Patents

Literature

51results about How to "No burrs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

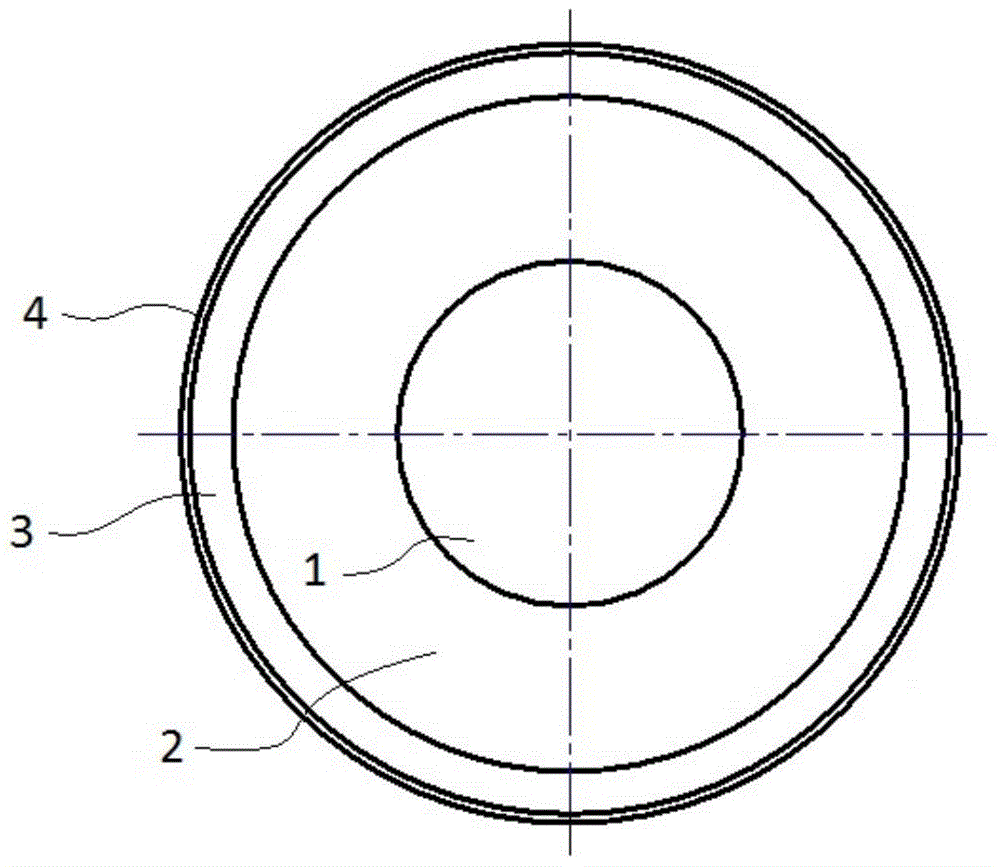

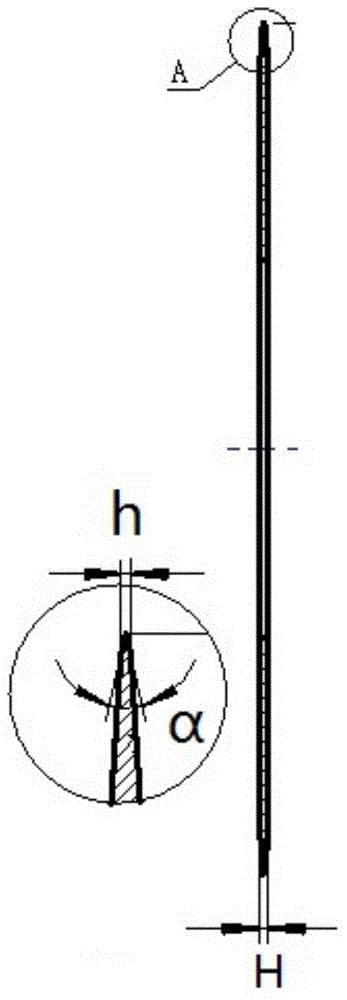

Slitting cutting disc and preparation method thereof

The invention discloses a slitting cutting disc and a preparation method thereof, which belong to the process field of cutters. The slitting cutting disc is of a circle blade, and comprises a center hole, a cutter disc and a blade, wherein the center hole is arranged in the center of the cutter disc, the blade is arranged on an outer ring of the cutter disc, a blade opening is arranged on an outer ring of the blade, and the opening angle delta ( ) of blade opening is 23-27 degrees. The opening thickness h of the blade opening is 0.24-0.26mm. The materials which are made into the slitting cutting disc comprise components with percentage by weight: carbon (C) 1.15-1.33%, nitrogen (N) 0.2-0.4%, manganese (Mn) 0.30-0.40%, silicon (Si) 0.52-1.20%, chromium (Cr) 8.50-10.50%, tungsten (W) 1.50-2.50%, vanadium (V) 0.35-0.50%, molybdenum (Mo) 0.25-0.4%, nickel (Ni) 0.30-0.40%, copper (Cu) <=0.30%, sulphur (S)<=0.020% and phosphorus (P)<=0.027%, and the allowance is ferrum (Fe). The slitting cutting disc has the advantages that the slitting cutting disc is excellent in abrasive resistance and is not easy to deform, and the blade opening resists abrasion, not easy to crack, long in service life and easy to make.

Owner:安徽华天机械股份有限公司

Self adhesive label and special film thereof

InactiveCN102163386ALow costPromote environmental protection and low carbonStampsLayered productsEngineeringRough surface

The invention provides a self adhesive label and a special film thereof. The self adhesive label is composed of a baseband layer and a transfer layer, wherein, the transfer layer comprises a disengaging layer, a paper / film layer, a printing information layer and a hot melt adhesive layer. The transfer layer undergoes die cutting and is discharged waste to become label units separated from each other. The self adhesive label and special film thereof solve the disadvantages that the base paper, the face material and the adhesive layer of the self adhesive label are thick, the self adhesive label is convenient to uncover, the formula needs to be adjusted in accordance with the season climates and the release force needs to be adjusted in accordance with the thickness of material; and solve the disadvantages that the thermal transfer label can not be used as a product sealing label, and is not suitable for using on uneven rough surfaces; and the special film of the self adhesive label is convenient for users to produce self adhesive label.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

Production technology of double-sided PCB

ActiveCN105555046AThe mass concentration is reasonableImprove air tightnessConductive material chemical/electrolytical removalCircuit precursor manufactureResistMetallurgy

The invention relates to the technical field of PCBs, in particular to a production technology of a double-sided PCB. The technology sequentially comprises the following steps: double-sided copper foil substrate pretreatment, line coating and exposure treatment, line development, etching, de-inking treatment, solder resist pretreatment, solder resist development, lettering treatment, molding treatment, testing and antioxidant treatment. A copper foil substrate is subjected to surface polish-brush treatment through a polish-brush; a photosensitive ink layer and a solder resist ink layer coat the surface of the copper foil substrate; relatively high adsorption force is provided among the photosensitive ink layer, the solder resist ink layer and the copper foil substrate; the photosensitive ink layer and the solder resist ink layer are good in quality; and the produced PCB is good in quality. Cutting treatment is carried out on the copper foil substrate by a V-Cut technology; and the minimum thickness of the formed substrate corresponding to a V-shaped plate-dividing groove is controlled at 0.4-0.5mm, so that subsequent plate division is facilitated; and no burr is left.

Owner:湖北碧辰科技股份有限公司 +1

Production technology for single-sided PCB

InactiveCN105578784AQuality improvementImprove adsorption capacityInsulating substrate metal adhesion improvementNon-metallic protective coating applicationResistPre treatment

The invention relates to the technical field of PCBs, in particular to a production technology for a single-sided PCB. The technology sequentially comprises a single-sided copper foil substrate pretreatment step, a line coating and exposing treatment step, a line developing, etching and de-inking treatment step, a targeting hole treatment step, a solder resist pretreatment step, a solder resist developing step, a lettering treatment step, a molding treatment step, a testing step and an antioxidant treatment step. Surface polish-brush treatment is carried out on a copper foil substrate in a polish-brush manner; a photosensitive ink layer and a solder resist ink layer coat the surface of the copper foil substrate; relatively high adsorption capacity is provided among the photosensitive ink layer, the solder resist ink layer and the copper foil substrate; and the produced PCB is good in quality. A V-shaped board-dividing groove formed by cutting treatment on the copper foil substrate by a V-Cut process is free of a burr in subsequent board division. According to the production technology provided by the invention, targeting hole treatment is firstly carried out on the copper foil substrate; and then solder resist and baking treatment is carried out on the copper foil substrate, so that the dimensional accuracy of a targeting hole is high.

Owner:湖北碧辰科技股份有限公司 +1

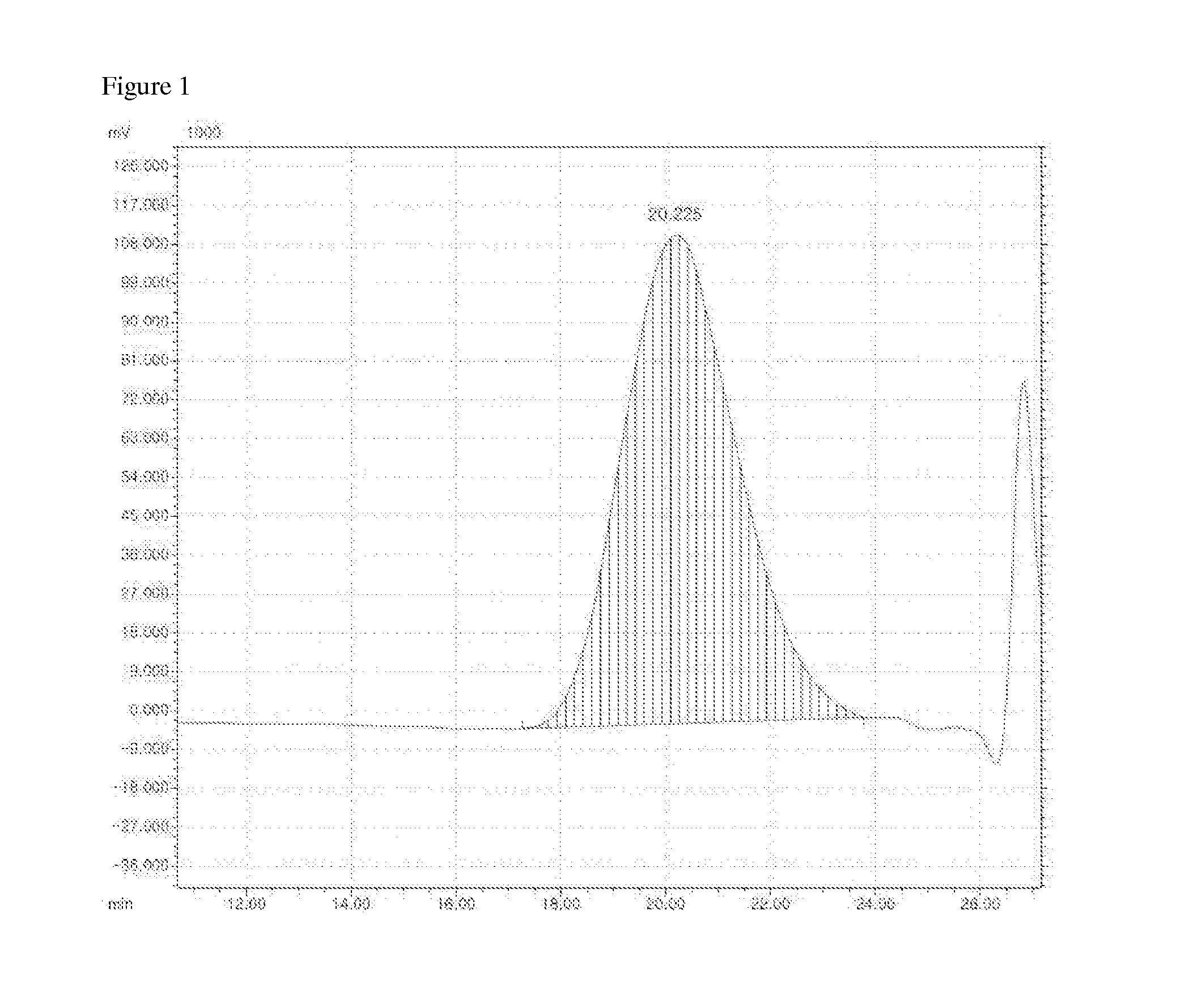

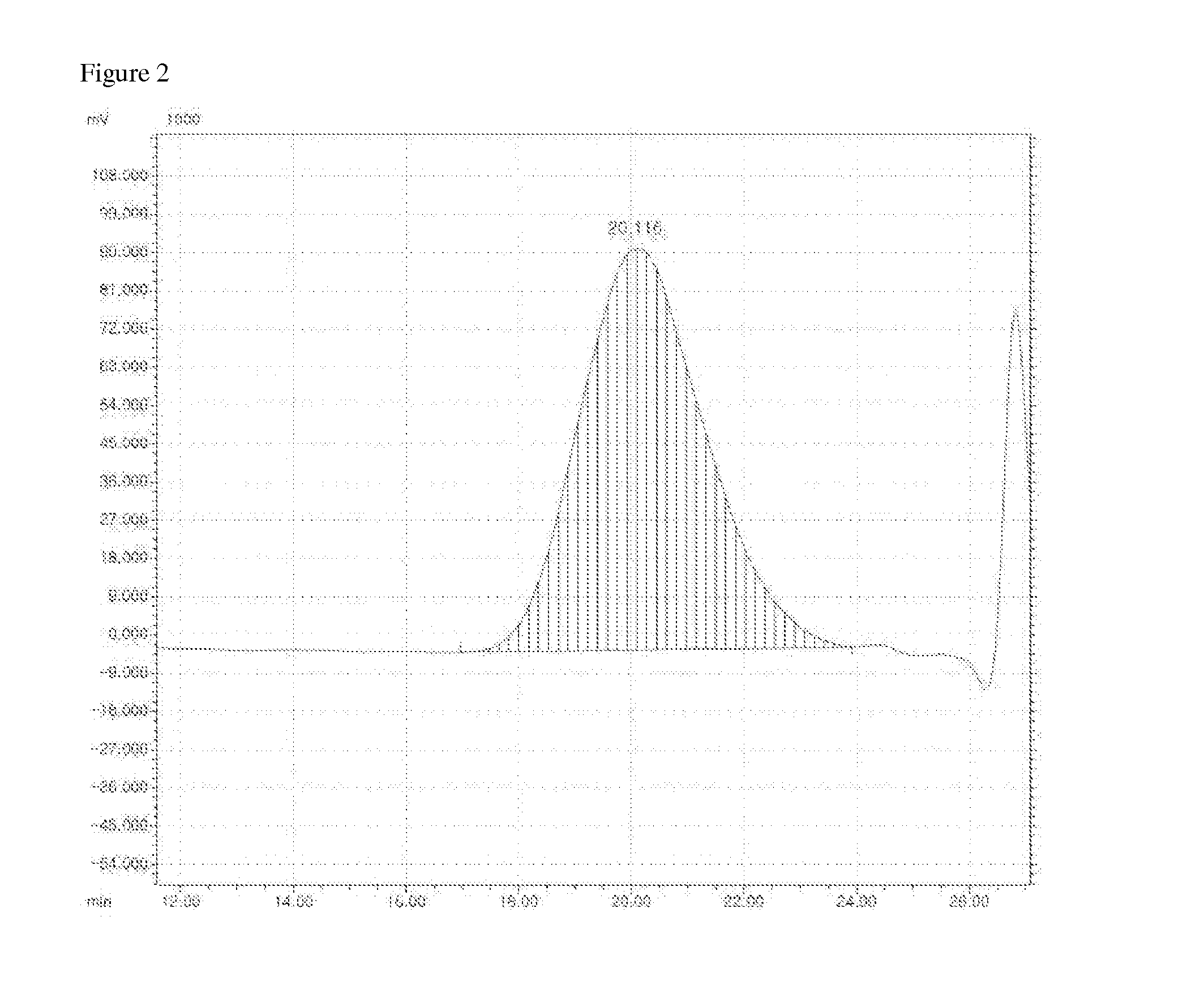

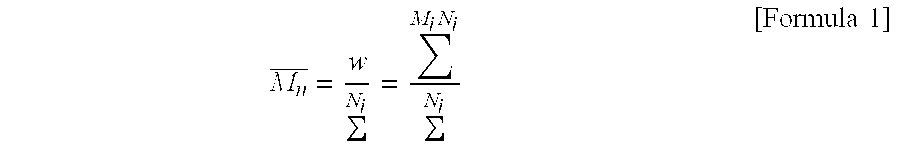

Polyarylene sulfide having excellent processability and preparation method thereof

ActiveUS20130115438A1Easy to processImprove accuracyAnimal housingThin material handlingPolymer sciencePolystyrene

The present invention relates to polyarylene sulfide, in which a ratio of a peak area of a polymer chain of a second polyarylene sulfide having a lower molecular weight than the maximum peak molecular weight to a peak area of a polymer chain of a first polyarylene sulfide having a higher molecular weight than the maximum peak molecular weight is 1.3 or less in the molecular weight distribution of the polyarylene sulfide, as measured by gel permeation chromatography using polystyrene as a standard, and a preparation method thereof. This polyarylene sulfide exhibits excellent processability and generates no burrs (flashes) or the like, and can satisfactorily mold a product requiring high molding precision.

