Patents

Literature

287results about How to "Lightweight and high strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

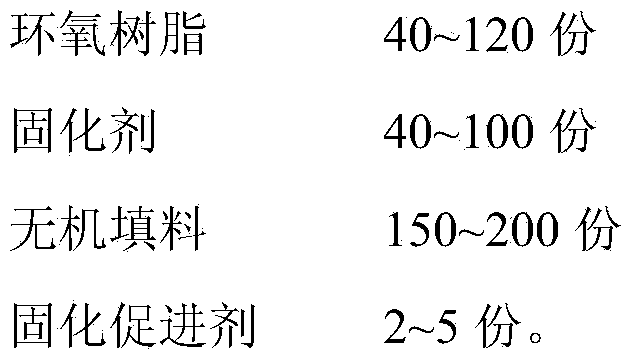

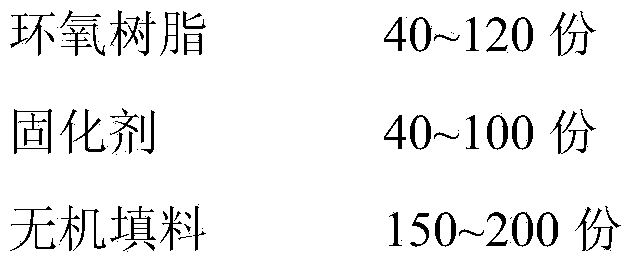

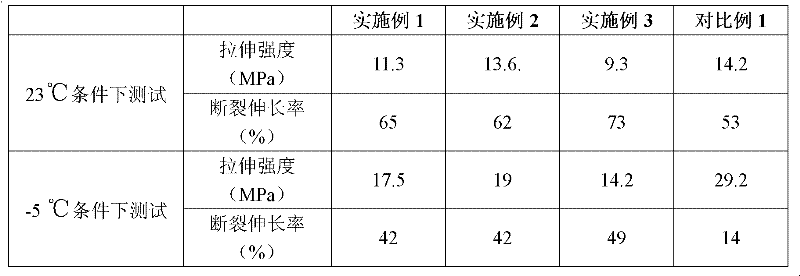

Outdoor electric-insulation modified epoxy resin composition

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

Flexible epoxy adhesive and application

InactiveCN102408860AGood flexibilityImprove mechanical propertiesPolyureas/polyurethane adhesivesMacromolecular adhesive additivesAging resistanceRoad surface

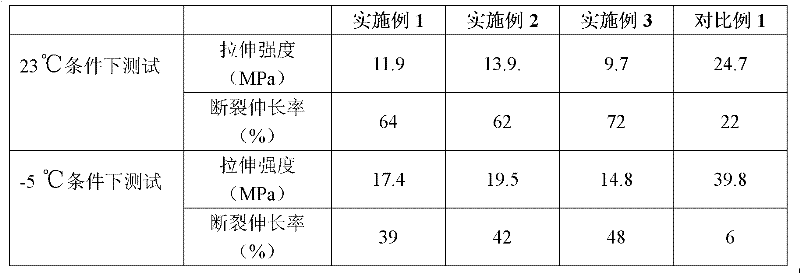

A flexible epoxy adhesive and application thereof are disclosed, wherein the flexible epoxy adhesive comprises a component A and a component B; the component A is composed of the following components according to part by weight: 100 parts by weight of epoxy resin, 30-50 parts by weight of polyurethane blocked by acrylate groups, 15-20 parts by weight of diluting agent and 1-2 parts of coupling agent; and the component B is composed of the following components according to part by weight: 100 parts by weight of modifying curing agent, 1-2 parts by weight of accelerator and 0.1-0.5 parts by weight of defoamer, and wherein the weight ratio of the component A to the component B is 2: 0.8-1.2. In addition, the invention also relates to the application of the epoxy adhesive as an adhesive for aroad surface coating. The flexible epoxy adhesive of the invention not only keeps good mechanical properties of the epoxy resin, but also has excellent properties as quick curability at normal temperature, excellent ageing resistance, low temperature resistance, good flexibility, high elongation at break and the like. Besides, the road surface coating formed from the flexible epoxy adhesive and abrasive aggregates is anti-skid and wearable, high in road surface comfort, excellent in durability, economic and environment-friendly, etc.

Owner:湖南固特邦土木技术发展有限公司

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

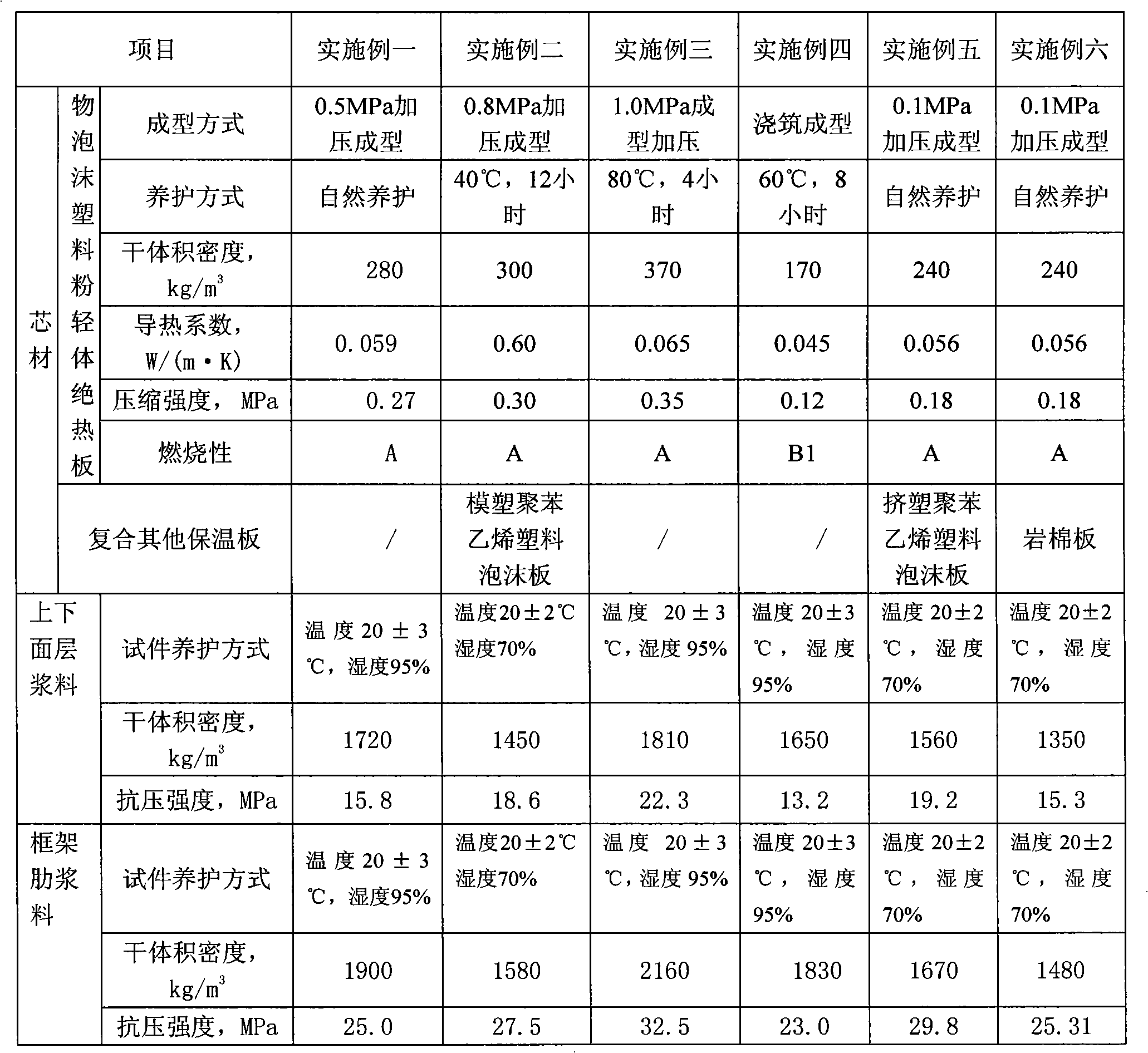

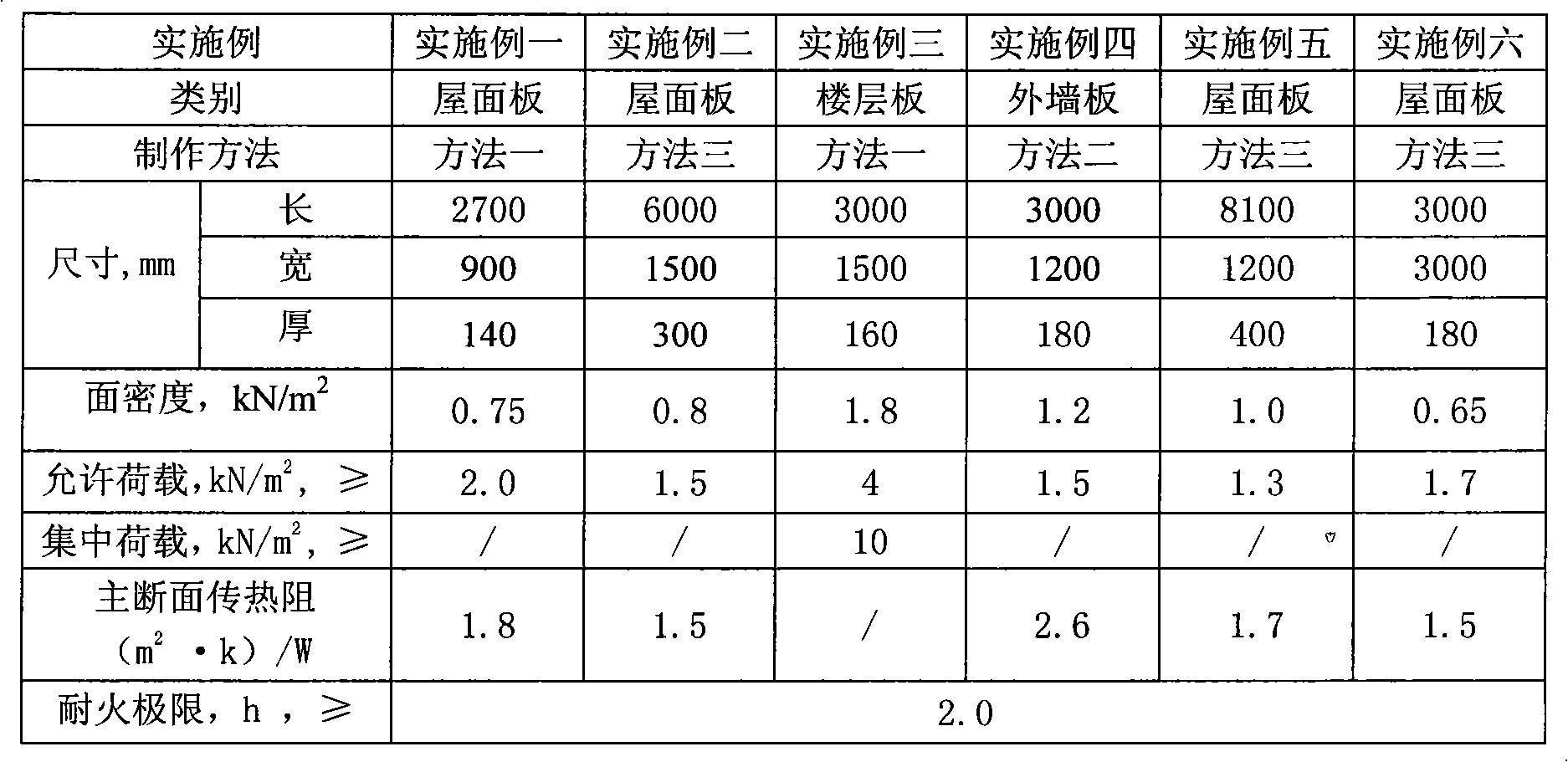

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

Resin mixture and glass reinforced plastic section bar prepared thereby

InactiveCN101157795ALightweight and high strengthThermal insulationPolymer scienceLow temperature curing

The invention relates to a resin mixture used for producing FRP (fiberglass-reinforced plastics) profile, the FRP profile made from the mixture and a preparation method thereof. The resin mixture comprises the following materials according to weight proportion: 10 of resin, 0.4 to 3 of low shrinkage agent, 2 to 15 of fillers, 0.05 to 0.2 of low temperature curing agent, 0.05 to 0.2 of high temperature curing agent, 0.05 to 0.2 of parting agent, 0.02 to 0.5 of pigment and appropriate amount of coupling agent and ultraviolet absorbent. The preparation method of the FRP profile by using the mixture is that: a reinforcing material is immersed into the resin mixture. The obtained material is extruded to get forming under high temperature and high pressure through a die; during the extrusion forming, the die is heated after being separated into three segments, and the temperature of the three segments is respectively 60 DEG C to 100 DEG C of a first segment, 100 DEG C to 150 DEG C of a second segment, 100 DEG C to 148 DEG C of a third segment; the haulage speed is 320 mm / min.

Owner:潘锦荣

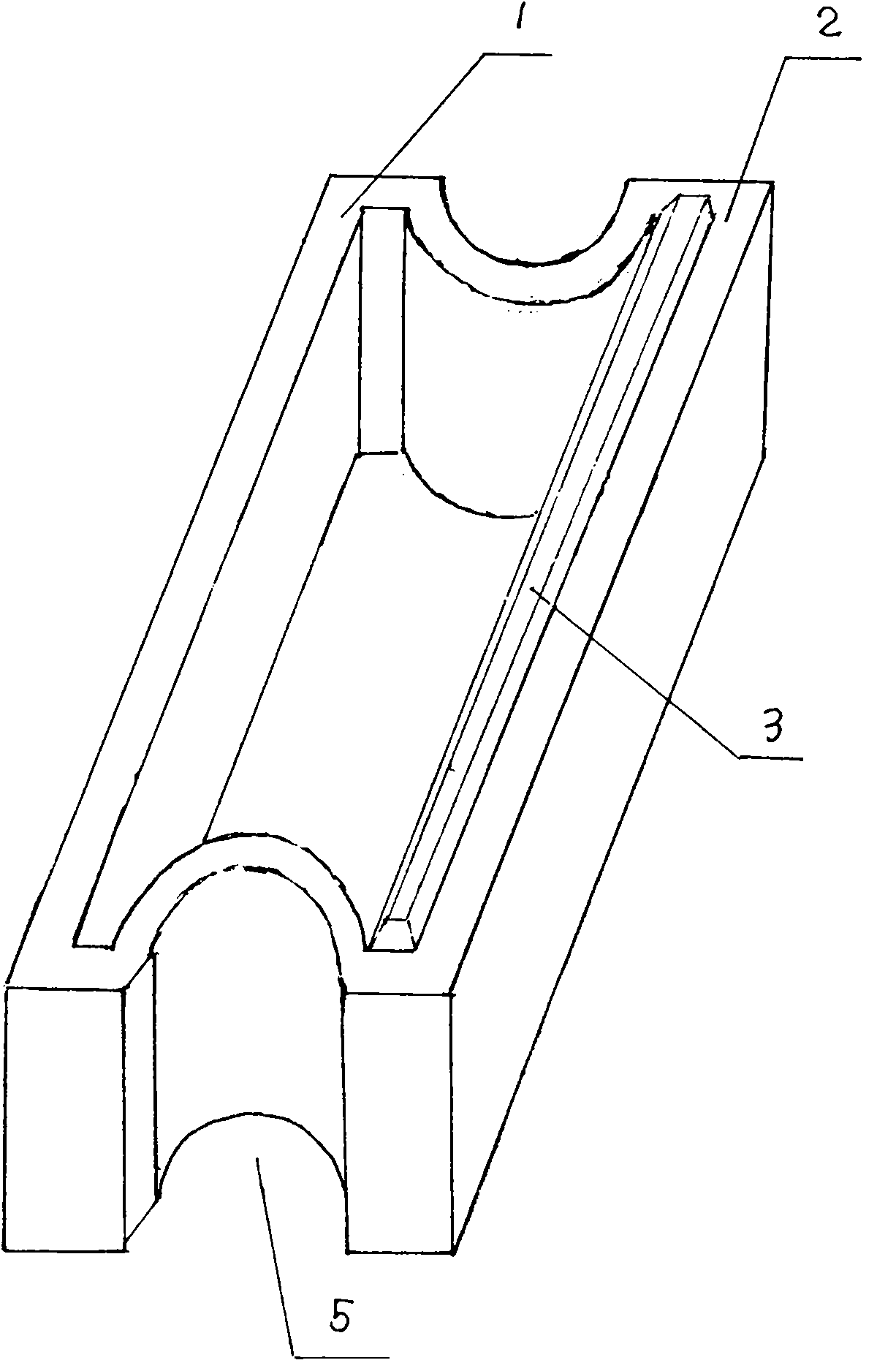

Heat-storage heat-preserving building block and manufacturing and installation method

InactiveCN101858121ATight gapLightweight and high strengthConstruction materialGreenhouseArchitectural engineering

The invention relates to a heat-storage heat-preserving building block and a manufacturing and installation method. The heat-storage heat-preserving building block comprises a shell, a heat-preserving layer and a heat-storage layer, and is manufactured in a fractional step method or a one-step method: two ends of the building block are provided with a groove; when installing the building block on the construction field, concrete is poured inside the groove to form a bearing structural column, so the building block is independent from the bearing structural column; the wall body built by the building block has compact seam, light weight, high strength and heat storage and preservation, is not only applicable to the building wall body of house, but also is particularly applicable to the building wall body of sunlight green house.

