Patents

Literature

323results about How to "Fast heat absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

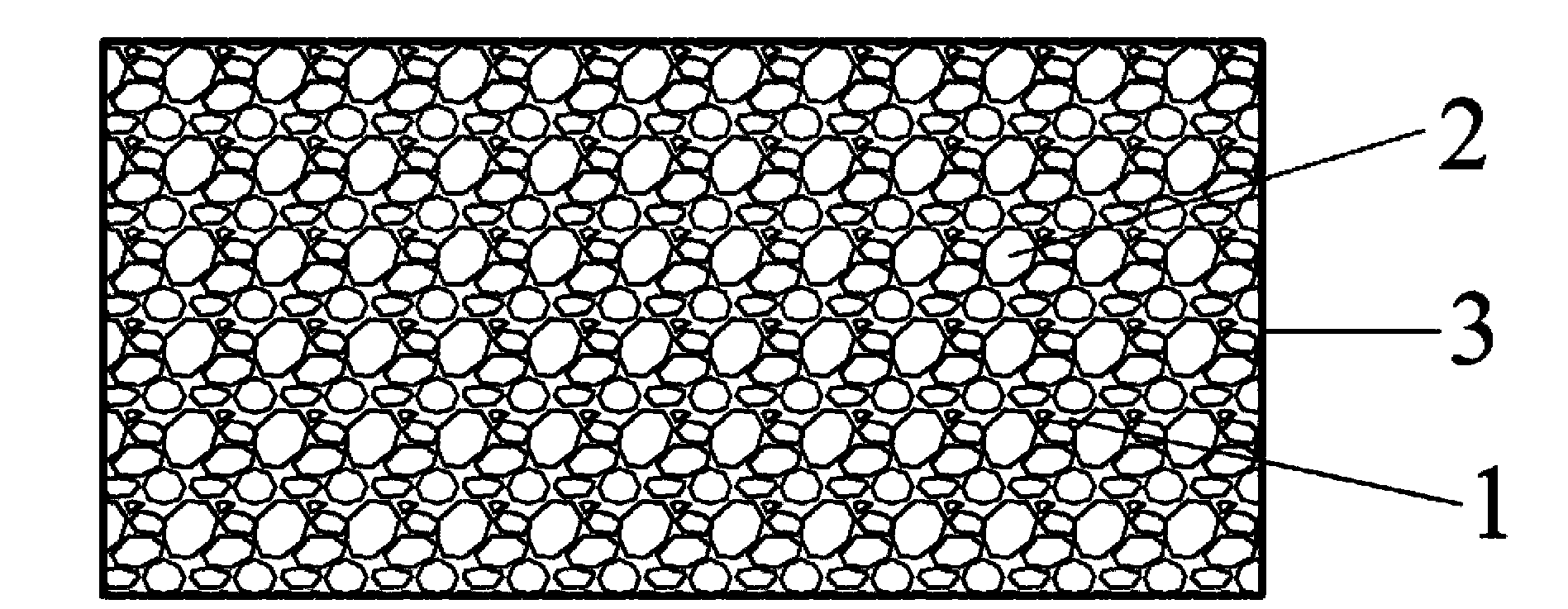

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Novel phase-change material composition

ActiveCN104726069AImprove thermal performanceGood dispersionHeat-exchange elementsParticulatesCarbon nanotube

The invention discloses a novel phase-change material composition. The novel phase-change material composition mainly comprises carbon nanotubes, graphene, fumed silica, metal or metal oxide particles and a phase-change material. The carbon nanotubes, graphene and metal or metal oxide particles can further accelerate heat transmission. The phase-change material is used for improving a hot end initial temperature absorption rate. The fumed silica has effects of precipitation prevention and thickening and can prevent graphene and particle aggregation settlement after heat absorption liquefaction of the phase-change material. The carbon nanotubes, graphene and metal or metal oxides can finally form a full 3D network comprising particles (metal or metal oxides), wires (carbon nanotubes) and planes (graphene) in the fluid (of phase-change material subjected to heat absorption melting). The novel phase-change material composition has high heat conductivity and low thermal resistance value, has high specific heat capacity, greatly improves phase-change material heat absorption, heat storage and heat radiation efficiency and has a high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

Fire extinguishing composition generating fire extinguishing substance through high-temperature decomposition

InactiveUS20130181158A1Environment friendly and efficientPrevent wrong additionFire rescueFire extinguisherDecompositionEngineering

The present invention relates to a fire extinguishing composition generating fire extinguishing substance through high-temperature decomposition; the fire extinguishing composition includes a fire extinguishing material which can be decomposed to release substance with fire extinguishing properties during the heating process; the content of the fire extinguishing material is at least 80 wt %; a pyrotechnic agent is adopted as a heat source and a power source in a process of fire extinguishing; and the purpose of fire extinguishing is achieved by: igniting the pyrotechnic agent, generating a large quantity of fire substance from the fire extinguishing composition in the use of high temperature produced by burning pyrotechnic agent, and the fire substance sprays out together with the pyrotechnic agent. Compared with the traditional aerosol fire extinguishing systems, the gas fire extinguishing systems and the water type extinguishing systems, the present invention provides a more efficient and safer fire extinguishing composition.

Owner:XIAN J&R FIRE FIGHTING EQUIP

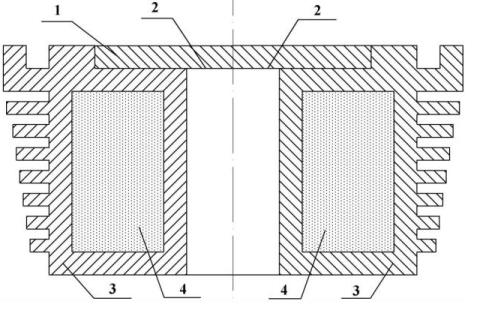

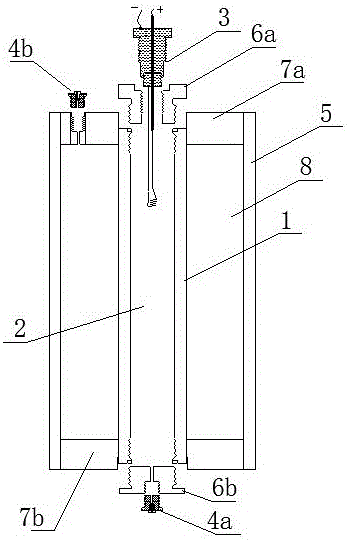

Heat dissipation method of LED (light-emitting diode) device and device

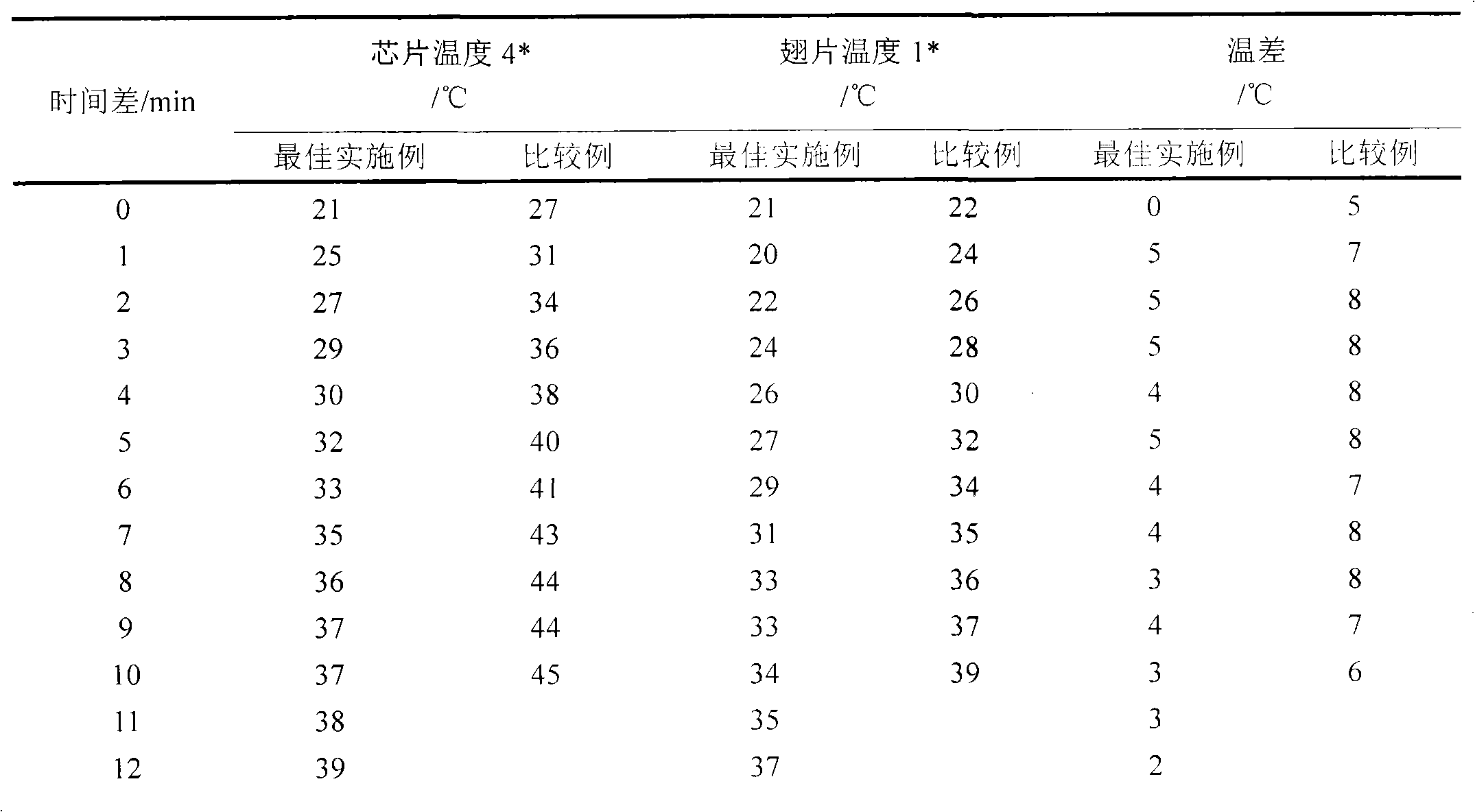

InactiveCN102155729AFast absorptionExtended service lifePoint-like light sourceLighting heating/cooling arrangementsJunction temperatureHeat sink

The invention discloses a heat dissipation method of an LED (light-emitting diode) device, which comprises the following steps of: conducting the heat of the LED device into a phase change material which emits heat with the external environment. The invention also discloses a heat sink of the LED device; the heat sink comprises a metal shell, a heat dissipation baseboard and a heat-conducting fin, wherein the metal shell is internally filled with the phase change material, and the heat dissipation baseboard is connected with the metal shell by the heat-conducting fin. The invention also discloses another heat sink of the LED device; the heat sink comprise the metal shell, the heat dissipation baseboard, a heat pipe and a metal outer cover, wherein the metal shell and the metal outer cover are internally filled with the phase change material, and the heat dissipation baseboard is connected with the metal shell by the heat pipe. The phase change materials of the invention is a composite phase change material of an organic matter and an inorganic metal, has faster heat response rate and heat storage capacity, can rapidly absorb the heat generated by the LED device, and controls the junction temperature of the LED device to be within 60 DEG C, thereby avoiding the luminous decay phenomenon caused by the overheating of the LED device and prolonging the service life of the LED device.

Owner:SOUTH CHINA UNIV OF TECH

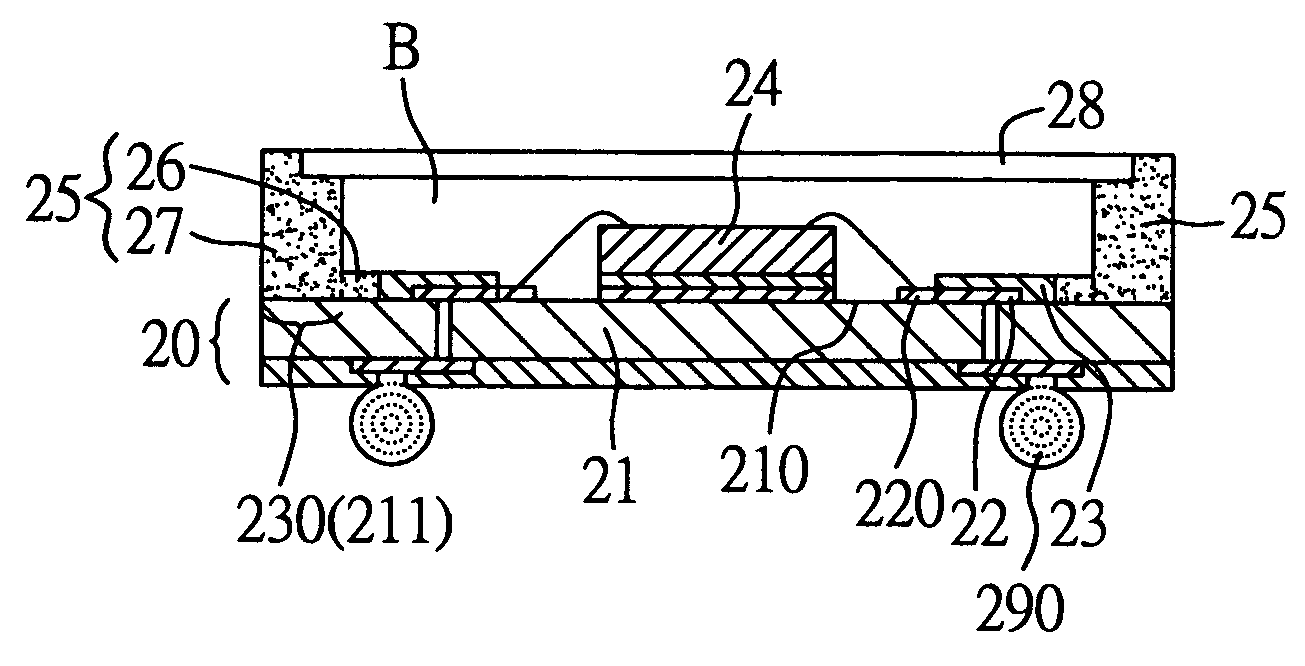

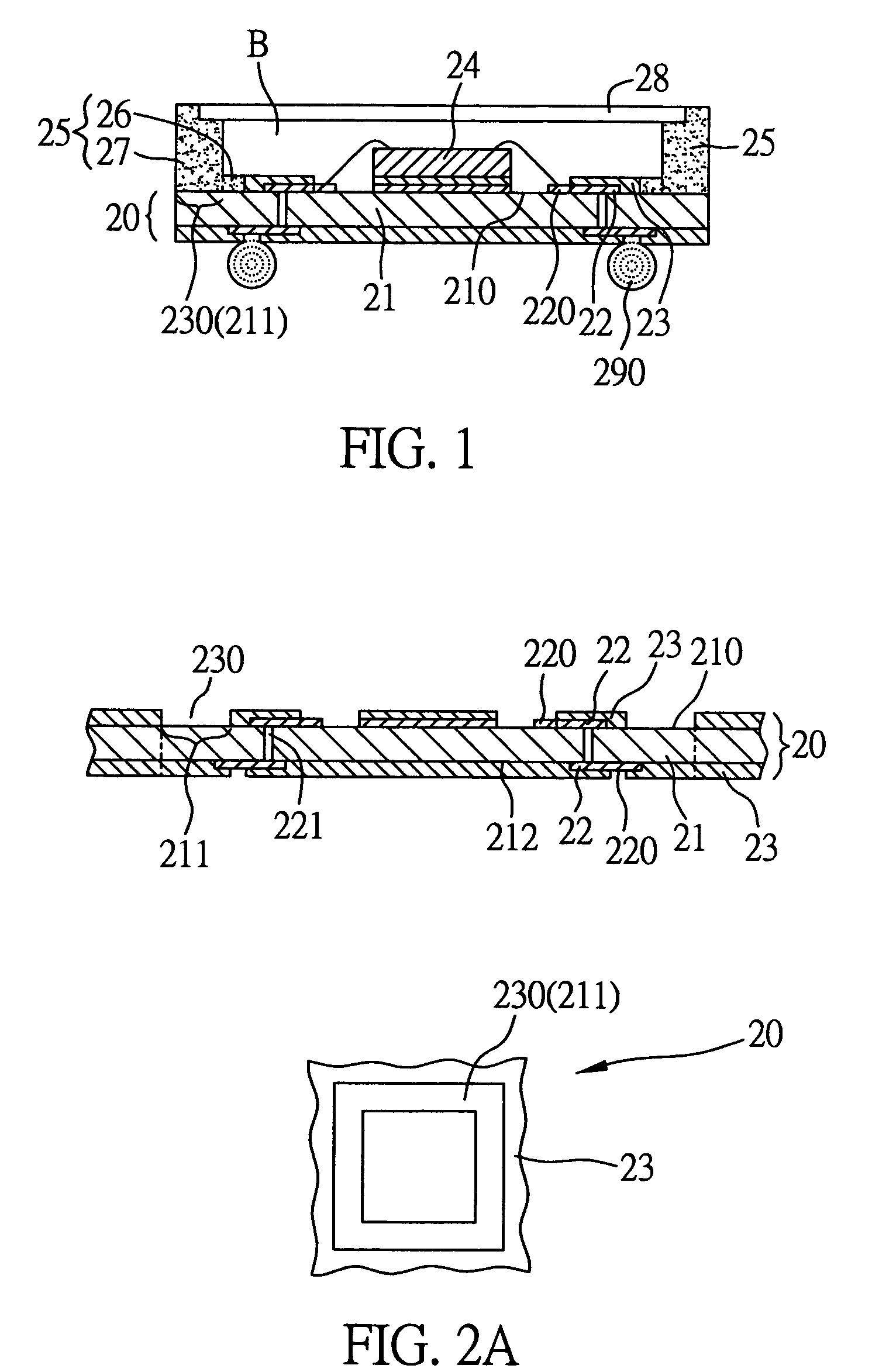

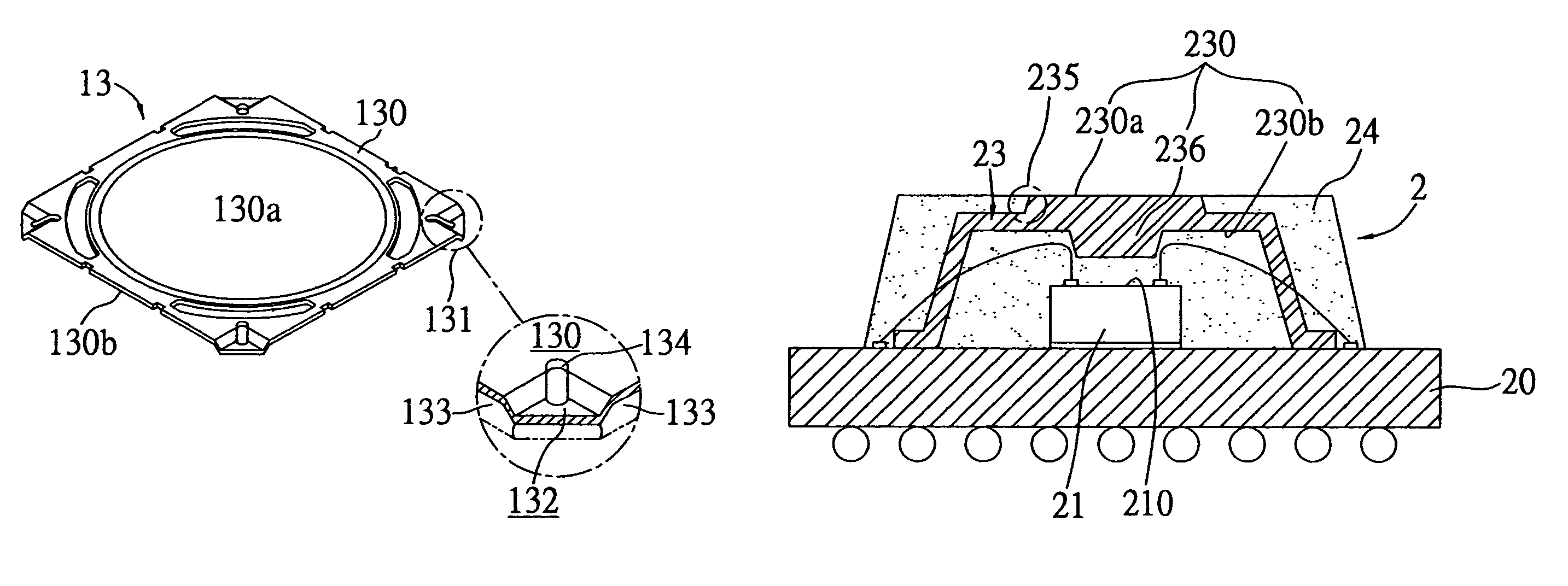

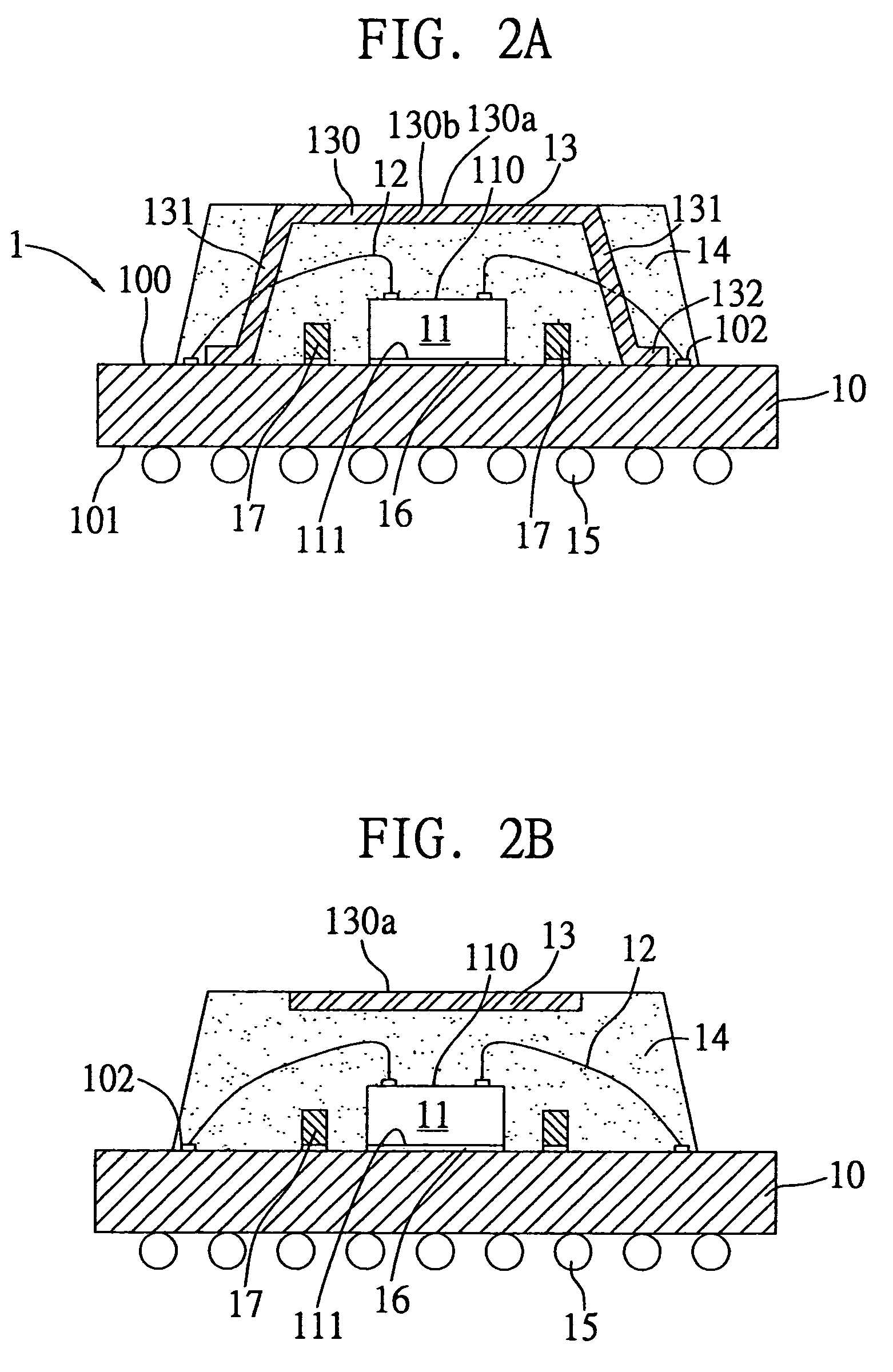

Semiconductor package with photosensitive chip and fabrication method thereof

InactiveUS7005720B2Improve adhesionAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesSolder maskSemiconductor package

A semiconductor package with a photosensitive chip and a fabrication method thereof are provided. A substrate having a core is prepared. A solder mask layer is applied over a surface of the core and formed with an opening to expose a continuous peripheral portion on the surface of the core. At least one photosensitive chip is mounted on and electrically connected to the substrate. An encapsulation dam is formed on the continuous peripheral portion of the core and surrounds the chip. The dam includes a shoulder portion adjacent to and flush with the solder mask layer, and a protruded support portion surrounding the shoulder portion. A lid is attached to the support portion of the dam for sealing the dam such that the chip is received in a space defined by the substrate, the dam and the lid.

