Patents

Literature

1538results about How to "Save labor costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

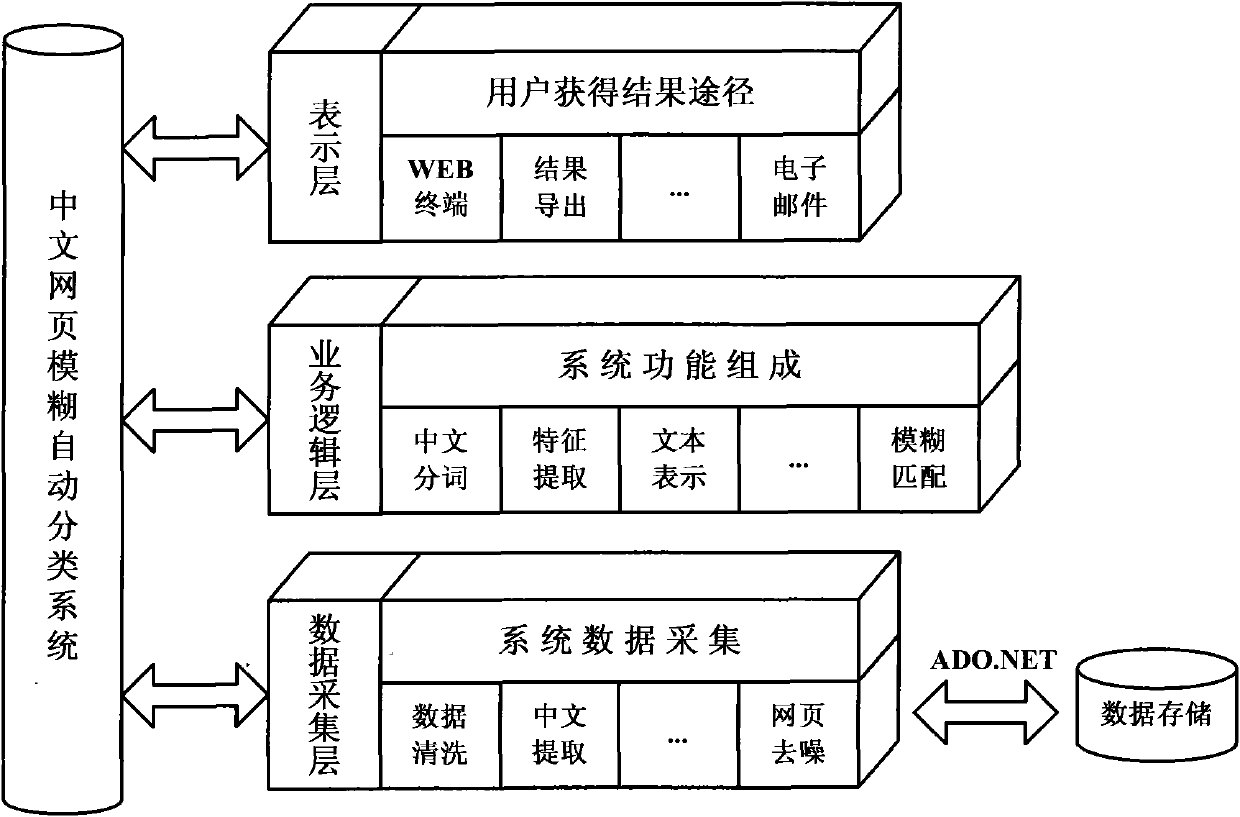

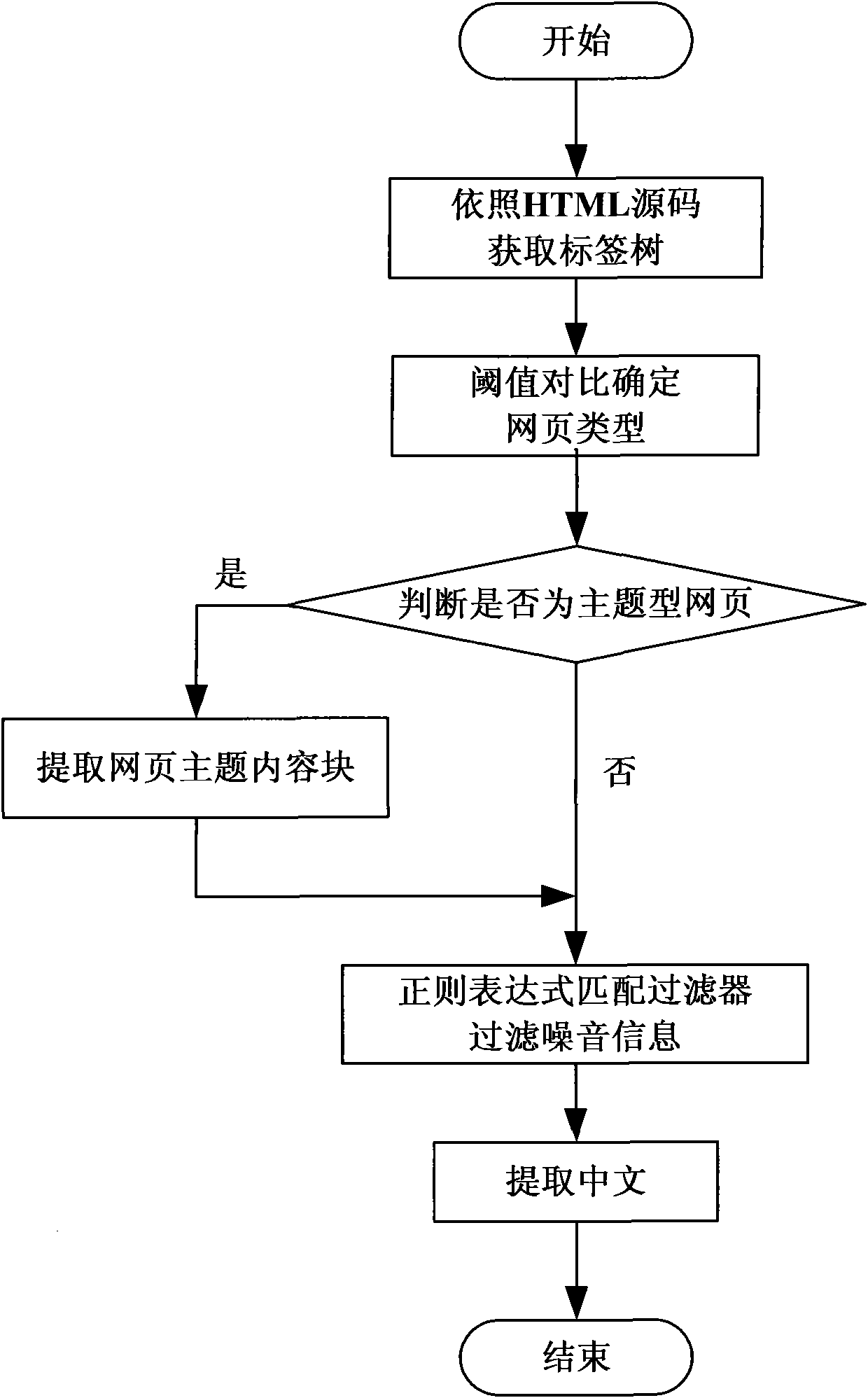

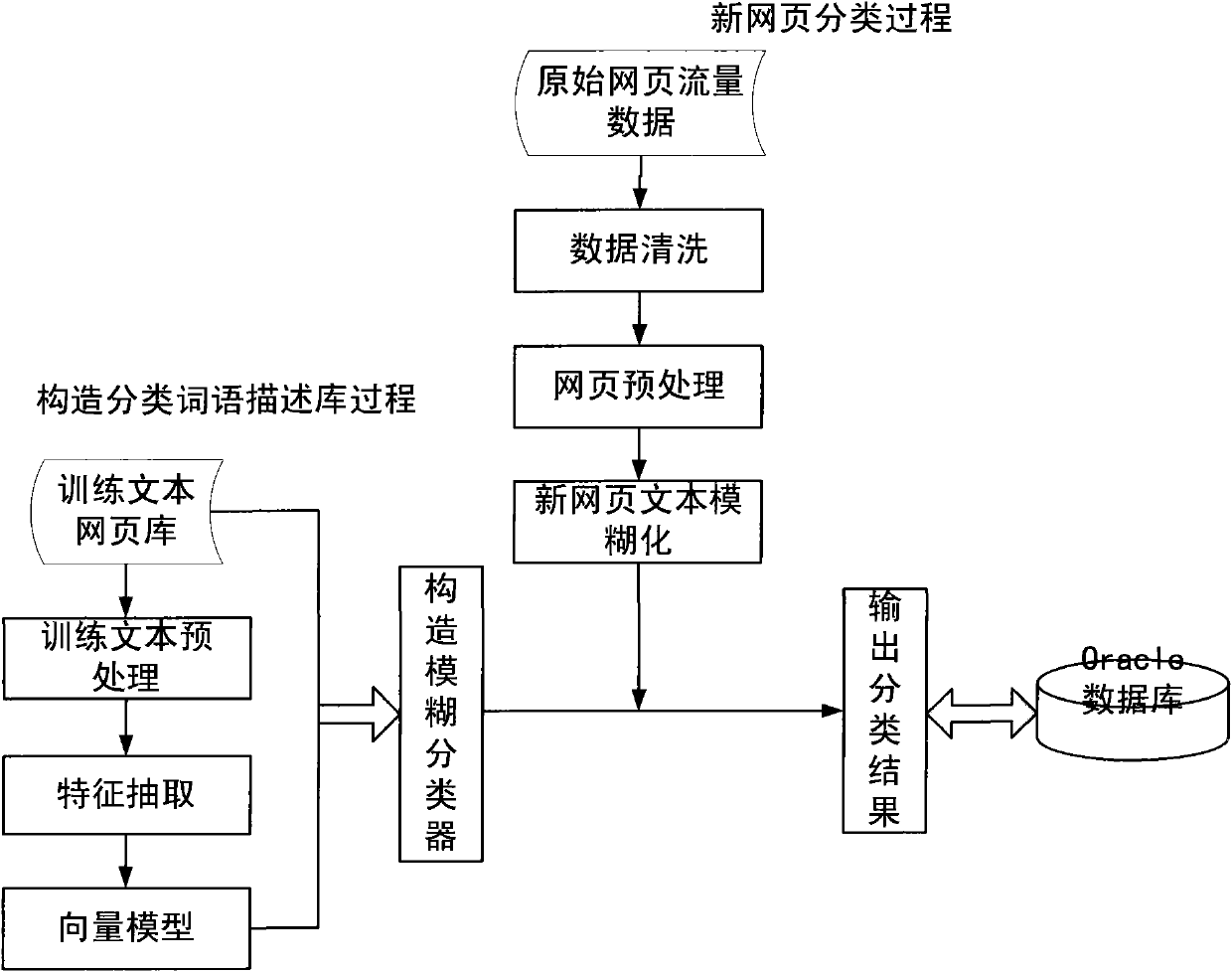

Fuzzy data mining based automatic classification method of Chinese web pages

InactiveCN101794311ASave labor costsImprove efficiencySpecial data processing applicationsMachine learningFuzzy data mining

The invention discloses a fuzzy data mining based automatic classification method of Chinese web pages. A classification word description library construction part, a new web page preprocessing part, a fuzzy classification matcher part and a classification result fuzzy judgment part are provided in the method. By applying a method of fuzzy comprehensive judgment, the fuzzy classification operation is carried out on a training set characteristic word vector fuzzy matrix generated when a classification word description library is constructed and a web page characteristic word fuzzy vector generated by the new web page preprocessing part, and finally the fuzzy classification of the Chinese web pages is obtained through classification result fuzzy judgment. The method can effectively improve the classification efficiency and solve the classification fuzziness problem and has favorable expandability, simple and convenient operation and easy popularization.

Owner:NANJING UNIV OF POSTS & TELECOMM

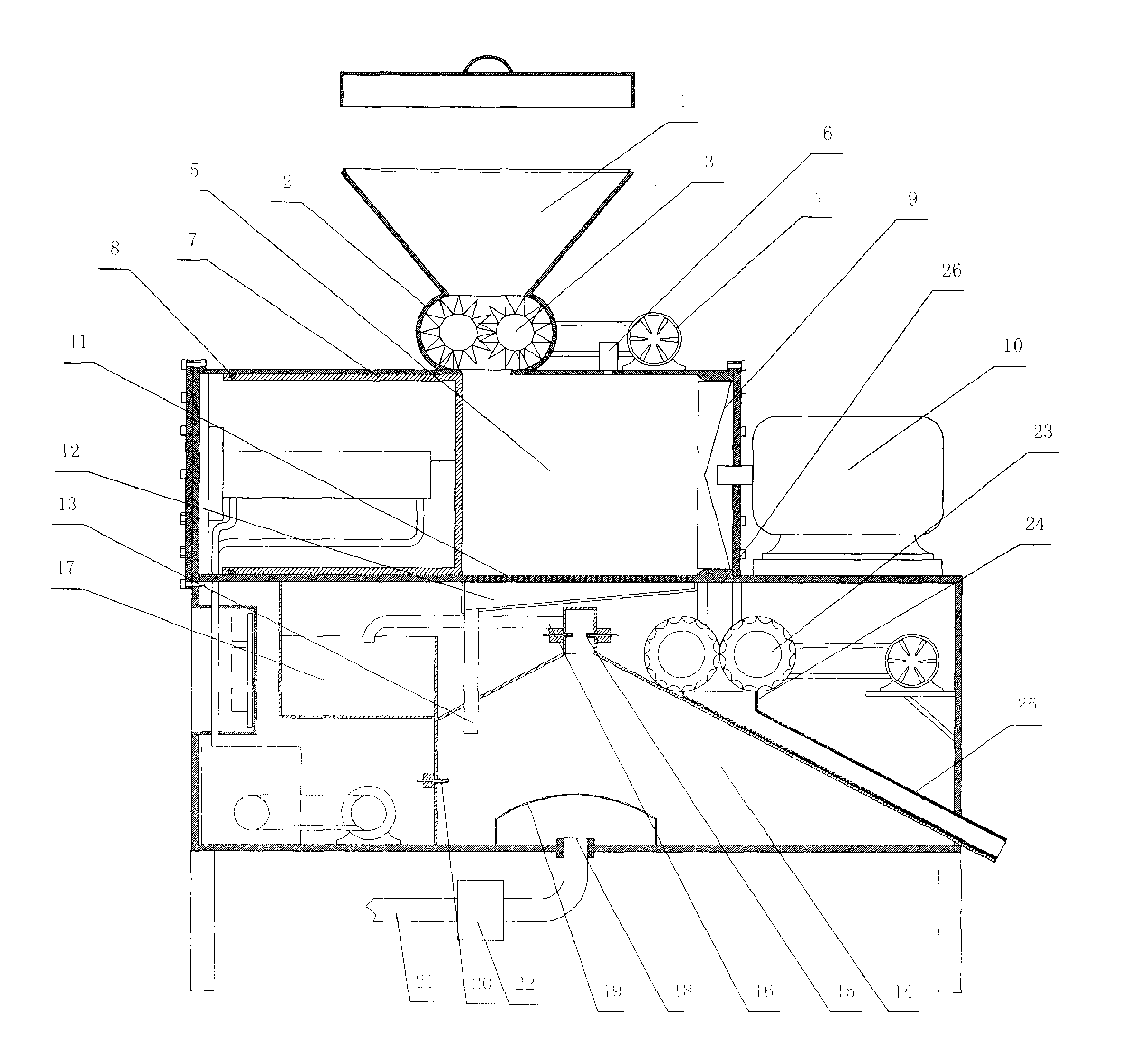

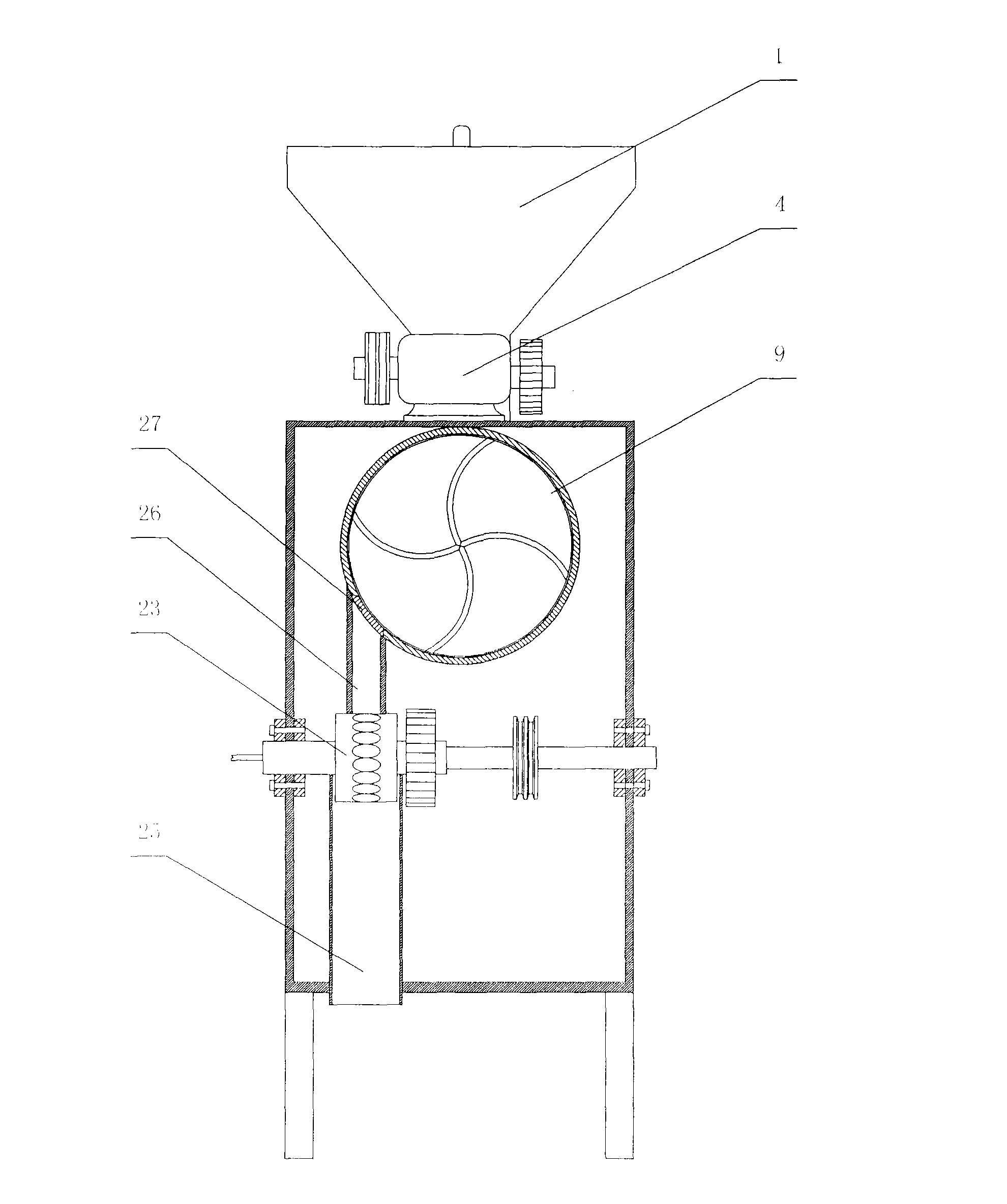

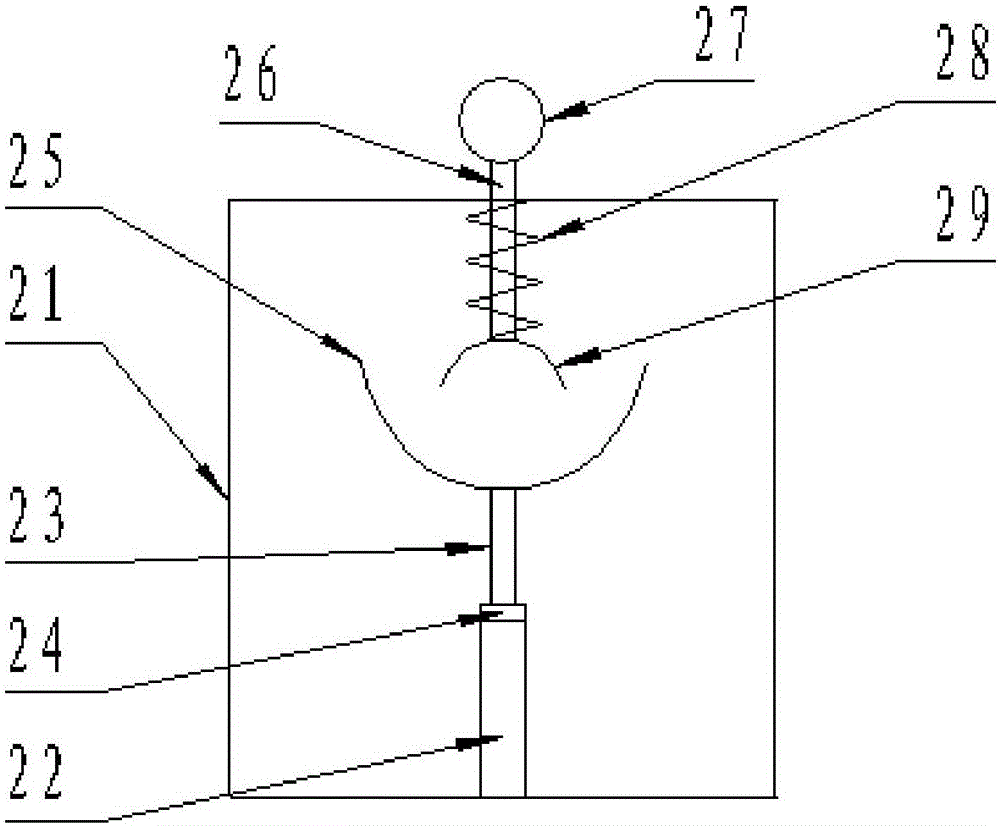

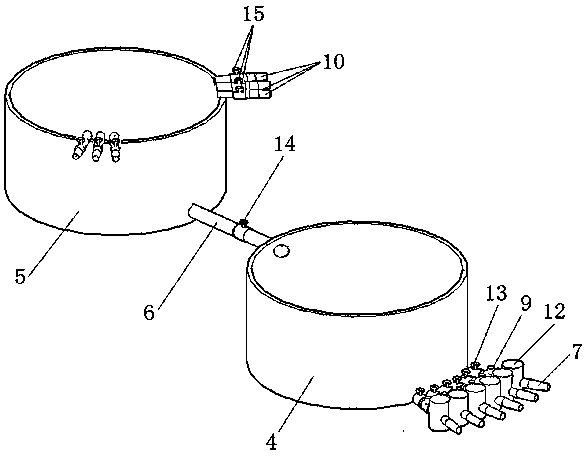

Food residue disposal

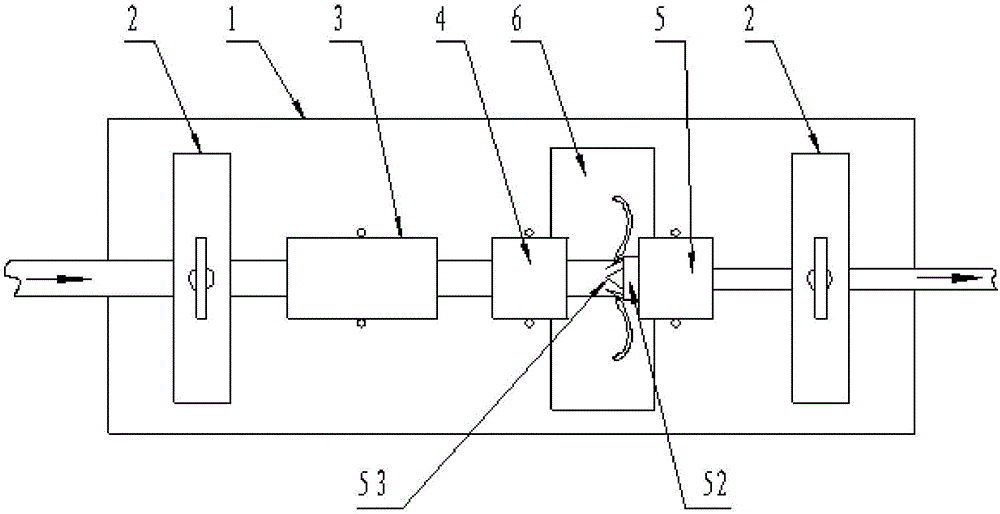

InactiveCN101664754ASave labor costsReduced entry into the oil-water separatorSolid waste disposalLiquid separationFertilizerAutomatic control

The invention discloses a food residue disposal, comprising a rack which is characterized in that the rack is provided with a crushing device, a press device, a solid forming device and an oil-water separation device, wherein one end of the crushing device is provided with a feed hopper, and the other end thereof is connected with the press device; and the press device is provided with a solid discharge hole and a liquid outlet, one end of the solid discharge hole is connected with the solid forming device, and one end of the liquid outlet is connected with the oil-water separation device. Thefood residue proposal has the advantage that all processes of the device are controlled by an automatic control system arranged in a control box on the rack, reduces labor cost, enables original discard residue which can pollute the environment to form solid residue capable of being used as fertilizer or feed after the original residue is processed by the food residue disposal, and can reuse oiland water, thereby realizing the purpose of turning waste into wealth.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