Owner:白建国

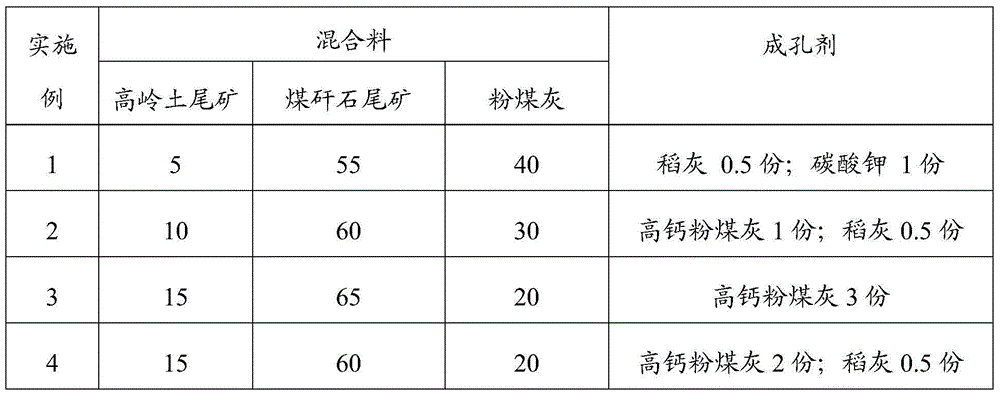

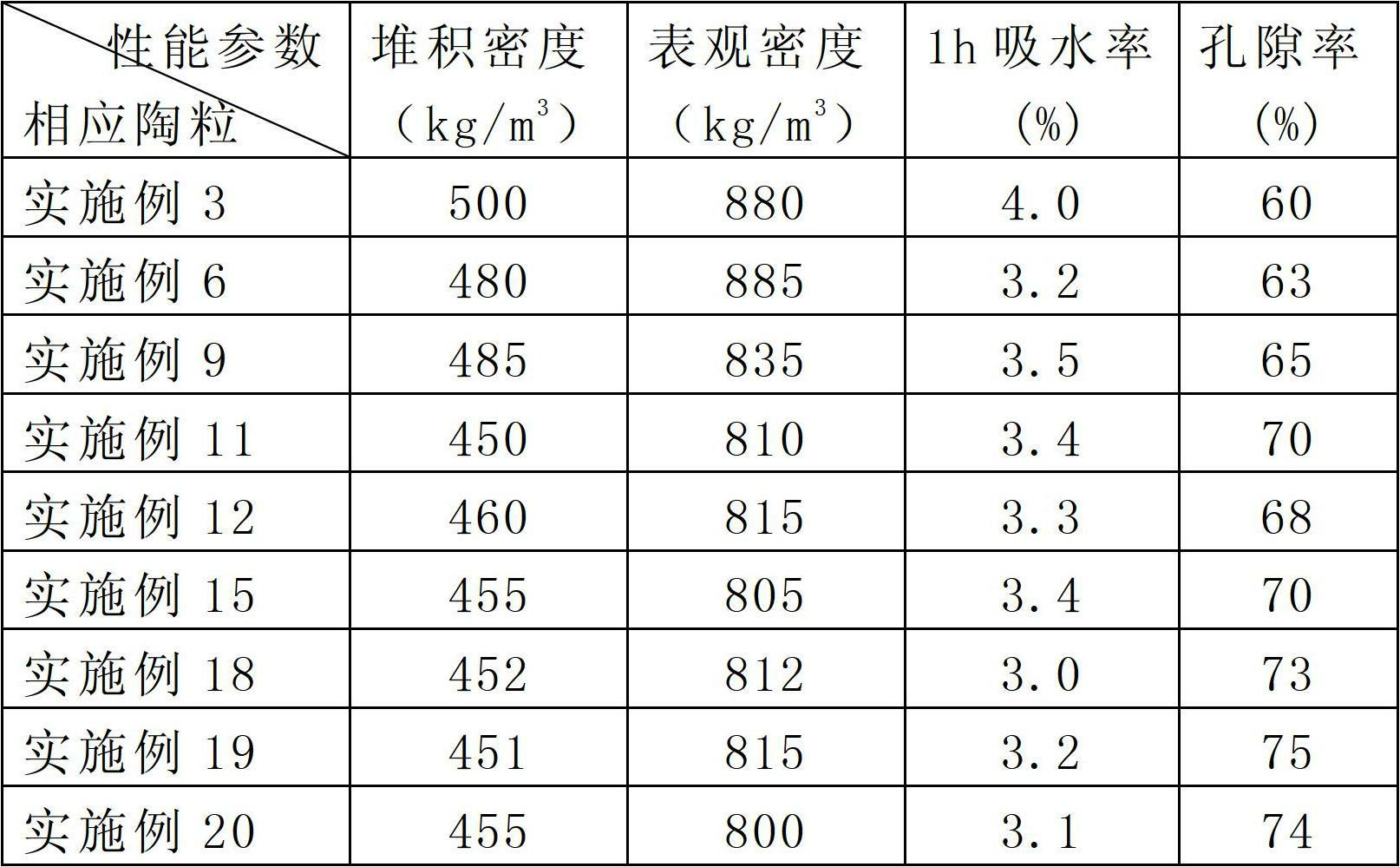

Lightweight high-strength ceramsite and preparation method thereof

InactiveCN104909799ALightweight and high-strengthCeramic materials productionCeramicwareThermal insulationExpanded clay aggregate

The invention provides a lightweight high-strength ceramsite and a preparation method thereof. The lightweight high-strength ceramsite comprises a mixed material and a pore forming agent at a mass ratio of 100:1.5-3; the mixed material comprises, by weight, 5 to 15 parts of kaolin tailing, 55 to 65 parts of coal gangue, and 20 to 40 parts of fly ash. The preparation method comprises following steps: kaolin tailing, coal gangue, and fly ash are mixed, and an obtained mixture is subjected to grinding, and sieving using a sieve of 0.16mm; the pore forming agent is added, an obtained product is mixed uniformly, water is added, and an obtained material is stirred and is subjected to moulding until desired size is achieved so as to obtain a ceramsite raw batch; the ceramsite raw batch is delivered into a high temperature furnace for 10 to 20min of thermal insulation at 1050 DEG C so as to finish sintering. According to the preparation method, the raw materials are all wastes; waste utilization rate is as high as 100%; and the lightweight high-strength ceramsite can be obtained via sintering at low temperature.

Owner:福建省建筑科学研究院

Glass fiber reinforced plastic curing agent composition and glass fiber reinforced plastic composite material prepared by same as well as cable trough

ActiveCN102977574AGood anti-aging performanceHigh strengthElectrical apparatusGlass fiberBenzoyl peroxide

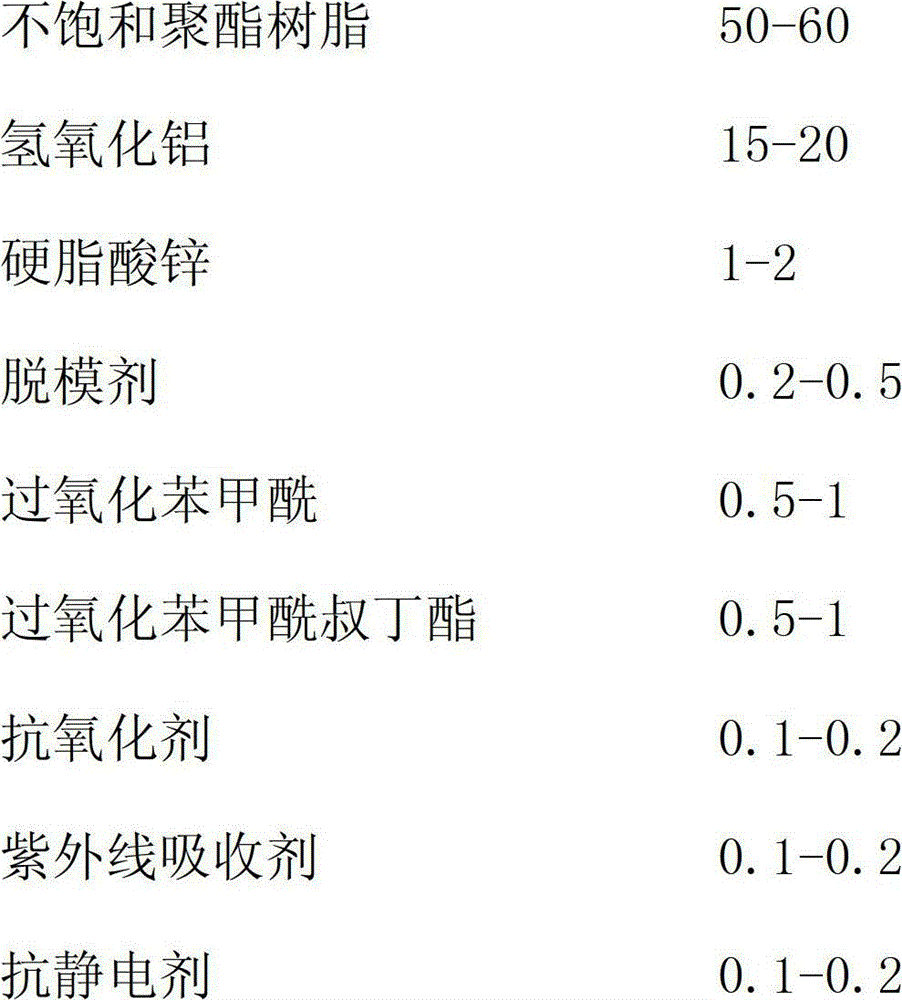

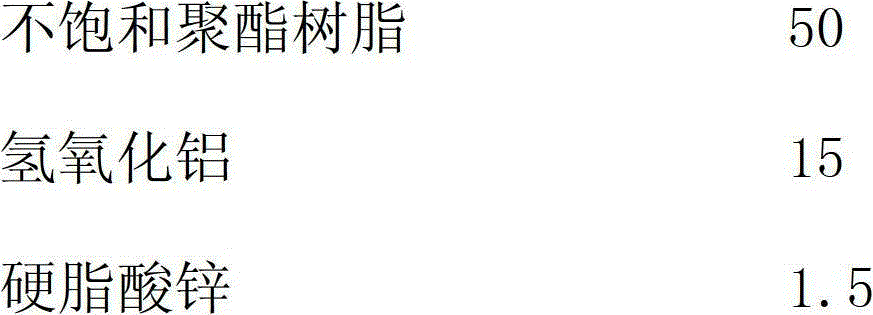

The invention discloses a glass fiber reinforced plastic curing agent composition and a glass fiber reinforced plastic composite material prepared by the same as well as a cable trough. The glass fiber reinforced plastic curing agent composition is formed by the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 15-20 parts of aluminum hydroxide, 1-2 parts of zinc stearate, 0.2-0.5 part of de-molding agent, 0.5-1 part of benzoyl peroxide, 0.5-1 part of benzoyl peroxide tert-butyl ester, 0.1-0.2 part of antioxidant, 0.1-0.2 part of ultraviolet absorbent, and 0.1-0.2 part of antistatic agent. A glass fiber reinforced plastic material is prepared by an extruding and molding process. The glass fiber reinforced plastic material prepared by the curing agent composition disclosed by the invention is low in production cost, has light weight and high strength, and has good weather resistance even under an extreme hygrothermal environment.

Owner:ELECTRICITY AFFAIR ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

Method for in-situ preparation of TiBO2 reinforced magnesium-based composite material

The invention relates to a method of in-situ preparing TiB2 granule strengthening Mg-based composite material in the composite material technical field. The steps are that: powder of K2TiF6, KBF4 and Na3AlF6 are mixed uniformly and then put into a kiln for drying, thus obtaining waterless powder. Aluminum ingot is melted in a resistance furnace with heat preservation and uniformity; the waterless powder after dried is added to the melting Al melt liquid by batch and then is stirred with a graphite disc, and scum on the surface of the melt liquid is removed after stirred and stewed, thus obtaining TiB2-Al intermediate alloy; magnesium alloy is smelted with the protection of SF6 and CO2 mixing gas, and flame retardant element beryllium is added; the TiB2-Al intermediate alloy is added into the magnesium alloy melting solution slowly, stirred, stewed and cast. The technology of the invention is comparatively simple, has low cost, and the density of TiB2 / Mg composite material is between 1.8-2.0g / cm<3> and tensile strength thereof is increased by more than 60 percent than base alloy.

