Sludge treatment process

A sludge treatment and sludge technology, applied in the field of sludge treatment process, can solve the problems of not getting better treatment effect, uneven sludge content, complex composition, etc., and achieve excellent adsorption performance and ion exchange performance, good water absorption and water retention Sexuality and gravity concentration have obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

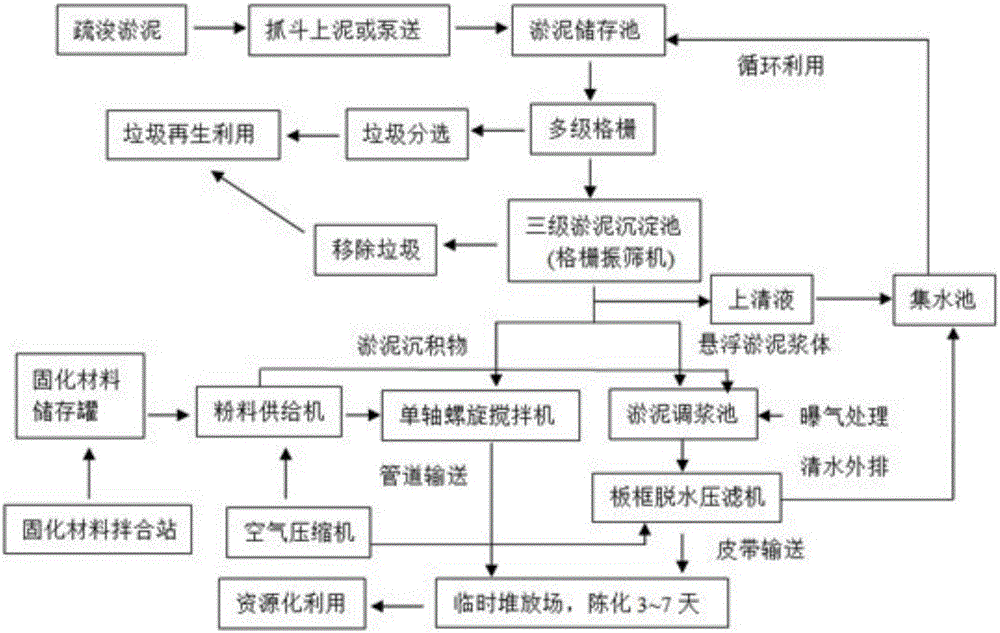

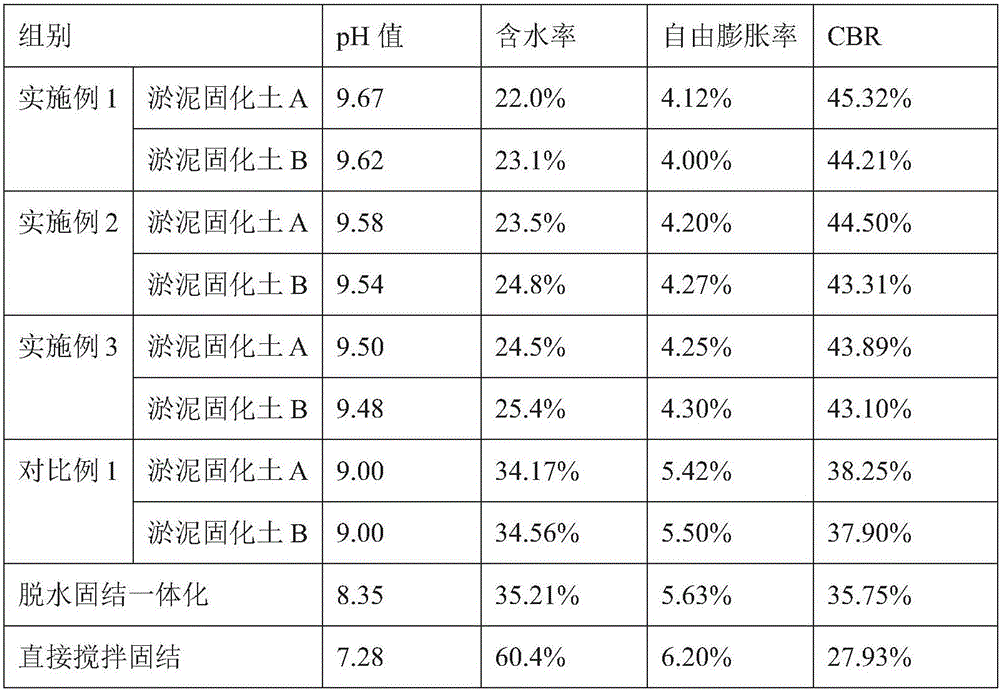

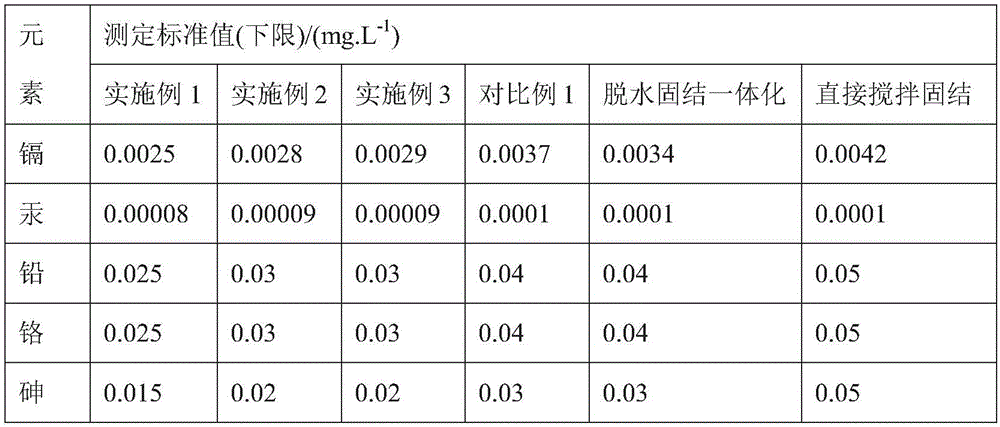

[0038] The sludge treatment process of the embodiment of the present invention 1 is characterized in that comprising the following steps:

[0039] (1) Impurity removal: use multi-stage grille to filter out the garbage in the sludge;

[0040] (2) Pretreatment: add water to the silt of step (1) to filter out the garbage, adjust the mud-water ratio of the silt to 1:6, and then place it in a three-stage sludge settling tank for pretreatment, and the described silt is settled through the first stage After the pond settles, the mud tail water enters the second-stage sedimentation tank to continue to settle, and then enters the third-stage sedimentation tank for sedimentation, and obtains the sludge in the first, second and third-stage sludge sedimentation tanks, and the sludge after sedimentation in the third-stage sludge sedimentation tank sludge slurry and supernatant;

[0041] (3) Solidification treatment: Mix the silt in the first, second and third silt sedimentation tanks even...

Embodiment 2

[0045] The sludge treatment process of the embodiment of the present invention 2 is characterized in that comprising the following steps:

[0046] (1) Impurity removal: use multi-stage grille to filter out the garbage in the sludge;

