Pneumatic double-plate optical fiber tester for LED (Light Emitting Diode) indicating lamp

A technology of LED indicator light and tester, which is applied in the direction of lamp testing, instrumentation, measuring electricity, etc., can solve the problems of high manpower consumption, high cost, cumbersome test operation process, etc., to improve production efficiency, simplify operation procedures, and improve test efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

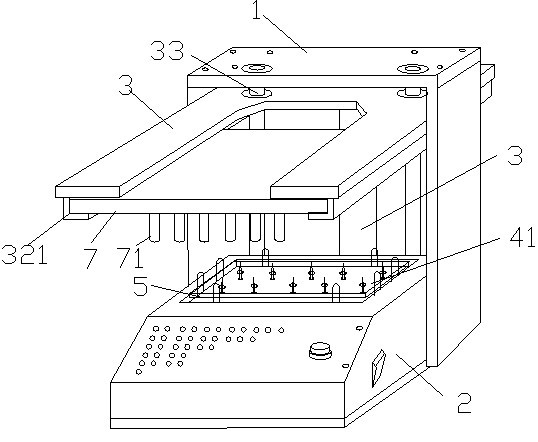

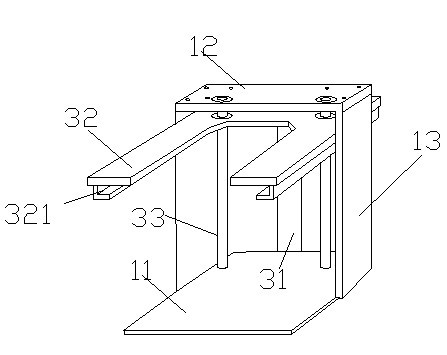

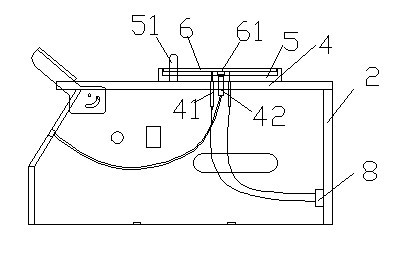

[0020] Such as Figure 1 to Figure 5 As shown, a pneumatic double-plate optical fiber LED indicator light tester includes a test console and a test circuit. The test console is composed of a support 1, a control box 2 and a pneumatic device 3; the support 1 is composed of a base plate 11, an upper cover plate 12 and The side plate 13 is formed; with the bracket 1 as the support body, the control box 2 is fixed on the bottom plate 11 of the bracket 1; the inner side of the control box 2 is provided with a test needle bed 4, and the upper part of the test needle bed 4 is the positioning of the circuit board (PCB) plate 5, the positioning plate 5 is inlaid on the opening on the top of the box body, the surface of the positioning plate 5 has a structure through hole and a positioning column 51, the positioning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com