Patents

Literature

540 results about "Light pillar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A light pillar is an atmospheric optical phenomenon in which a vertical beam of light appears to extend above and/or below a light source. The effect is created by the reflection of light from tiny ice crystals that are suspended in the atmosphere or that comprise high-altitude clouds (e.g. cirrostratus or cirrus clouds). If the light comes from the Sun (usually when it is near or even below the horizon), the phenomenon is called a sun pillar or solar pillar. Light pillars can also be caused by the Moon or terrestrial sources, such as streetlights.

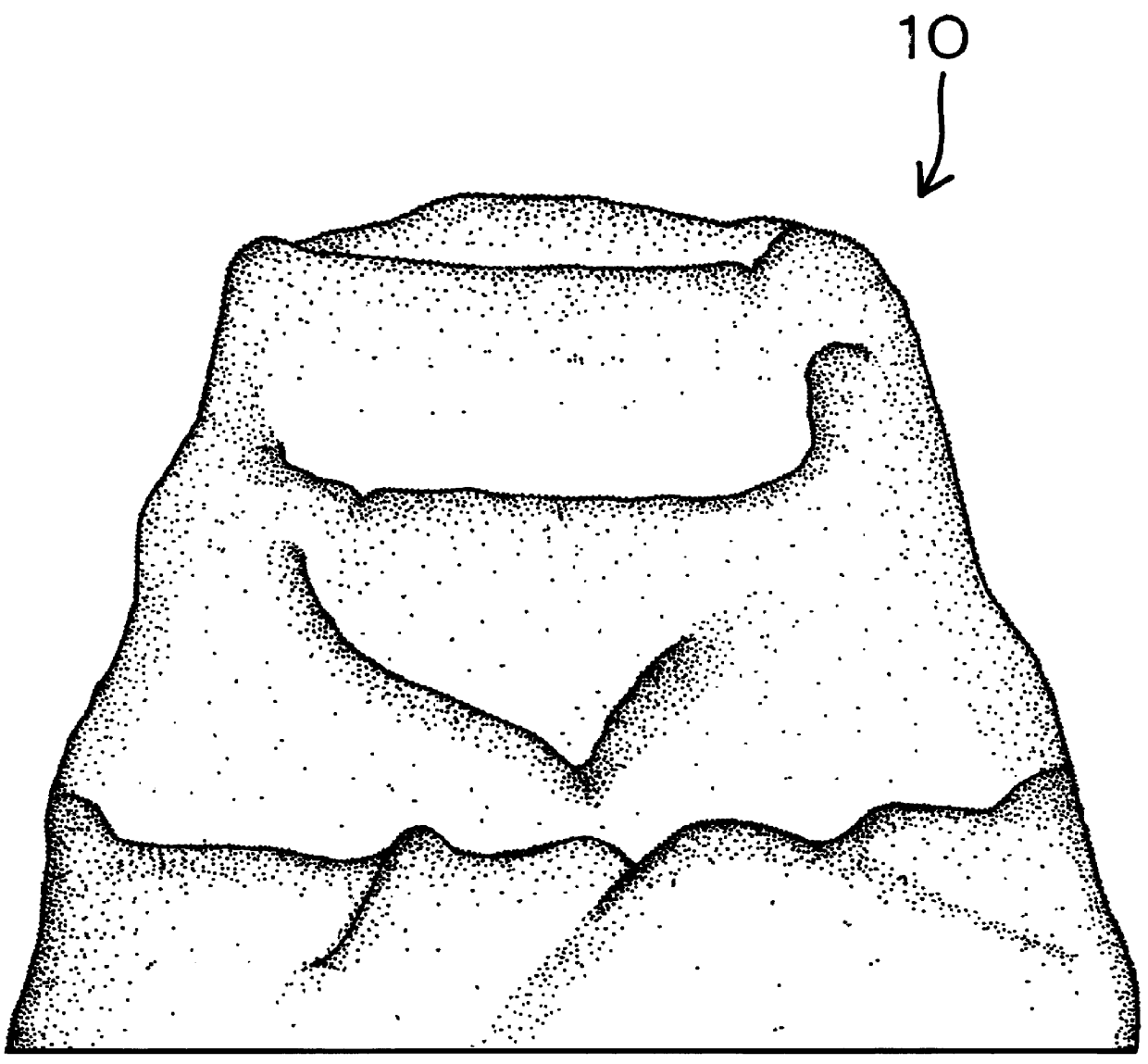

Simulated rock and method of making same

A simulated rock and a method of producing it, using Portland Cement, Bentonite or lime, polystyrene, and water. Ground polystyrene is mixed with cement, Bentonite or lime, and water, to form a settable cement formulation which is poured into removable forms. Reinforcing members are included in the mold, and a lifting hook is provided for later lifting and transporting of the resultant simulated rock. One or more base coats can be applied using a different formula, and a color coat can be applied. The method is use for making landscaping rocks, rock fountains, stone barbecues, light pillars, planters, room dividers, artificial masonry panels, and any structure which uses rocks or masonry.

Owner:CALLAHAN HARVEY J

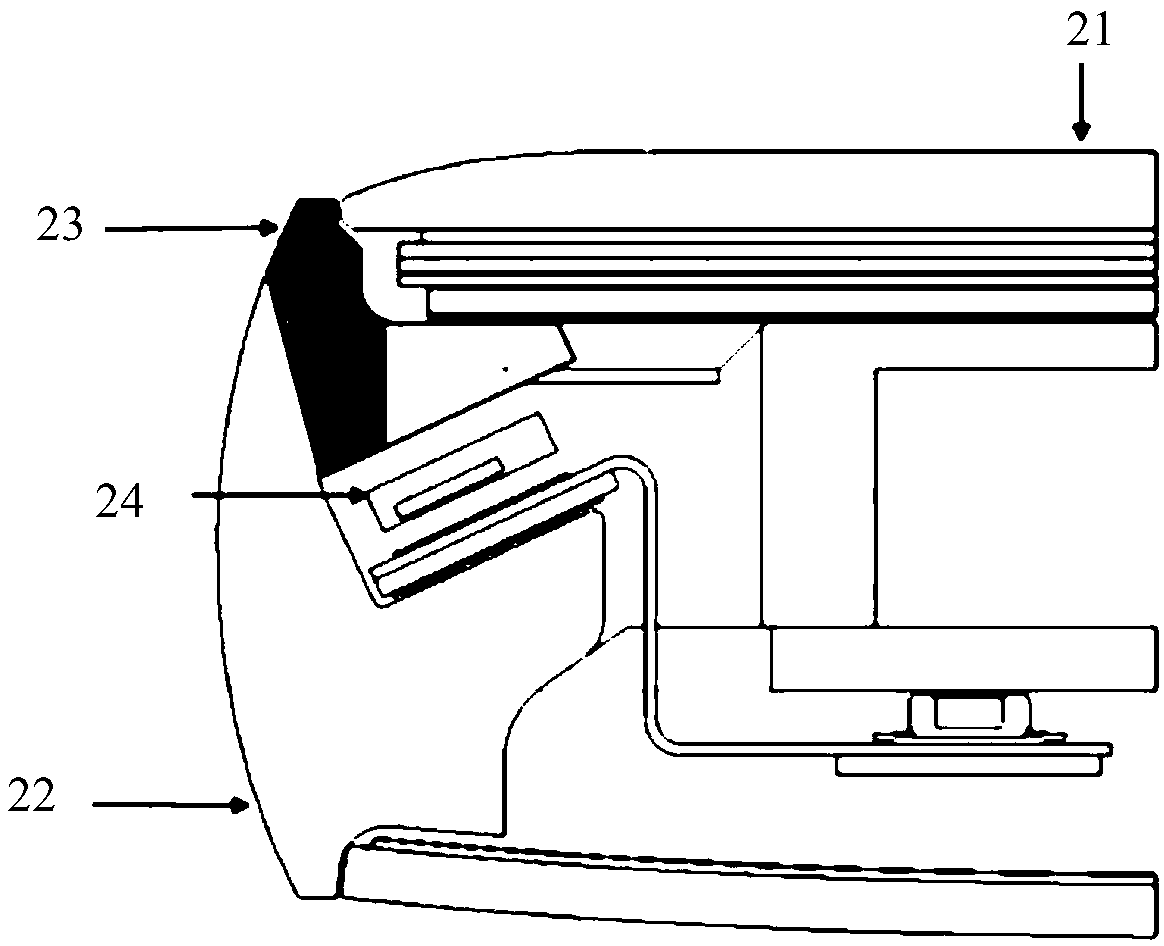

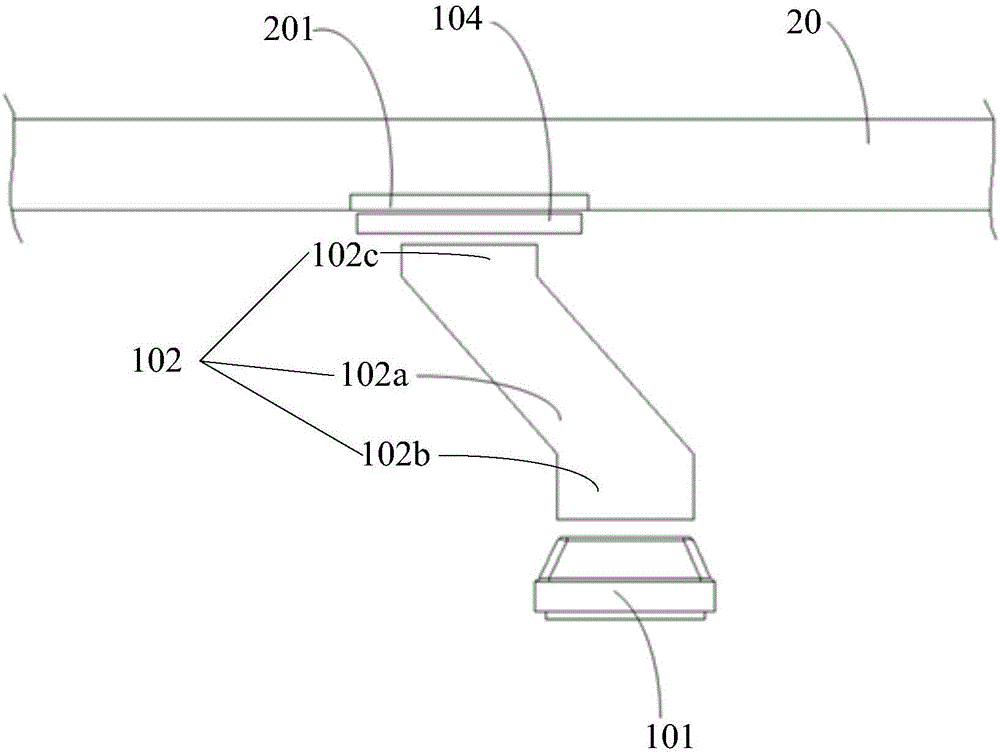

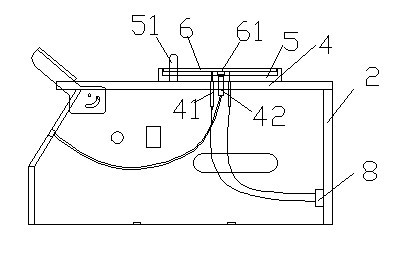

Terminal equipment

ActiveCN107945661ADoes not affect the overall screen ratioConducive to full screen designStatic indicating devicesDevices with sensorLight guideTerminal equipment

The invention relates to the technical field of terminal equipment, in particular to terminal equipment. The terminal equipment is used for solving the problem in the prior art that layout of an ambient light sensor limits a full screen design. The terminal equipment mainly comprises a display module, a middle frame for fixing the display module, a light guide column embedded in the middle frame and an ambient light sensor located at the bottom of the light guide column. The light inlet surface of the light guide column guides ambient lights to the ambient light sensor. Therefore, the ambientlight sensor does not occupy the frame of the terminal equipment, does not affect the screen-to-body ratio of the whole machine, and facilitates the full screen design of the terminal equipment.

Owner:VIVO MOBILE COMM CO LTD

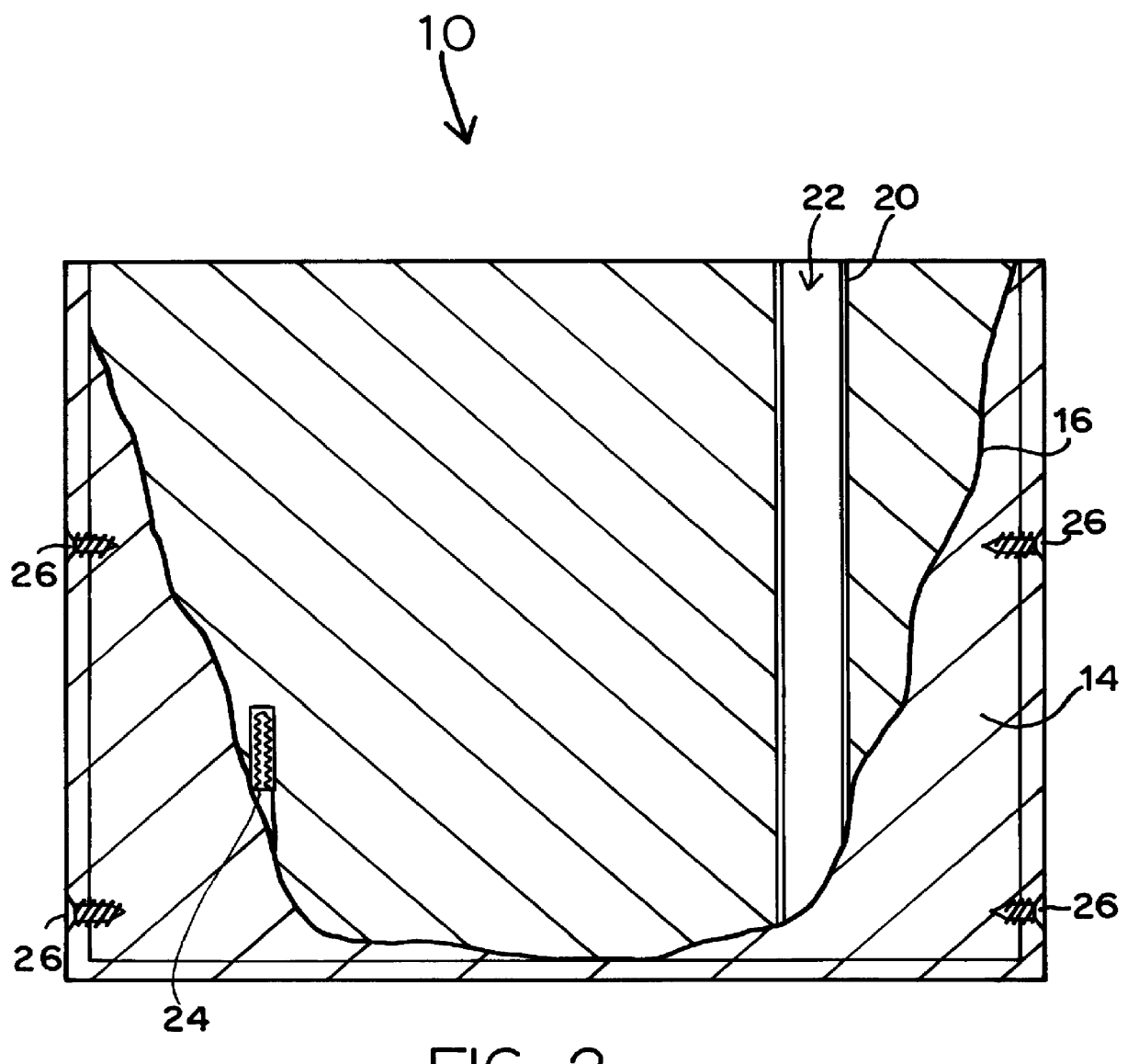

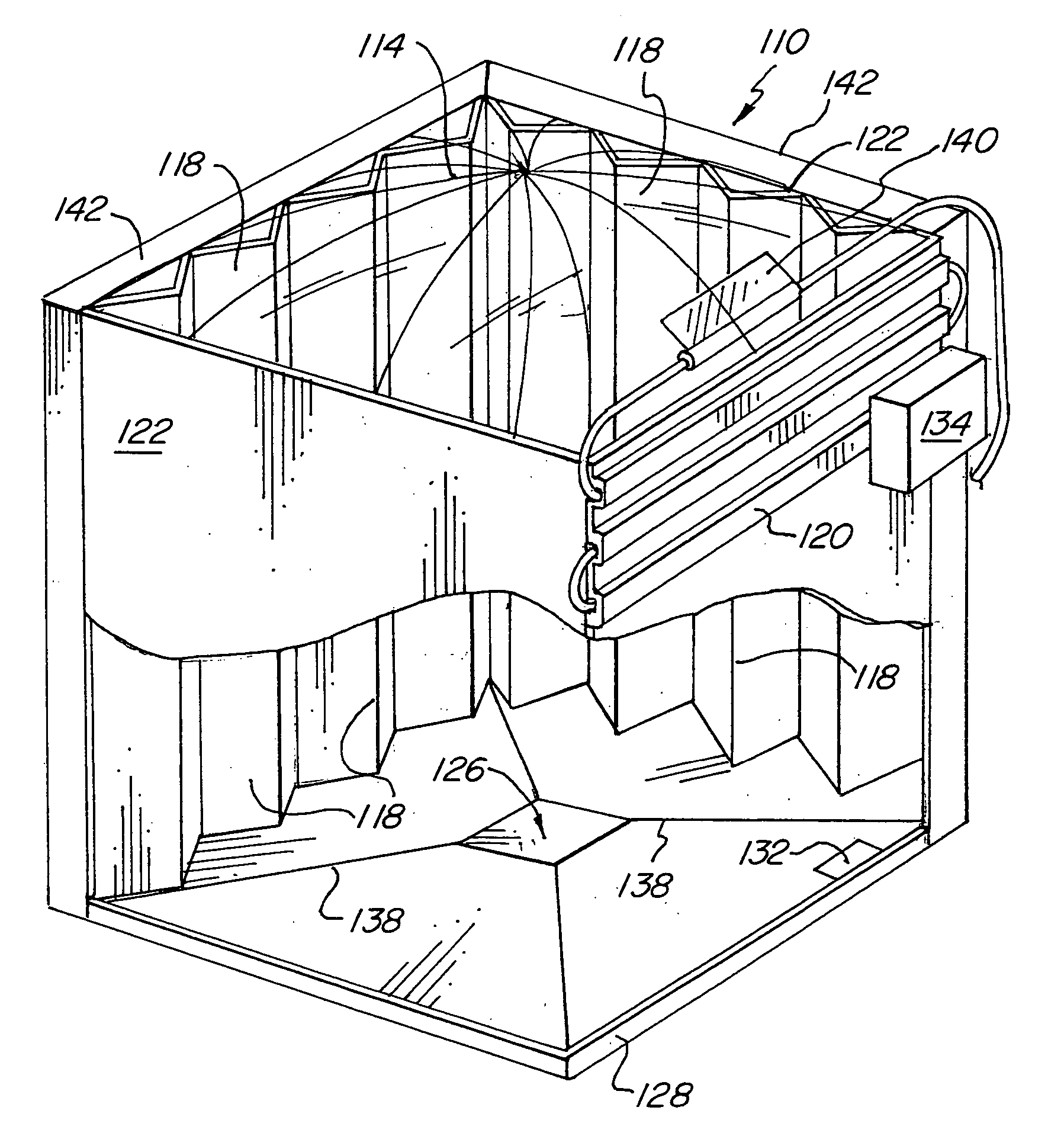

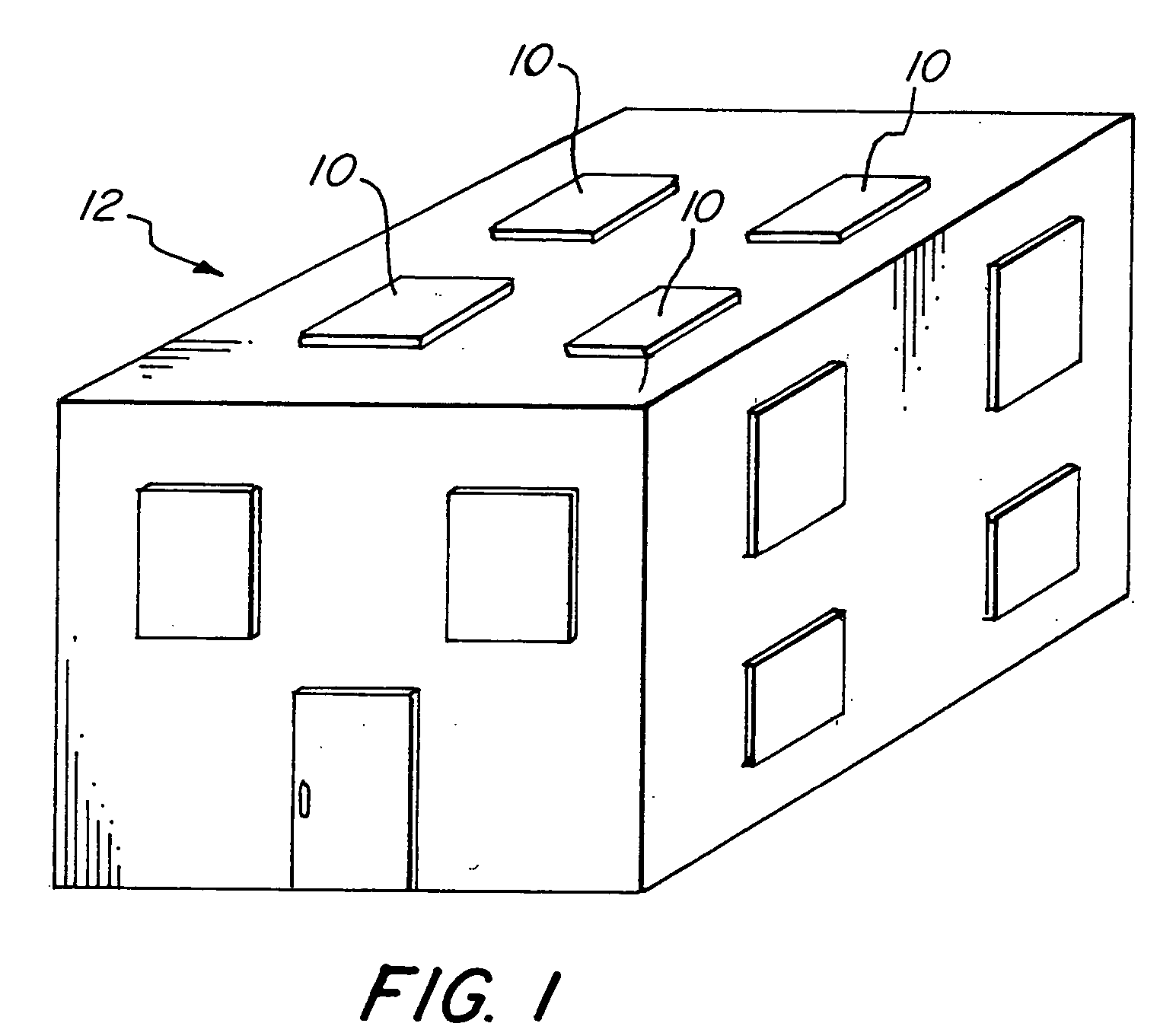

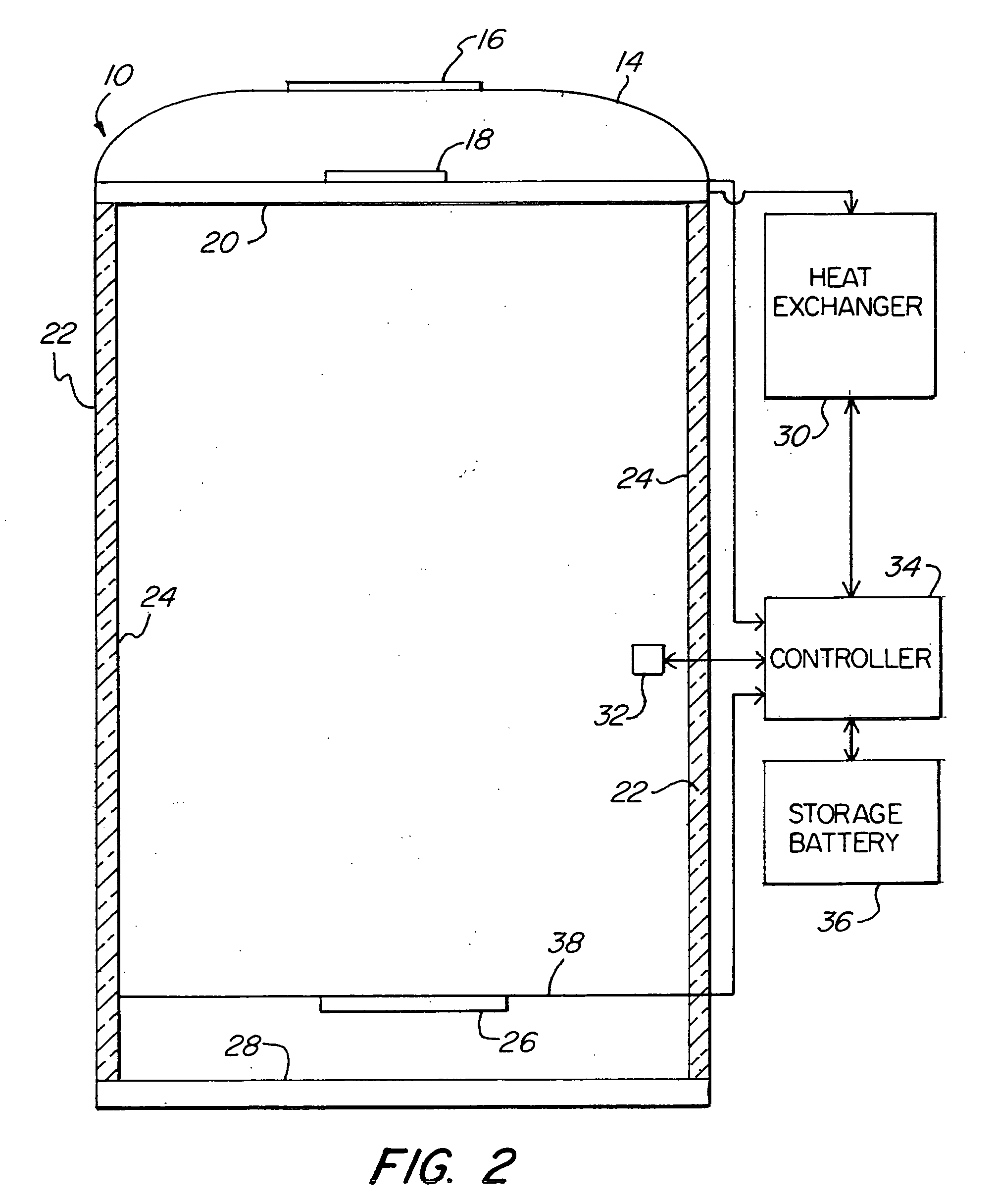

Integrated artificial and natural lighting system

ActiveUS20060007549A1Reduce heat buildupEasy to modifyLight source combinationsPoint-like light sourceElectrical batteryEffect light

An artificial and natural lighting system placed in the roof of a building that is substantially self-contained and powered. A photovoltaic cell provides electricity stored in a battery to power light emitting diodes. A highly reflective interior coating applied to the light shaft maximizes lighting intensity. A sensor detects illumination intensity and temperature within the light shaft to control the balance of natural and artificial light provided to maintain predetermined illumination intensity. The light shaft is insulated to reduce heat transfer and a thermal collector removes heat from the building. In one embodiment, a Fresnel lens is utilized to focus natural light onto the photovoltaic cell. In another embodiment, conventional fluorescent lighting powered by external line voltage is combined with light emitting diodes powered primarily by a rechargeable battery. The present invention, being substantially self-contained, is easily retrofitted to existing buildings with a minimum of connections and provides substantial energy efficiencies in illuminating the building.

