Glass fiber reinforced plastic engineering anchor rod and manufacturing method thereof

A technology of glass fiber and manufacturing method, which is applied to the installation of bolts, infrastructure engineering, earthwork drilling and mining, etc. It can solve the problems of increasing project cost and increasing the complexity of bolts, so as to improve labor efficiency, save steel, and save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

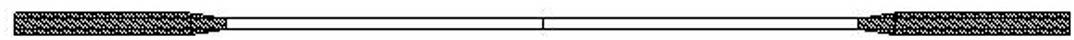

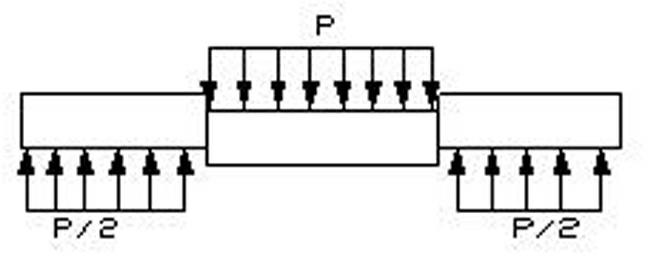

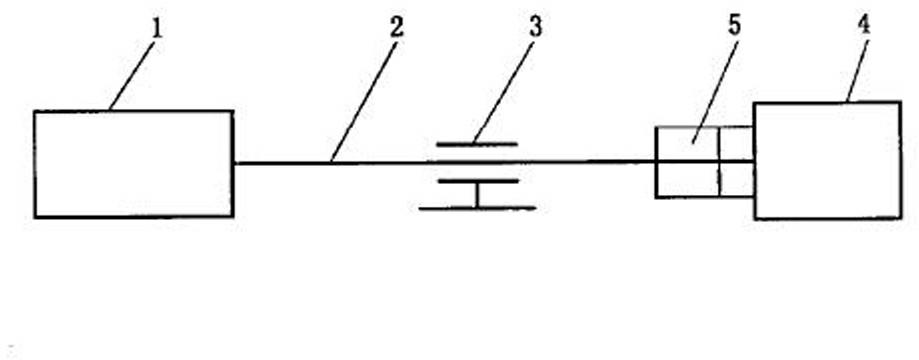

[0029] Embodiment: The present invention adopts the production process of glass fiber reinforced plastic products, which belongs to pultrusion molding, has high degree of mechanization and production efficiency, and can produce continuous length fully threaded glass fiber reinforced plastic anchor rods. The products can be solid and hollow, or straight rods with no thread on the surface, and special-shaped ribs can also be produced. Product diameter specifications can be designed according to needs. The FRP material used in the present invention is made of multi-strand fibers (such as glass fiber, carbon fiber, aramid fiber, etc.) glued with base materials (polyamide resin, polyethylene resin, or epoxy resin, etc.), and extruded through a special mold. Pressed and drawn.

[0030] The raw material of the present invention is GFRP material, that is, glass fiber reinforced polymer, which is mainly composed of glass fiber, resin and additives through special processing. The conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com