Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

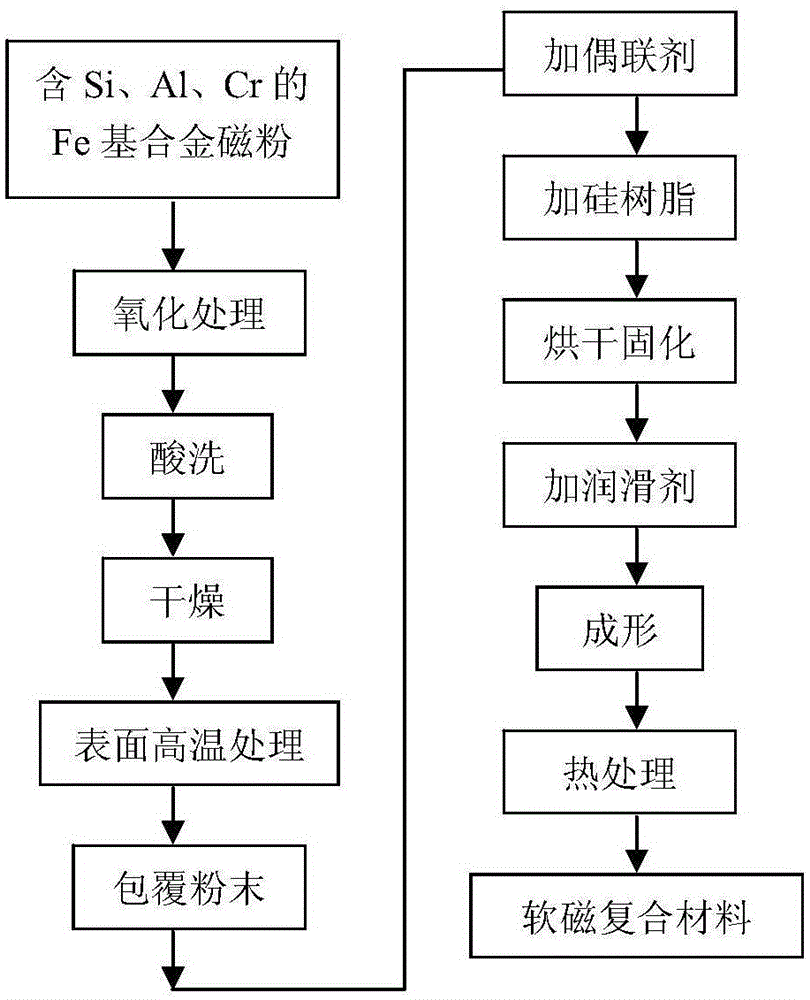

A soft magnetic alloy and powder technology is applied in the field of coating powder to prepare soft magnetic composite materials, and the field of powder coating of iron-based alloy soft magnetic composite materials, which can solve the problems of limited powder quantity, complicated process and low production efficiency, etc. Achieve good magnetic properties and frequency stability, improve compactness and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

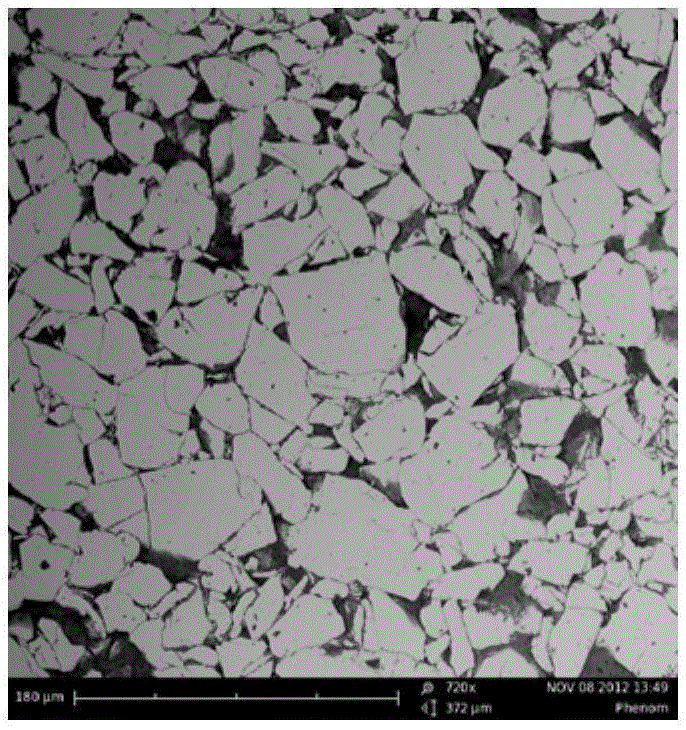

[0043] Take 100 grams of Fe-9Si-6Al alloy powder with an average particle size of 41 μm, keep it in a muffle furnace at 800 ° C for 20 minutes, and cool with the furnace; put the cooled powder into a beaker filled with 40 ml of hydrochloric acid with a concentration of 1 mol / L , and stirred with a glass rod for 20mim to clean the powder surface; then washed several times with deionized water until the pH was about 6-7; dried the cleaned powder at 120°C for 120min; then put the powder in a hydrogen furnace Keep the temperature at 1000°C for 60 minutes, and cool down with the furnace to get the desired coating powder. Add 0.4% silane coupling agent to the coated powder and mix evenly, then add 1% silicone resin and mix evenly; put the mixed material in a drying oven at 120°C for 120 minutes; disintegrate the cooled material 100-mesh sieve; add 0.3% zinc stearate lubricant to the obtained under-sieve powder and mix evenly; then press 1000MPa to form a ring, and the size of the ri...

Embodiment 2

[0048] Take 100 grams of Fe-3.5Si alloy powder with an average particle size of 32 μm, heat it in a muffle furnace at 900 ° C for 30 minutes, and cool with the furnace; in a beaker, and stirred with a glass rod for 30 minutes to clean the powder surface; then washed several times with deionized water until the pH was about 6-7; dried the cleaned powder at 150°C for 100 minutes; then put the powder in Heat it at 900°C for 60 minutes in a hydrogen furnace, and get the desired coating powder after cooling; add 0.5% silane coupling agent to the coating powder and mix evenly, then add 0.8% silicone resin and mix evenly; mix well Put the material into a drying oven at 150°C for 90 minutes; disintegrate the cooled material and pass it through a 100-mesh sieve; add 0.4% lithium stearate lubricant to the obtained powder and mix evenly; then press 900MPa to form an outer diameter of 20 × inner diameter 12 × height 5 rings. The obtained sample was heat-treated at 750°C in a sintering fu...

Embodiment 3

[0053] Take 200 grams of Fe-6.5Si alloy powder with an average particle size of 36 μm, keep it in a muffle furnace at 900 ° C for 30 minutes, and cool with the furnace; put the cooled powder into a beaker with 100 ml of 3 mol / L hydrochloric acid, Stir with a glass rod for 40 minutes to clean the powder surface; then wash it several times with deionized water until the pH is about 6-7; dry the cleaned powder at 140°C for 90 minutes; then put the powder under argon protection Heat treatment at 900°C for 30 minutes in a heat treatment furnace, and the desired coated powder can be obtained after cooling. Add 0.7% silane coupling agent to the coating powder and mix evenly, then add 0.4% silicone resin and mix evenly; put the mixed material in a drying oven at 130°C for 90 minutes; disintegrate the cooled material 60 mesh sieve; the obtained powder is added with 0.3% content of zinc stearate lubricant and mixed evenly; then pressed into an outer diameter 20 × inner diameter 12 × hei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com