Patents

Literature

33results about How to "Efficient cutting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

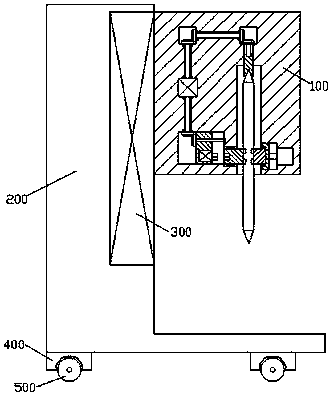

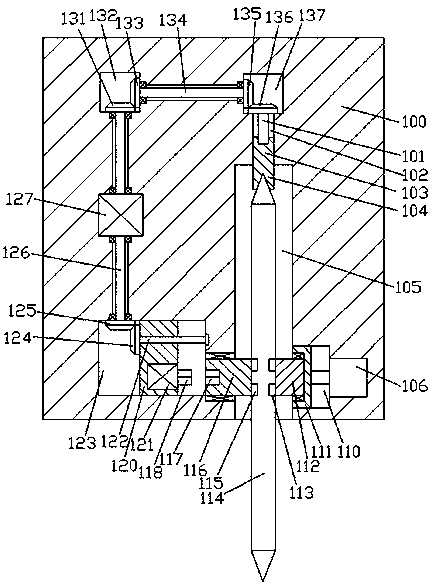

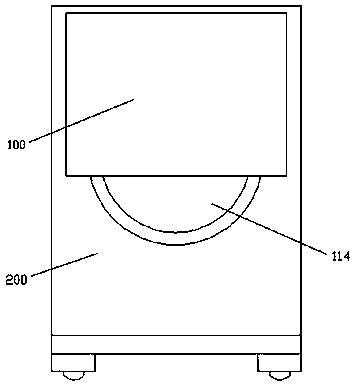

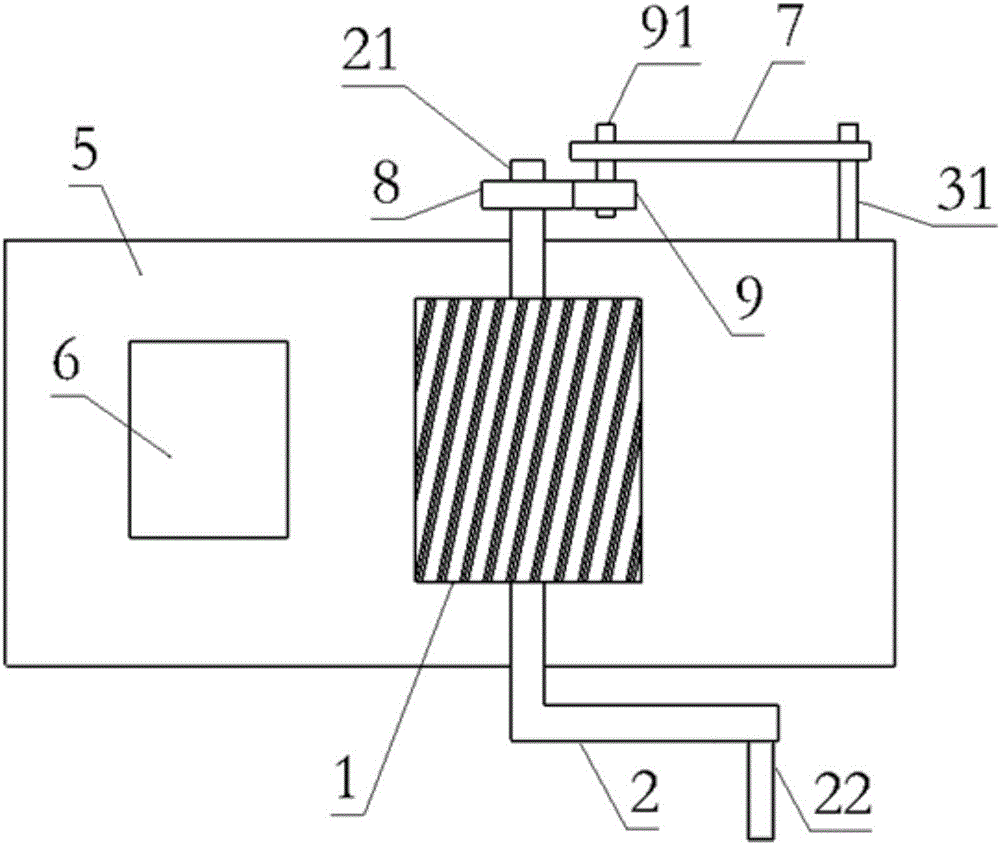

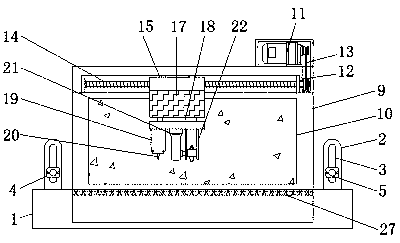

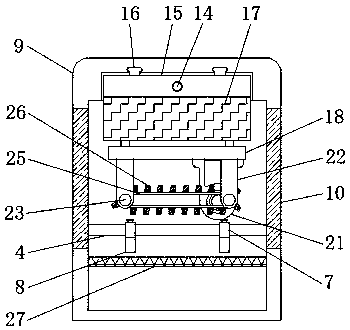

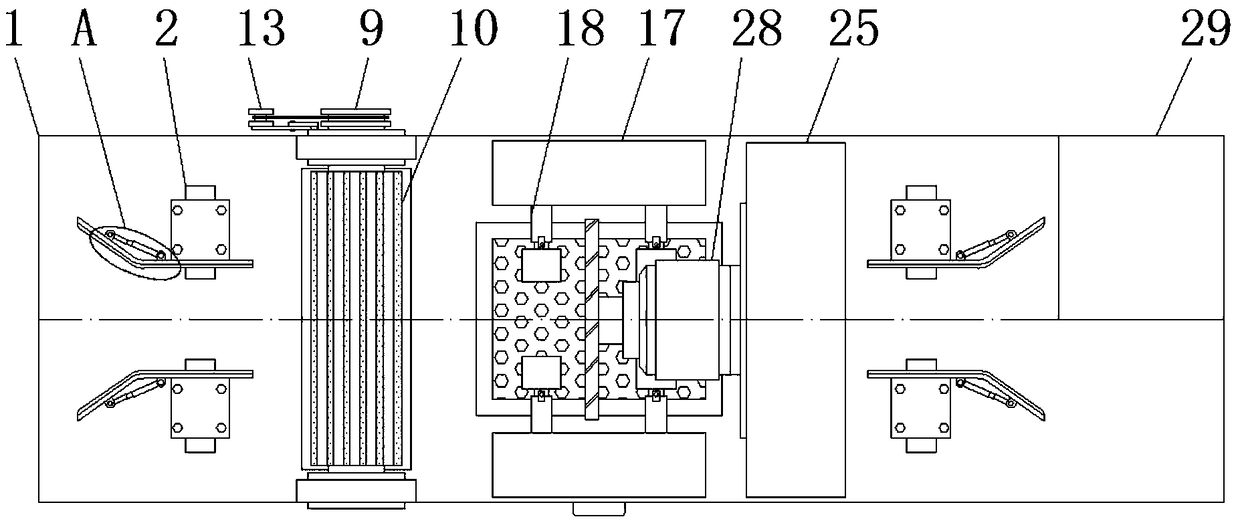

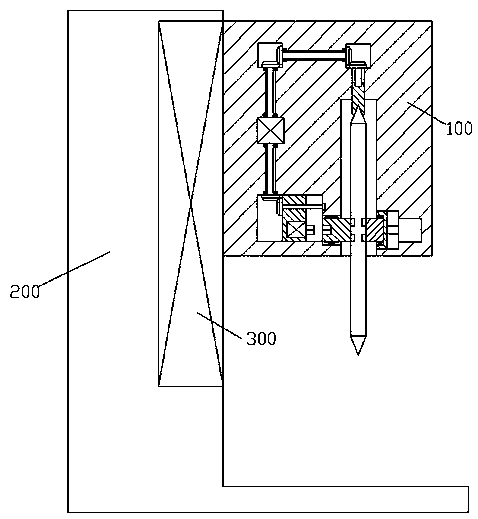

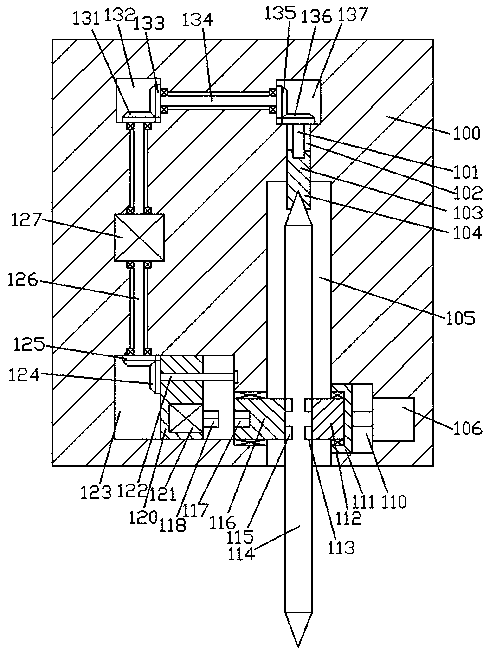

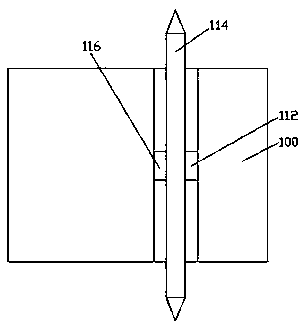

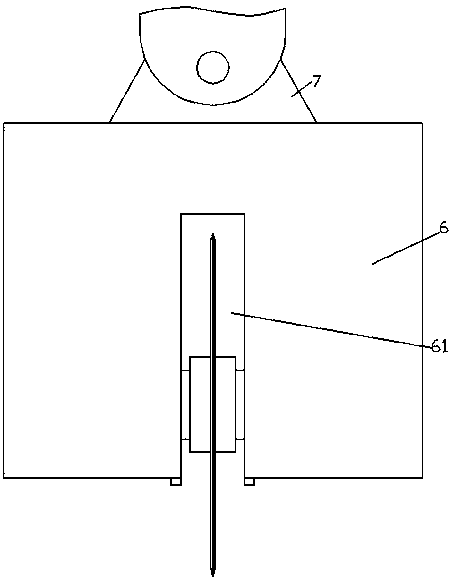

Automatic cutting machine with vision alignment function, and control method thereof

ActiveCN105690480AAccurately cut workEfficient cutting workShoemaking devicesMetal working apparatusComputer scienceVisual perception

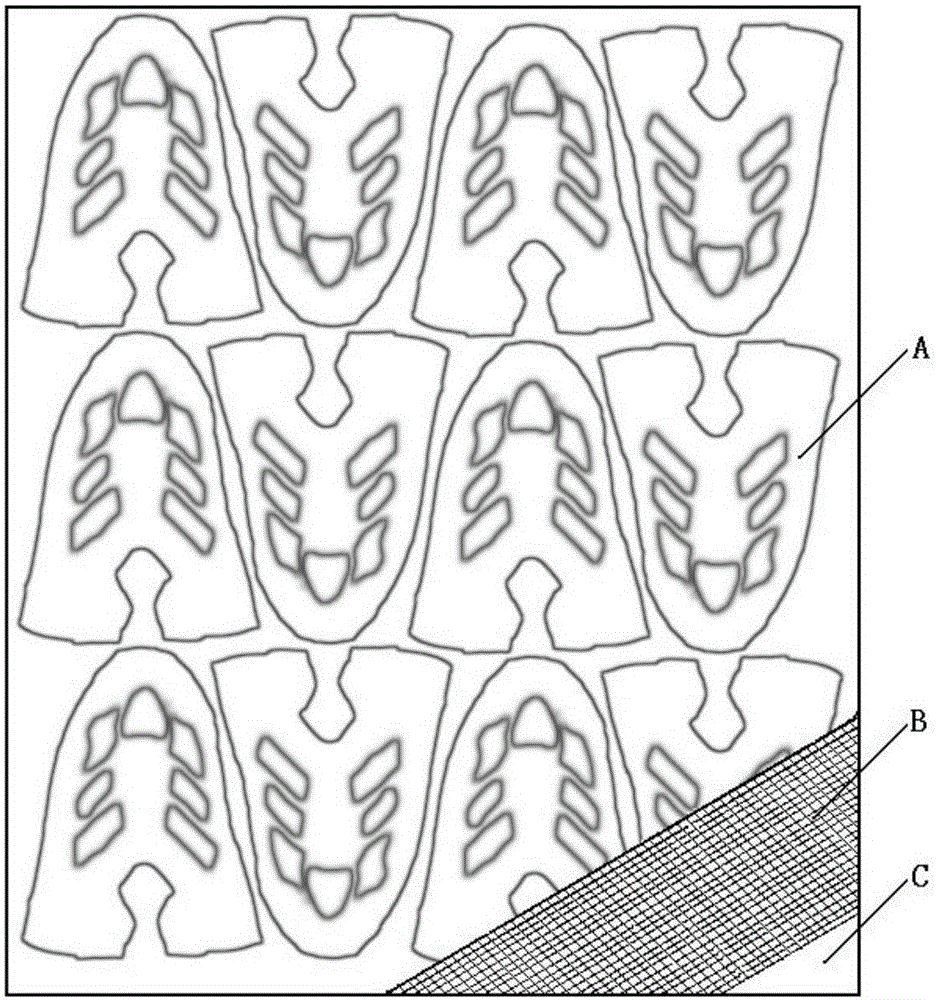

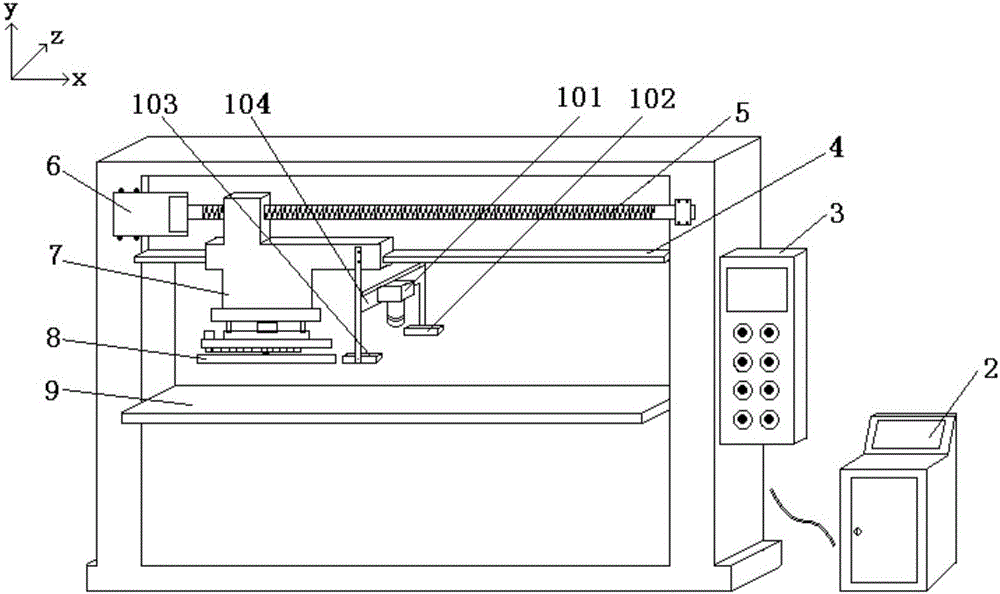

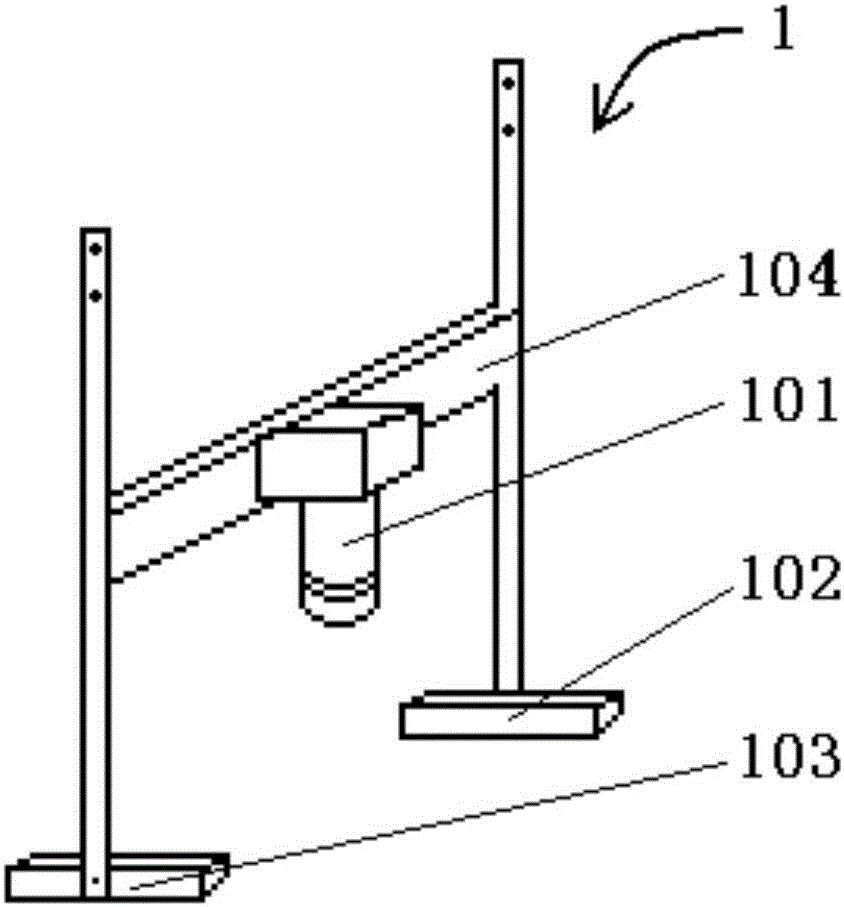

The invention discloses an automatic cutting machine with a vision alignment function, and a control method thereof. A vision photographing assembly and an alignment calculation system are additionally designed on the basis of the main body frame and system of the existing cutting machine. Before each cutting action, the vision photographing assembly photographs a pre-cut fabric area, shoots a fabric outline position into a picture, and conveys the picture to the alignment calculation system; the alignment calculation system calculates the movement distances of the driven cutting die base and blanking table surface, and the rotation angle of a cutting die disc according to the deviation position of an outline in the picture relative to a reference point; and a PLC drives the cutting die base and the blanking table surface to displace, and drives the cutting die disc to rotate an angle according to the allowance transmitted by the alignment calculation system, so that a cutting die is accurately located above a fabric, and the cutting die is pressed to complete cutting. The system continuously repeats the steps of photographing, offset calculation, and alignment cutting, thus efficiently, accurately and fully automatically completing the cutting working for the fabric.