Owner:SILICONWARE PRECISION IND CO LTD

Method for preparing temperature-adjusting humidity-adjusting material

InactiveCN101624435ALower phase transition temperatureIncrease moisture contentOther chemical processesViscous liquidPolyethylene glycol

The invention relates to a method for preparing a temperature-adjusting humidity-adjusting material, which is characterized by adopting the following steps: (A) adding activated meerschaum, artificial zeolite, gelatin and urea into deionized water sequentially and stirring to react for 4-6h at the temperature of 50-60 DEG C; (B) adding acrylic acid, polyethylene glycol, ammonium persulphate and the deionized water into a reactant in the step (A) sequentially and stirring for 3-5h at 50-60 DEG C; and (C) cooling a mixture formed in the step (B) to room temperature, forming viscous liquid, drying at the temperature of 80-90 DEG C and preparing the temperature-adjusting humidity-adjusting material. Compared with the prior humidity-adjusting material, the invention has the following outstanding advantages of quick response of the temperature and the humidity, low phase change temperature of the material, high moisture content, quick heat absorption, good kept balance of the temperature and the humidity, and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

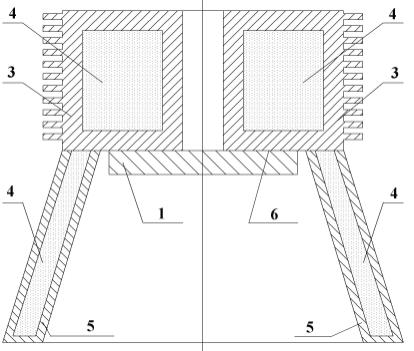

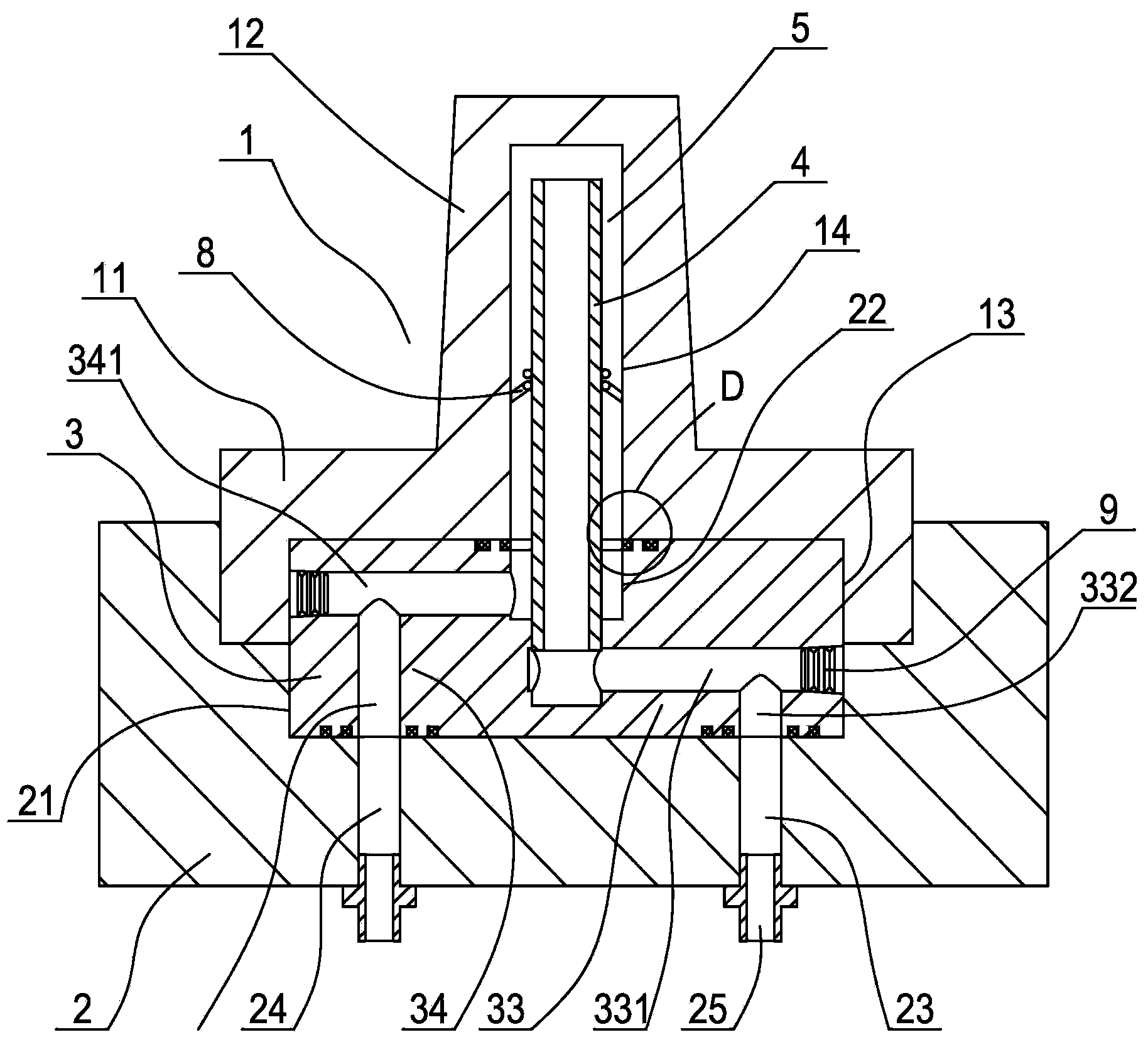

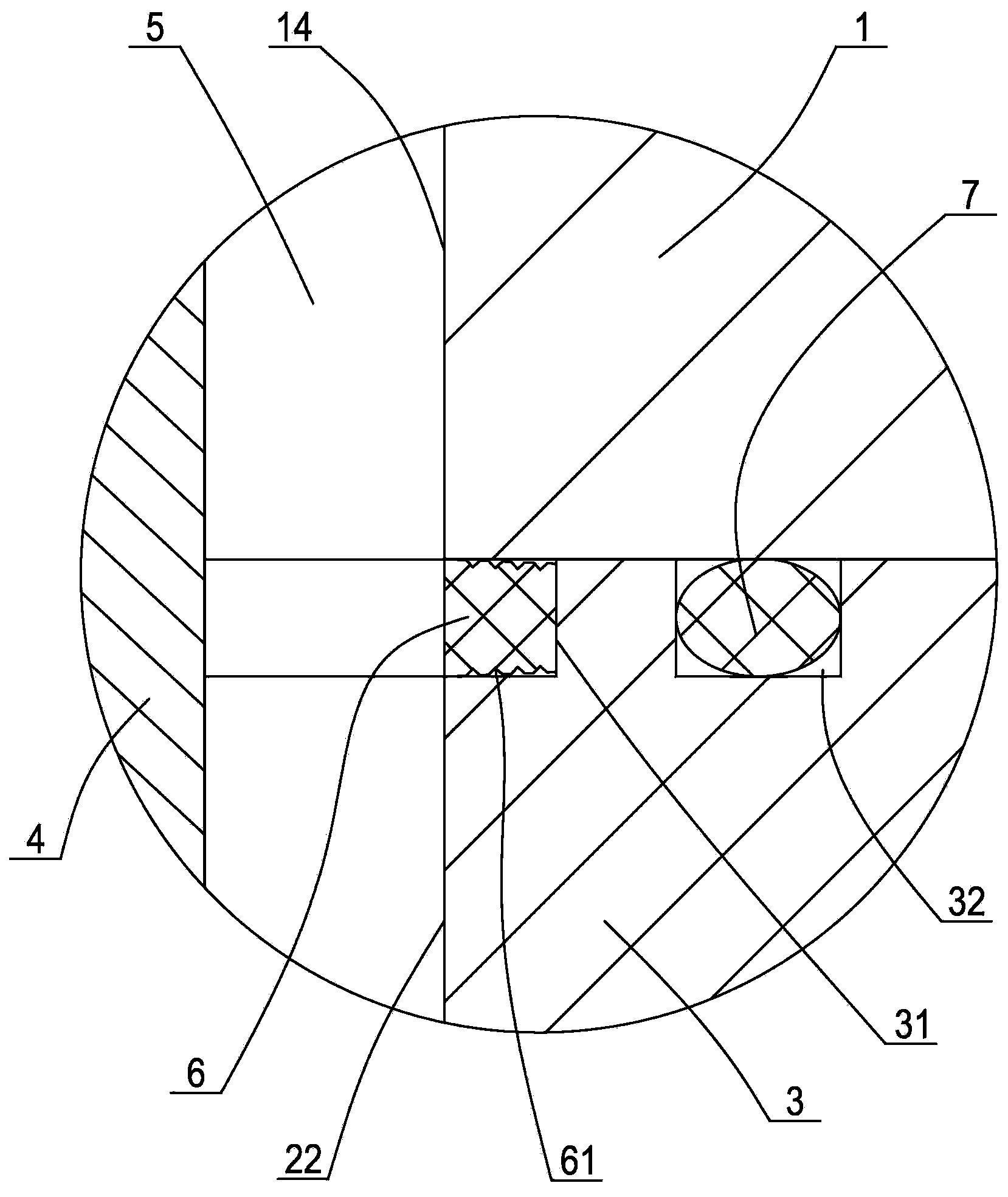

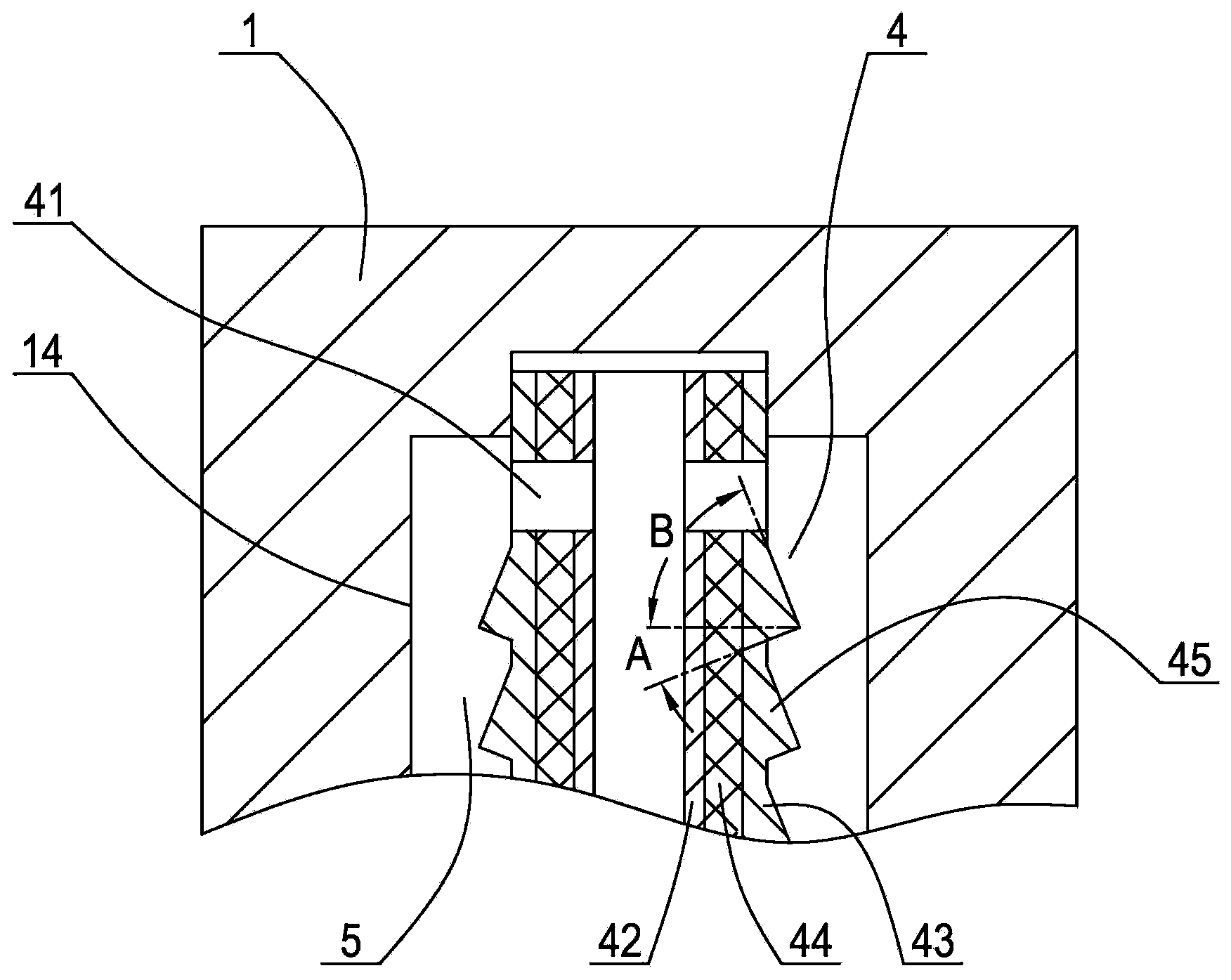

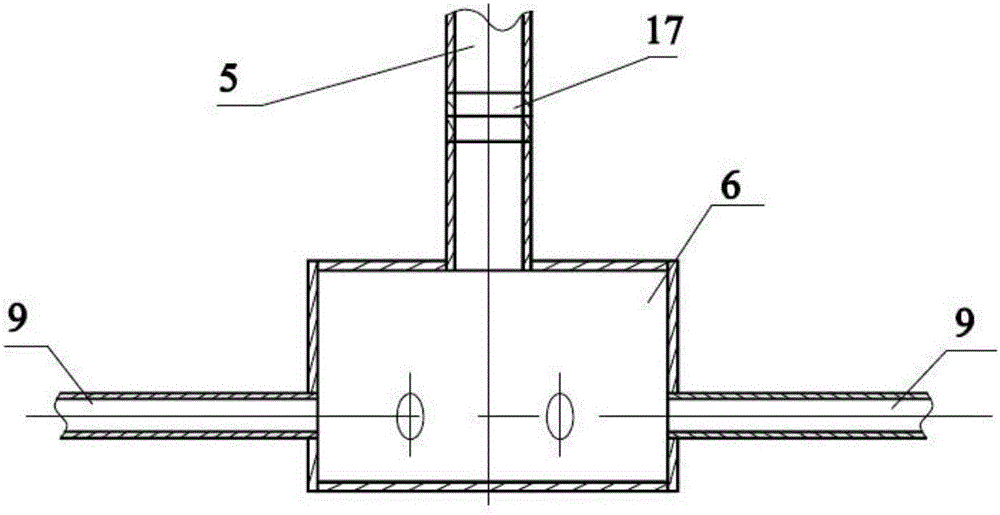

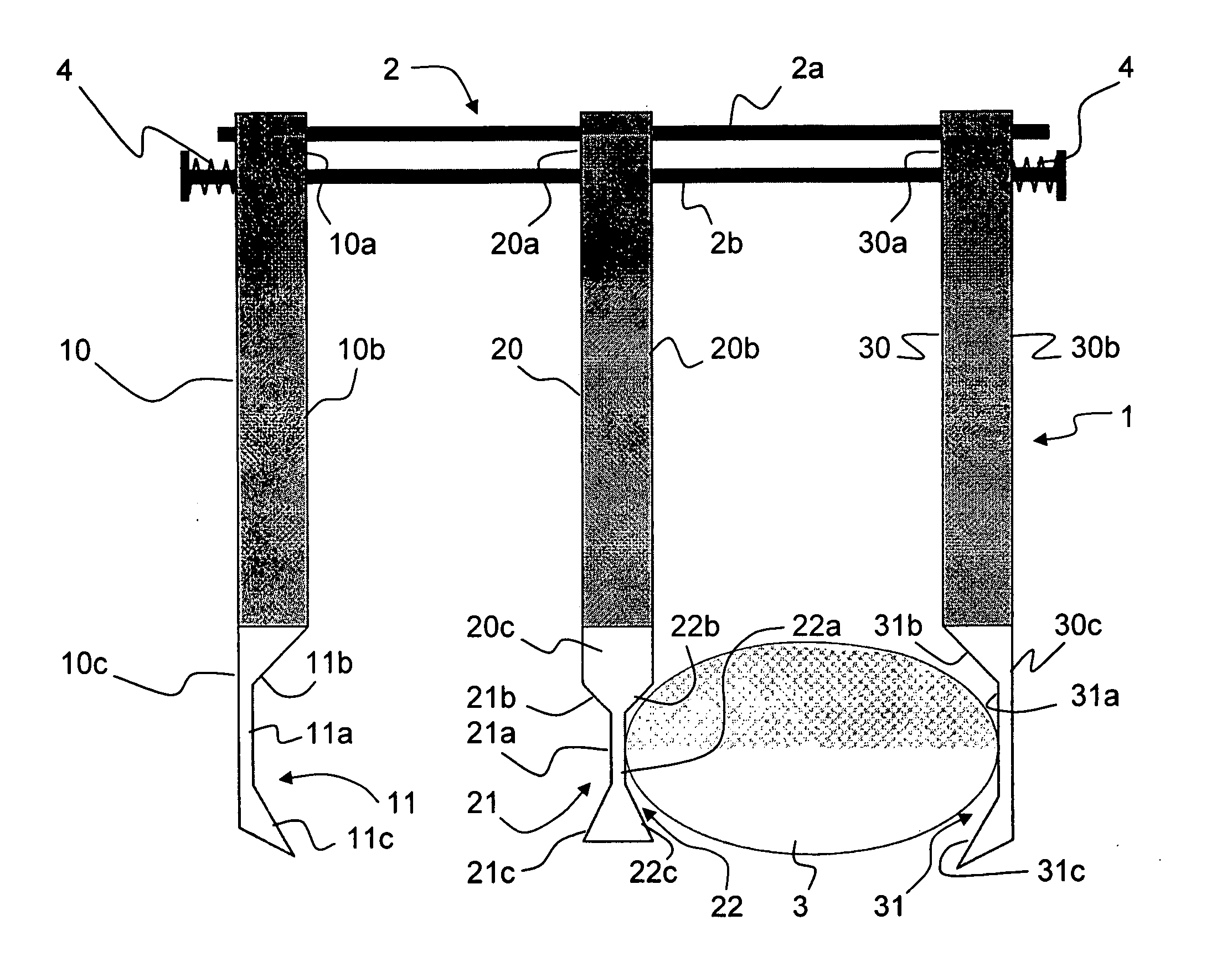

Mold cooling system

The invention discloses a mold cooling system, which comprises a mold core fixation seat and a mold core embedded on the mold core fixation seat, wherein the bottom surface of attaching of the mold core and the mold core fixation seat is provided with an upper concave cavity, the mold core fixation seat position corresponding to the upper concave cavity is provided with a lower concave cavity, a cluster cooling seat extending to the bottom surface of the lower concave cavity is embedded inside the upper concave cavity, a column-shaped upper cooling well is arranged inside the mold core, the cluster cooling seat position corresponding to the upper cooling well is provided with a lower cooling well, the bottom surface of the lower cooling well is provided with a cooling pipe extending to the upper cooling well, water flowing channels are arranged between the cooling pipe and the upper cooling well, and the cooling pipe and the lower cooling well, a water inlet pipeline for communicating a cooling pipe inner hole and a water outlet pipeline for communicating the lower cooling well are arranged inside the cluster cooling seat, and a cooling water sealing structure is arranged between the mold core and the cluster cooling seat and is positioned on the docking position of the upper cooling well and the lower cooling well. According to the present invention, when the mold cooling system is used for cooling a mold core, a cooling temperature can remain uniform, a cooling effect is good, and arrangement of the cooling water pipeline is convenient.

Owner:NINGBO JUNLING MOLD TECH

Multistage double effect distillation seawater desalination technology with heating seawater by solar energy

InactiveCN102190340AIncrease productionRelieve pressureGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention relates to a multistage double effect distillation seawater desalination technology with heating seawater by solar energy. The technology comprises the following steps: seawater is delivered to a high cistern by a seawater pump; the seawater in the high cistern is delivered to a system for water supply through a water supply tube and a condenser inlet tube; the seawater is heated to a certain temperature by adsorbing latent heat of steam in an evaporator through all condensers of the system, and enters the evaporator after being heated to a designed temperature by a rapid heater with solar energy; the seawater enters the evaporator, becomes superheated water and is gasified rapidly and partially because a pressure in the evaporator is controlled to be lower than a saturation vapor pressure corresponding to a temperature of hot seawater; and a part of ungasified hot seawater enters a next stage evaporator and a part enters heat-collecting tubes at two sides of the evaporator. The heat-collecting tubes are provided with annular imbibition films, and the hot seawater flows from top to bottom after entering the heat-collecting tubes. In a flow process, the hot seawater is delivered to upper half parts of inner cavities of the heat-collecting tubes because of capillary imbibition actions of the imbibition films. The hot seawater is evaporated to steam because the heat-collecting tubes have a high temperature under the sunlight, the steam rises along the inner cavities of the heat-collecting tubes and enters the condenser to obtain fresh water which flows into a fresh water tank and then is output by a fresh water tube. Unevaporated concentrated seawater enters a concentrated water tank and is ouput by an inlet / outlet tube.