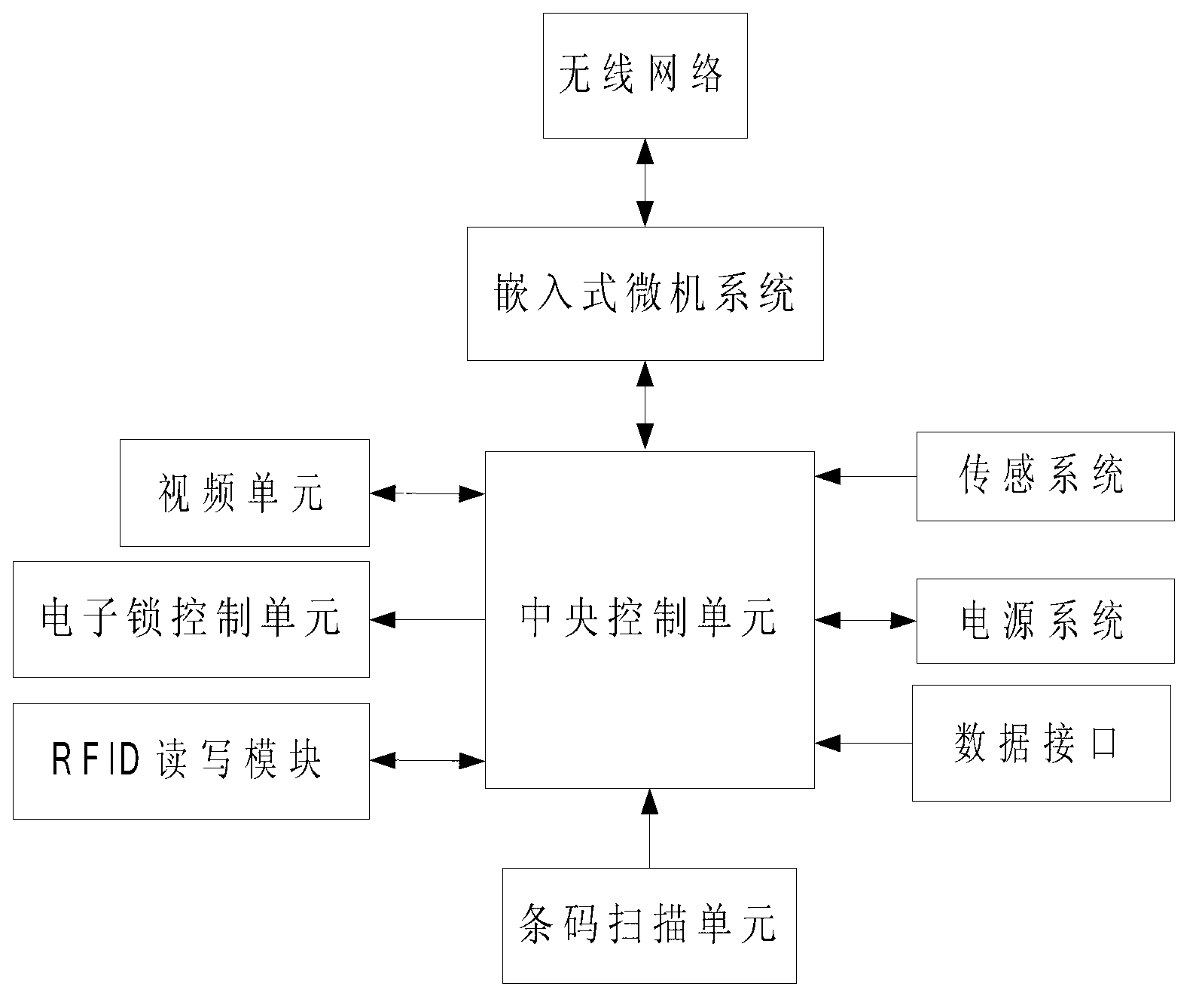

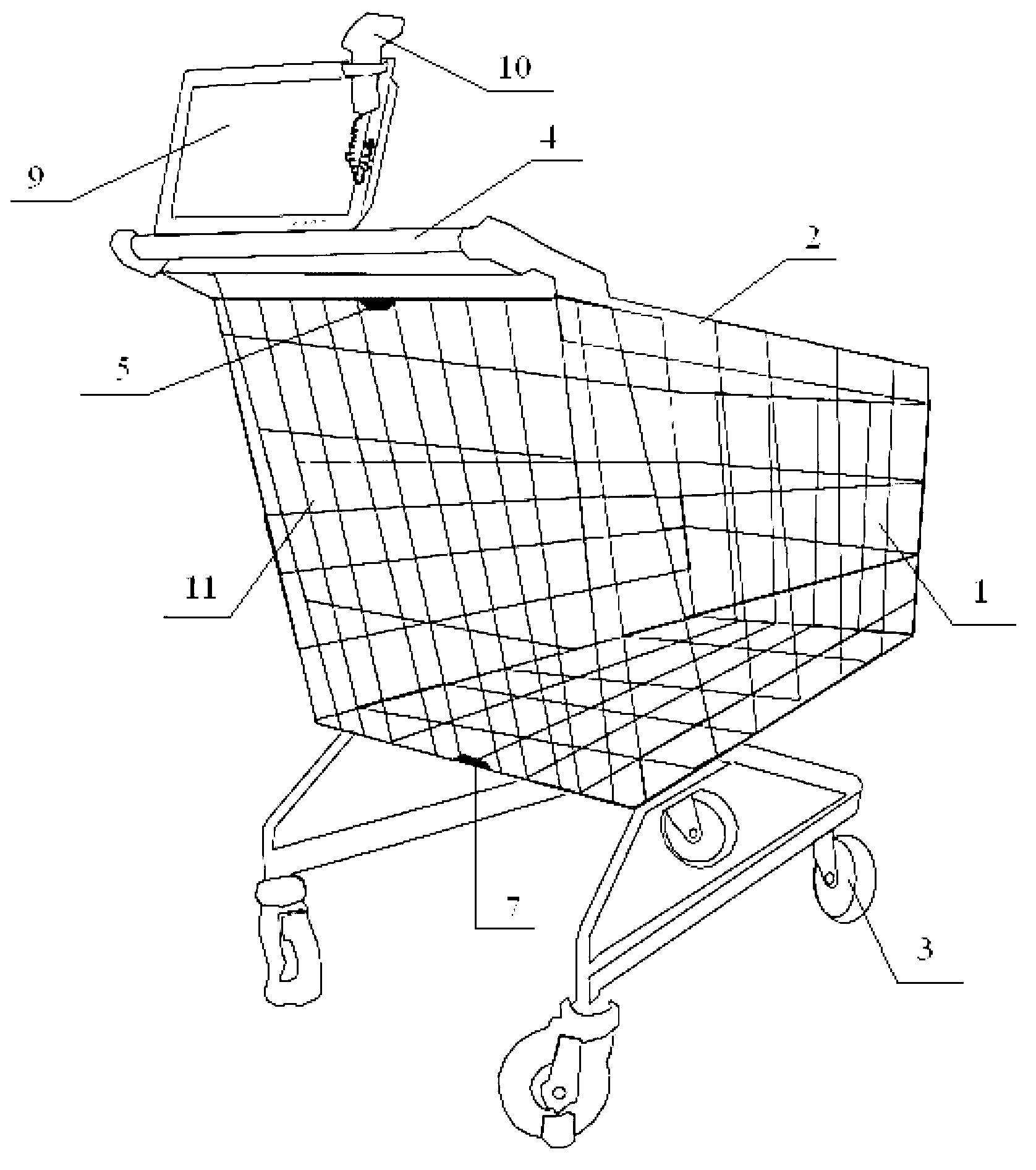

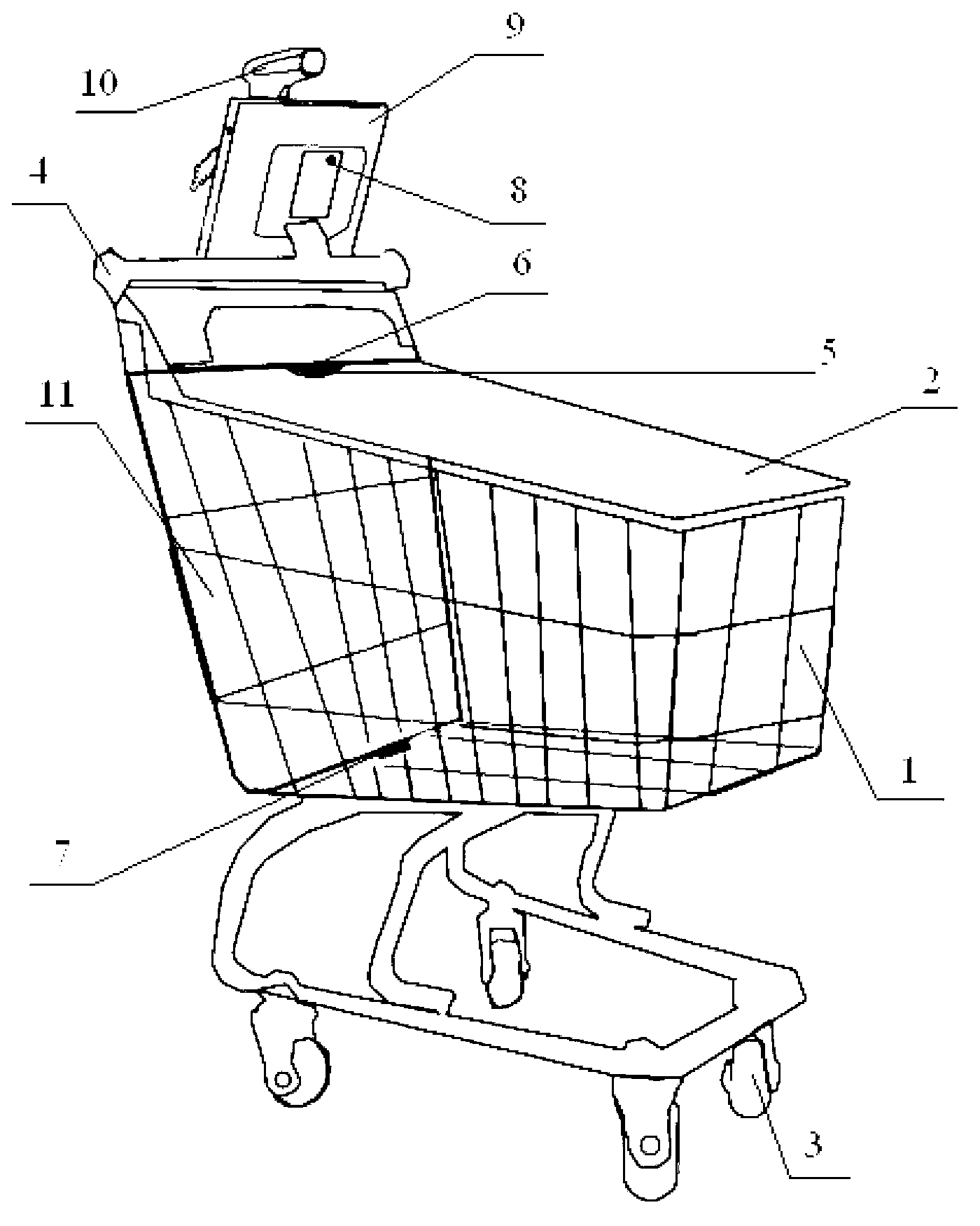

Novel self-help shopping checkout system and method for supermarkets

InactiveCN103236006APrevent theftSave labor costsSensing record carriersCommerceInformation deliveryService quality

The invention relates to novel self-help shopping checkout system and method for supermarkets, relates to automatic checkout system and method and solves the problems of the existing self-help shopping systems. The novel self-help shopping checkout system transmits commodity information through a wireless network system. A body of each shopping cart is fully closed. A barcode scanning unit inputs barcode information of a scanned commodity into a central control unit. Information is transmitted between customers and the novel self-help shopping checkout system through a central processing unit and an embedded microcomputer system provided with a touch screen. Signals are received and transmitted between the novel self-help shopping checkout system and the intelligent shopping carts through the wireless network system. The received information is transmitted to a rapid channel server. The rapid channel server stores barcode information and checkout information of the commodities. The novel self-help shopping checkout system requires no queuing, makes the checkouts in supermarkets more efficient, and improves service quality.

Owner:战国新 +1

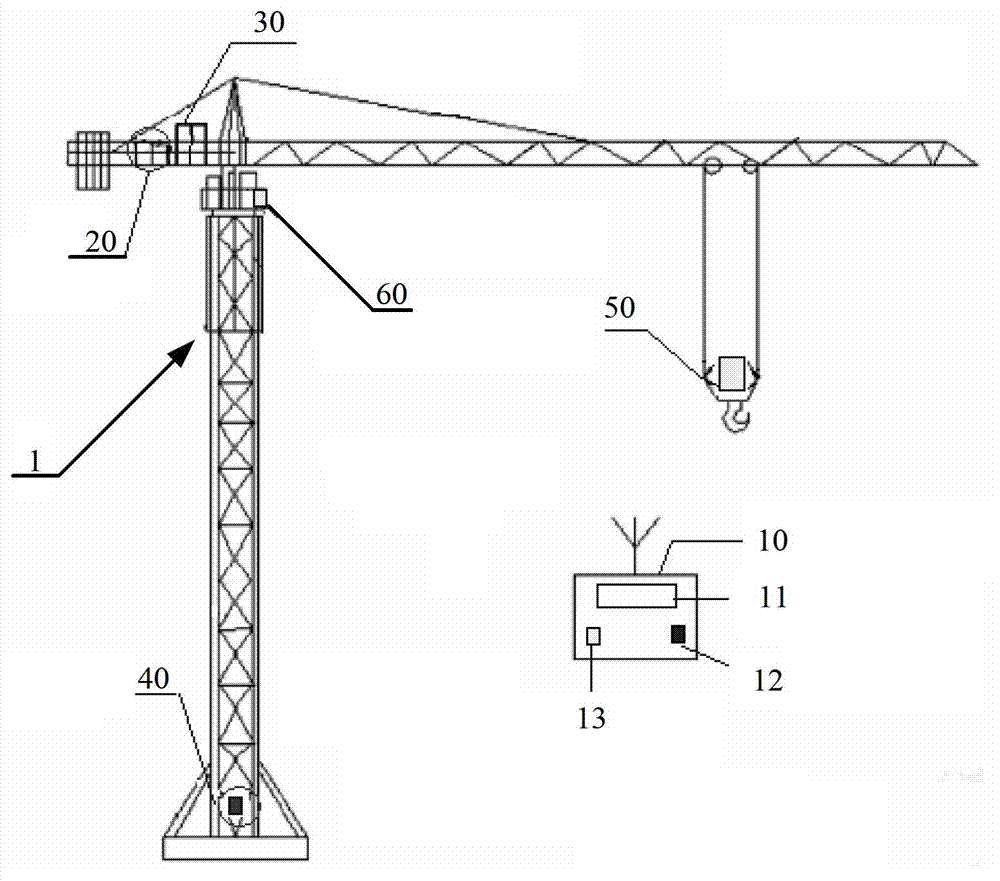

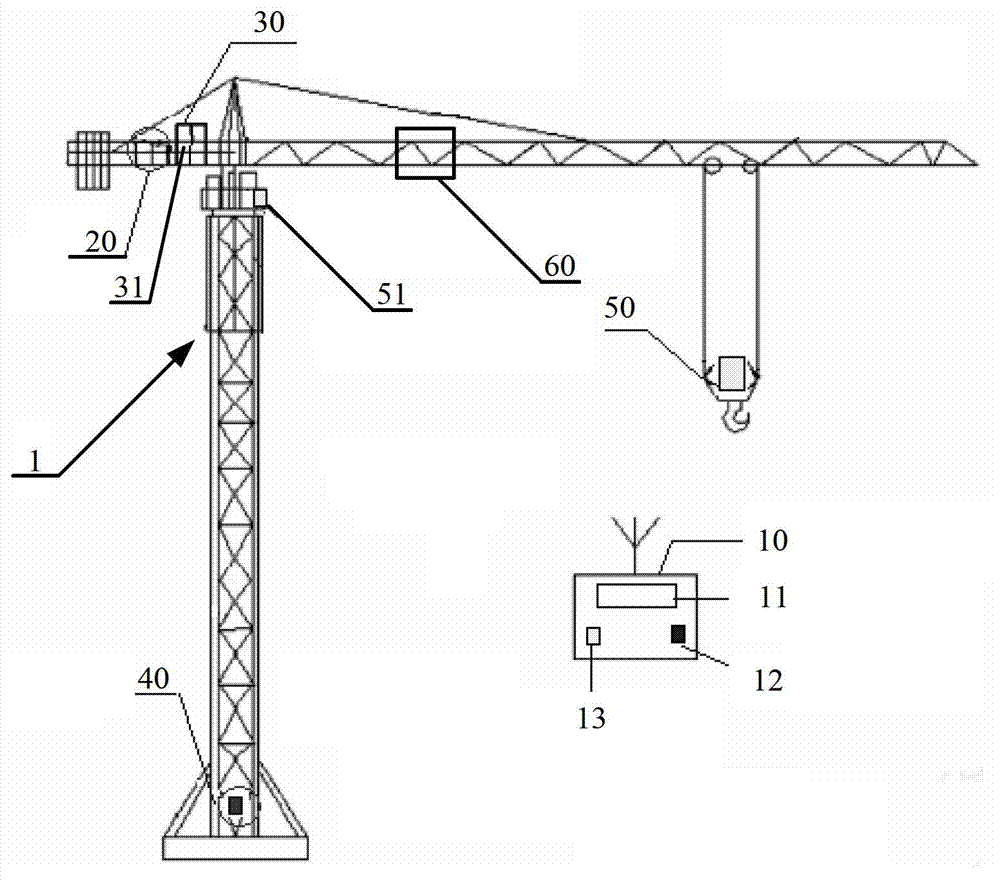

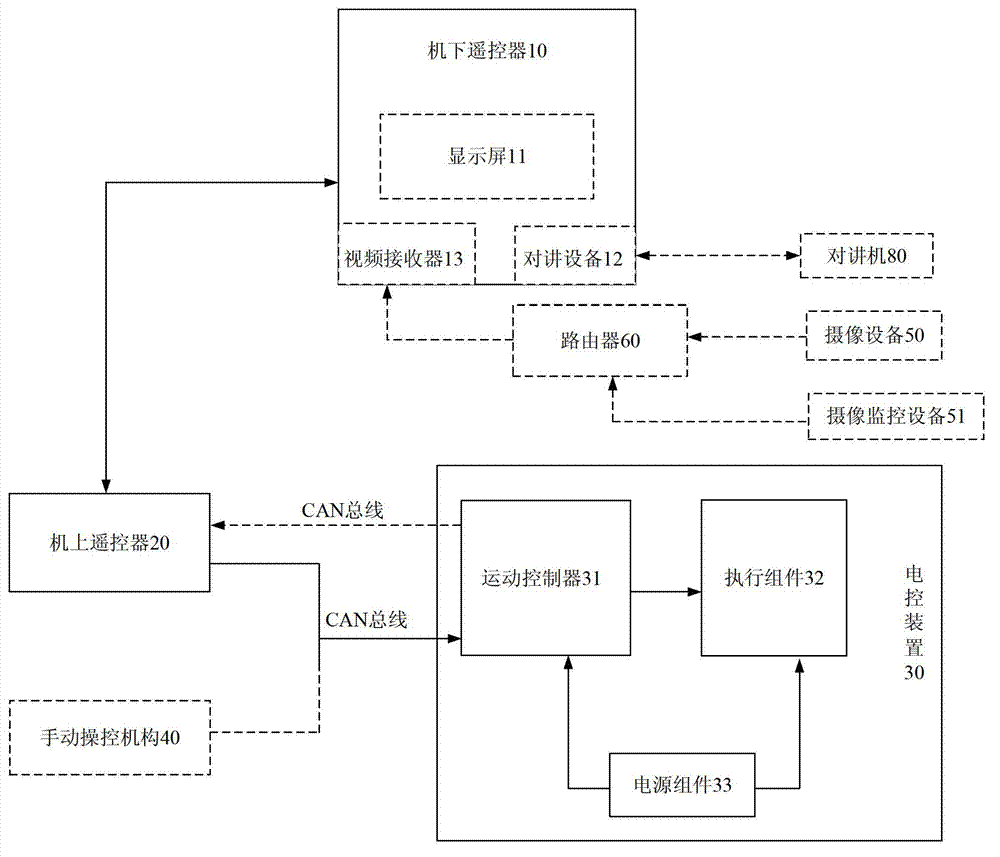

Tower crane intelligent control system and tower crane

ActiveCN102786002ARich operation functionAvoid visual blind spotsLoad-engaging elementsCranesCommand and controlElectric control

The invention discloses a tower crane intelligent control system and a tower crane. The tower crane intelligent control system comprises an off-crane remote controller, an on-crane remote controller and an electric controller, wherein the off-crane remote controller is arranged off the tower crane, is communicated with the on-crane remote controller and sends a control command to the on-crane remote controller; the on-crane remote controller is arranged on the tower crane, receives the control command and sends the control command to the electric controller; and the electric controller is arranged on the tower crane, receives the control command and controls the movement execution mechanism of the tower crane according to the control command. So the tower crane intelligent control system has the advantages of comprehensive operation functions, avoiding of visual blind areas, flexible position, and realization of selecting a relative ideal position to operate according to the situation on the ground.

Owner:SANY HEAVY IND CO LTD (CN)

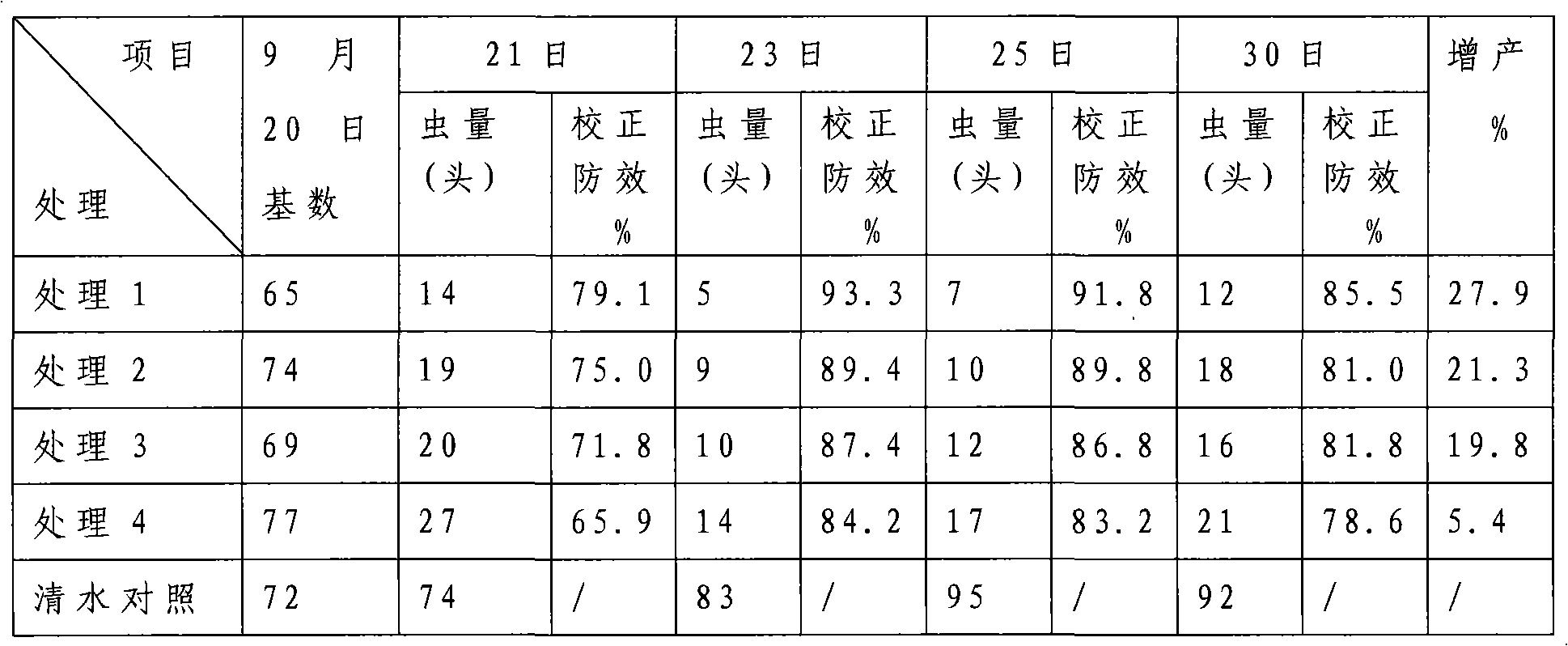

Microcapsule insecticide-fertilizer preparation, preparation method and application thereof

InactiveCN101857482ANo pollutionSlow release rateBiocidePlant growth regulatorsChemical compatibilitySolvent

The invention discloses a microcapsule insecticide-fertilizer preparation, a preparation method and application thereof. The preparation consists of the following components in part by weight: 1 to 30 parts of pesticide microcapsules and 70 to 99 parts of nutrient substance. The preparation method mainly comprises the following steps of: after fully dissolving a pesticide with a solvent, adding a wall material monomer into solution and mixing uniformly; transporting a mixture into a shear dispersion reaction kettle which is filled with smashed capsule bodies; stirring the mixture and the capsule bodies so that the capsules fully absorb the solution; performing a shear dispersion reaction to form capsules; performing solid-liquid separation and drying to prepare the pesticide microcapsules; adding the nutrient substances into the pesticide microcapsules; and fully stirring and uniformly mixing to prepare the microcapsule insecticide-fertilizer preparation. By using the microcapsule insecticide-fertilizer preparation and the preparation method, the problems of the chemical compatibility and the physical stability of the conventional insecticide-fertilizer preparation in the same system are solved effectively. A product of the invention has the advantages of: shielding and slow-releasing functions, high chemical compatibility and physical stability, lasting pesticide effect, natural degradability, no environment pollution, low use cost and simple production process.