Owner:SHANGHAI JIAO TONG UNIV

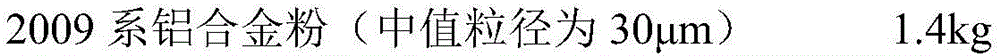

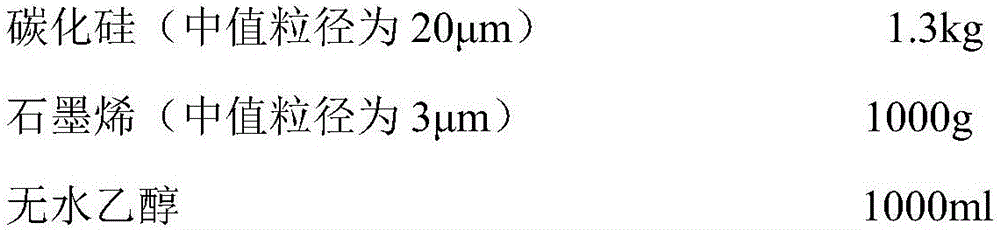

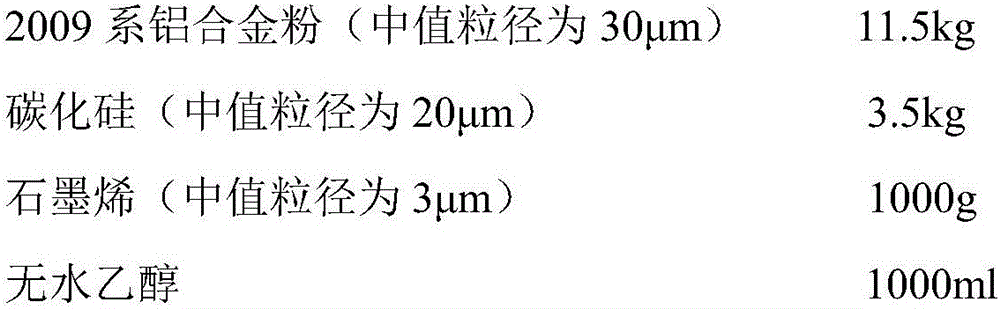

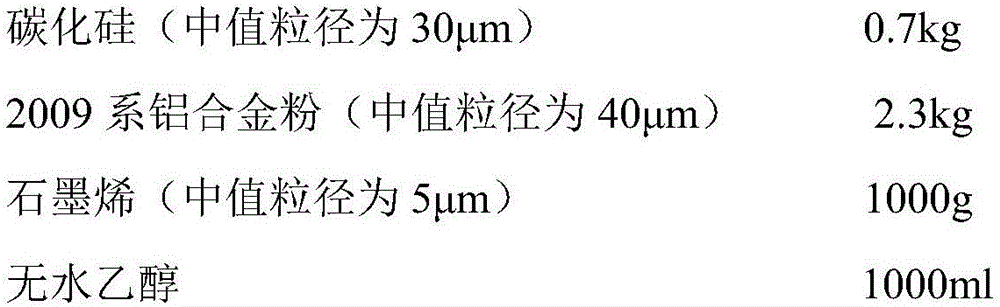

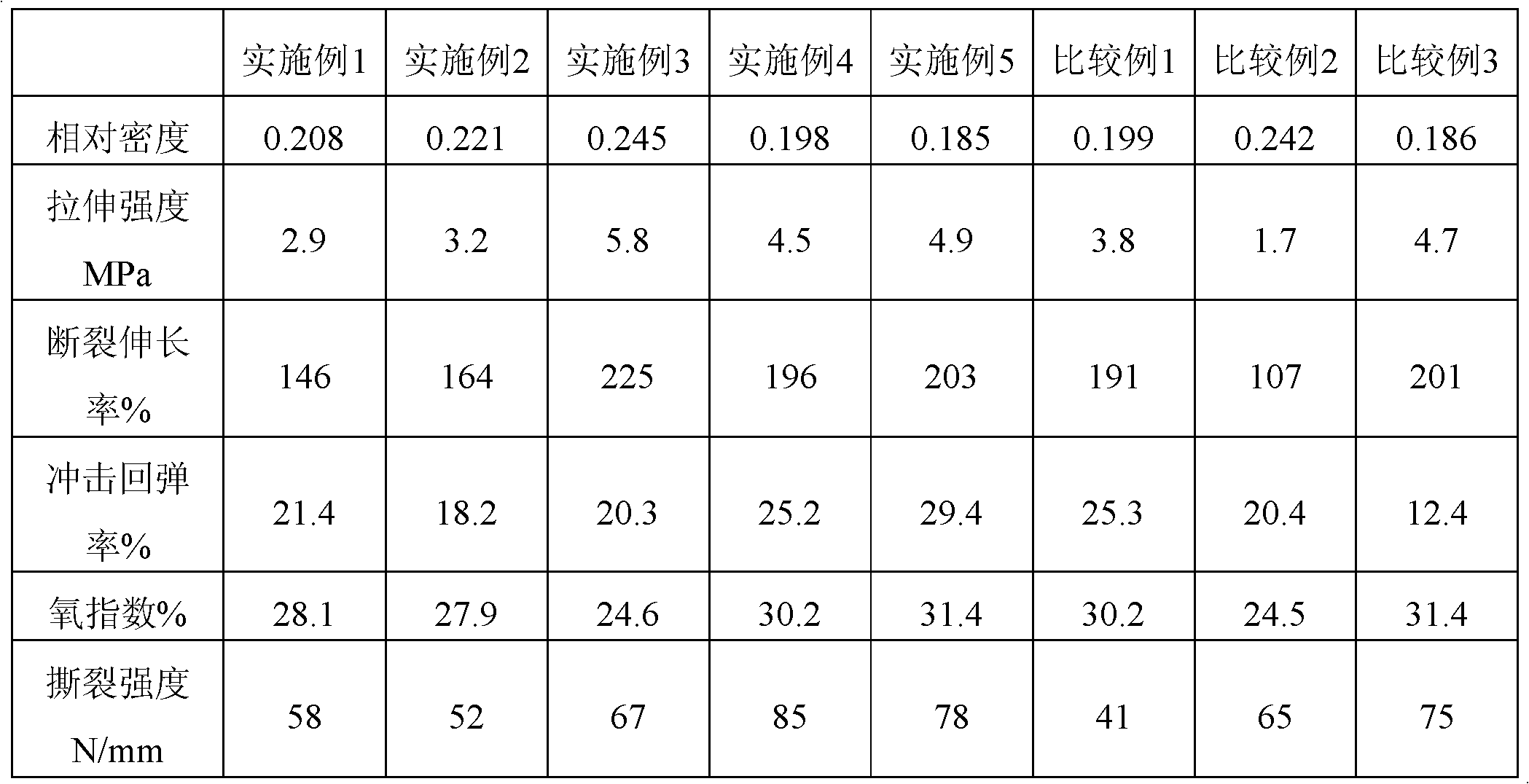

Graphene enhanced aluminium-based silicon carbide composite, preparation method and application thereof

ActiveCN106591666AImprove reliabilityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal diffusivityElectronic packaging

The invention relates to a graphene enhanced aluminium-based silicon carbide composite and a preparation method thereof. The composite comprises the following substances by volume percent: 40% to 70% of silicon carbide and 0.5% to 5% of graphene, and the balance being aluminium alloy. The composite is prepared through the powder metallurgy method and is obtained through the steps of blending, powder mixing, bagging, vacuum degassing and hot iso-hydrostatic forming treatment. The composite has the advantages of high thermal conductivity, high strength, high plasticity, light weight, good thermal diffusivity, isotropy, and the like, and becomes a second-generation electronic packaging material with wide application.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

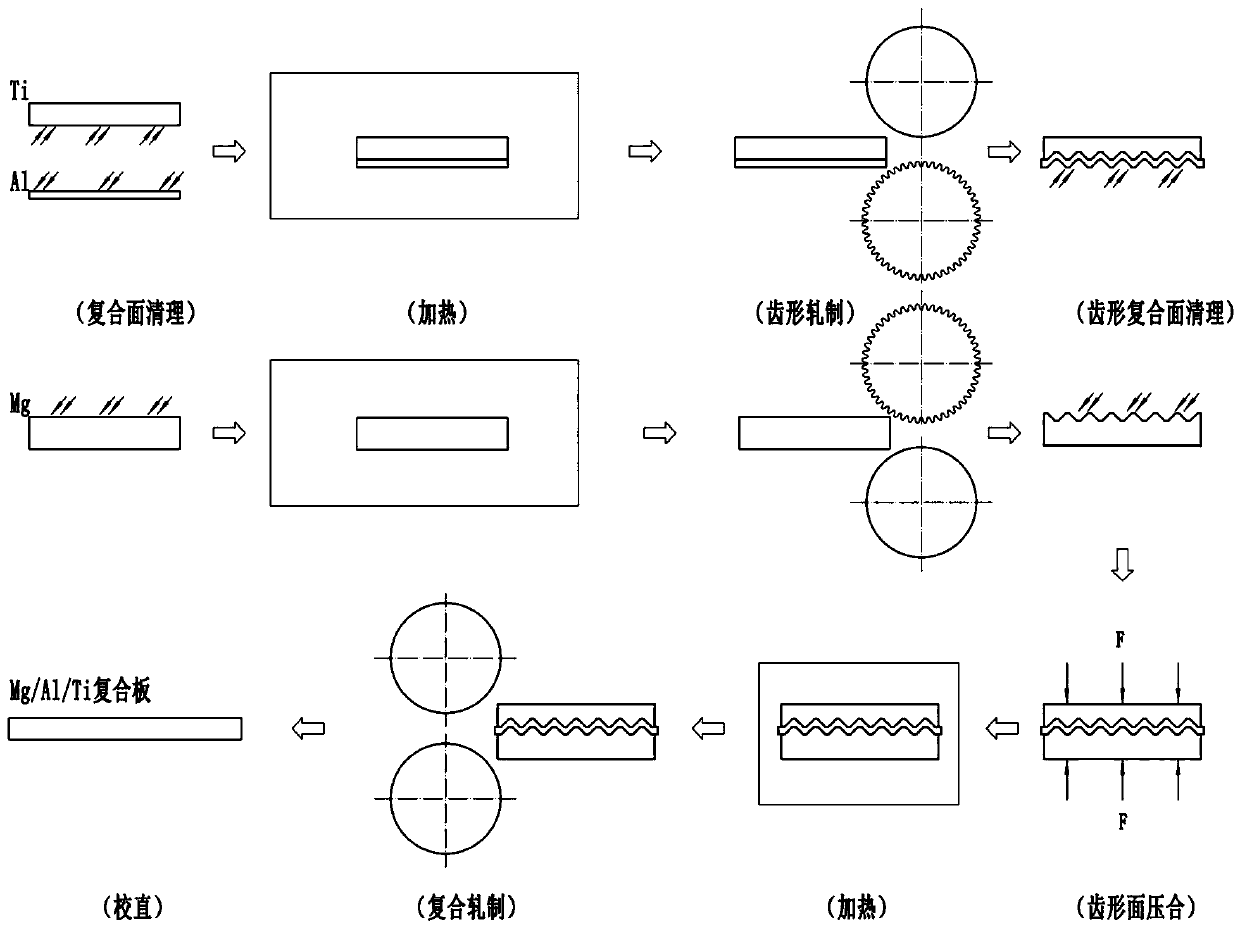

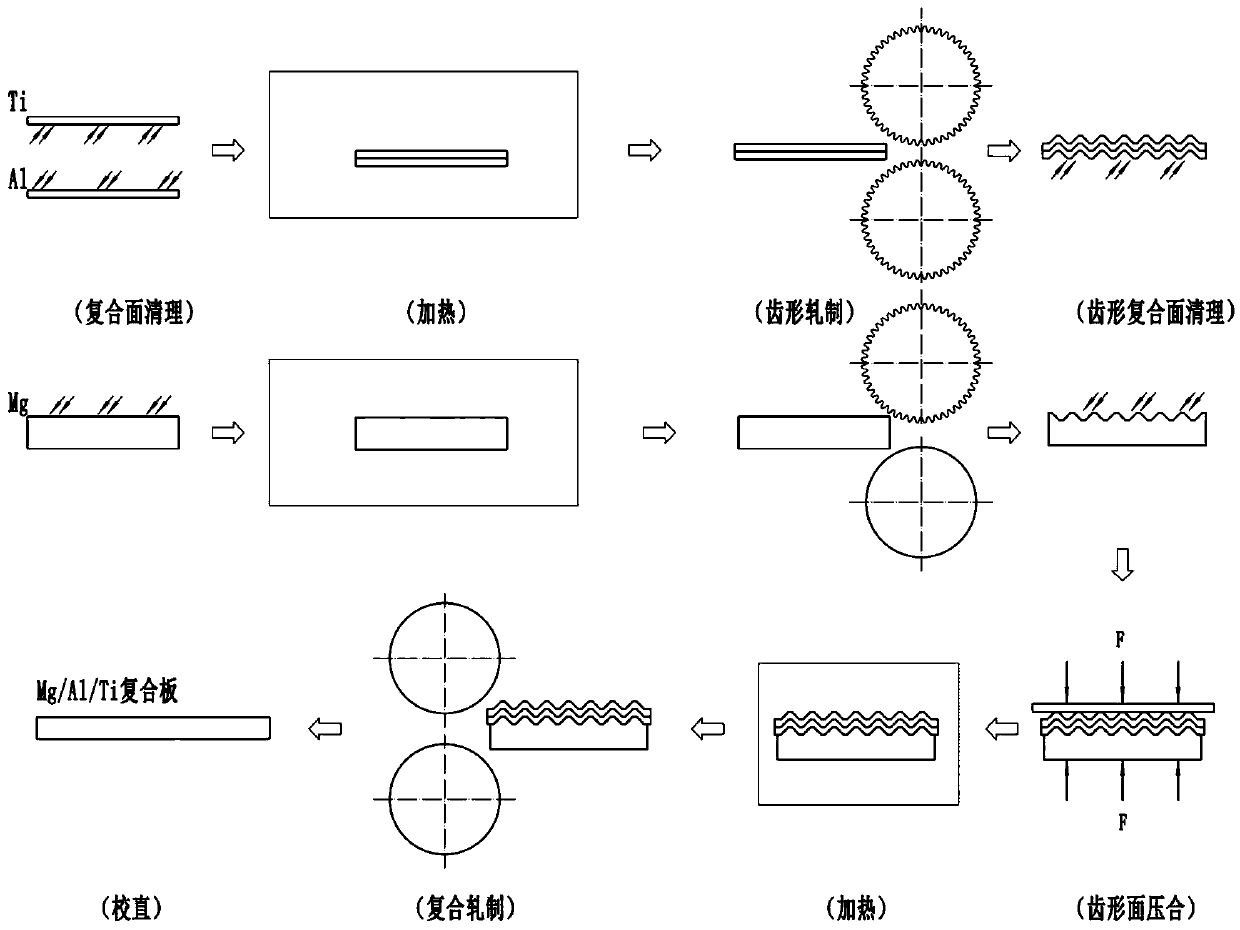

Rolling preparing method of tooth-shaped junction surface of titanium/aluminum/magnesium composite board

InactiveCN109731912APrevent oxidationImprove interface qualityMetal rolling arrangementsTitaniumStressed state

The invention discloses a rolling preparing method of a tooth-shaped junction surface of a titanium / aluminum / magnesium composite board. According to the method, an aluminum alloy sheet serves as a middle transition layer, finally, titanium alloy and aluminum alloy boards are rolled and composited under the high temperature, a composite face is a tooth-shaped face, a magnesium alloy board is rolledunder the high temperature, the face to be composited is the tooth-shaped face, and the tooth-shaped faces of the titanium / aluminum composite board and the magnesium alloy board are engaged and pressed, rolling compositing is carried out at the high temperature, and the titanium / aluminum / magnesium composite plate finished product is obtained. The titanium / aluminum tooth-shaped face composite rolling, magnesium alloy tooth-shaped face rolling and titanium / aluminum / magnesium composite rolling after tooth-shaped face engaging can be carried out under the different temperatures, and rolling composite is achieved; after tooth-shaped composite face engaging, rolling is carried out, synchronous engaging of multiple layers of alloy boards can be facilitated, the composite contact area can be effectively increased, composite face high-temperature oxidization is prevented, the stress state of the composite board interface can be changed, and the advantages that the composite board interface isgood in quality, and strength is high are achieved.

Owner:JILIN UNIV

Antimicrobial sheet molding compound and preparation method thereof

InactiveCN101619160AAntibacterial broad spectrumImprove antibacterial propertiesGlass fiberLow shrinkage

The invention relates to the field of composite materials, in particular to an antimicrobial sheet molding compound and a preparation method thereof. The antimicrobial sheet molding compound comprises the following raw material components in parts by weight: 15-30 parts of unsaturated polyester resin, 5-15 parts of low shrinkage agent, 10-30 parts of fibre glass, 35-55 parts of inorganic filler, 0.2-1 part of evocating agent, 0.2-1 part of thickening agent, 1-3 parts of mold lubricant and 0.5-5 parts of antibacterial agent. The invention has the advantages of reasonable prescription design, high efficiency, innocuity and good antimicrobial effect.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

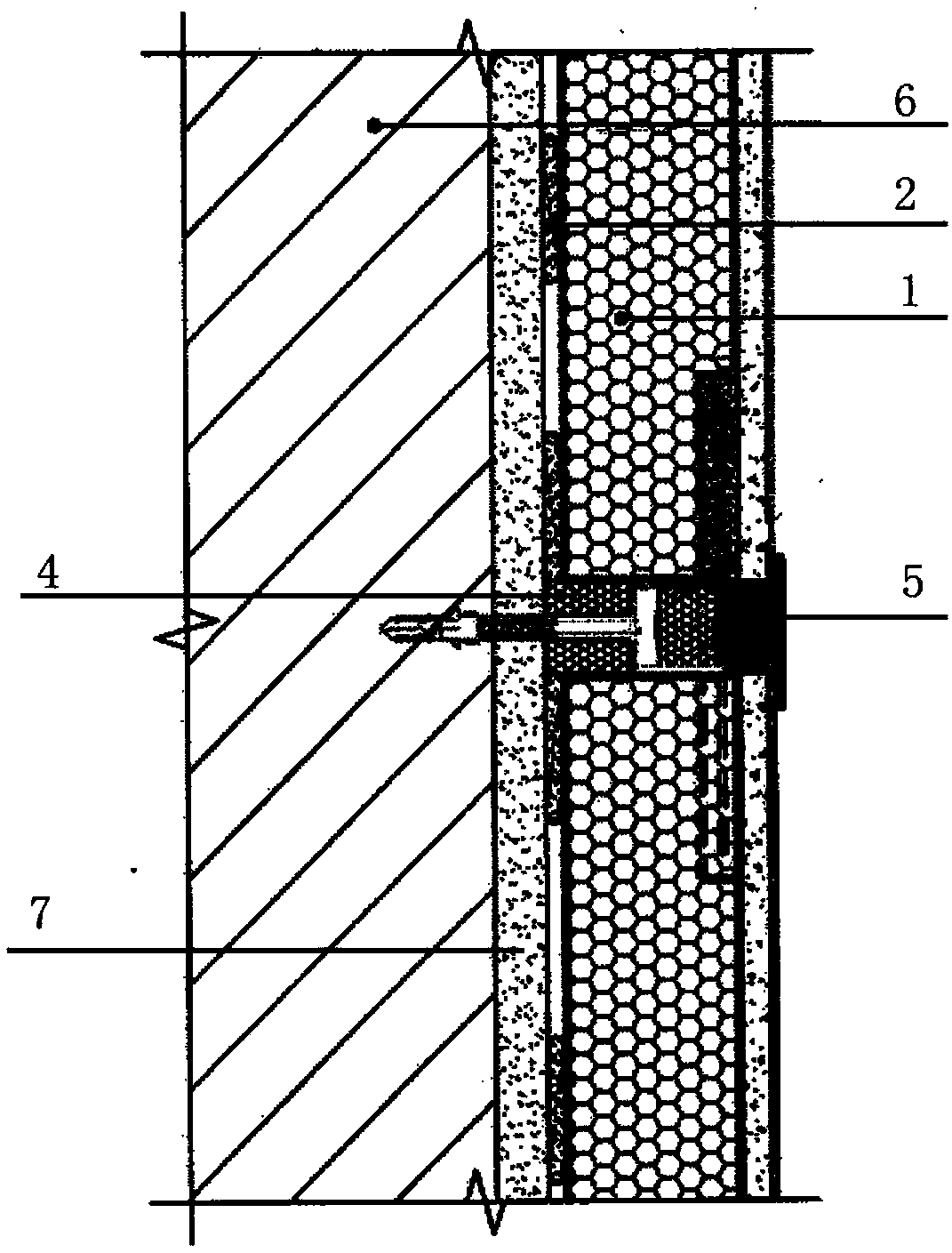

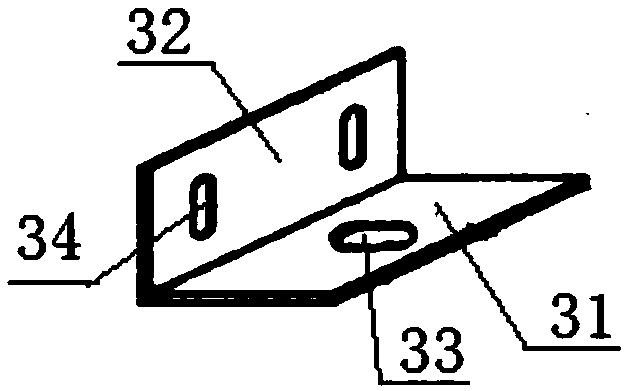

Insulation and decoration integrated plate, insulation and decoration system and construction technology thereof