Owner:东莞市陆陆兴工业自动化科技有限公司

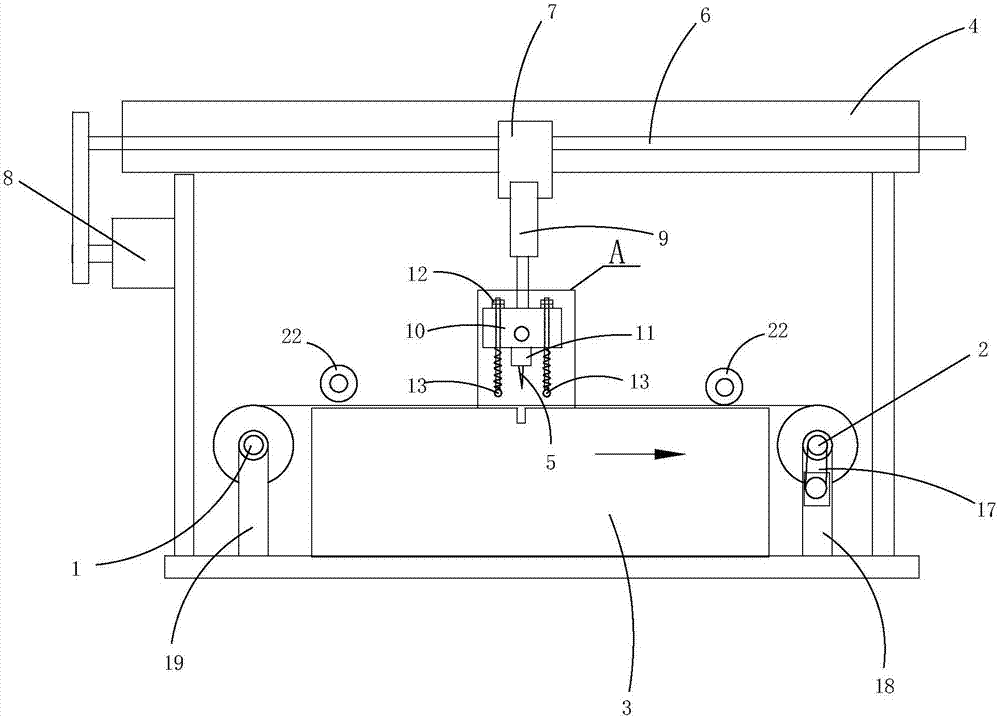

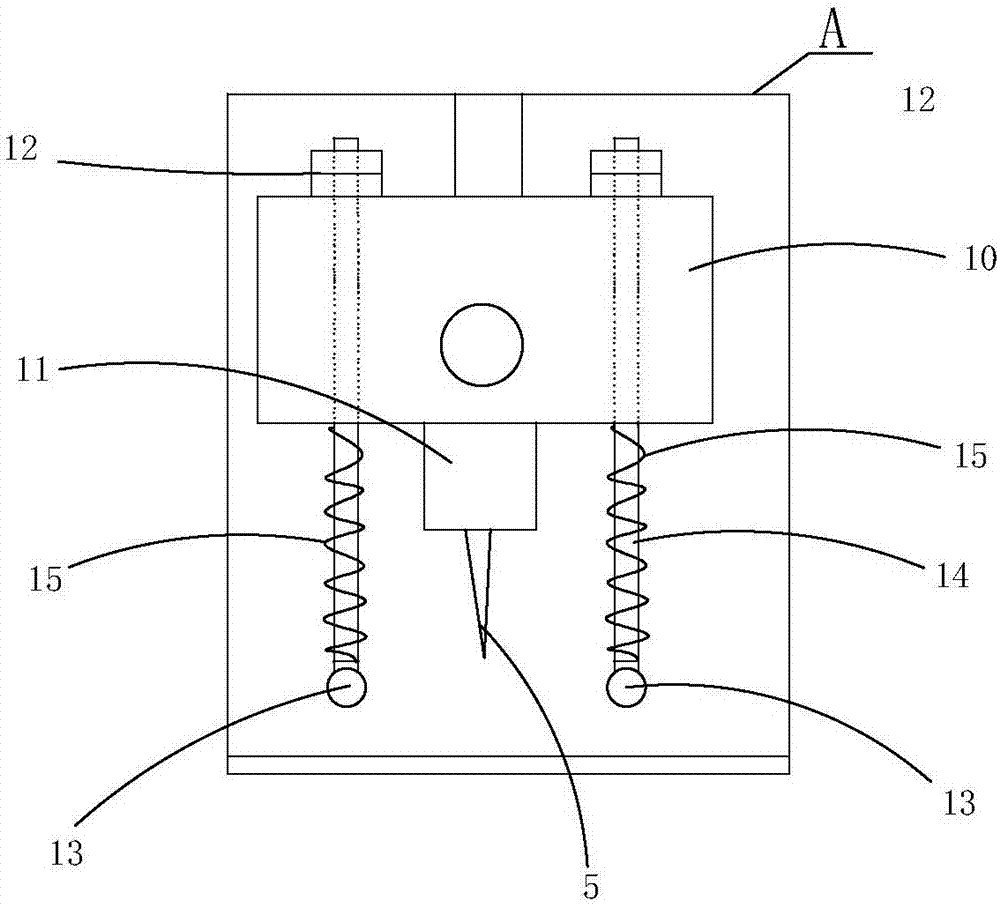

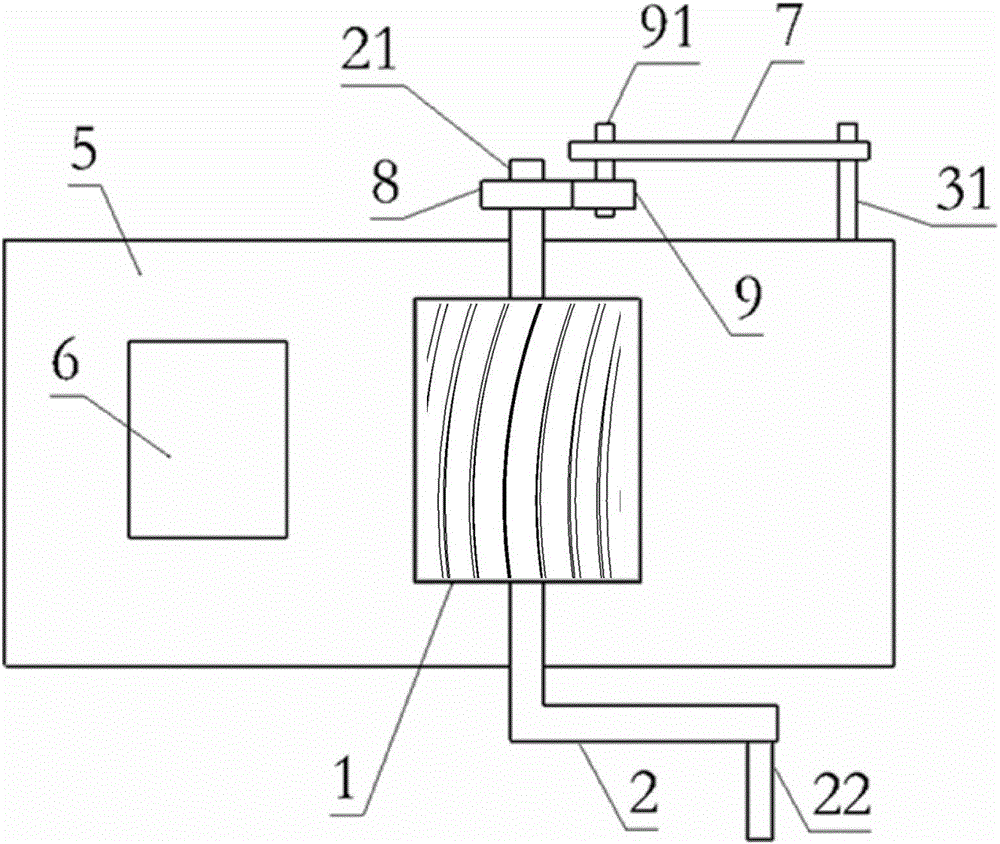

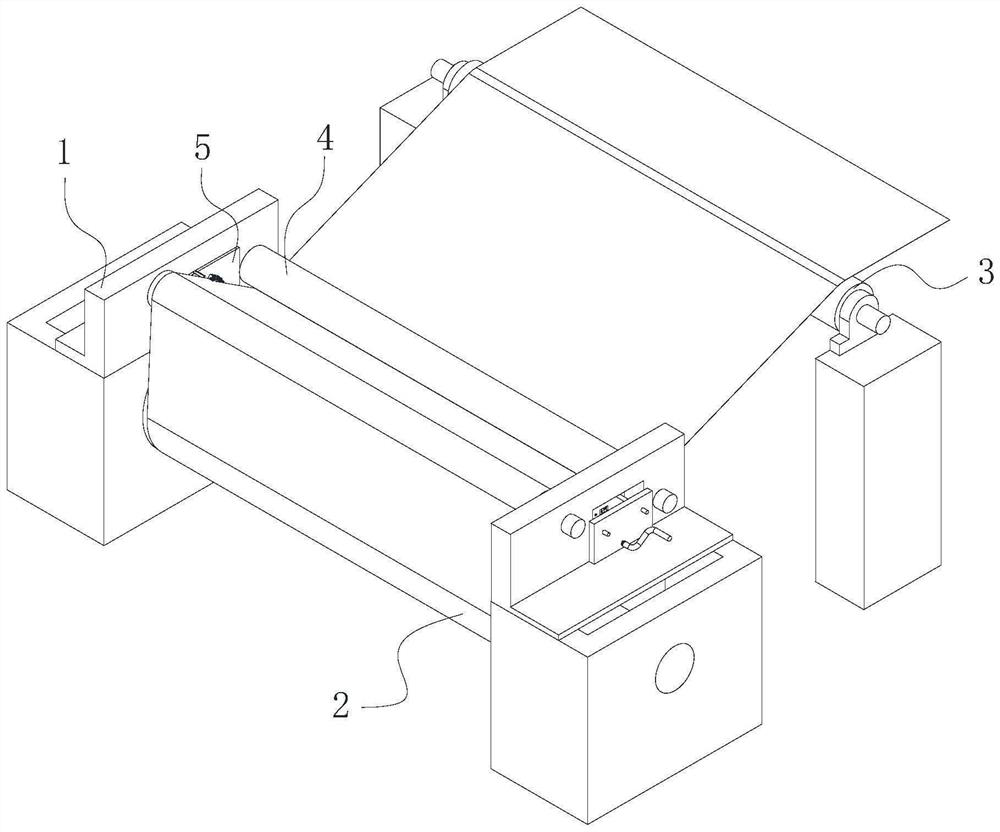

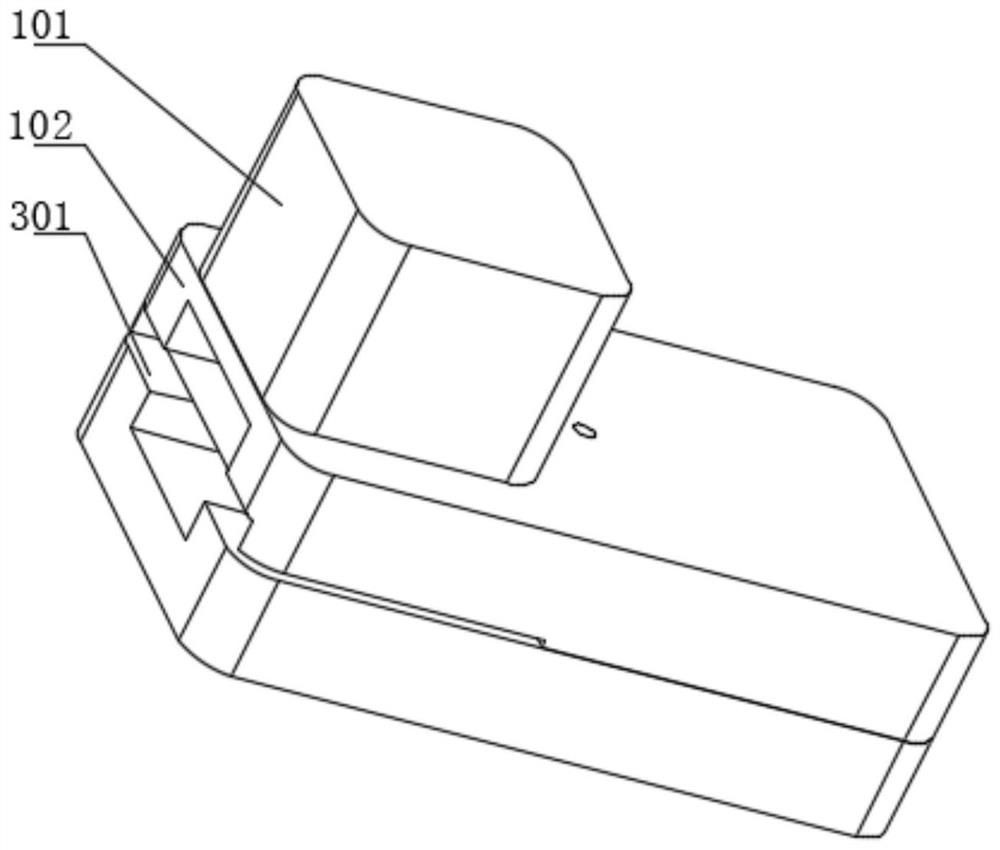

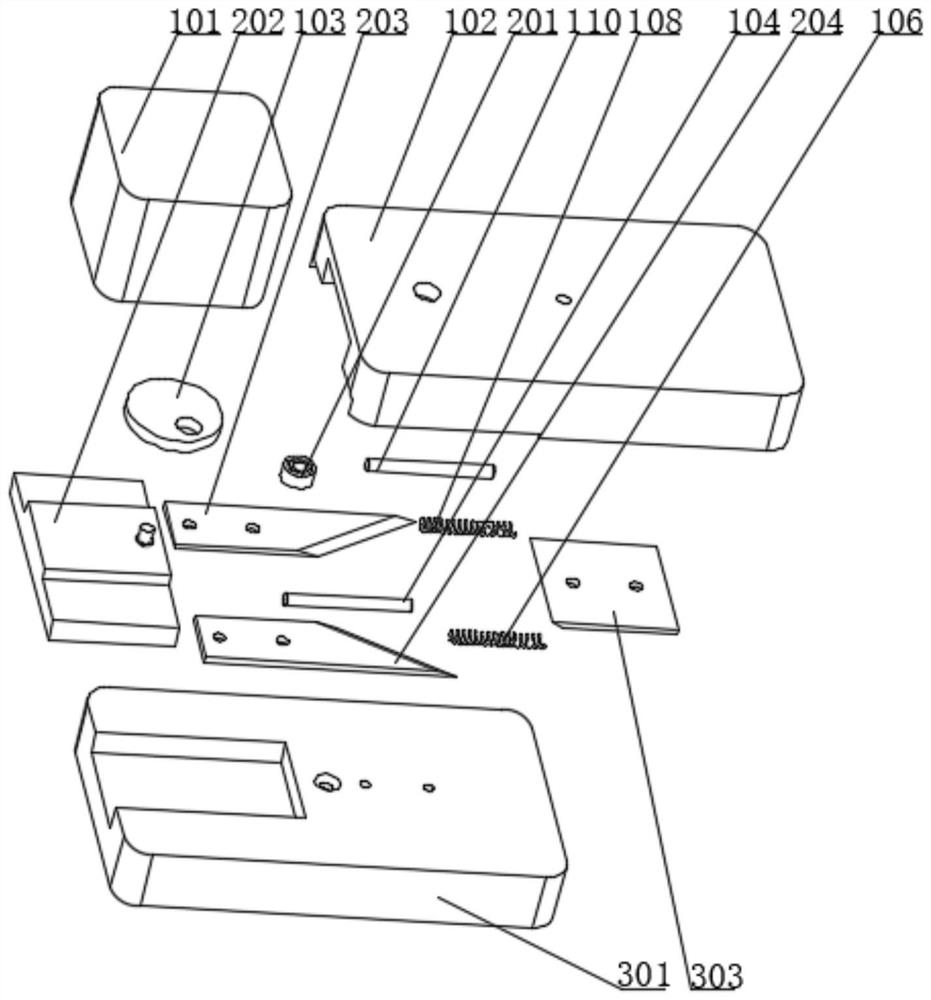

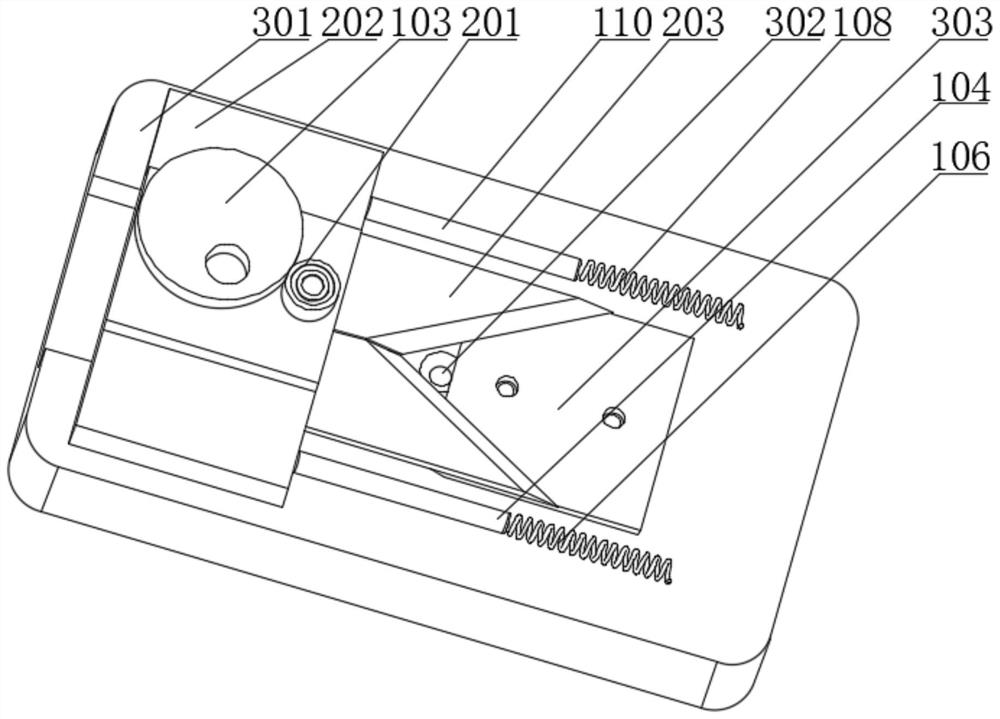

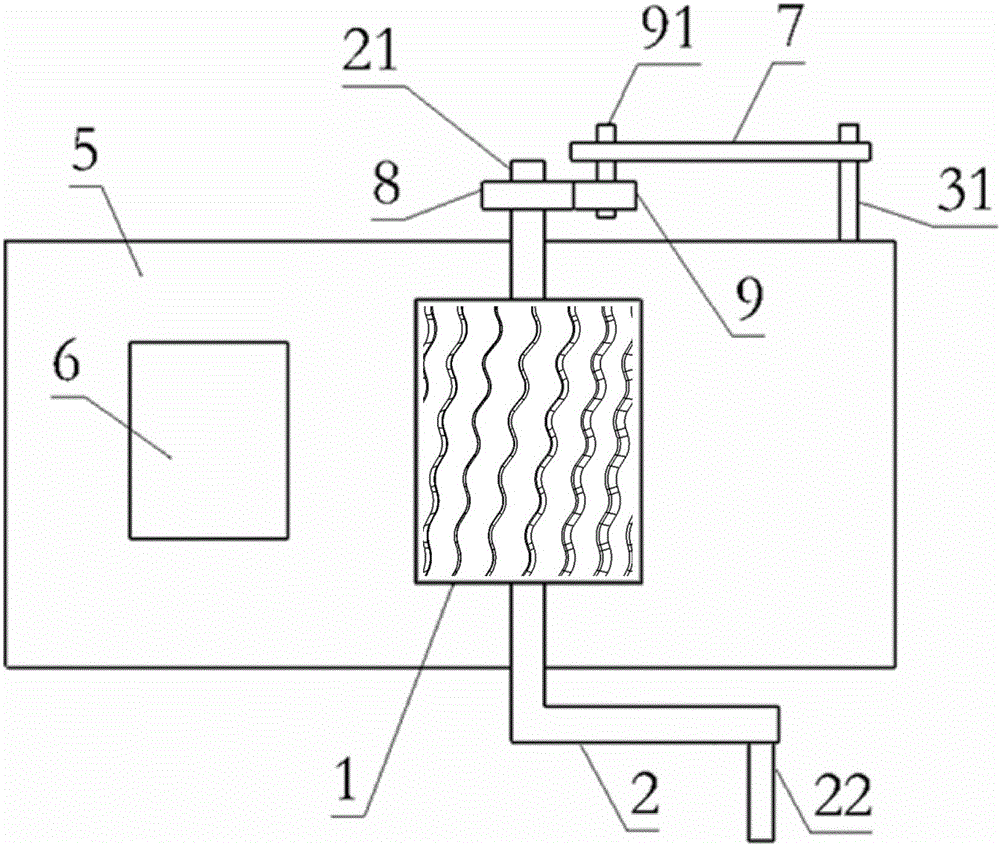

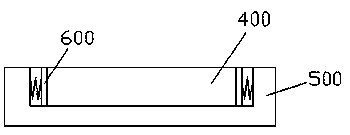

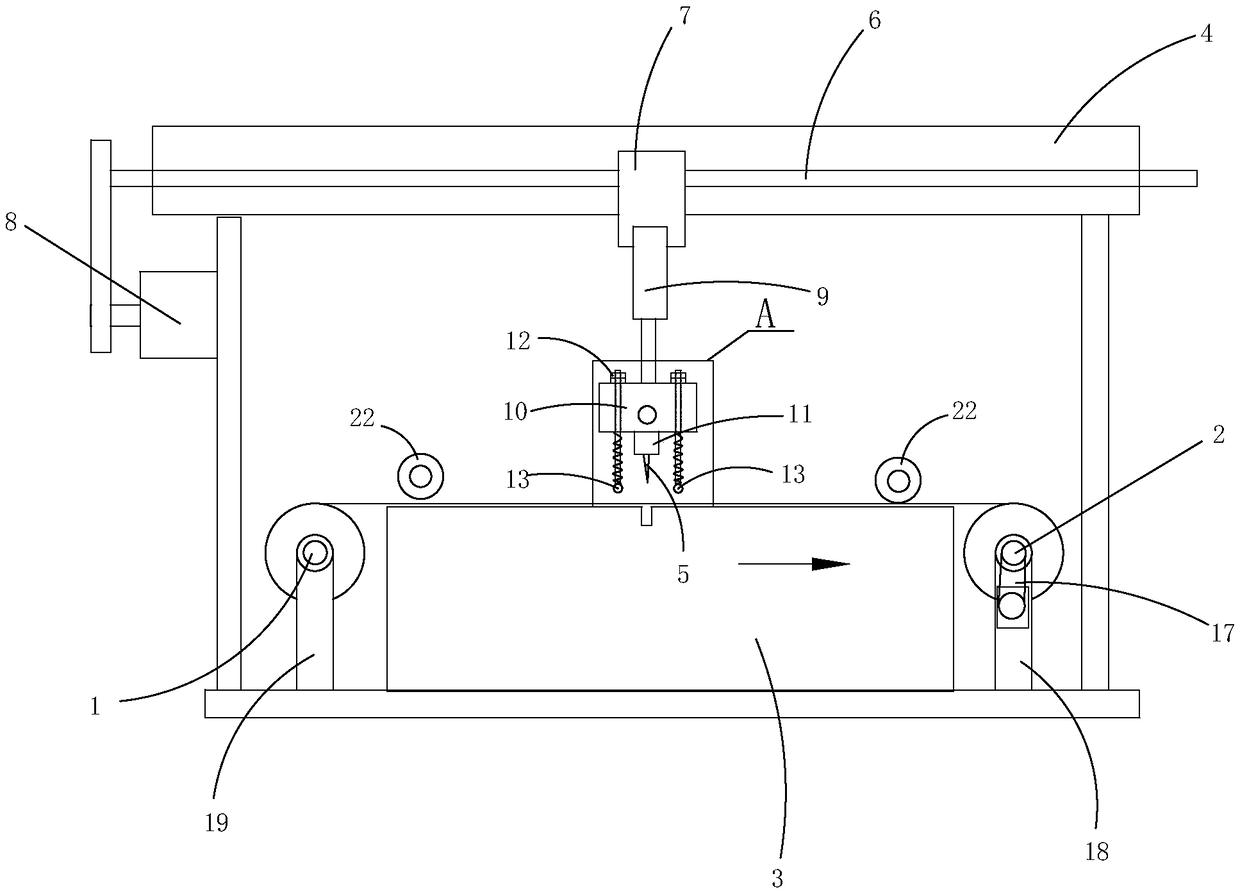

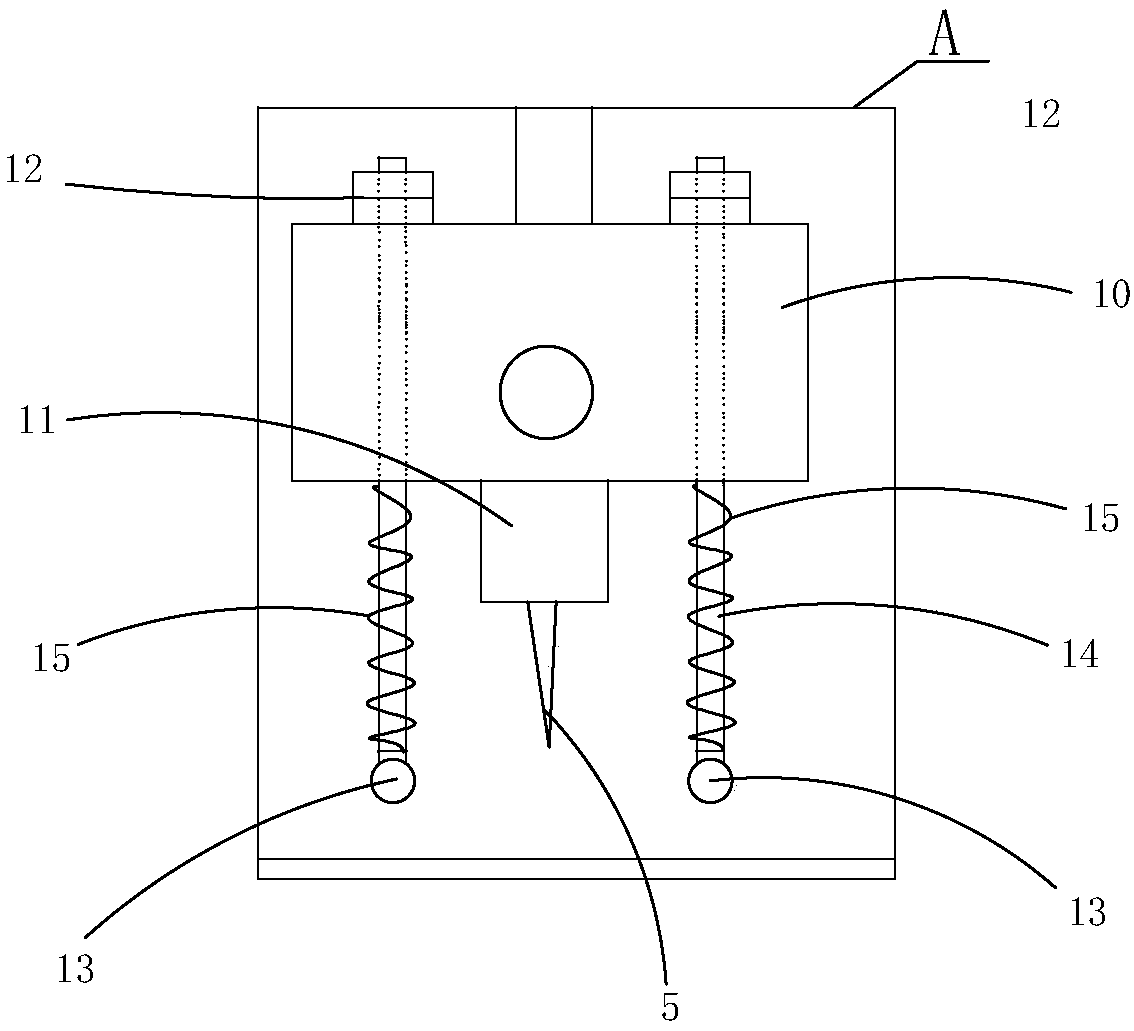

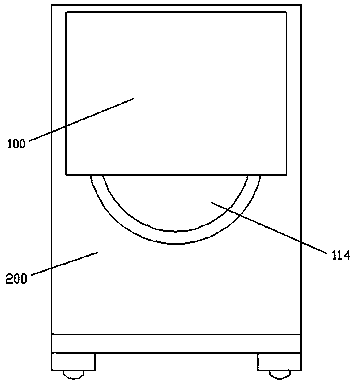

Cloth cutting device

ActiveCN106891365AEfficient cutting workGood practicalitySevering textilesMetal working apparatusAgricultural engineeringCoil spring

The invention discloses a cloth cutting device. The cloth cutting device comprises an uncoiling positioning rotary shaft, a supporting platform, a gantry, a cutter and a driving mechanism, wherein the driving mechanism comprises a screw rod, a moving rack, a motor, a cylinder, an assembly rack, a cutter rest and a driving mechanism; the cutter is arranged on the cutter rest; cloth pressing bars are arranged on two sides of the cutter rest on the assembly rack; the cloth pressing bars are arranged along the width direction of a cloth; the length of the cloth pressing bars is not smaller than the width of the cloth; the cloth pressing bars are movably arranged on the assembly rack through a plurality of elastic connection components; each elastic connection component comprises a connection rod and a spiral spring; the lower end of each connection rod is fixedly connected with the corresponding cloth pressing bar through welding; the upper end of each connection rod penetrates through a vertical through hole in the moving rack and then is fixedly connected with a baffle block; the outer diameter of each baffle block is larger than the hole diameter of each vertical through hole, so that each connection rod is limited in the corresponding vertical through hole to move vertically; and the upper and lower ends of each spiral spring are separately resisted against the assembly rack and the corresponding cloth pressing bar. By adopting the cloth cutting device, the cloth can be cut high efficiently; and the cloth cutting device has very good practicability.