Owner:侯金荣 +1

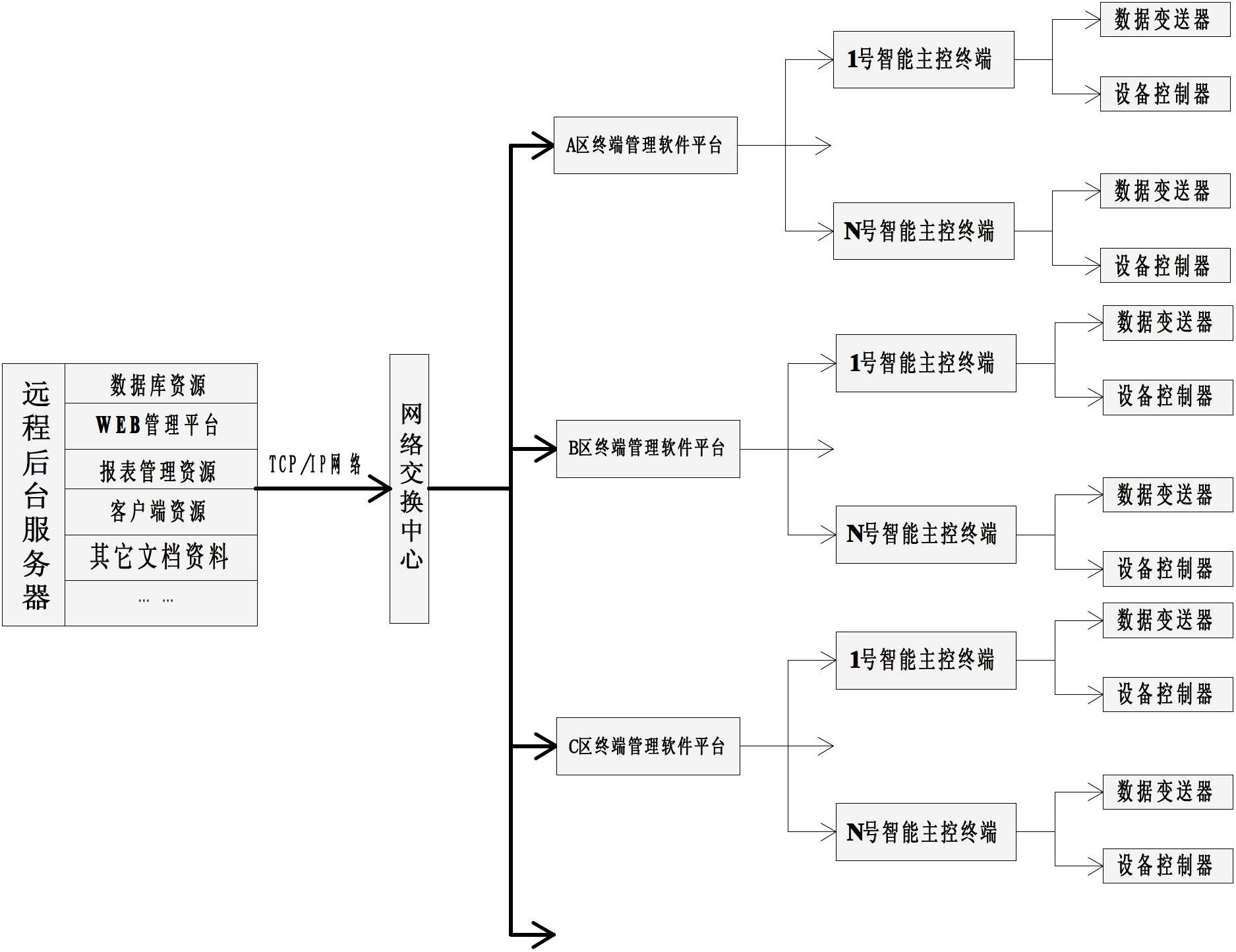

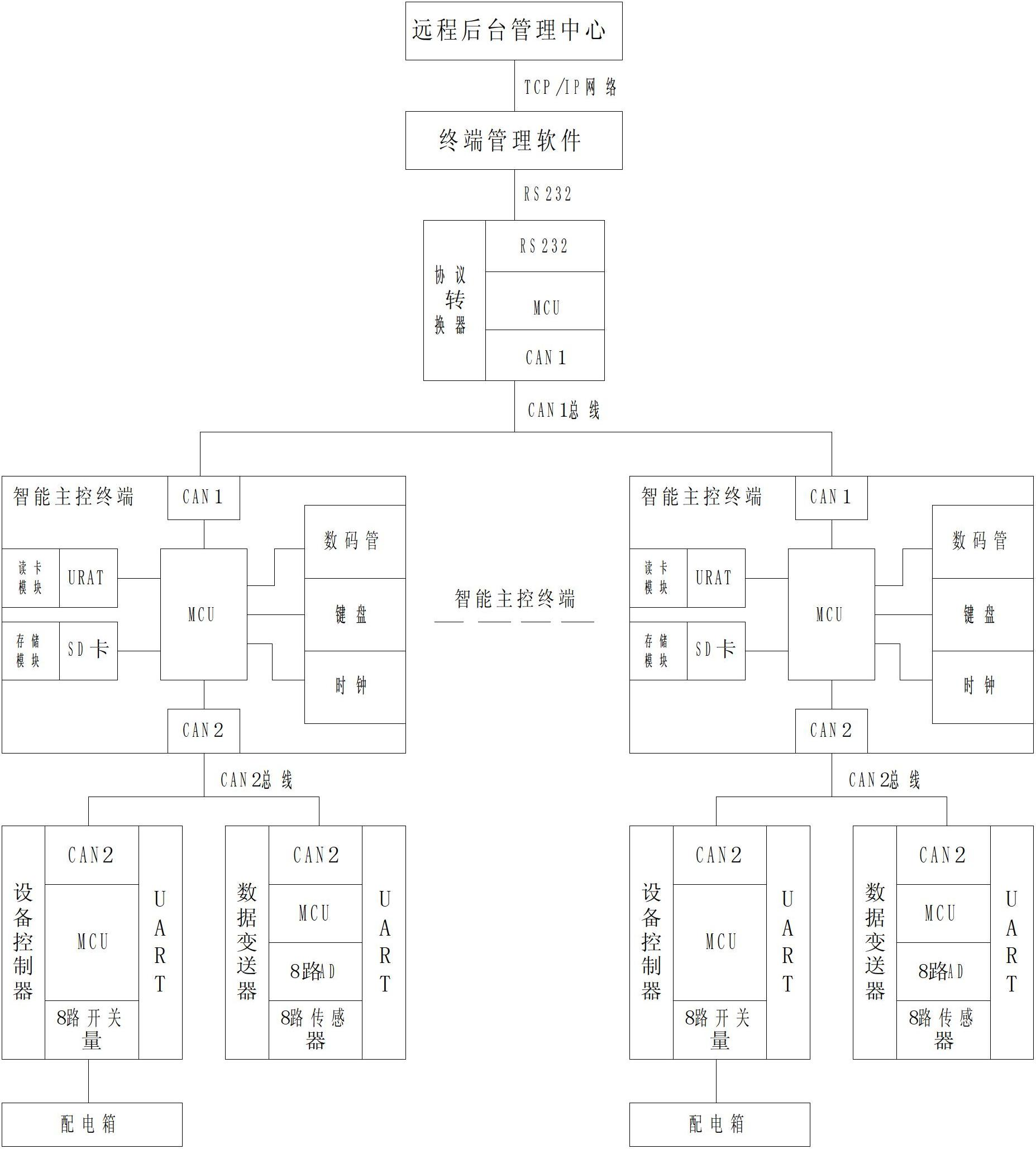

Data information acquisition intelligent managing and controlling system based on Internet of things

ActiveCN102681511AShorten the timeRealize fully automatic unmanned monitoringTotal factory controlProgramme total factory controlArea networkData information

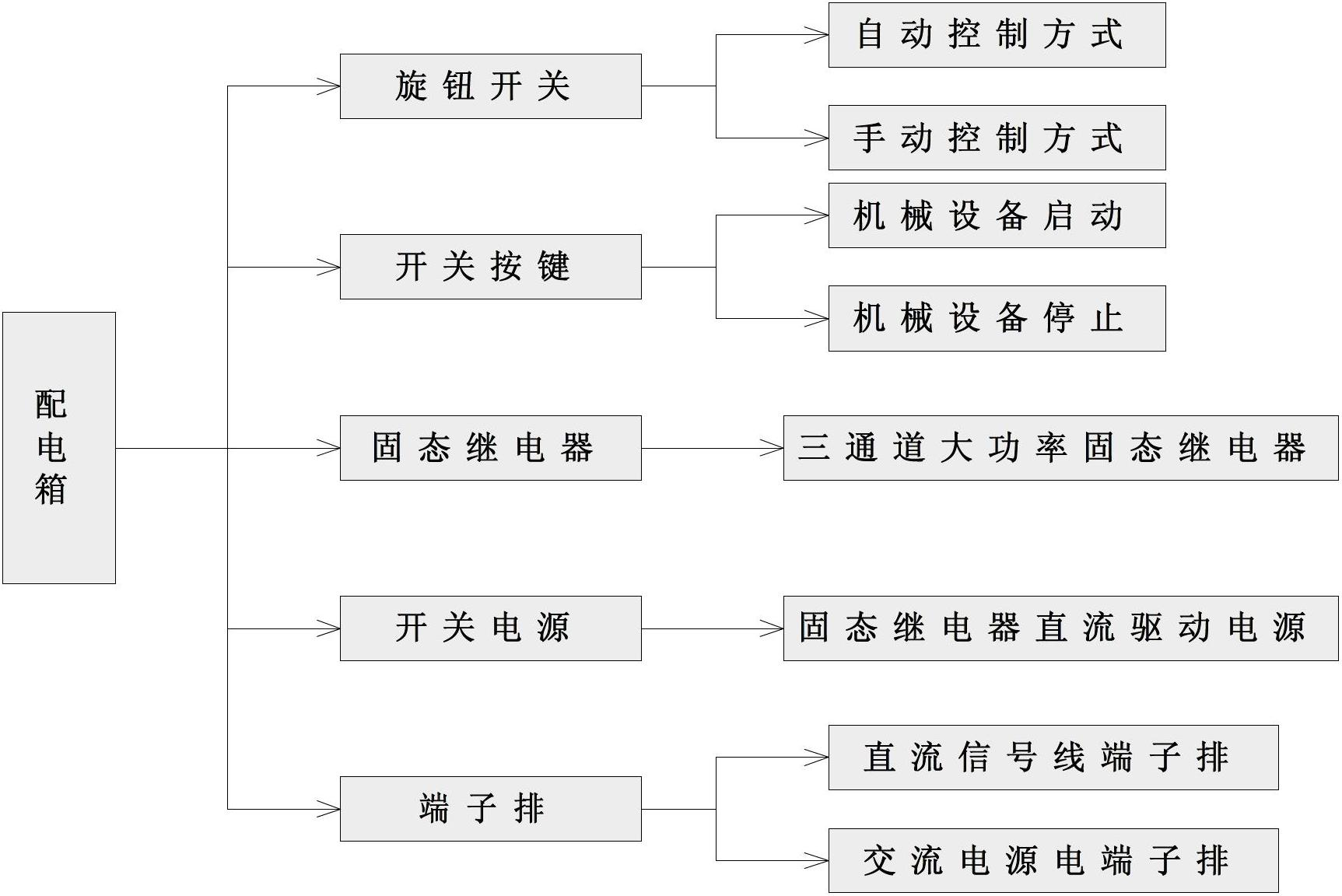

The invention discloses a data information acquisition intelligent managing and controlling system based on the Internet of things, which belongs to the field of data information acquisition intelligent managing and controlling systems based on the Internet of things. The system comprises a remote background managing center, a TCP / IP (Transmission Control Protocol / Internet Protocol) network system and a terminal machine system, wherein a terminal machine comprises terminal managing software and terminal data acquiring equipment; the terminal managing software is communicated with the remote background managing center through a network; the terminal data acquiring equipment comprises an intelligent main control terminal and the like; one path of the intelligent main control terminal is connected with a protocol converter; the other path of the intelligent main control terminal is connected with a data transmitter and an equipment controller; the protocol converter is connected with the terminal managing software through a serial port line, and is connected with the background managing center through a network system; a distribution box is connected with an equipment controller; and the equipment controller is communicated with the intelligent main control terminal through a CAN (Controller Area Network) bus. The data information acquisition intelligent managing and controlling system has the advantages of high intelligent degree, high stability and easiness for operating equipment; and a diverse and open Internet of things information acquisition system capable of realizing intelligent identification data acquisition, processing and management is provided.

Owner:CHANGCHUN WHY E SCI & TECH

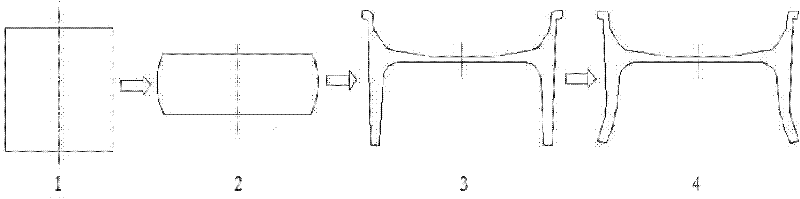

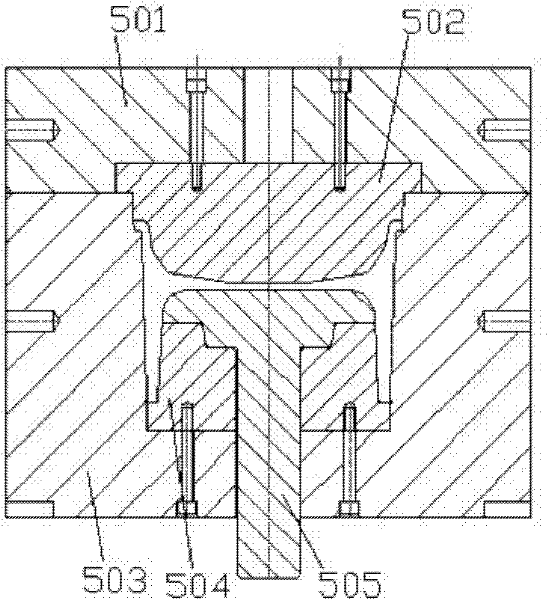

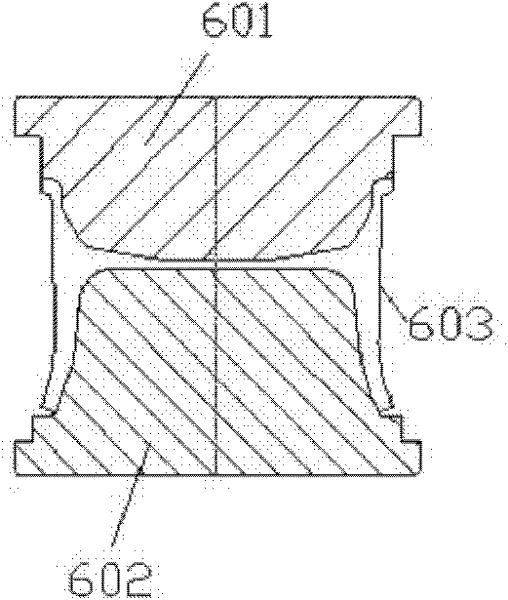

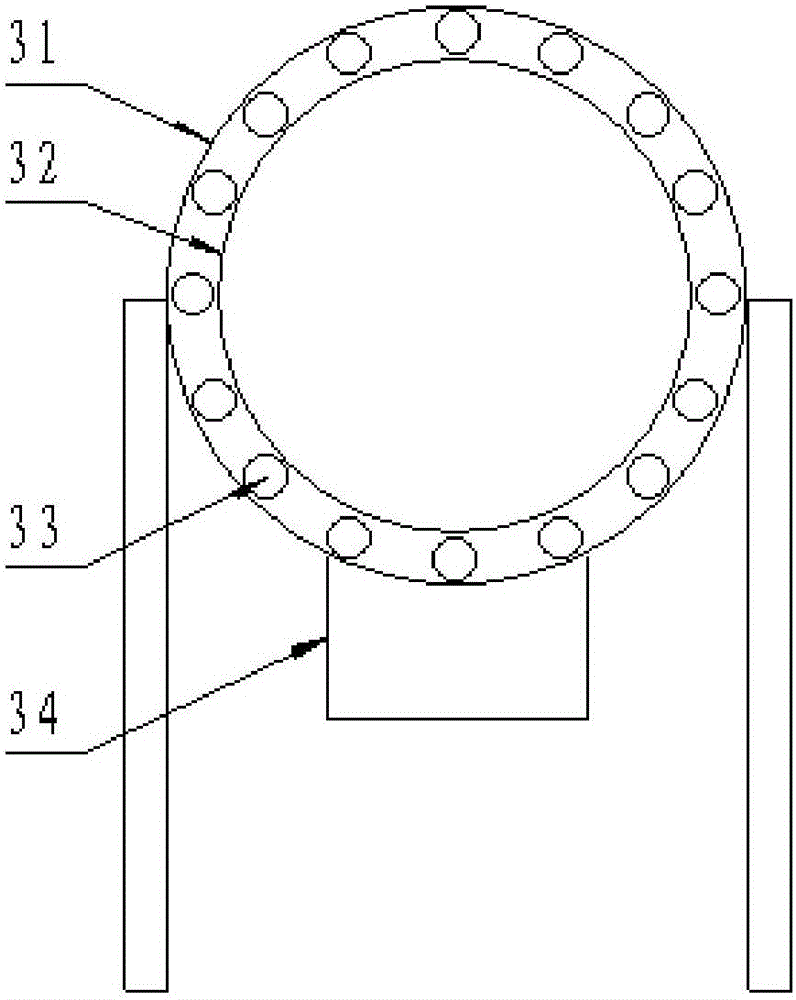

Chambering-forging forming method for aluminum alloy hub with complex structure and die thereof

InactiveCN102228951AReduce maintenance costsIncrease profitForging/hammering/pressing machinesWheelsAlloy wheelMaterials science

The invention provides a chambering -forging forming method for an aluminum alloy hub with a complex structure and a die thereof. The forming method comprises the steps of: preparing for materials; heating blanks; upsetting; mould-pressing and chambering a rim. The die for realizing the chambering-forging forming method for the aluminum alloy hub with the complex structure comprises a forging die and a rim-chambering die, wherein an upper die of the forging die consists of an upper die body and an upper die core which are sequentially nested and mounted, a lower die consists of a lower die body, a lower die core and an ejector rod which are sequentially nested and mounted; and the bottom and the side wall of the assembling part of the lower die core and the lower die body are uniformly provided with 4-8 R3 penetrating exhaust grooves, the rim-chambering die consists of an upper chambering die and a lower chambering die, and the size of a cavity of the upper chambering die is same as the size of the cavity of the upper die core of the forging die. The invention realizes once-heating forming; a non-burr forging and rim-chambering forming process is adopted, thus two trimming procedures are eliminated, material utilization rate is improved, and number of equipment is reduced; and the rim-chambering die has a simple structure and is convenient for operation.

Owner:HARBIN HAFEI IND

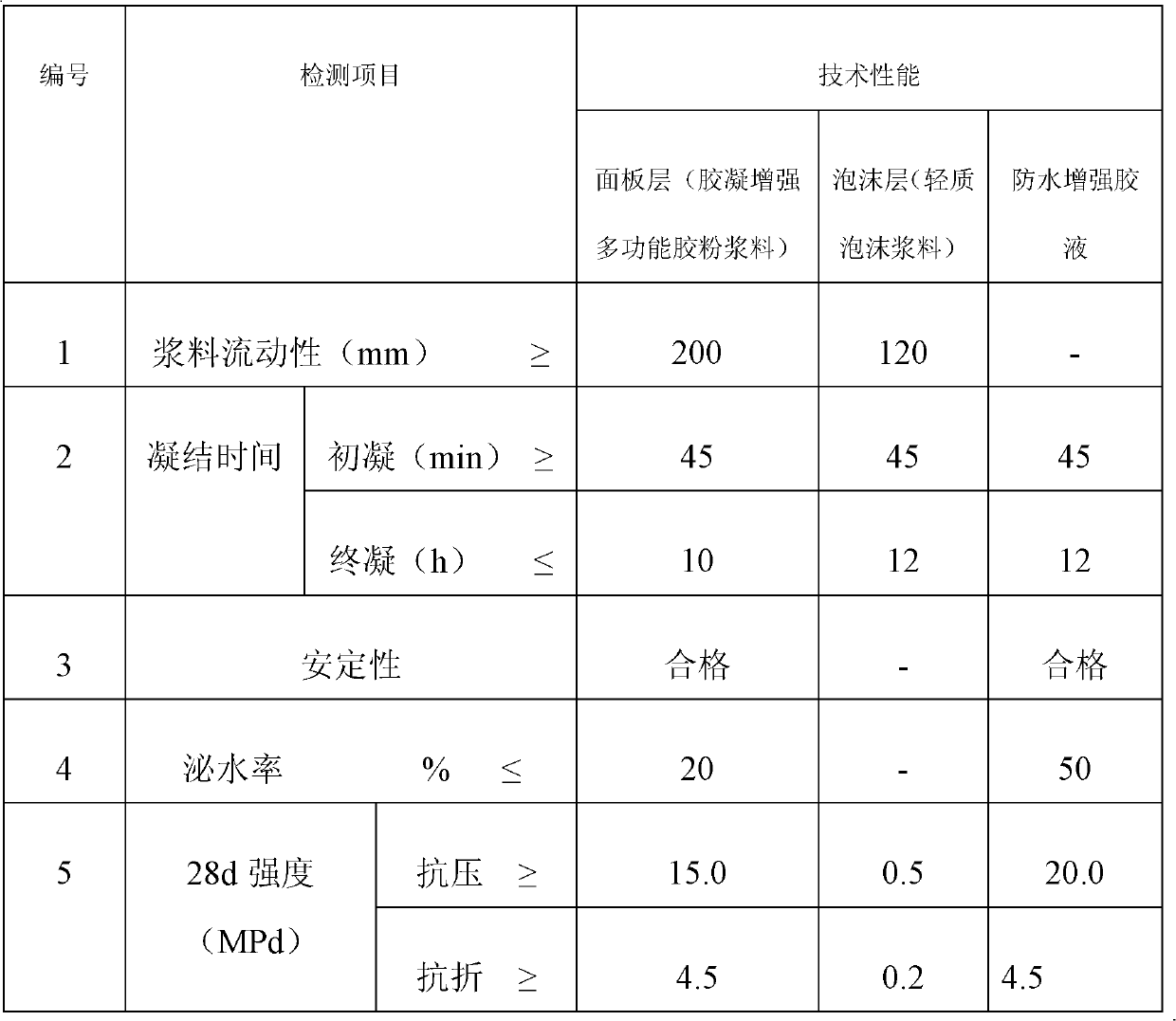

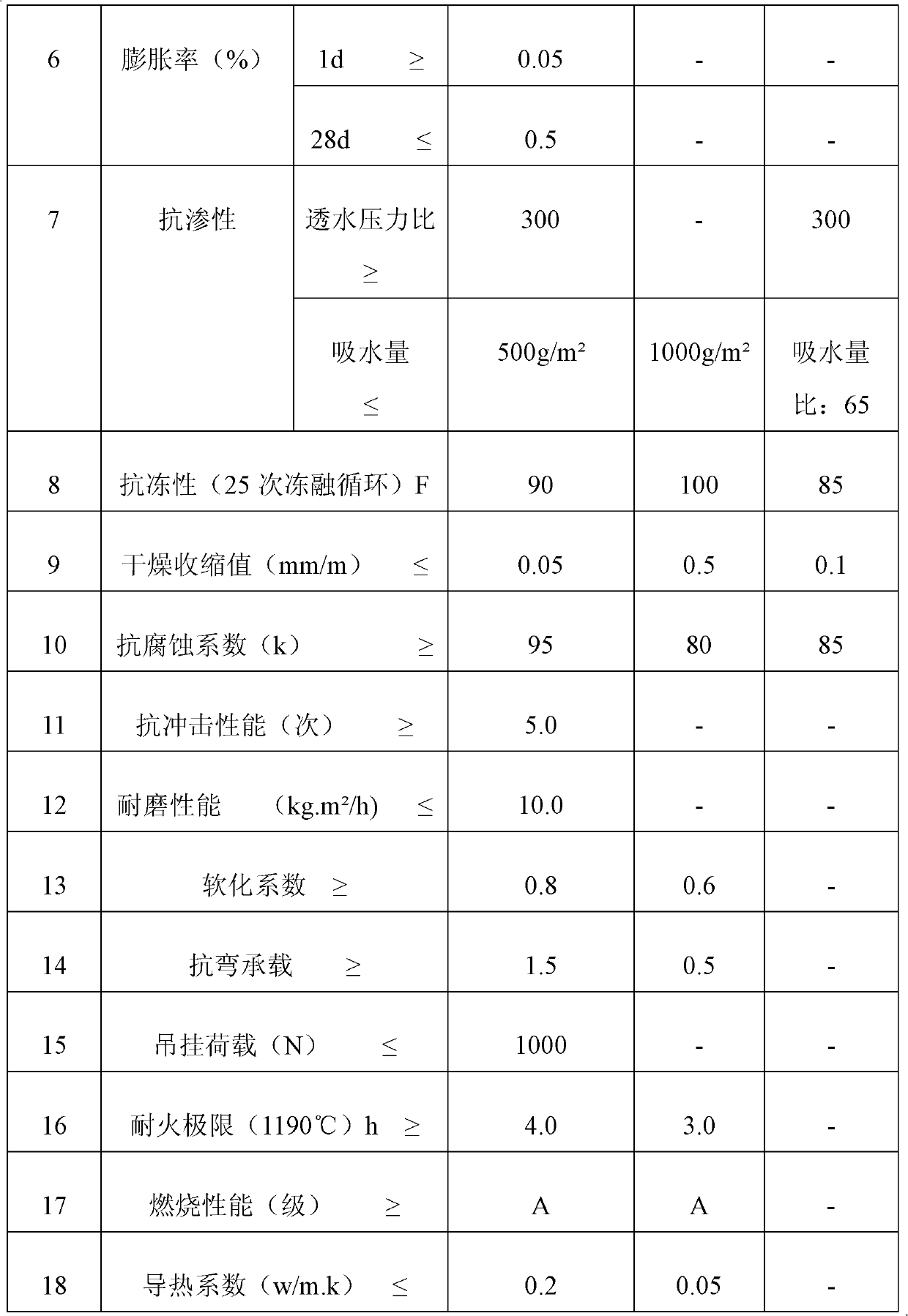

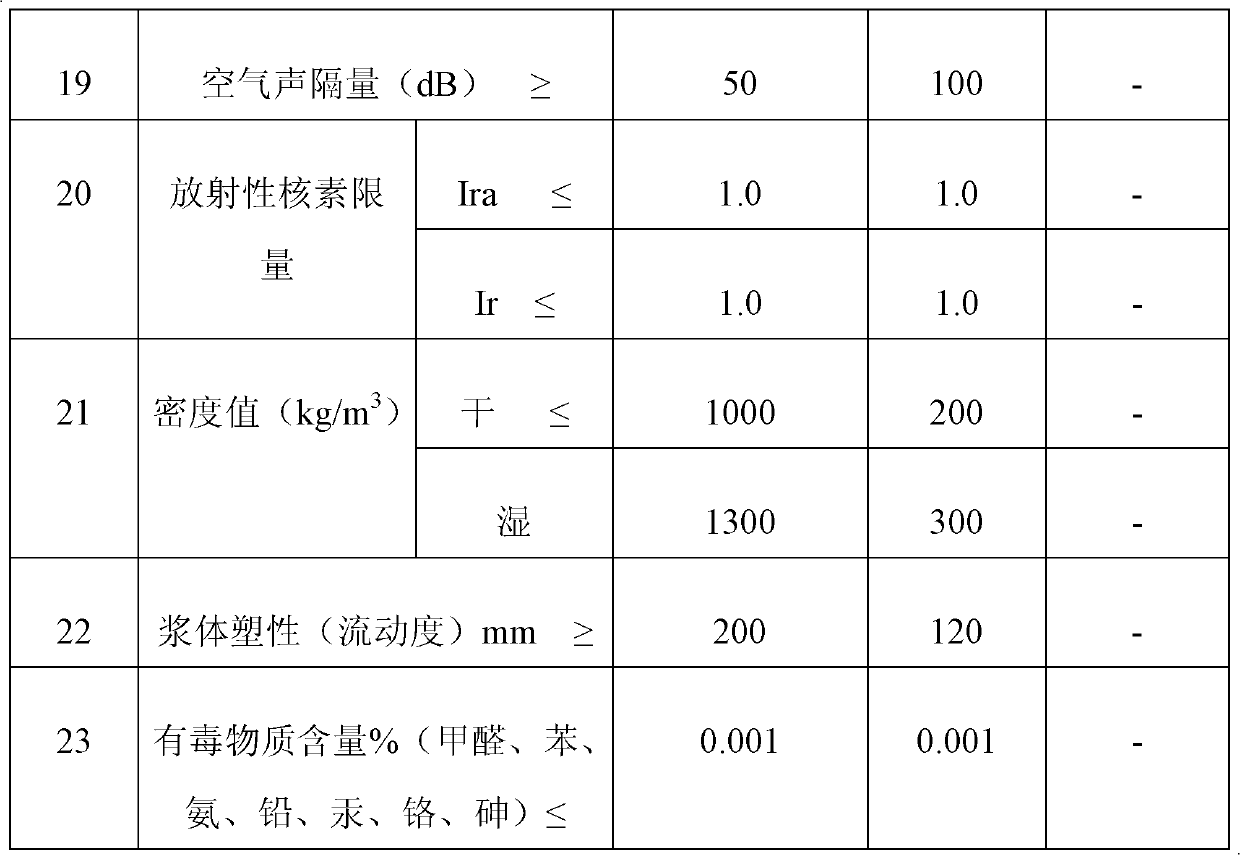

Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

The invention provides a multifunctional inorganic thermal insulation material composition, a multifunctional inorganic thermal insulation material product prepared from the multifunctional inorganic thermal insulation material composition and a preparation method of the multifunctional inorganic thermal insulation material product. By substantially utilizing industrial and construction wastes as a gel enhancement and inorganic thermal insulation system and adding a little amount of cement as well as a proper amount of regulator, the multifunctional inorganic thermal insulation material composition is molded in a casing mode by one step, thereby forming a wall plate, a block material (wall materials decorated by wall floor tiles) and a roof. Therefore, the wall body, the block material and the roof have the multifunction and the characteristics of thermal insulation, fire prevention, water resistance, freezing resistance, crack resistance, sound insulation, light weight, corrosion resistance, weather resistance, decoration, energy conservation, environmental friendliness, safety, sanitation, work saving, time saving, cost saving and the like.

