Patents

Literature

118results about How to "Improve bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

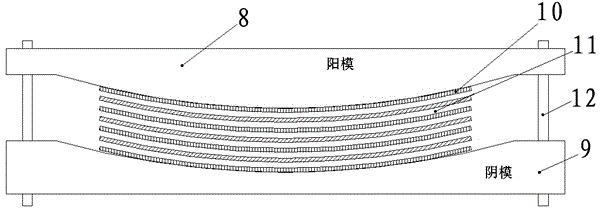

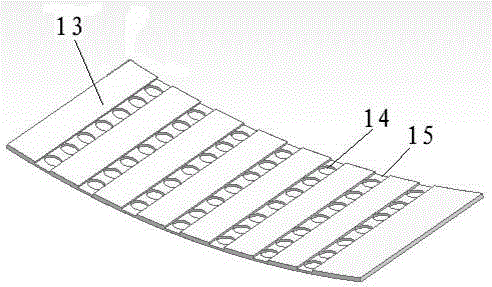

Manufacturing method of bent bamboo furniture and bent bamboo rod pieces

The invention provides a manufacturing method of bent bamboo furniture and bent bamboo rod pieces. The manufacturing method involves manufacturing of the bent bamboo rod pieces and bent bamboo plate pieces. According to the method, bamboo is divided into long-strip-shaped bamboo filaments or bamboo splits after bamboo skin and bamboo pith which can affect the bonding performance are removed; adhesives are arranged on the surfaces of the bamboo filaments or the bamboo splits after the bamboo filaments or the bamboo splits are dried; plate blank is formed in a planar cold press in a cold pressing mode; the plate blank is arranged in a bending forming die in an overlaying mode, pressing is conducted to enable the plate blank to form bent-plate-shaped bent bamboo rod plates, the bent bamboo rod plates and the die are sent into a heating chamber to be heated and cured, after the die is disassembled, according to the requirements of bent bamboo rods, the plates are cut into bent bamboo rods in a sawing mode in the bending direction of the bamboo filaments, and the bent bamboo rod pieces are formed after the surfaces are smoothed; meanwhile, the bamboo is sawed off at fixed length and divided into rectangular bamboo strips, assembly is conducted according to the requirements of the plate blank, the plate blank is arranged in a drying and shaping die to be compressed, and drying, heating and shaping are conducted to form bent bamboo plate piece panels; the surfaces of the panels are coated with adhesives, the panels are laid in a heat curing die, and pressing, heating and curing are conducted to obtain the bent bamboo plate pieces.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

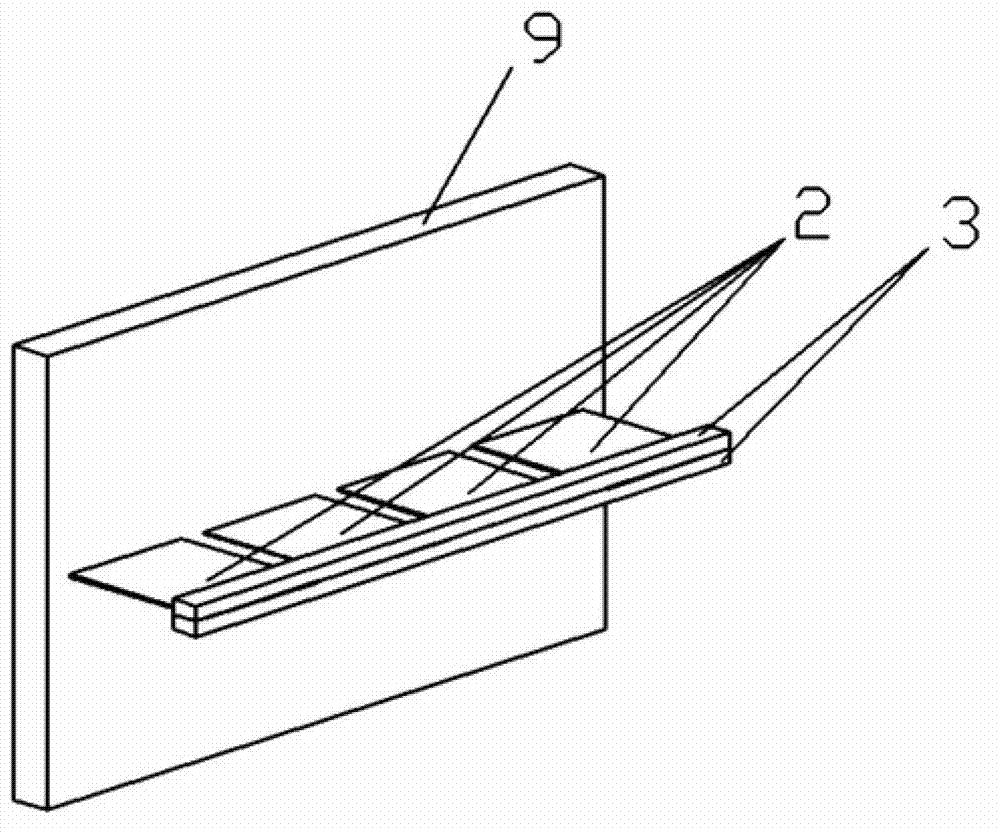

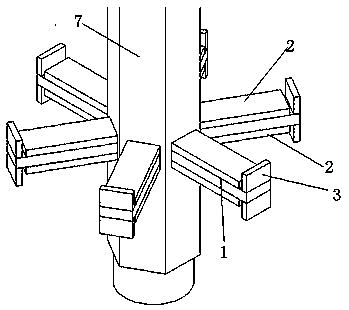

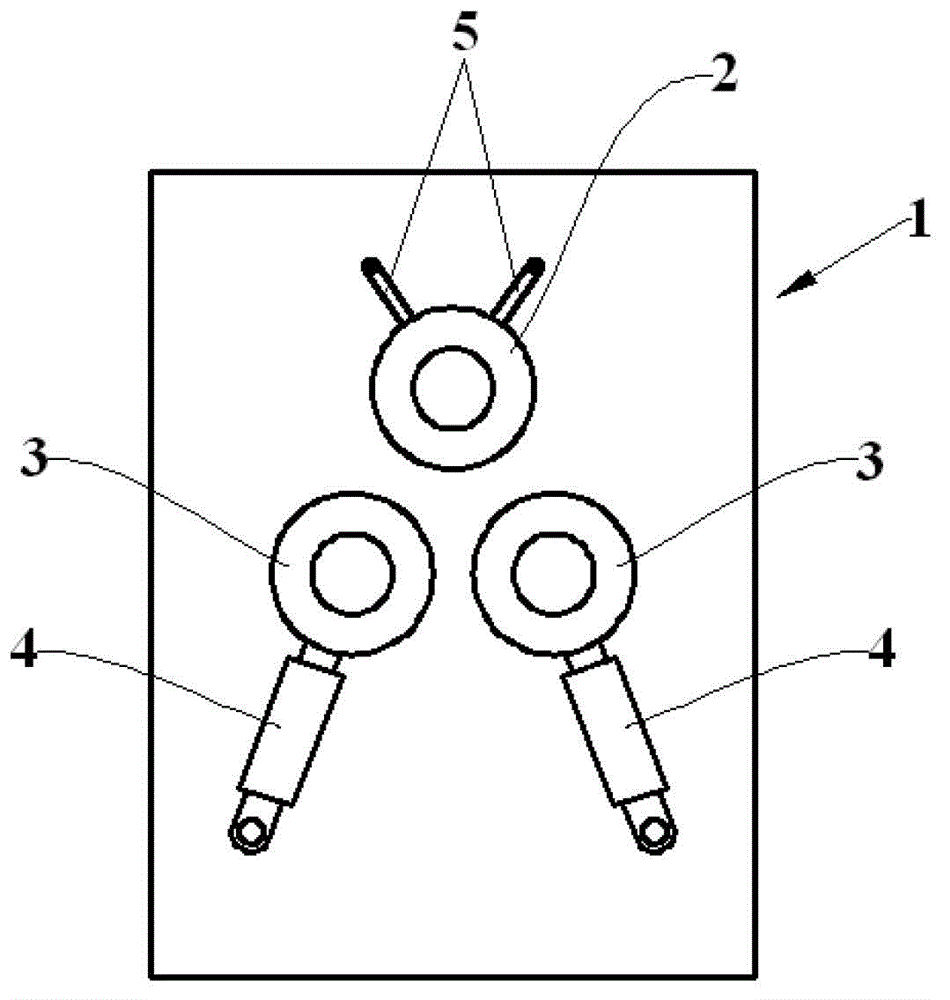

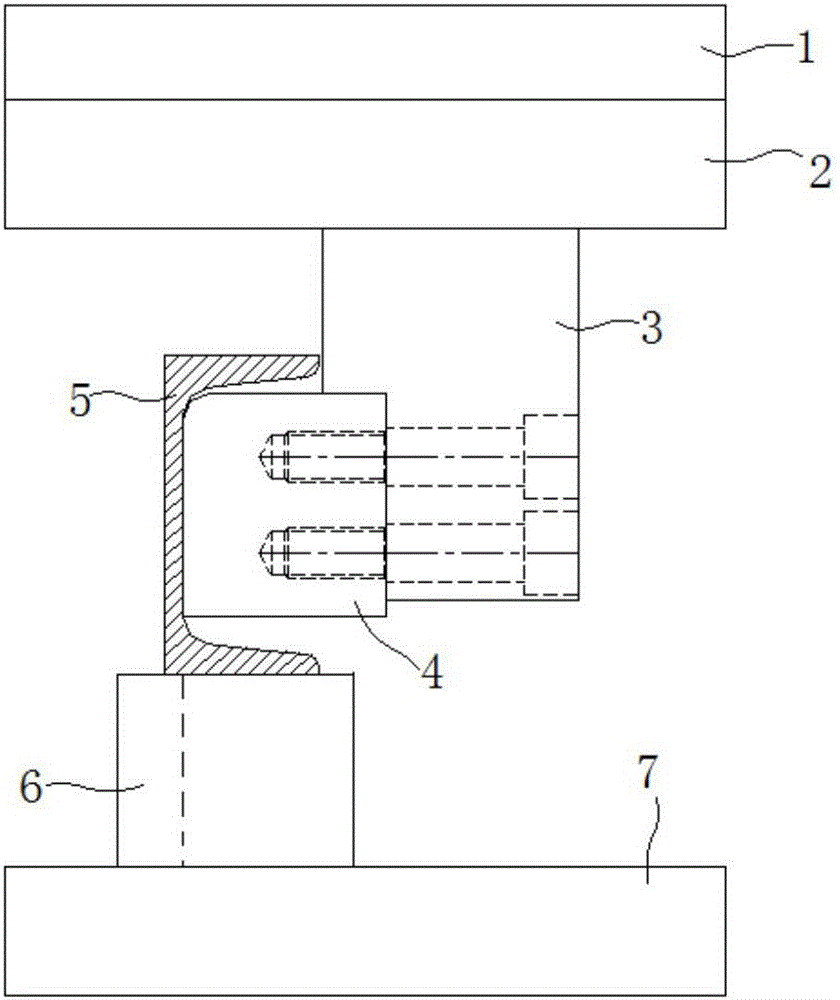

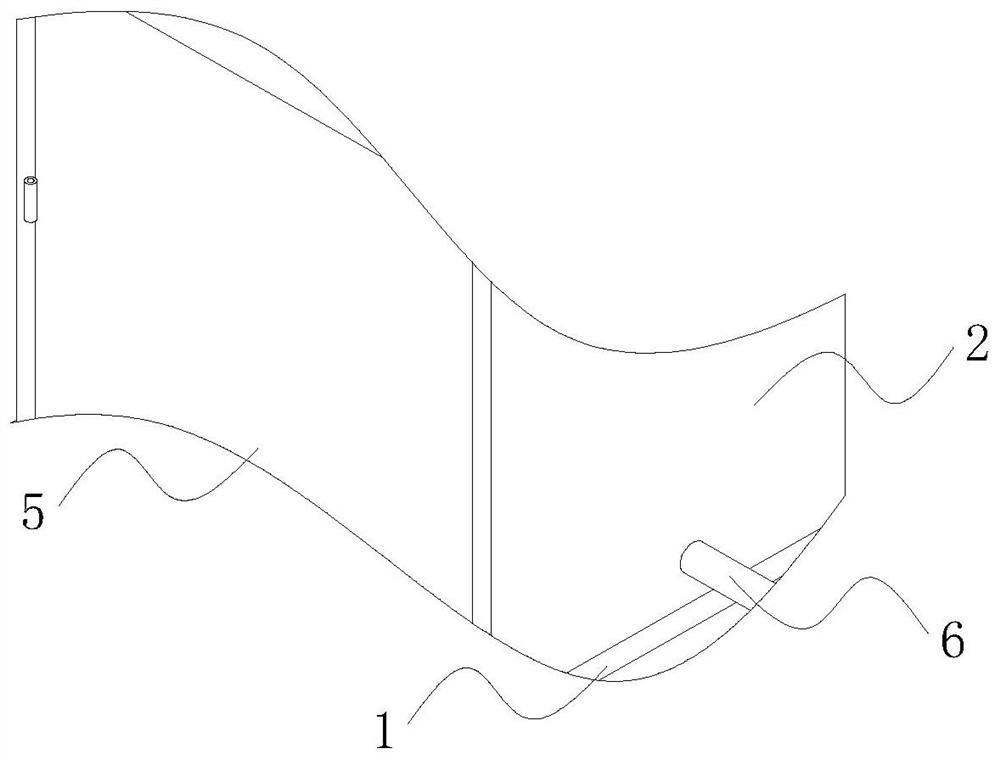

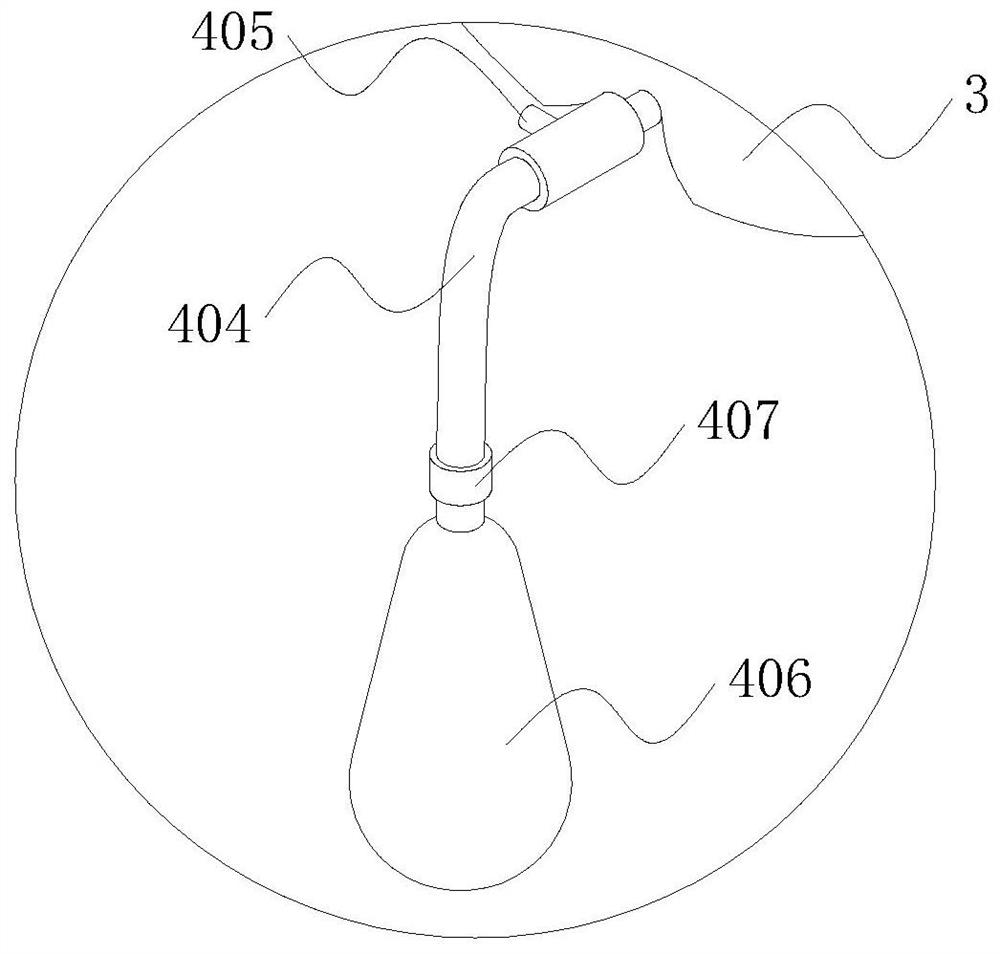

Piezoelectric energy harvesting device for bus

InactiveCN103166503ALarge output energyPlay the role of adjusting the vibration amplitudeBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesAdhesiveMechanical energy

The invention relates to a piezoelectric energy harvesting device for a bus. The piezoelectric energy harvesting device comprises a plurality of cantilever beams of piezoelectric vibrators, the cantilever beams are horizontally and parallelly arranged, the ends of the cantilever beams on one side share a mass block (3), the mass block is connected with a lever (5) and used for increasing inertia of the piezoelectric vibrators and transferring stress, the lever leads out vibration, piezoelectric ceramic pieces (2) are positioned on the upper side and the lower side of a cantilever beam substrate (1), the piezoelectric ceramic pieces (2) and the substrate (1) are adhered through conductive adhesives, so that weak mechanical energy in an environment is converted into electric energy, a piezoelectric energy storage device comprises a voltage reduction circuit, a rectifier circuit, a filter circuit and a protection circuit, and stable direct current used or stored by loads is obtained when unstable current generated by the piezoelectric vibrators flows through each regulating circuit. The stored energy can be used for low-power instruments such as a bus detector, an electronic display guideboard, a self-service ticketing device and front-rear television inspection systems, energy-saving effects are achieved, and the piezoelectric energy harvesting device is simple in structure.

Owner:WUHAN UNIV OF TECH

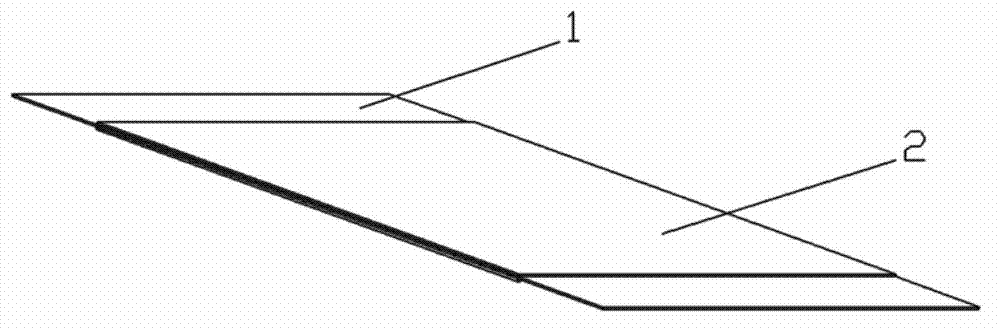

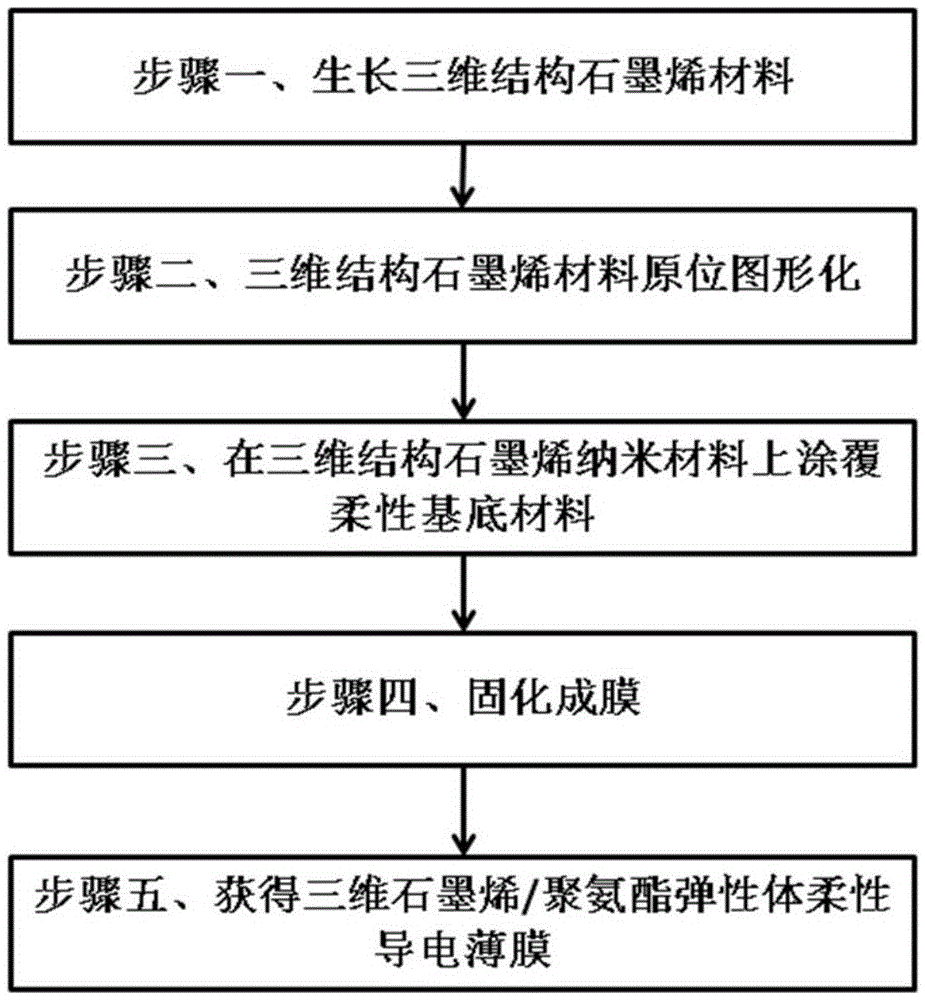

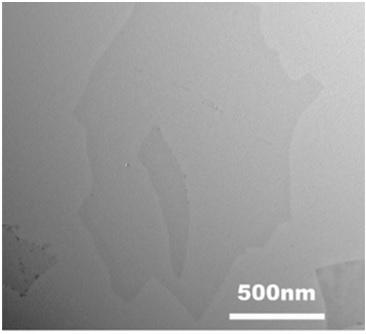

Preparation method of graphical three-dimensional graphene/polyurethane flexible conductive film

InactiveCN105590703AIncrease elasticityImprove flexibilityCarbon-silicon compound conductorsCable/conductor manufactureCvd grapheneSmart transducer

The invention relates to a preparation method of a graphical three-dimensional graphene / polyurethane flexible conductive film. The preparation method comprises the steps of growing a three-dimensional structured graphene material; performing original-position patterning; applying a flexible substrate material on the three-dimensional structured graphene material; solidifying the flexible substrate material for forming a film; and directly peeling from a growth substrate for obtaining the three-dimensional graphene / polyurethane flexible conductive film, wherein the three-dimensional graphene has a three-dimensional continuous structure with a nanometer-size. The film substrate is made of a polyurethane elastomer high-polymer material with certain flexibility. Patterning technology comprises the steps of nanoimprinting, ion beam direct writing, etc. The graphical three-dimensional graphene / polyurethane flexible conductive film has high performance at aspects of electric conductivity, flexibility, etc. The graphical three-dimensional graphene / polyurethane flexible conductive film has wide application prospect in the fields of nanometer photoelectric device, super-capacitor, flexible intelligent sensor, wearable equipment, electronic skin and flexible solar cell.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