PendingCN108678314AImprove insulation effectEasy constructionCovering/liningsFlooringArchitectural engineeringFluorocarbon

The invention relates to an insulation and decoration integrated plate, an insulation and decoration system and a construction technology thereof, which are used for the insulation and decoration of building external walls. The insulation and decoration integrated plate includes a backing substrate, an insulation core layer and a decorative panel which are overlaid successively; wherein the backing substrate and the insulation plate as well as the insulation plate and the decorative panel are connected through an adhesive layer; facing of the decorative panel is provided with a fluorocarbon paint facing layer; the back surface of the backing substrate is connected to the building external walls through a plurality of bonding points formed by point frame coating adhesive mortar. The insulation and decoration system is composed of the insulation and decoration integrated plate, an anchoring part, a sealing foam strip and sealant and utilizes proper construction technology. Compared withthe prior art, the insulation and decoration integrated plate, the insulation and decoration system and the construction technology thereof have the advantages of sound insulation effect, convenient construction and high construction intensity, long longevity, good weather ability, strong function, excellent performance, good stability of products and stable and beautiful system.

Owner:蚌埠市建筑设计研究院集团有限公司

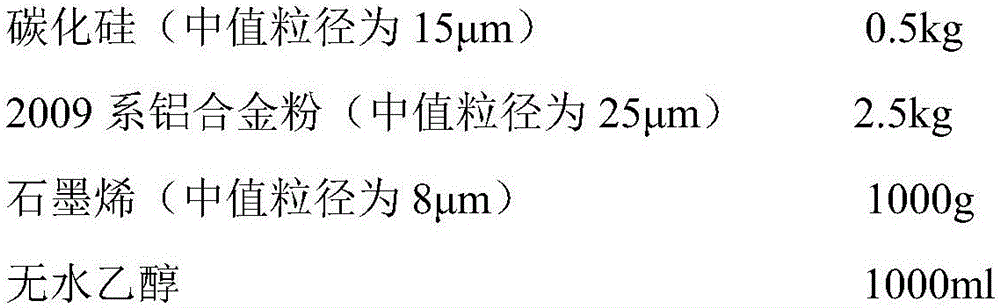

Graphene, aluminum and silicon carbide composite material and preparation method and application thereof

The invention relates to a graphene, aluminum and silicon carbide composite material and a preparation method thereof. The composite material is prepared from of constituents of 10-40 vol% of silicon carbide, 0.5-2 wt% of graphene, and the balance aluminum alloy. The composite material is prepared through a powder metallurgic method and can be obtained through proportioning, powder mixing, packaging, vacuum degassing and hot isostatic forming. The composite material has the advantages of low density, low weight, high hardness, high tensile strength and the like, the strength, fatigue resistance and toughness of the material are remarkably improved through addition of a proper amount of graphene, and thus the composite material has broader application prospects in the field of structural pieces.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

Preparation method and applications of polyethylene foaming calcic-plastic composite material

ActiveCN103122089ALightweight and high strengthGood environmental stress cracking resistanceLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical fields of polymer modification and processing, and relates to a preparation method and applications of a polyethylene foaming calcic-plastic composite material. The polyethylene foaming calcic-plastic composite material is prepared from the following components in parts by weight: 100 parts of low-density polyethylene resin, 10-30 parts of linear low-density polyethylene resin, 80-130 parts of calcic-plastic stuffing, 5-20 parts of foaming agent, 0.8-11 parts of cross-linking agent, 2-4.5 parts of accelerant, 40-60 parts of elastic toughening material and 9-15 parts of composite fire retardant. The polyethylene foaming calcic-plastic composite material has the advantages of light weight, high strength, goog heat insulation property, environmental stress resistance, good impact resilience, fire retardant property, corrosion resistance and the like, and can be used for manufacturing ceilings, vehicle door sheets, float products, decorative plates of acid-alkali corrosion resistant material producing workshops in chemical enterprises, and the like.

Owner:滁州格美特科技有限公司

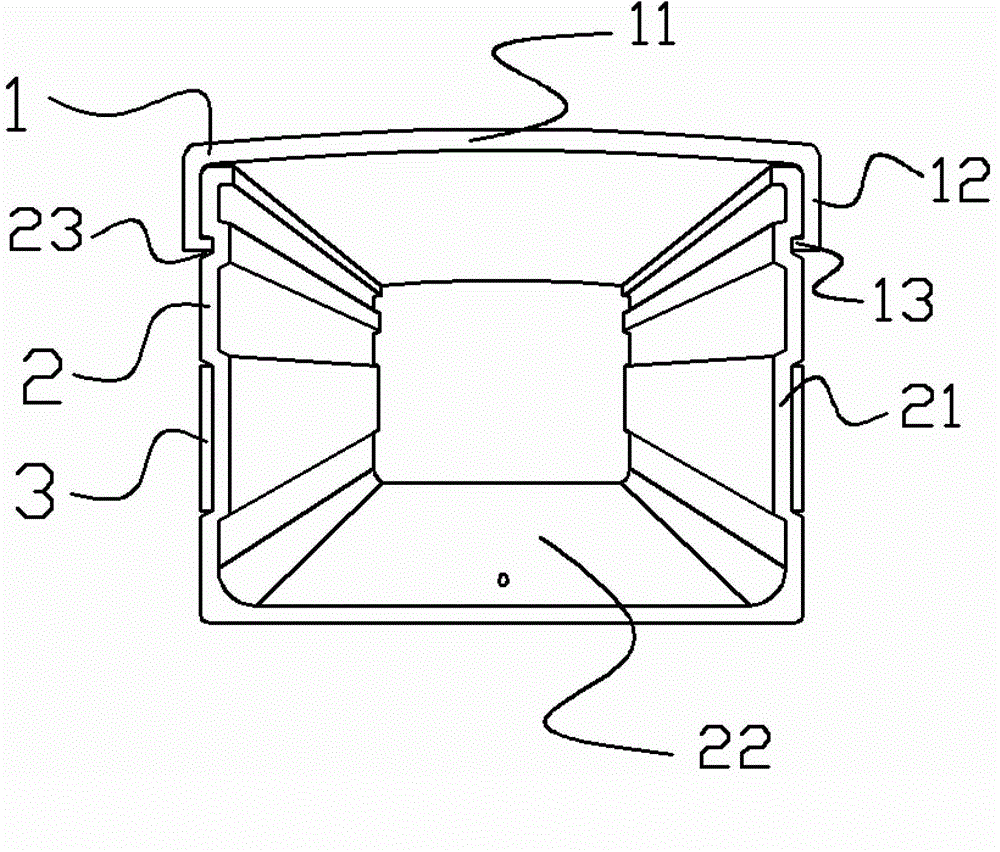

Concrete composite wallboard

InactiveCN1480604ALightweight and high strengthReduce weightBuilding componentsHigh resistanceSteel bar

A composite concrete wall slab is composed of bar-mat reinforcement, concrete layer, and sound-isolating heat-insulating plate in said concrete layer. Said bar-mat reinforcement with rectangular cross-section consists of primary reinforcing mat and steel grids arranged at intervals. Its advantages are light weight, high strength, high resistance to fire and water, and high sound and heat insulation.

Owner:张英保

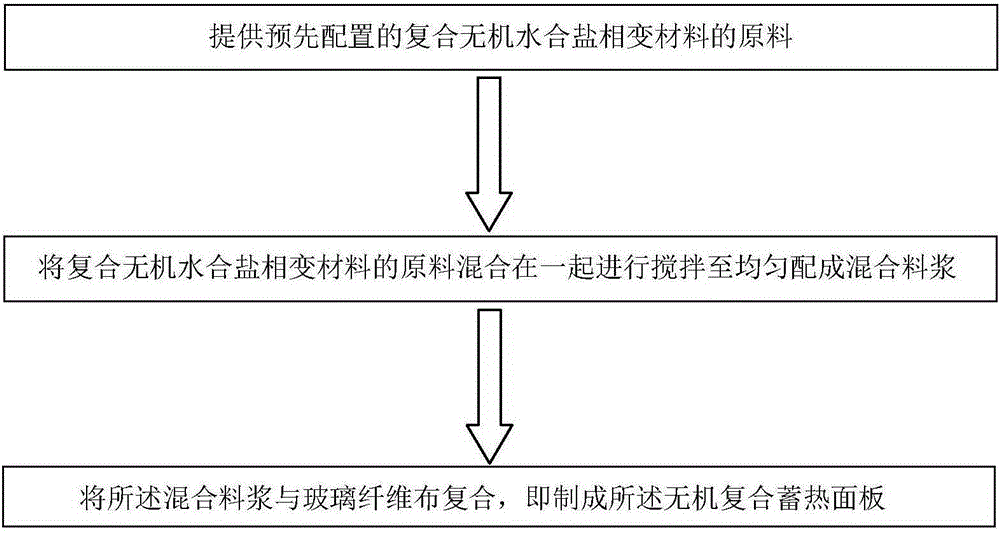

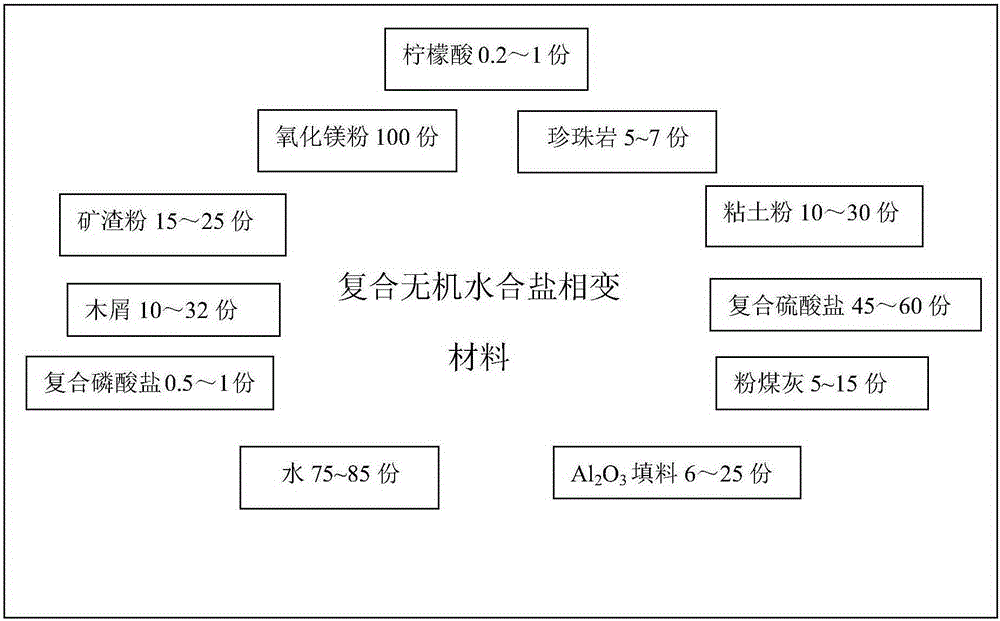

Composite inorganic hydrous salt phase-change material and preparation method of inorganic composite phase-change plate

The invention relates to the field of composite building and ornament materials, in particular to a composite inorganic hydrous salt phase-change material and a preparation method of an inorganic composite phase-change plate. The preparation method comprises the steps that the pre-configured composite inorganic hydrous salt phase-change material raw materials comprising 100 parts of magnesia powder, 10-30 parts of clay powder, 15-25 parts of slag powder, 6-25 parts of Al2O3 padding, 45-60 parts of composite sulfate, 10-32 parts of wood flour, 0.5-1 part of composite phosphate, 5-7 parts of perlite, 75-85 parts of water and 0.2-1 part of citric acid are provided; the raw materials are mixed and evenly stirred into mixed slurry; the mixed slurry is compounded with glass fiber cloth to form an inorganic composite heat accumulation panel. The inorganic composite phase-change plate has the advantages of being low in weight and high in strength, saving energy, preserving moisture, resisting water, being good in toughness, absorbing sound, being environmentally friendly and high in ornamental performance and the like, meanwhile, has the high energy storage density and low degree of supercooling, is free of layering and good in stability, has impermeability, and does not corrode metal.

Owner:上海唐盾材料科技有限公司

Phosphogypsum-based lightweight plastering gypsum product

The invention relates to a phosphogypsum-based lightweight plastering gypsum product. The phosphogypsum-based lightweight plastering gypsum product is prepared from the following components: phosphogypsum powder, an alkaline agent, aggregate, a retarder, a thickner and a water-retaining agent. The phosphogypsum-based lightweight plastering gypsum product provided by the invention has the advantages of light weight and high strength, capability of being firmly bonded with a base layer, no cracking, no hollowing and no odor; the phosphogypsum-based lightweight plastering gypsum product is suitable for indoor plastering construction in winter, has moisture absorption and moisture exhaust functions, and is fireproof and incombustible and the like; the phosphogypsum-based lightweight plasteringgypsum product is an excellent material for indoor plastering and has a good application prospect.

Owner:宁波荣山新型材料有限公司

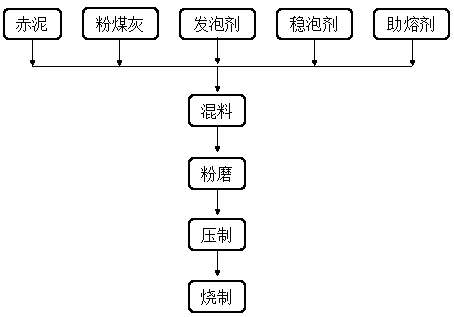

Method for preparing foam microcrystalline glass through red mud

The invention relates to a preparing method for foam microcrystalline glass, in particular to a method for preparing the foam microcrystalline glass through red mud. The preparing method aims at preparing the foam microcrystalline glass with the industrial solid waste red mud, the low energy consumption and the excellent performance. The preparing method includes the following steps that (1) industrial waste residues, fluxing agent, foaming agent and foam stabilizer are mixed to be even according to the weight ratio to form a batch mixture; (2) the mixed batch mixture is put into a ball mill and powdered; (3) the powdered batch mixture is put into a grinding tool and pressed and formed; (4) a pressed sample is put into a reacting furnace and fired. The method has the advantages that the problems that in aluminum industry of China, the discharging quantity of waste residues is large, waste residues are difficult to treat are solved, the comprehensive utilization level of the industrialwaste is improved, sustainable development of building materials in China can be achieved, and social economical benefits can be remarkably improved.

