Copper foil trimming device

A copper foil and edge trimming technology is applied in the field of copper foil auxiliary processing devices, which can solve the problems of dull cutter wear, ruffles, affecting product quality, etc., and achieve smooth cutting, smooth end face, long-term high efficiency The effect of the clipping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

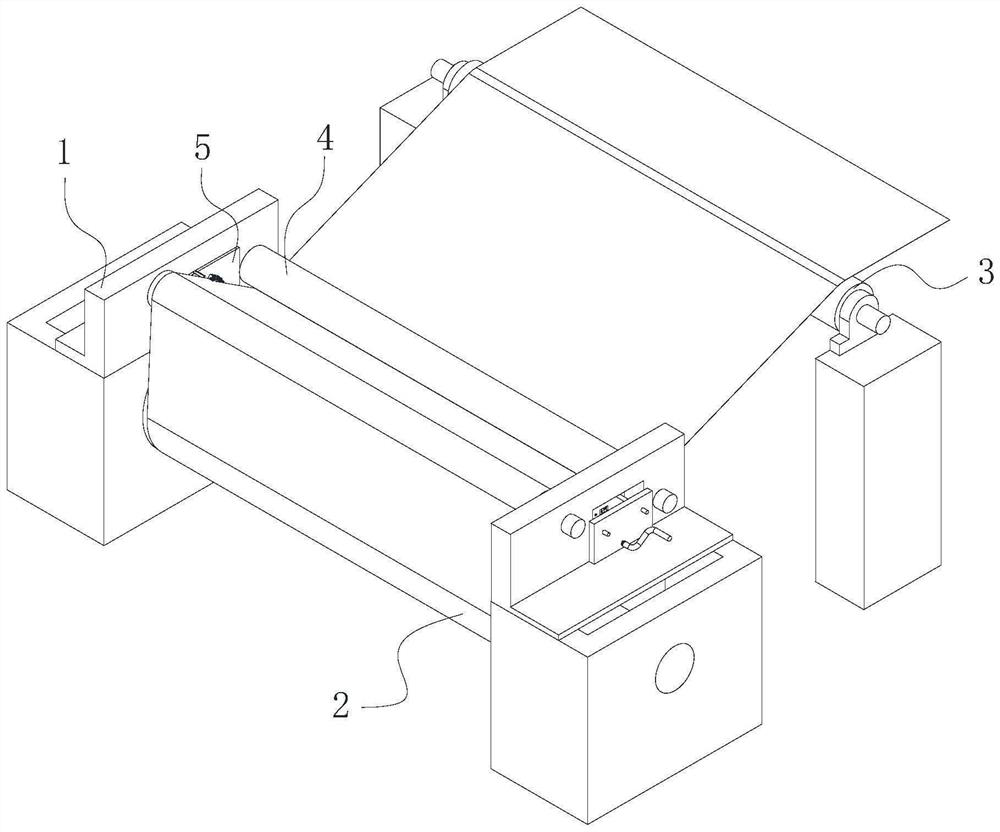

[0034] see Figure 1-5 As shown in the figure, a copper foil trimming device of the present invention includes a frame 1, and an unwinding roller 2 for placing copper foil rolls is arranged on the frame 1, and a conveying copper foil is arranged on the front side of the unwinding roller 2 in the output direction. For the foil conveying roller 3, two guide rollers 4 are arranged in parallel and spaced apart on the frame 1 between the conveying roller 3 and the unwinding roller 2. A mounting plate 5 is provided on the frame 1 between the two guide rollers 4 .

