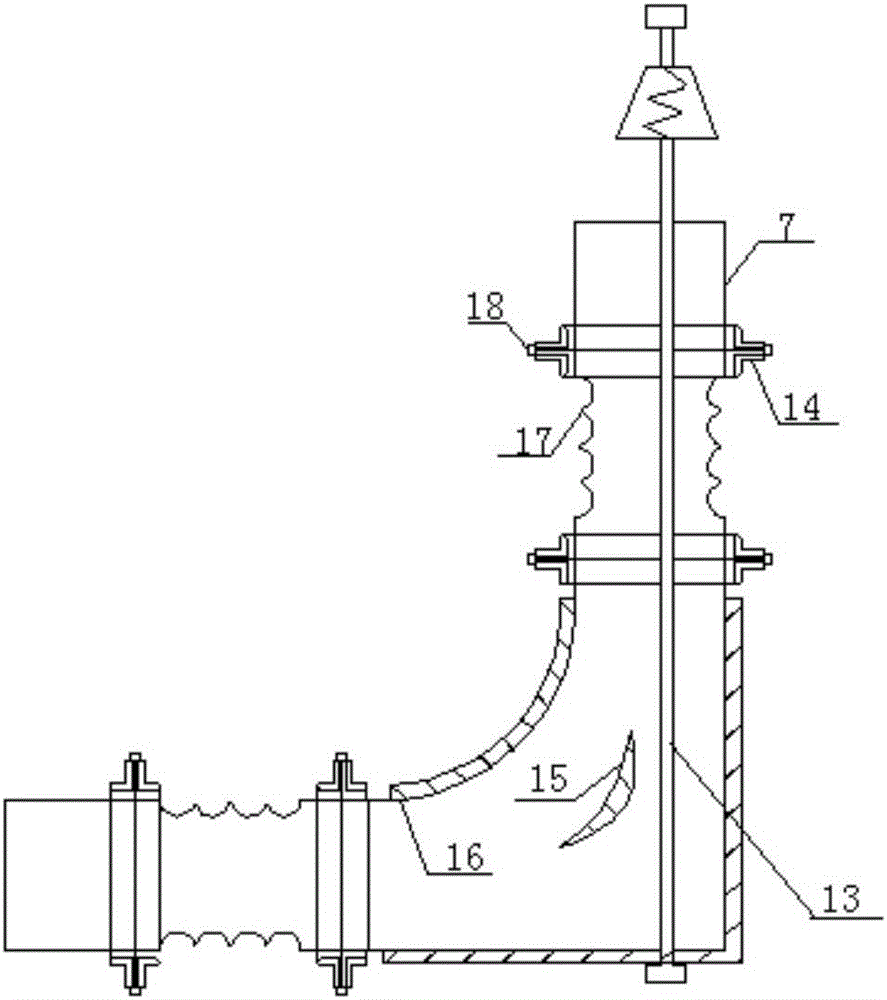

Vibration isolation noise reduction type air conditioner system for floating building and installation method thereof

InactiveCN105972802AImprove comfortReduce or reduce vibrationLighting and heating apparatusNoise suppressionSound sourcesBearing vibration

Aiming at the problem that only noise with one frequency or one sound source is improved, eventually, noise reduction is not thorough, and the using quality of a delivered building is affected in the prior art, the invention discloses a vibration isolation noise reduction type air conditioner system for a floating building and an installation method thereof. In the vibration isolation noise reduction type air conditioner system for the floating building, a machine room is located in a pipeline room; the floating building is located above the pipeline room; the space is saved, and the characteristics of noise reduction and energy conservation are achieved; the vibration isolation noise reduction type air conditioner system is suitable for music halls and other places; bearing vibration isolators are installed on vertical columns in the pipeline room, so that the whole floating building is suspended on the bearing vibration isolators; most of the weight of the floating building can be borne, and noise produced in the pipeline room and the machine room of the pipeline room can be prevented from being conducted into the floating building through a building envelope structure; tiny vibration and noise which are produced due to the flow velocity change of fluid inside an air hose can be absorbed through a noise isolation blanket attached to the air hose; and the interior of a ladder type stand is of a static pressure box structure, seating area noise absorption materials are pasted inside the ladder type stand, and noise reduction can be further achieved.

Owner:SHANGHAI INSTALLATION ENG GRP

Ultra-low-nitrogen combustion equipment with post-premixing cold flame combustion coupling matrix tube mode wall structure

ActiveCN112815312AGuaranteed stabilityReduce the temperatureGaseous fuel burnerCombustion chamberAir volume

The invention relates to ultra-low-nitrogen combustion equipment with a post-premixing cold flame combustion coupling matrix tube mode wall structure. The ultra-low-nitrogen combustion equipment comprises a fuel gas regulation and control device, an air volume regulation and control device, an air-gas mixing device, a cold flame combustion device, a matrix tube and mode wall device and a comprehensive controller. The fuel gas regulation and control device provides fuel gas for the air-gas mixing device; the air volume regulation and control device provides combustion-supporting air for the air-gas mixing device; the air-gas mixing device conducts jet flow mixing on combustible gas provided by the fuel gas regulation and control device and the combustion-supporting air provided by the air volume regulation and control device, and the combustible gas and the combustion-supporting air are evenly mixed through the air-gas mixing device and then injected into the cold flame combustion device; the mixed gas sequentially passes through a double-layer rectifying plate, a hexagonal heat pipe type cooling fire-retardant tube nest and a flame cooling tube nest in the cold flame combustion device and then enters a combustion chamber for combustion; and after combustion, high-temperature flue gas is subjected to radiation and convective heat exchange in the combustion chamber, then exchanges heat with a medium in the matrix tube and mode wall device and then is discharged into a flue.

Owner:BEIJING BOOSTER BOILER

Method and acid distributor for uniformly distributing sulfuric acid

ActiveCN106044722AEvenly distributedDistribution does not affectSulfur compoundsDistributorChemistry

The invention discloses a method and an acid distributor for uniformly distributing sulfuric acid. The method for uniformly distributing the sulfuric acid is implemented by the aid of a pre-distribution cavity. A main acid distribution component which is communicated with the pre-distribution cavity is arranged on the lower side of the pre-distribution cavity, and a plurality of acid distribution branch pipes with equal heights are arranged on the main acid distribution component; the pre-distribution cavity, a cavity of the main acid distribution component and cavities of the acid distribution branch pipes are connected with one another to form a closed acid liquor channel, only acid liquor inlets are only formed in the pre-distribution cavity, and acid liquor outlets are uniformly formed in the lower portions of the acid distribution branch pipes; the circulation cross section of the pre-distribution cavity, the total circulation cross section of the main acid distribution component and the total circulation cross section of the acid distribution branch pipes are larger than the section of the acid liquor inlets. The method and the acid distributor have the advantages that acid liquor can be uniformly distributed by the aid of the method and the acid distributor; the flow rate of the acid liquor is controlled, the acid liquor in the pre-distribution cavity, the main acid distribution component and the acid distribution branch pipes is in un-full states, partial air in acid liquor unfilled spaces is exhausted, and accordingly stable flow of acid liquor discharged from the various acid liquor outlets can be uniformly distributed.

Owner:云南化铸科技有限责任公司

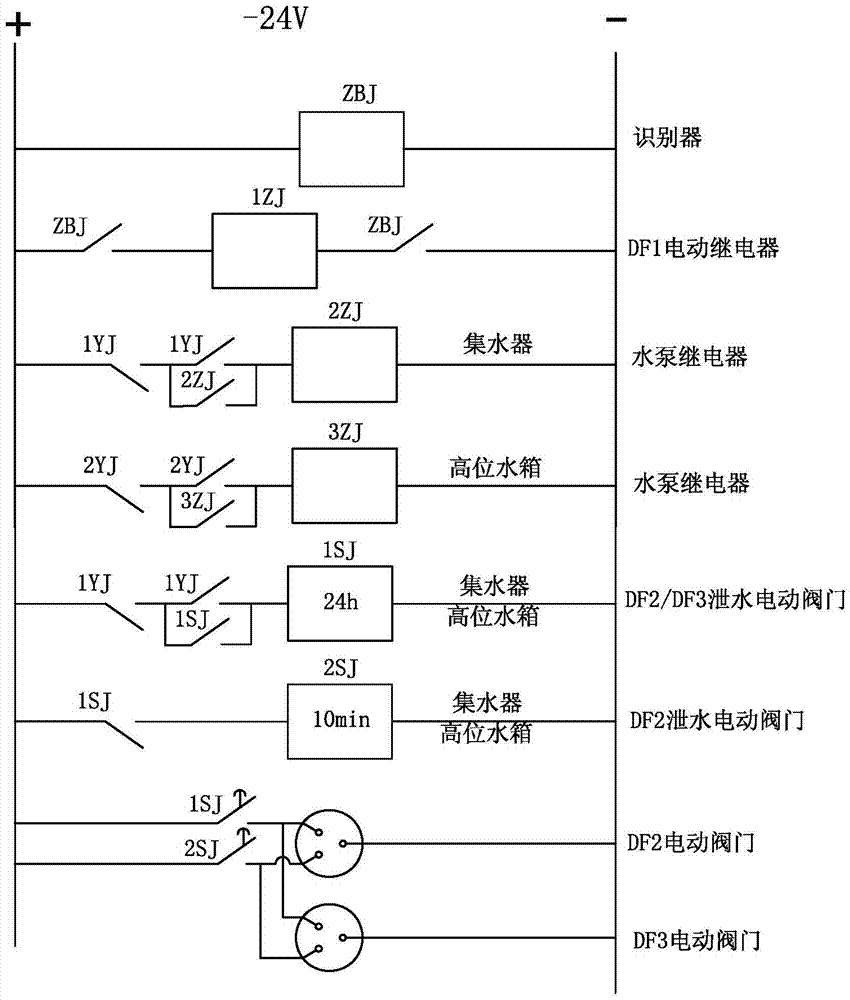

Water-saving machine for providing secondary water for flushing toilets in public washroom

ActiveCN105442665AFair useReduce pressure headFlushing devicesService pipe systemsWater savingWater source

The invention provides a water-saving machine for providing secondary water for flushing toilets in a public washroom. The water-saving machine comprises a water collecting box and a high-position water tank. A secondary water inflow pipeline is connected to a water inlet of the water collecting box. A secondary water source pipe is connected to the water inlet of the water collecting box. A filtering device is arranged in the water collecting box and comprises a filter screen. The filter screen divides the water collecting box into a filtering space and a water collecting space. A secondary water drain opening is formed in the lower portion of the water collecting space, and the upper portion of the water collecting space is connected with a secondary water conveying pipeline and leads to a water inlet of the high-position water tank. A conveying pump is arranged on the conveying pipeline. The water collecting space is provided with a liquid level controller. The high-position water tank is arranged above a toilet flushing water pipe, a water outlet is connected with a toilet flushing branch pipe at the toilet position, and a liquid level controller is arranged in the high-position water tank. The liquid level controller in the water collecting space and the liquid level controller in the high-position water tank are correlated with the conveying pump, and when the secondary water level in the water collecting tank is higher than the set water level and the liquid level of the high-position water tank is lower than the set water level, the conveying pump is started and stopped until the liquid level in the high-position water tank reaches the set high water level. According to the water-saving machine, the secondary water is used for flushing the toilets in the public bathroom.