Owner:SK CHEM CO LTD

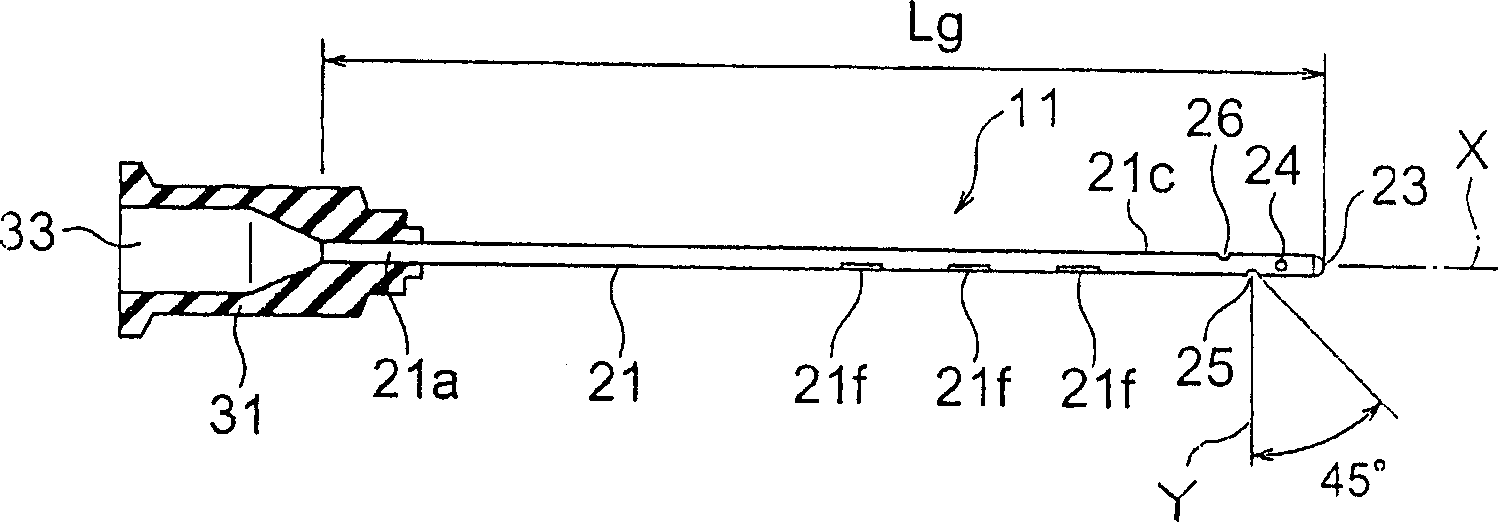

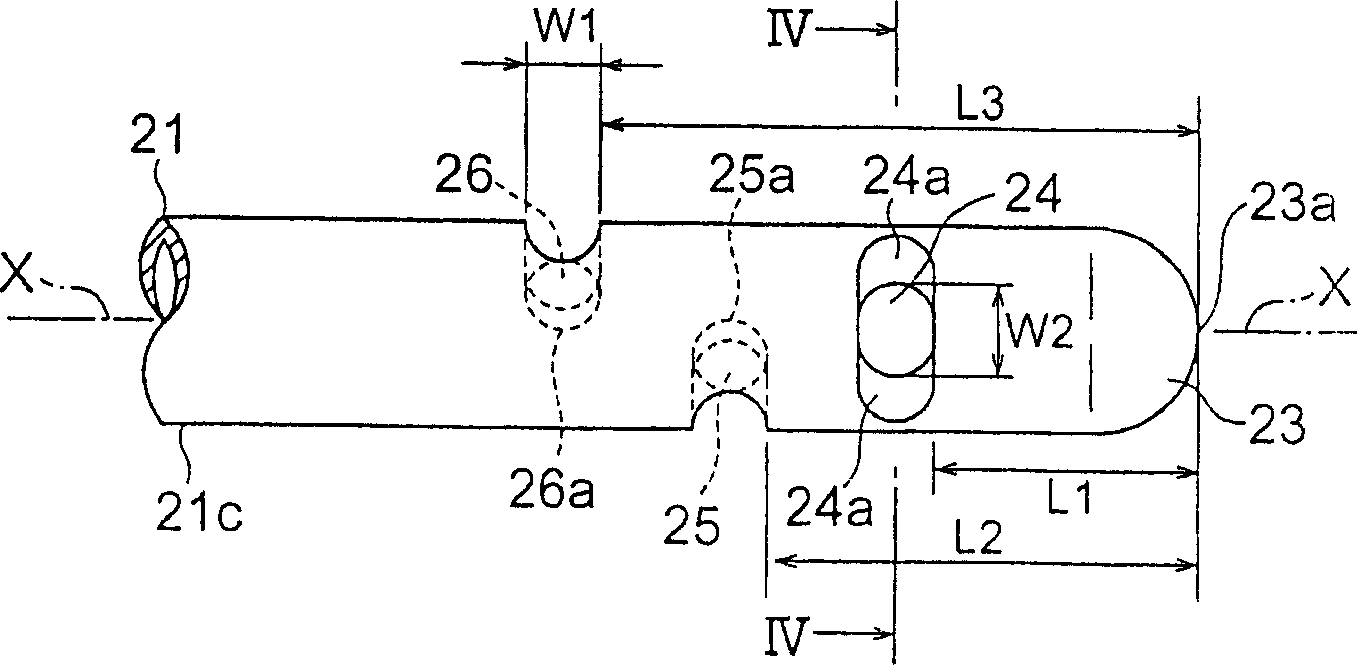

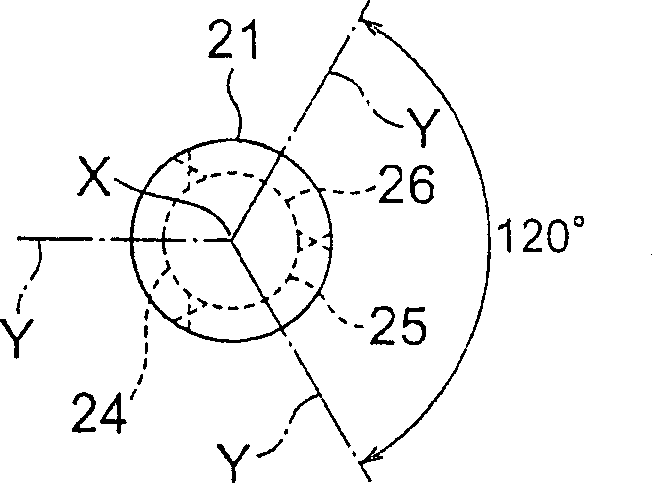

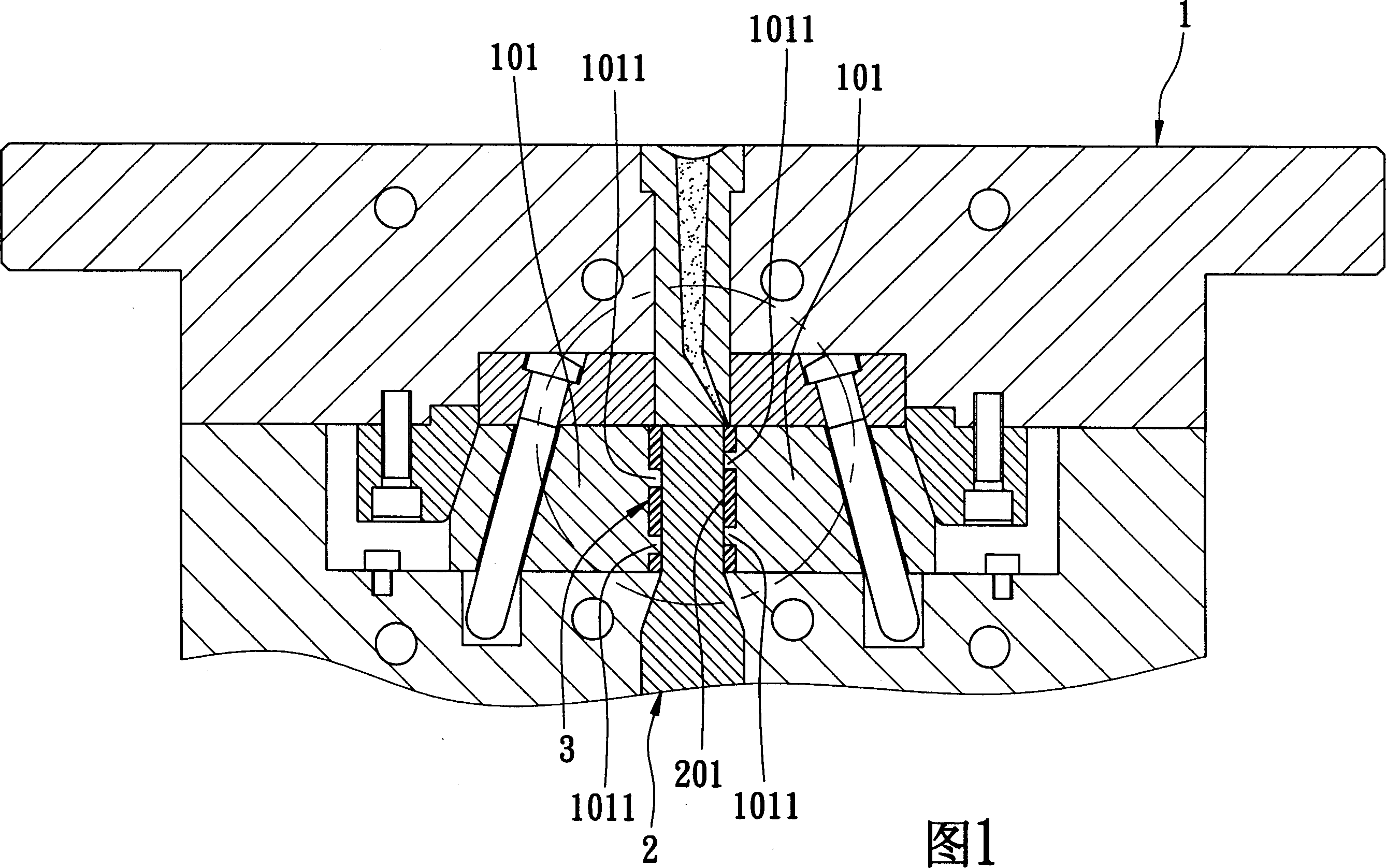

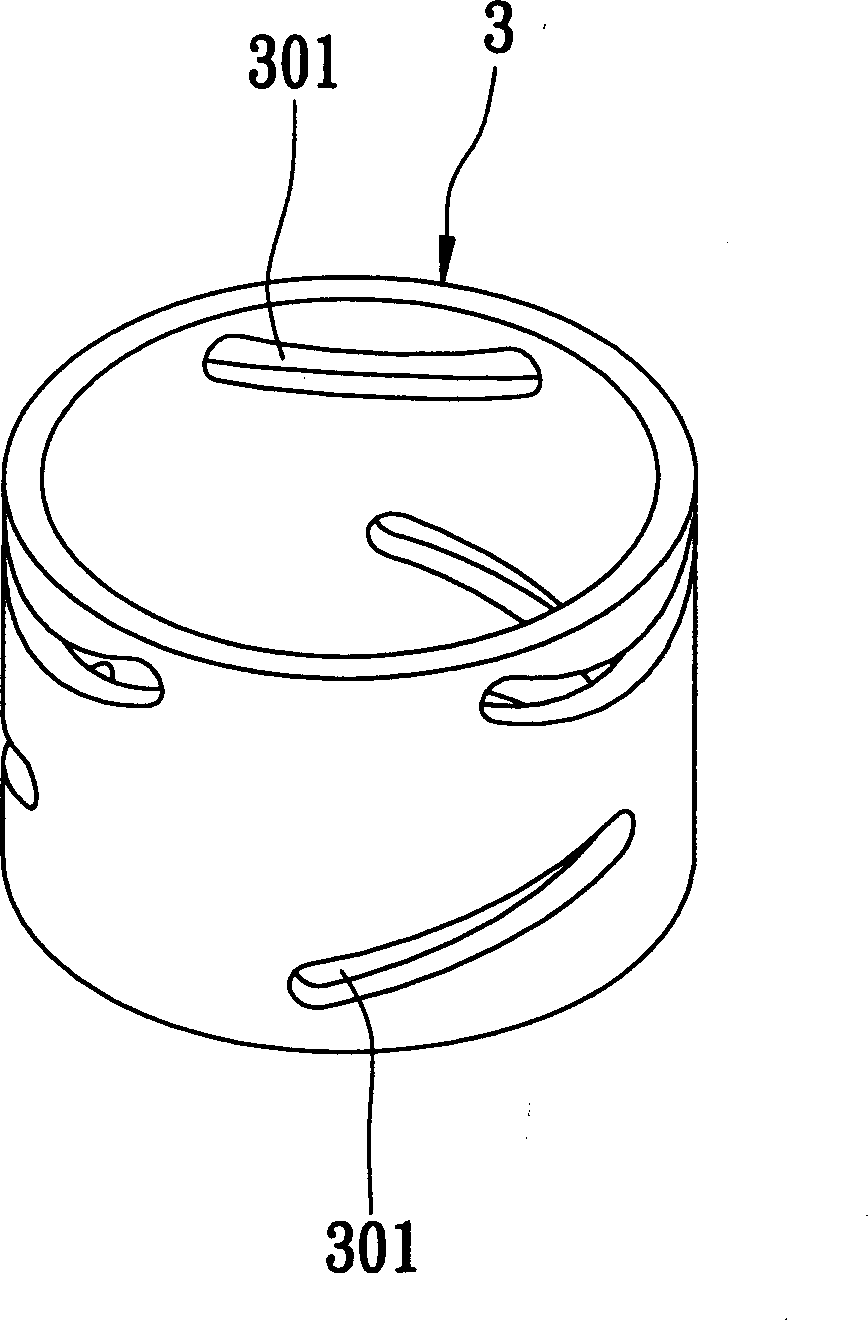

Liquid injection needle for jetting a liquid in a predetermined angle range and method of producing the same

InactiveCN1839772APrecise and Efficient JettingPrevent dripLiquid surface applicatorsGum massageMedicineEngineering

A cannula (21) has a front part (21 c) in a direction of a center axis X with its forward end portion (23) closed. The front part has a plurality of nozzle orifices (24, 25, 26) each of which has an orifice axis Y intersecting the center axis X. Each of the nozzle orifices has a first diameter in a first direction parallel to the center axis X and a second diameter in a second direction perpendicular to the first direction. The first diameter ranges between 0.1 mm and 0.5 mm while the second diameter ranges between 0.1 mm and 0.3 mm so that a liquid in the cannula is jetted from the nozzle orifices in an angle range of 45 degrees towards the forward end portion with respect to the orifice axis.

Owner:MATSUMOTO DENTAL UNIVERSITY

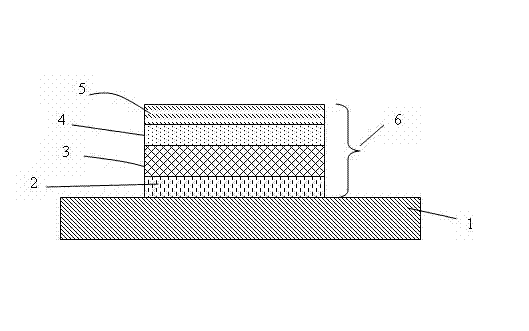

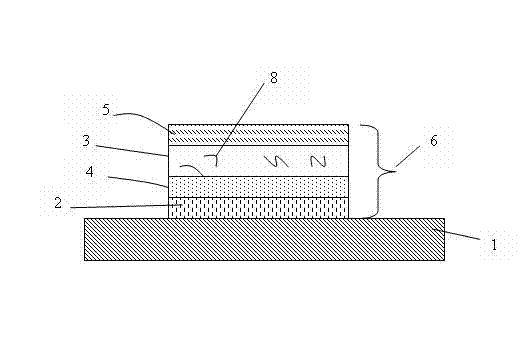

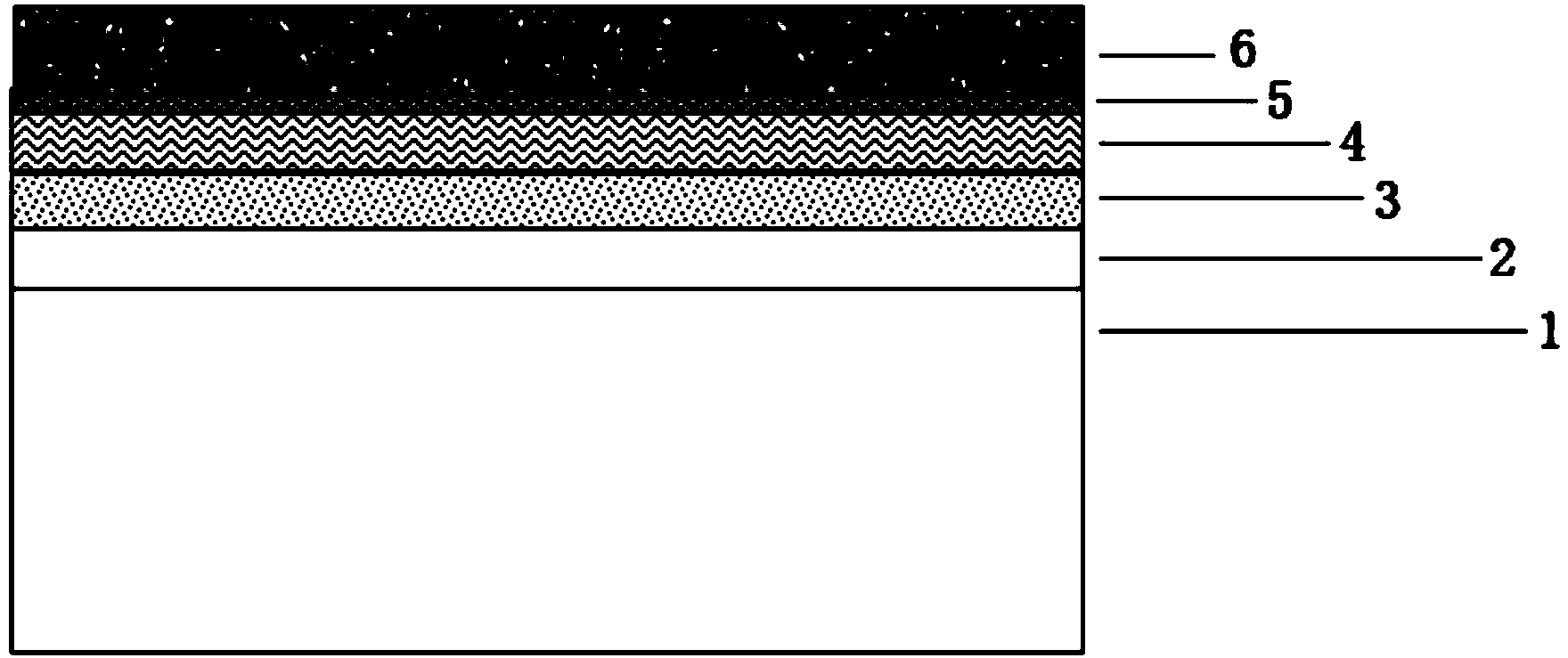

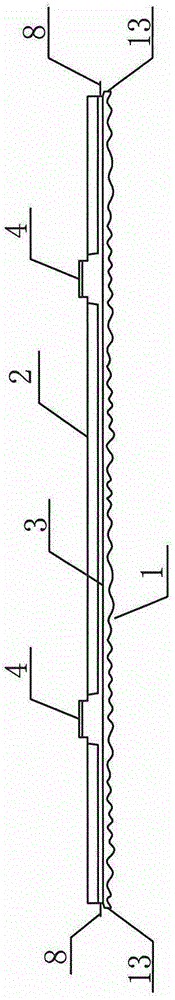

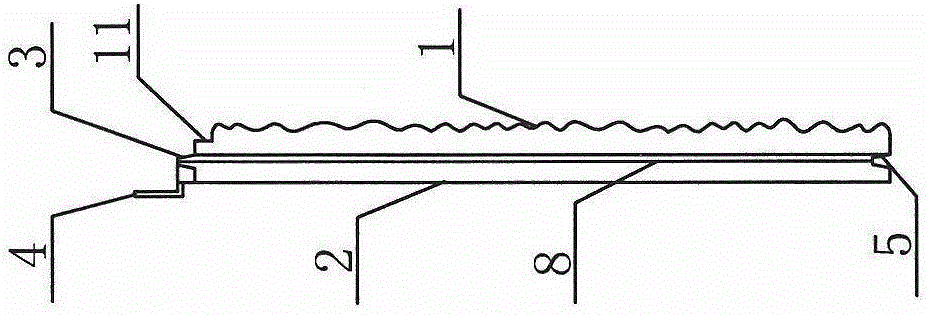

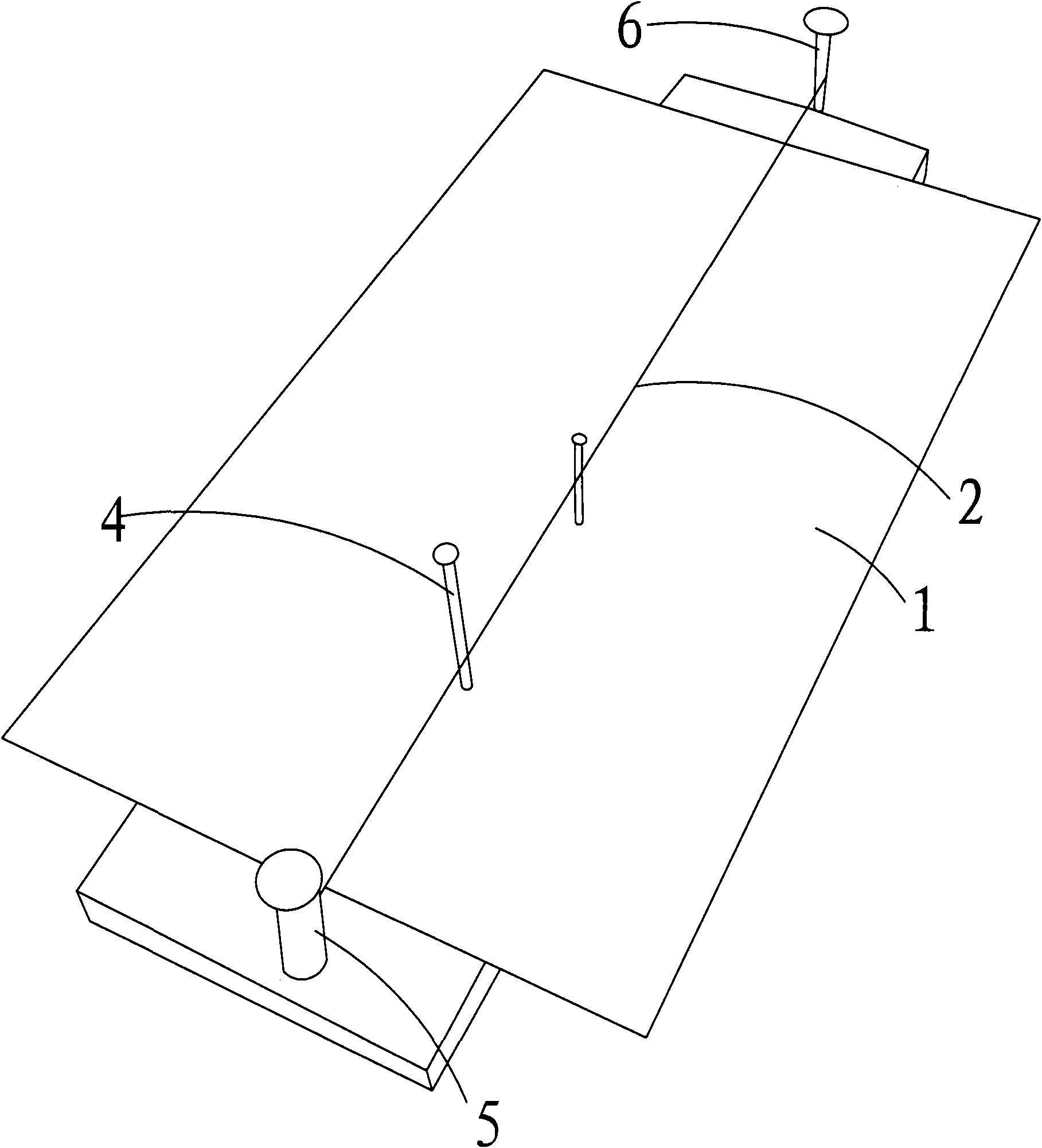

Transfer type perspective safe-guarding and anti-counterfeiting film and method for protecting certificate security

InactiveCN104103215AMeet the needs of protectionNo burrsStampsIdentification meansHigh resistanceInformation layer

The invention relates to the field of public security identification, and mainly relates to a transfer type perspective safe-guarding and anti-counterfeiting film for protecting certificate security. The film consists of at least six layers of different chemical materials, wherein the first layer is a basic layer 1 of which the thickness is 15-25 microns; the second layer is a separation layer 2 of which the thickness is 1-2 microns; the third layer is a protection layer 3 of which the thickness is 2-4 microns; the fourth layer is an information layer 4 of which the thickness is 2-3 microns; the fifth layer is a medium film layer 5 of which the thickness is 0.04-0.1 micron; the sixth layer is a bonding layer 6 of which the thickness is 2-5 microns. The perspective safe-guarding and anti-counterfeiting film is attached to the surface of a certificate to generate a visible diffraction optical anti-counterfeiting image. The transfer type perspective safe-guarding and anti-counterfeiting film has the advantages that a six-layer structure needs to be adopted, and a design layer is added to completely meet the requirement of certificate protection; the film has high resistance to scratching, wiping, sweat stain, oil stain, weak acids and alkalis as well as solvent erosion, has high flexibility in comparison to an ordinary laser holographic film, and contributes to effective prolonging of the service life of the certificate; a high polymer chemical material process is adopted.