Owner:SUNPORT IND

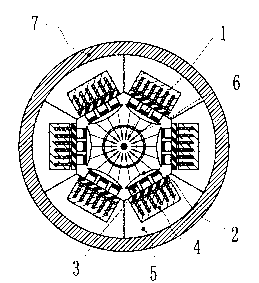

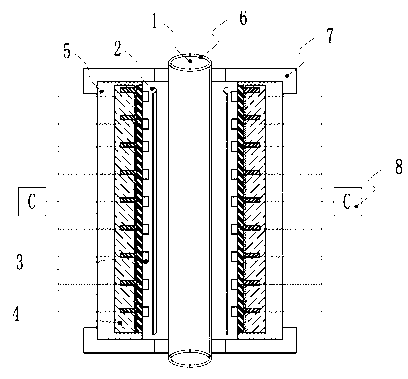

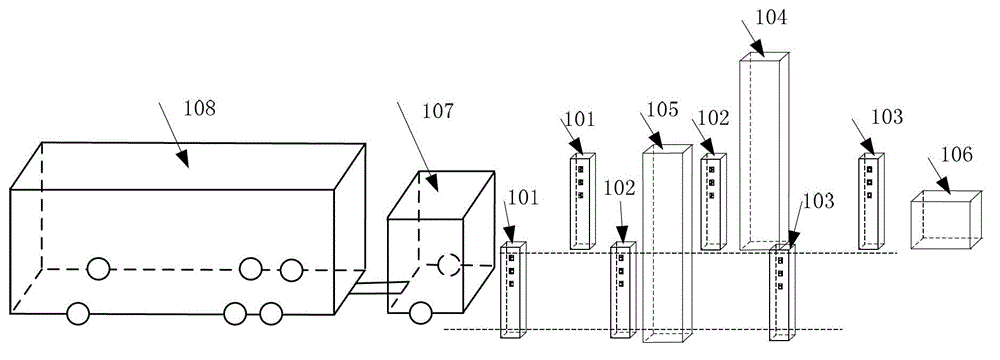

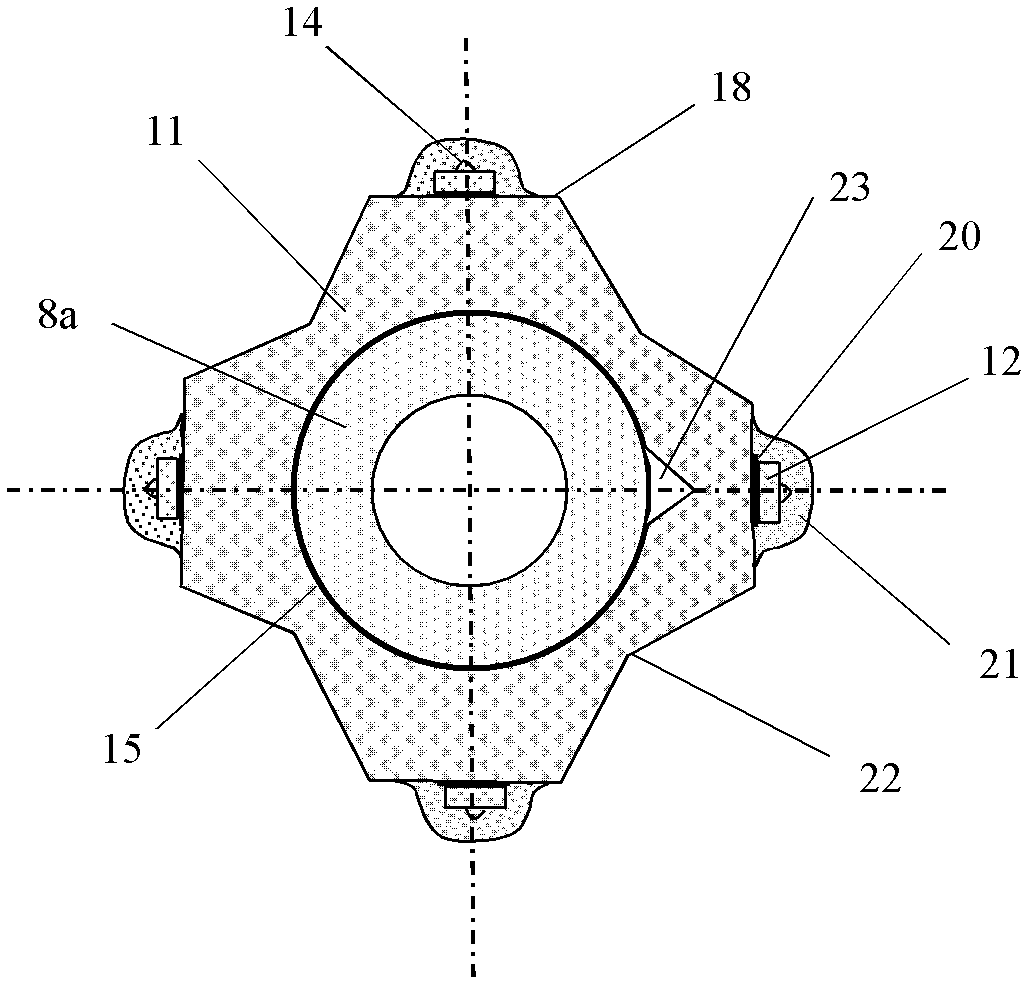

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

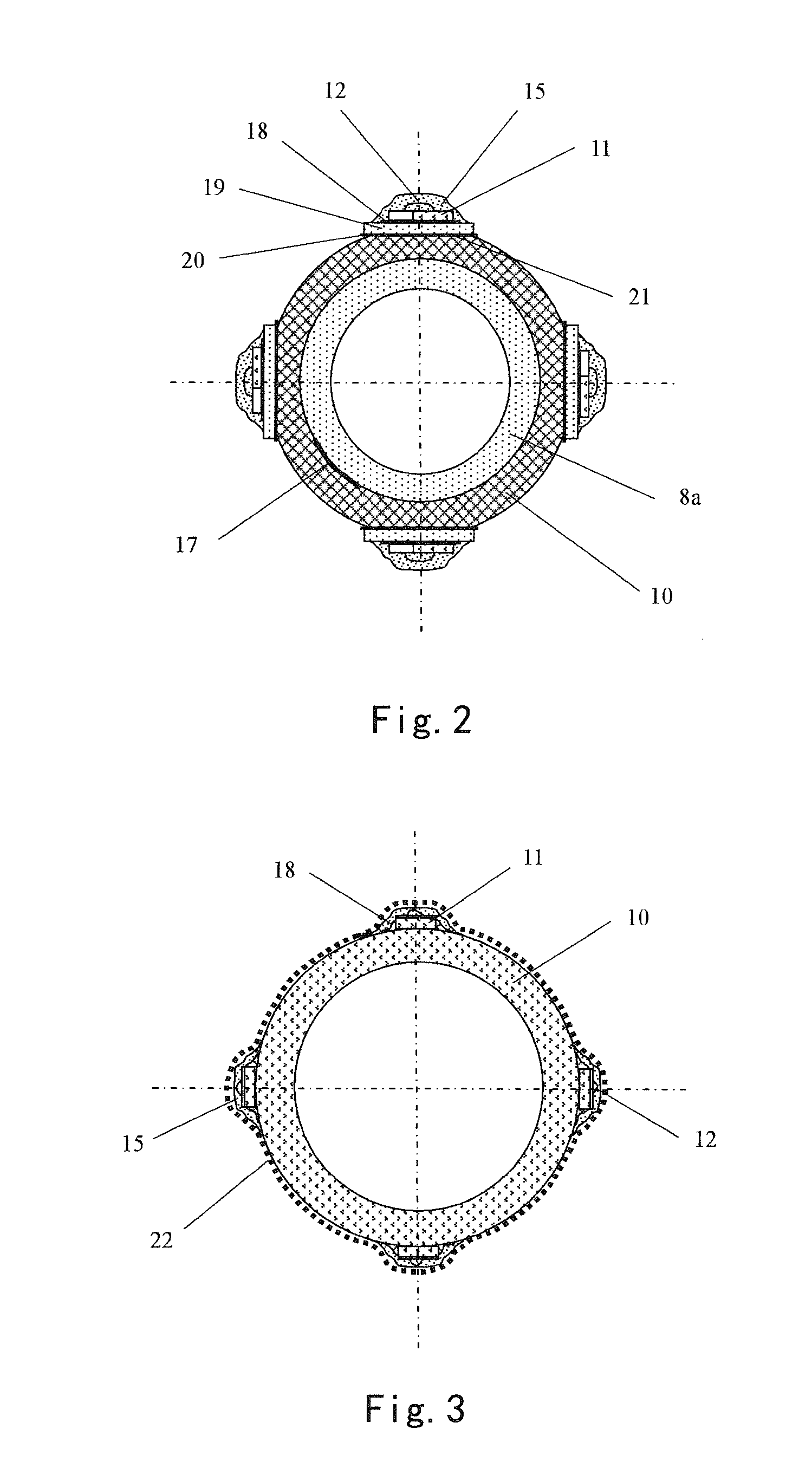

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

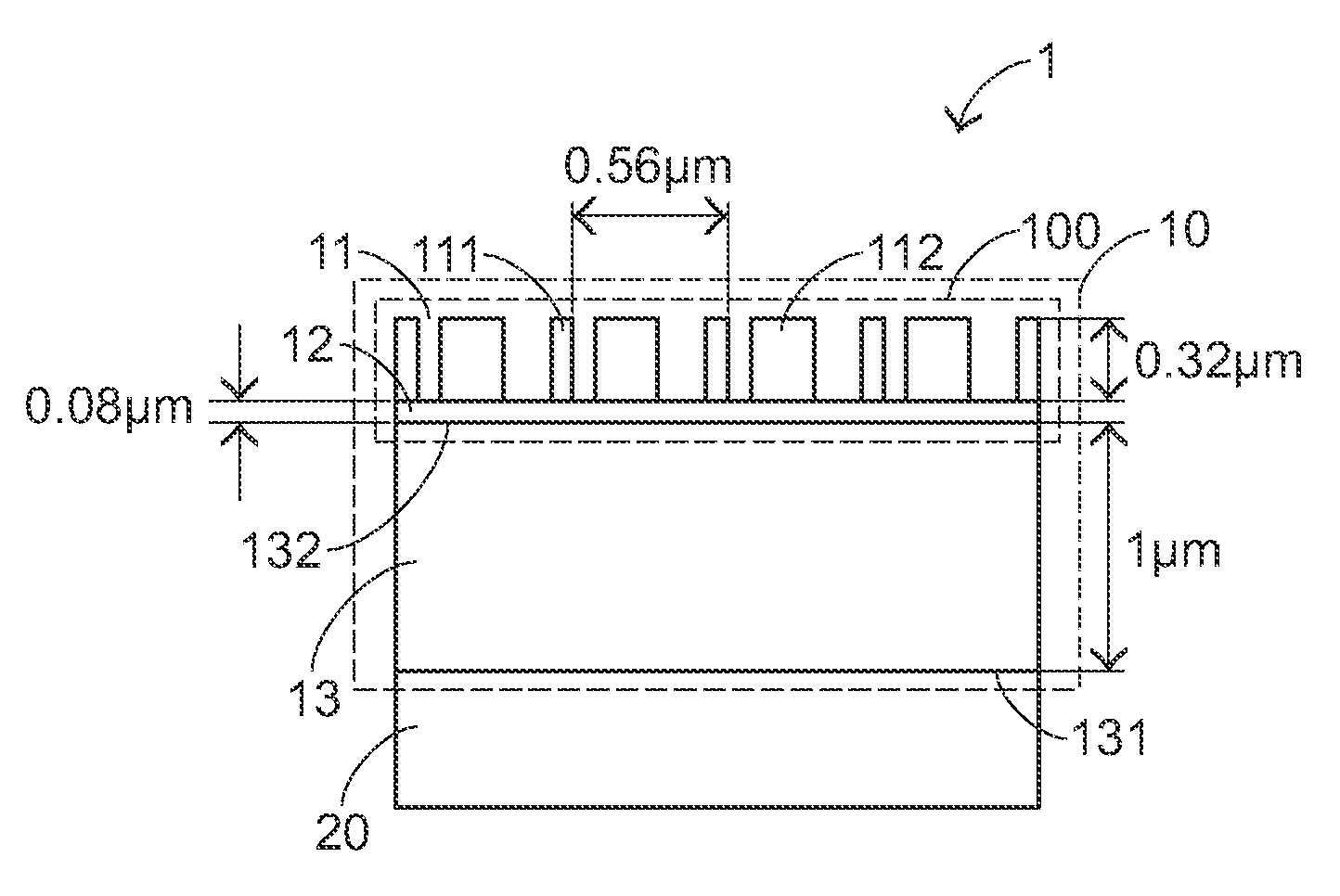

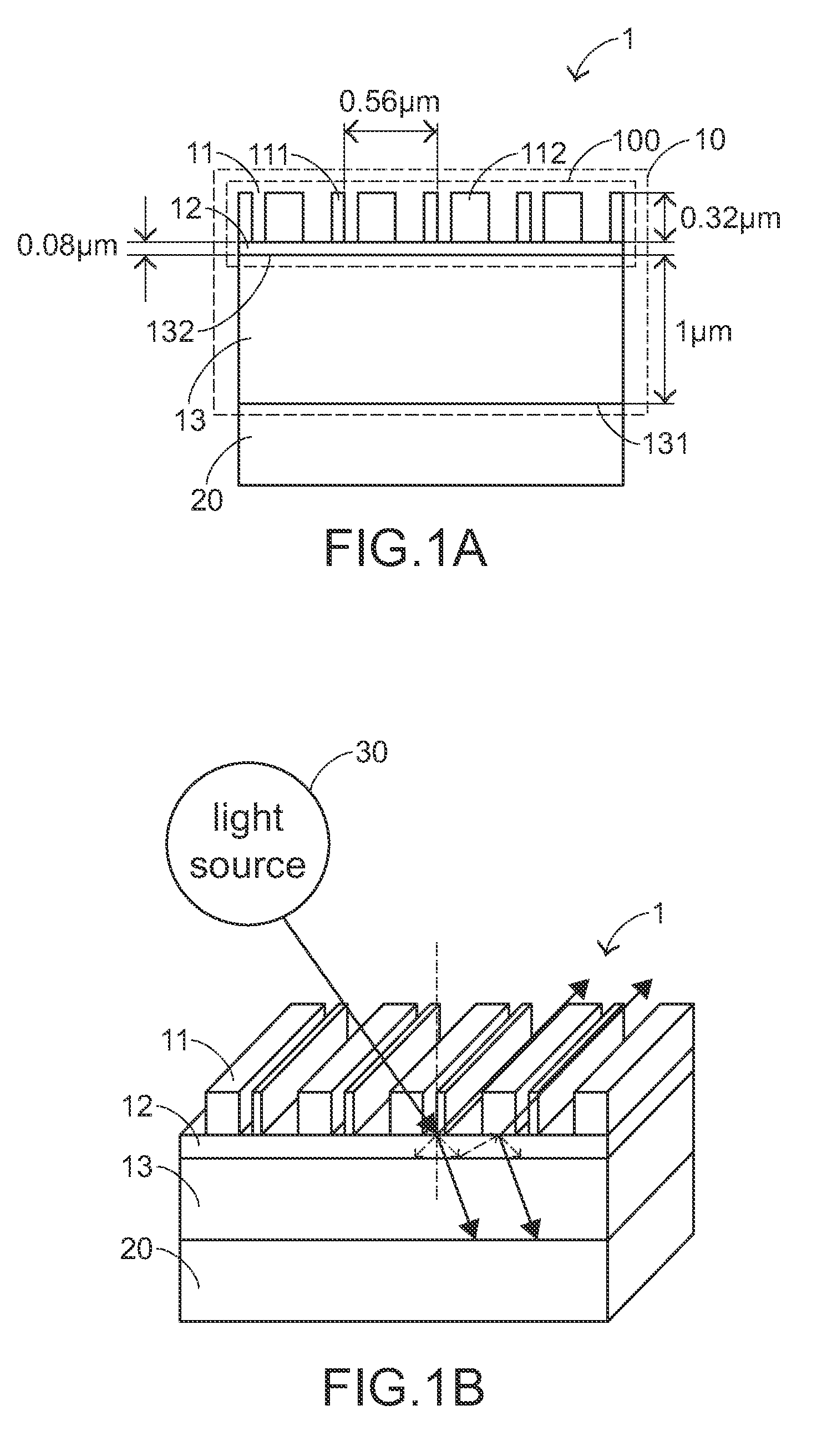

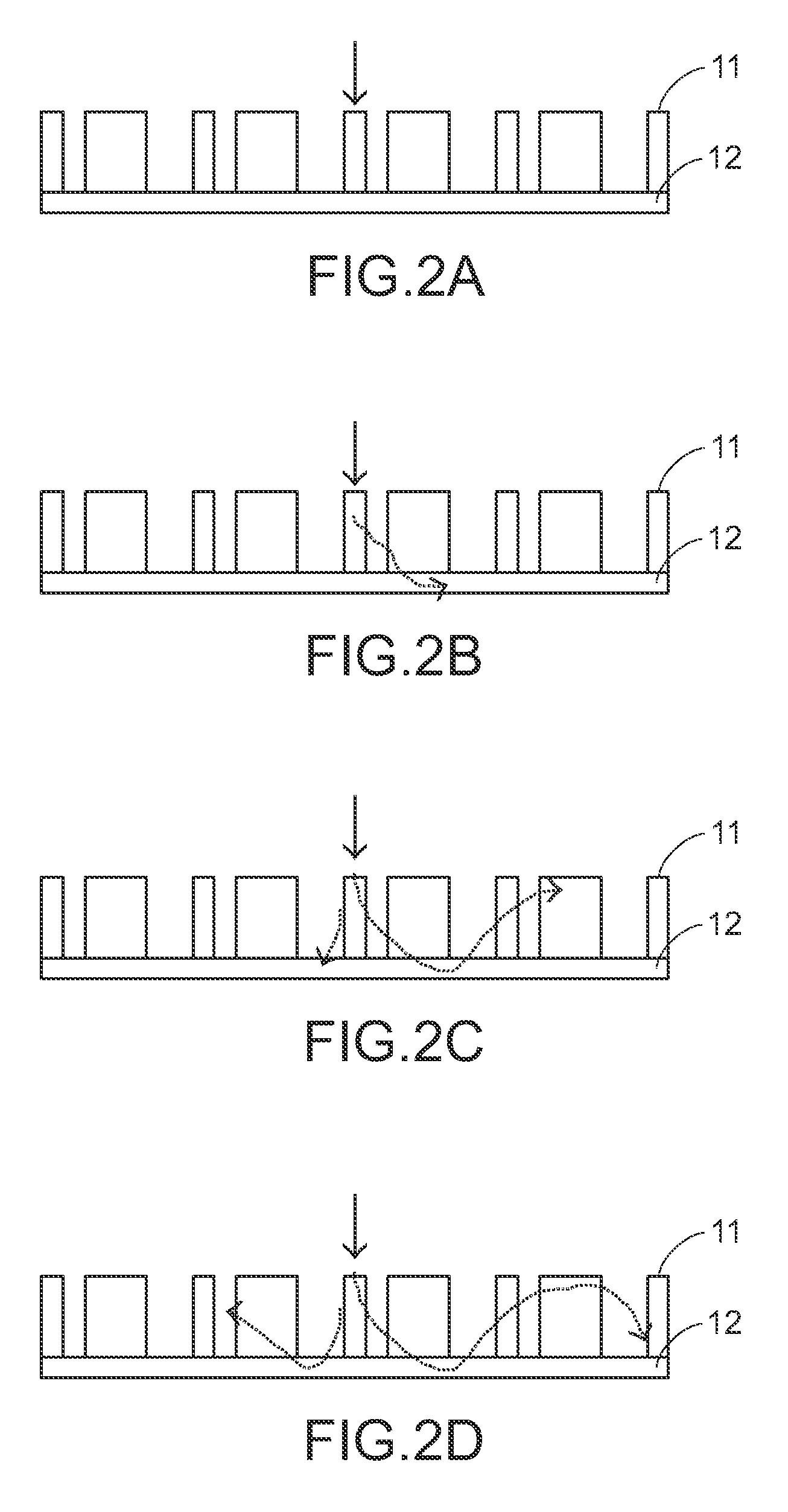

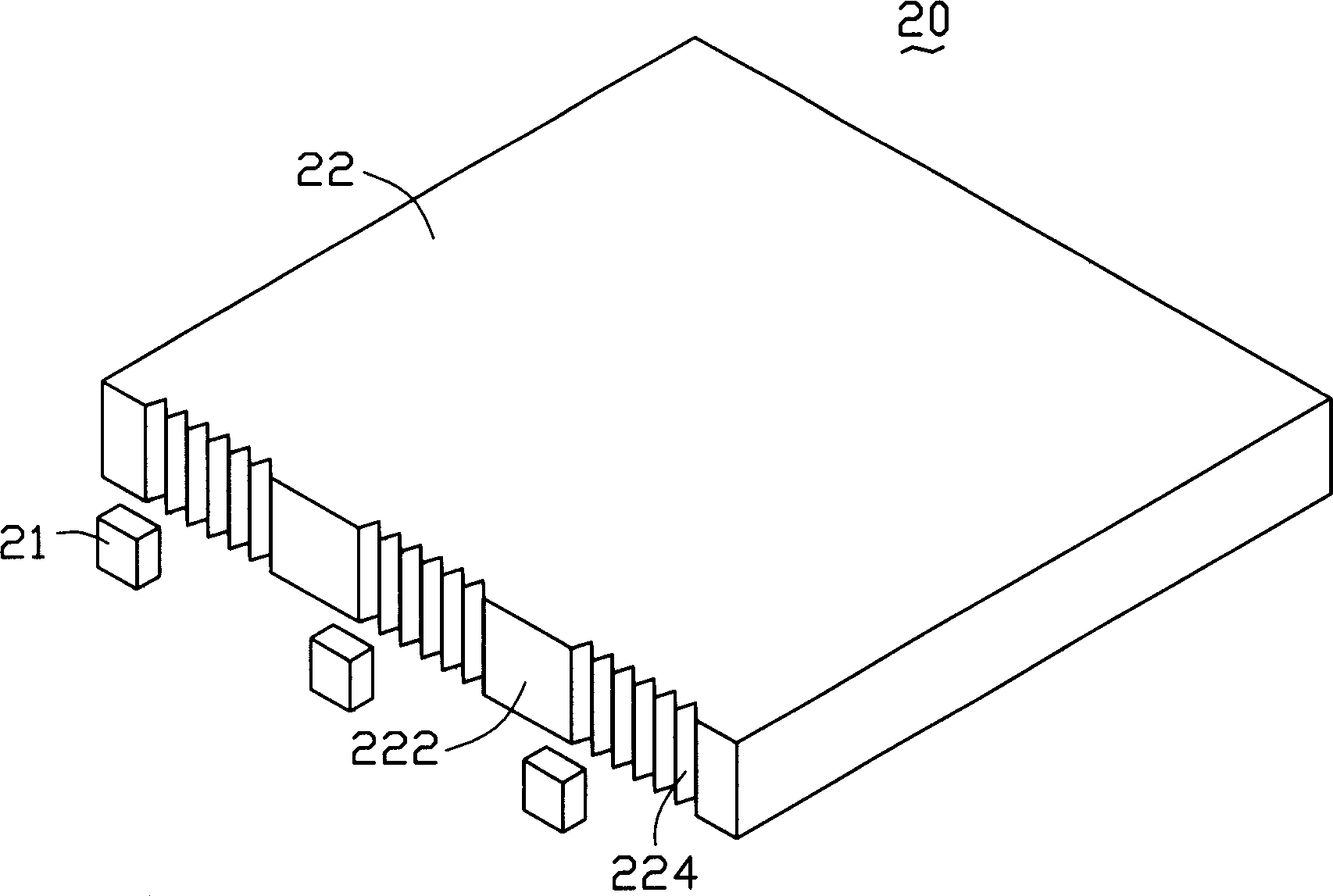

Guided mode resonance solar cell

InactiveUS20100126577A1Easy to trapOptical path lengthCoupling light guidesPhotovoltaic energy generationGratingLight pillar

A guided mode resonance solar cell includes a solar cell body and a guided mode resonance unit. The solar cell body is used for converting optical energy into electrical energy. The guided mode resonance unit is formed on the solar cell body, and includes a grating structure and a waveguide structure. The grating structure includes multiple sub-wavelength light pillars. When a light emitted from a light source is incident onto the grating structure, a resonant of the light occurs in the grating structure to facilitate trapping the light in the waveguide structure and elongating an optical path length.

Owner:NAT CENT UNIV

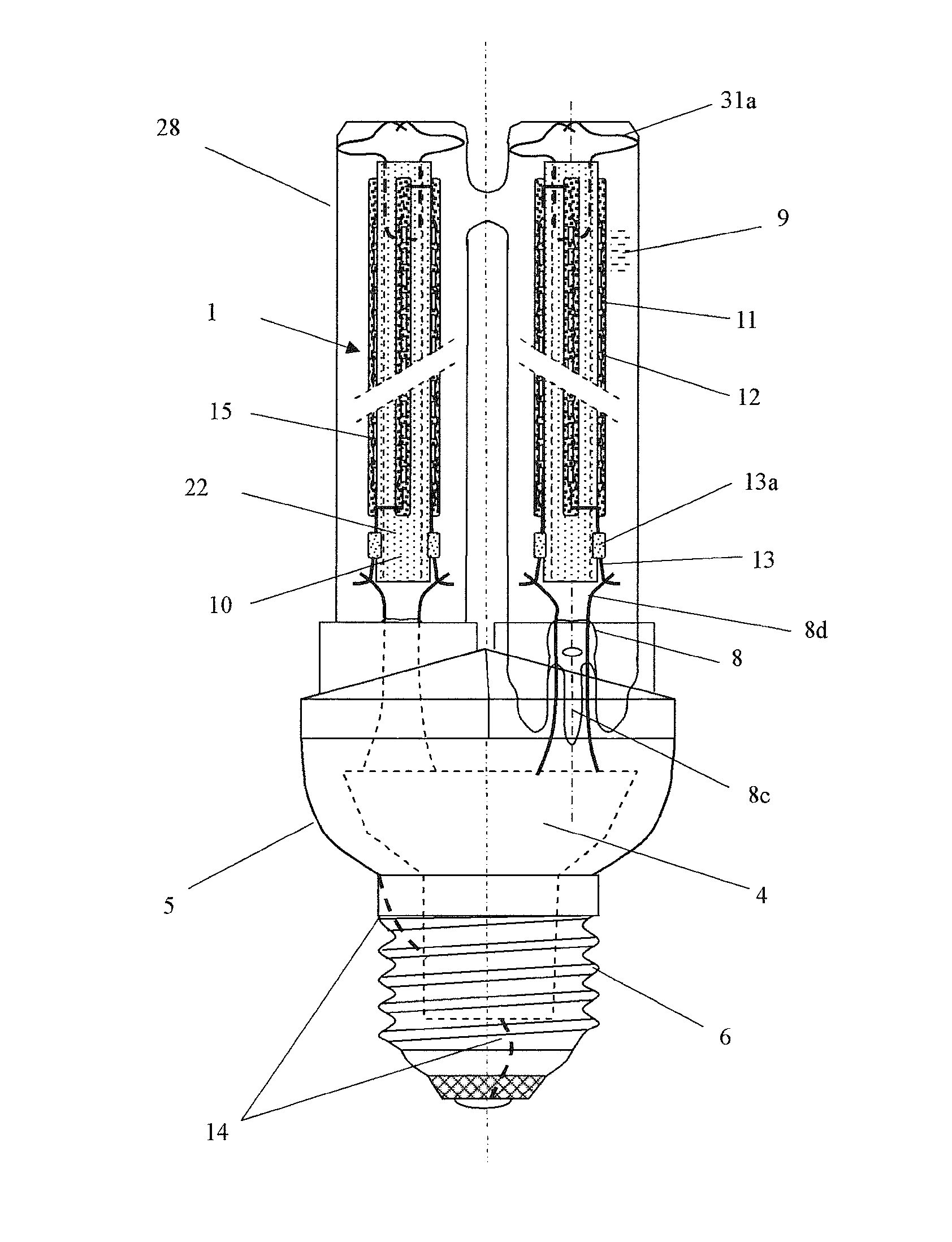

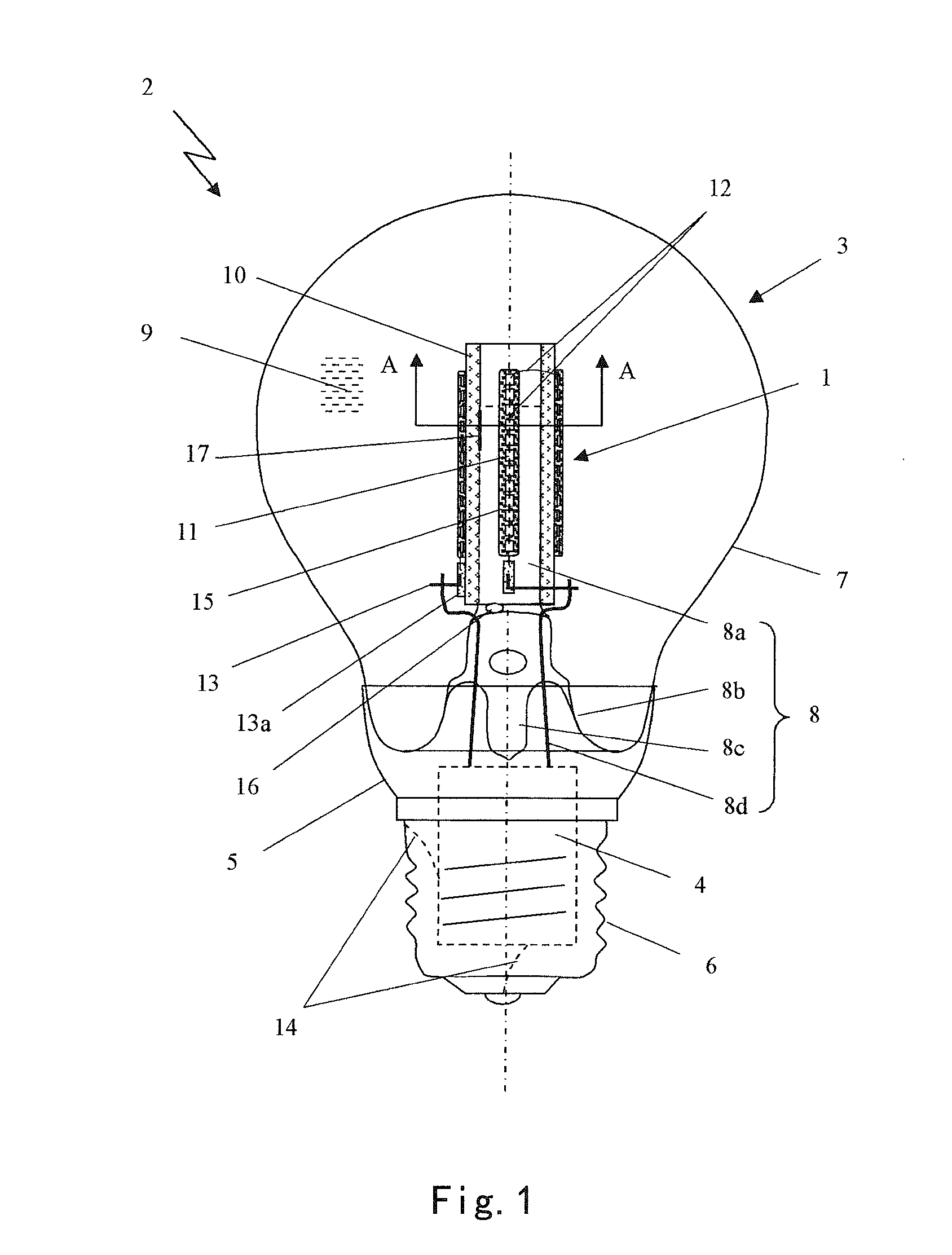

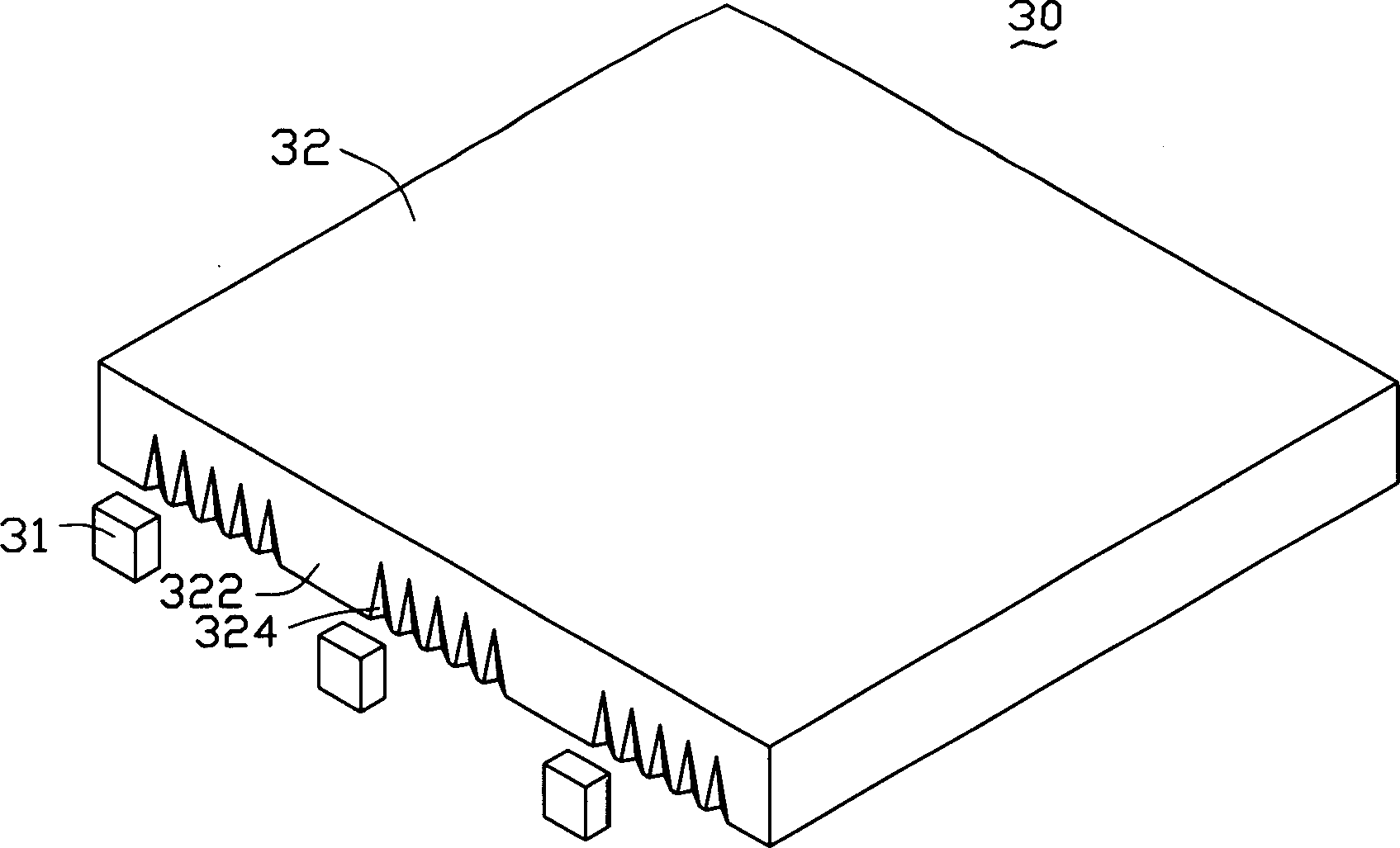

LED light-emitting column and LED light using the same

InactiveUS20150036341A1Improve featuresIncrease output brightnessLight source combinationsPoint-like light sourceShielding gasLight pillar

The present invention discloses a LED light-emitting column and a LED light using the same. The LED light-emitting column comprises a high thermal conductivity tube and at least one series of LED chips disposed on an outer surface of the high thermal conductivity tube. The LED light comprises a light-transmitting bulb shell vacuum-sealed and filled with a heat dissipation and protection gas, a LED driver and an electrical connector. The LED light-emitting column is fixed within the bulb shell. Electrical lead of the LED light-emitting column is connected with an outer power supply through the driver and the electrical connector. The LED light is a single bulb shell light, a multi-tube light or a U-type light.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

Lightung module and illuminant decice having the same

InactiveUS20130083555A1Effectively enlarge lighting angle of light passingEfficient amplificationMechanical apparatusPoint-like light sourceLight guideOptical axis

A lighting module includes an illuminant unit, a light guide pillar and a first reflecting member. The illuminant unit has an optical axis and includes at least a LED. The light guide pillar includes a base and a light guide part, the LED disposed on the base, the light guide pillar is extended from the base along the optical axis and an end of the light guide pillar has a top surface. The top surface is concave toward the base and is continuous. The first reflecting member is disposed on the top surface. Wherein a partial light emitted by the illuminant unit is travelling to the first reflecting member through the light guide pillar, the first reflecting member reflects the partial light such that the partial light emits from the light guide part.