Owner:孙元新

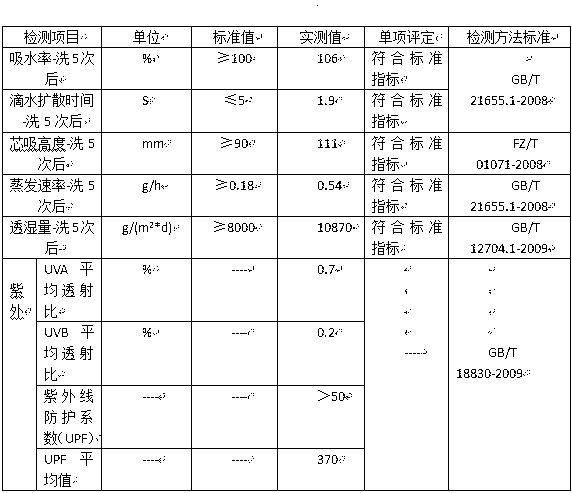

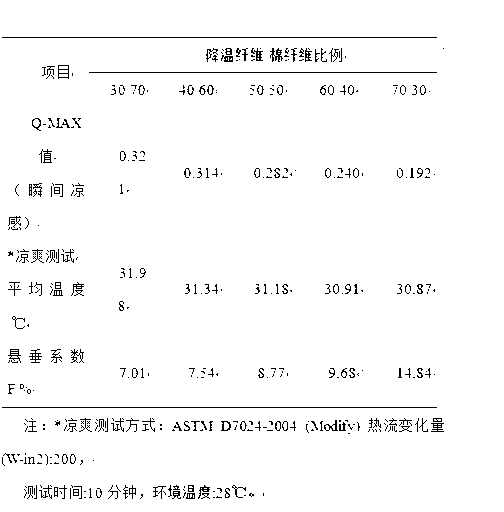

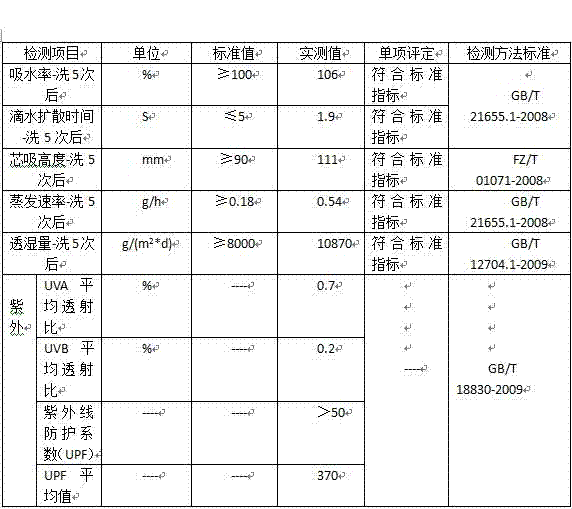

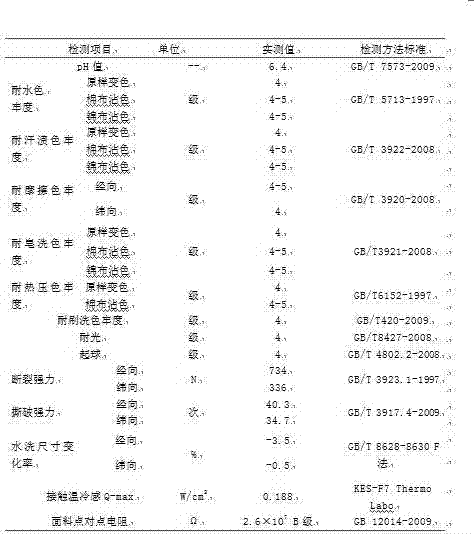

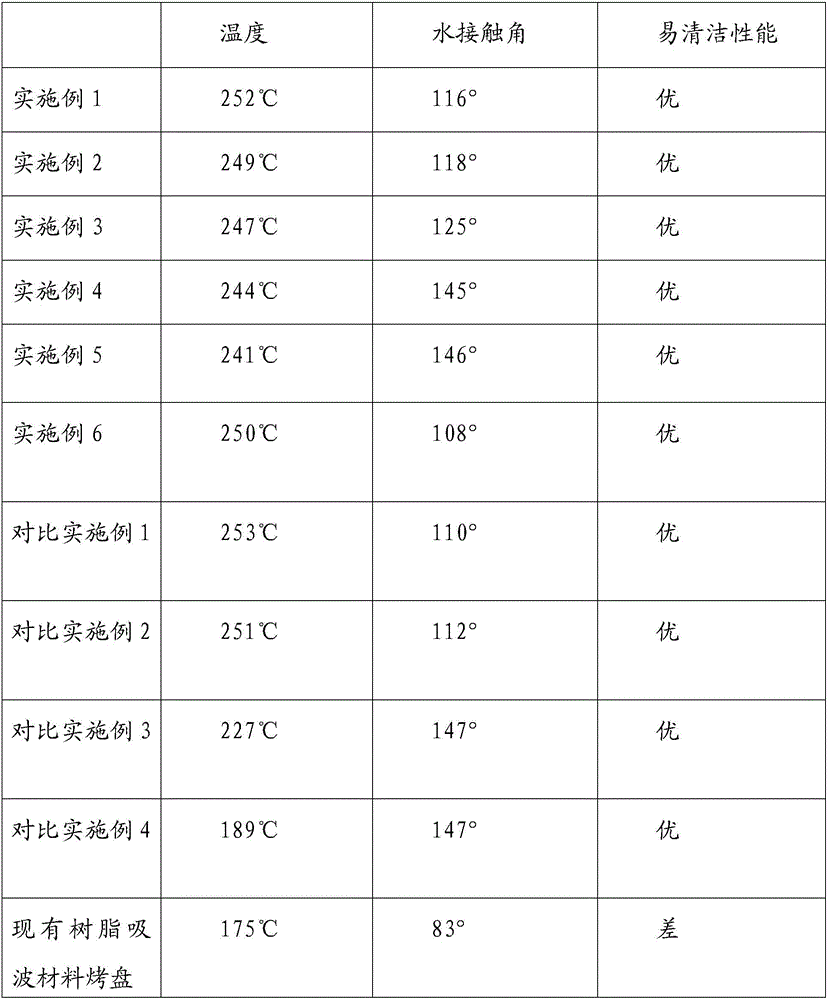

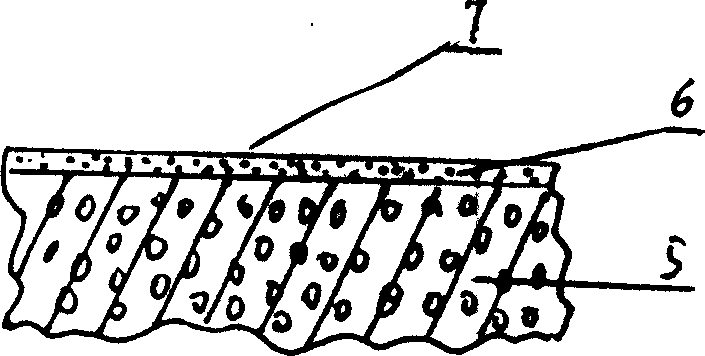

Tooling fabric with cooling function and uvio-resistant function

The invention relates to tooling fabric with a cooling function and an uvio-resistant function. A method for manufacturing the tooling fabric with the cooling function and the uvio-resistant function comprises a first step of using cooling master batch as raw materials and manufacturing the cooling master batch to slicing sheets, a second step of drying the slice sheets, a third step of carrying out spinning on the slicing sheets through a spinning box to manufacture nylon base cooling fibers, a fourth step of adopting a siro spinning technology to spin cotton fibers and the nylon base cooling fibers into blended yarn, and a fifth step of adopting technological measures of 'early opening, later weft insertion and on-machine tension slightly larger' to carry out weaving. A formula of the cooling master batch comprises PA6, bowlder powder, zirconium dioxide powder, silicon dioxide powder, stearic acid dispersants, polystyrene dispersants, low molecular wax dispersants and titanate coupling agents. The tooling fabric has functions of fast heat absorption and fast heat dissipation, and an everlasting cooling feature is guaranteed. Meanwhile, the tooling fabric further has a notable uvio-resistant feature.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

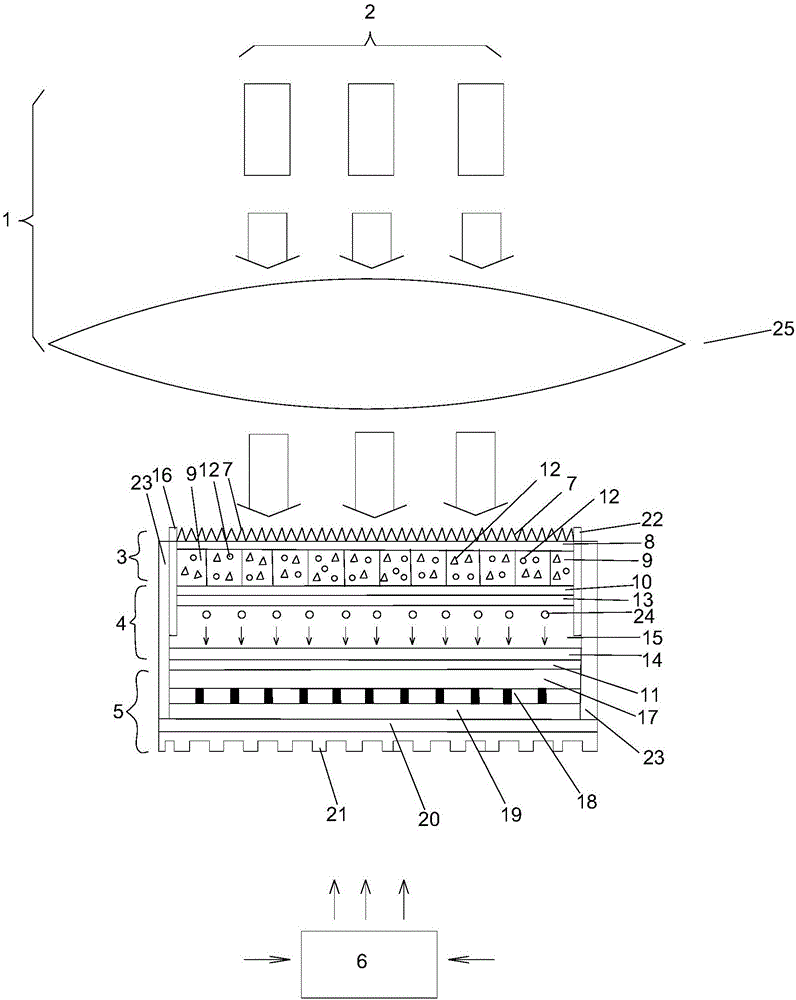

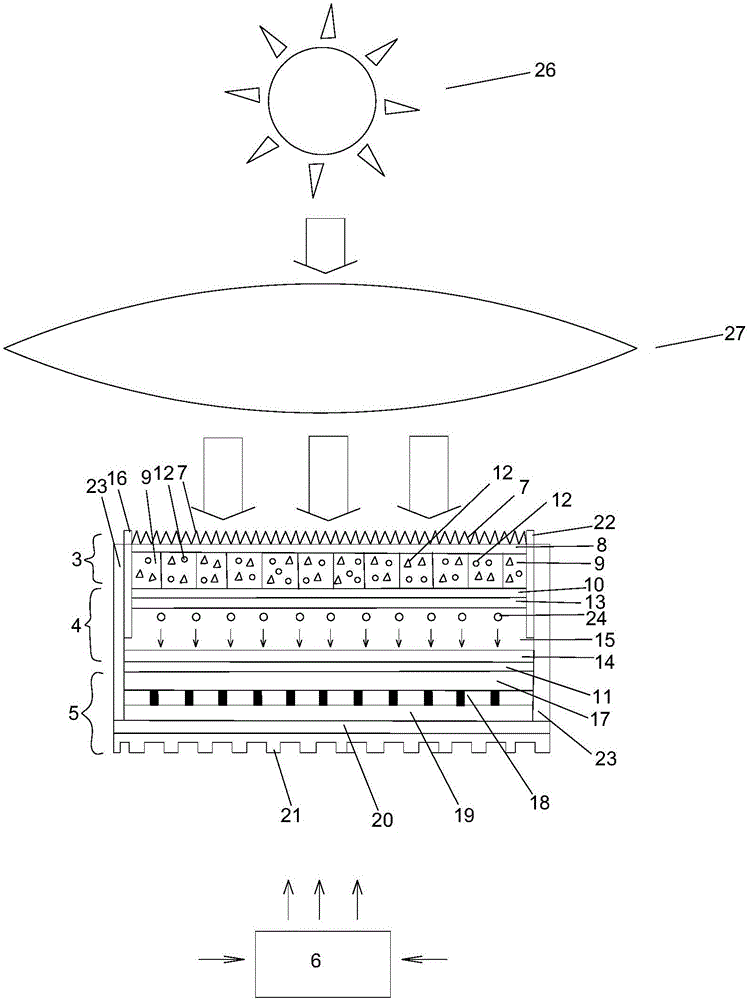

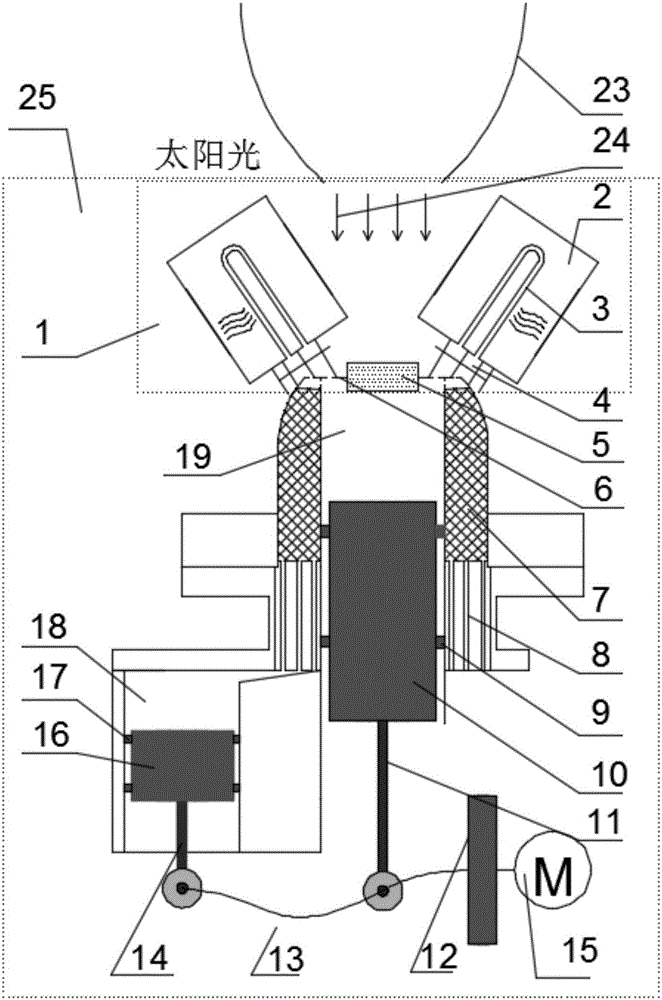

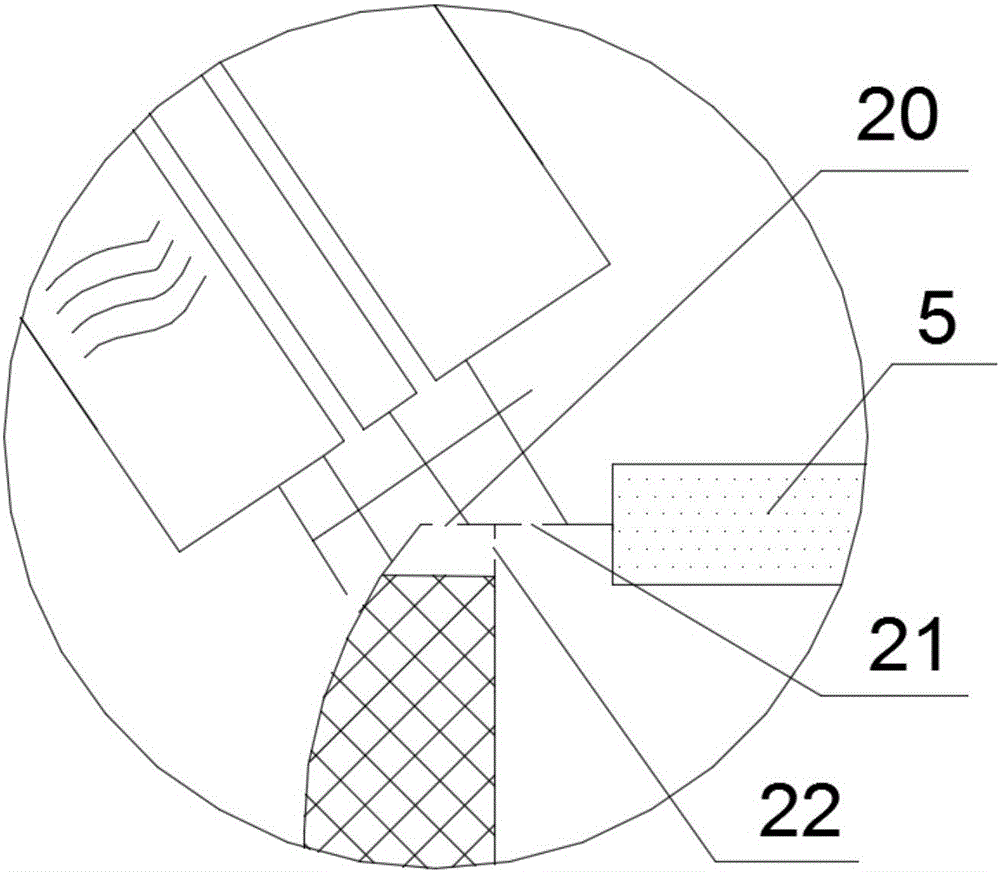

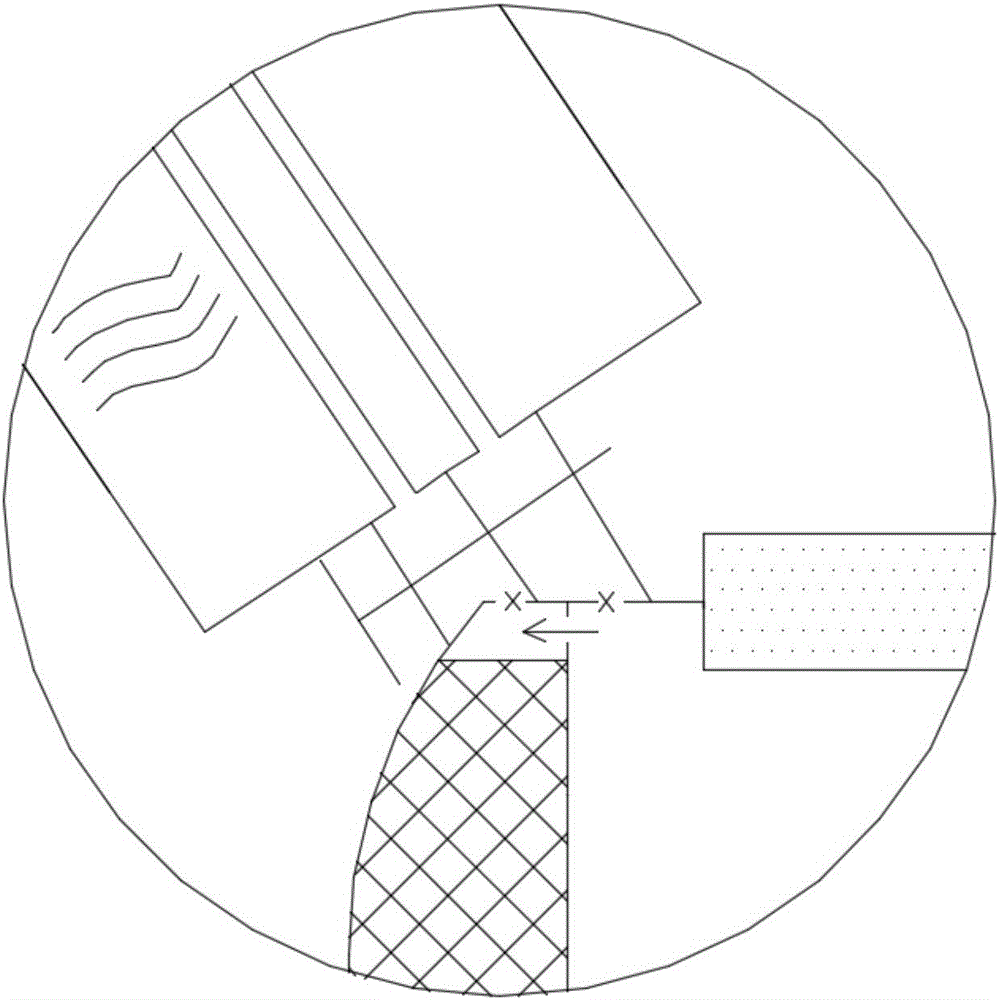

Micro-nano light trap honeycomb energy storage composite power generation device

InactiveCN106452287AReduced reflection lossImprove light harvesting efficiencyPV power plantsPhotovoltaic energy generationThermal energyMicro nano

The invention relates to a micro-nano light trap honeycomb energy storage composite power generation device which comprises two types: a laser type micro-nano light trap honeycomb energy storage composite power generation device and a solar concentration type micro-nano light trap honeycomb energy storage composite power generation device, wherein the laser type micro-nano light trap honeycomb energy storage composite power generation device implements composite power generation by use of laser for wireless transmission of energy; the laser type micro-nano light trap honeycomb energy storage composite power generation device comprises a laser part, a micro-nano light trap honeycomb energy storage part, a thermal battery part, a thermal energy power generation part and an intelligent controller; and the micro-nano light trap honeycomb energy storage part can generate a light trap effect as well as absorb laser or solar concentration and store and convert the energy transmitted by laser or solar concentration, and can transmit and provide work energy to the thermal battery part and the thermal energy power generation part respectively in the daytime or at night. The device can outward output comprehensive electric quantity generated by thermophotovoltaic power generation and thermal energy power generation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

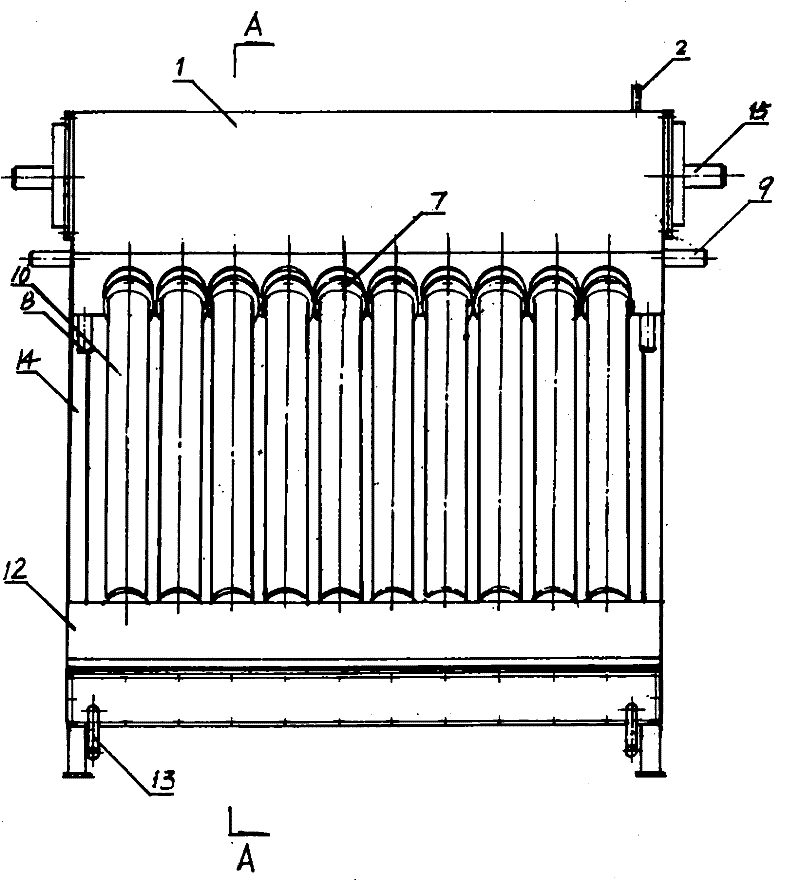

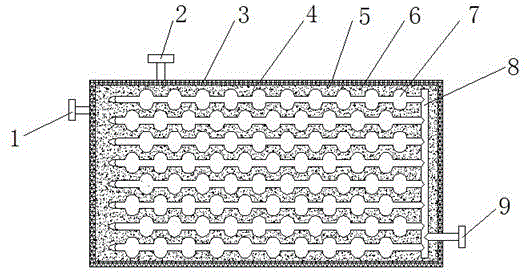

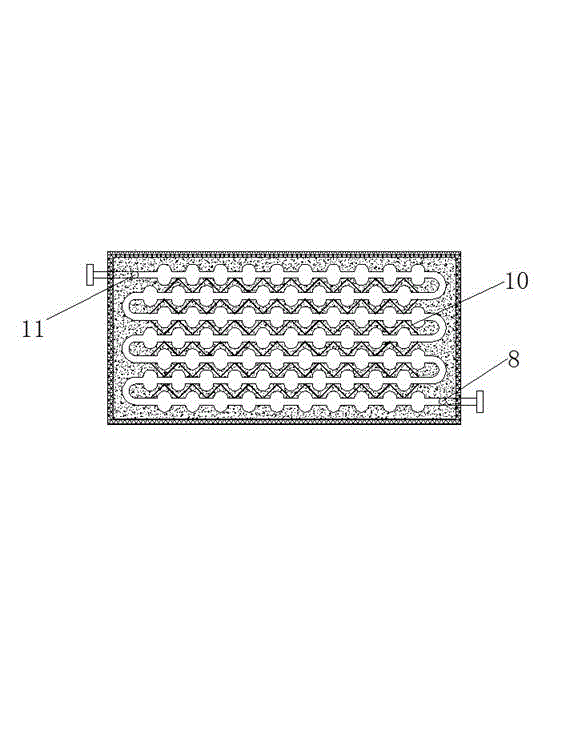

Metal net base corrugate pipe type phase change heat storage device

InactiveCN103148723AReduce heat storageShorten the timeHeat storage plantsEngineeringHeat transfer efficiency

The invention relates to a metal net base corrugate pipe type phase change heat storage device, which comprises an outer housing and a heat storage box body, wherein the heat storage box body is divided into multiple layers and consists of a housing, corrugate pipes, fluid distributing pipes and fluid collecting pipes; the corrugate pipes on each layer are communicated with the fluid collecting pipes through the fluid distributing pipes; the corrugate pipes between layers are placed inside the heat storage box body in a tight and staggered manner; in the same layer, wave nodes and wave troughs in two adjacent rows of the corrugate pipes correspondingly form tight and staggered arrangement; meanwhile, metal wires are twisted in the two adjacent rows of the corrugate pipes to form a net structure so as to strengthen heat transfer, and other spare parts of the heat storage box body are filled with heat storage phase change material. The device is simple in structure and large in heat exchange area, a turbulent flow can be formed when a fluid flows in the corrugate pipes, the heat transfer efficiency is improved, the heat absorption and heat discharge speed is quick, the heat storage material capacity is large, and the heat storage capacity is improved; and the phase change heat storage device can fully utilize solar energy and industrial exhaust heat to carry out high efficiency waste heat recovery utilization.