Owner:上海冠众光学科技有限公司 +1

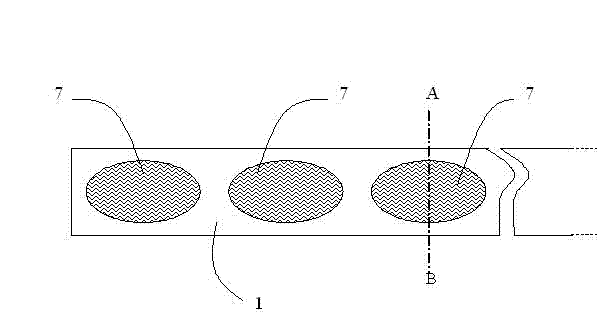

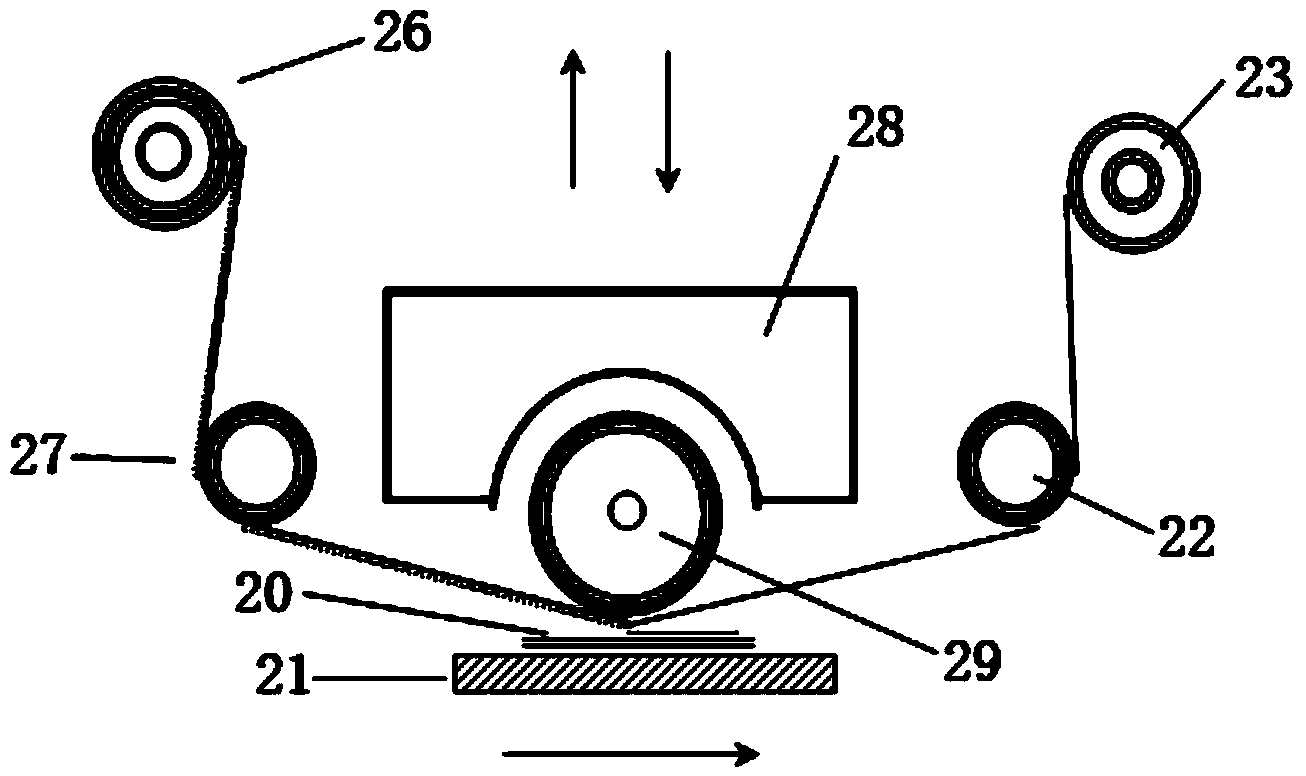

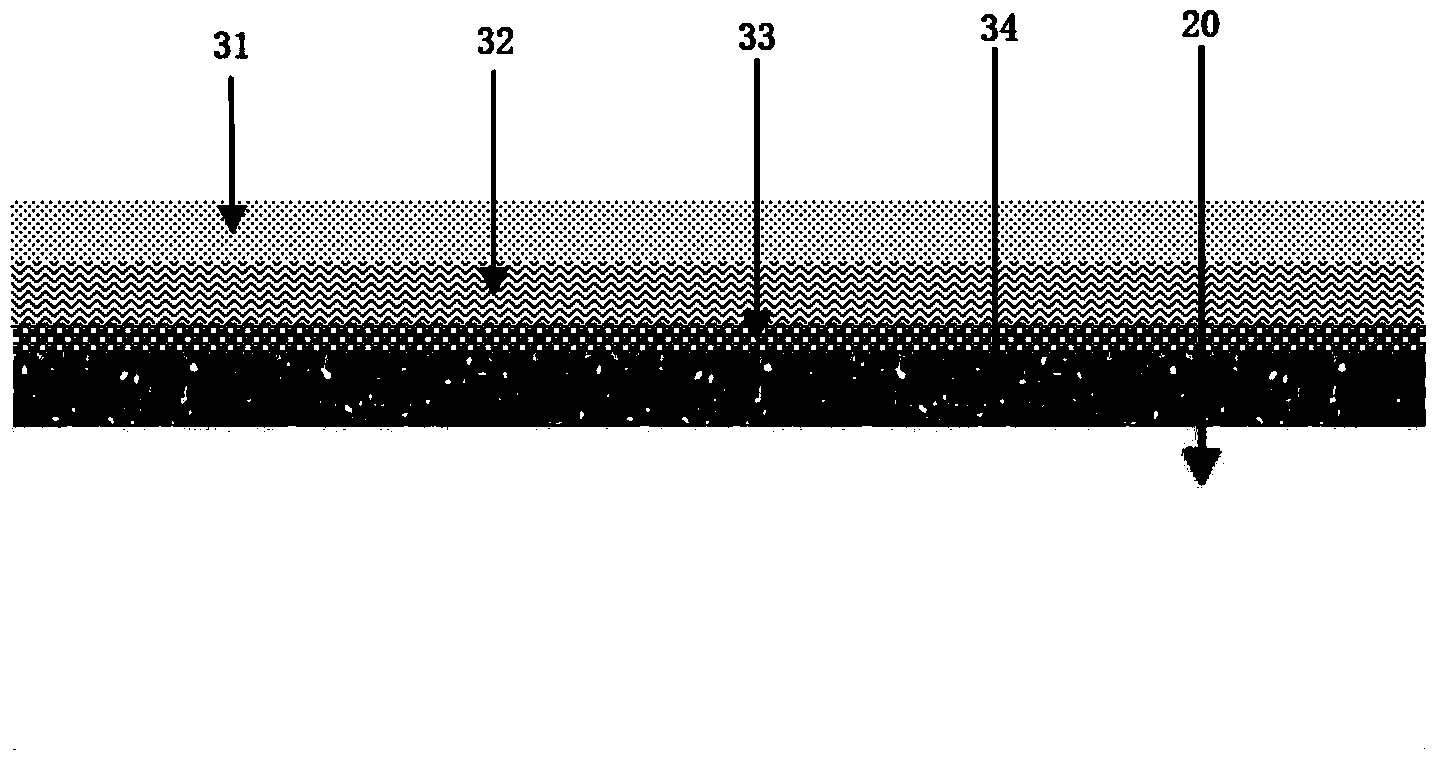

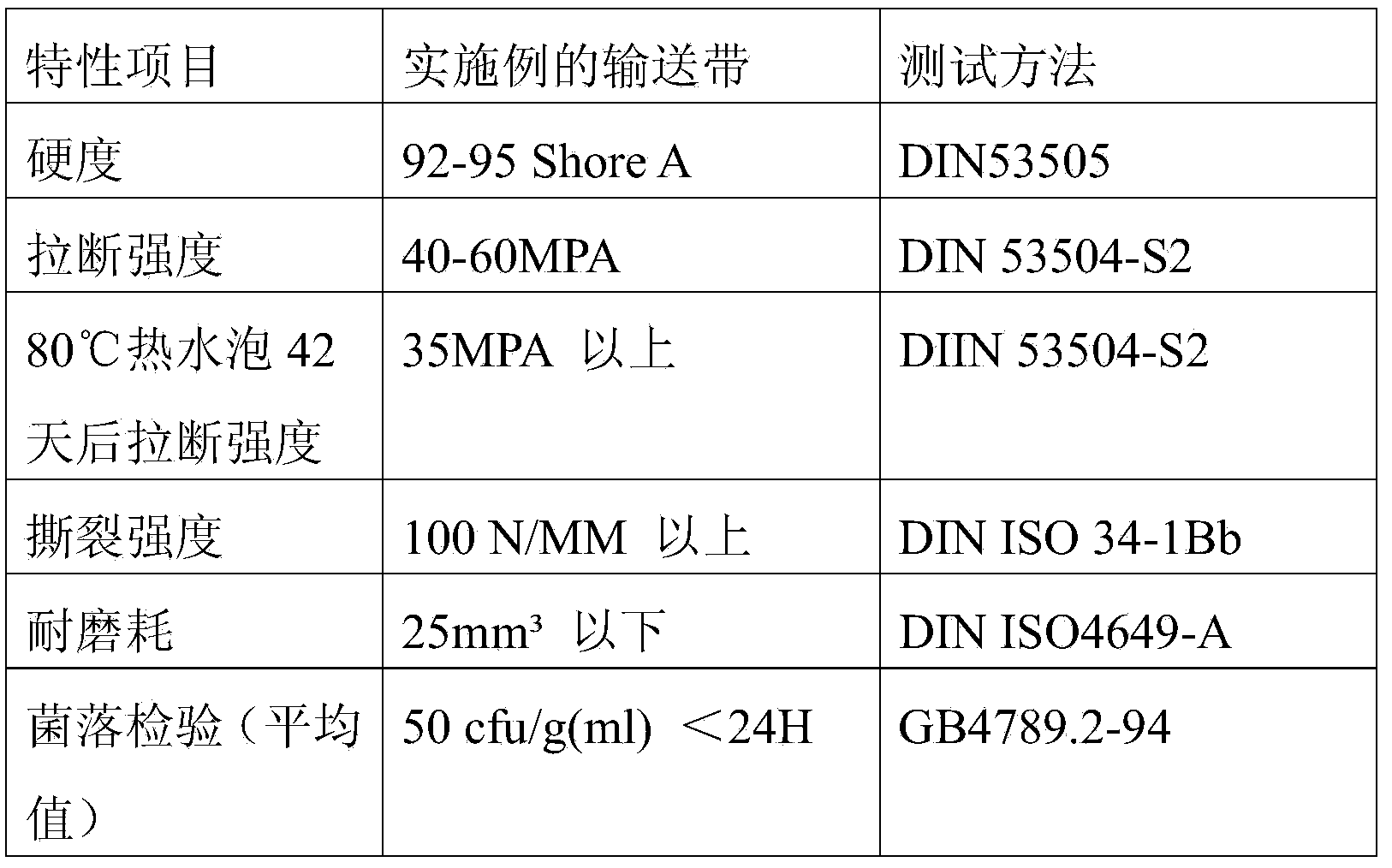

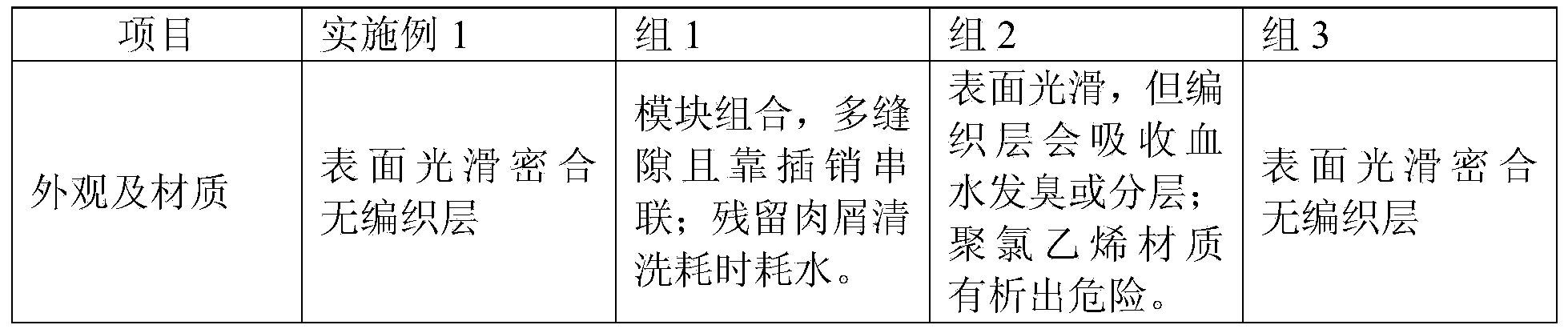

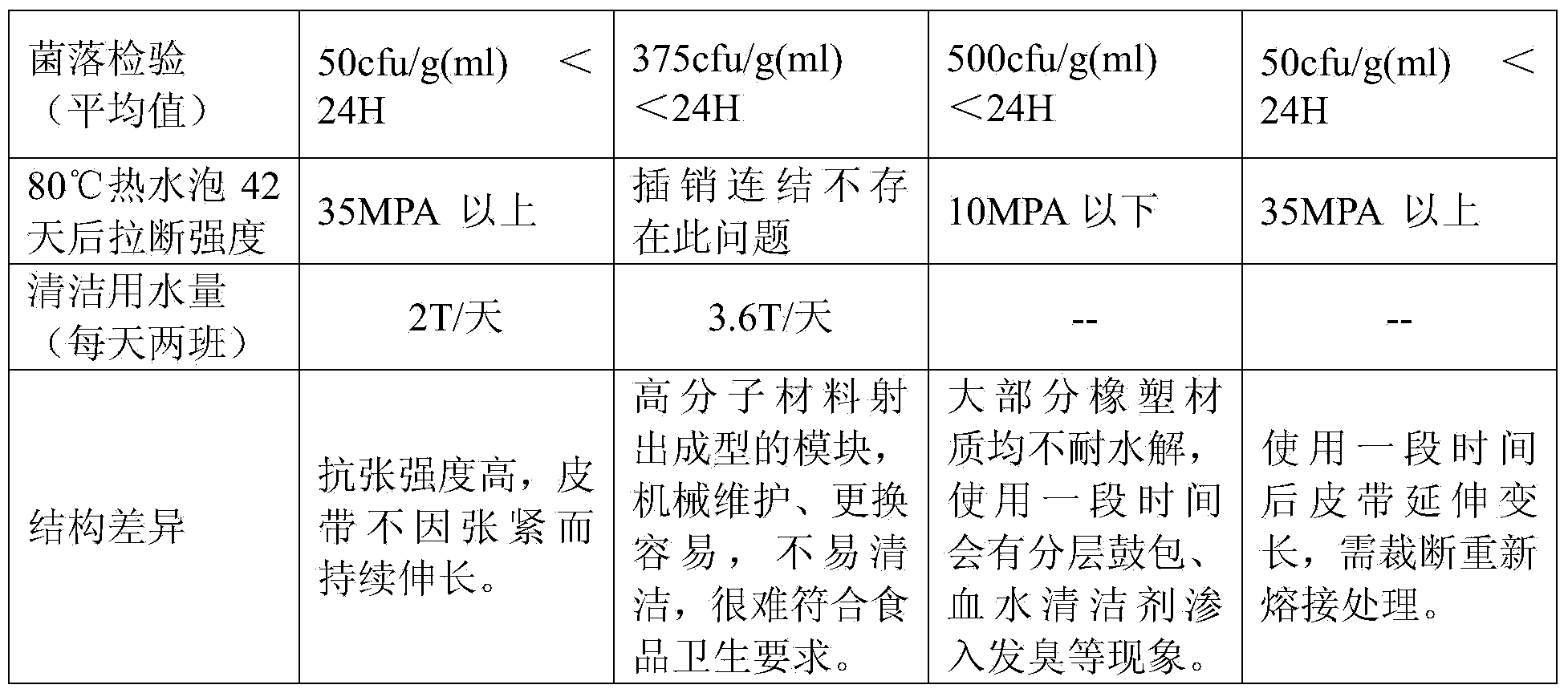

Conveying belt and preparation method thereof

The invention discloses a conveying belt and a preparation method of the conveying belt. The method comprises the following steps of (1) arranging para-position aramid yarns in parallel, wherein the interval between the para-position aramid yarns is 7-10mm, and each para-position aramid yarn is stretched by force of 2.94N-4.9N; and (2) mixing, calendering, extruding, and integrally forming the arranged para-position aramid yarns and polyether-type thermoplastic polyurethane. The conveying belt provided by the invention conforms to the food hygiene and safety requirement, is high in hardness, is abrasion resistant, does not generate burr phenomenon, and is durable in stretching.

Owner:AA IND BELTING (SHANGHAI) CO LTD +1

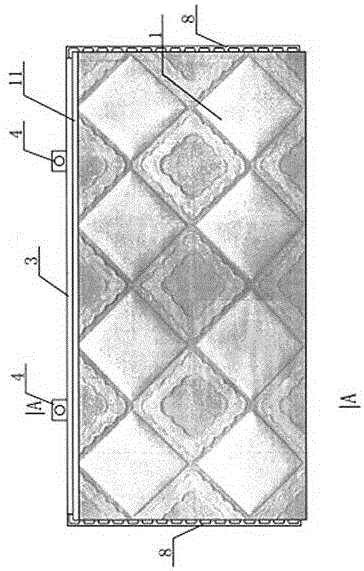

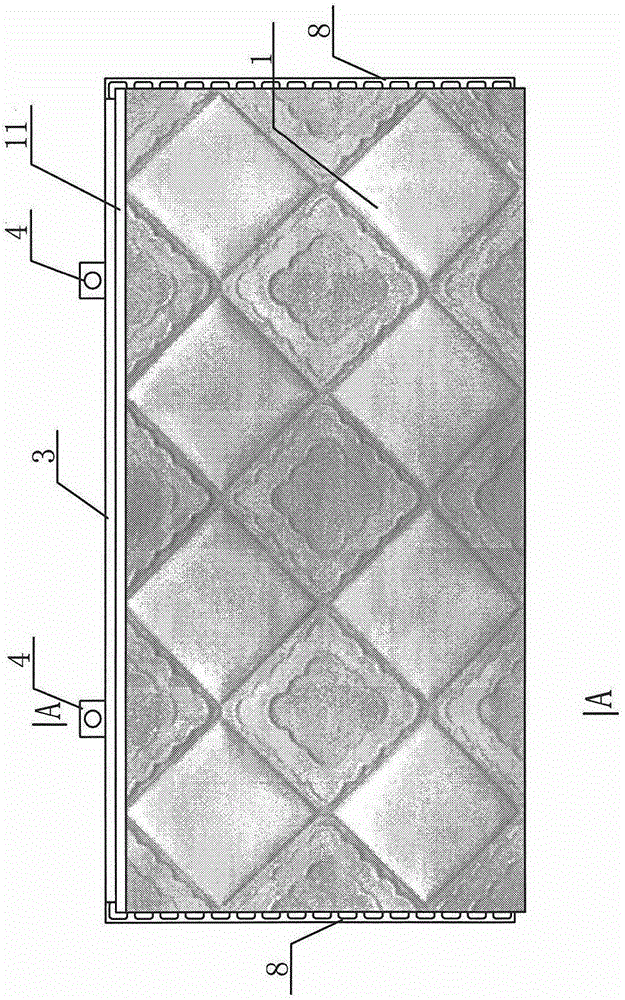

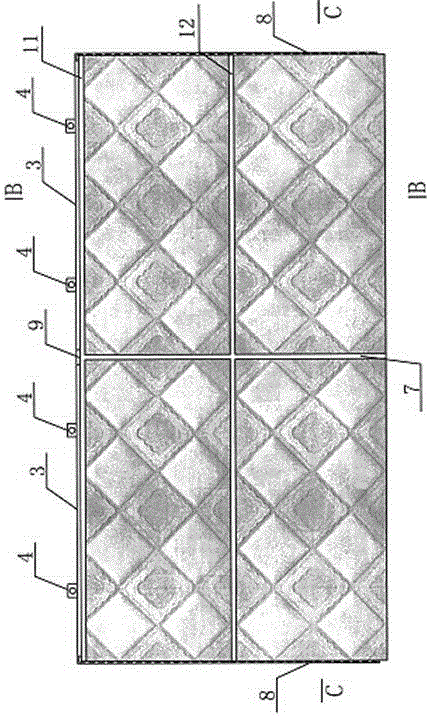

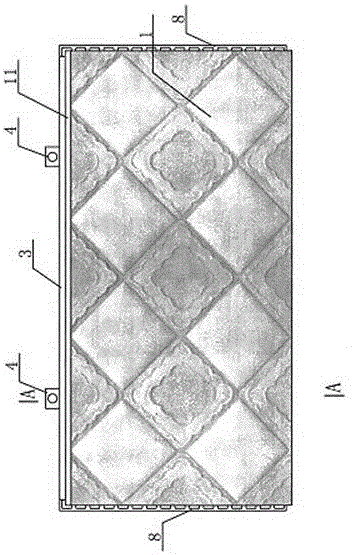

External thermal insulation cement decoration panel provided with concave edge and sunk key type joint and mounting and leveling method thereof

InactiveCN105735580AImprove flatnessAdapt to production process requirementsCovering/liningsThermal insulationPerforated metal

The invention relates to an external thermal insulation cement decoration panel provided with a concave edge and sunk key type joint and a mounting and leveling method thereof. The external thermal insulation cement decoration panel is characterized in that the cement decoration panel is internally provided with a metal or non-metal net; a three-dimensional decorative pattern is preformed on the outer side face of the cement decoration panel; the upper edge of the cement decoration panel is provided with a concave edge with an appropriate width and depth; the upper end face of the cement decoration panel is provided with a full-length convex key and metal hanging parts at certain intervals; and the two side end faces of the cement decoration panel are planes or the outer edges of the cement decoration panel are provided with convex edges with an appropriate height, and perforated metal plate strips are embedded in the two side end faces or the outer edges of the cement decoration panel. During construction and assembly of the cement decoration panel, horizontal joints serve as sunk key type joints, the concave edges form horizontal grid division joints, vertical joints serve as perforated metal plate strip coped joints, special mortar is embedded in the joints compactly in a filling mode, and vertical grid division joints with the same depth as the horizontal grid division joints are formed. The perforated metal plate strips are good in flatness, accurate in shape and size and capable of well meeting the requirements of the production process of the cement decoration panel. The perforated metal plate strip coped joints have good tensile strength and can effectively protect the mortar joints against cracking and leakage.

