Light supplementary component and electronic equipment

A technology of electronic equipment and components, which is applied in the field of light source application, and can solve the problem of insufficient fill light brightness of fill light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

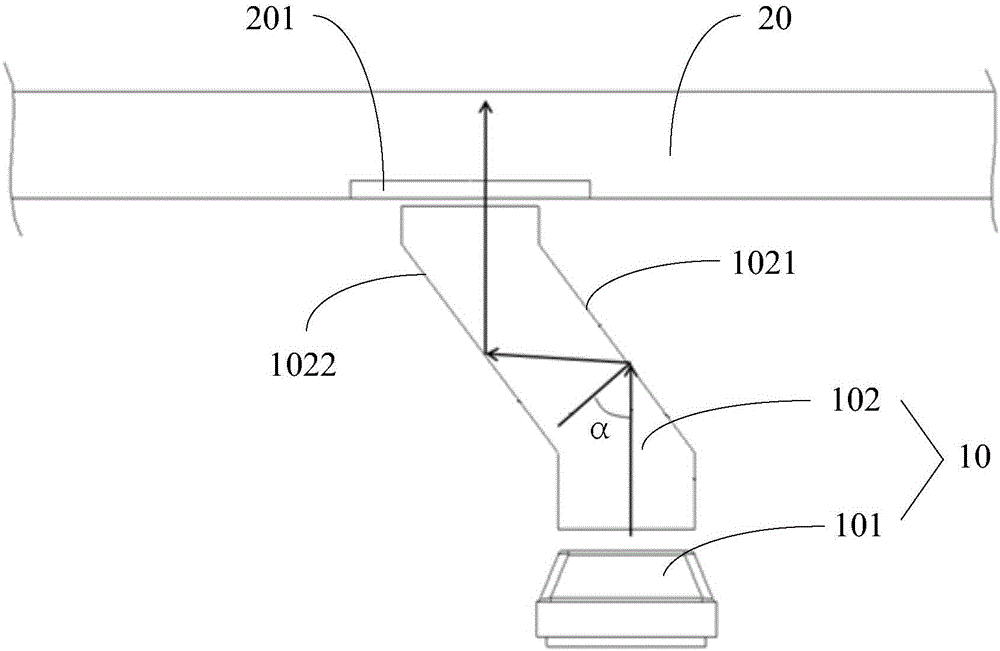

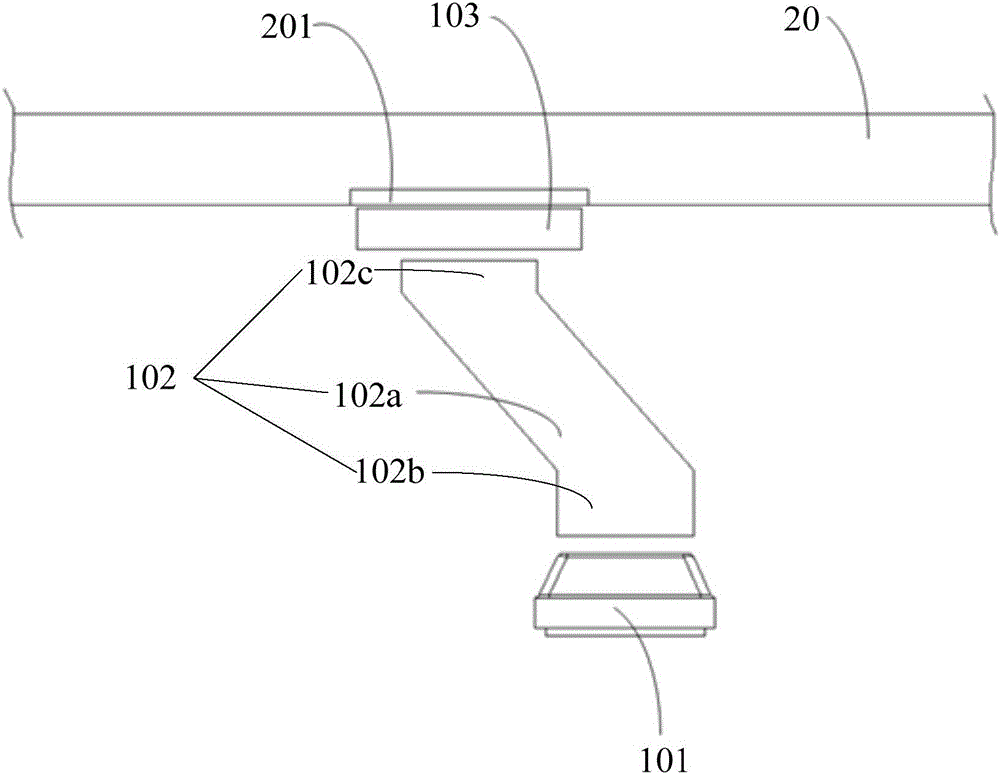

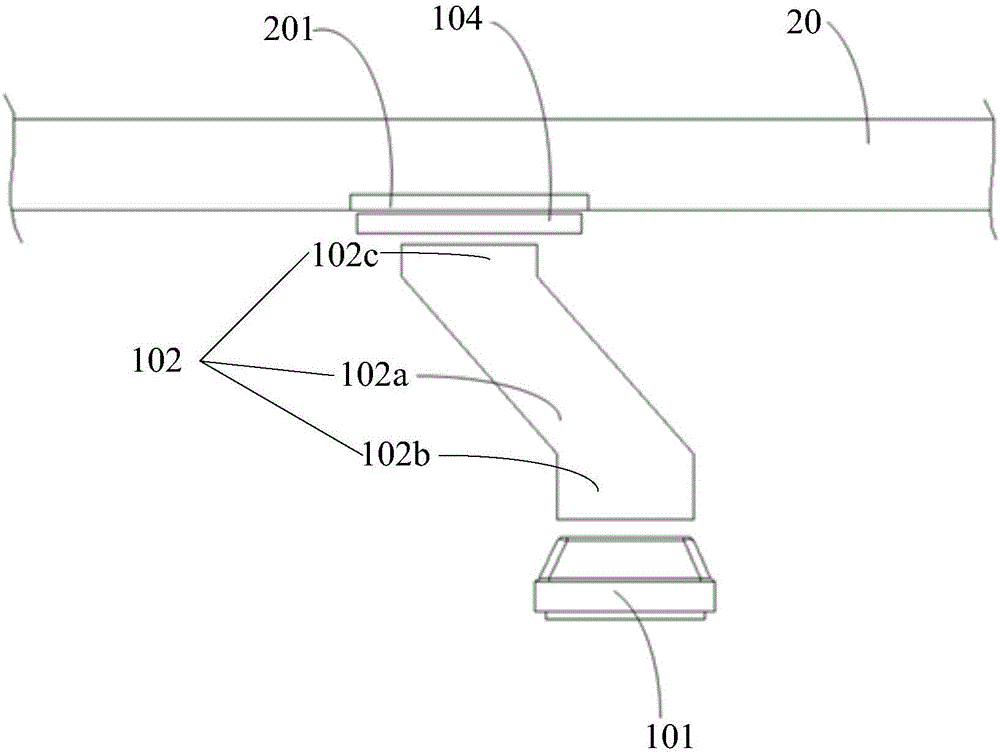

[0016] refer to figure 1 and figure 2 , provides an assembly structure diagram of the supplementary light assembly of the present invention. The supplementary light assembly 10 provided by the embodiment of the present invention is applied to electronic equipment. The supplementary light assembly 10 includes a light source 101 and a light guide column 102. The first end of the light guide column 102 is arranged facing the light source 101, and the second end of the light guide column is directed towards the output light of the electronic device. The hole 201 is set so that the light emitted from the light guide column 102 exits the electronic device through the light exit hole 201, and the light guide column 102 is provided with a first reflective surface 1021 and a second reflective surface 1022;

[0017] The light from the light source 101 enters from the first end of the light guide bar 102 , is reflected by the first reflective surface 1021 and the second reflective surf...

no. 2 example

[0029] see Figure 4 , Figure 4 It is a structural diagram of the electronic equipment provided by the implementation of the present invention.

[0030] Such as Figure 4 As shown, the electronic device 400 includes a radio frequency (Radio Frequency, RF) circuit 410 , a memory 420 , an input unit 430 , a display unit 440 , a processor 450 , an audio circuit 460 , a communication module 470 , a power supply 480 and a supplementary light assembly 490 .

[0031] Optionally, the supplementary light assembly 490 includes a light source and a light guide post, the first end of the light guide post is set facing the light source, and the second end of the light guide post is set facing the light exit hole, so that the light emitted from the light guide post exits the electronic device through the light exit hole, A first reflective surface and a second reflective surface are arranged in the light guide column;

[0032]Wherein, light from the light source enters from the first en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com