Owner:NANJING UNIV OF TECH

Titanium dioxide production process calcining tail gas processing method

ActiveCN105561721AHigh utilization rate of waste heat recoveryReduce consumptionCombination devicesGas treatmentProduction lineUtilization rate

The present invention discloses a titanium dioxide production process calcining tail gas processing method comprising the following steps: 1) dust removal; 2) preliminary heat exchange, to be more specific, calcining tail gas after the dust removal is discharged into a waste heat boiler system for heat exchange with process water, and the calcining tail gas is preliminarily calcined; 3) further heat exchange, to be more specific, the preliminarily-calcined calcining tail gas enters a venturi system and further cooled by spraying with spent sulfuric acid; and 4) desulfurization. According to the titanium dioxide production process calcining tail gas processing method, waste heat boiler system with high heat recovery utilization rate is used, and by step-by-step heat exchange, heat can be efficiently recovered from the calcining tail gas, and can be used for other processes in a titanium dioxide production line, energy and water consumption can be greatly saved, and by the desulfurization, desulfurization rate of the calcining tail gas is significantly increased.

Owner:SHANGHAI TITANOS IND

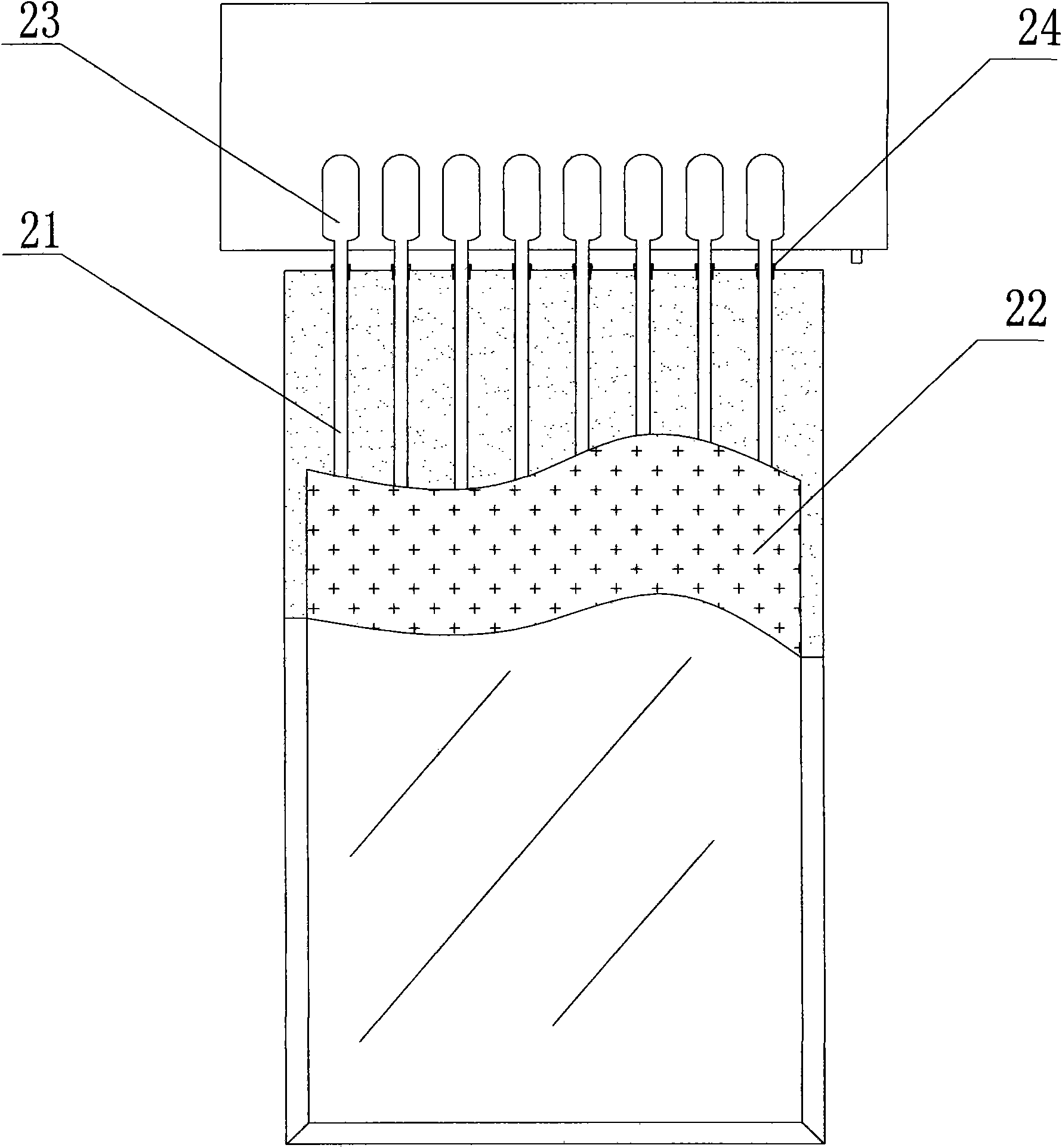

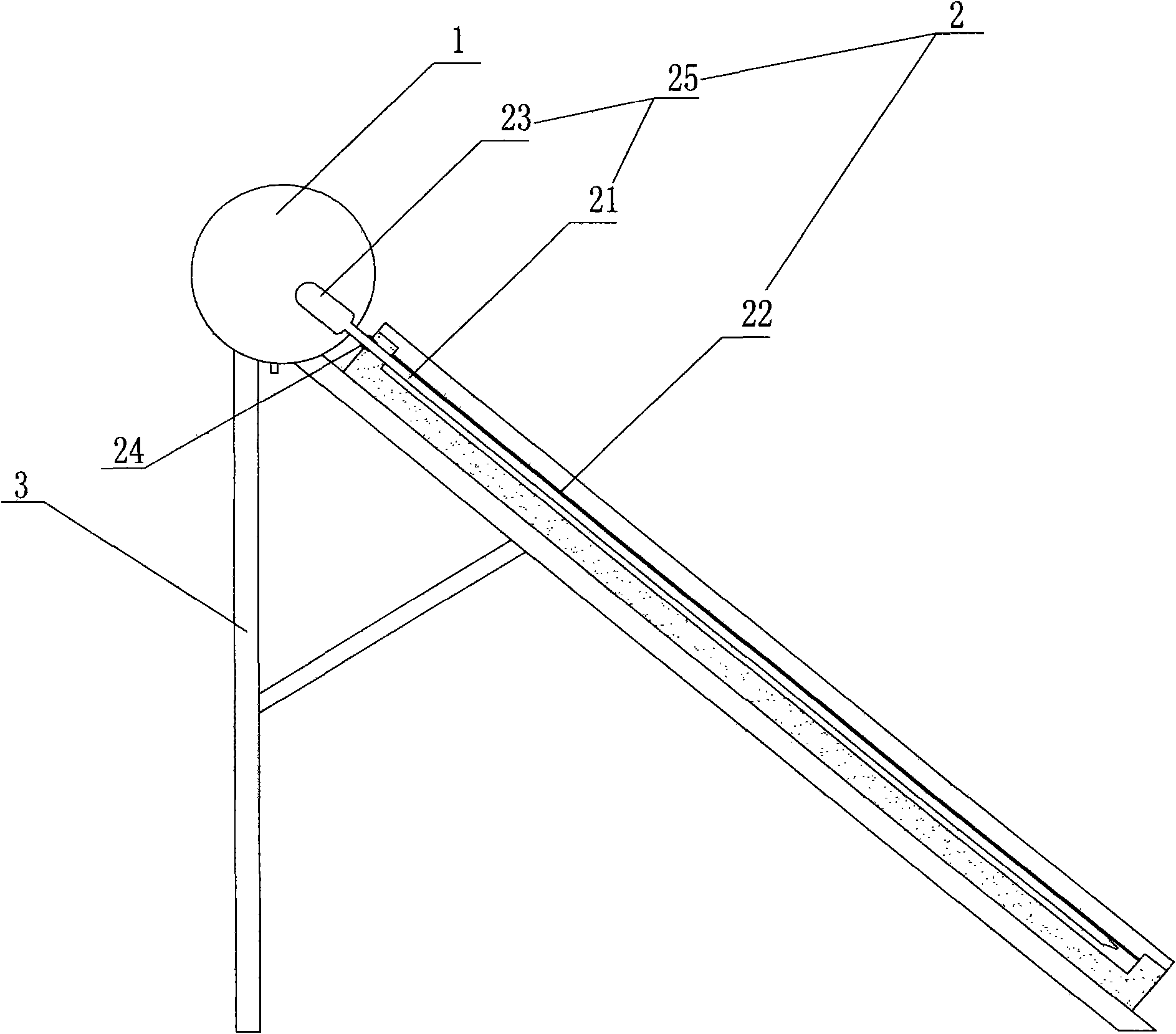

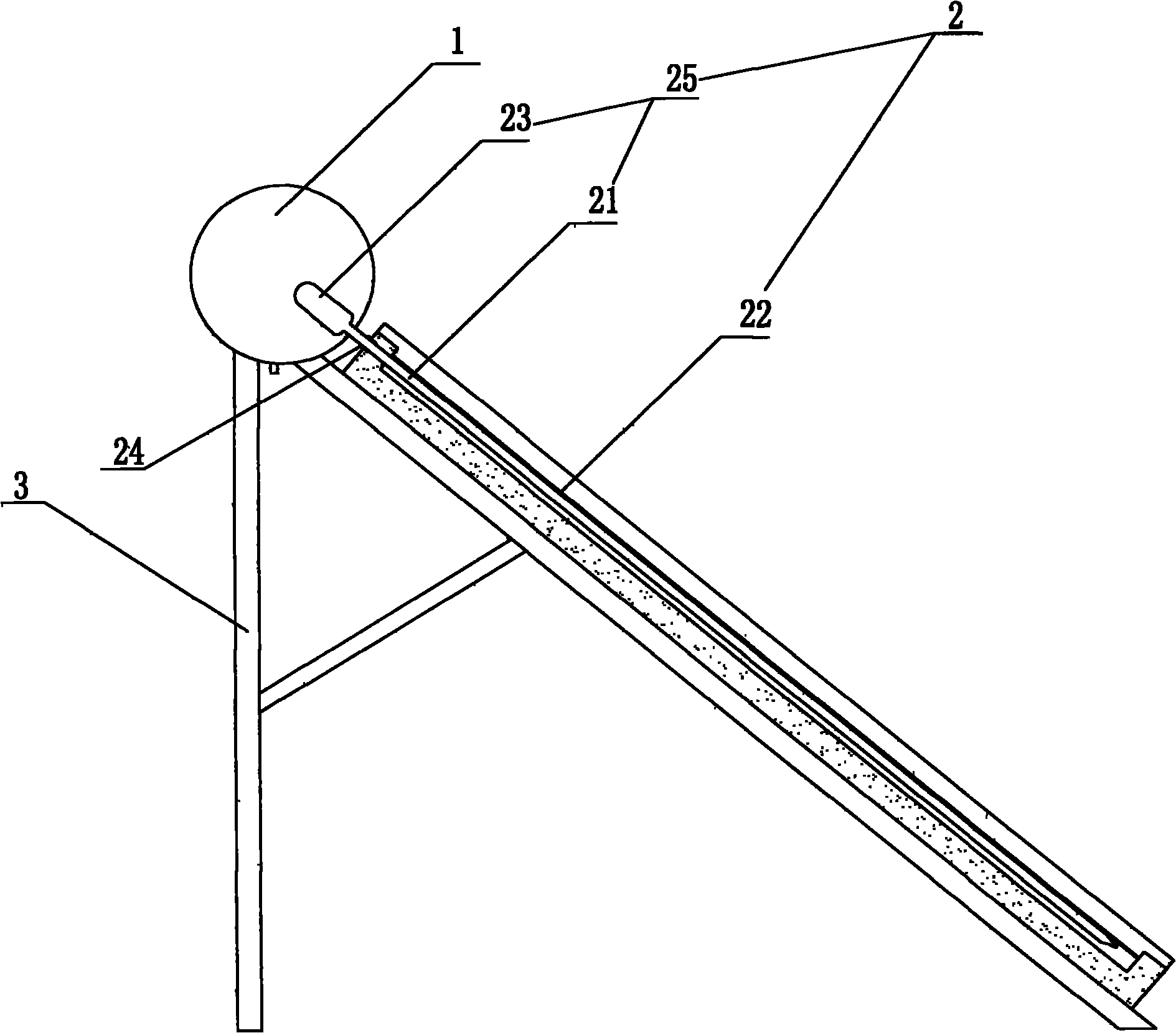

Integrated pressure-bearing heat pipe flat-plate solar water heater

InactiveCN102032679AStrong resistance to external impactExtended service lifeSolar heating energySolar heat devicesFrostSolar water

The invention discloses an integrated pressure-bearing heat pipe flat-plate solar water heater and belongs to the field of flat-plate solar water heaters. The solar water heater comprises main components, such as a water tank, a flat-plate heat collector, a bracket and the like, wherein a heat absorption plate core of the flat-plate heat collector is formed by welding a heat pipe and an aluminum plate or a copper plate on which a heat absorption coating is plated; and a condensation section of the heat pipe is positioned outside the heat collector and inserted into the water tank and directly exchanges heat with water in the water tank. Due to an integrated design, the flat-plate solar water heater has the characteristics of high heat collection efficiency and heat absorption speed, compression resistance, frost resistance, high impact resistance, long service life and the like.

Owner:浙江梅地亚新能源科技有限公司

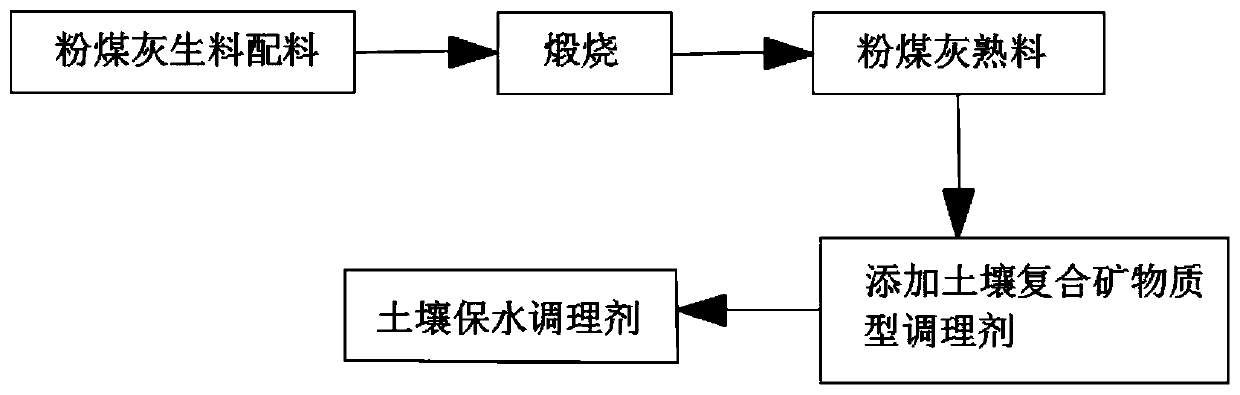

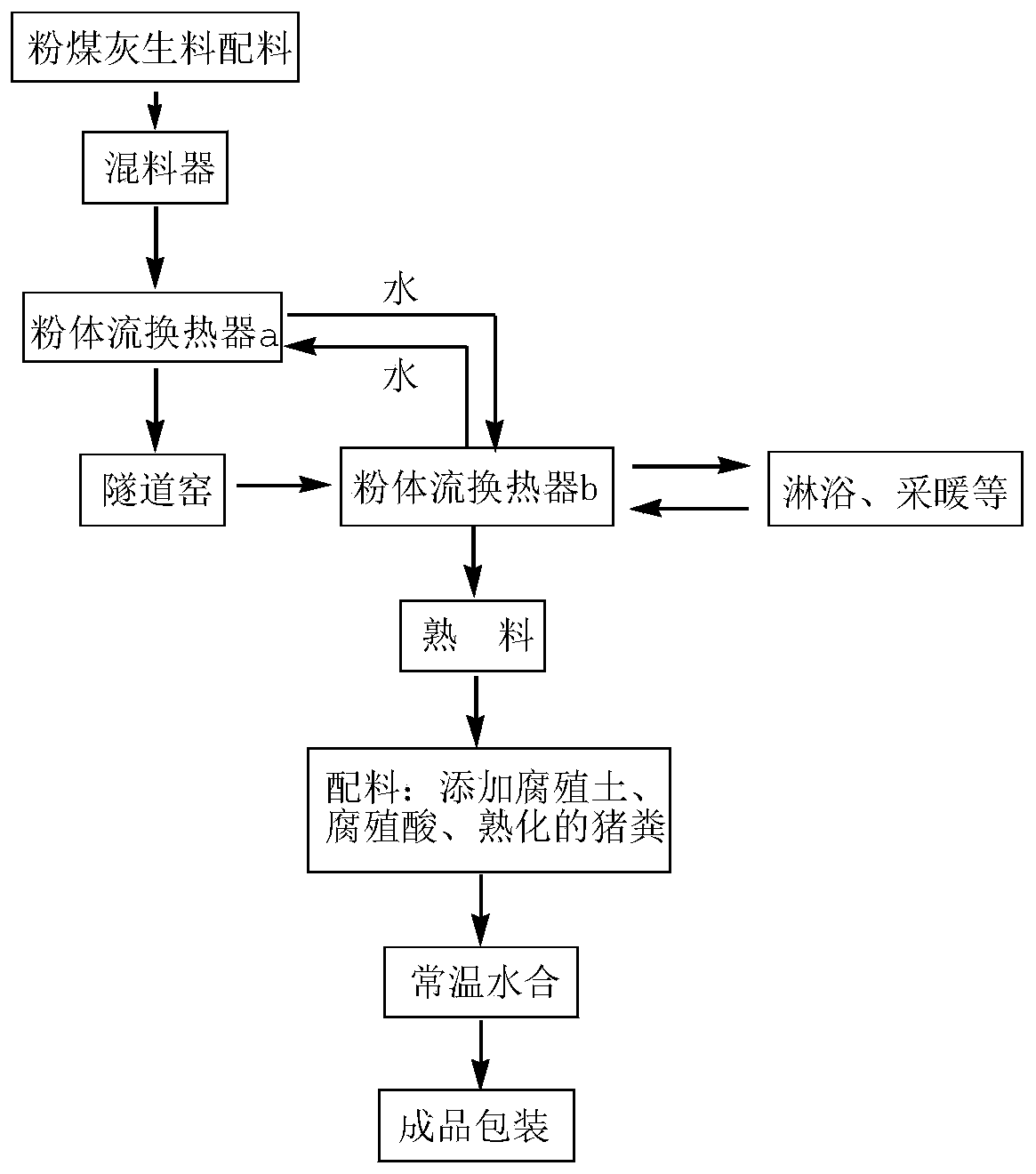

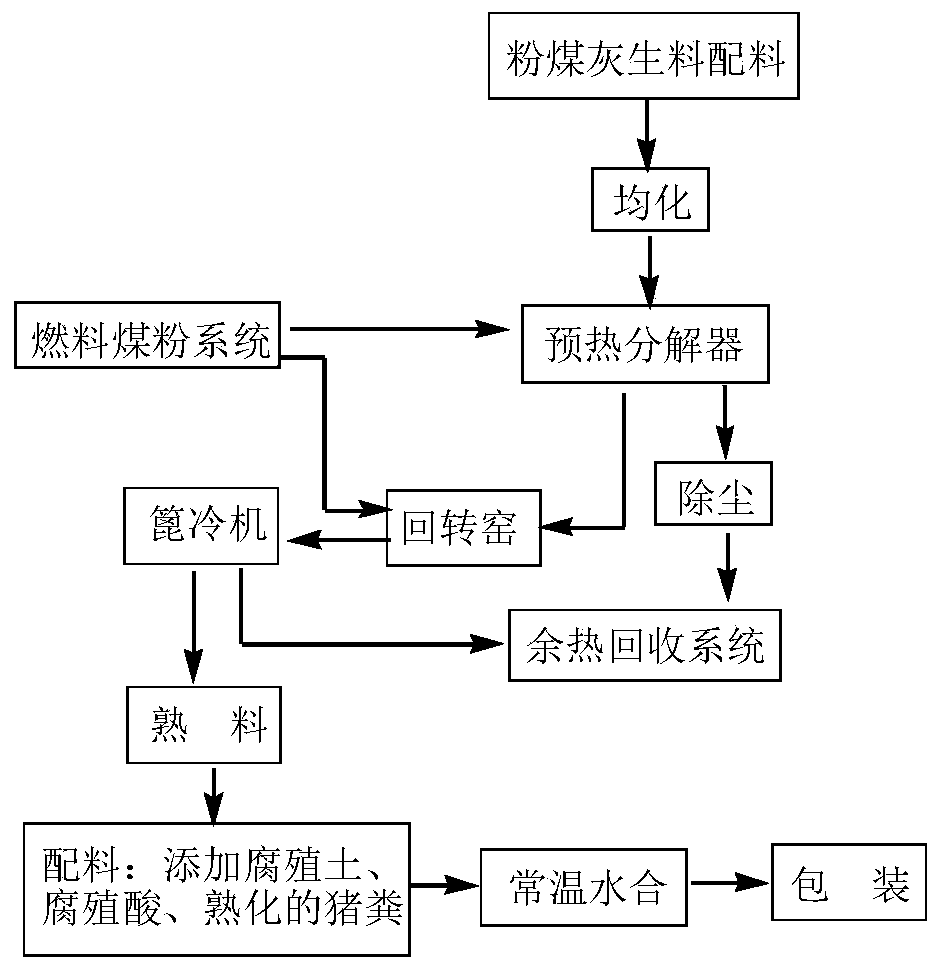

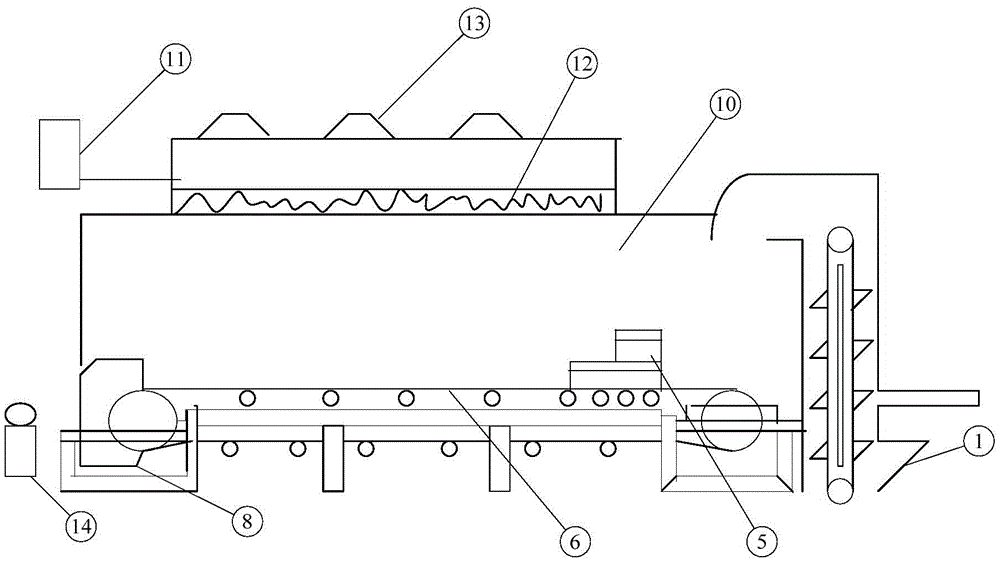

Fly ash-based soil water-retaining conditioner and preparation method thereof

ActiveCN110699090AImprove water absorptionImprove water retentionOther chemical processesExcrement fertilisersSilicic acidEdaphic