Owner:上海紫霓节能科技有限公司

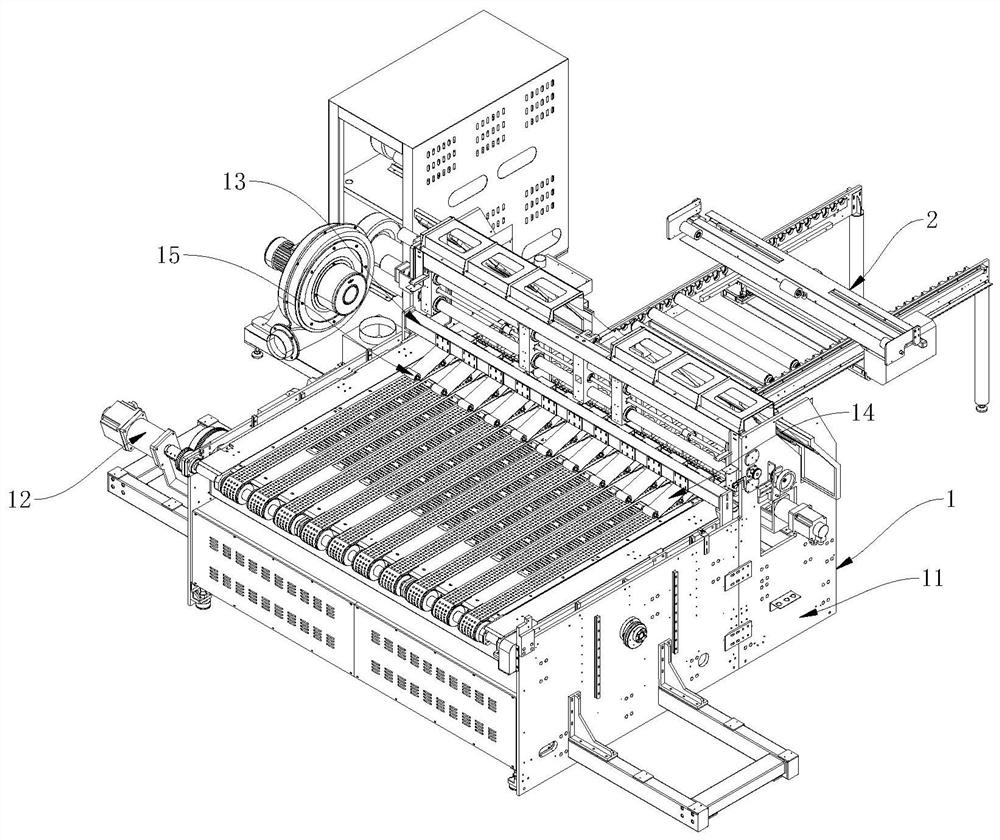

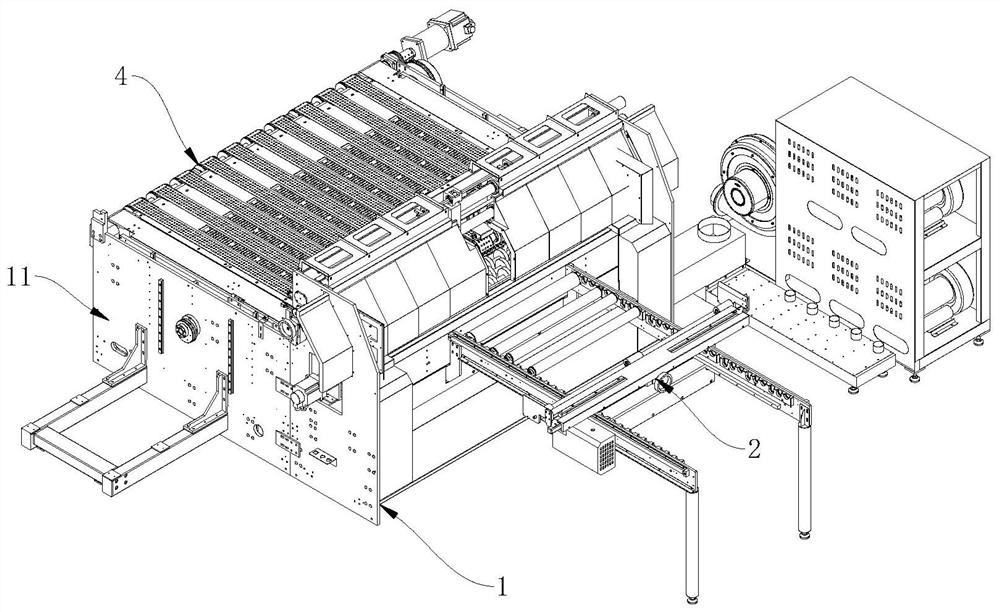

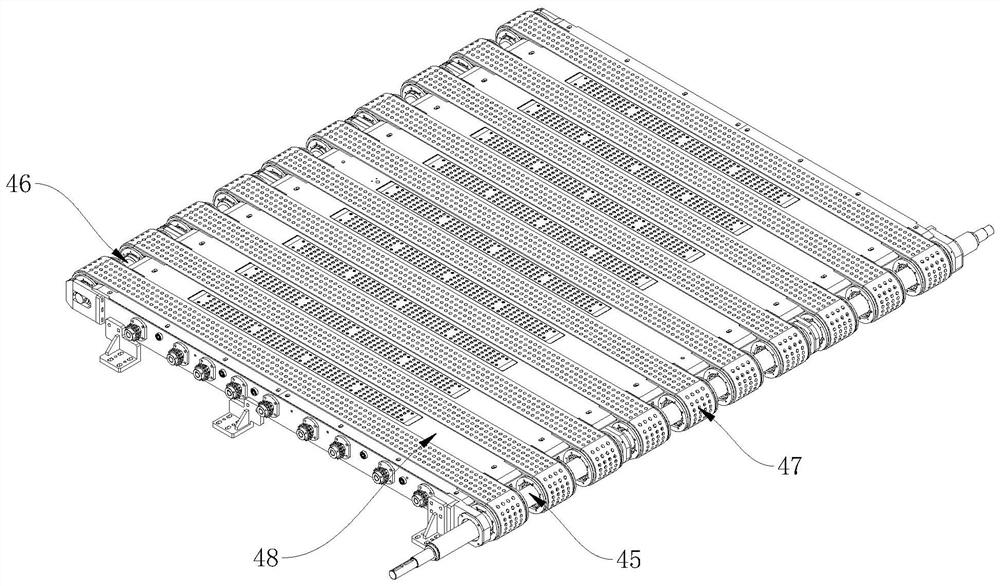

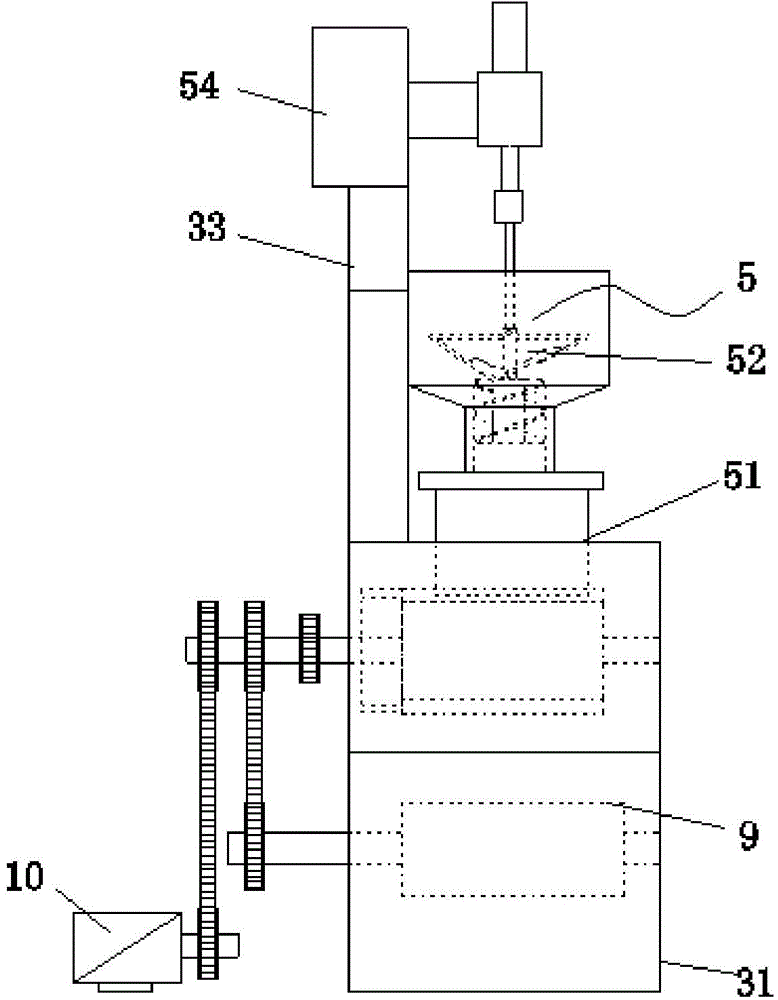

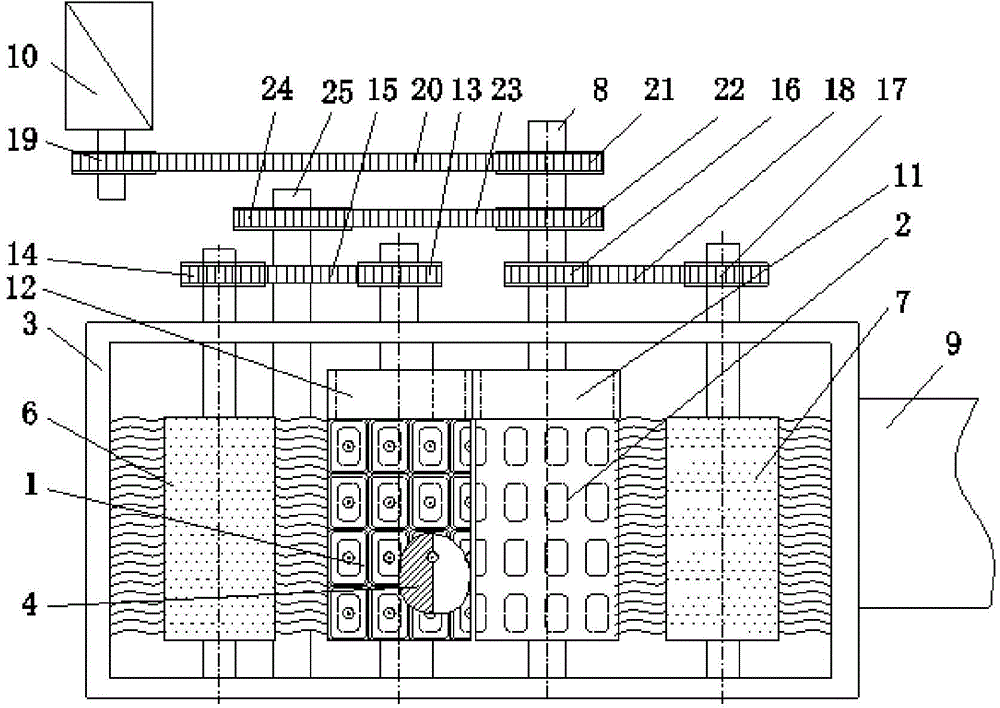

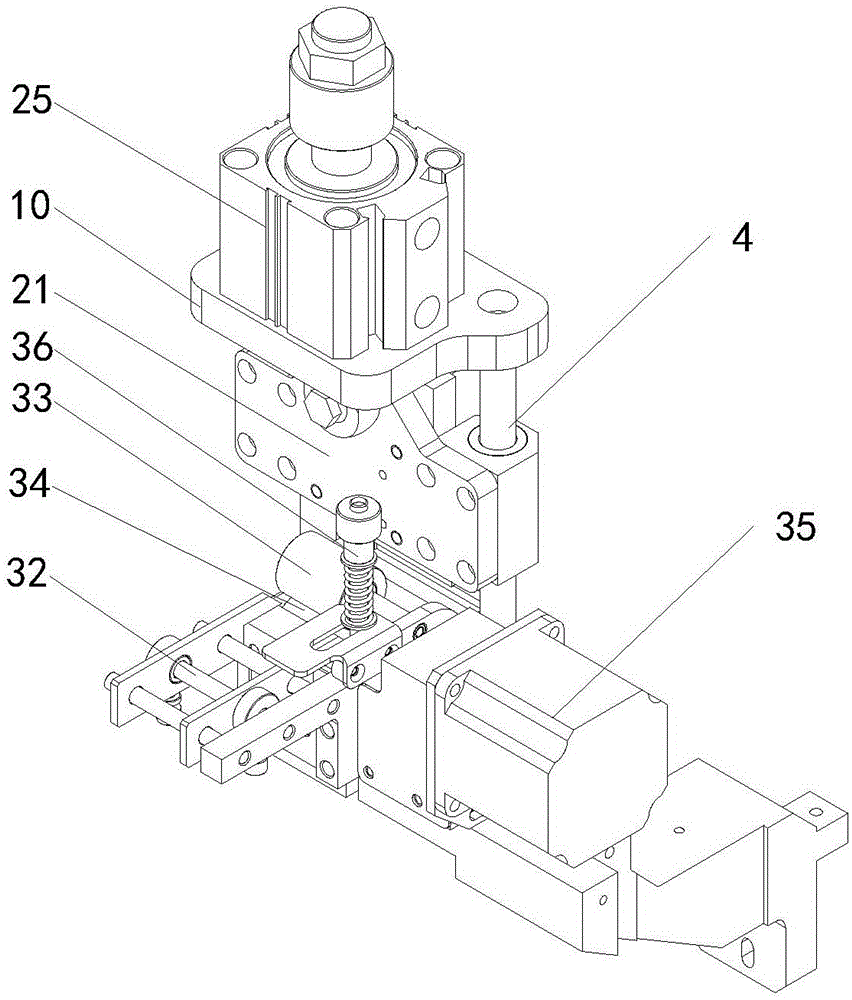

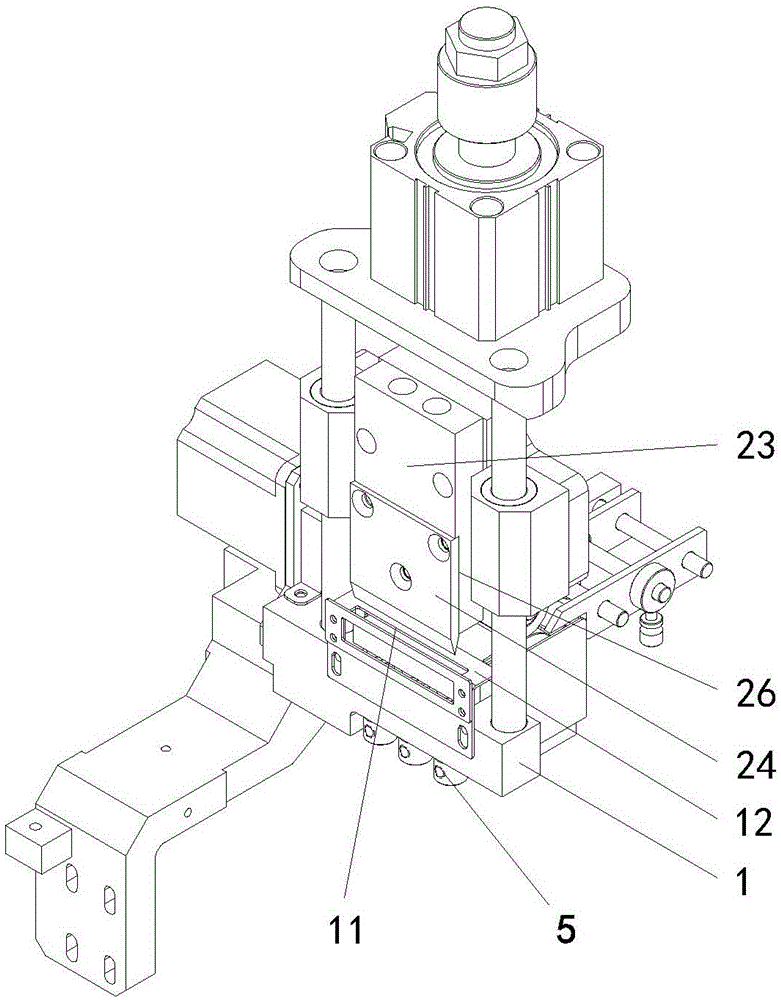

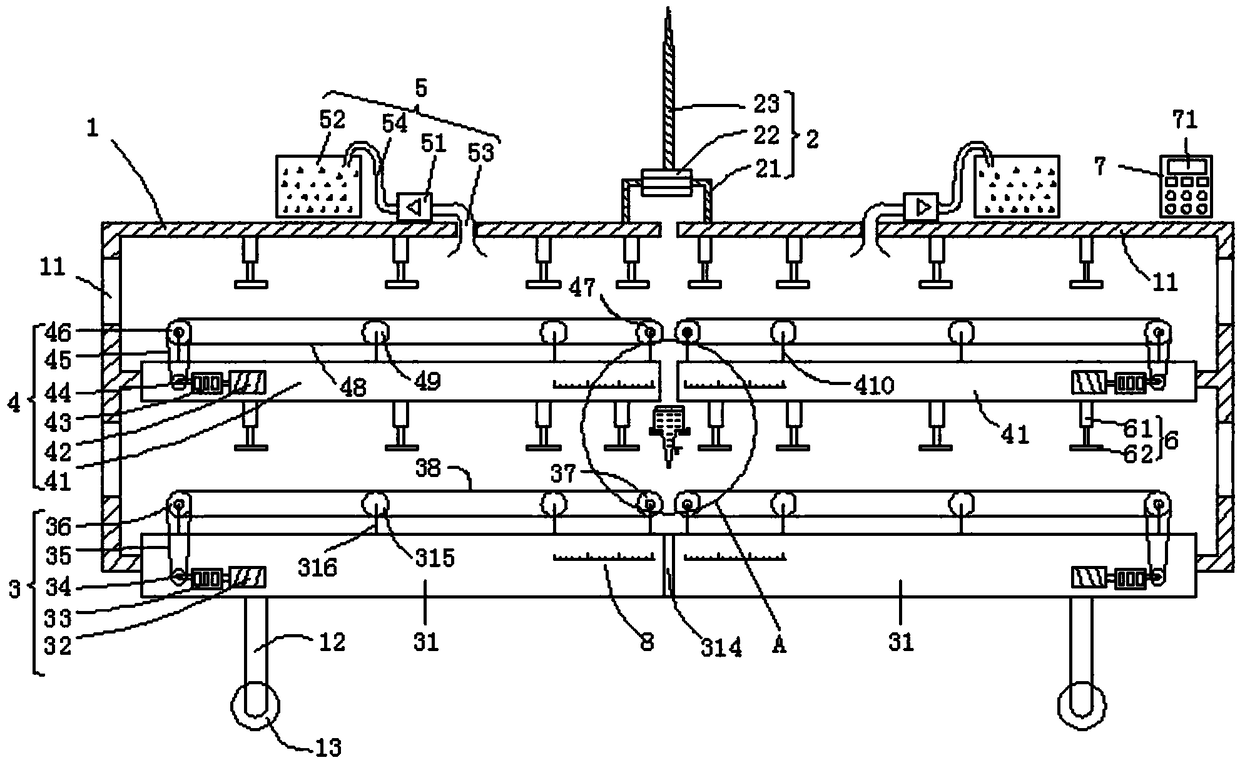

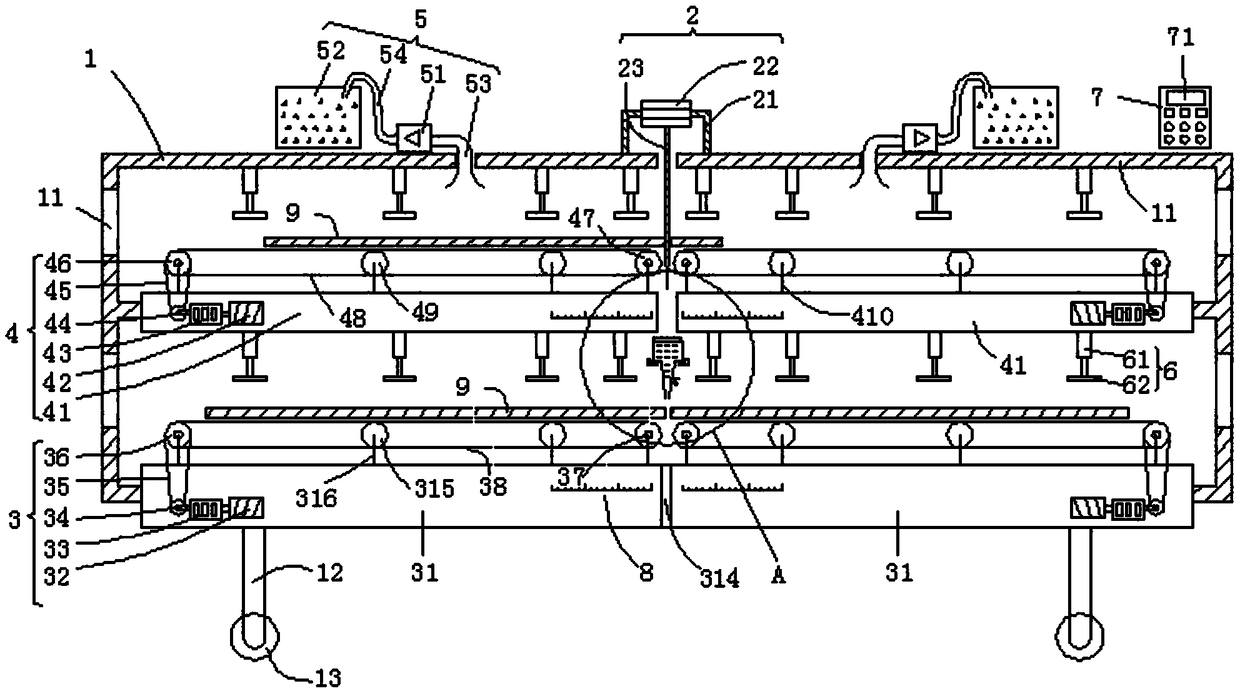

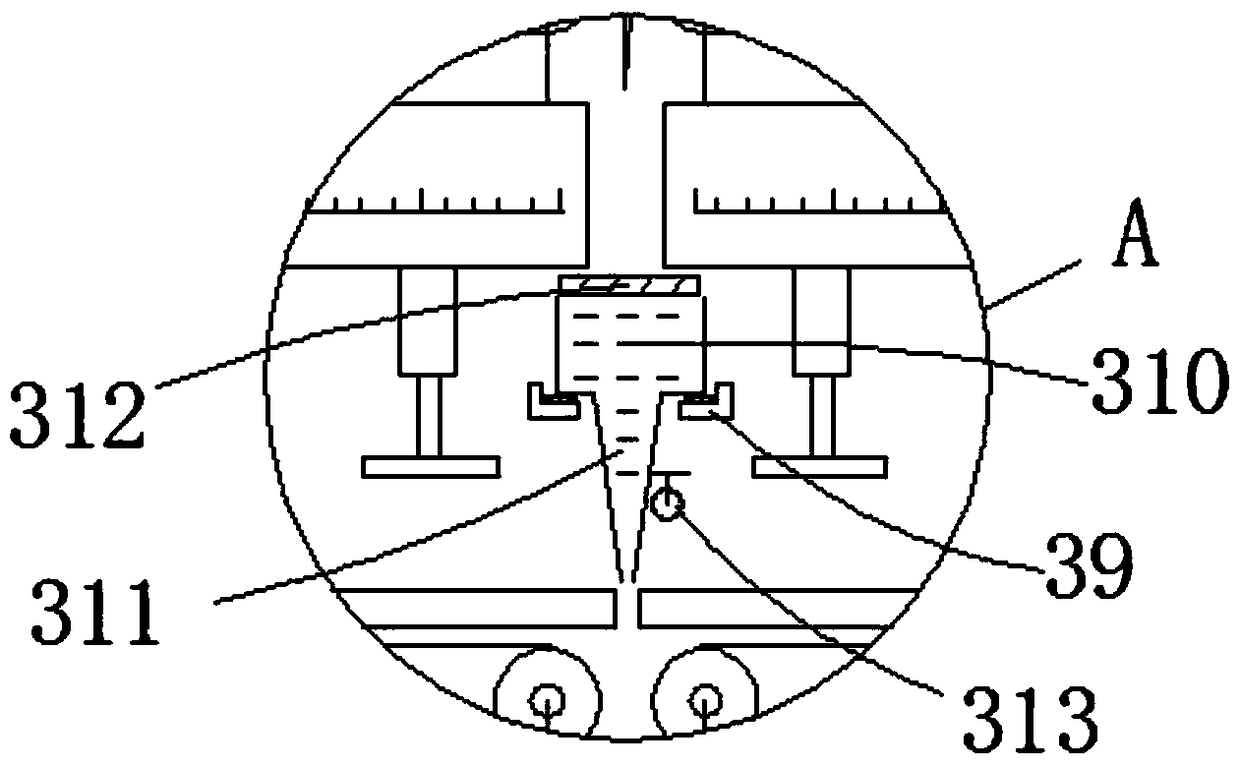

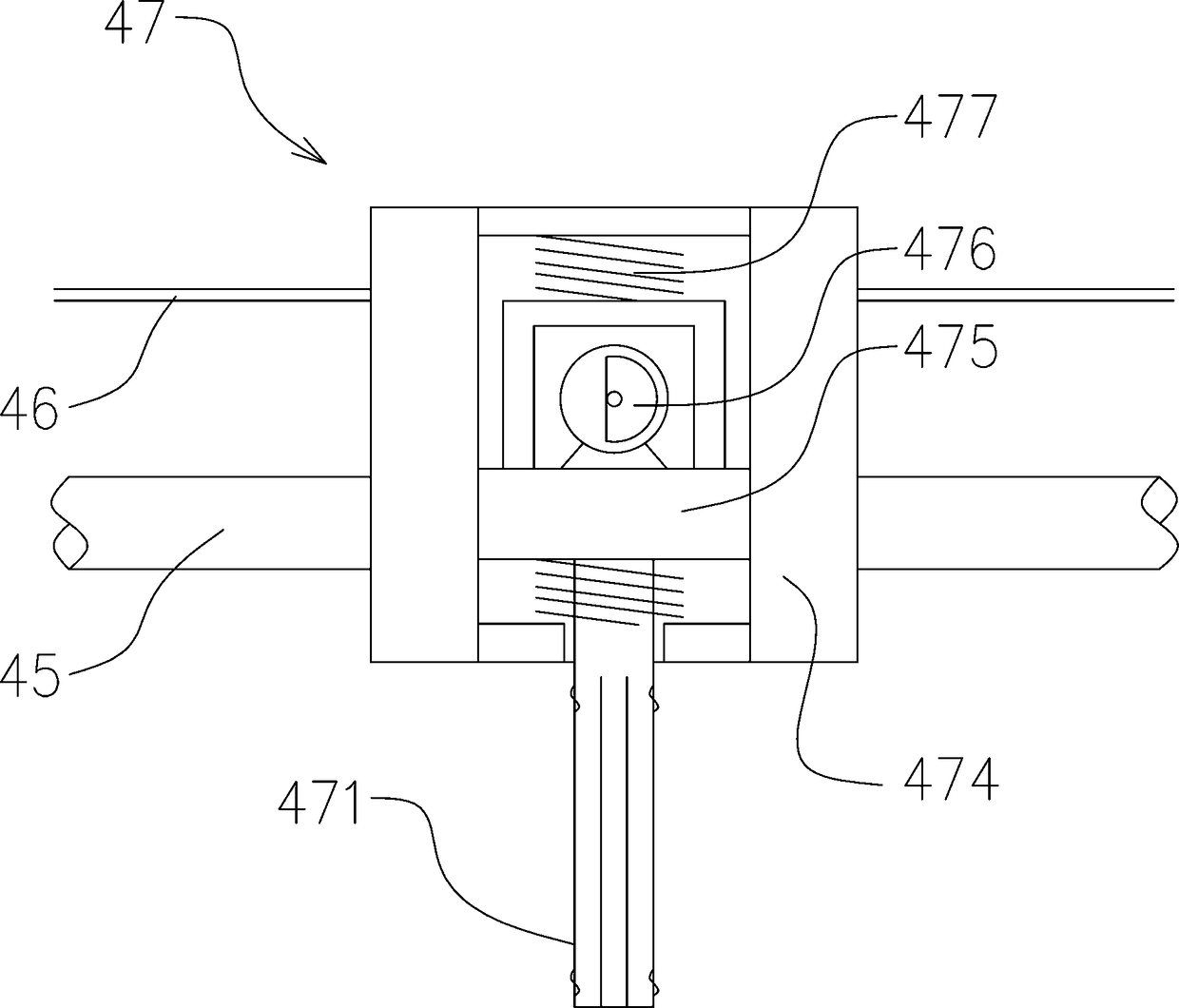

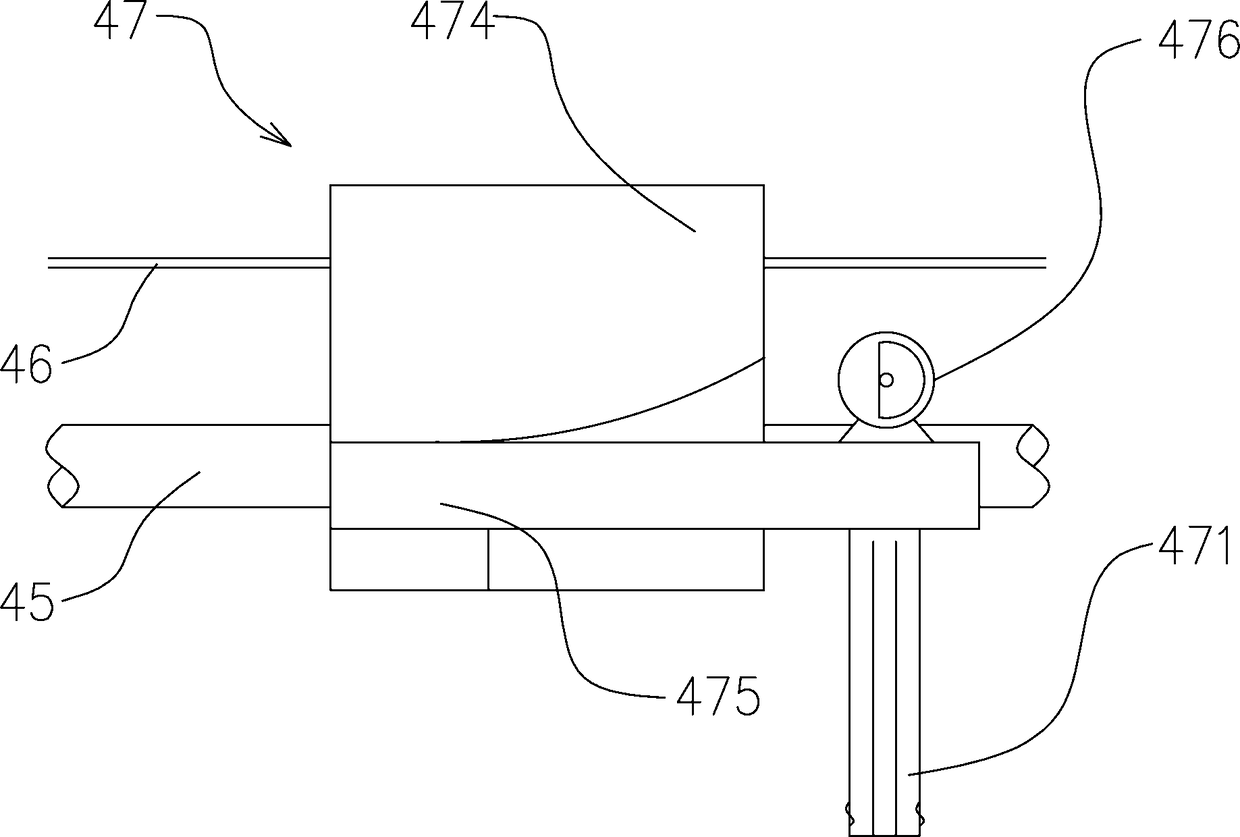

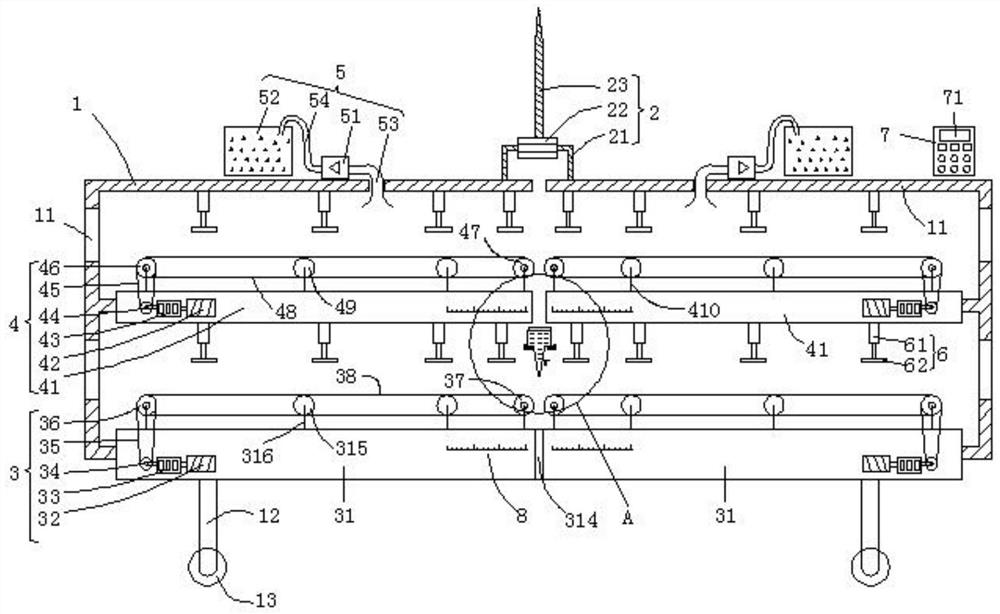

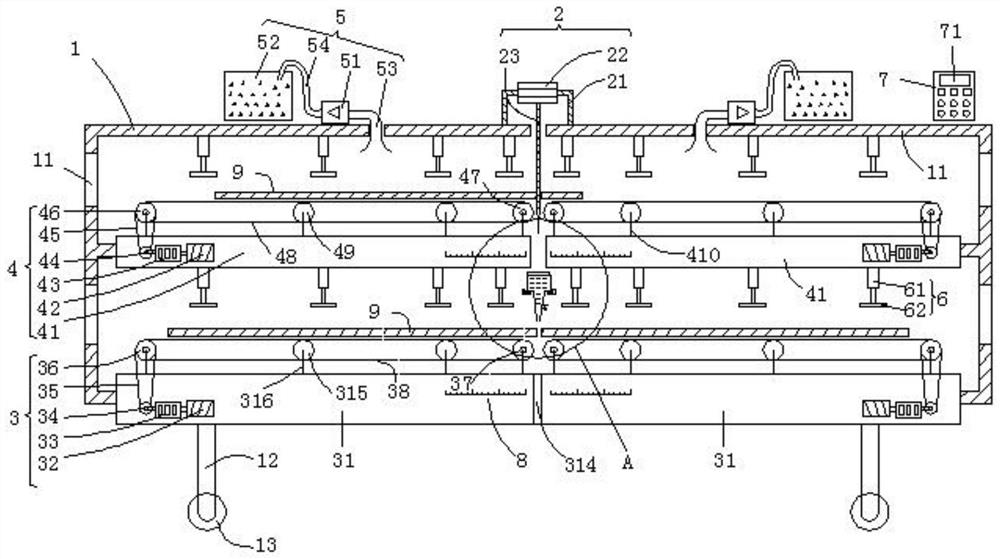

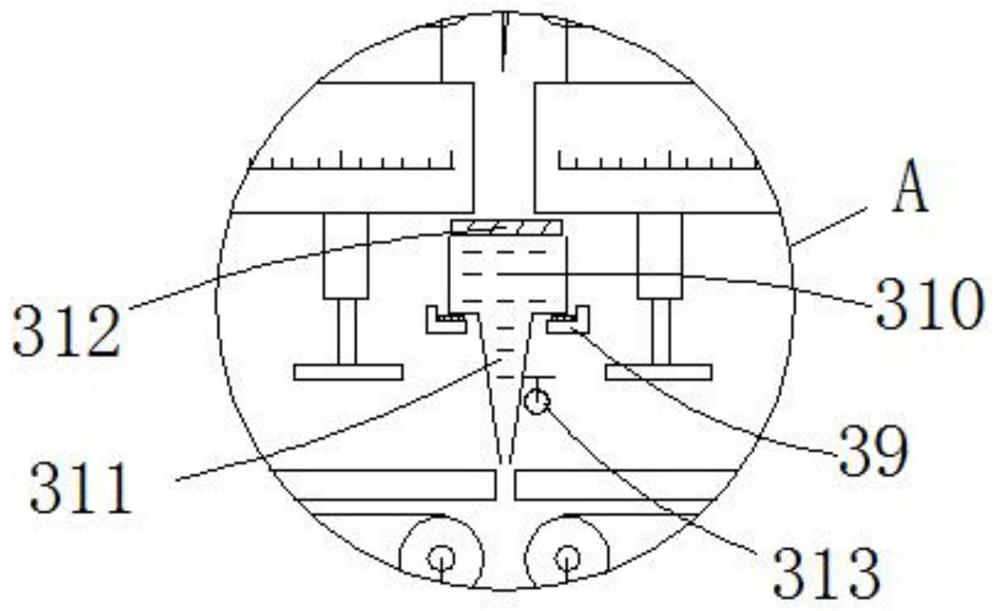

Platform air suction shutter device of high-speed corrugated board digital printing machine

InactiveCN113386476APrecise positioningSimple structureTypewritersPower drive mechanismsMotor speedDigital printing

The invention discloses a platform air suction shutter device of a high-speed corrugated board digital printing machine, and relates to the technical field of corrugated board digital printing machines. The platform air suction shutter device comprises a printing machine assembly, a rear paper supporting machine table, a driving module, an air suction platform module and an air suction shutter module, wherein the printing machine assembly comprises a printing machine body, a conveying motor used for driving the air suction platform module is arranged on one side of the printing machine body, and the driving module comprises a chain wheel adjusting support and a motor speed reducer. According to the platform air suction shutter device, the printing machine assembly, the air suction platform module and the air suction shutter module are arranged, opening and closing of a shutter air opening blocking piece are controlled through a telescopic electromagnet, and thus, the purpose that any negative pressure cavity can be quickly released from negative pressure control is achieved; and the device is simple in structure and easy to control, so that the corrugated board is more accurate in positioning, it is ensured that that the printed product does not generate ink floating or burrs, the printed pattern is more exquisite, the economic benefit is met, and the application prospect is wide.

Owner:深圳市万德环保印刷设备有限公司

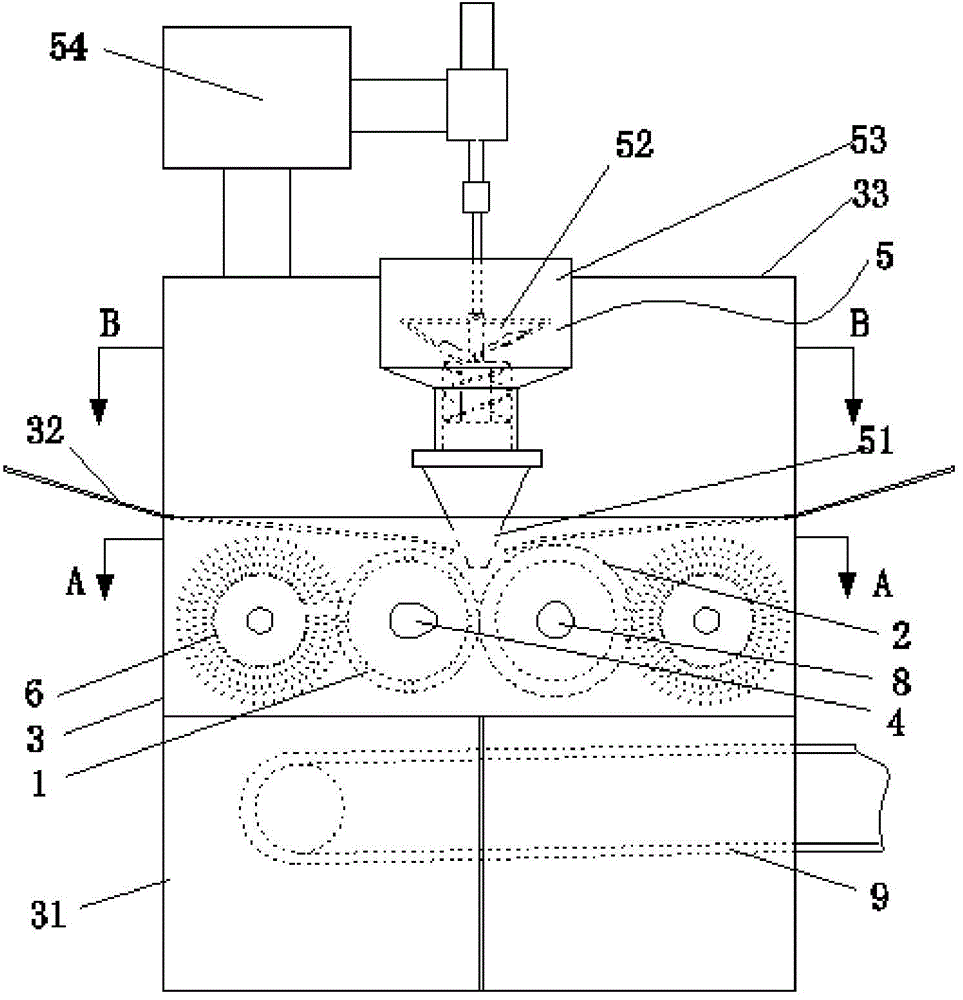

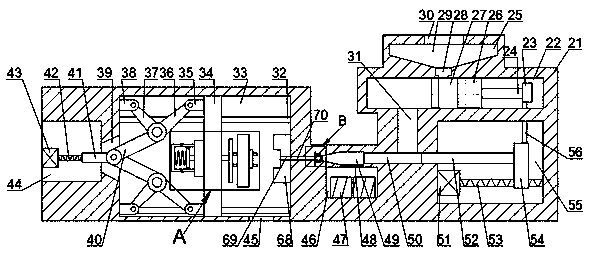

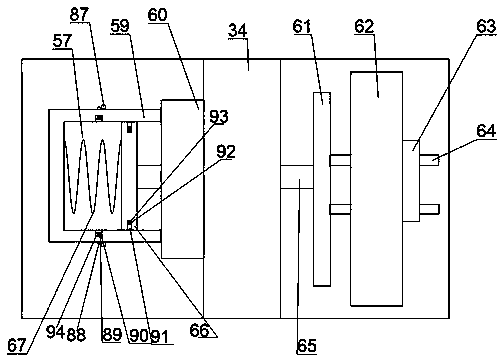

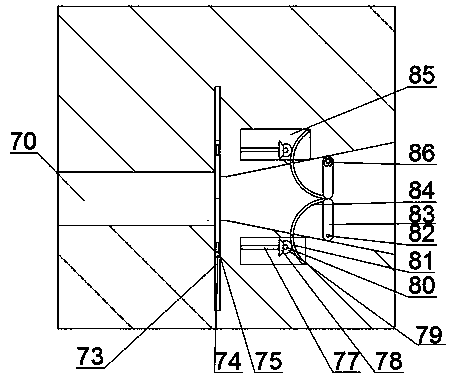

Dumpling processing machine and processing method thereof