Owner:浙江斯泰堡纺织有限公司

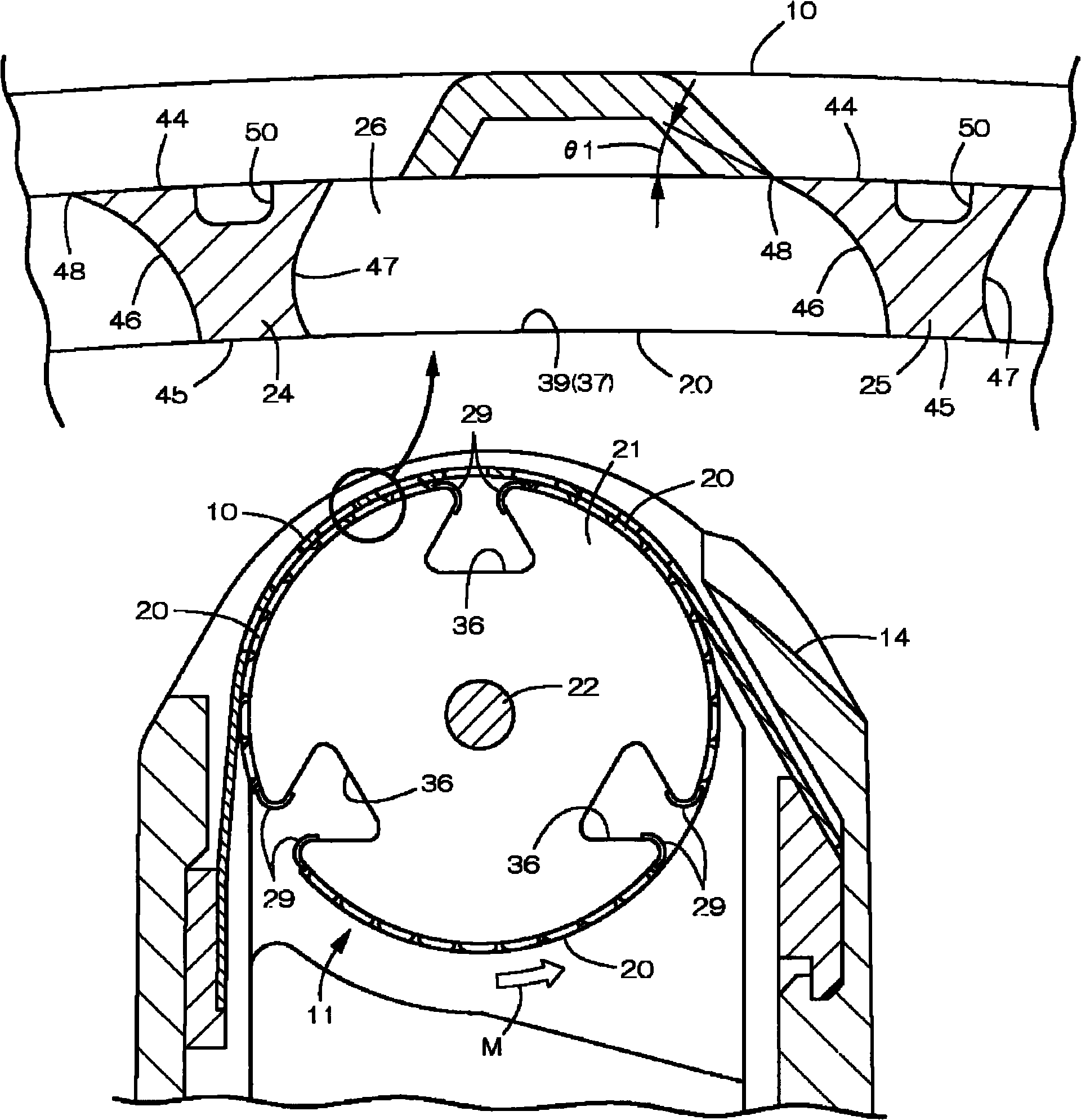

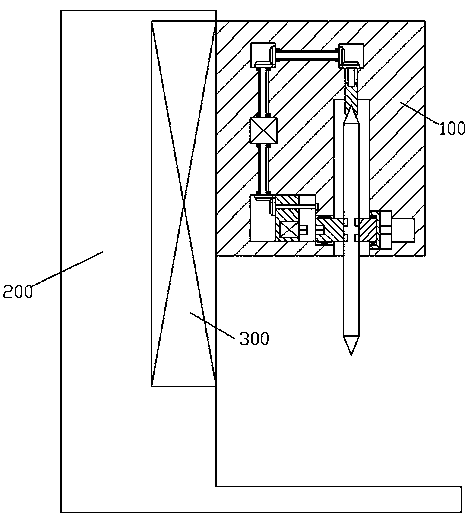

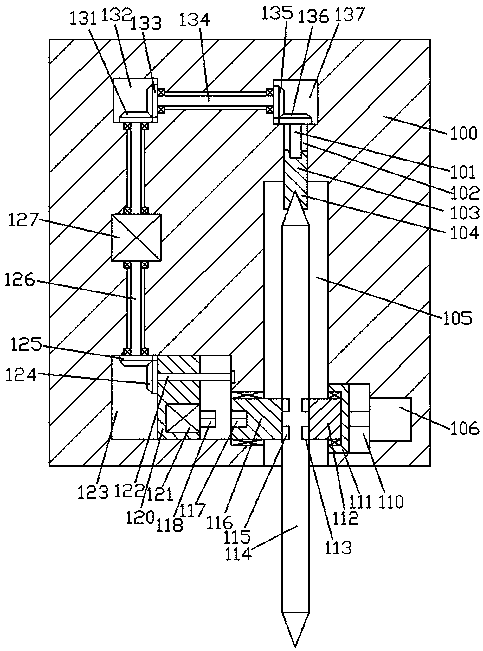

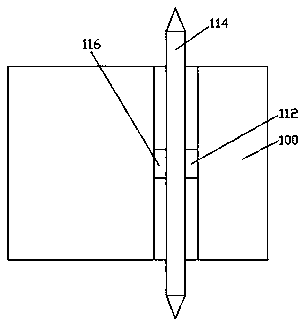

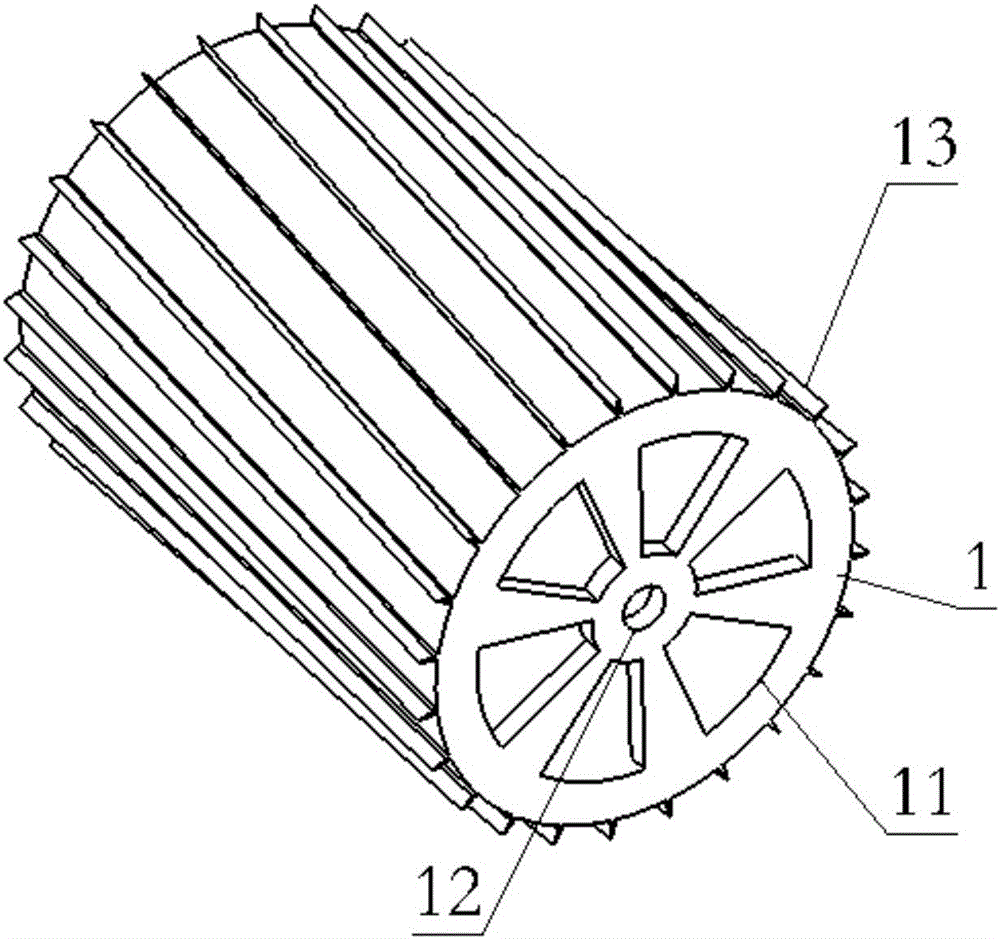

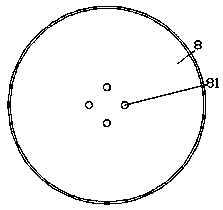

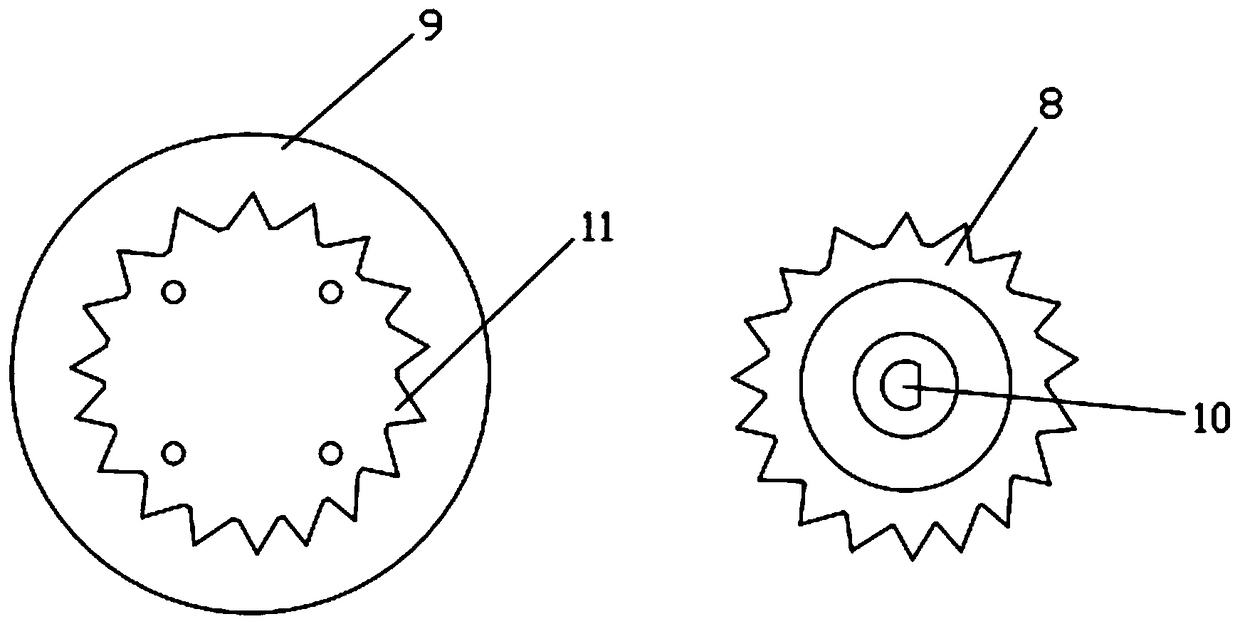

Rotator blade and small electric instrument having rotator blade

ActiveCN102039604ACutting sharpEffectively cut offMetal working apparatusEngineeringElectrical equipment

The present invention provides a rotary blade and a small electric instrument having the rotator blade, wherein the rotator blade which can effectively introduce and efficiently cut off the beard and has easy cleaning of flock is provided. The rotator blade which comprises a blade body and a blade bracket that supports the blade body is composed. Etching treatment is performed for stainless steel plate thereby forming a group of rib-shaped small cutting edge and a group of cutting blade holes in the blade body. A plurality of blade bodies are fixed on a circumferential surface of the blade bracket and the rotator blade is composed to a cylinder shape. Each small cutting edge is provided with the following components: a cutting surface of an external surface; a non-cutting surface of an inner surface; a side edge part for connecting the cutting surface with the non-cutting surface; a cutting edge which is formed at an upstream side in a rotation direction of the cutting surface; and a back clearance surface edge which is formed at the downstream side in the rotation direction of the cutting surface. A width center of the non-cutting surface deviates from a width center of the cutting surface to the downstream side of the rotation direction. A cutting edge angle of the cutting edge, which is smaller than an edge angle of the back clearance surface edge, is formed.

