Patents

Literature

38results about How to "Excellent unidirectional moisture transfer performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of one-way wet conduction nano-fiber multilayer composite membrane with wettability gradient

InactiveCN107059251AExcellent unidirectional moisture transfer performanceWaterproofNon-woven fabricsFiberHydrophobic polymer

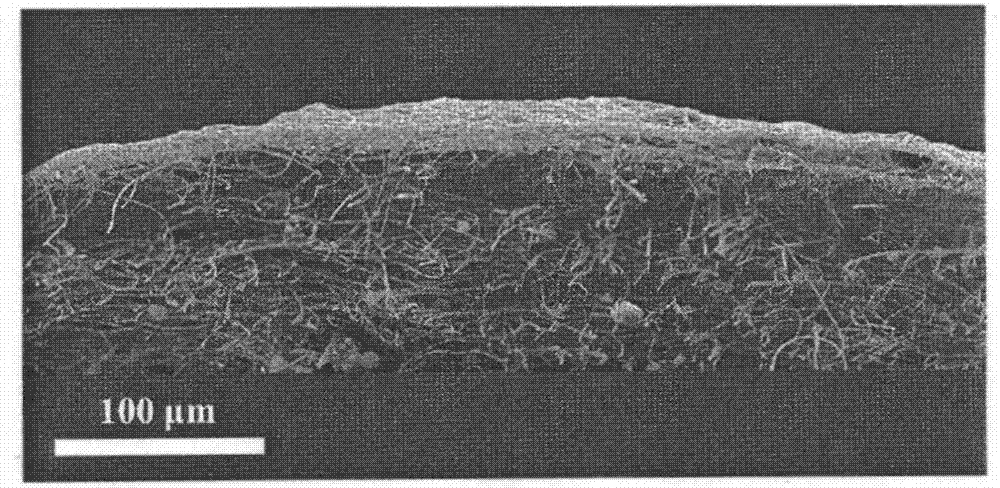

The invention discloses a preparation method of a one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient. The method comprises the following steps that hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, a spinning solution A1 is obtained, and a hydrophilic nano-fiber membrane is deposited on a receiving base material through an electrostatic spinning method; hydrophilic nano materials are dispersed in solvent, the nano materials are dispersed uniformly through the ultrasound, a hydrophilic polymer is dissolved in the dispersing agent, and a spinning solution A2 is obtained; a hydrophobic polymer is dissolved in solvent, and a spinning solution B1 is obtained; the two spinning solutions are deposited on the hydrophilic nano-fiber membrane to form at least one diversion layer through the electrostatic spinning method; a hydrophobic polymer is dissolved in solvent, a spinning solution B2 is obtained, a hydrophobic nano-fiber membrane is deposited on the diversion layers through the electrostatic spinning method, and the one-way wet conduction nano-fiber multilayer composite membrane with the wettability gradient is obtained.

Owner:DONGHUA UNIV

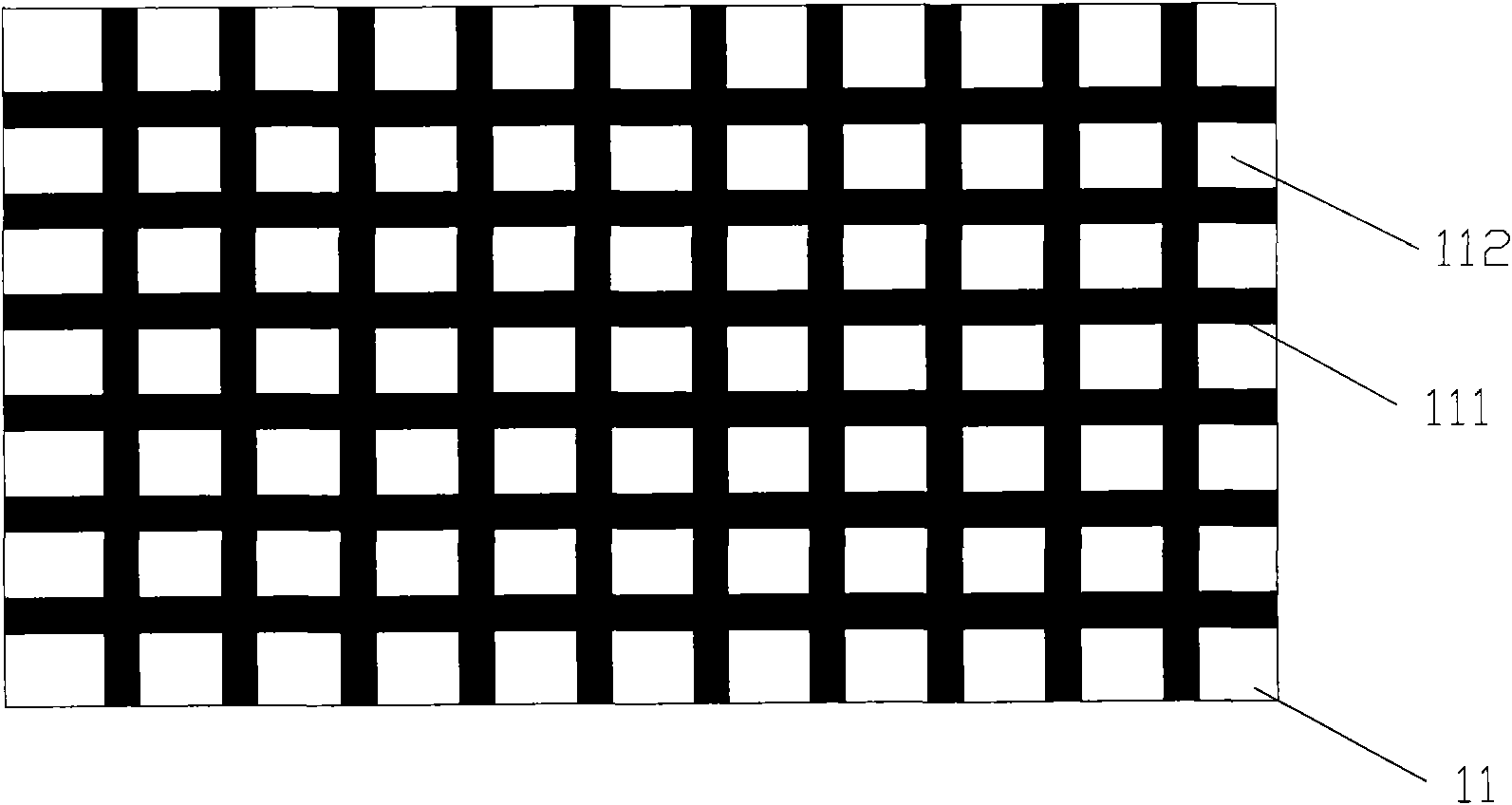

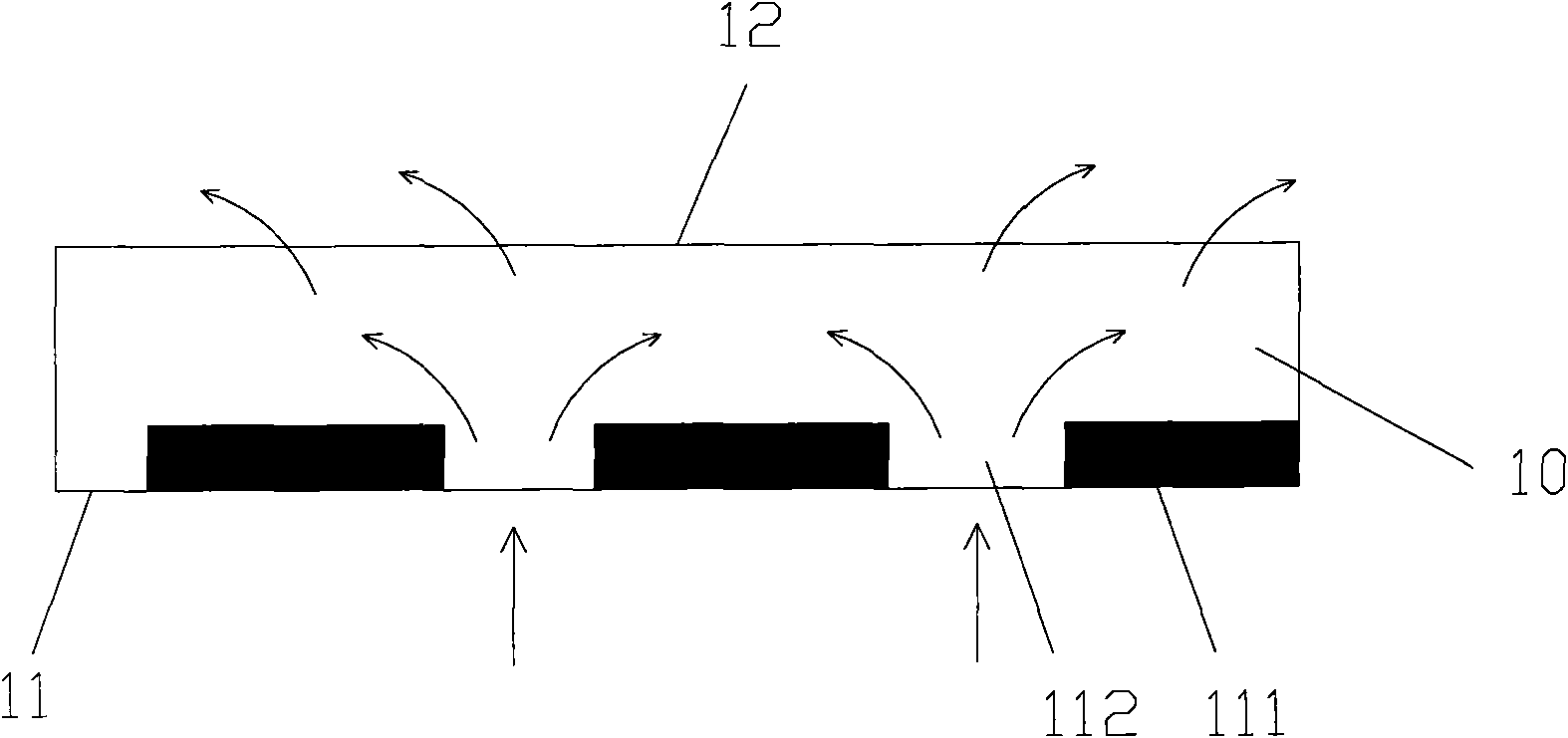

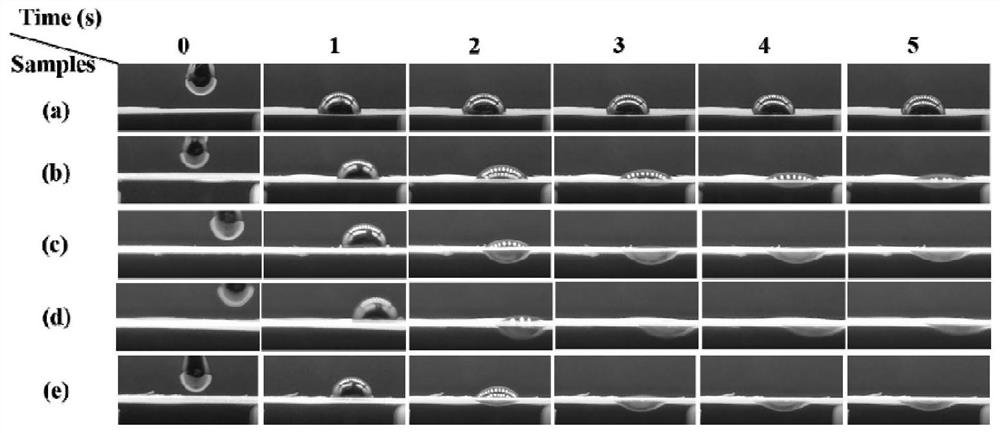

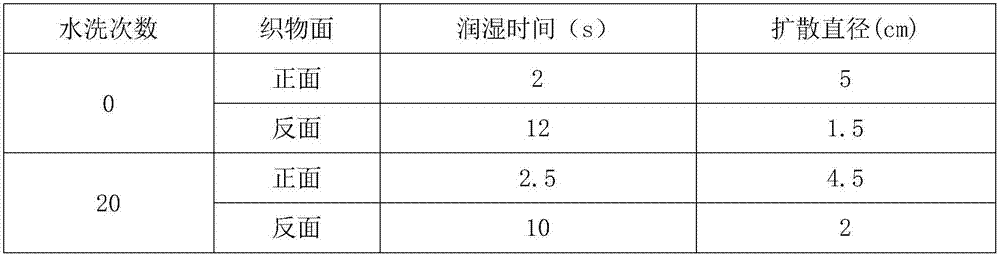

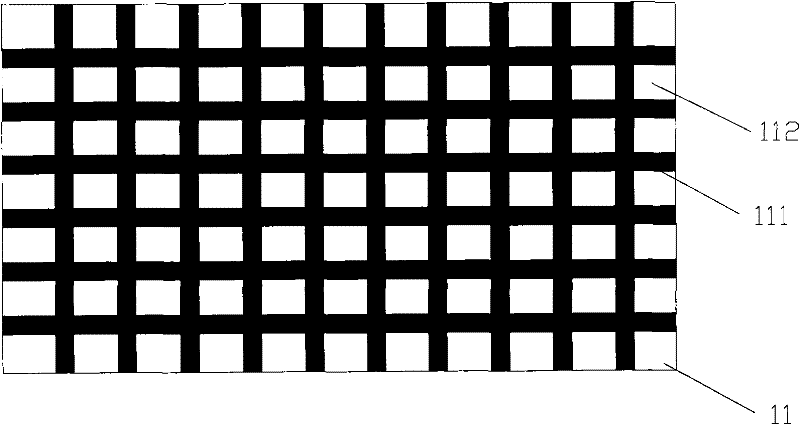

One-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and processing method thereof