The invention discloses a fly ash-based soil water-retaining conditioner and a preparation method thereof, belonging to the technical field of soil water-retaining conditioners. The fly ash-based soilwater-retaining conditioner comprises fly ash clinker and a soil composite mineral type conditioner. The fly ash clinker is prepared from the following components in parts by mass through a calciningprocess, and the mass ratio of fly ash to calcium oxide or calcium carbonate to sodium carbonate to potassium carbonate is 1: (0-1) or (0-1.4): (0-0.5): (0-0.5). Through the water absorption and drainage principle of the generated dicalcium silicate, the effect of keeping moisture in the soil is achieved; the soil composite mineral conditioner is composed of humus soil, humic acid and cured pig manure, and can improve physical, chemical and microbial reactions of soil and increase fertility of the soil.

Owner:刘建森

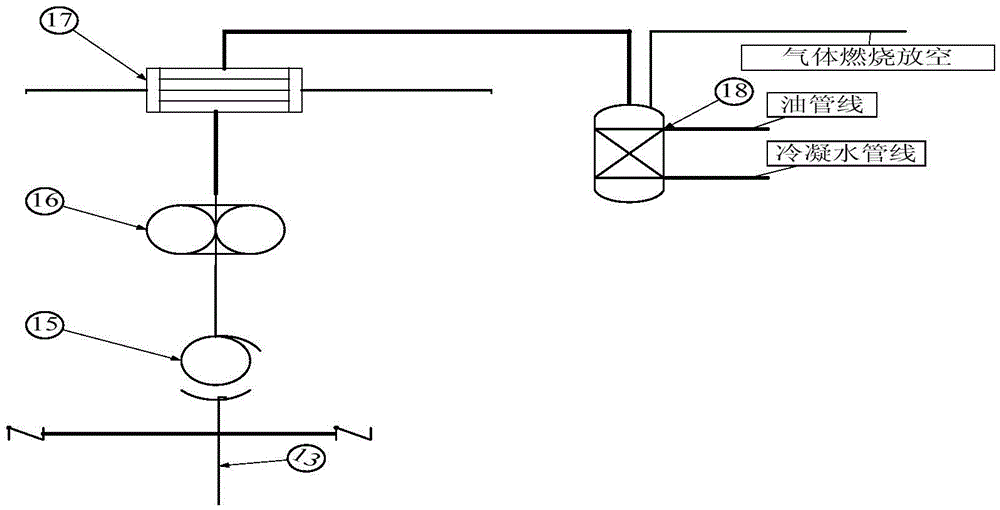

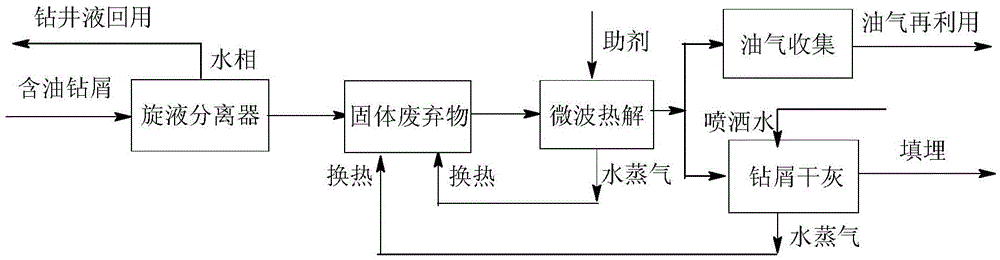

Harmless treatment method and harmless treatment device for industrial petroleum wastes

InactiveCN105414155ATake advantage ofReduce consumptionTransportation and packagingSolid waste disposalMicrowave pyrolysisProcess engineering

The invention provides a harmless treatment method and a harmless treatment device for industrial petroleum wastes. The method comprises the following steps: performing microwave heating treatment by taking industrial petroleum wastes or pre-treated industrial petroleum wastes as a microwave pyrolytic raw material; heating to a temperature of 500 to 1400 DEG C; controlling the temperature increment speed in a temperature increasing process in which the material is heated to the temperature of 350 to 400 DEG C to be 10 to 50DEG C / min; controlling the microwave treatment time after the material is heated to the temperature of 350 to 400 DEG C to be 5min to 30min; carbonizing and pyrolyzing the raw material into a gas phase part and a solid phase part during the microwave heating process, and respectively recycling the gas phase part and the solid phase part. The invention also provides the harmless treatment device for the industrial petroleum wastes. In the method provided by the invention, heat energy can be fully utilized; energy consumption is relatively low; the method has the advantages of good operability, stable system, low cost, totally-harmless treatment products and the like.

Owner:BEIJING UPC ENERGY TECH SERVICE CO LTD

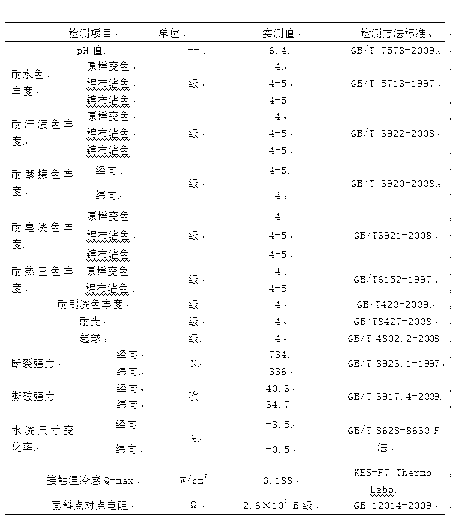

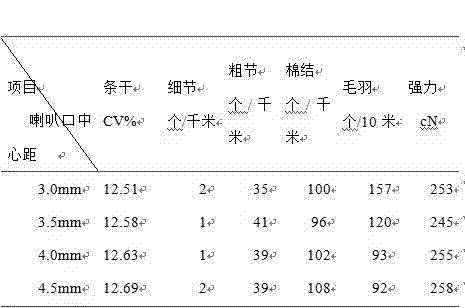

Polyamide-based cooling fiber and yarn

The invention relates to functional fiber and particularly relates to polyamide-based cooling fiber and yarn. The polyamide-based cooling fiber is prepared by the following method: (1) taking cooling masterbatch as a raw material, and cutting the cooling masterbatch into slices; (2) drying the slices; and (3) spinning the slices through a spinning box to produce the polyamide-based cooling fiber, wherein a formula for the cooling masterbatch comprises the following components: PA6, jade powder, zirconium dioxide powder, silica powder, stearic acid dispersant, polystyrene dispersant, low molecular wax dispersant and titanate coupling agent. The polyamide-based cooling fiber and yarn have the functions of fast heat absorption and fast heat dissipation so as to ensure lasting cooling characteristic.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

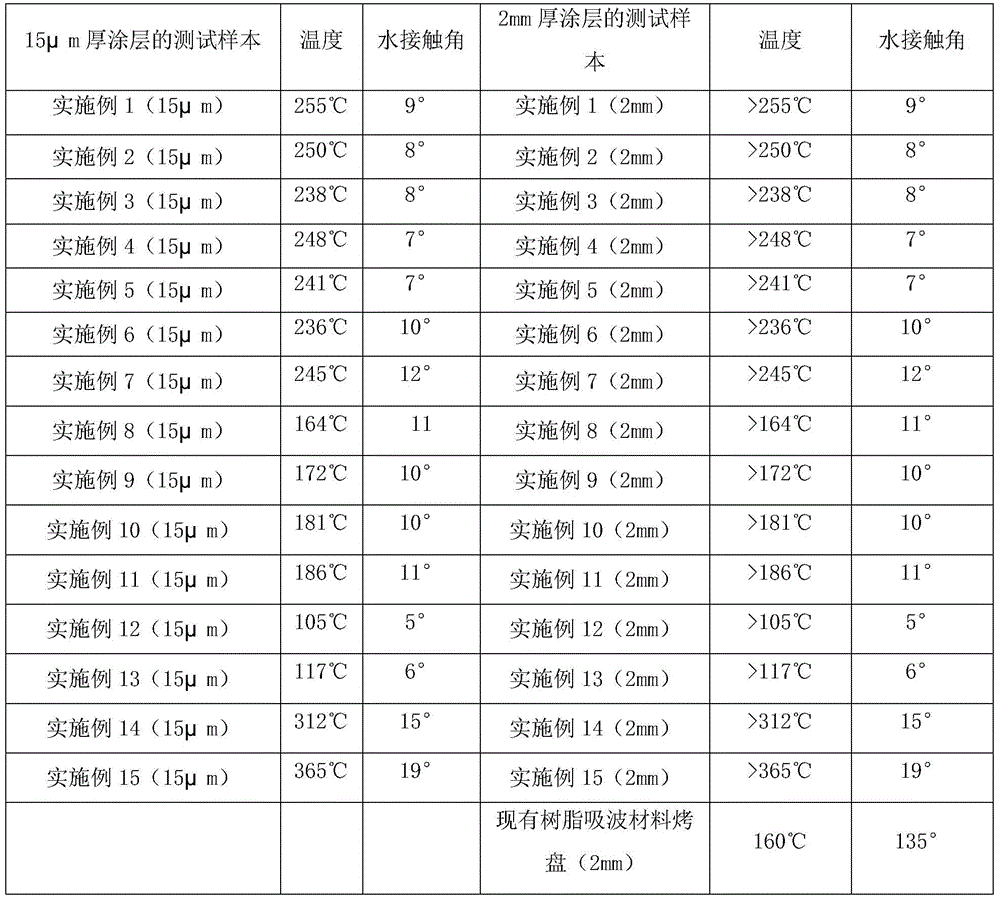

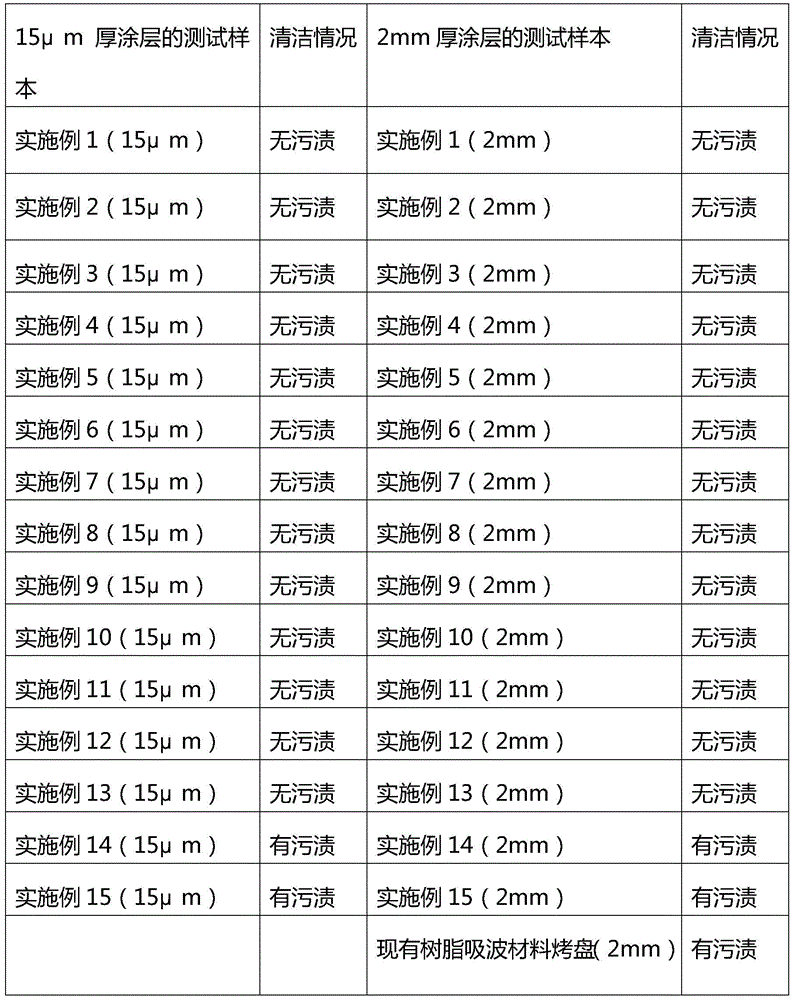

Lyophobic and oleophobic wave absorption material and preparation method thereof

ActiveCN105925023AHydrophobic and oleophobicNot easy to stickFireproof paintsRadiation-absorbing paintsMaterials scienceCoating

The invention relates to a lyophobic and oleophobic wave absorption material and a preparation method thereof. The lyophobic and oleophobic wave absorption material is prepared from the following ingredients in percentage by weight: 87 percent to 93 percent of wave absorption material bonding agents with lyophobic and oleophobic performance, 6 percent to 12 percent of wave absorption materials and 0.5 percent to 1 percent of auxiliary agents. During the preparation, all ingredients are uniformly mixed. The lyophobic and oleophobic wave absorption material can be used for coatings of kitchen electric products. The lyophobic and oleophobic wave absorption material has the advantages that the lyophobic performance is good; the cleaning is easy; high temperature resistance is realized; the health and environment protection are realized, and the like.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

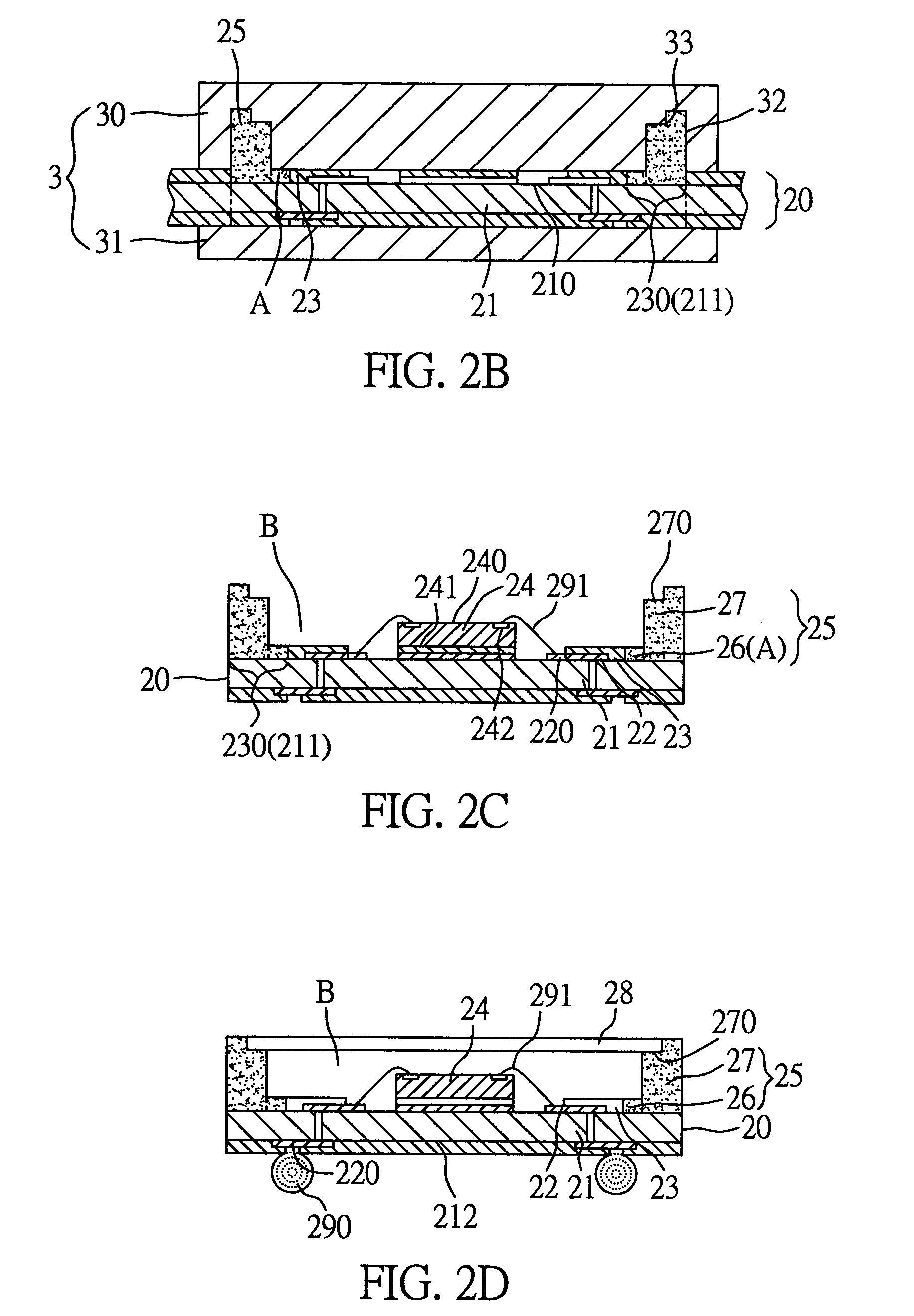

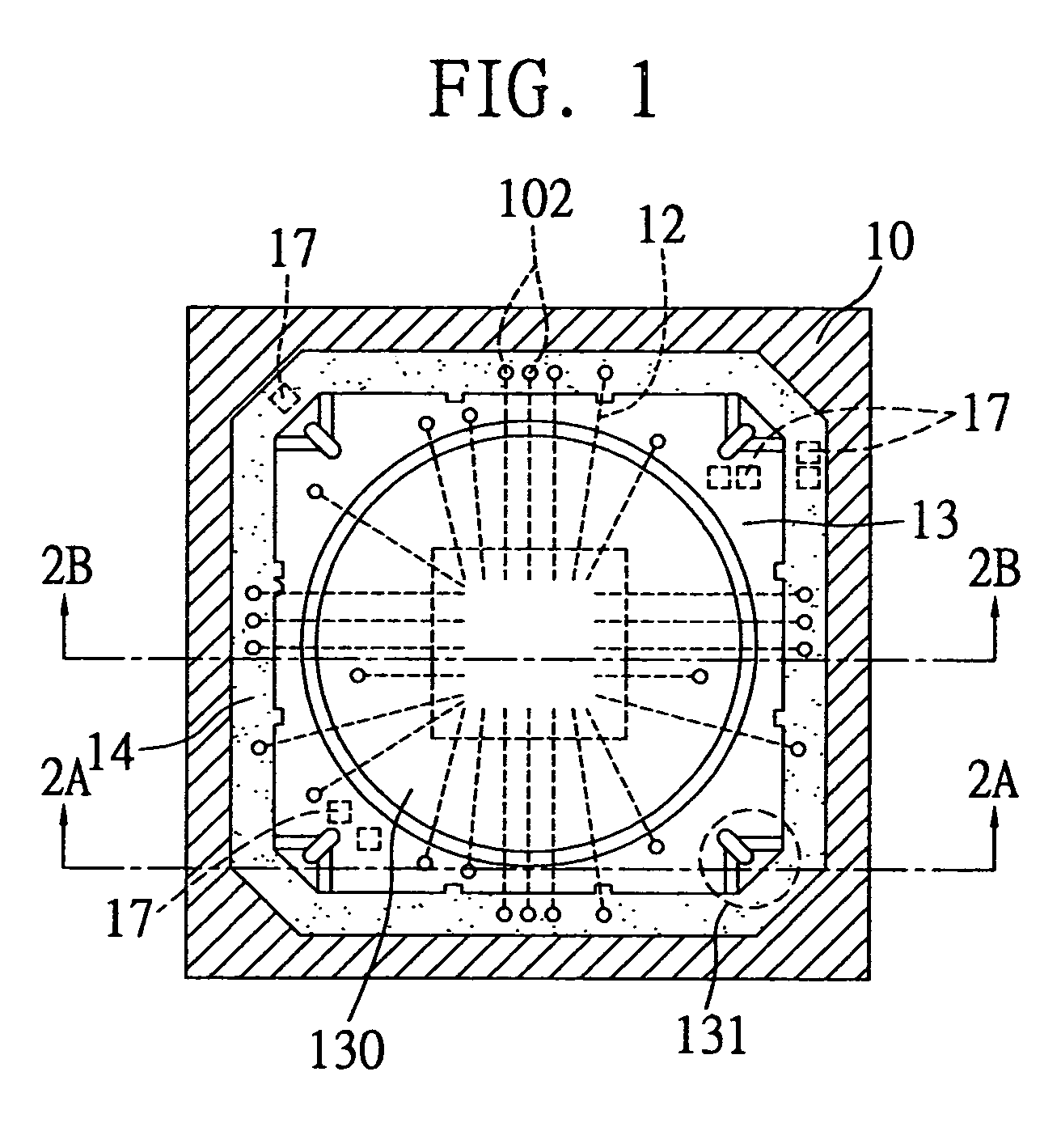

Semiconductor package with heat dissipating structure

InactiveUS7342304B2Increase flexibilityIncrease layout areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package with a heat dissipating structure is provided. The heat dissipating structure includes a flat portion, and a plurality of support portions formed at edge corners of the flat portion for supporting the flat portion above a chip mounted on a substrate. The support portions are mounted at predetermined area on the substrate without interfering with arrangement of the chip and bonding wires that electrically connect the chip to the substrate. The support portions are arranged to form a space embraced by adjacent supports and the flat portion, so as to allow the bonding wires to pass through the space to reach area on the substrate outside coverage of the heat dissipating structure; besides, passive components or other electronic components can be mounted on the substrate at area within or outside the coverage of the heat dissipating structure, thereby improving flexibility in component arrangement in the semiconductor package.