Owner:苏琳

Processing method for instant sheet jelly and bean jelly

ActiveCN101341944AAvoid secondary pollutionReduce manual operationsFood preparationPotassiumChloride

The invention relates to a processing method of instant sheet jelly and bean jelly, which comprises: mixing and pulping, i.e. starch and water are mixed by the ratio of 1:2 to 9 to prepare starch sirup; and then citric acid with 0.01 weight percent to 0.9 weight percent of starch sirup and 0.01 percent to 1.2 percent of edible potassium chloride or 0.01 percent to 1.2 percent of edible calcium carbonate are added in to be evenly mixed, to obtain ground paste; the ground paste is measured, filled, sealed, cooked and cooled to obtain sheet jelly and bean jelly products. The processing method of the invention can prevent secondary pollution in production and other links and effectively reduce manual operation, the production process is simple, the product quality is good, the product guarantee period can be 3 to 9 months prolonged compared with the prior products on the market, and the product can be directly eaten after being unpackaged, or eaten by being mixed with accessorial seasoning, which is convenient to be eaten.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Operation method of electric peeling device for protective cores of waste cables

ActiveCN106329410AReduce labor intensitySave labor costsApparatus for removing/armouring cablesEngineeringProtective relay

Provided is an operation method of an electric peeling device for the protective cores of waste cable. Clamping mechanisms are arranged at the two ends on an operation table. A heater, a cutting mechanism and a stripping mechanism are sequentially arranged along the running direction of cables between the two clamping mechanisms. An insulating layer collection hole is arranged between the cutting mechanism and the stripping mechanism. The operation method comprises the following steps: adjusting the height of the telescopic rods on the clamping mechanisms; adjusting the distance between the blade of a cutter on the cutting mechanism and the inner core of a cable and the distance between the blade of a separator on the stripping mechanism and the inner core of the cable; adjusting the centers of the mechanisms to the same axis line; and heating, cutting and stripping the insulating layer of a to-be-processed cable in sequence. The device has a simple structure. The operation method is simple. The use effect is good. Operation by workers is facilitated. The labor intensity of workers is reduced greatly. The stripping effect is good, and the production efficiency is high. The method is suitable for stripping the rubber sheaths of all kinds of cables. High cable core recovery efficiency is achieved.

Owner:HUATONG CABLE INC

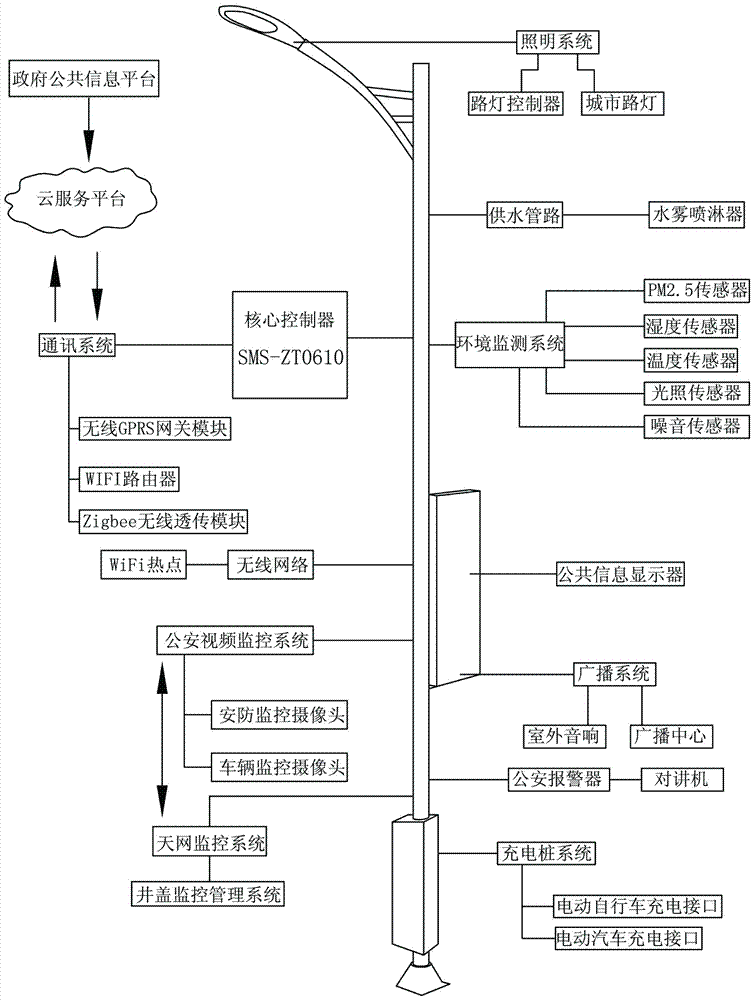

City management intelligent streetlamp

PendingCN107062108AEnsure safetyReduce the temperatureProgramme controlMechanical apparatusVideo monitoringDisplay device

The invention discloses a city management intelligent streetlamp which comprises a streetlamp body arranged on a municipal road. A core controller is arranged in a lamp post of the streetlamp body. The core controller is connected with an illumination system, a water supply pipeline, an environment monitoring system and a communication system. The illumination system comprises a city streetlamp and a streetlamp controller. The streetlamp controller is in controlled connection through the core controller. The communication system comprises a wireless GPRS gateway module, a WiFi router and a ZigBee wireless unvarnished transmission module. The communication system is connected to a cloud service platform. The cloud service platform is connected with a government public information platform. A public information display is installed on the streetlamp body. The core controller is connected to a public security video monitoring system, a sky net monitoring system and a well lid monitoring managing system. By means of the city management intelligent streetlamp, the air humidity and temperature can be adjusted to a certain degree, the PM2.5 value in the air is reduced, the public information display is further arranged and can play government public information in real time, and due to the arranged public security video monitoring system and the interconnected sky net monitoring system and well lid monitoring managing system, good security work can be done.

Owner:江西中天景建设有限公司

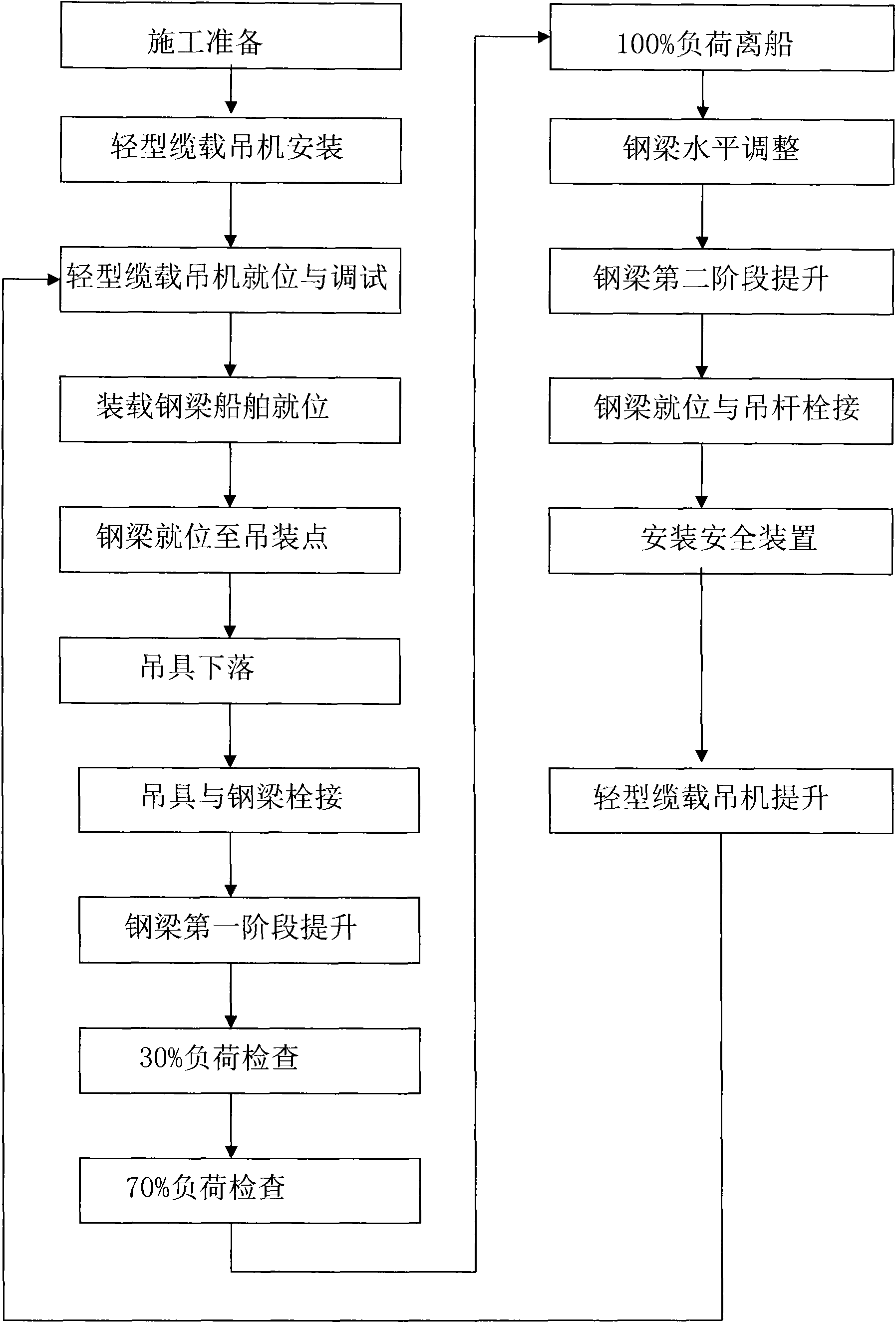

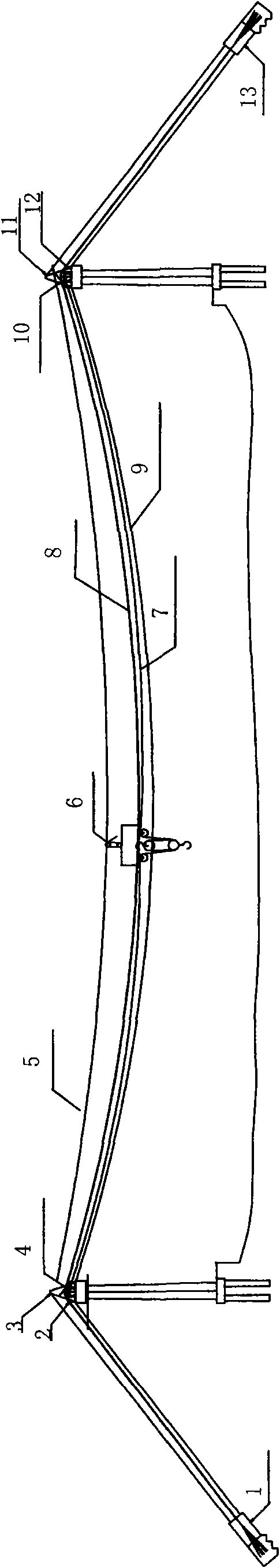

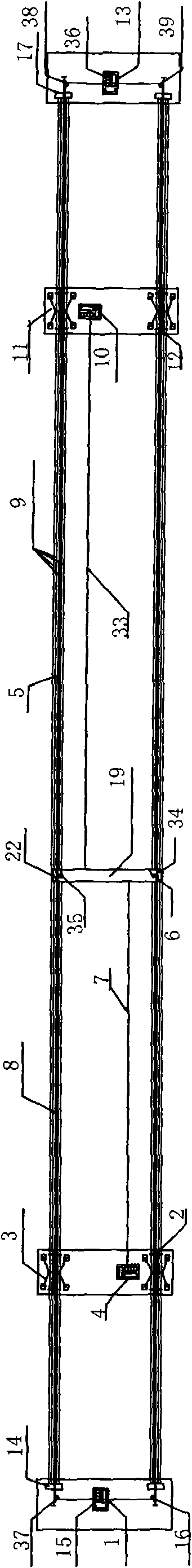

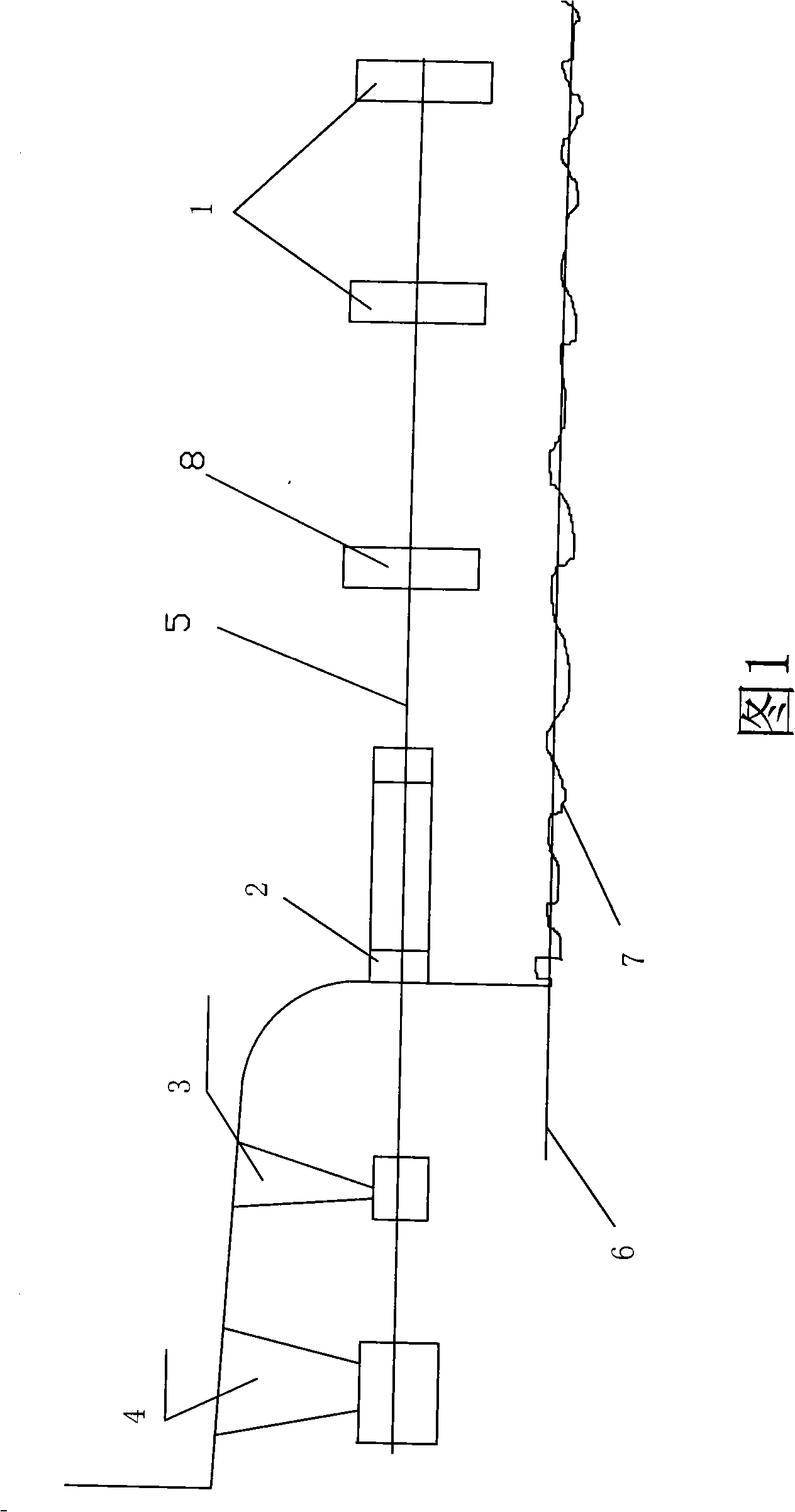

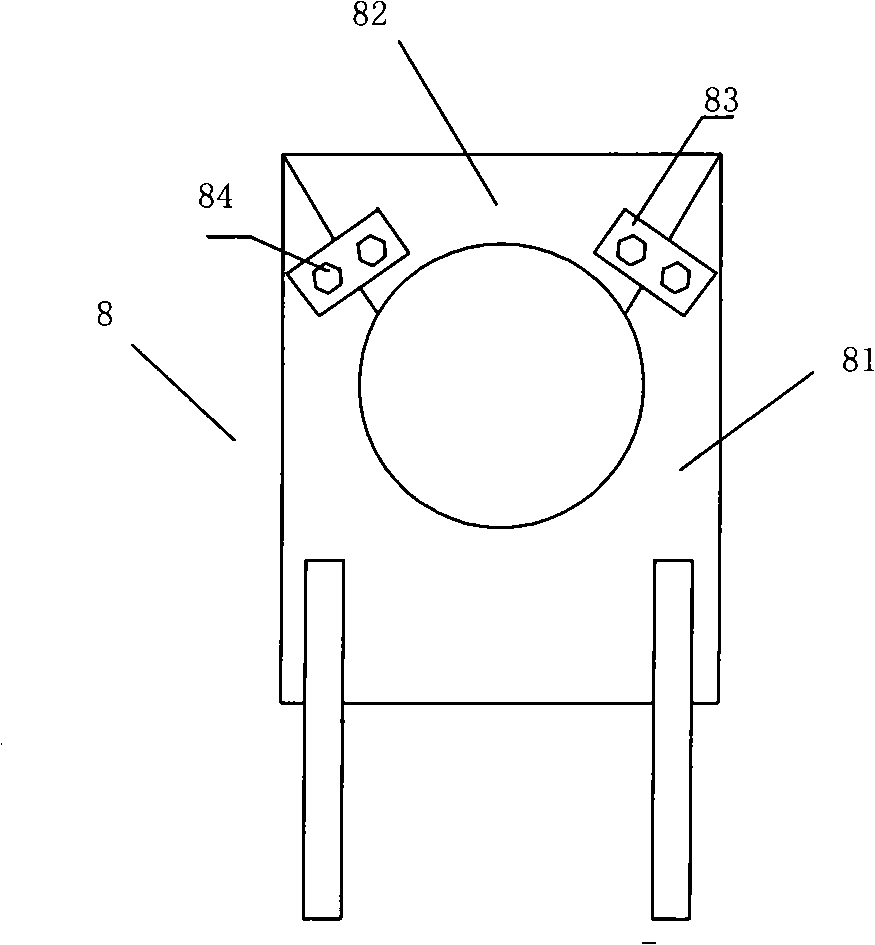

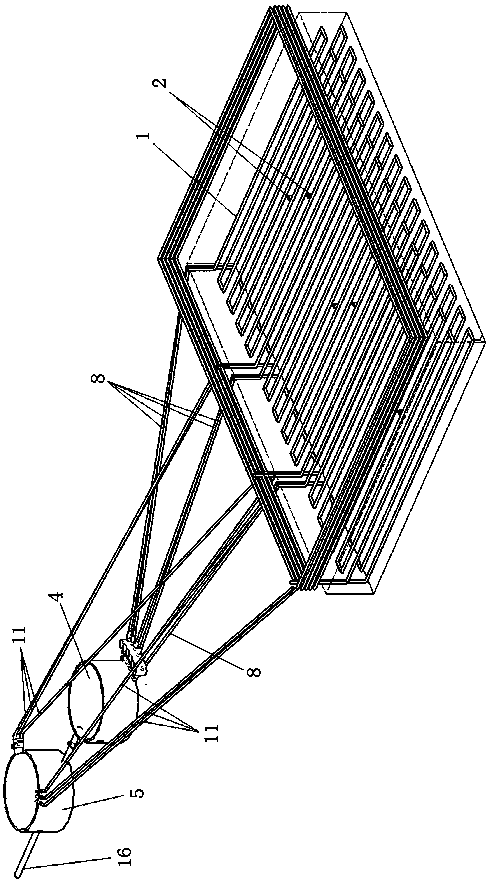

Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

InactiveCN101684639AReduce weightSimple structureSuspension bridgeBridge erection/assemblyStructural engineeringLightering

The invention provides a process method for the construction of a steel-structured suspension bridge and a light type cable carrying crane specially used in the same, wherein the process flow comprises the steps of construction preparation, assembly of the light type cable carrying crane, the positioning and debugging of the light type cable carrying crane, the positioning of a ship carrying steelbeams, the lifting of the steel beams up to the hoisting point, the descent of a lifting device, the bolting connection of the lifting device and the steel beams, the first stage lifting of the steelbeams, the 30-percent load detection, the 70-percent load detection, the 100-percent load detection, the horizontal adjustment of the steel beams, the second stage lifting of the steel beams, the positioning of the steel beams and boiling connection of a lifting rod, the assembly of a security device, the lifting of the light type cable carrying crane, the movement positioning of the light type cable carrying crane; and the special light type cable carrying crane consists of a load-bearing mechanism, a load-lifting mechanism, a traveling mechanism, an anchoring mechanism and a weight-balancing beam. The process method and the special light type cable carrying crane have the advantages of light weight, simple structure, easy processing, convenient assembly and disassembly, no waterway occupation, big free space brought to transport barges and waterway traffic, high flexibility and maneuverability, high lifting speed, low construction cost, low labor intensity of workers and the suitability for the construction of the suspension bridge.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for melting copper by using waste copper and concentrate of copper sulfide as raw materials

The invention discloses a method for melting copper by using waste copper and concentrate of copper sulfide as raw materials. The method comprises the following steps of: in a mass ratio of the copper content of waste copper to the copper content of the concentrate of copper sulfide of 1:1.3-10, mixing the waste copper and the concentrate of copper sulfide, adding a raw material containing silicon dioxide into the mixture, recycling, continuously putting the mixture into a melting pond, adding fuel and controlling the temperature of the melt to be between 1,100 and 1,300 DEG C, charging oxygen-enriched air, of which the volume concentration is 23 to 85 percent, in the melting pond, and stirring and melting the materials in an oxidizing atmosphere in the melting pond until slag and copper matte are separated by melting; transferring the separated copper matte to an air refining procedure for air refining to obtain raw copper products; transferring the slag to a common electric furnace for melting to further lower the copper content of the slag to below 0.5 percent, and performing water quenching of the slag; and transferring smoke to an acid-making procedure for preparing sulfuric acid. By the method, a large amount of waste copper can be treated, and simultaneously due to the adoption of the waste copper, the slag type of the concentrate of copper sulfide in melting is improved.