Owner:CHICONY POWER TECH CO LTD

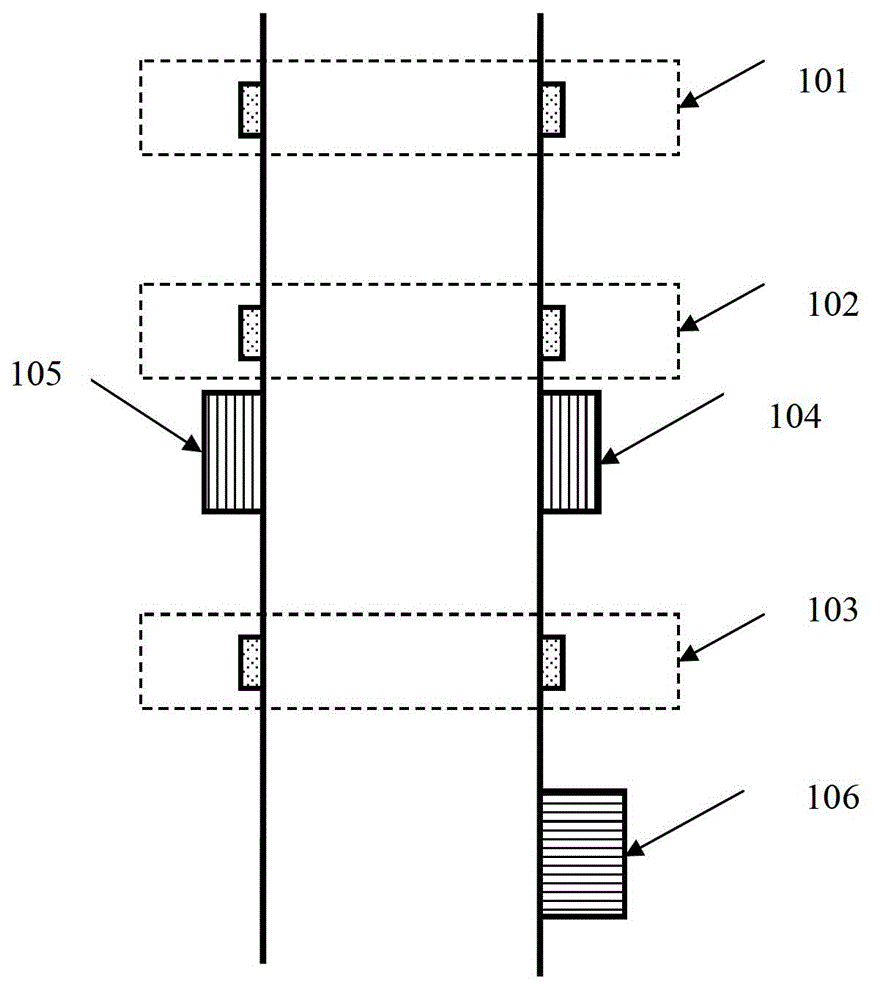

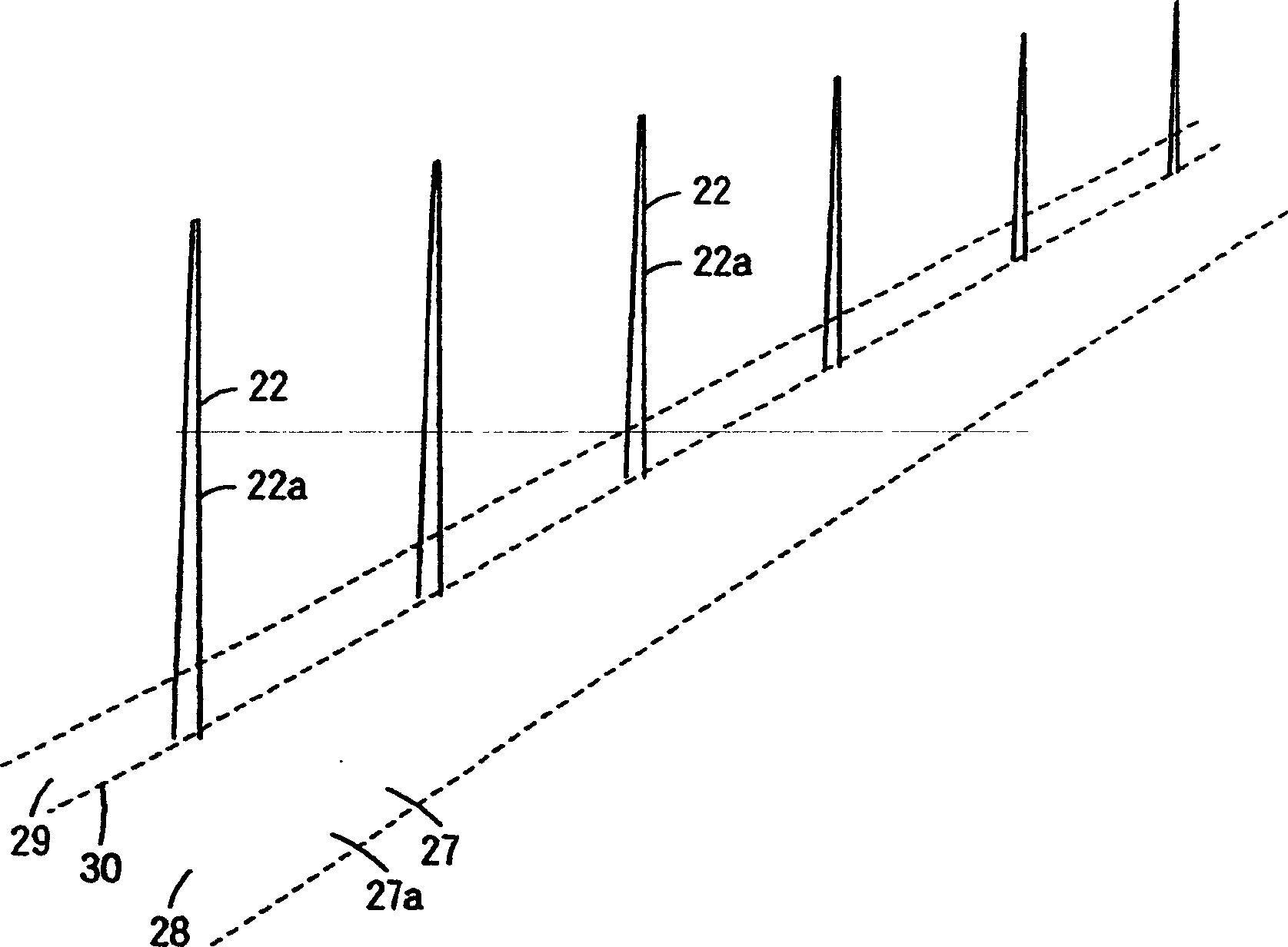

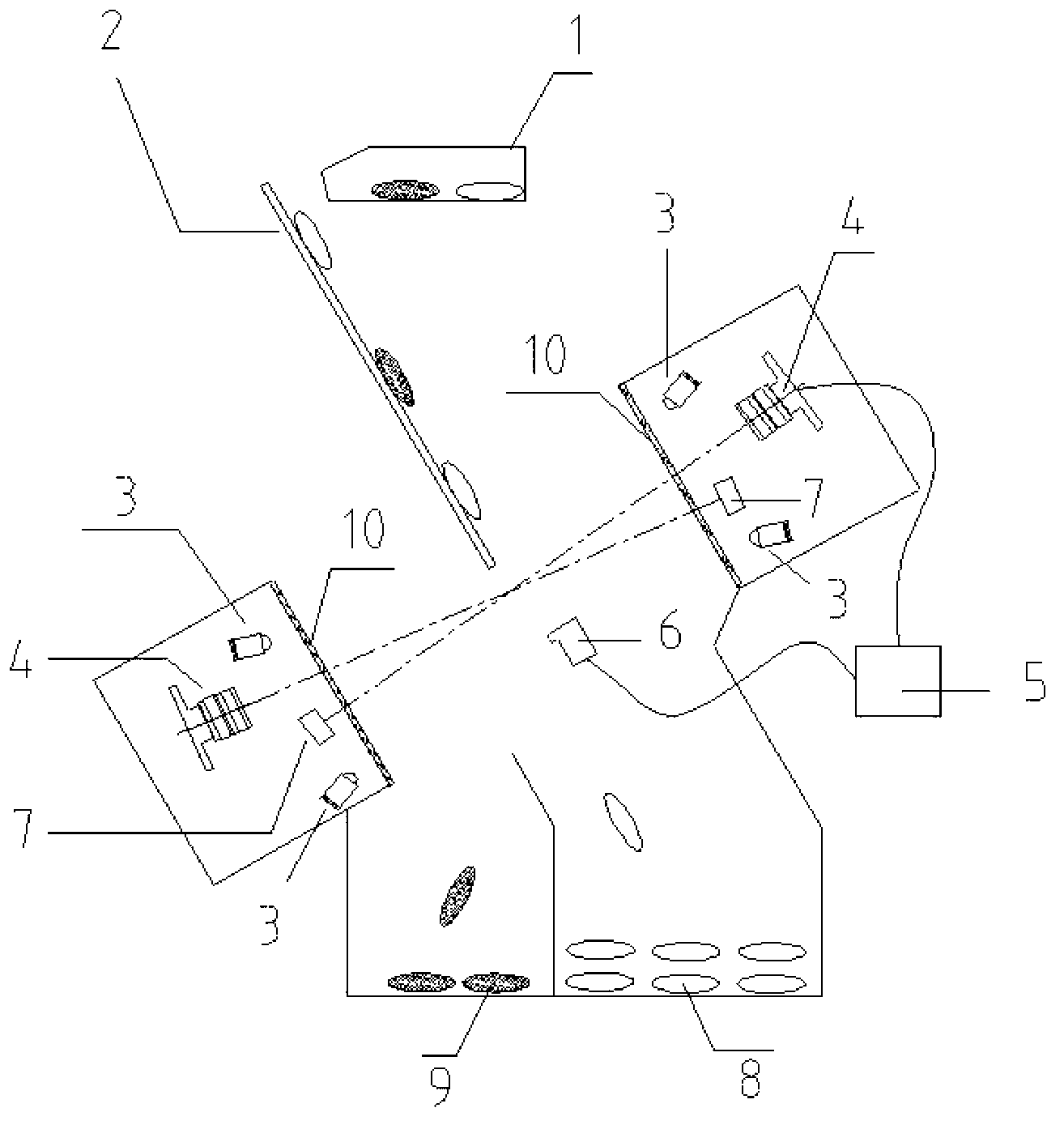

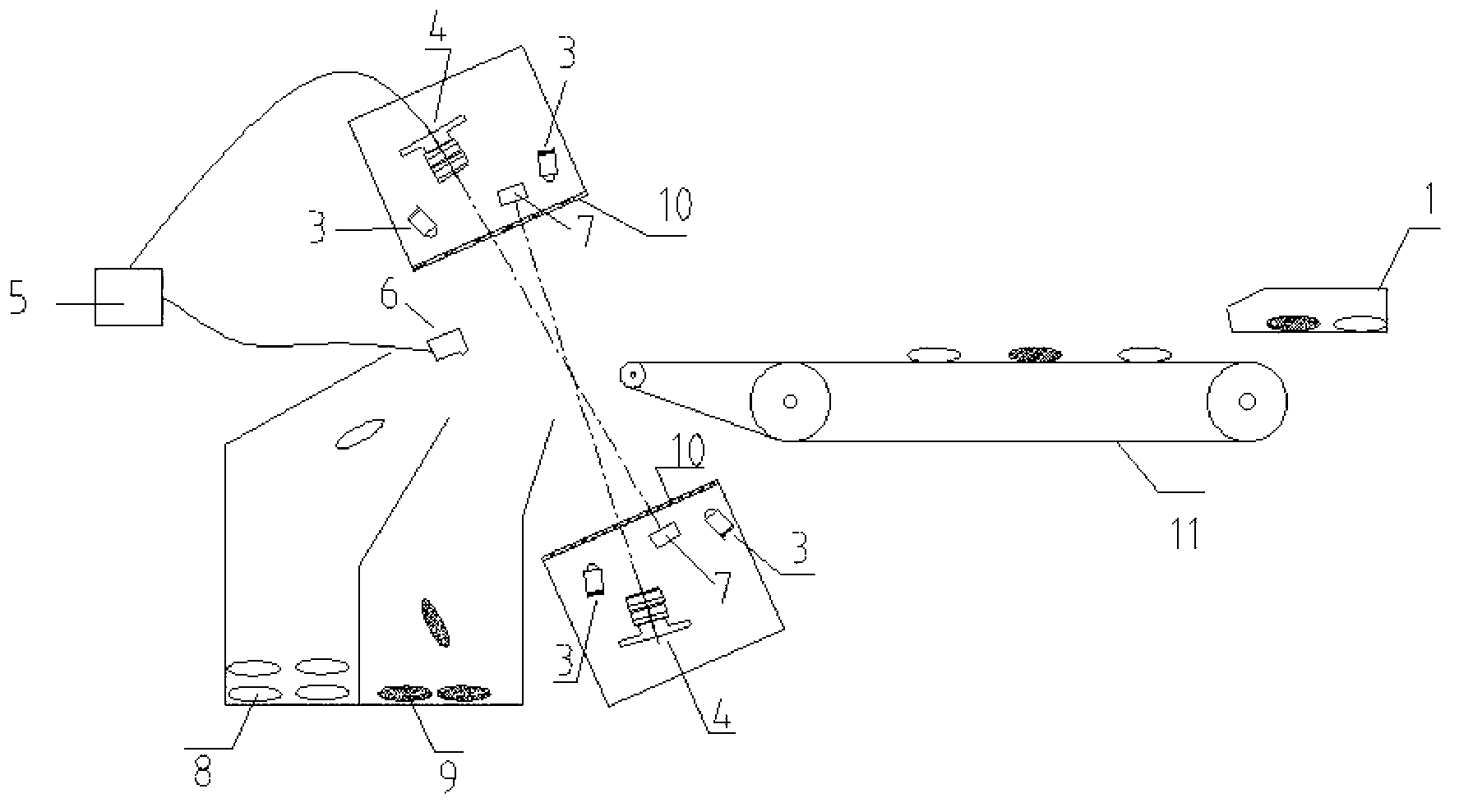

System and method for cab avoidance of vehicles of highway green detection channel

InactiveCN103149599AAccurateEfficient graspOptical detectionMaterial analysis by transmitting radiationSensor nodeEngineering

The invention relates to a system and a method for cab avoidance of vehicles of a highway green detection channel. The system comprises a first group of sensor nodes, a second group of sensor nodes, a third group of sensor nodes, a ray generator, a ray detector and a controller, wherein each group of sensor nodes consists of a pair of light pillars, each pair of light pillars is provided with three pairs of photoelectric switches, the controller is used for preprocessing the vehicle information, the vehicles are classified into trailer vehicles and non-trailer vehicles, and a proper time is obtained by analysis and judgment to open and close the ray generator. The system and the method have the advantages that the problem of the cab avoidance of the detected vehicles of the highway green detection channel is solved, the safety of driving persons is ensured, the efficiency is high, the cost is low, and the practicality is high.

Owner:吉林省高速公路管理局

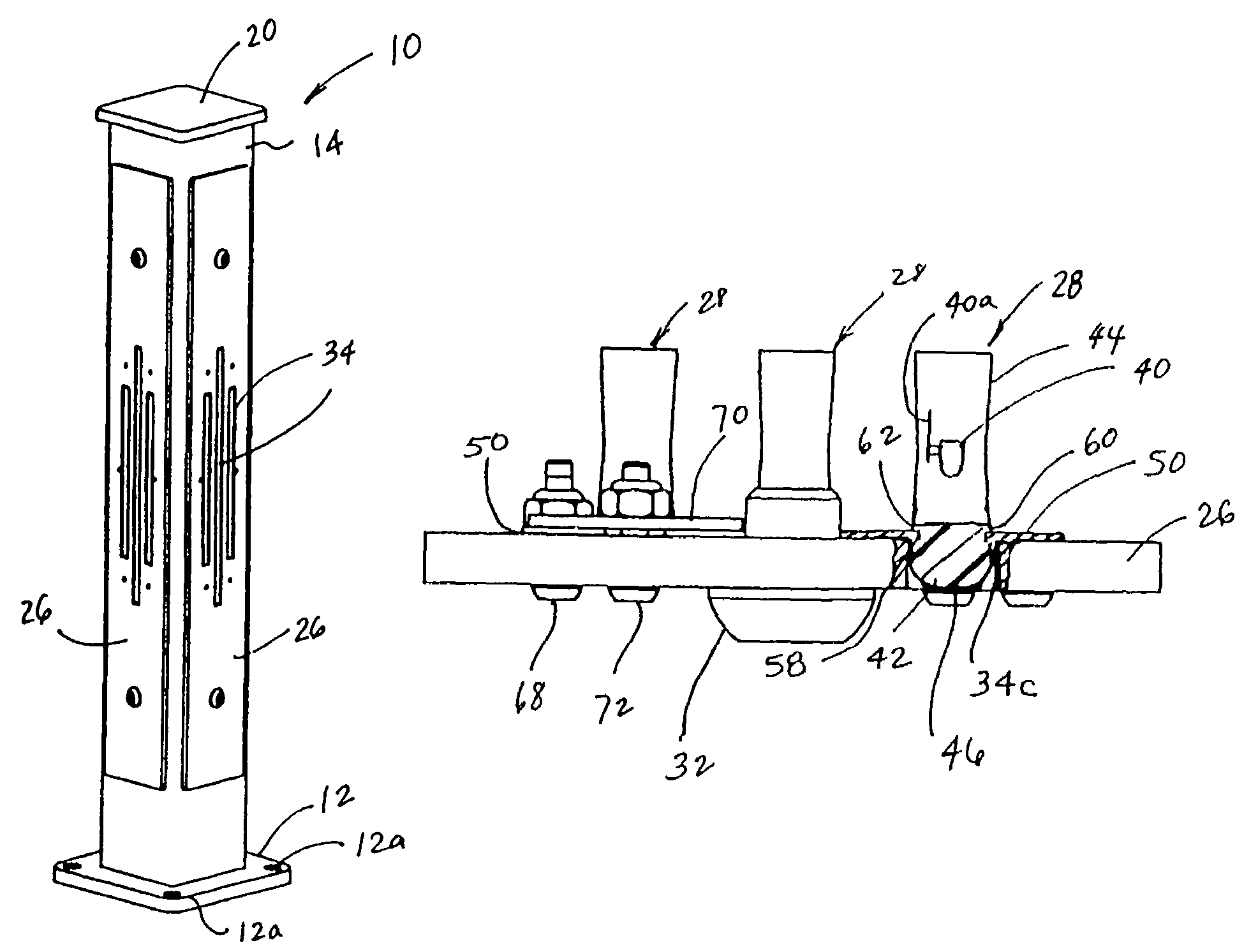

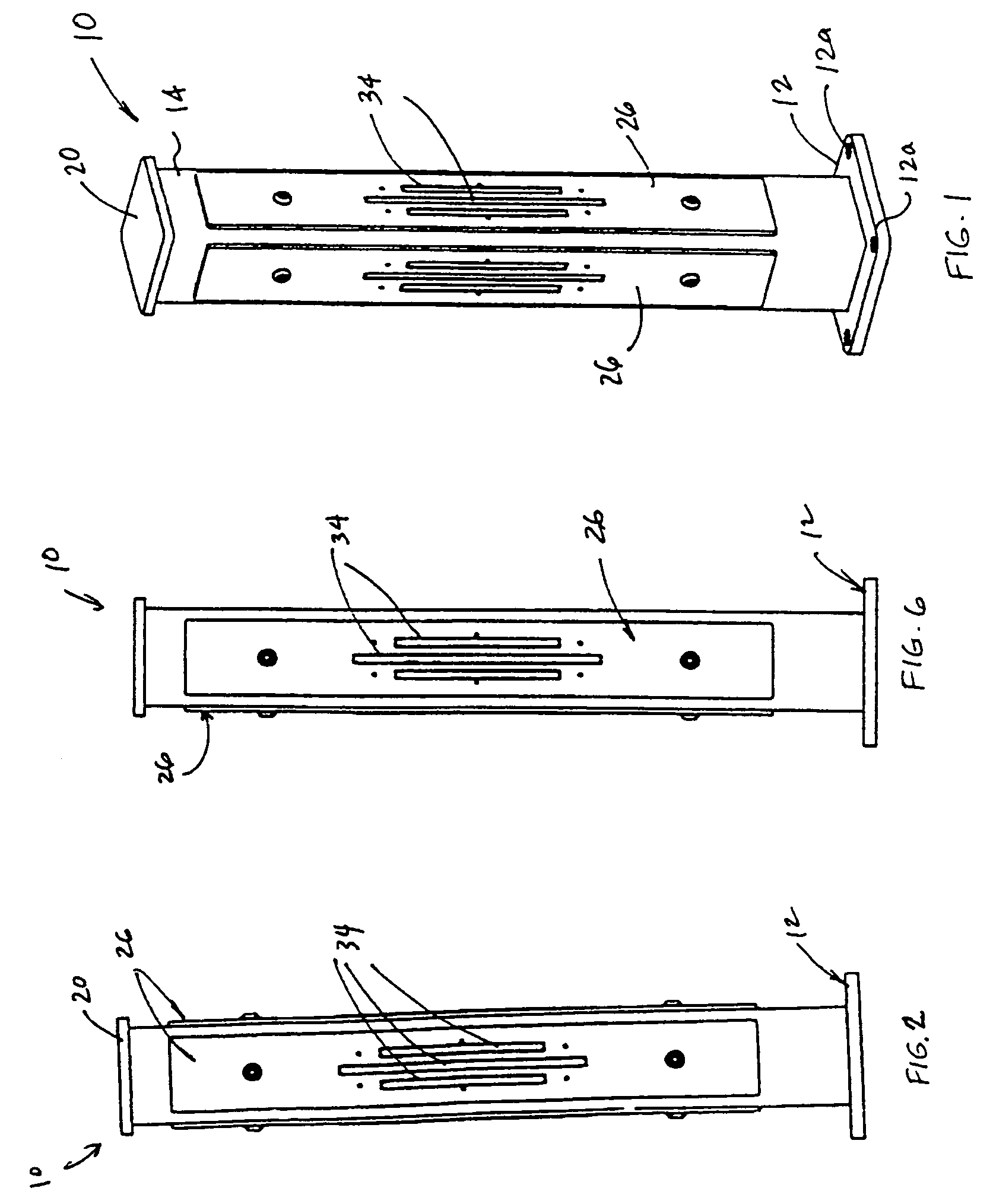

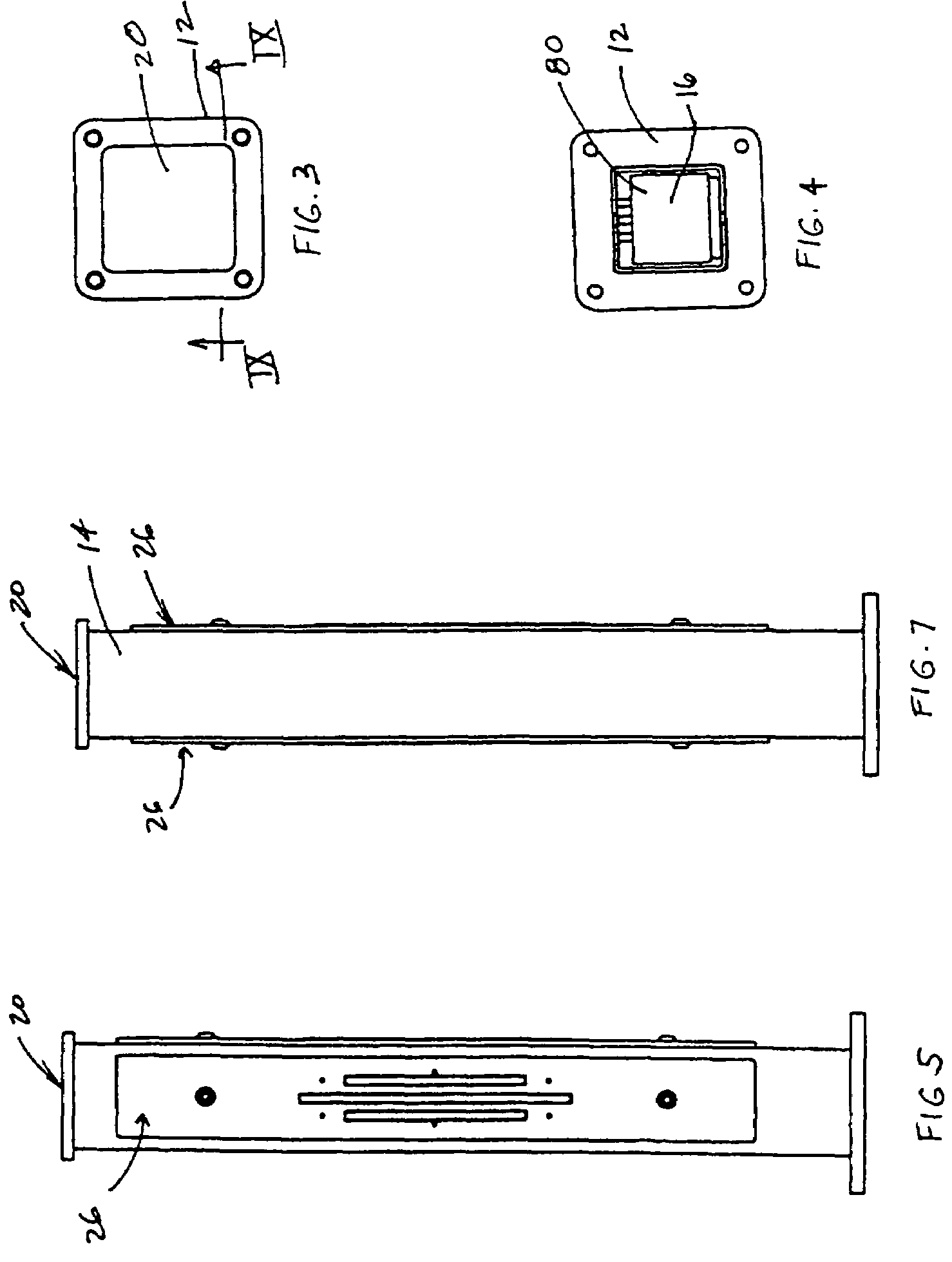

Lighted bollard

InactiveUS7473016B2Reduce or minimize the bug and dirt intrusion into the postReduce power consumptionMechanical apparatusPoint-like light sourceLight pillarOptoelectronics

A lighted post includes a stanchion and a light assembly. The light assembly includes a body, with a light emitting surface, and a light source that is coupled to the body. The light assembly is adapted for coupling to a power source for powering the light source. When powered light from the light source is directed into the body and is directed from the body through the light emitting surface. The light assembly is mounted to the stanchion, with the body being located in a light transmitting opening provided in the stanchion, such that the light emitting surface faces outwardly from the stanchion to thereby direct light outwardly from the stanchion.

