Light pole laser paper and printed matter color difference measurement method

A measurement method and printing technology, applied in the direction of optical radiation measurement, color measurement using electric radiation detectors, color measurement devices, etc., can solve the problems of poor repeatability and inability to better reflect the overall quality of paper or printed matter, and achieve The effect of accurate color information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

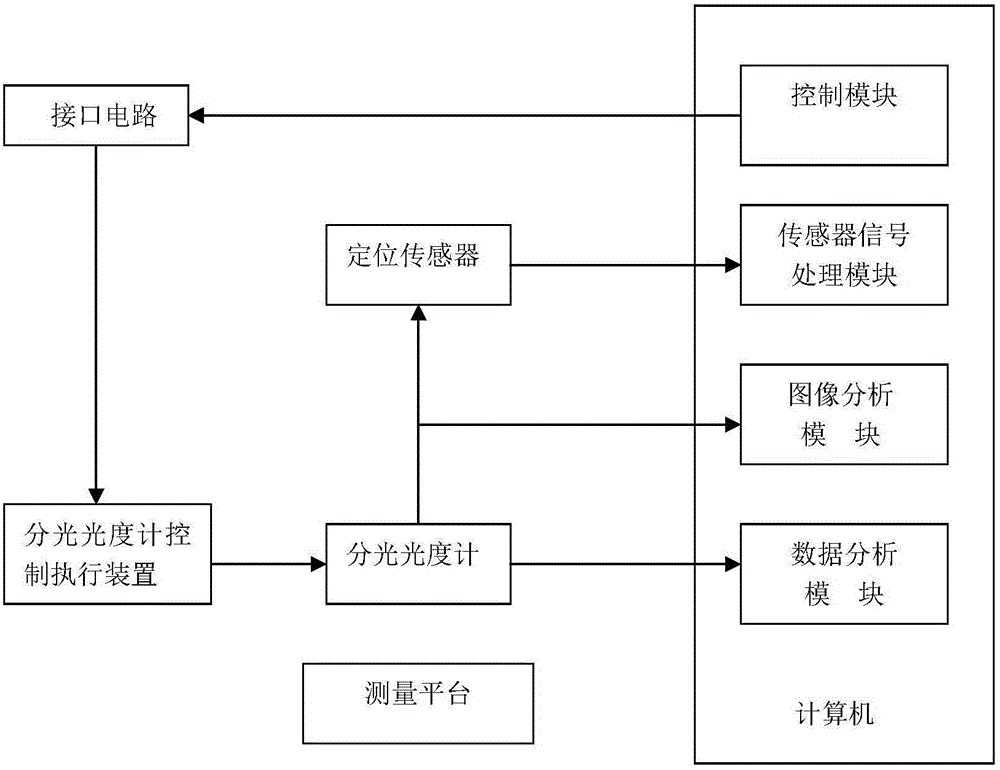

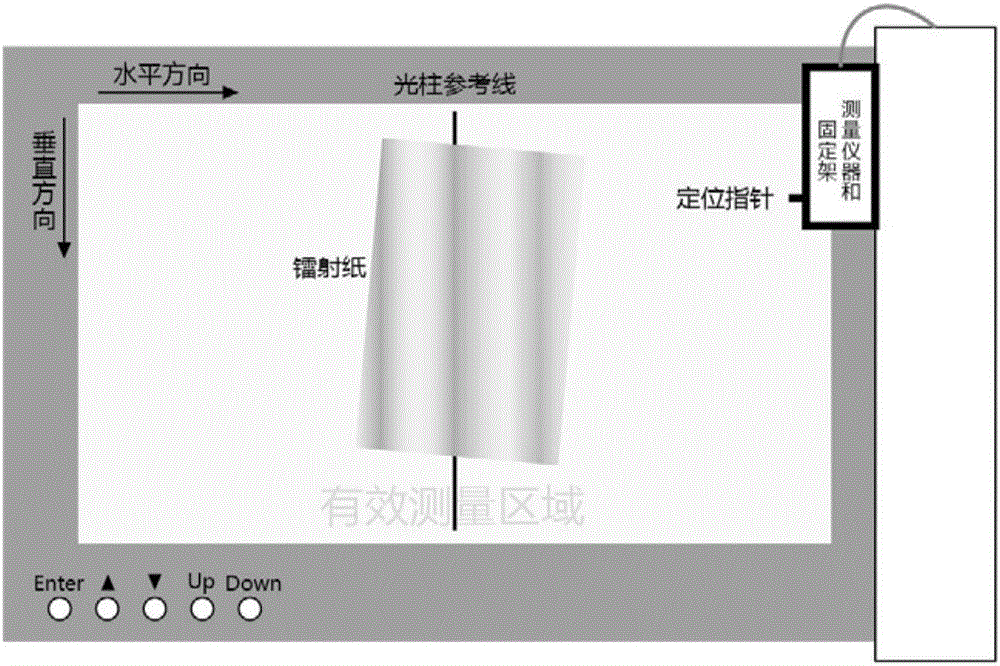

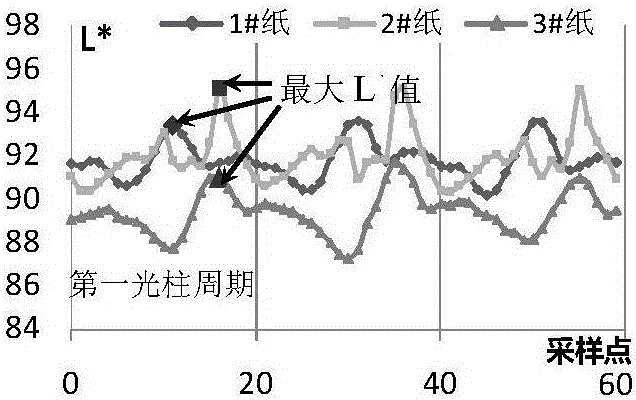

[0031]The present invention needs to collect the color and chromaticity values of the standard sample and the test sample respectively. First, the standard sample (or test sample) needs to be placed and fixed on the automatic measurement platform, and the operator should try to place the sample at the level of the light column and the measurement platform direction perpendicular to each other. Then determine the sampling point interval and the number of sampling points of the color measuring instrument on the sample sheet, and the measurement system accurately controls the position of the measuring point of the color measuring instrument on the sample, so that the color measuring instrument can measure along the X and Y directions at a certain step length , to automatically measure color values at different locations on the paper. Adjust the collected chromaticity values of the standard sample and the test sample to the same periodic position of the light column to compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com