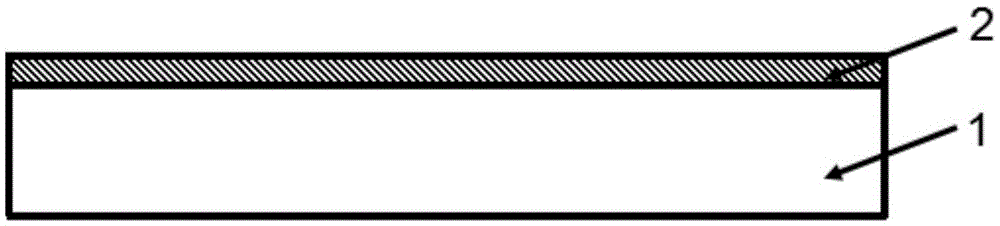

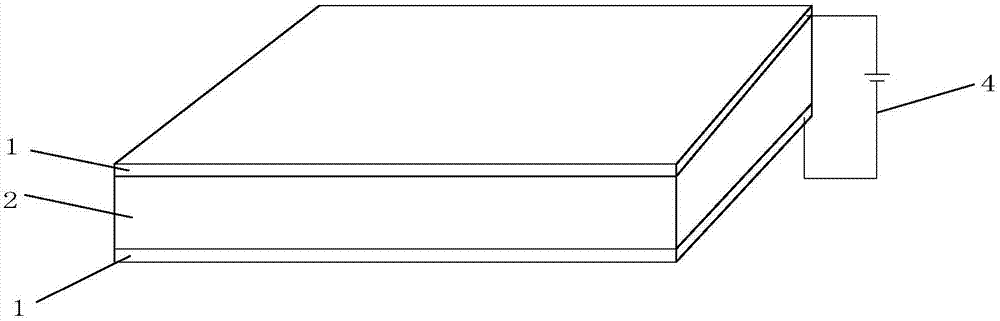

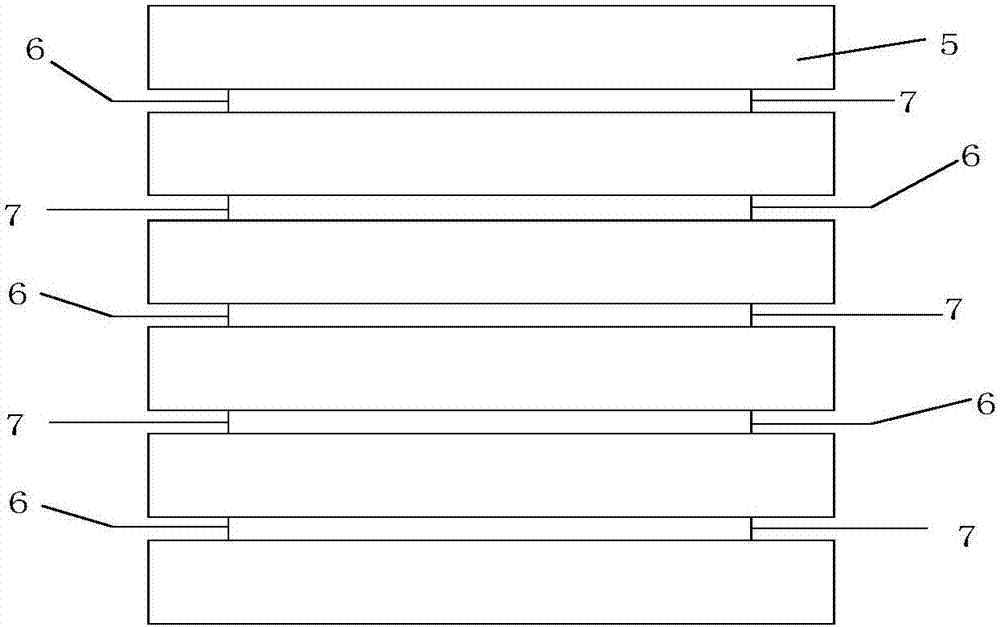

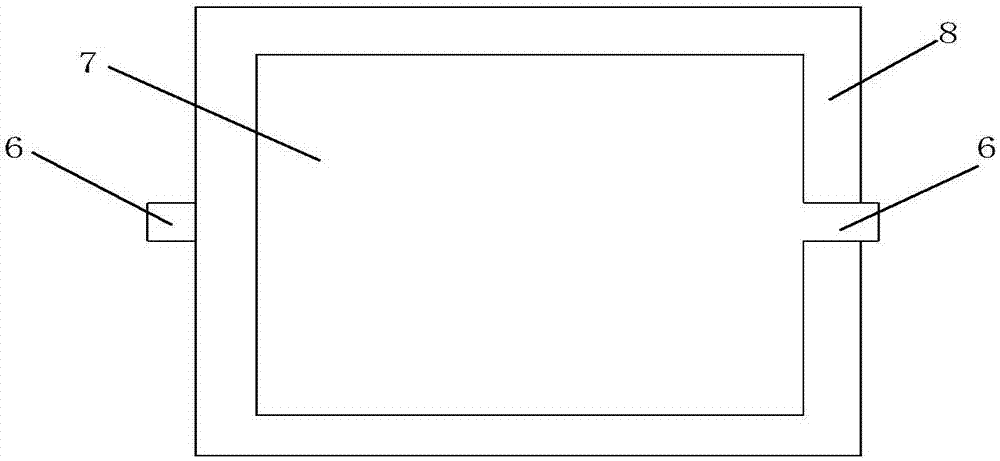

Graphene electrode dielectric elastomer driver

PendingCN107493035AExcellent performance indexHigh electrical conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesGraphene coatingGraphene electrode

The invention relates to a graphene electrode dielectric elastomer driver. Graphene electrodes are arranged on the two side surfaces of the dielectric elastomer to form a sandwich structure, and a graphene electrode dielectric elastomer thickness displacement driver and a graphene electrode dielectric elastomer plane displacement driver are obtained by deformation in different directions; each graphene electrode comprises a graphene layer and an extraction electrode; the graphene layer is a graphene thin film, a graphene coating layer or a graphene composite material layer; and the graphene electrode dielectric elastomer driver is a graphene electrode single-layer dielectric elastomer driver, a graphene electrode stacked type dielectric elastomer driver, a graphene electrode tubular dielectric elastomer driver or a graphene electrode roll type dielectric elastomer driver. The graphene electrode dielectric elastomer driver can be widely applied to the fields of a robot, aerospace, a mechanical arm, a joint prosthesis, an automobile, artificial muscle, airship tail vane adjustment, a diaphragm pump, intelligent driving, biological medical treatment and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

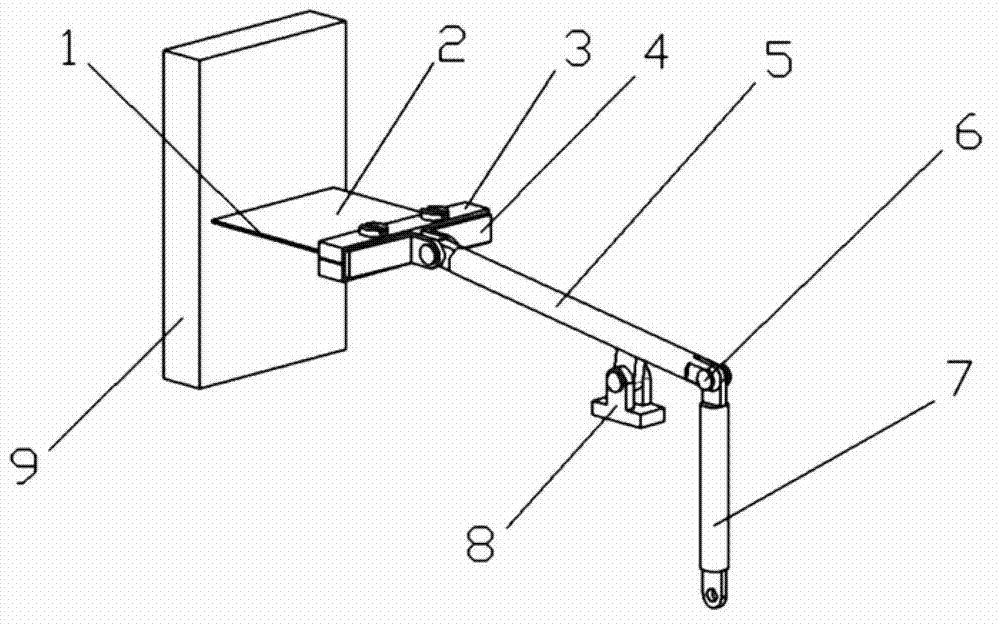

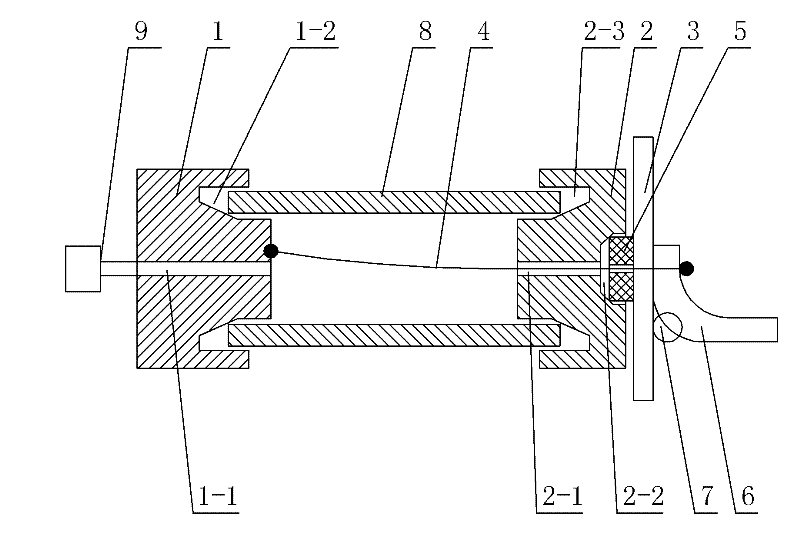

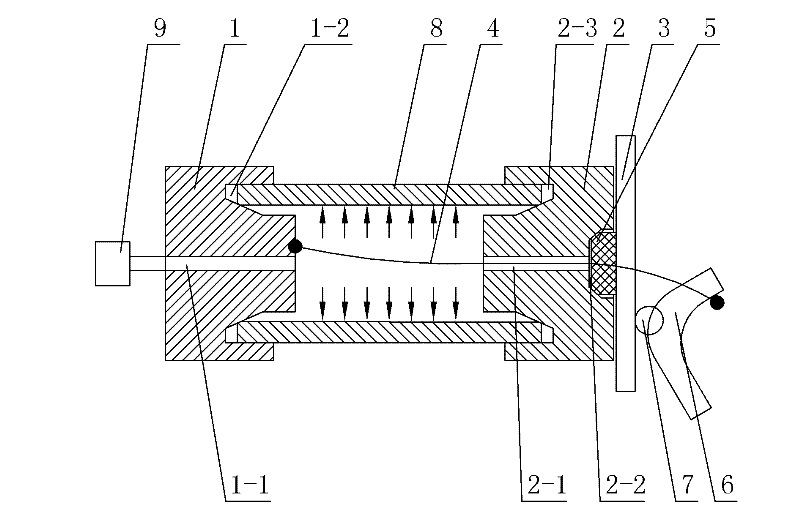

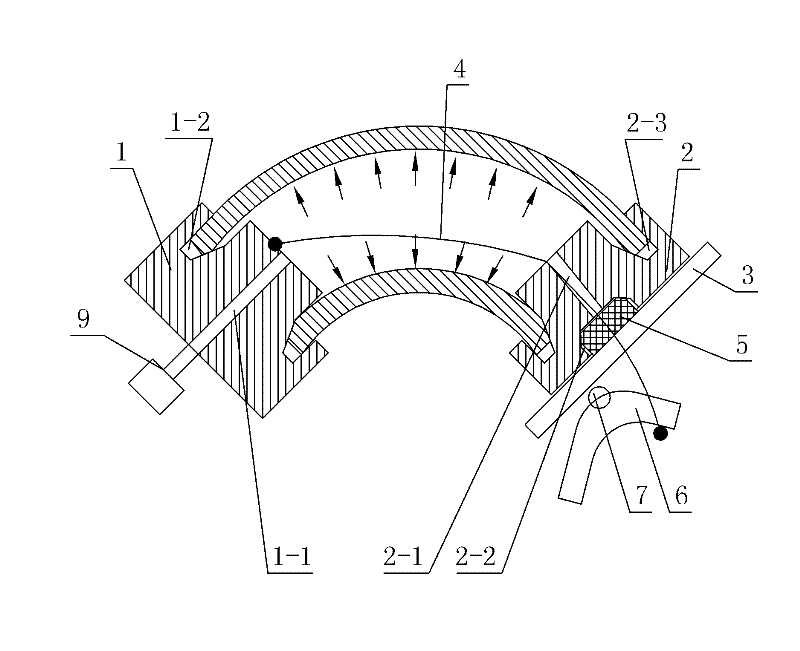

Device and method for bending pipe with sealed end by using tension rope or plug

The invention discloses a device and a method for bending a pipe with a sealed end by using a tension rope or plug, which relate to a pipe bending device and a pipe bending method. The invention solves the problems of unreliable sealing and low forming efficiency in a pipe internal pressure bending forming process. In the device, plugs are arranged at the two ends of a pipe, the plugs and the pipes are sealed by the annular grooves with slant walls on the inner sides of the plugs, a tension rope sealing ring is arranged in a counter bore, the outer end face of the tension rope sealing ring isprovided with a pressure plate, one end of the tension rope is connected with the inner end face of the first plug, the other end of the tension rope passes through a tension rope central hole, the tension rope sealing ring and the pressure plate to be connected with a tensioning wrench, and the tensioning wrench is arranged on the pressure plate through a rotating shaft. The method comprises: assembling the bending device, and tensioning the rope by using the tensioning wrench; filling high-pressure medium under the pressure of 0.5 to 100MPa into the pipe by using a pressurizing cylinder, and bending the pipe; and discharging the high-pressure medium, taking the tensioning rope and plugs, and accomplishing the bending forming of the pipe. The device and the method are used for bending forming of pipes.

Owner:HARBIN INST OF TECH

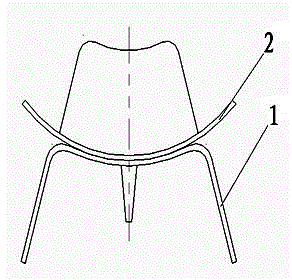

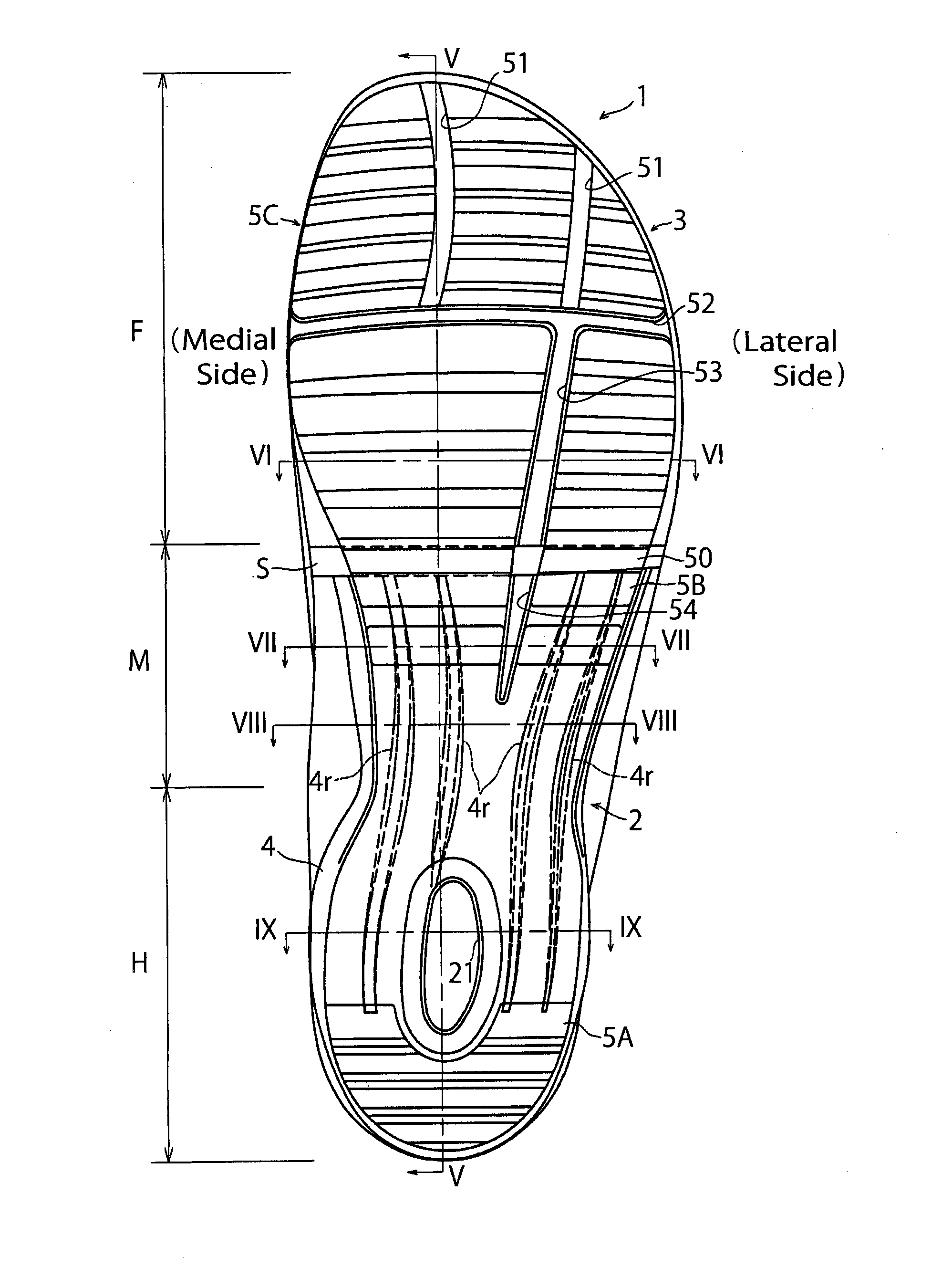

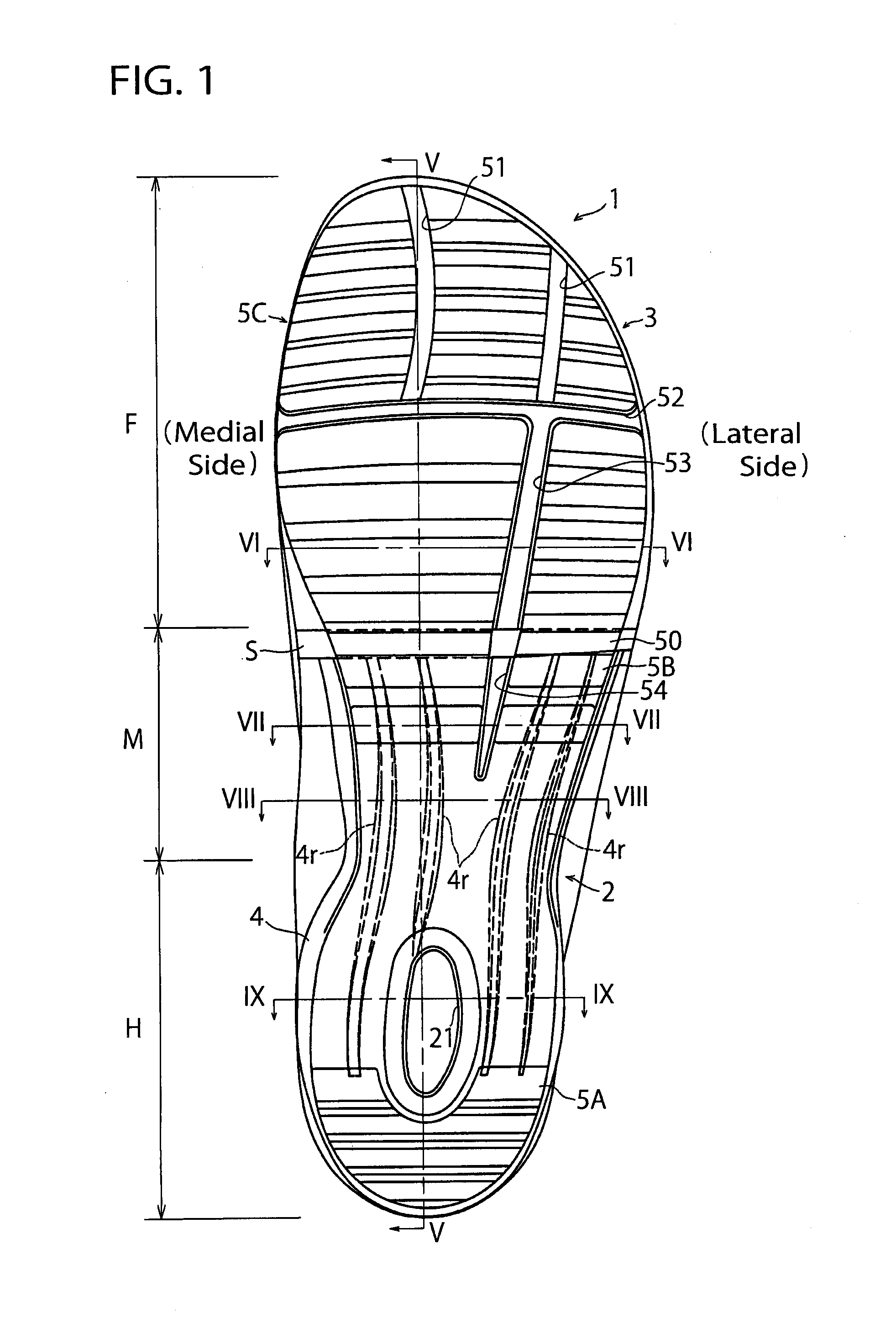

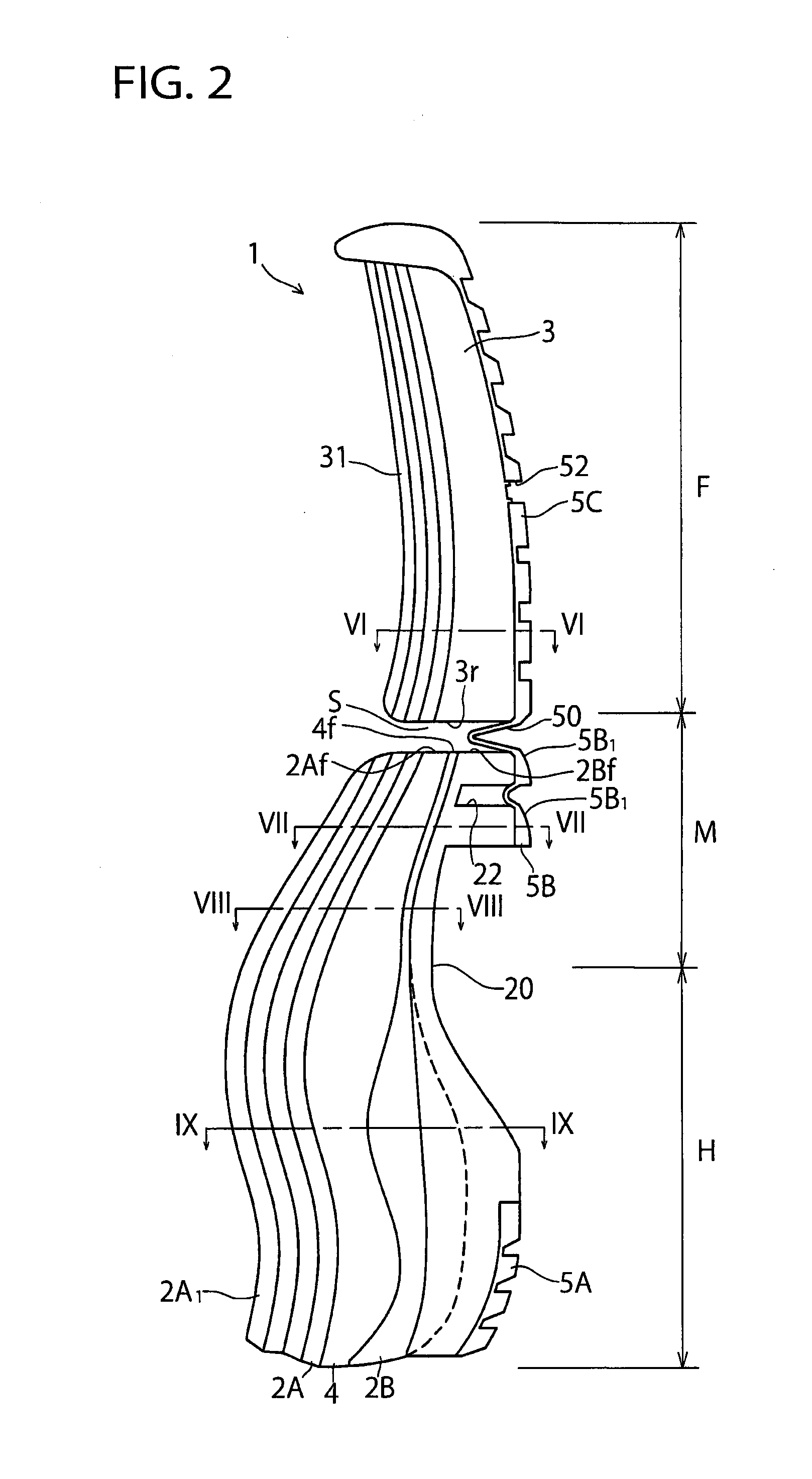

Sole Structure for a Shoe

InactiveUS20160081427A1Improve bending deformationDeterioration of cushioning performance of the rear foot region of the sole structure can be preventedSolesFoot regionCurve shape

The invention provides a sole structure that can not only prevent deterioration of cushioning performance and improve cushioning properties but also enhance flexibility. The sole structure 1 includes a rear foot sole 2 disposed at a rear foot region of the sole structure 1, a forefoot sole 3 disposed at a forefoot part F of the sole structure 1, and a plate 4 disposed at the rear foot region of the sole structure 1 and having an upwardly convexly curved shape along a heel part H to a midfoot part M of the sole structure 1. A front end portion 4f of the plate 4 is disposed at a front end portion 2Af, 2Bf of the rear foot sole 2 (i.e. upper and lower soles 2A, 2B). There is formed a gap S in front of the front end portion 4f of the plate 4 between the front end portion 2Af, 2Bf of the rear foot sole 2 and a rear end portion 3r of the forefoot sole 3.

