Hard alloy forming agent capable of being rapidly dried and material mixing process thereof

A cemented carbide, fast drying technology, used in metal processing equipment, transportation and packaging, etc., can solve the problems of easy segregation, poor shape retention, easy to crack, etc., to balance volatility and mixing stability, Stable and fast drying, the effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

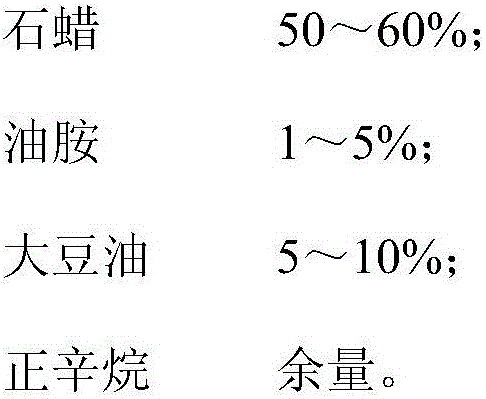

[0020] A fast-drying cemented carbide forming agent of the present invention is composed of the following components by weight percentage, wherein:

[0021] Paraffin 50%;

[0022] Oleylamine (ETHOMEEN) 5%;

[0023] soybean oil 10%;

[0024] The balance of n-octane is 35%.

[0025] A kind of cemented carbide mixing material process based on above-mentioned molding agent of the present invention, comprises the steps:

[0026] A. Premix the above-mentioned molding agent; that is, paraffin wax of 50% of the total weight of the molding agent, oleylamine (ETHOMEEN) of 5% of the total weight of the molding agent, soybean oil of 10% of the total weight of the molding agent and 35% of the total weight of the molding agent % n-octane mixed together;

[0027] B. Seal the cemented carbide powder and the pre-mixed forming agent with heat and mix, so that the forming agent and the cemented carbide powder are evenly mixed; take a certain amount of cemented carbide powder and a certain am...

Embodiment 2

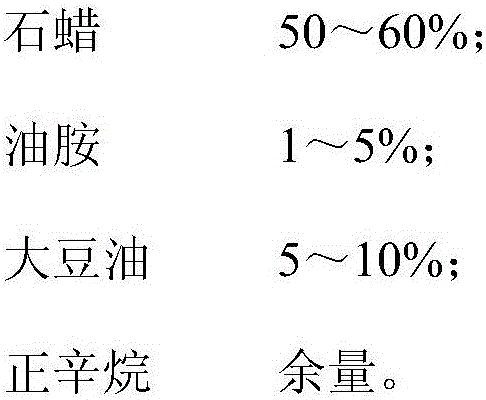

[0037] A fast-drying cemented carbide molding agent of the present invention is different from Embodiment 1 in that the cemented carbide molding agent is composed of the following components by weight percentage, wherein:

[0038] Paraffin 52%;

[0039] Oleylamine (ETHOMEEN) 1%;

[0040] soybean oil 5%;

[0041] The balance of n-octane is 42%.

Embodiment 3

[0043] A fast-drying cemented carbide molding agent of the present invention is different from Embodiment 1 in that the cemented carbide molding agent is composed of the following components by weight percentage, wherein:

[0044] Paraffin 55%;

[0045] Oleylamine (ETHOMEEN) 4%;

[0046] soybean oil 8%;

[0047] The balance of n-octane is 33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com