[0047] (2) Pretreatment: add water to the silt of step (1) to filter out the garbage, adjust the mud-water ratio of the silt to 1:6, and then place it in a three-stage sludge settling tank for pretreatment, and the described silt is settled through the first stage After the pond settles, the mud tail water enters the second-stage sedimentation tank to continue to settle, and then enters the third-stage sedimentation tank for sedimentation, and obtains the sludge in the first, second and third-stage sludge sedimentation tanks, and the sludge after sedimentation in the third-stage sludge sedimentation tank sludge slurry and supernatant;

[0048] (3) Solidification treatment: Mix the silt in the first, second and third silt sedimentation tanks even...

Embodiment 3

[0052] The sludge treatment process of the embodiment of the present invention 3 is characterized in that comprising the following steps:

[0053] (1) Impurity removal: use multi-stage grille to filter out the garbage in the sludge;

[0054] (2) Pretreatment: add water to the silt of step (1) to filter out the garbage, adjust the mud-water ratio of the silt to 1:6, and then place it in a three-stage sludge settling tank for pretreatment, and the described silt is settled through the first stage After the pond settles, the mud tail water enters the second-stage sedimentation tank to continue to settle, and then enters the third-stage sedimentation tank for sedimentation, and obtains the sludge in the first, second and third-stage sludge sedimentation tanks, and the sludge after sedimentation in the third-stage sludge sedimentation tank sludge slurry and supernatant;

[0055] (3) Solidification treatment: Mix the silt in the first, second and third silt sedimentation tanks even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com