Patents

Literature

55results about How to "Implement automatic cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

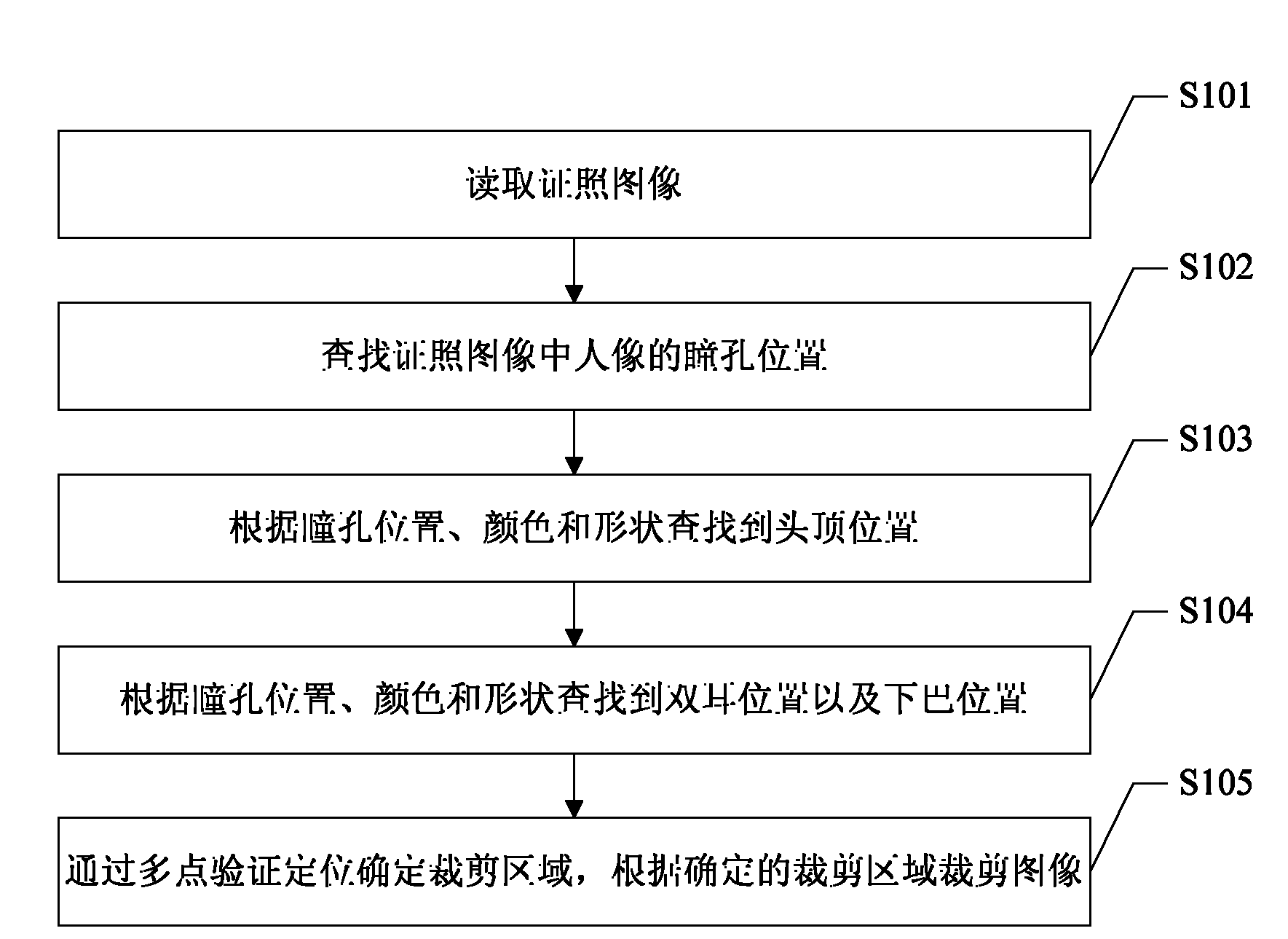

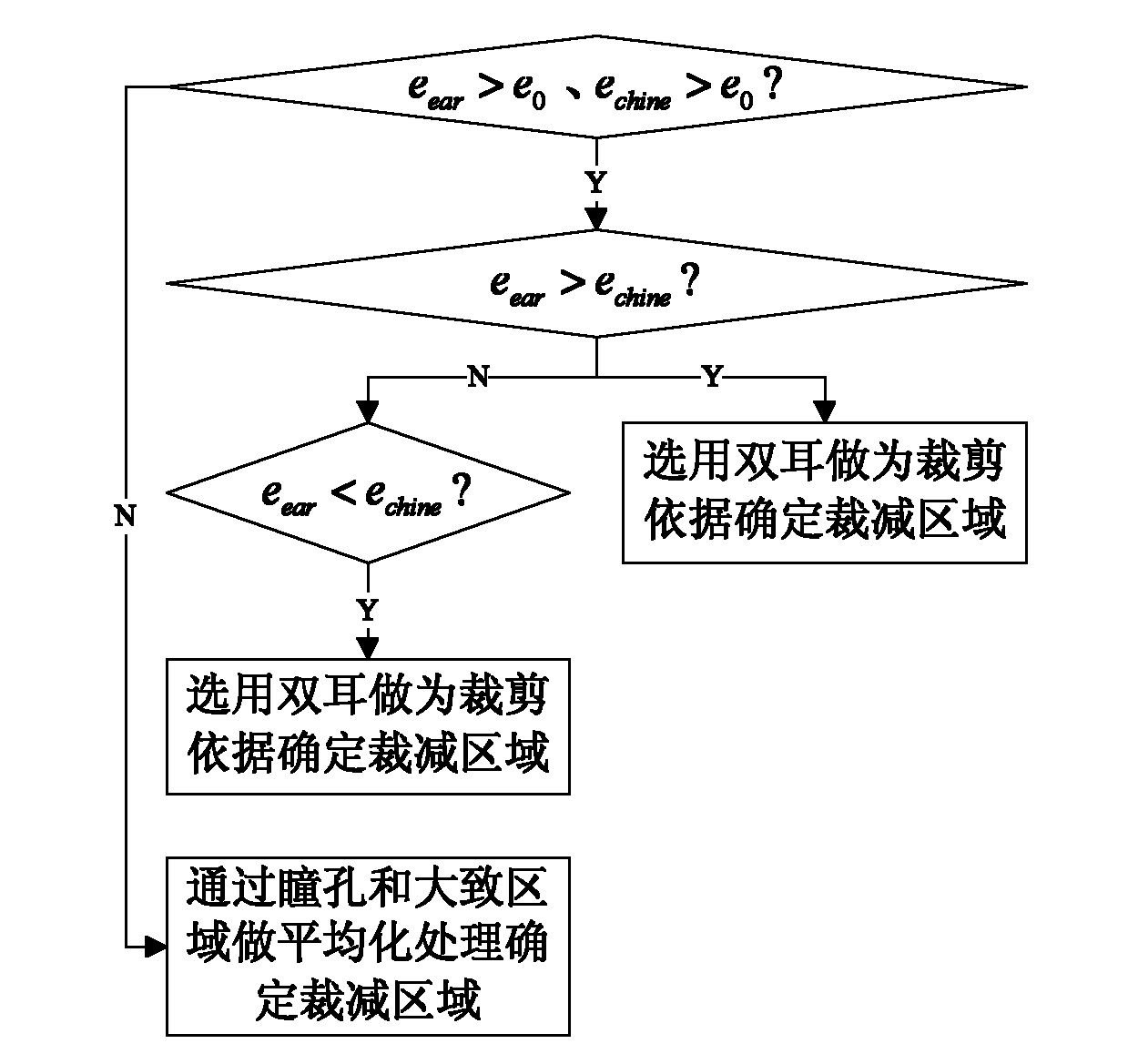

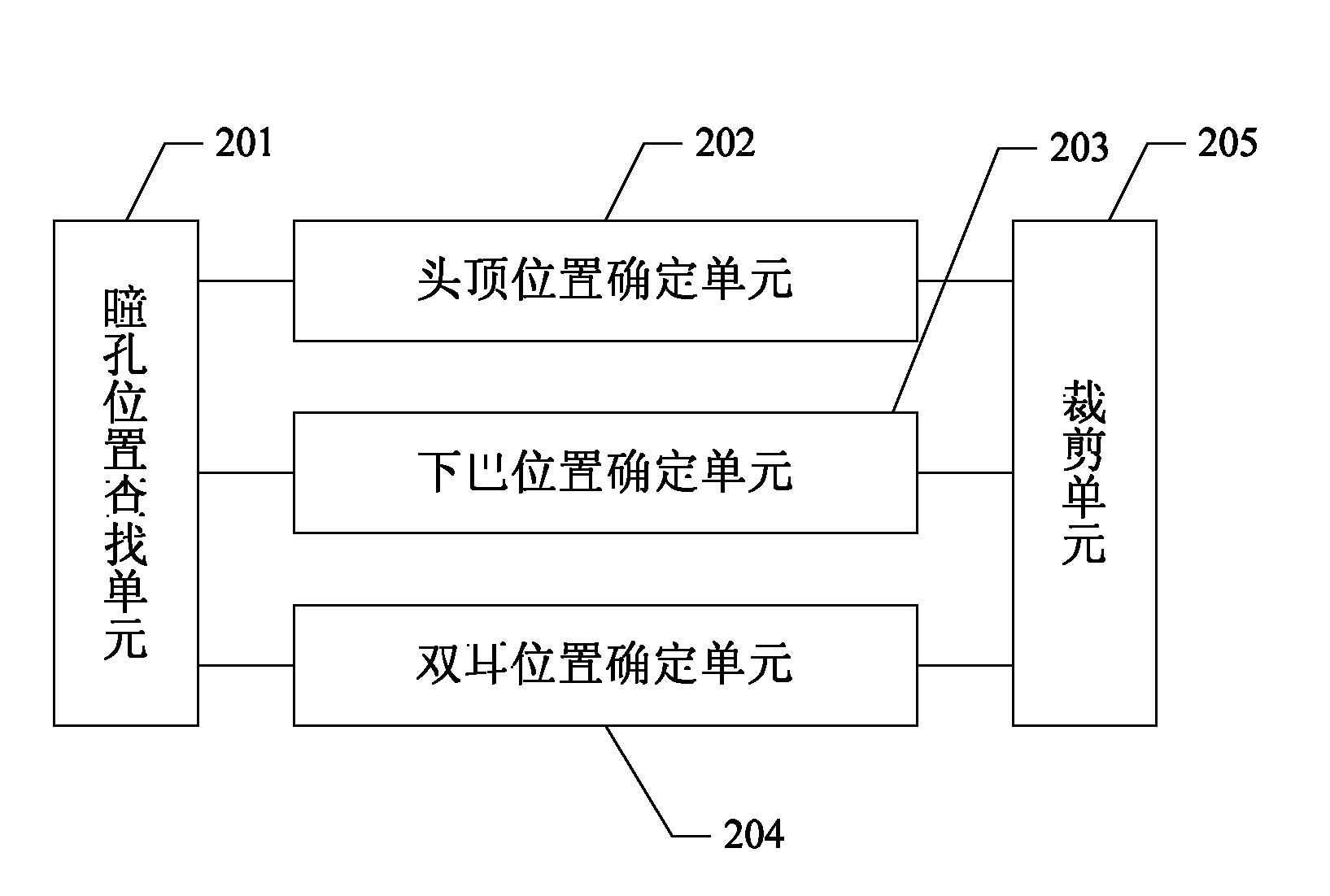

Certificate image cutting method and system

ActiveCN102592260AImprove production efficiencyImplement automatic croppingGeometric image transformationPupilComputer science

The invention provides a certificate image cutting method and a system. The method comprises the following steps of: reading a certificate image and finding pupil positions of a portrait in the certificate image; determining a head position of the portrait in the certificate image according to the pupil positions; determining a lower jaw position and two ear positions of the portrait in the certificate image according to the pupil positions; determining a cutting region according to the determined head position, lower jaw position and two ear positions; and cutting the certificate image according to the determined cutting region. According to the certificate image cutting method and the system, disclosed by the invention, the disadvantage of manually selecting the cutting region to cause low efficiency in a traditional certificate manufacturing process is overcome; the automatic cutting of the certificate image based on multi-point checking and positioning is realized; the certificateimage cutting region can be rapidly, efficiently and accurately positioned so as to automatically cut out a photo meeting the requirements; and therefore, the certificate image cutting method and thesystem can be widely applied to automatically cutting out the certificate image meeting the requirements by self-help photographing equipment, and can also help non-professional ordinary people to have the convenience effect of photographing a certificate photo by oneself.

Owner:广州商景网络科技有限公司

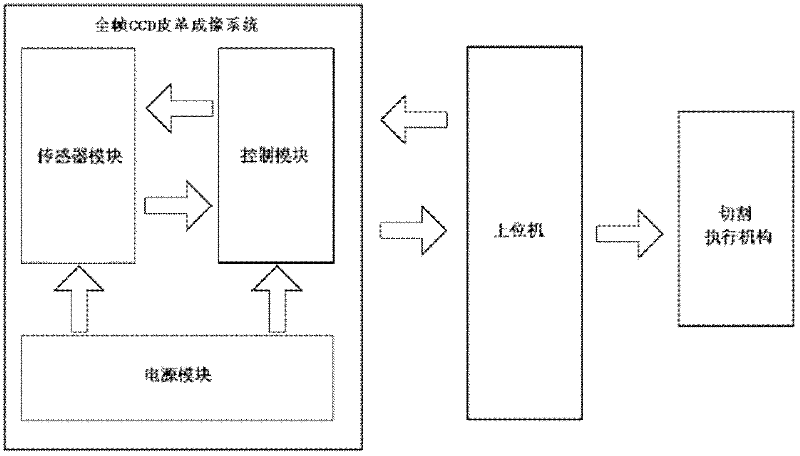

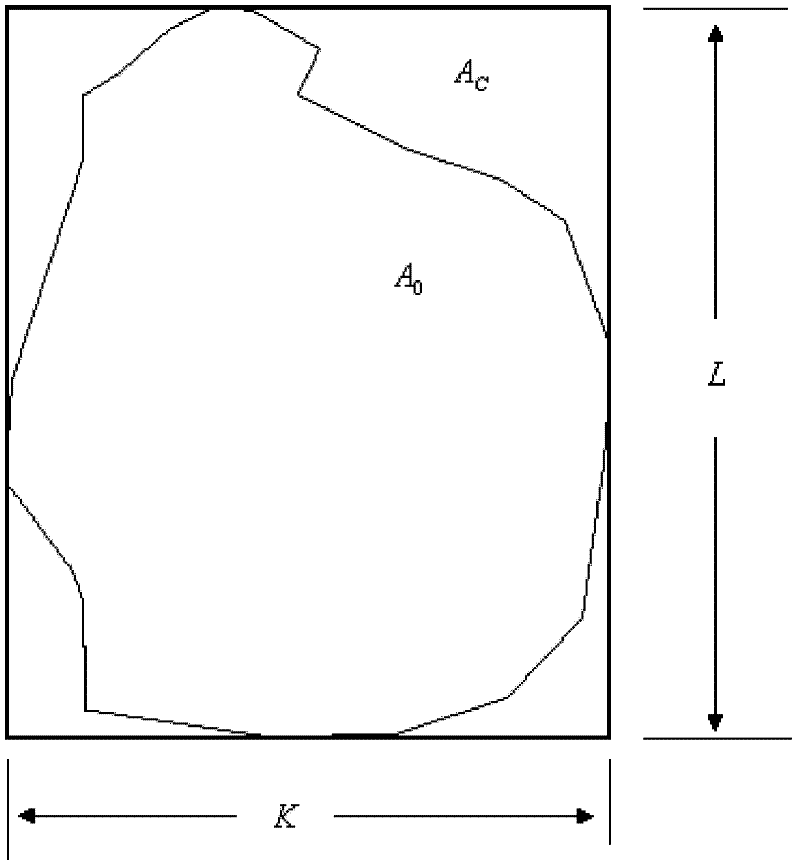

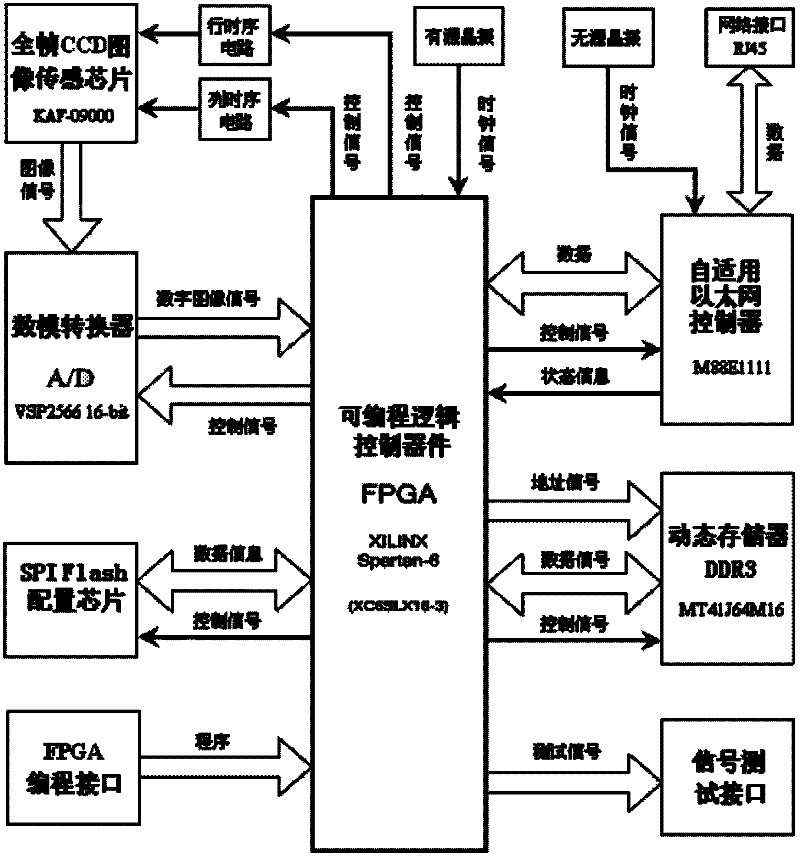

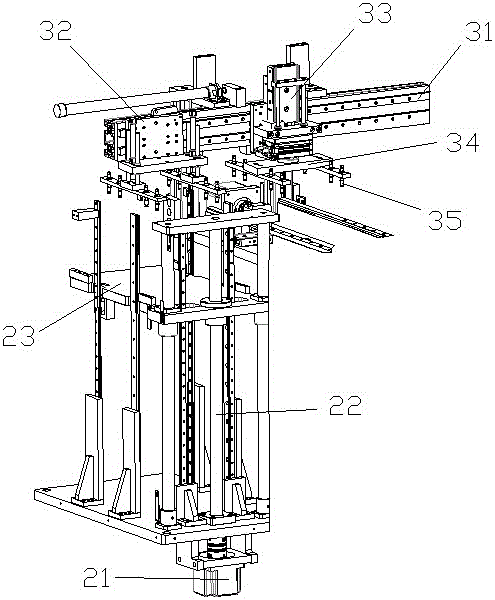

Automatic two-dimensional irregular leather sample layout and cutting method

InactiveCN102508938APromote overall optimizationImprove productivityImage enhancementSpecial data processing applicationsImage signalClipping path

The invention relates to an automatic two-dimensional irregular leather sample layout and cutting method, which includes the following steps of calibrating a full-frame CCD (charge coupled device) imaging system, labeling defect spots and regional quality of leather, acquiring two-dimensional image signals of the leather by the full-frame CCD imaging system and sending the same to an upper computer, eliminating introduced noise of acquired leather images during imaging by the upper computer, geometrically correcting the leather images imaged at one step, and accordingly acquiring distortionless and clear leather images; realizing automatic sample layout on the leather images according to prestored shape, size and amount of clothes style modular images in a computer and by means of the optimal policy for removing surplus, and finally determining the optimum cutting path; vectoring the optimum cutting path and controlling a cutting system to cut the leather. By the aid of the automatic two-dimensional irregular leather sample layout and cutting method, affection caused by irregular cutting samples can be reduced and utilization rate of the leather is increased.

Owner:DONGHUA UNIV

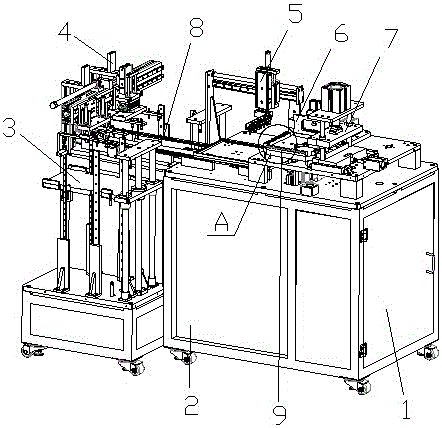

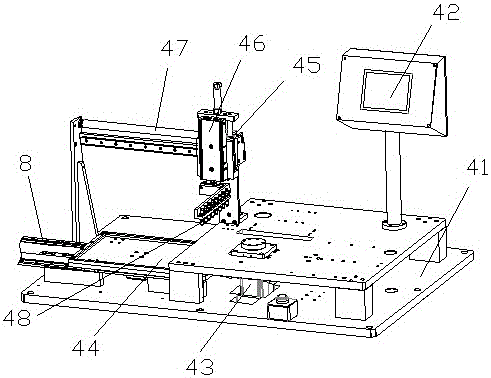

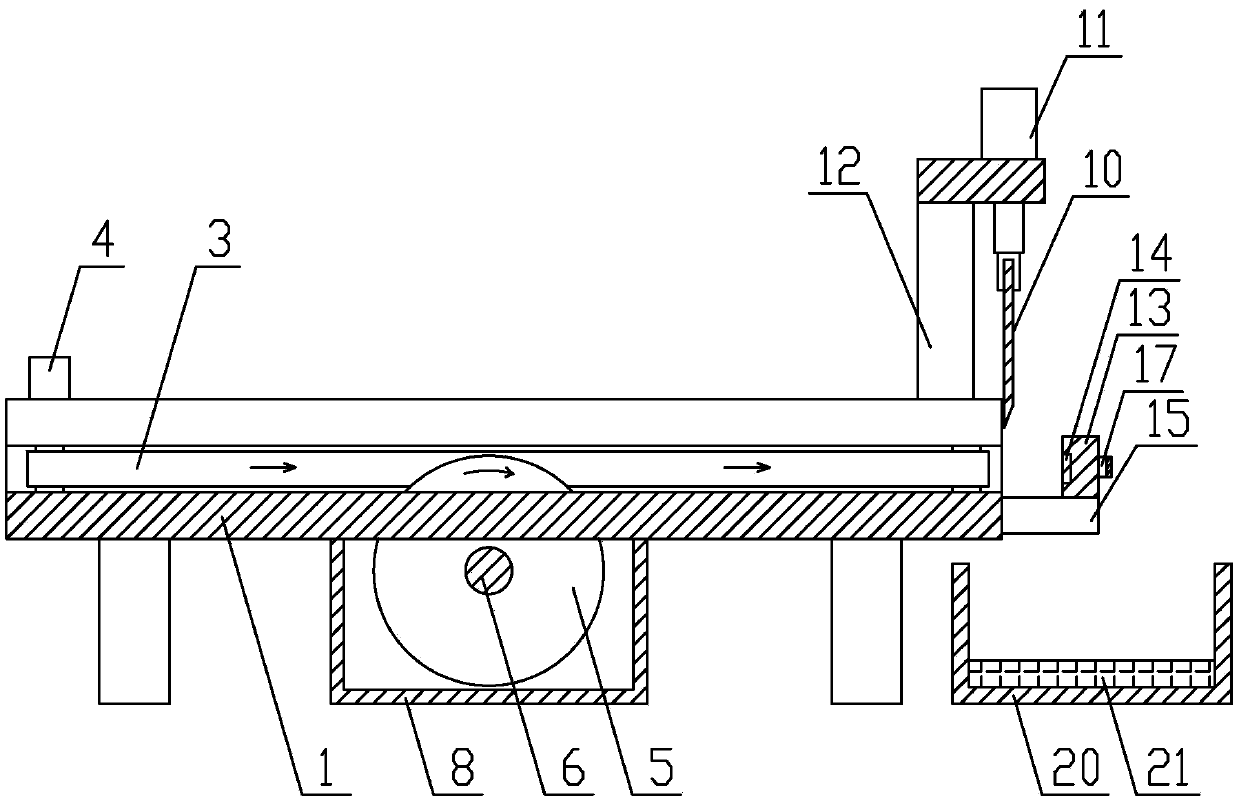

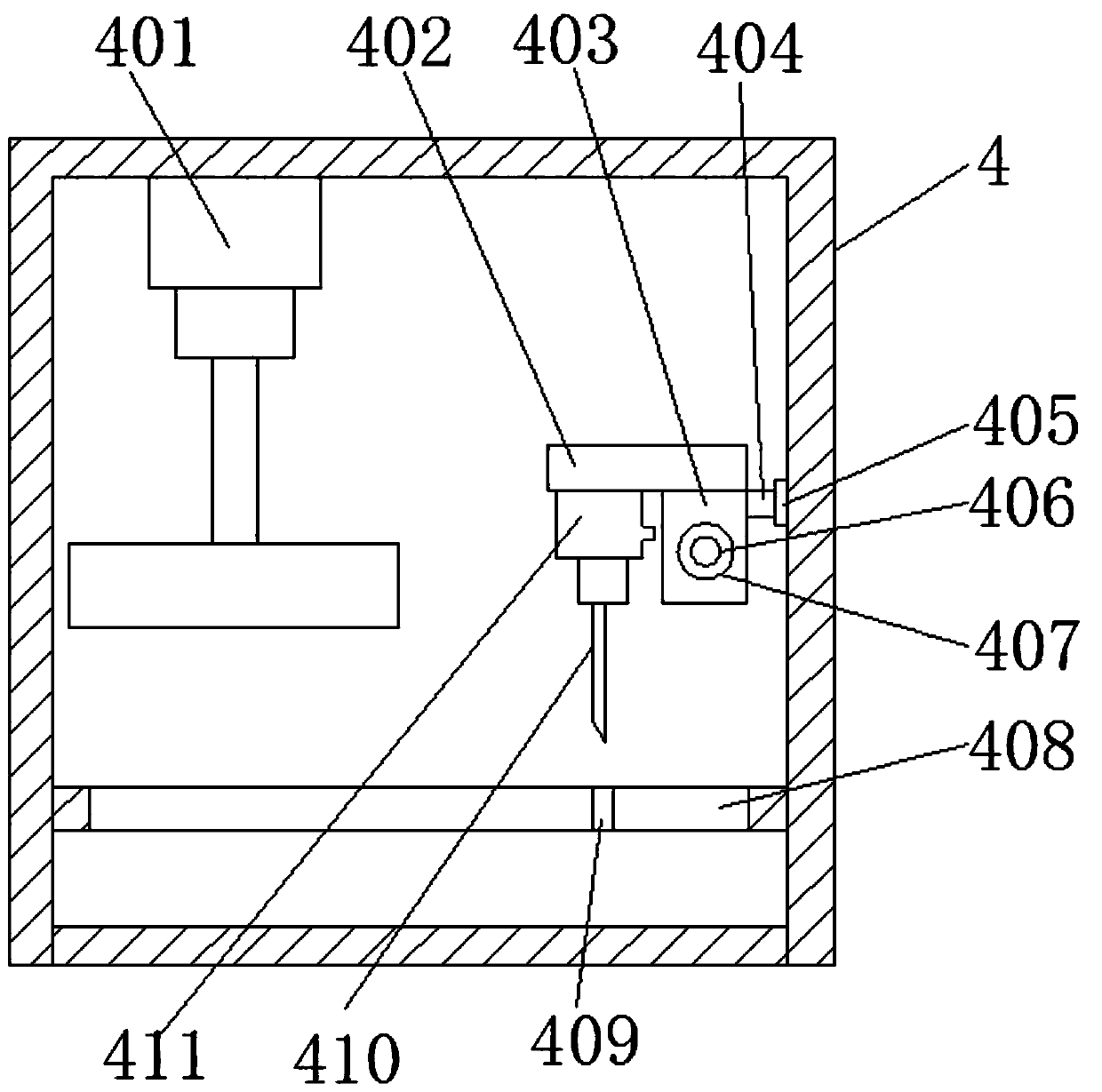

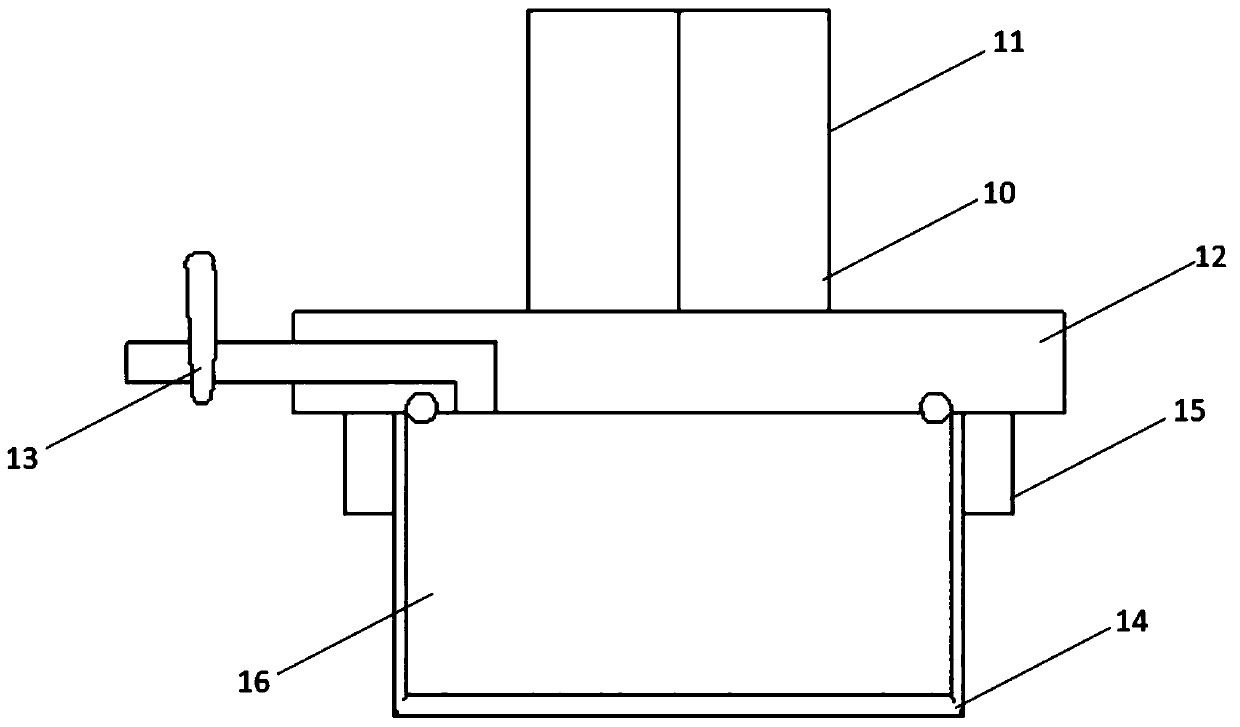

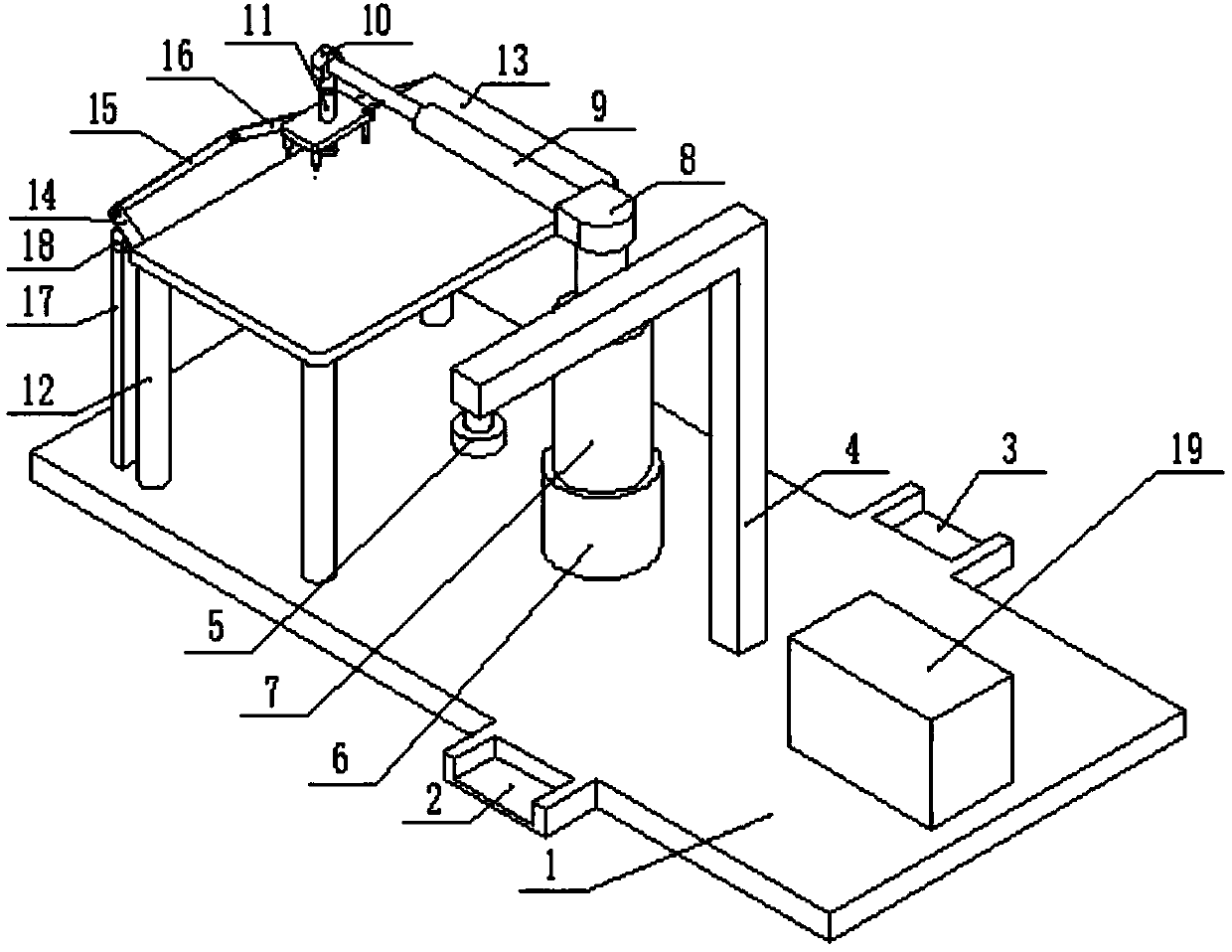

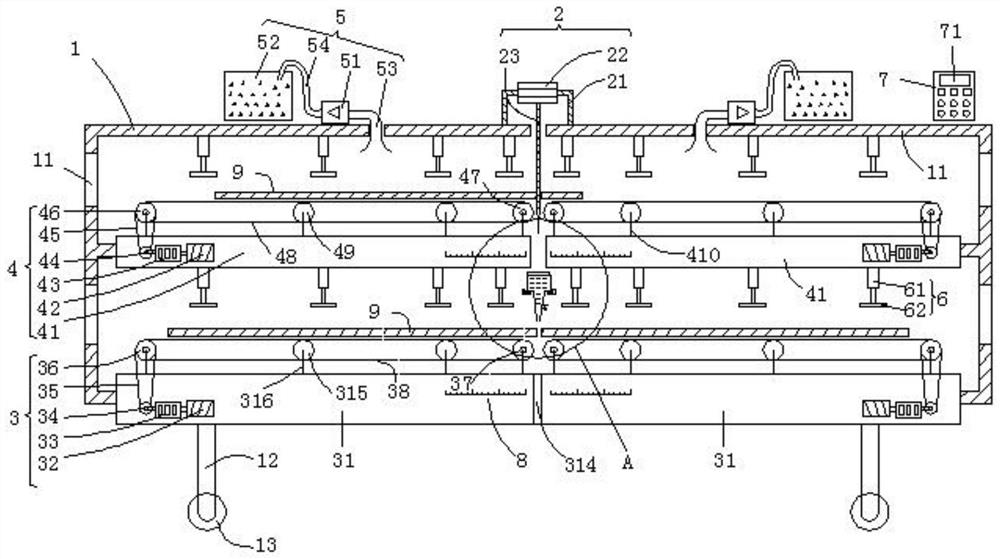

Full-automatic cutting machine

ActiveCN106563946AReduce energy consumptionImplement automatic croppingOther manufacturing equipments/toolsLarge fixed membersDistribution controlEngineering

The invention relates to a full-automatic cutting machine. The full-automatic cutting machine comprises a machine frame; the machine frame is provided with a power distribution control box and a touch operation screen which are matched with each other; the power distribution control box is provided with a workbench platen; the workbench platen is provided with a bracket and a rotary motor extending out of the bracket; the rotary motor is provided with a square rotary platform; a material loading mold is arranged on the rotary platform, and the rear side and the right side of the rotary platform are provided with a creasing device and a cutting device which are matched with the material loading mold correspondingly; the cutting device comprises a shearing frame arranged on the workbench platen; the shearing frame is connected with a propelling air cylinder arranged on the right side of the workbench platen and is provided with a shearing air cylinder, and a cutting knife is arranged below the shearing air cylinder. According to the full-automatic cutting machine, the square rotary platform is adopted, the four edges of the square rotary platform are provided with metal sheet material loading molds, and metal sheets are sequentially matched with the creasing device and the cutting device through the rotary platform, so that energy consumption is reduced, automatic cutting can also be achieved, the labor intensity is greatly relieved, and the cutting quality is improved.

