Easy-to-clean coating with high microwave absorbing property as well as preparation method and application thereof

A technology of easy-to-clean and wave-absorbing materials, applied in the field of coatings, can solve the problems of poor wave-absorbing performance, decreased wave-absorbing performance, less microwave energy absorption, etc., so as to solve the problems of poor wave-absorbing performance, improved wave-absorbing performance and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

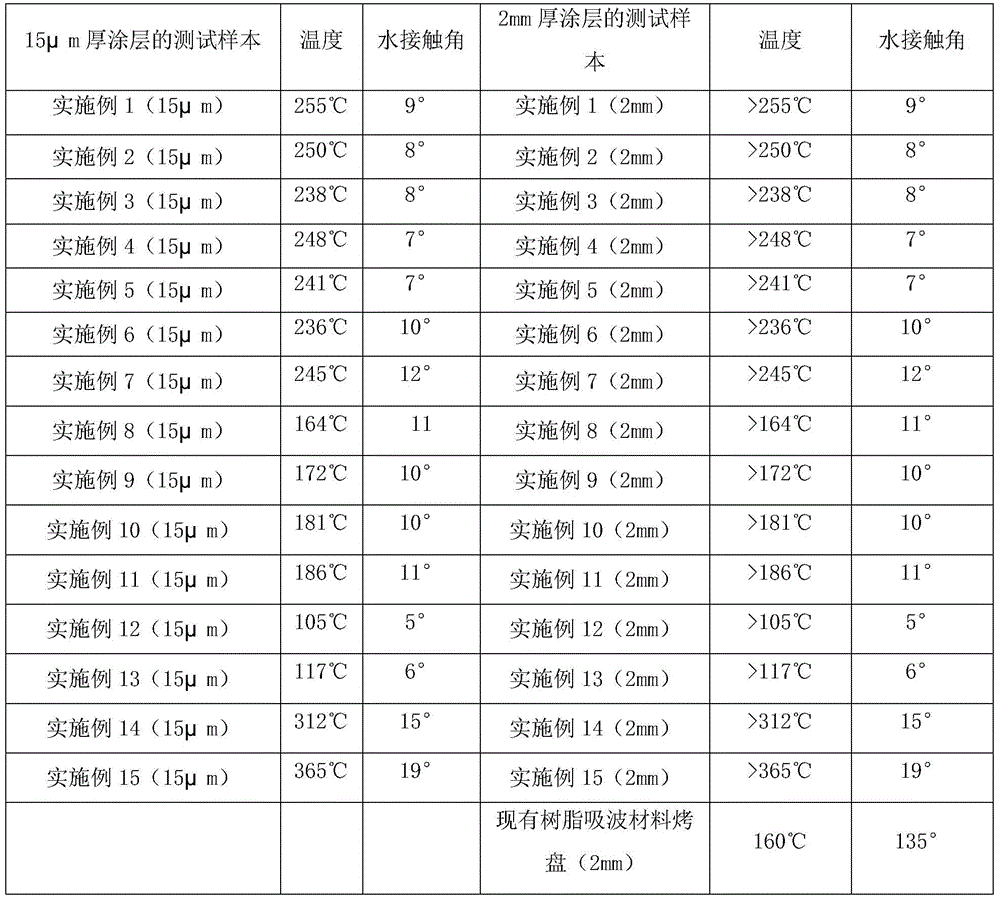

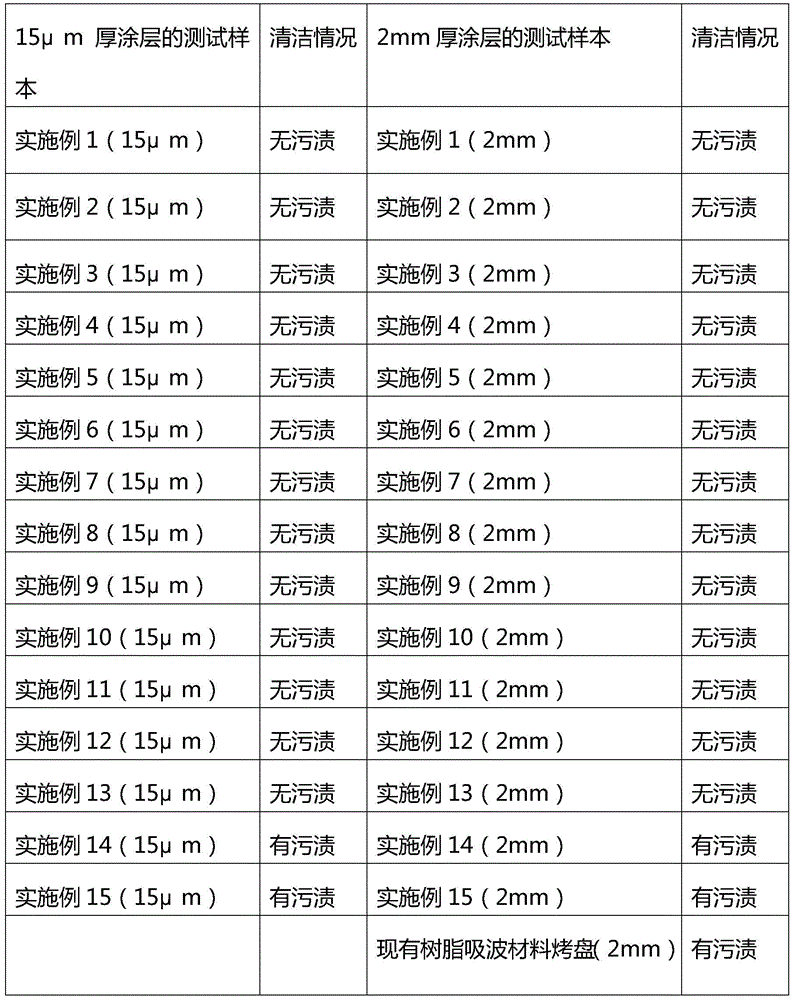

Examples

preparation example Construction

[0072] According to the above formula, the preparation method of the high-wave-absorbing and easy-to-clean coating of the present invention specifically includes the following steps:

[0073] 1) Preparation of absorbing coating components:

[0074] Combine nano β-SiC, nano graphite, Si 3 N 4 Add it to the silica sol according to the proportion, and add the proportion of the wetting agent, and mechanically stir until the absorbing powder is completely immersed in the silica and mixed uniformly to obtain a mixed solution I;

[0075] 2) Preparation of hydrophilic easy-to-clean materials:

[0076] Mix the proportioned amount of silica sol, titanium sol and the alkali metal silicate solution, and add the proportioned amount of dispersant to mechanically stir until the components are evenly mixed to obtain mixed solution II;

[0077] 3) Preparation of high-absorption, easy-to-clean coatings:

[0078] Mix the mixtures prepared in steps 1) and 2), add the coupling agent in a proportion, and mech...

Embodiment 1

[0081] An easy-to-clean paint with high microwave absorbing performance. Each component is calculated by mass percentage. The binder of the absorbing material is 28%, the absorbing material is 10%, the hydrophilic easy-to-clean material is 60%, and the auxiliary is 2 %.

