High-strength high-toughness self-leveling light aggregate concrete and preparation method thereof

A lightweight aggregate concrete, high-strength and high-toughness technology, applied in the field of cement-based composite materials, can solve the problems of reduced concrete compressive strength, concrete segregation, and high brittleness, and achieve improved stability, small volume shrinkage, and high compressive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] Specific embodiment 1 is as shown in table 1.

[0027] Table 1 Specific embodiment 1

[0028]

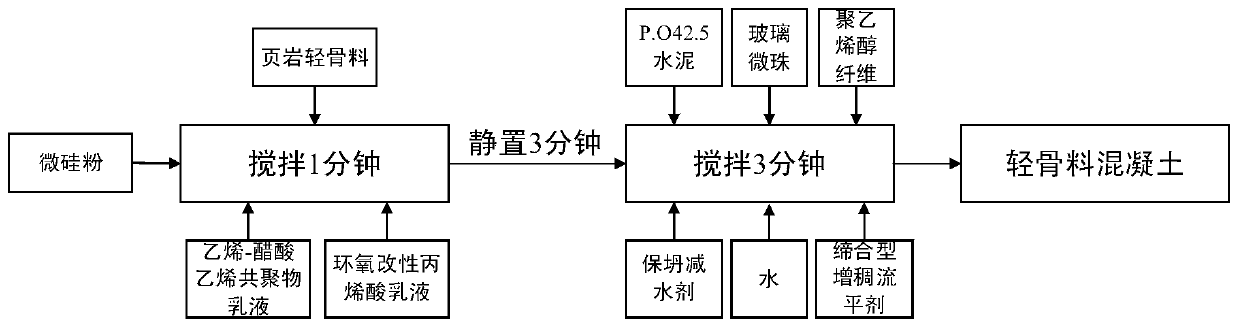

[0029] according to figure 1 The preparation method is stirred in batches, and the implementation effect of specific embodiment 1 is shown in Table 2.

[0030] Table 2 Performance of the lightweight aggregate concrete produced according to specific example 1

[0031] serial number Pilot projects Implementation Effect 1 Expansion of machine (mm) 580 2 30min extension (mm) 550 3 Concrete dry density (kg / m 3 )

specific Embodiment 2

[0033] Specific embodiment 2 is as shown in table 3.

[0034] Table 3 Specific embodiment 2

[0035]

[0036] according to figure 1 The preparation method is stirred in batches, and the implementation effect of specific embodiment 2 is shown in Table 4.

[0037] Table 4 The performance of the lightweight aggregate concrete produced according to specific example 2

[0038] serial number Pilot projects Implementation Effect 1 Expansion of machine (mm) 590 2 30min extension (mm) 556 3 Concrete dry density (kg / m 3 )

specific Embodiment 3

[0040] Specific embodiment 3 is as shown in table 5.

[0041] Table 5 Specific embodiment 3

[0042]

[0043] according to figure 1 The preparation method is stirred in batches, and the implementation effect of specific embodiment 3 is shown in Table 6.

[0044] Table 6 The performance of the lightweight aggregate concrete produced according to specific example 3

[0045] serial number Pilot projects Implementation Effect 1 Expansion of machine (mm) 620 2 30min extension (mm) 580 3 Concrete dry density (kg / m 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com