Owner:周树

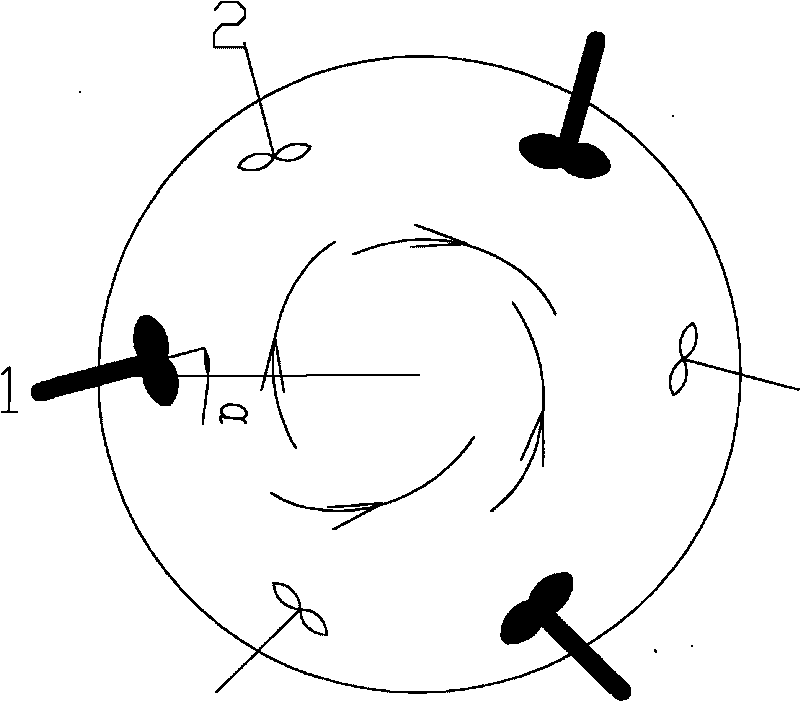

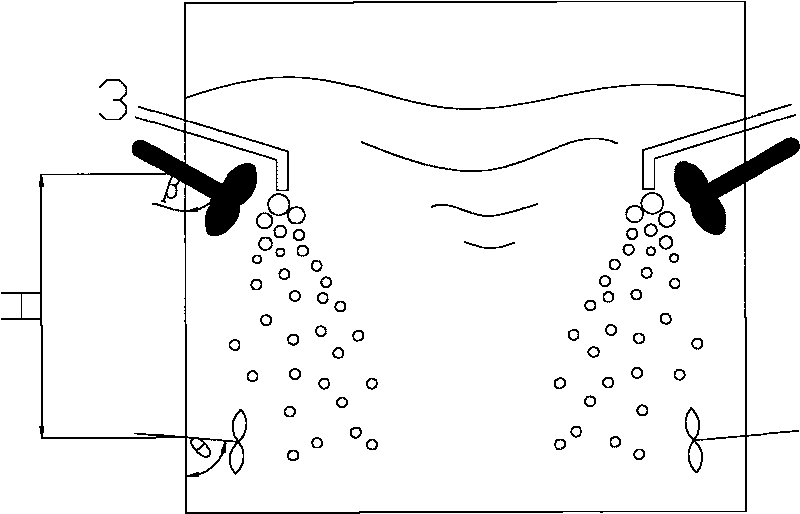

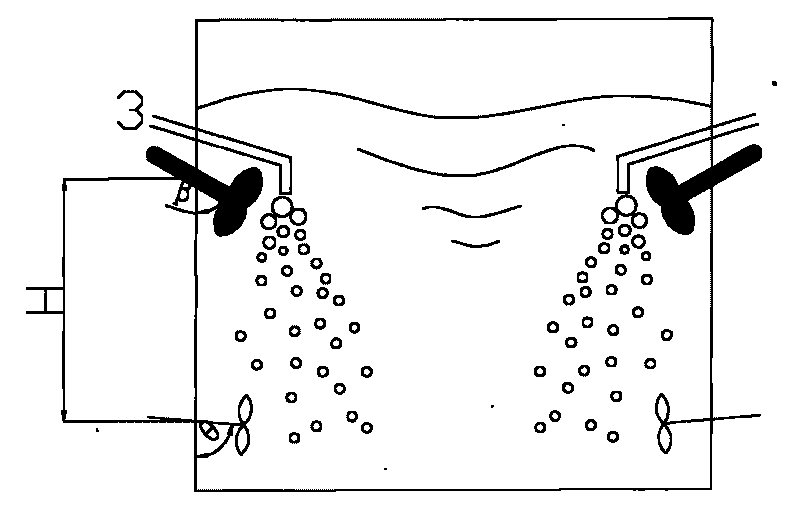

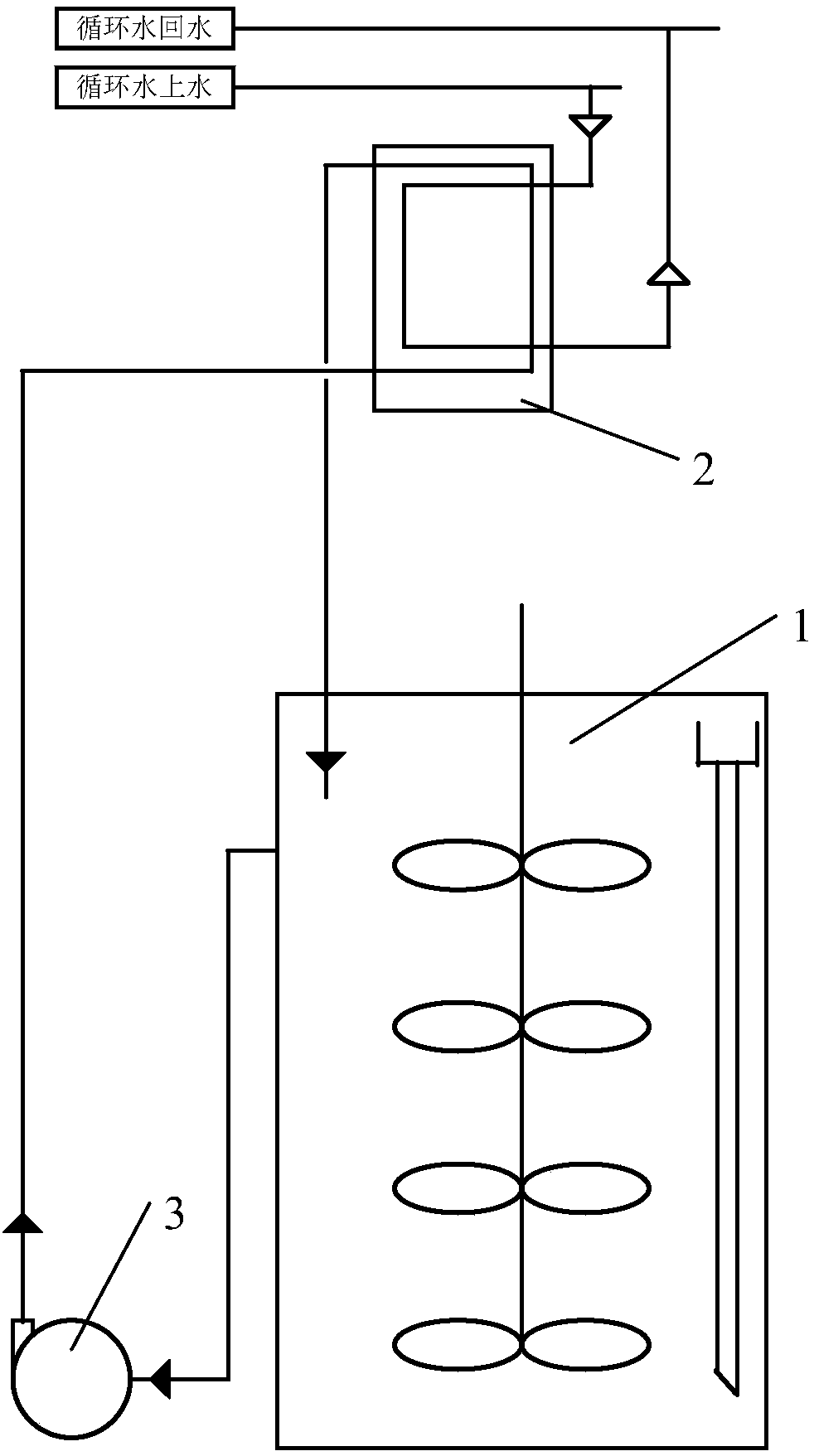

Stirring device for improving oxidation characteristic

InactiveCN101721935AIncrease usageReduce consumptionRotary stirring mixersDispersed particle separationSlurryStreamflow

The invention relates to a stirring device for improving an oxidation characteristic, which is set for improving the oxidation characteristic and reducing oxidation air flow and pressure energy in a WFGD or a similar field, comprises a serous fluid pool, side-entering agitators and an oxidation air pipe, and is characterized in that the side-entering agitators of 2-5 grades are provided and are sequentially arranged on the height direction of the serous fluid pool, and the oxidation air pipe is arranged near the side-entering agitators at the topmost end. The device for improving the oxidation characteristic can improve the reliability of system operation, improve the oxidation speed of a serous fluid, enhance the oxidation effect of the serous fluid, lower the oxidation fan flow and pressure energy and increase the pH value of the upper-grade serous fluid, and has a great promoting action on the stable and high-efficiency operation of a desulphurization system.