Owner:MAXELL HLDG LTD

Automatic robot

The invention discloses an automatic robot. The automatic robot comprises a cutting machine body, and the cutting machine body is arranged on the right end surface of a supporting base through a lifting driving device; an embedding cavity is formed in the end surface of the bottom of the cutting machine body; a cutting blade is arranged in the embedding cavity in a rotating fit mode; a clamping mechanism used for being connected to the cutting blade in a locking fit mode is arranged in the inner wall of the right side of the embedding cavity; a sliding cavity is formed in the position, on theleft side of the embedding cavity, of an inner wall body of the cutting machine; a left clamping joint is arranged in a wall body between the sliding cavity and the embedding cavity in a rotating fitmode; a spline cavity is formed in the left end surface of the left clamping joint; a sliding block is arranged in the sliding cavity in a sliding fit mode; a first motor is fixedly arranged in the right end surface of the sliding block; and a spline shaft which is in spline fit connection with the spline cavity is arranged on the right end of the first motor in a power fit mode.

Owner:苏州济和精密传动系统有限公司

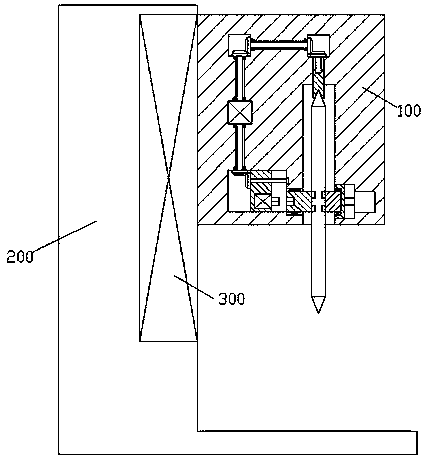

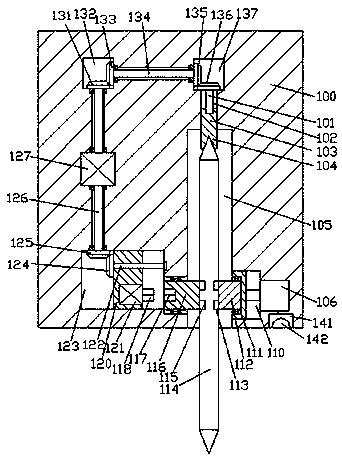

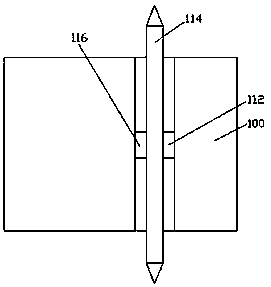

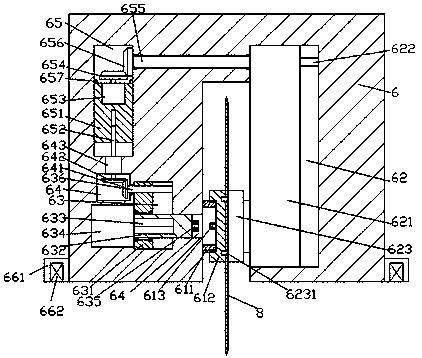

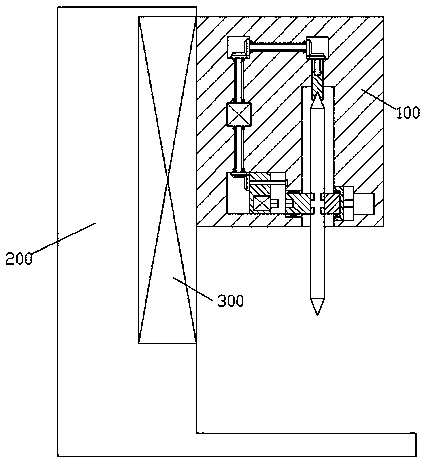

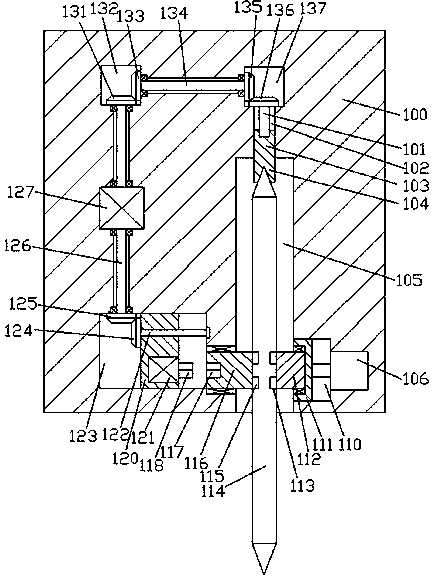

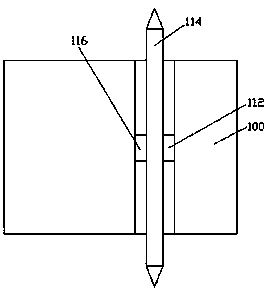

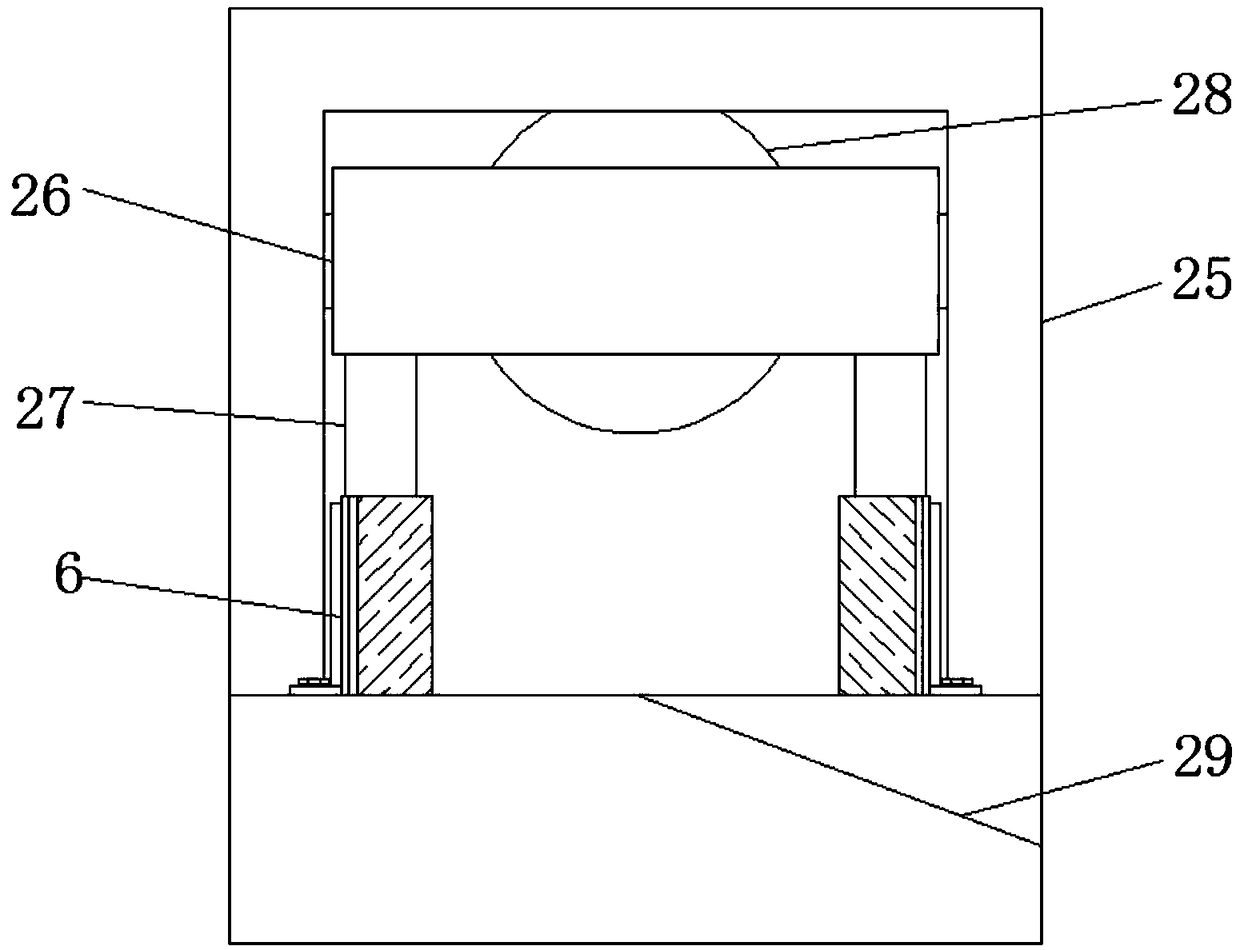

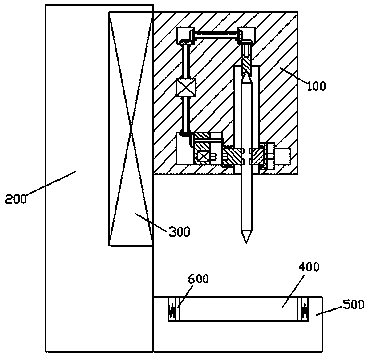

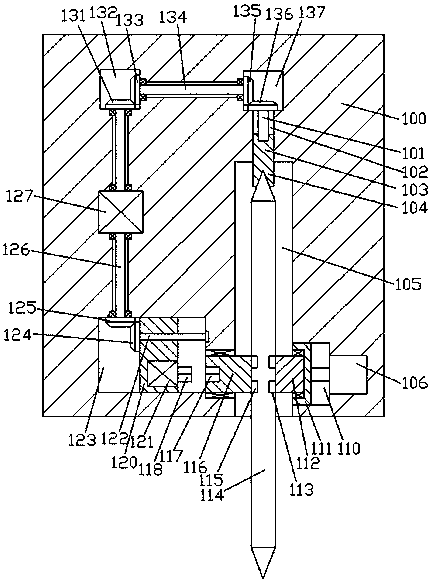

Fabrication equipment of semiconductor light-emitting diode

ActiveCN108400208ASimple structureEasy to operateSemiconductor devicesEngineeringLight-emitting diode

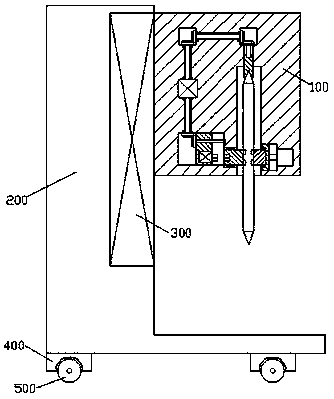

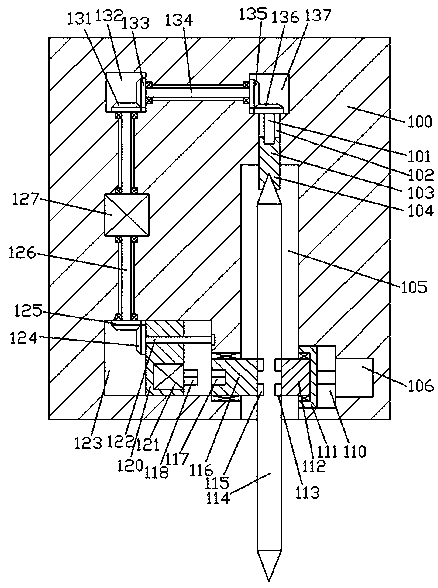

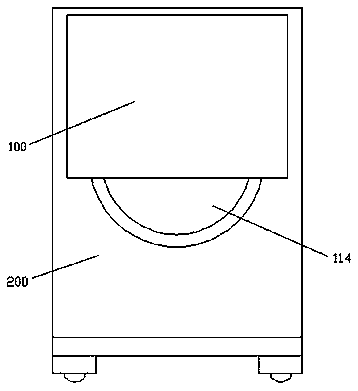

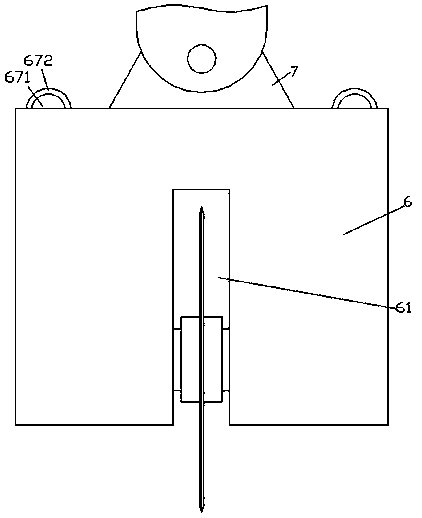

The invention discloses fabrication equipment of a semiconductor light-emitting diode. The fabrication equipment comprises a fabrication rack, wherein the fabrication rack is arranged on an end surface of a right side of a support by a lifting device, legs are fixedly arranged around an end surface of the bottom of the support, rollers are arranged in end surfaces of the bottoms of the legs in a rolling and matching way, an installation cavity is formed in an end surface of the bottom of the fabrication rack, a rotation cutter is rotatably arranged in the installation cavity in a matching way,a clamping assembly is arranged in an inner wall of a right side of the installation cavity and is used for being locked and connected with the rotation cutter in a matching way, a sliding cavity isformed in an inner wall body of the fabrication rack at a left side of the installation cavity, a left rotation connection head is rotatably connected with a wall body between the sliding cavity and the installation cavity in a matching way, a spline hole is formed in an end surface of a left side of the left rotation connection head, a sliding block is arranged in the sliding cavity in a slidingand matching way, a first motor is fixedly arranged in an end surface of a right side of the sliding cavity, and a spline arm is arranged at a right side end of the first motor in a power matching wayand is in spline connection with the spline hole in a matching way.