InactiveCN101649558ASolve moisture absorptionSolve the contradiction of dehumidificationVegetal fibresAnimal fibresEngineeringMoisture absorption

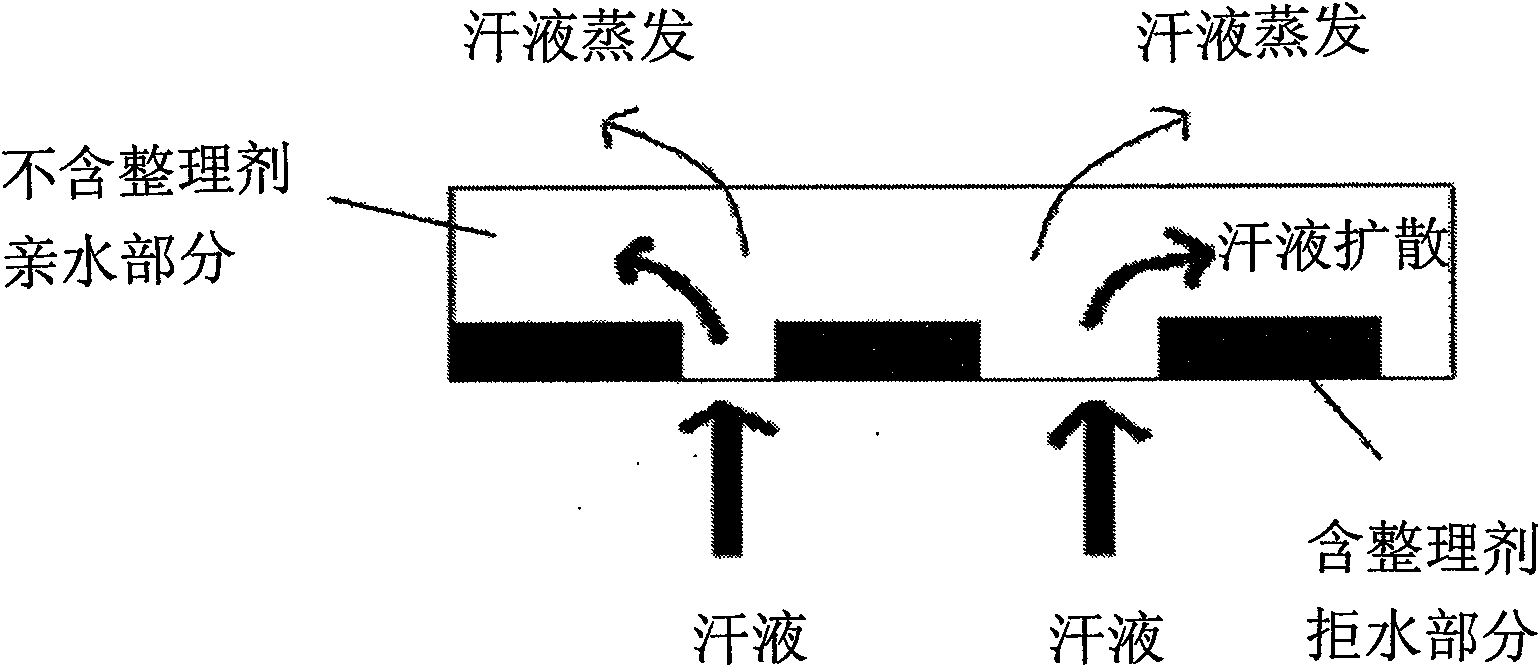

The invention relates to a one-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and a processing method thereof. A double-lateral surface structure with differenthydrophilic and hydrophobic properties is constructed at the front and reverse sides of the woven fabric product in a single-face liquid feeding way, wherein the front sides of the products are all hydrophilic sides with favorable hygroscopic property, hydrophobic areas with a hydrophobic structure are discontinuously distributed at the reverse side of the product, and the hydrophobic area occupies 20-80 percent of the total area of the lateral side. The processing method comprises the steps of preprocessing fabric, mixing printing paste and finishing agent, printing or feeding liquid at single side, drying, washing and shrinking, processing flexibly, drying again and finally ironing. The invention has the advantages of reasonably solving the contradiction between moisture absorption and moisture discharge as well as the contradiction between hydrophilic and hydrophobic of the fabric, ensuring favorable one-way moisture-conducting effect, achieving the aim of conducting sweat from oneside clinging to the skin to outside and maintaining relatively dry and comfortable efficiency at one side of the skin.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

Processing method of one-way moisture-guiding fabric

InactiveCN101845702ASimple fabric specification requirementsGood one-way moisture transfer effectWeft knittingWarp knittingYarnEngineering

The invention relates to a processing method of one-way moisture-guiding fabric, which comprises the following basic steps of: preparing gray fabric; singeing; blanching; presetting; mercerizing; whitening / dying / printing; forming or drying; carrying out single-face finishing; carrying out hydrophilic finishing; washing with water; and forming. In the method, the single-face finishing is carried out by adopting a circular screen decorating machine or a flat screen decorating machine, and padding finishing liquor can be carried out by adopting an open-width pad dyeing machine or a boarding machine. The gray fabric of the one-way moisture-guiding fabric manufactured in the method can be formed by various common clothes fiber. Compared with other processing technology, the method for processing the one-way moisture-guiding fabric has simple requirement on fiber, yarns and fabric and is suitable for most shell fabrics. The one-way moisture-guiding fabric has obvious moisture-guiding effect, is produced stably and has good consistence of performance. When a person wears clothes made of the one-way moisture-guiding fabric in sports, sweat on the skin surface inside the clothes can be guided to the outer surface of the clothes through the shell fabric and is continuously evaporated, thereby the degree of sticking the body of the shell fabric is reduced, and the wearing comfort is effectively improved.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

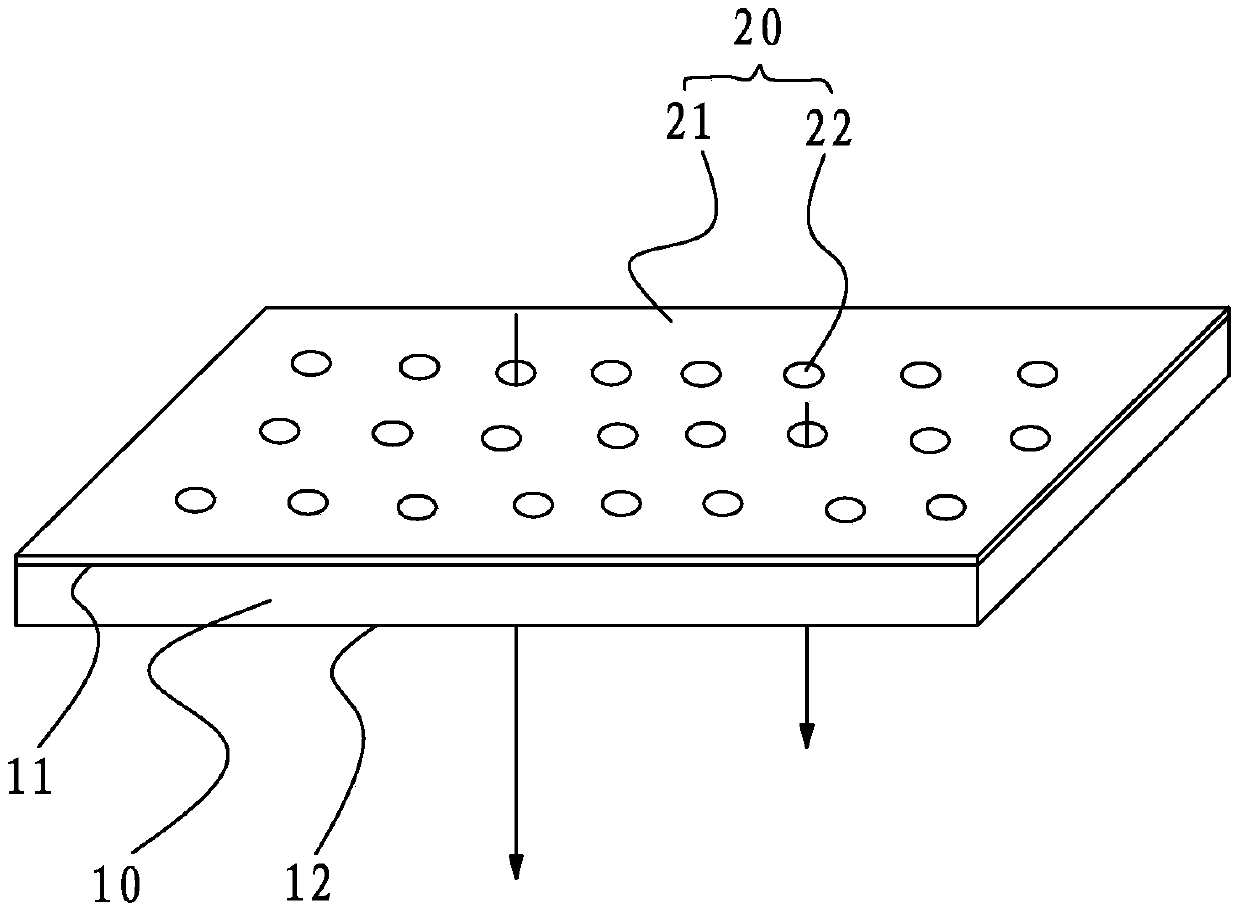

One-way moisture-transfer all-cotton spunlaced nonwoven as well as product and preparation method thereof

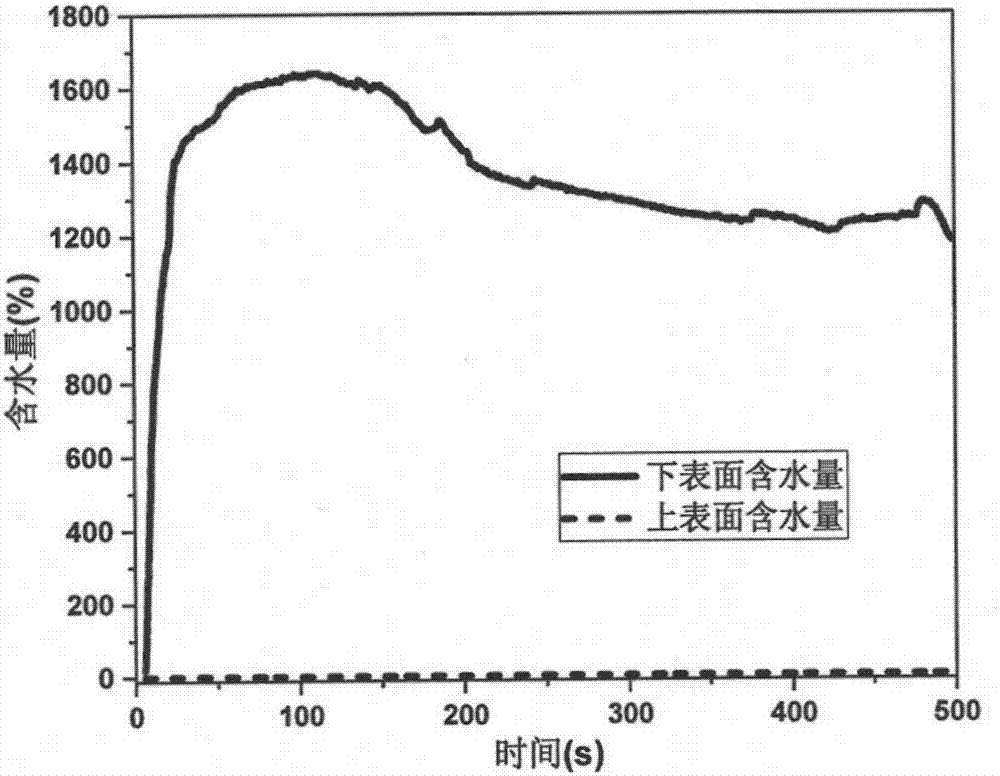

ActiveCN101775701AExcellent unidirectional moisture transfer performanceEffective absorptionNon-woven fabricsVegetal fibresSubstance useNonwoven fabric