Owner:中建中环新能源有限公司

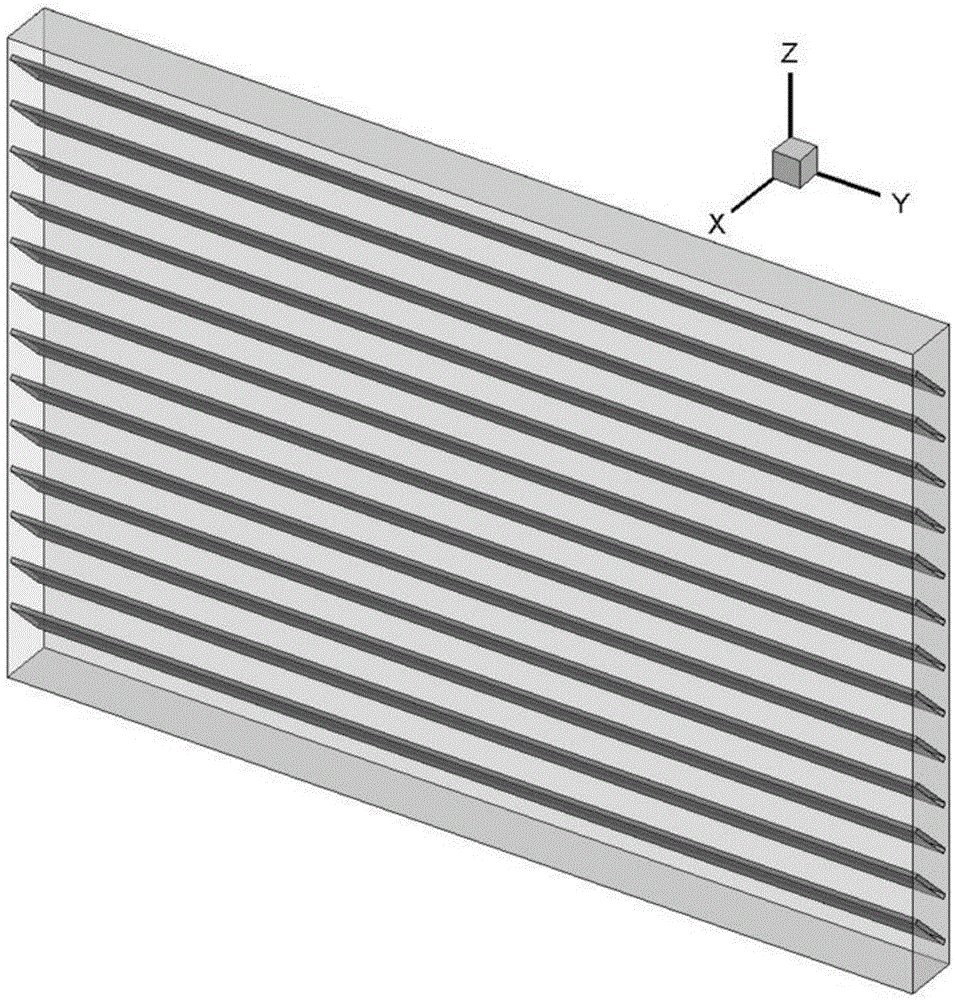

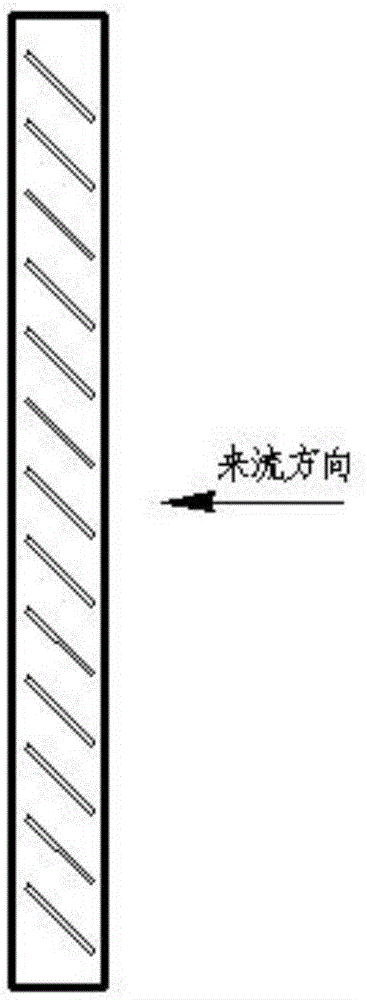

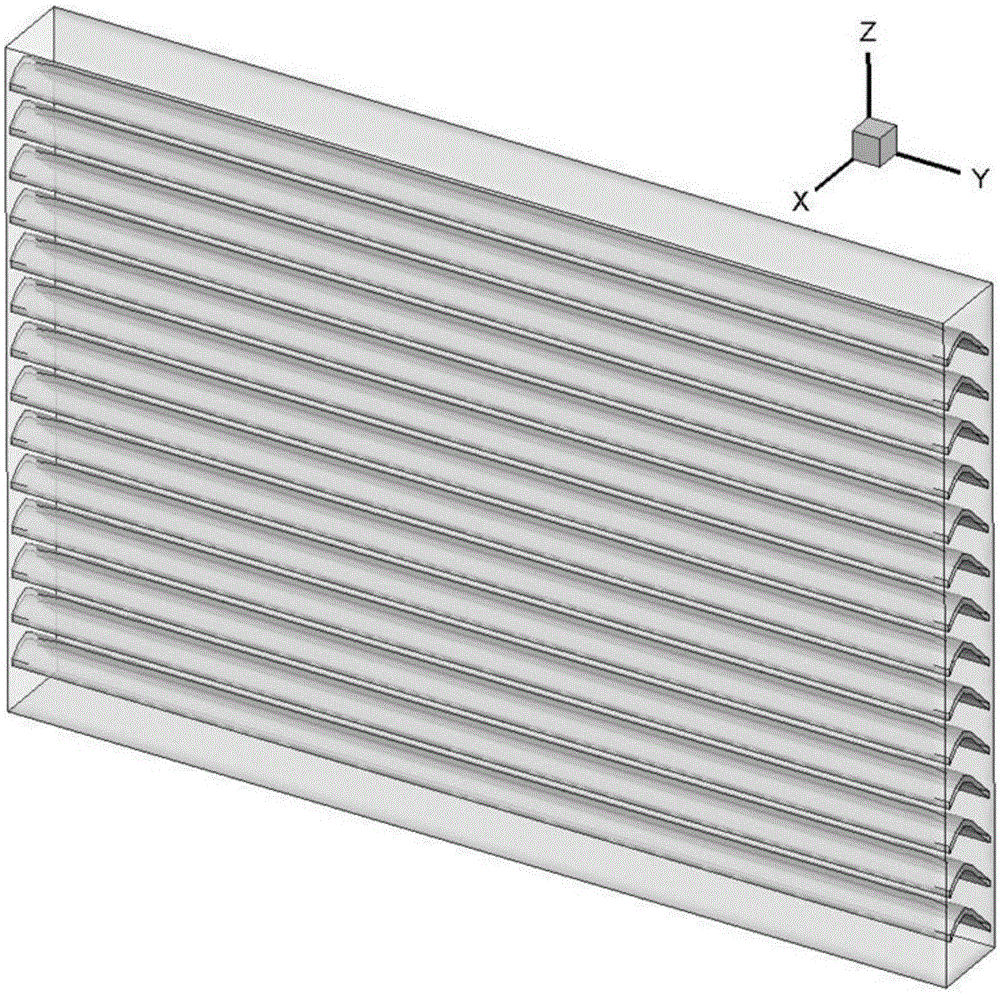

Air inlet diversion type blade blind window for ship

InactiveCN105625913ASmooth correction flowOptimize the regional flow fieldDoor/window protective devicesVentilation arrangementWindow shutterPulp and paper industry

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

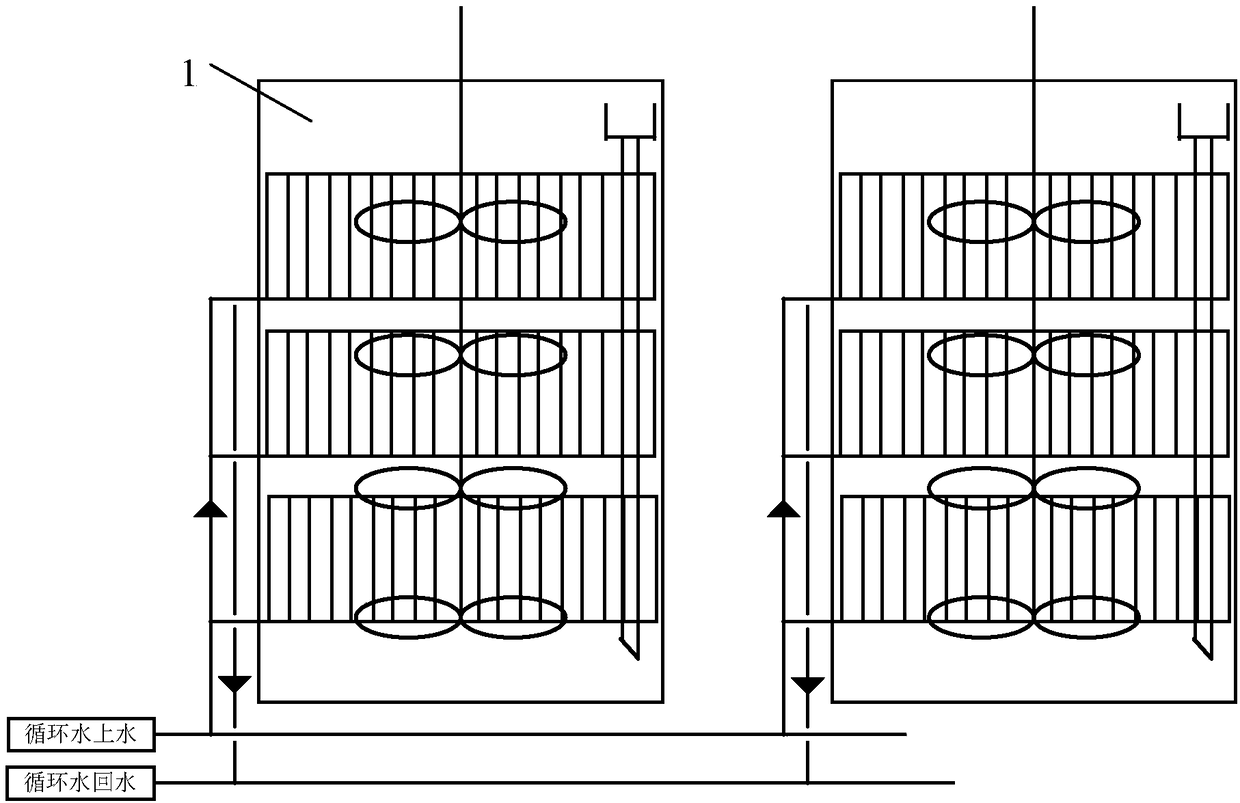

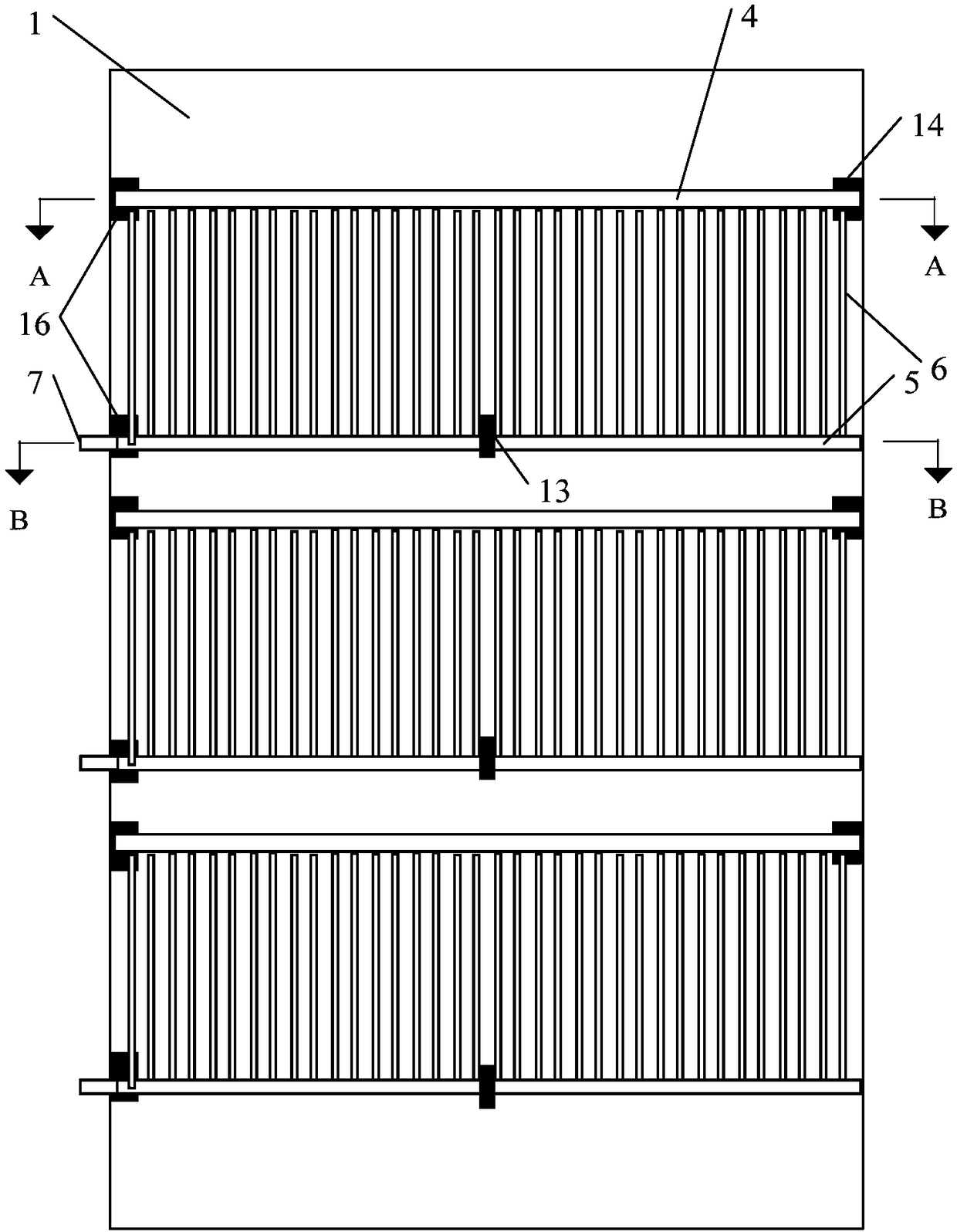

Sectional tube nest cooling device in decomposing tank

InactiveCN108131966AReduce power consumptionAccelerate evaporationStationary tubular conduit assembliesAluminium oxides/hydroxidesSlurryEngineering

The invention provides a sectional tube nest cooling device in a decomposing tank. The sectional tube nest cooling device is composed of multiple sections of cooling tube nests arranged in the decomposing tank, each decomposing tank is divided into multiple sections of heat exchange area from top to bottom, a section of cooling tube nest is arranged in each heat exchange area, and all sections ofcooling tube nests in the same decomposing tank are in parallel connection; each section of cooling tube nest is constituted by an upper annular pipe, a lower annular pipe and a tube nest cluster between the upper annular pipe and lower annular pipe, and the tube nest cluster is constituted by several vertical pipes parallel to the axis of the decomposing tank; water inlets of all sections of cooling tube nests are all communicated with a water inlet main pipe, and water outlets of all sections of cooling tube nests are all communicated with a water return main pipe. Decomposing slurry is directly cooled through sectional tube nest cooling devices in the decomposing tanks, the cooling procedure outside the tank is replaced, equipment investment and running cost are saved, and meanwhile, the work of the operating amount of workers and daily maintenance is reduced.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