Owner:XIZHI ELECTRONICS MATERIALS BRANCH YUNNAN COPPER IND GRP +3

Optical alignment method for shipbuilding central axis

InactiveCN101306717AImprove construction efficiencySave material costVessel partsStructural deformationMarine engineering

The invention relates to a shafting optical alignment method for ship construction, which comprises the following steps: (1) constructing an auxiliary engine room and hermetically finishing all cabins below the deck; (2) welding a stern tube and a front and a rear shaft brackets; (3) lifting a main engine and a gear box in the engine room and sealing a main deck; (4) measuring the baseline of the hull, and trimming according to the structural deformation of the hull; and (5) carrying out shafting optical alignment. According to the shafting optical alignment method, the shafting optical alignment method is carried out after lifting and arranging the main engine and sealing the deck, so that the ship can be constructed simultaneously in multiline to greatly improve the ship construction efficiency.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

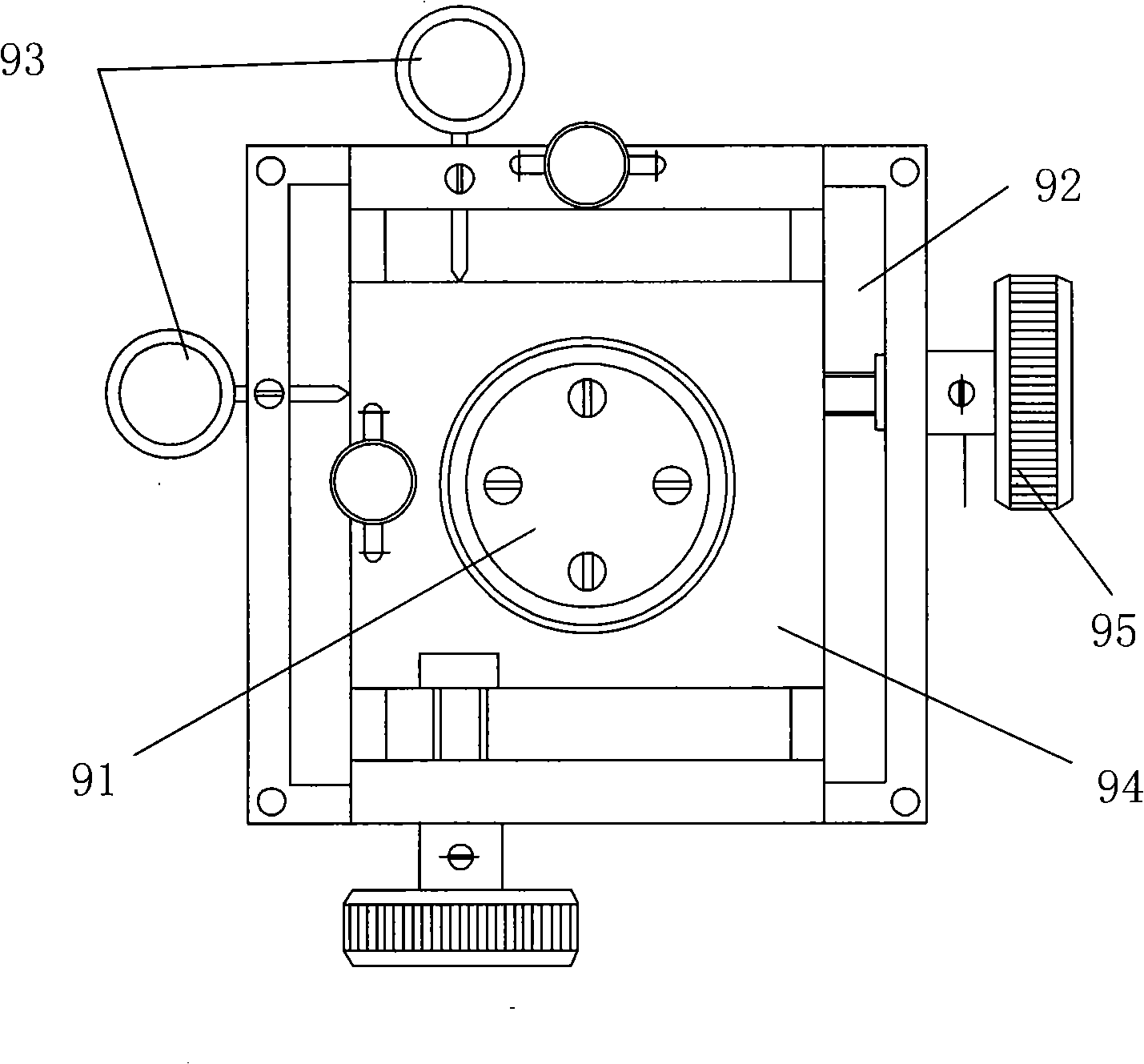

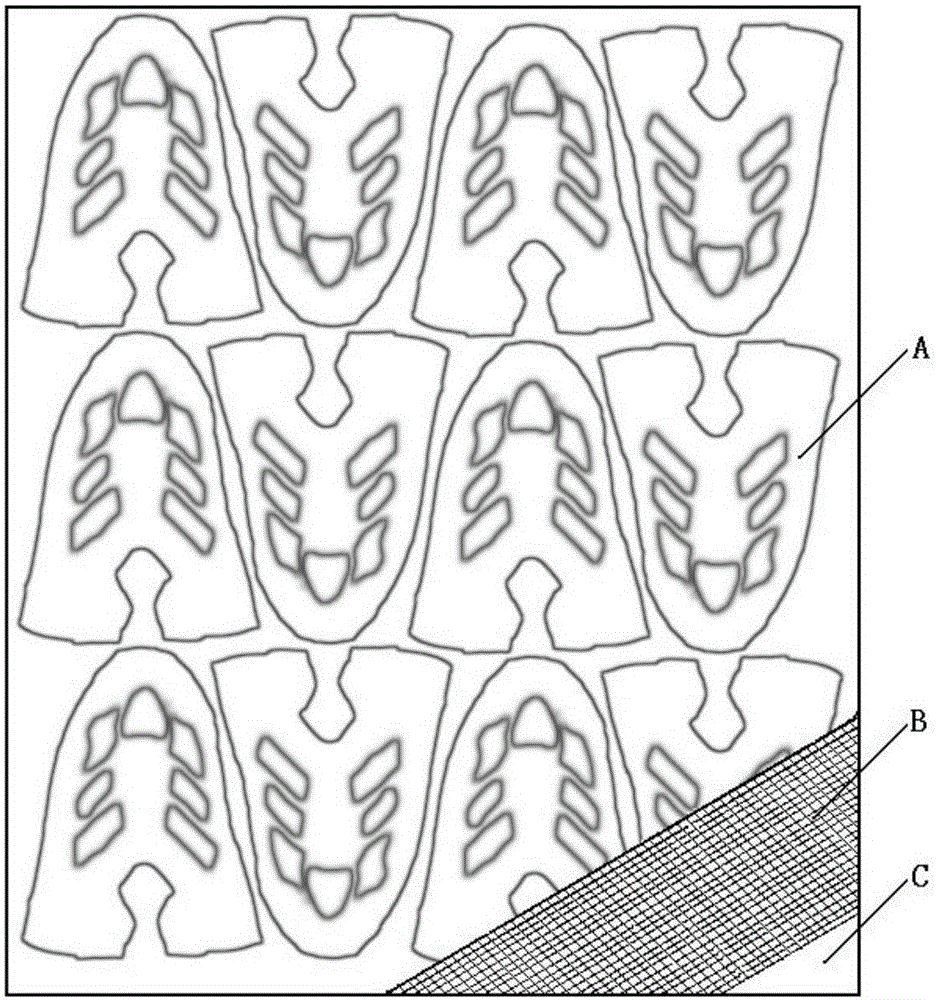

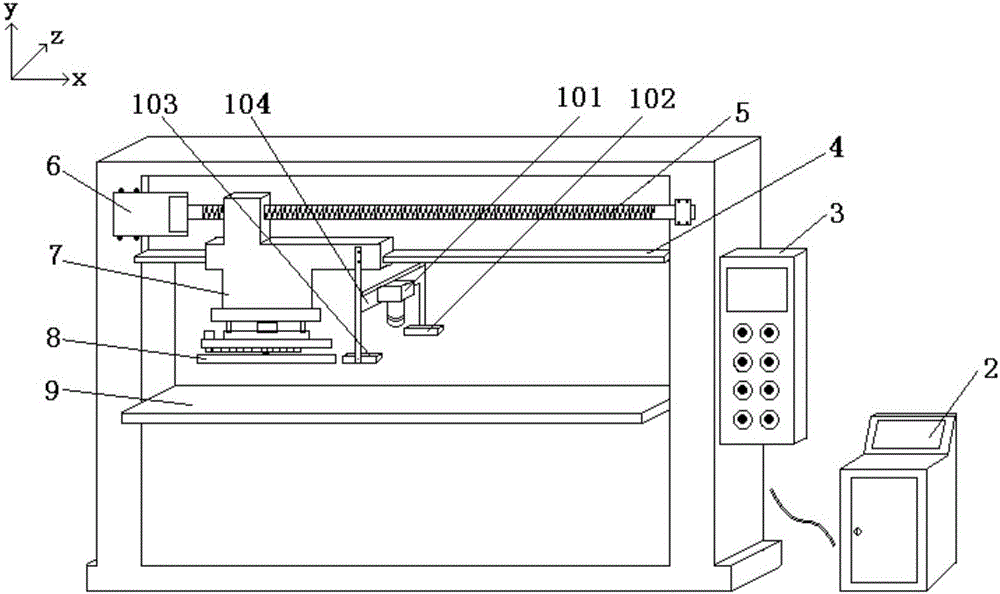

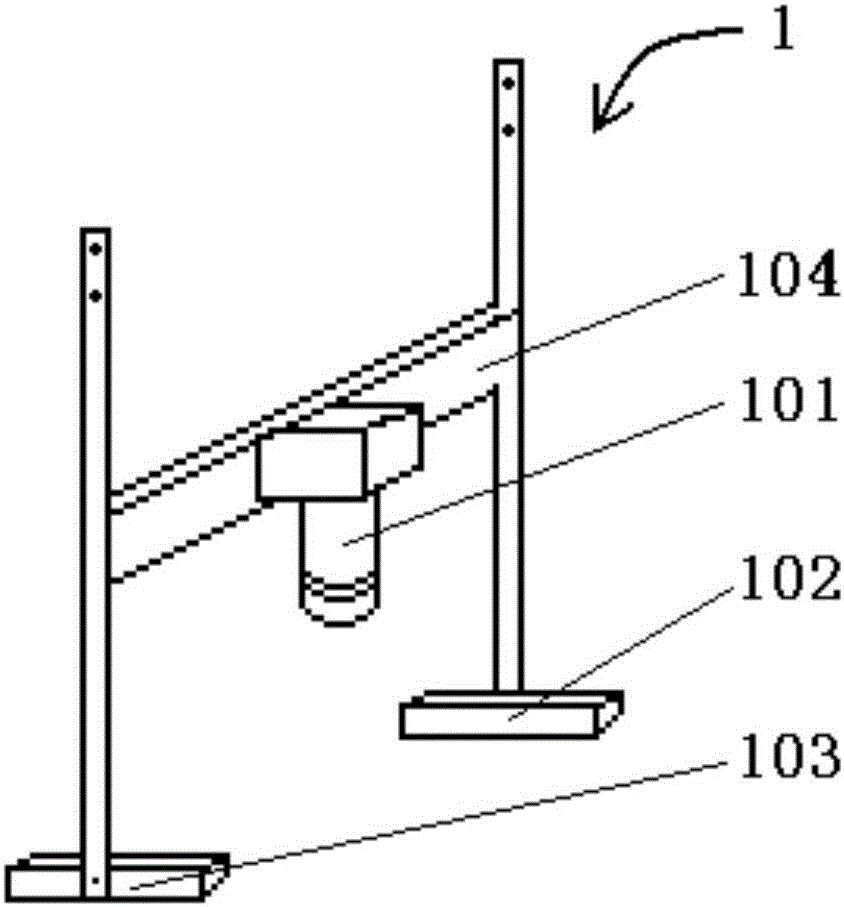

Automatic cutting machine with vision alignment function, and control method thereof

ActiveCN105690480AAccurately cut workEfficient cutting workShoemaking devicesMetal working apparatusComputer scienceVisual perception

The invention discloses an automatic cutting machine with a vision alignment function, and a control method thereof. A vision photographing assembly and an alignment calculation system are additionally designed on the basis of the main body frame and system of the existing cutting machine. Before each cutting action, the vision photographing assembly photographs a pre-cut fabric area, shoots a fabric outline position into a picture, and conveys the picture to the alignment calculation system; the alignment calculation system calculates the movement distances of the driven cutting die base and blanking table surface, and the rotation angle of a cutting die disc according to the deviation position of an outline in the picture relative to a reference point; and a PLC drives the cutting die base and the blanking table surface to displace, and drives the cutting die disc to rotate an angle according to the allowance transmitted by the alignment calculation system, so that a cutting die is accurately located above a fabric, and the cutting die is pressed to complete cutting. The system continuously repeats the steps of photographing, offset calculation, and alignment cutting, thus efficiently, accurately and fully automatically completing the cutting working for the fabric.

Owner:东莞市陆陆兴工业自动化科技有限公司

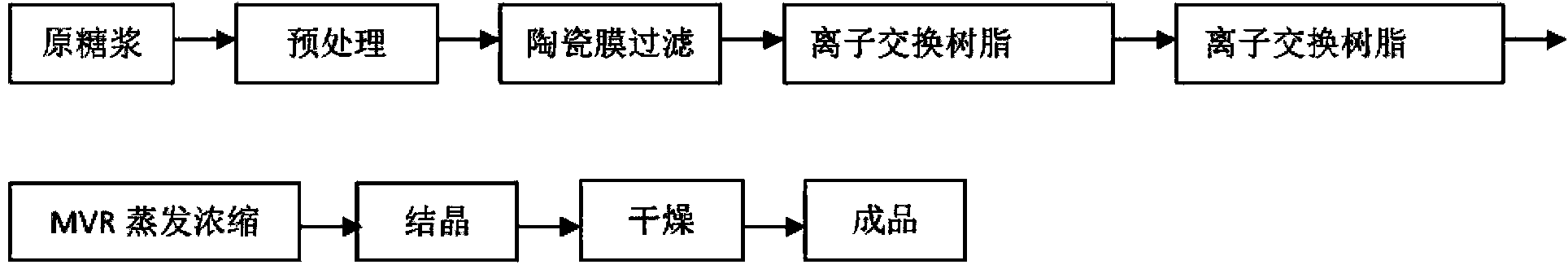

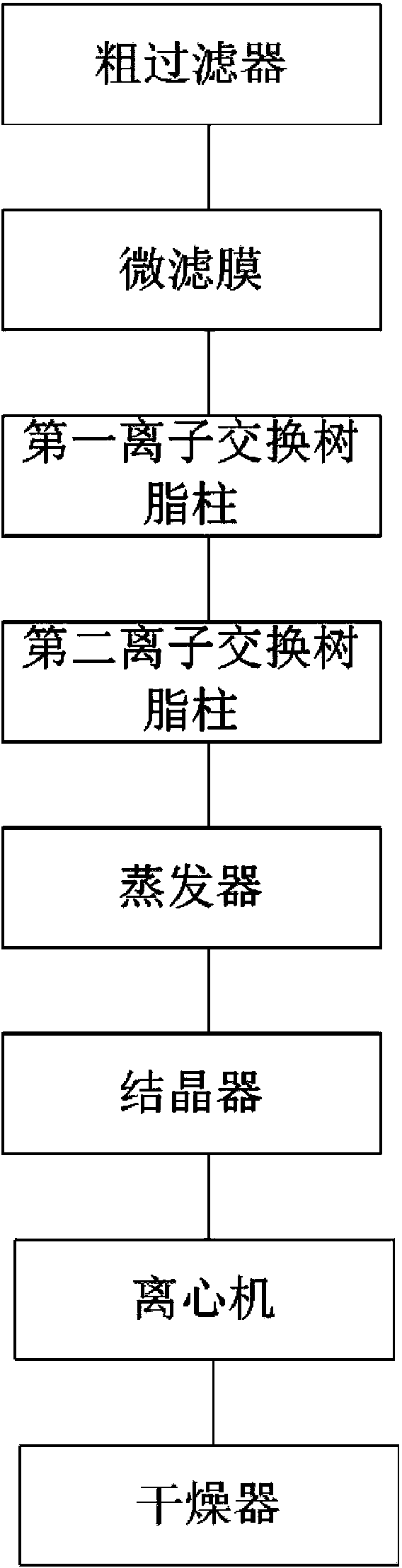

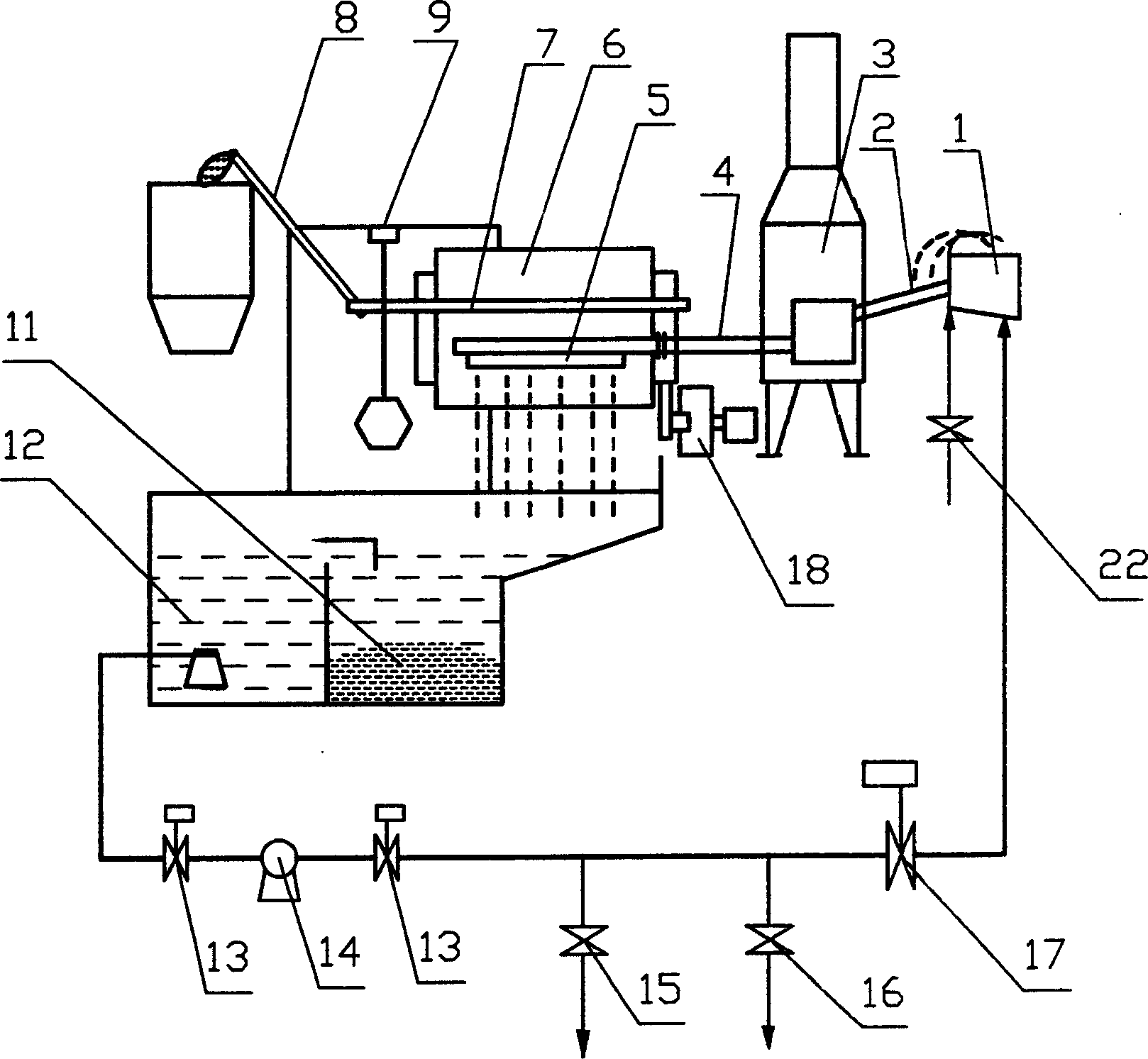

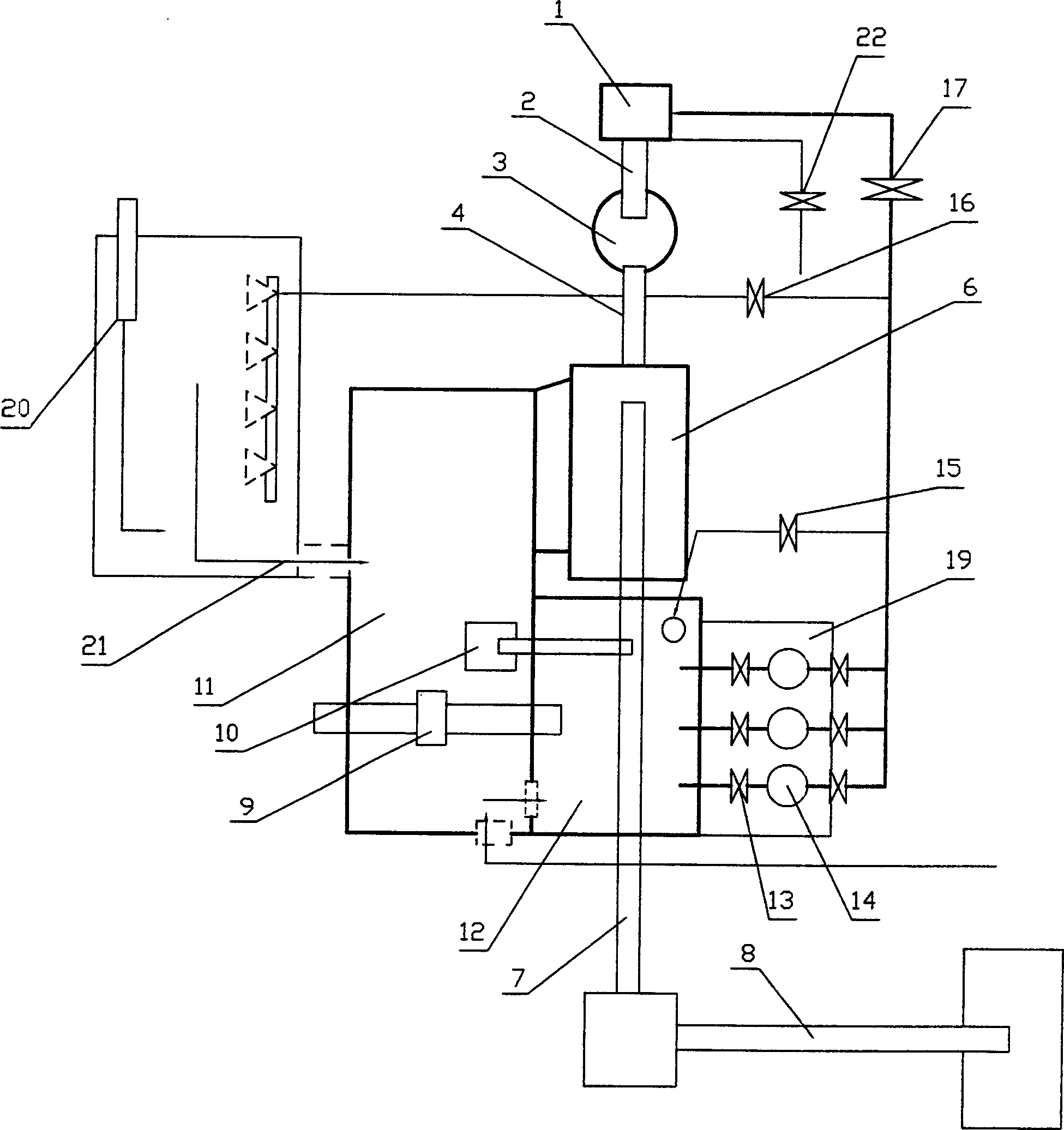

Process for preparing sugar by two-step method and device thereof

ActiveCN103710470ANo color reversionOptimal production process parametersSugar productsSucroseIon exchange

The invention discloses a process for preparing sugar by a two-step method and a device thereof. The process comprises the following steps: adding water into crude sugar for dissolving to obtain crude syrup; feeding the crude syrup into a primary filter and a micro-filtration membrane in sequence for filtering to obtain filtrate; feeding the filtrate into a first ion exchange resin tower to obtain a first penetrating fluid, wherein the first ion exchange resin refers to macroporous strong-basicity anion exchange resin; feeding the first penetrating fluid into a second ion exchange resin tower to obtain a second penetrating fluid, wherein the second ion exchange resin refers to strong-acidity cation exchange resin, weak-acidity cation exchange resin or a mixing bed of anion and cation exchange resin; feeding the second penetrating fluid into an evaporator for concentrating to obtain sucrose concentrated liquor; and crystallizing, centrifuging and drying to obtain a sucrose finished product. The process disclosed by the invention can be used for producing high-purity refined sucrose in batch, wherein a pigment removal rate reaches 99.9%, a salt removal rate reaches 98%, and sucrose component of the product reaches 99.9% which reaches the standard of national senior sugar.