The invention discloses a one-way moisture-transfer all-cotton spunlaced nonwoven and as well as a product and a preparation method thereof. The all-cotton spunlaced nonwoven comprises an all-cotton spunlaced nonwoven matrix, the all-cotton spunlaced nonwoven matrix comprises a hydrophobic surface and a hydrophilic surface, wherein the hydrophobic surface contains hydrophobic substances used for transferring moisture from the hydrophobic surface to the hydrophilic surface. The one-way moisture-transfer all-cotton spunlaced nonwoven selects an all-cotton material, has light and soft texture and good one-way moisture-transfer effect and can effectively absorb and permeate the moisture and prevent the moisture from reversely flowing, thereby enabling the hydrophobic surface directly contacting with the skin of a human body to keep dry and bringing about more comfortable feeling for a user of a one-way moisture-transfer product.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

One-way moisture-guiding knitted double-faced fabric and processing method thereof

InactiveCN102443953AWidely sourced and cheapThe process steps are simpleWeft knittingHeating/cooling textile fabricsFiberProcess engineering

The invention relates to one-way moisture-guiding knitted double-faced fabric and a processing method thereof, belonging to the technical field of knitted fabric. The one-way moisture-guiding knitted double-faced fabric comprises a face structure and a bottom structure, wherein the face structure is made of hydrophilic fiber and the bottom structure is made of hydrophobic fiber. The processing method comprises the following steps of: weaving; preprocessing; presetting; dyeing; and after treatment. The invention has the advantages that since the hydrophilic fiber is used for the face structure and the hydrophobic fiber is used for the bottom structure, the one-way moisture guiding effect is excellent and durable, the material of the hydrophilic fiber and the hydrophobic fiber forming the face structure and the bottom structure is wide in source and low in price so as to be conductive to reducing the cost and lead the fabric to meet the popular consumption needs; the provided processing method does not need to put grey cloth into a cylinder in the pretreatment process like the existing technology; and the whole processing method is simple in the process steps, has no demanding requirement and can guarantee that the fabric has stable one-way moisture guiding property.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

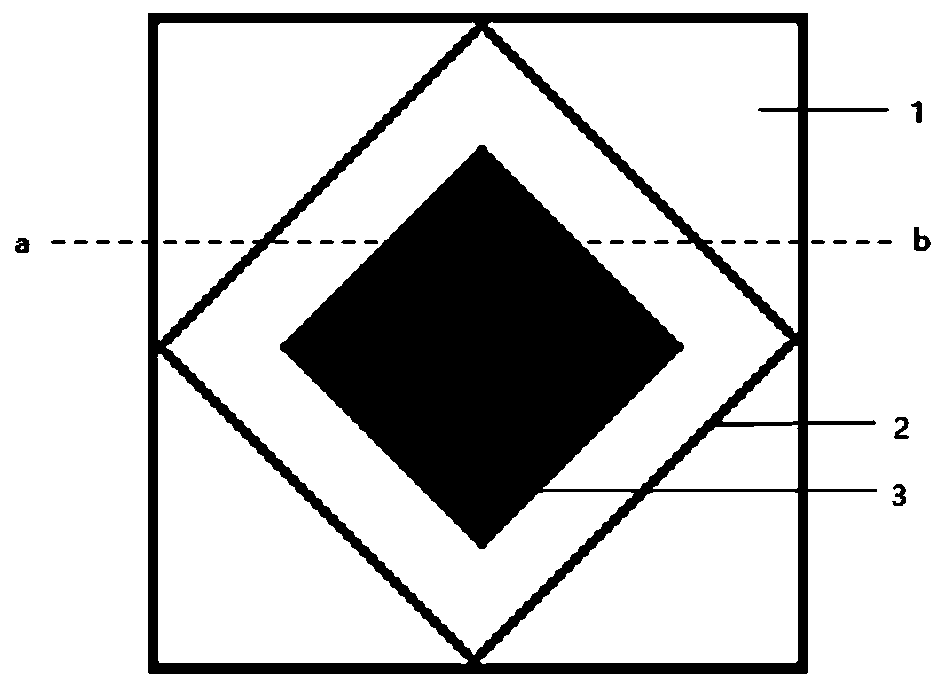

Wool fabric with one-way moisture-transferring function

InactiveCN101956327AExcellent unidirectional moisture transfer performanceFeel coolAnimal fibresEngineeringMoisture

The invention relates to a wool fabric with a one-way moisture-transferring function, which is characterized in that water-repellent areas are irregularly distributed on any one surface of the wool fabric, each water-repellent area is 0.01-4mm<2> in area and the space between every two water-repellent areas is 0.1-2mm. Particularly, the water-repellent areas on any one surface of the wool fabric are basically round and different in size. According to the wool fabric, a double side-face structure with a hydrophilic property and a hydrophobic property is structured on the two surfaces of the fabric, and the hydrophobic surface is provided with smaller water-repellent areas which are simpler in structure.

Owner:JIANGSU JIANLU WOOLEN +3

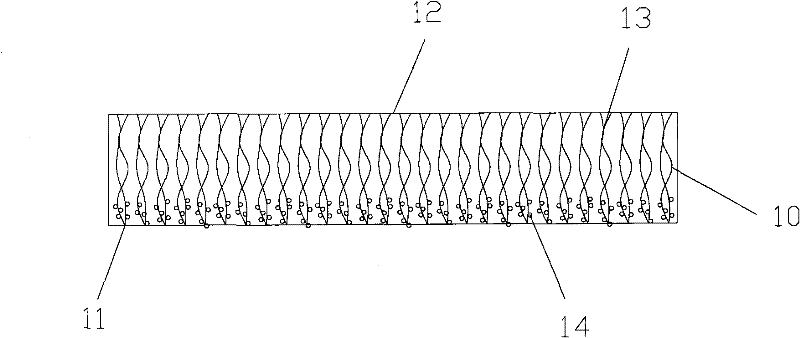

Double-layer single-side moisture transporting fabric and application thereof

InactiveCN106827730AGood moisture absorption and releaseReach the function of one-way moisture guideWeft knittingSynthetic resin layered productsYarnSingle fiber

The invention discloses a double-layer single-side moisture transporting fabric and an application thereof. The double-layer single-side moisture transporting fabric is formed by compounding two layers of fabric, namely an inner skin-friendly fabric layer and an outer fabric layer, wherein the inner skin-friendly fabric layer is a polypropylene fiber knitted fabric; the outer fabric layer is a modal fiber knitted fabric; the single fiber density of the inner skin-friendly fabric layer is greater than that of the outer fabric layer; the double-layer single-side moisture transporting fabric can be used for preparing an underwear fabric and a sportswear fabric. Through the design of the fabric texture structure, a double-sided isomeric knitted fabric is constructed by yarns with permanent functionality, thereby achieving single-side moisture transporting effect of the fabric.