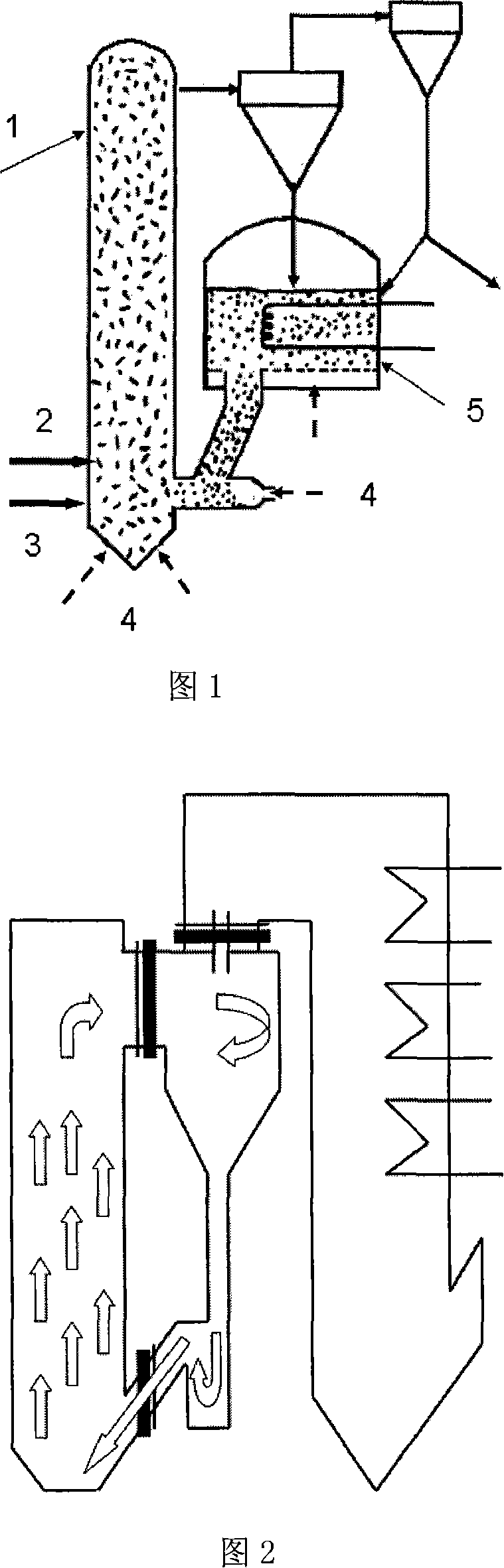

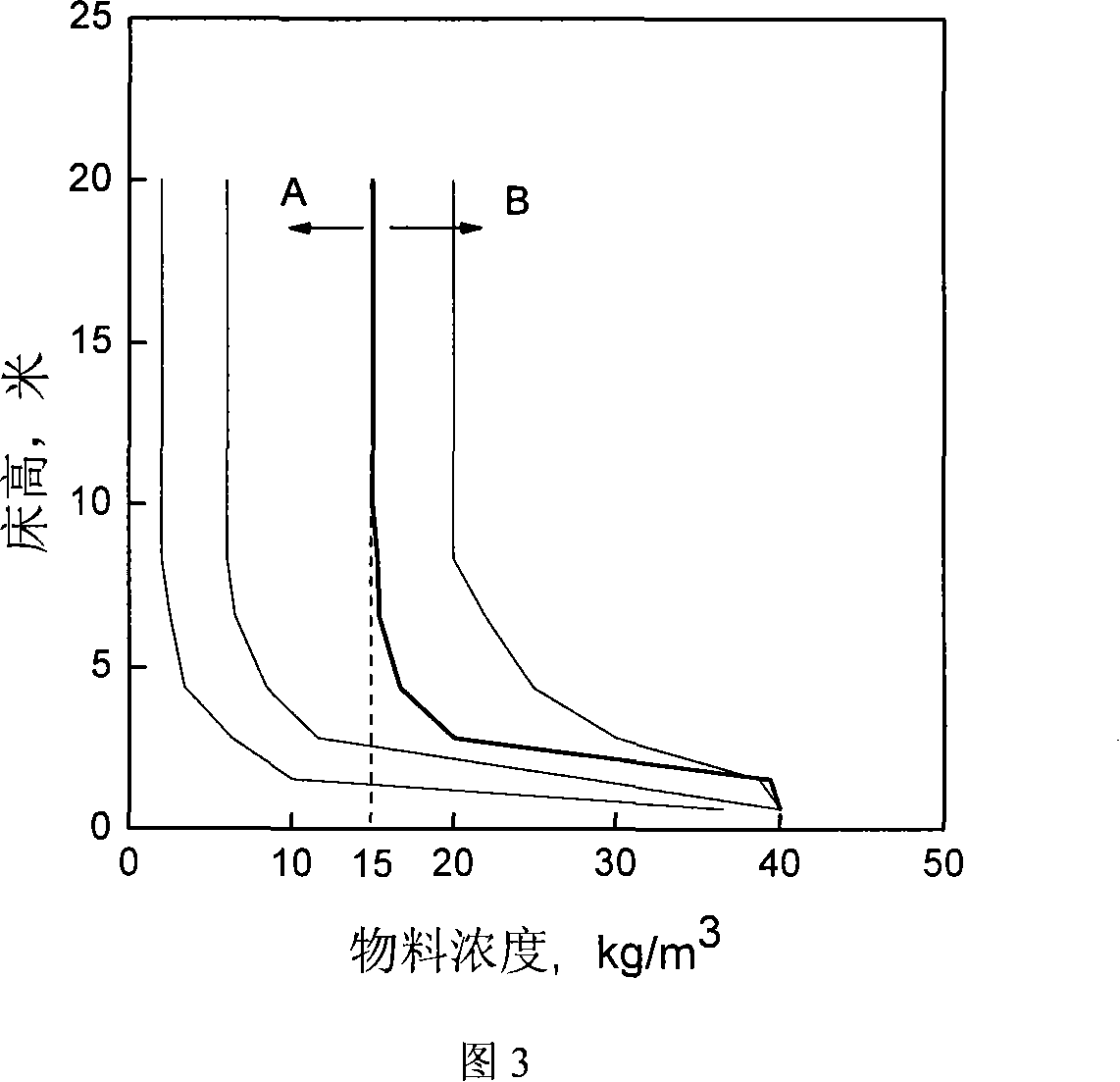

Low bed pressure-reducing circulated fluid bed boiler combustion process

ActiveCN101149146AReduce auxiliary power consumptionPromote combustionFluidized bed combustionApparatus for fluidised bed combustionWinding machineCirculating fluidized bed boiler

This invention is a low bed pressure drop circulating fluidized bed boiler combustion technical method, which relates to rapid circulating fluidized bed boiler combustion technique. It makes sure the circulating fluidized bed rapid bed fluid state. The inner bed temperature is controlled within 850-930 degree. The fluidizing wind speed is 4-6.2m / s. The average particle size of circulating materials is smaller than 300mum. The material concentration of the space above combustion chamber second air port is kept 1-15Kg / m3 rapid bed state. This invention can greatly reduce the pressure head of first and second wind machines. Thus, it effectively reduces the power dissipation of assisting engines. In addition, as the space material concentration decreased, gas mixture improved, combustion intensified, the combustion efficiency of boiler is further increased. This invention can also reduce the attrition rate of combustion chamber water-cooled wall heating surface.

Owner:北京杰创华睿科技有限公司

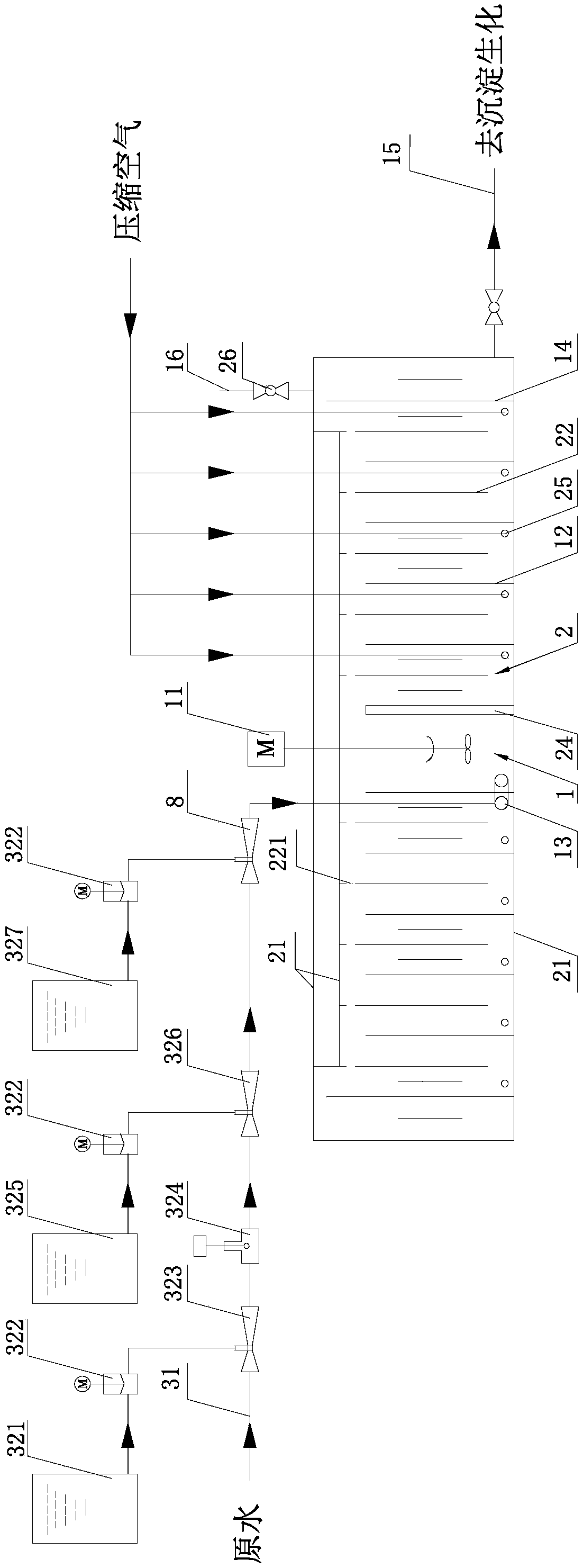

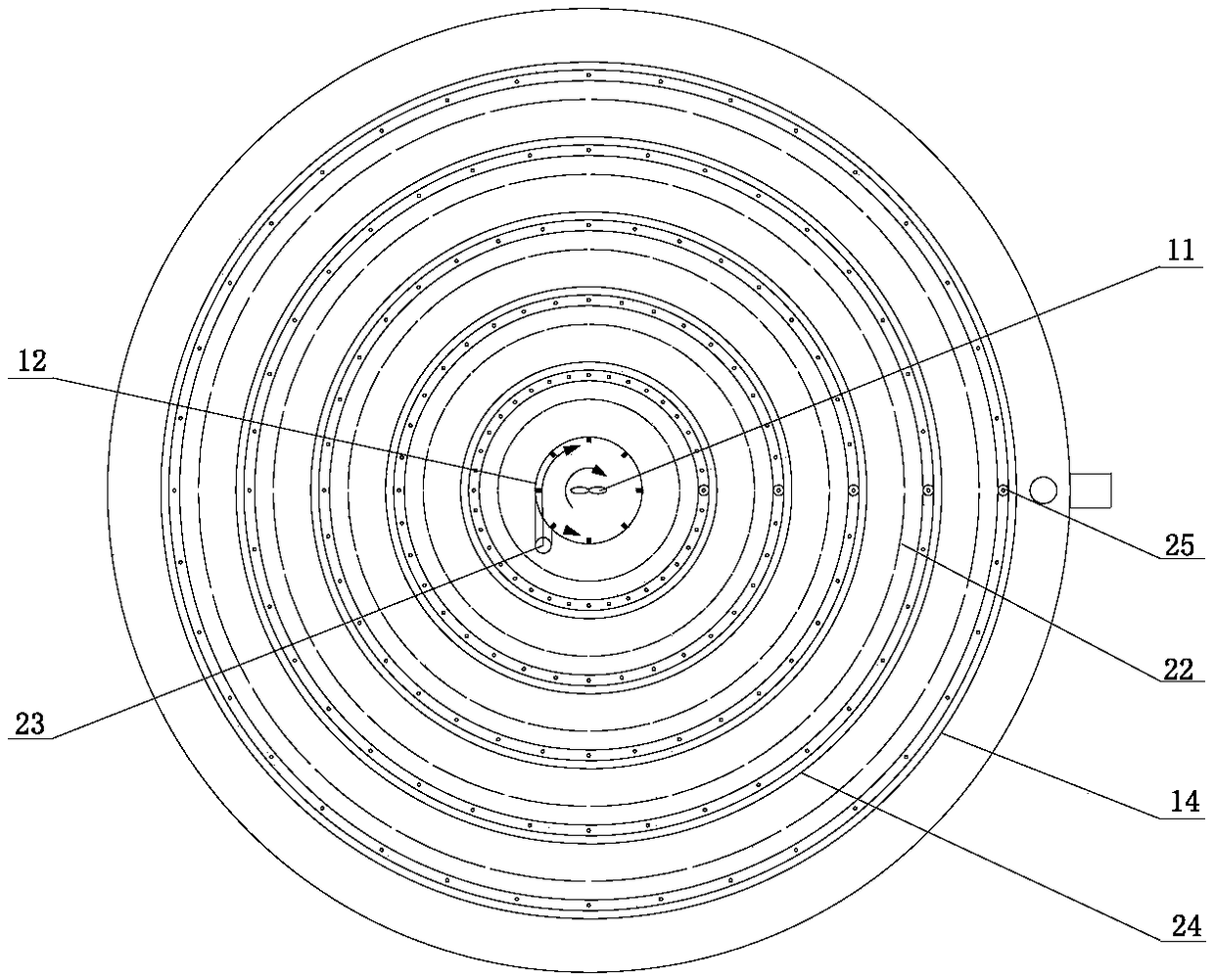

Baffled Fenton oxidation reactor and organic wastewater treatment method

ActiveCN108689475AMixing helpsIncreased turbulenceWater/sewage treatment apparatusWater/sewage treatment by oxidationFenton reactionFenton oxidation