ActiveCN104664177ASimple structureEasy to useDough shapingFood preparationEngineeringMechanical engineering

The invention discloses a dumpling processing machine. The dumpling processing machine comprises a stuffing conveying device and a dumpling forming die having a first roller die and a second die which are respectively used for disposing dumpling wrappers; and the two roller dies are respectively provided with a groove for forming a dumpling, respective dumpling wrappers are respectively pulled to move toward an occlusion position when the two roller dies rotate to bond the lower edges of the two dumpling wrappers together at the occlusion position in order to form a dumpling bag with a closed lower end, a stuffing output by the stuffing conveying device falls into the dumpling bag, the dumpling bag falls into the groove of the two roller dies, and continuously rotates with the two roller dies, and the upper end of the dumpling bag is bonded at the occlusion position to wrap the stuffing in the dumpling bag in order to form the dumpling. The dumpling processing machine has a simple structure, the dumpling making process is simple, and the dumpling formed in the invention has the advantages of consistent size and shape, good stuffing mouthfeel, high stuffing wrapping precision, high production efficiency and good quality. The invention also provides a dumpling processing method.

Owner:HAIXIN FOODS

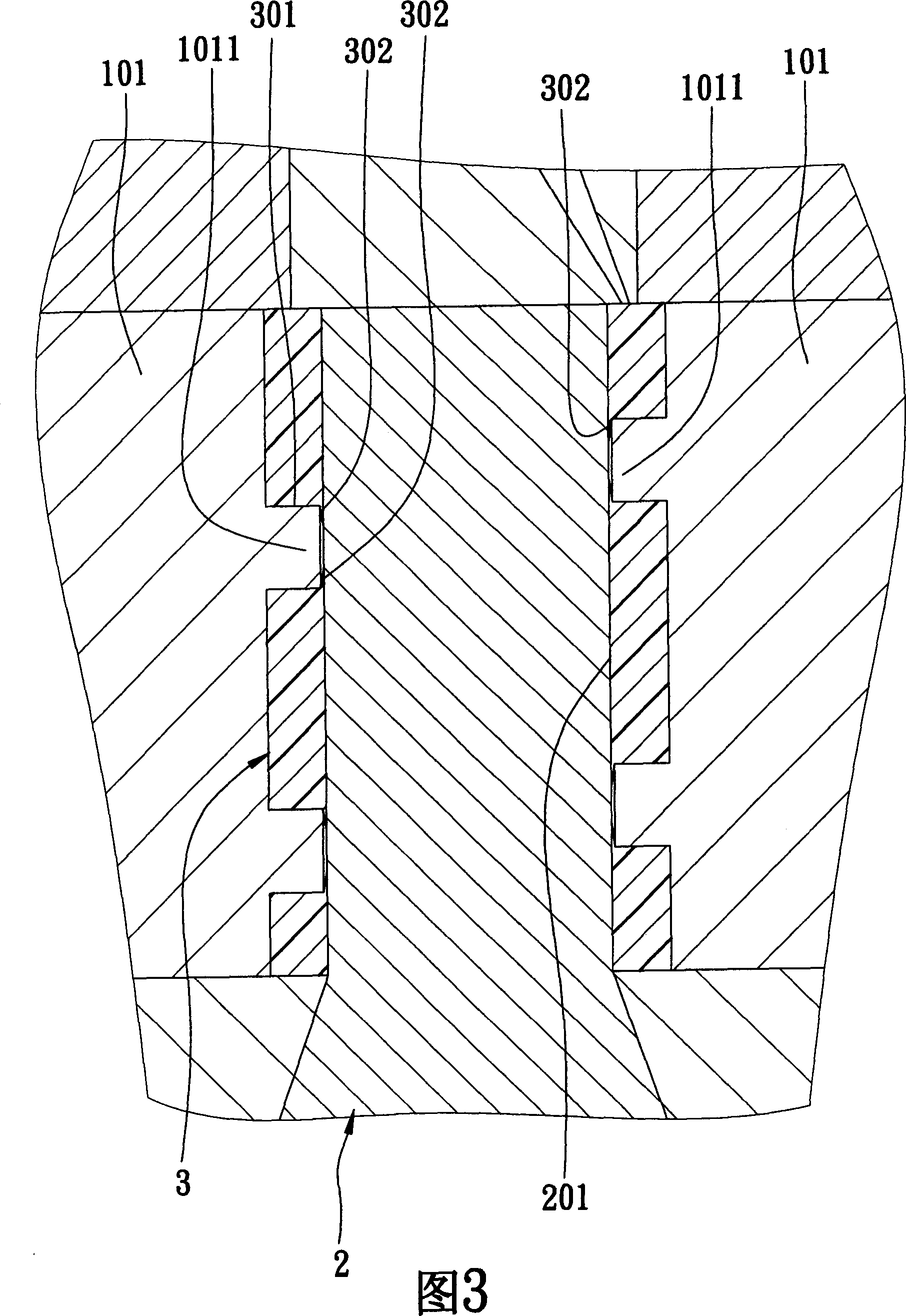

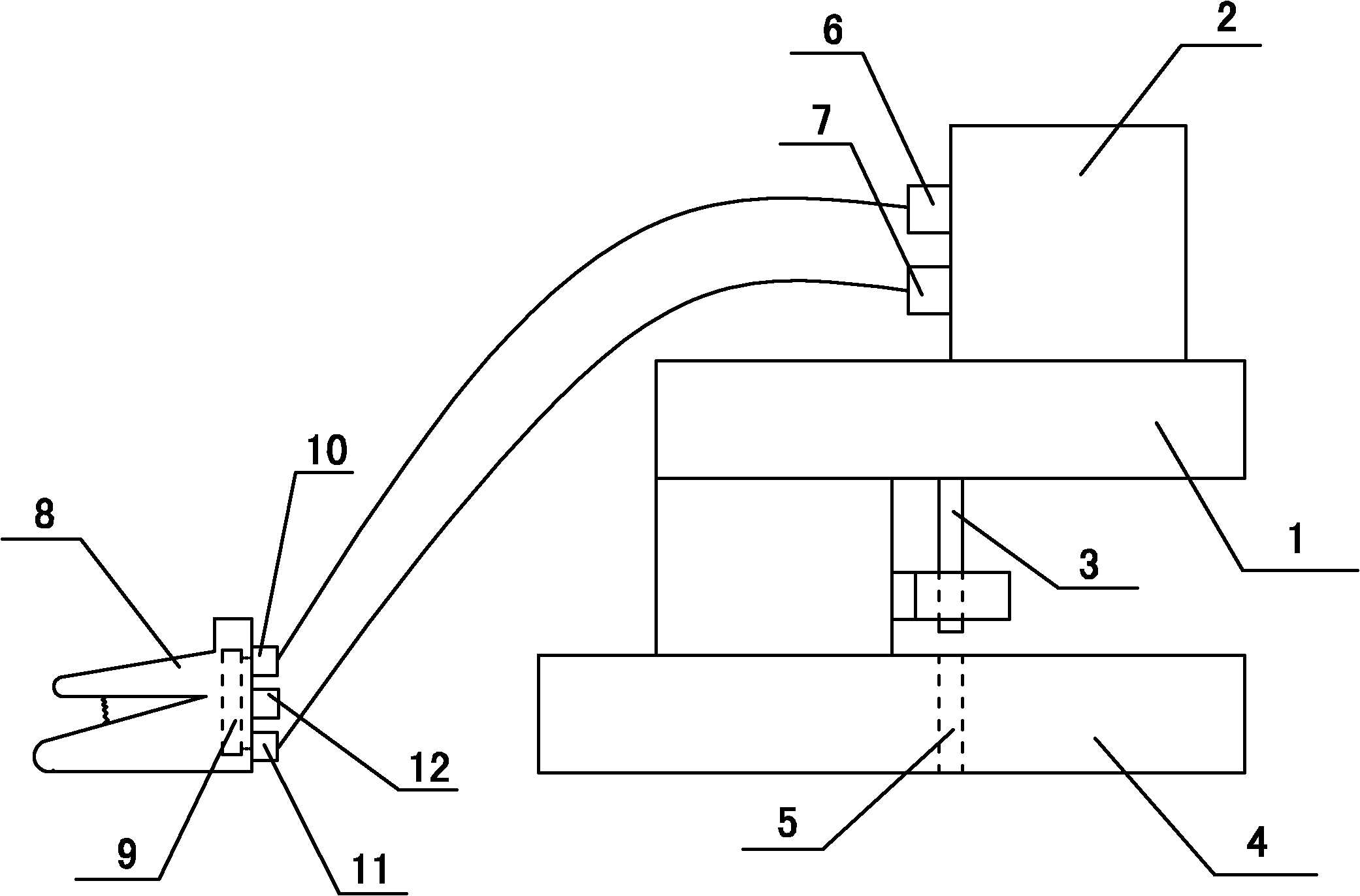

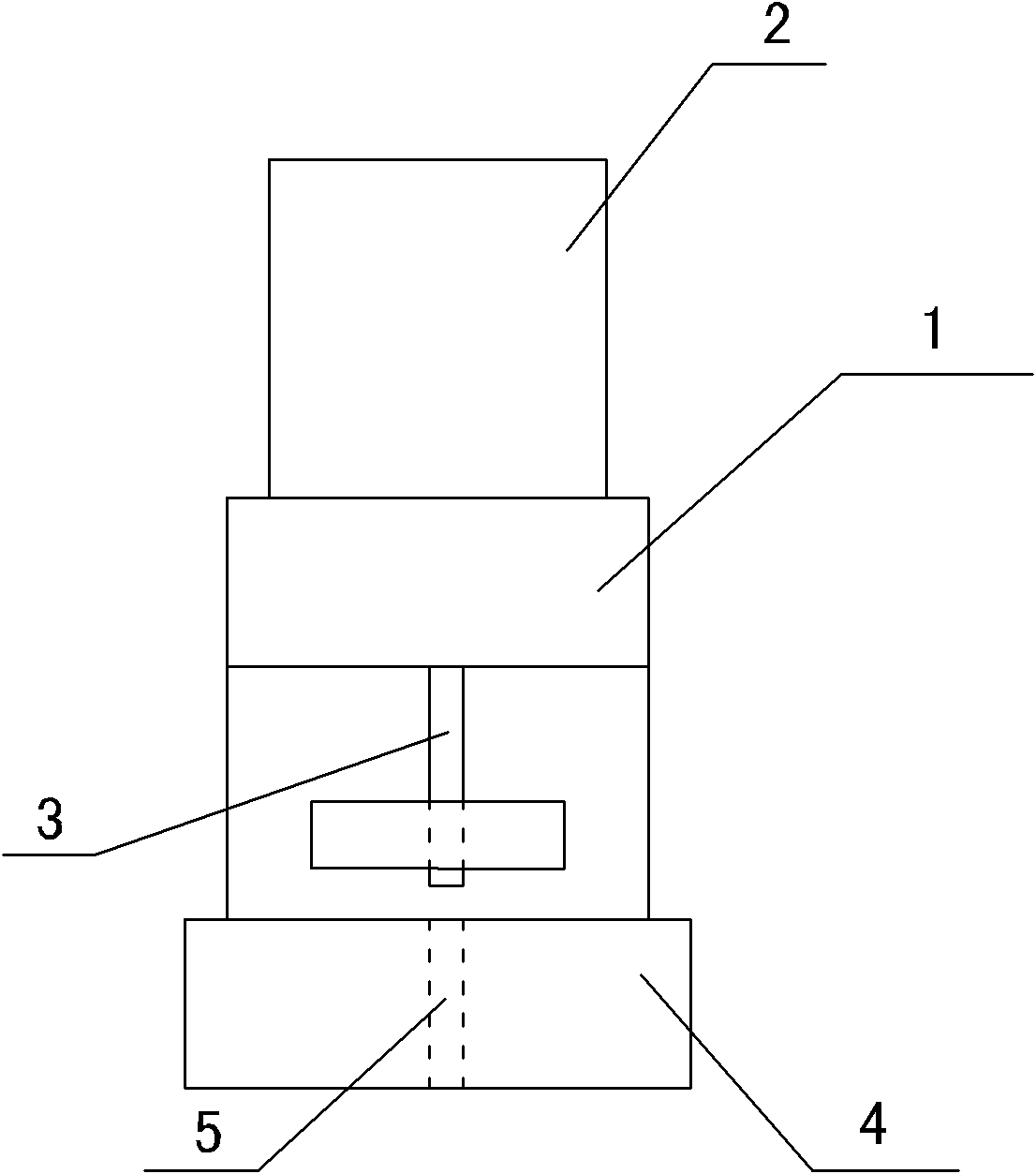

Fossula type cam canister production method

The invention discloses a making method of fossula-typed cam cylinder, which comprises the following steps: 1. moulding the easy-fusion alloy material into the low-temperature alloy core mould with peripheral surface and at least one cam bar on the peripheral surface; 2. forming a thermal insulating layer on the peripheral surface and cam bar; 3. placing the low-temperature alloy core mould in the moulding model nest of cam cylinder; 4. injecting the liquid plastics in the moulding model nest of cam cylinder; moulding the nest and alloy core model into a cam cylinder to make the cam cylinder possess an internal peripheral surface; 5. fetching the low-temperature alloy core model and cam cylinder out of the moulding nest; 6. heating the low-temperature alloy core model to make the low-temperature alloy core model melt and flow through the internal hole.