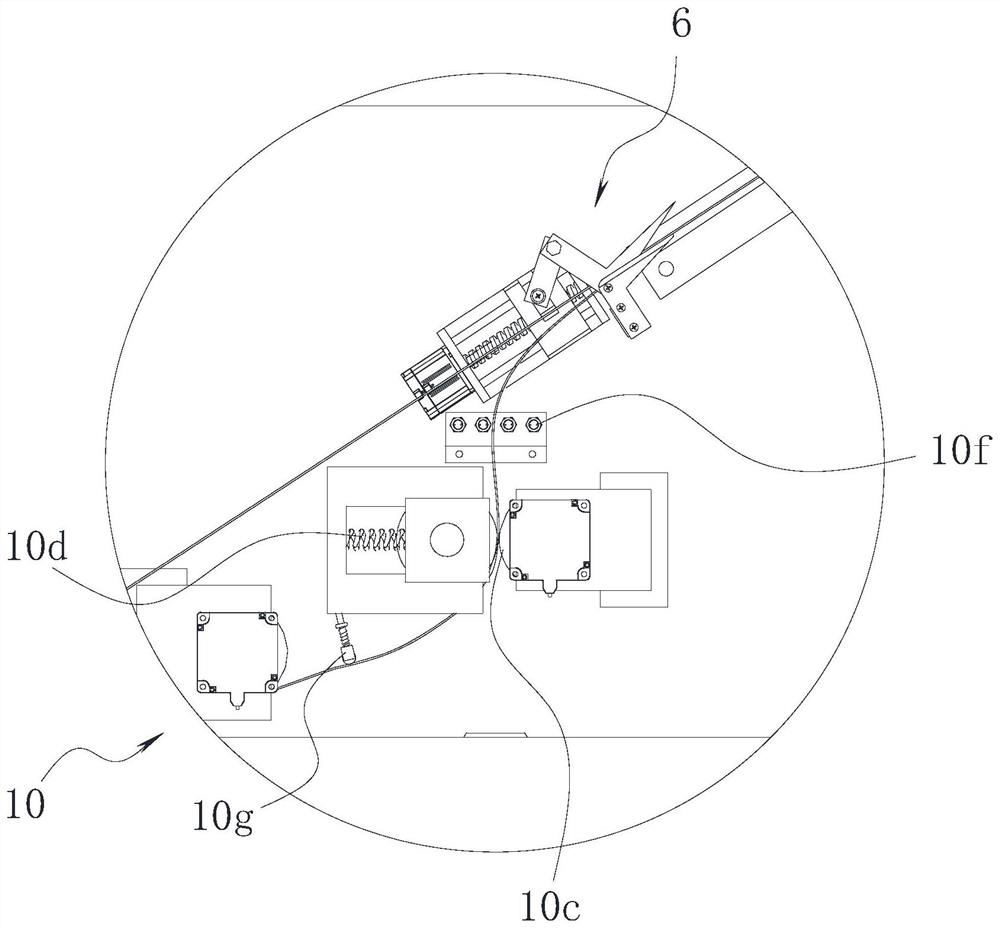

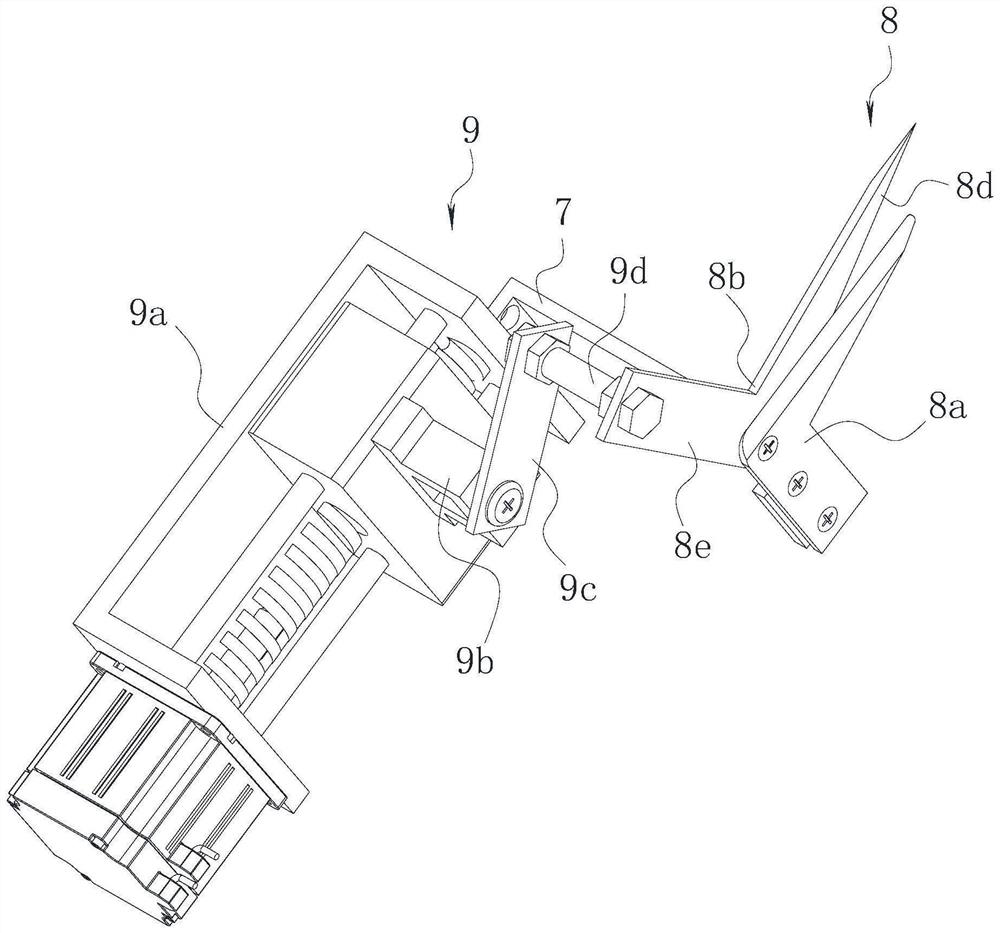

[0035] A trimming module 6 is provided on the mounting plate 5 , and the trimming module 6 includes a mounting bracket 7 arranged on the mounting plate 5 on the lower side of the copper foil. The shearing assembly 8 of the copper foil, the shearing assembly 8 is connected with a rotating module 9, and the cutting assembly 8 is controlled by the rotating module 9 to update the position of the cutting edge regularly or qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com