Patents

Literature

1134results about How to "Thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

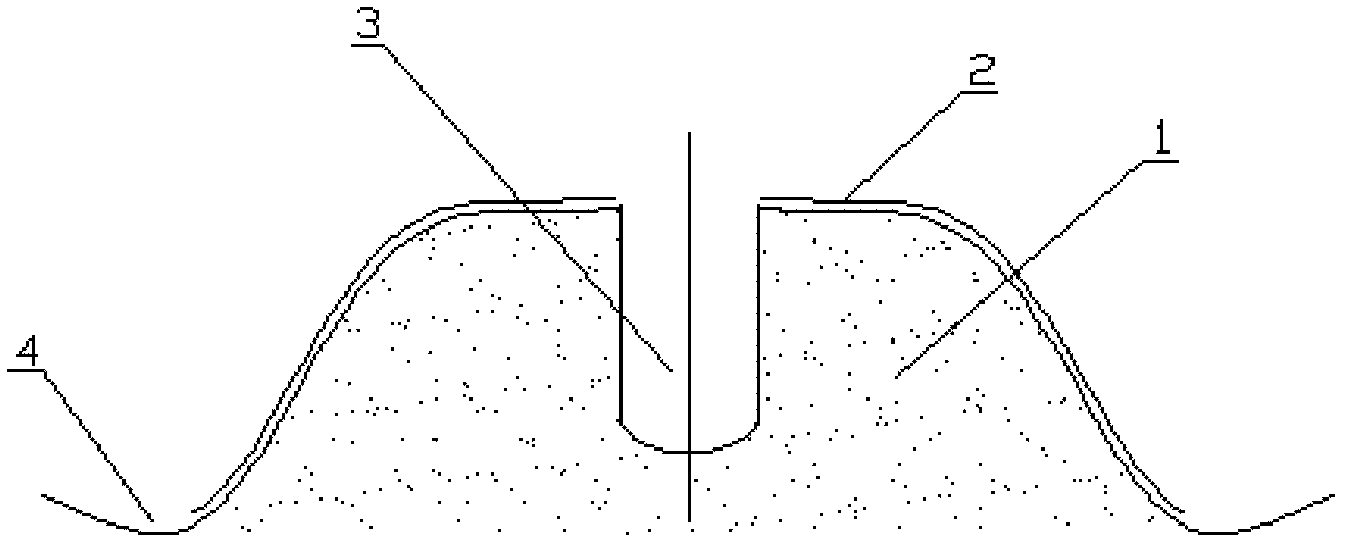

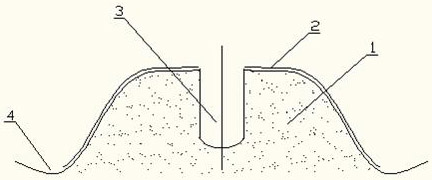

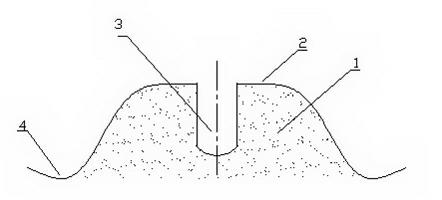

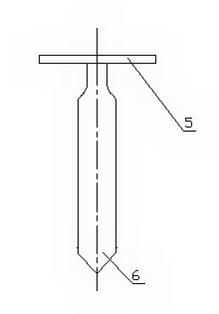

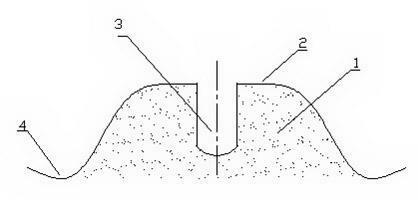

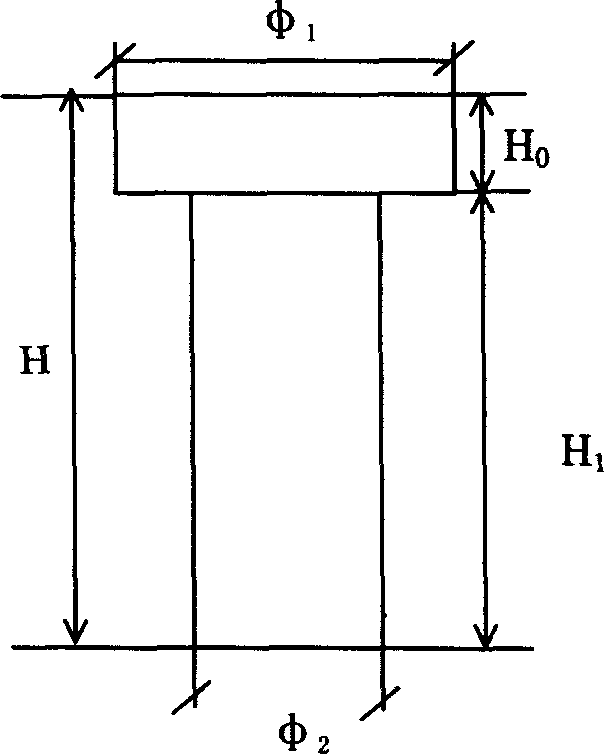

Flue-cured tobacco mulch film well cellar type seedling transplanting method

InactiveCN102365918ASeedling operation is simplifiedReduce the risk of infectionHorticultureFlueCuring of tobacco

The invention relates to a flue-cured tobacco mulch film well cellar type seedling transplanting method. The method comprises the following steps: (1) preparing soil, forming ridge and coating a film; (2) selecting a transplantation period; (3) digging a transplanting well cellar; (4) transplanting tobacco seedlings; (5) spraying root-fixing water and fertilizing; and (6) filling soil and sealingthe film. The method is a technical revolution of flue-cured tobacco mulch film cultivation and has the advantages of solving the problems caused by weak tobacco seedlings in the optimal transplanting period in a flue-cured tobacco cultivation district, the problem that weather is drought in the transplanting period so as not to be beneficial to transplantation, the problem caused by irregular transplantation, the problem that transplantation schedule is slow and the problems that seedling-returning period is long and the uniformity and consistency of field tobacco plants are poor, and also reducing the generation of aphid-transmitted virus diseases in the field period. The method is suitable for cultivation of crops such as flue-cured tobacco, burley tobacco, sun-cured tobacco and the like.

Owner:TONGREN CITY COMPANY OF GUIZHOU PROVINCE TOBACCO

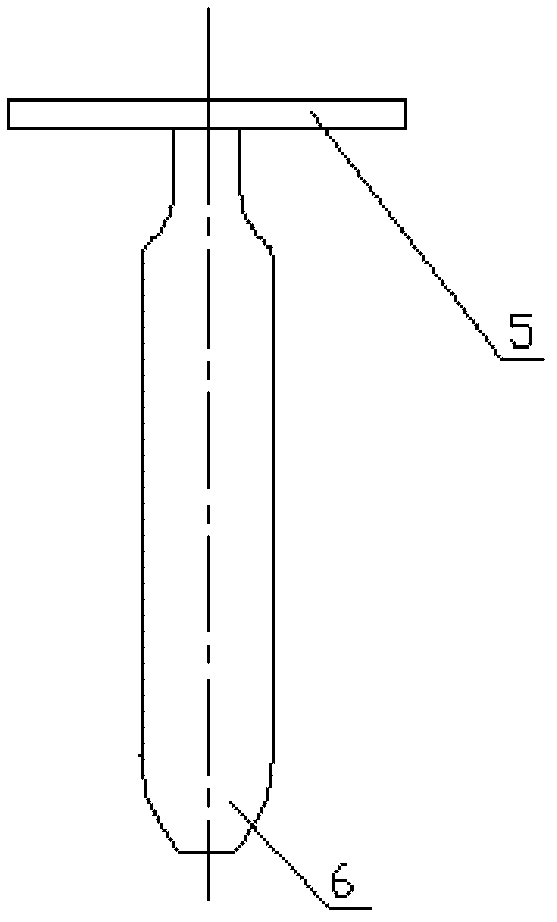

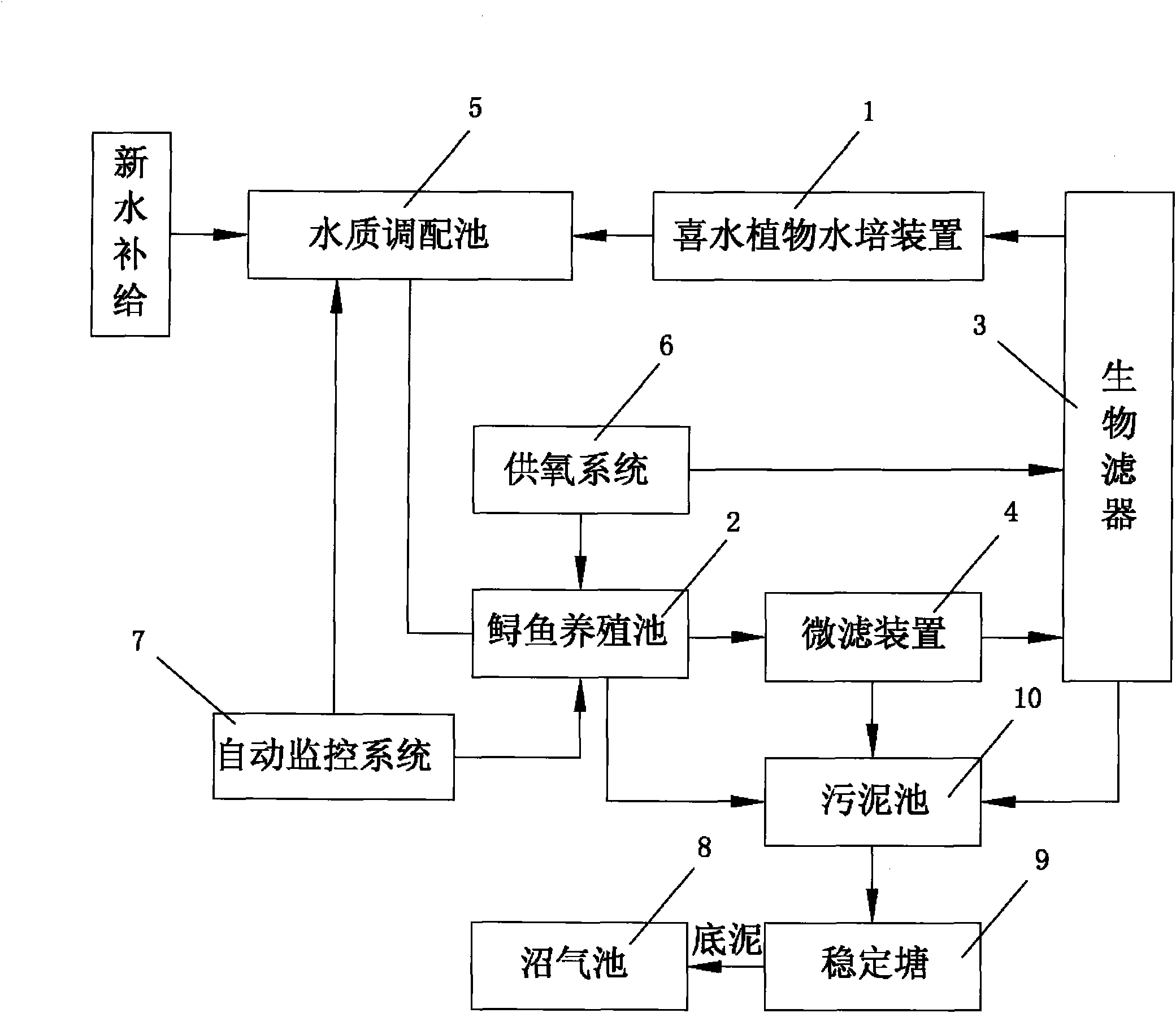

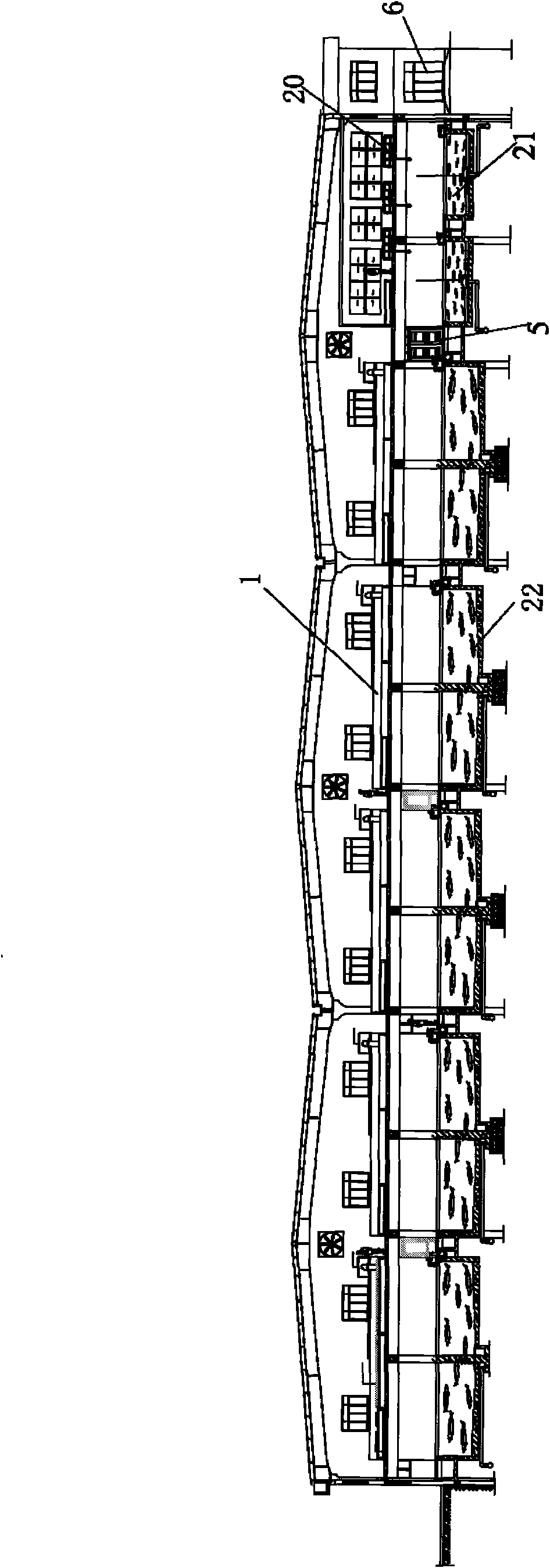

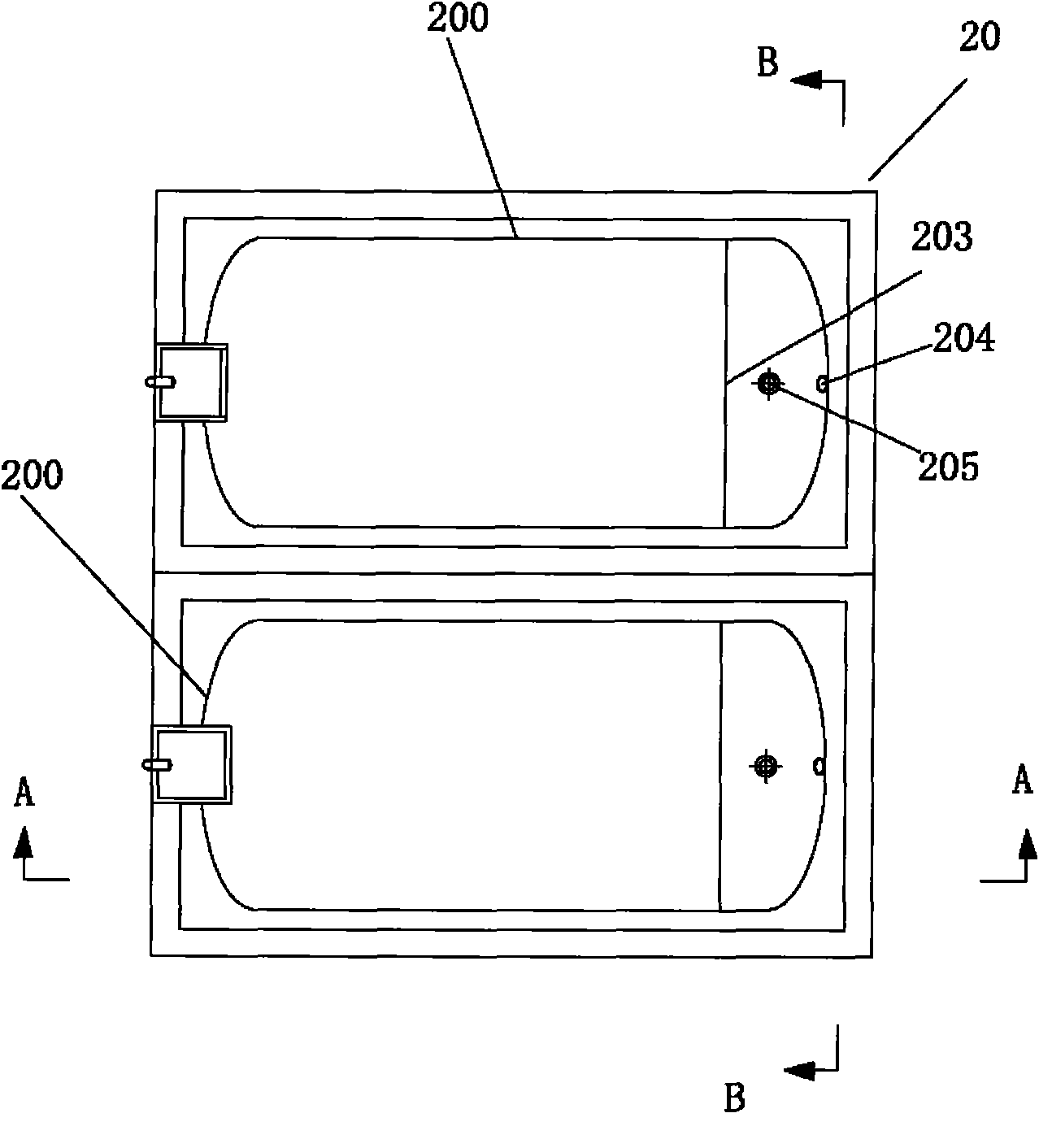

Double-layer fish and vegetable symbiotic industrial circulating water cultivating system

InactiveCN101785399AReduce energy consumption and operating costsPromote healthy and rapid growthWater/sewage treatment by irradiationClimate change adaptationBiomassWater quality

The invention discloses a double-layer fish and vegetable symbiotic industrial circulating water cultivating system. The system comprises a hydrophilous plant planting device arranged on an upper layer and a sturgeon cultivating device arranged on a lower layer, wherein one side of the sturgeon cultivating device and one side of the hydrophilous plant planting device are provided with micro-filtering devices and biological filters, and the other sides of the sturgeon cultivating device and the hydrophilous plant planting device are provided with water blending pools; water output by the sturgeon cultivating device sequentially enters the micro-filtering devices and the biological filters, and then enters the hydrophilous plant planting device; and water output by the hydrophilous plant planting device enters the water blending pools, and then circularly returns to the sturgeon cultivating device to form an enclosed circulating system. The cultivating system also comprises a cultivating system blow-off device which comprises a sludge pool communicated with the bottoms of the sturgeon cultivating device, the micro-filtering devices and the biological filters respectively, a stabilization pond communicated with the sludge pool and a biomass pool connected with the stabilization pond.