Owner:上海雅宸照明电器有限公司

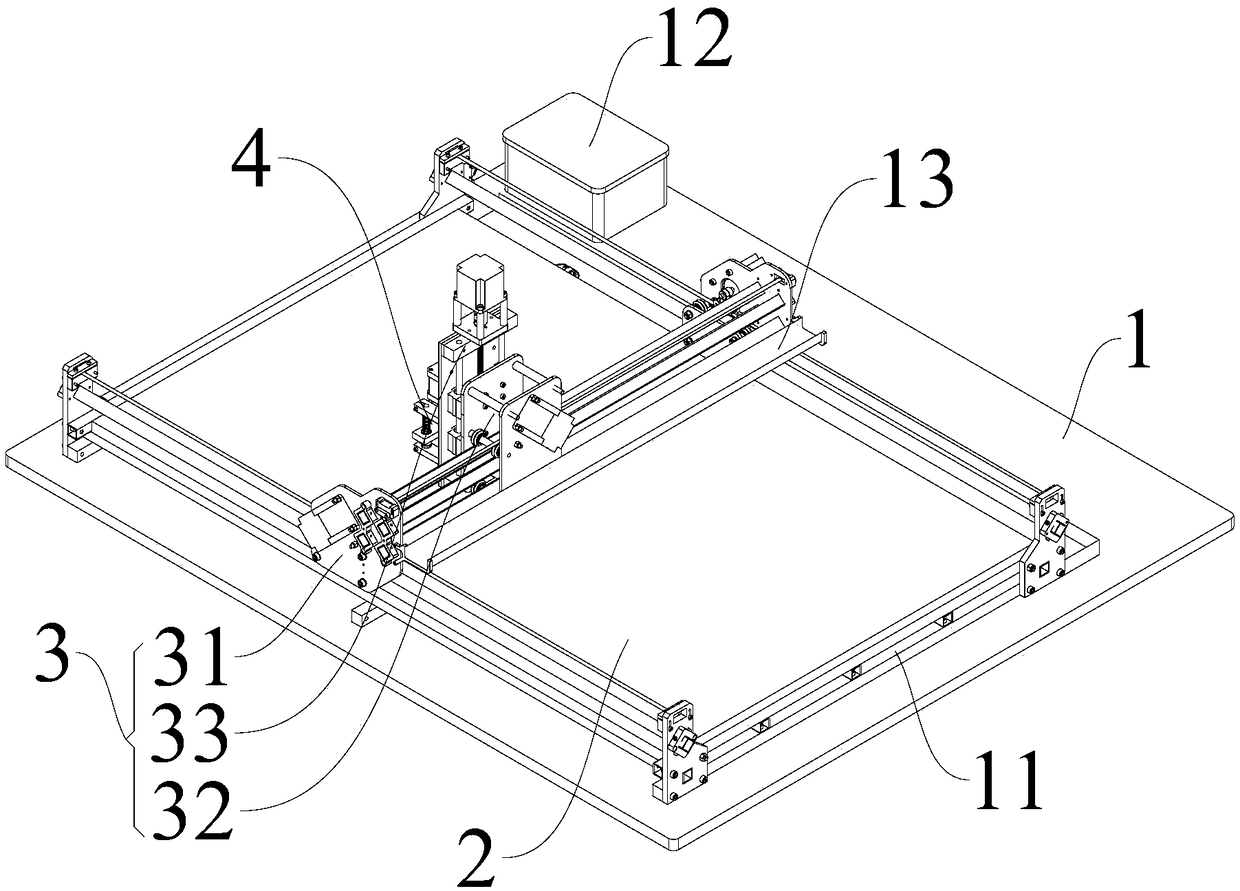

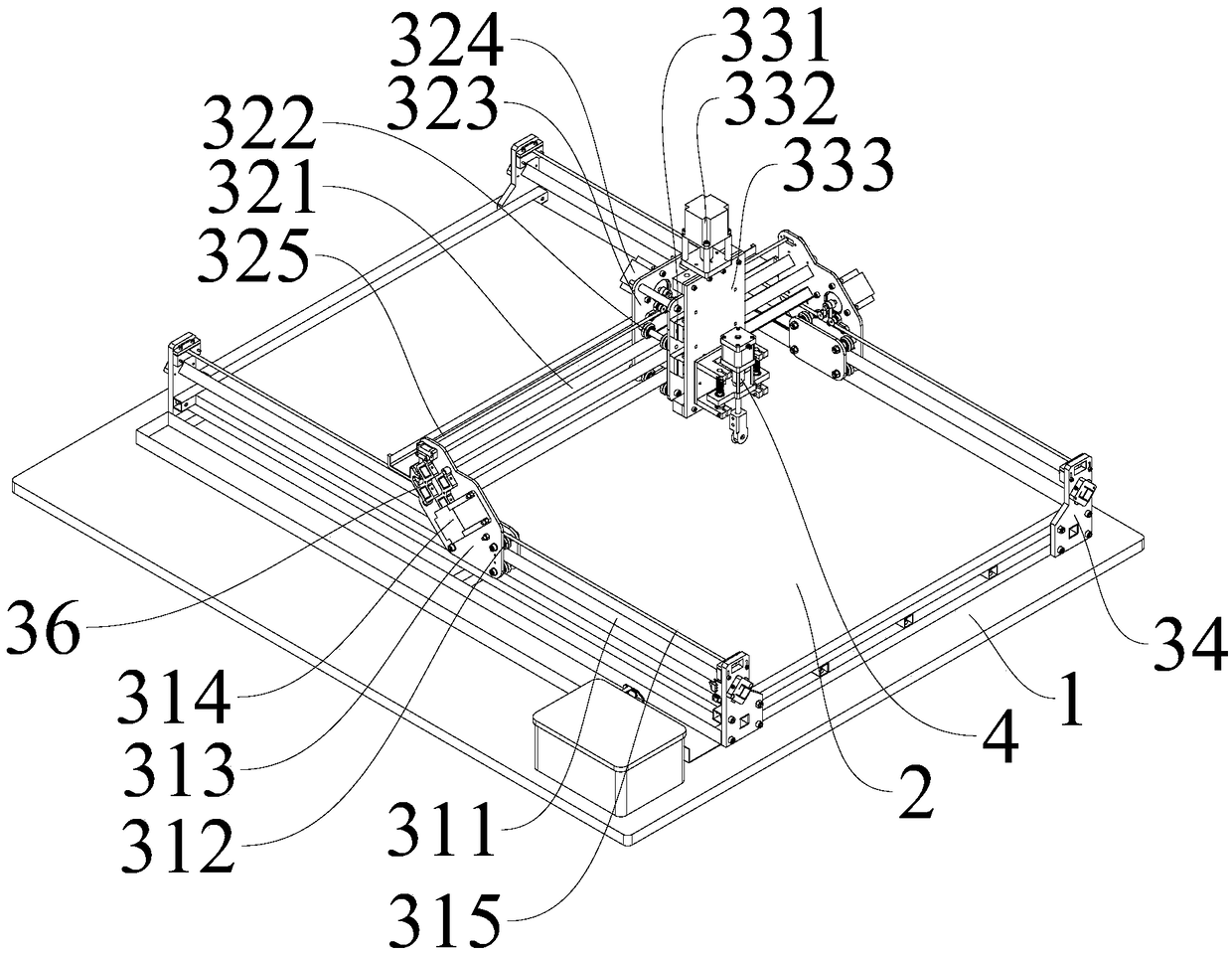

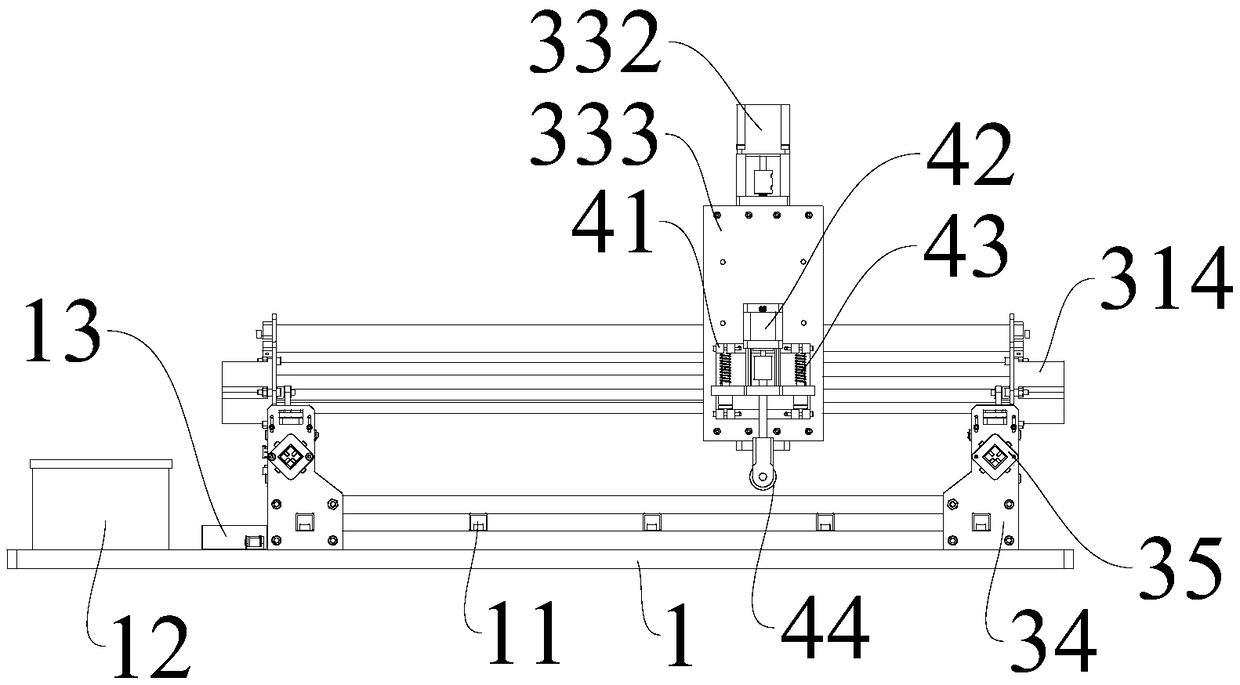

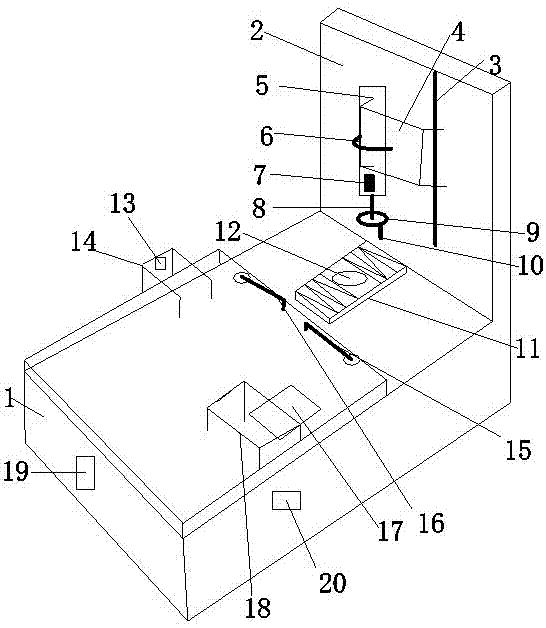

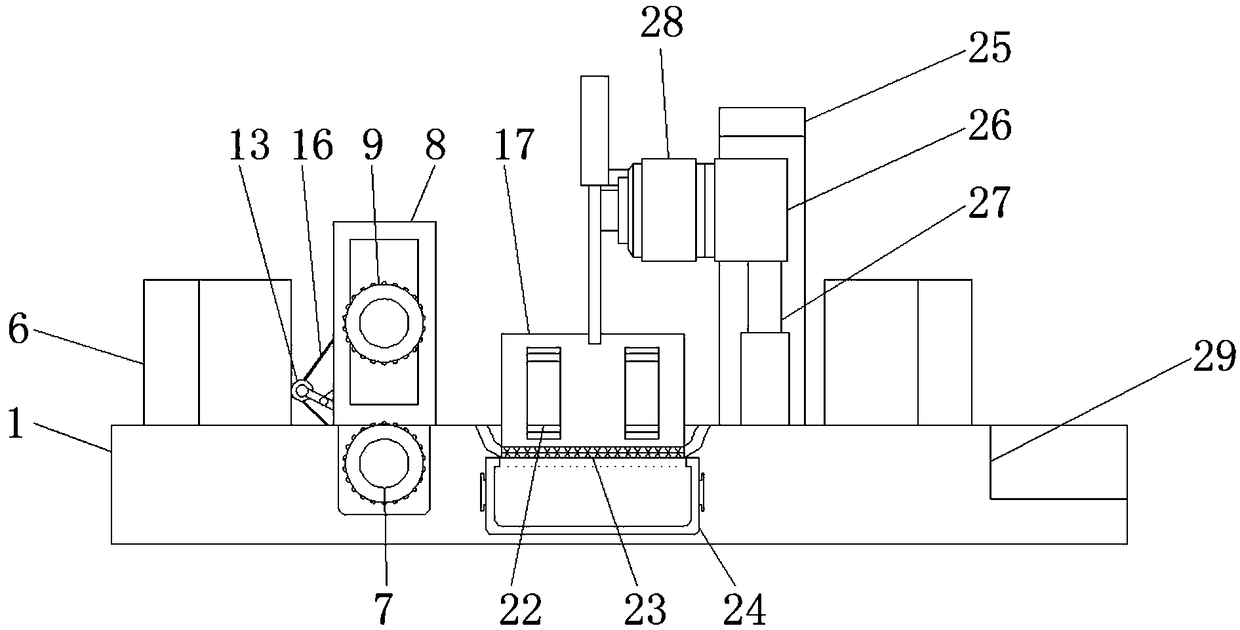

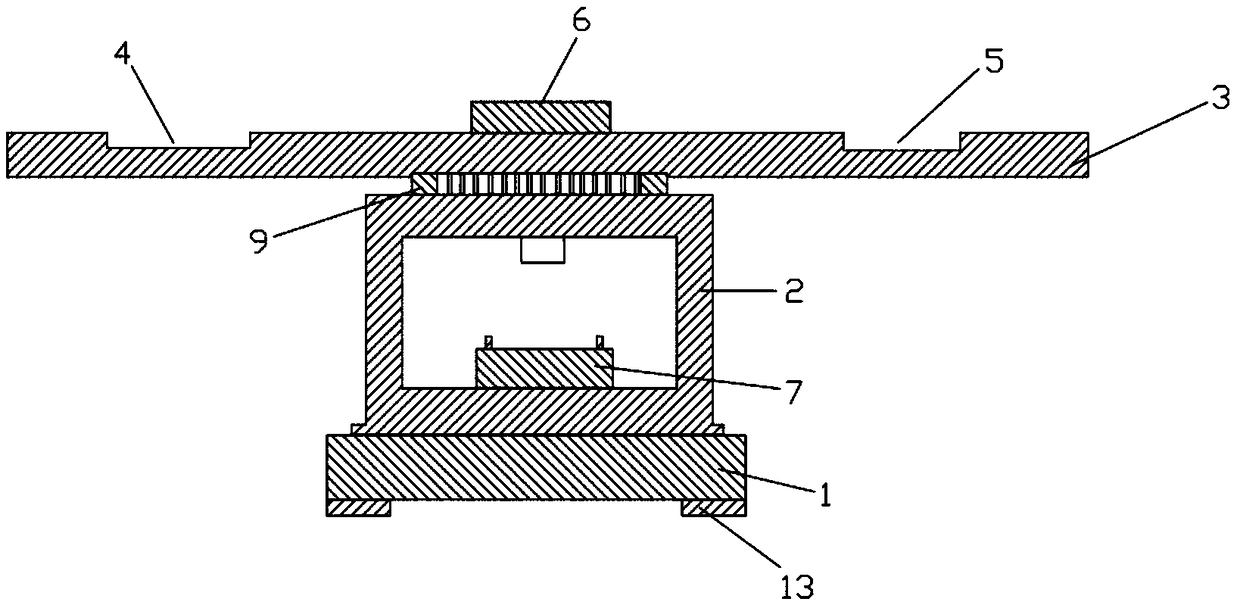

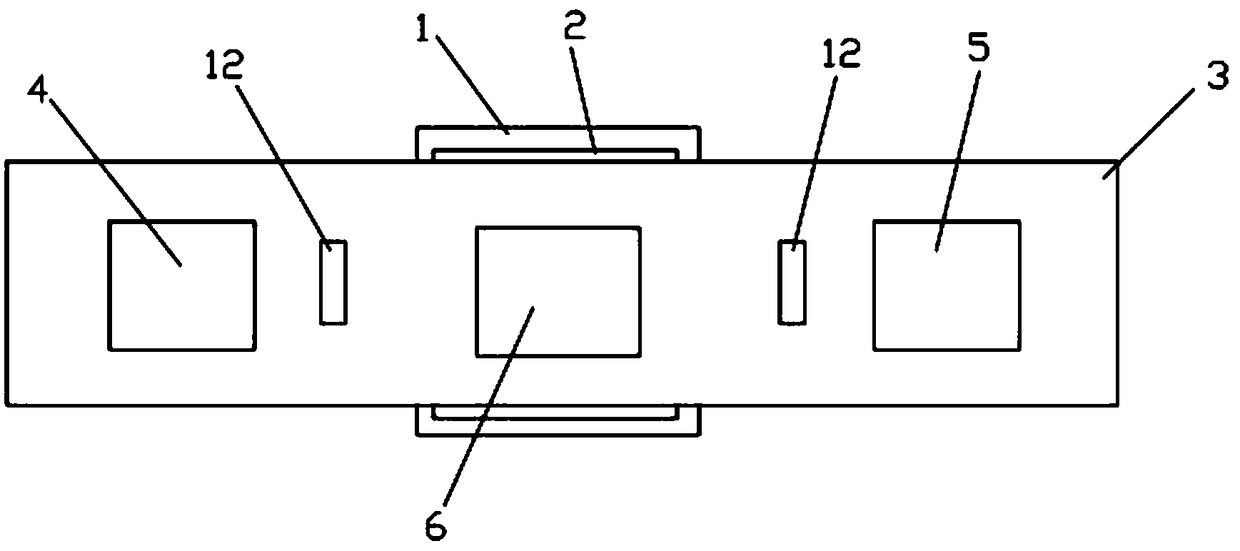

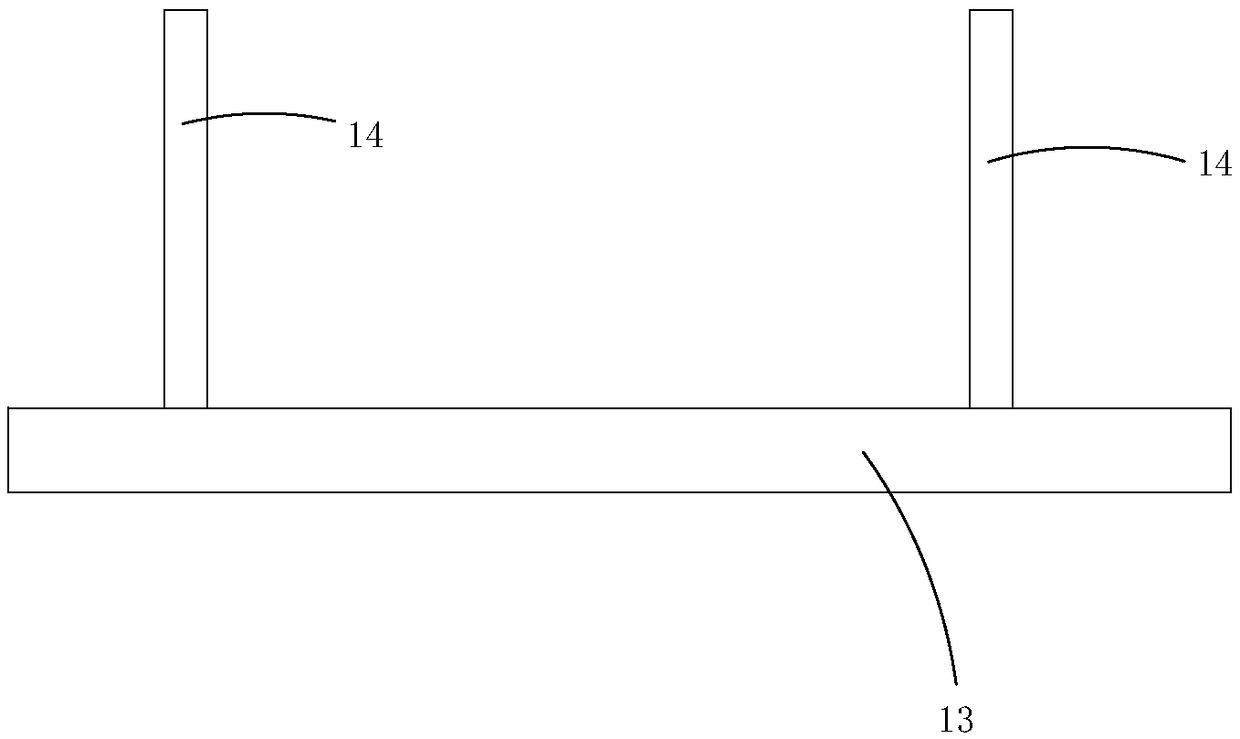

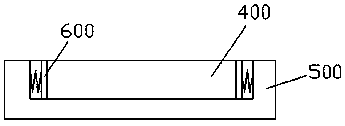

Numerically-controlled cutting machine for fabric

PendingCN109252351AImprove cutting efficiencyHigh degree of automationSevering textilesEngineeringPerpendicular direction

The invention discloses a numerically-controlled cutting machine for fabric. The numerically-controlled cutting machine comprises a base plate, a cutting platform, a three-dimensional moving componentand a cutting device, a detachable frame is arranged on the base plate, the cutting platform is arranged in the frame in an embedded manner, the three-dimensional moving component comprises a transverse moving mechanism, a longitudinal moving mechanism and a perpendicular moving mechanism, the transverse moving mechanism and the longitudinal moving mechanism move in a horizontal direction, the perpendicular moving mechanism moves in a perpendicular direction, the transverse moving mechanism is connected with the frame through a plurality of L-shaped support plates and is located at a preset position above the cutting platform, the longitudinal moving mechanism is arranged on the transverse moving mechanism, the perpendicular moving mechanism is arranged on the longitudinal moving mechanism, the cutting device is arranged on the perpendicular moving mechanism, and a control box used for controlling movements of the three-dimensional moving component and the cutting device is arranged on the base plate. The numerically-controlled cutting machine has the advantages of high automation degree, simple operation sequences, high cutting efficiency, long service life and the like.