Owner:DONGGUAN UNIV OF TECH

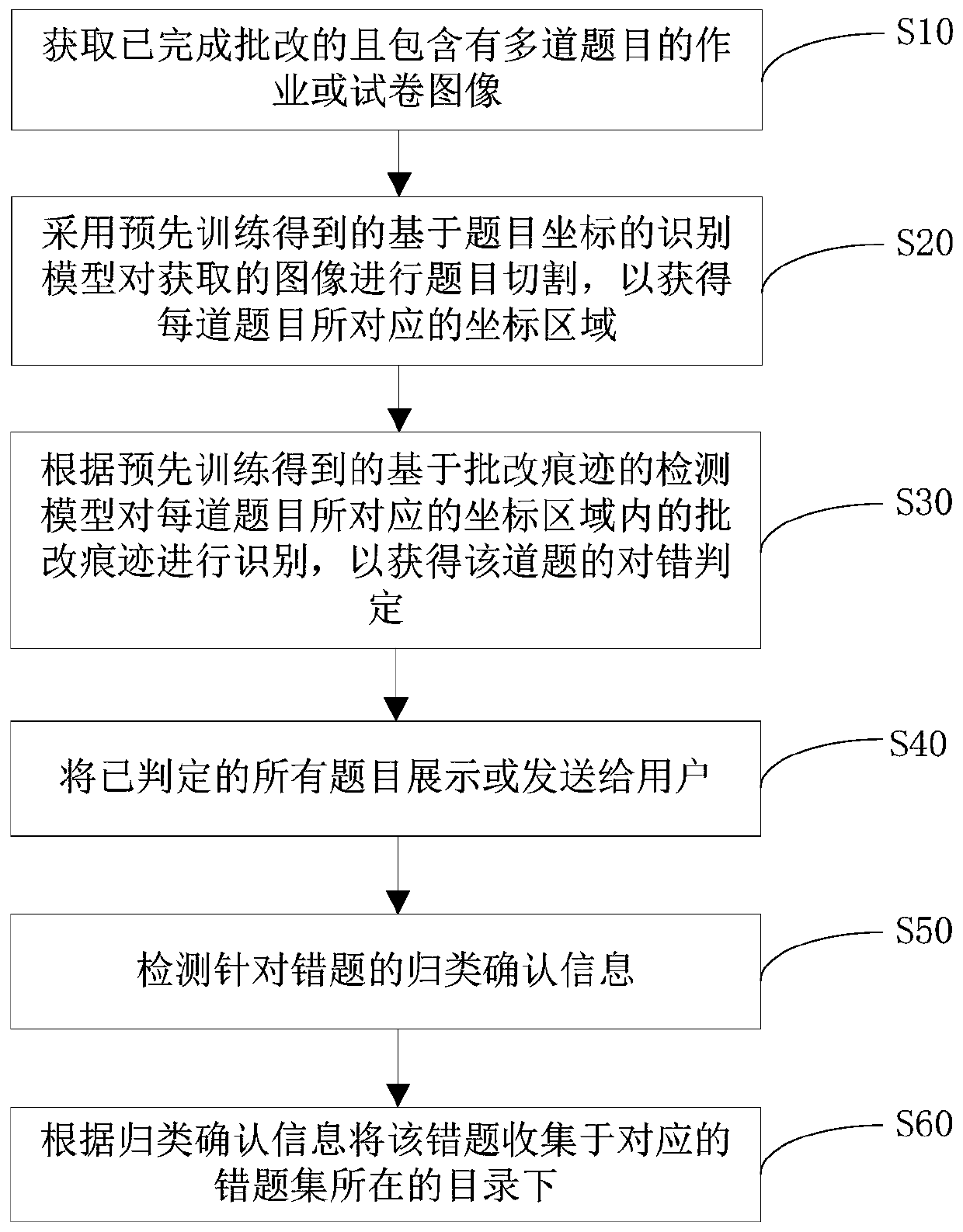

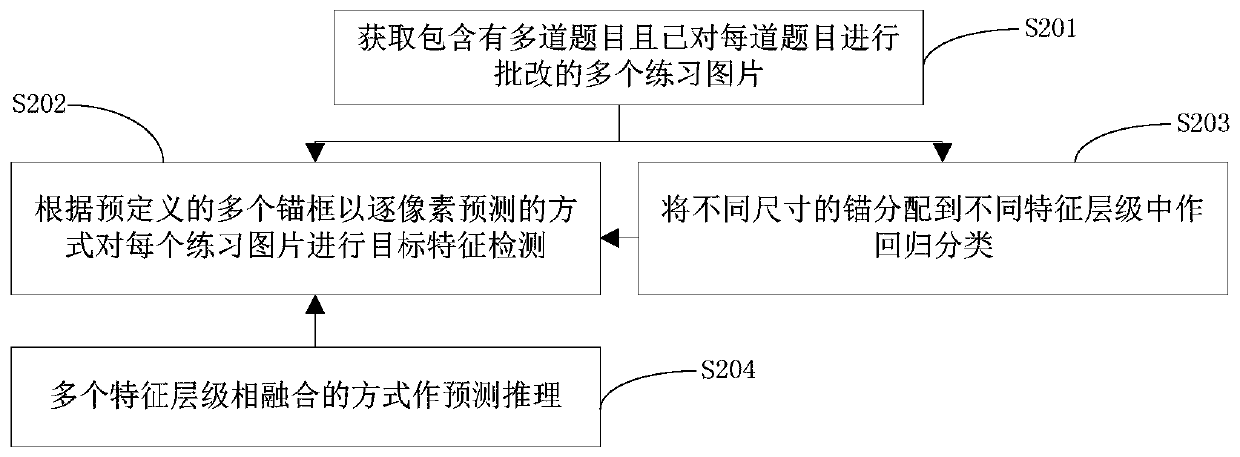

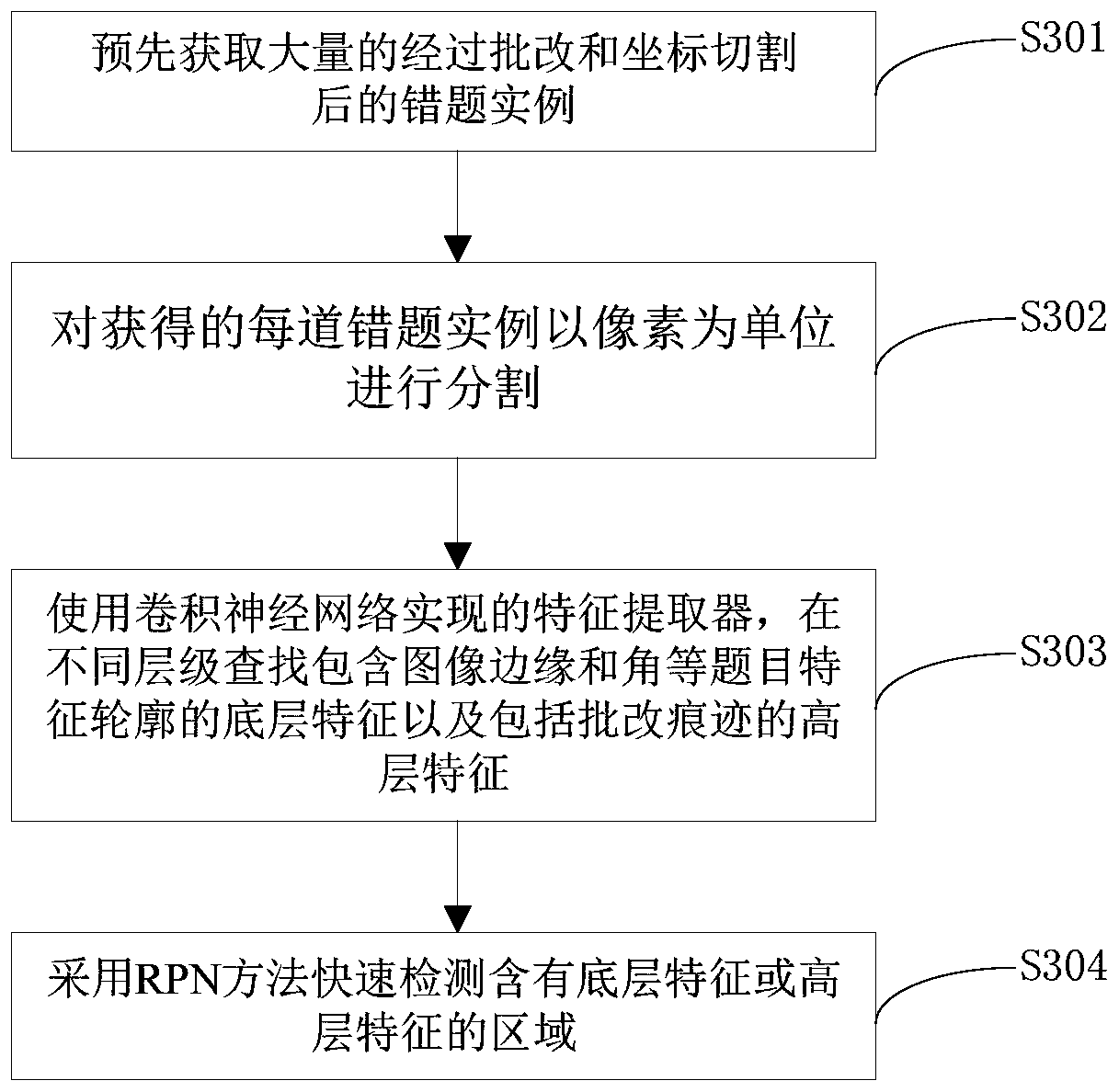

Error collection method, device and equipment based on deep learning

InactiveCN110348444AImplement automatic croppingEasy to useCharacter and pattern recognitionElectrical appliancesPattern recognitionCollection methods

The invention provides an error collection method, device and equipment based on deep learning. The method comprises: acquiring corrected homework or test paper images containing multiple questions; carrying out topic segmentation on the obtained image by adopting a pre-trained topic coordinate-based recognition model to obtain a coordinate region corresponding to each topic; and identifying the correction trace in the coordinate area corresponding to each question according to a pre-trained detection model based on the correction trace so as to obtain the right and wrong judgment of the question.

Owner:浙江米猪控股有限公司

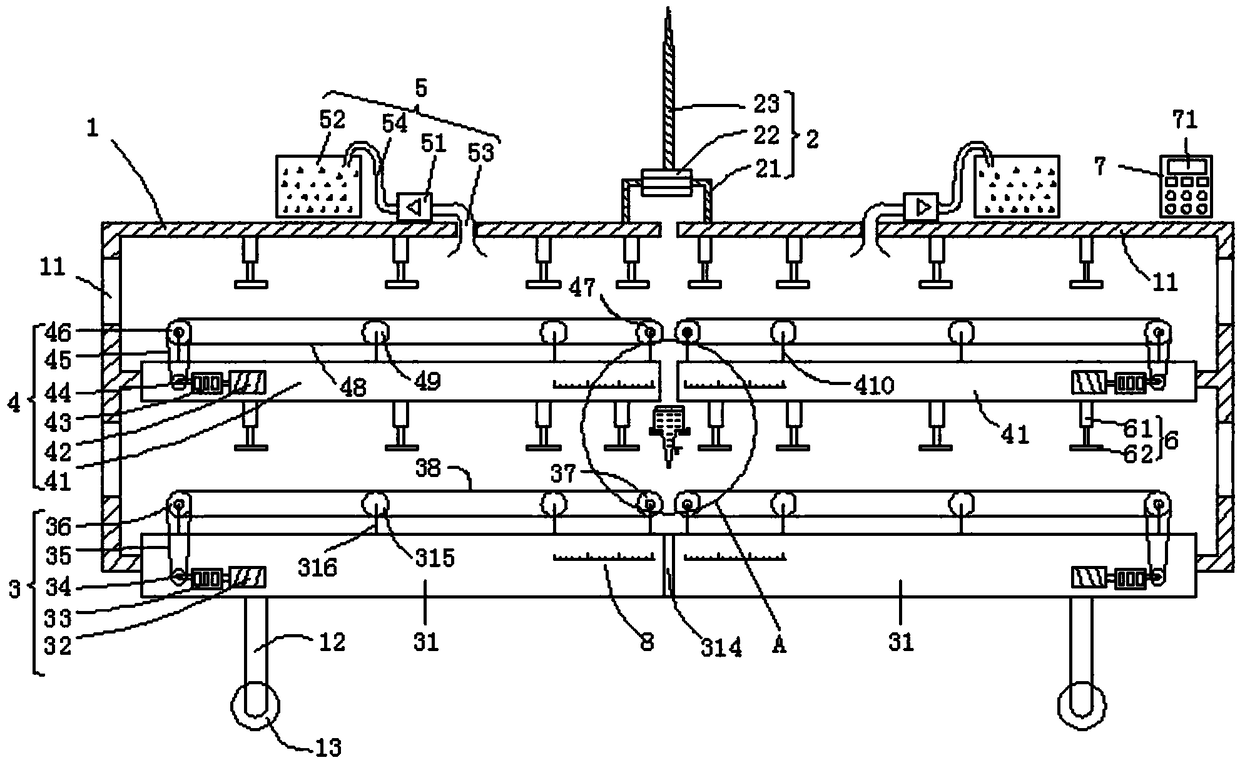

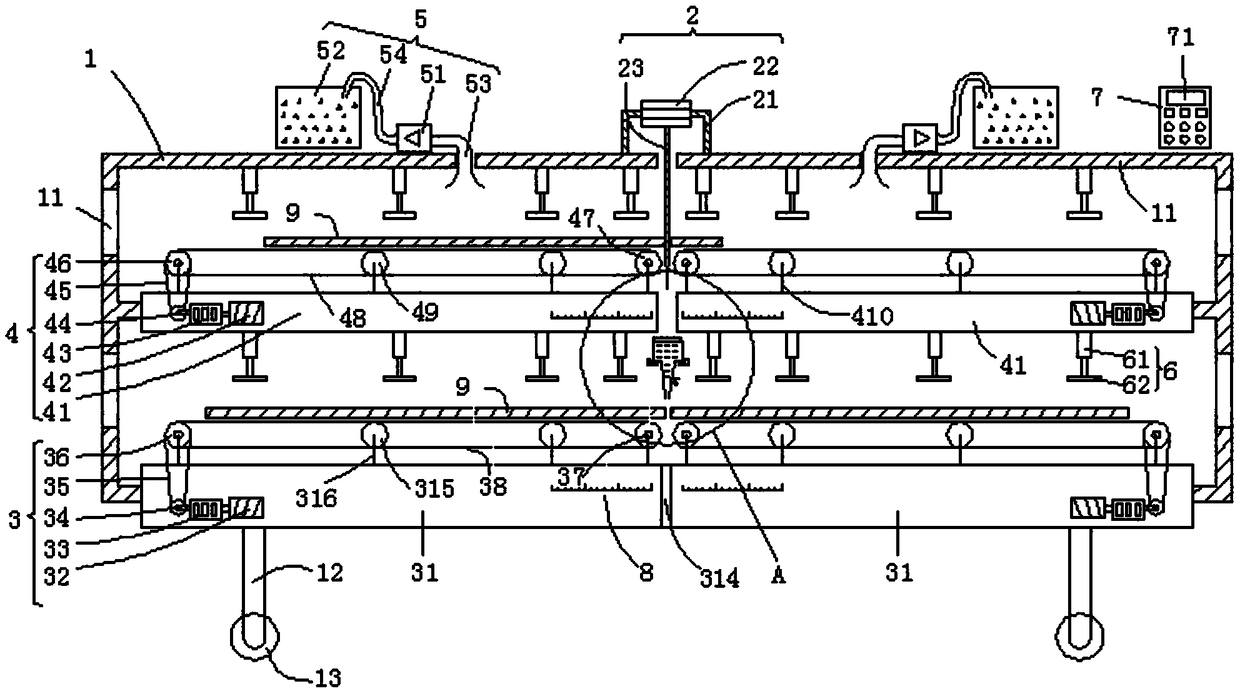

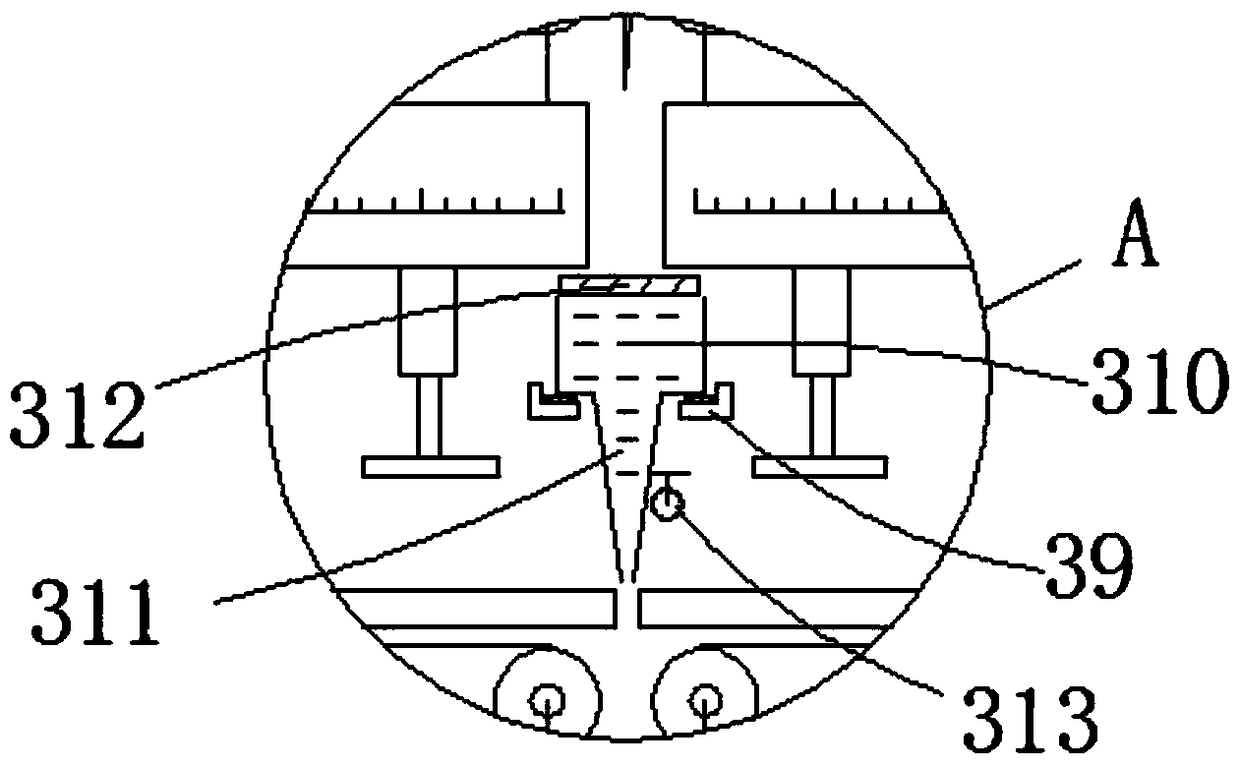

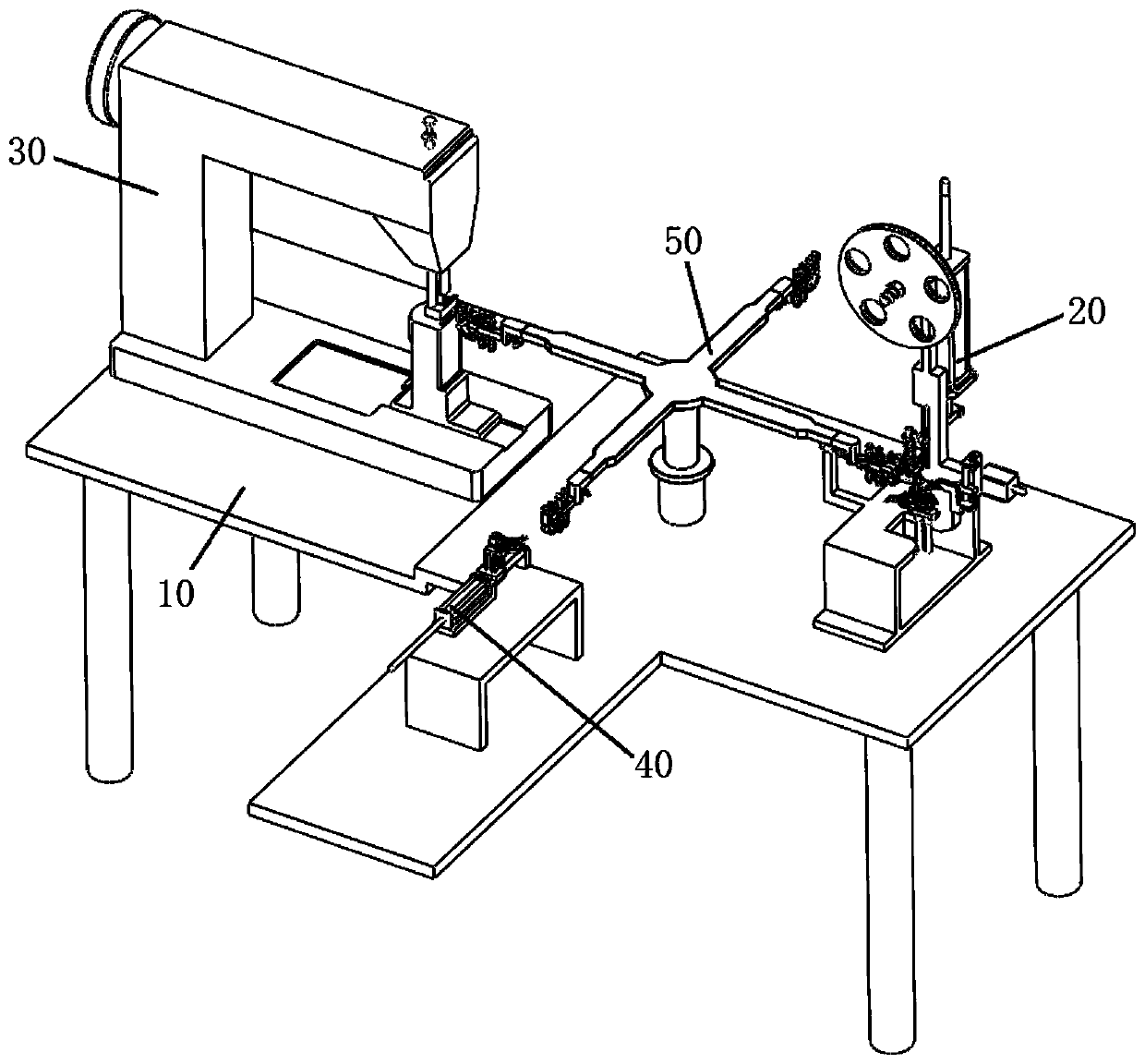

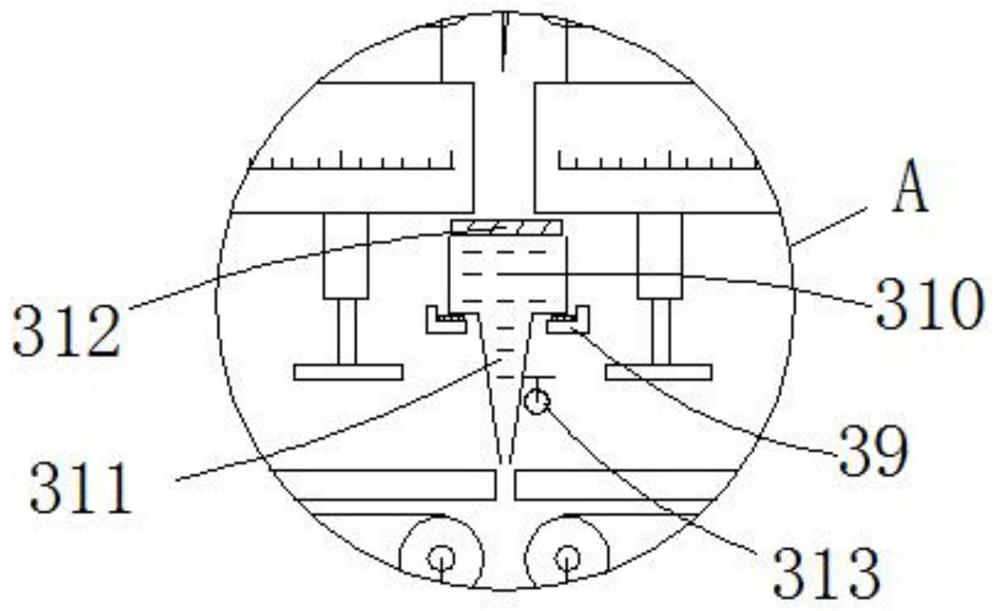

Automobile seat cover tailoring and sewing integral machine having dust removing device

InactiveCN107419439AImplement automatic croppingPlay the role of dust removalProgramme-controlled sewing machinesWorkpiece carriersDyeingMachining process

The invention provides an automobile seat cover tailoring and sewing integral machine having a dust removing device, and belongs to the technical field of weaving and dyeing, which can solve the problem that automobile seat covers are polluted by dust in the conventional processing stage. The automobile seat cover tailoring and sewing integral machine having the dust removing device includes a rack; a dust removing device for removing dust on an automobile seat cover fabric, a tailoring device for tailoring the automobile seat cover fabric, and a sewing device for sewing the tailored automobile seat cover fabric are arranged on the rack; the dust removing device, the tailoring device and the sewing device are successively arranged along the rack; the dust removing device includes an upper dust removing roller and a lower dust removing roller; and a first channel for allowing the automobile seat cover fabric to pass is formed between the upper dust removing roller and the lower dust removing roller. The automobile seat cover tailoring and sewing integral machine can remove dust on the automobile seat cover before processing.

Owner:海宁市现代汽车座套有限公司

Cutting device for garment processing

ActiveCN108797084ARealize automatic unloadingHigh degree of automationSevering textilesEngineeringAutomation

The invention discloses a cutting device for garment processing and relates to the technical field of garment processing equipment. The device comprises a box body, a placement shaft is rotatably connected to the left side of the back face of the inner wall of the box body, and a cutting table is fixedly connected to the bottom of the inner wall of the box body; limit plates are fixedly connectedto the left and right sides of the top of the cutting table, grooves are formed in the left and right sides of the top of the cutting table, and fixing plates are fixedly connected to the bottoms of the inner surfaces of the grooves; limit rods are fixedly connected to the front and rear sides of the tops of the fixing plates respectively, mobile pipes sleeve the surfaces of the limit rods, a cutting plate is rotatably connected to one side of each mobile pipe through a connection plate, and a first motor is fixedly connected to the middle of the back face of the inner wall of the box body. According to the cutting device, automatic cutting, discharging and leftover material collection can be achieved, the automation degree is high, and the work efficiency is greatly improved.

Owner:NANJING JIHUA NO 3503 GARMENT

Feeding mechanism for shaping steam box

ActiveCN111485349ARealize automatic fitImprove feeding efficiencyTextile treatment containersSevering textilesPaperboardStructural engineering

The invention discloses a feeding mechanism for shaping steam box. The feeding mechanism comprises a support, a lifting table and a pushing frame; a plurality of thin paperboards are stacked on the lifting table, and a wavy surface is arranged on the upper side of the lifting table; a wavy plate and a rotating assembly are arranged on the support, the wavy plate is rotationally connected to the support through a horizontal shaft, and a plurality of first pasting strips are arranged on the wavy plate; a second pasting strip and a plurality of pressing rods are fixed to the pushing frame, a driving assembly is arranged on the support, and the moving direction of the pushing frame is parallel to the rotating plane of the wave plate; a plurality of clamping units are arranged at the two ends of the horizontal shaft, a penetrating column is fixed to each clamping unit, and the lower end of each penetrating column is fixedly sleeved with a baffle ring; and driving assemblies are arranged atthe two ends of the horizontal shaft. By means of the mechanism, automatic attaching of curtain cloth and a thin paper board, automatic clamping of the curtain cloth and the thin paper board and automatic folding of the curtain cloth and the thin paper board are achieved, and therefore the cloth feeding efficiency is improved; and the feeding efficiency of cloth is improved.