Owner:孟翔麟 +1

Grape planting technique

ActiveCN103283557AInhibition of reproductionRoot Rot PreventionFertilising methodsCultivating equipmentsVitis viniferaPolyacrylamide

The invention discloses a grape planting technique. The technique includes that before planting grape seedings, soil and grape roots are differently treated respectively, in other words, straw is laid on the soil, germicidal constituents like quicklime, paulownia sawdust, castor bean leaf powder and distillers' grains are scattered on the soil, the soil is covered by films after deep tillage and exposed to highlight, and harmful bacteria in the soil can be effectively killed, so that a good environment is provided for grape growing; the straw play a certain role in heat insulation, so that the grape roots can be prevented from cold injury in winter; the roots are dipped in slurry prepared by nitrogen-phosphorus-potassium mixed fertilizer, calcium superphosphate, urea, attapulgite, polyacrylamide, bamboo vinegar, sea mud and the like and then coated by a layer of plant ash, and the slurry has characteristics of slow releasing of the fertilizer and water retention, so that the number of fertilizing and watering can be effectively reduced, and grape planting cost can be reduced; after planting, straw powder and vermiculite are applied at the roots, soil can be improved, loss of the slurry coated at the grape roots can be prevented, and utilization rate of the fertilizer can be increased. According to the technique, safe and environment-friendly biological prevention and control methods are adopted for preventing and controlling plant diseases and insect pests, so that the plant diseases and insect pests are greatly reduced and safety and freeness of pollution are realized.

Owner:胡志权

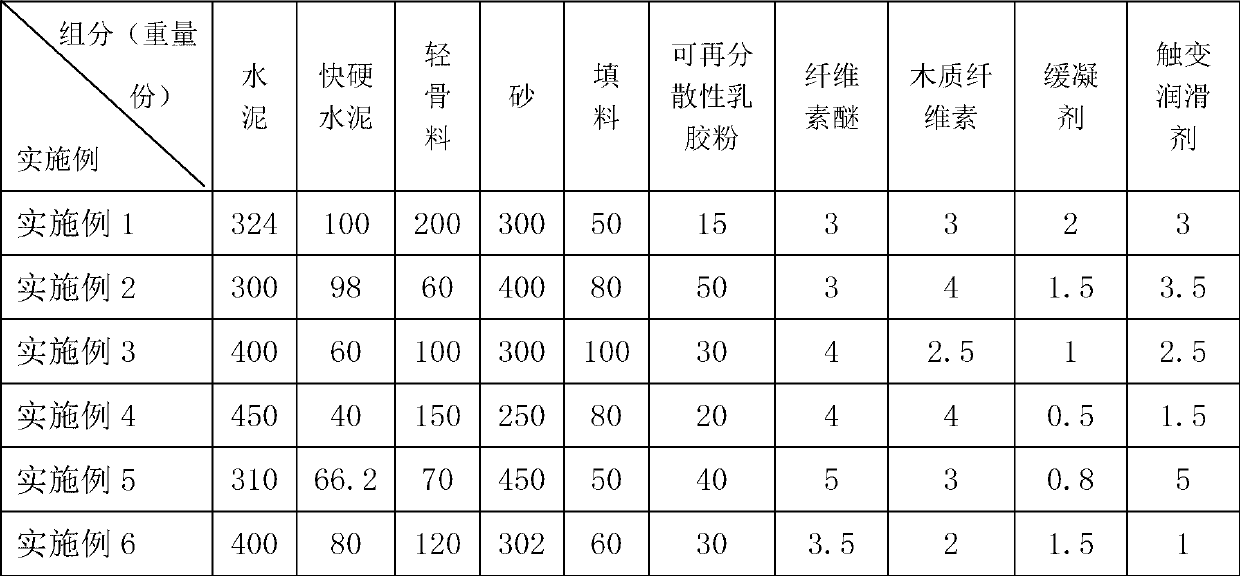

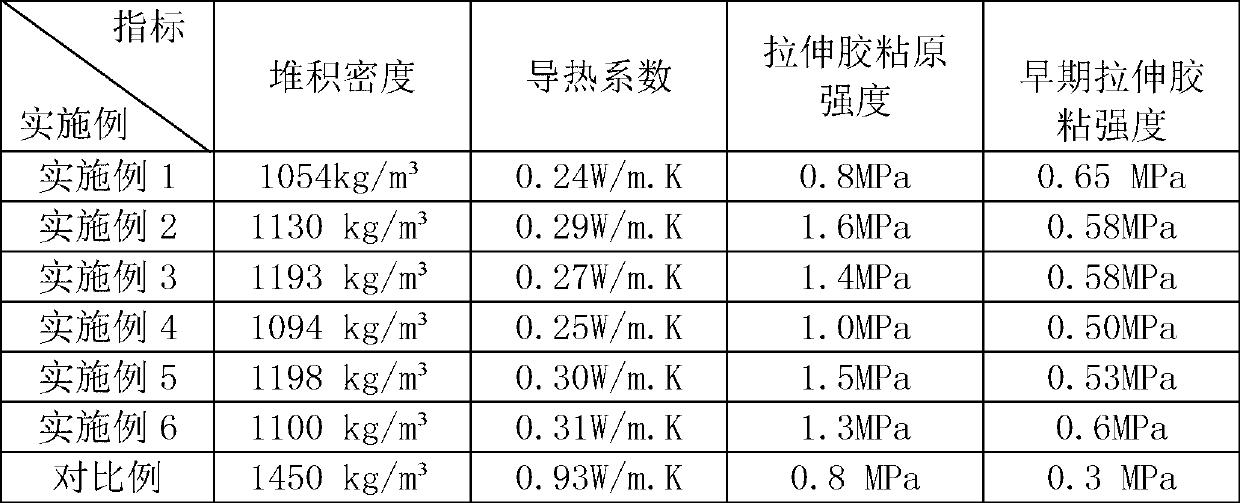

Binding mortar with light weight and high droop resistance and preparation and use methods

The invention provides binding mortar with light weight and high droop resistance, which consists of the following components in parts by weight: 300-450 parts of cement, 40-100 parts of rapid hardening cement, 60-200 parts of lightweight aggregate, 250-450 parts of sand, 50-100 parts of filling material, 15-50 parts of re-dispersible emulsion powder, 3-5 parts of cellulose ether, 2-4 parts of lignocellulose, 0.5-2 parts of retarder and 1-5 parts of thixotropic lubricant. The lightweight aggregates are glass microspheres, or hollow glass microspheres or ceramsite sand, of which the particle size is below 1.2mm and loose bulk density is below 0.8Kg / L. The invention has lower mortar density, good droop resistance, lower thermal conductivity and certain thermal insulation performance; the binding mortar can be hardened quickly, and the requirement of carrying out subsequent construction quickly is satisfied; the elastic modulus of the mortar is small, and deformation resistance is strong; and the mortar uses multiple polymer additives, and base materials have strong adaptability and strong binding performance.

Owner:深圳广田高科新材料有限公司

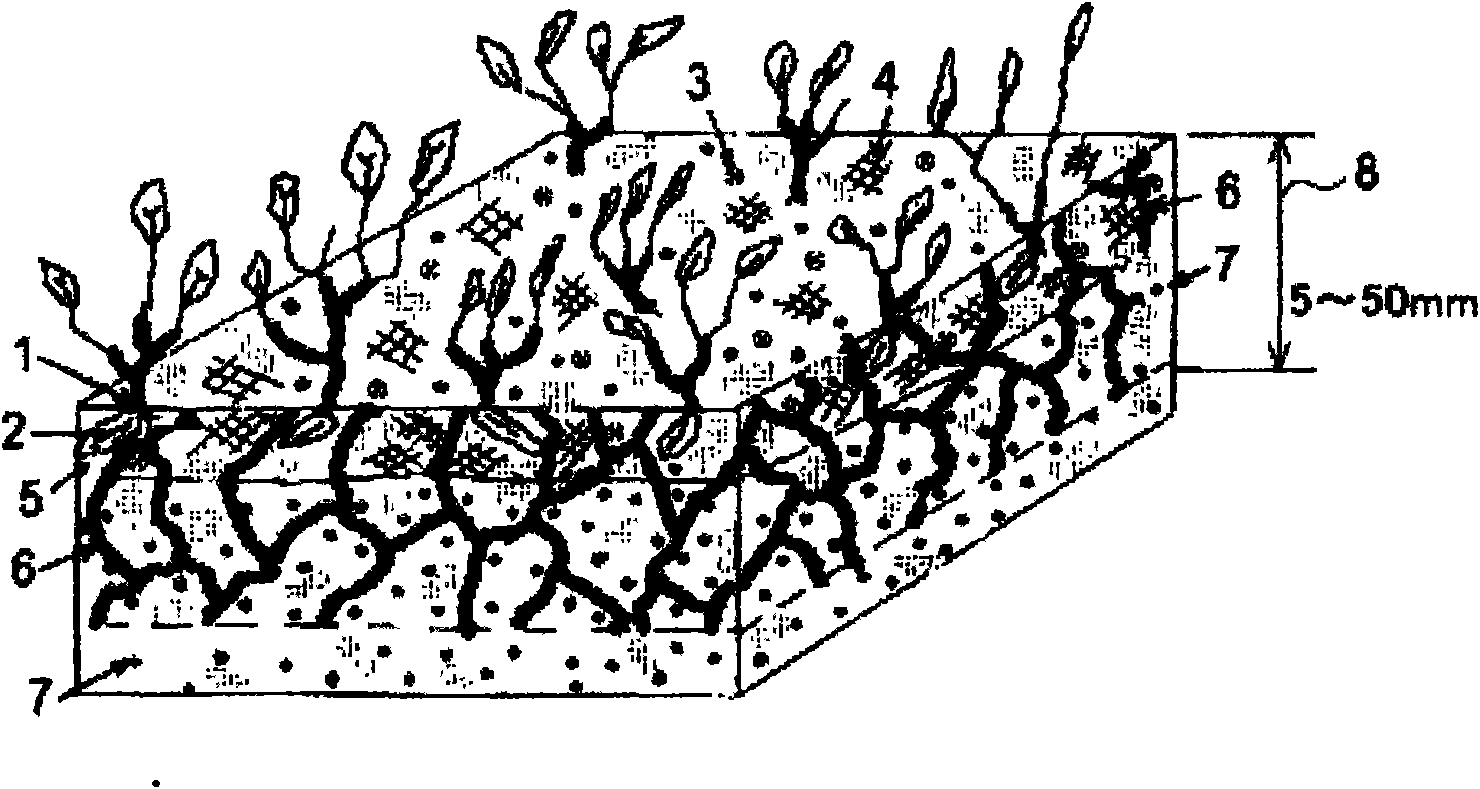

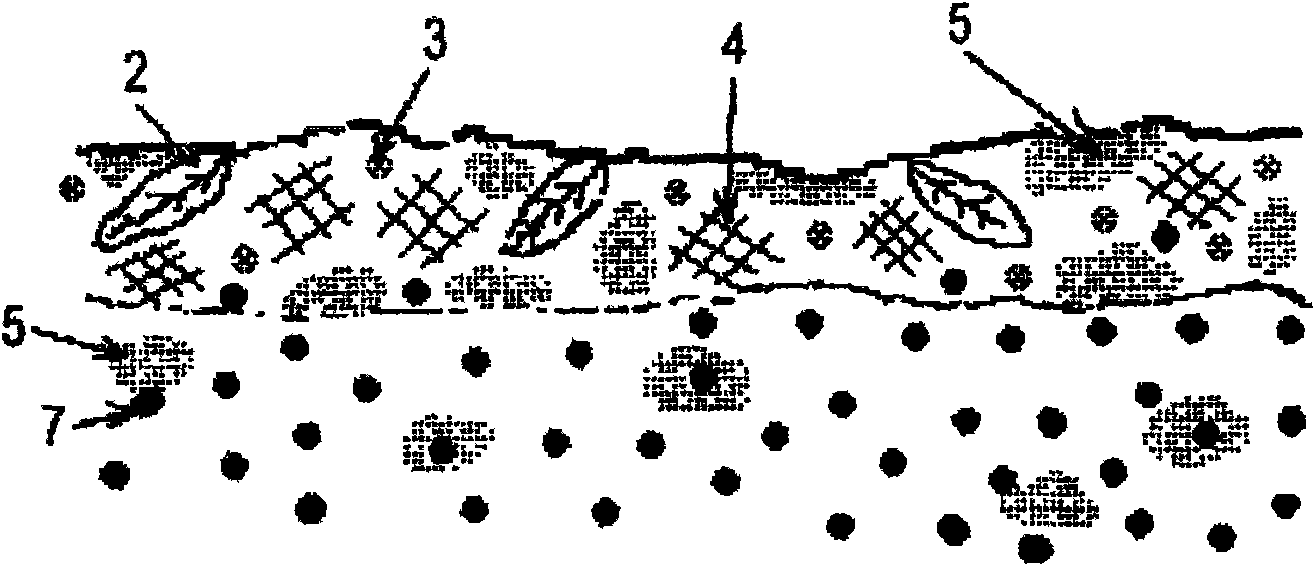

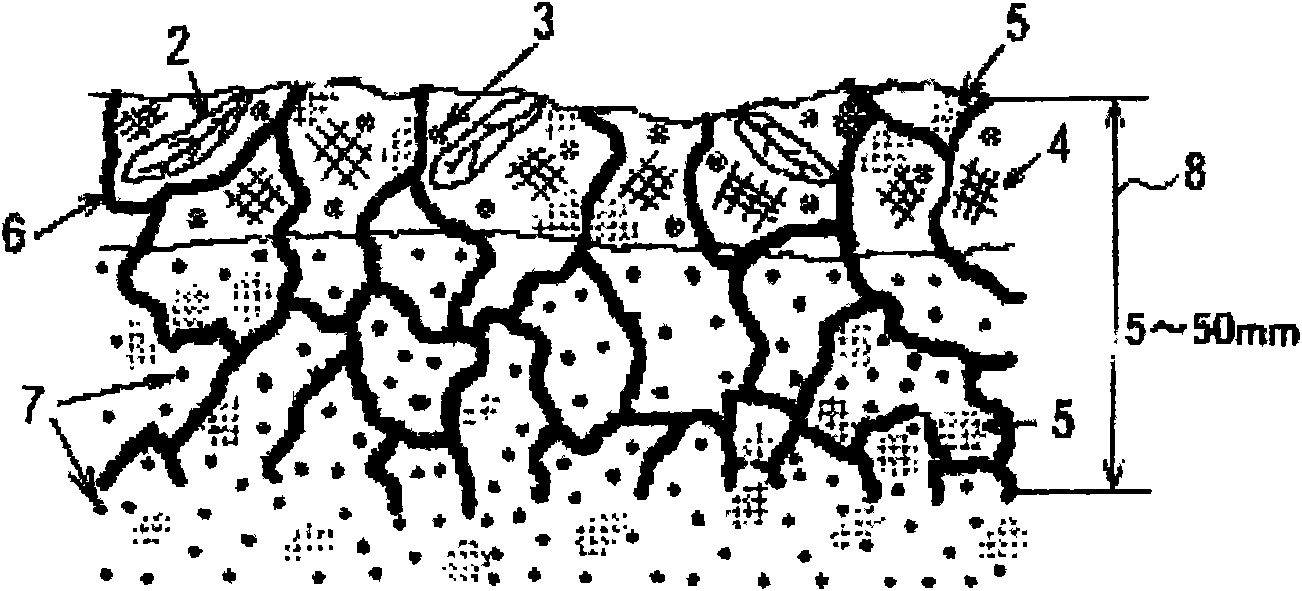

Desert control method of chemical sand-fixing greening technology based on organic composite materials

ActiveCN101548595AAvoid flowModerate thicknessClimate change adaptationAfforestationThermal insulationSoil horizon

The invention discloses a desert control method of a chemical sand-fixing greening technology based on organic composite materials, and the desert control method is characterized in that hydrophilic polyurethane resin curing agent solution is sprayed on a sand or soil layer of greening objects for sowing the vegetation for forming a porous fixed sand layer. The fixed sand layer formed by the method has appropriate thickness and strength, good durability, good anti-freeze and melt properties and functions of water retention, thermal insulation, ventilation, vegetation and the like. According to the method of the invention, the stable and effective solidifying can be carried out on sand even under the specific desert environments of no abundant groundwater sources and strong wind erosion, and the purpose of vegetation greening can be also realized. The method has large-scale construction properties and good economic performances, thereby being applicable to the needs of large-scale chemical sand fixing and vegetation greening of the vast desert and realizing the plant greening function and the ecological restoration and the control of desertified land.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