The invention relates to a baffled Fenton oxidation reactor and an organic wastewater treatment method. The baffled Fenton oxidation reactor comprises a chemical mixing area, a baffled reaction area ,and four pipeline connectors, the chemical mixing area and the baffled reaction area are sequentially arranged from the inside to the outside of concentric sleeves, wherein the bottom central area isprovided with a wastewater inlet, a series of compressed air connectors are arranged on the bottom of the reaction area, and a drain outlet and an exhaust outlet are arranged at a position far from the center. The organic wastewater treatment method comprises the following steps: after wastewater is filtered and pH is regulated, metering pumps quantitatively add FeSO4 solution and H2O2 solution in sequence into a water inlet pipeline by means of a jet device to get into the reactor, an aerator is switched on, the mixed wastewater gets into the chemical mixing area in a tangential feeding manner, and rapidly spirals upwards along the internal wall of the barrel under the action of an agitating pump, the disturbance and turbulence of the wastewater are further intensified by fin baffles, and thereby the uniform mixing of the wastewater and chemical is promoted; in the baffled reaction area, and the mixed wastewater passes through in the form of plug flow, carries out rapid Fenton reaction, and flows out of the reactor via a downflow weir.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

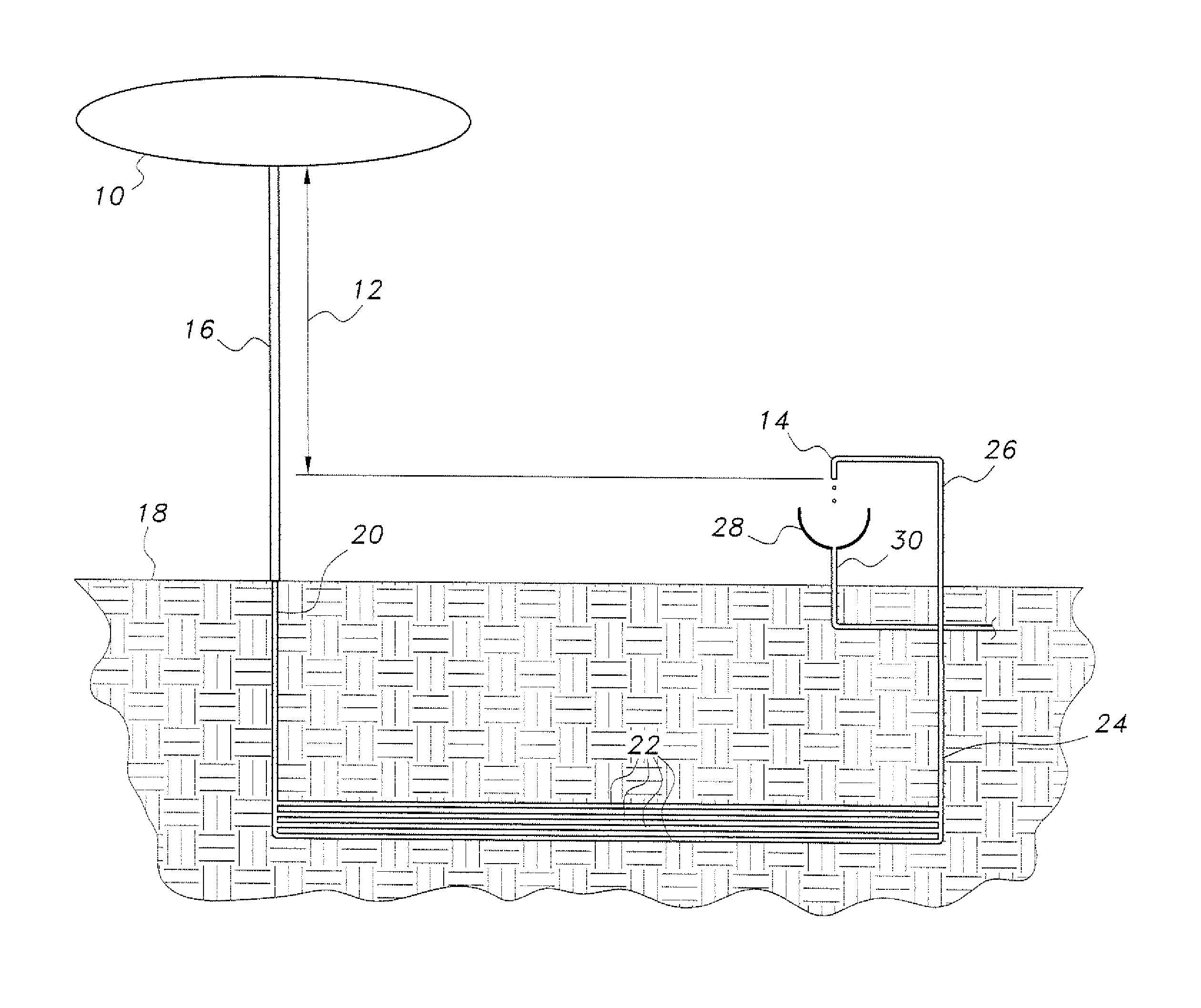

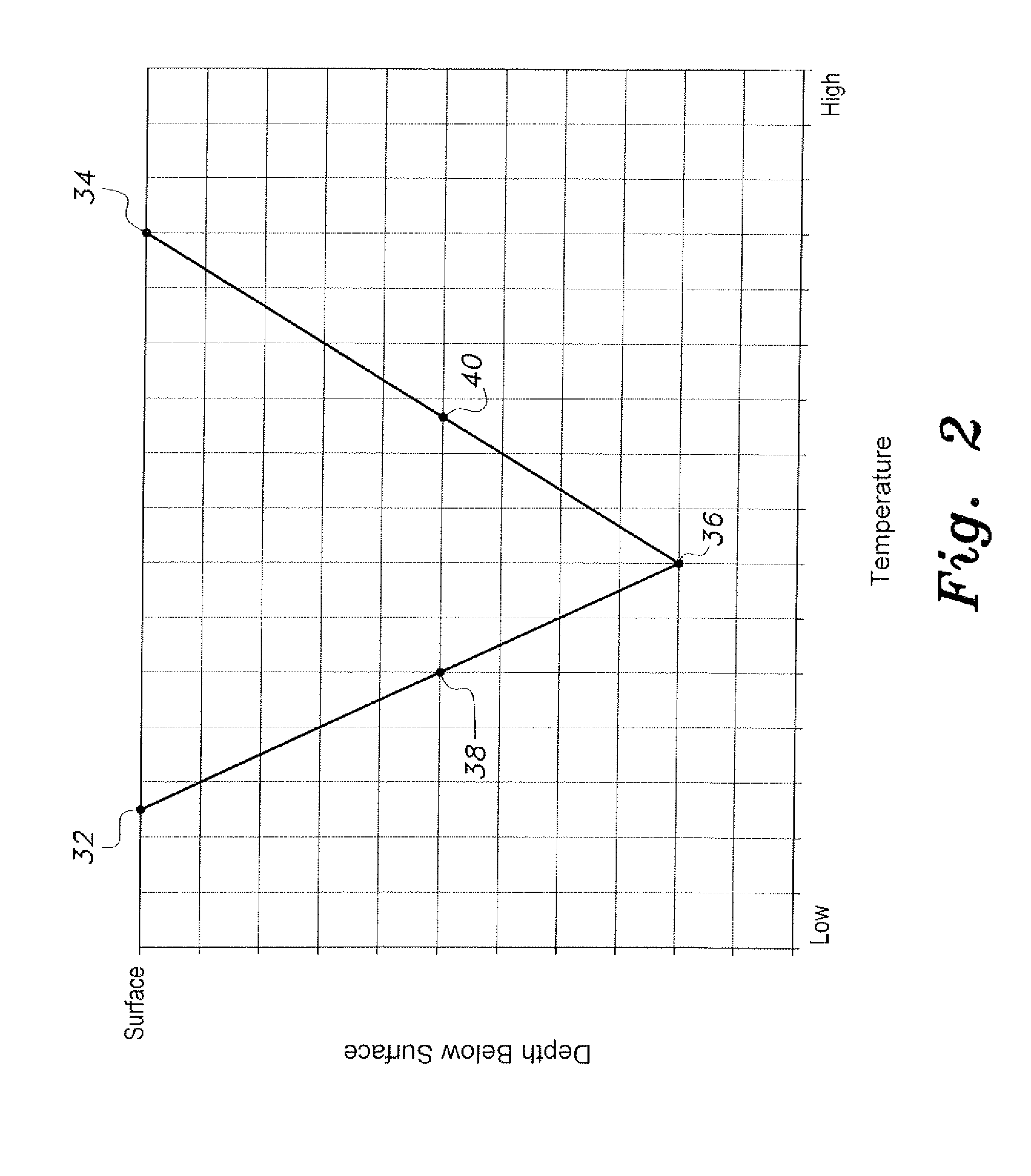

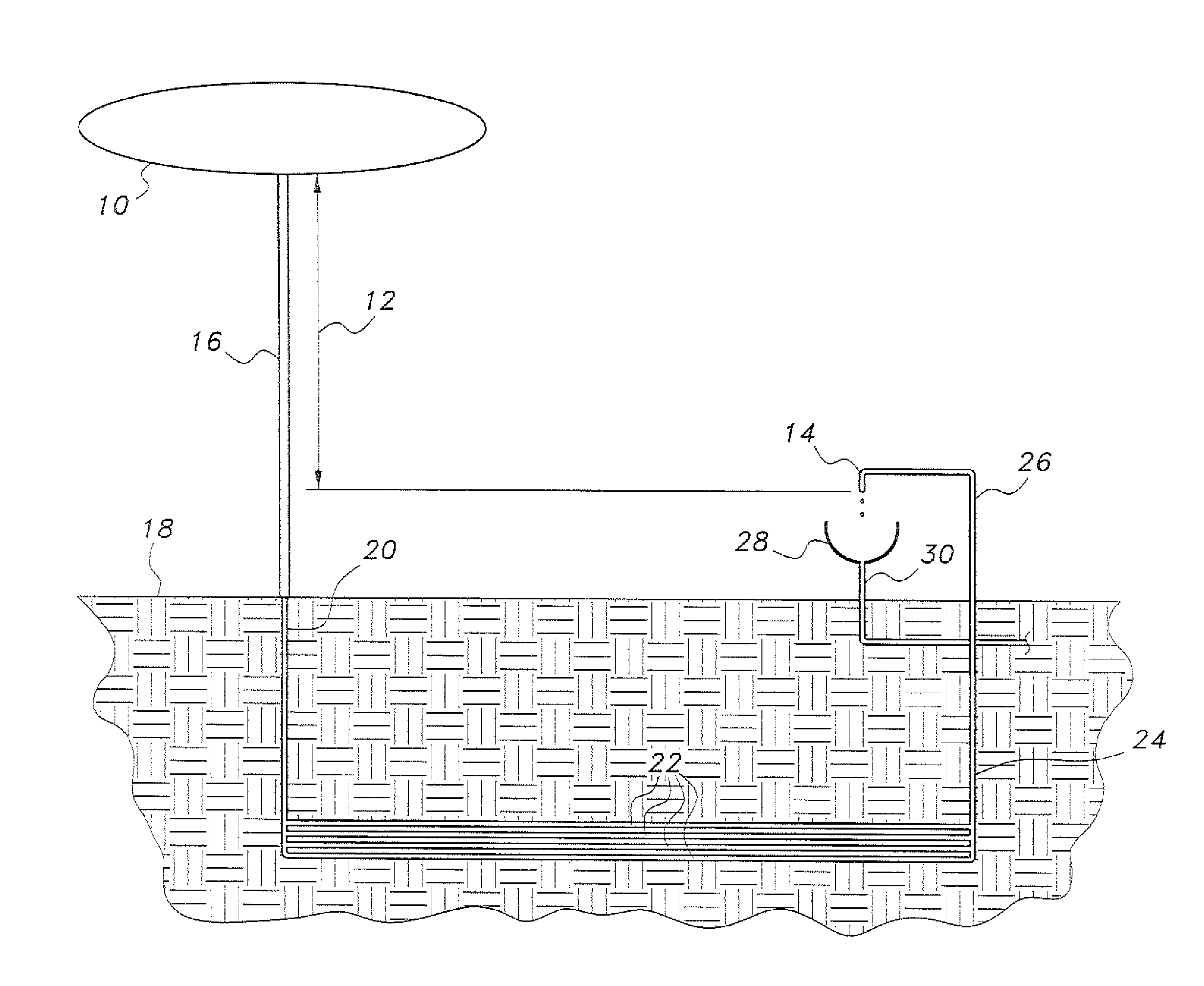

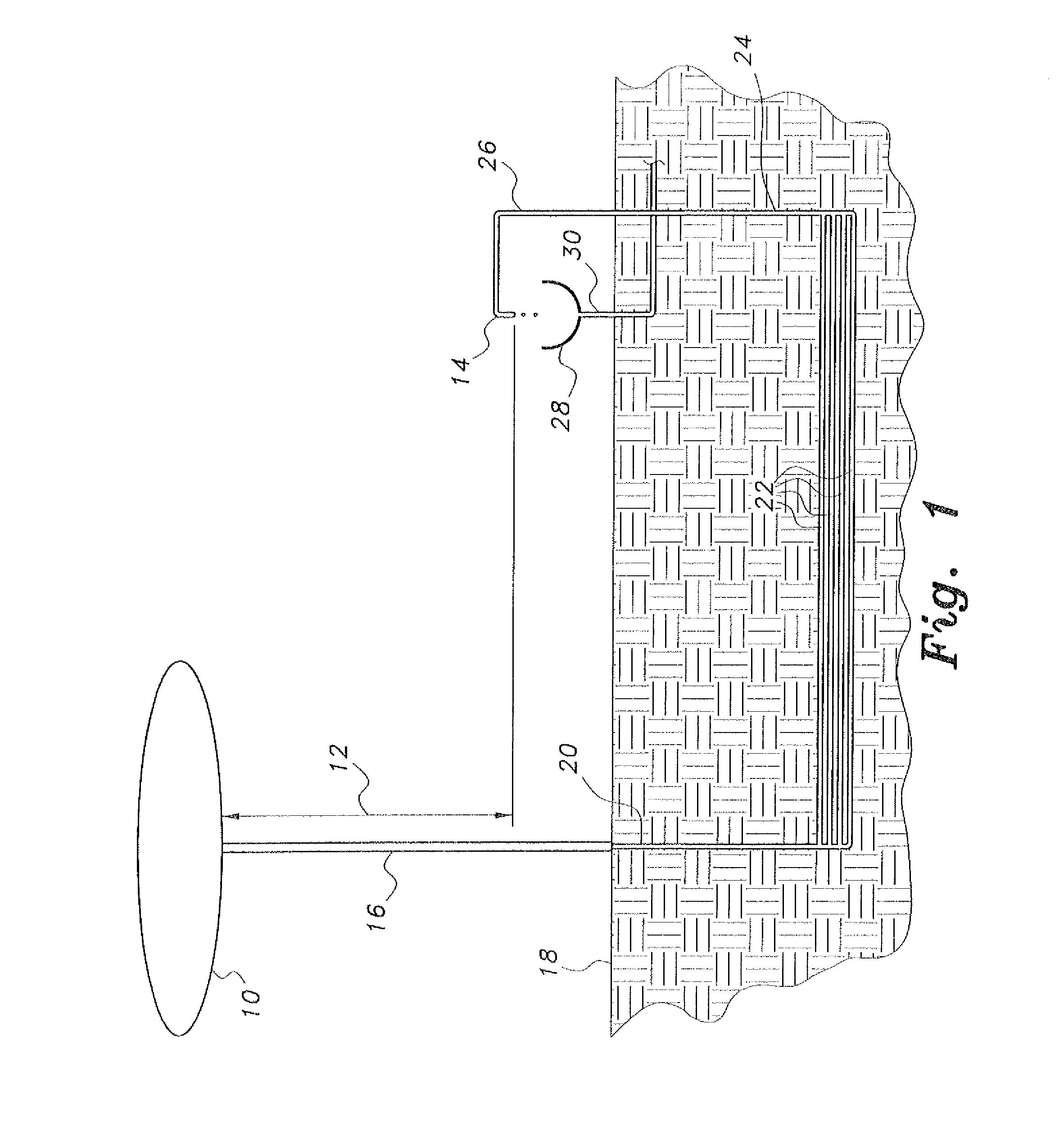

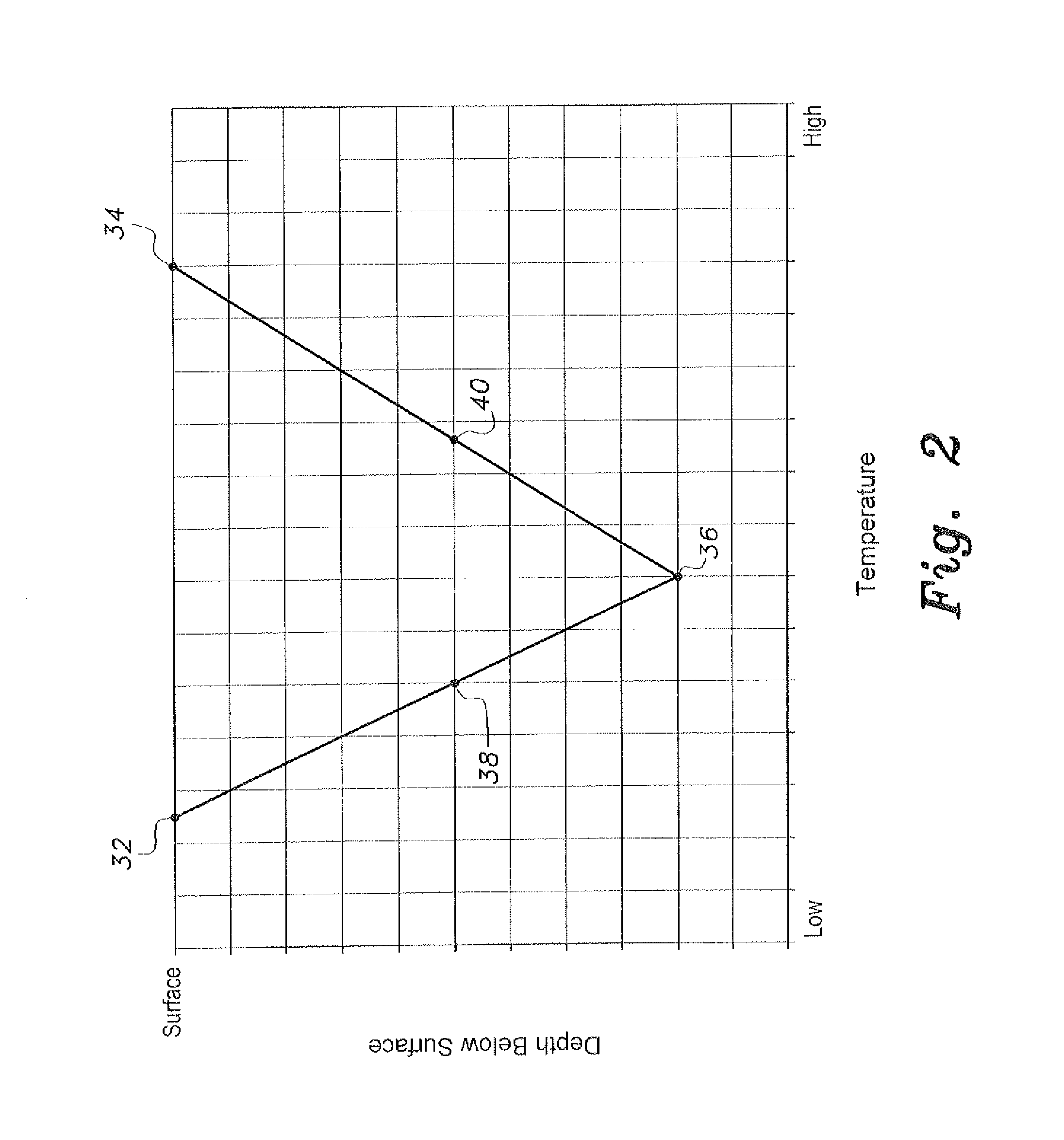

Geothermal heat exchange system for water supply

InactiveUS20130081780A1Not consume any other energyReduce laborOther heat production devicesGeothermal energy generationPipeflowGeothermal heating

The geothermal heat exchange system for a water supply is an open system, i.e., water flows into the system for consumption and use and is then drained from the system, as opposed to a closed system where the water is recycled through the system. The present system receives water from an elevated source, e.g., a hilltop tank or an elevated community water supply tank, through a relatively large diameter pipe. The water is then delivered to a subsurface pipe system of one or more relatively small diameter pipes for more efficient thermal exchange. The subsurface pipes are preferably manufactured of material having relatively high thermal conductivity. The subsurface pipe system is preferably buried at an intermediate depth between the surface and the depth where constant temperature occurs in order to provide most of the benefits of a subsurface system while reducing the labor required to bury the pipe system.