Owner:杭州富阳数马装饰工艺品有限公司

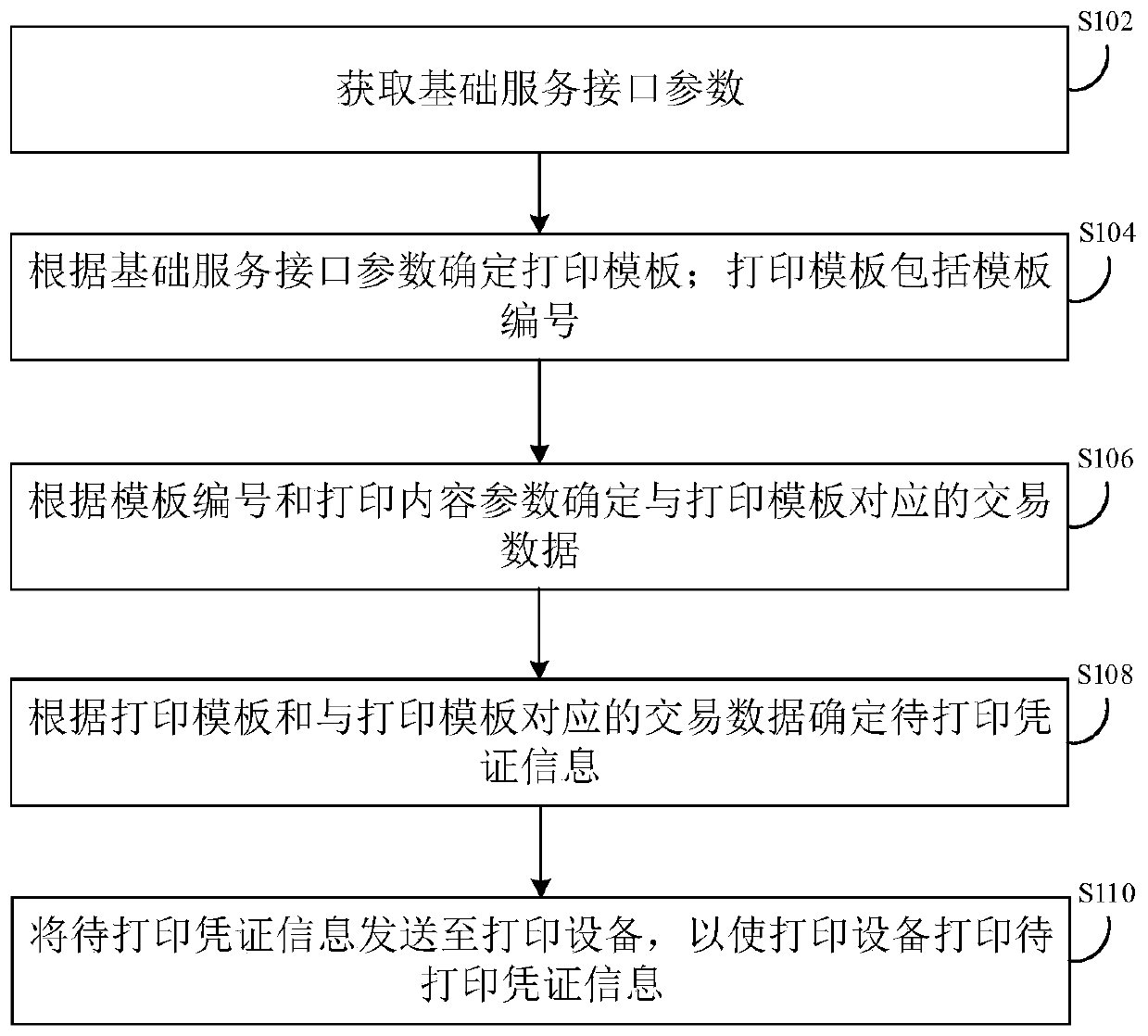

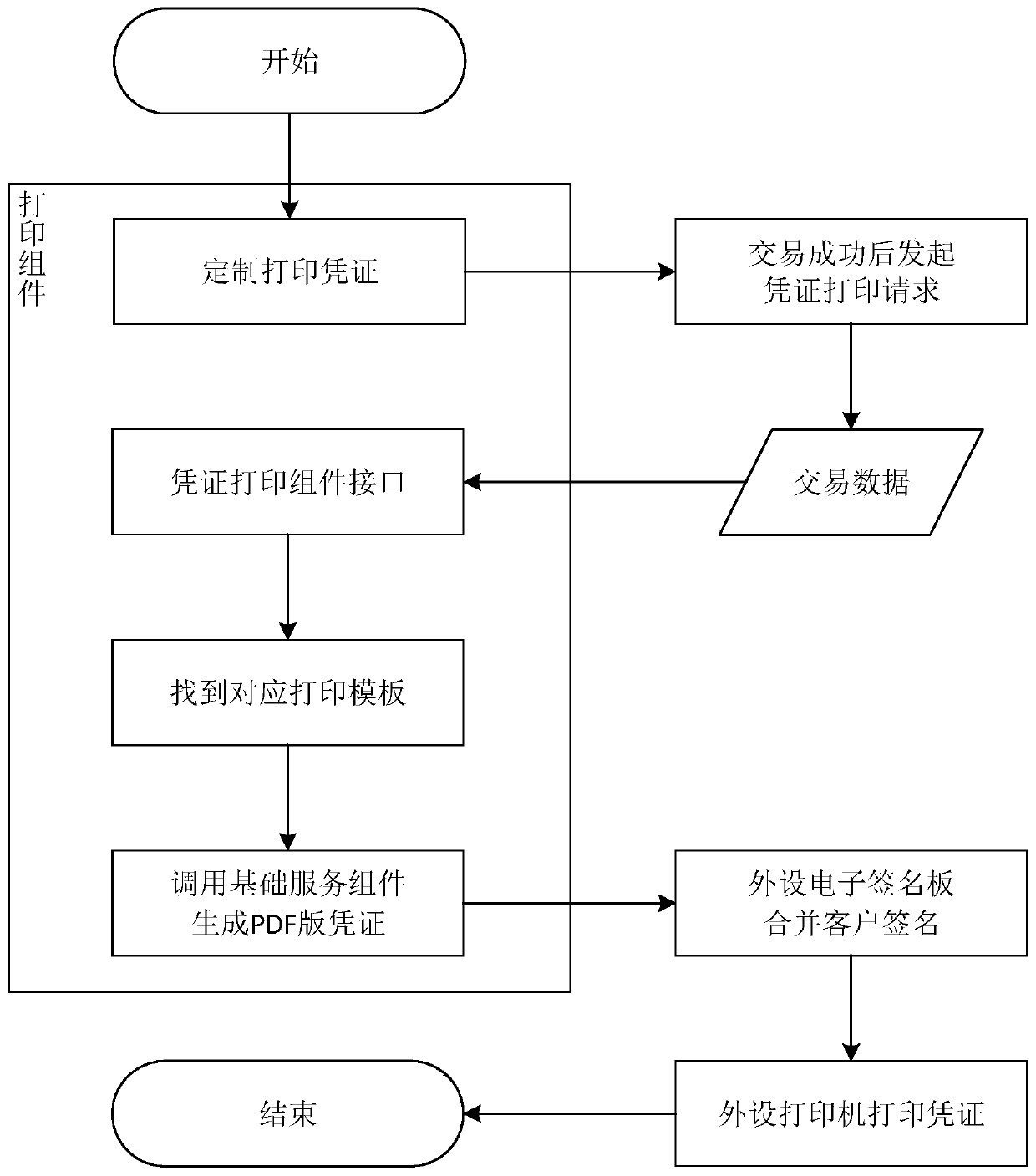

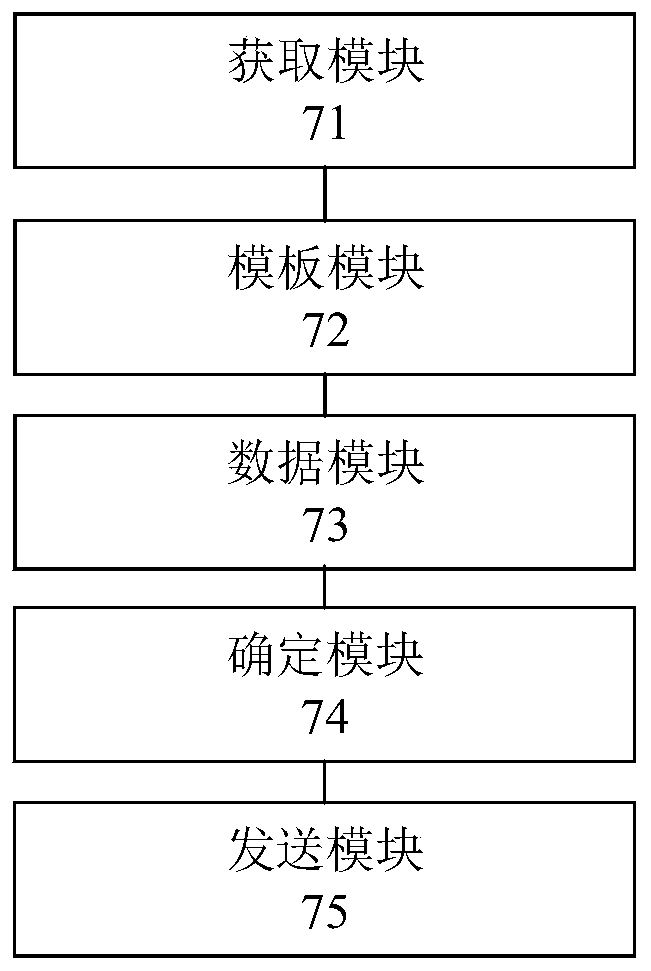

Voucher printing method and device

PendingCN111124324ASimplify the modification processImplement automatic croppingDigital output to print unitsComputer printingTransaction data

The invention provides a certificate printing method and device. The method comprises the steps: acquiring basic service interface parameters, wherein the basic service interface parameters at least comprise a printing format parameter, a printing content parameter and a printing condition parameter; determining a printing template according to the basic service interface parameters, wherein the printing template comprises a template number; determining transaction data corresponding to the printing template according to the template number and the printing content parameter; determining to-be-printed voucher information according to the printing template and the transaction data corresponding to the printing template; and sending the to-be-printed voucher information to printing equipment, thereby enabling the printing equipment to print the to-be-printed voucher information. According to the invention, the printing template can be dynamically customized, the certificate information can be modified by modifying the basic service interface parameters, the modification is convenient, the automatic cutting of the certificate information can be realized, the certificate information tobe printed can be printed through various printers, and the printing efficiency is improved.

Owner:BANK OF CHINA

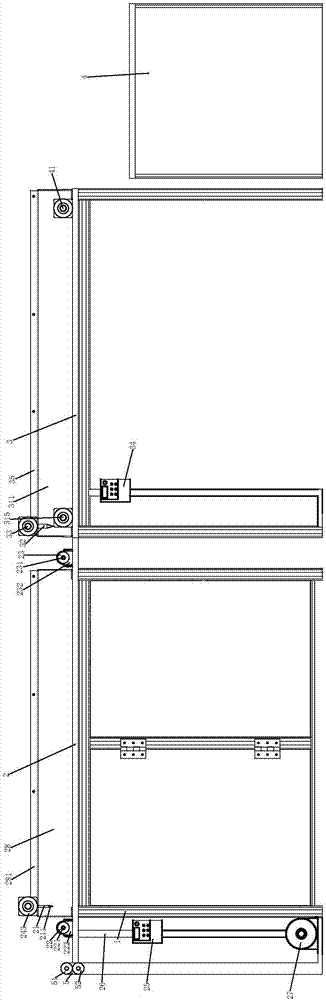

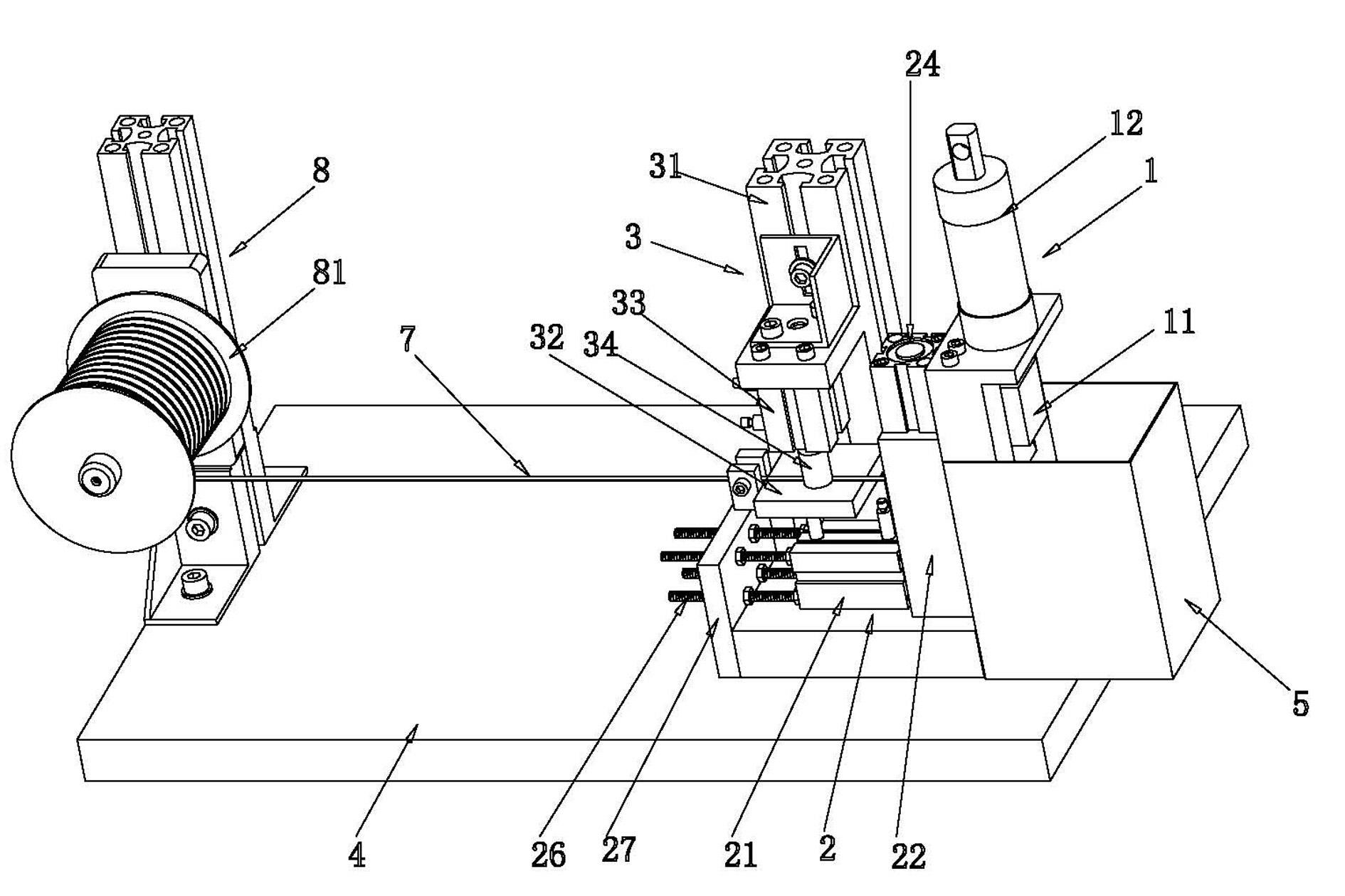

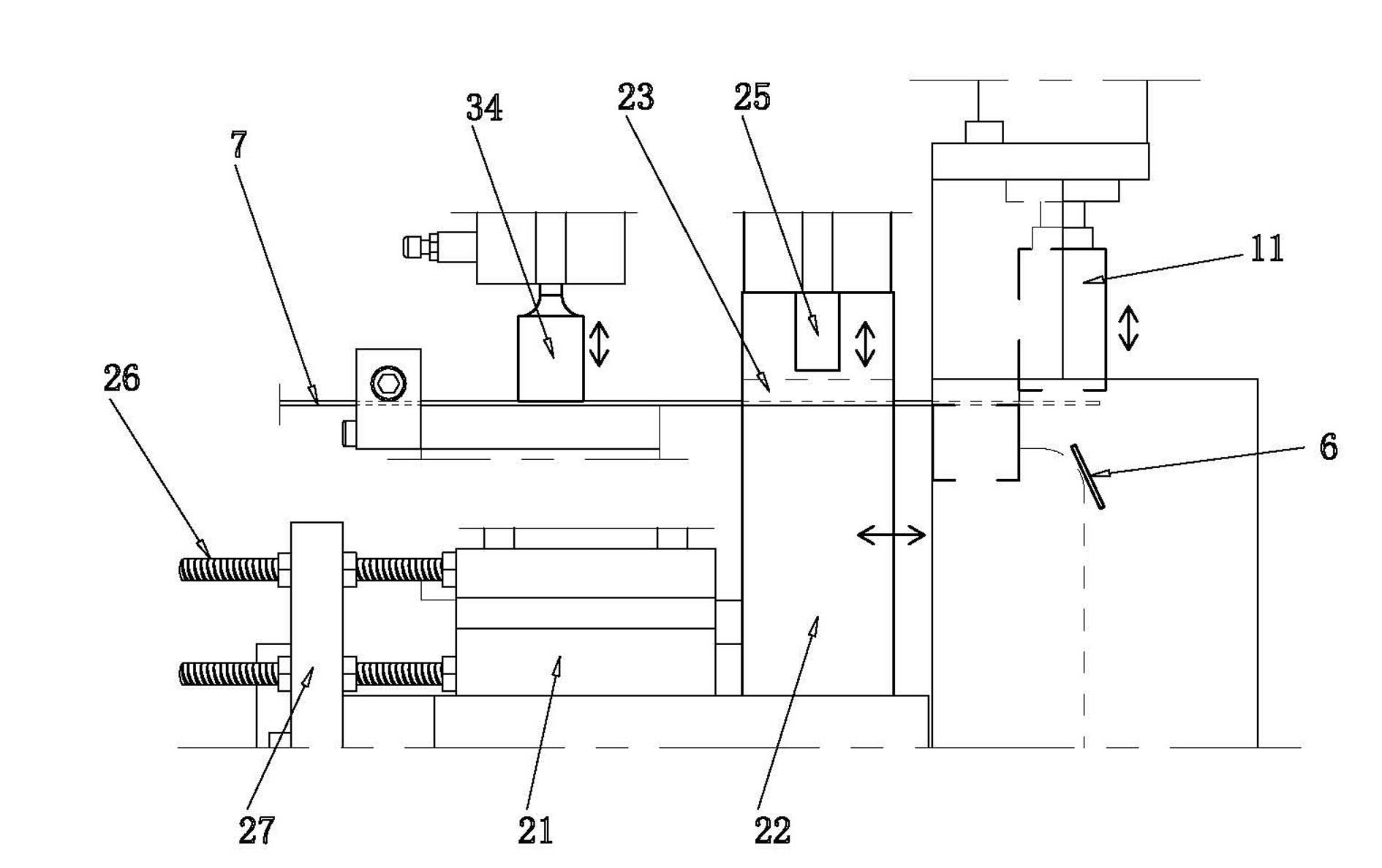

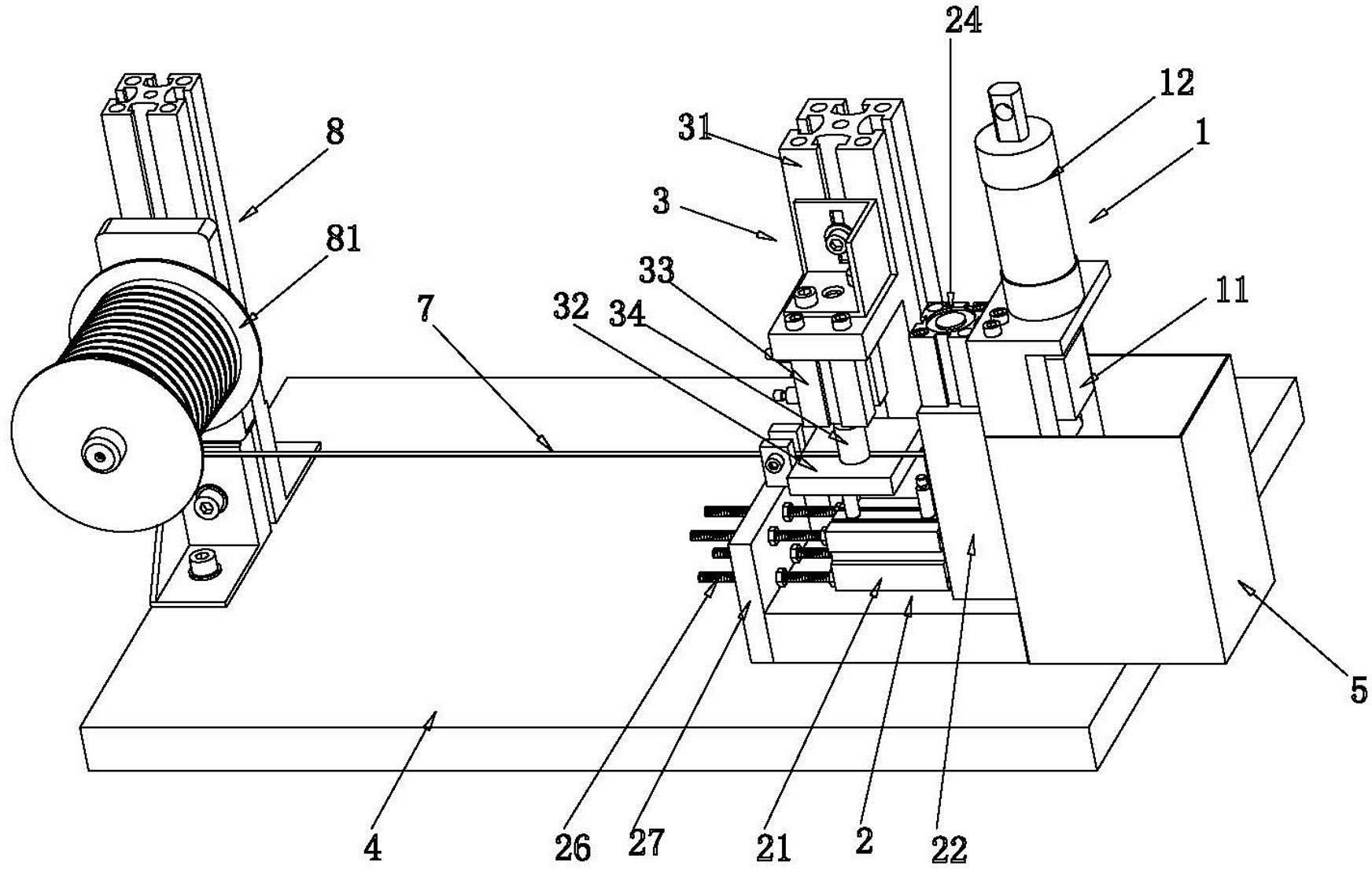

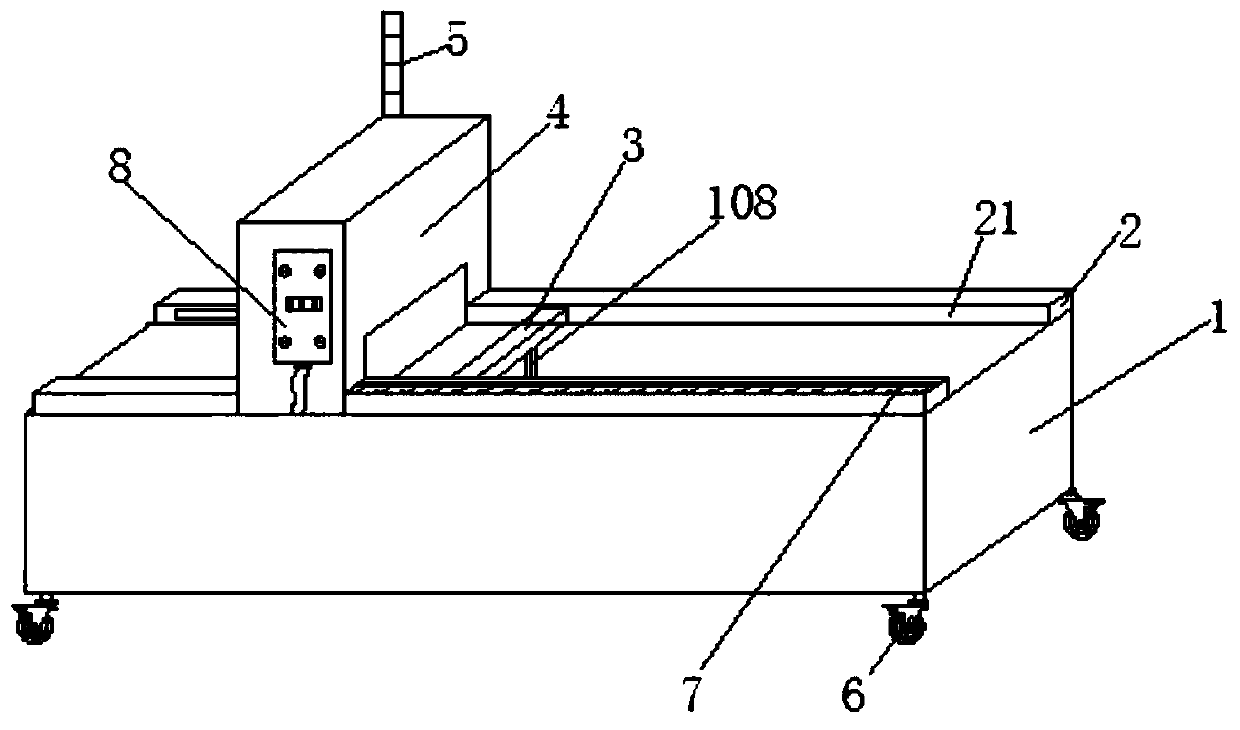

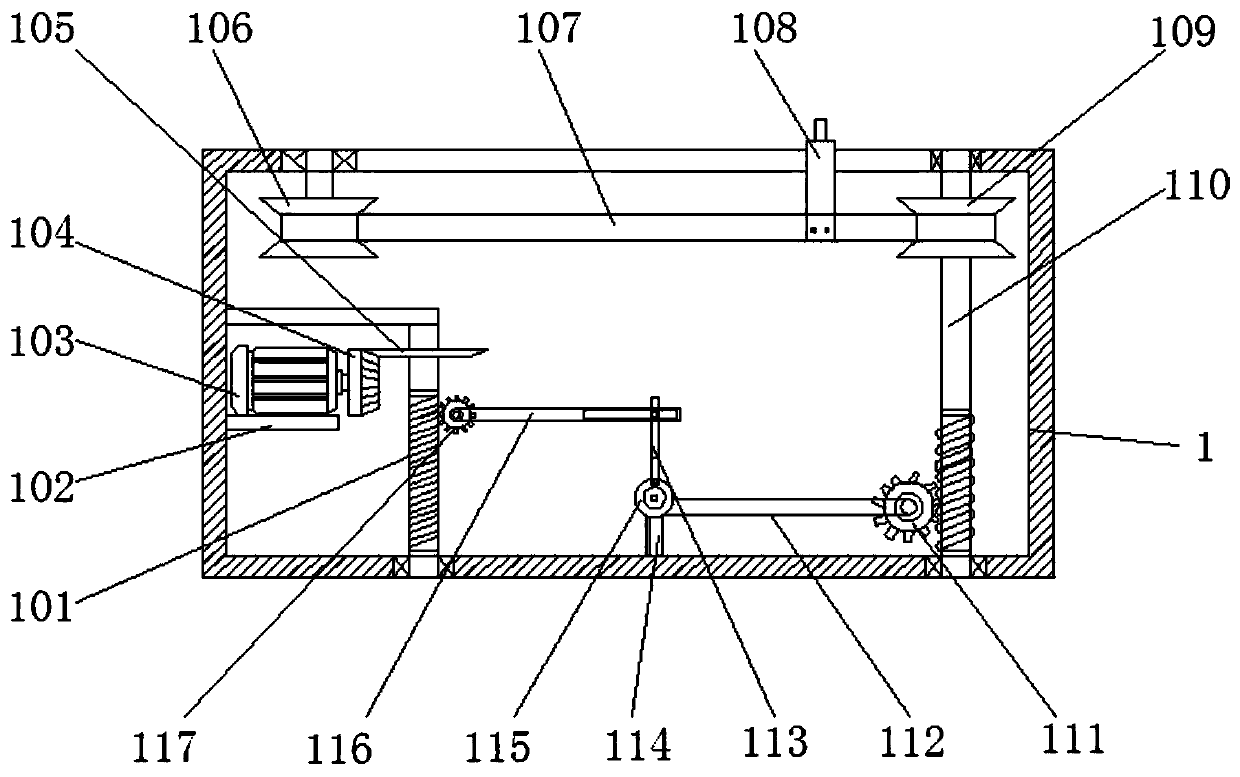

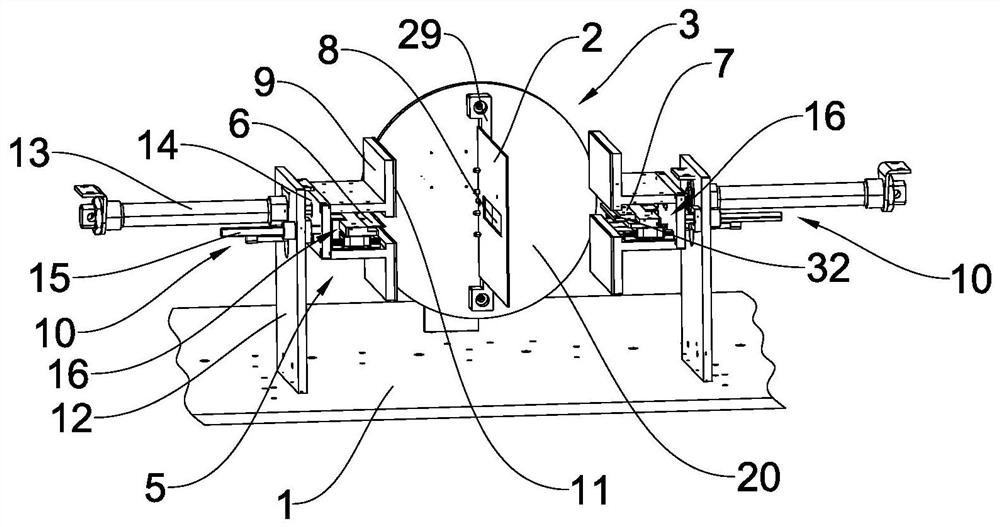

Full-automatic cut-off machine

InactiveCN102101197ARealize automatic deliveryImplement automatic croppingShearing machinesShearing machine accessoriesAutomatic controlReciprocating motion

The invention discloses a full-automatic cut-off machine. The full-automatic cut-off machine comprises a material cutting device, a feeding device, and a material band positioning device; the material cutting device comprises a cutoff tool and a material cutting air cylinder; the cutoff tool is arranged on the piston rod of the material cutting air cylinder; the feeding device comprises a feeding air cylinder and a feeding push block; the piston rod of the feeding air cylinder is fixedly connected with the feeding push block; the feeding push block can make reciprocating motion along with the piston rod of the feeding air cylinder and is provided with a feeding passage through which a feeding band can pass, and a material compressing air cylinder, and the piston rod of the material compressing air cylinder is provided with a material compressing block which can compress the material band on the feeding passage; and the material band positioning device comprises a base and a positioning platform, a positioning air cylinder is arranged on the base, and the piston rod of the positioning air cylinder is provided with a positioning compression block which is matched with the positioning platform. Due to the adoption of automatic control, the material band can be automatically conveyed and cut, the full-automatic cut-off machine has the characteristic of time and labor saving, improves the efficiency of cutting the material band, and reduces the processing cost of metal sheets or metal strips.