Owner:ASIA OPTICAL CO INC

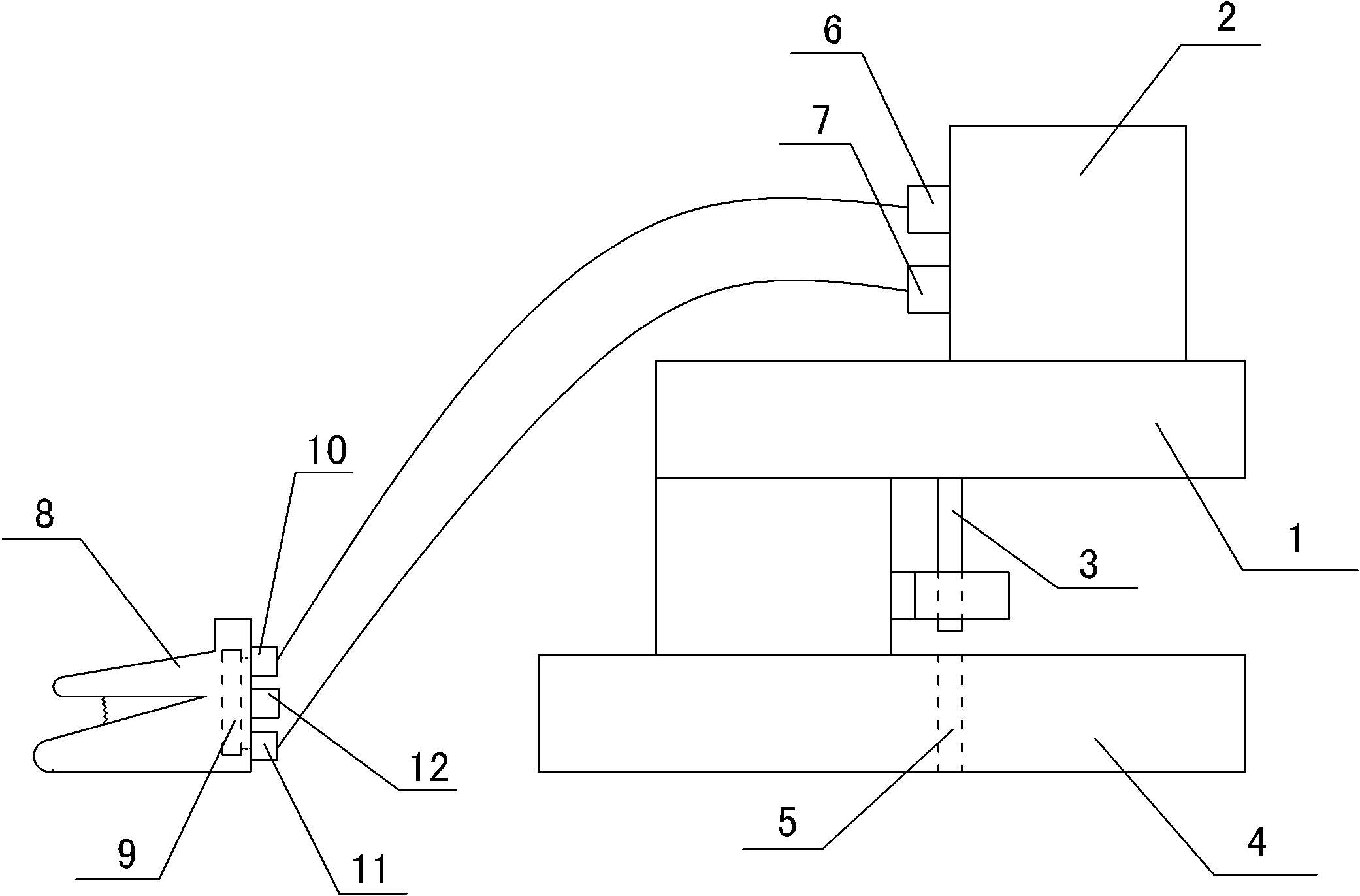

Hot cutting machine

InactiveCN105077850AThe cut surface is neat and smoothNo burrsHeelsEngineeringMechanical engineering

The invention discloses a hot cutting machine which comprises a rack, wherein a material table, a cutter mechanism and a feed mechanism are arranged on the rack, the cutter mechanism is positioned above the material table, the feed mechanism is arranged on one side of the material table, the cutter mechanism comprises a cutter with a heating mechanism, and a cutter driving mechanism for driving the cutter mechanism to cut the material, the feed mechanism conveys a belt-shaped material on the material table, and the cutter driving mechanism drives the hot cutter to carry out hot cutting on the material on the material table.

Owner:KUSN TIANCUN PRECISION MACHINERY

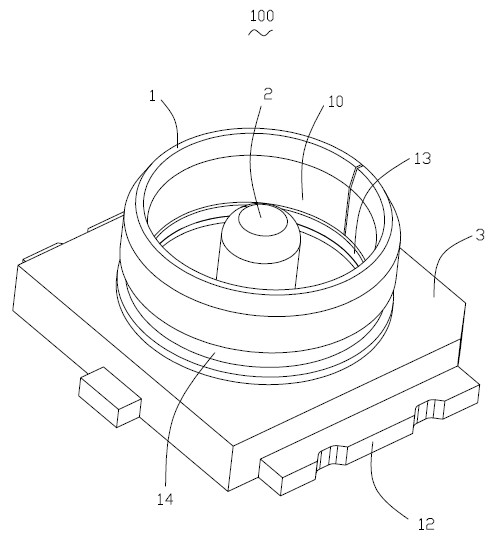

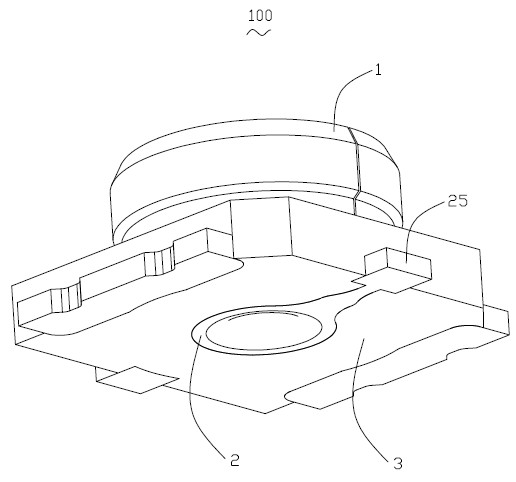

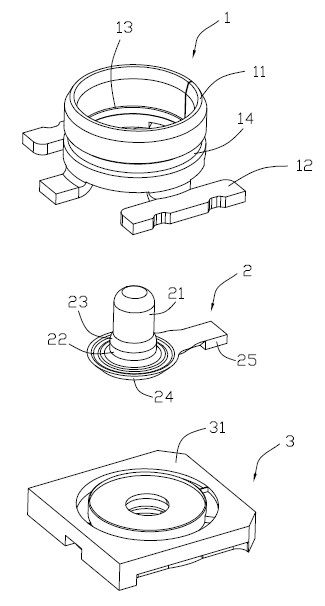

Coaxial connector

InactiveCN102683952AAvoid glue overflowEasy injection moldingCoupling contact membersTwo-part coupling devicesElectrical conductorEngineering

Owner:KUNSHAN JIAHUA ELECTRONICS

Semi-automatic hole puncher for producing plastic dropping labels

The invention discloses a semi-automatic hole puncher for producing plastic dropping labels, comprising a base and a frame body arranged on the base. The semi-automatic hole puncher is characterized in that: an air cylinder is arranged on the frame body, a hole punching rod is connected at the bottom of the air cylinder, a guide hole is correspondingly arranged on the base below the hole punching rod, two vacuum inlet holes are arranged in the air cylinder, one foot pedal switch is arranged at one side of the frame body, a solenoid valve is arranged in the foot pedal switch, two vacuum outlet holes and an air-path vacuum hole are arranged on the foot pedal switch, the solenoid valve is connected with the vacuum outlet holes, the two vacuum inlet holes are respectively connected with the two vacuum outlet holes by a pipeline, and an air-path vacuum hole is connected with an air source pipeline. In the invention, the air cylinder is controlled by the solenoid valve in the foot pedal switch to drive the hole punching rod to punch holes; the dynamics for punching is uniform, the artistic degree of a product is improved, time and labor are saved, the efficiency is improved, batch production can be realized, equipment does not needed to be adjusted before production, and hands of workers can not be damaged in working.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Insulating pad cutting and bonding integrated machine

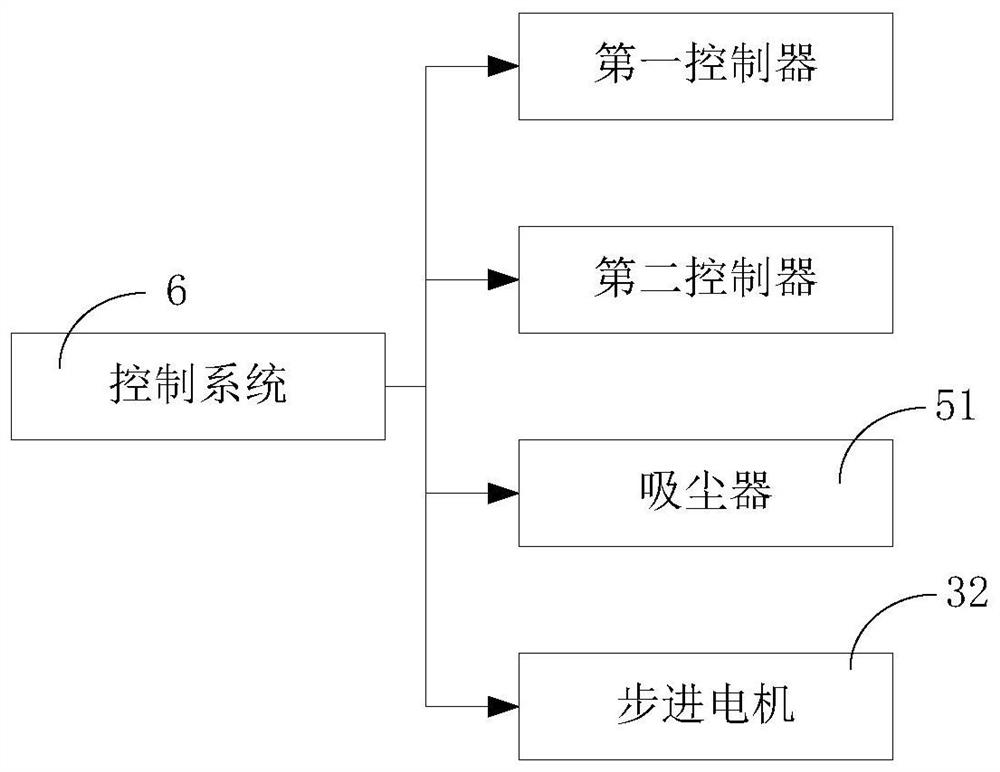

InactiveCN108908956AImprove work efficiencyImplement automatic croppingDirt cleaningDomestic articlesEngineeringControl system

The invention provides an insulating pad cutting and bonding integrated machine, which belongs to the technical field of electric power construction facility. The machine comprises a frame and a cutting mechanism, a material inlet and outlet are arranged on both sides of the frame, a cutting table for cutting an insulating rubber pad and a bonding mechanism for bonding a plurality of the insulating rubber pads are arranged at the frame, a pressing mechanism for pressing the insulating rubber pad is arranged at top of the cutting table and frame, a dust removing mechanism for sucking the insulating rubber pad debris is disposed at the upper portion of the frame, and a control system for controlling the cutting mechanism, the bonding mechanism, the pressing mechanism and the dust removing mechanism are arranged at the upper part of the frame. According to the insulating rubber pad cutting and bonding integrated machine, by arranging the cutting mechanism, the bonding mechanism and the cutting table on the frame, the control system controls the cutting and bonding parameters, the automatic cutting and automatic bonding of the insulating rubber pad can be realized, and the machine hasthe advantages of no gap, no foaming, no burrs for bonding, and increases the working efficiency of the insulating rubber pad.

Owner:STATE GRID CORP OF CHINA +1

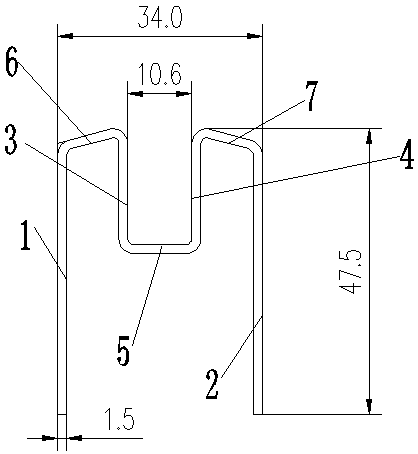

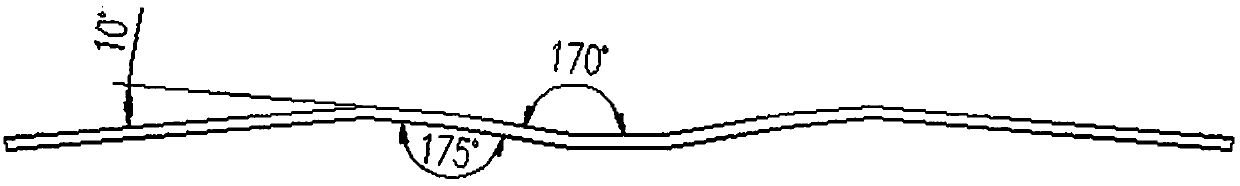

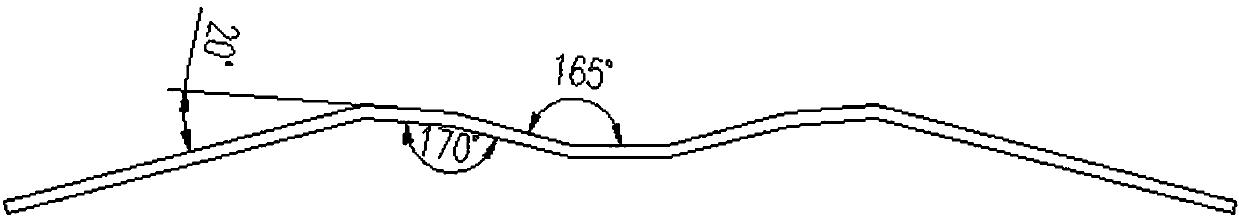

Heightened lug-free armrest support and bending forming method thereof

ActiveCN107720511AUnchanged thicknessNo burrsMetal working apparatusEscalatorsEngineeringRoll forming

The invention discloses a heightened lug-free armrest support and further discloses a bending forming method. The heightened lug-free armrest support comprises a first side wall and a second side wall; a third side wall and a fourth side wall are arranged between the first side wall and the second side wall and connected through a flat and straight plate; the first side wall and the third side wall are connected through a first inclined side wall; and the second side wall and the fourth side wall are connected through a second inclined side wall. A cold-rolling mill conducts rolling forming onthe lug-free armrest support through a roller, an X5Cr18Ni9 plate is bent, and thus a large number of technological processes are reduced; and after rolling, the out-of-tolerance phenomenon or the torsion phenomenon of a sectional material does not occur, the thickness of the plate is unchanged, and the rough edge phenomenon is avoided.

Owner:JIANGSU TONGLI MACHINERY

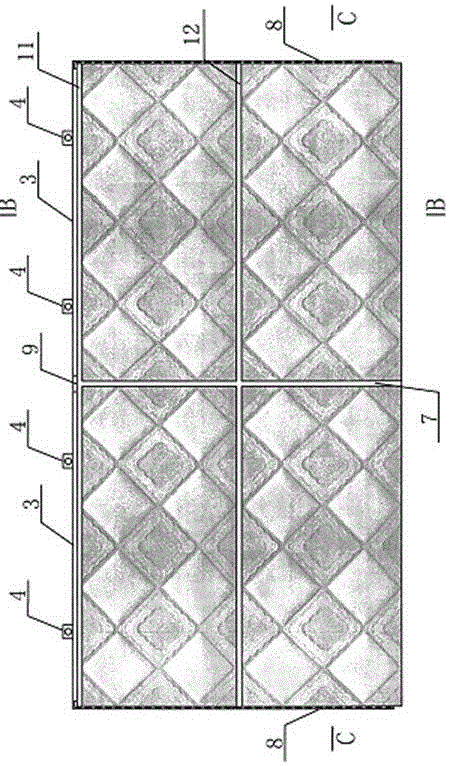

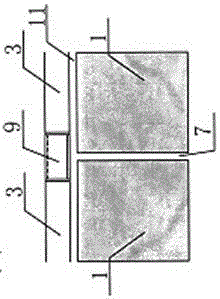

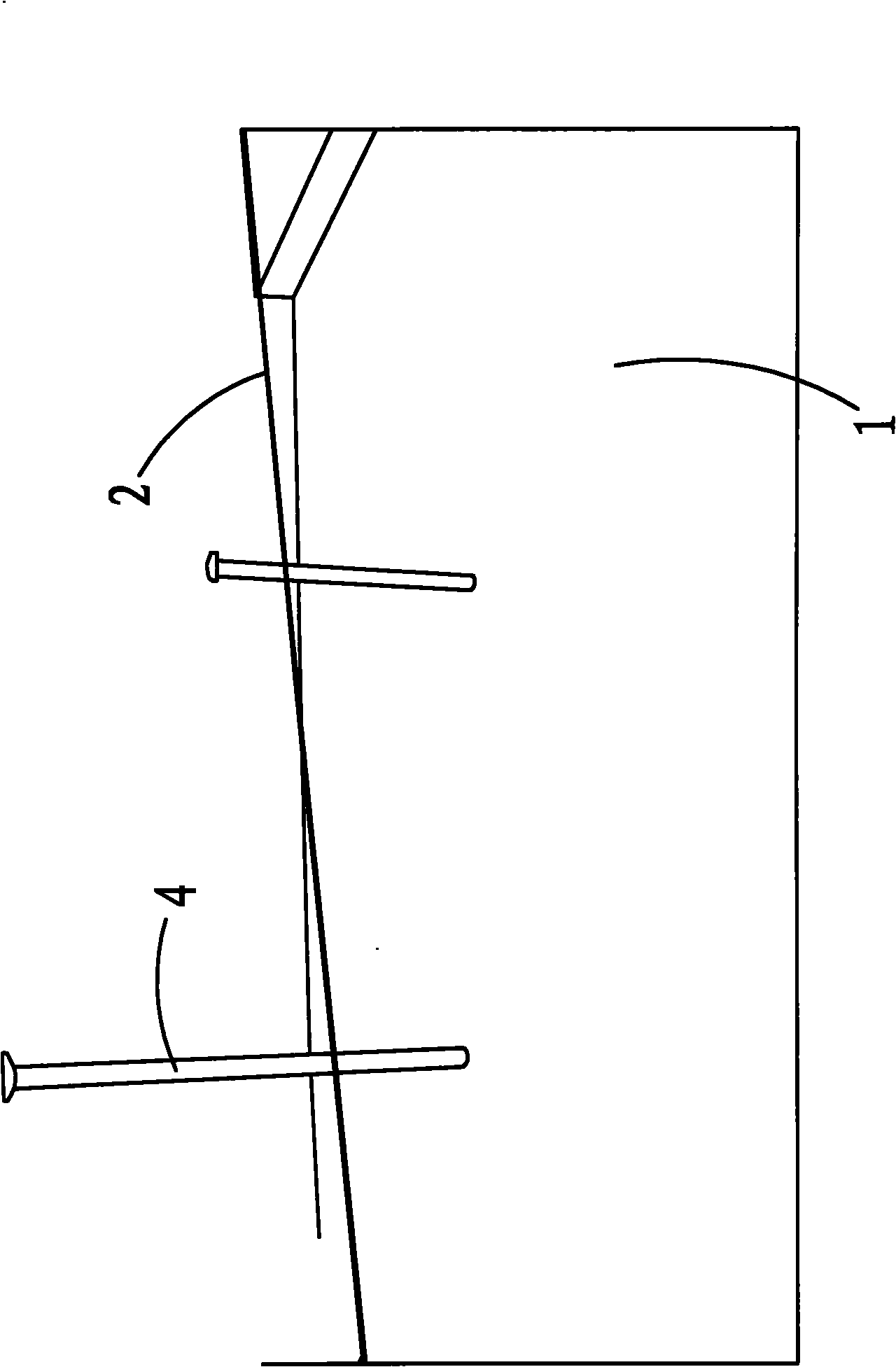

External thermal insulation cement decoration panel with punching metal strips pre-embedded in end surfaces on two sides of same

InactiveCN105464320APrecise in shape and sizePrecise embedded positioningCovering/liningsFlooringMetal stripsPunching

The invention discloses an exterior wall external thermal insulation cement decoration panel with punching metal strips pre-embedded in end surfaces on the two sides of the same. The decoration panel is characterized in that the decoration panel is internally provided with a metal or nonmetal net; three-dimensional decorative patterns are prefabricated on the outer side surface of the decoration panel; an concave edge having appropriate width and depth is arranged on the upper edge of the decoration panel; a full-length bulged key is arranged on the upper end surface of the decoration panel; metal hangers are arranged on the upper end surface of the decoration panel at a certain interval; the end surfaces on the two sides are flat surfaces or flanges with appropriate height are arranged on the edges of the outer sides of the end surfaces; and the punching metal strips are pre-embedded in the end surfaces on the two sides of the decoration panel. When cement decoration panels are assembled, horizontal seams are sunk-key type seams; horizontal dividing seams are formed by the concave edges; vertical seams are punching metal strip lap seams filled with mortar; and vertical dividing seams having the depth identical to that of the horizontal dividing seams are formed. The punching metal strips are high in flatness and high in shape and size accuracy, and well meet requirements of cement decoration panel production. The punching metal strip lap seams are high in tensile strength, and motor can be effectively prevented from cracking and leaking.

Owner:上海丽祥节能科技股份有限公司

External thermal insulation cement decoration panel provided with embedded punched metal strips at two side ends and assembling method thereof

InactiveCN105735581APrecise in shape and sizePrecise embedded positioningCovering/liningsMetal stripsThermal insulation

The invention relates to an external thermal insulation cement decoration panel provided with embedded punched metal strips at the two side ends and an assembling method thereof. The external thermal insulation cement decoration panel is characterized in that the cement decoration panel is internally provided with a metal or non-metal net; a three-dimensional decorative pattern is preformed on the outer side face of the cement decoration panel; the upper edge of the decoration panel is provided with a concave edge with an appropriate width and depth; the upper end face of the cement decoration panel is provided with a full-length convex key and metal hanging parts at certain intervals; and the two side end faces of the cement decoration panel are planes or the outer edges of the cement decoration panel are provided with convex edges with an appropriate height, and the punched metal strips are embedded in the two side ends of the cement decoration panel. During construction and assembly of the cement decoration panel, horizontal joints serve as sunk key type joints, the concave edges form horizontal grid division joints, vertical joints serve as punched metal strip coped joints, special mortar is embedded in the joints compactly in a filling mode, and vertical grid division joints with the same depth as the horizontal grid division joints are formed. The punched metal strips are good in flatness, accurate in shape and size and capable of well meeting the requirements of the production process of the cement decoration panel. The punched metal strip coped joints have good tensile strength and can effectively protect the mortar joints against cracking and leakage.