Owner:LILANG CHINA

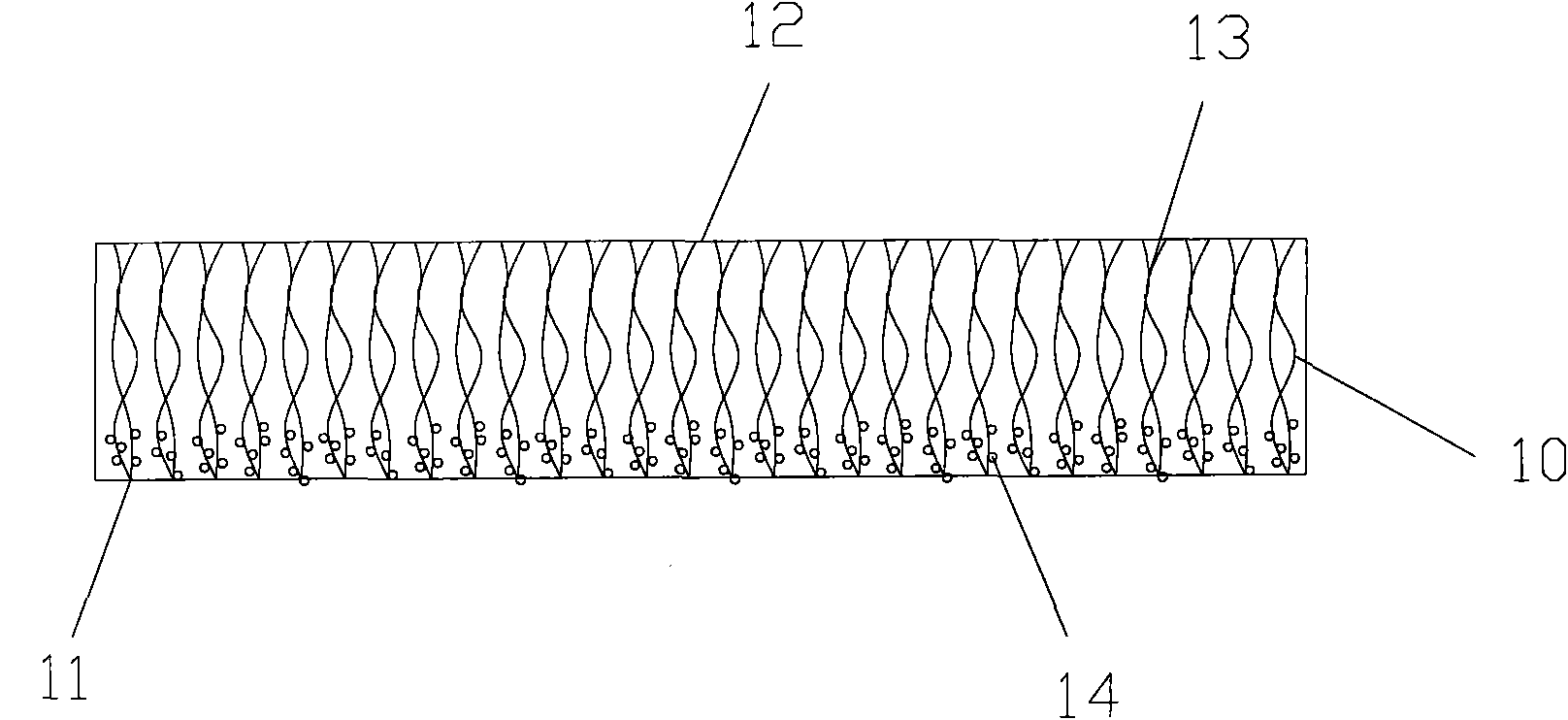

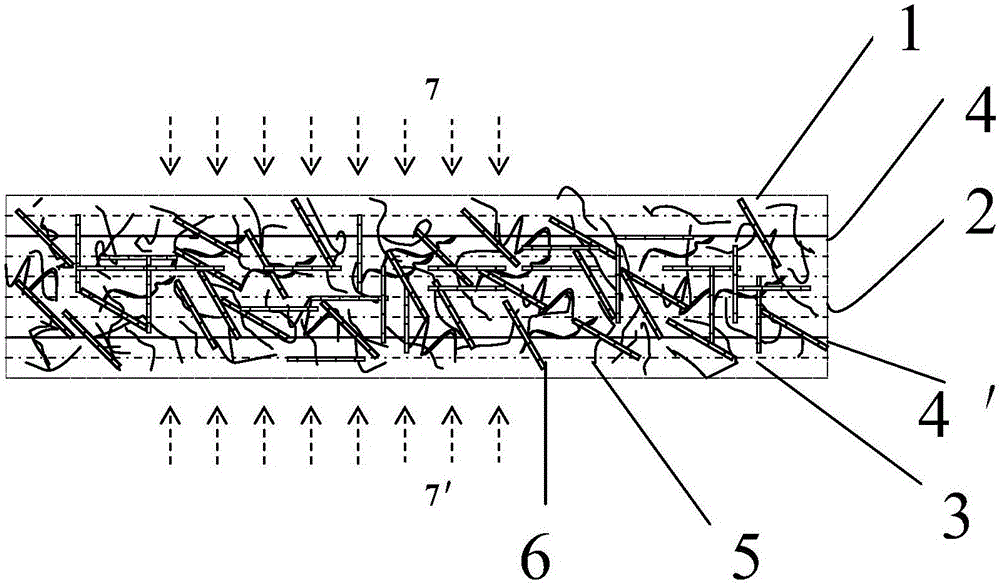

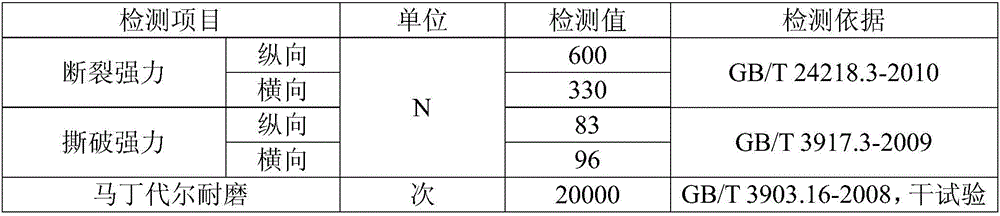

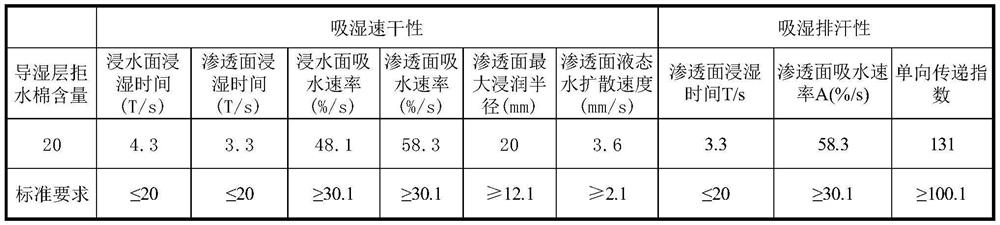

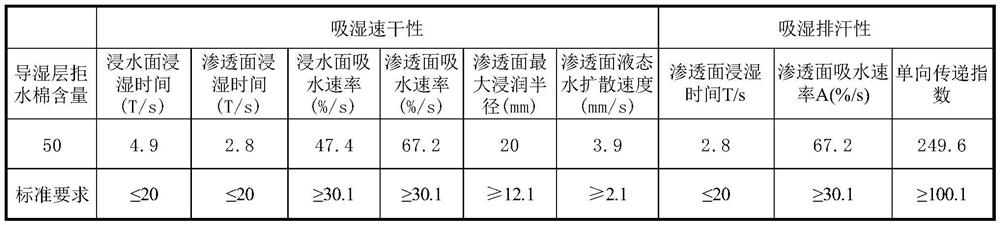

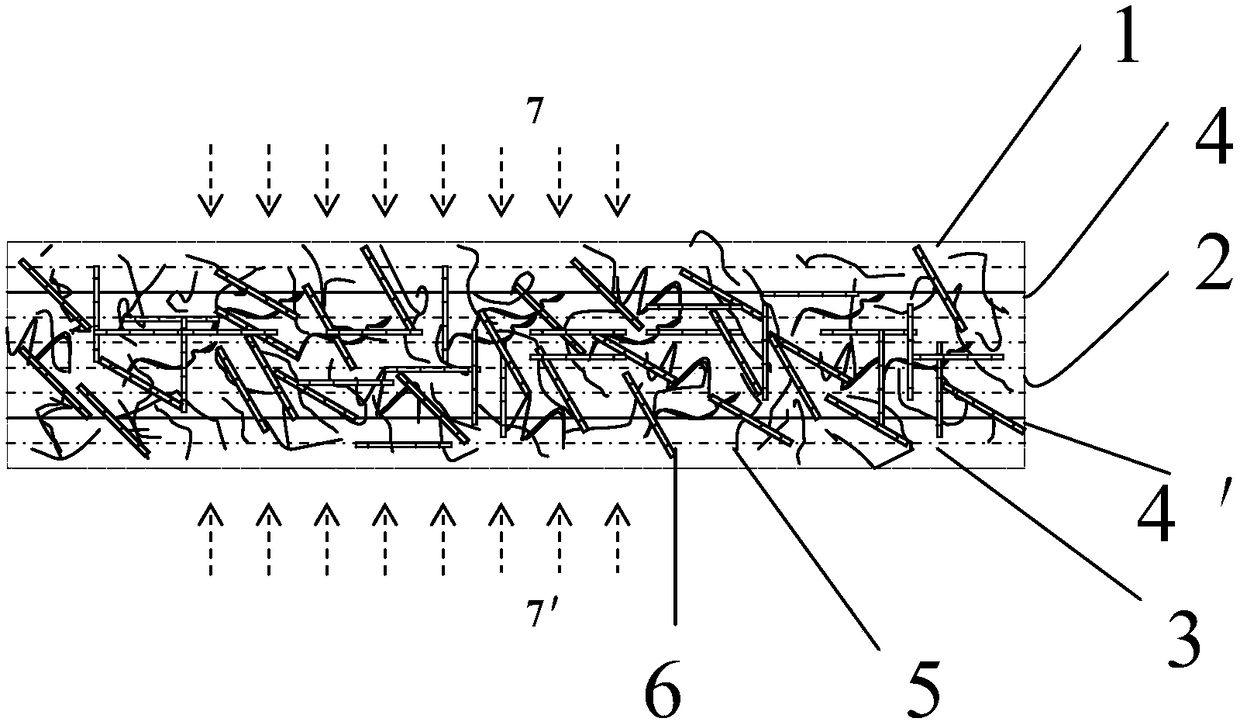

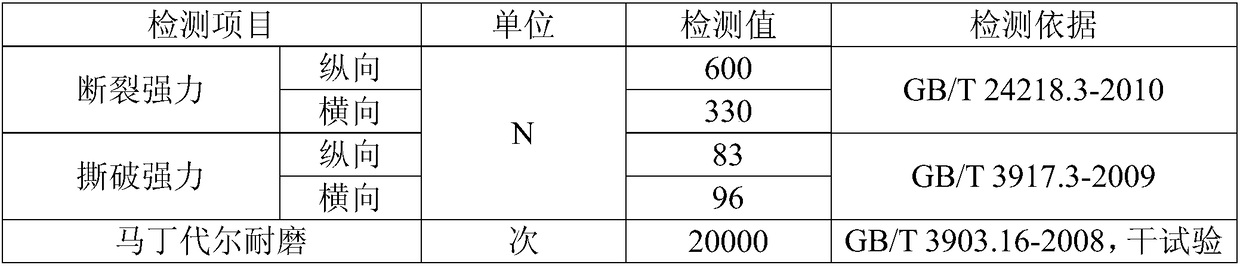

Functional stitch-bonded non-woven fabric and preparation method thereof

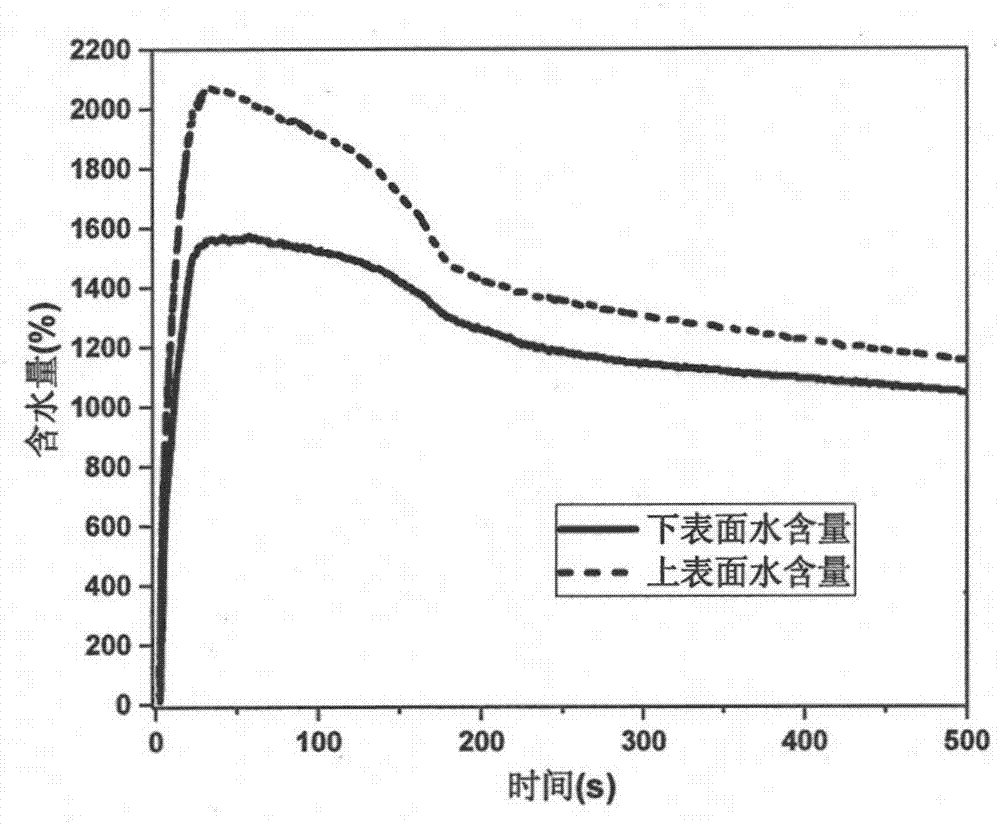

ActiveCN105970488AReduced antibacterial effectHigh content of hydrophilic fiberNon-woven fabricsPolyesterPolymer science

The invention discloses functional stitch-bonded non-woven fabric and a preparation method thereof. The functional stitch-bonded non-woven fabric comprises a hydrophobic layer I, a hydrophilic layer and a hydrophobic layer II which are stacked sequentially together, wherein all of the hydrophobic layer I, the hydrophilic layer and the hydrophobic layer II are made of hydrophobic fibers, hydrophilic fibers and hot-melt bonding fibers. The stitch-bonded non-woven fabric has function gradients comprising intensity gradients, moisture absorption gradients and antibacterial gradients and has the effects of breathability, high strength, wear resistance, tear resistance, moisture absorption, fast drying and bacterial resistance. The provided stitch-bonded non-woven fabric has a one-way moisture conducting property and can be used for manufacturing an insole of a shoe, and the comfort degree of feet is improved. Ramie-polyester blended materials are selected, the non-woven fabric has light and soft texture, high strength and good one-way moisture conducting effect and can effectively absorb moisture, moisture loss is avoided, a hydrophobic surface contacted with skin of feet is kept dry, and more comfortable feelings are brought to users using the one-way moisture-conducting product.