Owner:ALRASHIDI THAMER B

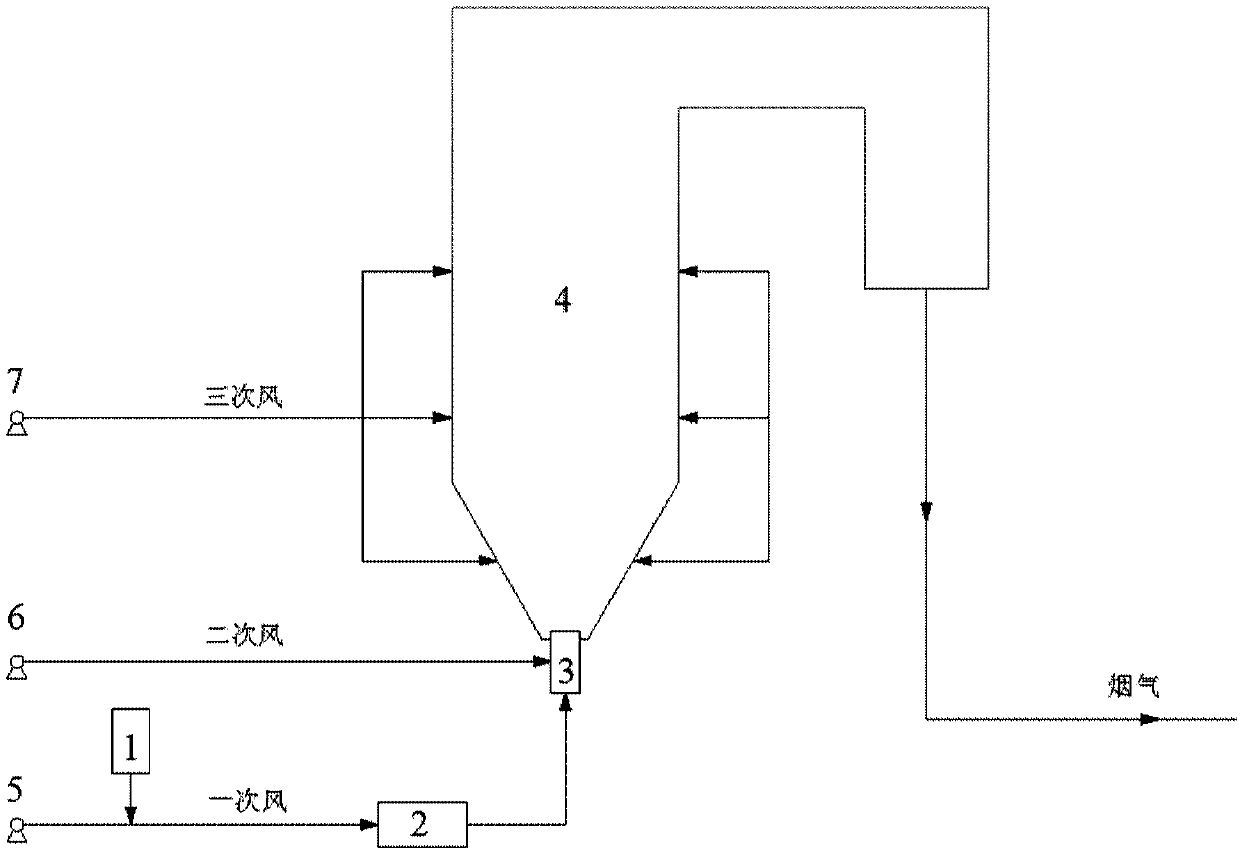

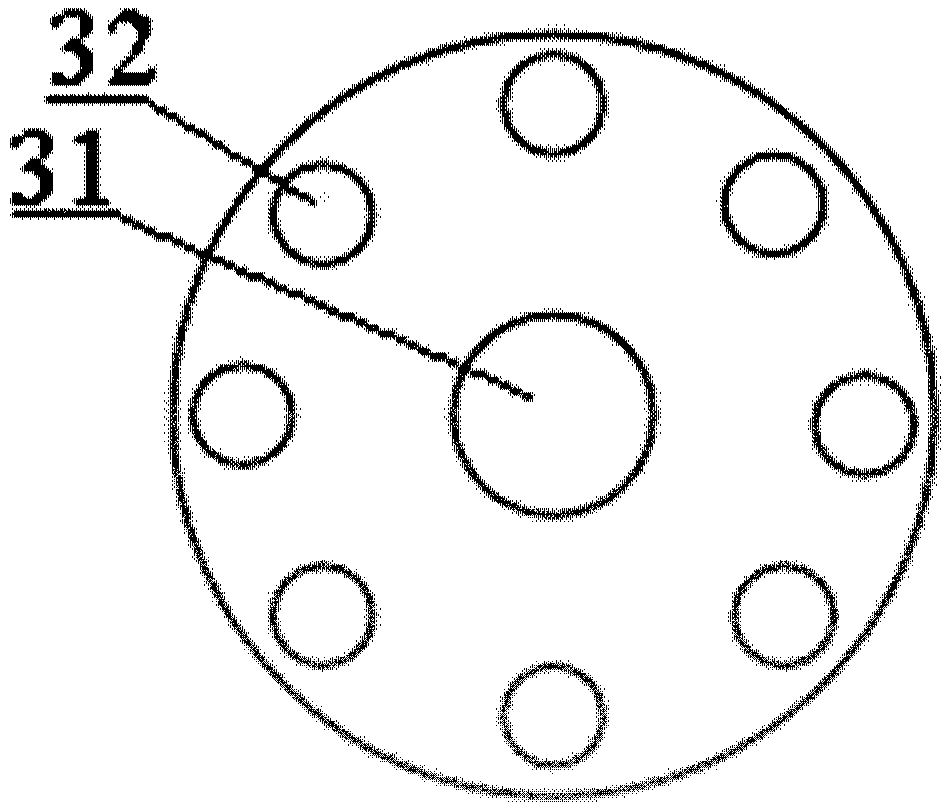

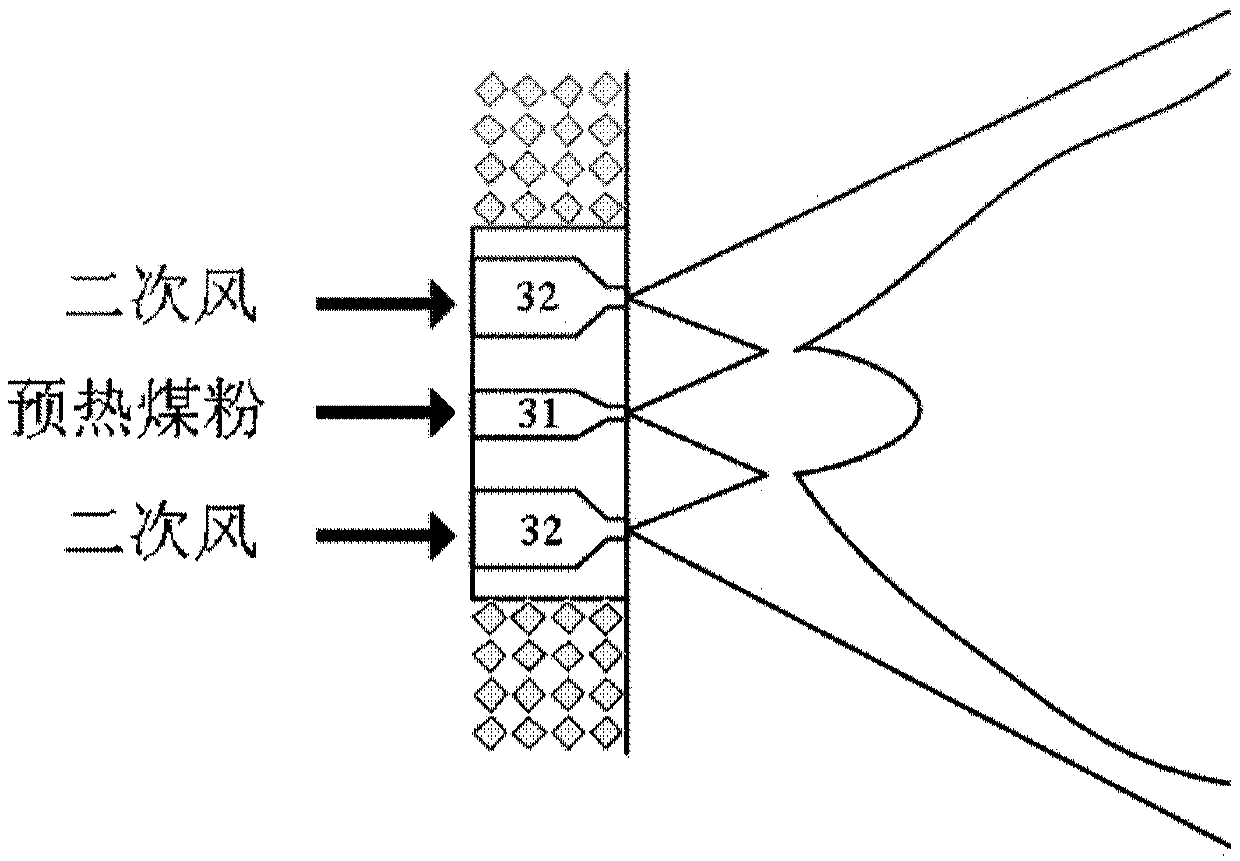

Pulverized coal flameless combustion system and method

InactiveCN110307538AReduce jet velocityReduce pressure headPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCoalPower consumption

The invention provides a pulverized coal flameless combustion system and method. The system comprises a hearth body and a pulverized coal preheater, wherein the hearth body comprises a pulverized coalflameless burner arranged at the bottom of the hearth body and tertiary air nozzles which are divided into at least two layers in the axial direction of the hearth body and arranged on the side wallof the hearth body, the pulverized coal flameless burner comprises a preheating fuel nozzle and a plurality of secondary air nozzles, and the pulverized coal preheater is connected to the preheating fuel nozzle and used for preheating pulverized coal and conveying the preheated pulverized coal to the pulverized coal flameless burner. The invention further provides the pulverized coal flameless combustion method using the system. By means of preheating fuel and grading air distribution, uniform flameless combustion is realized, the secondary air injection speed can be reduced, and fan pressurehead and power consumption can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Production string optimization device for oil well in case of electric submersible pump gas-locking

InactiveCN103573194AWith anti-CO2 functionAvoid corrosionDrilling rodsWell/borehole valve arrangementsExhaust valveGas lift

A production string optimization device for an oil well in case of electric submersible pump gas-locking comprises a production casing, an electric submersible pump unit, an oil pipe, a packer, a gas exhaust valve, a small-diameter continuous oil pipe, a gas lift valve, a sliding sleeve, a subsurface safety valve, a Y-shaped tool, a working barrel plug and a pump outlet one-way valve, wherein the oil pipe is mounted in the production casing; the working barrel plug is mounted at the lower part of the oil pipe; the Y-shaped tool is mounted at the upper end of the working barrel plug; the pump outlet one-way valve is mounted at one end of the Y-shaped tool and connected with the electric submersible pump unit; the packer is mounted at the upper end of the Y-shaped tool; the sliding sleeve is mounted in a position of the oil pipe between the packer and the subsurface safety valve; the gas exhaust valve is mounted at one end of the packer and connected with the gas lift valve mounted at the upper part of the oil pipe through the small-diameter continuous oil pipe; and the gas lift valve is mounted at the lower end of the subsurface safety valve at the upper part of the oil pipe. According to the device, an original production Christmas tree is not required to be replaced, and under the condition that neither ground control equipment nor supercharging equipment is increased, gas lift production can be maintained for a long time, and gas locking can be effectively restrained.