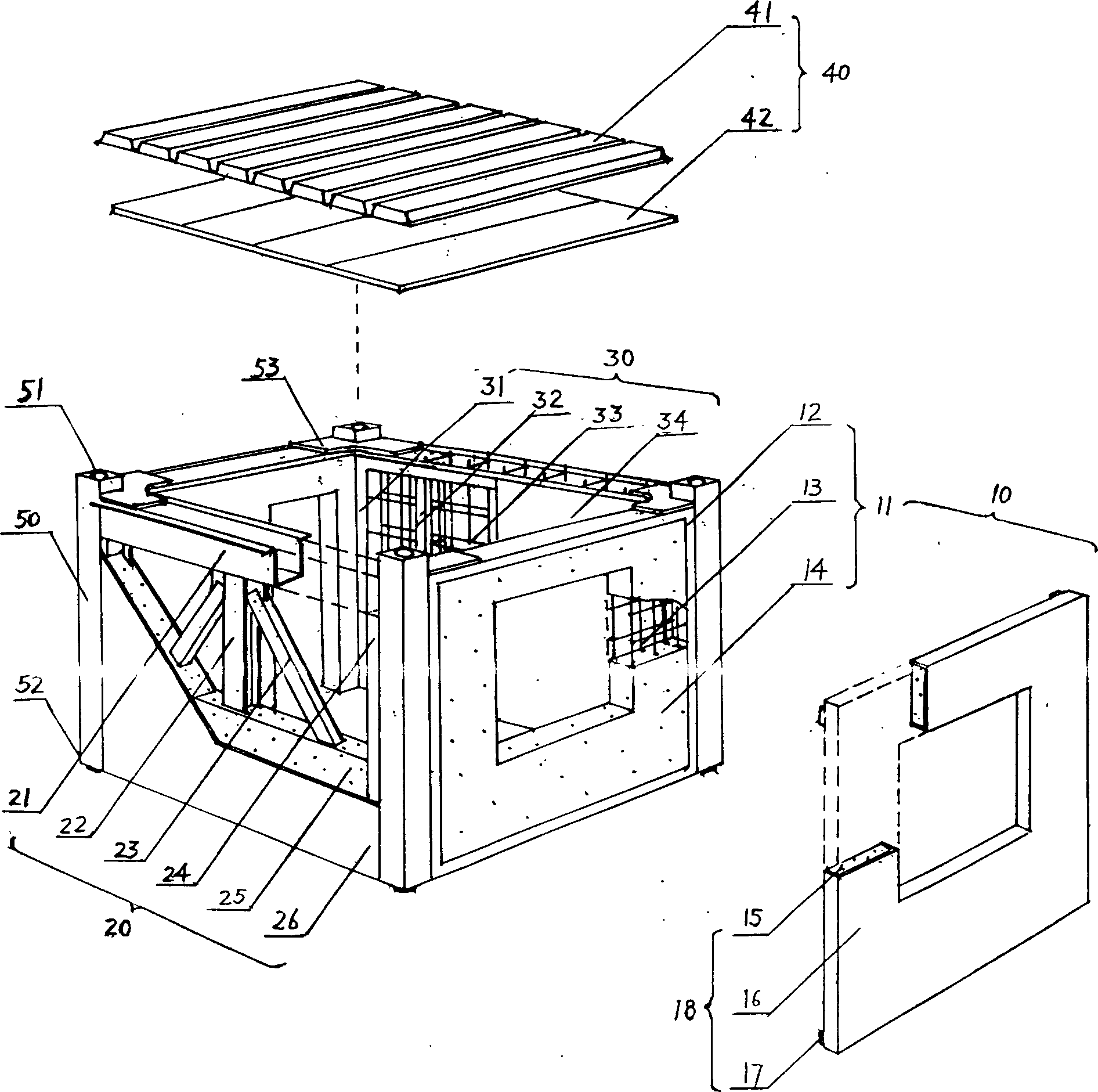

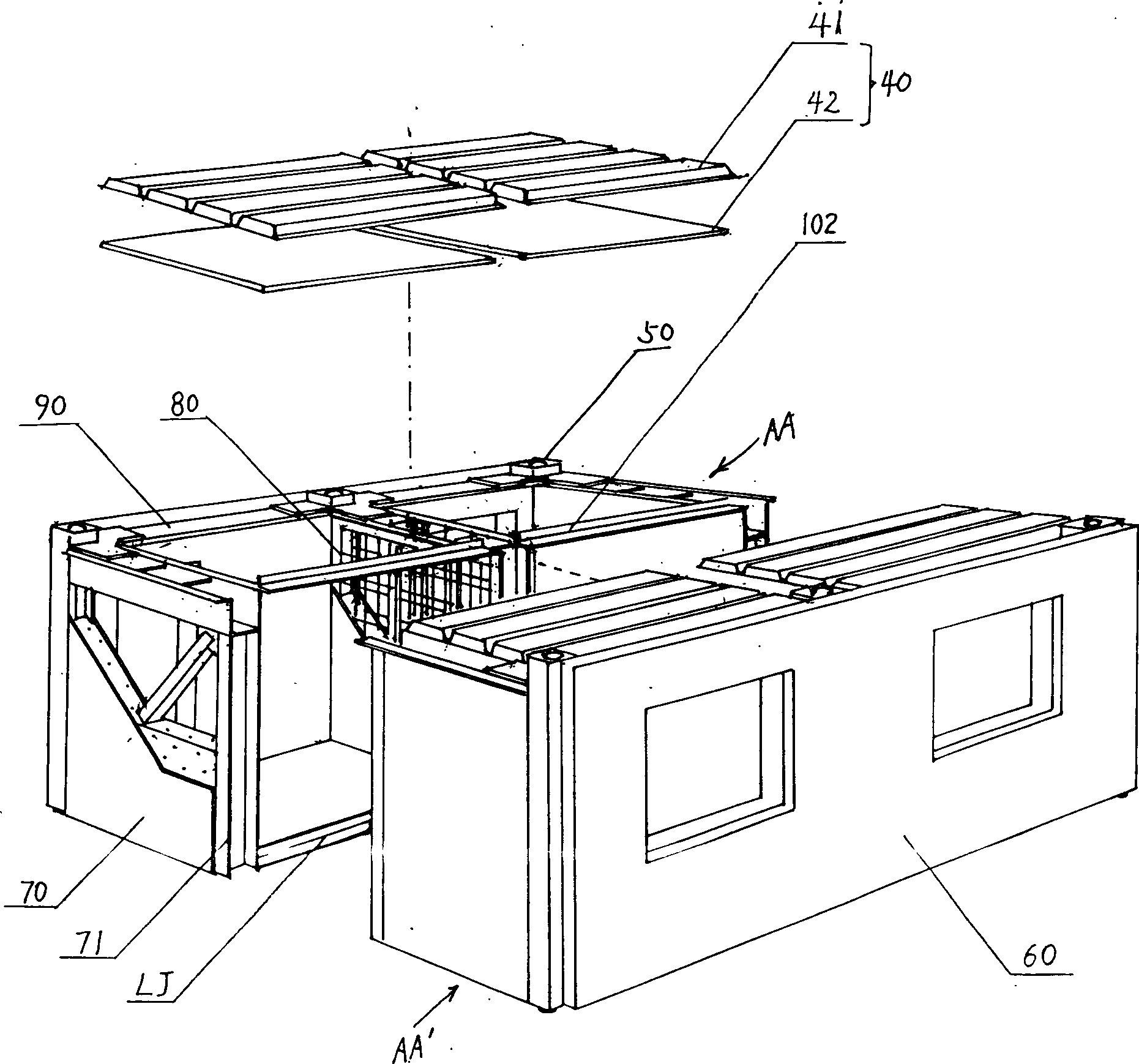

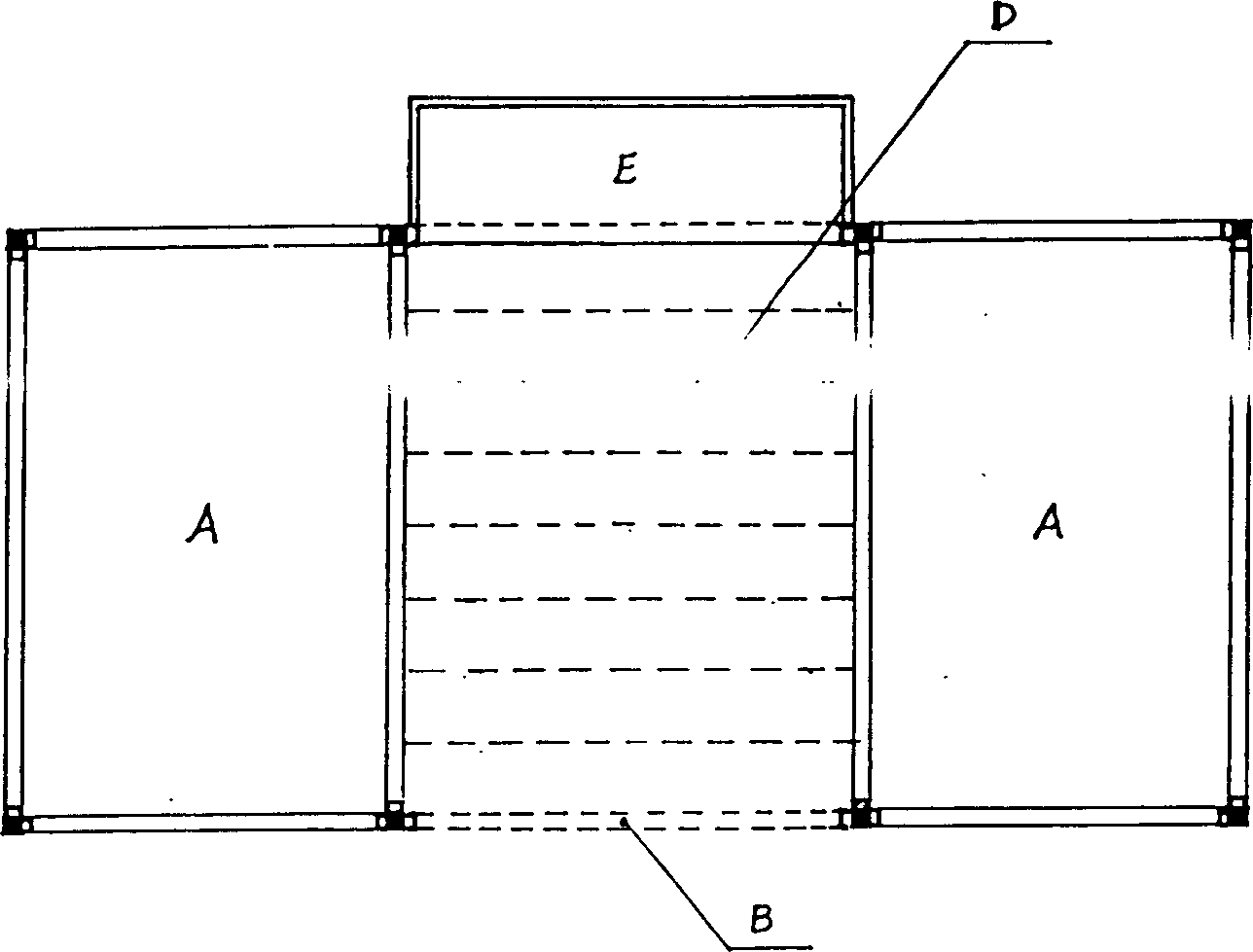

Box shaped house model of construction and fabricating method

A box type of house mould used on building consists of outer wall formed by steel frame, steel screen frame and aero ¿C concrete plate; inner wall formed by hollow wall plate and composite frame wall plate; top plate mould formed by pressed steel bearing plate and light thin plate and steel tube. It is featured as enclosing box type of house mould by one outer wall and three inner walls and furthermore forming stereo structure house mould with five surfaces by welding said box type of house mould with top plate mould.

Owner:张东川

Non-mulching-film well pit type cured tobacco young seedling transplanting method

InactiveCN102498920ARealize deep plantingStay hydratedFertilising methodsHorticultureDiseasePlastic mulch

The invention disclosed a non-mulching-film well pit type cured tobacco young seedling transplanting method which comprises the following steps of: (1) preparing land and ridging; (2) determining transplanting time; (3) forming transplanting well pits; (4) transplanting tobacco seedlings; (5) spraying root fixing water and carrying out top dressing; and (6) filling with soil and sealing. The method is a technological innovation of the mulching film cultivation of the cured tobacco, and has the advantages that: the problems of seedlings with high and slim stems as well as exposure of tobacco stems brought by non-standard conventional transplanting method, the problem that the drought climate at the transplanting time is unfavorable to transplanting, the problems in the improving the survival rate of planted tobacco seedlings and shortening the seedling restitution stage and the problem of slow transplanting progress are solved; the characteristics of relatively maintaining the heat and humidity of the well pits are utilized to realize young seedling transplanting and to finish cultivation and field deep-planting of high and strong seedlings in the well pits at one time; the seedling raising time is shortened, the seedling raising cost and facility investment are reduced, and the comprehensive utilization benefit of the seedling raising greenhouses is improved; and the disease infection opportunity during the leaf cutting link is reduced, the utilization rate of the fertilizer is improved, the root systems of the young seedling are flourishing and the drought defying capability is enhanced. The method is suitable for planting of cured tobacco, burley tobacco, sun-cured tobacco and other crops.

Owner:TONGREN CITY COMPANY OF GUIZHOU PROVINCE TOBACCO

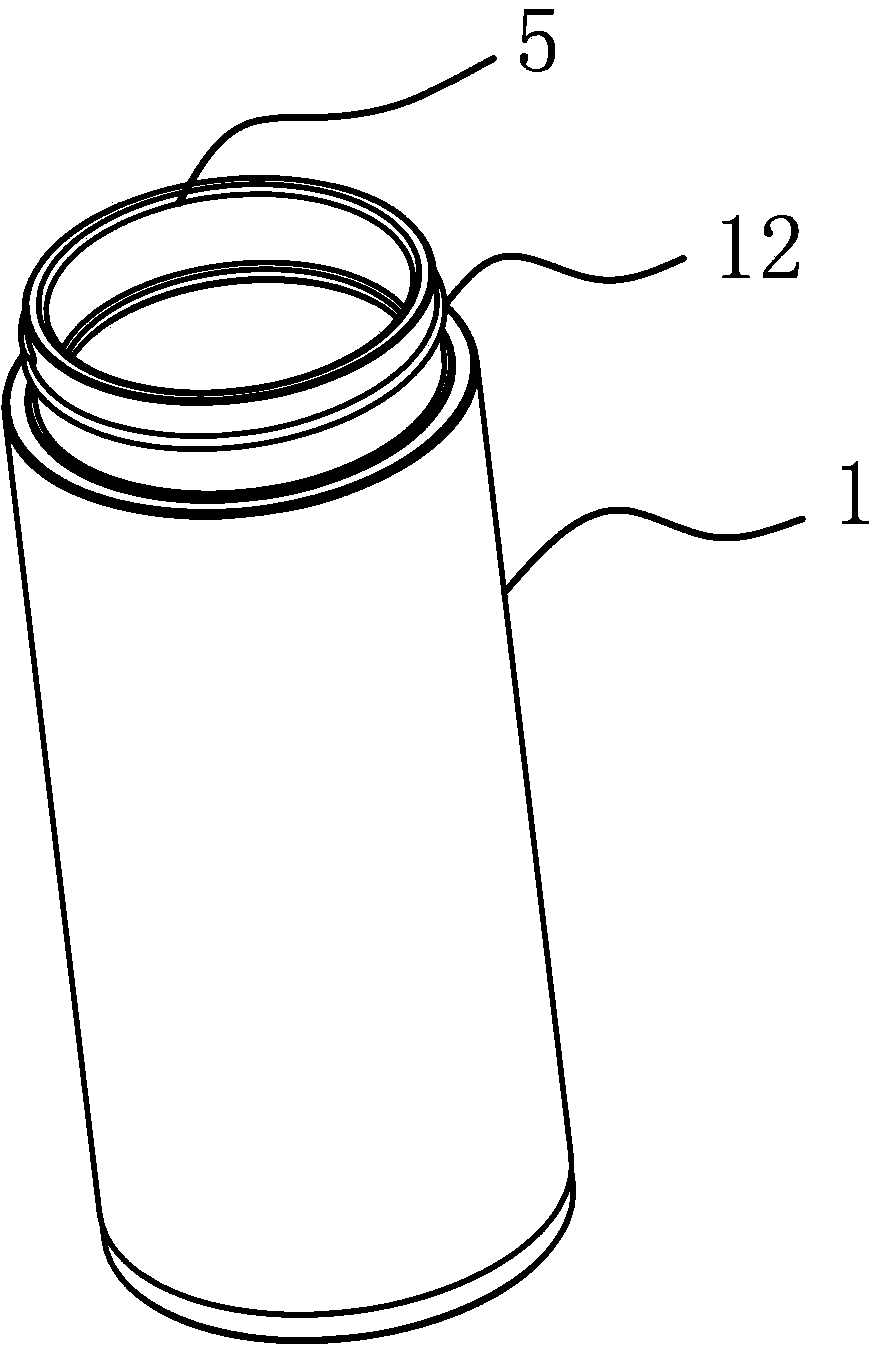

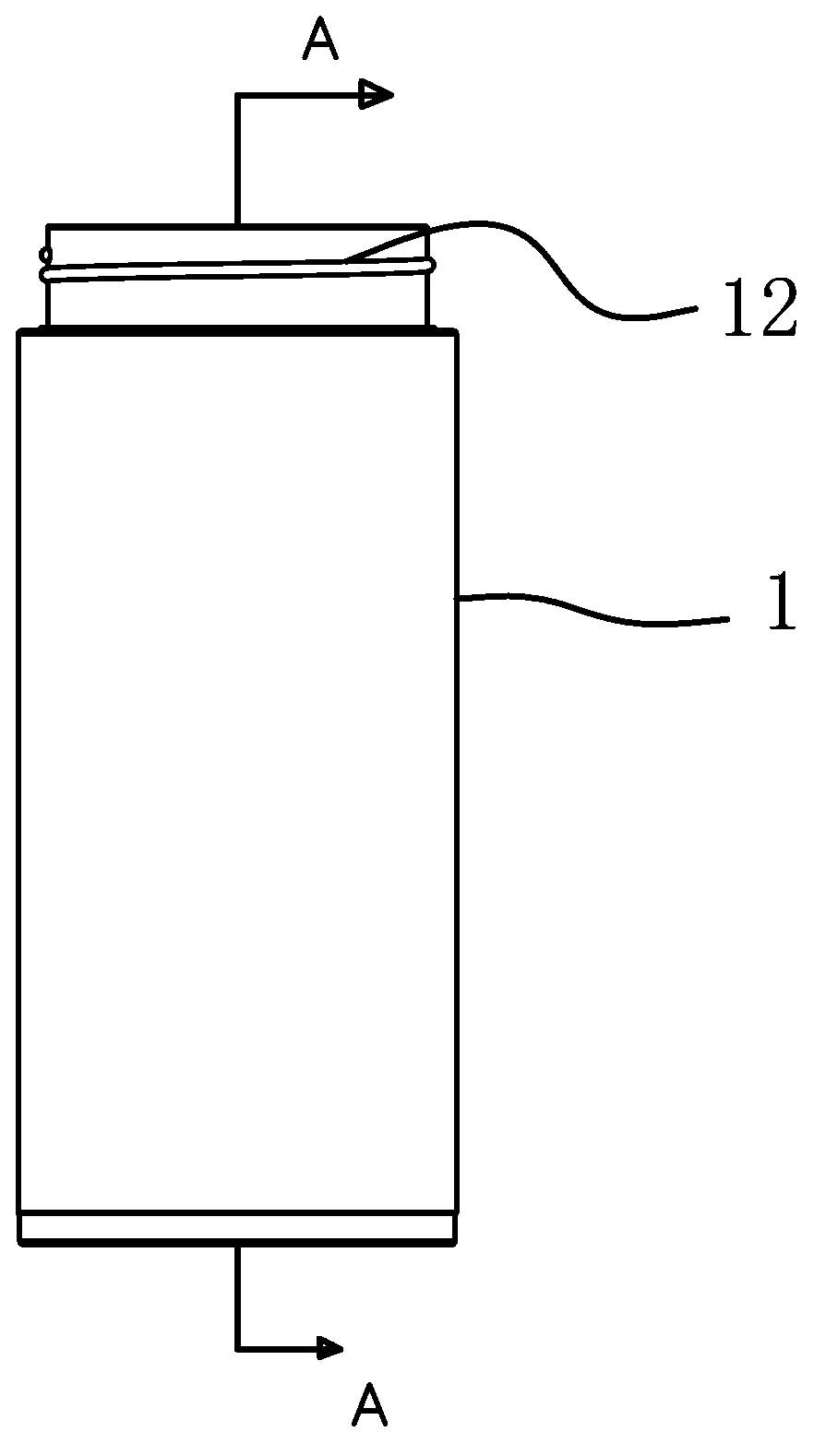

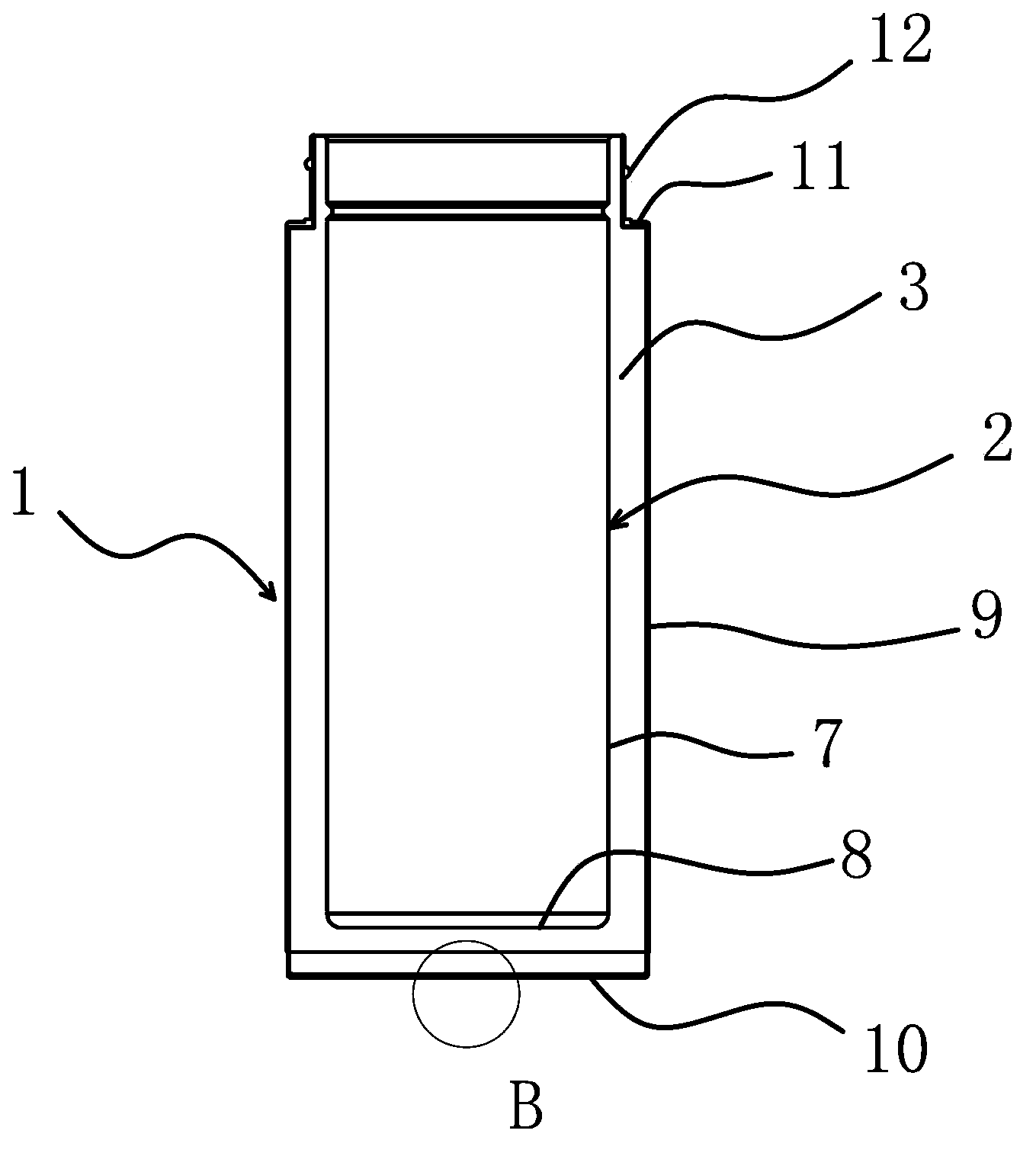

Titanium metal vacuum cup and manufacturing method thereof

ActiveCN103405104AThermal insulationImprove corrosion resistanceDrinking vesselsVacuum pumpingTitanium metal

The invention provides a titanium metal vacuum cup and a manufacturing method thereof, belongs to the technical field of daily necessities, and solves the technical problems that a conventional vacuum cup is lower in corrosion resistance and attractiveness and the like. The vacuum cup comprises an outer cup body and an inner cup body, wherein the inner cup body is sleeved with the outer cup body; the orientation of cup rims of the inner cup body and the outer cup body is identical; the inner cup body and the outer cup body are sealed and fixed annularly at the cup rims; a vacuum interlayer is arranged between the inner cup body and the outer cup body; and both the outer cup body and the inner cup body are made of titanium metal pieces. The manufacturing method of the vacuum cup comprises the procedures as follows: a, blank preparation; b, expansion molding; c, cup bottom sheet installation; d, tailless vacuum pumping; and e, finished product blanking. The titanium metal vacuum cup has the advantages of good corrosion resistance, high attractiveness and the like.