Owner:LEADER MFG

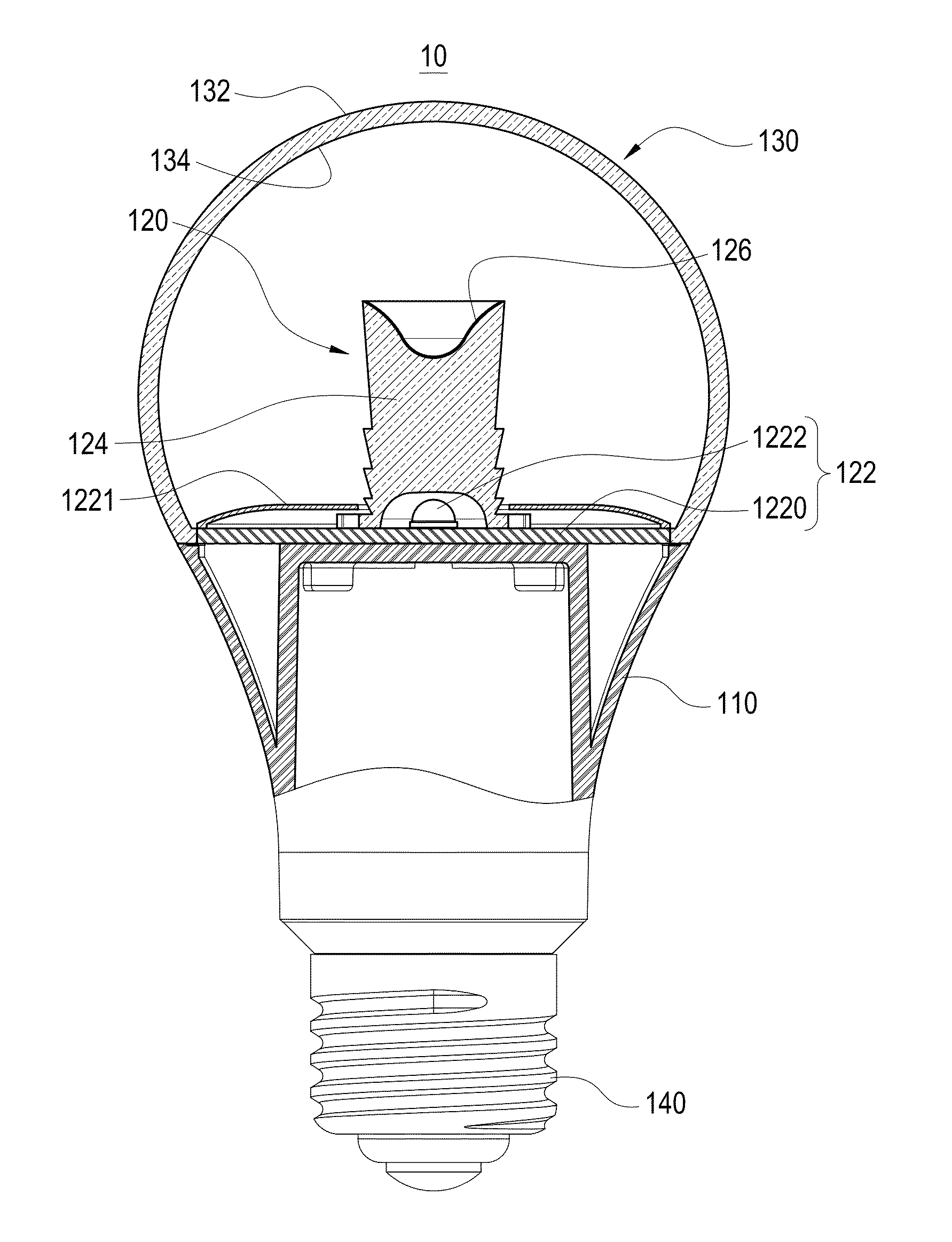

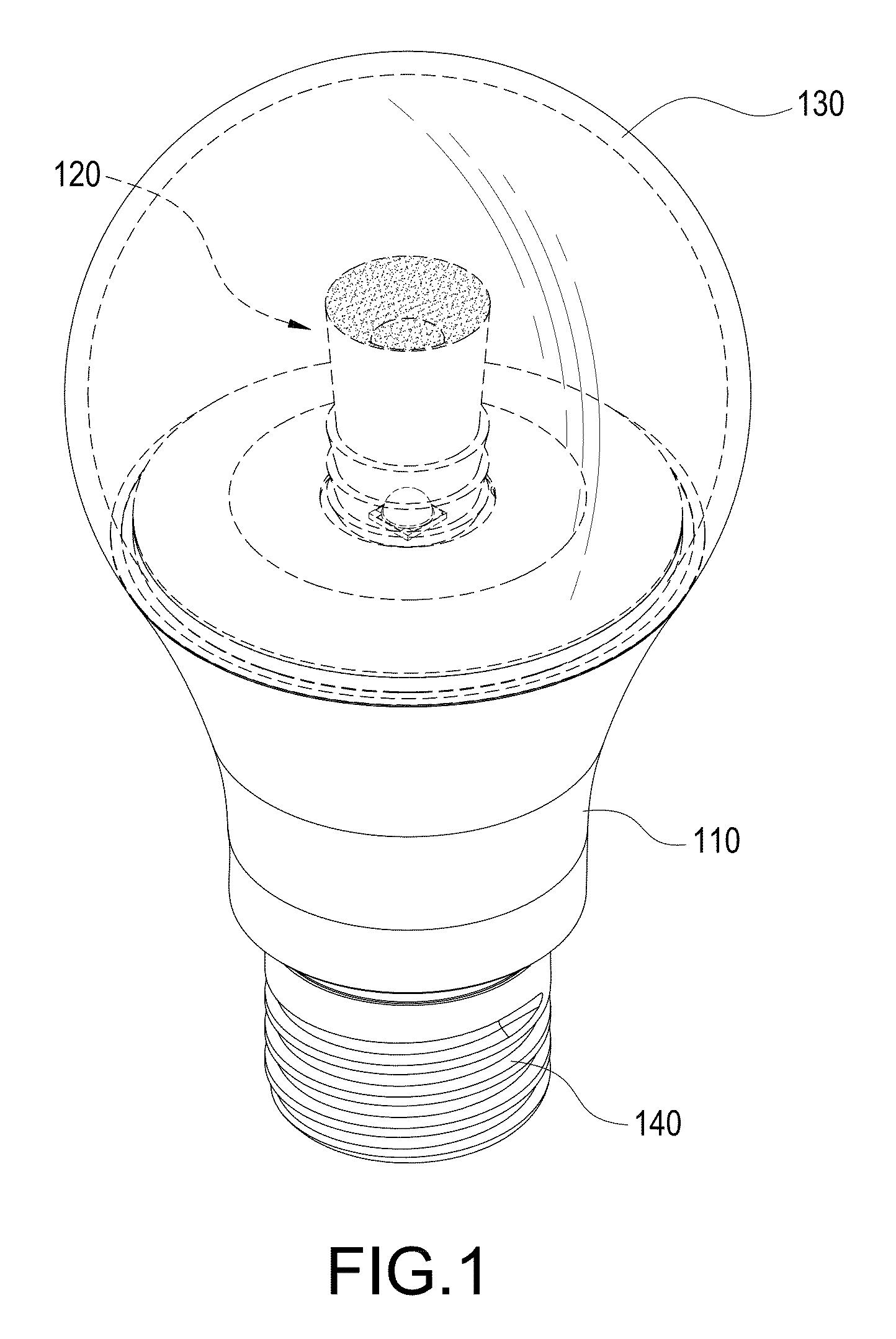

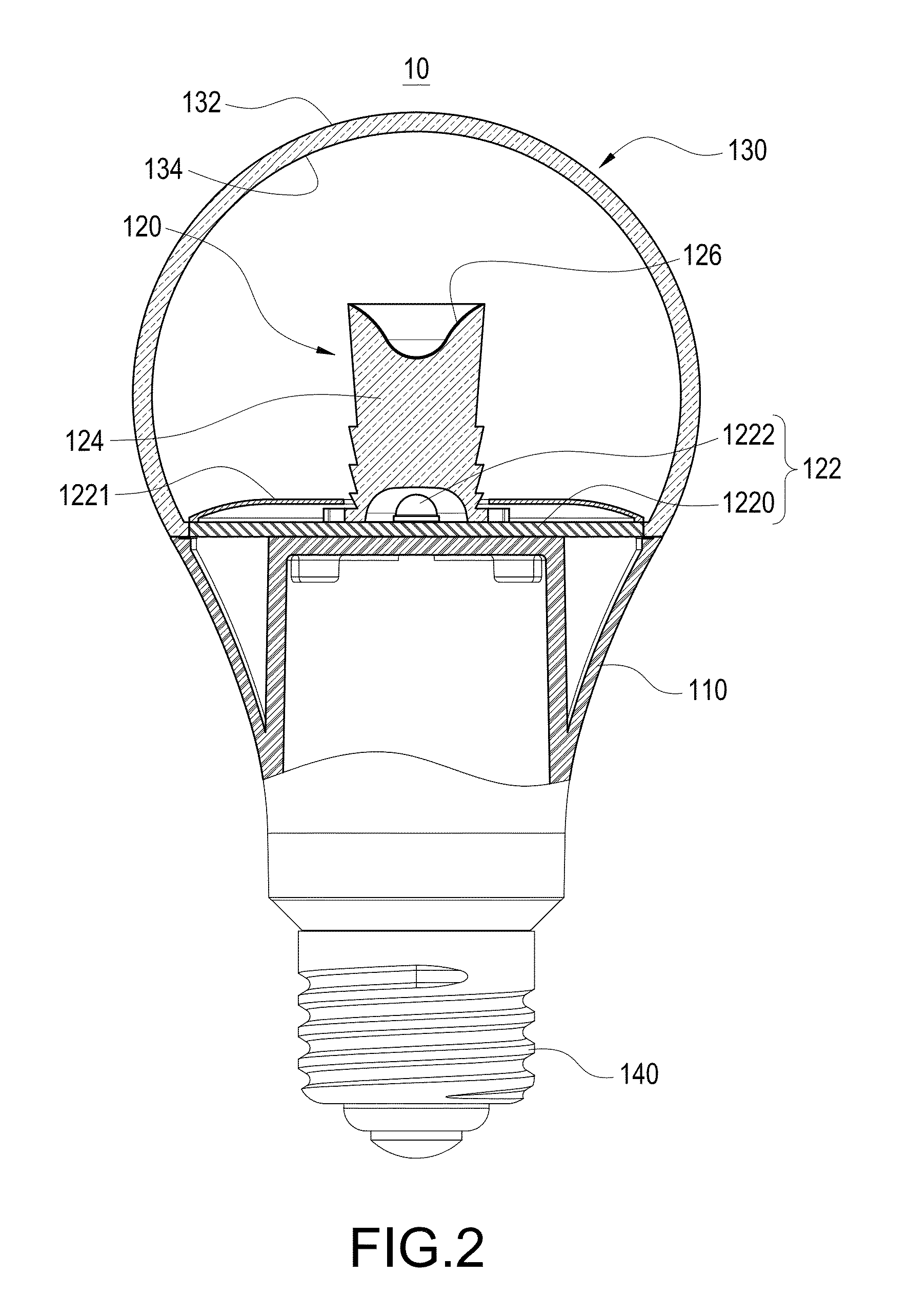

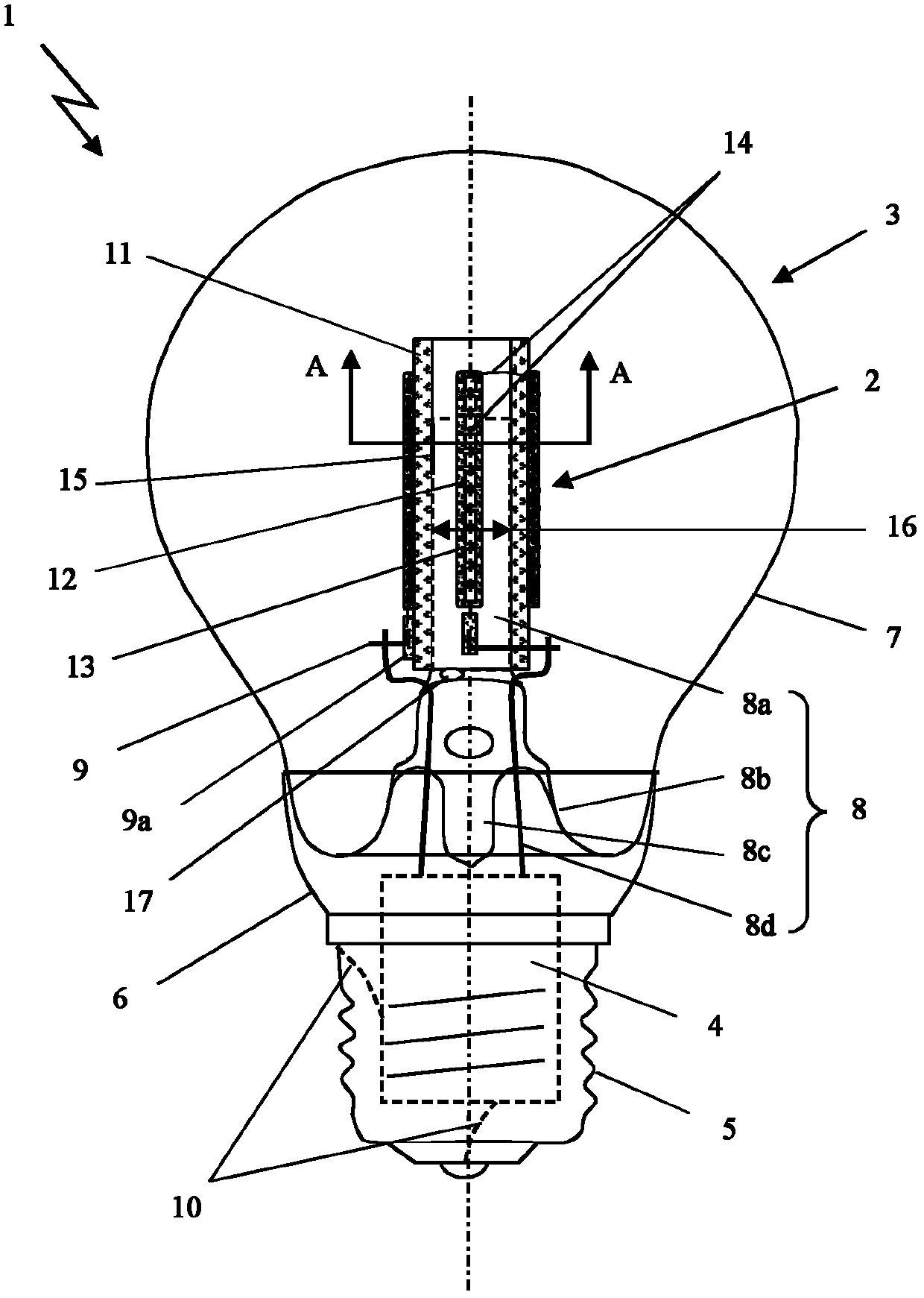

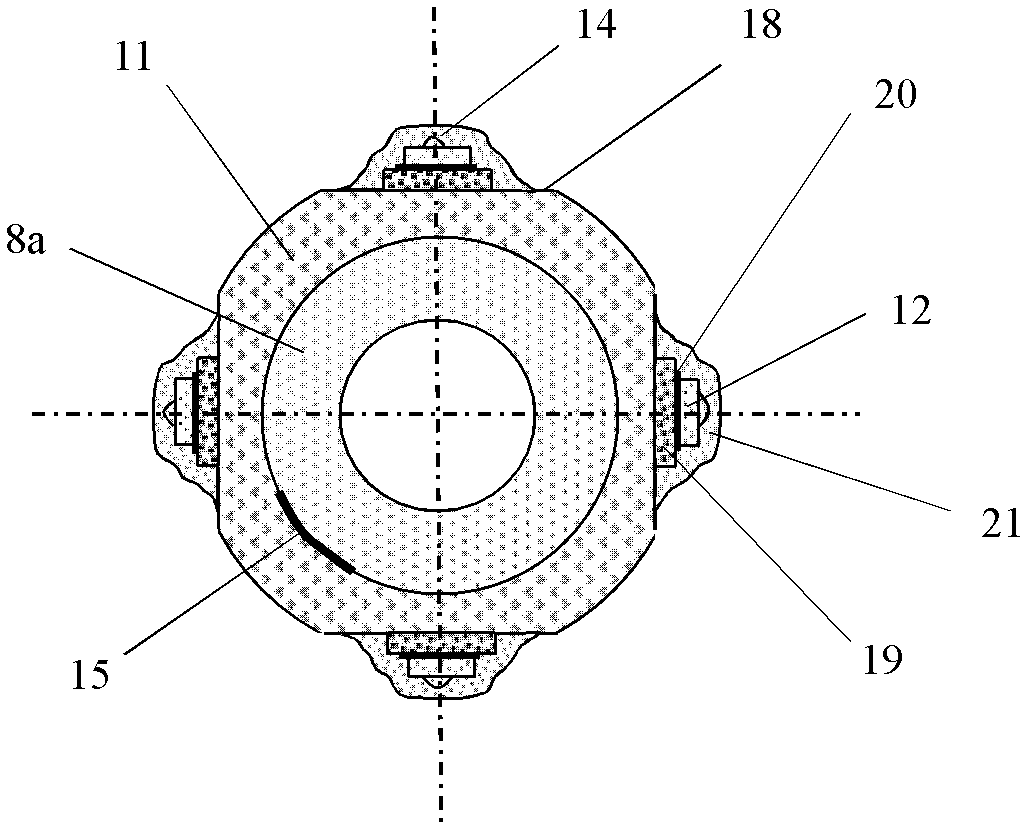

Light-emitting diode (LED) bulb

ActiveCN103307464AImprove cooling effectIncrease luminous fluxPoint-like light sourceElectric circuit arrangementsElectrical connectionEngineering

A light-emitting diode (LED) bulb comprises a light-permeable bulb shell, an LED luminous source, a stem, a driver and an electric connector, wherein the stem is provided with a support pillar, a horn tube, an exhaust tube and electric lead wires; the bulb shell and the stem are sealed in a vacuum mode, and low-viscosity high-thermal-conductivity gas is filled in the bulb shell; the LED luminous source is composed of at least one transparent LED light-emitting column; the LED light-emitting column comprises a high-thermal-conductivity transparent tube inserted in the outer surface of the support pillar; at least one string of LED chips and a luminescent powder layer are arranged on the surface of the transparent tube; the chips are in series connection or in series-parallel connection, electric lead wires of chip electrodes are connected with the electric lead wires of the stem, a stem electrical connection wire is connected with the output end of the driver, the input end of the driver is connected with the electric connector, and the electric connector is communicated with an external alternating current (AC) or direct current (DC) power supply. The LED bulb has the advantages that thermal resistance between the LED chips and the heat dissipation gas is low, heat dissipation effect is good, an LED bulb with higher luminous flux and higher luminous efficiency can be manufactured, the light-emitting component is firmly fixed, can withstand strong shock, and is high in reliability, and the LED bulb is simple in manufacturing process and low in cost.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

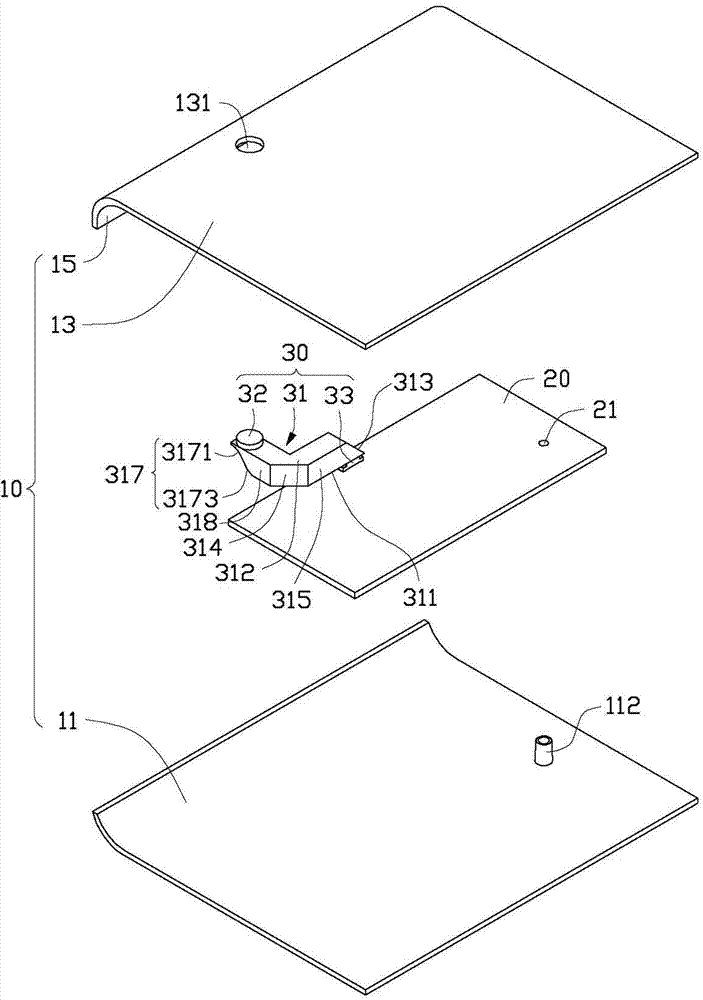

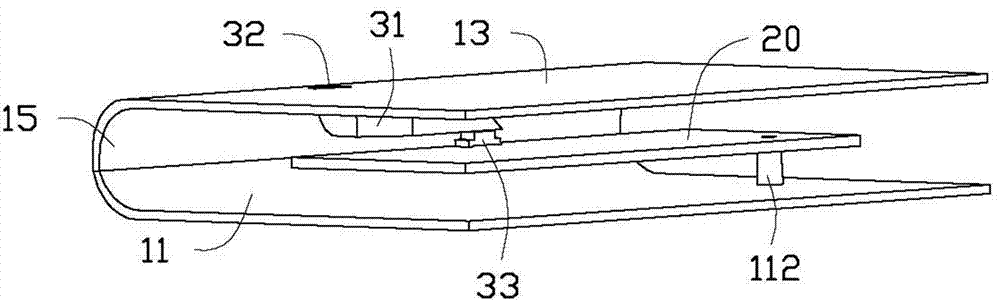

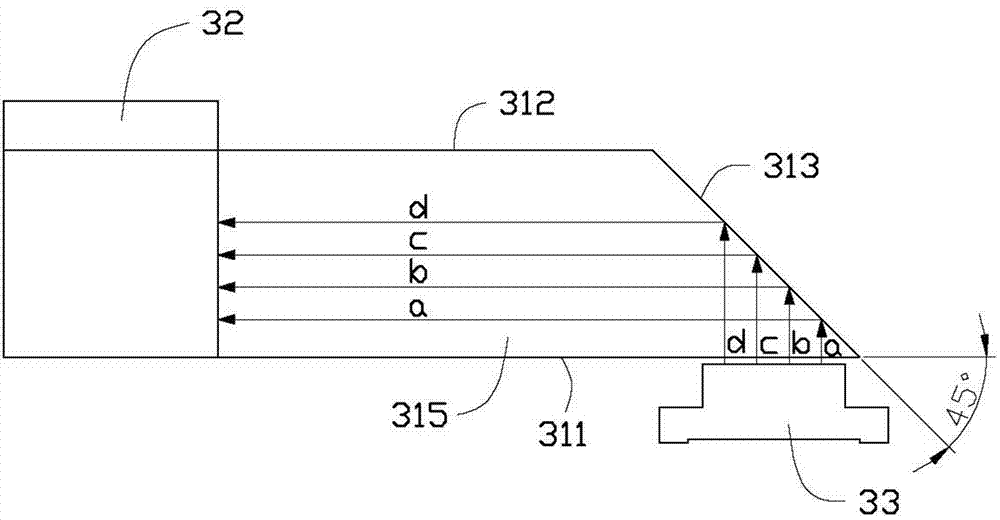

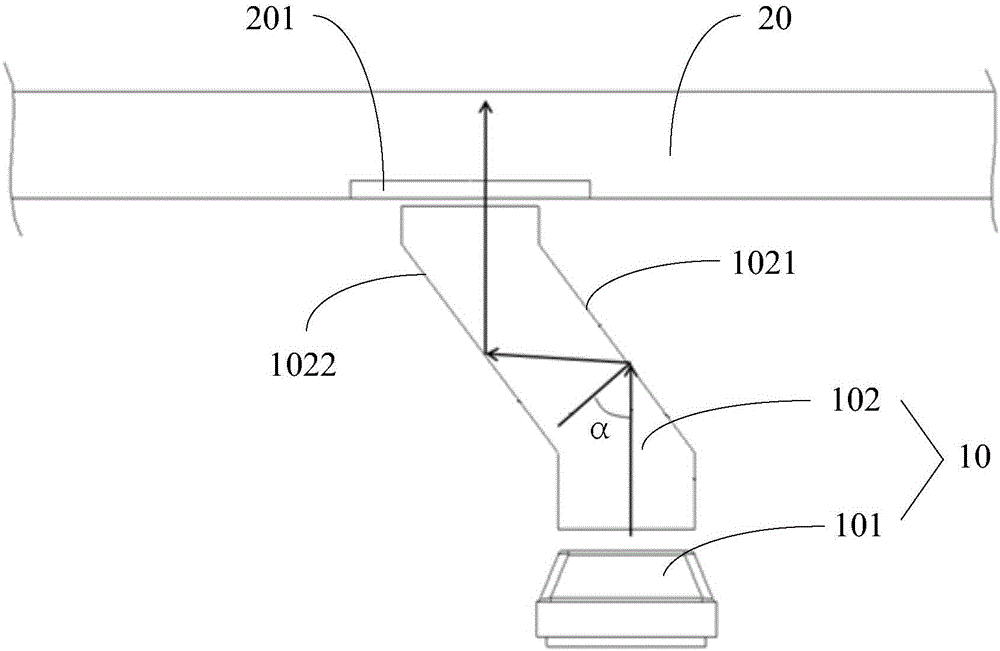

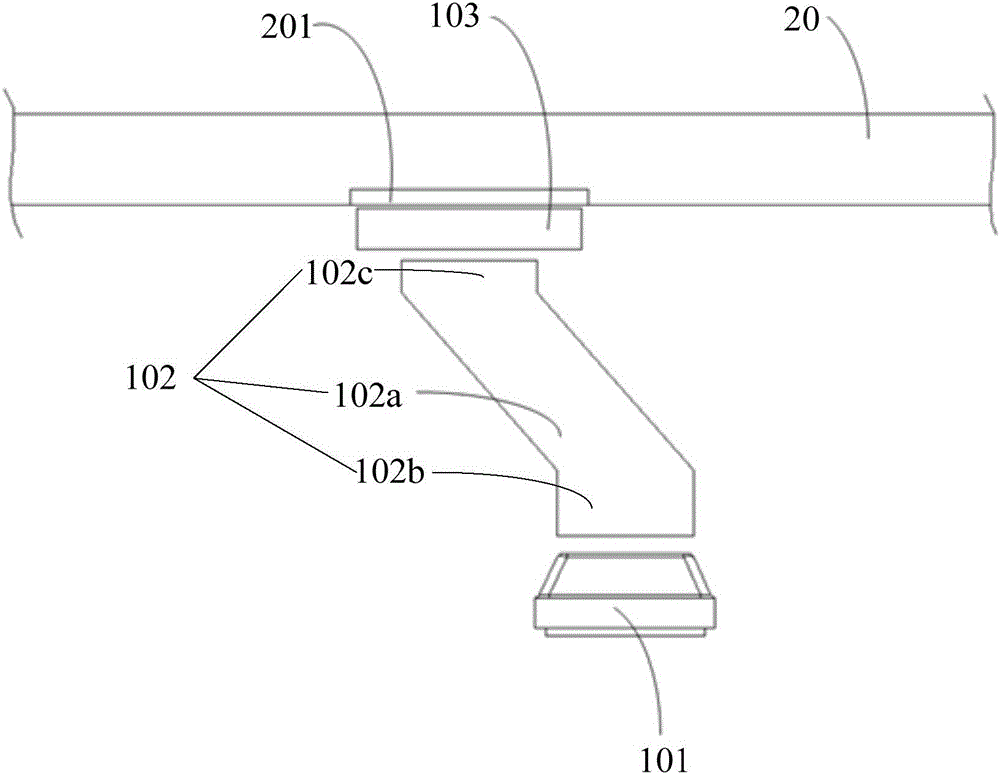

Electronic device

An electronic device comprises a casing and a light guiding structure. The casing comprises a bottom wall and a top wall which is approximately parallel to the bottom wall, and a circuit board is mounted on the bottom wall. The light guiding structure comprises a light source, an indicator lamp cap and a light guide column between the light source and the indicator lamp cap, the light source is electrically connected with the circuit board and used for generating plurality of parallel light rays which are perpendicular to a plane of the circuit board, the indicator lamp cap is mounted on the top wall, a line between the indicator lamp cap and the light source forms an acute angle with the plane of the circuit board, the light guide column comprises at least one reflection surface, and the parallel light rays can be emitted into the indicator lamp cap after being reflected at least for one time by the at least one reflection surface.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

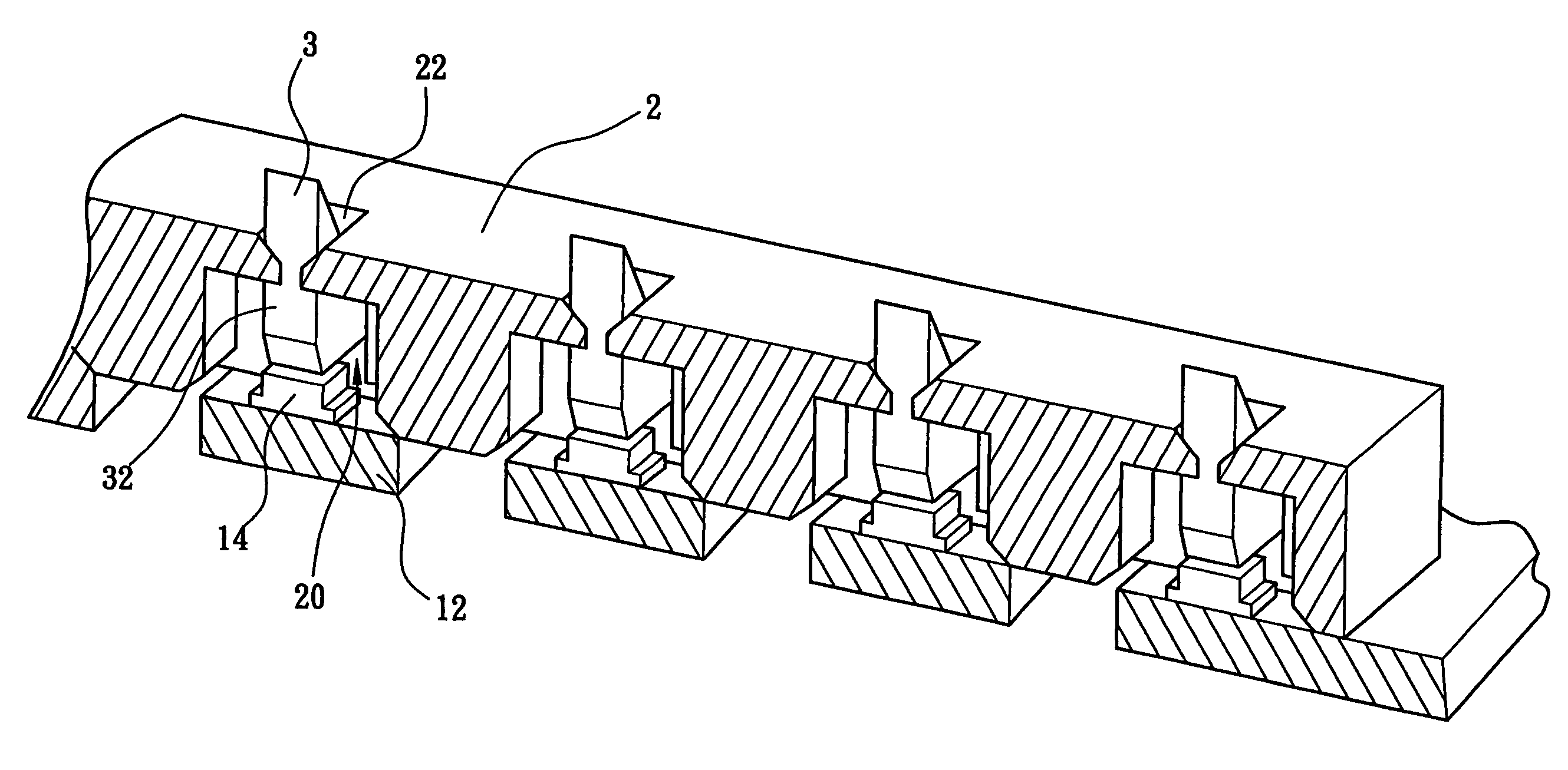

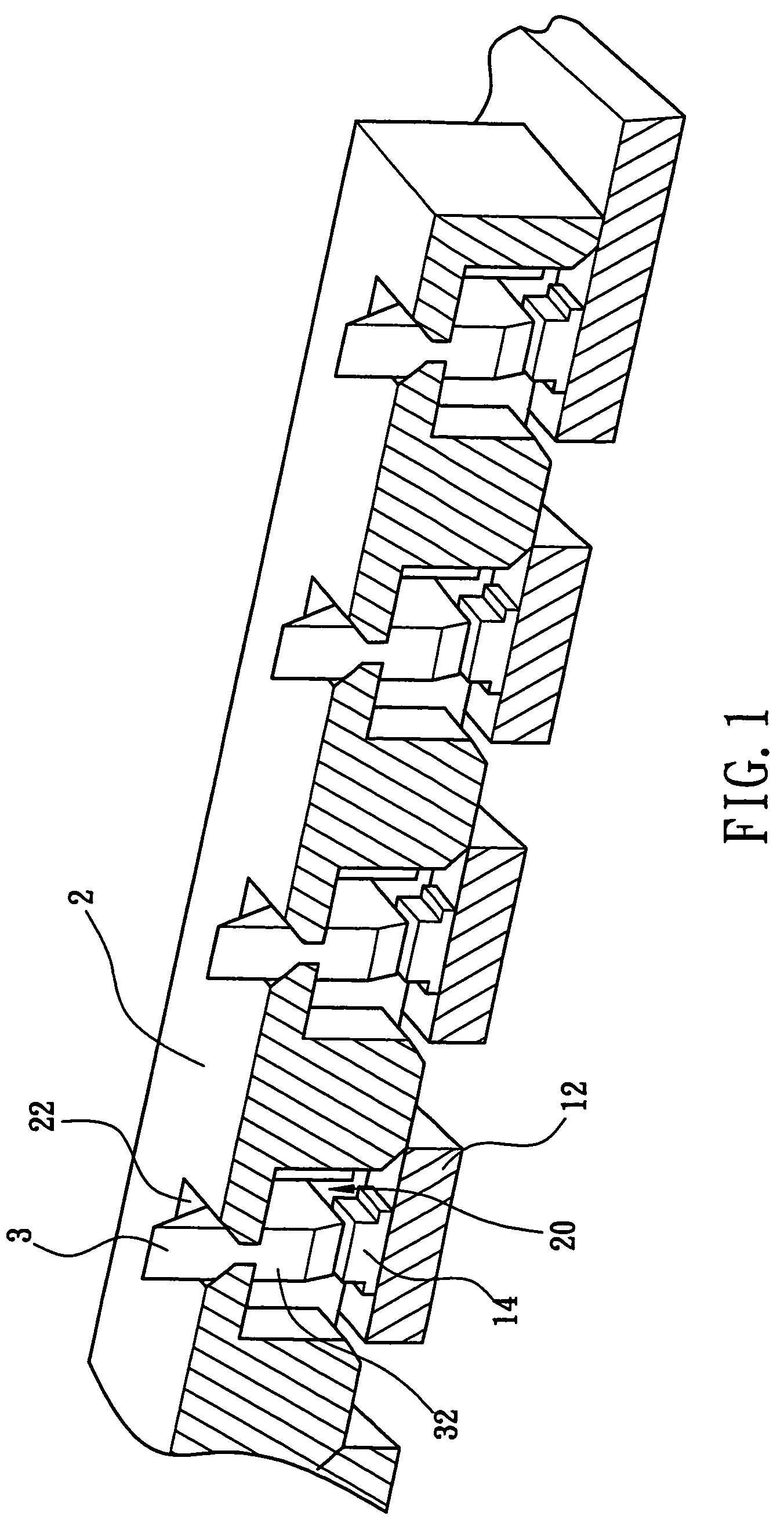

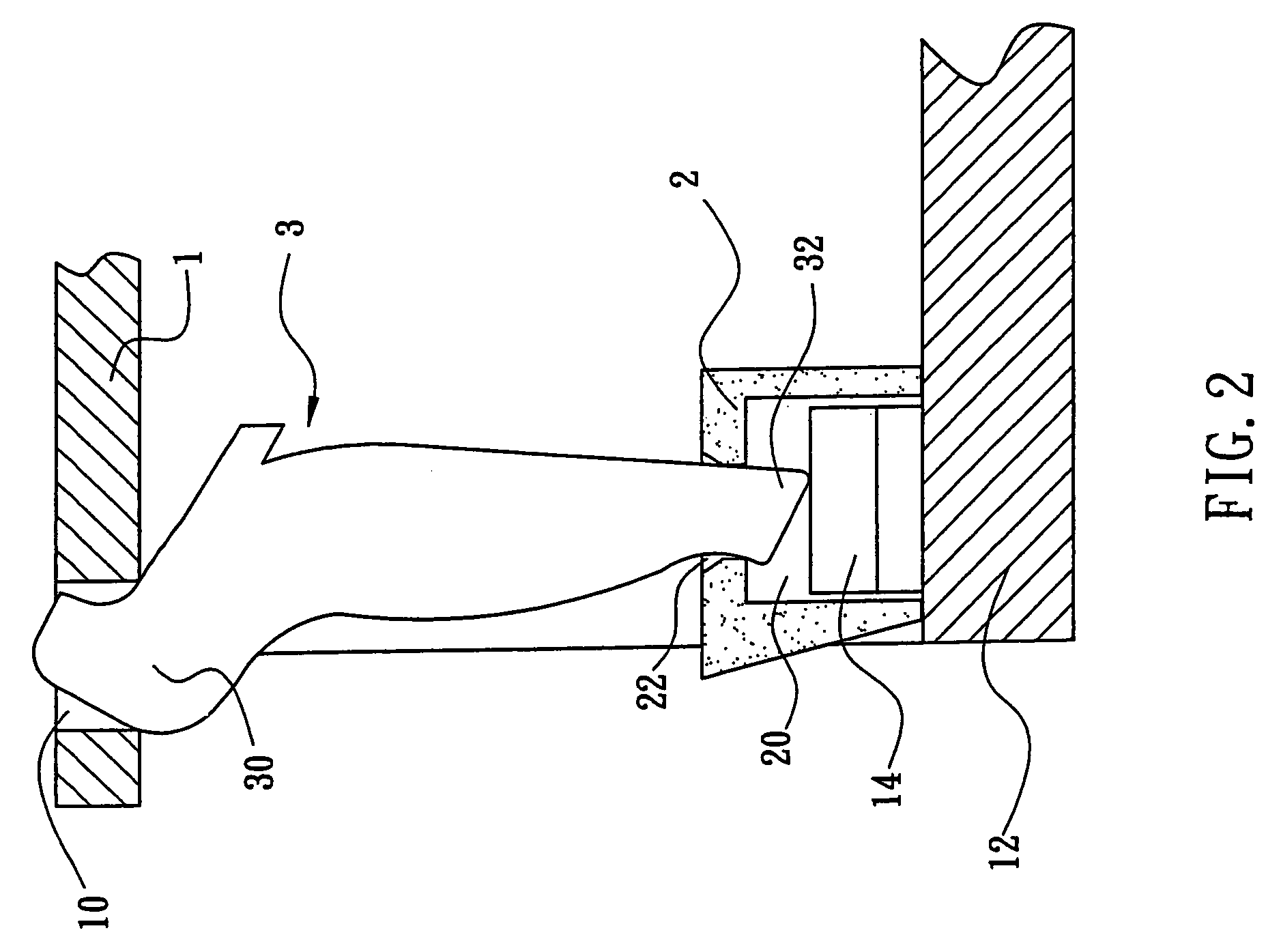

Light guide pillar

InactiveUS7046906B1Planar/plate-like light guidesOptical waveguide light guideLight guideLight pillar

The present invention is to provide a light guide pillar disposed on a circuit board of an electronic apparatus having a light emitting element disposed thereon, where the light guide pillar includes a bulk opaque and disposed on the circuit board for covering the light emitting element and a pillar with one end inserted into the bulk while the other end thereof extended outside of the electronic apparatus, enabling the light source generated from the light emitting element to be guided and displayed outside of the electronic apparatus via the light guide pillar and enabling the bulk to stop the light source emitted from the light emitting element from dispersing. Therefore, the light source can be guided to outside of the electronic apparatus without interference.

