Light-emitting diode (LED) bulb

A technology of LED bulbs and LED chips, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of affecting cost and reliability, low luminous efficiency, large volume, etc. Good luminous efficiency and heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

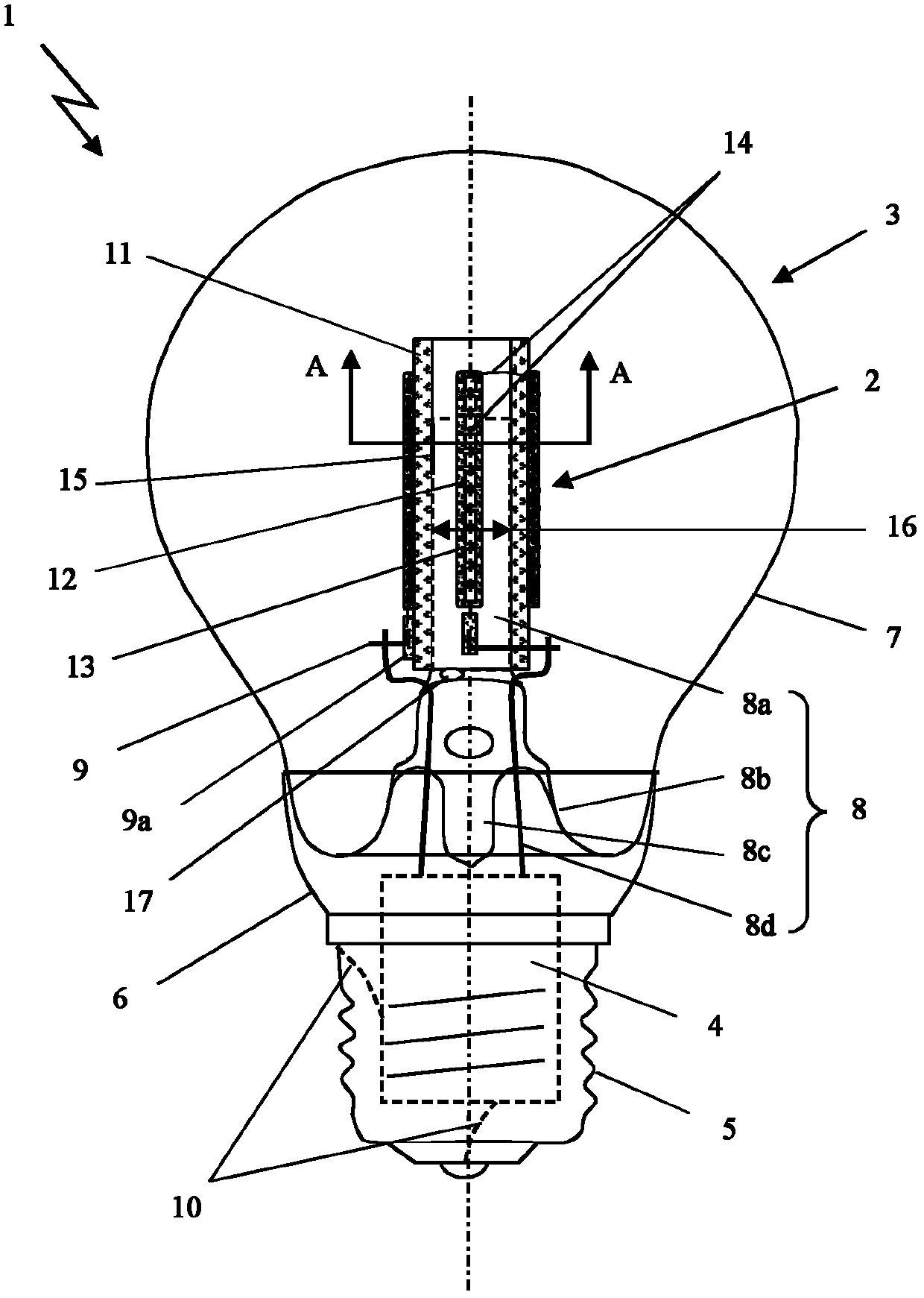

[0037] figure 1 It is a structural schematic diagram of an embodiment of the LED light bulb of the present invention.