Owner:LI NING CHINA SPORTS GOODS +2

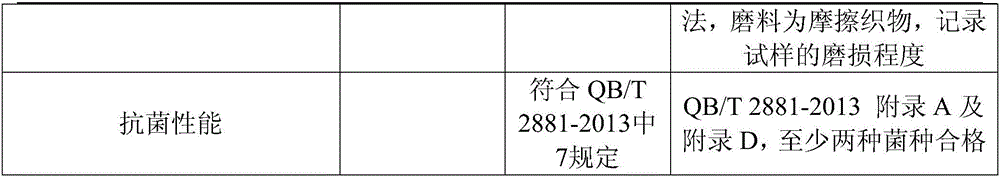

Anti-ultraviolet unidirectional-moisture-permeable fiber composite and preparing method thereof

InactiveCN109322058AGood one-way moisture transferFunction increaseArtificial filaments from cellulose derivativesNon-woven fabricsMicro nanoPolymer science

The invention belongs to the field of functional micro-nano fiber composites, and particularly relates to an anti-ultravoilet unidirectional-moisture-permeable fiber composite and a preparing method thereof. The fiber composite comprises a polypropylene layer and a hydrophilic polymer and ultraviolet absorber mixture layer which are integrally combined. Polydopamine deposits on and adheres to thesurfaces and the interiors of the polypropylene layer and the hydrophilic polymer and ultraviolet absorber mixture layer. The preparing method includes the steps of dissolving an ultraviolet absorberand a hydrophilic polymer in an organic solvent to form a spinning solution, conducting static spinning and then hot-pressing treatment with a melt static spinning polypropylene fiber material as thereceiving substrate, and placing the material in a Tris-HCl buffer solution with dissolved dopamine for impregnation modification to prepare the anti-ultravoilet unidirectional-moisture-permeable fiber composite. The material has good unidirectional moisture-permeable and anti-ultraviolet functions and is stable in integration structure, simple in composition and structure, simple in preparing process and wide in application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

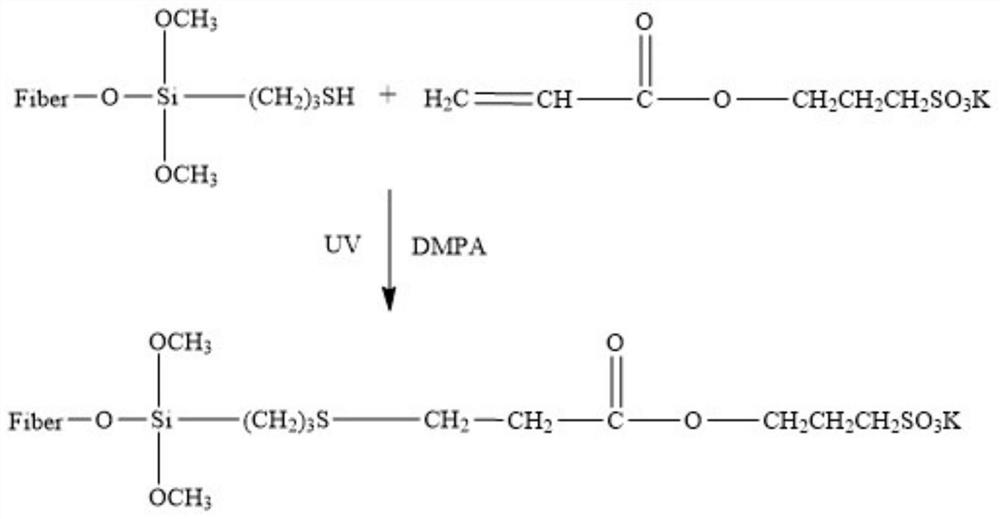

Preparation method of green light-cured durable one-way moisture-diversion finishing agent

InactiveCN103276585AAchieve chemical modificationExcellent unidirectional moisture transfer performancePhysical treatmentPotassiumCarbon chain

The invention relates to a preparation method of a green light-cured durable one-way moisture-diversion finishing agent. The preparation method comprises the following steps of 1, adding 3 to 20wt% of sodium or potash water glass into a mixture of water and ethanol, adding greater than or equal to 4wt% of an ammonium salt aqueous solution into the mixed solution, adjusting a pH value, and carrying out stirring at a room temperature, 2, orderly adding 0.5 to 1wt% of gamma-azidopropyltriethoxysilane and 2 to 4wt% of a hydrophobic long-carbon chain alkyl siloxane into the mixed solution obtained by the step 1 with stirring, and sequentially carrying out stirring to obtain a modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and 3, sequentially adding 0.5 to 15wt% of a thickener into the modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and carrying out stirring to obtain the green light-cured durable one-way moisture-diversion finishing agent. The preparation method adopts the raw materials having wide sources and has a low cost. The green light-cured durable one-way moisture-diversion finishing agent has stable properties. A fabric treated by the green light-cured durable one-way moisture-diversion finishing agent has excellent one-way moisture-diversion performance and washing endurance and has wide market application prospects and good social benefits.

Owner:DONGHUA UNIV +1

Method for preparing product with one-way moisture-conducting function

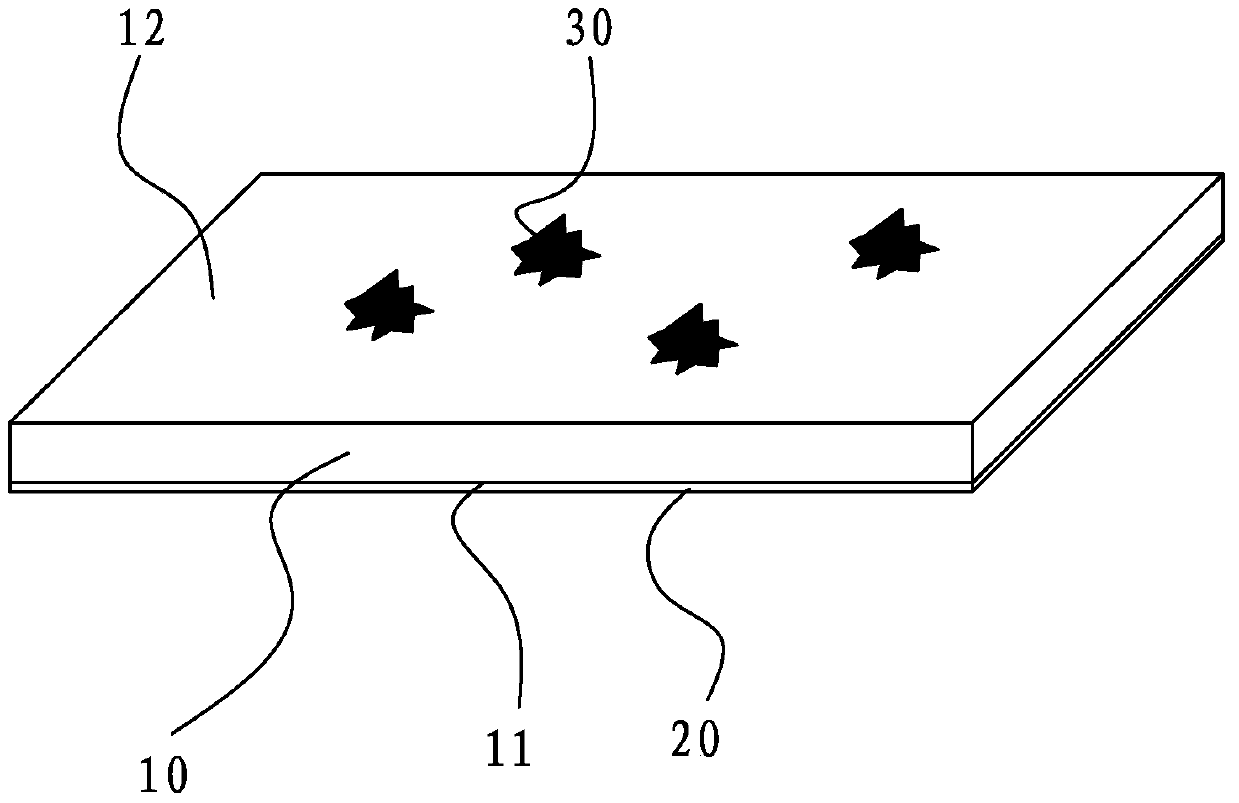

InactiveCN101962885BExcellent unidirectional moisture transfer performanceFeel coolTextile treatment by spraying/projectingVegetal fibresHydrophilizationEngineering

The invention relates to a method for preparing a product with a one-way moisture-conducting function. The method comprises the following steps of: 1) performing hydrophilization pretreatment on a textile; and 2) spraying water repellent finishing agent-containing working solution on one face of the treated textile, so that liquid drops with diameter of 0.1 to 2mm and spacing of 0.1 to 2mm are formed on the face of the textile and the product with the one-way moisture-conducting function is obtained. Fabrics prepared by the method has the advantages of greatly reducing the using amount of a plurality of resources such as water, energy and the like and solving the environmental problems of pollution discharge and the like, along with the one-way moisture-conducting property.

Owner:CHINA TEXTILE ENG SOC +3

Unidirectional moisture-conducting fabric and preparation method thereof

InactiveCN112251919AImprove wearing comfortBalance the effect of internal and external humidityFibre typesFilament/thread formingFiberPolymer science

The invention provides a fabric with good unidirectional moisture conductivity and a preparation method thereof. The preparation method comprises the following steps that firstly, a fabric base material is pretreated by a calcium salt solution; then fibers are formed by using a polyvinyl alcohol / sodium alginate solution through an electrostatic spinning method and deposited on a single surface ofthe fabric; a polyvinyl alcohol / calcium alginate gel layer is formed on the surface of the fabric in situ by using polyvinyl alcohol / sodium alginate; and the spinning layer is further cross-linked byusing a crosslinking agent, a cross-linked polyvinyl alcohol / calcium alginate (PVA / SA) functional layer is formed, and the unidirectional moisture-conducting fabric is obtained. By means of the treatment mode, the unidirectional moisture-conducting fabric can be obtained, and the obtained fabric has good air permeability and antistatic performance. The unidirectional moisture-conducting fabric canbe used for manufacturing clothes, outdoor jackets, masks, shoes, hats, medical supplies and the like, and the obtained product has the effects of discharging internal sweat and balancing internal and external humidity; and meanwhile, the unidirectional moisture-conducting fabric has good air permeability and antistatic performance, and the wearing comfort of the clothes can be improved.