Owner:MIZUNO CORPORATION

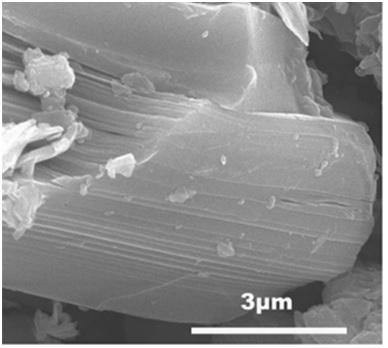

Mxene-PDMS composite foam with hollow structure, and preparation method and application of Mxene-PDMS composite foam

ActiveCN110387061AImprove bending deformation abilityReduce oxidationForce measurement using piezo-resistive materialsMaterials science

The invention relates to Mxene-PDMS composite foam with a hollow structure, and a preparation method and application of the Mxene-PDMS composite foam. A sensing active part of a sensor is the Mxene-PDMS hollow foam. In the hollow Mxene-PDMS foam, Mxene is dispersed in inner surfaces of the foam holes. According to the invention, the Mxene-PDMS foam with a well-bent hollow structure can be obtainedby optimizing the impregnation times of Mxene nanosheets in a process of preparing the sensor and by optimizing the treatment steps of the usage amount of a PDMS curing agent required in the preparation process and the like. Due to lap joint of a Mxene sheet layer on the inner surfaces of the holes, the Mxene sheet layer is shaken when being subjected to external micro stimulation, and the Mxenesheet layer is more sensitive to detection under micro pressure. According to the design of the hollow structure, stable circulation performance and sensitivity can be achieved when large-angle bending and compression are carried out.

Owner:BEIJING UNIV OF CHEM TECH

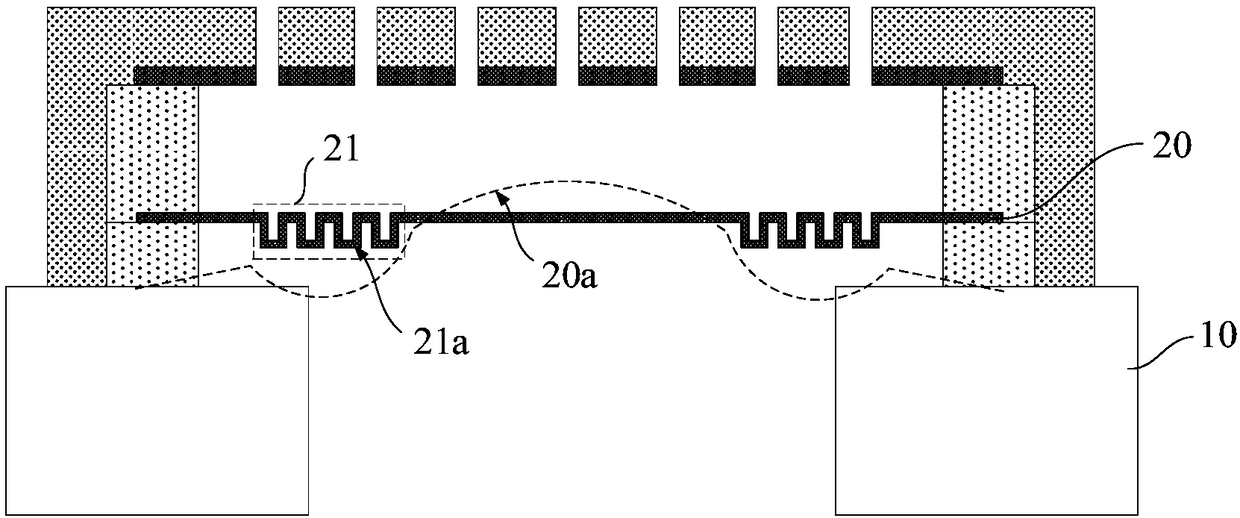

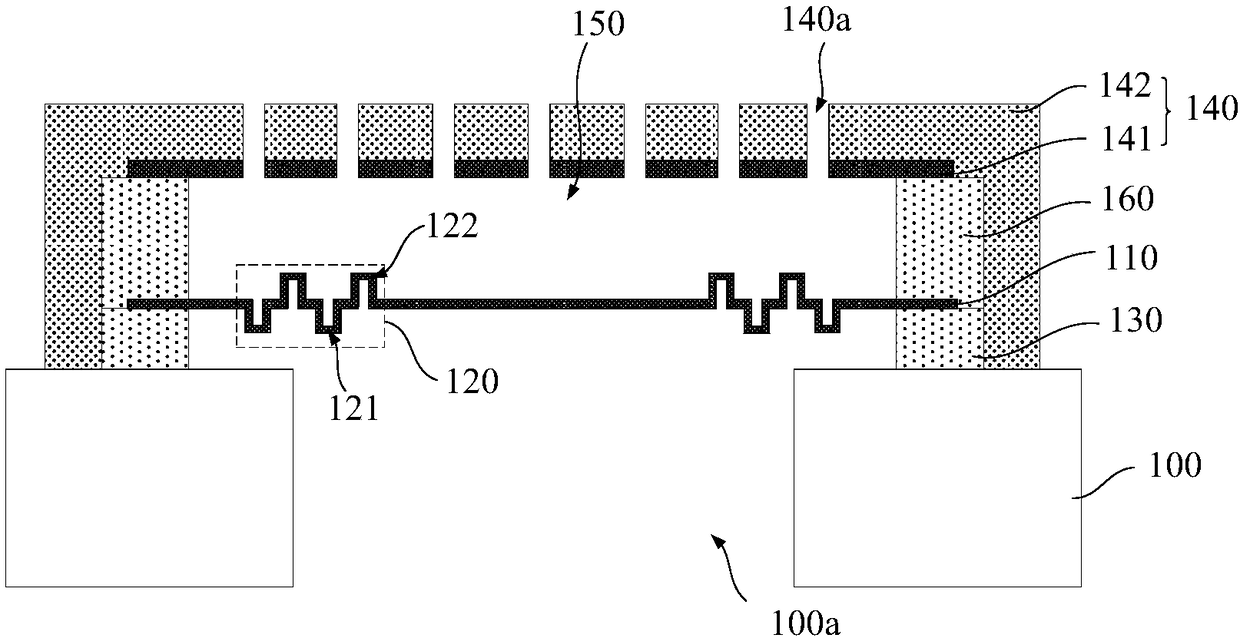

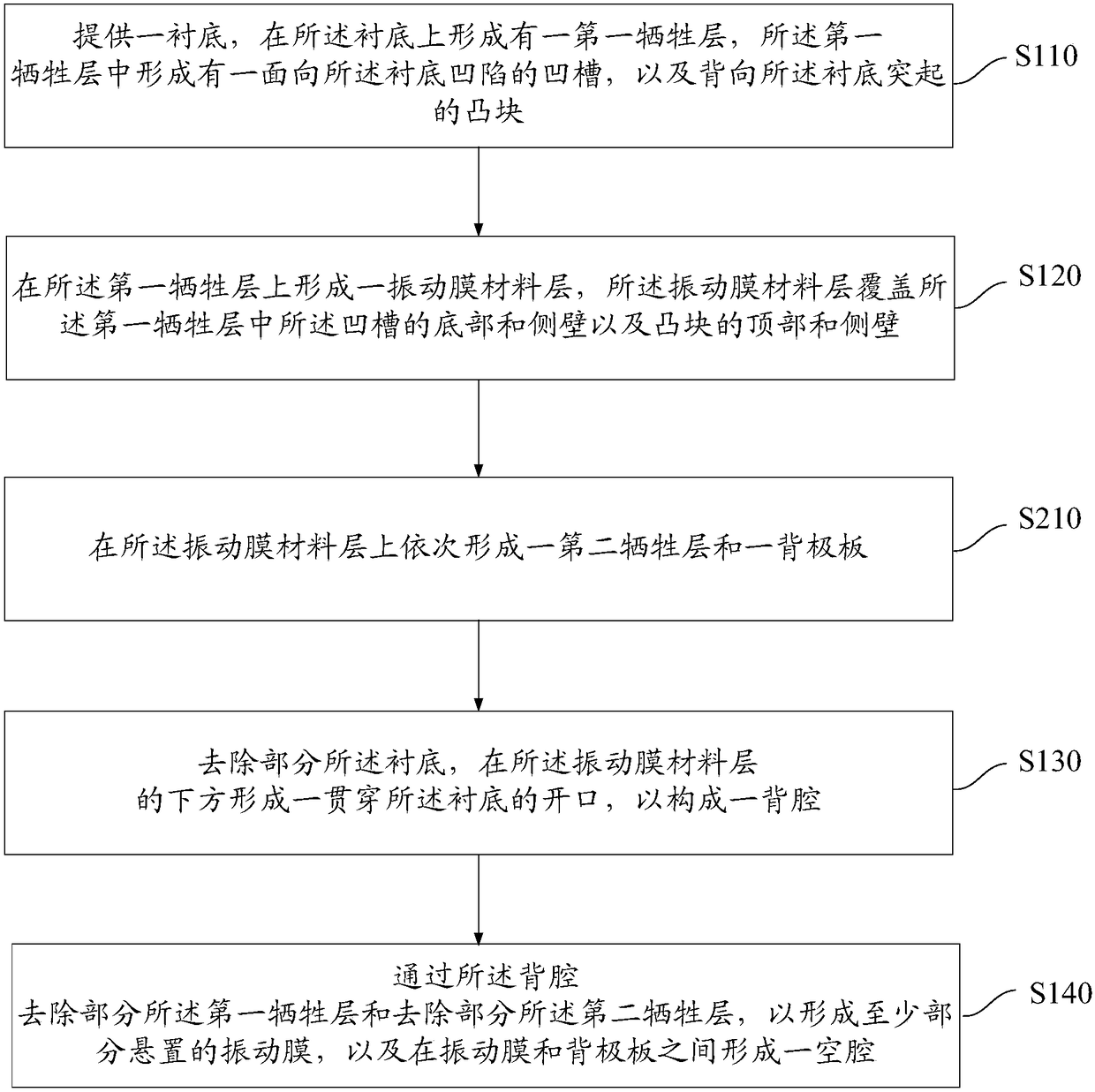

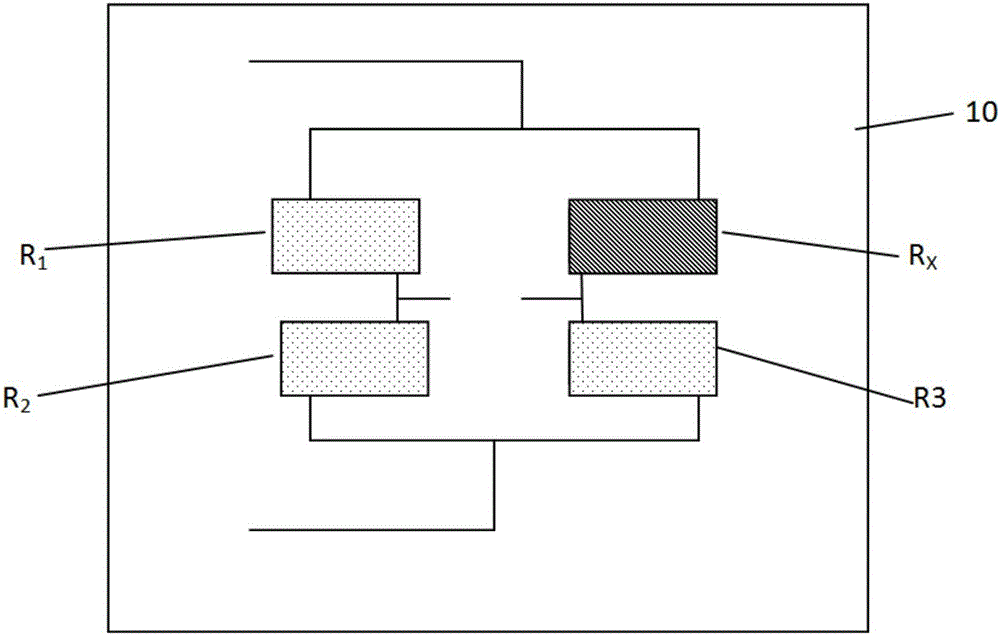

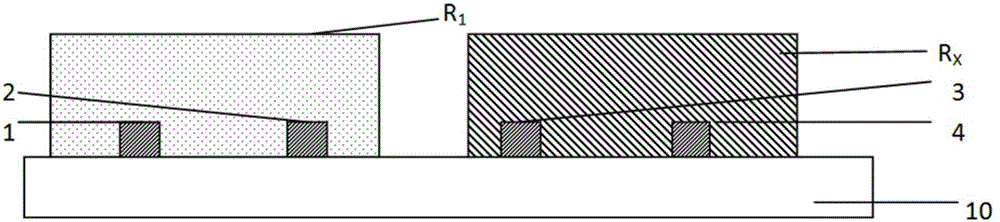

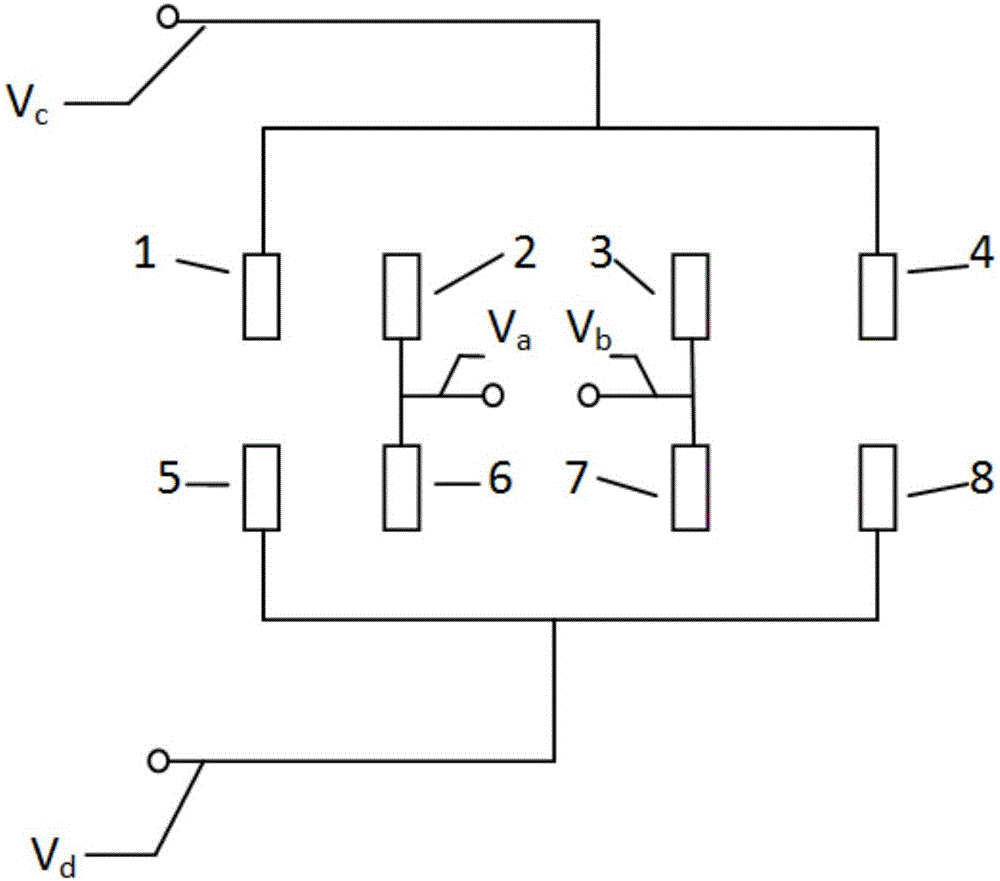

MEMS device and forming method thereof

InactiveCN108996466AIncreased reproducibility sensitivityHigh mechanical strengthTelevision system detailsImpedence networksVibrating membraneInternal stress

The invention provides an MEMS device and a forming method thereof. The device includes a vibrating membrane forming on a substrate. The vibrating membrane includes a first protrusion and a second protrusion that protrude in opposite directions. The first protrusion protrudes toward the substrate. Among a plurality of protrusions, the protrusions respectively extend in two different directions, thereby avoiding occurrence of internal stress in a corresponding direction due to the corrugation. Therefore, the internal stress in the vibrating membrane can be effectively released when the vibrating membrane is formed, and additional generation of the internal stress can be prevented, so that the formed deformation amount of the vibrating membrane is improved, and the sensitivity of the MEMS device is improved.

Owner:SEMICON MFG INT TIANJIN +1

Flexible graphene composite material pressure sensor and preparation method thereof

ActiveCN106382998ASave raw materialsSimple processFluid pressure measurement using ohmic-resistance variationForce measurementScreen printingInterconnection

The invention discloses a flexible graphene composite material silk screen printing pressure sensor and a preparation method thereof. The flexible graphene composite material silk screen printing pressure sensor comprises a flexible substrate, an electrode and metal interconnection line, a force-sensitive resistive layer and a reference resistive layer. The electrode and metal interconnection line, the force-sensitive resistive layer and the reference resistive layer are printed on the flexible substrate in turn through the mode of silk screen printing. The invention also discloses a preparation method of the flexible graphene composite material silk screen printing pressure sensor. The method is characterized in that the required sensor and the circuit thereof are enabled to be graphical so as to perform large-scale industrial production. The senor is light and flexible and has the advantages of being wearable, attachable and great in tensile deformation performance.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

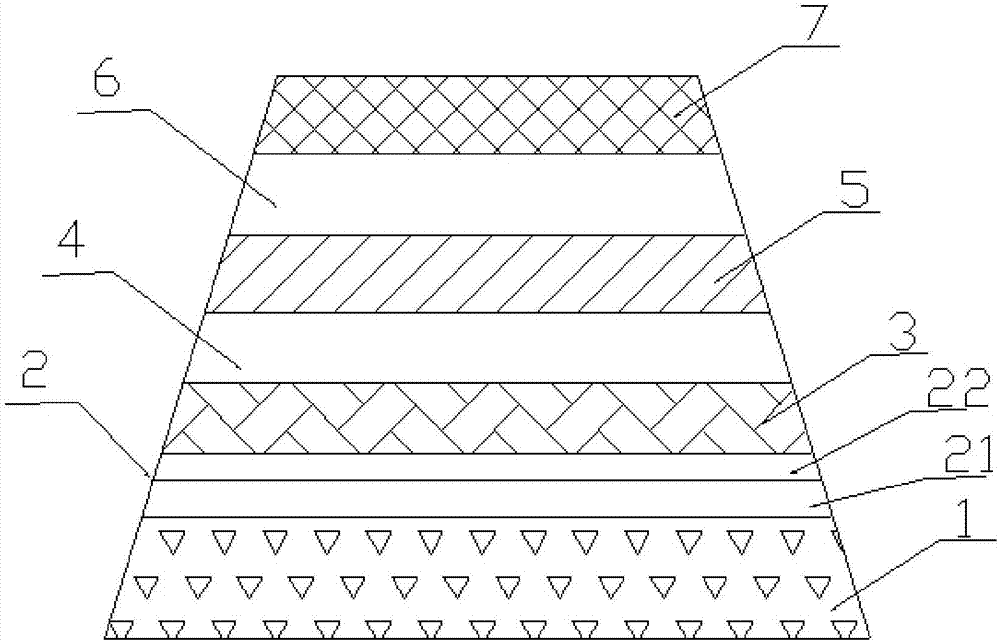

Asphalt pavement structure suitable for Tibet plateau area and construction method thereof

PendingCN106868972AImprove road performanceImprove bending deformationIn situ pavingsCushionSubgrade

The invention relates to an asphalt pavement structure suitable for the Tibet plateau area and a construction method thereof. The asphalt pavement structure suitable for the Tibet plateau area sequentially comprises a cushion layer, a semi-rigid base layer, a penetrable layer, an SBR emulsified asphalt lower sealing layer, a lower surface layer, a bonding layer and an upper surface layer from bottom to top. The construction method of the asphalt pavement structure suitable for the Tibet plateau area comprises the following steps of (1) tamping and leveling a roadbed, (2) laying the cushion layer on the roadbed, (3) laying a cement stabilized sand gravel layer on the cushion layer, (4) flatly laying a low-shrinkage super-early-strength cement stabilized macadam layer, (5) laying the penetrable layer, (6) laying the SBR emulsified asphalt lower sealing layer, (7) laying the lower surface layer, (8) laying the bonding layer, and (9) laying the upper surface layer.