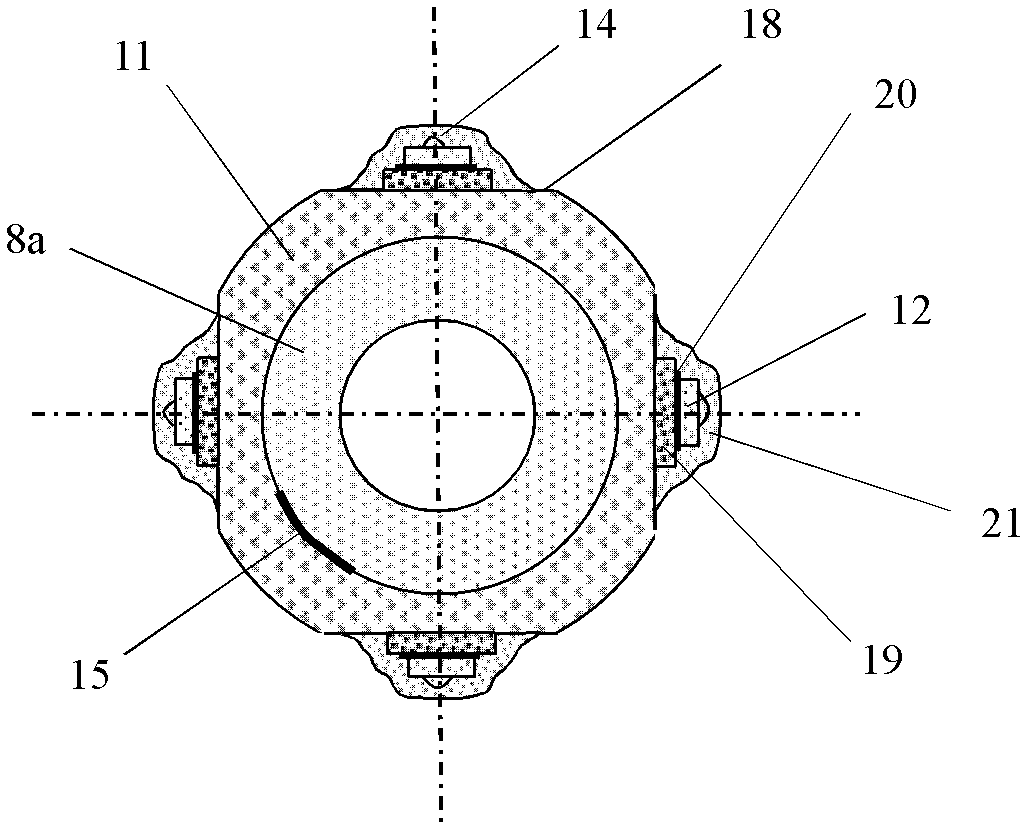

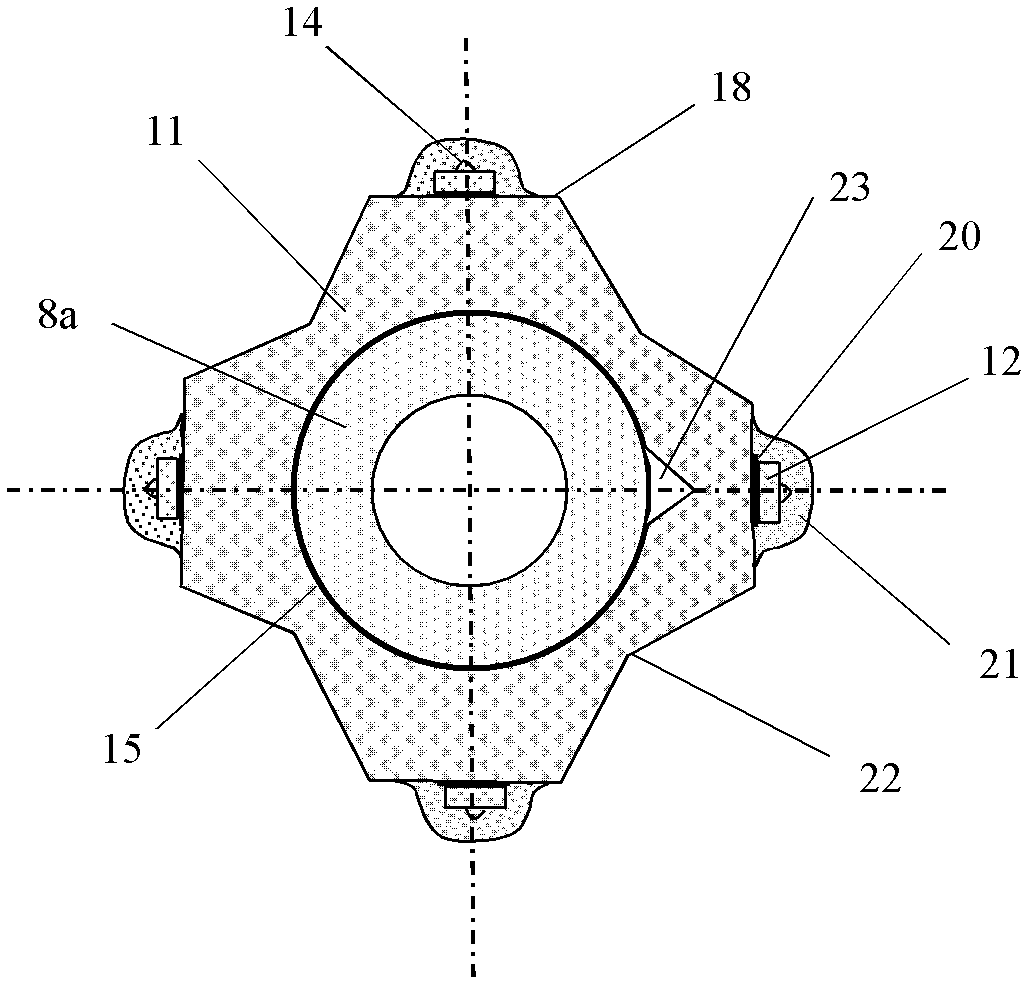

[0038] The LED light bulb of this embodiment comprises: a light-transmitting bulb 3, an LED light source 2, a stem 8 with a pillar 8a, a trumpet tube 8b, an exhaust pipe 8c and an electric lead-out wire 8d, an LED driver 4 and An electrical connector 5; the light-transmitting bulb shell 3 and the stem 8 are vacuum-sealed to form a vacuum-tight bulb shell 7, and the bulb shell 7 is filled with a gas with low viscosity and high thermal conductivity; the LED light source 2 is composed of at least one transparent LED lighting column; the transparent LED lighting column includes: a high thermal conductivity transparent tube 11 inserted on the outer surface of the pillar 8a, and the outer surface of the high thermal conductivity transparent tube 11 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com