Owner:中山凯韦电机有限公司

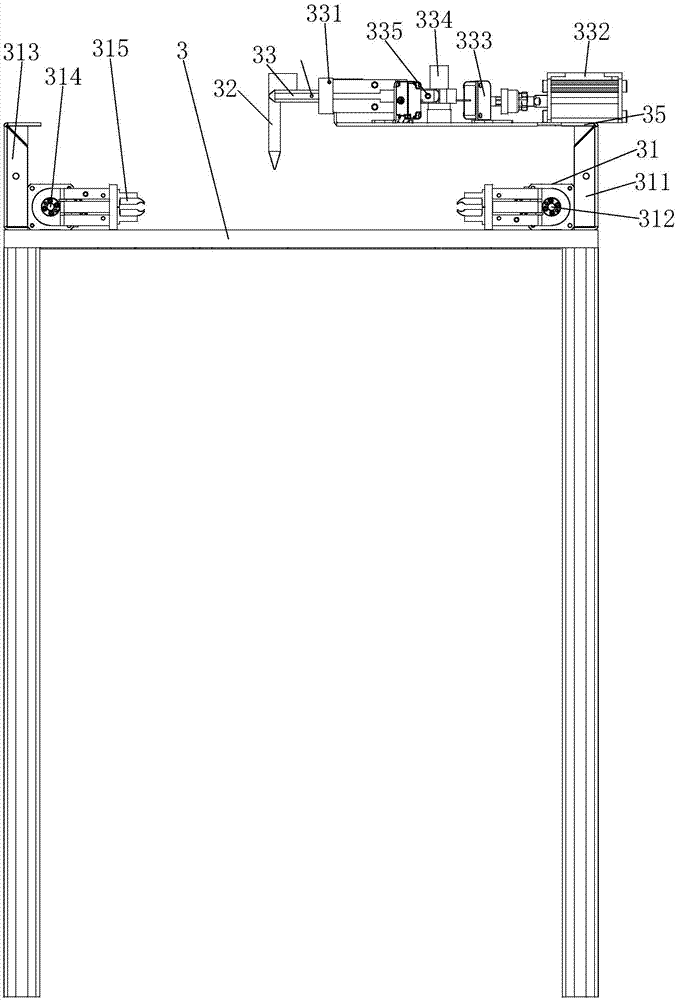

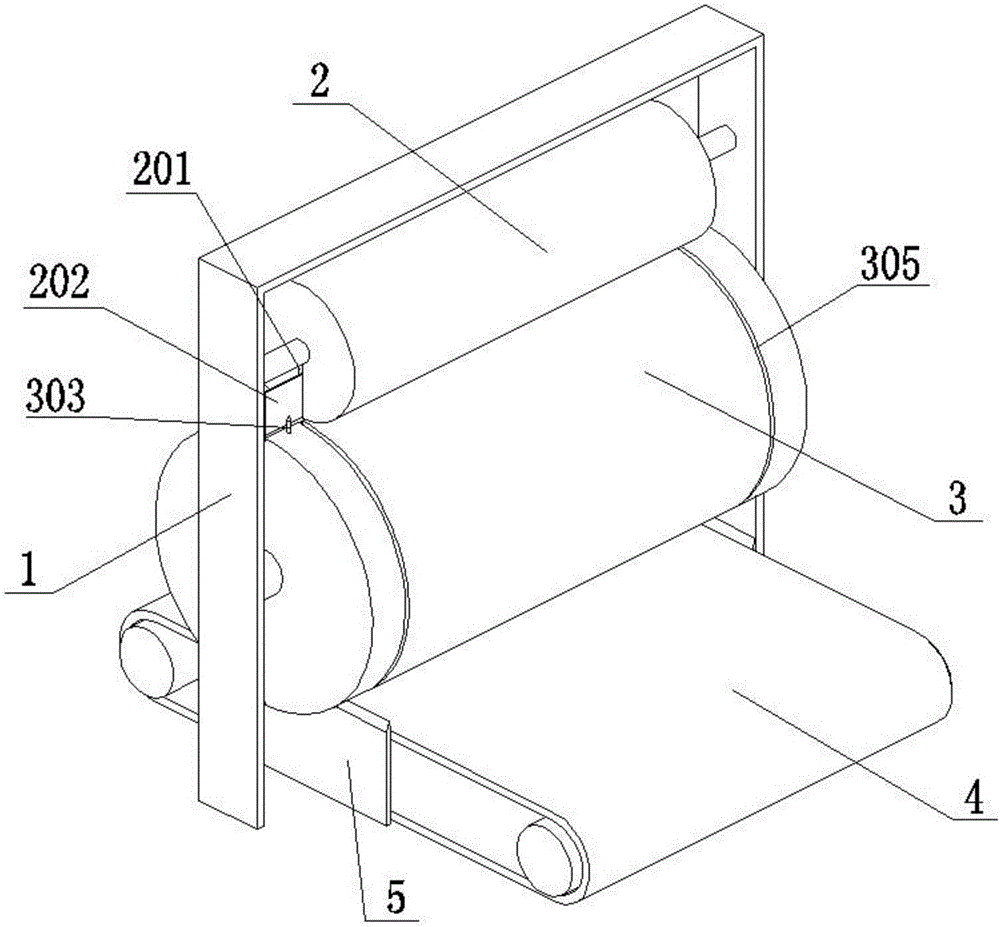

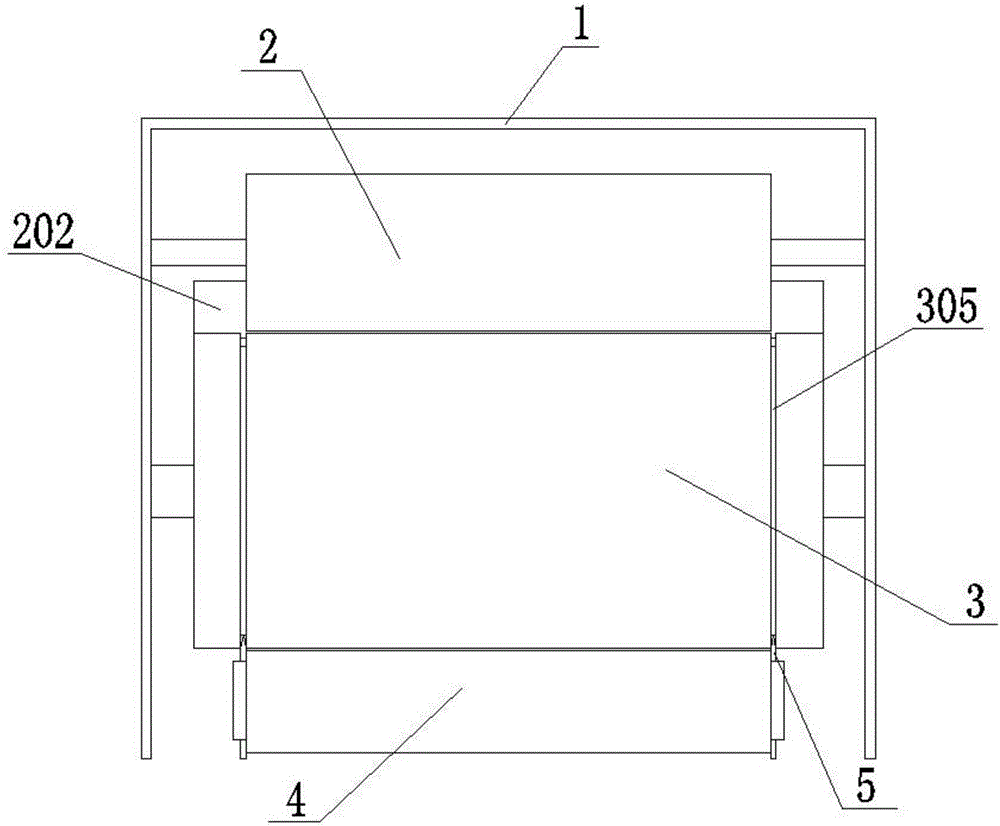

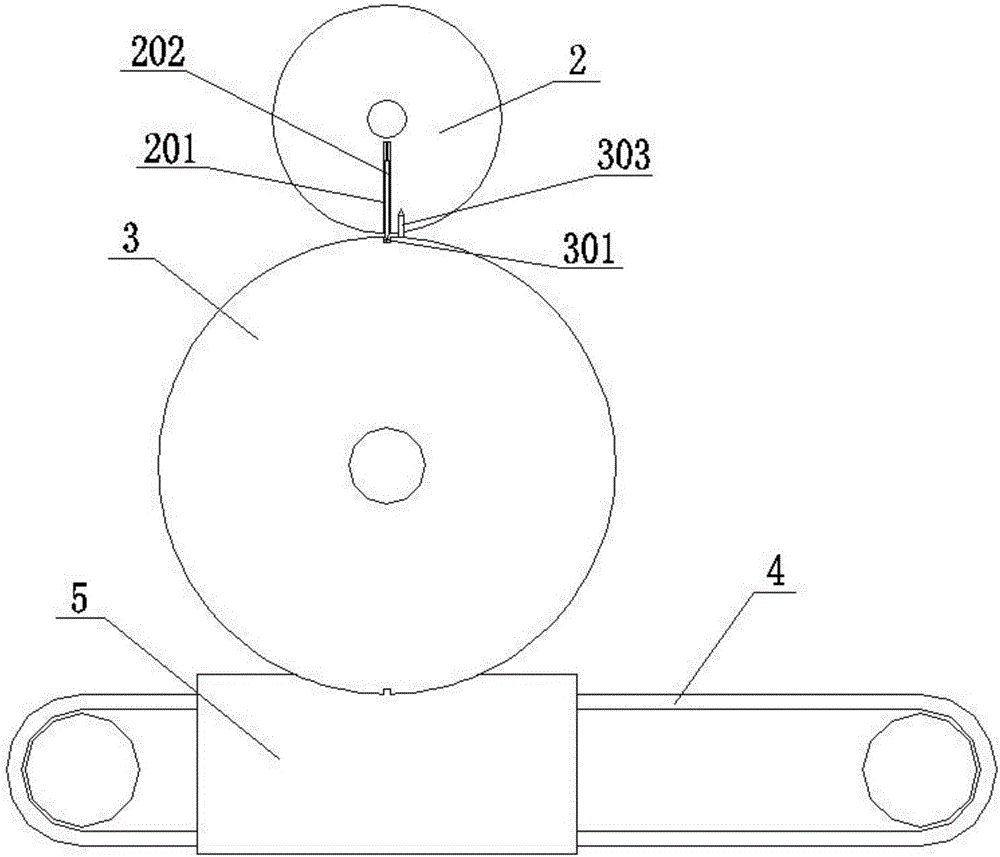

Circular glass cutting device

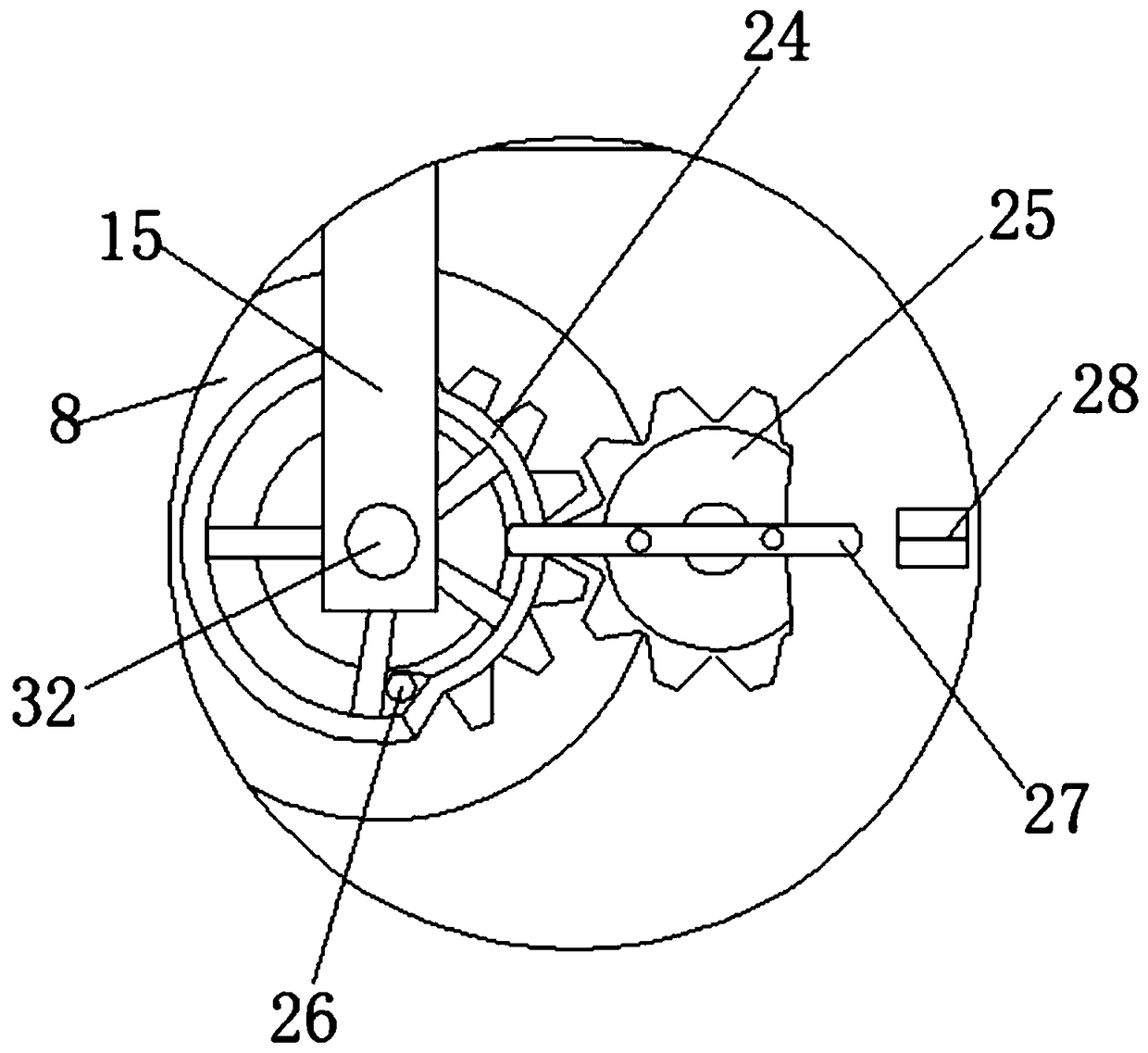

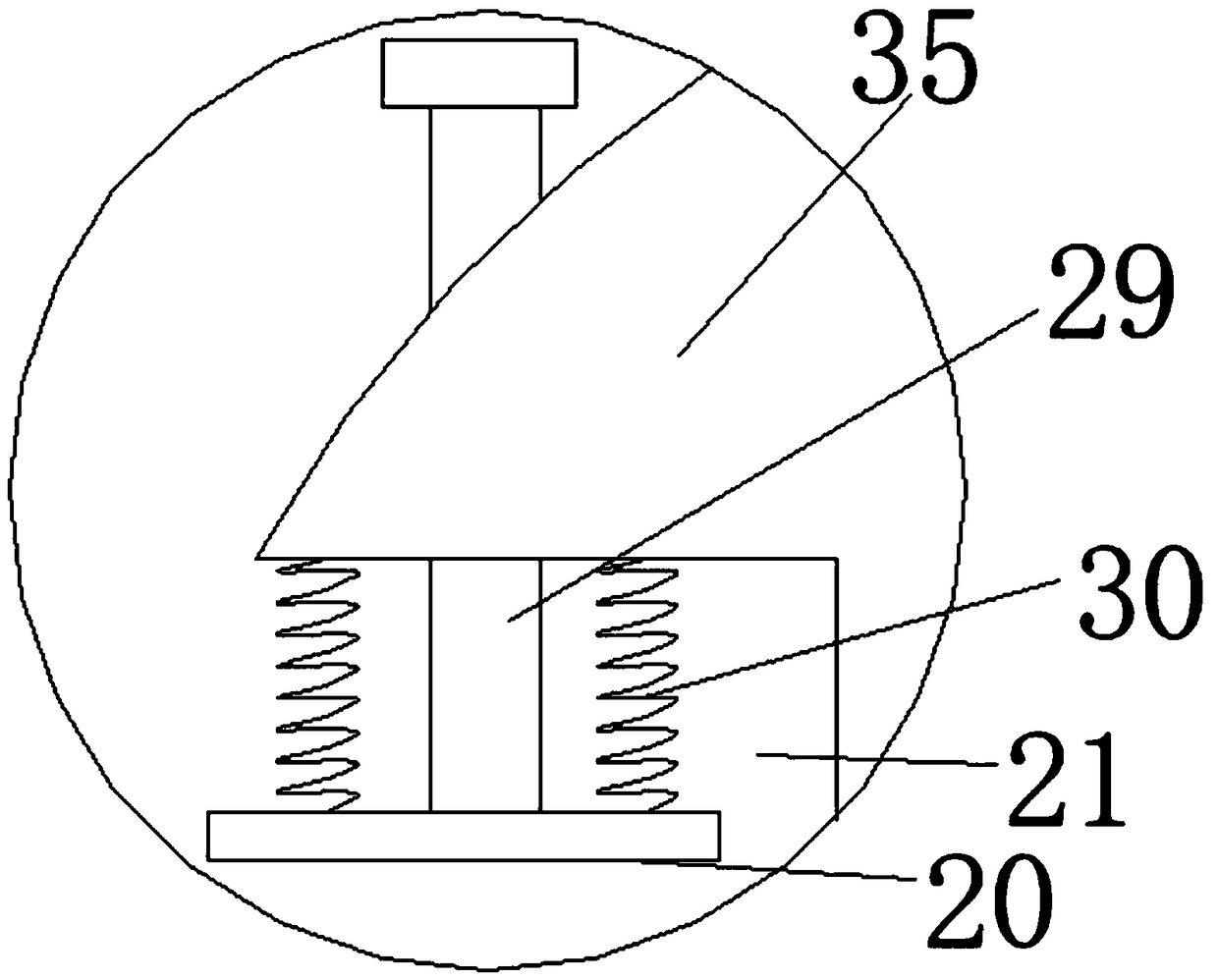

ActiveCN111499175ASame distanceMaximize utilizationGlass severing apparatusGlass productionElectric machineEngineering

The invention relates to a cutting device, in particular to a circular glass cutting device. The technical problem to be solved is to provide the circular glass cutting device which can realize automatic intermittent movement of a glass plate, does not need manual operation and improves the cutting efficiency. According to the technical scheme, the circular glass cutting device comprises: a mounting base, wherein a motor is mounted on the side portion of the mounting base, and a main shaft supporting frame is arranged on the side, close to the motor, of the mounting base; the output main shaftthat is rotatably arranged at the upper part of the main shaft supporting frame far away from one side of the motor, and the end part of the output main shaft close to one side of the motor penetrates through the main shaft supporting frame. The intermittent movement mechanism drives the long-strip-shaped glass plate to move intermittently, the long-strip-shaped glass plate does not need to be pushed manually and intermittently, and automatic cutting of round glass is achieved through the cutting mechanism, meanwhile, under the action of the supporting rolling wheels, a conical cutting knifecan move upwards automatically when the long-strip-shaped glass plate moves.

Owner:南京俊佑光电科技有限公司

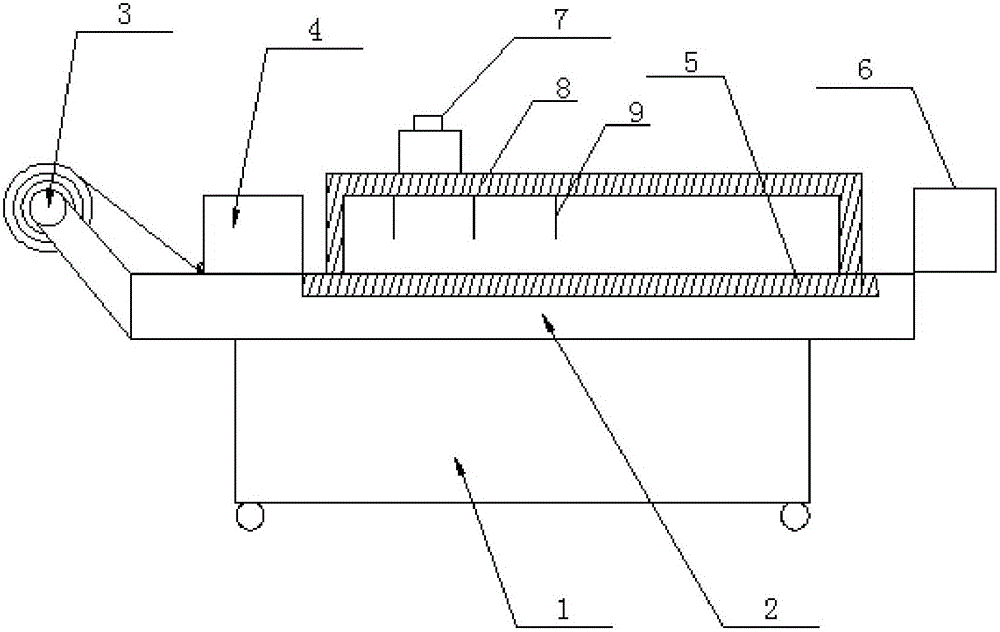

Automatic fabric cutting machine for agricultural production

The invention provides an automatic fabric cutting machine for agricultural production. The automatic fabric cutting machine comprises a base body. A workbench is arranged at the upper end of the base body. A fabric roller is arranged at the left end of the workbench. An ironing device is arranged on the left side of the upper end of the workbench. A graduated scale is arranged on the workbench. A knife rest is arranged on the workbench. Multiple saw blades are connected to the knife rest and can move left and right on a sliding groove of the knife rest. The knife rest can be driven by a motor to move up and down. A fabric collecting device is arranged at the right end of the workbench. The automatic fabric cutting machine for agricultural production is simple in structure, ingenious in design and suitable for agricultural production activities, and can achieve automatic cutting.

Owner:ZHEJIANG DIYE AGRI EQUIP

Circuit board cutting device

InactiveCN111185963ARealize automatic positioningImplement automatic croppingMetal working apparatusSlide plateConveyor belt

The invention provides a circuit board cutting device which comprises a main body. A sliding plate groove for limiting the movement locus of a circuit board, and a vertical cutting mechanism and a horizontal cutting mechanism for cutting the circuit board are arranged on the main body; a conveyor belt for conveying the circuit board is arranged in the sliding plate groove; a limiting mechanism isarranged under the horizontal cutting mechanism, and comprises a limiting plate, a pressure sensor arranged on the limiting plate, and two slide rails fixedly connected to two ends of the limiting plate; dividing rulers are arranged on the outer sides of the slide rails; sliding chutes adaptive to the slide rails are arranged on two sides of the main body; and locking bolts for limiting the sliderails from sliding are in threaded connection to the outer sides of the sliding chutes. According to the circuit board cutting device provided by the invention, the extension length of the circuit board is limited through adjusting the distance between the limiting plate and the main body, so that circuit boards with different lengths are automatically positioned, the cutting error is effectivelyreduced, and the cutting quality is improved; and the pressure sensor on the limiting plate is utilized for controlling a horizontal cutter to undercut, so that the circuit board is automatically cut,and the production efficiency is improved.

Owner:江苏盐湖电子科技有限公司

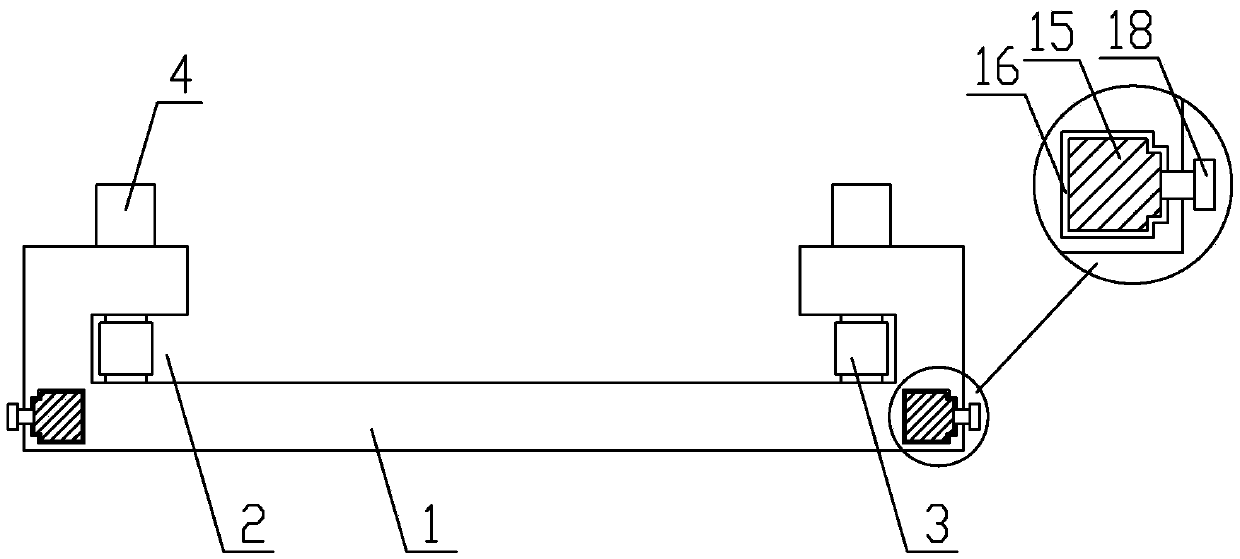

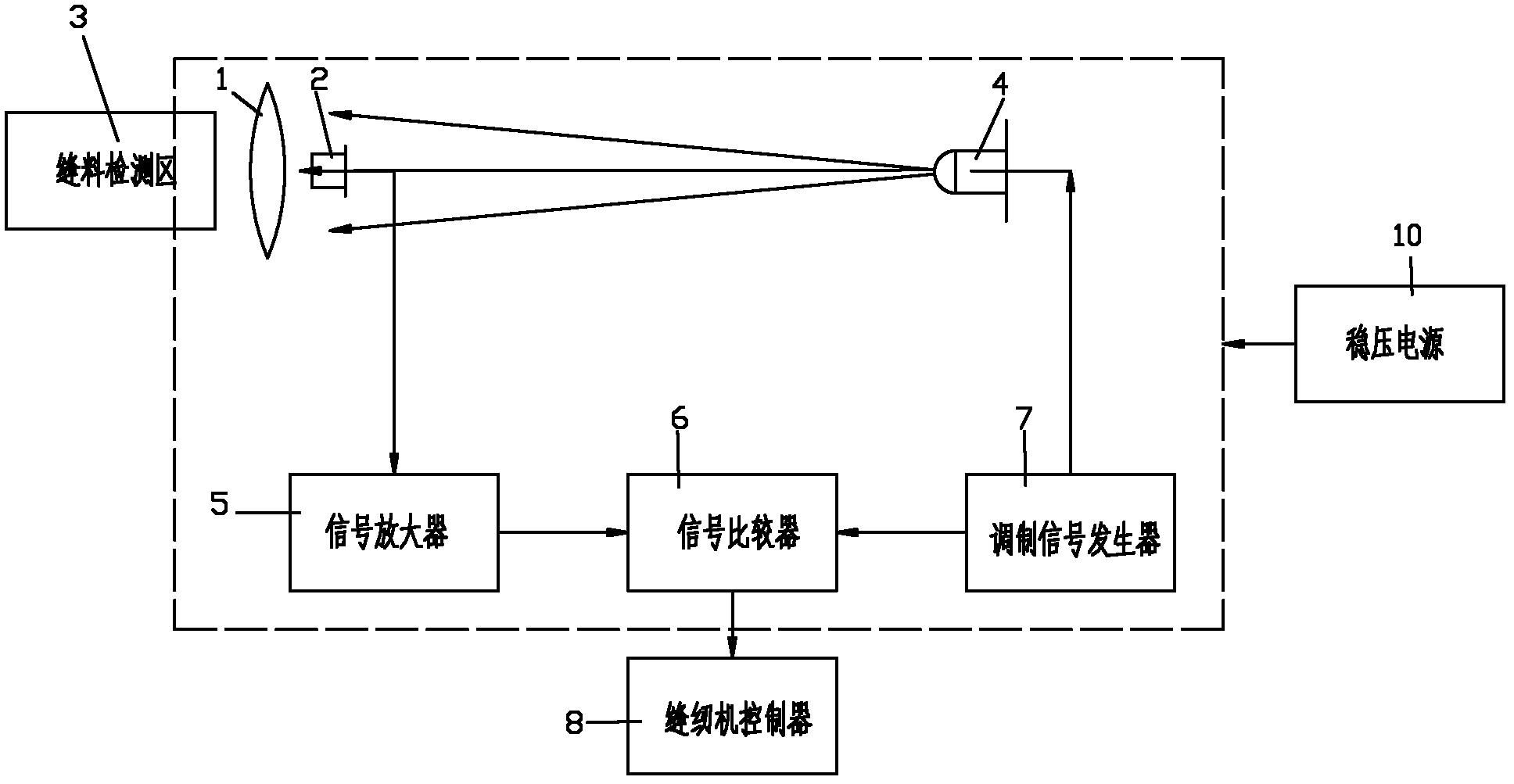

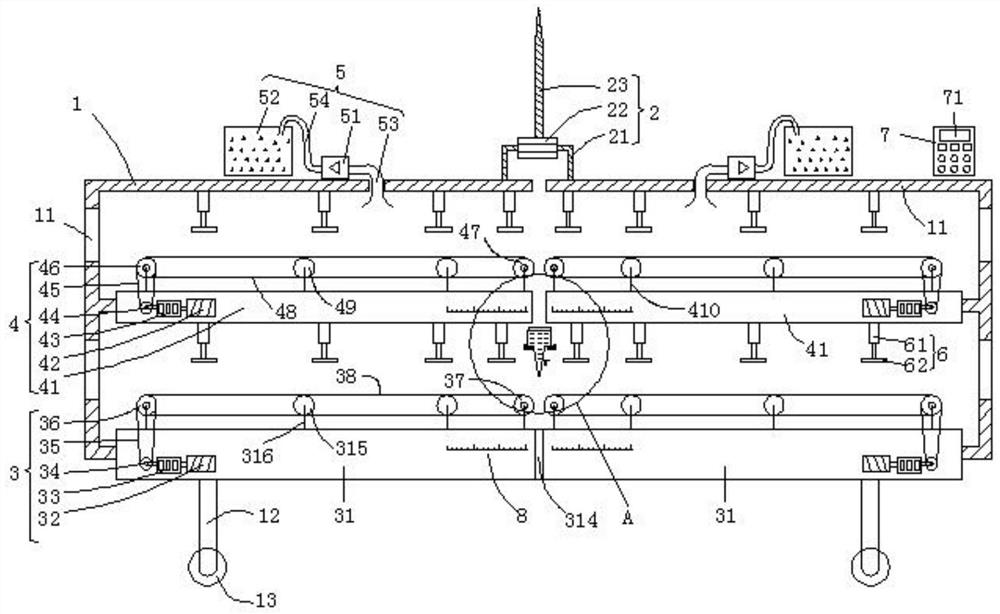

Sewn material detection system of sewing machine

InactiveCN103173946ASimple structureHigh resolutionWorkpiece carriersNeedle severing devicesProduction rateAudio power amplifier

The invention discloses a sewn material detection system of a sewing machine. The system comprises a sewing machine controller, a detection device connected with the sewing machine controller and a stabilized voltage power source providing power for the detection device and the sewing machine controller. The detection device comprises a modulating signal generator, an emitter emitting modulating light rays output by the modulating signal generator, a photosensitive element arranged in the projection direction of the emitter in a parallel mode, a lens group arranged on the left side of the photosensitive element in a parallel mode and converging the modulating light rays to a sewn material detection area, a signal amplifier for amplifying electric signals which are output by the photosensitive element and converted by the light rays reflected by the sewn material detection area and a signal comparator for comparing and calculating signals output by the signal amplifier and modulating signals generated by the modulating signal generator and outputting results to the sewing machine controller. The system is simple in structure, high in resolution ratio, low in manufacture cost, and stable and reliable in operation, achieves automatic cutting and line shearing, and greatly improves productivity and production quality.