Owner:青海省交通科学研究院 +1

Nano polyvinyl chloride pipe and preparation method thereof

InactiveCN101157784AShorten plasticizing timeGood uniformity of plasticizationPolyvinyl chlorideResin-Based Composite

The invention relates to a nanometer polyvinyl chloride pipe and a preparation method thereof. According to weight ratio, raw materials of the nanometer polyvinyl chloride pipe comprise nanometer polyvinyl chloride resin, calcium carbonate, and PME-100 strengthening and toughening agent, etc. The preparation method is that: first, the raw materials needed are fully mixed in a high level mixing pot and a low level mixing pot; then the materials mixed are transported to an extruder production line to do extruding molding, thereby gaining the nanometer polyvinyl chloride pipe. The invention is characterized in that the invention is not only environment-friendly, but also solves the problems of insufficiency of thermal stability, initial coloring and products reddened and zinc burned, bad weather resistance and copper erosion, etc. During the mixing process of the preparation method, the plasticizing time is shortened, leading to a good plasticizing uniformity and being in favor of the basic extrusion molding process to the modification polyvinyl chloride. The mechanical property of the invention is distinctively higher than the common polyvinyl chloride resin and nanometer blending composite resin. The anti-impact performance and other performances are greatly enhanced The shock strength is two times the common resin products, and in particular the products has good shock strength in low temperature; in addition, the invention has good bending performance, thus being applied to no digging laying and repairing, etc.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK

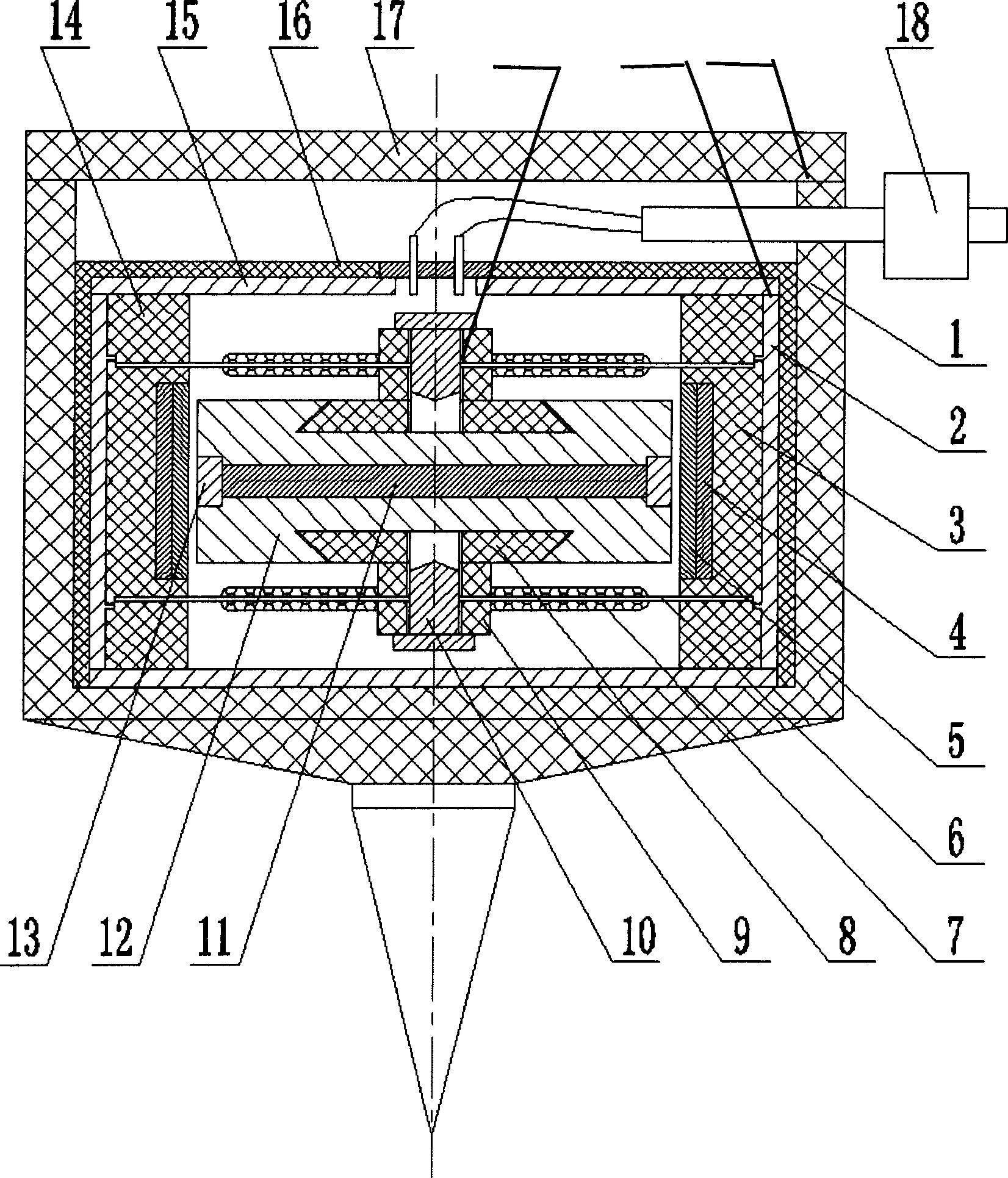

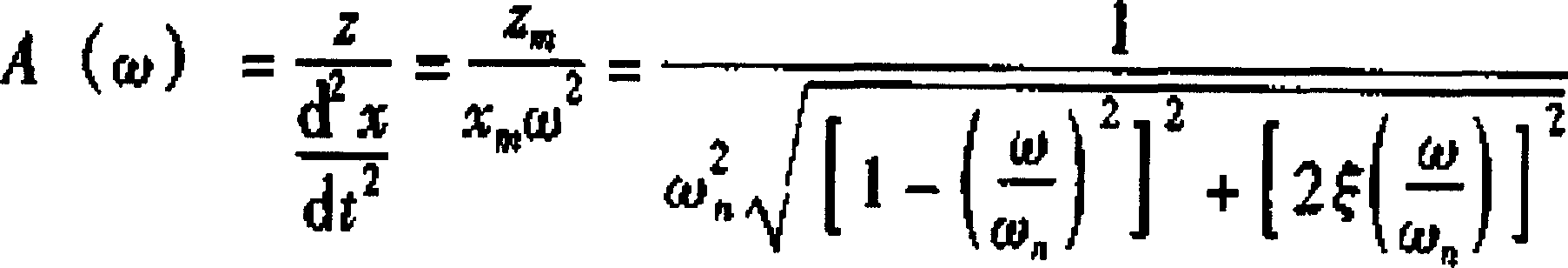

Core of piezoelectric acceleration seismic detector

InactiveCN1800878AImprove collection effectTaking into account low frequency signalsSeismic signal receiversElectricityVibration amplitude

The machine core for piezoelectric acceleration detector comprises: arranging a inertial groupware between two piezoelectric conversion members and fixing three in one piece; embedding the permanent magnet in center of inertial groupware between two magnetic pole pieces and an insulation cap outside the magnetic pole piece; crossing a fix screw the center hole of conversion member to fix two members on outside of the magnetic pole pieces; supporting the conversion members and inertial groupware on spring-flake insulation vibrator bracket and insulation spacing ring; embedding a vortex ring inner side of the vibrator bracket. This invention separates the damping source and inertial body, and solves the problem in the current technique. The piezoelectric detector with this invention has high output amplitude, strong anti-aftervibration ability and broad frequency band.

Owner:SHANDONG CHANGAN TEYI OPTICAL TECH

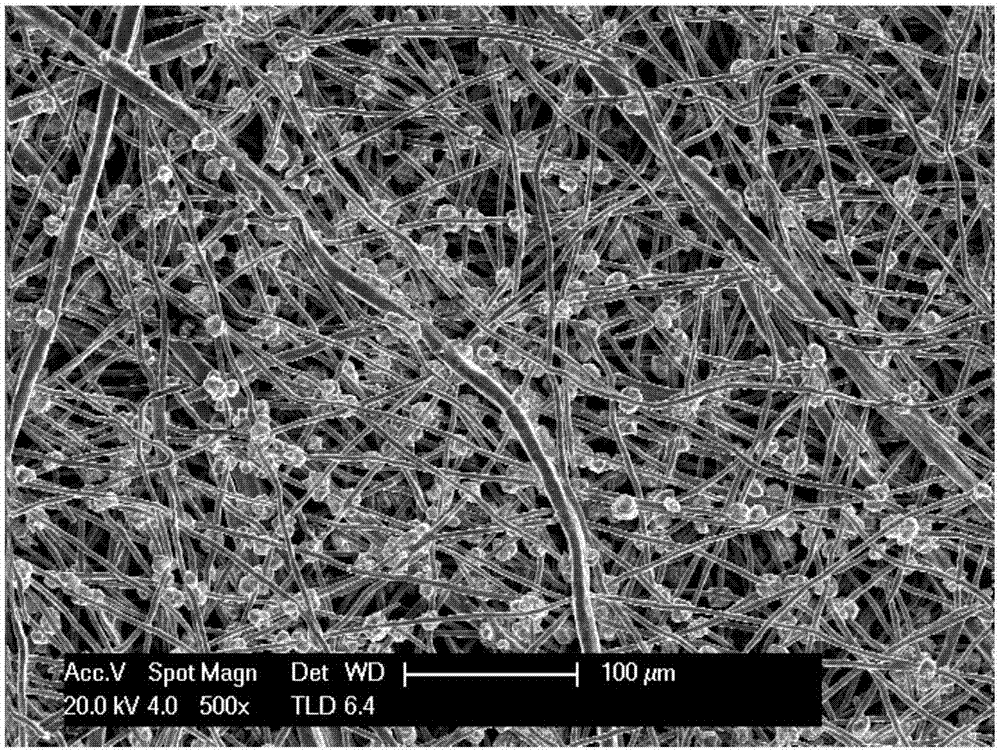

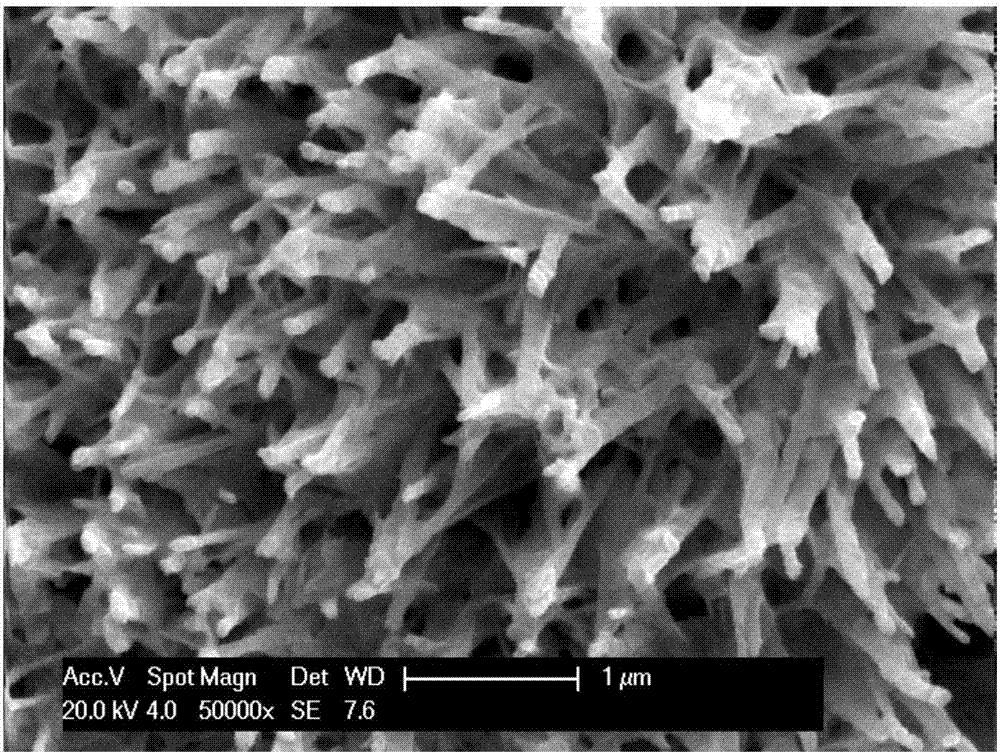

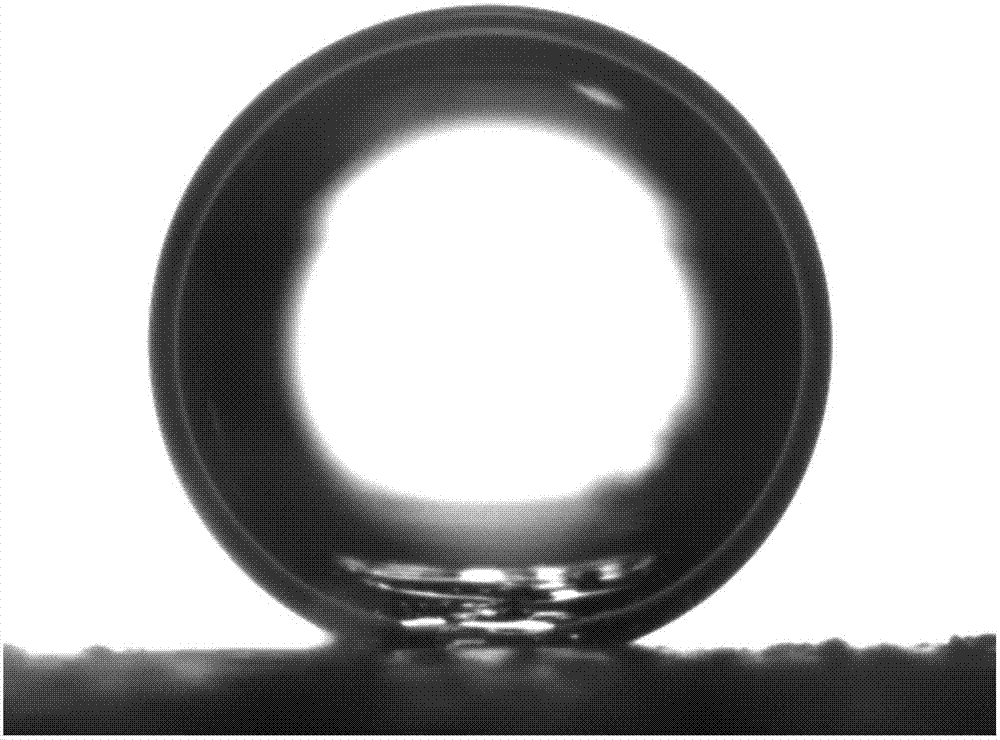

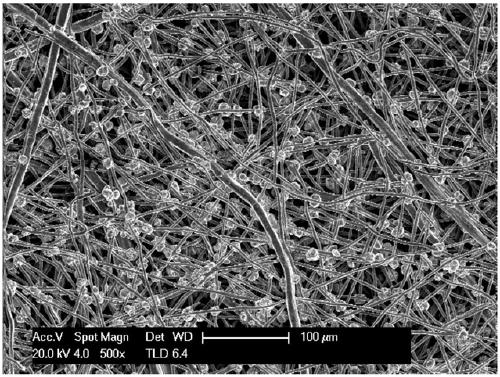

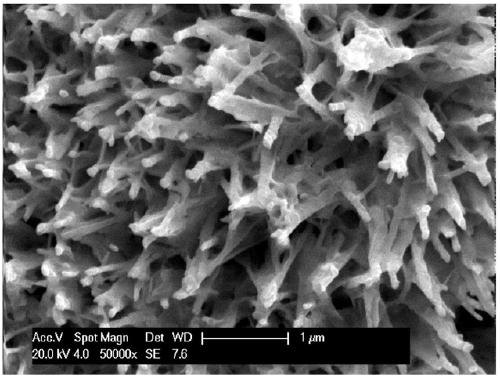

Preparation and using methods of ultra-infiltrating strain-resistant stainless steel fiber felt for emulsion separation

ActiveCN106929894AHigh strengthImprove toughnessAnodisationNanotechnologyMicro nanoStainless steel fiber

The invention relates to preparation and using methods of ultra-infiltrating strain-resistant stainless steel fiber felt for emulsion separation. Firstly, micron-sized copper particles are electrically deposited on stainless steel fibers through a double-anode electroplating method, and then the copper particles are oxidized into copper hydroxide of a micro-nano structure through an electrochemical oxidation method. The ultra-infiltrating characteristics such as super-hydrophilicity and super-hydrophobicity are obtained after modification of different surface energy substances, and efficient separation of an oil-water stratified mixture and oil-in-water emulsion or water-in-oil emulsion is achieved. According to the methods, facilities and the process are simple, operation is convenient, raw materials are easily obtained, cost and energy consumption are low, and the methods are suitable for surface roughening of other stainless steel products made of the same materials and can be applied to industrial production on a large scale.

Owner:SOUTHEAST UNIV

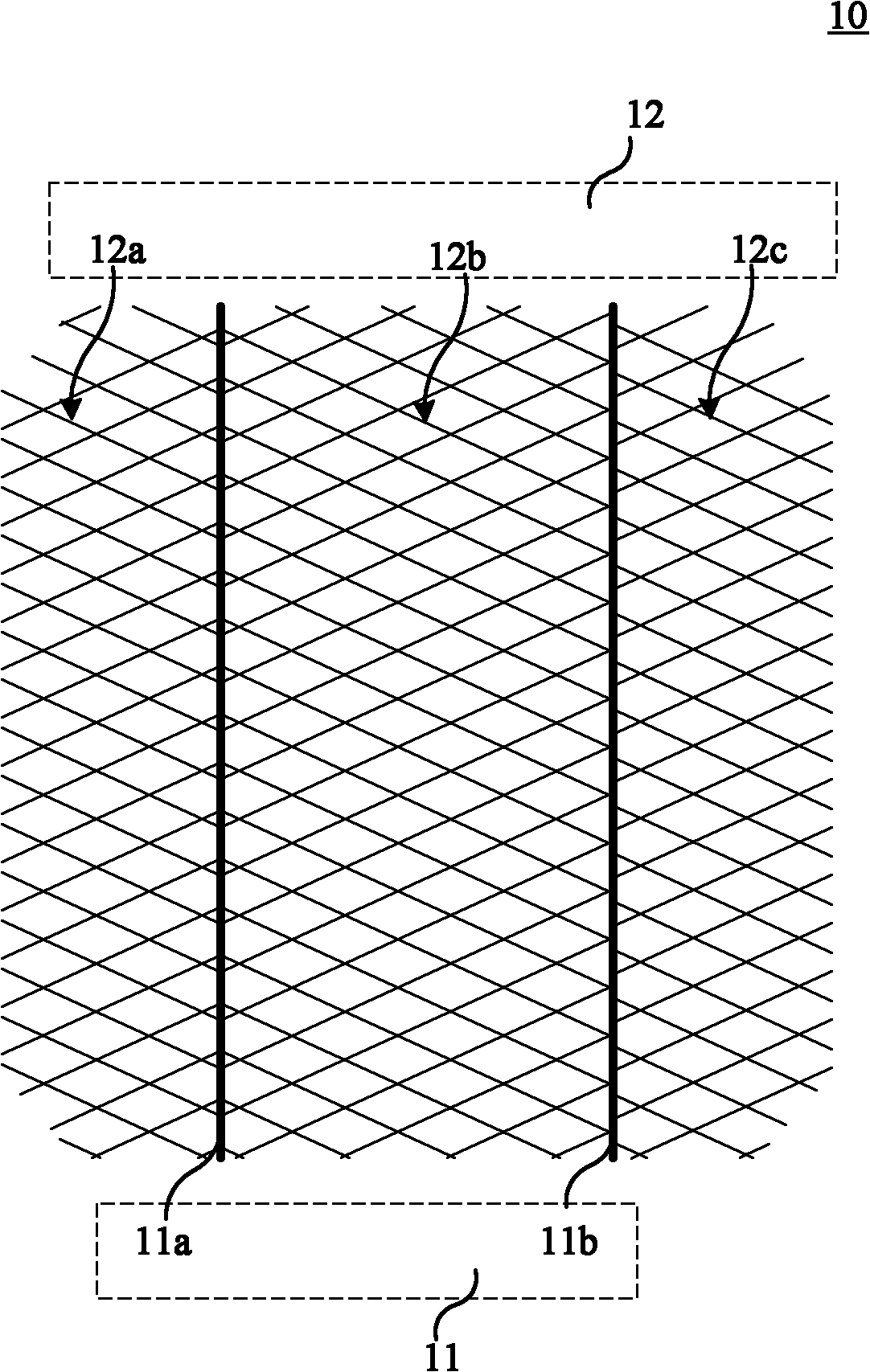

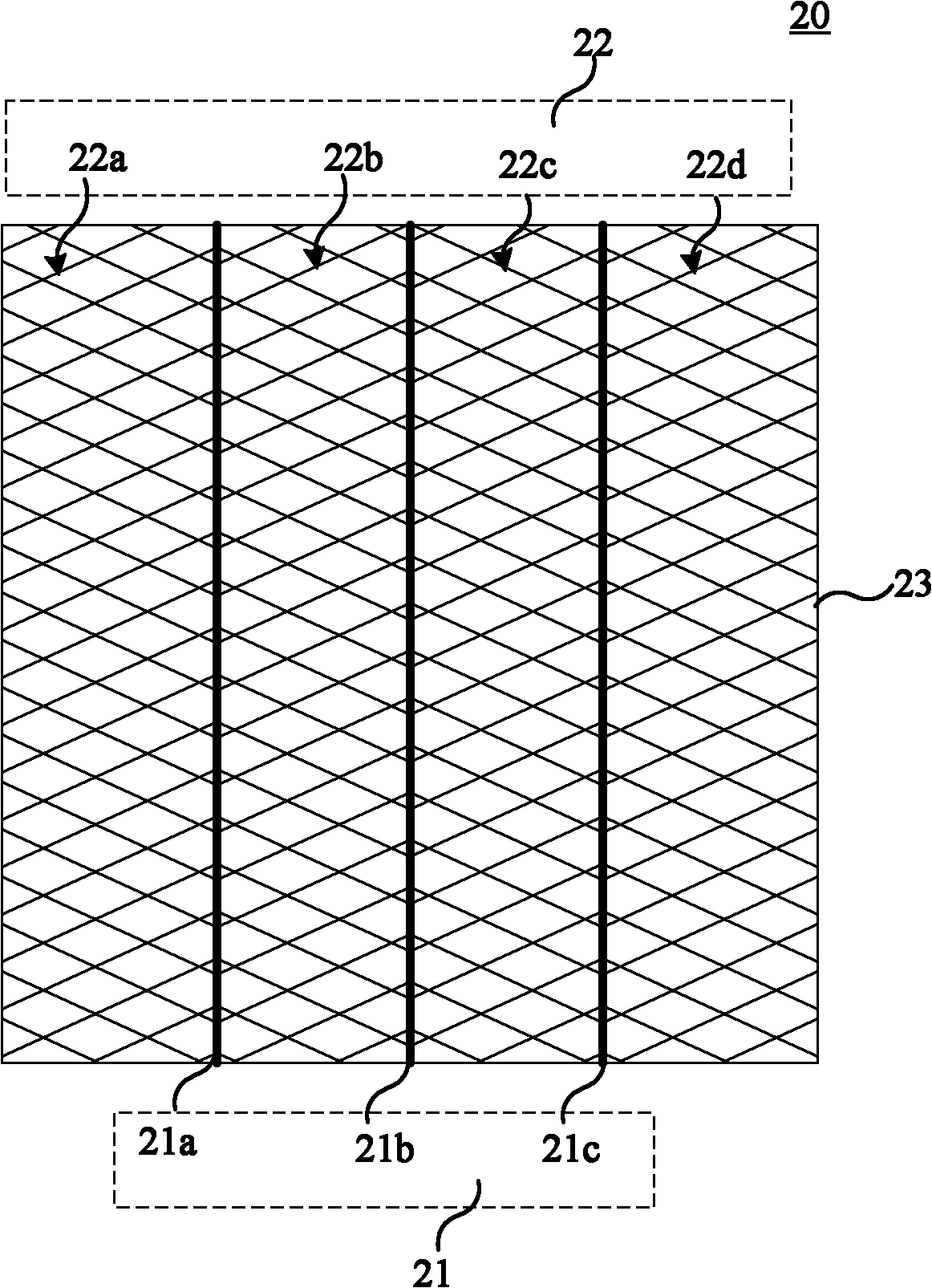

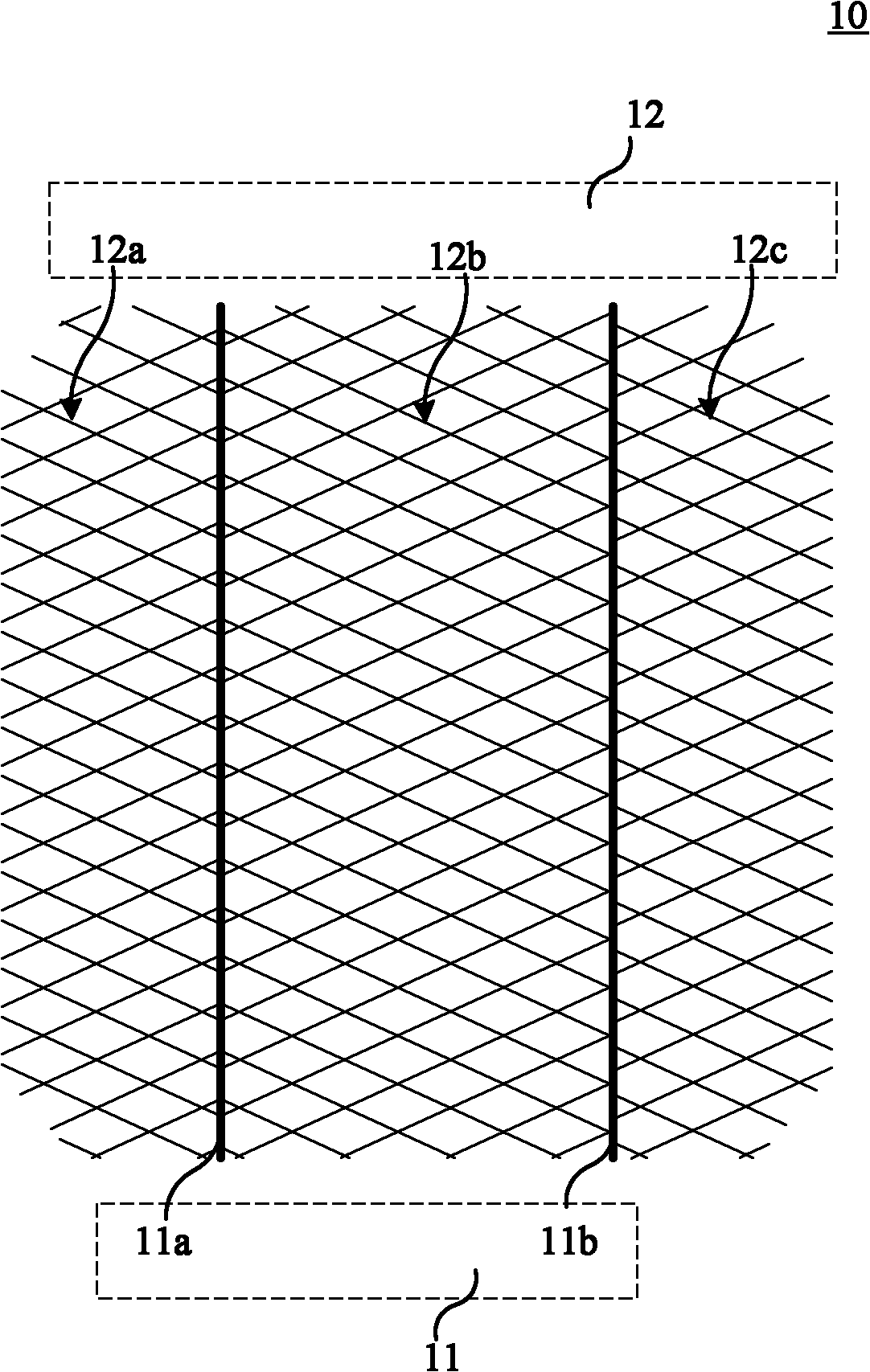

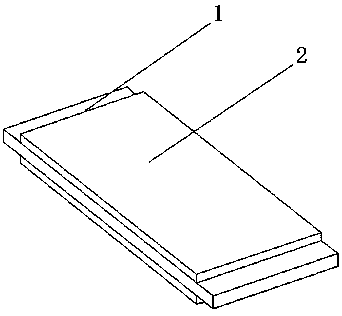

Front-face gate electrode of solar cell

InactiveCN102157574AImprove bending deformationReduce Fragmentation RateSemiconductor devicesEngineeringSolar cell

The invention provides a front-face gate electrode of a solar cell. The front-face gate electrode is distributed on the surface of a solar cell plate and comprises a main gate line and a minor gate line, wherein the minor gate line is connected with the main gate line and is distributed in shape of a net. In the front-face gate electrode of the solar cell, disclosed by the invention, the minor gate line is distributed on the surface of the solar cell plate in shape of the net, thus photo-induced carriers of each region of the surface of the solar cell plate are provided with multiple paths to reach the main gate line; and when a certain part of the minor gate line is broken or incompletely printed, the photo-induced carriers can finish the collection and the conveyance through the minor gate line which is close to the certain part of the surface of the solar cell and communicated with the main gate line, and the efficiency reduction of the solar cell is avoided.