[0082] Among them, the absorbing material binder is silica sol; the absorbing materials are nano silicon carbide (β-SiC), nano graphite and silicon nitride (Si 3 N 4 ) Mixture; the additives include wetting agent PE-100, dispersant SN5040 and coupling agent KH553; the hydrophilic easy-to-clean materials include silica sol, titanium sol and Li 2 SiO 3 Solution.

[0083] The specific preparation method is as follows:

[0084] 1) Preparation of absorbing coating components:

[0085] 4g nano silicon carbide (β-SiC), 4g nano graphite, 2gSi 3 N 4 Add to 28g of the wave-absorbing material binder, and add 1g of wetting agent PE-100, and mechanically stir at 900r / min until the wave-absorbing powder is completely immersed in t...

Embodiment 2

[0091] An easy-to-clean paint with high absorbing performance. The components of the paint are calculated by mass percentage. The adhesive of the absorbing material is 20%, the absorbing material is 8%, the hydrophilic easy-to-clean material is 70%, and the additives are 2%.

[0092] Wherein, the absorbing material binder is silica sol; the absorbing material is nano silicon carbide (β-SiC), nano graphite and silicon nitride (Si 3 N 4 ) Mixture; the hydrophilic easy-to-clean material includes silica sol, titanium sol, Li 2 SiO 3 Solution and K 2 SiO 3 Solution; The additives include wetting agent PE-100, dispersing agent SN5040 and coupling agent KH560.

[0093] The preparation method is as follows:

[0094] 1) Preparation of absorbing coating components:

[0095] Combine 2g nano-silicon carbide (β-SiC), 3g nano-graphite, 3gSi 3 N 4 Add to 20g of absorbing material binder, and add 0.8g of wetting agent PE-100, mechanically stirring at 800r / min until the absorbing powder is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com