Owner:陕西银星科技有限公司

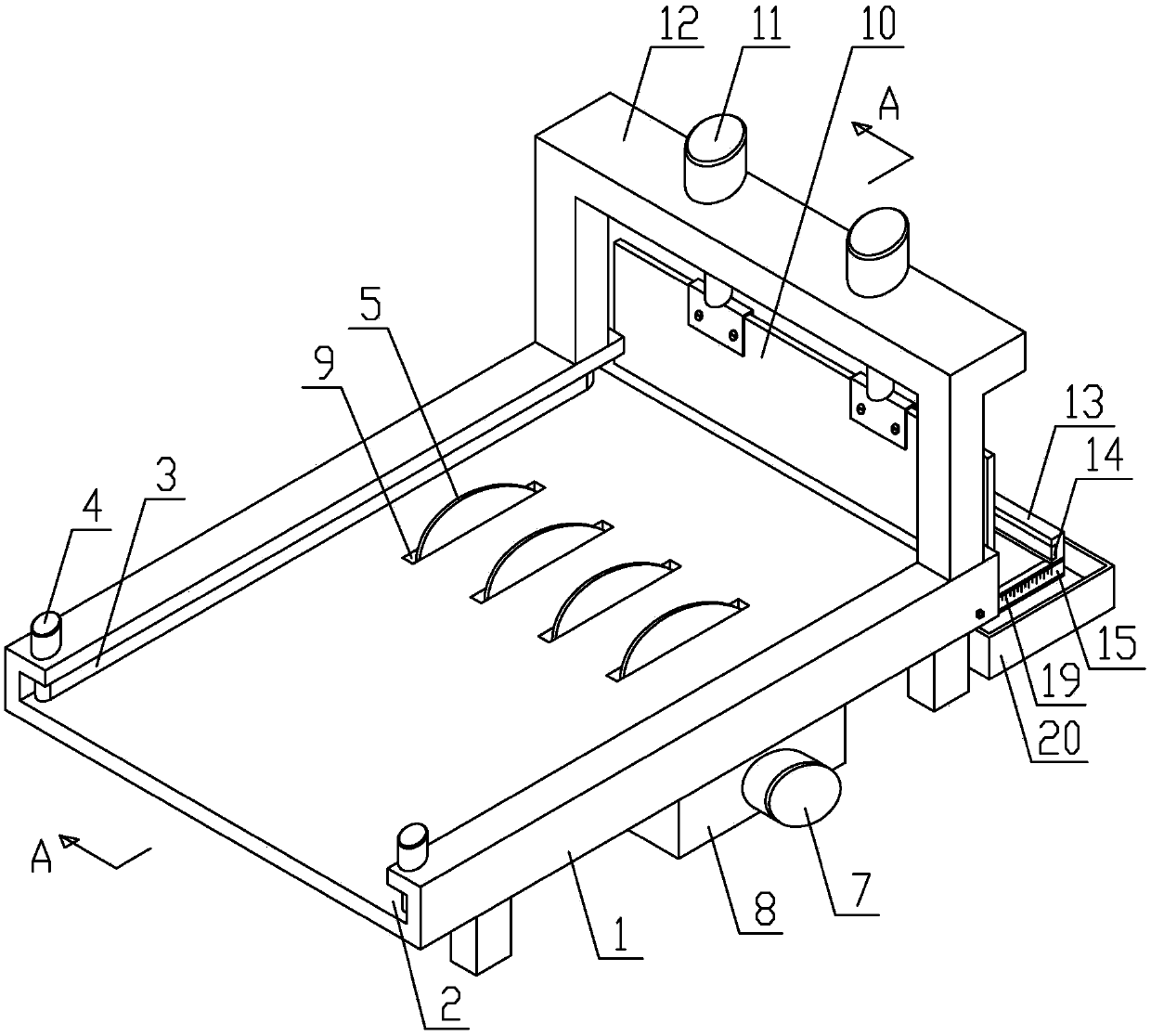

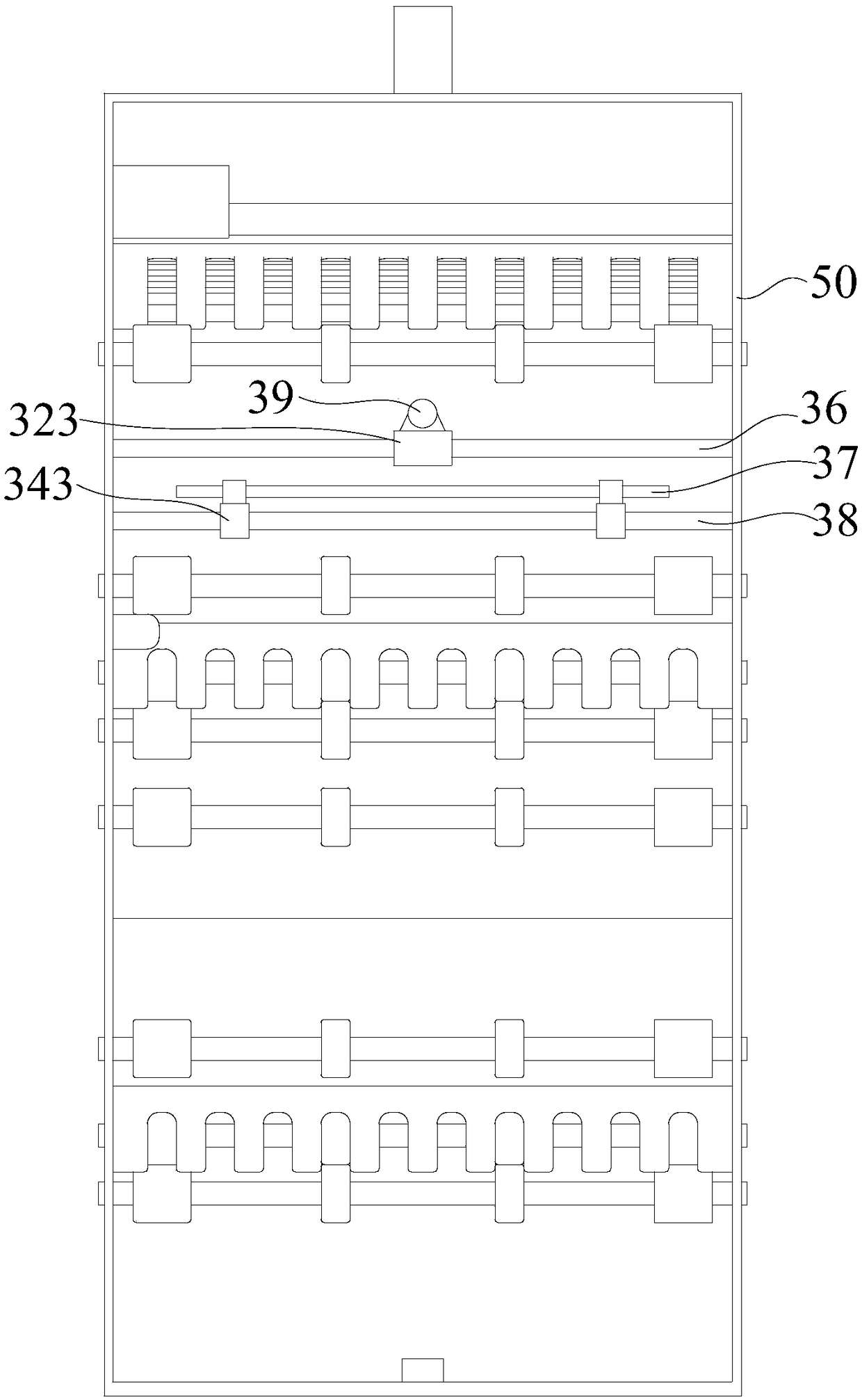

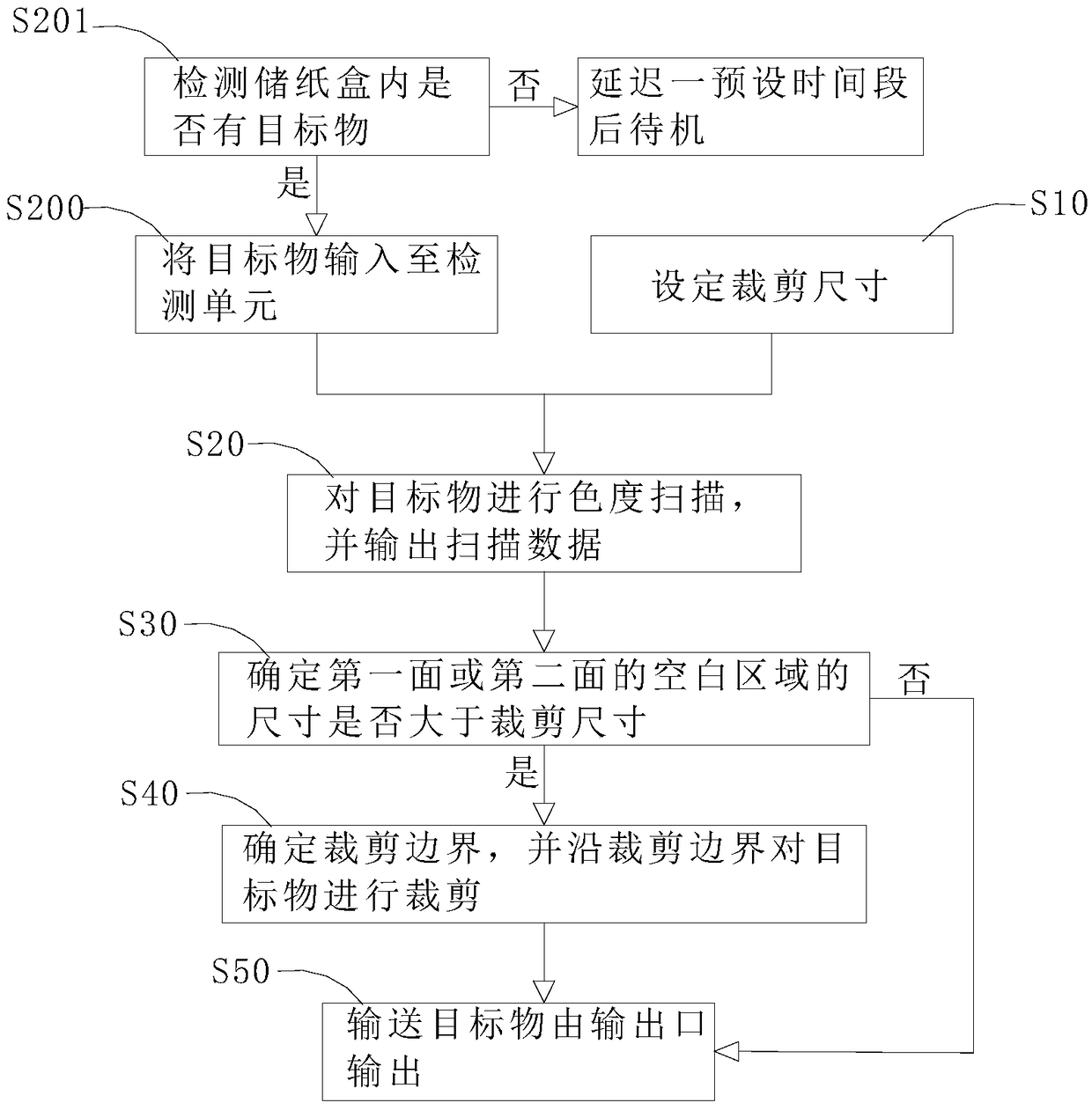

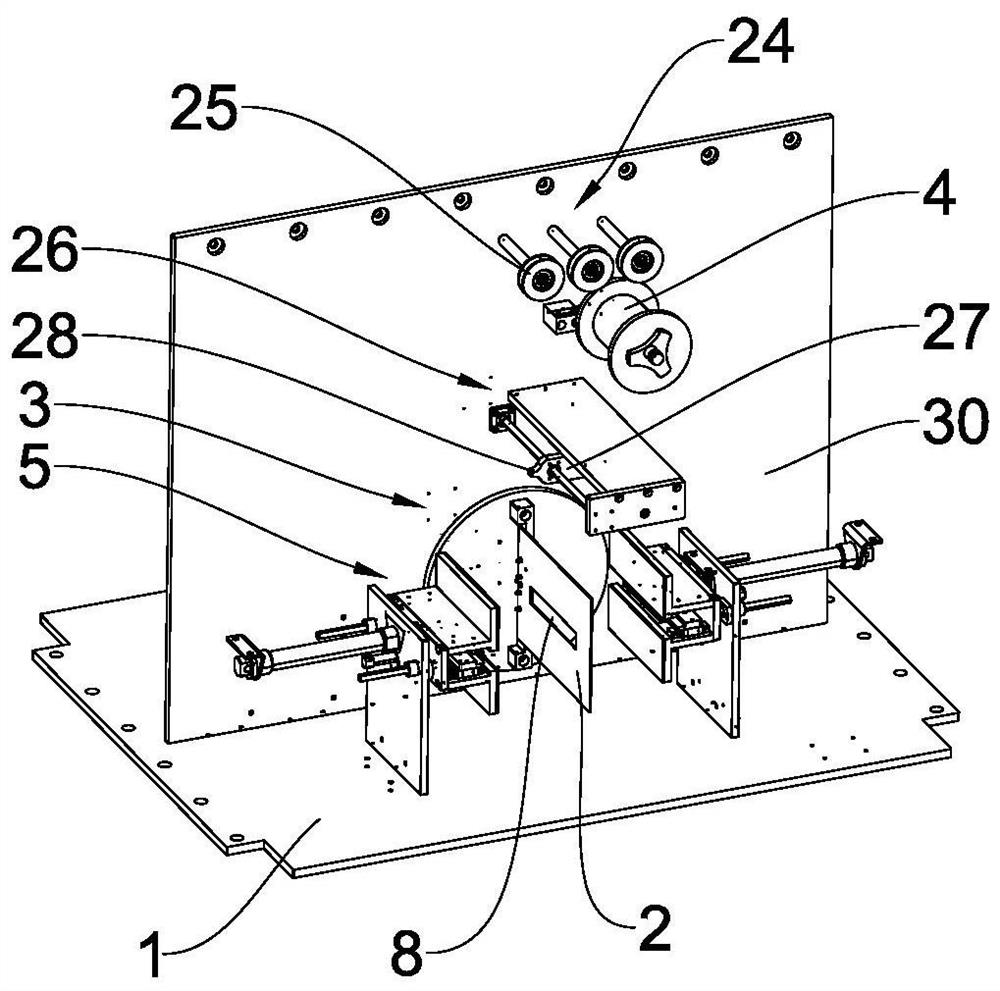

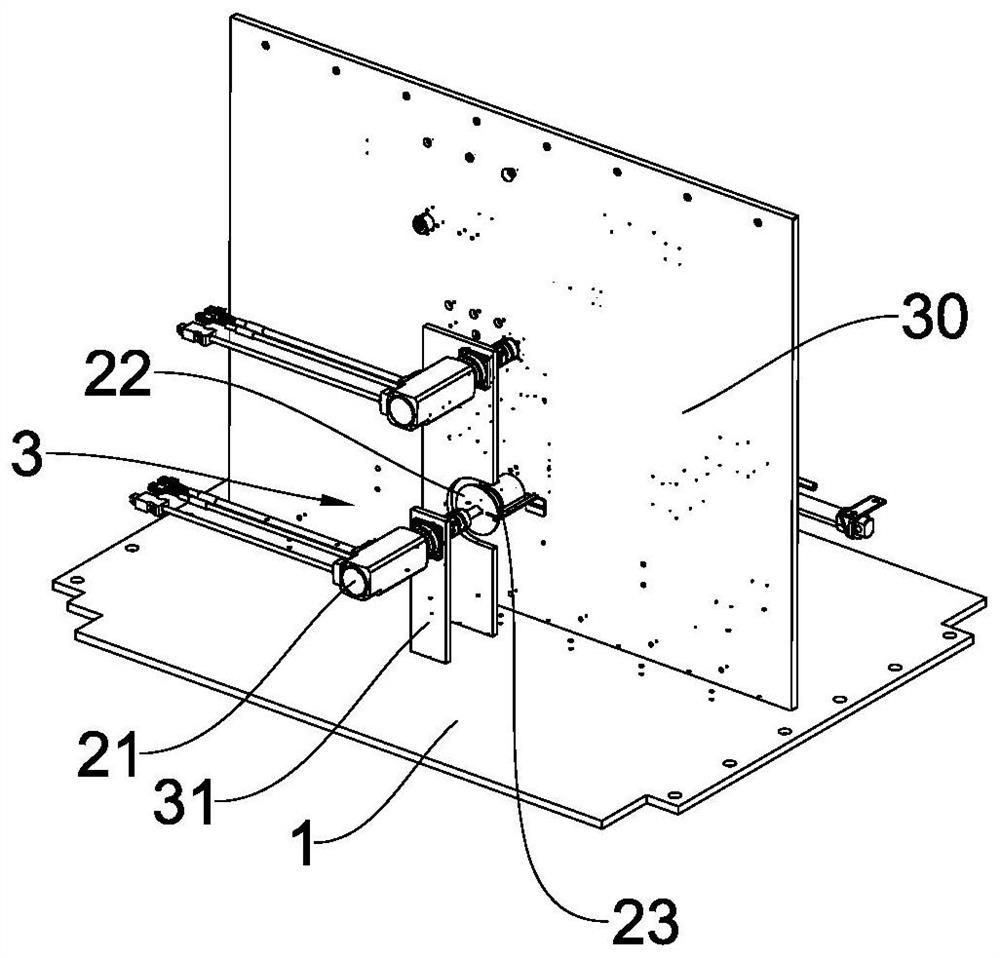

Tailoring system and tailoring method

PendingCN108724317AImprove cutting efficiencyReduce labor costsMetal working apparatusElectricityCUTEr

The invention relates to a tailoring system and a tailoring method. The tailoring system comprises a detection unit, a conveying unit, a tailoring unit and a control device, wherein the detection unitcomprises a first detection part and a second detection part arranged oppositely; the conveying unit is provided with a paper conveying channel which is successively provided with an input port and an output port; the tailoring unit comprises a first tailoring cutter and a second tailoring cutter, the first tailoring cutter is used for tailoring a target along a first direction, and the second tailoring cuter is used for tailoring a target along a second direction; and the control device is electrically connected to the detection unit, the conveying unit and the tailoring unit, separately, for determining a tailoring boundary according to scanning data of the first detection part and the second detection part and controlling the conveying unit to convey the target to a preset position, sothat the first tailoring cutter and the second tailoring cutter tailor the target along the tailoring boundary. The tailoring system tailors the target automatically, so that the labor cost is lowered and the tailoring efficiency is improved.

Owner:GUANGDONG BAIYUN UNIV

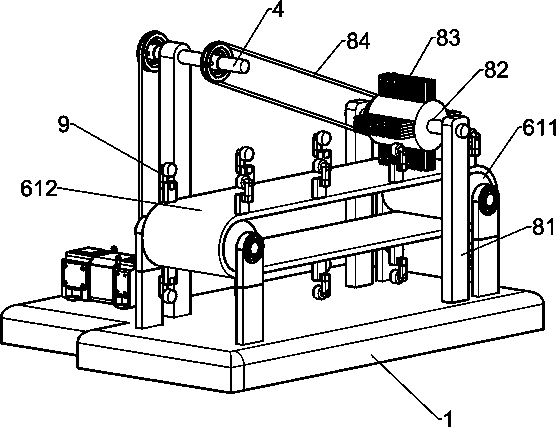

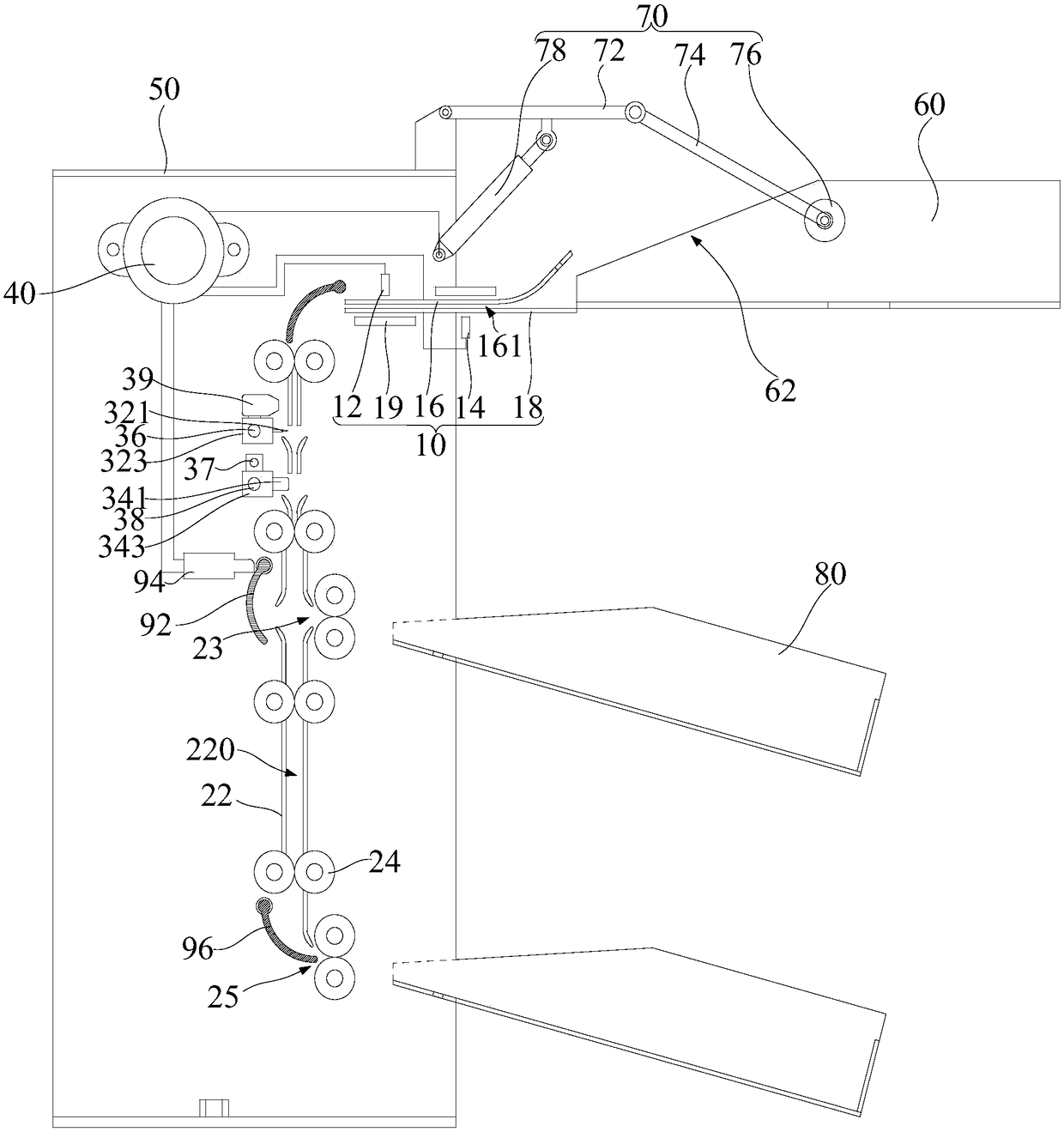

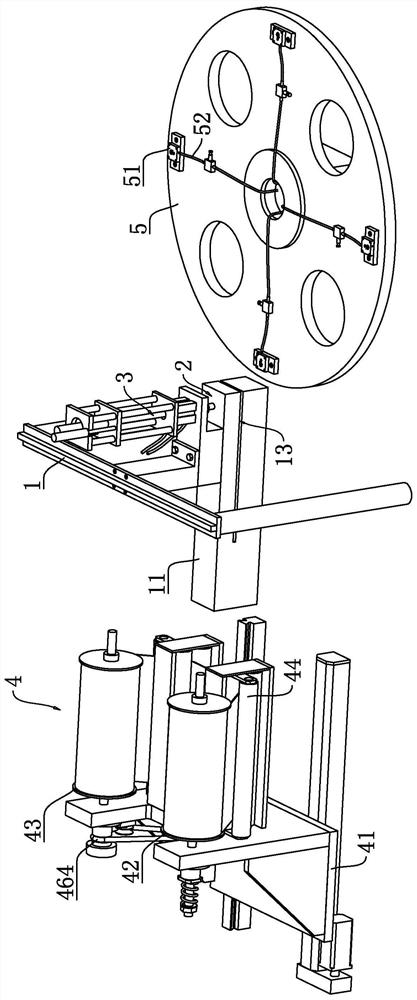

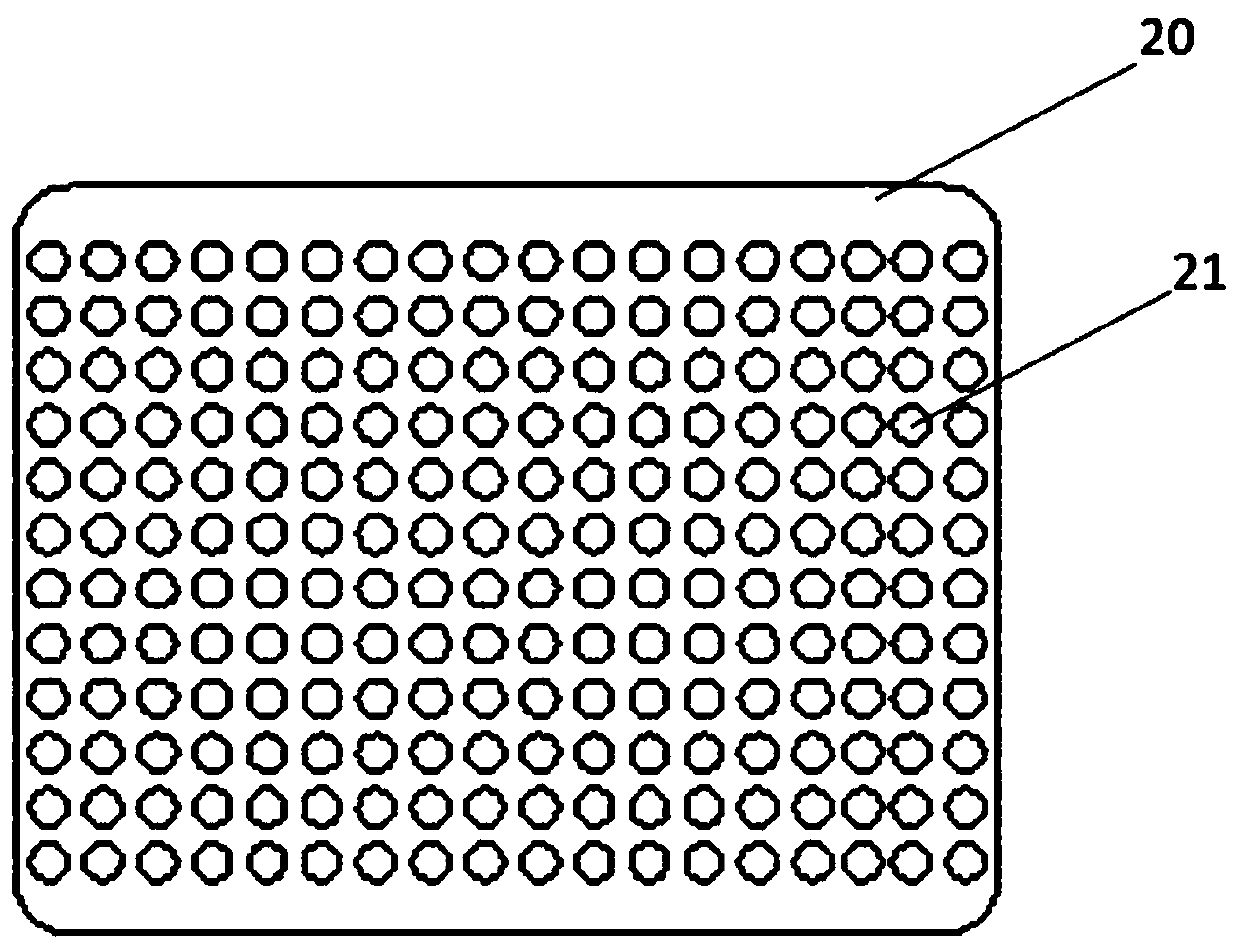

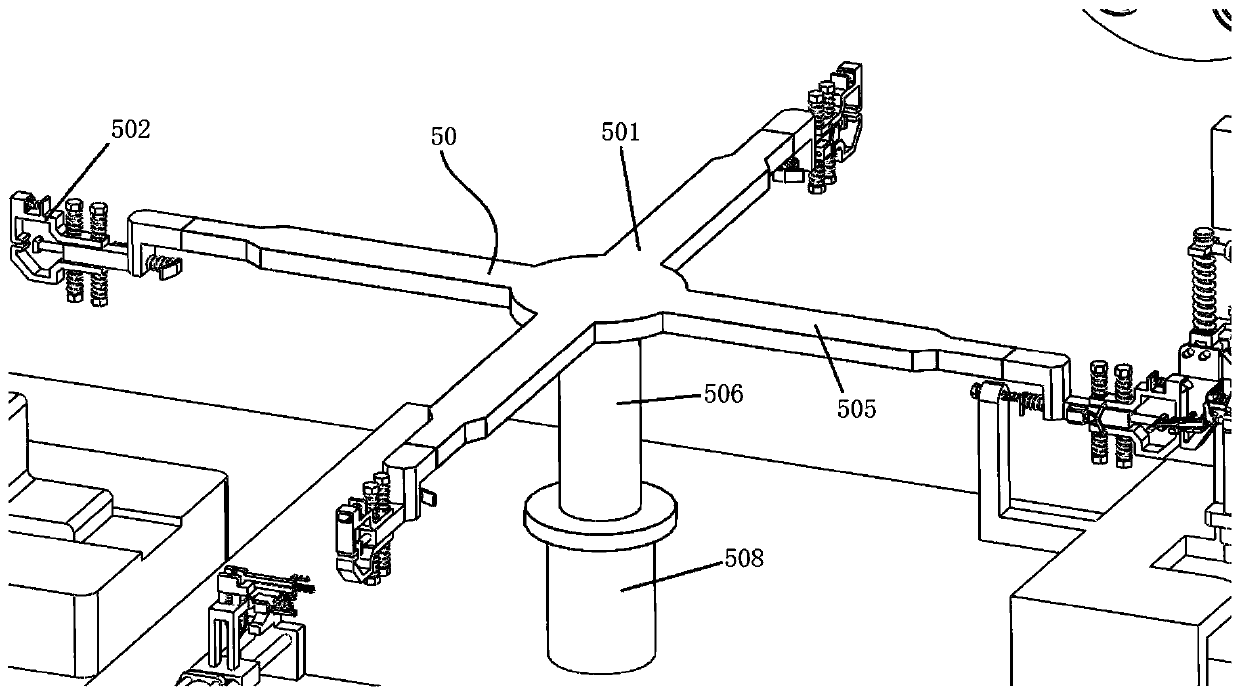

Belt ring processing device with automatic transferring function

ActiveCN109207648AImplement automatic croppingAchieve stitchingMechanical cleaningPressure cleaningClosing loopsRaw material

The invention relates to a belt ring processing device with an automatic transferring function. The belt ring processing device with the automatic transferring function is characterized by comprisinga working platform, and a feeding and cutting unit, a closing unit, an overturning unit and a transferring unit are arranged on the working platform; and the transferring unit comprises a transferringpart and a clamping part, the transferring part is used for enabling the clamping part to sequentially pass through the located positions of the feeding and cutting unit, the closing unit and the overturning unit, so that raw material leather strips sequentially realize cutting, closing loop formation and overturning inside and outside. According to the belt ring processing device with the automatic transferring function, automatic cutting, closing and overturning of the raw material leather strips can be realized, thus the raw material leather strips is processed into finished belt rings, very high processing efficiency is achieved, the processing quality can be guaranteed, and processing errors are reduced.

Owner:宋任菊

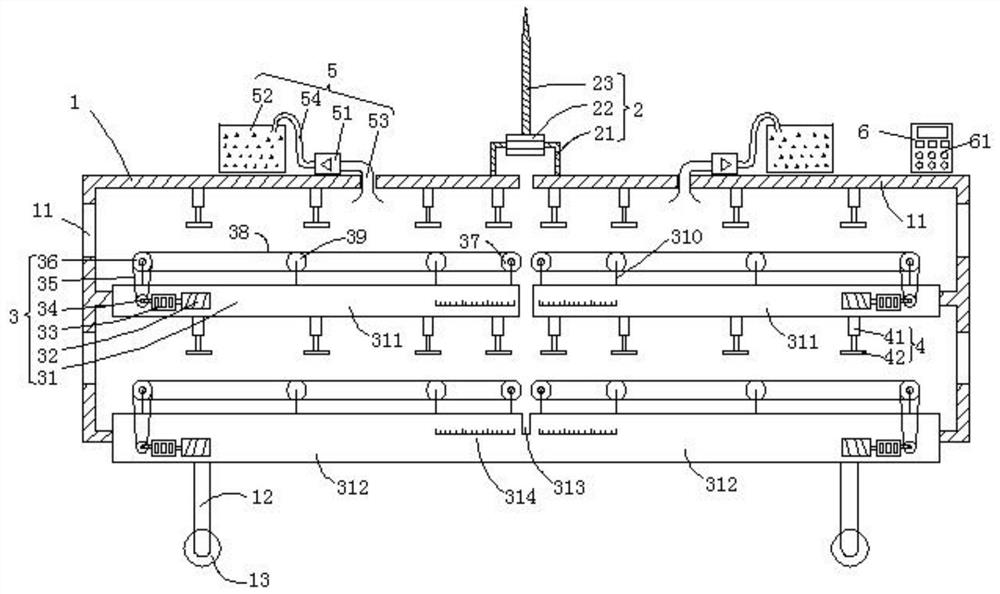

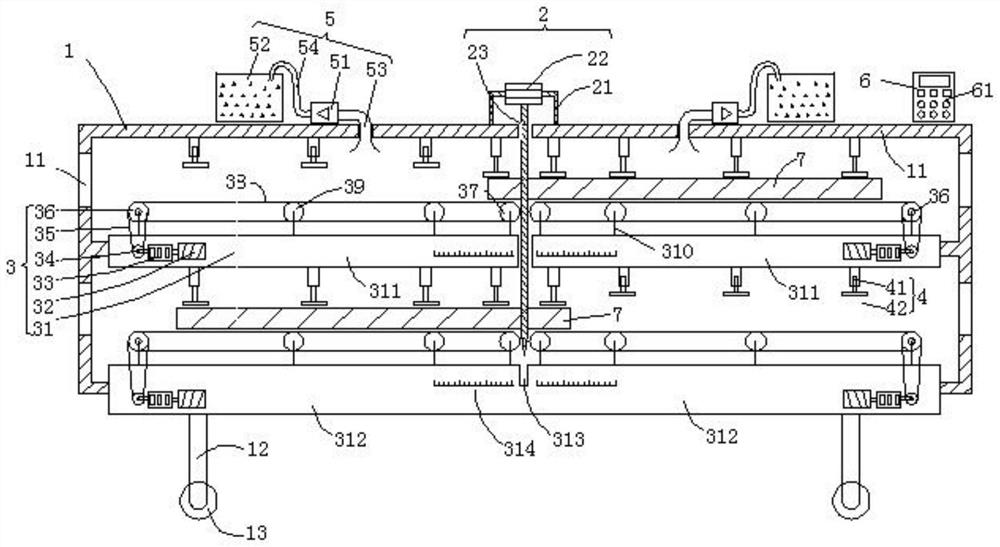

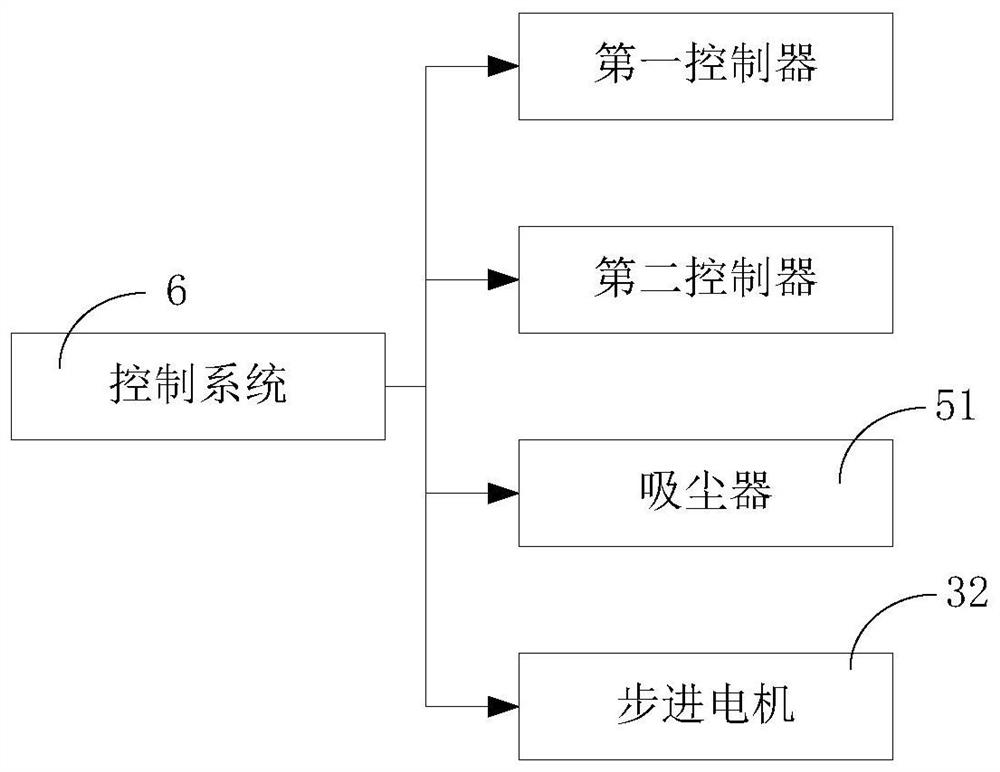

Insulating pad cutting and bonding integrated machine

InactiveCN108908956AImprove work efficiencyImplement automatic croppingDirt cleaningDomestic articlesEngineeringControl system

The invention provides an insulating pad cutting and bonding integrated machine, which belongs to the technical field of electric power construction facility. The machine comprises a frame and a cutting mechanism, a material inlet and outlet are arranged on both sides of the frame, a cutting table for cutting an insulating rubber pad and a bonding mechanism for bonding a plurality of the insulating rubber pads are arranged at the frame, a pressing mechanism for pressing the insulating rubber pad is arranged at top of the cutting table and frame, a dust removing mechanism for sucking the insulating rubber pad debris is disposed at the upper portion of the frame, and a control system for controlling the cutting mechanism, the bonding mechanism, the pressing mechanism and the dust removing mechanism are arranged at the upper part of the frame. According to the insulating rubber pad cutting and bonding integrated machine, by arranging the cutting mechanism, the bonding mechanism and the cutting table on the frame, the control system controls the cutting and bonding parameters, the automatic cutting and automatic bonding of the insulating rubber pad can be realized, and the machine hasthe advantages of no gap, no foaming, no burrs for bonding, and increases the working efficiency of the insulating rubber pad.

Owner:STATE GRID CORP OF CHINA +1

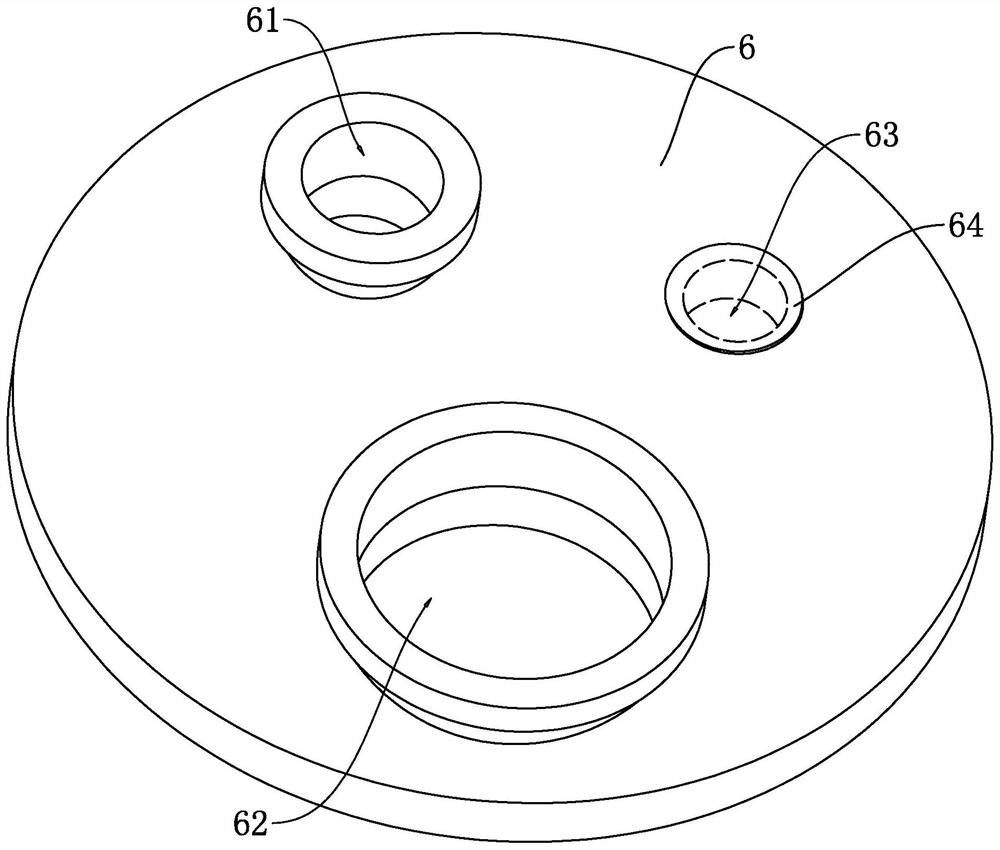

Test tube cover and bacteria blocking membrane automatic membrane pasting and welding device

The invention relates to a test tube cover and bacteria blocking membrane automatic membrane pasting and welding device, and belongs to the technical field of blood sampling test tube production. The device comprises a rack and a punching mechanism, a bearing table is mounted on the rack, bacteria blocking membranes are arranged on the bearing table, and a material falling hole channel penetrates through the bearing table in the thickness direction; a punching mechanism comprises a punching air cylinder and a punching pipe, the punching air cylinder is mounted on the rack, the punching pipe is arranged in the material falling hole channel in a penetrating manner, and a piston rod of the punching air cylinder drives the punching pipe to descend so as to punch the bacterium blocking membranes and push the bacterium blocking membranes to air holes of test tube covers. According to the device, the function of automatically cutting the bacterium blocking membranes can be achieved, and the cut bacterium blocking membranes can automatically cover the air holes of the test tube covers, so that the manual labor is reduced, and the working efficiency is improved.