Owner:江苏伯乐达光伏有限公司

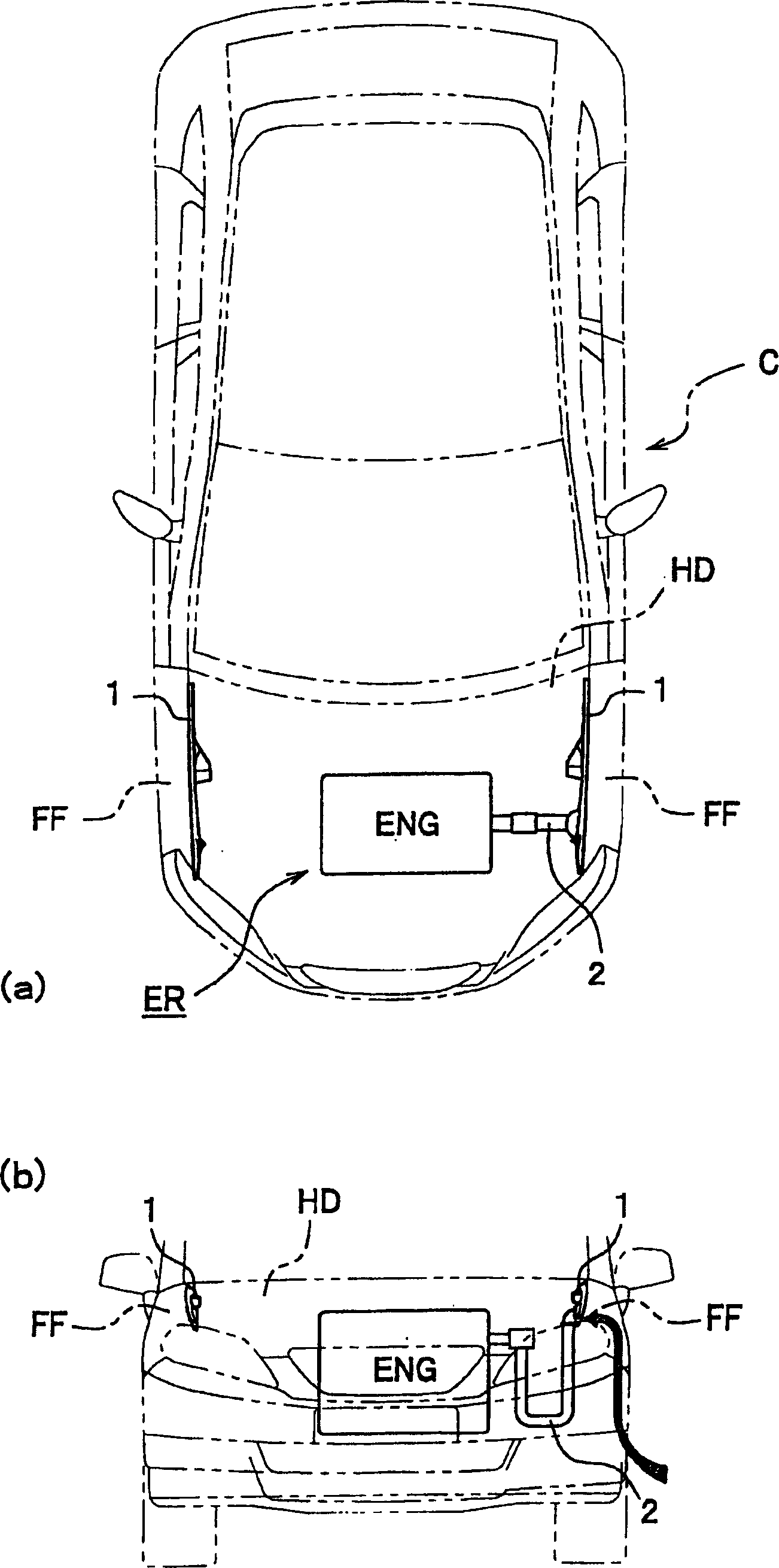

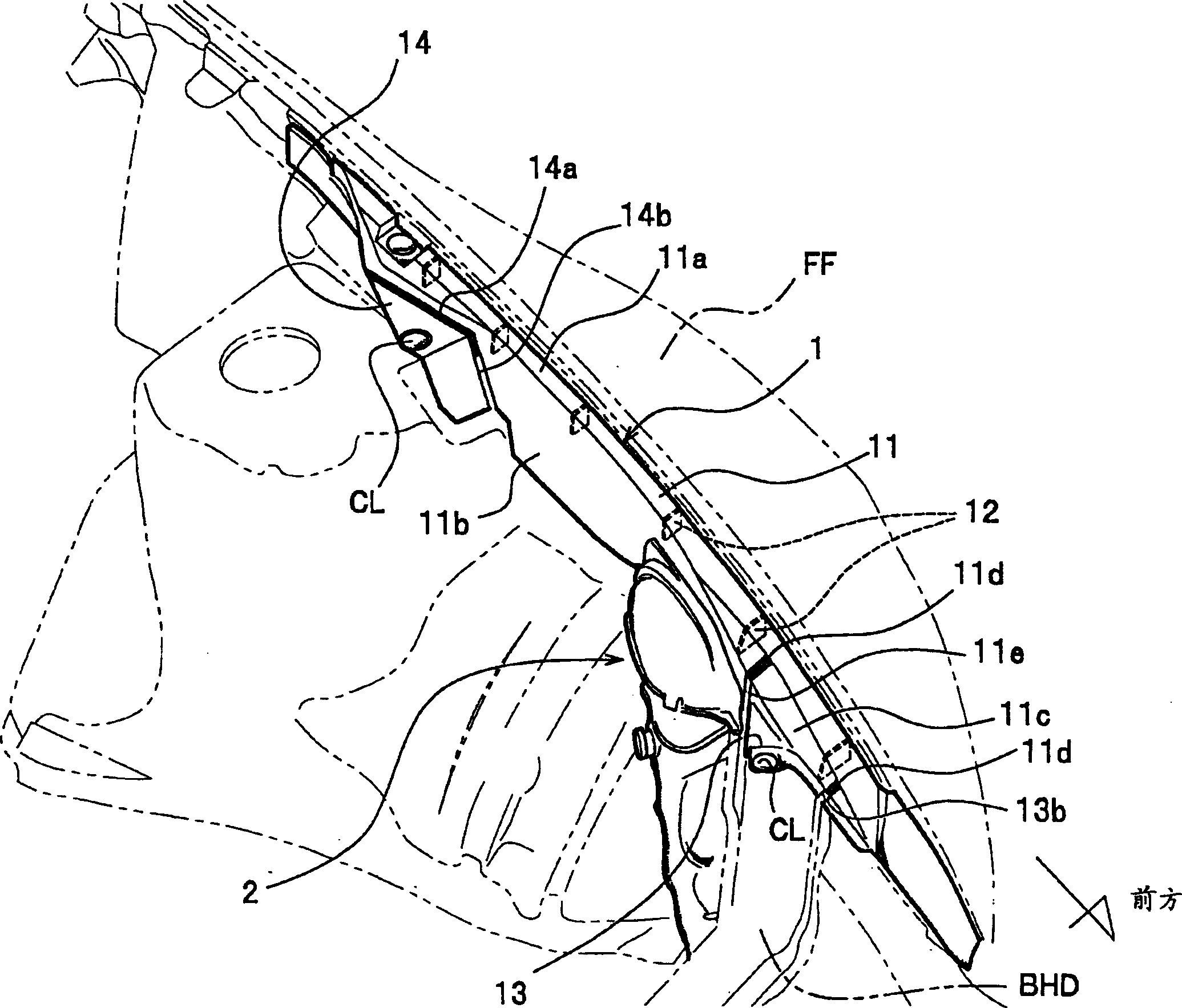

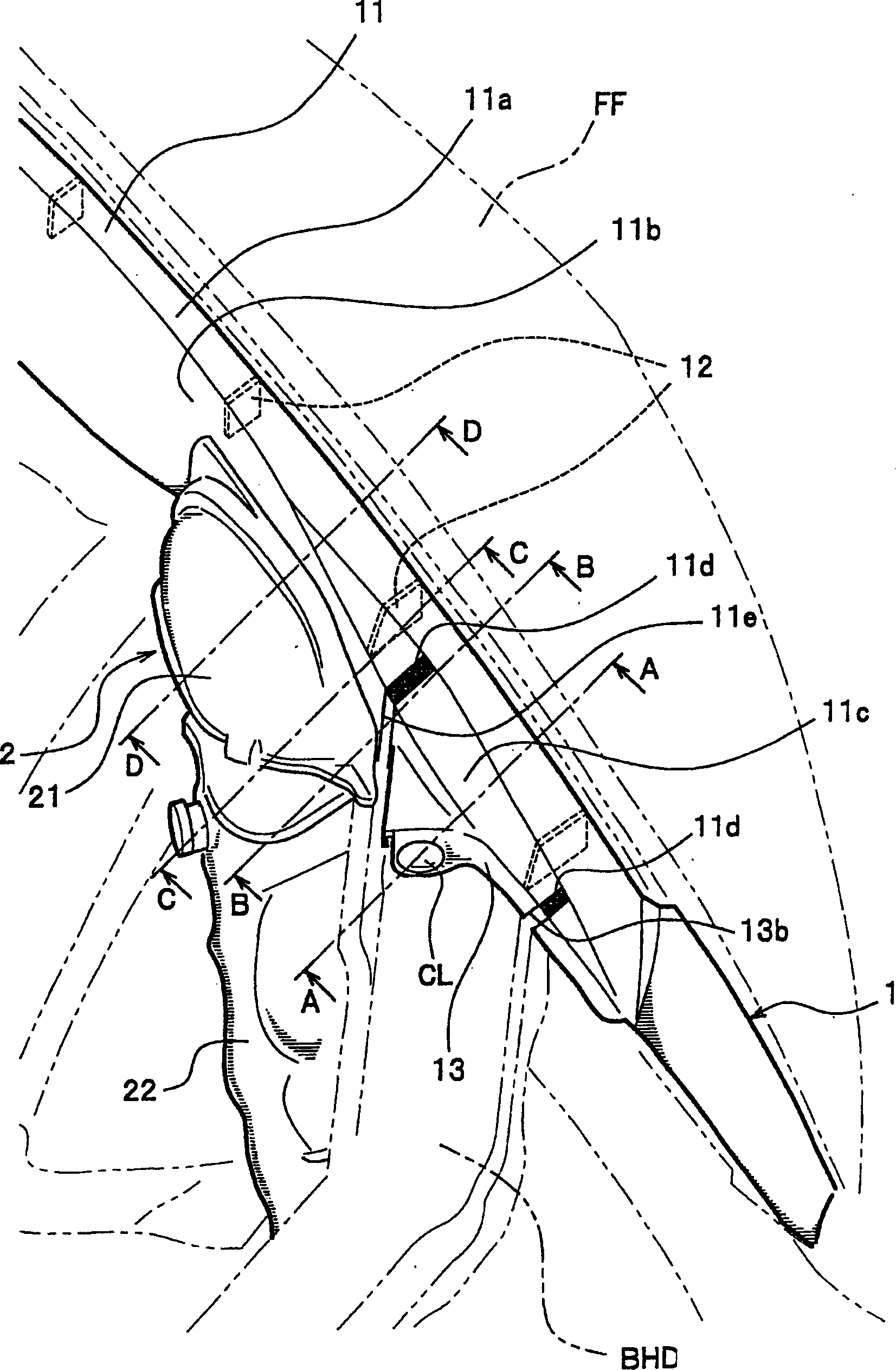

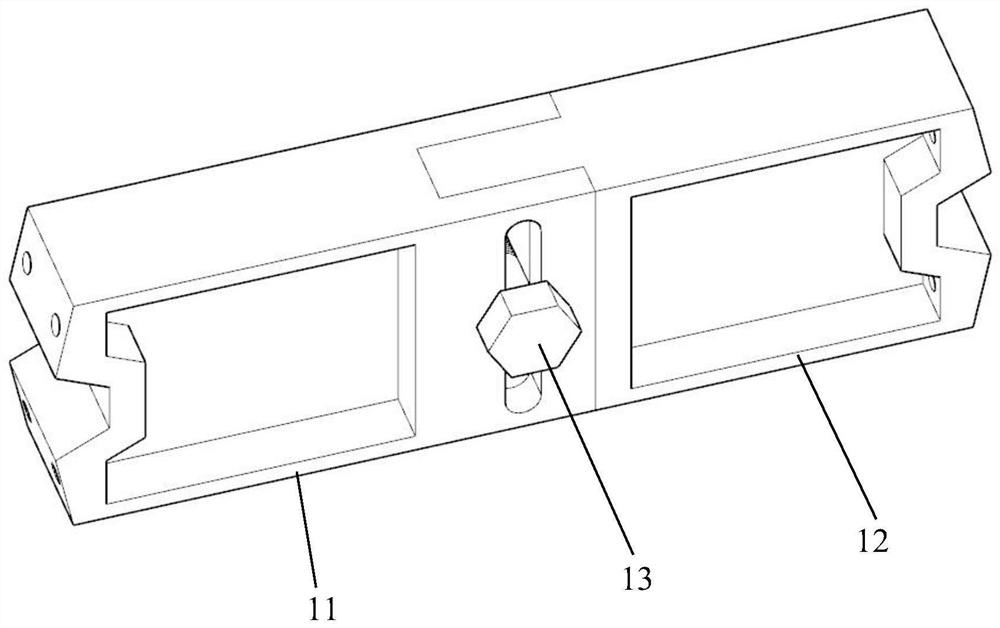

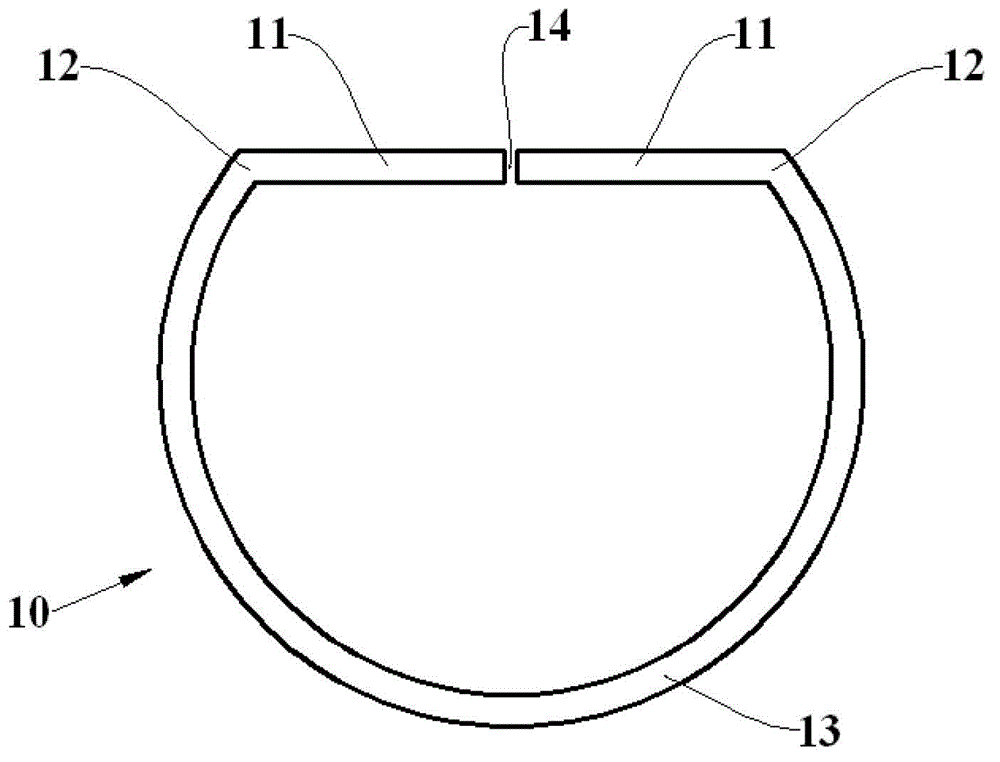

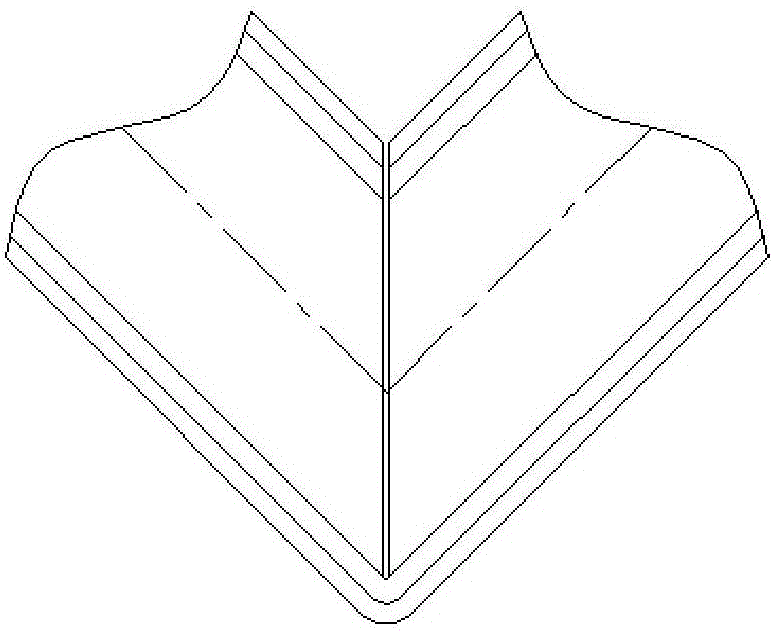

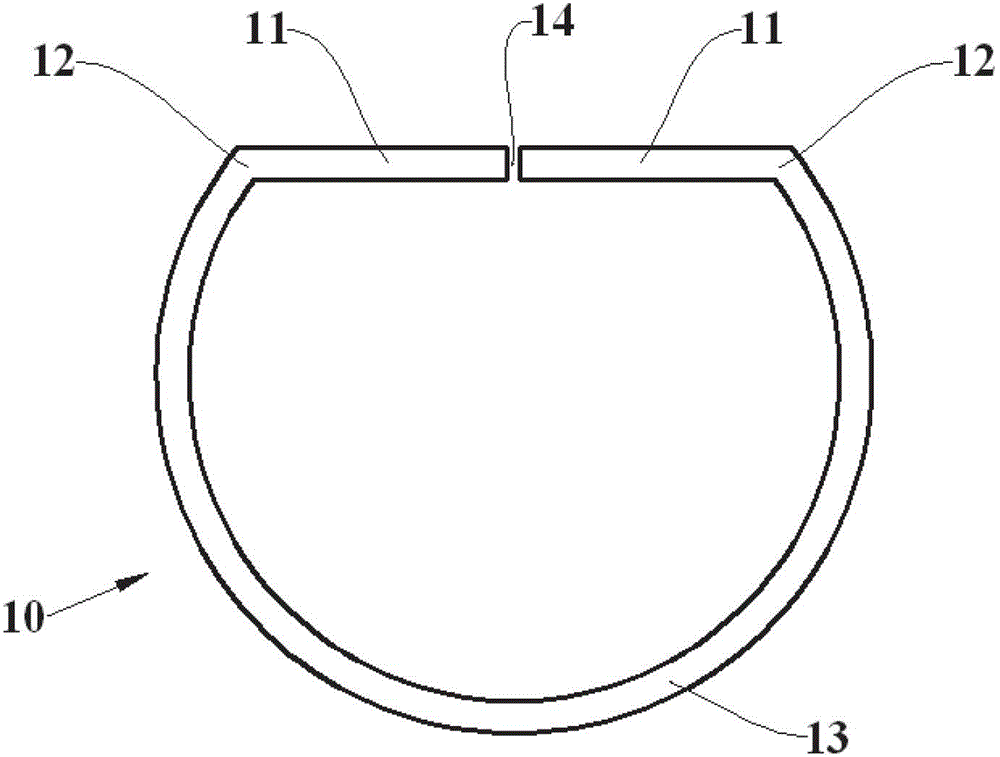

Fender garnish structure

InactiveCN1854007AImprove bending deformationFully absorbedSuperstructure subunitsPropulsion unit gas exhaustTrim tabFlange

Disclosed is a fender garnish structure (1) which includes a garnish main body (11) for covering a flange of a fender. Furthermore, the garnish main body (11) is provided with a plurality of ribs (12) for creating a clearance between the flange and the garnish main body (11), a plurality of fixtures (13, 14) for securing the garnish main body (11) to a vehicle body member being located near the fender, and a plurality of rupture triggering portions for causing a breakage between the ribs (12) and both fixtures (13, 14).

