Composition for preparing coating slurry and preparation method of fabric

A technology for coating pulp and composition, applied in the directions of plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of affecting wearer's comfort, weakening water repellency, affecting wearing comfort, etc., and achieves good unidirectional moisture conduction function. , good perspiration, quick drying, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0023] The cotton-containing base fabric used in the present invention is a knitted product or a woven product with any structure. In order to ensure a better processing effect, the base fabric usually needs to be used after conventional processes such as dyeing, pretreatment, and dyeing.

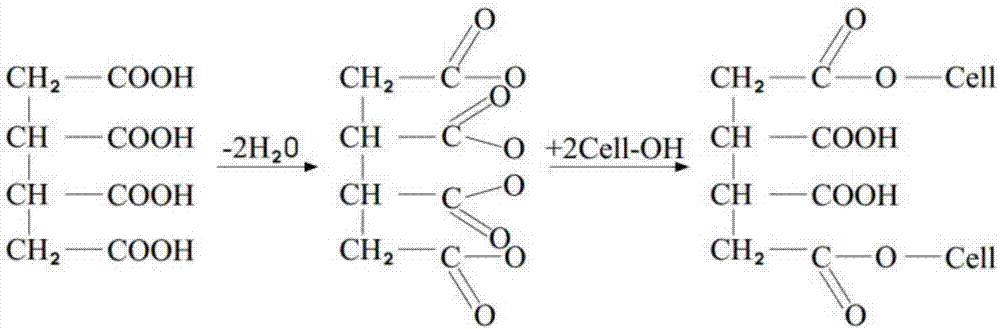

[0024] The mechanism that butane tetracarboxylic acid adopted in the present invention reacts with the hydroxyl of cotton fiber molecule is:

[0025]

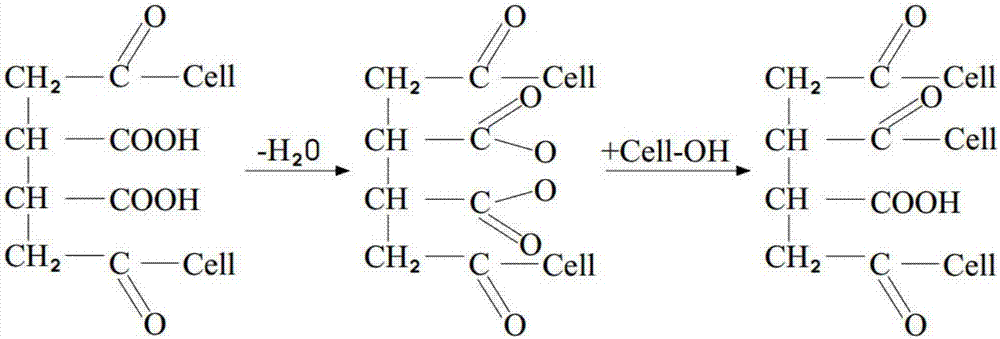

[0026] Further reactions are possible:

[0027]

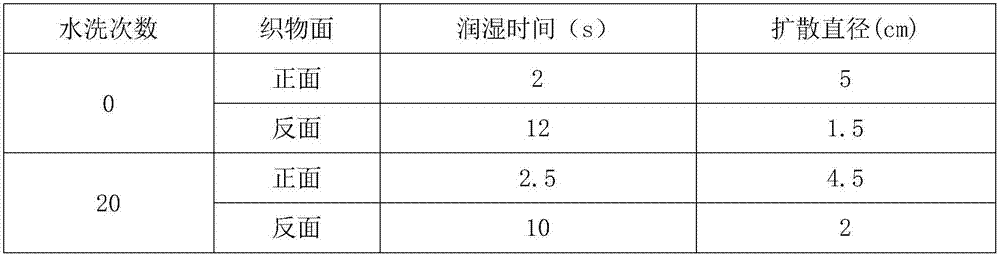

[0028] The present invention is equipped with three kinds of compositions that are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com