Owner:江苏神力医用制品有限公司

Automatic cloth shearing machine

The invention discloses an automatic cloth shearing machine, comprising a vertical bracket, a transverse arm, a first manipulator, a second manipulator, an electromagnet work bench, a fixing frame, fixed iron blocks, a vibration plate, a sodium silicate aqueous solution nozzle and a shearing head. The electromagnet work bench is located on the lower end of the transverse arm. The electromagnet work bench is used for placing a cloth and absorbing the fixed iron block. The fixing frame is mounted above the electromagnet work bench. The number of the fixed iron blocks is multiple, and the fixed iron blocks are adsorbed on the electromagnet work bench through the cloth. The sodium silicate aqueous solution nozzle squeezes the fixed iron block under the control of the first manipulator and applies a sodium silicate aqueous solution shearing path on the cloth. The shear head cuts along the sodium silicate aqueous solution shearing path under the control of the second manipulator. The automatic cloth shearing machine has novel structure and ingenious design, and can realize automatic cutting of the cloth by controlling mechanical arms. The machine provides convenience for designing and researching and developing in a production process.

Owner:NINGBO EASTSUN TEXTILES

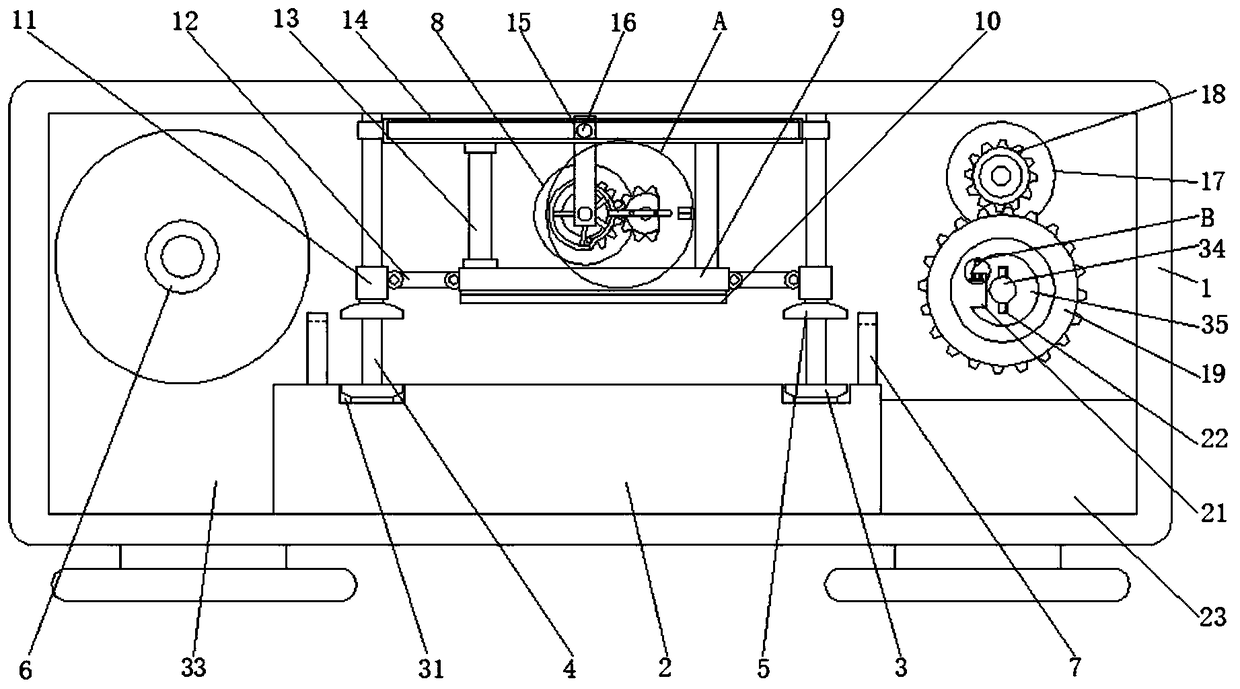

Fixed cloth cutting device

InactiveCN109676658AImplement automatic croppingNo crop wrinklesSevering textilesMetal working apparatusEngineeringSprocket

The invention discloses a fixed cloth cutting device. The fixed cloth cutting device comprises a bin body, baffles, a fixed bin and a cutting mechanism, wherein the middle position of the bin body ishollowed out, the baffles are arranged on the two sides of the bin body, sliding chutes are arranged on the inner sides of the baffles, a ruler is arranged on the baffle on the other side of the bin body, the cutting mechanism is arranged at the left end of the bin body, a work light is arranged at on end of the top of the cutting mechanism, and a control panel is arranged on one side of the cutting mechanism; the bin body comprises a first rotating shaft, a base, a first motor, a first bevel gear, a second bevel gear, a first chain wheel, a chain, a clamping pin, a second chain wheel, a second rotating shaft, a first gear, a swing rod, a first connecting rod, a fixed rod, a rotating wheel, a second connecting rod and a second gear; and the first motor is installed on the base. No cuttingwinkle occurs, and the fixed cloth cutting device reduces manpower, improves the work efficiency and also improves the cutting quality.

Owner:安徽兴永锦针织有限公司

Printing device with automatic cutting and edge trimming functions

InactiveCN106626728AImplement automatic croppingSimple structureRotary pressesEngineeringAssembly line

The invention discloses a printing device with automatic cutting and edge trimming functions. A cutting knife is arranged on a printing roller, cutting grooves are formed in a driving roller, and the cutting knife is driven by a telescopic air cylinder to realize automatic cutting of printed materials. Z-shaped fixing parts are arranged on the driving roller, the printed materials are fixed through fixing pins at the two ends of each Z-shaped fixing part, and the fixing parts are driven by the telescopic air cylinder to realize fixation and release of the printed materials. A conveying belt is arranged below the driving roller, edge-trimming cutters are arranged on two sides of the conveying belt, edge-trimming grooves are formed in the driving roller, automatic edge-trimming of the printed materials is realized through the edge-trimming cutters, and the printed materials subjected to cutting, printing and edge trimming are conveyed through the conveying belt. The printing device with automatic cutting and edge trimming functions has the advantages that the structure is simple, use is convenient, full-automatic assembly line work for printing, cutting and edge trimming of the printed materials are realized, the production time is greatly saved, and the production efficiency is improved.

Owner:ANHUI QINGFENGYU ANTI COUNTERFEITING TECH

Shielding PI film sticking tool

InactiveCN110480997AImplement automatic croppingIncrease productivityMetal working apparatusEngineeringAtmospheric pressure

The invention provides a shielding PI film sticking tool. The shielding PI film sticking tool comprises a device main body, a film absorbing member and a fixing block; the fixing block is disposed onthe lower part of the device main body, and the film absorbing member is disposed on the lower part of the device main body; and the device main body comprises a mold handle, a main body panel, an airvalve and a cutting die. Through the structure, the situation that the device main body automatically absorbs and shields a PI film during lowering is achieved by arrangement of the air valve and thefilm absorbing member, and during sticking, the shielding PI film can be automatically stuck by the way of opening the air valve to send air pressure without manual sticking. The efficiency of sticking is improved, the automatic cutting of the shielding PI film is realized by arrangement of the cutting die without manual cutting, and the production efficiency of users is further improved.

Owner:闽侯福怡塑料制品有限公司

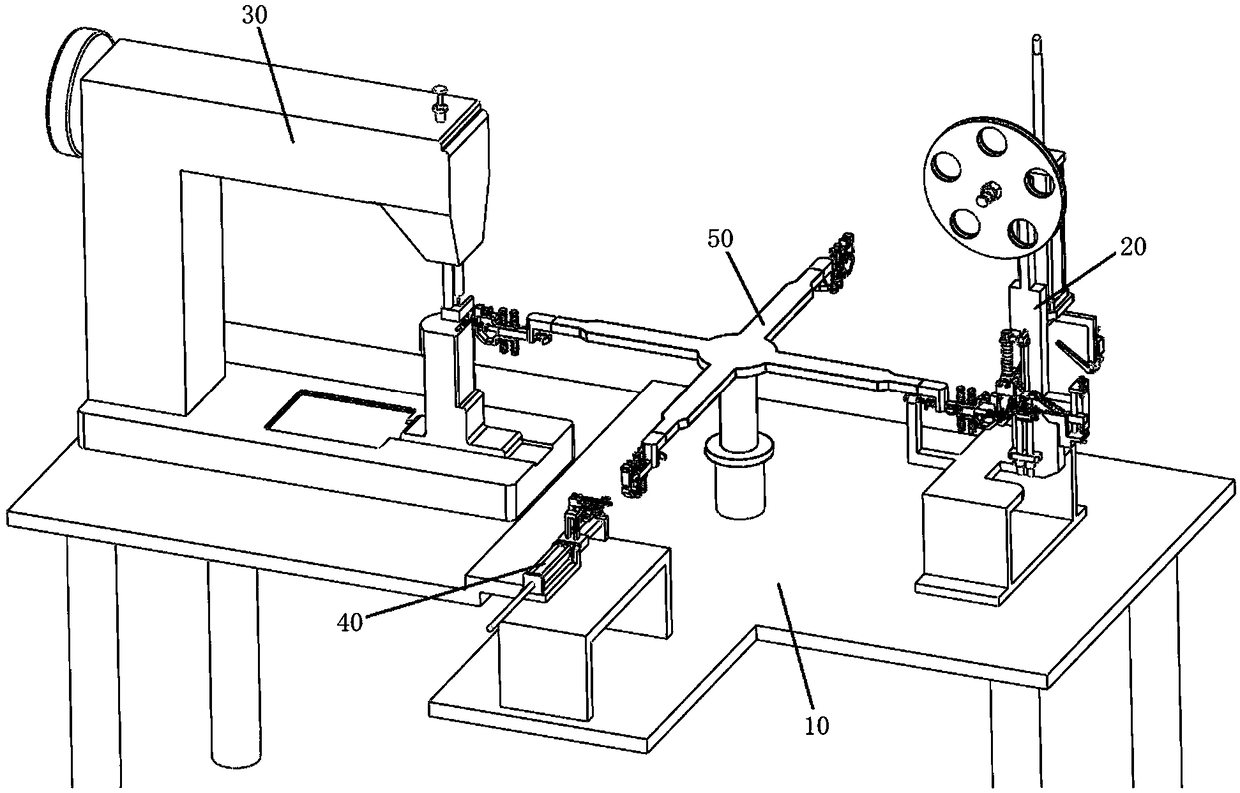

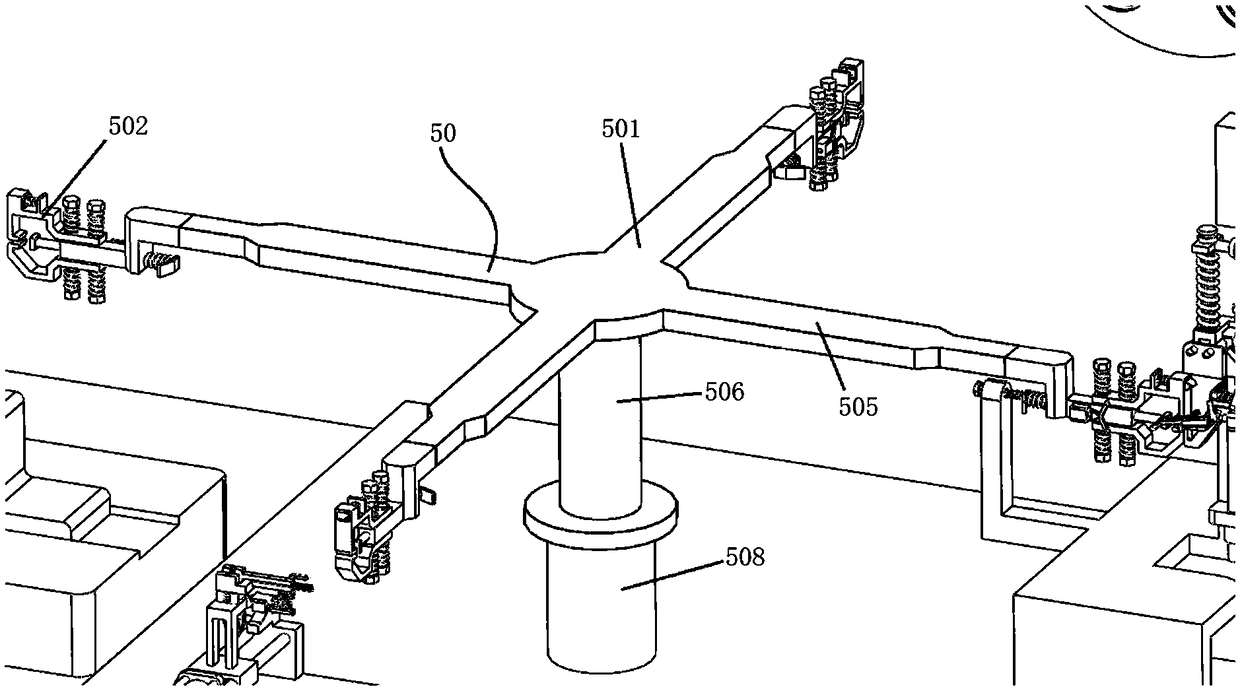

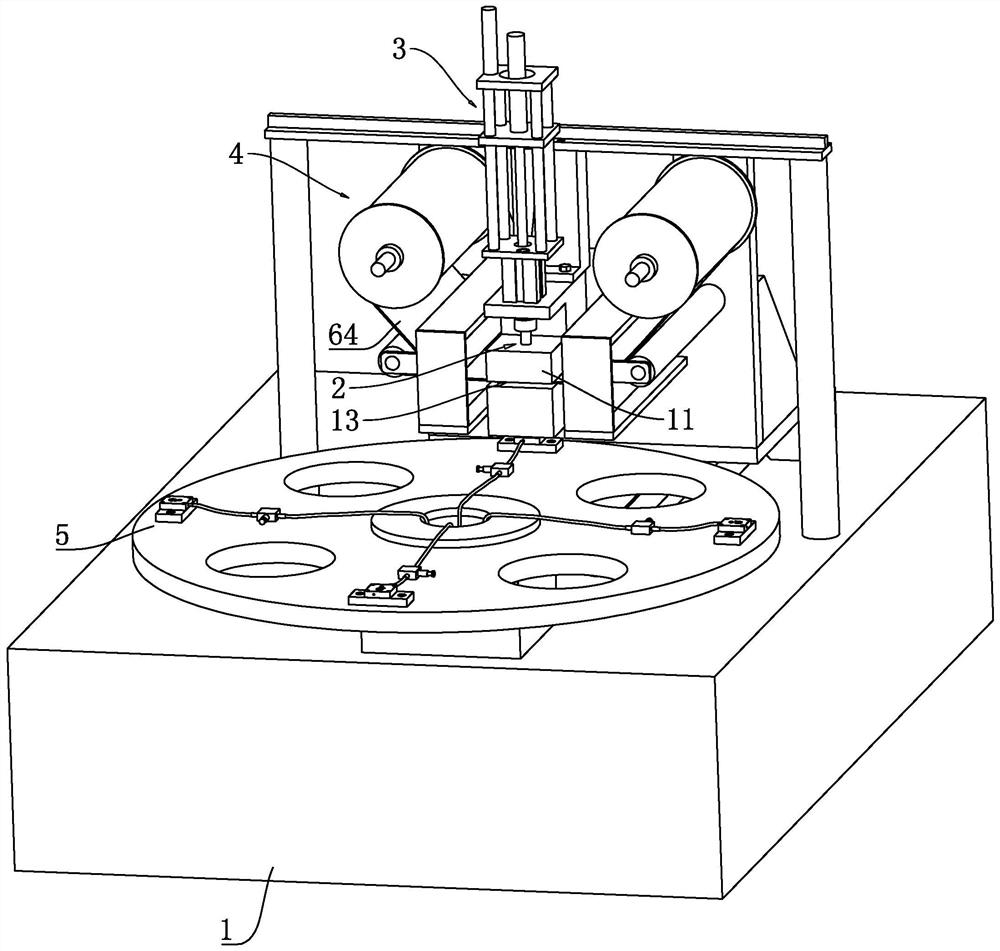

A belt loop automatic processing device

ActiveCN109082485BImplement automatic croppingImprove processing efficiencyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusMachiningIndustrial engineering

The invention relates to a novel leather belt ring automatic machining device. The novel leather belt ring automatic machining device is characterized in that the novel leather belt ring automatic machining device comprises a working platform, and a supplying and cutting unit, a sewing unit, a turning-over unit and a transferring unit are arranged on the working platform; and the transferring unitcomprises a transferring part and a clamping part, the transferring part is used for enabling the clamping part to sequentially pass through the positions where the supplying and cutting unit, the sewing unit and the turning-over unit are located, and thus a raw material leather strip is sequentially cut, sewed into a ring and turned over inwards and outwards. The novel leather belt ring automatic machining device can automatically cut, sew and turn over the raw material leather strip, accordingly, the raw material leather strip is machined into a finished leather belt ring, not only is the quite high machining efficiency achieved, but also the machining quality can be ensured, and the machining error is reduced.

Owner:威海高新园区运营管理有限公司

Lifting beauty line cutting device

The invention relates to a lifting beauty line cutting device, which belongs to the technical field of beauty line cutting. The lifting beauty line cutting device comprises a base and a wire winding plate which is located above the base and horizontally extends front and back, one extending end of the wire winding plate is connected with a rotating assembly, a coil capable of synchronously rotating with the wire winding plate is arranged above the wire winding plate, cutting assemblies are arranged on the two transverse sides of the wire winding plate and comprise cutting knives horizontally extending front and back and cutting edge blocks used for being matched with the cutting knives, and the cutting knives and the cutting edge blocks are located on the left side and the right side of the wire winding plate correspondingly and can horizontally move in the thickness direction of the wire winding plate; a penetrating groove allowing the cutter to horizontally penetrate through is formed in the wire winding plate in a penetrating mode. According to the lifting beauty line cutting device, automatic cutting of beauty lines can be achieved, multiple beauty lines meeting the use requirement can be obtained through one-time cutting, and efficiency is high.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL

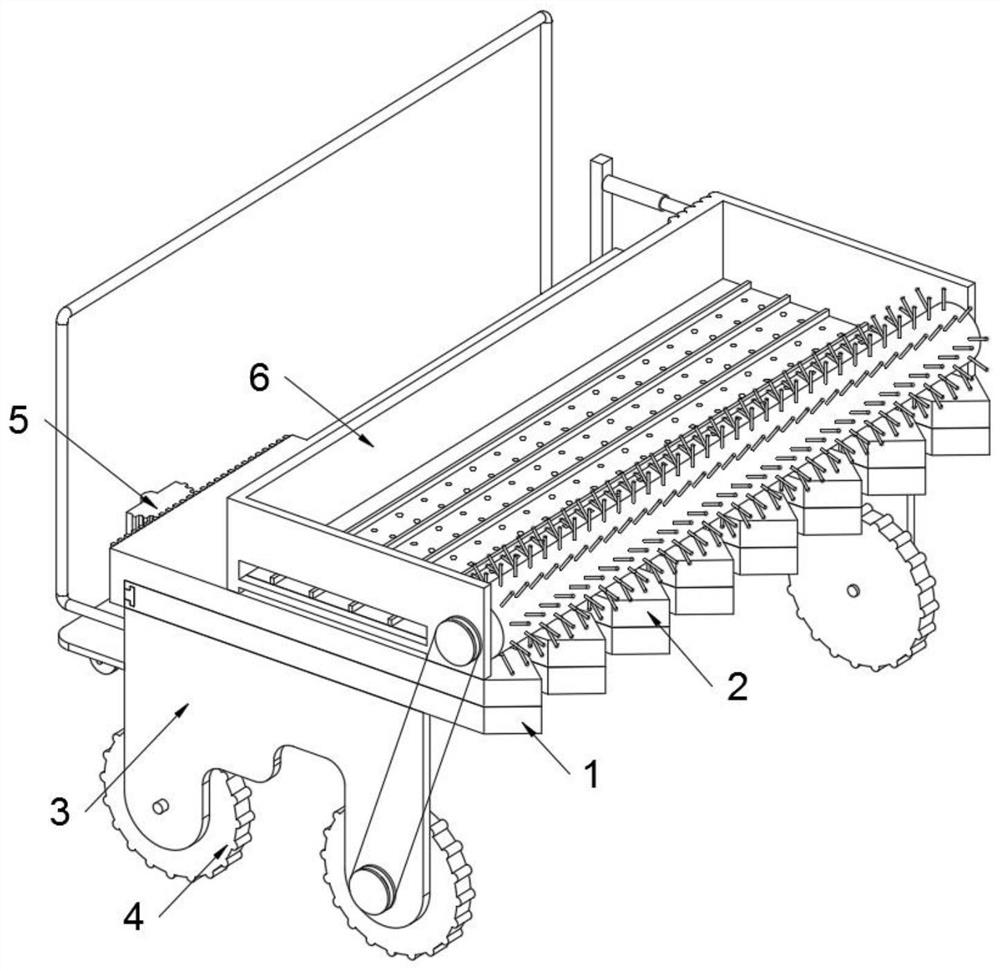

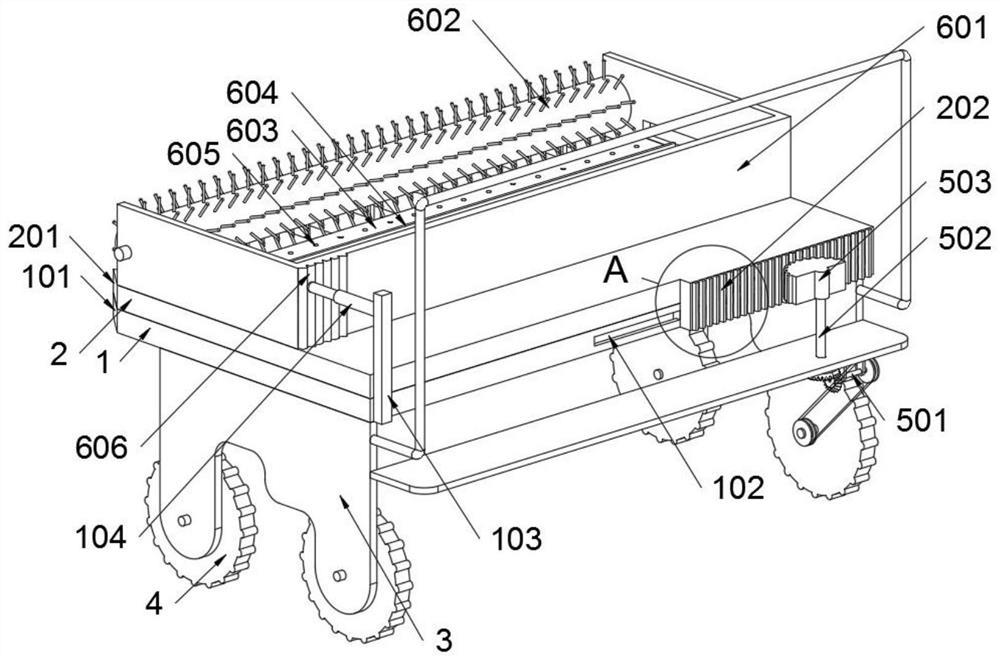

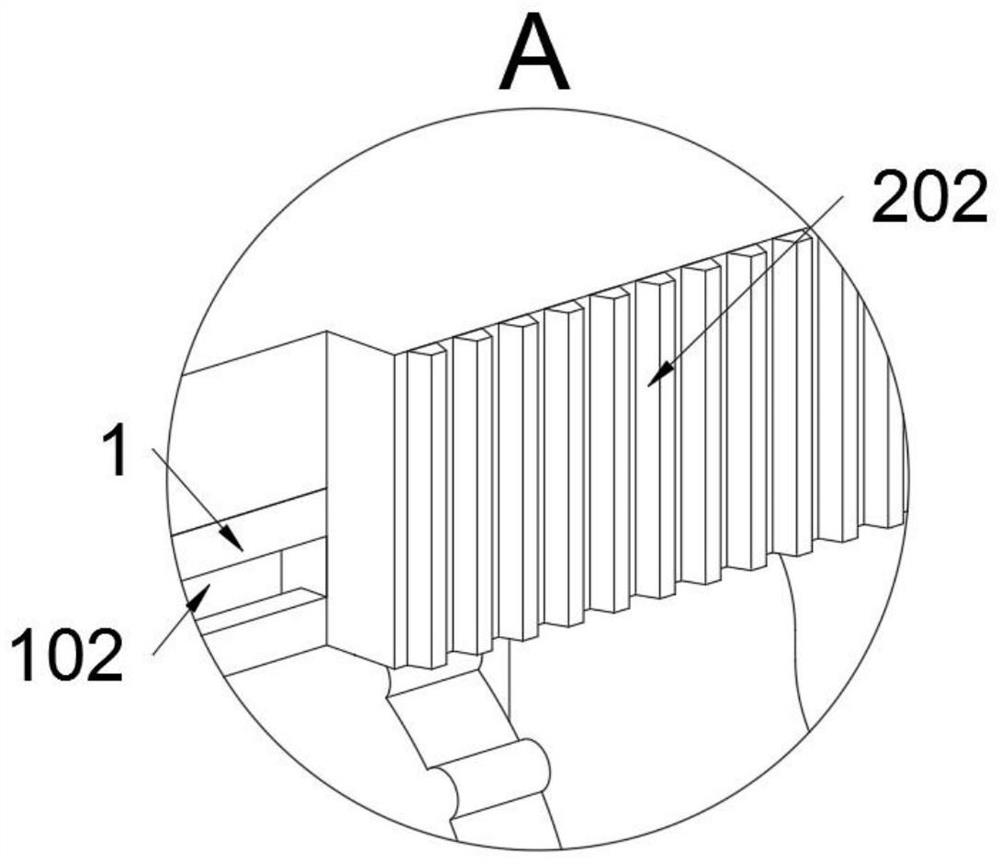

Operation robot used for agricultural planting

ActiveCN112136481AAchieve reductionImplement automatic croppingSievingScreeningReciprocating motionAgricultural engineering

The invention provides an operation robot used for agricultural planting, and relates to the technical field of agricultural picking. The problems that leek flowers cannot be picked through structurallinkage cooperation in the advancing process of a picking device, and impurities on the leek flowers cannot be screened and removed in leek flower picking linkage through structural improvement are solved. The operation robot used for agricultural planting comprises a body plate, a cutting plate is slidably connected to the body plate, a rolling wheel seat is welded to the bottom end face of thebody plate, and four rolling wheels are rotatably connected to the rolling wheel seat. Due to the fact that the number of protrusions is six, the six protrusions are all of semi-cylindrical structures, the six protrusions are all welded to the rear end face of a frame body, the head end of an elastic telescopic rod makes contact with the protrusions, and the frame body is still in a vibration state when doing reciprocating motion along with the cutting plate, vibration of a screen plate is achieved, and then vibration screening of plant fruits is achieved while the plant fruits are shaken andscreened.