Owner:JIANGSU JIUWU HITECH

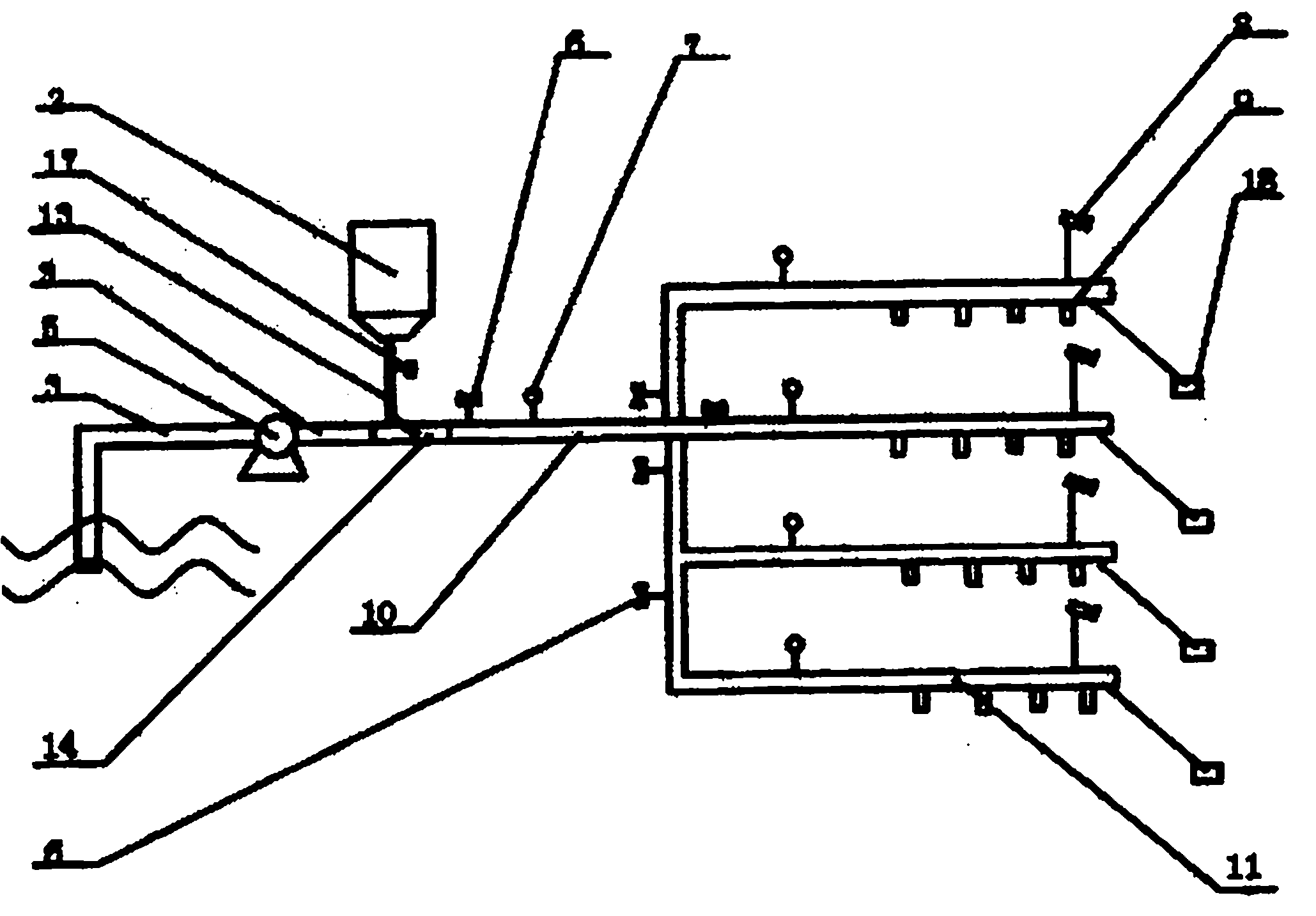

Cloud-based water-saving irrigation automatic control and information management system

ActiveCN105706860AReduce in quantitySave labor costsData processing applicationsWatering devicesAutomatic controlAgricultural irrigation

The invention discloses a cloud-based water-saving irrigation automatic control and information management system and relates to the field of agricultural irrigation, in particular to a cloud-based water-saving irrigation automatic control and information management system which can automatically diverting water for irrigation by monitoring water quantity, climates and soil conditions.The management system is characterized in that the irrigation system conducts data exchange and calculation through a remote database and a remote computer by monitoring the soil conditions in real time, and irrigation is conducted in time according to the growing demands of crops.The management system can be widely applied to waterline building projects, agricultural automation irrigation projects, and water conservancy automation monitoring and controlling projects in agricultural efficient water-saving irrigation.The system is high in automation and information management degree, compared with a traditional offline management mode, the system has the advantages that at least one half or above number of system operation managers (such as charging people, line patrol people and equipment maintenance people for later-period operation and maintenance) can be reduced, and the labor cost for later-period operation and maintenance can be greatly saved.

Owner:YUNNAN JUNLIAN TECH CO LTD

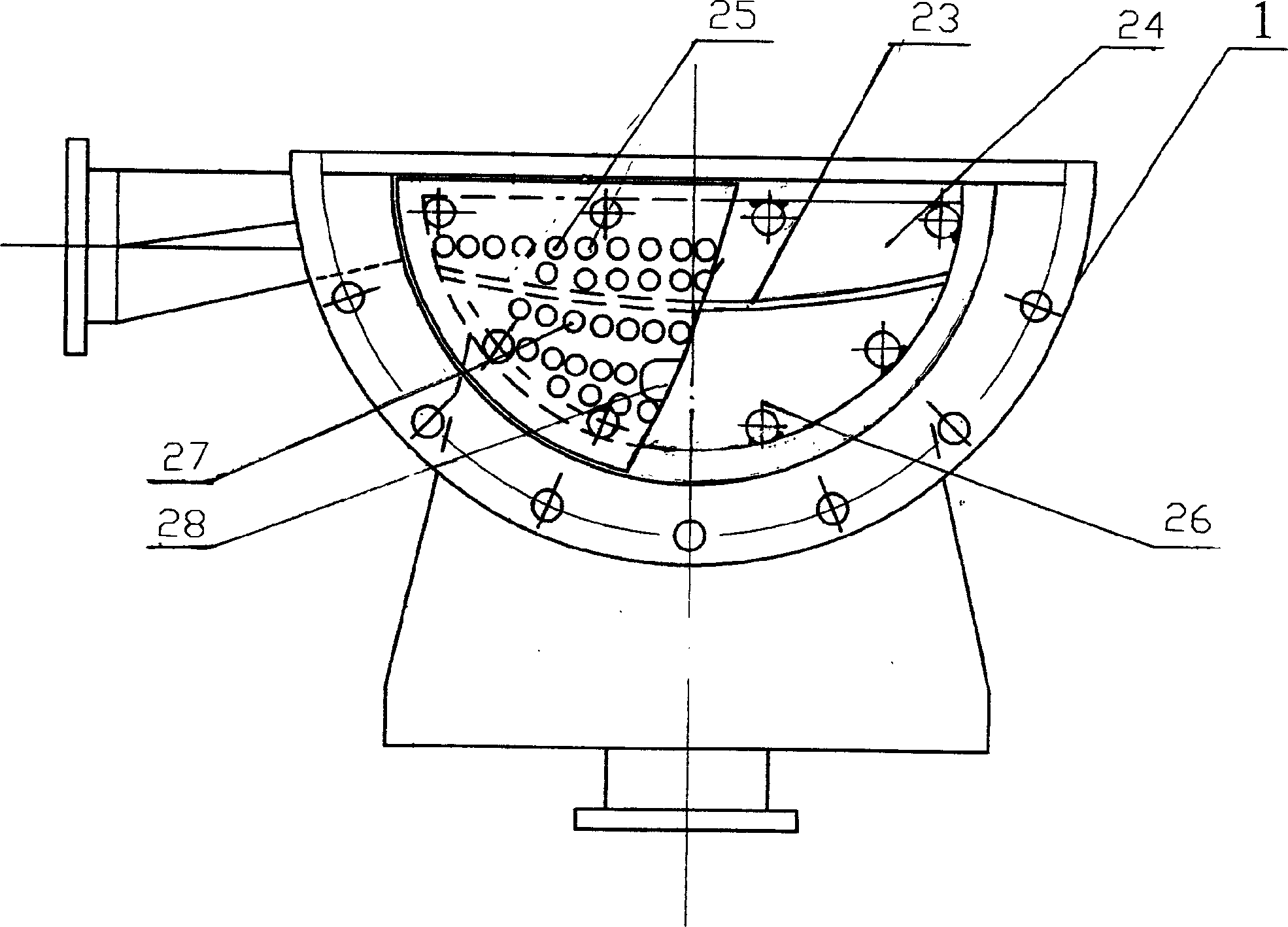

Blast furnace cinder water quenching processing unit

ActiveCN1769498ASimple configurationReasonable configurationRecycling and recovery technologiesCooling towerQuenching

This invention belongs to the molten slag treatment, especially relates to the blast furnace molten slag treating apparatus. The slag ditch connects with the granulating device and slag flume, the down part of the slag flume connects with the communicating pipe, the distributing trough that connects with the communicating pipe extends into the rotating drum filter, the belt device in the canister connects with the rotating belt device to form a finished articles warehouse; the down part of the rotating filter is arranged with the storage cabinet, laying-up basin, which are connected by the overflow on the pool wall, the dregs cleaning device is arranged on the storage cabinet the laying-up basin connects with the granulating device by the tube connector, valve and dregs cleaning pump. The device fault rate is low, the dregs punching out rate reaches up to more than 99úÑ, which is propitious to the operation and steady production of the blast furnace. And the dreg cleaning water and the sewage is used in closed cycle, so it can save a lot of pure water.

Owner:MAANSHAN IRON & STEEL CO LTD

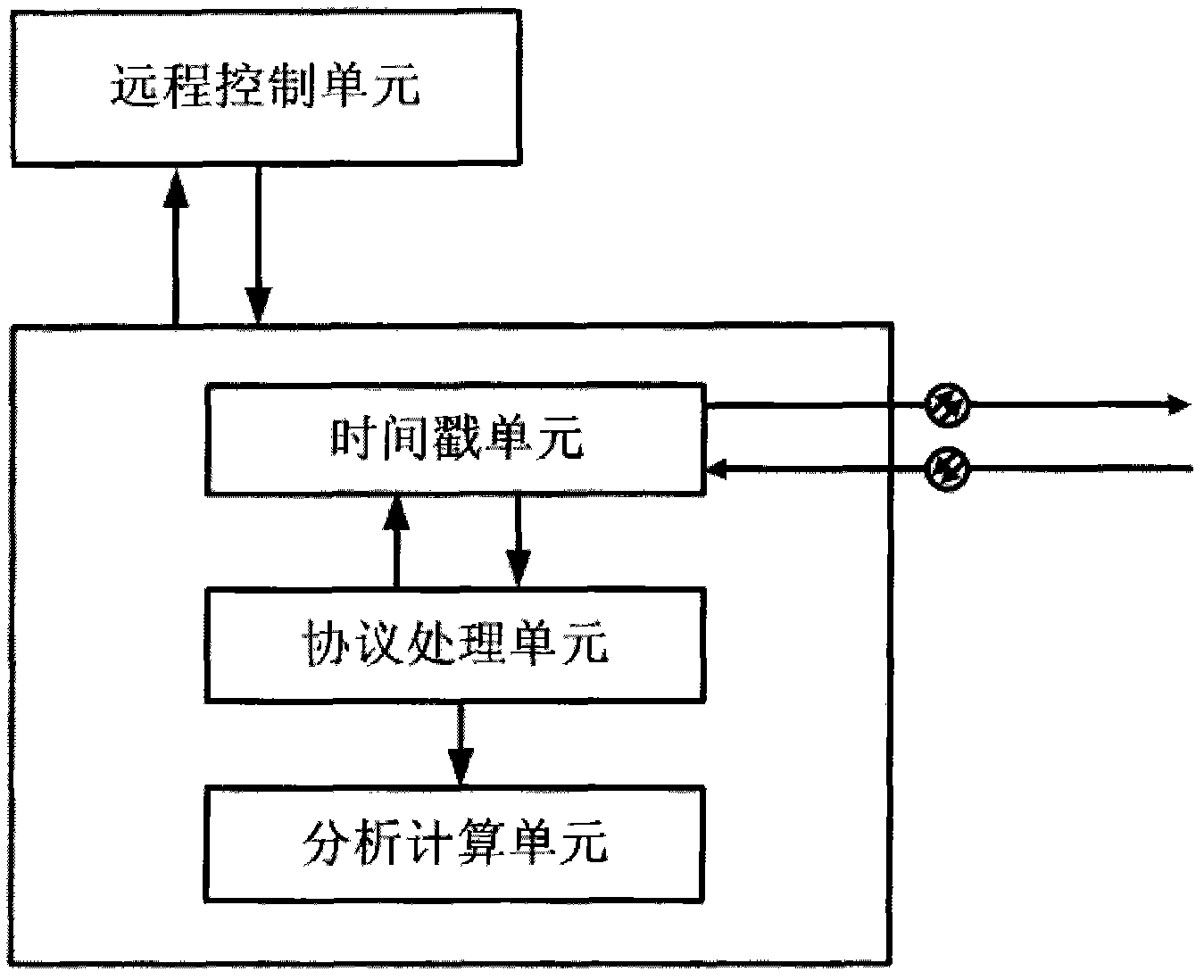

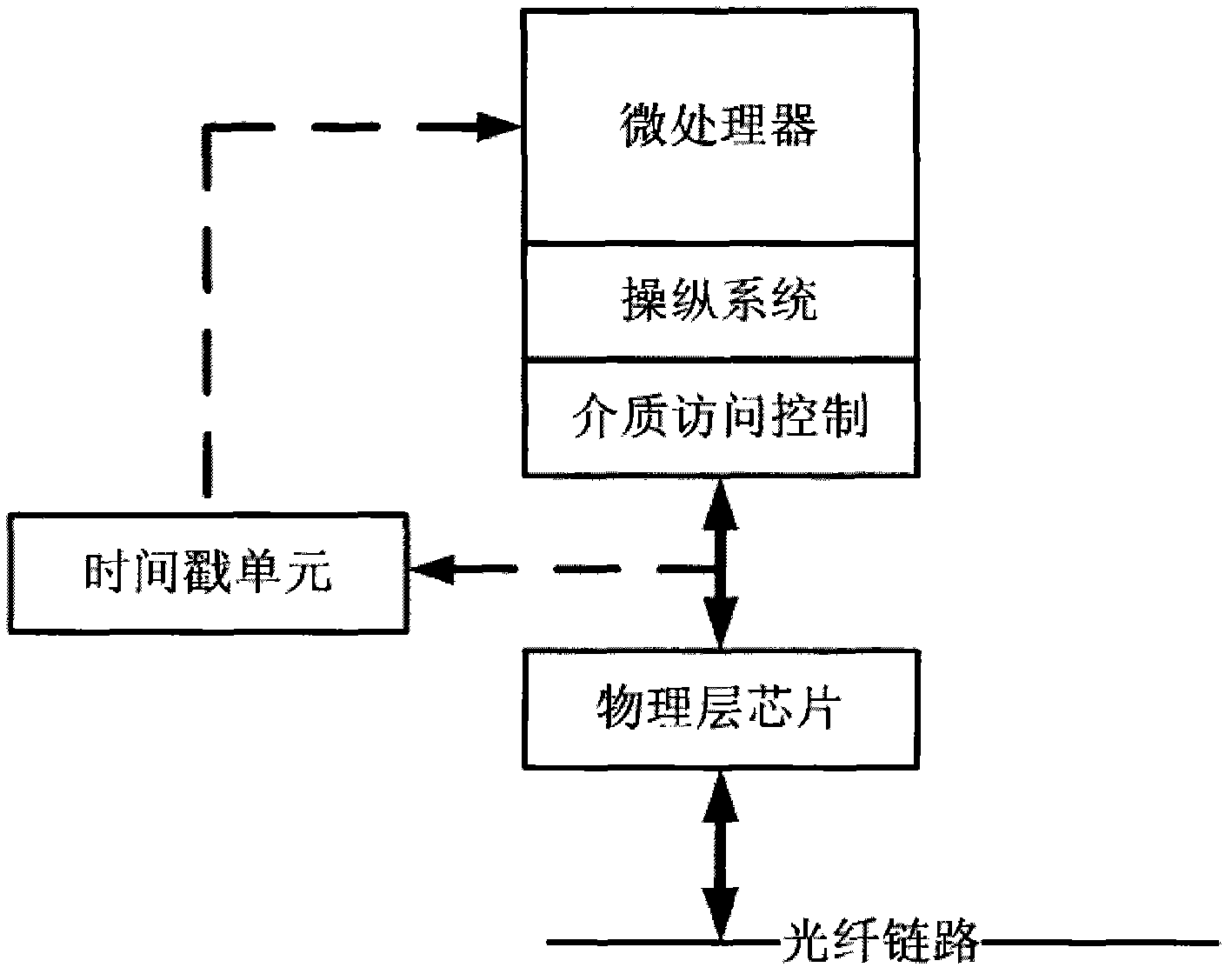

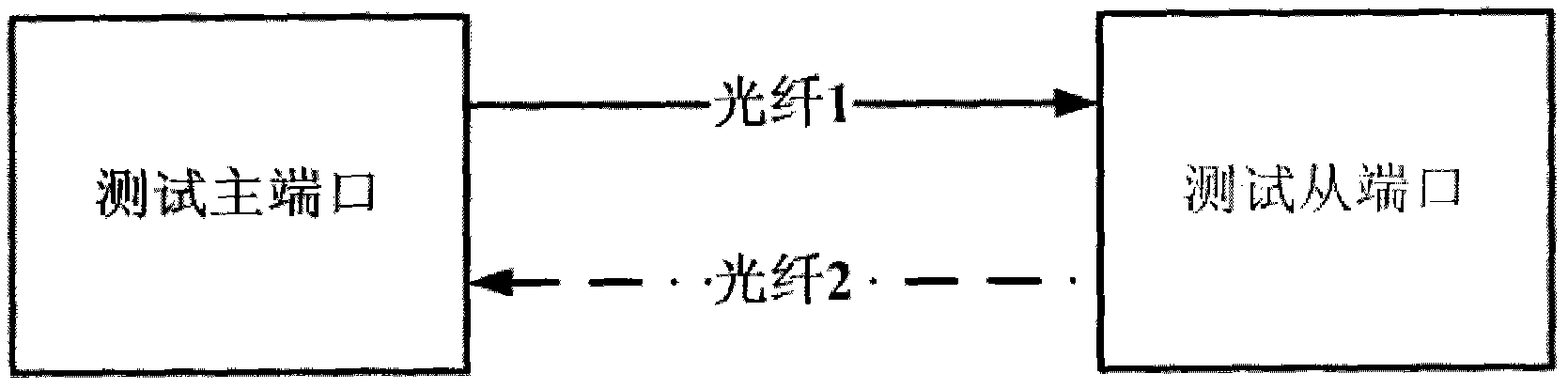

Method and device for measuring optical fiber asymmetry time delay

ActiveCN102291178ASave moneySave labor costsTime-division multiplexElectromagnetic transmissionTime delaysFiber

Disclosed are a method and apparatus for measuring optical fiber asymmetry time delay. The method comprises: an RTU configuring working states of a Master and a Slave at two ends of an optical fiber line; the RTU delivering an instruction to measure a first optical fiber, and a Master side PPU sending a message, recording a sending time stamp t1 and transmitting the sending time stamp t1 to the Slave; a Slave side PPU receiving the message, recording an arrival time stamp t2, and storing the arrival time stamp t2 corresponding to t1; the RTU displaying that measurement for the first optical fiber is completed, preparing to measure a second optical fiber, and swapping the two optical fibers; the RTU delivering an instruction to measure the second optical fiber, and the Master side PPU sending a message, recording a sending time stamp t'1 and transmitting the sending time stamp t'1 to the Slave; the Slave side PPU receiving the message, recording an arrival time stamp t'2, and storing the arrival time stamp t'2 corresponding to t'1; and an ACU calculating an asymmetry time delay compensation value and sending the asymmetry time delay compensation value to the RTU. The present invention is not limited by sites, saves cost and labor, is simple and fast, and has short stabilization time as well as high testing efficiency and precision.

Owner:FENGHUO COMM SCI & TECH CO LTD

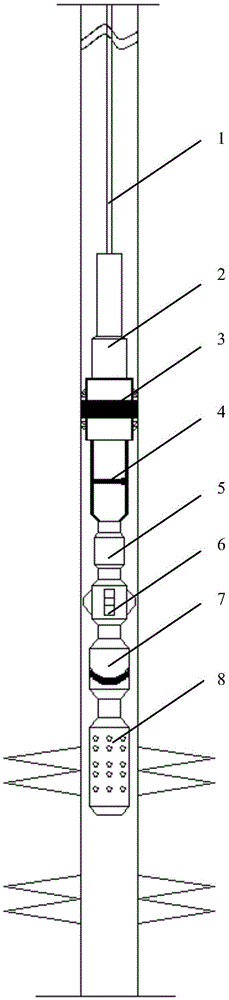

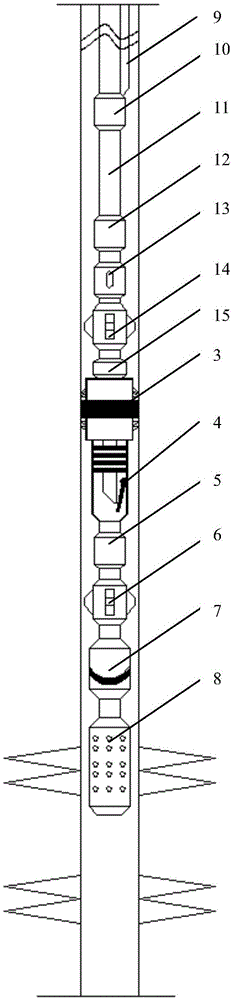

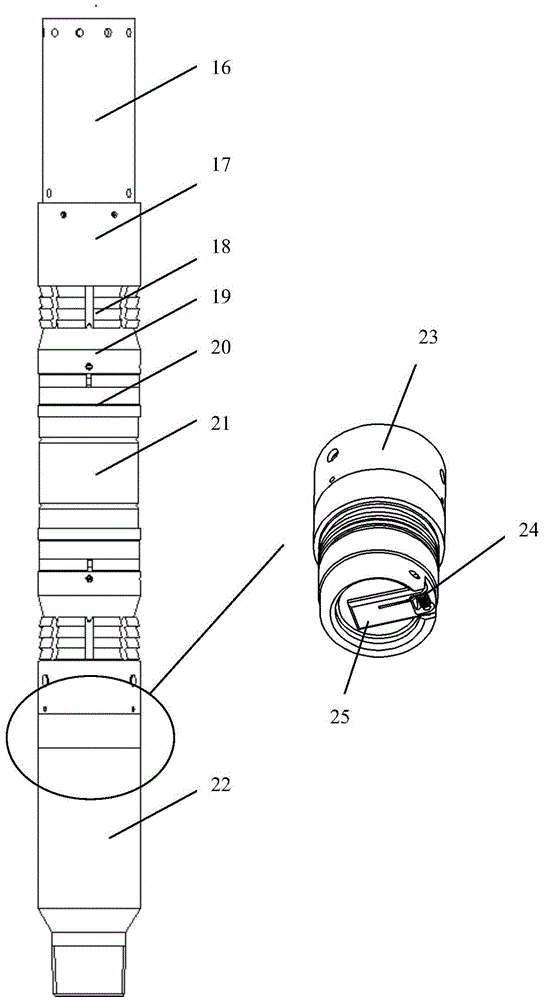

Shale gas well no-killing production tubular column capable of being lifted up and put down under no pressure and construction method

ActiveCN105545221AAvoid construction risks and costsConstruction safetyDrilling rodsWell/borehole valve arrangementsShale gasCheck valve

The invention discloses a shale gas well no-killing production tubular column capable of being lifted up and put down under no pressure and a construction method. The tubular column comprises a packer setting-releasing tubular column body and a tie-back completion tubular column body. The packer setting-releasing tubular column body comprises an up-down tool, a setting tool, a permanent type tube insert packer, a lower working cylinder, a centering guide, a cracking disc and a screen tube. An ejecting type check valve is arranged in the permanent type tube insert packer. The tie-back completion tubular column body comprises an underground hydraulic control safety valve, an upper working cylinder, a circulating slide sleeve, a centering guide and a sealed insert tube. The sealed insert tube is inserted in the packer and pushes open the ejecting type check valve to form a production channel. When needing to be taken out, the tie-back completion tubular column body is lifted up and rotates forwards, the sealed insert tube retreats out of the packer, and the ejecting type check valve is automatically closed. By arranging the ejecting type check valve in the permanent type tube insert packer, after a well shaft is packed by the packer, an upper well shaft is under no pressure; the tubular column can be lifted up and put down through a conventional workover rig, construction efficiency is improved, and under-pressure construction expanses are saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