Owner:WUHAN TEXTILE UNIV

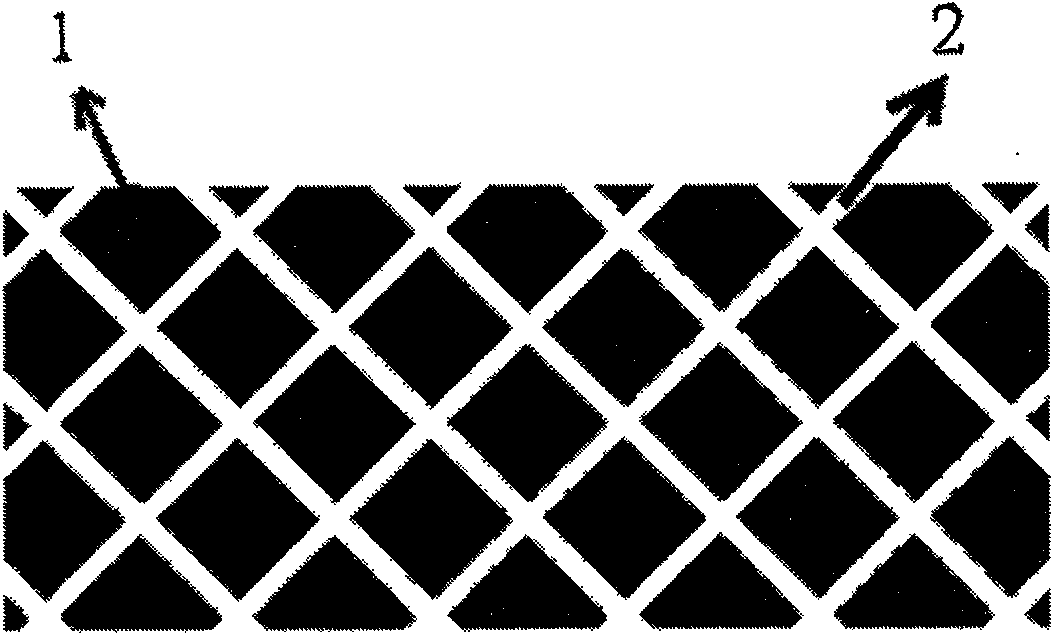

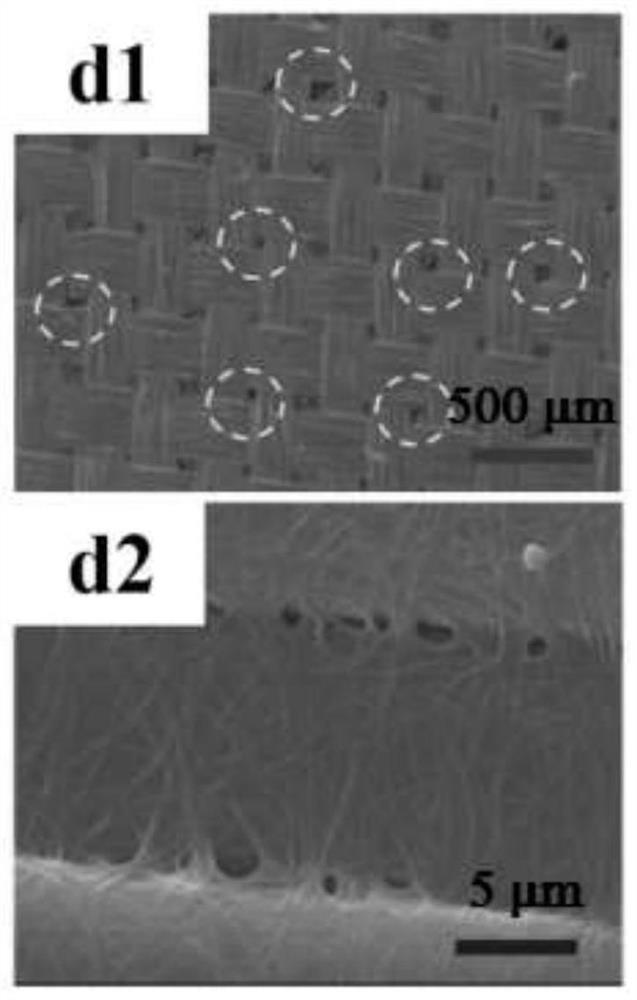

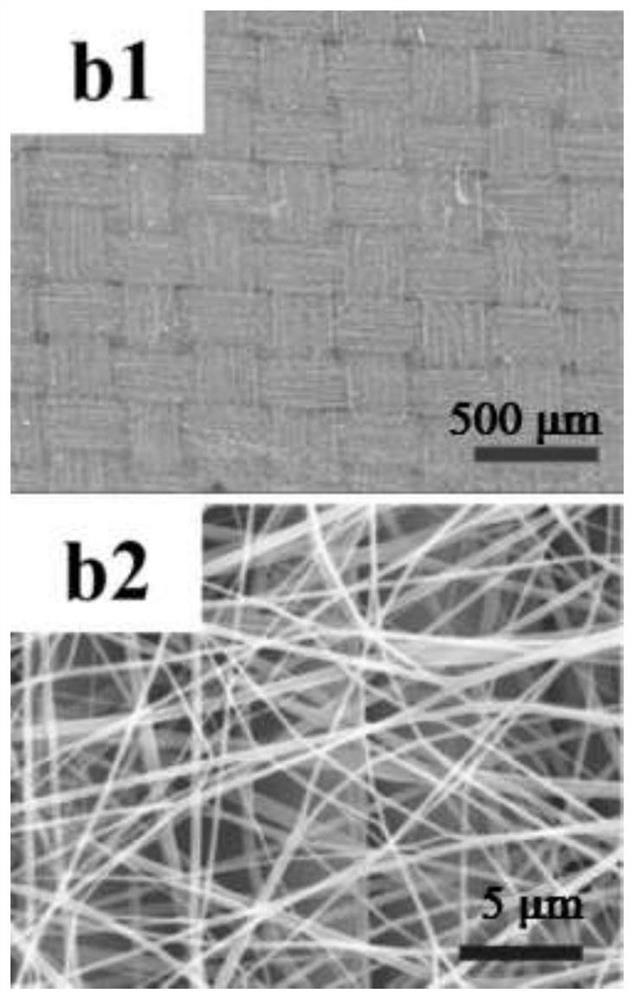

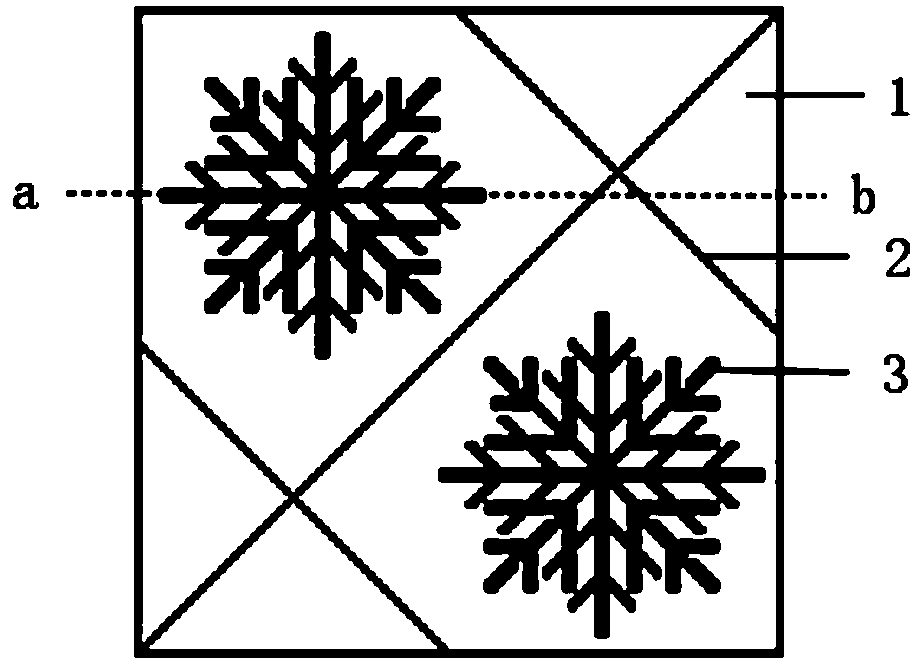

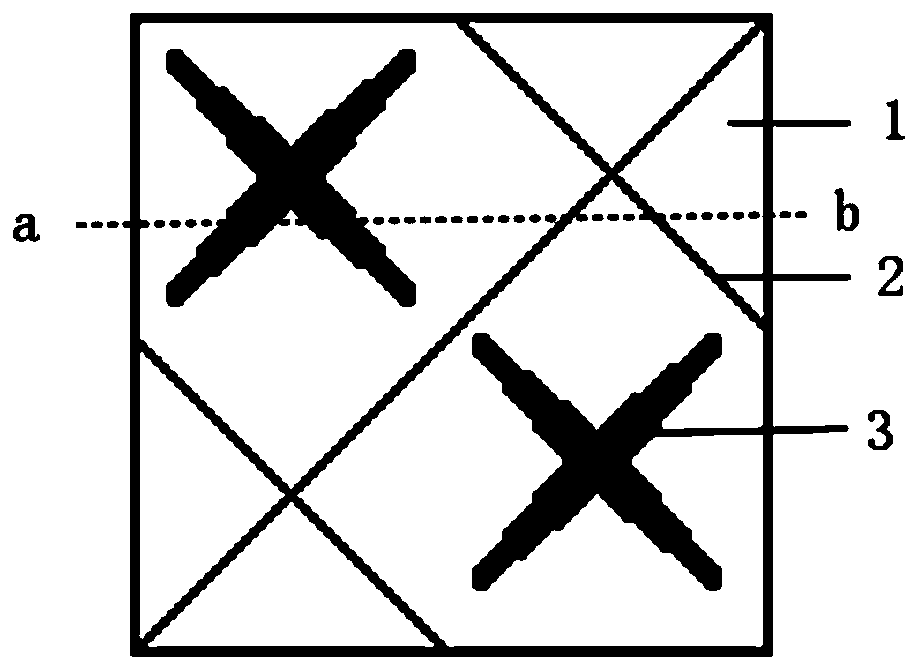

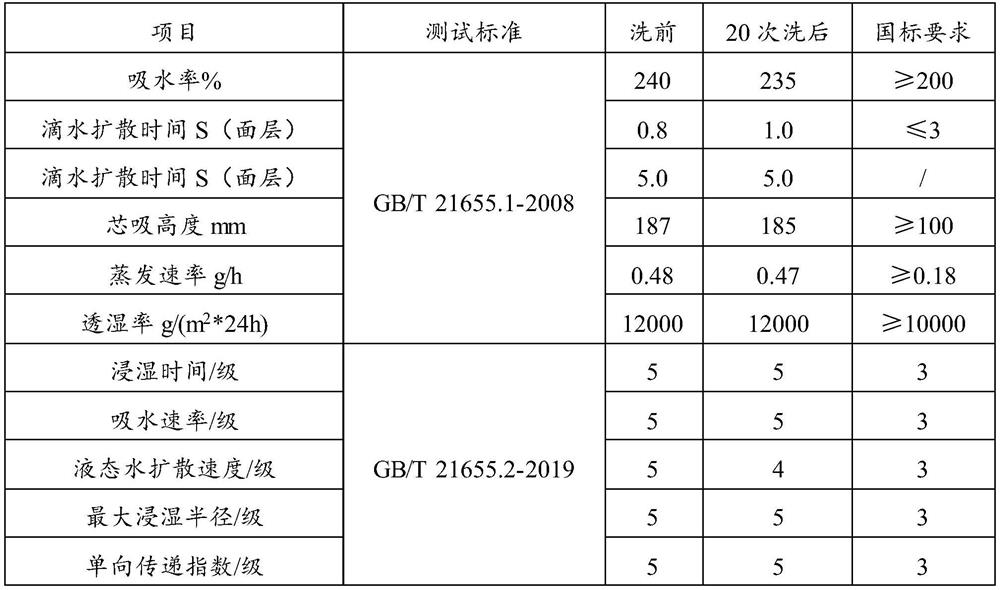

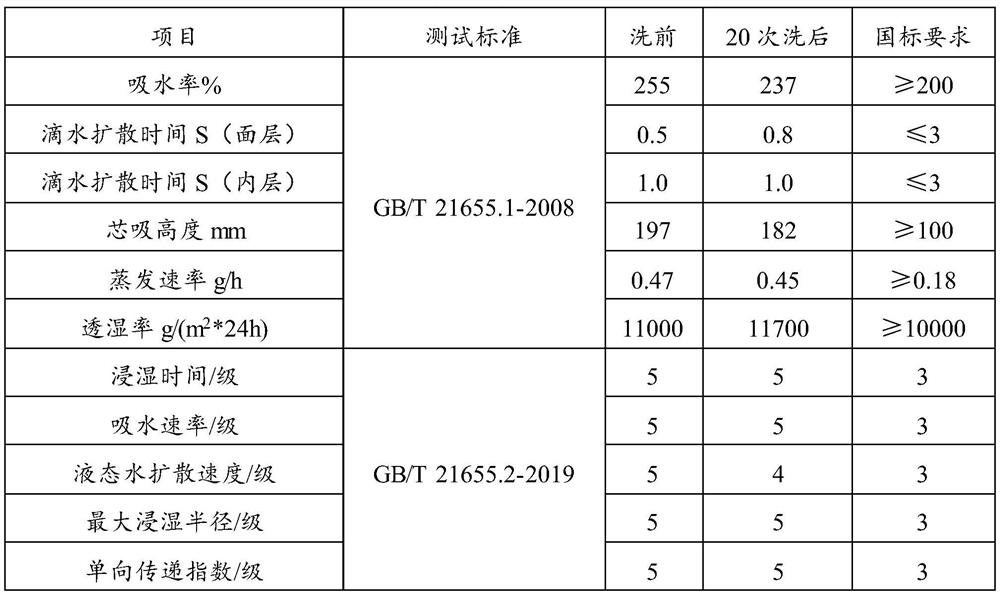

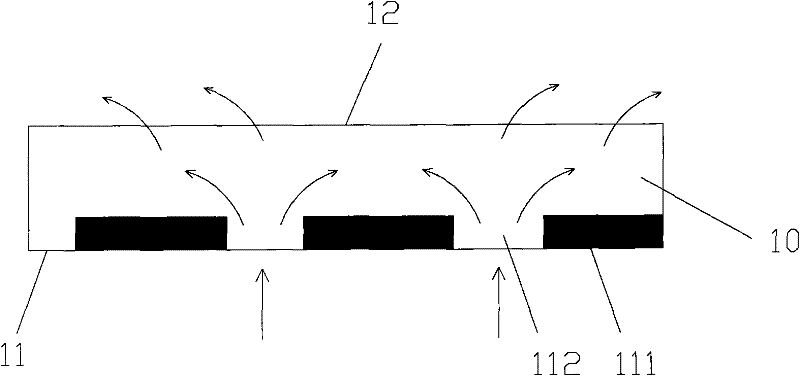

Preparation method of knitted fabric with bionic composite structure

ActiveCN110952215AUniversalDyeing and finishing technical requirements are simplePhysical treatmentLiquid repellent fibresStructural engineeringMechanical engineering

The invention relates to a preparation method of knitted fabric with a bionic composite structure. The preparation method comprises the step of knitting by using a computerized flat knitting machine after designing the organization structure of the knitted fabric, wherein the main body area of the knitted fabric is of a single-sided structure, a plurality of local areas dispersed in the main bodyarea are of double-sided structures, and the coil density of the single-sided structure, the coil density of the outer layers of the double-sided structures and the coil density of the inner layers ofthe double-sided structures are sequentially decreased; when knitting begins, the double-sided structure is knitted firstly, specifically, a needle selection device of the flat knitting machine headis controlled to select knitting needles of a front needle bed and a rear needle bed at the same time, meanwhile, the knitting needle of the needle bed I is controlled to perform looping knitting every other drawing needle, and the knitting needle of the needle bed II is controlled to firstly perform drawing needle looping and then perform tucking for 0-3 times on the same knitting needle of the needle bed I; and the knitting process of the single-sided structure comprises the steps of controlling the needle selection device of the flat knitting machine head to only select the knitting needleof the needle bed I to perform full-needle knitting, and controlling the knitting needle of the needle bed II not to perform knitting. The fabric prepared by the method is light, thin and good in one-way moisture conductivity.