Owner:HONDA MOTOR CO LTD

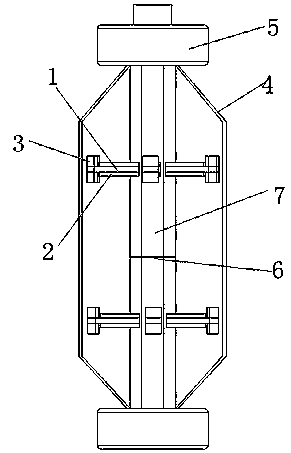

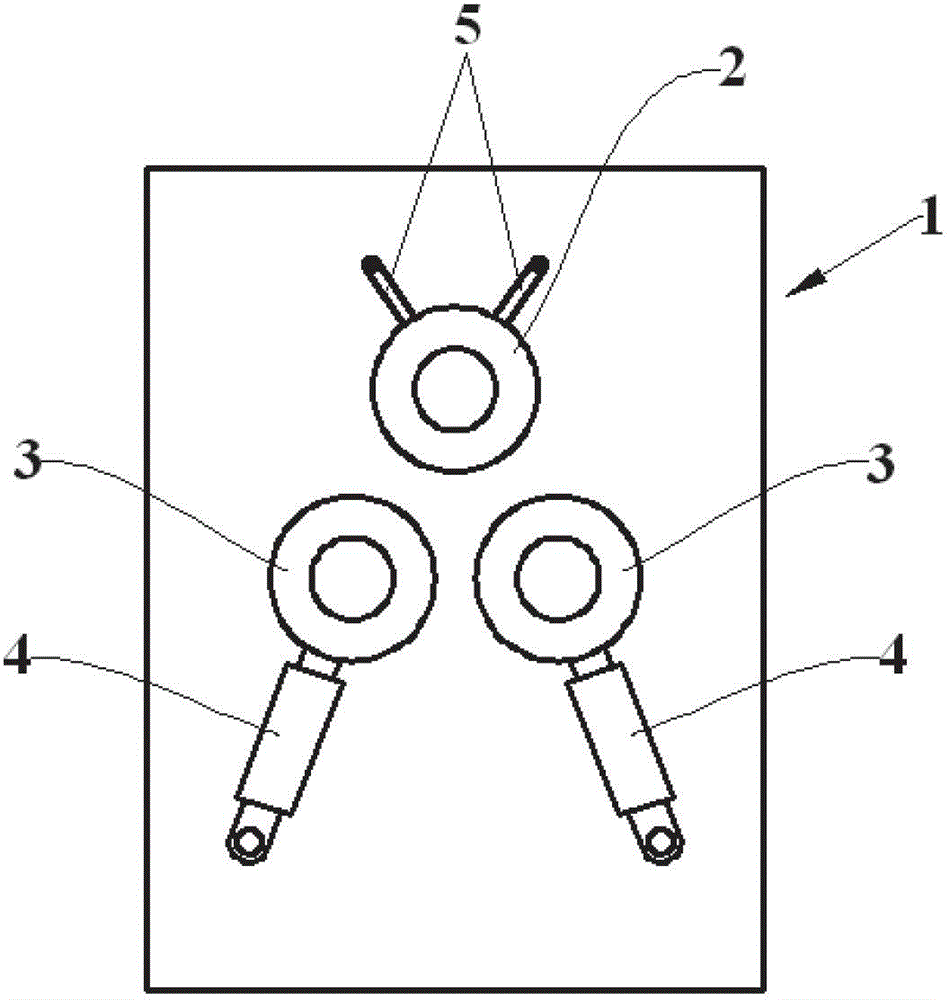

Piezoelectric energy storage device for oil well downhole detection equipment

ActiveCN108649837ASmall circuit sizeLow costPiezoelectric/electrostriction/magnetostriction machinesAdhesivePower flow

The invention discloses a piezoelectric energy storage device for oil well downhole detection equipment. The upper and lower ends of a cylindrical body are provided with threaded screw threads; the threaded screw threads are connected with a sucker rod string; multiple rows of cantilever beam substrates are arranged on the circumference of the cylindrical body in parallel; piezoelectric ceramic pieces are adhered to the upper and lower sides of the cantilever beam substrates through a conductive adhesive; a mass block is arranged at the tail end of each cantilever beam substrate; the mass block is not in contact with the sucker rod string; a protective cover is also arranged outside the cylindrical body; a circuit board is arranged at the middle part of the cylindrical body; and an unstable current generated by the piezoelectric ceramic pieces passes through a booster circuit, a rectifying circuit and a load matching circuit to obtain a stable direct current for storage so as to be used by a load. The piezoelectric energy storage device for the oil well downhole detection equipment provided by the invention is simple in structure; and energy generated by the vibration shock of a downhole fluid in the oil pumping process can be converted into available electric energy, and the electric energy is stored in a rechargeable battery to be used by the downhole detection equipment.

Owner:NORTHEAST GASOLINEEUM UNIV

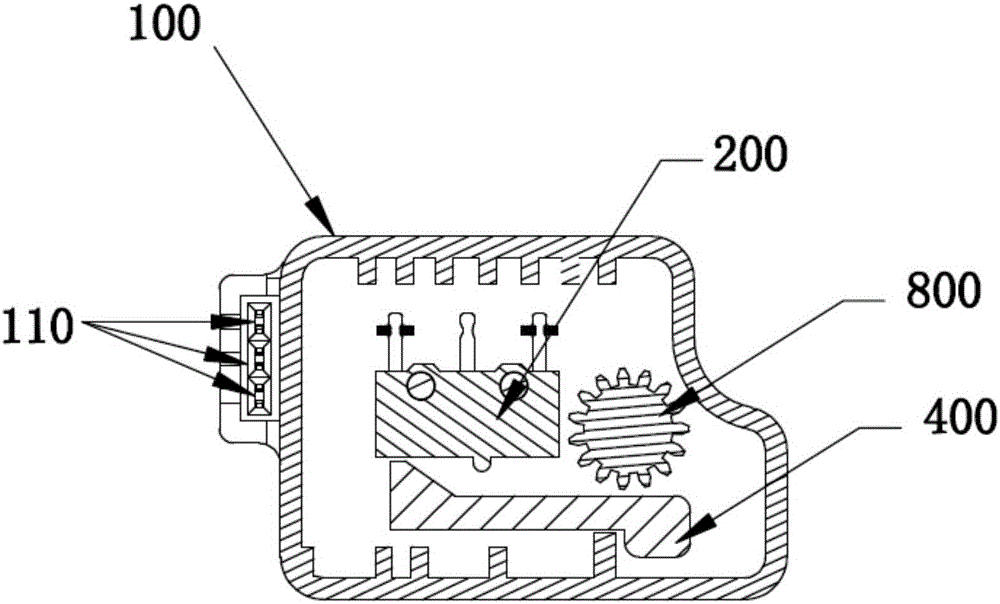

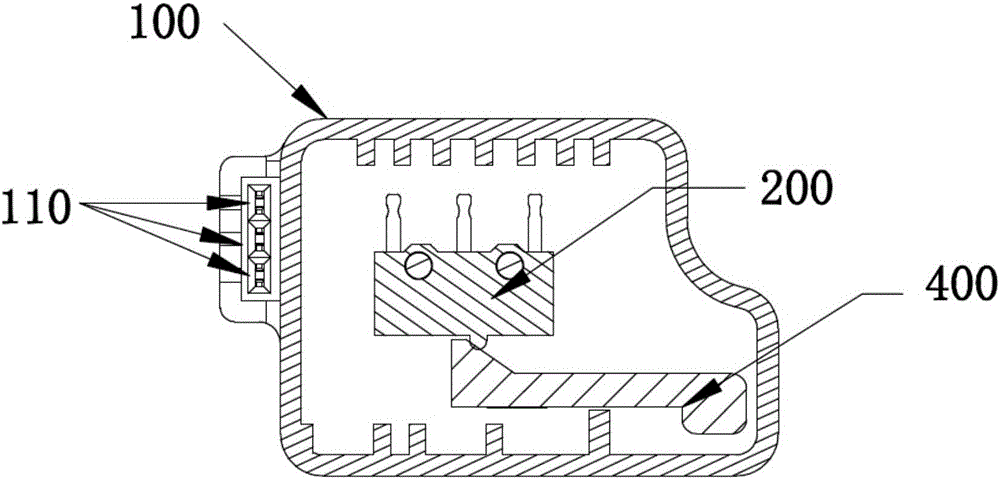

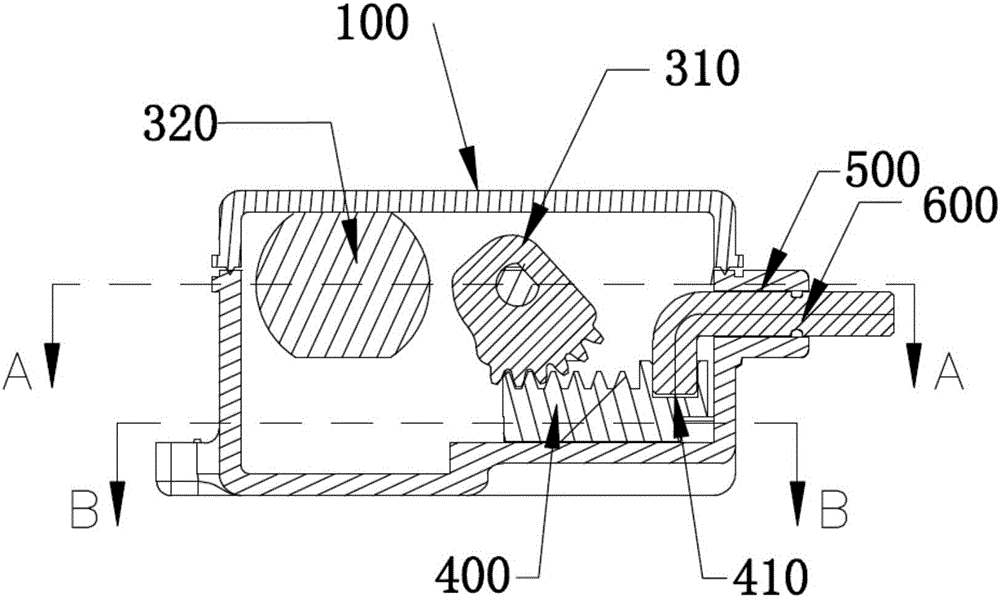

Electronic lock device of chargeable gun and chargeable gun

ActiveCN106246002AImprove bending deformationAdjustable speedNon-mechanical controlsElectric controlElectrical and Electronics engineering

The invention provides an electronic lock device of a chargeable gun. The electronic lock device of the chargeable gun comprises a shell, an electric control device, a signal switch mechanism, a drive mechanism and a rack, wherein the signal switch mechanism, the drive mechanism and the rack are installed in the shell. The electric control device is connected with the signal switch mechanism and the drive mechanism. The drive mechanism is provided with a transmission gear engaged with the rack. A shaft hole is formed in one side portion of the shell, and a lock shaft is installed in the shaft hole. The lock shaft is connected with one end of the rack. According to the design, the motor transmission mode is converted into the gear and rack motion, and accordingly stretching and retraction of an electronic lock bar are achieved; and meanwhile, when the lock bar moves, the action state signal of an electronic lock is transmitted through correlation with a signal switch. As the motor transmission mode is converted into the mechanical transmission mode, the speed is adjustable, the structure is stable, and the service life is long. In addition, the electronic lock device has the manual unlocking function, and under the situation that the circuit is abnormal, the locking and unlocking functions can be achieved by carrying out manual rotation to make the lock shaft on the rack move back and forth.

Owner:LUXSHARE PRECISION IND (JIANGSU) CO LTD

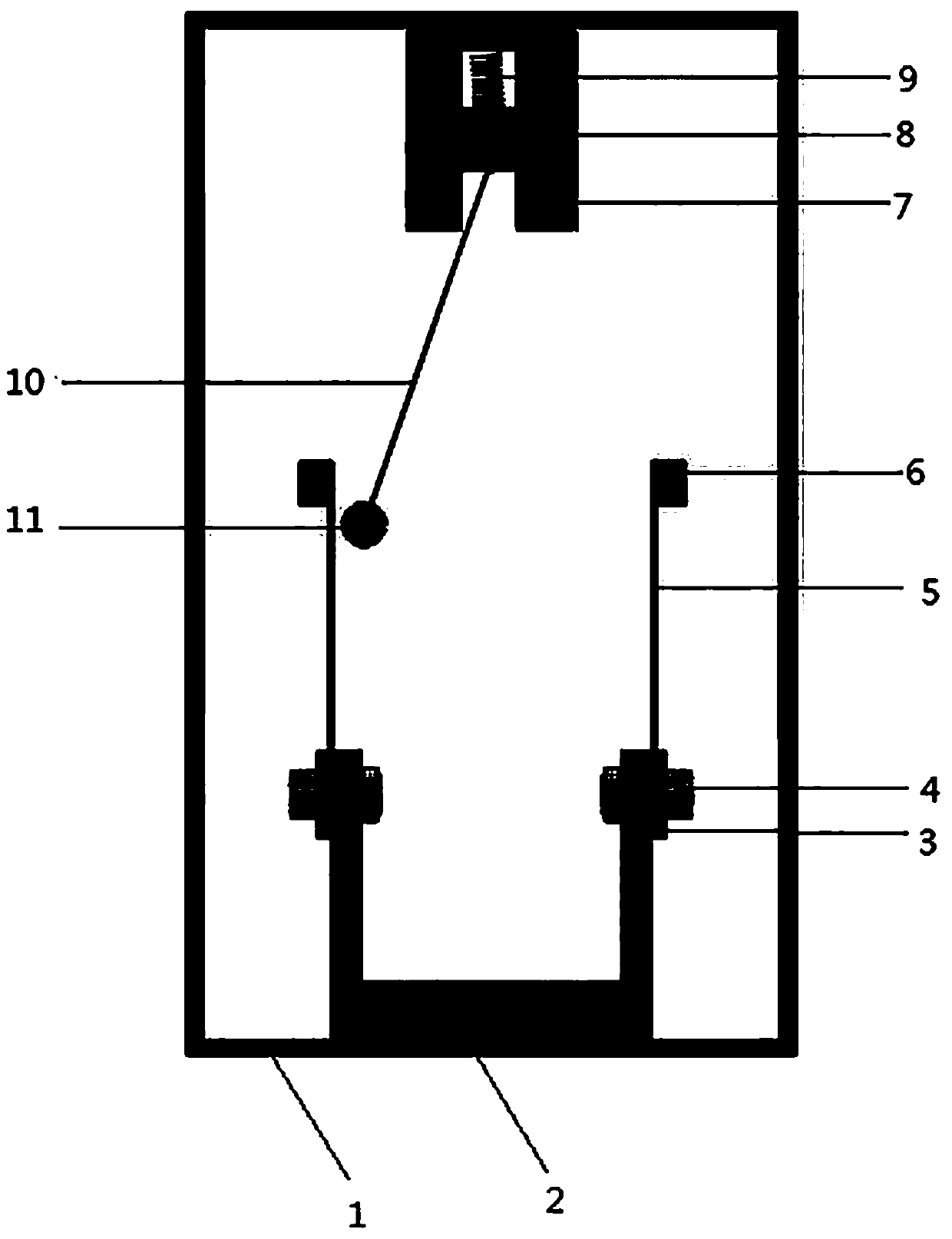

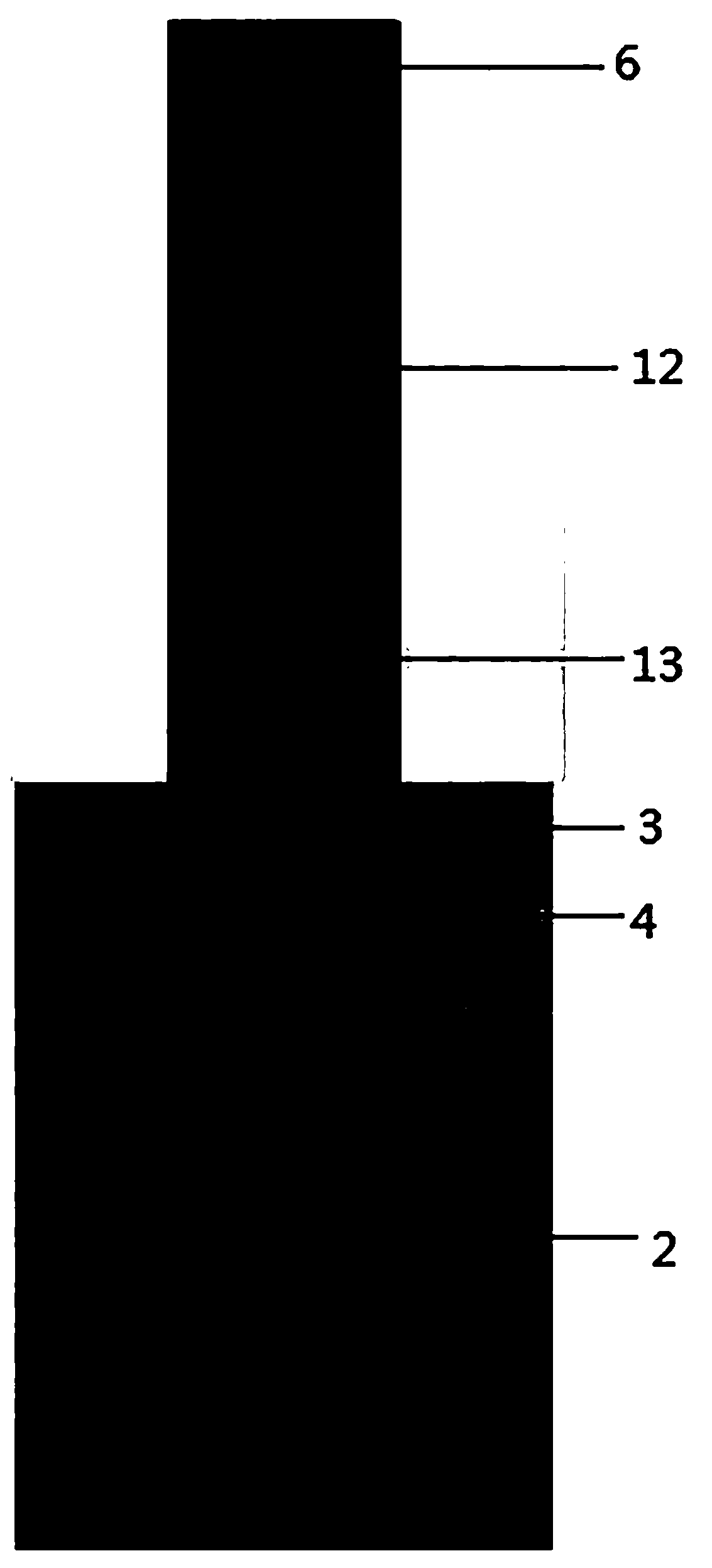

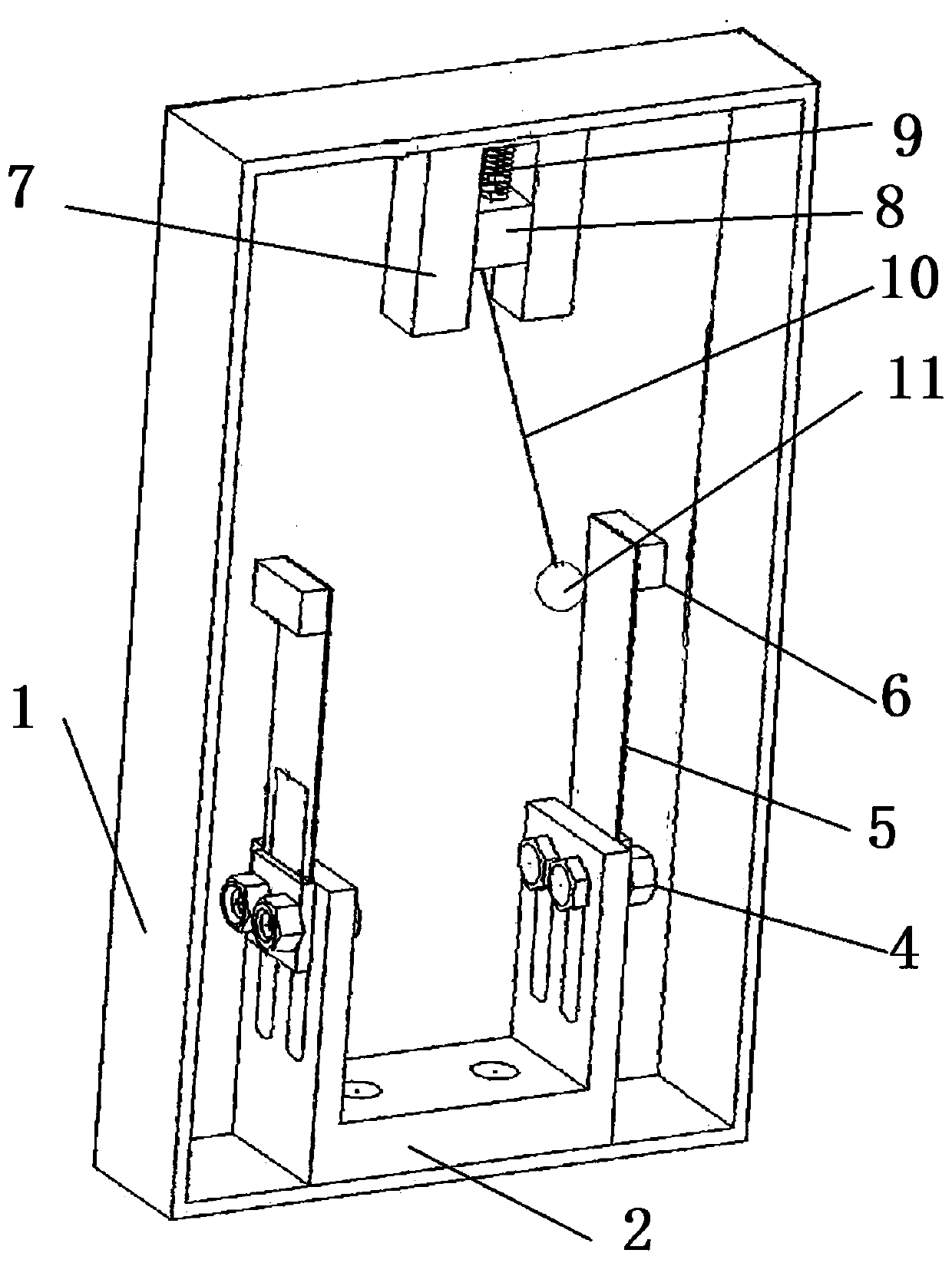

Experience type horizontal collision vibration energy acquisition device for teaching

PendingCN110889996AWon't collideIncreased swing amplitudePiezoelectric/electrostriction/magnetostriction machinesEducational modelsCantilevered beamPiezoelectric cantilever

The invention relates to an experience type horizontal collision vibration energy collection device for teaching. The horizontal collision vibration energy collecting device comprises a U-shaped base,a piezoelectric cantilever beam, a U-shaped guide rail, a sliding block, a spring and a collision steel ball, one end of the piezoelectric cantilever beam is fixed to the U-shaped base, a mass blockadheres to the free end of the piezoelectric cantilever beam, and the U-shaped base and the U-shaped guide rail are oppositely and fixedly arranged; the collision mechanism-based vibration energy collection device for experience teaching can provide energy for low-power-consumption interaction equipment, is safe and efficient, does not cause environmental pollution, can promote popularization andapplication of the experience teaching equipment, and has a wide application prospect in the field of teaching equipment.