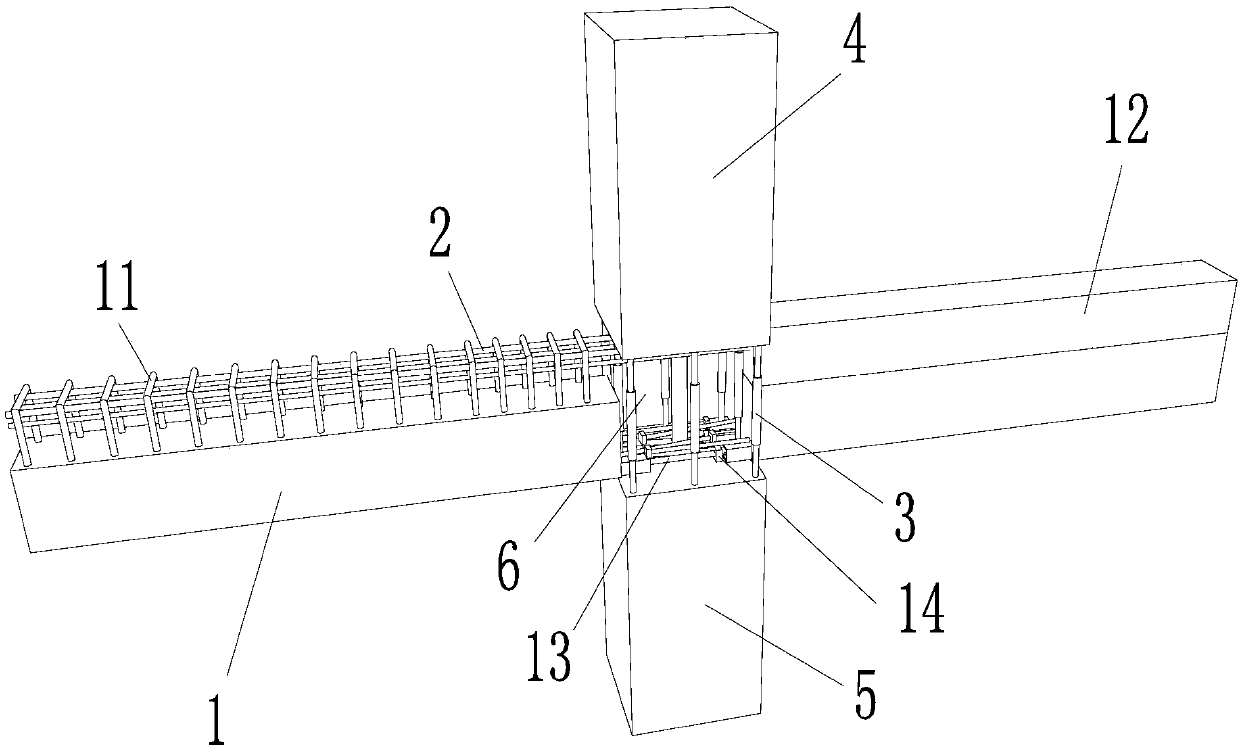

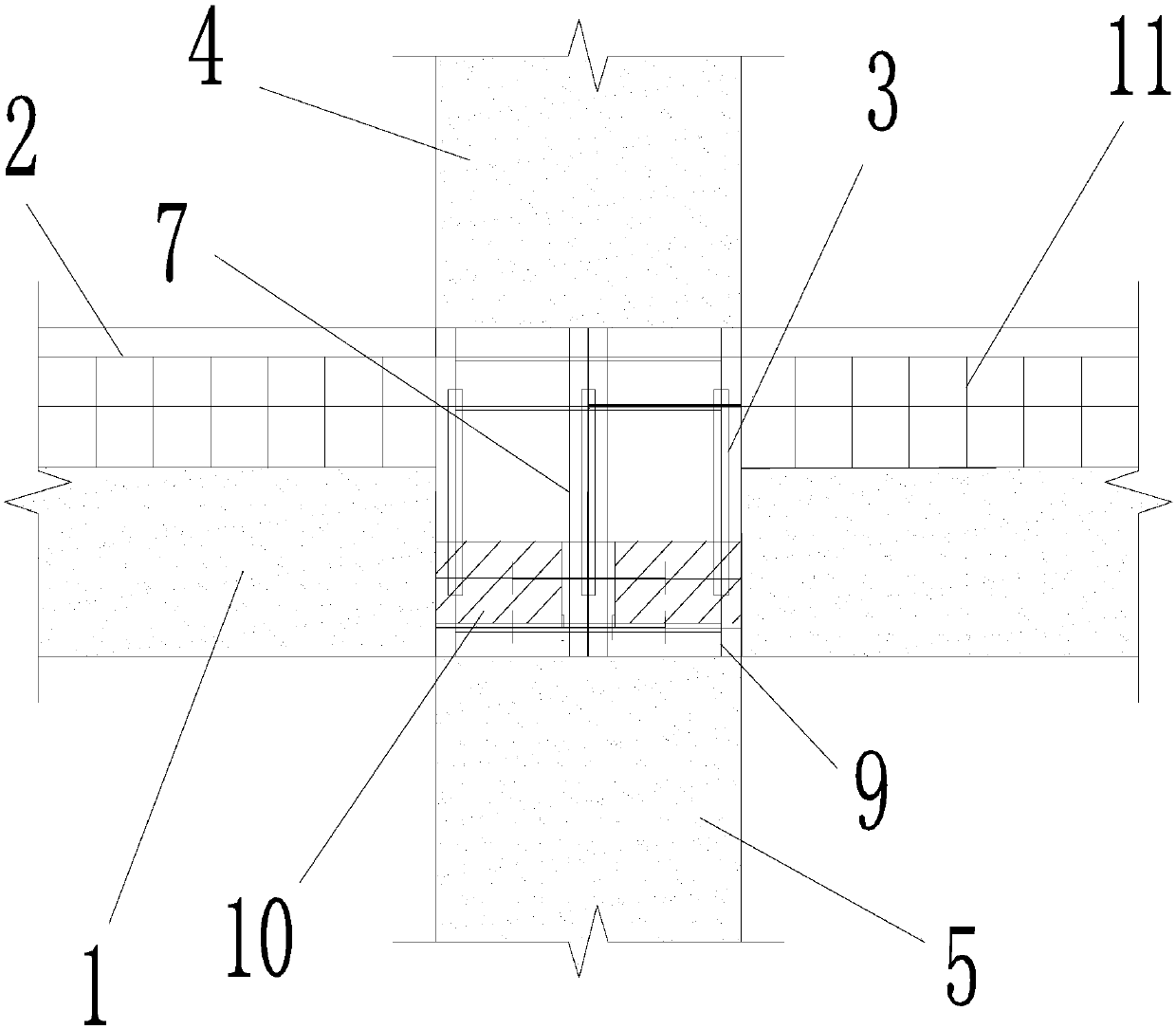

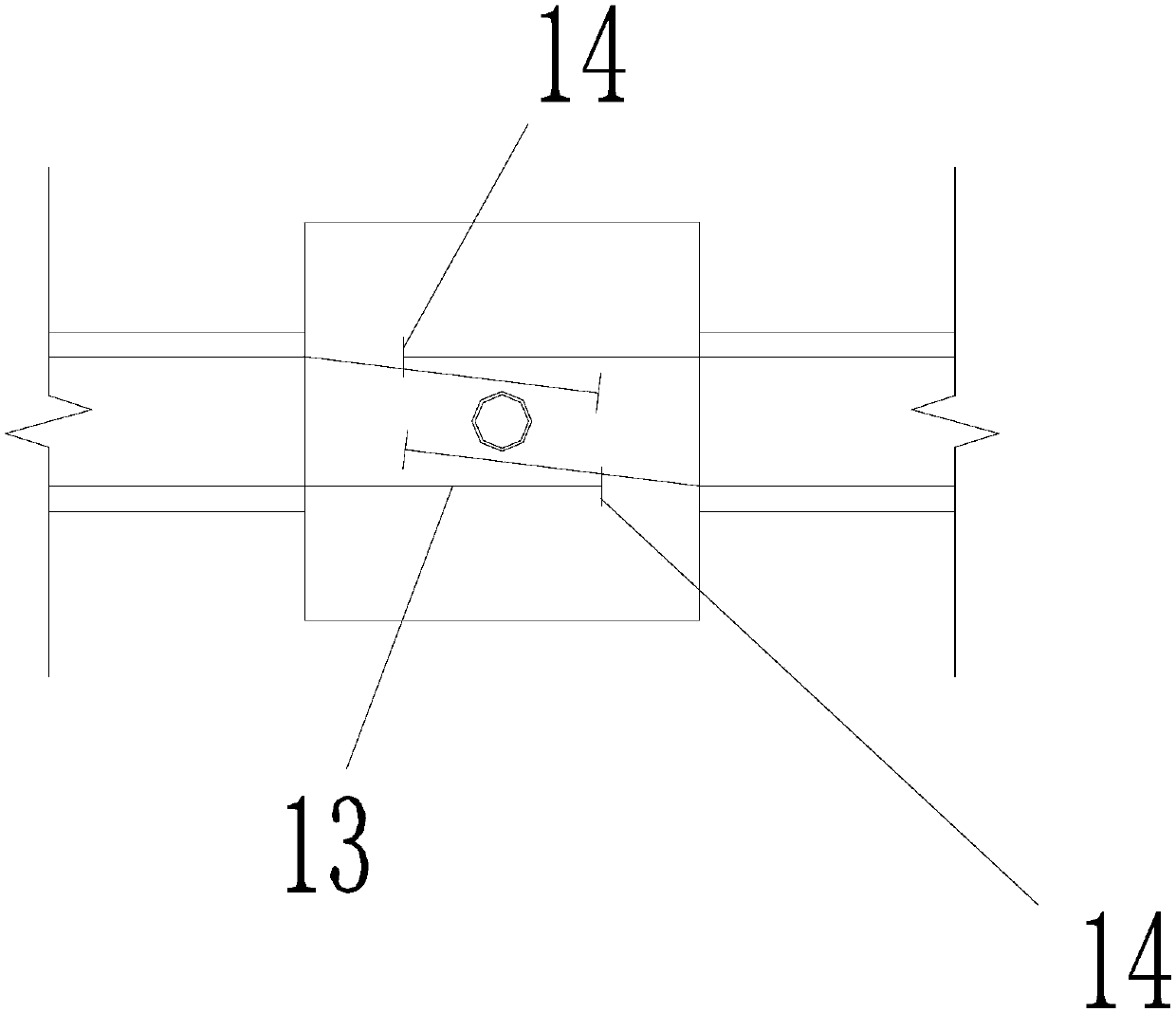

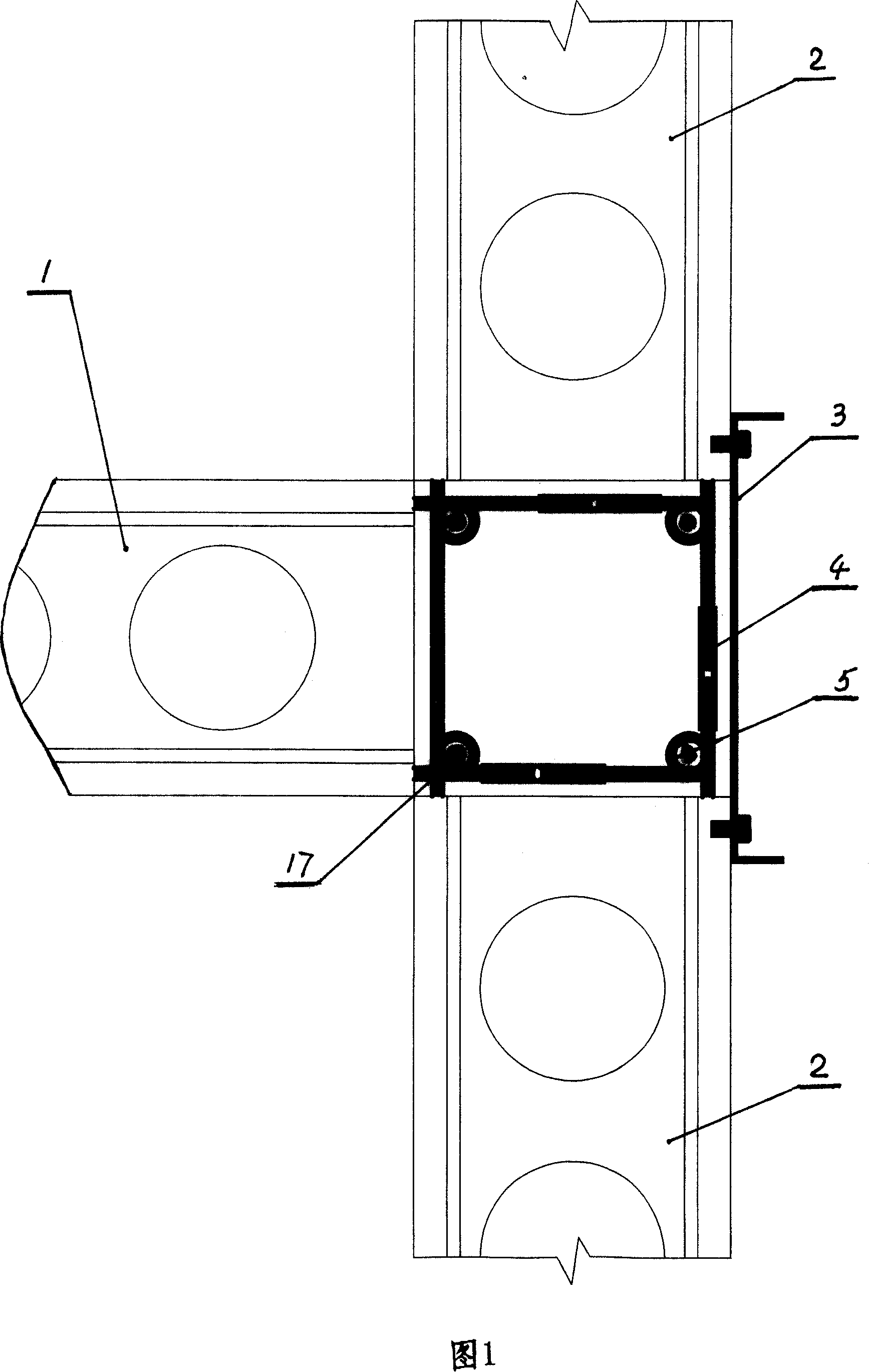

Prefabricated beam-column joint and construction method thereof

PendingCN107795010AHigh speedSimplify the construction processBuilding constructionsArchitectural engineeringRebar

The invention discloses a prefabricated beam-column joint and a construction method thereof. The prefabricated beam-column joint comprises a prefabricated beam, a prefabricated column, a beam connecting rib and a joint rebar sleeve; the prefabricated column comprises a prefabricated upper column and a prefabricated lower column; the prefabricated beam is divided into two sections, and one ends ofthe two sections of prefabricated beam bodies are correspondingly arranged between the prefabricated upper column and the prefabricated lower column; and a joint area is formed between the prefabricated upper column, the prefabricated lower column and the two sections of prefabricated beam bodies, and the joint area is filled with concrete to form a joint section. According to the prefabricated beam-column joint and the construction method thereof, pre-embedded U-steel is arranged in the prefabricated beam so that the prefabricated beam can be directly erected on the prefabricated lower columnduring construction, and the construction speed of the structure is increased; and brackets or other structures are not required to be manufactured at the edge of the column to conveniently erect theprefabricated beam on the prefabricated lower column, so that the construction process is simplified.

Owner:广东精宏建设有限公司 +1

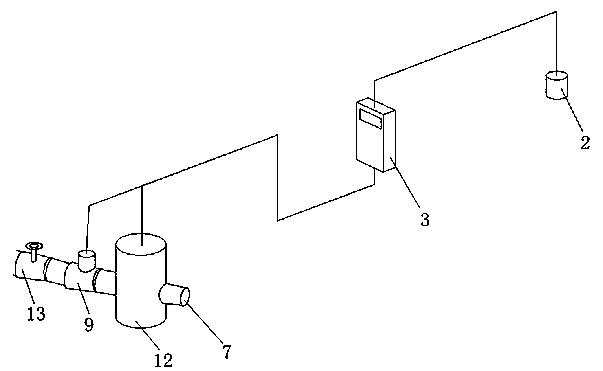

Mass concrete circulating cooling water automatic control cooling system and method

PendingCN107700489AReduce the risk of gapsReduce labor intensityFoundation engineeringBuilding material handlingTemperature controlAutomatic control

The invention discloses a mass concrete circulating cooling water automatic control cooling system and method, and belongs to the technical field of concrete cooling. The system comprises water collection boxes, cooling pipes, temperature measuring elements, a circulating mechanism connected with the water collection boxes and the cooling pipes and temperature switches connected with the temperature measuring elements and the circulating mechanism. The cooling pipes and the temperature measuring elements are pre-buried in mass concrete. The cooling pipes are pre-buried in the mass concrete ina layered manner, and each layer of cooling pipe is composed of multiple independent sub-pipes. Each sub-pipe is provided with the corresponding temperature measuring element. The temperature switchesare used for controlling the magnitude of the water conveying quantity generated after the circulating mechanism is shut down and started up according to the temperature, measured by the temperaturemeasuring elements, in the mass concrete. According to the system, zoning cooling can be carried out on the mass concrete, the temperature difference between various zones and the residual stress difference generated after hardening can be reduced, the risk that clearances appear in a concrete structure can be reduced, and the structural quality of the mass concrete structure can be improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

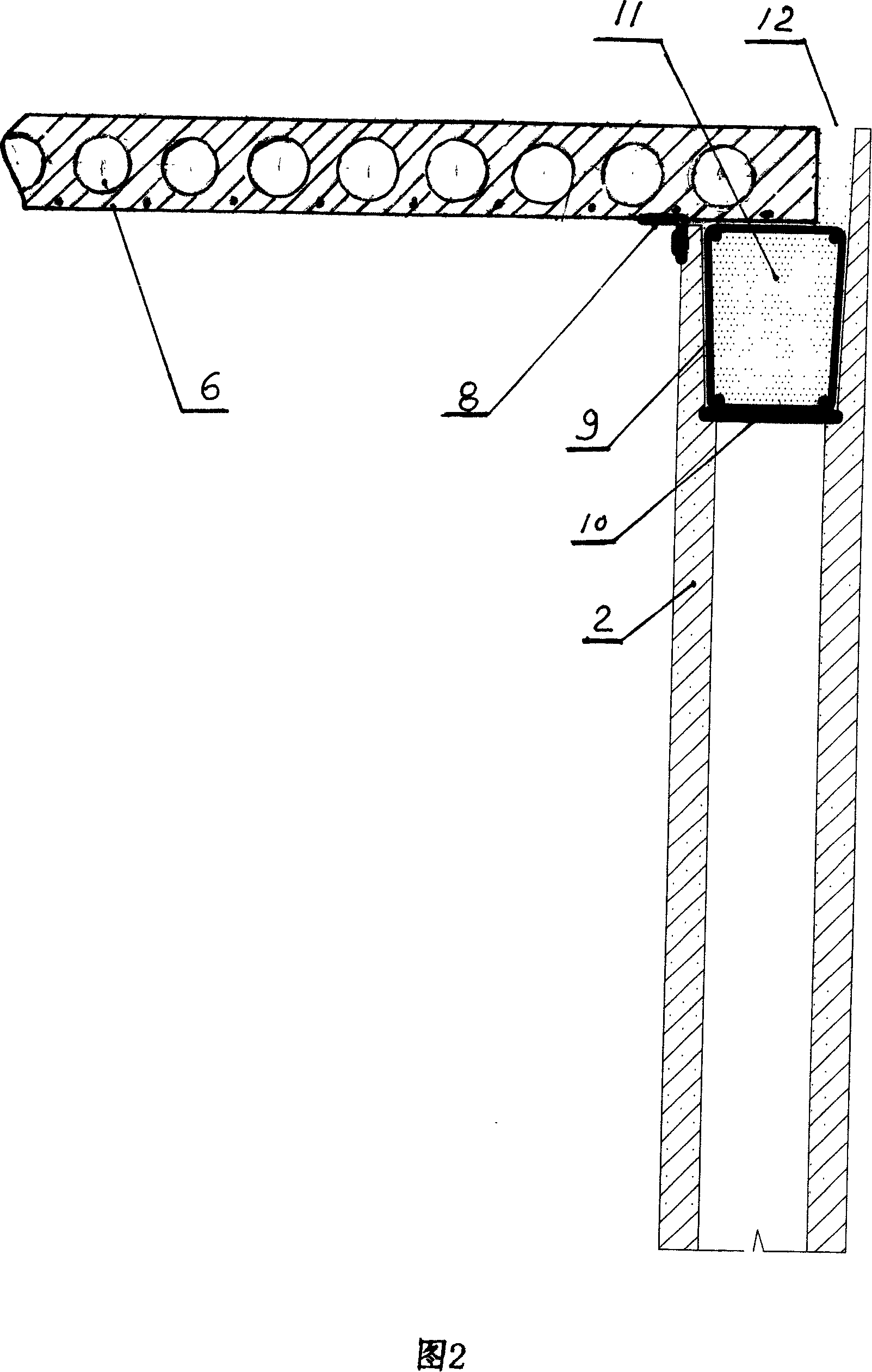

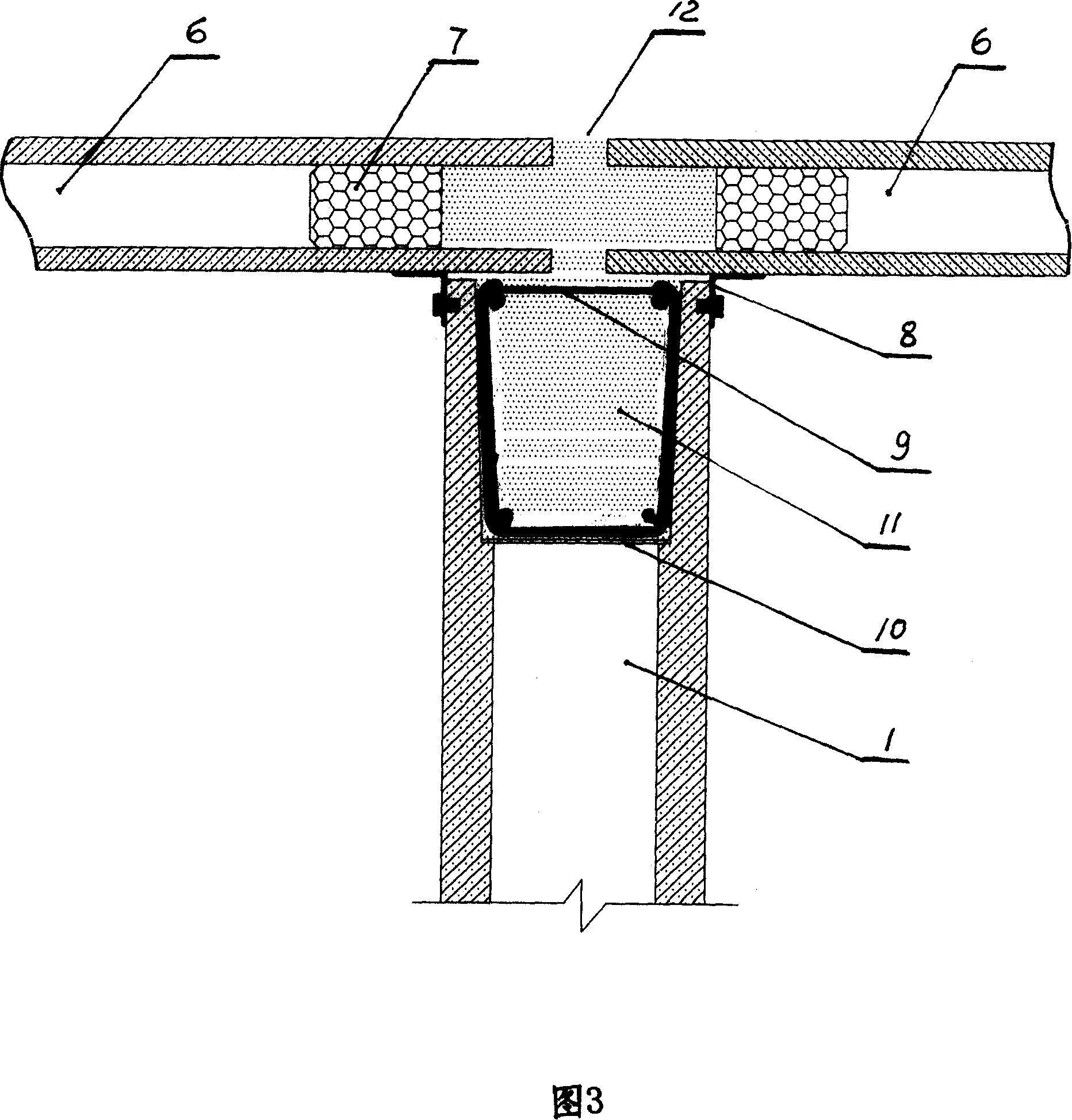

Modular building component and on-site hoisting building method

The invention relates to the fields of building materials and architectural technologies, in specific to a composite building member and an architectural method for field craning of cast-in-site beams and columns. At present, most of buildings in our country still follow the prior arts of manual masonry and painting for wall bodies, so that such problems as wasting time, wasting labor force and high labor intensity and etc are caused. The target of the invention is to fabricate all kinds of building members through industrialized production, and then, to transport to the construction site for craning and assembly. The technical scheme is as follows: Wall panels are supported through adjusting bracing rod assembly; partition wall panels and external wall panels are embedded with hooked nuts on side walls; the hooked nuts are connected with externally-arranged hoops; studs for fixed construction columns are put through upper rings and lower rings of the hoops, so that structural column bodies can be formed through pea gravel concrete casting and ramming. The invention has the following effects: Precast integrated large wall bodies, slabs and etc., so that no joggle seam appears on the panels after assembly, and neither face needs screeding or painting; meanwhile, the invention has advantages of safe, convenient, fast and smooth on-site execution, saving large number of form panels and scaffoldings, simple and convenient process, high integrated strength and perfect shockproof performances.

Owner:张兴汉

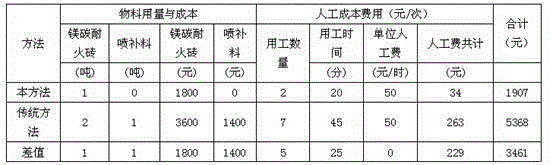

Method for rapidly maintaining converter lining

InactiveCN104673966AEasy to obtainEasy to burn throughManufacturing convertersProcess efficiency improvementBrickSlag

The invention discloses a method for rapidly maintaining a converter lining. The method comprises the following steps of: remaining slag after tapping of converter, pouring magnesia-carbon refractory brick blocks in the converter, shaking the converter till the magnesia-carbon refractory brick blocks and remained slag in the converter are flatly spread at a repaired part of the converter lining, and standing so that the mixture of the magnesia-carbon refractory brick blocks and the remained slag are stuck to the repaired part of the converter lining. According to the method disclosed by the invention, the converter repairing time is effectively shortened; the disadvantage that the time for pouring materials to repair the converter and sintering is long is changed; the operability of the converter is increased; high-temperature converter slag is easy to burn thoroughly; furthermore, a part of clearances can be filled by the molten part of converter repairing bricks; the erosion resistance and the scouring resistance are increased; the material collapse phenomenon due to non-thorough burning and half-baking of a part of positions in the event of traditionally repairing can be effectively avoided; the labour safety coefficient of workers is increased; a part of converter repairing materials and the labour cost are saved; the converter repairing cost is effectively reduced; compared with the original depletion speed, the depletion speed of the converter lining after the method is implemented is reduced; and therefore, the method has the characteristics of being rapid in maintenance speed, high in efficiency and safety and low in cost.

Owner:HEBEI IRON AND STEEL

Greenhouse cultivation and management method of high-yield watermelons growing with multiple crops in one year

ActiveCN103875438AExtended supply timeSpeed up circulationHorticultureFruit setGreenhouse cultivation

The invention discloses a greenhouse cultivation and management method of high-yield watermelons growing with multiple crops in one year. The method is characterized in that the greenhouse technology is improved; the planting distance ratio is made to be reasonable; the continuous fruit setting technology is adopted, vegetative growth and reproductive growth are adjusted, watermelon fruit setting and watermelon seedling growth are controlled, the fruit setting number and the weight of a single watermelon are increased, and the yield per plant is guaranteed; nutrient and water management is conducted, wherein base fertilizer is applied to the whole layer, organic fertilizer and inorganic fertilizer are combined, nitrogen fertilizer, phosphorus fertilizer, potassium fertilizer, calcium fertilizer and magnesium fertilizer are in coordination, topdressing is conducted after watermelons are harvested, the amount of fertilizer is determined according to the yield, drop irrigation is conducted with a small amount of water, and water and fertilizer are combined. Compared with the prior art, the cultivation and management method has the advantages that high yield and high efficiency are achieved, under the condition that watermelons can be produced and supplied all year around, two times to three times of seedling culture, two times to three times of field plantation, seedling management, field operation and other operations can be omitted, and seedling planting cost, labor cost and the like are lowered.