Owner:UNIV OF JINAN

Efficient sound-absorbing ceramsite

InactiveCN102633491AImprove the sound absorption coefficientLightweight and high strengthCeramic materials productionCeramicwarePorositySludge

The invention relates to an efficient sound-absorbing ceramsite, belonging to the technical field of a building material. Aiming to solve the problems that city pollution can not be well solved, product properties are poor, the poor sound-absorbing effects are poor and the production cost is high in the prior art by mainly using the shale as ceramsite, can be solved, The invention provides the efficient sound-absorbing ceramsite, which is prepared from raw materials mainly consisting of raw materials of 60-80% of sludge, 5-20% of the shale, 5-20% of coal ash and 1.0-10% of additive. The efficient sound-absorbing ceramsite provided by the invention has the properties of wide sound-absorbing frequency band, fire resistance, good durability, freezing resistance, seismic resistance, high sound-absorbing coefficient, high porosity, light weight, high strength, heat resistance, anti-permeability and the like. The efficient sound-absorbing ceramsite further can be used for preparing a road barrier and a metro sound-absorbing material and has wide application prospect. Furthermore, the efficient sound-absorbing ceramsite provided by the invention mainly uses city sludge, so that not only can the problem of the city sludge be solved well, but also the overuse of a natural resource of the shale is reduced.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

Manufacturing method of industrial logistics supporting plate by using wood plastic die-casting

InactiveCN101905537ALightweight and high strengthGood weather resistanceBio-packagingRigid containersWhole bodyKeel

The invention discloses a manufacturing method of an industrial logistics supporting plate by using wood plastic die-casting, which relates to industrial logistics supporting plates. The manufacturing method comprises the following process steps of: pulverizing waste bamboo woods into needle-like chips, pulverizing waste rubber into powder, pulverizing waste plastics into sheets or particles, mixing the needle-like chips, the powder-shaped waste rubber, the sheet-shaped or particle-shaped waste plastics, and uniformly stirring the mixture to prepare core materials; paving the core materials, keel materials and surface materials into a mould; then feeding the core materials, the keel materials and the surface materials into a hot press; and applying high-temperature high-pressure to the hot press to perform high-pressure formation, pressure maintaining and nature determination, and demoulding to prepare a finished product. The manufacturing method has the advantages that: the high-temperature high-pressure die-casting process is adopted and materials are scientifically mixed; compared with the prior art, the method has the characteristics of hot melt cementation and condensation solidification by adding raw materials of the waste rubber, and combining the raw materials of the waste rubber with other waste wood materials and keel materials to form a whole body; the materials are paved reasonably in layers to effectively improve intensity and rigidity of a layered supporting plate; and the waste materials are fully utilized to prepare the industrial logistics supporting plate with high quality and long service life.

Owner:许文涛

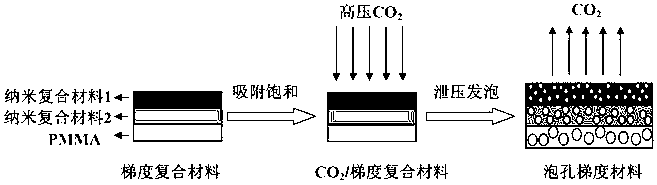

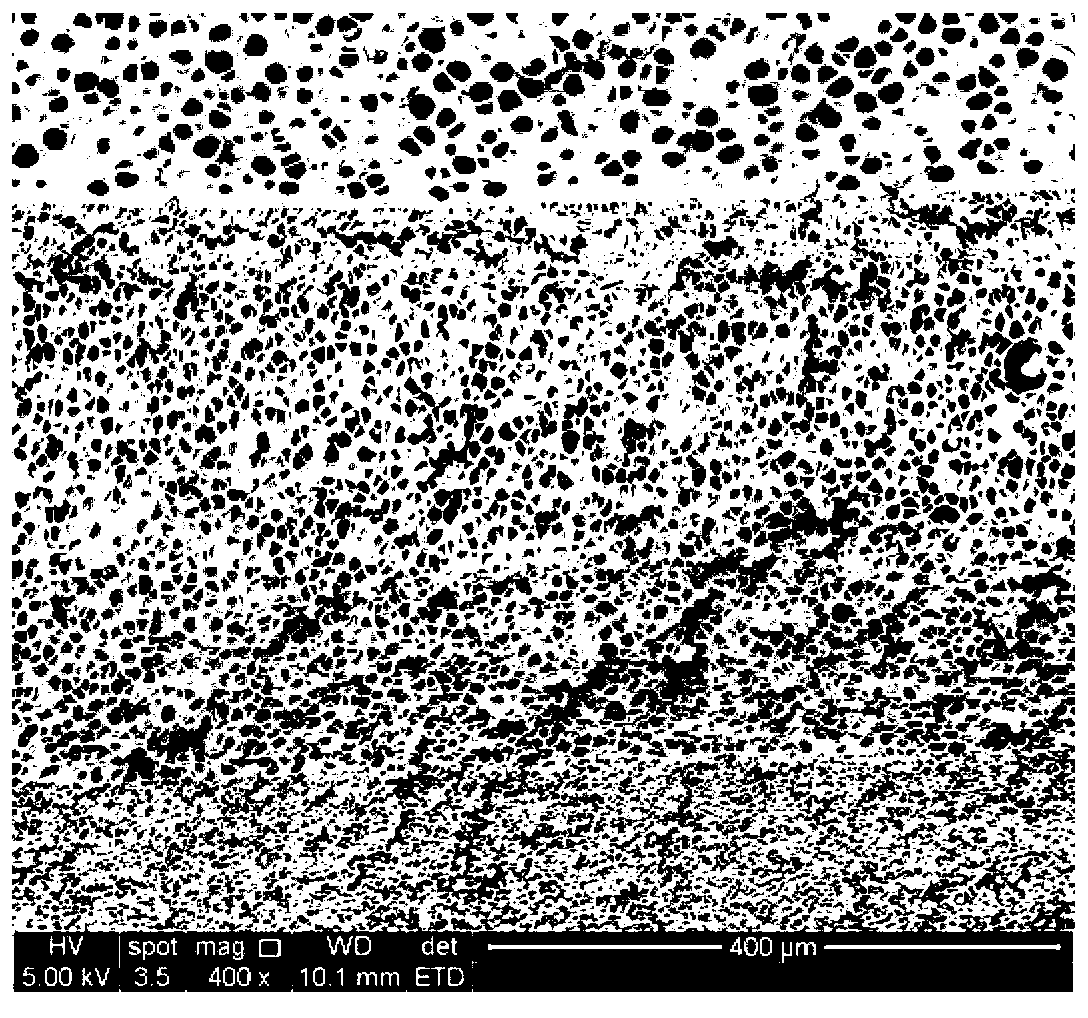

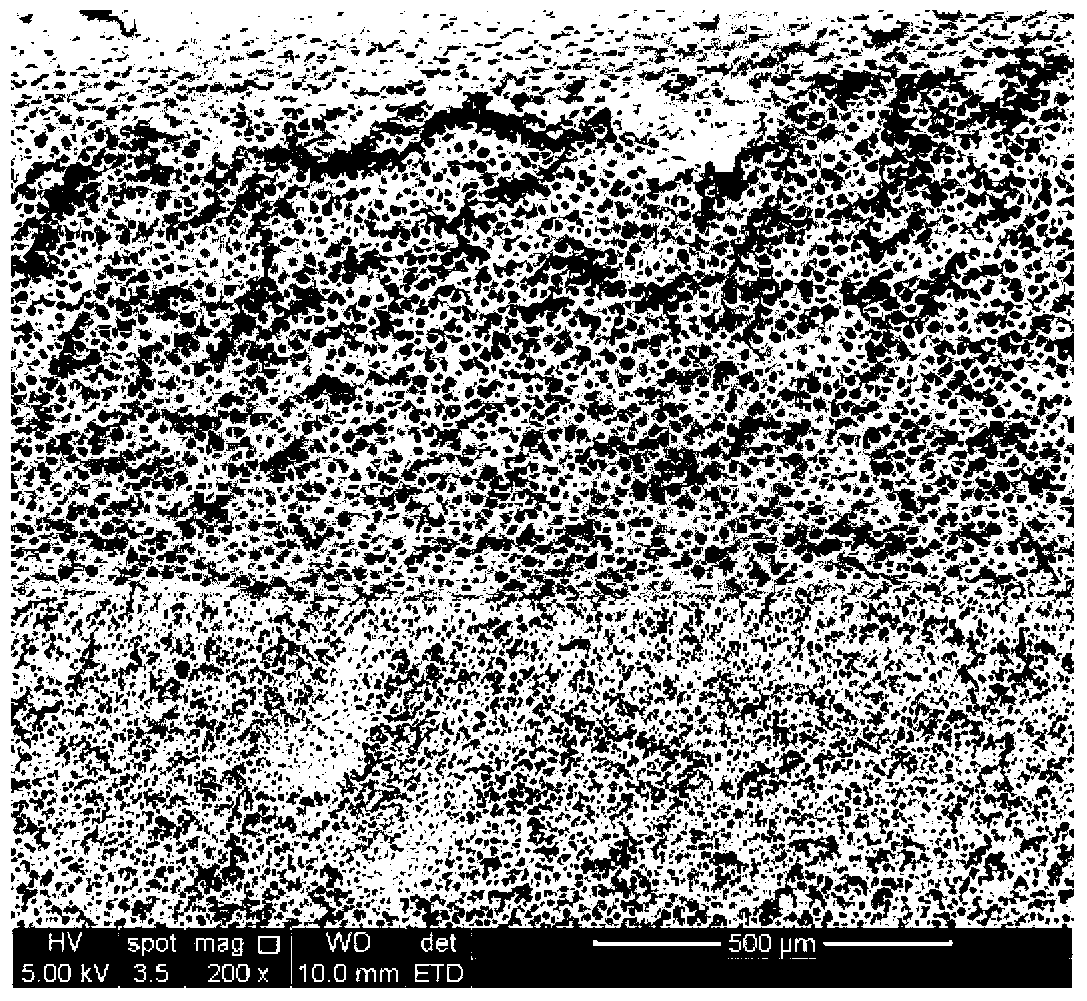

Preparation method of polymethyl methacrylate based cell gradient material

The invention discloses a preparation method of a polymethyl methacrylate based cell gradient material. The preparation method comprises the following steps of: laminating, heating and softening the polymethyl methacrylate based nanometer composite material which comprises a carbon nono-tubes (CNTs) filling or an Argentine nanometer particle (Ag) filling, melting and hot-pressing the treated material to obtain a gradient composite material, adding the gradient composite material into a supercritical carbon dioxide fluid, and carrying out quick release foaming, wherein the foaming process comprises the following steps of: adding the gradient composite material into a high-pressure kettle, filling the supercritical carbon dioxide fluid into the kettle, adjusting the pressure of the fluid to 7.5-20MPa and the temperature to 50-140 DEG C, maintaining the pressure for 6-10 hours, turning on a pressure release valve to fast release the pressure to normal pressure, and cooling the resulting material to room temperature after 10-180 seconds to obtain the cell gradient material. As for the material prepared by using the preparation method disclosed by the invention, the cell diameter is controlled at micron dimension, the volume density is small, the cell density can be designed and controlled, the mechanical strength and the size stability are good, and therefore the material has wide application prospect in the fields of space flight and aviation, electronic packaging, building construction and the like.