Owner:上海紫霓节能科技有限公司

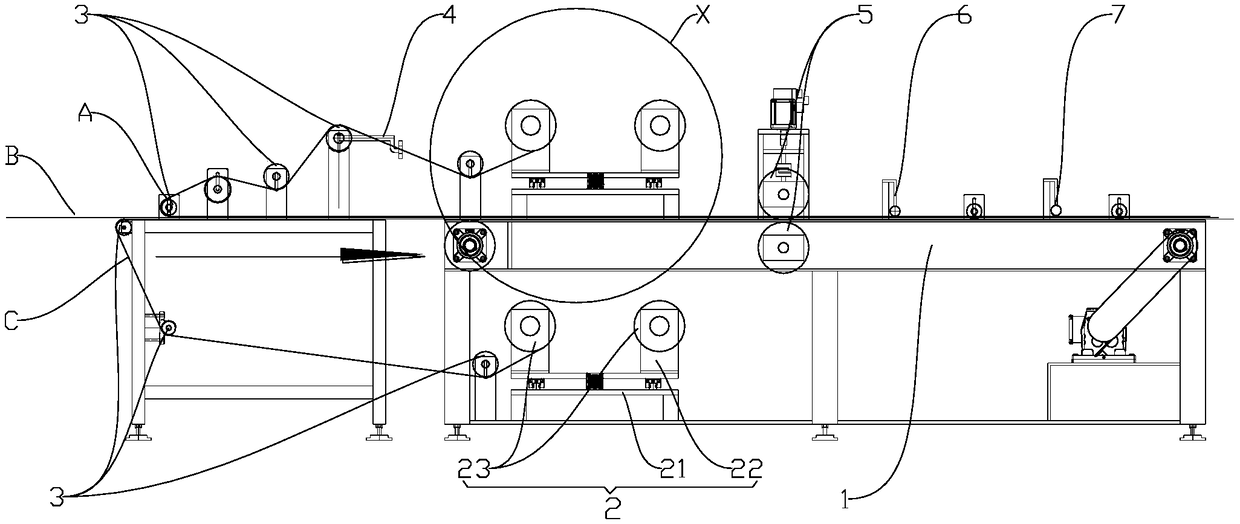

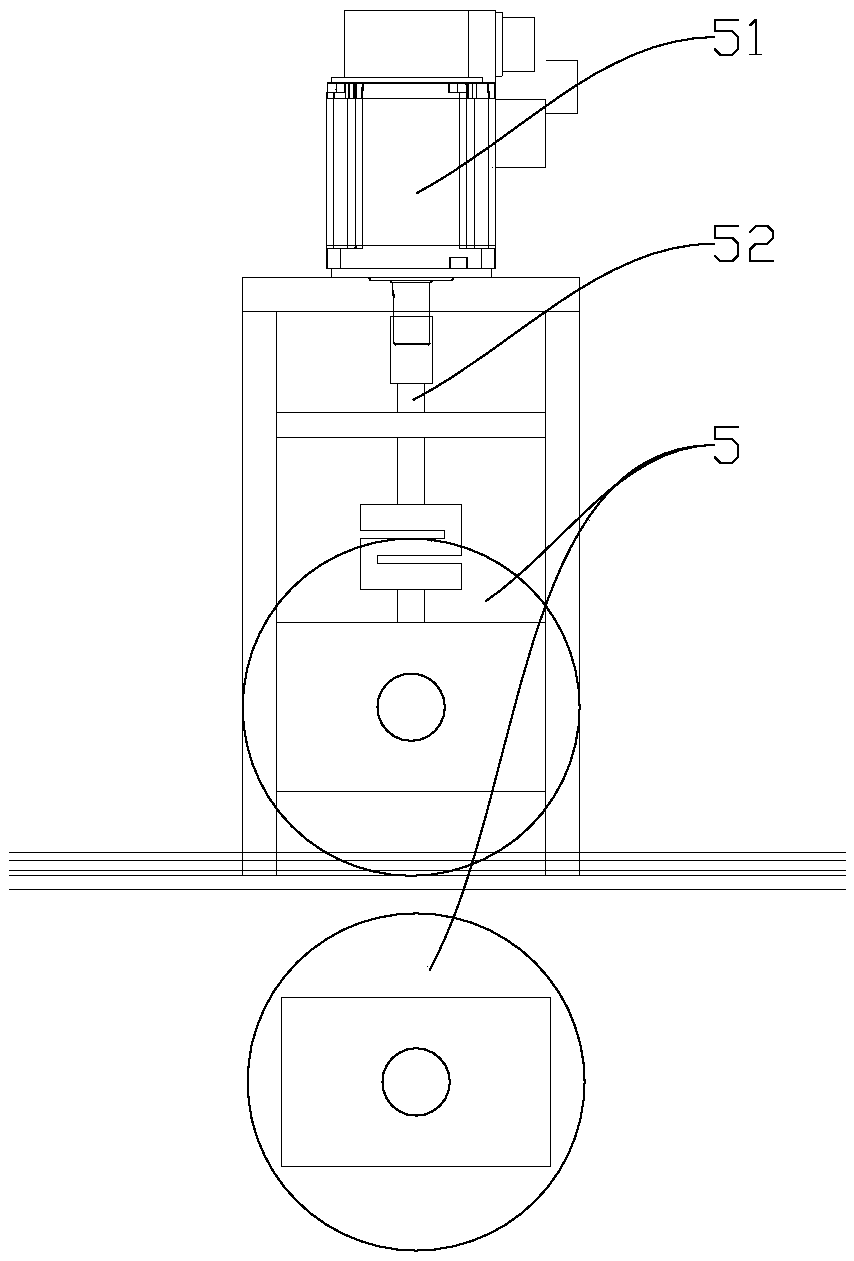

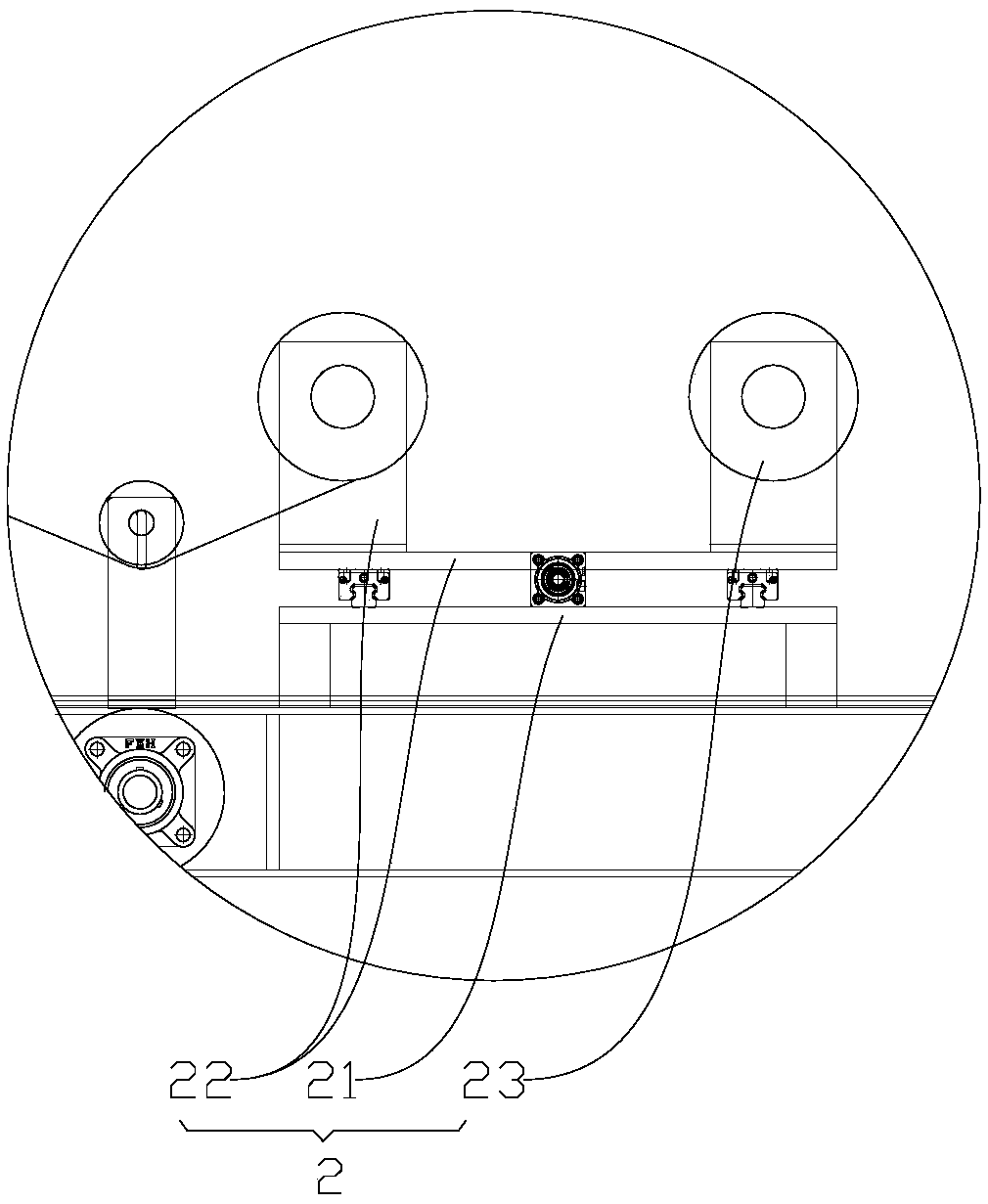

Damping fin dragging device and damping fin composite production system

ActiveCN109368344ANo burrsAccurate realizationLaminationLamination apparatusPulp and paper industryAluminum foil

The invention discloses a damping fin dragging device. Pay-off devices are arranged above and below a composite table and used for containing aluminum foil coils and isolation paper coils, movable seats of the pay-off devices can transversely move relative to fixed seats, during work, the transverse position of aluminum foil or isolation paper is detected through a position sensor, a signal is transmitted to a drive device, then the aluminum foil coils and the isolation paper coils are driven to move transversely, the output positions of the aluminum foil and the isolation paper are adjusted,and deviation rectifying is achieved; and the aluminum foil and the isolation paper obtained after deviation rectifying can be aligned with a rubber pad, the rubber pad is sandwiched between the aluminum foil and the isolation paper, a damping pad with the two aligned sides is formed, the damping pad is conveyed forwards on the composite table, and no burr problem is generated on the two sides ofthe finally-formed damping pad.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

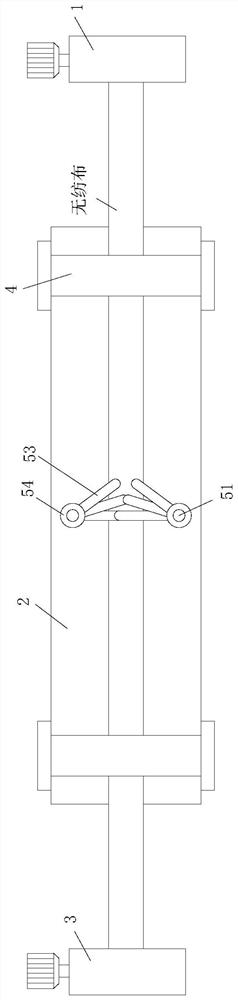

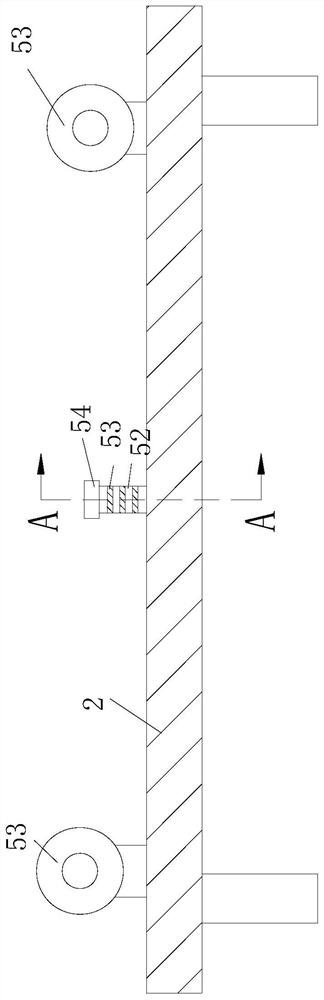

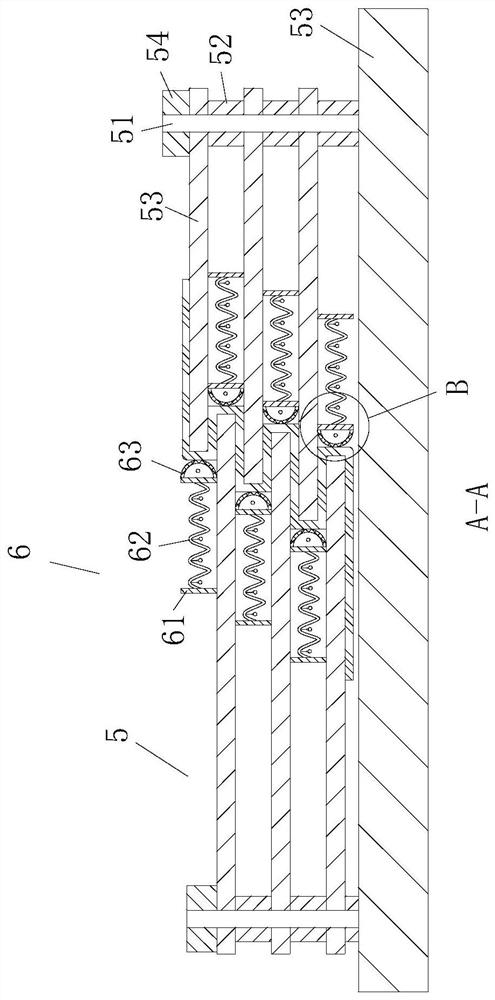

Non-woven fabric pleating device and mask production line

ActiveCN112981838APrevent crushingImprove the efficiency of wrinklingMechanical cleaningPressure cleaningWinding machineNonwoven fabric

The invention discloses a non-woven fabric pleating device and a mask production line. The non-woven fabric pleating device comprises an unwinding machine, a machine table and a winding machine, wherein a pressing roller is arranged on each of the two sides of the machine table, a gap is reserved between each pressing roller and the machine table, a pleating mechanism is arranged in the machine table and comprises two fixing rods symmetrically distributed on the machine table, circular rings, pleating plates and locking nuts, threads are arranged on the outer rings of the upper ends of the fixing rods, and the locking nuts are in threaded connection with the upper ends of the fixing rods. According to the non-woven fabric pleating device and the mask production line, the pleating mechanism is matched with a supporting mechanism, so that the non-woven fabric can be sufficiently supported when being squeezed into a wrinkled shape, the situation that the non-woven fabric between an upper pleating plate and a lower pleating plate is squeezed to be broken due to lack of supporting is avoided, and the non-woven fabric pleating efficiency is greatly improved.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Soft porcelain tile cutting tool bit

InactiveCN109203197AQuick cutGuaranteed to be verticalCeramic shaping apparatusEngineeringWork in process

The invention provides a soft porcelain tile cutting tool bit. A tool holder and a tool holder body are of an elastic connection structure, a cutting blade is fixedly connected with the tool holder, and a vibration device is fixedly arranged on the tool holder. By adopting the structure of which the elastic connection matched with the vibration device, the cutting blade can rapidly cut a soft porcelain semi-finished product under high-speed vibration, and burrs are not generated due to the fact that the vibration frequency is higher to reach 20-50Hz, so that the appearance quality is better, and the later construction and laying are facilitated. According to the arrangement of transverse movement and follow-up structures, the movement of the cutting blade is enabled to be synchronized withthe movement of the soft porcelain semi-finished product, and it is ensured that a cutting edge is perpendicular to the two side edges.

Owner:HUBEI YAOMEI FLEXIBLE CERAMICS

Decorative ribbon cutting machine

The invention relates to a decorative ribbon cutting machine. The decorative ribbon cutting machine comprises a stand, an electric heating wire and a power supply, wherein the electric heating wire is arranged on the stand, and the power supply is electrically connected with the electric heating wire. In the invention, an operator places a decorative ribbon on the decorative ribbon cutting machine for cutting, and the decorative ribbon is cut through the heating of the electric heating wire; high work efficiency is achieved; and a cut edge part generates no burr.

Owner:WUJIANG YUANXING SHOES

A kind of production technology of double-sided pcb board

ActiveCN105555046BThe mass concentration is reasonableImprove air tightnessConductive material chemical/electrolytical removalCircuit precursor manufactureResistMetallurgy

The invention relates to the technical field of PCBs, in particular to a production technology of a double-sided PCB. The technology sequentially comprises the following steps: double-sided copper foil substrate pretreatment, line coating and exposure treatment, line development, etching, de-inking treatment, solder resist pretreatment, solder resist development, lettering treatment, molding treatment, testing and antioxidant treatment. A copper foil substrate is subjected to surface polish-brush treatment through a polish-brush; a photosensitive ink layer and a solder resist ink layer coat the surface of the copper foil substrate; relatively high adsorption force is provided among the photosensitive ink layer, the solder resist ink layer and the copper foil substrate; the photosensitive ink layer and the solder resist ink layer are good in quality; and the produced PCB is good in quality. Cutting treatment is carried out on the copper foil substrate by a V-Cut technology; and the minimum thickness of the formed substrate corresponding to a V-shaped plate-dividing groove is controlled at 0.4-0.5mm, so that subsequent plate division is facilitated; and no burr is left.

Owner:湖北碧辰科技股份有限公司 +1

Push discharging injection molding machine

ActiveCN111497111AAvoid wastingQuality improvementCoatingsProcess engineeringManufacturing engineering

The invention discloses a push discharging injection molding machine. The push discharging injection molding machine comprises a machine body. The machine body is provided with a feed port with an upward opening. The lower sidewall of the feed port communicates with a raw material space. The lower sidewall of the raw material space communicates with a raw material port. The lower sidewall of the raw material port communicates with a push space. A baffle slideway is arranged on the left side of each baffle power space. A mold space is arranged on the left side of a heating space. The right sidewall of the mold space communicates with an injection molding material flow channel. The left sidewall of a sliding space communicates with an injection molding power space. The push discharging injection molding machine can control feeding of raw materials. Compared with an existing screw type feeding mode, the push discharging injection molding machine greatly avoids waste of the raw materials,guarantees that no burrs occur to molded plastic bodies, greatly improves the quality of finished plastic products, ensures that the thicknesses of all parts of each finished plastic product are uniform, ensures the melting degree of the raw materials better through an intermediate heat conducting plate better and further ensures the quality of the finished plastic products.

