Ultra-low-nitrogen combustion equipment with post-premixing cold flame combustion coupling matrix tube mode wall structure

A technology of coupling matrix and combustion equipment, applied in the direction of burner, combustion method, combustion type, etc., can solve problems such as reducing user satisfaction, reducing equipment life, and increasing flue gas volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

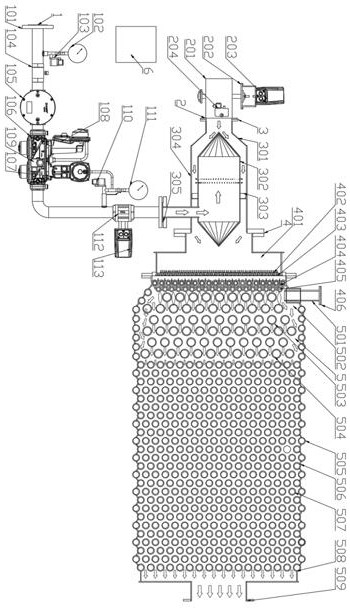

[0033] Combine below figure 1 , the present invention is further described:

[0034] Such as figure 1 As shown, the post-premixed cold flame combustion coupling matrix tube mode wall structure ultra-low nitrogen combustion equipment of the present invention includes a gas control device 1, an air volume control device 2, an air mixing device 3, a cold flame combustion device 4, a matrix tube and a mode wall device 5 and integrated controller 6.

[0035] Among them, the gas control device 1 includes an interface flange 101, a primary pressure gauge 102, a gas low pressure sensor 103, an emergency cut-off ball valve 104, a gas filter 105, a double valve body combination cut-off pressure regulating valve 106, and a cut-off pressure regulation actuator 107 , emergency cut-off actuator 108, gas leakage detection sensor 109, gas high pressure detection sensor 110, secondary gas pressure direct reading pressure gauge 111, gas flow regulating valve 112 and gas flow regulating actuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com