Owner:亚钛军创(金华)控股有限公司

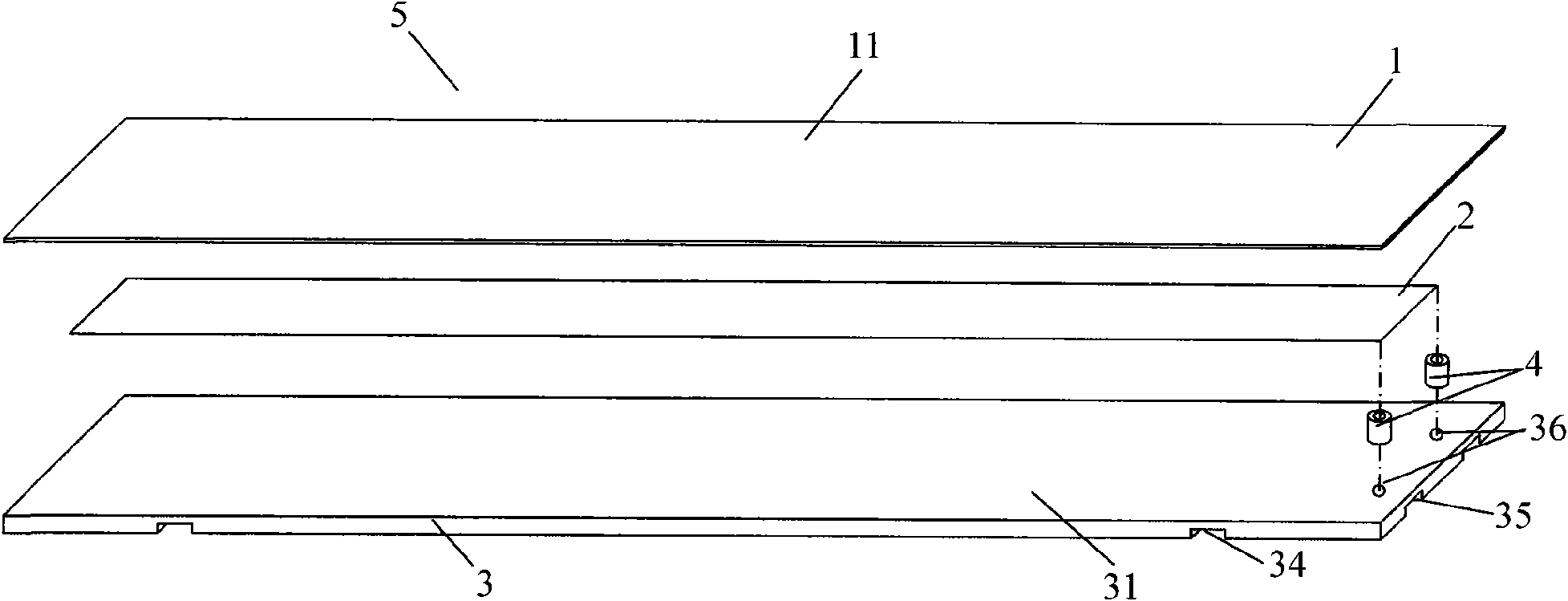

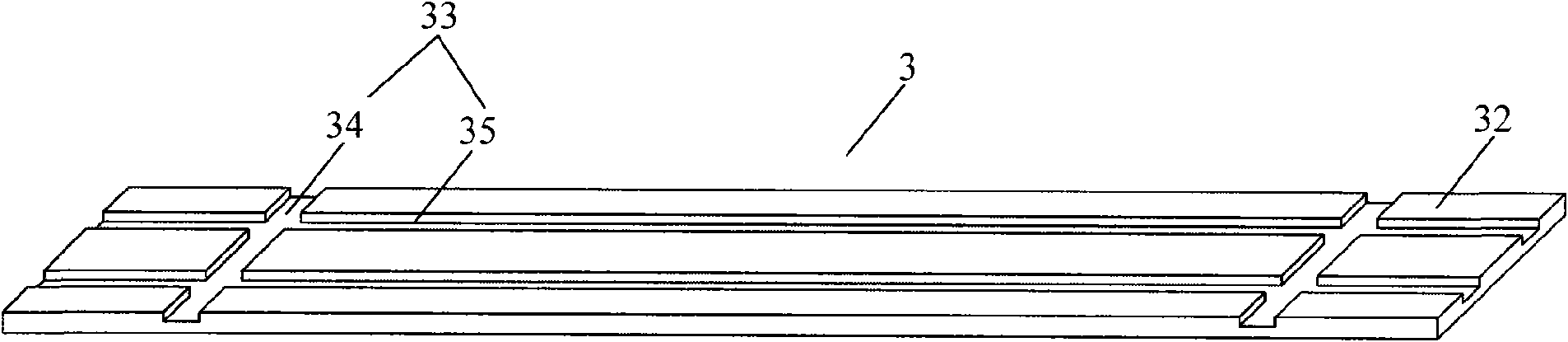

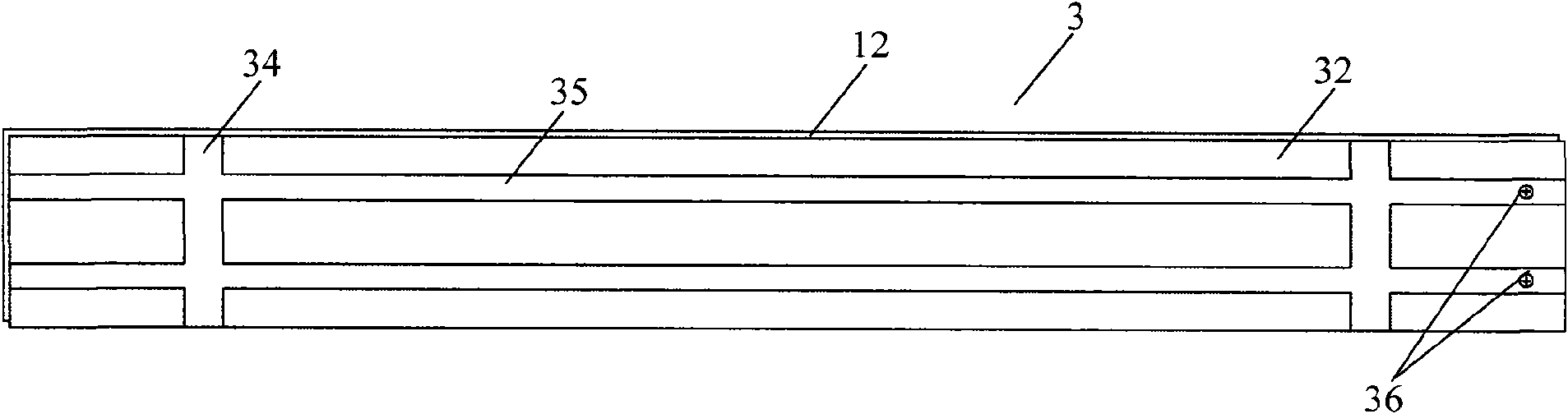

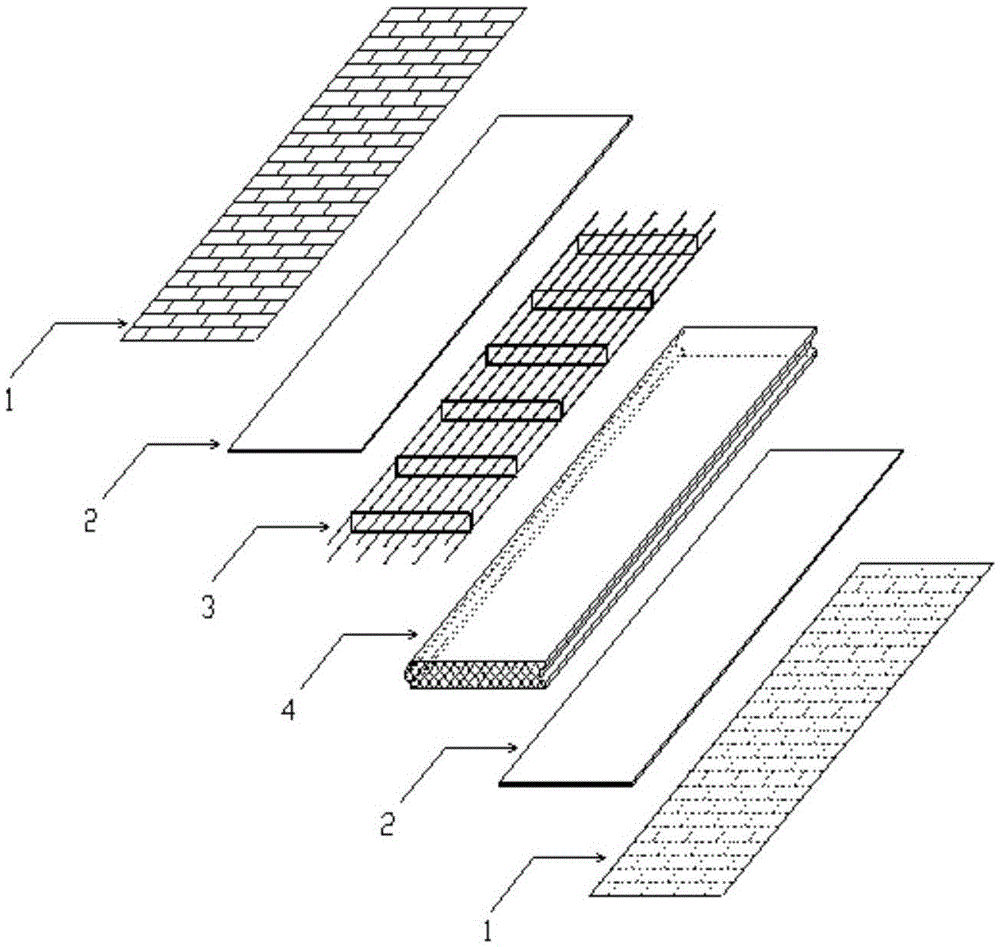

Far-infrared heat energy wood floor and manufacturing method and paving method thereof

InactiveCN101660803AIngenious designBreak through the natural functionLighting and heating apparatusElectric heating systemElectric heatingHardwood

The invention relates to a far-infrared heat energy wood floor, the carbon crystal electric heating material sheets of which are respectively pasted on the second surface of a surface board of the wood floor and the third surface of a base board of the wood floor. Preferably, the surface board of the wood floor is a hardwood board, the air-dry density of which is 0.5-0.7g / cm<3>, the thickness of which is 2-4mm and the moisture content of which is 6-8%; the thickness of each of the carbon crystal electric heating material sheets is 0.2-0.5mm; and the base board of the wood floor is a softwood board, the air-dry density of which is 0.3-0.6g / cm<3>, the thickness of which is 13-16mm and the moisture content of which is 6-8%. The far-infrared heat energy wood floor comprises an even number of layers of wood boards which are sequentially pasted, and the textures of the wood boards are crisscrossed; and air guiding grooves are arranged on the fourth surface of the base board of the wood floor. The invention also provides a manufacturing method and a paving method. The invention has the advantages of skillful design, safety, environment protection, energy saving and automatic adjustment oftemperature, breaks through the natural functions of the wood floor, organically combines a far-infrared heat energy heating element and the wood floor, has important breakthrough in the aspects of service life, energy saving, safety, environment protection, health, physical therapy and the like of the geothermal heating materials, and is a revolution in the international wood floor industry.

Owner:陆上驰 +1

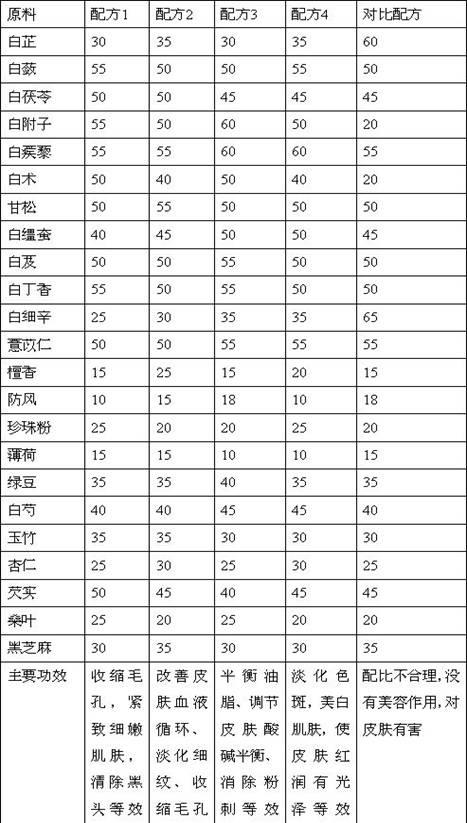

Traditional Chinese medicine beauty mask

InactiveCN102525870AImprove microcirculationTo promote metabolismCosmetic preparationsToilet preparationsFine lineBletilla striata

The invention provides a traditional Chinese medicine beauty mask which is prepared from the following raw materials in parts by weight radix angelicae, ampelopsis japonica, Indian buead, giant typhonium rhizome, tribulus terrestris, white atractylodes rhizome, rhizoma nardostachyos, white silkworm, bletilla striata, white lilac, white asarum, semen coicis, sandalwood, divaricate saposhnikovia root, pearl powder, mint, mung bean, radix paeoniae alba, radix polygonati officinalis, almond, gorgon fruit, folium mori and semen sesami nigrum. The raw materials are crushed into powder and mixed uniformly. The powder prepared from the raw materials is uniformly blended with egg white and then applied to the face, various traditional Chinese medicine components in the mask enter the human body through skin and pores, and active components of the raw materials interact so as to improve the blood circulation of skin, eliminate fine lines, contract the pores, tighten skin, remove color mottles and nourish skin, after being used for a long time, the beauty mask has beautifying and anti-aging functions and can remove blackheads and acne. The traditional Chinese medicine beauty mask is reasonable in proportioning and has no side effect on the skin of people.

Owner:李进

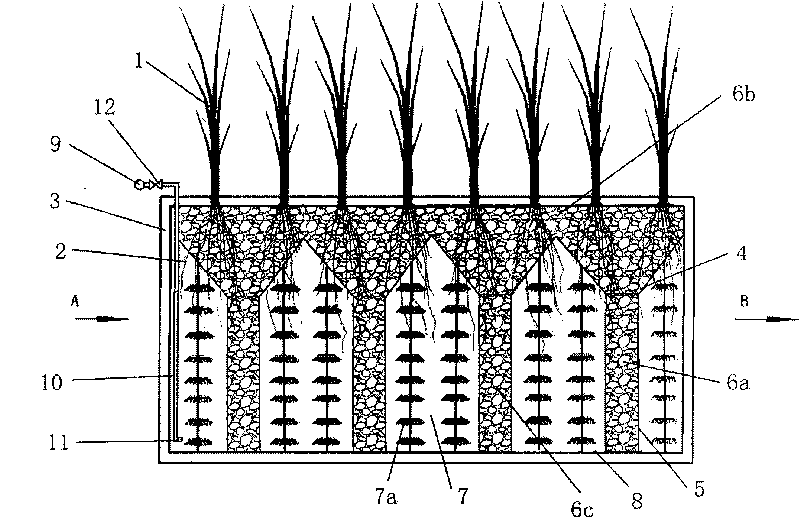

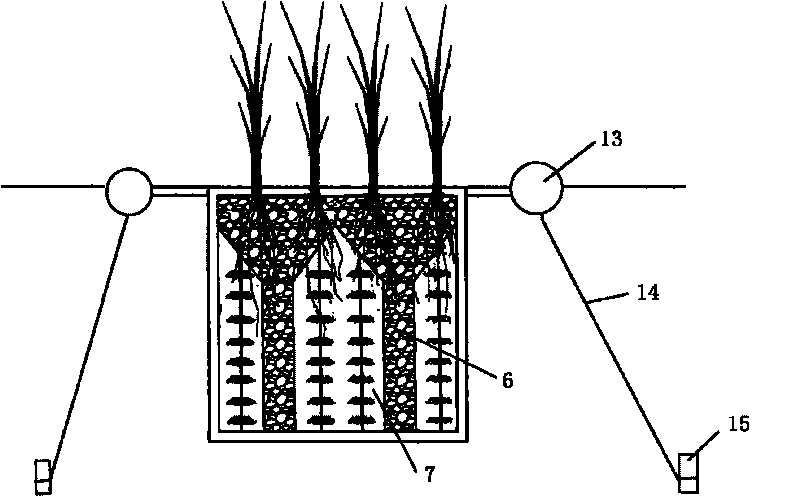

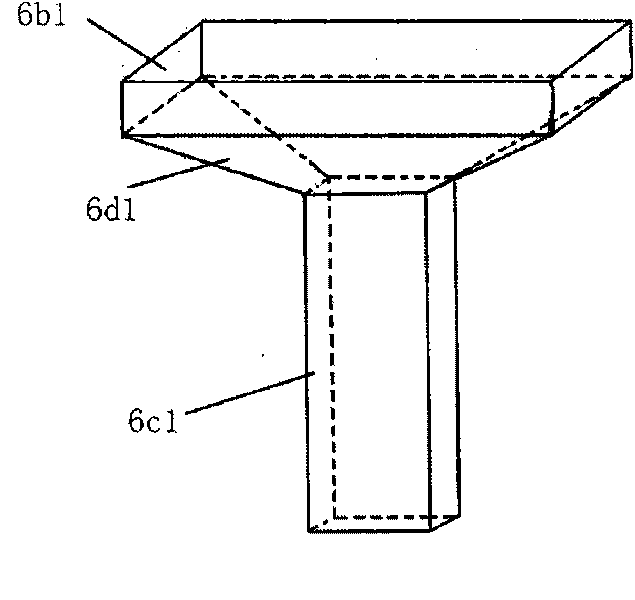

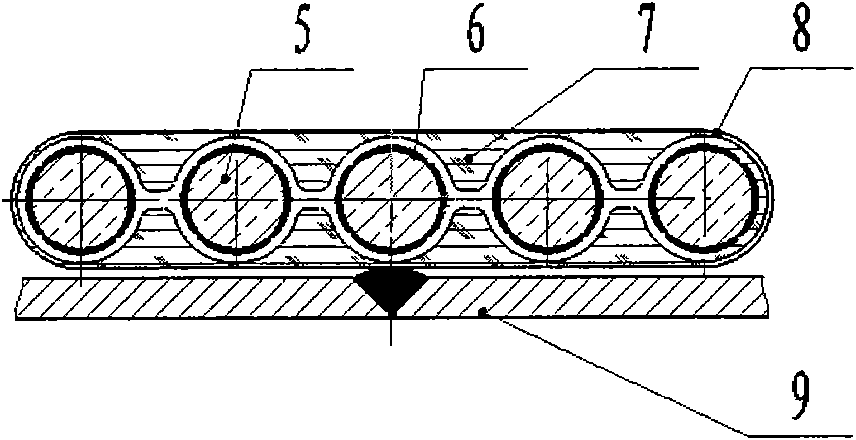

Method and device for purifying combined-flow artificial floating island water body

ActiveCN101734783AConstituent flow rate is highLarge specific surface areaSustainable biological treatmentBiological water/sewage treatmentEutrophicationPorous medium

The invention relates to a method and a device for purifying combined-flow artificial floating island water bodies. The device is provided with an artificial floating island frame; particle filling areas (6) are arranged in the artificial floating island frame; tightly accumulated particle fillers (6a) are filled in the particle filling areas; the particle filling areas are distributed at the lower part of the artificial floating island frame in a dispersed manner; sparse fillers (7a) with good overflowing property are arranged between the dispersed particle filling areas (6c) to form a sparse filling area (7) in which the flow is obviously higher than the osmosis flow in the particle filling areas; the particle filling areas are distributed at the upper part of the artificial floating island frame in a whole area or in sub-area to form an upper layer particle filling area on which humidogene emergent aquatic plants can be planted. In the invention, different filling areas are arranged to form combined flow of coexistence of porous media seepage and space continuity flow, thus fully purifying water bodies under the actions of physics, chemistry, plants and microorganisms and the like, and achieving the high effects of nitrogen and phosphorus removal by adopting the invention to process eutrophic surface water bodies, such as rivers and lakes and the like.