Owner:INVENTEC CORP

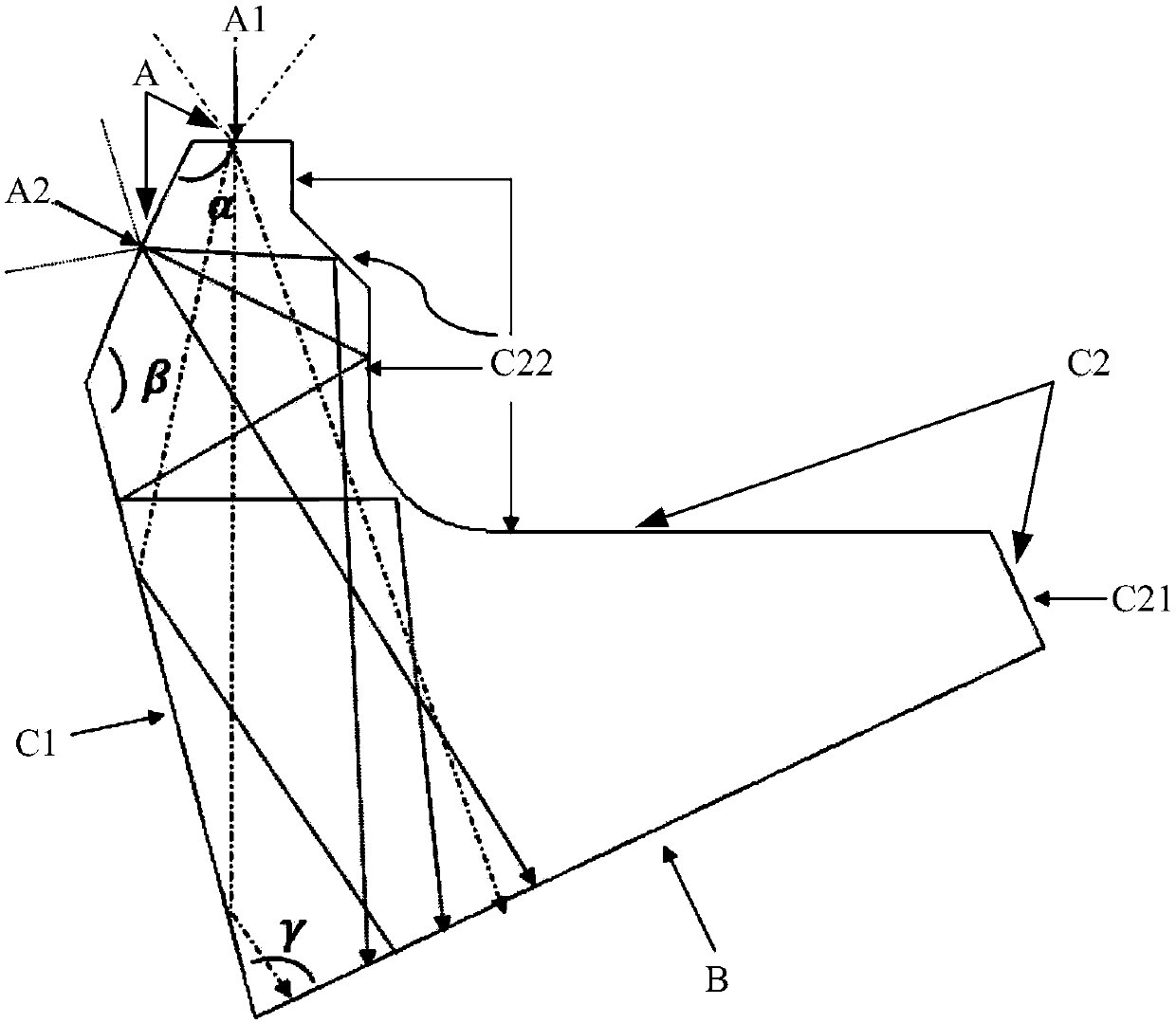

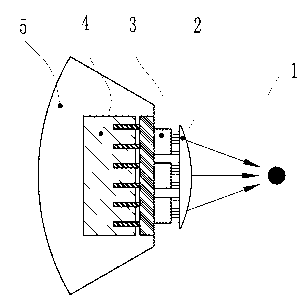

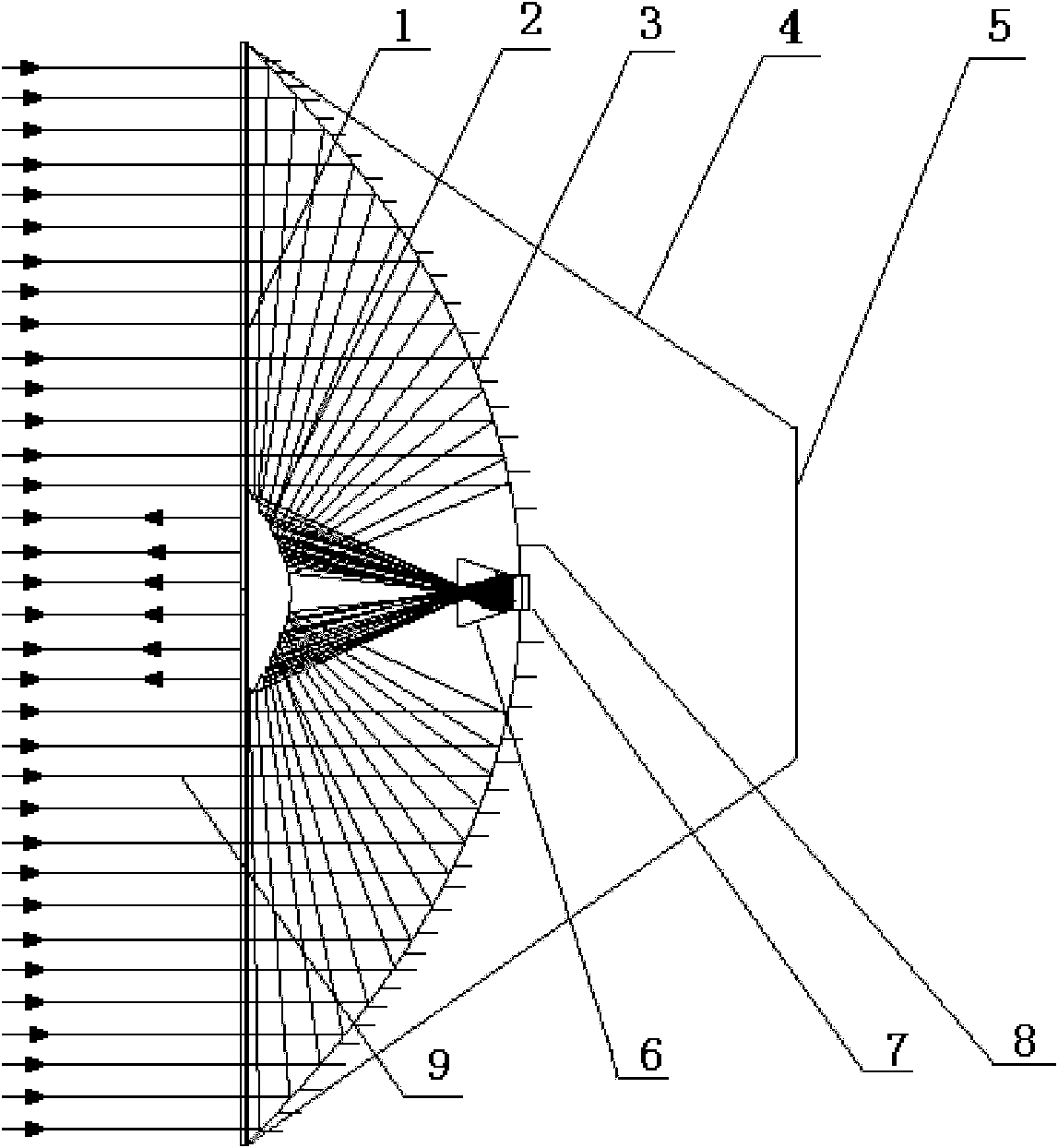

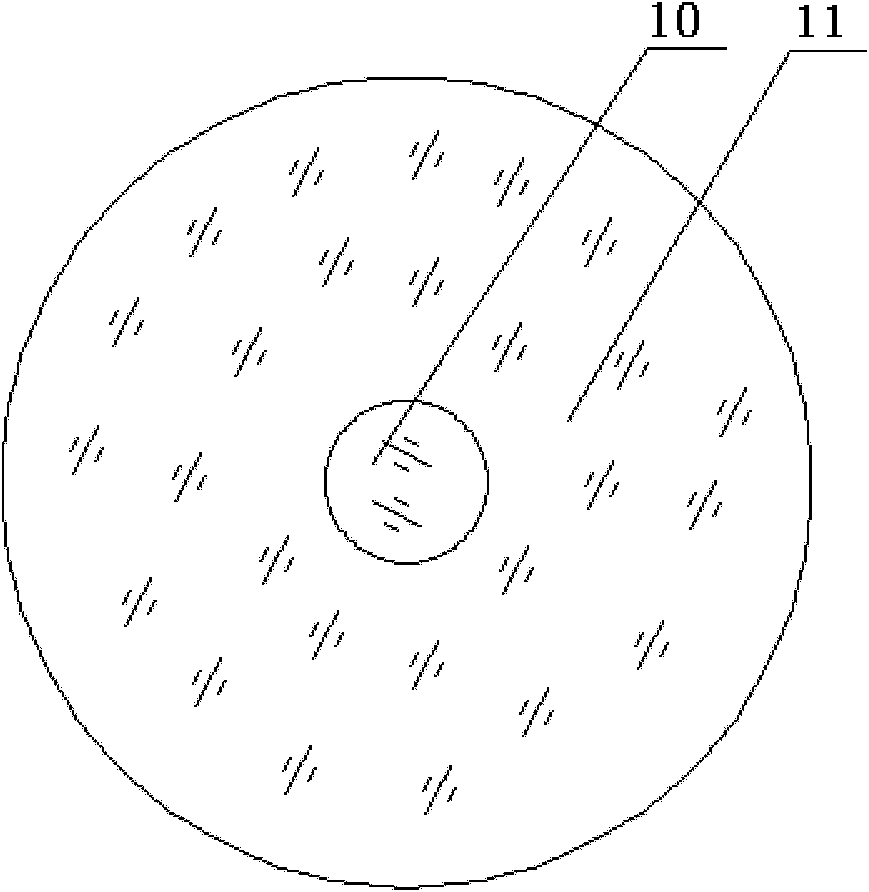

High-power solar energy concentrated photovoltaic system based on Cassegrain structure

The invention discloses a high-power solar energy concentrated photovoltaic system based on a Cassegrain structure, which belongs to the technical field of solar energy photovoltaic generating application. The system comprises a plain glass cover board, a hyperbolic convex secondary reflector, a parabolic concave primary reflector, a supporting structure, a base, a dodging column and a solar battery; the base is fixed on a two-dimensional solar-tracking system to realize solar tracking in real time; the parabolic concave primary reflector is confocal with the hyperbolic convex secondary reflector; a light ray meets a total reflection condition when passing through walls of the dodging column; and the dodging column can be used for uniformly coupling a sun ray converged by the parabolic concave primary reflector and the hyperbolic convex secondary reflector onto the working surface of the solar battery. The high-power solar energy concentrated photovoltaic system can be used for converting the solar energy into electric energy with high efficiency and low cost so as to realize environmentally-friendly and sustainable use of the energy source.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

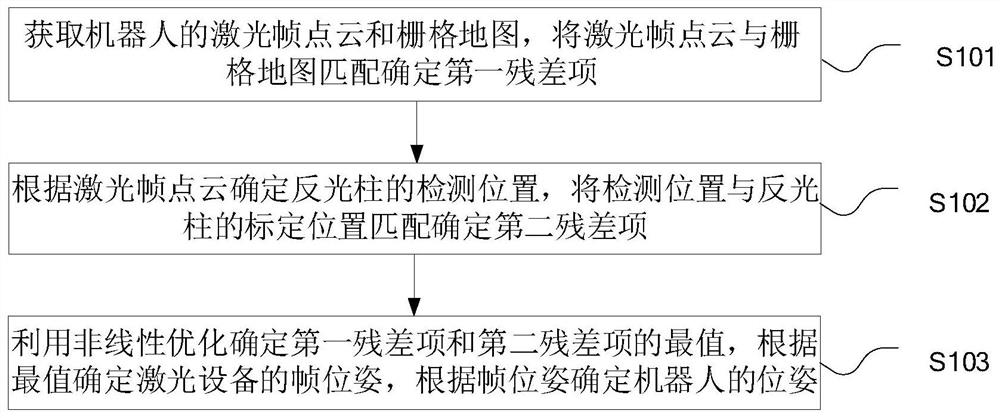

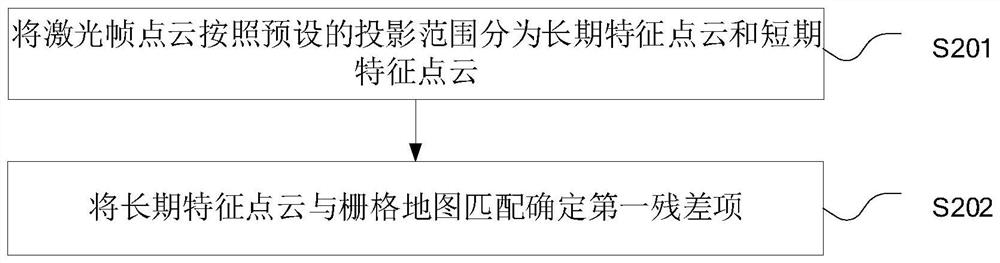

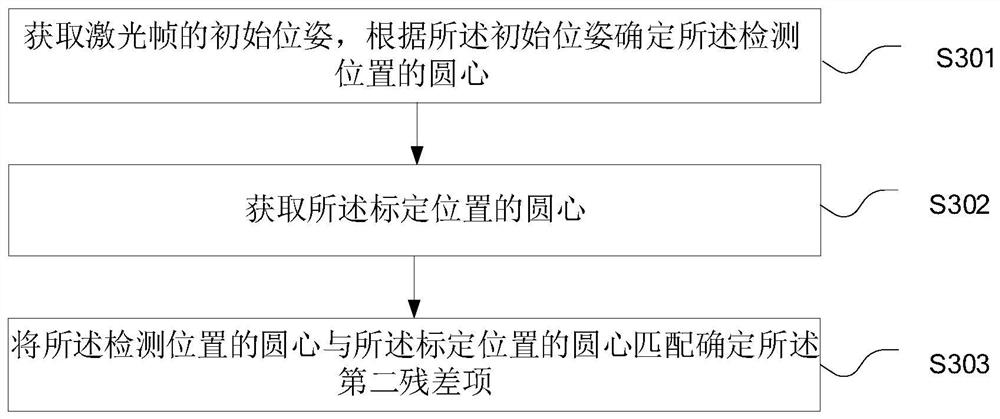

Robot positioning method and device and electronic equipment

PendingCN111895989ASolve the problem of low pose accuracyHigh positioning accuracyNavigational calculation instrumentsElectromagnetic wave reradiationContour matchingPoint cloud

The application relates to a robot positioning method and device and electronic equipment. The method comprises the steps: determining a first residual item through matching of a laser point cloud anda grid map through the obtaining of the laser point cloud and the grid map of a robot; determining a detection position of a reflective column according to the laser point cloud, and matching the detection position with the calibration position of the reflective column to determine a second residual term; determining the maximum and minimum values of the first residual term and the maximum and minimum values of the second residual term by using nonlinear optimization; determining a frame pose of laser equipment according to the maximum and minimum values; and determining the pose of the robotaccording to the frame pose. Therefore, a problem that the pose precision of the robot obtained after fusion is low when the deviation of observation information or prediction information is large due to the fact that filtering fusion is conducted on the pose matched with the contour and the pose matched with the light reflection column based on a filtering mode is solved, and the positioning precision of the robot is improved.

Owner:ゼジャンハーレイテクノロジーカンパニーリミテッド

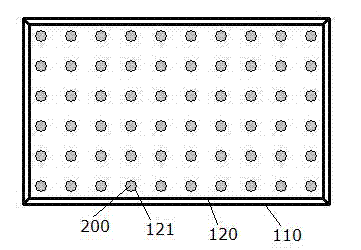

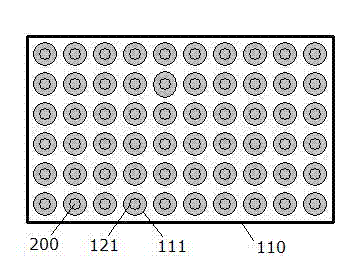

A seamless splicing display device and a seamless splicing method thereof

ActiveCN102270411AEliminate stitching gapsRealize the trapezoidal magnifying glass effectIdentification meansLight guideMagnifying glass

The invention discloses a seamless splicing display screen device and a seamless splicing method thereof. The device comprises a transparent box and conical light guide pillars; the box has a trapezoid structure and a small end of the box is arranged on a display panel; a plurality of installation holes which are matched with the light guide pillars are formed in the box along the direction vertical to the display panel; two end faces of each light guide pillar are polished surfaces; and the light guide pillars are arranged in the installation holes and the cone directions of the light guide pillars are consistent with the trapezoid direction of the box; and the aperture of the small end of the installation hole is less or equal to the space between the small end of the light guide pillars. The transparent trapezoidal box with the conical installation holes is adopted, and the conical light guide pillars are arranged in the conical installation holes, and the light guide pillars correspond to pixels on the display panel, so that the trapezoidal magnifier effect of the whole box is achieved by using the function of amplifying and conducting pixel light points by the light guide pillars; therefore, the splicing gap between the display screens in a splicing screen or a splicing wall is eliminated, and the device is low in cost and has high operability.

Owner:SHENZHEN PROTRULY ELECTRONICS CO LTD

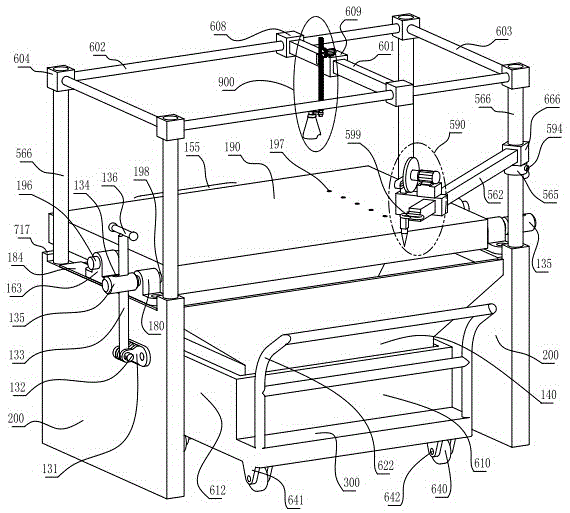

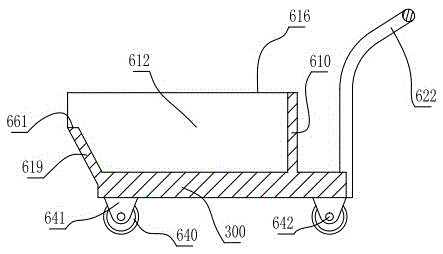

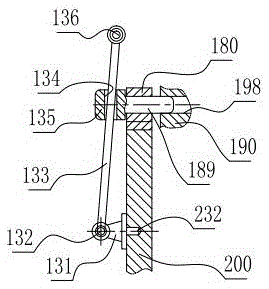

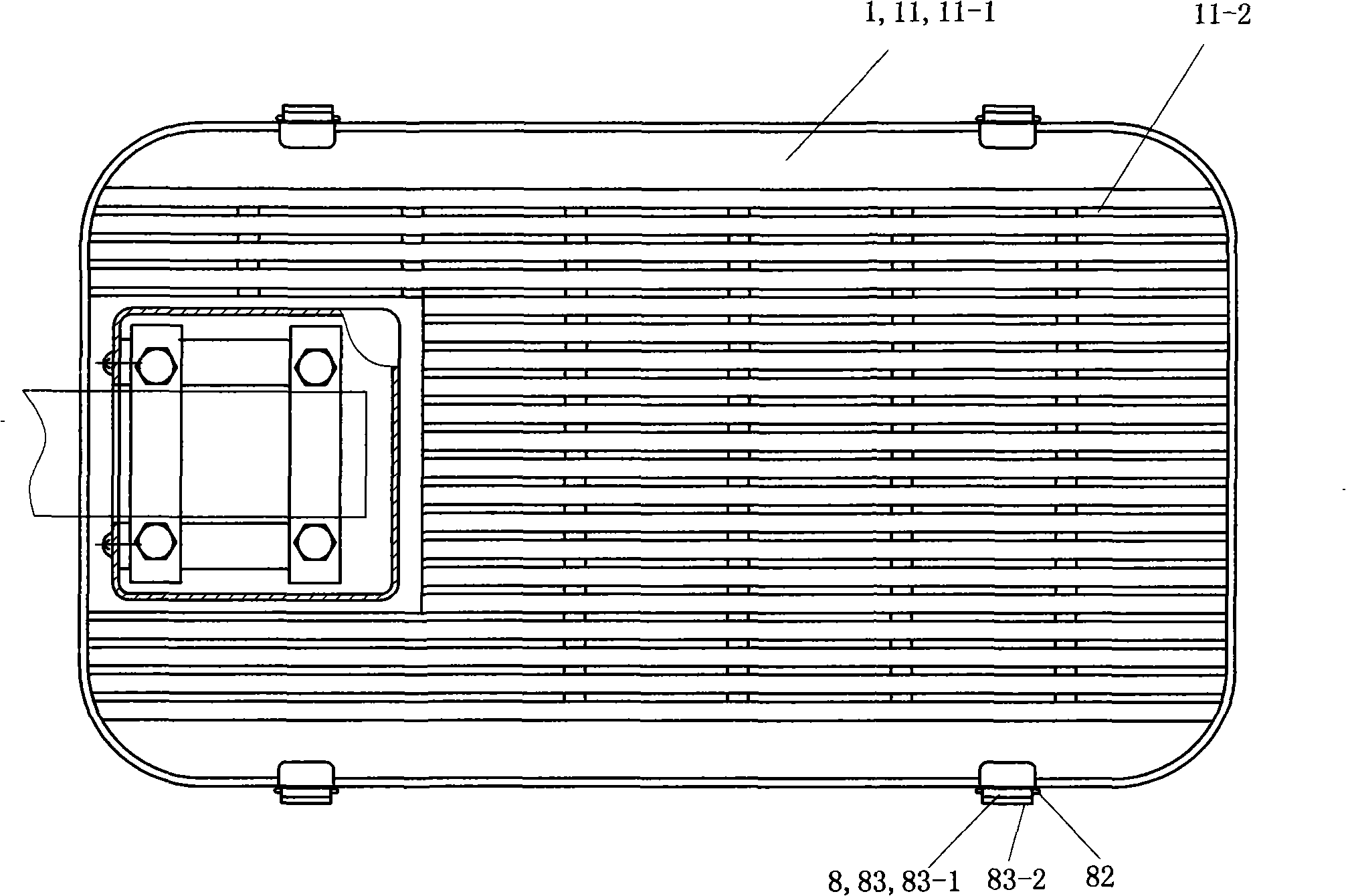

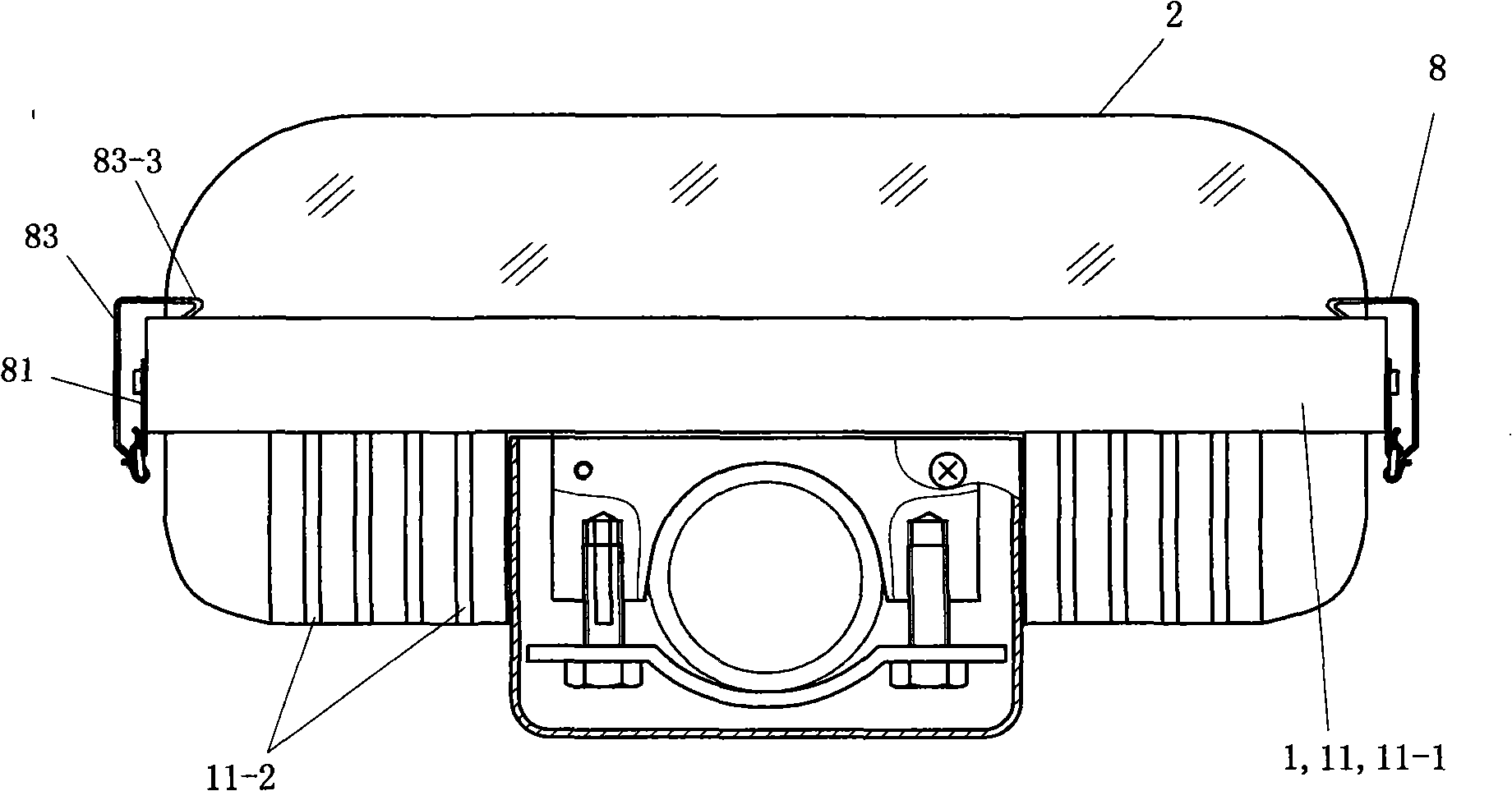

Handle rotary table rack camera-shooting round pressing plate copper alloy glass inspection equipment

PendingCN105547807AChange labor intensityOvercome the defect of no self-lockingMaterial strength using single impulsive forceEngineeringLight pillar

The invention relates to toughened glass test and inspection equipment, in particular to handle rotary table rack camera-shooting round pressing plate copper alloy glass inspection equipment. The equipment is improved in that a platen handle is arranged on the rear end vertical face of a test platen, handle ends are arranged at the two bent ends of the platen handle, and both the handle ends at the two bent ends are fixed to the rear end vertical face of the test platen; a movable camera assembly is arranged on a square camera shooting rod, a rotation impactor is slidably fixed to an impacting cross-bar, a circular orbit pressing plate assembly is fixed to the plane of the test platen, a cullet guider is fixed among a platen support, lock pin supports and the upper planes of support side plates, and a lower end opening of the cullet guider falls into an upper end opening of a cullet collecting cart. By means of the equipment, labor intensity of the fragmentation test is changed, camera shooting is conducted, and fragment images are transmitted to a computer processing center; the test platen is provided with the platen handle, light pillar lock pins are combined to be locked and located in pulling-and-insertion lock holes in the two sides of the test platen, and the defect that the platen handle does not have the self-locking function is overcome.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

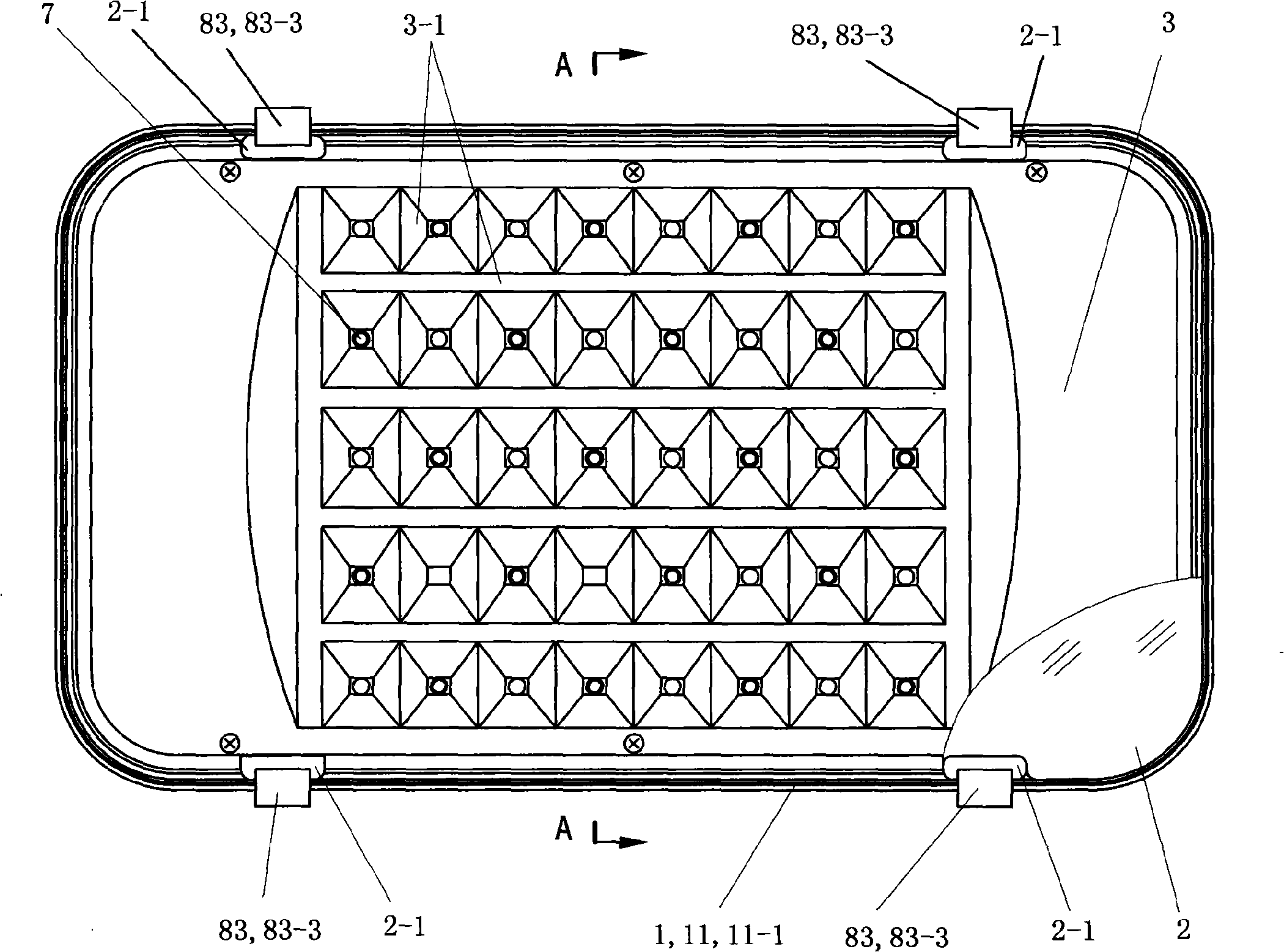

High-power LED road lamp

InactiveCN101280897AConducive to expanding the lighting areaExpand the lighting areaPoint-like light sourceLighting support devicesEngineeringRoad surface

The invention relates to a high-power LED road lamp including a metallic heat radiation base panel, a reflecting, a LED lamp bead array and LED electric power drive circuit; the heat radiation base panel has a arch column casing, the LED lamp bead array is arranged on circular arc surface of the arch column casing; the reflecting panel has a reflecting section matching with arch column casing circular arc surface of the heat radiation base panel; the reflecting section mainly comprises panel bodies array with quadrangular frustum casing shape, and lamp bead holes are arranged at center of each panel body with quadrangular frustum casing shape; each LED lamp bead of the LED lamp bead array is in the lamp bead hole with quadrangular frustum casing shape corresponding with the reflecting section of the reflecting panel. In use, according to the invention, light reflected by the reflecting section of the reflecting panel forms a rectangular light beam to project on road, which achieves effect of uniformly irradiating reflection ray on road; the whole configuration of the reflecting section of the reflecting panel is crown face, which is favor for extending illumination area of road lamps.

