Concrete composite wallboard

A composite wall panel and concrete technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems that it is difficult to adapt to the multi-functional and high-performance requirements of wall materials, and achieve a wide market application basis and good performance-price ratio , complete set and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

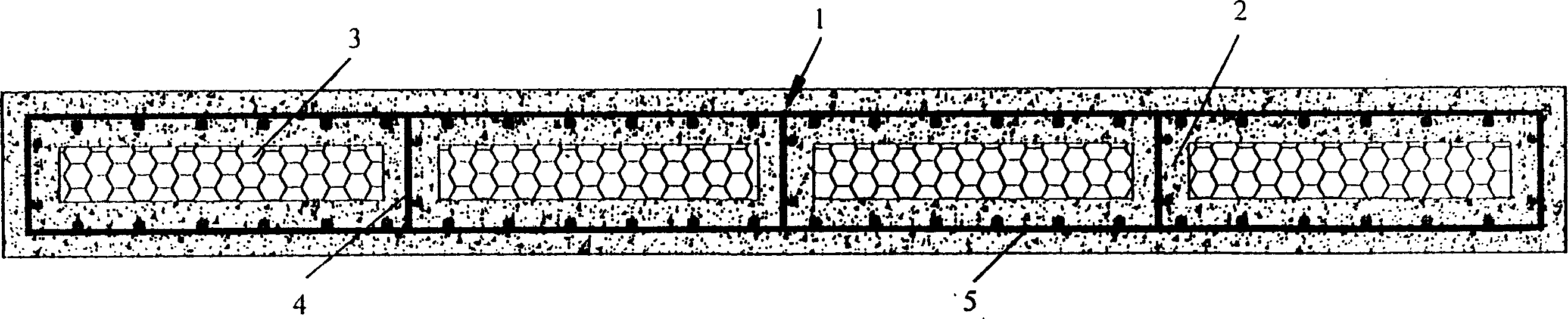

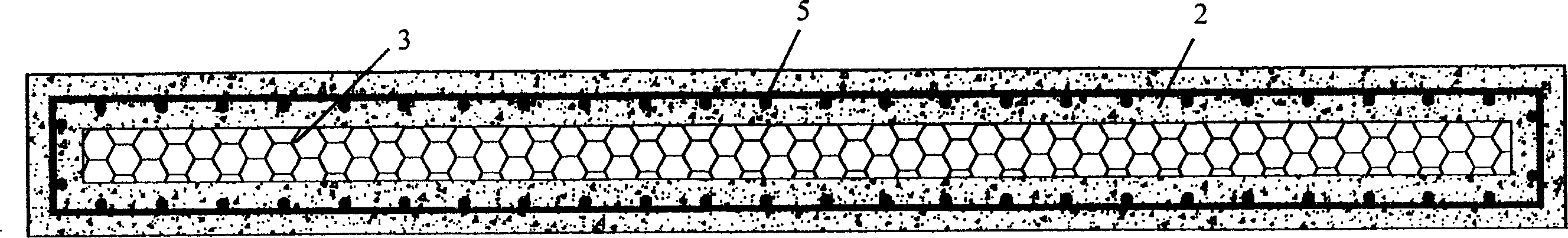

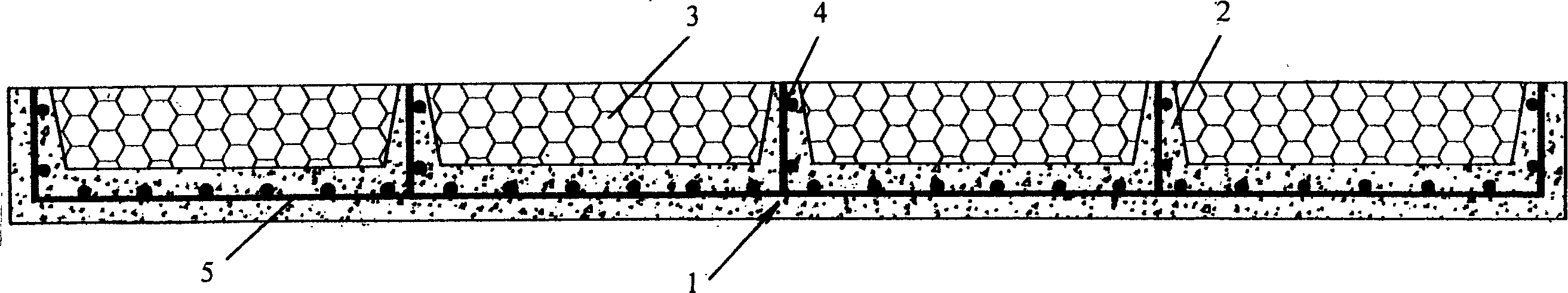

[0023] Concrete composite wallboard of the present invention, as figure 1 As shown, it is a cuboid large-cavity concrete structure, which is composed of a steel grid frame 1 and a concrete layer 2 poured around the steel grid frame 1. The thickness of the concrete layer 2 is 20-50 mm on average. The longitudinal section of the steel grid frame 1 is The rectangular main network frame 5 and the three rows of grid steel bars 4 fixedly connected to the upper and lower floors of the main network frame are formed inside, and the large cavity formed by reinforced concrete is a sound insulation board 2 . The main network frame 5 is single-layer, also can be double-layer. Wire mesh or glass fiber mesh cloth can also be provided on the inside or outside of the main network frame 5 to enhance the strength and crack resistance.

[0024] The sound insulation boa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com