Owner:山东沃川智能科技有限公司

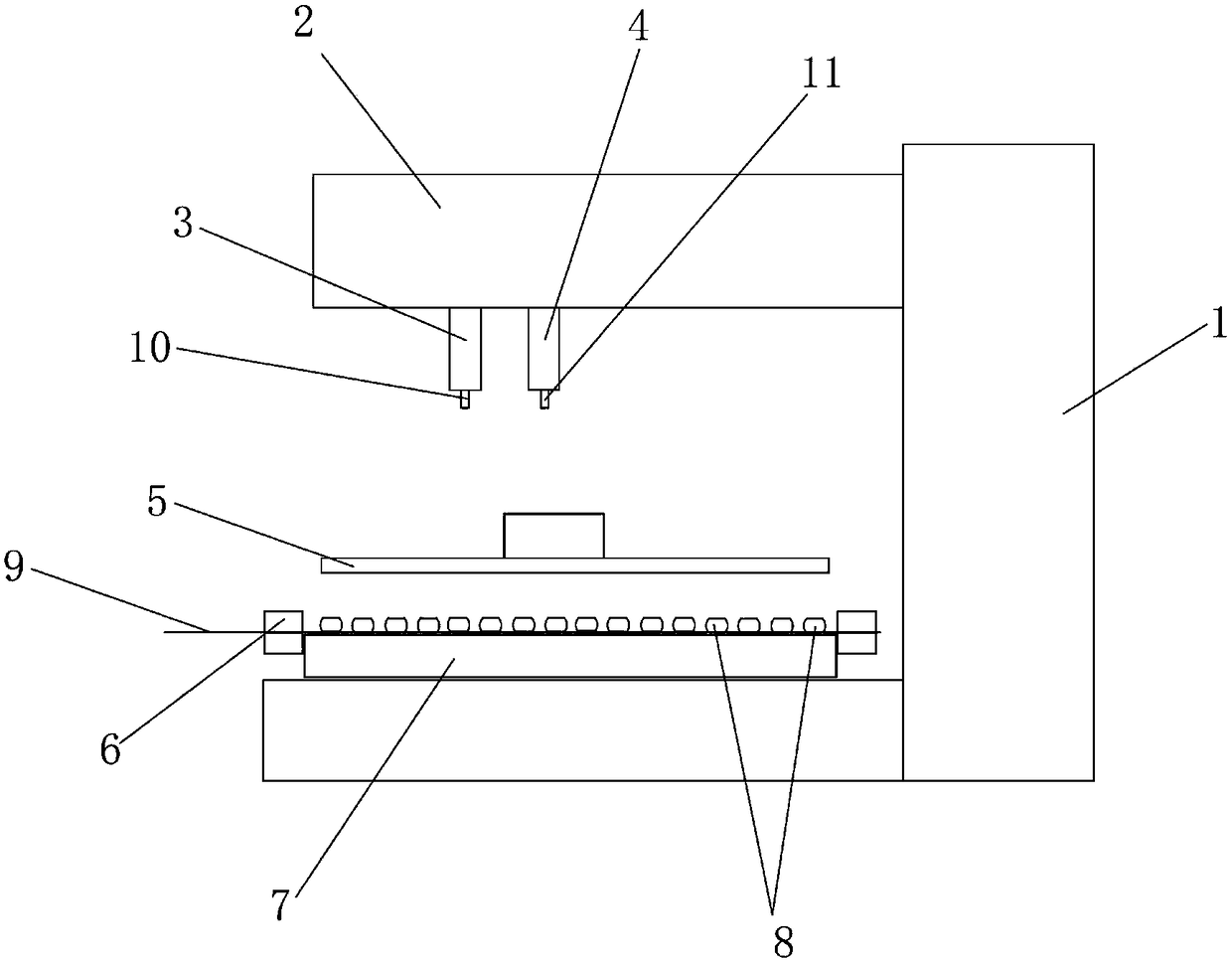

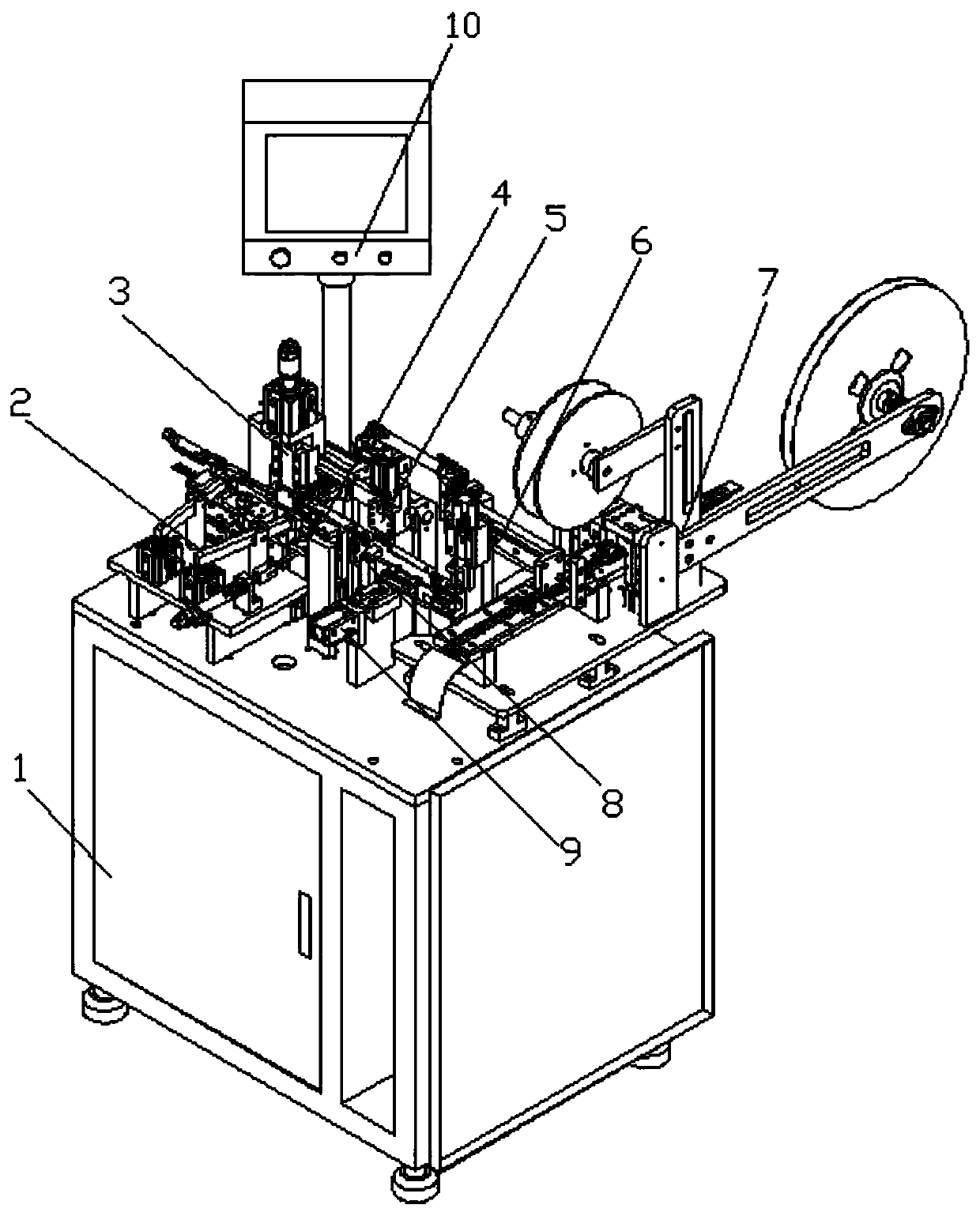

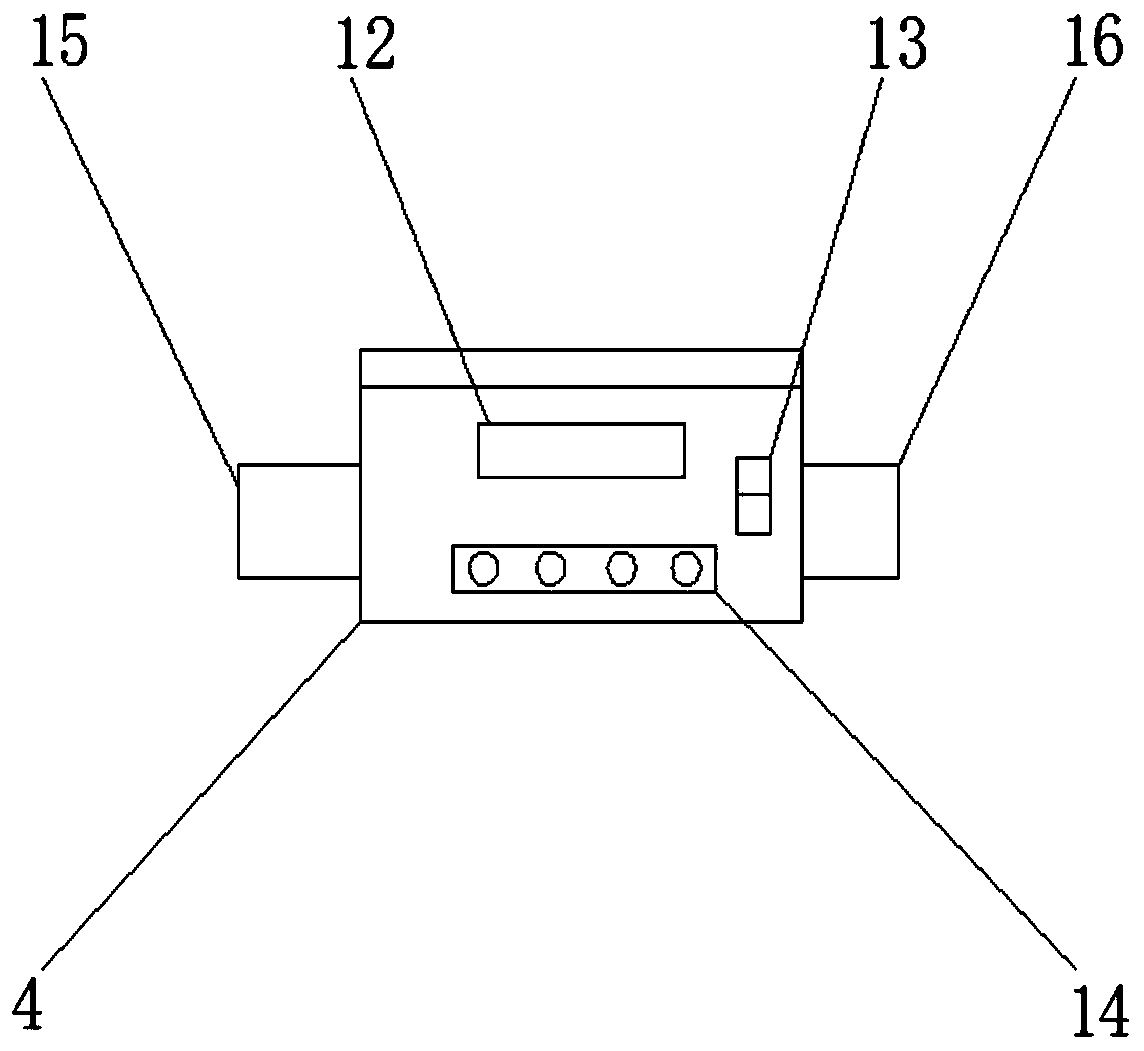

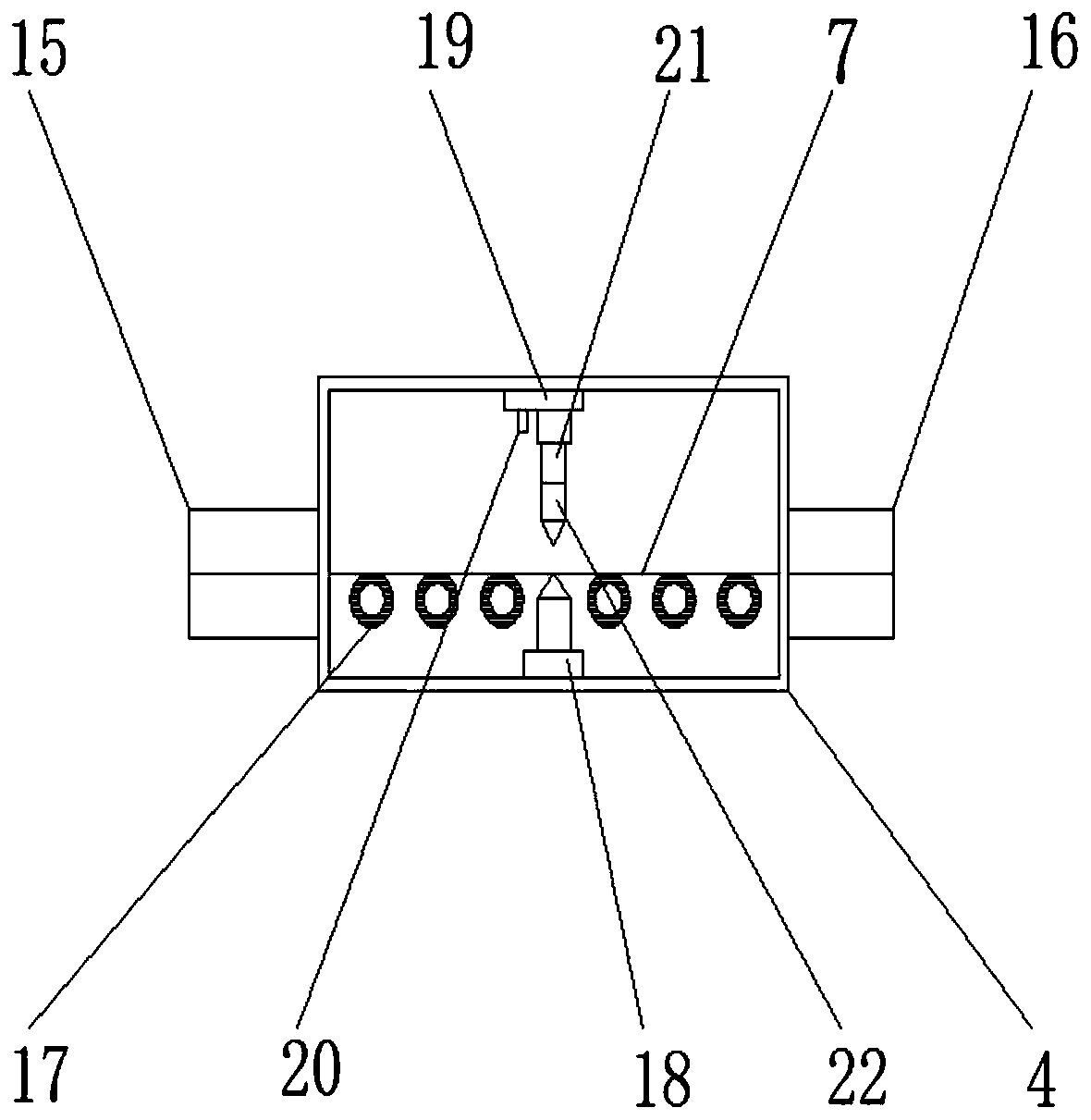

A usb female head automatic assembly machine

InactiveCN107971575BImplement automatic croppingRealize pushMetal working apparatusHuman–machine interfaceDistribution control

The invention relates to an automatic assembling machine for a USB female contact. The automatic assembling machine comprises a frame and a power distribution control cabinet which is arranged insidethe frame; the middle part of the upper end of the frame is provided with an iron shell trimming device; one side of the iron shell trimming device is sequentially provided with a human-computer interface, a tongue piece cutting device, a tongue piece conveying mechanism, an iron shell pin riveting device and a corner pressing device from left to right; the other side of the iron shell trimming device is sequentially provided with a material transferring device and a finished product transporting device from left to right; and a finished product packaging device fixed to the frame is arrangedbelow the finished product transporting device. By arranging the iron shell trimming device at a feeding position, the automatic assembling machine provided by the invention can realize automatic trimming and feeding of an iron shell; the opposite side of the iron shell trimming device is provided with the tongue piece cutting device in order to realize automatic cutting and feeding of a tongue piece; butting assembly is implemented inside the iron shell trimming device, so the cutting quality of the iron shell and the tongue piece is guaranteed, the assembly quality of the USB female contactis further guaranteed, and the machining efficiency is greatly improved as well.

Owner:DONGGUAN UNIV OF TECH

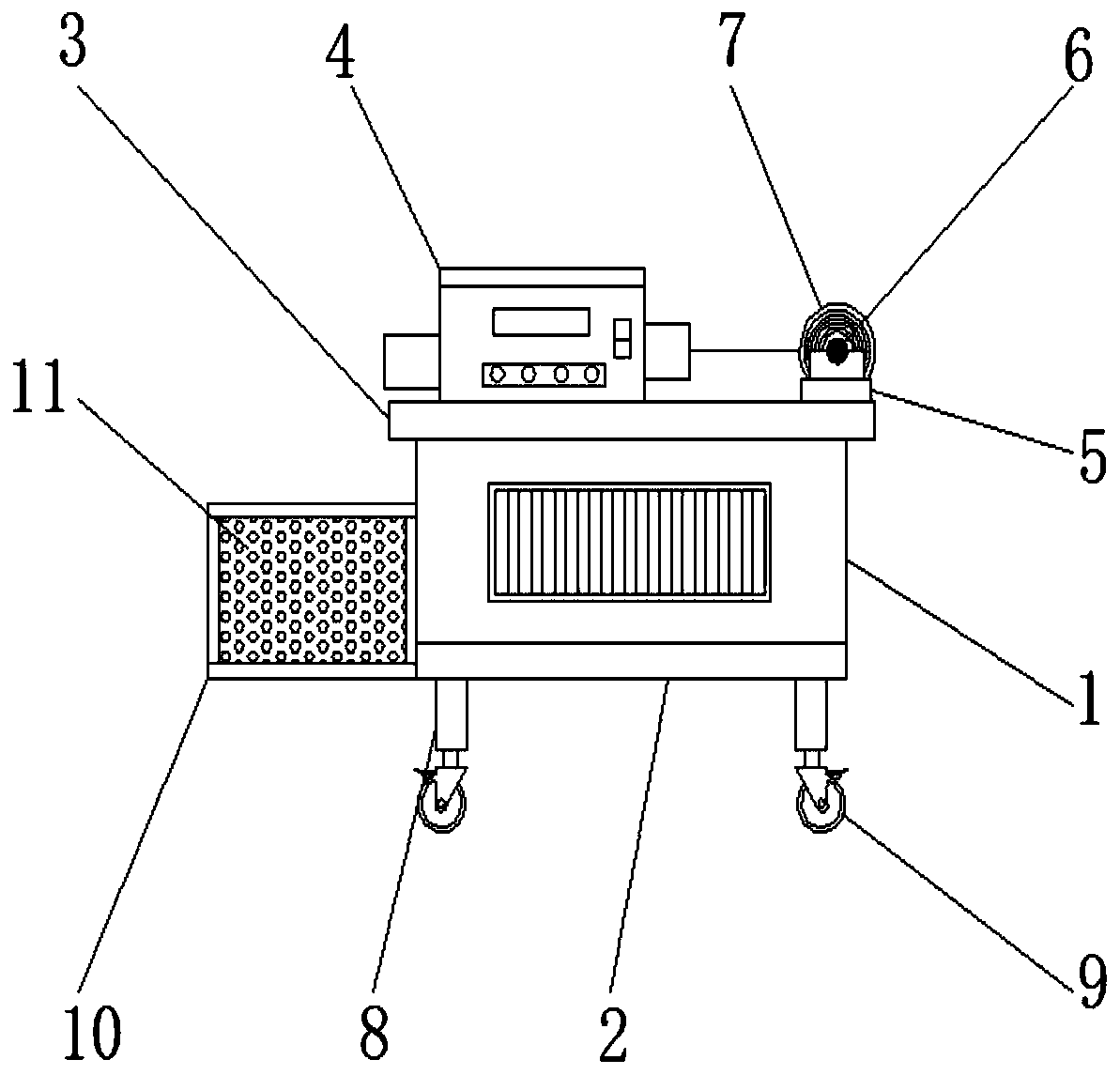

Tailoring equipment for producing antioxidant compound wave-absorbing material

The invention discloses tailoring equipment for producing an antioxidant compound wave-absorbing material and relates to the field of shearing equipment. The tailoring equipment comprises a distribution box, wherein an underframe plate is arranged on the outer surface of the lower end of the distribution box, a worktable is arranged on the outer surface of the upper end of the distribution box, acutter and a rolling device are arranged on the outer surface of the upper end of the worktable, and the rolling device is located on one side of the cutter. By arranging universal wheels, it is beneficial to move the tailoring equipment. It is more convenient and rapid to move the tailoring equipment, the manpower can be saved and it is relatively convenient to use the tailoring equipment. By arranging a laser mekometer, it is beneficial to be more precise in tailoring dimension of the wave-absorbing material without waste of material. By arranging a microprocessor, it is beneficial to control a tailoring knife to tailor the wave-absorbing material. Manpower can be reduced during use, automatic tailoring can be achieved, and the using effect is better than that of a conventional mode.

Owner:官雅康

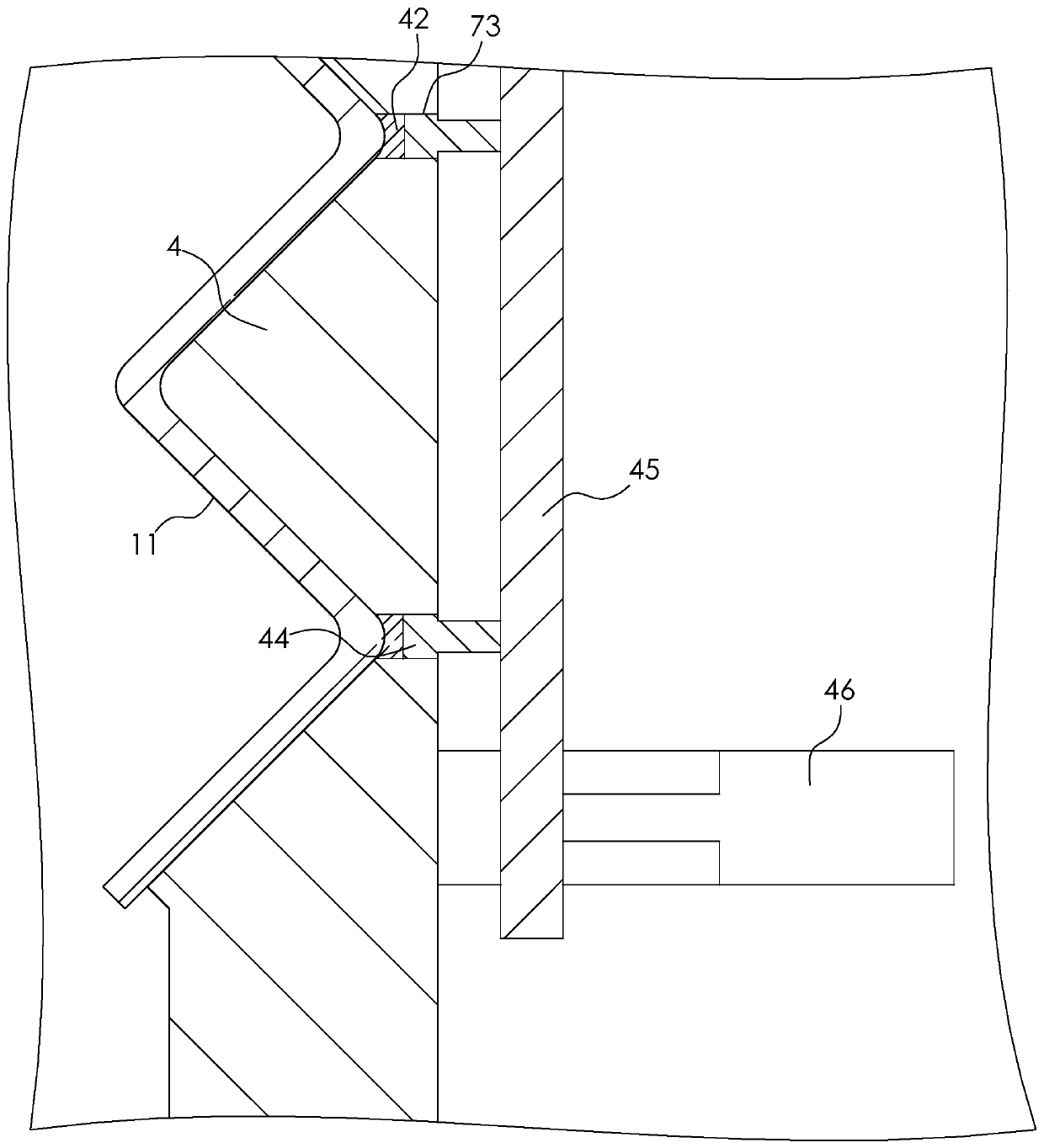

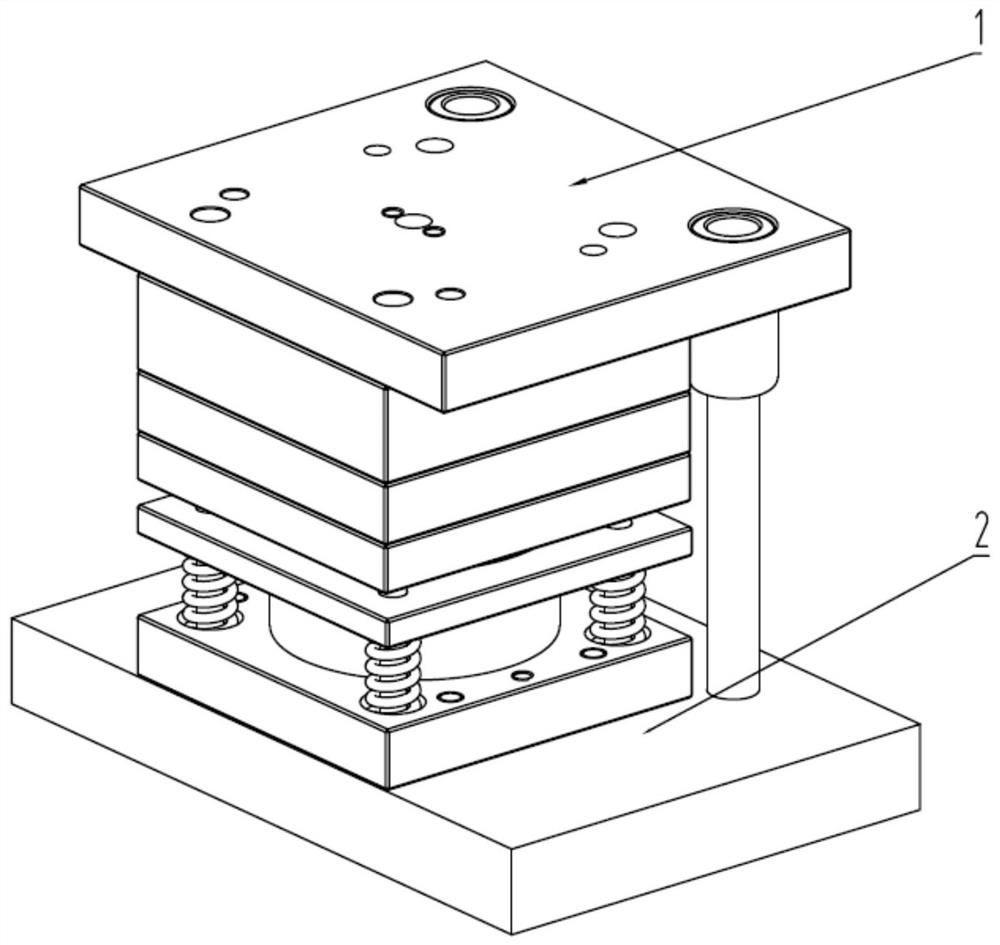

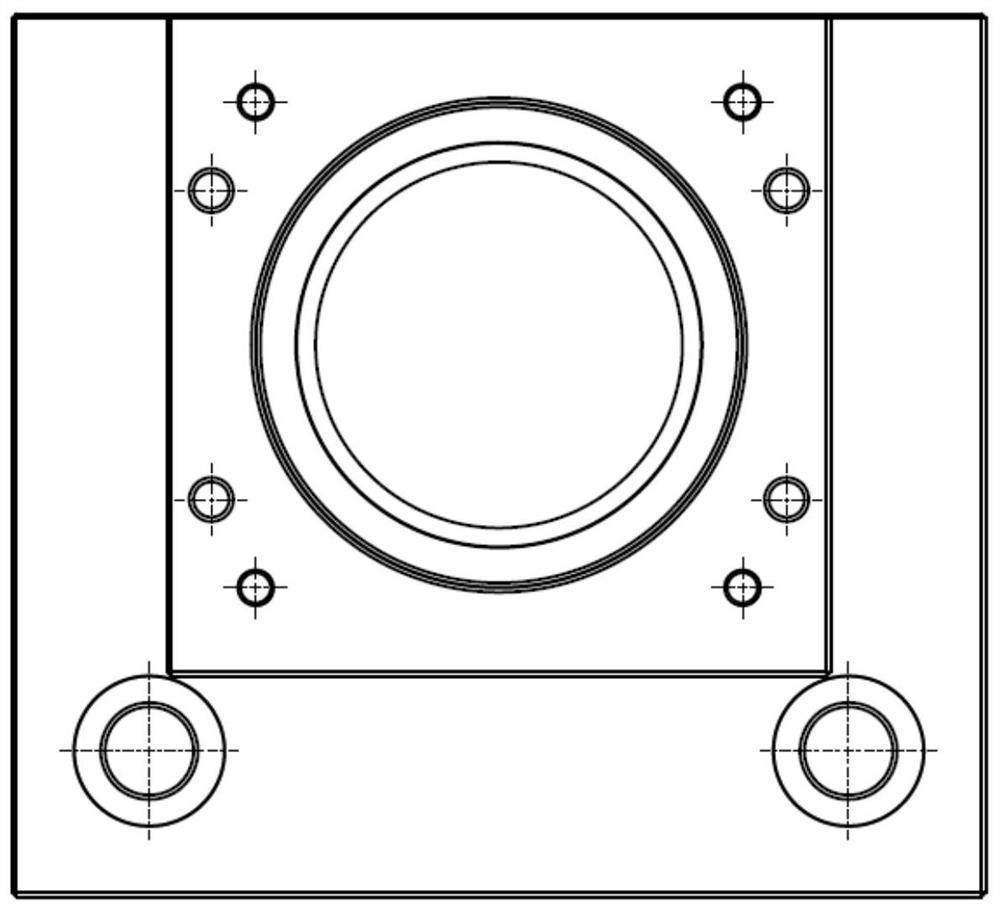

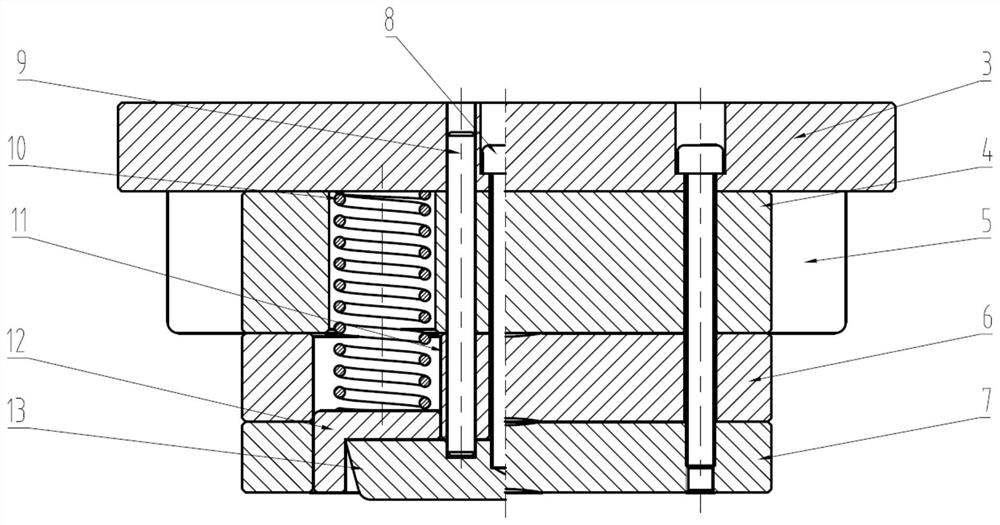

Solid rocket engine jet pipe blanking cap blanking die

ActiveCN113399539AImplement automatic croppingRealize automatic unloadingStripping-off devicesEngine componentsPunchingRocket engine nozzle

The invention discloses a solid rocket engine jet pipe blanking cap blanking die. The blanking die comprises an upper die and a lower die; the upper die is installed on a sliding block of a punching machine tool and used for achieving forming of the inner surface of a blanking cap. and the lower die is installed on a working table of the punching machine tool and used for achieving forming of the outer surface of the blanking cap and discharging. By means of the solid rocket engine jet pipe blanking cap blanking die, the machining efficiency of the solid rocket engine jet pipe blanking cap is improved, and the consistency of products is guaranteed.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Insulation pad butt cutting machine

InactiveCN108943750BImplement automatic croppingImprove cutting work efficiencyDirt cleaningDomestic articlesControl systemDust control

The invention provides an insulating rubber pad butt joint cutting machine, which belongs to the technical field of electric power construction equipment, and includes a frame and a cutting mechanism. Material inlets and outlets are arranged on both sides of the frame, and two layers are arranged on the frame for cutting insulating rubber pads. The cutting table, the pressing mechanism set on the top of the cutting table for pressing and positioning the insulating rubber pad, the dust removal mechanism set on the upper part of the frame for absorbing the debris of the insulating rubber pad and used to control the cutting mechanism, the The control system of the pressing mechanism and the dust removal mechanism. The insulating rubber pad docking cutting machine provided by the present invention, through the two-layer cutting table on the frame, the control system controls the cutting parameters, and automatically cuts two insulating rubber pads, which has the advantages of straight cutting, seamless butt joint, and no burrs, which improves the The technical effect of the cutting work efficiency of the insulating rubber pad.