Owner:DONGHUA UNIV

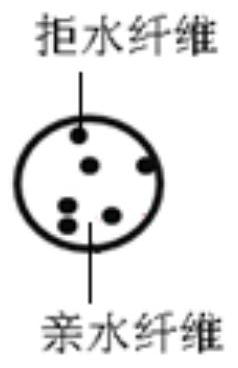

Moisture-absorbing and sweat-releasing yarn and fabric and garment thereof

InactiveCN112695394AGood moisture absorption and quick dryingExcellent unidirectional moisture transfer performanceWeft knittingWarp knittingYarnPolymer science

The invention provides a moisture-absorbing and sweat-releasing yarn and fabric and clothing thereof. The moisture-absorbing and sweat-releasing yarn is provided with a multilayer structure formed by composite melt spinning or composite spinning, the outer layer fiber of the multilayer structure is exposed to the environment, the hydrophilicity of the outer layer fiber is superior to that of the inner layer fiber of the multilayer structure, the fineness of the outer layer fiber is smaller than that of the inner layer fiber, the outer layer fiber has a circular cross section, and the inner layer fiber has a special-shaped cross section. According to the embodiment of the moisture-absorbing and sweat-releasing yarn, the yarn is ingeniously designed and combined, so that sweat absorbed by the yarn is distributed to the outer layer fiber as much as possible and is quickly evaporated in an external environment, and the inner layer fiber retains moisture as little as possible through moisture transfer. The moisture-absorbing and sweat-releasing yarn is better in moisture absorption, quick drying and one-way moisture conduction performance. Moisture-absorbing and sweat-releasing fabric is woven from the moisture-absorbing and sweat-releasing yarn, sweat management is achieved on the fiber and yarn layer, and sports clothes with the sweat management function can be further manufactured.

Owner:ANTA CHINA

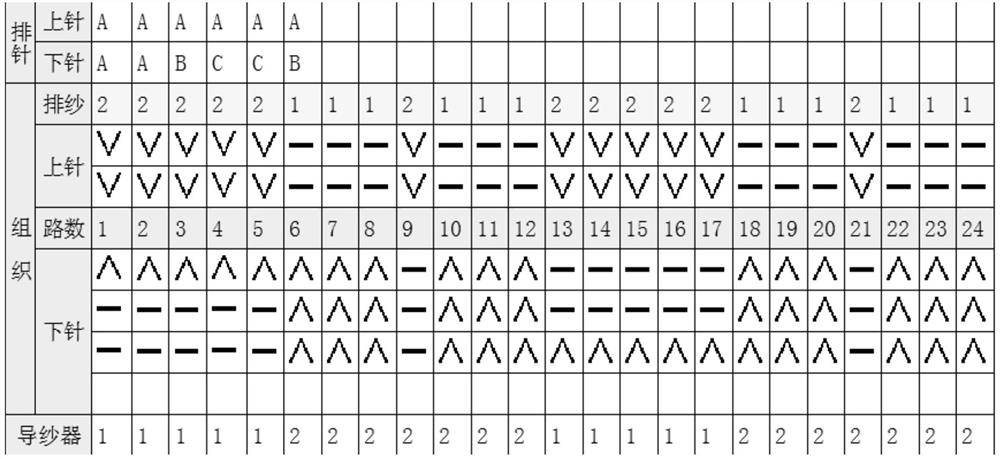

Preparation method of bionic composite structural knitted fabric

ActiveCN110725050AUniversalDyeing and finishing technical requirements are simpleWeft knittingStructural engineeringMechanical engineering

The invention relates to a preparation method of a bionic composite structural knitted fabric. Since the stitch structure of the knitted fabric is designed, a circular weft knitting machine having a loop transferring function is adopted for knitting; the primary area of the knitted fabric is in a single-sided structure, a plurality of local areas distributed in the primary area are in double-sidedstructure, and the stitch density of the single-sided structure, the stitch density of the outer layer of the double-sided structure and the stitch density of the inner layer of the double-sided structure are decreased gradually; at beginning of the knitting, the double-sided structure is formed by purl stitch and knit stitch simultaneously, the purl stitch forms loop alternatively one by one, the knit stitch forms loop alternatively one by one, and the number of tucking of the knit stitch is 0-3; in the process of converting the knitting of the double-sided structure into the knitting of thesingle-sided structure, the purl stitch and knit stitch are selected as needed to perform the loop transferring motion, and by the loop transferring motion, the loops on the knit stitch are transferred to the position, at where there are no loops, on the purl stitch which forms loop alternatively, so as to form the single-sided structure; in the process of converting the knitting of the single-sided structure into the knitting of the double-sided structure, latches of needles of the purl stitch and the knit stitch are opened. The knitted fabric is light and thin and has good unidirectional moisture-guide effect.

Owner:DONGHUA UNIV

Preparing method for unidirectional wet-conduction pure cotton fabric based on nano-zinc oxide

InactiveCN109778529AExcellent unidirectional moisture transfer performanceExcellent moisture absorption and cooling effectVegetal fibresCooking & bakingHot weather

The invention relates to a preparing method for a unidirectional wet-conduction pure cotton fabric based on nano-zinc oxide. The preparing method includes the steps that (1) nanometer ZnO powder and aphthalic-ester coupling agent are mixed, then Tween-80 is added, dispersion is conducted, and modified nanometer ZnO finishing liquid is obtained; (2) the cotton fabric is soaked into the modified nanometer ZnO finishing liquid, two times of soaking and two times of rolling are conducted, then pre-baking and baking are conducted, and the nanometer-ZnO-finished cotton fabric is obtained; (3) printing net is put on the nanometer-ZnO-finished cotton fabric, slurry is put, slurry is scraped at constant speed, then the fabric is pre-baked, baked, soaped and dried, and the unidirectional wet-conduction pure cotton fabric is obtained. According to the preparing method for the unidirectional wet-conduction pure cotton fabric based on the nano-zinc oxide, through compound function finishing, the fabric has the excellent moisture absorption and nice and cool effect, and the thermal-wet comfort requirement when people are in hot weather and strenuously exercise is met.

Owner:DONGHUA UNIV +1

Preparation method of multi-layered wet gradient shell fabric

InactiveCN109049901AEnhance capillary wicking effectImprove breathabilitySynthetic resin layered productsLaminationPolyesterMoisture absorption

The invention relates to a preparation method of multi-layered wet gradient shell fabric, and belongs to the technical field of textiles. The wet permeability of polypropylene fiber and spandex is good, the moisture absorption rate is approximately zero, the capillary tubes are thin and the number is large so that the capillary wicking effect of the textiles can be remarkably enhanced, polypropylene fiber and spandex combine with acrylic fiber filament which can improve the air permeability and the wet permeability of the textile to serve as a wet permeable fiber net, the wet permeable fiber net is tiled on an inner layer of moisture absorption net, then a layer of TPU thin film covers the wet permeable fiber net, a moisture diffusing fiber net composed of polyester fiber with triangular cross section and polyester fiber with the cross-shaped cross section covers the TPU thin film, a one-way wet permeable fiber water-jetting cloth with the good continuity of wetting gradient and outstanding differential capillary effect is formed, thus sweat is adsorbed to the outer surface of the textiles and volatilized rapidly under the differential capillary effect, the gas and wet permeabilityis improved, and the comfort level is improved.

Owner:黄勇

Knitted fabric with one-way moisture guiding function

InactiveCN103966784AExcellent unidirectional moisture transfer performanceFeel coolTextile treatment by spraying/projectingEngineeringMoisture

The invention relates to a knitted fabric with a one-way moisture guiding function. The knitted fabric is characterized in that water repellent areas distributed irregularly are arranged on any side of the knitted fabric, the areas of the water repellent areas are in a range of 0.01mm2 to 4mm2, and the distance among one another is between 0.1mm and 2mm. Particularly, the water repellent areas on any side of the knitted fabric are basically circular and different in size. 'Two side structures' different in hydrophilia and hydrophobicity are constructed on the two sides of the fabric, the water repellent areas on the side with hydrophobicity are smaller, and the structure is simpler.

Owner:CHINA TEXTILE ENG SOC +4

Composition for preparing coating slurry and preparation method of fabric

The invention discloses a composition for preparing coating slurry and a preparation method of a fabric. Three compositions for preparing the coating slurry are prepared according to different coating modes; the reverse side of a cotton-containing base fabric is coated through three coating techniques including a roller, mould or plain net technique, a foam coating technique and a spray coating technique, wherein the vehicle speed is 15 to 30m / min; the application amount of the coating slurry is 25 to 35 percent of the weight of the fabric; baking is performed for 1.5 to 3.5min at the baking temperature of 150 to 170 DEG C; finally hydrophilic setting is performed by adopting a setting machine, wherein the vehicle speed of the setting machine is 15 to 20m / min, and the drying temperature for setting is 150 to 170 DEG C. By adopting the fabric prepared by the technique provided by the invention, a gradient water-retaining function of the fabric in the thickness direction is realized, a siphon-like effect can be realized through the water-retaining power difference, so that a persistent one-way moisture conducting function is formed, when a human body sweats, moisture on the fabric can realize gradient transfer from inside to outside, so that the fabric is ensured to have the functions of quickness in perspiration and comfort in wearing.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

Heat-conducting fabric and preparation method thereof

PendingCN112575437AExcellent unidirectional moisture transfer performanceWeft knittingFibre typesPolyesterYarn

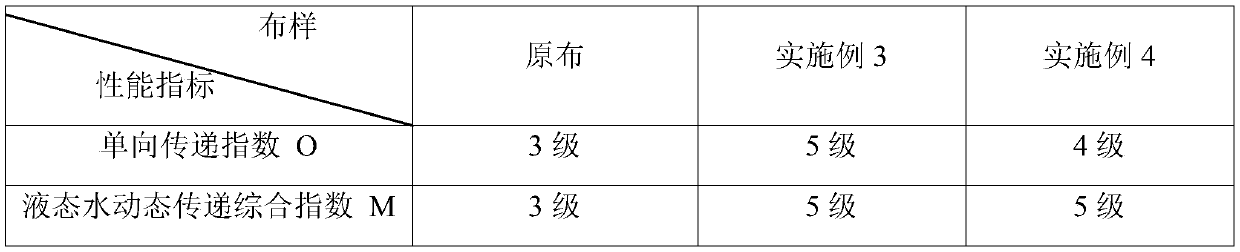

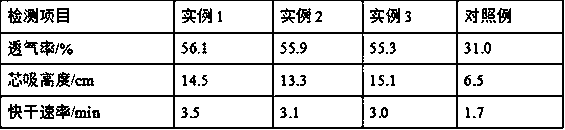

The invention provides heat-conducting fabric and a preparation method thereof. The heat-conducting fabric comprises polyester surface yarn, bottom yarn and connecting yarn, wherein the bottom yarn and the connecting yarn are sheath-core structure yarn having polyester covered with nylon; the yarn specification ratio of the surface yarn to the bottom yarn is (2-4):1; and the ratio of the number ofthe surface yarn to the number of the bottom yarn is (4-8):1. According to the fabric provided by the invention, the polyester spun yarn is used as the surface yarn and accounts for 50%-75%, so thatthe distribution proportion of moisture on the surface layer can be increased, and the one-way moisture conduction effect is achieved; and the bottom yarn is the sheath-core structure yarn having polyester covered with nylon, and a nylon surface layer is used for leading out heat more quickly, so that better thermal comfort is realized. Experimental results show that the thermal conductivity of the fabric is 0.092 to 0.103; the contact cool feeling is 0.23 to 0.26; the MMT is 3-4 after the fabric is washed for 20 times.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

One-way moisture-transfer all-cotton spunlaced nonwoven as well as product and preparation method thereof

ActiveCN101775701BExcellent unidirectional moisture transfer performanceEffective absorptionNon-woven fabricsVegetal fibresSubstance useNonwoven fabric

The invention discloses a one-way moisture-transfer all-cotton spunlaced nonwoven and as well as a product and a preparation method thereof. The all-cotton spunlaced nonwoven comprises an all-cotton spunlaced nonwoven matrix, the all-cotton spunlaced nonwoven matrix comprises a hydrophobic surface and a hydrophilic surface, wherein the hydrophobic surface contains hydrophobic substances used for transferring moisture from the hydrophobic surface to the hydrophilic surface. The one-way moisture-transfer all-cotton spunlaced nonwoven selects an all-cotton material, has light and soft texture and good one-way moisture-transfer effect and can effectively absorb and permeate the moisture and prevent the moisture from reversely flowing, thereby enabling the hydrophobic surface directly contacting with the skin of a human body to keep dry and bringing about more comfortable feeling for a user of a one-way moisture-transfer product.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