Owner:江苏悦达家纺制品有限公司

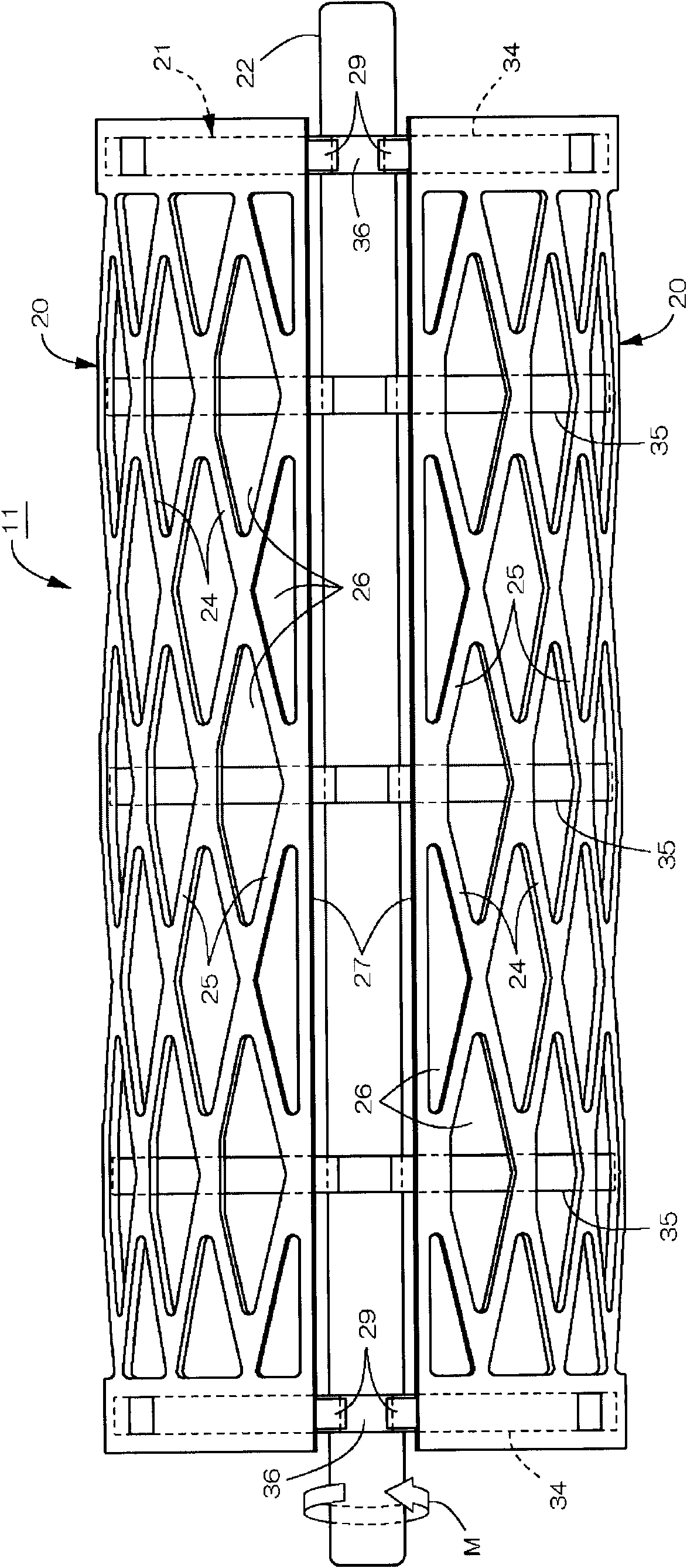

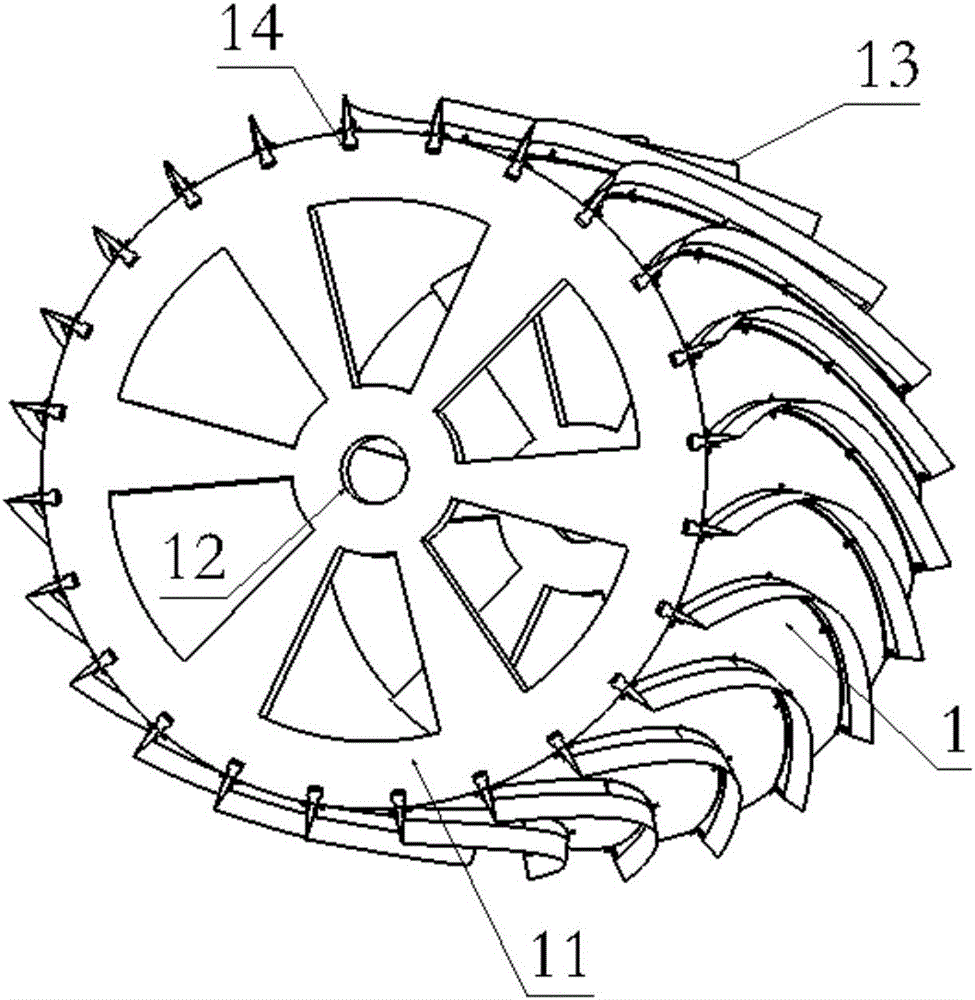

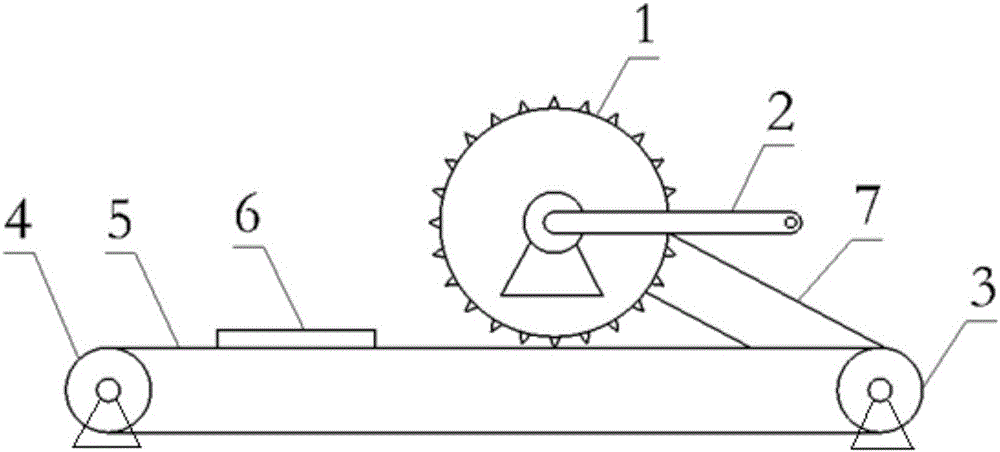

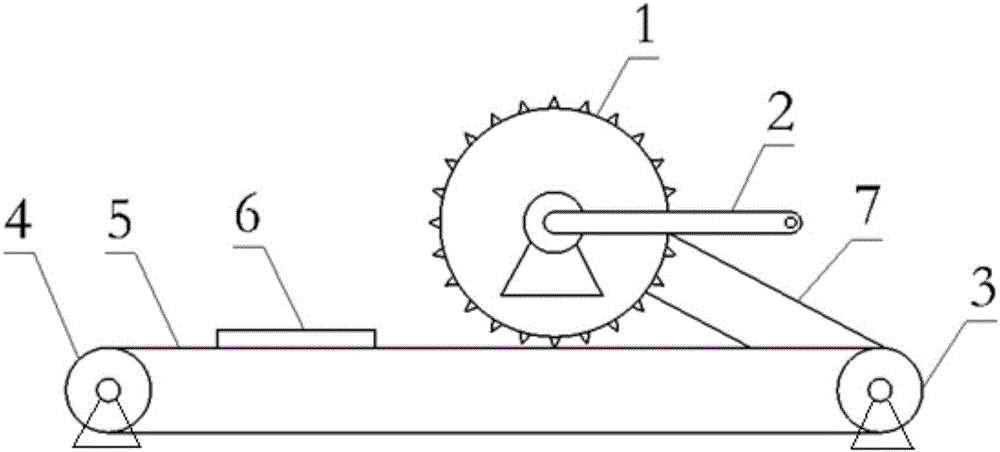

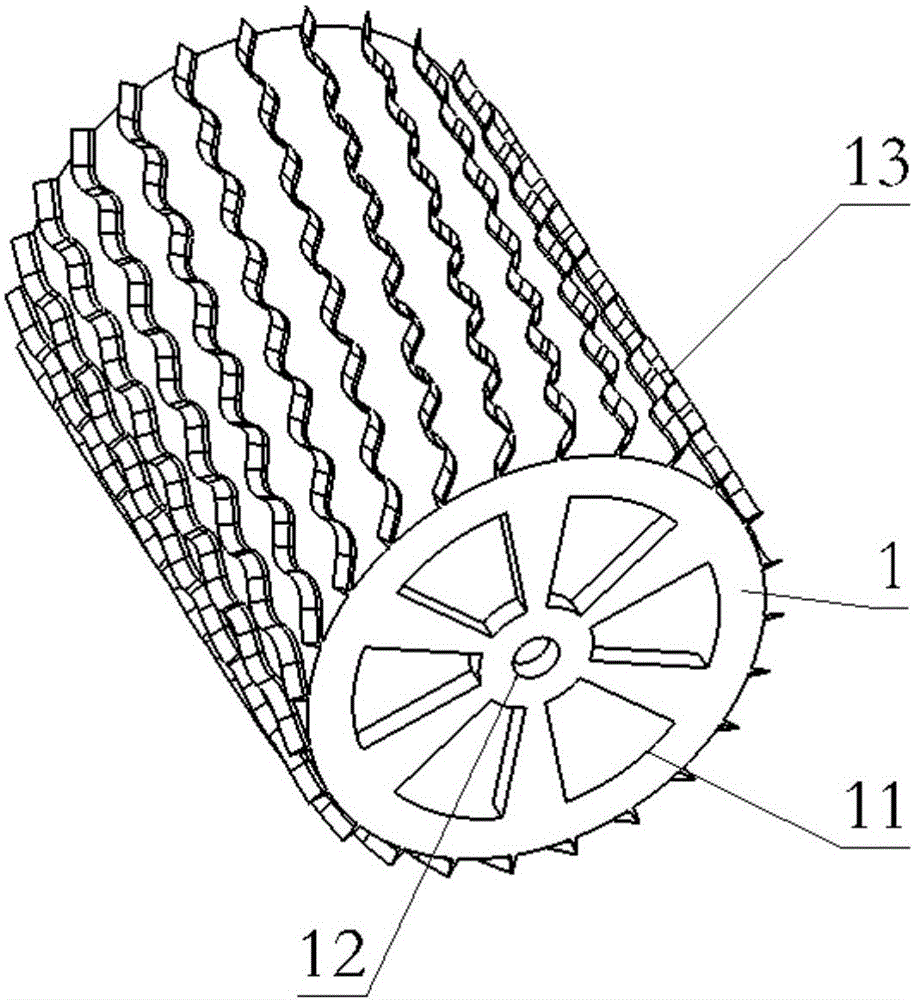

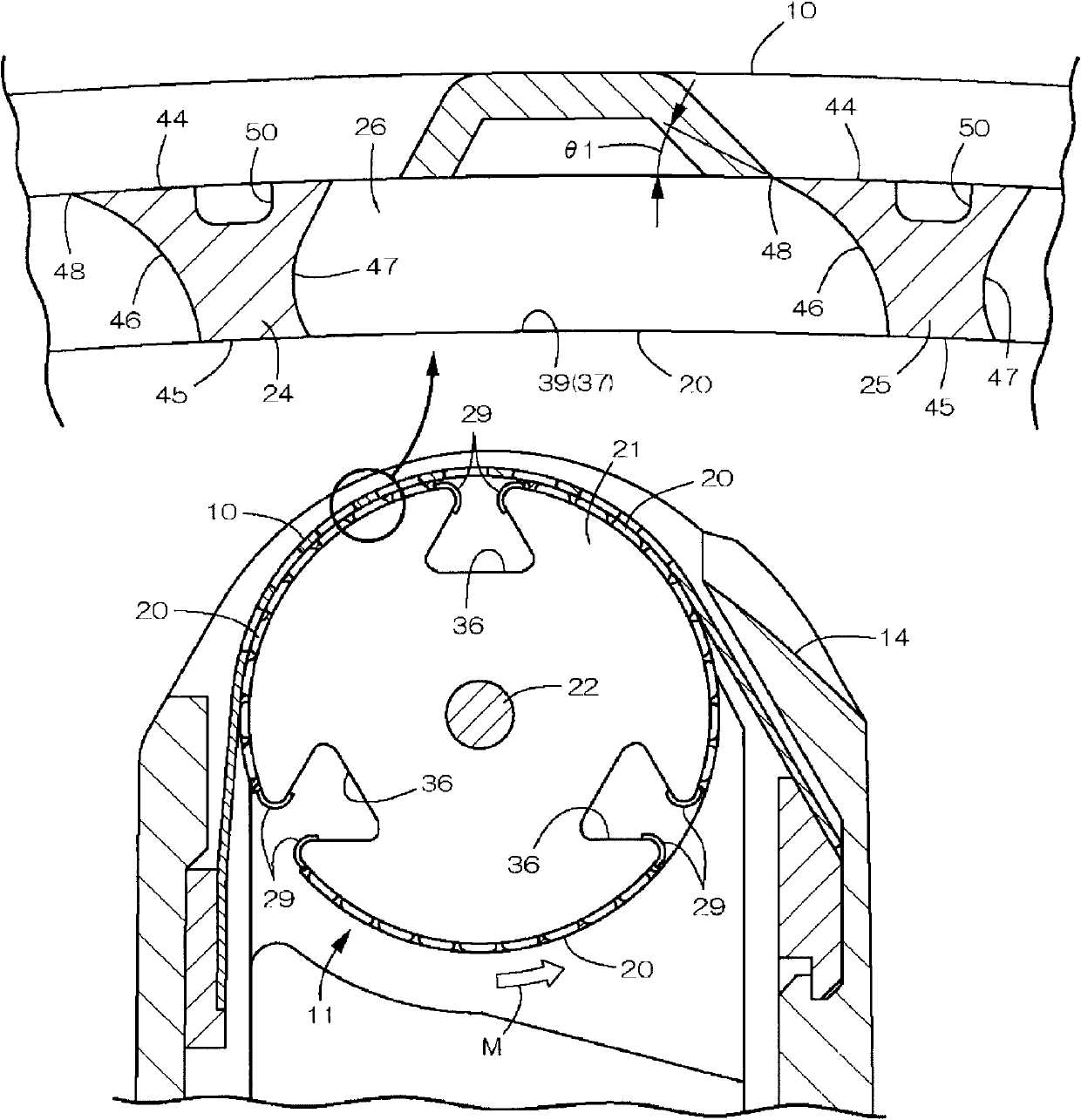

Novel drum-type arc-shaped cutting device

InactiveCN106272642AEfficient cutting workEasy to operateMetal working apparatusDrive shaftGear wheel

A novel drum-type arc-shaped cutting device comprises a drum-type cutter, a curved bar, a driving belt wheel and a driven belt wheel. The drum-type cutter is a hollow cylinder, a plurality of mounting grooves are obliquely and evenly formed in the side face of the drum-type cutter, a plurality of mounting bases are arranged in each mounting groove, and an arc-shaped blade is mounted through each mounting base. The curved bar is provided with a driving shaft which penetrates through middle holes in two bottom faces of the drum-type cutter, a driving gear is mounted at the tail end of the driving shaft and engaged with a driven gear, and a gear shaft on the driven gear is in transmission connection with a belt wheel shaft on the driving belt wheel through a shaft belt. The driving belt wheel and the driven belt wheel are in transmission connection through a conveying belt which is located under the drum-type cutter. The novel drum-type arc-shaped cutting device can conduct food cutting work rapidly and efficiently, and is simple, convenient to use, easy to operate, capable of saving time and labor, safe, reliable, high in practicality and convenient to popularize.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Reliable automatic robot

The invention discloses a reliable automatic robot. The reliable automatic robot comprises a cutting machine body, the cutting machine body is installed on the right end face of a supporting base through a lifting driving device, an embedded and connecting cavity is formed in the end face of the bottom of the cutting machine body, and a cutting blade is rotationally installed in the embedding andconnecting cavity in a rotating fit mode; a clamping mechanism used for being connected with the cutting blade in a locking fit mode is arranged in the inner wall of the right side of the embedding and connecting cavity, a sliding cavity is formed in an inner wall body of the cutting machine on the left side of the embedding and connecting cavity, and a left clamping joint is rotationally installed with a wall body between the sliding cavity and the embedding and connecting cavity in a cooperating mode; a spline cavity is formed in the left end face of the left clamping joint, a sliding blockis installed in the sliding cavity in a sliding fit mode, a first motor is fixedly arranged in the right end face of the sliding block, and a spline shaft which is connected with the spline cavity spline in a cooperating mode is installed on the right end of the first motor in a power fit manner.

Owner:吴扬华

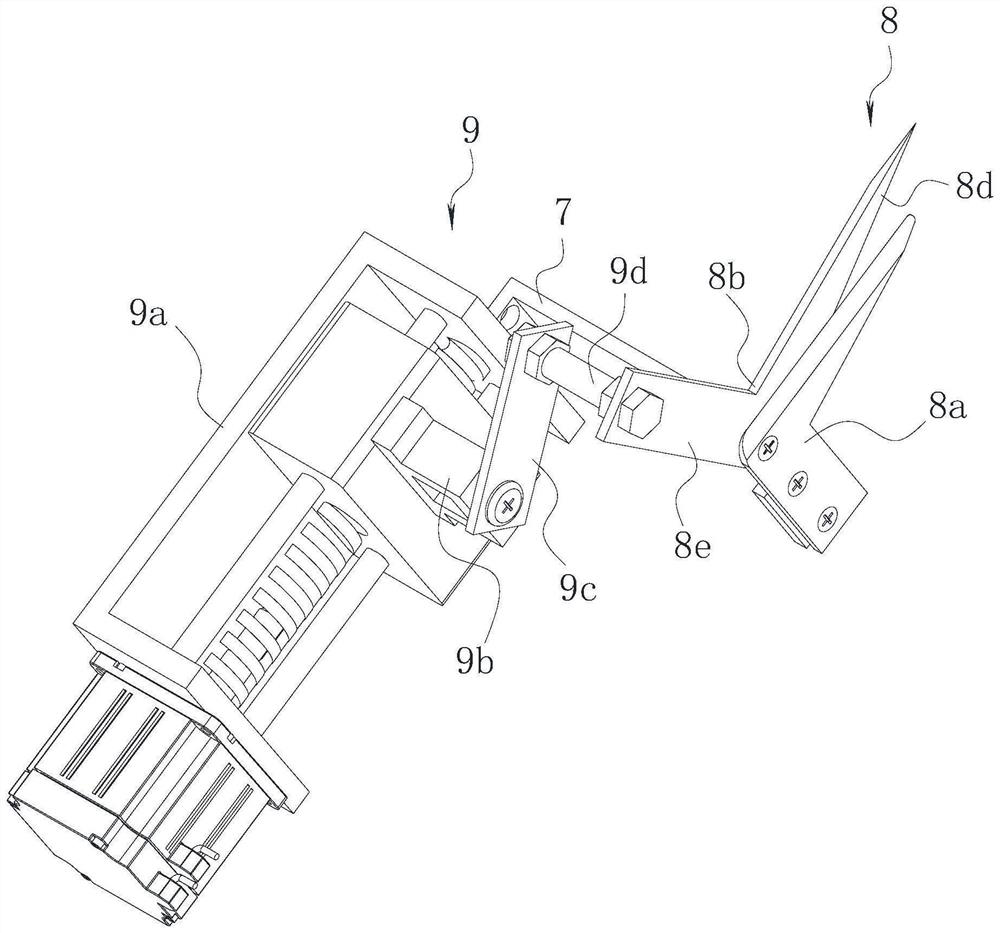

Copper foil trimming device

ActiveCN114800632ALong and efficient cutting workSmooth cutMetal working apparatusCopper foilEngineering

The invention discloses a copper foil edge cutting device. Belongs to the technical field of electrolytic copper foil production. According to the technical scheme, the copper foil winding device comprises a rack, an unwinding roller used for containing a copper foil roll is arranged on the rack, a conveying roller used for conveying copper foil is arranged on the front side of the output direction of the unwinding roller, and two guide rollers are arranged on the portion, between the conveying roller and the unwinding roller, of the rack in parallel at intervals; a mounting plate is arranged on the rack between the two guide rollers; an edge cutting module is arranged on the mounting plate, the edge cutting module comprises a mounting bracket arranged on the mounting plate on the lower side of the copper foil, a shearing assembly used for shearing the copper foil is connected to the mounting bracket below the copper foil, the shearing assembly is connected with a rotating module, and the shearing assembly is controlled by the rotating module to update the position of a cutting edge regularly or quantitatively; a rolling module is arranged on the mounting plate below the trimming module; the invention aims to provide the copper foil edge cutting device capable of adjusting the position of the cutting edge. The device is used for copper foil trimming.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

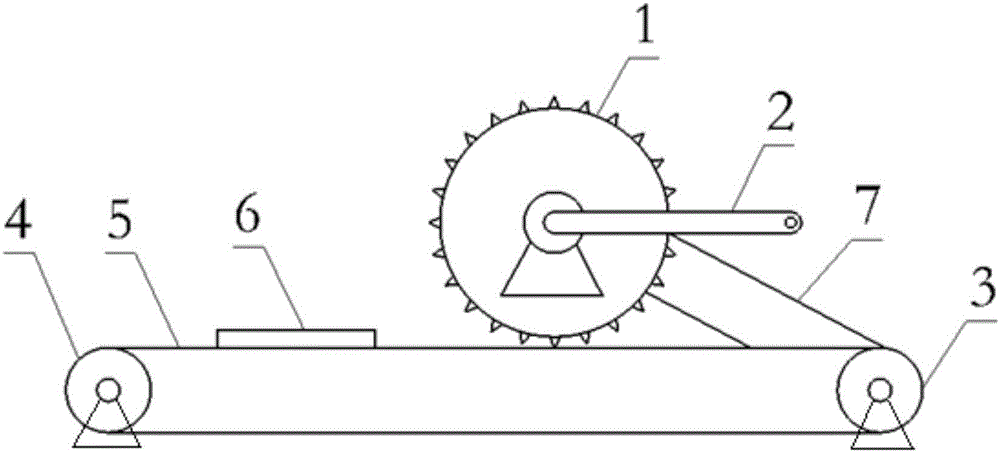

Drum-type straight line cutting device

InactiveCN105856302AEfficient cutting workEasy to operateMetal working apparatusDrive shaftGear wheel

A drum-type straight line cutting device comprises a drum-type cutter, a cranked lever, a driving belt wheel and a driven belt wheel. The drum-type cutter is a hollow cylinder, a plurality of straight line blades are evenly distributed on the lateral surface of the hollow cylinder obliquely. The cranked lever is provided with a driving shaft which penetrates through middle holes in two bottom surfaces of the drum-type cutter, and a driving gear is installed at the tail end of the driving shaft and engaged with a driven gear. A gear shaft on the driven gear is in transmission connection with a belt wheel shaft on the driving belt wheel through a shaft belt. The driving belt wheel and the driven belt wheel are in transmission connection through a conveying belt which is located under the drum-type cutter. The drum-type straight line cutting device can cut food rapidly and efficiently, is easy and convenient to operate, safe, reliable, high in practicability and convenient to popularize, and saves time and labor.