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS +1

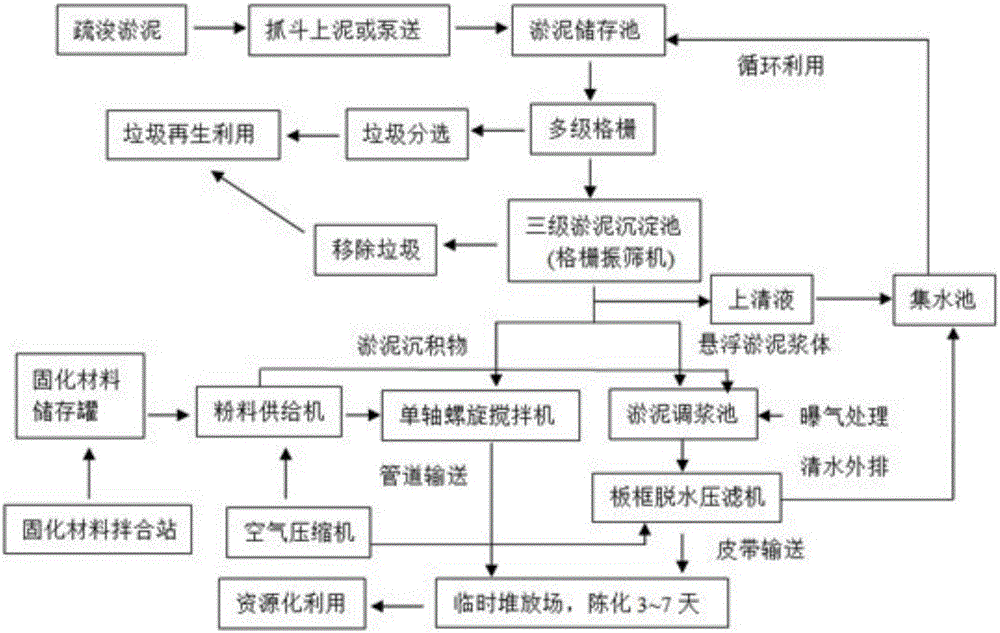

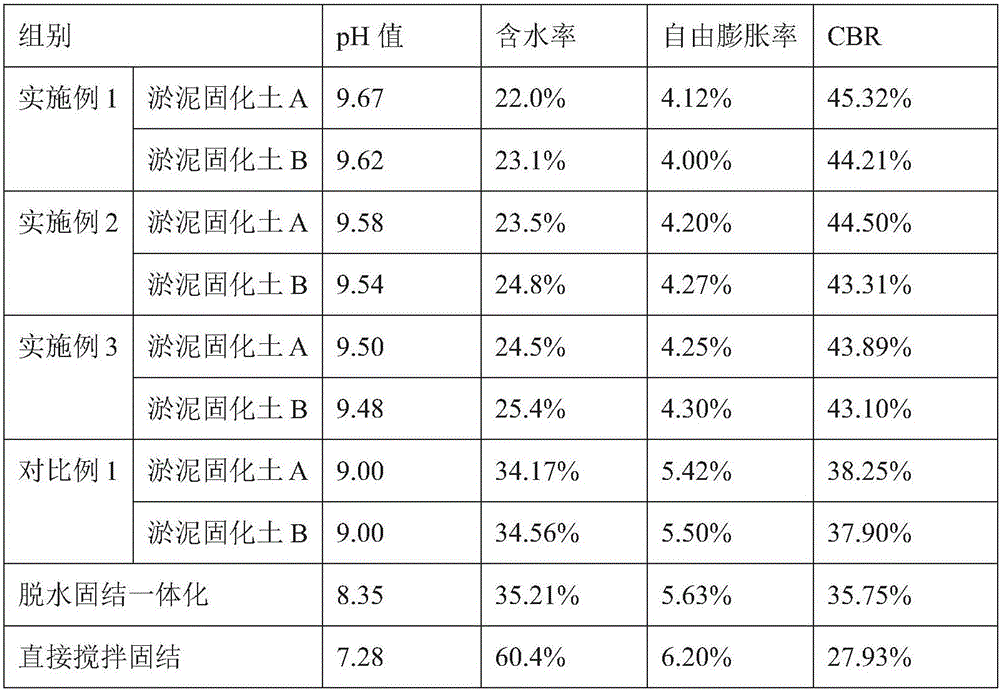

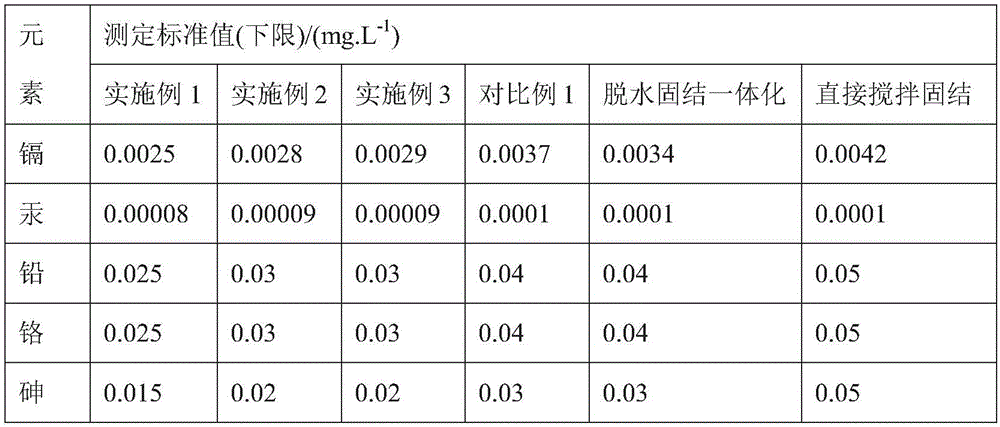

Sludge treatment process

The invention belongs to the field of environmental protection, and in particular relates to a sludge treatment process. The sludge treatment process comprises the following steps: 1) impurity removal: use multi-stage grille to filter out the garbage in the sludge; 2) pretreatment: utilize the three-stage sludge settling tank to pretreat the sludge to obtain the first, second, and The sludge in the three-stage sludge settling tank, the sludge slurry and the supernatant after being settled in the three-stage sludge settling tank; 3) solidification treatment: respectively adopt mixing solidification and dehydration solidification methods for the first, second, and third-stage sludge sedimentation The silt and silt slurry in the pond are dehydrated and solidified to obtain silt-solidified soils A and B; 4) stacking and aging: transport the silt-solidified soils A and B to a temporary storage yard and age them for 3 to 7 days to complete the treatment. The sludge treatment process of the present invention can simultaneously process particles and sludge with high viscosity and low water content, as well as sludge slurry with fine particles, organic matter and high water content, and is especially suitable for river courses with complex components, wide particle distribution, and large water content differences silt.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Foam concrete function gradient composite board and preparing method thereof

ActiveCN105604239ALight weightWith heat insulationClimate change adaptationBuilding componentsFoam concreteThermal insulation

The invention discloses a foam concrete function gradient composite board and a preparing method thereof. The foam concrete function gradient composite board is a board body, comprising an upper protection layer and a lower protection layer as well as a thermal insulation layer between the two protection layers; two transverse ends of the board body are respectively provided with a groove and a tenon for connecting and positioning; a frame layer is paved in the thermal insulation layer and longitudinally penetrates through the thermal insulation layer and extends into the upper and lower protection layers to connect the upper and lower protection layers and the middle thermal insulation layer into a whole; the thermal insulation layer and the protection layers are formed by adopting continuous pouring; decoration layers are arranged at outer surfaces of the two protection layers; the frame layer is woven by FRB ribs. The foam concrete function gradient composite board prepared by the preparing method can be used for construct a novel building wall body and a roof surface system integrating multiple functions of fire prevention, thermal insulation, decoration and durability and has very wide popularization and application values.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Resin mixture and glass reinforced plastic section bar prepared thereby

InactiveCN101157795ALightweight and high strengthThermal insulationPolymer scienceLow temperature curing

The invention relates to a resin mixture used for producing FRP (fiberglass-reinforced plastics) profile, the FRP profile made from the mixture and a preparation method thereof. The resin mixture comprises the following materials according to weight proportion: 10 of resin, 0.4 to 3 of low shrinkage agent, 2 to 15 of fillers, 0.05 to 0.2 of low temperature curing agent, 0.05 to 0.2 of high temperature curing agent, 0.05 to 0.2 of parting agent, 0.02 to 0.5 of pigment and appropriate amount of coupling agent and ultraviolet absorbent. The preparation method of the FRP profile by using the mixture is that: a reinforcing material is immersed into the resin mixture. The obtained material is extruded to get forming under high temperature and high pressure through a die; during the extrusion forming, the die is heated after being separated into three segments, and the temperature of the three segments is respectively 60 DEG C to 100 DEG C of a first segment, 100 DEG C to 150 DEG C of a second segment, 100 DEG C to 148 DEG C of a third segment; the haulage speed is 320 mm / min.

Owner:潘锦荣

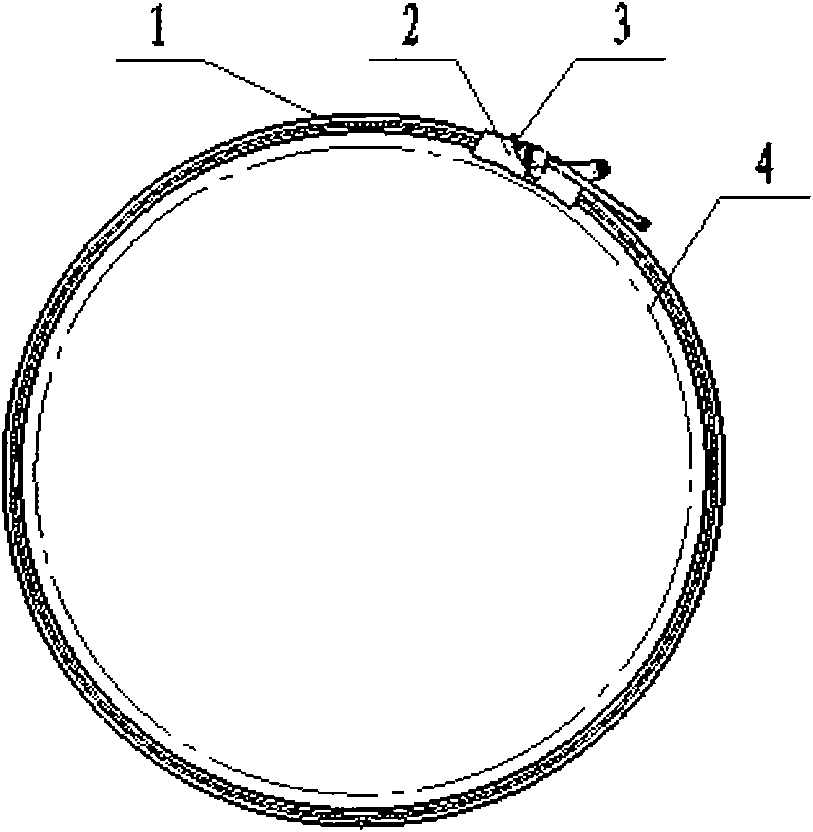

Soft belt type electromagnetic induction heater

InactiveCN101868076AReduce weightReliable electrical contactWelding/cutting auxillary devicesAuxillary welding devicesElectromagnetic inductionCaliber

The invention provides a soft belt type electromagnetic induction heater used for butt welding in pipeline engineering, which relates to the technical field of pipeline systems. The soft belt type electromagnetic induction heater comprises an induction heating ring. The invention is characterized in that high-temperature-resistance insulation fiber (7) and high-temperature flame-retardant cloth (8) are adopted to be covered outside a high-frequency soft cable (5) to be made into heating soft belts (1) in different specifications according to different diameters of steel pipes, both ends of the heating soft belts (1) are provided with purpose-made electric connectors (2) so that the high-frequency soft cable (5) forms a spiral wire heating ring, and the output current of a middle-frequencypower supply is communicated with both ends of the spiral wire for heating pipe openings. The invention has the advantages that the installation / dismounting operation of the soft belt type electromagnetic induction heater on / from the steel pipes is convenient, the use is safe and reliable, the problem of the existing middle-frequency induction heating technology in the large-caliber long oil transmission gas pipeline welding preheating construction is solved, and the requirement of high-efficiency welding construction of the engineering is met.

Owner:CHINA PETROLEUM PIPELINE BUREAU

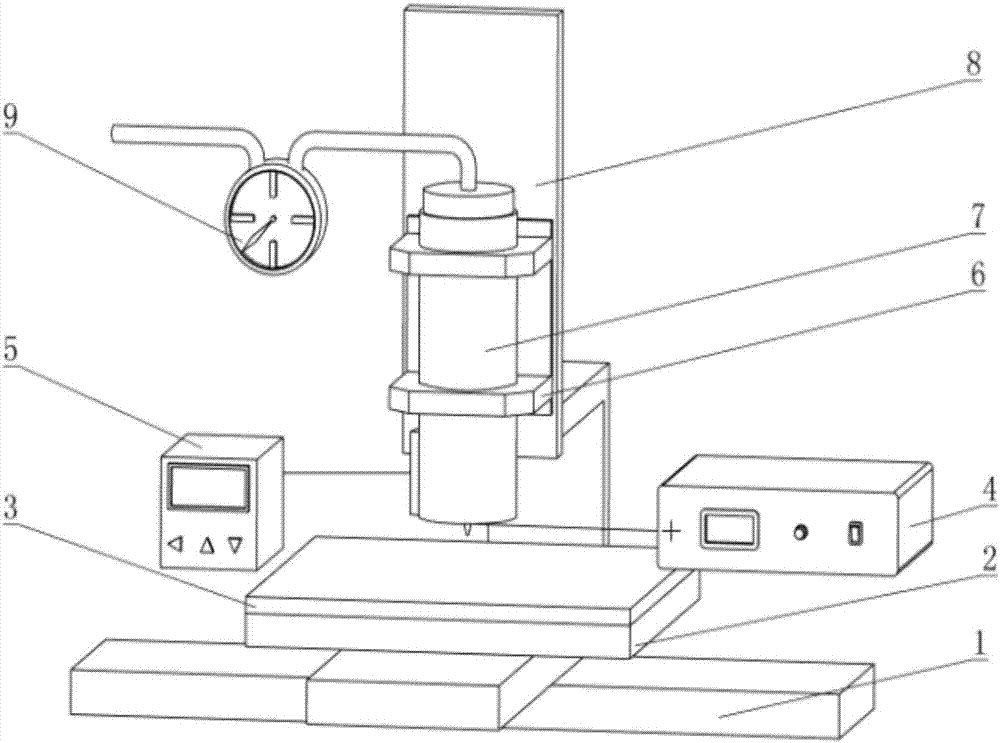

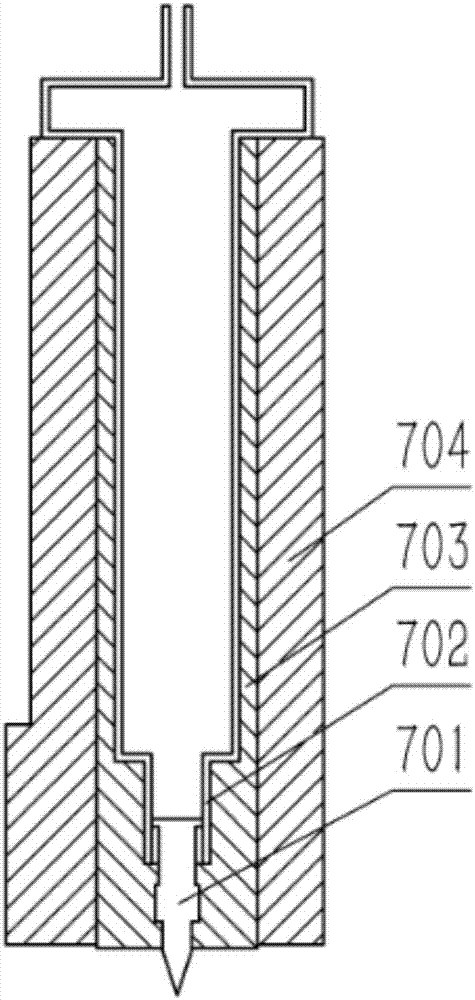

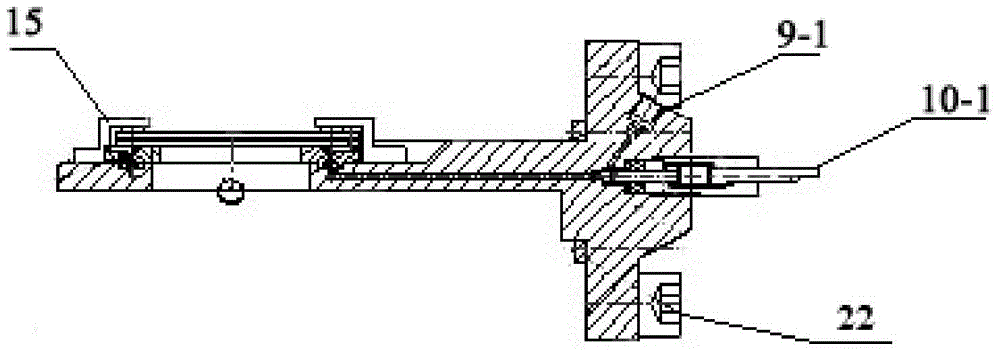

Molten jetting deposition 3D printing device driven by electric field, and working method thereof

InactiveCN107160685AAvoid cloggingEvenly heatedManufacturing heating elements3D object support structuresScale structureHigh pressure

The invention discloses a molten jetting deposition 3D printing device driven by an electric field, and a working method thereof. The problems that the molten droplet jetting 3D printing accuracy is low, the printing materials are limited and the micro-scale structure printing is hard to achieve are solved, and the high-accuracy and high-efficiency macro / micro-scale manufacturing of complex 3D structures using thermal phase transition and thermoplastic polymer materials and composite materials is achieved. According to the technical scheme, the 3D printing device comprises a two-dimensional stage which is provided with a printing bed, and an insulating thermal-conductive substrate is attached to the printing bed; a jetting unit is arranged above the insulating thermal-conductive substrate, and connected to a Z-axis workbench; the jetting unit comprises a print head comprising a nozzle and a material storage barrel which are connected to each other, and the print head is connected to the anode of a high-voltage pulse power supply; the nozzle is a musashi conductive nozzle; the material storage barrel is connected to a backpressure control unit; and a heater is sheathed outside the print head, and connected to a temperature control unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