One-way moisture-conducting blank-dyed fabric

PendingCN113215714ALow costUniform coloringWeft knittingLiquid repellent fibresWoven fabricMoisture transfer

The invention provides a one-way moisture-conducting blank-dyed fabric. The one-way moisture-conducting blank-dyed fabric is of a double-layer structure; an inner layer and an outer layer have the difference of hydrophilicity and hydrophobicity; the outer layer is a hydrophilic layer formed by hydrophilic yarn; the inner layer is a moisture conducting layer formed by hydrophobic yarn; and the outer layer and the inner layer are connected through fabric weave points. The one-way moisture-conducting blank-dyed fabric is obvious in moisture-absorbing and sweat-releasing effects, soft and comfortable in hand feeling and skin-friendly and breathable to wear, still has relatively good one-way moisture-conducting performance after being washed for multiple times, and meets the moisture-absorbing and sweat-releasing requirements of a dynamic moisture transfer method in a second part of GB / T21655.2-2019 evaluation of moisture absorption and quick drying of textiles.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

One-way moisture-conducting fabric and preparation method and application thereof

ActiveCN112921482AHydrophilic point and hydrophobic point distributionReduce the risk of getting into the car wrongWeft knittingWarp knittingYarnPolymer science

The invention provides a one-way moisture-conducting fabric and a preparation method and application thereof. The one-way moisture-conducting fabric is of a double-layer structure, an outer layer and an inner layer have the difference of hydrophilicity and hydrophobicity, the outer layer is a hydrophilic layer formed by weaving yarn with moisture-absorbing and quick-drying functions, and the inner layer is a hydrophobic layer formed by weaving cotton yarn with a hydrophobic function; the outer layer and the inner layer are connected through weave points of the fabric; and the yarns with the moisture-absorbing and quick-drying functions at least adopt 20wt% of moisture-absorbing and quick-drying cotton fibers, and the cotton yarns with the hydrophobic function are 100wt% of cotton. According to the one-way moisture-conducting color spinning fabric, the natural skin-friendly characteristic of a pure cotton product is reserved in the inner layer, and a skin-friendly and comfortable sportswear fabric is provided for sportsmen loving sportswear.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

A kind of preparation method of knitted fabric with bionic composite structure

ActiveCN110952215BUniversalDyeing and finishing technical requirements are simplePhysical treatmentLiquid repellent fibresStructural engineeringMechanical engineering

The invention relates to a preparation method of knitted fabric with a bionic composite structure. The preparation method comprises the step of knitting by using a computerized flat knitting machine after designing the organization structure of the knitted fabric, wherein the main body area of the knitted fabric is of a single-sided structure, a plurality of local areas dispersed in the main bodyarea are of double-sided structures, and the coil density of the single-sided structure, the coil density of the outer layers of the double-sided structures and the coil density of the inner layers ofthe double-sided structures are sequentially decreased; when knitting begins, the double-sided structure is knitted firstly, specifically, a needle selection device of the flat knitting machine headis controlled to select knitting needles of a front needle bed and a rear needle bed at the same time, meanwhile, the knitting needle of the needle bed I is controlled to perform looping knitting every other drawing needle, and the knitting needle of the needle bed II is controlled to firstly perform drawing needle looping and then perform tucking for 0-3 times on the same knitting needle of the needle bed I; and the knitting process of the single-sided structure comprises the steps of controlling the needle selection device of the flat knitting machine head to only select the knitting needleof the needle bed I to perform full-needle knitting, and controlling the knitting needle of the needle bed II not to perform knitting. The fabric prepared by the method is light, thin and good in one-way moisture conductivity.

Owner:DONGHUA UNIV

A kind of preparation method of knitted fabric with bionic composite structure

ActiveCN110725050BUniversalDyeing and finishing technical requirements are simpleWeft knittingStructural engineeringMechanical engineering

The invention relates to a preparation method of a bionic composite structural knitted fabric. Since the stitch structure of the knitted fabric is designed, a circular weft knitting machine having a loop transferring function is adopted for knitting; the primary area of the knitted fabric is in a single-sided structure, a plurality of local areas distributed in the primary area are in double-sidedstructure, and the stitch density of the single-sided structure, the stitch density of the outer layer of the double-sided structure and the stitch density of the inner layer of the double-sided structure are decreased gradually; at beginning of the knitting, the double-sided structure is formed by purl stitch and knit stitch simultaneously, the purl stitch forms loop alternatively one by one, the knit stitch forms loop alternatively one by one, and the number of tucking of the knit stitch is 0-3; in the process of converting the knitting of the double-sided structure into the knitting of thesingle-sided structure, the purl stitch and knit stitch are selected as needed to perform the loop transferring motion, and by the loop transferring motion, the loops on the knit stitch are transferred to the position, at where there are no loops, on the purl stitch which forms loop alternatively, so as to form the single-sided structure; in the process of converting the knitting of the single-sided structure into the knitting of the double-sided structure, latches of needles of the purl stitch and the knit stitch are opened. The knitted fabric is light and thin and has good unidirectional moisture-guide effect.

Owner:DONGHUA UNIV

A kind of preparation method of green photocuring durable unidirectional moisture-conducting finishing agent

InactiveCN103276585BAchieve chemical modificationExcellent unidirectional moisture transfer performancePhysical treatmentPotassiumCarbon chain

The invention relates to a preparation method of a green light-cured durable one-way moisture-diversion finishing agent. The preparation method comprises the following steps of 1, adding 3 to 20wt% of sodium or potash water glass into a mixture of water and ethanol, adding greater than or equal to 4wt% of an ammonium salt aqueous solution into the mixed solution, adjusting a pH value, and carrying out stirring at a room temperature, 2, orderly adding 0.5 to 1wt% of gamma-azidopropyltriethoxysilane and 2 to 4wt% of a hydrophobic long-carbon chain alkyl siloxane into the mixed solution obtained by the step 1 with stirring, and sequentially carrying out stirring to obtain a modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and 3, sequentially adding 0.5 to 15wt% of a thickener into the modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and carrying out stirring to obtain the green light-cured durable one-way moisture-diversion finishing agent. The preparation method adopts the raw materials having wide sources and has a low cost. The green light-cured durable one-way moisture-diversion finishing agent has stable properties. A fabric treated by the green light-cured durable one-way moisture-diversion finishing agent has excellent one-way moisture-diversion performance and washing endurance and has wide market application prospects and good social benefits.

Owner:DONGHUA UNIV +1

A low-carbon light-curing one-way moisture-conducting finishing agent and its preparation method and application

InactiveCN103061106BExcellent unidirectional moisture transfer performanceIncreased durabilityPhysical treatmentSocial benefitsChain length

The invention relates to a preparation method for low-carbon photocuring single-side moisture transport finishing agent. The method comprises the following steps: (1) a precursor is poured in a mixture of ethanol and de-ionized water, and is acutely stirred at the temperature of 10-40 DEG C; and (2) catalyst-ammonia water is slowly dripped to stir, then different-chain-length alkyl containing an azide group or siloxane of aromatic hydrocarbon is added to continuously stir in order to obtain low-carbon and energy-conservation single-side moisture transport finishing agent containing an azide functional group. The finishing agent has stable properties; finished fabrics obtain excellent single-side moisture transporting performance and durability, and need no heat baking, so that a large amount of energy is saved; the finishing agent accords with the national modern economic development theme of environmental protection and low energy consumption, and has wide market application prospect and excellent social benefit.

Owner:DONGHUA UNIV +1

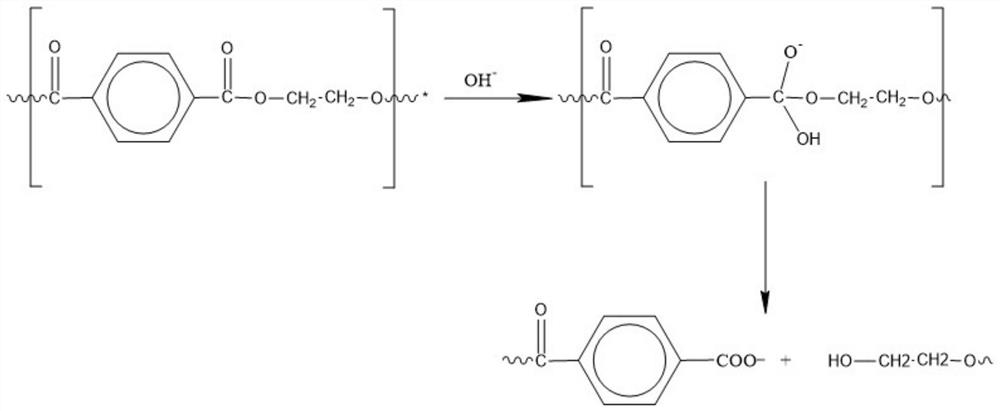

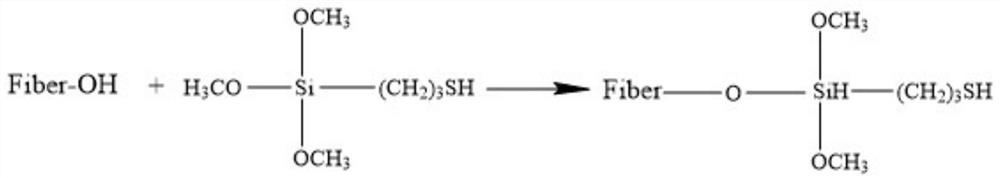

A unidirectional moisture-wicking asymmetric polyester fabric and its preparation and application

ActiveCN110067135BGood moisture conductivityEasy to operateLiquid repellent fibresPolyesterPolymer science

The invention relates to a one-way moisture-guiding asymmetric polyester fabric and its preparation and application. Preparation: the mercapto-modified polyester fabric is immersed in a finishing solution mixed with 3-sulfopropyl acrylate and a photoinitiator, and is exposed to one side of ultraviolet light Under the irradiation, that is. The invention utilizes the click chemical reaction to form a chemical bond combination between the fabric and the hydrophilic finishing agent, effectively improves the moisture-conducting performance of the polyester fabric and has durability after washing.

Owner:DONGHUA UNIV

A functional stitch-bonded non-woven fabric and its preparation method

ActiveCN105970488BReduced antibacterial effectHigh content of hydrophilic fiberNon-woven fabricsPolyesterPolymer science

The invention discloses functional stitch-bonded non-woven fabric and a preparation method thereof. The functional stitch-bonded non-woven fabric comprises a hydrophobic layer I, a hydrophilic layer and a hydrophobic layer II which are stacked sequentially together, wherein all of the hydrophobic layer I, the hydrophilic layer and the hydrophobic layer II are made of hydrophobic fibers, hydrophilic fibers and hot-melt bonding fibers. The stitch-bonded non-woven fabric has function gradients comprising intensity gradients, moisture absorption gradients and antibacterial gradients and has the effects of breathability, high strength, wear resistance, tear resistance, moisture absorption, fast drying and bacterial resistance. The provided stitch-bonded non-woven fabric has a one-way moisture conducting property and can be used for manufacturing an insole of a shoe, and the comfort degree of feet is improved. Ramie-polyester blended materials are selected, the non-woven fabric has light and soft texture, high strength and good one-way moisture conducting effect and can effectively absorb moisture, moisture loss is avoided, a hydrophobic surface contacted with skin of feet is kept dry, and more comfortable feelings are brought to users using the one-way moisture-conducting product.

Owner:LI NING CHINA SPORTS GOODS +2

A moisture-absorbing and sweat-wicking invisible graphic fabric and its production method

ActiveCN104647930BImprove wearing comfortGood moisture absorption and air permeabilityOther printing apparatusPrinting after-treatmentPolyesterFiber

The invention relates to a moisture-absorbing and perspiration-displaying graphic fabric, which includes a fabric, the inner surface of the fabric is pressed with a unidirectional moisture-wicking slurry layer, the outer surface of the fabric is pressed with a first invisible printed graphic, and the fabric is made of highly hydrophilic The unidirectional moisture-wicking slurry layer includes a hydrophobic area and a hydrophilic area, and the hydrophilic area penetrates from the side of the hydrophobic area away from the inner surface of the fabric to the inner surface of the fabric. The first invisible The printed graphics are formed by pressing the second hydrophobic unidirectional moisture-conducting slurry, and the components of the first hydrophobic unidirectional moisture-conducting slurry and the second hydrophobic unidirectional moisture-conducting slurry are the same. The fabric adopting the solution has the characteristics of good moisture-conducting effect, simple fabric structure, and convenient processing; meanwhile, the invention also provides a processing method for the above-mentioned fabric, which is simple and has high production efficiency.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com