Device and method for bending pipe with sealed end by using tension rope or plug

A technology of bending device and tensioning rope, which is applied in the field of pipe bending device, can solve problems such as unreliable sealing and forming efficiency, achieve the effect of eliminating sealing failure, improving forming efficiency, and realizing pipe end sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

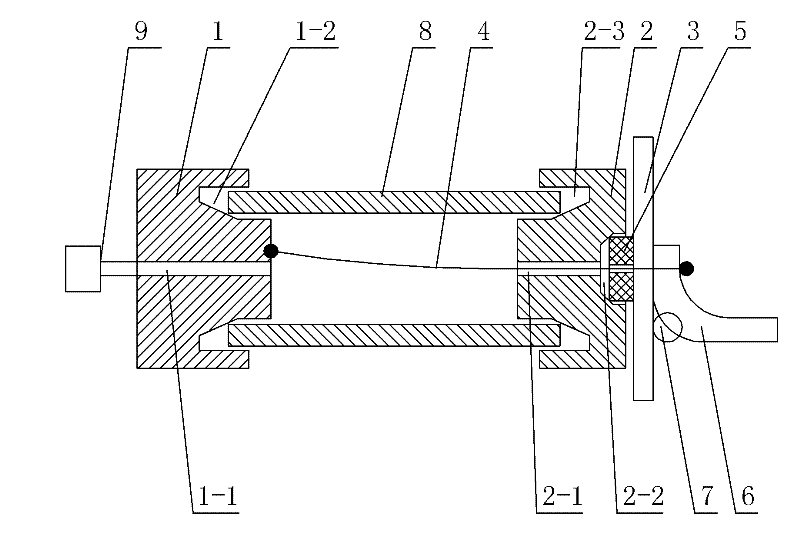

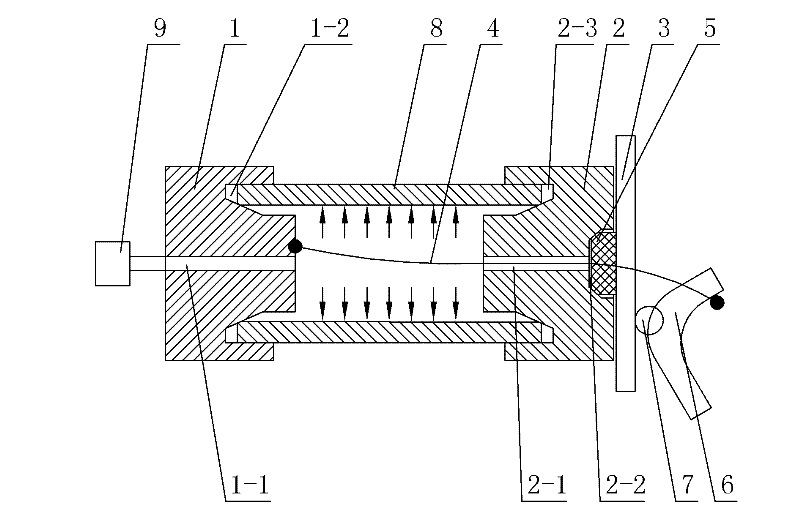

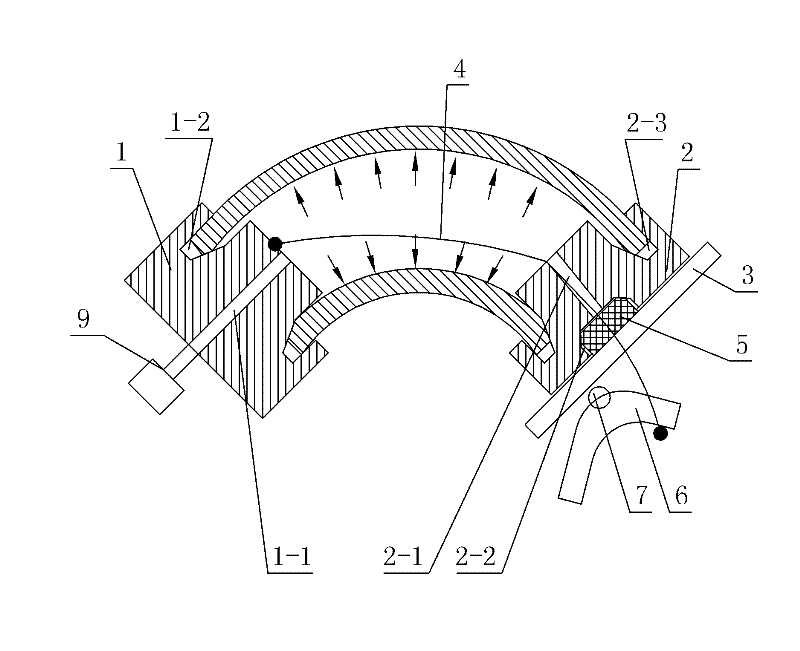

[0018] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, the pipe bending device of this embodiment that utilizes the tension rope and the plug to realize the sealing of the pipe end includes a booster cylinder 9, a first plug 1, a second plug 2, a pressure plate 3, a tension rope 4, Tension rope sealing ring 5, tension wrench 6 and rotating shaft 7, the first plug 1 is provided with a charging center hole 1-1, the booster cylinder 9 is connected to the charging center hole 1-1, the first plug One end face of 1 is provided with the first annular groove 1-2, the cross section of the first annular groove 1-2 is a right angle trapezoid, the outer wall of the first annular groove 1-2 is a straight wall, the first annular groove The inner wall of 1-2 is an inclined wall, the width of the groove bottom of the first annular groove 1-2 is smaller than the wall thickness of the pipe 8 to be bent, the second plug 2 is provided with a tension rope p...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1 ~ Figure 3 The present embodiment will be described, and the booster cylinder 9 of the present embodiment is a hydraulic pressure booster cylinder. Such an arrangement is suitable for bending and forming with high-pressure liquid. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 1 ~ Figure 3 The present embodiment will be described. The booster cylinder 9 of the present embodiment is a pneumatic booster cylinder. Such an arrangement is suitable for bending and forming using high-pressure gas. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com