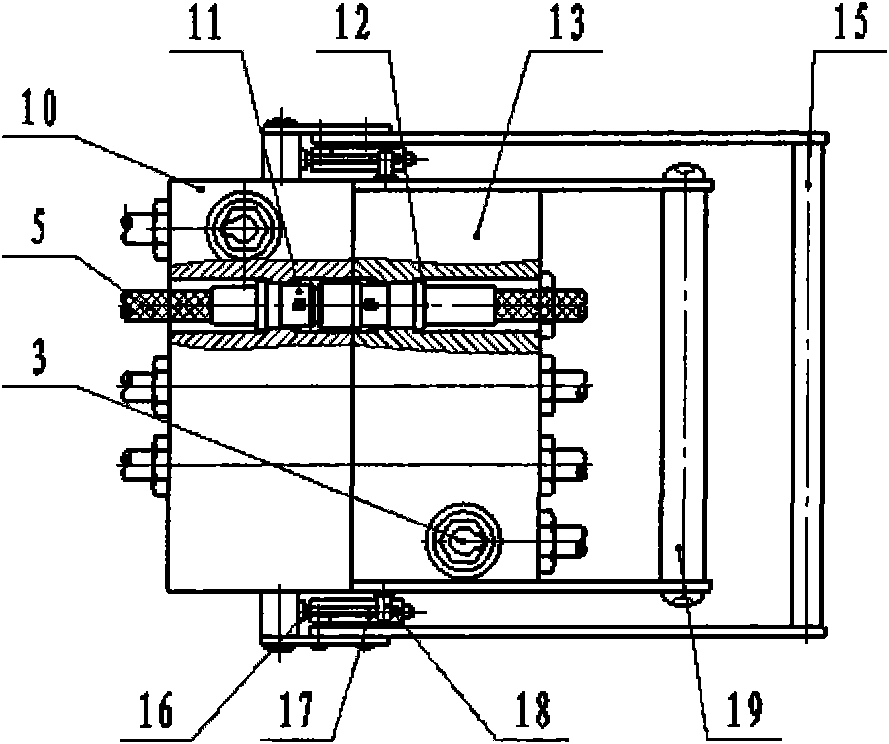

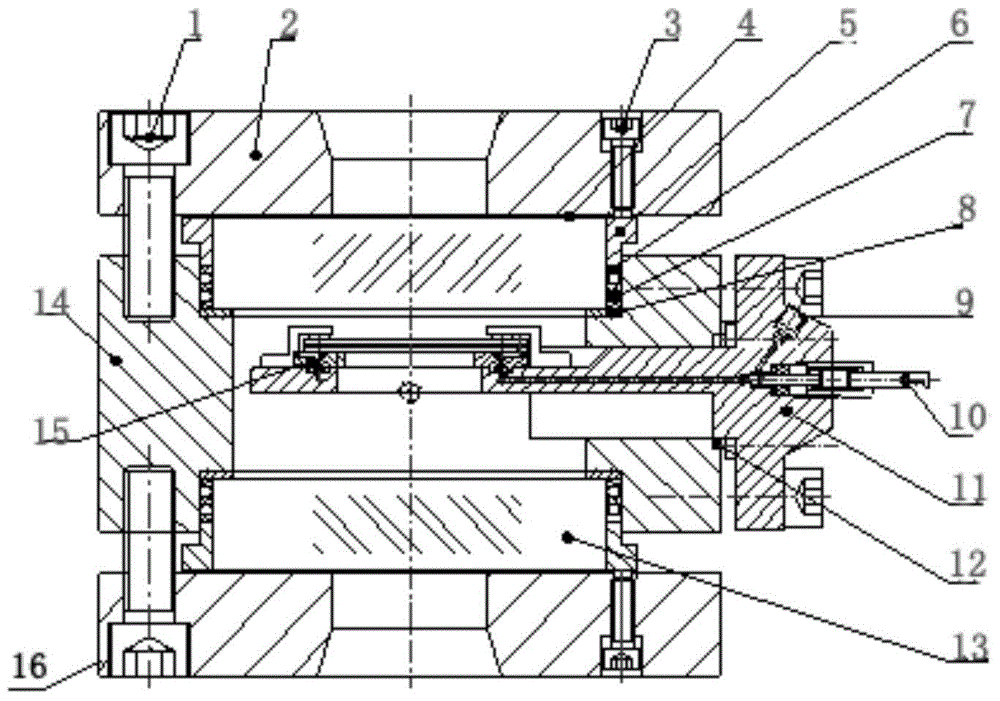

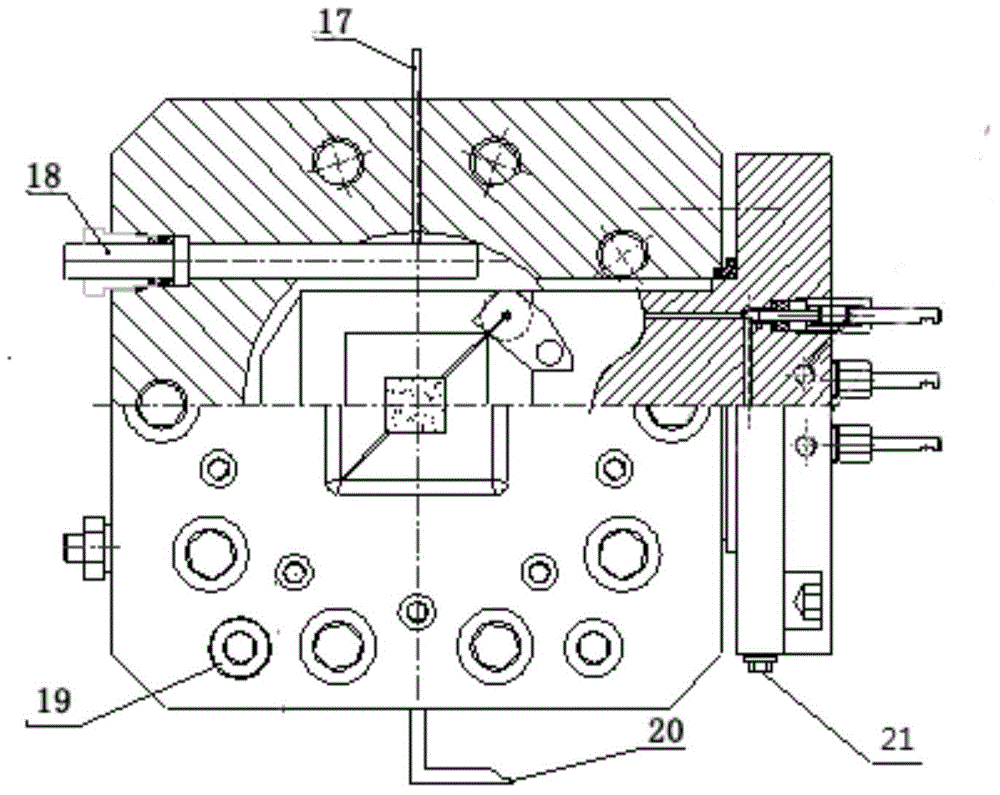

High-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery

The invention discloses a high-temperature high-pressure glass micro model gripper used for heavy oil thermal recovery. The high-temperature high-pressure glass micro model gripper comprises a high-temperature high-pressure bin and high-pressure glass visual windows and further comprises a drawer type micro model support, upper pressing plates and lower pressing plates. The high-temperature high-pressure bin is a square-cylinder-shaped bin body. The upper portion and the lower portion of the inner wall of the bin body are each provided with an annular step. One high-pressure glass visual window is fixed to each annular step. The upper pressing plates and the lower pressing plates are arranged on the outsides of the high-pressure glass visual windows correspondingly. The high-temperature high-pressure bin is provided with a heater leading to an inner cavity of the bin body. The side face of the bin body is further provided with a model support inlet. The drawer type micro model support is pushed into the bin body from the model support inlet. Through the drawer type high-temperature high-pressure gripper, operation is simple, fast and convenient, and the problem of the unreliability of the leakproofness of the bin body due to repeated disassembly and assembly of the visual windows is avoided. A plurality of injection openings and control valves, bull plugs and back-pressure valves of the injection openings are adopted, so that noninterference between injection fluid is achieved, and meanwhile, the continuity of the injection fluid and pressure is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

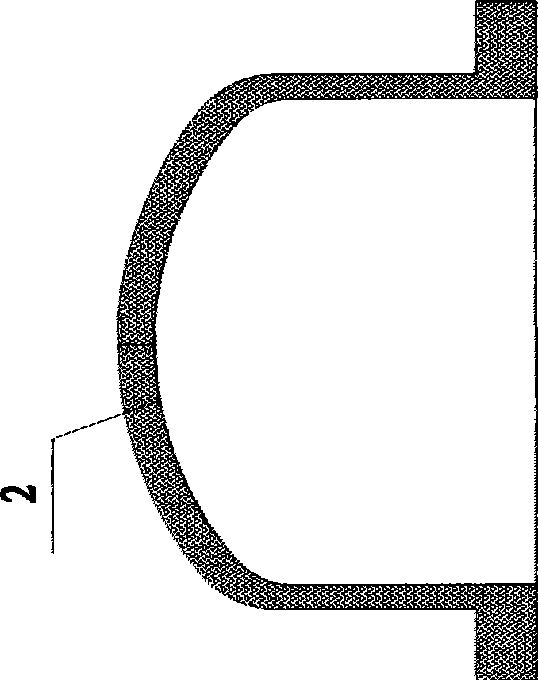

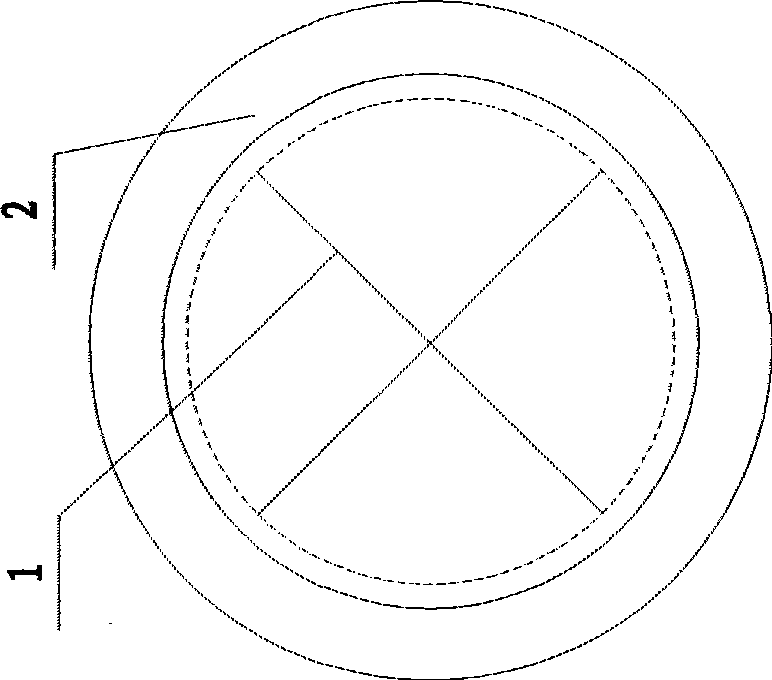

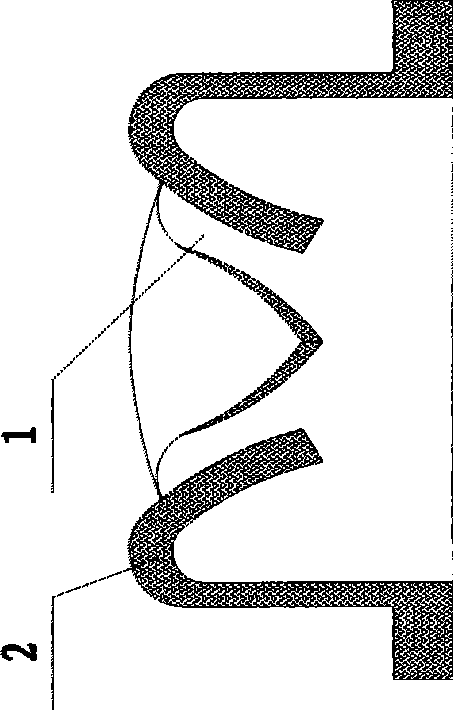

Multipurpose thimbleshaped valve respiration valve

The invention discloses a multipurpose cap-shape valve respiratory valve, comprising a valve seat, a valve core and a fixed sleeve; the valve core is of cap shape and made of elastic rubber; the cap rim of the valve core is fixed between the valve seat and the fixed sleeve; the cap body is sheathed in the central hole of the valve seat or the fixed sleeve; furthermore, the top of the cap of the valve core is provided with at least two lancings so that at least one valve clack is formed at the top of the cap. the lancings are distributed all around in a radial pattern from the axle center projected at the top of the cap to form a taper angle shape valve clack, or a C shape, V shape, U shape or opening polygon shape valve clack to cause the end part projected at the top of the cap to form a flip-shell valve clack or cause the lateral side projected at the top of the cap to form at least two valve clacks. The invention has the advantages of simple structure, few faults, long service life, low manufacturing cost, multiple functions and extensive usage, is favorable for environment protection, and has good social and economical benefits.

Owner:刘景福

Aquosity heat insulating heat preserving paint manufacturing method thereof

InactiveCN101108930ALow toxicityImprove insulation effectFireproof paintsChemical industryEpoxyWater based

The invention discloses a water-base heat insulation coating with good heat insulation property. The raw material of the invention comprises the components and the weight ratios of the components are as follows: 30 per cent to 40 per cent of elastic modified acrylic emulsion (water-base), 5 per cent to 7 per cent of epoxy resin (water-base), 3 per cent to 5 per cent of ethylene glycol, 10 per cent to 15 per cent of hollow glass bead, 8 per cent to 12 per cent of functional filler, 15 per cent to 20 per cent of kaolin, 0.8 per cent to 1.2 per cent of French chalk, 0.5 per cent to 0.7 per cent of dispersant, 0.3 per cent to 0.5 per cent wetting agent, 0.4 per cent to 0.6 per cent of antifoamer, 0.1 per cent to 0.3 per cent of antibacterial agent, 0.2 per cent to 0.4 per cent of mildewproof agent, 1.5 per cent to 2.5 per cent of flatting agent, 0.8 per cent to 1.2 per cent of thickener and 8 per cent to 12 per cent of water. The invention also discloses a production method of the water-base heat insulation coating, which is that the stirring speed of the motor is less than 900r / h during adding the hollow glass bead. The invention has little toxin and is beneficial for the environment protection, and has better heat insulation effect because of the heat reflection of the hollow bead and the hollow heat insulation effect and improves the energy saving property obviously.

Owner:庾庆荣

Potato planting method

ActiveCN103907459AIncrease productionStrong disease resistanceFertilising methodsPlant protective coveringsDiseased plantSolanum tuberosum

A potato planting method comprises the following steps of (a), preparation before planting, (b), planting, (c), field management and (d), harvesting. By using the planting method, planted new Daping level potatoes are high in yield and high in disease resistance, and the shortcoming that the new Daping level potatoes planted by using the traditional planting mode are not high in yield, late blight resistance is not high and the like is overcome. Compared with the traditional cultivation technology, the potato planting method has the advantages that the yield and the quality of potatoes are greatly improved, the yield is improved by 15%, the dry matter content is increased by 12.53%, the reducing sugar content is increased by 20.00%, the soluble protein content is increased by 6.76%, the starch content is increased by 19.07%, and the Vc content is increased by 18.39%; and in 3-5 days before the late blight center diseased or infected plants of the potatoes are found out, the blight of the potatoes can be effectively prevented and cured by using bactericide, and the disease rate is reduced by 27.89%.

Owner:GANSU AGRI UNIV

Coating material with characteristics of efficiency, energy saving, heat shield, cooling and corrosion resistance

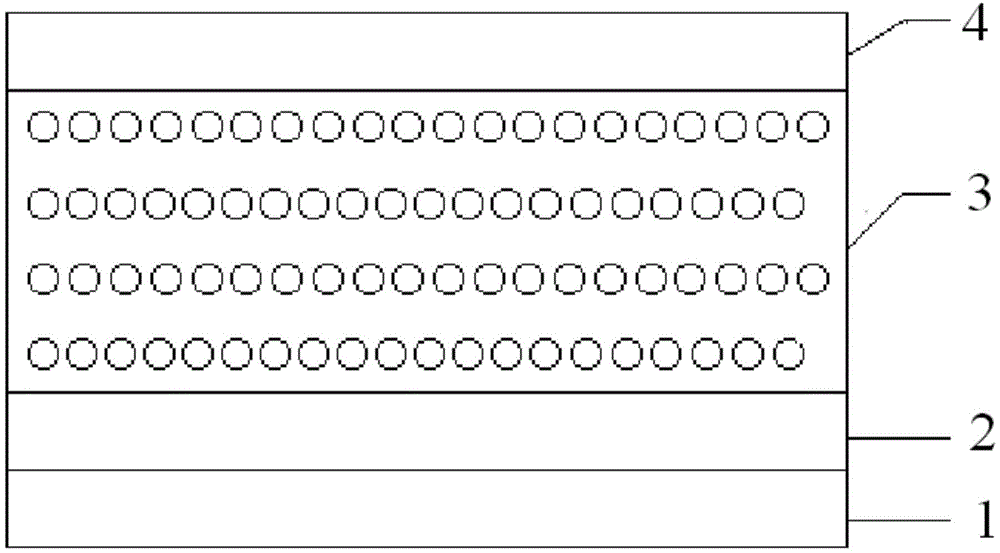

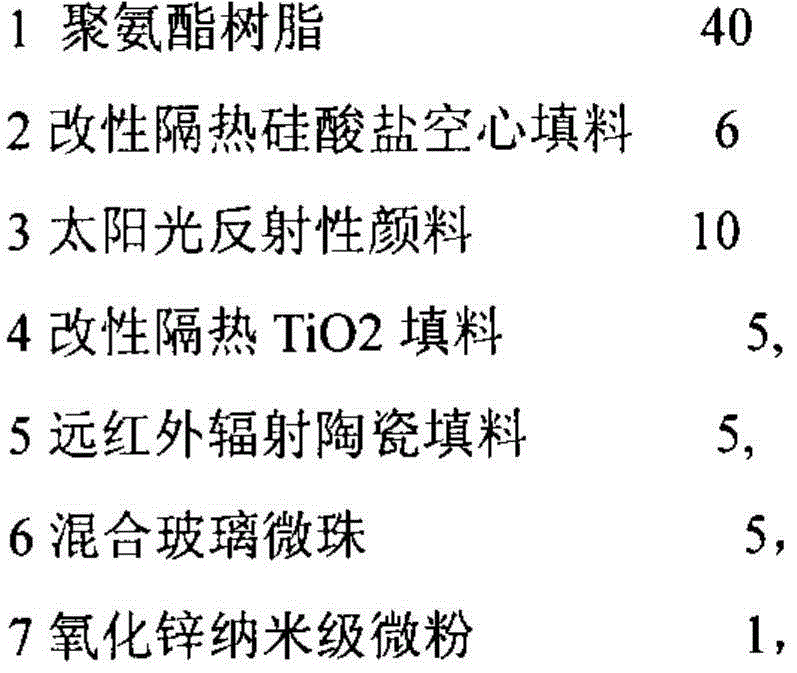

InactiveCN104985891AImprove infrared reflectivityGood dispersionSynthetic resin layered productsPolyurea/polyurethane coatingsSurface layerThermal insulation

The present invention relates to a coating material with characteristics of efficiency, energy saving, heat shield, cooling and corrosion resistance, wherein the coating material is a three-layer composite material formed from a corrosion resistance bottom layer, a thermal insulation middle layer and a heat radiating surface layer, the corrosion resistance bottom layer is epoxy zinc-rich paint, the thermal insulation middle layer comprises a three-component coating material and a curing agent according to a weight ratio of 35-50:1, and the heat radiating surface layer is a composite surface layer adopting a polyurethane resin as a film forming substance. Compared with the coating material in the prior art, the coating material of the present invention integrates advantages of corrosion resistance, thermal barrier, heat reflection, and heat radiation.