Owner:黄爱国

Light supplementary component and electronic equipment

InactiveCN106603766ASolve the problem of insufficient illumination brightnessTelephone set constructionsPhotographyLight guideLight beam

The present invention provides a light supplementary component and electronic equipment. The light supplementary component comprises a light source and a light guiding column. The first end of the light guiding column faces the light source, the second end of the light guiding column faces the light out hole of the electronic equipment, and thus the light emitted out of the electronic equipment from the light guiding column through the light out hole. The light guiding column is internally provided with a first reflection surface and second reflection surface. The light beam of the light source is emitted into the first end of the light guiding column, and the light beam is emitted out of the second end of the light guiding column after the light beam passes the first reflection surface and the second reflection surface. Since the light guiding column is added between the light source and the light out hole, the light beam emitted by the light source can be emitted out of the light out hole via the light column guide, a problem of insufficient light intensity of the light source caused by the eccentric phenomenon of the light source and the light out hole is solved.

Owner:VIVO MOBILE COMM CO LTD

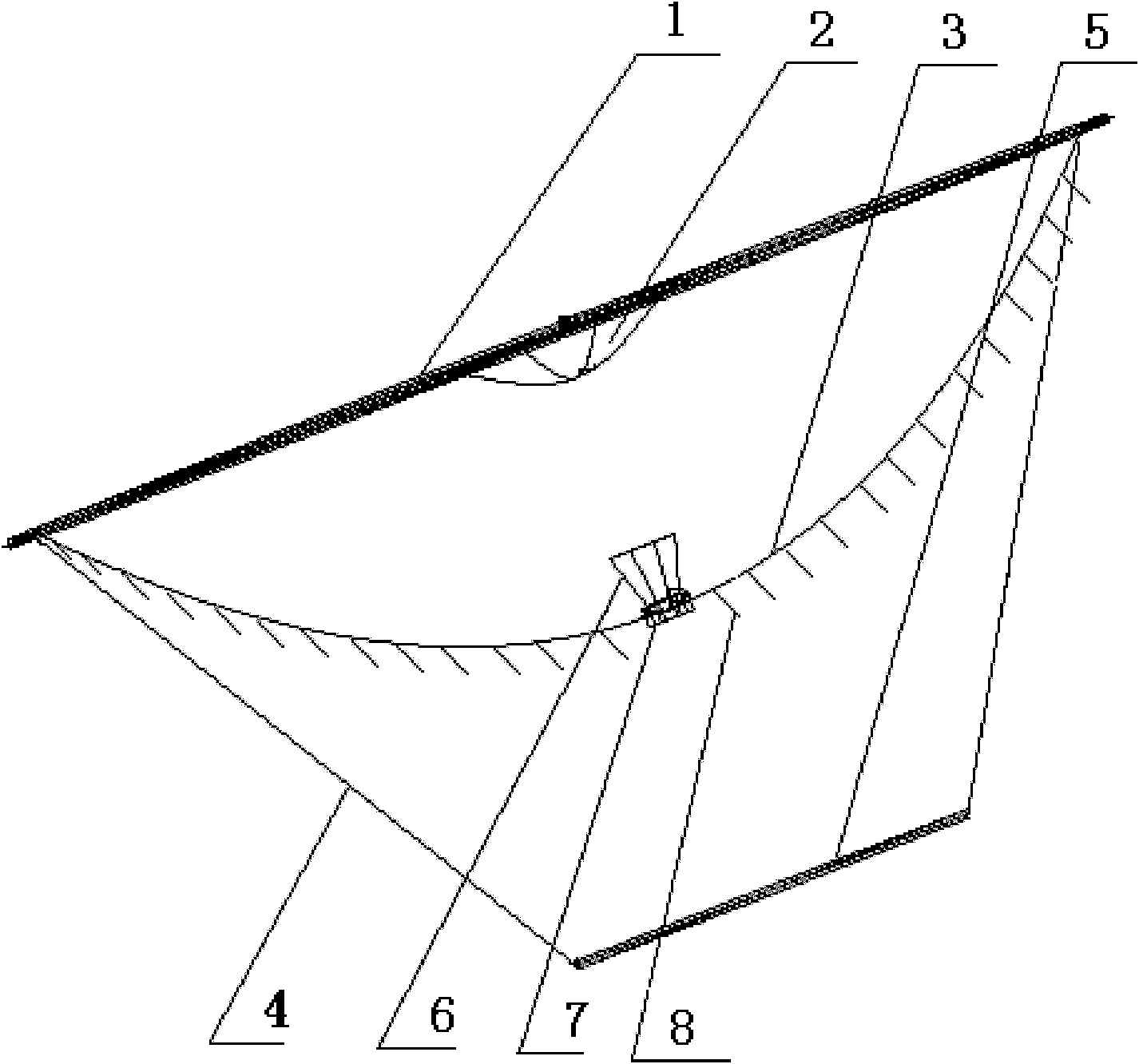

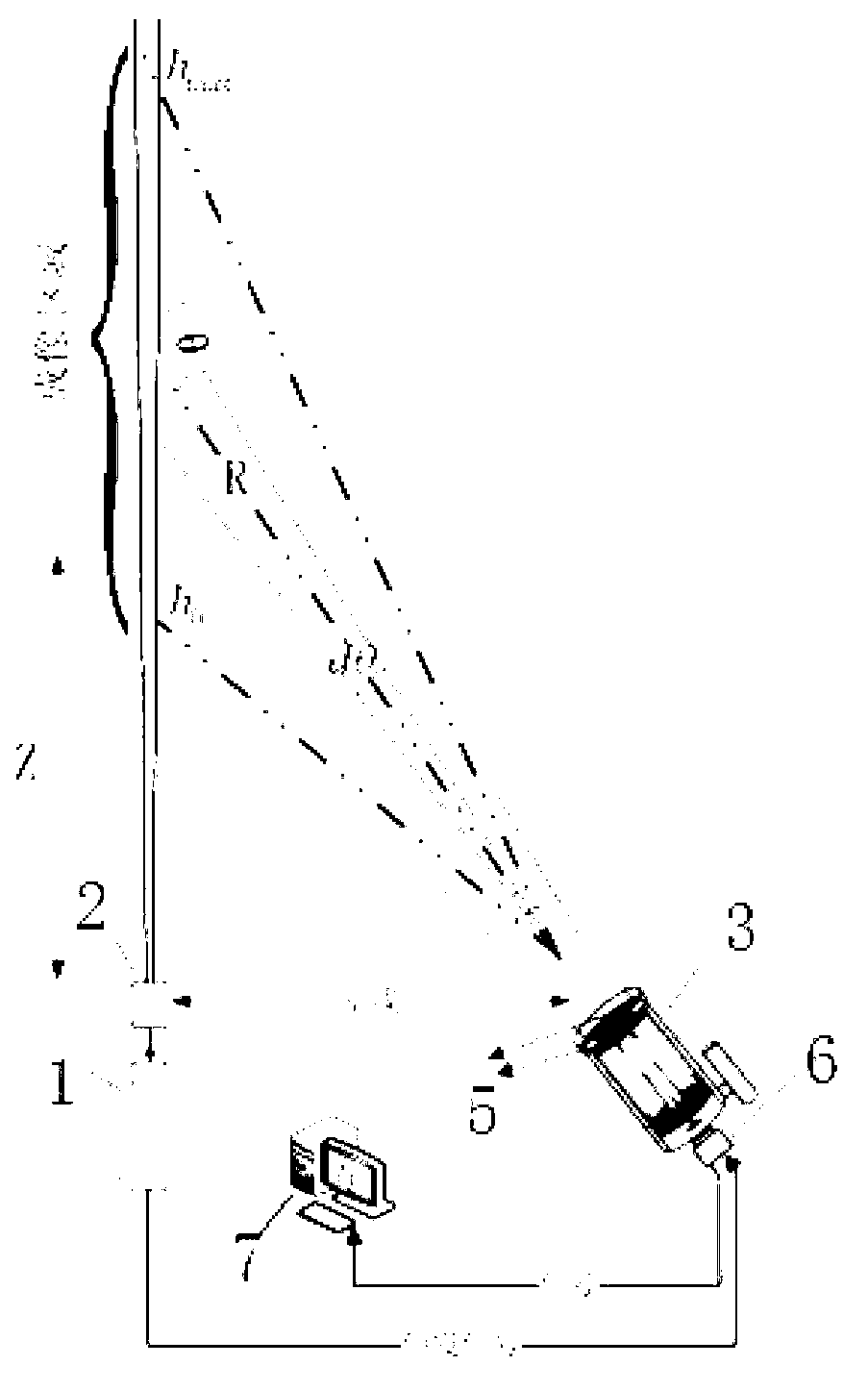

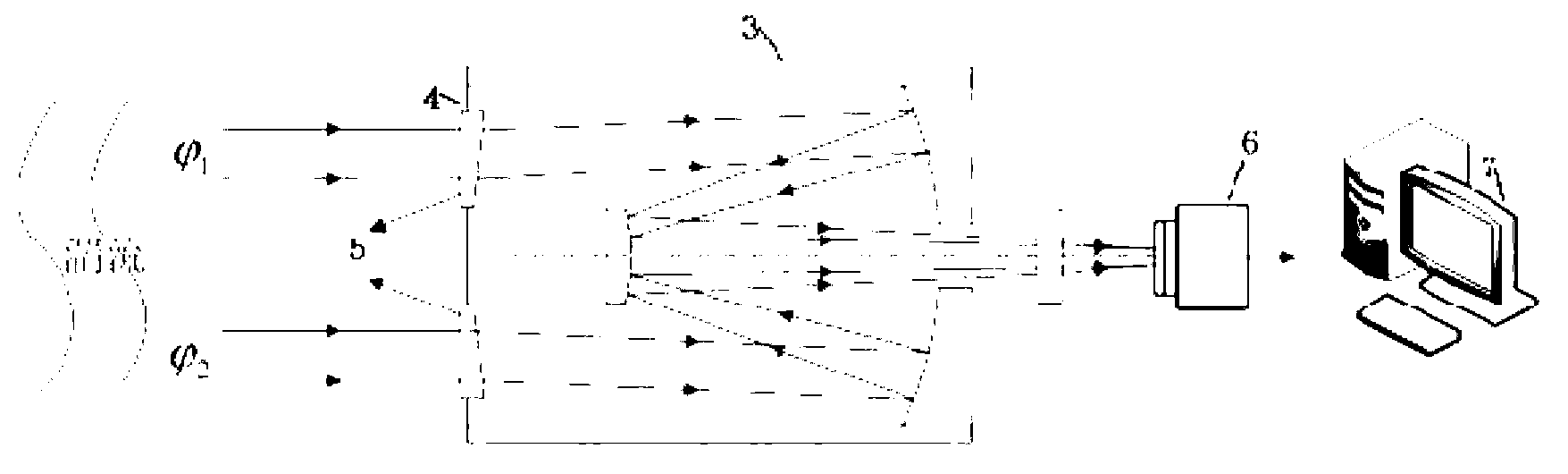

Method for measuring atmospheric optical turbulent current profile based on imaging laser radar of laser light beam

ActiveCN103267969ARealize measurementImprove time resolutionElectromagnetic wave reradiationRadarDivergence angle

The invention discloses a method for measuring an atmospheric optical turbulent current profile based on an imaging laser radar of a laser light beam. Laser light is emitted vertically upward by a laser emission unit, beam expanding is carried out on the laser light through a beam expanding mirror to reduce a divergence angle of the laser light, and the light beam is formed; a pupil plate is installed at the front end of a telescope objective lens of an optical receiving unit, an optical wedge mirror is installed on the pupil plate, a CCD is installed at the rear end of a telescope, and when the telescopic mirror is aligned to the laser light beam to image the light beam, due to beam split action of a light wedge, two light beam images in the vertical direction occur on a CCD target face; light beam images formed by various image elements of the CCD correspond to light beams on different heights, the jitter amount of the CCD images in the horizontal direction on the different heights are counted through the adoption of a differential image moving method, turbulent current information in the route of an imaging receiving face of the laser light beam can be obtained, then turbulent current information on different integral paths is analyzed, and a turbulent current strength profile is obtained. The method has high time resolution and space resolution, and is easy to implement and complete in theory.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Optical element and illuminant device using the same

ActiveUS20130063962A1Efficient amplificationMechanical apparatusLighting heating/cooling arrangementsLight guideLight pillar

An optical element is assembled to a light emitting diode (LED) to form an illuminative light source. The optical element includes a transparent main body having a light guiding pillar and an extending part. The light guiding pillar has a top surface and a bottom surface having a recess. The extending part is extended from the circumference of the top surface and an end of the extending part has at least a light-emitting surface. Wherein the LED is disposed on the recess and emits light to the optical element. The extending part guides the light and enlarges the light-emitting angle.