Owner:WUHAN UNIV OF TECH

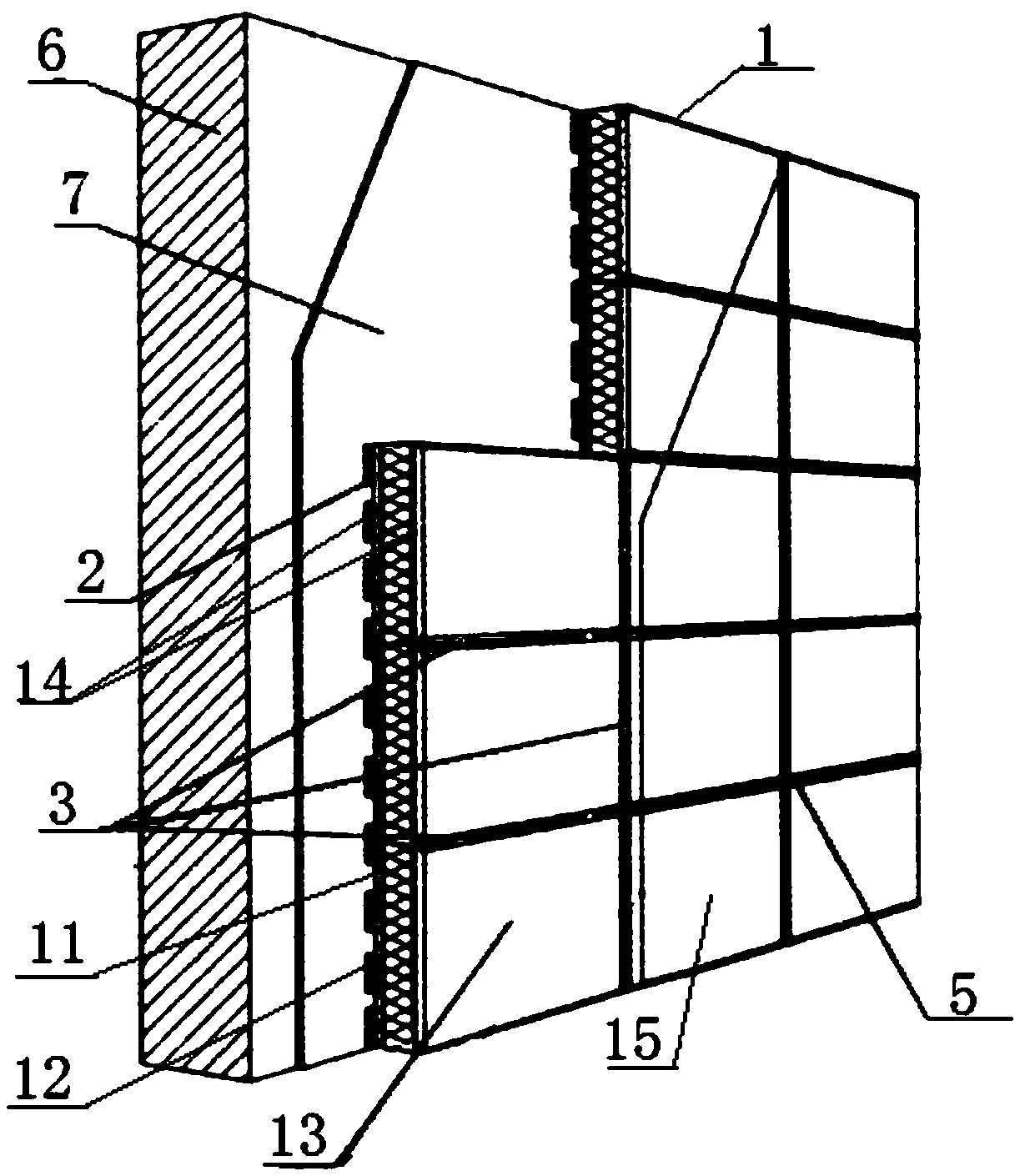

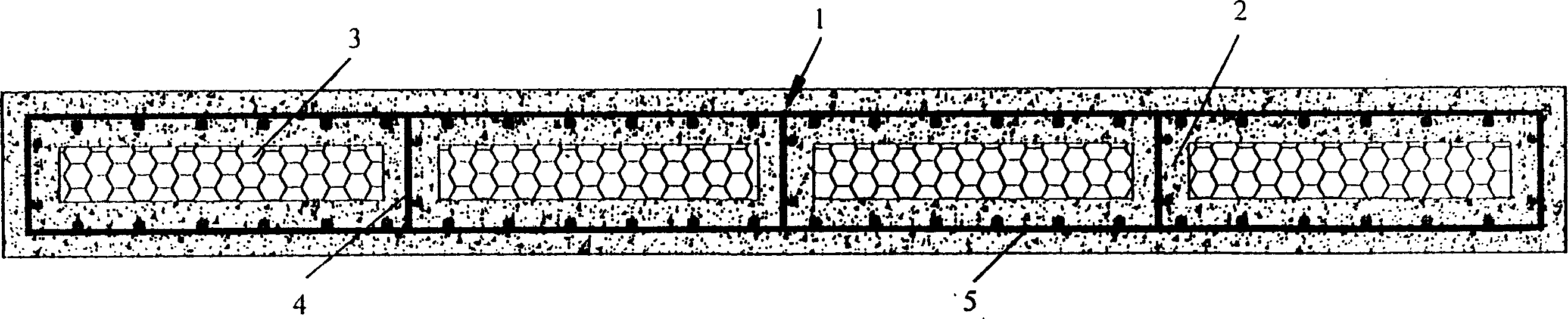

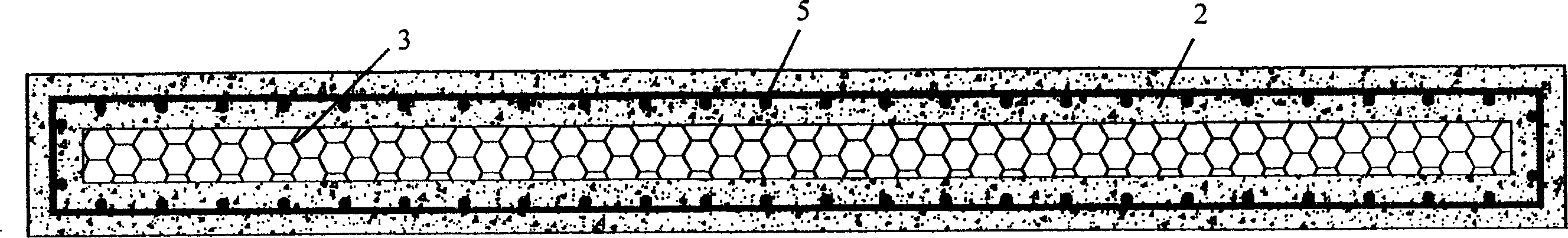

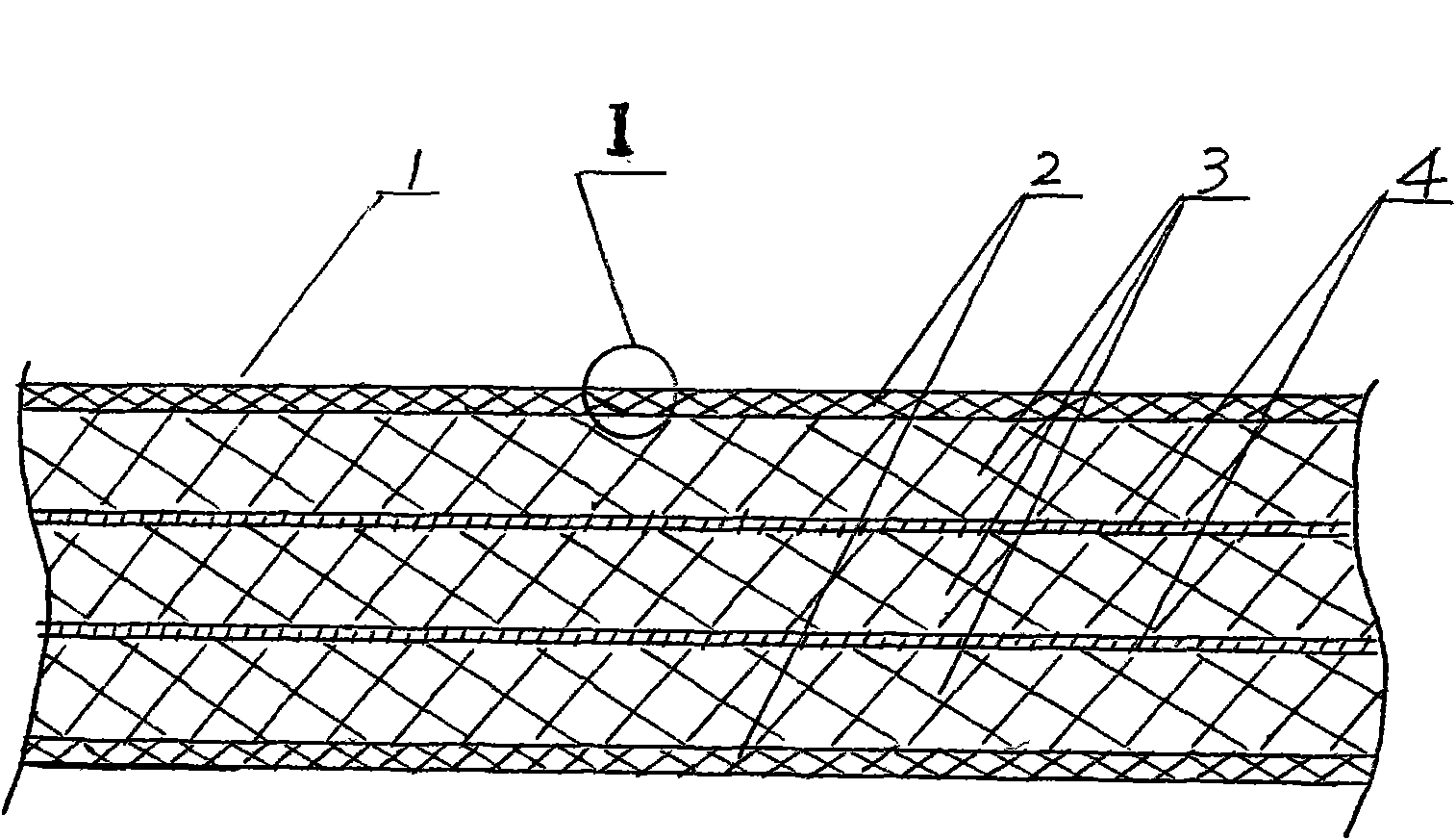

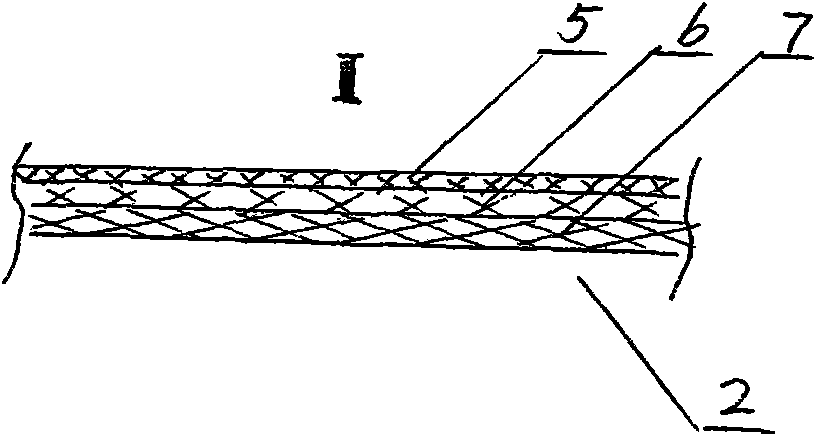

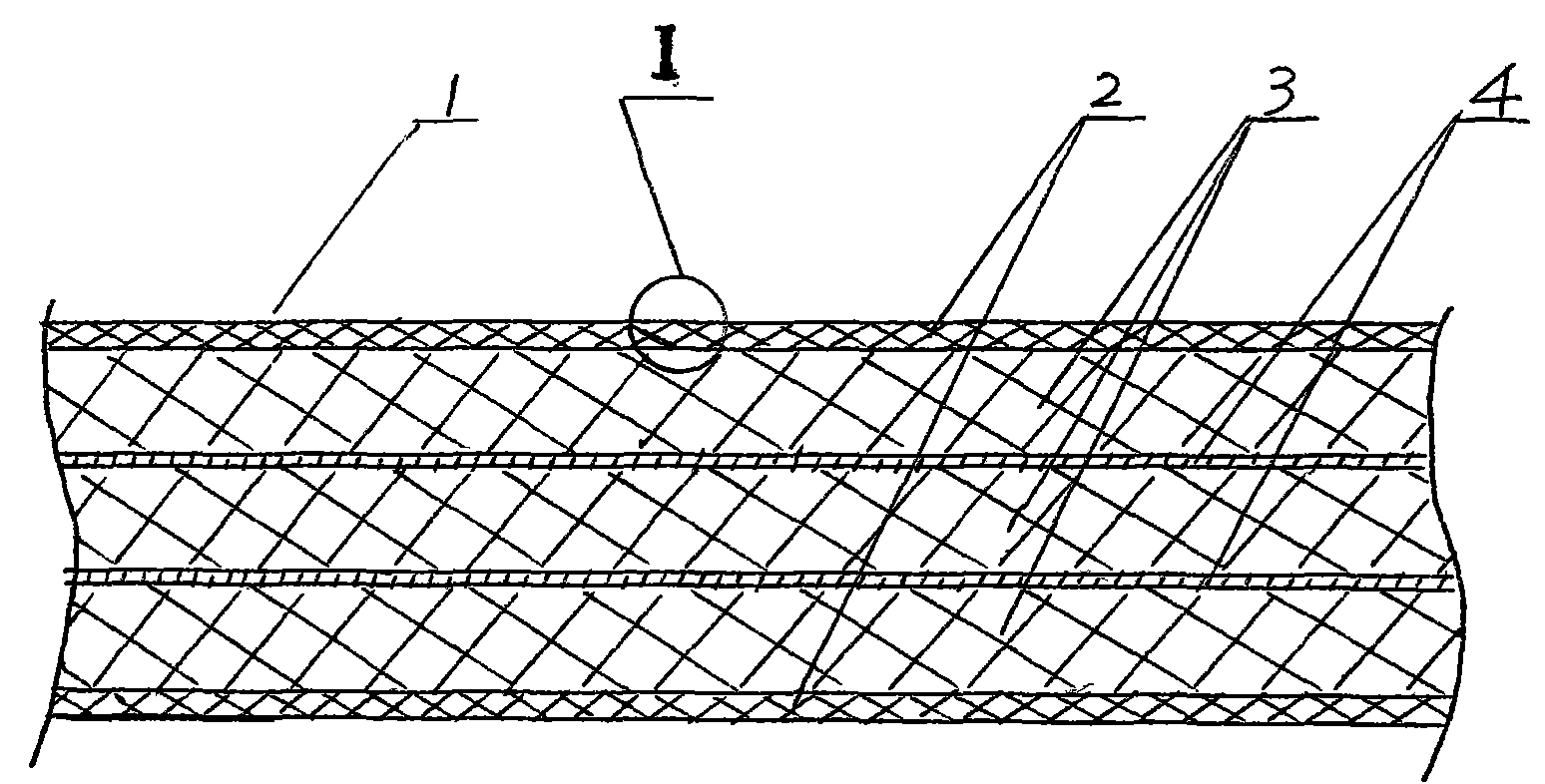

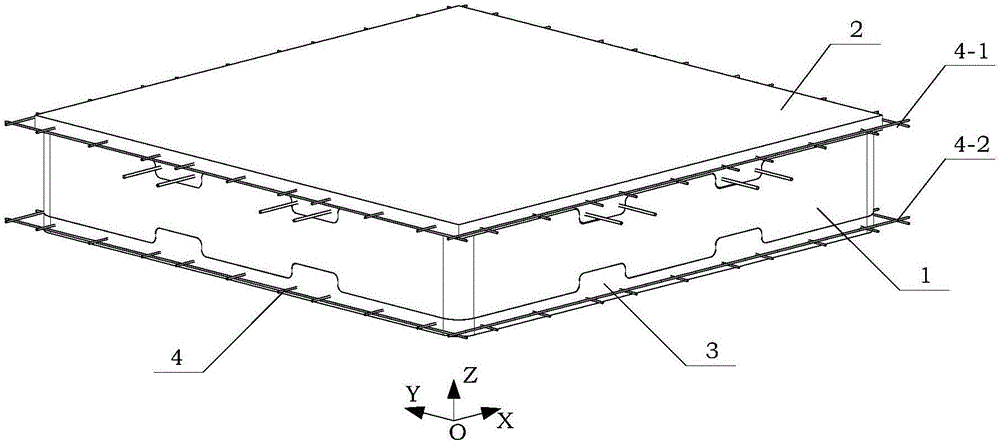

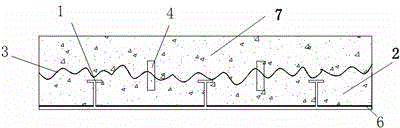

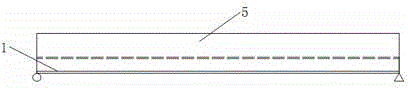

Lightweight preform and preparation method thereof

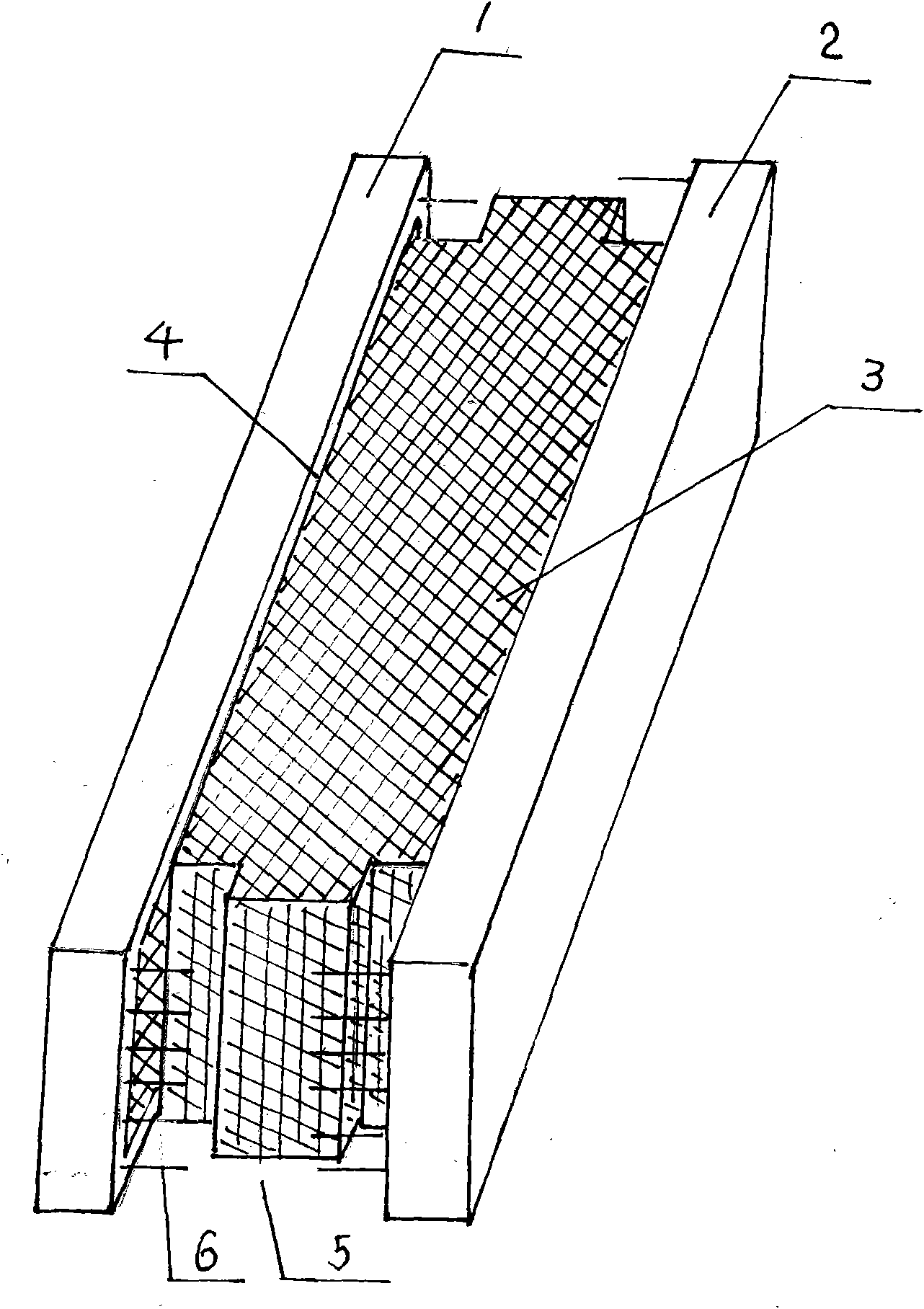

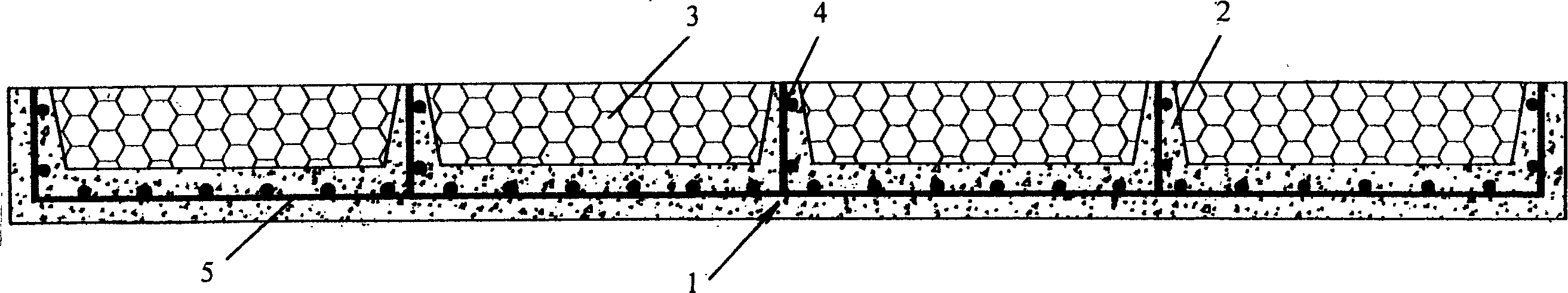

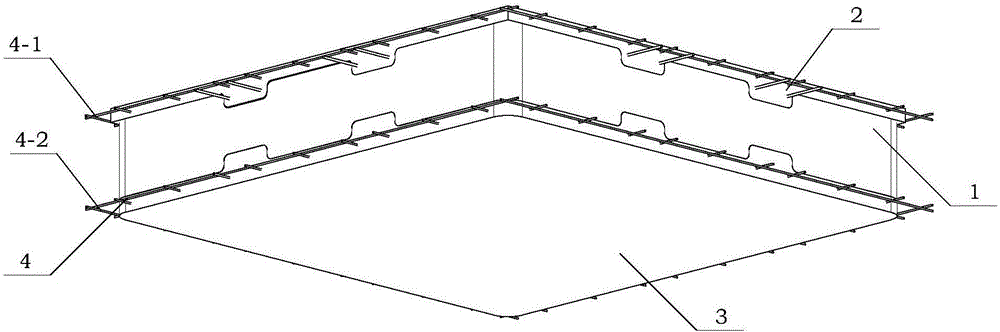

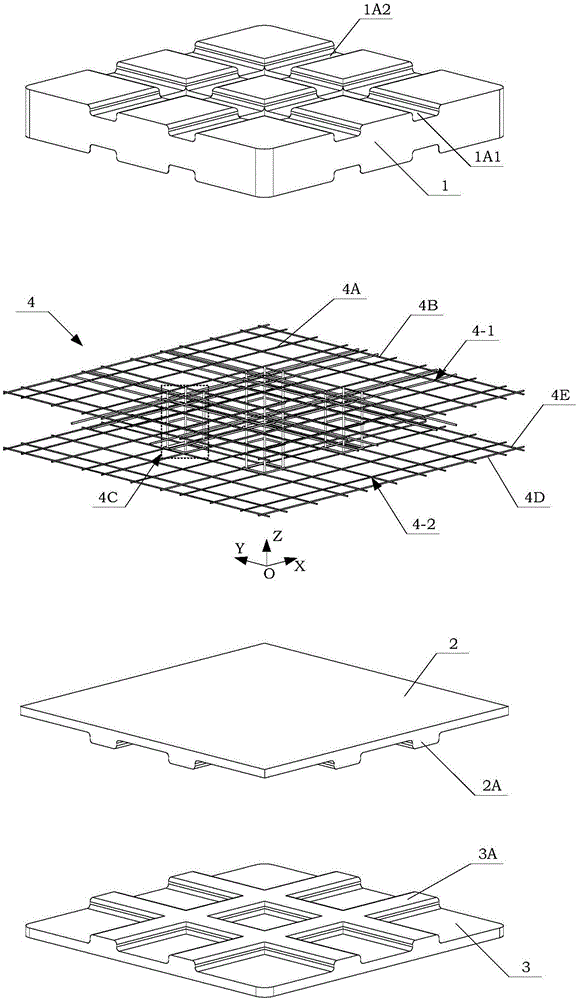

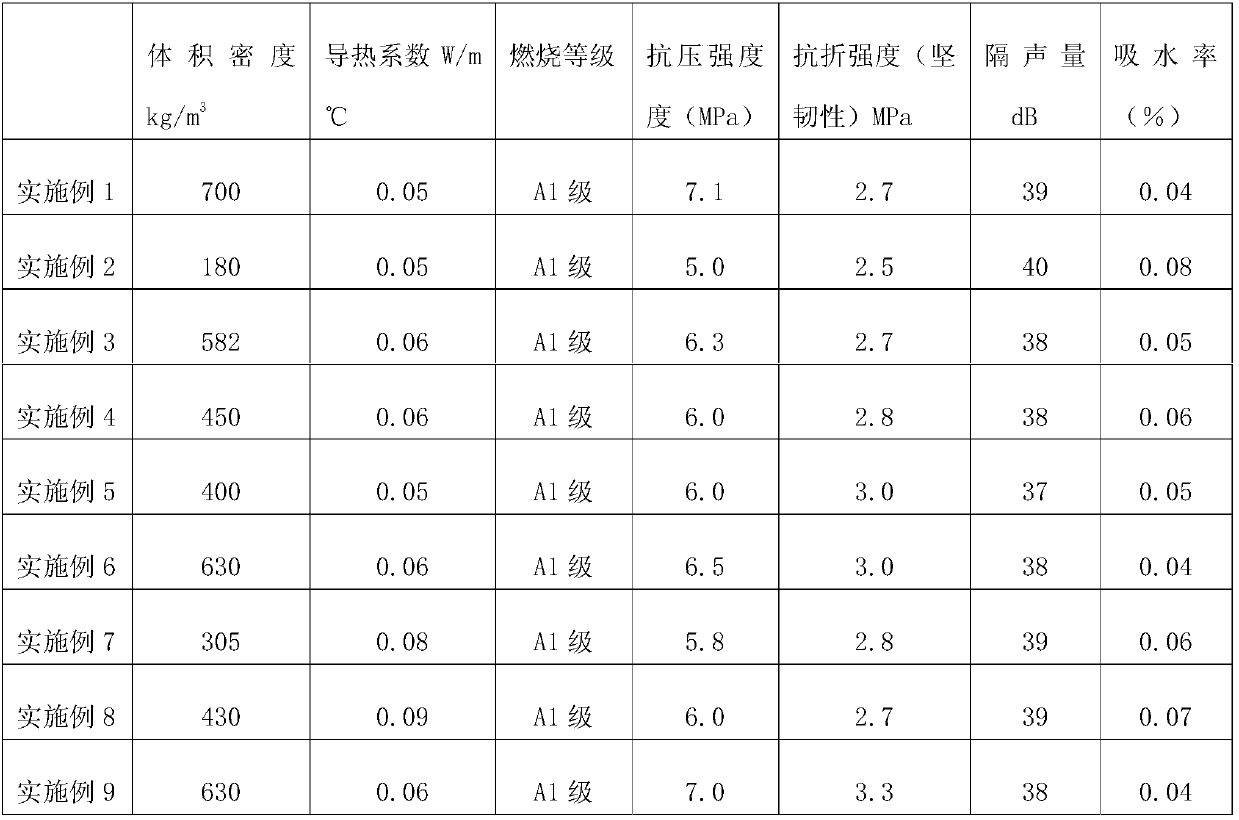

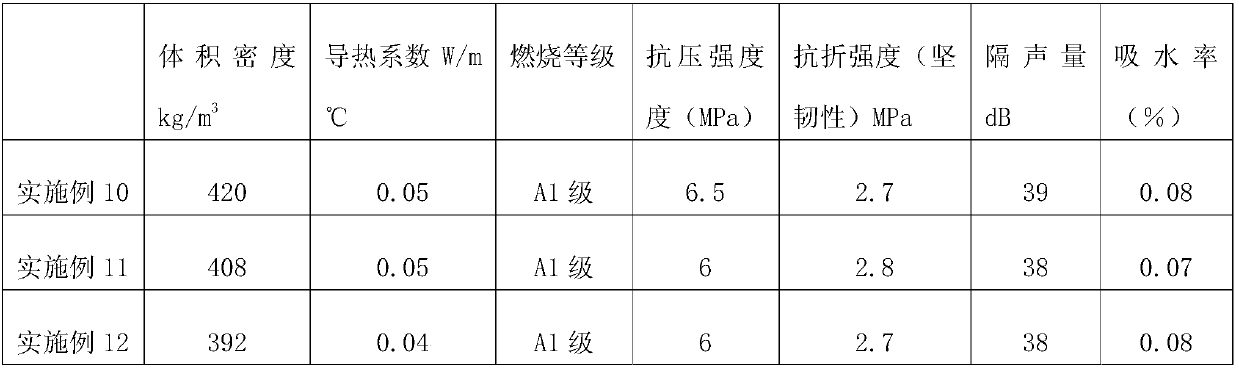

ActiveCN106760143AImprove mechanical propertiesLightweight and high strengthCeramic shaping apparatusBuilding componentsRebarNanotechnology

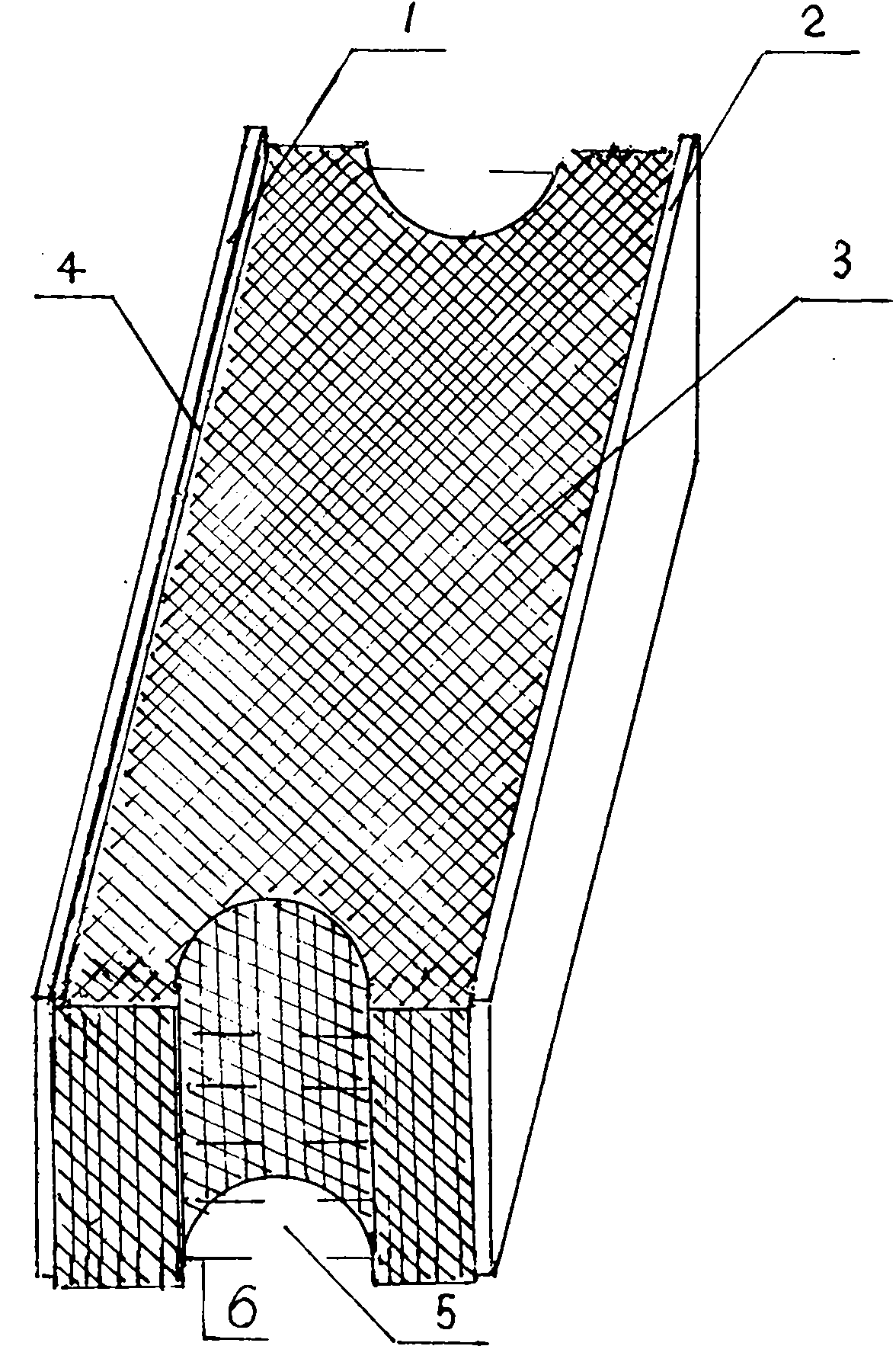

The invention discloses a lightweight preform and a preparation method thereof. The lightweight preform comprises a hollow substrate (1) or a solid lightweight substrate (5), an upper-layer plate (2), a lower-layer plate (3) and a rebar assembly (4), wherein an upper-layer steel mesh in the rebar assembly (4) is located at the upper parts of the substrates (1 and 5); a lower-layer steel mesh in the rebar assembly (4) is located at the lower parts of the substrates (1 and 5); a Z-axis upright post rebar (4C) in the rebar assembly (4) passes through rectangular through holes of the substrates (1 and 5); the upper-layer plate (2) made of concrete contains the upper-layer steel mesh; and the lower-layer plate (3) made of the concrete contains a lower-layer steel mesh. The lightweight preform is reinforced by adopting hollow substrate (1) or the solid lightweight substrate (5) supplemented by rebar in three directions; and an upper panel, a lower panel and a Z-axis support (6) are formed through concrete injection to form the lightweight preform with spatial mechanical characteristics.

Owner:张效思 +2

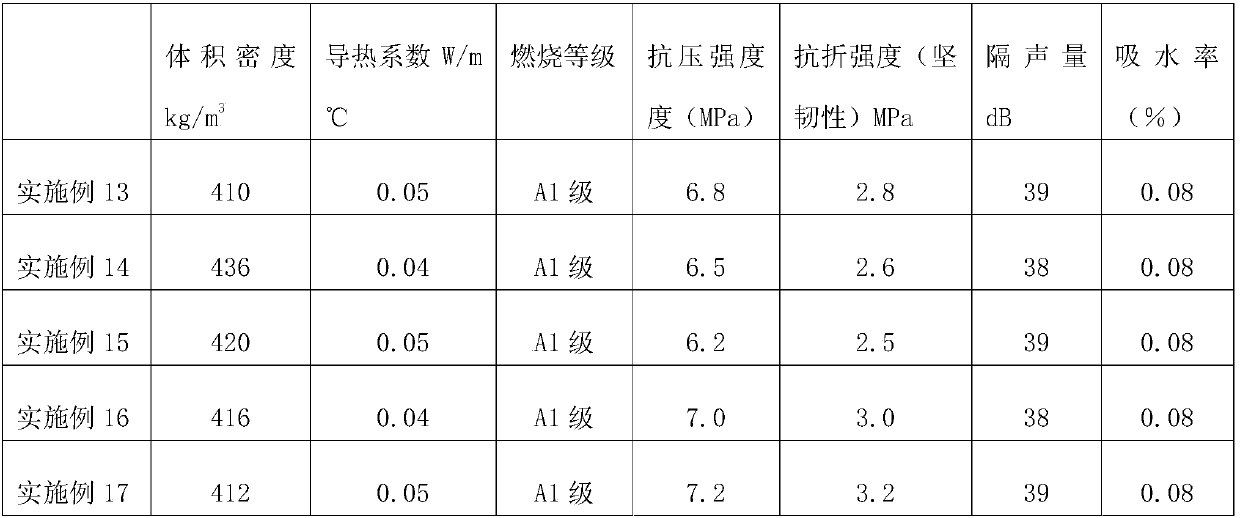

Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

InactiveCN107602106AImprove fire insulation and weather resistanceImprove fire performanceCeramicwarePore distributionEnvironmental resistance

The invention provides a graphene-based foamed ceramic insulation wallboard, which is made of the following components: potassium sodium feldspar, ceramic waste residue, graphene, vermiculite, high-temperature co-solvent, expanded graphite, zirconia, clay, stable agent and debonding agent. Using potassium sodium feldspar and ceramic waste slag as the base material, adding graphene and vermiculite to make the board more lightweight, high-strength, thermal