Owner:ZHENGZHOU UNIV

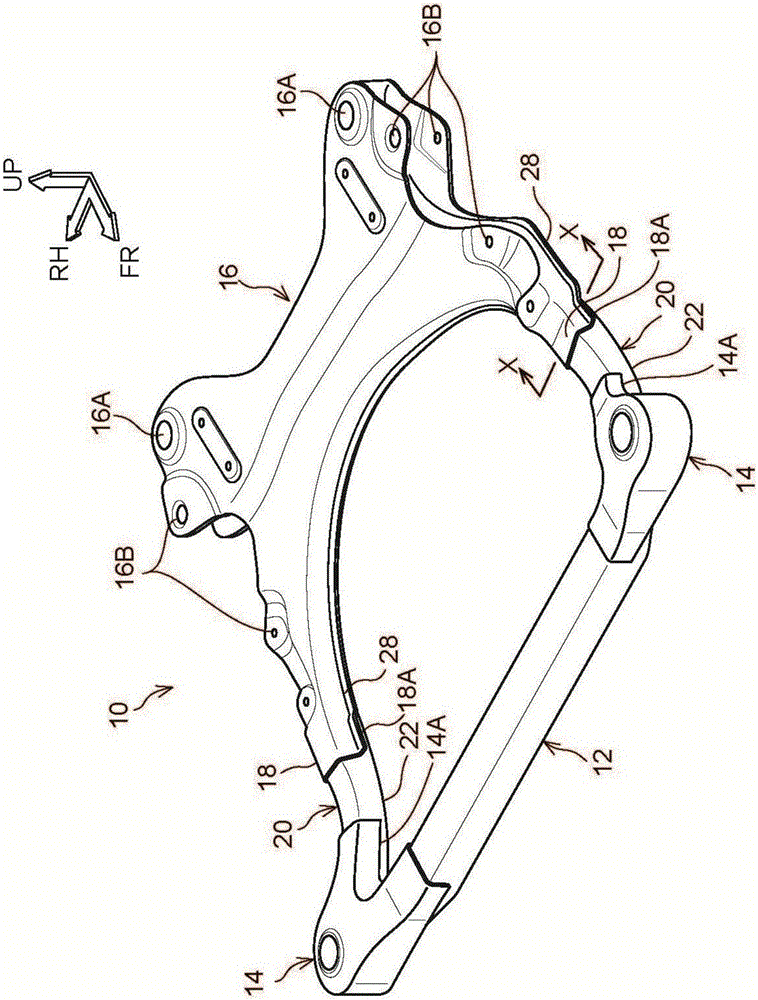

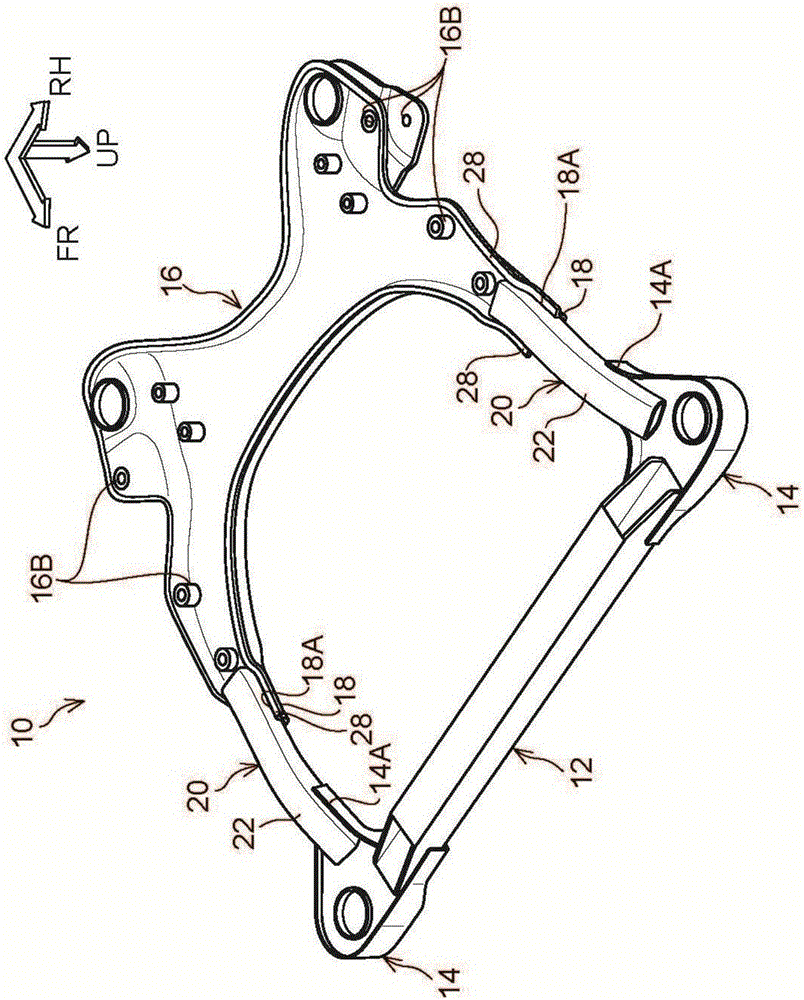

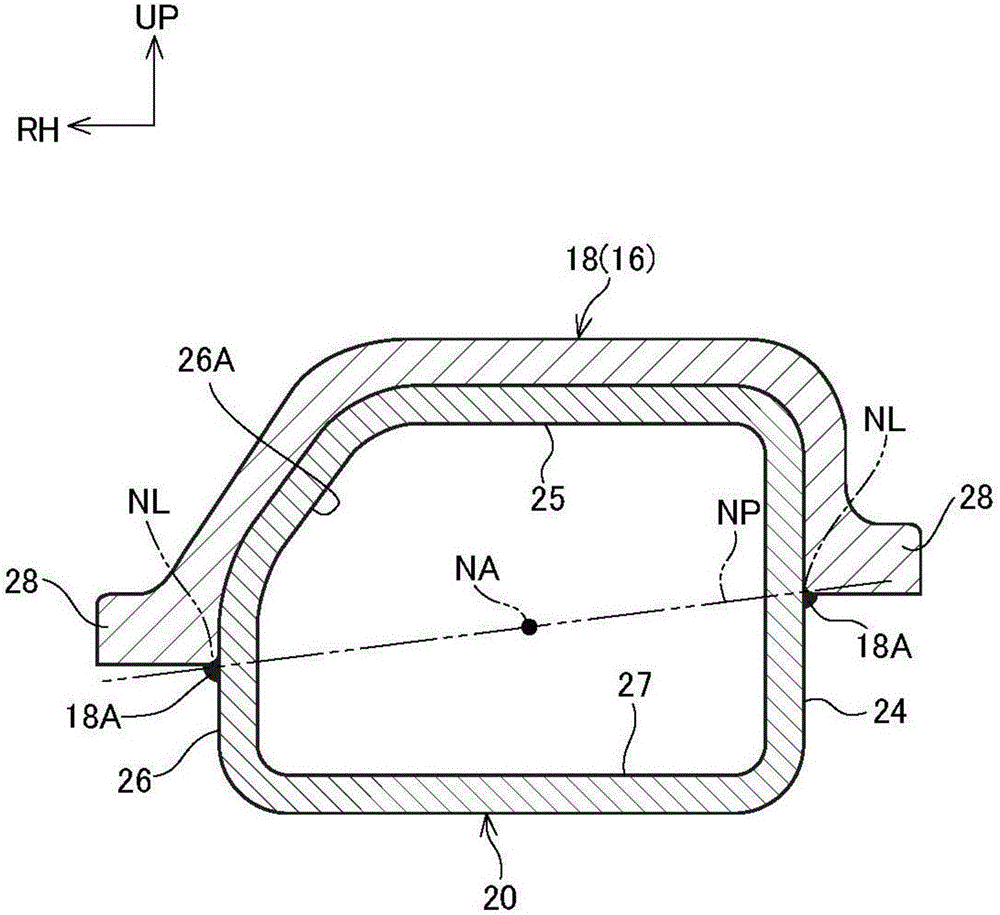

Suspension member

InactiveCN106275088AEffective absorptionEasy to bend and deformUnderstructuresSuperstructuresEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

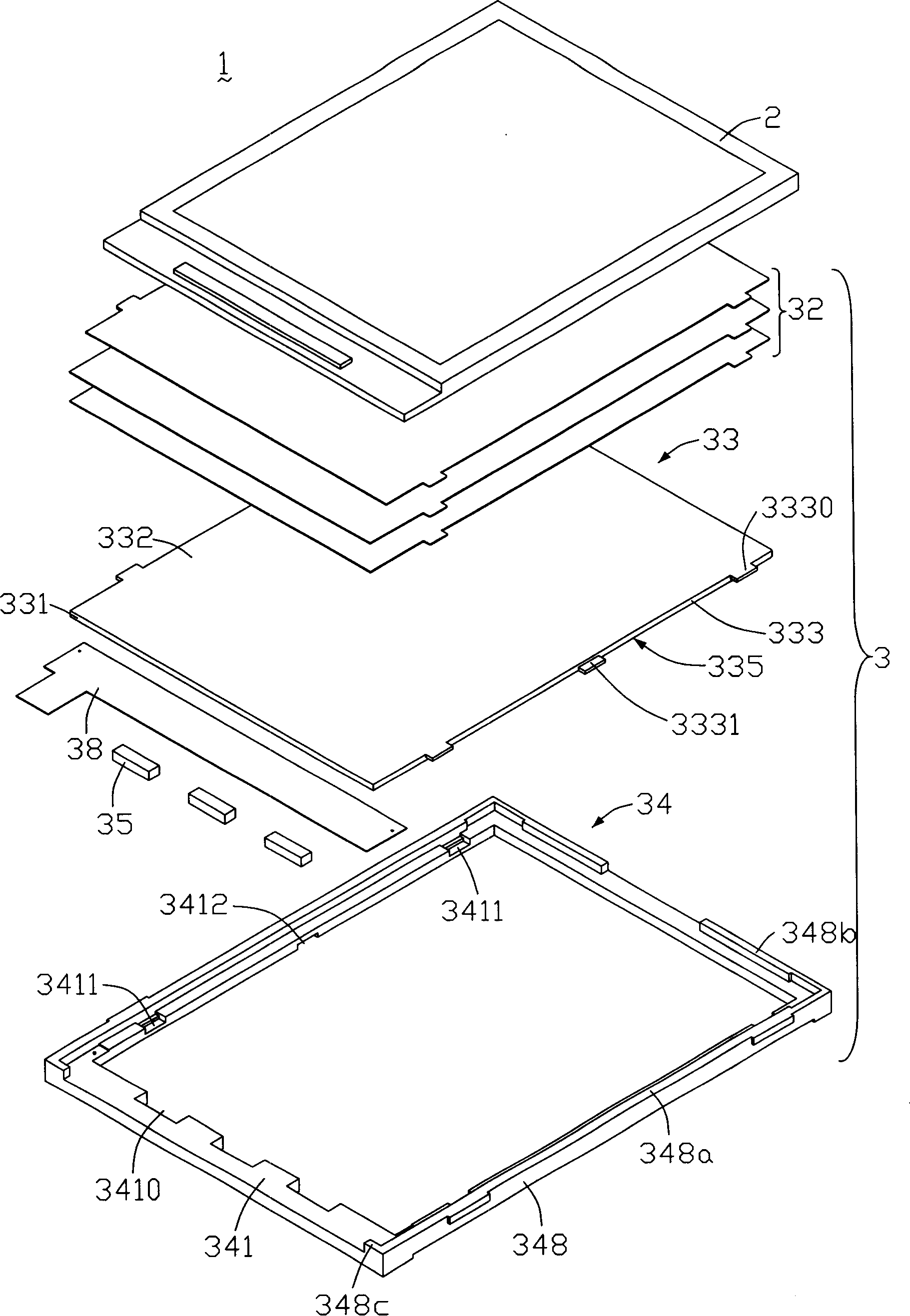

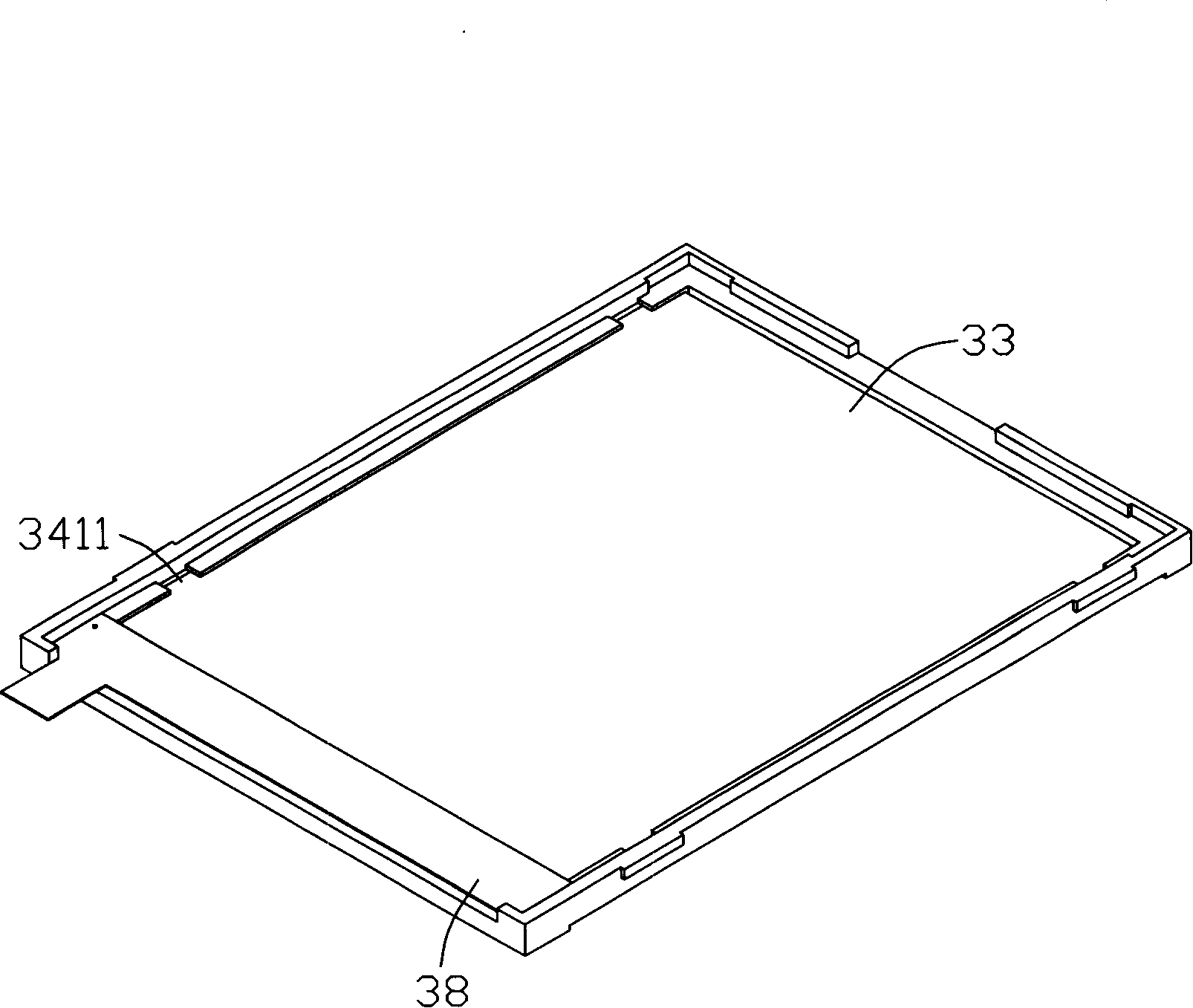

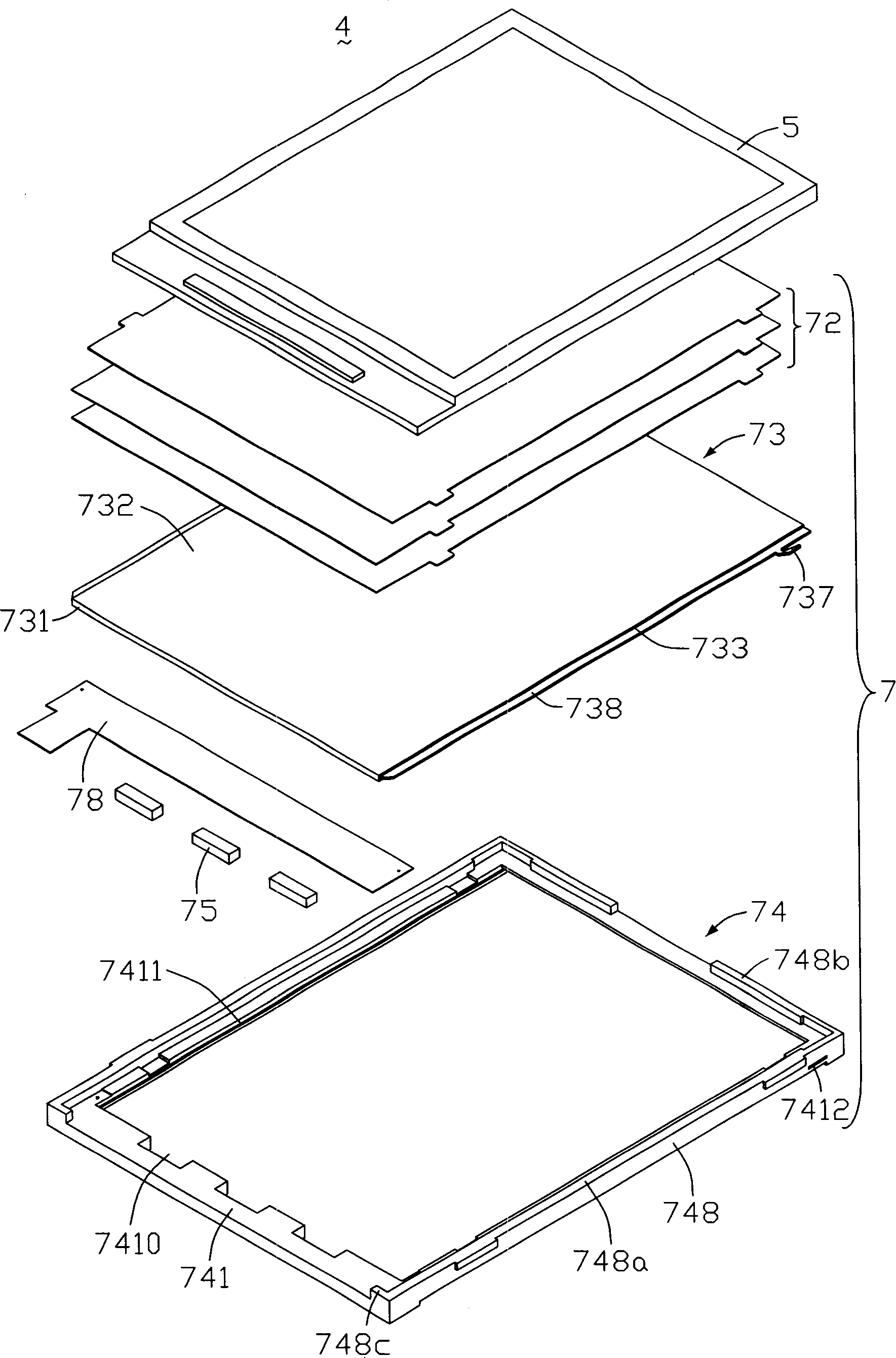

Back light module unit and LCD device

InactiveCN101174057AEasy squeezeImprove bending deformationStatic indicating devicesNon-linear opticsLiquid-crystal displayLight guide

The invention relates to a backlight module group and a liquid crystal display device adopting the backlight module group. The backlight module group comprises a light guide plate and a frame holding the light guide plate. The light guide plate comprises an elastic member extending outward along the side of the light guide plate. The frame comprises a slot correspondingly clipping the elastic member, and the slot penetrates the frame. In the process of assembling and disassembling the backlight module group and the liquid crystal display device, the frame is uneasy to be damaged.

Owner:INNOCOM TECH SHENZHEN +1

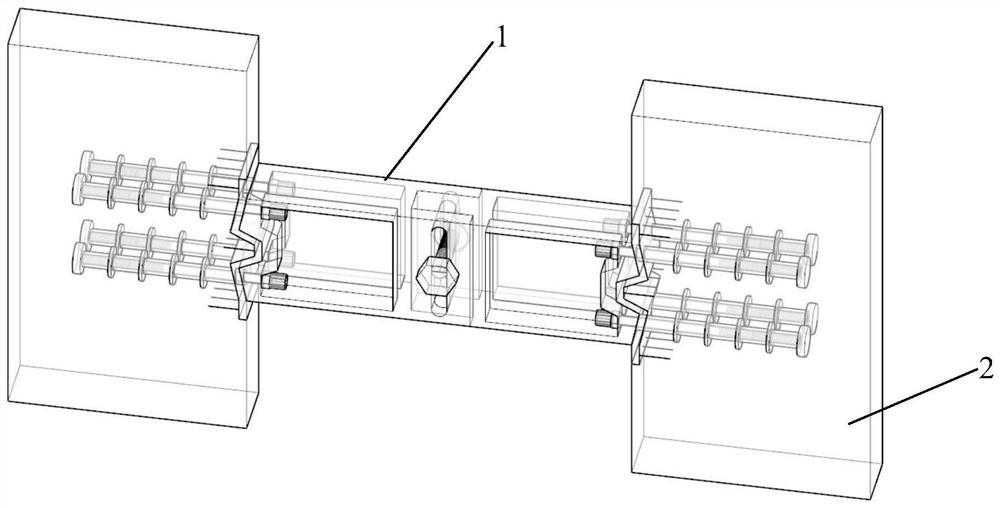

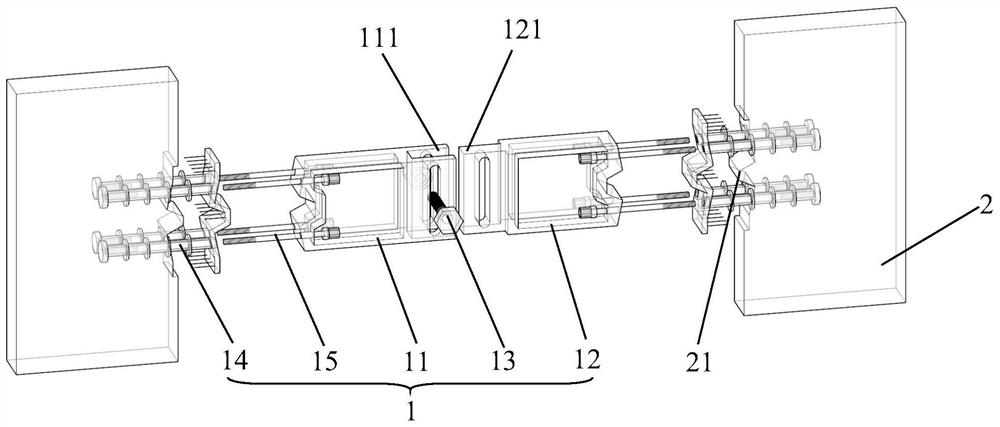

Post-earthquake function recoverable coupling beam with bending shear sub-control energy consumption mechanism

ActiveCN112982823ARecovery functionQuickly restore the initial positionWallsGirdersCouplingShape-memory alloy

The invention discloses a post-earthquake function recoverable coupling beam with a bending shear sub-control energy consumption mechanism. The post-earthquake function recoverable coupling beam comprises a first elastic coupling beam, a second elastic coupling beam, a connecting bolt and an anchoring part, wherein one end of the first elastic coupling beam and one end of the second elastic coupling beam are connected with an inserting convex block through a connecting inserting groove in an inserting mode and are connected through the connecting bolt, the contact surface of the connecting inserting groove and the inserting convex block is a friction surface, the other end of the first elastic coupling beam and the other end of the second elastic coupling beam are anchored on a wall limb of a shear wall through a shape memory alloy lengthened screw rod and the anchoring part respectively, an n-shaped anti-shearing inserting key is arranged on the wall limb of the shear wall, and the shapes of the other end surface of the first elastic coupling beam and the other end surface of the second elastic coupling beam are n-shaped inserting surfaces matched with the n-shaped anti-shearing inserting key. During an earthquake, the first elastic coupling beam and the second elastic coupling beam shear up and down and move in a staggered mode to drive the friction surface to consume energy, the end parts of the coupling beams rotate with the wall limb, the shape memory alloy lengthened screw rod is driven to generate plastic deformation to participate in energy consumption, and the use function can be quickly recovered after the earthquake.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

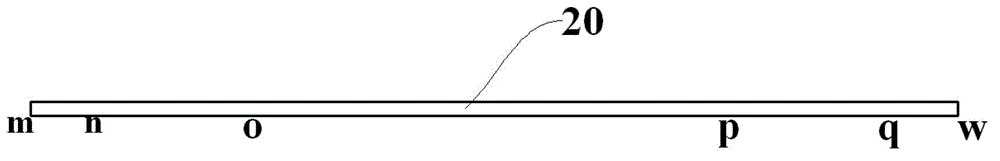

Bending blank manufacturing method for stainless steel flash welding thin-wall ring profiles

