High-power LED road lamp

A technology for LED street lamps and LED lamp beads, which is applied in circuit layout, cooling/heating devices of lighting devices, outdoor lighting, etc., can solve the problems of high cost, inconvenient installation, complex structure, etc., and achieve high efficiency, sufficient reflection, and expansion Effects of lighting areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

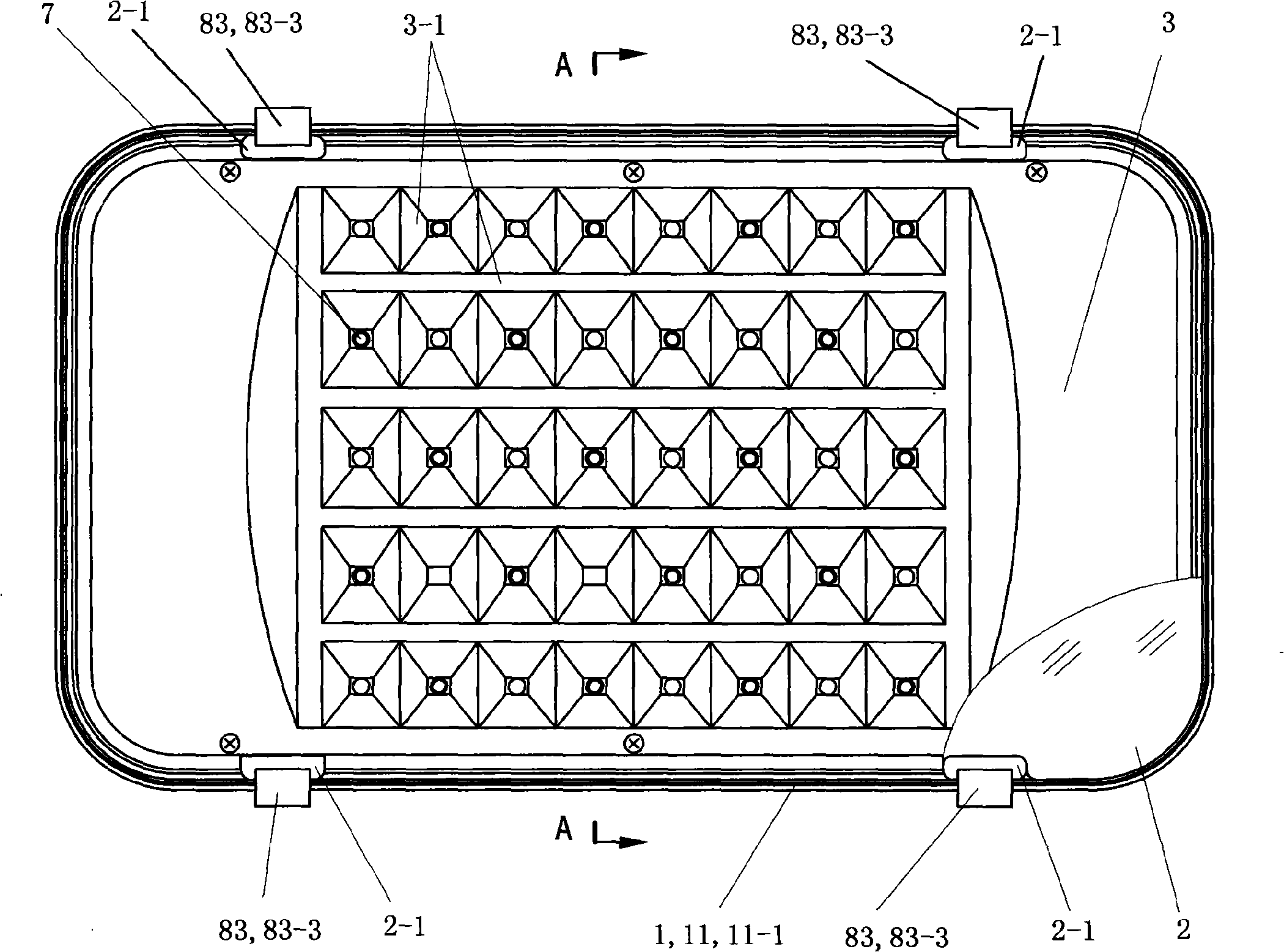

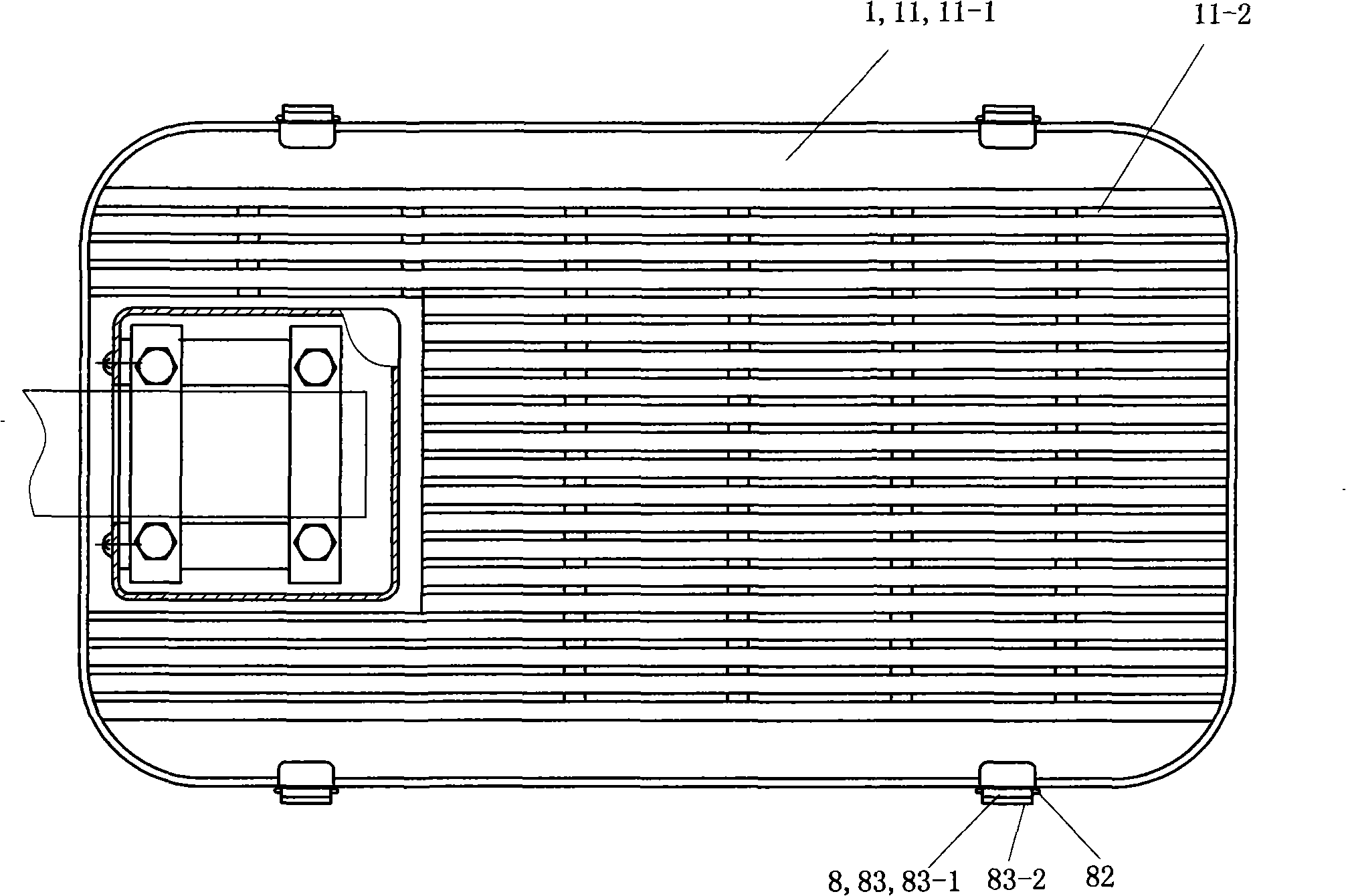

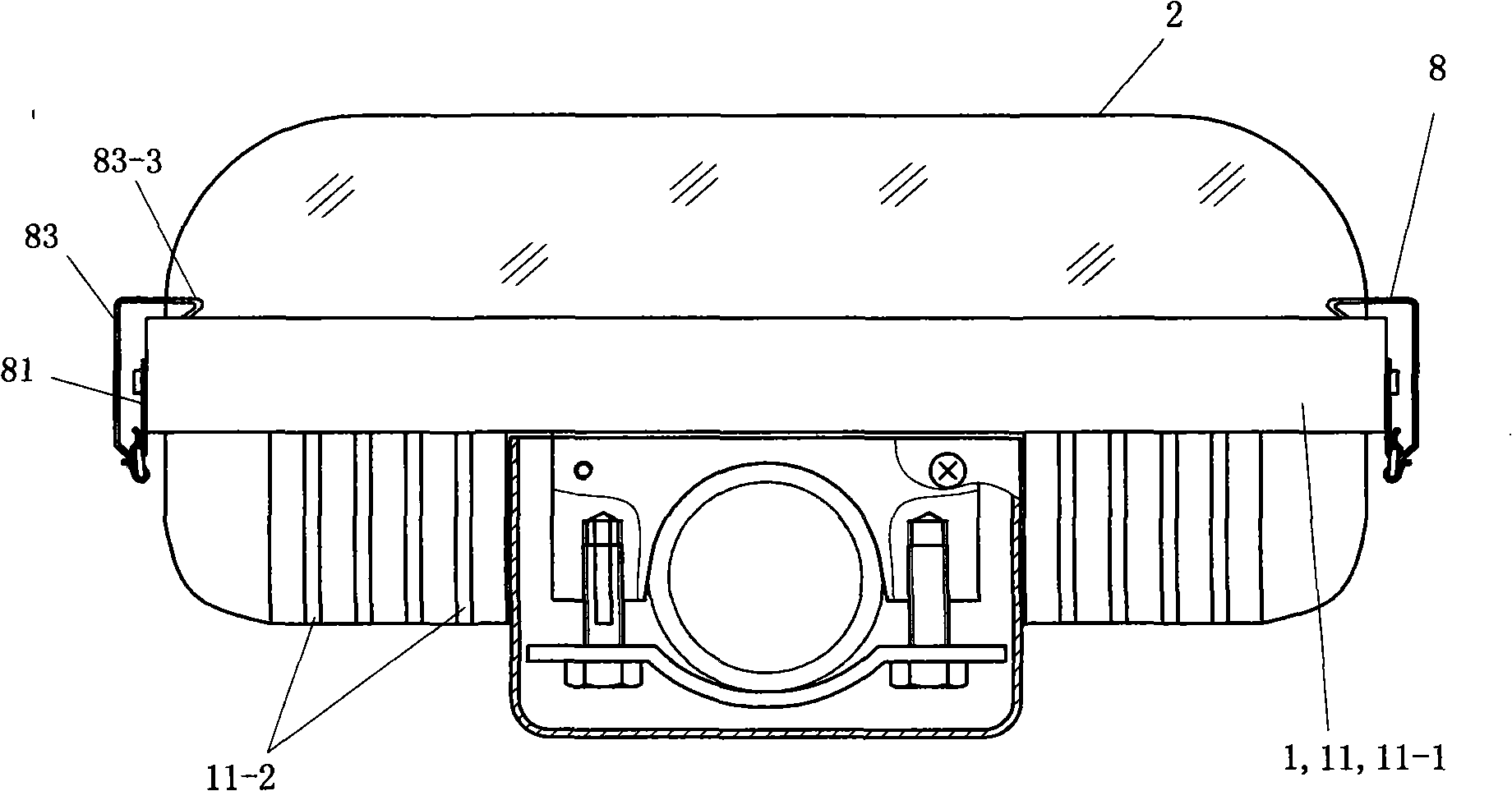

[0026] See Figure 1 to Figure 5 , Figure 8 As shown in Fig. 9, the high-power LED street lamp of this embodiment includes: an aluminum metal heat dissipation base 1, a transparent cover 2, a reflective panel 3, an aluminum substrate 4, an insulating barrier 5, an LED power drive circuit 6 and an LED bead array 7 . The LED lamp bead array 7 is composed of 5 rows of LED lamp beads. Both the aluminum substrate 4 and the insulation barrier 5 are strip-shaped, and each has five strips.

[0027] See Figure 4 The heat dissipation base 1 has an arcuate column housing 12-1, and the LED bead array 7 is arranged on the arcuate surface of the arcuate column housing 12-1.

[0028] See Figure 7 , Figure 4 and Figure 5 , The reflective panel 3 is an aluminum metal panel formed by one stamping after being coated with a reflective film. The reflective panel 3 has an arcuate surface ( Figure 4The reflective part 3-1 matched with the circular arc face upward); the reflective part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com