Light conductive plate and back light module

A technology of backlight module and light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of unsuitable mold design simplification requirements, small microstructure size, etc., to eliminate light beam phenomenon, design simplification, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

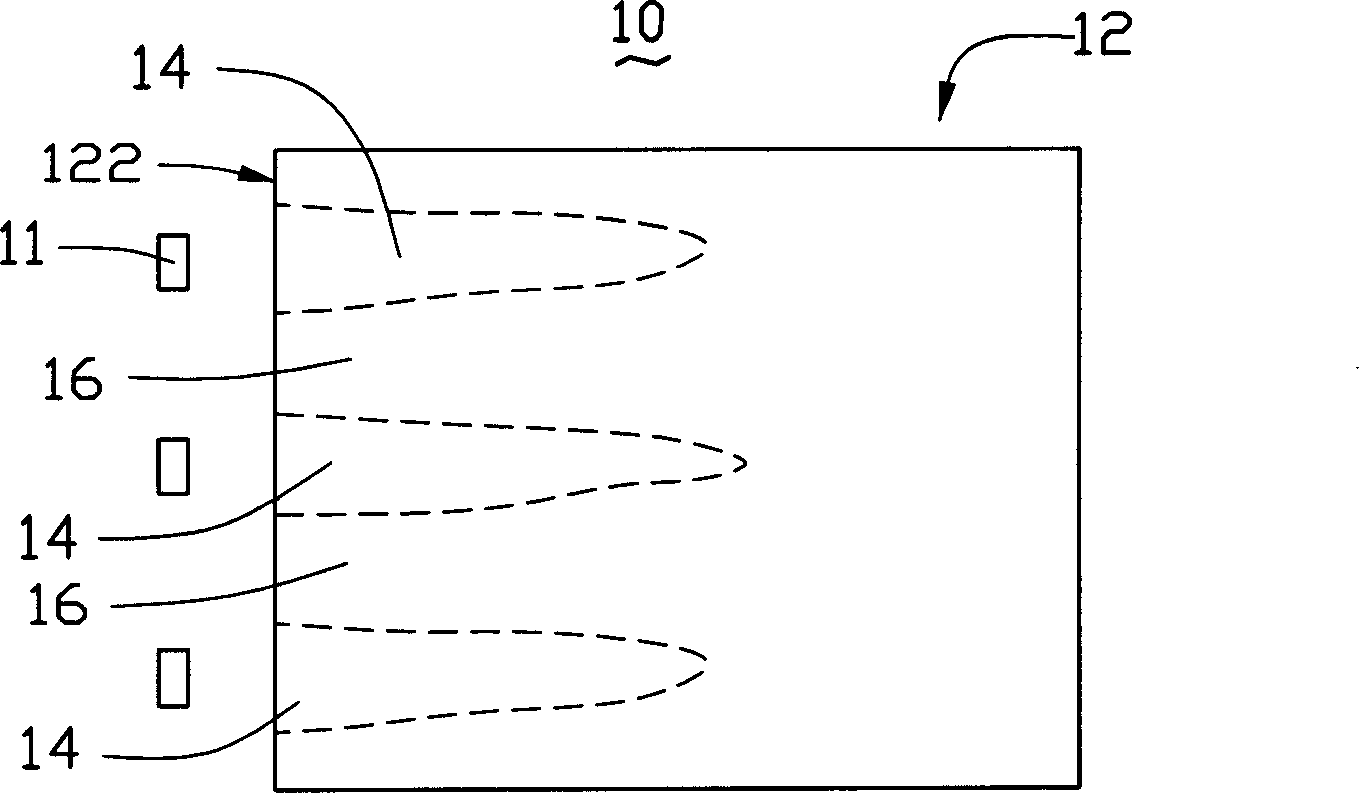

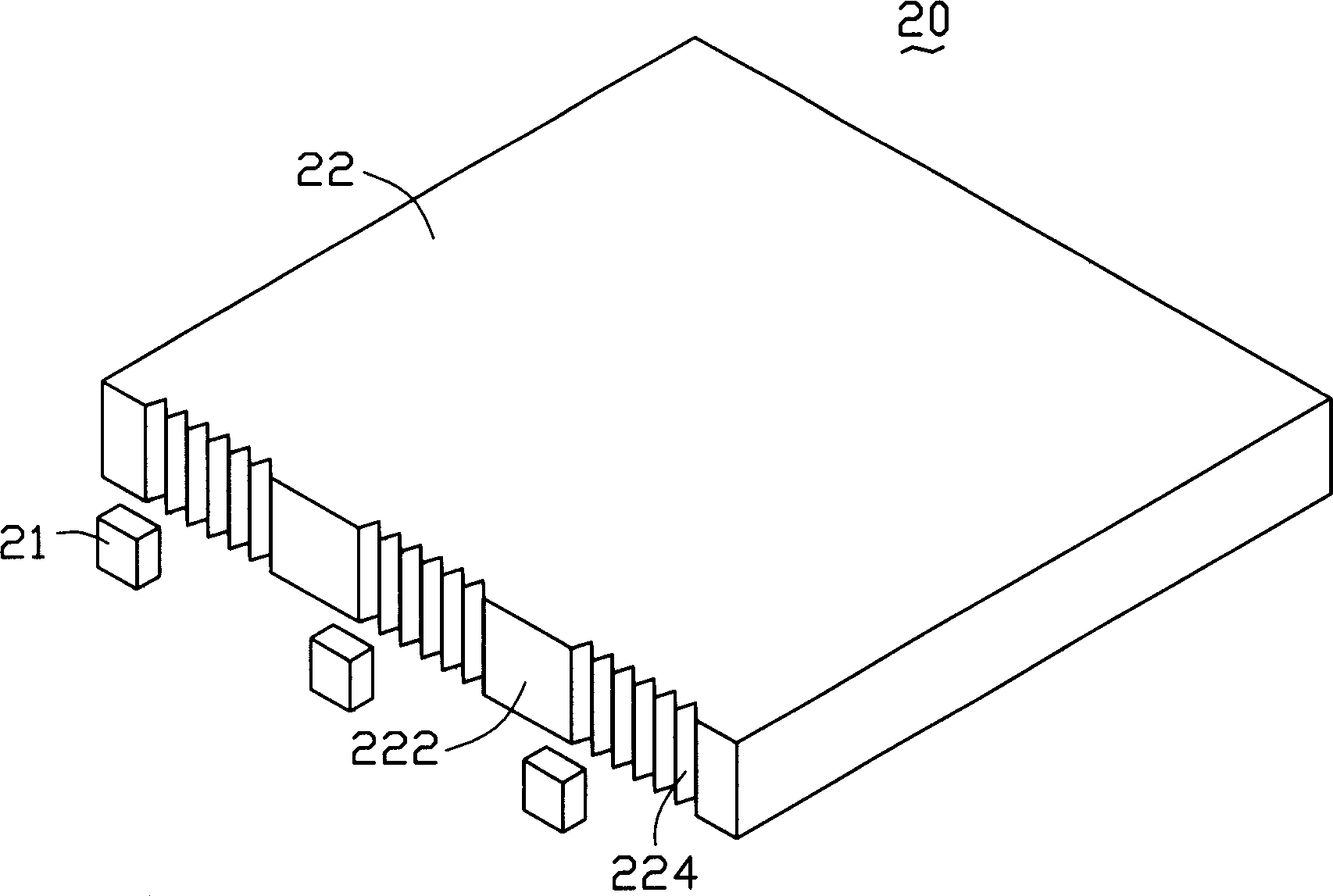

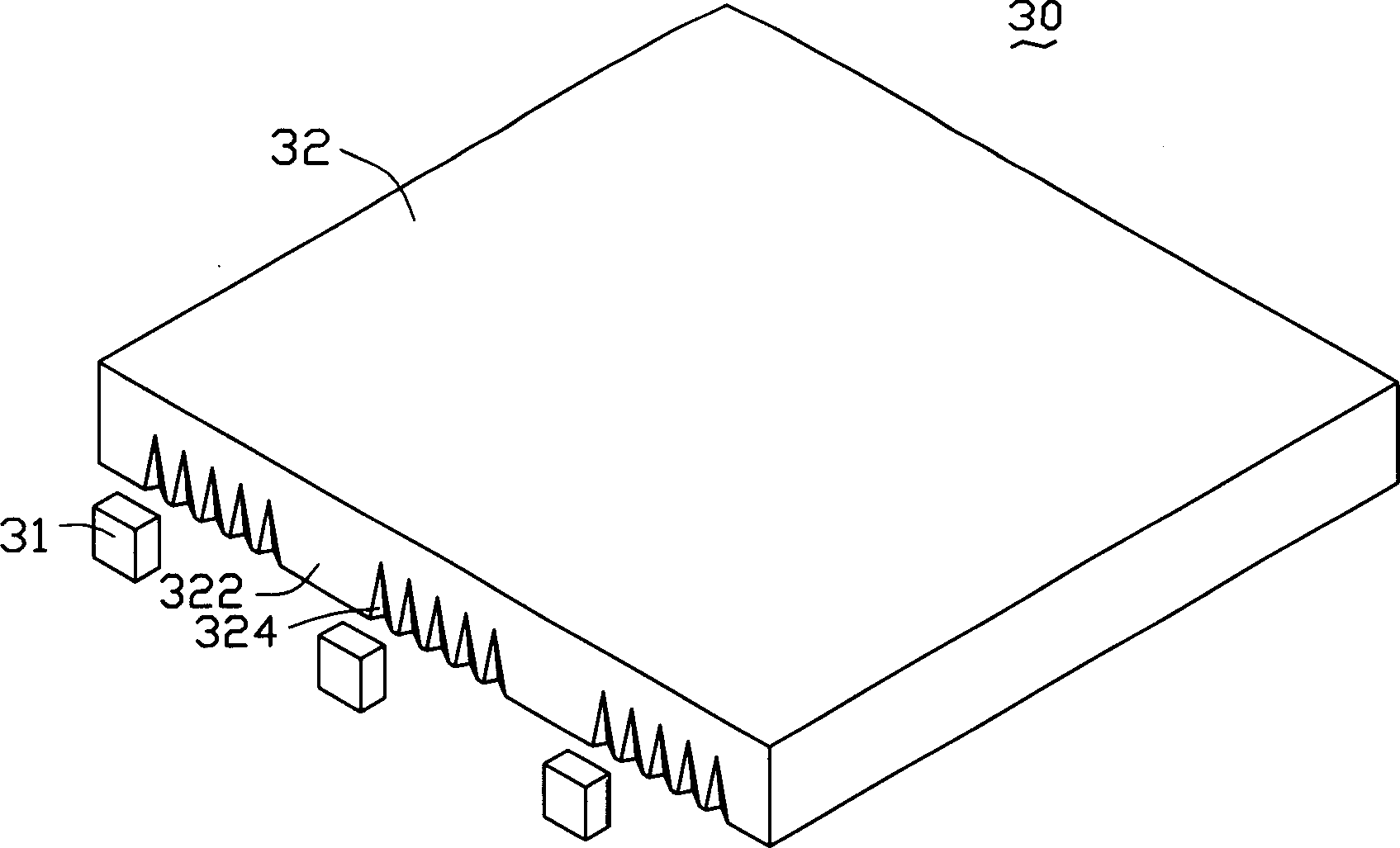

[0026] See Figure 4 , the first embodiment of the present invention provides a backlight module 40 , which includes a plurality of LED point light sources 41 , a light guide plate 42 and a plurality of reflectors 43 . The light guide plate 42 includes a light incident surface 422, a light exit surface 425 connected to the light incident surface 422, and a bottom surface 426 opposite to the light exit surface 425. Protrusion 424, the protrusion 424 is a triangular cylinder arranged along the direction perpendicular to the axis of the light incident surface 422, which protrudes outward from the light incident surface 42, and a multi-layer reflective film is formed on the surface of each protrusion 424 (not shown in the figure) Show). Each LED point light source 41 is correspondingly close to each protrusion 424 . Each reflector 43 has a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com