Flue gas baffling double-slurry pool absorbing tower

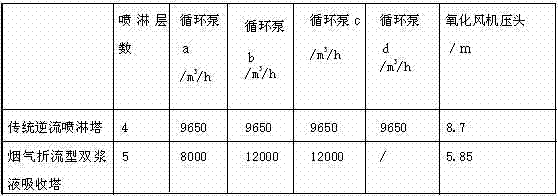

A slurry tank and double slurry technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of limited desulfurization capacity, difficulty in slurry absorption, and increase in the amount of entrained slurry, so as to reduce the number of spray layers. , High SO2 removal rate, the effect of reducing operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

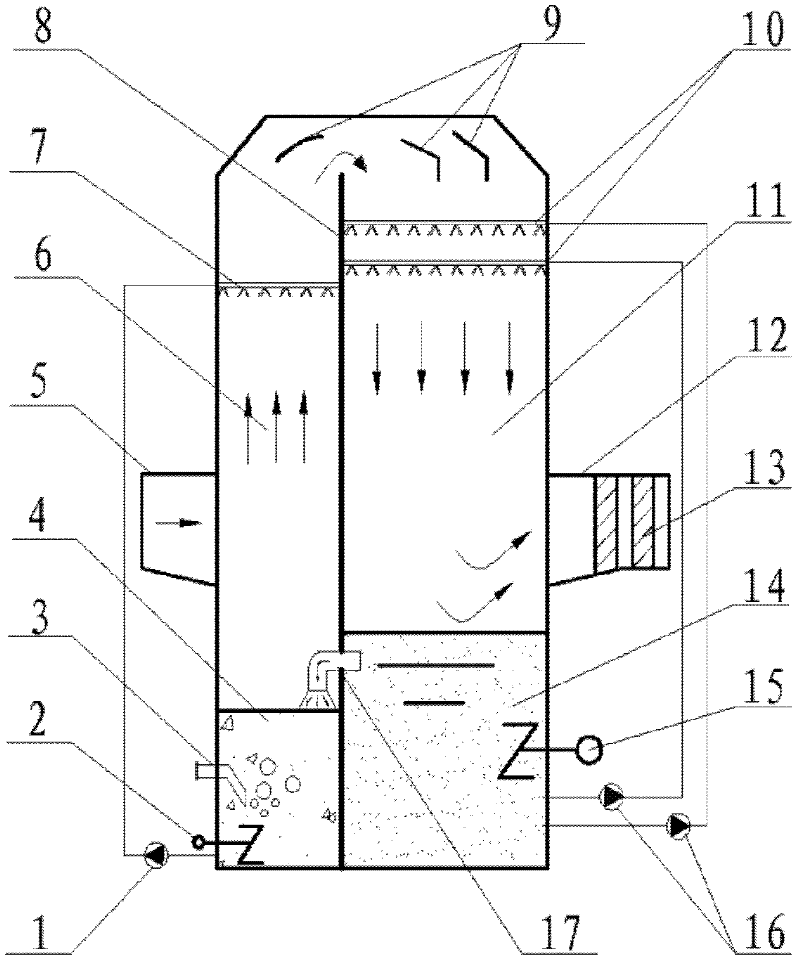

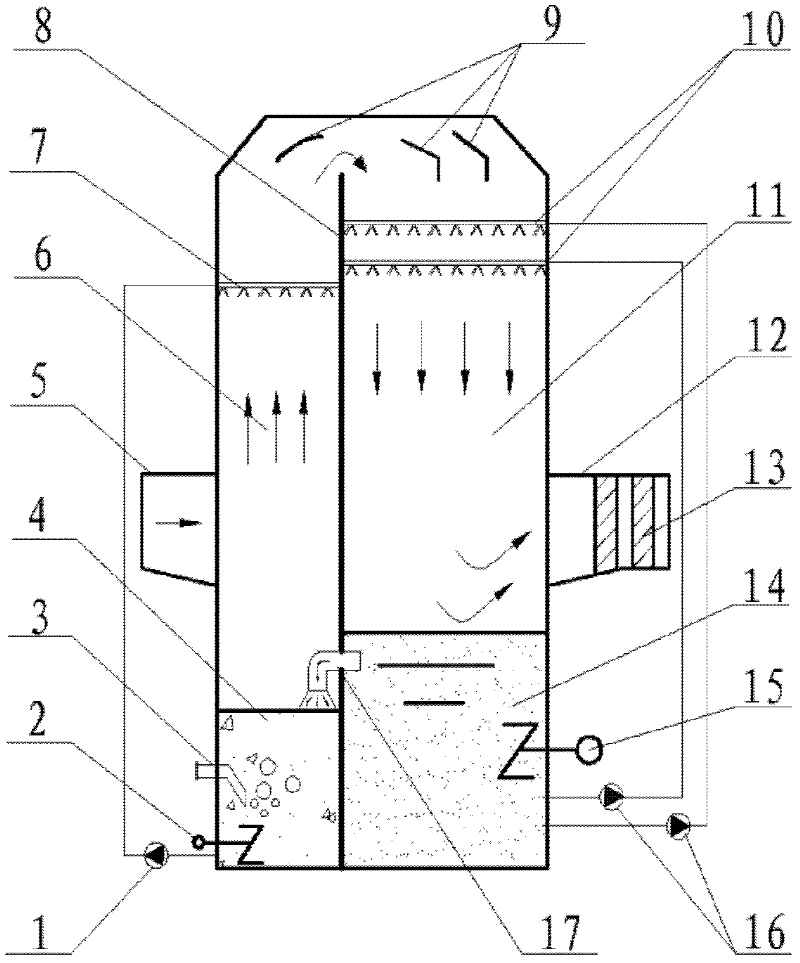

[0025] Such as figure 1 As shown, a flue gas baffle type double slurry pool absorption tower includes a pre-washing area slurry pool 4, a pre-washing area 6, an absorption area 11, and an absorption area slurry pool 14; the washing area slurry pool 4 and the absorption area slurry pool 14 1. The slurry pool 4 in the washing area is separated from the pre-washing area 6 by a tower baffle 8. A certain distance is reserved between the partition and the top of the absorption tower, and guide vanes are arranged on the top of the tower. Spray layers 7 and 10 are respectively arranged on the upper part of the pre-washing area 6 and the absorption area 11. The number of spray layers is determined according to the actual situation. Pipelines are arranged, and circulating pumps 1 and 16 are installed on the pipelines to facilitate the delivery of the slurry to the spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com