Owner:德邦新材料有限公司 +1

Method for producing high strenght flyash ceramic sand

InactiveCN1900008ALight weightHas high strengthCeramic materials productionClaywaresGranularityHigh intensity

The high strength fly ash haydite producing process belongs to the field of fly ash utilizing and new building material technology. The high strength fly ash haydite is produced with fly ash, clay, saw dust and coal powder, and through mixing in a stirrer, adding certain amount of water glass and controlling water content of about 20 %, pelletizing, sintering and cooling. The high strength fly ash haydite product has granularity of 3-5mm, bulk density of 800-900kg / cu m, and compression strength of 10-20 MPa, and may be used as aggregate of wall board.

Owner:JILIN ACAD OF AGRI MACHINERY

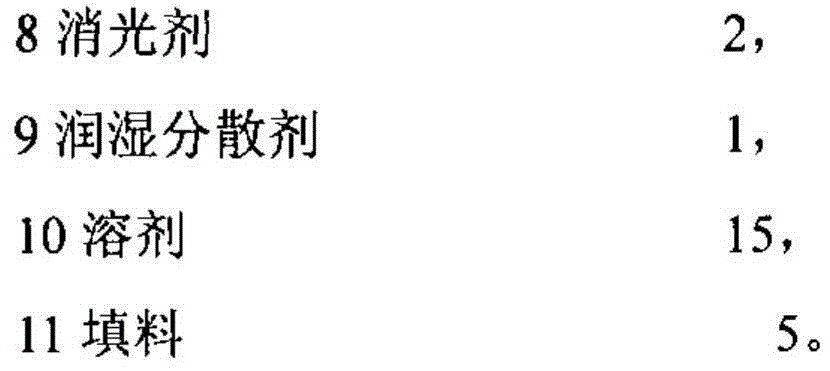

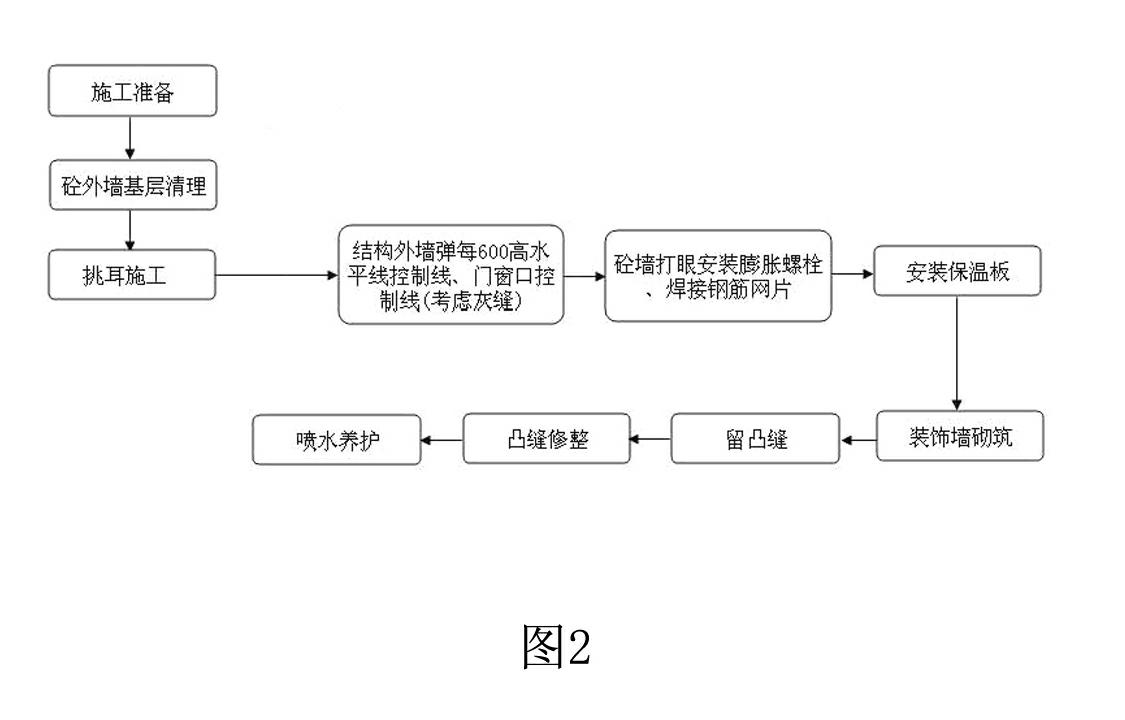

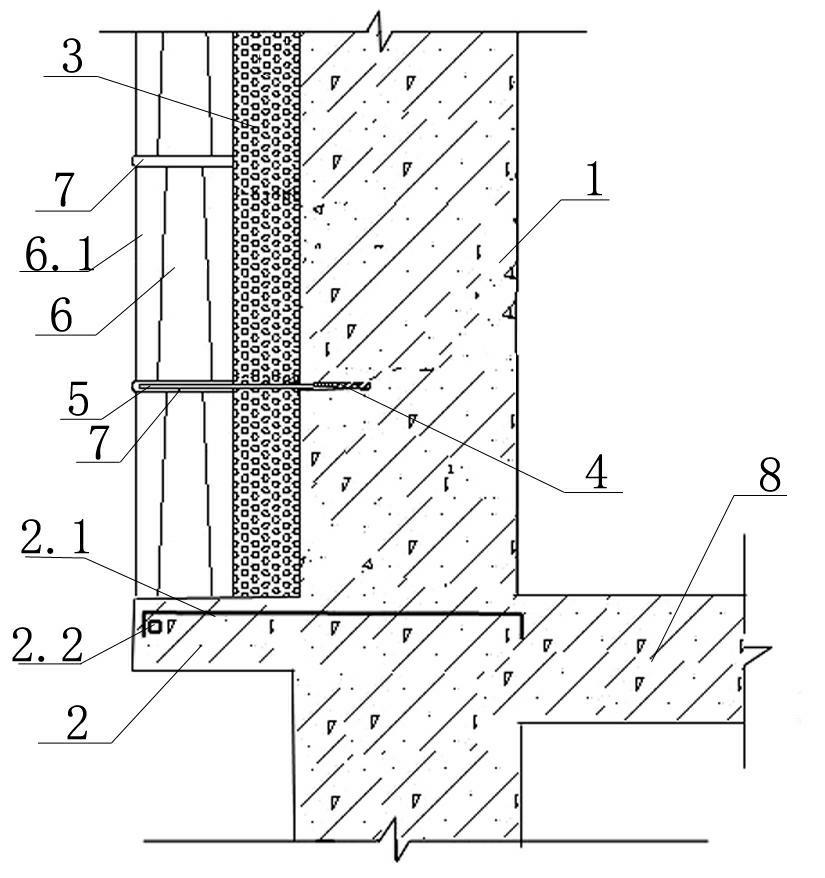

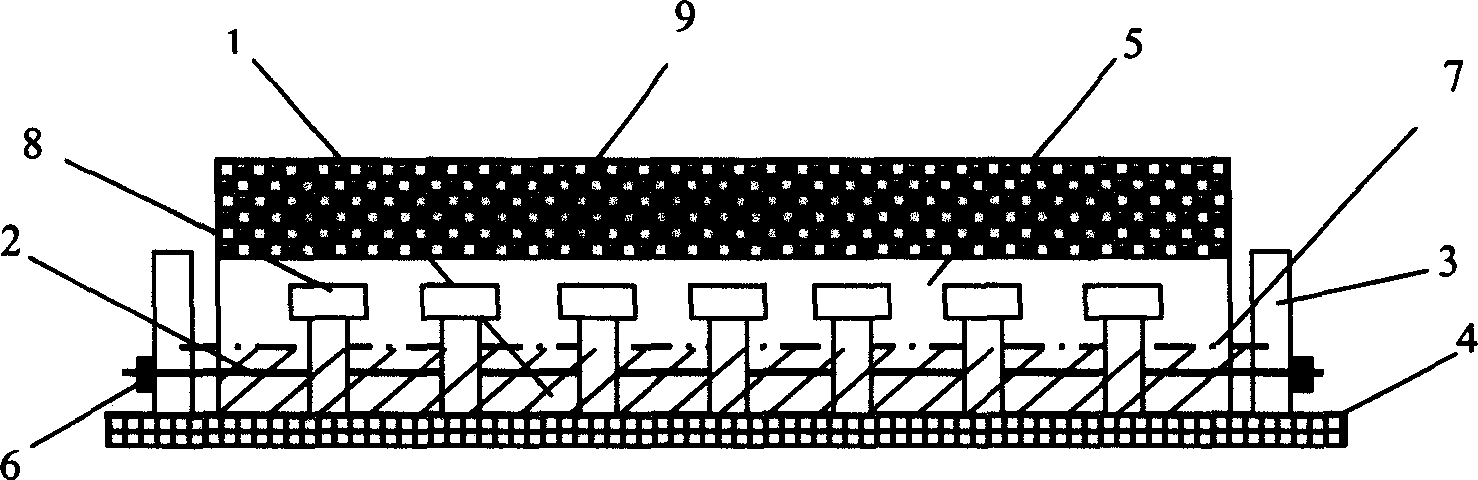

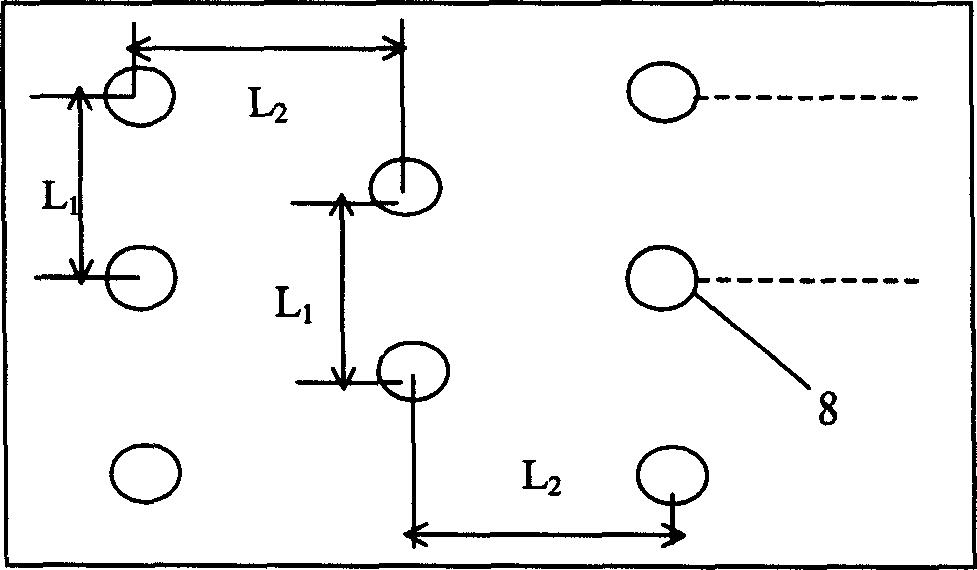

Composite exterior wall decorated with energy-saving blocks and construction method thereof

InactiveCN102094470AHas insulation effectThermal insulationConstruction materialWallsInsulation layerReinforced concrete

The invention relates to a composite exterior wall decorated with energy-saving blocks and a construction method thereof, and belongs to the technical fields of a building engineering component and a construction process. Concrete hollow blocks are taken as the external decorative layer; reinforced concrete raising ears are raised outside the intersection between a reinforced concrete structural wall and floors; the concrete hollow blocks are built on the top of the reinforced concrete raising ears; horizontal mortar joints between the neighboring concrete hollow blocks protrude outside the outer surfaces of the blocks; full steel tie bar meshes are alternately pre-embedded in the horizontal mortar joints and are welded on expansion bolts which are horizontally and alternately embedded into the reinforced concrete structural wall; and insulation boards are filled in gaps formed by the neighboring steel tie bar meshes, the reinforced concrete structural wall and the concrete hollow blocks. By utilizing the composite exterior wall and the construction method thereof, the problem of combination between concrete and an insulation layer as well as the blocks is solved; and the composite exterior wall and the construction method have the advantages of decoration and heat insulation double efficacies, high safety, beautiful appearance and the like, and can be widely applied to decoration and construction of the exterior wall.

Owner:BEIJING CENTGATE DEV & CONSTR

Sludge environmental protection block

The invention discloses a sludge environmental protection block and relates to a building block. Present blocks are clay or cement and bath brick. Chamotte brick needs a lot of clay. A lot of fine fields will be destroyed, cement-bath brick will destroy massif and river, and disasters are brought to humans. Therefore, both clay and sand should not be used as a brick-making material. Furtherly, a lot of sludge left after sewage treatment is not effectively utilized. The invention provides the environmental protection block with sludge used as a raw material. The formula of the environmental protection block contains: by weight, 18-25 parts of portland cement, 0.5-1.5 parts of expanded perlite, 25-35 parts of sludge, 8-12 parts of pulverized limestone, 30-40 parts of small broken stone, 5-12 parts of building garbage, 0.5-1 part of foamed plastic fragments and 1-3 parts of industrial fiber. The invention relates to the green industry for environmental protection, and has beneficial effects of excellent product performance, multi-purposes, simple manufacturing industry, energy conservation, low cost and the like.

Owner:周中德

Paving method of sleel bridge surface composite layer

This invention relatesto a paving method of one pavement material of steel bridge surface, including the following steps: 1) preparation of lightweight concrete of steel mixing fiber and plain lightweight concrete; 2) pre-treatment of steel bridge surface; 3) peg soldering by the method of arc stud welding; 4) steel net bonding: to bind the steel net to the peg by steel thread; 5) choice of inherent stress steel thread and infliction of inherent stress: inherent stress steel thread situates below the natural axis, inflict the inherent stress by pretensioned system, with the controlling stress between 38-42%fptk; 6) pave one layer of lightweight concrete of steel mixing fiber on the steel bridge surface, and then pave one layer of plain light concrete to the light weight concrete of steel mixing fiber; 7) pave one layer of asphalt conctete on the plain light weight concrete. This invention can efficiently solve such technical difficulties as rutting, traction and cuddling, improve greatly road qualities of the pavement and prolong the application life of steel bridge.

Owner:WUHAN MUNICIPAL CONSTR GROUP

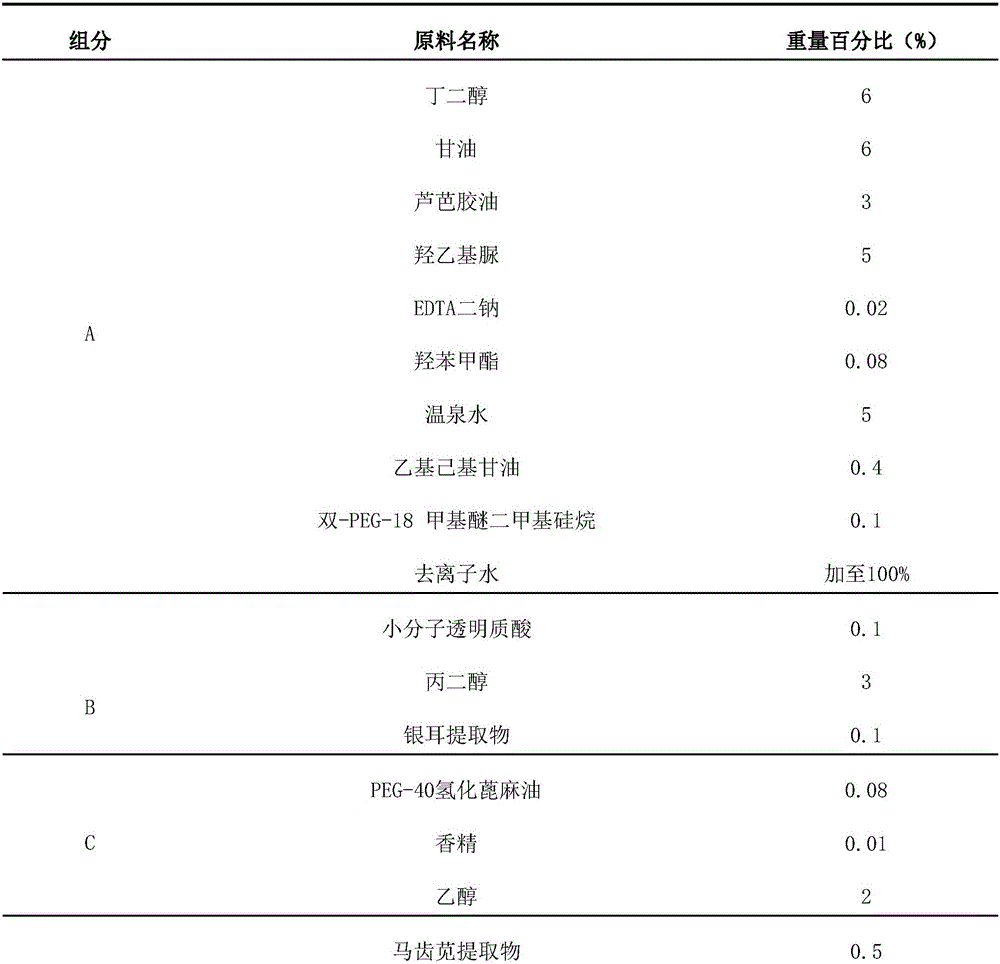

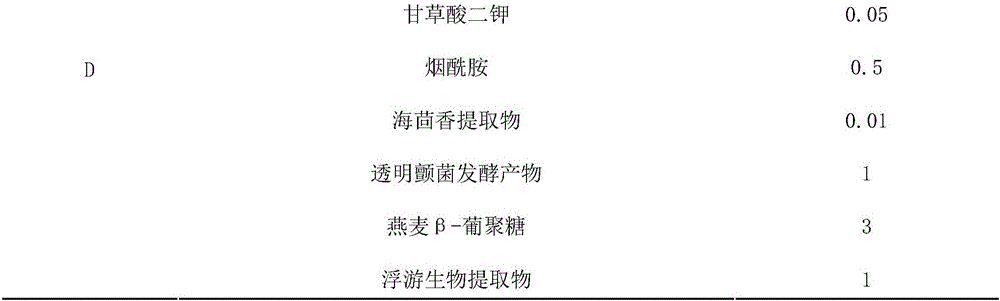

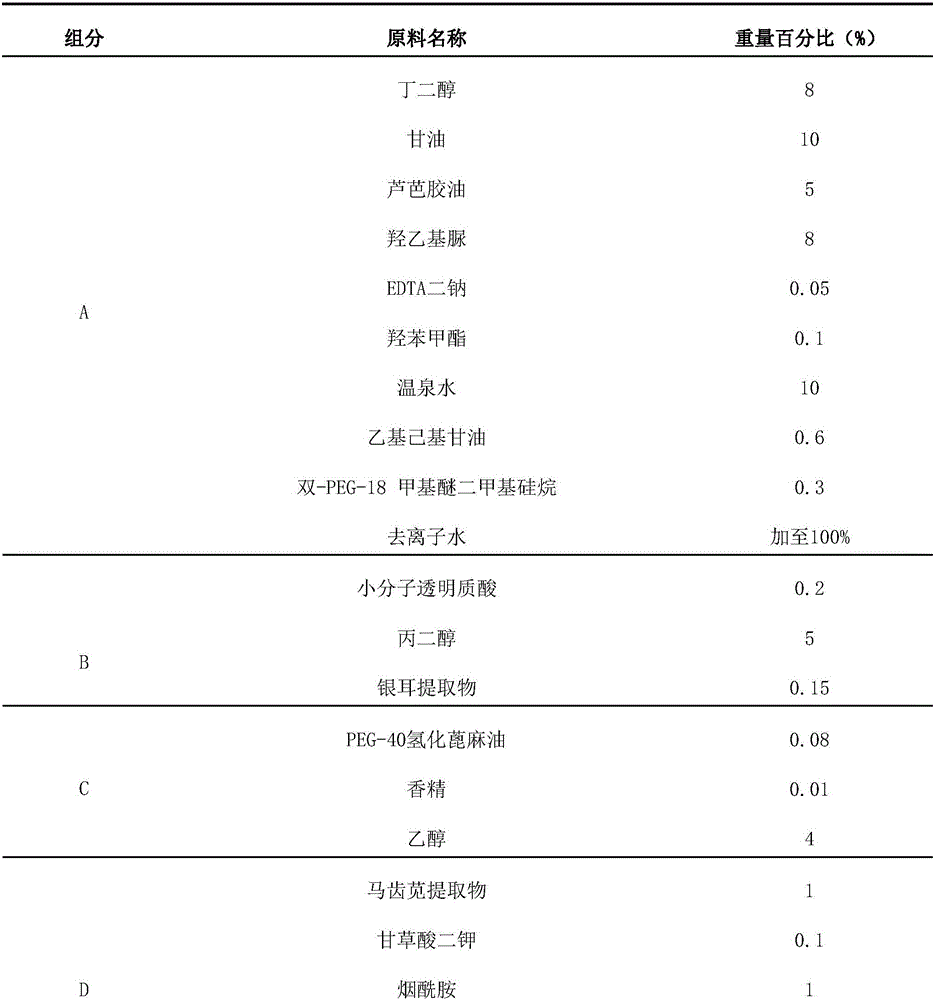

Moistening and moisturizing essence and preparation method thereof

InactiveCN105943491AHigh densityReduce penetrationCosmetic preparationsToilet preparationsSkin penetrationPreservative

The invention relates to a moistening and moisturizing essence, which is prepared from the following components in percentage by weight: a component A: 20.1 to 31.3 percent of a moisturizer, 5 to 10 percent of thermal spring water and 0.48 to 0.7 percent of a preservative; a component B: 3.2 to 5.35 percent of a moistening agent; a component C: 0.08 percent of a solubilizer and 2 to 4 percent of an odor remover; a component D: 2.51 to 6.02 percent of a skin conditioning agent and 3.05 to 5.1 percent of a skin penetration promoter. The invention also discloses a preparation method for the moistening and moisturizing essence. The moistening and moisturizing essence is mild and nonirritating in component formula and high in skin penetration, and has synergistic effects, rapid and persistent moisturizing and moisture locking effects and the effects of obviously softening skin and delaying senescence, and the skin can be moistened most rapidly and effectively.

