Multipurpose thimbleshaped valve respiration valve

A breathing valve, a multi-purpose technology, applied in the field of breathing valves, can solve the problems of corrosion of springs and limit valve plates, expensive manufacturing costs, and reduced spring elasticity, and achieves reduced energy consumption and waste, good load bearing effect, and large elastic deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

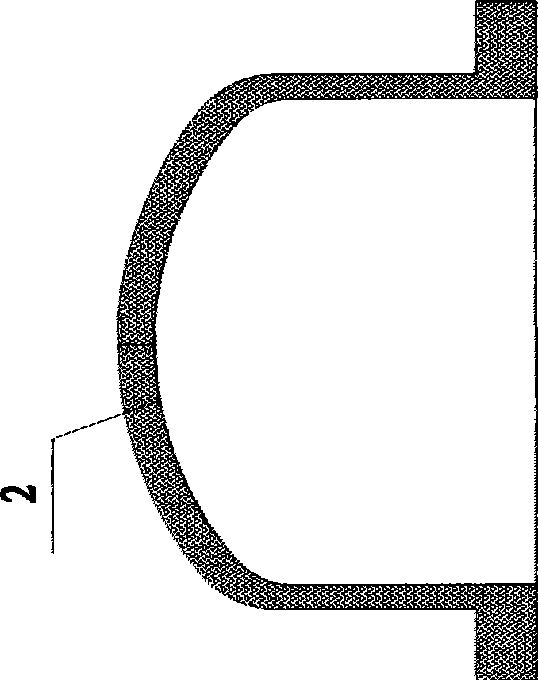

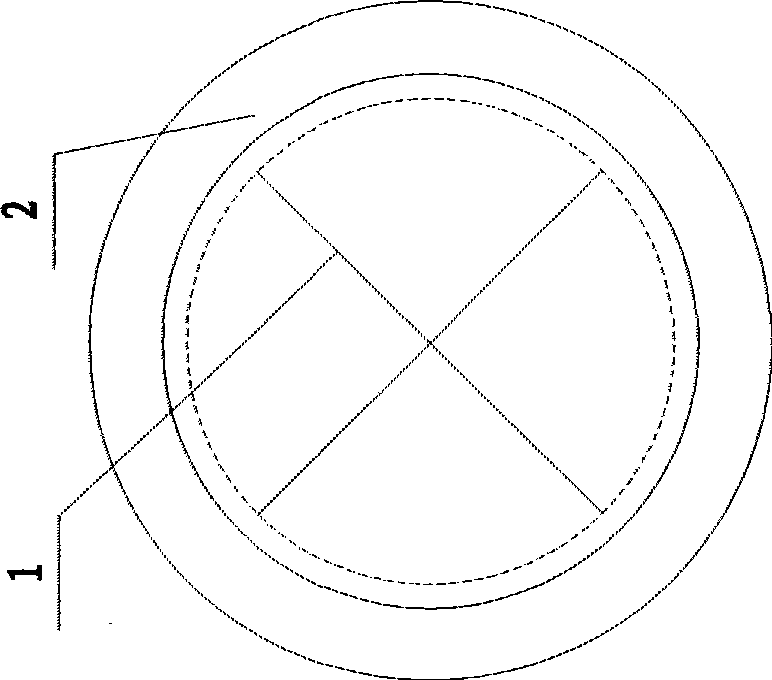

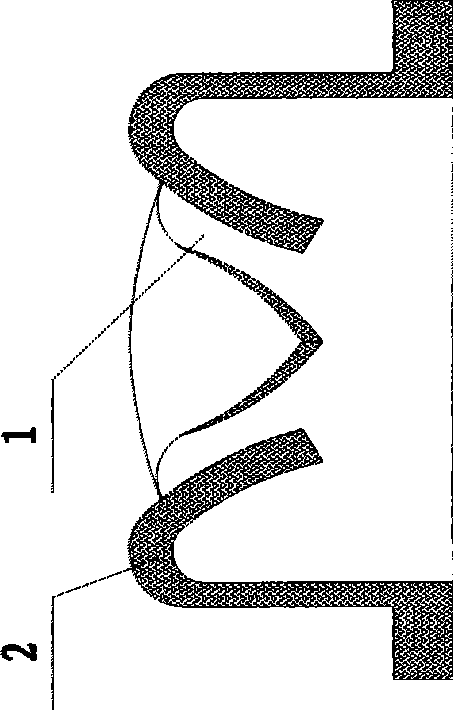

[0045]Embodiment one: see Figure 1-Figure 9 , in the figure, the valve core 2 of the multi-purpose hat-shaped valve breathing valve is hat-shaped, and is made of rubber-like elastic material (or made of silicon rubber), and the brim of the valve core 2 is fixed on the valve seat 4 and the fixed sleeve 3 Between them, the cap body is set in the central hole of the fixed sleeve 3 (or valve seat 4), and the top of the cap body of the valve core 2 protrudes into an arc-shaped surface (according to needs, it can also be made into a conical surface or a pyramid Shape surface.), the top of the cap body is provided with four slits 1, and the four slits 1 all start from the convex axis of the cap body top and distribute radially around to form four pointed valve flaps.

[0046] The valve seat 4 is made of alloy material, ceramic material or engineering plastic, and the fixed sleeve 3 is made of metal material, ceramic material or engineering plastic. In addition, according to needs, ...

Embodiment 2

[0049] Embodiment two: see Figure 7 , This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that there are six slits 1 arranged in a quincunx shape to form six valve discs.

Embodiment 3

[0050] Embodiment three: see Figure 8 , this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that there are eight slits 1, which are set in the shape of a rice to form eight valve discs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com