Owner:SILICONWARE PRECISION IND CO LTD

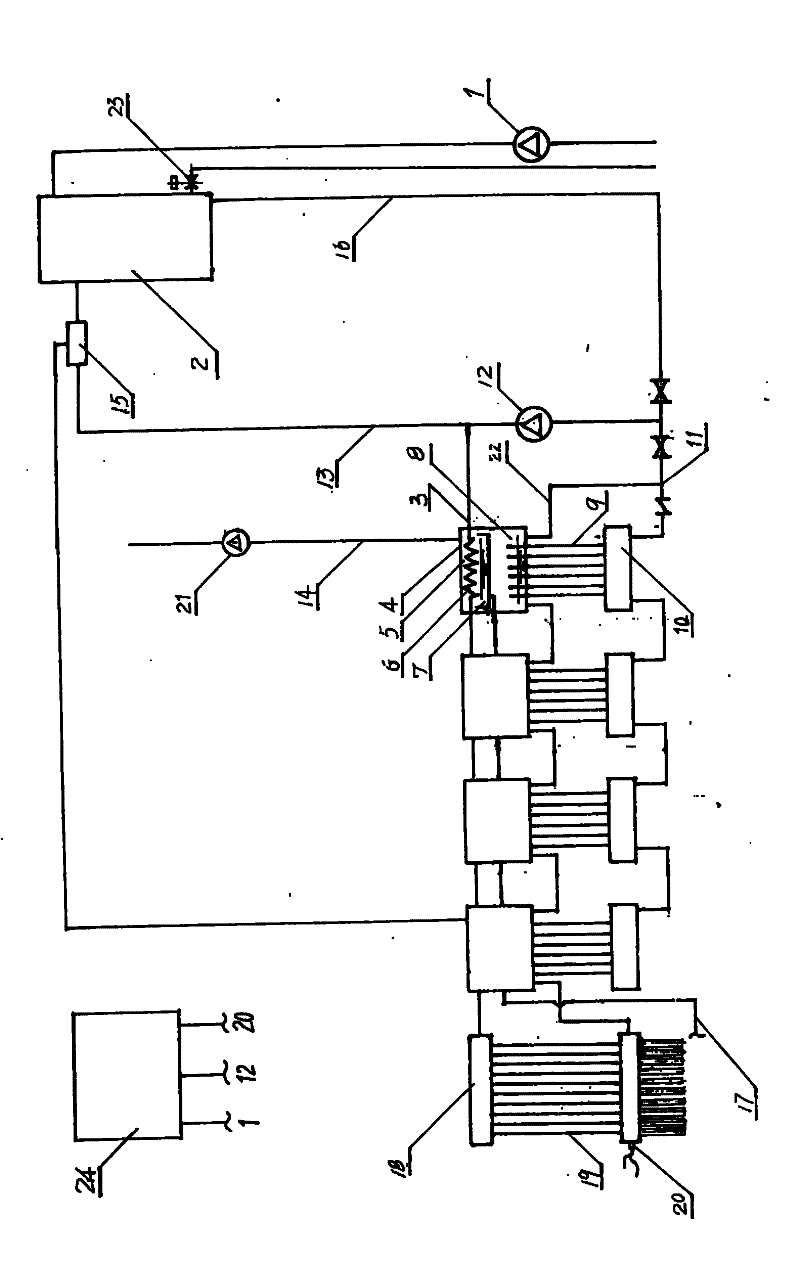

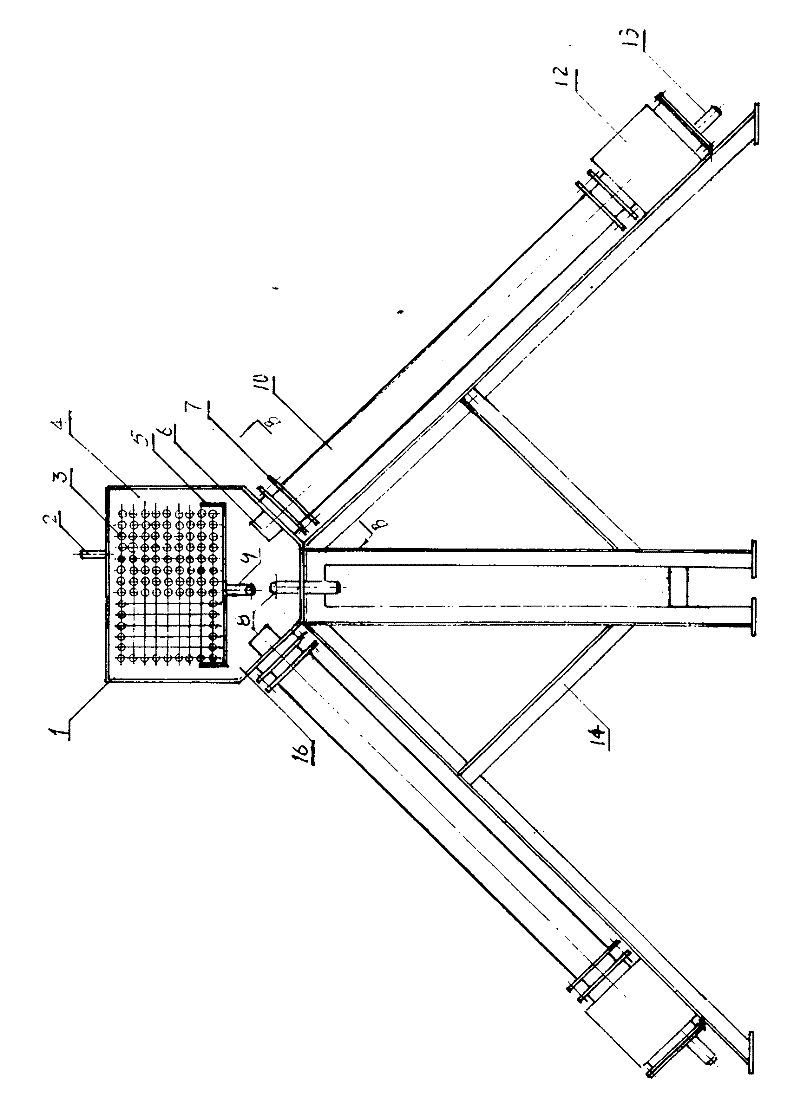

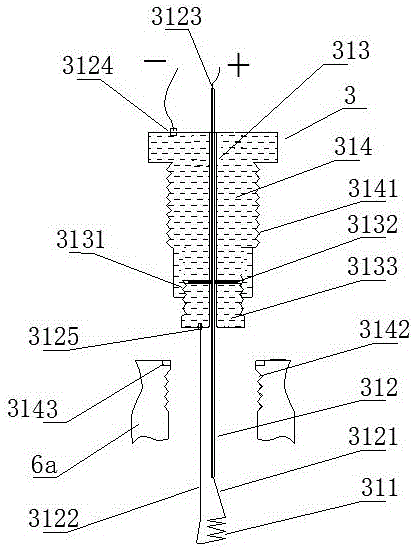

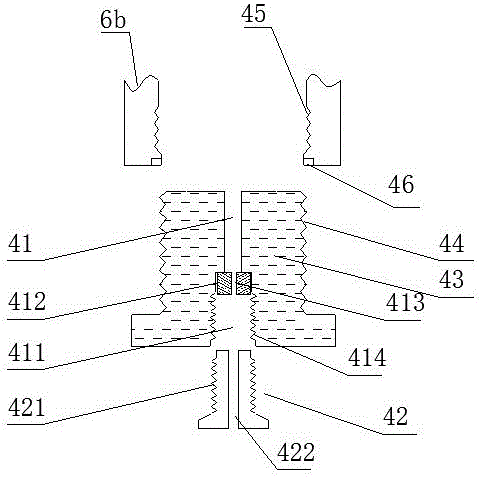

Characteristic absorption spectrum radiation heat absorber, Stirling engine and operation method

ActiveCN106089612AFast absorptionEffective absorptionSolar heating energyFrom solar energyEngine efficiencyCombustion chamber

The invention relates to a characteristic absorption spectrum radiation heat absorber, a Stirling engine and an operation method. By means of the radiation heat absorber, radiation energy can be fast absorbed by working medium gas in the Stirling engine, and when solar energy is insufficient, stable operation of the Stirling engine is ensured by adopting an auxiliary heating mode. A fast heat absorbing heater adopting characteristic absorption spectrum gas to absorb heat mainly comprises a heater base, an optical energy converting device, a heating tube, a combustion chamber and a heating tube valve. The optical energy converting device converts solar energy into radiation energy adjacent to a characteristic absorption peak of the working medium gas, and the working medium directly absorbs radiation energy stereoscopically. The radiation heat absorber is beneficial for enhancing radiation heat exchange at the hot end of the Stirling engine, efficiently using high-temperature energy of a focus sunlight center and reducing the dead volume of the hot end, solves the tube bursting problem of the Stirling heater, improves the engine efficiency, achieves photo-thermal complementary utilization and improves stability of the engine.

Owner:ZHEJIANG UNIV

Automobile control arm forging production line and forging forming technology

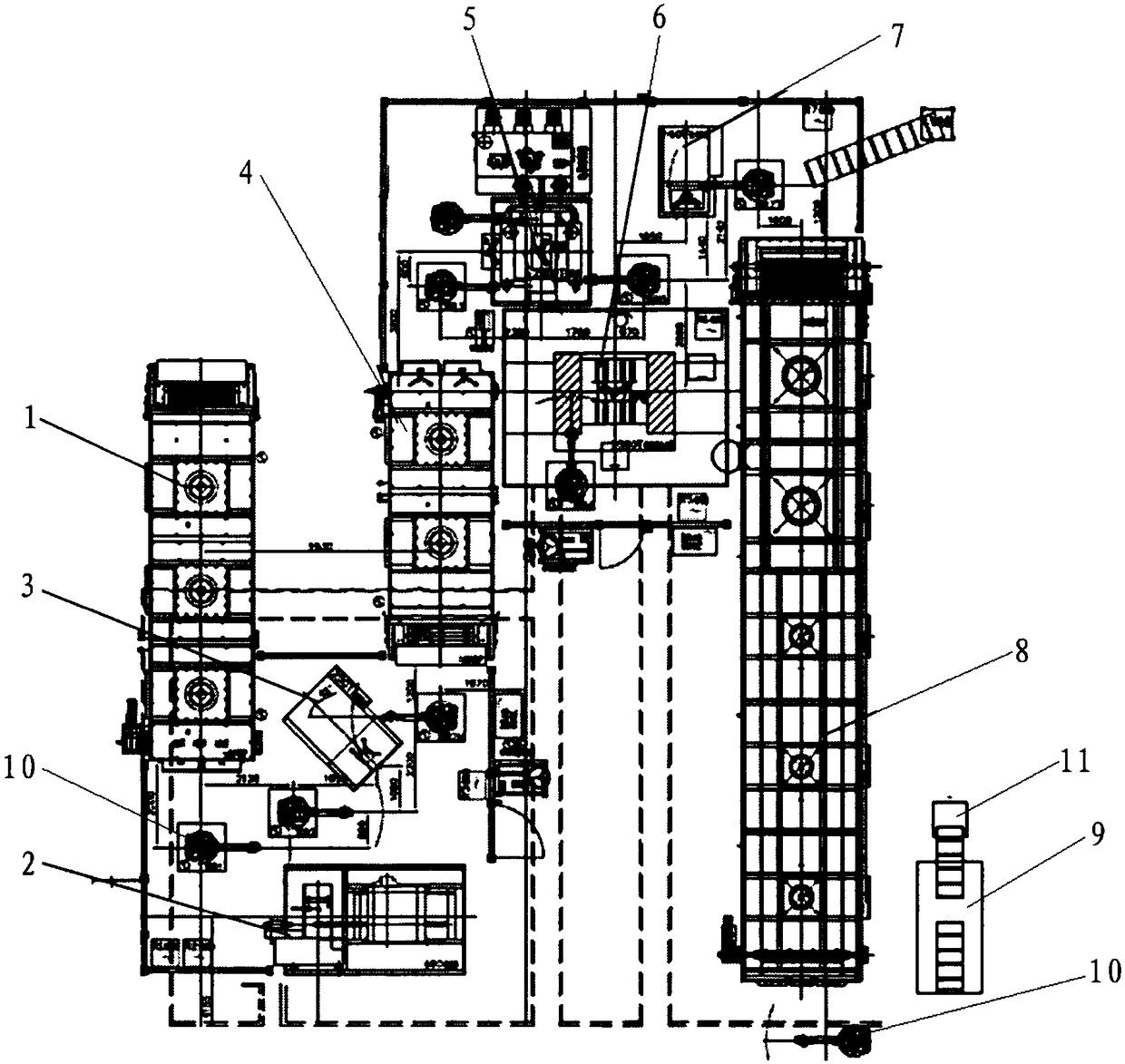

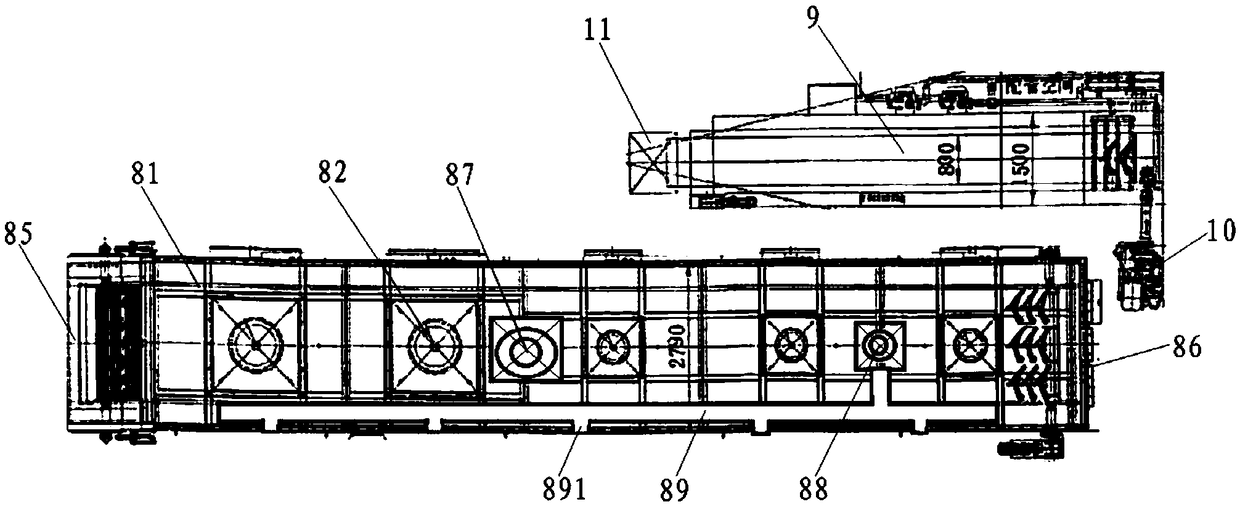

PendingCN108817307AReduce labor intensityImprove working environmentRailway componentsForging/hammering/pressing machinesSolution treatmentProduction line

The invention discloses an automobile control arm forging production line. The production line comprises a blank making area, a die forging area and a heat treatment area which are sequentially arranged according to a production technology. A plurality of mechanical arms used for conveying workpieces are arranged among the areas. The blank making area comprises a first heating furnace and a rollerforging machine. The die forging area comprises a second heating furnace and a die forging press machine set, the die forging press unit is used for forging forming of a blank obtained after secondary heating, and the workpieces are conveyed to the heat treatment area through the mechanical arms. The heat treatment area comprises a solution treatment furnace and a cooling device, the solution treatment furnace is used for carrying out solution treatment on the forged workpieces, the workpieces are conveyed to the cooling device through the mechanical arms, and a finished product bin is connected to a discharge port of the cooling device. The automobile control arm forging production line is reasonable in layout, high in automation degree and good in stability; the heat treatment area is additionally arranged, so that the production time is shortened, and the production efficiency is improved; and the heating process adopts jet flow heating, so that the heating speed and heating uniformity of the blank are improved, and the product quality is effectively improved.

Owner:海安金锻工业有限公司

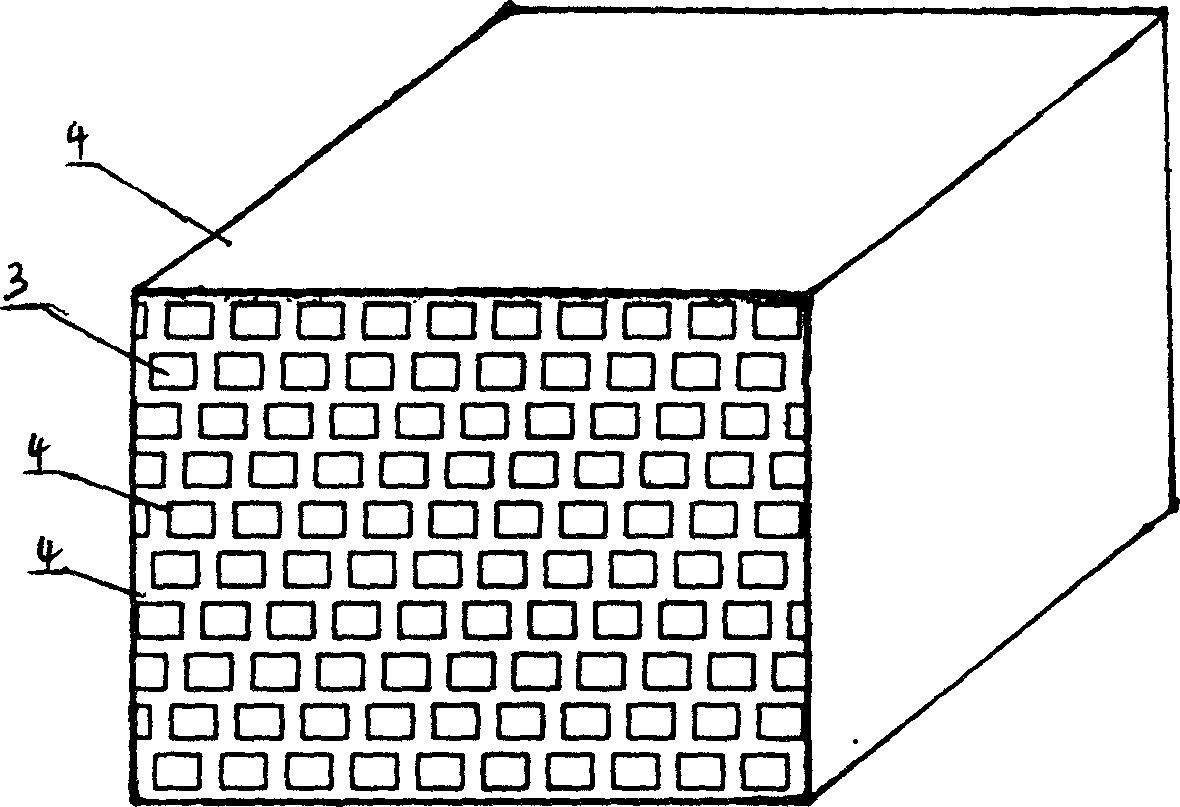

Heat exchanger with covering layer

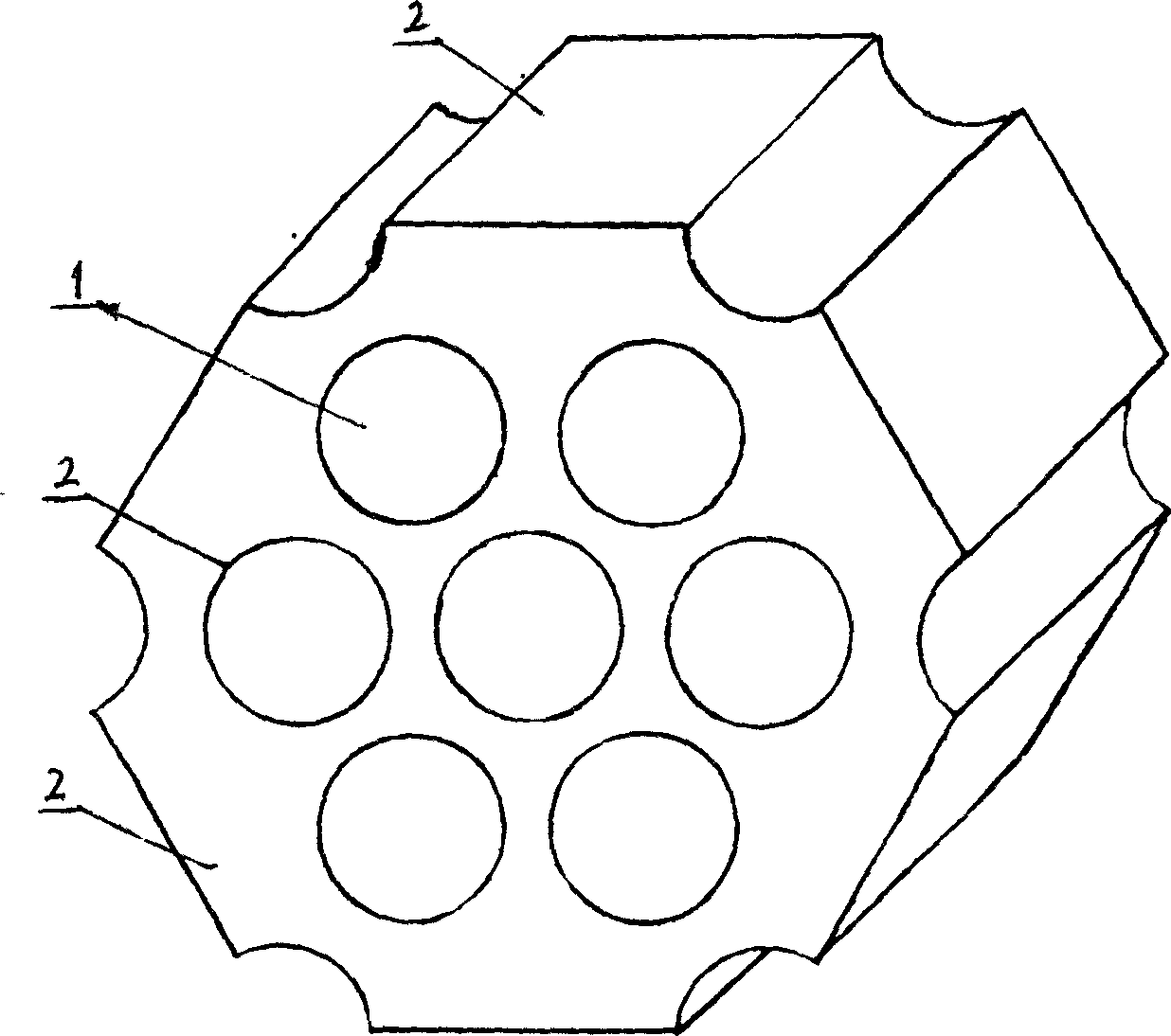

ActiveCN1696596AIncrease heat absorptionIncrease heat releaseBrick-hot blast stovesFurnace componentsPlate heat exchangerEmissivity

The present invention relates to a heat exchanger with covering layer, belonging to the field of heat exchanger technology. Said heat exchanger is characterized by that one side or several sides of surface of its heat storage body are coated with a layer of high radiation material, whose radiation factor is higher than that of heat storage body base material. The heat storage body form can be honeycomb, fin form, ball form or plate form, and base body of heat storage body is made up by using refractory material, ceramic material or metal material.