Owner:CHUN KUANG OPTICS CORP

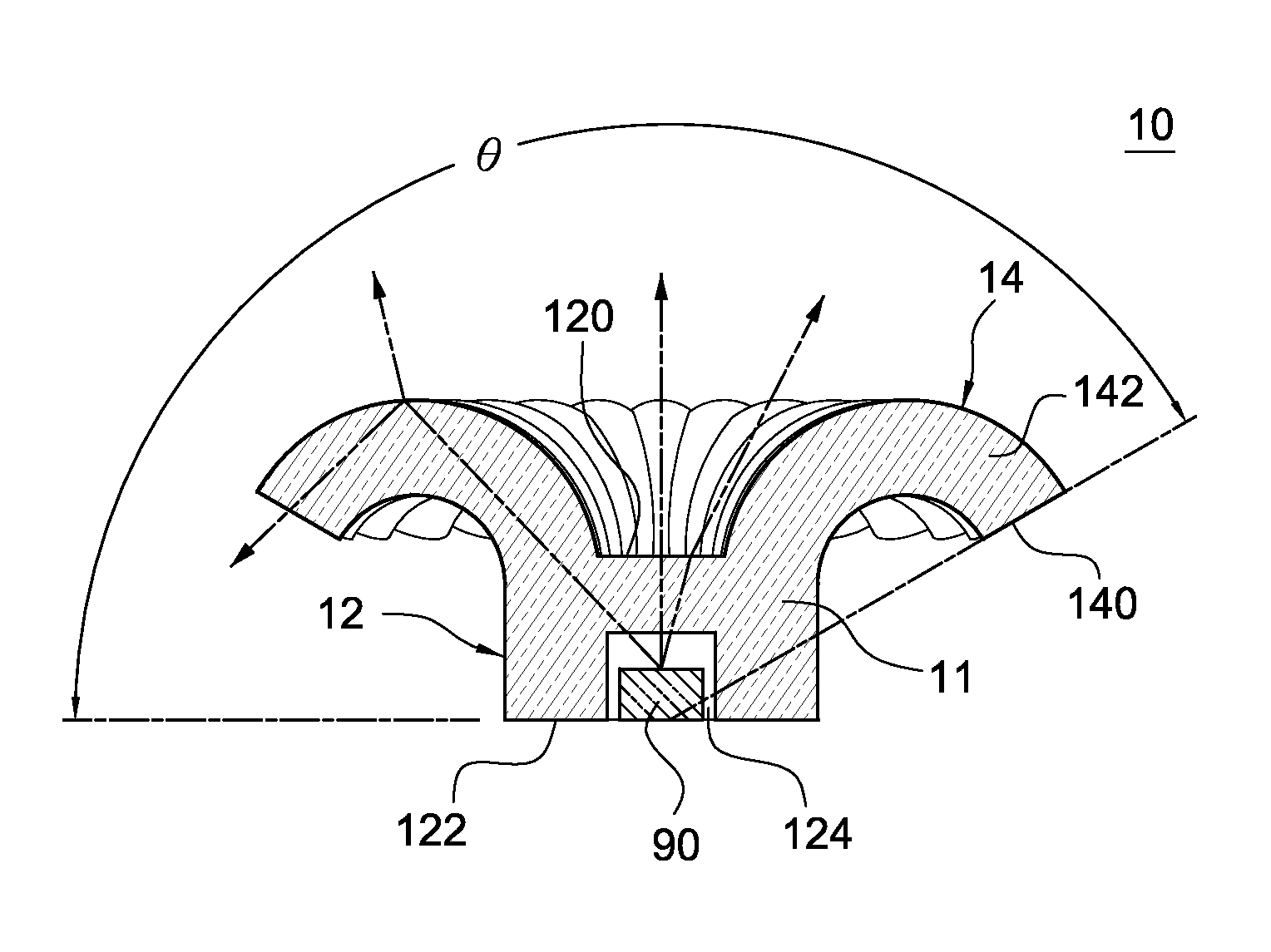

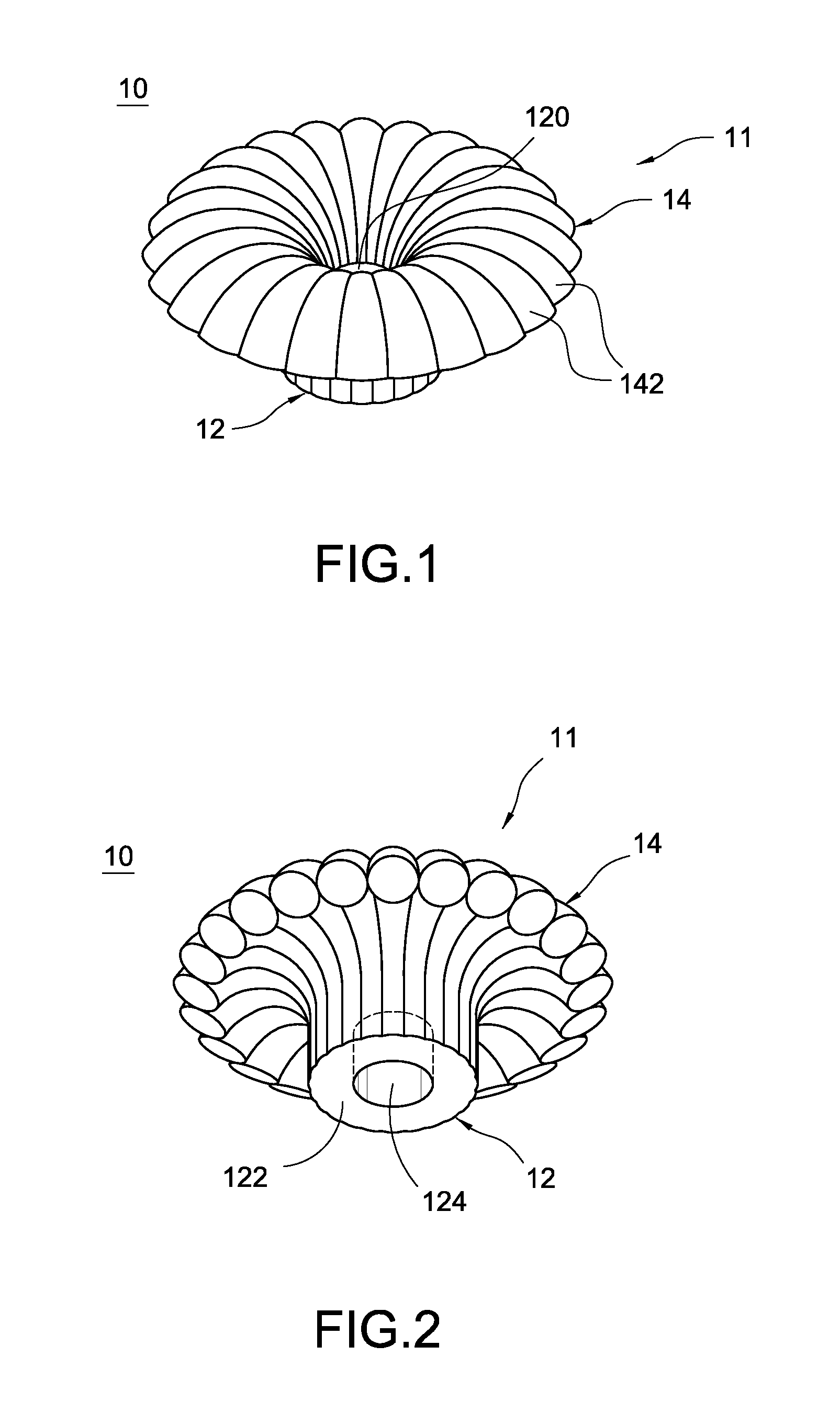

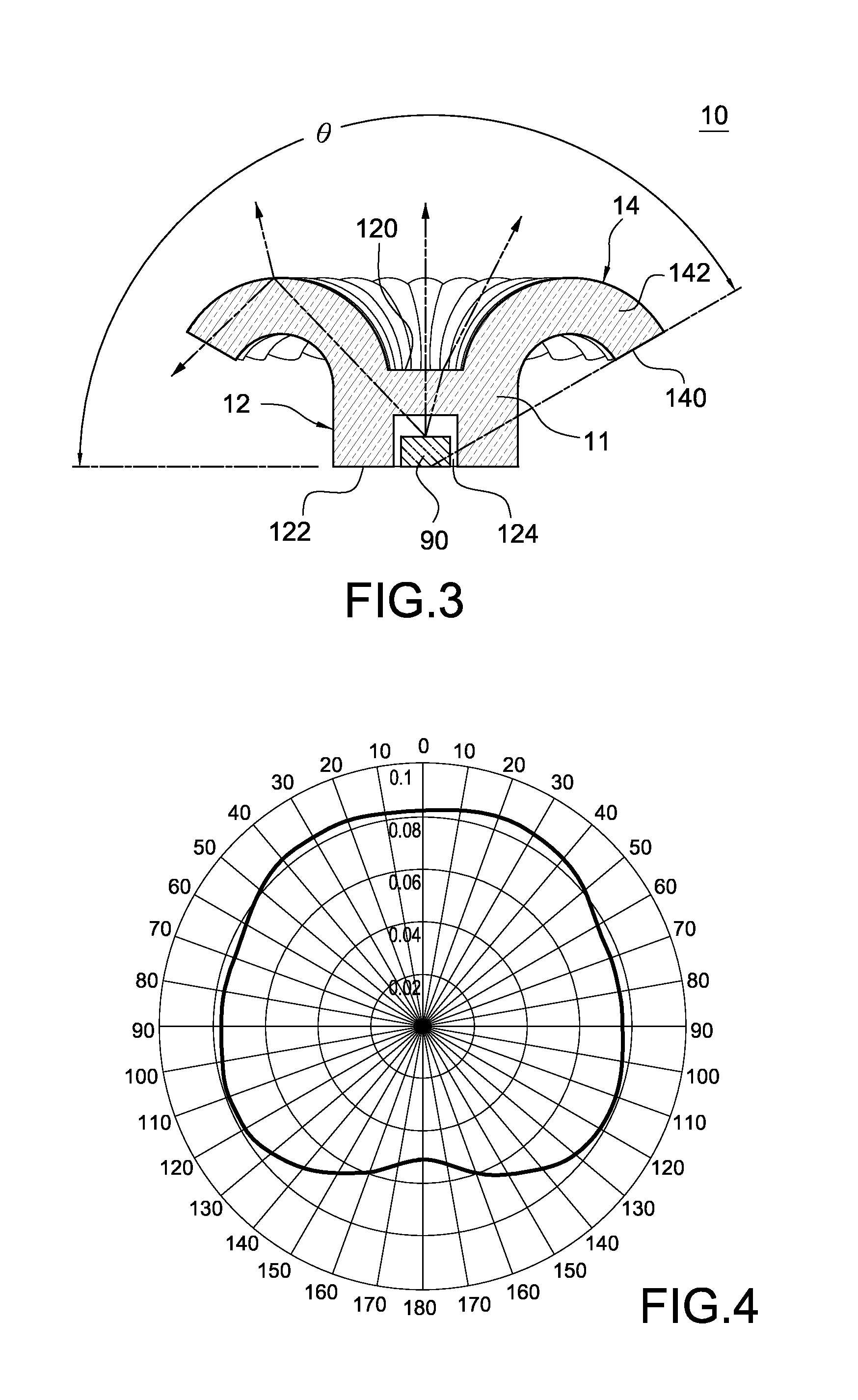

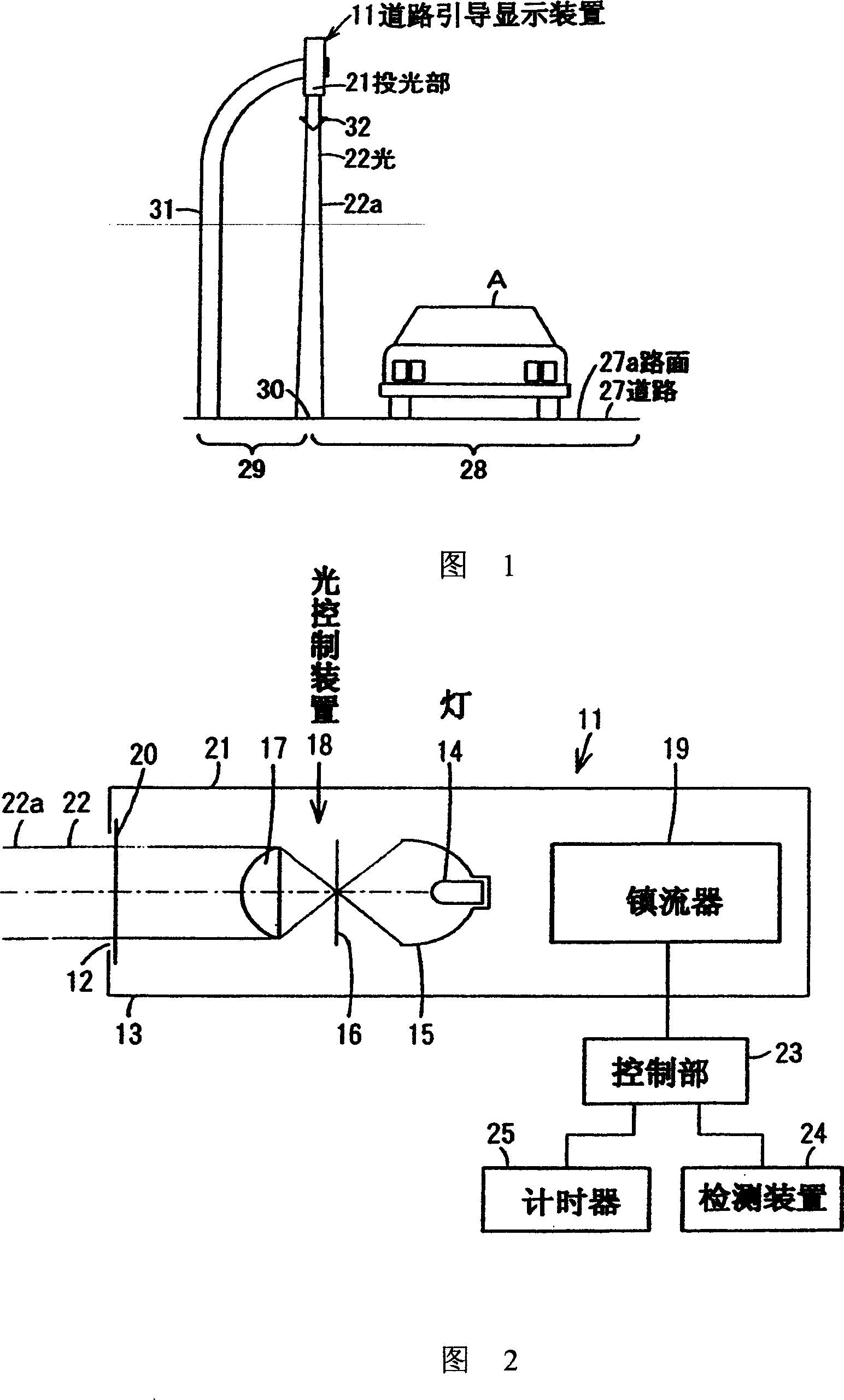

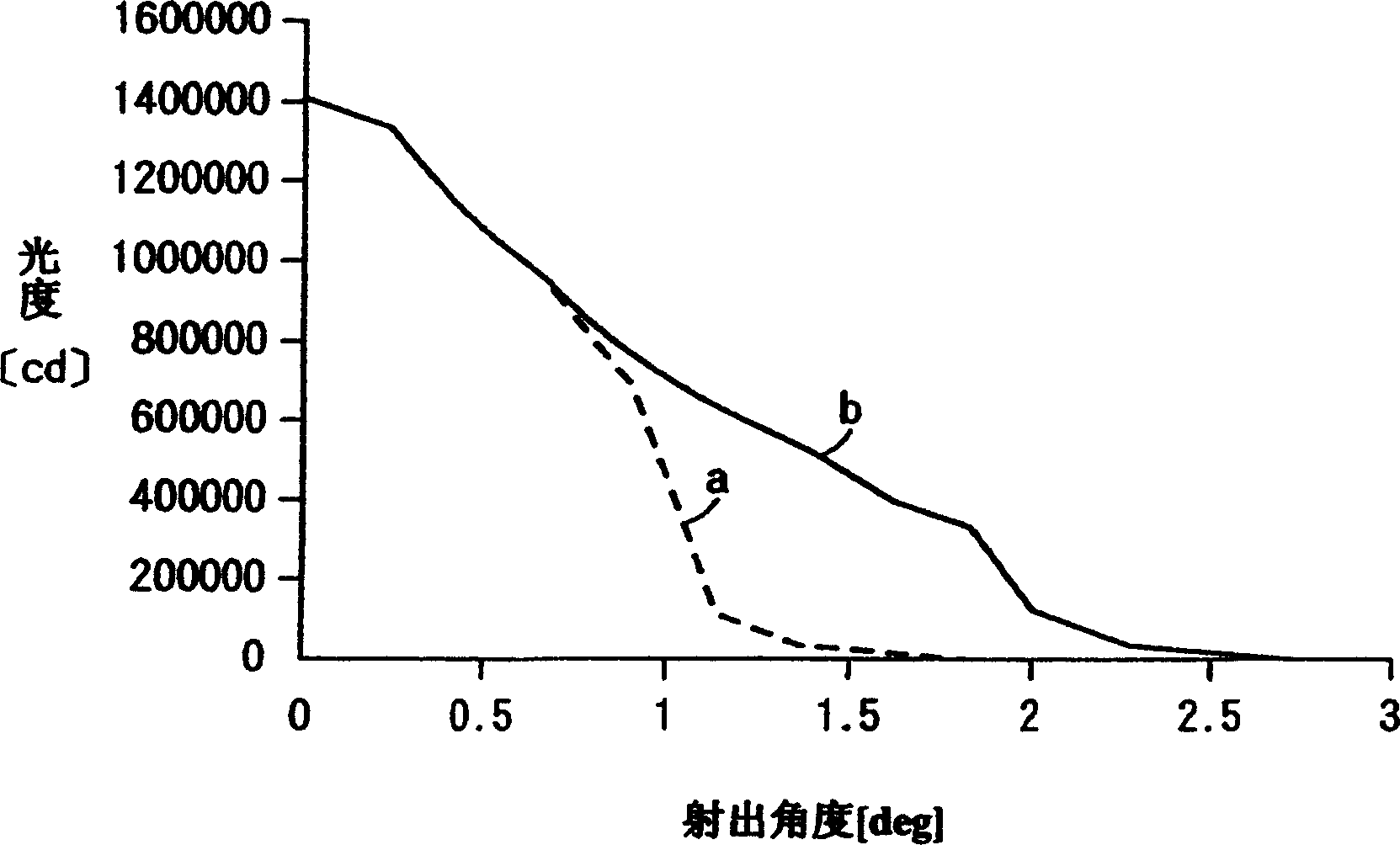

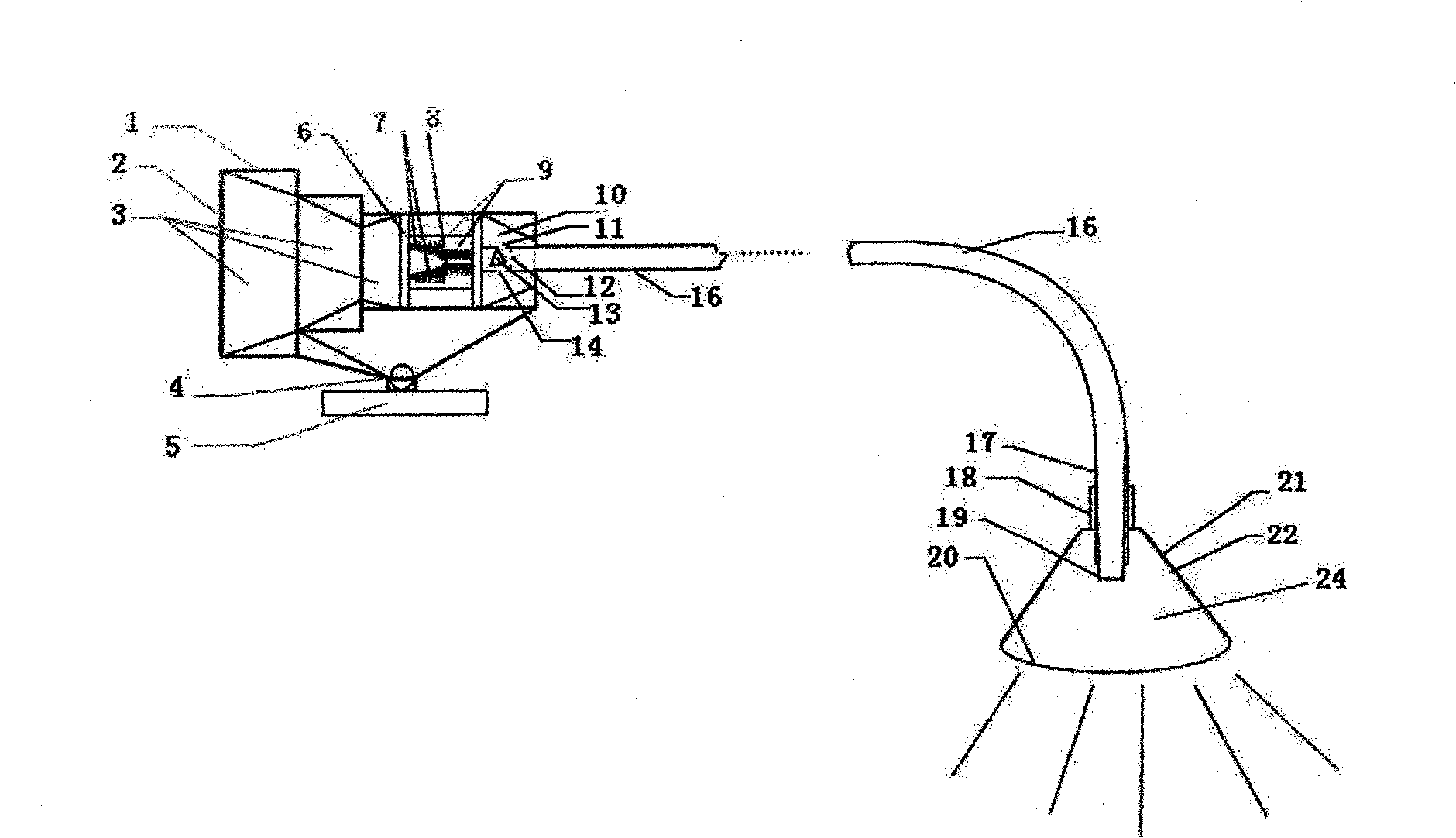

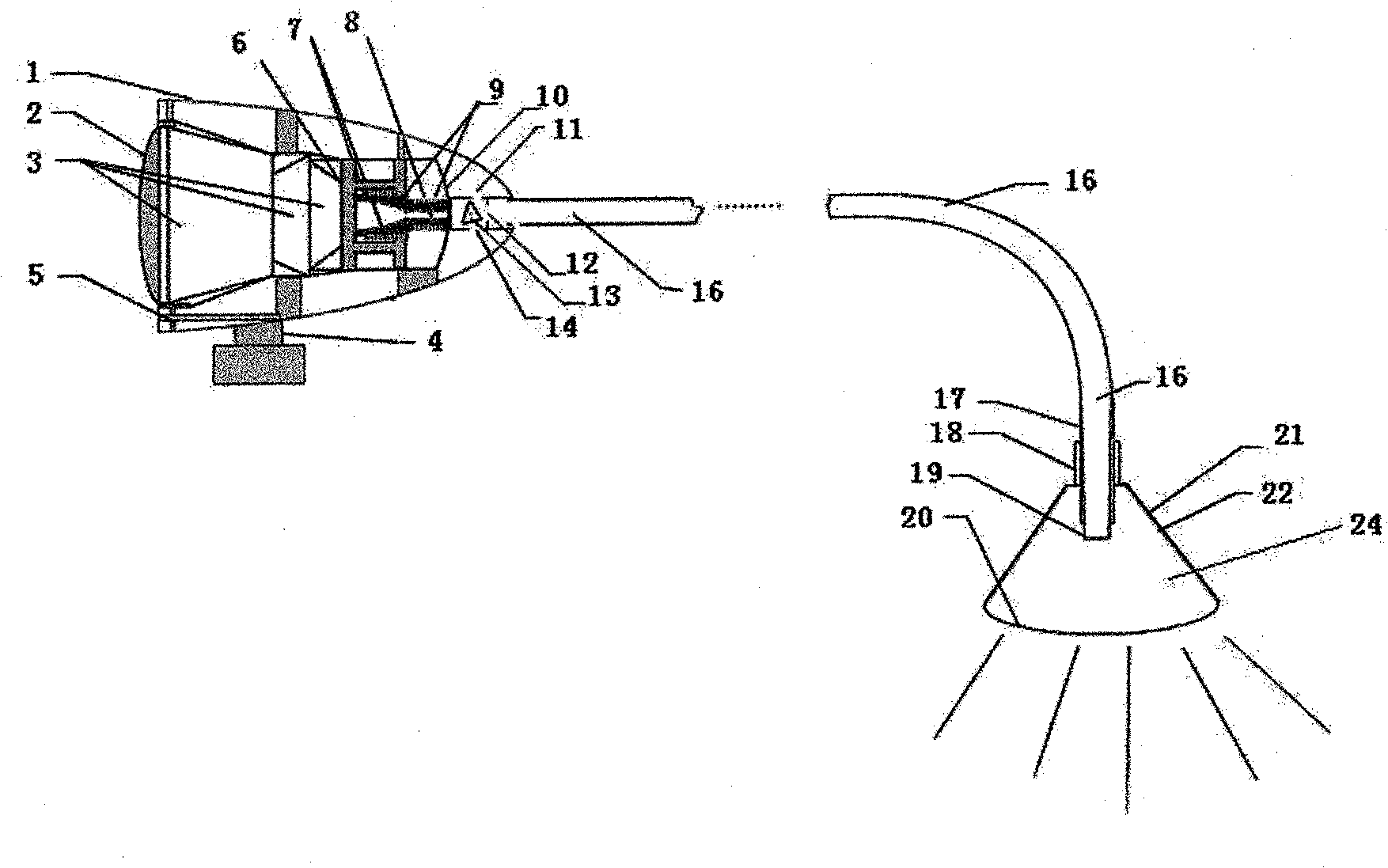

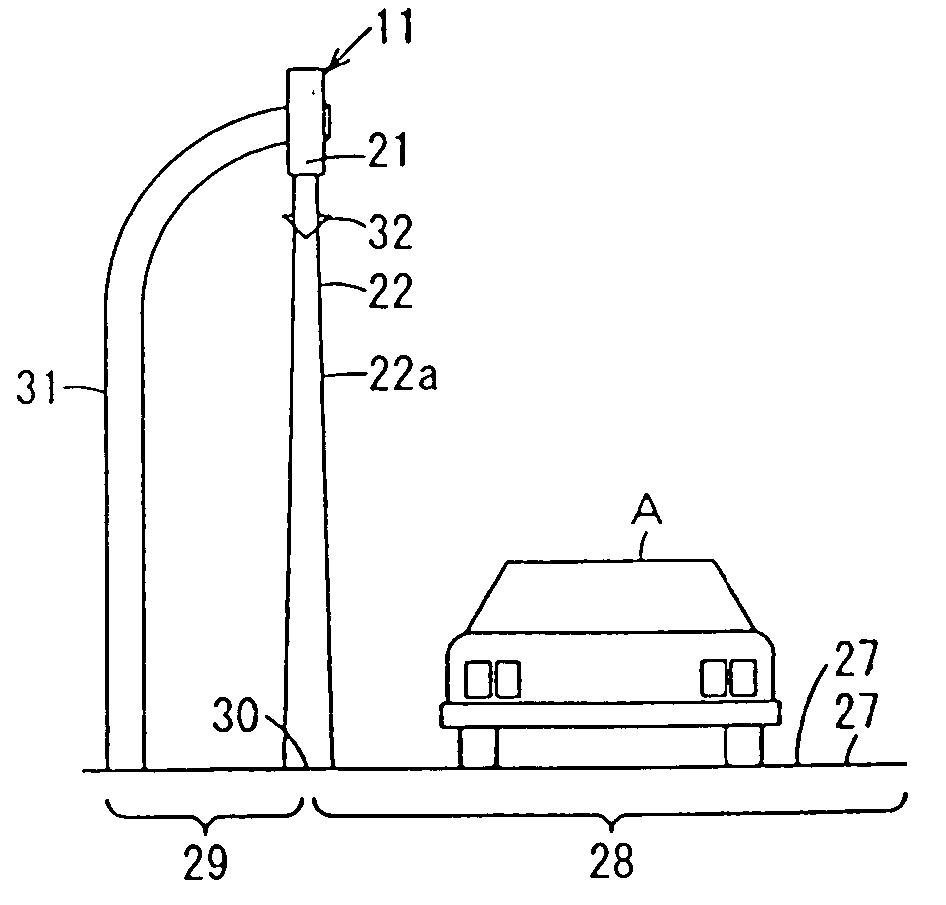

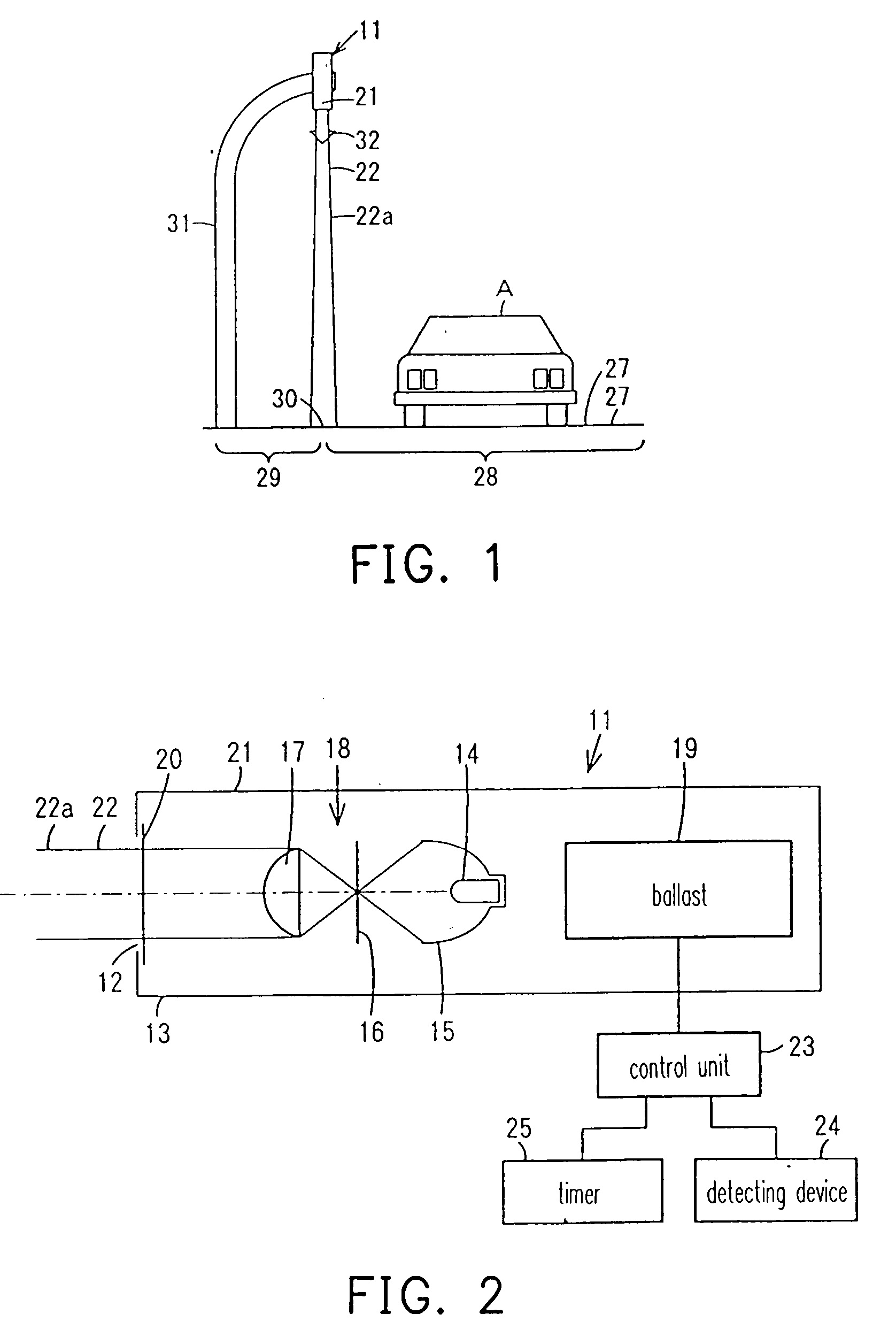

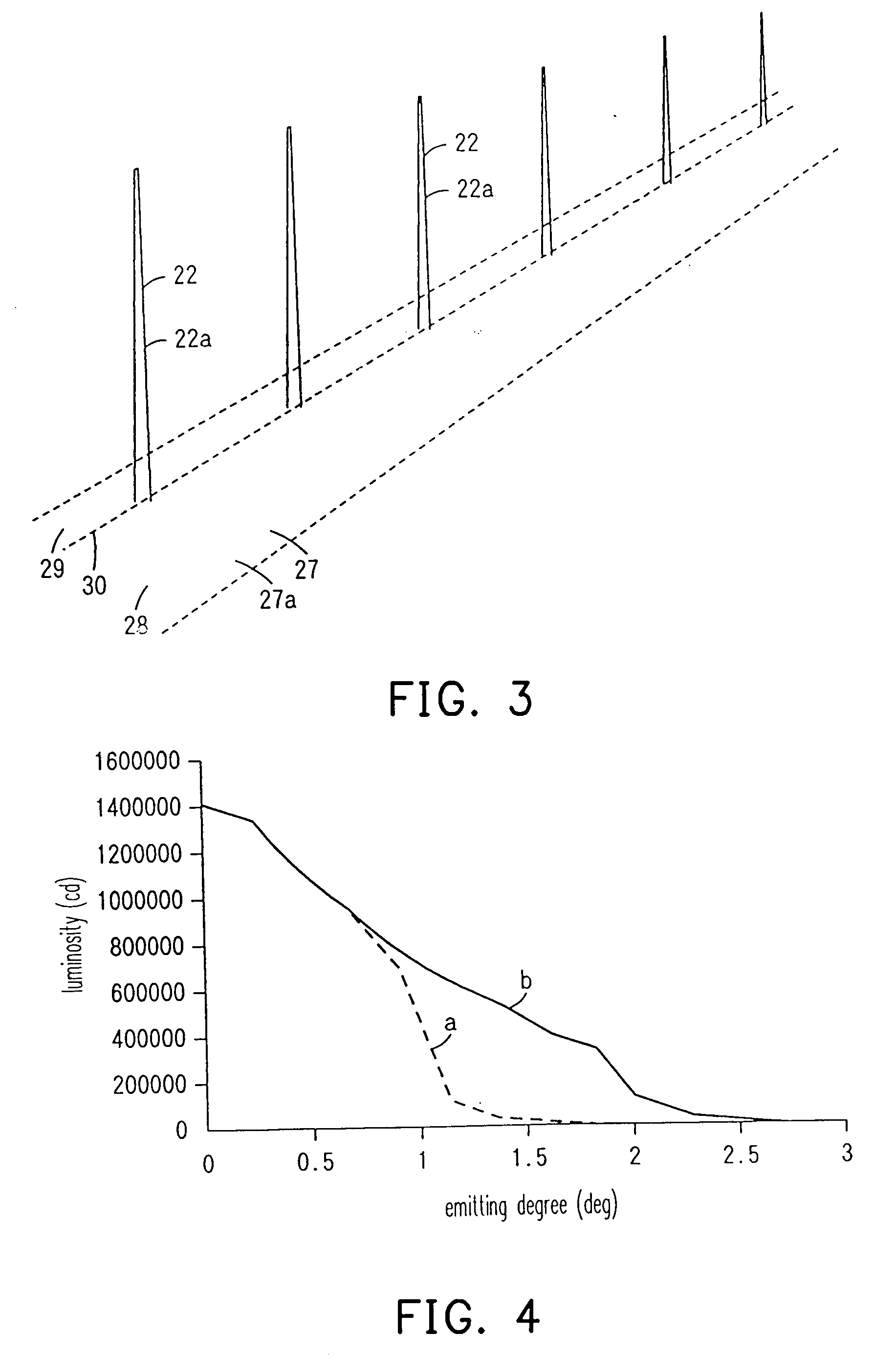

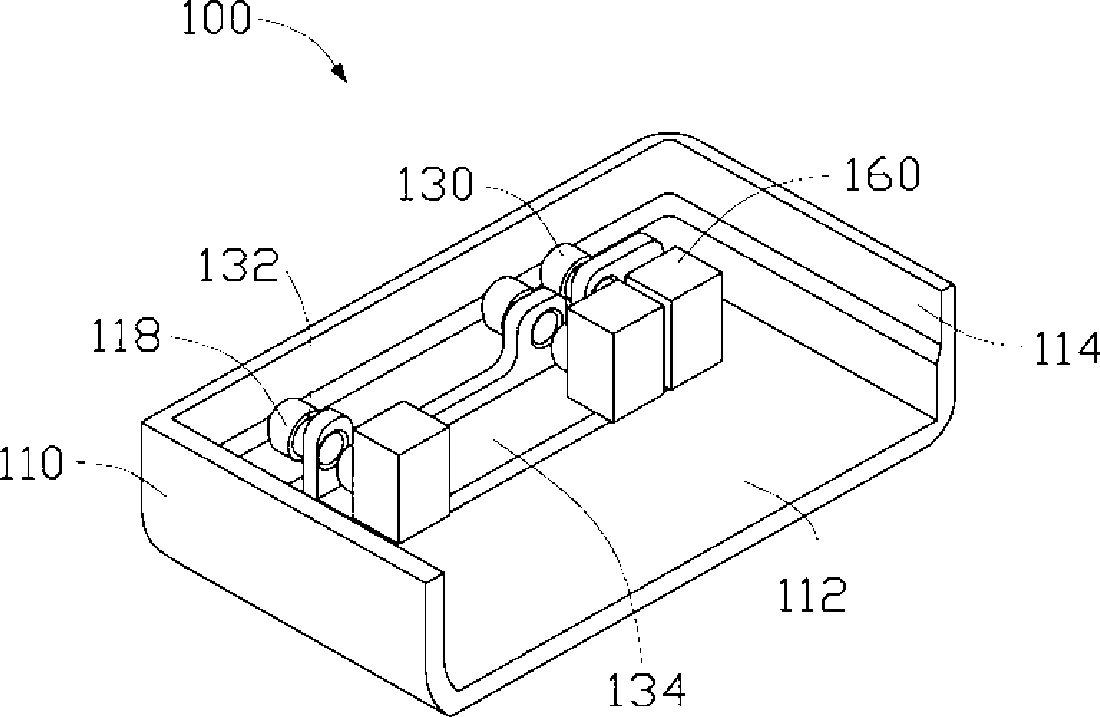

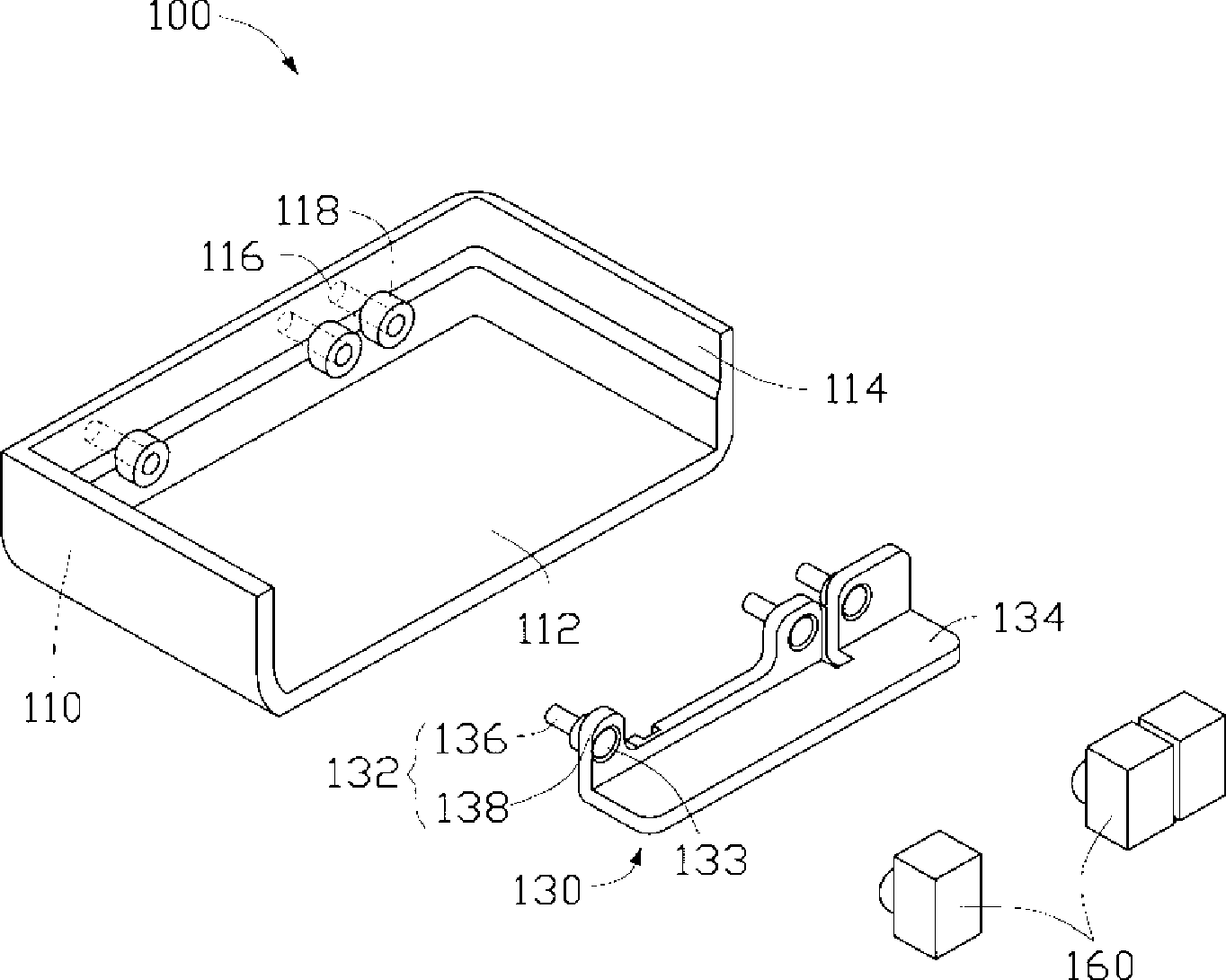

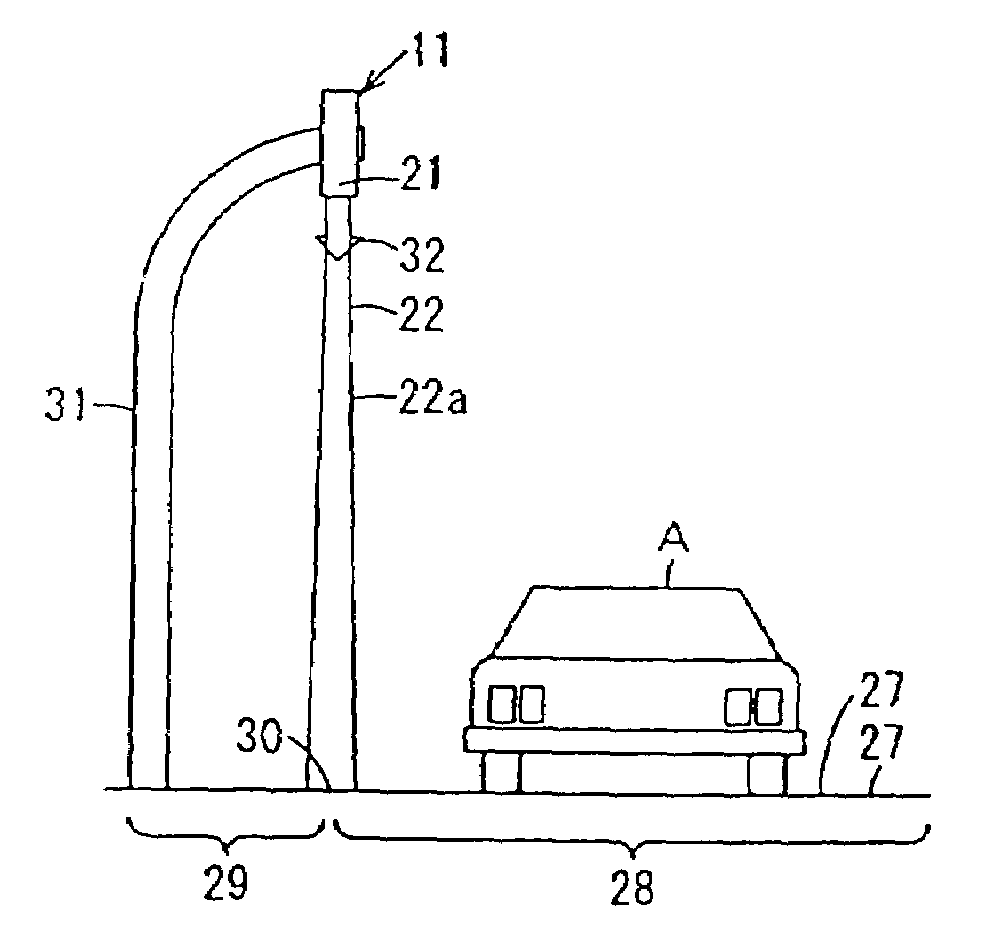

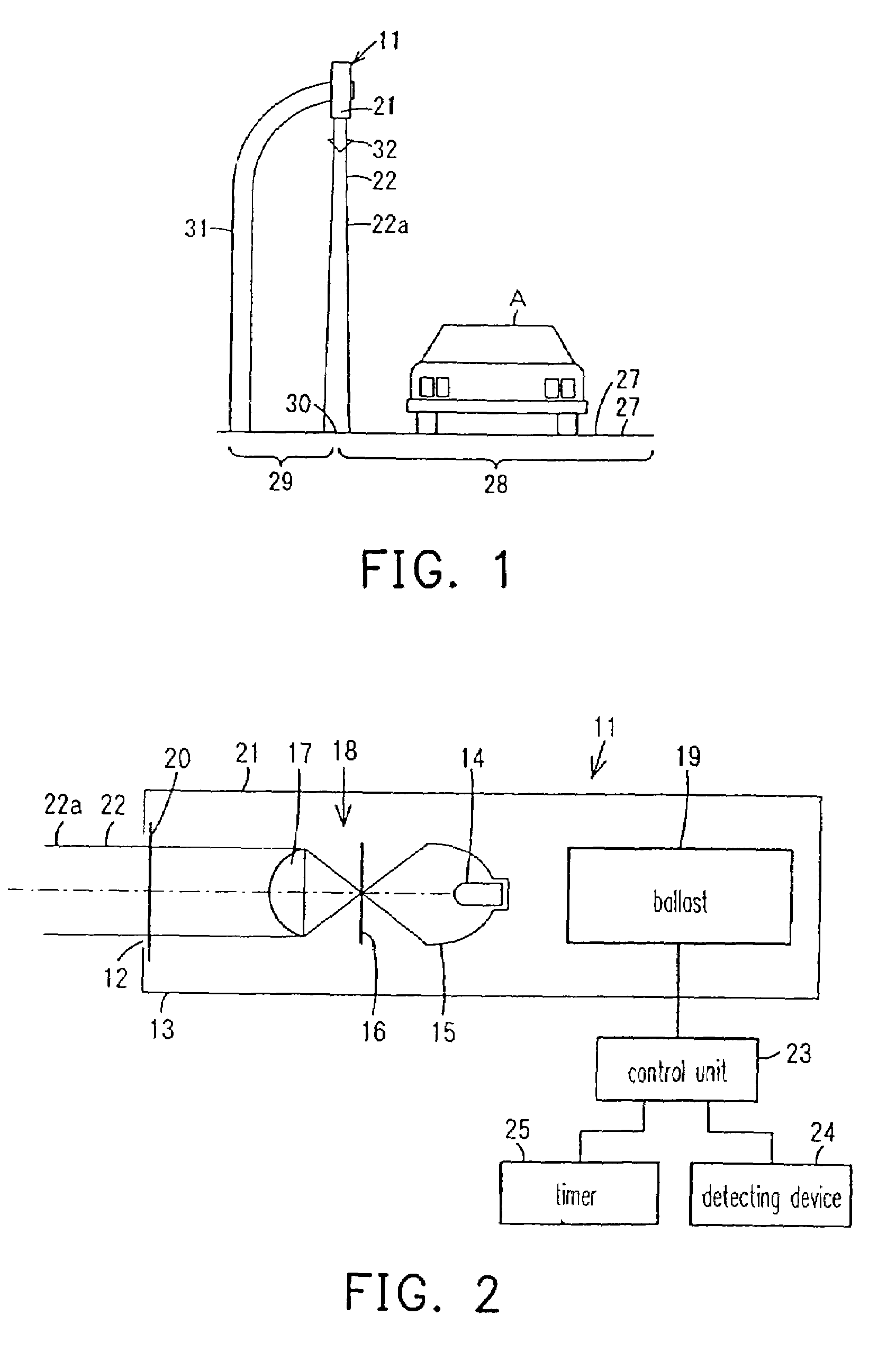

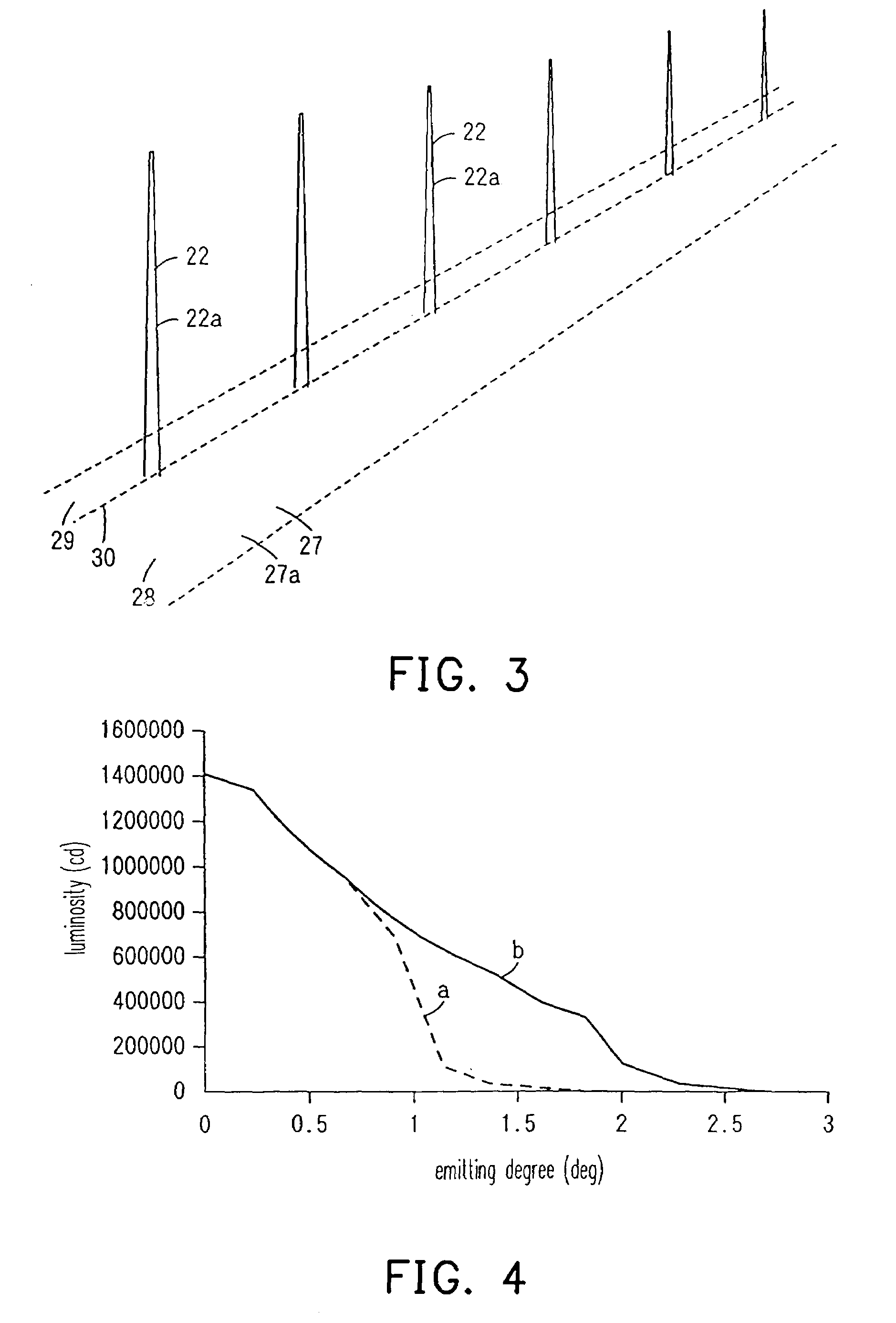

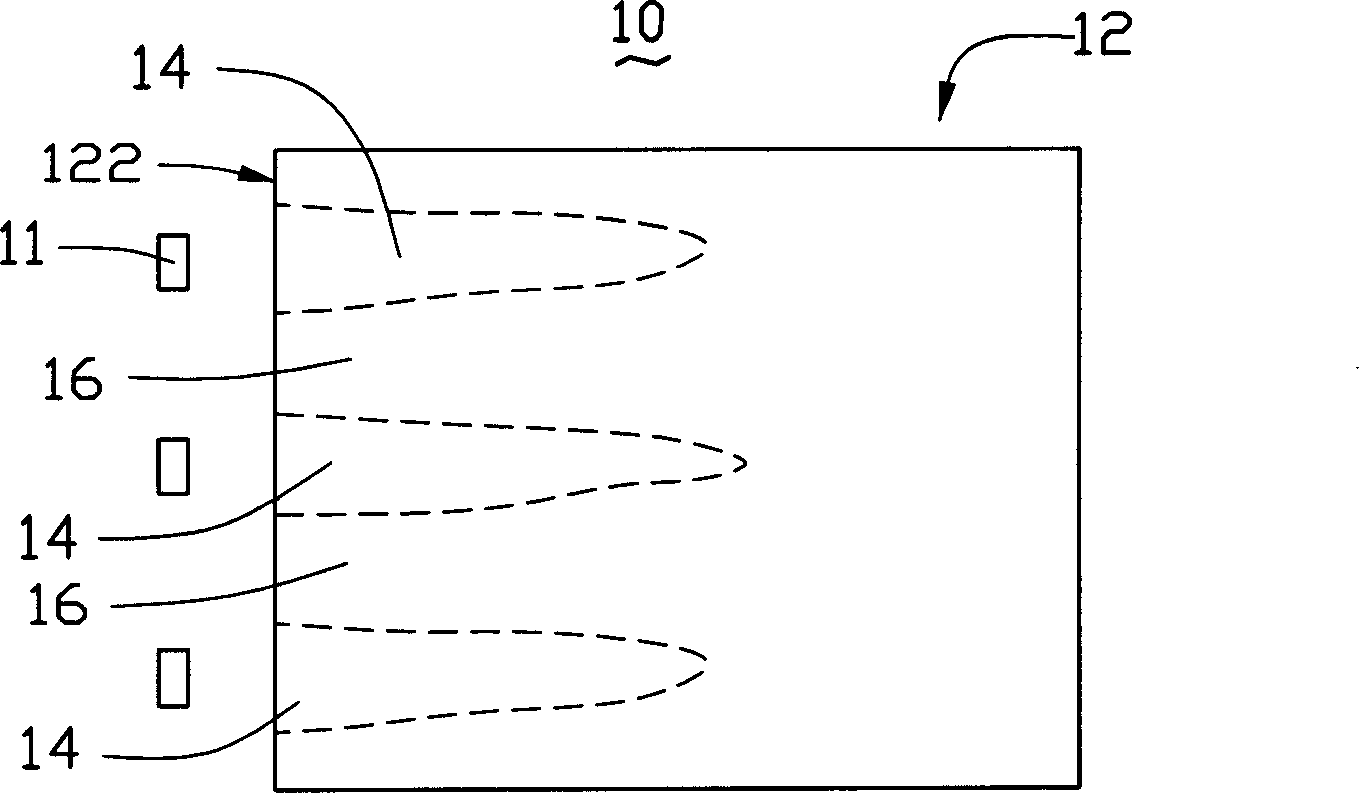

Road indication device

InactiveCN1572976AEasy to identifyIncrease freedomAdvertisingTraffic signalsLuminosityOptoelectronics

A road indication device is provided. The road-guidance indicating device has a light projection unit including light control means for controlling a lamp and light emitted from the lamp. The light projection unit project a light whose peak luminosity is 30000 cd or more, i.e., the light has a luminosity equal to or larger than a peak luminosity of a headlight of a car running on the road. Since a light pillar of light having a high light output and a thick light pillar is projected from the light projection unit, the visuality of the light pillar is improved even in the bad weather and the boundary between the driveway and the shoulder on the road can be affirmatively guided and indicated.