Owner:CHINA NAT OFFSHORE OIL CORP +1

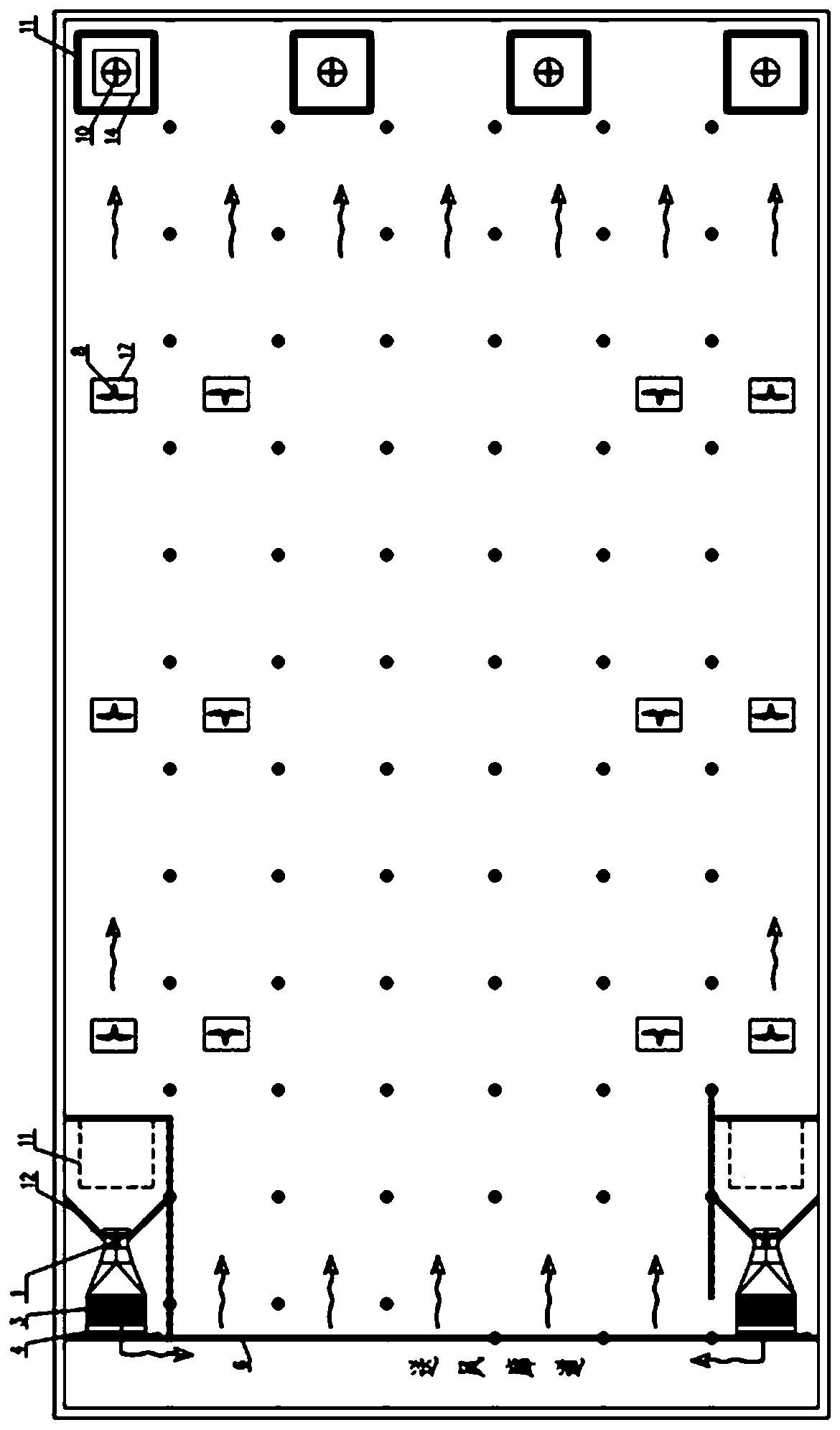

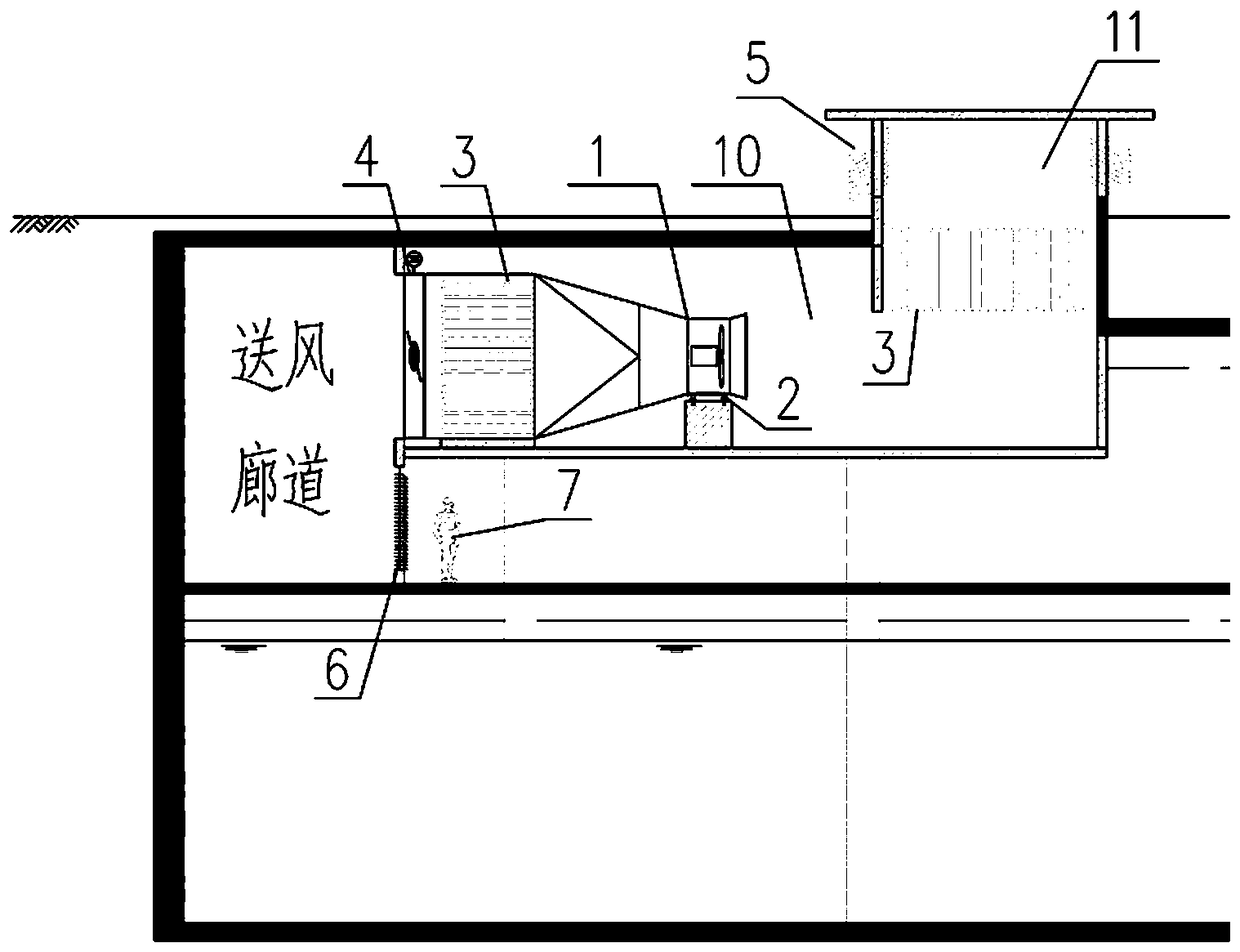

Ductless ventilation method for underground water treatment structure

PendingCN109440910AReduce buried depthReduce running noiseSewerage structuresSewage treatmentMuffler

The invention discloses a ductless ventilation method for an underground water treatment structure. The method includes the following steps that after an air supply fan is turned on, outdoor fresh airenters an air supply well; the fresh air enters the air supply well after passing through an array muffler located in the air supply well; after being pressurized with a pressure fan, fresh air reaches the array muffler at an air outlet of the pressure fan and then is introduced to an air supply corridor through an electric regulating valve, an outlet louver of the air supply corridor is adjusted, and fresh air is sent to a target ventilation area in the form of one-way piston flow through the air supply corridor, and air carrying indoor gaseous pollutants is discharged by an exhaust fan. A ductless ventilation system is arranged in the target ventilation area, thus the system is attractive, the burial depth of an underground sewage treatment plant is reduced, and the initial investment in civil engineering is reduced, the air age and the pollutant concentration in the patrol area of large space are reduced, and the ventilation efficiency and the sewage discharge efficiency are improved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Flexible pipe joint having an annular flexible boot thermally or chemically insulating an annular elastomeric flexible element

ActiveUS10337655B2Reduce manufacturing costLess sensitive to bucklingDrilling rodsThermal insulationElastomerEngineering

A flexible pipe joint has a body and an annular elastomeric flexible element flexibly coupling an extension pipe to the body for pivoting of the extension pipe with respect to the body. The flexible pipe joint also has an annular flexible boot for thermally or chemically insulating the annular elastomeric flexible element from the fluid flowing through a lumen of the flexible pipe joint. The annular flexible boot encircles the lumen, and the annular flexible boot has a first annular end attached to the extension pipe and a second annular end mounted so that pivoting of the extension pipe with respect to the body causes a flexing of the annular flexible boot, and a majority of the annular flexible boot has a shape conforming to shape of neighboring components of the flexible pipe joint.

Owner:WELLS FARGO BANK NAT ASSOC +1

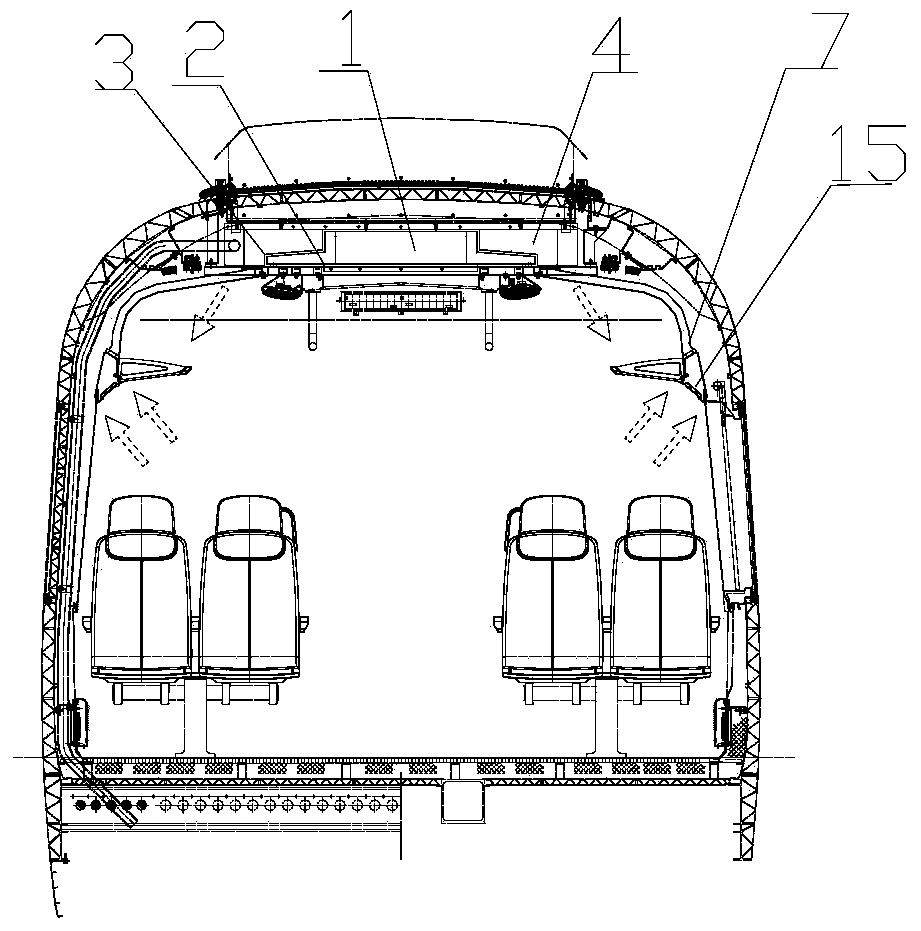

Low-noise air conditioner air duct of railway passenger car

PendingCN113928358AReduce resistanceReduce pressure headRailway heating/coolingSound producing devicesLow noiseRailway passenger car

The invention discloses a low-noise air conditioner air duct of a railway passenger car. The low-noise air conditioner air duct comprises an air conditioner return air inlet (3), an air conditioner air supply outlet (2), an air supply channel and an air return channel (11), the air conditioner air supply outlet is connected with the air supply channel, a silencer (7) is arranged in the air supply channel below the air conditioner air supply outlet, and the silencer comprises a left arc plate (701) and a right arc plate (702); the adjacent sides of the left arc plate and the right arc plate are connected into a whole, and the opposite sides of the left arc plate and the right arc plate extend towards one end of the air supply channel in an arc shape. The two ends of the left arc plate and the two ends of the right arc plate are sealed through reinforcing rib plates (704) correspondingly, so that a sound absorption cavity is defined by the left arc plate, the right arc plate, the air supply channel bottom plate and the reinforcing rib plates at the two ends. Sound absorption micropores (03) are evenly distributed in the left arc plate and the right arc plate respectively, and the sound absorption cavity is filled with sound absorption cotton used for absorbing noise of the air conditioning unit. The low-noise air conditioner air duct is convenient to process, and the riding comfort of passengers in the passenger compartment is greatly improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

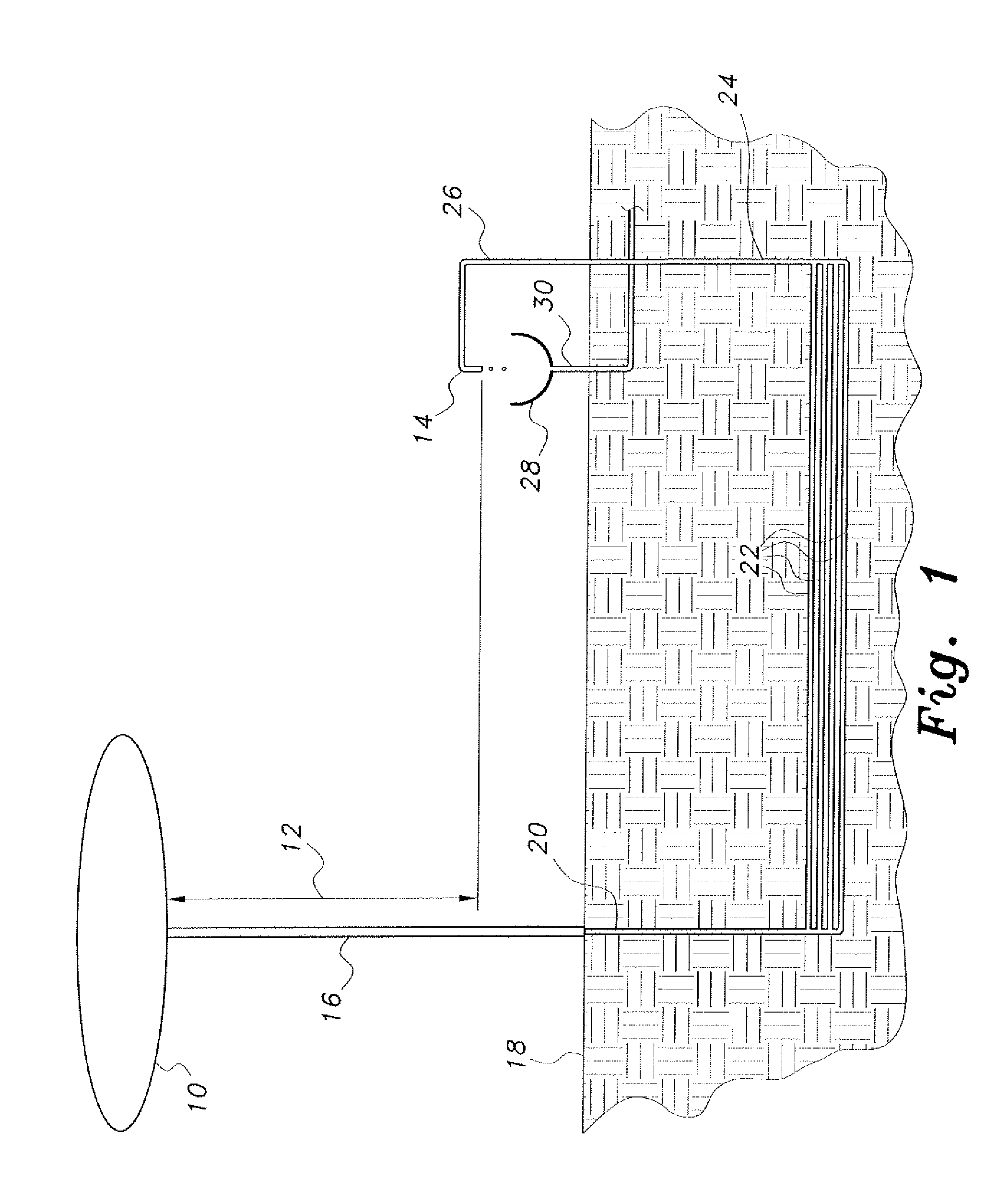

Geothermal heat exchange system for water supply

InactiveUS20130081782A1Not consume any other energyReduce laborOther heat production devicesGeothermal energy generationGeothermal heatingWater flow

The geothermal heat exchange system for a water supply is an open system, i.e., water flows into the system for consumption and use and is then drained from the system, as opposed to a closed system where the water is recycled through the system. The present system receives water from an elevated source, e.g., a hilltop tank or an elevated community water supply tank, through a relatively large diameter pipe. The water is then delivered to a subsurface pipe system of one or more relatively small diameter pipes for more efficient thermal exchange. The subsurface pipes are preferably manufactured of material having relatively high thermal conductivity. The subsurface pipe system is preferably buried at an intermediate depth between the surface and the depth where constant temperature occurs in order to provide most of the benefits of a subsurface system while reducing the labor required to bury the pipe system.

Owner:ALRASHIDI THAMER B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com