Owner:山东慧敏科技开发有限公司

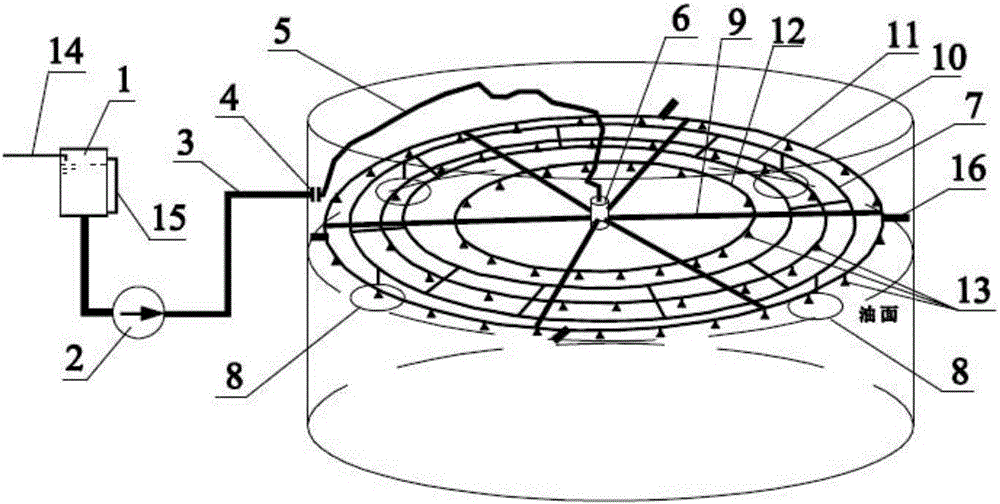

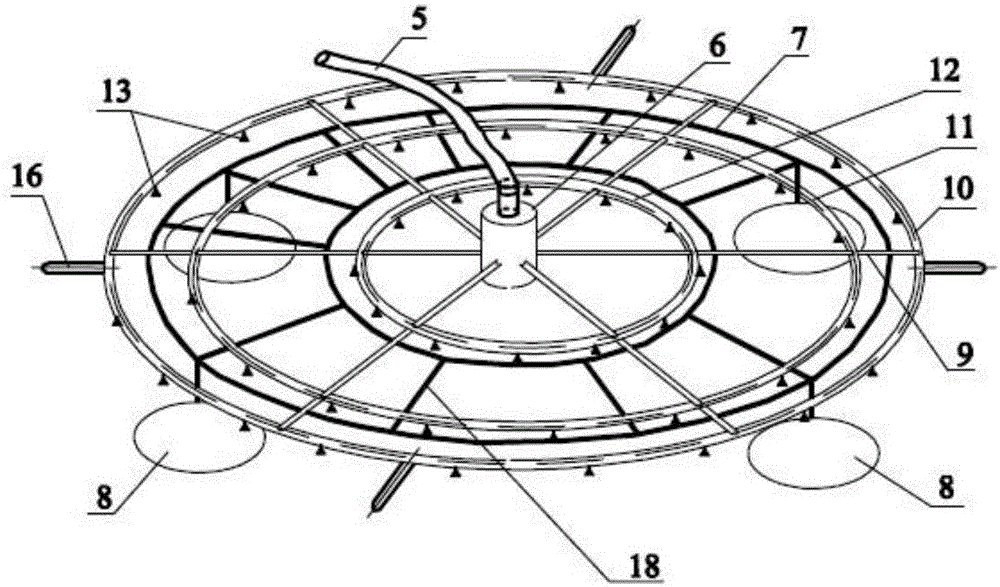

Annular water mist fire extinguishing system of oil storage tank

InactiveCN105727474AReduce the temperatureFire extinguishing speedFire rescueSpray nozzleCombustible gas

The invention discloses an annular water mist fire extinguishing system of an oil storage tank. The annular water mist fire extinguishing system is characterized in that a metal bracket floating on the oil surface is arranged inside the oil storage tank; a water mist spraying device is arranged on the metal bracket; the spraying device communicates with a high pressure water feeding device at the outer part of the oil storage tank; the water mist spraying device comprises a water collector arranged at the circle center part of an aluminum alloy ring and six radial metal tubes, and further comprises an inner annular metal water tube, a middle annular metal water tube and an outer annular metal water tube which form a concentric circle structure; the near-ends of the metal tubes communicate with the water collector, and the far-ends of the metal tubes communicate with the inner annular metal water tube, the middle annular metal water tube and the outer annular metal water tube; and a plurality of water mist nozzles are uniformly arranged on each of the inner annular metal water tube, the middle annular metal water tube and the outer annular metal water tube in the circumferential direction. According to the annular water mist fire extinguishing system, with the fire extinguishing conditions met, the fire extinguishing water mist is directly sprayed to ignition combustion areas in the tank, so that the purpose that the fire is extinguished more quickly and effectively is achieved, the temperature of combustible gases in the tank can be decreased more quickly, and secondary combustion and explosion are prevented.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Gas-inflating-and-locking-integrated gas blaster

InactiveCN106643314AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesCheck valvesEngineeringLiquid carbon

The invention discloses a gas-inflating-and-locking-integrated gas blaster. The gas-inflating-and-locking-integrated gas blaster comprises an inner tube, an inner-tube filling cavity, an ignition mechanism, an inner-tube gas inflating mechanism and an outer tube. The inner-tube filling cavity is formed in the inner tube, a first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner tube in a sealed mode respectively, the outer tube is arranged on the outer layer of the inner tube, a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealed mode, the ignition mechanism and the inner-tube gas inflating mechanism are installed on the first sealing inner cover or the second sealing inner cover, and an outer-tube gas inflating mechanism is installed on the first sealing outer cover or the second sealing outer cover; a sealed cavity between the inner tube and the outer tube is an outer-tube filling cavity, the inner-tube filling cavity is filled with supercritical oxygen and carbonaceous organic materials, and the outer-tube filling cavity is filled with liquid easy-to-gasify materials such as liquid carbon dioxide or liquid nitrogen. The gas-inflating-and-locking-integrated gas blaster has the advantages that the manufacturing cost is low, the mixing uniformity of reaction materials is high, the heat releasing efficiency is high, the transportation safety is good, and the blasting power is large.

Owner:郭远军

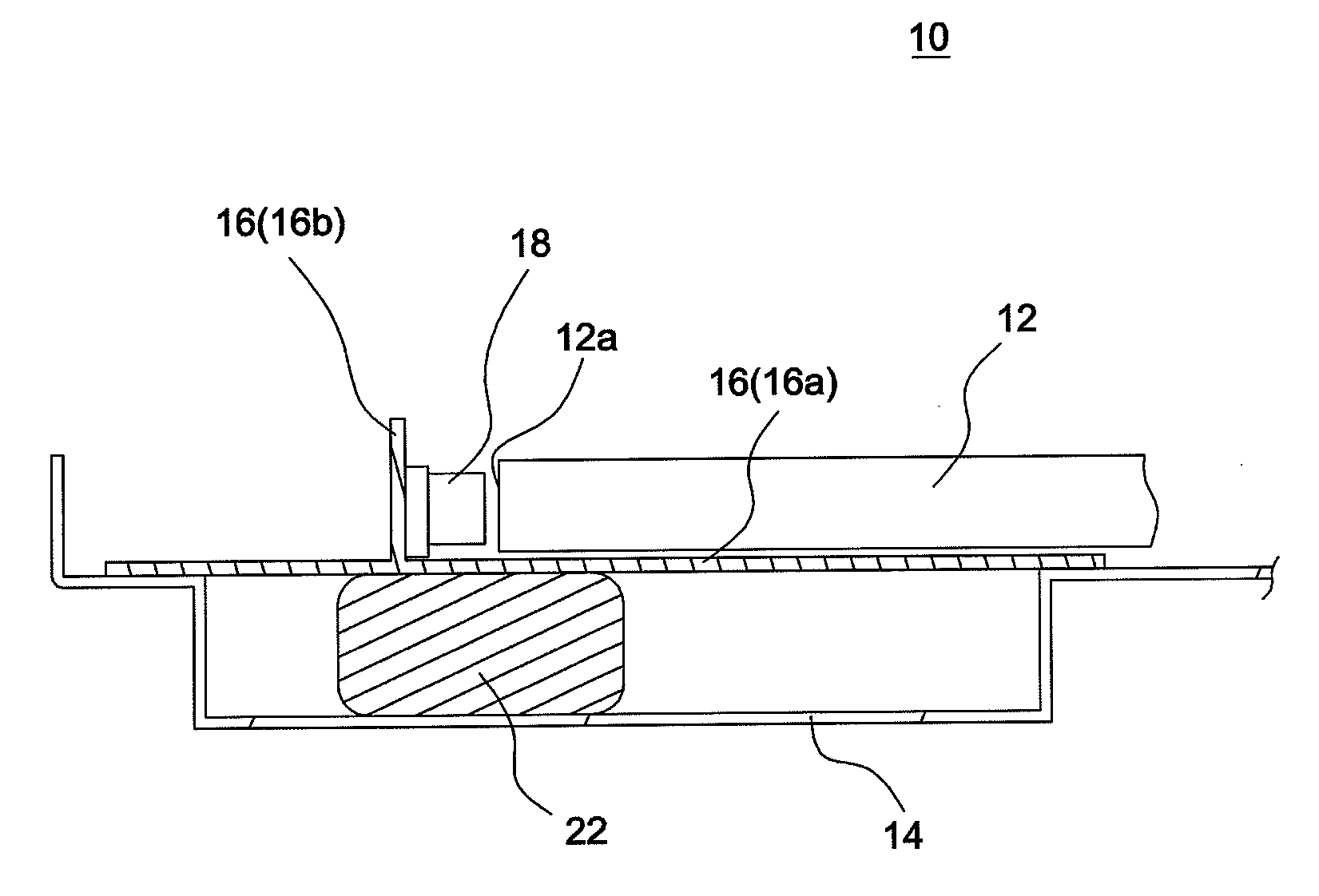

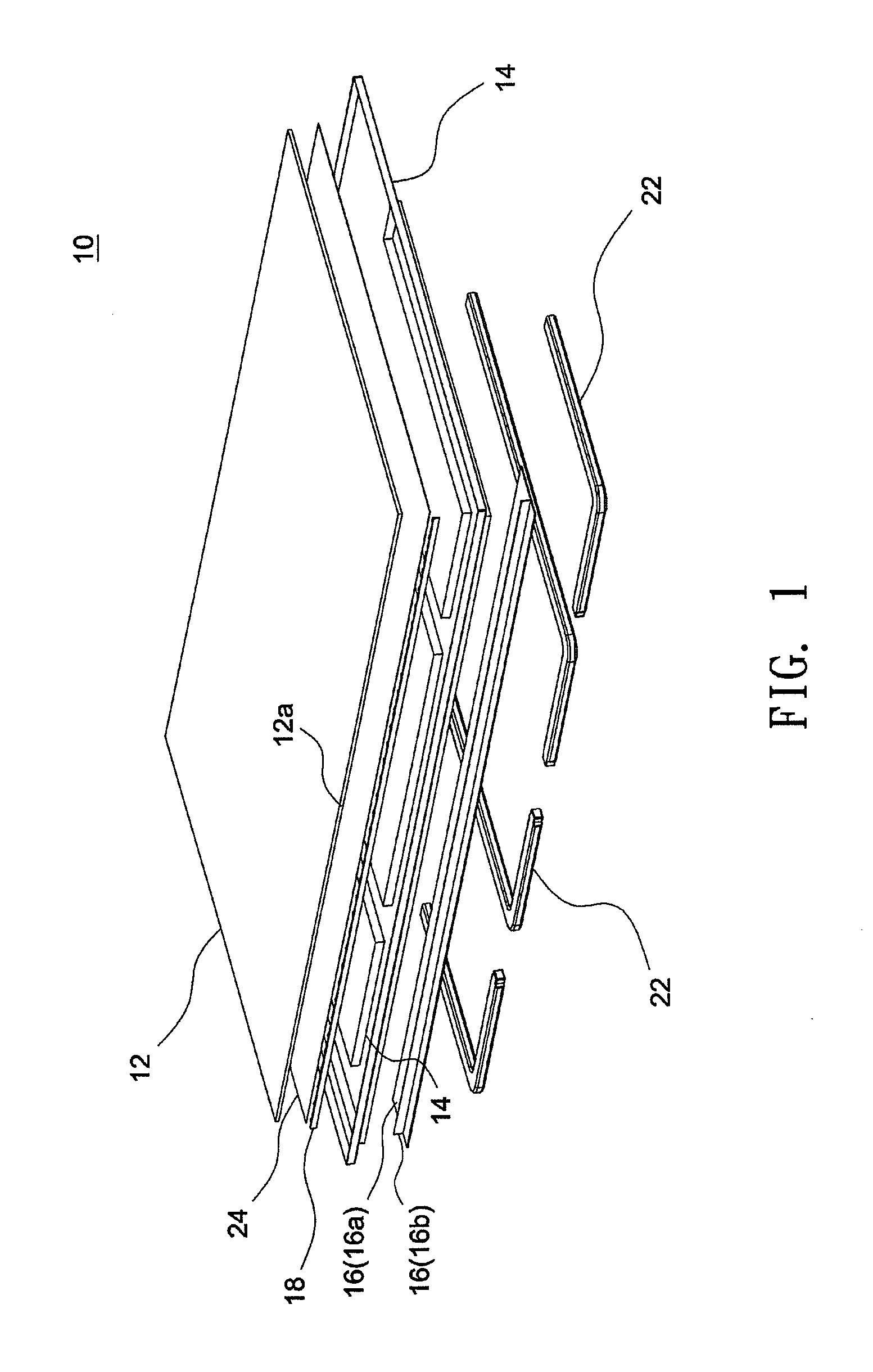

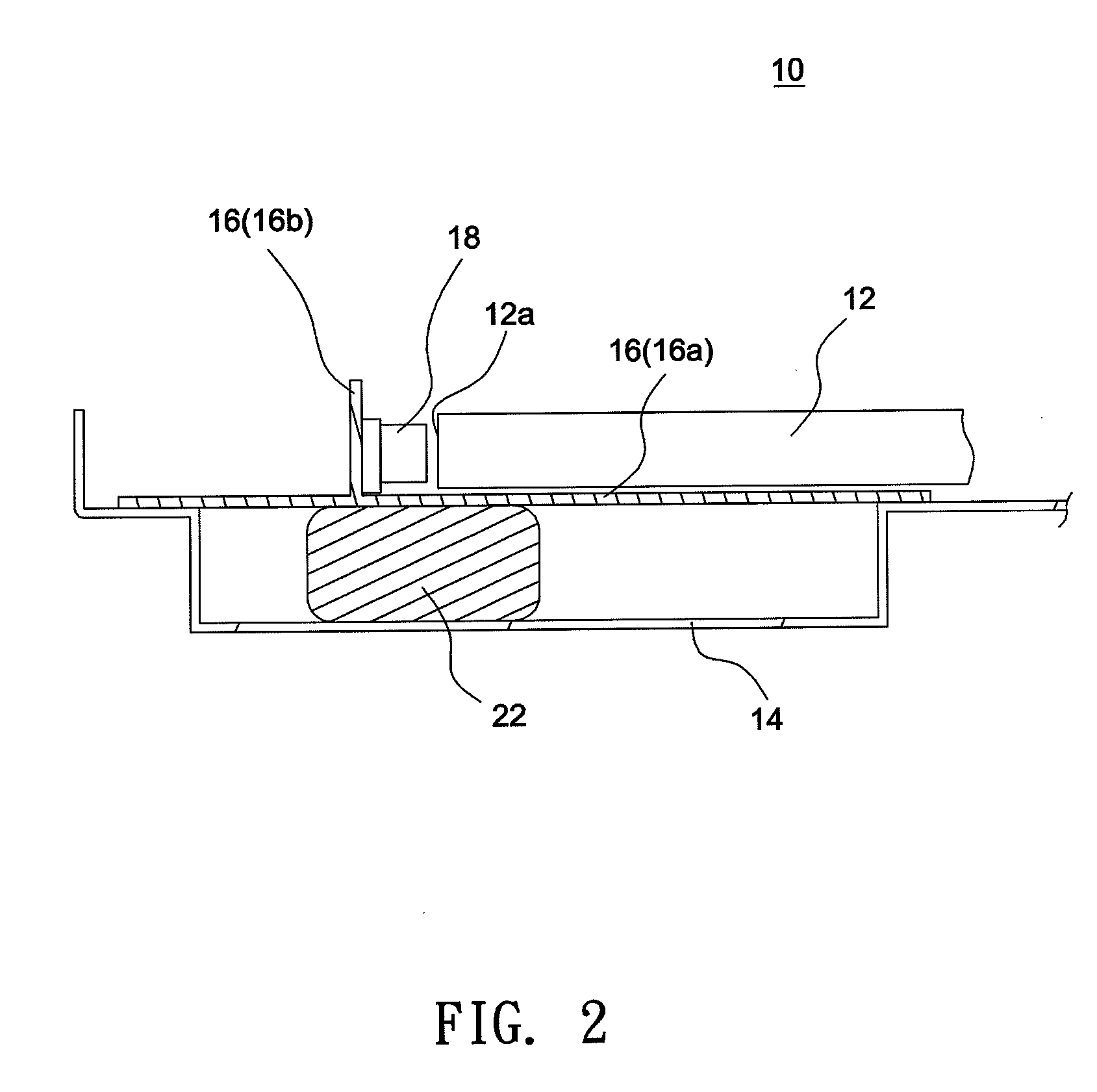

Backlight module

InactiveUS20110249470A1Improve thermal uniformitySolve the low heat dissipation efficiencyLighting heating/cooling arrangementsOptical signallingLight guideEngineering

A backlight module includes a light guide plate, a back plate, a heat-dissipating element, a light-emitting element, and at least one high-performance heat sink. The heat-dissipating element is disposed adjacent to a light incident surface of the light guide plate, and the heat-dissipating element has a bottom portion and a side portion forming an angle with the bottom portion. The light-emitting element is disposed on one side of the heat-dissipating element facing the light guide plate. The high-performance heat sink is disposed on the back plate, one end of the high-performance heat sink overlaps the heat-dissipating element, and another end of the high-performance heat sink extends away from the light-emitting element.

Owner:CORETRONIC

Easy-to-clean coating with high microwave absorbing property as well as preparation method and application thereof

The invention relates to an easy-to-clean coating with high microwave absorbing property as well as a preparation method and an application thereof. The easy-to-clean coating with high microwave absorbing property comprises 10-40wt% of microwave absorbing material binder, 5-10wt% of microwave absorbing material, 50-80wt% of hydrophilic easy-to-clean material and 1-2wt% of auxiliary. In preparation, all raw materials are proportionally mixed together. The easy-to-clean coating with high microwave absorbing property provided by the invention can be widely applied to kitchen electric products and has the properties such as thin coating, high microwave absorbing property and easiness in cleaning.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

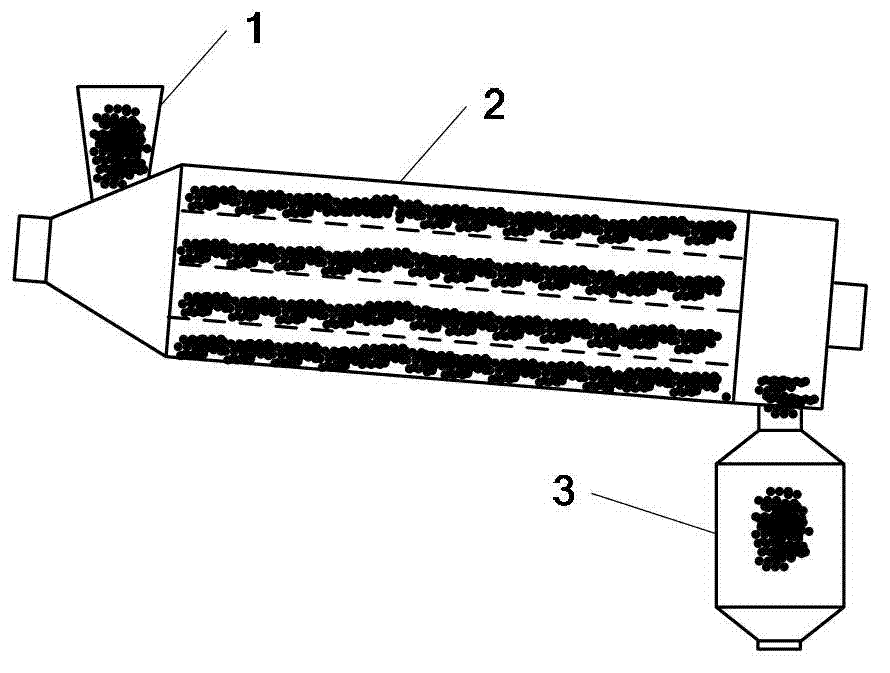

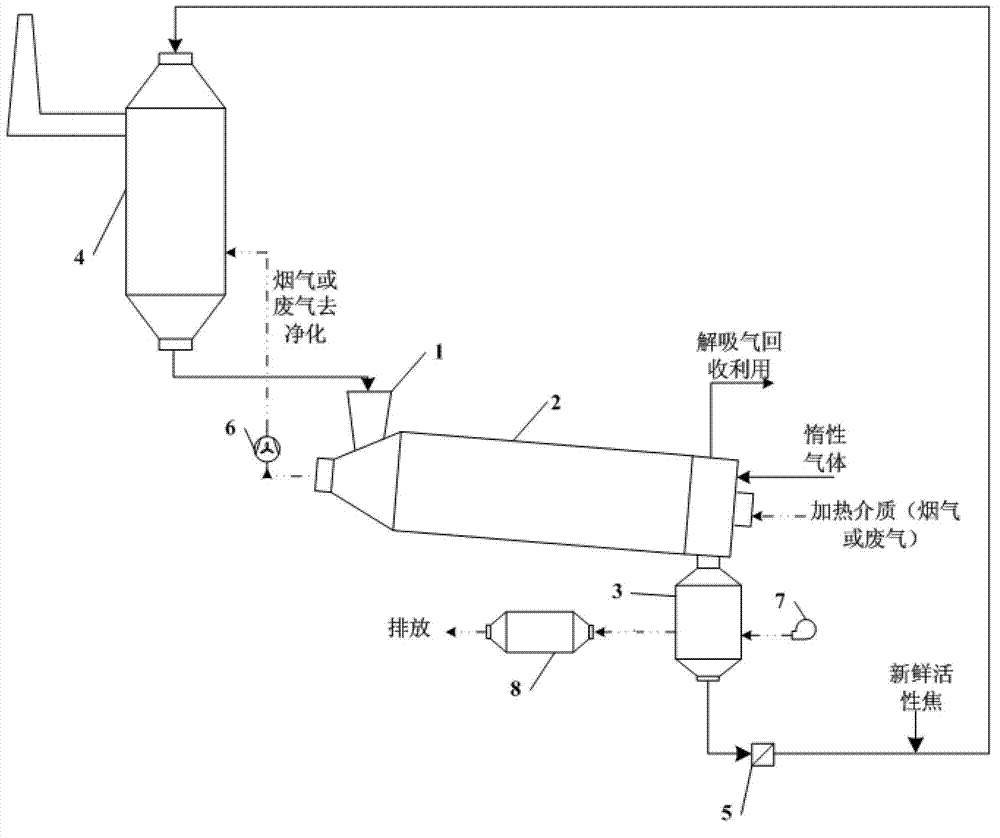

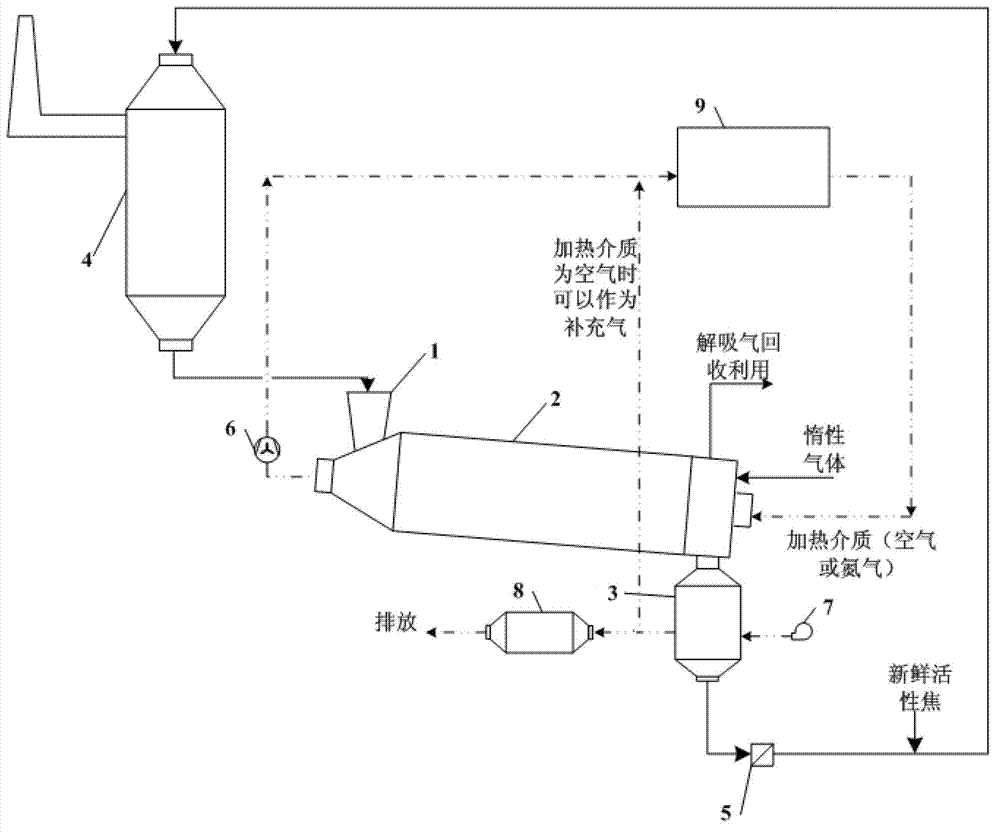

Regeneration method of desulphurization, denitration and demercuration combined activated coke and special-purpose device thereof