Owner:刘福久

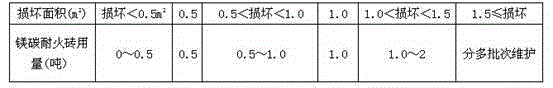

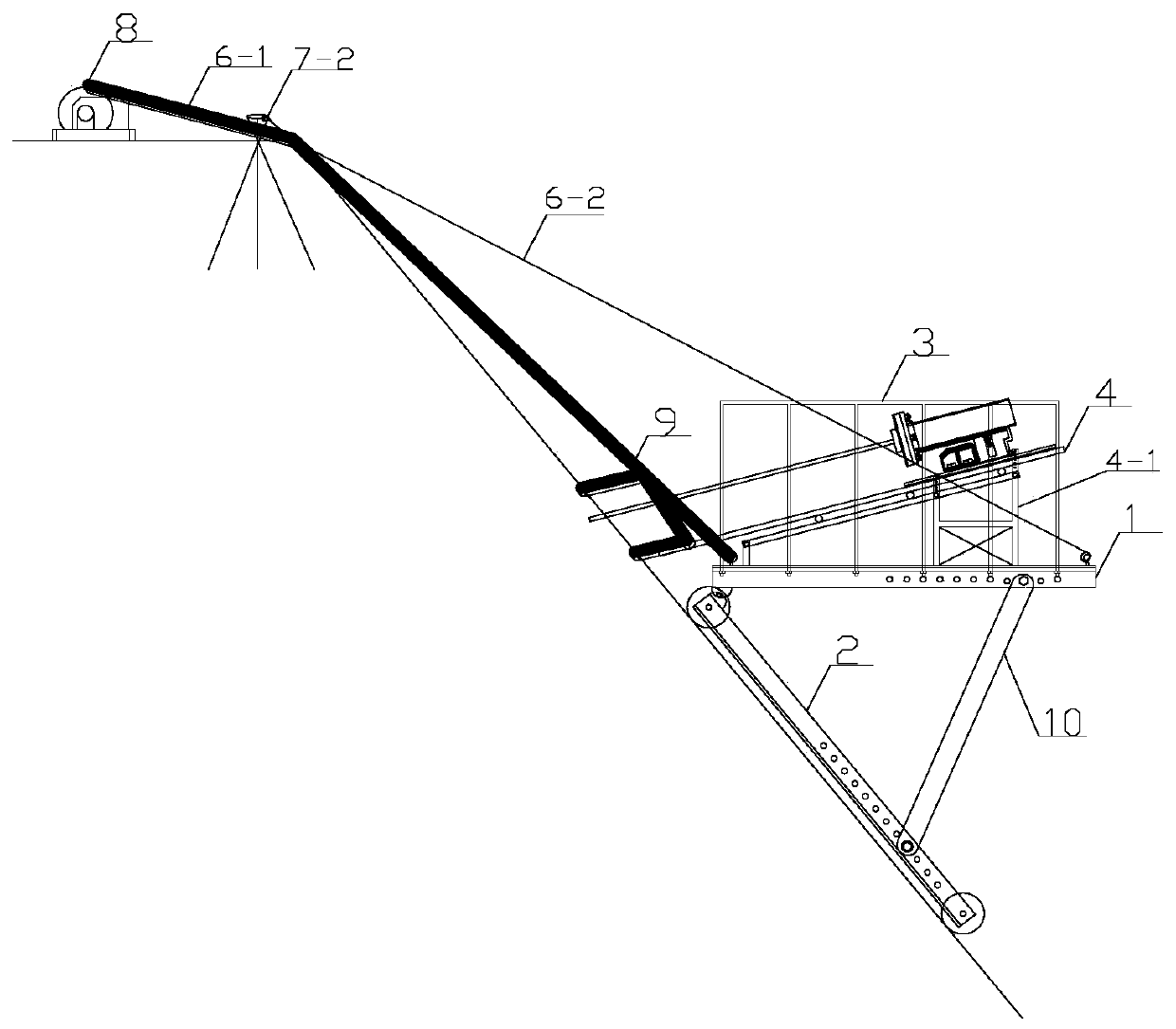

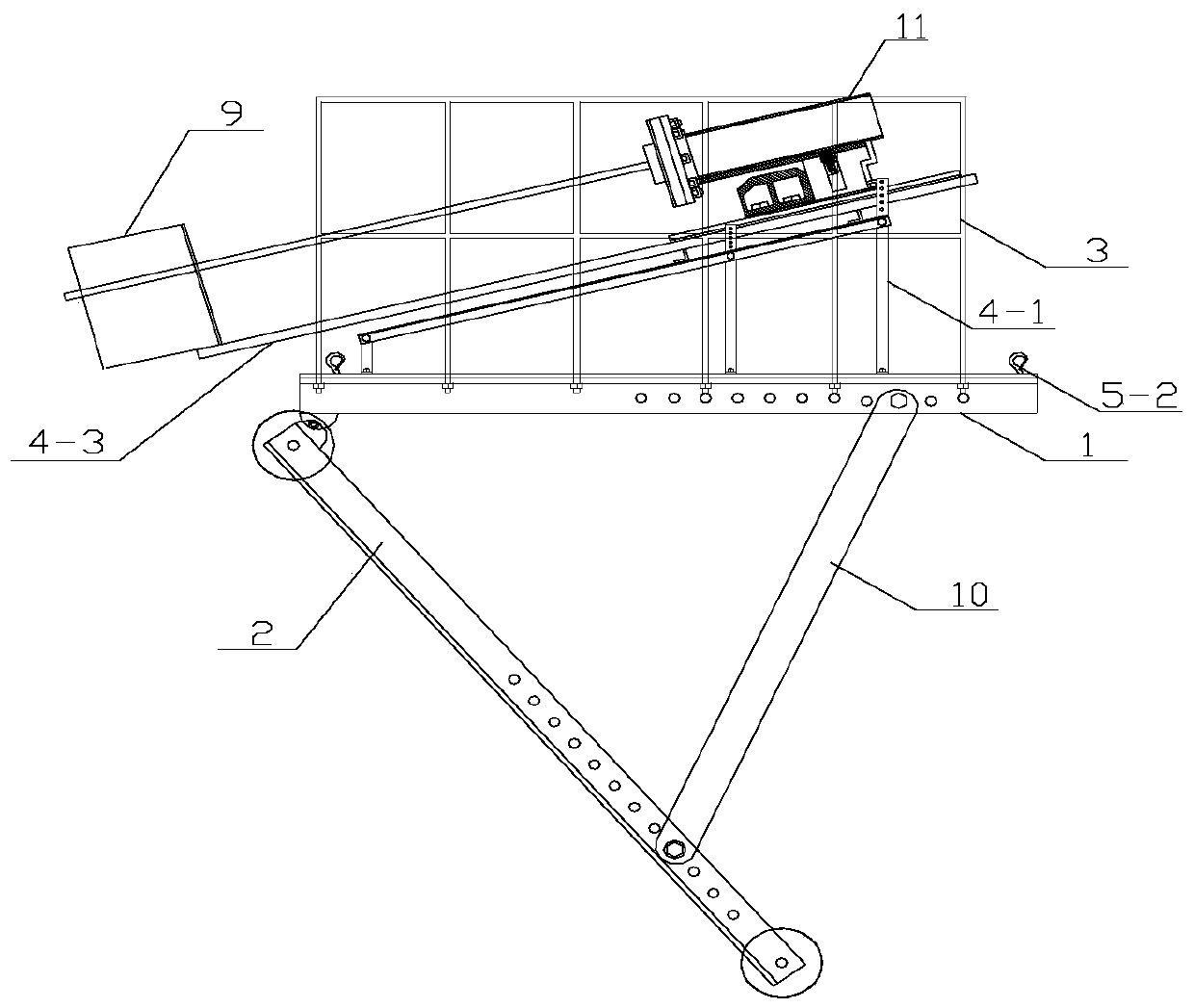

Operating platform for high slope anchor rod support construction

The invention discloses an operation platform for high slope anchor rod support construction. The operation platform comprises a mobile operation platform, wherein the mobile operation platform is provided with a horizontal operation platform and a slope walking trolley fixedly connected with the horizontal operation platform; a safety enclosure structure is arranged around the horizontal operation platform; a drill supporting frame is fixed on the horizontal operation platform, an anchor rod drill is installed on the drill supporting frame, and a guide rail of the anchor rod drill is fixed onthe drill supporting frame through a detachable connecting structure; a traction hook is arranged at the front end of the horizontal operation platform, and the traction hook is connected with a winch arranged at the top of the slope through a traction steel wire rope; and a safety hook is arranged at the rear end of the horizontal operation platform, and the safety hook is connected with an anchoring structure arranged at the top of the slope through a safety steel wire rope. According to the operation platform, the construction cost can be reduced, the construction safety can be ensured, the hole forming efficiency can be improved, the hole forming quality can be ensured conveniently, and the green and environmental protection construction concept can be implemented.

Owner:中建六局第一建设有限公司

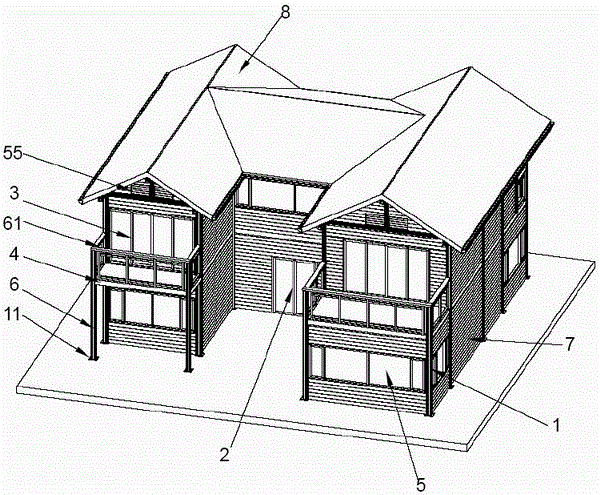

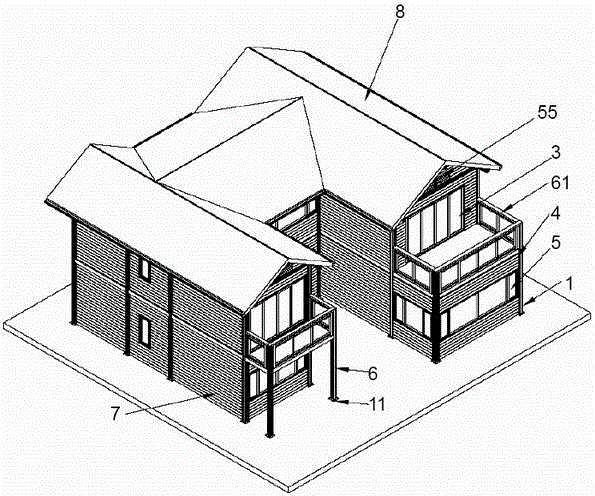

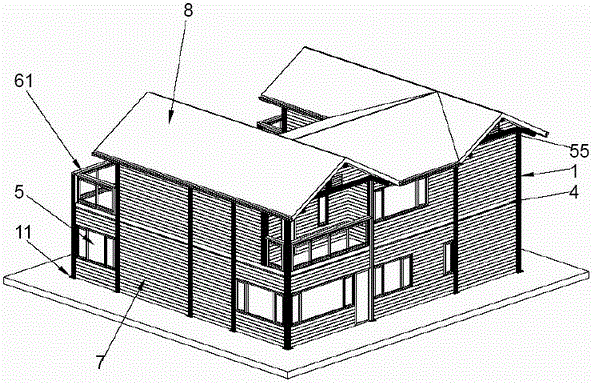

Aluminum alloy house

ActiveCN105040812AFirmly connectedShort design and manufacturing cycleBuilding roofsFloorsSection planeUltimate tensile strength

The invention relates to an aluminum alloy house. Aluminum alloy stand columns are arranged on the periphery and the inner ring of the house at intervals. Aluminum alloy beams are connected to the middle positions, in the height direction, of the aluminum alloy beams on the periphery and the inner ring of the house in a longitudinal and transverse segmented mode to form structures of the bottom layer and the second layer of the aluminum alloy house. Roof supporting columns are arranged on the aluminum alloy beams of the second layer. A roof is arranged on the roof supporting columns and the aluminum alloy stand columns. Three inwards-concave vertical face aluminum alloy combined wall plates are arranged in the middle of the aluminum alloy house in the foresight direction. An aluminum alloy gate is arranged in the middle of the front vertical face aluminum alloy combined wall plate, and therefore an inwards-concave space is formed in the aluminum alloy gate. Reverse Y-shaped sectional structures are arranged on the two sides of the roof. The front portion and the rear portion of the middle part of the roof are each in a slope shape. The two ends of each slope shape are connected with the middle rear portions of the reverse Y shapes on the two sides respectively. The aluminum alloy house is simple and firm in arrangement and connection structure, short in construction period, convenient to install, high in roof bearing strength and excellent in anti-seismic property.

Owner:ALUHOUSE TECHGD CO LTD

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

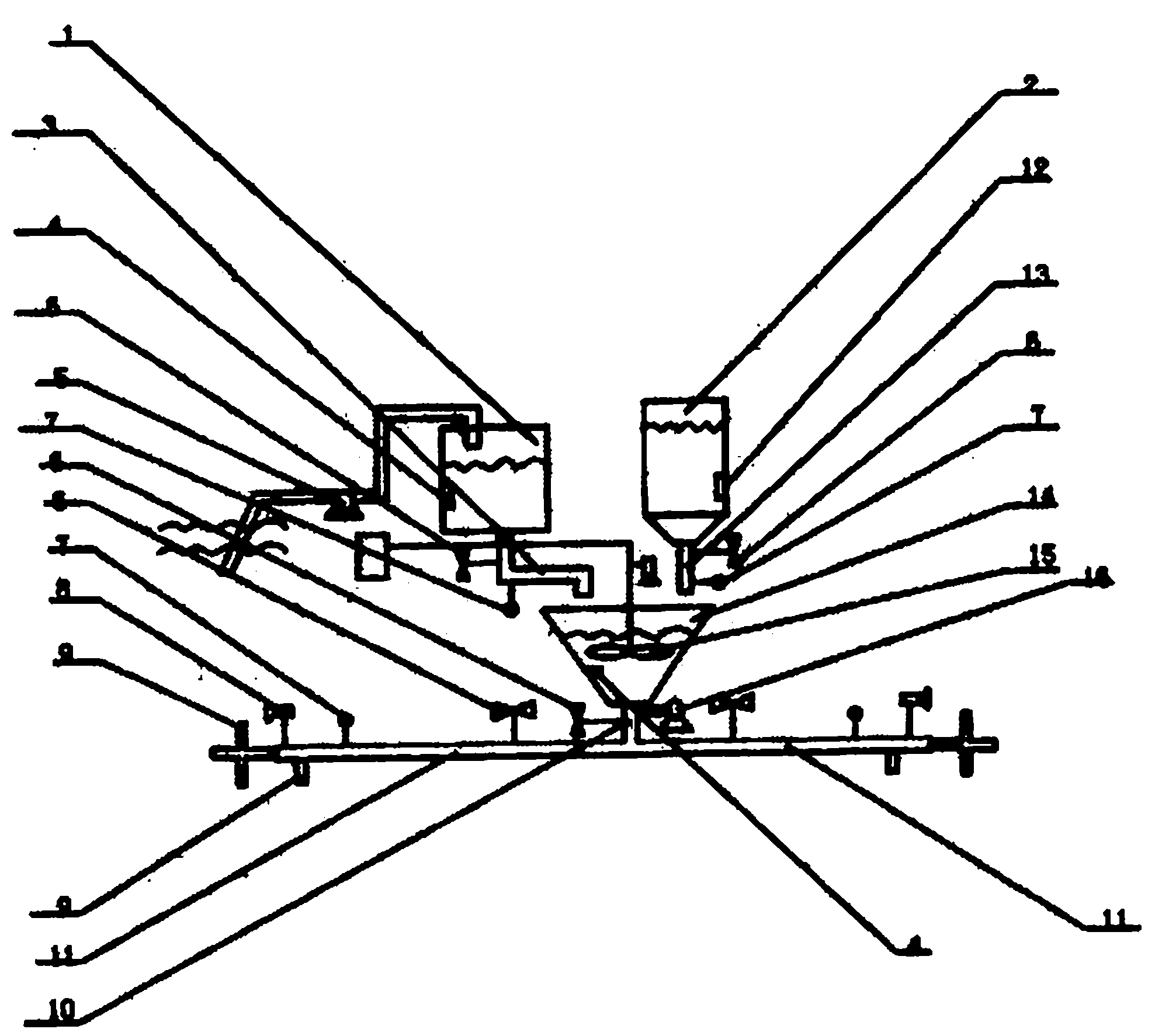

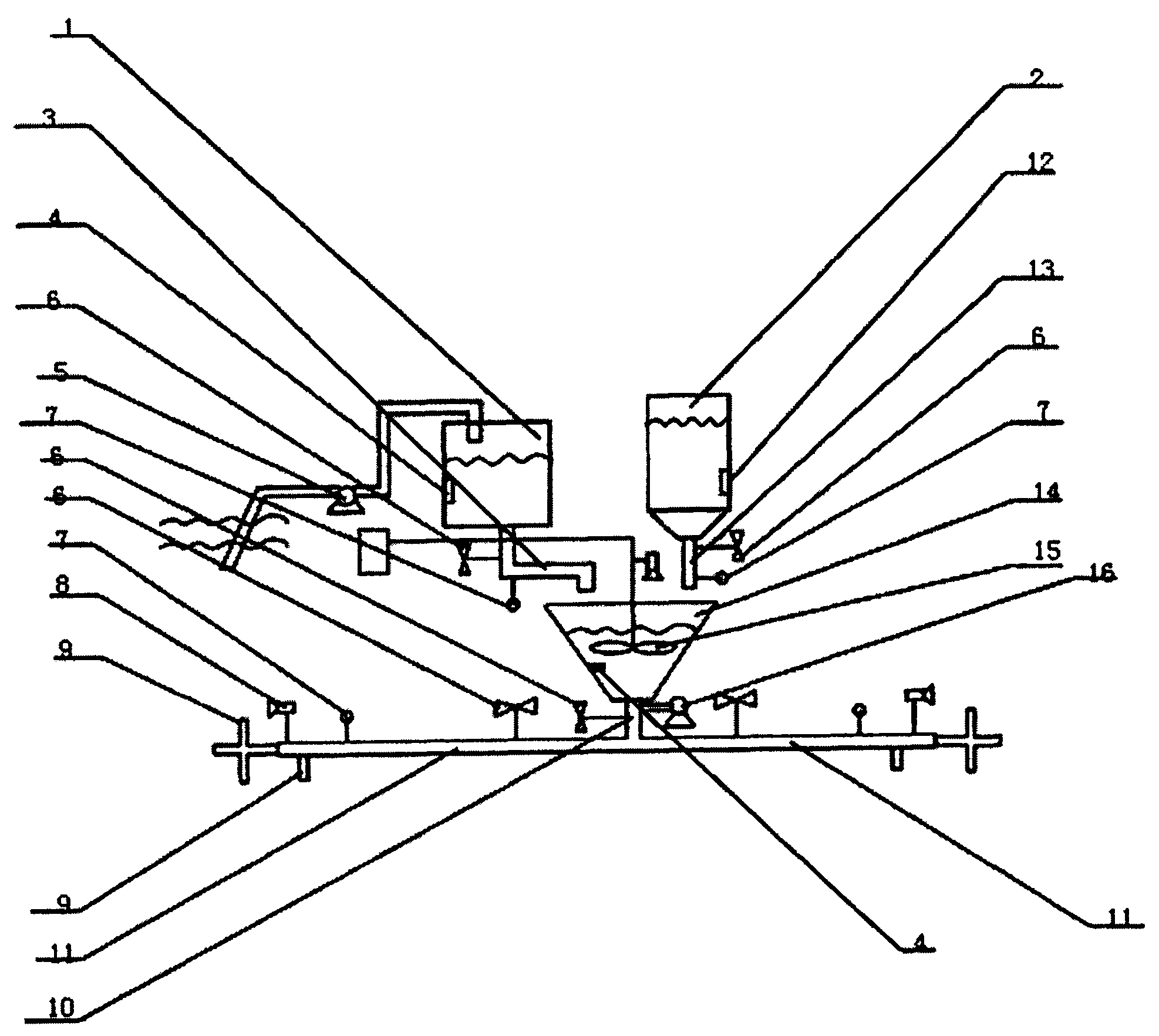

Low-carbon and environment-friendly feeding system

The invention discloses a low-carbon and environment-friendly feeding system. The feeding system adopting the structure of the invention breaks through the inertial thinking of the aquiculture breeding industry and creatively proposes a method of utilizing water as a feed transmission carrier so as to greatly decrease the feed packaging cost in one aspect, turn an aquiculture feed feeding process to be simple and high-efficiency and save mass labor in the other aspect. Meanwhile, the mixture of feed and water is transmitted so that a common automatic feeding machine can be canceled. The embodiment of the invention can decrease the cost of the breeding industry to a great extent, is more low-carbon and environment-friendly and has the advantages of low cost, good effect, packaging cost and mass labor cost saving, easy maintenance and little weather influence.

Owner:秦琳玲

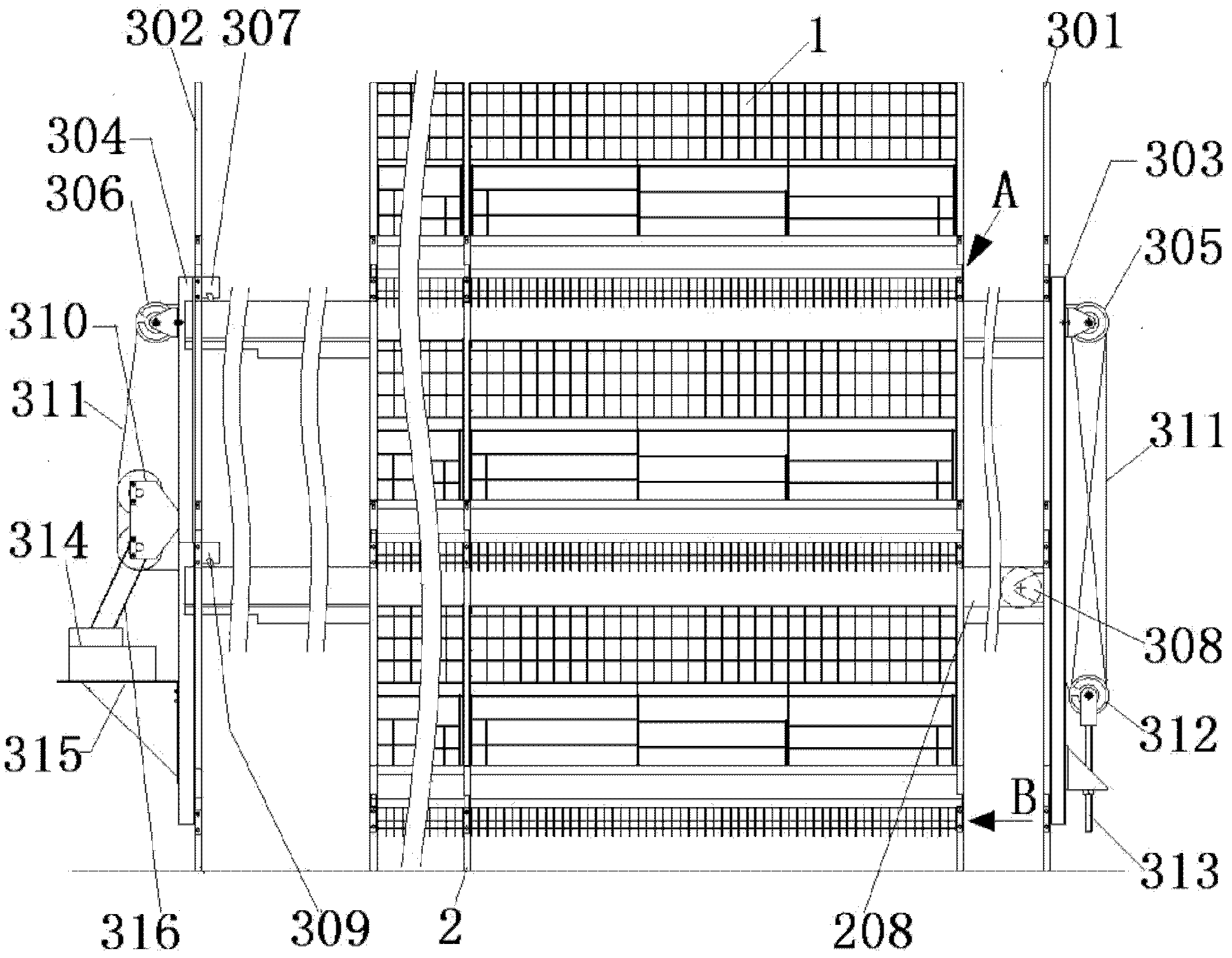

Small stepped type natural mating breeding equipment for breeding poultry

ActiveCN102422819AGuaranteed ventilation effectGuaranteed lighting effectsBird housingsMatingEnvironmental standard

The invention belongs to the technical field of stockbreeding machines, relating to small stepped type natural mating breeding equipment for breeding poultry. The small stepped type natural mating breeding equipment comprises a small stepped type natural mating cage and a manure removing device, wherein the small stepped type natural mating cage is formed by combining small stepped type natural mating cage units comprising six chicken cages and two three-layer trapezoid cage frames; every two adjacent stepped type natural mating cage units form a feeding unit; a top-layer chicken cage rear net is opened up and side nets of each layer of two adjacent chicken cages are opened up; and all cage tools of the whole cage groups respectively form a two-in-one large cage. The manure removing device comprises a manure removing machine driving mechanism and two manure removing machines which are respectively arranged below a bottom net of the top-layer chicken cage and bottom nets of two layers of chicken cages; and the manure removing machine driving mechanism can be used for simultaneously driving the two manure removing machines to alternatively carry out manure removing progress and manure removing return, so that the manure removing operation at the top of the cage is implemented. According to the small stepped type natural mating breeding equipment disclosed by the invention, the requirements of welfare breeding of the poultry and natural mating of the breeding poultry can be met; and the small stepped type natural mating breeding equipment is matched with feeding, drinking, trench manure removing and egg collecting systems and is suitable for large-scale intensive breeding poultry farms having high requirement on environmental standard.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com