Owner:STATE GRID CORP OF CHINA +1

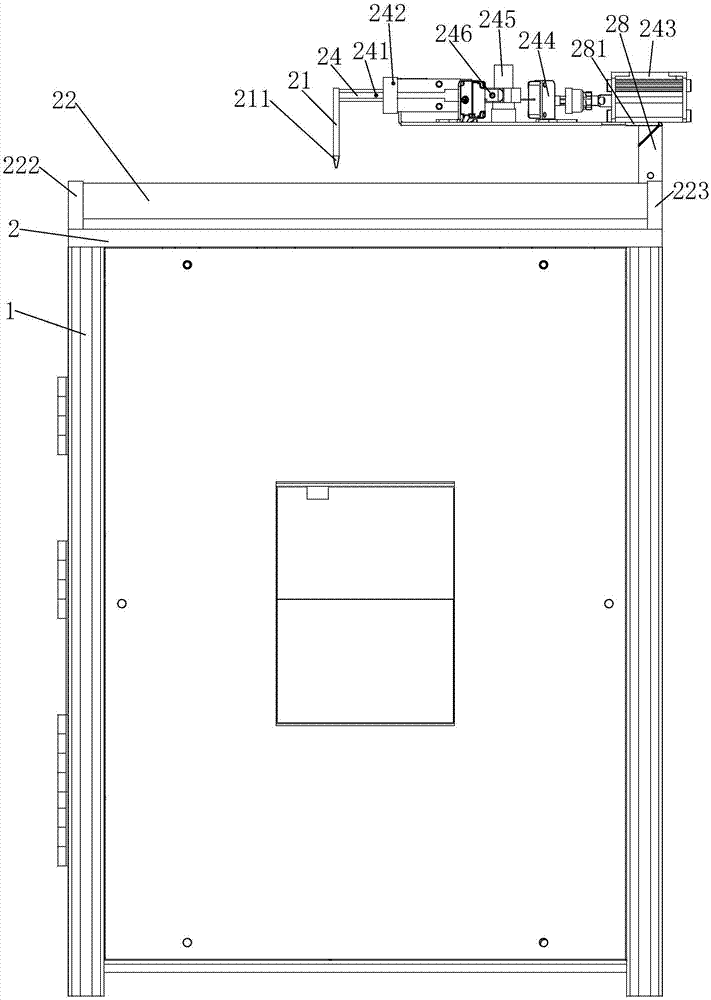

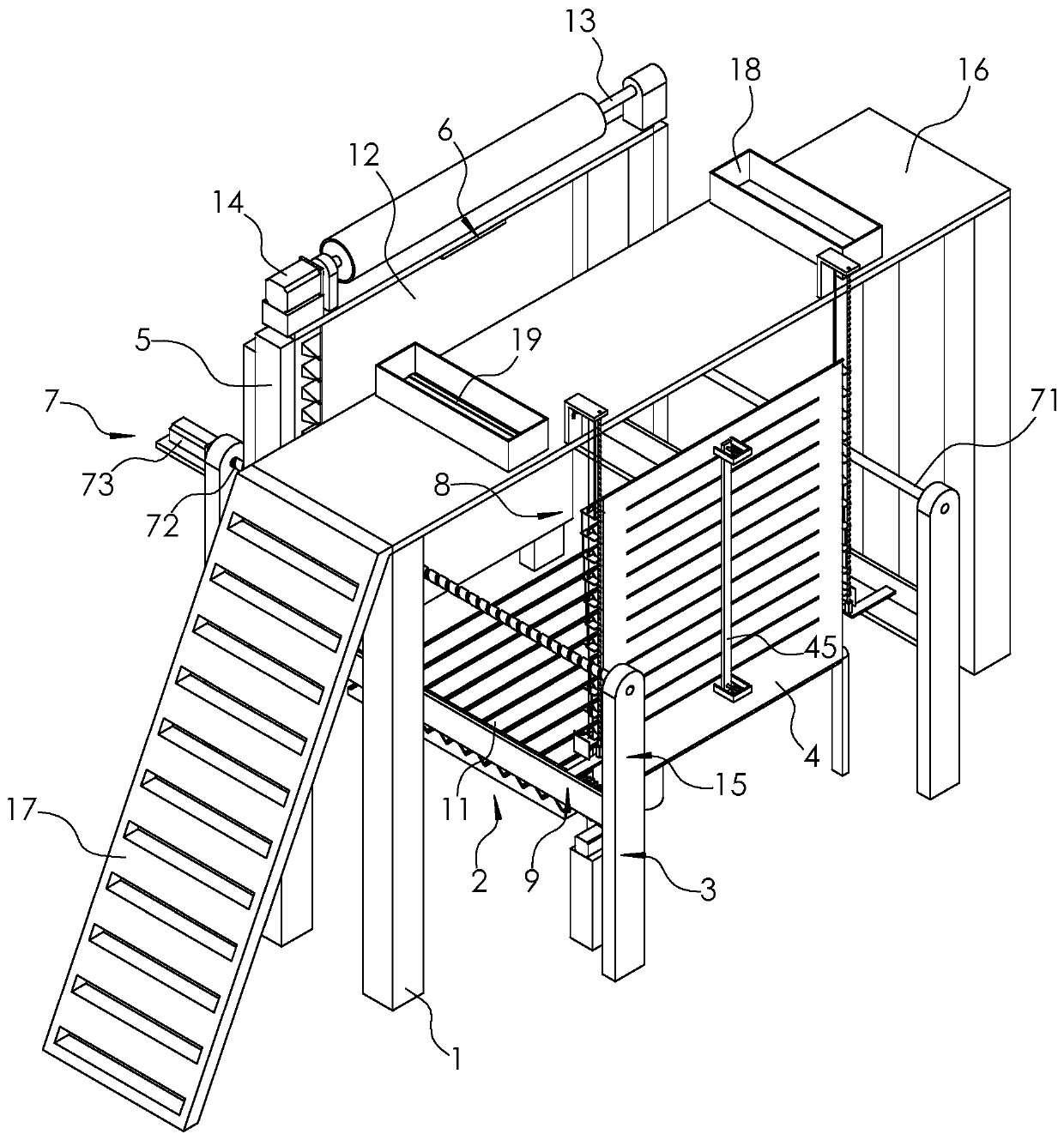

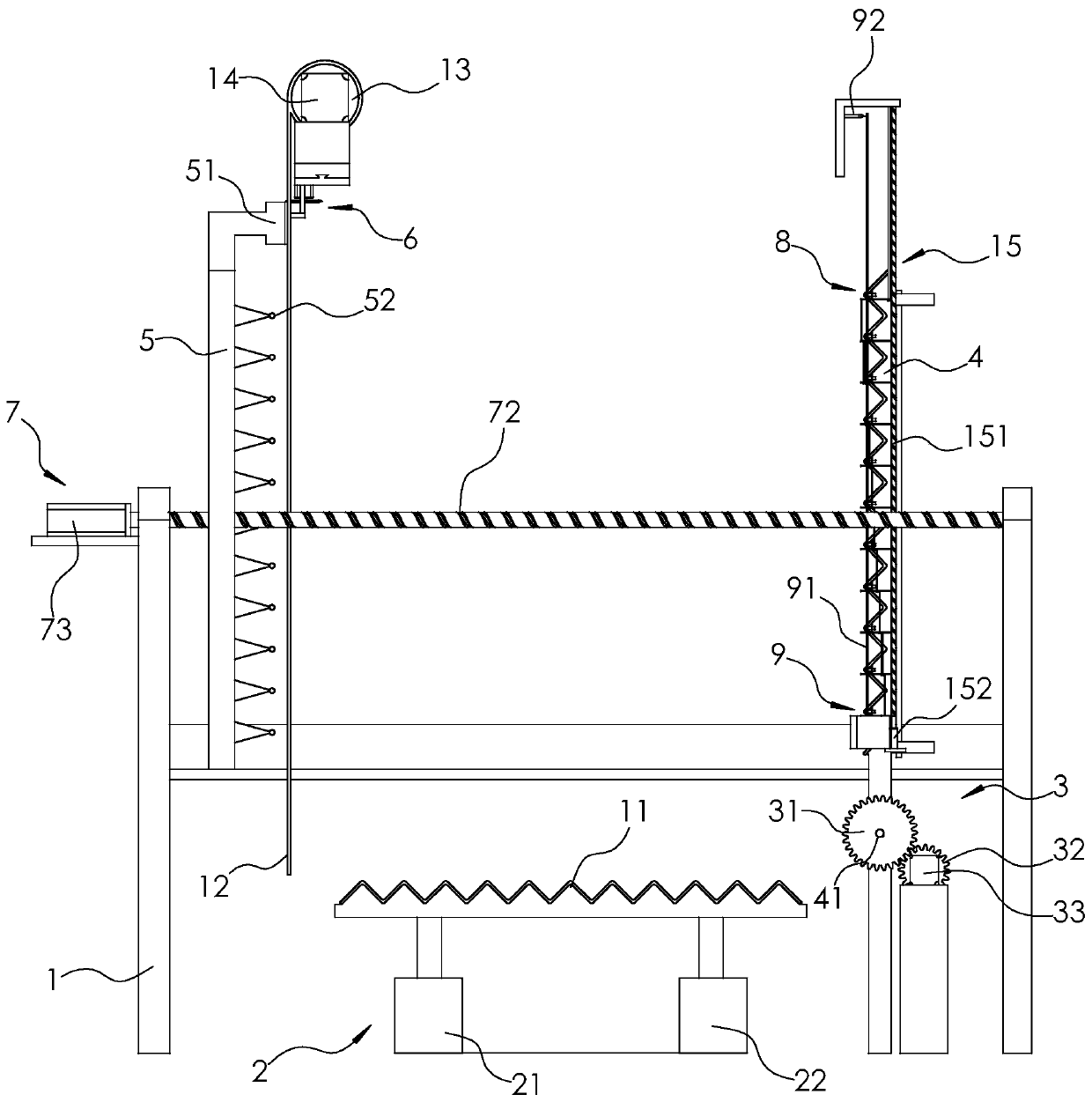

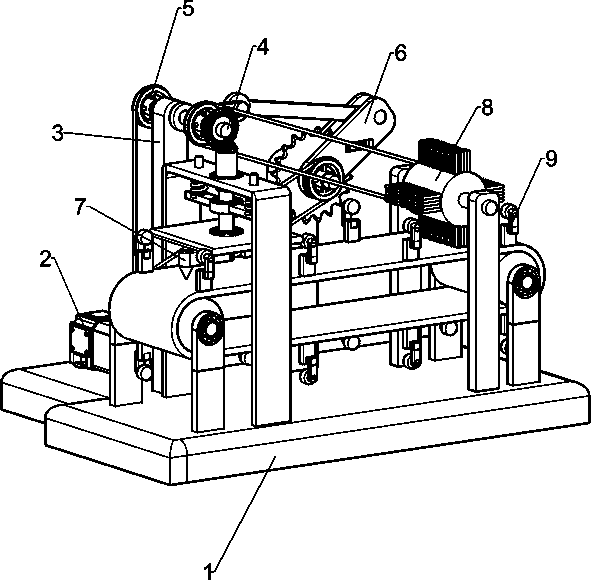

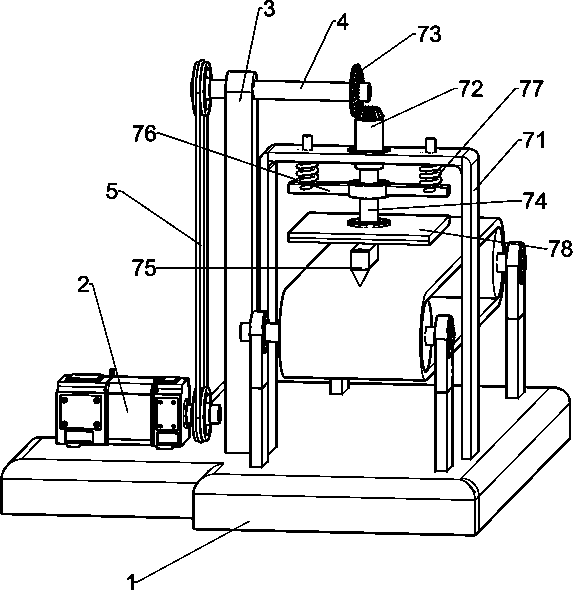

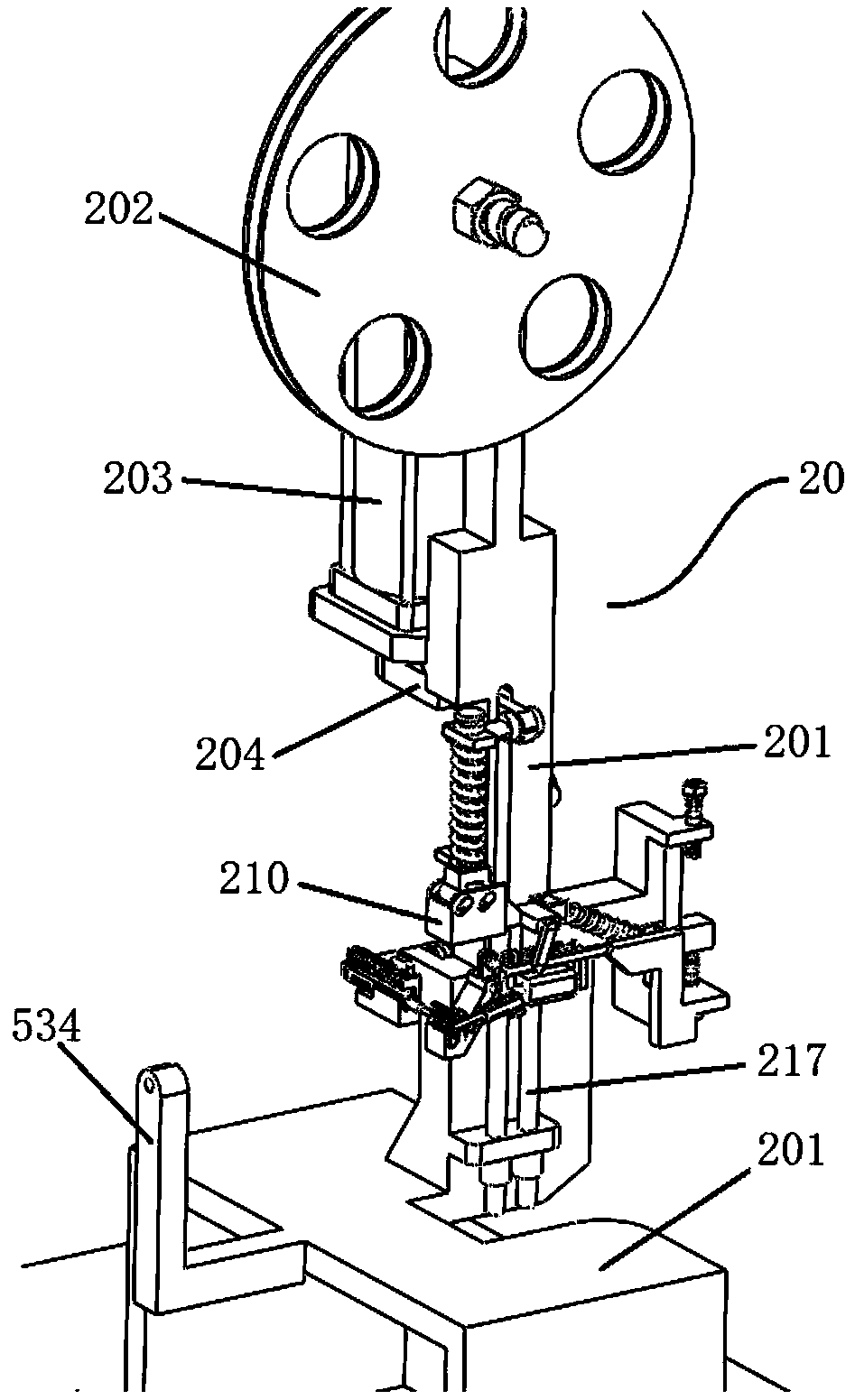

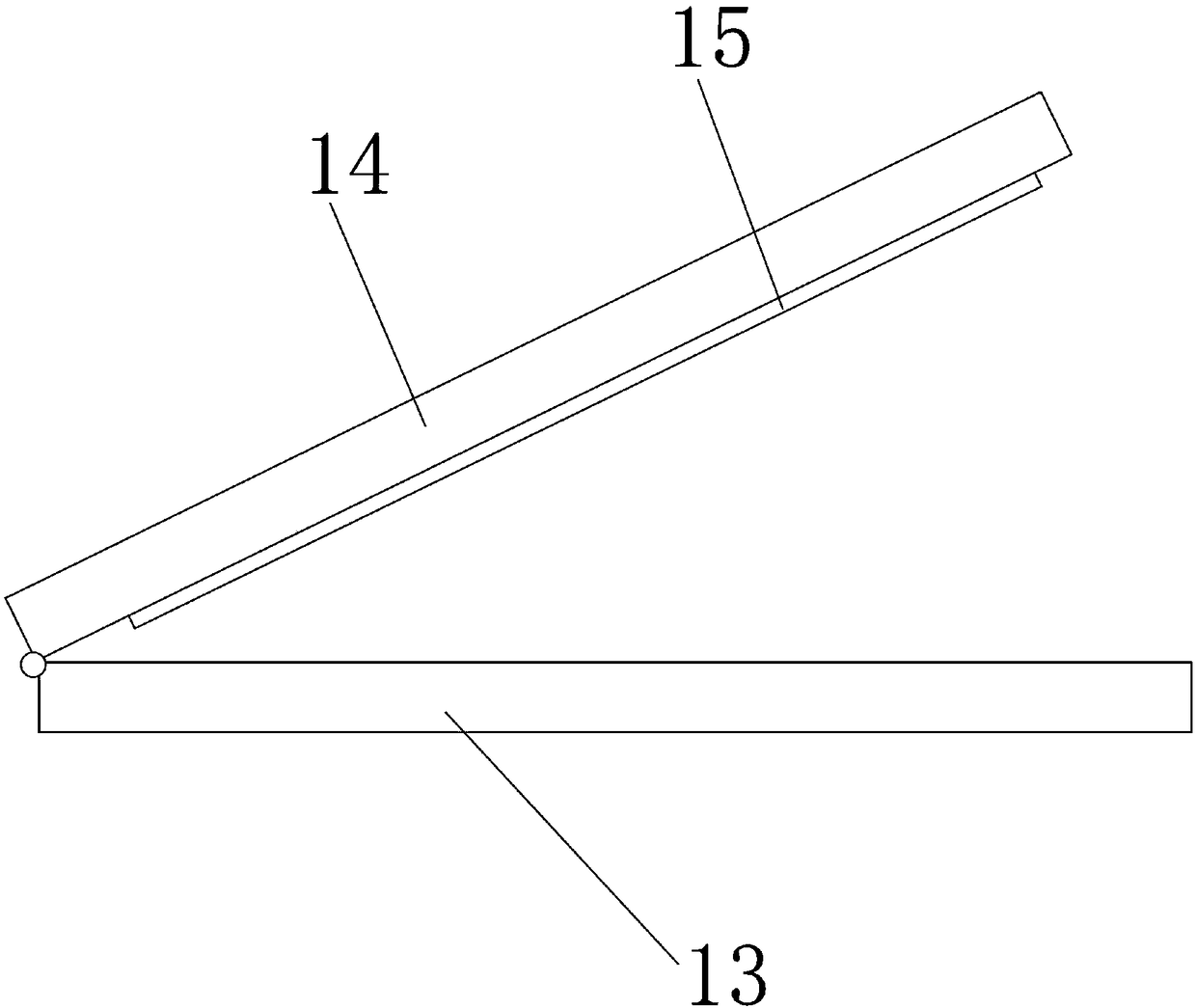

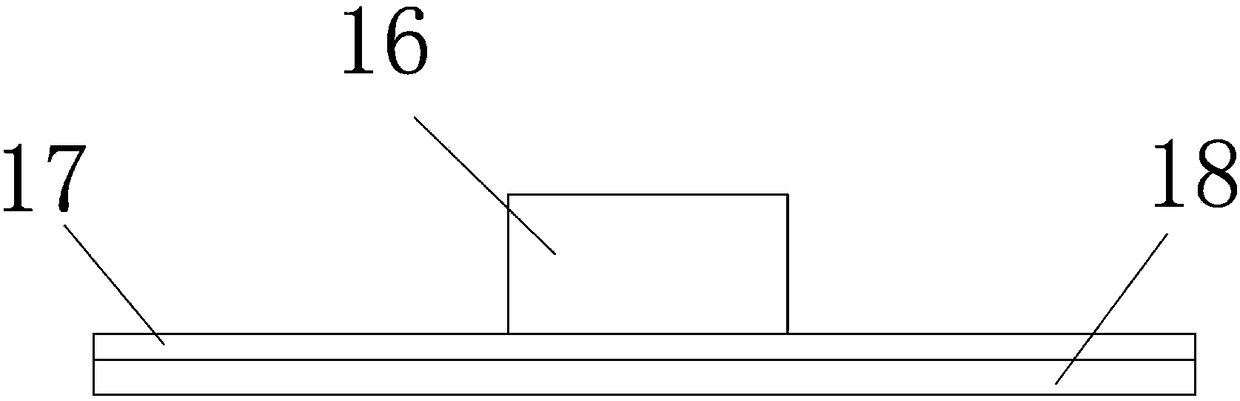

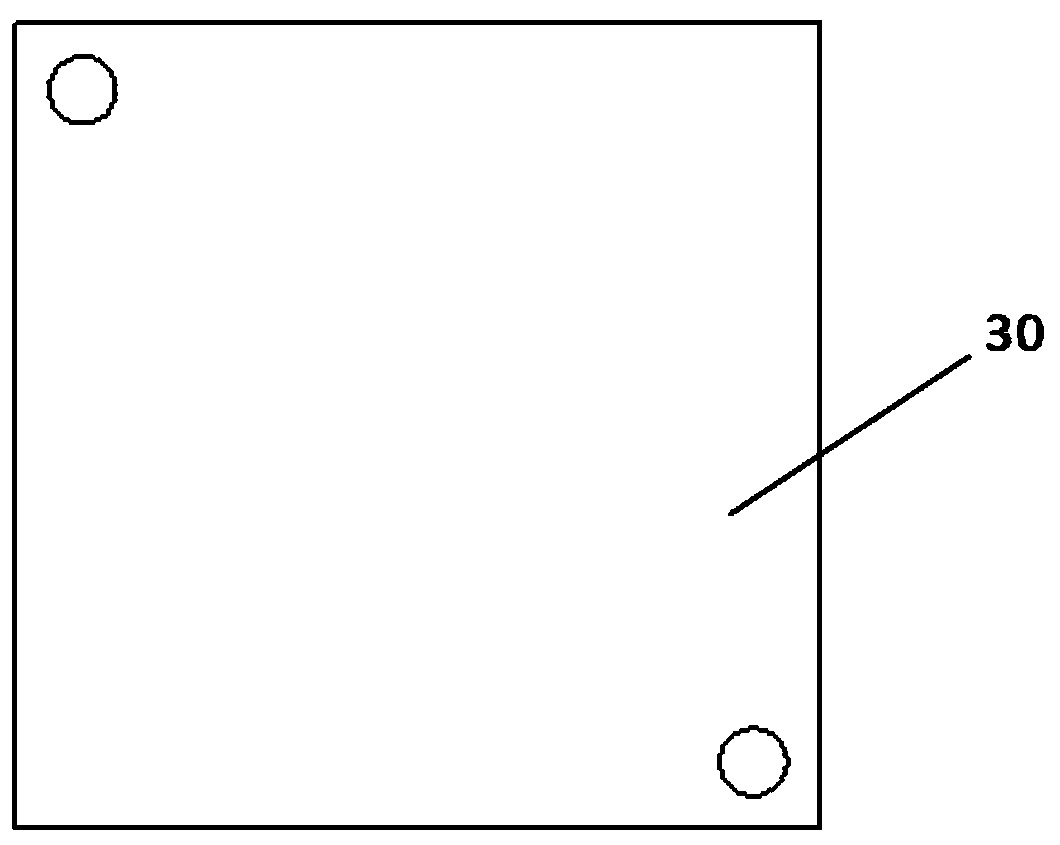

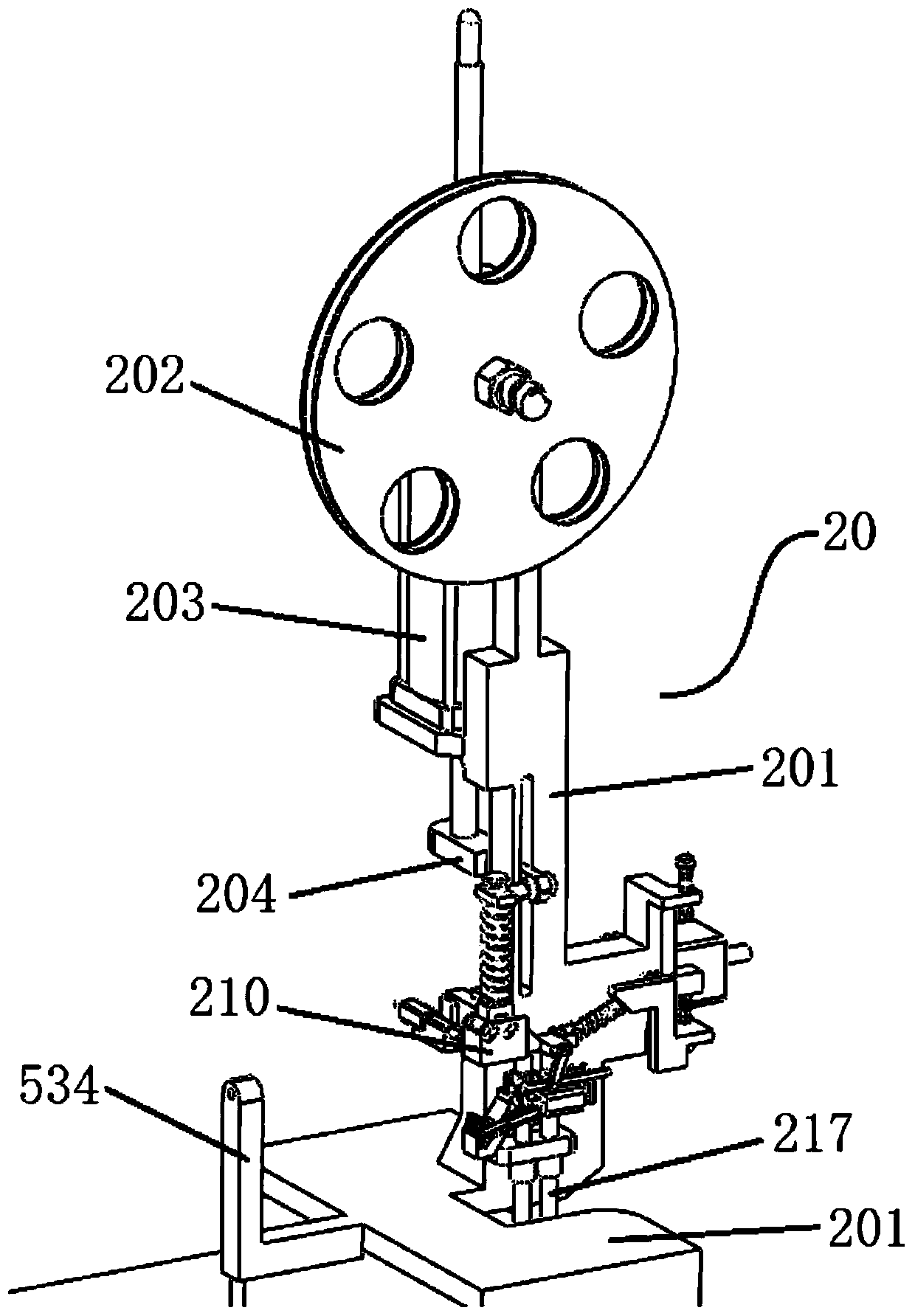

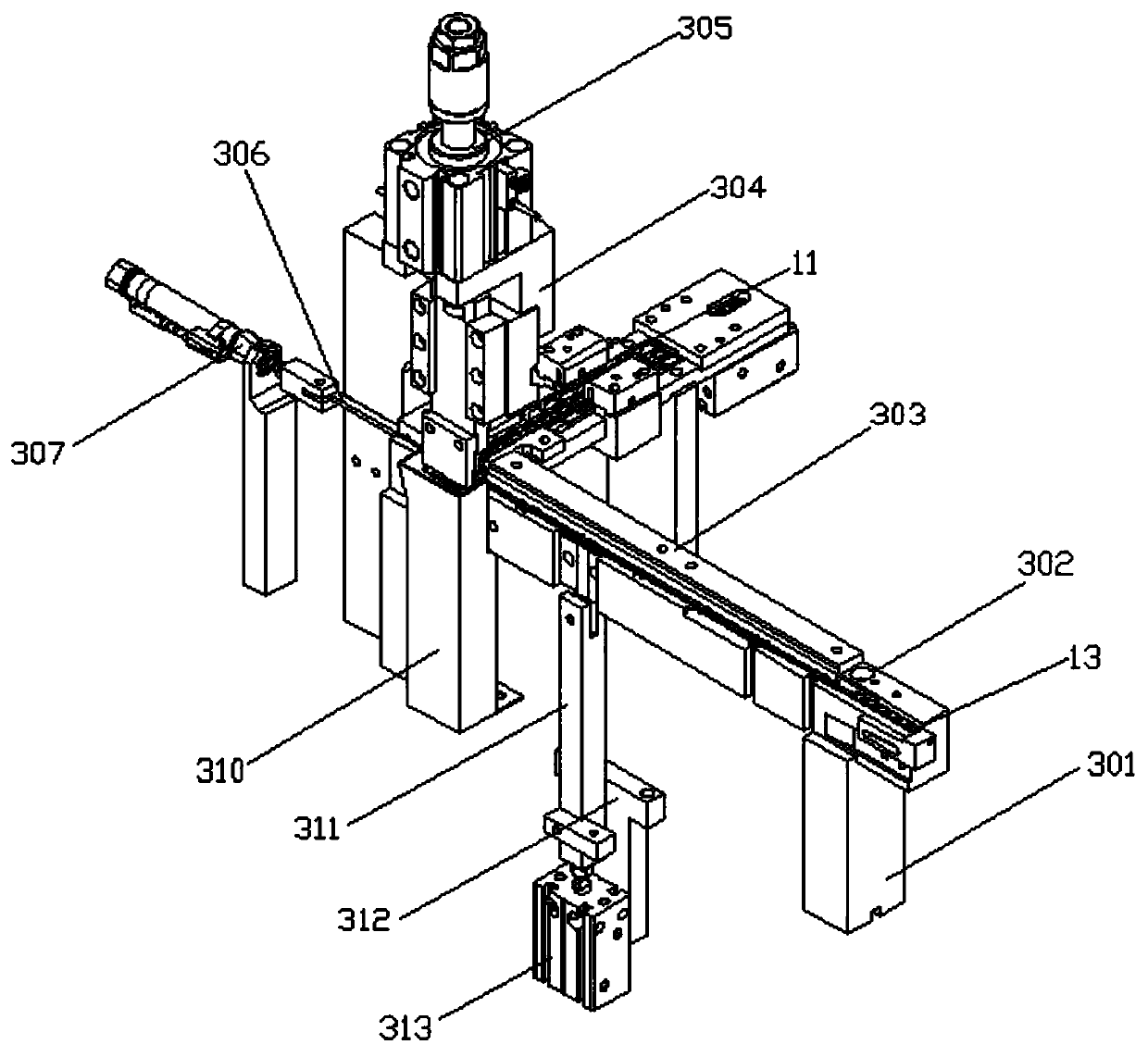

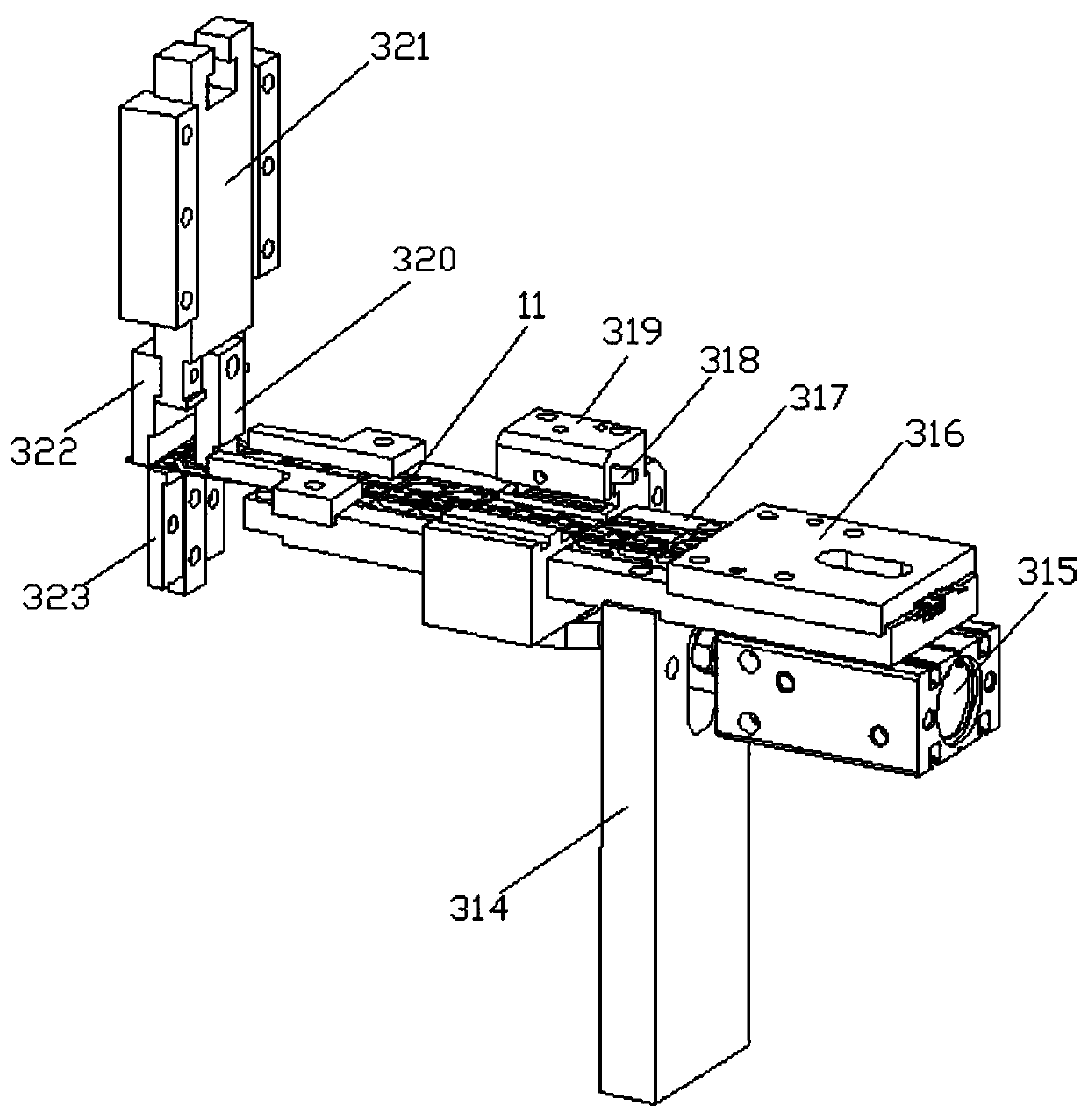

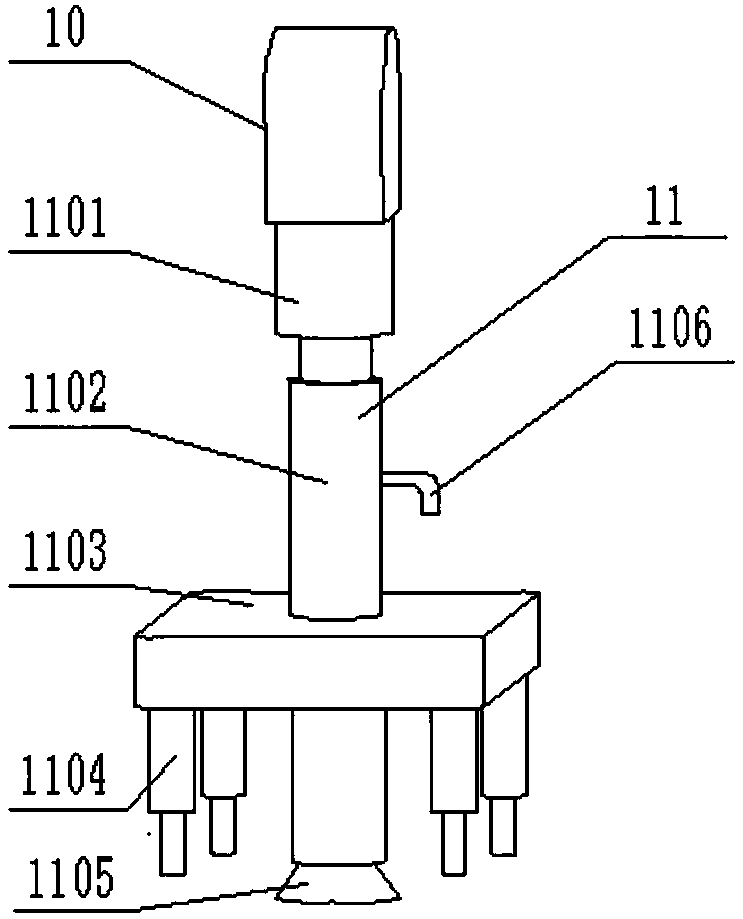

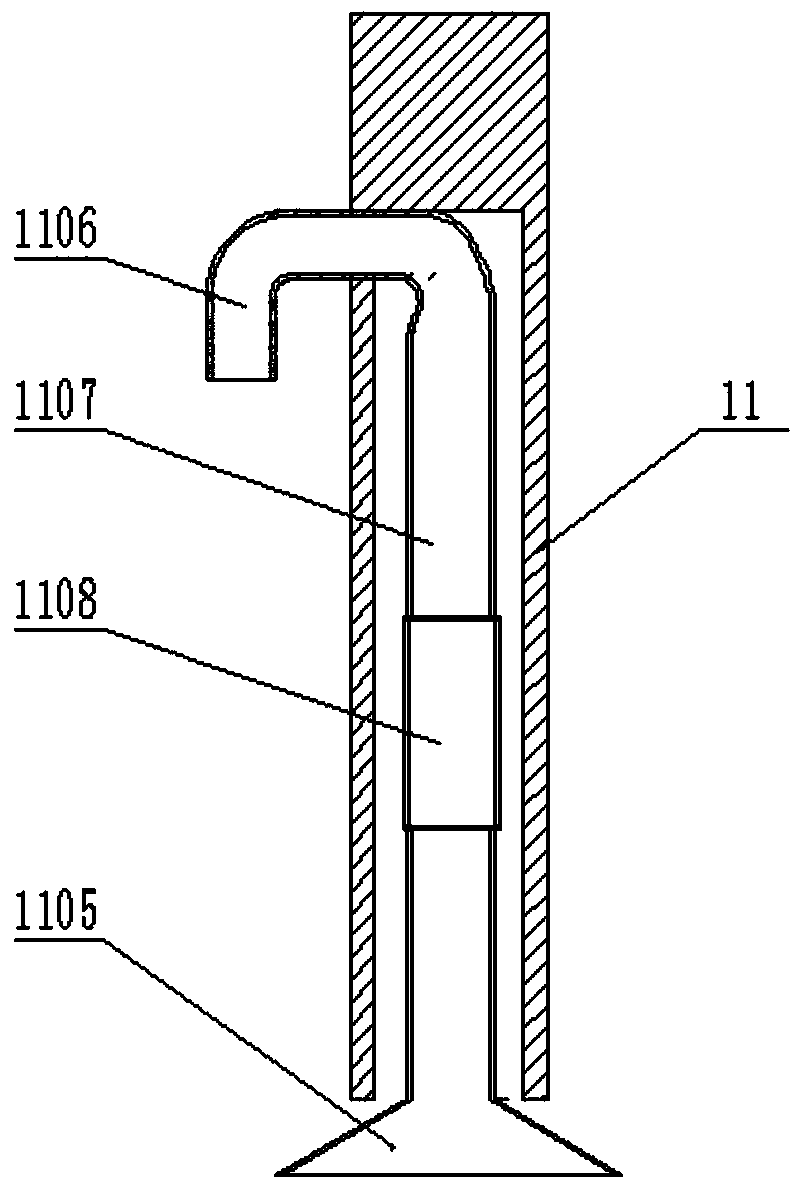

A photo automatic cropping robot

InactiveCN107520881BImplement automatic croppingGuaranteed accuracyMetal working apparatusEngineeringCcd camera

An automatic photo cutting robot a base, a photo placing box, a photo taking box, a CCD (charge coupled device) support, a CCD camera, a base motor, a vertical cylinder, a vertical-cylinder connecting block, a horizontal cylinder, a horizontal-cylinder connecting block, a gripper, a fixing-plate support, a fixing plate, a crank, a connecting rod, a cutter, a crank motor support, a crank motor and a control box. The automatic photo cutting robot is characterized in that the photo placing box, the photo taking box, the CCD support, the base motor, the fixing-plate support and the control box are fixed on the base, the CCD camera is installed on the CCD support, the vertical cylinder is installed on the base motor, the horizontal cylinder and the vertical cylinder are connected through the vertical-cylinder connecting block, the gripper is connected onto the horizontal cylinder through the horizontal-cylinder connecting block, the fixing plate is mounted on the fixing-plate support, the crank, the connecting rod, the cutter and the fixing plate are mutually connected, the crank motor is connected with the crank, and the crank motor is fixed on the base through the crank motor support. By the arrangement, photos can be cut automatically.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Insulation pad cutting and bonding machine

InactiveCN108908956BImplement automatic croppingImprove work efficiencyDirt cleaningDomestic articlesButt jointControl system

The invention provides an insulating rubber pad cutting and bonding integrated machine, which belongs to the technical field of electric power construction facilities and includes a frame and a cutting mechanism. Material inlets and outlets are provided on both sides of the frame, and a window for cutting insulating rubber pads is provided on the frame. Cutting table, a bonding mechanism for bonding several pieces of insulating rubber pads, a pressing mechanism for pressing insulating rubber pads on the top of the cutting table and inside the frame, and a mechanism on the upper part of the frame for absorbing broken insulating rubber pads The dust removal mechanism for chips and the control system for controlling the cutting mechanism, bonding mechanism, pressing mechanism and dust removal mechanism. The insulating rubber pad cutting and bonding machine provided by the present invention realizes the automatic cutting and bonding of the insulating rubber pad by setting a cutting mechanism, a bonding mechanism and a cutting table on the frame, and controlling the cutting and bonding parameters by the control system. It has the technical effect of seamless butt joint, no bubbling and no burrs in bonding, and the working efficiency of the insulating rubber pad is improved.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com