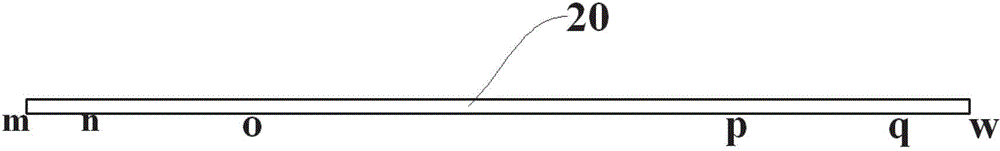

The invention discloses a bending blank manufacturing method for stainless steel flash welding thin-wall ring profiles. The method comprises the steps that a stainless steel profile fed according to specifications is divided into five segments of mn, no, op, pq and qw, heated to a temperature of 720 DEG C+ / -20 DEG C and fed in a bending machine for positioning. The op segment is bent, rotation linear speeds of an upper roller and two lower rollers are 2400 mm / min, the upward moving speeds of the two lower rollers are 10.0 mm / min, the bending is repeated for 3 times, and the op arc segment at this moment achieves a preset curvature radius; and the no segment and the pq segment are bent, the rotation linear speeds of the upper roller and the two lower rollers are 1200 mm / min, the downward moving speeds of the two lower rollers are 12.7 mm / min, the bending is repeated for 3 times, and the no and pq arc segments at this moment achieve preset curvature radii. The profile is bent and deformed into a D-shaped ring blank, two straight sides and an arc portion of the ring blank are connected through a transition arc segment, and phenomena of bent angles at connection positions of the two straight sides and the arc portion and indentations on the surface of the ring blank are eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

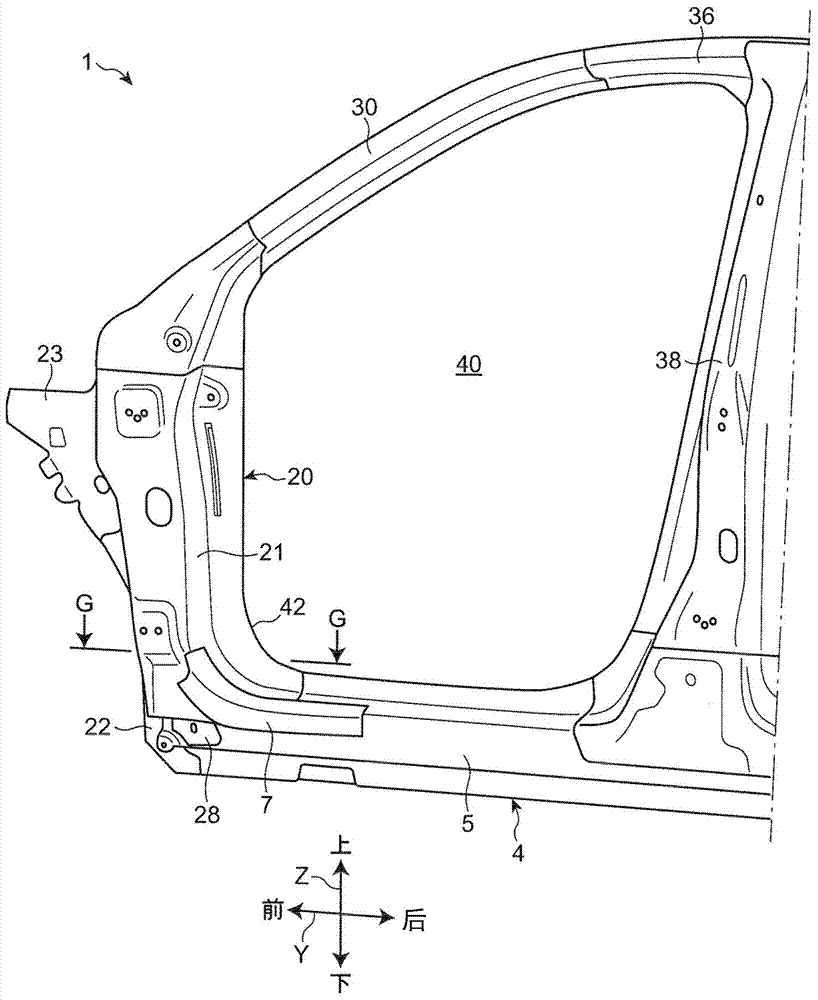

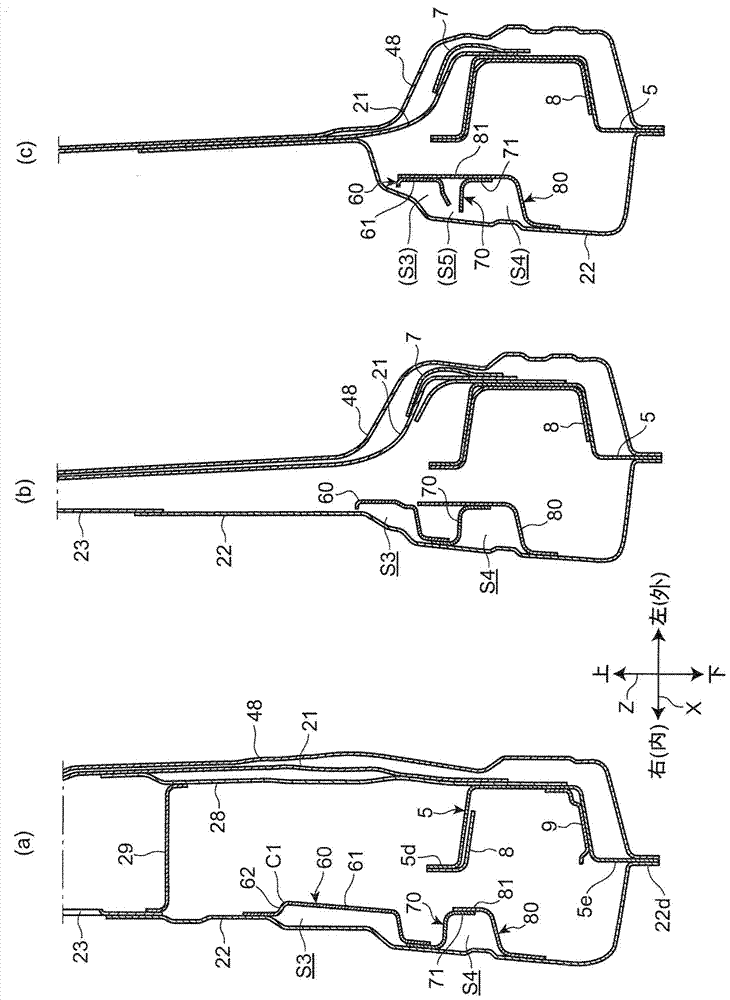

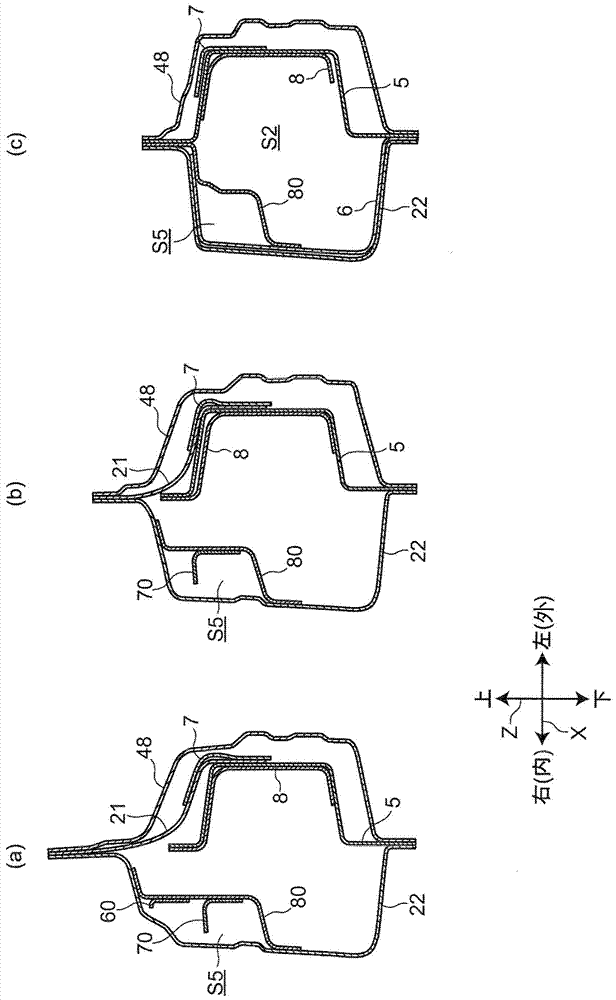

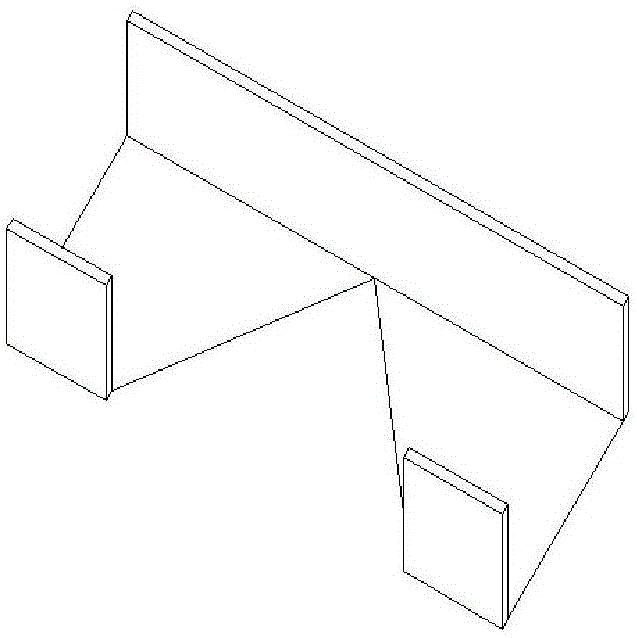

Side body structure of vehicle

The present invention provides a side body structure of a vehicle. The present invention aims to effectively reduce rearward movement of a hinge pillar and a dashboard, and further reduce a deformation of a cabin, by stably distributing an impact load applied to the hinge pillar from a vehicle front to rear side. A vehicle side body structure is provided, an inner hinge pillar member (22) is formed with a bend-facilitating portion (90) extending continuously or intermittently in the vertical direction Z of the vehicle and for facilitating a bending deformation of the inner hinge pillar member by protruding outwardly in the width directions X of the vehicle due to a concentration of a stress caused by an impact load applied to a hinge pillar (20) from the front side of the vehicle, and the bend-facilitating portion (90) is adjacently disposed on the front side of a front end part of the closed section space component (60) (70) (80) forming a closed section space (S1) (S2) (S3) extending continuously in the longitudinal directions Y of the vehicle along an outer surface of the inner hinge pillar member (22) in width directions X of the vehicle.

Owner:MAZDA MOTOR CORP

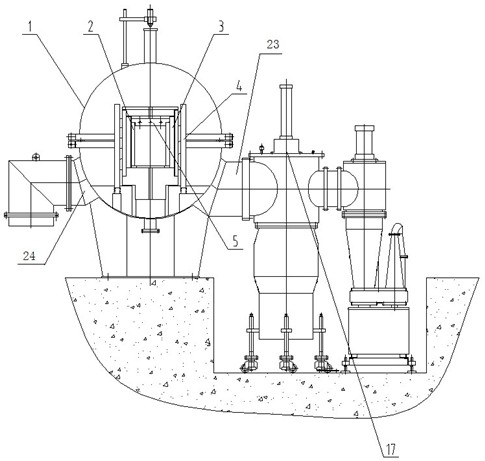

Machining device and method for steel channel grooving and bending combined assembly

ActiveCN106734518AAvoid bending deformationImprove processing efficiencyShaping toolsEngineeringMechanical engineering

The invention discloses a machining device and method for a steel channel grooving and bending combined assembly and belongs to the technical field of shearing and bending machining. The machining device comprises a rectangular groove cutting machining mold, a triangular groove cutting machining mold and a bending machining mold, wherein the rectangular groove cutting machining mold comprises a first movable cutter and a first fixed cutter; the first movable cutter is fixedly connected with a first movable cutter base, and the shearing edge face of the first movable cutter is a V-shaped face with the middle portion sunken downwards; the first fixed cutter is installed on a first fixed cutter base and forms a "rightward-right-angle-u-shaped" structure; the triangular groove cutting machining mold comprises a second fixed cutter and a second movable cutter; the second movable cutter is fixedly connected with a second movable cutter base; the shearing edge face of the second movable cutter is a plane inclined to the other side from the position of a sharp corner of the plane; and the second fixed cutter is installed on a second fixed cutter base and forms an "L-shaped" structure. By adopting the machining device to perform grooving and bending machining on steel channels, the machining efficiency and the machining quality can be remarkably improved, and the precision and the quality of the combined assembly are made to meet the using requirements.

Owner:马鞍山市欧姆科技发展有限公司

Hard alloy extrusion molding agent as well as preparation and application thereof to superfine hard alloy rod material

ActiveCN106735240AGood shaping performanceImprove bending deformationTransportation and packagingMetal-working apparatusWater bathsPolyethylene glycol

The invention discloses an extrusion molding agent applicable to a superfine hard alloy PCB (Printed circuit board) rod material. The extrusion molding agent is prepared from 8%-20% of a bonding agent, namely polymethylmethacrylate, 4%-10% of a surfactant, namely glyceryl stearate, and 70%-90% of a solvent, namely methyl benzoate. All the raw materials are added into a water bath stirrer and mixed and stirred to obtain the hard alloy extrusion molding agent. The application of the hard alloy extrusion molding agent to preparation of the superfine hard alloy PCB rod material comprises the following steps: directly adding the superfine hard alloy raw material and 0.8 percent to 3.0 percent of PEG (Polyethylene Glycol) into a ball grinding mill containing a grinding ball and a wet grinding medium, and mixing and carrying out ball grinding; drying and granulating ball grinding paste in vacuum or through atomizing, so as to obtain a hard alloy mixed material containing the PEG; adding the mixed material and 7%-15% of the hard alloy extrusion molding agent into a mixer and uniformly mixing; adding an extruded material into an extruding machine and extruding a superfine PCB rod material blank; drying to remove the solvent in the hard alloy extrusion molding agent; semi-machining the blank and cutting length to form a semi-finished product; and sintering to obtain the superfine hard alloy PCB rod material. The superfine hard alloy PCB rod material is small in bending deformation; the inner part of the product has no defects including pores, cracks and the like; and the performance of the product is stable and controllable.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Bent blank manufacture method of section bar of aluminum alloy flash-welded thin-wall ring

The invention discloses a bent blank manufacture method of a section bar of an aluminum alloy flash-welded thin-wall ring. The bent blank manufacture method comprises the steps of dividing the aluminum alloy section bar blanked according to dimensions into an mn section, an no section, an op section, a pq section and a qw section, heating the five sections to 330 DEG C + / -20 DEG C, and then feeding the five sections into a bending machine to perform positioning; firstly, bending the op section, and performing repeated bend for 2 times, wherein the rotation linear speed of an upper roller and two lower rollers of the bending machine is 2400mm / min, the upward moving speed of the two lower rollers is 15mm / min, and at this time, the op arc section reaches the predetermined curvature radius; and then bending the no section and the pq section, and performing repeated bend for 2 times, wherein the rotation linear speed of the upper roller and the two lower rollers is 1200mm / min, the upward moving speed of the two lower rollers is 19mm / min, and at this time, the no arc section and the pq arc section reach the predetermined curvature radiuses. The section bar is bent into a D-shaped ring blank. Two straight sides of the ring blank are connected with an arc section through a transition arc section, and the break angle due to connection of the two straight sides and the arc section and creasing on the surface of the ring blank are eliminated.

Owner:GUIZHOU ANDA AVIATION FORGING

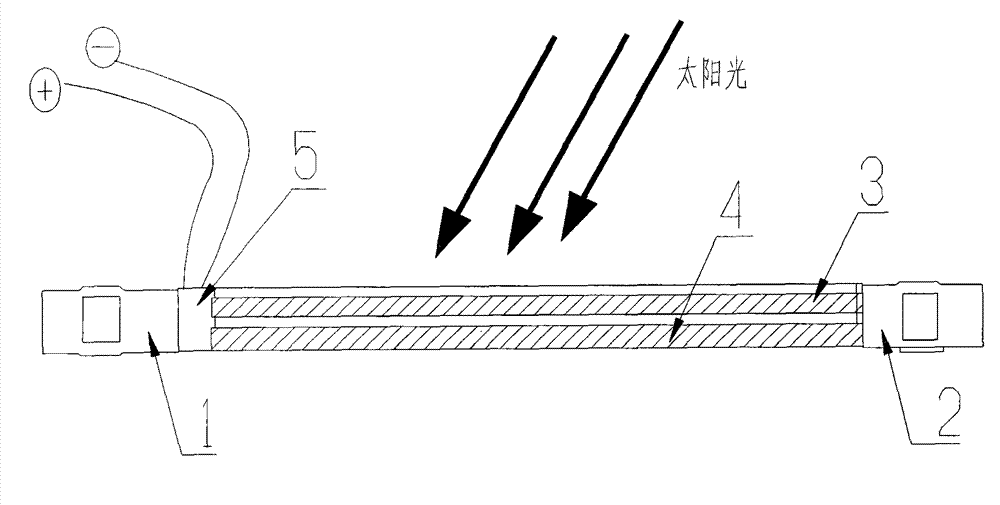

Splicing flexible film photon silicon lithium integral battery for military use

The invention discloses a splicing flexible film photon silicon lithium integral battery for military use. The battery comprises a first fastener fixed support lug, a second fastener fixed support lug, a solar battery, a ceramic lithium battery and a charging and discharging controller. One end of the solar battery and one end of the ceramic lithium battery as well as the other end of the solar battery and the other end of the ceramic lithium battery are respectively fixedly connected by the first fastener support lug and the second fastener support lug. The ceramic lithium battery is installed at the bottom end of the solar battery. The charging and discharging controller is fixed in the solar battery and the ceramic lithium battery and is connected with a load through a lead. The integral battery combines the flexible film amorphous solar battery and soft board thin ceramic lithium battery, and combines electricity generation and electricity storage, is light and thin, has small volume, reduces electric energy loss, does not need support of a large storage battery, and has high working efficiency.

Owner:新疆九龙电子科技发展有限公司

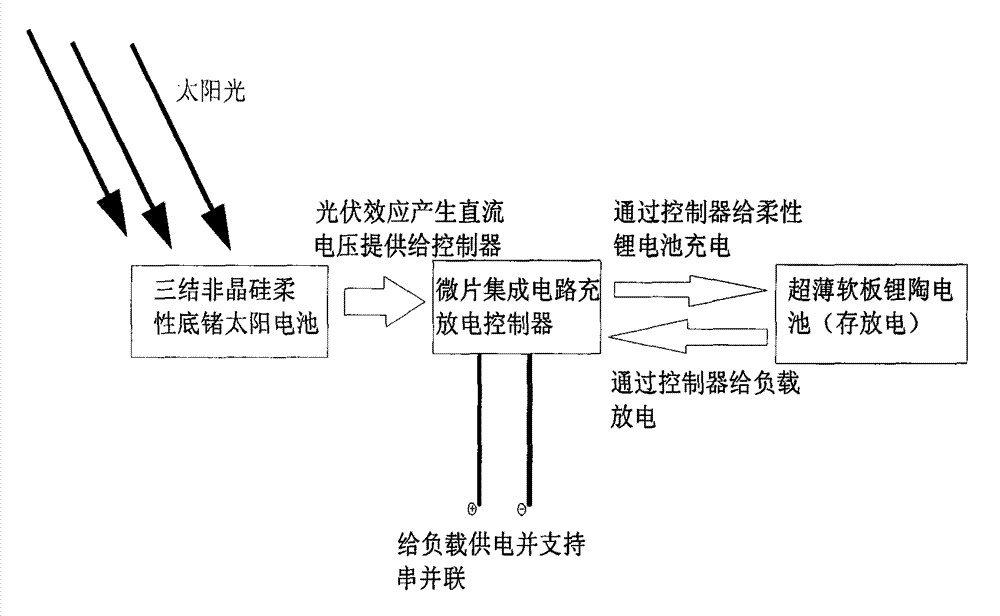

Medical instrument cleaning device capable of preventing aerogel infection

PendingCN113058919AAchieve cleaningImprove cleanlinessDirt cleaningCleaning using liquidsVentilation tubeEngineering

The invention relates to the technical field of medical instruments, in particular to a medical instrument cleaning device capable of preventing aerogel infection. The medical instrument cleaning device capable of preventing the aerogel infection comprises a table body, a cover door is arranged on one side of a cover body, a high-pressure water gun is further arranged on the cover body, the cover body is arranged at the top end of the table body, at least two openings are formed in the front side of the cover body, gloves are arranged on the openings, a ventilation pipe is further arranged on a top plate of the cover body and is connected with air draft equipment, and an ultraviolet lamp sterilization device is further arranged in the cover body and is used for irradiating the interior of the cover body. According to the medical instrument cleaning device, the cleaning effect of instrument cleaning is improved, in addition, air in the cover body is sterilized and disinfected, the content of pollutants and germs in pumped air is decreased, and therefore the risk of outdoor pollution and infection is reduced.

Owner:陈晓琳 +1

Preparation and application method of super-wetting stain-resistant stainless steel fiber felt for emulsion separation

ActiveCN106929894BHigh strengthImprove toughnessAnodisationNanotechnologyMicro nanoStainless steel fiber

The invention relates to preparation and using methods of ultra-infiltrating strain-resistant stainless steel fiber felt for emulsion separation. Firstly, micron-sized copper particles are electrically deposited on stainless steel fibers through a double-anode electroplating method, and then the copper particles are oxidized into copper hydroxide of a micro-nano structure through an electrochemical oxidation method. The ultra-infiltrating characteristics such as super-hydrophilicity and super-hydrophobicity are obtained after modification of different surface energy substances, and efficient separation of an oil-water stratified mixture and oil-in-water emulsion or water-in-oil emulsion is achieved. According to the methods, facilities and the process are simple, operation is convenient, raw materials are easily obtained, cost and energy consumption are low, and the methods are suitable for surface roughening of other stainless steel products made of the same materials and can be applied to industrial production on a large scale.

Owner:SOUTHEAST UNIV

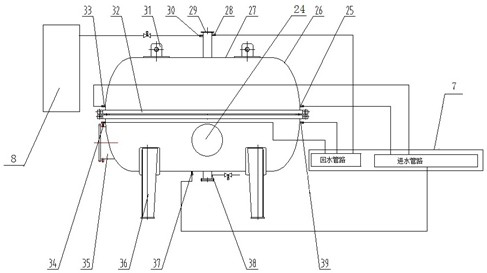

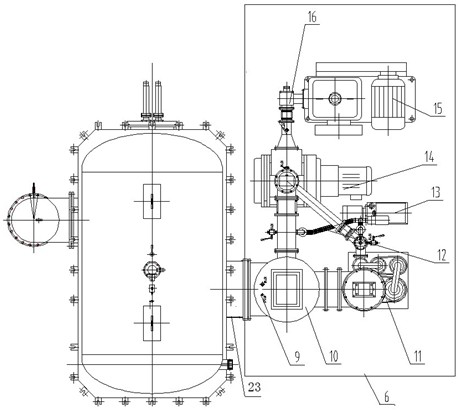

Box-type vacuum and atmosphere medium-frequency induction sintering furnace and using method

PendingCN112683049AReduce straightening and leveling processImprove bending deformationFurnace componentsMuffle furnacesRefractoryMolybdenum

The invention belongs to the field of tungsten-molybdenum processing equipment, and particularly relates to a box-type vacuum and atmosphere medium-frequency induction sintering furnace. The box-type vacuum and atmosphere medium-frequency induction sintering furnace comprises a furnace shell, a furnace core assembly positioned in the furnace shell, a vacuum system connected with the furnace shell, a water path system and a gas path system, and the furnace core assembly is of a cuboid box type structure; a heating body, a refractory material and an induction coil are sequentially arranged around the cuboid box-shaped structure from inside to outside, and a furnace top cover is arranged at the top of the cuboid box-shaped structure; and the vacuum system is used for providing a vacuum environment for the interior of the furnace shell, the water path system is used for providing cooling water for the furnace shell, and the gas path system is used for providing working gas for the furnace shell. By the adoption of a hearth of the box type structure, a sintered tungsten-molybdenum plate blank product is horizontally placed on a discharging bottom support, bending deformation of the sintered material is improved to the maximum extent, the straightening and leveling procedures of the tungsten-molybdenum product are reduced, and the production cost is reduced.

Owner:西安成航炉业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com