Owner:TOSHIBA LIGHTING & TECH CORP

Multifunction green environment protection sunlight acquisition method, apparatus and use

InactiveCN101493205ALow costSave on electricity billsMechanical apparatusLight guides for lighting systemsLight pipeElectric consumption

The invention discloses a multifunctional environmental protection sunshine collection method, a device and application thereof. The multifunctional environmental protection sunshine collection method comprises the following steps: sunshine is highly compressed into an ultrahigh light pillar, after being cooled, the light pillar is sent into a spectrum separation and deployment storehouse and then the incident light is deployed, separated, combined, and the like; the ultra-intense visible light is led into a light pipe, optical lines are transmitted and then uniformly diffused. The invention has the advantages that according to statistics made by experts, electric consumption on daytime illumination occupies more than 40% of electric consumption on illumination, therefore, employing the multifunctional environmental protection sunshine collection device can use free sunshine light instead of electric light illumination during daytime; the device is the popularized, only China can save about 82 billion degrees of electricity per year, calculated as 0.8 Yuan per degree, 65.6 billion Yuan can be saved per year, besides, the device also has no pollution and can reduce the emission and pollution brought by generating electricity.

Owner:周治军

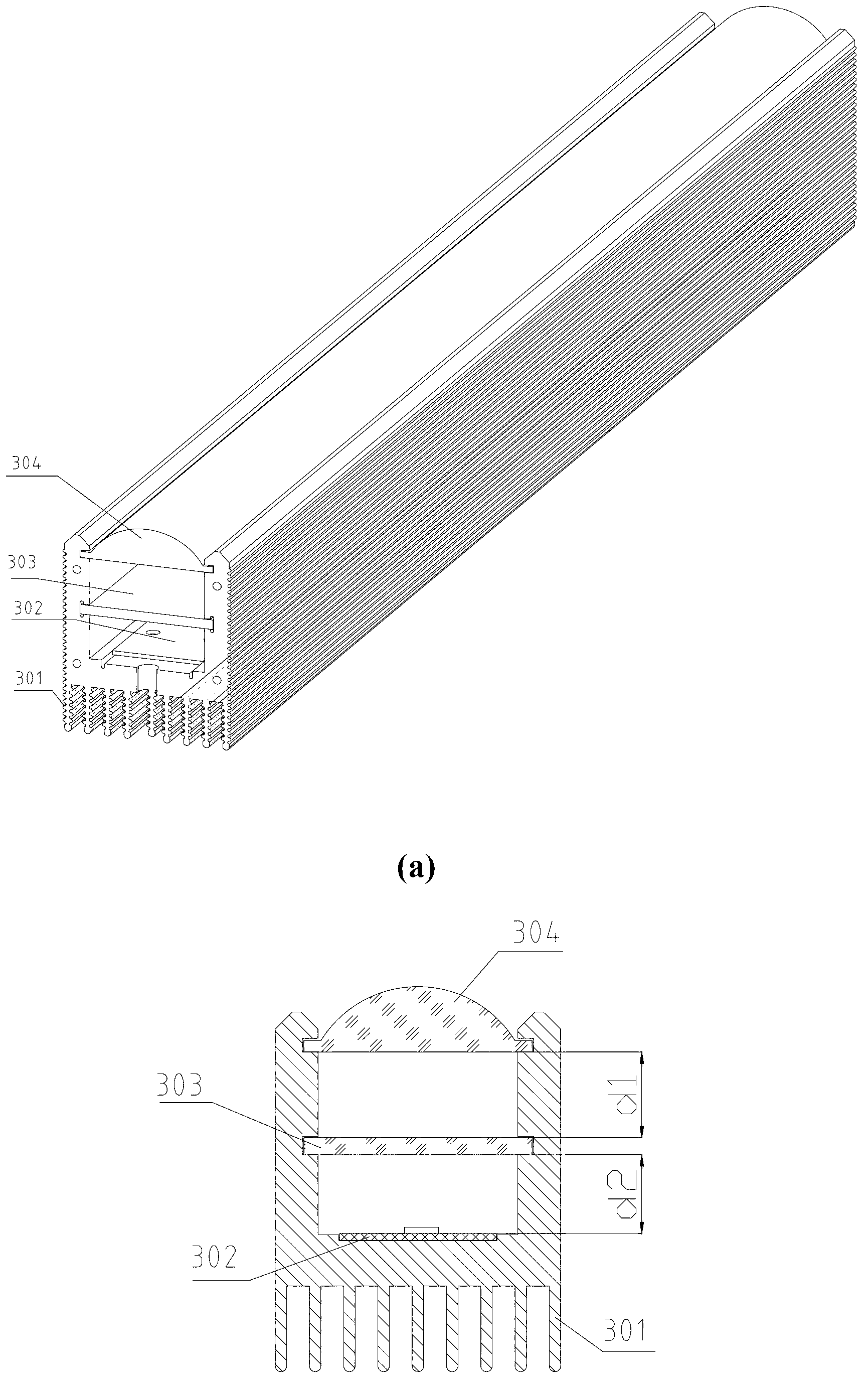

LED condensation light source and material sorting device based on same

ActiveCN103307492AReduce bumpsSolve the sticky problemLighting applicationsPoint-like light sourceLed arrayEffect light

The invention provides an LED condensation light source applicable to the photoelectric sorting, which comprises an LED linear array, a fixing support, a scattering uniform light plate, a condensation pillar lens, wherein the condensation pillar lens is a plano-convex cylindrical surface lens; the LED linear array, the scattering uniform light plate and the condensation pillar lens are parallelly and fixedly mounted on the fixing support at certain intervals; the scattering uniform light plate is positioned between the LED linear array and the condensation pillar lens; light sent out by the LED linear array scatters through the scattering uniform light plate, and converges after penetrating the condensation pillar lens. The invention further provides a material sorting device based on the LED condensation light source. The LED condensation light source and the material sorting device have the advantages that emergent light of the LED condensation light source converges through the control of the angle of the emergent light, longer distance lighting can be realized, besides, the lighting luminance and uniformity can be guaranteed, the photoelectric sorting device provided by the invention can enlarge the distance from the LED condensation light source to a material detecting area, the problem of sticky glass window surface when the conventional sorting equipment is used for sorting materials is solved, and the sorting precision is improved.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

Road indication device

InactiveUS20050002203A1Simple instructionsIncrease awarenessNon-electric lightingAdvertisingLuminosityOptoelectronics

A road indication device is provided. The road-guidance indicating device has a light projection unit including light control means for controlling a lamp and light emitted from the lamp. The light projection unit project a light whose peak luminosity is 30000 cd or more, i.e., the light has a luminosity equal to or larger than a peak luminosity of a headlight of a car running on the road. Since a light pillar of light having a high light output and a thick light pillar is projected from the light projection unit, the visuality of the light pillar is improved even in the bad weather and the boundary between the driveway and the shoulder on the road can be affirmatively guided and indicated.

Owner:TOSHIBA LIGHTING & TECH CORP

Indicating lamp structure

The invention provides a structure of a pilot lamp. The structure of the pilot lamp comprises a shell, a light guiding component and a light source, wherein, the shell comprises a bottom plate and side walls enclosing the bottom plate and a plurality of light outlet holes are arranged on the side walls; the light guiding component comprises a plurality of light guiding columns arranged between the light source and the light outlet holes of the shell and is used for transmitting the light emitted by the light source to the light outlet holes of the shell; the light source comprises a plurality of light emitting parts which are respectively corresponding to the light guiding columns, and is arranged in the shell corresponding to the light guiding columns and electrically connected with a control circuit. As to the light guiding columns which are adjacent to each other, at least one light guiding column is wrapped with a shading element in the side wall and one end of each light guiding column stretches into the light outlet hole of the shell. Additionally, the structure of the pilot lamp can prevent light leak.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Road indication device

A road indication device is provided. The road-guidance indicating device has a light projection unit including light control means for controlling a lamp and light emitted from the lamp. The light projection unit project a light whose peak luminosity is 30000 cd or more, i.e., the light has a luminosity equal to or larger than a peak luminosity of a headlight of a car running on the road. Since a light pillar of light having a high light output and a thick light pillar is projected from the light projection unit, the visuality of the light pillar is improved even in the bad weather and the boundary between the driveway and the shoulder on the road can be affirmatively guided and indicated.

Owner:TOSHIBA LIGHTING & TECH CORP

Light conductive plate and back light module

InactiveCN1900786ASimple structureEliminate the beam phenomenonNon-linear opticsComing outLight guide

The light guiding plate includes following parts: an incident lightface of containing at least one bulge or groove; a light coming out face connected to the incident lightface; back plane opposite to the light coming out face; multiple layers of reflecting film formed on surface of the bulge or groove. Using the light guiding plate, a backlight module disclosed in the invention includes at least one spot light source and at least reflex housing cooperated with the light guiding plate. Each spot light source is corresponding to bulge or groove on incident lightface of the light guiding plate. Being near to and enclosing the spot light source, the reflex housing is in use for reflecting and returning part of light back to enter to the light guiding plate again. The disclosed backlight module eliminates phenomena of light columns on incident lightface so as to raise evenness of emergence light.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

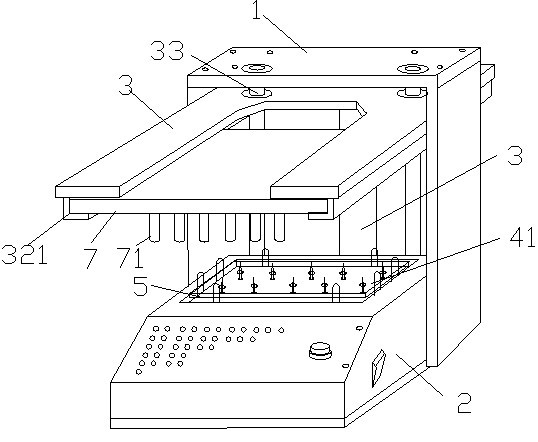

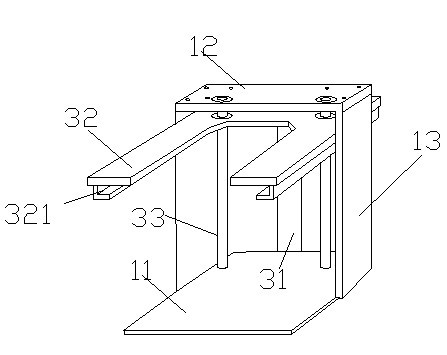

Pneumatic double-plate optical fiber tester for LED (Light Emitting Diode) indicating lamp

The invention relates to a pneumatic double-plate optical fiber tester for an LED (Light Emitting Diode) indicating lamp. A test operation board comprises a bracket, a control box and a pneumatic device; the bracket is taken as a support body; a test needle bed is arranged at the inner side of the control box; a positioning board for a circuit board is arranged above the test needle bed and is embedded in an open pore at the upper part of a box body; the pneumatic device comprises an air cylinder, a lifting stand and guide posts; the lifting stand is driven by the air cylinder to downwards move and press the circuit board, so that LED test points on the back of the circuit board are in contact with test needle heads; glass light posts are in contact with the LED surface of the circuit board; during testing, a power supply of a test circuit is connected and the LED is lightened; light transmits to a tester panel window of the test operation board through the glass light posts and optical fibers; and whether the LED is qualified or not is judged by visually observing the luminous state of the LED; and according to the test instrument, test efficiency of the LED can be increased, quality of products can be improved, operation work procedures are simplified and production efficiency can be increased.

Owner:TIANJIN ZHONGHUAN ELECTRONICS COMP

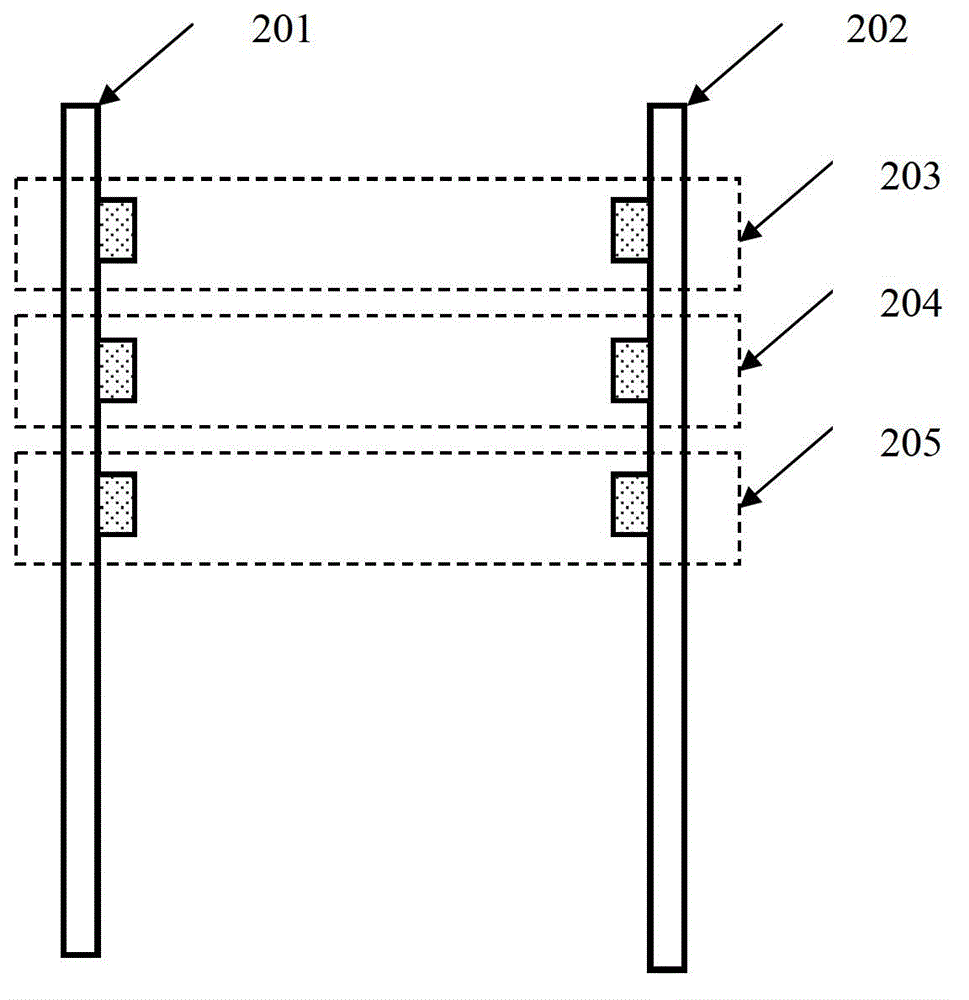

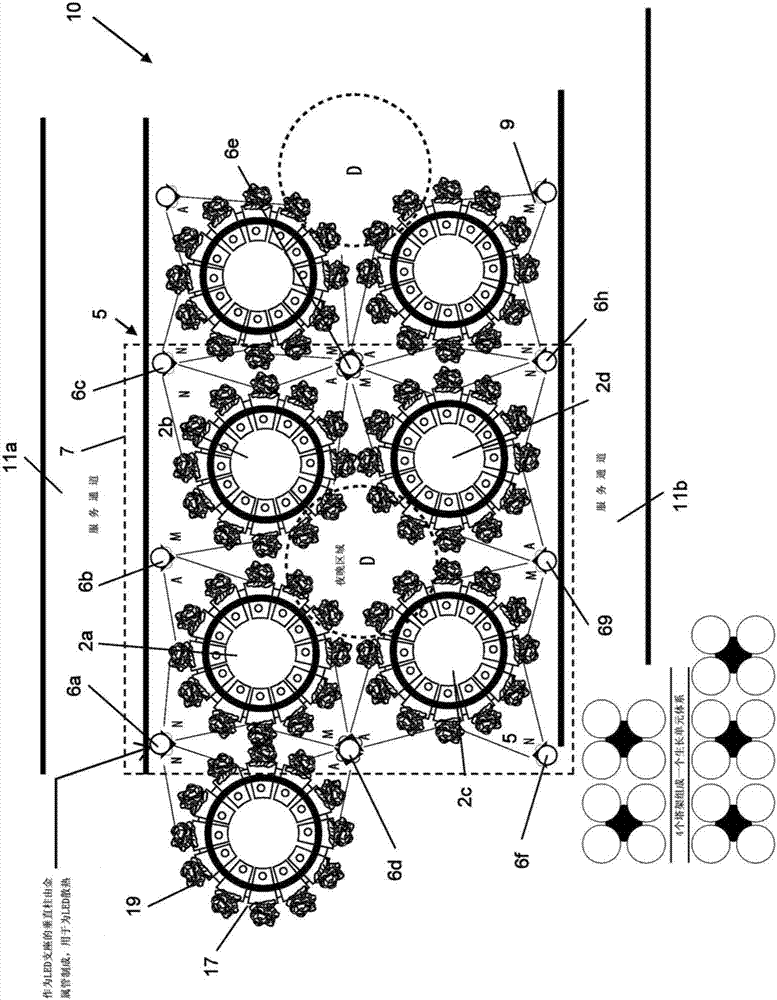

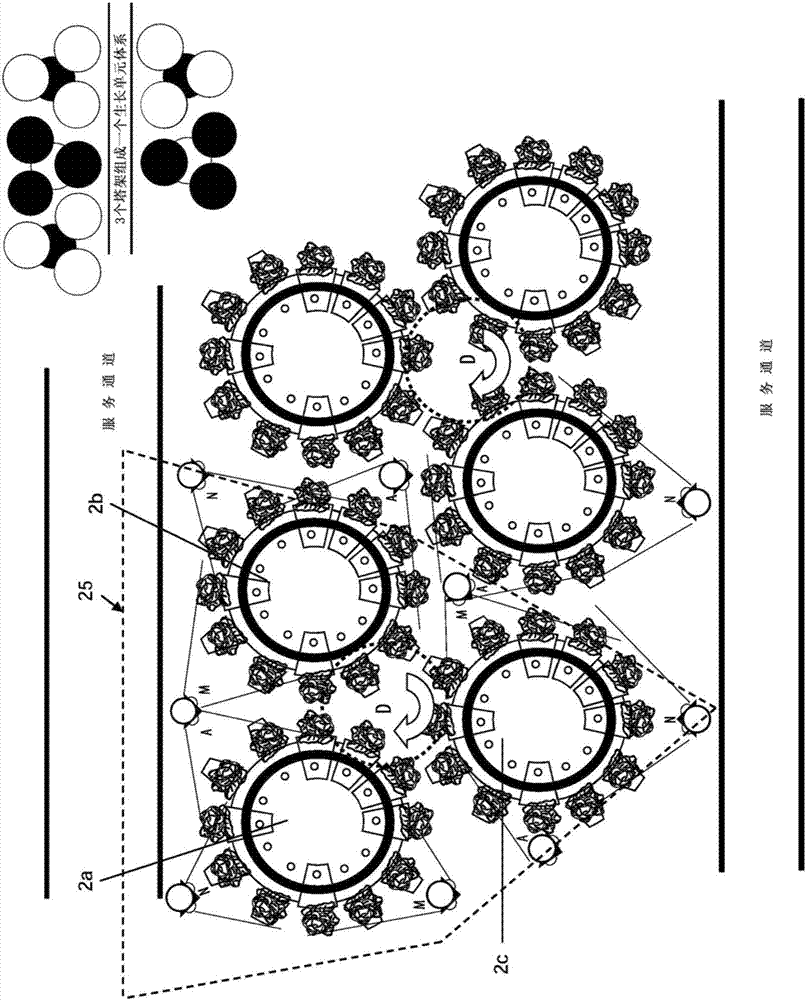

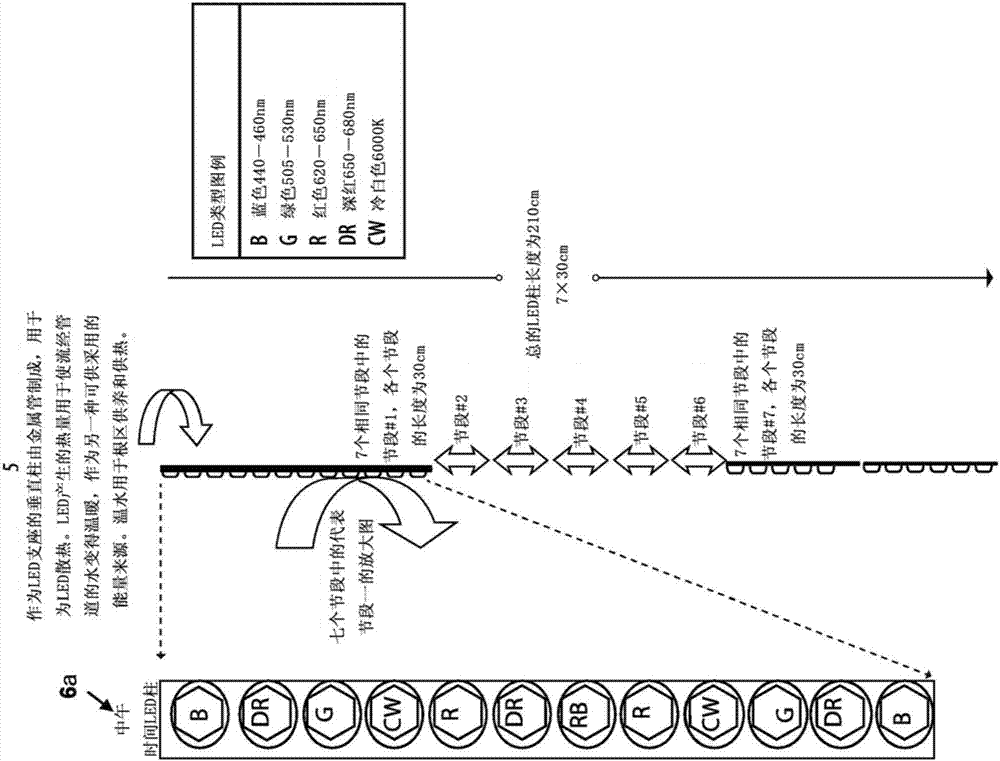

A system for indoor cultivation of plants with simulated natural lighting conditions

ActiveCN107426977AEasy to transportEasy constructionClimate change adaptationAgriculture gas emission reductionAgricultural engineeringEngineering

An indoor soilless plant cultivating system, comprising a plurality of stationary light posts, each of which adapted to illuminate a predetermined sector of an indoor facility in accordance with a predetermined illumination signature; a plurality of plant growth towers that are rotatable about a substantially vertical axis in accordance with a predetermined timing sequence so as to be exposable to the light generated at any given time by one or more of the light posts and that are arranged by at least one module defining a module darkened interior region within which plants being instantaneously positioned receive a sensation of nighttime; and irrigation means for supplying the plants being cultivated in each of said towers with a nutrient-rich solution. Moreover, an artificial pollination system based on compressed air nozzles is incorporated within the light posts.

Owner:ROKEHA LTD

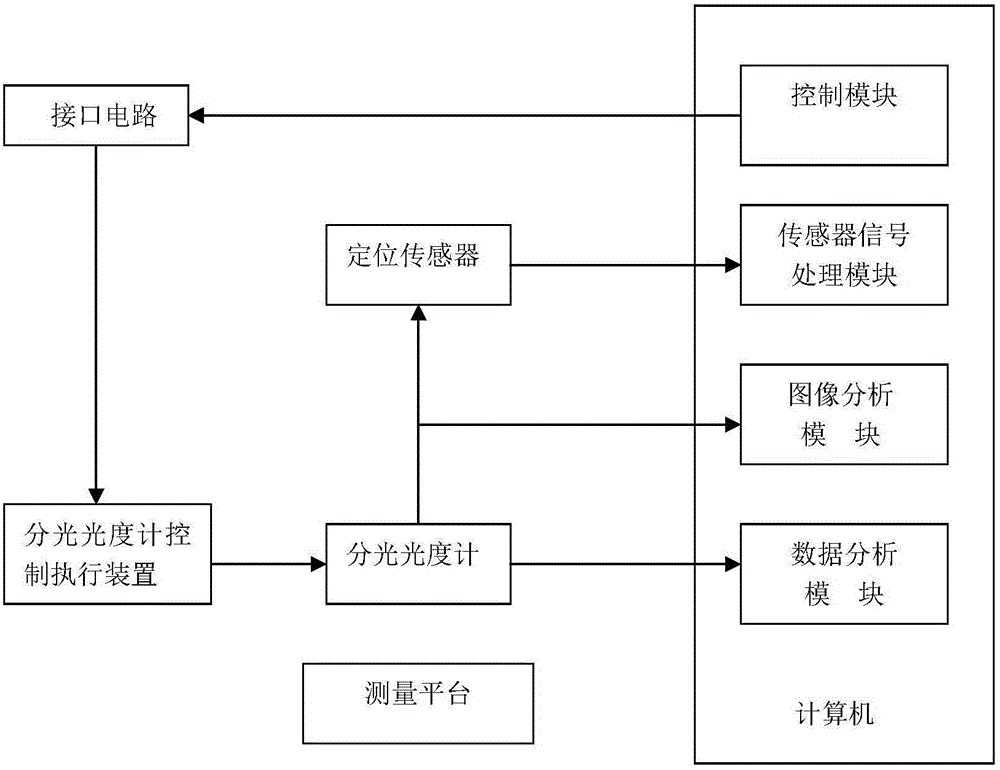

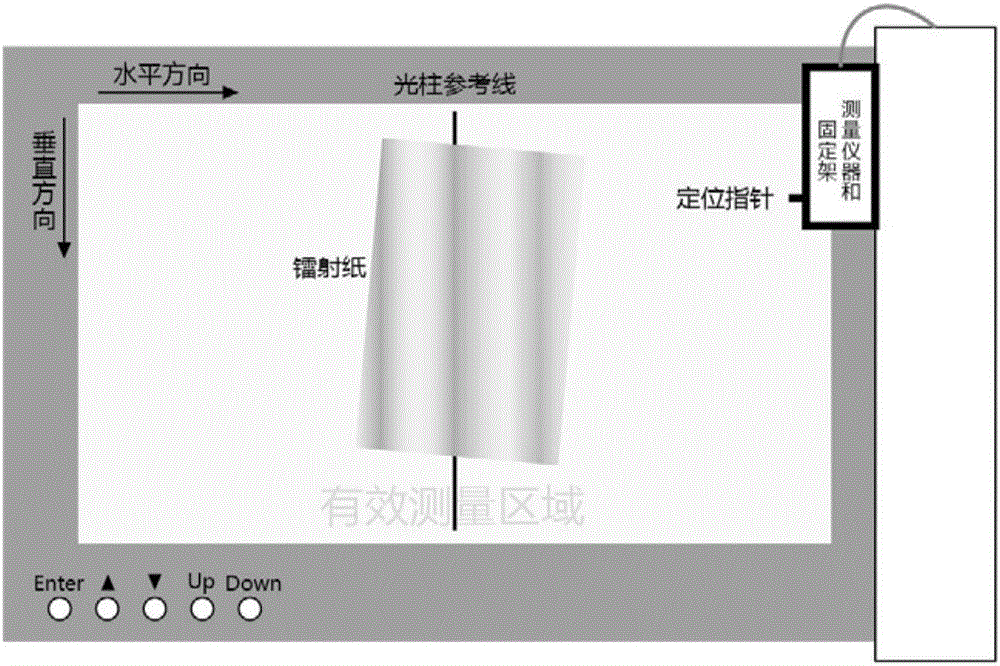

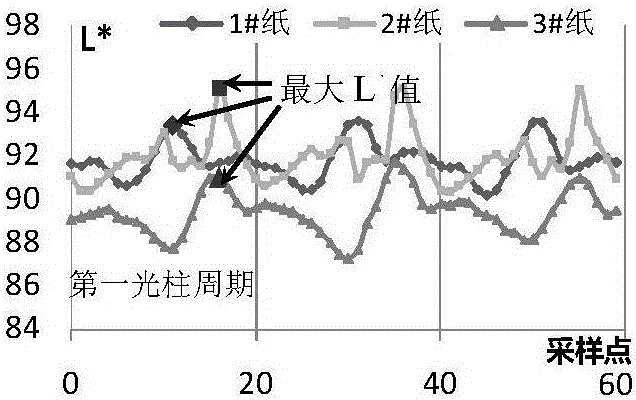

Light pole laser paper and printed matter color difference measurement method

ActiveCN106052876AFully reflectAccurately reflectColor measuring using electric radiation detectorsReverse orderTest sample

The invention relates to light pole laser paper and a printed matter color difference measurement method. a color measurement automatic detection system is adopted, and in the case of measurement, the light pole direction of the light pole laser paper is vertical to the horizontal direction of a measurement platform; the distance between adjacent sampling points of a color measurement instrument in the horizontal direction of the measurement platform and the number are set, and color information of a sample at different positions is measured; in raw chroma data of a standard sample and a test sample and turnover chroma data obtained by arranging sampling point data in a reverse order, sampling points with the maximal L<*> value, the a<*> value and the b<*> value in a first light pole period are found out, and with the sampling points as reference, all chroma values are translated; and color differences and average color difference values are calculated, different alignment modes are taken to calculate the minimal color different value in the obtained average color difference value to serve as the final color different value for the standard sample and the test sample. All to-be-tested samples are unified to be positioned to corresponding positions on the light pole laser paper for sampling and comparison, and the measurement precision is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com