Owner:江西亚中电子科技股份有限公司

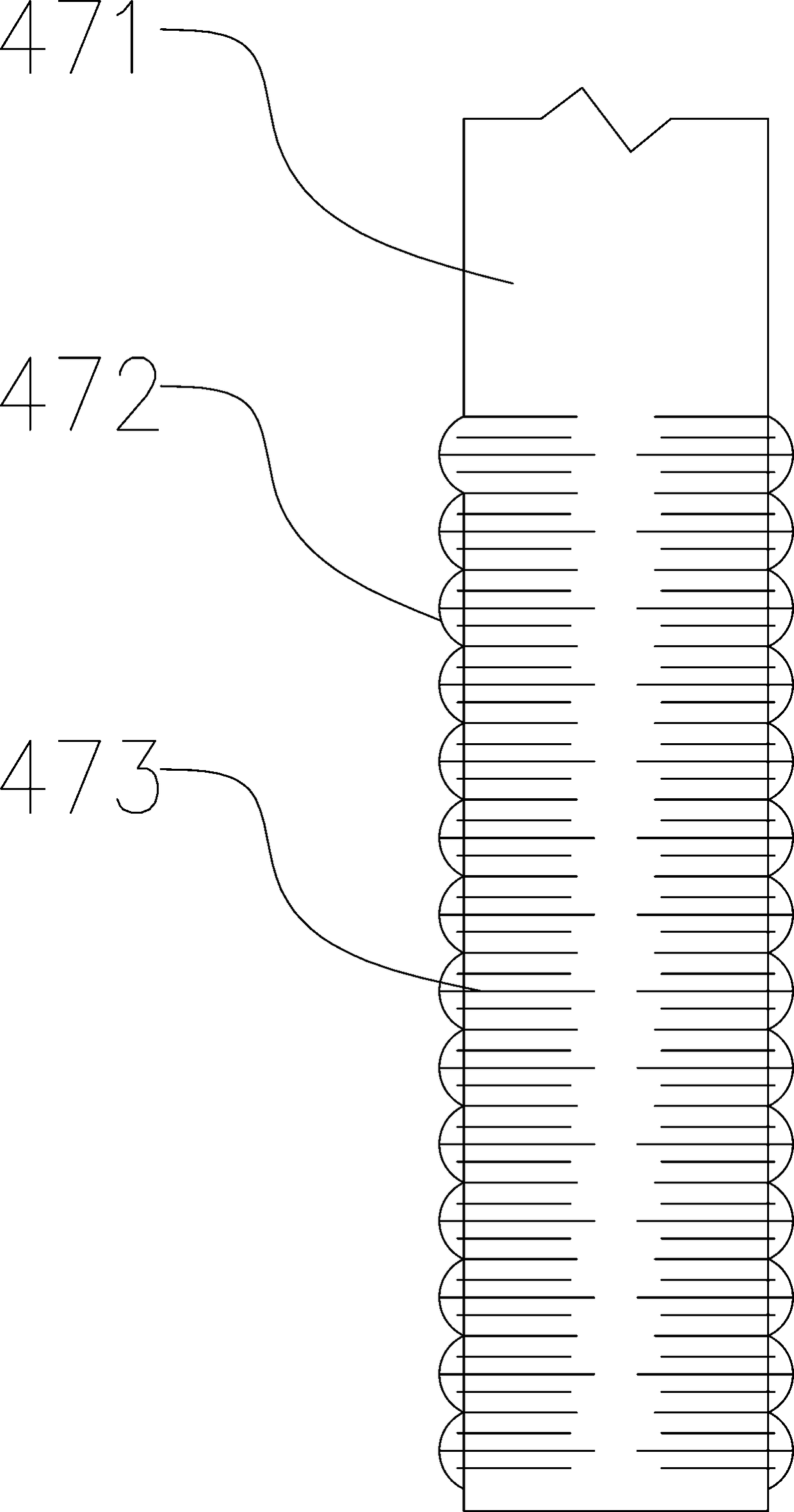

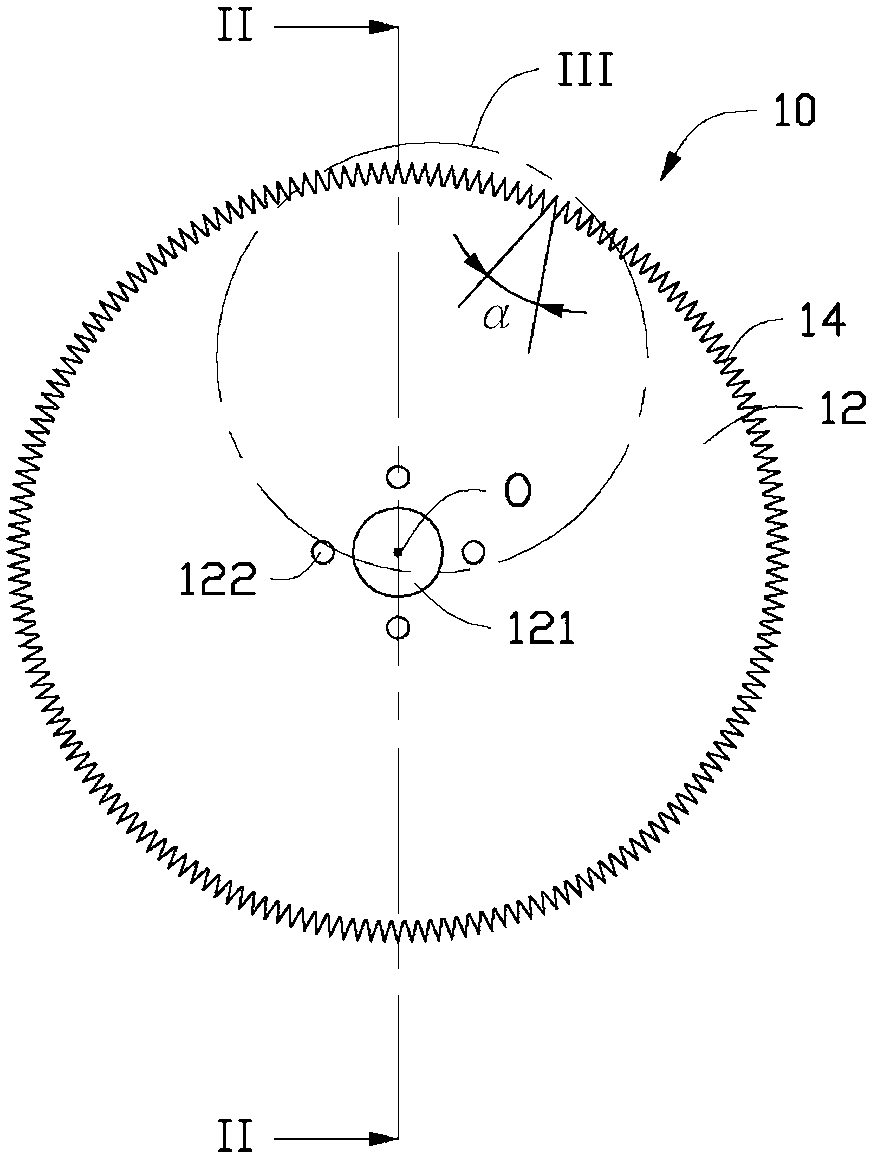

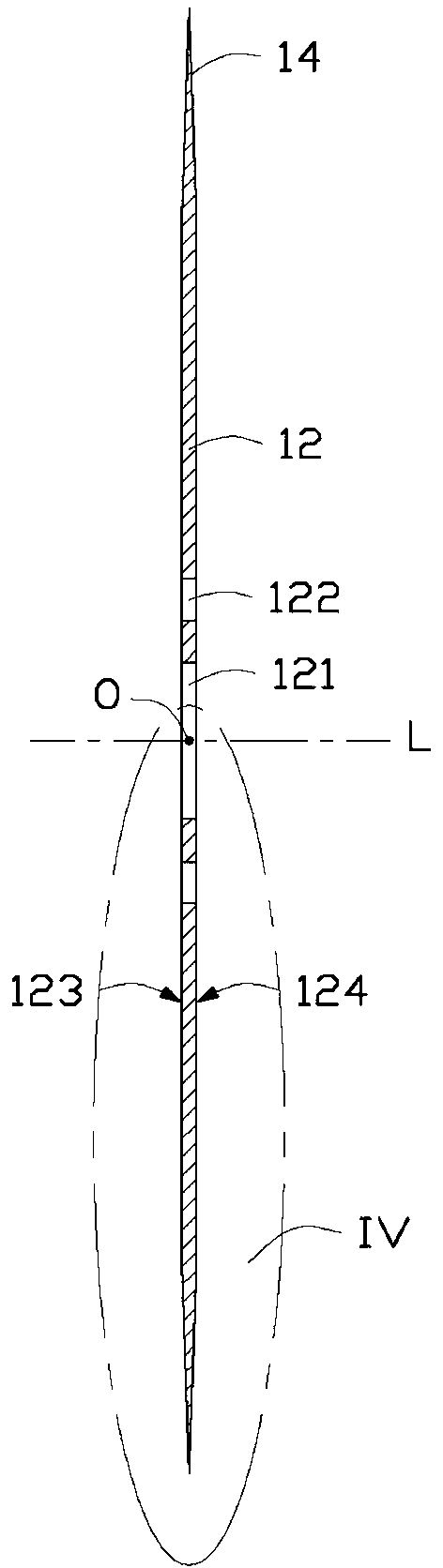

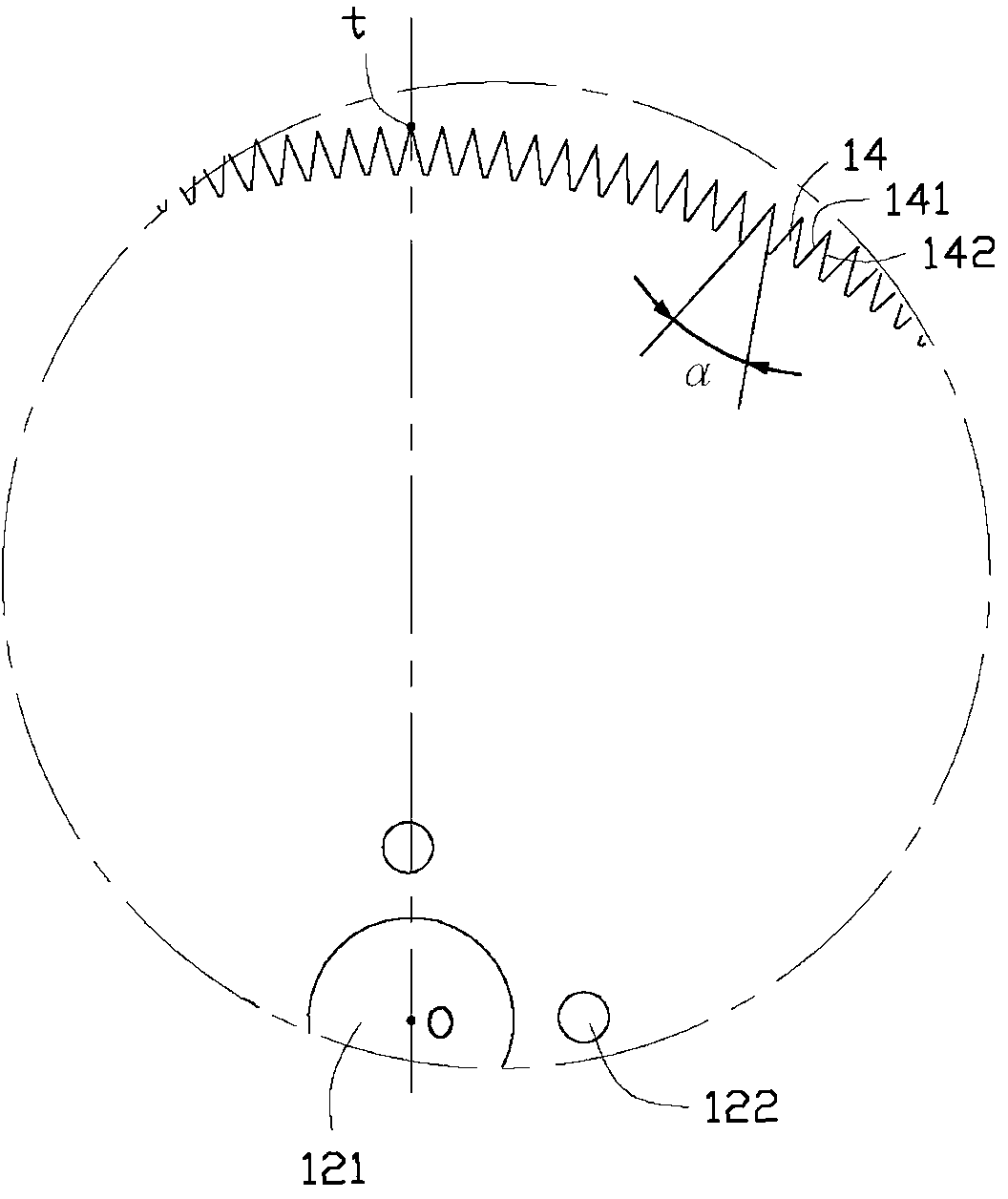

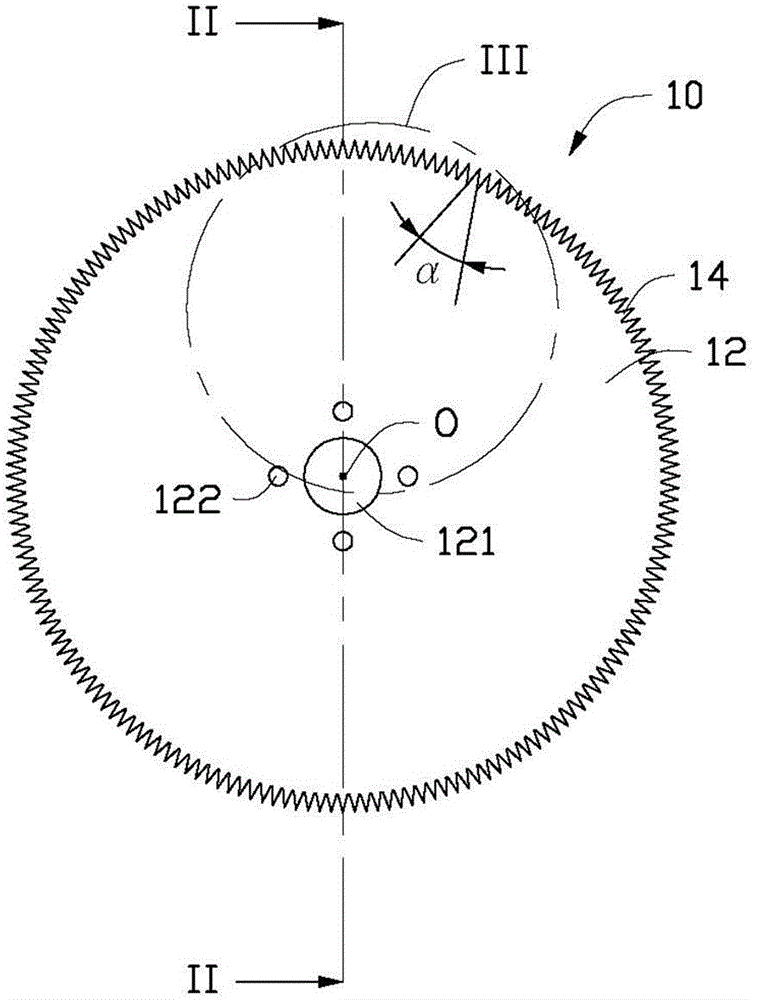

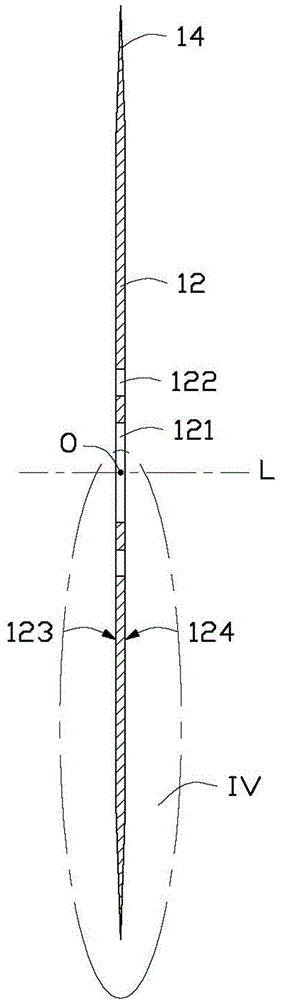

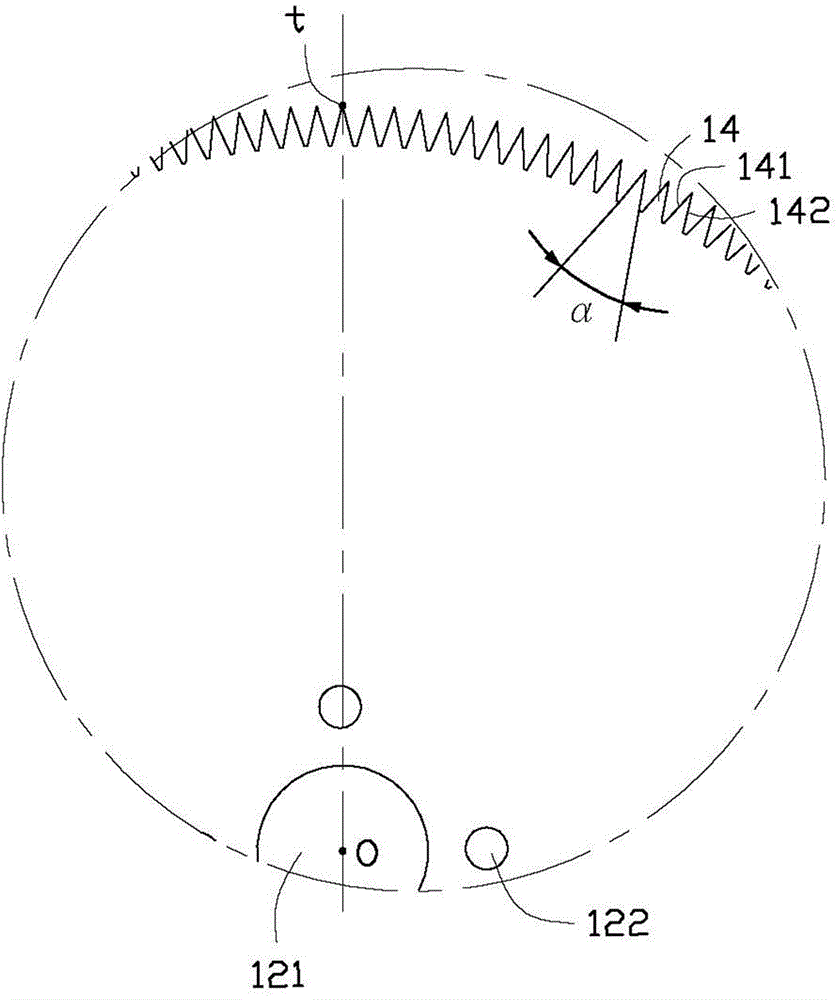

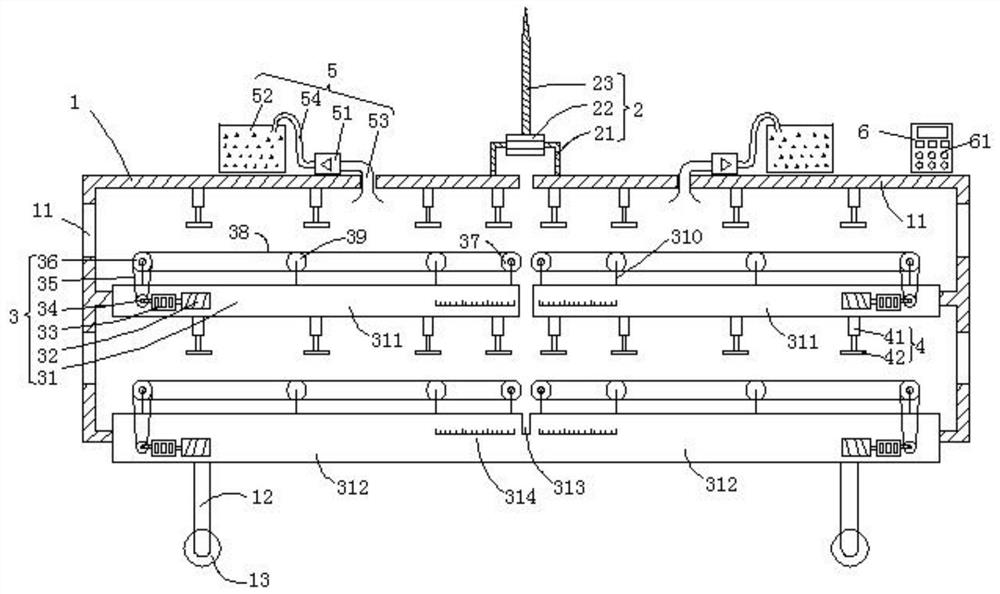

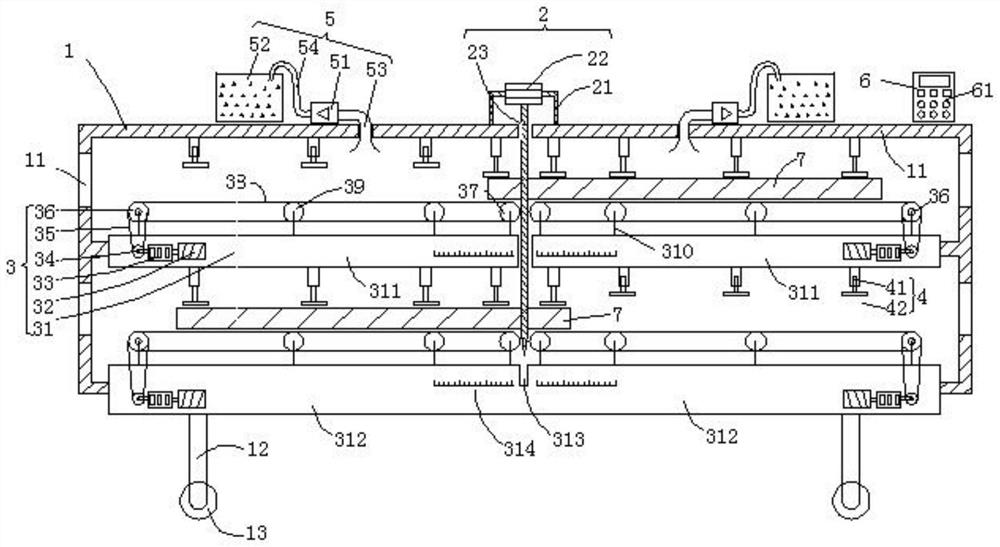

Splitting circular knife and splitting machine

A splitting circular knife comprises a circular knife body and knife teeth distributed on the periphery of the circular knife body; each knife tooth comprises two opposite side faces and two opposite end faces; the side face and the end face of each knife tooth are intersected at the peak of the knife tooth; edges of the two end faces of the knife tooth are distributed symmetrically through the straight line between the peak of the corresponding knife tooth and the midpoint of the axle wire of the knife body; and edges of the two side faces of the knife tooth are distributed symmetrically as per the straight line between the peak of the corresponding knife tooth and the midpoint of the axle wire of the knife body. The invention further provides a splitting machine with the splitting circular knife. Due to unique design of the knife teeth of the splitting circular knife, no burrs are generated in splitting thin materials, which reduces the loss and facilitates subsequent process of the thin materials.

Owner:GOLD HONG YE PAPER

Splitting circular knife and splitting machine

A splitting circular knife comprises a circular knife body and knife teeth distributed on the periphery of the circular knife body; each knife tooth comprises two opposite side faces and two opposite end faces; the side face and the end face of each knife tooth are intersected at the peak of the knife tooth; edges of the two end faces of the knife tooth are distributed symmetrically through the straight line between the peak of the corresponding knife tooth and the midpoint of the axle wire of the knife body; and edges of the two side faces of the knife tooth are distributed symmetrically as per the straight line between the peak of the corresponding knife tooth and the midpoint of the axle wire of the knife body. The invention further provides a splitting machine with the splitting circular knife. Due to unique design of the knife teeth of the splitting circular knife, no burrs are generated in splitting thin materials, which reduces the loss and facilitates subsequent process of the thin materials.

Owner:GOLD HONG YE PAPER

Insulation pad butt cutting machine

InactiveCN108943750BImplement automatic croppingImprove cutting work efficiencyDirt cleaningDomestic articlesControl systemDust control

The invention provides an insulating rubber pad butt joint cutting machine, which belongs to the technical field of electric power construction equipment, and includes a frame and a cutting mechanism. Material inlets and outlets are arranged on both sides of the frame, and two layers are arranged on the frame for cutting insulating rubber pads. The cutting table, the pressing mechanism set on the top of the cutting table for pressing and positioning the insulating rubber pad, the dust removal mechanism set on the upper part of the frame for absorbing the debris of the insulating rubber pad and used to control the cutting mechanism, the The control system of the pressing mechanism and the dust removal mechanism. The insulating rubber pad docking cutting machine provided by the present invention, through the two-layer cutting table on the frame, the control system controls the cutting parameters, and automatically cuts two insulating rubber pads, which has the advantages of straight cutting, seamless butt joint, and no burrs, which improves the The technical effect of the cutting work efficiency of the insulating rubber pad.

Owner:STATE GRID CORP OF CHINA +1

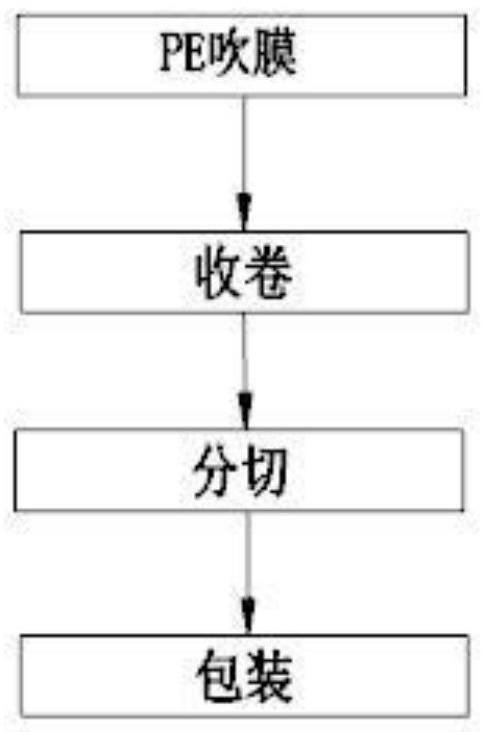

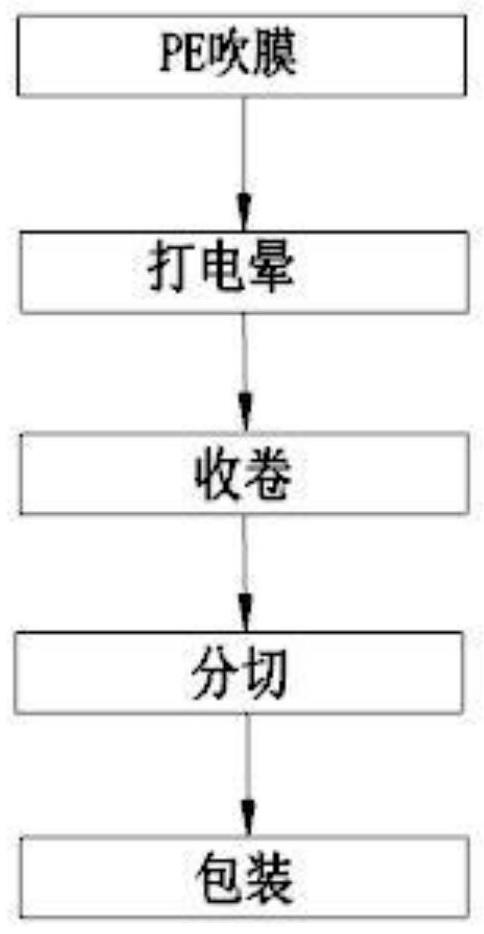

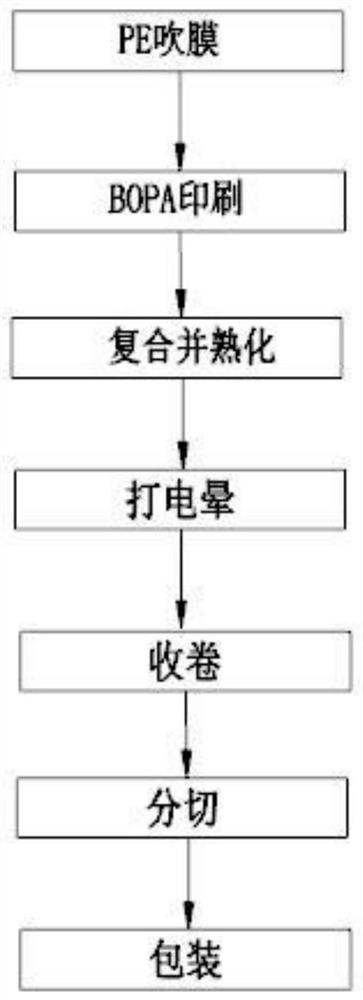

Packaging film without fuzzing in bag making and manufacturing method thereof

PendingCN114801388ALow elongation at breakQuality is not affectedFlexible coversWrappersLinear low-density polyethyleneLow-density polyethylene

The invention discloses a packaging film without fuzzing in bag making and a making method thereof.The packaging film comprises a three-layer co-extrusion film blowing machine for film blowing to form a three-layer co-extrusion layer, the three-layer co-extrusion layer is composed of an inner-layer base film, a middle-layer base film and an outer-layer base film, the inner-layer base film is a heat-sealing layer, the outer-layer base film is a corona treatment layer or a composite layer, and the middle-layer base film is a heat-sealing layer. The inner-layer base film comprises the following components in percentage by mass: 40%-50% of LLDPE (Linear Low Density Polyethylene), 50%-53% of LDPE (Low Density Polyethylene), 5%-8% of MLLDPE (Metallocene Leverage Polyethylene), 0.5%-2.5% of an opening slipping agent and 0.2%-0.4% of PPA ( The middle-layer base film is prepared from the following components in percentage by mass: 49 to 51 percent of LLDPE (Linear Low Density Polyethylene), 50 to 52 percent of LDPE (Low Density Polyethylene) and 0.2 to 0.4 percent of PPA (Polypropylene Acrylate); and the outer-layer base film comprises the following components in percentage by mass: 49%-51% of LLDPE (Linear Low Density Polyethylene), 50%-52% of LDPE (Low Density Polyethylene) and 0.2%-0.4% of PPA (Polypropylene Acrylate). By increasing the proportion of LDPE, adjusting the proper proportion and reducing the elongation at break of the PE film, the effects that fuzzing is avoided during bag cutting, and the other physical properties do not affect the quality of a finished product are achieved; and finished product bag making feedback is achieved, through multiple times of batch bag making, the burr problem is basically avoided during bag cutting each time, and the defect that burrs are likely to be generated in the prior art is overcome.

Owner:珠海市德燊环保包装有限公司

Insulation pad cutting and bonding machine

InactiveCN108908956BImplement automatic croppingImprove work efficiencyDirt cleaningDomestic articlesButt jointControl system

The invention provides an insulating rubber pad cutting and bonding integrated machine, which belongs to the technical field of electric power construction facilities and includes a frame and a cutting mechanism. Material inlets and outlets are provided on both sides of the frame, and a window for cutting insulating rubber pads is provided on the frame. Cutting table, a bonding mechanism for bonding several pieces of insulating rubber pads, a pressing mechanism for pressing insulating rubber pads on the top of the cutting table and inside the frame, and a mechanism on the upper part of the frame for absorbing broken insulating rubber pads The dust removal mechanism for chips and the control system for controlling the cutting mechanism, bonding mechanism, pressing mechanism and dust removal mechanism. The insulating rubber pad cutting and bonding machine provided by the present invention realizes the automatic cutting and bonding of the insulating rubber pad by setting a cutting mechanism, a bonding mechanism and a cutting table on the frame, and controlling the cutting and bonding parameters by the control system. It has the technical effect of seamless butt joint, no bubbling and no burrs in bonding, and the working efficiency of the insulating rubber pad is improved.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com