Owner:胡莉琦

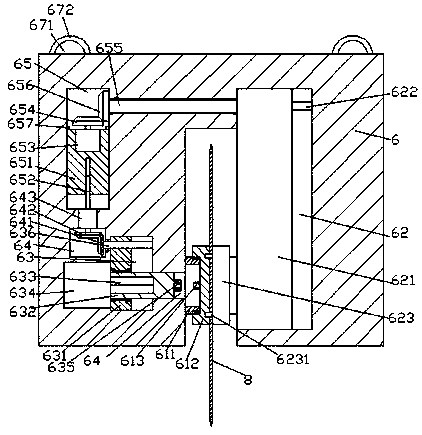

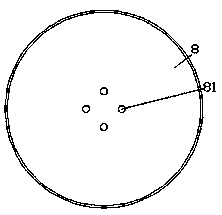

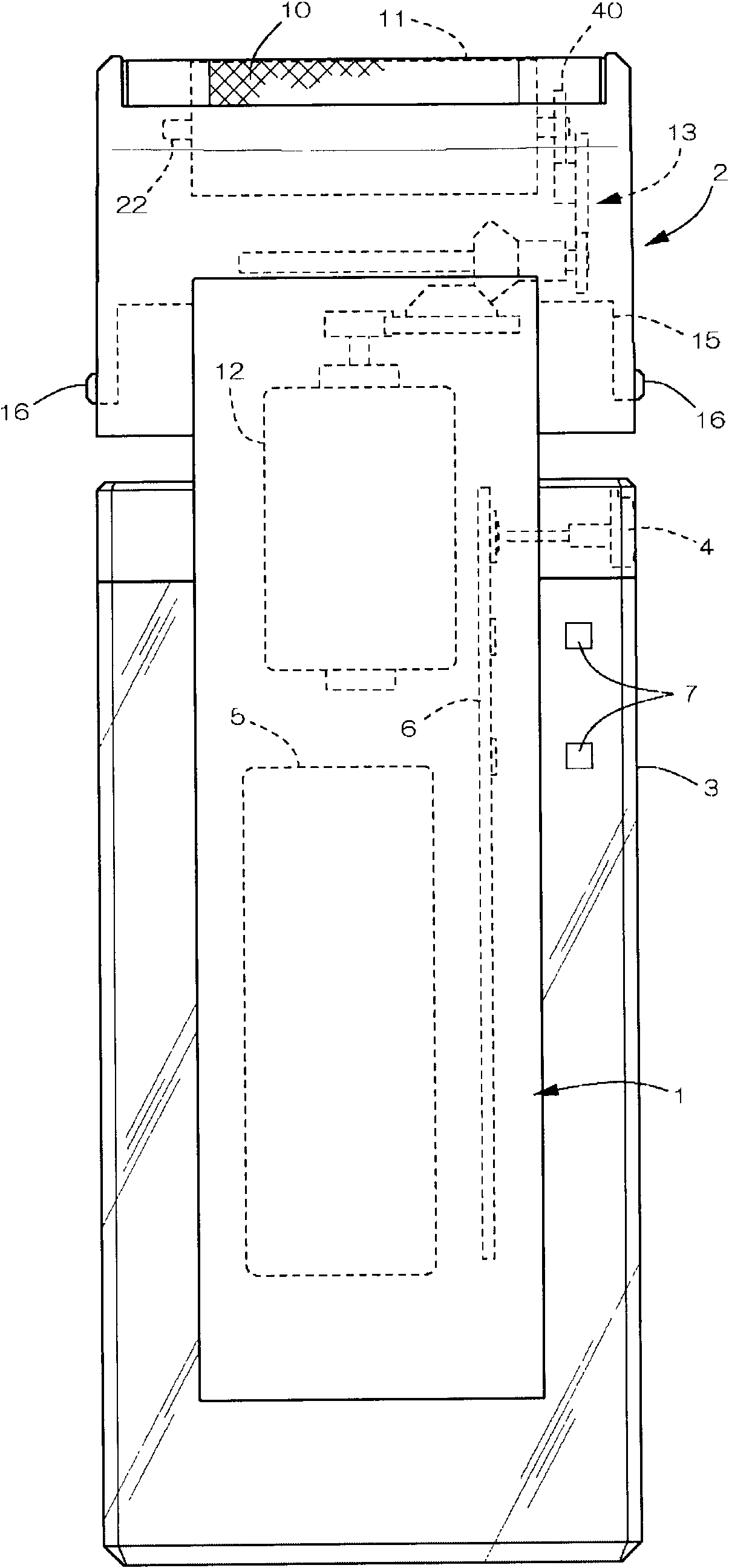

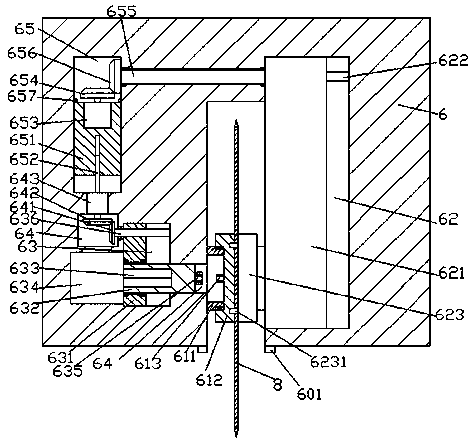

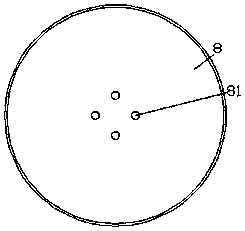

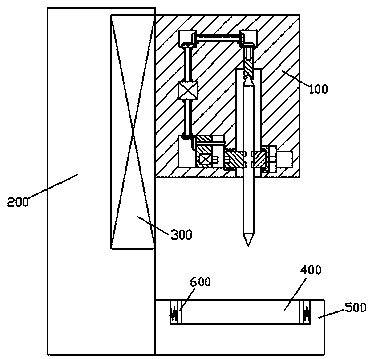

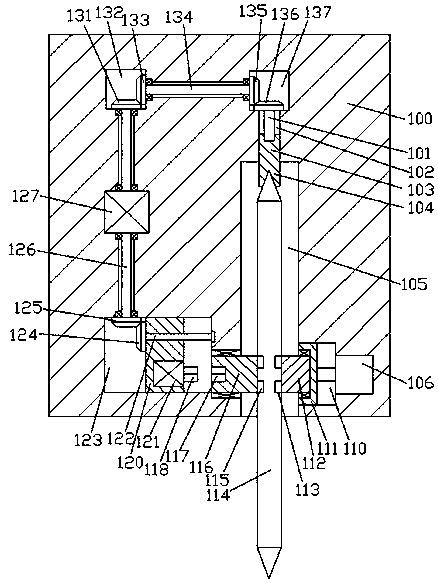

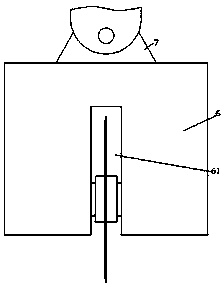

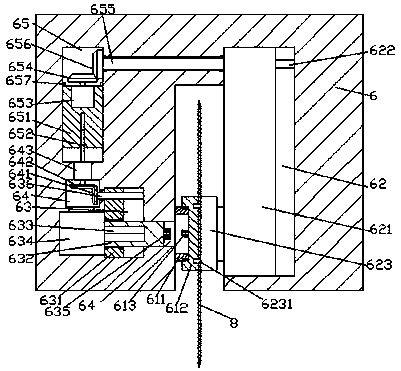

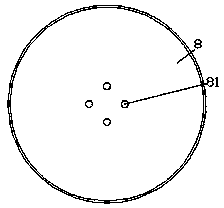

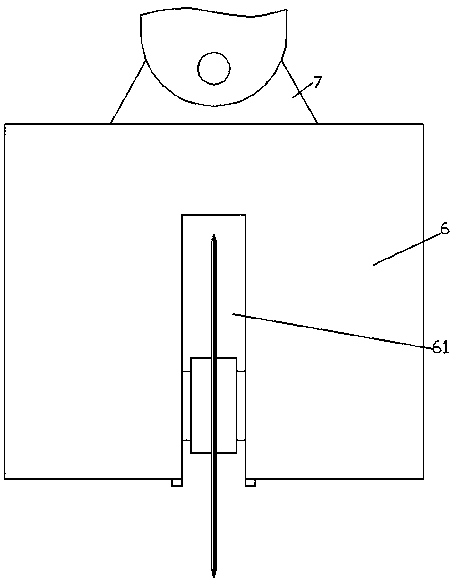

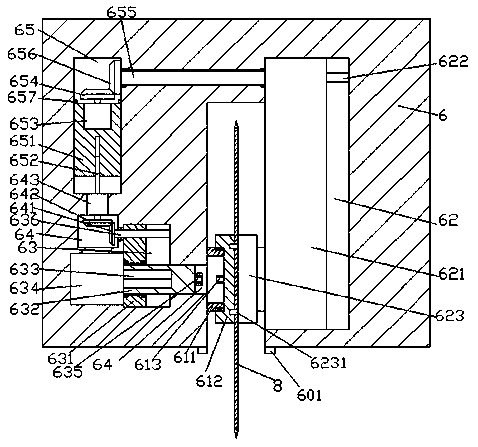

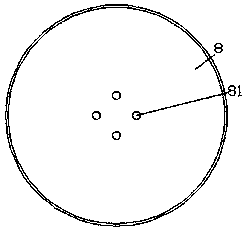

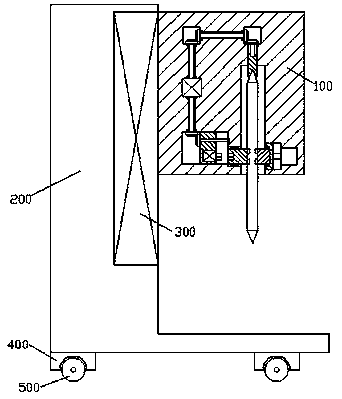

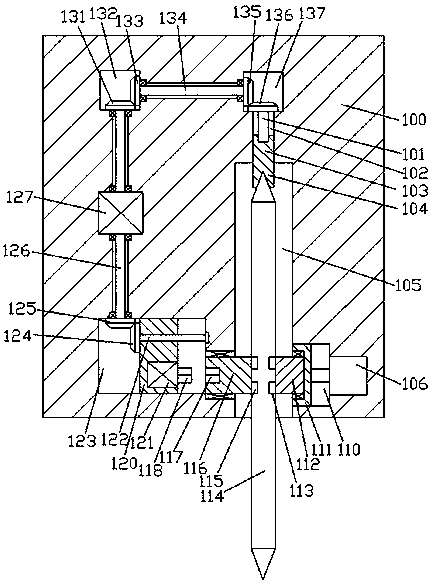

Intelligent wafer cutting machine

InactiveCN105437392AIntelligent working methodImprove cutting accuracyWorking accessoriesFine working devicesWafer dicingMachine tool

The invention relates to the field of mechanical cutting and specifically relates to an intelligent wafer cutting machine. The present invention provides the wafer cutting machine; an intelligent control module is adopted to control the machine, such that the cutting accuracy is improved; meanwhile, the modules and design of the cutting machine are optimized such that the cutting work is more effective. The intelligent control module is introduced in the intelligent wafer cutting machine to improve the cutting accuracy of the cutting machine; and the modules and design of the cutting machine are optimized such that the cutting work is more effective; as a result, the cutting success rate is increased and the production cost is reduced.

Owner:HENAN GUANGDU SUPERHARD MATERIAL CO LTD

Stable cutting type robot

ActiveCN108437092ASimple resultEasy to operateProfiling/shaping machinesRotary cutting toolsEngineeringMechanical engineering

The invention discloses a stable cutting type robot. The stable cutting type robot comprises a main machine body, wherein an opened groove is formed in the bottom end surface of the main machine body;a hollow seat body is fixedly arranged on the inner wall of the left side of the opened groove; a first chuck which is connected to one side of the inner wall of the left side, far away of the openedgroove, of the hollow seat body in a rotating fitting manner; a first empty chamber which extends up and down is arranged in the main machine body at the left side of the hollow seat body; a first sliding block is connected into the first empty chamber in a sliding fitting manner; a through groove is arranged between the empty chamber and the hollow seat body in a communication manner; a rotatingshaft which extends toward the left side is connected into the first sliding block in a rotating fitting manner; the extending tail end of the right side of the rotating shaft extends into the through groove, and an inner spline sleeve is fixedly arranged on the tail end surface; an outer spline connector, which extends into the hollow seat body and is opposite to the inner spline sleeve, is fixedly arranged on the left side end surface of the first chuck.

Owner:平湖市涌金机械有限公司

Building abrasion-proof material cutting device capable of cleaning sweeps

InactiveCN109278105AEasy to adjustEfficient cutting workMetal working apparatusFixed frameArchitectural engineering

The invention discloses a building abrasion-proof material cutting device capable of cleaning sweeps. The device comprises a bottom plate, a fixing frame, a lead screw and a conveyor belt, wherein a fixing plate is fixedly welded to the side part of the top end of the bottom plate; a connecting plate is connected to the outer side of a mounting groove; a sliding block is connected to the outer side of a pressing rod; the fixing frame is arranged at the inner side of the fixing plate; a first motor is fixedly connected to the upper right end of the fixing frame; the lead screw is arranged in the fixing frame; a first hydraulic cylinder is fixedly mounted at the lower part of a mainboard; a shaft rod is mounted at the bottom part of a limiting plate; the conveyor belt is connected to the outer side of a convex plate; and a bearing plate is arranged in the middle part of the bottom plate. With the adoption of the device, abrasion-proof materials with different rigidity can be effectivelycut in different manners, and moreover, a cutting position can be conveniently adjusted; and meanwhile, the materials can be limited, so that the cutting work can be efficiently and quickly carried out.

Owner:WUHU HUANGSHANSONG IND FLOOR NEW MATERIAL CO LTD

Automated robot

InactiveCN108406800ASimple structureEasy to operateLarge fixed membersPositioning apparatusEngineeringMechanical engineering

The invention discloses an automated robot. The automated robot comprises a cutting machine body, wherein the cutting machine body is installed on the right end face of a supporting base through a lifting drive device, an embedding cavity is formed in the bottom end face of the cutting machine body, and a cutting blade is installed in the embedding cavity in a rotating fit manner; a clamping mechanism used for being connected with the cutting blade in a locking fit manner is arranged in the right inner side of the embedding cavity; a sliding cavity is arranged in the inner wall body, on the left side of the embedding cavity, of the cutting machine body; a left clamping head is installed in the wall body between the sliding cavity and the embedding cavity in a rotating fit manner; a splinecavity is arranged in the left end face of the left clamping head, a sliding block is installed in the sliding cavity in a sliding fit manner, and a first motor is fixedly arranged in the right end face of the sliding block; and a spline shaft connected with the spline cavity in a spline fit manner is installed at the right end of the first motor in a power fit manner.

Owner:吴扬华

Water pipe cutting device capable of achieving precise guiding and avoiding water pipe brittle failure

InactiveCN108748360AAvoid the phenomenon of brittle fractureEasy to fixMetal working apparatusHydraulic cylinderEngineering

The invention discloses a water pipe cutting device capable of achieving precise guiding and avoiding water pipe brittle failure. The water pipe cutting device comprises a base seat, extending-and-contracting rods, a tightening wheel, a hydraulic cylinder, a gantry and a discharging plate. Sliding grooves are formed inside the left end of the base seat. An adjustment plate is connected to the outer side of each fixing plate, and a lubricating pad is arranged on the outer end face of each adjustment plate. Each extending-and-contracting rod is mounted on the inner end face of the correspondingfixing plate, and a driving roller is arranged at the right sides of the fixing plates. A cutting groove is formed below heat transfer plates, and a collection groove is formed below the cutting groove. Ascending-and-descending rods are arranged below a connecting plate. The discharging plate is arranged above the left portion of the base seat. By means of the water pipe cutting device capable ofachieving precise guiding and avoiding water pipe brittle failure, guiding can be conducted precisely, and a water pipe can be fixed conveniently; the brittle failure phenomenon generated when the water pipe is cut can be avoided; the cutting success rate of the water pipe can be increased conveniently; and the water pipe cutting work can be completed rapidly, efficiently and conveniently.

Owner:芜湖市奥尔特光电科技有限公司

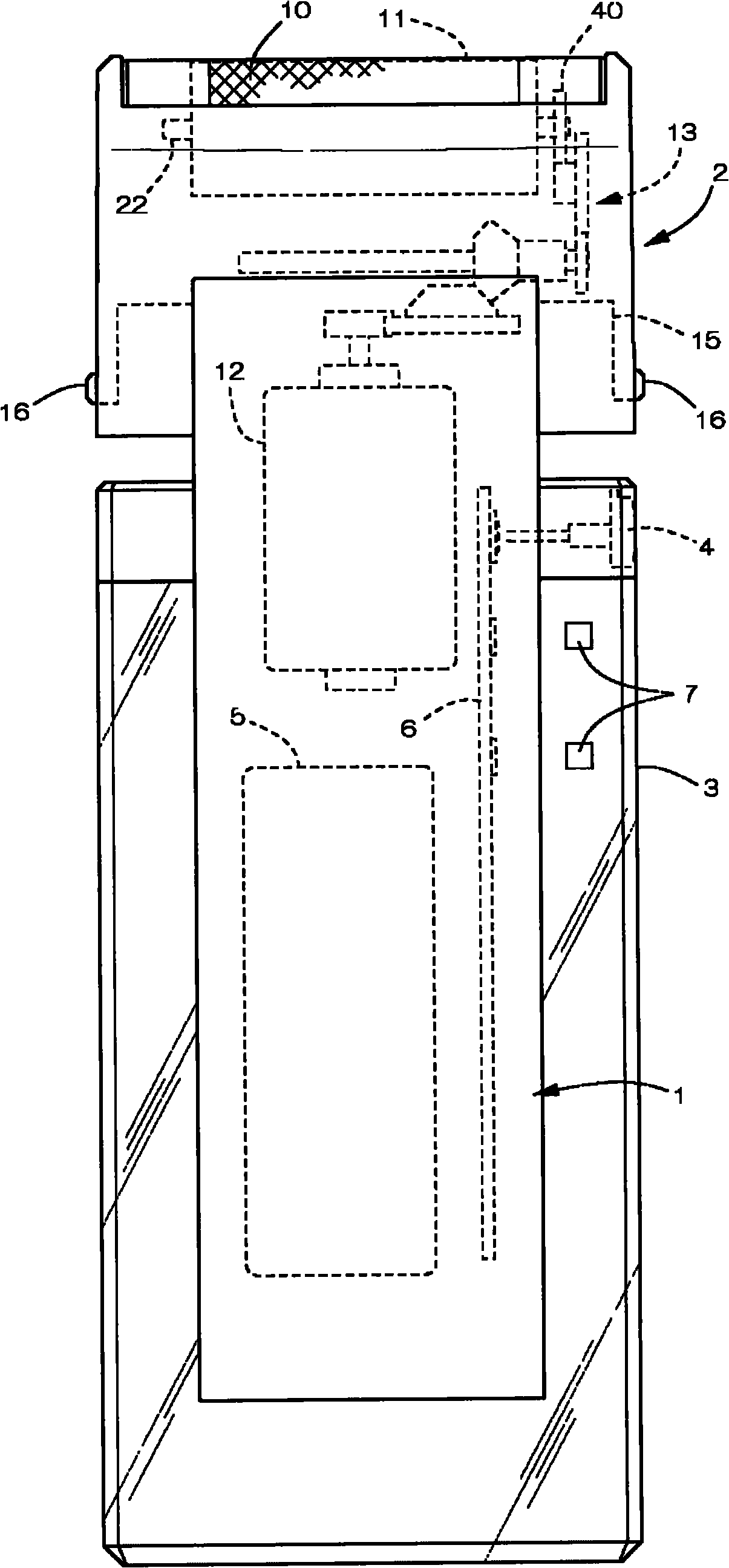

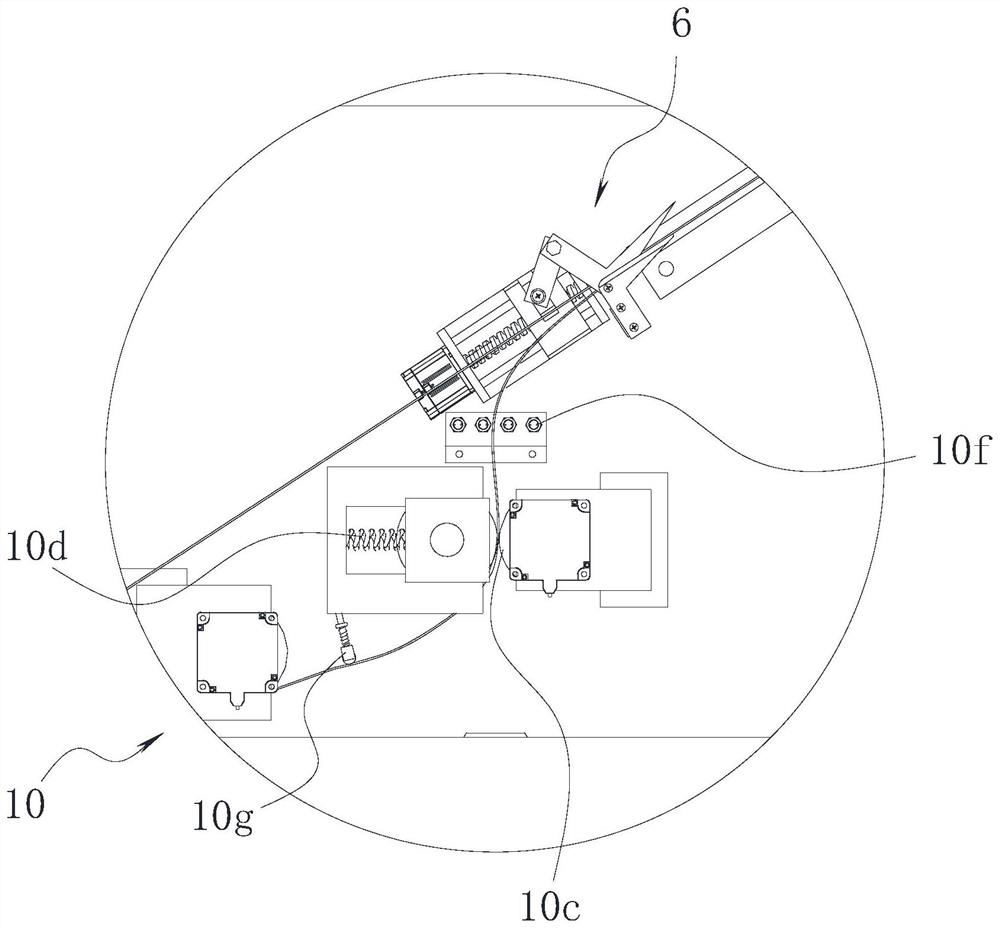

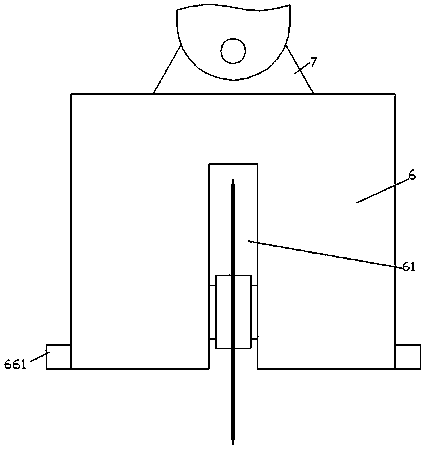

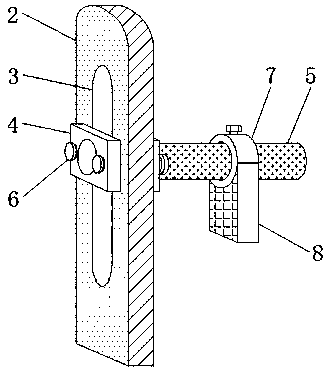

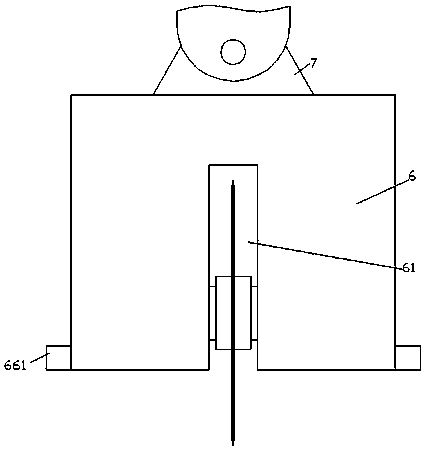

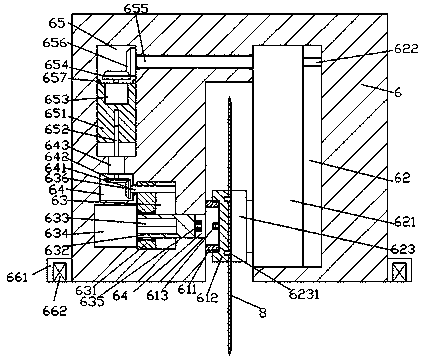

Fuse deposition type 3D printing wire shearing device and operation method

PendingCN113752546ACompact structureEasy to operateAdditive manufacturing apparatusManufacturing material handlingBackplaneCam