insulation, and improve the performance of the board such as fire resistance, insulation and weather resistance, using expanded graphite as a foaming agent, using high temperature The foaming process can better control the density, pore distribution and pore size of the board, achieve better heat preservation and light weight effects, and make a board with remarkable anti-aging, corrosion resistance, heat insulation, sound insulation, waterproof and impervious, fireproof and fireproof. , lightweight, high-strength, non-cracking, green and environmental protection and other comprehensive performance in one foam lightweight wallboard.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Mothproof down feather composite fiber and preparation method thereof

InactiveCN104264277AAntibacterial and mothproofLightweight and high strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureAluminium silicateGluconates

The invention discloses a mothproof down feather composite fiber. The mothproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-18 parts of duck's down, 15-19 parts of chicken feather, 11-13 parts of mercerized wool fibers, 12-14 parts of mercerization cotton fibers, 4-7 parts of copper ammonia fibers, 15-19 parts of straw stalk, 4-6 parts of closed cell perlite powder, 1-3 parts of angelica sinensis, 2-4 parts of gastrodia elata, 2-3 parts of ligusticum wallichii, 0.2-0.4 part of zinc gluconate, 0.3-0.6 part of aluminium silicate, 100-105 parts of 1-butyl-3-methyl imidazole acetate, 110-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. The down feather composite fiber prepared by the invention has the advantages of sterilization, moth prevention, light weight, high intensity, thermal preservation, flame retardance and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

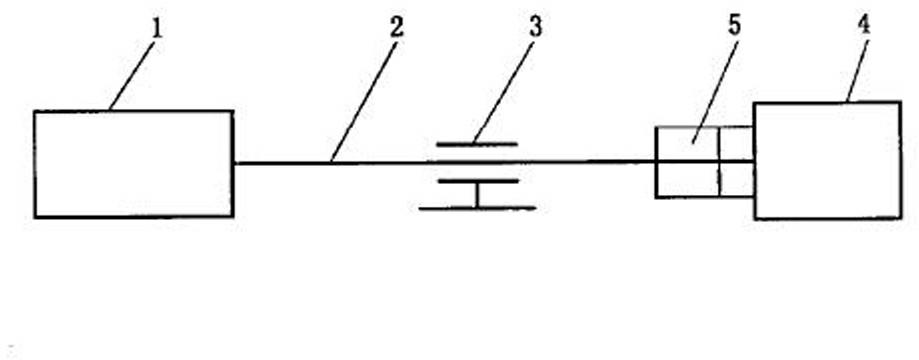

Single layer FRP concrete composite bridge slab construction method

InactiveCN104674658ALightweight and high strengthReduce distortionBridge structural detailsBridge erection/assemblyMaterials scienceConcrete composites

The invention discloses a single layer FRP concrete composite bridge slab construction method. The method includes erecting a FRP board, processing the connection boundary of the FRP board and concrete, pouring a first layer of concrete, processing the surface of the first layer of concrete and pouring the second layer of concrete till meeting the designed thickness. The vertical deformation of a bridge slab can be reduced during construction effectively, the stability of the FRP board is improved during construction, the FRP material can be saved, and the cost of the FRP-concrete combined bridge slab is reduced.