InactiveCN102728332ARealize recycling of resourcesHigh degree of automationOther chemical processesCombustible gas purificationFlue gasProcess engineering

The invention discloses a regeneration method of desulphurization, denitration and demercuration combined activated coke and a special-purpose device thereof. The regeneration device comprises a tilting furnace and a material cooler. The tilting furnace is arranged aslant relative to the horizontal plane and a feed inlet of the tilting furnace is higher than a discharge port of the tilting furnace. The feed inlet of the tilting furnace is provided with a feed bin which communicates with a ring cavity of the tilting furnace. The material cooler communicates with the ring cavity of the tilting furnace. The juncture is near the discharge port of the tilting furnace. The invention provides the method for regenerating activated coke by the use of the above device. In comparison with processing capacity of an industrial vertical regeneration reactor, the processing capacity of the tilting furnace in the regeneration device provided by the invention is greatly raised. The device is especially suitable for an utility boiler or other large-scale boiler by large-scale adoption of a flue gas purification technology with activated coke.

Owner:CCTEG CHINA COAL RES INST

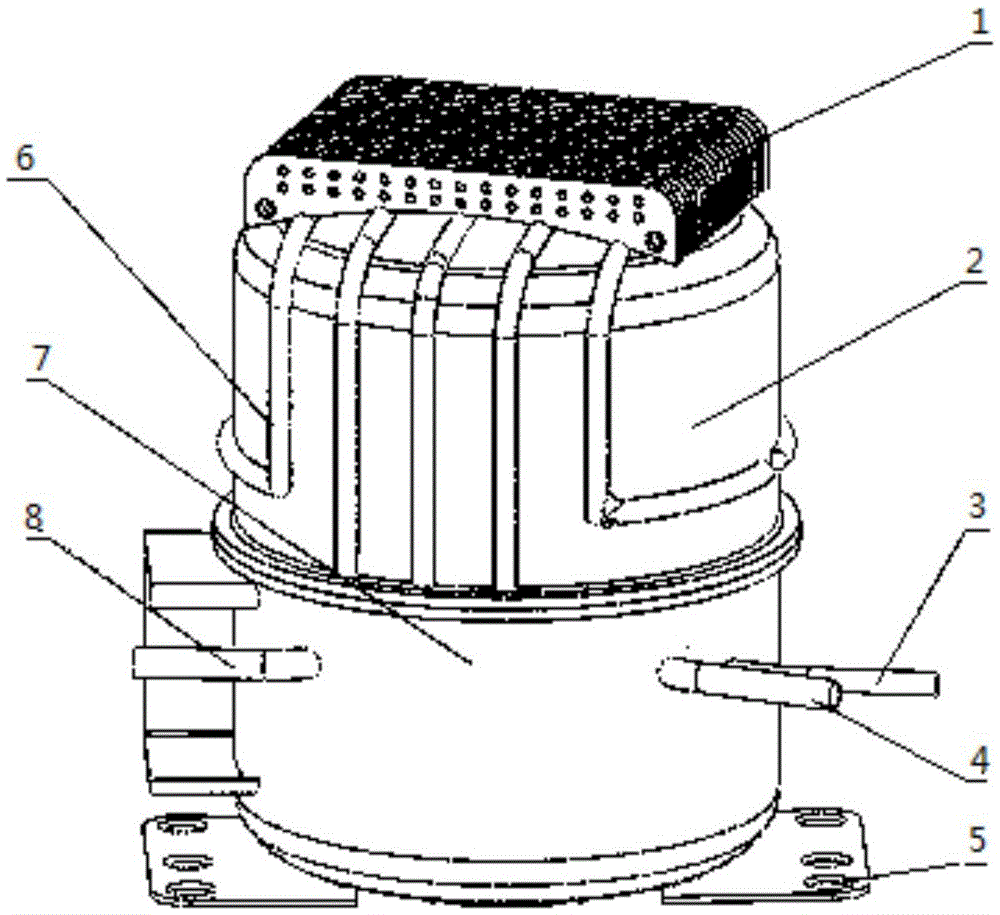

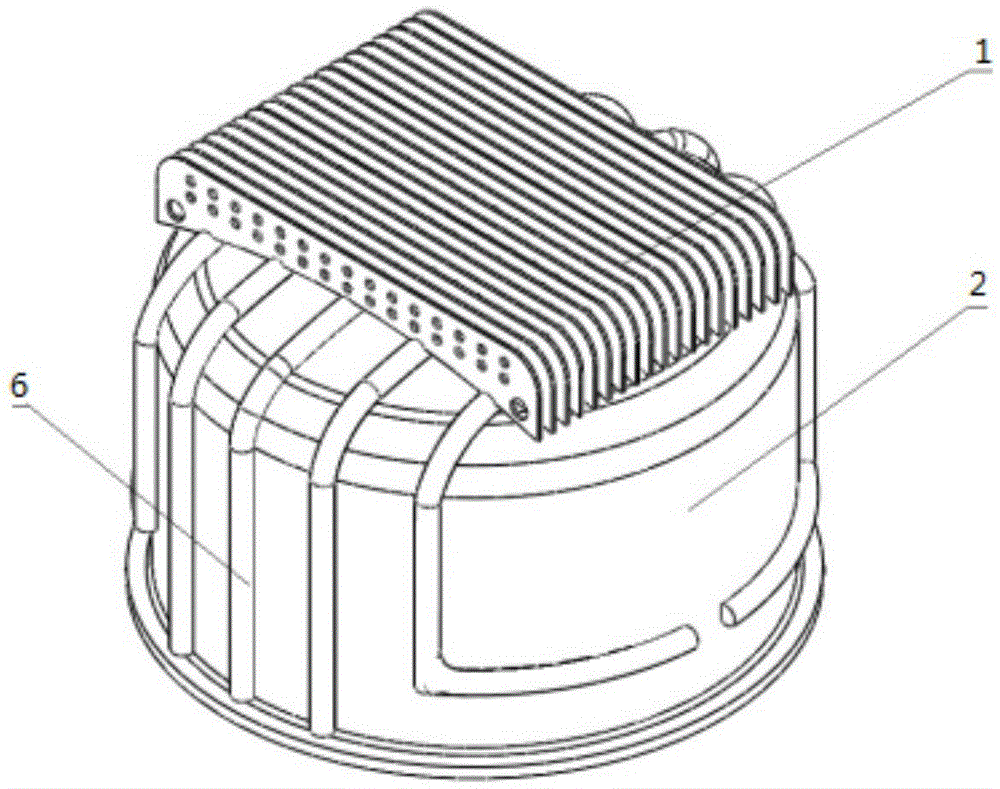

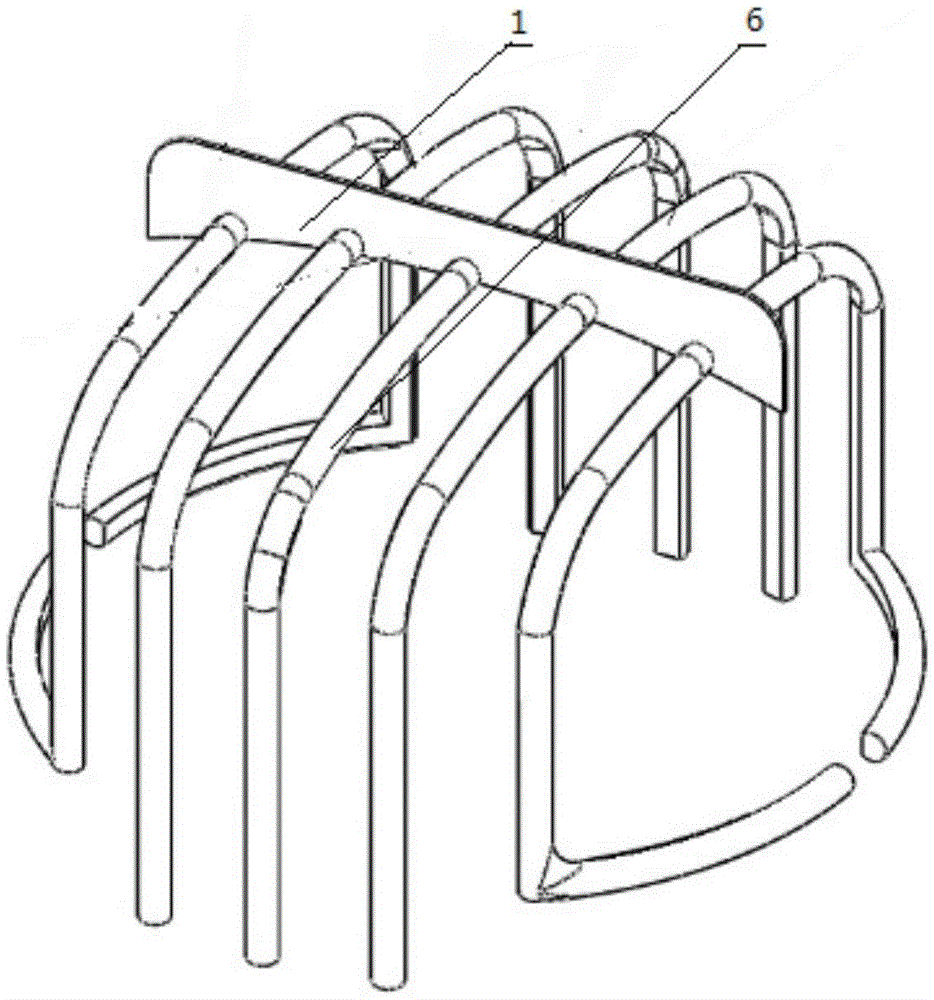

Device for enhancing heat dissipation performance of freezer compressor shell

ActiveCN105464948AMake good use of heat dissipationEasy to passPositive displacement pump componentsPositive-displacement liquid enginesEngineeringHeat pipe

The invention discloses a device for enhancing the heat dissipation performance of a freezer compressor shell. The device comprises heat pipes and heat dissipation fins; the heat pipes are arranged on the top part and the side surface of the upper shell of a compressor, and are closely connected with the shell; the heat dissipation fins are embedded on the heat pipes, and are uniformly distributed on the top part of the upper shell of the compressor; one side of each heat pipe is semicircular, and the other side is flat, and clings to the upper shell of the compressor; the heat pipes are arch-shaped; the multiple heat pipes are arranged at intervals; the middle part of each heat pipe is arranged on the top end of the upper shell of the compressor, and two ends of each pipe cling to the cylindrical cover-shaped periphery of the upper shell of the compressor from the top end; the distance between every two adjacent fins is 5mm; the lower end of each heat dissipation fin is arc-shaped; the upper end of each heat dissipation fin is linear; the sharp corners of each heat dissipation fin are rounded; and multiple round holes which are regularly arrayed are formed in each heat dissipation fin. According to the device, two phase change heat transfer cycles of each heat pipe share the same condensation end; working mediums at two sides absorb heat from hot ends to be evaporated, and encounter and are mixed in the middle part of each heat pipe, so that strong turbulent convection heat exchange is formed, and the heat dissipation effect is enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of microenvironment conditioned paper of museum

InactiveCN101624801AFast phase transition temperatureFast heat absorptionSpecial paperPaper/cardboardPolyethylene glycolPollution

The invention relates to a preparation method of microenvironment conditioned paper of a museum, which is characterized by comprising the following steps: (A) adding sepiolite, decalso, isinglass and urea into deionized water, stirring and reacting for 4-6h at 50-60 DEG C; (B) adding cyclic acid, polyethylene glycol, ammonium persulfate and the deionized water into reactant of the (A), stirring and reacting for 3-5h at 50-60 DEG C; (C) cooling mixture obtained by the (B) to be room temperature, drying to obtain temperature and humidity adjustment material; (D) adding the temperature and humidity adjustment material and magnesium sulfate into paper pulp for manufacturing paper to prepare the microenvironment conditioned paper of the museum. Compared with the conditioned paper, the invention has rapid humidity adjustment response, low material phase-transition temperature, high humidity content, rapid heat absorption, good balance of humidity maintenance, simple and convenient manufacture, low cost, good effect, no toxicity, harm or pollution to the environment, and the like, and accords with the trend of the environment protection development.

Owner:ZHEJIANG SCI-TECH UNIV +1

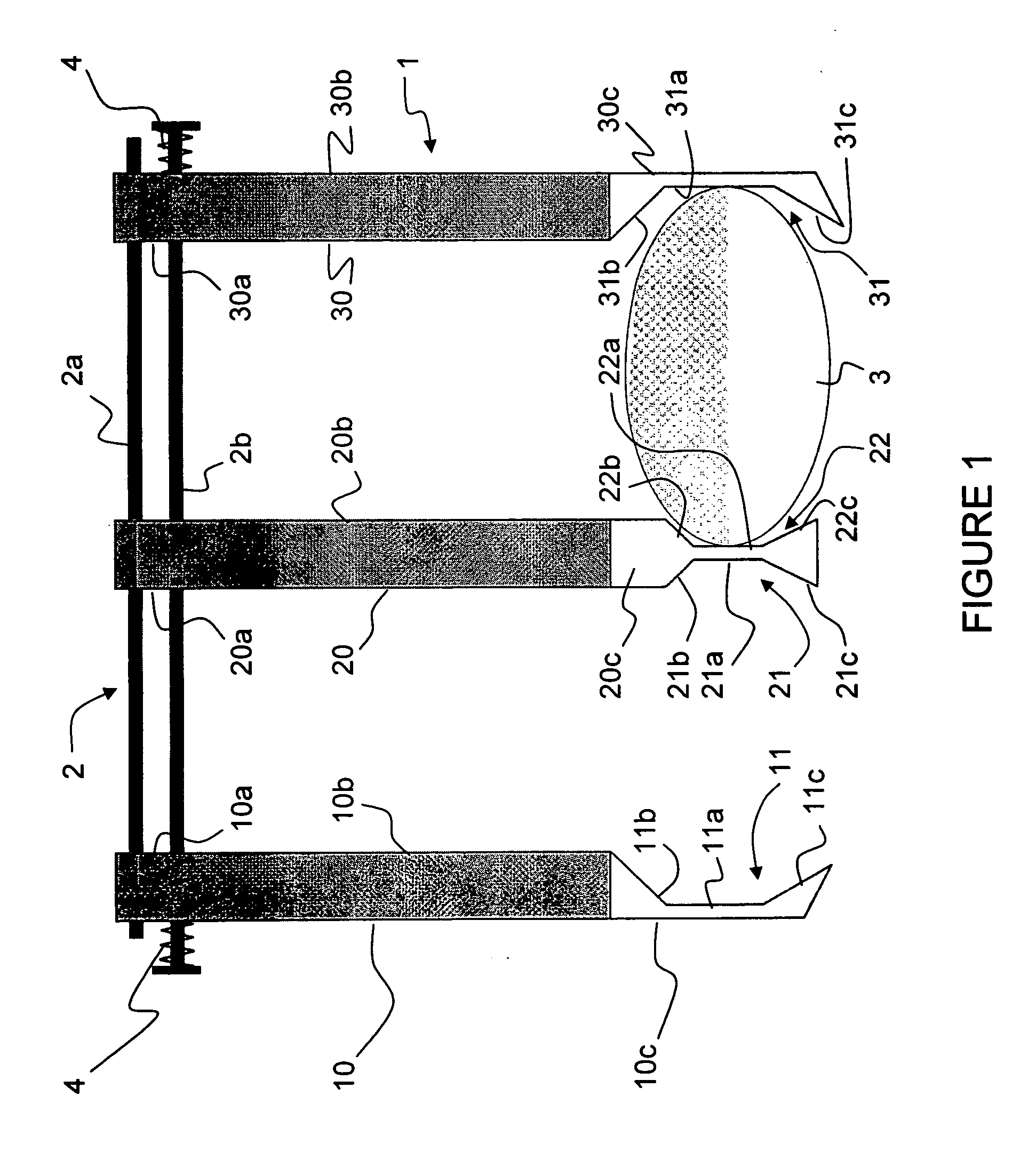

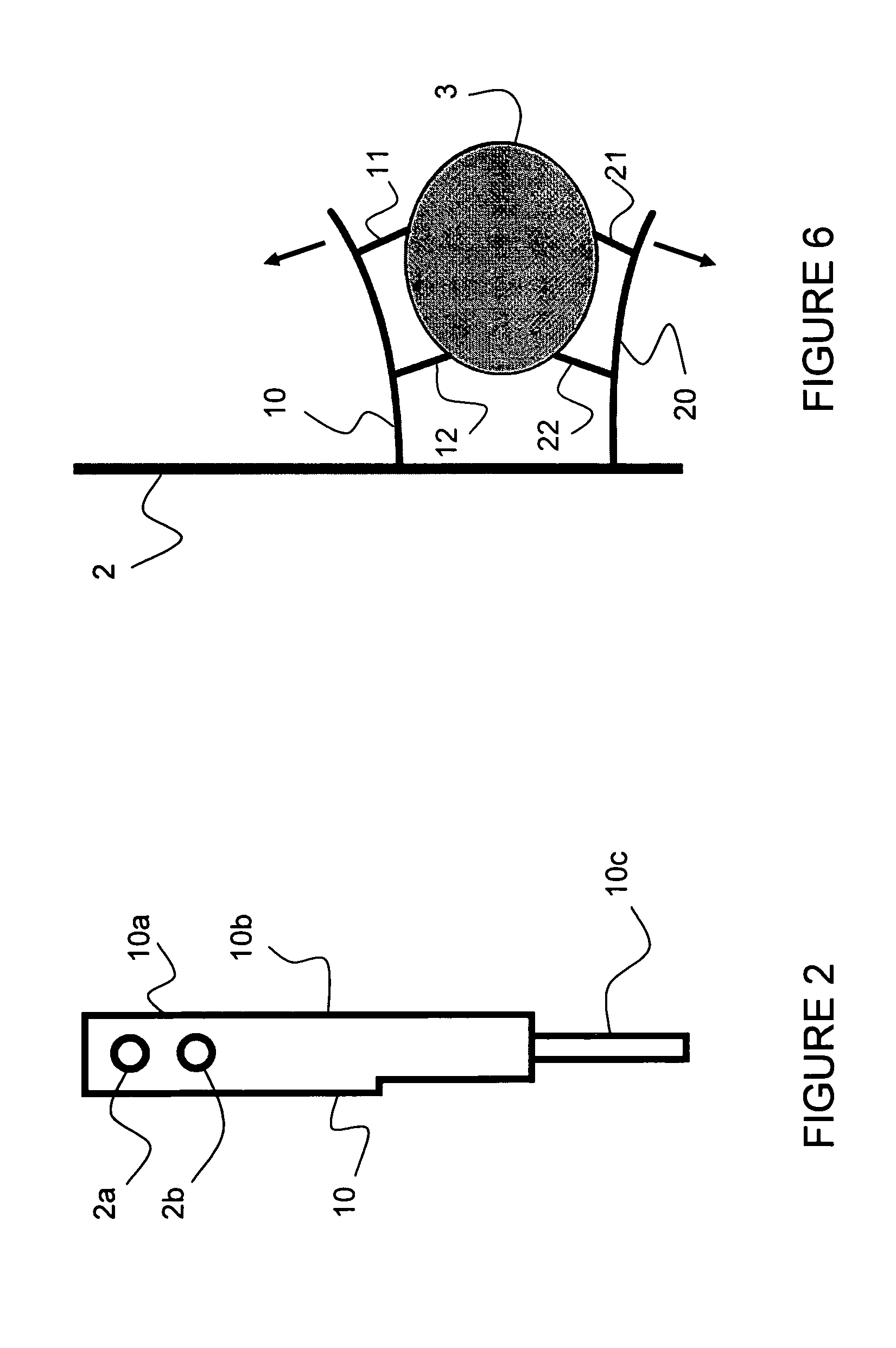

Optical lens holder

ActiveUS20050207033A1Fast heat absorptionQuick breathDriving/moving recording headsVacuum evaporation coatingOptical axisLens materials

The invention relates to an optical lens holder comprising a supporting means and a first and a second arm defining a lens holder general plane, first and second arms being relatively movable with regards to each other and each arm having spaced apart first and second end portions and an intermediate portion, the arms being mounted on the supporting means through their first end portions and the second end portions of each arm comprising an optical lens accommodating means facing each other, whereby an optical lens can be maintained within the accommodating means of the first and second arms with its optical axis orthogonal to the general plane of the lens holder through at least one, preferably one or two contact points between the lens periphery and each of the first and second lens accommodating means, wherein at least the second end portion of each arm comprises a material having a dielectric constant at 1 MHz equal to or higher than the dielectric constant of the optical lens material.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com