Owner:广州市巧美化妆品有限公司

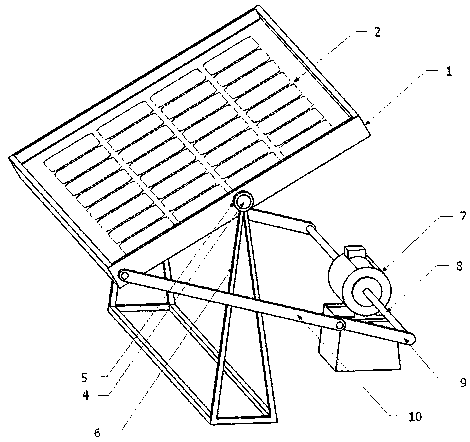

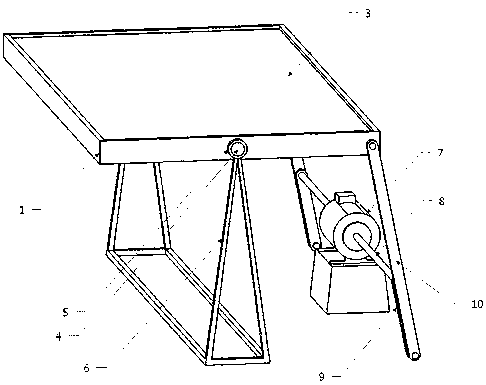

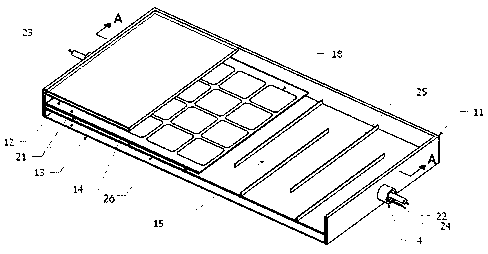

Photovoltaic photo-thermal integrated device with night radiation refrigeration function

ActiveCN109631417AImprove utilization efficiencyMake up for the limitation of single functionSolar heating energyPhotovoltaicsGlass coverFull wave

The invention discloses a photovoltaic photo-thermal integrated device with a night radiation refrigeration function. The device comprises a body module and a transmission module; the body module is abox body with openings in the top surface and the bottom surface, a heat collecting plate and a radiation refrigerating plate are arranged in the box body, the heat collecting plate and the radiationrefrigerating plate form a closed cavity with four side walls of the box body, the closed cavity forms a fluid heat exchange cavity, and a water inlet and a water outlet are formed in the two side walls of the box body; photovoltaic cells are uniformly arranged on the outer surface of the heat collecting plate of the closed cavity, a glass cover plate covers the position, corresponding to the opening of the box body, of the heat collecting plate, and a full-wave-band high-transmittance material film covers the position, corresponding to the opening of the box body, of the radiation refrigerating plate; and the transmission module comprises a motor, two connecting rods, two cranks, two rotating shafts, two supporting shafts and a bracket, so that the top surface and the bottom surface of the box body can be freely switched by starting the motor. The device integrates photovoltaic power generation, solar heat collection and night radiation refrigeration functions, and has the advantagesof being high in heat collecting efficiency, adjustable in angle, good in practicability and the like.

Owner:CHONGQING UNIV

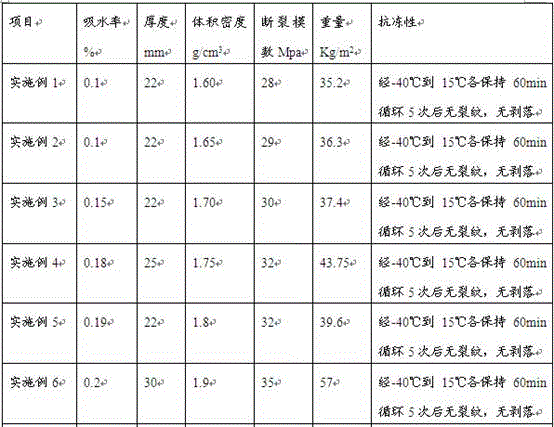

Light-weight high-strength ceramic plate and preparation method thereof

ActiveCN106431488AConducive to environmental protection and recyclingSave installation costCeramic materials productionCeramicwareSludgeHoneycomb like

The invention discloses a light-weight high-strength ceramic plate. The light-weight high-strength ceramic plate is a light-weight ceramic plate which is fired at a firing temperature of 1050-1120 DEG C and has a honeycomb-like sealed pore internal structure, the volume weight is 1.55-2.1g / cm<3>, the thickness is 18-30mm, the water absorptivity is 0.1-0.5%, and the rupture modulus is no less than 20MPa.The light-weight high-strength ceramic plate is mainly prepared from the following raw materials: 1-3 parts of silicon carbide, 15-50 parts of ceramic waste solid, 10-35 parts of sludge or sediment, 10-35 parts of bentonite, 0.1-2 parts of green body enhancer and 0.1-3 parts of dispergator. Correspondingly, the invention also provides a preparation method of the light-weight high-strength ceramic plate. The light-weight high-strength ceramic plate has the advantages of light weight, high strength, low water absorptivity and high stone simulation degree, and can be dimensionally enlarged and thickened. When being used as an outdoor high-altitude curtain wall, the light-weight high-strength ceramic plate is very safe and convenient to construct, and the hanging cost is saved.

Owner:佛山市奥幕新型建材科技有限公司

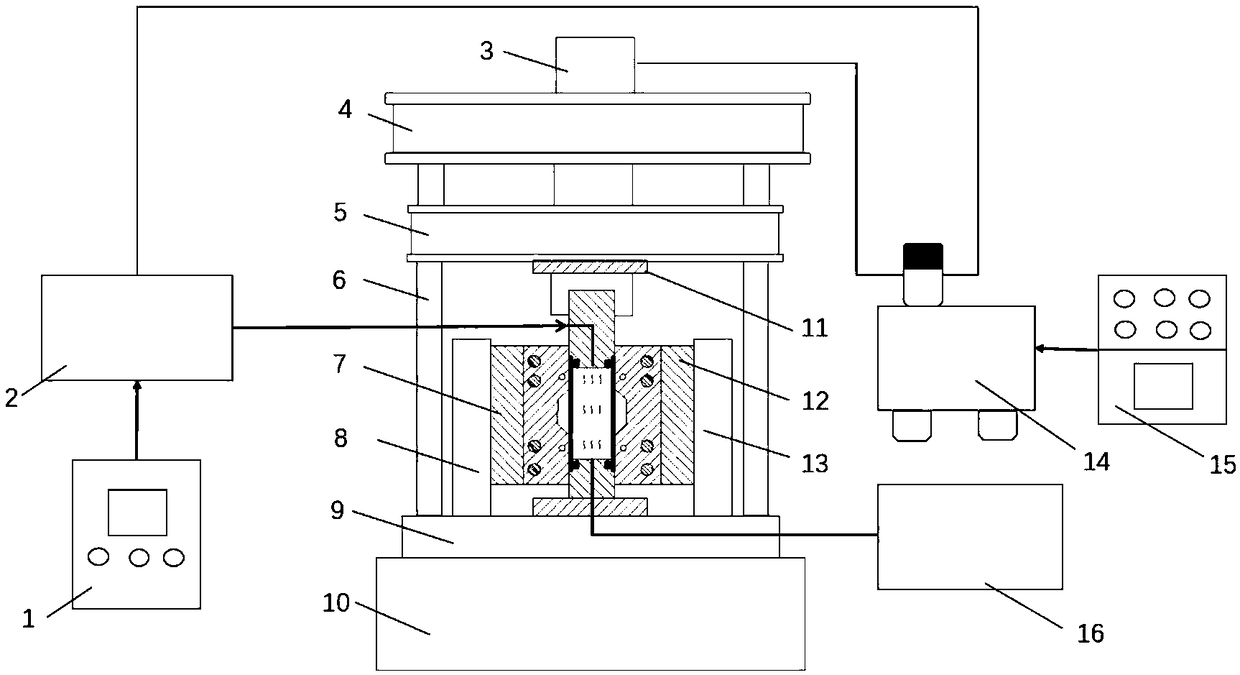

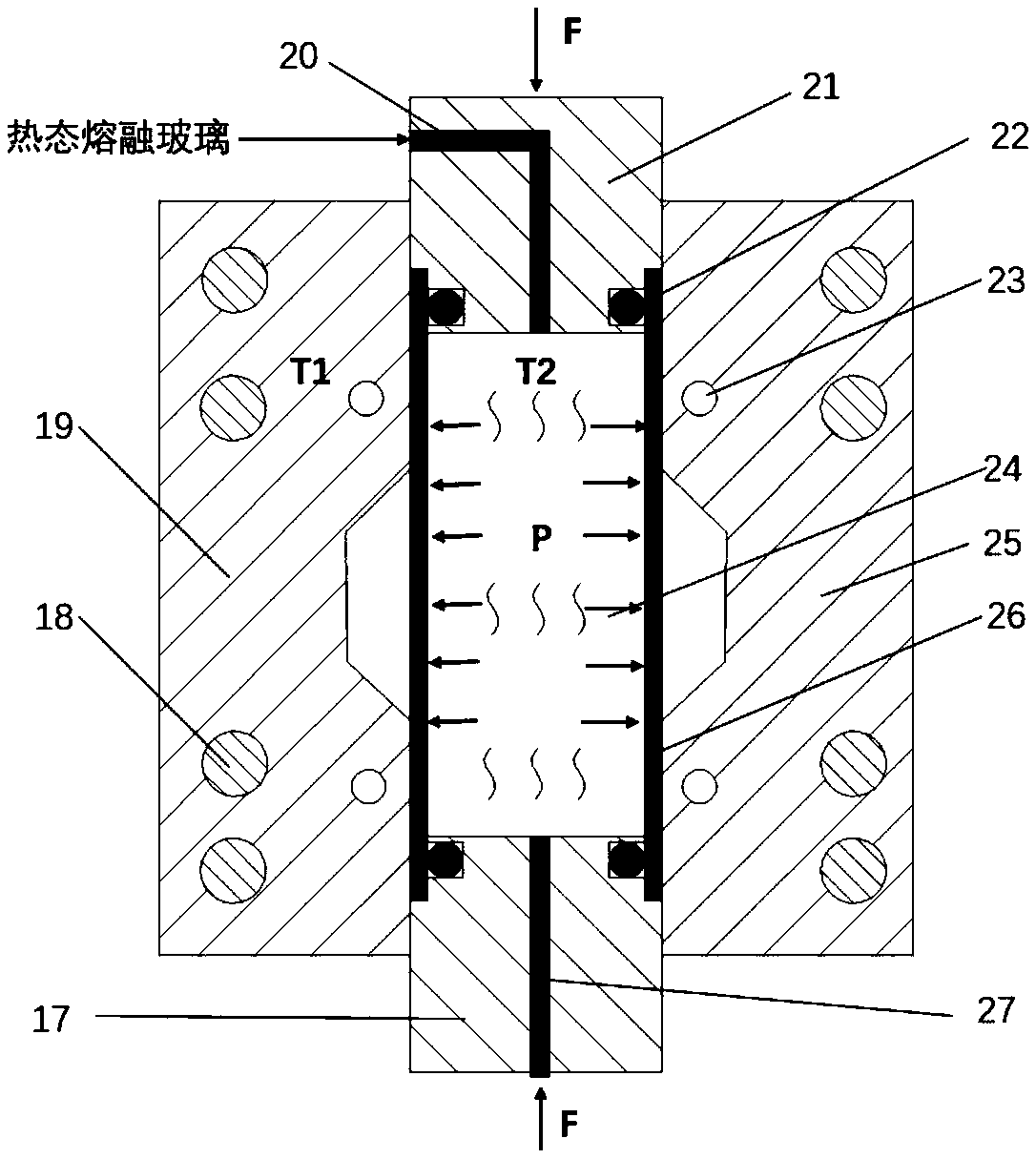

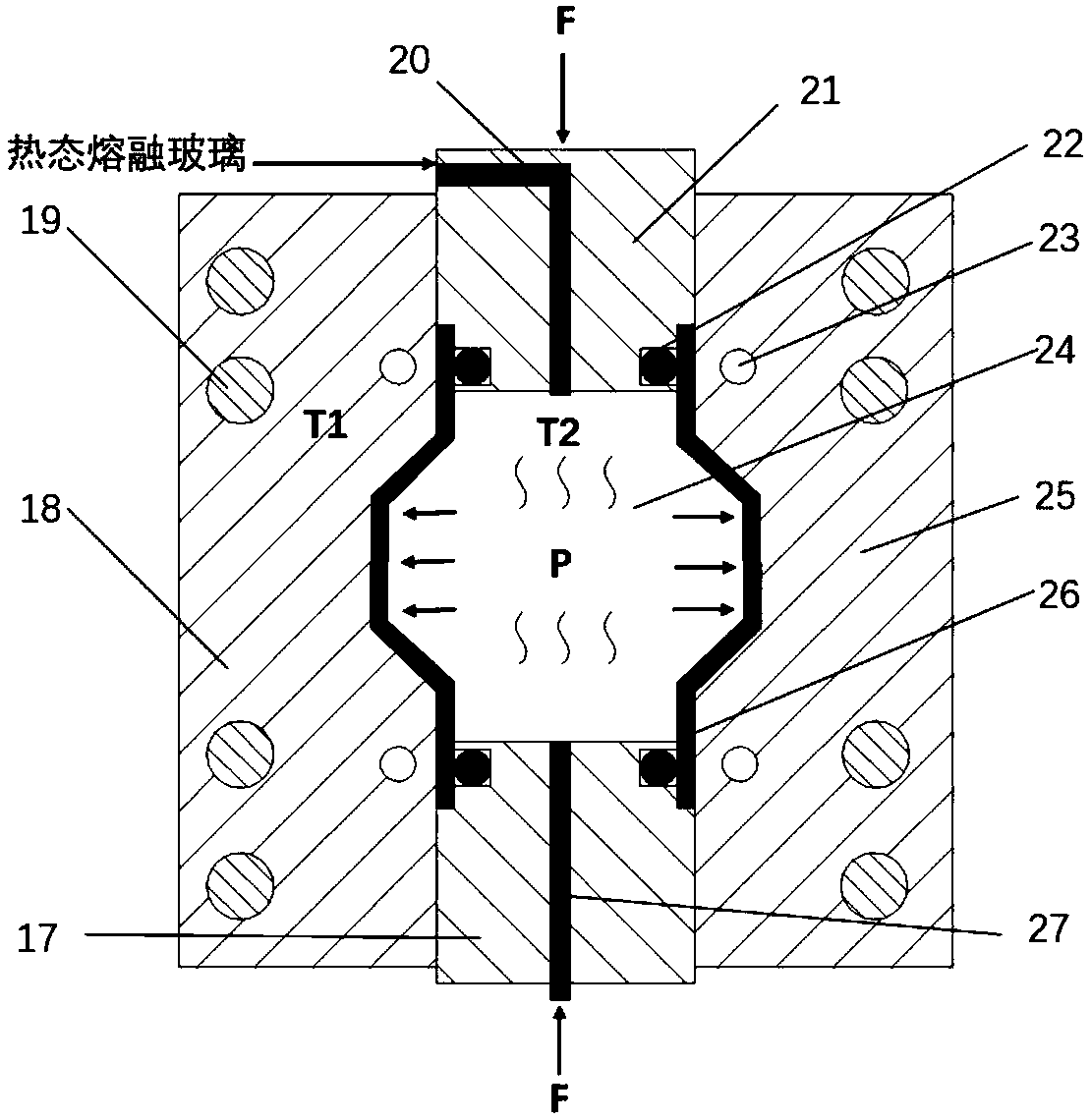

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

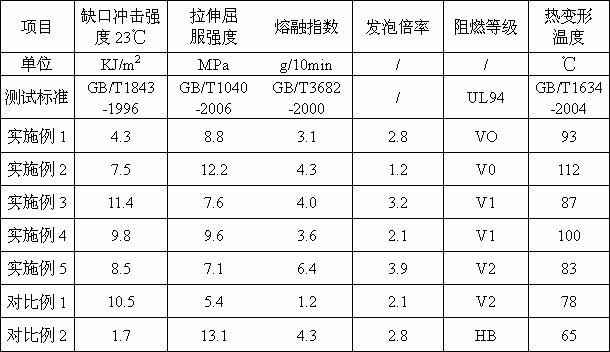

Flame retardant low foaming polypropylene material and preparation method thereof

The invention discloses a flame retardant low foaming polypropylene material and a preparation method thereof. The material comprises, by mass, 10 to 90% of polypropylene, 5 to 30% of a thermally decomposing inorganic substance, 3 to 40% of a halogen-free fire retardant, 1 to 20% of a thermoplastic elastomer, 0.1 to 1% of an anti-oxidant, 0.1 to 3% of a lubricant and 0 to 5% of a functional auxiliary agent. According to the invention, the inorganic substance with low thermal decomposition temperature is added into a polypropylene resin as a foaming agent, and water vapor generated in the decomposition of the inorganic substance is utilized for formation of bubbles; the halogen-free fire retardant is added at the same time, which enables the polypropylene resin to have a certain degree of flame resistance, thereby enlarging the utilization scope of the polypropylene resin; a pre-foaming polypropylene material is obtained through blending fusion extrusion and granulation of an obtained mixture with an extruder, and then a variety of foaming products are produced by utilizing molding equipment like injection molding or mould pressing equipment.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com