The invention relates to a fuse deposition type 3D printing wire shearing device and an operation method. The fuse deposition type 3D printing wire shearing device comprises a bottom plate, a blade mounting plate and a top plate, a motor is fixed on the upper surface of the top plate, and a cam is mounted on an output shaft at the tail end of the motor after penetrating through the top plate; a pit is formed in the upper surface of one end of the bottom plate, a blade mounting plate is placed at the pit, a roller is mounted on the top surface of the blade mounting plate, the roller and the cam are located at the same plane position, and the roller is in contact with a base ring of the cam; a first blade and a second blade which are opposite to each other are mounted on the bottom surface of the blade mounting plate, and the first blade and the second blade form a V-shaped cutting edge; and a flat blade is fixed to the upper surface of the bottom plate, and the cutting edge of the flat blade corresponds to the V-shaped cutting edge. Working is reliable, operation is easy and convenient, working efficiency is improved, and use requirements are met.

Owner:JIANGNAN UNIV +1

A stable cutting robot

ActiveCN108437092BSimple resultEasy to operateProfiling/shaping machinesRotary cutting toolsEngineeringMechanical engineering

Owner:平湖市涌金机械有限公司

Roller-type wavy stripe cutting device

InactiveCN106003195AEfficient cutting workEasy to operateMetal working apparatusDrive shaftGear wheel

The invention discloses a roller-type wavy stripe cutting device. The roller-type wavy stripe cutting device comprises a roller-type cutting knife, a cranked lever, a driving belt wheel and a driven belt wheel, wherein the roller-type cutting knife is a hollow cylinder; a plurality of wavy stripe blades are obliquely and uniformly distributed on the side surface of the roller-type cutting knife; a driving shaft is arranged on the cranked lever and passes through middle holes in two bottom surfaces of the roller-type cutting knife; a driving gear is mounted at the tail end of the cranked lever and is meshed with a driven gear; a gear shaft on the driven gear is in transmission connection with a belt wheel shaft on the driving belt wheel through a shaft belt; the driving belt wheel is in transmission connection with the driven belt wheel through a conveying belt; the conveying belt is positioned under the roller-type cutting knife. The roller-type wavy stripe cutting device can be used for quickly and efficiently cutting foods and is simple, convenient and easy to operate, capable of saving time and labor, safe, reliable, high in practicability and convenient to popularize.

Owner:王翔

Semiconductor light-emitting diode manufacturing equipment

ActiveCN108400208BSimple structureEasy to operateSemiconductor devicesEngineeringLight-emitting diode

The invention discloses fabrication equipment of a semiconductor light-emitting diode. The fabrication equipment comprises a fabrication rack, wherein the fabrication rack is arranged on an end surface of a right side of a support by a lifting device, legs are fixedly arranged around an end surface of the bottom of the support, rollers are arranged in end surfaces of the bottoms of the legs in a rolling and matching way, an installation cavity is formed in an end surface of the bottom of the fabrication rack, a rotation cutter is rotatably arranged in the installation cavity in a matching way,a clamping assembly is arranged in an inner wall of a right side of the installation cavity and is used for being locked and connected with the rotation cutter in a matching way, a sliding cavity isformed in an inner wall body of the fabrication rack at a left side of the installation cavity, a left rotation connection head is rotatably connected with a wall body between the sliding cavity and the installation cavity in a matching way, a spline hole is formed in an end surface of a left side of the left rotation connection head, a sliding block is arranged in the sliding cavity in a slidingand matching way, a first motor is fixedly arranged in an end surface of a right side of the sliding cavity, and a spline arm is arranged at a right side end of the first motor in a power matching wayand is in spline connection with the spline hole in a matching way.

Owner:上海雅宸照明电器有限公司

Novel cutting robot

InactiveCN109129734ASimple resultEasy to operateProfiling/shaping machinesWood working safety devicesEngineeringMechanical engineering

The invention discloses a novel cutting robot. The robot comprises a main robot body, an open groove is formed in the end face of the bottom of the main robot body, and a hollow base is fixedly arranged on the inner wall of the left side of the open groove; a first clamping disc is rotatably and cooperatively connected to the side, away from the inner wall of the left side of the open groove, of the hollow base, a first cavity extending up and down is formed in the portion, in the main robot body, of the left side of the hollow base, and a first slide block is slidingly and cooperatively connected to the interior of the first cavity; a through groove is communicated between the first cavity and the hollow base, a rotation shaft part extending rightwards is rotatably and cooperatively connected to the interior of the first slide block, the extension tail end of the right side of the rotation shaft part extends into the through groove, and an internal spline sleeve part is fixedly arranged on the end face of the tail end of the rotation shaft part; an outer spline connector opposite to the internal spline sleeve part is fixedly arranged on the end face of the left side of a first clamping disc and extends into the hollow base.

Owner:楼天涯

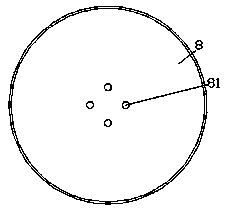

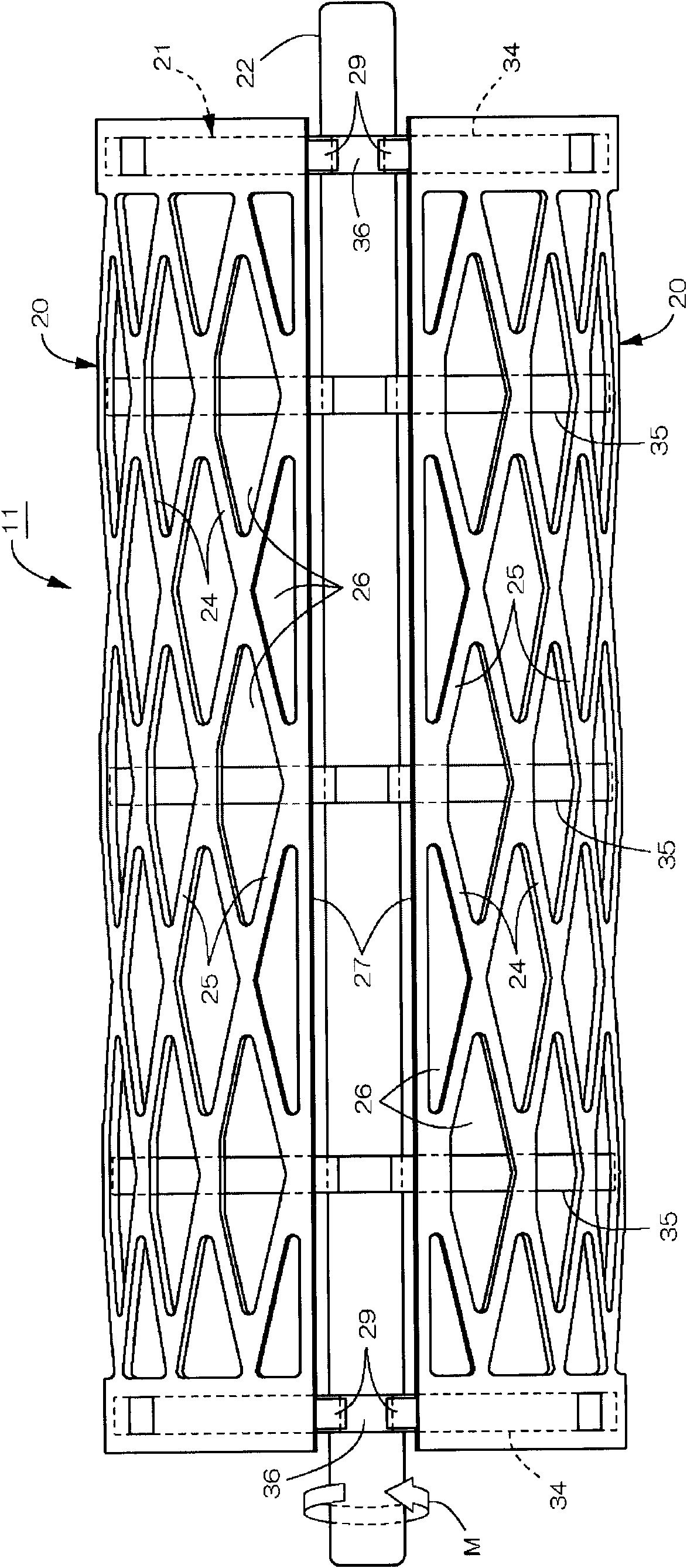

Lathe bed of rotary cutting machine

InactiveCN109454287ASmall footprintEfficient cutting workTube shearing machinesGlass severing apparatusGear driveEngineering

The invention discloses a lathe bed of a rotary cutting machine, and belongs to the technical field of cutting machines. The lathe bed comprises a lathe bed base and a lathe bed main body, a rotatingmechanism is arranged in the lathe bed main body, and a workbench is arranged at the top of the rotating mechanism; the workbench comprises a first installing groove used for installing a glass tube cutting mechanism and a second installing groove used for installing an aluminum tube cutting mechanism, and the middle of the workbench is provided with a mounting table used for installing a length metering device in a protruding mode; the rotating mechanism comprises a motor mounting frame, a gear and a rotating disc, wherein the motor mounting frame is used for installing a driving motor, the center of the gear is provided with a center hole allowing a shaft of the driving motor to penetrate thereinto, the top of the rotating disc is fixed to the bottom of the workbench, a toothed rail is arranged on the inner wall of the rotating disc in a surrounding mode, the gear is meshed with the toothed rail of the rotating disc and the gear drives the rotating disc to enable the workbench to rotate clockwise or anticlockwise.

Owner:尹四霞

Rotator blade and small electric instrument having rotator blade

ActiveCN102039604BCutting sharpEffectively cut offMetal working apparatusElectrical equipmentRazor Blade

Owner:MAXELL HLDG LTD

an automatic robot

Owner:苏州济和精密传动系统有限公司

Device for preparing drug for preventing and curing avian influenza

The invention discloses a device for preparing a drug for preventing and curing avian influenza. The device comprises a preparation machine body, wherein an opening cavity is formed in the end surfaceof the bottom of the preparation machine body, elastic lugs are fixedly arranged on the left side and the right side, located at the end surface of the bottom of the preparation machine body, of theopening cavity, and a hollow frame is fixedly arranged on the inner wall of the left side of the opening cavity; a first clamping disc is in rotating fit connection with the side, far away from the inner wall of the left side of the opening cavity, of the hollow frame, a first hollow cavity which extends up and down is formed in the position, located on the left side of the left side of the hollowframe, in the preparation machine body, and a first sliding block is arranged in the first hollow cavity in a sliding fit mode; a through cavity is formed between the first hollow cavity and the hollow frame in a communicating mode, a steering shaft extending towards the right side is arranged in the first sliding block in a rotating fit mode, the extending tail end of the right side of the steering shaft extends into the through cavity, and a spline sleeve is fixedly arranged on the end surface of the tail end of the steering shaft; and a spline shaft which extends into the hollow frame andis opposite to the spline sleeve is fixedly arranged on the left side end surface of the first clamping disc.

Owner:奉节县疾病预防控制中心

A mailbox device

InactiveCN108422027BSimple structureEasy to operateShearing machinesMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a letterbox device. The letterbox device comprises a processing rack; the processing rack is installed at the end face of the right side of a bracket through a lifting device;a mounting seat is fixedly arranged at the bottom position of the end face of the right side of the bracket; a mounting chamber is embedded inside the top end face of the mounting seat; the end facesof the left and right sides of the mounting chamber are symmetrically fixedly provided with elastic clamping plates; an installation chamber is formed inside the bottom end face of the processing rack; a processing cutter body is installed inside the installation chamber in a running fit manner; the inner wall of the right side of the installation chamber is internally provided with a locking andlinking member which is connected with the processing cutter body in a locking and matching manner; the inner wall body, positioned at the left side of the installation chamber, of the processing rackis internally provided with a slidable connection chamber; the wall body between the slidable connection chamber and the installation chamber is internally provided with a left rotating connector ina running fit manner; the end face of the left side of the left rotating connector is internally provided with a spline notch; a slidable connecting block is installed inside the slidable connection chamber in a sliding fit manner; and a first electromotor is fixedly arranged inside the end face of the right side of the slidable connecting block.

Owner:PUJIANG HUIYI INTELLIGENT TECH CO LTD

Cloth cutting device

ActiveCN106891365BEfficient cutting workImprove practicalitySevering textilesMetal working apparatusCoil springAgricultural engineering

The invention discloses a cloth cutting device. The cloth cutting device comprises an uncoiling positioning rotary shaft, a supporting platform, a gantry, a cutter and a driving mechanism, wherein the driving mechanism comprises a screw rod, a moving rack, a motor, a cylinder, an assembly rack, a cutter rest and a driving mechanism; the cutter is arranged on the cutter rest; cloth pressing bars are arranged on two sides of the cutter rest on the assembly rack; the cloth pressing bars are arranged along the width direction of a cloth; the length of the cloth pressing bars is not smaller than the width of the cloth; the cloth pressing bars are movably arranged on the assembly rack through a plurality of elastic connection components; each elastic connection component comprises a connection rod and a spiral spring; the lower end of each connection rod is fixedly connected with the corresponding cloth pressing bar through welding; the upper end of each connection rod penetrates through a vertical through hole in the moving rack and then is fixedly connected with a baffle block; the outer diameter of each baffle block is larger than the hole diameter of each vertical through hole, so that each connection rod is limited in the corresponding vertical through hole to move vertically; and the upper and lower ends of each spiral spring are separately resisted against the assembly rack and the corresponding cloth pressing bar. By adopting the cloth cutting device, the cloth can be cut high efficiently; and the cloth cutting device has very good practicability.

Owner:浙江斯泰堡纺织有限公司

Cutting robot

InactiveCN108481453ASimple resultEasy to operateProfiling/shaping machinesWood working safety devicesEngineeringMechanical engineering

The invention discloses a cutting robot which includes a main body. An opening groove is formed in the bottom end surface of the main body; a hollow base is fixedly arranged on the left inner wall ofthe opening groove; a first chuck is rotatably connected to one side, far away from the left inner wall of the opening groove, of the hollow base in a fitting manner; a first cavity extending up and down is formed in the main body at the left side of the hollow base; a first sliding block is connected into the first cavity in a sliding fit manner; a through groove is formed between the first cavity and the hollow base in a communicating manner; a rotating shaft piece extending rightwards is rotatably connected into the first sliding block in a sliding fit manner; the extending tail end of theright side of the rotating shaft piece extends into the through groove and an inner spline sleeving piece is fixedly arranged on the end face of the tail end; and an outer spline connecting piece opposite to the inner spline sleeving piece and extending into the hollow base is fixedly arranged on the end face of the left side of the first chuck.

Owner:楼天涯

A preparation device for preventing and treating avian influenza

The invention discloses a device for preparing a drug for preventing and curing avian influenza. The device comprises a preparation machine body, wherein an opening cavity is formed in the end surfaceof the bottom of the preparation machine body, elastic lugs are fixedly arranged on the left side and the right side, located at the end surface of the bottom of the preparation machine body, of theopening cavity, and a hollow frame is fixedly arranged on the inner wall of the left side of the opening cavity; a first clamping disc is in rotating fit connection with the side, far away from the inner wall of the left side of the opening cavity, of the hollow frame, a first hollow cavity which extends up and down is formed in the position, located on the left side of the left side of the hollowframe, in the preparation machine body, and a first sliding block is arranged in the first hollow cavity in a sliding fit mode; a through cavity is formed between the first hollow cavity and the hollow frame in a communicating mode, a steering shaft extending towards the right side is arranged in the first sliding block in a rotating fit mode, the extending tail end of the right side of the steering shaft extends into the through cavity, and a spline sleeve is fixedly arranged on the end surface of the tail end of the steering shaft; and a spline shaft which extends into the hollow frame andis opposite to the spline sleeve is fixedly arranged on the left side end surface of the first clamping disc.

Owner:奉节县疾病预防控制中心

A semiconductor light-emitting diode manufacturing equipment

ActiveCN108461585BSimple structureEasy to operateSemiconductor devicesEngineeringMechanical engineering

The present invention discloses a novel semiconductor light emitting diode manufacturing device. The manufacturing device comprises a manufacturing rack body, the manufacturing rack body is installedat the end face of the right side of a support through a lifting device, legs are fixedly arranged at the periphery of the end face of the bottom portion of the support, rollers are in rolling fit installation in the end faces of the bottom portions of the legs, the end face of the bottom portion of the manufacturing rack body is internally provided with a mounting and combination cavity, a rotating blade is in rotation fit installation in the mounting and combination cavity, a clamping module being in locking fit connection with the rotating blade is arranged at the inner wall of the right side of the mounting and combination cavity, a slipping cavity is arranged in an inner wall body of the manufacturing wall body at the left side of the mounting and combination cavity, a left turning connection head is in rotation fit installation in a wall body between the slipping cavity and the mounting and combination cavity, a splined hole is internally provided with the end face of the left side of the left turning connection head, a slipping block is in slipping fit installation in the slipping cavity, a first motor is fixedly arranged in the end face of the right side of the slipping block, and a splined arm being in spline fit connection with the splined hole is in power fit installation with the right side end of the first motor.

Owner:广东安林电子科技股份有限公司

Letterbox device

InactiveCN108422027ASimple structureEasy to operateShearing machinesMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a letterbox device. The letterbox device comprises a processing rack; the processing rack is installed at the end face of the right side of a bracket through a lifting device;a mounting seat is fixedly arranged at the bottom position of the end face of the right side of the bracket; a mounting chamber is embedded inside the top end face of the mounting seat; the end facesof the left and right sides of the mounting chamber are symmetrically fixedly provided with elastic clamping plates; an installation chamber is formed inside the bottom end face of the processing rack; a processing cutter body is installed inside the installation chamber in a running fit manner; the inner wall of the right side of the installation chamber is internally provided with a locking andlinking member which is connected with the processing cutter body in a locking and matching manner; the inner wall body, positioned at the left side of the installation chamber, of the processing rackis internally provided with a slidable connection chamber; the wall body between the slidable connection chamber and the installation chamber is internally provided with a left rotating connector ina running fit manner; the end face of the left side of the left rotating connector is internally provided with a spline notch; a slidable connecting block is installed inside the slidable connection chamber in a sliding fit manner; and a first electromotor is fixedly arranged inside the end face of the right side of the slidable connecting block.

Owner:PUJIANG HUIYI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com