Owner:SOUTHEAST UNIV

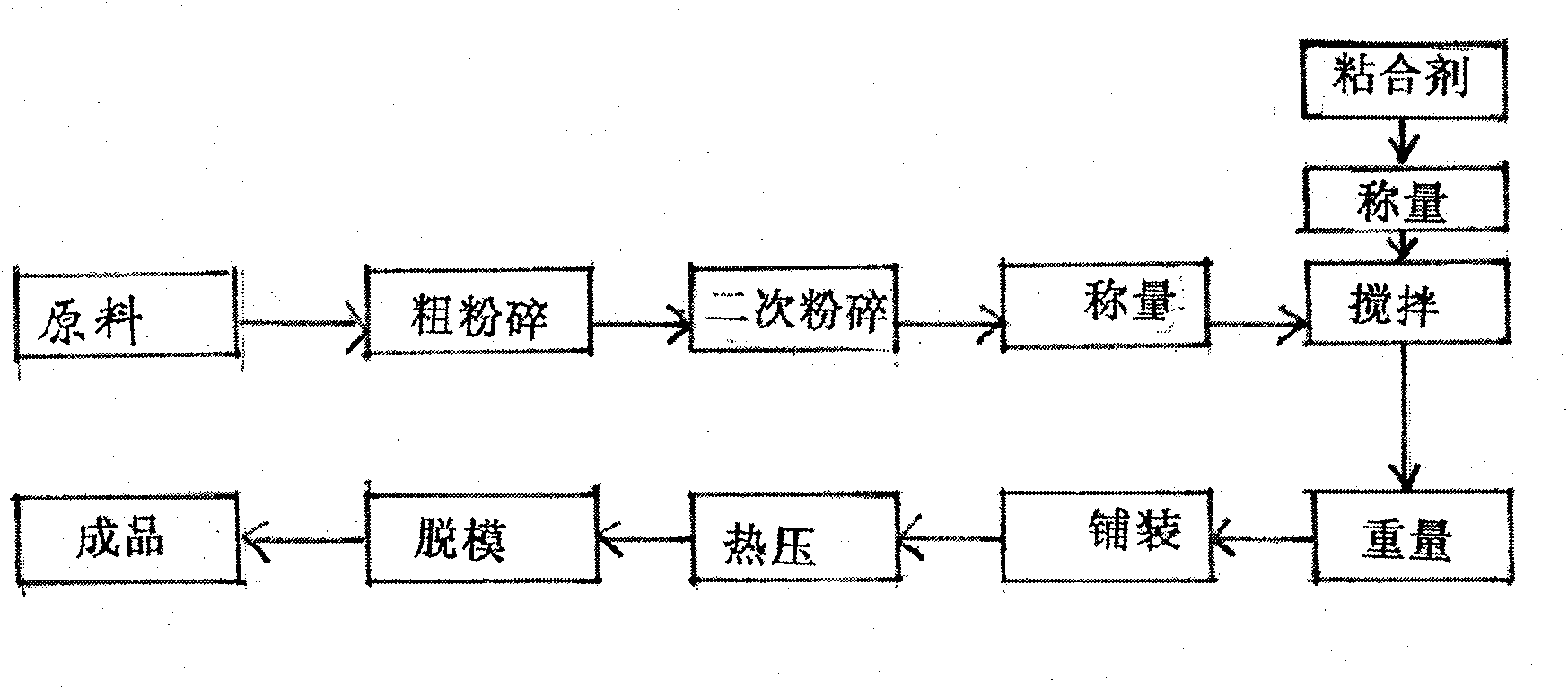

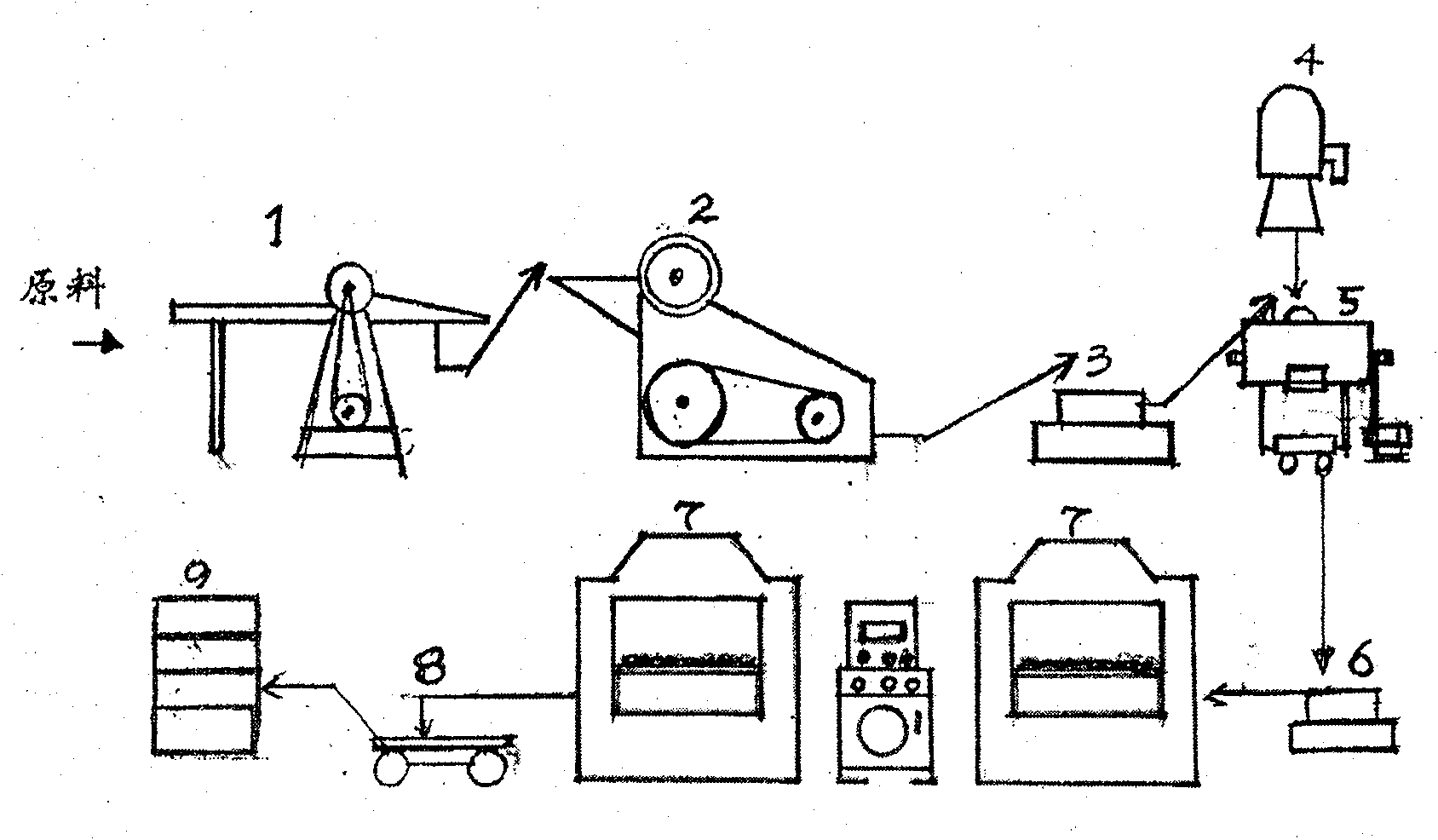

Production method and manufacturing technology for corn stalk moulded board

InactiveCN101898382AAvoid emissionsEvenly gradedWood working apparatusDomestic articlesManufacturing technologyMechanical index

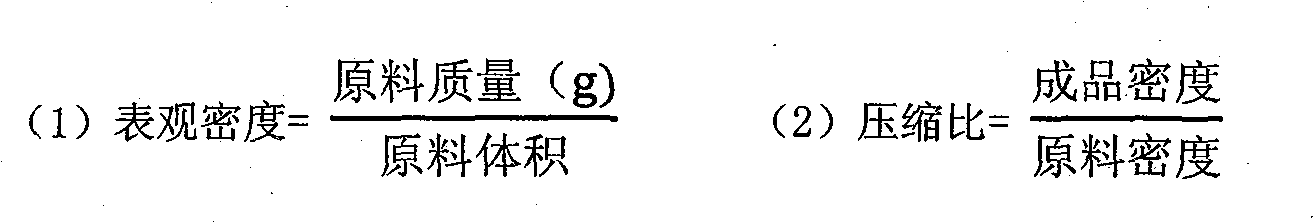

The invention relates to a production method and manufacturing technology (attached drawings) for a moulded board from corn stalk serving as raw materials, and mainly solves the problems of energy consumption, three wastes, density, internal bond strength, expansion ratio and formaldehyde release in the prior art. The method is mainly characterized by comprising the following steps of: crushing the raw materials twice to achieve the grain diameter of 1 to 15 mm and the moisture content of 15 percent or below, and determining the apparent density of the raw materials to between 0.09 and 0.13 g / cm<3> after three kinds of size grading; determining the finished product density to between 0.4 and 0.55 g / cm<3> by contrasting the density of wood; solving the compression ratio of 2.5 to 4.5 by using the ratio of two densities; stirring 70 to 80 mass percent of raw materials and 20 to 30 mass percent of adhesive for 10 to 15 minutes, putting into a mould, and performing hot press molding at the temperature of between 135 and 170 DEG C for 25 to 40s / mm under the pressure of between 2.0 and 3.5 MPa. The method has the advantages that: by modifying parameters of a material preparing stage, and transforming crushing, stirring and hot-pressing equipment in the operation process and modifying the hot-pressing technological parameters, the method reduces the density deviation, improves the internal bond strength, reduces the expansion ratio and free formaldehyde release amount and makes physical and mechanical indexes of the finished products exceed the standard of the like products.

Owner:宋庆华

Preparation method of HDPE injection molding inspection well

The invention discloses a preparation method of an HDPE injection molding inspection well. The method comprises the following steps of: raw material mixing, plasticizing injection, die molding, cooling, finishing and warehousing. The method adopts an HDPE material to produce the plastic inspection well through injection molding. As the product is molded through injection molding and pressure maintaining, it has stable quality, and has all performances exceeding those of traditional rotational molding products. The invention makes use of the recycled HDPE raw material, and adds reinforced materials for filling, thus being in favor of waste utilization. The prepared inspection well has the advantages of: low cost, light weight, great strength, convenient construction, and excellent toughness.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

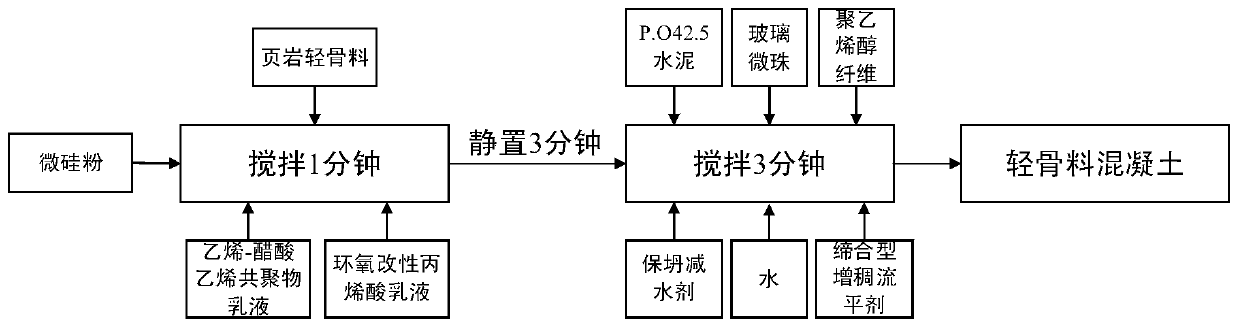

High-strength high-toughness self-leveling light aggregate concrete and preparation method thereof

The invention relates to high-strength high-toughness self-leveling light aggregate concrete and a preparation method thereof. The light aggregate concrete is made of cementing materials, leveling agents, toughening materials, sand, a crude aggregate and water through mixing, wherein the cementing materials are ordinary Portland cement, glass beads and nano micro silicon powder; the leveling agents are a slump-prevention type water reducing agent and an associated thickening leveling agent; the toughening materials are an ethylene-vinyl acetate copolymer emulsion, an epoxy modified acrylic emulsion and a polyvinyl alcohol fiber; the sand is medium sand; and the crude aggregate is shale macadam ceramsite. The preparation method comprises the following steps: firstly, uniformly stirring theethylene-vinyl acetate copolymer emulsion, the epoxy modified acrylic emulsion, the nano micro silicon powder and the shale macadam ceramsite for 1 minute, leaving the mixture to stand for 3 minutes,and further stirring the mixture with the sand, the cement, the glass beads, the water, the polyvinyl alcohol fiber and the associated thickening leveling agent for 3 minutes. The light aggregate concrete provided by the invention has the characteristics of being light in weight, high in strength, free of light aggregate floating, good in flowability, high in toughness and small in shrinkage, canbe applied to large-span bridges and auxiliary structures thereof, and can be also applied to industrial and civil high-rise buildings.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Glass fiber reinforced plastic engineering anchor rod and manufacturing method thereof

The invention relates to the field of engineering building materials, belongs to the category of new materials, and in particular relates to a glass fiber reinforced plastic (FRP) engineering anchor rod and a manufacturing method thereof. The invention is characterized in that: raw materials mainly comprise glass fibers, resins and additives, wherein the glass fibers account for 70 to 85 weight percent of the raw materials. The invention has the advantages that: the FRP material has the advantages of light weight, high strength, corrosion resistance, capacity of being easily cut, insulativity (not conducting electricity or magnetism), flame retardancy, low-temperature resistance, fatigue resistance and the like; the anchor rod can locally replace steel bars according to the characteristics of the FRP material so as to fulfill the aim of saving steel and labor cost, the labor efficiency can be greatly improved, and the cost is saved; the anchor rod can be applied to environments with serious corrosion of corrosive media for a long time, can maintain the strength and service life, and meet the requirement of structure durability; the anchor rod can be applied to structure with special requirements; and prestress loss due to concrete creep and shrinkage can be reduced, and the prestress loss due to prestressed reinforcing steel loosening can be reduced.

Owner:CHINA RAILWAY SHANGHAI DESIGN INST GRP

Composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and preparation method thereof

ActiveCN105042219AImprove adhesionAvoid safety hazardsFlexible pipesLow-density polyethyleneCorrosive chemical

The invention discloses a composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and a preparation method thereof. Low density polyethylene, ultra-high molecular weight polyethylene and macromolecule cross-linked polyethylene serve as raw materials; after scientific compound and vulcanization of a rubber hose, a chemical substance with a good adhesive property is obtained for preparing a liner film; meanwhile, corona treatment is carried out on the bonding face of the liner film and the bonding face of the rubber hose, and fiberglass reinforcing fiber with radiation protection performance is compounded on the surface layer; therefore, the surface layer of the rubber hose has good radiation protection performance, hidden danger of conveying pipelines caused by ionizing radiation is avoided, and finally the composite rubber hose which has the firmly bonded liner film, and is high in radiation protection and capable of conveying LPG, LNG and strongly corrosive chemical solvents is prepared, the hose can absorb as much as 97.5% to 99.5% of X-rays, gamma-rays and various neutrons in nuclear radiation, and the adhesive force (N / 25mm) between the liner film and a rubber layer reaches 160-180.

Owner:河北泽邦塑胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com